Liquid-Vapor Separator For A Minichannel Heat Exchanger

a minichannel heat exchanger and liquid-vapor separator technology, which is applied in the direction of refrigeration machines, compression machines with several evaporators, lighting and heating apparatus, etc., can solve the problems of significant evaporator and overall system performance degradation, improper heat exchanger orientation, and possible misdistribution of refrigeran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

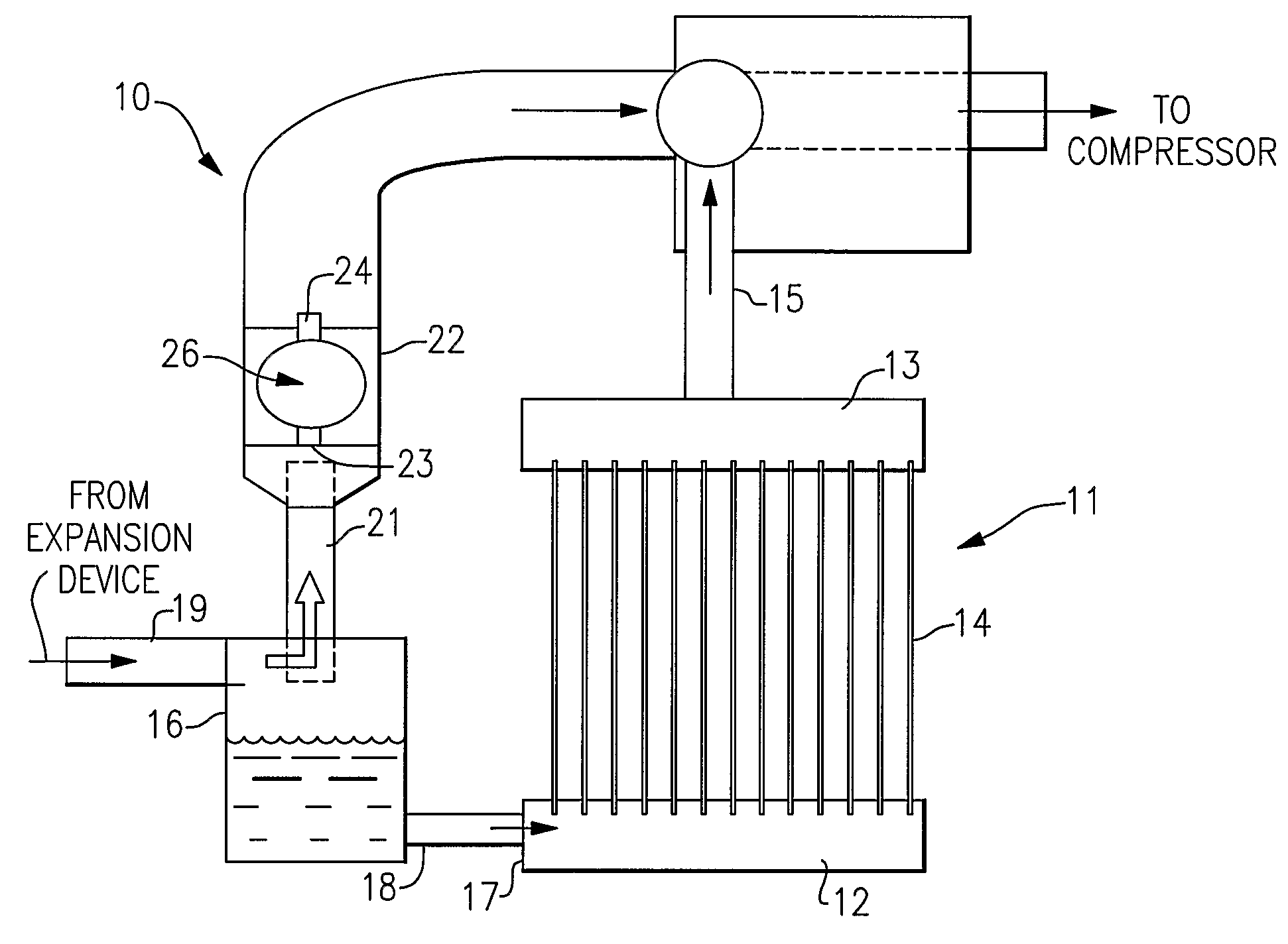

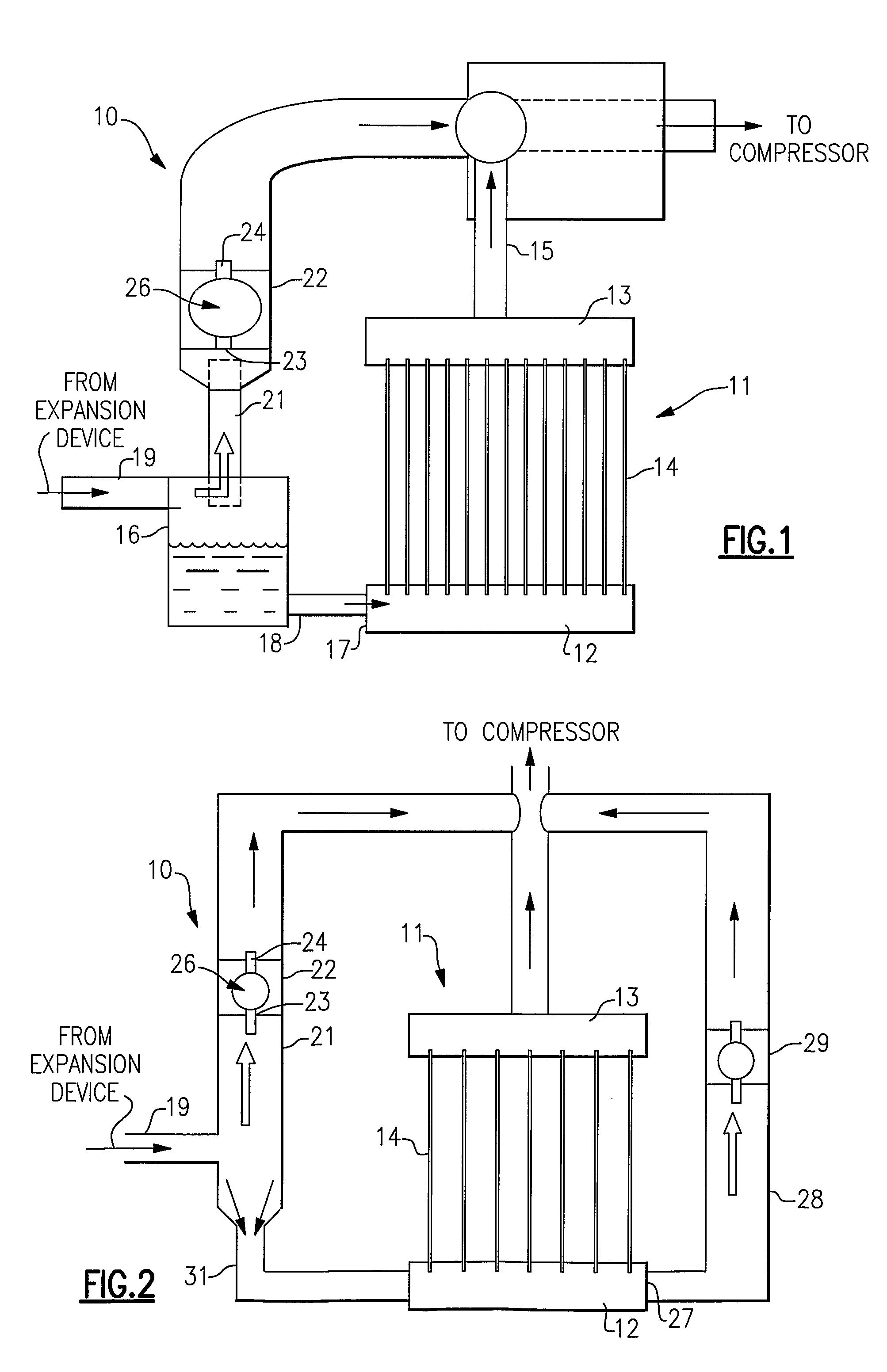

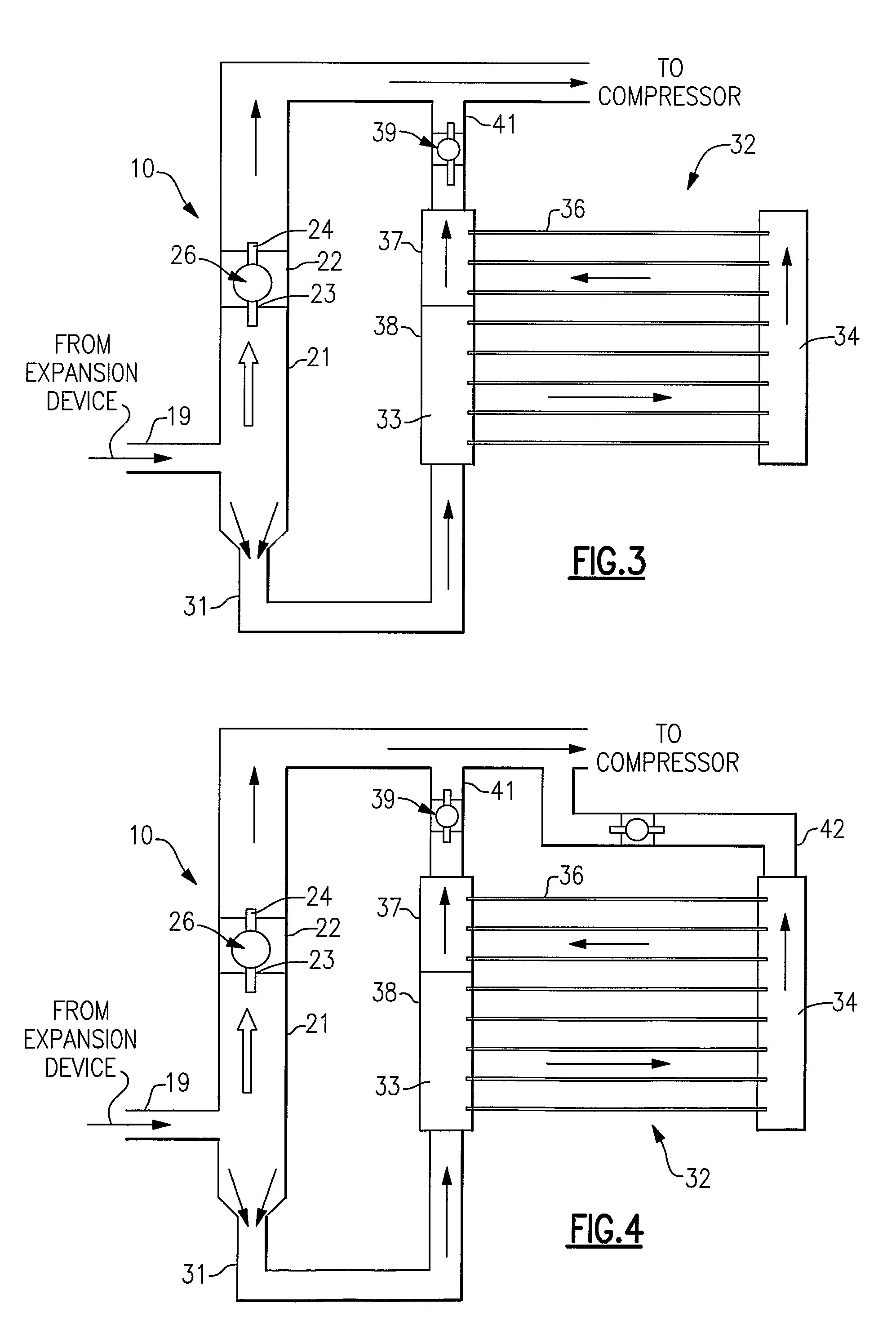

[0018]Referring now to FIG. 1, the invention is shown generally at 10 as applied to a minichannel heat exchanger 11 having an inlet manifold 12, an outlet manifold 13, and a plurality of parallel microchannels 14 interconnecting the inlet manifold 12 to the outlet manifold 13.

[0019]An inlet chamber 16 is fluidly connected to the upstream end 17 of the inlet manifold 12 by way of conduit 18. At an upper portion of the inlet chamber 16 an inlet line 19 provides fluid communication from an expansion device such that a mixture of liquid and vapor refrigerant flows into the upper portion of the inlet chamber 16. The heavier liquid refrigerant tends to fall to the bottom of the inlet chamber 16 and flow through the conduit 18 to the inlet manifold 12 such that each of the parallel minichannels 14 have single phase liquid refrigerant presented at their inlet ends.

[0020]Also connected at the upper portion of the inlet chambers 16 is a bypass duct 21 for conducting the flow of refrigerant va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com