Compressor cooling type fully sealed high-efficiency radiating electronic cabinet

A case and electronic technology, applied in the field of compressor refrigeration type fully sealed high-efficiency heat dissipation electronic case, can solve the problems of large volume, low power and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

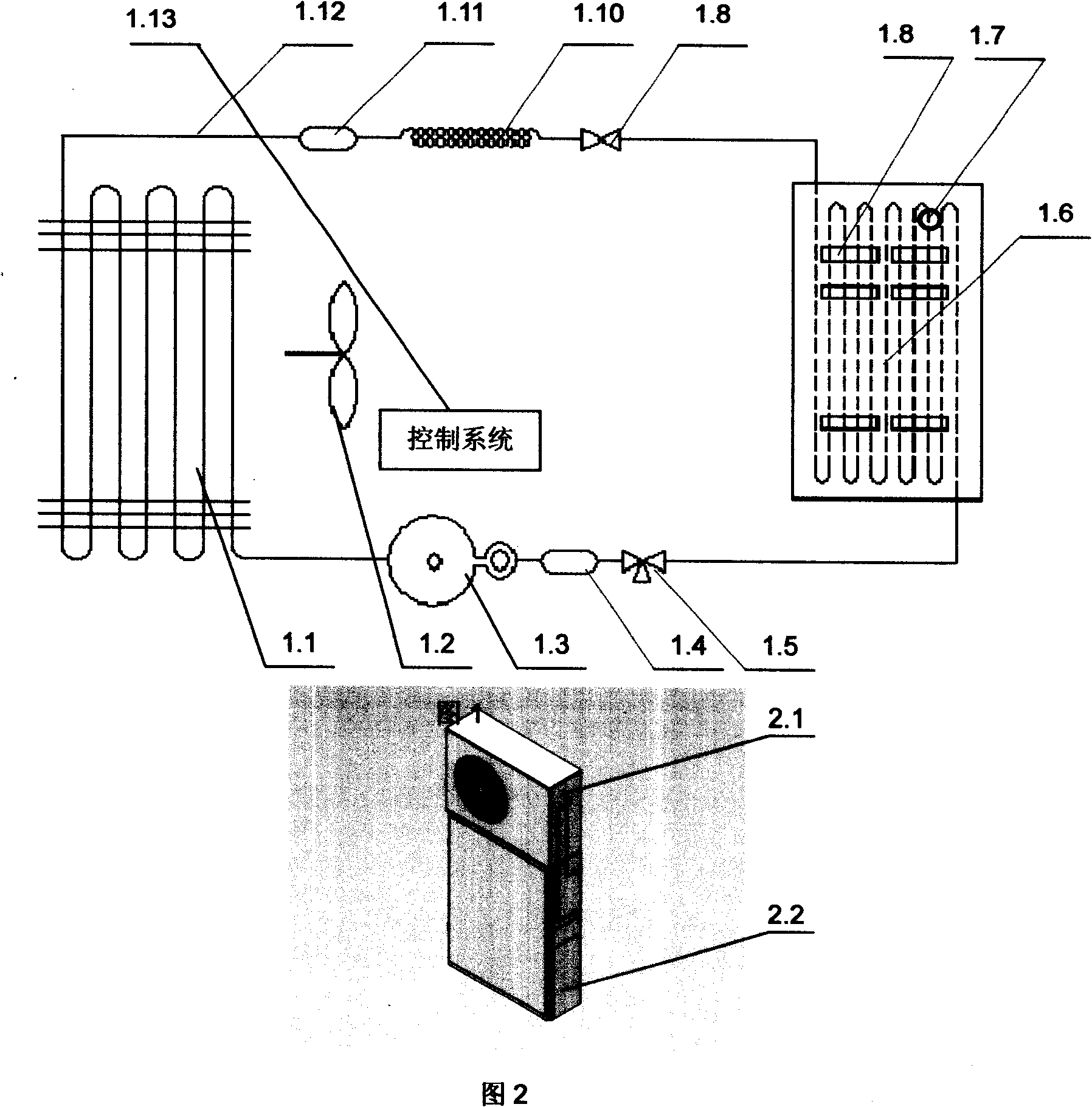

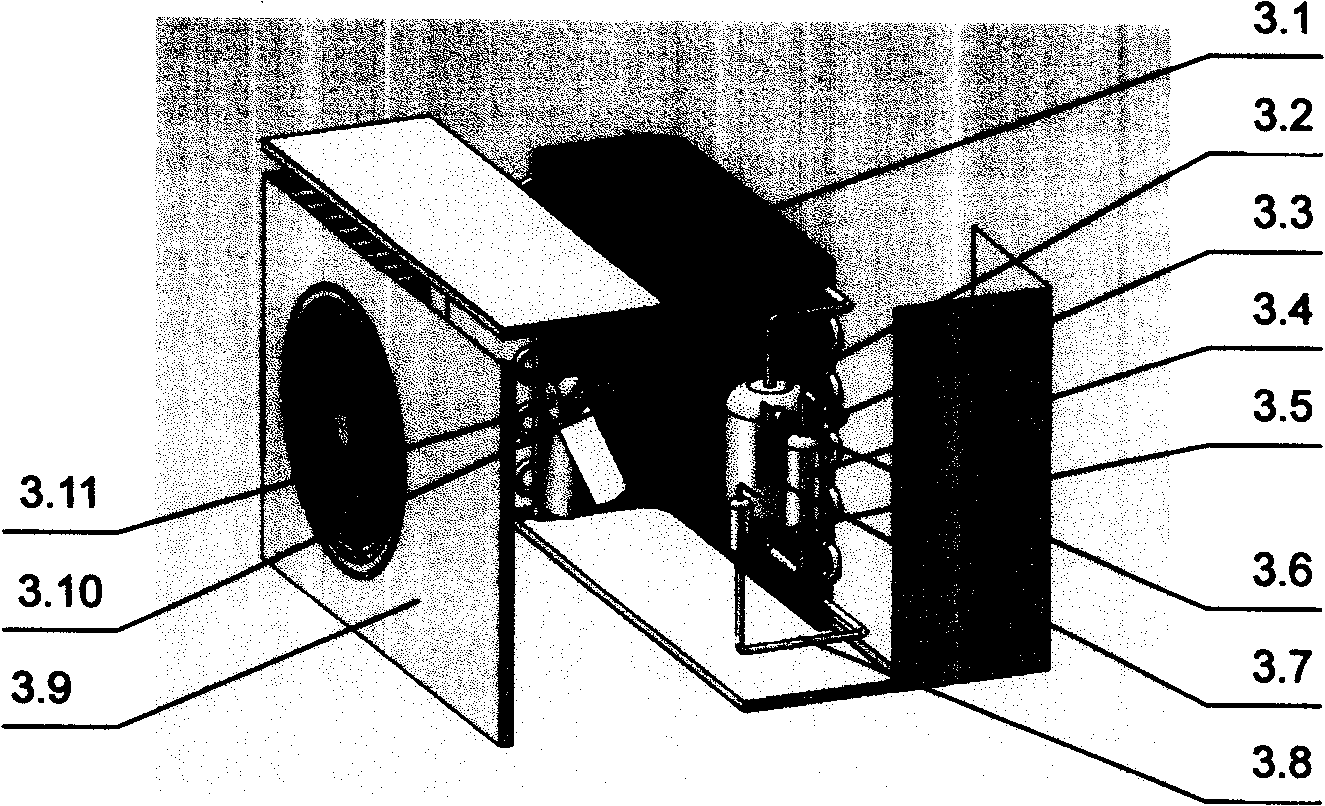

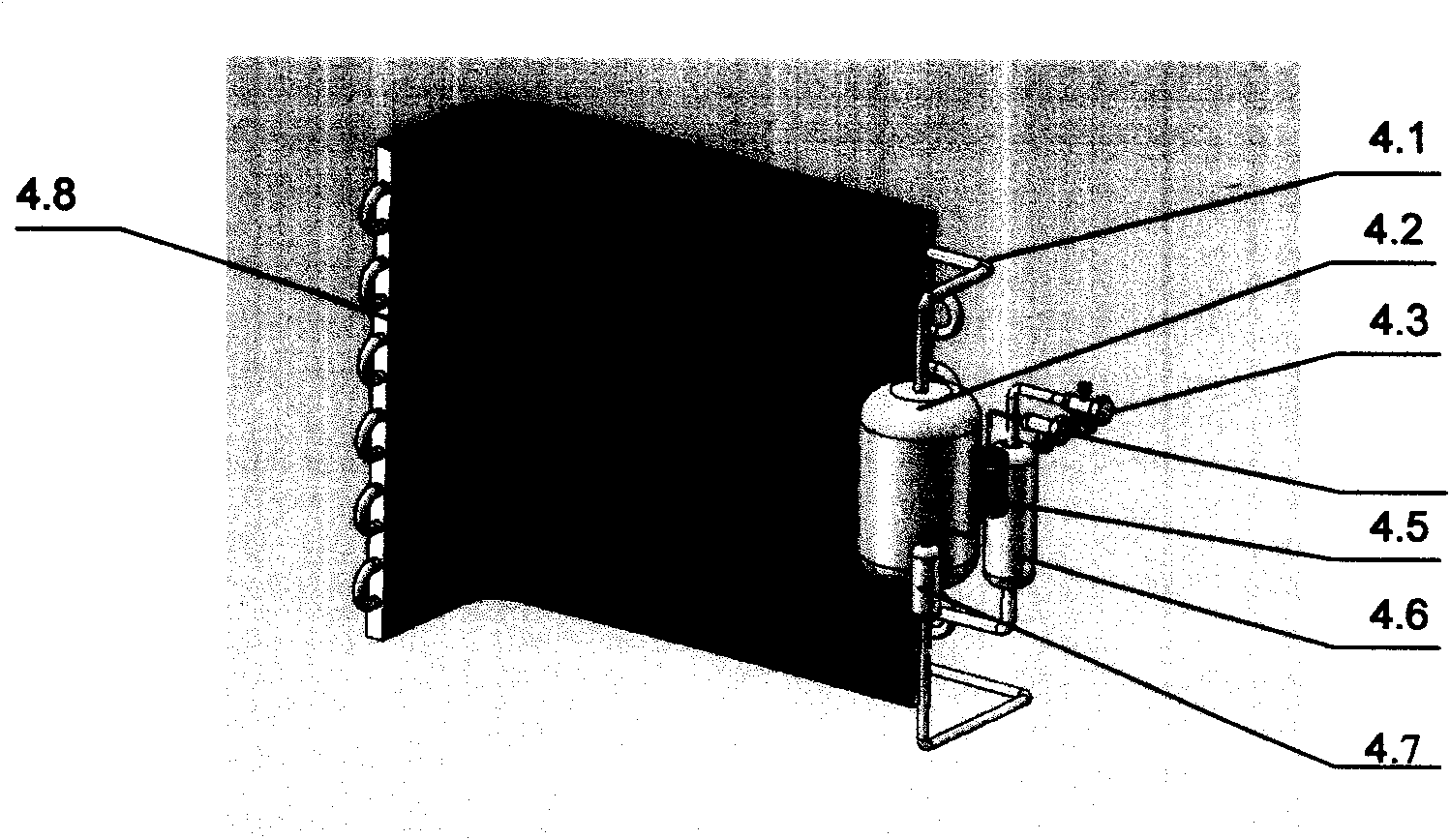

[0030] The present invention provides a heat dissipation method and heat dissipation device for a fully enclosed electronic chassis that requires waterproof, moisture-proof, dust-proof and electromagnetic shielding. In order to realize the complete enclosure of the main engine of the electronic chassis; the heating electronic components are fixed on the cold plate radiator inside the main engine. The cold plate radiator is made of high thermal conductivity metal materials such as aluminum, copper, etc., and the circulation in the cold plate radiator The phase change cooling medium undergoes a phase change when heated and vaporized, and absorbs a large amount of heat, and then is exported to the external heat exchanger by a pipeline for compression, cooling, and liquefaction, so as to achieve the purpose of efficient circulating cooling.

[0031] The circulating cooling medium in the circulating cooling device adopts F407C or R22 and the like.

[0032] The present invention als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com