Space butt-joint capturing device for non-cooperative target satellites

A non-cooperative target and capture device technology, which is applied in the field of space capture devices, can solve the problems of high motion control accuracy requirements for non-cooperative target docking mechanisms, and achieve the effects of low rendezvous and motion control accuracy requirements, simple control, and reliable capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

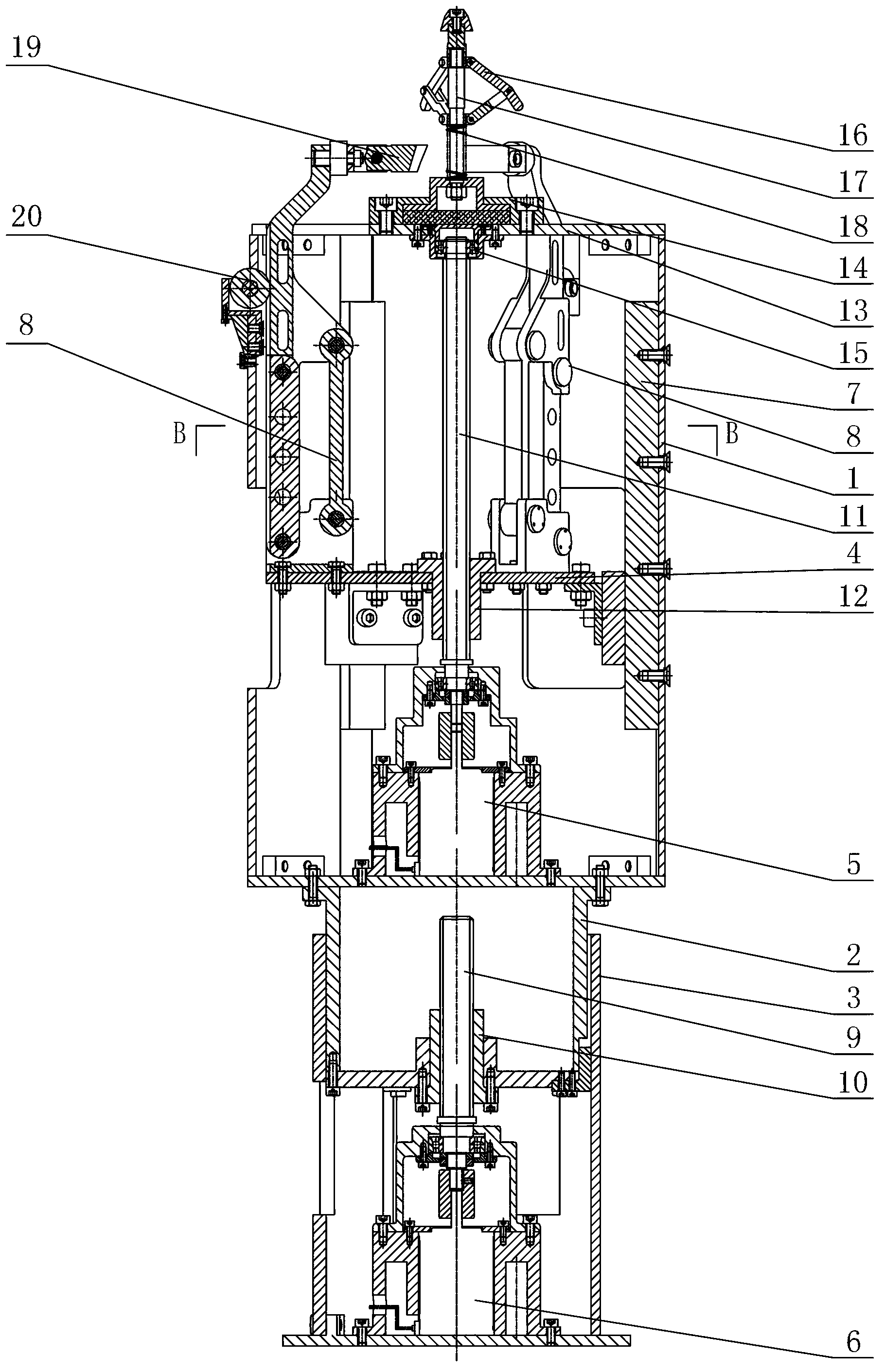

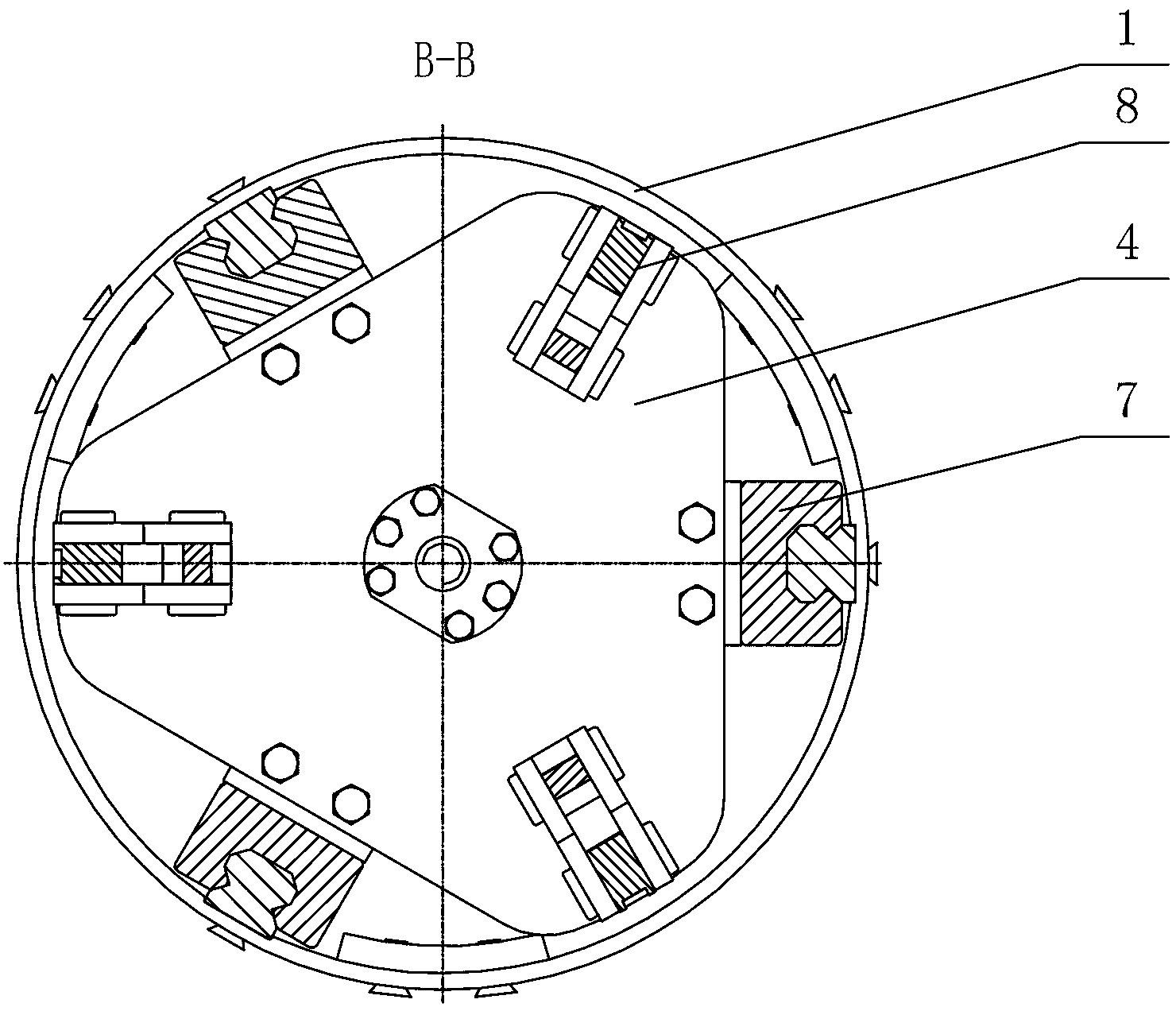

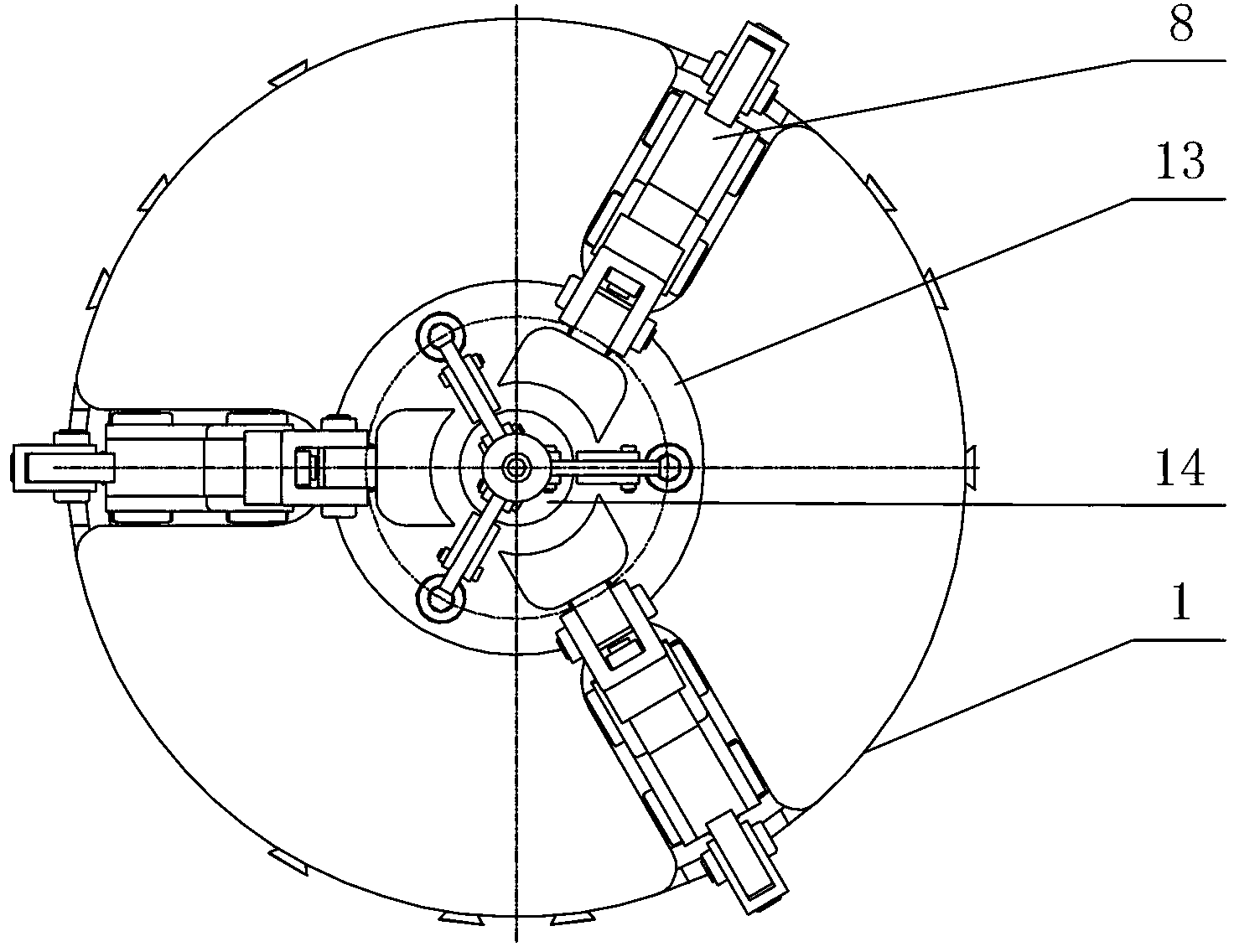

[0007] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment, the docking and capturing device of a space non-cooperative target satellite described in this embodiment includes an upper casing 1, a sliding body 2, a lower casing 3, a connecting plate 4, an upper motor 5, a lower motor 6, a first The screw nut mechanism, the second screw nut mechanism, three slide rail mechanisms 7 and three mechanical arms 8, the upper casing 1, the sliding body 2, and the lower casing 3 are arranged in sequence from top to bottom, and the upper casing 1 The lower surface is fixedly connected with the upper surface of the sliding body 2, the sliding body 2 is inserted in the lower casing 3, the lower motor 6 is fixedly installed on the bottom surface of the lower casing 3, and the output shaft of the lower motor 6 passes through the first screw nut mechanism Connected with the lower surface of the sliding body 2, the upper motor 5 is fixedly ins...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 , figure 2 and image 3 Describe this embodiment, the first lead screw and nut mechanism of the docking capture device of a space non-cooperative target satellite described in this embodiment includes a first lead screw 9 and a first nut 10, the lower end of the first lead screw 9 is connected to the lower motor 6 output shaft connection, the first nut 10 is installed in the middle of the lower surface of the sliding body 2, and the first nut 10 is sleeved on the first leading screw 9.

[0010] In this embodiment, the first lead screw 9 is a trapezoidal lead screw with self-locking function.

[0011] The technical effect of this embodiment is: set in this way, the output shaft of the lower motor 6 drives the first lead screw 9 to rotate, and the first lead screw 9 pushes the sliding body 2 to move linearly up and down along the inner side wall of the lower housing 3 through the first nut 10 . Other components a...

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 , figure 2 and image 3 Describe this embodiment, the second lead screw nut mechanism of the docking capture device of a space non-cooperative target satellite described in this embodiment includes a second lead screw 11 and a second nut 12, the lower end of the second lead screw 11 is connected to the upper motor 5 output shaft connection, the second nut 12 is installed in the middle of the lower surface of the connecting plate 4, and the second nut 12 is sleeved on the second lead screw 11.

[0013] In this embodiment, the second lead screw 11 is a trapezoidal lead screw with self-locking function.

[0014] The technical effect of this embodiment is: set in this way, the output shaft of the upper motor 5 drives the second lead screw 11 to rotate, and the second lead screw 11 pushes the connecting plate 4 to move linearly up and down along the inner side wall of the upper housing 1 through the second nut 12 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com