Terminating set used for elevator device

A technology for terminal connection devices and elevators, which is applied in transportation, packaging, elevators, etc., and can solve problems such as failure of terminal connection devices, uneven pressure, uneven pressure of bearing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

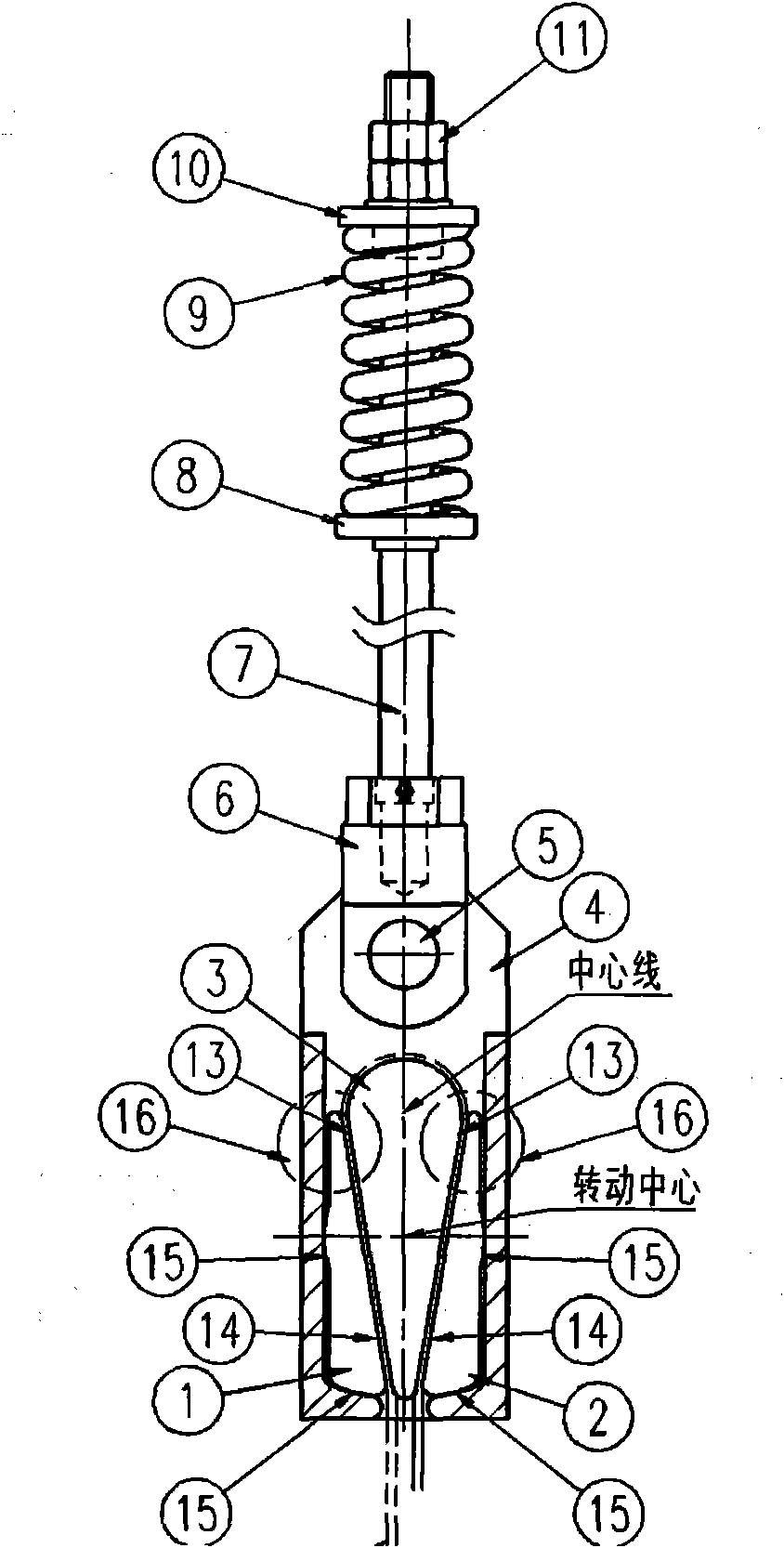

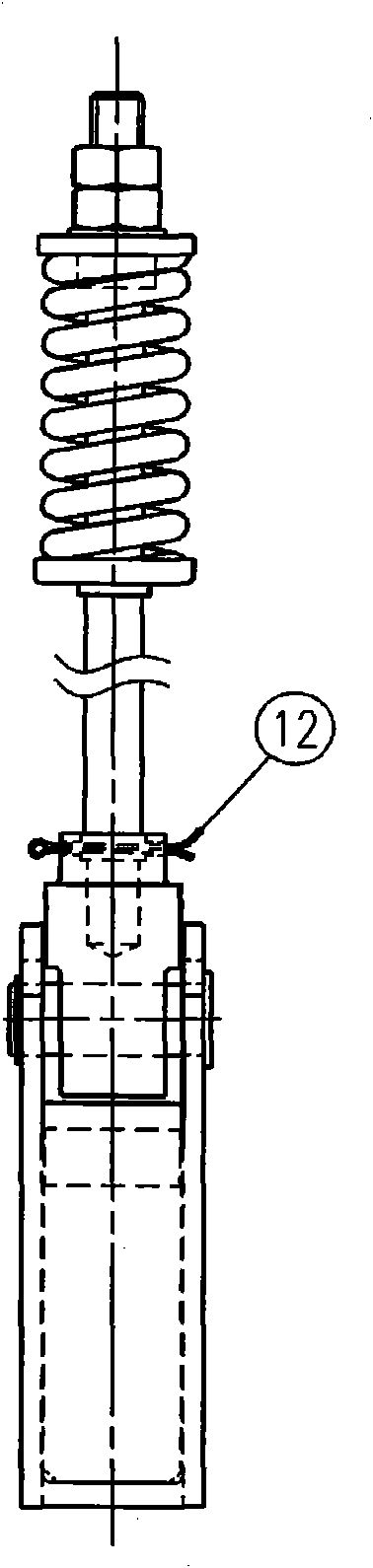

[0011] like figure 1 , 2 As shown, in an embodiment of the present invention, the termination device includes a support 1 , a support 2 , a wedge 3 , and a socket 4 . The termination device utilizes pin shaft 5, connector 6, screw rod 7, spring mounting seat 8, spring 9, spring mounting seat 10, nut 11 and split pin 12 to be connected to other parts of the elevator.

[0012] The wedge 3 has two and its center (see figure 1 marked center line) form a certain included angle, relative to the set first profile surface 13, the included angle ranges from 5° to 15°. In such an included angle range, the normal pressure on the load-bearing element can be reduced, thereby reducing the surface pressure of the load-bearing element.

[0013] In a preferred embodiment, the wedge 3 has two symmetrically arranged first contour surfaces 13, and the angle between the two first contour surfaces 13 is 10°-30°. The wide end of the wedge 3 is connected to the first contour surface 13 at the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com