Method for preparing supported iron oxide series desulfurizing agent

An iron oxide-based, supported technology, applied in the direction of sulfur preparation/purification, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problem of uneven loading of active components, affecting the desulfurization effect and desulfurization efficiency of iron oxide desulfurizers and other problems, to achieve uniform distribution, ensure desulfurization activity, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

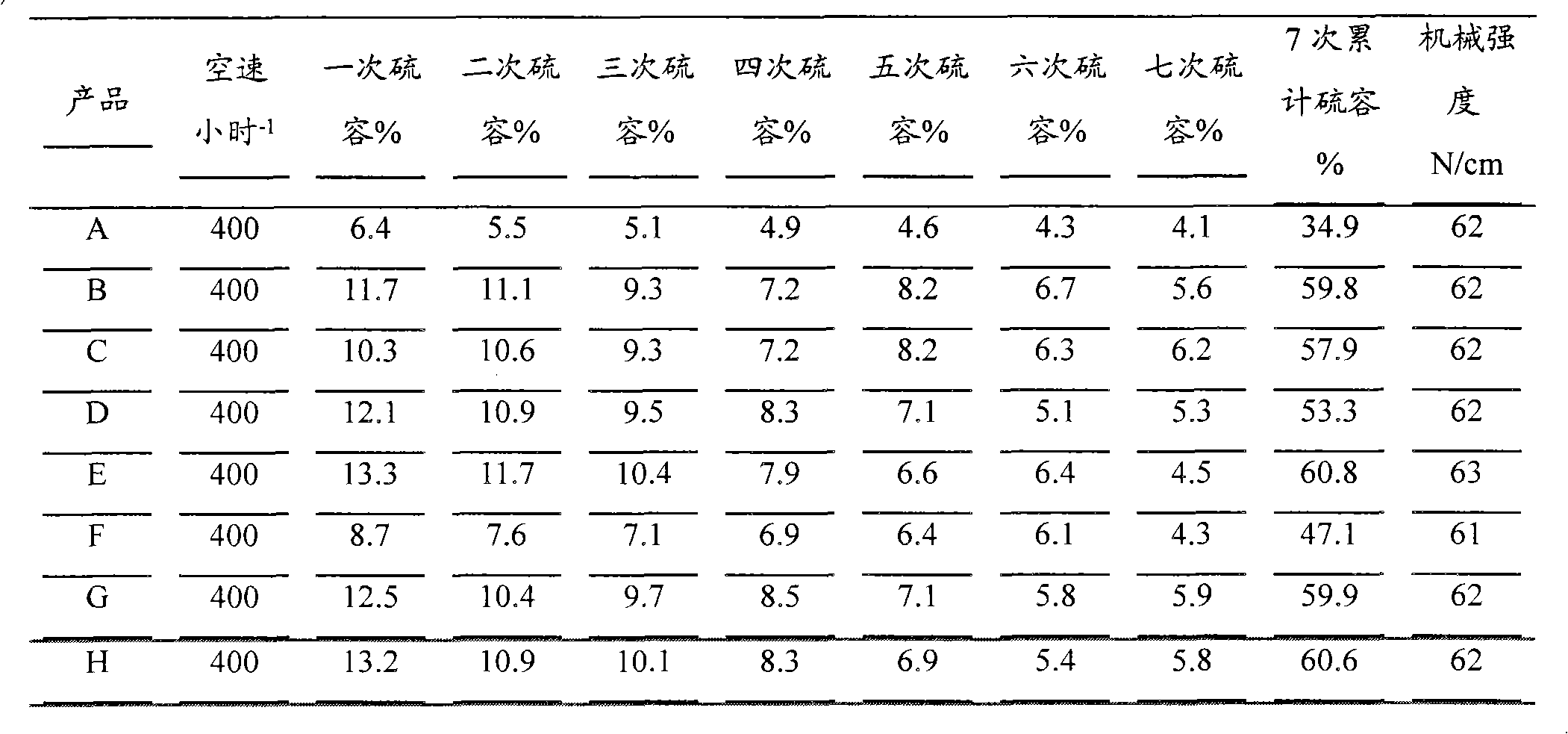

Examples

Embodiment 1

[0028] Take 30g of ferrous sulfate heptahydrate and dissolve it in 70g of water to make a solution, measure 20g of alumina spheres with a diameter of 5mm and immerse in 30ml of ferrous sulfate heptahydrate solution, put it into the container and seal it, and use a vacuum pump to make the pressure inside the container reach -0.08MPa , soaked for 2 hours. Take it out, drain the excess ferrous sulfate heptahydrate solution, drain the sphere, and dry it at 85°C for 1 hour.

[0029] Put the obtained alumina sphere into the ferrous sulfate heptahydrate solution with a mass concentration of 30%, put it into a container and seal it, use a vacuum pump to make the pressure in the container reach -0.08MPa, and soak for 2 hours. Take it out, drain the excess ferrous sulfate heptahydrate solution, and dry it at 50°C for 10 hours.

[0030] Put the dried sphere into 39.7ml of potassium hydroxide solution with a concentration of 3mol / L, put it into a container and seal it, use a vacuum pump ...

Embodiment 2

[0032] Dissolve 90g of ferric chloride in 110ml of water, measure 30g of alumina spheres with a diameter of 3mm, put them into 50ml of ferric chloride solution, put them into a container and seal them, use a vacuum pump to make the pressure in the container reach -0.1MPa, and soak for 8 hours. Take it out, filter out the excess ferric chloride solution, drain the spheres, and dry them at 85°C for 1 hour.

[0033] Put the dried sphere into 83.3ml of 3mol / L sodium hydroxide solution, put it into a container and seal it, use a vacuum pump to make the vacuum in the container reach 0.07MPa, and soak for 2 hours. Remove the spheres and drain the water.

[0034] Then wash with water at 40°C until there is no chloride ion in the eluent. Then dry at 85°C for 1 hour to obtain hydrated iron oxide desulfurizer B.

Embodiment 3

[0036] Dissolve 80g of ferric chloride in 120ml of water, measure 30g of alumina spheres with a diameter of 6mm, put them into 50ml of ferric chloride solution, put them into a container and seal them, use a vacuum pump to make the pressure inside the container reach 3MPa, and soak for 16 hours. Take it out, filter out the excess ferric chloride solution, drain the spheres, and dry them at 70°C for 3 hours.

[0037] Put the dried sphere into 62.5ml of 4mol / L sodium hydroxide solution, put it into a container and seal it, use a vacuum pump to make the vacuum in the container reach 0.09MPa, and soak for 2 hours. Remove the spheres and drain the water.

[0038] Then wash with water at 60°C until there is no chloride ion in the eluent. Then dry at 70°C for 3 hours to obtain hydrated iron oxide desulfurizer C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com