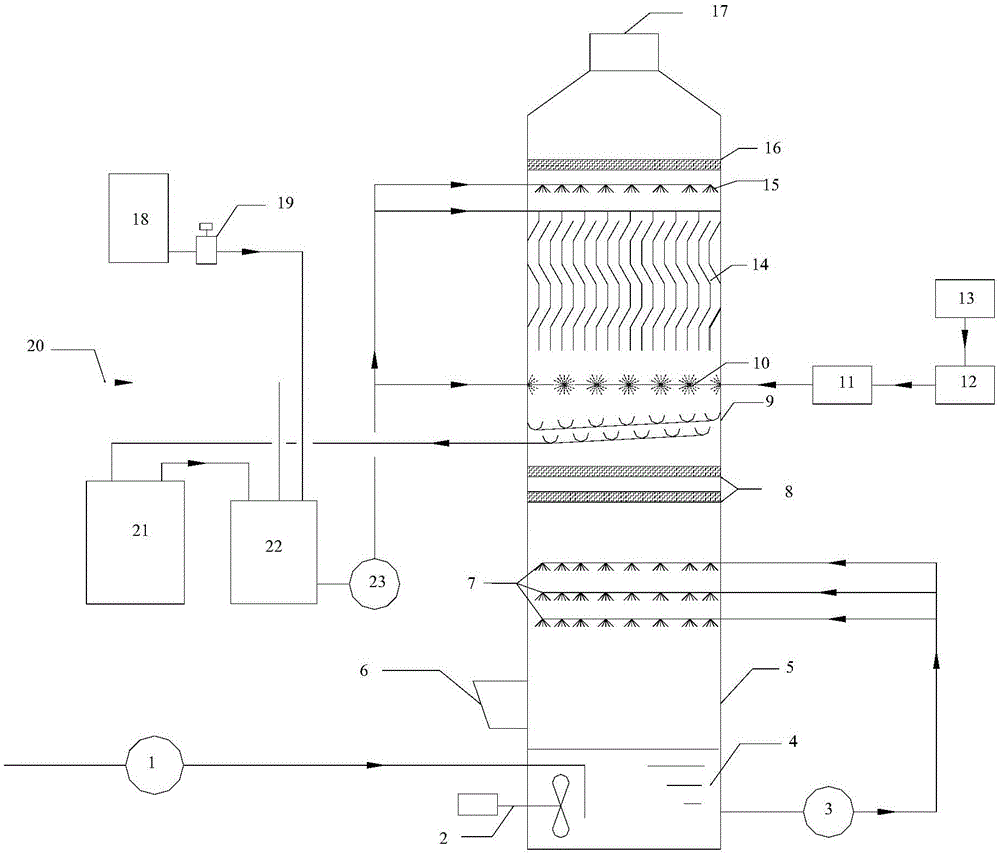

Super-clean exhausting integral tower and treating technology for coal-fired boiler exhaust gas

A coal-fired boiler, ultra-clean technology, applied in the direction of electrode cleaning, external electrostatic separator, electrode structure, etc., to achieve the effects of reducing the probability of electric sparks, stable installation, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

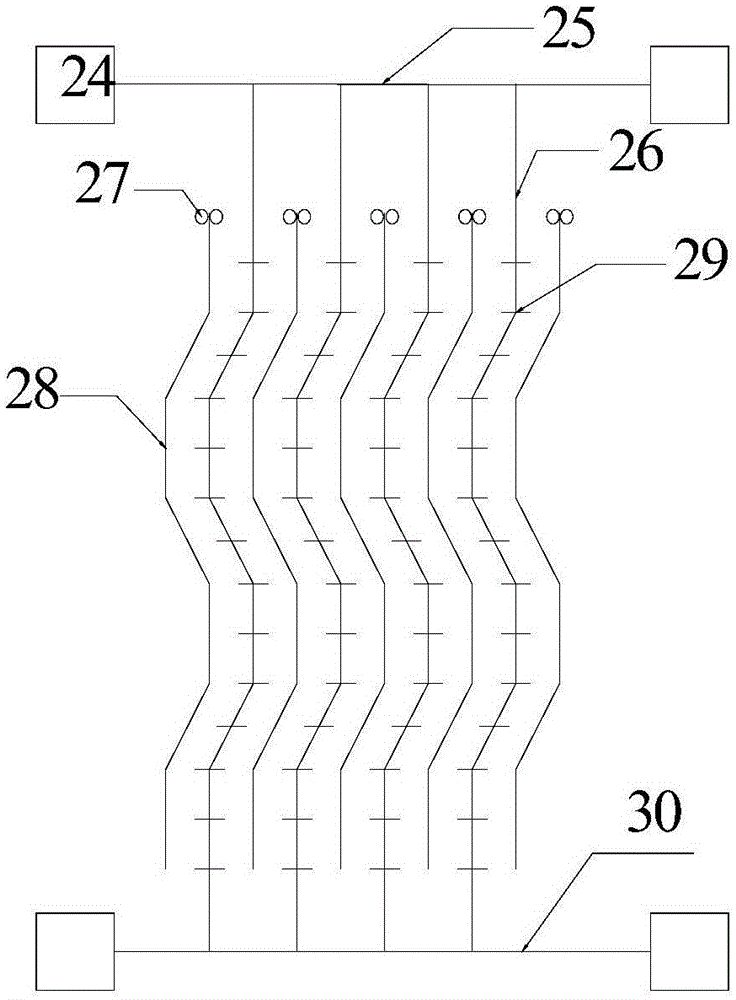

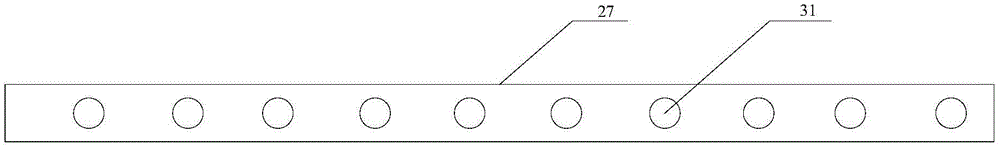

Embodiment 1

[0109] The flue gas volume of a coal-fired boiler is 59723m3 / h, NOx349mg / Nm 3 , SO 2 1501mg / Nm 3 After the initial flue gas enters the ultra-clean integrated tower, the flue gas is subjected to ultra-clean treatment in the tower, and the molar ratio of ozone injected into the gas path to nitrogen oxides in the flue gas is n O3 :n NO =2.5; the molar ratio of the liquid-gas ratio of the denitrification spray gun to the injected NaOH solution and the nitrogen oxides in the flue gas is n NaOH :n NO = 1.5, the temperature of the alkaline solution is 5°C, the liquid-gas ratio of the sprayed lye flow rate and the flue gas volume is 0.05, the atomized particle size D50 is 30 μm, the discharge voltage at the wet electricity place is 72KV, the length of the anode plate is 8m, and the spacing is 280mm , the burr length is 25mm, and the burr spacing is 50mm. Tower outlet NOx9mg / Nm 3 , SO 2 4mg / Nm 3 , Dust 3mg / Nm 3 , water vapor content 2mg / Nm 3 .

Embodiment 2

[0111] The flue gas volume of a coal-fired boiler is 60023m3 / h, NOx351mg / Nm 3 , SO 2 1487mg / Nm 3 After the initial flue gas enters the ultra-clean integrated tower, the flue gas is subjected to ultra-clean treatment in the tower, and the molar ratio of ozone injected into the gas path to nitrogen oxides in the flue gas is n O3 :n NO =2.1; Denitrification spray gun liquid-gas ratio injected K 2 CO 3 The molar ratio of nitrogen oxides in the solution to the flue gas is n K2CO3 :n NO = 1.4, the temperature of the alkaline solution is 10°C, the liquid-gas ratio of the sprayed lye flow rate and the flue gas volume is 0.04, the atomized particle size D50 is 50 μm, the discharge voltage at the wet electricity place is 70KV, the length of the anode plate is 7m, and the spacing is 300mm , the burr length is 20mm, and the burr spacing is 75mm. Tower outlet NOx14mg / Nm 3 , SO 2 8mg / Nm 3 , Dust 4mg / Nm 3 , water vapor content 6mg / Nm 3 .

Embodiment 3

[0113] The flue gas volume of a coal-fired boiler is 59887m3 / h, NOx352mg / Nm 3 , SO 2 1470mg / Nm 3 After the initial flue gas enters the ultra-clean integrated tower, the flue gas is subjected to ultra-clean treatment in the tower, and the molar ratio of ozone injected into the gas path to nitrogen oxides in the flue gas is n O3 :n NO =2.0; the molar ratio of the liquid-gas ratio of the denitrification spray gun to the nitrogen oxides in the sprayed KOH solution and the flue gas is n KOH :n NO = 1.4, the temperature of the alkaline solution is 10°C, the liquid-gas ratio of the sprayed lye flow rate and the flue gas volume is 0.02, the atomized particle size D50 is 80 μm, the discharge voltage at the wet electricity place is 65KV, the length of the anode plate is 6m, and the spacing is 320mm , the burr length is 20mm, and the burr spacing is 75mm. Tower outlet NOx19mg / Nm 3, SO 2 12mg / Nm 3 , dust 4.5mg / Nm 3 , water vapor content 10mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com