Auto-cascade injection low-temperature refrigeration circulating device

A circulation system and injection technology, which is applied in the field of self-cascading injection low-temperature refrigeration circulation system, can solve the problem of low working pressure of the condenser, and achieve the effects of less mechanical power consumption, lower refrigeration temperature and higher working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

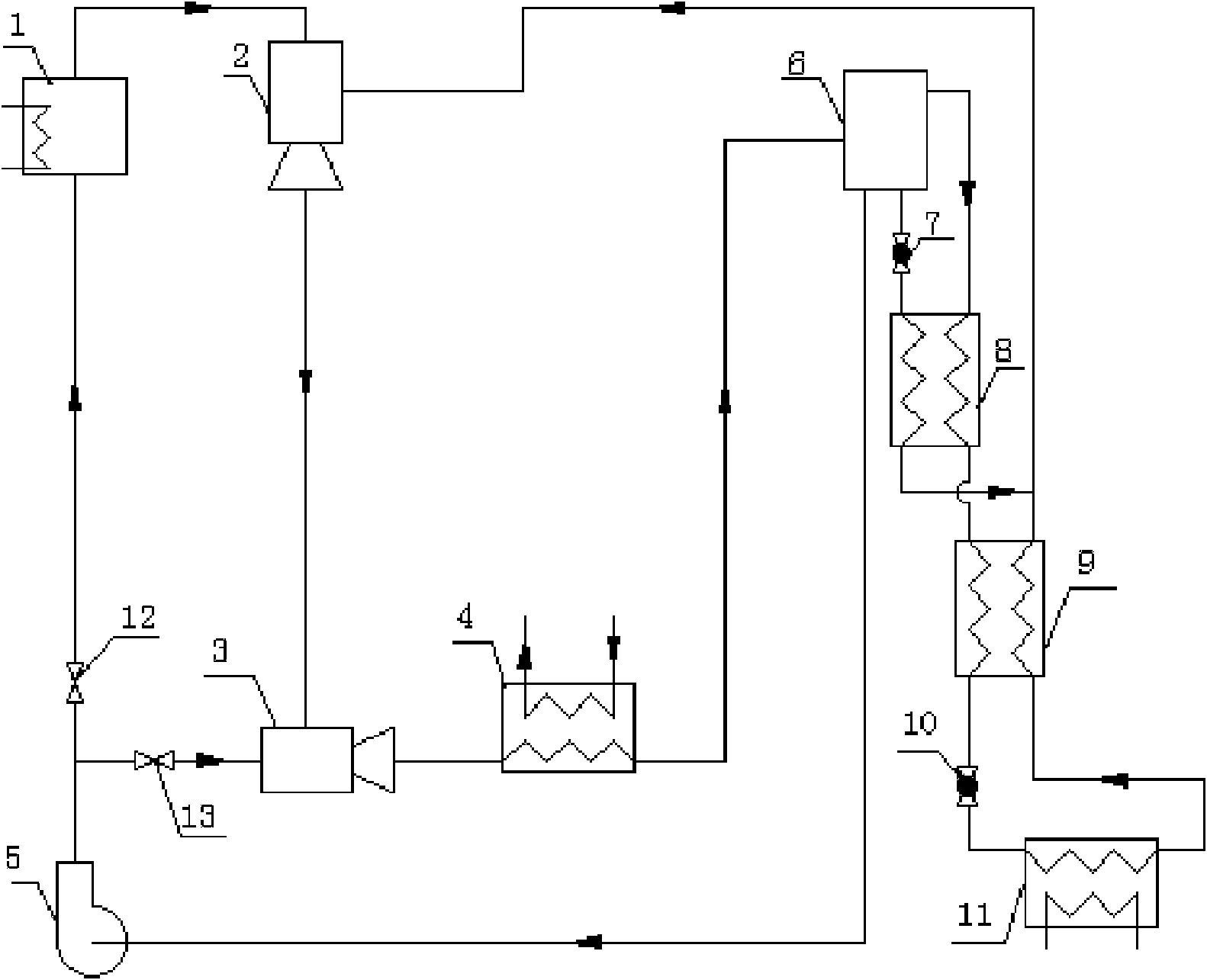

[0017] exist figure 1 Among them, a self-cascading ejector low-temperature refrigeration cycle system, including a generator 1, a gas ejector 2, a working medium pump 5, a condenser 4, a gas-liquid separator 6, a condensation evaporator 8, and a third regenerator 9 and the evaporator 11, the liquid mixed refrigerant in the generator 1 is heated and vaporized into a high-pressure superheated refrigerant vapor, which enters the gas injector 2 as working gas to inject the low-pressure side outlet of the condensing evaporator 8 and the third regenerator 9 The low-pressure mixed refrigerant steam at the outlet of the low-pressure side, the injected low-pressure mixed refrigerant steam is mixed and pressurized by the gas injector 2, and the gas at the outlet of the gas injector 2 is a superheated refrigerant mixed steam at an intermediate pressure state, and the working medium pump The supercooled liquid at outlet 5 passes through the condensing injector 3 and injects the superheate...

Embodiment 2

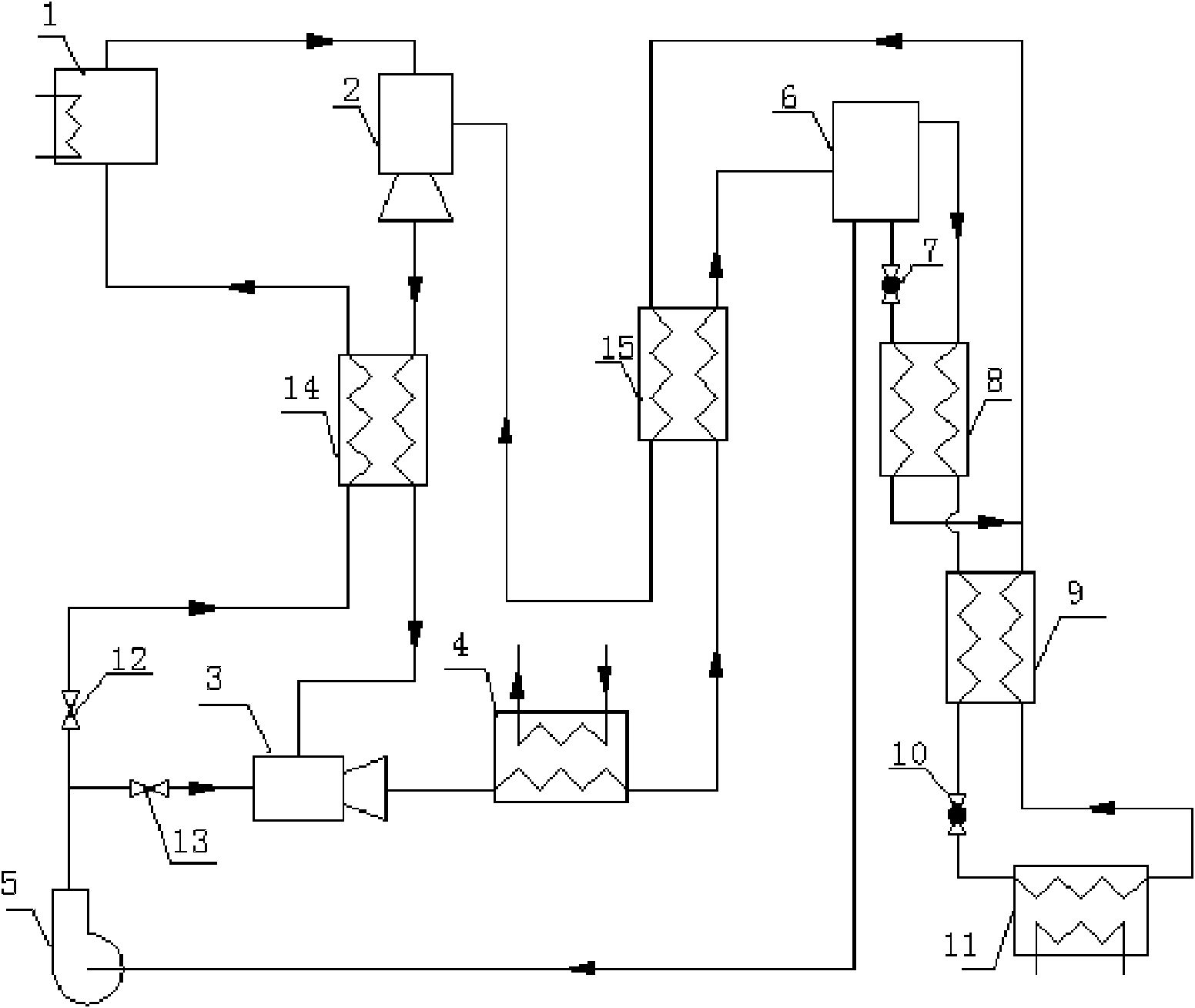

[0019] exist figure 2 In the generator 1, the liquid mixed refrigerant in the generator 1 is heated and vaporized into a high-pressure superheated refrigerant vapor, which enters the gas injector 2 as a working gas to inject the low-pressure refrigerant from the second regenerator 15, and is mixed by the gas injector 2 Supercharging effect, the superheated refrigerant mixed steam in the intermediate pressure state from the outlet of the gas injector 2 enters the first regenerator 14 for heat exchange, and is injected into the condensing injector 3 by the supercooled liquid pressurized by the working medium pump 5 Internal condensation and further pressurization, the high-pressure gas-liquid two-phase mixture refrigerant coming out of the outlet of the condensing injector 3 enters the condenser 4, and part of the gas-liquid two-phase mixture refrigerant is condensed, and passes through the second regenerator 15 After heat exchange, the gas-liquid two-phase mixed refrigerant en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com