Seal for an endless track

A crawler and bushing technology, which is applied in the directions of crawler vehicles, engine seals, engine components, etc., can solve the problems of shortened seal life and small wear amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

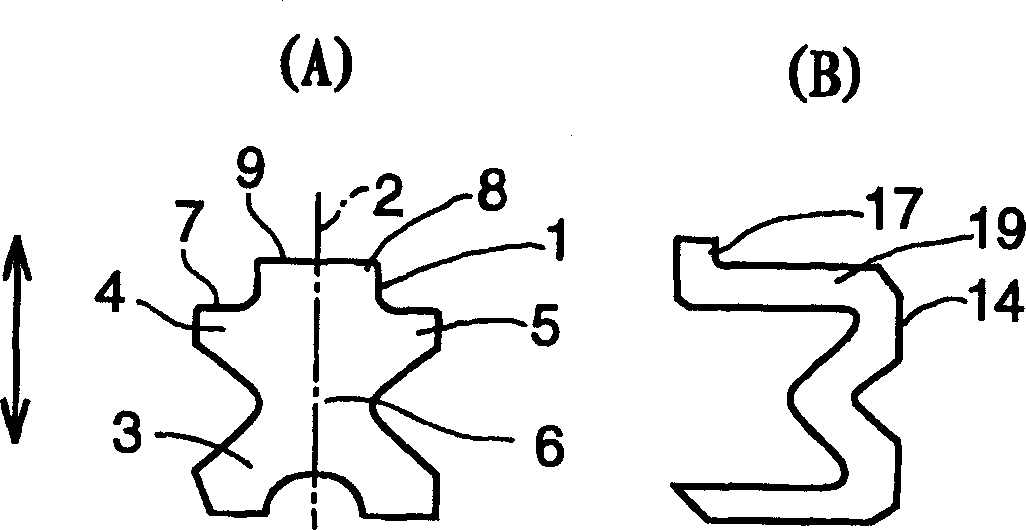

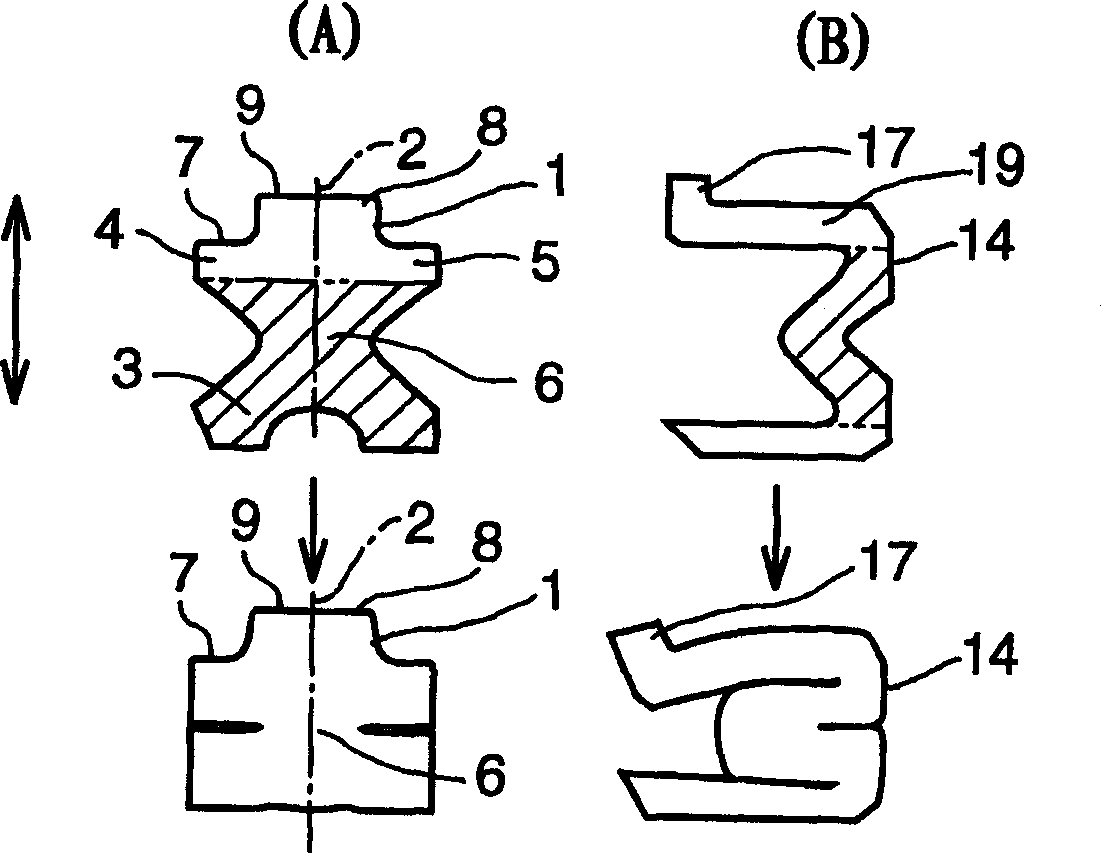

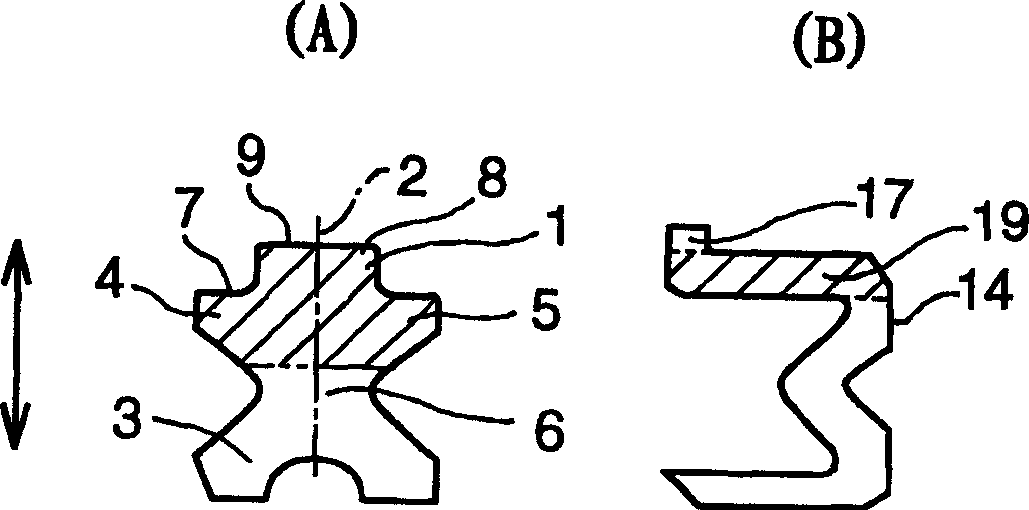

[0027] refer to Figure 1-Figure 4 ( Figure 4 Common to the conventional crawler belt), the seal for the crawler belt according to the embodiment of the present invention will be described. exist Figure 1-Figure 3 In each figure, (A) shows the crawler belt seal 1 of this invention, and (B) shows the conventional M type seal 14 for comparison.

[0028] The crawler belt seal (hereinafter simply referred to as the seal) 1 according to the embodiment of the present invention is an annular seal without slits in the circumferential direction, and is installed between the bushing 11 of the crawler belt 10 and the counterweight hole bottom surface 13 of the link 12 . The axial center of the seal 1 and the axial center of the bushing 11 are approximately on the same straight line. On the seal 1, a surface pressure is applied from the bush 11 in the direction of the bush axis.

[0029] The material of the track seal 1 is generally synthetic rubber such as urethane rubber or vulcani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com