Patents

Literature

590results about How to "Avoid tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

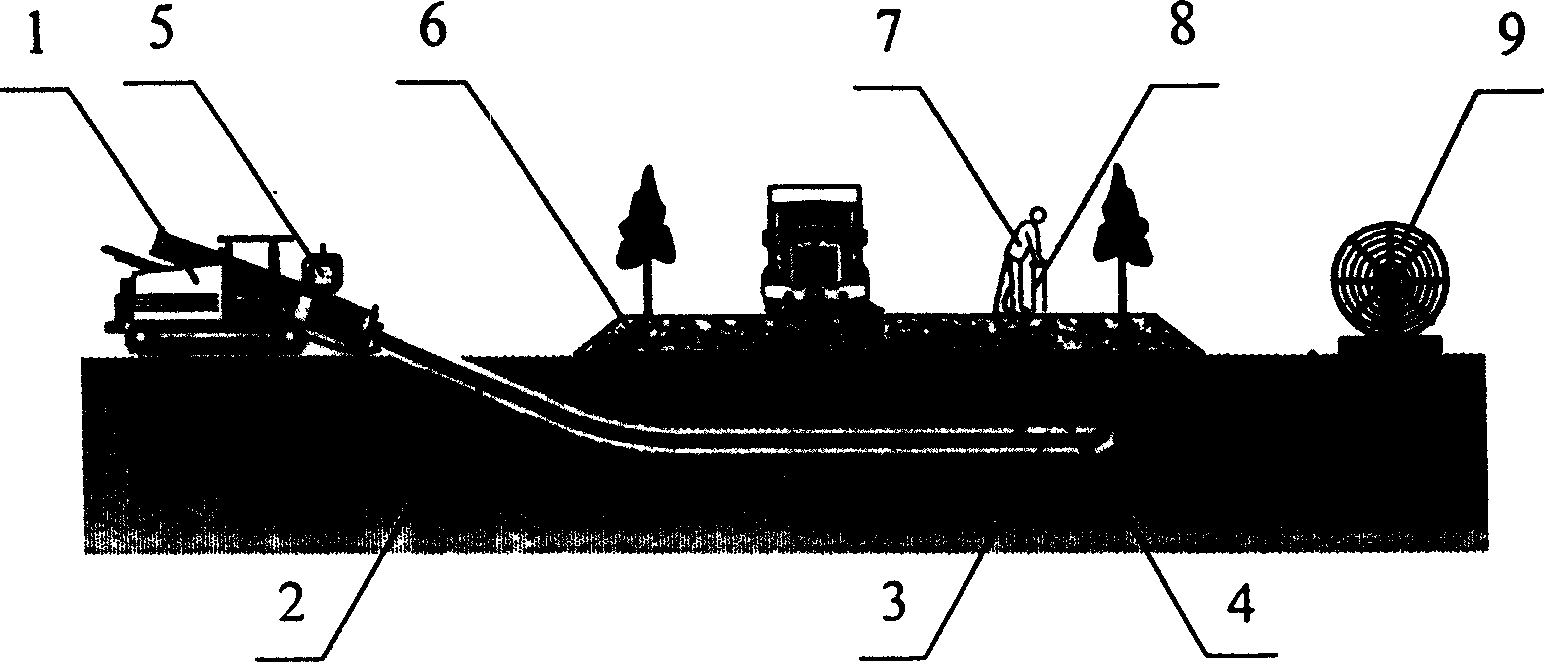

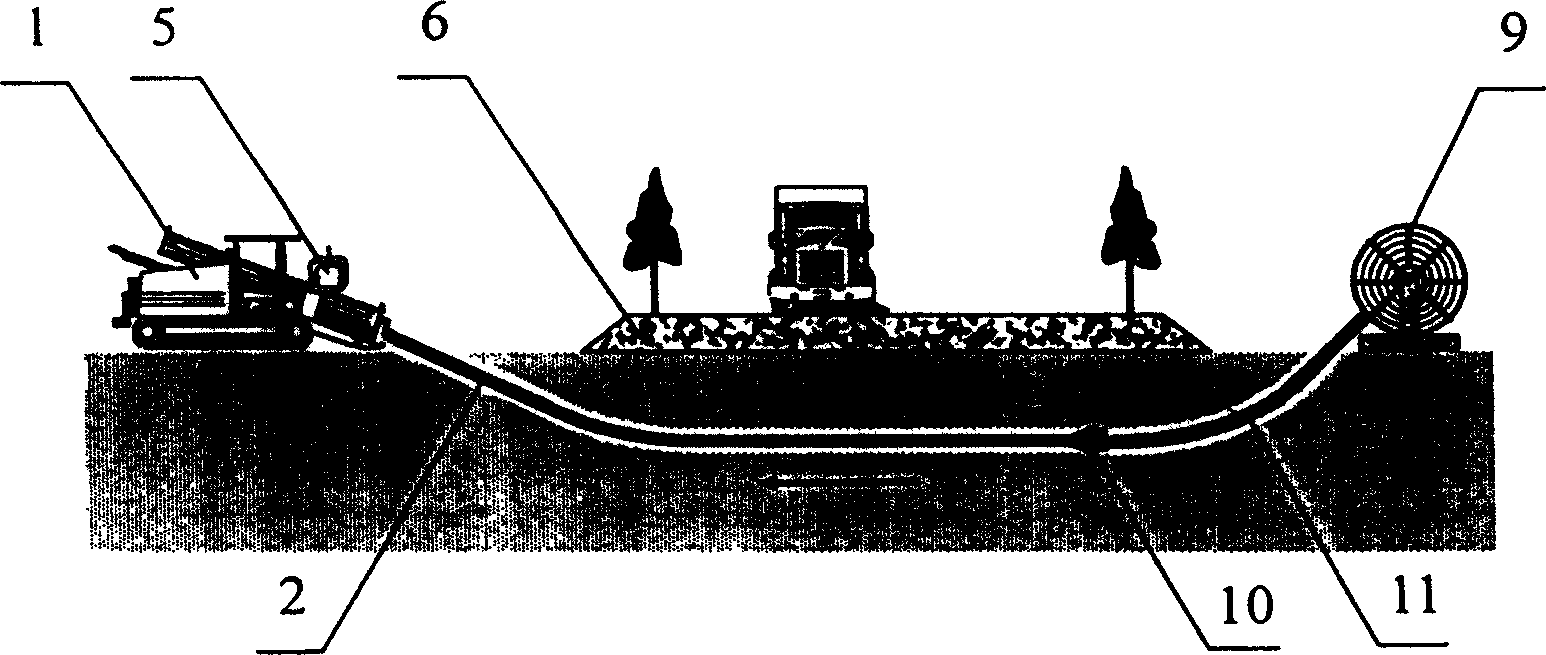

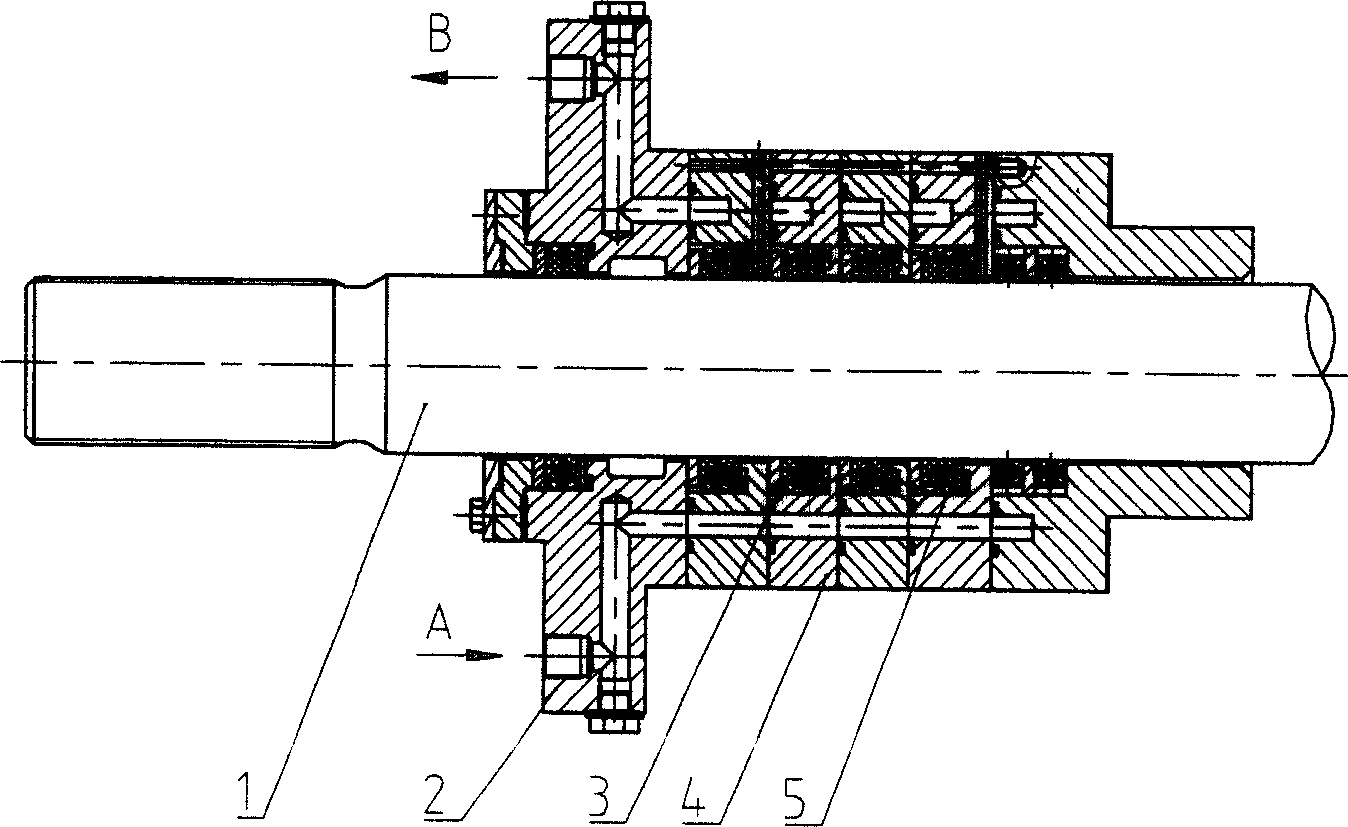

Real time measuring method and apparatus for horizontal directional drilling

InactiveCN1603576AReduce volumeAchieve modularitySurveyDirectional drillingMeasurement deviceUnit operation

One kind of horizontal direction detection sneaks in along with drills the measuring technique and the equipment, uses in the horizontal direction detection sneaks in when the fact to survey underground drilling tool inclining, parameter and so on rotation and temperature, and the measurement result will transmit the ground through the transmitting coil by the radio magnetic wave way. The method use underground drilling tool interior along with drills in the metering equipment the inclination angle, the appearance angle and the temperature sensor surveys the corresponding parameter, after signal processing and transmission unit operation, use wireless launch unit to ground receiver real-time transmission. Its metering equipment has two sections of metals shells and center the compartment insulation shell seal becomes. In an end shell is loaded with the power source; The wireless radiating element installs in the insulator shell; Is loaded with electric circuit of board the signal processing and the transfer element, the inclination angle sensor, the appearance angle sensor and the temperature sensor sets in another end shell. The invention volume small, structure simple, cost inexpensive, the antijamming ability is strong, works reliably under the adverse circumstance, can suit the majority direction detection to sneak in the equipment request.

Owner:ZOOMLION HEAVY IND CO LTD

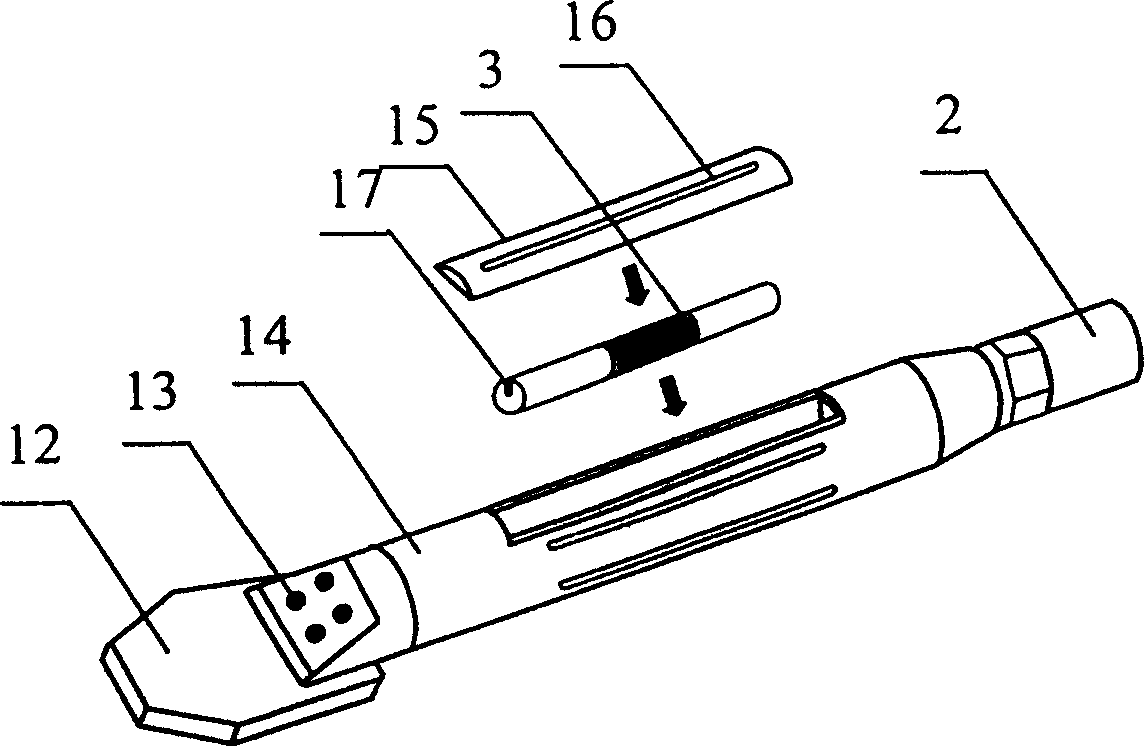

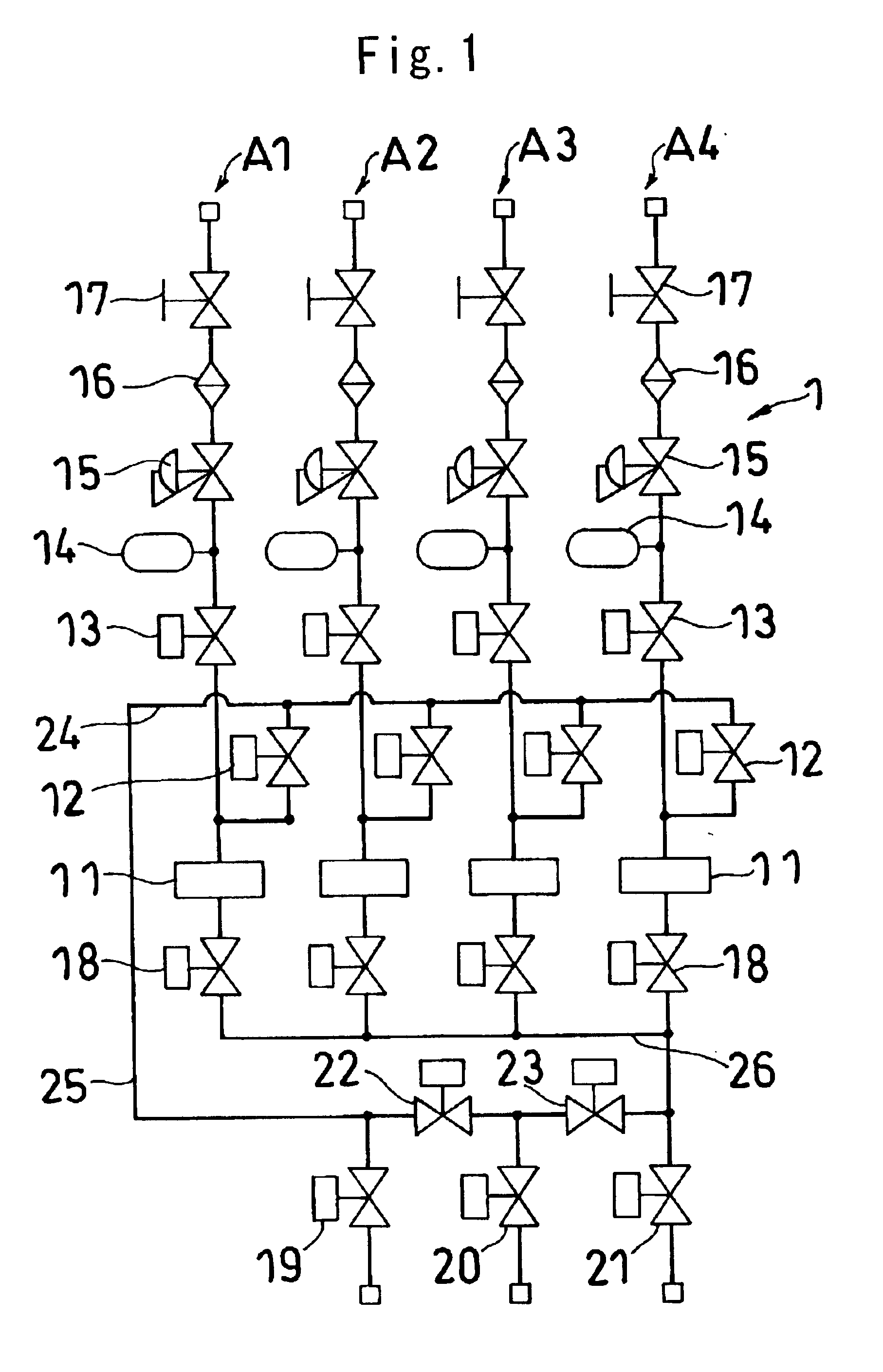

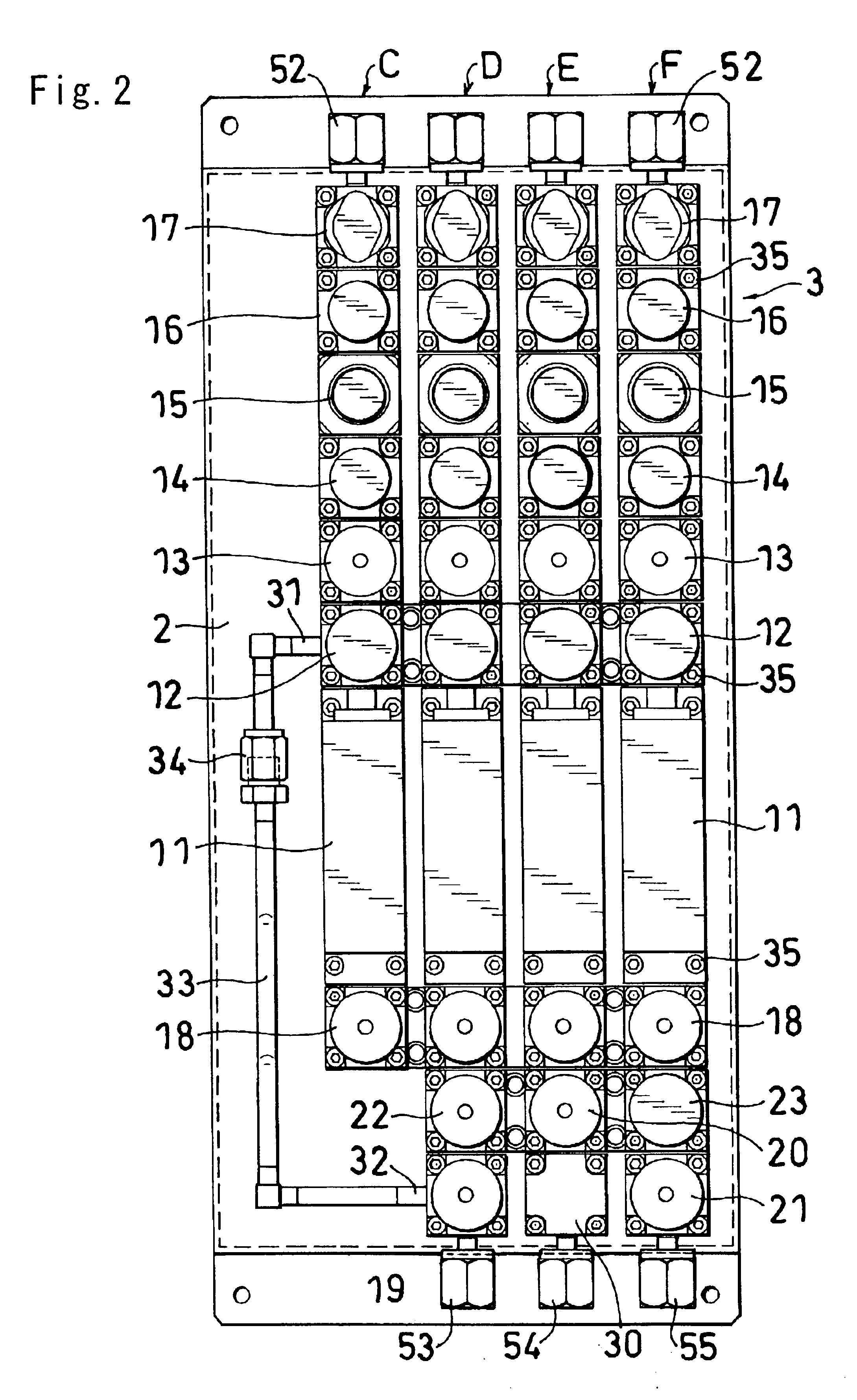

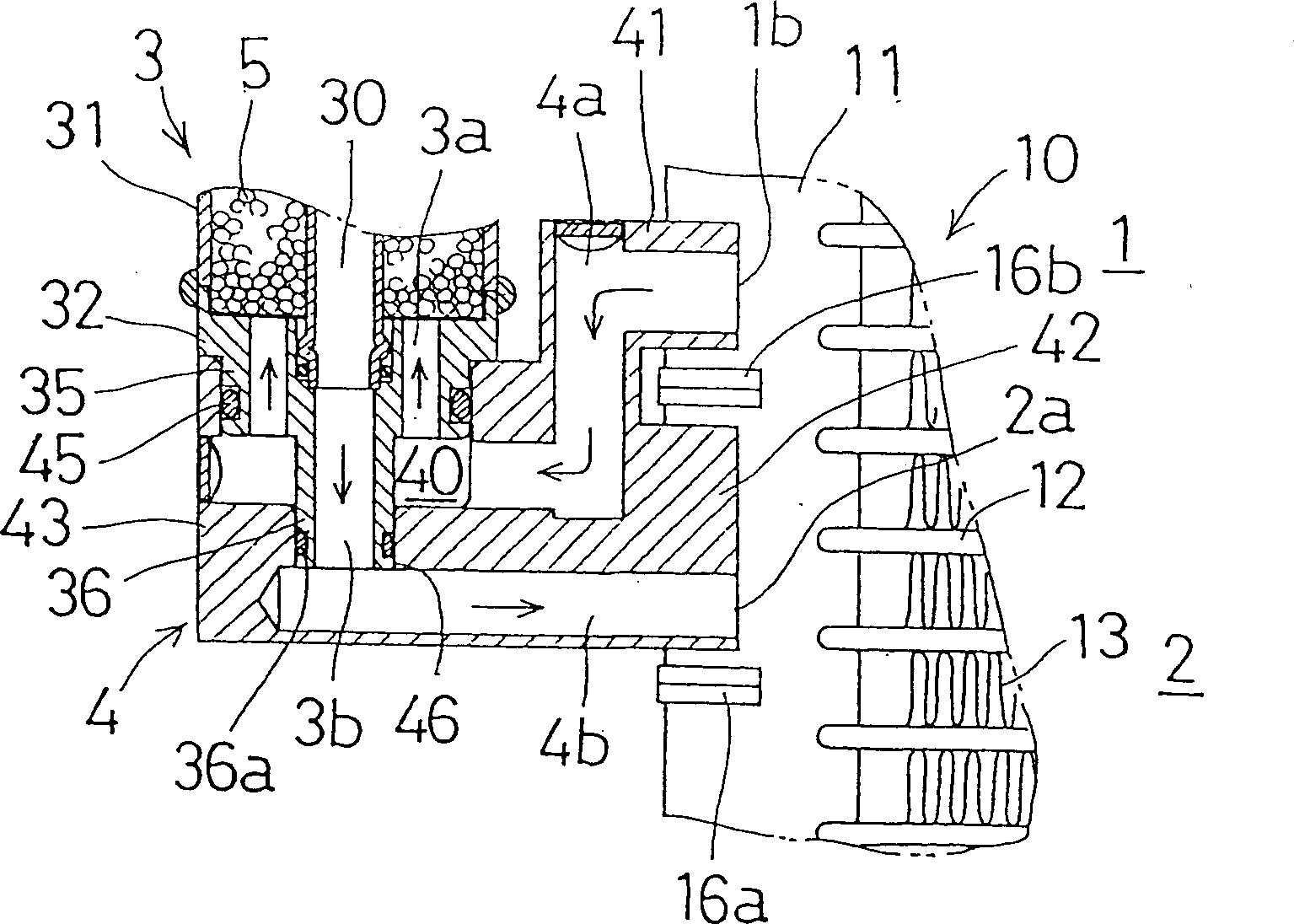

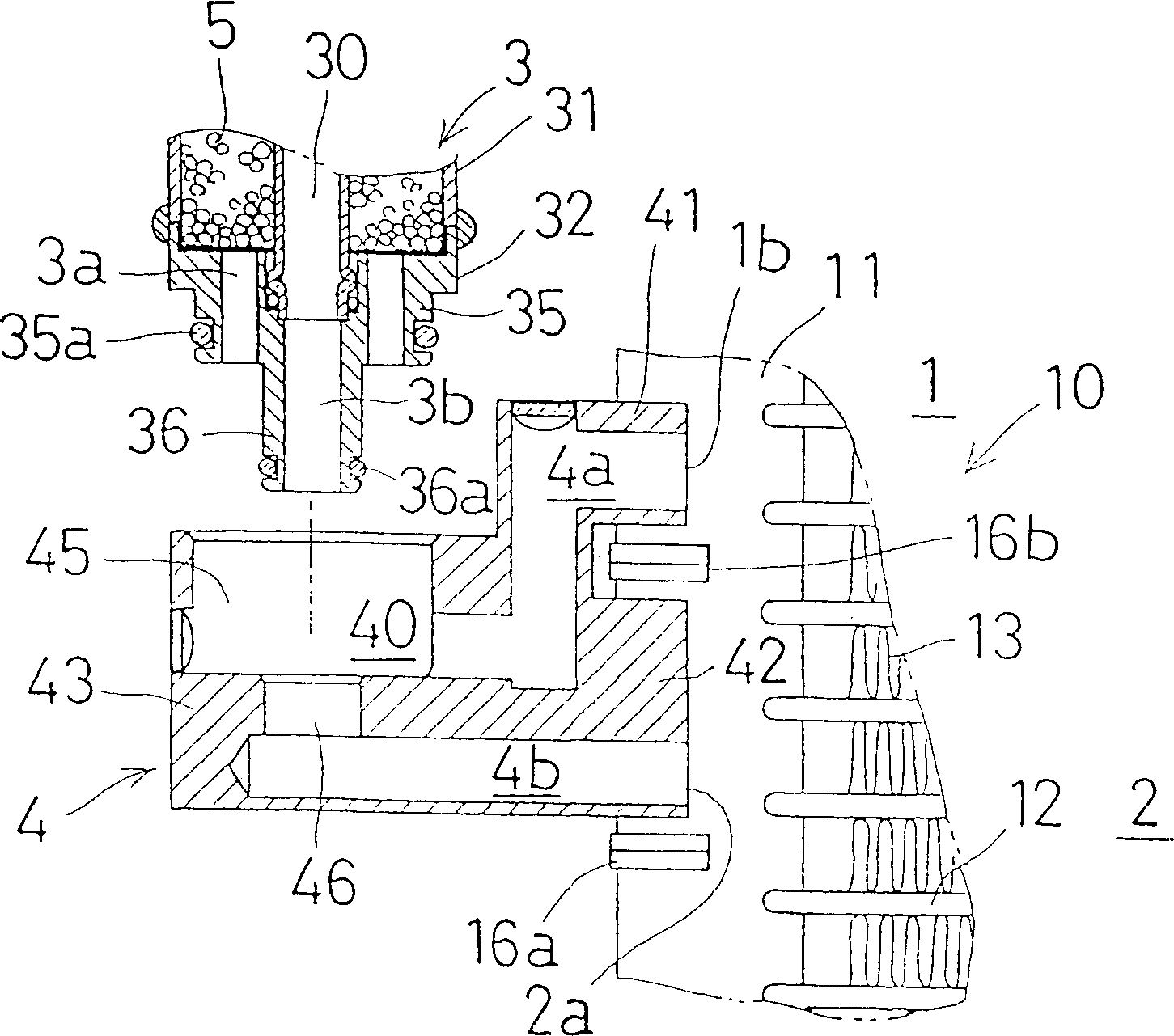

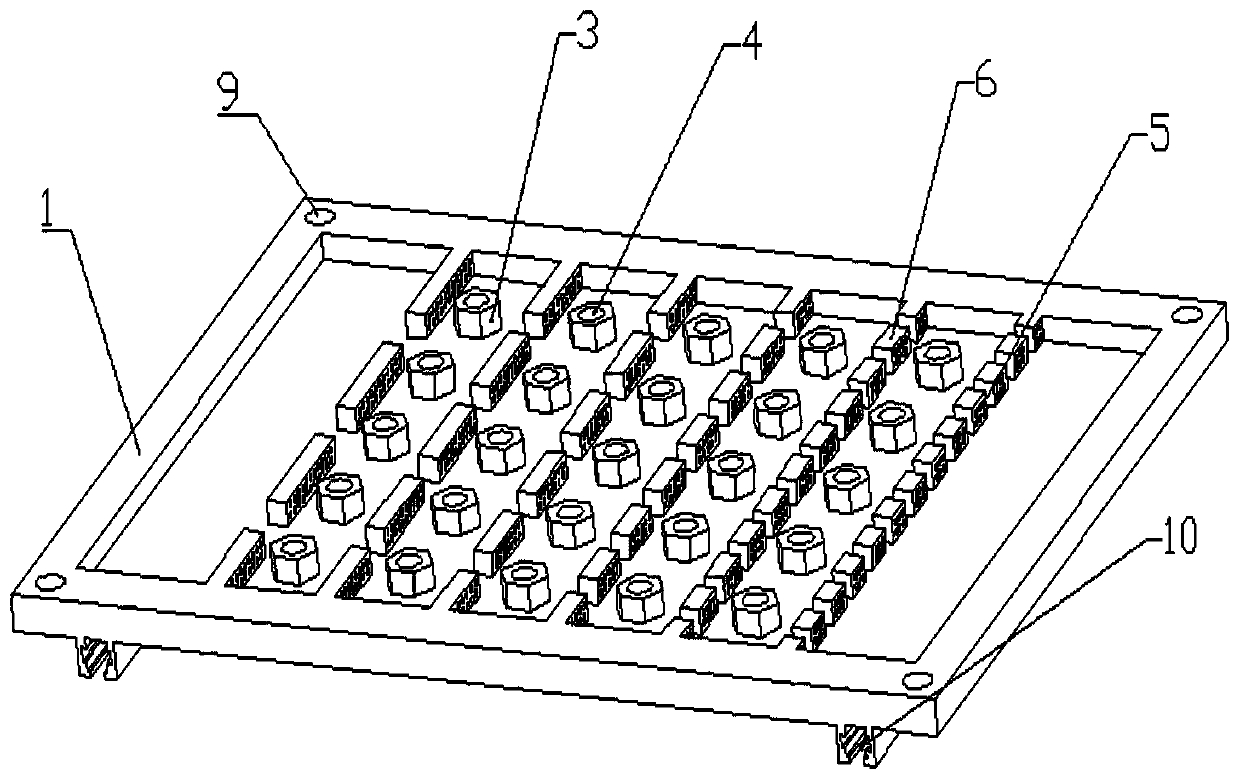

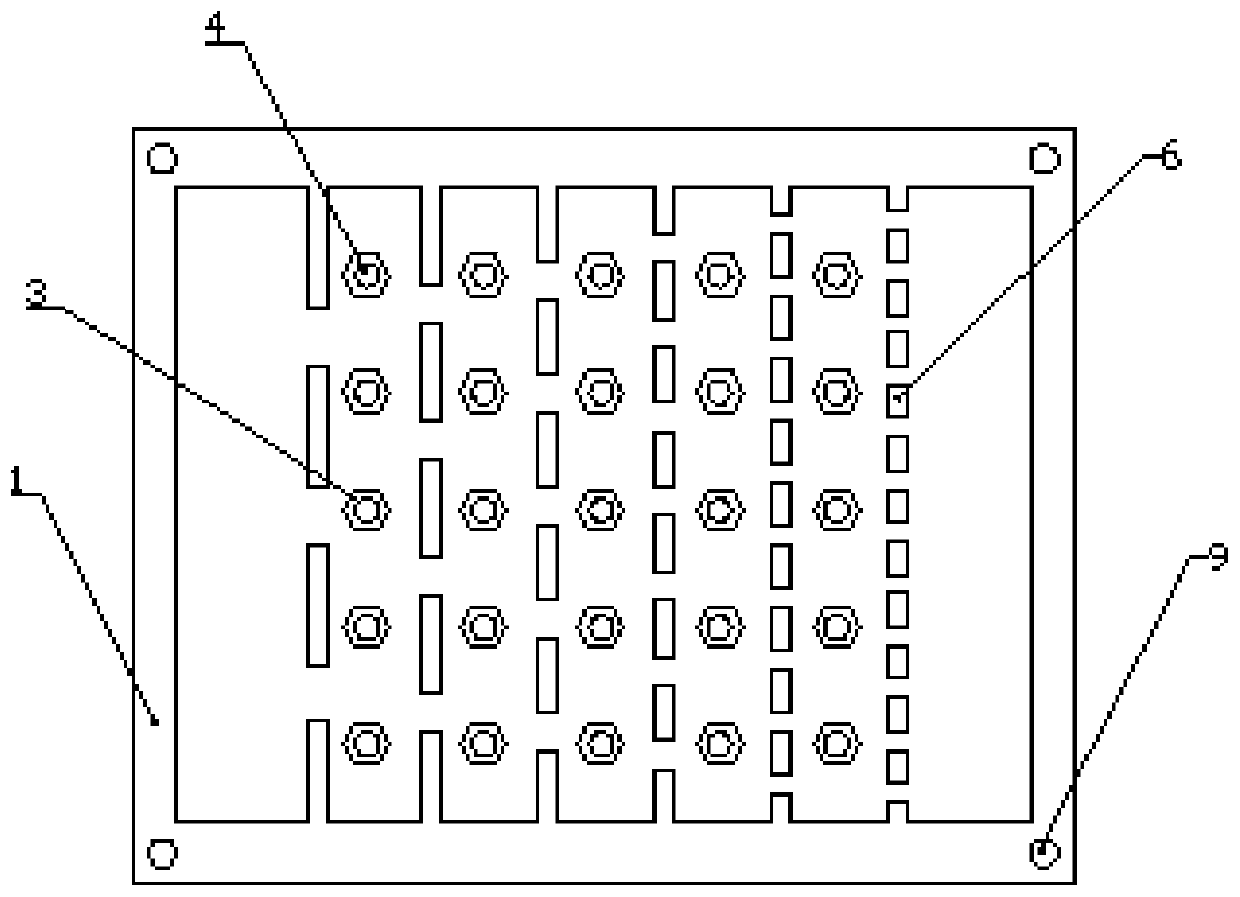

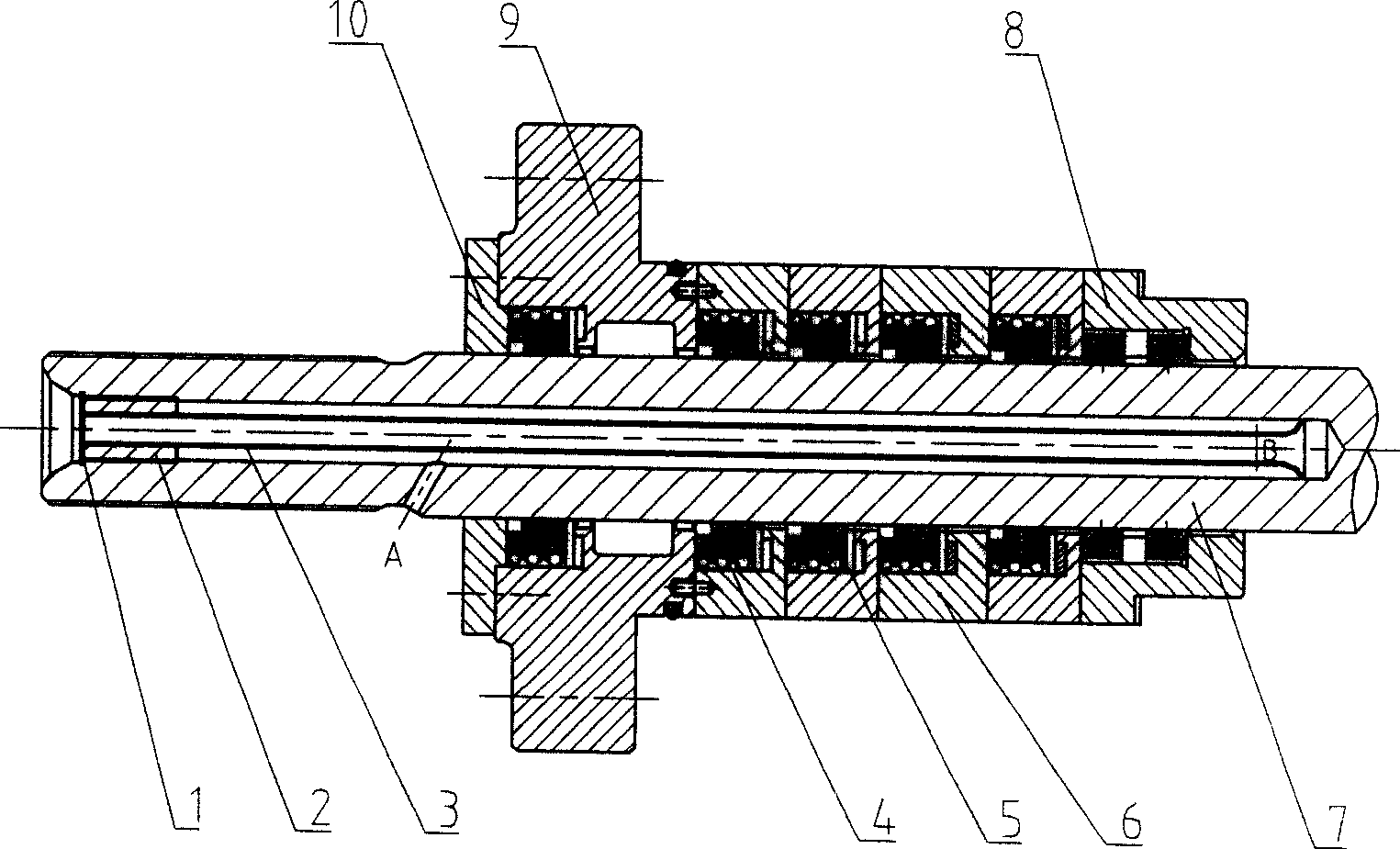

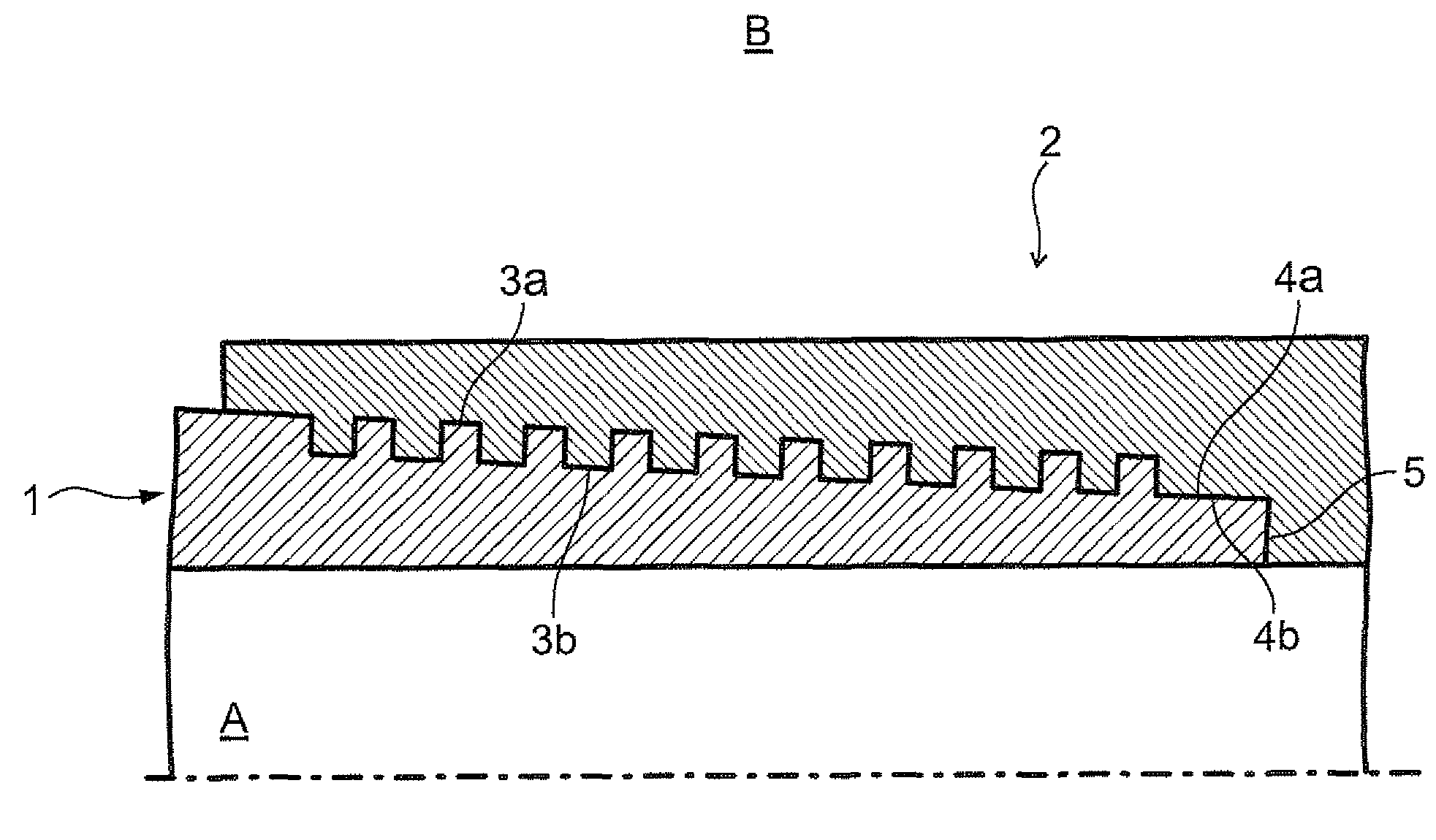

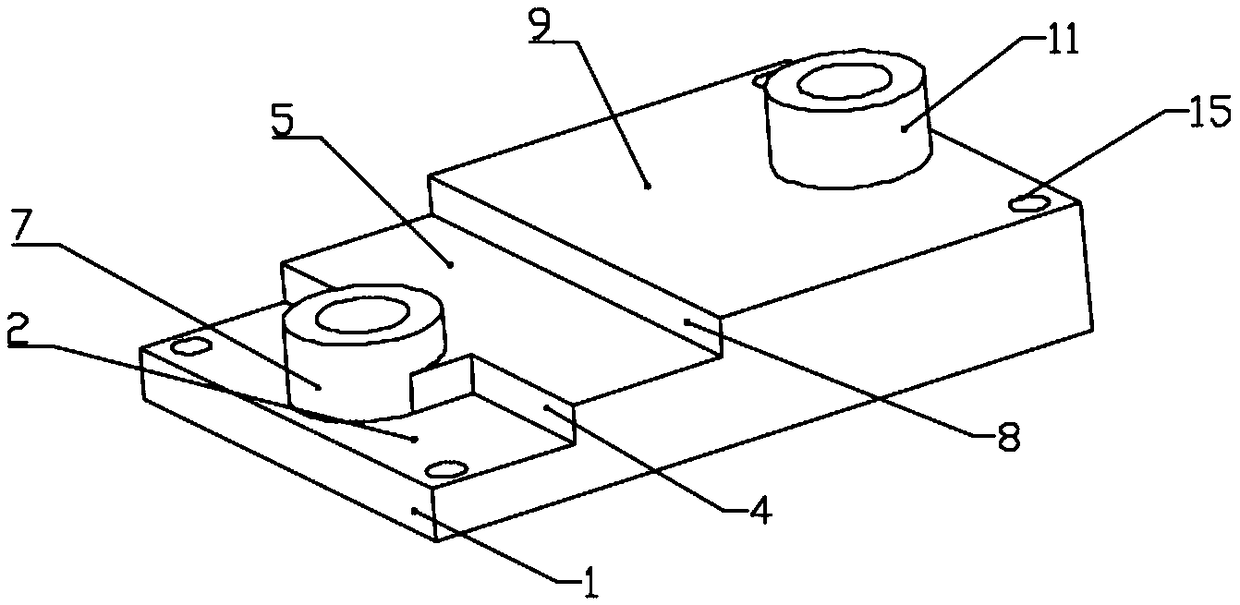

Fluid control apparatus

InactiveUS6868867B2Reduce in quantityEasy to disassembleServomotor componentsSemiconductor/solid-state device manufacturingFluid controlCoupling

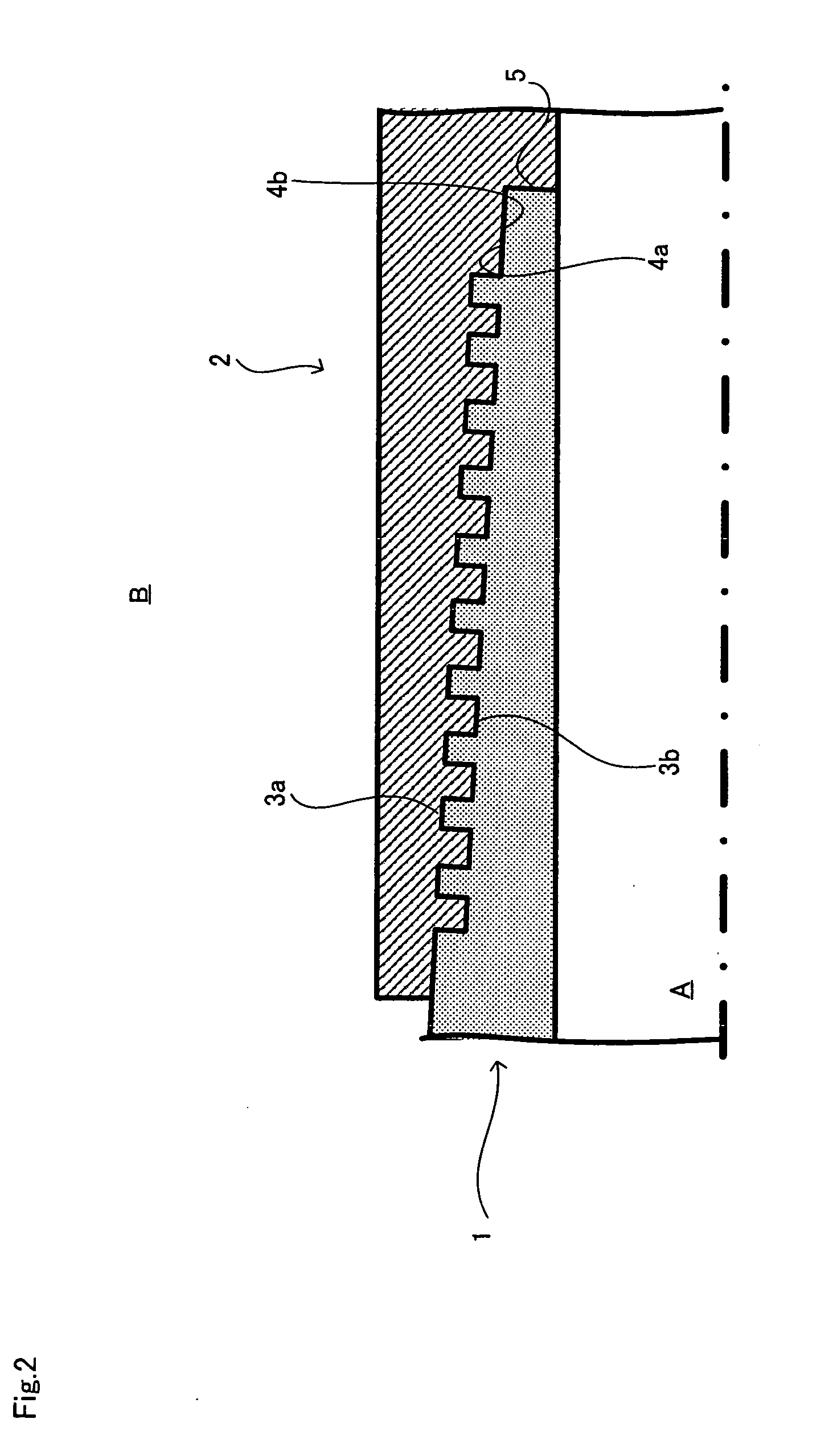

A connecting layer for interconnecting fluid control devices in series and in parallel comprises an upper connecting layer 4 and a lower connecting layer 5. The upper connecting layer 4 is provided by parallel rows each comprising block couplings 41, 42, 43, 44 arranged longitudinally of the apparatus, each of the block couplings having a longitudinal channel 61 for interconnecting the adjacent fluid control devices in the row and a through channel 62 communicating with the fluid control device. The lower connecting layer 5 is provided by block coupling 56, 57, 58 each having a lateral channel 64 for interconnecting the through channels 62 of the block couplings 41, 42, 43, 44 of the upper connecting layer 4 which are arranged laterally and by block couplings 51 each adapted to cause the through channel 62 of the block coupling 41, 43, 44 of the upper connecting layer 4 to communicate with an inlet-side or outlet-side coupling 52, 53. The couplings 51, 56, 57, 58 of the lower connecting layer 5 are attached to a base plate 2 with screws from above, and the couplings 41, 42, 43, 44 of the upper connecting layer 4 are attached to the couplings 51, 56, 57, 58 of the lower connecting layer 5 with screws form above.

Owner:FUJIKIN INC

Screw Joint for Steel Pipe and Process for Manufacturing Thereof

A threaded joint for a steel pipe comprises a pin and a box with a contact surface having a threaded part and a unthreaded metal contact part, wherein a solid lubricating film containing one or more kinds of lubricating powders selected from graphite, mica, calcium carbonate and kaolin, a copper powder, and a binder is formed on at least one contact surface of the pin and the box.An object of the present invention is to provide a threaded joint for a steel pipe which allows for repeated fastening and loosening of a threaded joint without adversely influencing on a human body and environment, and is excellent in galling resistance, rust preventing property and gas tightness.

Owner:VALLOUREC OIL & GAS FRANCE SAS

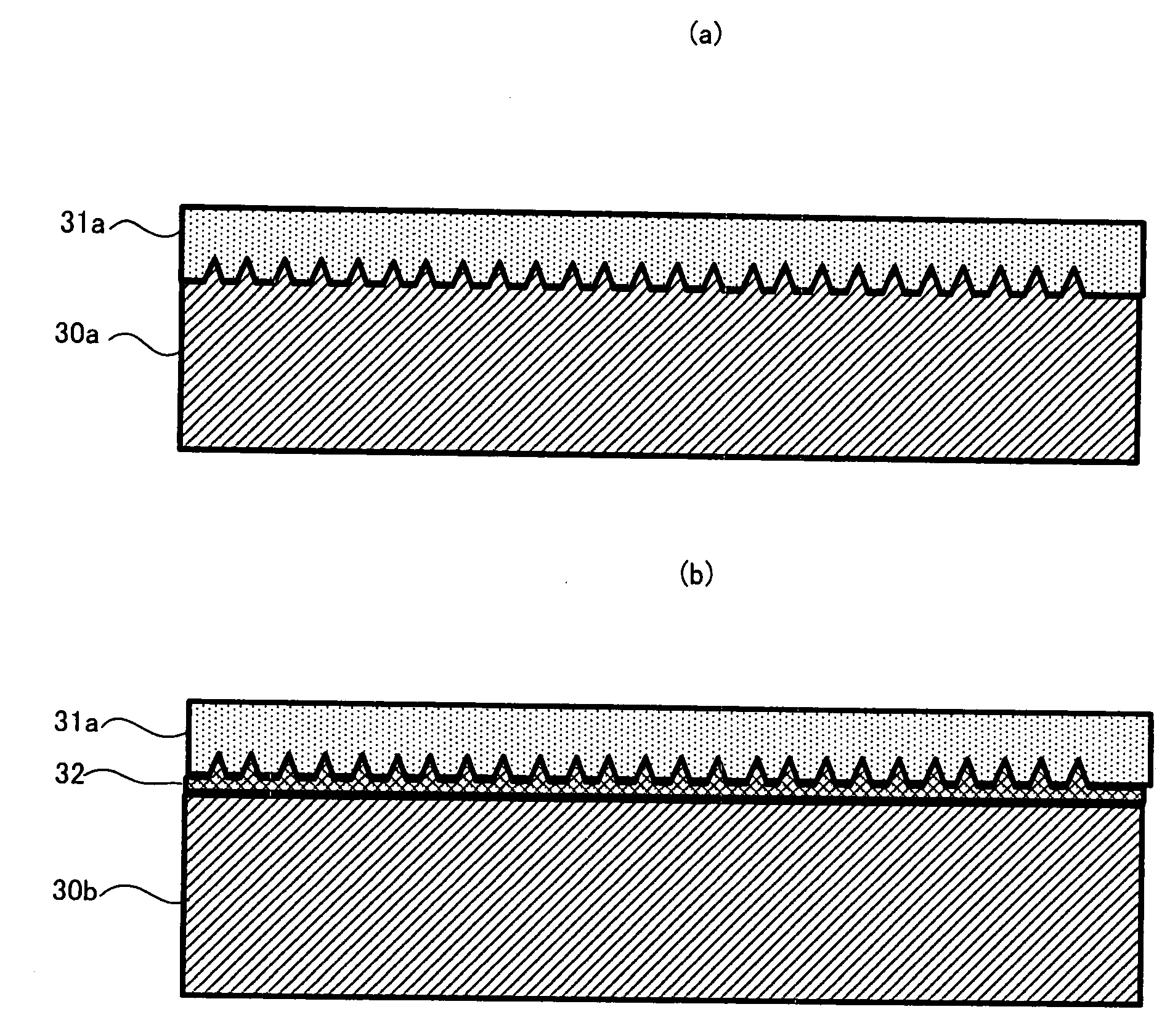

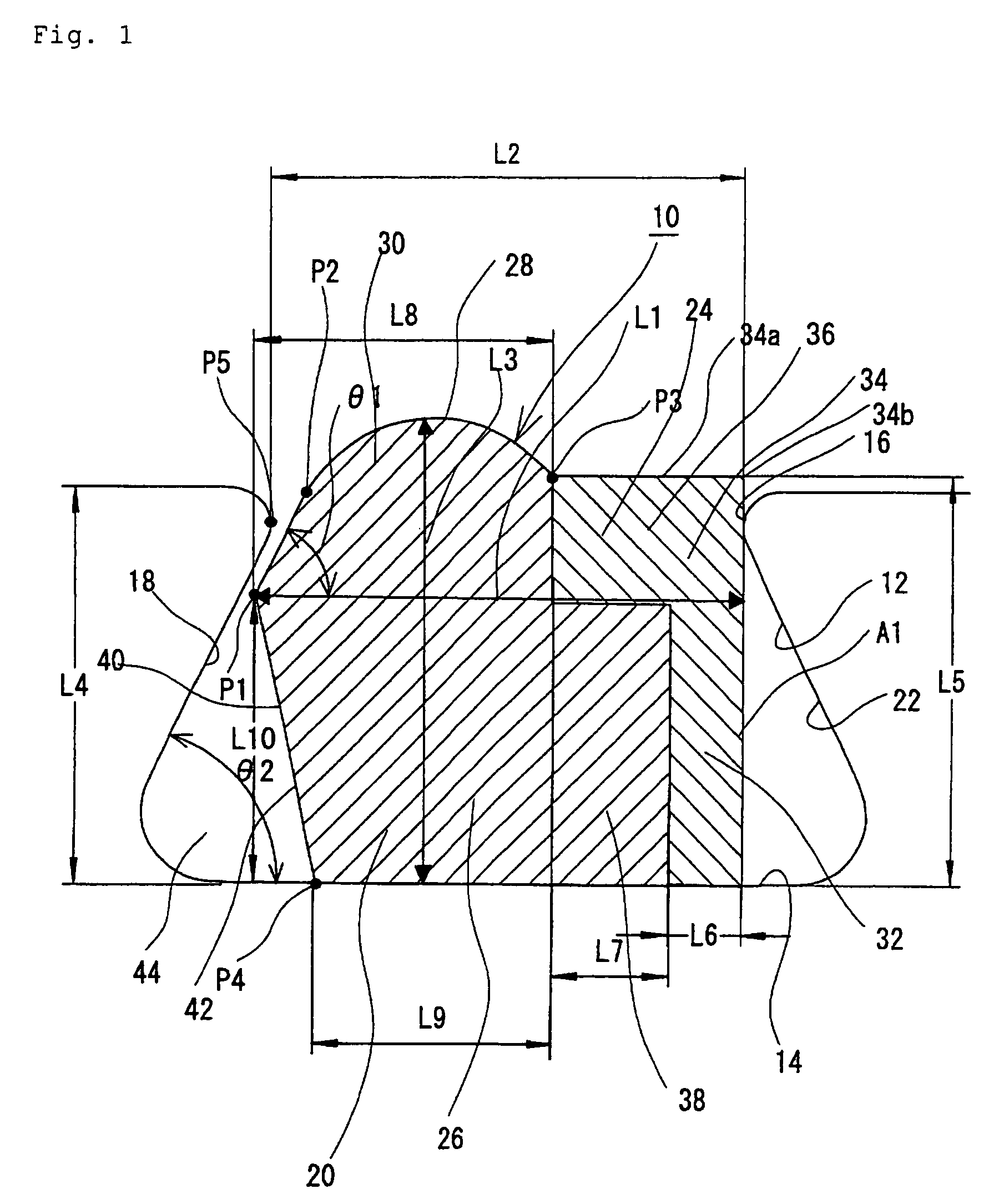

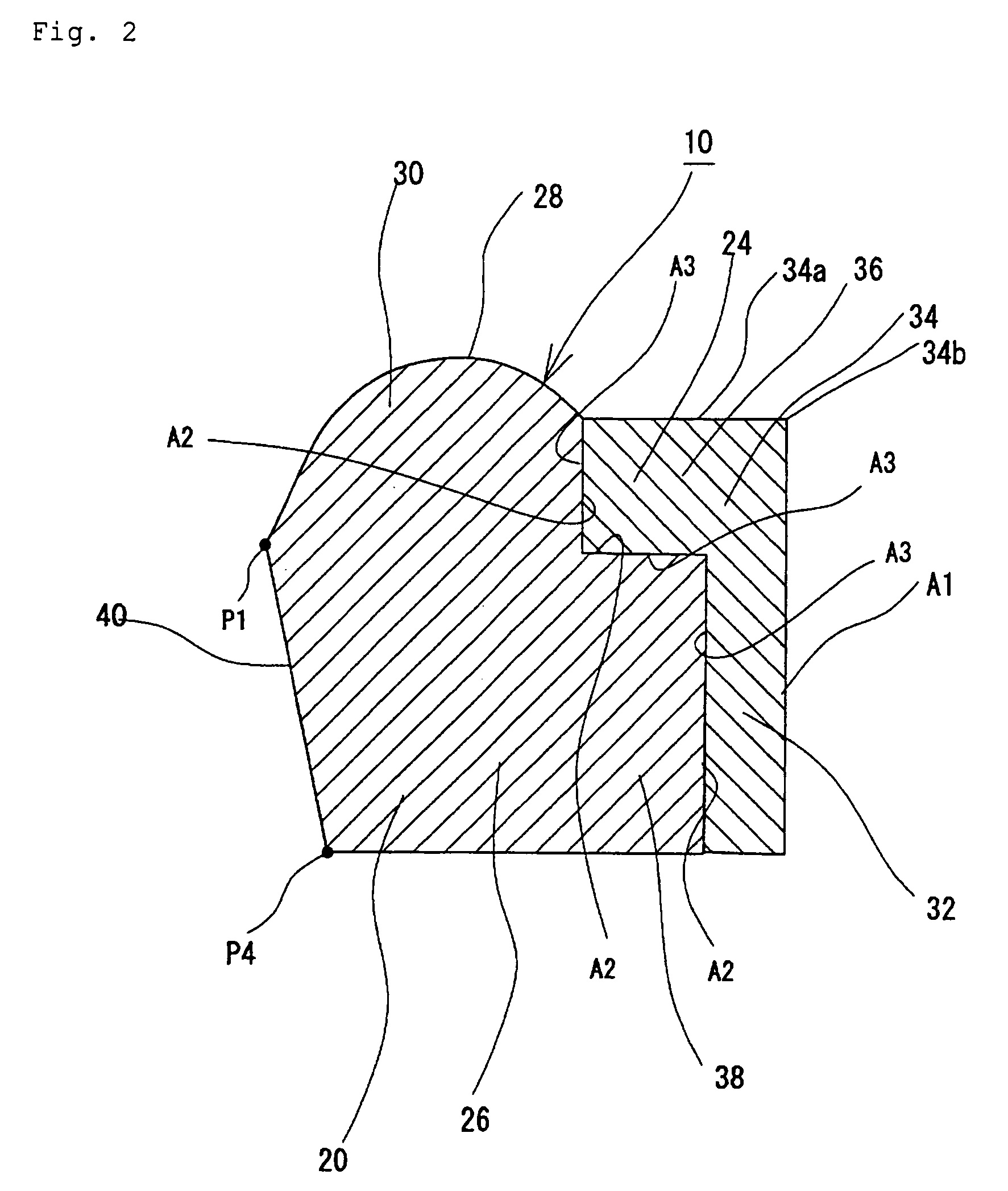

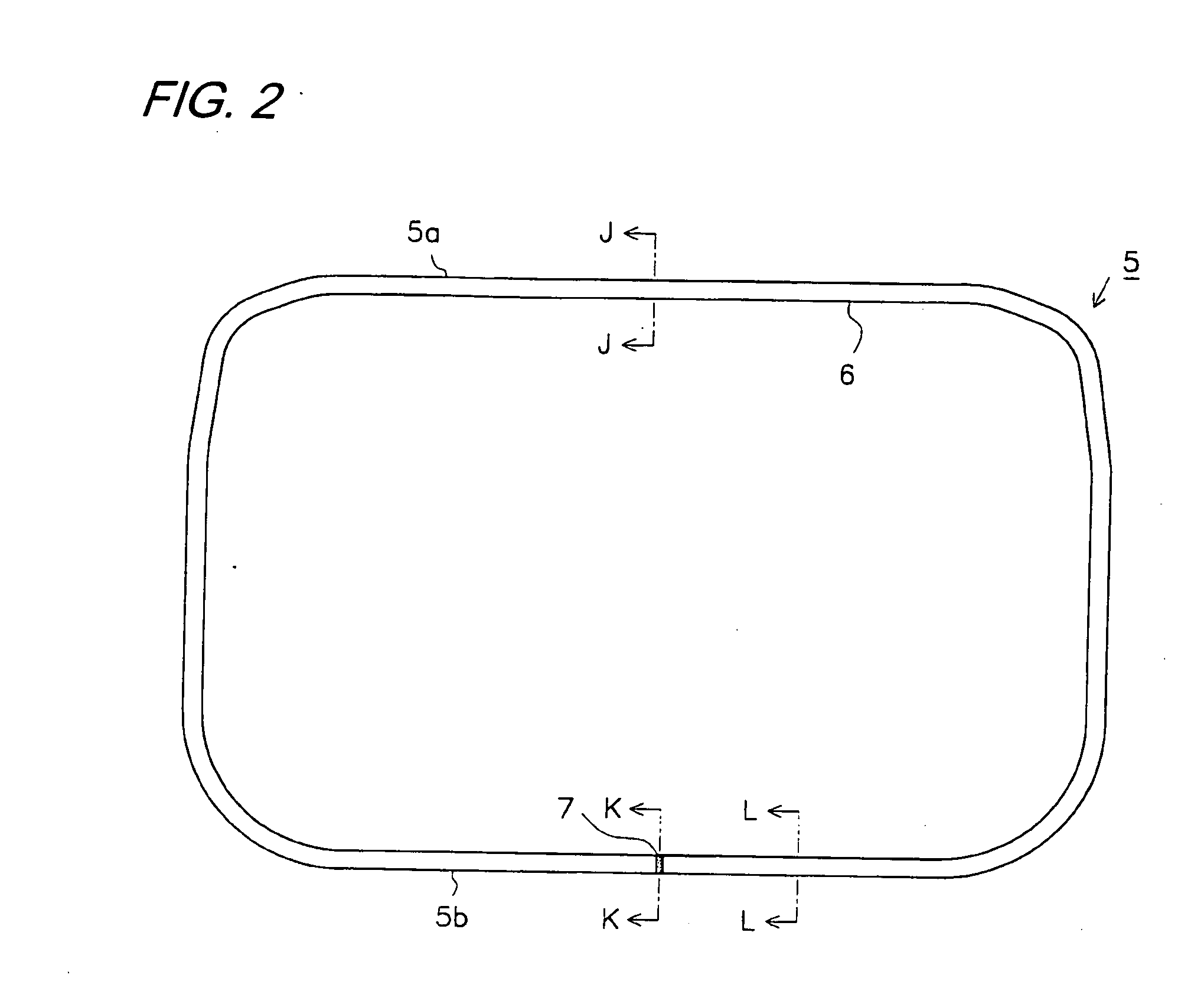

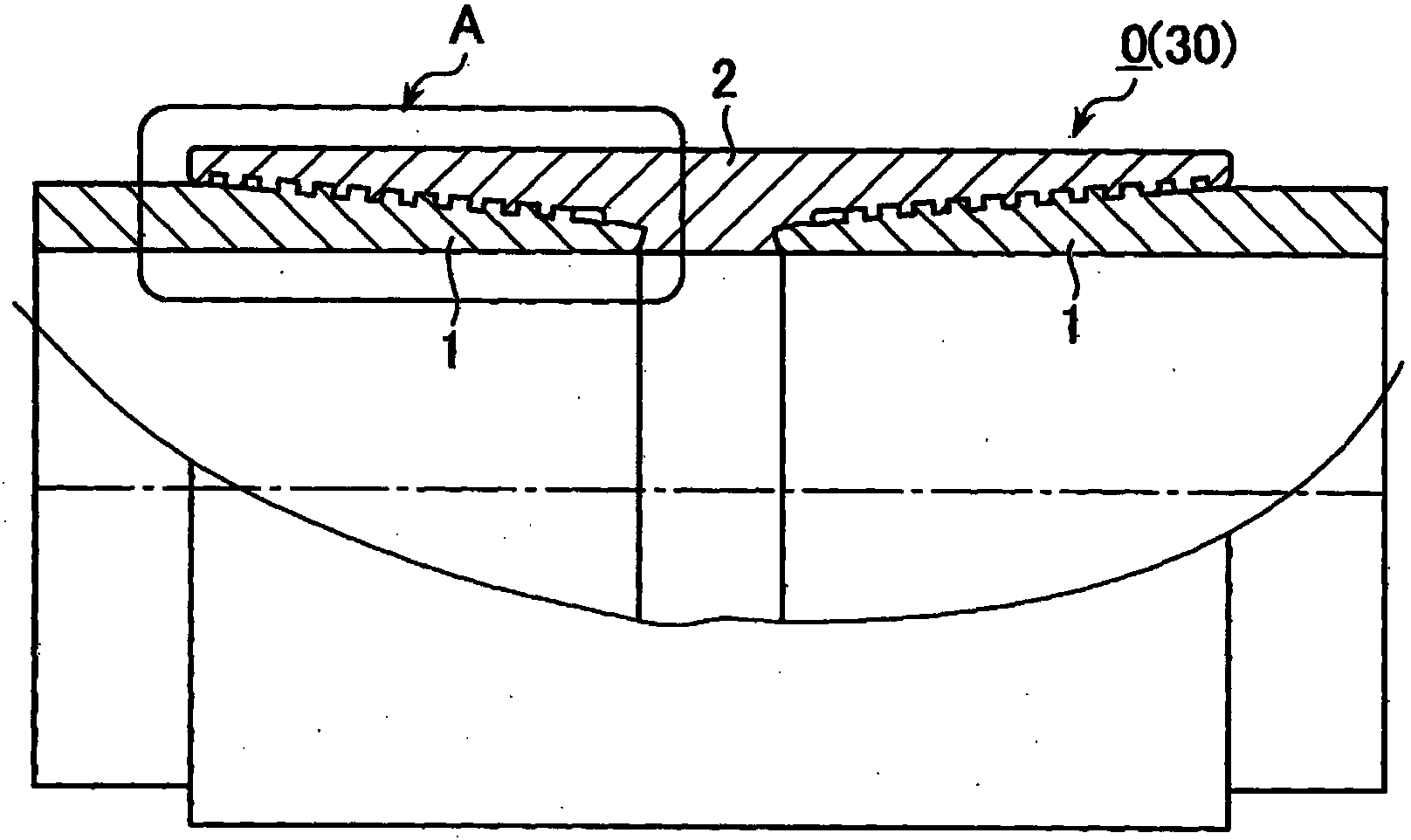

Metal gasket

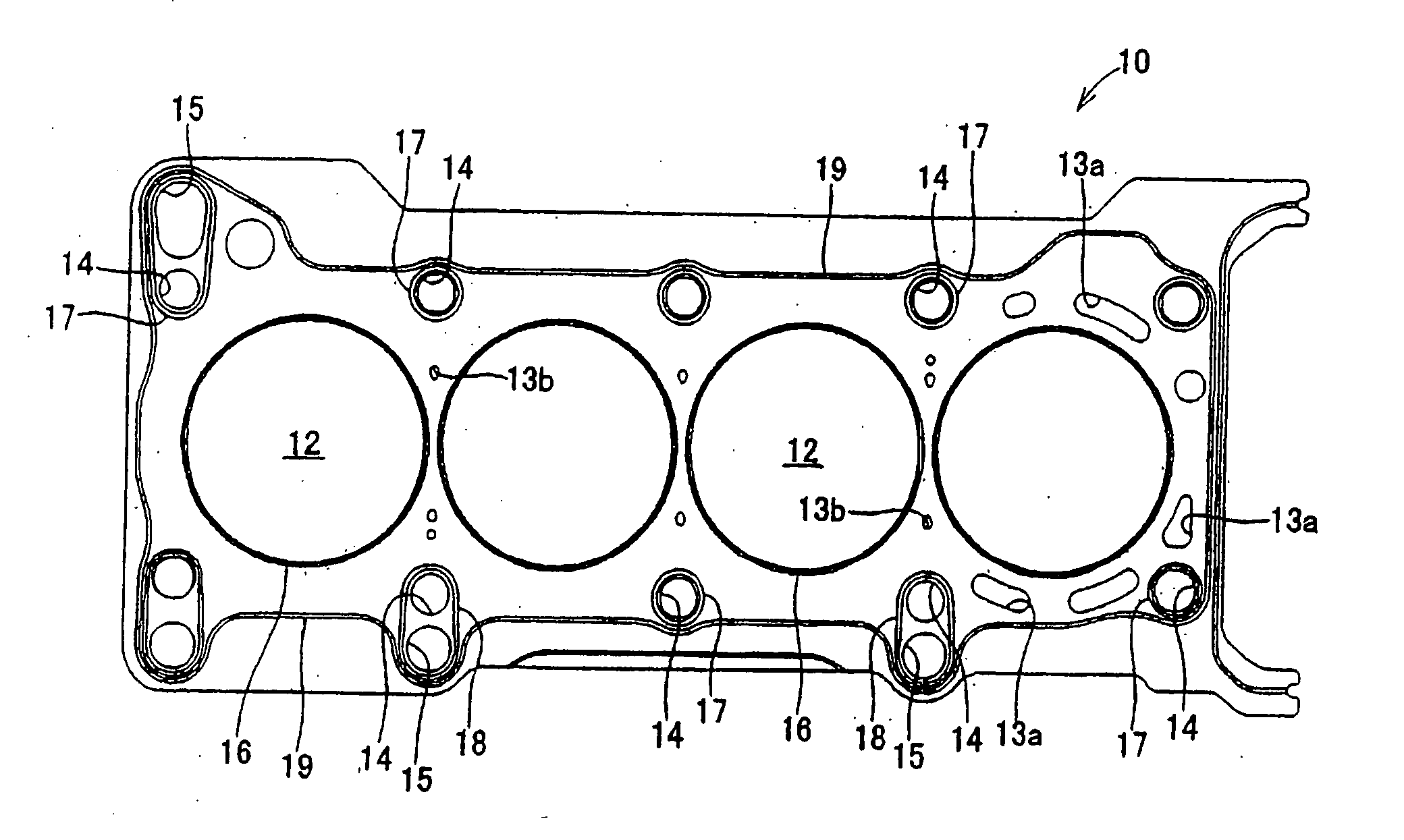

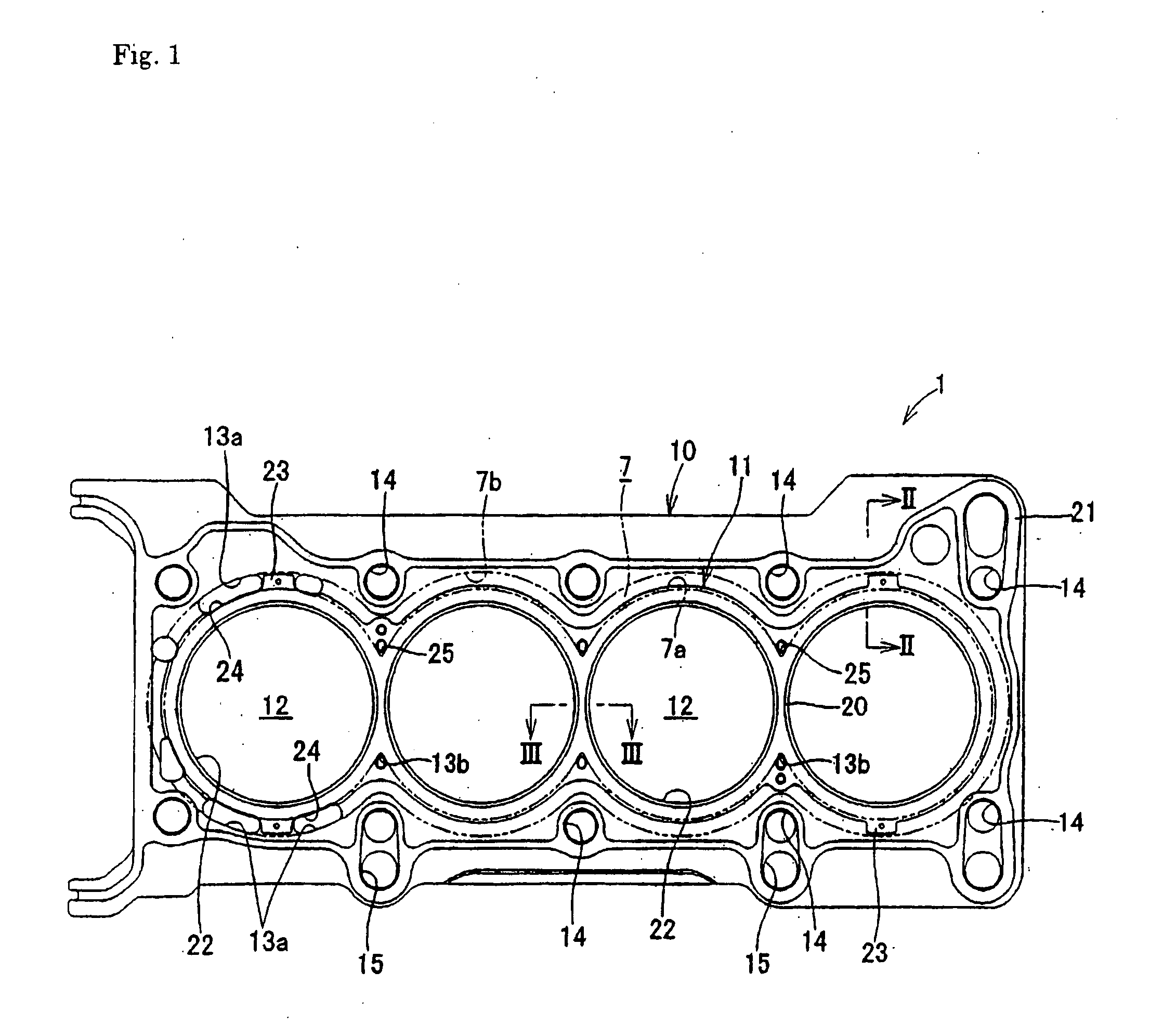

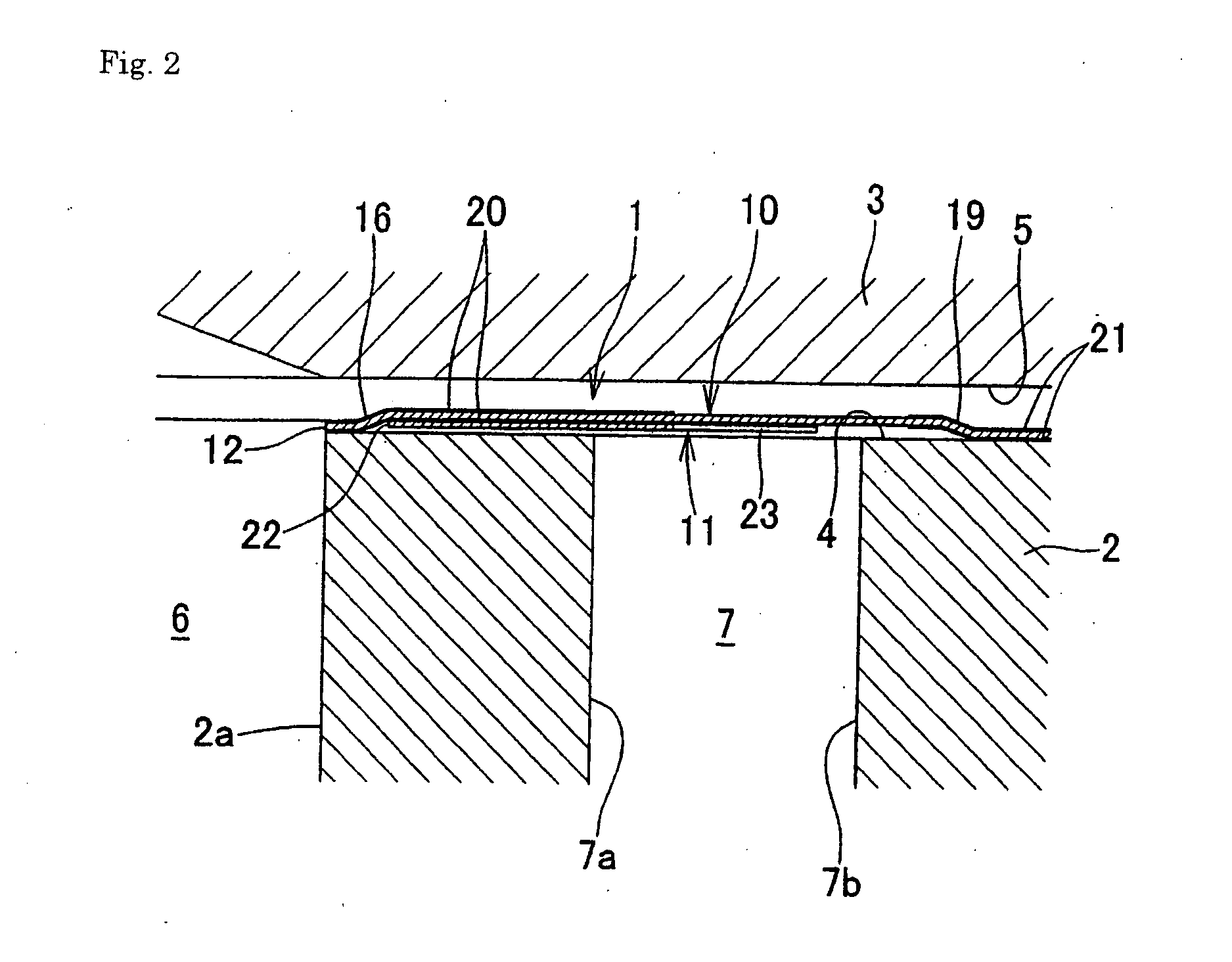

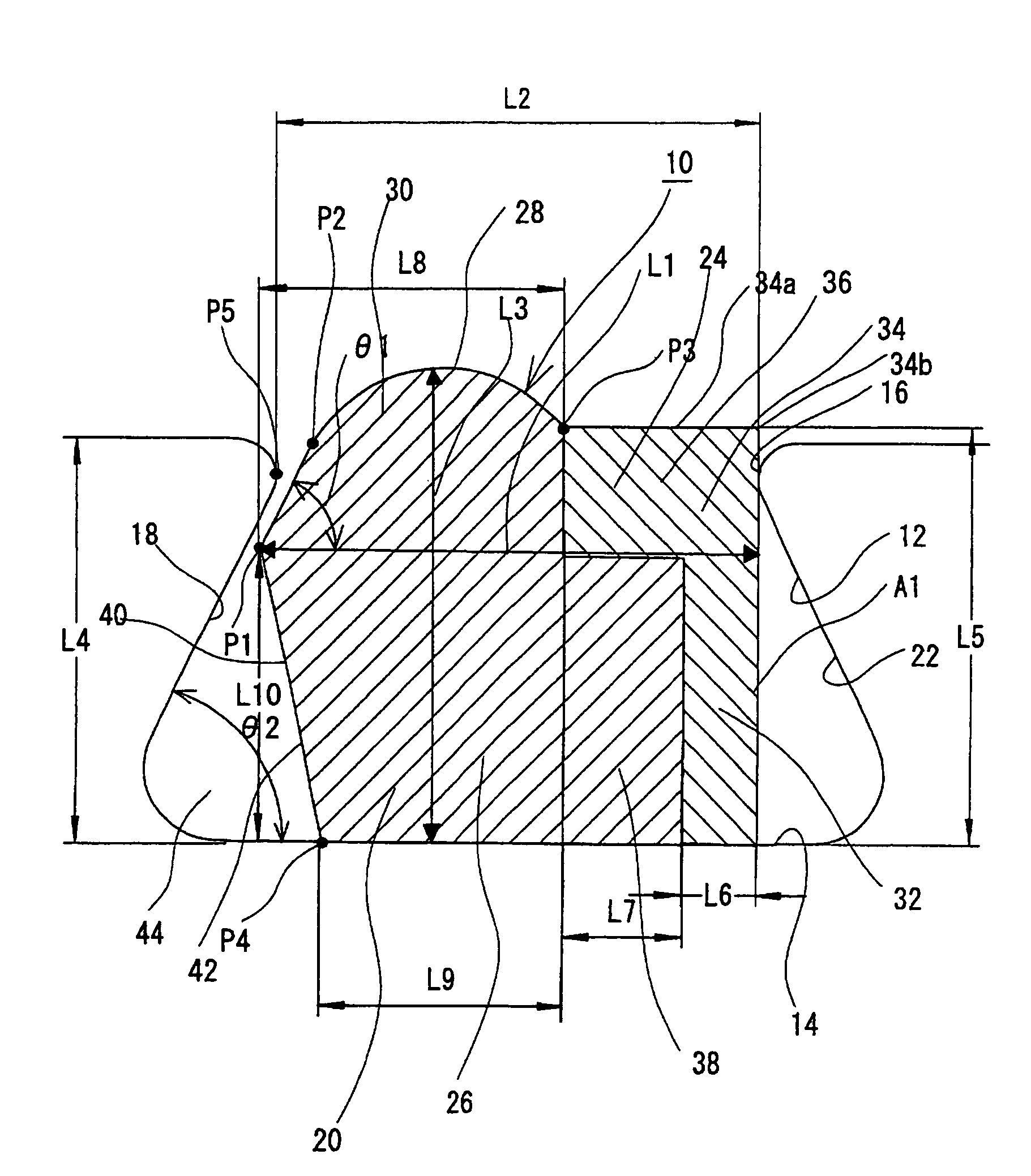

InactiveUS20080023922A1Improve sealingUniform surface pressureEngine sealsSealing arrangements for enginesCombustion chamberEngineering

To provide a metal gasket that can be manufactured at an inexpensive cost and provides sufficient sealing performance around a combustion chamber while preventing a bore bead from fully bending. A metal gasket 1 is constructed from one or more gasket component sheets 10 with an opening 12 formed at a position corresponding to a combustion chamber 6 of an engine, and at least one gasket component sheet 10 has a bore bead 16 formed so as to surround the opening 12. In this metal gasket, a shim sheet 11 for controlling the full bending of the bore bead 16 is fixed to the gasket component sheet 10 in an area between the outer peripheral edge of the bore bead 16 and the inner periphery 7a of a water jacket 7 formed on a cylinder block 2 of the engine.

Owner:KOKUSAN BUHIN INDS

Timed passive air sampler

ActiveCN103033398AGuaranteed tensionAvoid contactWithdrawing sample devicesAutomatic controlEngineering

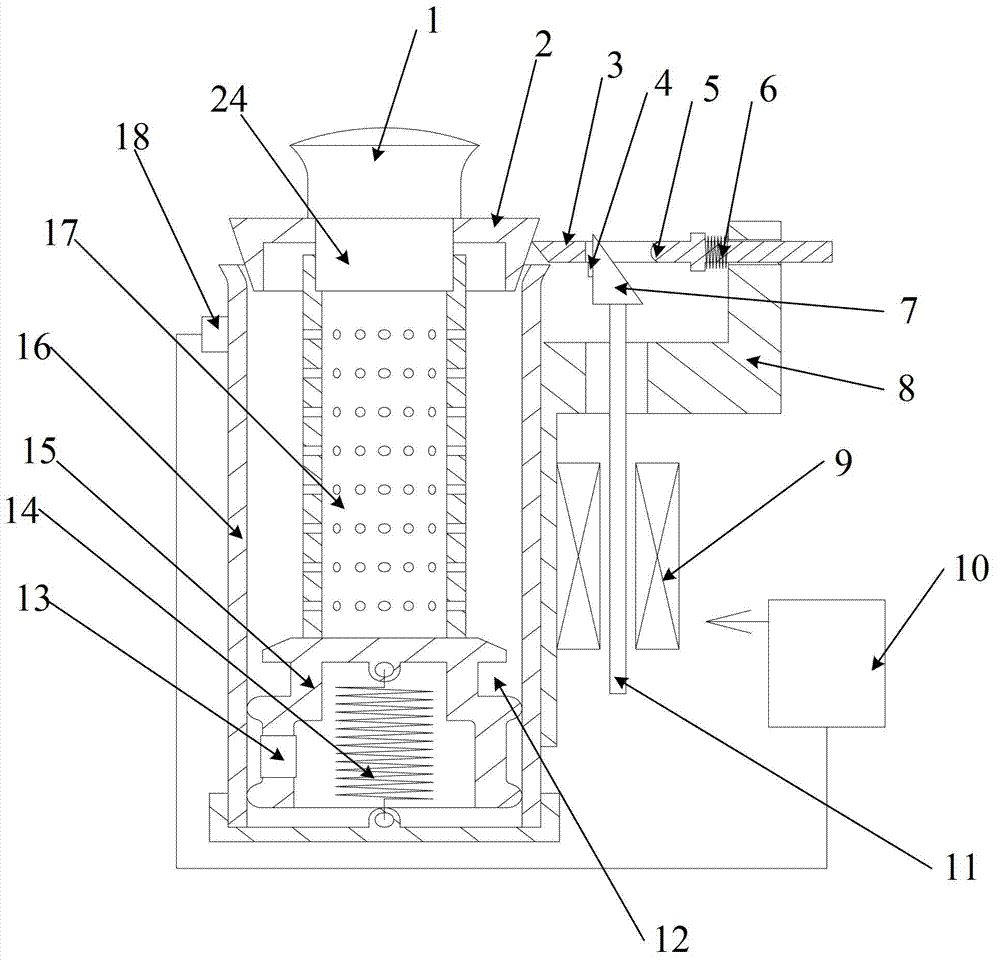

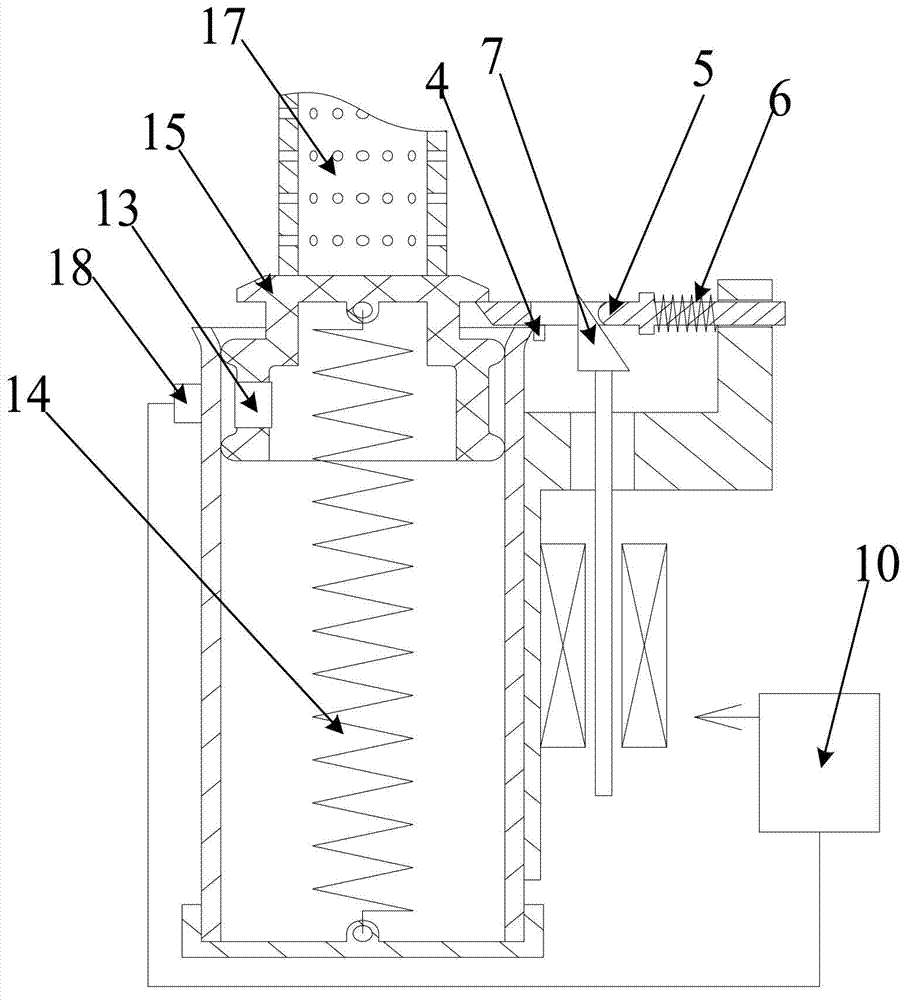

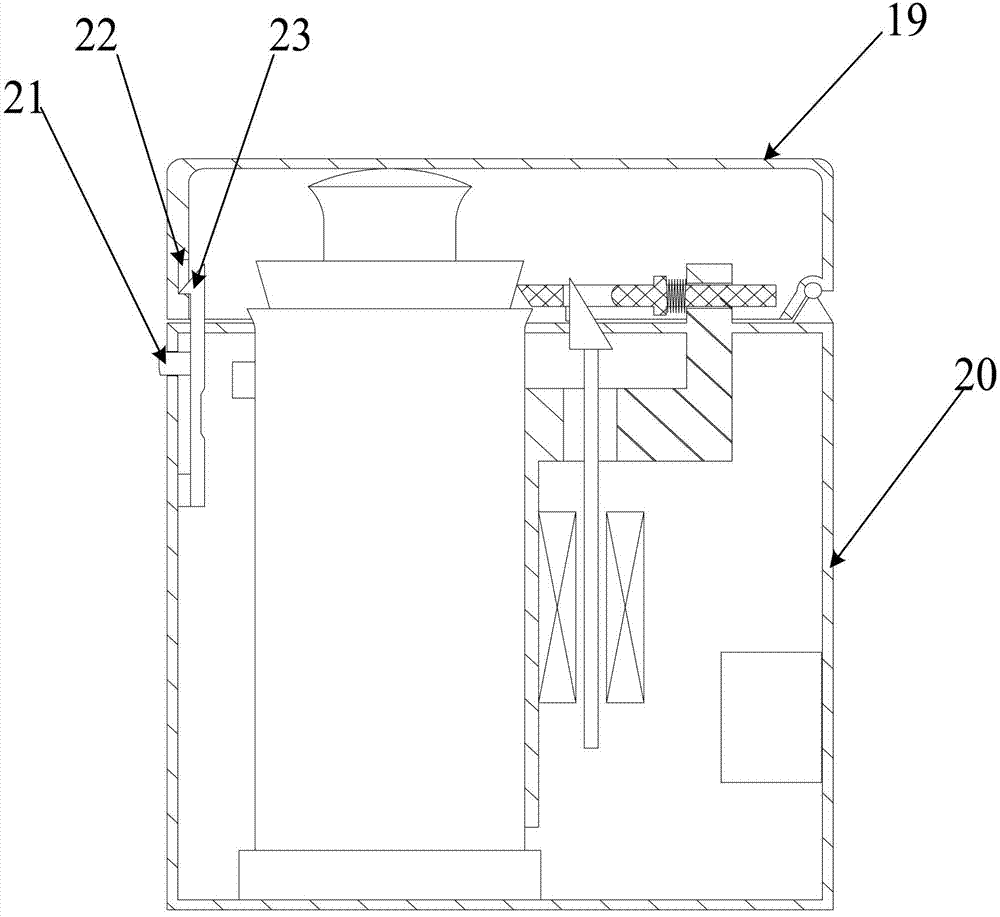

The invention discloses a timed passive air sampler, which comprises an air sampler main body, wherein the air sampler main body comprises a packaging barrel with an opening at the top, an adsorbent cage which is sheathed in the packaging barrel, a blocking pillar, an electromagnet and a timing driving circuit; a timing beginning sensor and a mounting bracket are arranged on the side wall of the packaging barrel; a rubber plug matched with the top of the packaging barrel is arranged at the top end of the adsorbent cage; a return spring is arranged between the bottom of the adsorbent cage and the bottom of the packaging barrel; a bayonet which can be pulled out to expose the packaging barrel and a sensing body corresponding to the timing beginning sensor are arranged on the adsorbent barrel; the blocking pillar is arranged on the mounting bracket and can move in the radial direction of the packaging barrel and be matched with the bayonet; the electromagnet is arranged on the outer wall of the bracket of the packaging barrel and can control the blocking pillar to be departed from the bayonet; and the timing driving circuit is connected with the timing beginning sensor and the electromagnet. The timed passive air sampler can implement the accurate automatic control of the sampling time, automatic packaging, and effectively improve the sampling accuracy of the passive air sampler.

Owner:SHENZHEN INST OF BUILDING RES

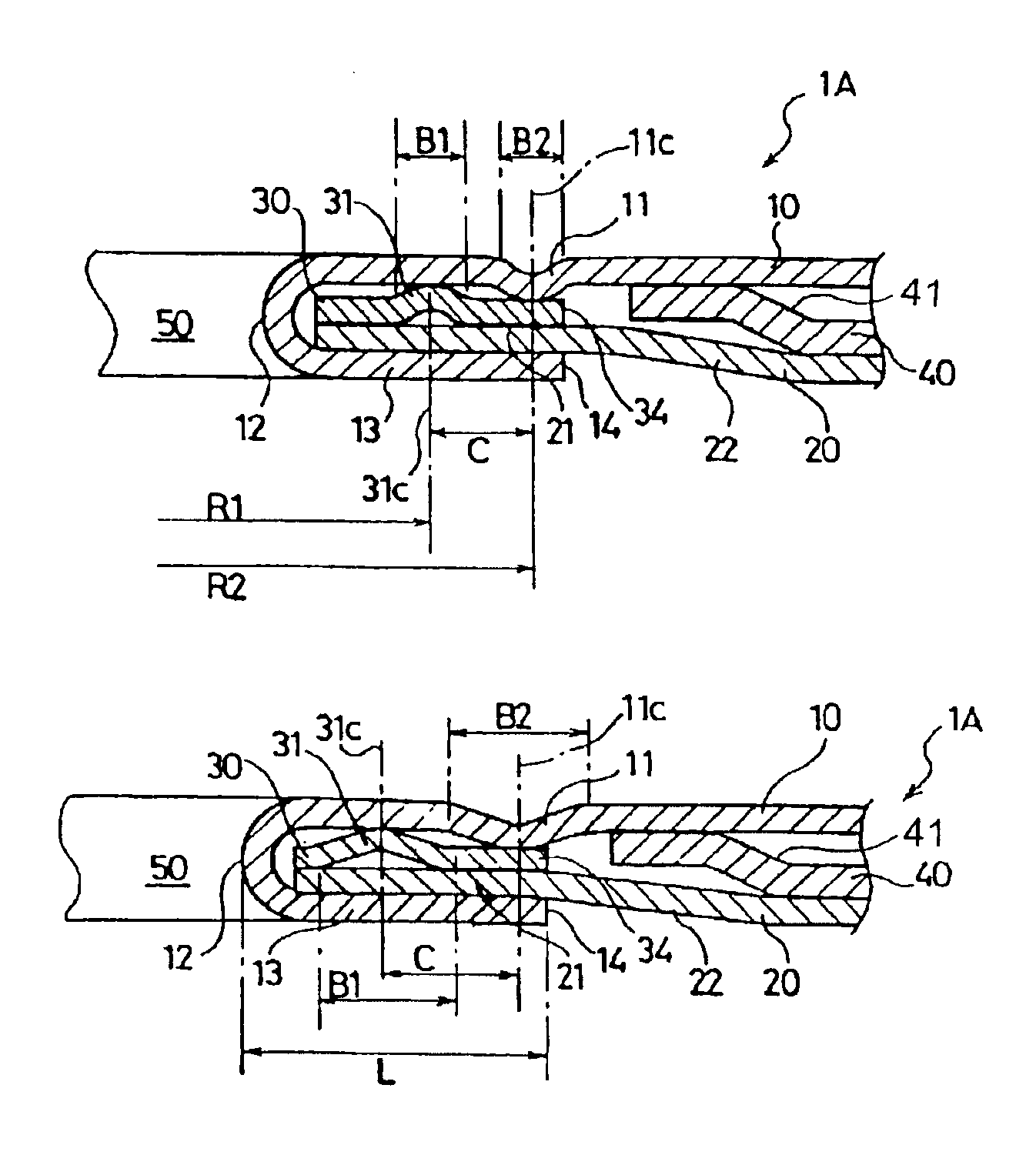

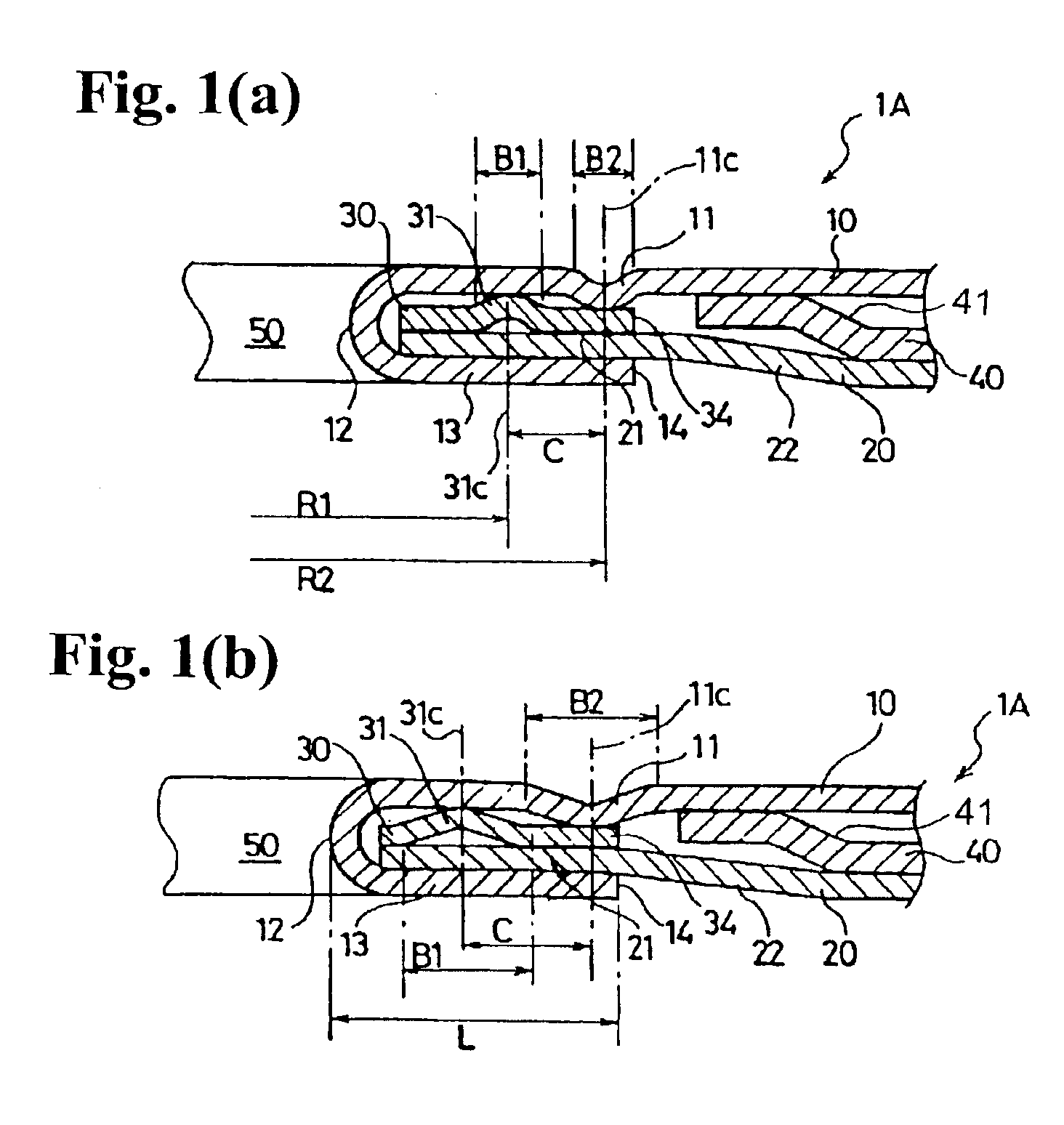

Composite sealing material

ActiveUS7866669B2Easy to manufactureAvoid tightnessEngine sealsFluid pressure sealed jointsEngineeringMechanical engineering

Owner:VALQUA LTD

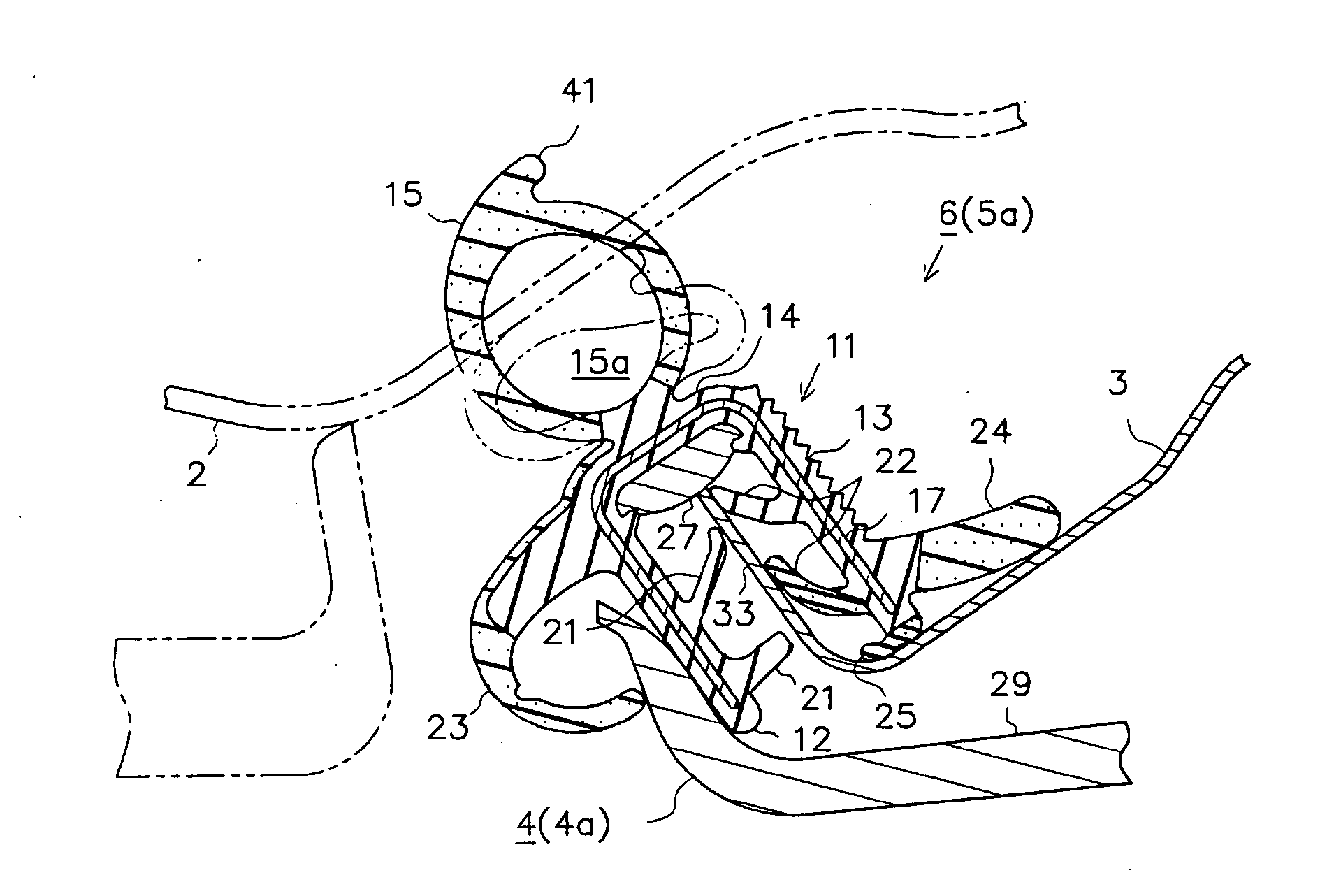

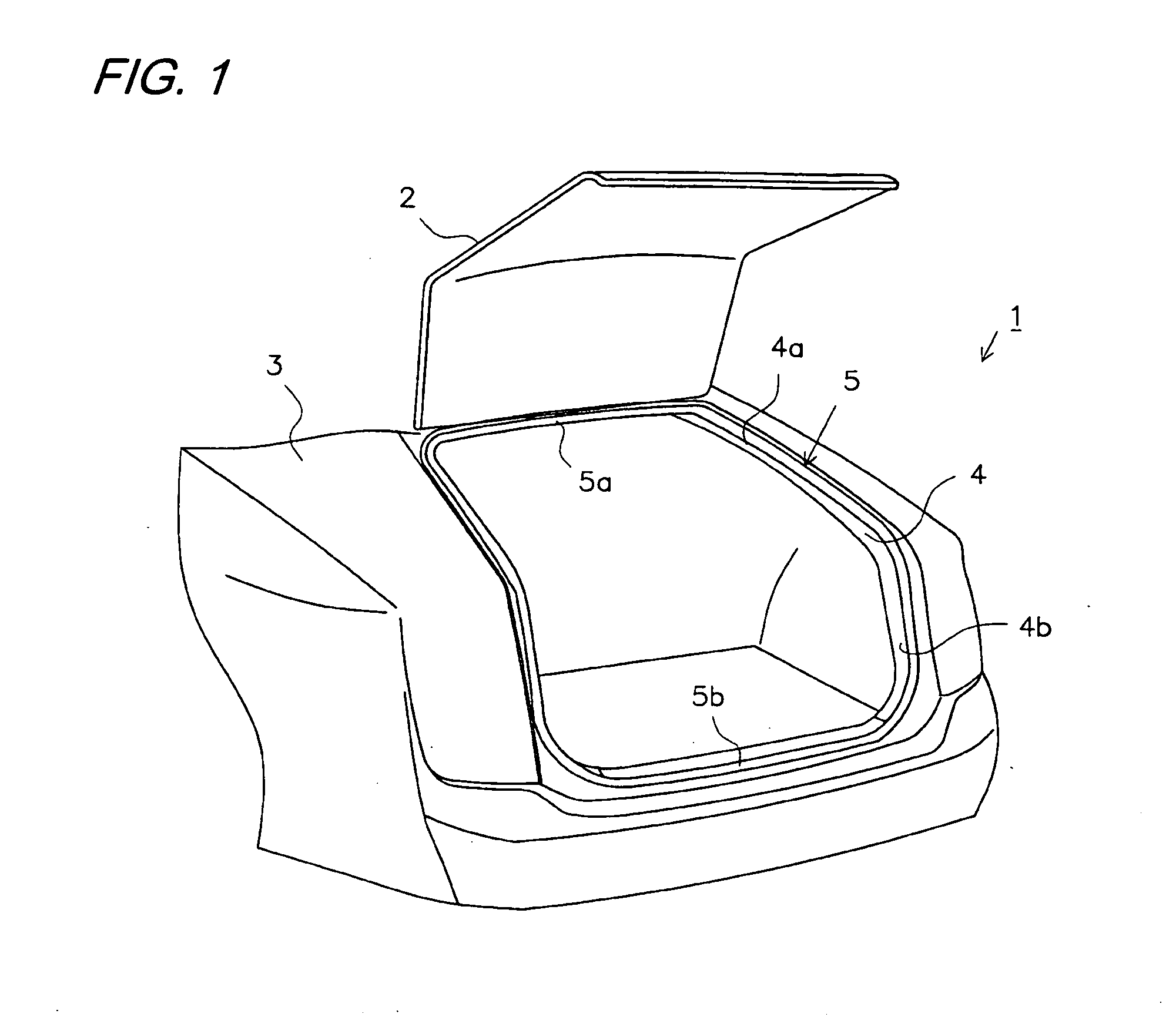

Weather strip and production method thereof

InactiveUS20120240473A1Improve appearance qualityAvoid tightnessCeramic shaping apparatusSealing arrangementsEngineeringMechanical engineering

A weather strip includes an extrusion molded extrusion molded portion, an injection molded portion which connects both ends of the extrusion molded portions in a straight line shape, a trim portion which is mounted on a circumferential edge of an opening of a luggage compartment, and a hollow sealing portion which protrudes from the trim portion. The injection molded portion is formed such that a width thereof is 2.0. The hollow sealing portion is provided with a core withdrawing hole, through which a core mold forming an inner peripheral surface of the hollow sealing portion is withdrawn after formation. The core withdrawing hole is formed such that a length thereof along a circumferential direction of the inner peripheral surface of the hollow sealing portion is 40% of a circumferential length of the inner peripheral surface.

Owner:TOYODA GOSEI CO LTD

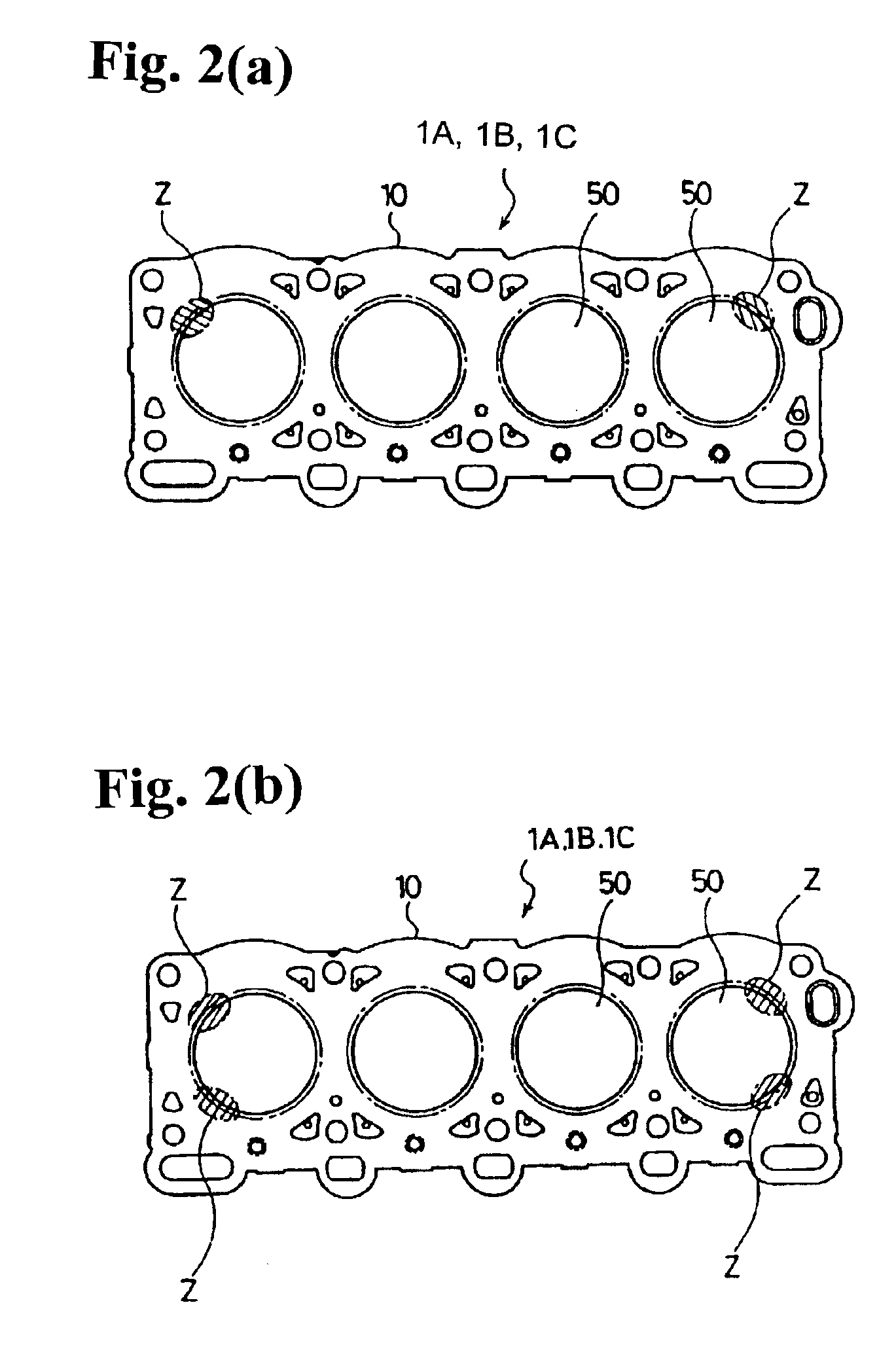

Cylinder head gasket

InactiveUS6851677B2Increase of bead widthReduce in quantityEngine sealsSealing arrangements for enginesSurface pressureHeat load

A cylinder head gasket for an internal combustion engine includes a first metal plate having first holes and first beads formed around the respective first holes, and a second metal plate disposed under the first metal plate and having a second bead extending toward the first metal plate. A distance between the first and second beads or a width of at least one of the first and second beads at a high heat load portion of the cylinder bore is formed to be greater than a distance between the first and second beads or a width of at least one of the first and second beads at a low heat load portion of the cylinder bore to thereby reduce a surface pressure at the high heat load portion.

Owner:ISHIKAWA GASKET CO LTD

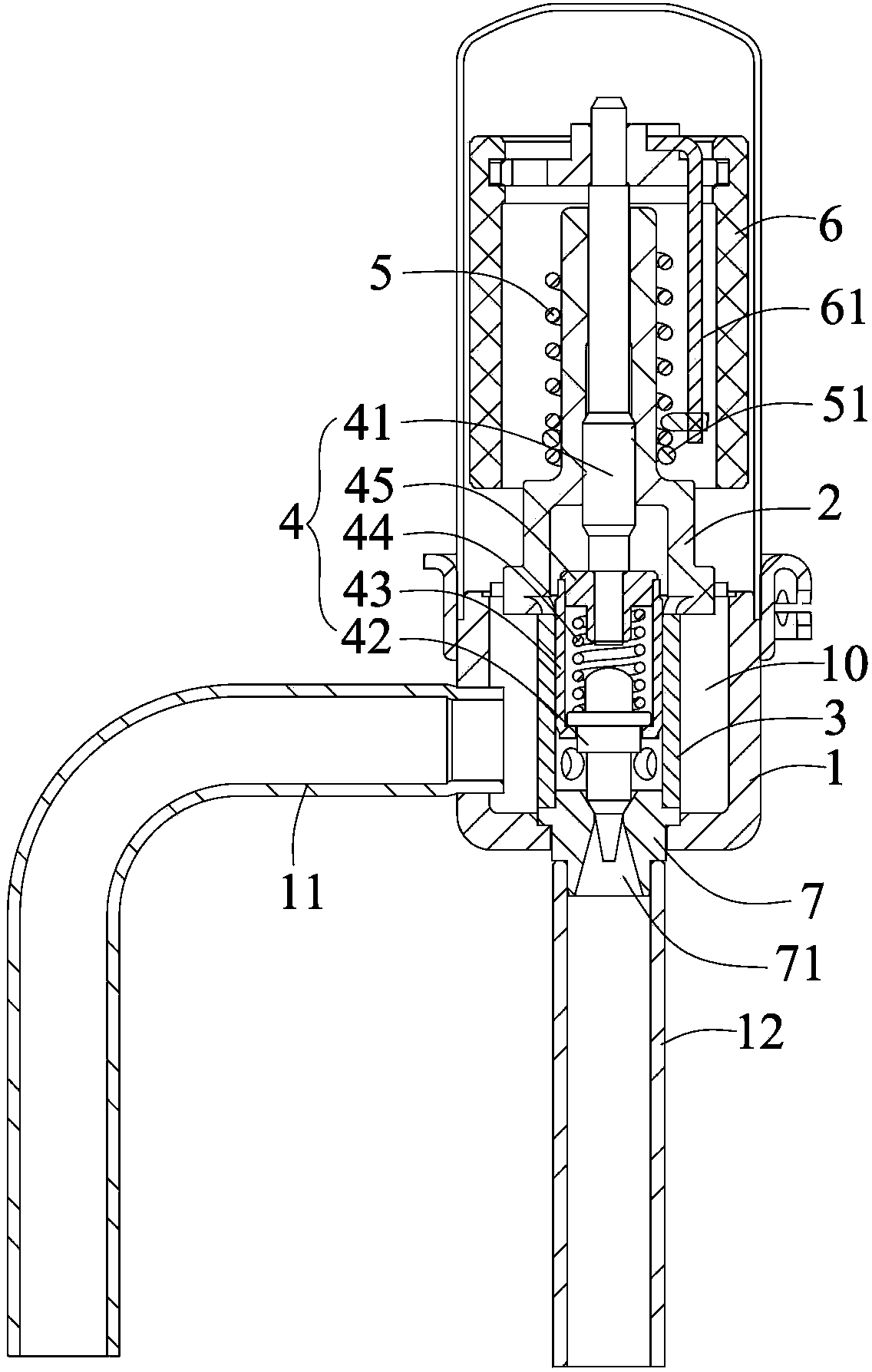

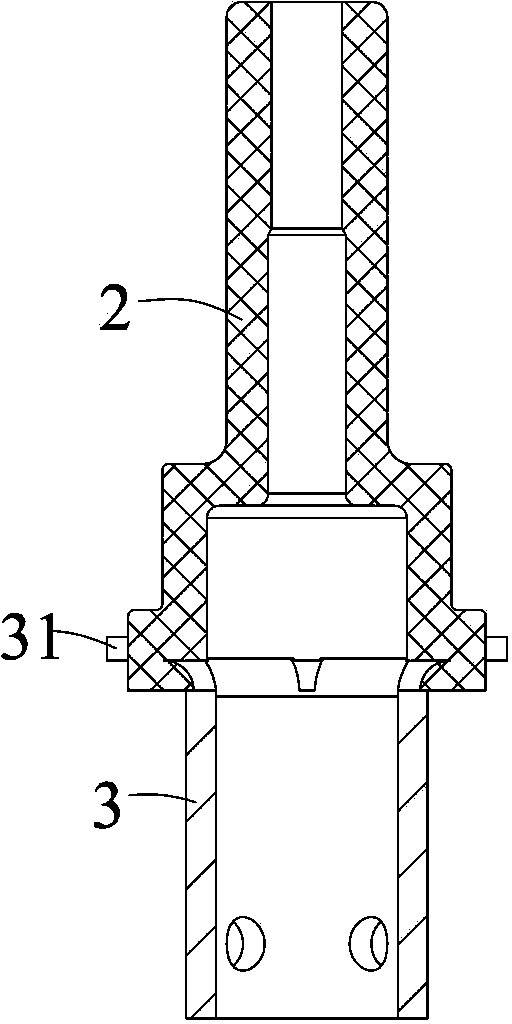

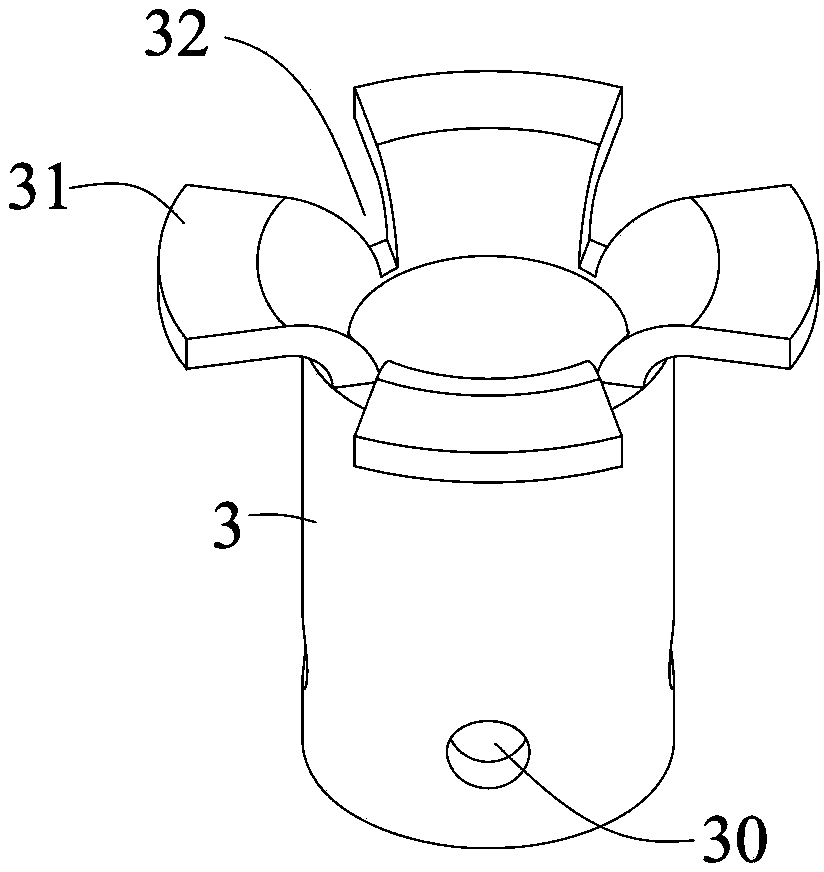

Electronic expansion valve

InactiveCN104279342AReduce wearImprove coaxialityEfficient regulation technologiesFluid circulation arrangementInjection mouldingRefrigeration

The invention discloses an electronic expansion valve, belongs to the technical field of refrigeration system control, and solves the technical problem of wear caused by the coaxiality difference between the existing electronic expansion valve nut and a valve needle assembly. The electronic expansion valve comprises a valve body, a nut, a valve needle assembly and a guide sleeve, wherein the nut and the guide sleeve are assembled on the valve body, and the valve needle is arranged on the nut; the nut and the guide sleeve are integrally molded by injection.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

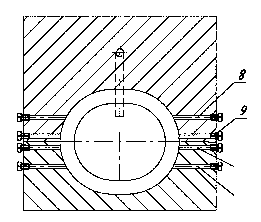

Integral forming process method of thin-wall hooped tube workpieces

The invention discloses an integral forming process method of thin-wall hooped tube workpieces. The technical scheme comprises the flowing steps of: 1, preparing a mould: firstly forming overflow holes in corresponding parts on the mould, welding reinforcing ribs in a thin-wall tubing without welded lines in advance and placing into a mould cavity, performing spotting on the mould, sealing ends of a tube blank, filling a strain rate sensitive medium between the mould and the tube blank, then filling liquid forming medium in the tube blank and applying certain pressure; 2, forming: increasing the pressure of the inside liquid, meanwhile adjusting the flow state of the strain rate sensitive medium to cause a tube body and a reinforcing plate to be deformed in a coordinated way to form qualified parts; and 3, picking up the parts: reducing the pressure to 0MPa, opening the mould and then taking out the parts from the mould. The integral forming process method of the thin-wall hooped tube workpieces has the advantages of few forming processes, low manufacturing cost, high mechanical property of formed members, high dimension precision and the like, and is particularly suitable for forming thin-wall hooped tube workpieces with a sealed complex section shape.

Owner:HARBIN INST OF TECH AT WEIHAI +1

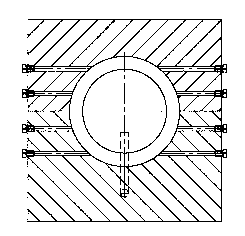

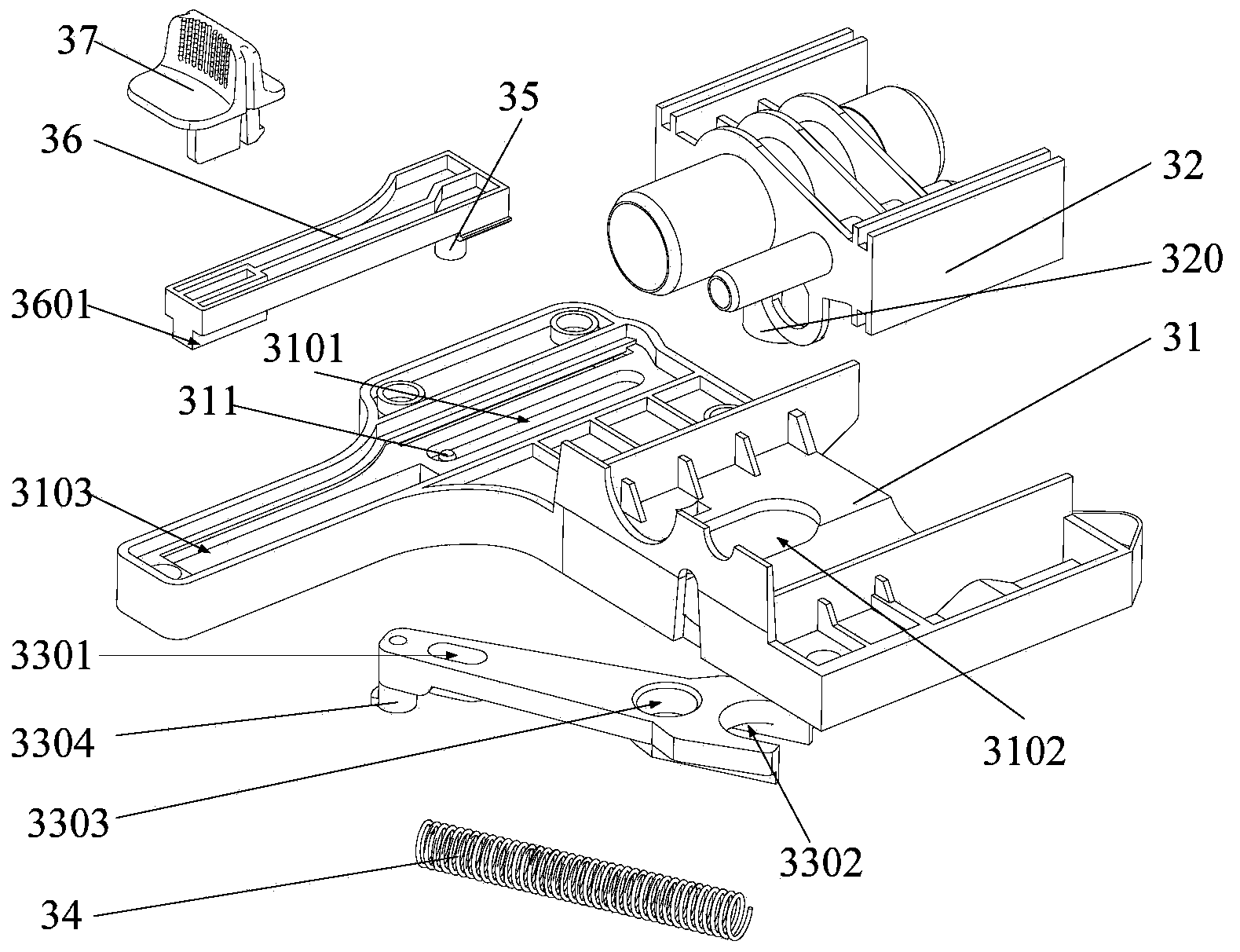

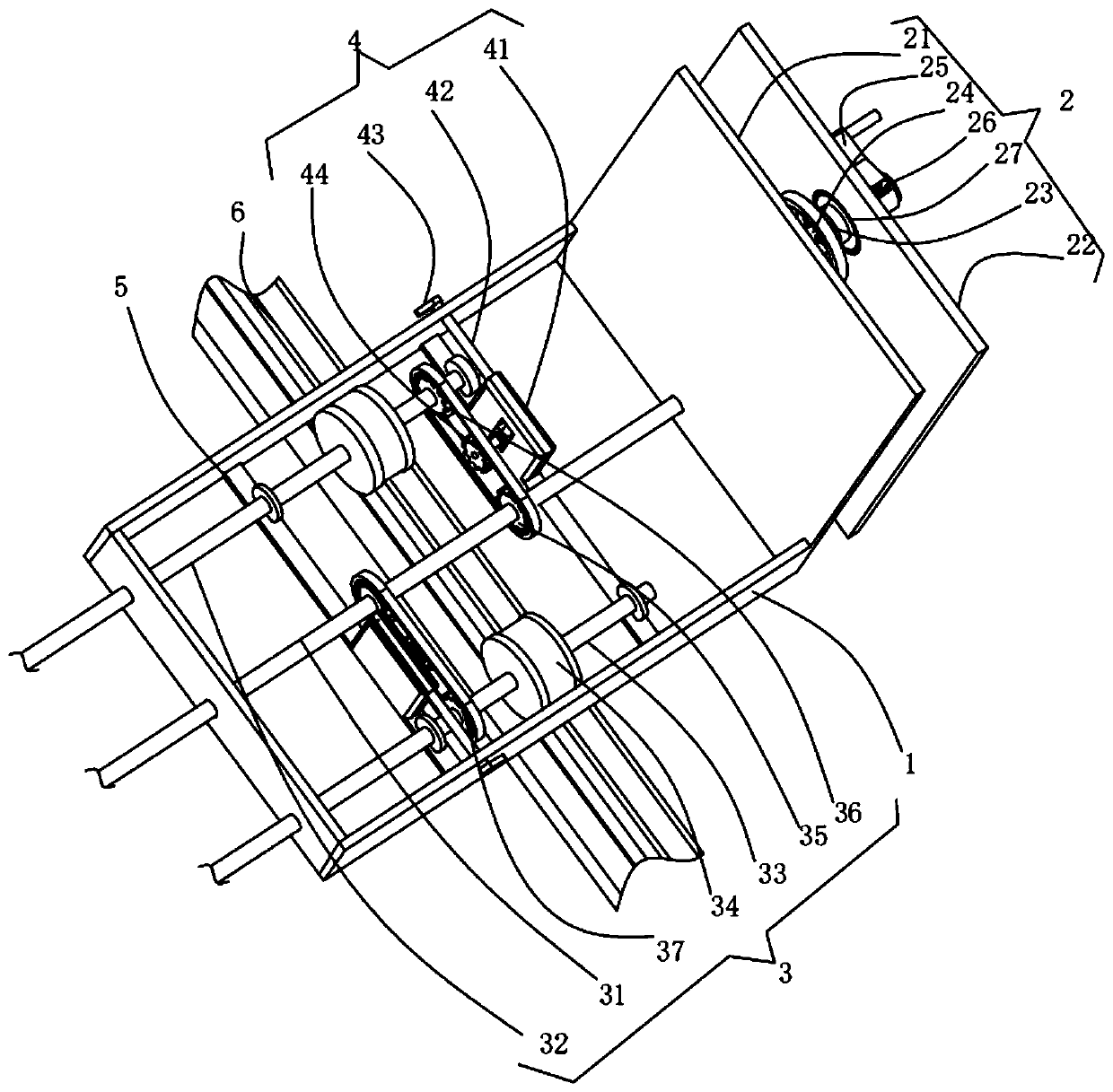

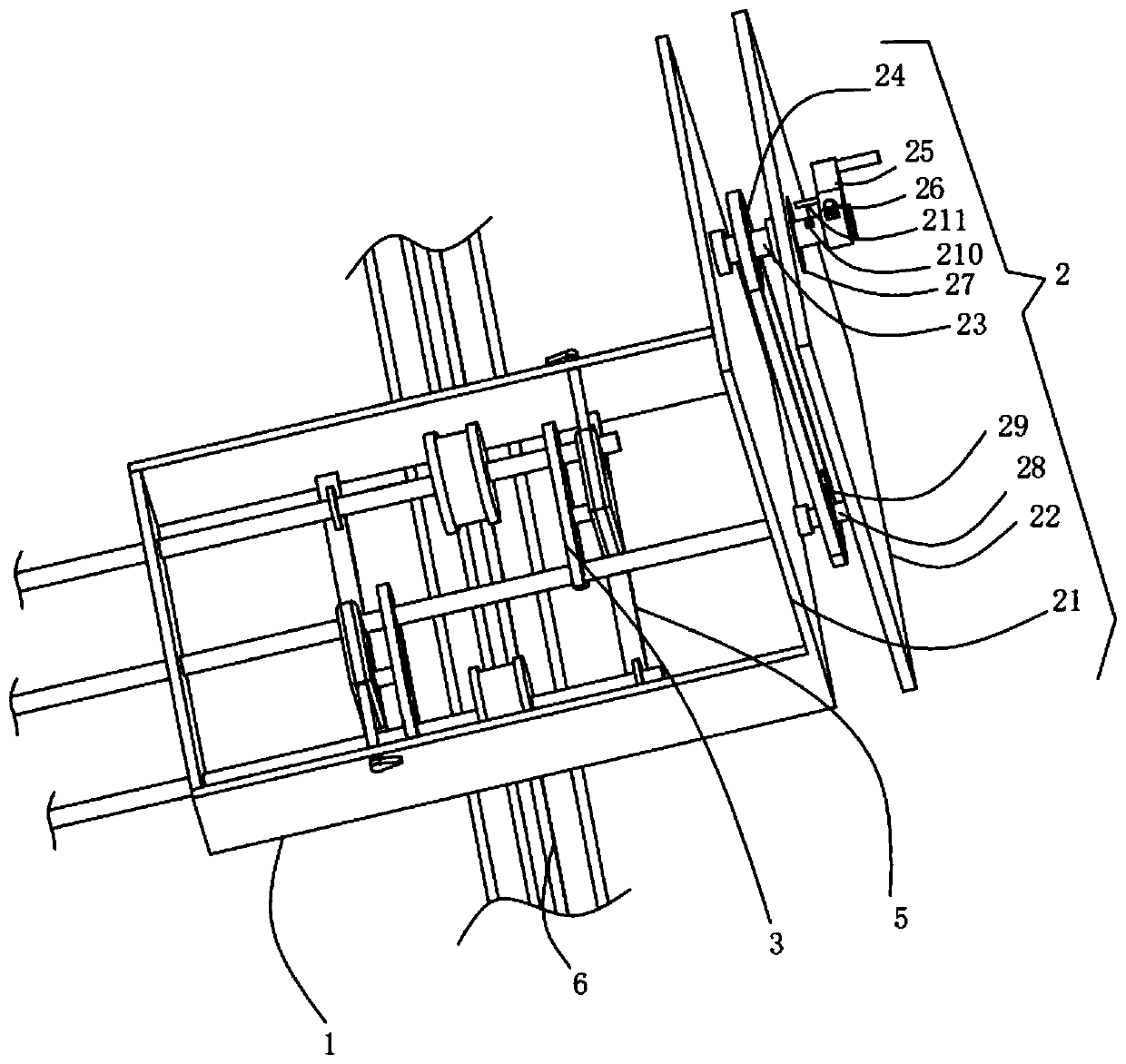

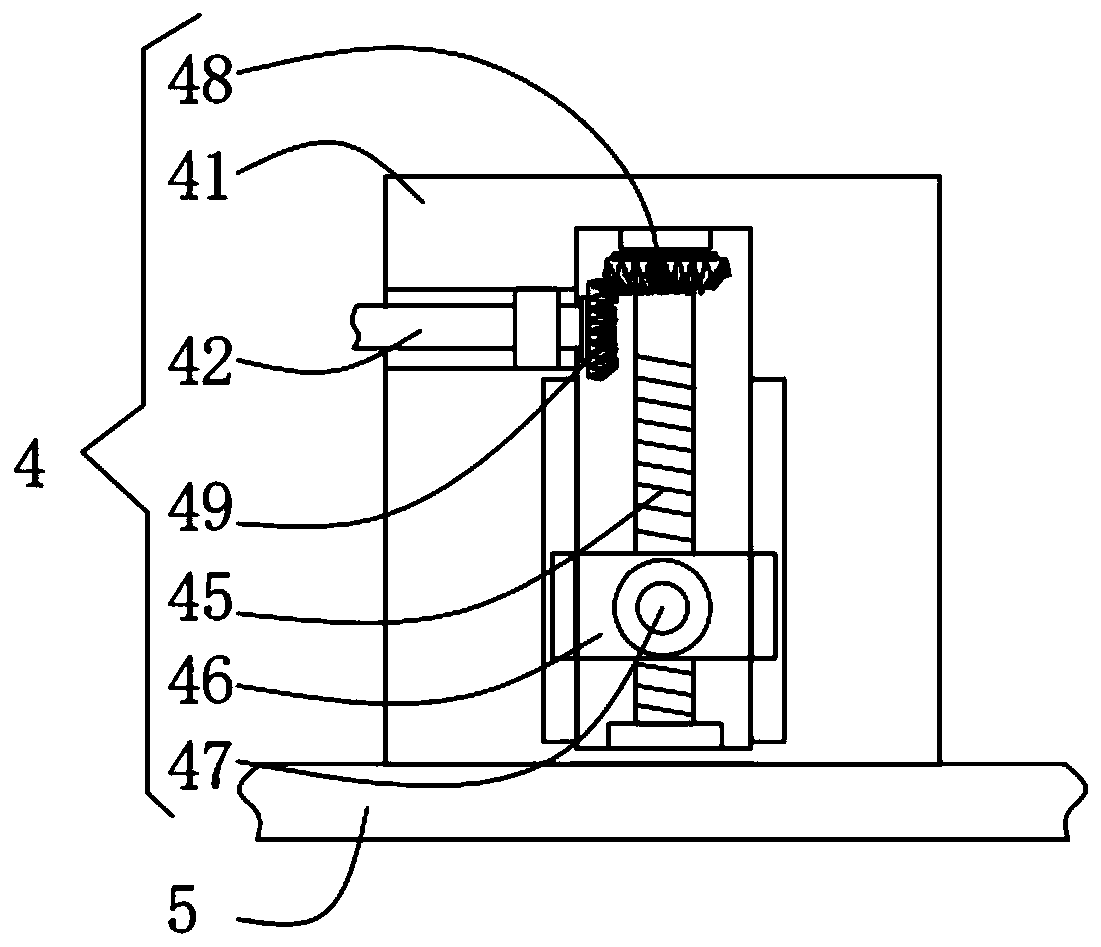

Automatic urinary and fecal nursing device

ActiveCN103750939AResolve insertionSolve the problem of incomplete escapeCleaning devicesBodily discharge devicesEngineeringAnus

The invention provides an automatic urinary and fecal nursing device which comprises a main unit, a feces collector, a directional sliding connector mechanism and a washing mechanism. A dirt storage tank is arranged on the main unit; the directional sliding connector mechanism is used for communicating the dirt storage tank with the feces collector; the feces collector comprises a feces collecting groove assembly and a body leaning mechanism, the body leaning mechanism is mounted on a mattress, and the feces collecting groove assembly is mounted in the body leaning mechanism; the washing mechanism is arranged in a feces collecting groove of the feces collecting groove assembly. The automatic urinary and fecal nursing device has the advantages that a long-term bedridden patent can act and turn over on the feces collector, the problem that the anus of a patient cannot be cleaned thoroughly after the patient defecates can be solved, problems that an existing dirt storage tank cannot be conveniently and reliably disconnected from an existing feces collector and connected with the existing feces collector and the like can be solved, and the comfort can be effectively improved for the patient when the automatic urinary and fecal nursing device is used.

Owner:XINHAI TECH GRP CO LTD

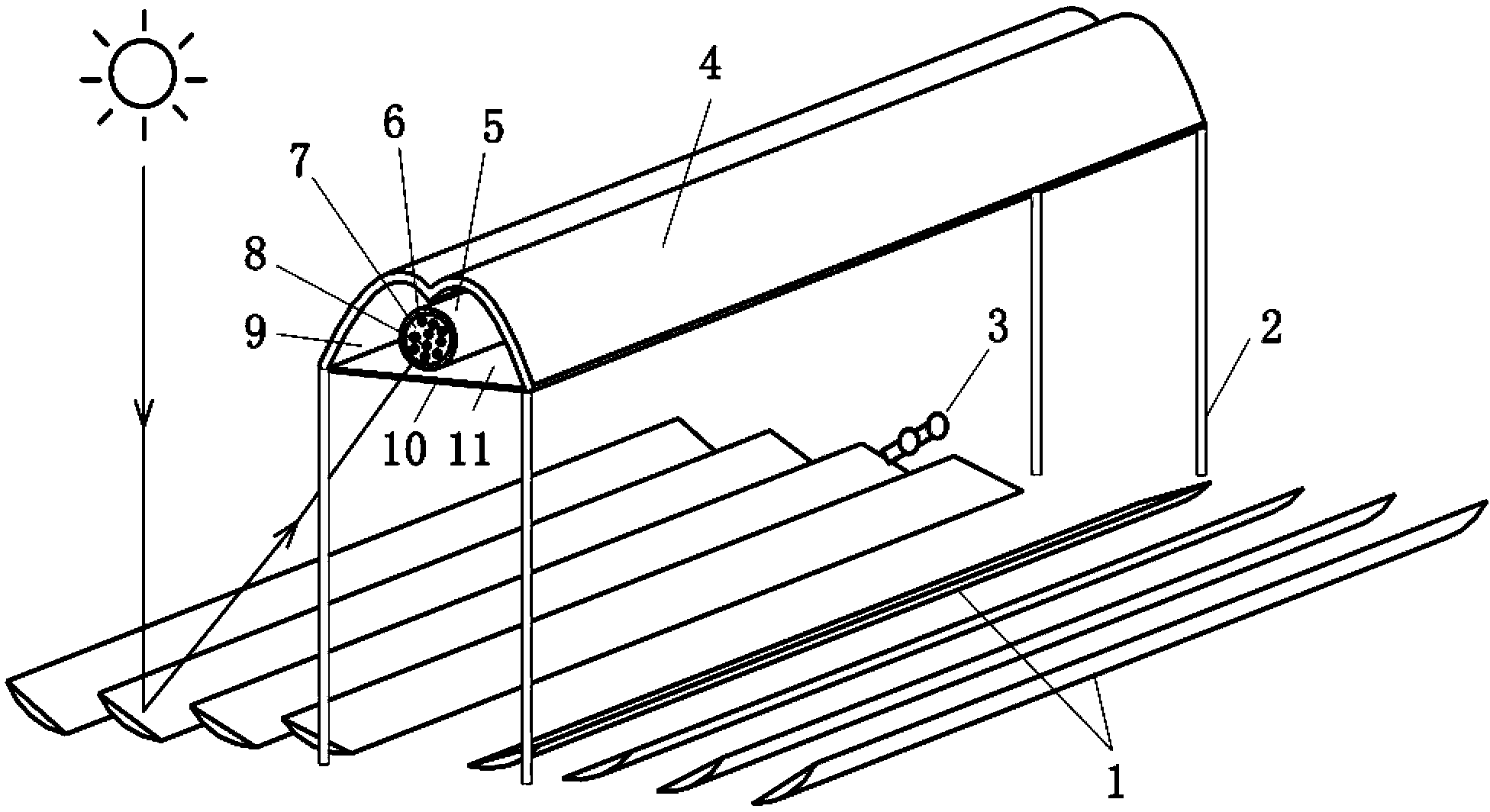

Linear Fresnel reflection type mid-and-low temperature solar energy thermochemical utilization device

InactiveCN103383150ASimple structureManufacturing and running costs are lowSolar heating energySolar heat devicesSystem integrationEnergy transfer

A linear Fresnel reflection type mid-and-low temperature solar energy thermochemical utilization device comprises a linear Fresnel reflection condensing mirror array driven by a solar tracking device to real timely track the sun, and a thermal absorber matched with the condensing mirror array and independently arranged, wherein the thermal absorber is tubular, a selective absorption coating is coated on the surface of the outer wall, and a chemical reactant medium and a catalyst are filled in the tube; a solar energy light-focusing system formed by the Fresnel reflection condensing mirror array and the solar tracking device is adopted and is well matched with the hot grade of thermal chemical reaction of mid-and-low temperature fossil fuel, the structure is simple, the manufacturing and running cost is low and the wing resistance is good when the solar energy thermochemical utilization device is mounted close to the ground; with the chemical reactant medium and the catalyst in the thermal absorber, the solar energy thermochemical utilization device can serve as the thermochemical reaction place while absorbing the solar energy, so that the heat can be directly absorbed and utilized, and the system integration complexity and energy transfer loss can be effectively reduced; as the thermal absorber is independently arranged, the safety and the stability are higher during the heat absorption and reaction process.

Owner:XI AN JIAOTONG UNIV

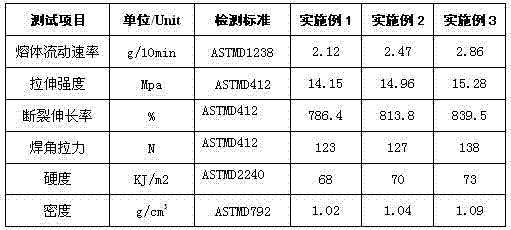

Thermoplastic vulcanizate (TPV) magnetic door seal and manufacture method thereof

ActiveCN102924828AIncrease elasticityImprove pressure resistanceDomestic cooling apparatusLighting and heating apparatusElastomerThermoplastic

The invention provides a thermoplastic vulcanizate (TPV) magnetic door seal and a manufacture method thereof. The TPV magnetic door seal comprises a TPV elastomer door seal rubber sleeve which is composed of ethylene-propylene-diene monomer (EPDM), polypropylene, naphthenic oil, cross-linking agents, lubricants and fillers. The TPV magnetic door seal contains highly vulcanized EPDM particles, so that the TPV magnetic door seal has good elasticity, compression deformation resistance and ageing resistance, and the application temperature range is wide (ranging from -60 DEG C to 150 DEG C). The TPV magnetic door seal has excellent using stability, prevents the phenomena of infirm sealing, cold leakage and the like, improves mechanical property and prolongs the service life.

Owner:ANHUI HIGASKET PLASTICS CO LTD

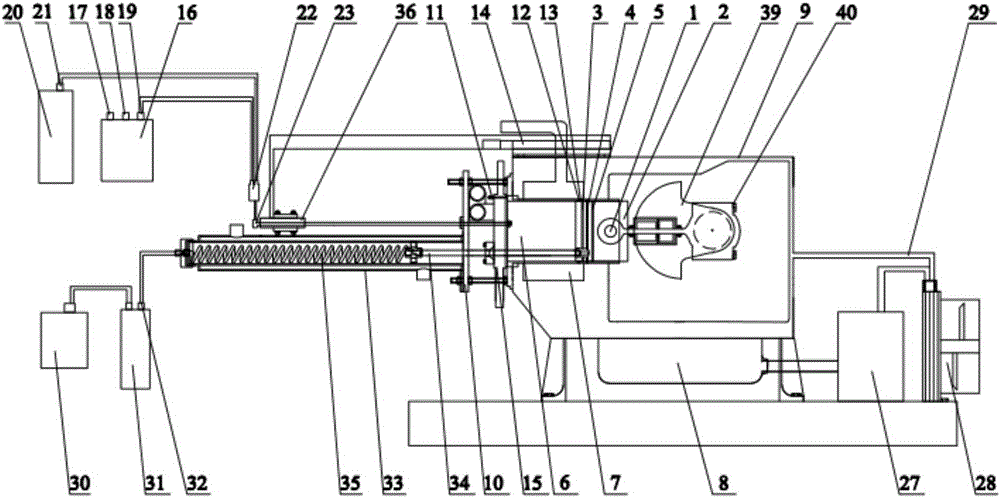

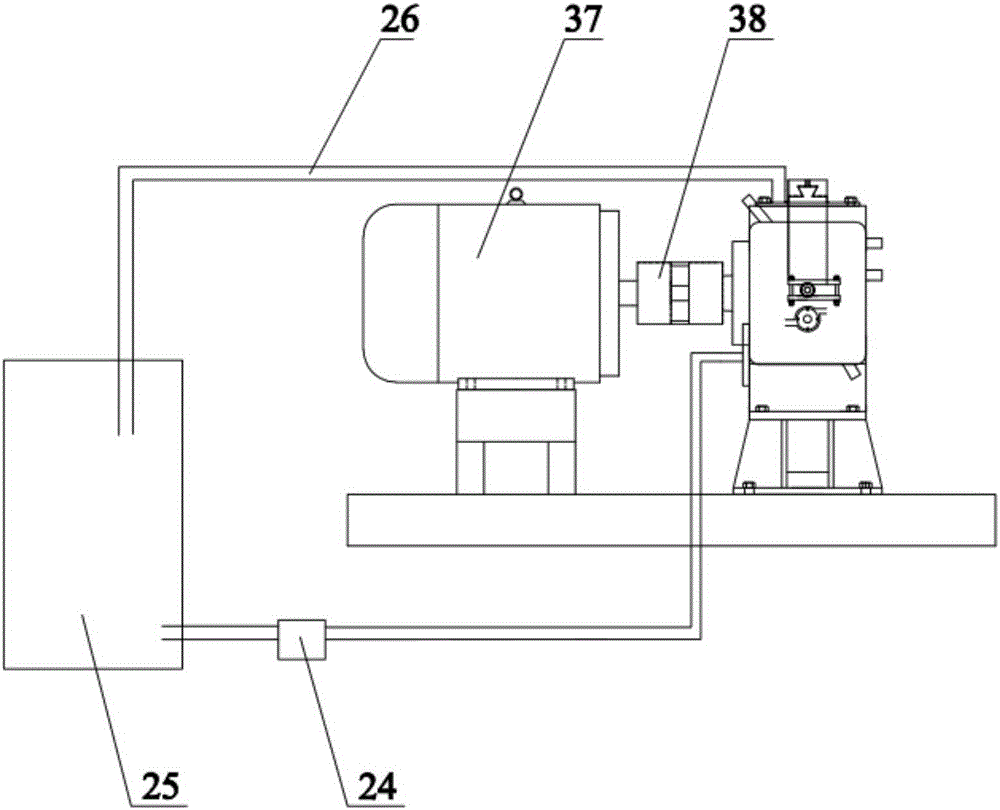

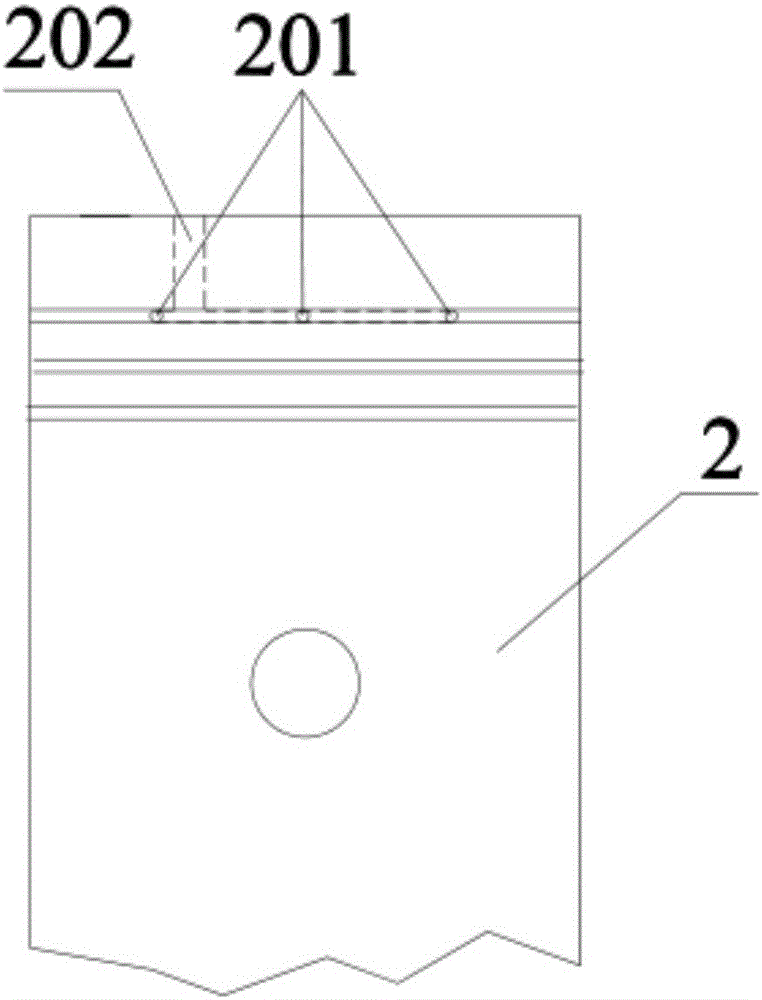

Cylinder liner and piston assembly friction online test device and test method

InactiveCN106092410AHeat load close toMechanical load close toApparatus for force/torque/work measurementPiston ringCooling chamber

The invention discloses a cylinder liner and piston assembly friction online test device and a test method. A power unit is connected with a piston through a piston pin. The piston is in sealing connection with a cylinder liner through a first gaseous ring, a second gaseous ring and an oil scraper ring installed in a ring slot of the piston. A baffle is fixed to a cylinder body in such a way that a gap is formed between the baffle and the cylinder body. The cylinder body is equipped with a cooling chamber and an oil pan. The cylinder liner is fixed in a sealing way inside the cylinder body. A friction force sensor is fixed into the gap between the baffle and the cylinder body, so one end of the friction force sensor is fixed to the baffle and the other end is fixed to the cylinder liner. Through the cylinder liner and piston assembly friction online test device and the test method of the invention, the thermal load under actual working condition and the cooling and lubricating of a cylinder liner and piston ring set can be simulated, a radial load can be applied to the piston ring to make the thermal load and mechanical load of the cylinder liner and piston ring set in test closer to those under actual working condition, and the test results are more accurate.

Owner:DALIAN MARITIME UNIVERSITY +1

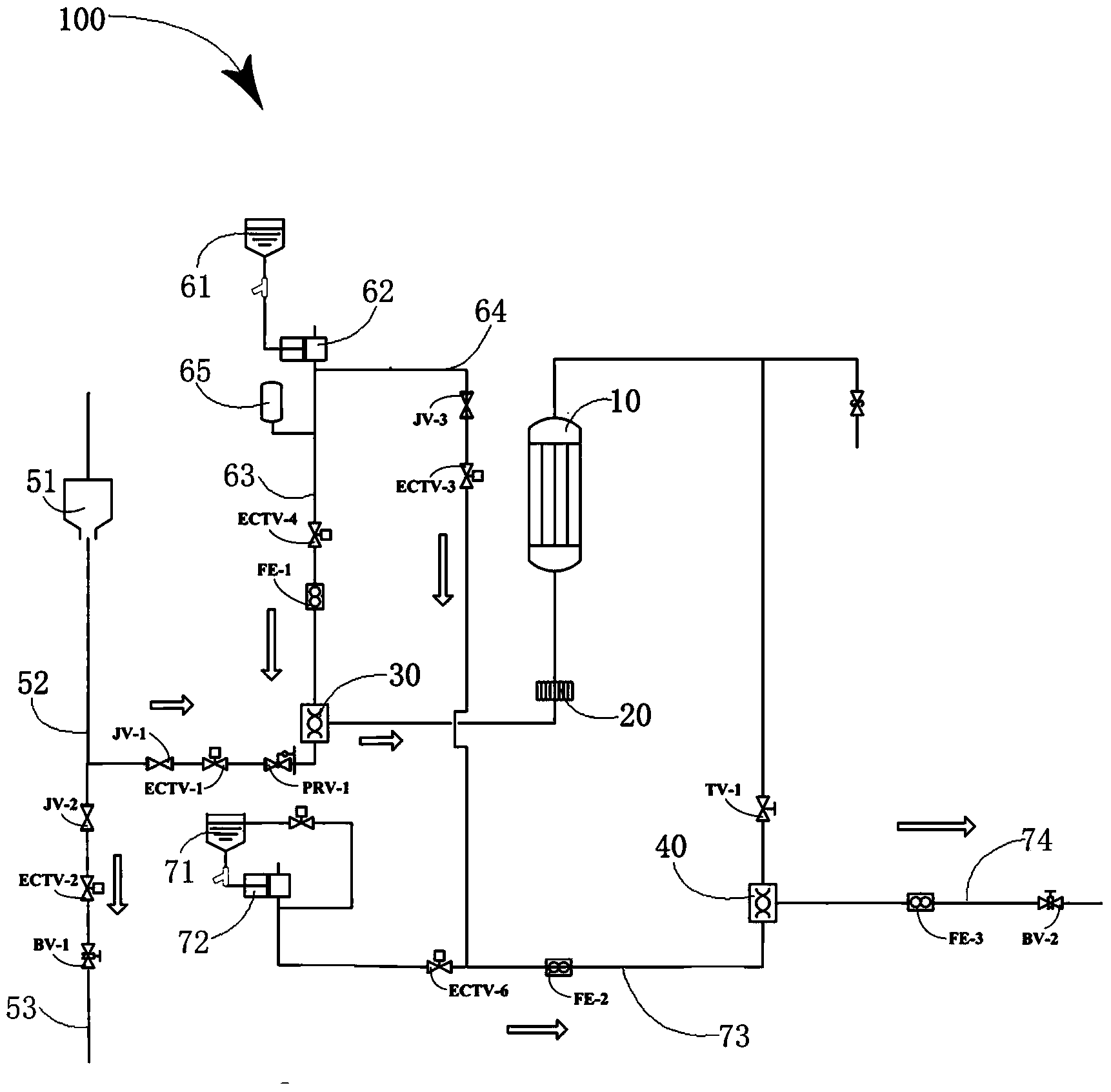

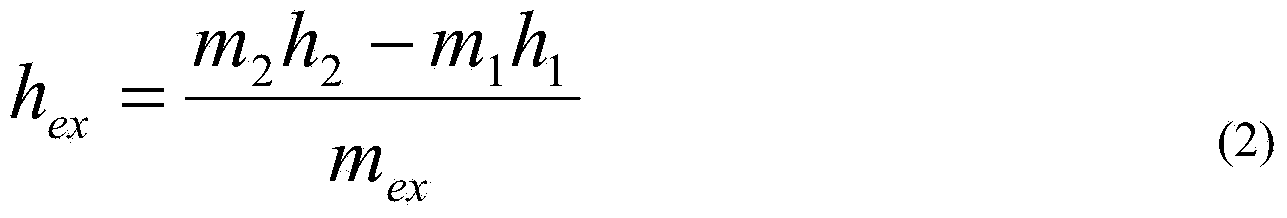

Experimental device for two-phase heat transfer characteristic research and method for measuring wet steam dryness

ActiveCN104330436AAvoid tightnessReduce experiment costMaterial heat developmentWet steamEngineering

The invention discloses an experimental device for two-phase heat transfer characteristic research and a method for measuring wet steam dryness. The experimental device comprises a steam boiler, a first steam-water mixer, an experimental body and a first water injection system for providing cooling water, wherein both the first water injection system and the steam boiler are communicated with the first steam-water mixer; the first steam-water mixer is communicated with the experimental body; the cooling water provided by the first water injection system is mixed with wet steam provided by the steam boiler in the first steam-water mixer and then the mixture flows into the experimental body. The experimental device for the two-phase heat transfer characteristic research has the characteristics that the steam boiler is adopted to provide high-temperature and high-pressure steam instead of a traditional electric heating manner, the wet steam provided by the steam boiler and the cooling water by the first water injection system are mixed reasonably to realize the experimental working conditions of high flow, high pressure and high dryness, and the problems of insulating sealing and critical boiling are avoided because the experimental device has no pre-heating section and the experimental body also does not need to be heated.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

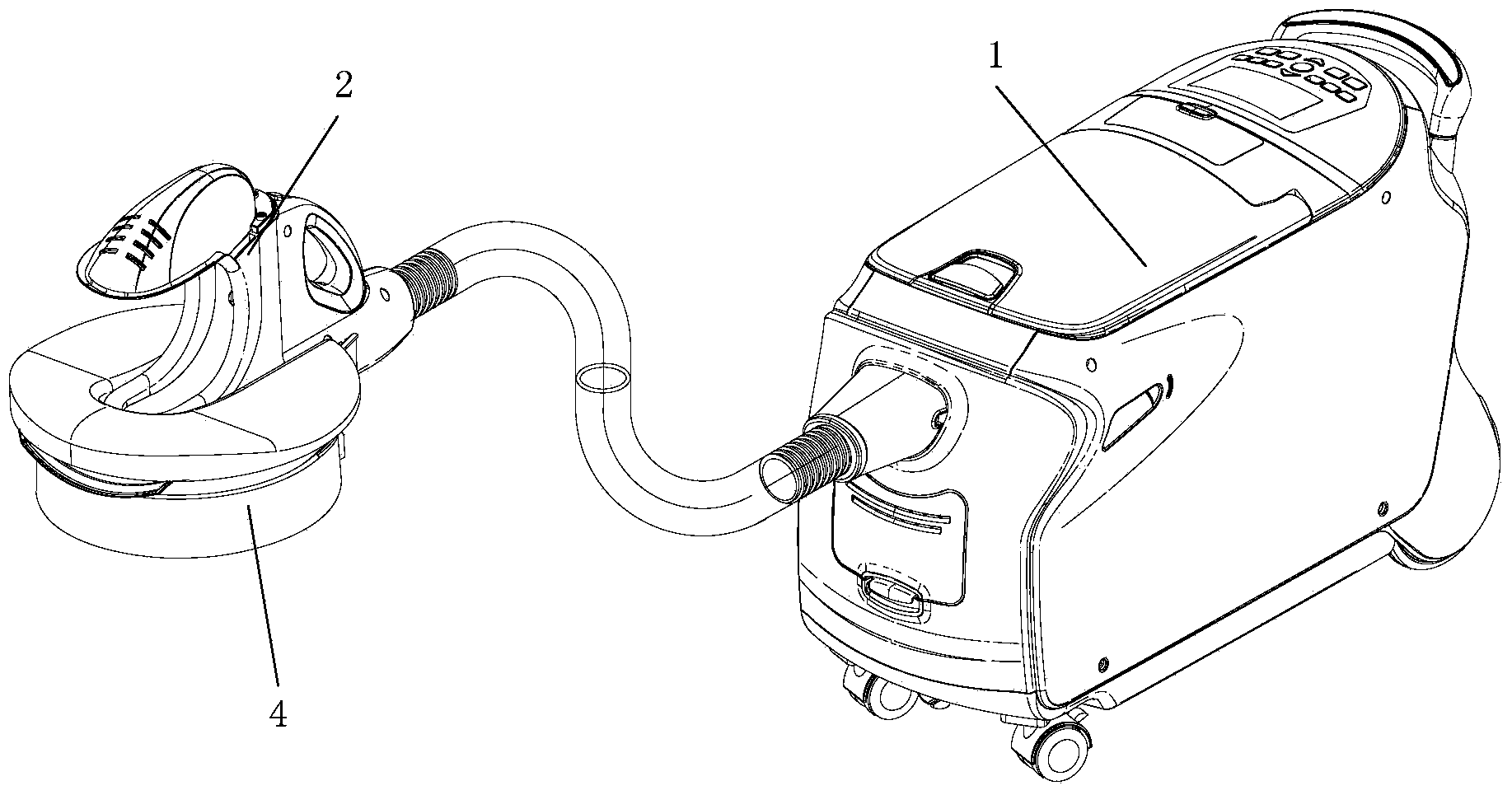

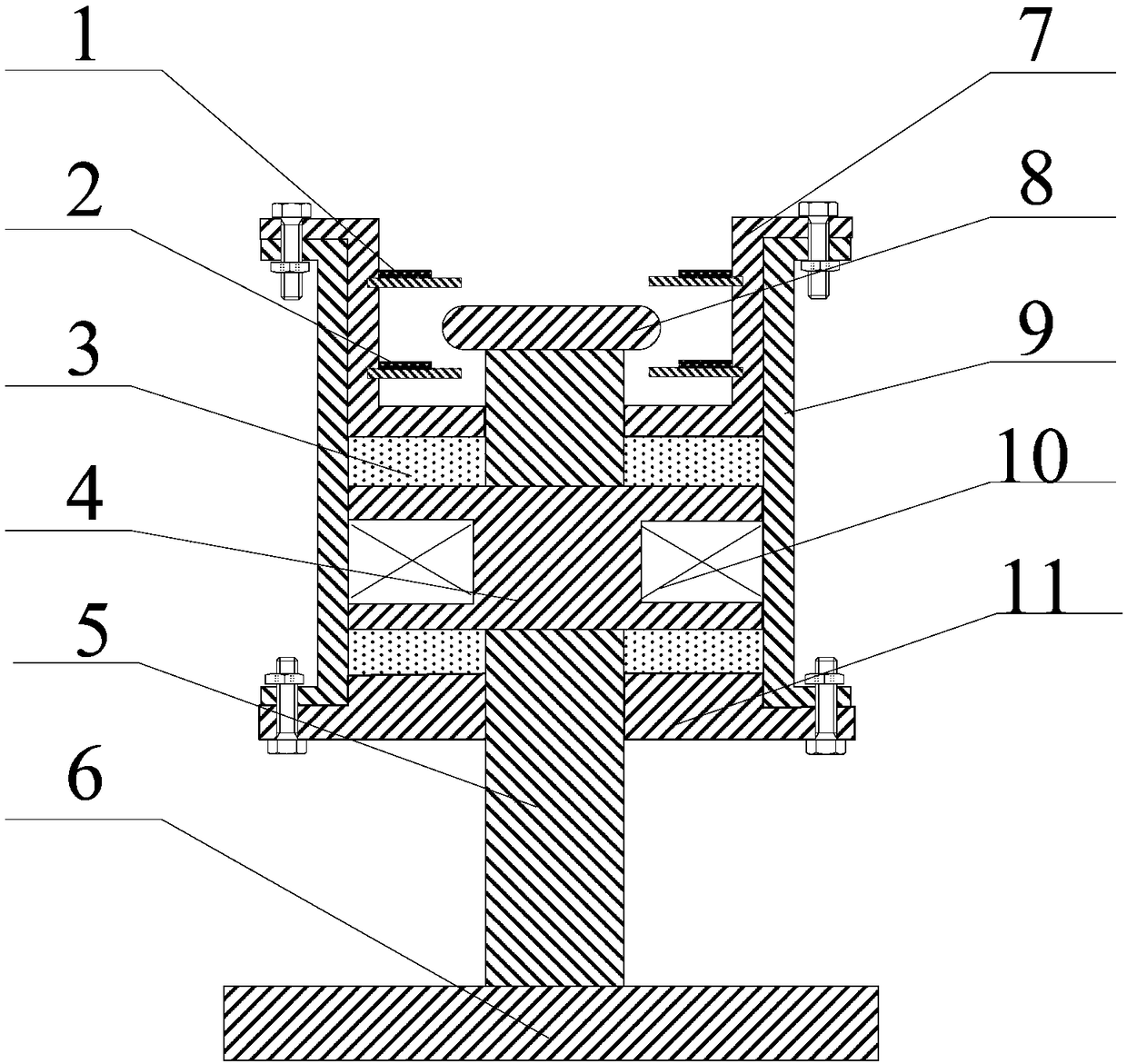

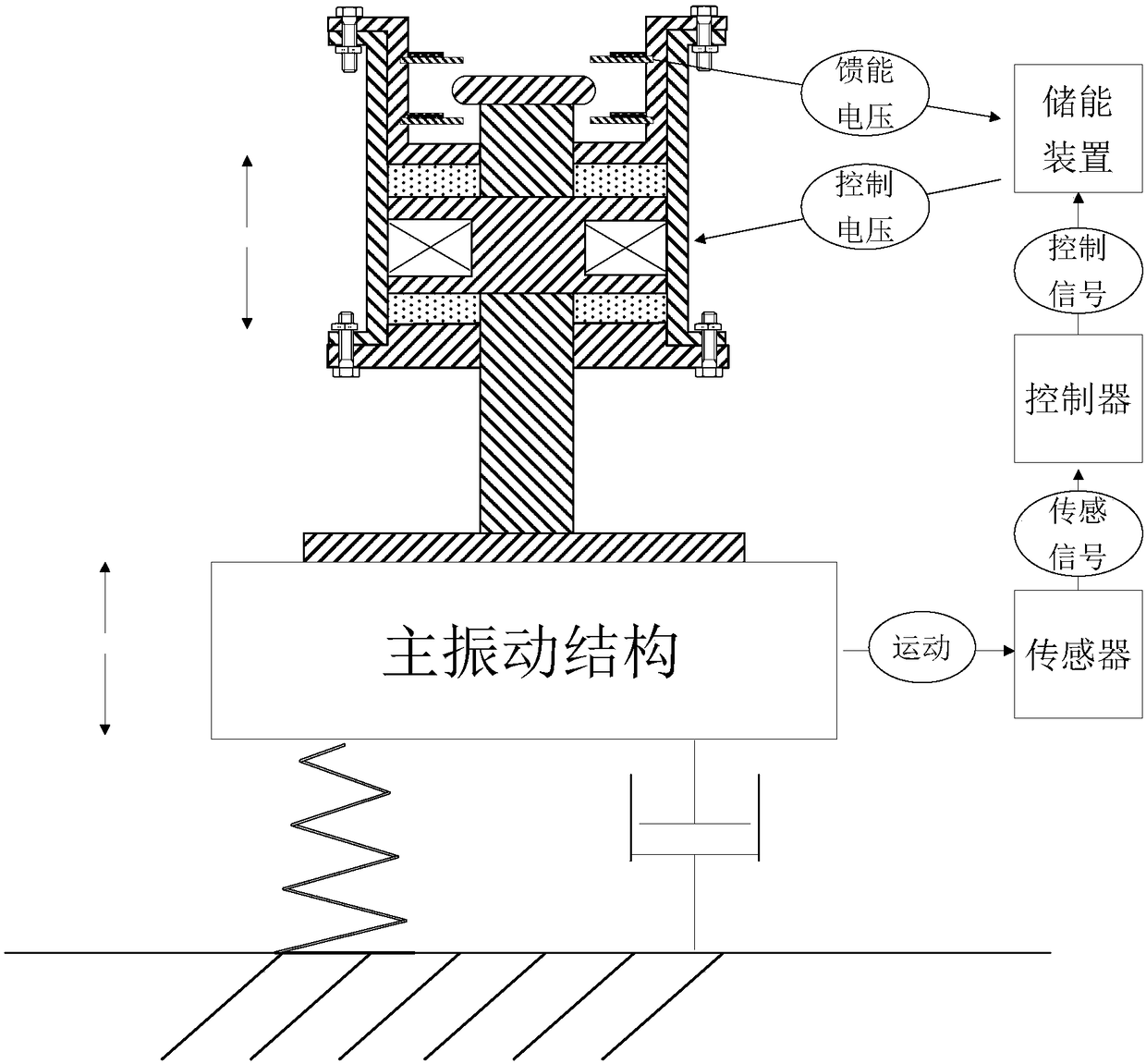

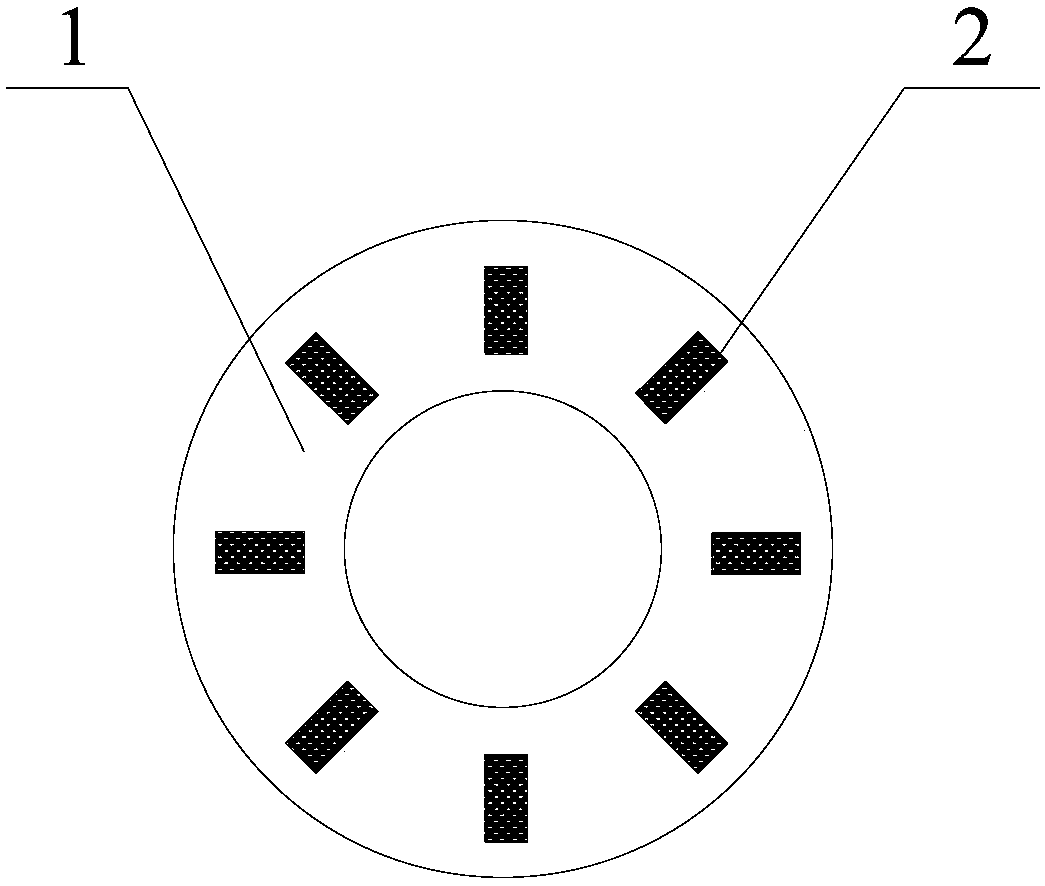

Method for up-conversion energy feeding of tuned mass of magnetorheological damper and damper

ActiveCN108087483AAchieve targeted deliveryRealize rationalitySpringsNon-rotating vibration suppressionSelf excitedEngineering

The invention discloses a method for up-conversion energy feeding of a tuned mass of a magnetorheological damper and the damper. The damper mainly comprises a piston rod, a piston and a cylinder block; a main vibrating structure and the piston are connected through the piston rod; an induction coil is arranged on the piston; and the cylinder block is filled with magnetorheological elastomers. A controllable electromagnetic field is produced through control on the current of the induction coil, so that the rigidity and the damping of the damper are adjusted. The cylinder block used as the tunedmass produce the inertia force reacting on the main vibrating structure, so that the purpose of reducing and even eliminating vibration of the main vibrating structure is achieved. An impact head isarranged at the tail end of the piston rod, an annular elastic membrane is fixed to the cylinder block, a piezoelectric material sheet is arranged on the elastic membrane, when the piston rod moves relative to the cylinder block, the impact head collides with the elastic membrane to produce high-frequency self-excited vibration, the piezoelectric material is subjected to high-frequency pulling andcompression, and efficient conversion of vibration energy is realized. The method and the damper have the advantages as follows: 1, targeted delivery of energy is realized; 2, the structure is compact and reliable; 3, the energy feeding efficiency is relatively high.

Owner:NORTHEASTERN UNIV

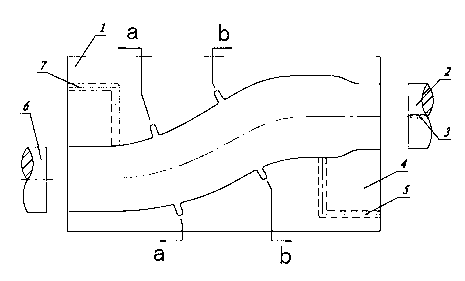

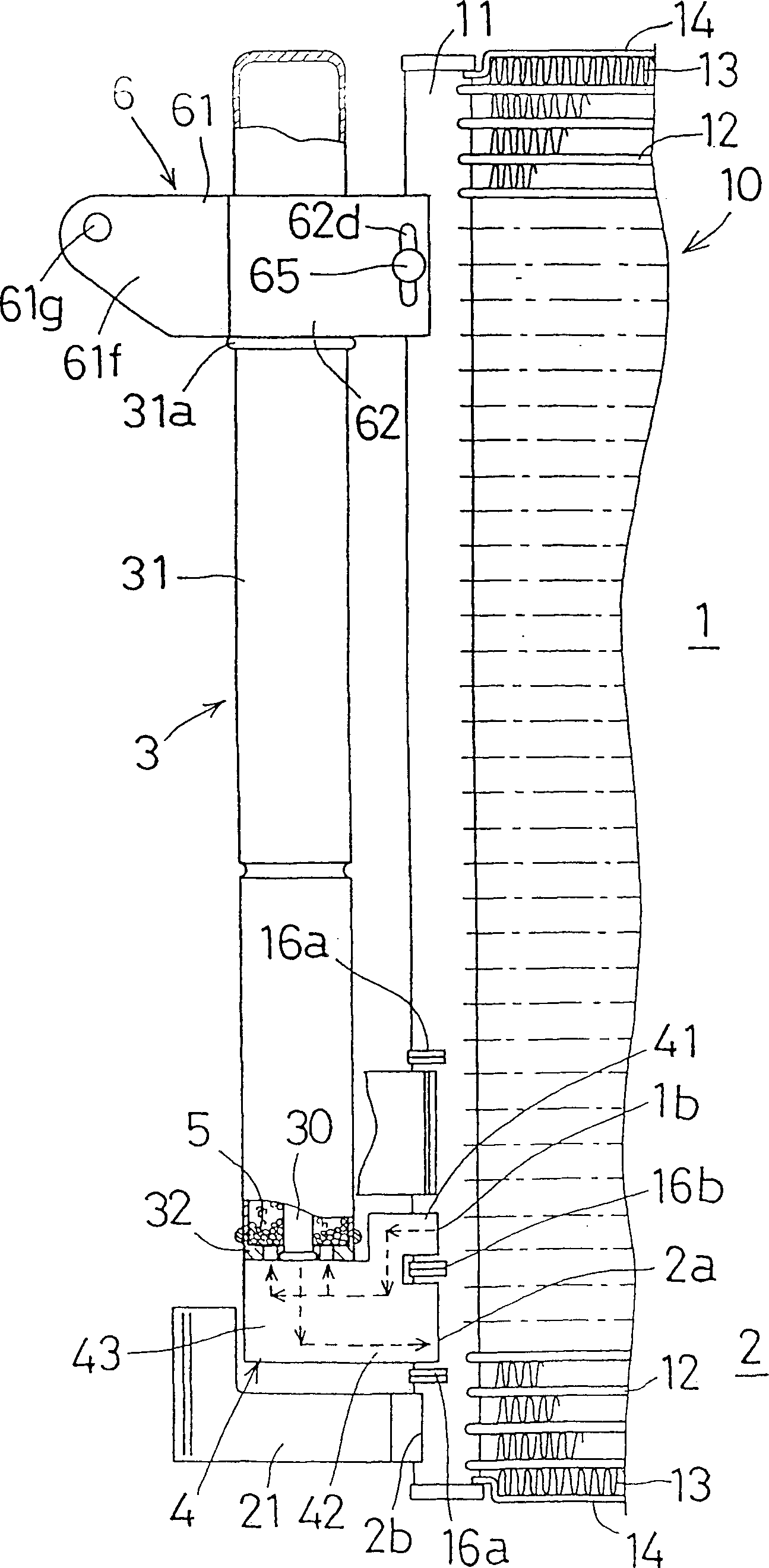

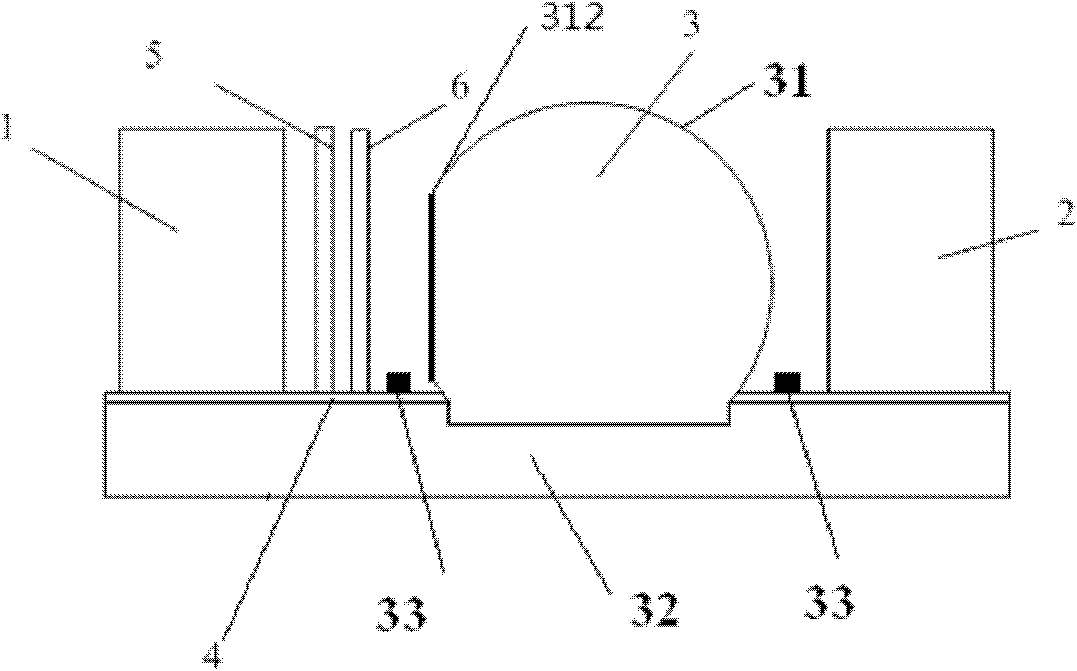

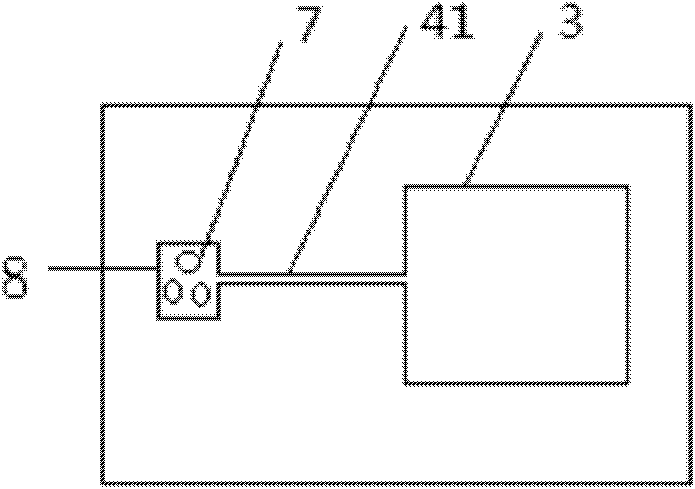

Heat excanger with receiver tank, and refrigeration system

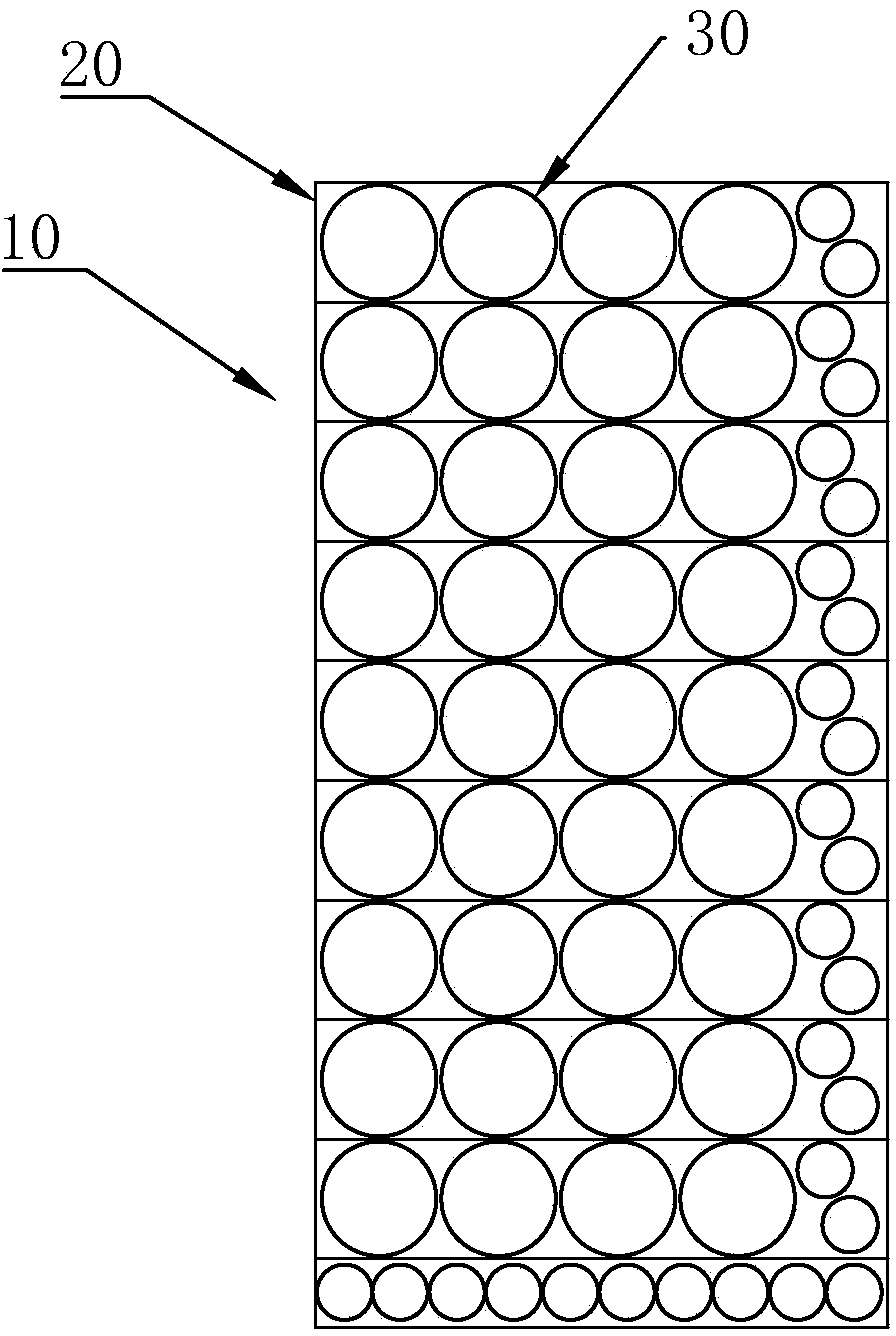

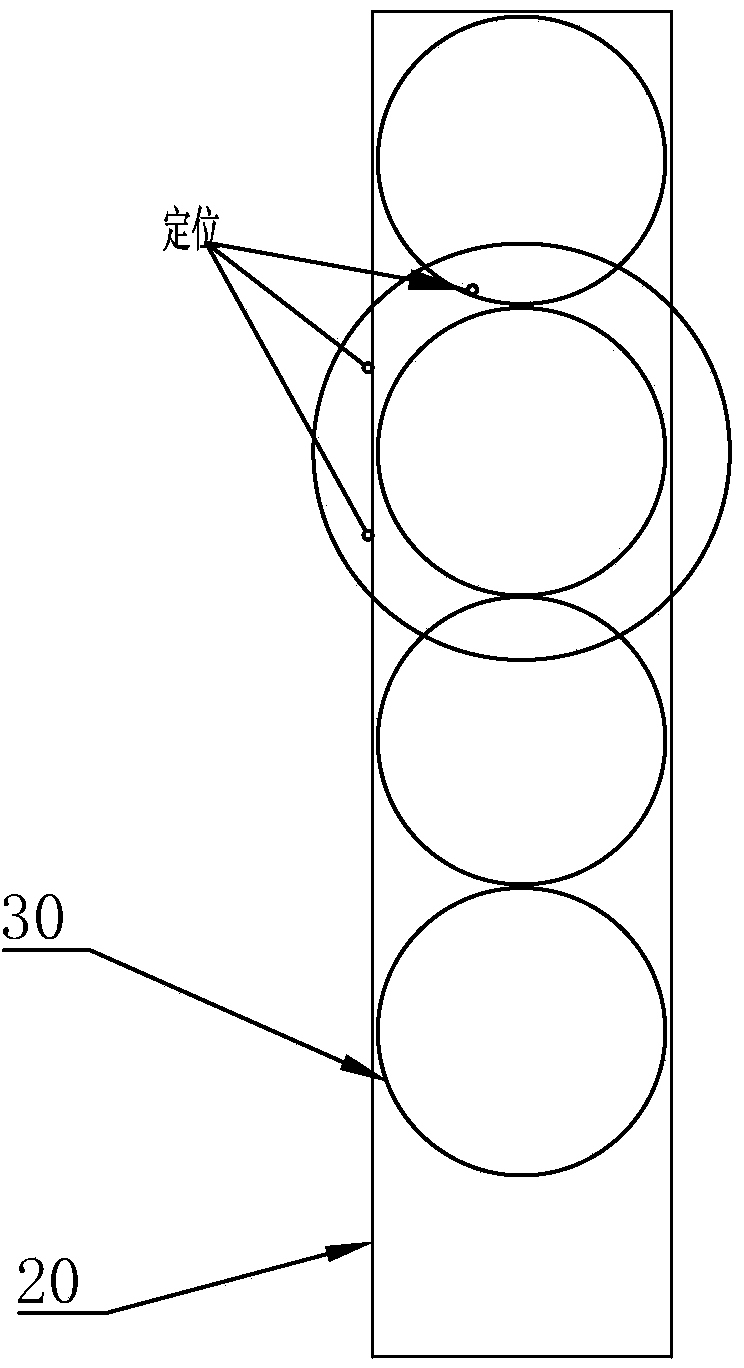

InactiveCN1494649AEasy to assembleIncrease volumeEvaporators/condensersSubcoolersEngineeringRefrigeration

A heat exchanger with a receiver tank is provided with a multi-flow type heat-exchange body (10), a receiver tank (3), a block flange (4) having a side surface connected to the periphery of a condensing portion outlet of the heat exchanger body (10) and an upper end to which a lower end of the receiver tank (3) is attached and a bracket (6) for supporting the upper part of the receiver tank (3) to the heat exchanger body (10). A flange-shaped pressing stepped portion (31a) is formed on the upper periphery of the tank main body (31) of the receiver tank (3). The bracket (6) is provided with a joint portion (61b) to be secured to the peripheral surface of one of headers (11) and embracing portions (61a) and (62a) that surround the periphery of the tank main body (31) and are engaged with the upper side of the pressing stepped portion (31a) to downwardly press the receiver tank (3). With this heat exchanger, stable refrigeration performance can be obtained and that the assembling operation can be performed easily.

Owner:SHOWA DENKO KK

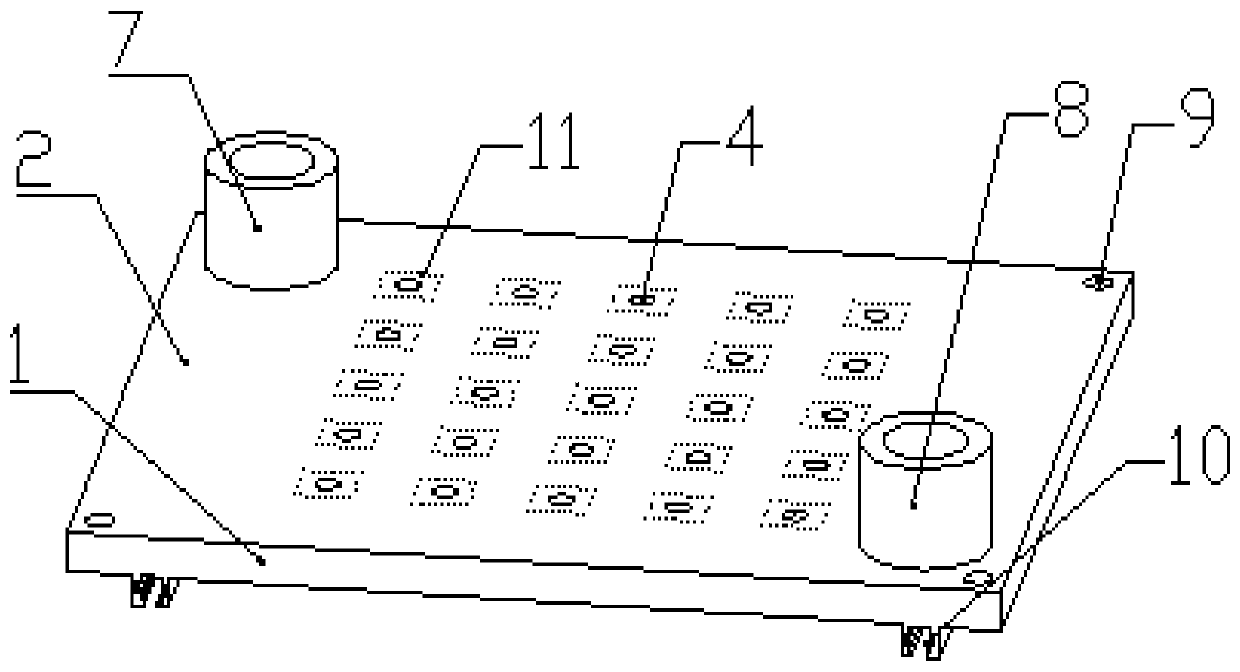

3D printing integrated radiator and application thereof in phased-array antenna

InactiveCN110165355ALowered byHelp passIndividually energised antenna arraysDe-icing/drying-out arrangementsEngineeringTemperature difference

The invention relates to the field of heat dissipation, in particular to a micro-channel radiator, integrated manufacturing and an application of the micro-channel radiator in a control array antenna.The radiator is manufactured through 3D printing. Through a fluid channel which is distributed in a gradually changed manner and a liquid injection port and a liquid outlet which are respectively formed at the biggest end and the smallest end of the flow channel, cooling liquid uniformly passes through the whole fluid channel. When the radiator is in use, the highest temperature of the radiator is 298K, the lowest temperature of the radiator is 295K, and the temperature difference after heat dissipation is 3 DEG C. Compared with a pure runner structure, the radiator is stronger in heat dissipation capability and more uniform in temperature distribution after heat dissipation, and has the characteristics of good heat dissipation performance and temperature uniformity, one-time forming, noneed of using a nut sealing ring and the like for packaging.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Black tea processing method

The invention discloses a black tea processing method. The method sequentially comprises the steps of raw material selection and picking, withering, rolling, fermentation, shaping and curing. In the rolling step, a rolling barrel is filled with withered tea leaves, empty rolling is carried out for 20-25 min, light pressing is carried out for 20-25 min, heavy pressing is carried out for 25-30 min, light pressing is carried out for 10-15 min, empty rolling is carried for 5 min, and then black tea is obtained, wherein the total tea rolling time is 80-100 min. Black tea obtained through the black tea processing method is compact, fine straight and upright in appearance, black and smooth in color, highly tender, red and bright in tea water color, fragrant, sweet and high in purity, mellow, brisk and sweet in taste, red, bright and fresh in leaf bottom, uniform and complete, straight and strong in appearance, red and bright in the tea water color, strong, fragrant and sweet in fragrance, bright-colored, red and bright in tea water color, and fresh, brisk and thick in taste.

Owner:CHONGQING YUNLING TEA IND TECH

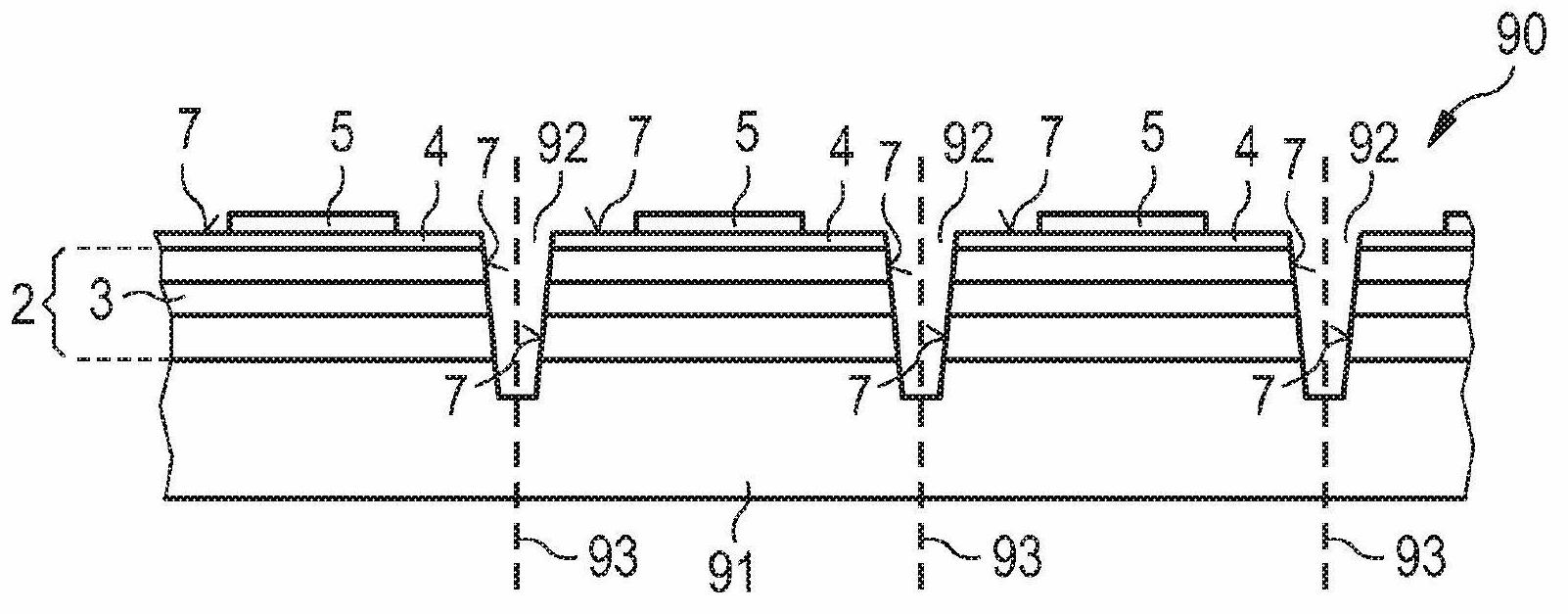

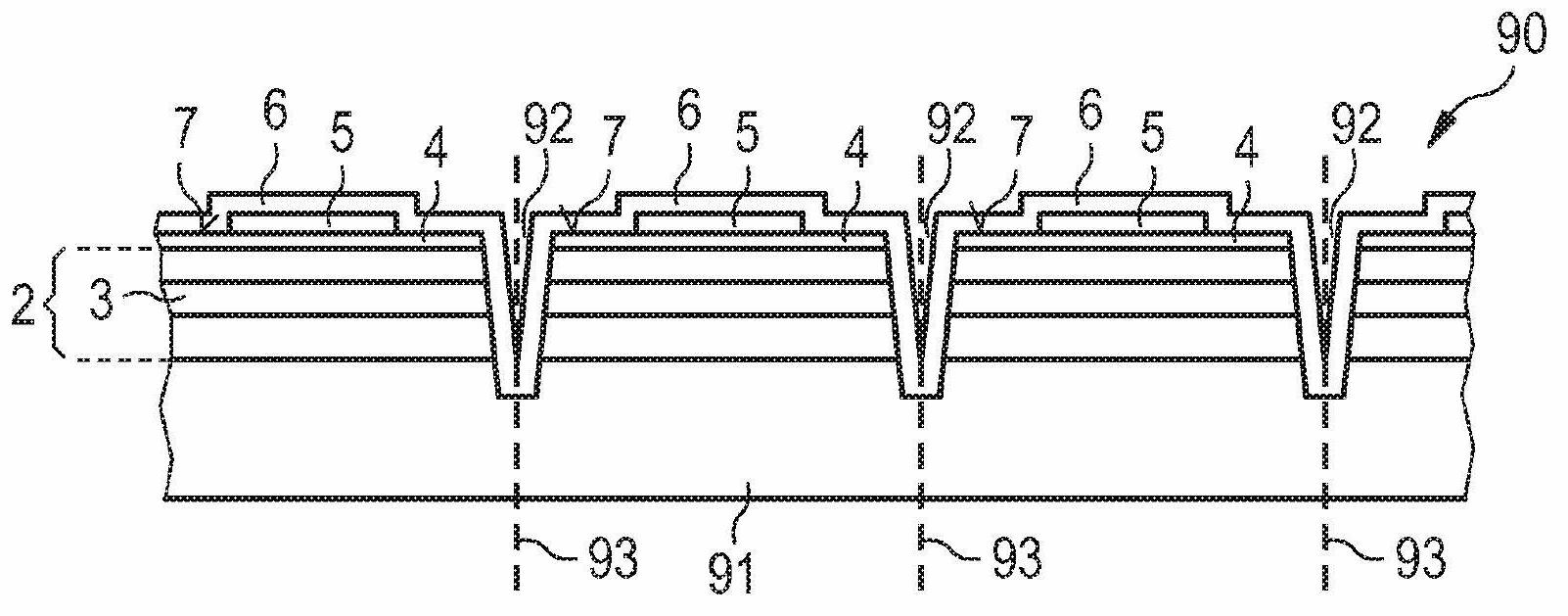

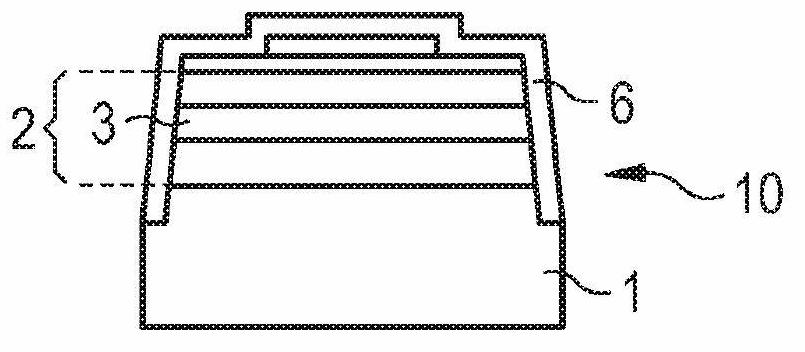

Optoelectronic component and method for producing an opto-electronic component

ActiveCN102668140ALow costAging stableOptical wave guidanceLaser detailsOpto electronicAtomic layer deposition

The invention relates to an optoelectronic component comprising at least one inorganic optoelectronically active semiconductor component (10) having an active region (3) suitable for emitting or receiving light during operation, and a sealing material (6) applied to at least one surface region (7) by means of atomic layer deposition, covering the surface region (7) in a hermetically sealing manner. The invention further relates to a method for producing an opto-electronic component.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

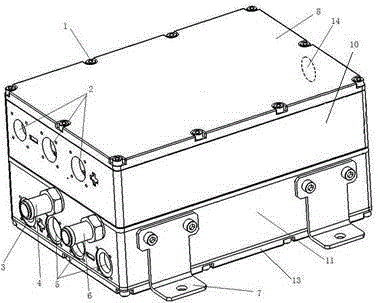

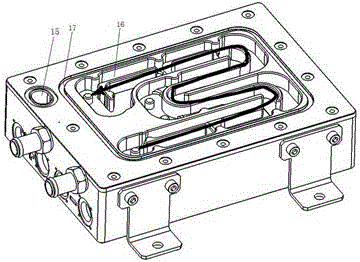

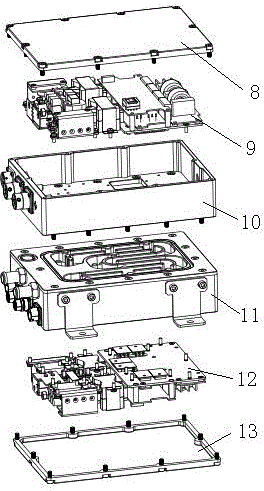

Integrated inverter structure

InactiveCN103956888ASmall footprintAvoid tightnessCooling/ventilation/heating modificationsPower conversion systemsEngineeringElectric vehicle

The invention relates to the field of electric vehicle manufacturing, and relates to an integrated inverter structure. The integrated inverter structure comprises two sets of inverters, an upper shell, a lower shell, an upper cover plate, a lower bottom plate and a fixing bracket. The upper shell and the lower shell are all in open box shapes, the upper shell and the upper cover plate form a box body, and the lower shell and the lower bottom plate form a box body, wherein the two box bodies are independent of each other. A set of 12 V inverters are arranged in the upper shell, a set of 24 V inverters are arranged in the lower shell, the two box bodies are combined into a whole through a plurality of bolts penetrating through the periphery of the box bodies, a fixing bracket is arranged around the lower shell body, a concave cooling water channel is formed in the upper surface of the lower shell, the side face of the lower shell is provided with an inlet tube and an outlet tube for connecting the cooling water channel and installing holes of connecting and inserting pieces of the inverters, circular grooves are formed in the periphery of the cooling water channel of the lower shell, the grooves are filled with sealant, and the installing holes of the connecting and inserting pieces of the inverters are formed in the side face of the upper shell. The integrated inverter structure is favorable for two kinds of inverter power supply systems for sharing one cooling system, and thus occupied space is reduced.

Owner:JIANGLING MOTORS

Oil cooling structure for piston rod of piston compressor

InactiveCN1766330AExtended service lifeGuaranteed to workPositive displacement pump componentsPositive-displacement liquid enginesCoolant flowOil cooling

The invention discloses a piston rod connection oil cooling structure of piston type compressor in the cooling device technique domain, which comprises the following parts: sealing ring, locking ring, filling box and piston rod, wherein the cooling hole is open on the rear of piston rod with an oil guiding pipe in the cooling hole to do circulating cooling through the cooling oil; the oil guiding pipe is pressed on the end of piston rod through the connector, which is pressed on the filling box and throttle case through gland and clamp plate. The invention guarantees the normal operation, which avoids the ineffective phenomenon of coolant flow and sealing due to friction and high temperature.

Owner:WUXI COMPRESSOR CO LTD

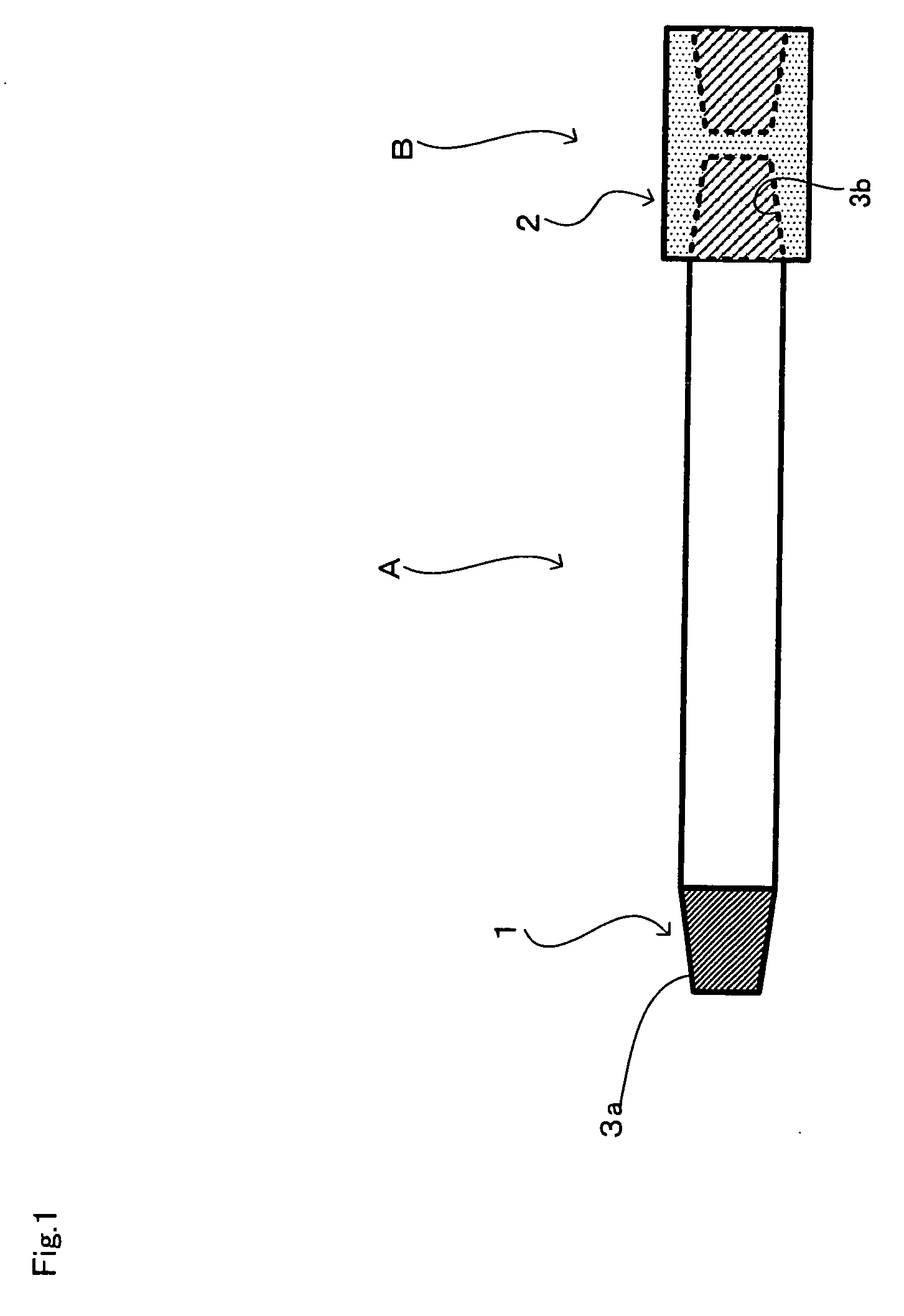

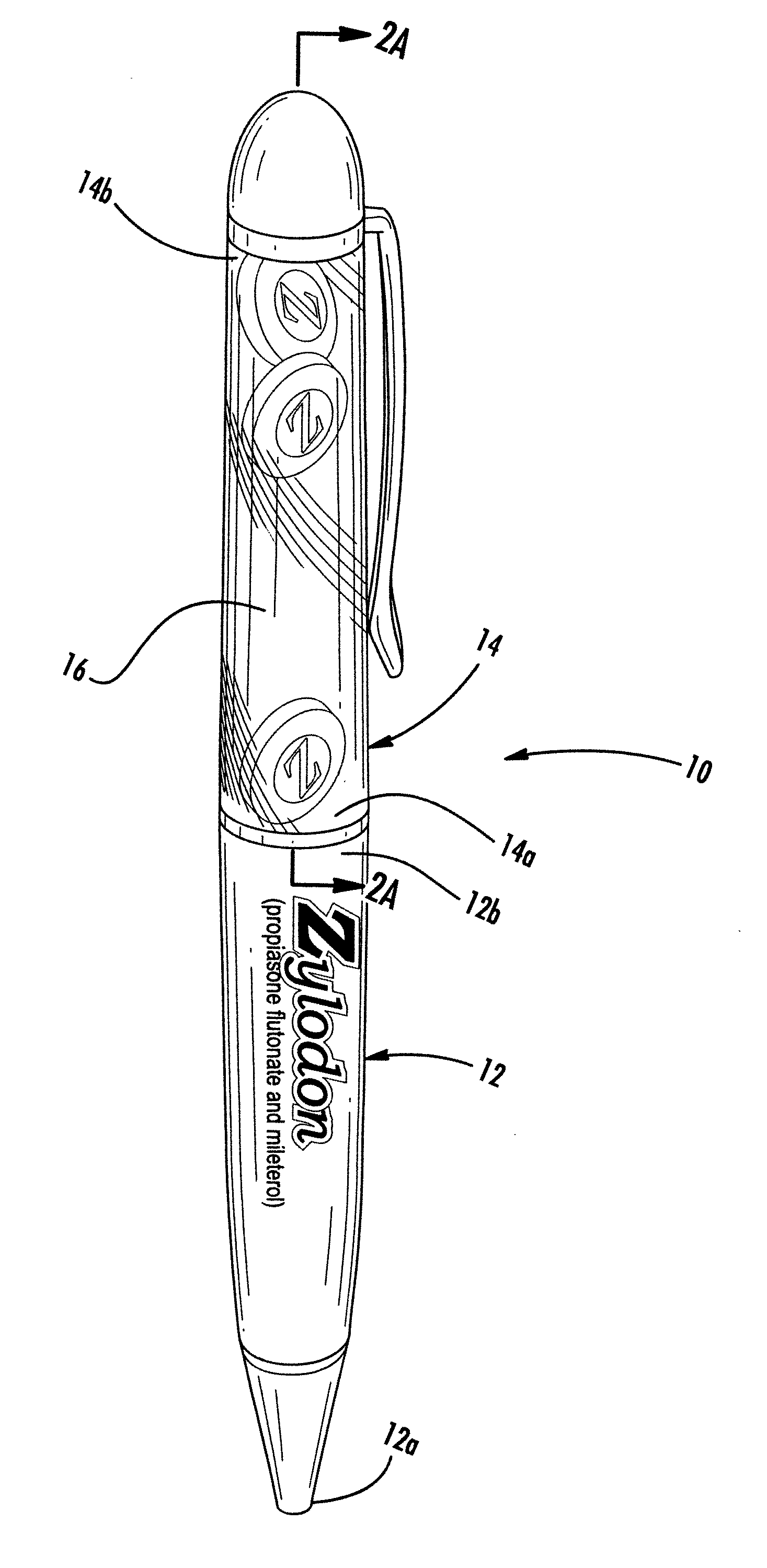

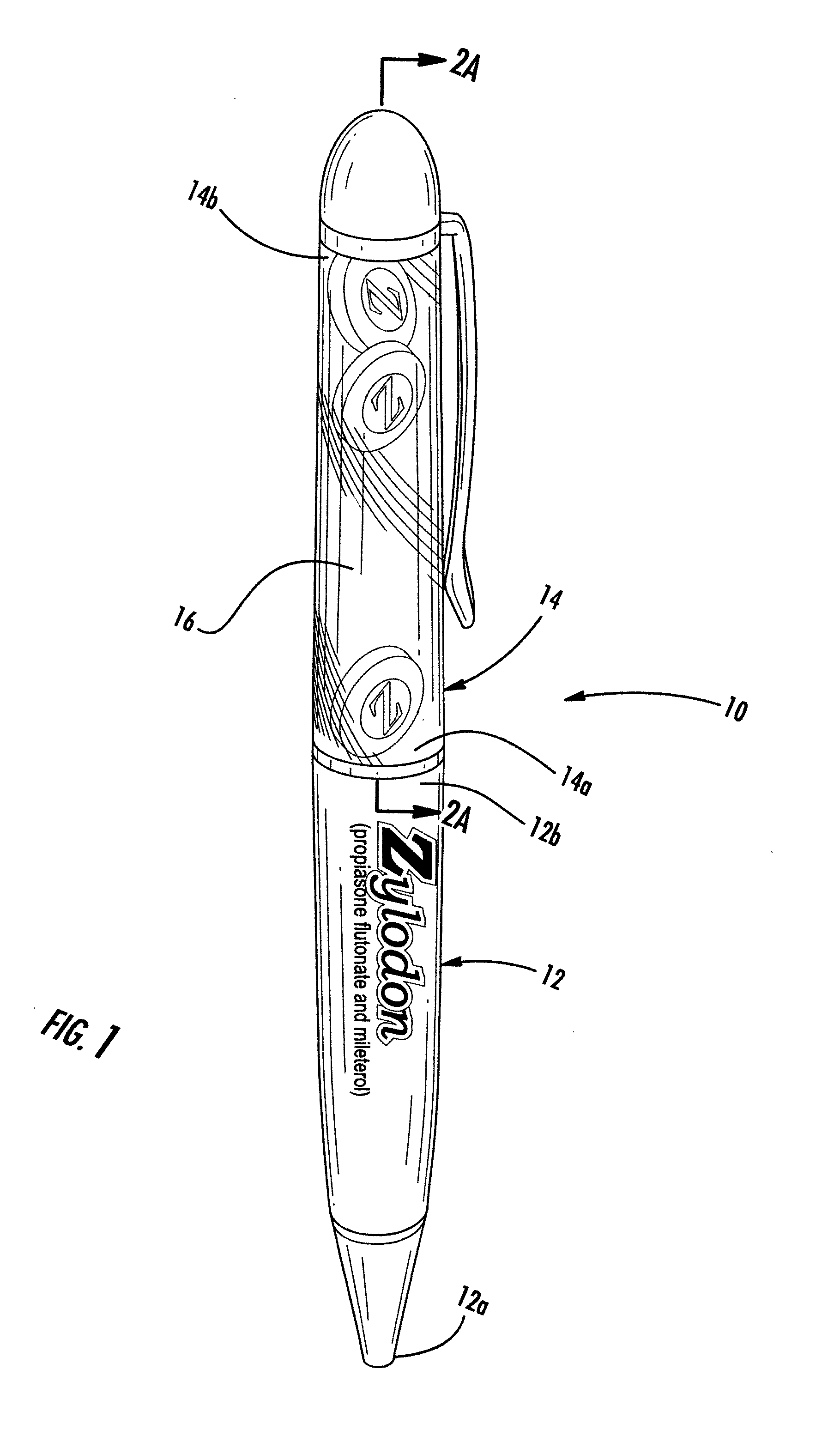

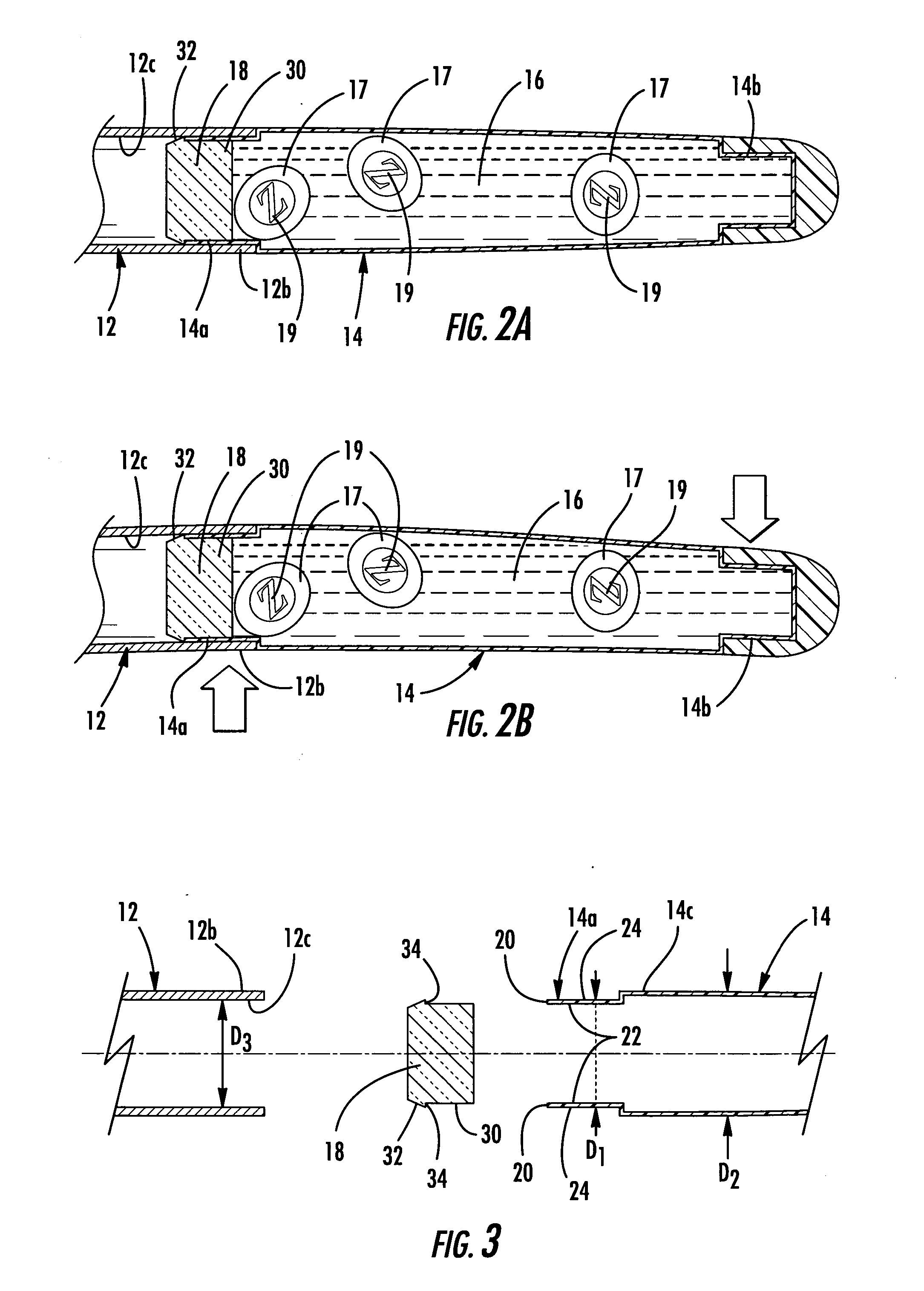

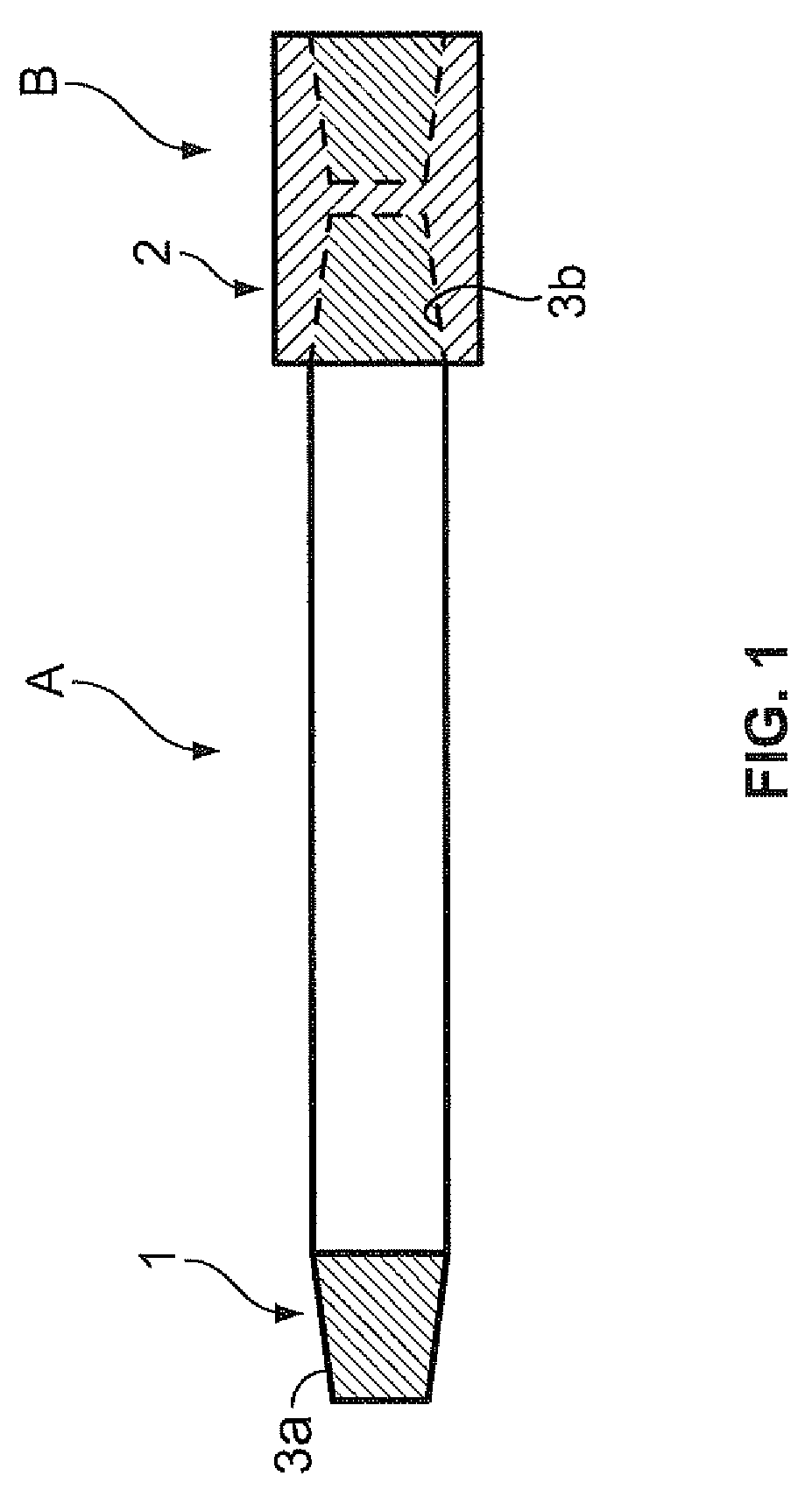

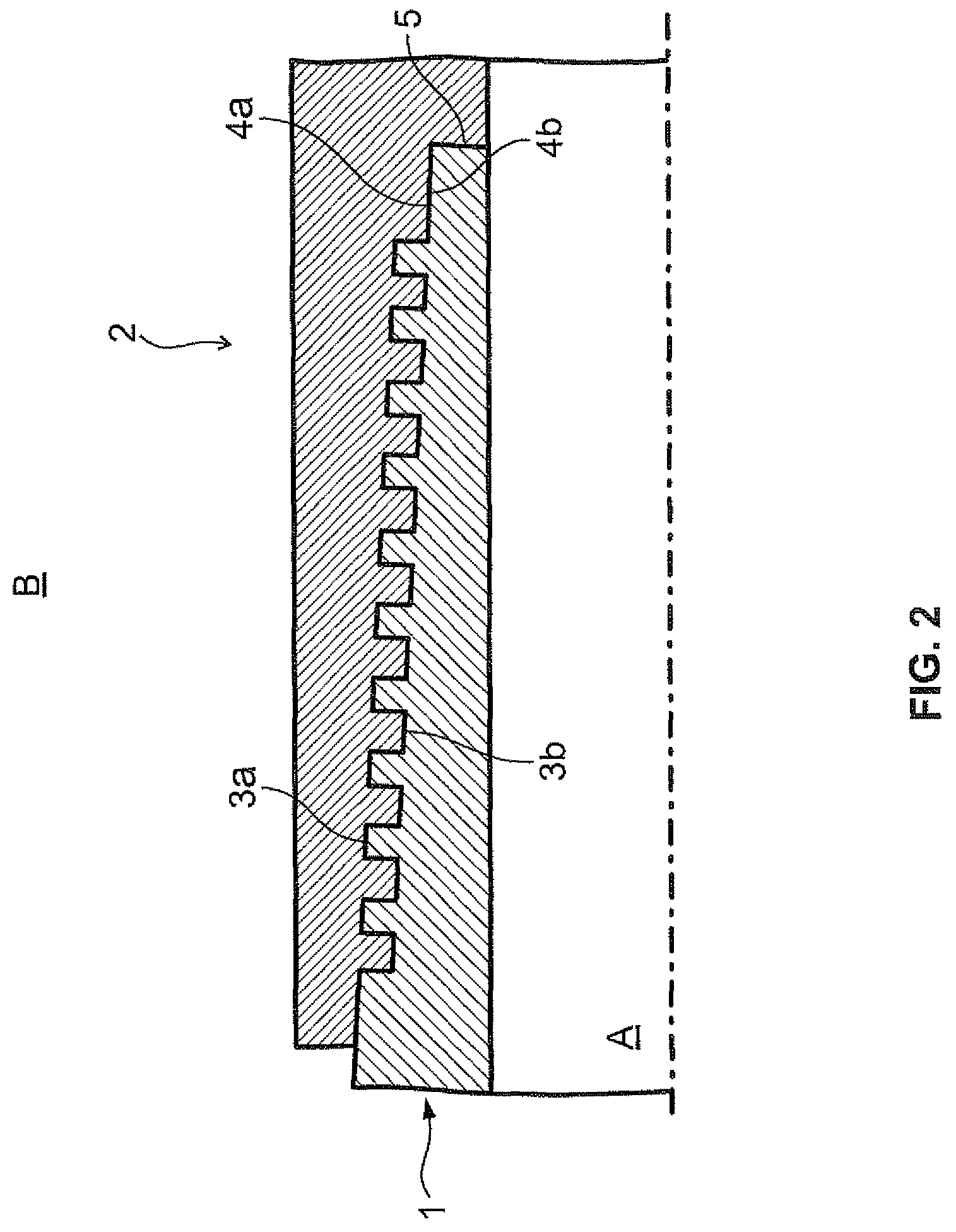

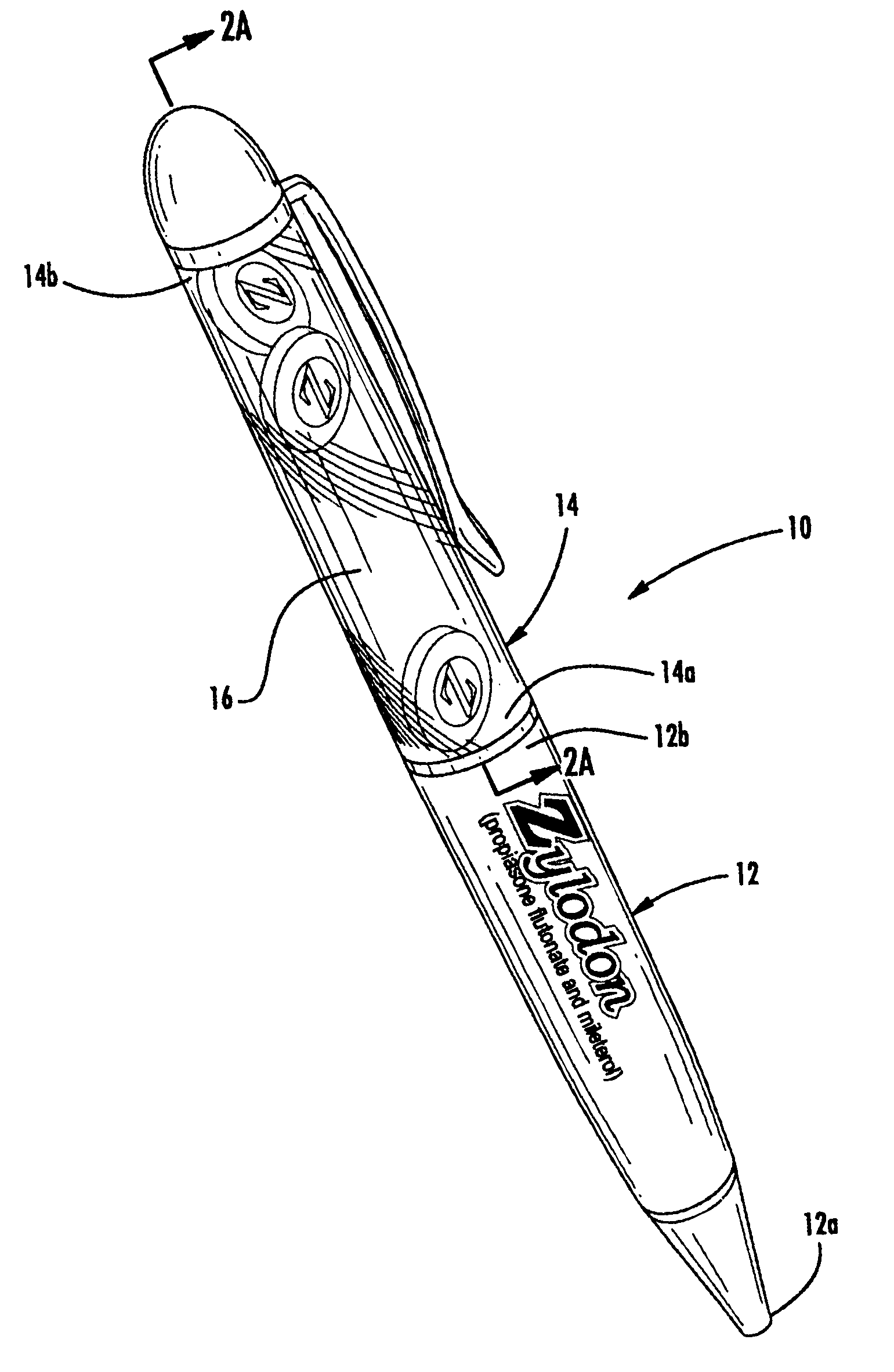

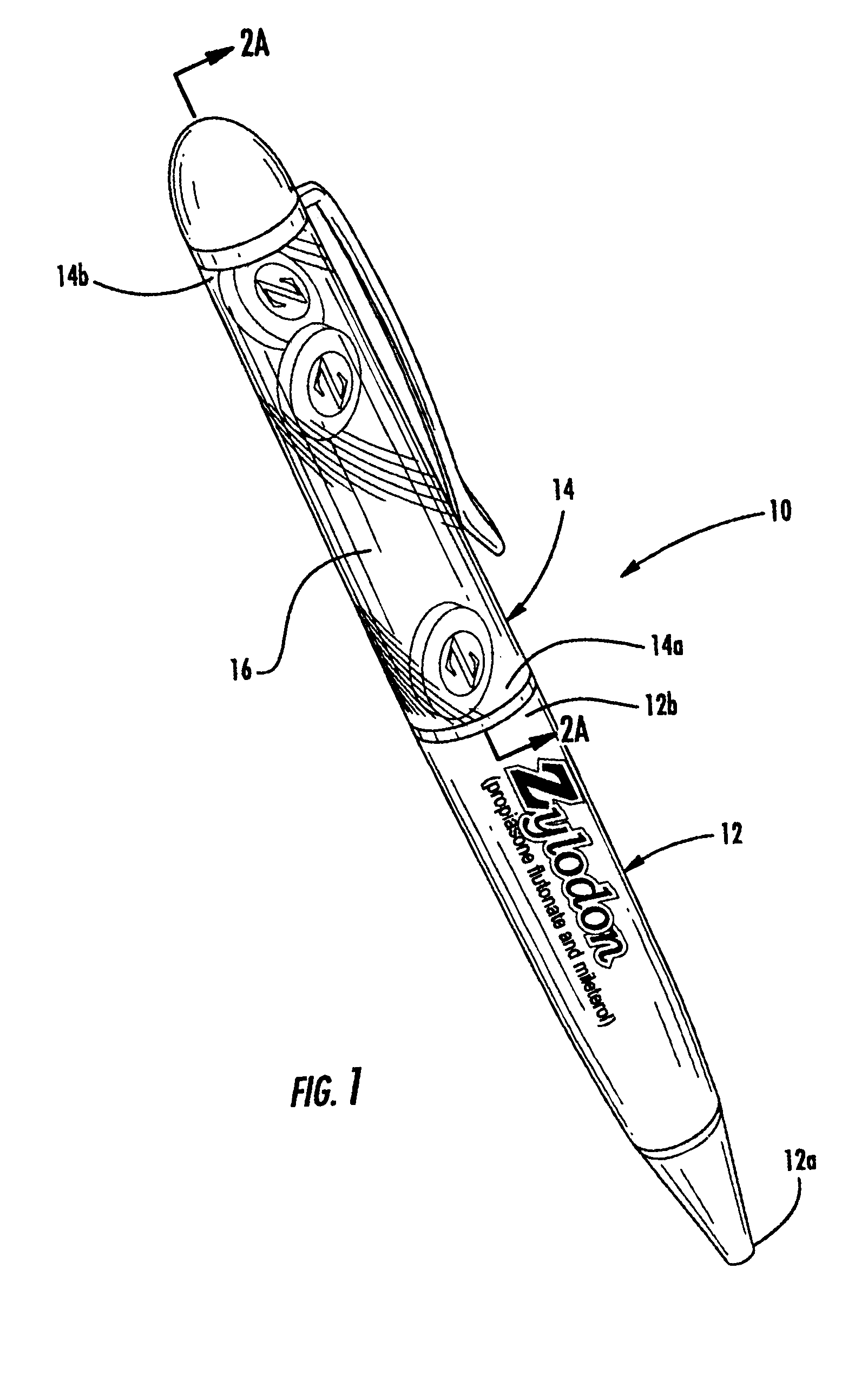

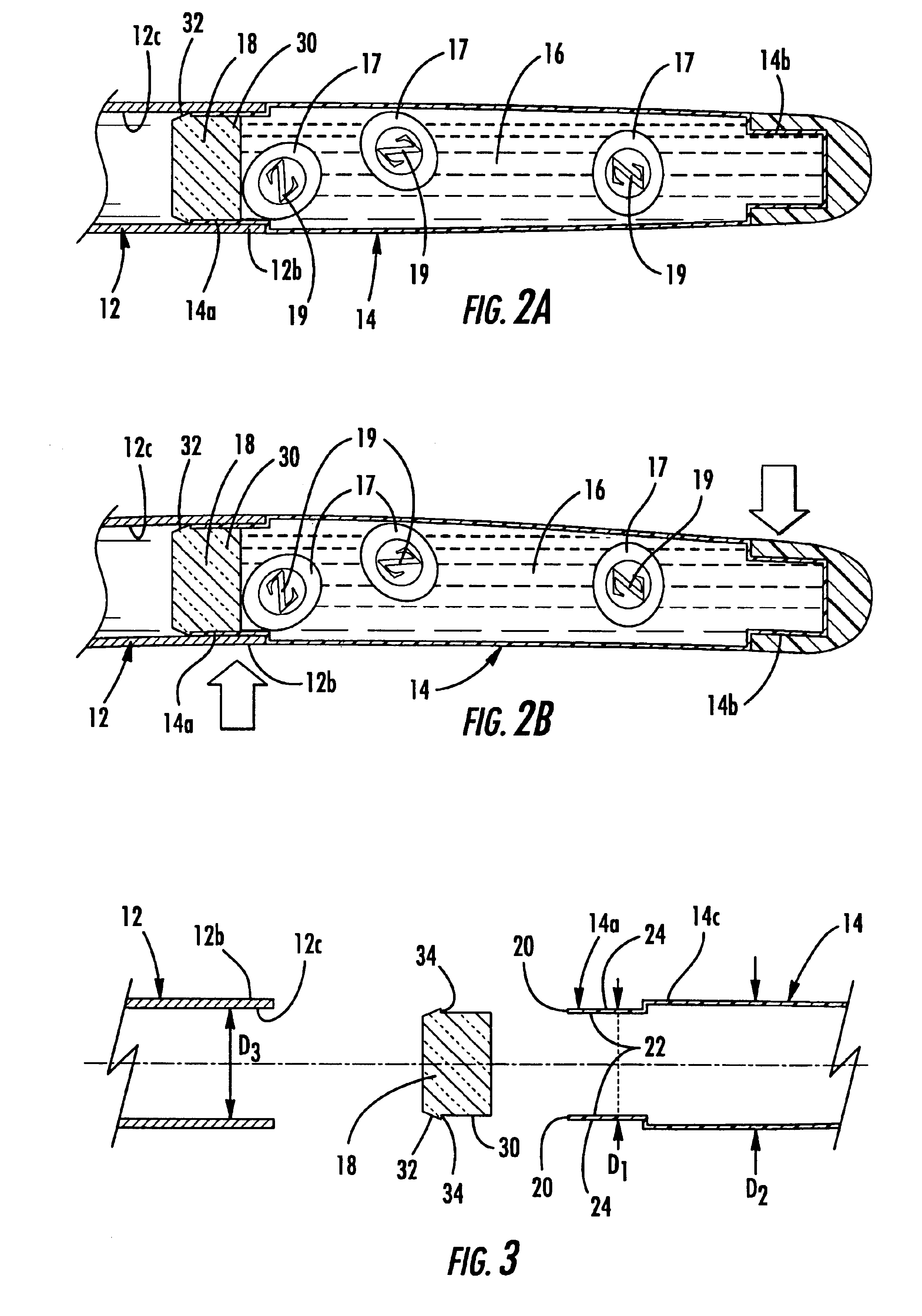

Writing instrument with fluid-containing barrel

A promotional writing instrument includes elongated first and second barrel portions. The second barrel portion is transparent and hollow and includes an open end and an opposite closed end. A fluid is disposed within the hollow second barrel portion and is viewable through the transparent second barrel portion. A plug seals the second barrel portion such that the fluid is prevented from escaping from the hollow second barrel portion. The plug is configured so as not to contact the inside surface of the first barrel portion even under flexure of the first and second barrel portions.

Owner:ADSTRACTS

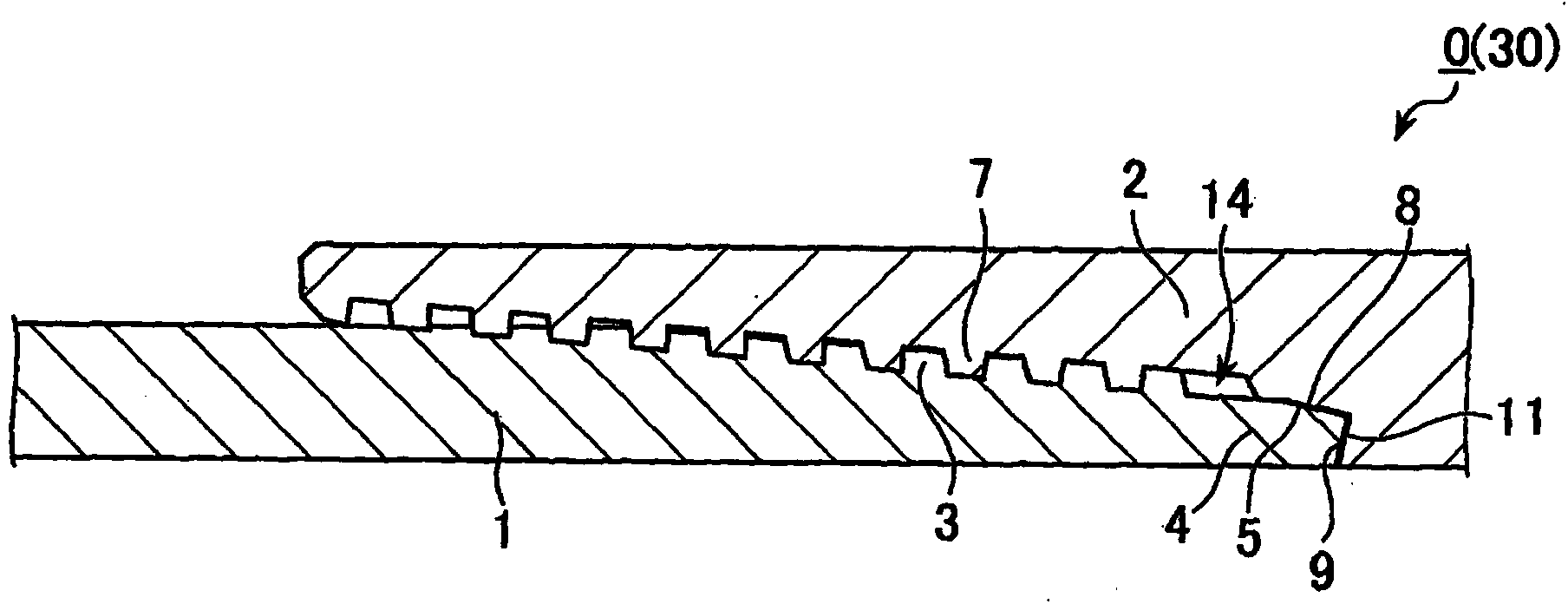

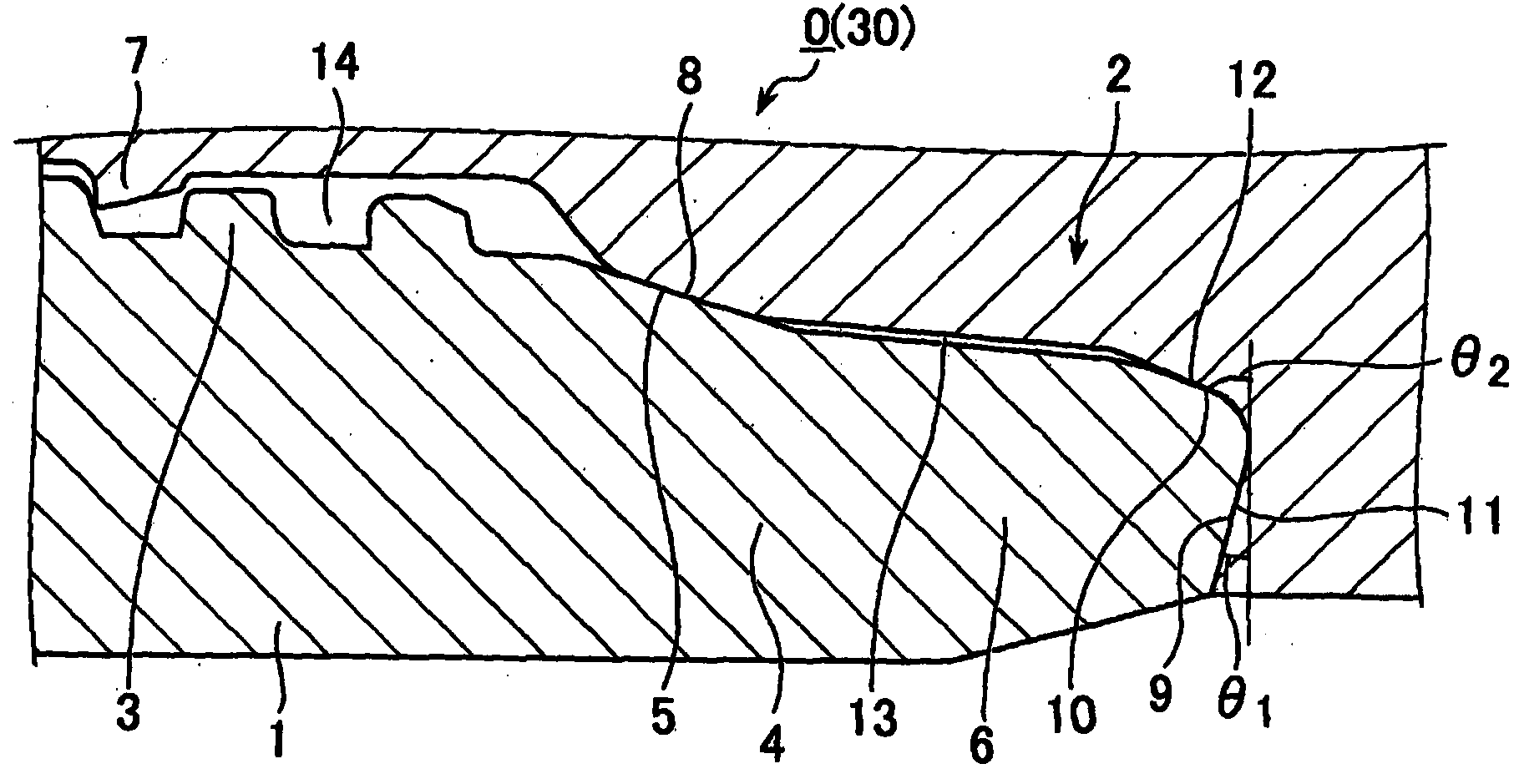

Threaded joint for pipes

ActiveCN104114926AImprove wear resistanceImprove rust resistanceDrilling rodsCorrosion preventionScrew threadBiomedical engineering

A threaded joint for pipes comprises a pin 1 and a box 2 each having a contact surface including a threaded portion 3,7 and an unthreaded metal contact portion. The unthreaded metal contact portion includes a sealing surface 5, 8 and a shoulder surface 9, 10, 11, 12. The shoulder surface of the pin is located on the end surface of the pin. A non-contacting region 13 in which the pin and the box do not contact each other is present between the sealing surfaces and the shoulder surfaces of the pin and the box. The threaded joint has one or more grooves formed in the shoulder surface of at least one of the pin and the box and extending to the non-contacting region and to the interior of the threaded joint. At least the contact surface of at least one of the pin and the box has a solid lubricating coating exhibiting plastic or viscoplastic rheological behavior formed thereon. The total volume V (mm3) of the grooves and the coating weight W (g) of the solid lubricating coating satisfy the equation V / W >= 24 (mm3 / g).

Owner:NIPPON STEEL CORP +1

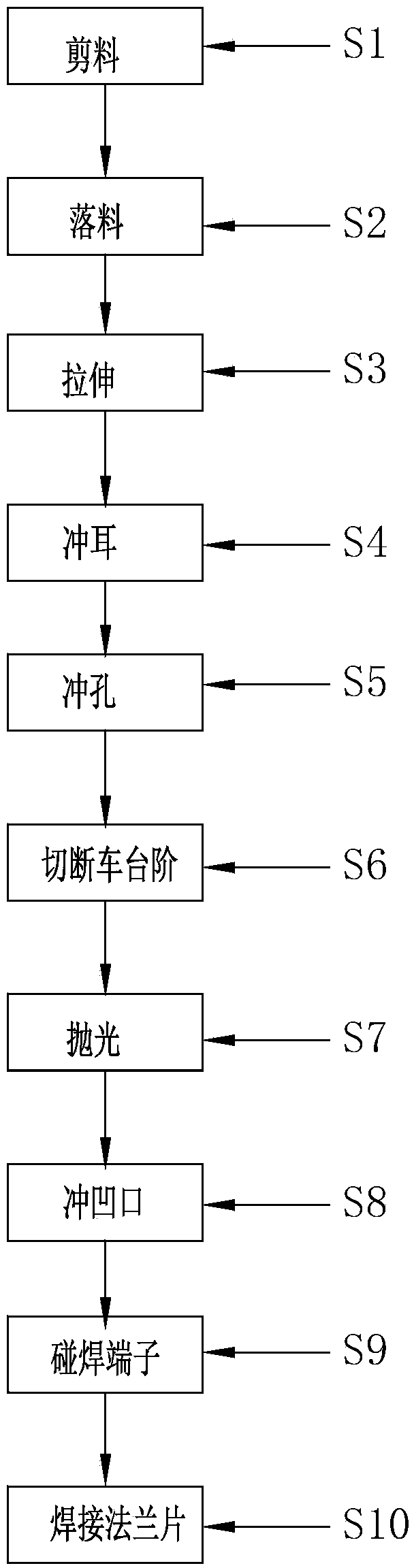

Manufacturing and processing technology of piston barrel

The invention discloses a manufacturing and processing technology of a piston barrel. The technology comprises steps as follows: S1, shearing; S2, blanking; S3, stretching; S4, lug stamping; S5, punching; S6, cutting and step turning, that is, the barrel bottom is cut off to form a communicated tubular structure, and a step is turned on the outer side surface of the lower part of the barrel; S7, polishing of the inner side wall of the barrel; S8, notch punching: a notch is punched in the end port of the top of the barrel in the radial direction; S9, welding of a terminal: the terminal is welded on the outer side surface of the upper part of the barrel; and S10, welding of a flange; the flange is welded on the step and is tightly attached to the end surface of the step. According to the manufacturing and processing technology, a stretching technology is firstly used for manufacturing the piston barrel of a coffee machine, and the problem of leakage caused by non-uniform thickness and insufficient sealing by a conventional rolling welding technology can be solved; and besides, by means of the stretching technology, bulges during welding cannot be caused, so that the bulge part is not required to be polished, the technological steps are omitted, and the production and processing efficiency is improved.

Owner:ZHONGSHAN HENGRUN METAL PROD

Threaded joint for steel pipe

InactiveUS7866706B2Inhibit wearImprove wear resistanceDrilling rodsPipe protection against corrosion/incrustationGraphiteCopper

A threaded joint for a steel pipe comprises a pin and a box with a contact surface having a threaded part and a unthreaded metal contact part, wherein a solid lubricating film containing one or more kinds of lubricating powders selected from graphite, mica, calcium carbonate and kaolin, a copper powder, and a binder is formed on at least one contact surface of the pin and the box. An object of the present invention is to provide a threaded joint for a steel pipe which allows for repeated fastening and loosening of a threaded joint without adversely influencing on a human body and environment, and is excellent in galling resistance, rust preventing property and gas tightness.

Owner:VALLOUREC OIL & GAS FRANCE SAS

Microfluidic atom cavity, on-chip atomic clock chip and preparation method

InactiveCN102515084AAvoid enteringReduce performanceApparatus using atomic clocksDecorative surface effectsChemical physicsMicrofluidics

The invention discloses a microfluidic atom cavity, an on-chip atomic clock chip and a preparation method. The method includes steps: a silicon substrate with a microfluidic channel and a borosilicate glass assembly wafer with a glass microcavity structure corresponding to the microfluidic channel are bonded to form a closed system, the closed system comprises a glass atom cavity, a reactant partition microfluidic channel and a reactant microcavity, reactant particles of materials necessarily required by atomic clock generation are arranged in the reactant microcavity, the glass atom cavity is communicated with the reactant microcavity through the reactant partition microfluidic channel, the aperture of the reactant microcavity on a bonding surface is smaller than that of the glass atom cavity, the minimum width of the reactant partition microfluidic channel is no larger than the minimum particle diameter of the reactant particles, and the glass micro cavity is provided with a light incidence plane. The smaller microcavity containing the reactant powder is connected with the larger microcavity required by forming of the spherical glass microcavity, forming of a spherical rubidium steam cavity and sealing of gas can be completed at one step, fine sealing performance is achieved, no impurities can be led in, performance of an atomic clock can be improved, the spherical rubidium steam cavity can be integrated into a microchip-level atomic clock system, planar packaging of the atomic clock can be realized, and size of the atomic clock is reduced effectively.

Owner:SOUTHEAST UNIV

Writing instrument with fluid-containing barrel

A promotional writing instrument includes elongated first and second barrel portions. The second barrel portion is transparent and hollow and includes an open end and an opposite closed end. A fluid is disposed within the hollow second barrel portion and is viewable through the transparent second barrel portion. A plug seals the second barrel portion such that the fluid is prevented from escaping from the hollow second barrel portion. The plug is configured so as not to contact the inside surface of the first barrel portion even under flexure of the first and second barrel portions.

Owner:ADSTRACTS

Transmission mechanism of compact shelf

ActiveCN110419872AEasy to operateExtended service lifeGearingCabinetsEngineeringMechanical engineering

The invention provides a transmission mechanism of a compact shelf. The transmission mechanism of the compact shelf comprises two bottom fixing plates, sliding rails, a driving assembly, two support plates, transmission assemblies and two adjusting assemblies, wherein the driving assembly is arranged on one sides of the bottom fixing plates; the support plates are fixed between one opposite sidesof the two bottom fixing plates; the transmission assemblies are arranged on the support plates; and the two adjusting assemblies are arranged on the two support plates. For the transmission mechanismof the compact shelf provided by the invention, the adjusting assemblies are arranged, a rotation handle is rotated at the outer side of the compact shelf, an adjusting gear is driven to tighten a chain, then the tightness of the chain is adjusted, the operation is simple and convenient, the compact shelf can normally move, the service life of the chain is prolonged, meanwhile, through the braking after movement of the compact shelf and no back pulling for a driving handle during the next-time movement, limiting grooves in the inner surface of the driving handle are matched with driving blocks on a first rotation shaft for driving the first rotation shaft to rotate, the operation is simple and convenient, and the adjusting precision is high.

Owner:广州冠唯实业有限公司

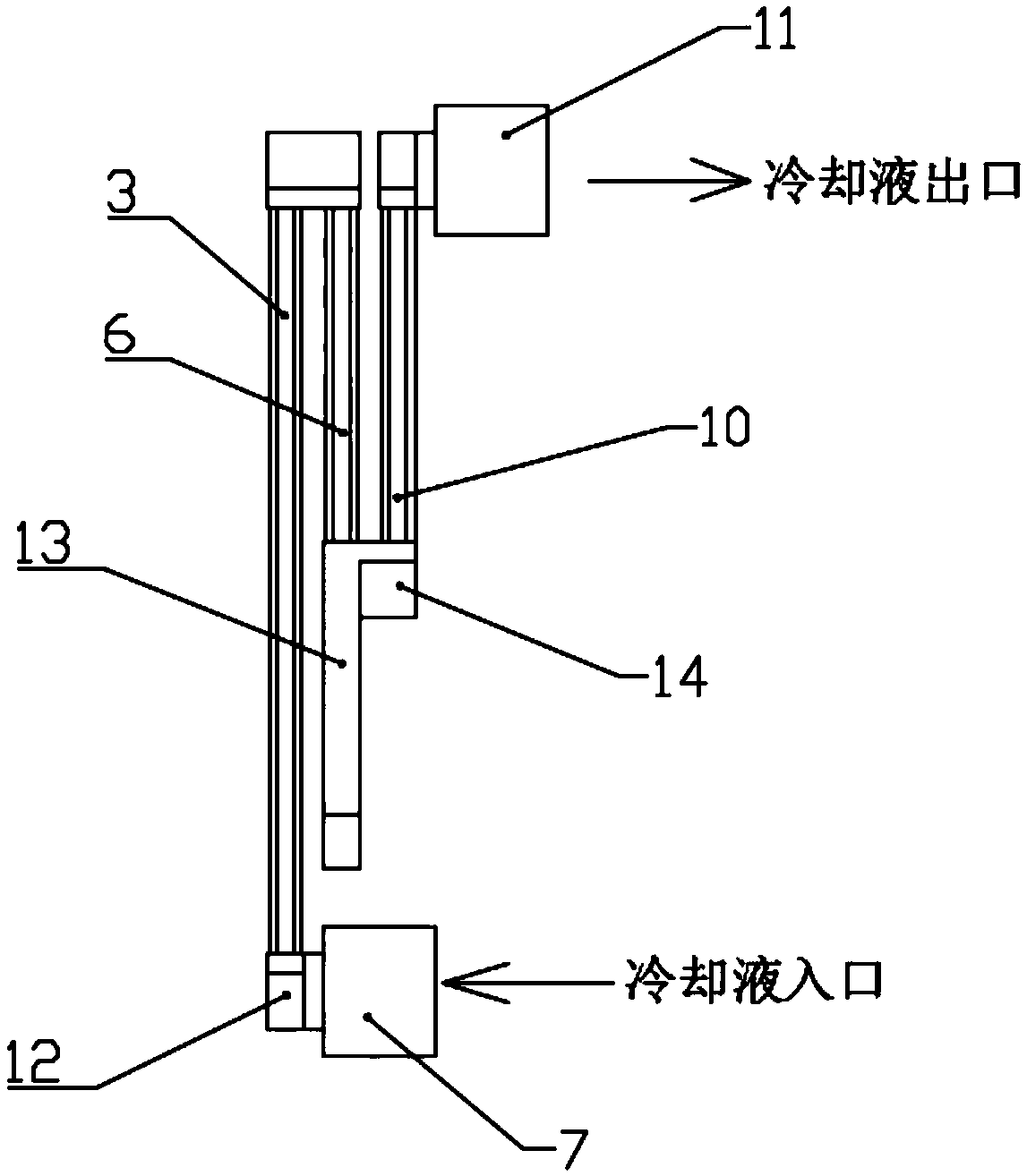

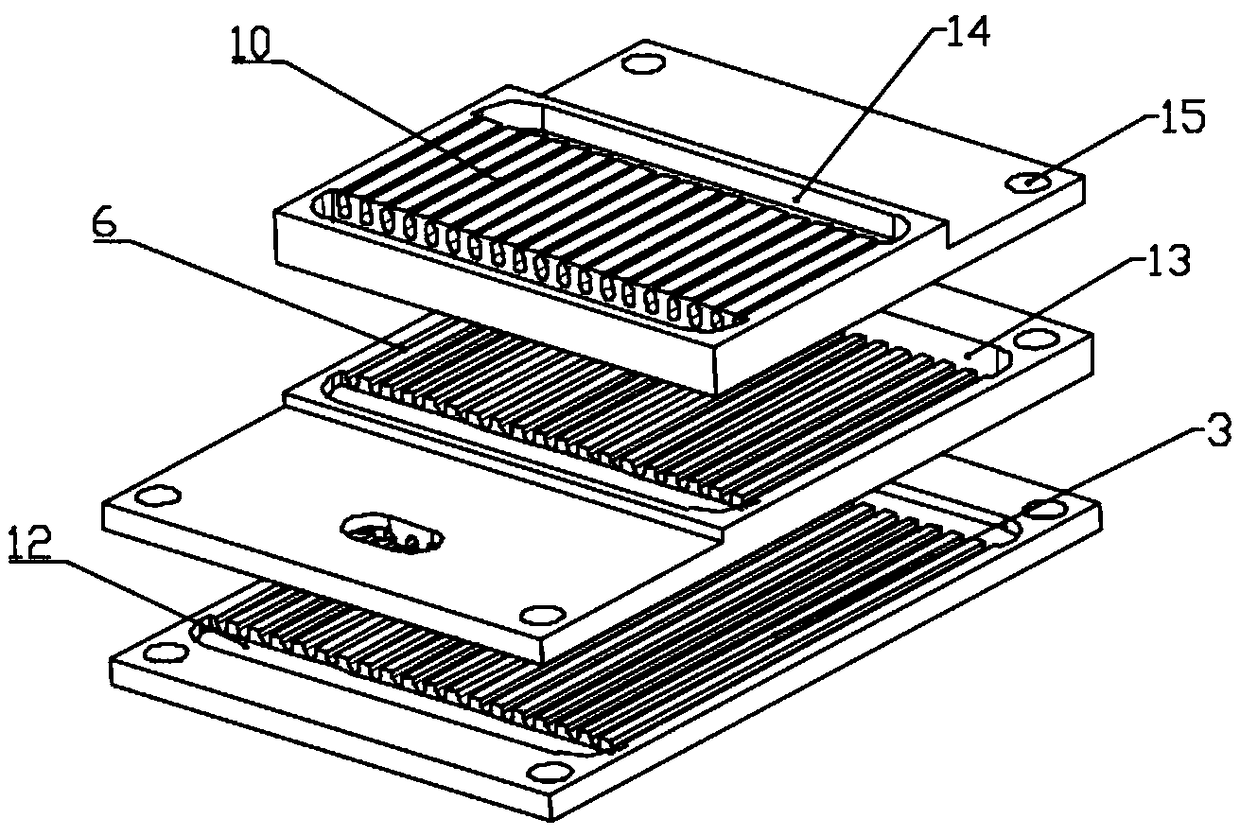

Three-dimensional micro channel and a pulsating flow heat dissipation device

ActiveCN109275311ARealize the printing functionAvoid tightnessModifications using liquid coolingEngineeringMicrochannel heat sink

The invention discloses a three-dimensional microchannel and pulsating flow heat dissipation device, which relates to the technical field of radiators, in particular to a novel three-dimensional microchannel heat dissipation device using pulsating or intermittent fluid and a 3D printing manufacturing method thereof. The heat dissipation device comprises a radiator, a pulse pump, a cooler and a connecting pipe; The heat sink is closely attached to the heat source, Connect the radiator by connecting the pipes, pulsating pump, cooler in series, The heat sink comprises a liquid injection port, a bottom layer heat dissipation structure, an intermediate layer heat dissipation structure, a top layer heat dissipation structure, a liquid outlet, the bottom layer heat dissipation structure, the intermediate layer heat dissipation structure and the top layer heat dissipation structure, which are stacked in turn, and have good heat dissipation effect, and the heat dissipation effect is further improved after the device is made into an organic whole by adopting the 3D printing method.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com