Electric brake

A technology of electric brakes and brake discs, applied in the types of brakes, axial brakes, brake actuators, etc., can solve the problems of difficulty in determining whether the braking force of the friction pads is sufficient, the braking response speed is slow, and the braking force is insufficient. , to achieve the effect of improving braking effect, fast response speed and uniform braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

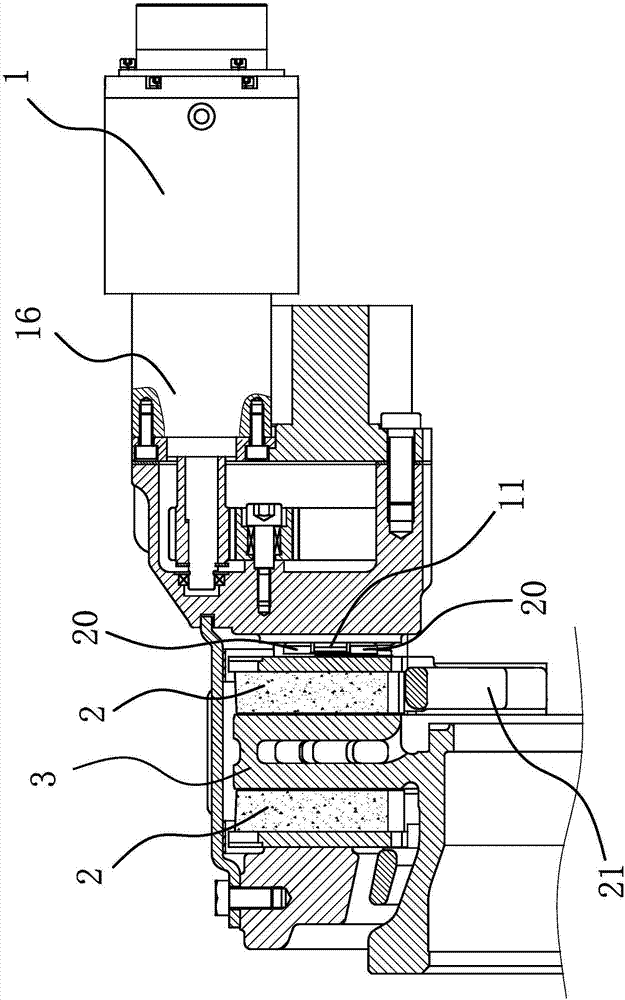

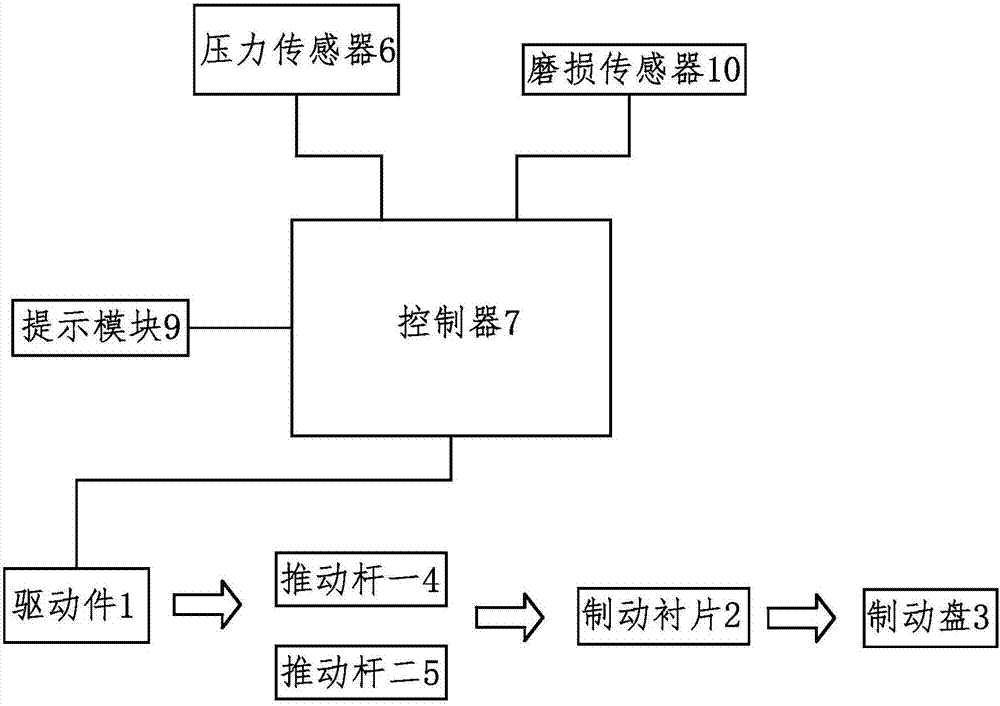

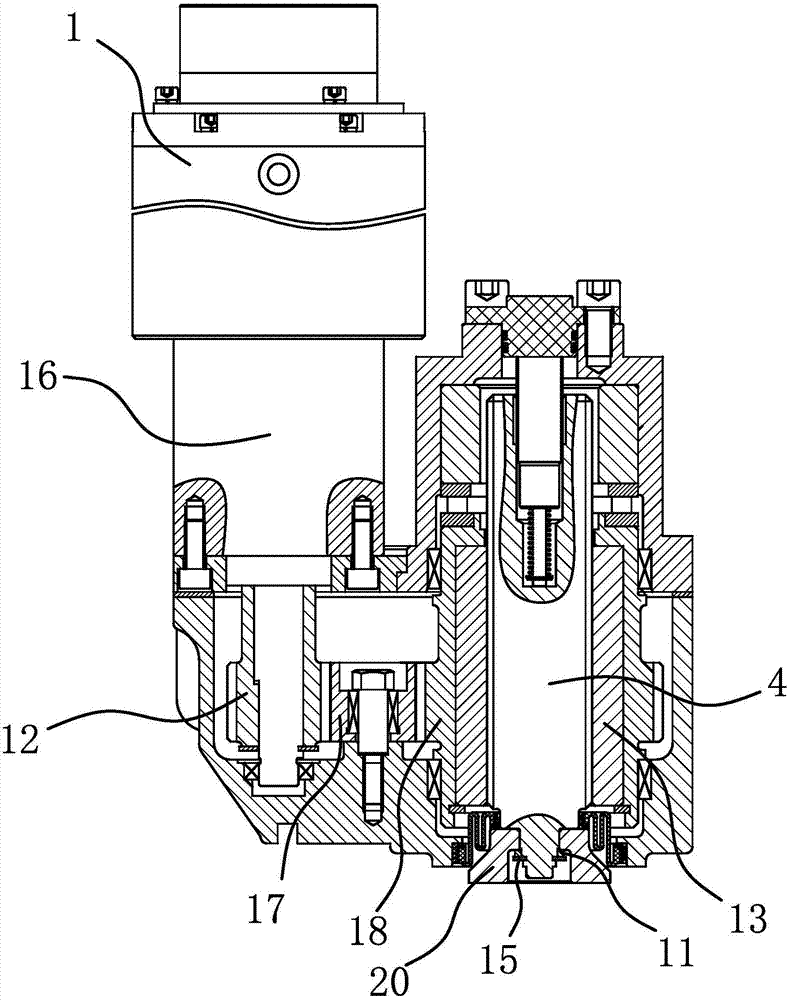

[0033] Such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the electric brake includes a driver 1, a brake lining 2 and a brake disc 3, and a rod-shaped push rod one 4 and a push rod two 5 are arranged between the drive member 1 and the brake pad 2, One end of the first push rod 4 and one end of the second push rod 5 is connected to the driving member 1 through a synchronous transmission structure, and the other ends are fixedly connected to a long plate-shaped synchronous member 11 . Simultaneously, the outer sides of one end of the push rod one 4 and the push rod two 5 for connecting with the synchronous member 11 are respectively sleeved and axially fixed with ring-shaped push discs 20, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com