Method for use of liquid/vapor ammonia absorption systems in unitary HVAC systems

a technology of liquid/vapor ammonia absorption and unitary hvac system, which is applied in the operation mode of machines, refrigeration machines, light and heating apparatus, etc., can solve the problem that a good portion of heat is generated in the absorber of the absorption system, and achieve the effect of facilitating the switching of the evaporator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

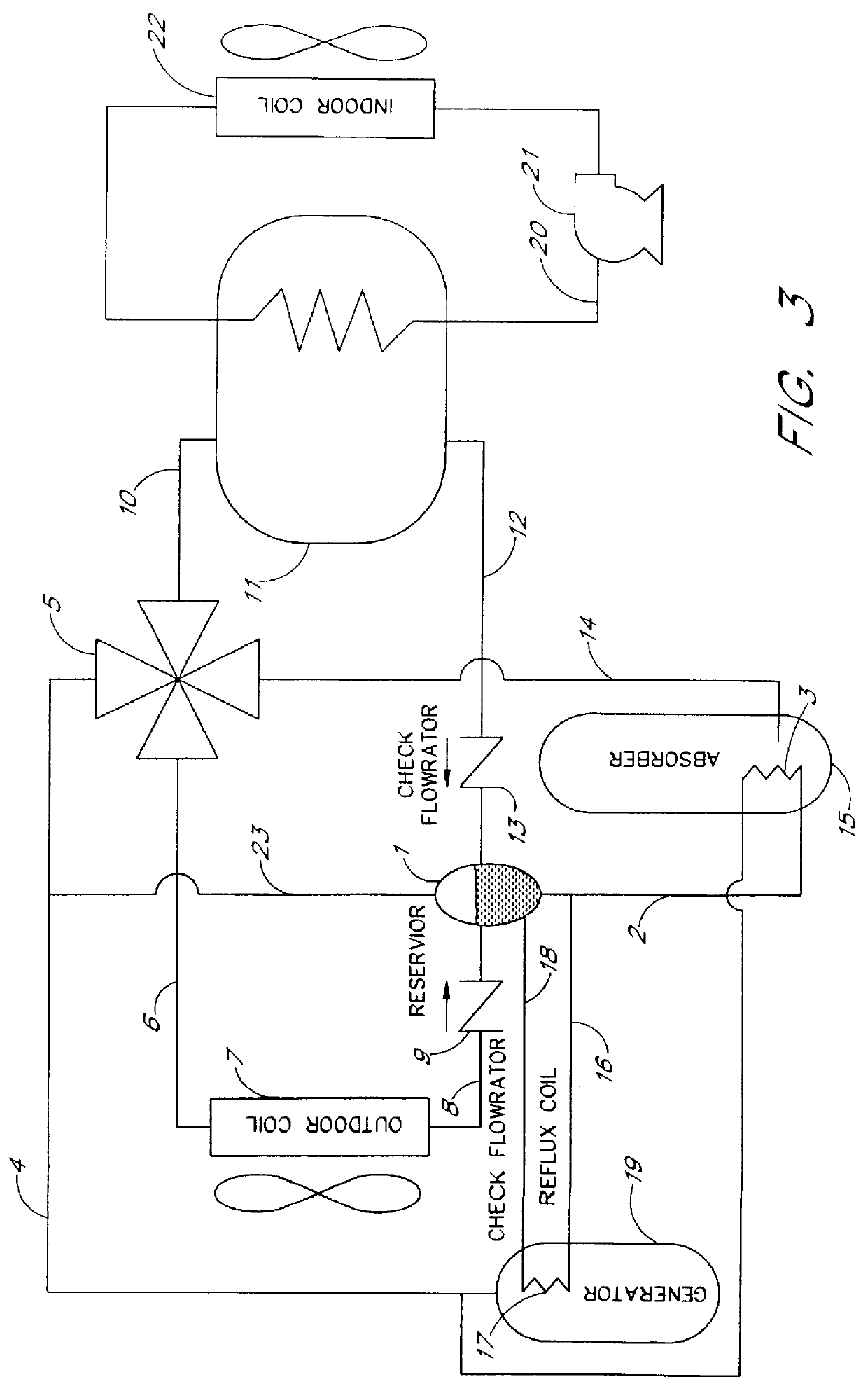

In FIGS. 3-8, the solution flow pathway including solution pump, absorber heat exchanger, generator heat exchanger, as well as any GAX fluid pathway using all or a portion of the liquor or a separate heat exchange loop is intentionally omitted as the present invention is not limited to any specific GAX or non-GAX cycle configuration.

FIG. 3 shows a basic cycle apparatus according to this invention. The main feature of this cycle is that phase change ammonia heat transfer is used to combine all heat rejection from the cycle into a single fluid stream so that a conventional reversing valve (4-way valve) can be used to switch between heating and cooling modes.

Condensed ammonia is collected in a reservoir 1. Liquid ammonia is allowed to flow from the reservoir through conduit 2 to a heat transfer coil 3 in the absorber 15. In this coil, ammonia is fully or partially vaporized. Vapor, with possibly some entrained liquid, flows from coil 3 through conduit 4 to reversing valve 5. In cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com