Combustible liquid vapor explosion and explosion suppression characteristic test system

A technology of characteristic testing and steam, which is applied in the direction of fuel oil testing and material inspection products, etc. It can solve the problem of heating method, heat preservation effect, pipeline gas distribution uniformity and accuracy affecting the accuracy of experimental data, and it is impossible to adjust the timing of explosion suppressant spraying in milliseconds , Inability to realize flammable liquids and other problems, to achieve the effect of precise and controllable throwing timing, diversified functions and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

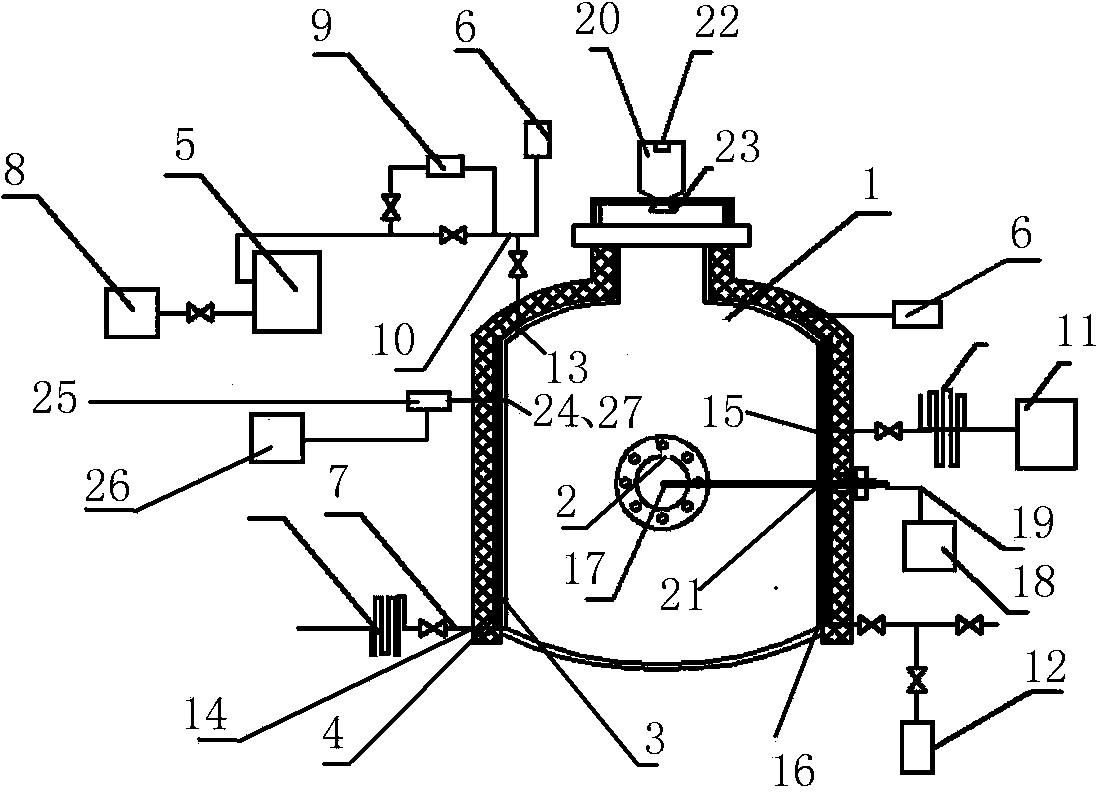

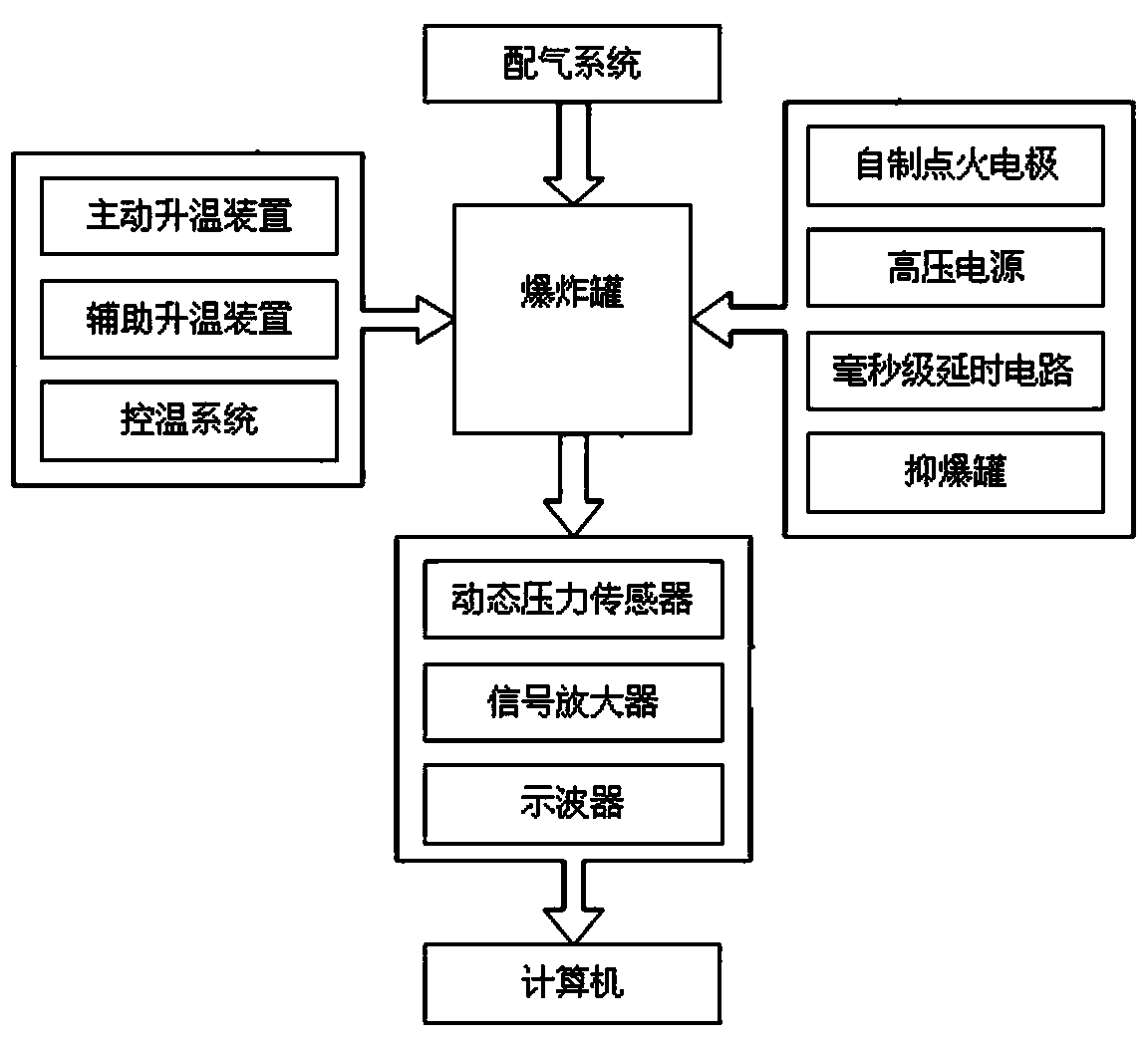

[0037] like figure 1 The shown flammable liquid vapor explosion and explosion suppression characteristic test system includes explosion tank 1, dual heating temperature control system, gas distribution system, dual ignition delay suppression system, and data test collection system;

[0038] A window 2 and six through holes are respectively provided on the side wall of the explosion tank 1;

[0039] The dual heating temperature control system includes a heating sheet 3, an insulating material 4, an air heater 5, and a temperature control system 6, wherein the heating sheet 3 is coated on the side wall of the explosion tank 1, and the insulating material 4 is fixed on the heating sheet 3 On, the temperature control system 6 is respectively connected to the heating plate 3 and the air heater 5;

[0040] The air distribution system includes an exhaust pipeline 7, an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com