Dry-type oxidation reactor

A dry oxidation and reactor technology, applied in the direction of chemical analysis using combustion, can solve problems such as poor air tightness, and achieve the effect of solving air tightness, occupying little space, and stable temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention.

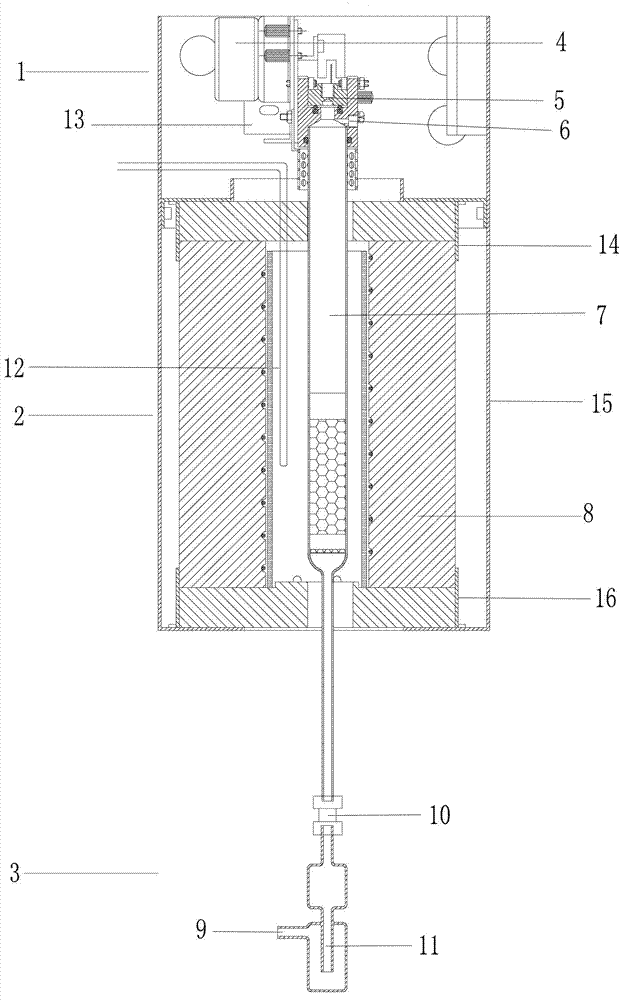

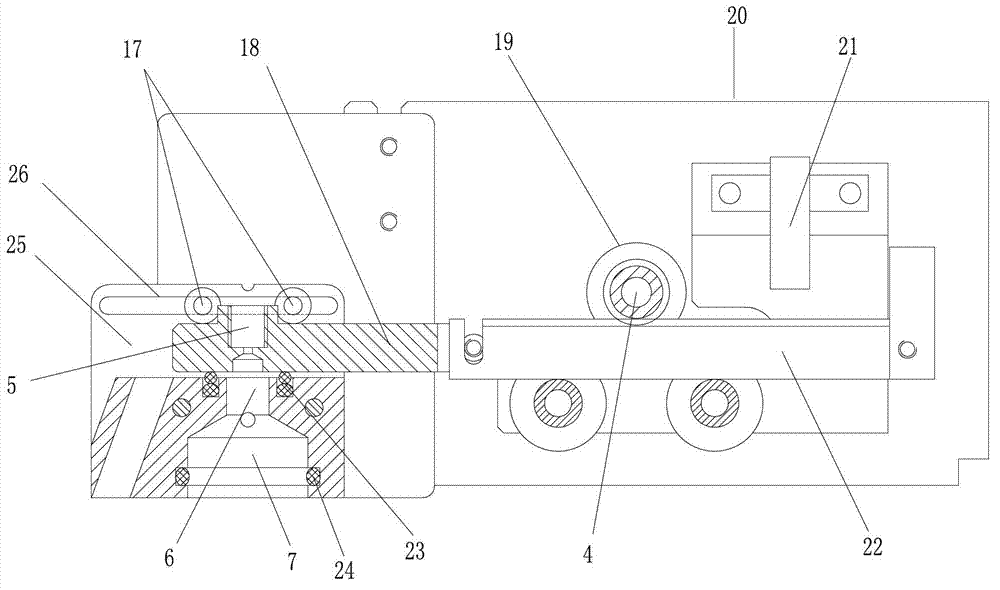

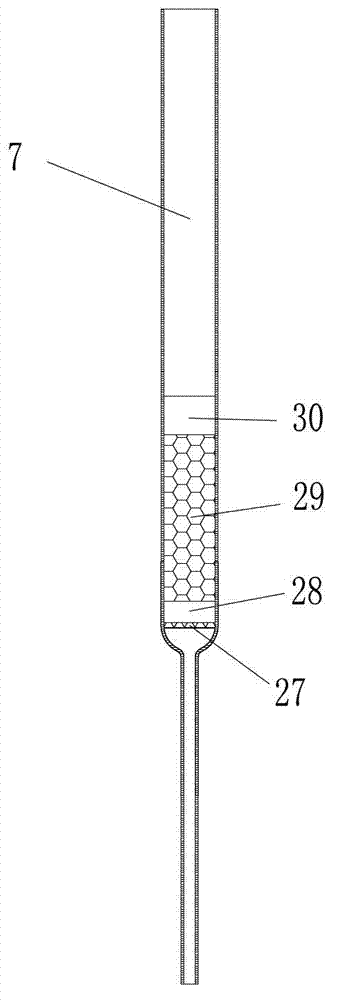

[0015] The embodiment of the invention discloses a dry oxidation reactor, such as figure 1 As described in -3, the reactor includes a sampling unit 1, a combustion unit 2 and a washing unit 3. Among them, the sampling unit 1 includes an injection hole 6, a slider 18, a slider base 25, and a driving device 20. The driving device 20 includes a motor 4, a photoelectric sensor 21, a gear 19, and a rack 22; the combustion unit 2 includes a combustion tube 7. Heating furnace 8 and temperature sensor 12; washing unit 3 includes airtight joint 10, scrubber 11 and air outlet 9.

[0016] The sliding block 18, the sliding block base 25 and the motor 4 are jointly fixed by the first mounting bracket 13 and the third mounting bracket 15. A first sealing rubber ring 23 and a second sealing rubber ring 24 are arranged around th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com