Preparation method for low-resistance injector

A technology of low-resistance syringes and core rods, applied in syringes, infusion sets, etc., can solve the problems of material debris, incomplete cleaning, and contamination of liquid medicine, and achieve the effects of avoiding pollution, improving sliding resistance, and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

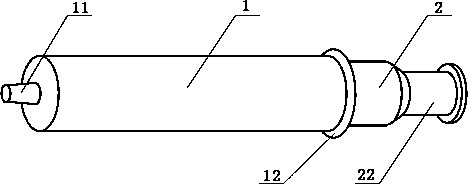

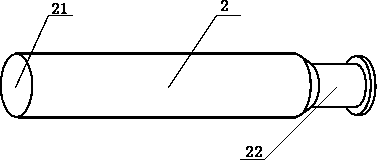

[0032] The low-resistance syringe prepared by the present invention, such as figure 1 , 2 As shown, it includes a core rod 2 and a jacket 1. The core rod 2 is a tubular body, one end of the core rod 2 has a datum plane 21 , and the other end is equipped with a core rod presser 22 . The jacket 1 is a tubular body, which is set outside the core rod 2 . A conical head 11 is installed at one end of the jacket 1 , and a crimp 12 is installed at the other end. The core rod 2 and the jacket 1 are made of polymethyl methacrylate (PMMA) through extrusion tube processing technology. The polymethyl methacrylate used to prepare the core rod 2 and the jacket 1 in the present invention is medical grade polymethyl methacrylate.

[0033] The above-mentioned low-resistance syringe is prepared through the following steps: firstly, the core rod 2 and the jacket 1 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com