Patents

Literature

58results about How to "Uniform surface pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

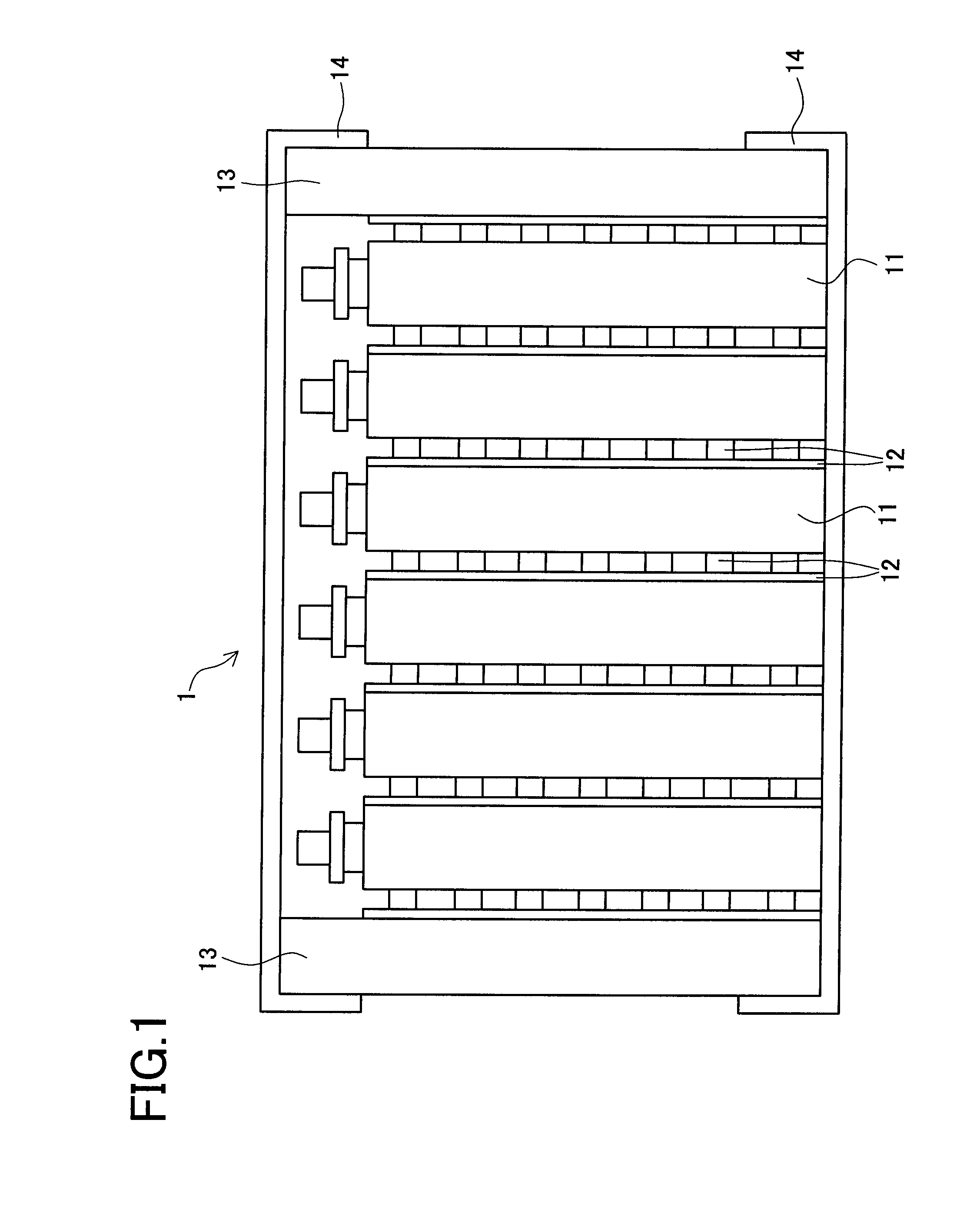

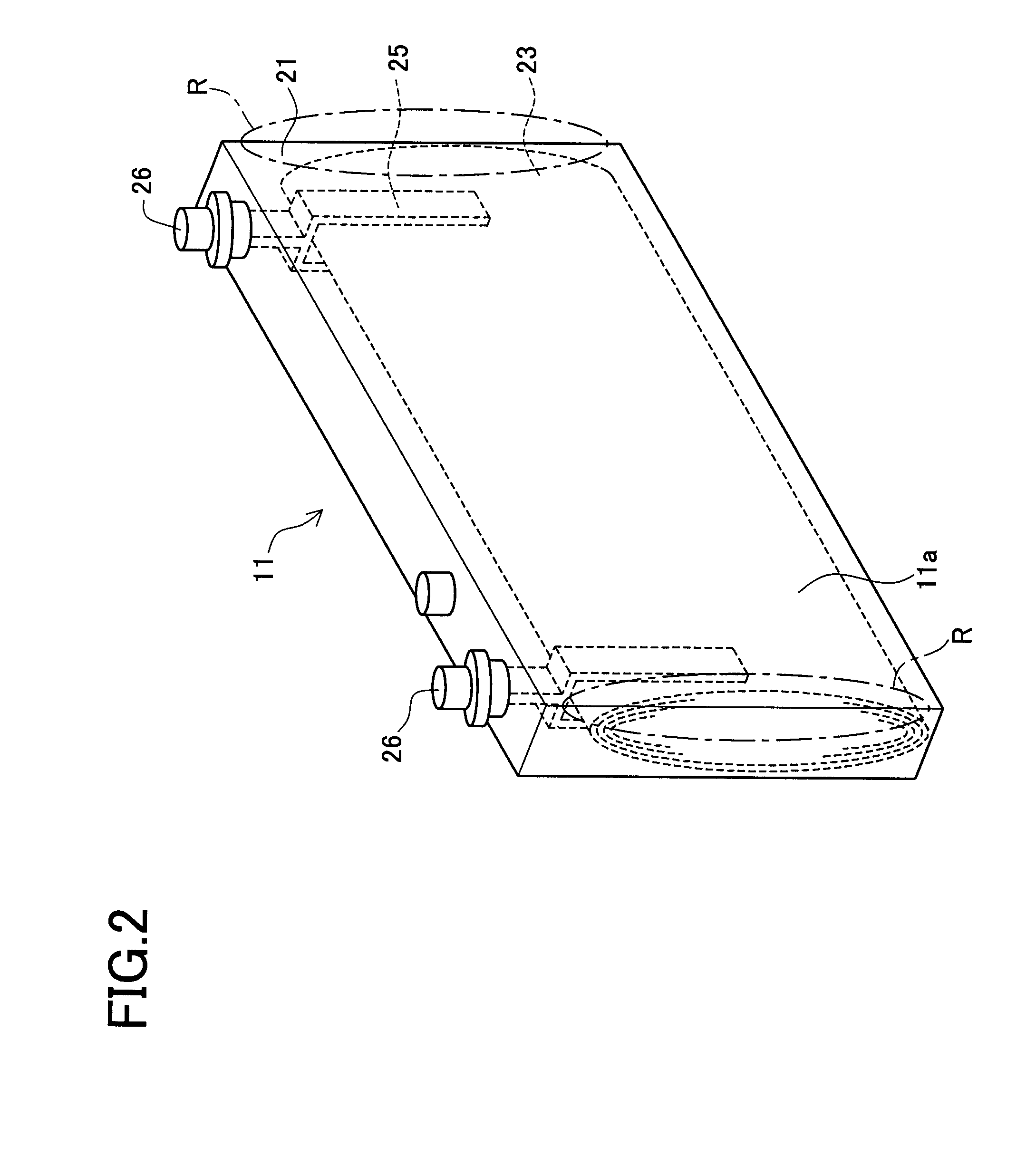

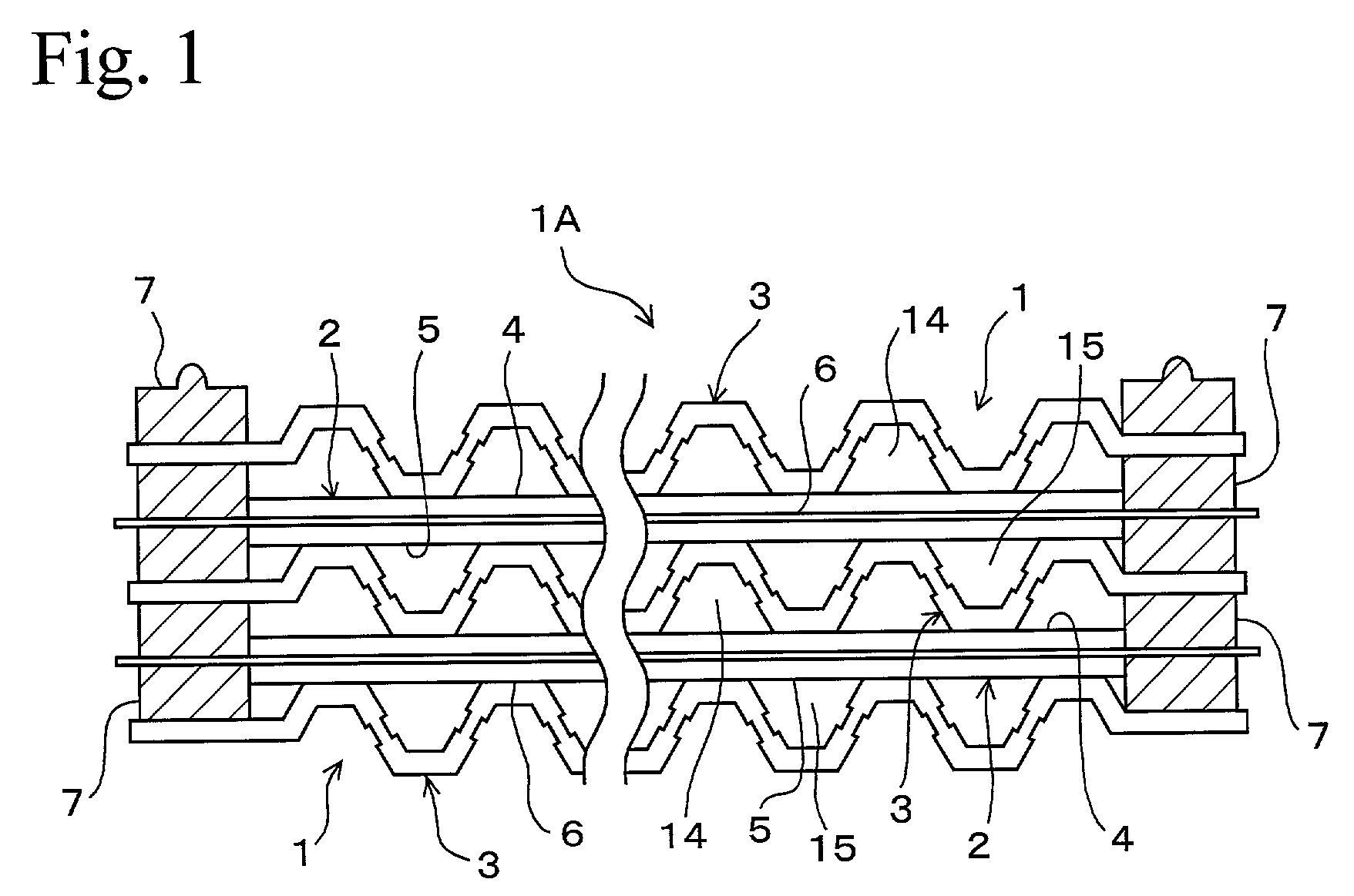

Fuel cell and fuel cell stack

InactiveUS20050136294A1Simple and compact structureSpeed up the flowFuel cells groupingFuel cell auxillariesFuel cellsOxygen

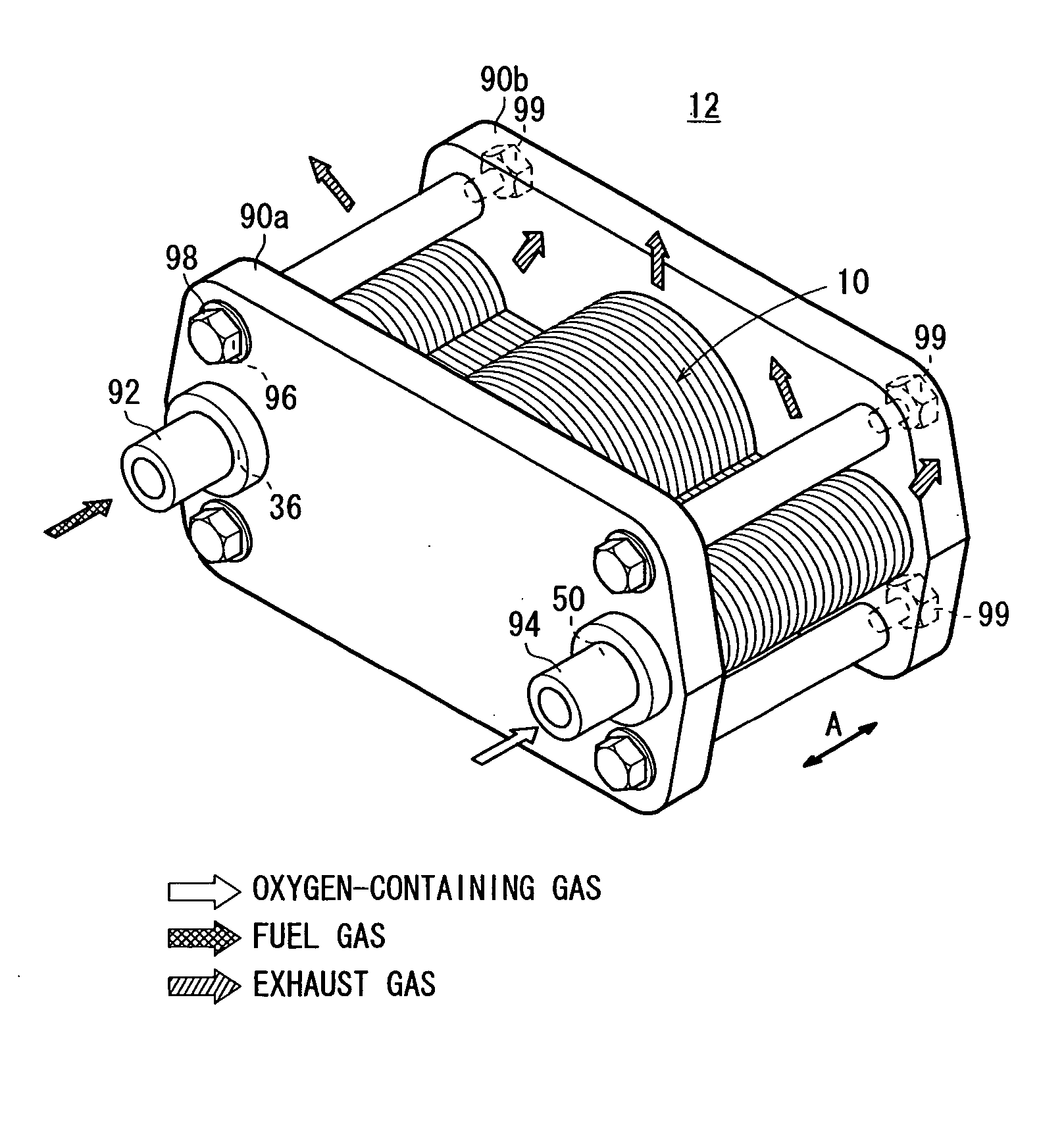

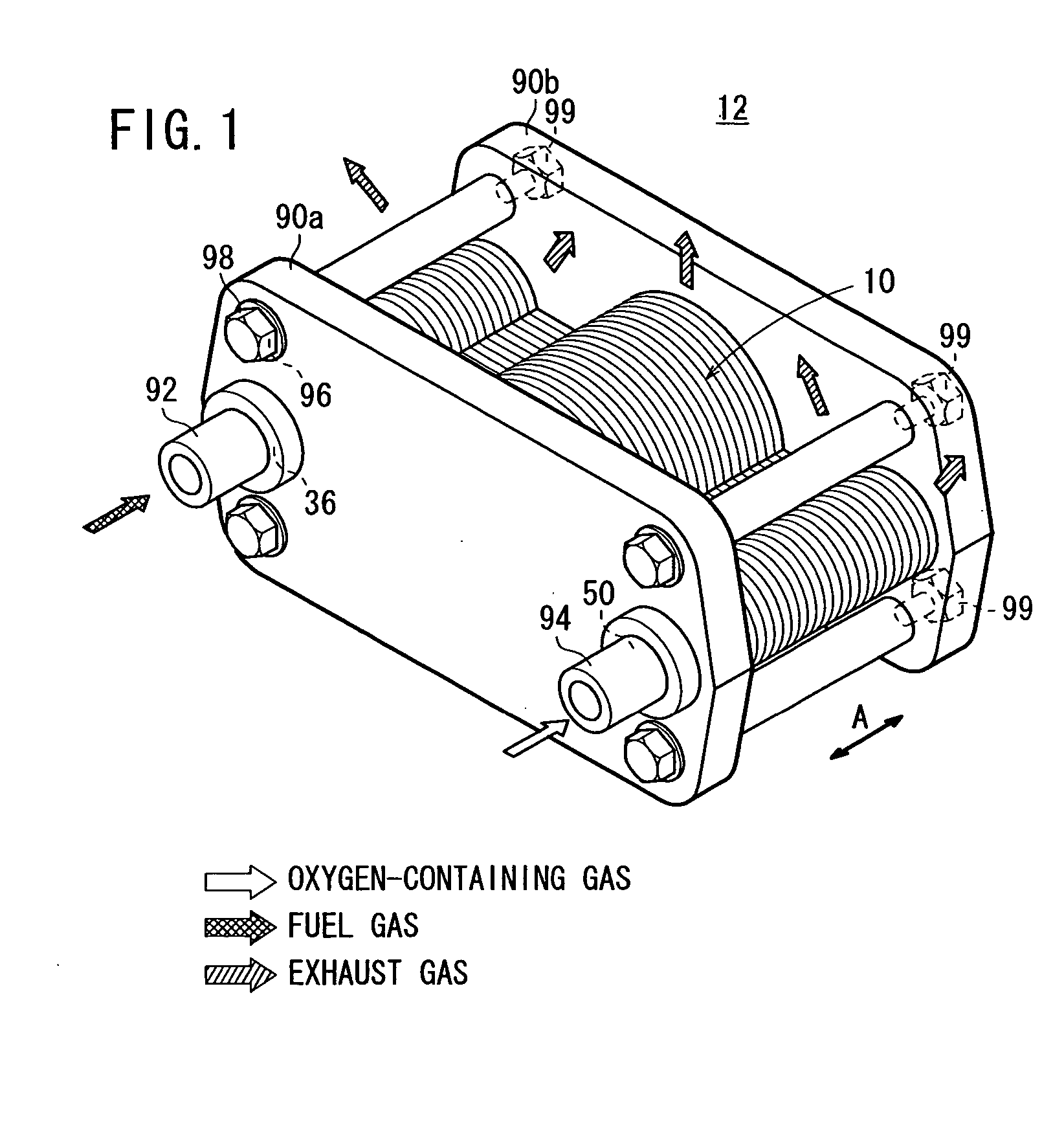

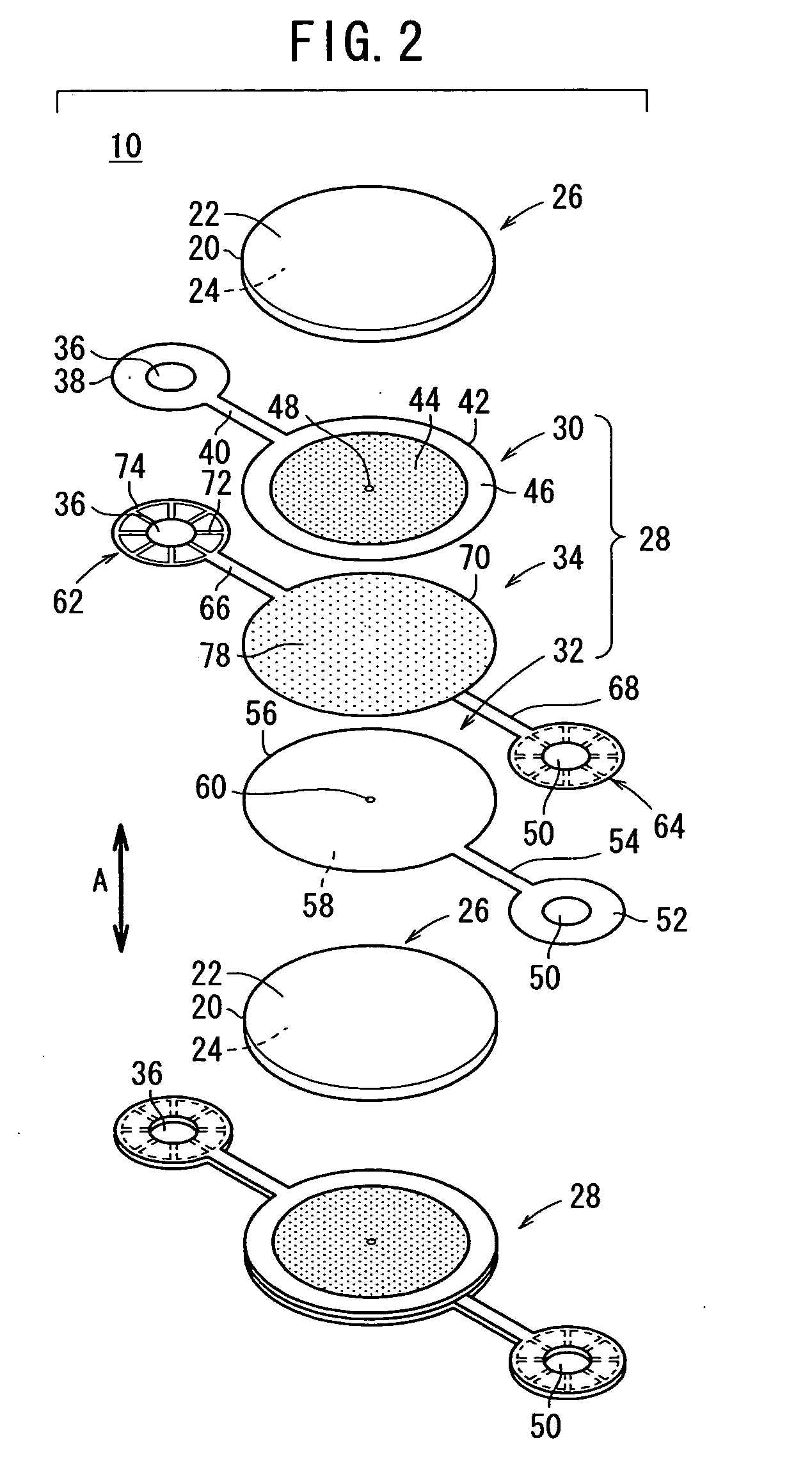

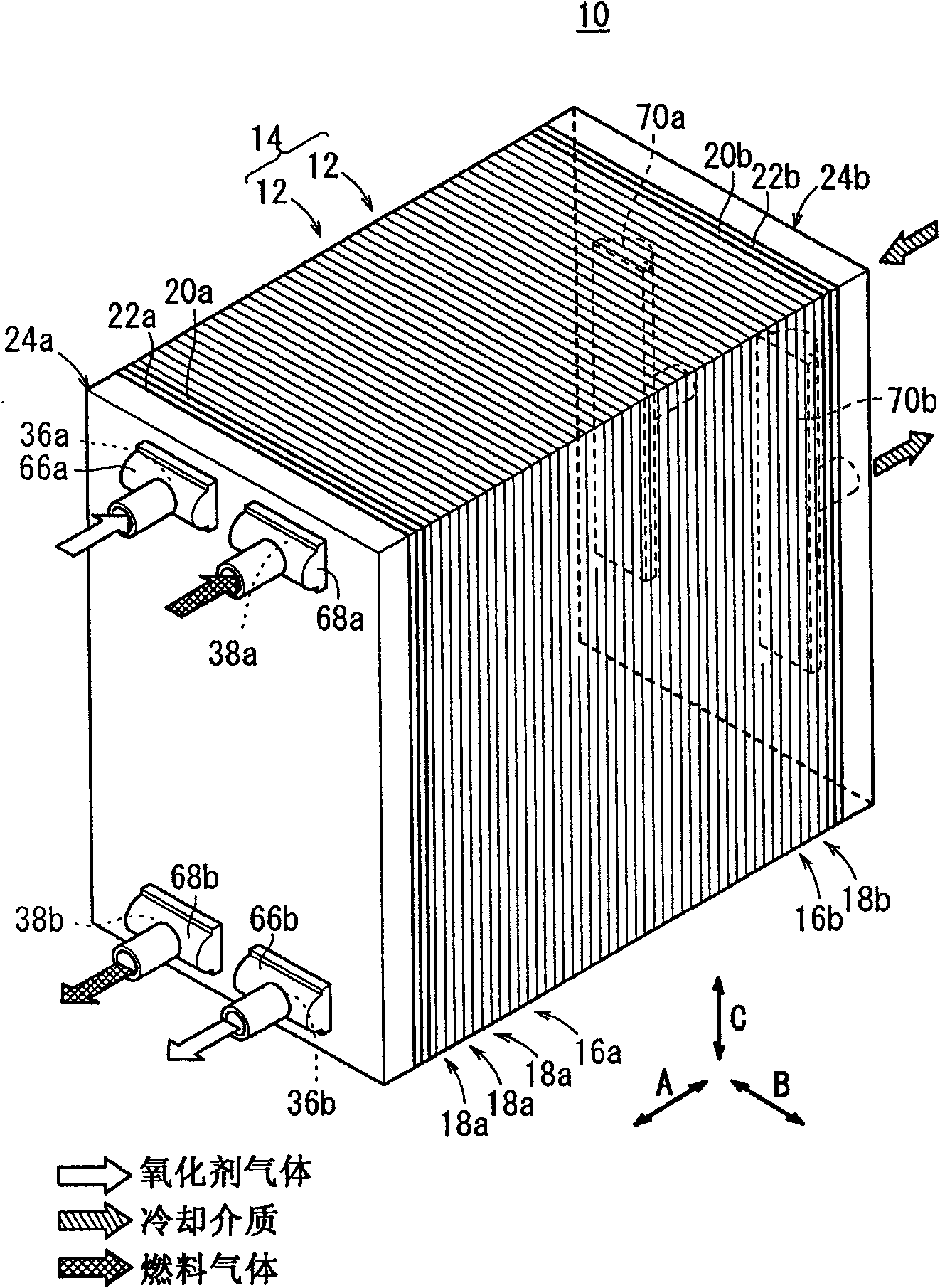

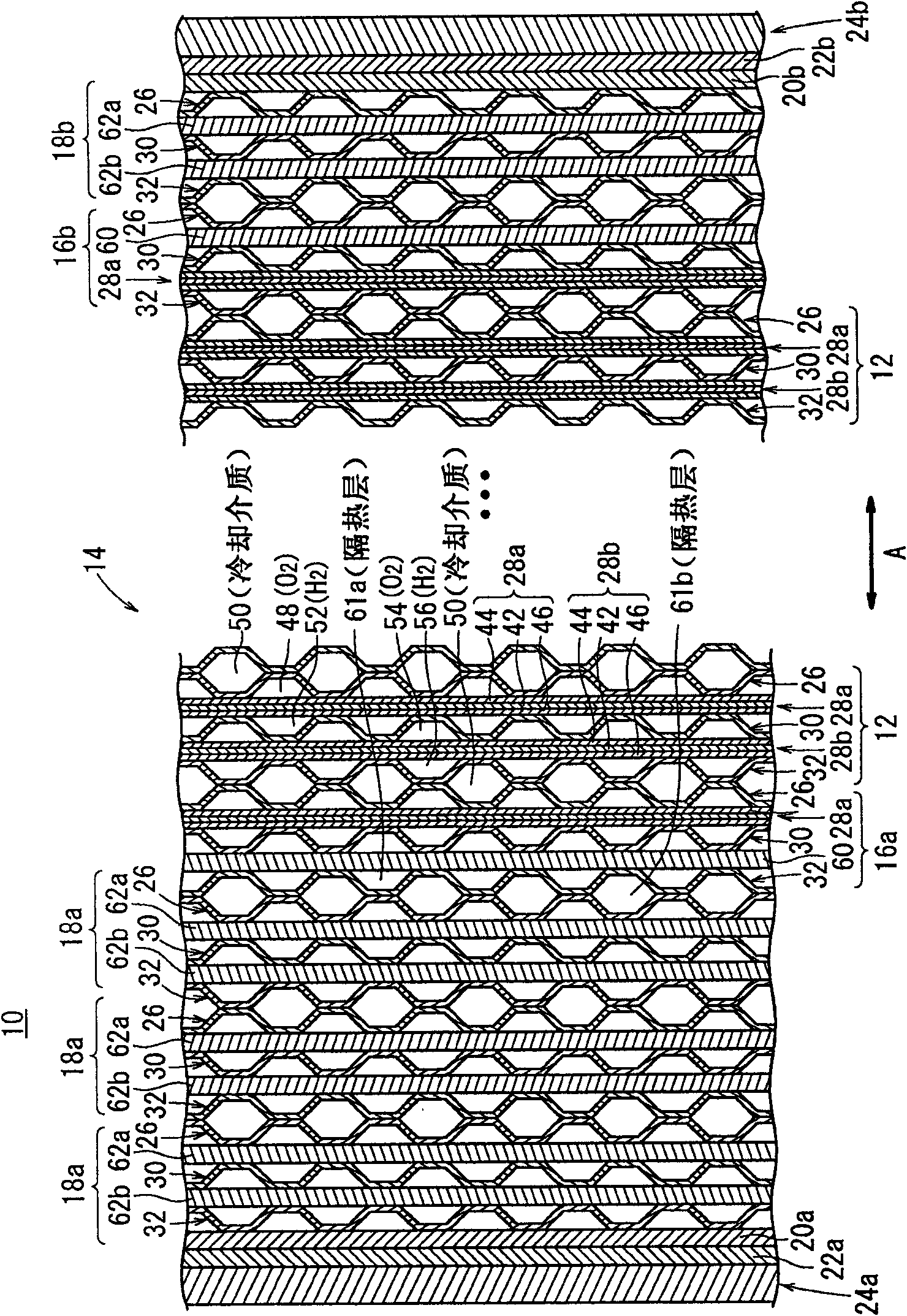

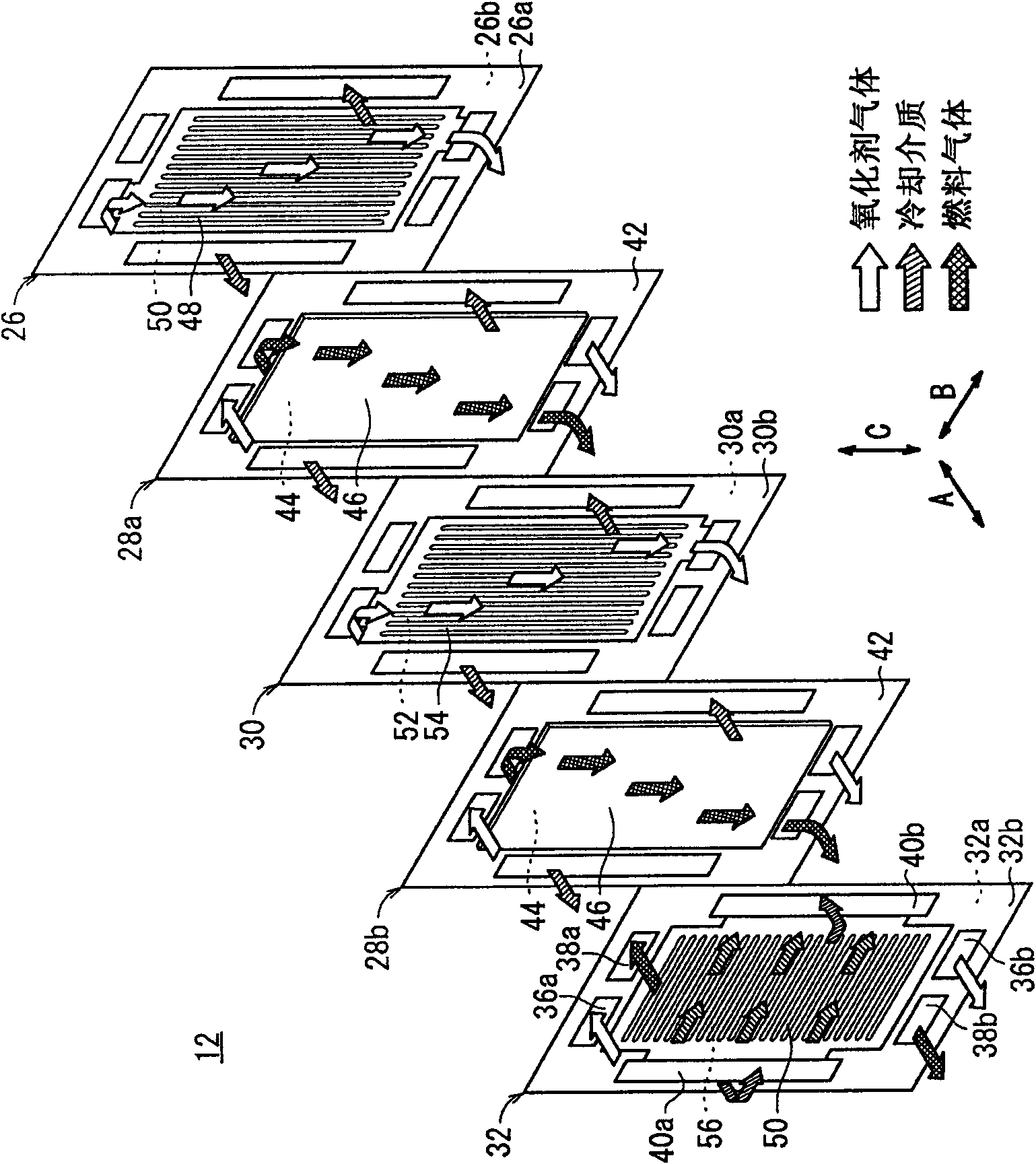

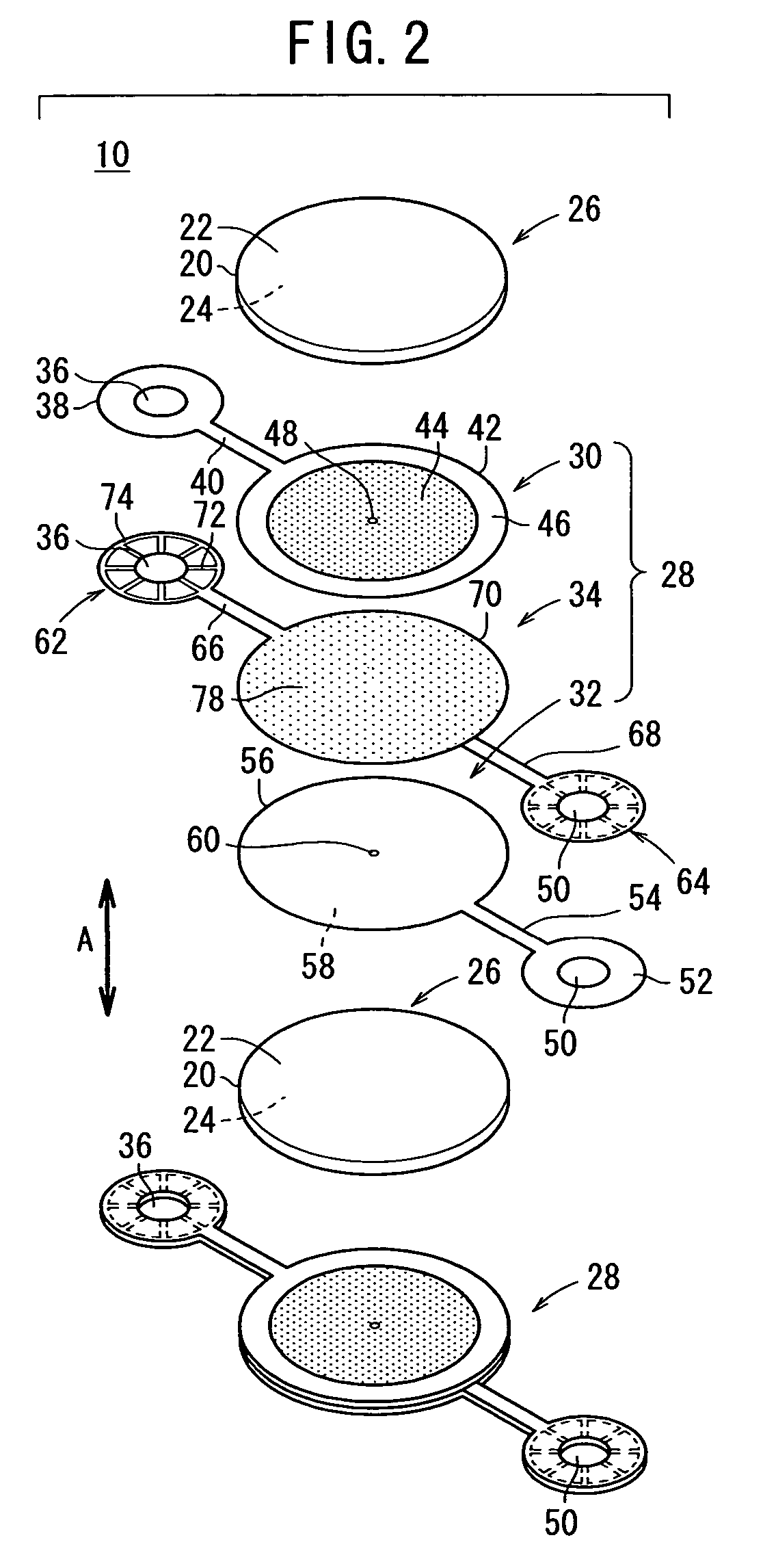

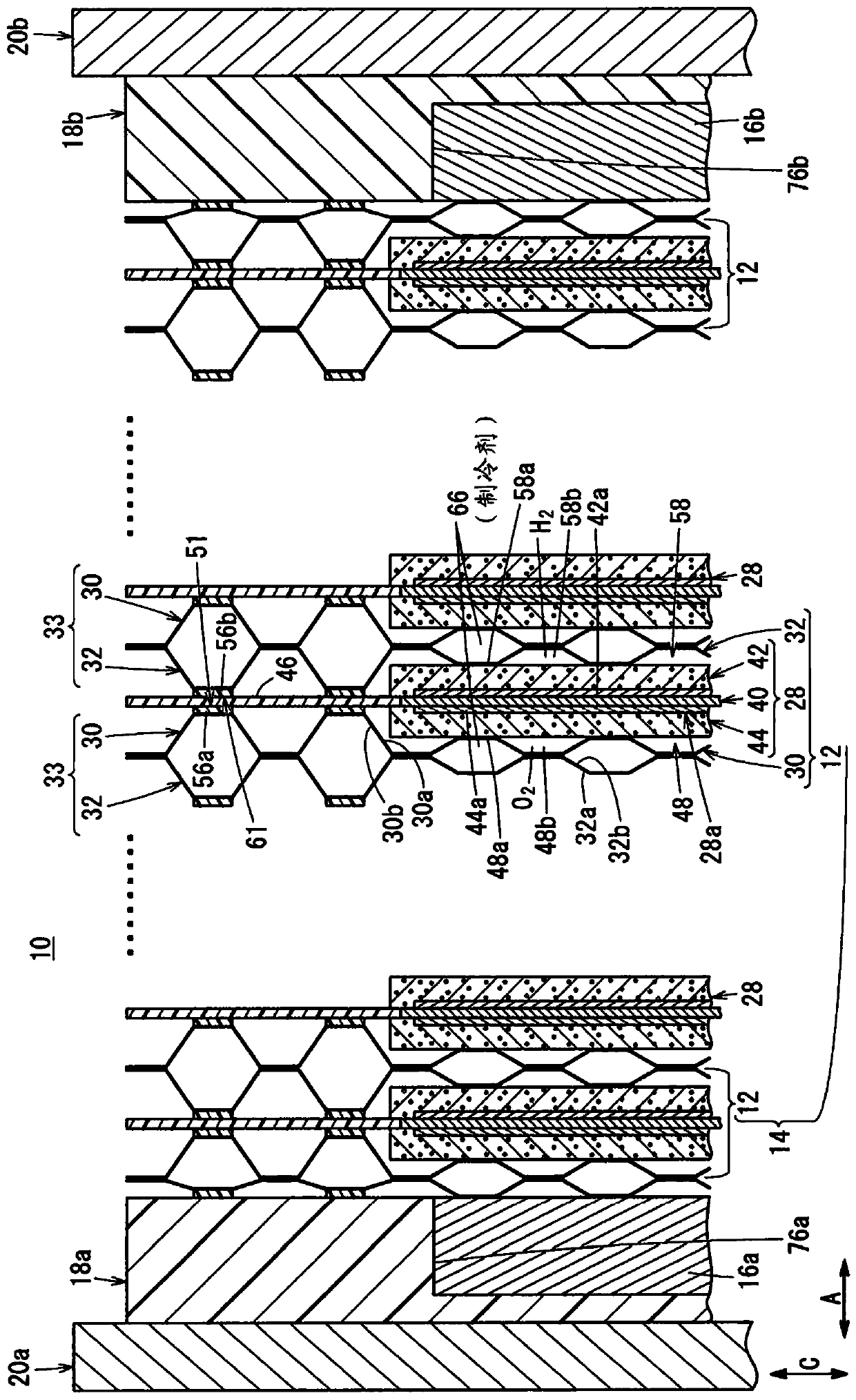

A fuel cell includes an electrolyte electrode assembly and separators. The separator includes first through third plates which are stacked together. A fuel gas channel connected to a fuel gas supply passage is formed between the first and third plates. The fuel gas channel forms a fuel gas pressure chamber between the first and third circular disks. Further, an oxygen-containing gas channel connected to an oxygen-containing gas supply passage is formed between the second and third plates. The oxygen-containing gas channel forms an oxygen-containing gas pressure chamber between the second and third circular disks.

Owner:HONDA MOTOR CO LTD

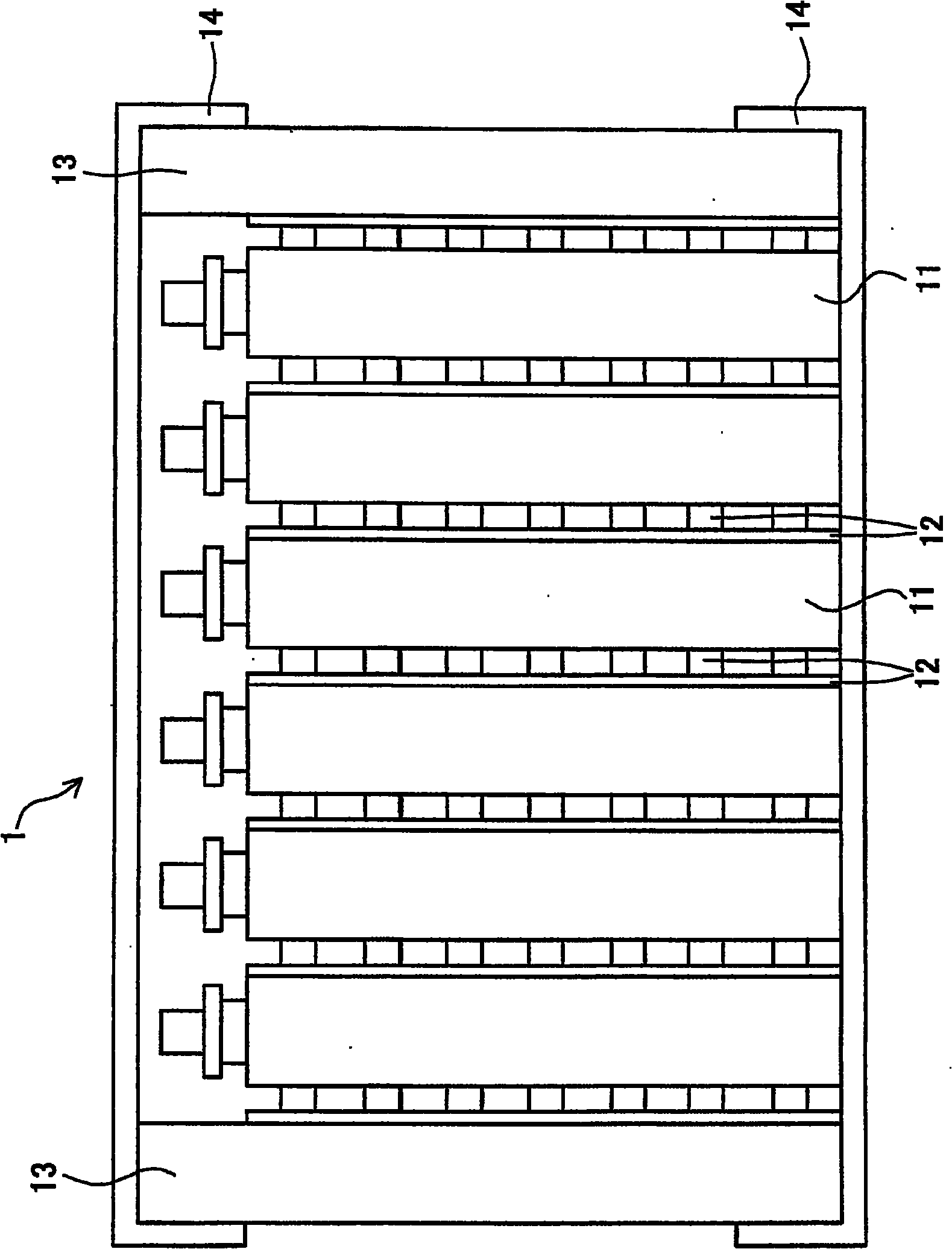

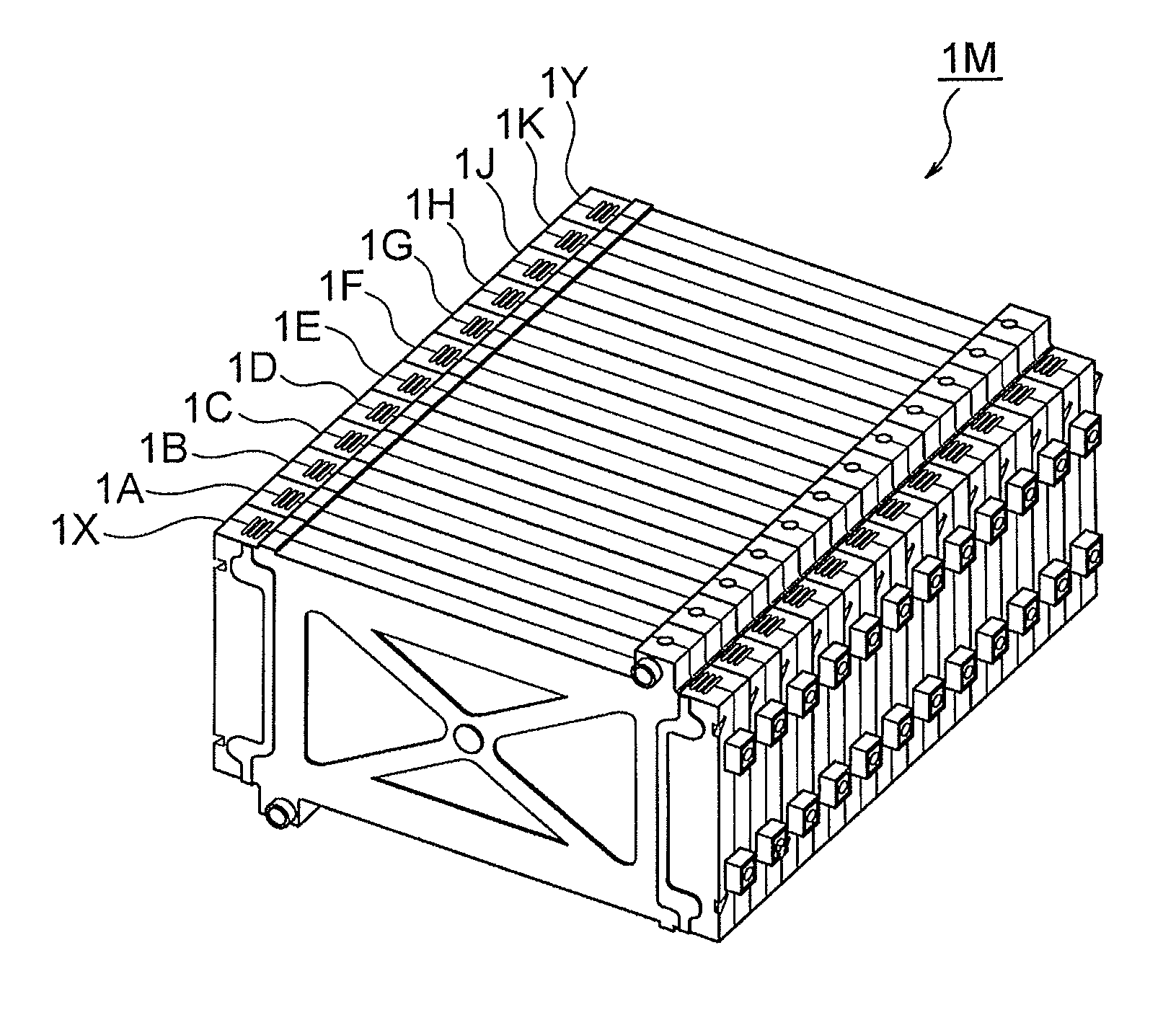

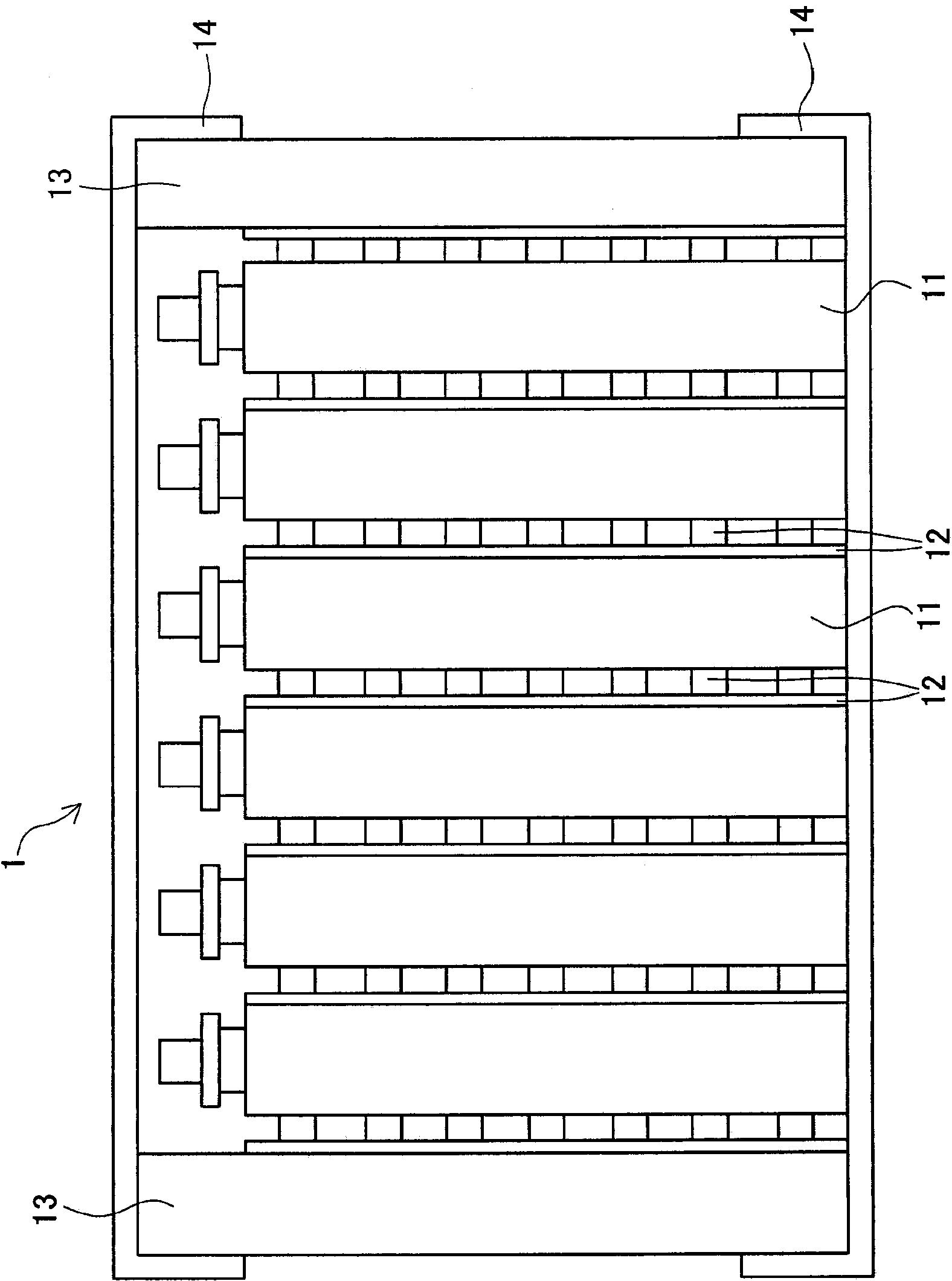

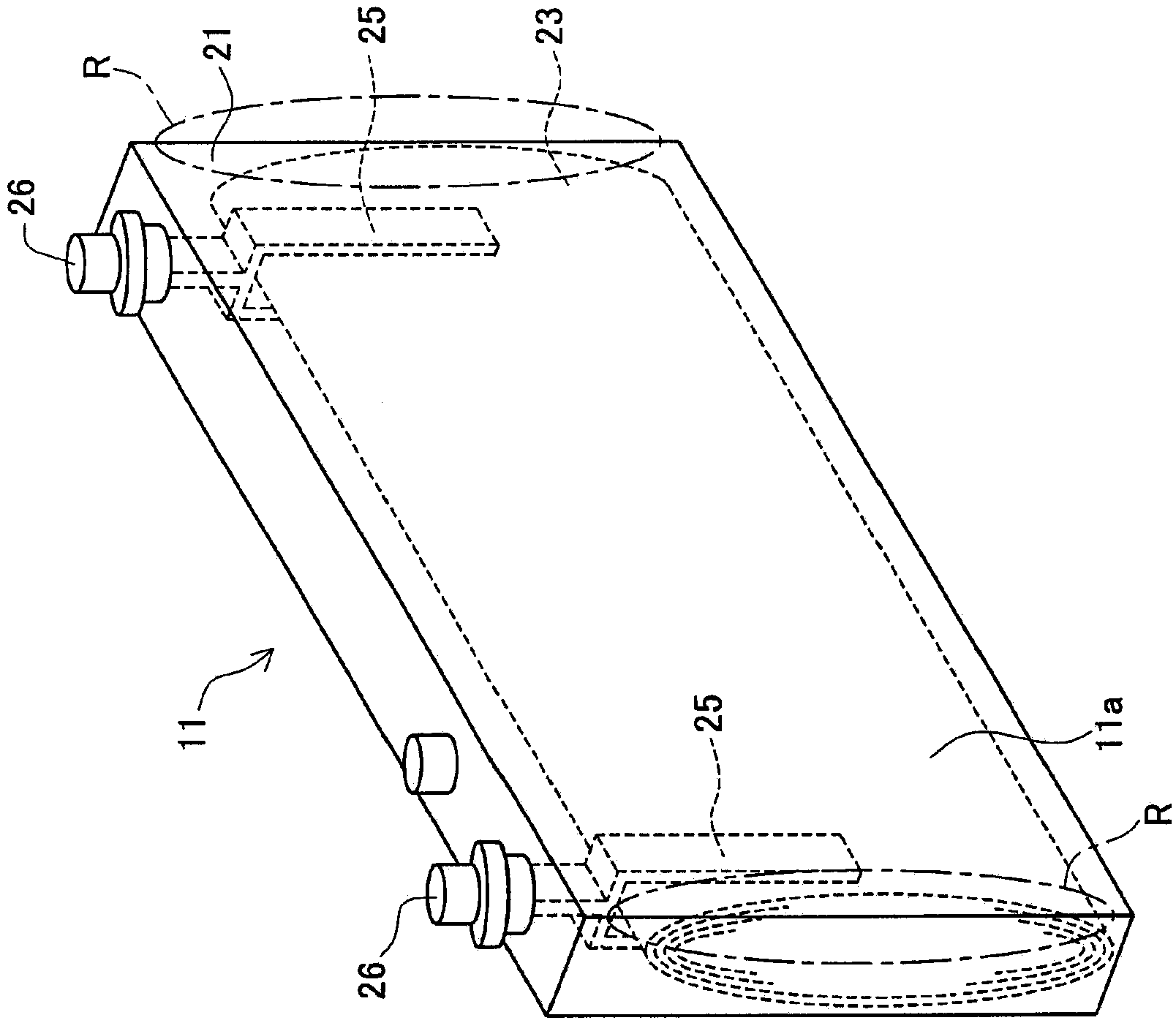

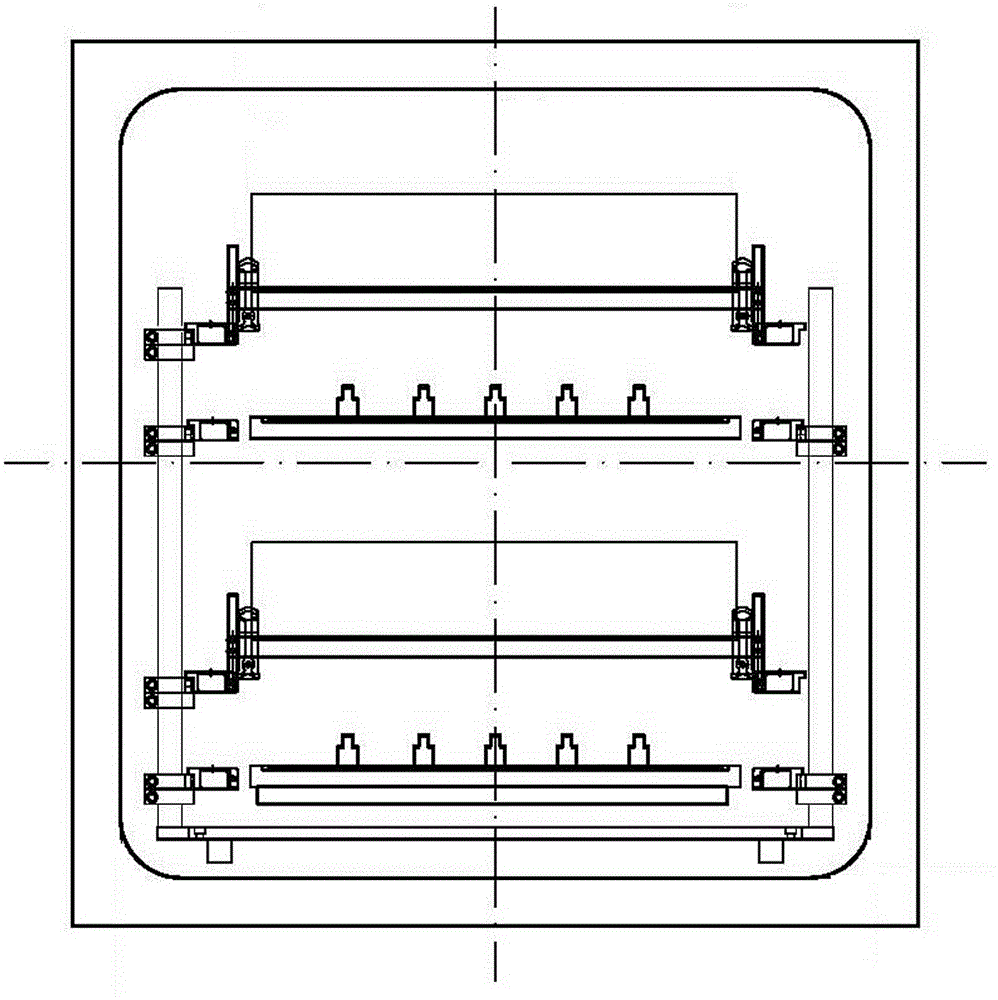

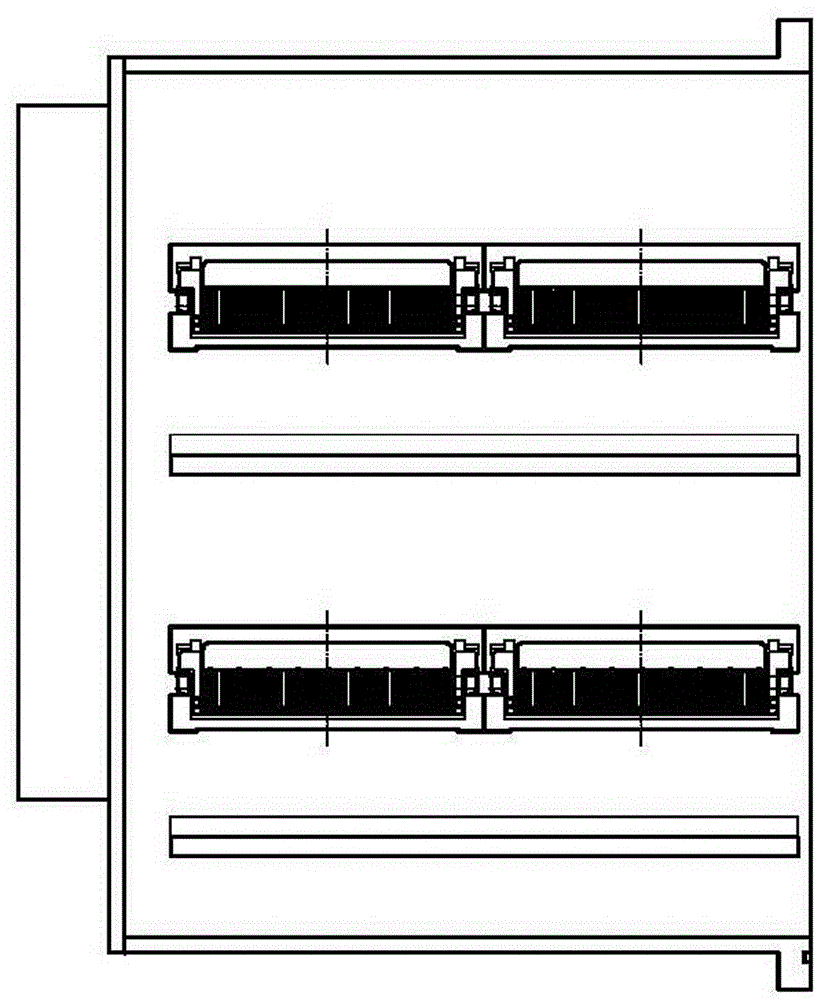

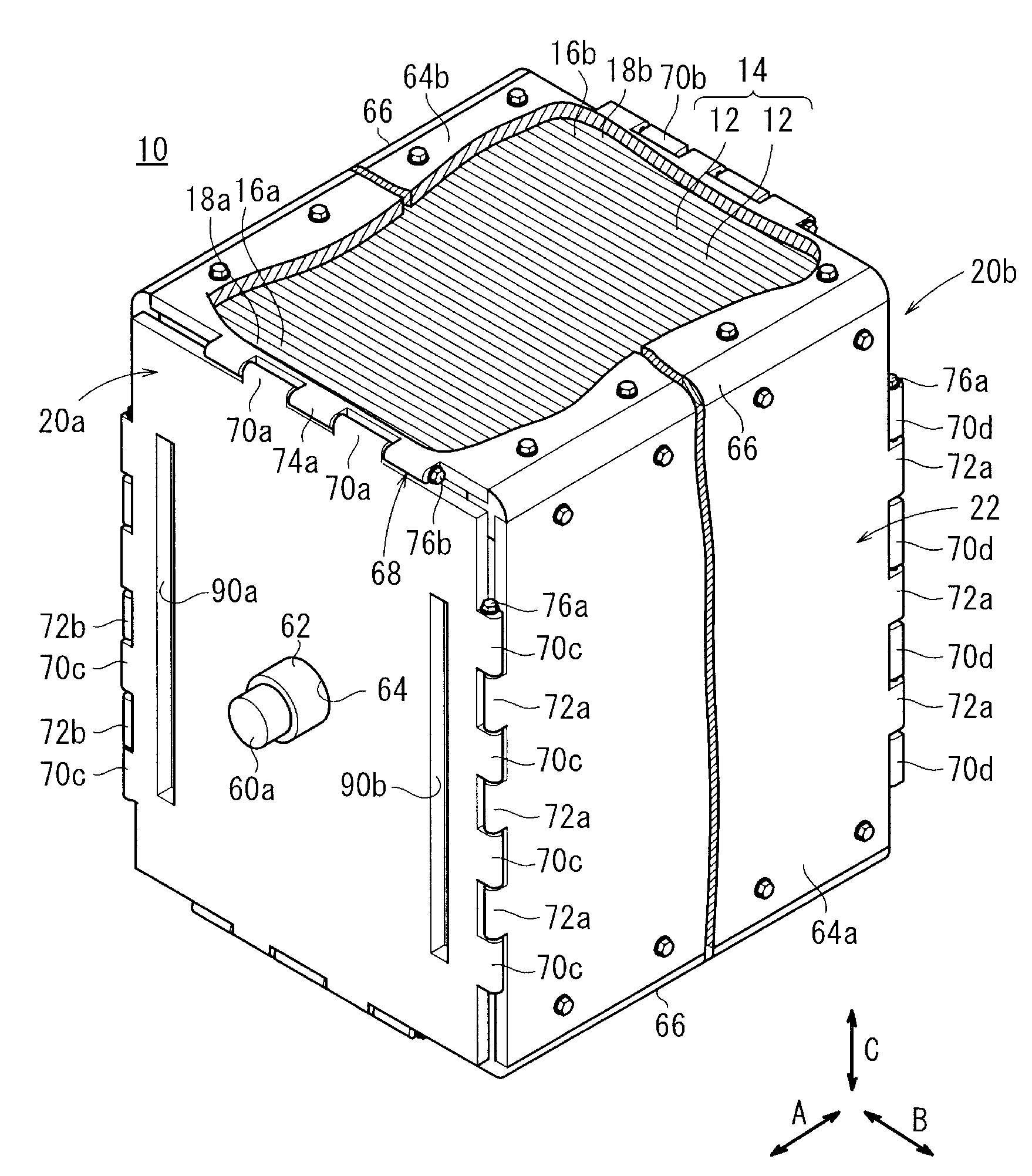

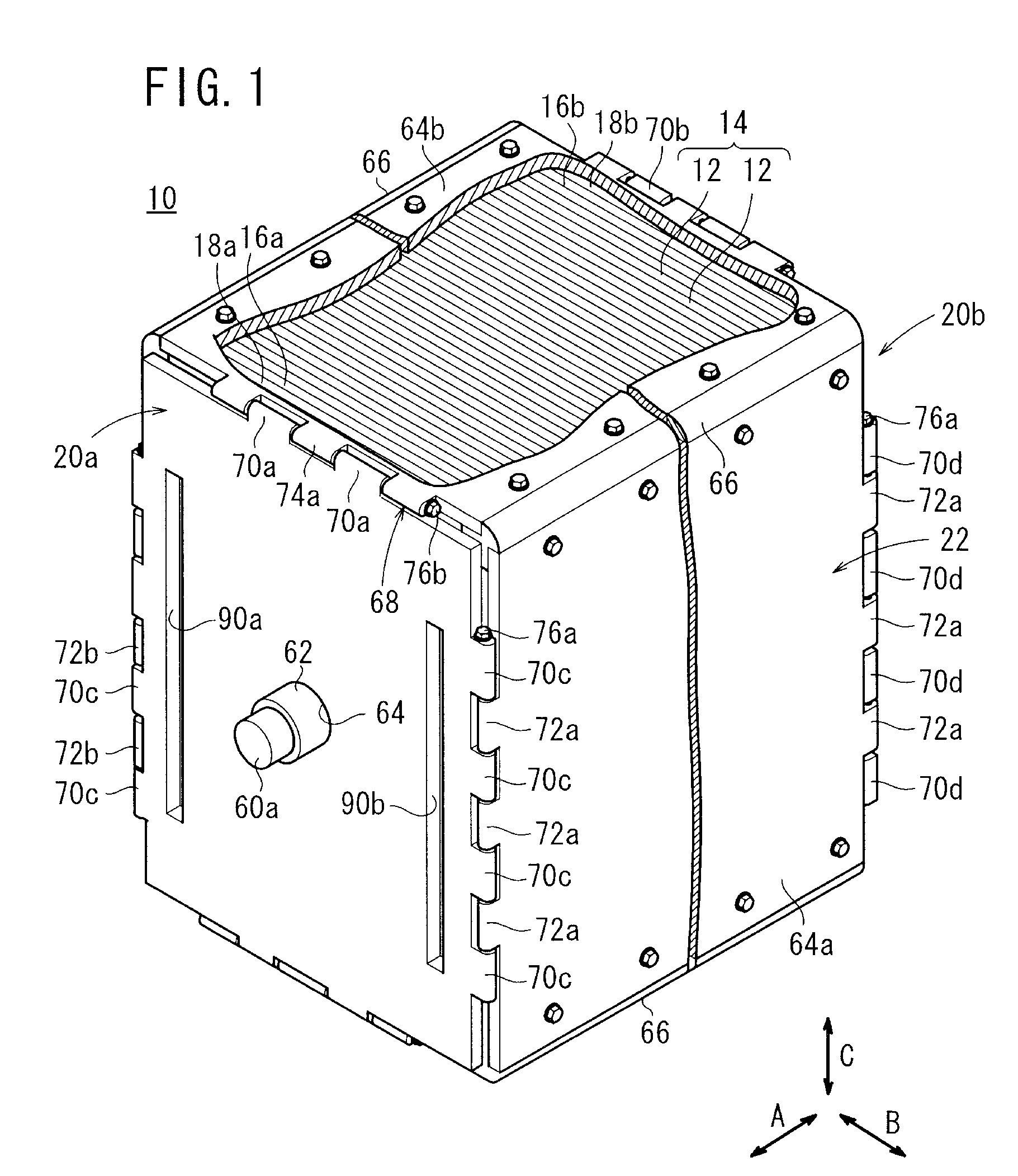

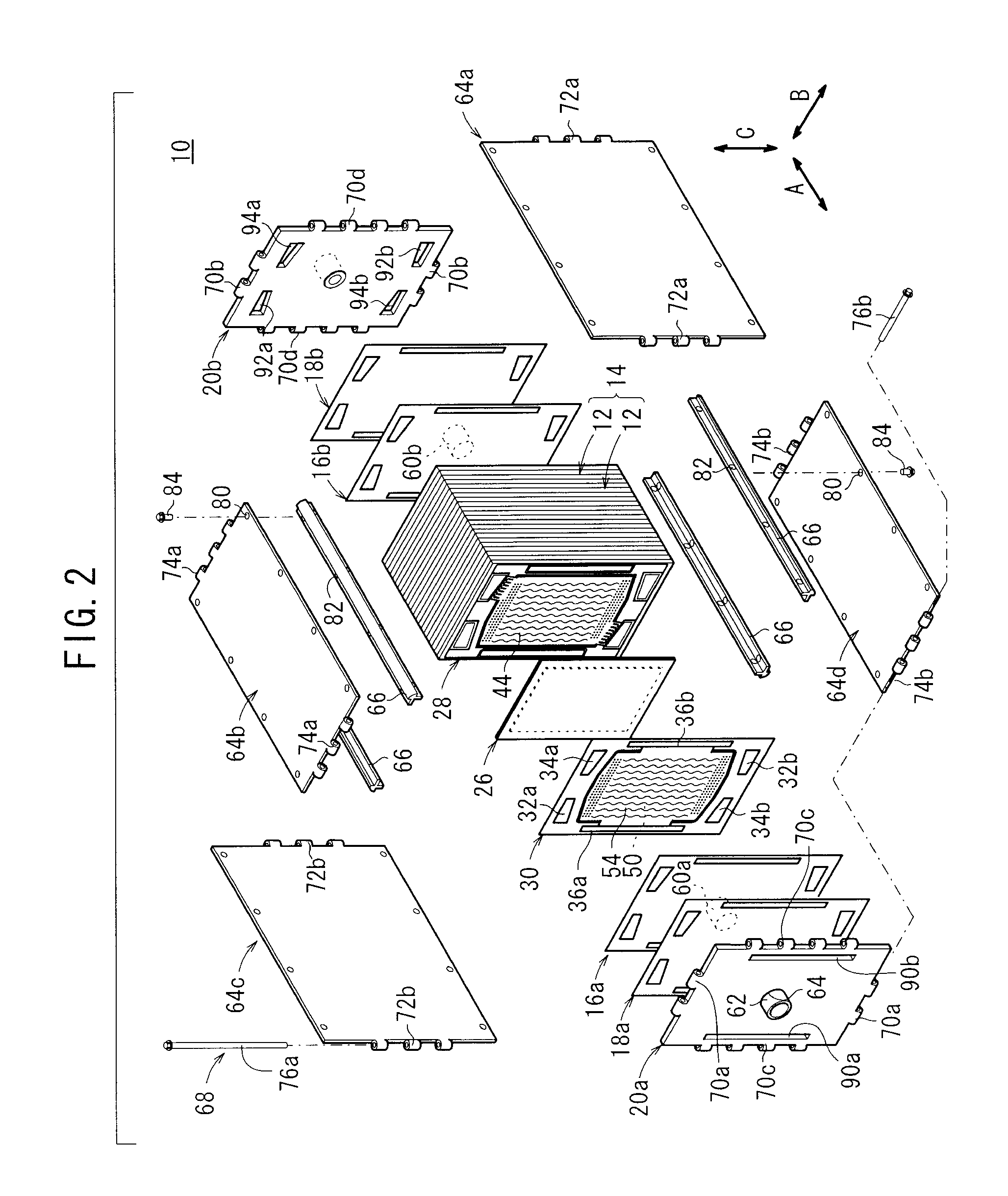

Fuel cell stack

ActiveCN101677129AReliable capturePrevent immersionFuel cells groupingFuel cell auxillariesFuel cellsEngineering

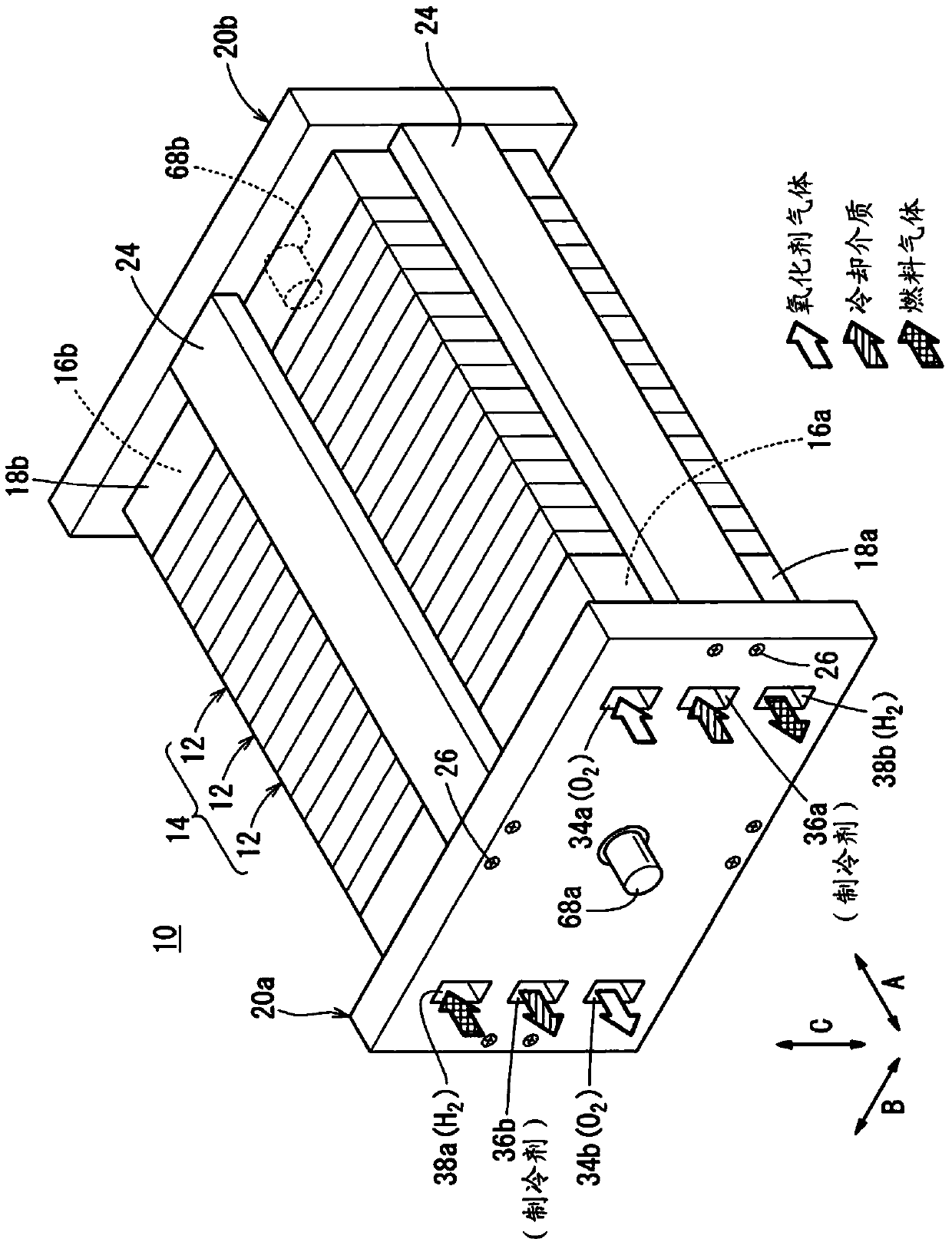

The invention provides a fuel cell stack having dummy cells to achieve the desired heat insulating capability, reliably prevent condensed water from flowing into power generation units, and achieve good power generation performance with a simple structure. The fuel cell stack includes a stack body formed by stacking a plurality of power generation units. A first end power generation unit and first dummy units are provided near an end plate where reactant gas pipes for the stack body are provided. A second end power generation unit and second dummy units are provided near an end plate of the stack body on the opposite side. The number of first dummy units is larger than the number of second dummy units.

Owner:HONDA MOTOR CO LTD

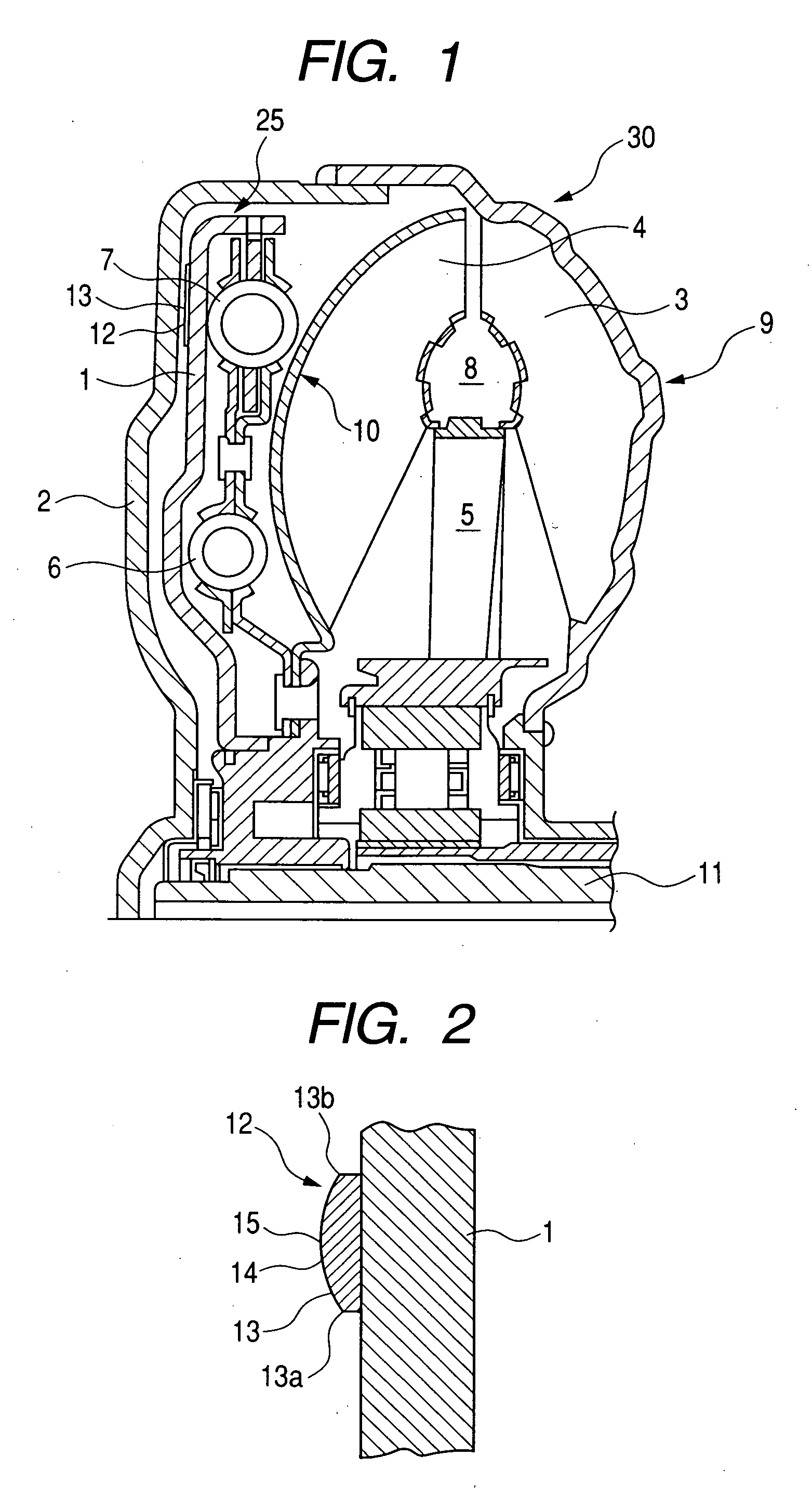

Lock-up clutch mechanism

ActiveUS20060118378A1Increase the friction surfaceImprove uniformityRotary clutchesFluid gearingsEngineeringFront cover

The present invention provides a lock-up clutch mechanism for a torque converter, comprising a lock-up clutch to which a friction material having a friction surface is secured and a front cover having an engagement surface with which the friction surface is engaged when the friction surface is urged in an axial direction and in which the friction surface of the friction material has a configuration including a protruded area protruding in the axial direction.

Owner:NSK WARNER

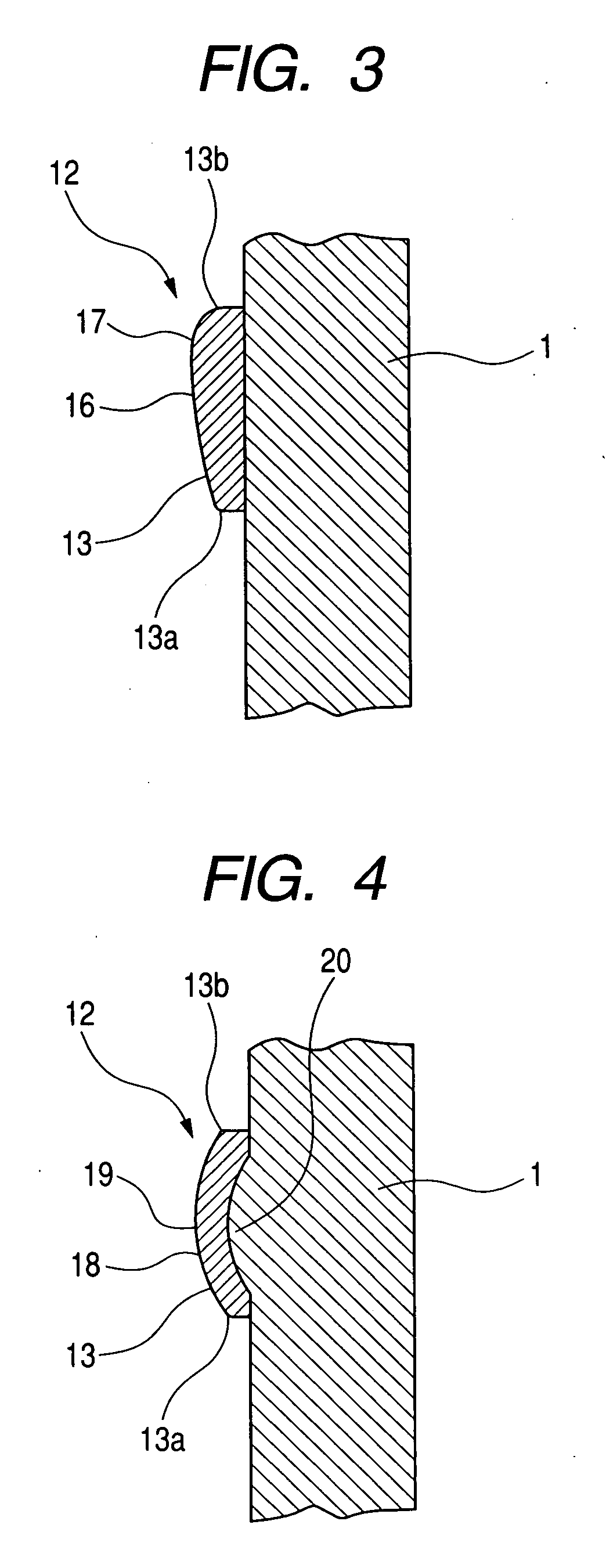

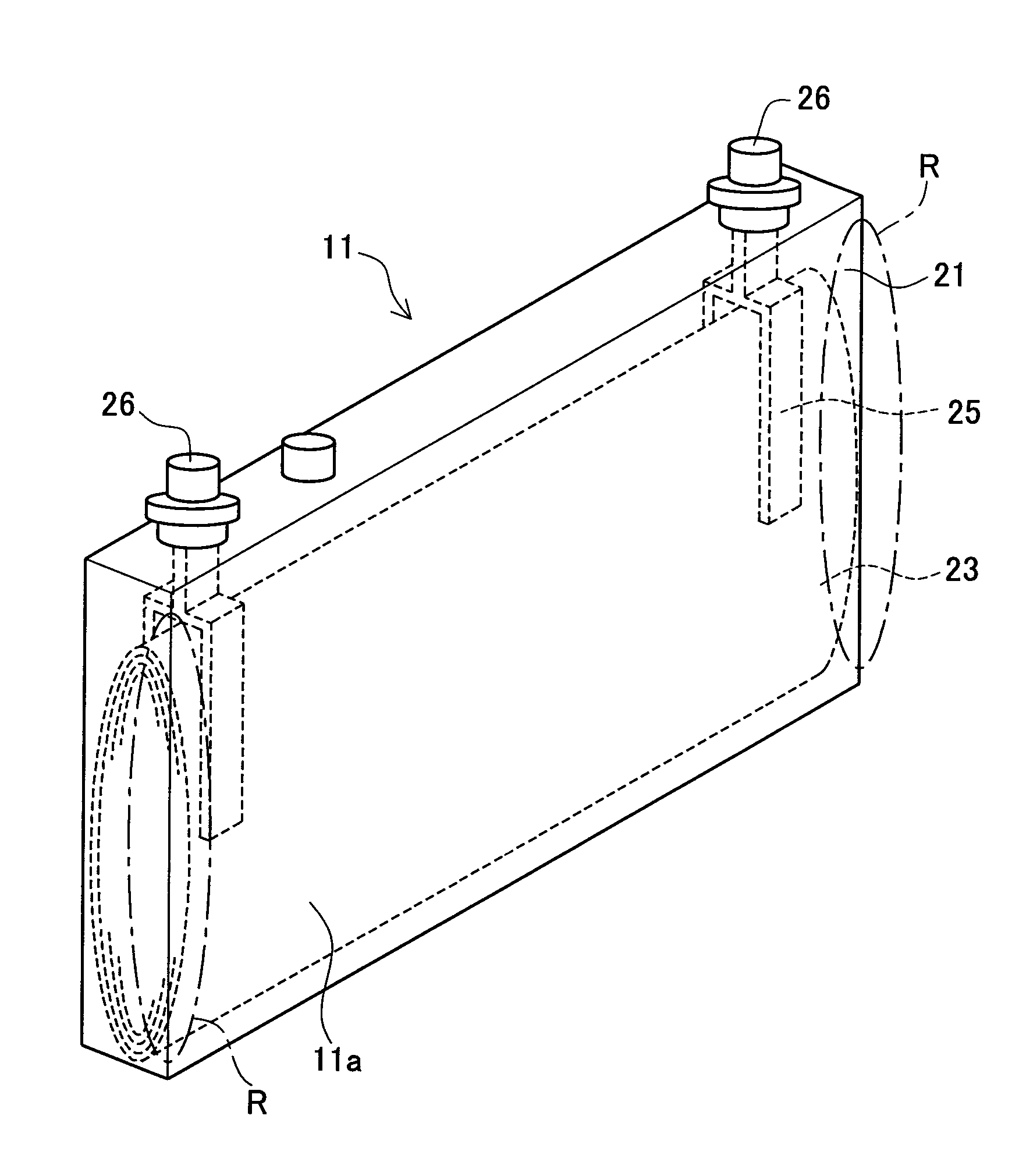

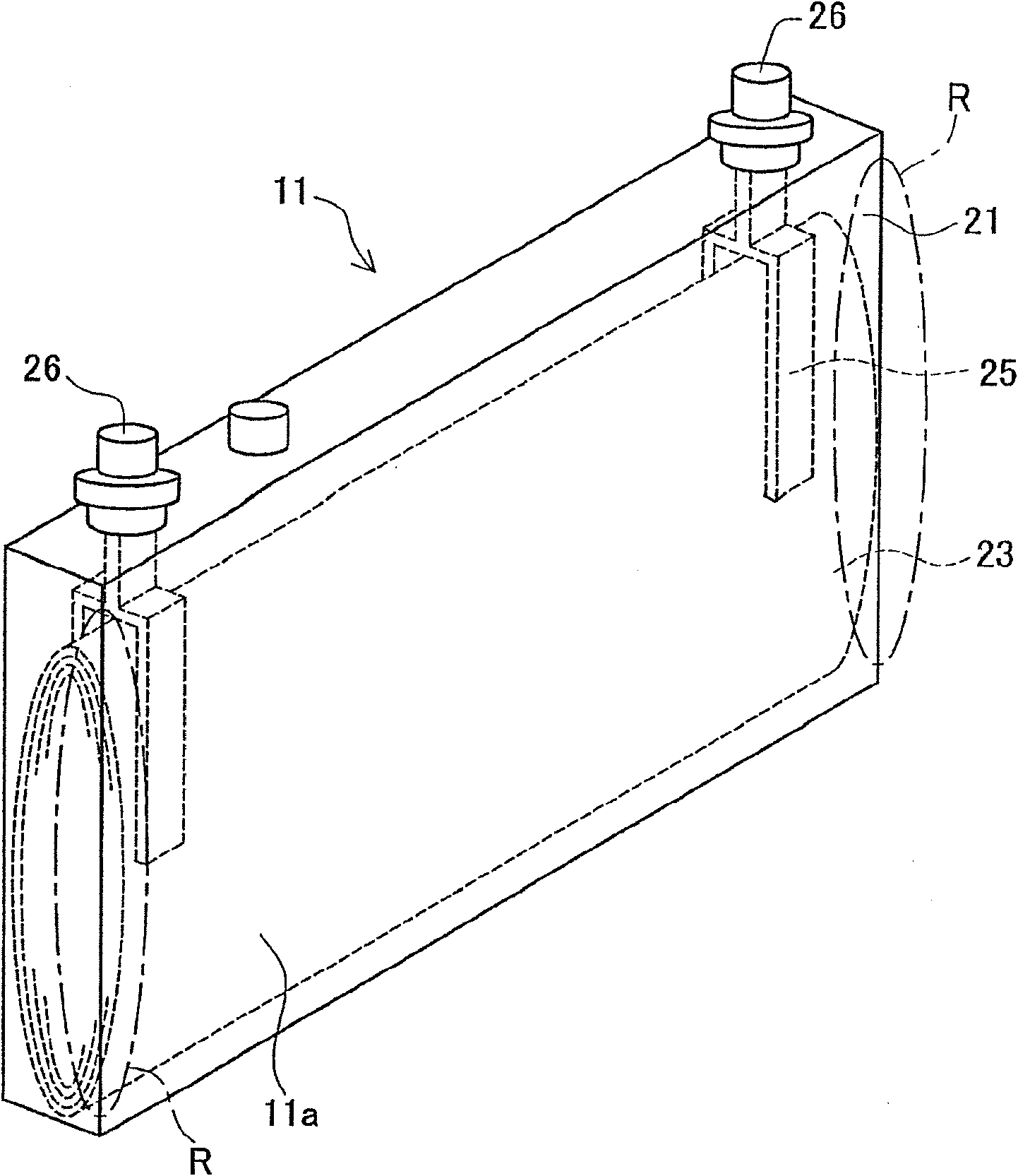

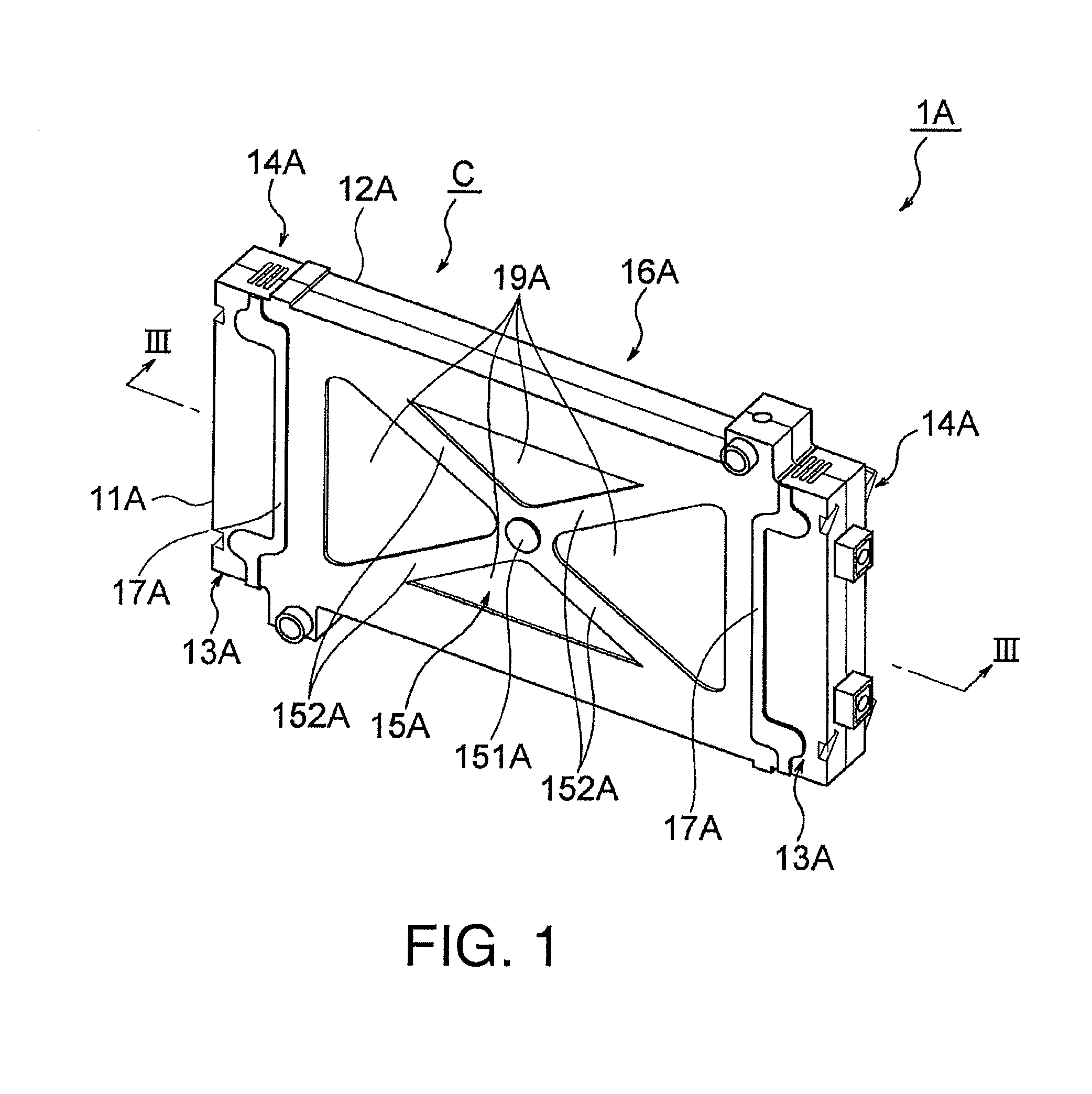

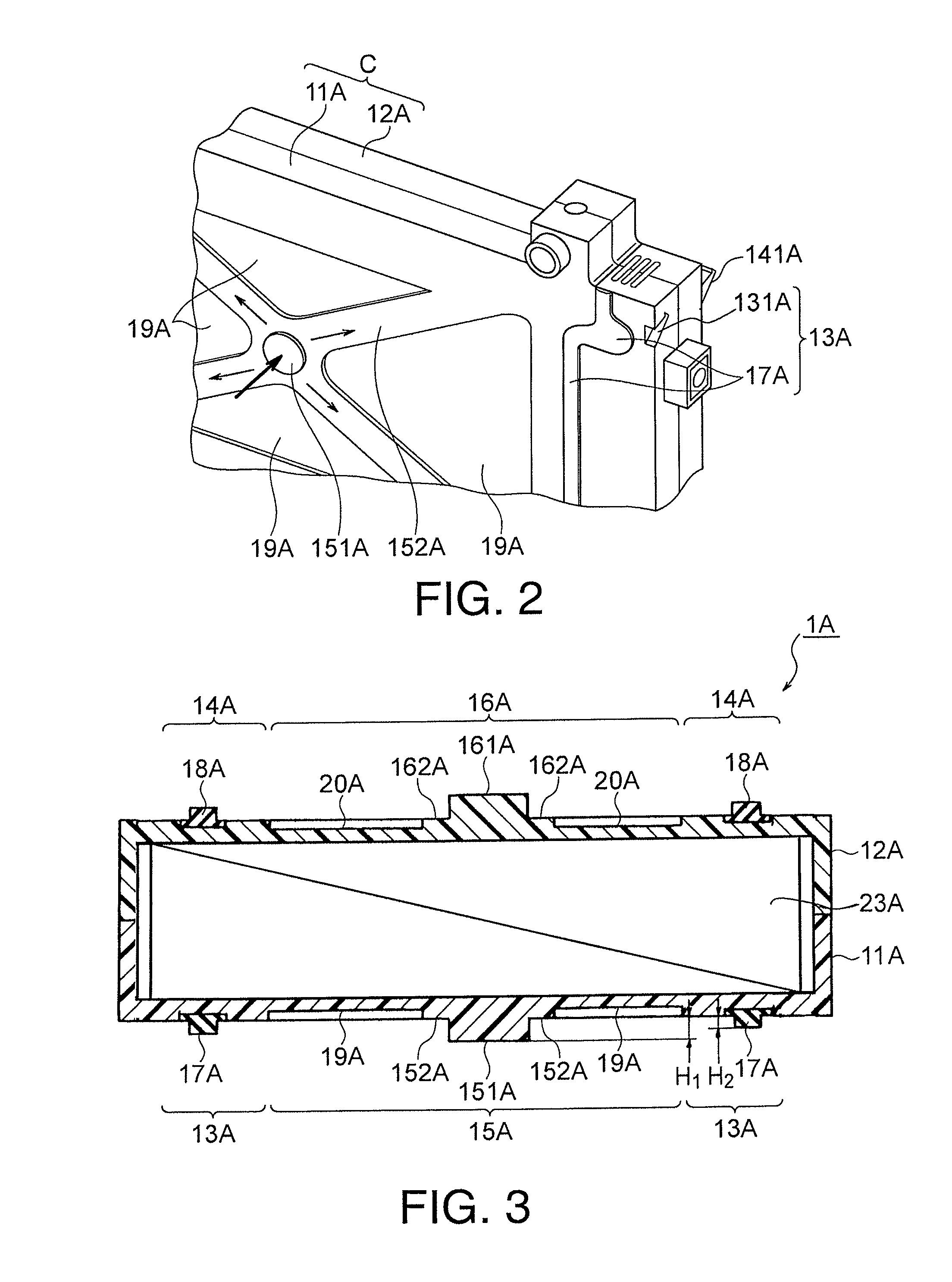

Secondary battery assembly

ActiveUS20130078491A1Increase chanceRestraining the deterioration of the secondary batteryCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrical batteryEngineering

A secondary battery assembly of the present invention comprises: a secondary battery including a wound electrode body enclosed in a flat rectangular case; a contact member partly contacting a side surface having a maximum area (pressed surface) of outer surfaces of the battery; and a binding member for binding the battery and the contact member, the binding member binding the contact member to partly press against the pressed surface. The contact member includes: a plurality of contact parts arranged discretely, each contact part being in contact with the pressed surface; and a connecting part connecting the contact parts. The contact parts are protruding from the connecting part toward the pressed surface, and to press more strongly both one-side regions of the pressed surface corresponding to portions off the center of the wound body in the winding axis direction, and to press less strongly a central region between the one-side regions.

Owner:TOYOTA JIDOSHA KK

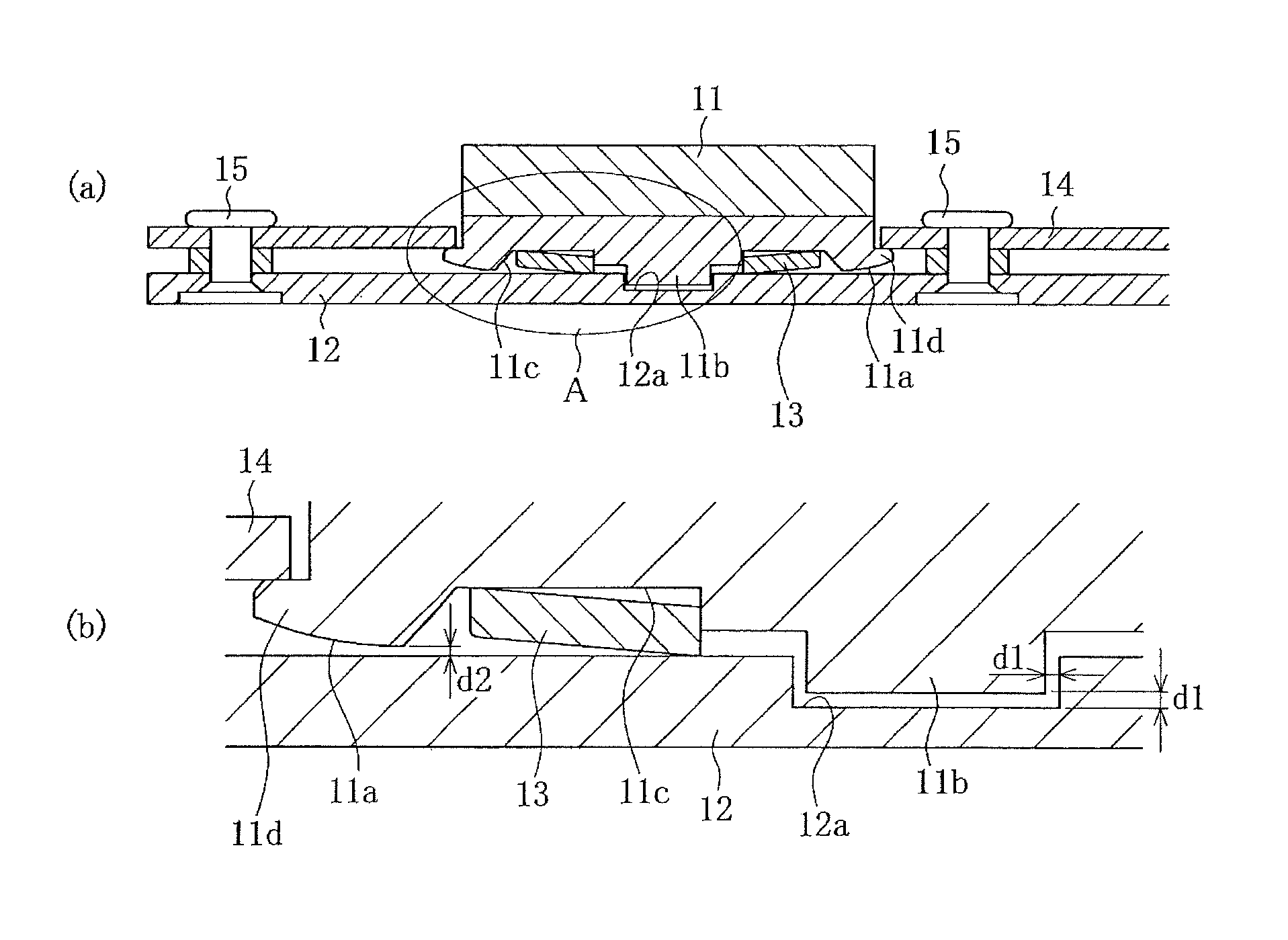

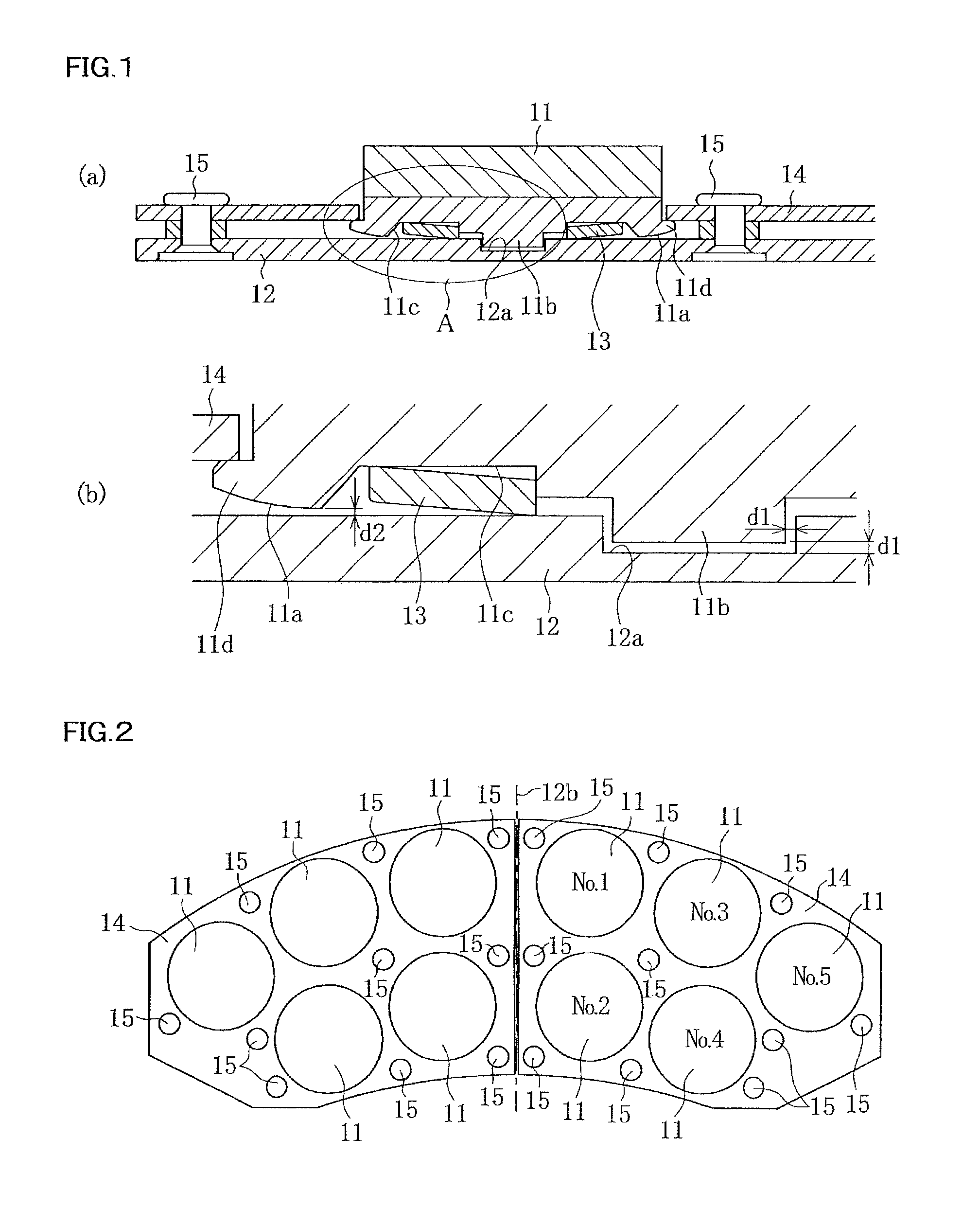

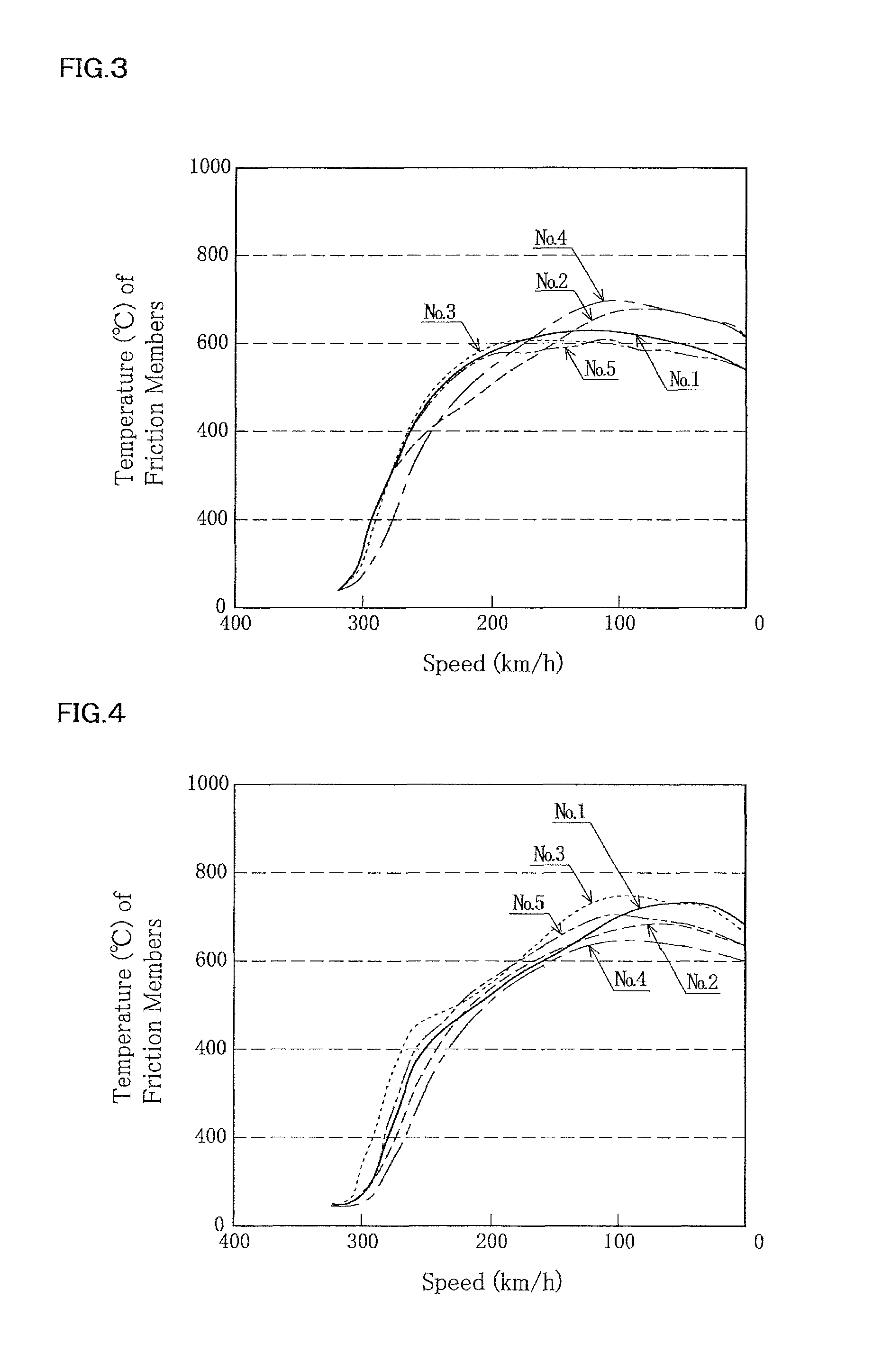

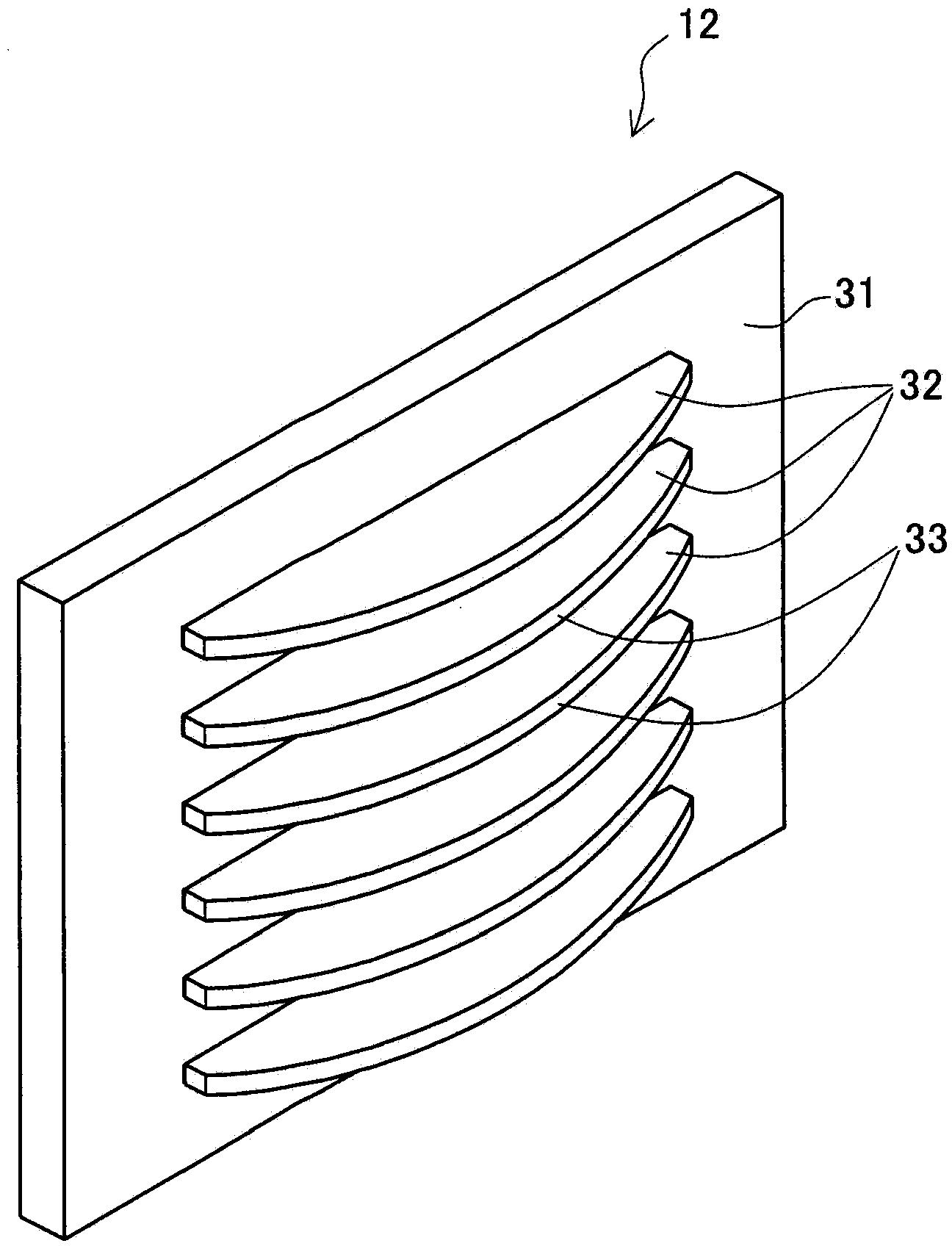

Brake lining for railroad car

InactiveUS8919503B2Prevent deformation and deteriorationUniform surface pressureAxially engaging brakesBraking membersEngineeringCalipers

A brake lining for a railroad car brake includes friction members which are pressed onto the sliding surface of a brake disc, and a back plate which is attached to a brake caliper in order to support the friction members. The friction members are dividedly arranged in a radial direction and in a circumferential direction of the brake disc. A disc spring is disposed between each respective friction member and the back plate. An outer peripheral surface of the friction members facing the back plate is formed in a convex curved shape in an area outside the elastic member. When a light pressing force is applied, a pressing force is transmitted from the back plate to the friction members via the disc springs. When a heavy pressing force is applied, the back plate and a rounded surface portion make contact, thereby directly transmitting a pressing force to the friction members.

Owner:NIPPON STEEL CORP

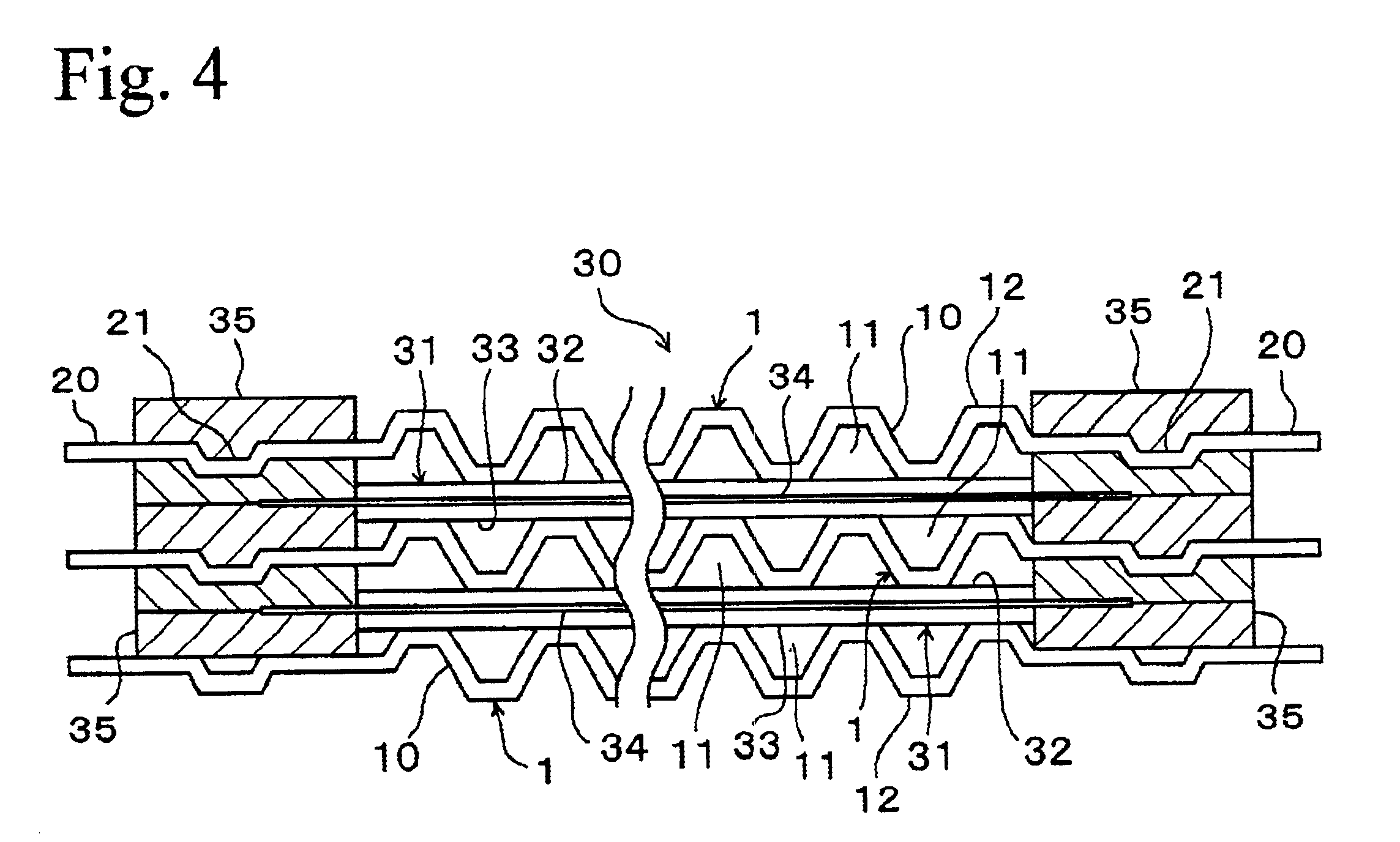

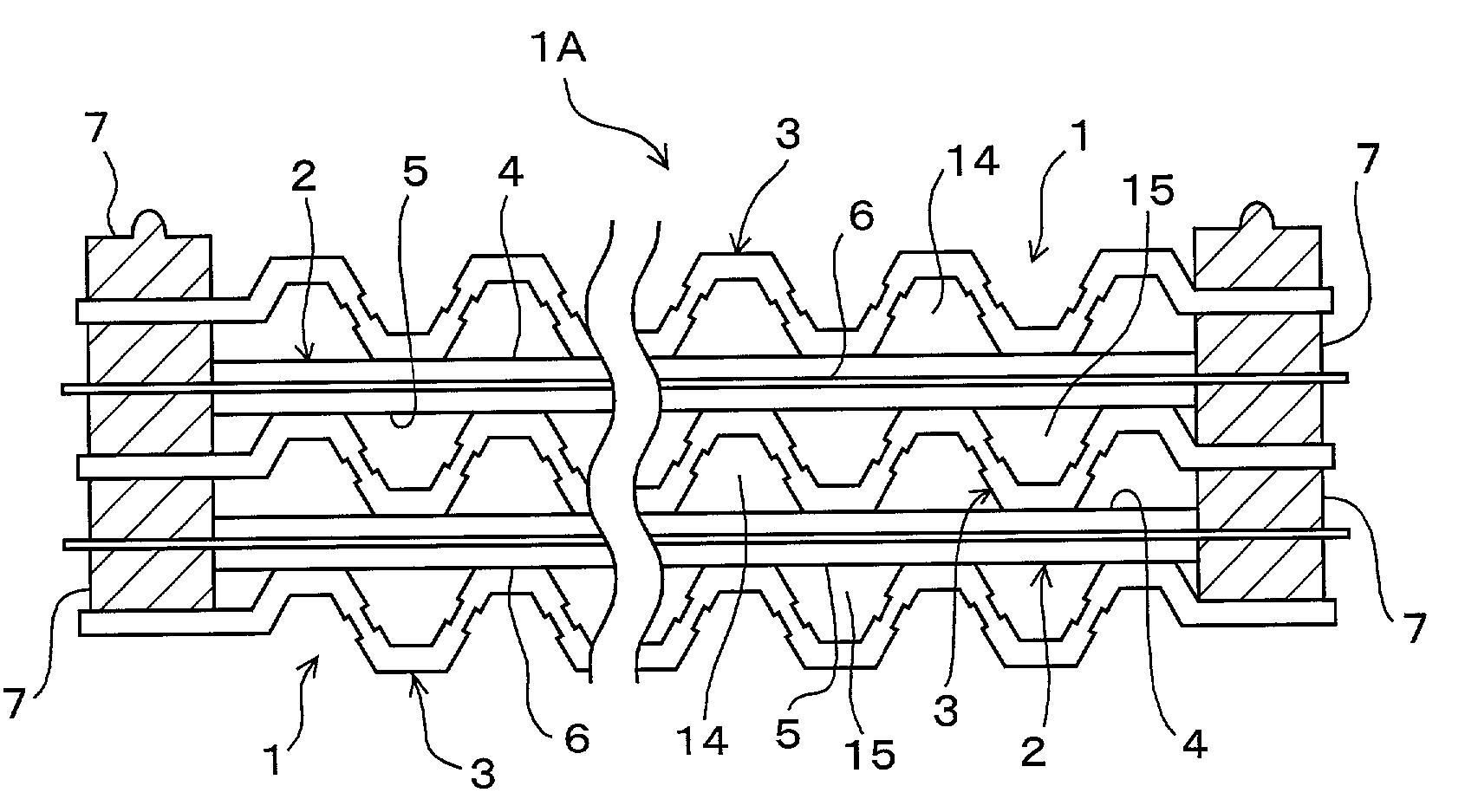

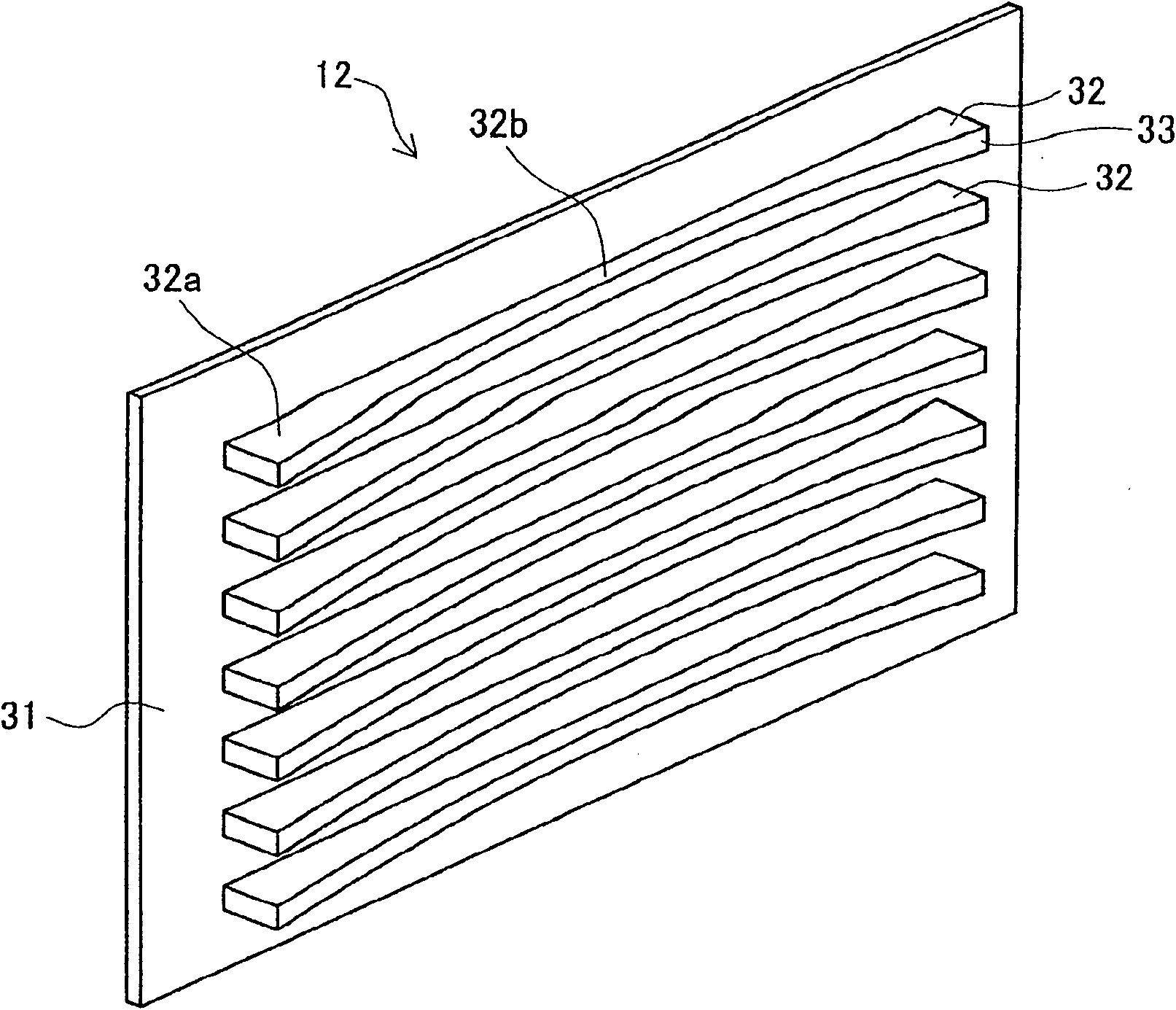

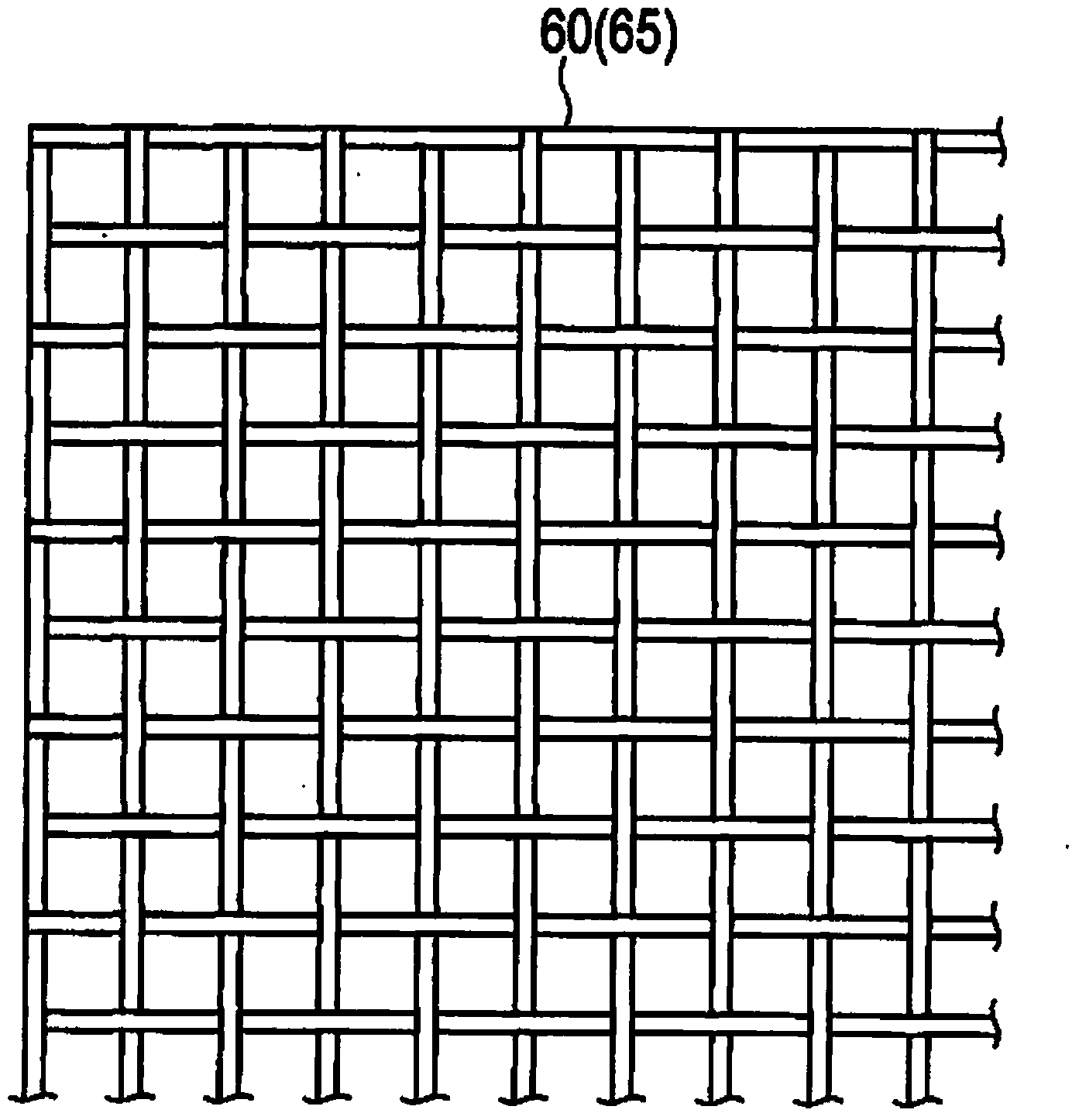

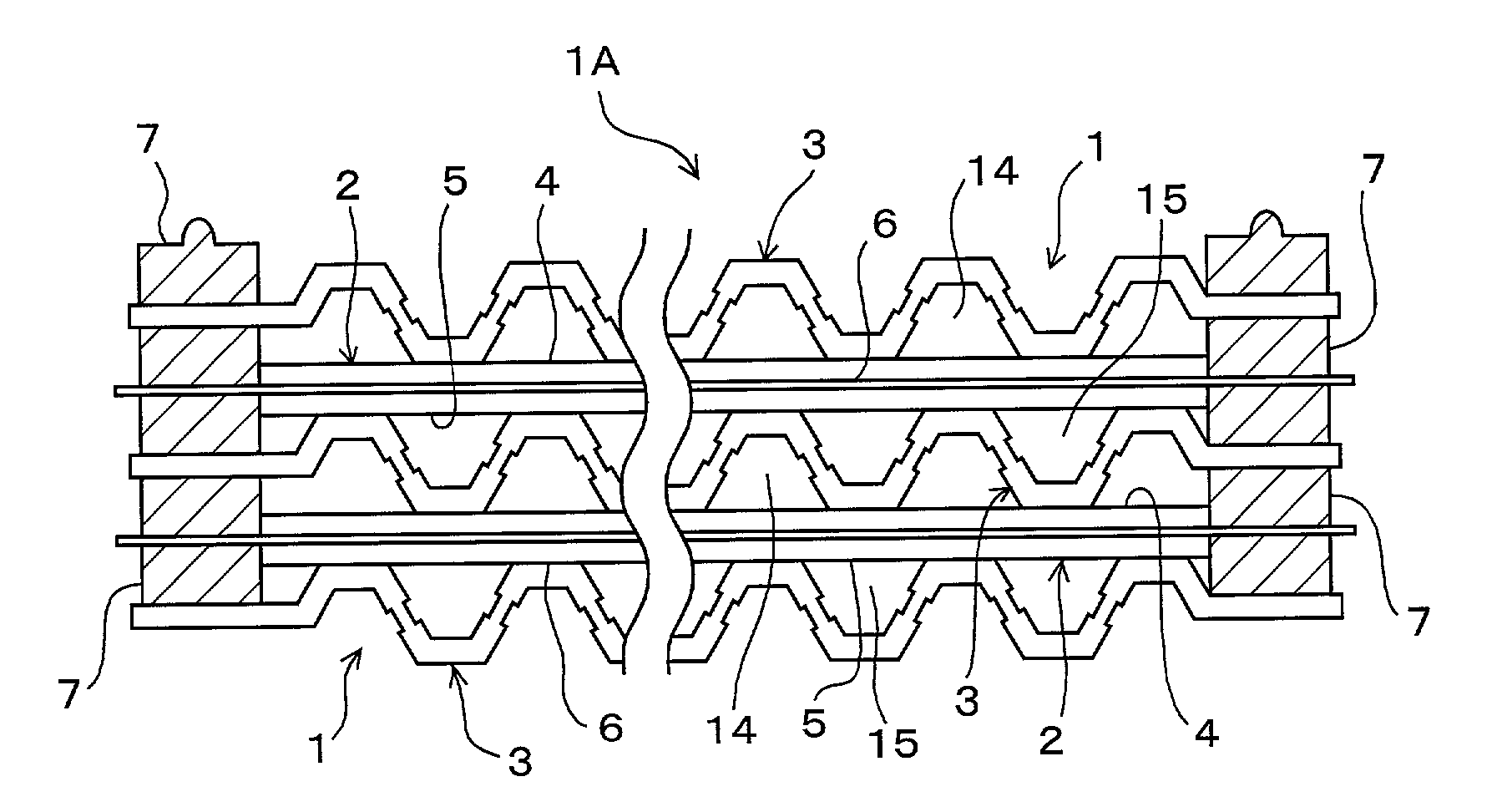

Separator for fuel cell and fuel cell

InactiveUS6858339B2Improve power generation performanceSimplify the assembly processElectrode carriers/collectorsCell component detailsFuel cellsEngineering

A fuel-cell-use separator is provided with a current collector unit having an irregular shape in its cross-section in which grooved gas passages and / or cooling medium passages and protruding portions contacting a membrane electrode assembly are alternately formed continuously, and a circumferential portion formed on the periphery of the current collector unit, the current collector unit and the circumferential portion being formed by press forming a sheet of metal plate, and in this arrangement, a rib is formed on the circumferential portion.

Owner:HONDA MOTOR CO LTD

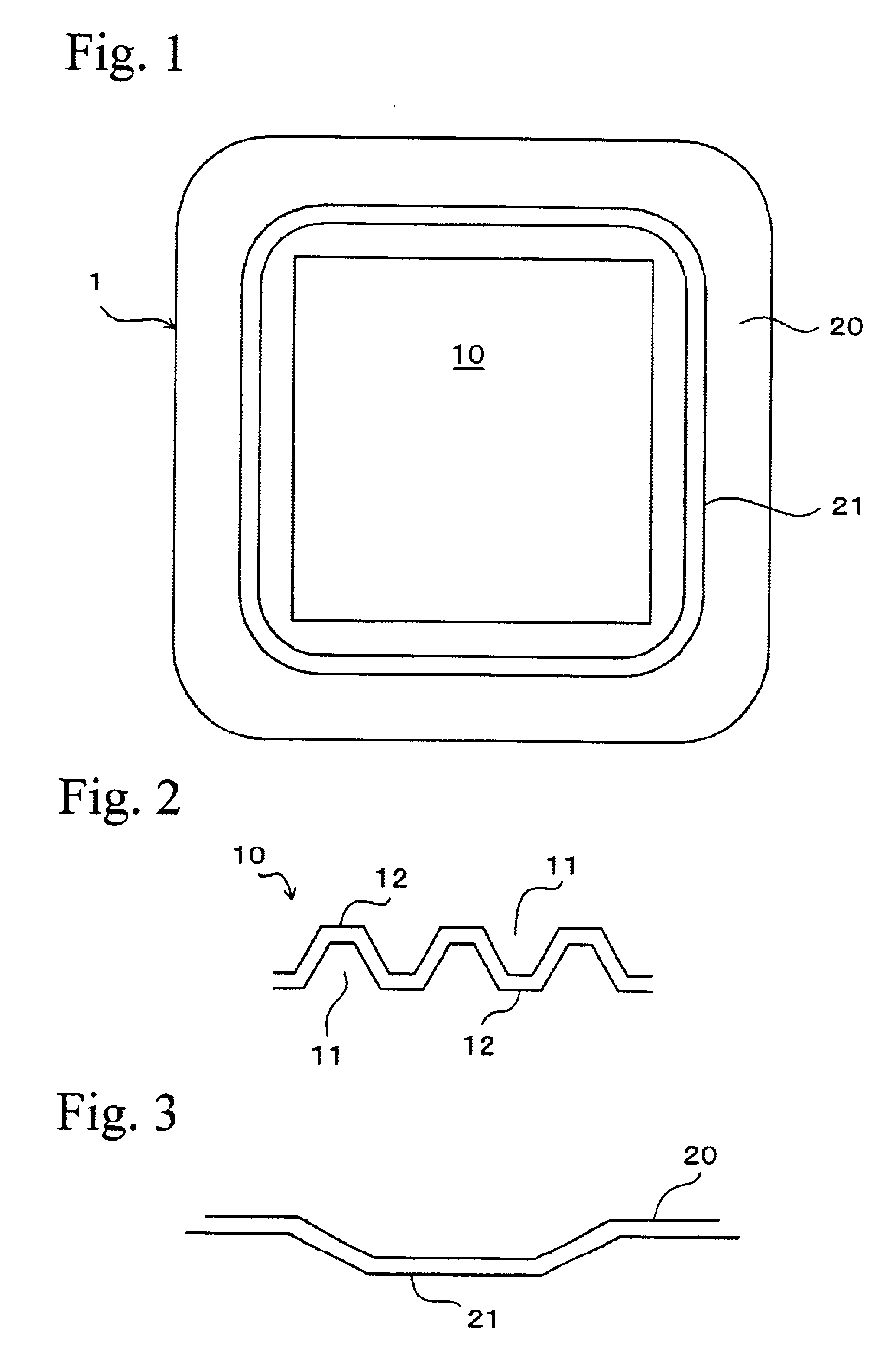

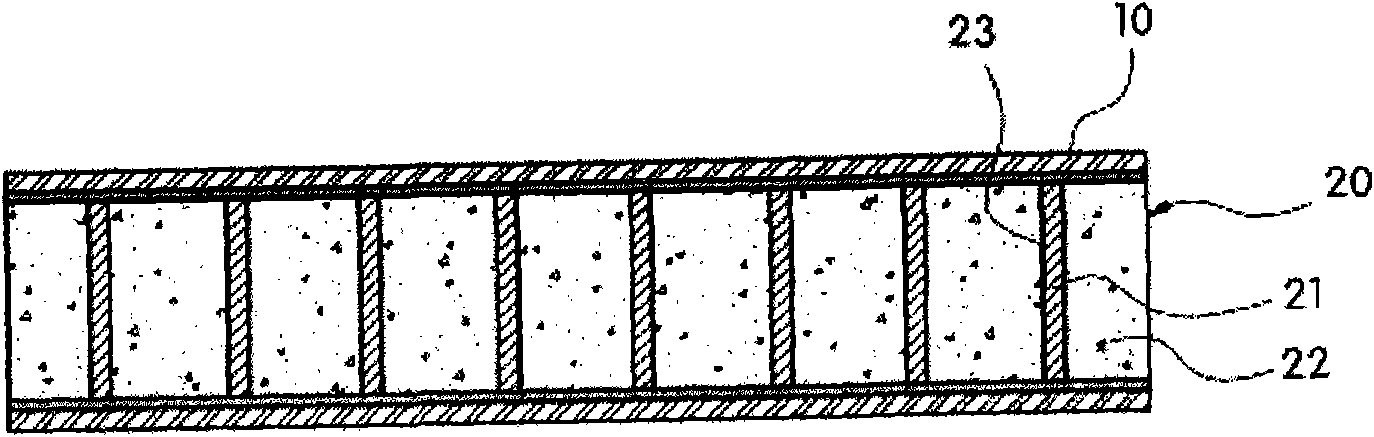

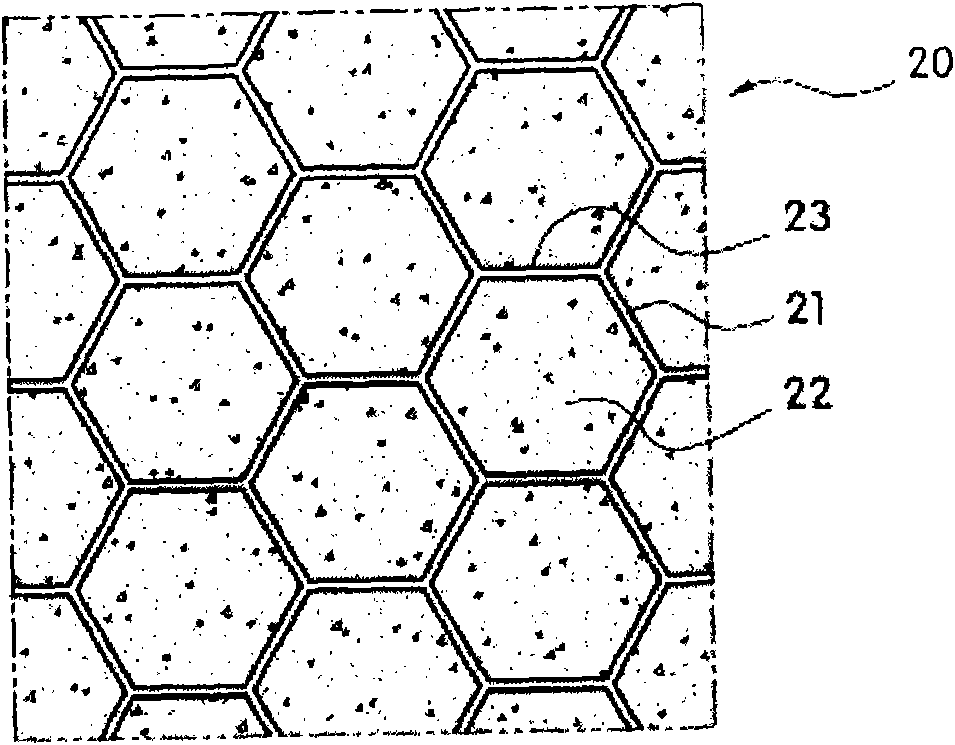

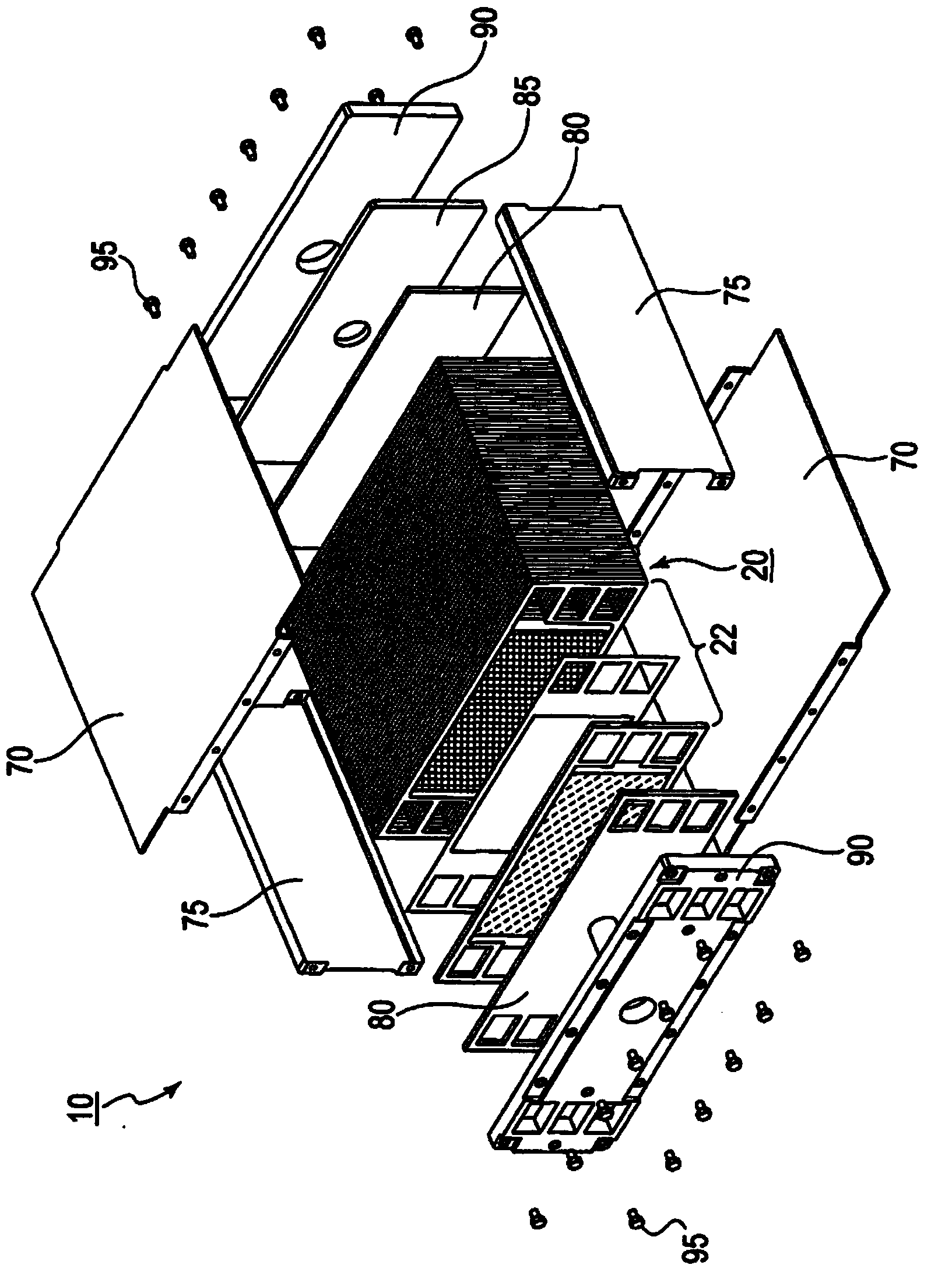

End plate for fuel cell stack and method for manufacturing the same

InactiveCN101582507AEasy to manufactureUniform surface pressureFuel cells groupingFinal product manufactureFuel cellsHeat transmission

The present invention provides an end plate for fuel cell stack and a method for manufacturing an end plate, which can increase flexural rigidity per weight, and improve strain at break, and reduce heat transmission by applying hybrid core element having honeycomb and form structures to an end plate having sandwich structure combined to both end portions of a fuel cell stack.

Owner:HYUNDAI MOTOR CO LTD +1

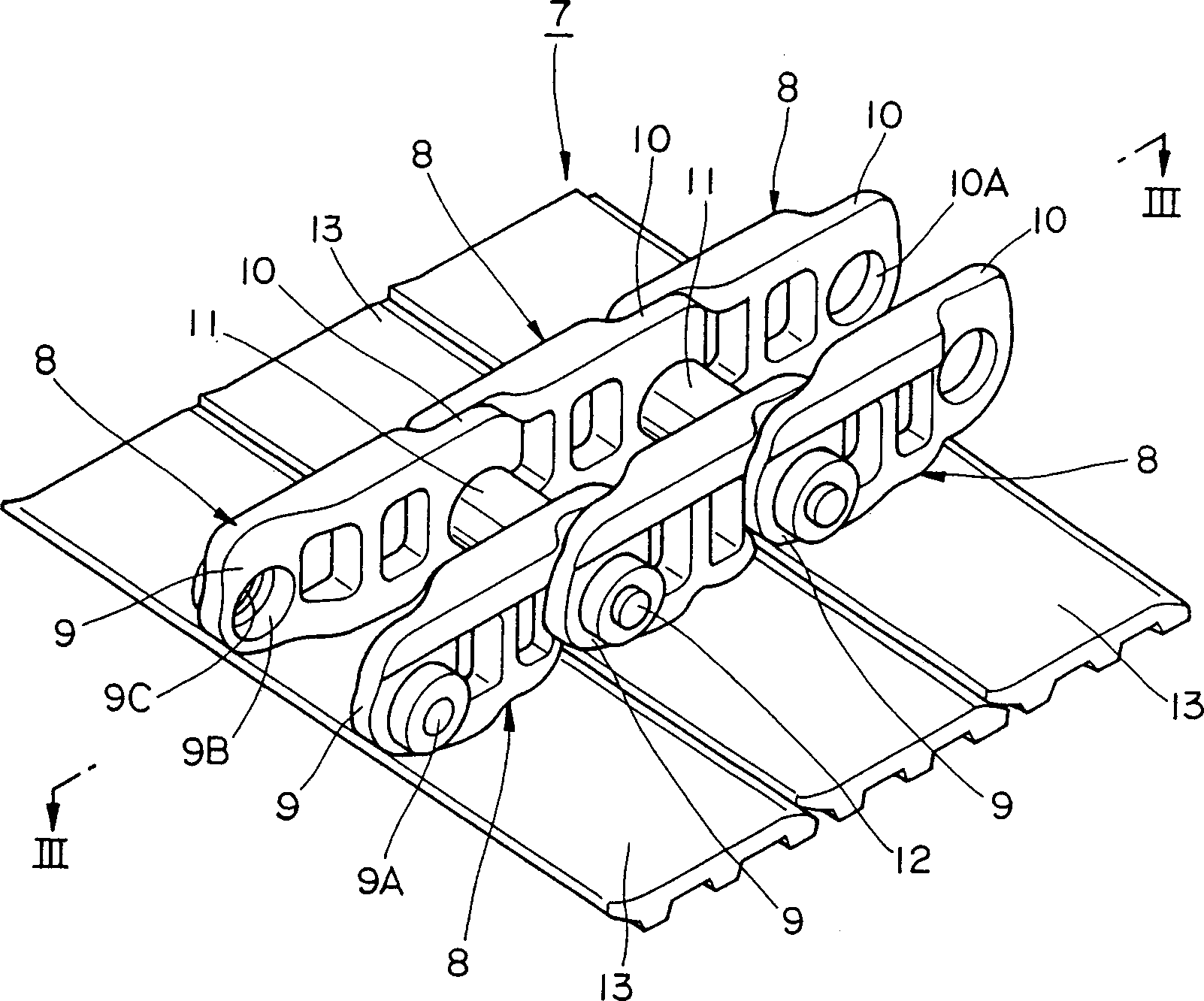

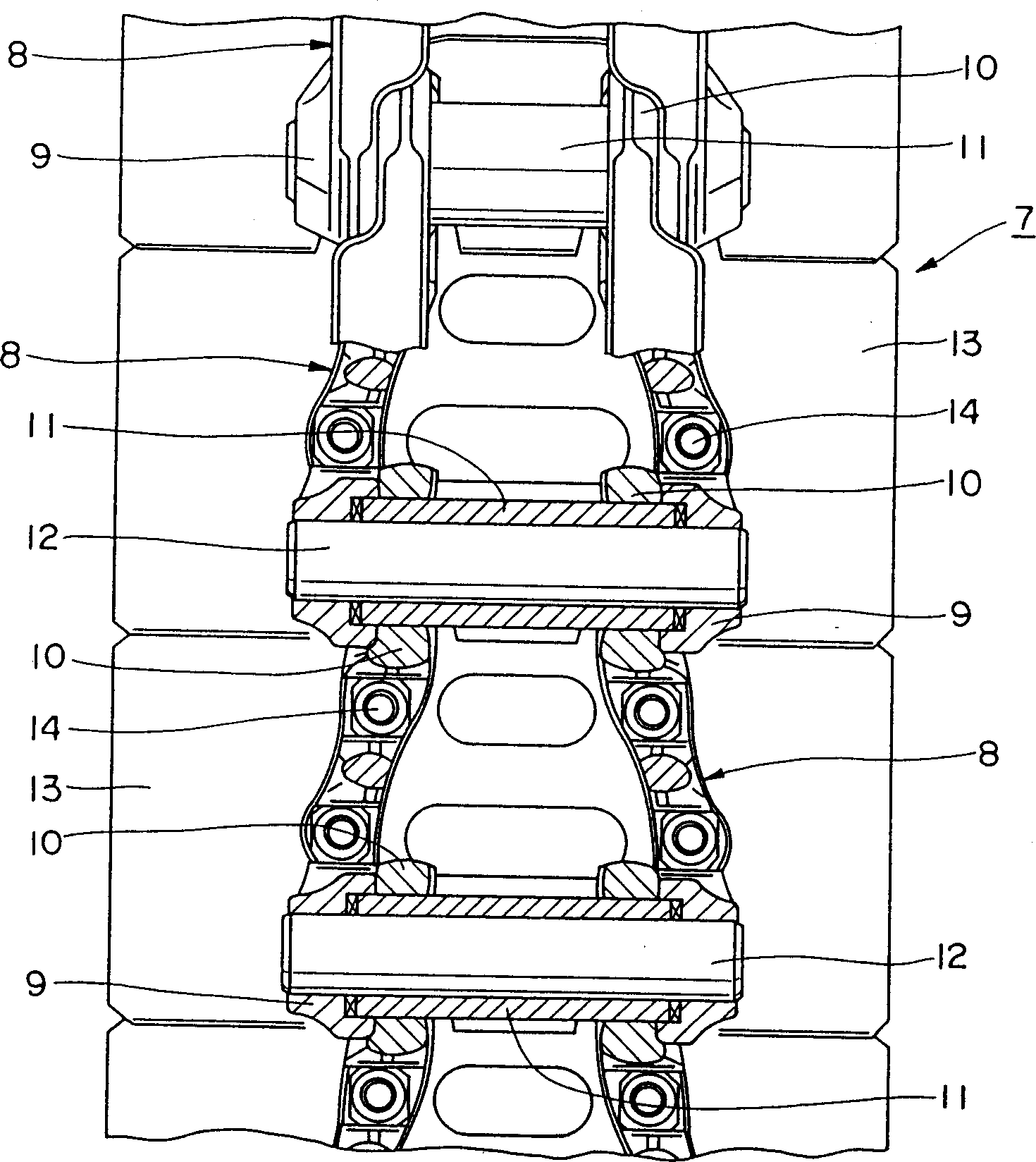

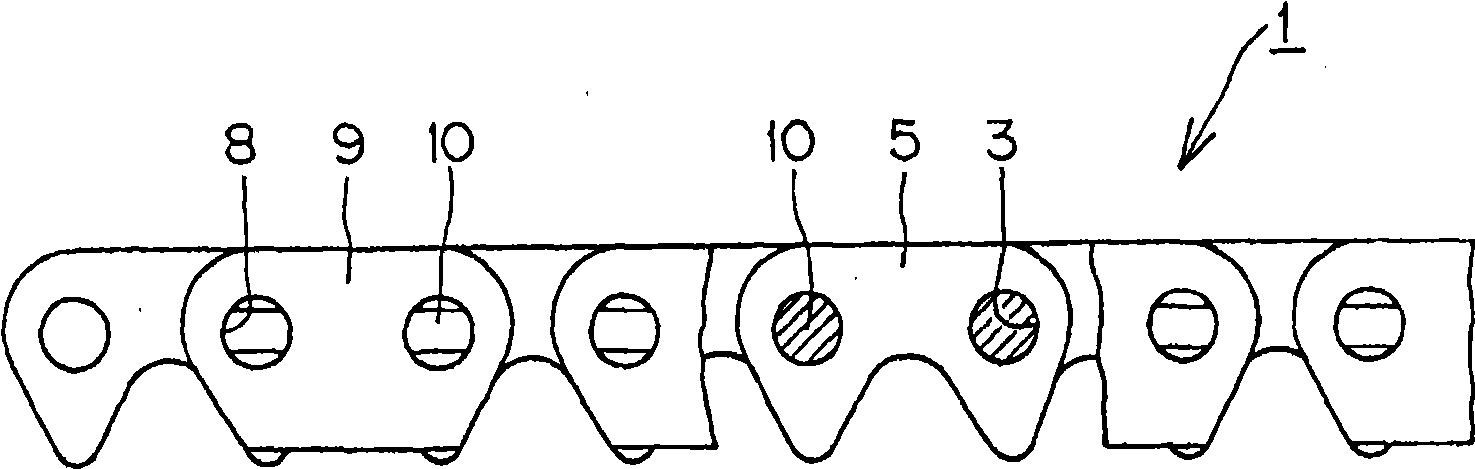

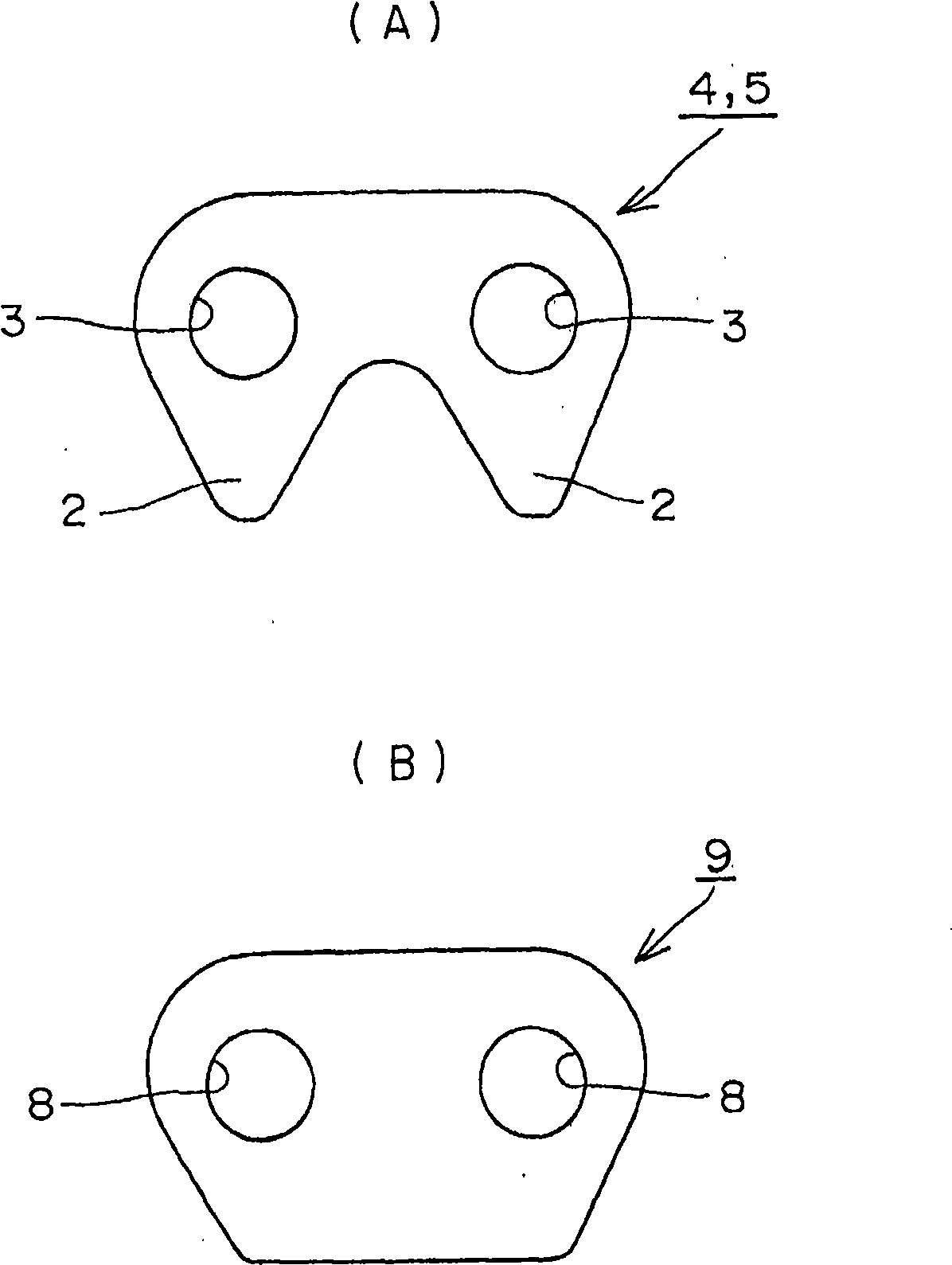

Seal for an endless track

InactiveCN1467122ANot easy to partial wearUniform surface pressureEngine sealsEndless track vehiclesContact pressureEngineering

Owner:TOPY INDUSTRIES +1

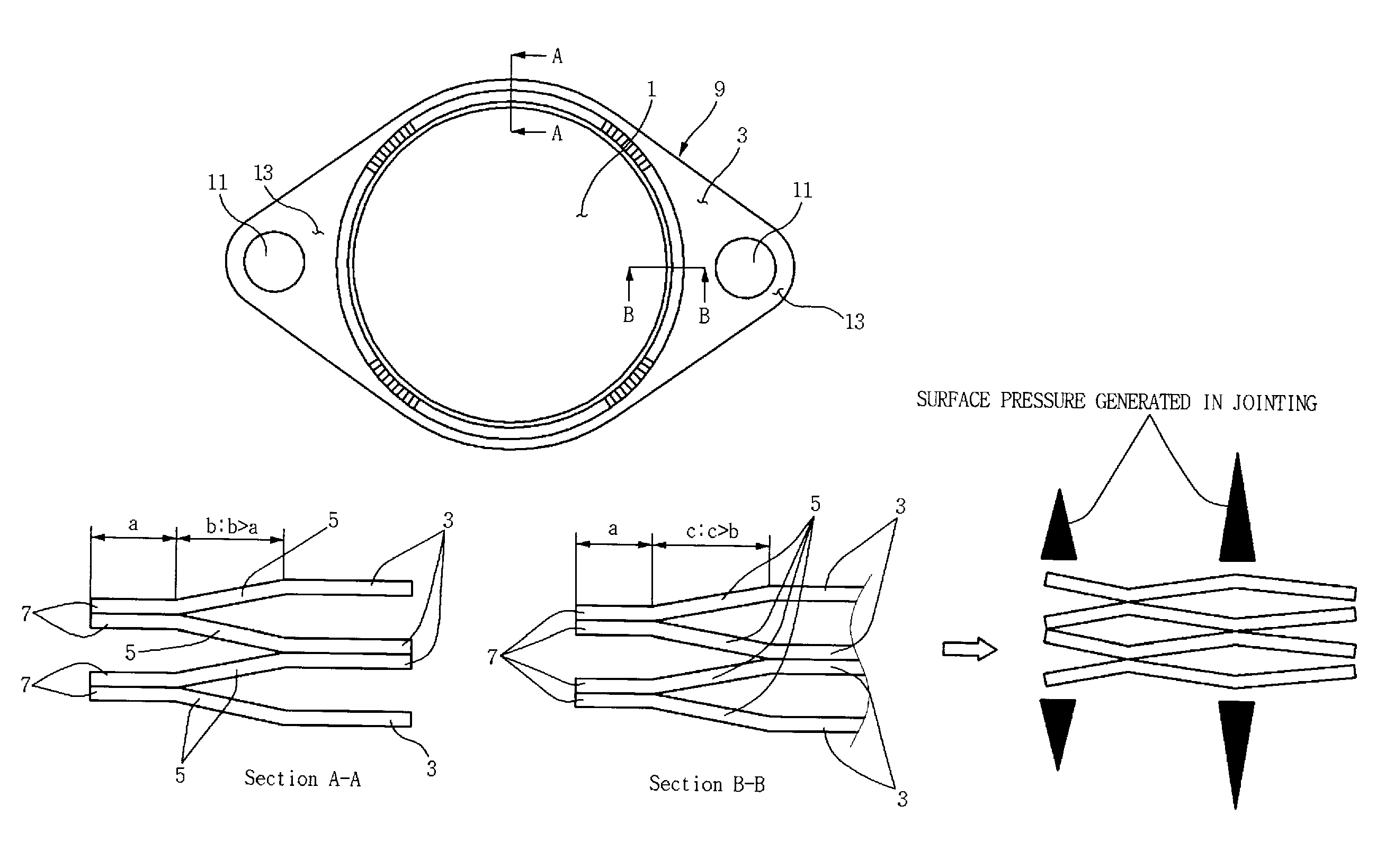

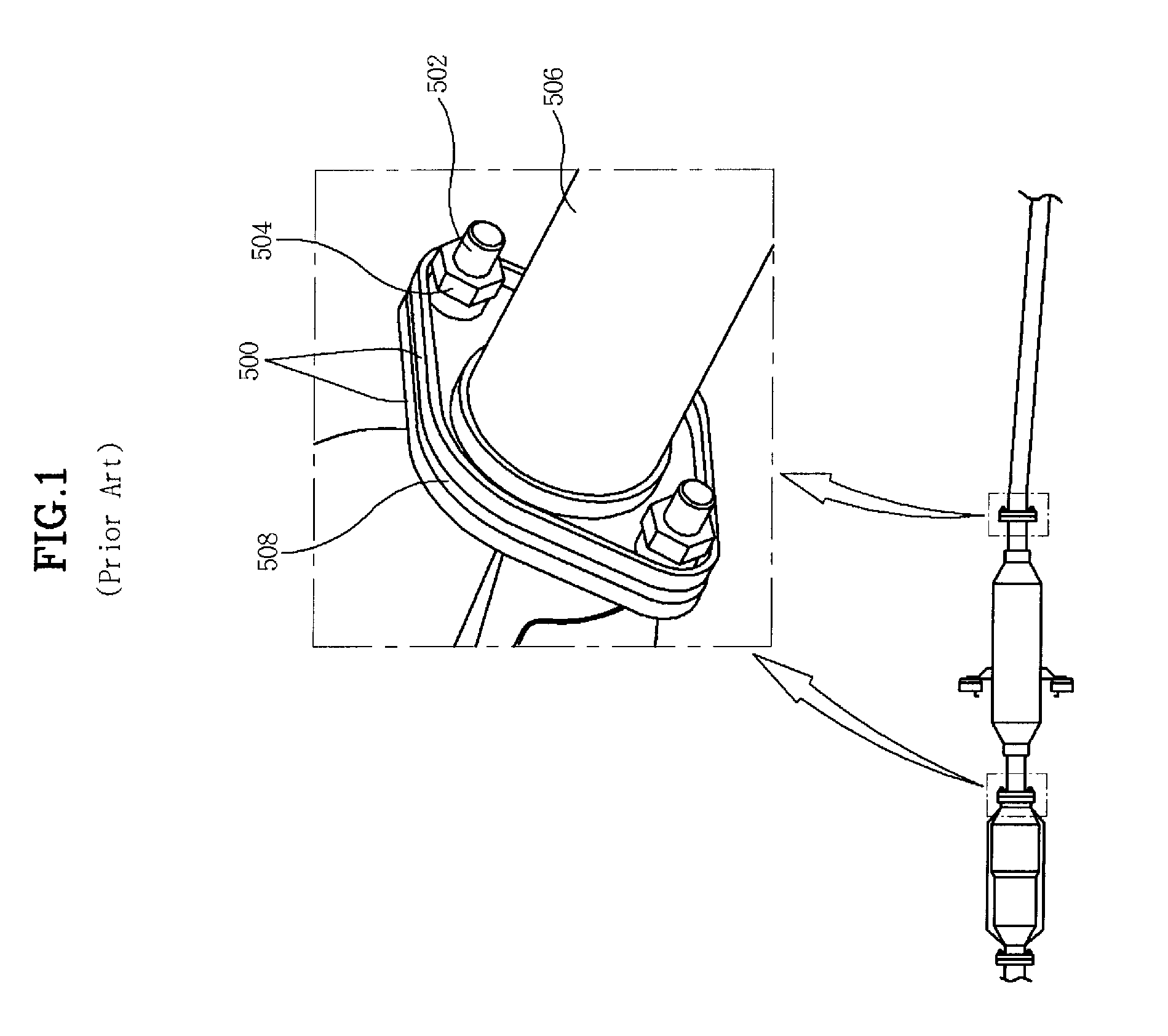

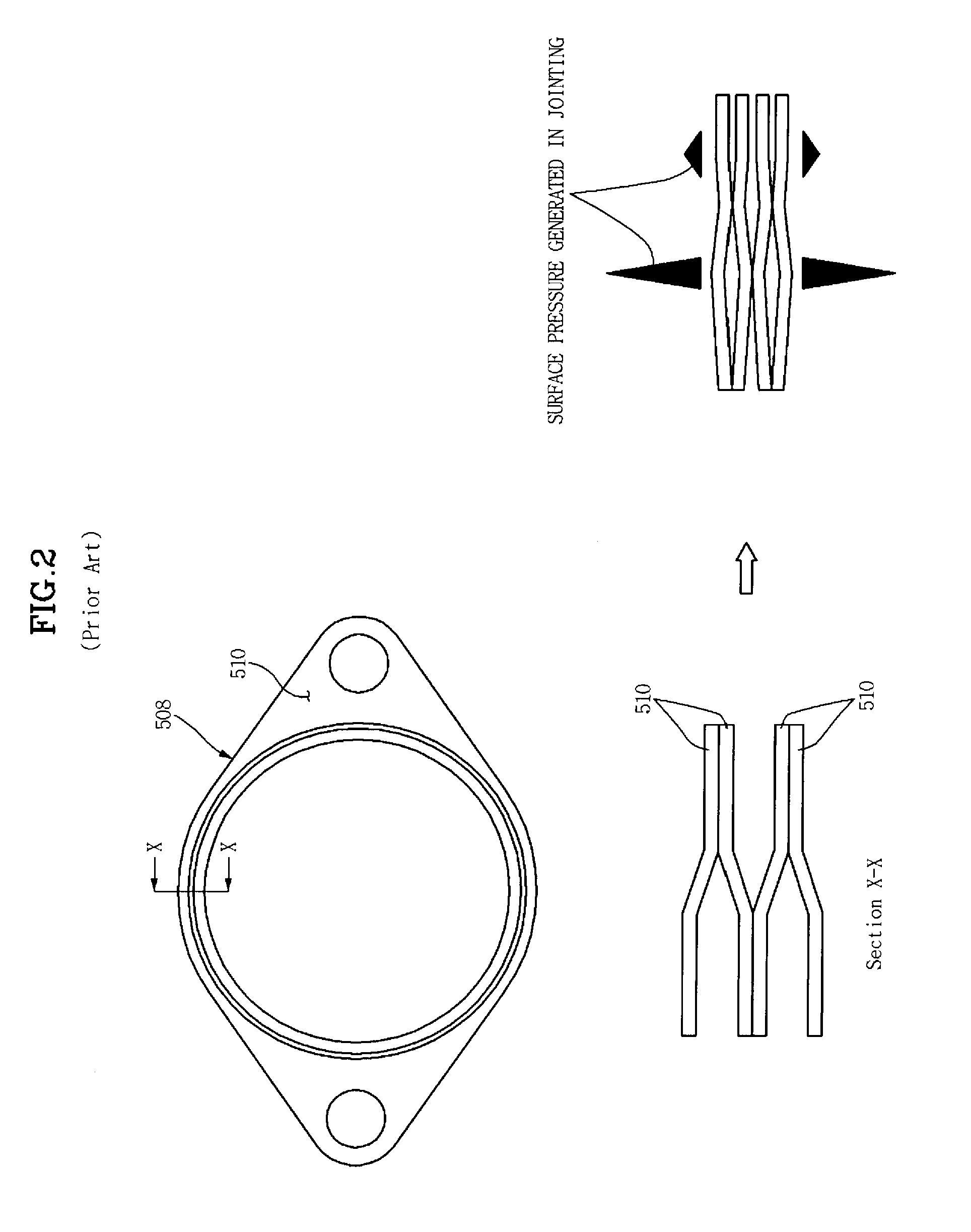

Gasket for exhaust pipe of vehicle

InactiveUS20110049813A1Improve heat resistanceUniform surface pressureEngine sealsFlanged jointsEngineeringExhaust pipe

A gasket for an exhaust pipe of a vehicle which is formed by overlapping a plurality of plates having a center hole in common, may include the plate having, in the cross section thereof, a bead plane formed along a circumference of the center hole of the plate, a bead slope portion extending from the bead plane and bent against a bead slop portion of an adjacent plate, and a plate portion extending from the bead slope portion outward the center hole, wherein the bead plane overlaps the bead plane of the adjacent plate.

Owner:HYUNDAI MOTOR CO LTD +1

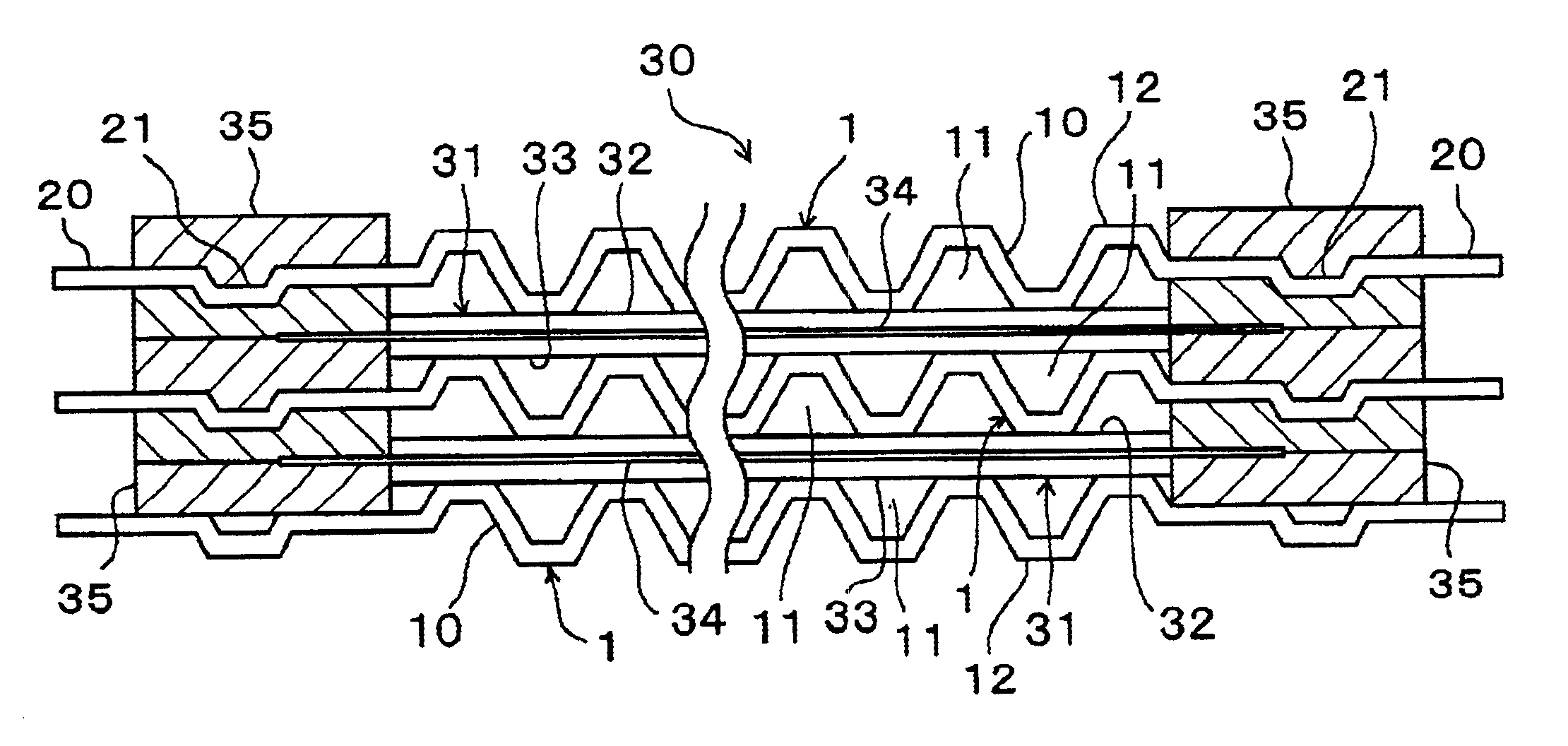

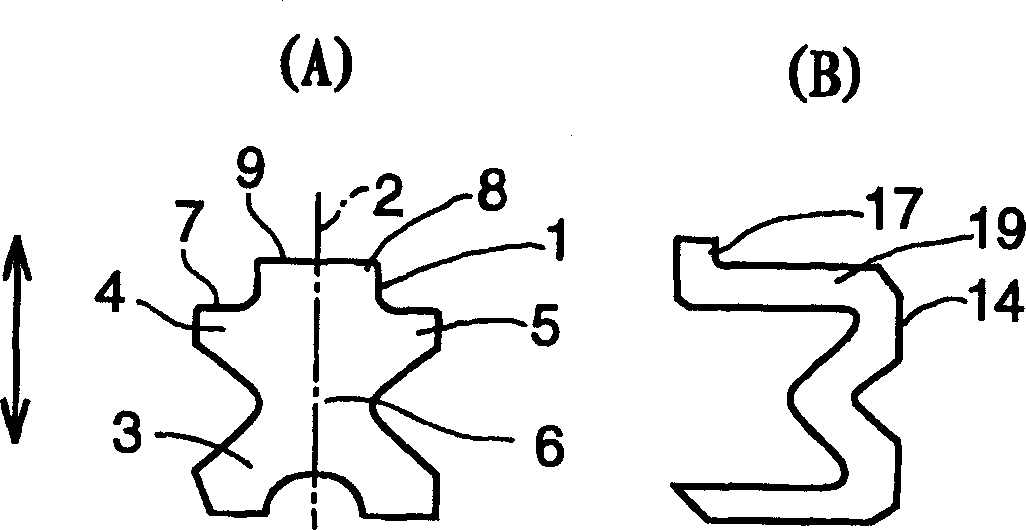

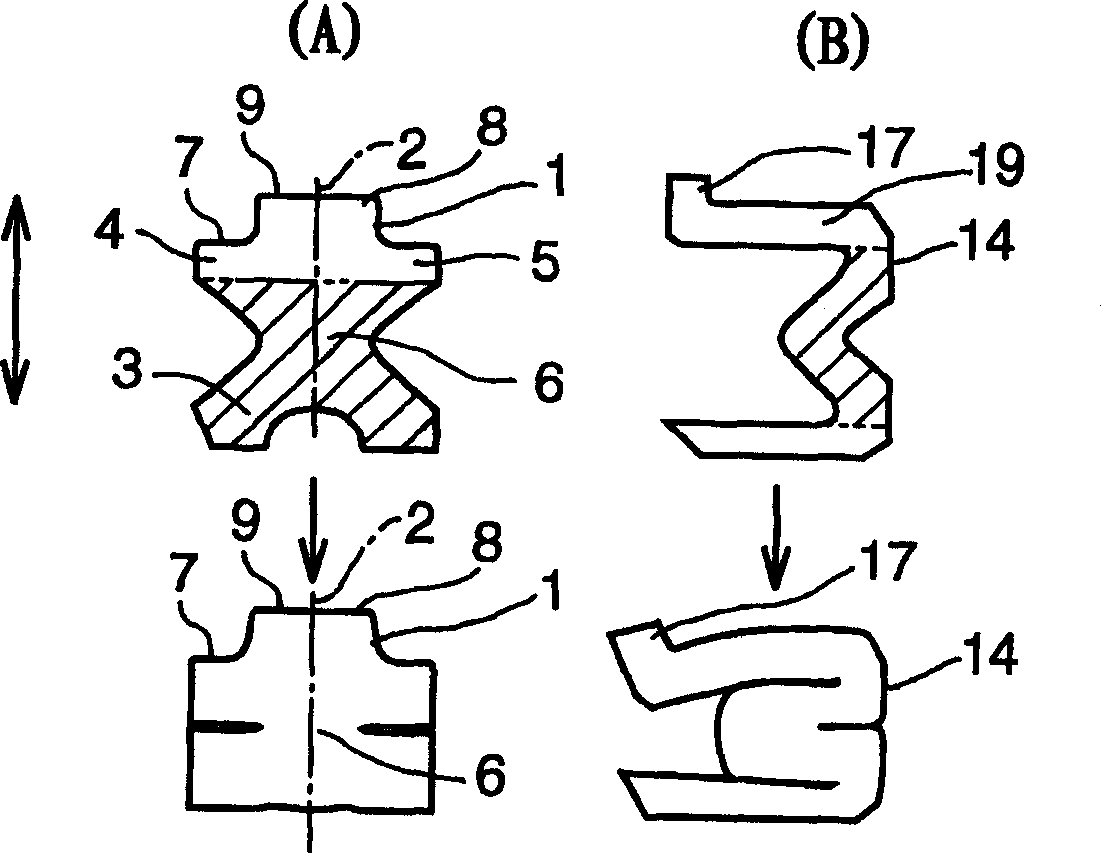

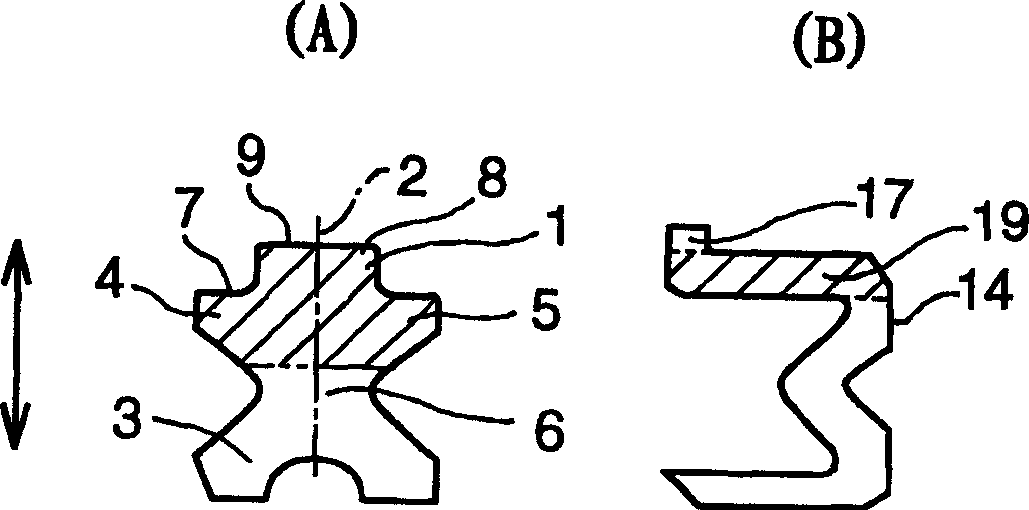

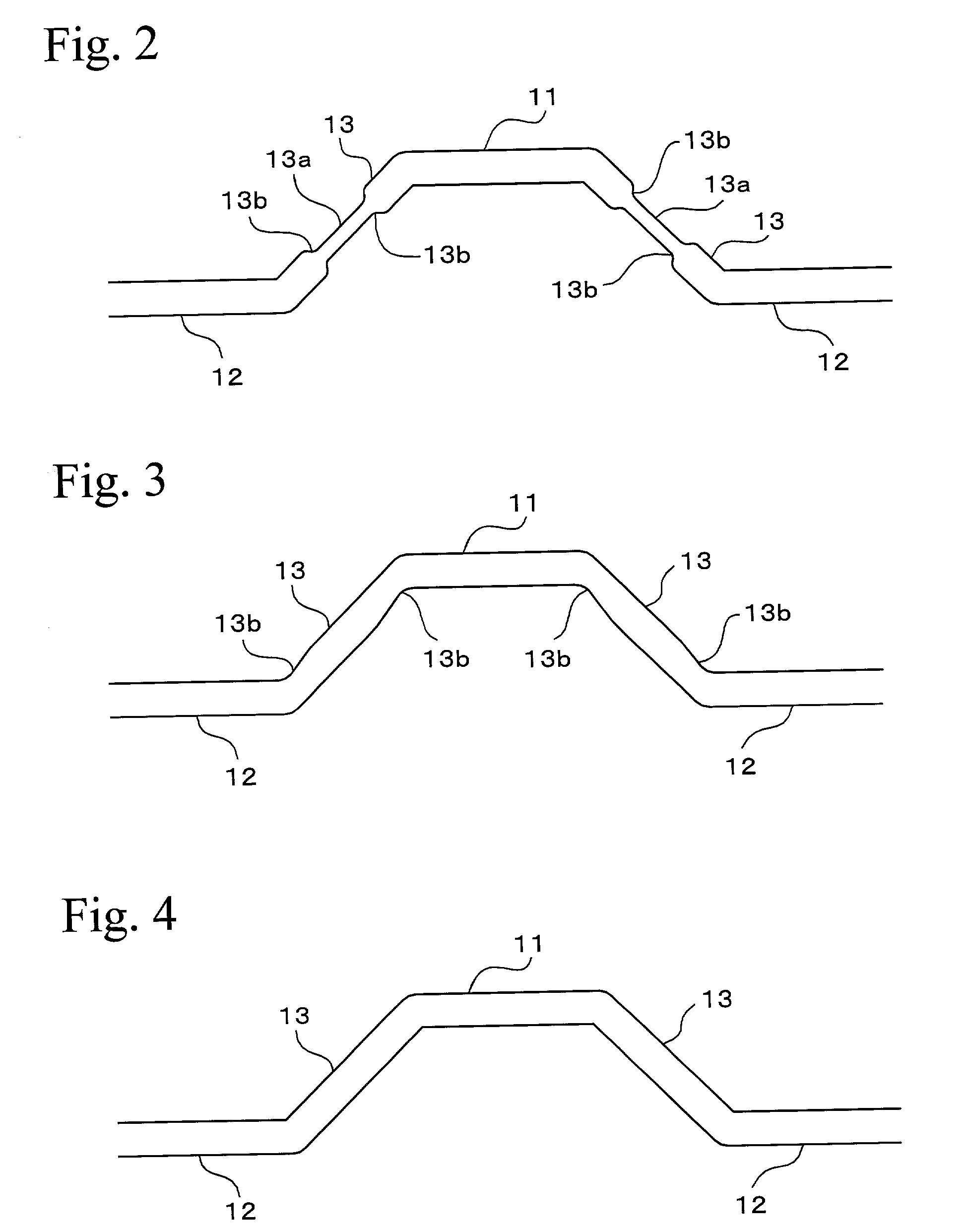

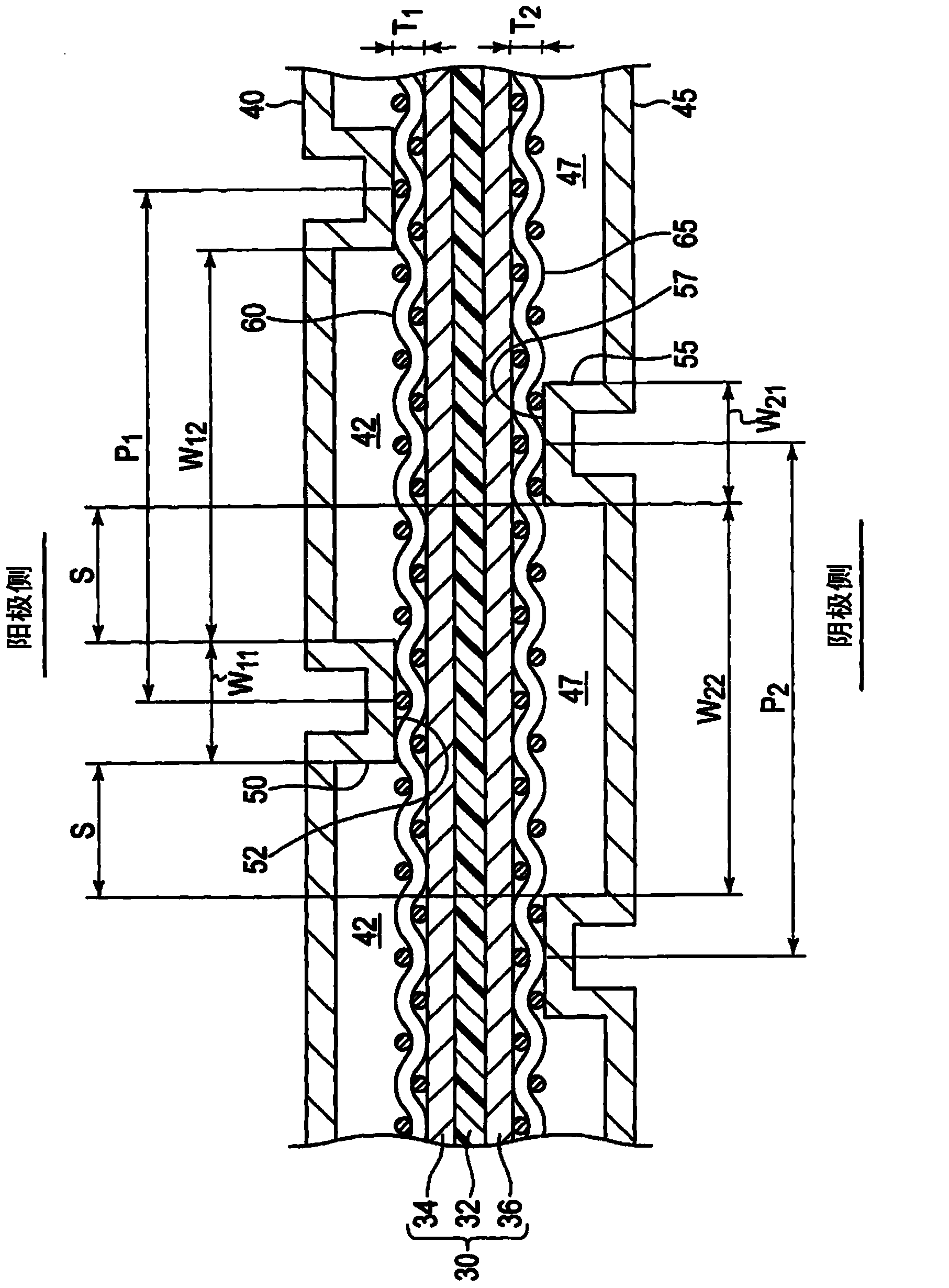

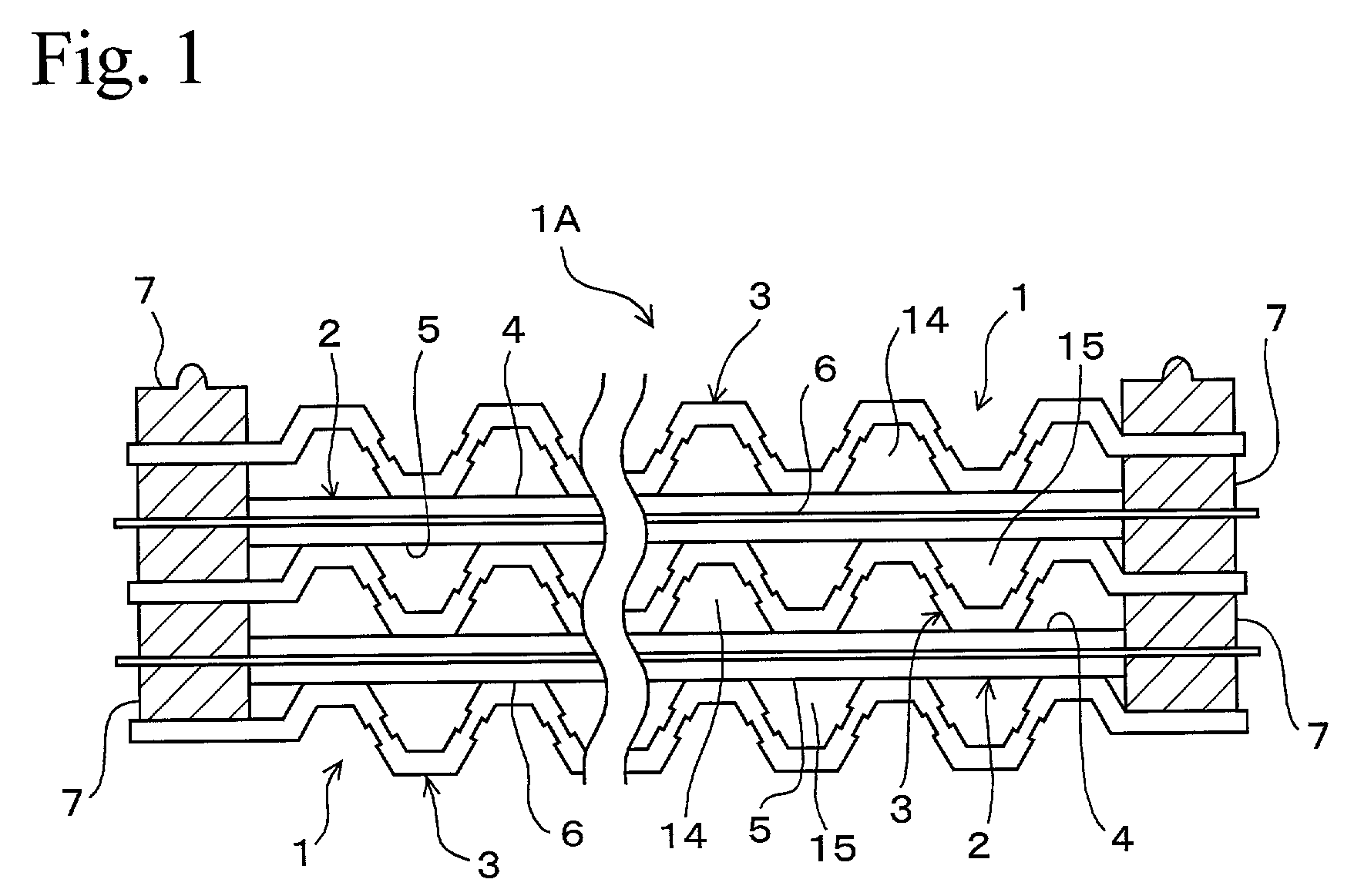

Fuel cell and separator therefor

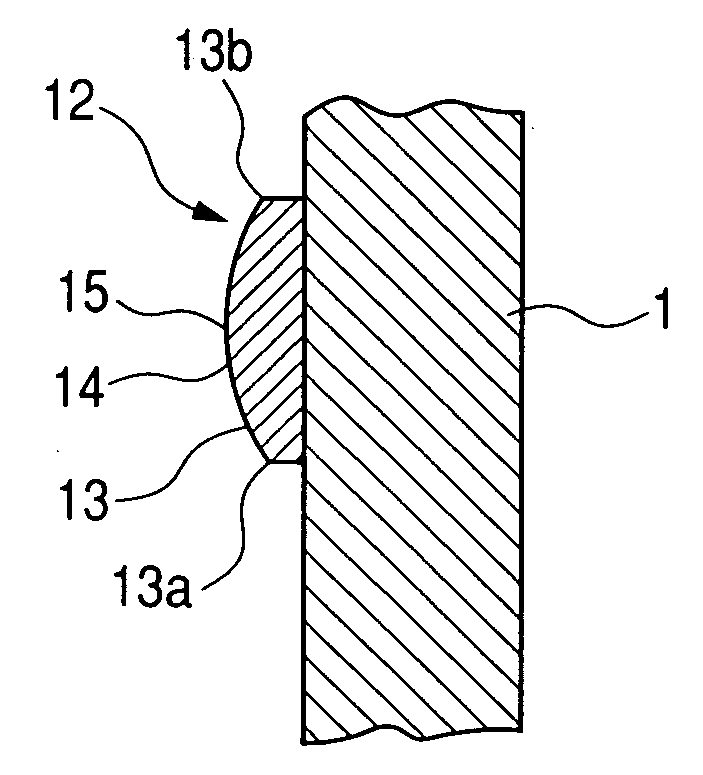

InactiveUS20020061428A1Bending angle of the spacer portion is largeContact resistanceFuel cell auxillariesCell component detailsFuel cellsForming gas

A fuel cell comprises an membrane electrode assembly formed by holding an electrolyte membrane between a pair of electrodes and a separator layered on both sides of the membrane electrode assembly for forming gas passages between the separator and the electrode. The separator includes protrusions formed on both surfaces thereof for contacting with the electrode, and a spacer portion disposed between the protrusions for substantially forming the gas passage. The protrusions and the spacer portions are arranged along a surface direction of the separator so as to form a corrugated plate. At least two drawn portions in which thickness of the spacer portion changes to a thin portion are formed between the protrusions in the spacer portion.

Owner:HONDA MOTOR CO LTD

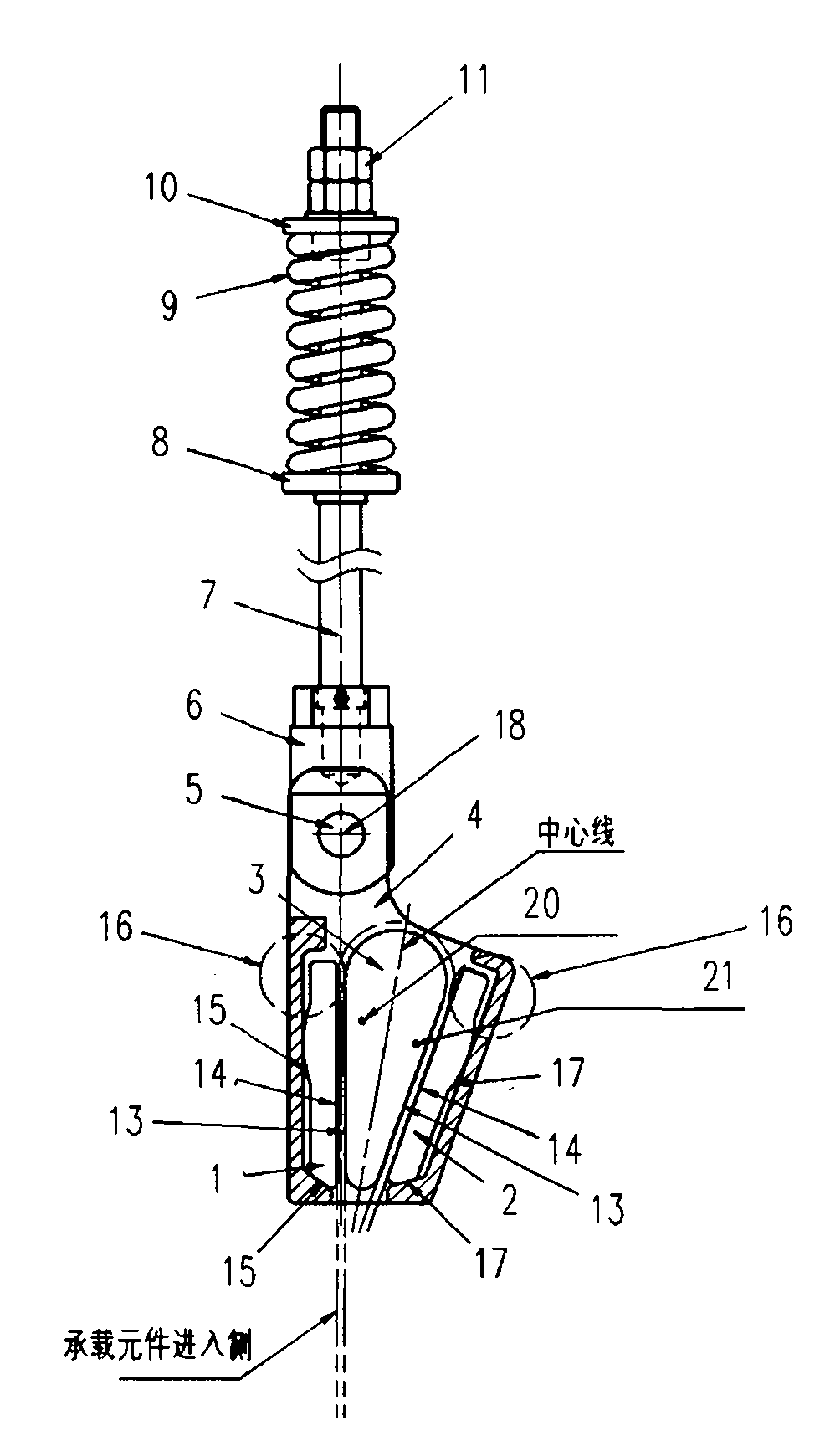

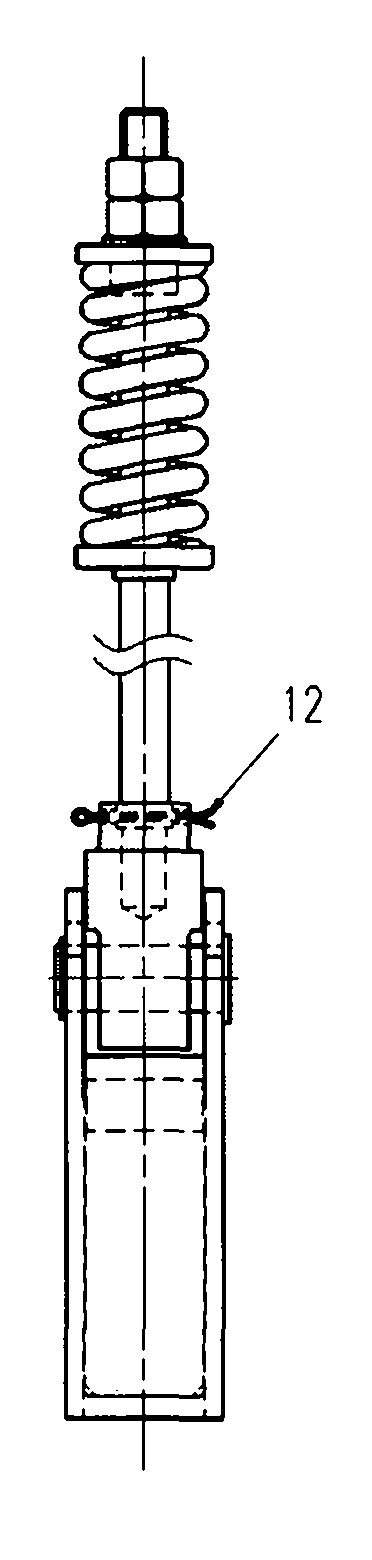

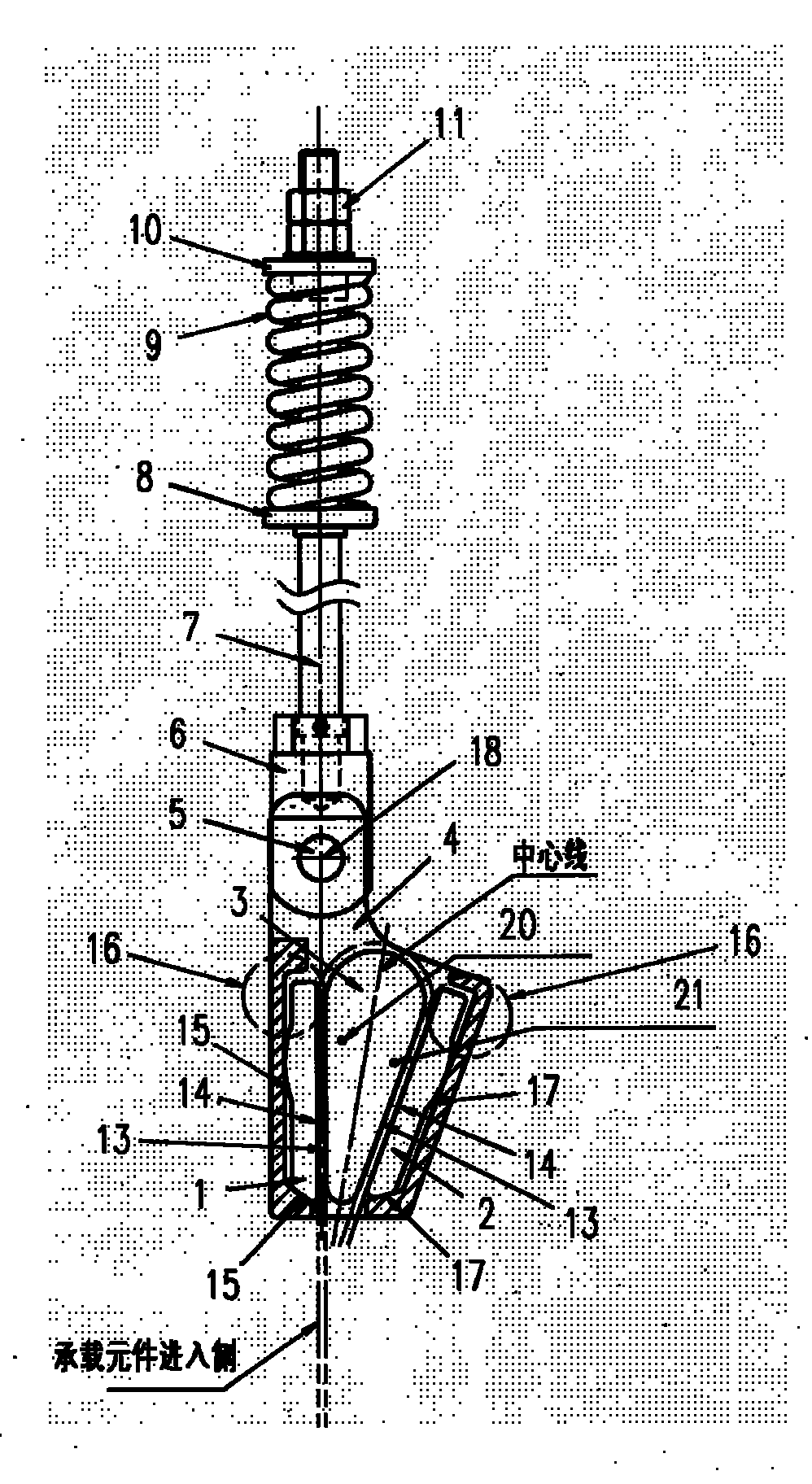

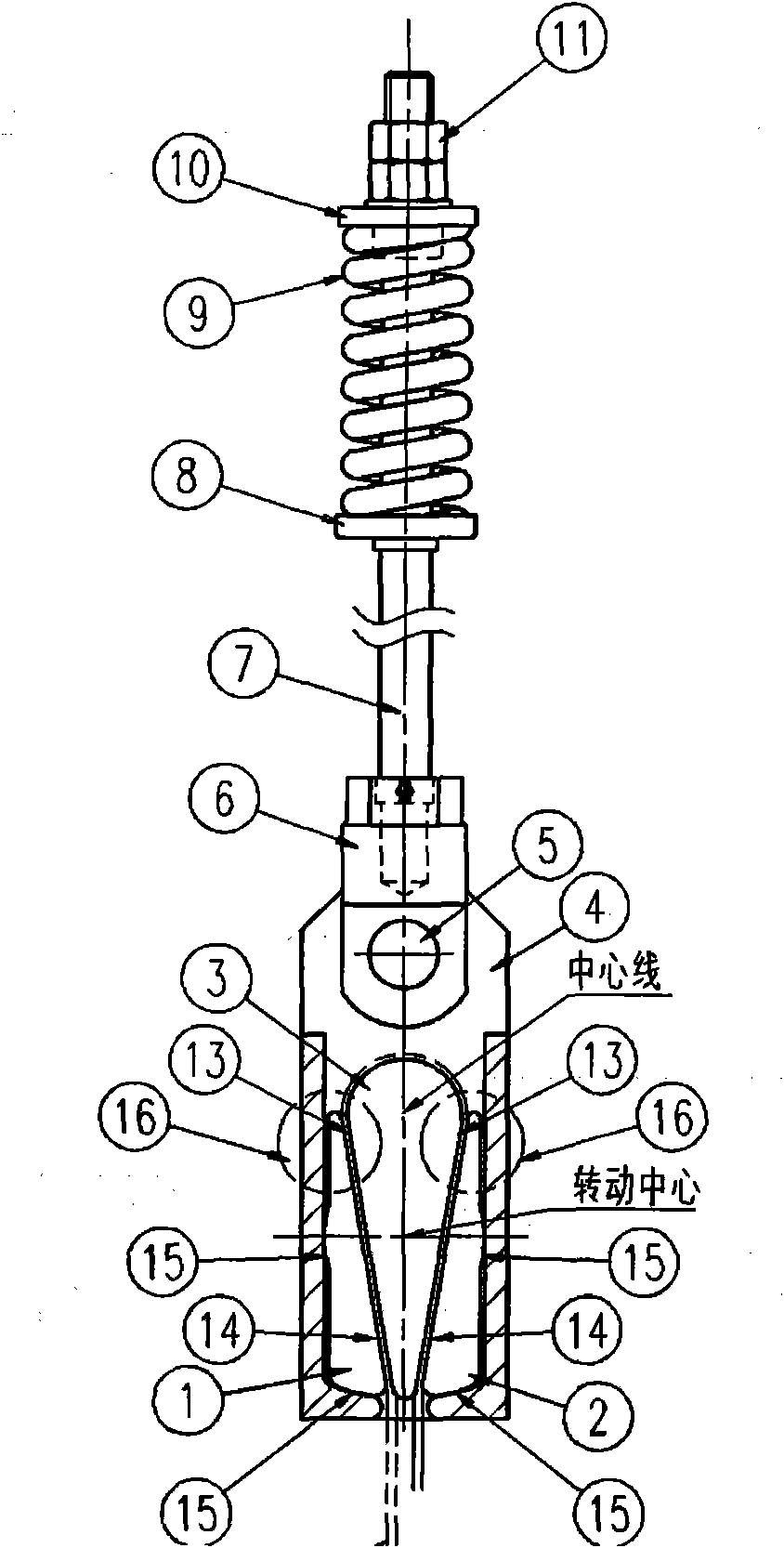

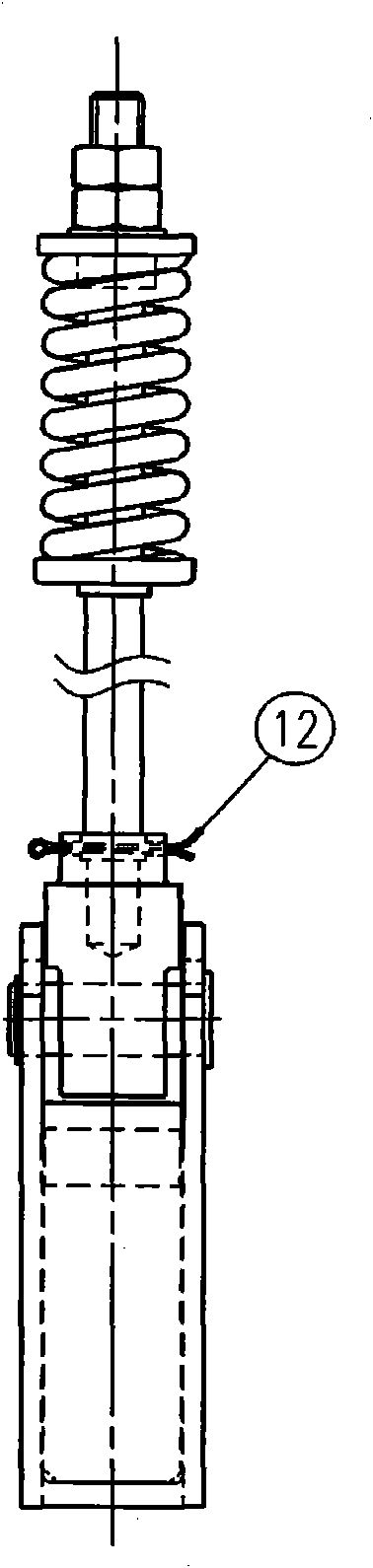

Terminating set for elevator device

The invention discloses a terminating set for an elevator device. The terminating set comprises a socket with a support point, wherein a wedge is arranged between two supporting pieces and provided with two first profile surfaces which form certain included angles with the center of the wedge and are arranged oppositely; the two supporting pieces are provided with second profile surfaces corresponding to the first profile surfaces; a bearing element for elevating the elevator device is clamped between the first profile surface and the second profile surface; the wedge and the supporting pieces are at least partially positioned inside the socket; each supporting piece is provided with at least one contact profile; the contact profile is positioned between the supporting piece and the socket and allows the two supporting pieces to rotate in the socket; the wedge is driven to rotate by the two supporting pieces; and when external force is applied to the bearing element, the two supporting pieces and the wedge rotate to a position at which the bearing element and the support point of the socket are basically on the same straight line. The terminating set has a simple and reliable structure, balances the pressure on the bearing element of the elevator device and prolongs the service life of the bearing element.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Secondary battery assembly

ActiveCN102439755AInhibit deteriorationUniform surface pressureCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrical batteryElectrical and Electronics engineering

The disclosed secondary battery assembly has: a secondary battery formed by enclosing a coiled electrode in a flat, square case; a contact member that is partially in contact with the surface that has the largest surface area (hereafter, the compressed surface) among the exterior surfaces of the secondary battery; and a restraining member that restrains the secondary battery and the contact member. In the secondary battery assembly, due to restraint by the restraining member, the contact member partially compresses the compressed surface. The contact member has multiple contact units, which are provided separately and are in contact with the compressed surface, and multiple connection units, which connect the multiple contact units to each other. The contact units are formed and positioned in such a manner that the contact units: are formed extending from the connection units towards the compressed surface; more strongly compress the compressed surface at offset regions on both sides, which correspond to points removed from the centre of the coiled electrode in the coil axis direction; and more weakly compress the compressed surface at central regions between the offset regions on both sides, which correspond to points more central to the coil axis direction of the coiled electrode.

Owner:TOYOTA JIDOSHA KK

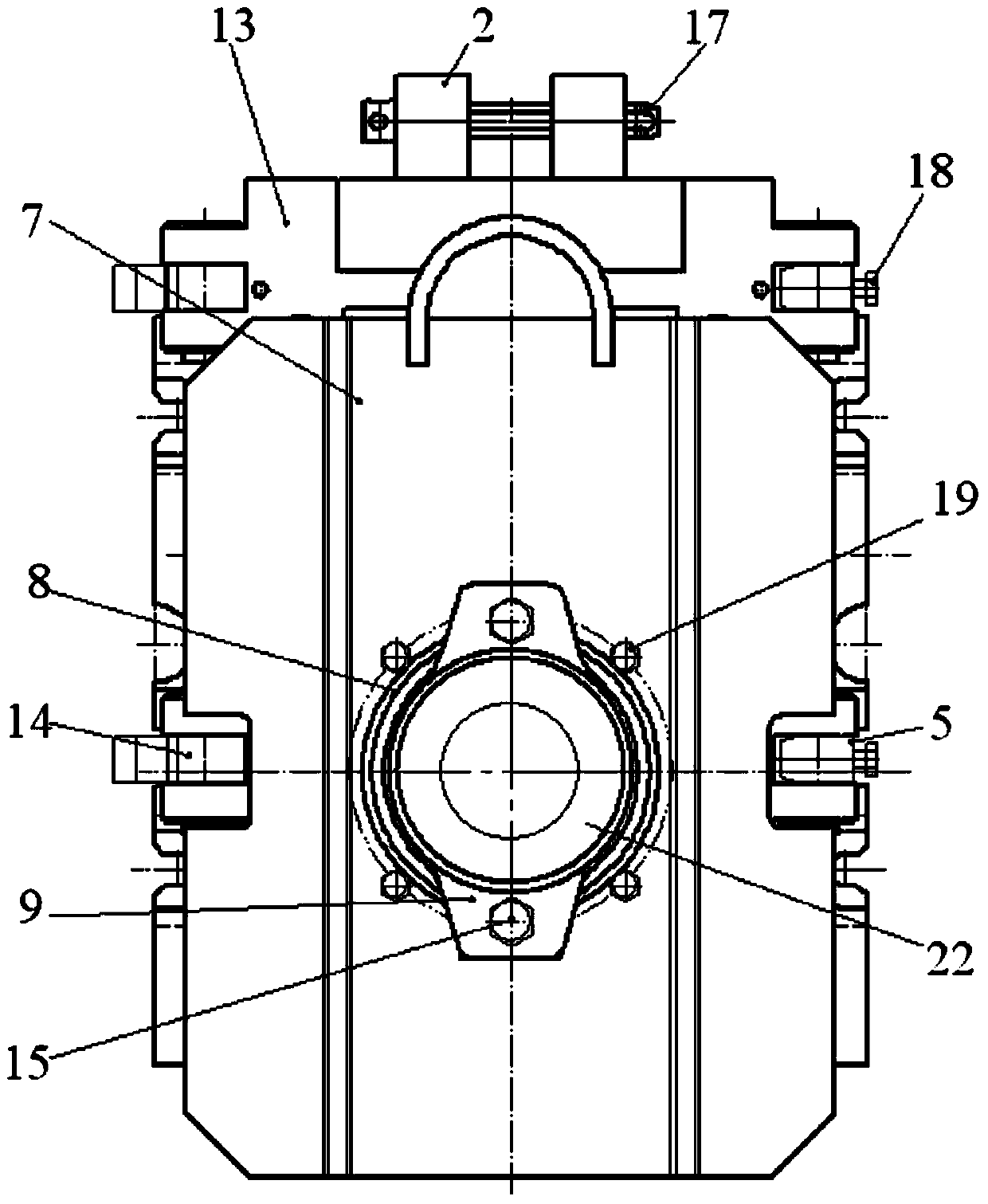

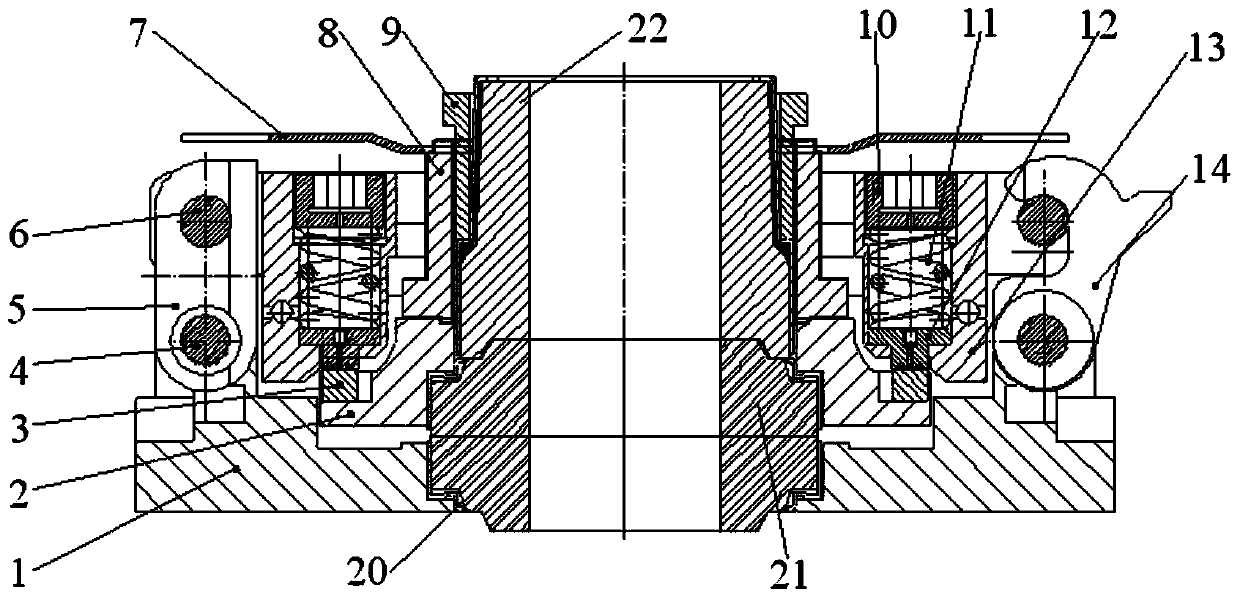

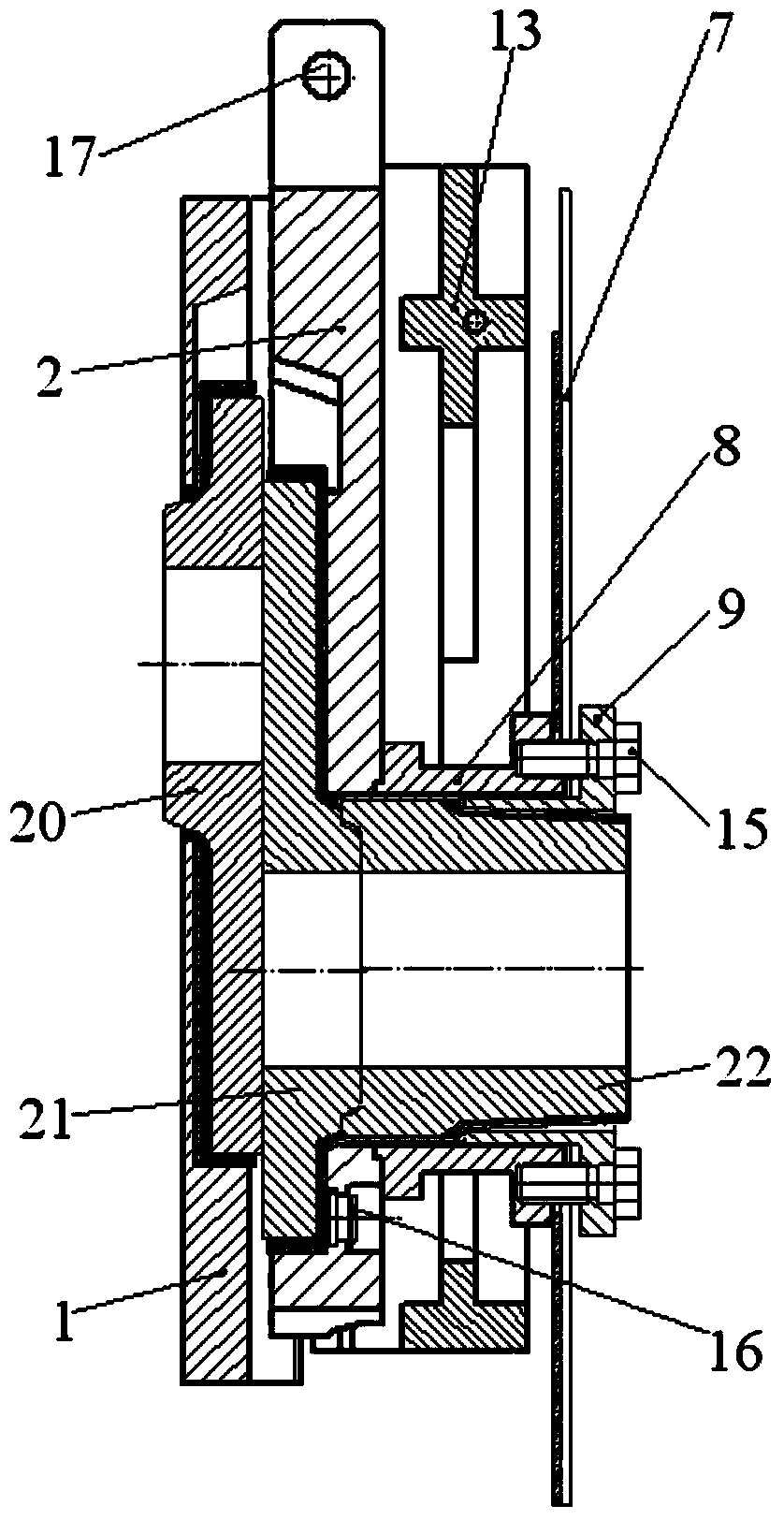

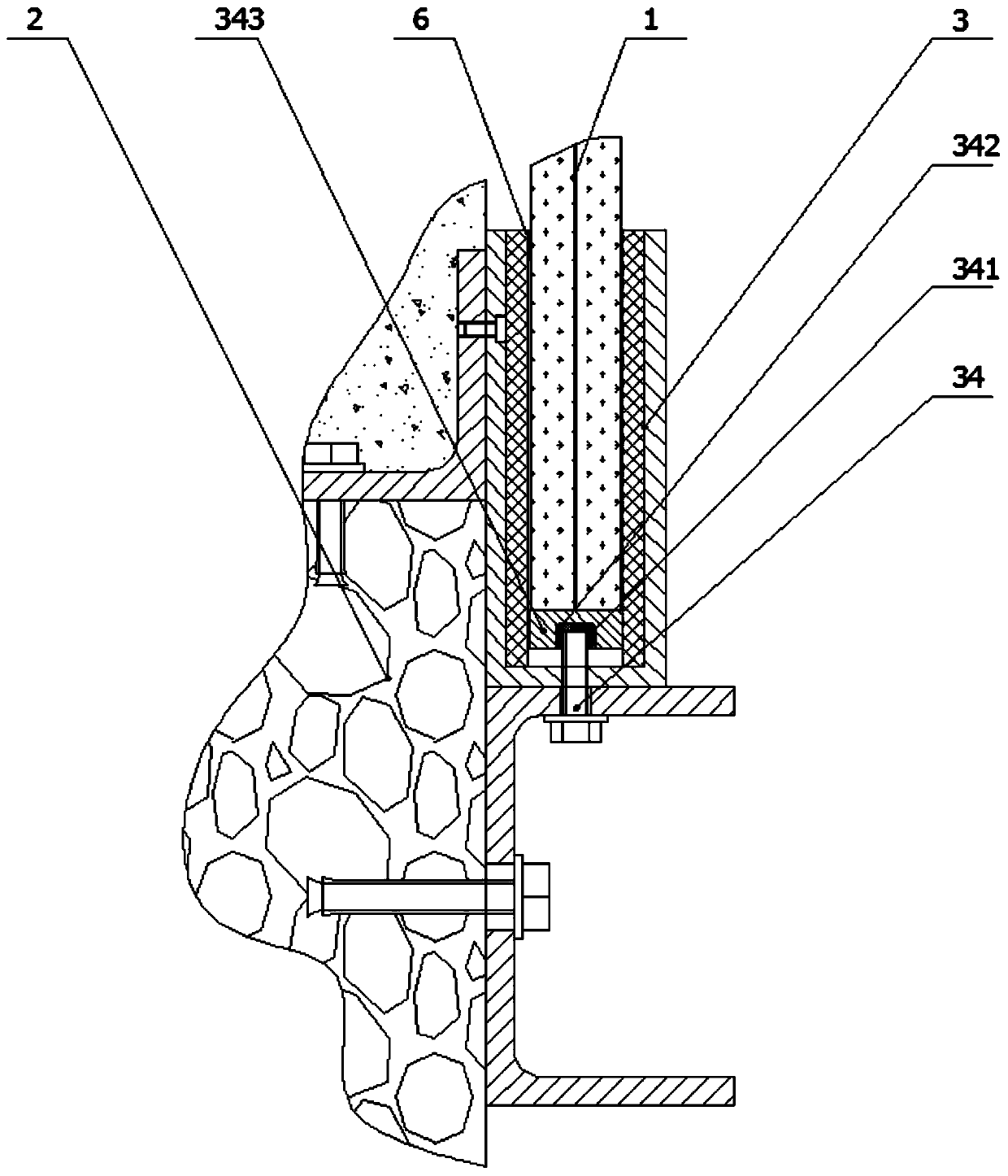

Sliding block type converter tapping hole sliding plate slag stopping device

The invention discloses a sliding block type converter tapping hole sliding plate slag stopping device. A sliding frame is arranged between a fixed frame and a pressing frame, and is matched with a sliding groove of the fixed frame in a sliding manner; a fixed nozzle brick is fixed in the fixed frame, and a sliding nozzle brick is arranged on the sliding frame; spring pressing components are arranged on the pressing frame, and are used for pressing the sliding nozzle brick on the fixed nozzle brick by virtue of the sliding frame. By adopting the technical scheme, a plurality of groups of independent and uniformly-distributed spring pressing components and sliding bars are used for forming a pressing mode that a plurality of points are in elastic contact so as to ensure that stable and uniform surface pressure can be generated between nozzle bricks of the sliding plate, and generation of the steel leakage phenomenon can be prevented. The sliding block type converter tapping hole sliding plate slag stopping device is reasonable in structure, good in interchangeability, convenient in disassembly, simple in operation and safe and reliable in use.

Owner:MAANSHAN SHUANGYI MACHINERY MFG

Terminating set used for elevator device

ActiveCN101580201AReliable contactUniform surface pressureElevatorsEngineeringMechanical engineering

The invention discloses a terminating set used for an elevator device, which comprises a socket, a wedge block and two supporting pieces, wherein the wedge block is arranged between the two supporting pieces; the wedge block is provided with two first outline surfaces which are arranged with respect to the center of the wedge block at a certain angle; the two supporting pieces are provided with second outline surfaces corresponding to the first outline surfaces; a bearing element lifting the elevator device is held between the first outline surfaces and the second outline surfaces; the wedge block and at least partial supporting pieces are positioned at the inner part of the socket; each supporting piece is provided with at least one contacting outline which is positioned between the supporting pieces and the socket, the contacting outline leads the two supporting pieces to be capable of rotating in the socket, and the rotating centers of the two supporting pieces are same. The terminating set has simple and reliable structure, uniform pressure of the bearing element of the elevator device, and long service life of the bearing element.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Battery module

ActiveUS8703316B2Uniform surface pressureSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsCouplingBattery cell

A battery module is provided with a battery cell and a case. The case houses the battery cell. The case includes a first main face, a second main face, a first battery module coupling structure and a first elastically deforming structure. The first battery module coupling structure is arranged and configured to retain a first additional battery module over the first main face. The first elastically deforming structure is arranged and configured with respect to the first main face to elastically deform inward towards the second main face upon stacking the first additional battery module onto the first main face while the first additional battery module is retained to the first main face of the case by the first battery module coupling structure.

Owner:ENVISION AESC JAPAN LTD

Secondary battery assembly

InactiveCN104011897AInhibition of deteriorationUniform surface pressureFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryStructural engineering

A secondary battery assembly includes: a secondary battery including a wound electrode body enclosed in a flat rectangular case; a contact member partly contacting a side surface as a pressed surface having a maximum area of outer surfaces of the secondary battery; and a binding member for binding the secondary battery and the contact member to partly press against the pressed surface. The contact member includes: contact parts arranged discretely in contact with the pressed surface; and a connecting part connecting the contact parts. The contact parts are formed to protrude from the connecting part toward the pressed surface, and into an arrangement or a shape to press more weakly both one-side regions of the pressed surface in a winding axis direction and more strongly a central region between the one-side regions.

Owner:TOYOTA JIDOSHA KK

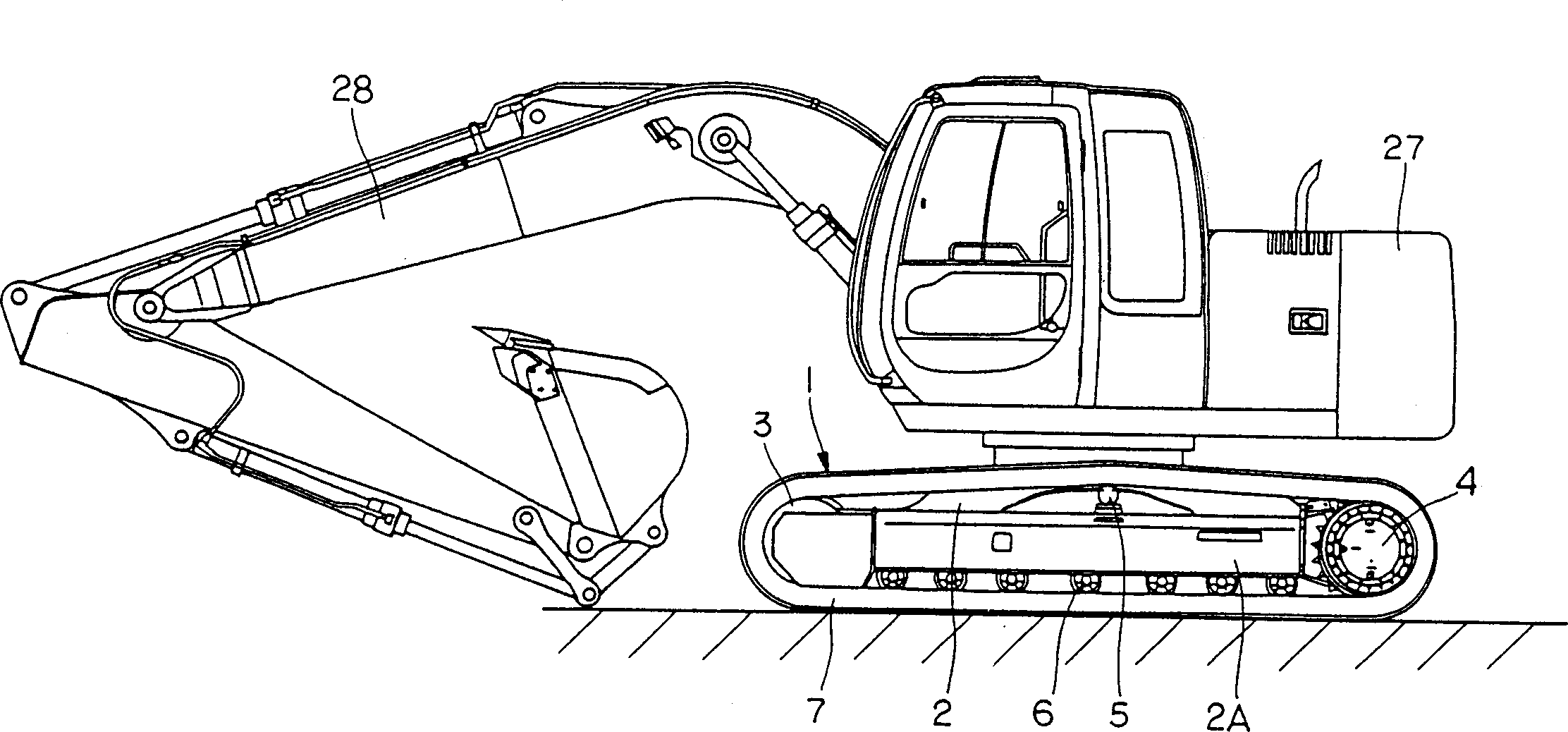

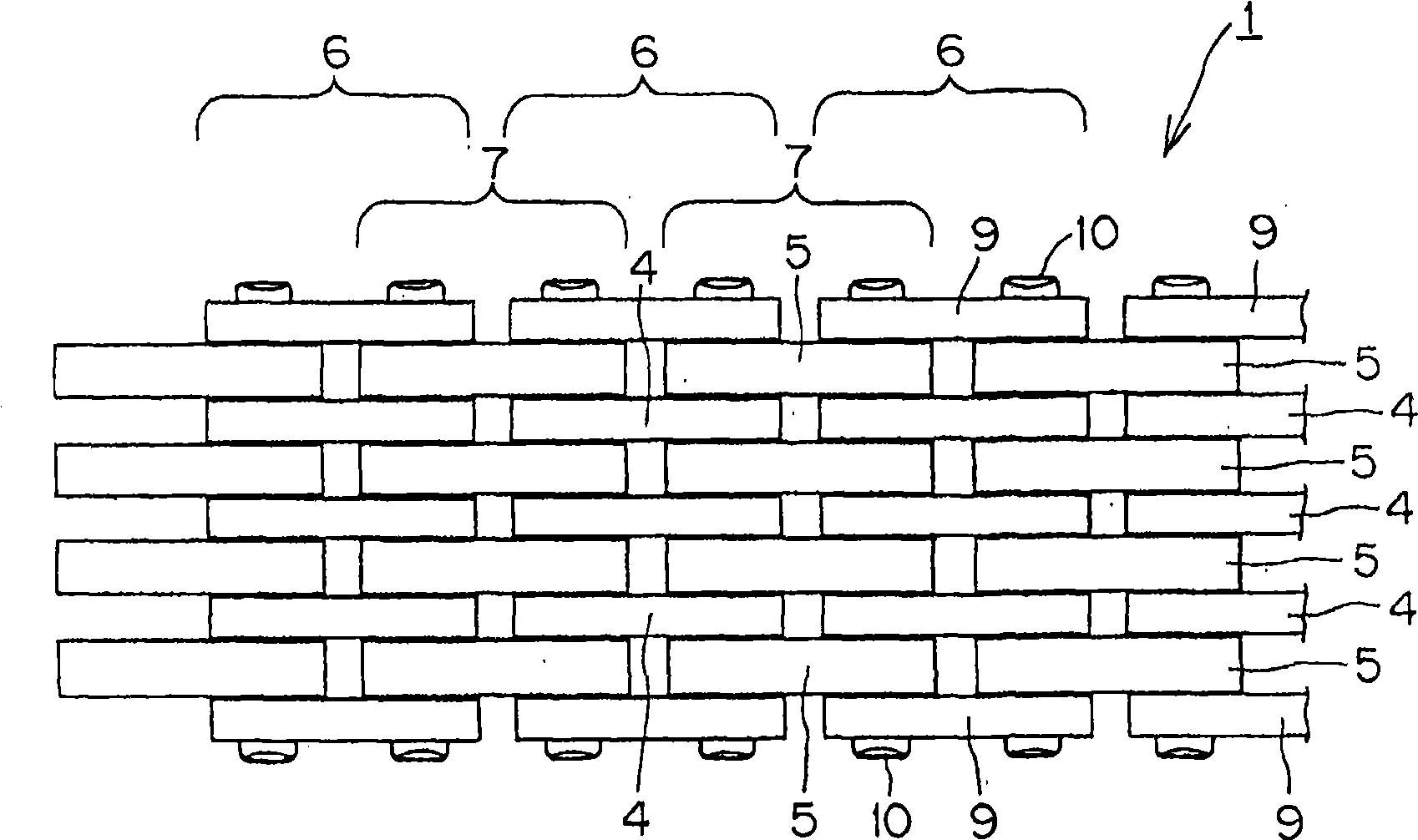

Crawler belt and sealt for use therein

InactiveCN1392852AUniform pressureUniform surface pressureMechanical power transmissionEndless track vehiclesEngineering

A seal ( 21 ) is constituted by an outer lip portion ( 22 ) to be held in abutting engagement with an outer link portion ( 9 ) of a crawler belt ( 7 ), an inner lip portion ( 23 ) to be held in abutting engagement with a bush ( 11 ), and an interconnecting bridge portion ( 24 ) bridged and connected between the outer and inner lip portions ( 22, 23 ). The outer lip portion ( 22 ) on the side of track link, the inner lip portion ( 23 ) on the side of bush, and outer bridge portion ( 24 A) and inner bridge portion ( 24 B) of the interconnecting bridge portion ( 24 ) are formed in thicknesses (T 1 , T 2 , T 1 ' and T 2 '), respectively, which are in the relations of (T 2≈ T 2 '>T 1 ≈T 1 '). A maximum outside diameter portion ( 24 C) of the interconnecting bridge portion ( 24 ) is located radially outward of a median point between inner and outer peripheral ends of the lip portion ( 23 ) on the side of bush. The inner lip portion ( 23 ) as a whole is uniformly pressed against an end face ( 11 A) of the bush ( 11 ) by the interconnecting bridge portion ( 24 ).

Owner:NIHON KENKI CO LTD

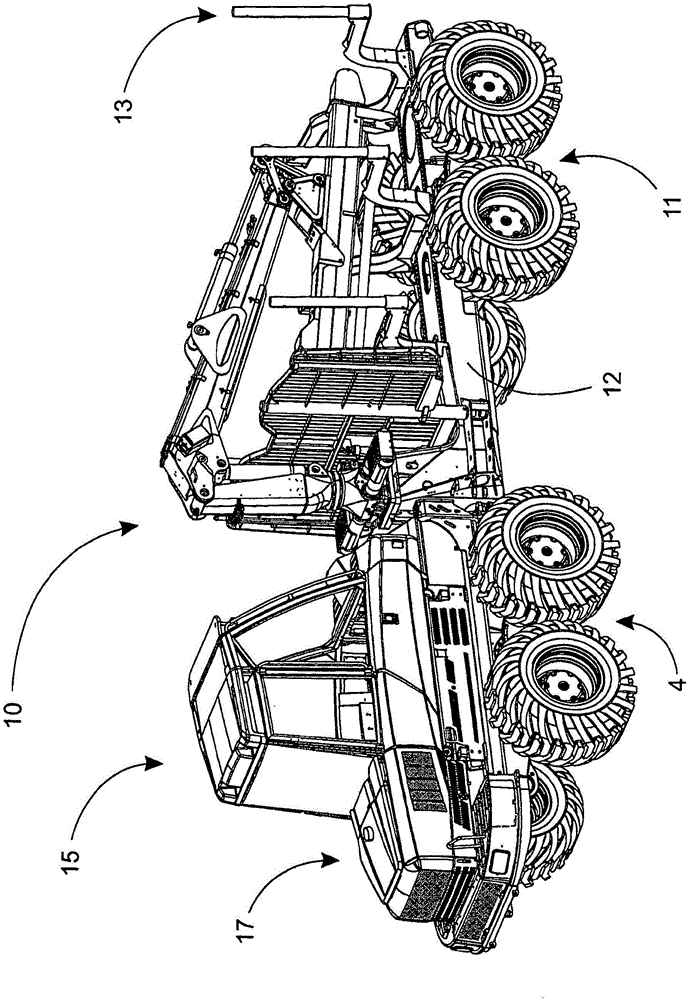

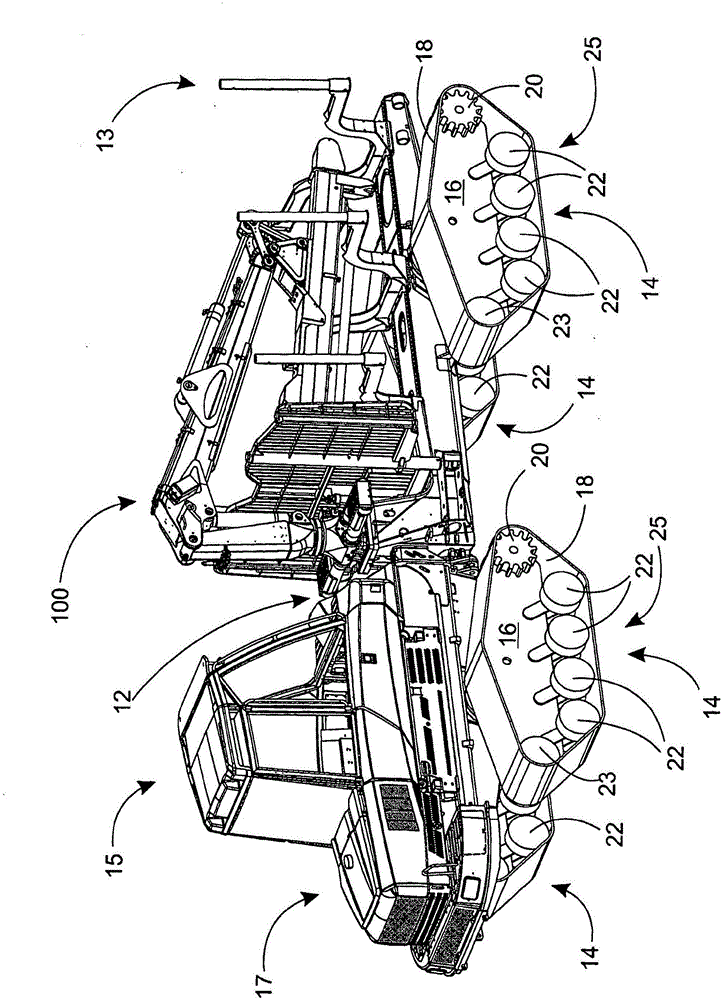

Photovoltaic cells with improved backsheet

ActiveCN106232464ASmall structureExcellent ground performanceSuspensionsRenewable energy machinesDrive wheelDrive shaft

The invention relates to a modular crawler-track unit for a forest machine, which crawler-track unit (14) includes - a crawler-track frame (16), a sleeve axle (77), for supporting the crawler-track frame in the forest machine, a crawler mat (18) arranged in a circulation, at least one drive wheel (20) mounted in bearings in the said crawler-track frame (16), at least one idler wheel (23) mounted in bearings in the said crawler-track frame (16), support means (25), which are arranged to conform according to the shape of the surface of the ground, in order to distribute the surface pressure of the crawler-track unit (14) evenly, and a drive shaft (60) mounted in bearings in the said crawler-track frame (16). The crawler-track unit (14) further includes - a shaft (80) mounted in bearings on the crawler-track frame (16) for pivoting the said drive wheel (20) to the crawler-track frame (16) at a distance from the drive shaft (60), and power-transmission means (41) fitted between the said shaft (80) and the drive shaft (60) for transmitting power from the drive shaft (60) to the drive wheel (20). The invention also relates to a corresponding forest machine.

Owner:PONSSE

Fuel cell

InactiveCN104170145AMiniaturizationGood gas diffusionElectrolyte holding meansSolid electrolyte fuel cellsFuel cellsEngineering

Owner:NISSAN MOTOR CO LTD

End plates for fuel cell stack and method of manufacturing the same

InactiveUS20090117416A1Uniform surface pressureFuel cells groupingFinal product manufactureEngineeringMechanical engineering

The present invention provides an end plate for a fuel cell stack and a method of manufacturing the same, in which the end plate connected to each of both ends of a fuel cell stack is manufactured in a hybrid structure using two kinds of materials having different coefficients of thermal expansion, thus providing a uniform surface pressure in the fuel cell stack.

Owner:HYUNDAI MOTOR CO LTD

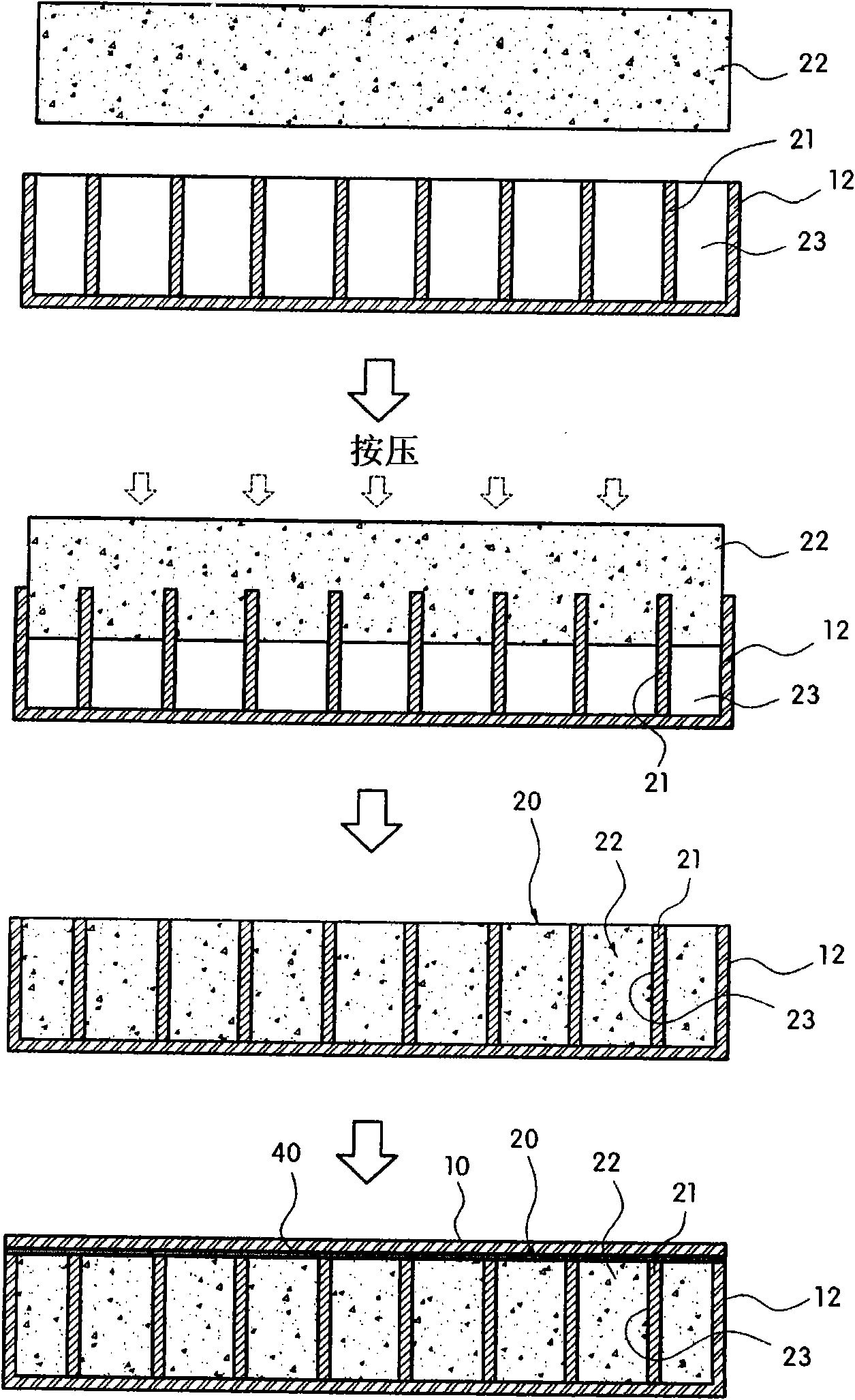

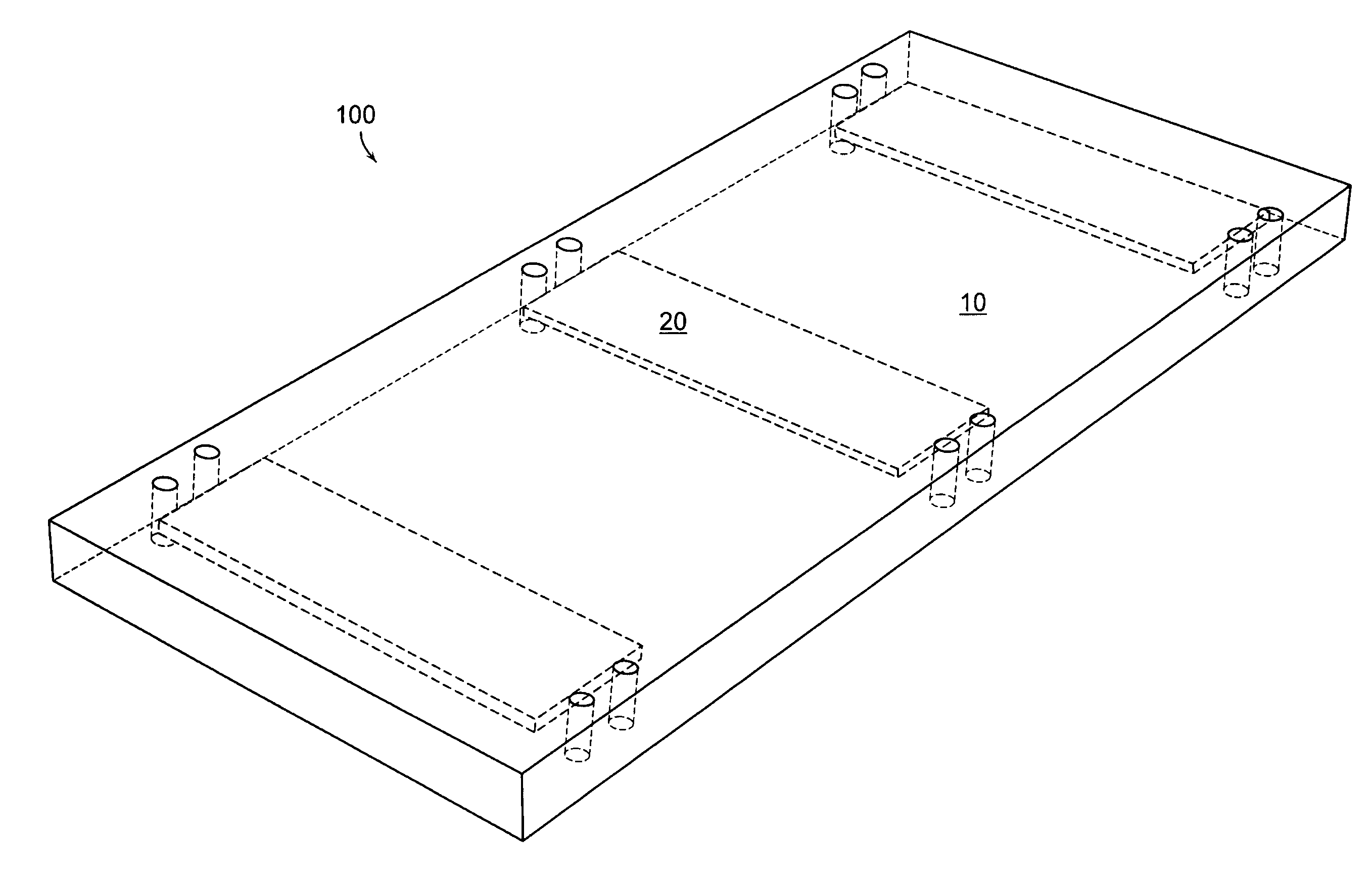

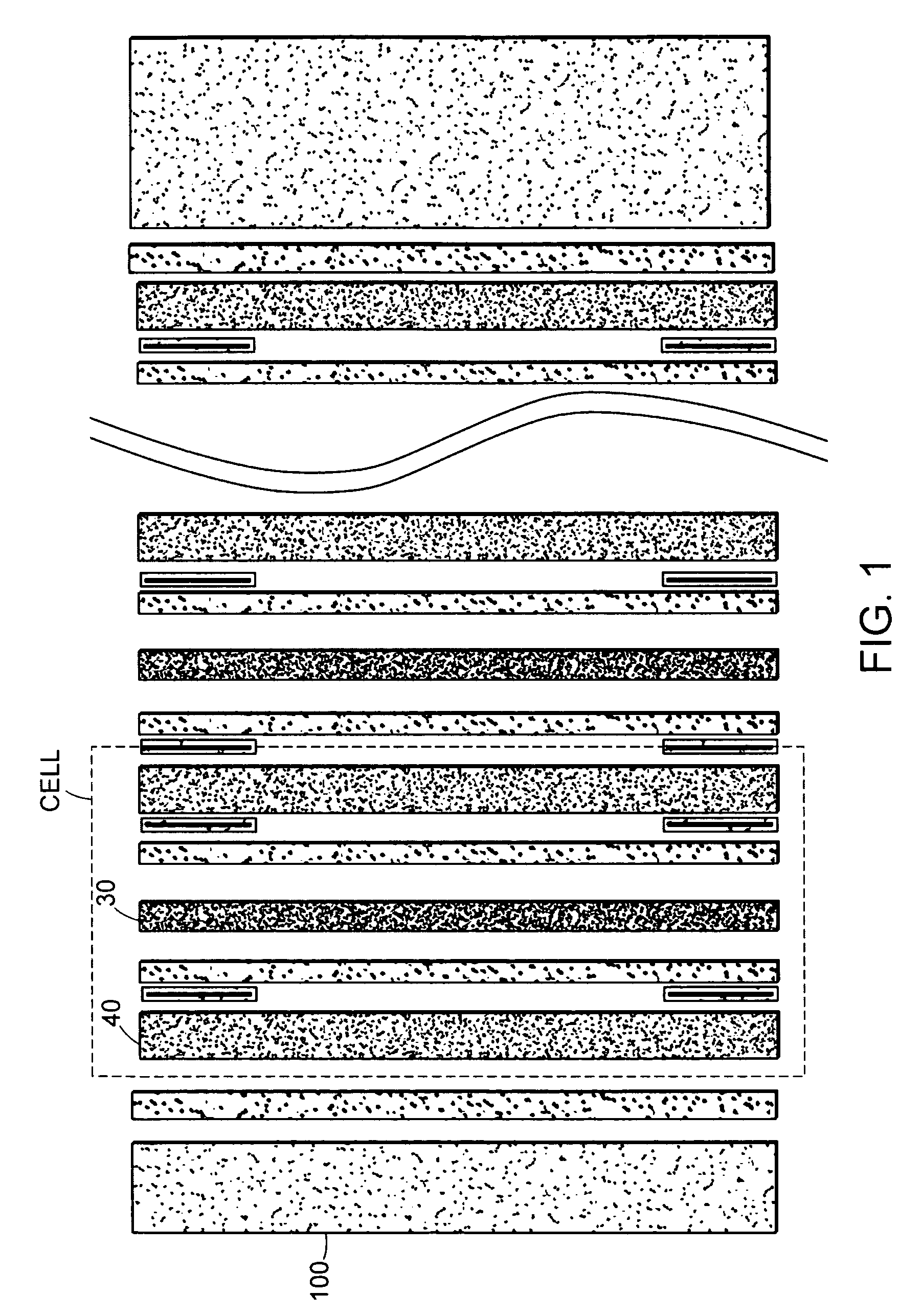

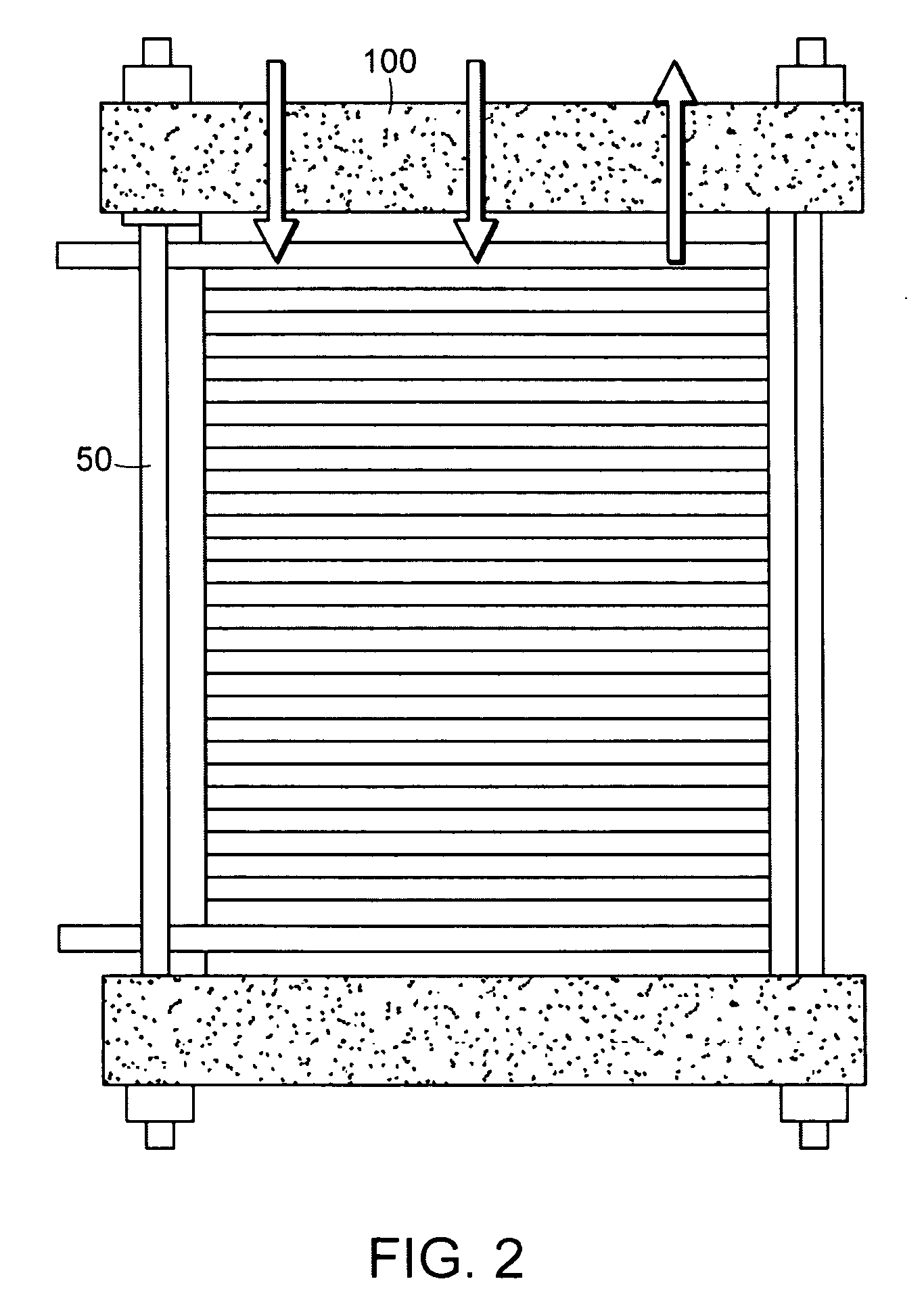

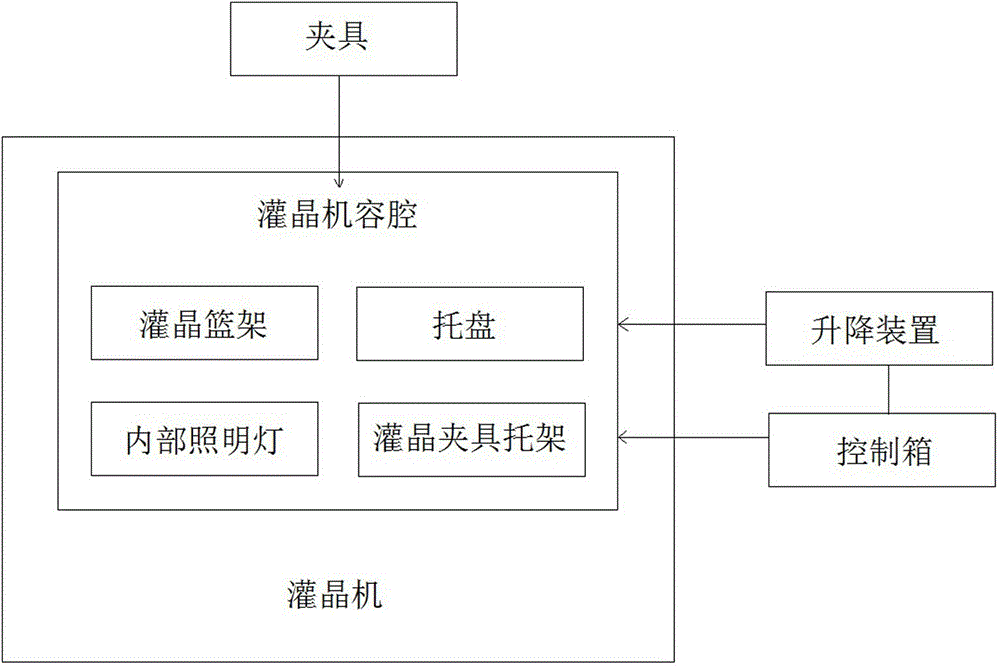

Crystal pouring device and method for flexible liquid crystal cell

InactiveCN104375335ASolve the inability to perfuseLow viscosityNon-linear opticsProduction rateEngineering

The invention discloses a crystal pouring device and method for a flexible liquid crystal cell. The device comprises a clamp, wherein the clamp is used for clamping the flexible liquid crystal cell into which crystal is to be poured and generating even surface pressure on the flexible liquid crystal cell. Before a crystal pouring machine is vacuumized, even surface pressure is generated on the surface of the flexible liquid crystal cell by means of the clamp, and liquid crystal is heated to reduce the viscosity of the liquid crystal. After the crystal pouring machine is vacuumized, the crystal pouring machine is in a pressure maintaining state to enable the interior vacuum degree of the flexible liquid crystal cell to be balanced, and then crystal pouring and inflation are conducted, so that pressure difference is prevented from being generated between the inside and outside of the flexible liquid crystal cell during vacuumization and cracking of the liquid crystal cell caused by expansion is avoided. The crystal pouring device and method for the flexible liquid crystal cell solve the problem that cracking of the liquid crystal cell can be caused by expansion due to the fact that pressure difference is generated between the inner surface and outer surface of the flexible liquid crystal cell during vacuumization for crystal pouring, productivity is increased, and production cost is reduced.

Owner:SINOFLEX OPTOELECTRONICS CHUZHOU

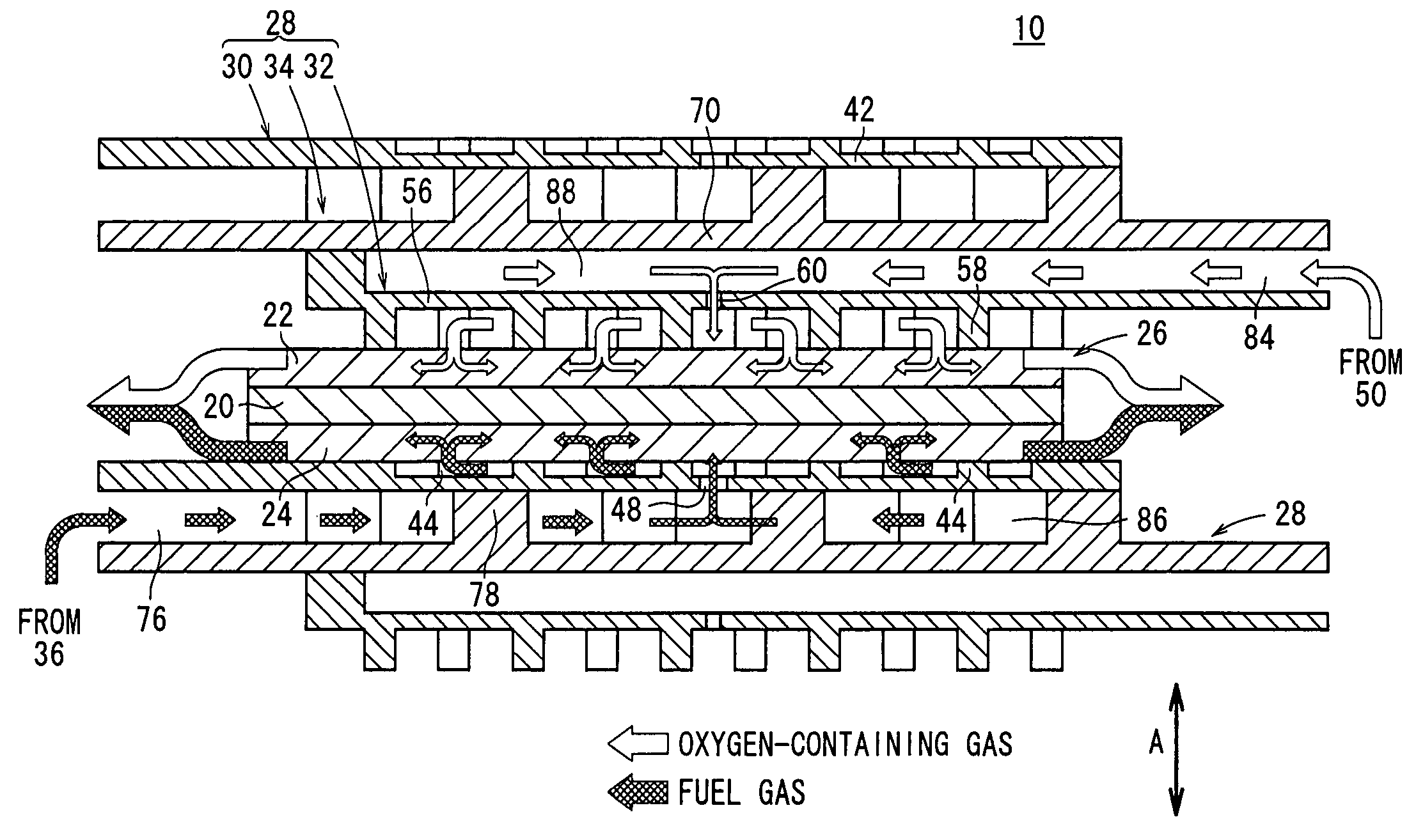

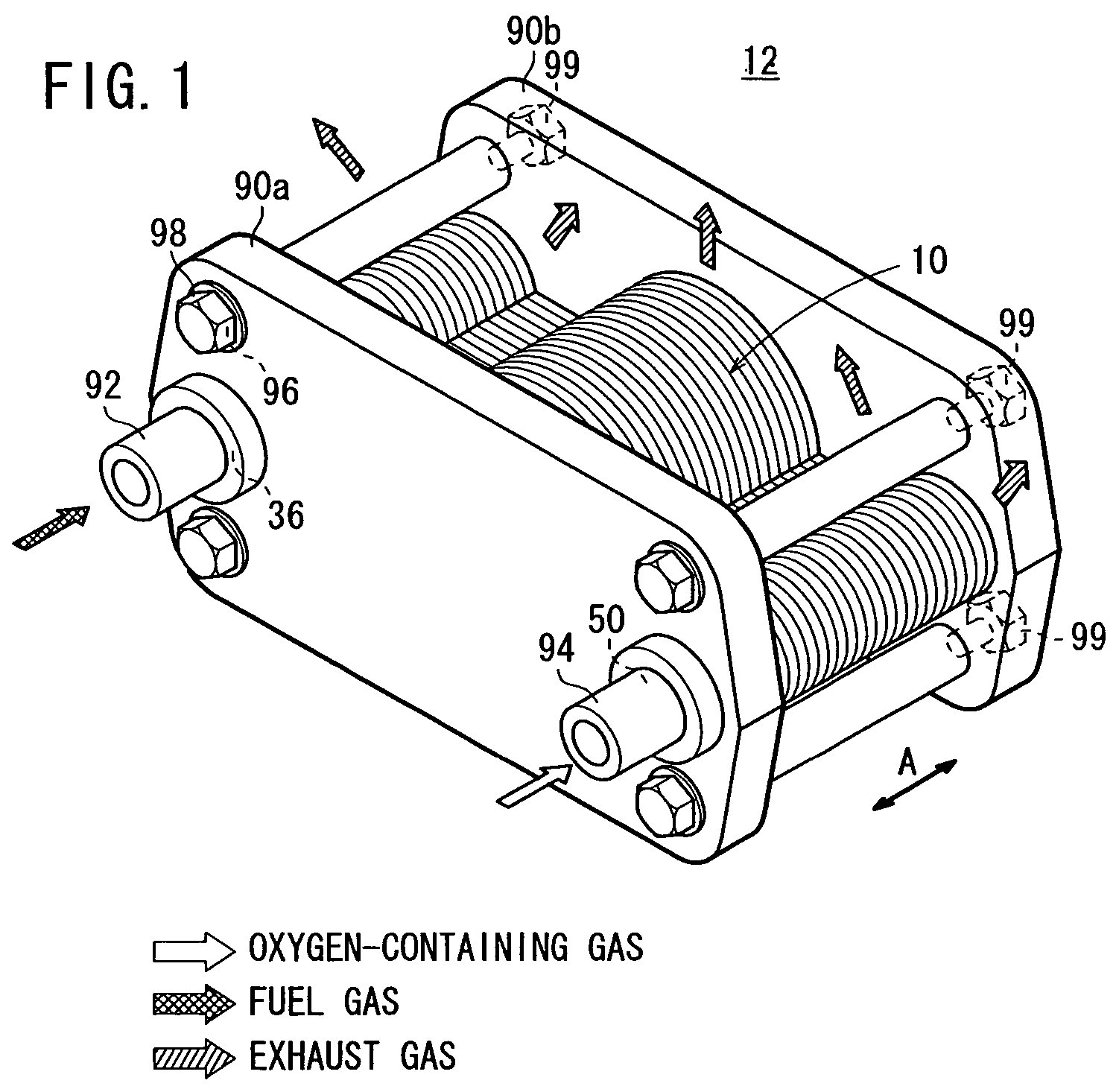

Fuel cell and fuel cell stack with pressure chambers

InactiveUS7670710B2Simple and compactSpeed up the flowFuel cells groupingFuel cell auxillariesFuel cellsOxygen

A fuel cell includes an electrolyte electrode assembly and separators. The separator includes first through third plates which are stacked together. A fuel gas channel connected to a fuel gas supply passage is formed between the first and third plates. The fuel gas channel forms a fuel gas pressure chamber between the first and third circular disks. Further, an oxygen-containing gas channel connected to an oxygen-containing gas supply passage is formed between the second and third plates. The oxygen-containing gas channel forms an oxygen-containing gas pressure chamber between the second and third circular disks.

Owner:HONDA MOTOR CO LTD

Isolation member for fuel cell and cell

ActiveCN109616681ASuppresses differences in rigidityUniform surface pressureCollectors/separatorsFuel cellsSurface pressure

The invention provides an isolation member for a fuel cell anda cell. A first metal isolation member constituting the cell has an oxidant gas inlet communication hole (34a) which is formed in the thickness direction of the isolation member in a penetrating manner; a communication hole pressing rib part (53) which surrounds the oxidant gas inlet communication hole (34a), and a plurality of channels, which press the ribs from the communicating holes (53) is protruded out of the side wall of the isolation part and is formed in the thickness direction of the isolation part. The plurality of channels (86) is the same as the cross section shape of the root part connected with the connecting hole pressing rib part (53). According to the invention, the device and the method can be operated simplyand economically so as to realize the homogenization of the surface pressure applied to the pressing rib sealing element surrounding the communication hole.

Owner:HONDA MOTOR CO LTD

Fuel cell and separator therefor

InactiveUS7147956B2Reduce resistanceExcellent power generation characteristicsFuel cell auxillariesCell component detailsFuel cellsForming gas

A fuel cell comprises an membrane electrode assembly formed by holding an electrolyte membrane between a pair of electrodes and a separator layered on both sides of the membrane electrode assembly for forming gas passages between the separator and the electrode. The separator includes protrusions formed on both surfaces thereof for contacting with the electrode, and a spacer portion disposed between the protrusions for substantially forming the gas passage. The protrusions and the spacer portions are arranged along a surface direction of the separator so as to form a corrugated plate. At least two drawn portions in which thickness of the spacer portion changes to a thin portion are formed between the protrusions in the spacer portion.

Owner:HONDA MOTOR CO LTD

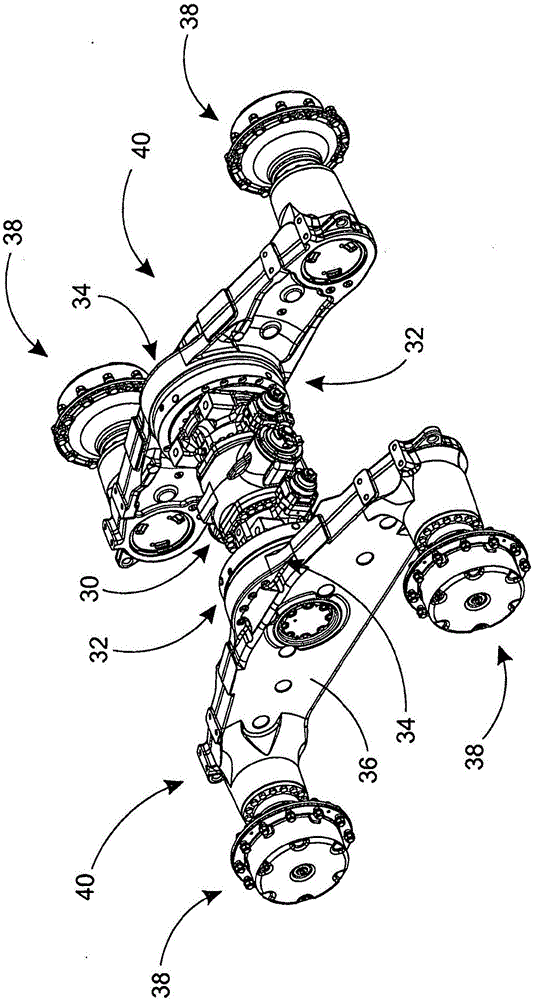

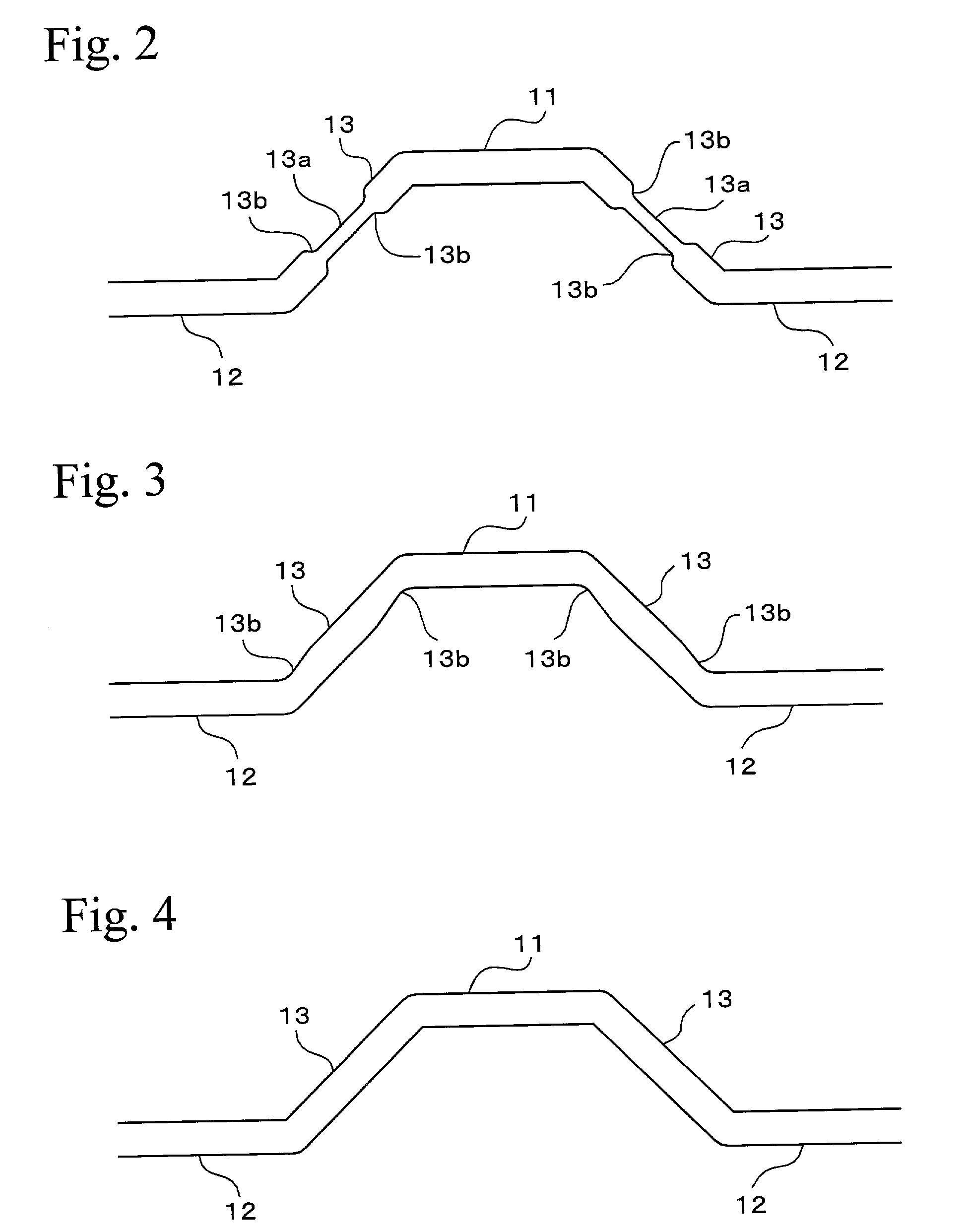

Rotary ring bearing structure

ActiveCN101194110AUniform surface pressureBearing assemblyWind motor controlRotational axisEngineering

A slewing bearing structure comprises:an outer ring (4) having first and second circumferential outer grooves formed on an inner circumferential surface in parallel;an inner ring (5) provided on an inner side of said outer ring section and having first and second circumferential inner grooves formed on an outer circumferential surface in parallel in correspondence to said first and second circumferential outer grooves of said outer ring section (4);a first row (6) of rolling elements provided in said first circumferential outer groove of said outer ring (4) and said first circumferential inner groove of said inner ring (5); and a second row (7) of rolling elements provided in said second circumferential outer groove of said outer ring (4) and said second circumferential inner groove of said inner ring ( 5 ) ,wherein said inner ring (5) rotates via said first and second rolling element rows (6, 7) around a rotation axis in a relatively opposite direction to said outer ring (4),wherein said outer ring (4) includesa first outer ring section (8) provided with said first circumferential outer groove; anda second outer ring section (9) provided with said second circumferential outer groove;wherein said inner ring (5) includesa first inner ring section (11) provided with said first circumferential inner groove; anda second inner ring section (12) provided with said second circumferential inner groove,wherein said slewing bearing structure further comprises a first pair of side plates (13), each plate of said first pair being fitted to a side circumferential surface of said first and second outer ring sections (8, 9), respectively, and / or a second pair of side plates (13'), each plate of said second pair being fitted to a side circumferential surface of said first and second inner ring sections (11, 12), respectively.

Owner:MITSUBISHI HEAVY IND LTD

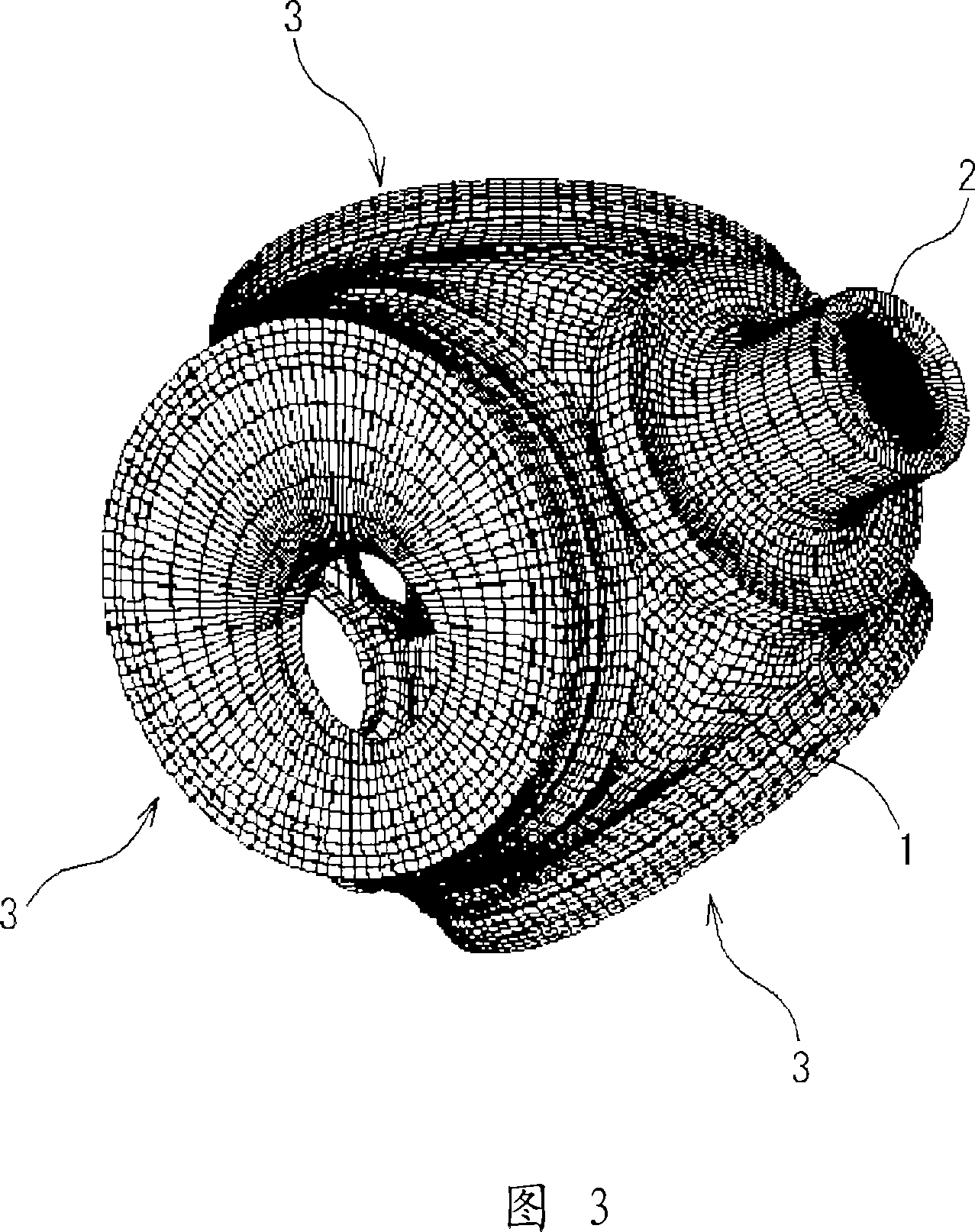

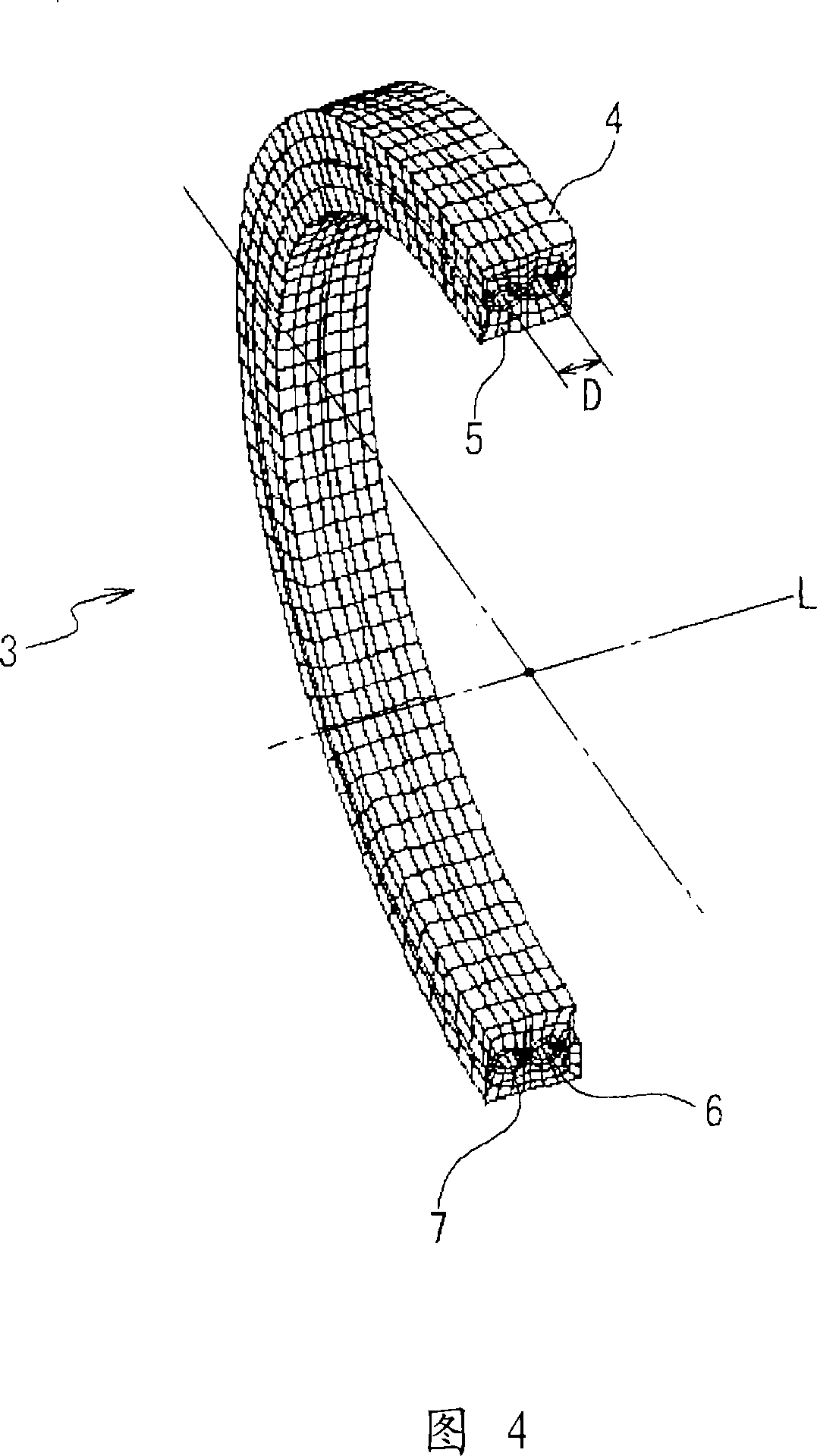

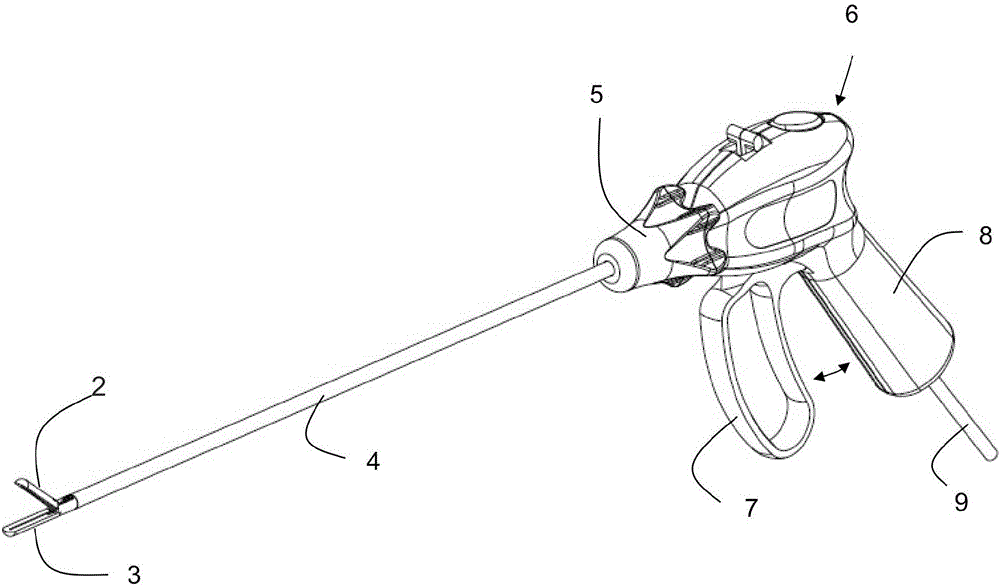

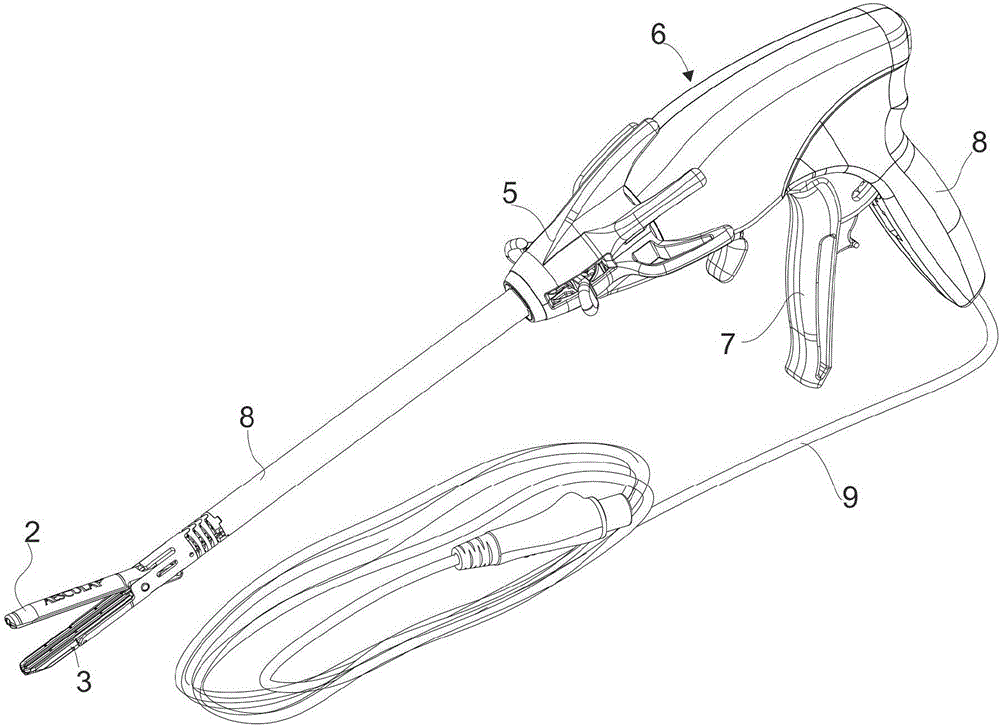

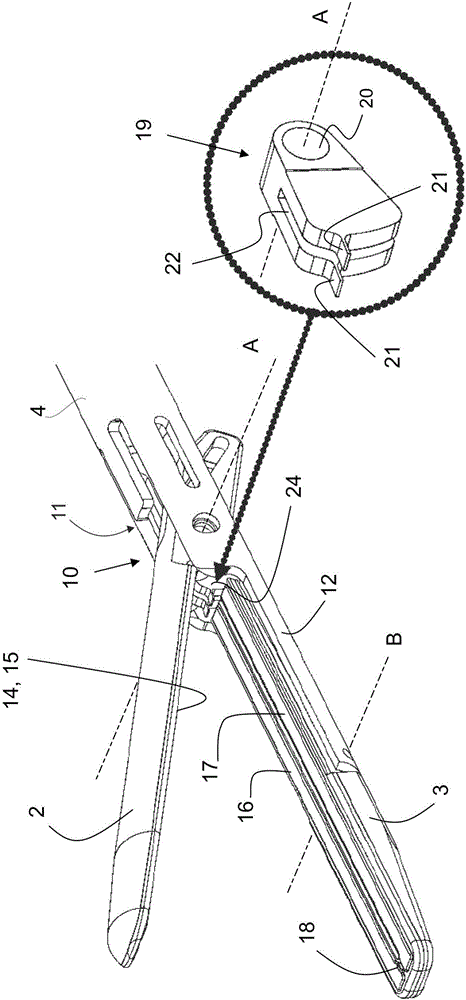

Electrosurgical instrument and jaw part for same

InactiveCN106456248AReduced risk of short circuitsUniform surface pressureDiagnosticsSurgical instruments for heatingConductive materialsBiomedical engineering

An electrosurgical instrument is disclosed having a jaw part composed of instrument branches which are movable towards each other and on each mutually facing side of which one or more electrode surfaces are arranged / formed, wherein the movement of the instrument branches relative to each other can be limited by at least one proximal spacer acting on proximal end portions of the instrument branches, at least one medial spacer acting on a medial portion, and at least one distal spacer acting on distal end portions of the instrument branches. According to the invention, the proximal and / or the distal spacer are made of electrically non-conductive material and the at least one medial spacer is composed of at least one electrode made of an electrically conductive material and connected electrically conductively to the electrode. Furthermore, the at least one medial spacer interacts with a local insulation component made of a non-conductive material, which insulation component is arranged in an electrically insulating manner on at least one opposite electrode.

Owner:AESCULAP AG

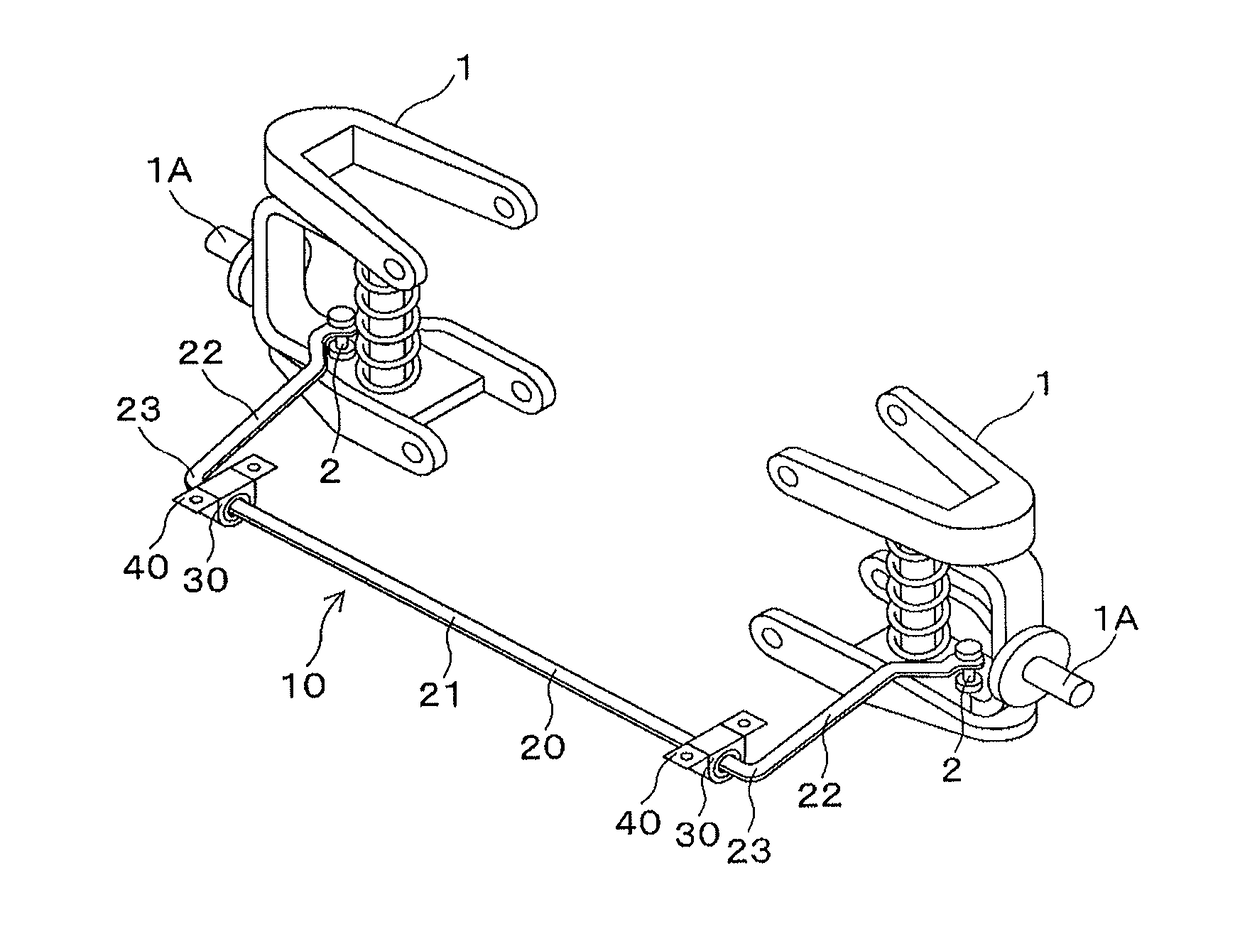

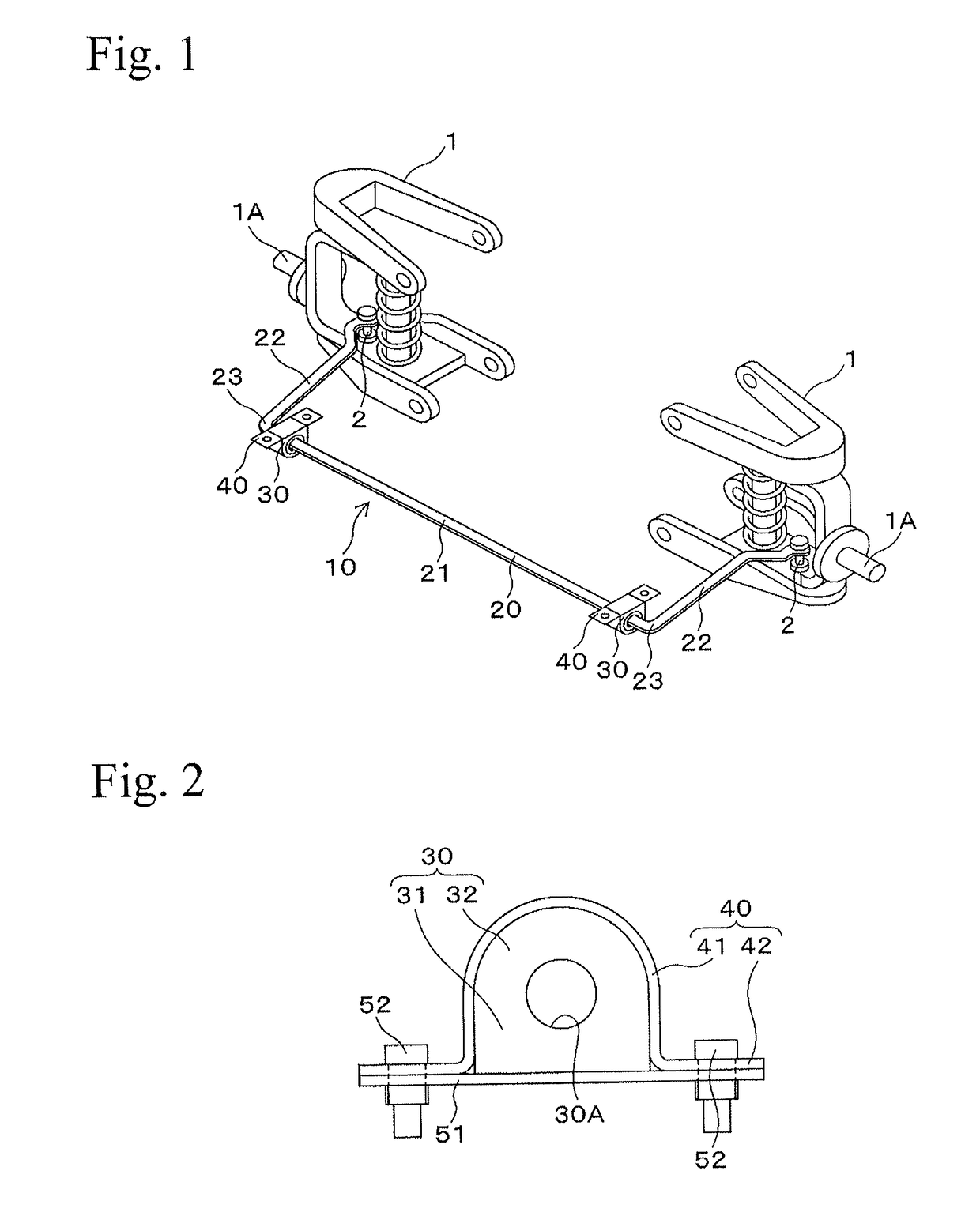

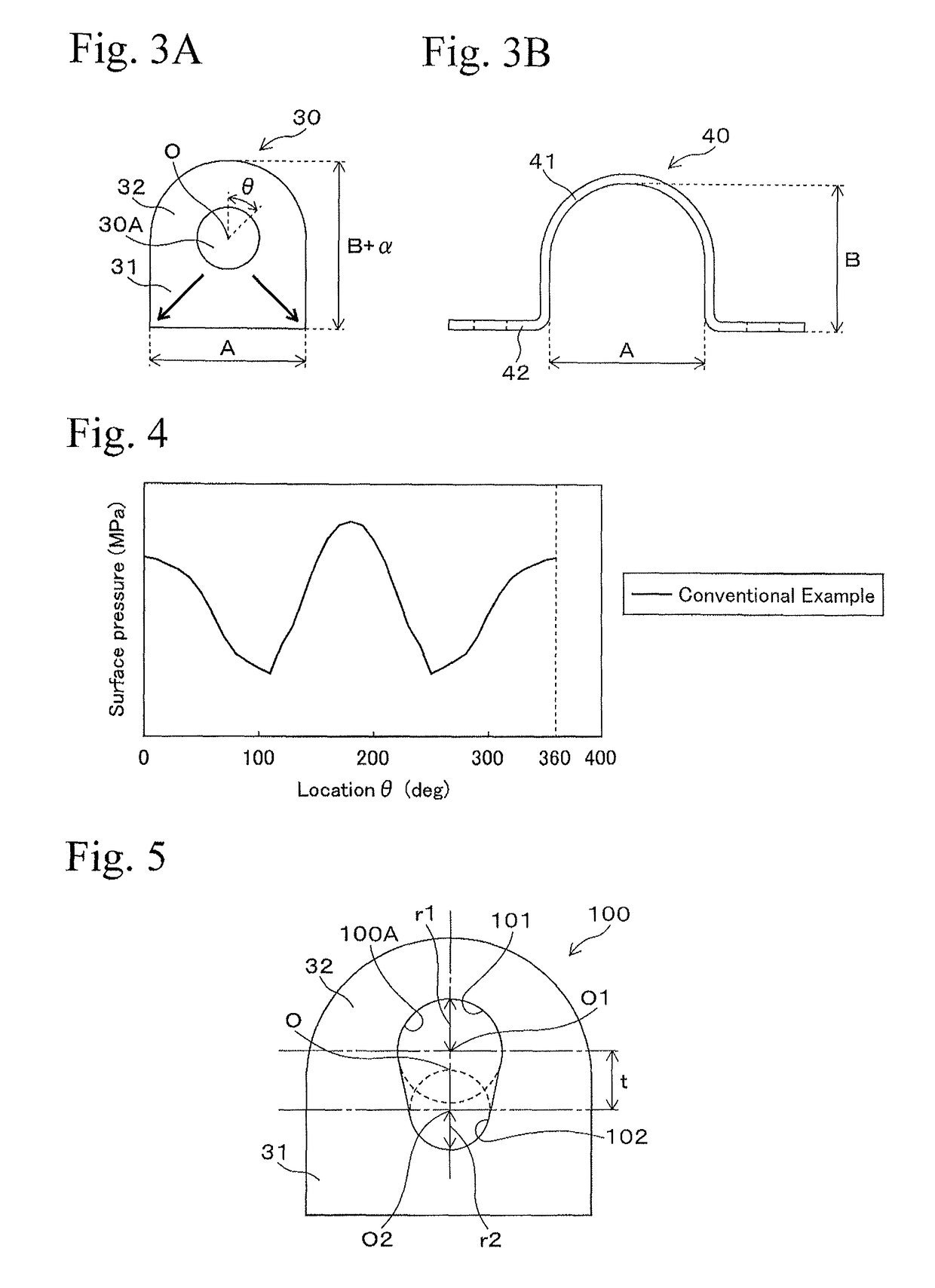

Bush for stabilizer, fastening tool, and fastening method

ActiveUS10052929B2Uniform surface pressureSmall surface pressureTorsion springsSpring mattressesEllipseSurface pressure

Bonding the bush to the stabilizer bar, by surface pressure in the bonding surface (inner circumferential surface) of the hole-part of the bush being made uniform, bonding strength is obtained. The first arc part is formed at the opposite side of the opening of the U-shaped part of the bracket in the bonding and second arc part is formed in the opening side, in the hole-part of the bush. The first and second arc parts are circular arc parts being formed in circular arc shape or approximately circular arc shape or are ellipse arc part being formed in the ellipse arc shape or approximately ellipse arc shape. In the hole-part, the center of the first and second arc parts are separated. The curvature radius of the second arc part gets smaller than the curvature radius of the first arc part. The hole-part is formed in an oval shape.

Owner:NHK SPRING CO LTD

Silent chain

InactiveCN101487513AAvoid breakingPrevents abrasion elongationDriving chainsEngineeringMechanical engineering

Owner:TSUBAKIMOTO CHAIN CO

Fuel cell stack

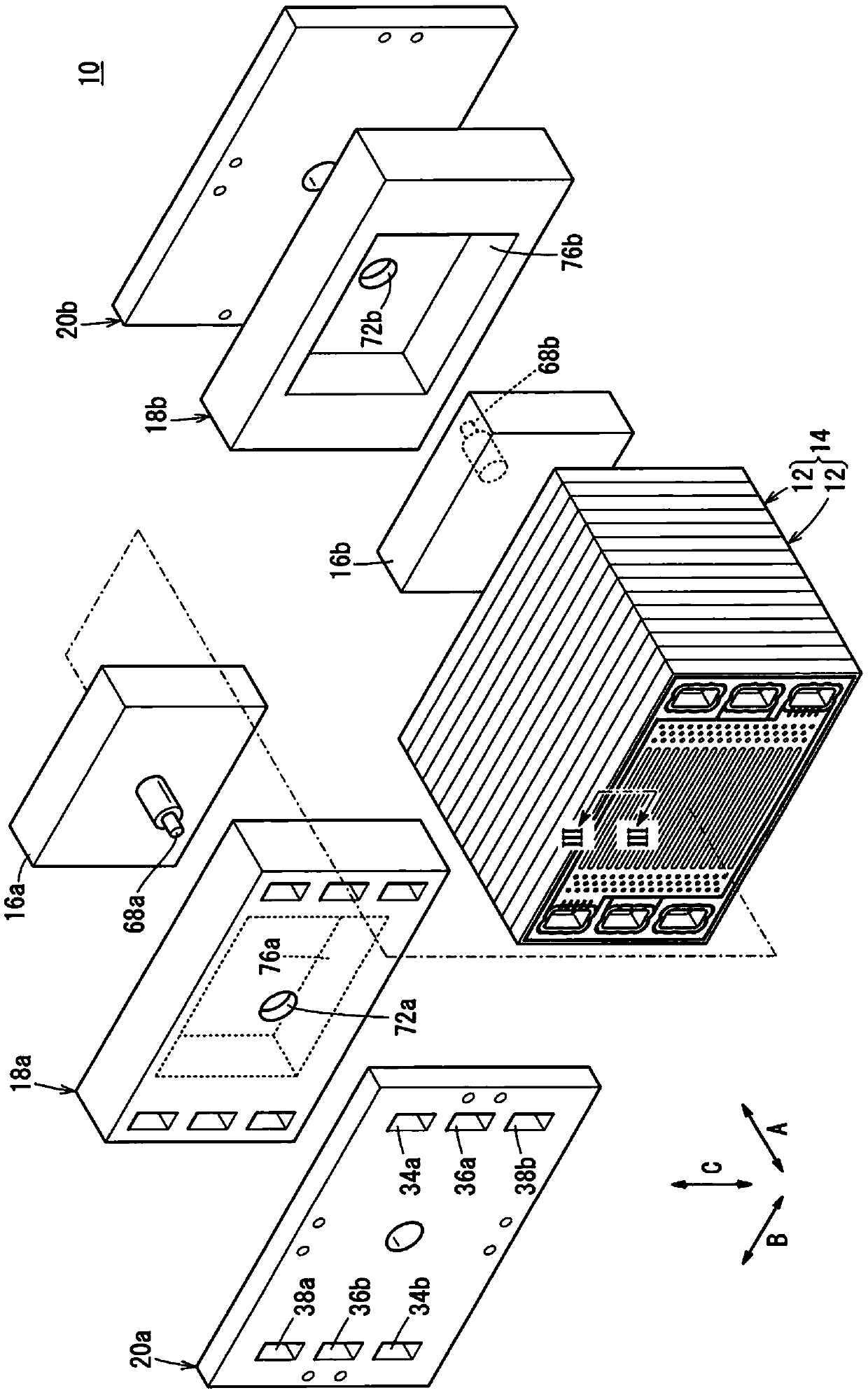

ActiveUS20080233459A1Relieve pressureSimple and economical structureFuel cells groupingCell component detailsFuel cellsCoupling

A casing includes end plates, side plates, and a hinge mechanism for coupling the end plates and the side plates. A power generation area is defined by the distance L1 and the distance L2. When first hinges and second hinges of the hinge mechanism are provided alternately, the first hinges and the second hinges are positioned within the distance L1. Preferably, the length of the shaft of a coupling pin is not more than the length L1. When the first hinges and the second hinges are provided alternately, the first hinges and the second hinges are positioned within the length L2. Preferably, the length of the shaft of a coupling pin is not more than the length L2.

Owner:HONDA MOTOR CO LTD

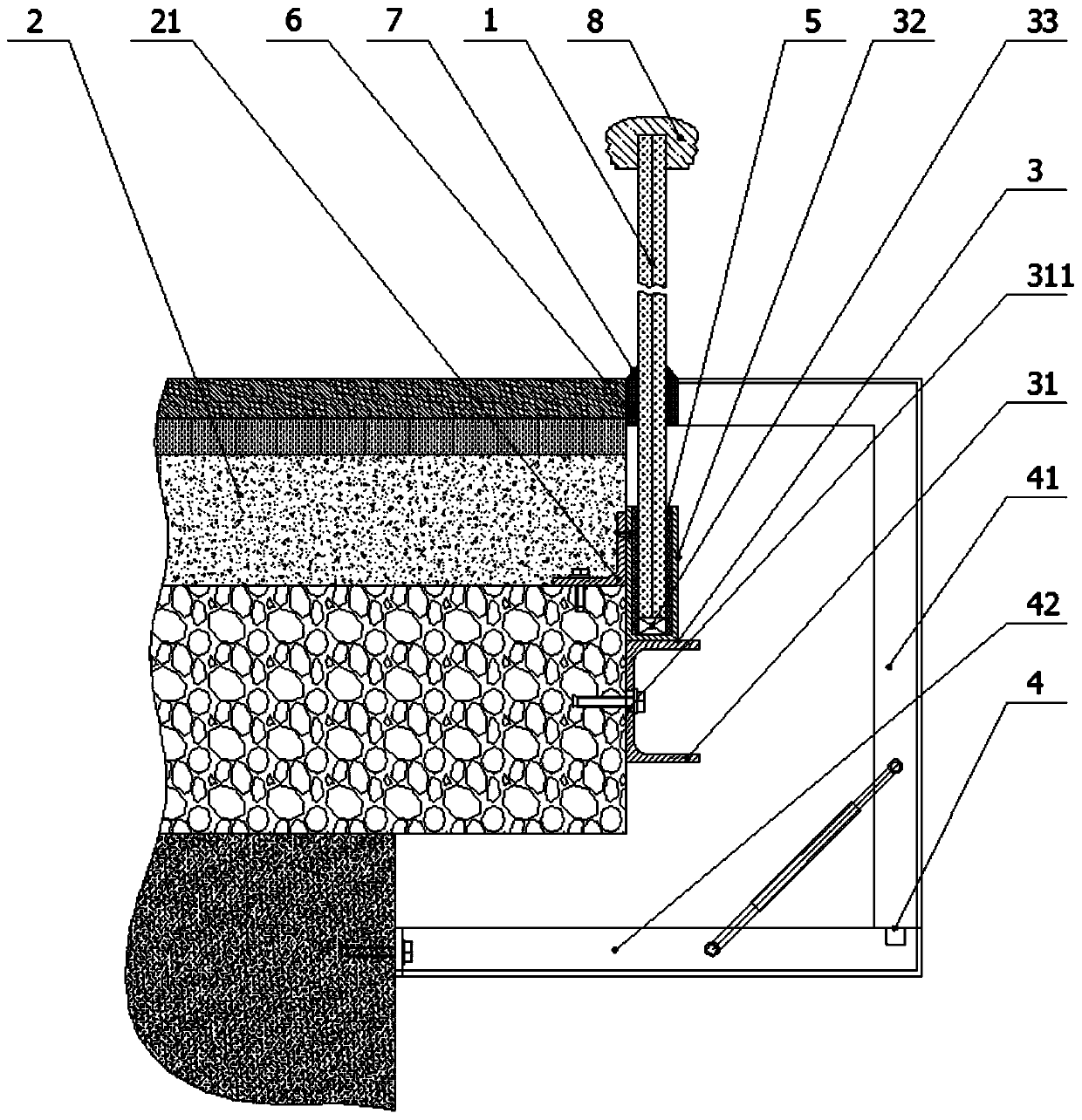

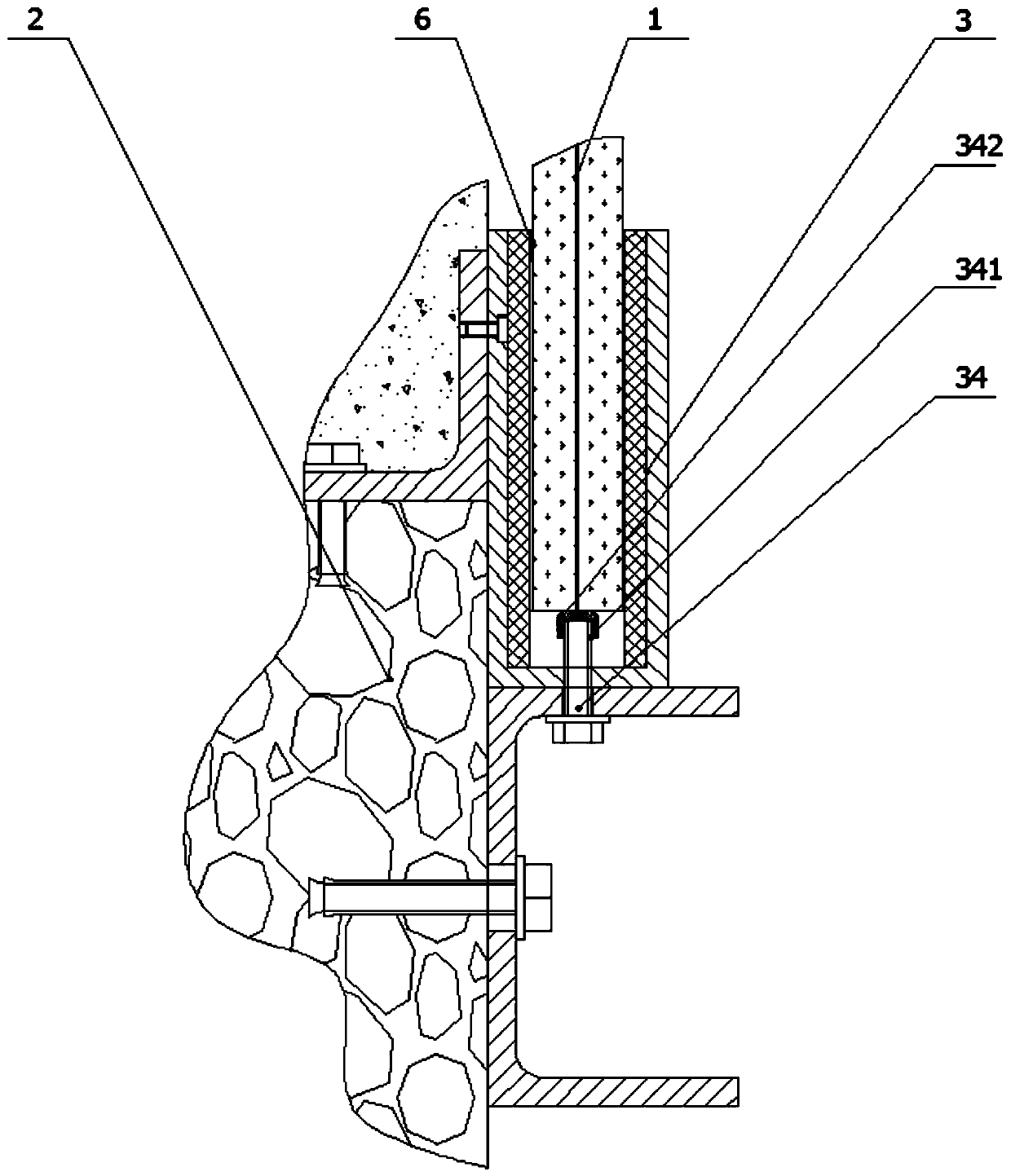

Mounting structure and mounting method for all-glass guardrail

PendingCN111219023AEasy to install and fixEasy to installBalustradesFloor slabStructural engineering

The invention discloses a mounting structure for an all-glass guardrail. The mounting structure for the all-glass guardrail comprises laminated glass, a cantilevered floorslab, a base structure and aprotective structure, wherein the cantilevered floorslab is provided with pre-embedded angle steel; the base structure is used for bearing and fixing the laminated glass and comprises a supporting steel and a U-shaped groove; the highest point of the supporting steel is lower than the pre-embedded angle; and the protective structure is arranged on the outer side of the laminated glass. By adoptionof the technical scheme, the mounting structure for the all-glass guardrail has the following beneficial effects: setting of the laminated glass makes full use of the excellent stability of temperedglass, the laminated glass is still stable even if the amplitude of a single piece of glass exceeds 1100 mm; the glass is simple and convenient to mount and fix, the relative construction period is short and labor cost is reduced; and more important, the base structure is arranged on a mounting wall surface, so that damage to the ground surface in the mounting process is avoided, and the mountingstructure for the all-glass guardrail is simple to mount, convenient to adjust, economic and practical.

Owner:GOLD MANTIS CONSTR DECORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com