Pipe joint

A technology for pipe joints and joint holes, which is applied in the field of pipe joints and can solve problems such as inability to ensure airtightness and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043](the whole frame)

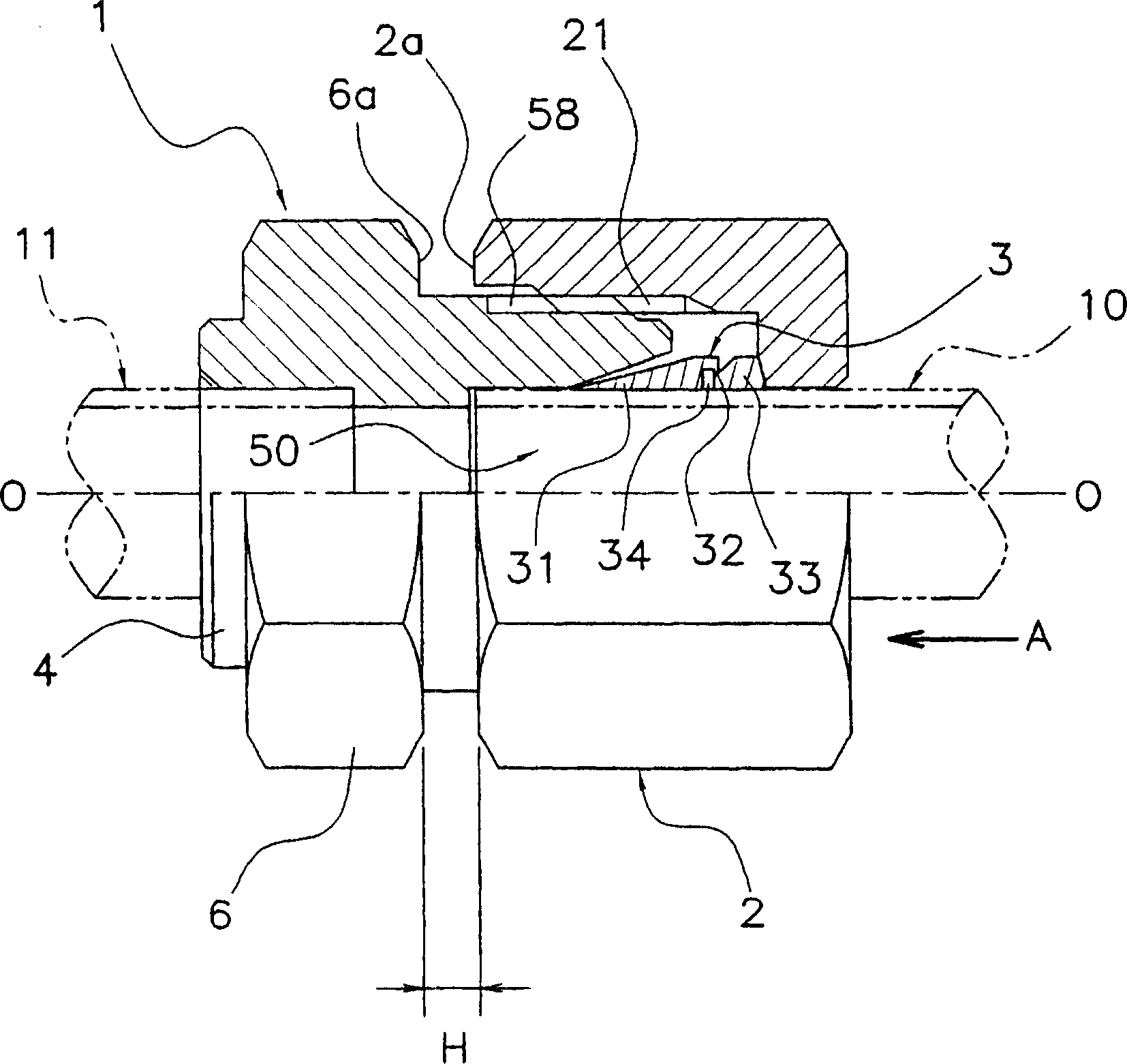

[0044] Such as figure 1 As shown, a pipe joint (cut joint) according to an embodiment of the present invention has a joint main body 1 , a nut 2 and a sleeve 3 . The joint of this embodiment is used to connect a pipe 10 which is a copper pipe or a thin-walled stainless steel pipe and a pipe 11 , and the pipe 10 is detachably engaged in an engaging hole 50 (described later) of the joint main body 1 .

[0045] (Structure of Joint Body 1)

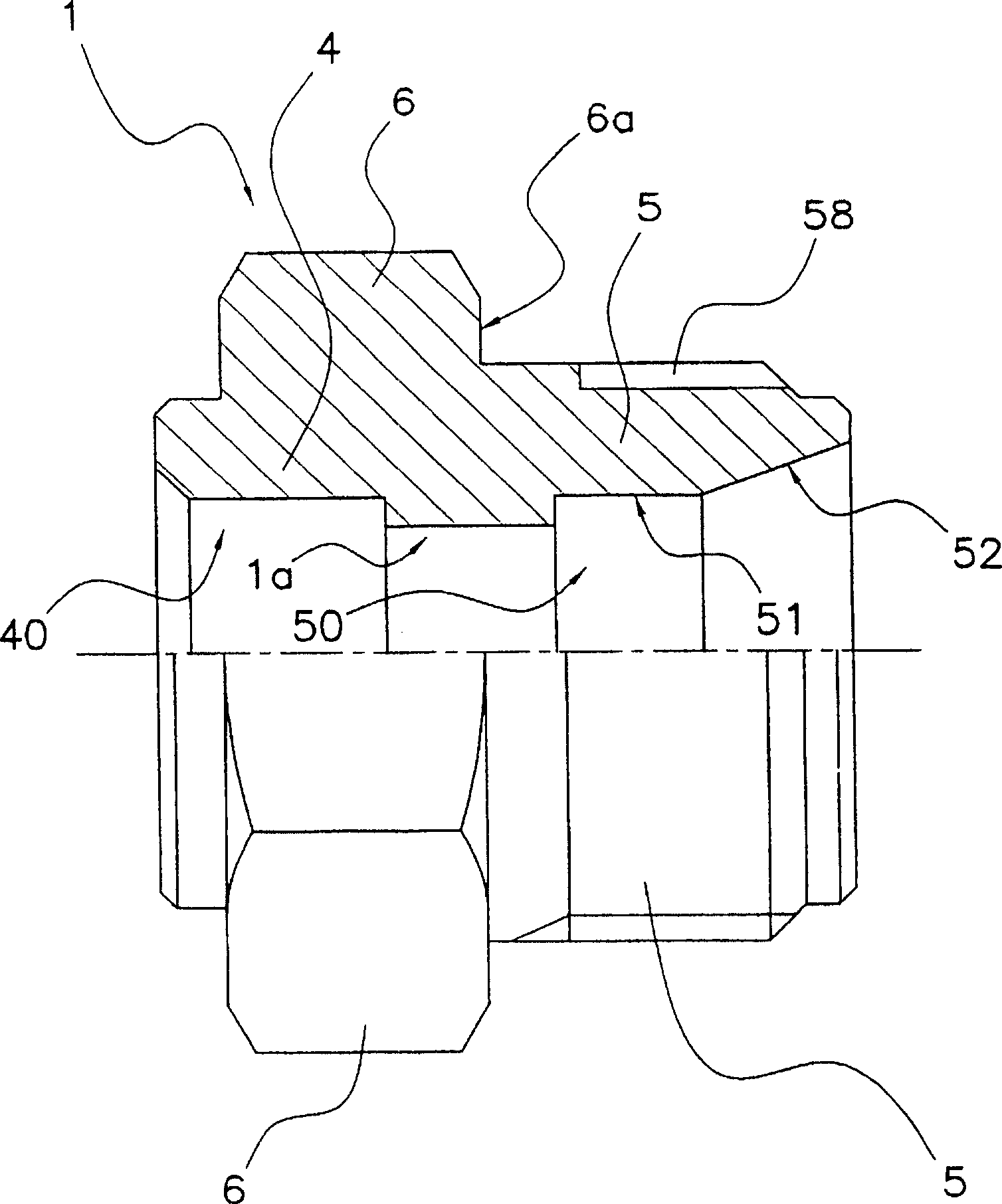

[0046] Such as figure 1 and figure 2 As shown, the joint main body 1 is composed of the following parts: a socket part 4 for inserting and brazing a pipe 11 in an inner hole 40; a pipe connecting part 5 for connecting the pipe 10; a nut part 6 provided on the outer periphery . The side surface 6a of the nut part 6 is an opposing surface which opposes the side surface 2a of the nut 2 mentioned later.

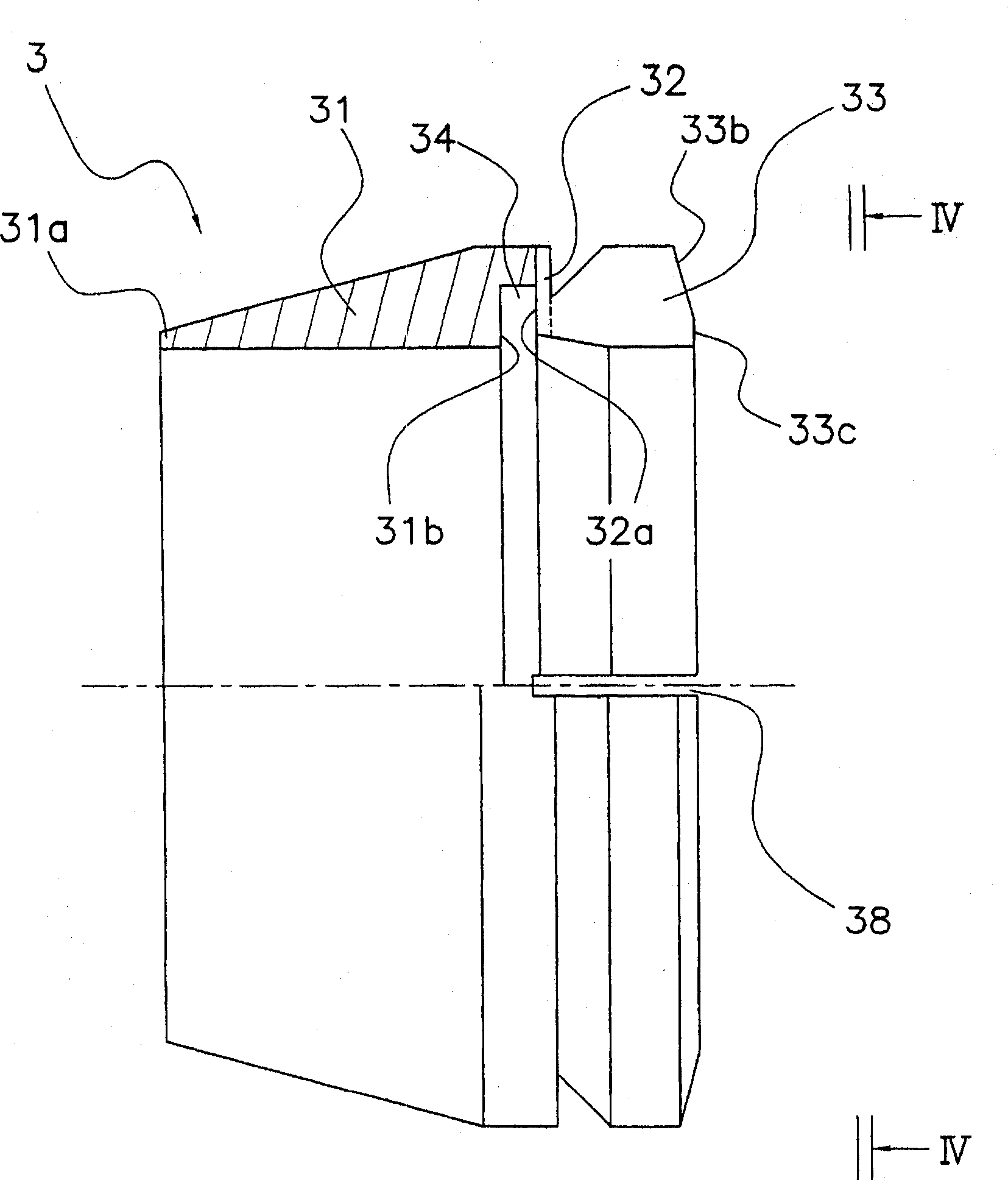

[0047] Such as figure 2 As shown, the inside of the pipe connection portion 5 has an engaging hole forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com