Optical fiber airtightly leading out method for GIS cavity

A technology of optical fiber and cavity, which is applied in the field of optical fiber airtight extraction for GIS cavity, which can solve the problems of high air pressure and inability to fully meet the requirements, so as to improve reliability, avoid breakage and damage, and solve airtightness difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

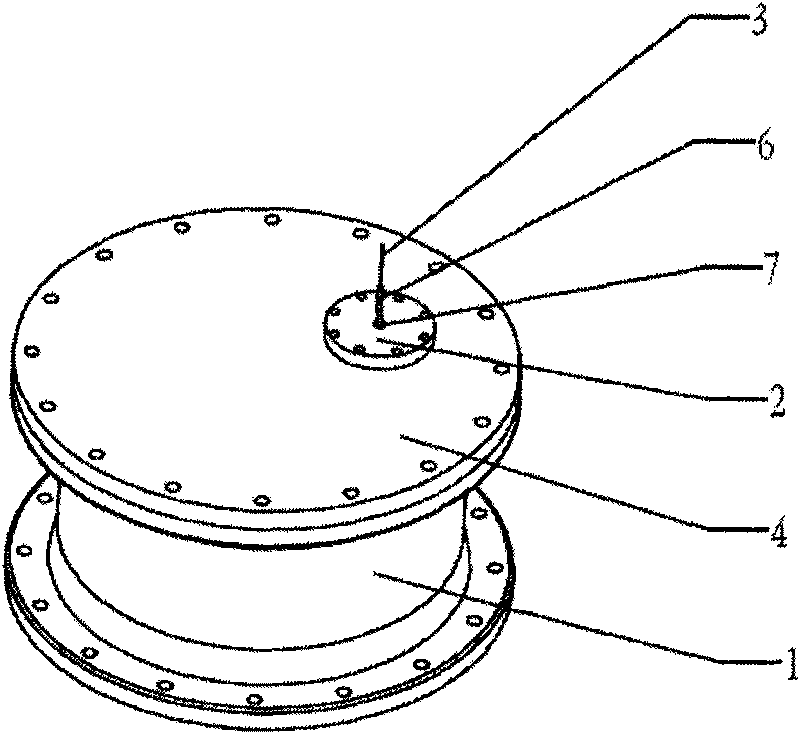

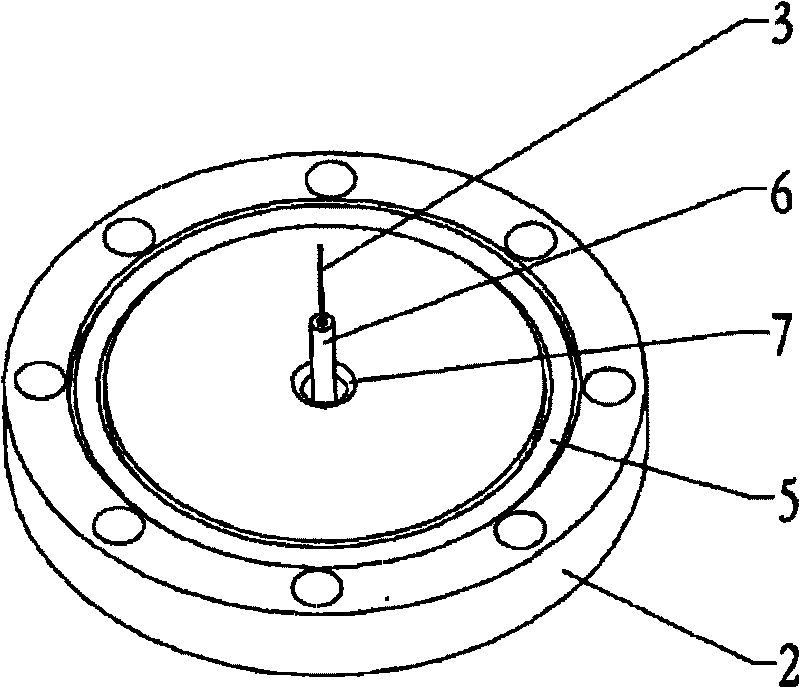

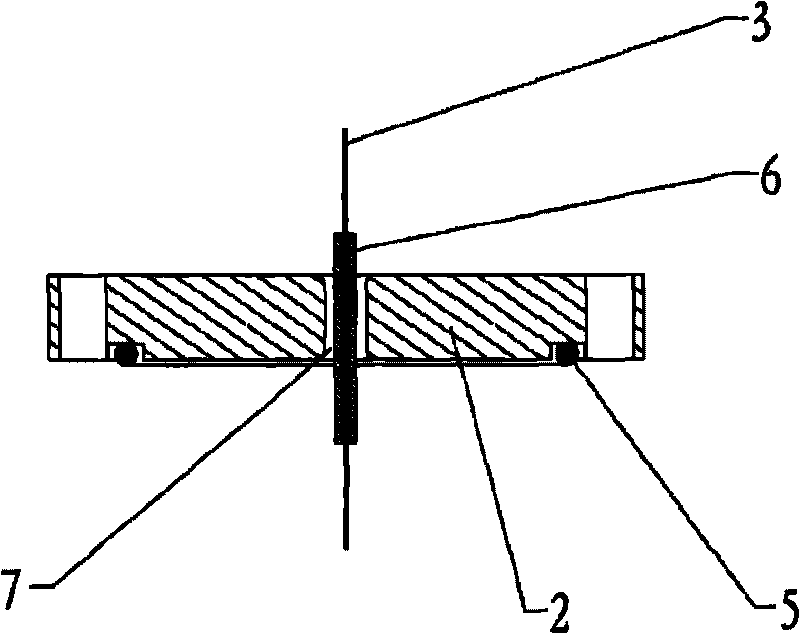

[0023] Such as figure 1 , figure 2 , image 3 As shown, it is a schematic diagram when the optical fiber of the GIS cavity is hermetically led out by the method of the present invention.

[0024] Firstly, an optical fiber lead-out flange 2 is required. There is a threaded hole solidified with the mounting flange 4 on the optical fiber lead-out flange 2 , and the sealing ring 5 is airtight with the mounting flange 4 . An optical fiber through-hole 7 is opened at the center of the optical fiber lead-out flange 2 and the mounting flange 4 of the GIS cavity 1 .

[0025] Secondly, the pigtails of the optical components in the GIS cavity 1 are directly metallized and packaged, so that the internal optical components and the metallized optical fiber 3 are integrated. The metallized package structure includes the metallized optical fiber 3 and the metal tube 6, and the metal tube 6 A nickel tube is used, and the space between the metallized optical fiber 3 and the metal tube 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com