Patents

Literature

318 results about "Liquid vapor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

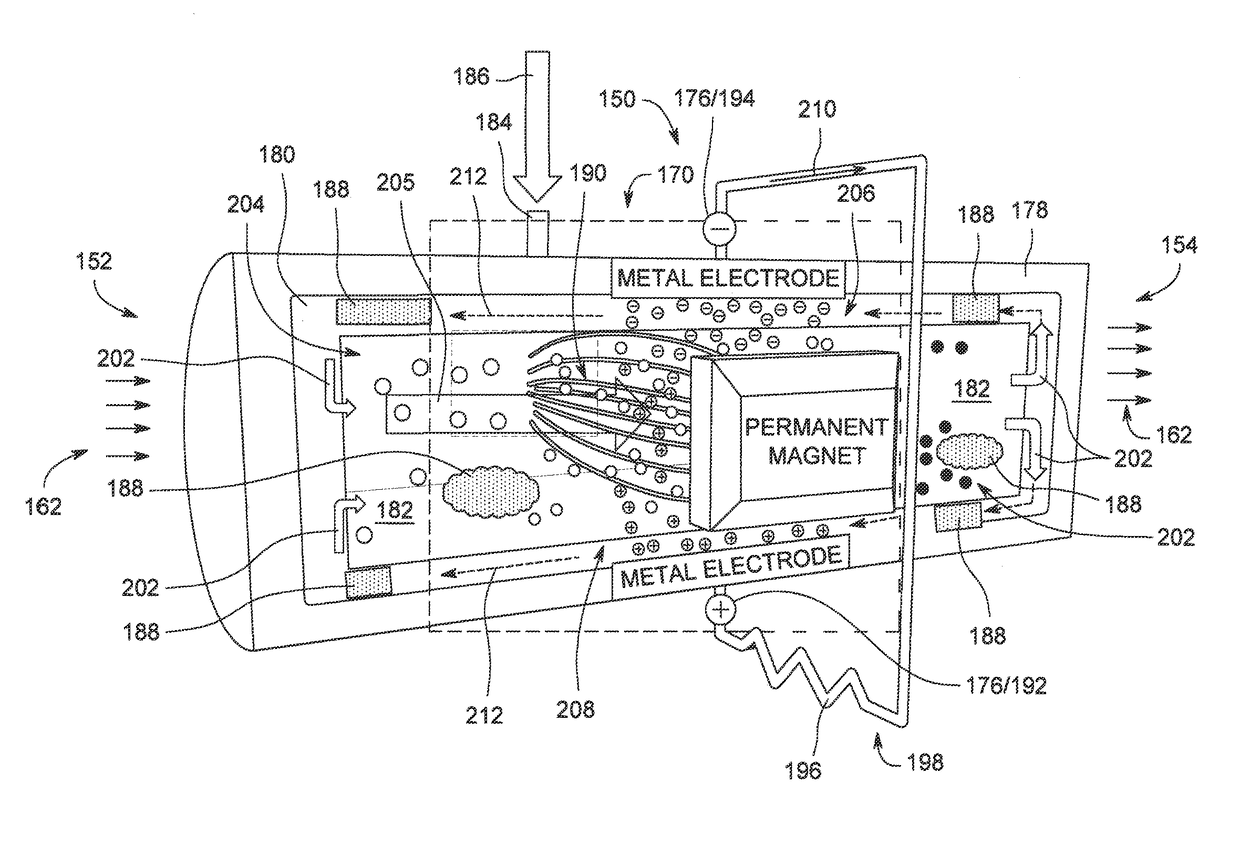

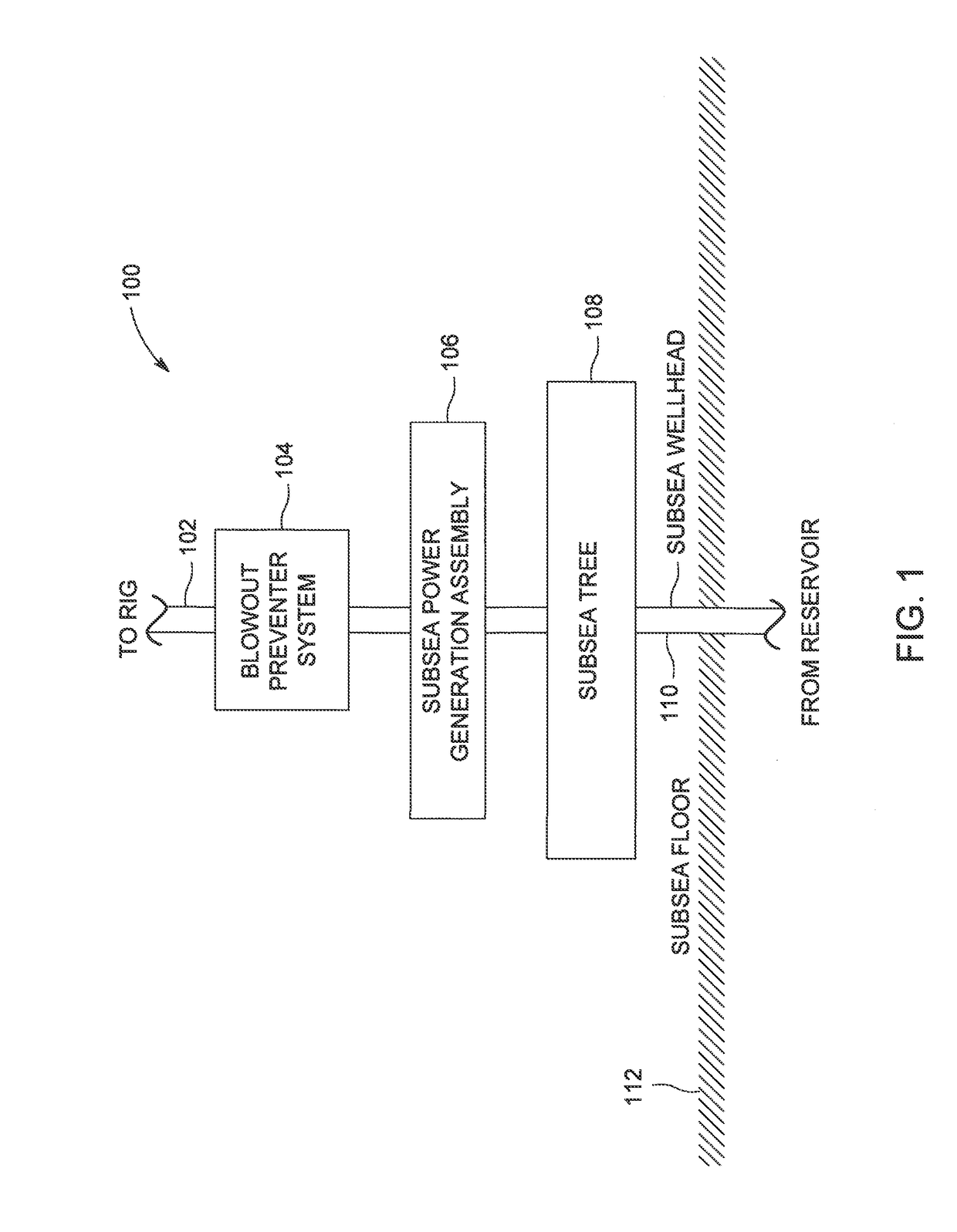

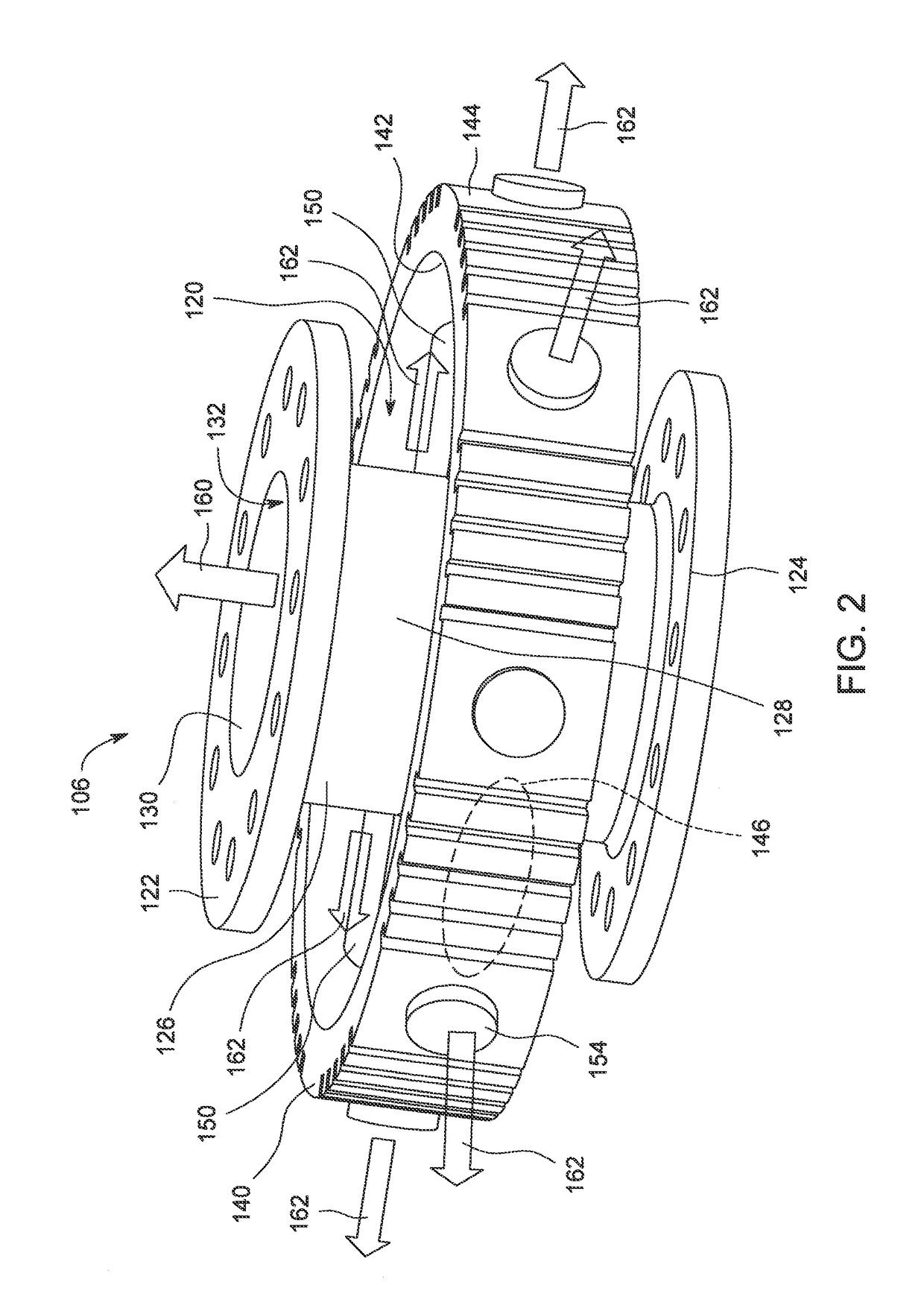

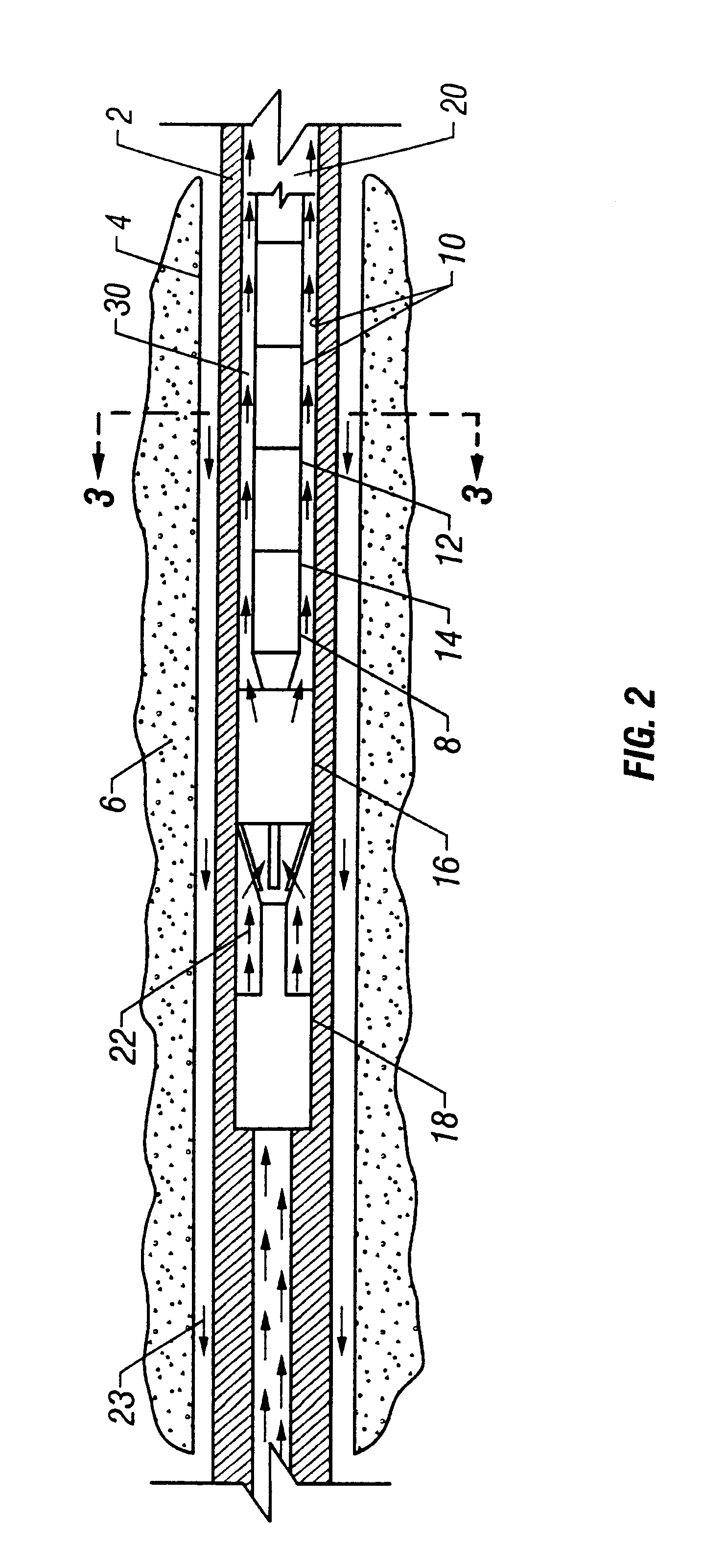

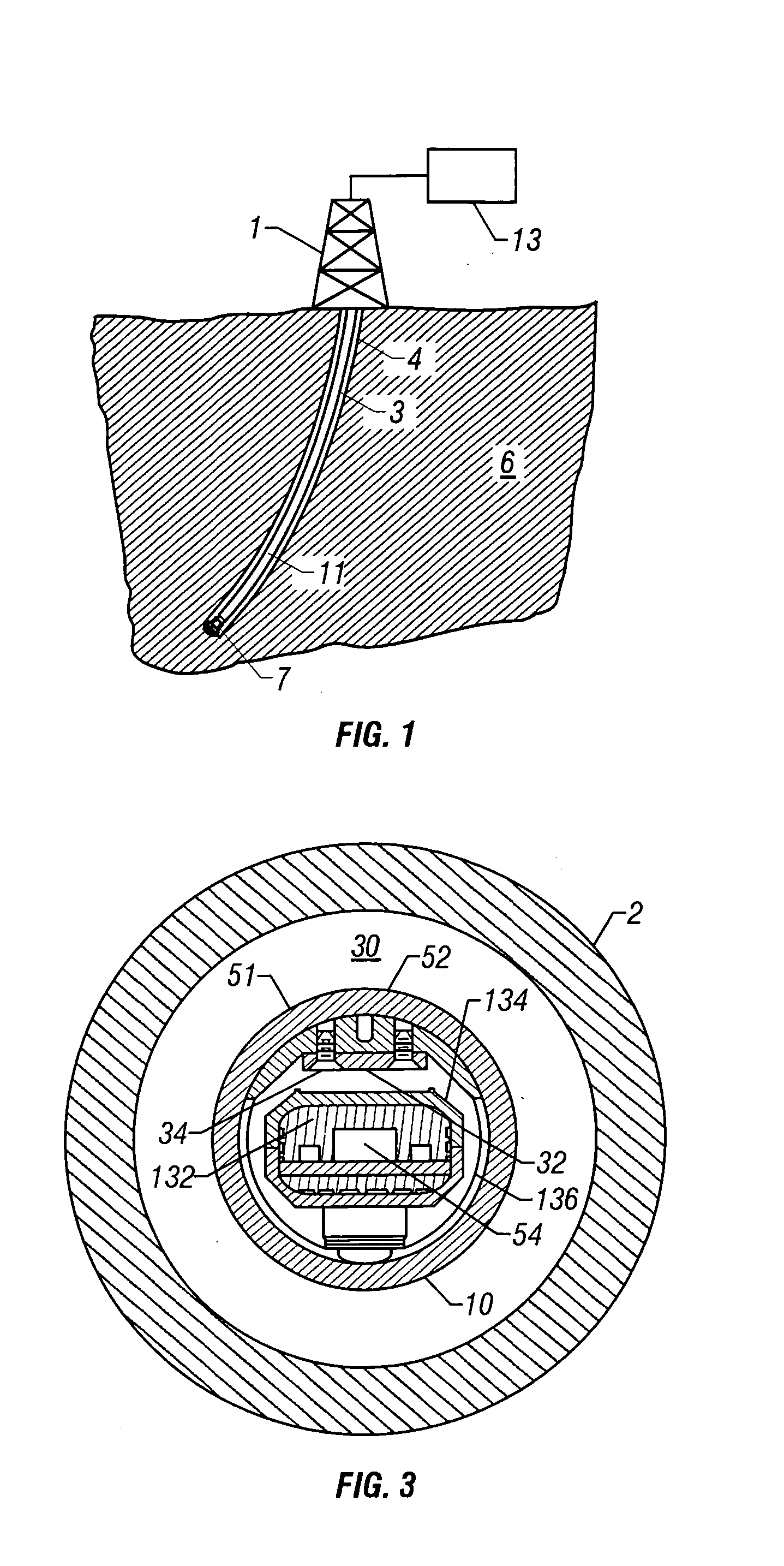

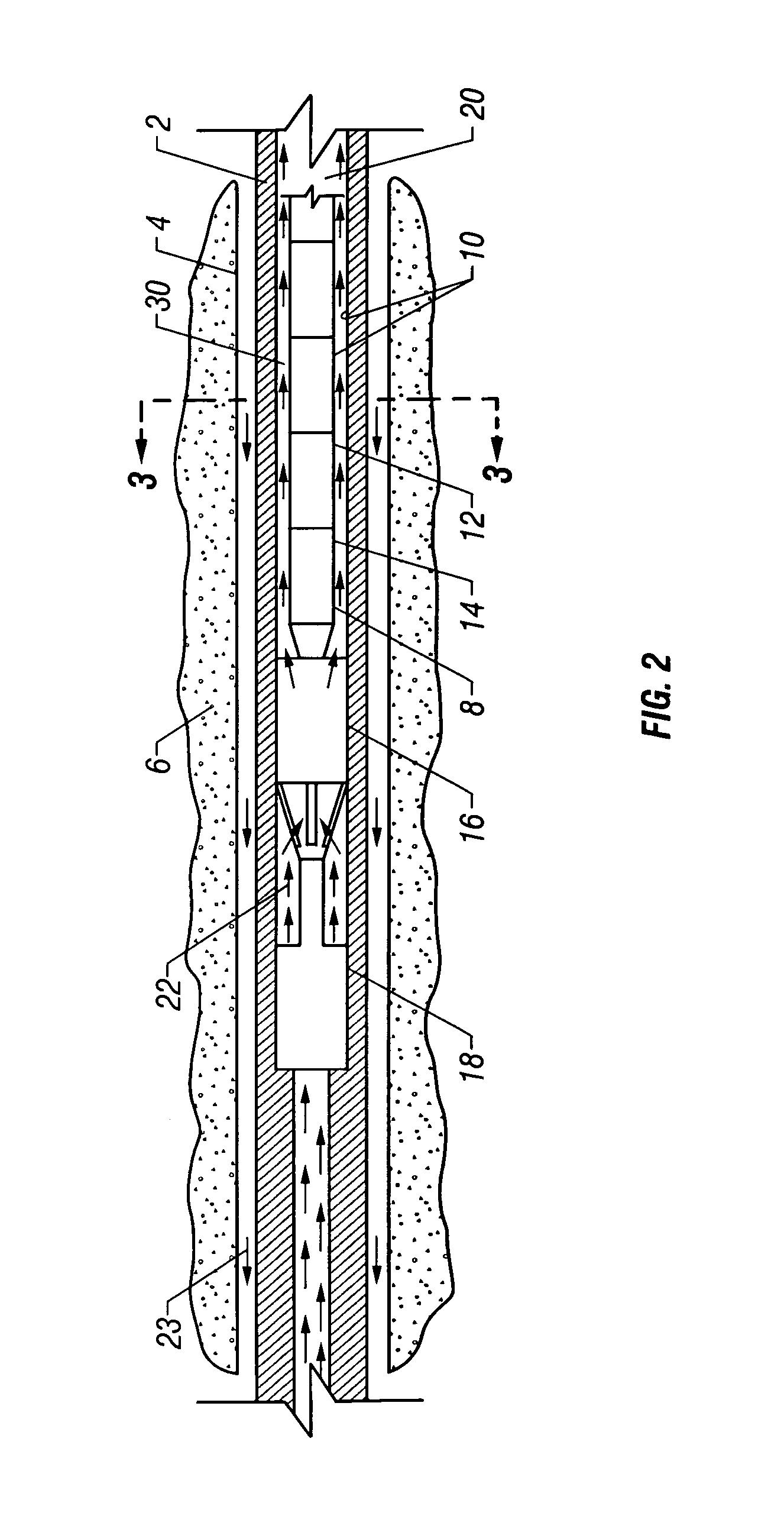

Submersible power generators and method of operating thereof

A submersible liquid-vapor generator (LVG) includes an evaporator portion in heat transfer communication with a heat energy source. The LVG also includes a magnetic field apparatus coupled in flow communication with the evaporator portion. The LVG further includes a condenser portion coupled in flow communication with the magnetic field apparatus. The LVG also includes a hybrid working fluid including nanoparticles. The evaporator portion, the magnetic field portion, and the condenser portion at least partially define a hybrid working vapor flow path. The LVG further includes an electrically non-conductive wick structure coupled in flow communication with the evaporator portion and the condenser portion. The wick structure at least partially defines a hybrid working liquid flow path extending between the condenser portion and the evaporator portion.

Owner:GENERAL ELECTRIC CO

Apparatus for equalizing air pressure in air respiratory system

InactiveUS6988497B2Accelerate liquid flowBurnersOther heat production devicesHigh concentrationBreathing gas

A humidifier apparatus for operating at an air pressure is disclosed for use with a respiratory therapy breathing apparatus that provides a breathable gas supply to patients requiring higher concentrations of liquid vapor and gas pressure. The humidifier apparatus includes a feed liquid supply bag in fluid communication with a humidifier cartridge via a conduit. The conduit enables air to flow therethrough to equalize air pressure between the humidifier cartridge and the feed liquid supply bag in response to liquid being supplied to the humidifier cartridge.

Owner:MEZZANINE OPPORTUNITIES LLC AS AGENT

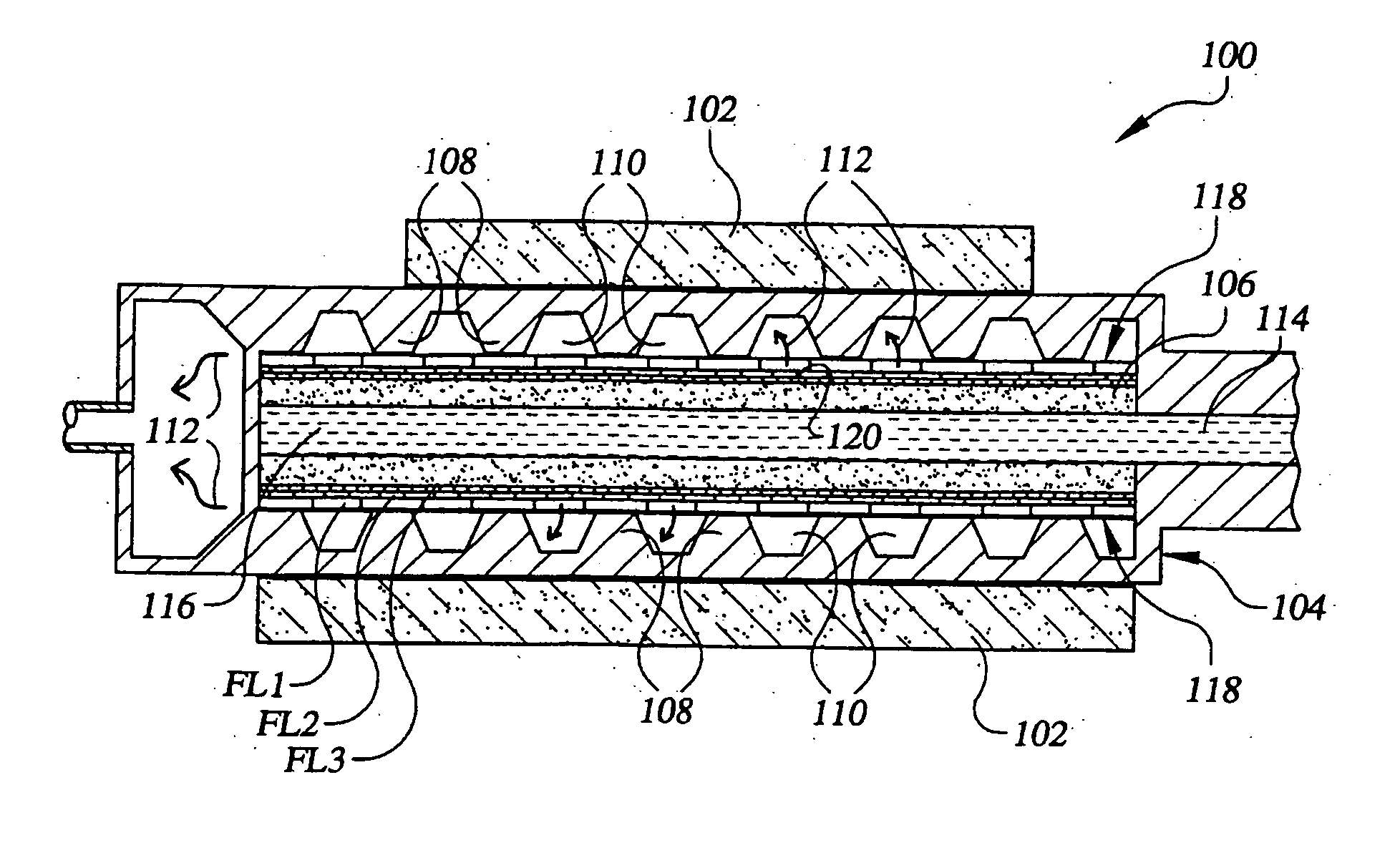

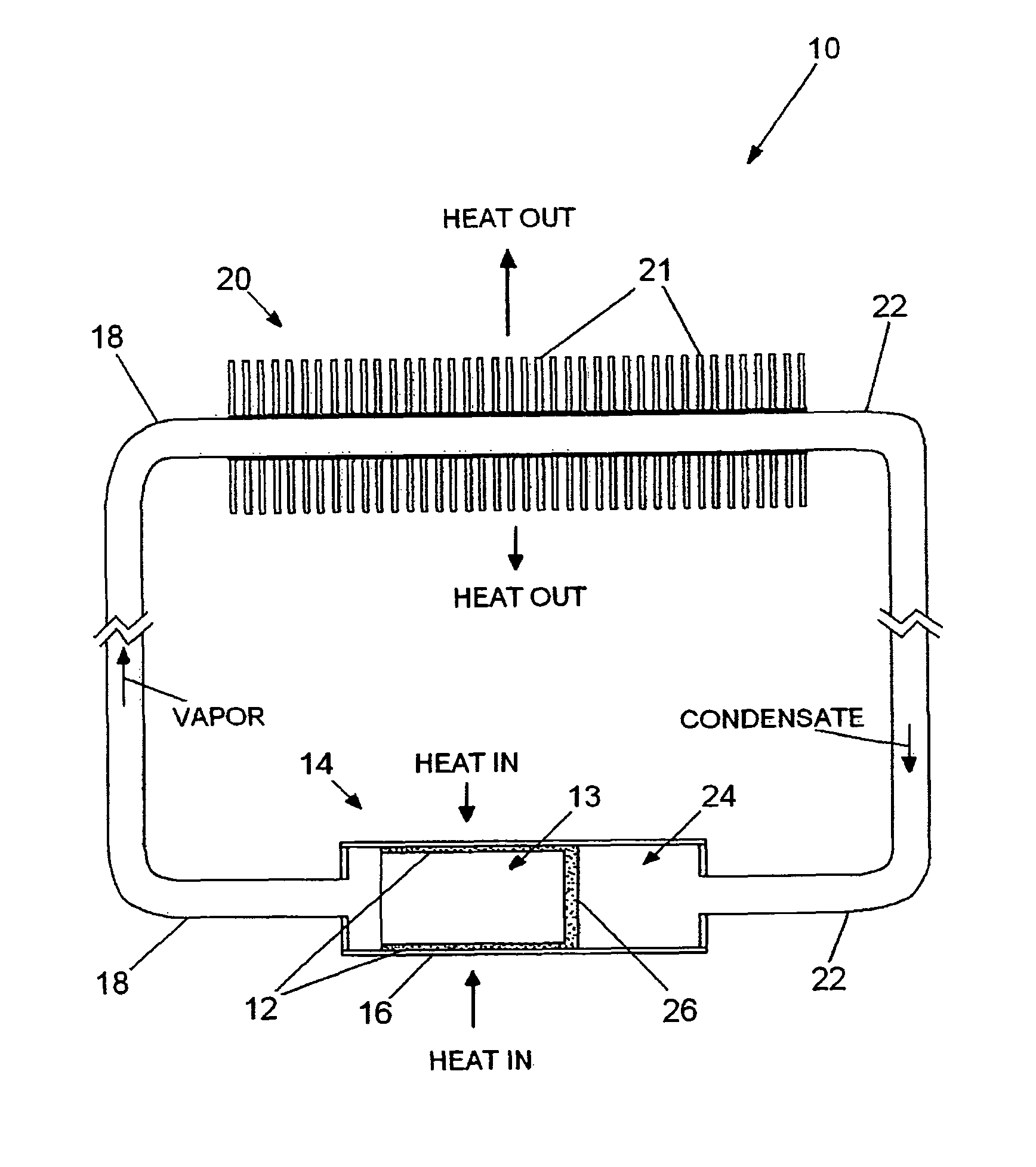

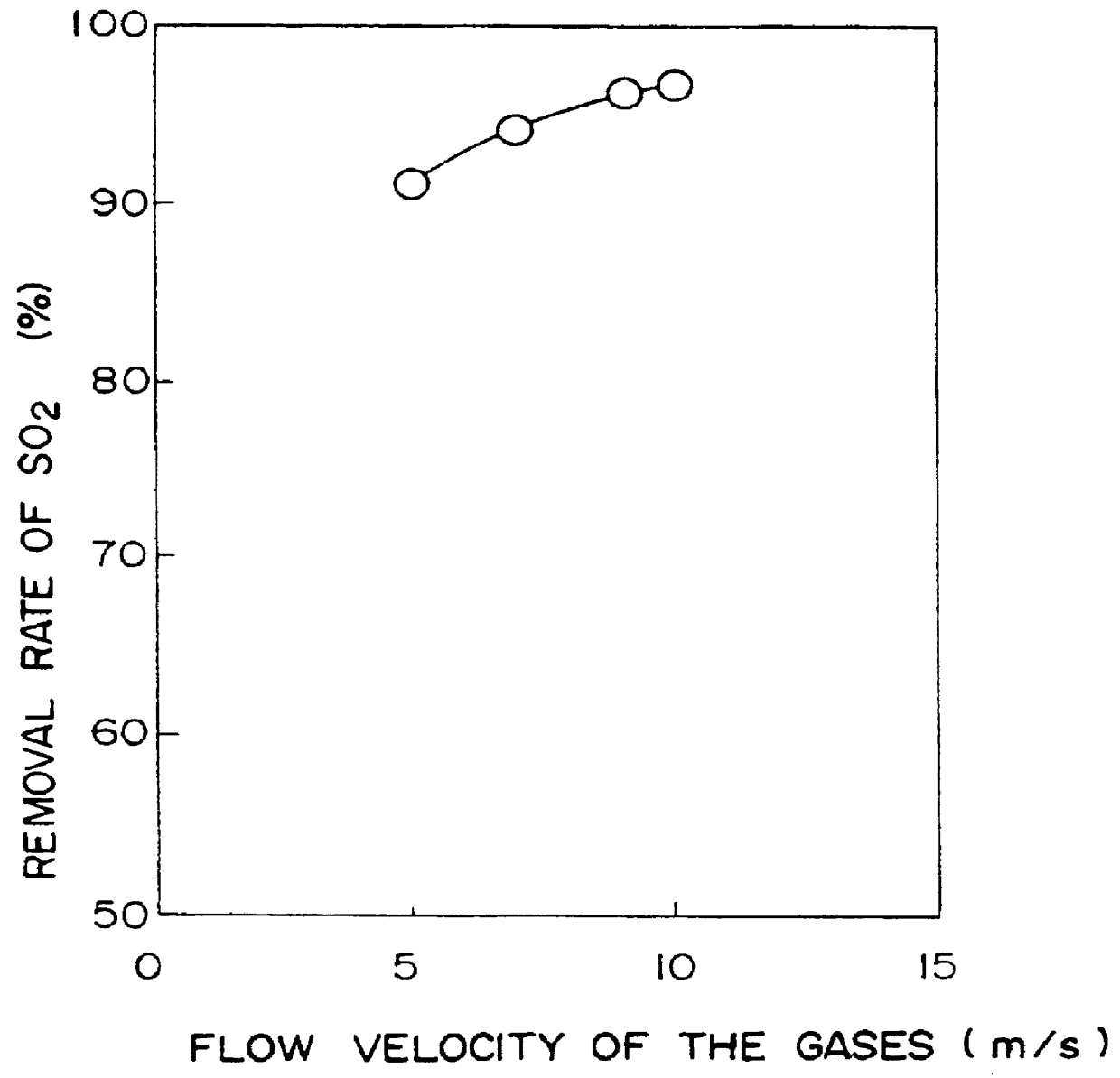

Capillary condenser/evaporator

ActiveUS20050230085A1Increase the cross-sectional areaReduce the cross-sectional areaIndirect heat exchangersCapillary condensationVapor liquid

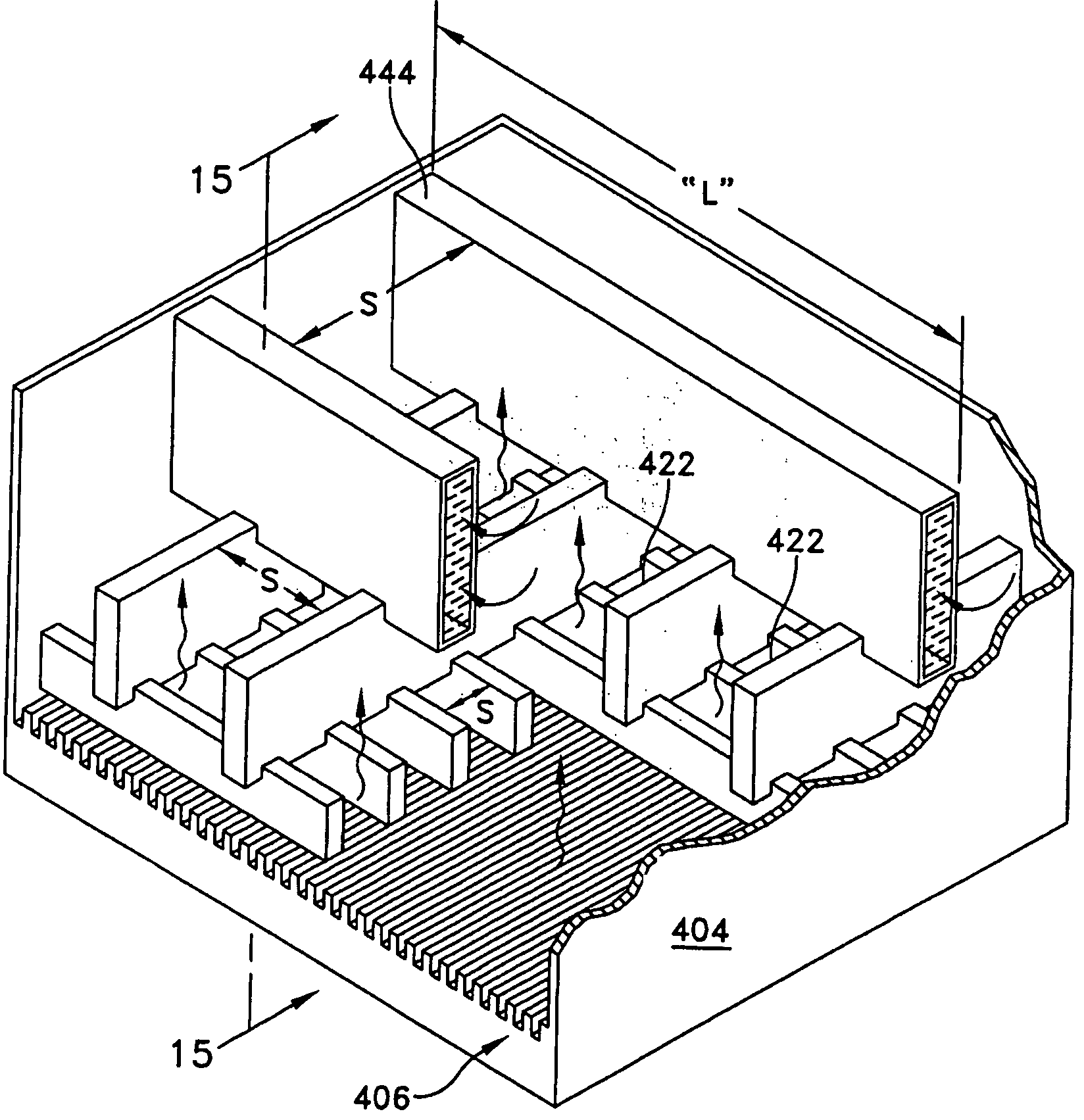

A heat transfer device is disclosed for transferring heat to or from a fluid that is undergoing a phase change. The heat transfer device includes a liquid-vapor manifold in fluid communication with a capillary structure thermally connected to a heat transfer interface, all of which are disposed in a housing to contain the vapor. The liquid-vapor manifold transports liquid in a first direction and conducts vapor in a second, opposite direction. The manifold provides a distributed supply of fluid (vapor or liquid) over the surface of the capillary structure. In one embodiment, the manifold has a fractal structure including one or more layers, each layer having one or more conduits for transporting liquid and one or more openings for conducting vapor. Adjacent layers have an increasing number of openings with decreasing area, and an increasing number of conduits with decreasing cross-sectional area, moving in a direction toward the capillary structure.

Owner:MIKROS MFG

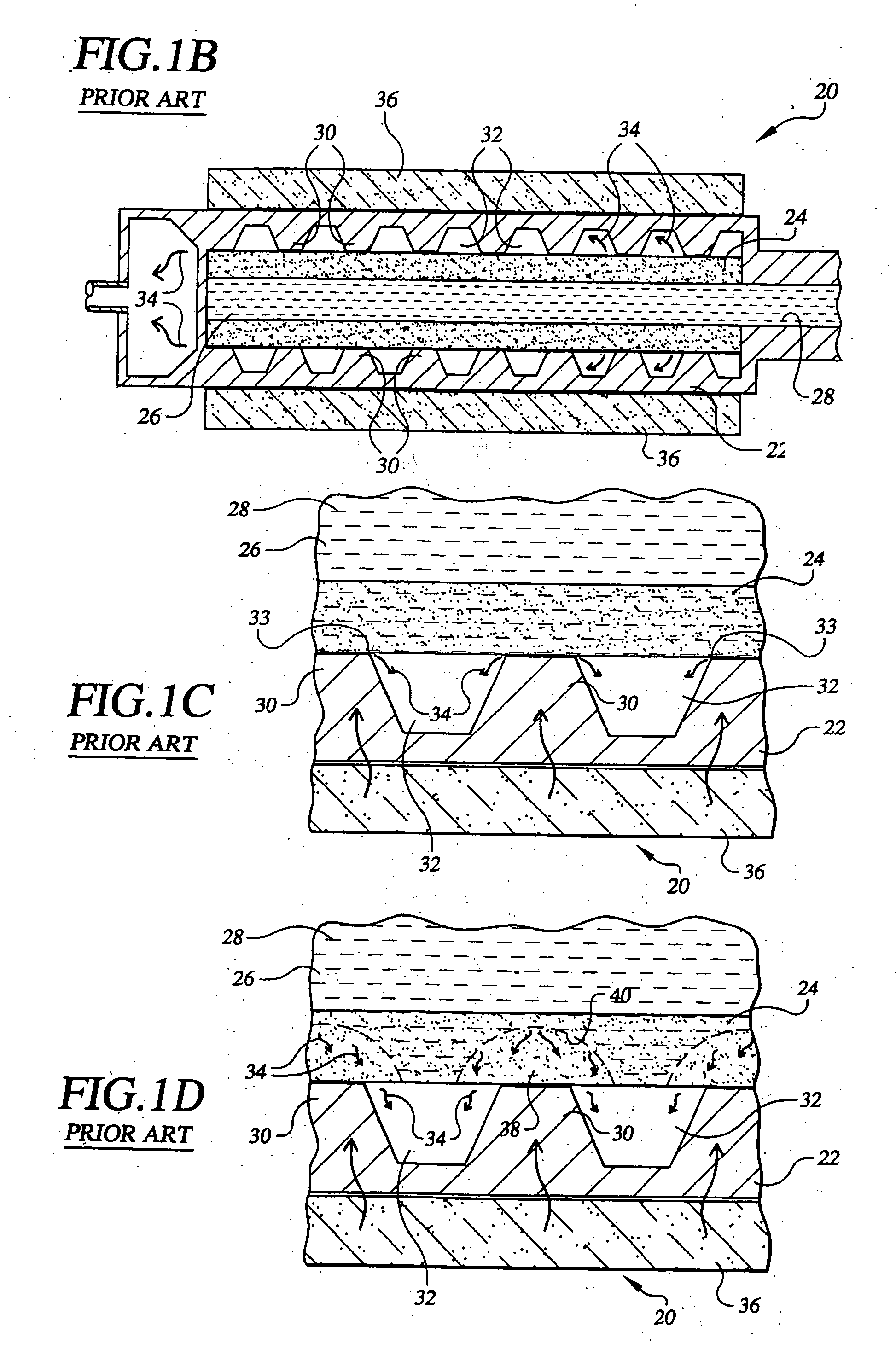

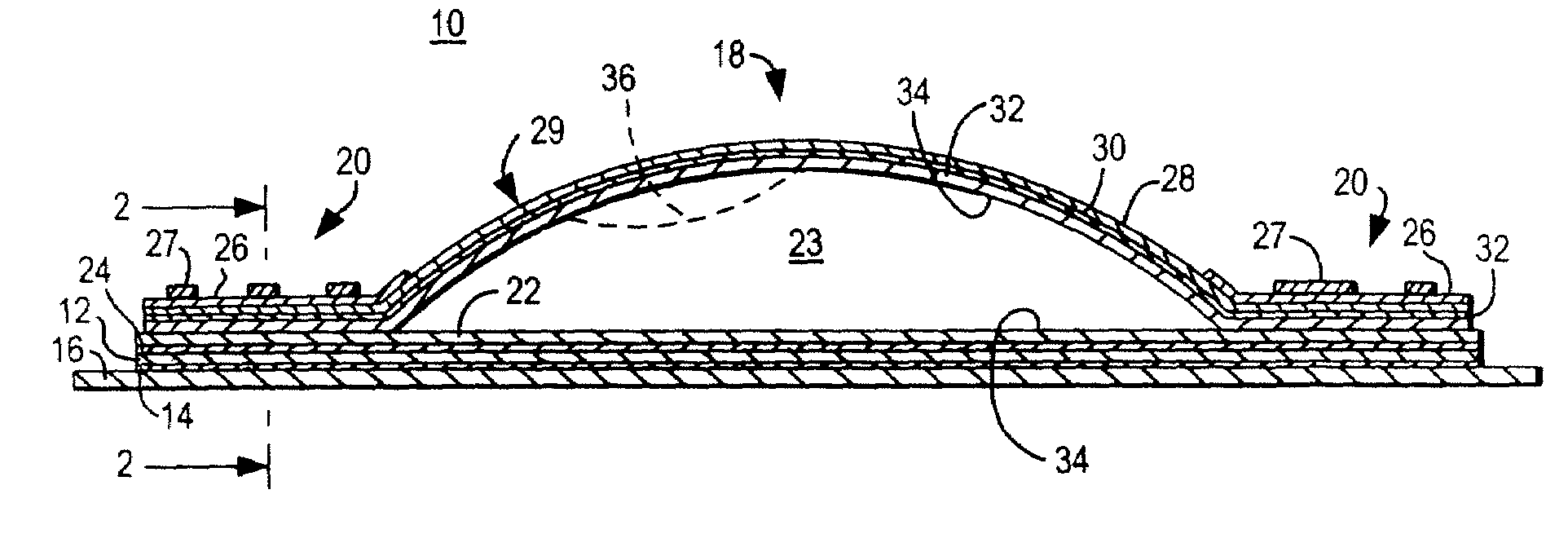

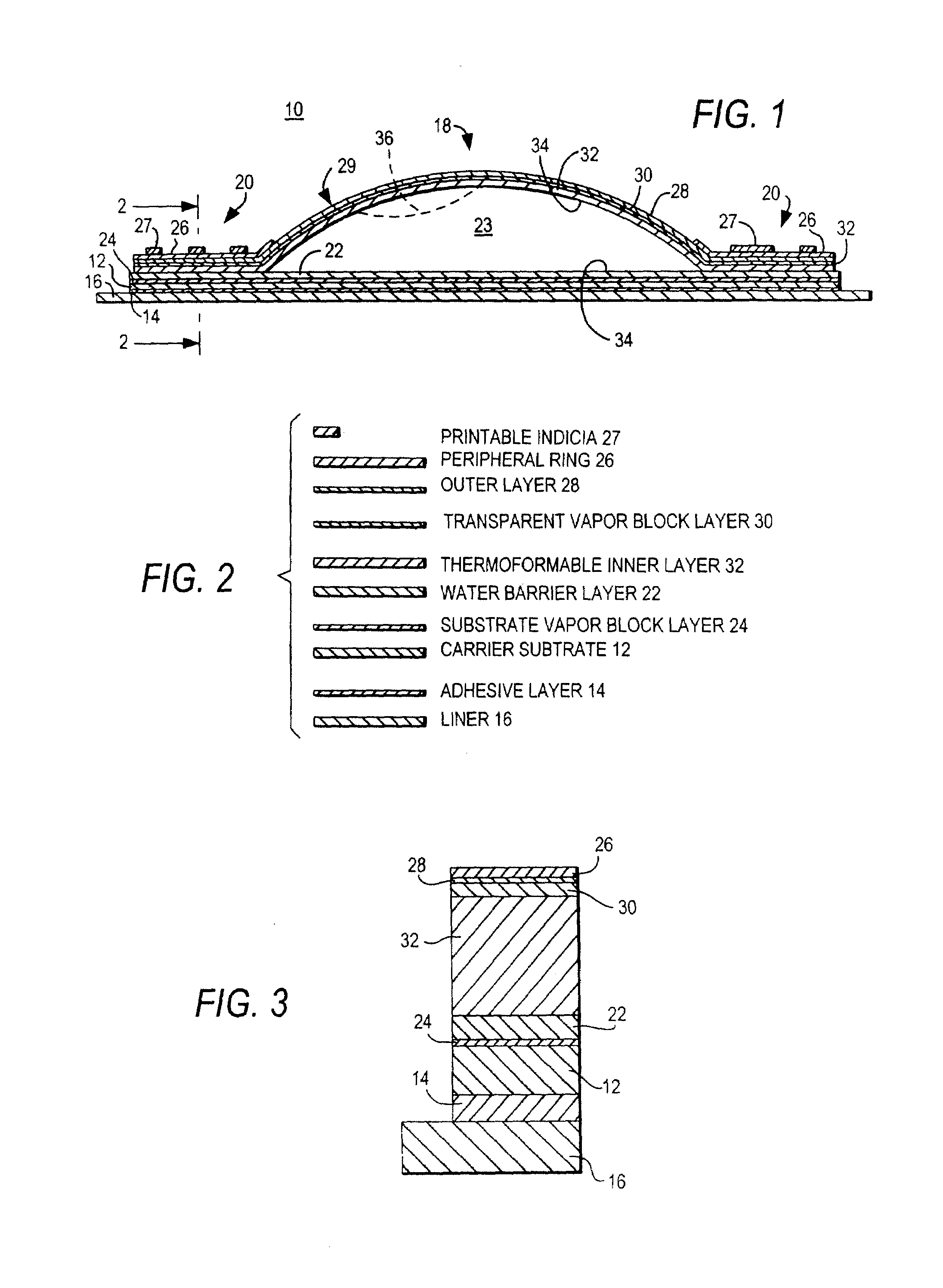

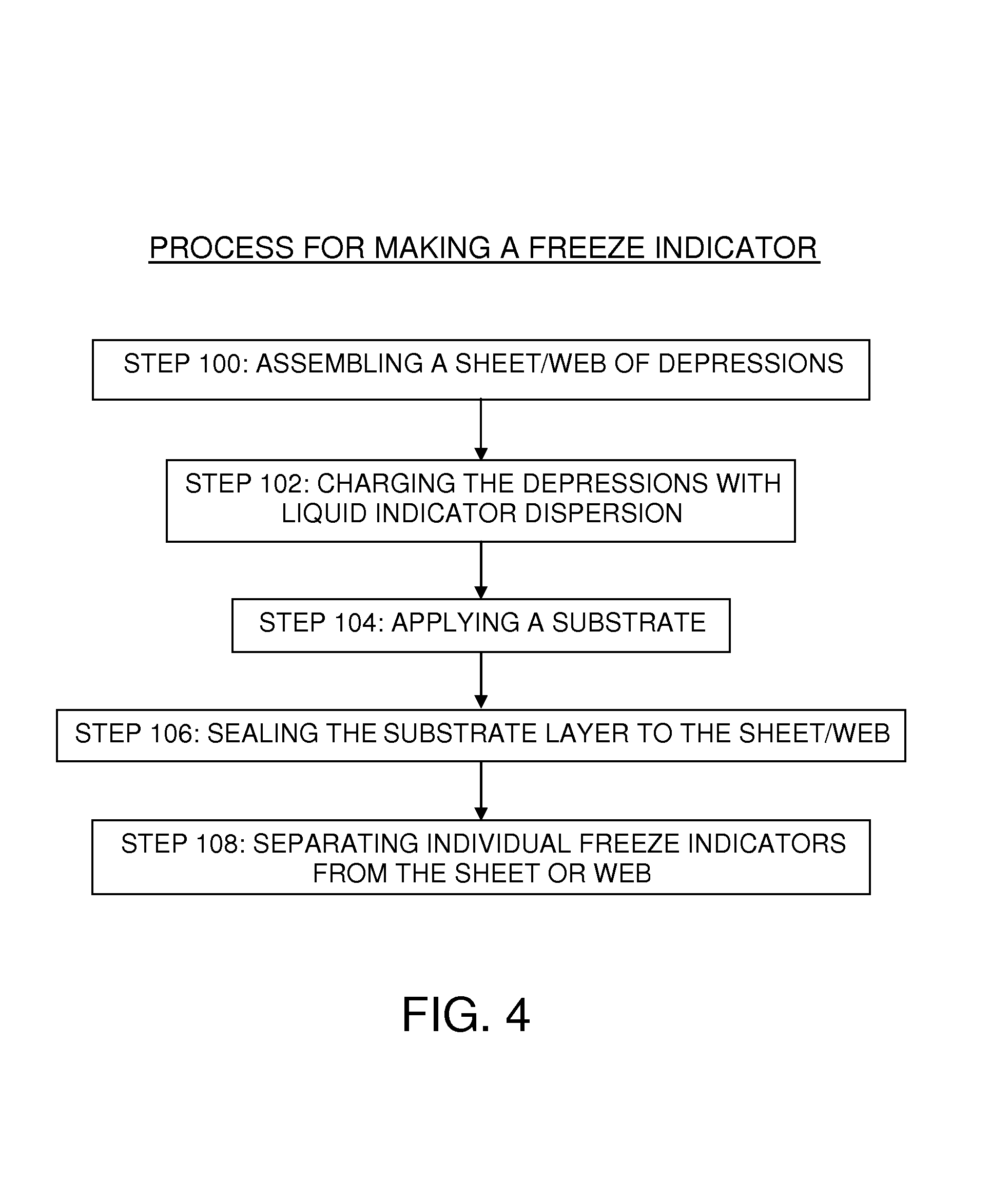

Freeze indicators suitable for mass production

ActiveUS7343872B2Good and extended shelf lifeUnanimous responseThermometer detailsTemperature measurement in household appliancesLiquid mediumWater vapor

A freeze indicator employs, as active indicator element, dispersion of solid particles in a liquid medium which can be water or aqueous and which coagulates to provide an irreversible appearance change when subject to freezing. The liquid dispersion can be contained in an indicator volume around which extends a vapor block layer. The vapor block layer can prevent loss of liquid vapor from the dispersion and consequent drying out and dysfunctionality of the freeze indicator. For containing an aqueous medium, bilayer and trilayer laminate materials can be used which have a low water vapor transmission rate. The active indicator element can be a dilute colloidal dispersion of a metal such as gold or silver or other inorganic pigment material in water or an aqueous medium. Some embodiments avoid use of dispersants and the like and employ an active indicator element consisting of inorganic pigment particles, water and optionally an ice nucleating agent. Heavy water, or deuterated water can be components of the water, if desired.

Owner:TEMPTIME CORP

Liquid vapor separation in transcritical refrigerant cycle

A refrigerant vapor compression system includes a flash tank disposed in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. The flash tank has a shell defining an interior volume having an upper chamber, a lower chamber and a middle chamber. A first fluid passage establishes fluid communication between the middle chamber and the upper chamber and a second fluid passage establishing fluid communication between the middle chamber and the lower chamber. An inlet port opens to the middle chamber. A first outlet port opens to the upper chamber and a second outlet port opens to the lower chamber.

Owner:CARRIER CORP

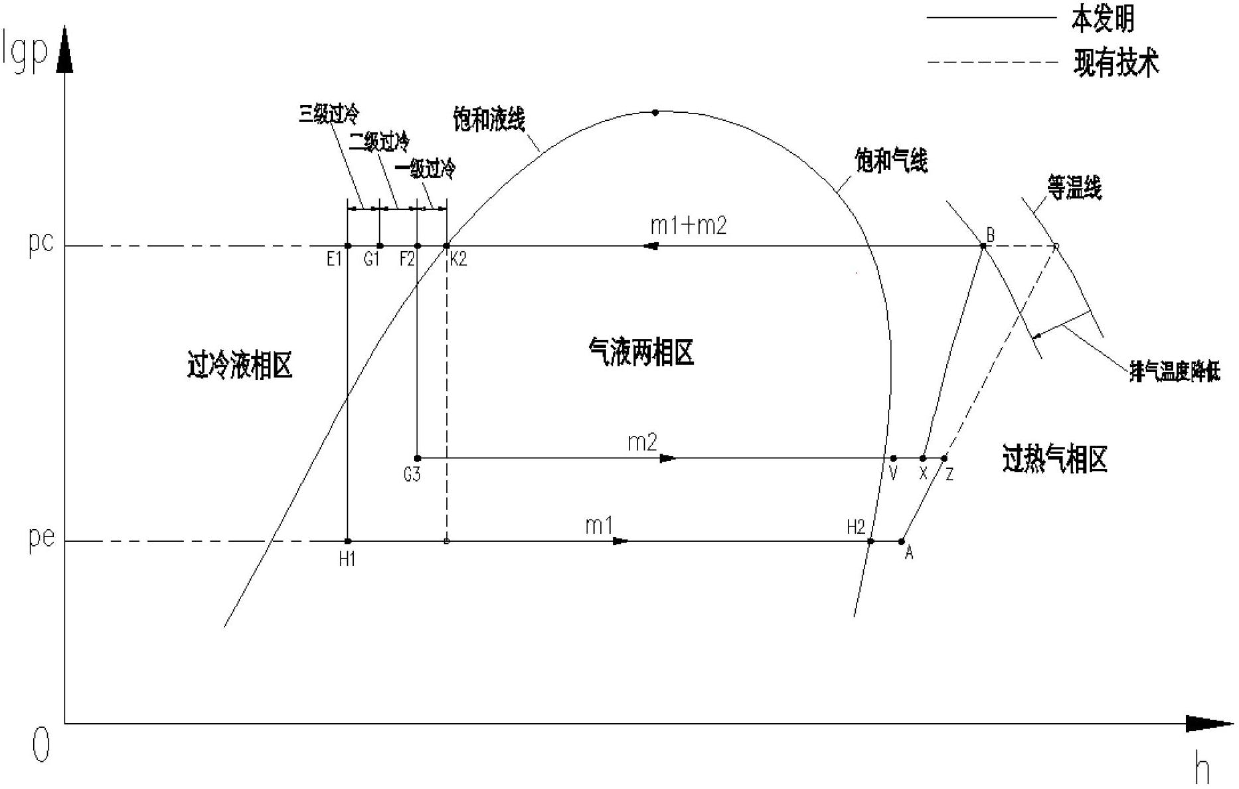

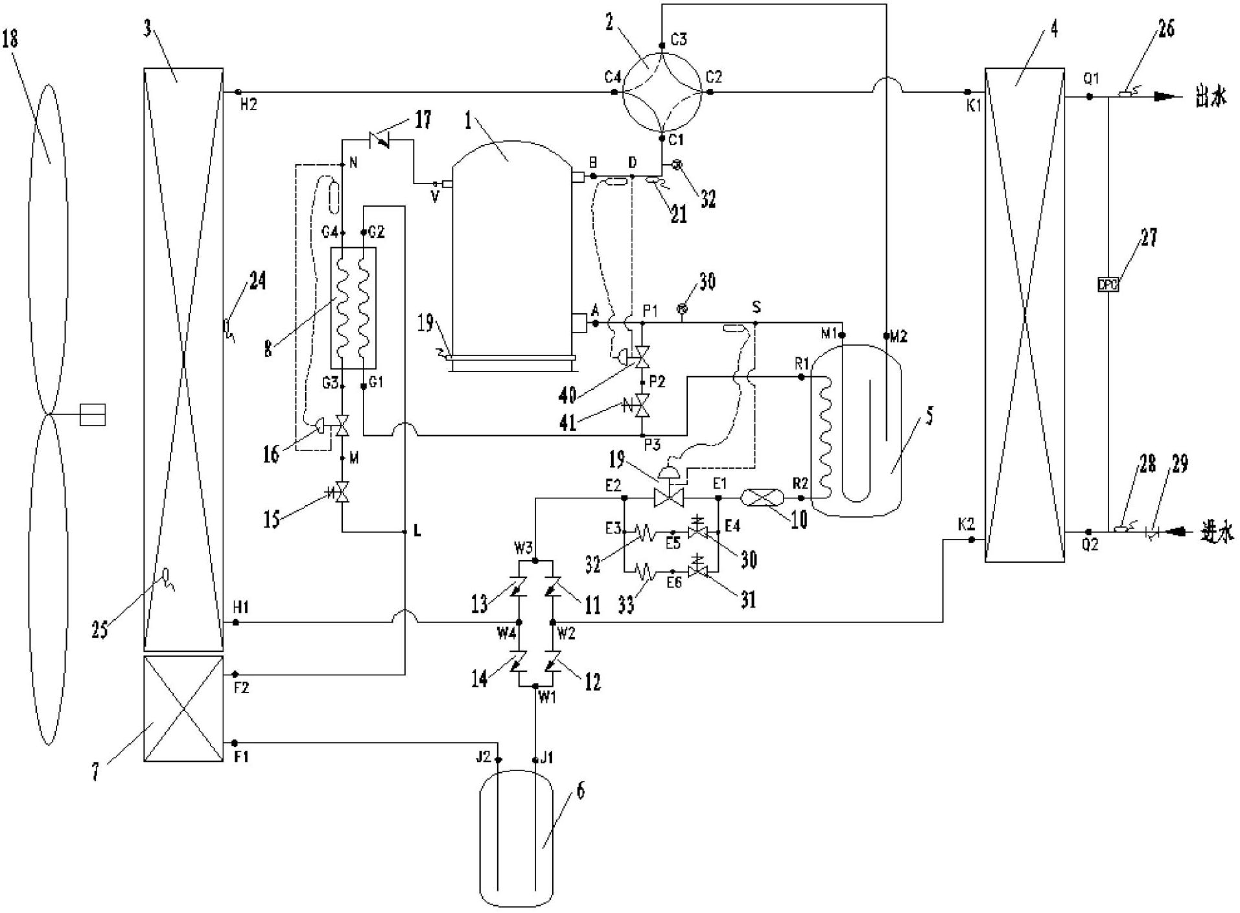

Air-cooled heat pump air conditioner

InactiveCN102679609AIncrease subcoolingLow heat recovery functionSubcoolersFluid circulation arrangementLiquid lineVapor–liquid separator

The invention discloses an air-cooled heat pump air conditioner which comprises a compressor, an outdoor coil, a heat exchanger, a main liquid line and supercooling devices, wherein the supercooling devices comprise two or three of a supercooling coil, an economizer and a liquid-vapor separator with a supercooling function, the supercooling devices are arranged on the main liquid line, and liquid state refrigerants which circulate in the main liquid line can achieve repeatedly the supercooling through the supercooling devices. According to the air-cooled heat pump air conditioner, the performance of cooling / heating circulation of the air-cooled heat pump air conditioner is effectively improved, so that the air-cooled heat pump air conditioner is stable and reliable in operation and energy saving in a low-temperature environment.

Owner:四川同达博尔置业有限公司

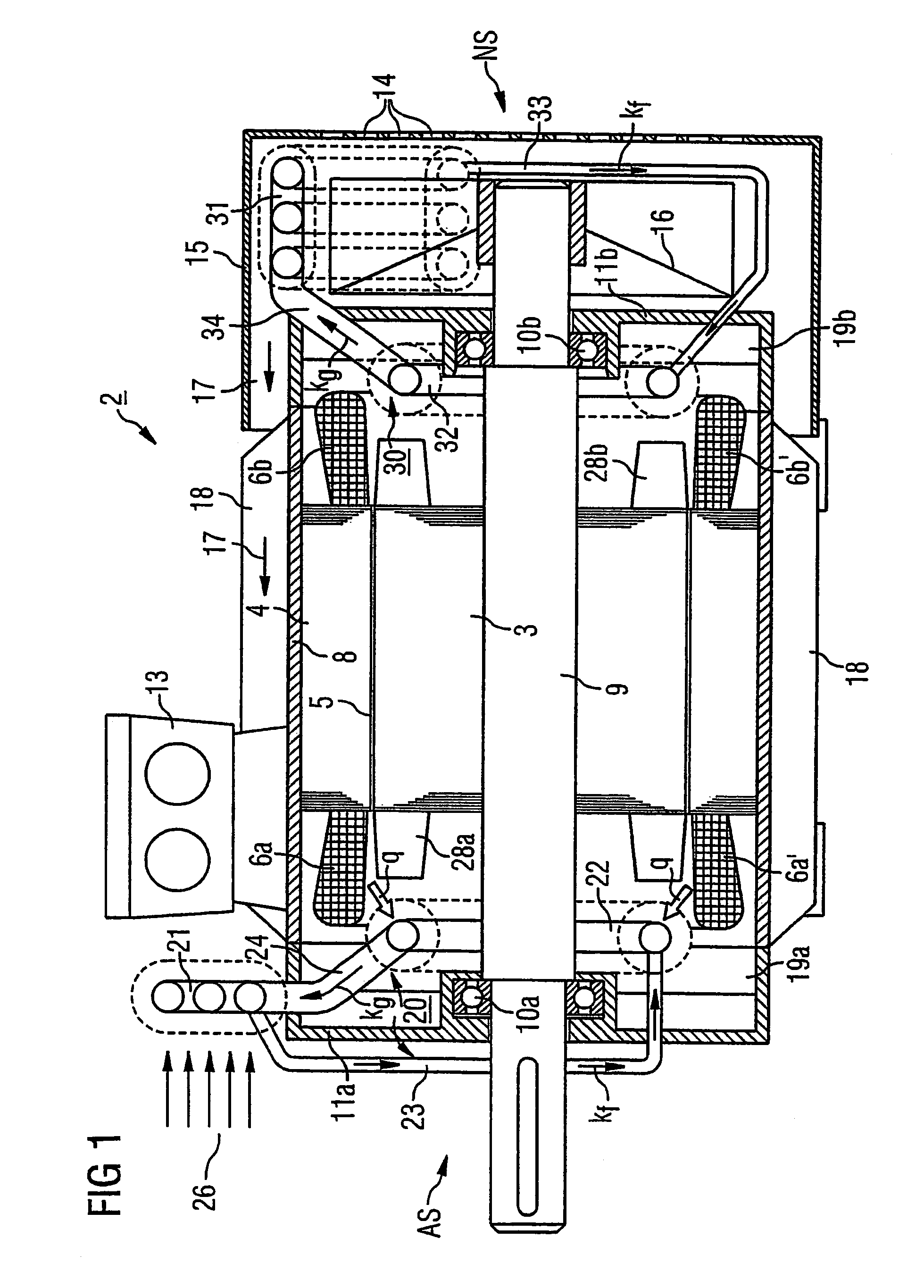

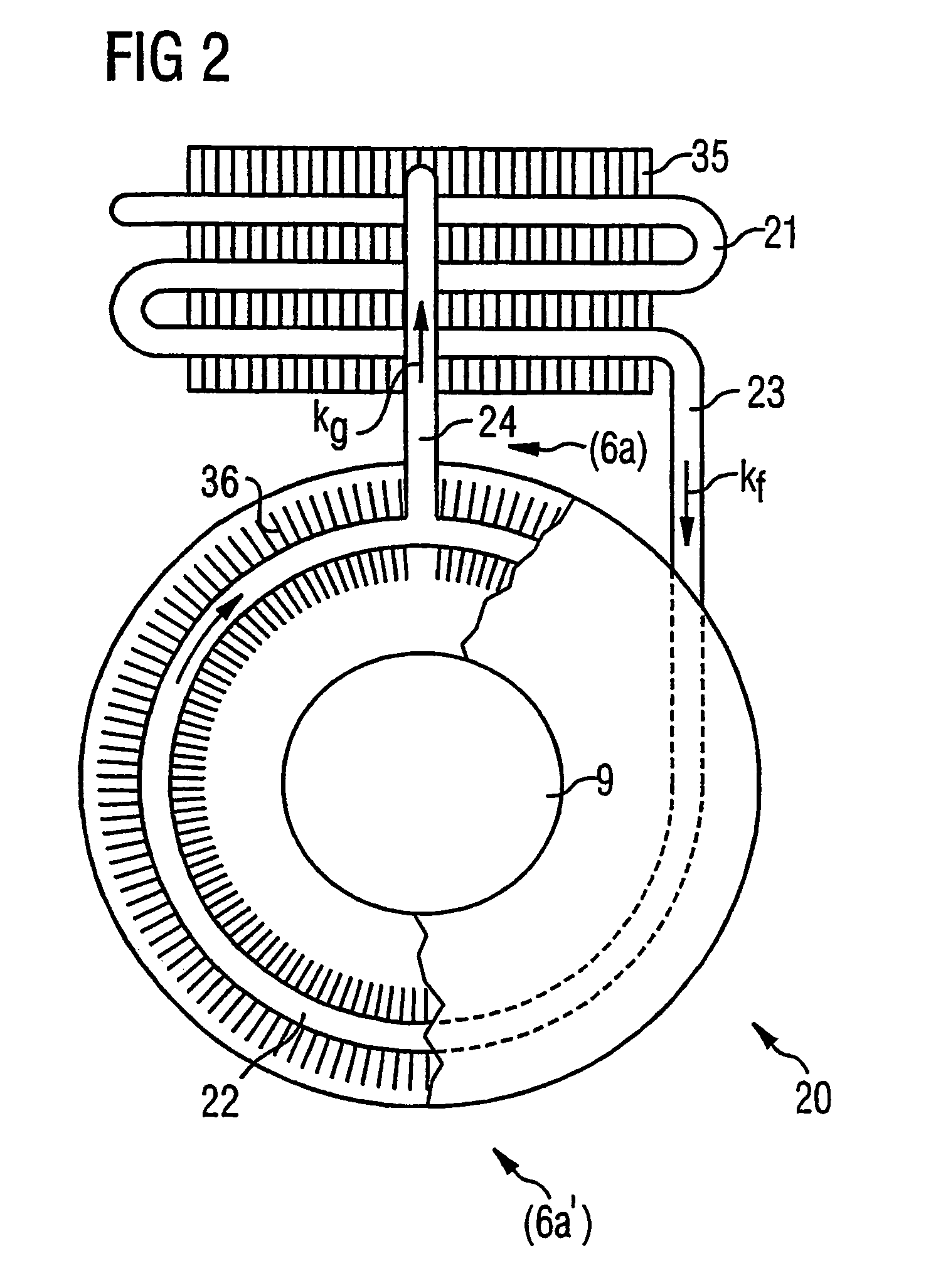

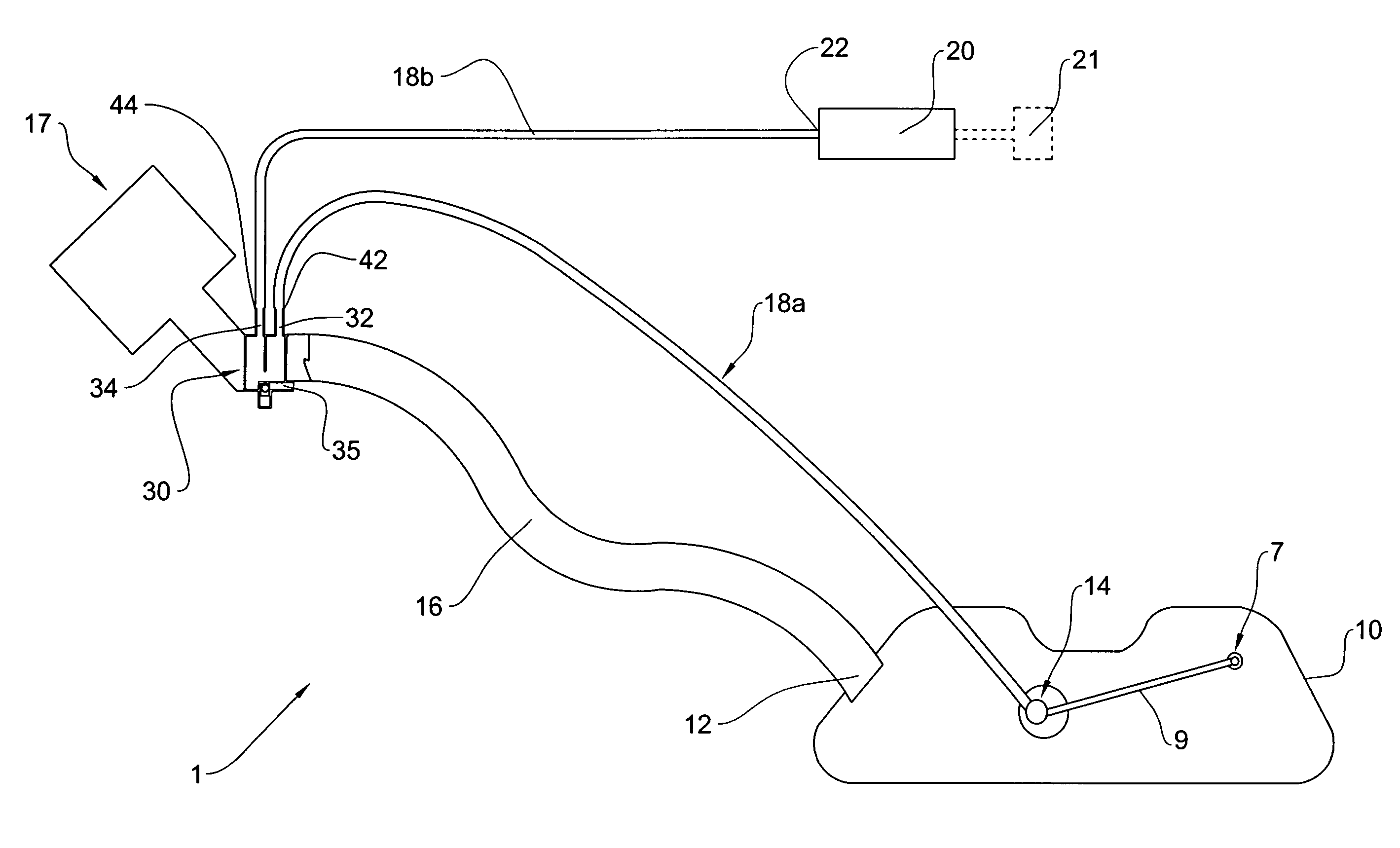

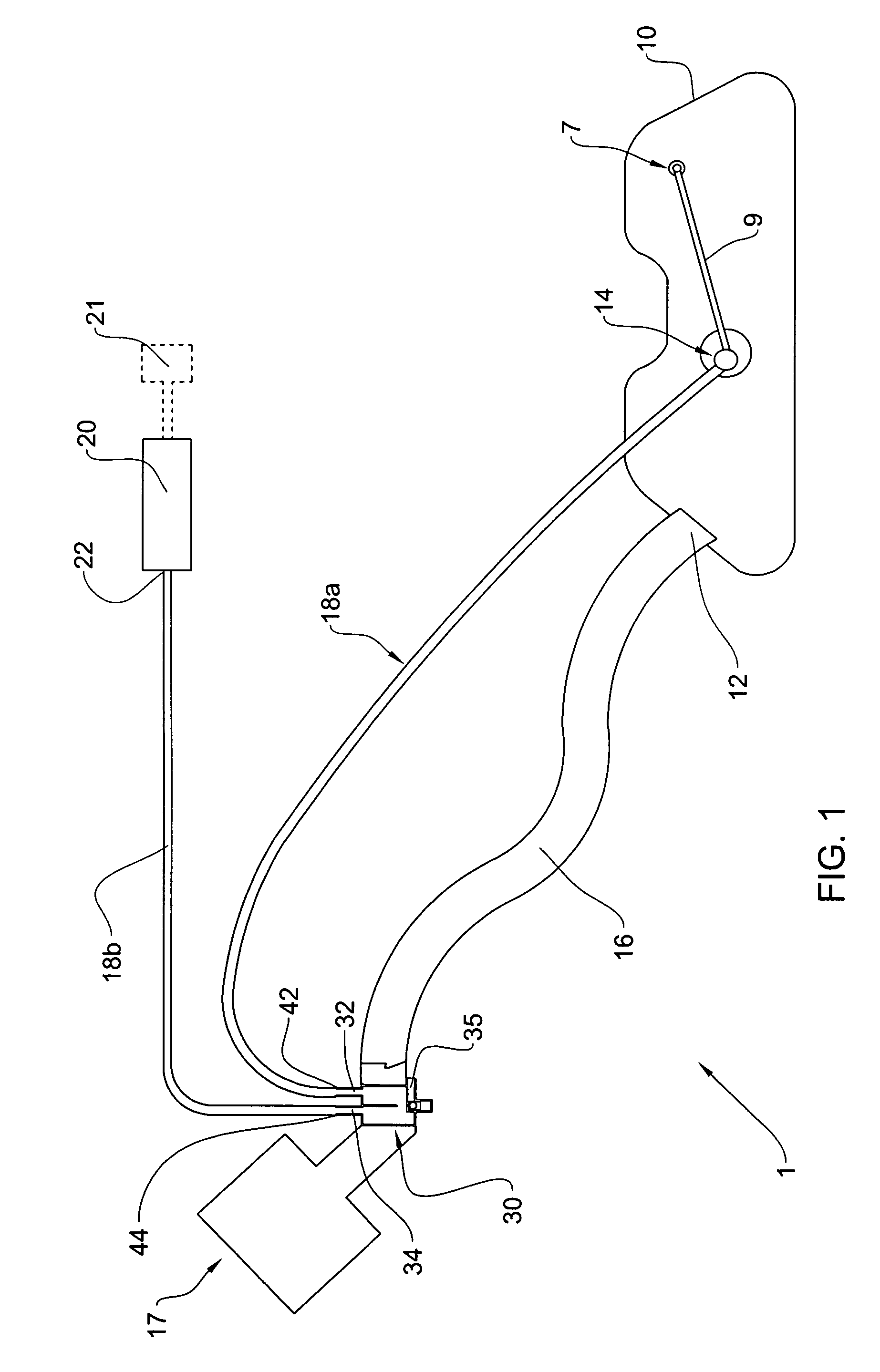

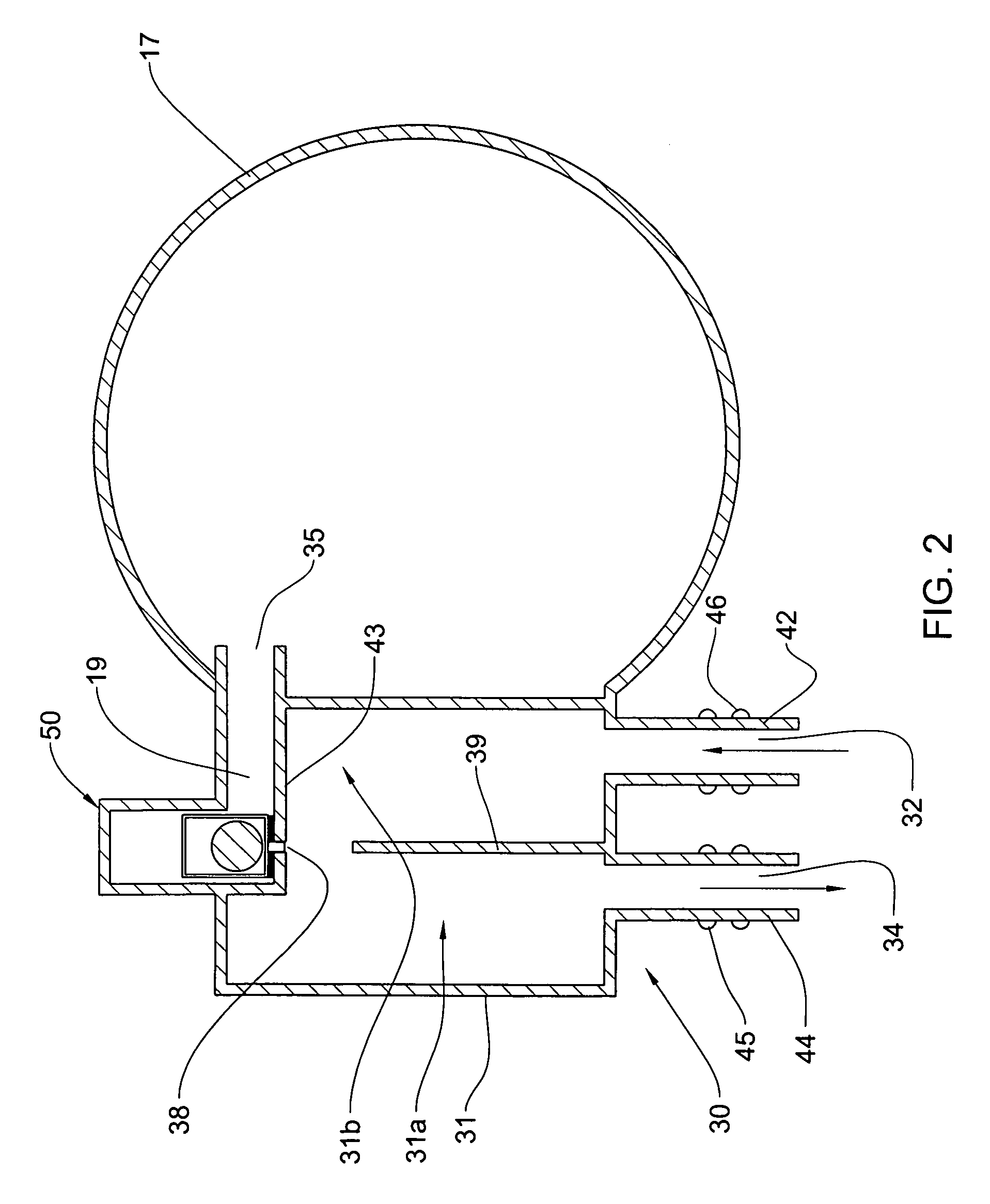

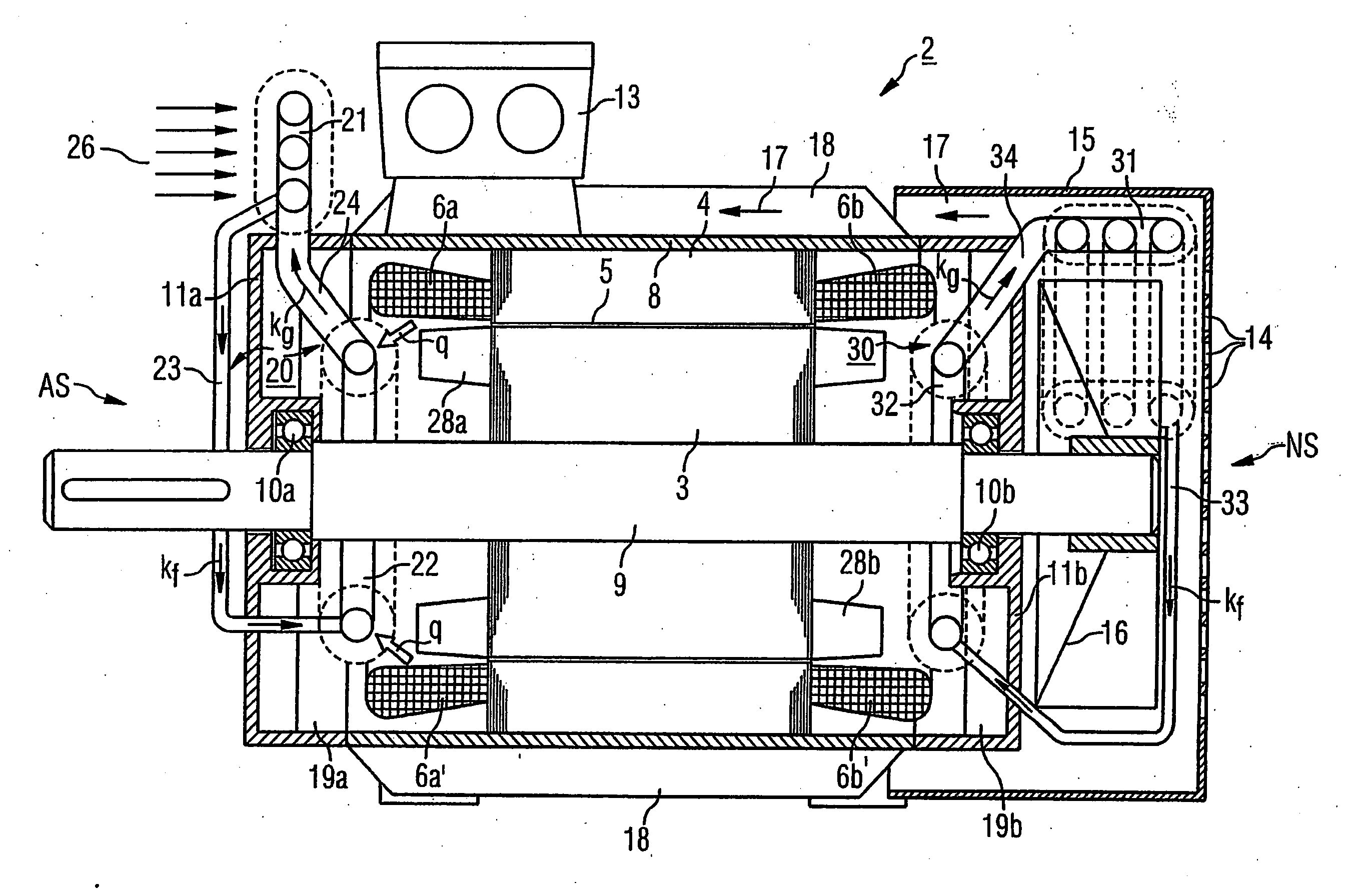

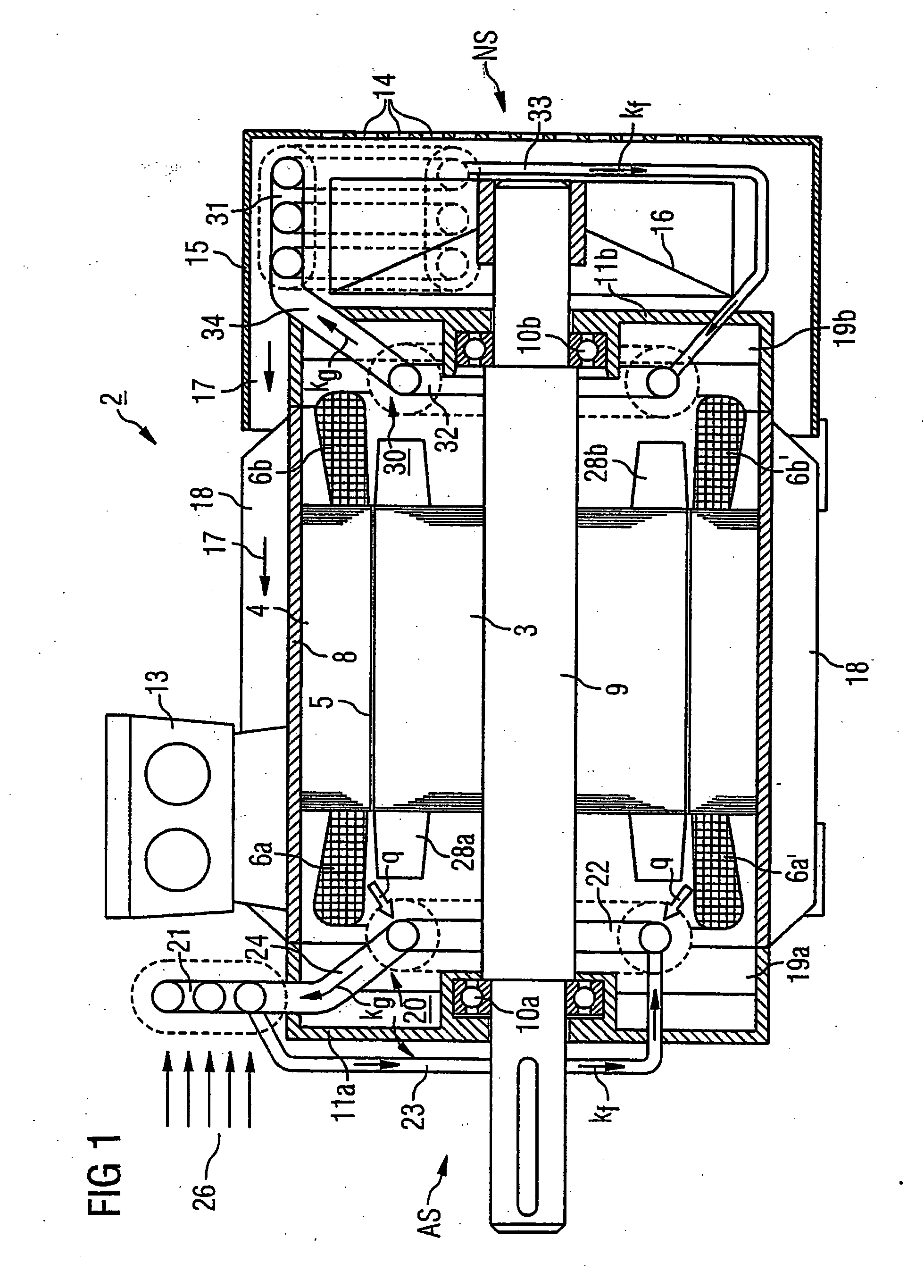

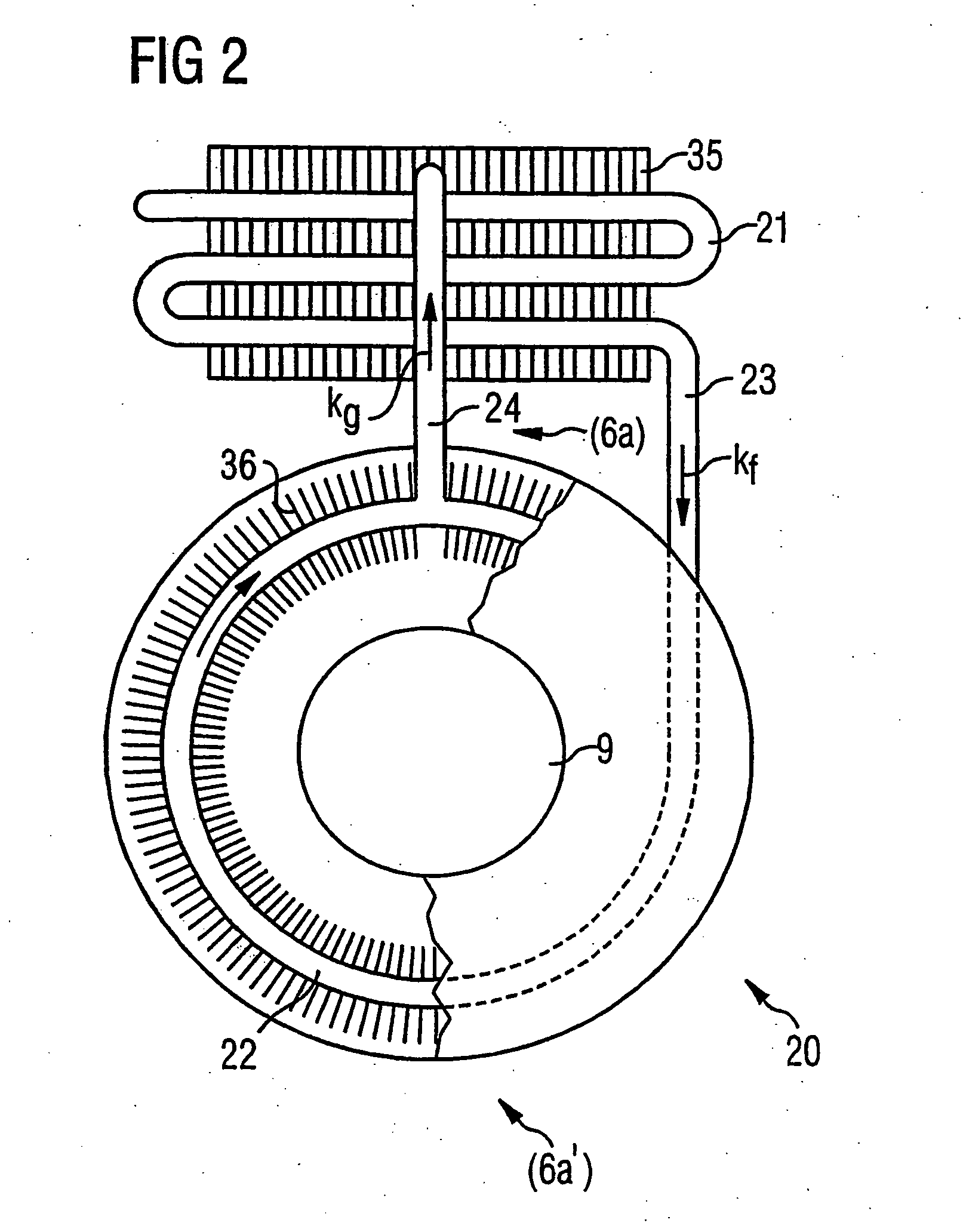

Electric machine with thermosiphon-type cooling system

InactiveUS7102267B2Efficient conductionReduce componentsMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineEngineering

An electric machine includes a housing for accommodating a rotatably supported rotor and a stationary stator, and a cooling device for cooling heat-generating components of the rotor and the stator. The cooling device includes a closed-flow system having an evaporator disposed in the housing, a condenser disposed outside the housing at a geodetically higher location, and a closed tube assembly, which connects the condenser and the evaporator, for circulating a coolant using a thermosiphon effect as a result of a difference in density between vapor and liquid portions of the coolant. The closed-flow system contains a liquid-vapor mixture of the coolant in a saturated state and includes a first tube for conducting coolant to the evaporator and a second tube for conducting coolant away from the evaporator. The first tube has hereby a cross section which is smaller than a cross section of the second tube.

Owner:SIEMENS AG

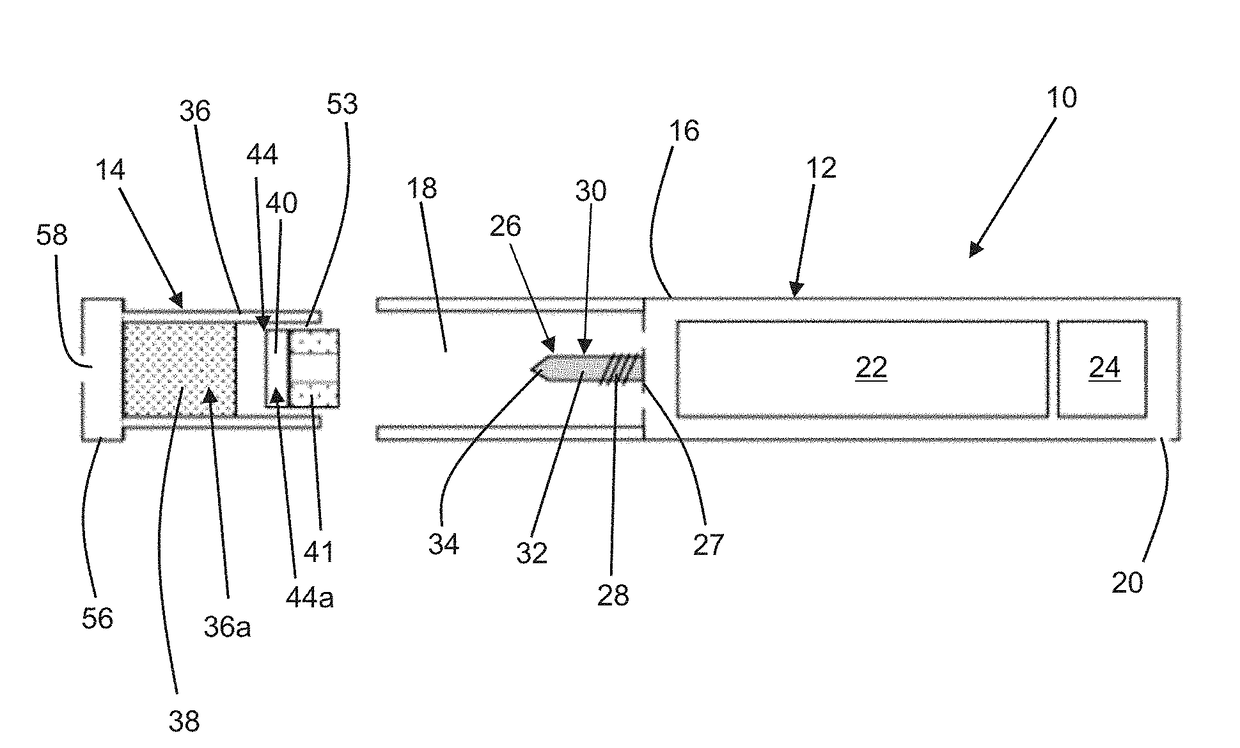

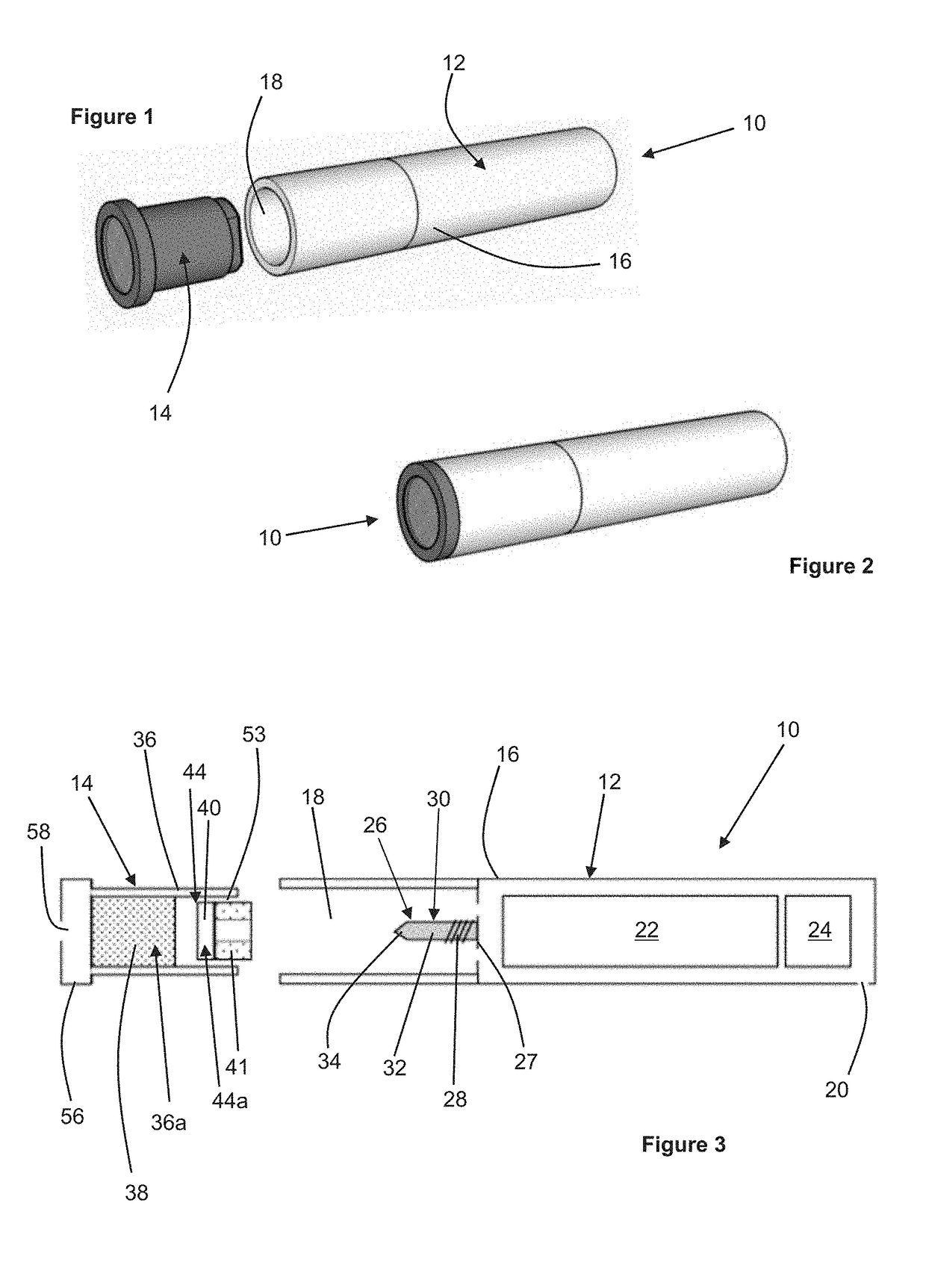

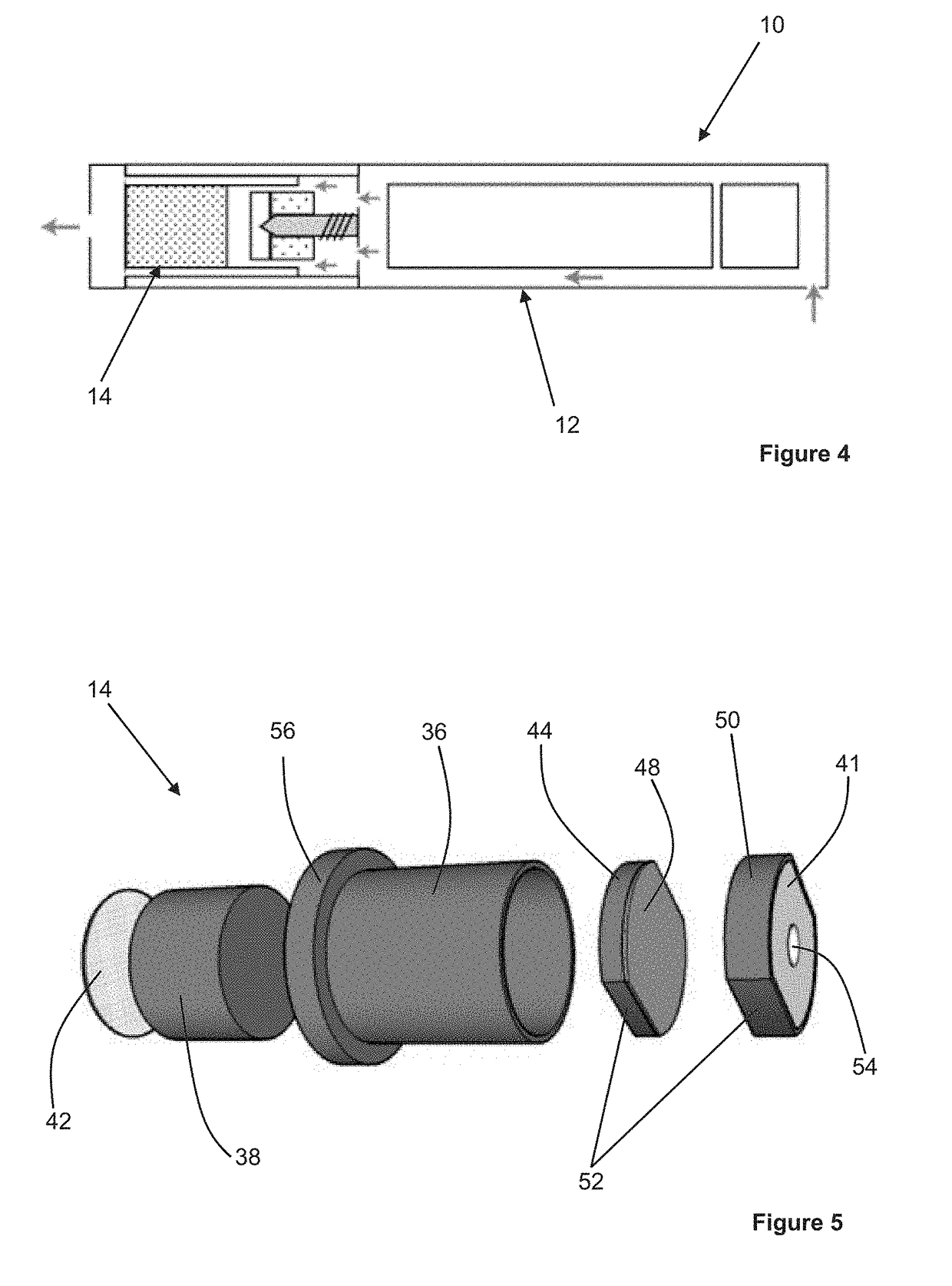

Vapor-generating systems

ActiveUS20180169355A1Medical devicesTobacco devicesElectricityElectrical and Electronics engineering

A vapor-generating system includes a cartridge, a vapor-generating device and a piercing element. The cartridge includes a cartridge housing configured to hold a solid vapor-forming substrate within the cartridge housing interior, a liquid storage housing configured to hold a liquid vapor-forming substrate within the liquid storage housing interior, and a frangible seal on the liquid storage housing. The vapor-generating device includes a device housing at least partially defining a cavity, an electric heater, and a power supply. The piercing element is configured to pierce the frangible seal of the cartridge to expose the liquid storage housing interior to be in fluid communication with the electric heater based on the vapor-generating device coupling with the cartridge such that the device housing at least partially receives the cartridge into the cavity. The electric heater is located externally from the piercing element.

Owner:AKRIA CLIENT SERVICES LLC

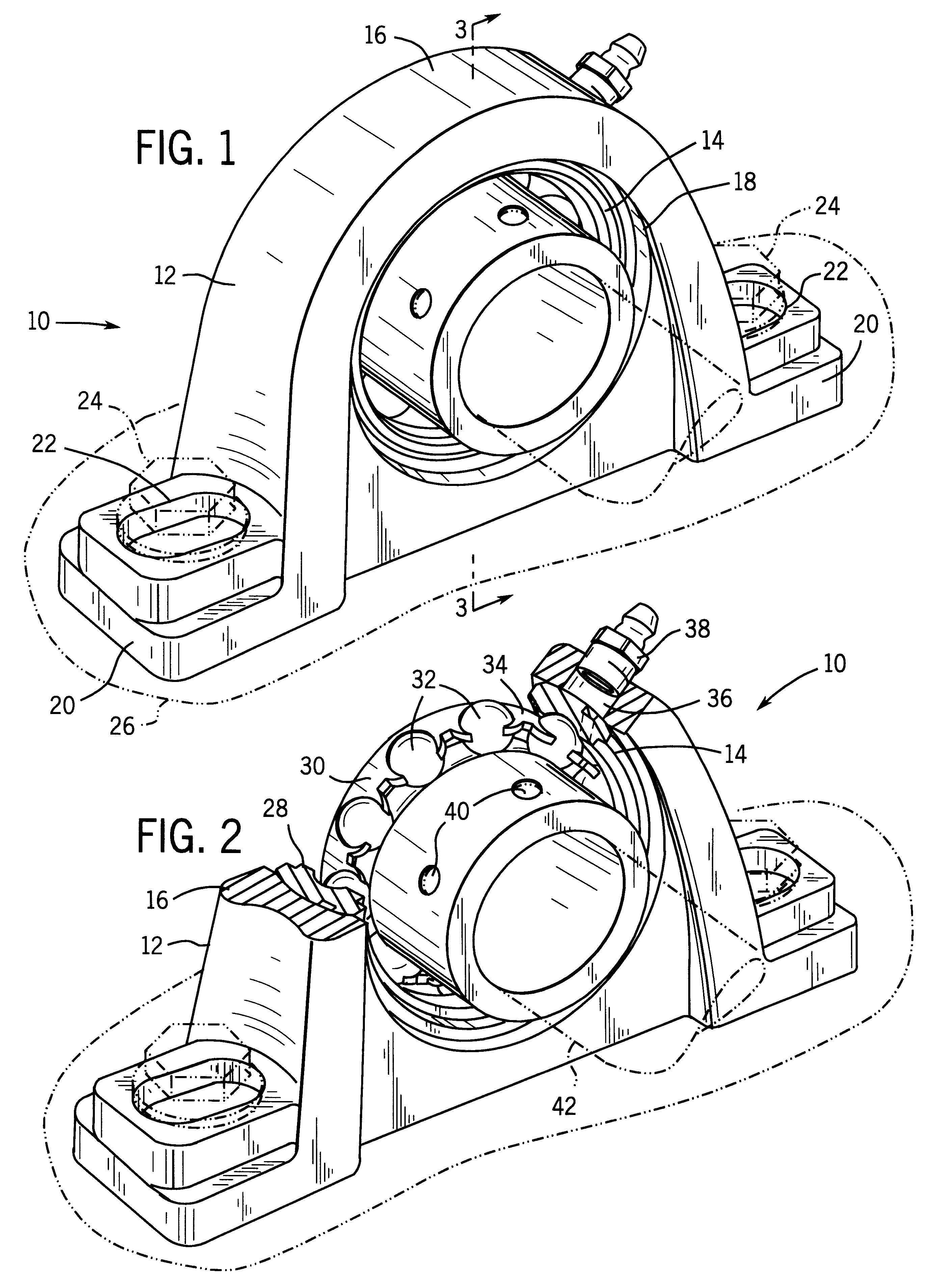

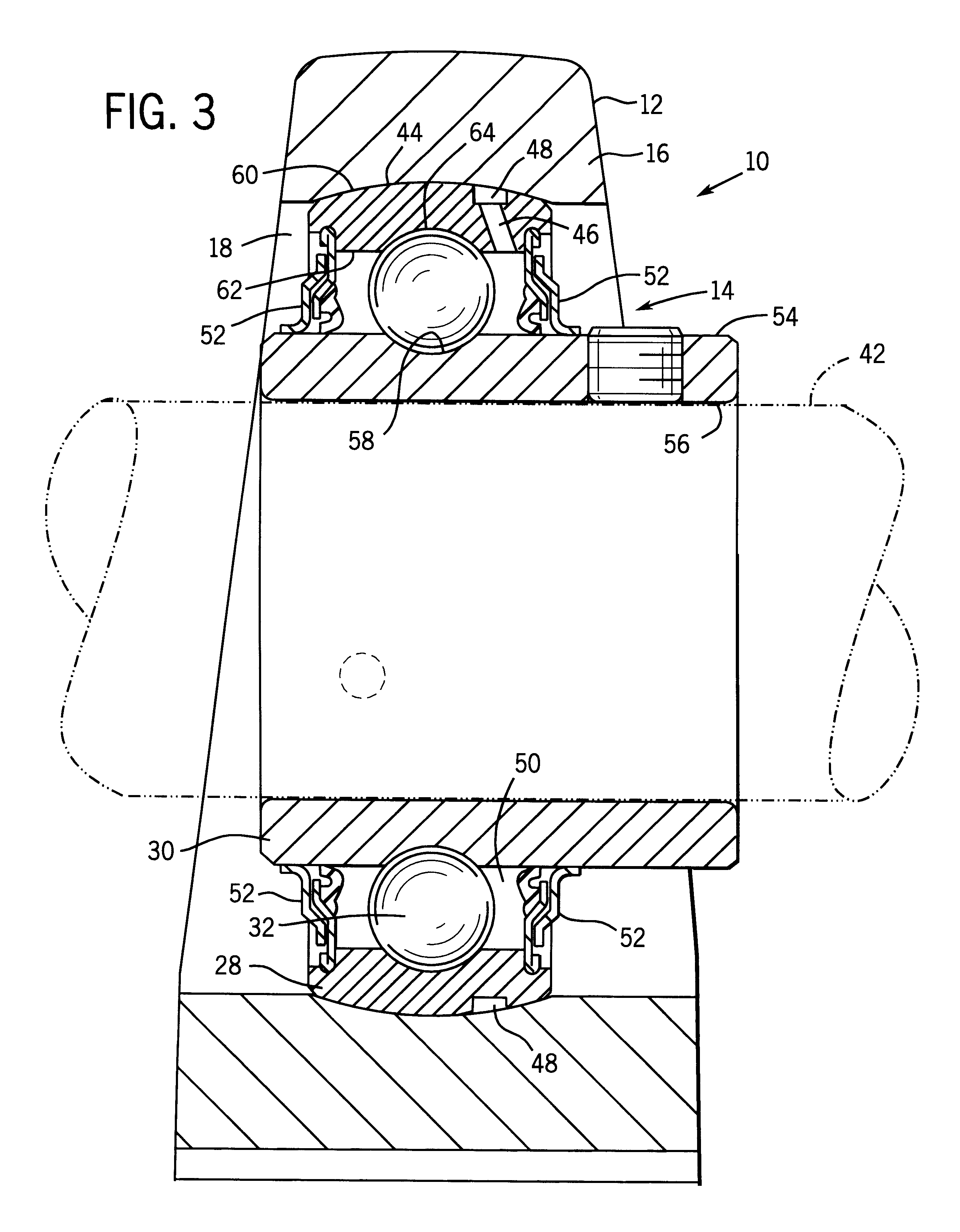

Corrosion-resistant bearing and method for making same

InactiveUS6318898B1Improve corrosion resistanceMore cost-effectiveBall bearingsBearing componentsAlloyProtection system

A corrosion-resistant antifriction bearing is disclosed that includes a multi-layer corrosion protection system over a metallic substrate. The corrosion-resistant system may be applied to a single or multiple components of the bearing, including inner and outer rings, bearing elements, collars, and so forth. The system includes a nickel-phosphorous alloy plating layer applied by an autocatalytic process after surface preparation of the protected component. The surface preparation aids in adherence of the nickel-phosphorous alloy plating layer to the substrate. The preparation may include the application of rust inhibitors, liquid vapor honing, acid neutralizing, and so forth. Additional topcoat layers may be applied to the nickel-phosphorous alloy plating layer. These may include a chromate conversion coating and a polymeric topcoat layer. The polymeric topcoat layer, such as polytetrafluoroethylene, may include a UV marker to enable identification of the bearing when placed in service and throughout its useful life.

Owner:BALDOR ELECTRIC COMPANY

Capillary condenser/evaporator

ActiveUS7775261B2Indirect heat exchangersCooling/ventilation/heating modificationsCapillary condensationEngineering

Owner:MIKROS MFG LLC

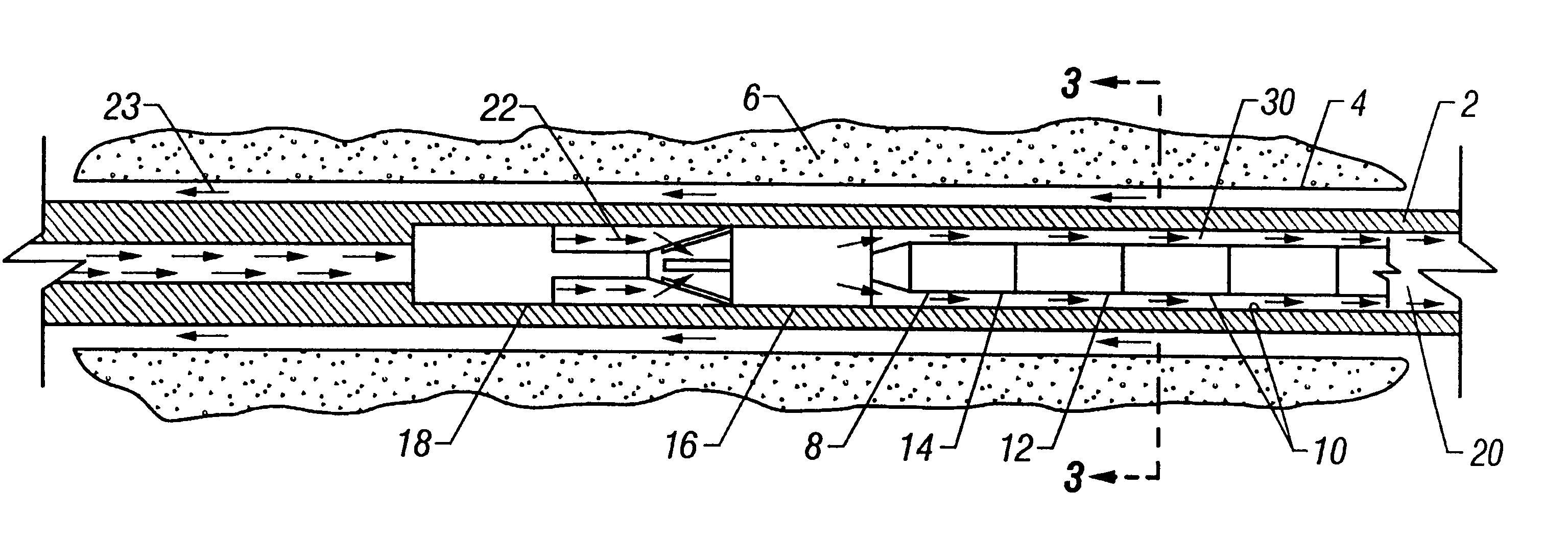

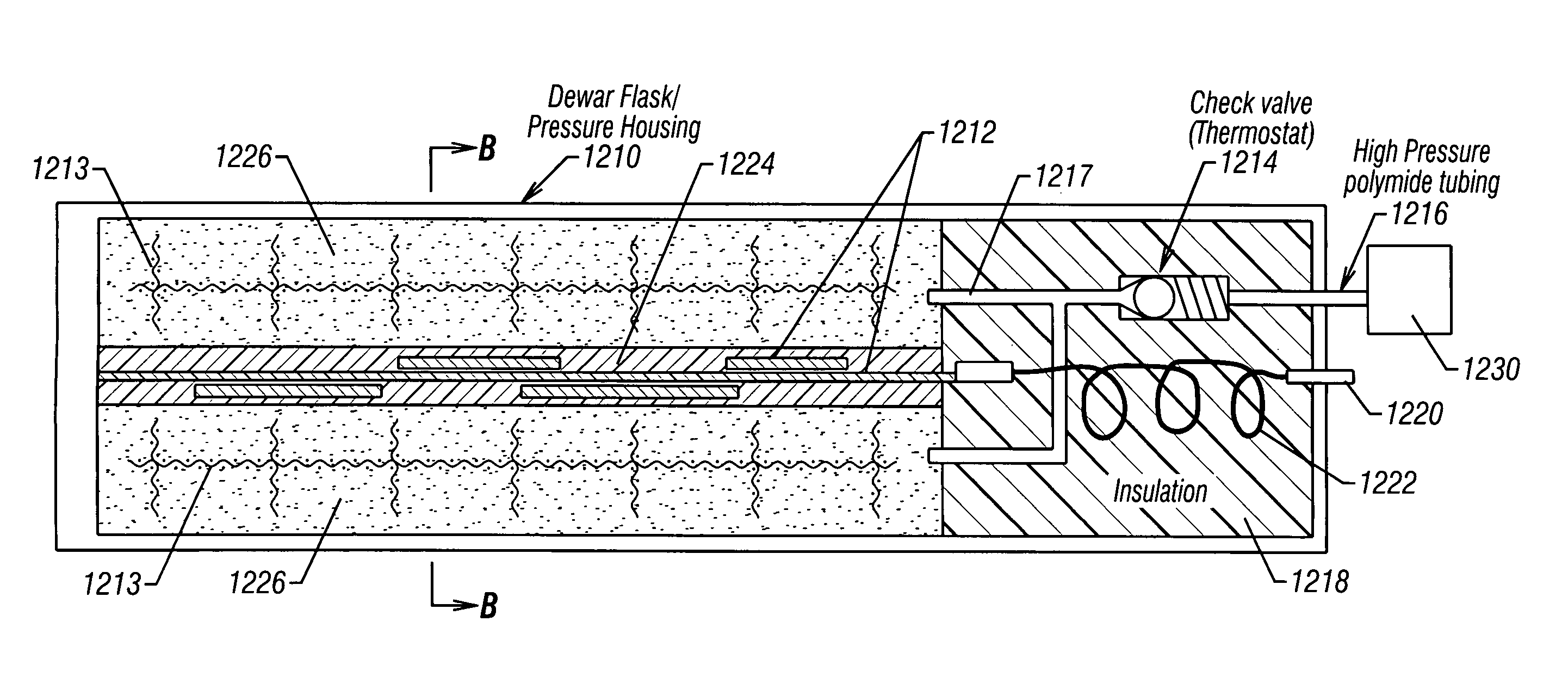

Downhole sorption cooling and heating in wireline logging and monitoring while drilling

InactiveUS6877332B2Easy transferComponents is relatively effectiveSurveyConstructionsSorbentWater vapor

A cooling system in which an electronic or other component is cooled by using one or more solid sources of liquid vapor in conjunction with one or more high-temperature vapor sorbents or desiccants that effectively transfer heat from the component to the fluid in the wellbore. The latent heats associated with phase changes and dehydration of a hydrate can provide substantial cooling capacity per unit volume of hydrate, which is particularly important in those applications where space is limited. According to the present invention, a sorption cooling and heating system is provided for use in a well, such as downhole tool which is in a drill string through which a drilling fluid flows, or in a downhole tool, which is on a wireline. Electronics, sensors, or clocks adjacent to a hydrate are not only kept cool by the heat sinking effect of hydrate phase changes and evaporation of water that is released but, during phase changes, they are being kept at a constant temperature for extended periods of time, which further improves their stability. Furthermore, such a system can also be used to heat a sample chamber or other component by placing it adjacent to the high-temperature sorbent or desiccant that heats up as it adsorbs the water vapor that was released by a low-temperature hydrate or desiccant during dehydration.

Owner:BAKER HUGHES INC

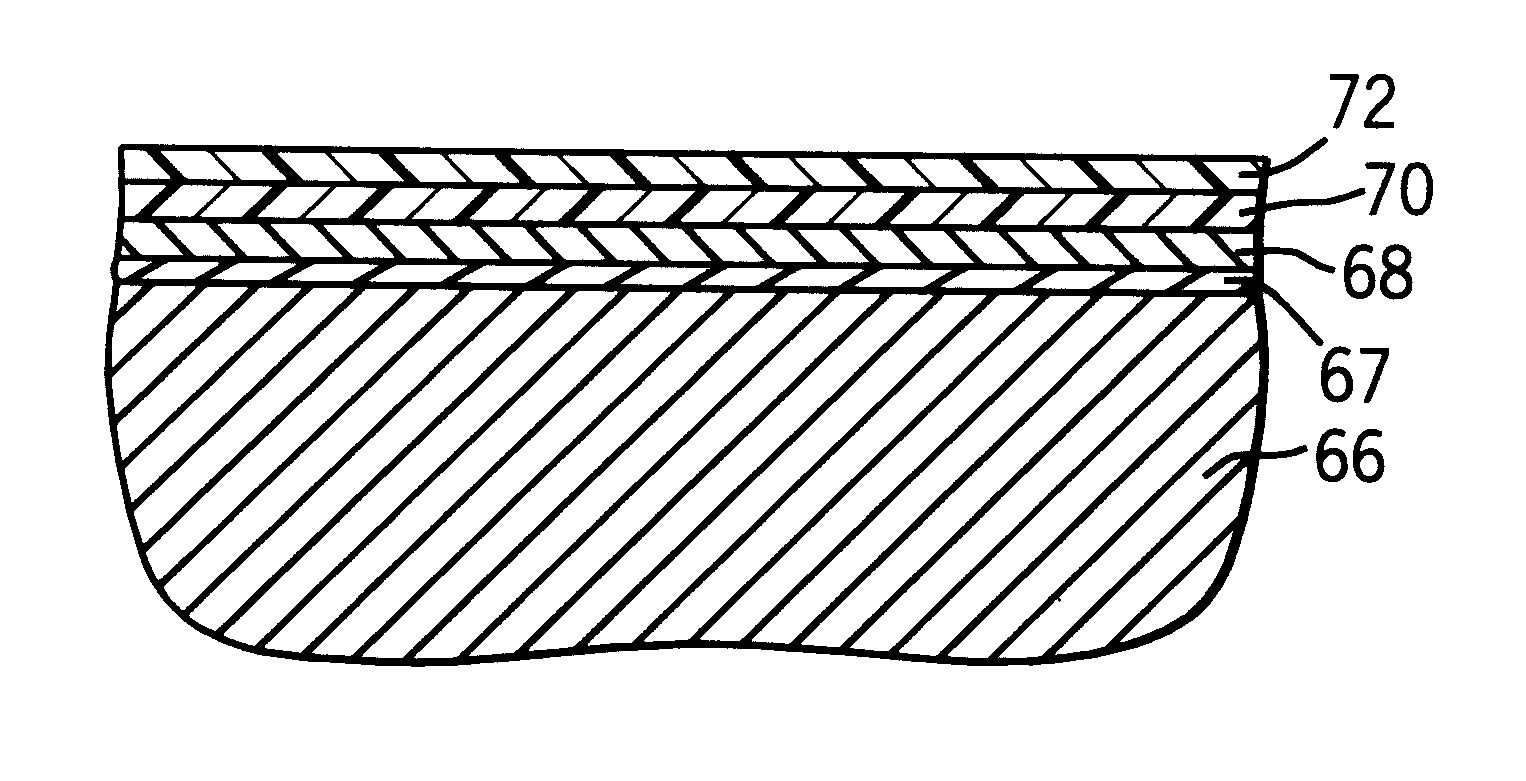

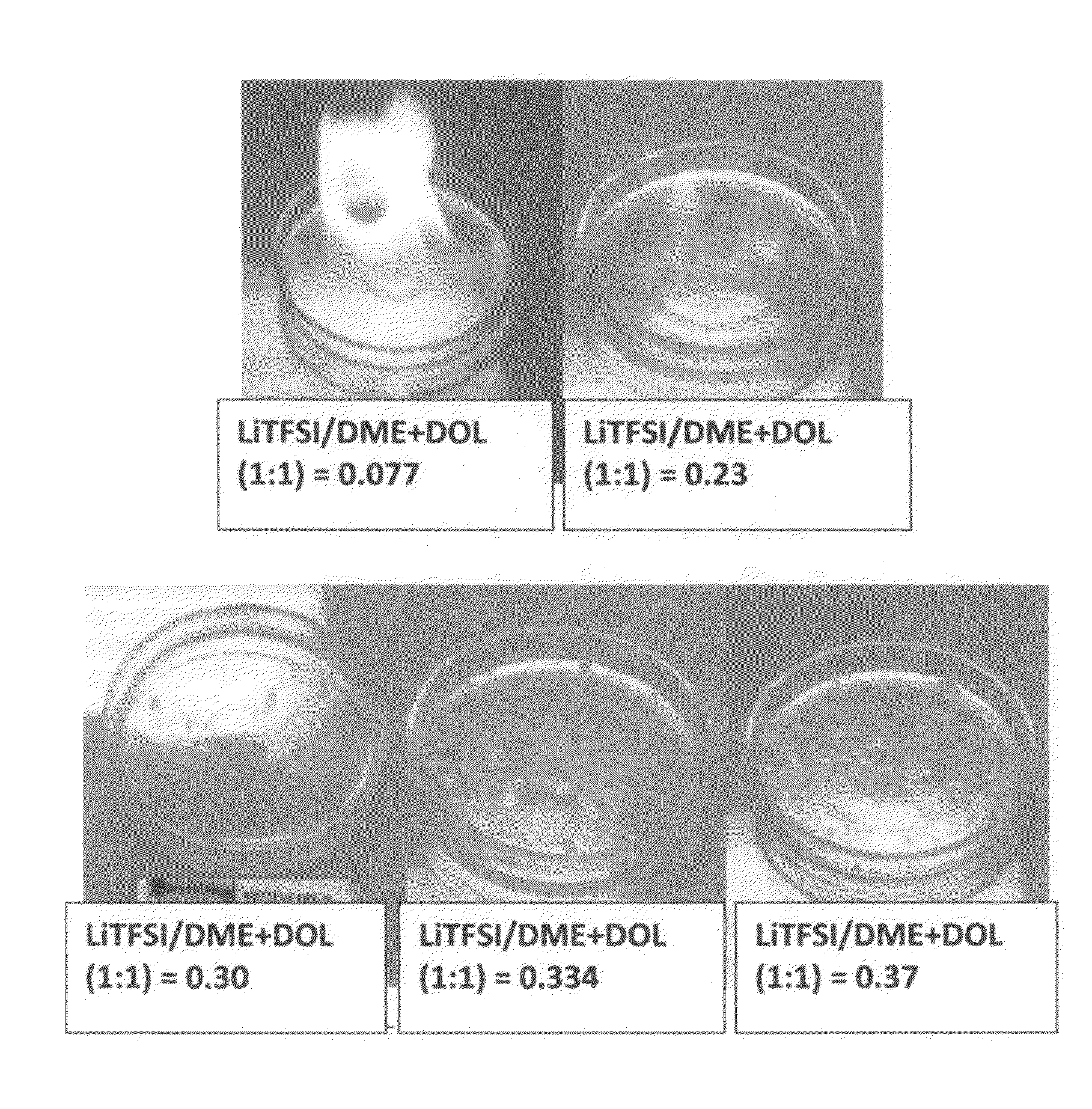

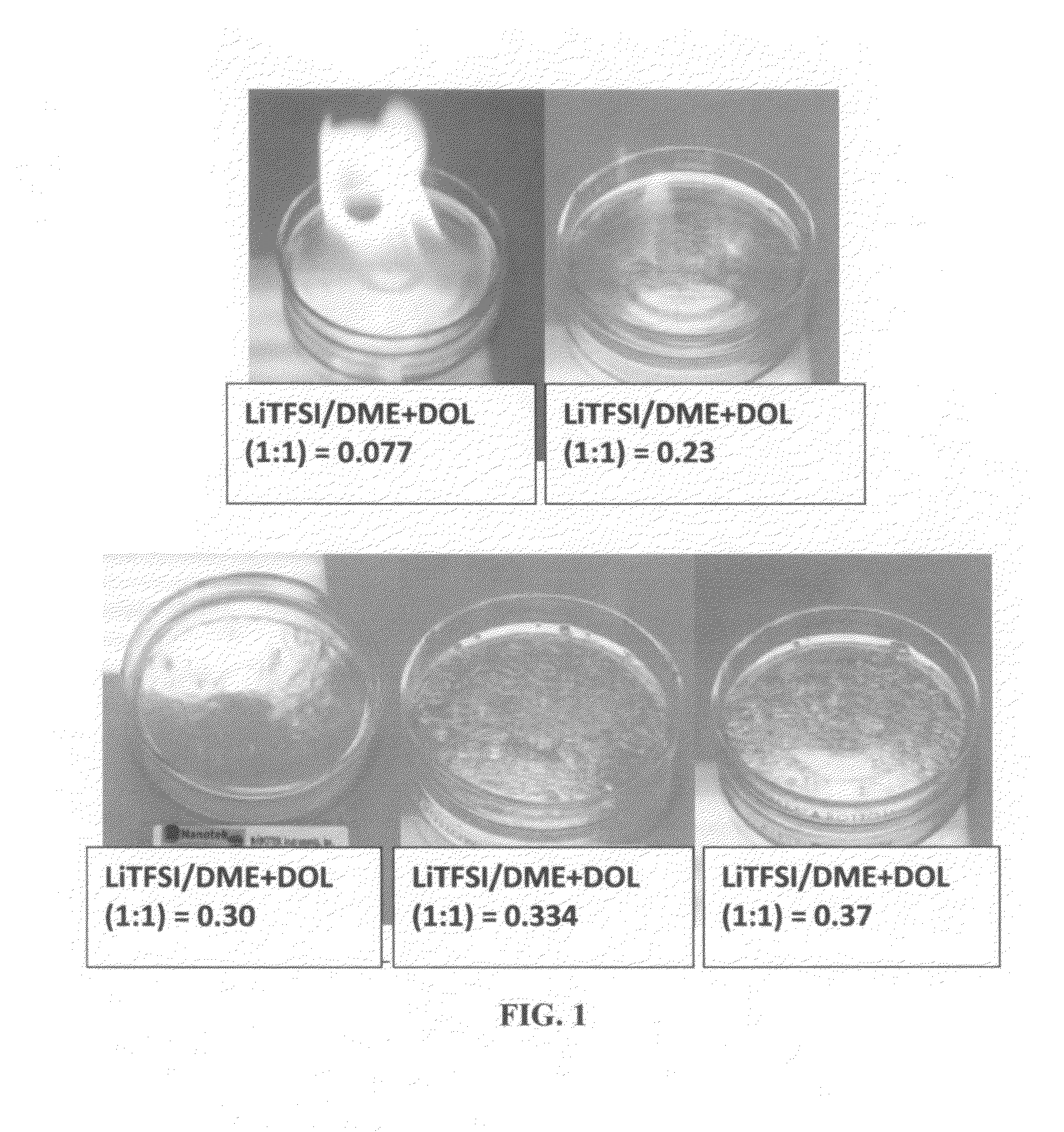

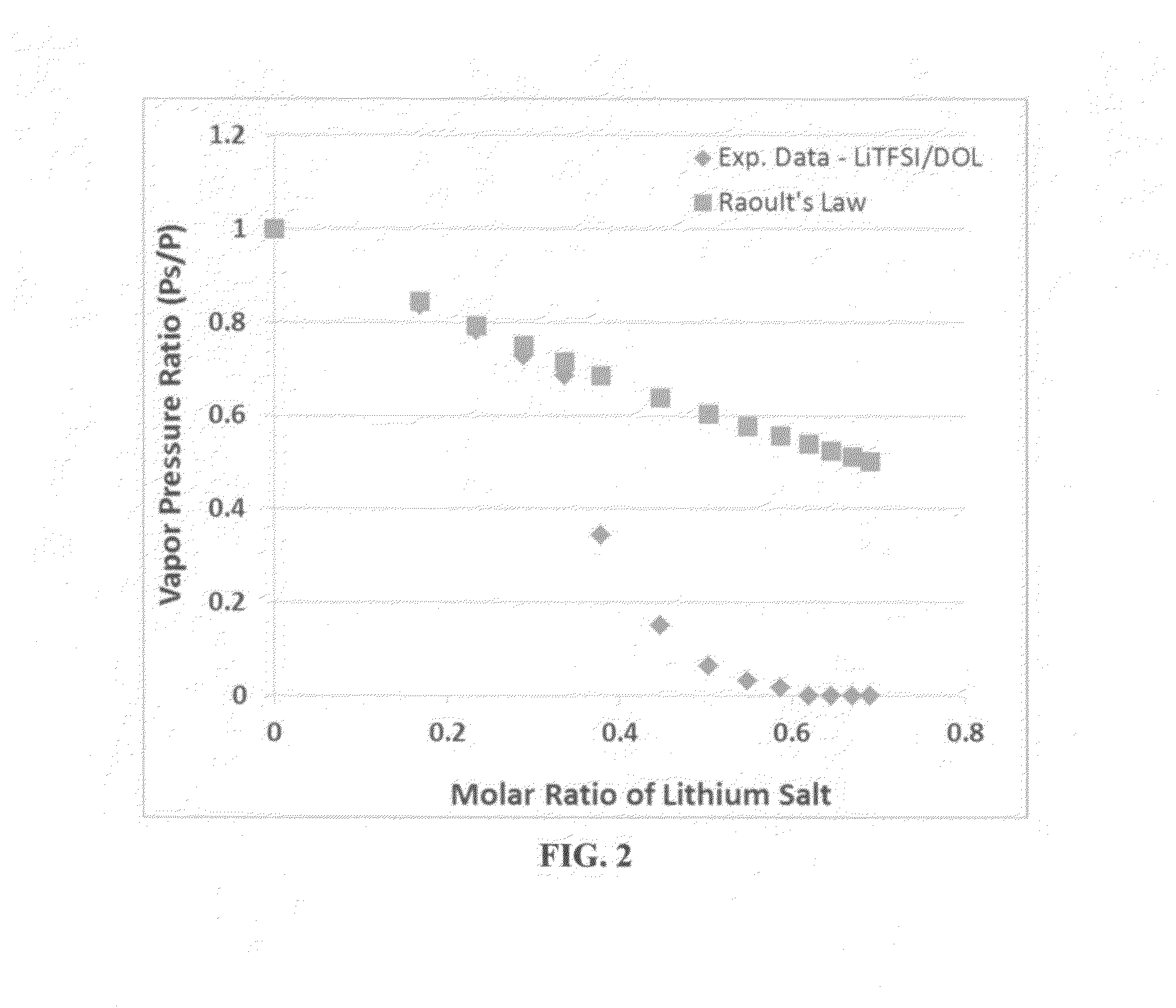

Non-flammable quasi-solid electrolyte-separator layer product for lithium battery applications

ActiveUS20150024248A1Reduce electrical conductivityLow ionic conductivityFinal product manufactureLi-accumulatorsGlass fiberCelsius Degree

A separator-electrolyte layer product for use in a lithium battery, comprising: (a) a porous thin-film separator selected from a porous polymer film, a porous mat, fabric, or paper made of polymer or glass fibers, or a combination thereof, wherein the separator has a thickness less than 500 μm; and (b) a non-flammable quasi-solid electrolyte containing a lithium salt dissolved in a liquid solvent up to a concentration no less than 3 M; wherein the porous thin-film separator is coated with the quasi-solid electrolyte so that the layer product exhibits a vapor pressure less than 0.01 kPa when measured at 20° C., a vapor pressure less than 60% of the vapor pressure of the liquid solvent alone, a flash point at least 20 degrees Celsius higher than a flash point of the first liquid solvent alone, a flash point higher than 150° C., or no detectable flash point.

Owner:GLOBAL GRAPHENE GRP INC

Liquid vapor separator

ActiveUS7694665B2Fuel dropletPrevented from reachingNon-fuel substance addition to fuelMachines/enginesFuel vaporLiquid vapor

Owner:KAUTEX TEXTRON

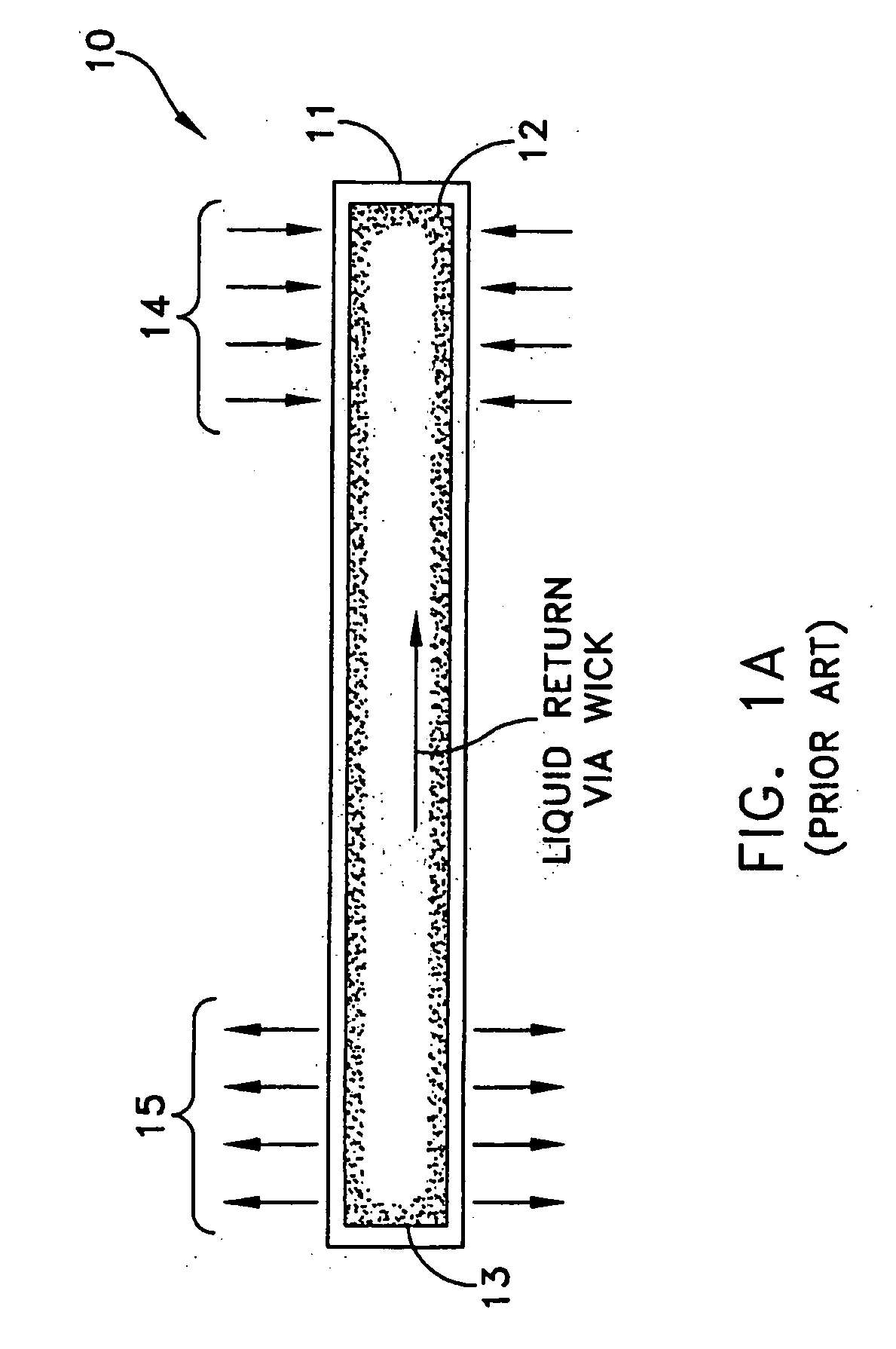

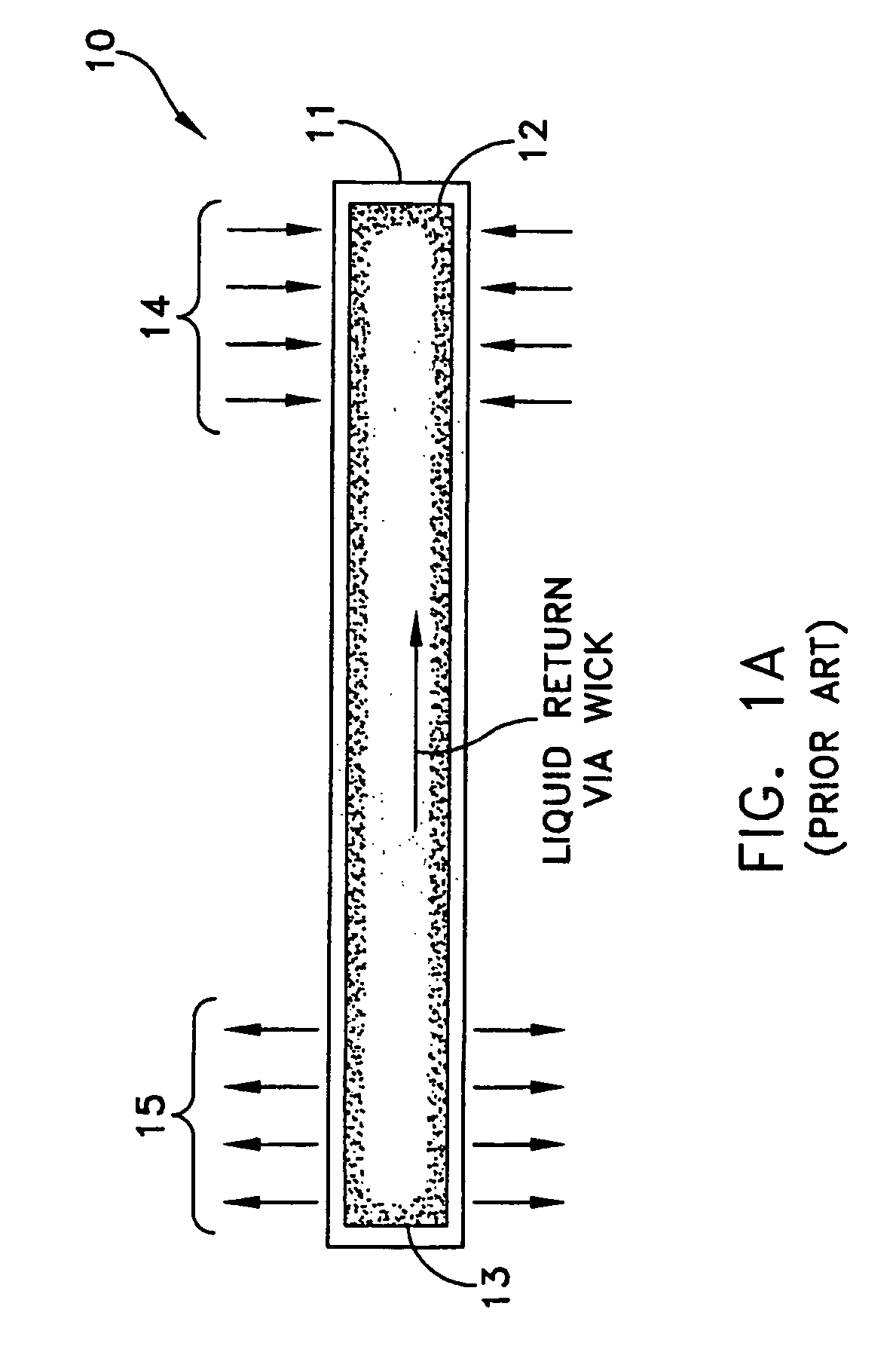

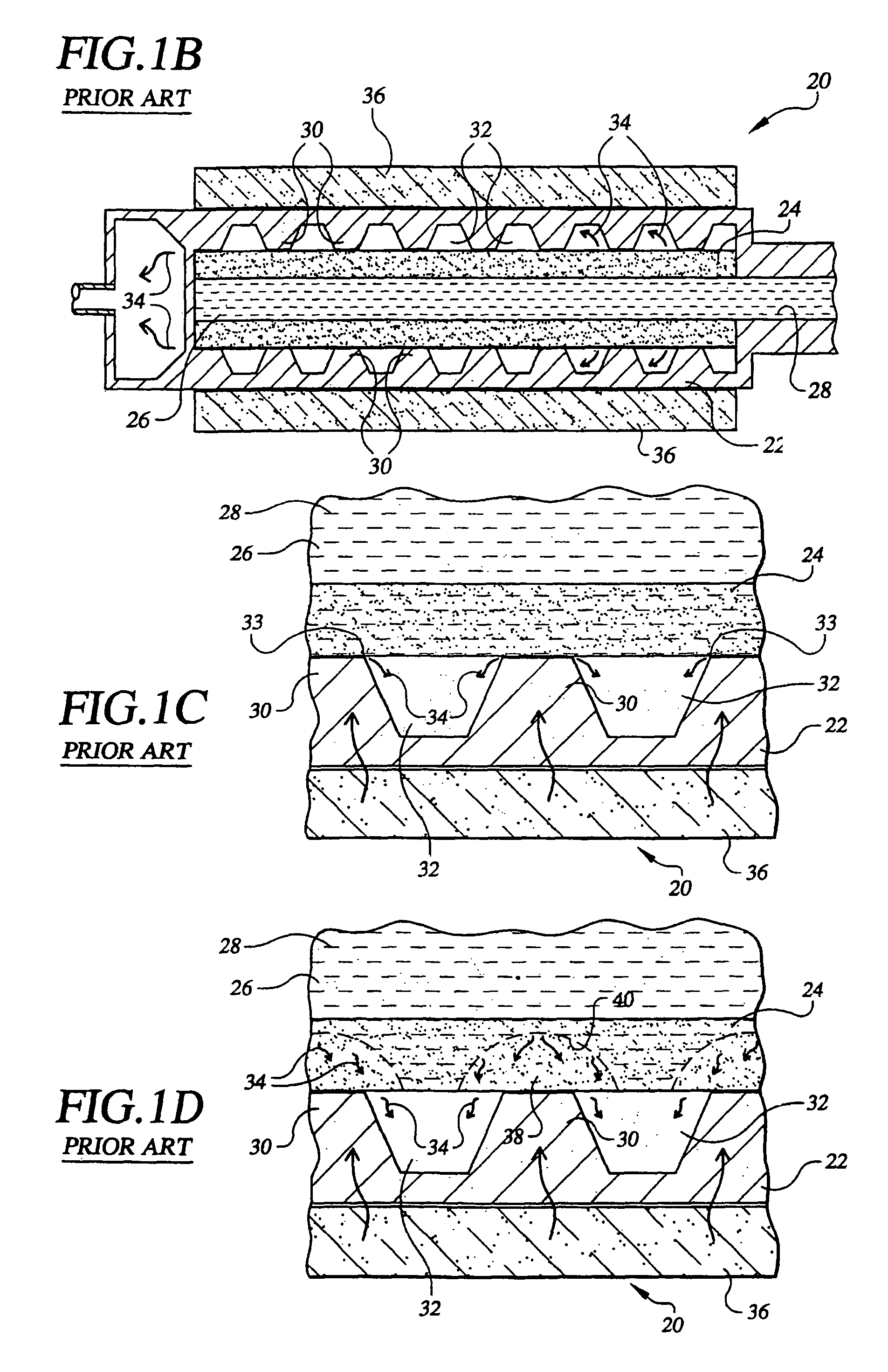

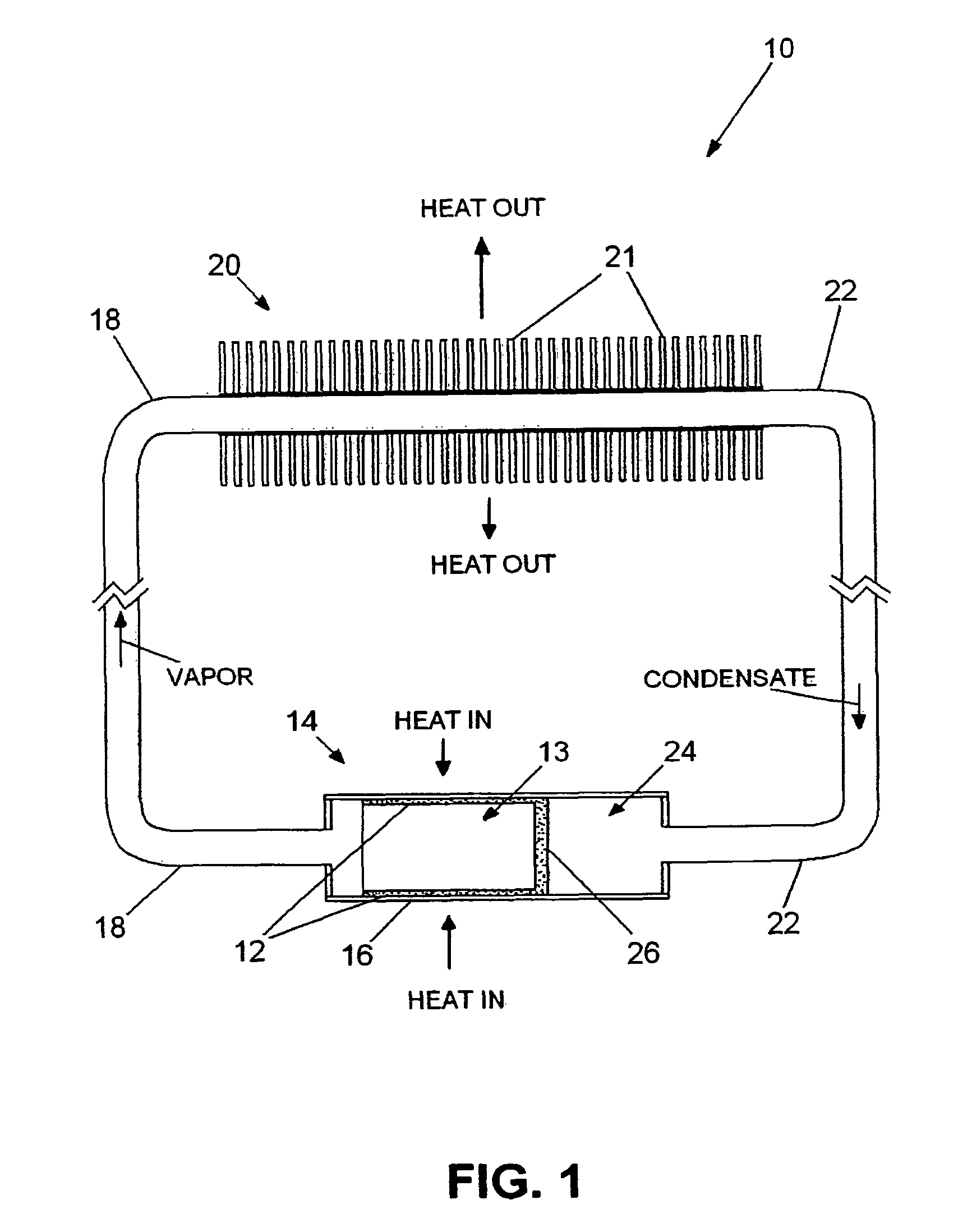

Evaporator for capillary loop

ActiveUS7748436B1Improve performanceImprove heat transfer performanceIndirect heat exchangersCooling/ventilation/heating modificationsThermal isolationHeat flow

The apparatus is a capillary loop evaporator in which the vapor space is the internal volume of a cup shaped evaporator wick with sidewalls in full contact with the outer casing of the evaporator. Liquid is furnished to the wick through thicker wick wall sections, slabs protruding from the liquid-vapor barrier wick, eccentric wick cross sections, or tunnel arteries. The tunnel arteries can also be formed within heat flow reducing ridges protruding into the vapor space. The tunnel arteries can be fed liquid by bayonet tubes or cable arteries, and can be isolated from the heat source with regions of finer wick to impede vapor flow into the liquid. Tunnel arteries also enable separation of the evaporator and the reservoir for thermal isolation and structural flexibility. A wick within the reservoir aids collection of liquid in low gravity applications.

Owner:ADVANCED COOLING TECH

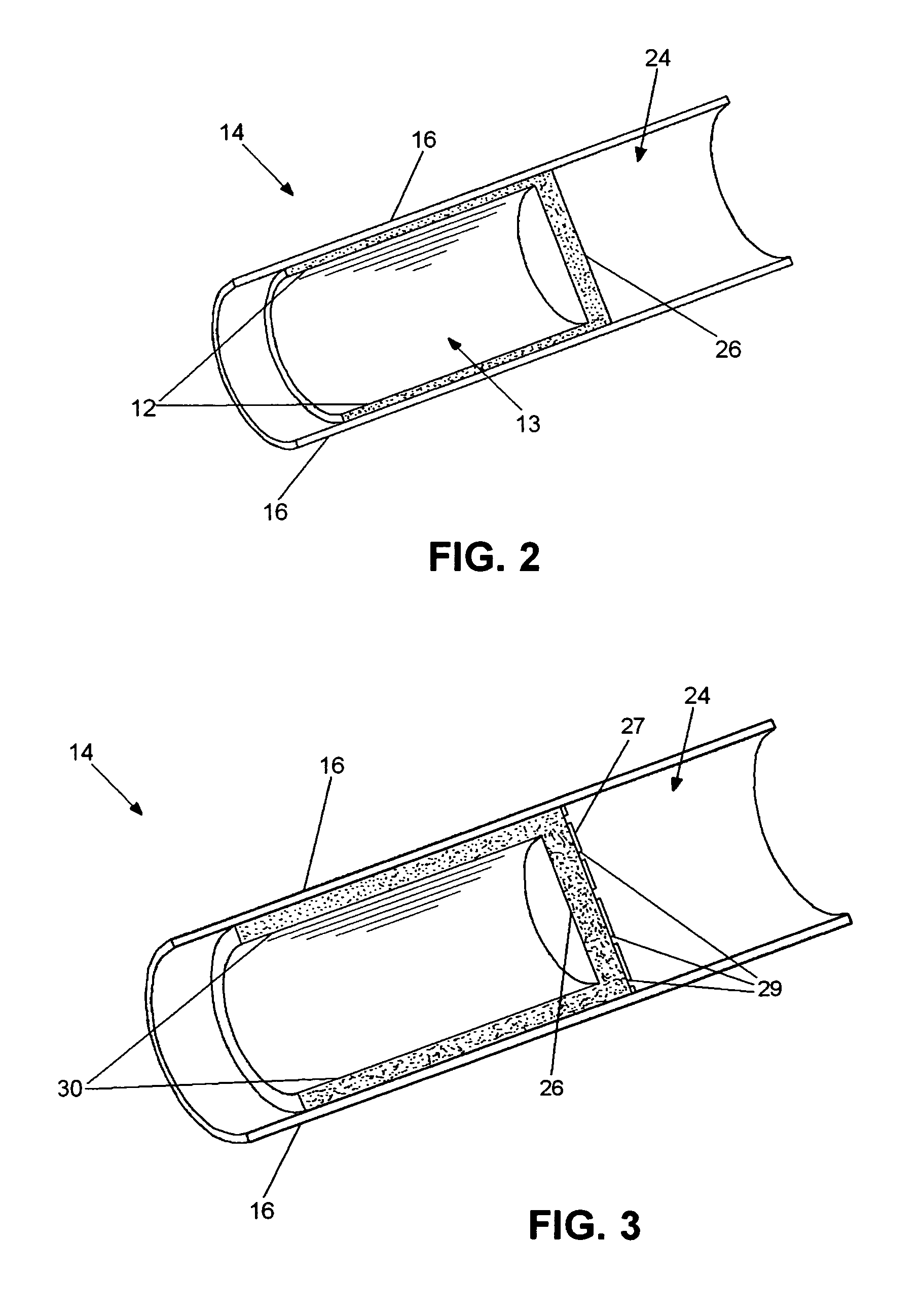

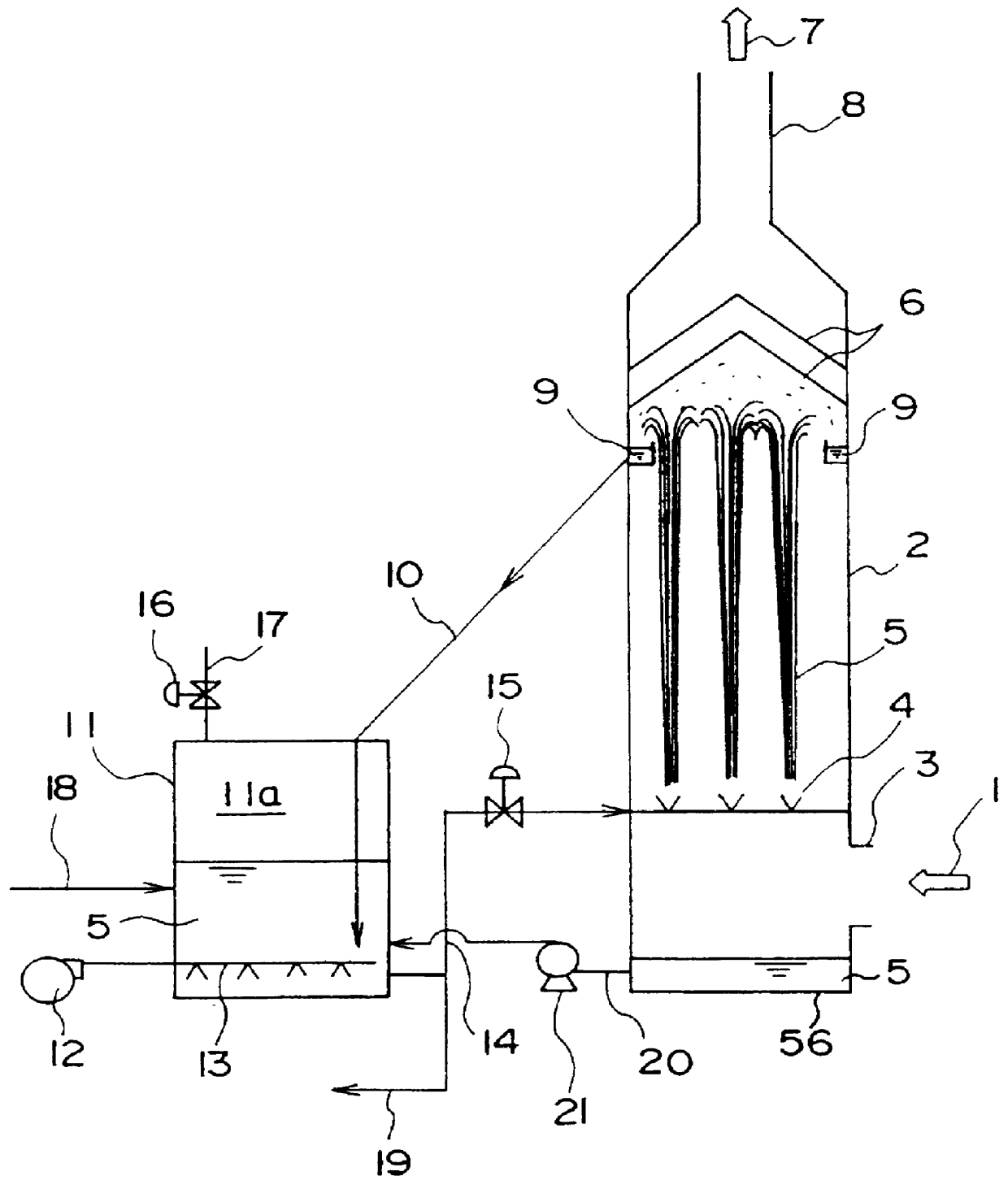

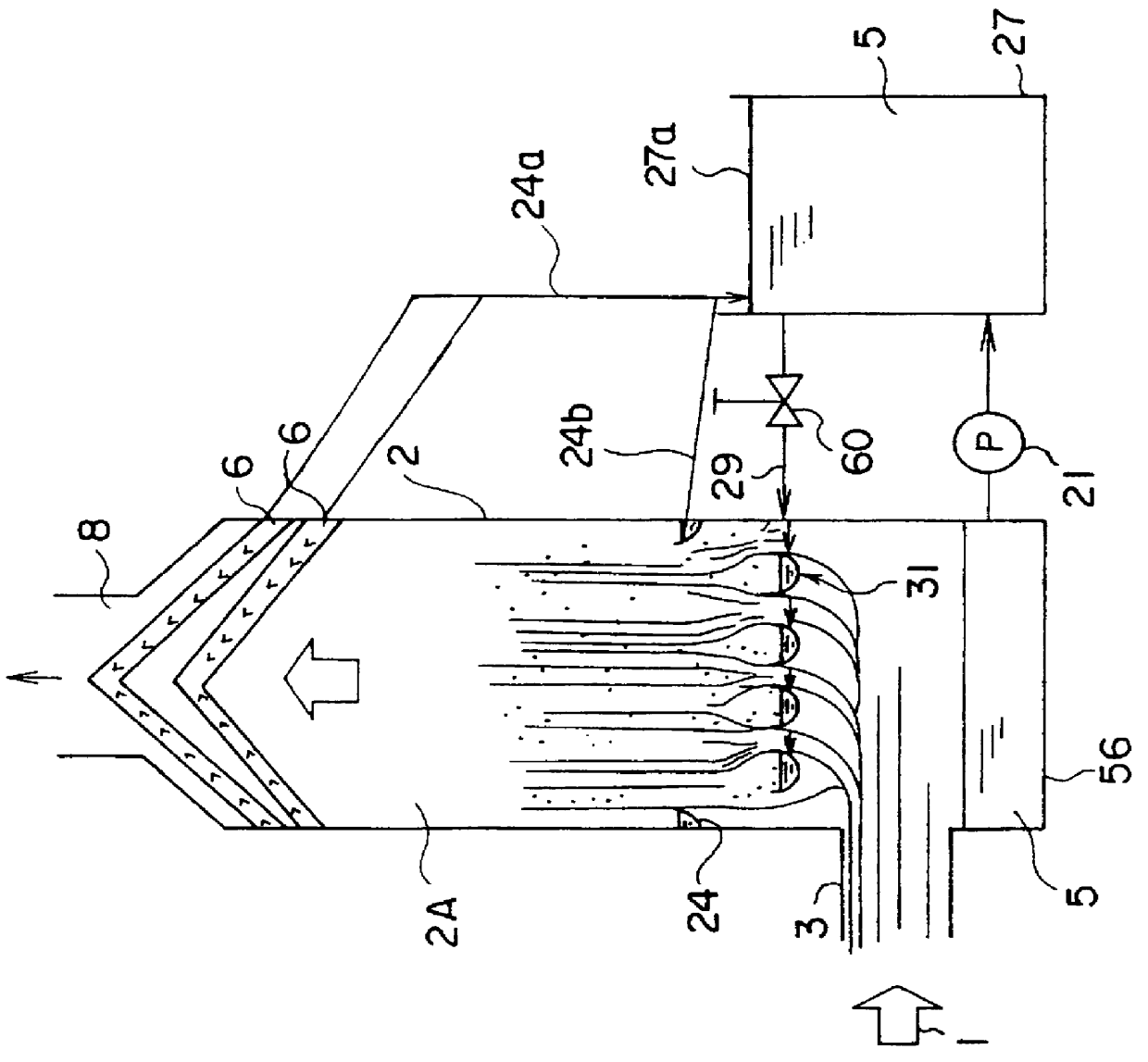

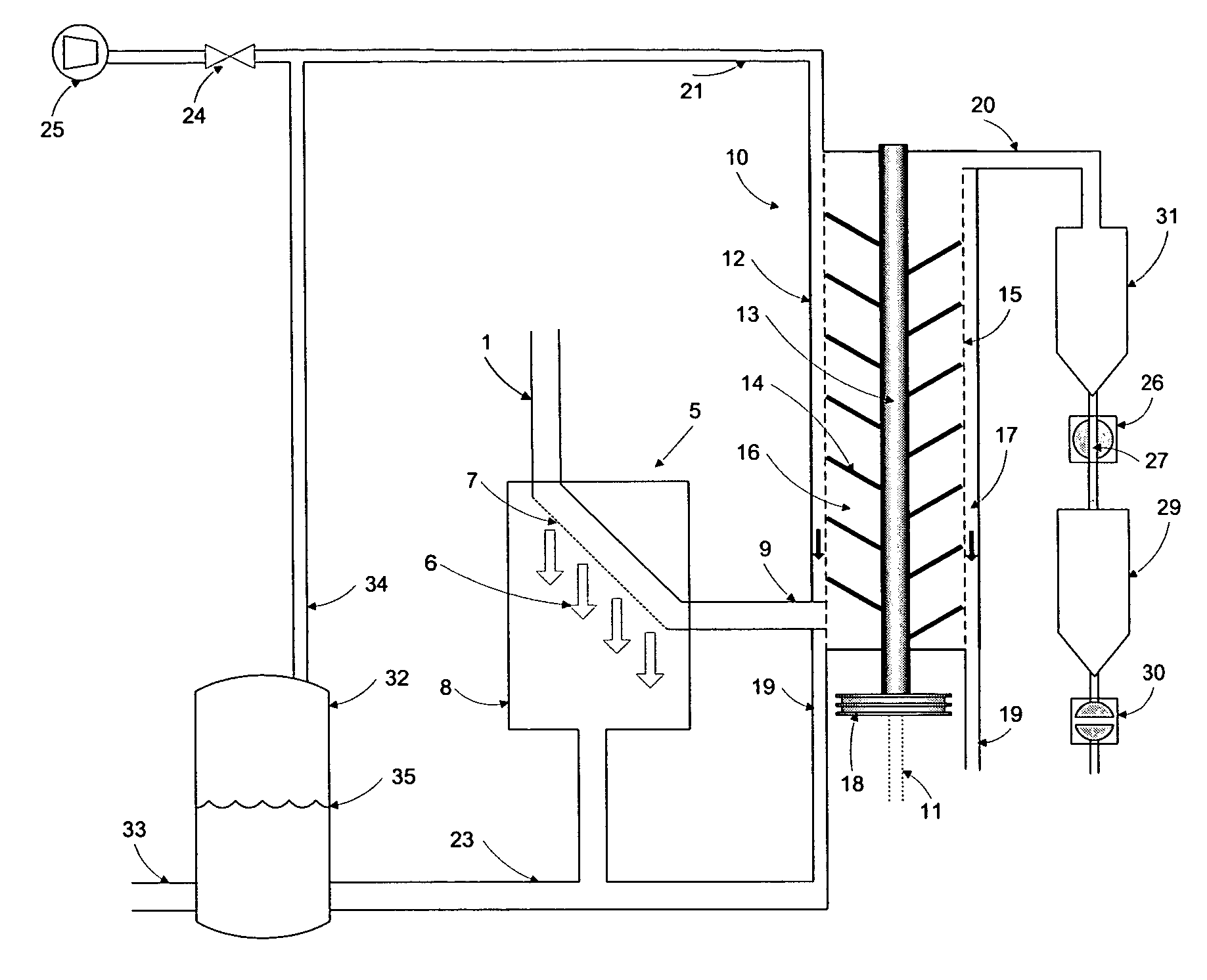

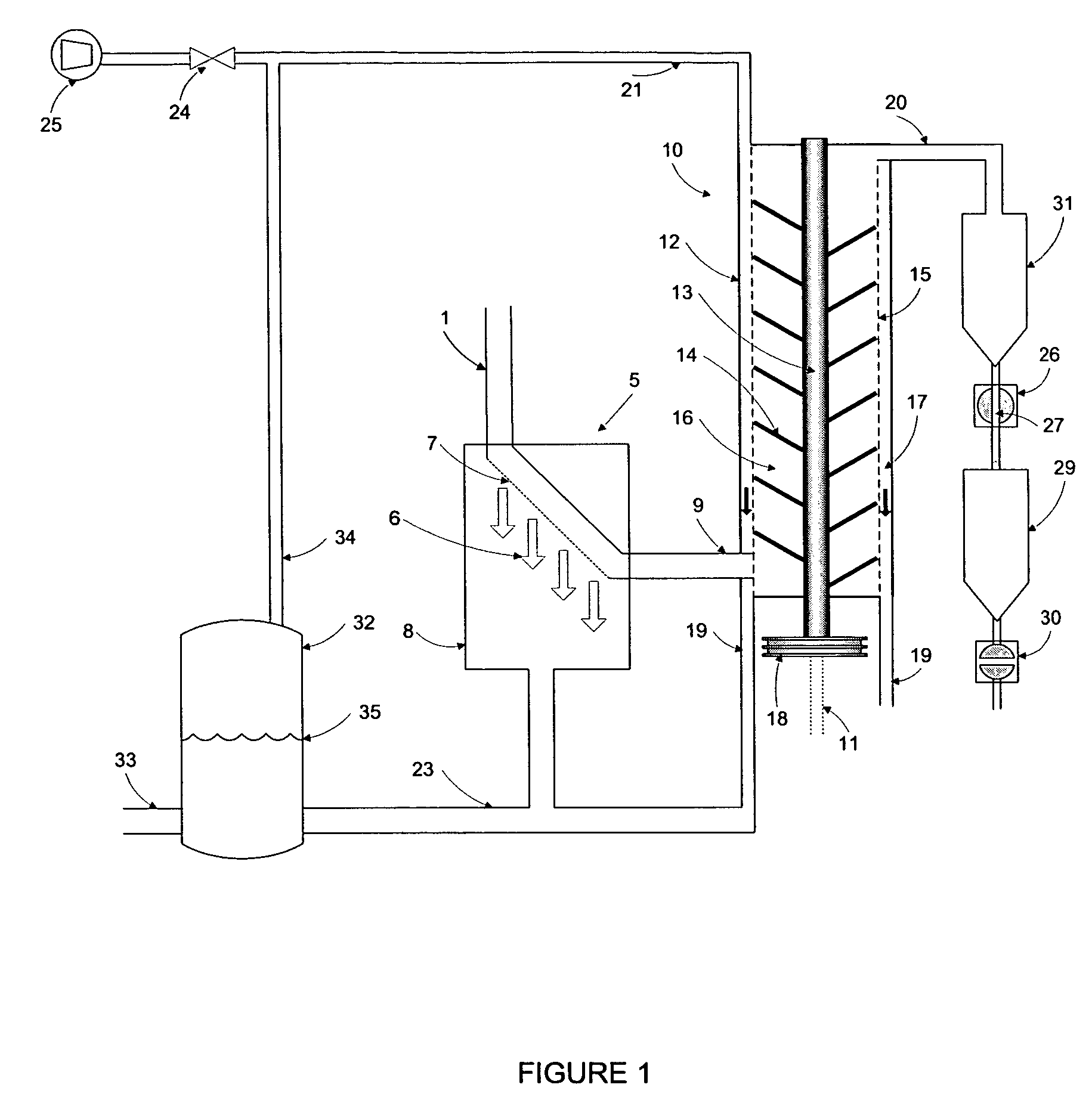

Wet gas processing method and the apparatus using the same

InactiveUS6138378AIncrease liquid volumeSmooth trafficCombination devicesDrying using combination processesSpray nozzleLiquid storage tank

PCT No. PCT / JP98 / 05062 Sec. 371 Date Sep. 8, 1999 Sec. 102(e) Date Sep. 8, 1999 PCT Filed Nov. 10, 1998 PCT Pub. No. WO99 / 24148 PCT Pub. Date May 20, 1999This invention is related to a wet gas process which would not require a spray pump, and which would allow the absorption liquid to be recovered smoothly even if the flow velocity of the gases entrained to the liquid should decrease. A wet gas processing apparatus in which the absorption liquid collected in the first liquid storage tank is sprayed in a specified direction (which may be upward, horizontal or downward) by a discharge unit consisting of spray nozzles (14) or the like in the absorption tower. The sprayed liquid is brought into contact with the exhaust gases which are conducted into the tower, and the targeted components of the gases are absorbed and removed. This processing apparatus is distinguished by the following. The first liquid storage tank for the absorption liquid comprises a pressure tank (11) which generates a pressurized gas in the space above the surface of the collected liquid (11a). The increased pressure of the pressurized gas is employed to spray the liquid collected in the pressurized tank from the spray nozzle unit in the absorption tower. This apparatus is further distinguished as the following. This invention has overflow ports which generate a virtually horizontal overflow or source flow. The absorption liquid propelled by the overflow ports makes orthogonal contact with the flow of exhaust gases, which results in both atomization of the liquid and liquid-vapor contact.

Owner:MITSUBISHI HEAVY IND LTD

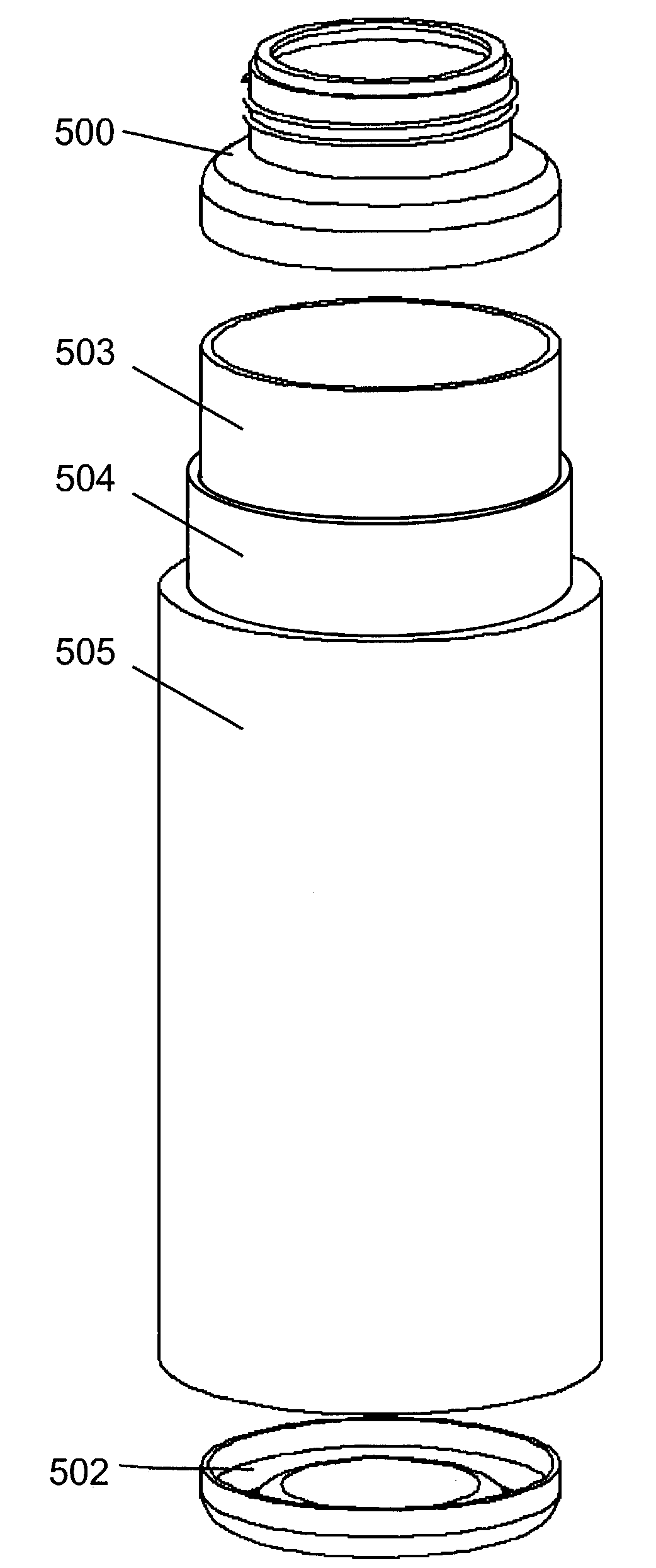

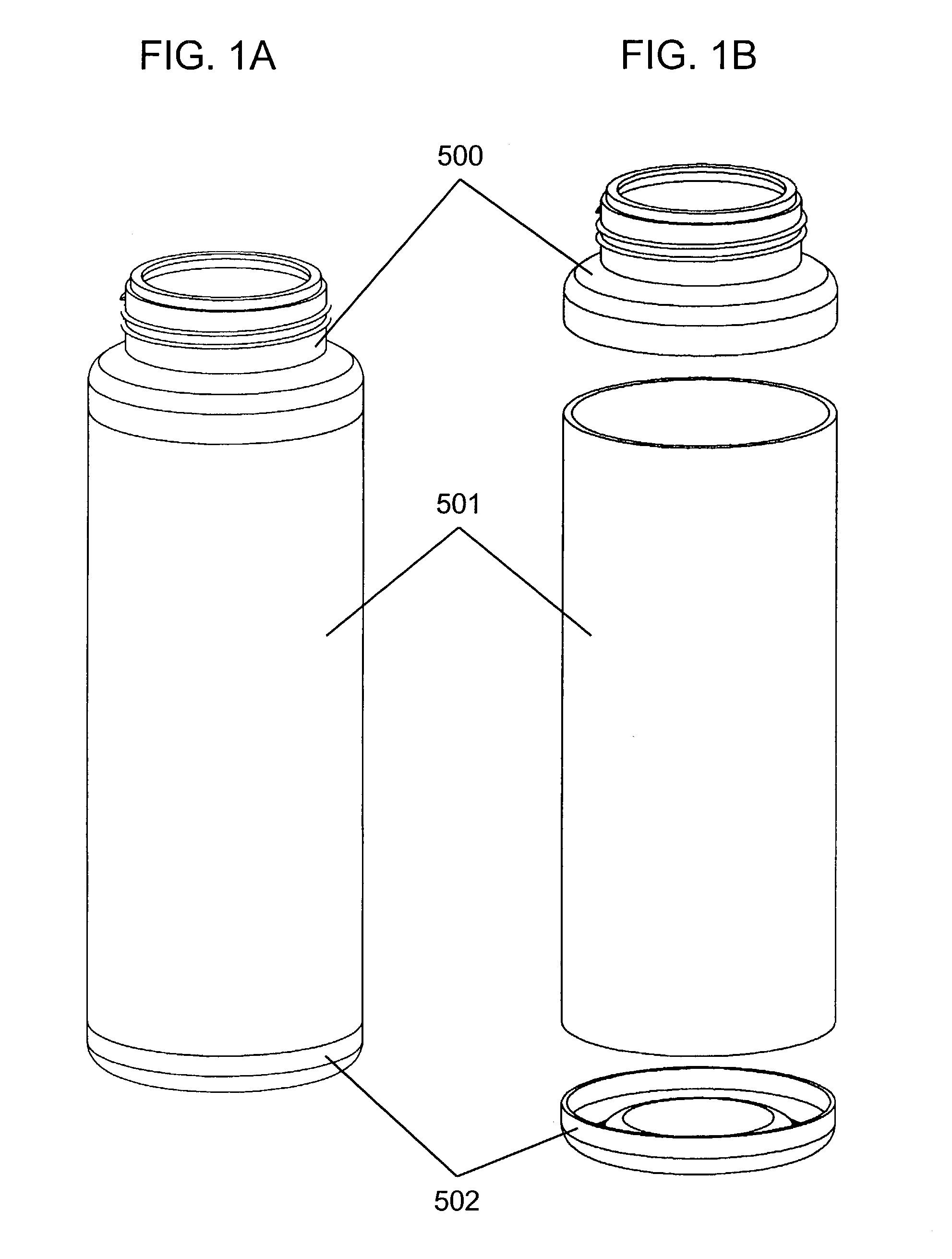

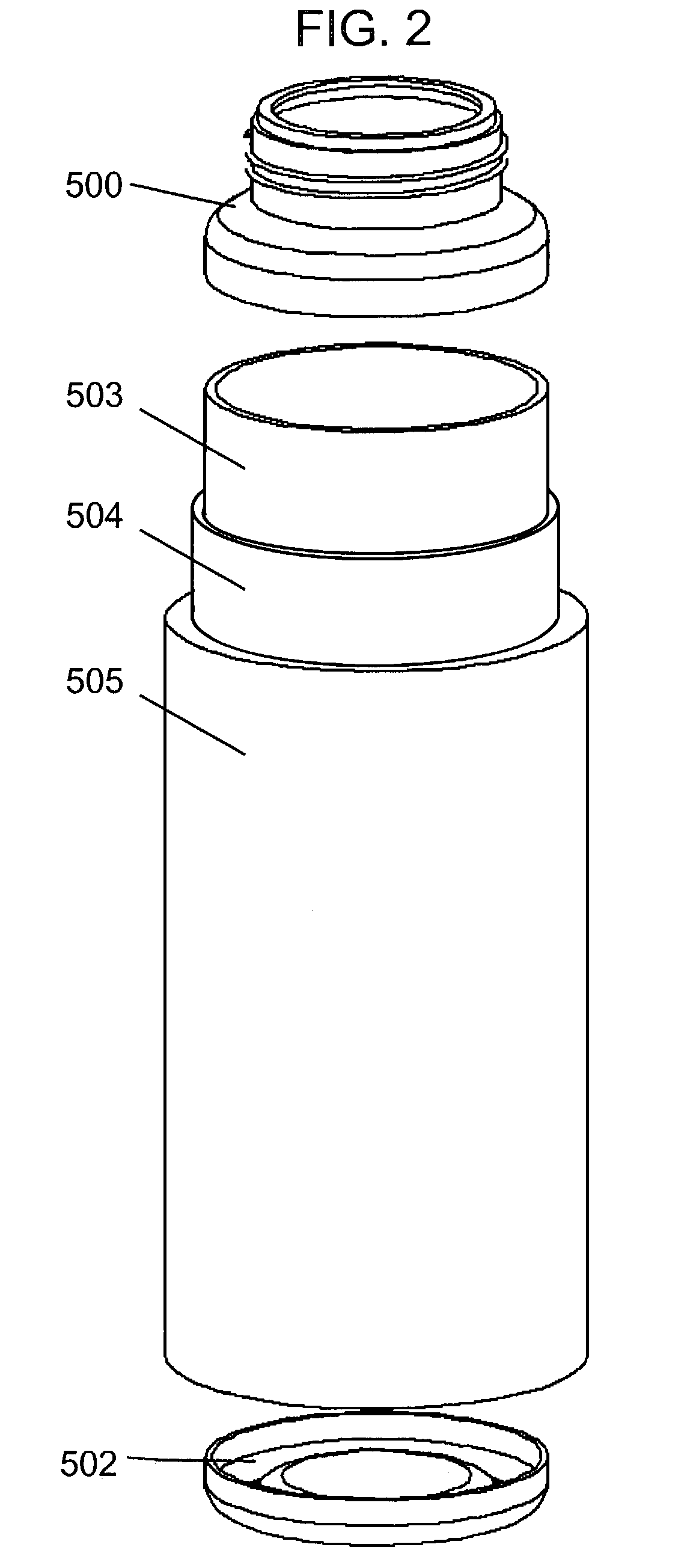

Self-cooling containers for liquids

InactiveUS7107783B2Improve cooling efficiencyTravelling sacksMedical devicesAs elementAbsorbent material

Disclosed are self-cooling containers for beverages and other liquids. Such containers comprise porous matrices as elements of the container bodies to effect the cooling of contained liquids by pervaporation. The liquid vapor can pass through the porous matrix directly to the environment or to a collector or trap comprising an absorbent material in contact with the container. Also disclosed are self-cooling containers incorporating insulative sleeves that reduce radiative warming of container surfaces yet permit sufficient pervaporative flux to cool containers residing within such sleeves.

Owner:ADVANCED POROUS TECH

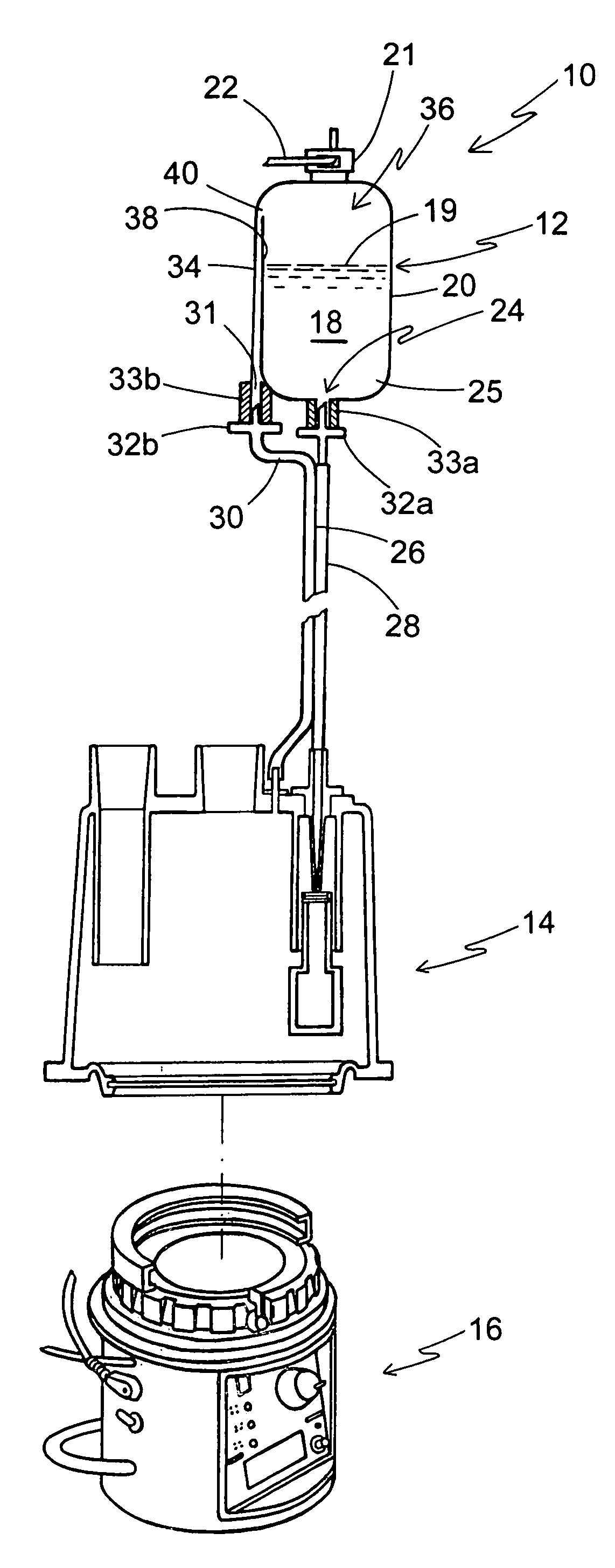

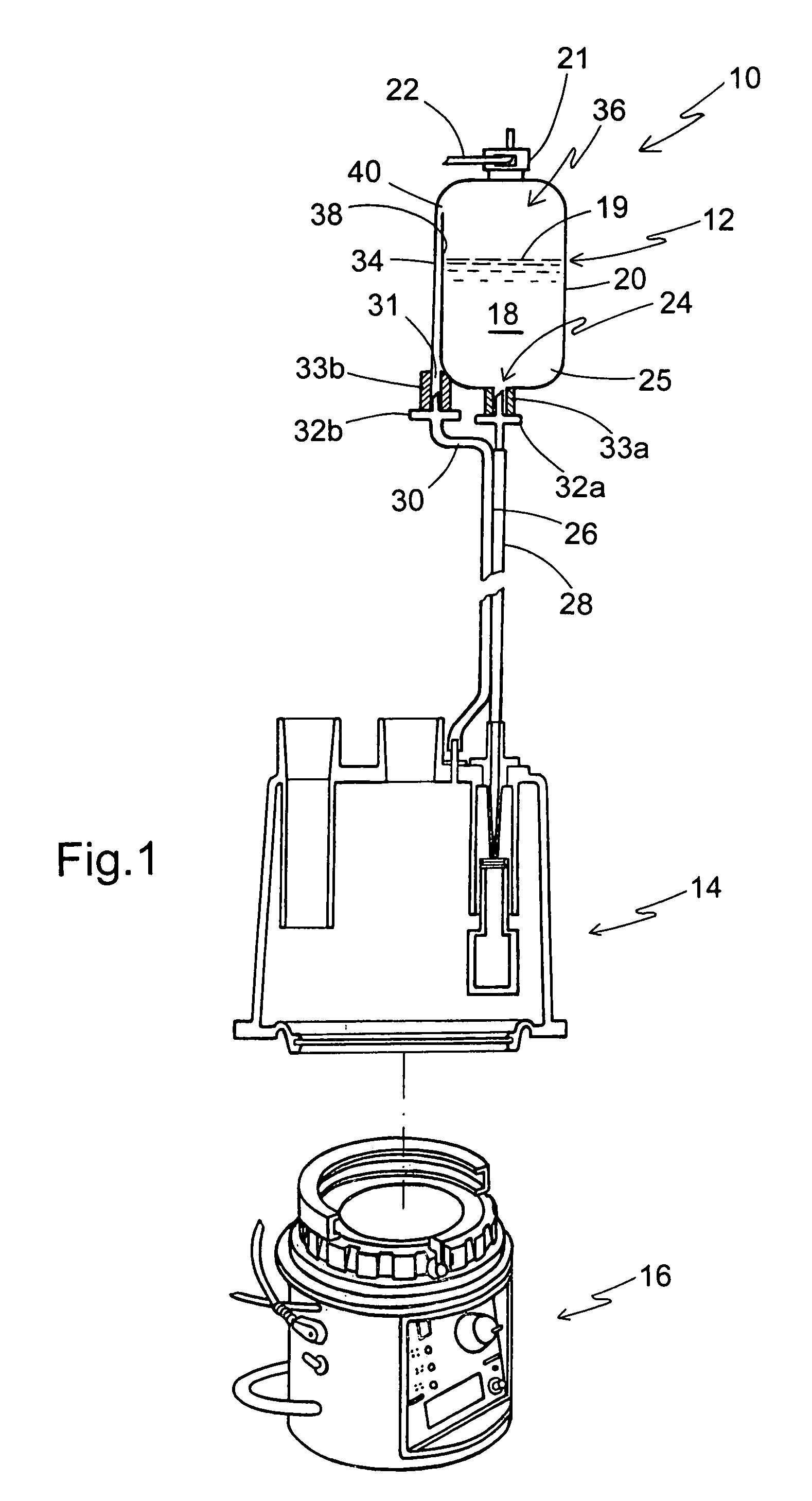

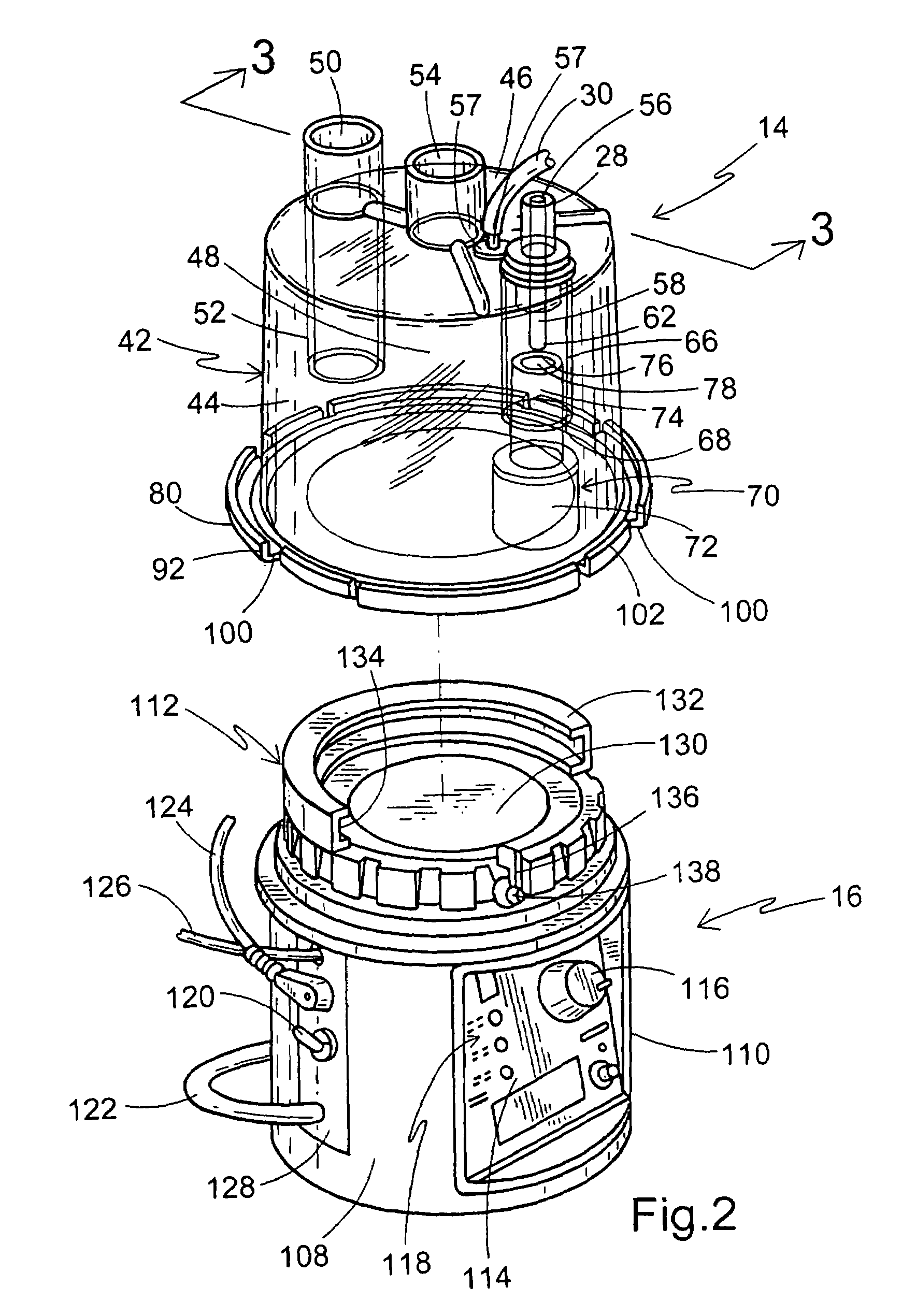

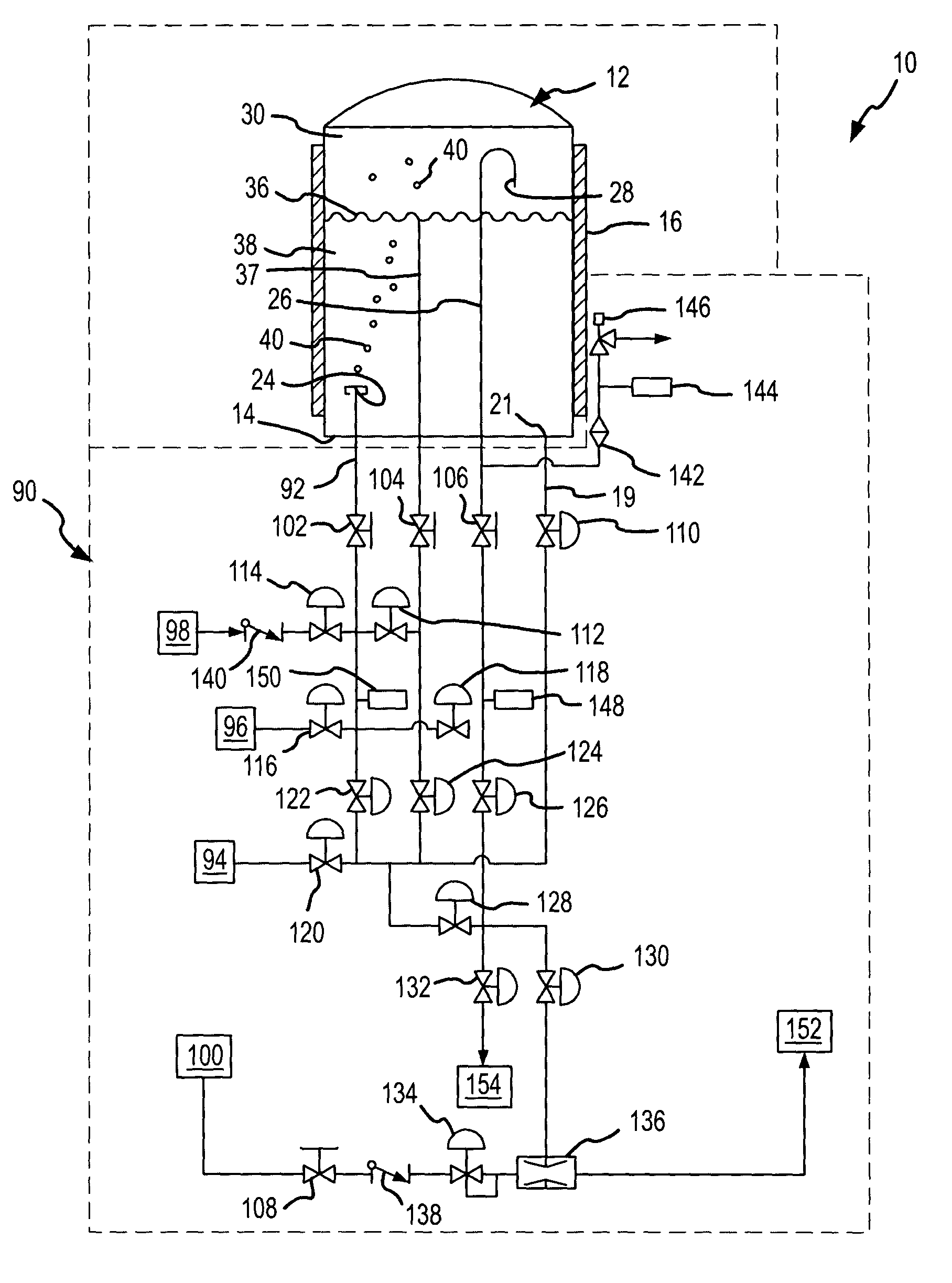

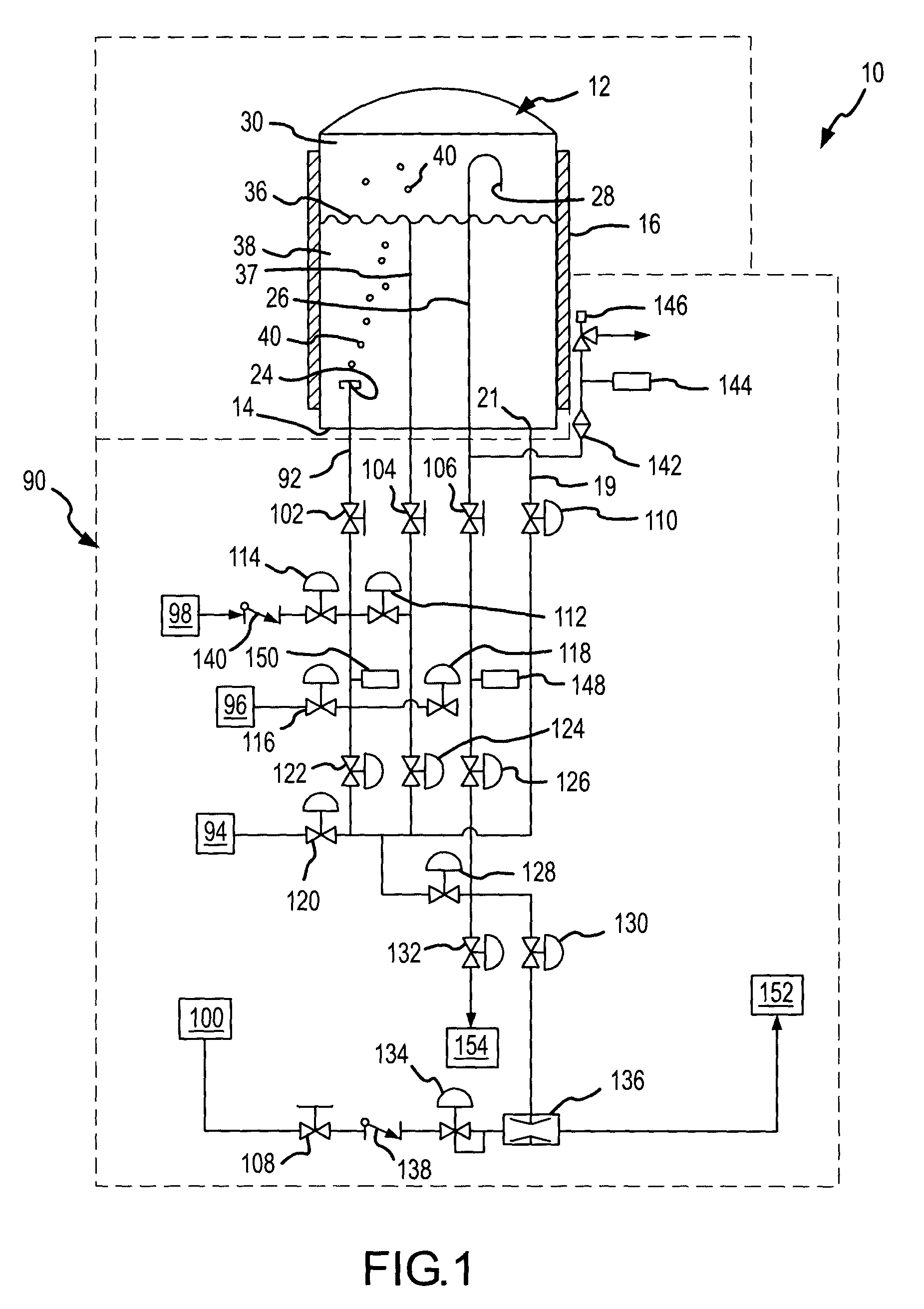

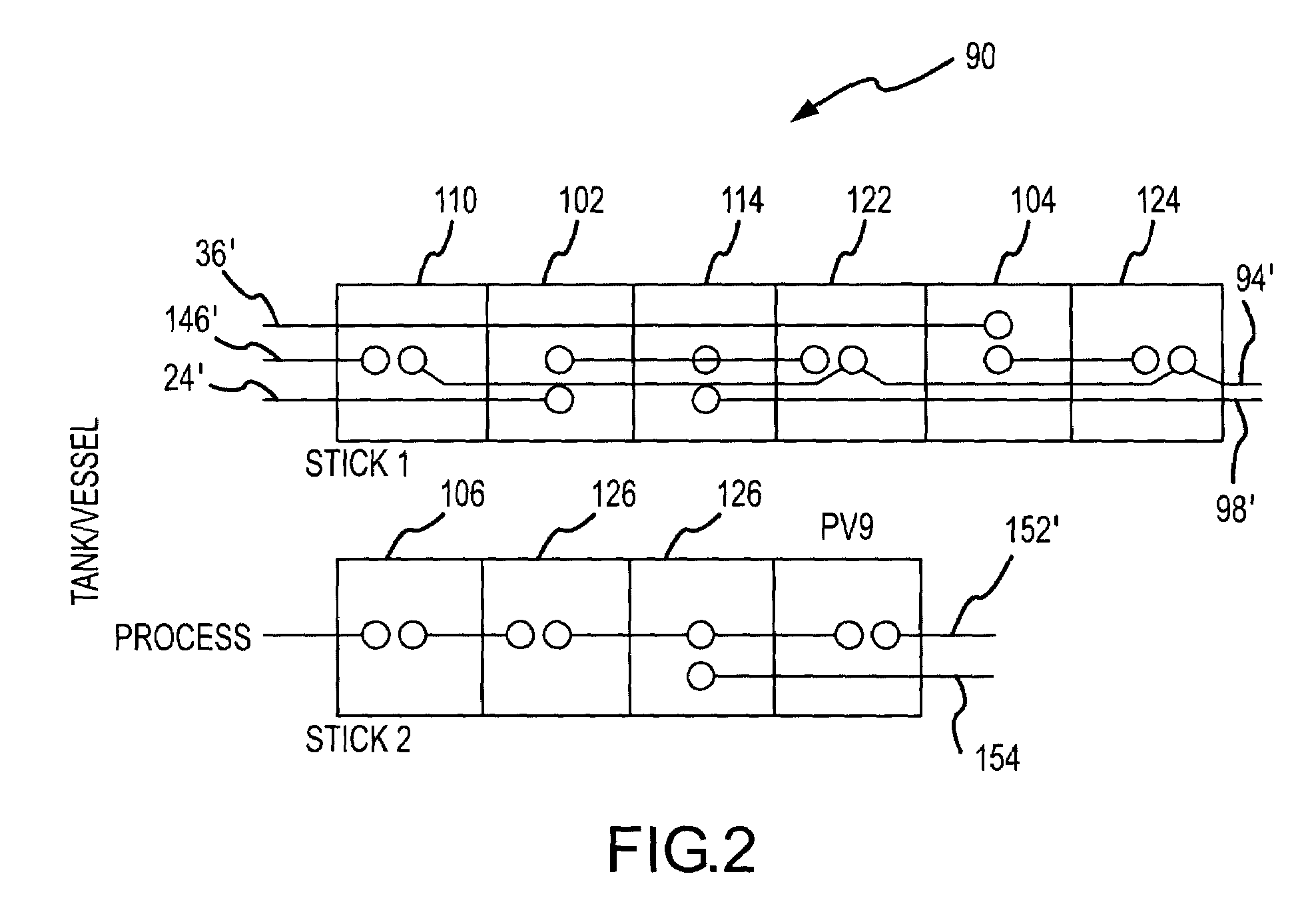

Liquid vapor delivery system and method of maintaining a constant level of fluid therein

InactiveUS7011299B2Easy to cleanCarburetting airLighting and heating apparatusLevel sensorEngineering

In accordance with the present invention, a method and system is described for controlling the delivery of vapor from a bubbler containing a supply of chemical fluid through which a carrier gas is bubbled and from which bubbler vapors are delivered in a vapor stream entrained with the carrier gas. In general, the present invention involves equilibrating the pressure within the head space to that of the chemical fluid fill line, thus maintaining a constant fluid level based on pressure and not relying on conventional level sensors and controllers.

Owner:MATHESON TRI GAS INC

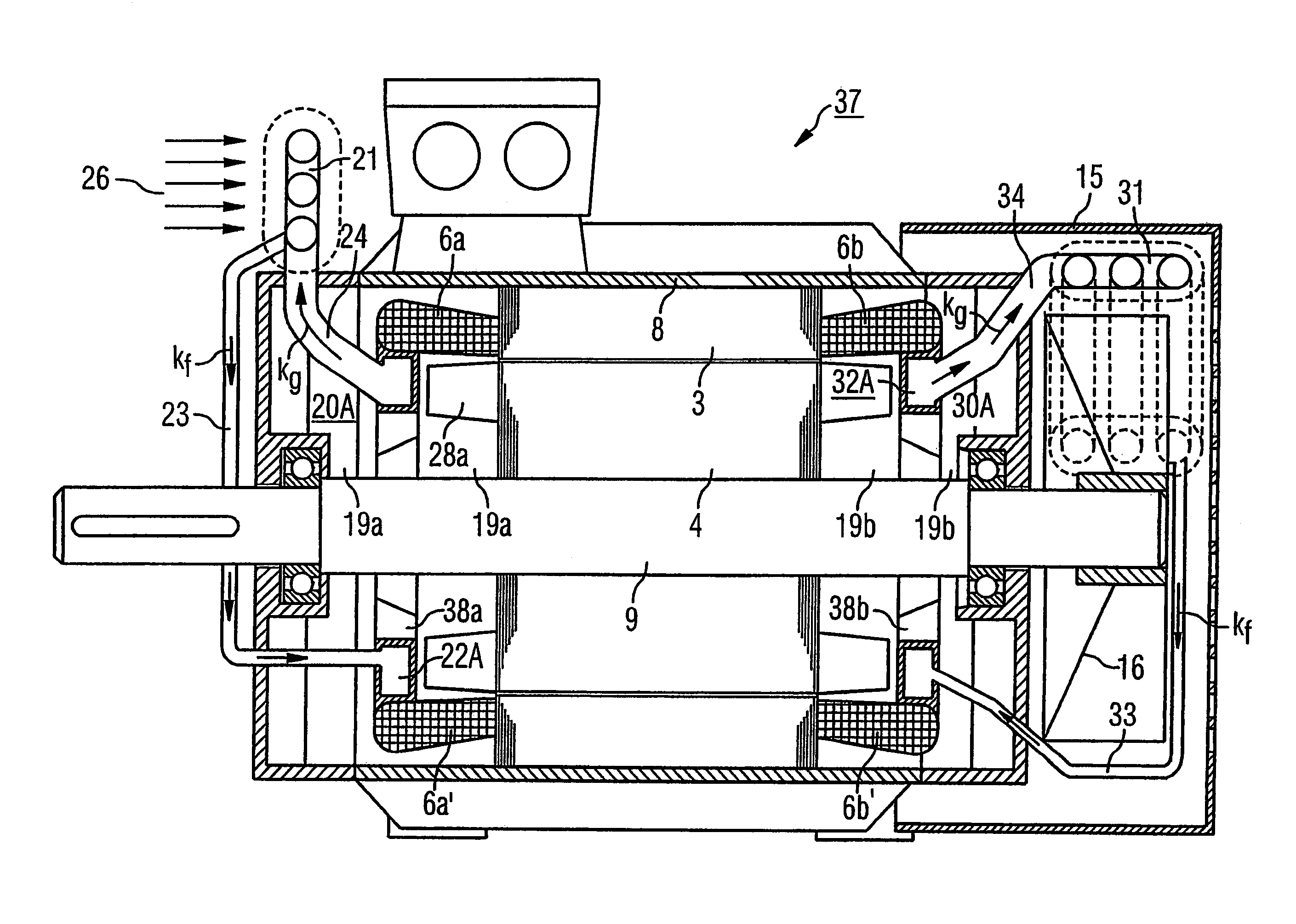

Electric machine with thermosiphon-type cooling system

InactiveUS20050194847A1Improve the heating effectEfficient conductionMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineEngineering

An electric machine includes a housing for accommodating a rotatably supported rotor and a stationary stator, and a cooling device for cooling heat-generating components of the rotor and the stator. The cooling device comprises a closed-flow system having an evaporator disposed in the housing, a condenser disposed outside the housing at a geodetically higher location, and a closed tube assembly, which connects the condenser and the evaporator, for circulating a coolant using a thermosiphon effect as a result of a difference in density between vapor and liquid portions of the coolant. The closed-flow system contains a liquid-vapor mixture of the coolant in a saturated state and includes a first tube for conducting coolant to the evaporator and a second tube for conducting coolant away from the evaporator. The first tube has hereby a cross section which is smaller than a cross section of the second tube.

Owner:SIEMENS AG

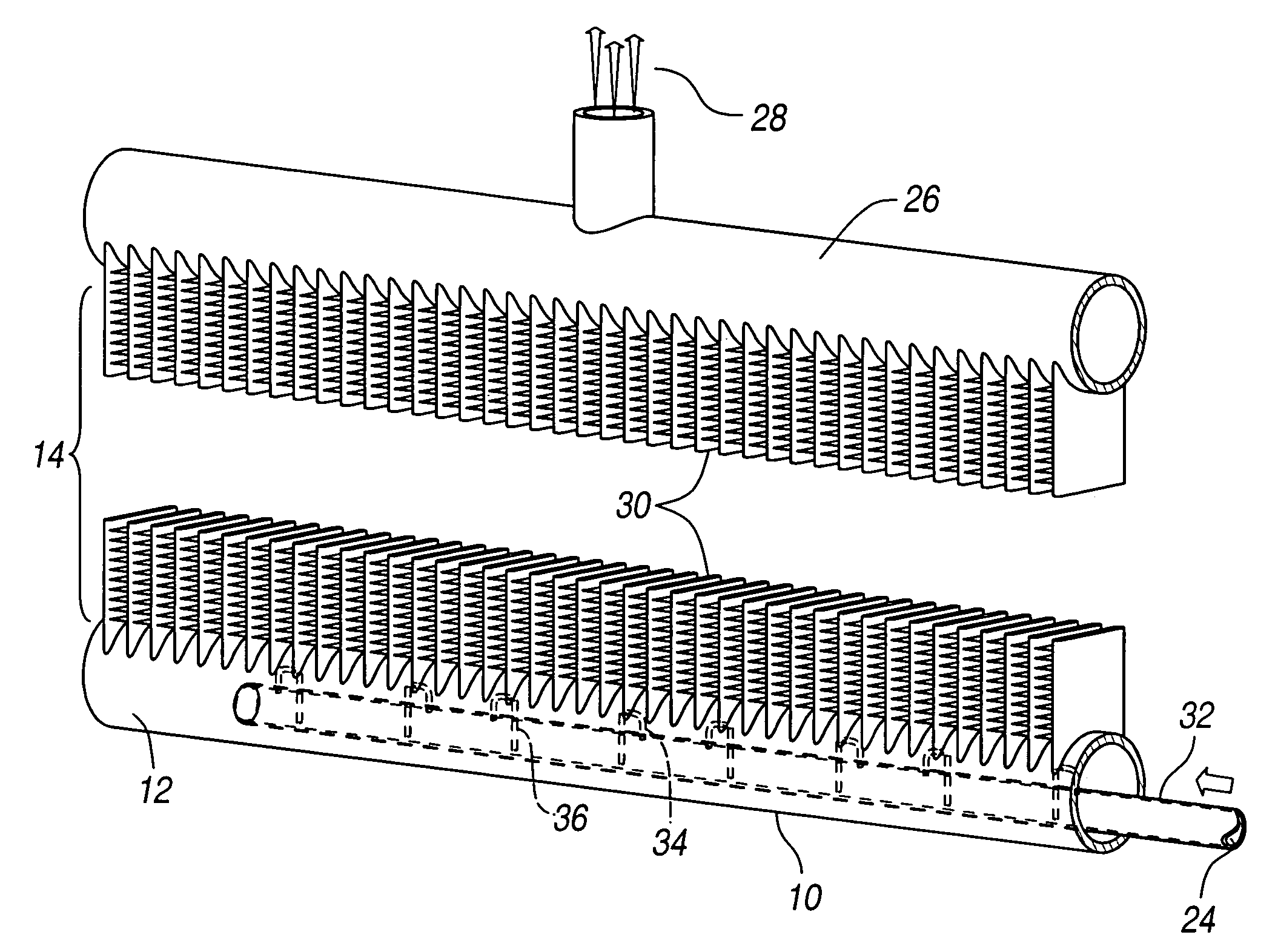

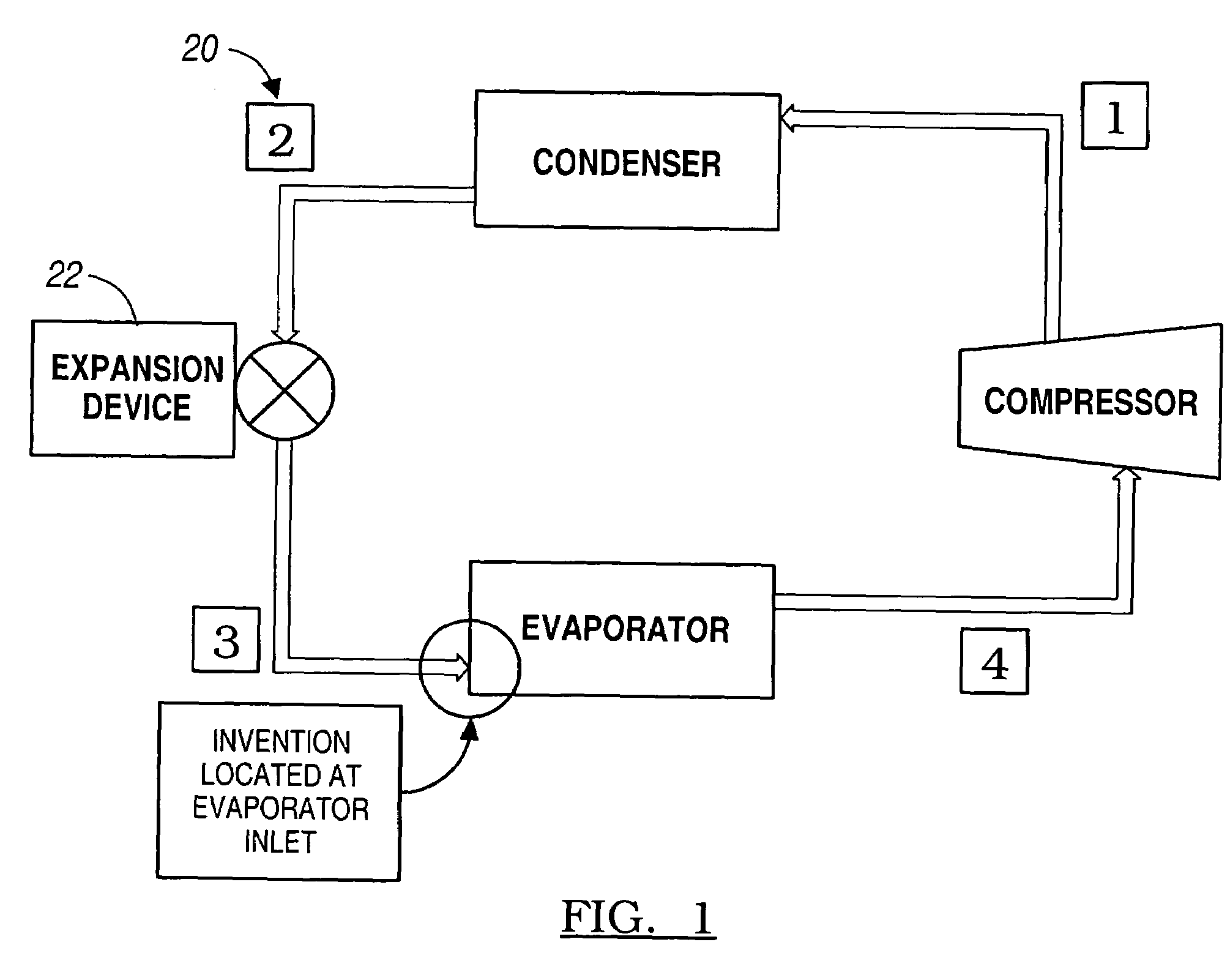

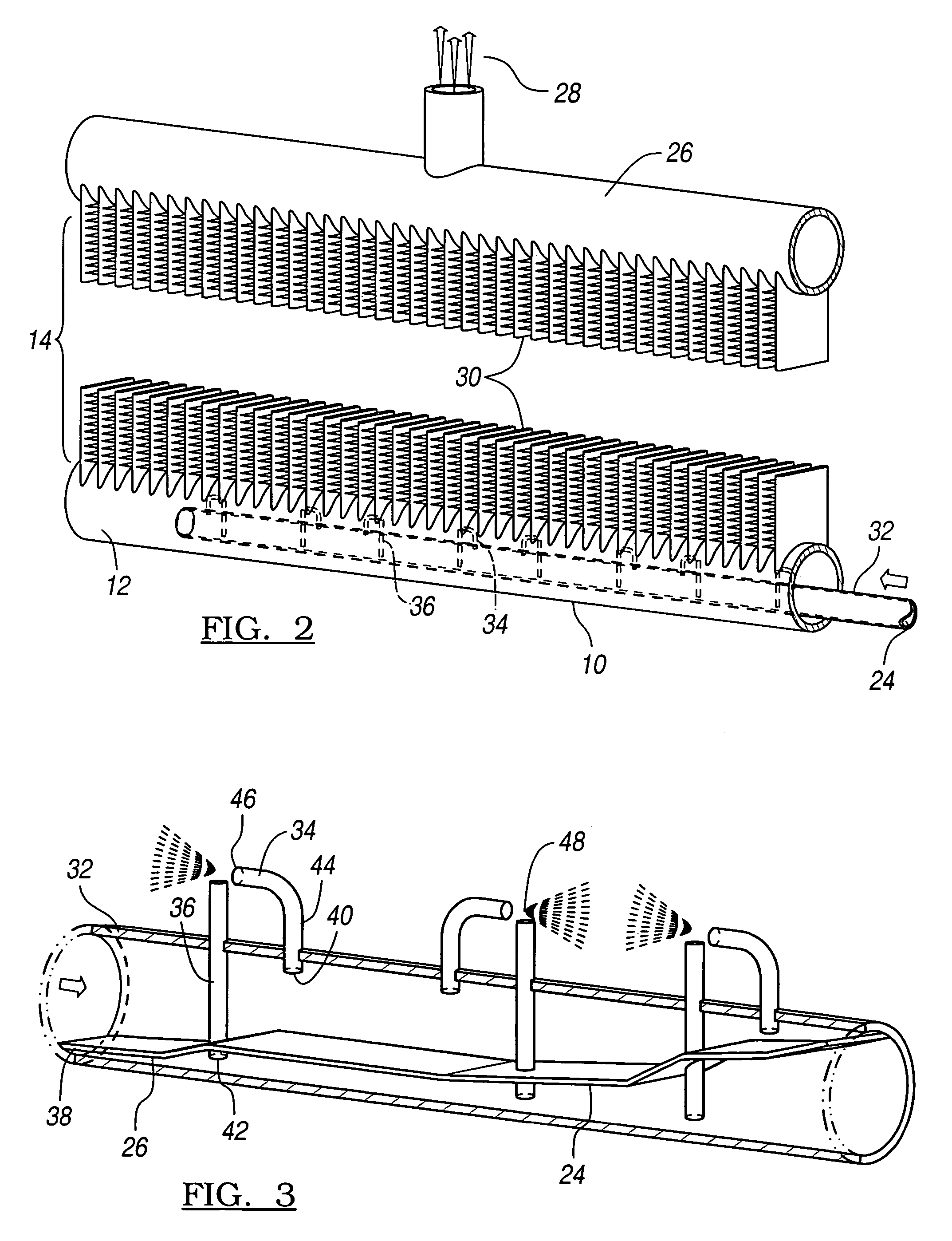

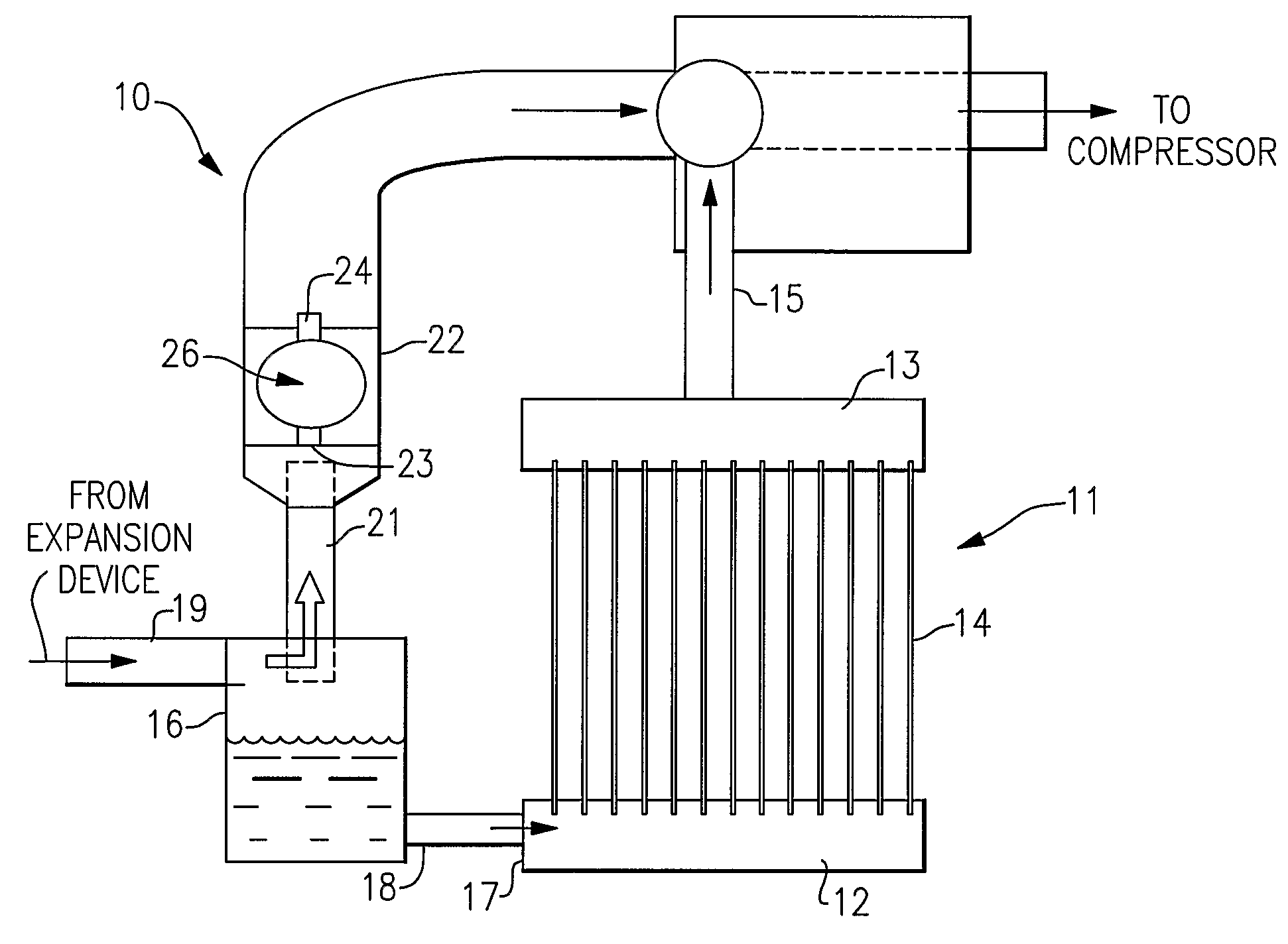

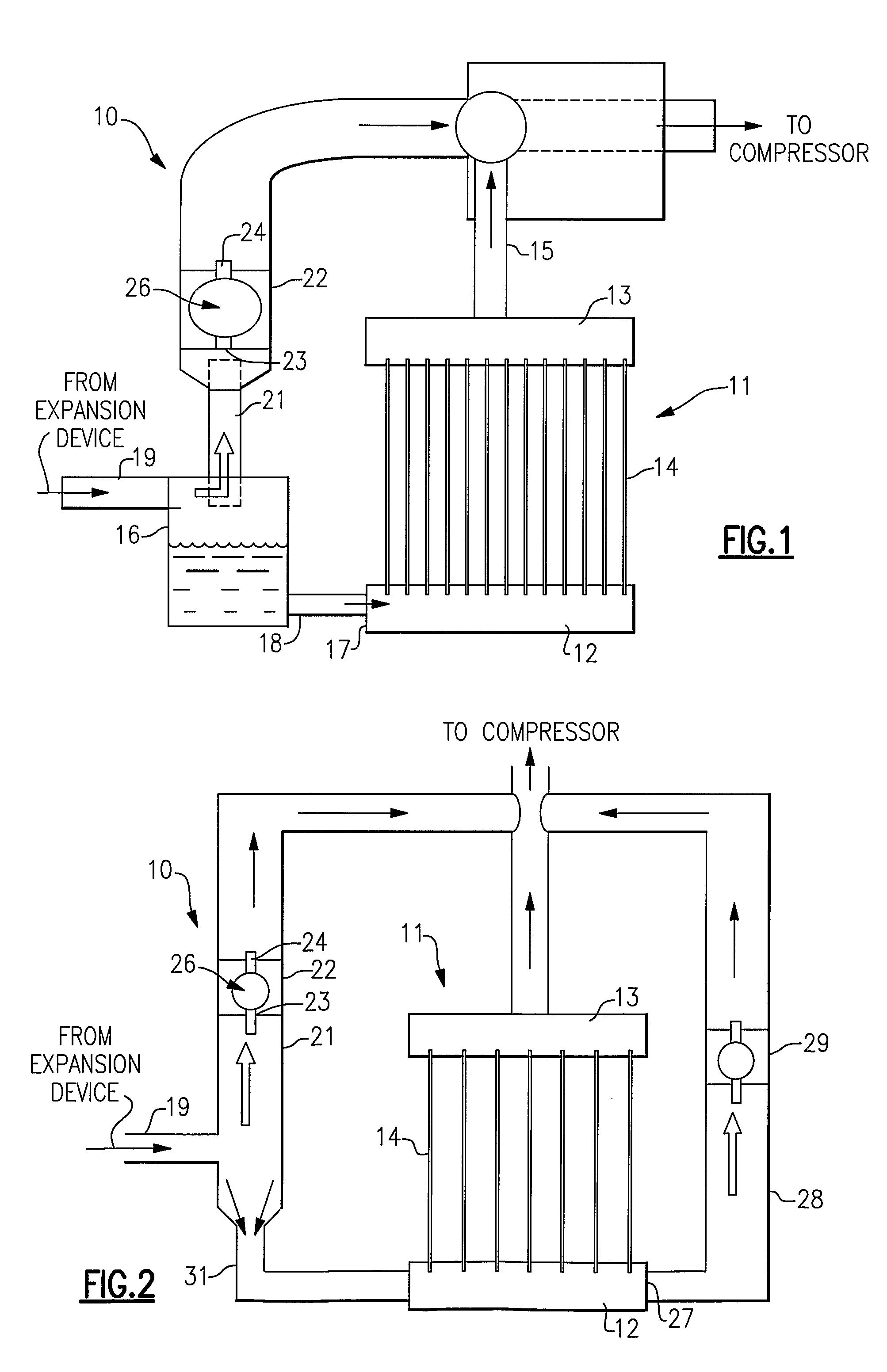

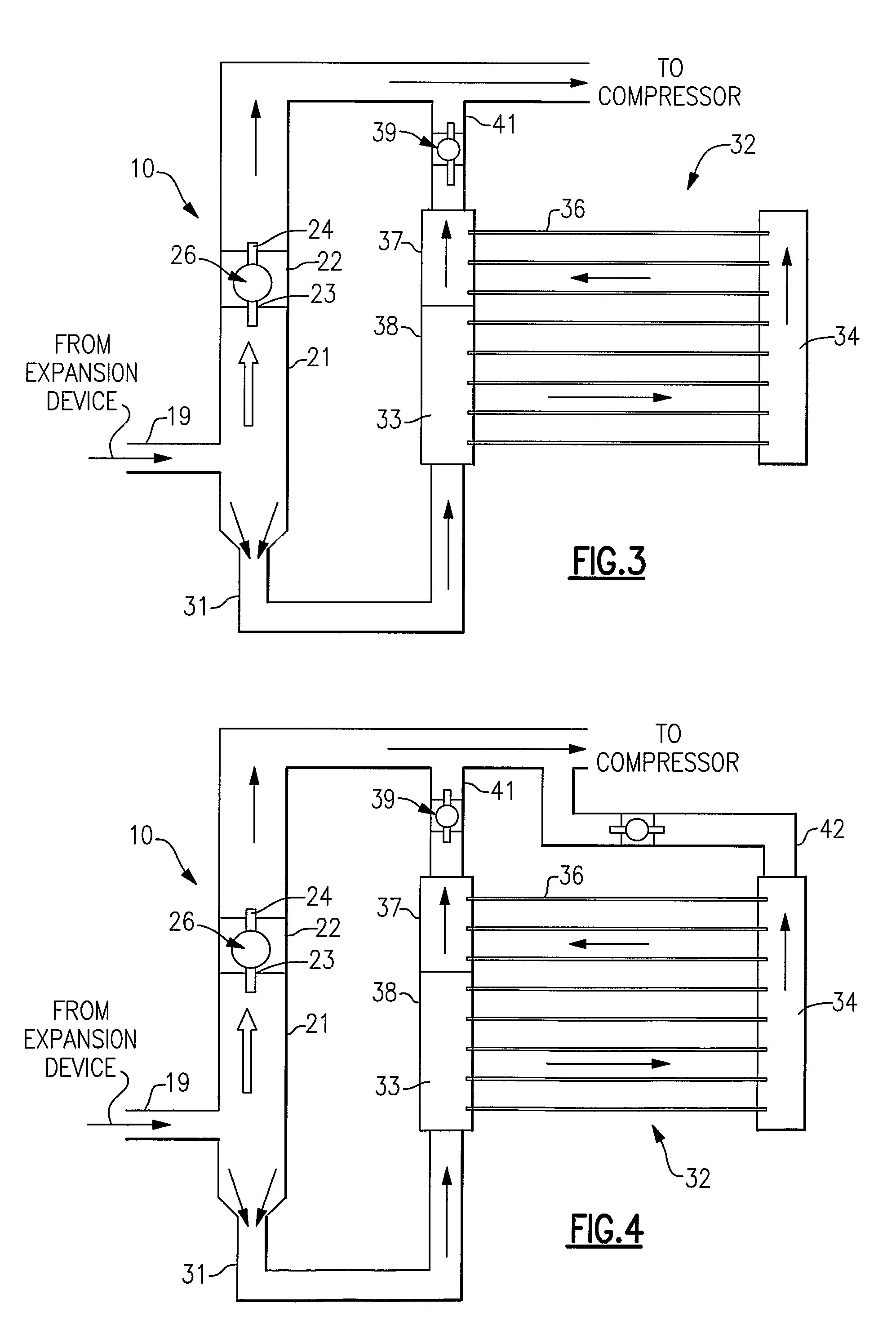

Refrigerant distribution device and method

ActiveUS7086249B2Smooth feedingUniform utilizationEvaporators/condensersHeat exchanger casingsRefrigerant distributionEngineering

A refrigerant distribution device 10 situated in an inlet header 12 of a multiple tube heat exchanger 14 of a refrigeration system 20. The device 10 includes an inlet passage 32 that is in communication with an expansion device. Small diameter nozzles 34 are disposed within the inlet header 12 and are in fluid communication with the inlet passage 32. Capillary liquid nozzles 36 also lie within the inlet header 12 and are in fluid communication with the inlet passage 32. A two-phase refrigerant fluid in the inlet passage 32 has a refrigerant liquid-vapor interface 38. The vapor nozzles 34 have vapor inlet ports 40 that lie above the refrigerant liquid-vapor interface 38. The capillary liquid nozzles 36 have liquid inlet ports 42 that lie below the refrigerant liquid-vapor interface 38. Vapor emerging from the vapor nozzles 34 blow onto and atomize liquid emerging from the liquid nozzle to create a homogeneous refrigerant that is uniformly delivered to the multiple tubes. The invention also includes a method for delivering a uniform distribution of a homogeneous liquid mixture of liquid and vaporous refrigerant through the heat exchanger tubes.

Owner:LENNOX INTERNATIONAL

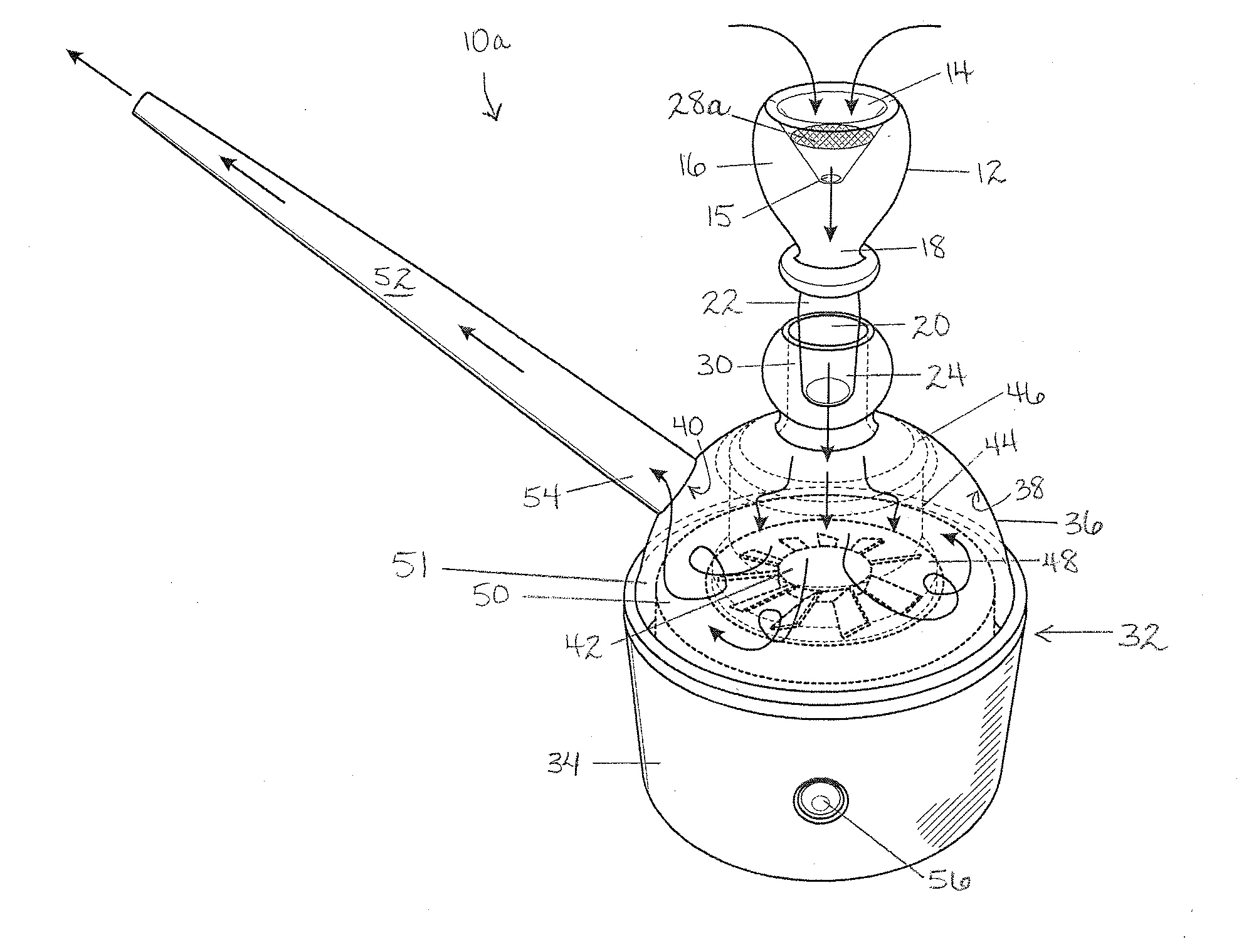

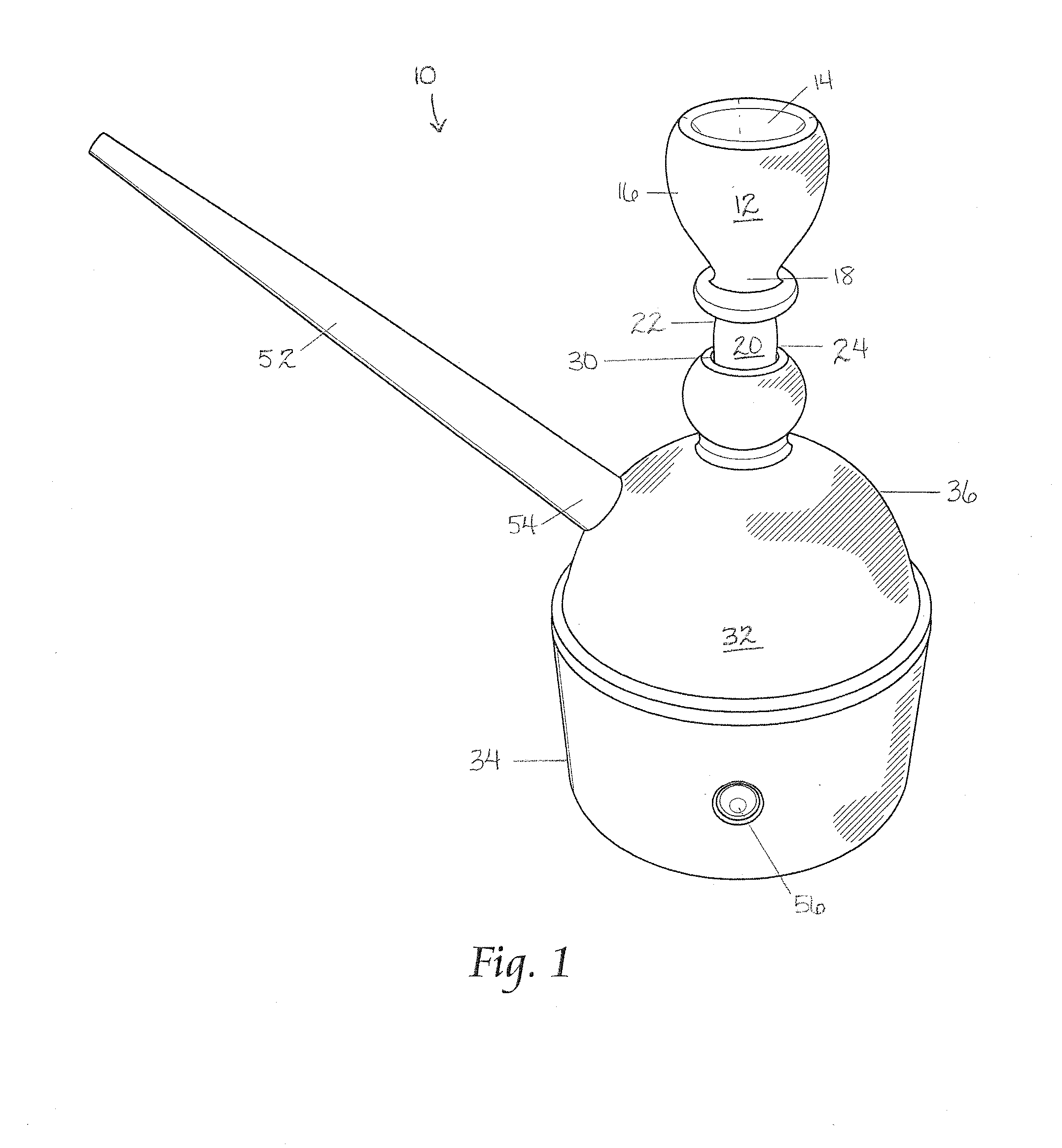

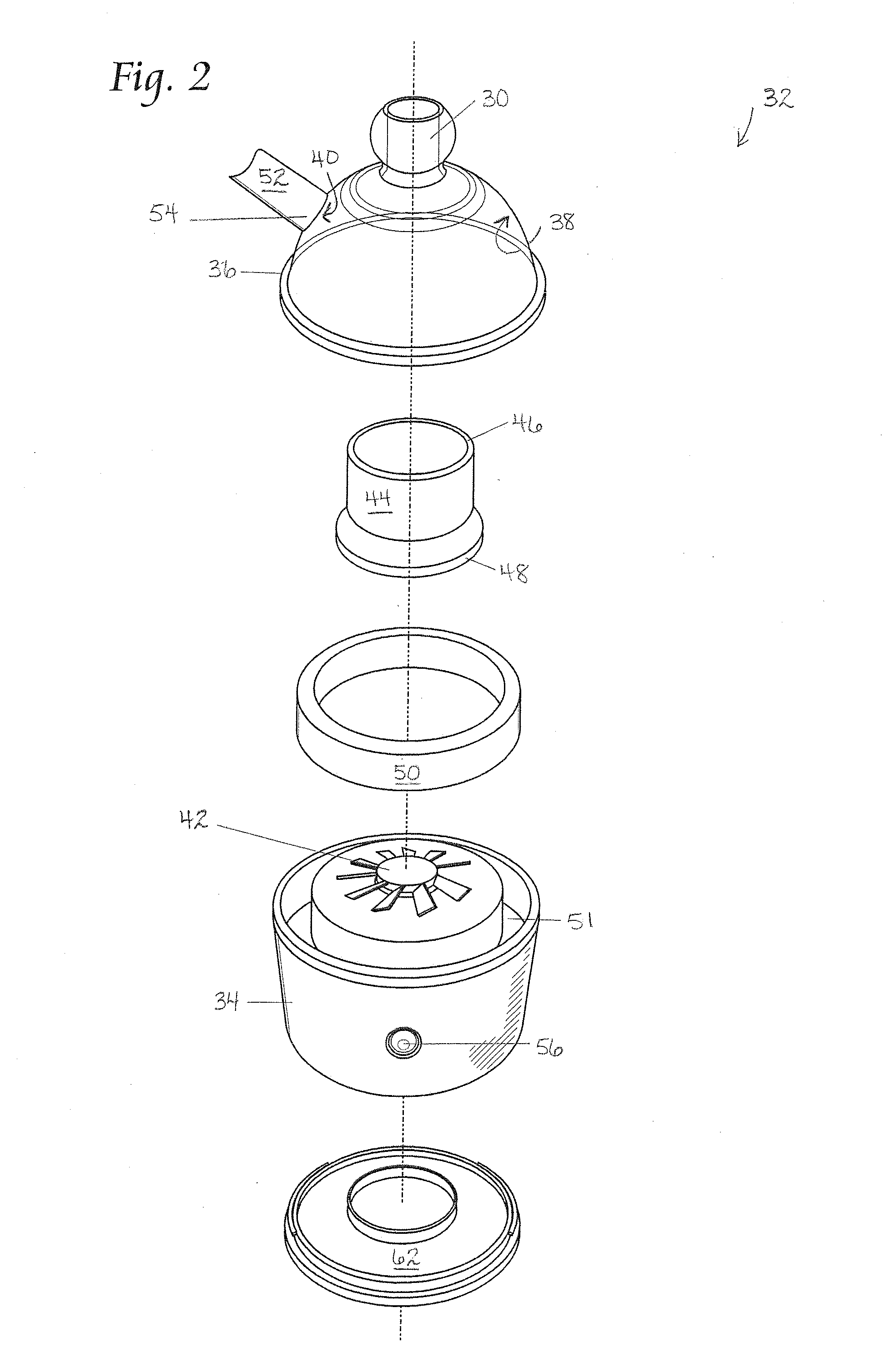

Smoke conditioning and filtration system and method therefor

A smoke conditioning and filtration system is disclosed. The system mixes smoke created from a burnable substance, such as tobacco or other herbal substances, with liquid vapor. This causes expanding of the inherent hot gases and moisturizing and cooling of the smoke, thereby creating a more pleasurable smoking experience. The system also conditions the smoke produced from tobacco or other herbal substances by filtering out a portion of the particulates and congeals a portion of the oil contained within the smoke. Furthermore, the system blows smoke from a spout, eliminating the need to put one's mouth on the spout, thus creating a more sanitary smoking experience.

Owner:RUFF BRUCE ALAN +1

Liquid-Vapor Separator For A Minichannel Heat Exchanger

InactiveUS20080104975A1Evenly distributedMechanical apparatusCompression machines with several evaporatorsEngineeringRefrigerant

A method and apparatus for promoting uniform refrigerant flow in a minichannel heat exchanger by providing a liquid-vapor separator between an expansion device and the inlet header such that the refrigerant vapor will pass directly to the compressor and only the liquid refrigerant will pass to the inlet header. The liquid-vapor separation is accomplished by way of a float valve which prevents the flow of liquid refrigerant to the compressor and the flow of refrigerant vapor from the outlet manifold, through the valve and back to the inlet manifold. A second float valve may be provided between a downstream end of the inlet manifold and the compressor for the purpose of removing any residual vapor from the liquid.

Owner:CARRIER CORP

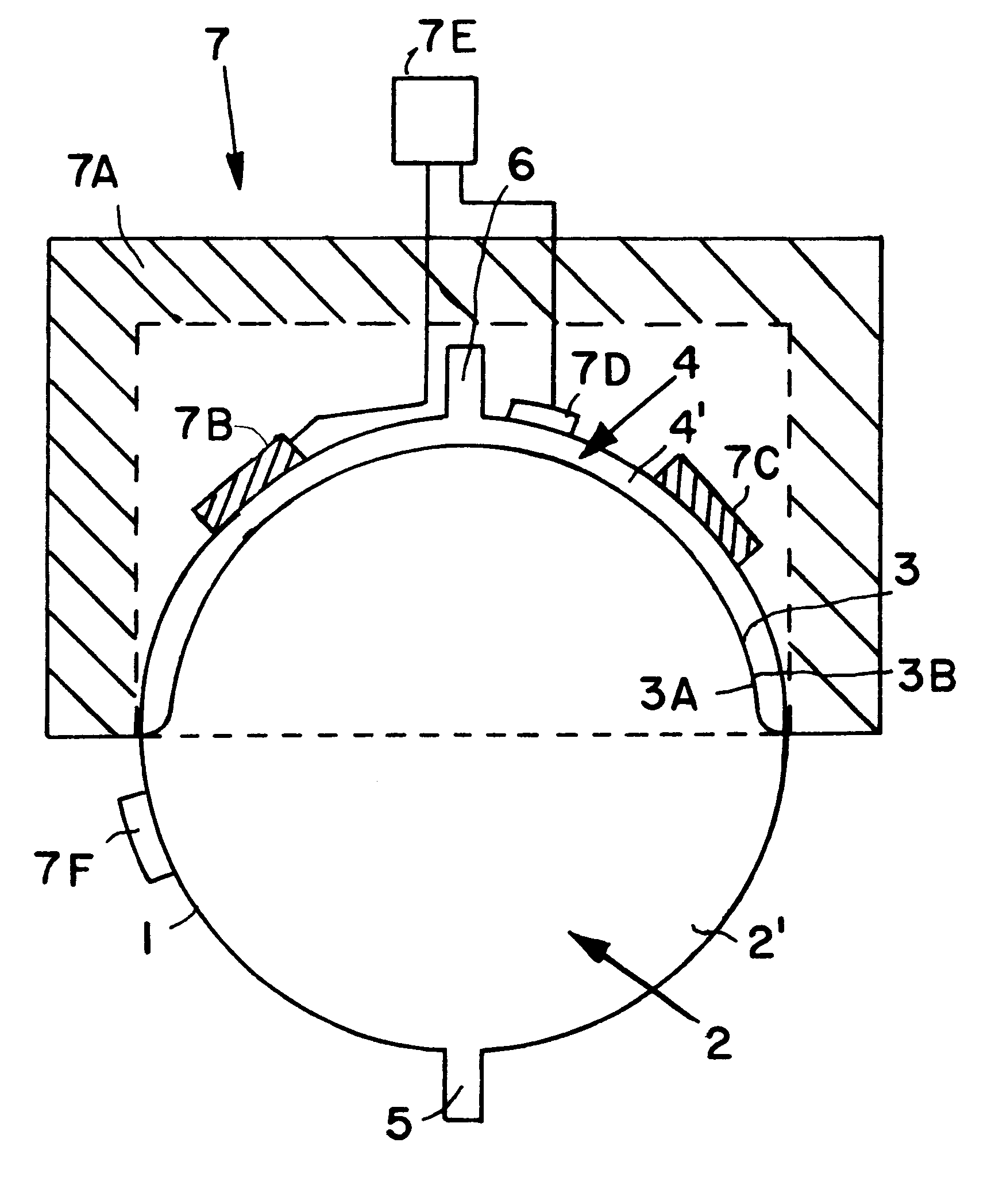

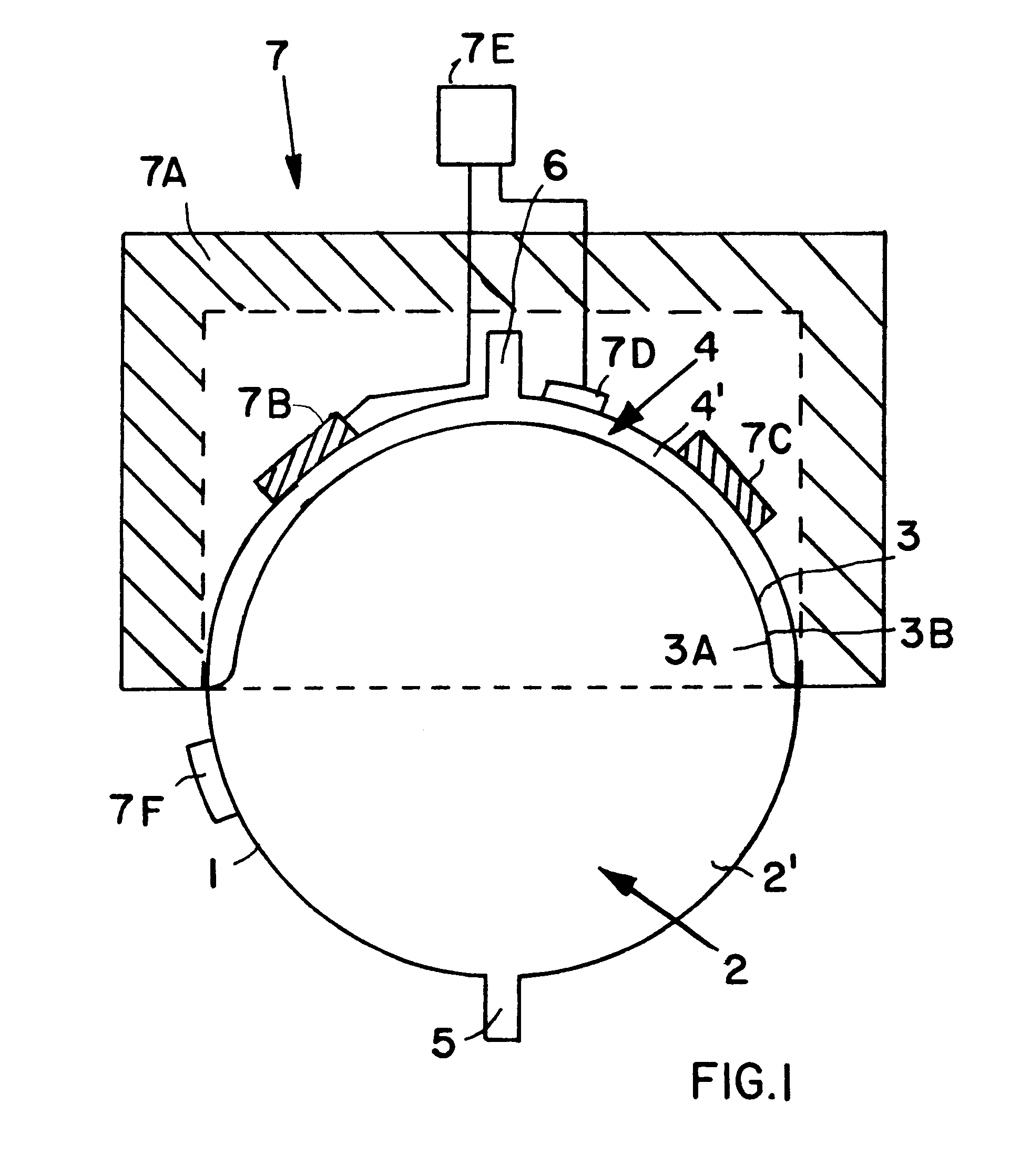

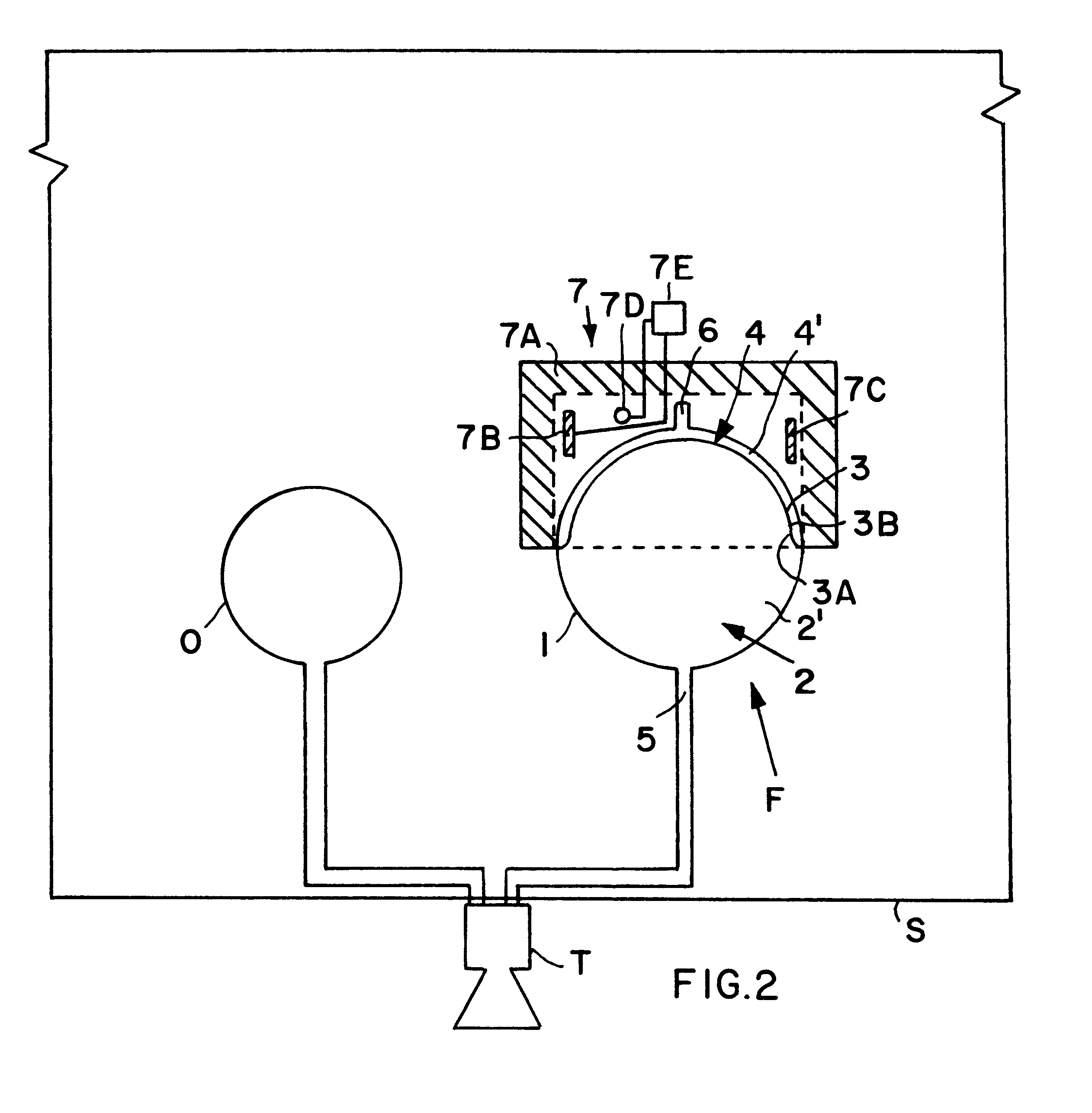

Method and liquid storage tank for minimizing permeation of liquid vapors through a tank dividing membrane

InactiveUS6231008B1Prevent penetrationAvoid condensationCosmonautic vehiclesPower plant fuel tanksThermal insulationLiquid storage tank

A temperature regulating arrangement (7) at least partially surrounds a fuel or oxidizer storage tank (1). The tank (1) is divided by a polymer membrane (3) into a first partial chamber (2) receiving the fuel (2') therein, and a second partial chamber (4) receiving a gaseous pressure medium (4') therein. The temperature regulating arrangement (7) includes thermal insulation, at least one heater, at least one heat sensor, and a temperature control and regulating unit. By heating the second partial chamber containing the gaseous pressure medium, any fuel vapor permeating through the membrane (3) from the first partial chamber (2) into the second partial chamber (4) is prevented from condensing within the second partial chamber (4). The permeation process is also limited. It is simply necessary to maintain the second partial chamber (4) at a temperature a few degrees Celsius higher than the temperature of the liquid fuel. This tank arrangement is especially suitable for use as a fuel tank or oxidizer tank in a satellite or orbital space station.

Owner:DAMELERKLESLER AVIATION

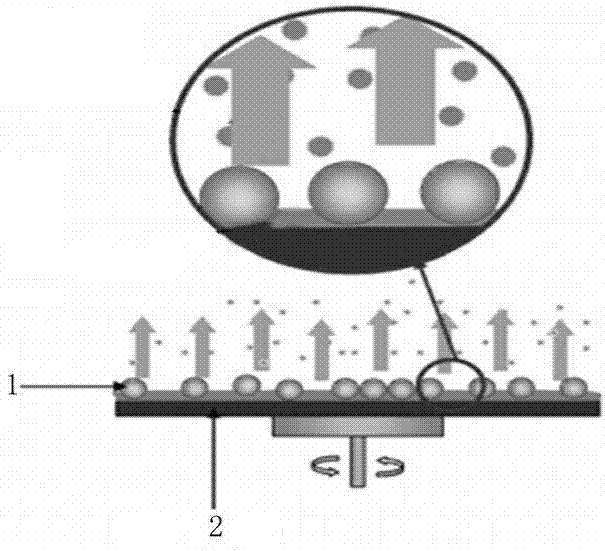

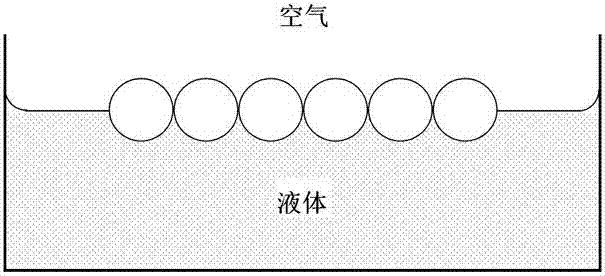

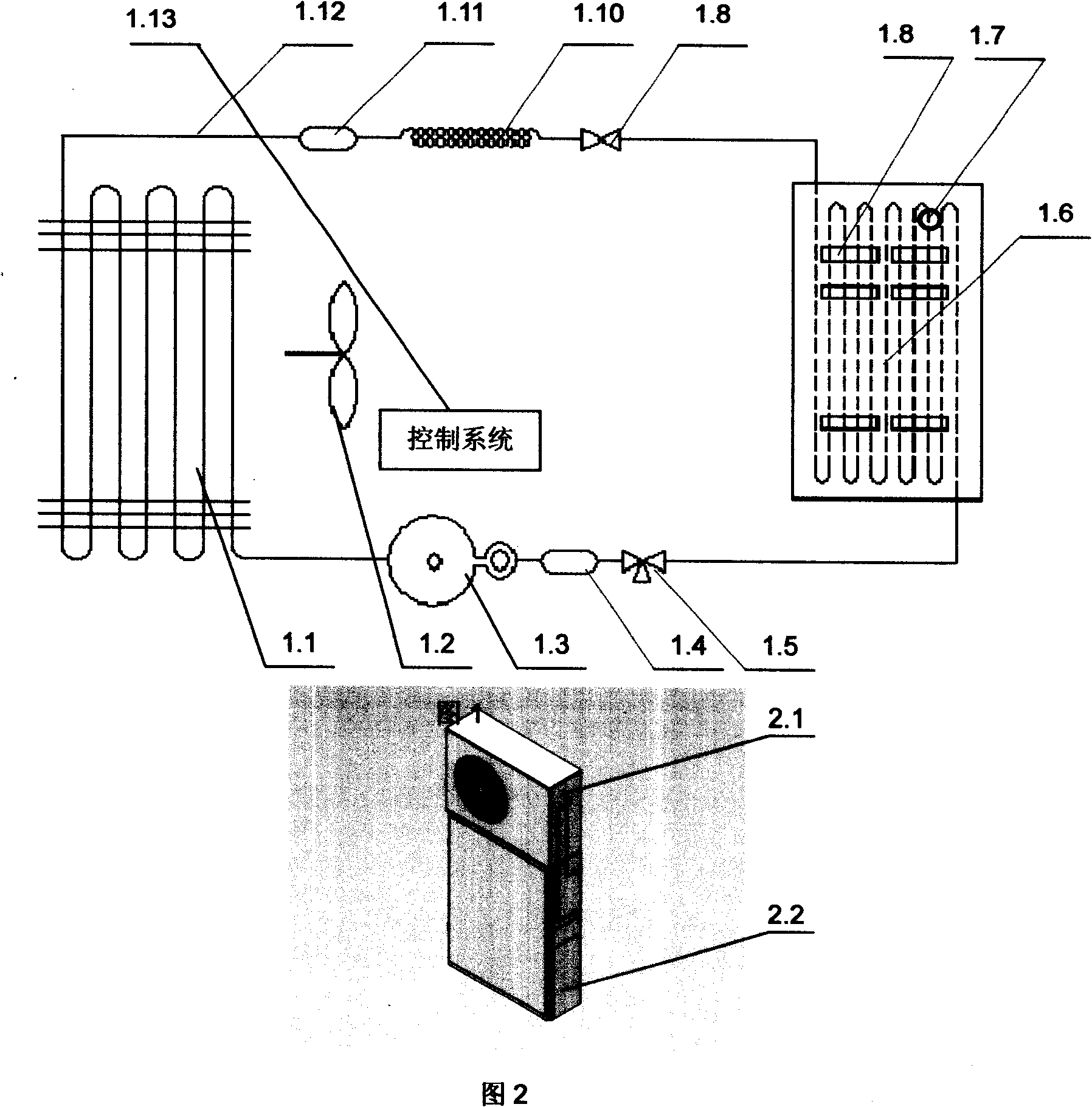

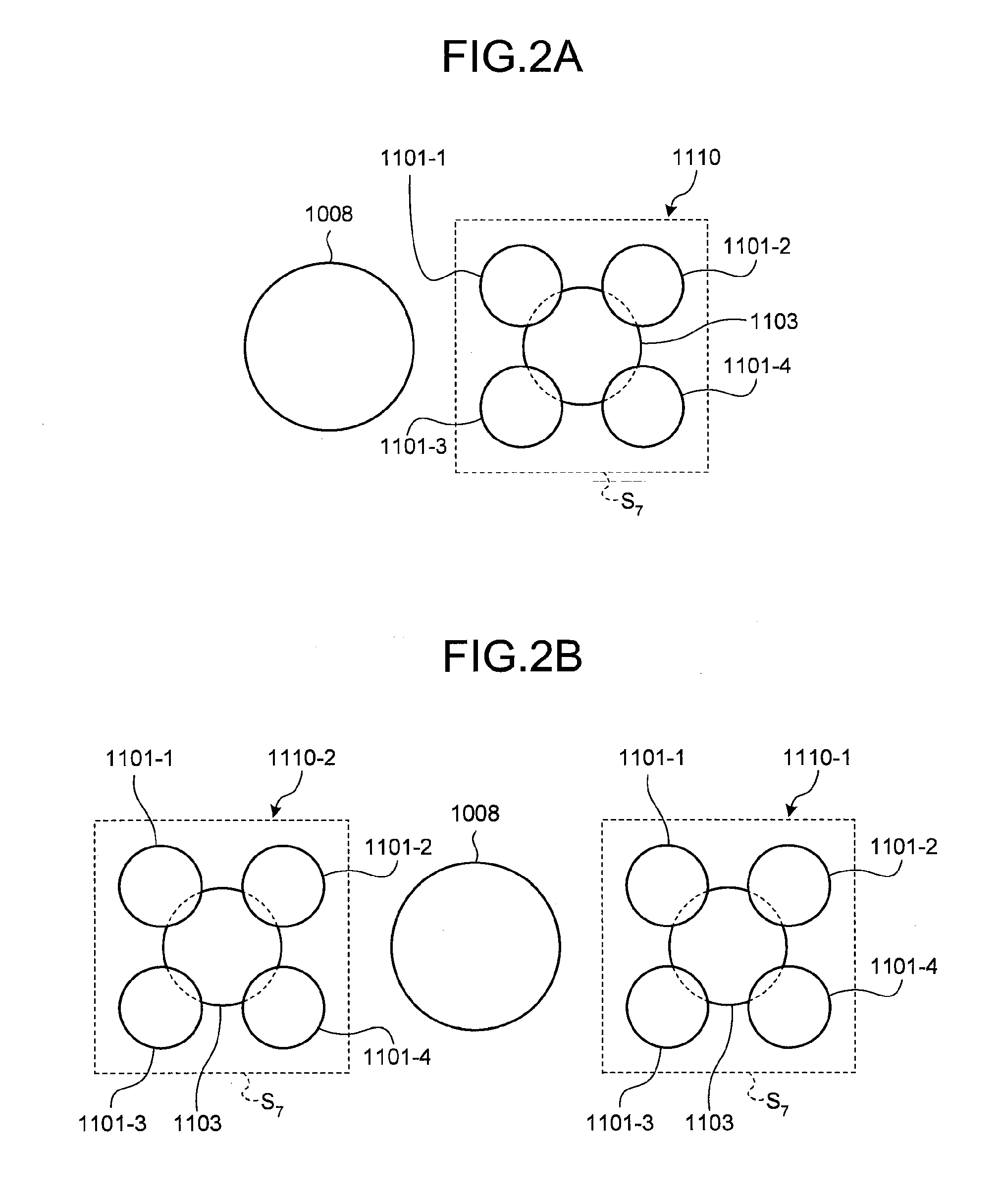

Self-assembly preparation method of colloid microsphere single-layer film

The invention discloses a self-assembly preparation method of a colloid microsphere single-layer film. In the self-assembly preparation method, after the colloid microsphere single-layer film with large area and high coverage rate is obtained by utilizing a spin-coating method, colloid microspheres are extruded into a compactly stacked hexagon array by adopting a liquid-vapor interface method and utilizing the surface tension of liquid. Equipment used in the self-assembly preparation method is simple and cheap and is simple to operate and controllable; and the colloid microsphere single-layer film array prepared by the method has high efficiency, high yield and good film formation quality.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Process for separating and drying thermoplastic particles under high pressure

ActiveUS20060042113A1Drying using combination processesDrying solid materials without heatLiquid temperatureEthylene Homopolymers

A process for feeding a slurry of thermoplastic synthetic polymer particles such as polyethylene terephthalate homopolymers and copolymers in combination with a liquid such as water at a liquid temperature greater than the normal boiling point of the liquid, under a pressure greater than the vapor pressure of the liquid at the liquid temperature, into a separation zone such as a centrifugal dryer, and within the separation zone: a. separating the liquid from the particles, and b. drying the particles; while under a high pressure equal to or greater than the vapor pressure of the liquid. There is also provided a process for decoupling the dried particles from the separation zone to an atmosphere having a pressure less than the vapor pressure of the liquid while maintaining the vapor pressure of the particles prior to decoupling equal to or above the vapor pressure of the liquid at the liquid temperature.

Owner:ALPEK POLYESTER SA DE CV

Compressor cooling type fully sealed high-efficiency radiating electronic cabinet

InactiveCN101610660ALow costImprove reliabilityMagnetic/electric field screeningCompression machines with non-reversible cycleLow noiseElectromagnetic shielding

The invention relates to radiating technology applied to fully sealed electronic cabinets, in particular to a radiating method and a radiating device applied to high power electronic equipment required to be fully sealed in outdoor severe environment. By adopting a Carnot refrigeration cycle principle, a low temperature and low pressure liquid cooling medium enters a cold plate radiator (also called internal heat exchanger) arranged in a sealed cabinet through a sealed pipe, absorbs heat generated when calorific electronic elements arranged on the cold plate radiator work, and is evaporated into low temperature and low pressure superheated steam; the low temperature and low pressure superheated steam passes through a liquid-vapor separator, and dried superheated gas is sent into a compressor, and compressed into high temperature and high pressure gas; the high temperature and high pressure gas is sent into a condenser to release heat, and is condensed into supercooled liquid; the supercooled liquid is subjected to pressure reduction by resistance of capillarity tubes into low temperature and low pressure two-phase fluid; and the fluid passes through a filter and a pipe, and is sent into the cold plate radiator, and the heat of the fluid is absorbed by the cold plate radiator to realize circulation, wherein an electronic mainframe adopts a fully sealed cabinet structure so as to achieve the waterproof, dampproof, dustproof and electromagnetic shielding aims. The device adopting the radiating technology has the advantages of high power, small volume, easy control of temperature, low noise, low cost, high heat exchange efficiency and the like.

Owner:沈国忠

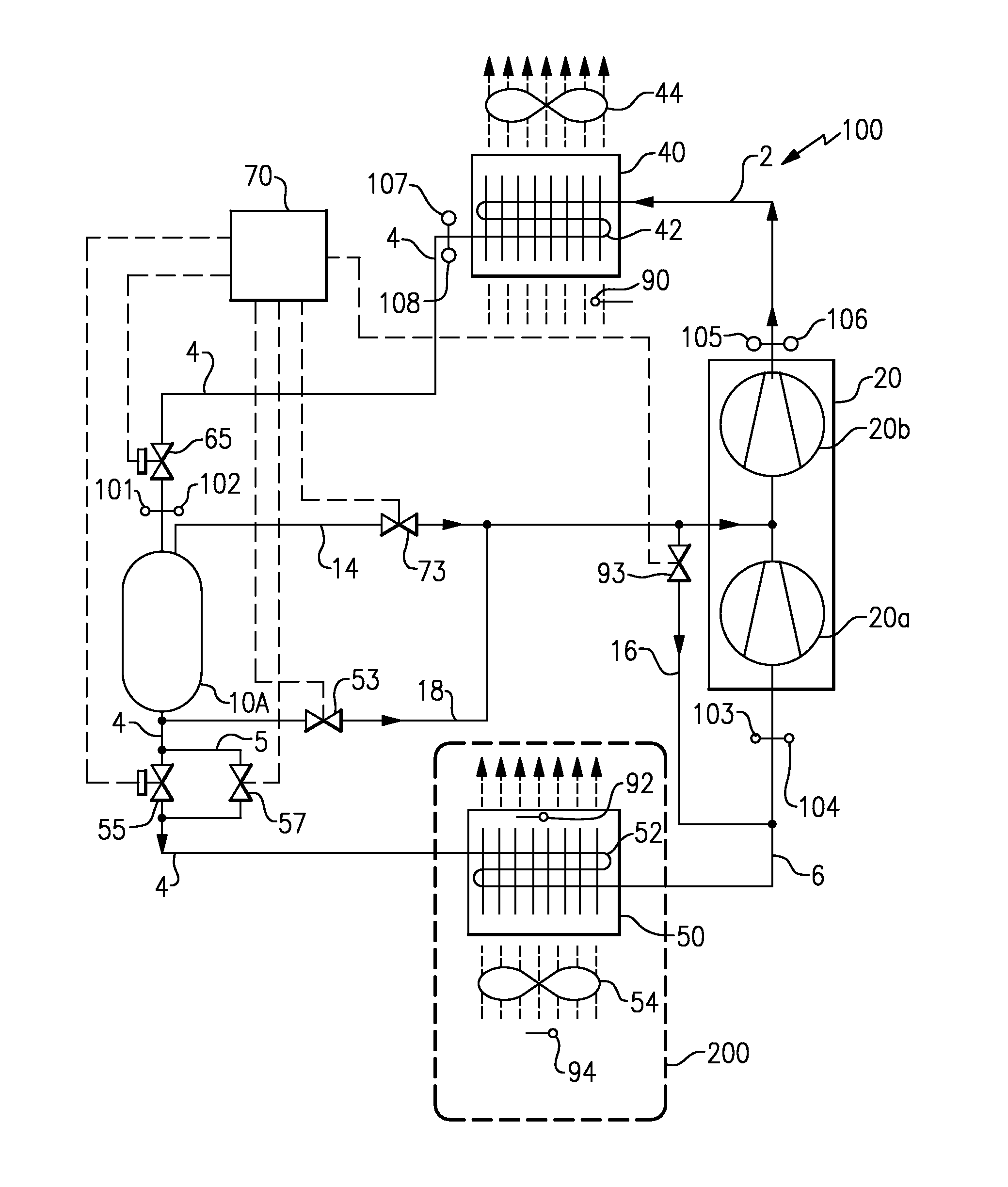

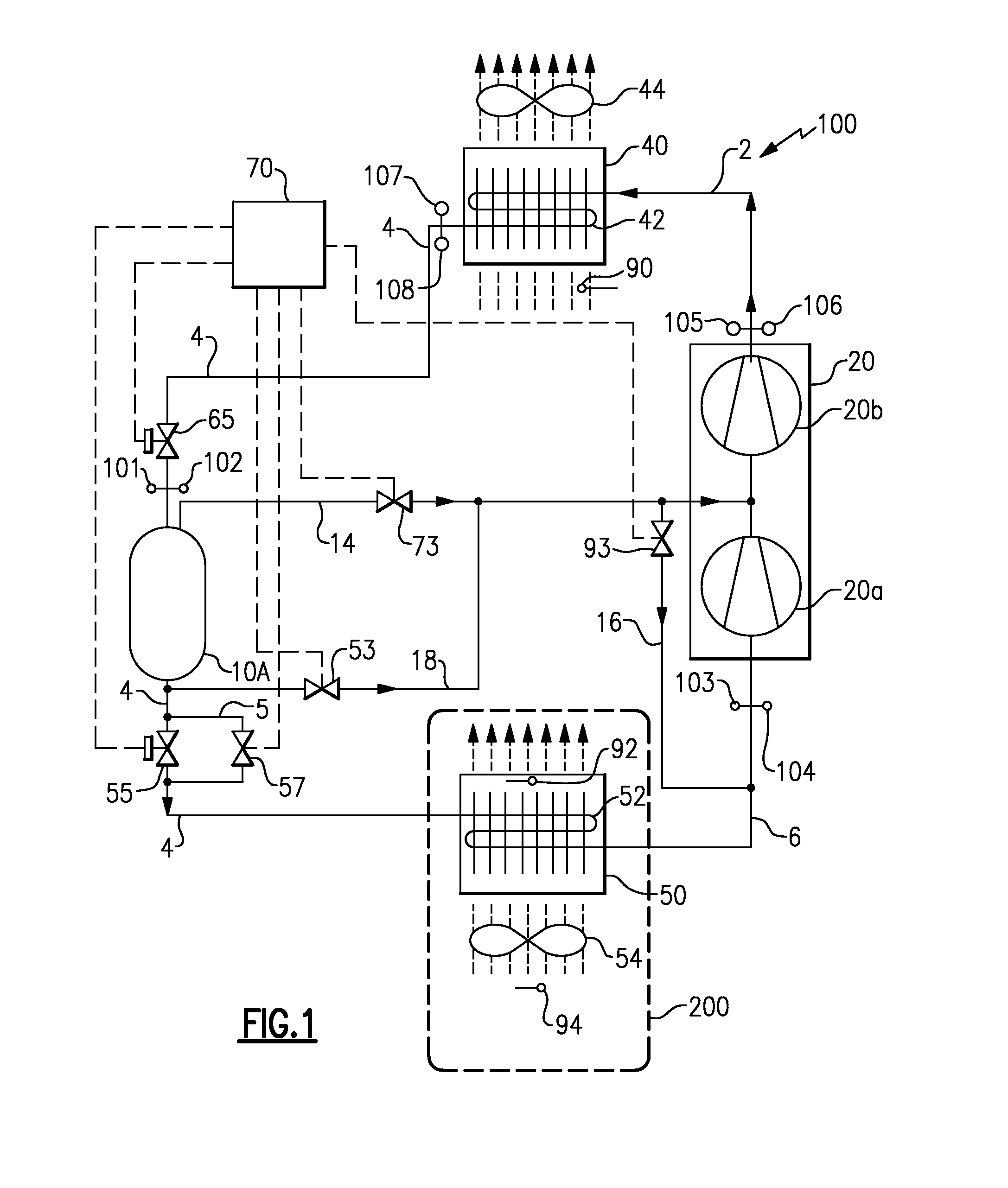

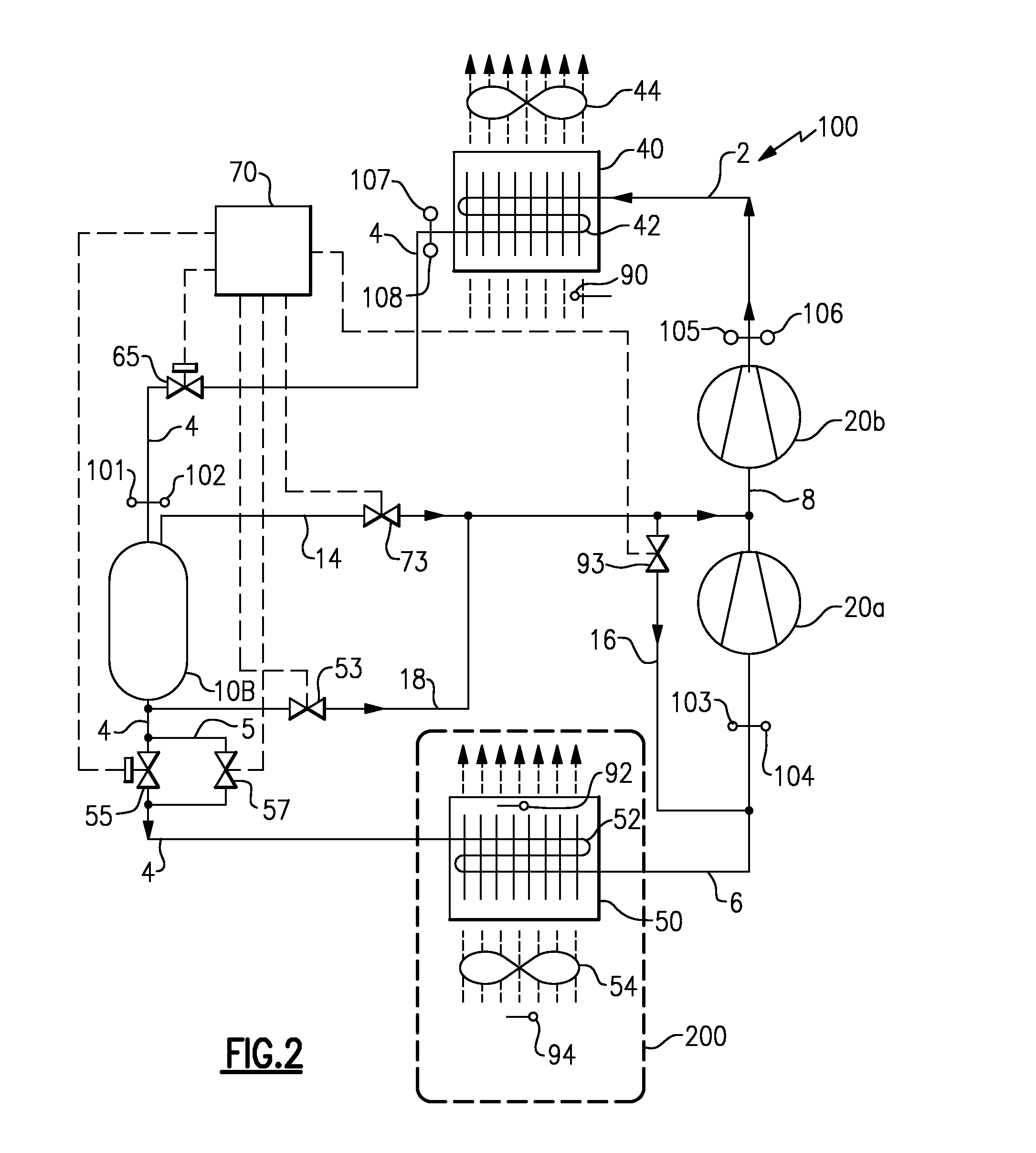

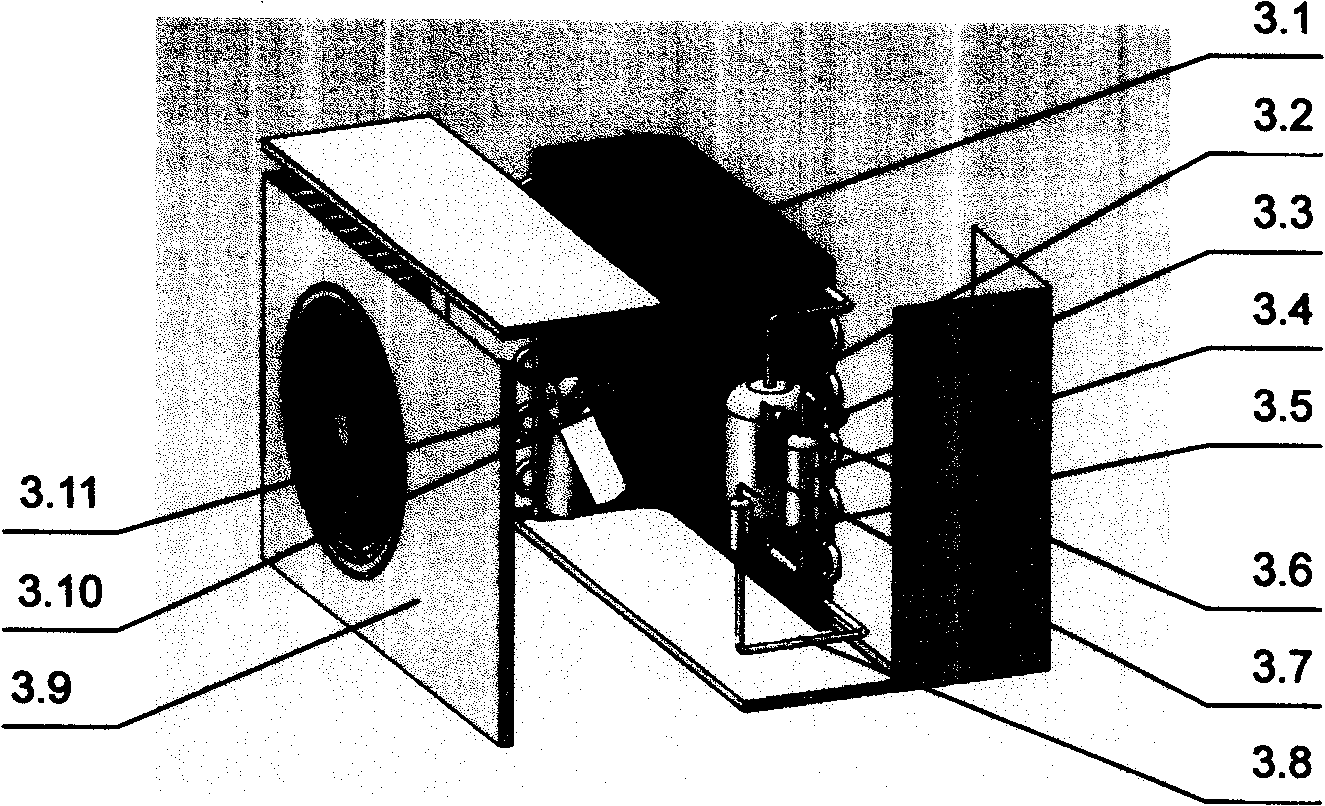

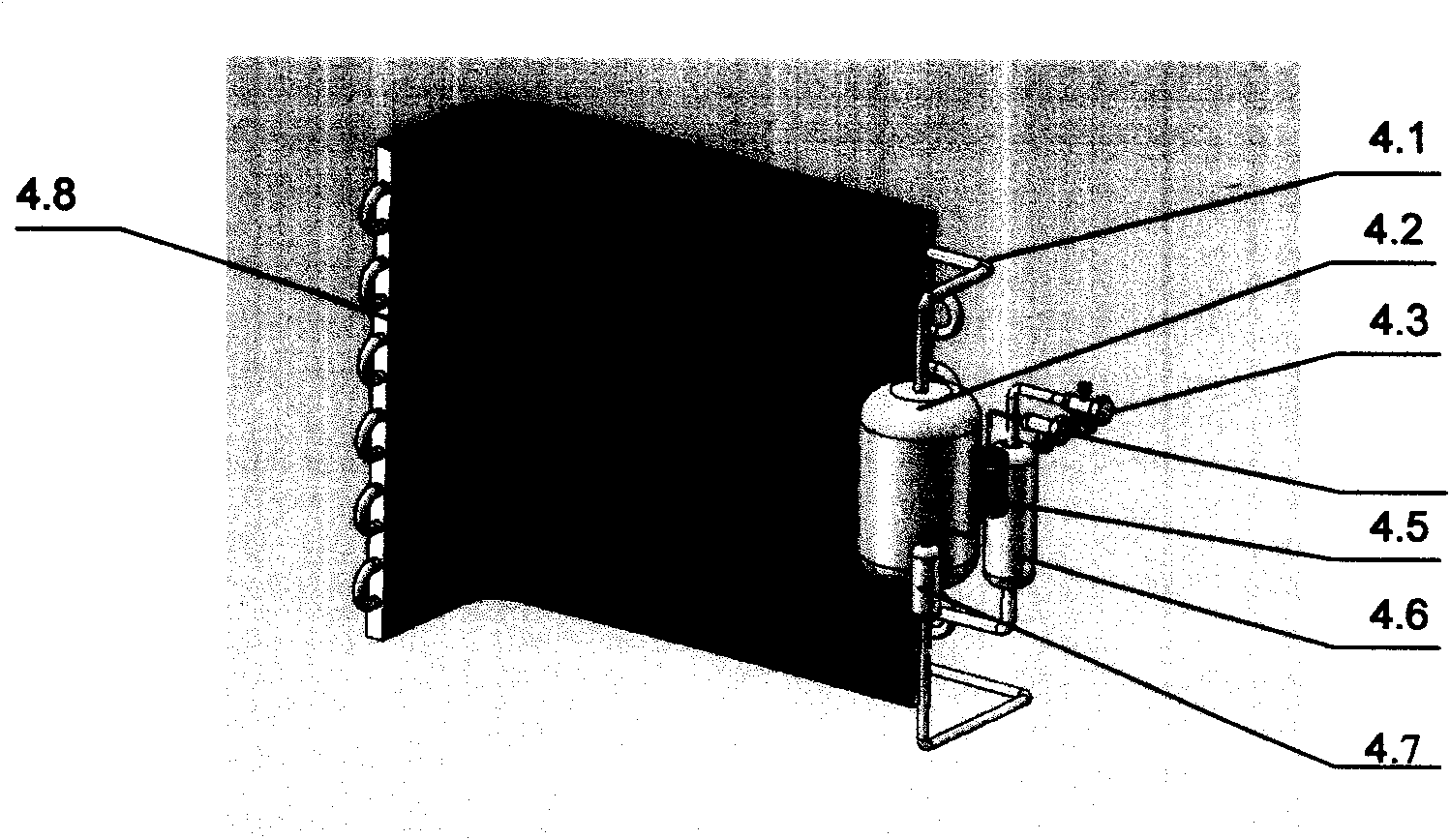

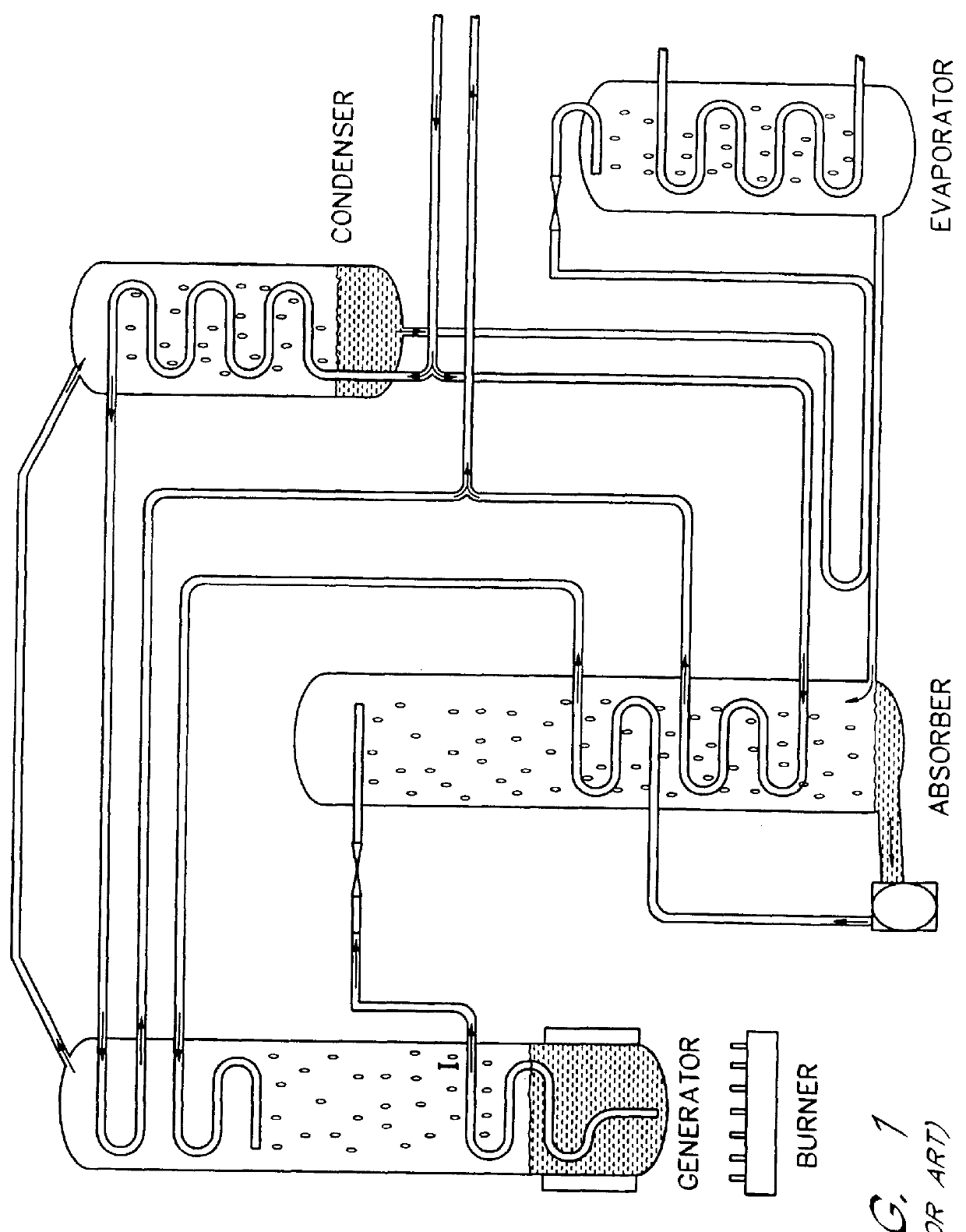

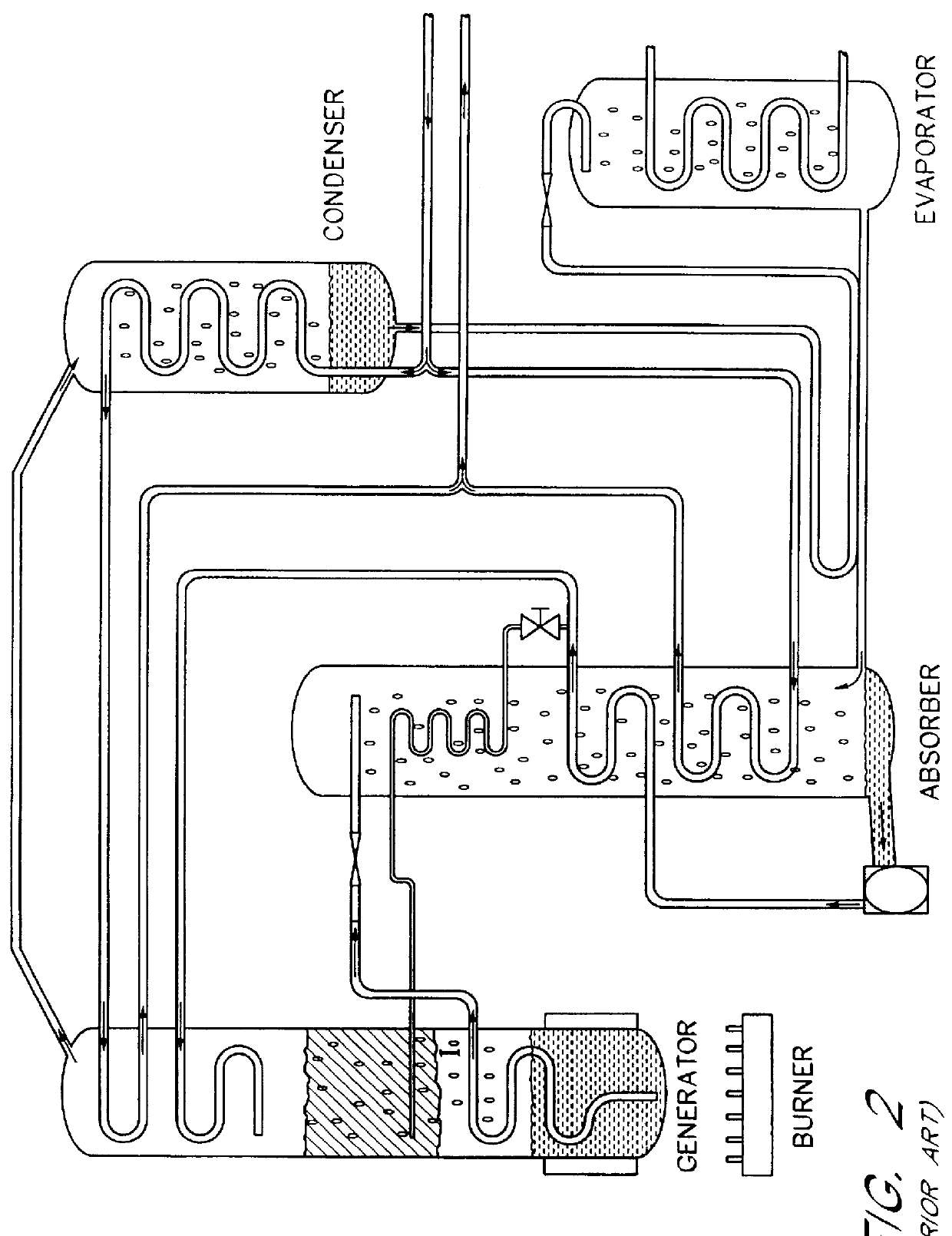

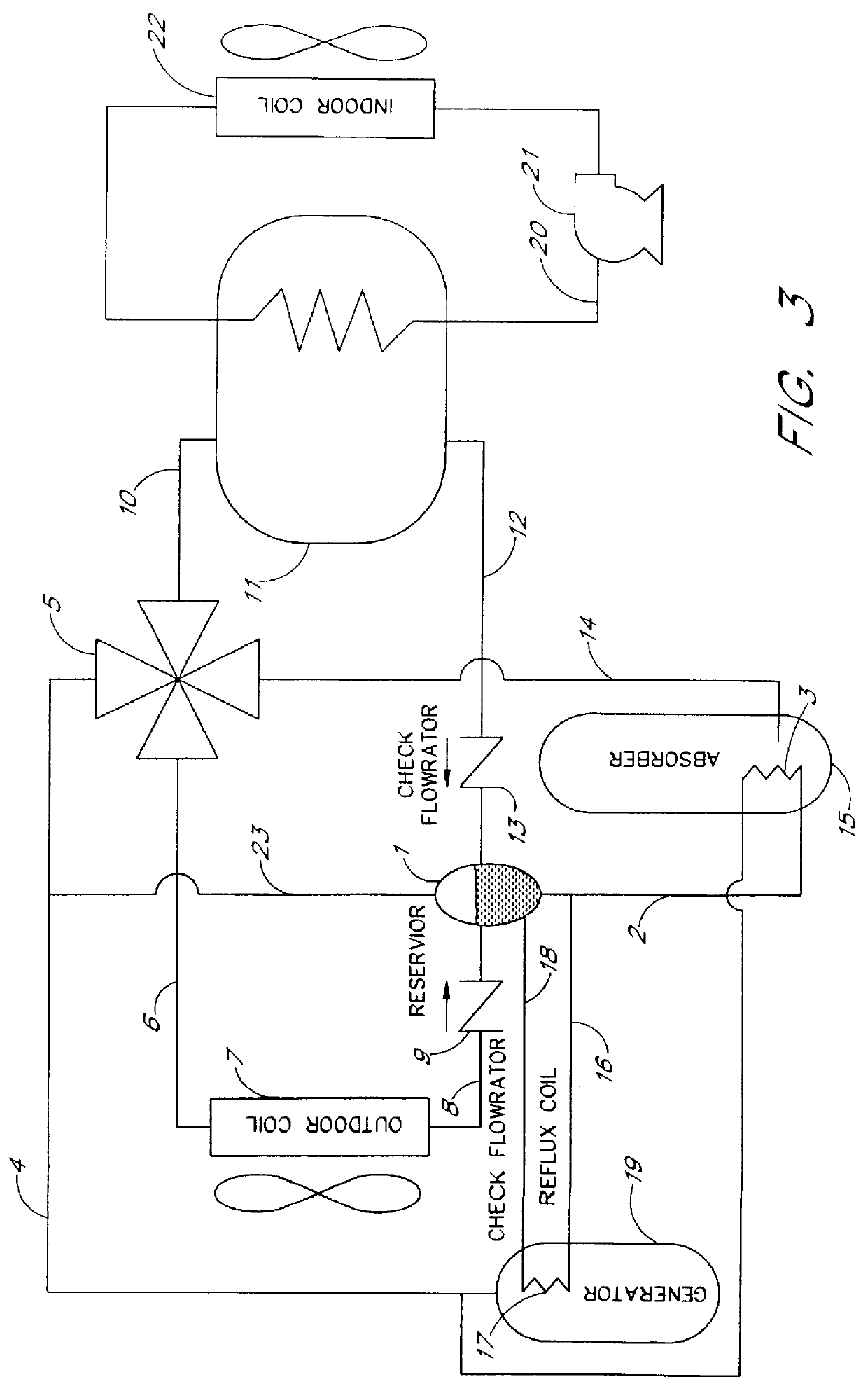

Method for use of liquid/vapor ammonia absorption systems in unitary HVAC systems

InactiveUSRE36684E1Easy to switchLess viscous fluidsClimate change adaptationEnergy efficient heating/coolingThermal energyEngineering

A liquid vapor absorption system comprises: one or more absorbers, one or more generators, and a fluid loop for directing refrigerant absorption fluid between the absorbers and generators, heat exchangers for selectively functioning as an evaporator or a condenser and cooperating with an indoor coil for recovering thermal energy, a reservoir for condensed refrigerant, a phase-change thermosyphon loop for directing condensed refrigerant from the reservoir to the heat exchange section of an absorber for removing heat of absorption, and a reversing valve means for selectively directing gaseous refrigerant to the heat exchangers functioning as a condenser, and for simultaneously directing gaseous refrigerant from the heat exchangers functioning as an evaporator to the absorber.

Owner:ROCKY RES

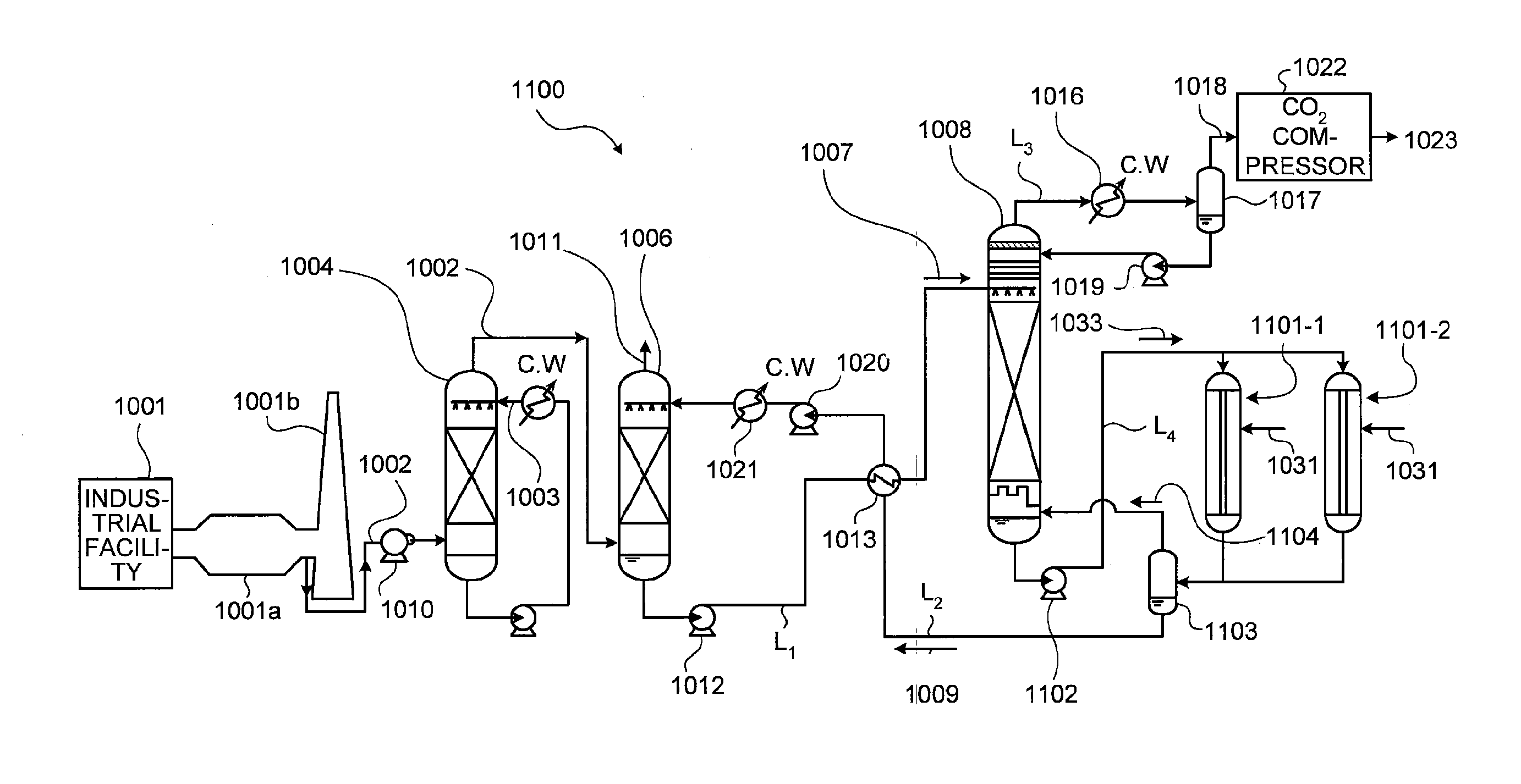

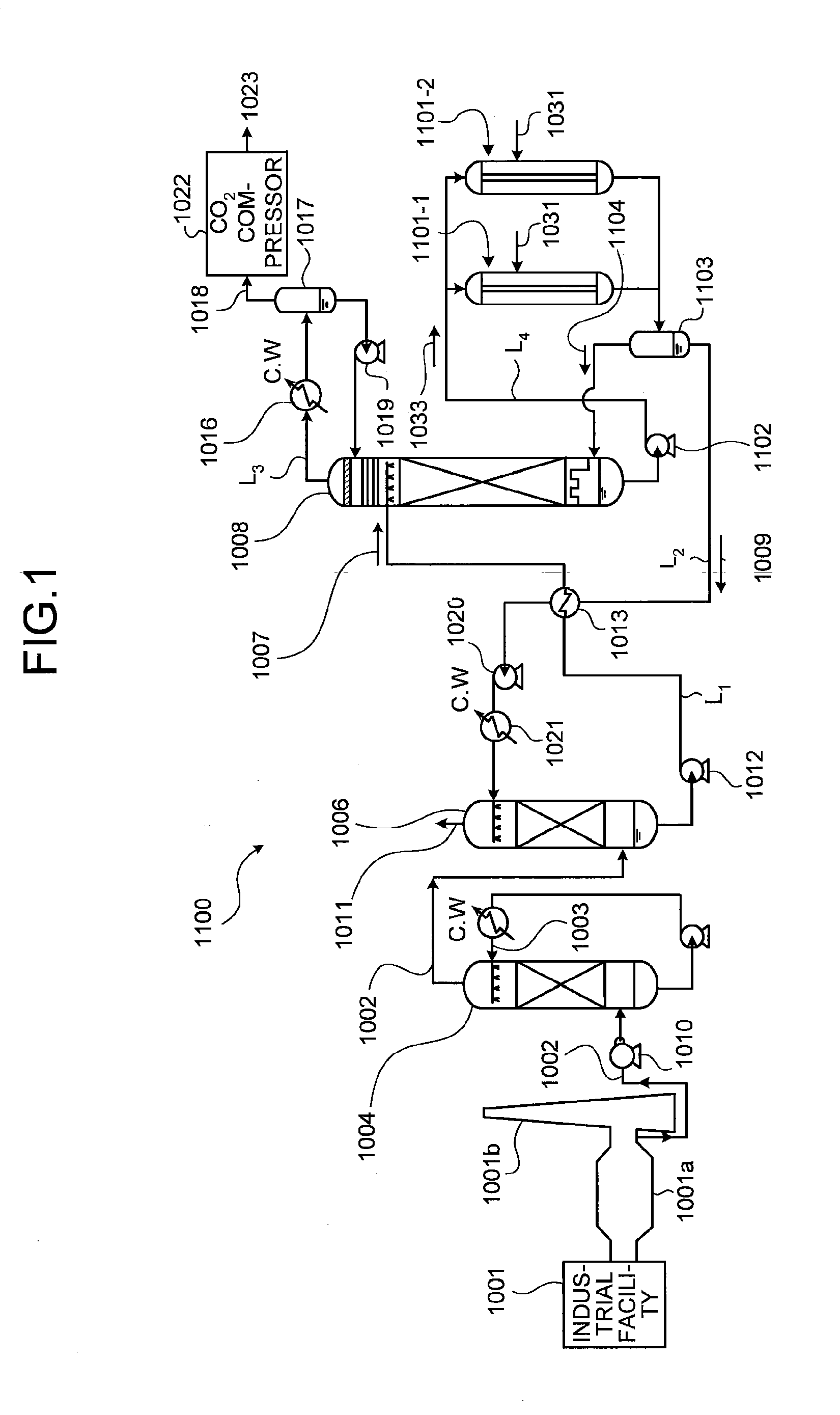

System for recovering carbon dioxide from flue gas

ActiveUS20110107916A1Reduce decompositionReduced installation areaGas treatmentCarbon compoundsFlue gasProcess engineering

To include an absorber (1006) that brings CO2 absorbent that absorbs CO2 contained in flue gas (1002) into contact with the flue gas to remove CO2 from the flue gas, a regenerator (1008) that strips CO2 from CO2 absorbent (rich solution), which is fed from the absorber through a first feed line L1 and has absorbed CO2, to regenerate CO2 absorbent, thereby acquiring regenerated CO2 absorbent (lean solution) (1009), falling film reboilers (1101-1 and 1101-2) that draw off CO2 absorbent (amine solution) (1033) from near the bottom of the regenerator and reheats regenerated CO2 absorbent via steam (1031), a first liquid-vapor separator (1103) that separates the CO2 absorbent reheated by the falling film reboilers into regenerated CO2 absorbent in which CO2 has been removed and vapor containing CO2, and a second feed line L2 for supplying the separated regenerated CO2 absorbent to the absorber.

Owner:MITSUBISHI HEAVY IND ENG LTD

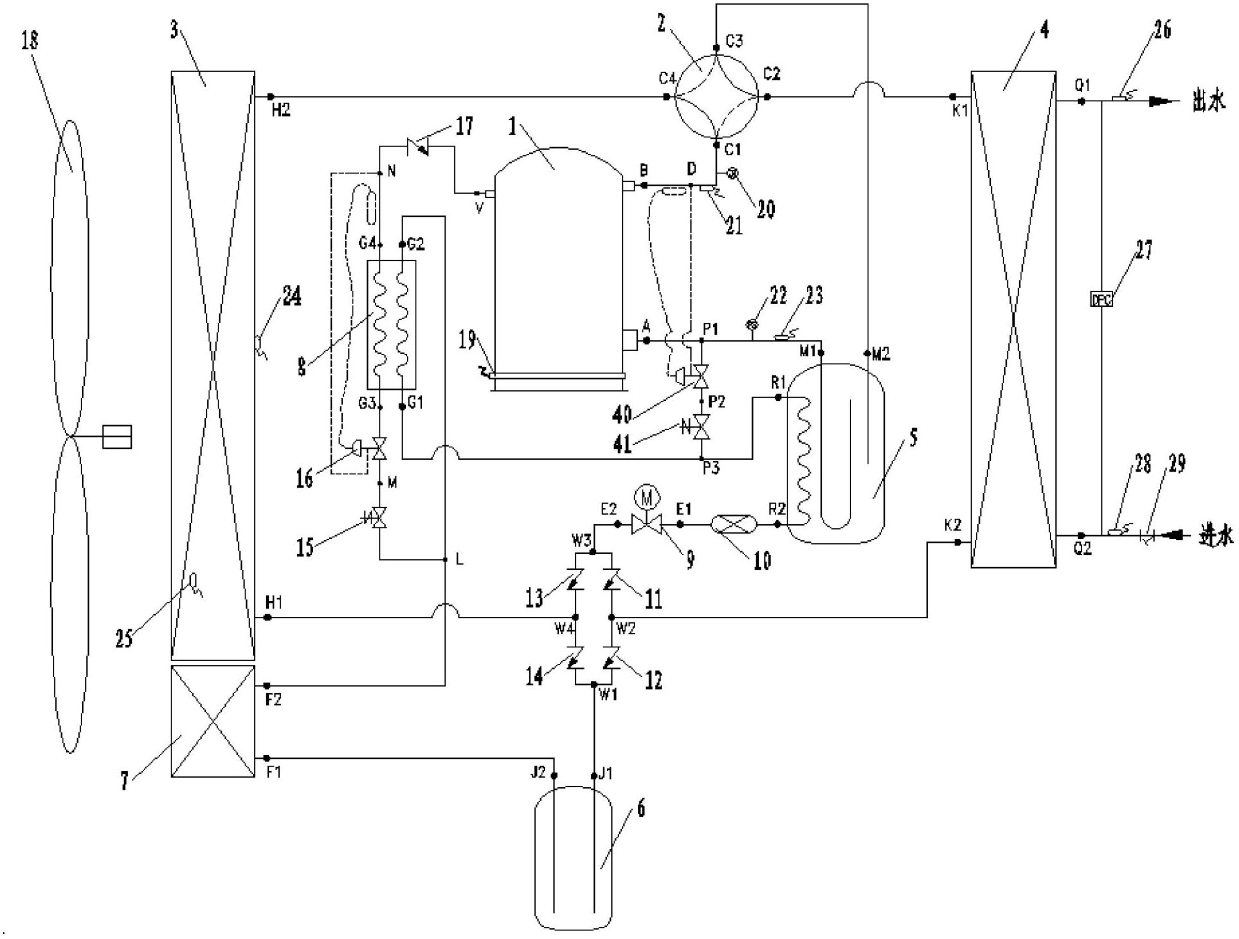

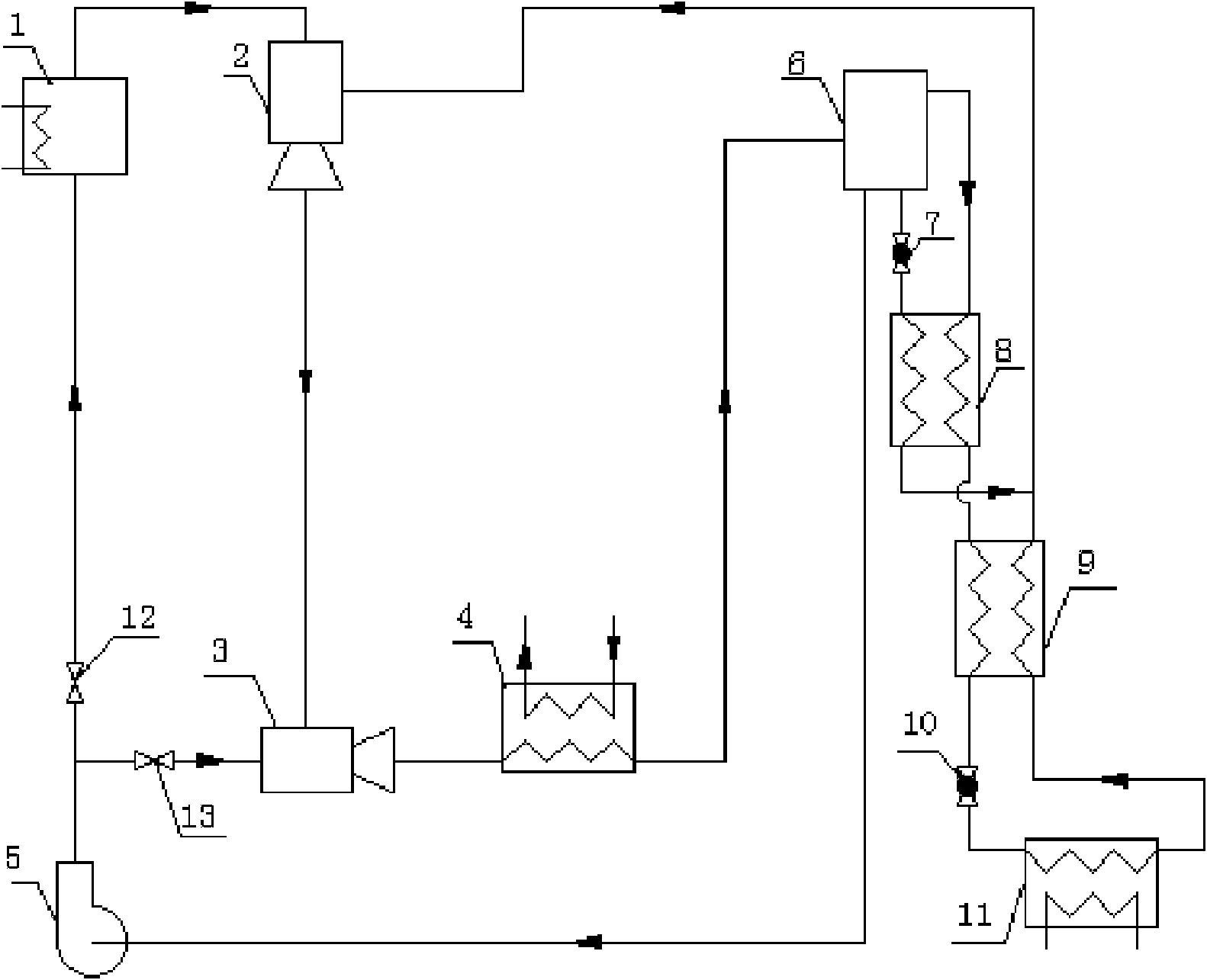

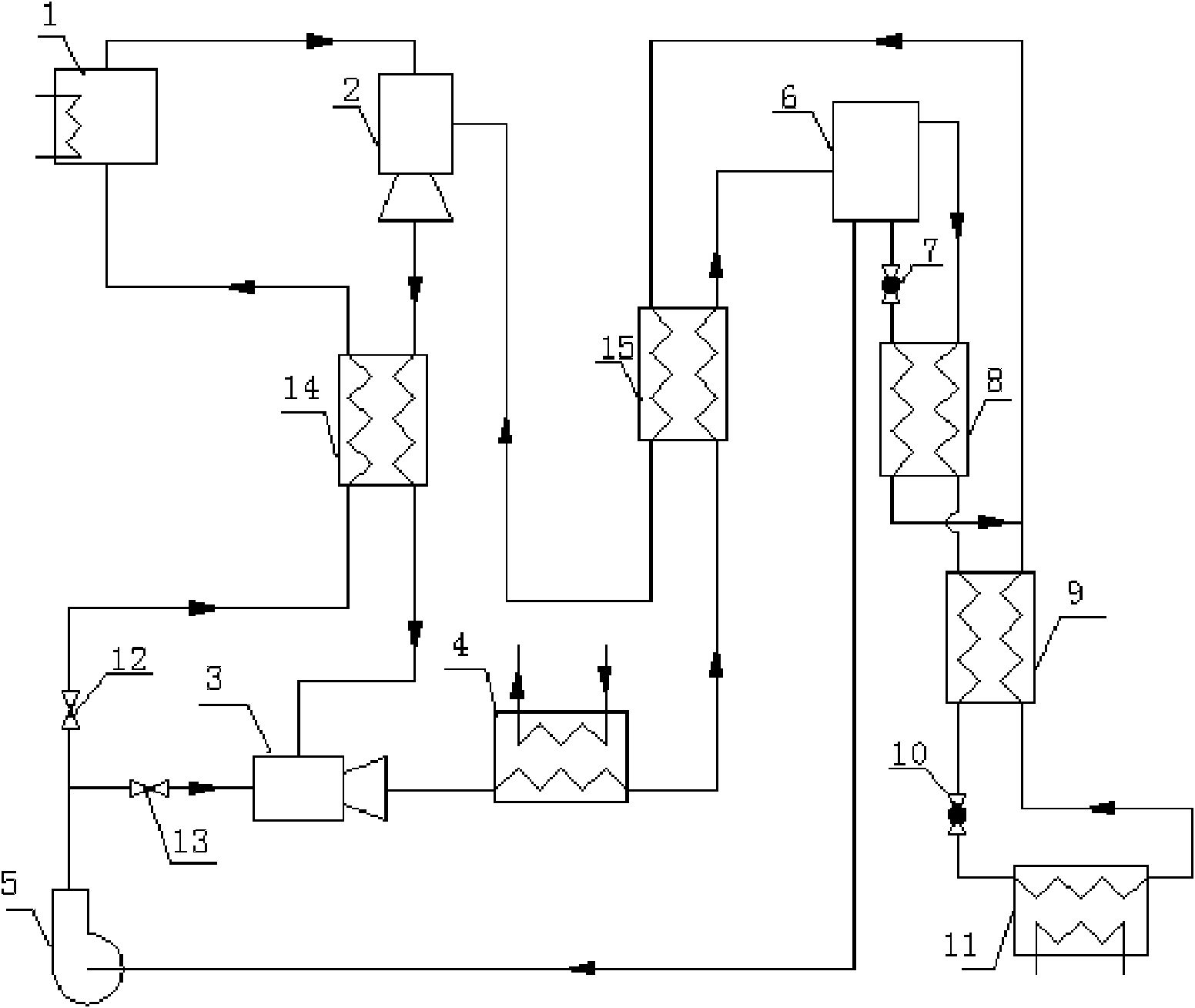

Auto-cascade injection low-temperature refrigeration circulating device

InactiveCN101603749AReduce consumptionHigh work pressureFluid circulation arrangementHeat-exchange elementsRefluxVapor–liquid separator

The invention discloses an auto-cascade injection low-temperature refrigeration circulating device, which comprises a generator, an air injector, a working medium pump, a condenser, a liquid-vapor separator, an evaporator unit and a condensing injector. An inlet of the condenser is connected with an outlet of the condensing injector. The outlet of the condensing injector is connected with an inlet of the liquid-vapor separator. The liquid-vapor separator is provided with two liquid outlets, wherein one outlet is connected to an inlet of the working medium pump. An outlet of the working medium pump is divided into two paths, wherein one path is connected to an inlet of the condensing injector, while the other path is connected to an inlet of the generator. An outlet of the generator is connected with an inlet of the air injector. An outlet of the air injector is connected with an injection inlet of the condensing injector. The other liquid outlet of the liquid-vapor separator is connected with an inlet of the evaporator unit. A reflux opening of the evaporator unit is connected with an injection inlet of the air injector. An air outlet of the liquid-vapor separator is connected with another inlet of the evaporator unit. The auto-cascade injection low-temperature refrigeration circulating device increases the working pressure of the condenser through the condensing injector and can realize the low-temperature deep refrigeration temperature of less than 30 DEG C below zero.

Owner:HENAN UNIV OF SCI & TECH

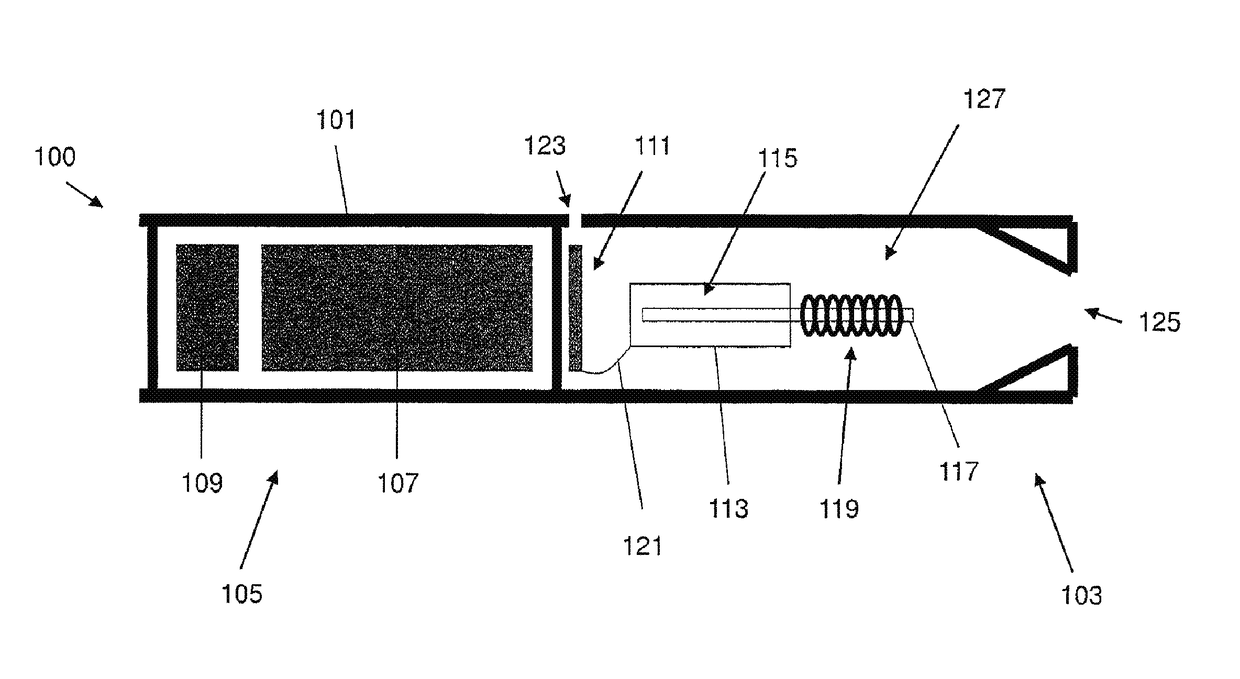

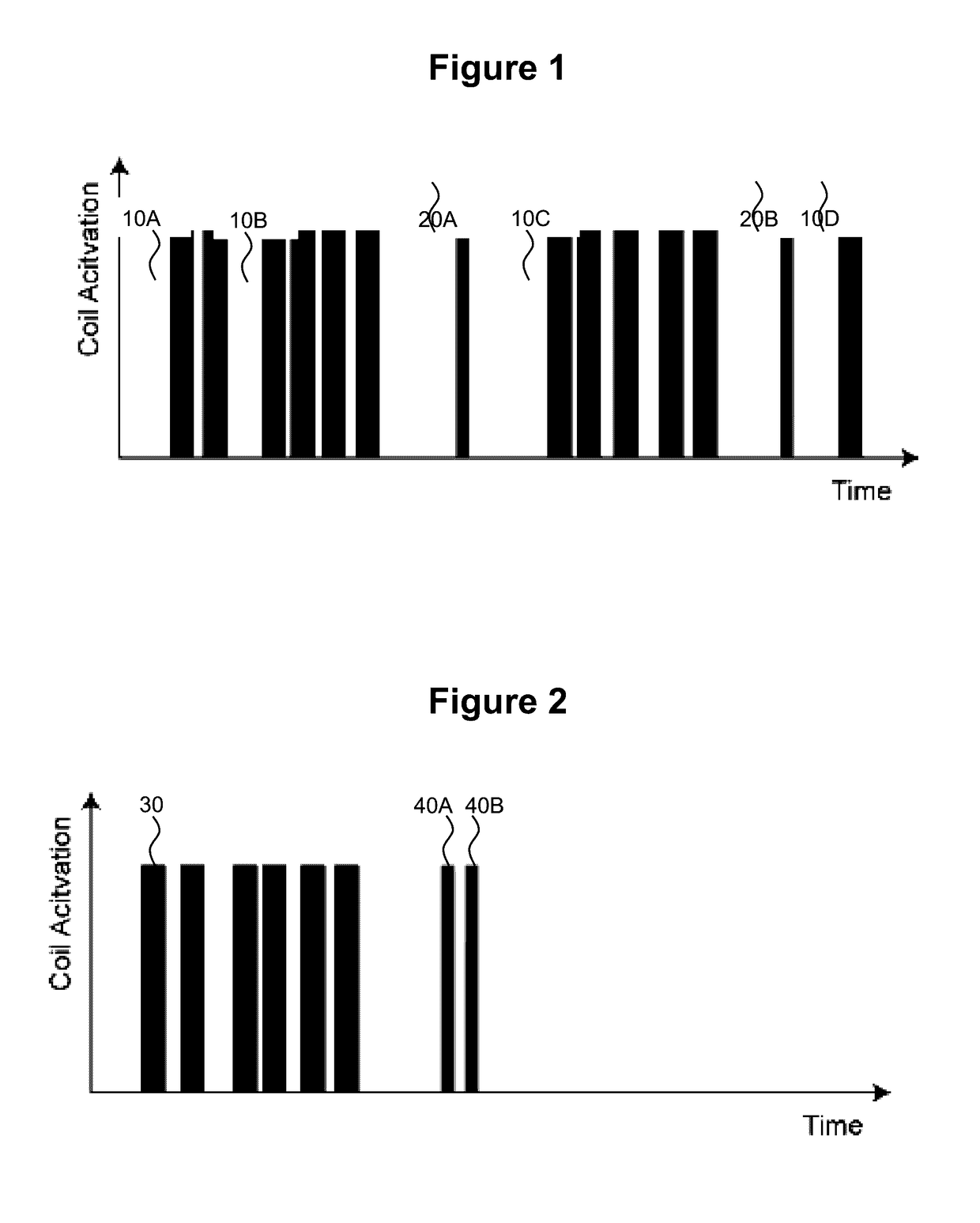

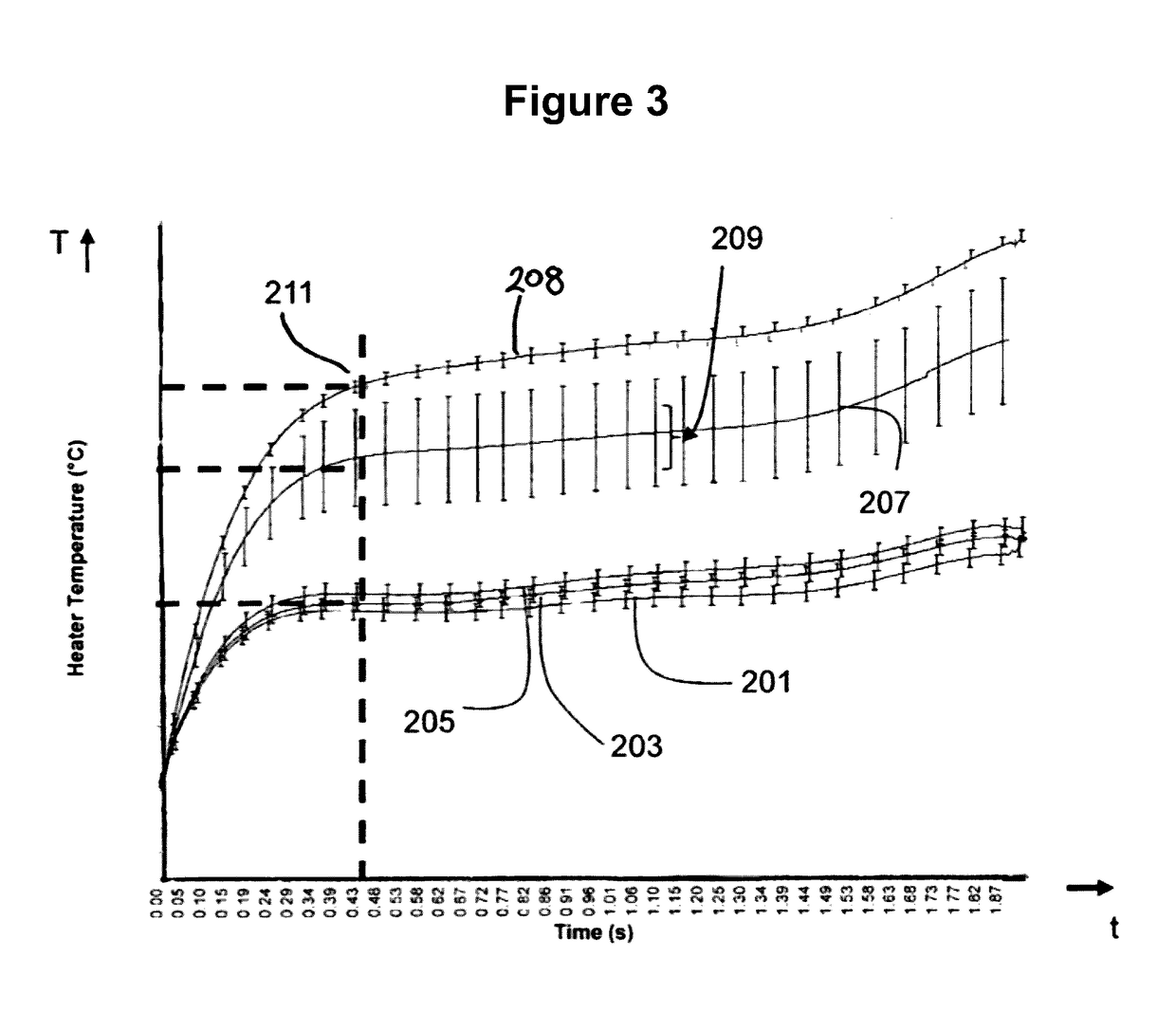

Aerosol-generating system with self-activated electric heater

ActiveUS20170135406A1High heating temperatureReduce the amount requiredOhmic-resistance waterproof/air-tight sealsTobacco devicesElectricityElectron

An electronic vaping device includes a liquid storage portion, an electric heater and electronic circuitry. The liquid storage portion is configured to store liquid vapor-forming substrate. The electric heater includes at least one heating element, the at least one heating element configured to heat the liquid vapor-forming substrate. The electronic circuitry is configured to self-activate the electric heater for a first time interval during a period of inactivity of the electric heater to determine depletion of the liquid vapor-forming substrate based on a relationship between a power applied to the at least one heating element and a resulting temperature change of the at least one heating element.

Owner:AKRIA CLIENT SERVICES LLC

Downhole sorption cooling and heating in wireline logging and monitoring while drilling

InactiveUS7124596B2Easy transferComponents is relatively effectiveSurveyConstructionsWater sourceWater vapor

A cooling system in which an electronic device or other component is cooled by using one or more solid sources of liquid vapor (such as polymeric absorbents, hydrates or desiccants that desorb water at comparatively low temperature) in conjunction with one or more high-temperature vapor sorbents or desiccants that effectively transfer heat from the component to the fluid in the wellbore. Depending on the wellbore temperature, desiccants are provided that release water at various high regeneration temperatures such as molecular sieve (220–250° C.), potassium carbonate (300° C.), magnesium oxide (800° C.) and calcium oxide (1000° C.). A solid water source is provided using a water-absorbent polymer, such as sodium polyacrylate. Heat transfer is controlled in part by a check valve selected to release water vapor at a selected vapor pressure.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com