Low resistance cyclonic liquid column type nozzle

A nozzle and anti-spin technology, which is applied in the field of low-resistance swirl liquid column nozzles, can solve the problems of lack of commercial desulfurization technology, incomplete design and manufacturing capabilities of flue gas desulfurization devices, and achieve high desulfurization efficiency and low operating costs. Reduction, construction cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

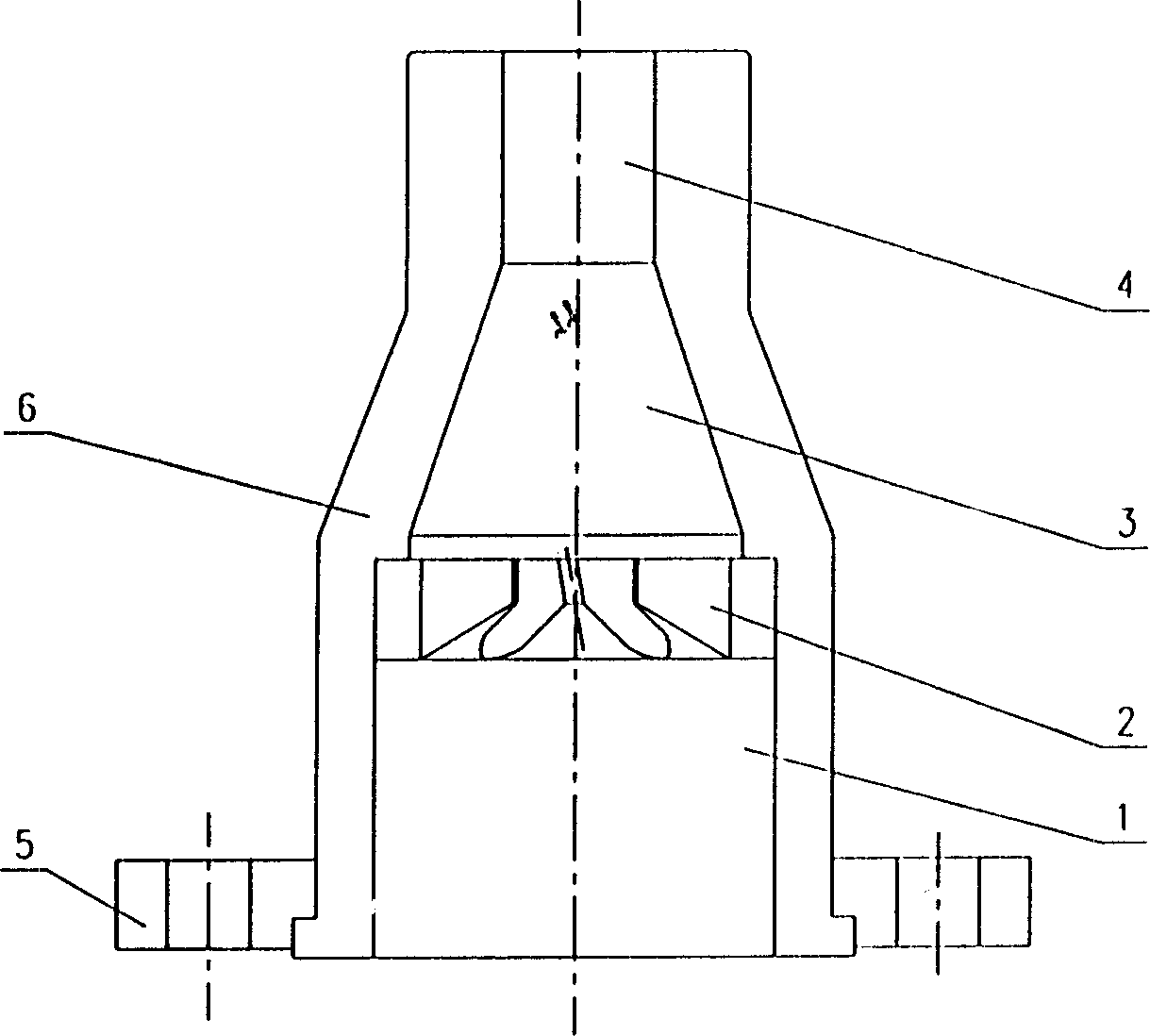

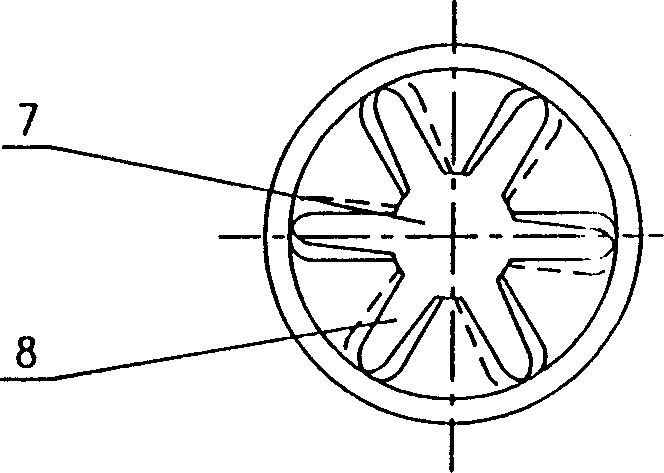

[0010] A nozzle applied to a high-efficiency pipe-type reaction desulfurization device for flue gas of a large-scale coal-fired unit in a thermal power plant. The steady flow section 1 is provided with a connecting flange 5 and a riser base 6 , and the riser 2 is provided with a central hole 7 and side flow holes 8 .

[0011] The liquid first passes through the steady flow section 1 to stabilize the flow, and distributes the throughput of the liquid through the center hole 7 and the side flow groove 8 of the riser core 2, so that part of the liquid obtains the initial rotational speed; the rotating liquid in the mixing cone 3 is further accelerated and The preliminary mixing of the rotating liquid and the direct injection liquid is completed, and the liquid is accelerated to the design flow rate through the acceleration tube 4, and the ejection nozzle is in contact with the gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com