Patents

Literature

120 results about "Burn units" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A burn center, burn unit or burns unit is a hospital specializing in the treatment of burns. Burn centers are often used for the treatment and recovery of patients with more severe burns.

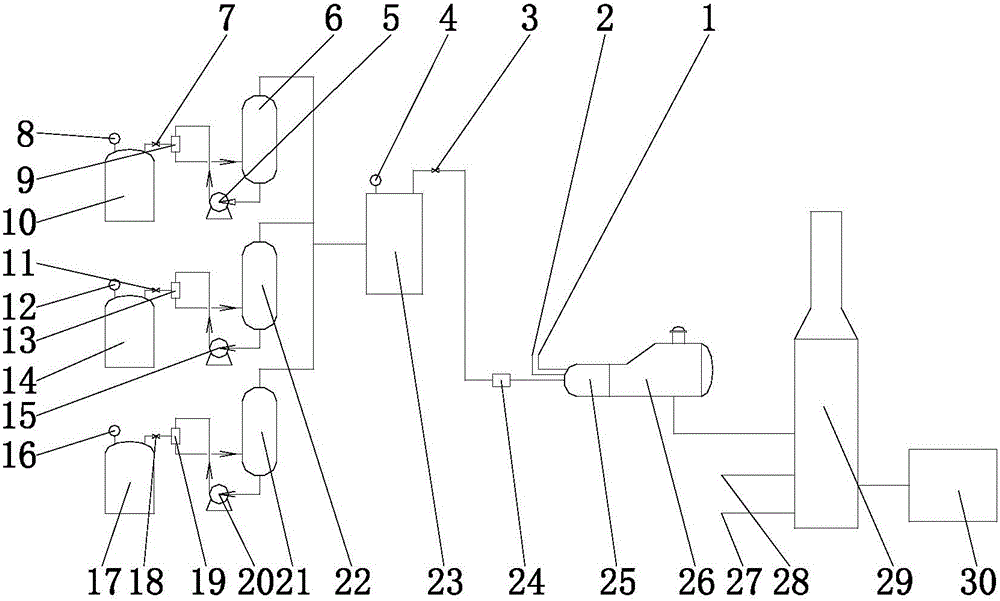

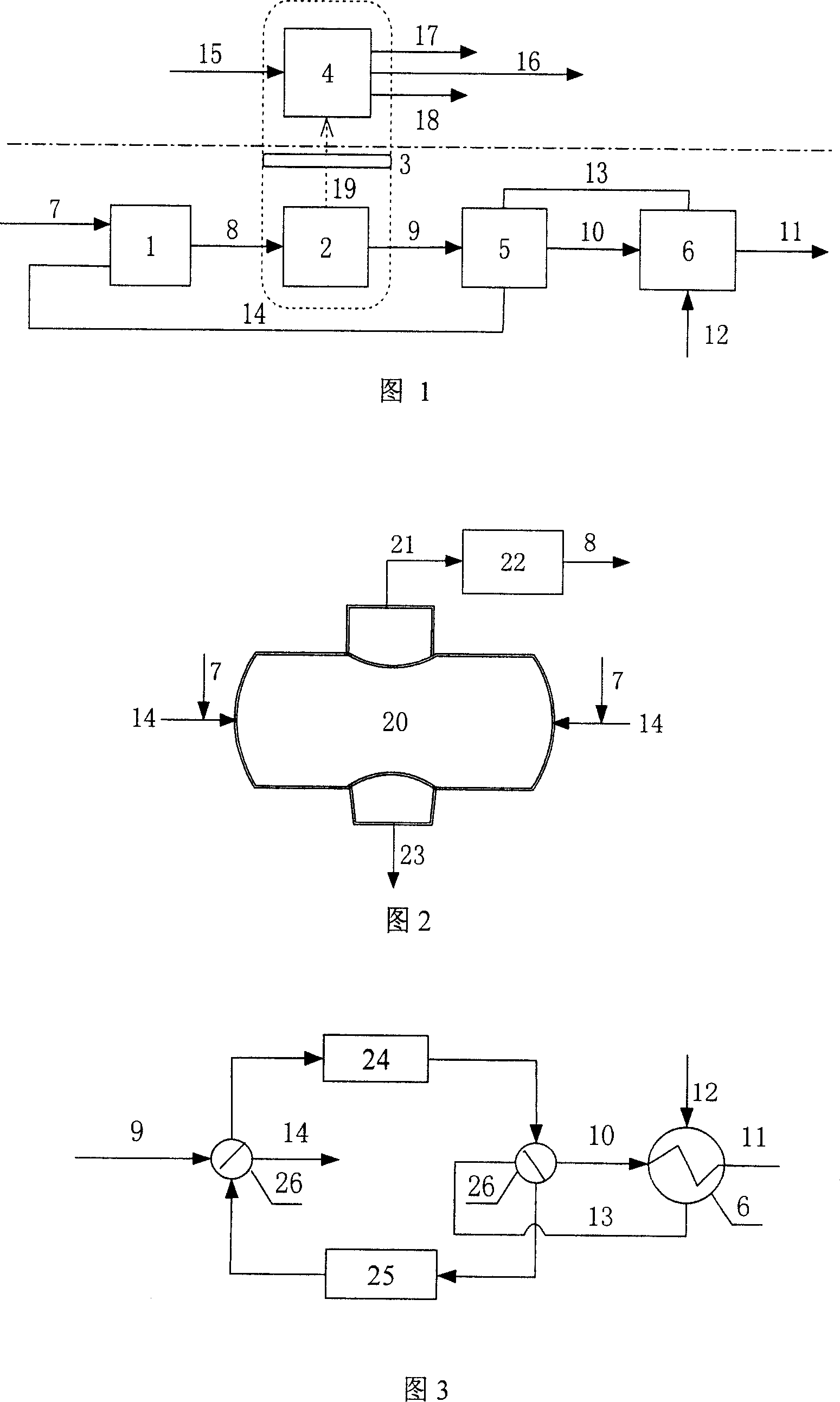

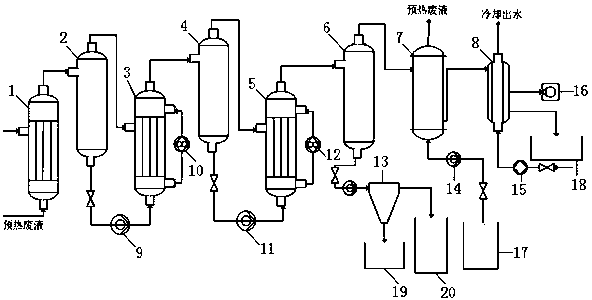

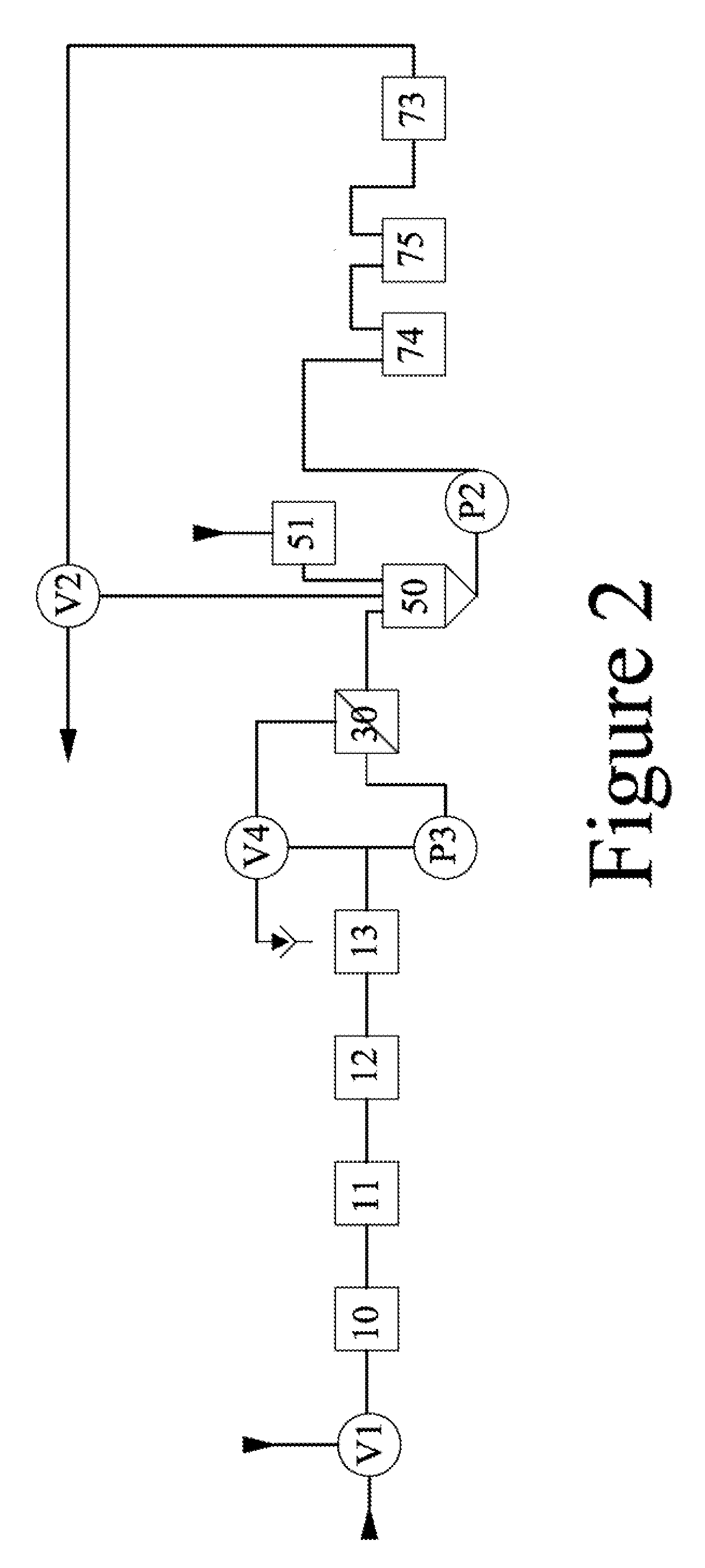

Integrated treatment method for malodorous VOCs gas of refining devices

InactiveCN105841168AReduce dosageSimple processDispersed particle separationIncinerator apparatusLiquid jetBurn units

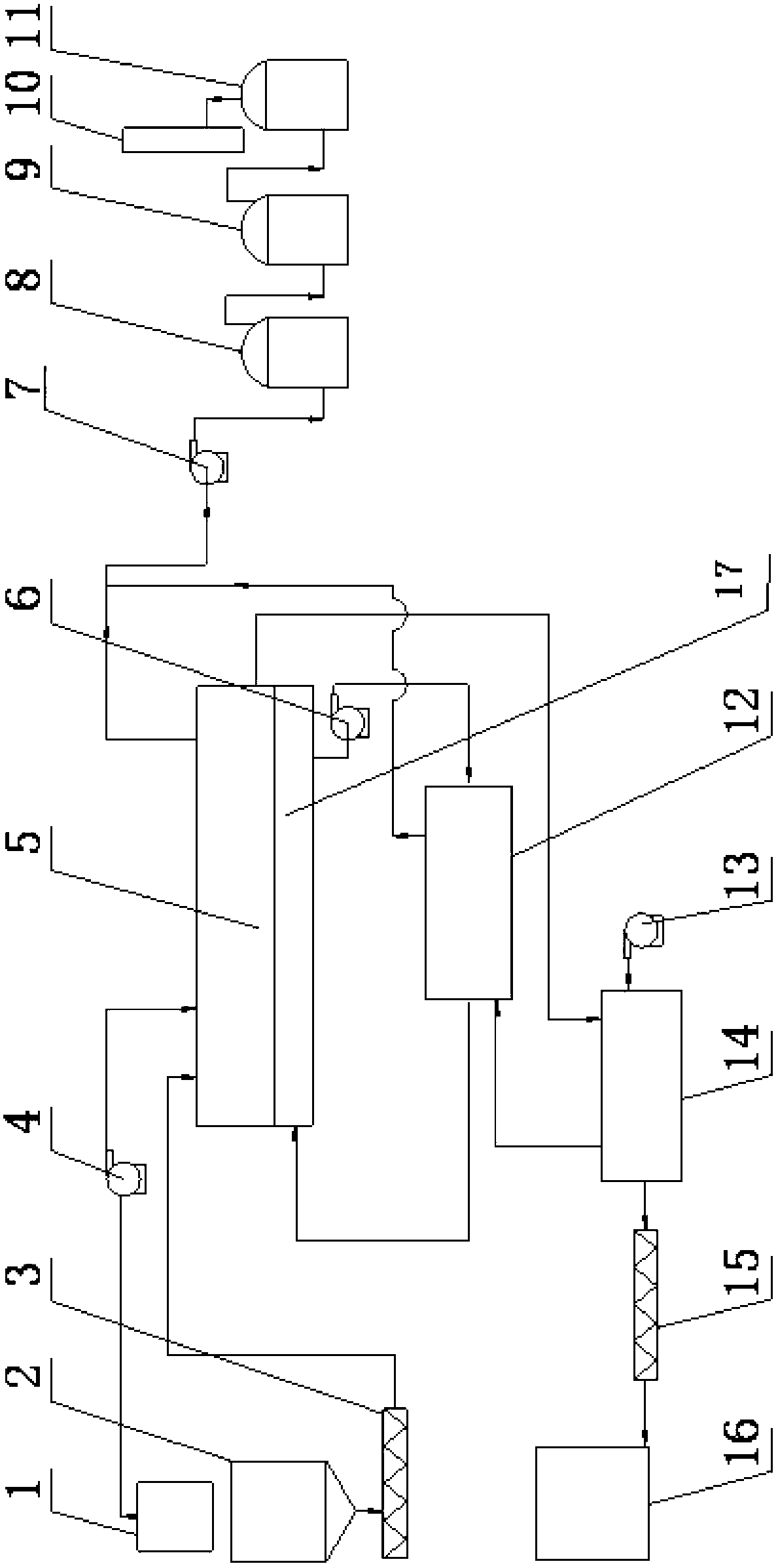

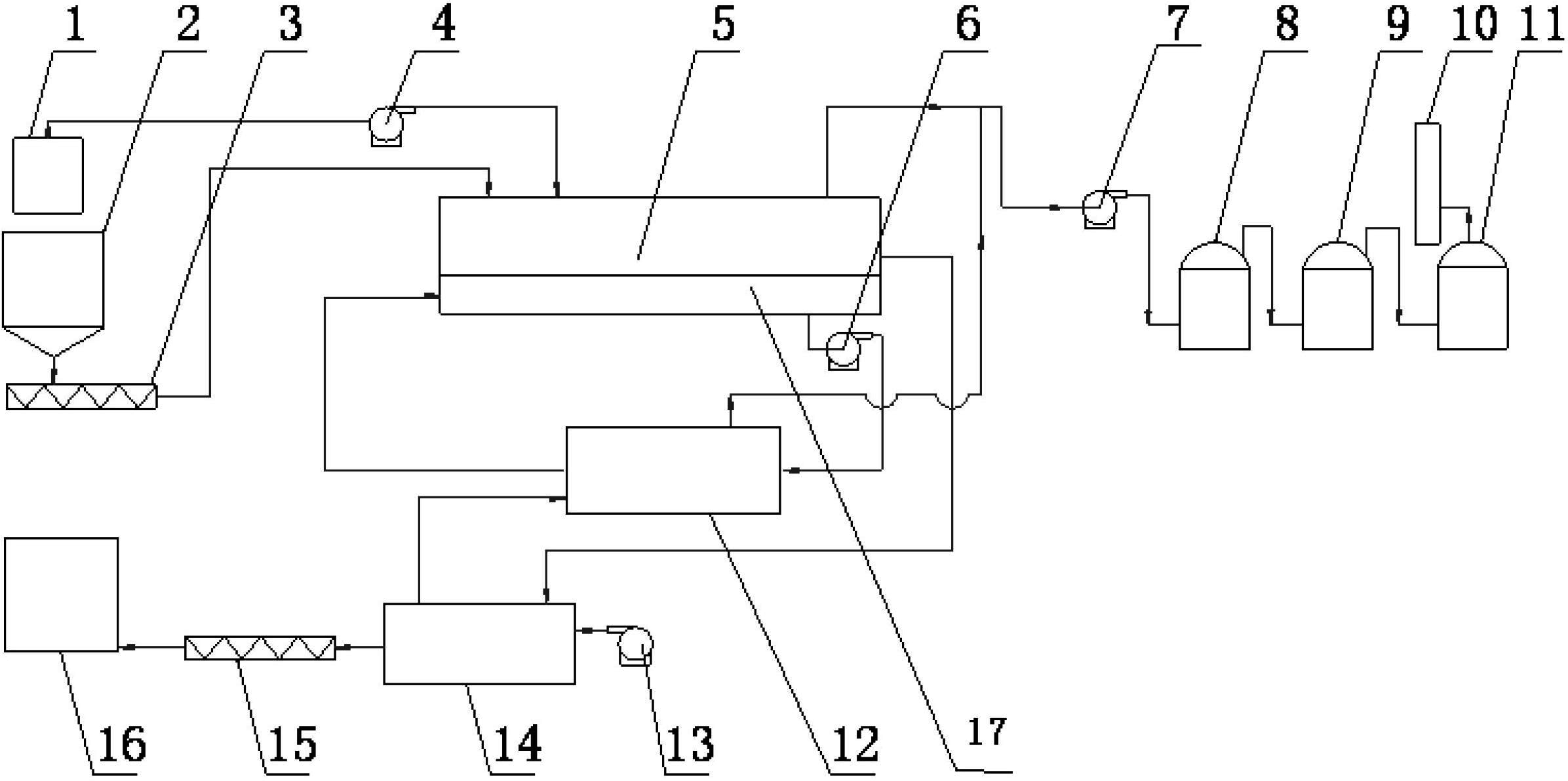

The invention discloses an integrated treatment method for unorganized emission of malodorous VOCs gas from refining and chemical equipment, which collects VOCs gas emitted from refining and chemical storage tanks including residual oil tanks, intermediate product tanks, and acid water tanks. The VOCs gas outlet of the tank is connected to the injection fluid inlet of the liquid jet vacuum pump; the working fluid inlet of the liquid jet vacuum pump is connected to the outlet of the circulation pump, and the mixed fluid outlet is connected to the gas-liquid separation tank; the inlet of the circulation pump is connected to the The liquid outlet of the gas-liquid separation device is connected; the gas outlet of the gas-liquid separation device is connected with the buffer tank; the inlet of the incineration unit is also fed with combustion-supporting gas and air in addition to the VOCs gas in the gas storage buffer tank. , VOCs gas and malodorous gas are incinerated in the incineration unit, and the incineration temperature is 800-1000°C.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

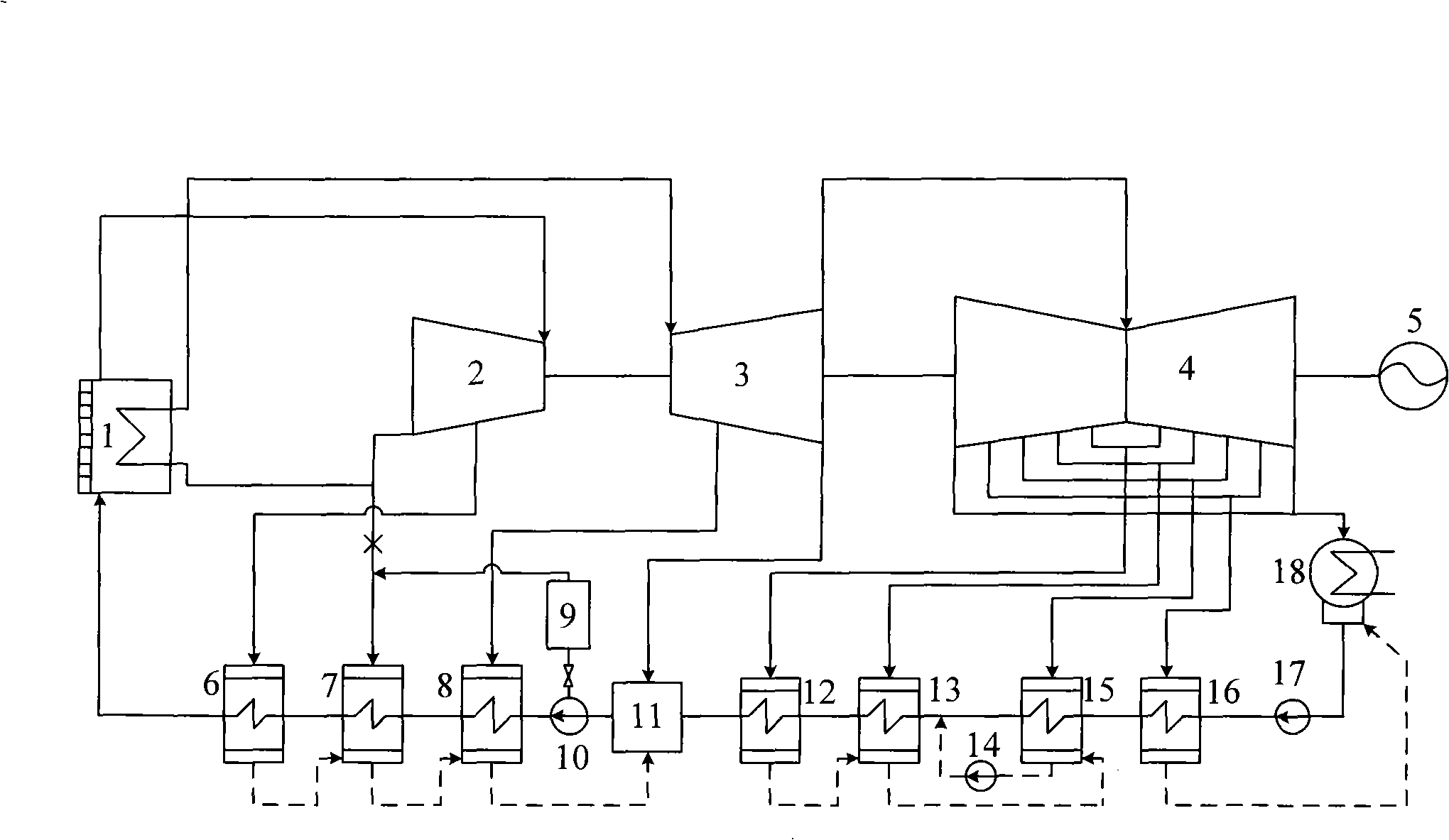

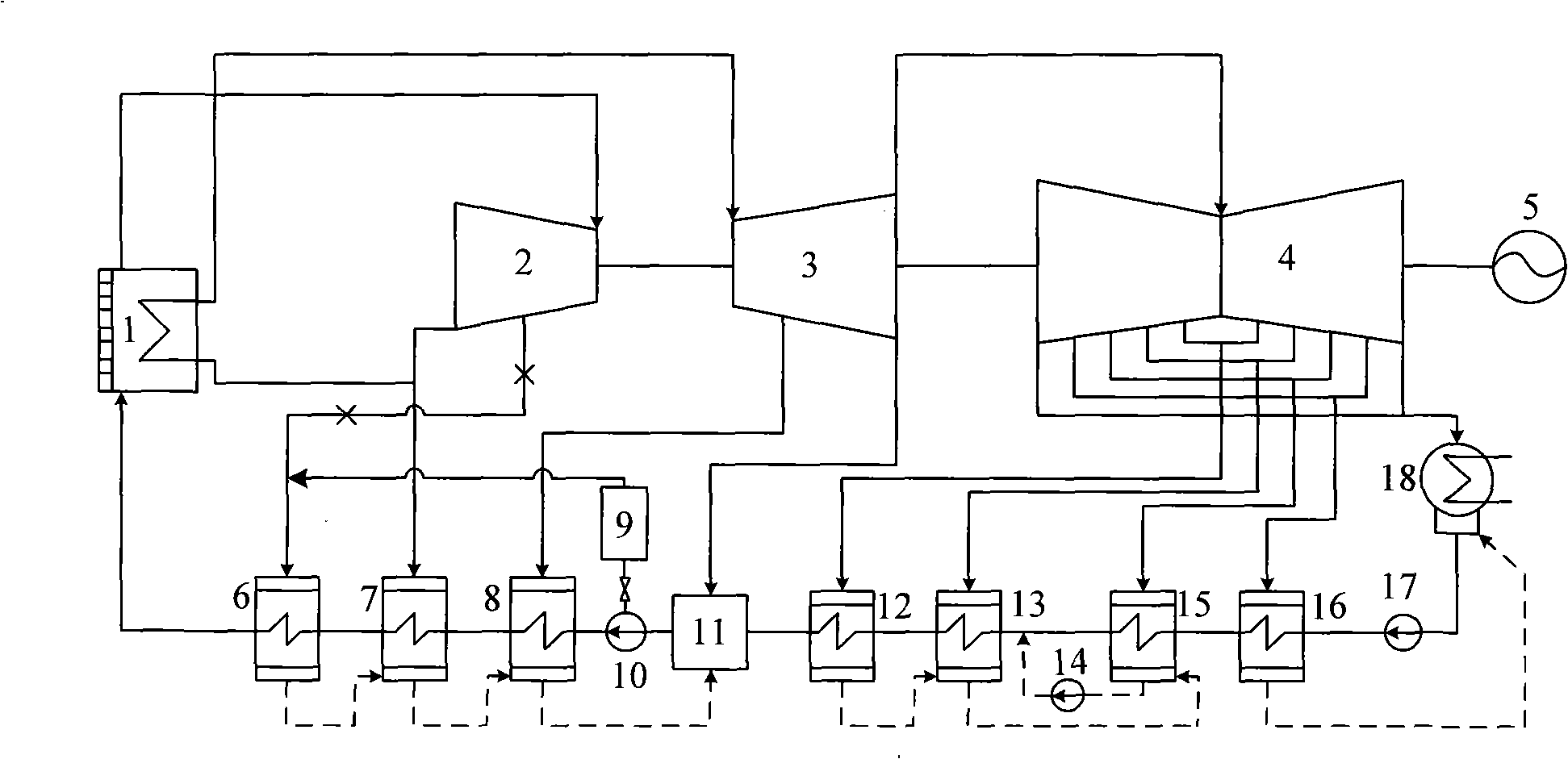

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

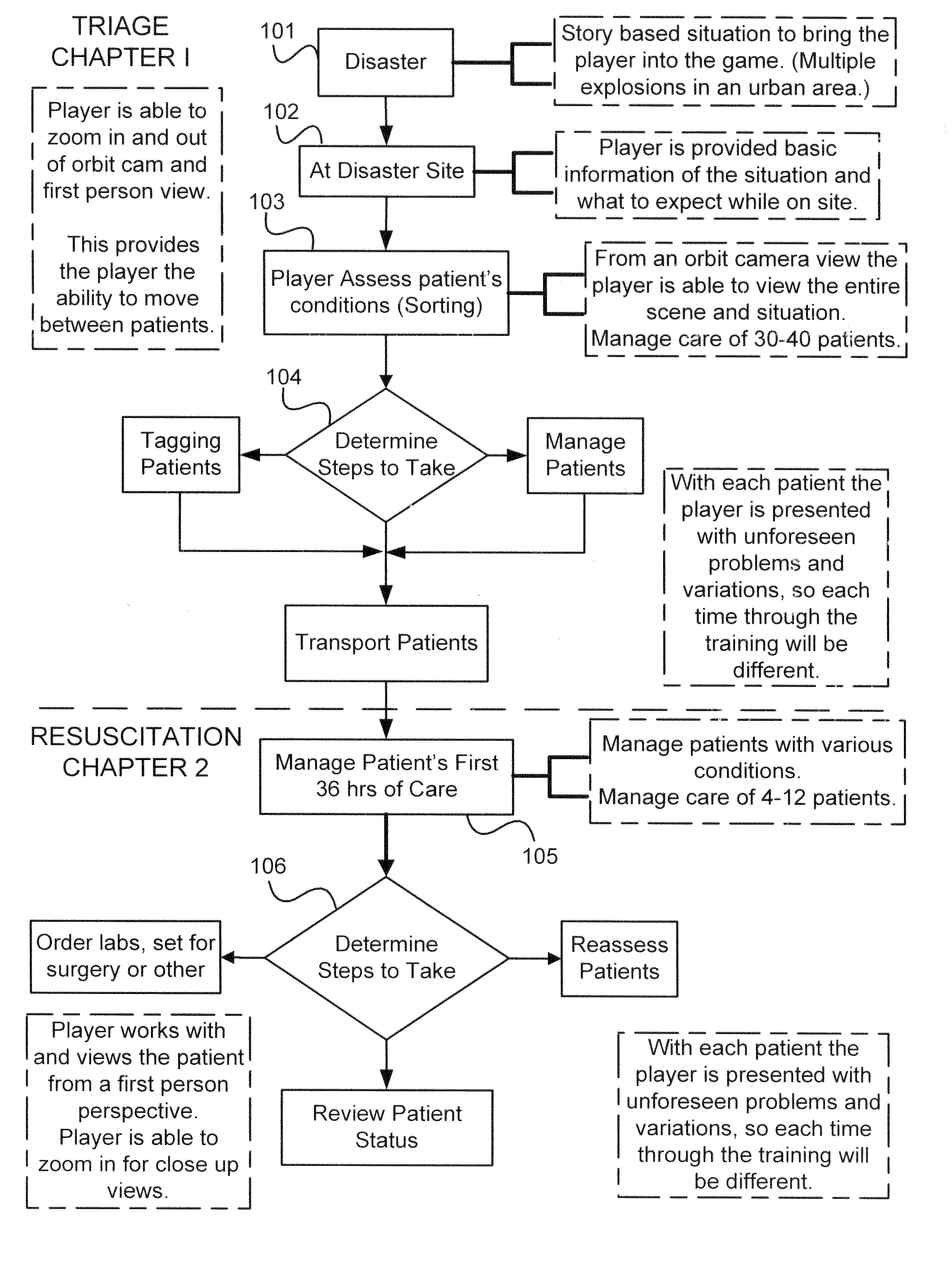

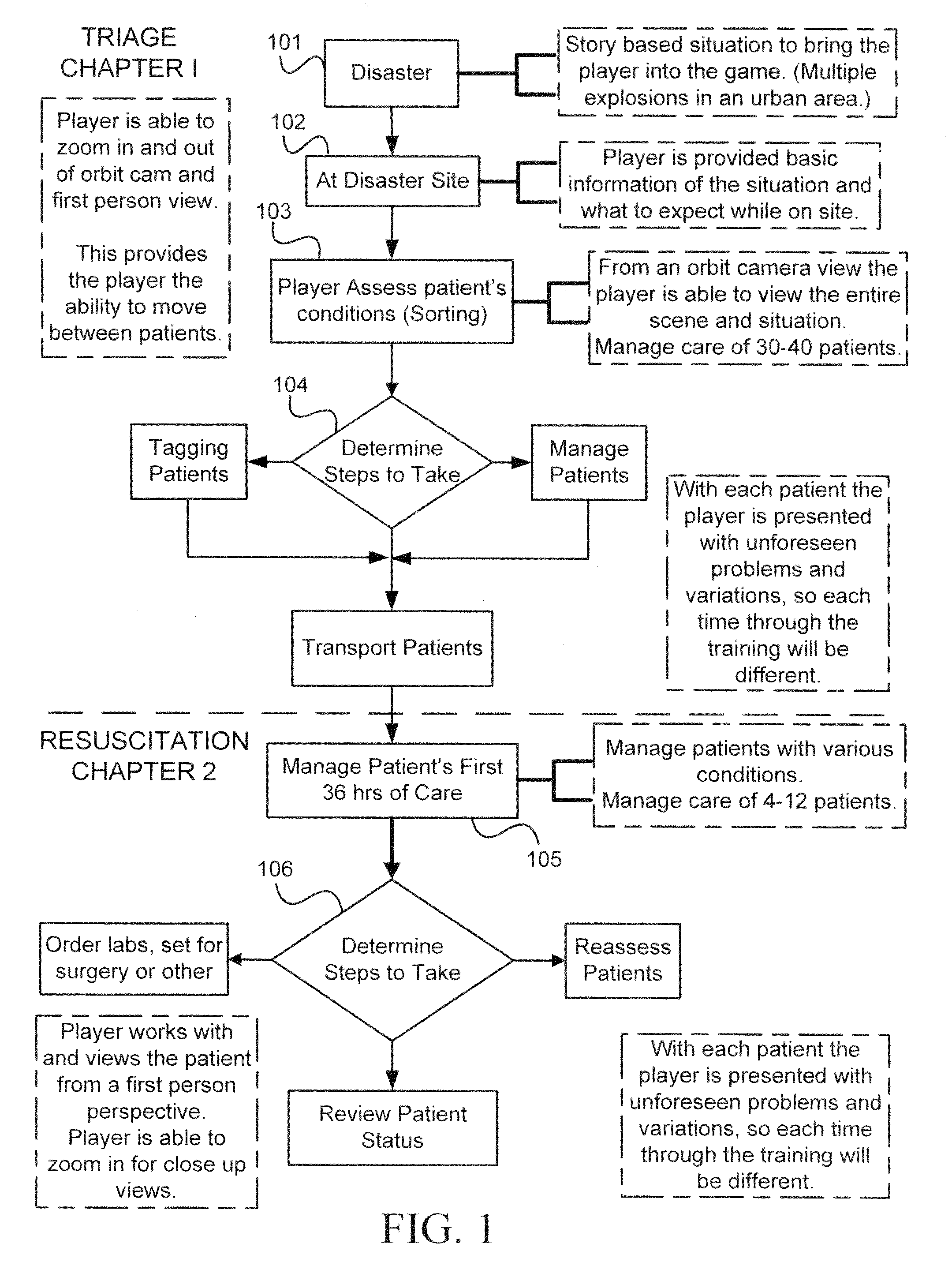

Video game-based, immersive, advanced burn care educational module

A video game-based medical simulation is provided. Disclosed embodiments pertain to mass-casualty simulation for burn disaster training. Game-play exercises direct a player through a mass-casualty event where triage management and patient assessment are tested, and then follow the player to a Burn Center where resuscitation through patient monitoring, reassessment, and managing are tested for the critical hours / days of recovery. Complication loops are included in the game system to provide random application of variation in patient response. The complication loops can insert semi-randomness of critical complication occurrences into the game such that patient simulation may vary each time the game is played.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

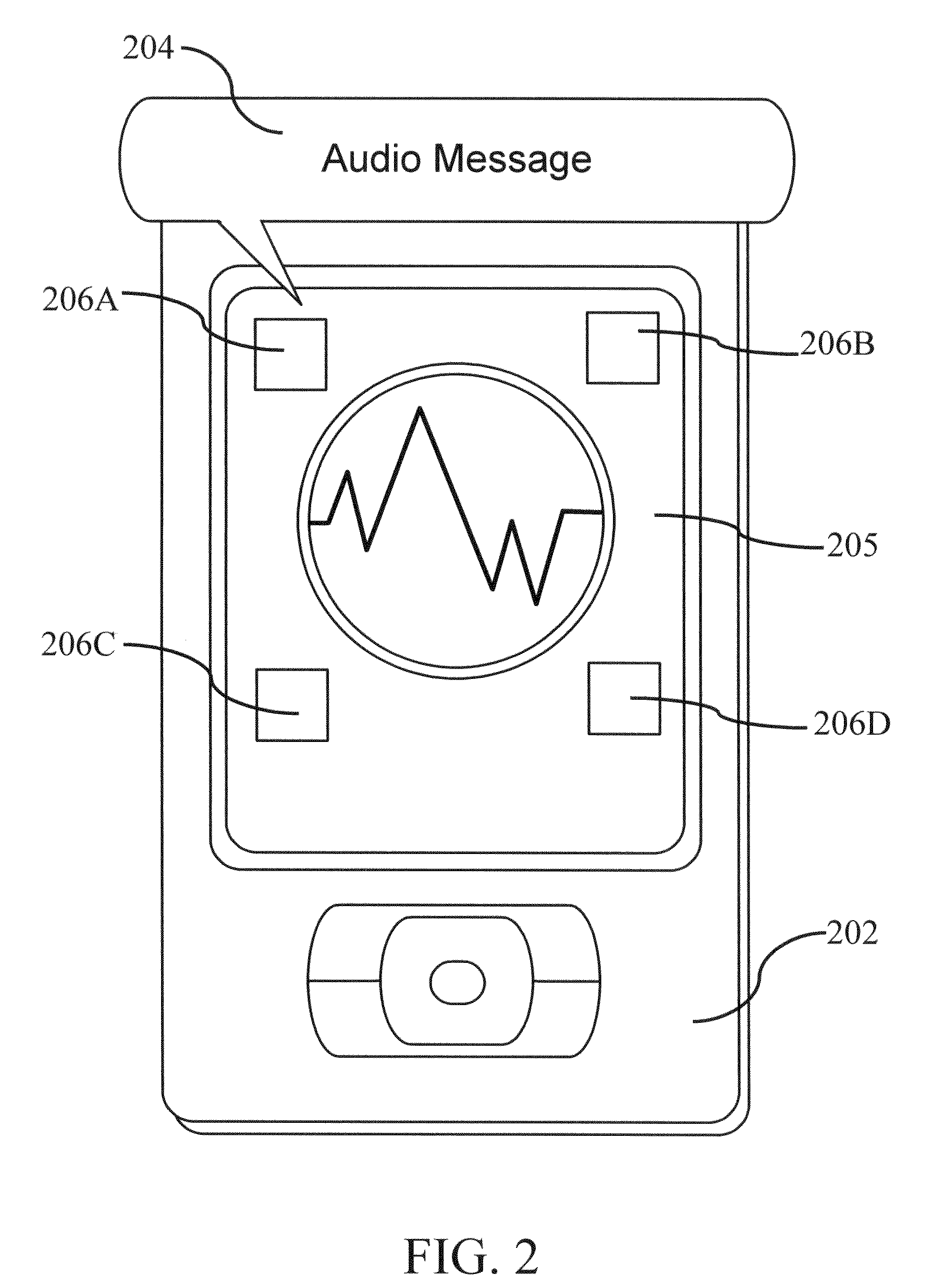

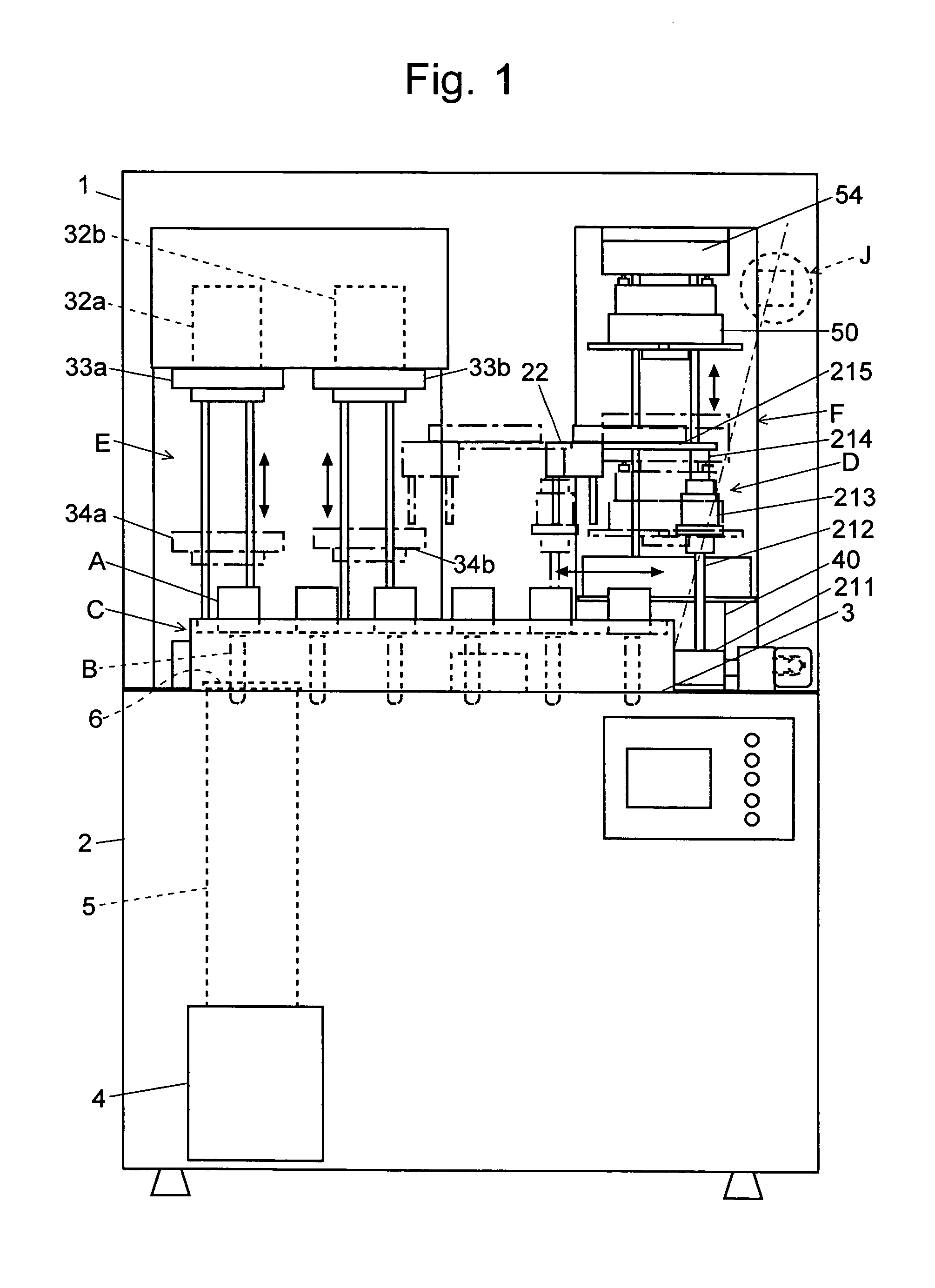

Printed circuit board assembly (PCBA) board testing system and PCBA board testing method

ActiveCN103149526ASave test toolingImprove efficiencyElectronic circuit testingBurn unitsEngineering

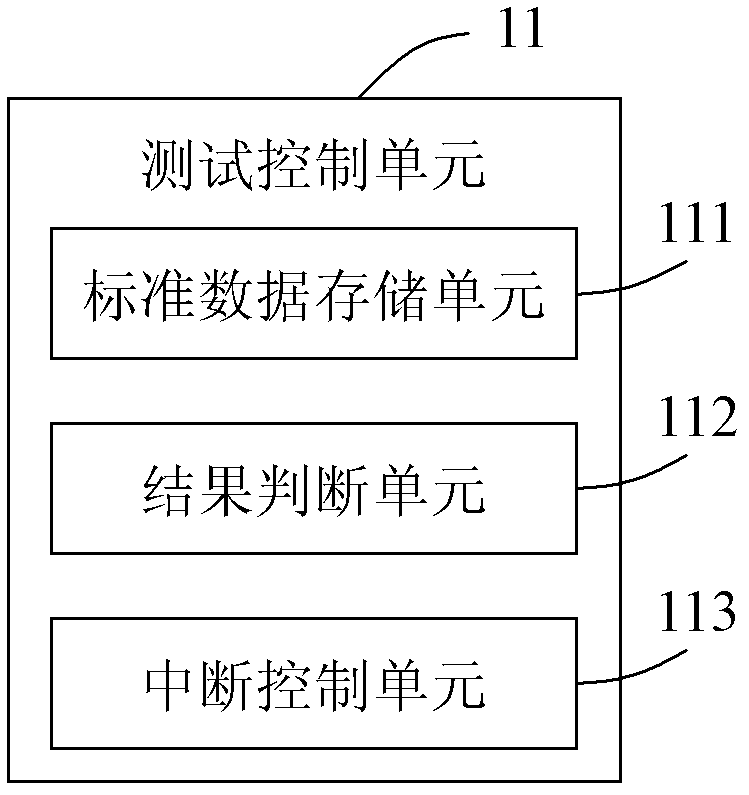

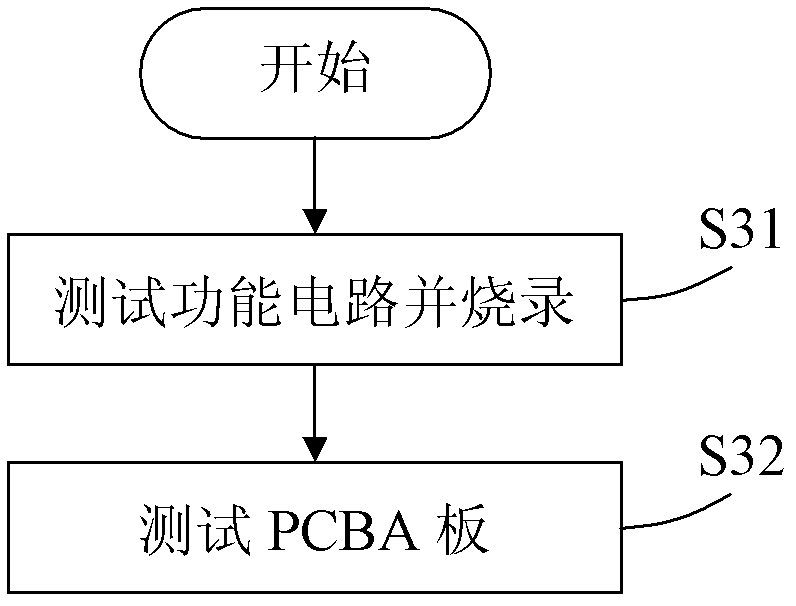

The invention provides a printed circuit board assembly (PCBA) board testing system. The PCBA board testing system comprises a control end and a testing tool. The testing tool comprises a testing unit, a burn unit and a connecting circuit, wherein the connecting circuit is connected with a testing pin and a burn pin of a PCBA board. The control end comprises a burn control unit and a testing control unit, the burn control unit is used for controlling the burn unit to carry out program burn on a programmable chip on the PCBA board. The testing control unit is used for controlling the testing unit to carry out testing on each function circuit of the PCBA board, calling the burn control unit to carry out burn control, and carrying out testing on the burnt programmable chip and a chip control circuit of the PCBA board. The invention further provides a PCBA board testing method. According to the PCBA board testing system and the PCBA board testing method, due to the fact that a burn program is inlaid into an automatic testing process, a function circuit testing process and a burn process are simultaneously carried out, not only is the testing tool saved, but also efficiency is improved.

Owner:SUZHOU INOVANCE TECH CO LTD

Pre-mixing burner

The pre-mixing burner includes one burning unit and one ignition unit, and features the burning unit including one gas mixing chamber with upper and lower openings, one air chamber connected to the lower end of the gas mixing chamber and with side opening, one gas inlet pipe stretched into the air chamber from the bottom, one main burning nozzle in the end of the gas inlet pipe, one perforated flame plate in the upper opening of the gas mixing chamber, and porous plates inside the gas mixing chamber to separate the gas mixing chamber into several cavities. The pre-mixing burner has well mixing between the fuel gas and air, complete combustion, high heat efficiency, stable flame and homogeneous heat load.

Owner:YUFUBAO KITCHENWARE EQUIP SHENZHEN CO LTD

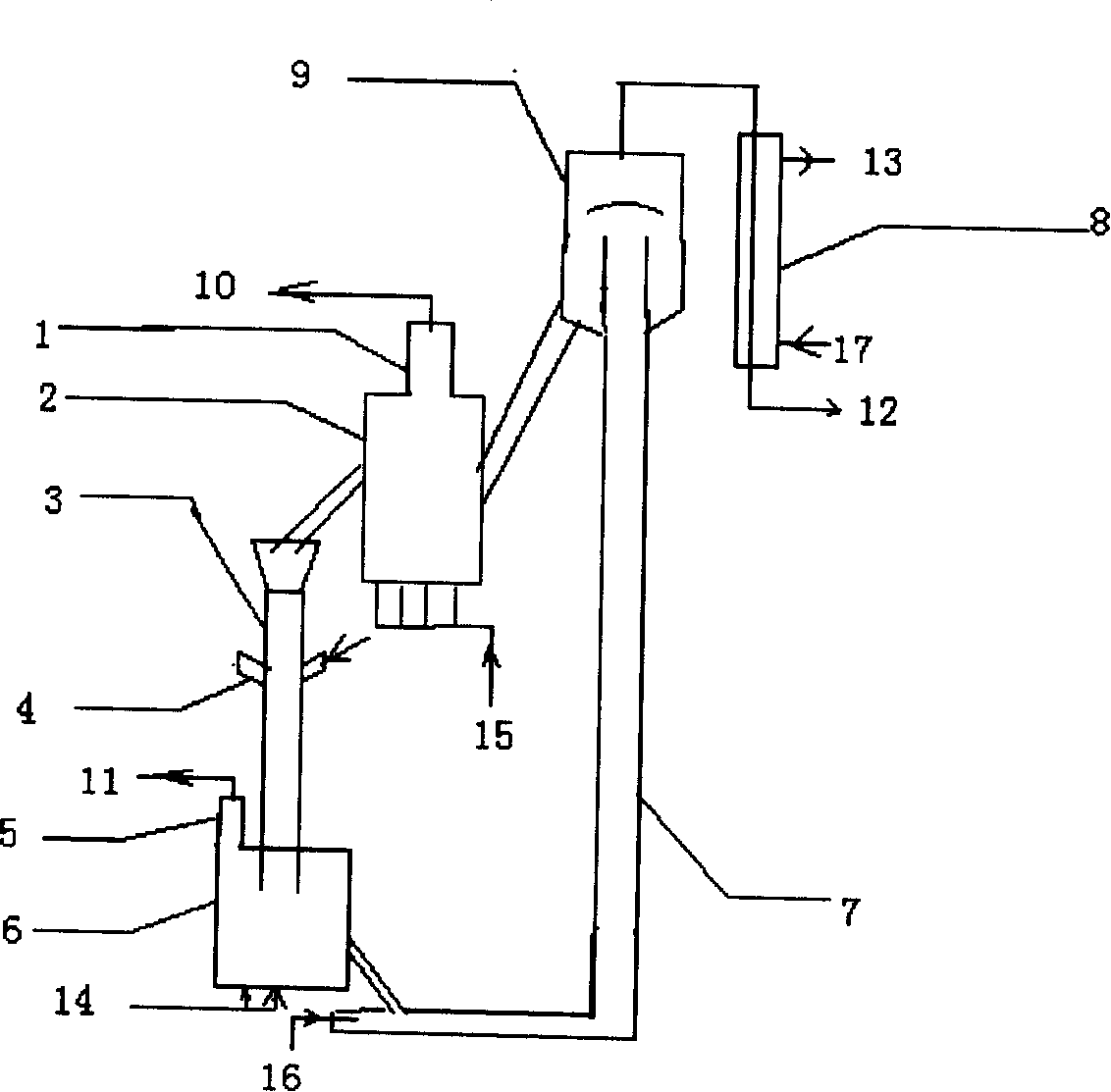

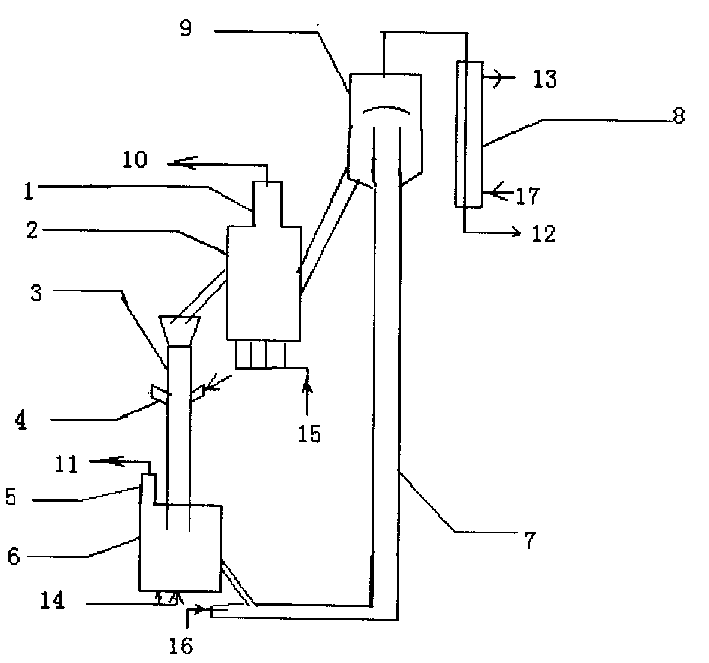

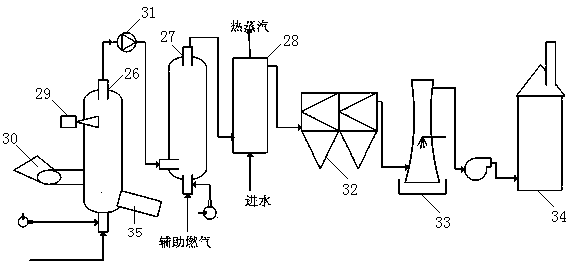

Oily sludge drying and burning integrated treatment technology

InactiveCN106746470AAchieve reductionRealize resourcesSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBurn unitsFlue gas

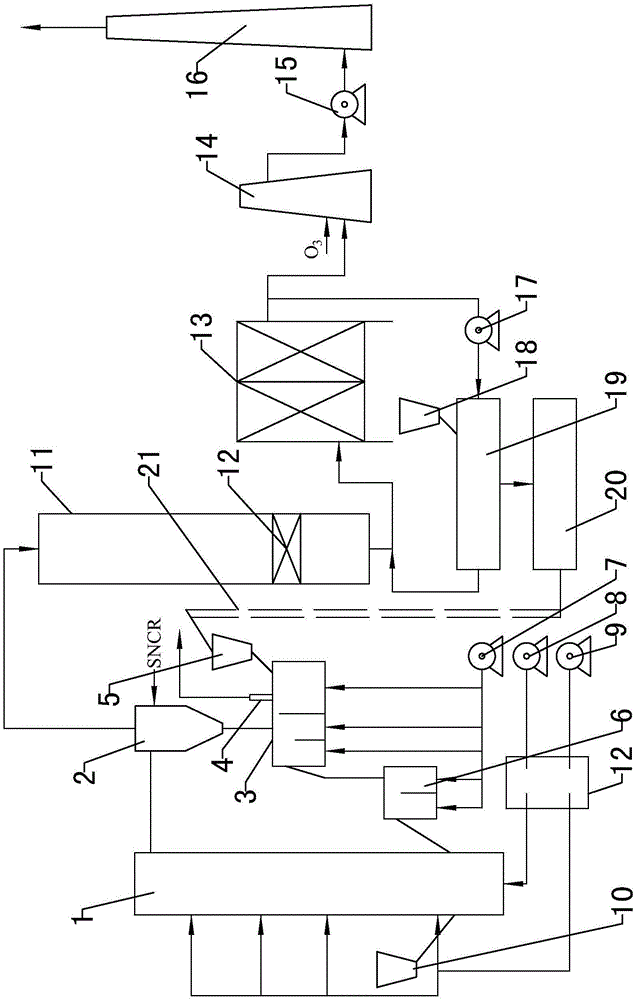

The invention discloses an oily sludge drying and burning integrated treatment technology and belongs to the technical field of oily sludge treatment. The oily sludge drying and burning integrated treatment technology is characterized by comprising the following steps of feeding; drying: repeatedly drying oily sludge through a high-temperature flue gas drying unit in an air drying mode and concentrating and collecting the dried sludge; pyrolysing: separating out pyrolysis gas, generating pyrolysis coke, exhausting the pyrolysis gas, congealing, concentrating and collecting the pyrolysis gas and conveying the pyrolysis coke into a burning unit; burning: burning the pyrolysis coke in a fluidized mode, utilizing a multidirectional air supply mode to adjust burning temperature of the pyrolysis coke and exhausting burned flue gas into a flue gas treating unit; treating flue gas: desulfurizing and denitrifying the flue gas. The oily sludge drying and burning integrated treatment technology disclosed by the invention forms an integrated treatment system with drying, pyrolyzing, burning, treating flue gas and recycling the flue gas integrated and achieves reduced and recycled comprehensive utilization of the oily sludge and emission reducing comprehensive utilization of pollutant.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

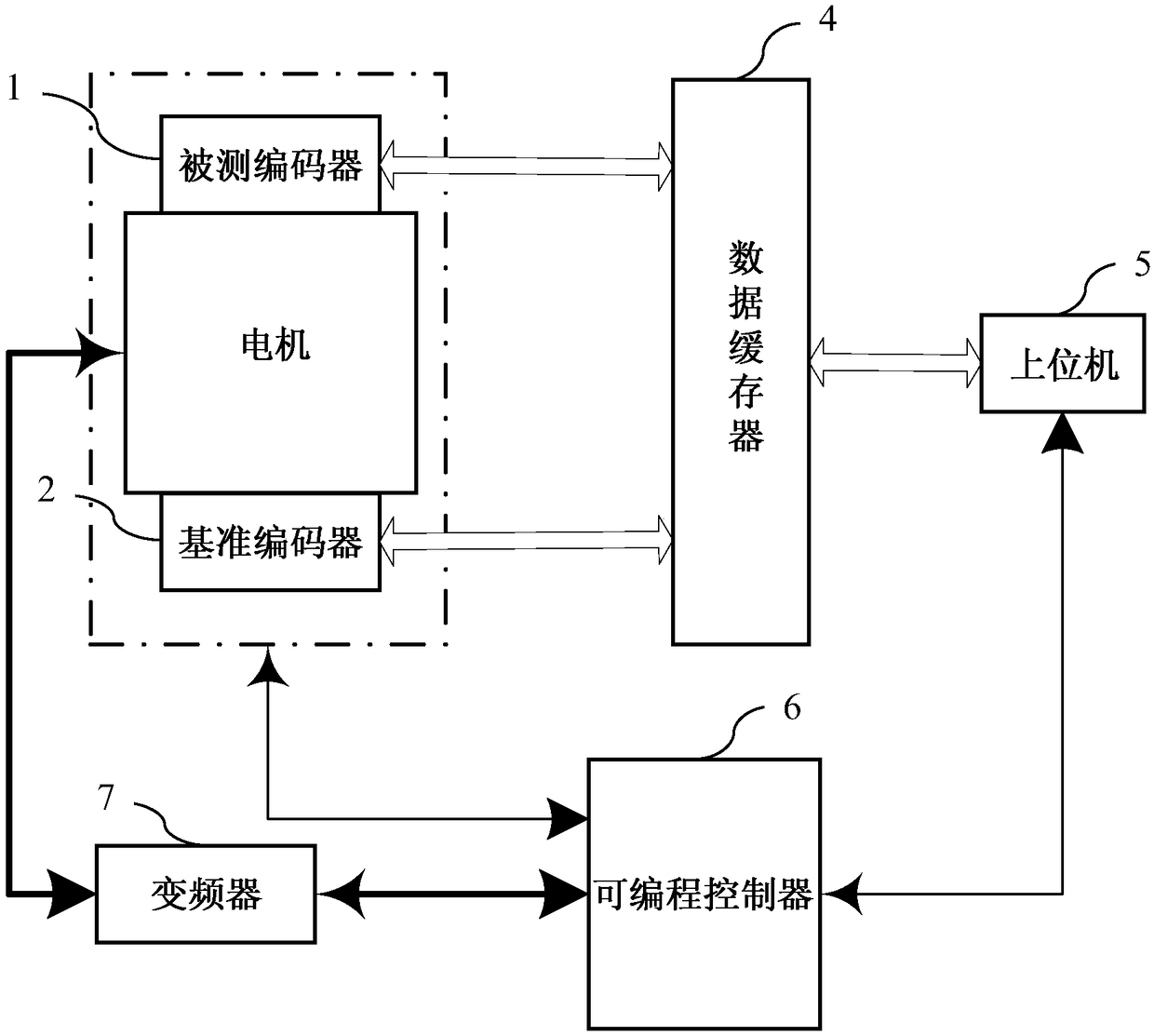

Encoder correction system and method

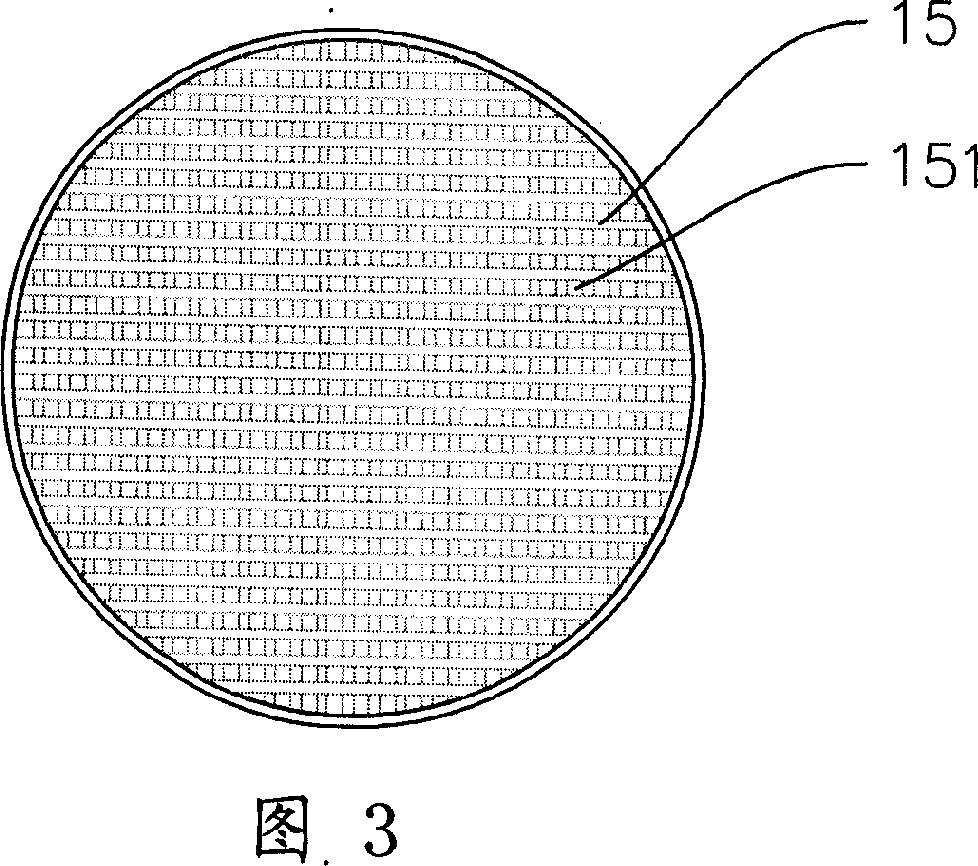

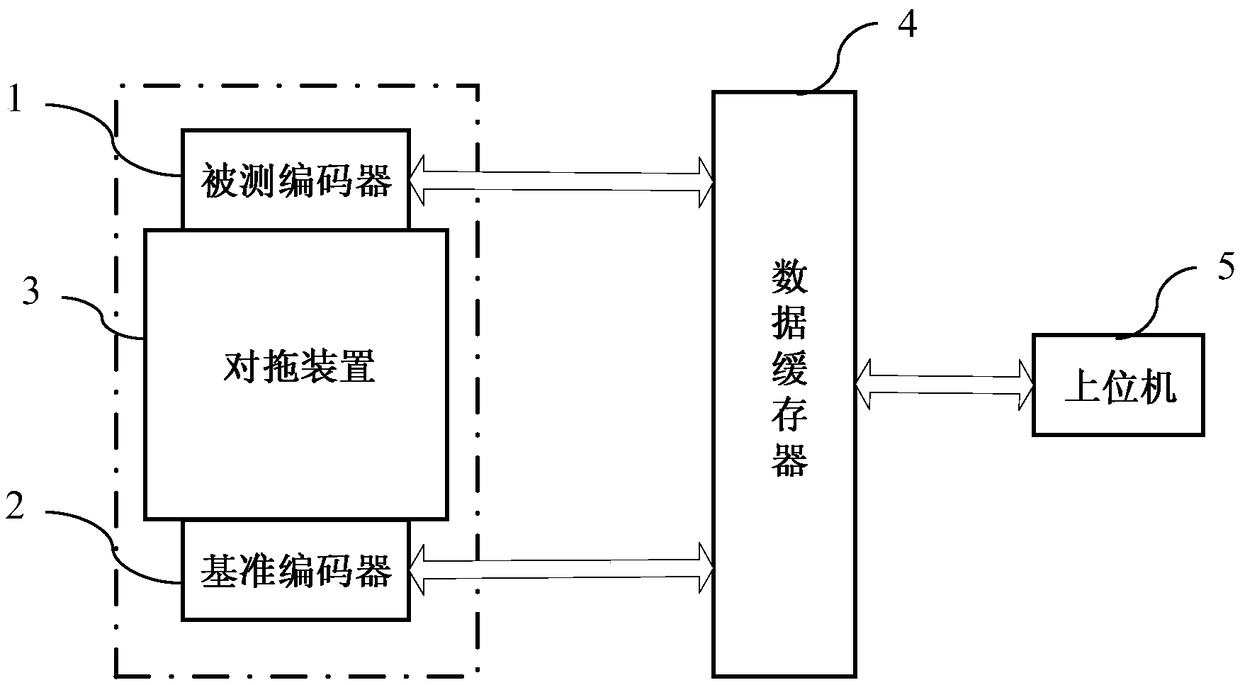

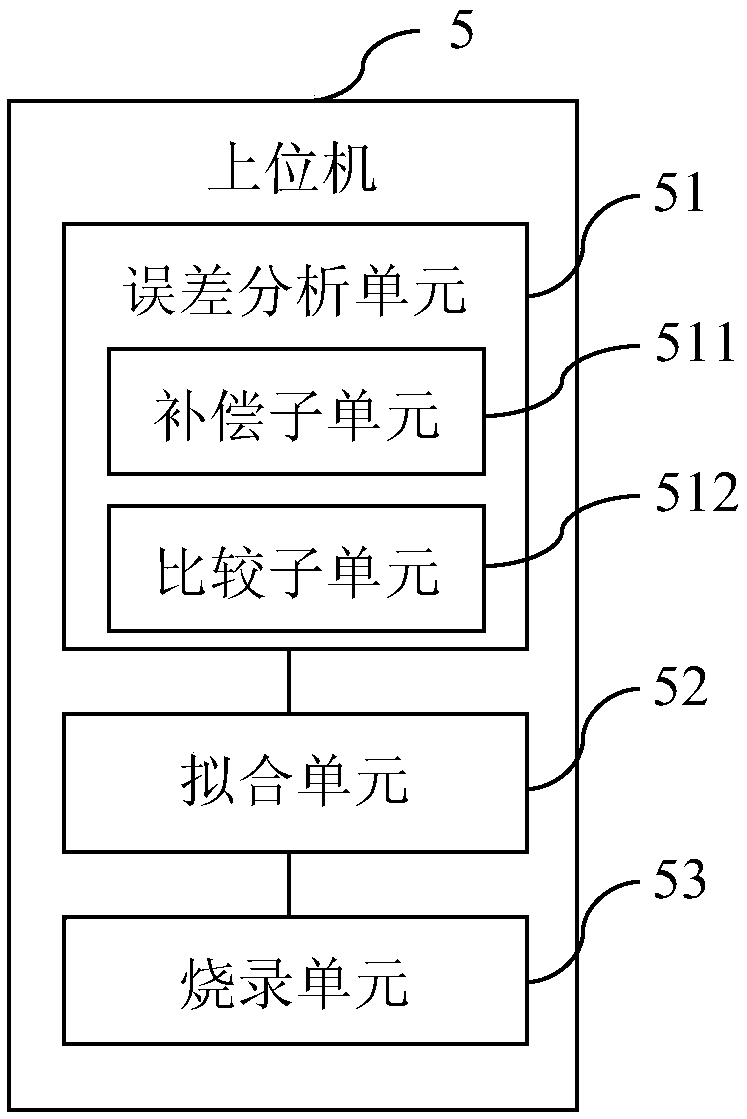

The present invention provides an encoder correction system and method. The system comprises a reference encoder, a twin trawling device, a data cache device and an upper computer; a detected encoderand the reference encoder are driven by the twin trawling device for rotation; the data cache device collects position signals output by the detected encoder and the reference encoder at the same timeat the same sampling period when the detected encoder and the reference encoder are synchronously rotated; the upper computer comprises an error analysis unit, a fitting unit and a burning unit, theerror analysis unit is configured to generate an original error curve according to the position signals, the fitting unit is configured to generate a correction curve according to the original error curve, and the burning unit is configured to write in the correction curve into the detected encoder. The detected encoder and the reference encoder are subjected to twin trawling, and the detected encoder is corrected according to the position signals of the reference encoders so as to greatly improve the output precision of the detected encoder.

Owner:SUZHOU INOVANCE TECH CO LTD

Coking technique using coal external burning to replace gas fuel burning

ActiveCN101100607ARealize rational utilizationReduce cleaningCombustible gas coke oven heatingEnergy inputBurn unitsHydrogen

A coking process for substituting gas fuel combustion with coal external combustion is carried out by preheating for fired coal by waste-heat recovering unit, burning in burning unit to obtain high-temperature smoke, collecting dust for high-temperature smoke, delivering it into heat-transferring unit, discharging heat to carbonizing chamber by partition, recovering most waste heat by regenerative and dividing-wall heat exchanger and exhausting. It consists of burning unit, heat-transferring unit, regenerative waste-heat recovering unit and dividing-wall waste-heat recovering unit. The energy-saving rate reaches to 20%, it costs low and has better energy utilization. It can be used for industrial production.

Owner:中科合肥煤气化技术有限公司

Cyclic cracking and gasification technology for heavy oil solid heat carrier

The heavy oil solid phase heat carrier circularly cracking and gasifying process includes spraying heavy oil from descending riser and preheated to 150-340 deg.c via high-efficiency atomizing nozzle to the middle part of the riser and heating the oil mist with the high temperature solid phase heat carrier at 750-950 deg.c from the gasifying fluidized bed; gas-solid separation of oil mist and solid phase heat carrier running to the bottom of the riser; oil-gas separation in the fractionating tower; air coking of the coke containing solid phase heat carrier in the coke burning unit in the ascending riser and solid-solid separation at 800-1200 deg.c; heat exchange with high temperature fume in waste heat boiler to produce 200-1000 deg.c overheat water vapor for gasification; gasifying the coke containing high temperature solid phase heat carrier in gasifying fluidized bed; gas-solid separation of the gasification produced water gas to output gas product and heat carrier for reuse.

Owner:田原宇

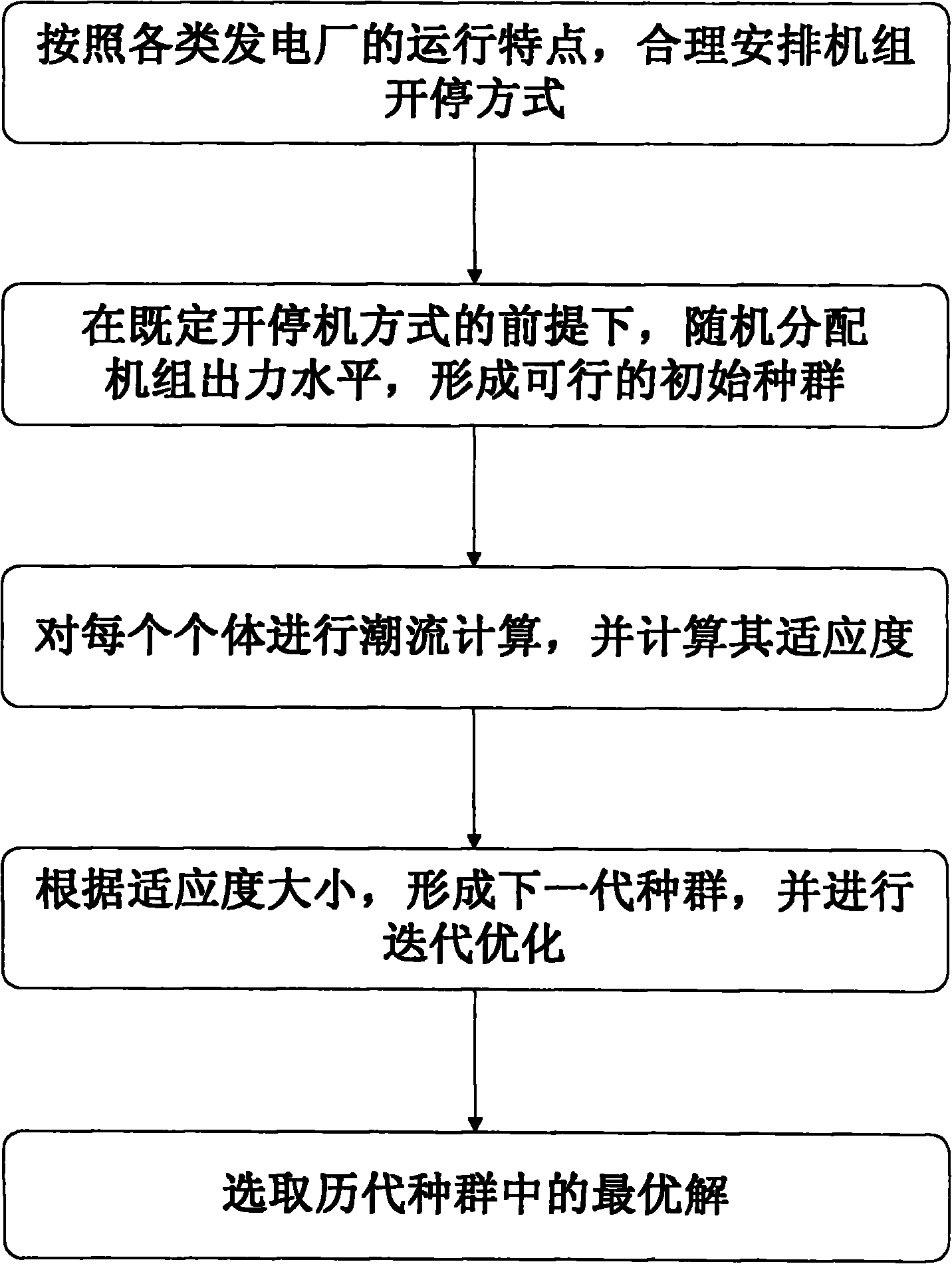

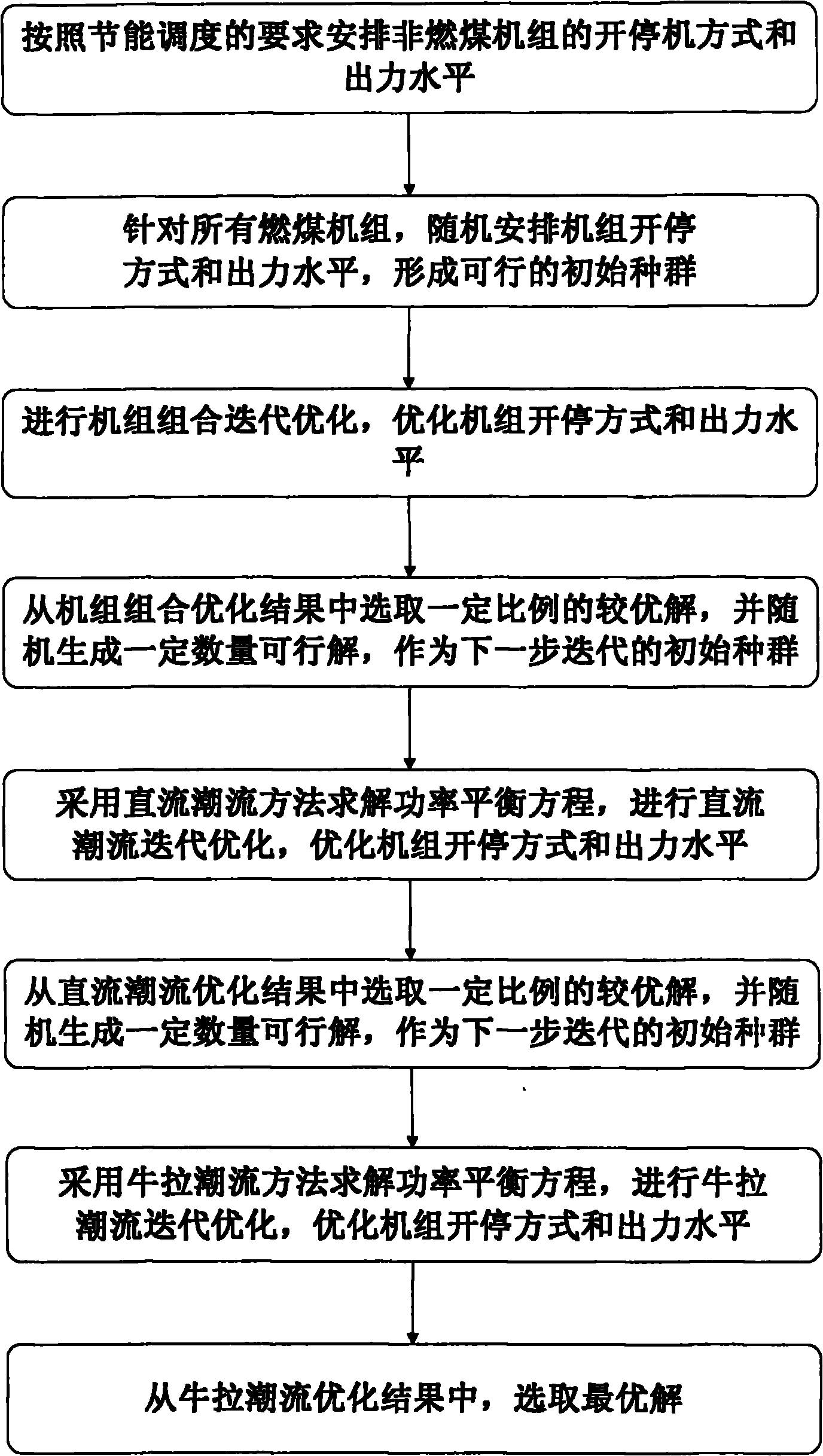

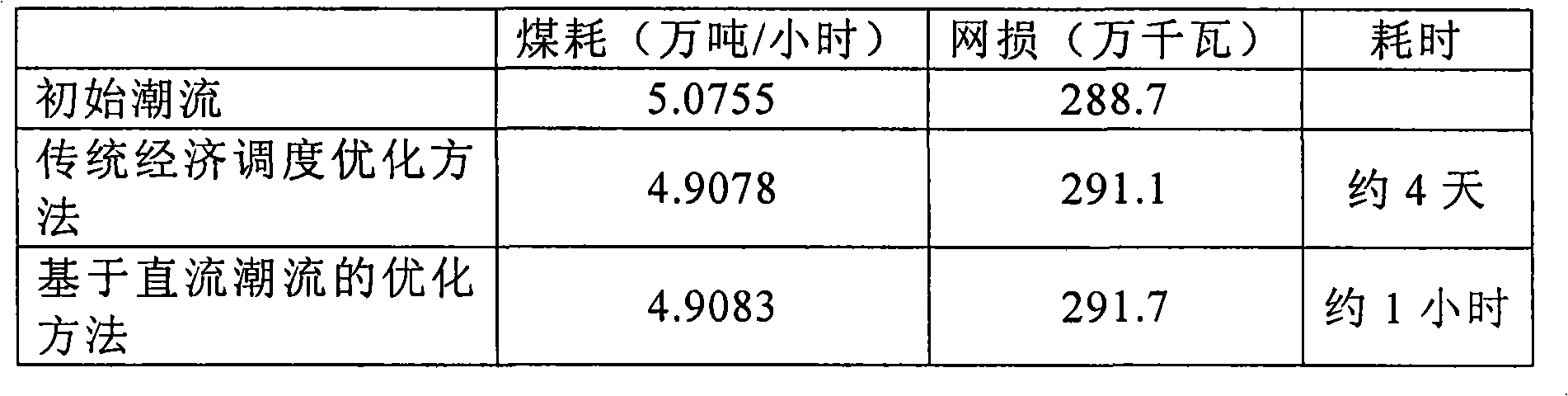

Energy-saving power generation dispatching optimization method based on direct current power flow

ActiveCN101989743AMeet the precision requirementsMeet speed requirementsSingle network parallel feeding arrangementsPower balancingEngineering

The invention relates to an energy-saving power generation dispatching optimization method based on direct current power flow. The method comprises the following steps: arranging the start-stop modes and output levels of non-coal burning units and all coal burning units according to the energy-saving dispatching requirement, and forming a feasible initial population; carrying out iterative optimization of unit combinations; selecting a plurality of better solutions, and randomly generating a plurality of feasible solutions; solving a power balance equation by a direct current power flow method, and carrying out iterative optimization of the direct current power flow; selecting a plurality of better solutions, and randomly generating a plurality of feasible solutions; solving the power balance equation by a newton-raphson power flow method, carrying out iterative optimization of the power flow, and optimizing the start-stop modes and output levels of the units; and finally selecting the optimum solution. In the invention, a genetic algorithm is adopted for carrying out optimization, and cyclic iteration is carried out by sequentially carrying out optimization of the unit combinations, optimization of the direct current power flow and optimization of the newton-raphson power flow, thus the optimum solution of energy-saving dispatching is obtained, and the requirements on calculation accuracy and speed of a large electric network are met.

Owner:EAST CHINA ELECTRIC POWER TEST & RES INST +1

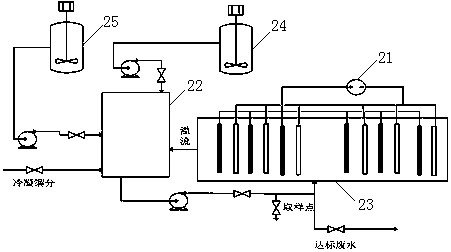

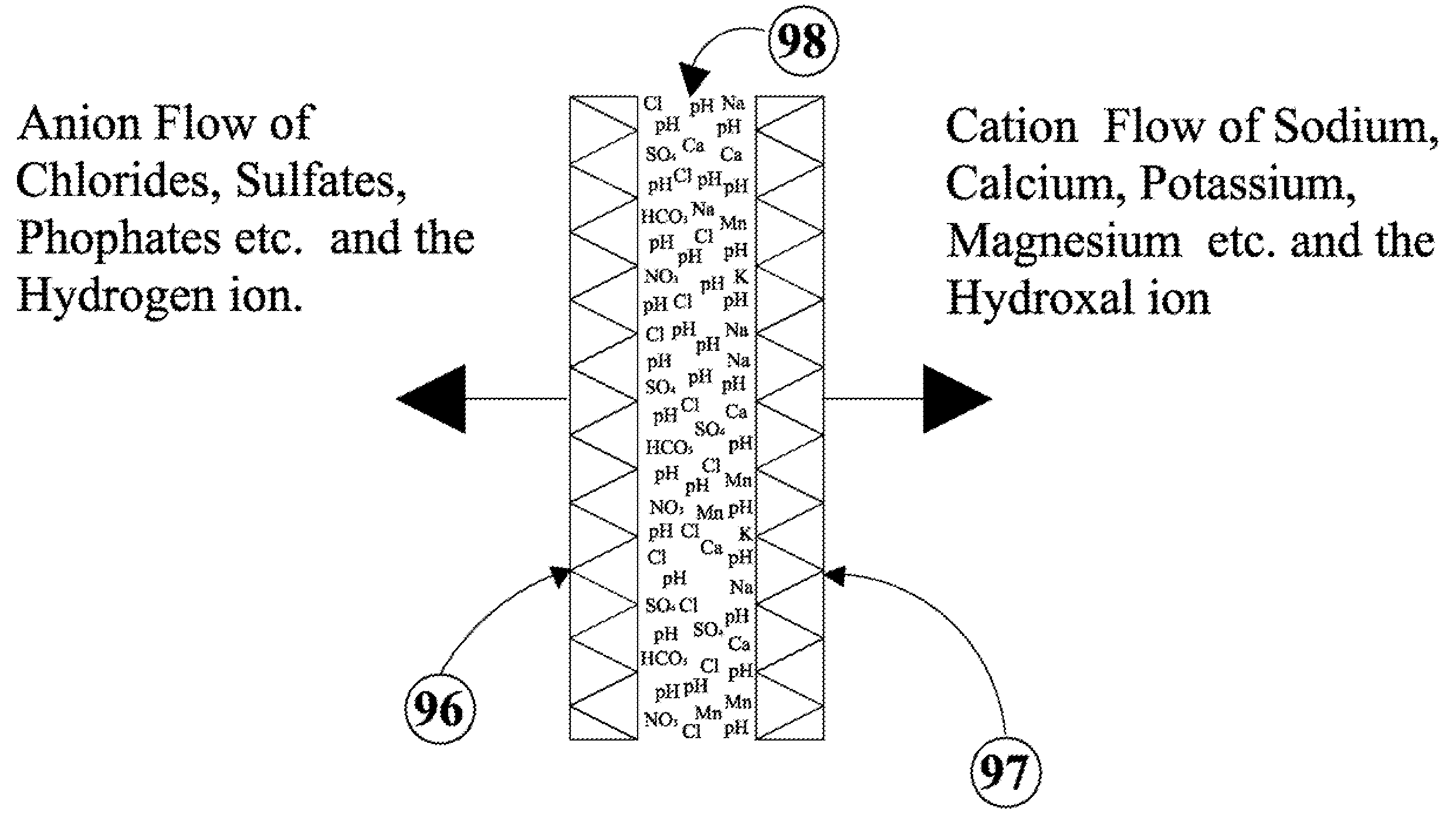

Treatment system for high-salt high-concentration organic wastewater and method

ActiveCN107601742AAvoid melting and cokingAvoid cloggingDispersed particle filtrationWater contaminantsHigh concentrationEvaporation

The invention relates to a treatment system for high-salt high-concentration organic wastewater and a method. The system comprises an evaporation concentration unit, an electrocatalytic oxidation unitand a burning unit, wherein the evaporation concentration unit comprises an evaporation concentrator, a separator, a preheater, a condenser, a vacuum pump and a conveying pump; the electrocatalytic oxidation unit comprises a direct current power supply, a circulating cylinder, an electrocatalytic oxidation tank and a drug dosing system; the burning unit comprises a low-temperature burning chamber, a high-temperature burning chamber, a waste heat recovering device and a tail gas purifying device. The invention also provides a treatment method for the high-salt high-concentration organic wastewater. According to the invention, the characteristics of evaporation concentration method, electrocatalytic oxidation method and burning method are combined, the treatment efficiency for the high-salthigh-concentration organic wastewater is high, the adaptability to the concentration change of the wastewater is high, the treatment cost is low and the requirement of wastewater emission after reaching standard is met.

Owner:湖南绿网环保科技有限责任公司

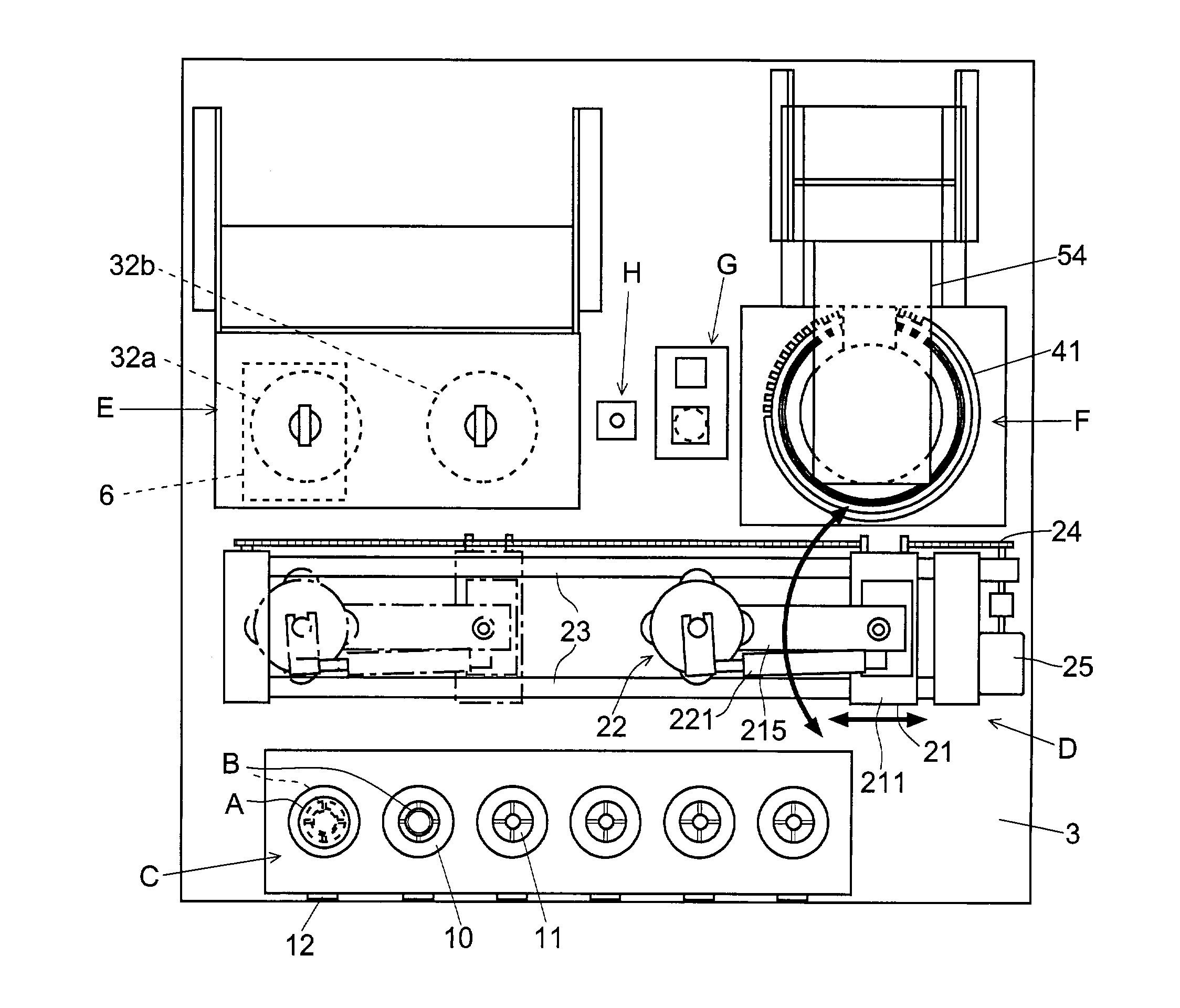

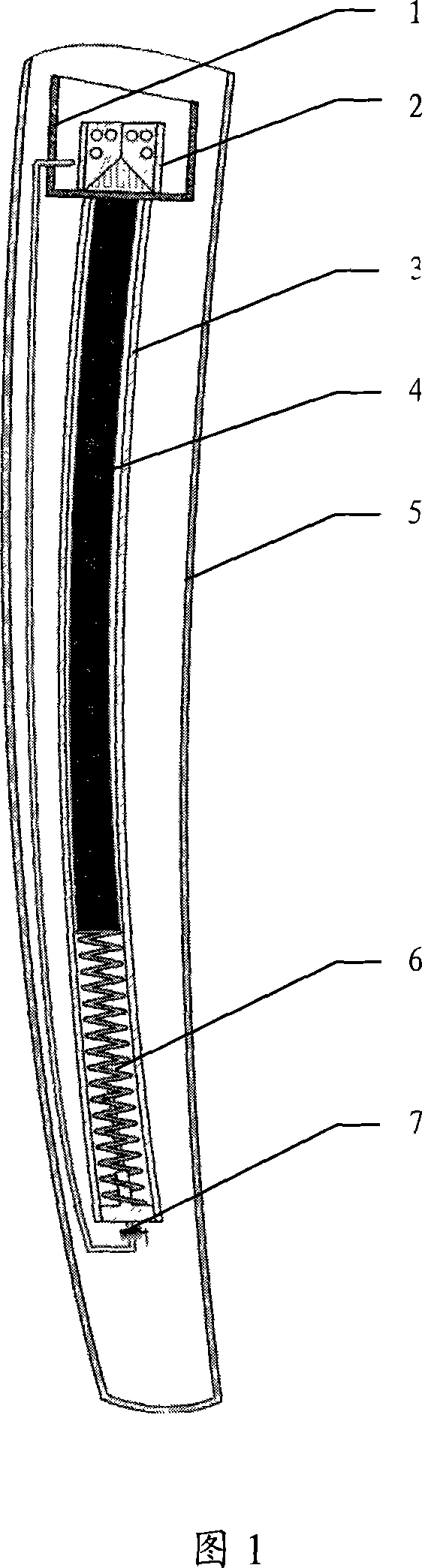

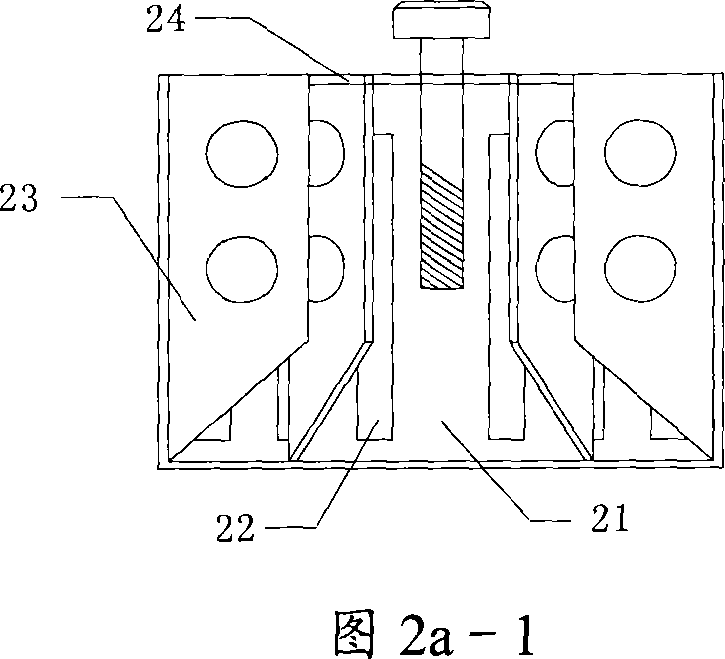

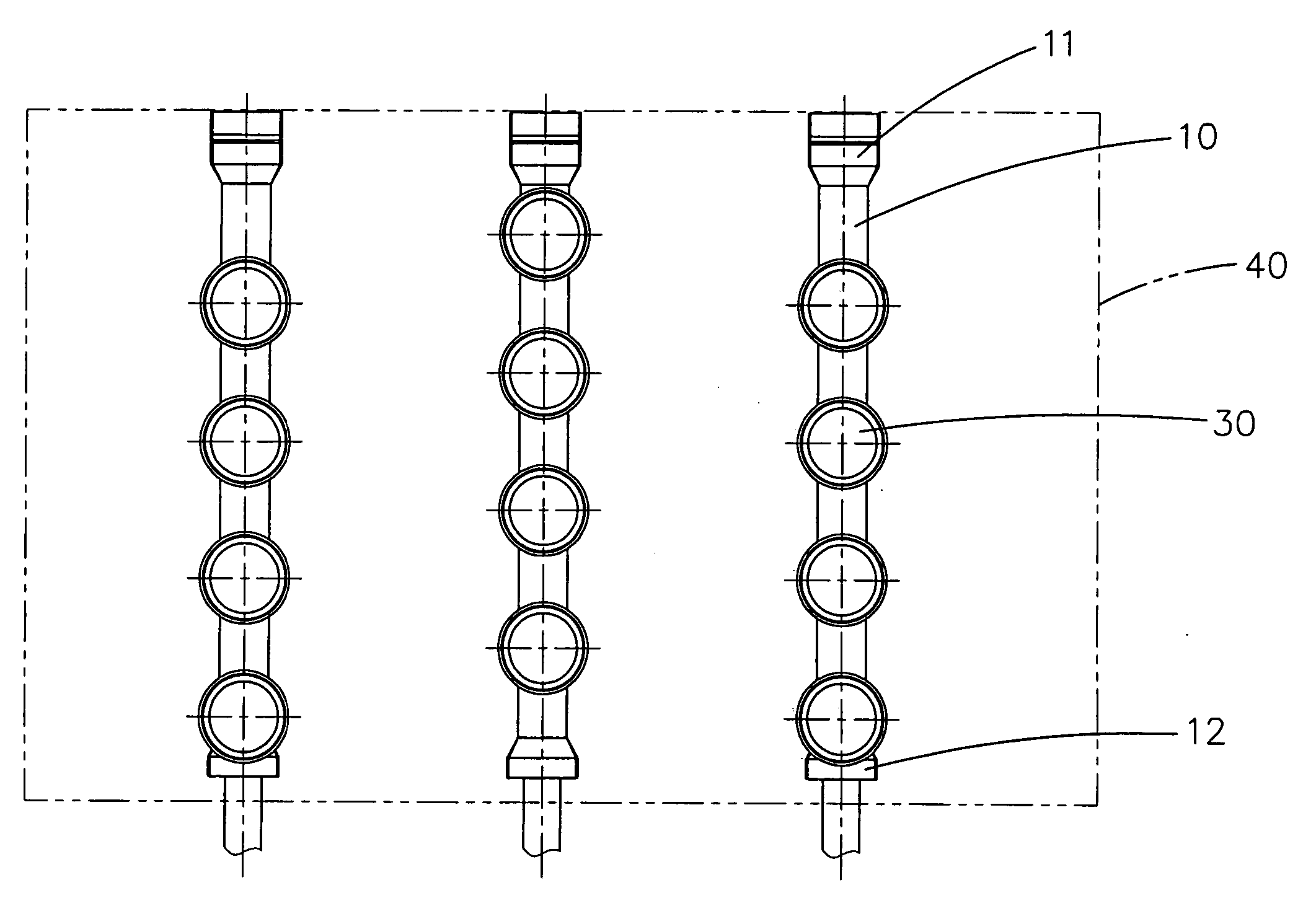

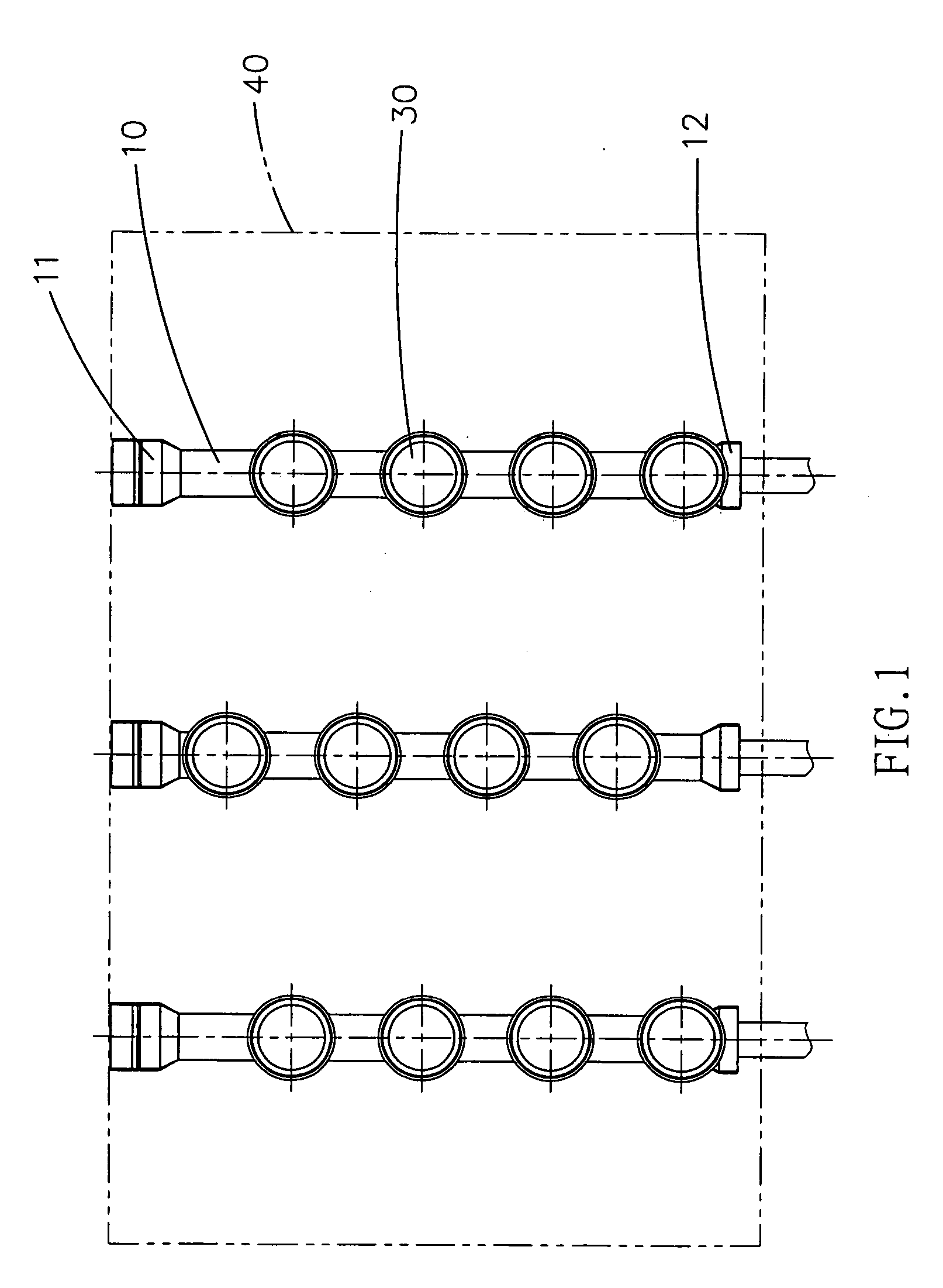

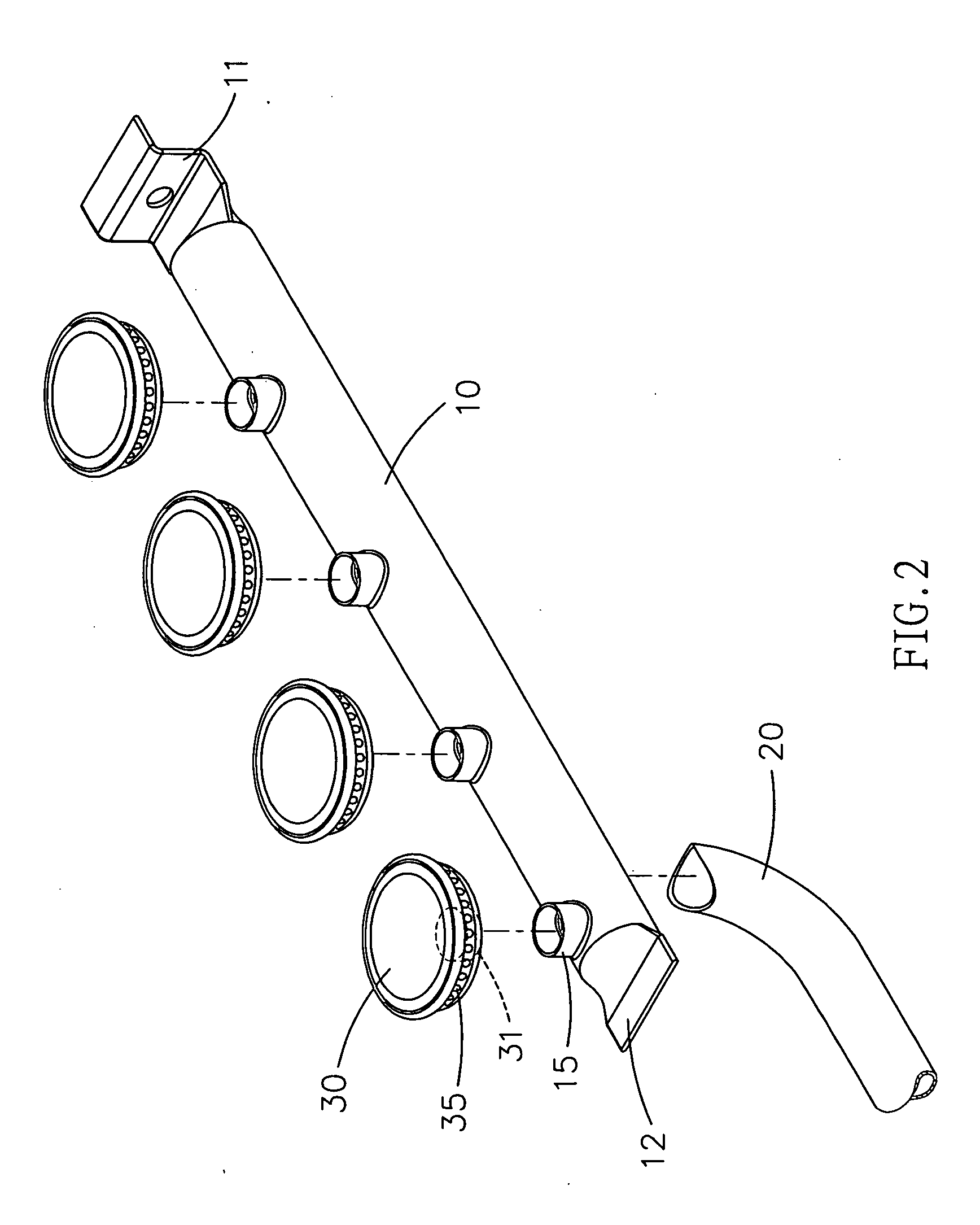

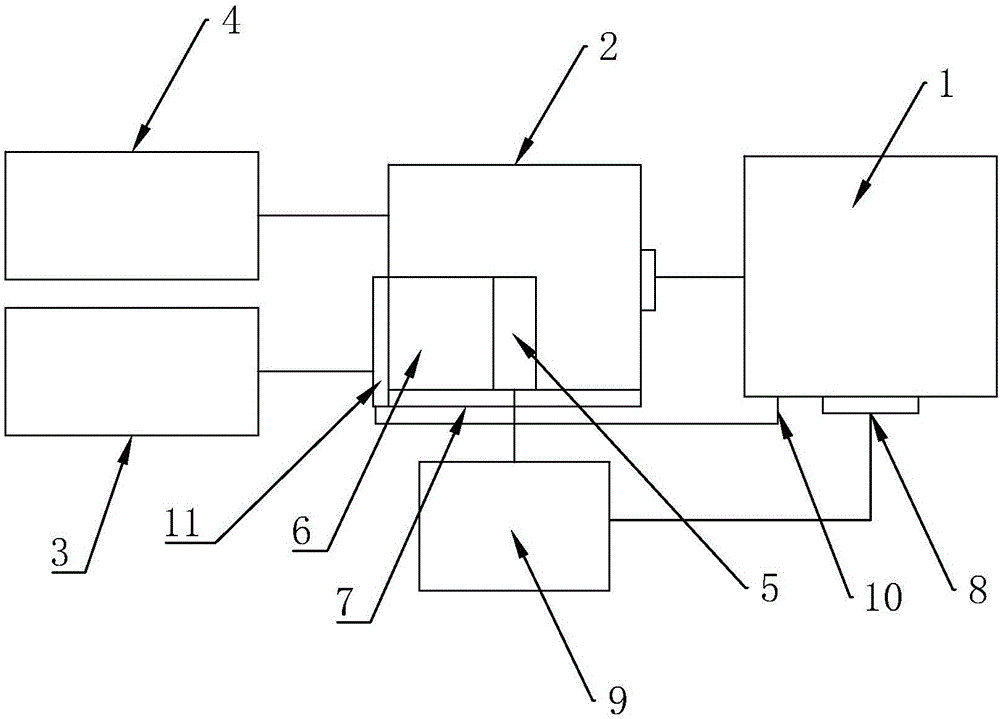

Apparatus for casting dental prosthesis

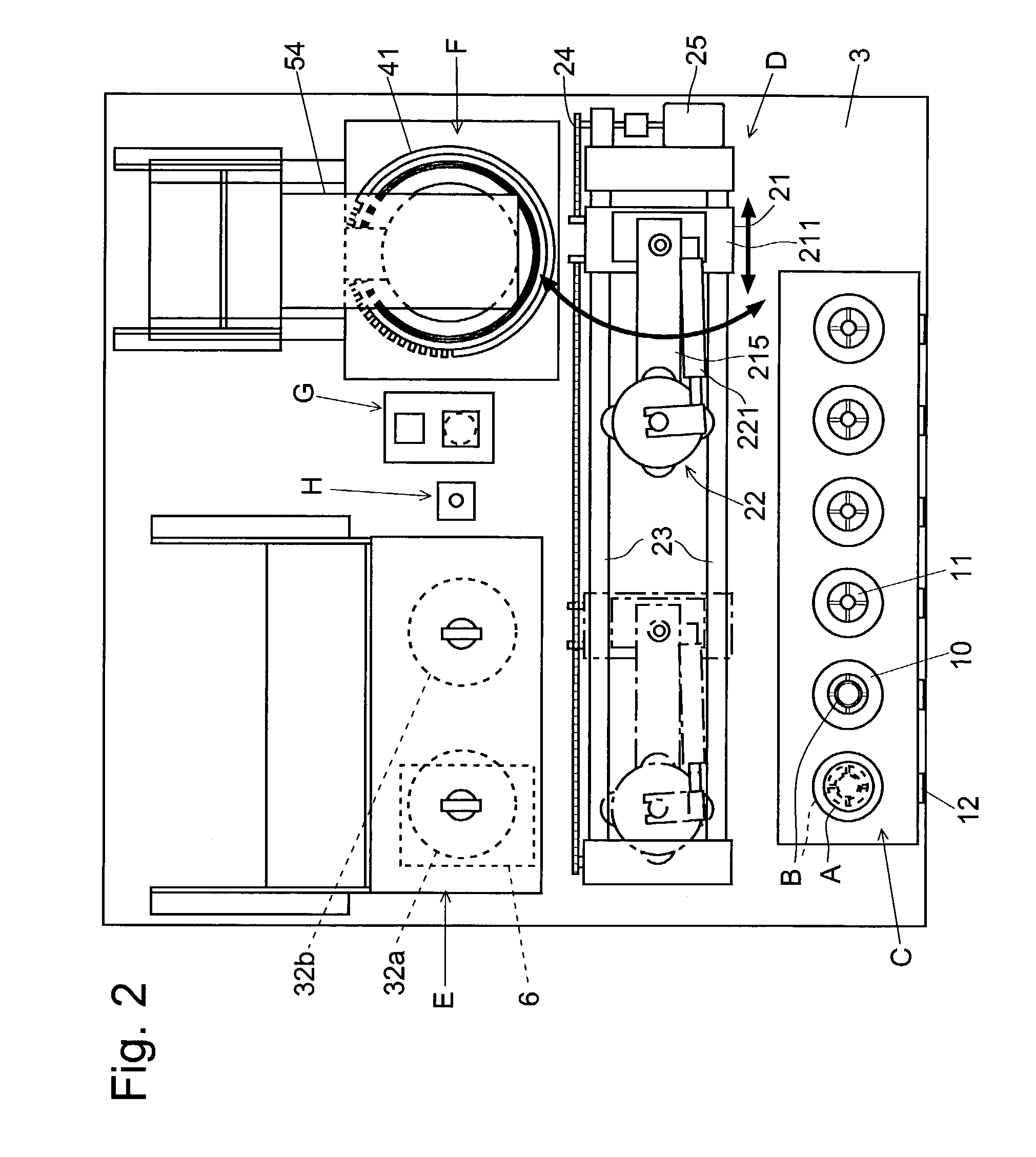

InactiveUS7048031B2Easy to checkEnhance the imageMelt-holding vesselsPig casting plantsBurn unitsDentures

A new apparatus for casting dental prosthesis has been proposed, comprising a ring-placing section onto which plural rings are to be placed, a crucible holder for holding plural cylindrical crucibles, a burning unit with a furnace, a casting unit and a conveyer for conveying the ring or the crucible. The lifting state of the burning unit includes a base capable of rotating around a substantially horizontal axis, an orientation-maintaining mechanism for maintaining the base substantially horizontal and an orientation-changing mechanism for exerting an external force onto the base. The conveyer performs a position-correcting motion for correcting the position of the ring by lowering the gripper. The apparatus provides a management code to each crucible for preventing troubles or delay of work caused by the breaking of crucibles due to the aging.

Owner:DENKEN

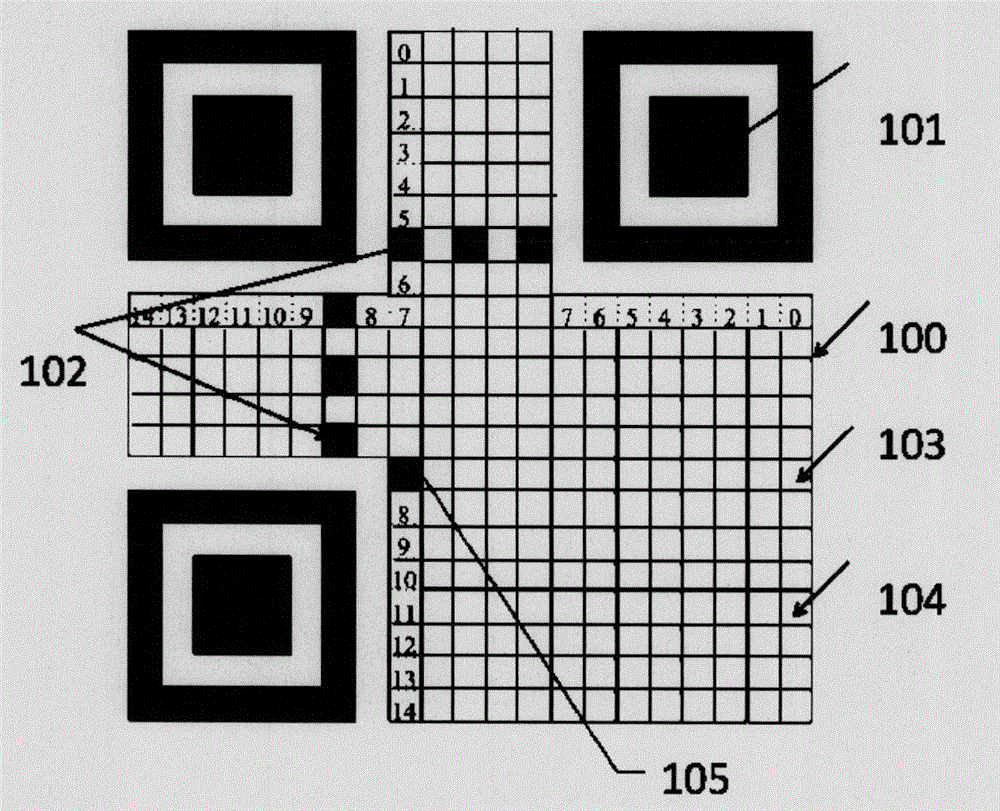

Coal field fire area determining method and device

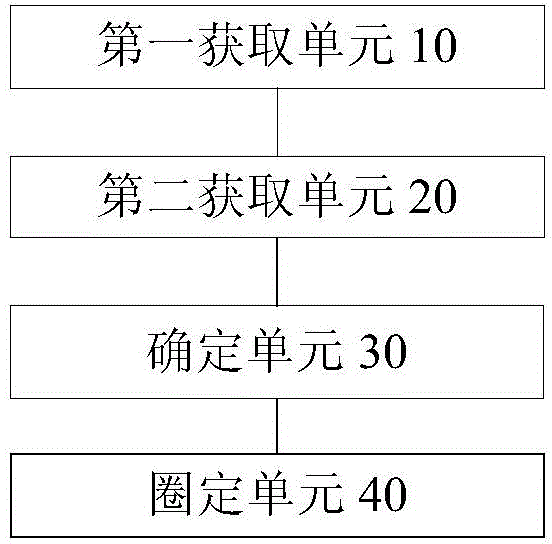

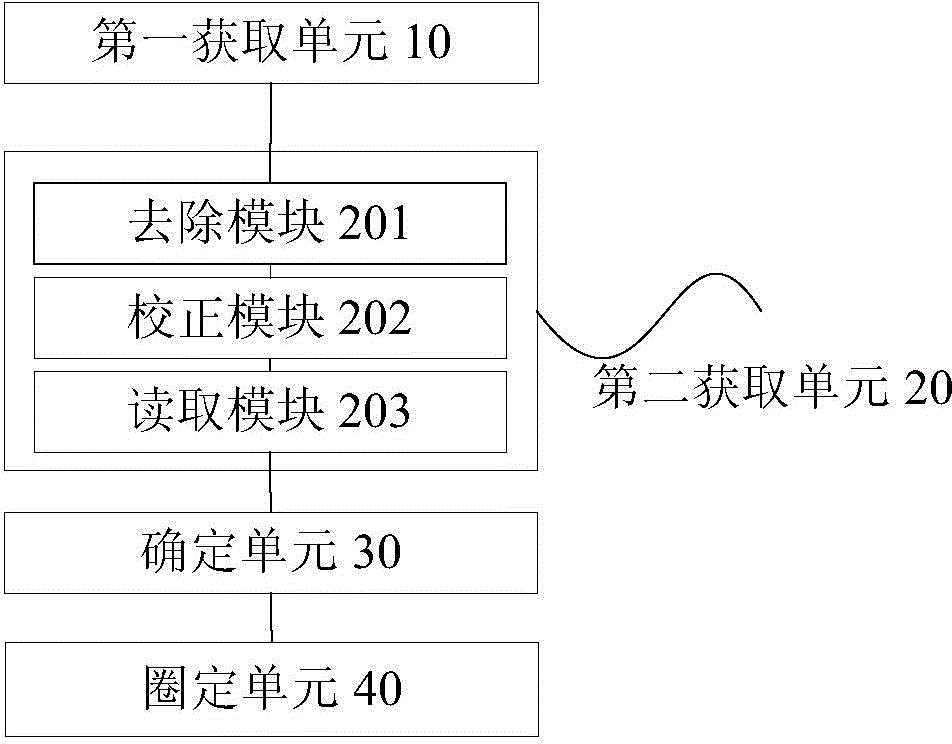

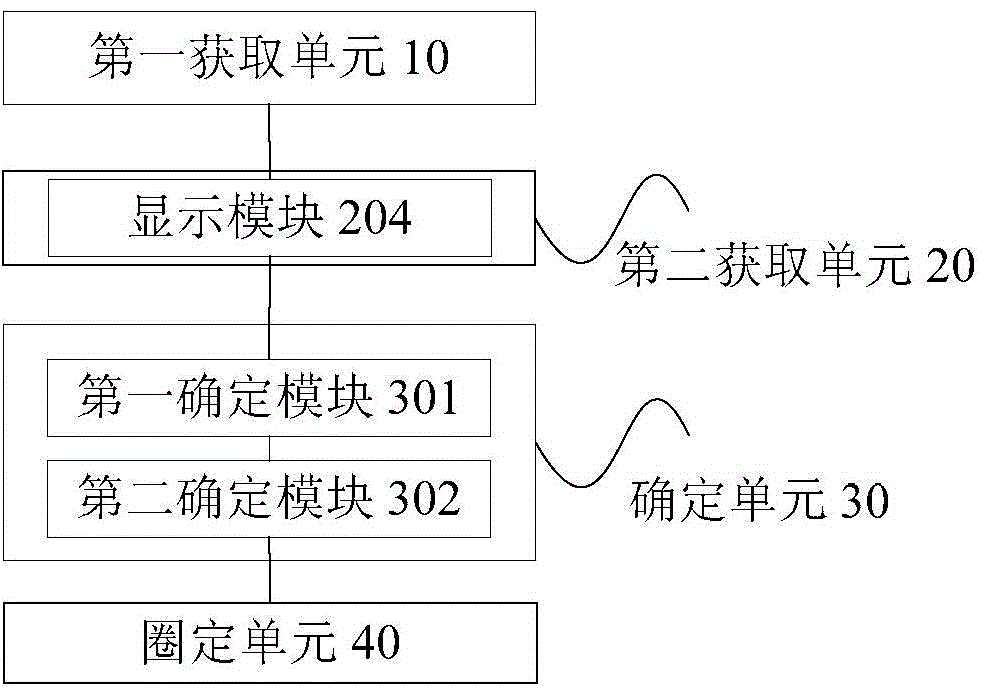

InactiveCN103605987AImprove monitoring accuracyEasy to determineOptical detectionCharacter and pattern recognitionBurn unitsLand surface temperature

The invention discloses a coal field fire area determining method and device. The coal field fire area determining method includes the steps of obtaining thermal infrared image data of a target area, obtaining land surface temperature information of the target area according to the thermal infrared image data of the target area, determining the position of the burning center of coal fire of the target area according to the land surface temperature information of the target area, and determining the burning area of a current coal field fire area in the target area according to the position of the burning center of the coal fire of the target area. By means of the coal field fire area determining method and device, the effect of improving monitoring accuracy of the coal field fire area is achieved.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Method and device for comprehensively treating sludge generated by sewage treatment plant and kitchen waste oil

InactiveCN102701559AShorten drying timeDry fastSludge treatment by de-watering/drying/thickeningBurn unitsSludge

The invention relates to a method for comprehensively treating sludge generated by a sewage treatment plant and kitchen waste oil, which comprises the following steps of: (1) sludge formation; (2) frying dehydration; (3) burning and heat exchange; (4) tail gas processing; and (5) slag collection. The invention also relates to a comprehensive treatment device which consists of a sludge forming unit, a frying and drying unit, a burning unit, a heat exchange unit, a solid slag processing unit and a waste gas processing unit. A discharge port of the sludge forming unit is connected to a feed inlet of the frying and drying unit; a discharge port of the frying and drying unit is connected with a feed inlet of the burning unit; a slag outlet of the burning unit is connected to a slag inlet of the solid slag processing unit; a high temperature flue gas exhaust port of the burning unit is connected with the heat exchange unit; the heat exchange unit is connected to a heating chamber of the frying and drying unit; and the frying and drying unit and a waste gas exhaust port of the heat exchange unit are connected to the waste gas processing unit. According to the method and device provided by the invention, the resource recovery, the reduction and the harmless treatment of two types of wastes in towns, i.e. the kitchen waste oil and the sludge generated by the sewage treatment plant, can be implemented.

Owner:TIANJIN UNIV OF SCI & TECH

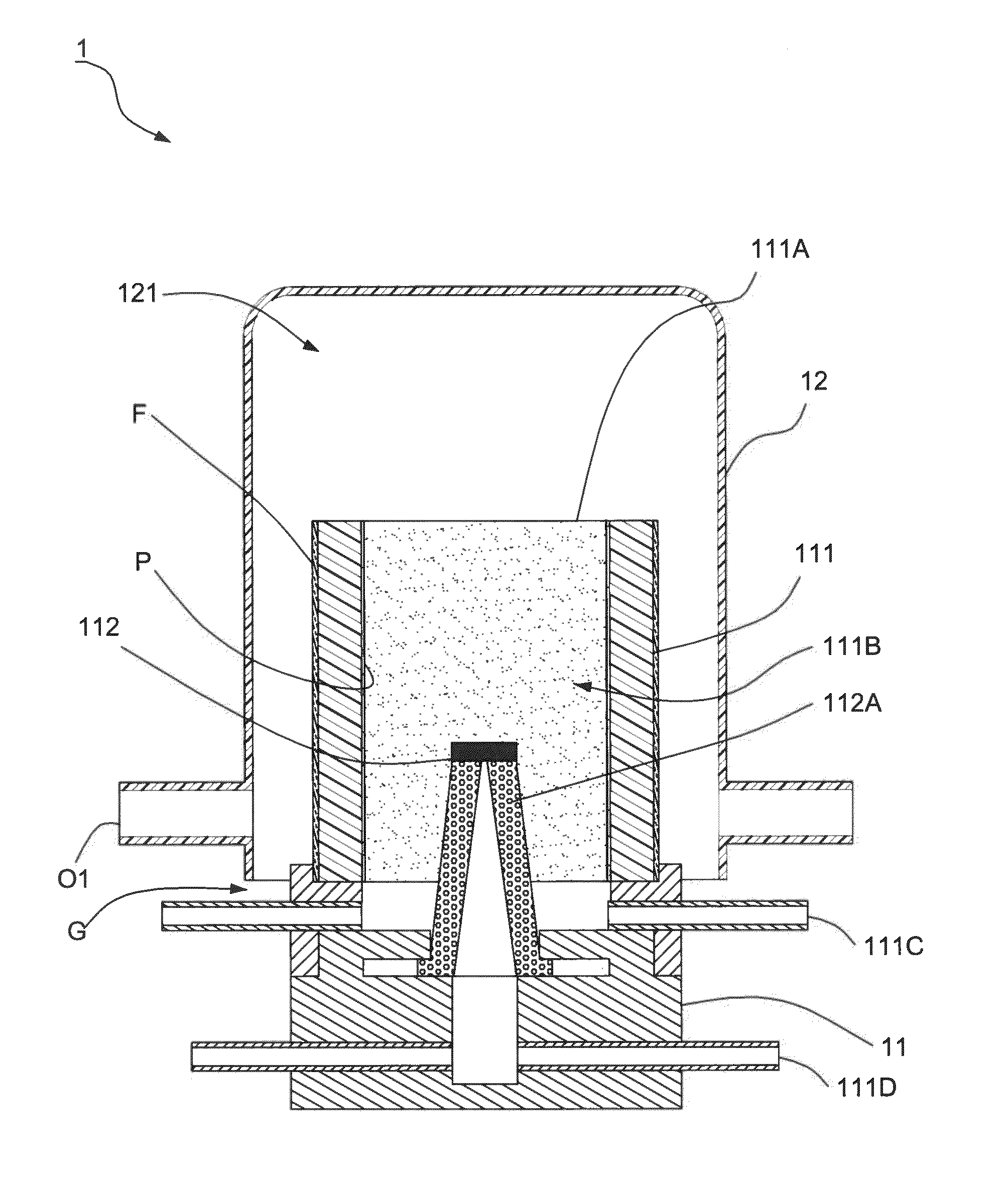

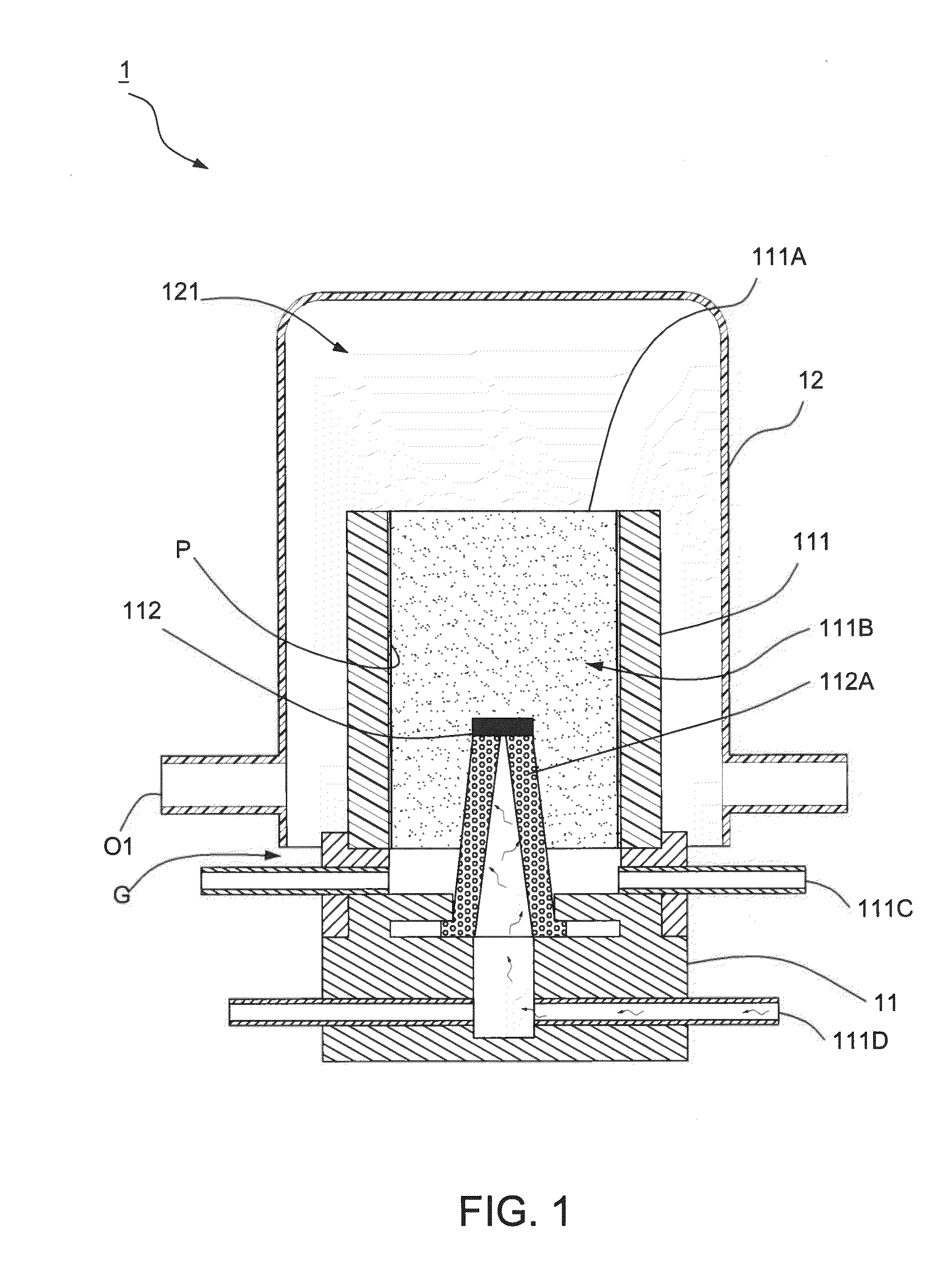

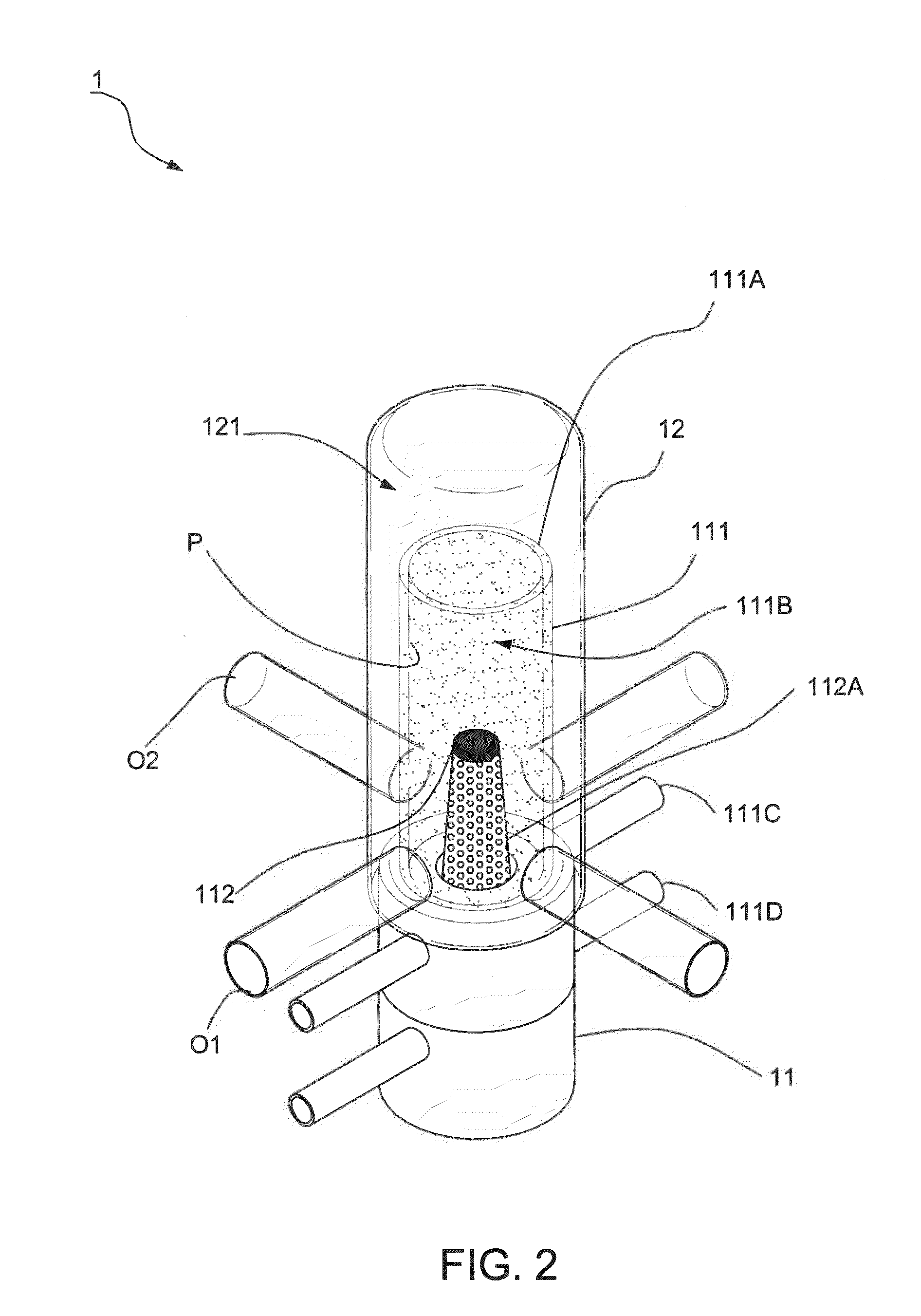

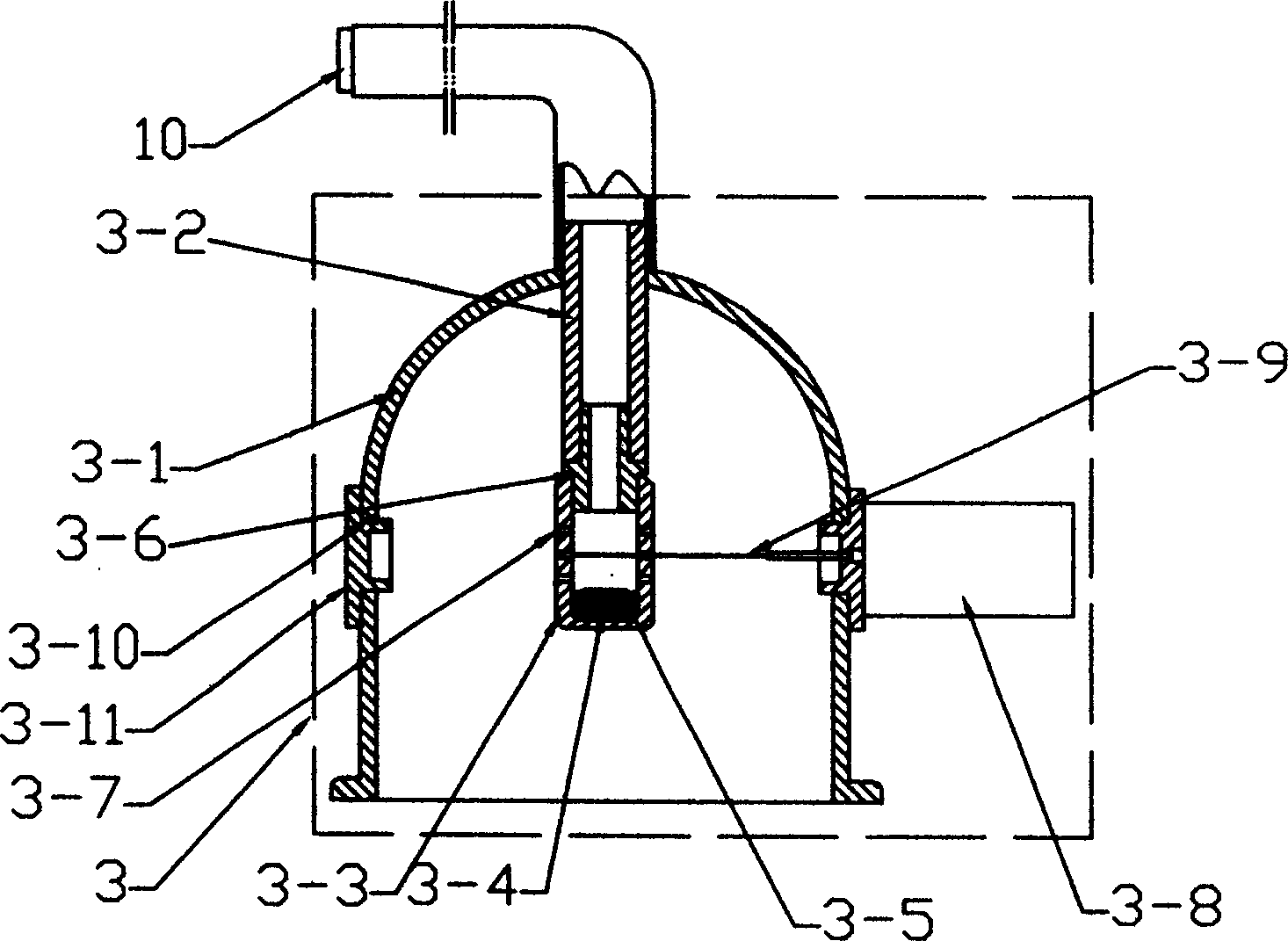

A combustor applied in thermophotovoltaic system

ActiveUS20130157206A1Easy to processIncrease energy densityPV power plantsLiquid fuel evaporation burnersElectricityBurn units

A combustor applied in thermophotovoltaic system comprises a combustion device and a reversed tube covering the combustion device. The combustion device includes a combustion body made of a transparent, and temperature resistant material and a burning unit disposed in the combustion body. When a burning-supported medium is adopted during burning via the burning unit, the radiant intensity is increased. The reversed tube thence further redirects the hot product gas for reheating an outer wail of the combustion body in combustion. Therefore, uniform illumination is accordingly resulted for enhancing the radiant intensity. Accordingly, a photovoltaic cell plate connected to the combustor preferably transforms light into electricity. The present invention fully utilizes a micro system as well as miniature energy to offer advanced electricity.

Owner:NAT CHENG KUNG UNIV

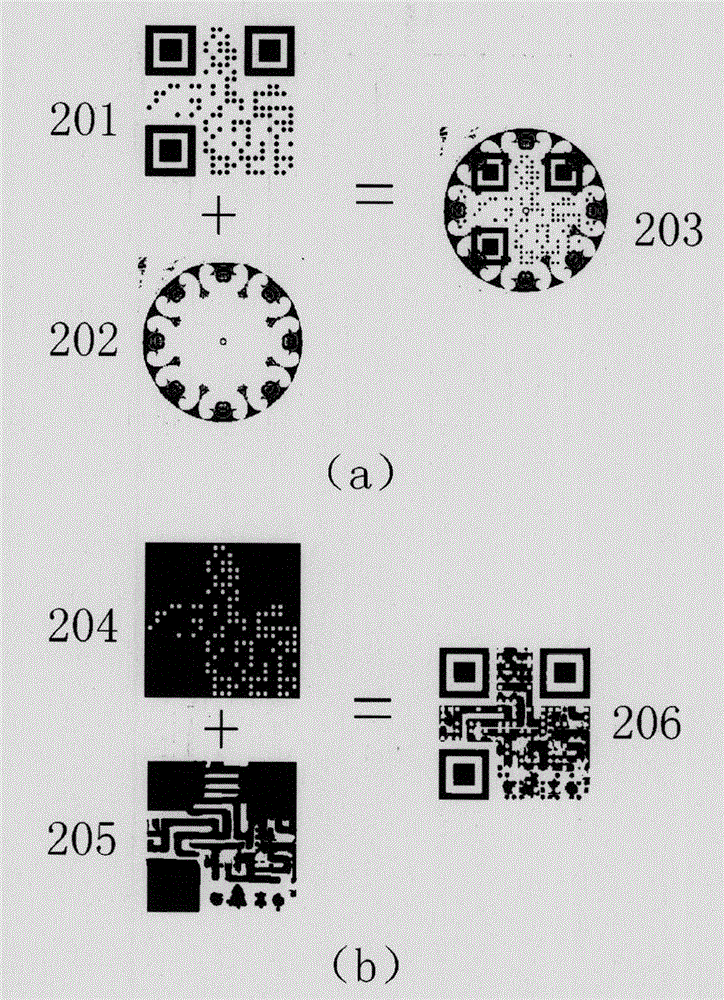

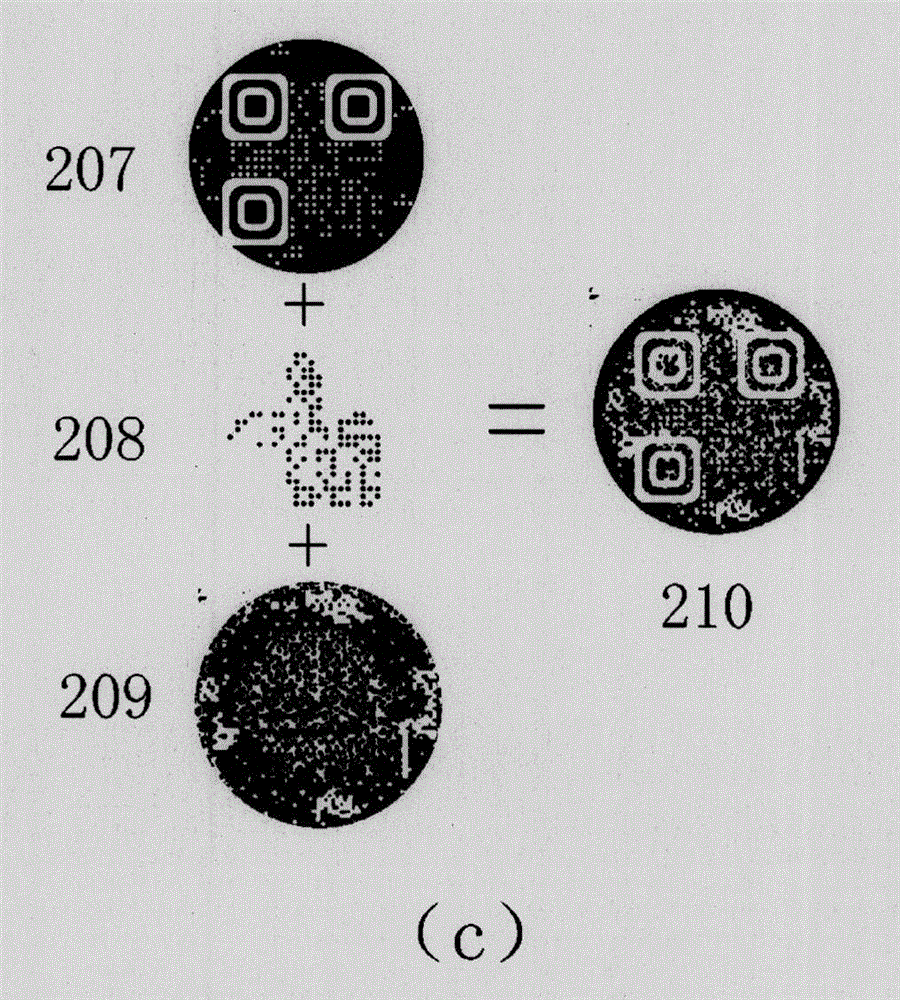

Bottle cap variable information on-line tagging device and identification method

InactiveCN106886808ALow costPrevent skimmingCo-operative working arrangementsTypewritersInformation processingBurn units

The invention relates to a bottle cap variable information on-line tagging device and identification method in the field of information processing, and is characterized in that the device stacks scattered bottle caps through a cap sorting unit, the bottle caps are sent to a conveying unit to sent to the following units, the bottle caps pass through a bottle cap burning unit, surface tension processing is performed on surfaces to be subjected to jet printing, the processed bottle caps are sent to a jet printing unit to be subjected to one-cap one-code tapping of all codes with optical readability including but not limited to a common QR two-dimensional code, a DM two-dimensional code, a decorative novel two-dimensional code, a color two-dimensional code, a vision code and an invisible code, the bottle caps after tapping are sent to an offset printing unit to perform printing of bottle cap images, the printed bottle caps are subjected to on-line detection and bad bottle caps are identified to be rejected, and the bottle caps that satisfy quality requirements are sent to the next process. The implementation effects of the bottle cap variable information on-line tagging device and identification method are that high-speed tapping can be performed on the bottle caps, the tapping cost is reduced, reading through stealing can be prevented, and a promotion activity of red envelope grabbing can be performed.

Owner:顾泽苍

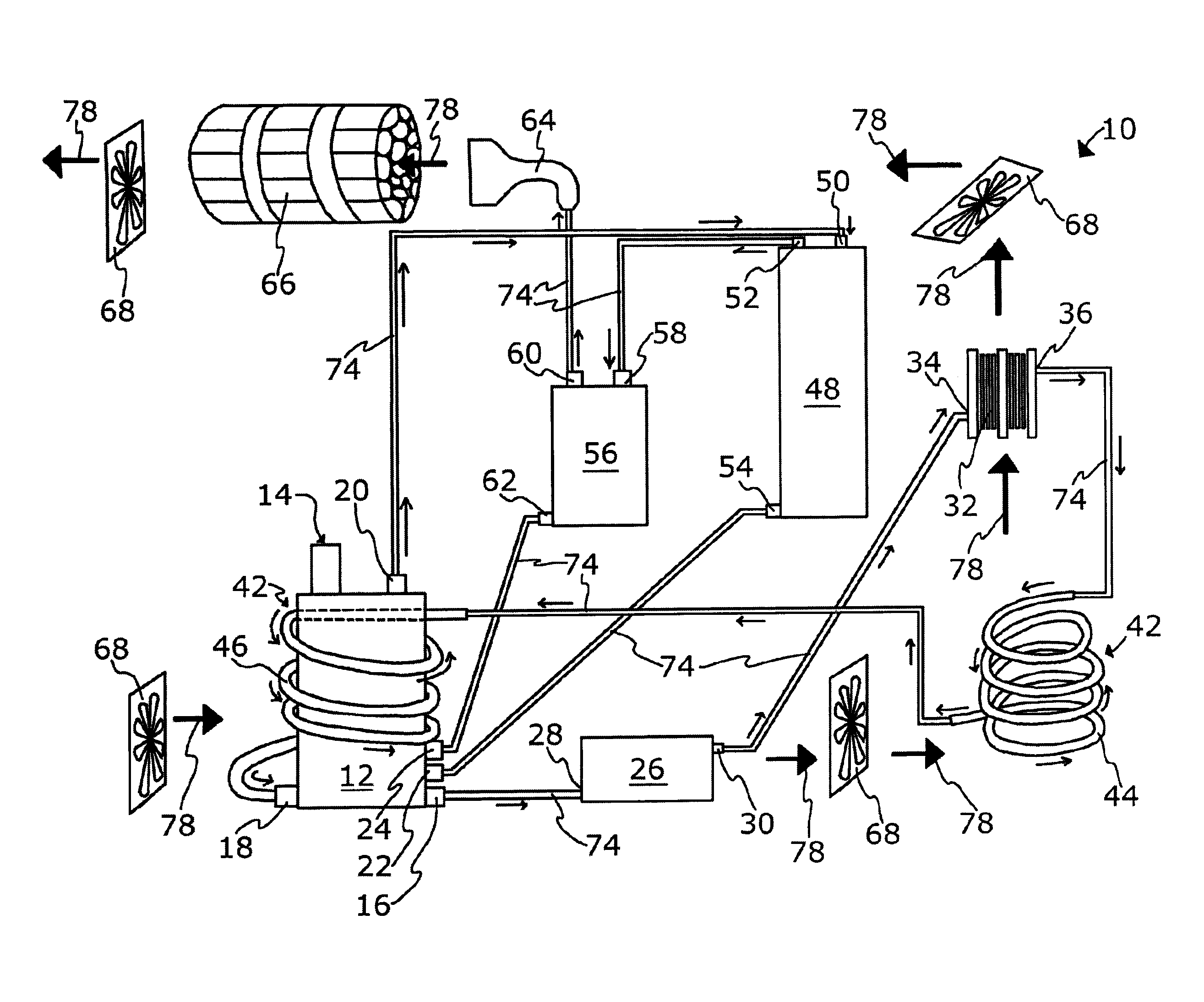

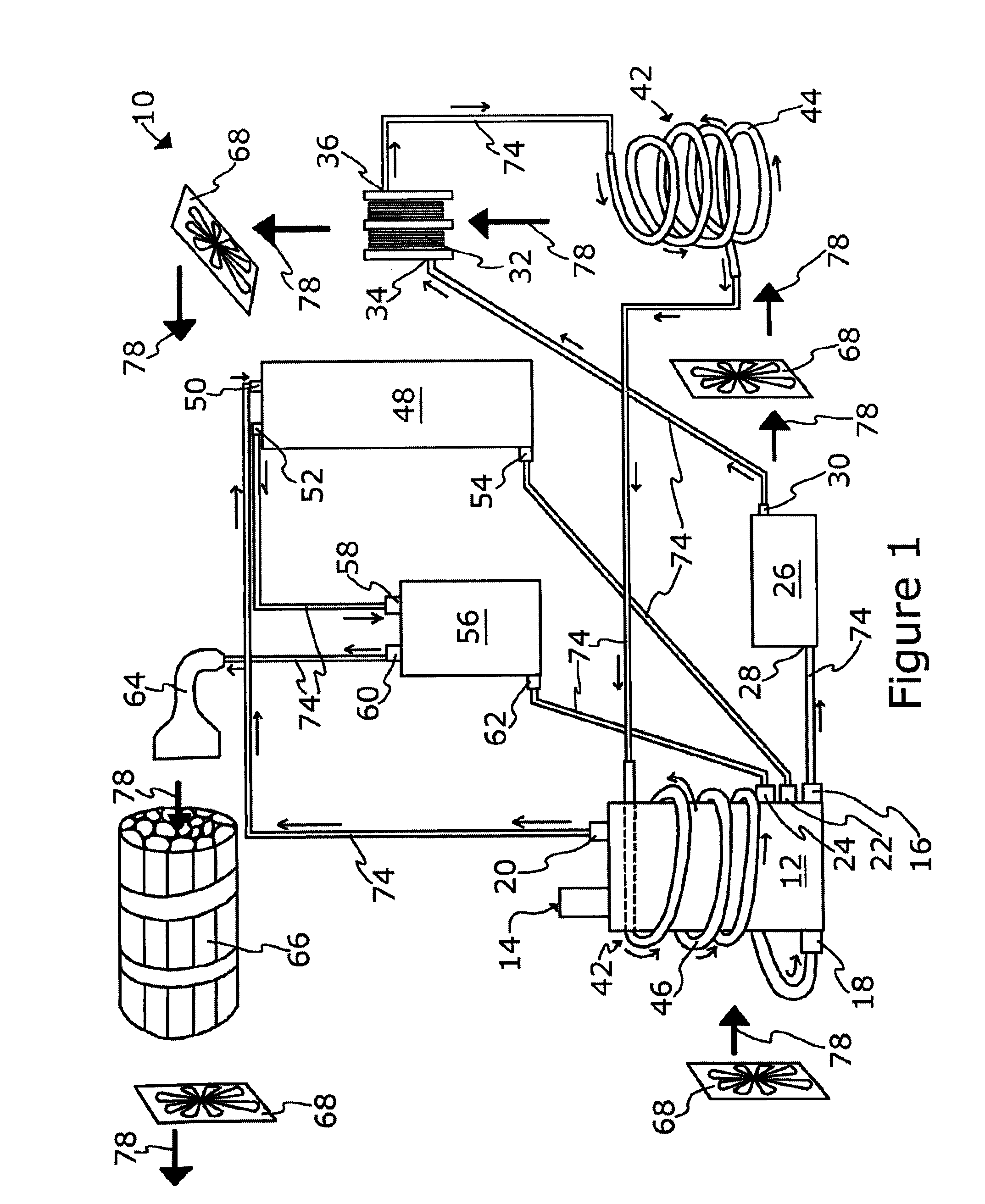

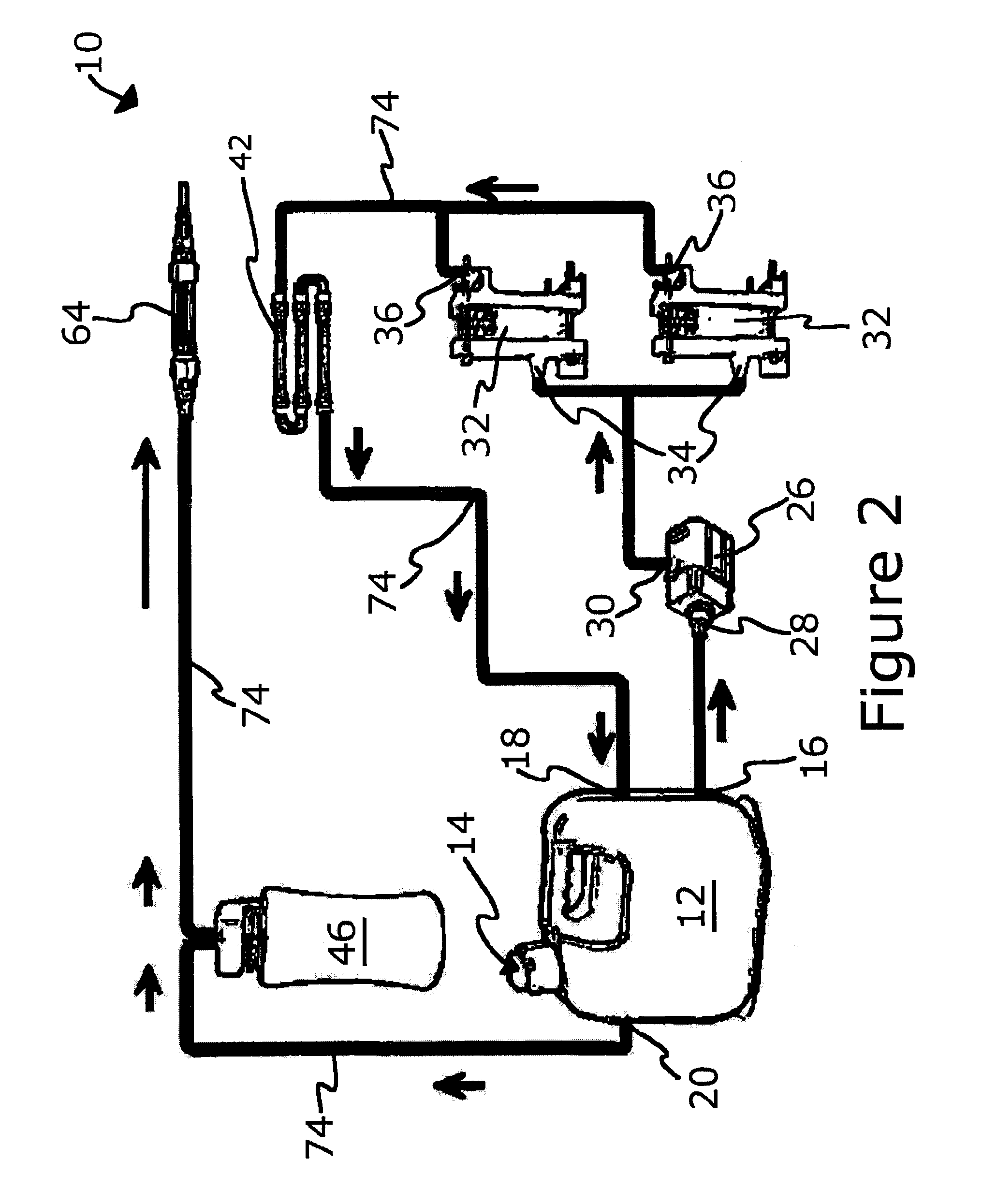

Home heating system utilizing electrolysis of water

InactiveUS20100187321A1Minimum total system costManufacturing cost to minimumElectrolysis componentsHot-air central heatingBurn unitsGas bubbler

Disclosed is a heating system utilizing electrolysis of water for heating a space. The system includes a tank configured to hold water, a separation cell configured to perform electrolysis of water, a first heat exchanger, a gas bubbler, a burn unit, and a second heat exchanger, where water from the tank is delivered to the separation cell where electrolysis is performed. The fluid produced from the electrolysis is delivered through the first heat exchanger back to the tank, then to the gas bubbler, and finally to the burn unit, where the hydrogen gas produced during electrolysis is burned to emit heat directed at the second heat exchanger. Through the process environment air is heated.

Owner:BUNN RANDY MORRELL +1

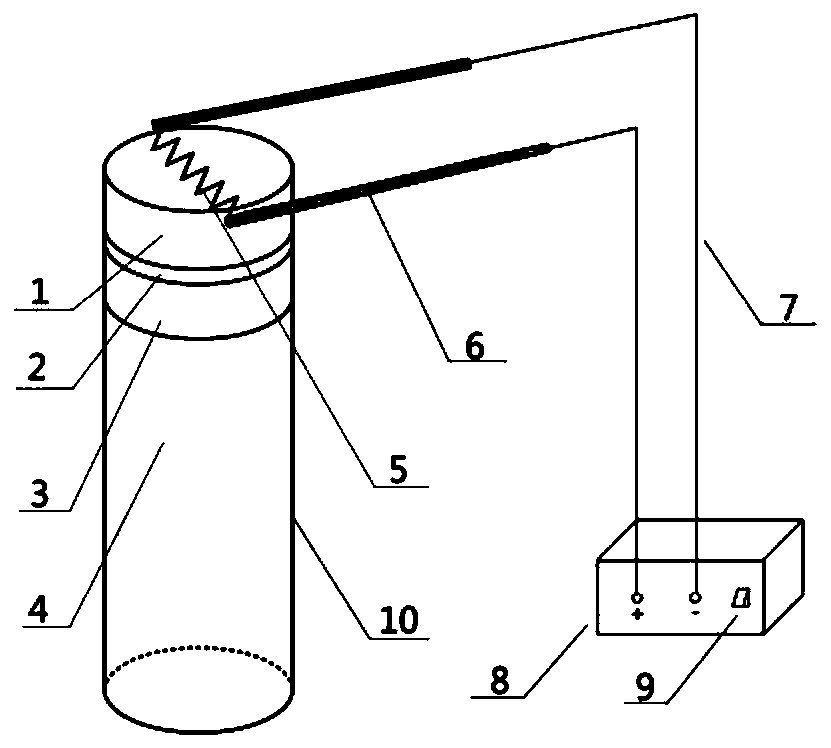

Ignition system for micron metal powder and liquid water mixture

ActiveCN109764355AGood ignition stabilityRaise the ignition temperatureFuel lightersBurn unitsLiquid water

The invention discloses an ignition system for a micron metal powder and liquid water mixture. The ignition system comprises a striking unit provided with heat by an oxidation reduction reaction, an ignition unit used for triggering the striking unit to burn, and a burning unit struck by the striking unit; the ignition unit is a control circuit including an electric heating wire; the burning unitis a gel system formed in the mode that micron metal powder is dispersed into water through gel, wherein an ignition reaction between the micron metal powder and the water is difficult; and the ignition unit comprises an ignition powder layer, a magnesium powder layer and an ignition gel layer, wherein the ignition powder layer is triggered by the electric heating wire and provided with the heat by the oxidation reduction reaction to uniformly heat the burning unit, the magnesium powder layer is used for blocking direct contact between the ignition powder layer and the burning unit and transmits heat generated by the ignition powder layer to the burning unit, and the ignition gel layer used for stably transmitting the heat of the magnesium powder layer to the burning unit so as to fully ignite the burning unit. The ignition system can achieve layered step-by-step ignition, the ignition temperature is high, and metal powder with any micron size and the water can be ignited stably.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

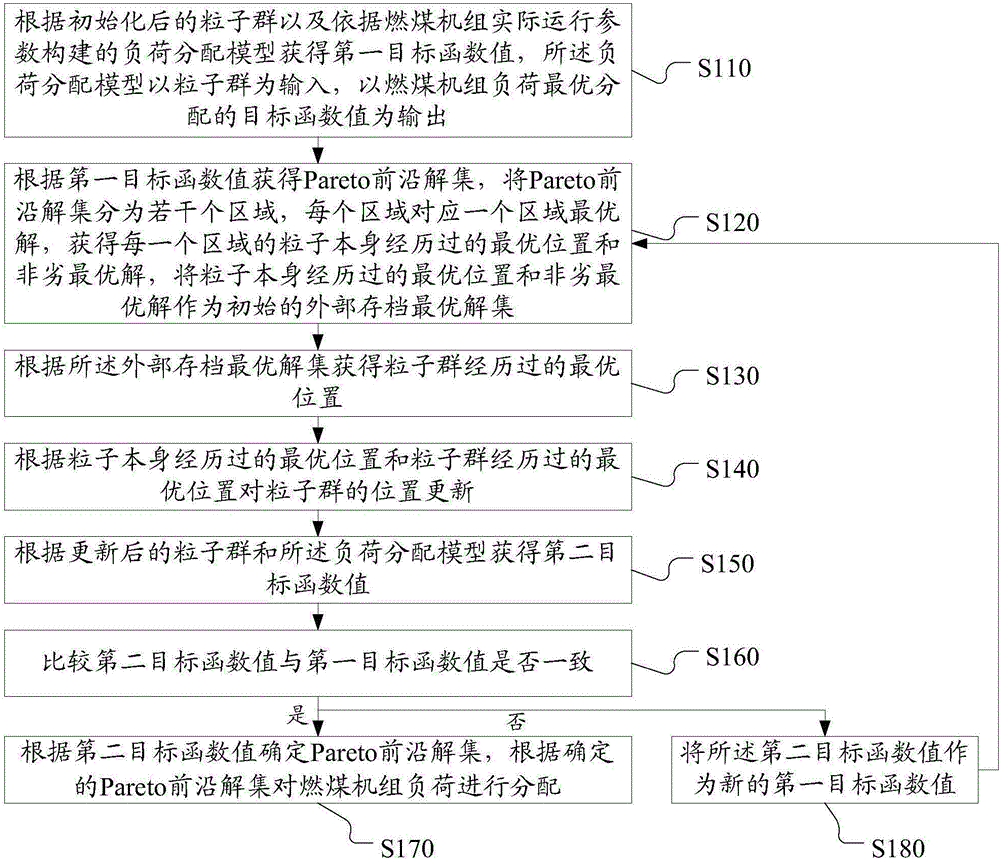

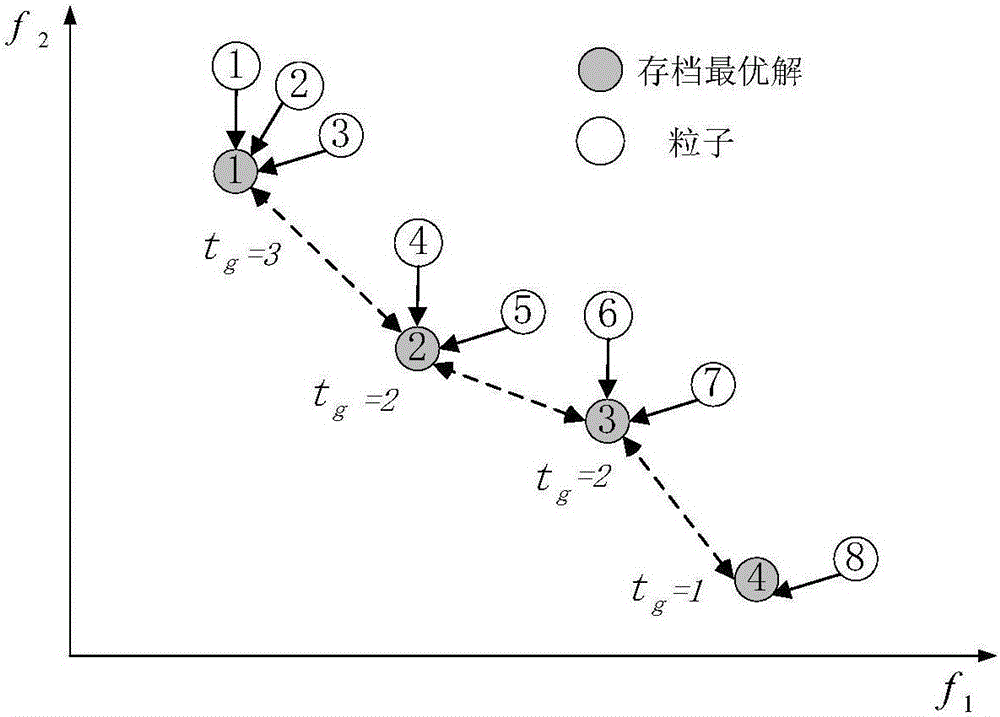

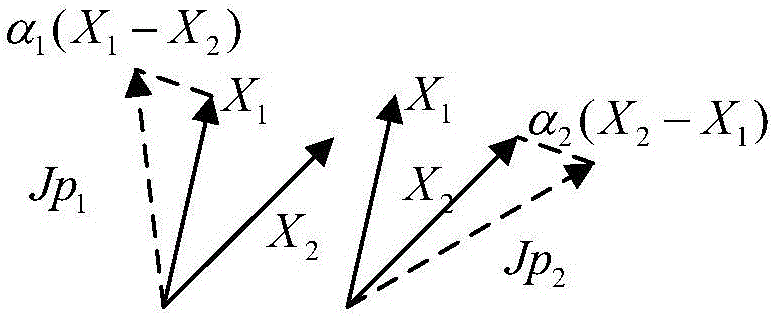

Coal-burning unit load distribution method and device

ActiveCN106447099ARealize a reasonable distributionIncrease diversityForecastingArtificial lifeBurn unitsDistribution method

The present invention relates to a coal-burning unit load distribution method and device. Based on a particle swarm optimization algorithm, a Pareto frontier solution set is divided into a plurality of regions by using a proportional balancing mechanism, wherein each region is corresponding to only one optimal solution; when the algorithm finds that a small part of non-inferior solutions exists in a certain region, a particle swarm obtains more solution sets according to the non-inferior solutions; and new particles are explored through using a jump mechanism so that the premature of the solution sets can be prevented. With the coal-burning unit load distribution method and device of the invention adopted, under a premise that a coal-burning unit can satisfy the compulsory requirement of a power grid for load adjustment and the constraint condition of the unit, the reasonable distribution of load can be realized, economic and environmental protection operation can be achieved, and the economic competitiveness of the power generation of a whole power plant can be improved.

Owner:广州粤能电力科技开发有限公司

Solid fuel torch

This invention discloses a solid fuel torch which cracks the problems as instable burning, short-time burning, light-color flame and low visibility when the torch is under low temperature, voltage and heavy wind. The torch includes the fuel bin that loads the solid or gel fuel, the burning unit that connects to the top of the fuel bin. The side wall of the burning unit has holes and the inside sets heat-feedback unit of which the bottom attaches to the fuel. The pusher which connects to the bottom of fuel bin pushes the fuel forward the burning unit. The structure of multi-hole and heat-feedback can keep the continue burning and improve the flame burning thickness when the torch is under heavy wind, low temperature and voltage so as to improve the flame color and visibility and satisfy many displaying function.

Owner:AEROSPACE HI TECH HLDG GROUP

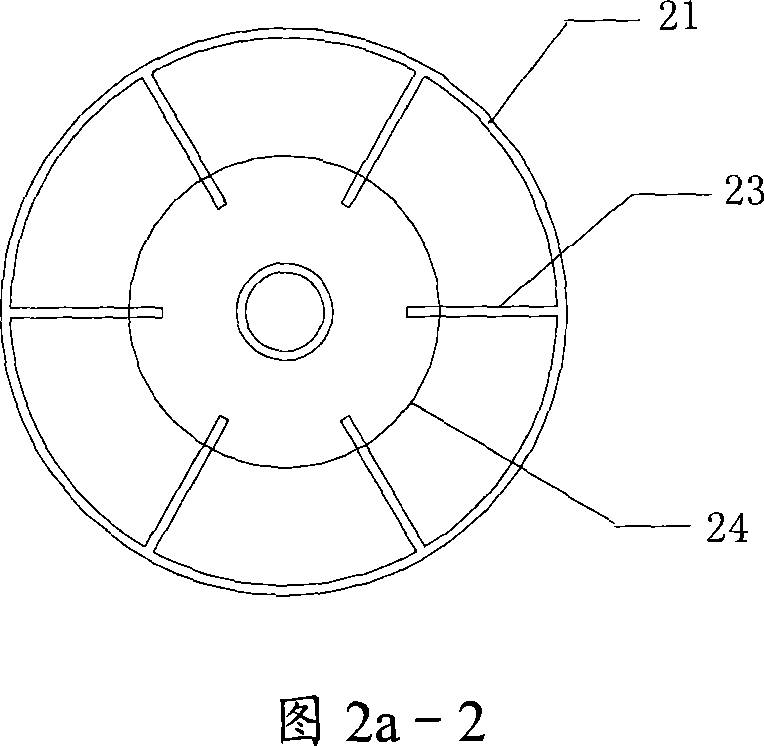

In vitro prophylactic on site ion-exchange purification process.

InactiveUS20080264773A1Easy to cleanDiscourages cell mitosisSludge treatmentEnergy based wastewater treatmentHemodialysisHaemodialysis machine

This invention describes a method and apparatus for the In Vitro treatment process of purifying and maintaining the sterility of water thereby replacing existing transient technology that is flawed by repeated handling inside and outside the medical environment where this technology is intended for use i. e. hemodialysis clinics, trauma centers, burn centers, general medical institutions the pharmaceutical packager and other locations and applications where purified sterile water is required.

Owner:SEARLES WARREN W

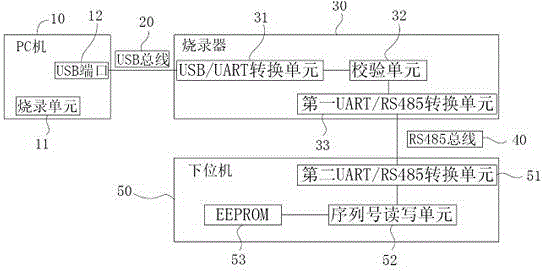

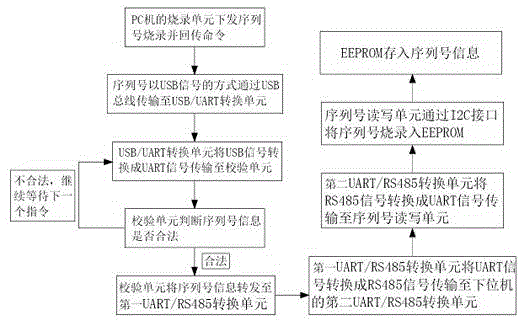

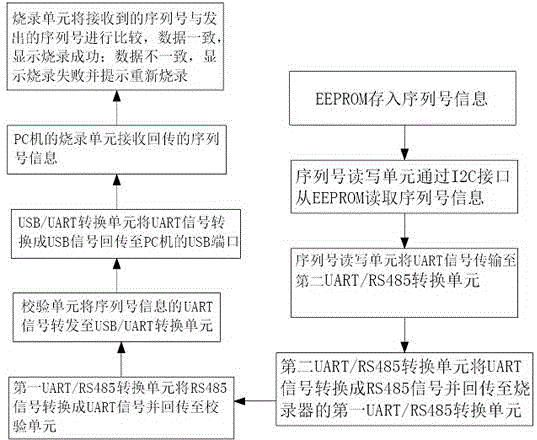

Device and method for burning serial number to lower computer containing RS (Recommended Standard) 485 bus from PC (Personal Computer) machine

InactiveCN105094886ATimely feedbackHigh burning success rateProgram loading/initiatingBurn unitsProgrammable read-only memory

The invention provides a device and a method for burning a serial number to a lower computer containing an RS (Recommended Standard) 485 bus from a PC (Personal Computer). The device comprises the PC, a burner and a lower computer, wherein the PC is provided with a burning unit and a USB (Universal Serial Bus) port; the burner comprises a USB / UART (Universal Asynchronous Receiver / Transmitter) conversion unit, a checkout unit and a first UART / RS485 conversion unit, wherein the USB / UART conversion unit, the checkout unit and the first UART / RS485 conversion unit are successively connected; the USB / UART conversion unit of the burner is connected with the USB port of the PC through a USB bus; the lower computer comprises a second UART / RS485 conversion unit and a serial number read-write unit with an I2C (Inter-Integrated Circuit) interface, wherein the UART / RS485 conversion unit and the serial number read-write unit are mutually connected; the second UART / RS485 conversion unit of the lower computer is connected with the first UART / RS485 conversion unit of the burner through the RS485 bus; and the I2C interface of the serial number read-write unit is connected with an EEPROM (Electrically Erasable Programmable Read-Only Memory) through an I2C bus. The device can burn the serial number to the lower computer containing the RS485 bus to the PC and can effectively verify whether burning is successful or not since the device is provided with a checkout program.

Owner:MEIBEIKE TECH CO LTD

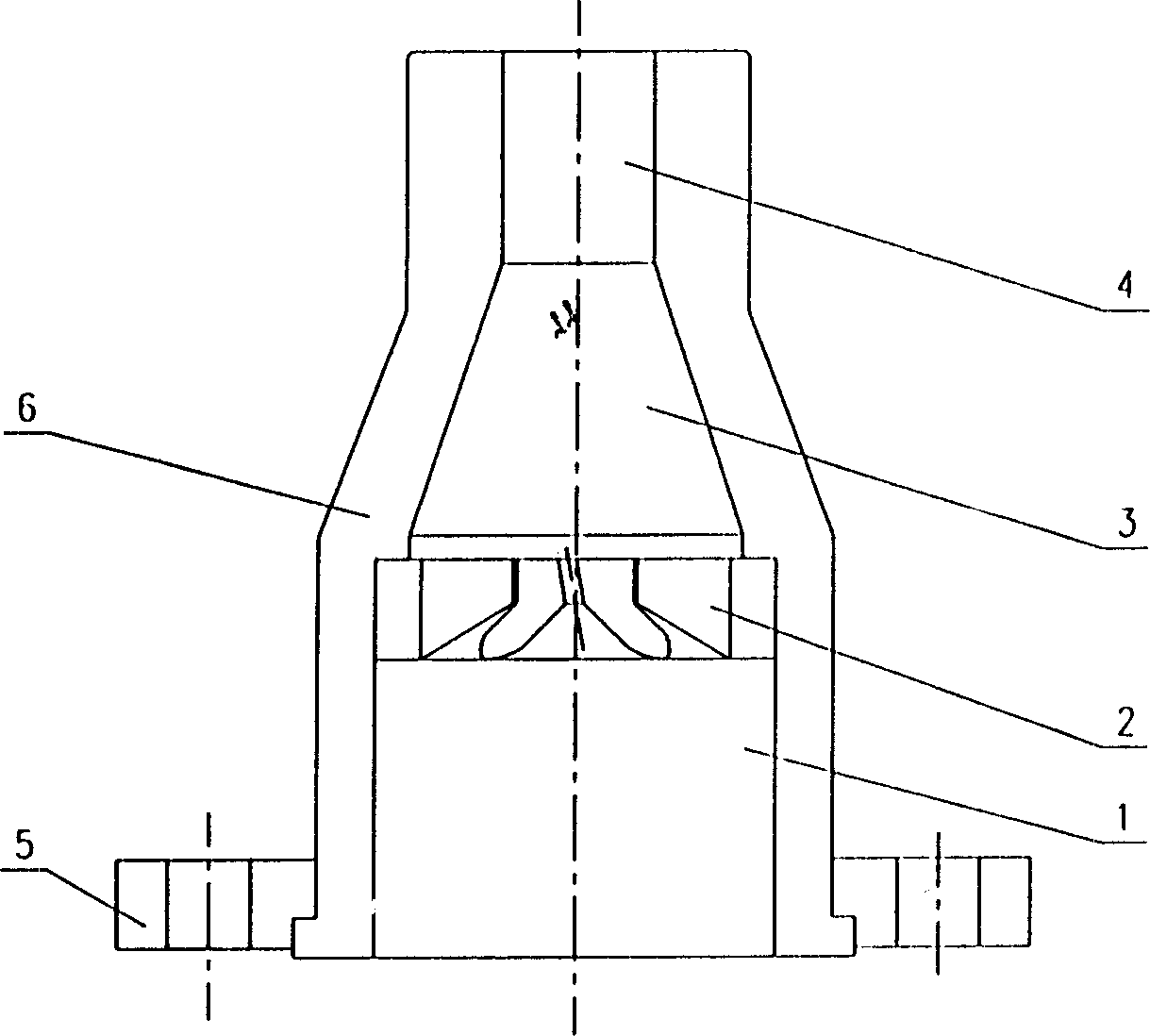

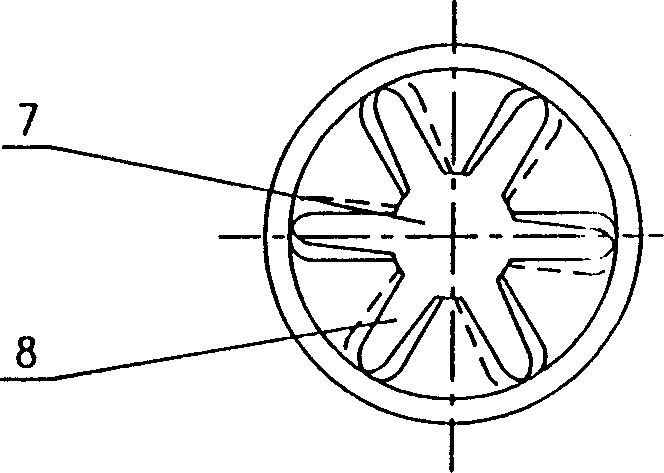

Low resistance cyclonic liquid column type nozzle

InactiveCN1887439AImprove desulfurization efficiencyLow construction costDispersed particle separationSpray nozzlesBurn unitsFriction loss

The present invention discloses one kind of nozzle for efficient tubular reaction desulfurizing device in large coal-burning unit of thermal power plant. The nozzle has the structure comprising a flow stabilizing section, a spraying core, a mixing conic pipe and a speeding pipe. The present invention has the advantages of adaptation to wet limestone-gypsum desulfurizing process, high jamming resistance, simple inner member and small nozzle body resistance loss.

Owner:南昌有色冶金设计研究院

Barbecue stove

InactiveUS20070221192A1Quality improvementEasy-to-assemble barbecueDomestic stoves or rangesPilot flame ignitersBurn unitsCombustor

A barbecue stove includes a plate and a plurality of burning units installed below the plate. Each of the burning units includes a tubular distributor and a plurality of burners. The tubular distributor includes a plurality of pipes formed thereon. Each of the burners includes a neck positioned around related one of the pipes and a plurality of vents evenly defined in a periphery thereof.

Owner:CHUNG KIOSKY

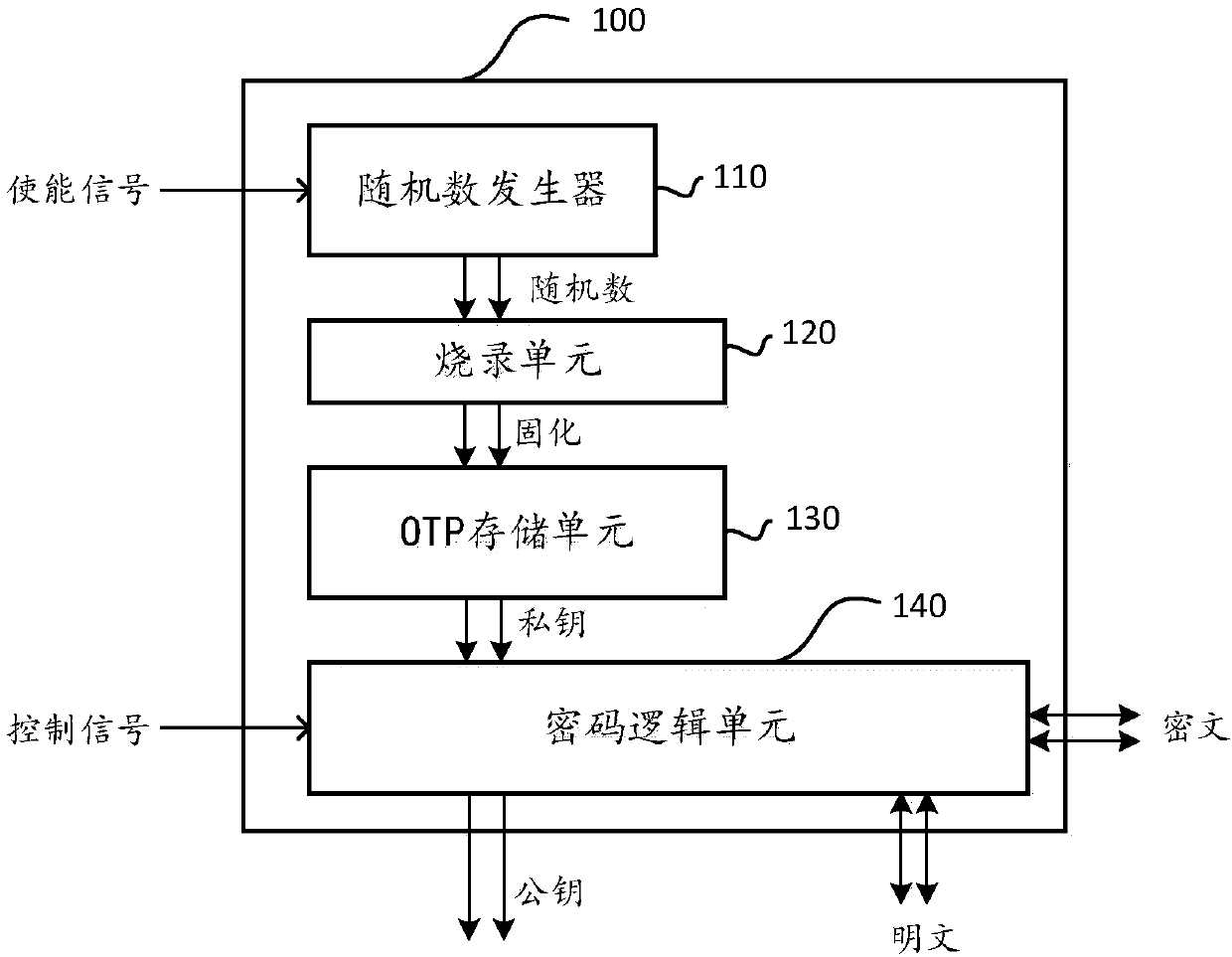

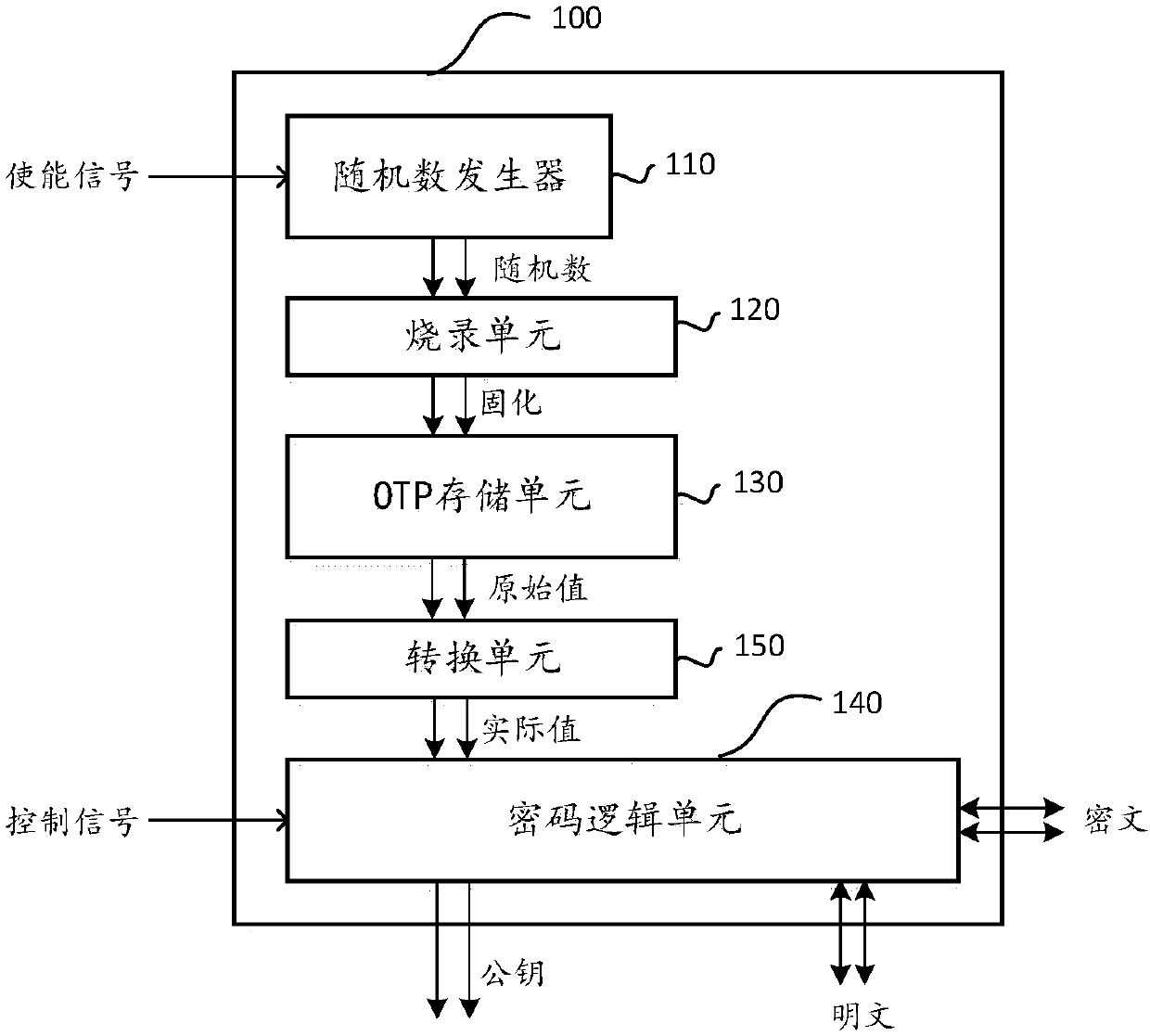

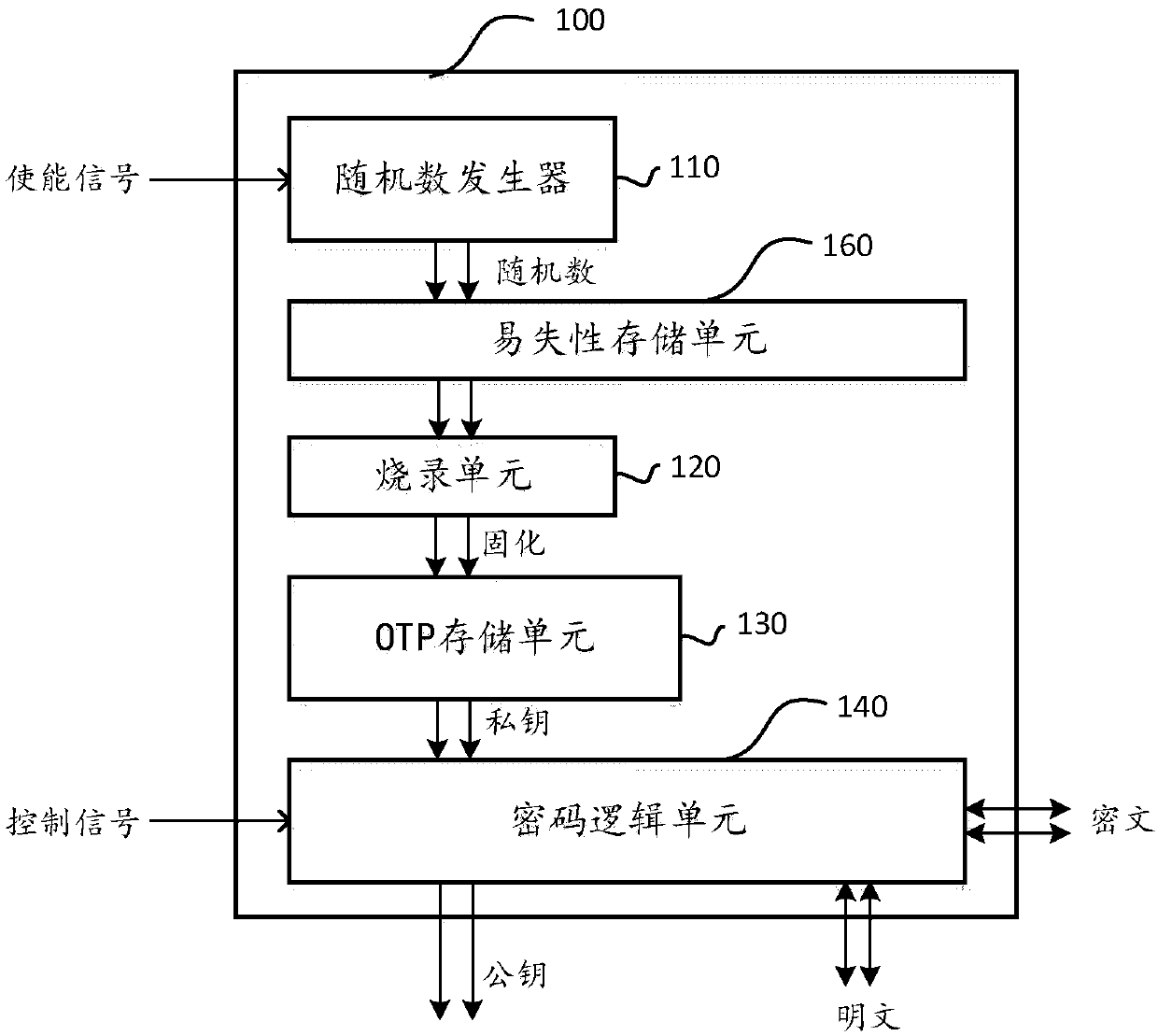

A key generation component for use within a physical chip

InactiveCN109842488AGuaranteed exclusivityEnsure safetyKey distribution for secure communicationBurn unitsComputer module

The invention provides a key generation assembly used in a physical chip, and the key generation assembly comprises a random number generator which is used for responding to a first signal so as to generate an unpredictable coding value; a burning unit which is used for executing the operation of burning the coded value into the OTP storage unit; and an OTP storage unit is used for solidifying thecoded value to serve as a private key. According to the invention, the private key in the key generation assembly is generated by the unpredictable random number in the chip; According to the invention, the private key value does not have any relation and interaction with the outside of the chip after being burnt into the OTP module, the uniqueness and undetectability of the private key are ensured, and the private key cannot be known no matter whether the component is externally provided with a development designer or an attacker, so that the security and reliability of the private key are ensured.

Owner:ANTAIOS (BEIJING) INFORMATION TECH

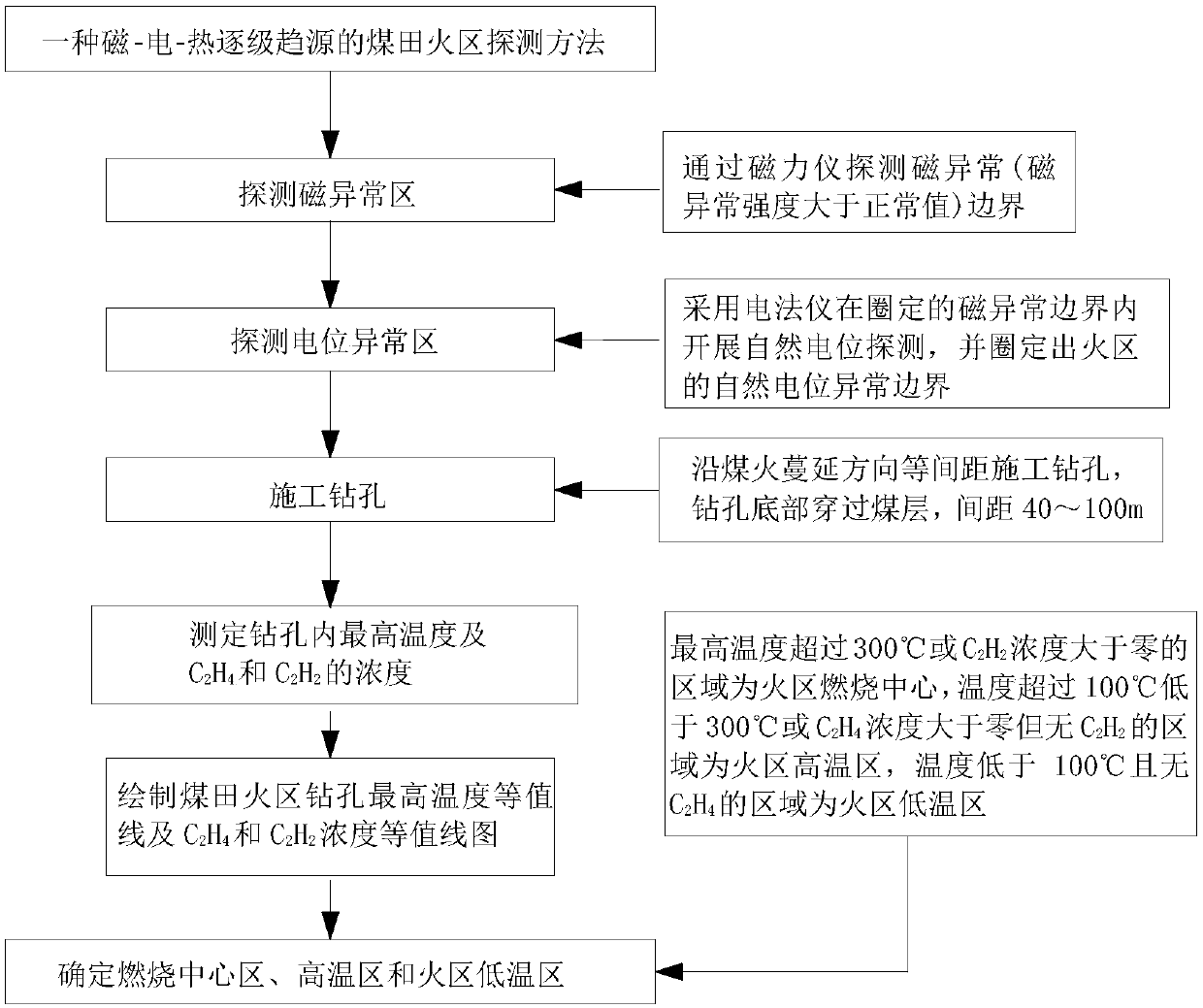

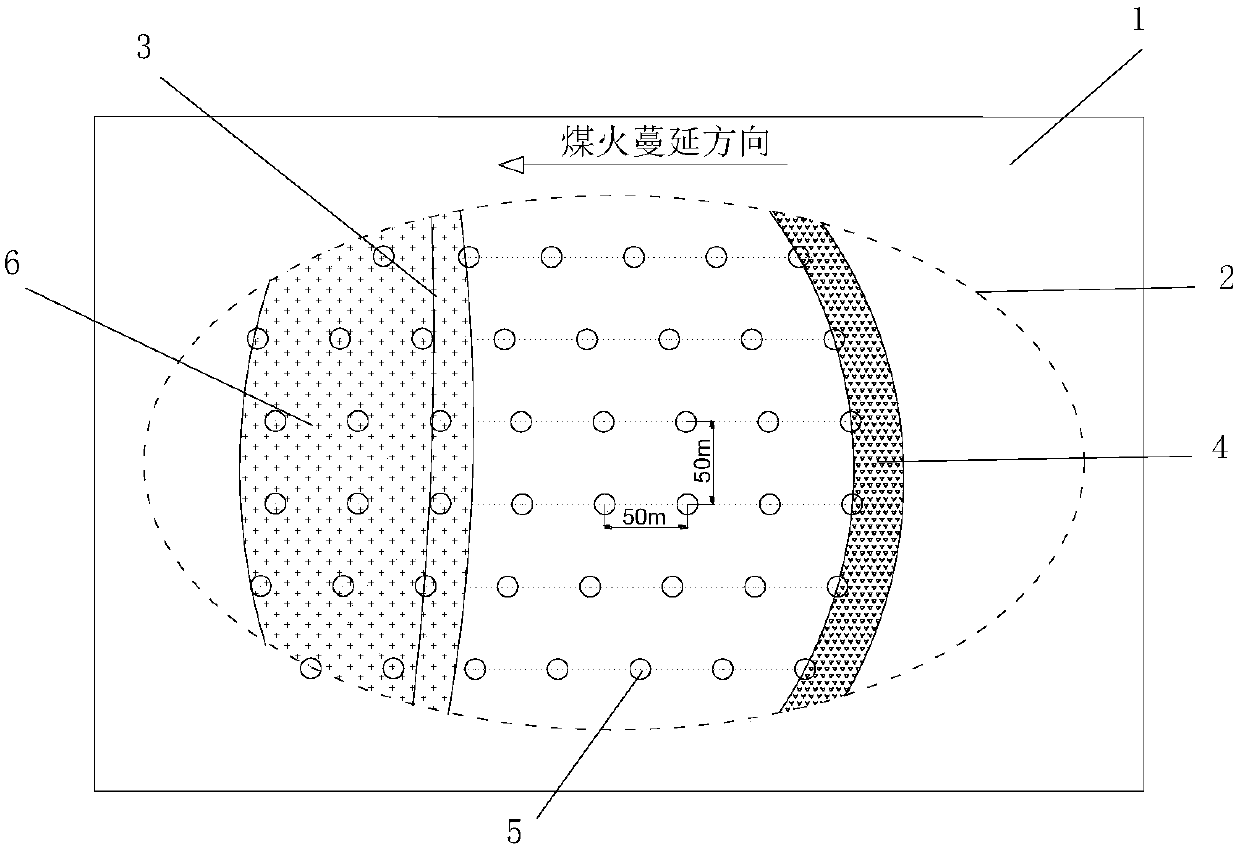

Coal field fire district detection method adopting magnetic-electric-heat gradual source seeking mode

ActiveCN107780971ATargetedReduce the number of boreholes for temperature measurementMining devicesBurn unitsEngineering

The invention relates to a coal field fire district detection method adopting a magnetic-electric-heat gradual source seeking mode. After the underground coal fire spreading direction is determined according to magnetic anomaly boundary, a magnetic anomaly maximum zone and a natural potential anomaly boundary of a fire district detection area, drilling construction is performed, and a burning center zone, a high-temperature zone and a low-temperature zone of the fire district are determined according to the highest temperature and concentrations of C2H4 and C2H2 in drilled holes. The magnetic-electric-heat gradual source seeking mode is adopted, the fire district detection range determined by detecting the coal loose area is narrowed, measurement of the high-temperature zone and the fire source position in the fire district is targeted, the drilling cost is reduced, the detection efficiency is improved, errors caused with a single drilling temperature measurement technology are reduced, the fire source position and the high-temperature zone range in the coal field fire district are efficiently detected, the construction amount of drilling for detection is reduced, and the method has broad practicability.

Owner:新疆维吾尔自治区煤田灭火工程局 +1

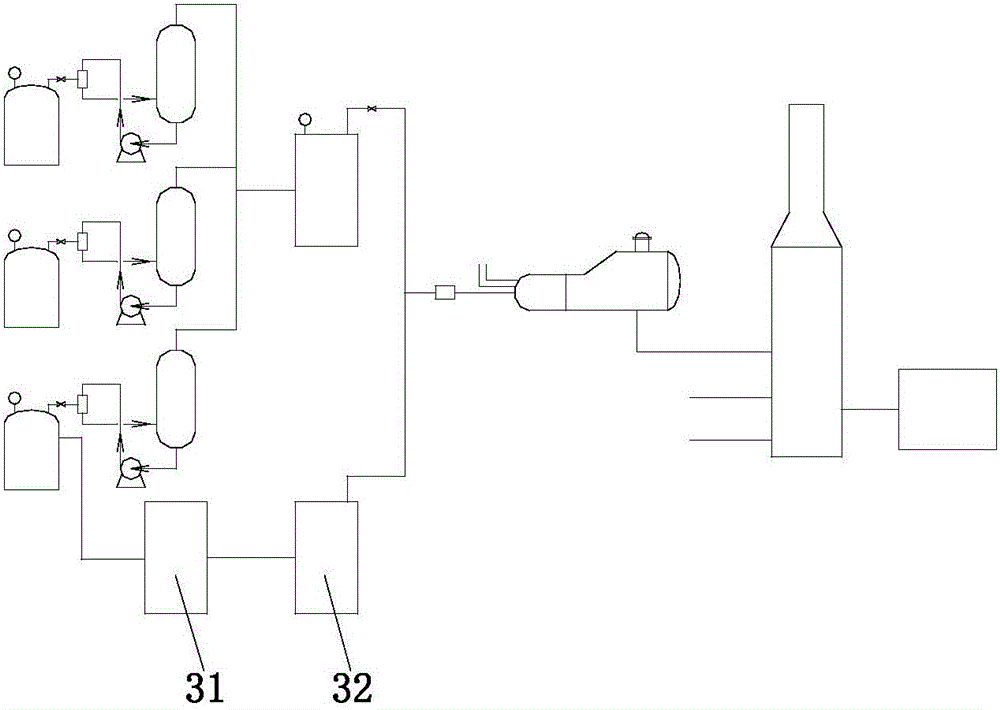

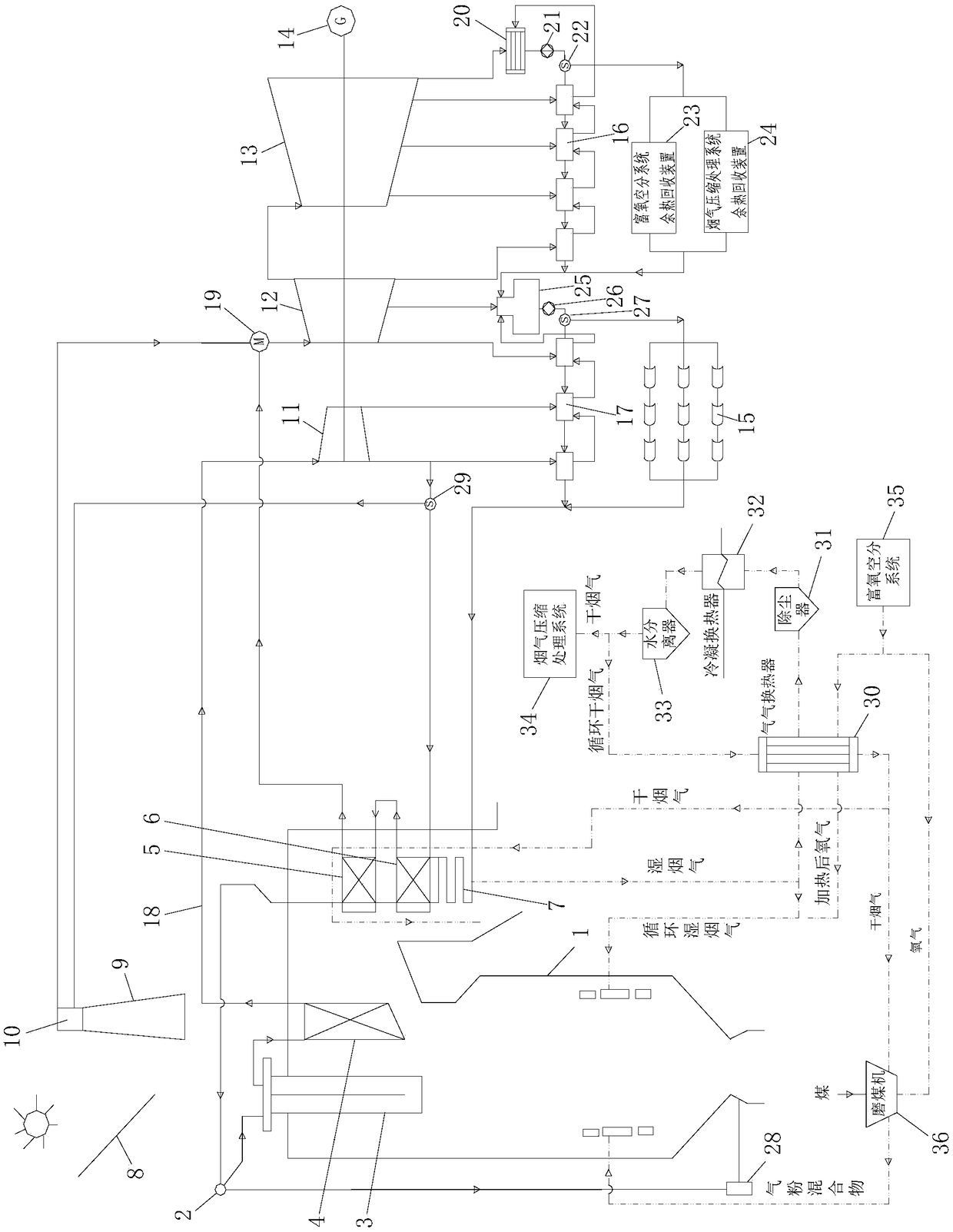

Tower and trough combined solar thermal and oxygen-rich coal-burning unit coupled power generation system

ActiveCN109057892AImprove utilization efficiencyRealize cascade utilizationFrom solar energyFeed water supplyEngineeringSolar power

The invention discloses a tower and trough combined solar thermal and oxygen-rich coal-burning unit coupled power generation system. The tower and trough combined solar thermal and oxygen-rich coal-burning unit coupled power generation system comprises a boiler system, a tower type solar heat collecting system, a turbine system, a trough type solar heat collecting system, an oxygen-rich air separation system waste heat recycling device, a smoke compression treatment system waste heat recycling device and an oxygen-rich smoke circulation system. According to the tower and trough combined solarthermal and oxygen-rich coal-burning unit coupled power generation system, tower type solar energy and an oxygen-rich coal-burning boiler are coupled, a trough type solar heat collecting field and a high pressure heater set are connected in parallel, the air separation system waste heat recycling device and the smoke compression treatment system waste heat recycling device are connected with a lowpressure heater set in parallel, gradient utilization of energy is realized, fuel consumption is lowered, gathering of carbon dioxide is facilitated, and meanwhile the problem of low stability of pure solar power generation is solved. The trough type solar heat collecting system and the high pressure heater set are connected in parallel, so that the sucking rate of a high pressure cylinder is reduced. The air separation system waste heat recycling device and the smoke compression treatment system waste heat recycling device are connected with the low pressure heater set in parallel, so that the sucking rate of a low pressure cylinder can be reduced. Stable operation of the system is guaranteed, the quantity of steam for power generation is increased, and electricity output of the system is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

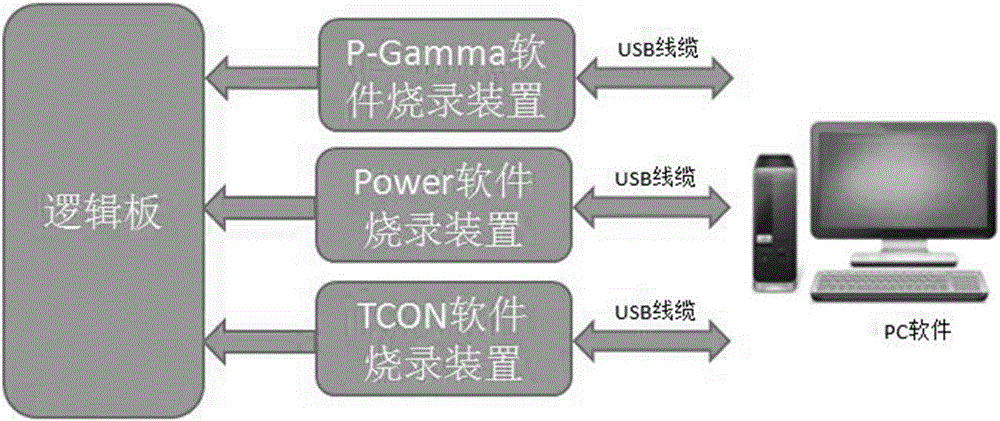

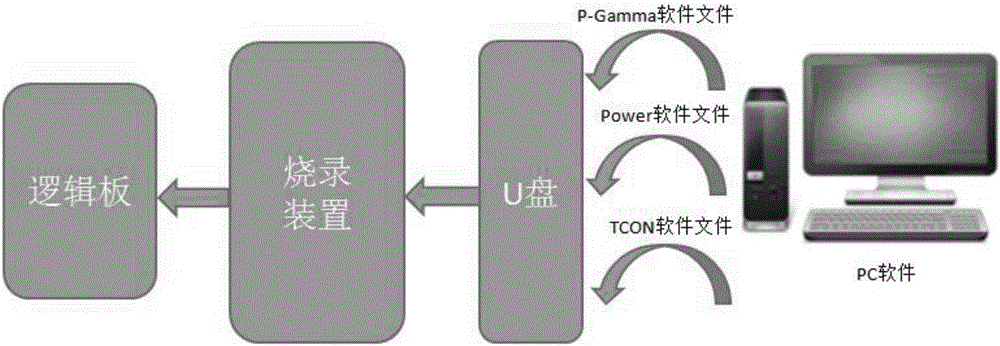

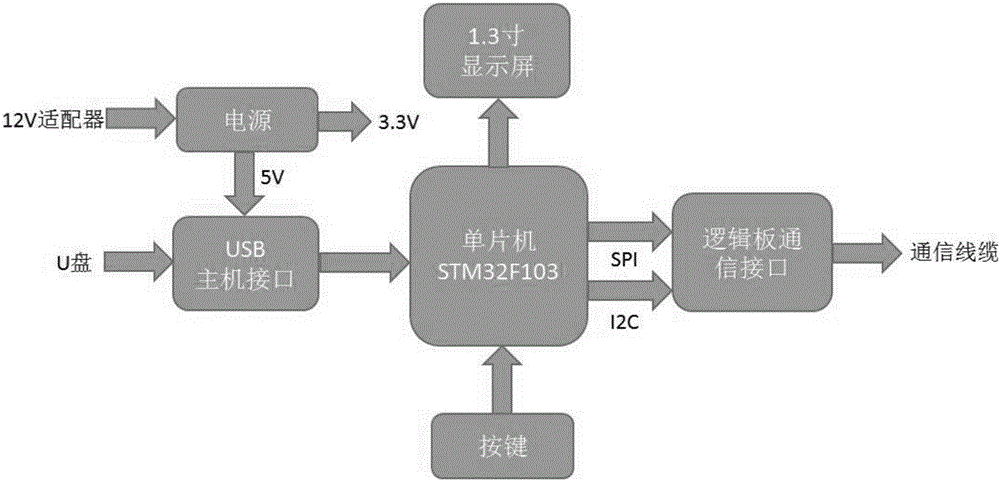

LCD (liquid crystal display) logic board software offline burning device and method

InactiveCN106843960AEasy to carryEasy to operateSoftware engineeringProgram loading/initiatingBurn unitsLiquid-crystal display

The invention relates to the technical field of LCD (liquid crystal display) logic boards, in particular to an LED logic board software offline burning device and method. The device comprises a PC (personal computer), a U disk, a burning unit and a logic board; the PC is used for copying program files to the U disk, the burning unit directly reads the program files in the U disk, and then a push button of 'one-key to burn' of the burning unit is clicked to have the program files in the U disk burnt to the logic board in one step. Software is stored in a mode of files placed in the U disk, the burning unit directly reads the program files in the U disk to have all the software burnt to the logic board in one step, the PC is not needed, and the LED logical board software offline burning device has the advantages of convenience in carry, simpleness in operation, offline burning and the like.

Owner:深圳市视显光电技术有限公司

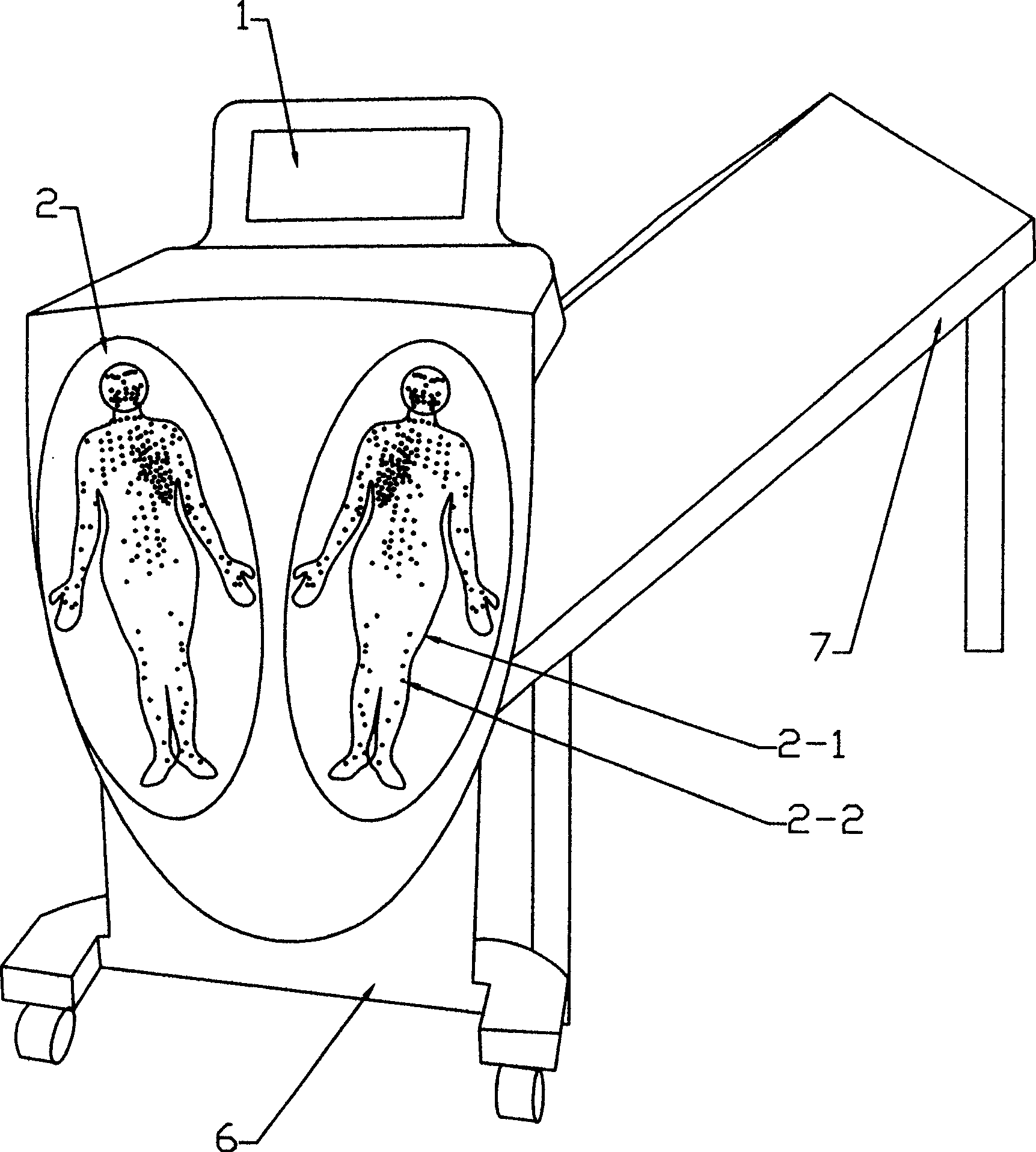

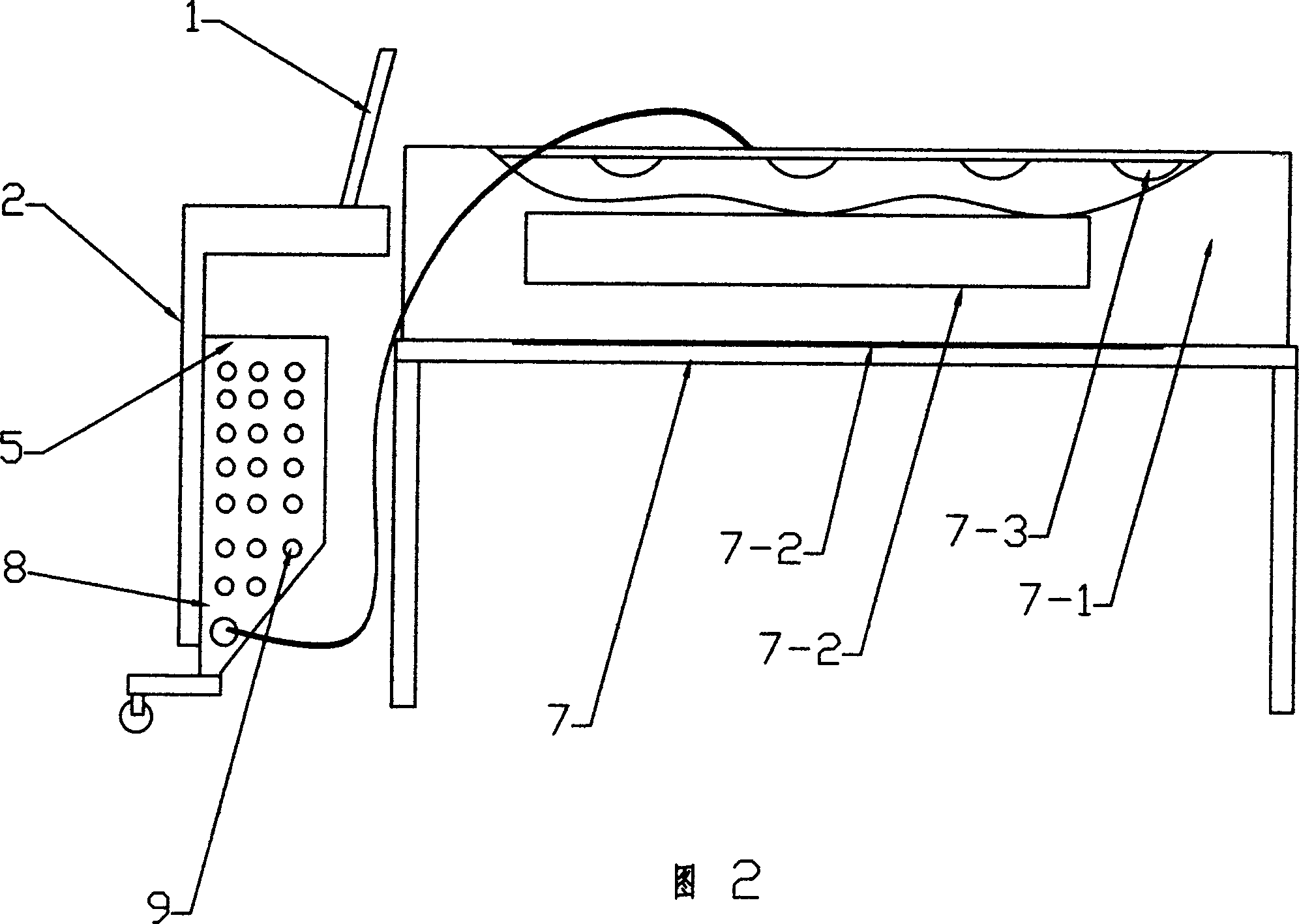

Sequencing whole body meridian balancing system

InactiveCN1833627AGood curative effectAcupunctureDevices for locating reflex pointsBurn unitsWhole body

A programmable channels and collaterals balancing system for taking care of health is composed of display and input device, human acupoints display device, therapeutic unit consisting of cupping therapy, magnetotherapy and moxa burning units, air channel system, and controller for storing information, and controlling the display and modification of acupoints, the rotation of metal needles, temp of moxa burning, and the cupping pressure by controlling the valves in air channel.

Owner:冯玉旭

Novel portable ethanol fuel battery

InactiveCN106450379AImprove heat utilizationEasy injectionFuel cell heat exchangeReactant parameters controlBurn unitsHydrogen

The invention discloses a novel portable ethanol fuel battery. The technical scheme of the invention is that the novel portable ethanol fuel battery comprises a galvanic pile power generation module, a reforming hydrogen generation module, an ethanol supply module and a water supply module, which are arranged in a modularization mode, wherein the ethanol supply module and the water supply module are connected to the reforming hydrogen generation module; the reforming hydrogen generation module is connected to the galvanic pile power generation module; the galvanic pile power generation module comprises an exhaust hole which is connected with a heat exchanger; the heat exchanger provides heat for ethanol vaporization in the reforming hydrogen generation module; the ethanol supply module is detachably connected with the reforming hydrogen generation module; the reforming hydrogen generation module comprises a flameless burning unit; and the galvanic pile power generation module comprises a residual gas exhaust hole which is connected to the flameless burning unit. The novel portable ethanol fuel battery provided by the invention is safe, convenient to carry, and higher in power generation capacity, and has energy-saving and environment-friendly effects.

Owner:苏州氢洁电源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com