Fuel cell stack

A fuel cell stack and electrolyte technology, applied in the direction of fuel cell grouping, fuel cells, fuel cell additives, etc., can solve problems such as poor distribution of fuel gas and oxidant gas, voltage drop, and deterioration of starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

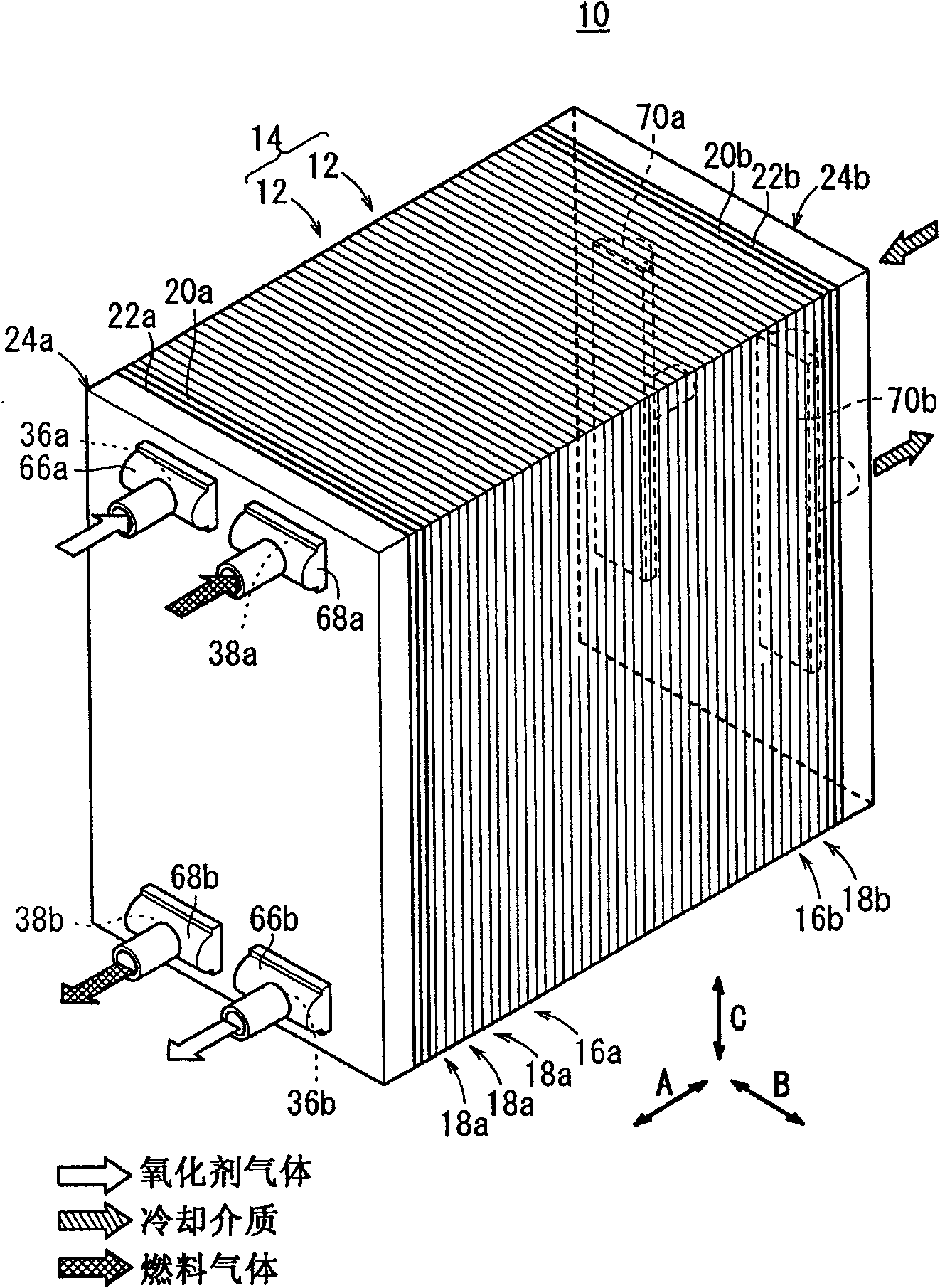

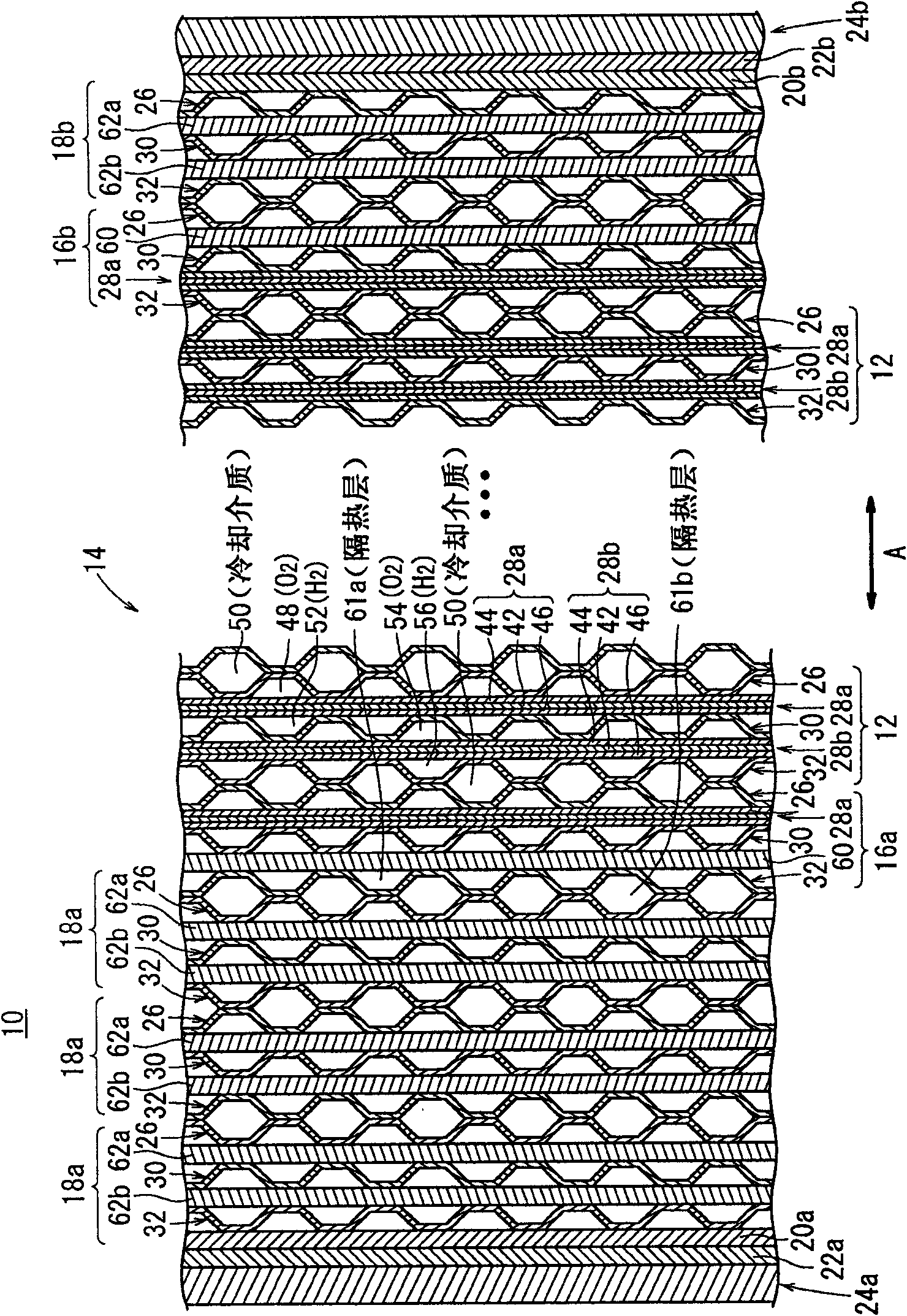

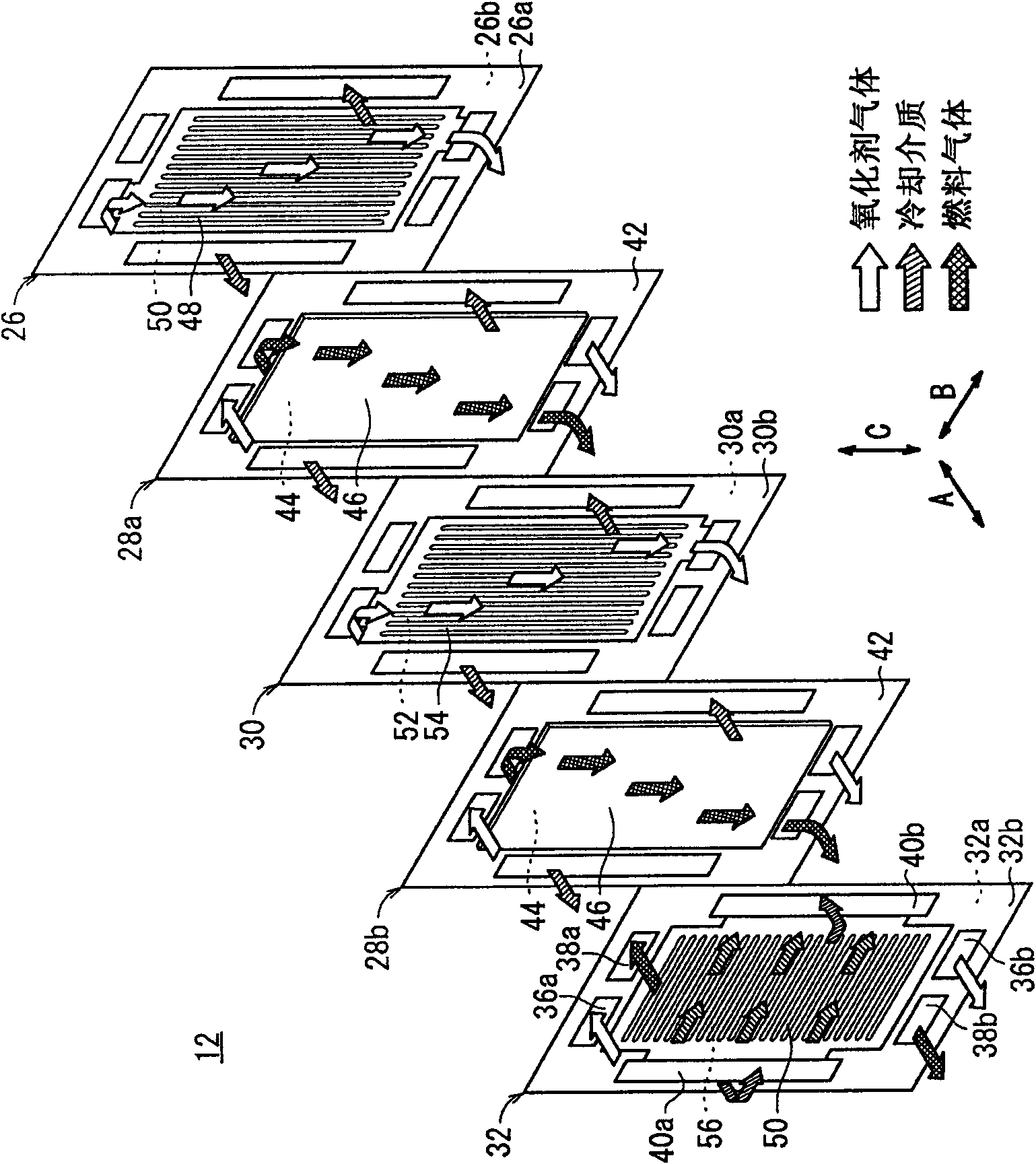

[0030] figure 1 is a schematic perspective explanatory view of a fuel cell stack 10 according to an embodiment of the present invention, figure 2 It is a cross-sectional explanatory view of main parts of the fuel cell stack 10 .

[0031] The fuel cell stack 10 includes a stacked body 14 in which a plurality of power generating units 12 are stacked in the arrow A direction. At one end of the stacked body 14 in the stacking direction, the first end power generation unit 16a and the plurality of first dummy cells 18a are arranged facing outward, and at the other end of the stacked body 14 in the stacking direction, the second end portion is disposed facing outward to generate electricity. A cell 16b and one or more second dummy cells 18b. Terminal plates 20a, 20b, insulating plates 22a, 22b, and end plates 24a, 24b are arranged facing outward on the first and second dummy cells 18a, 18b.

[0032] The fuel cell stack 10 is integrally held, for example, by a box-shaped case (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com