Patents

Literature

53results about How to "Reduce vibration stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

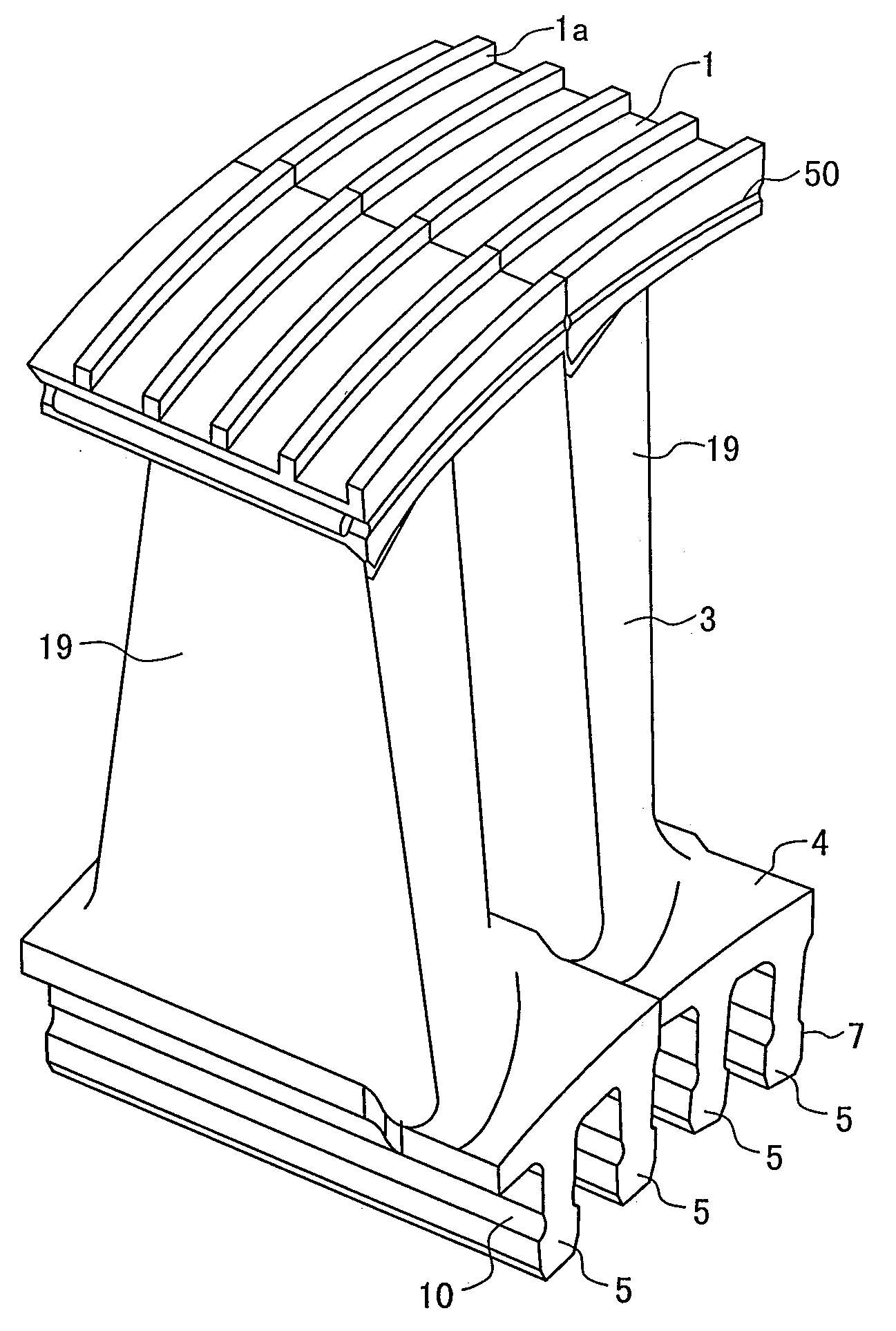

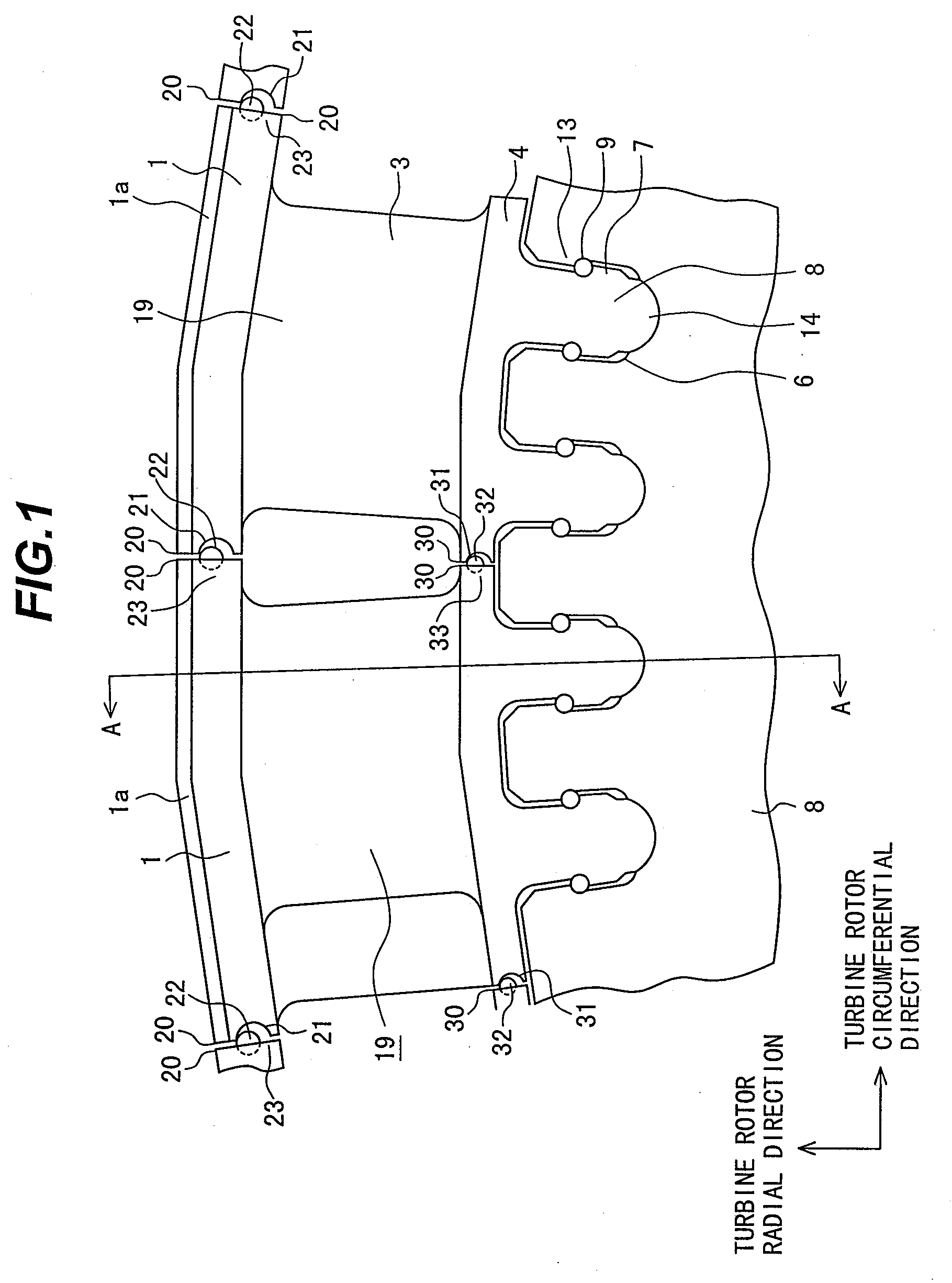

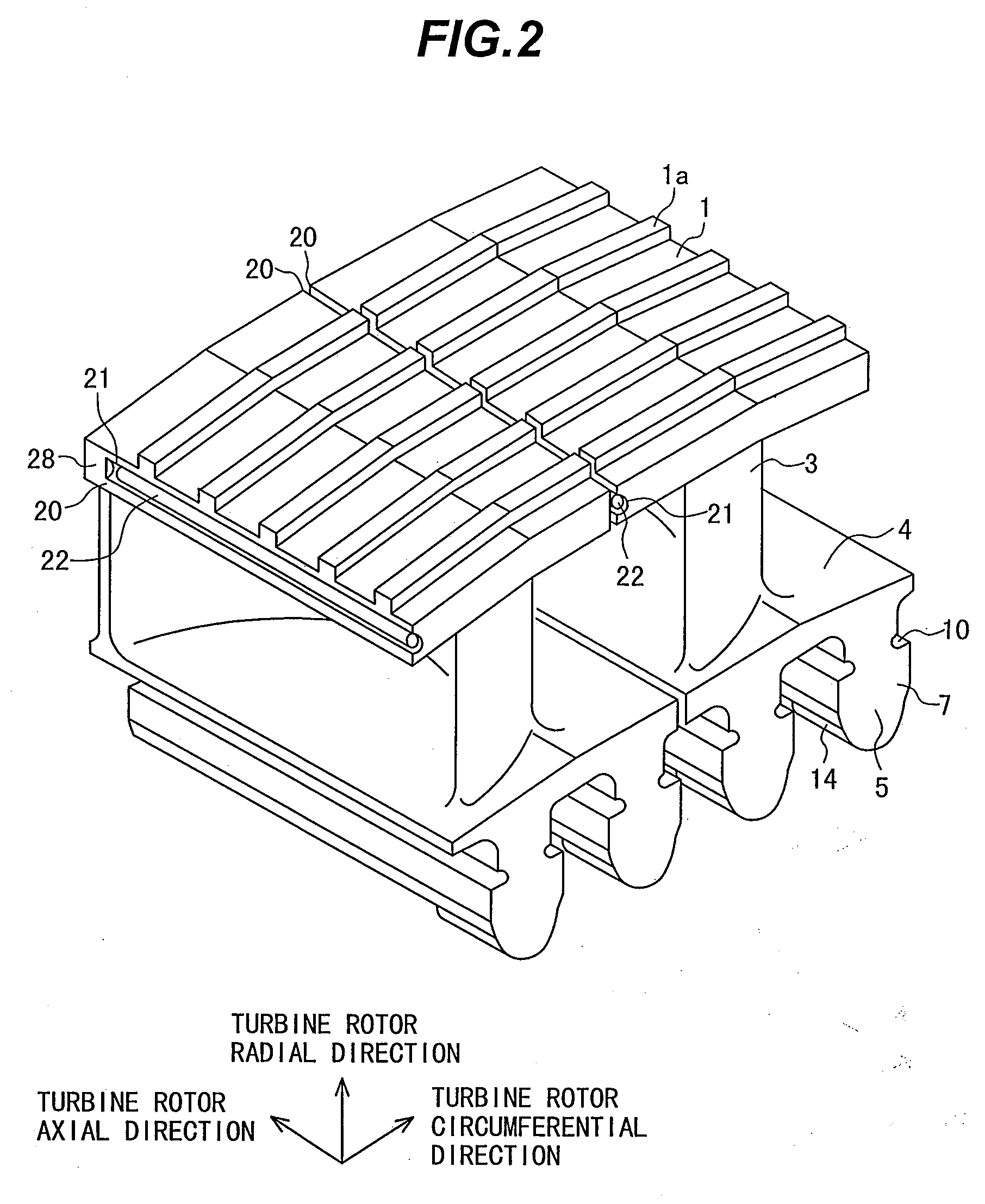

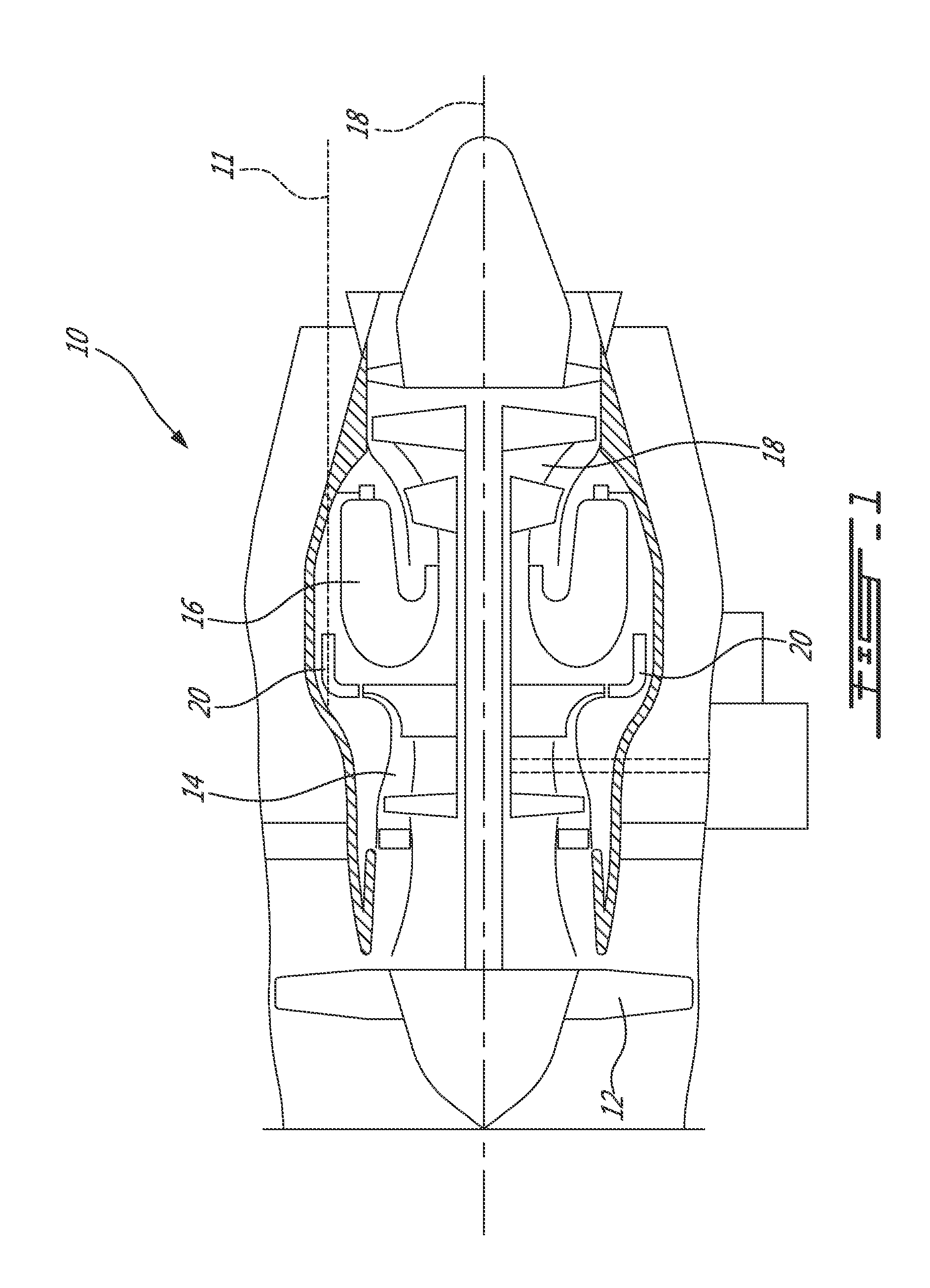

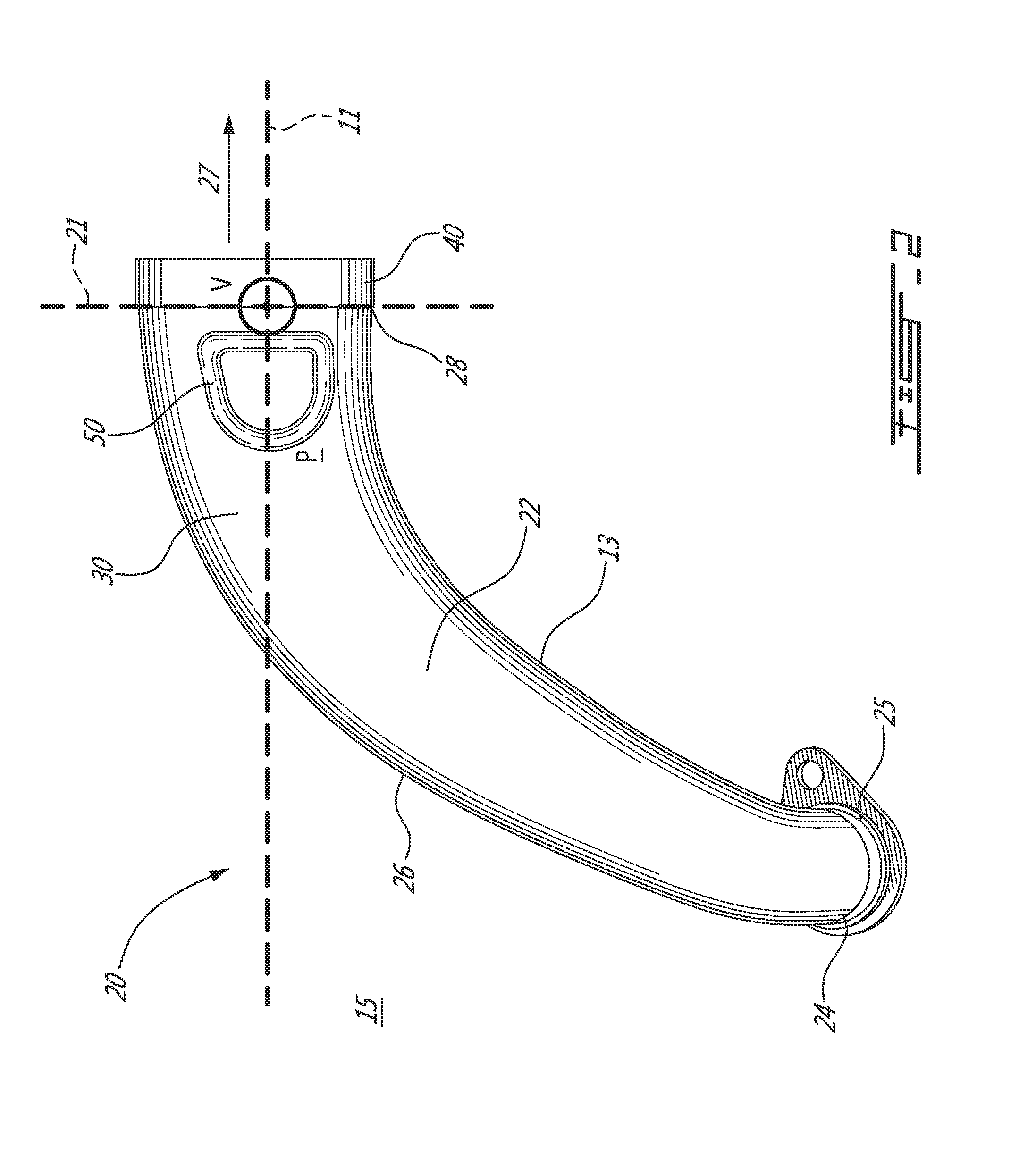

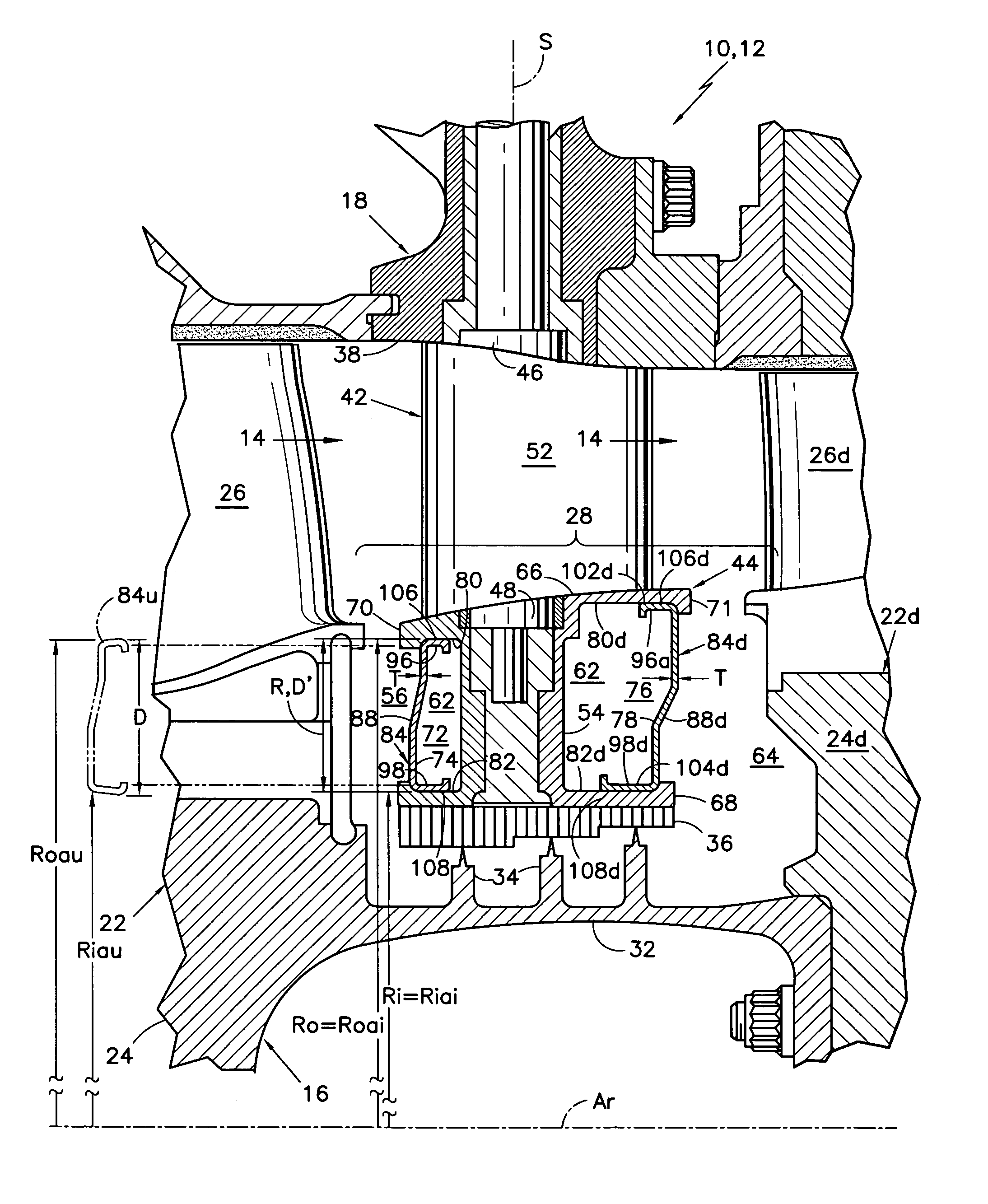

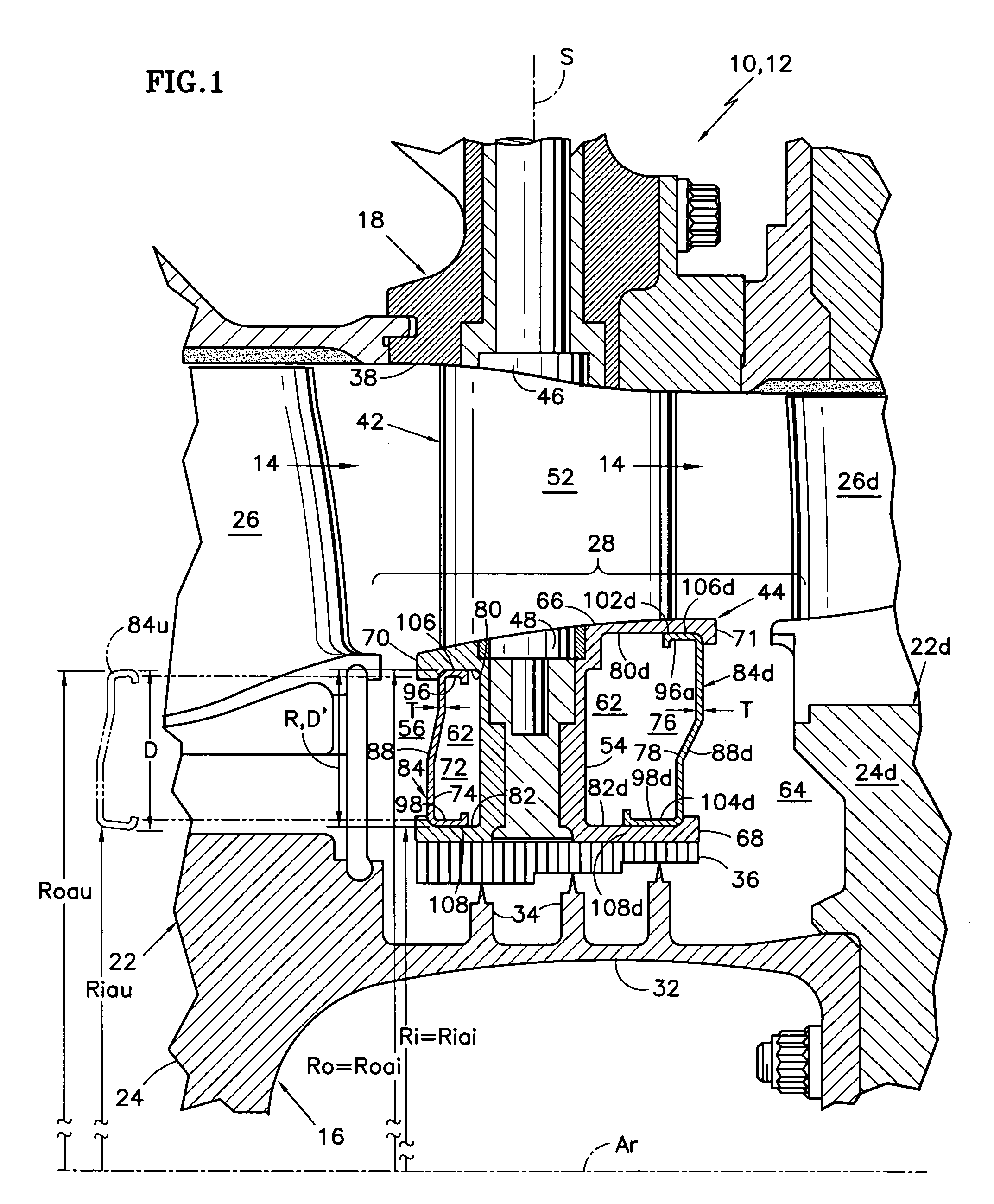

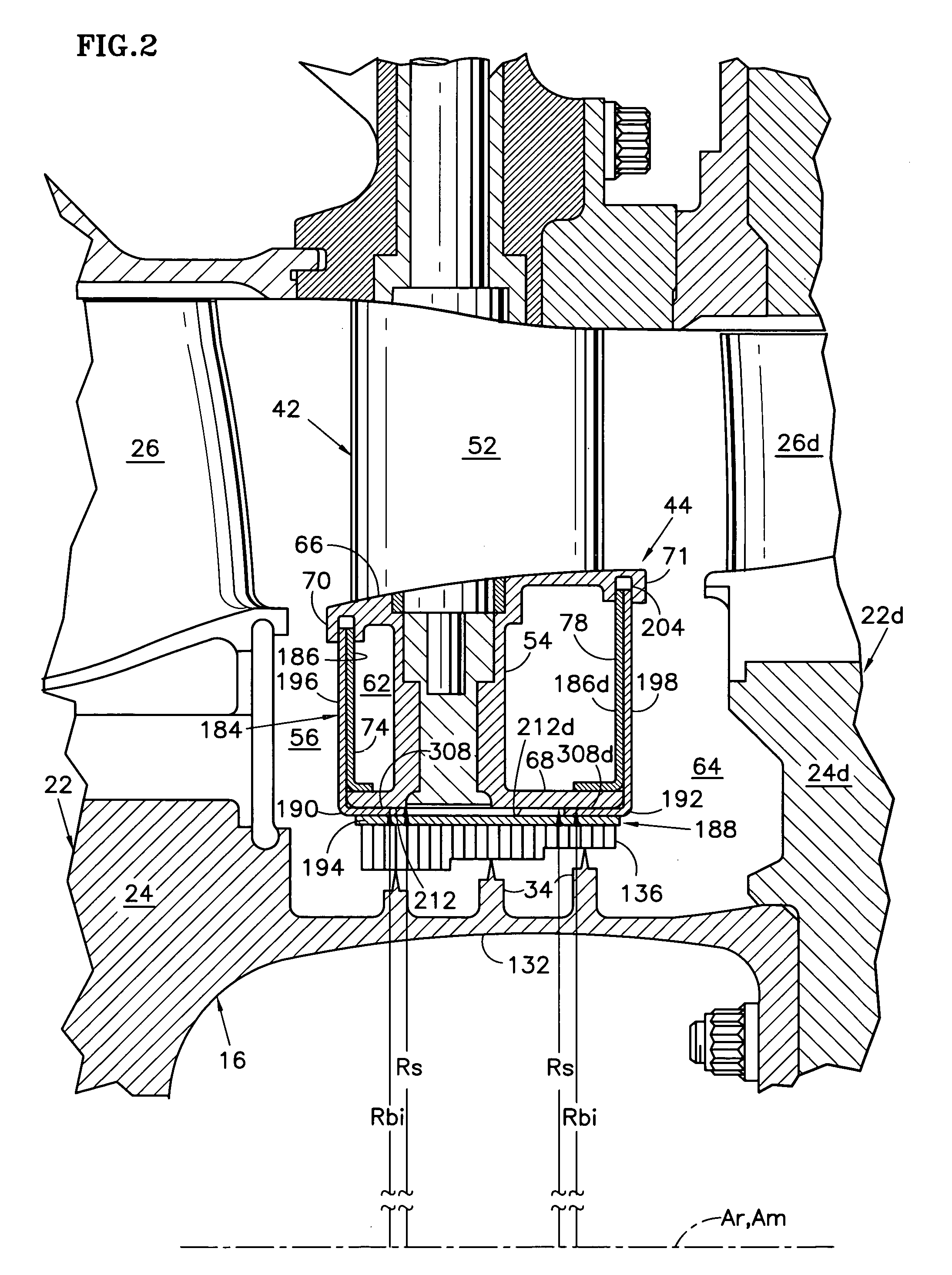

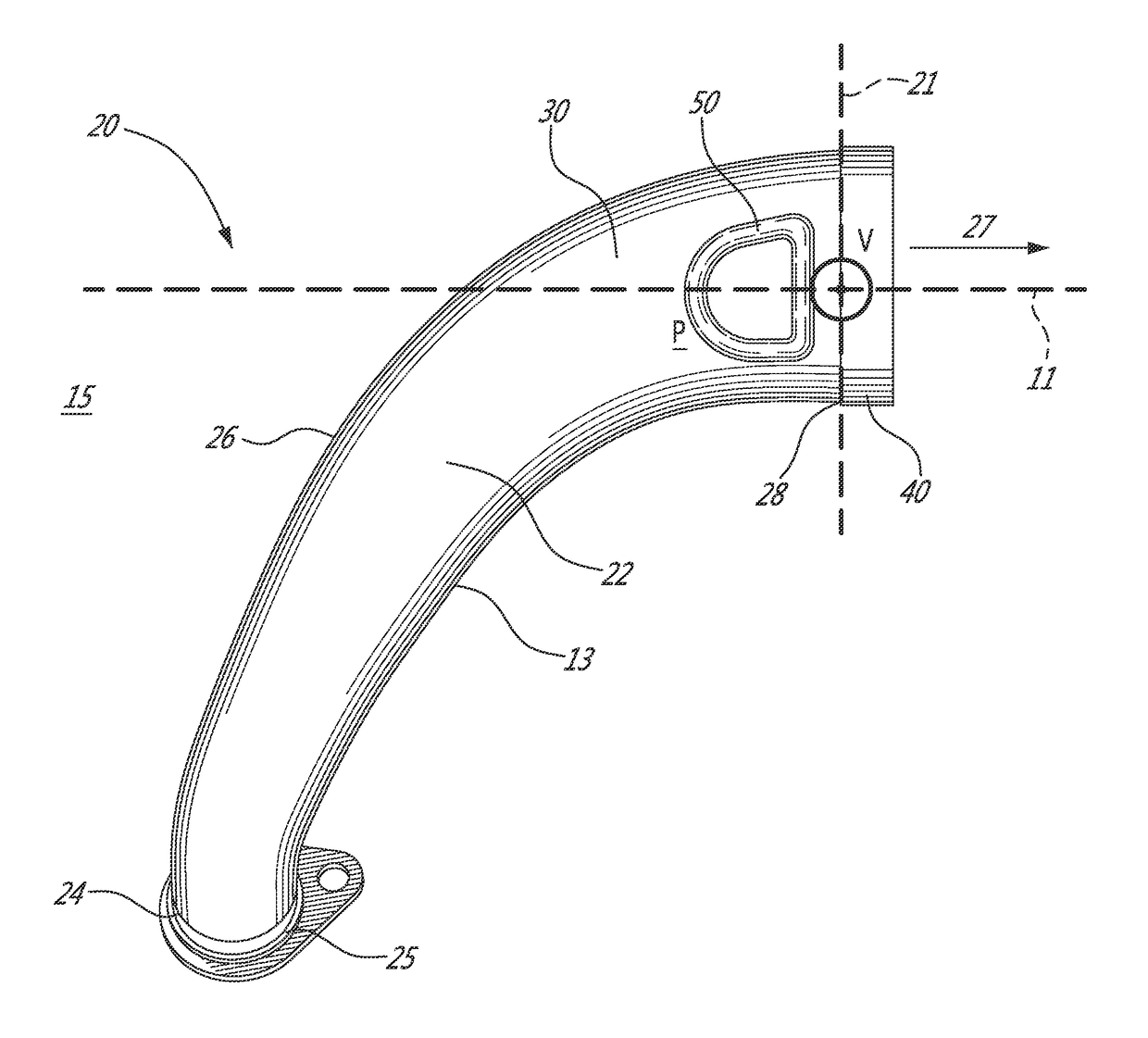

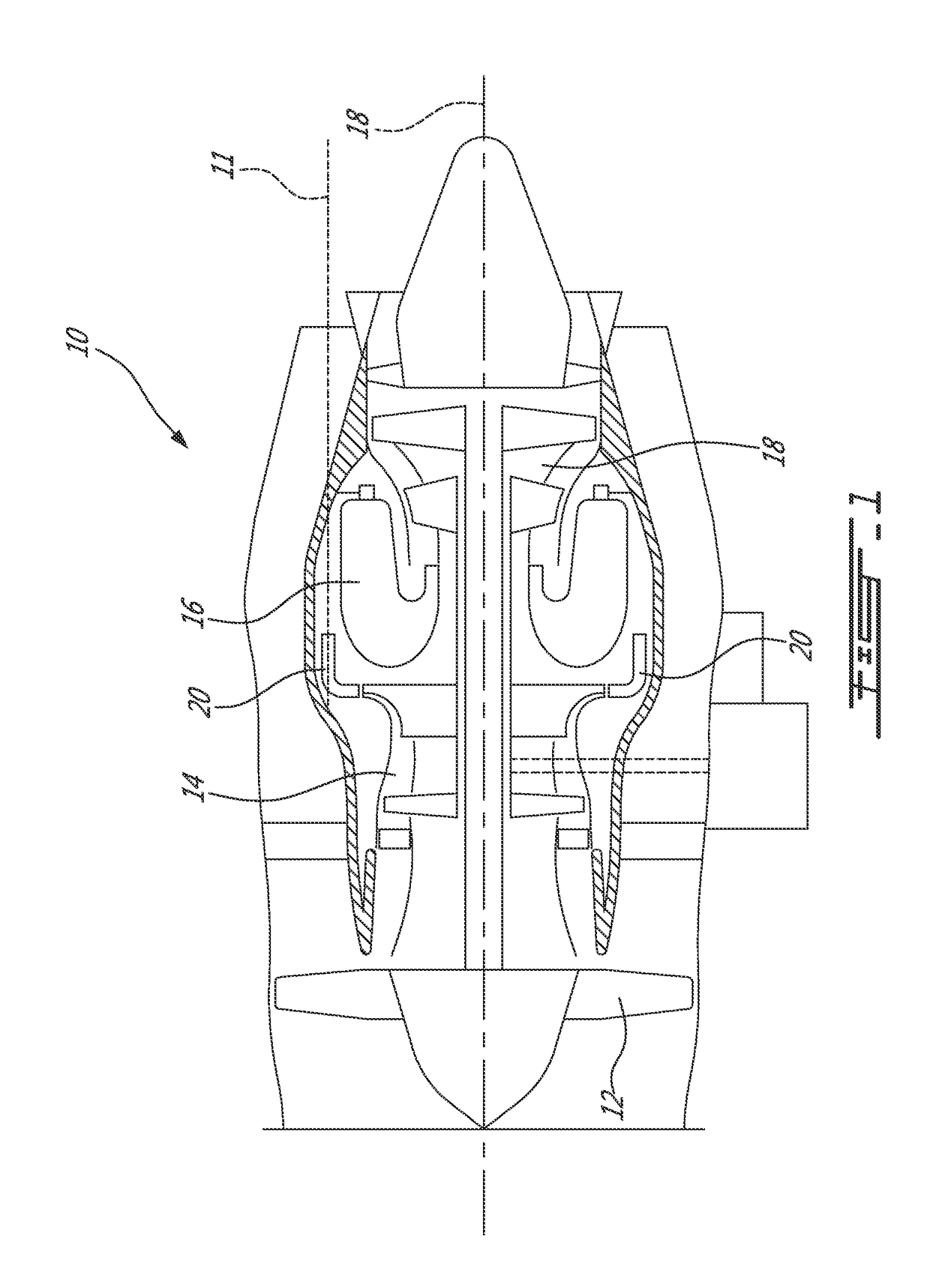

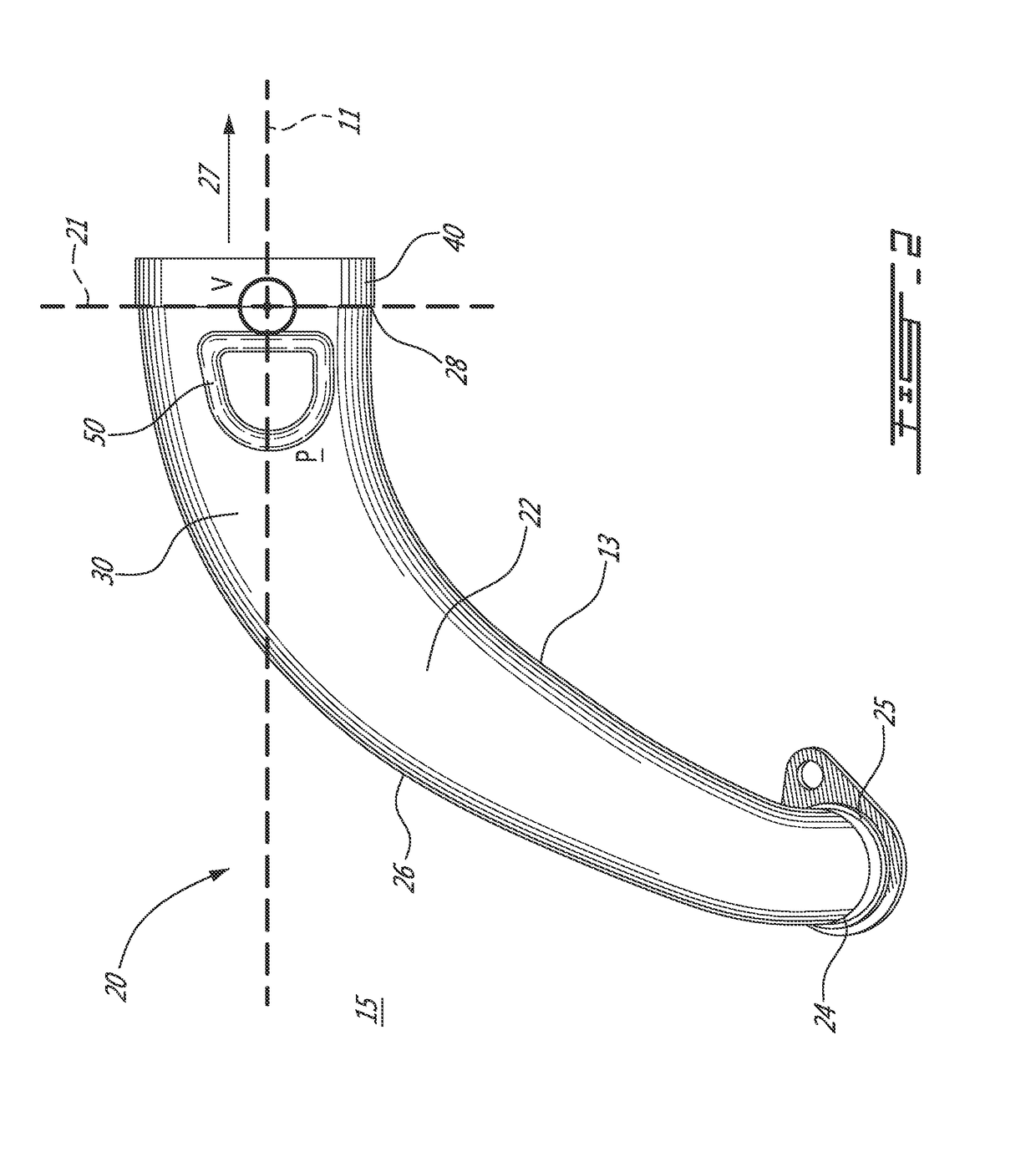

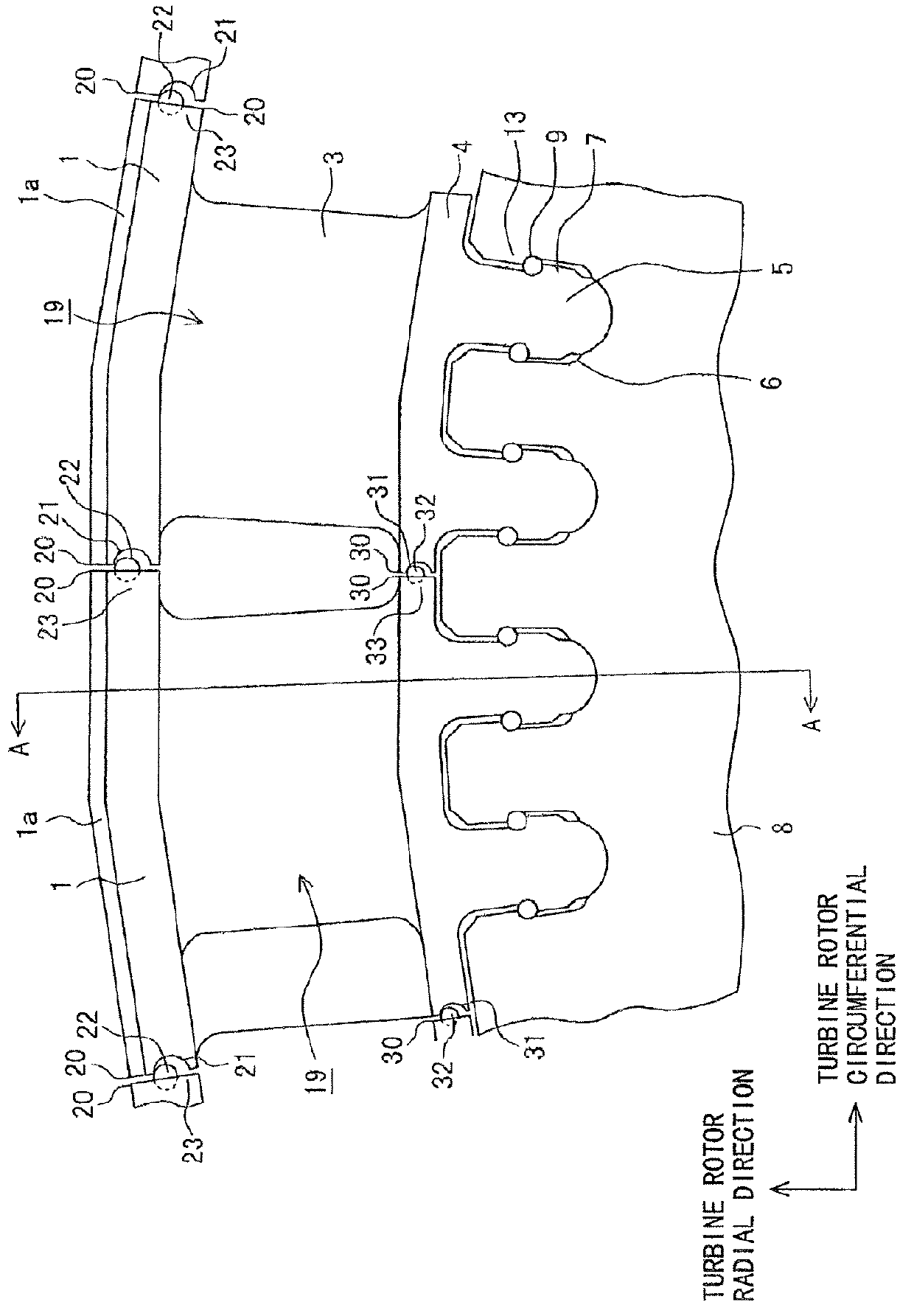

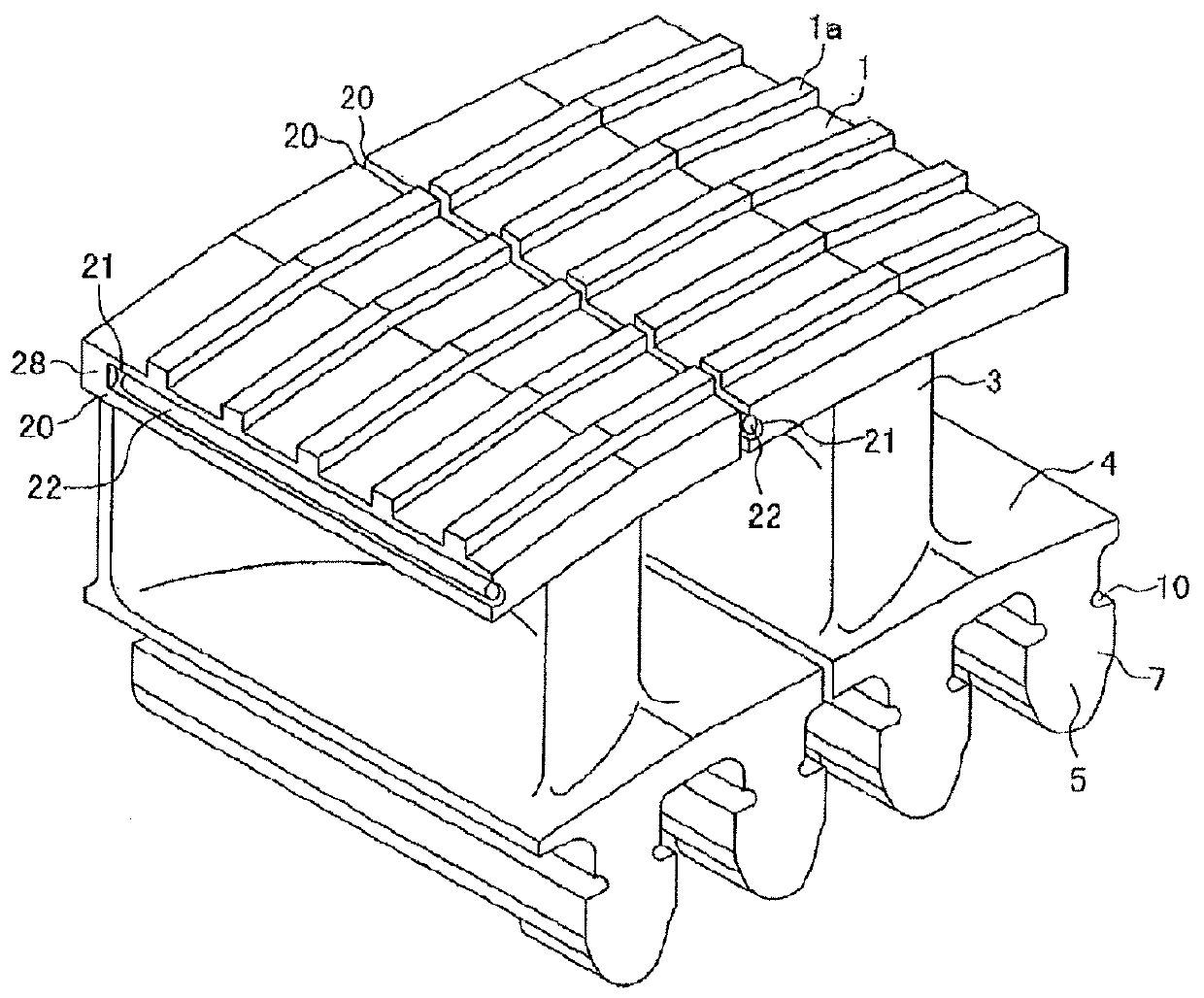

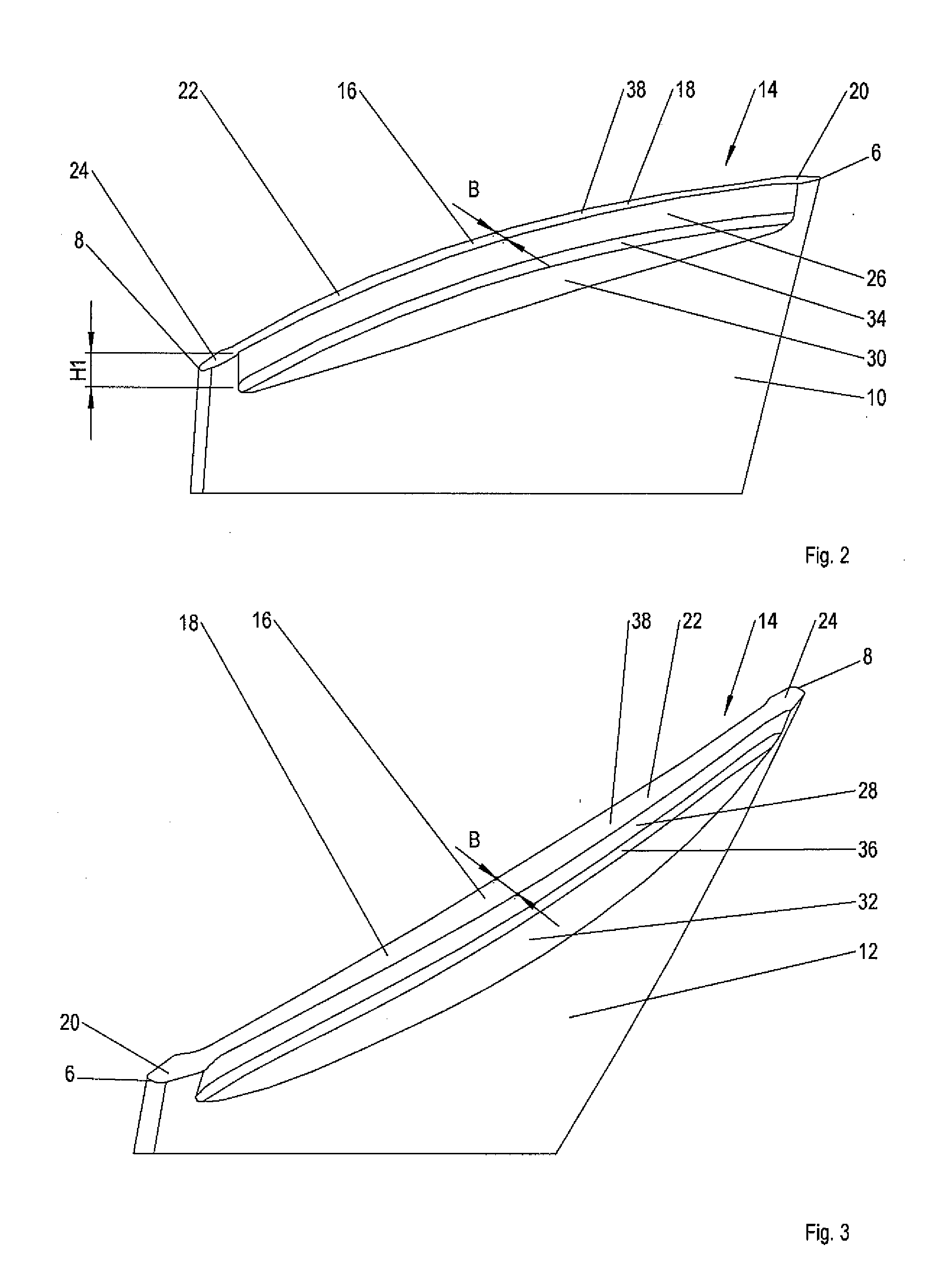

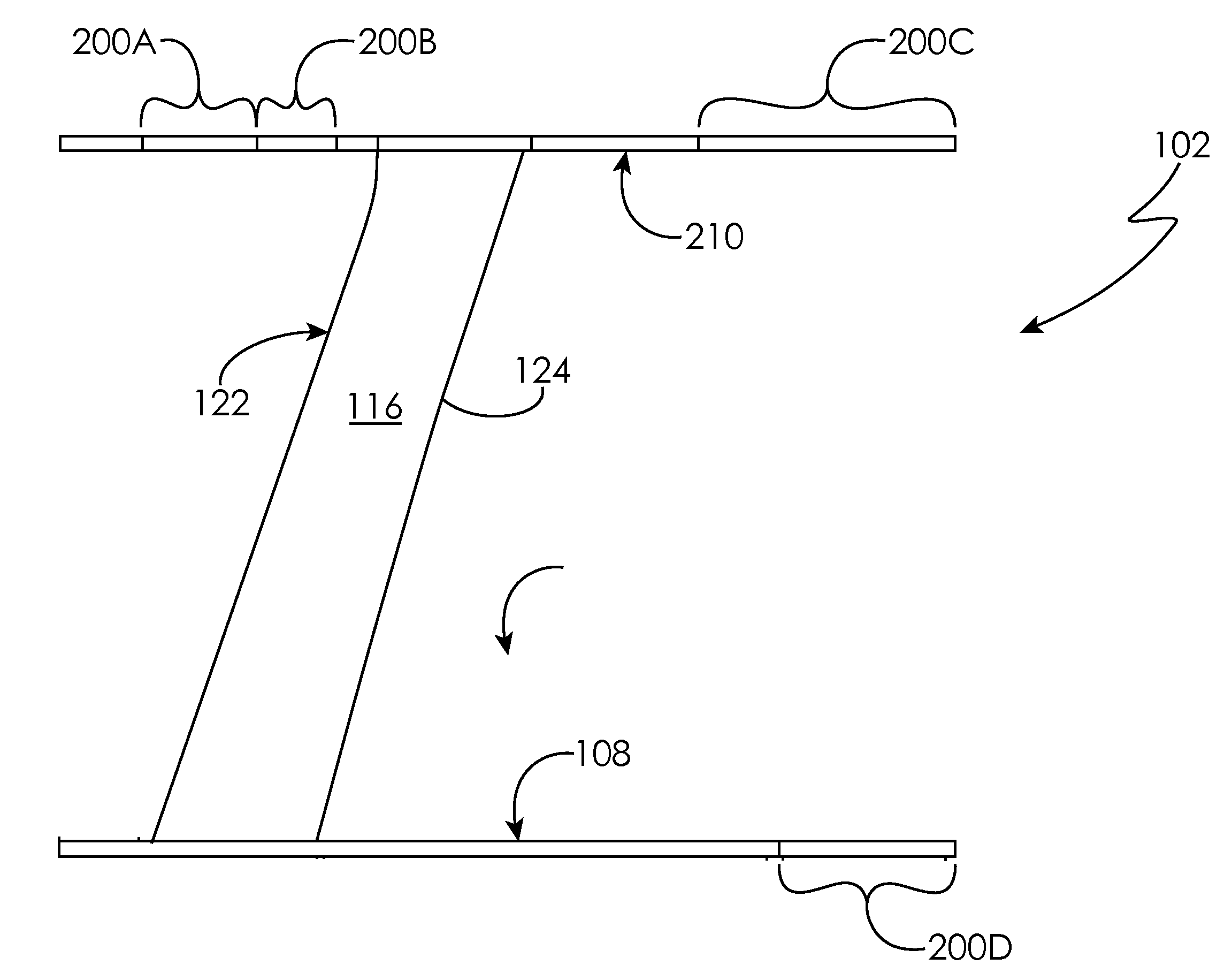

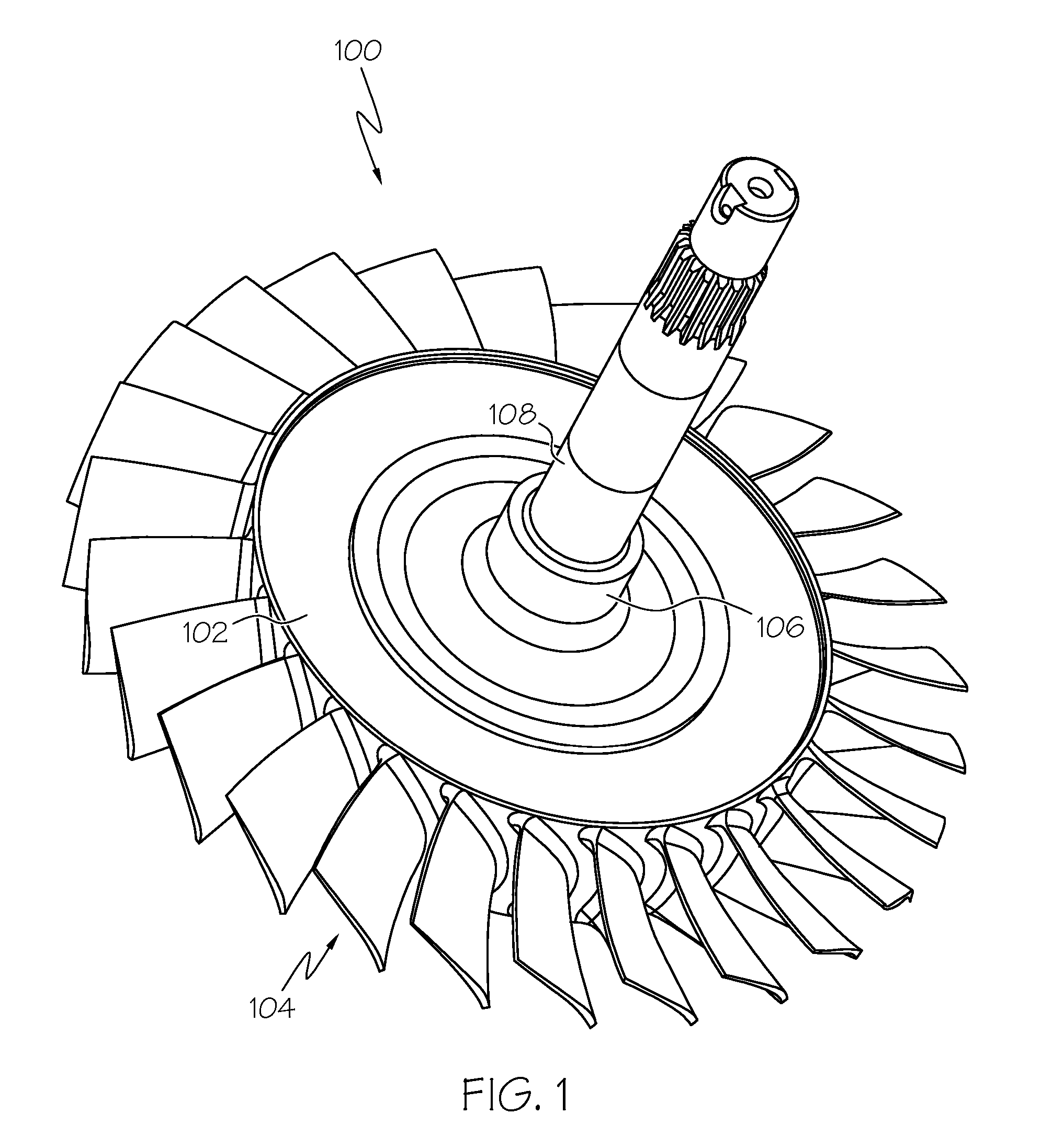

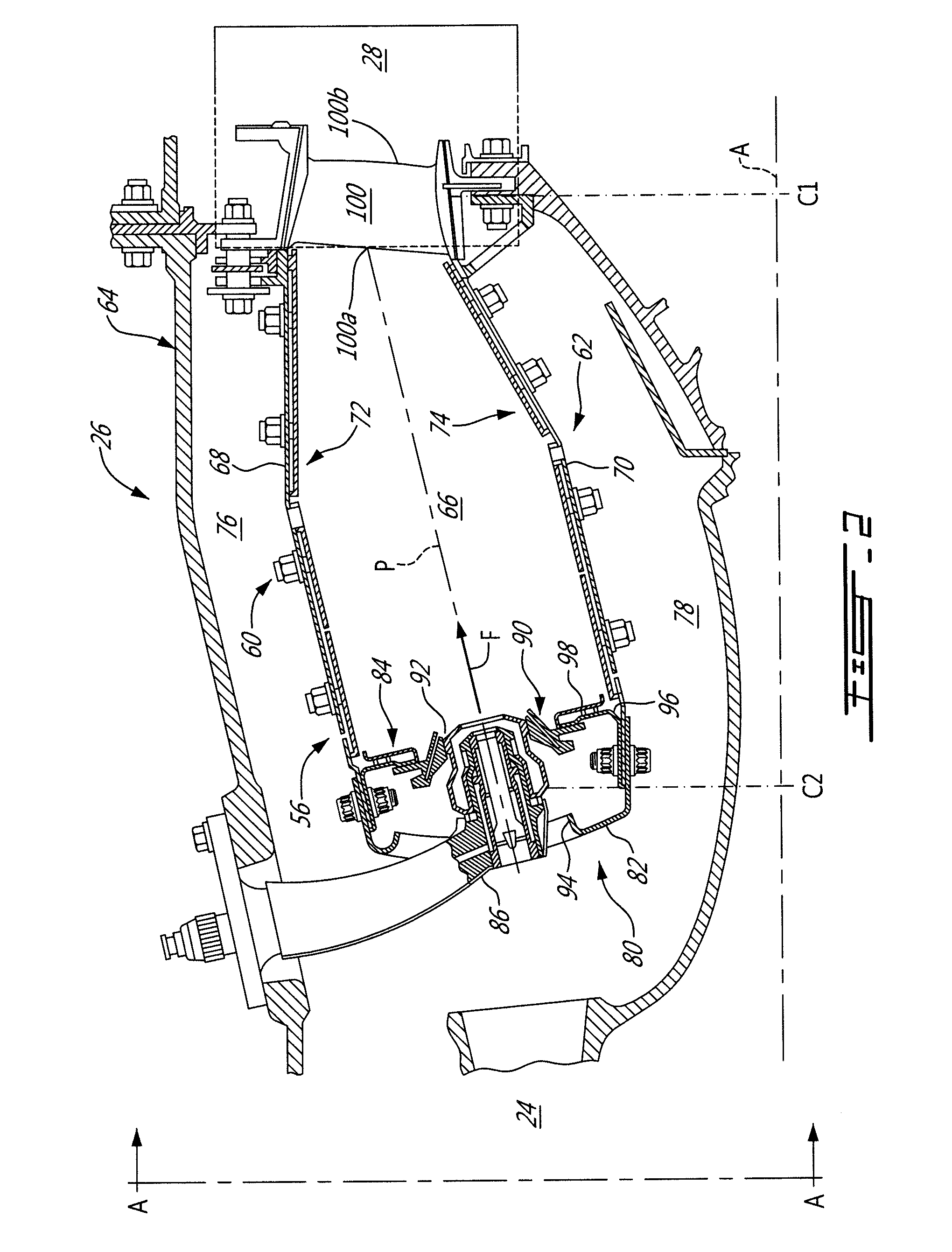

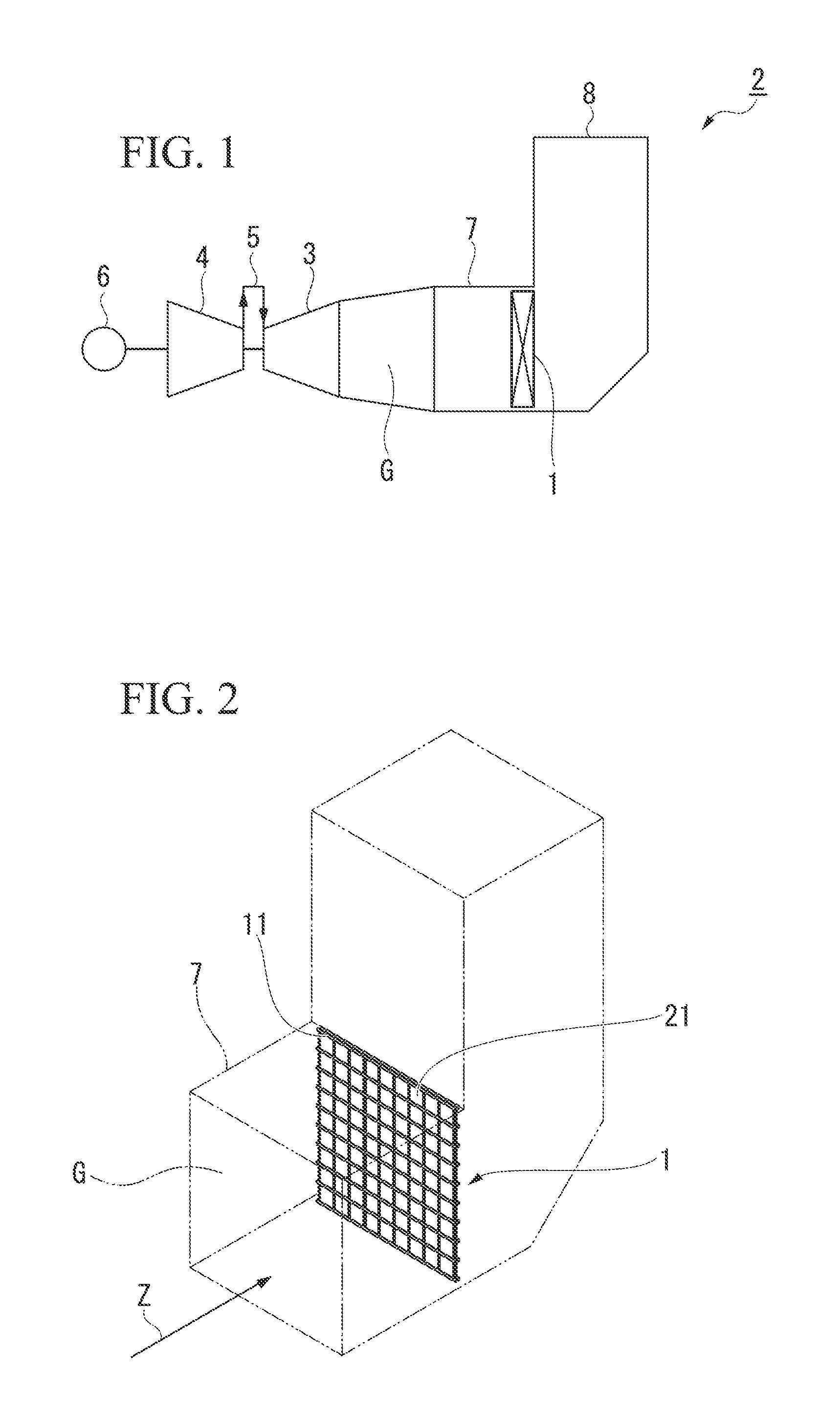

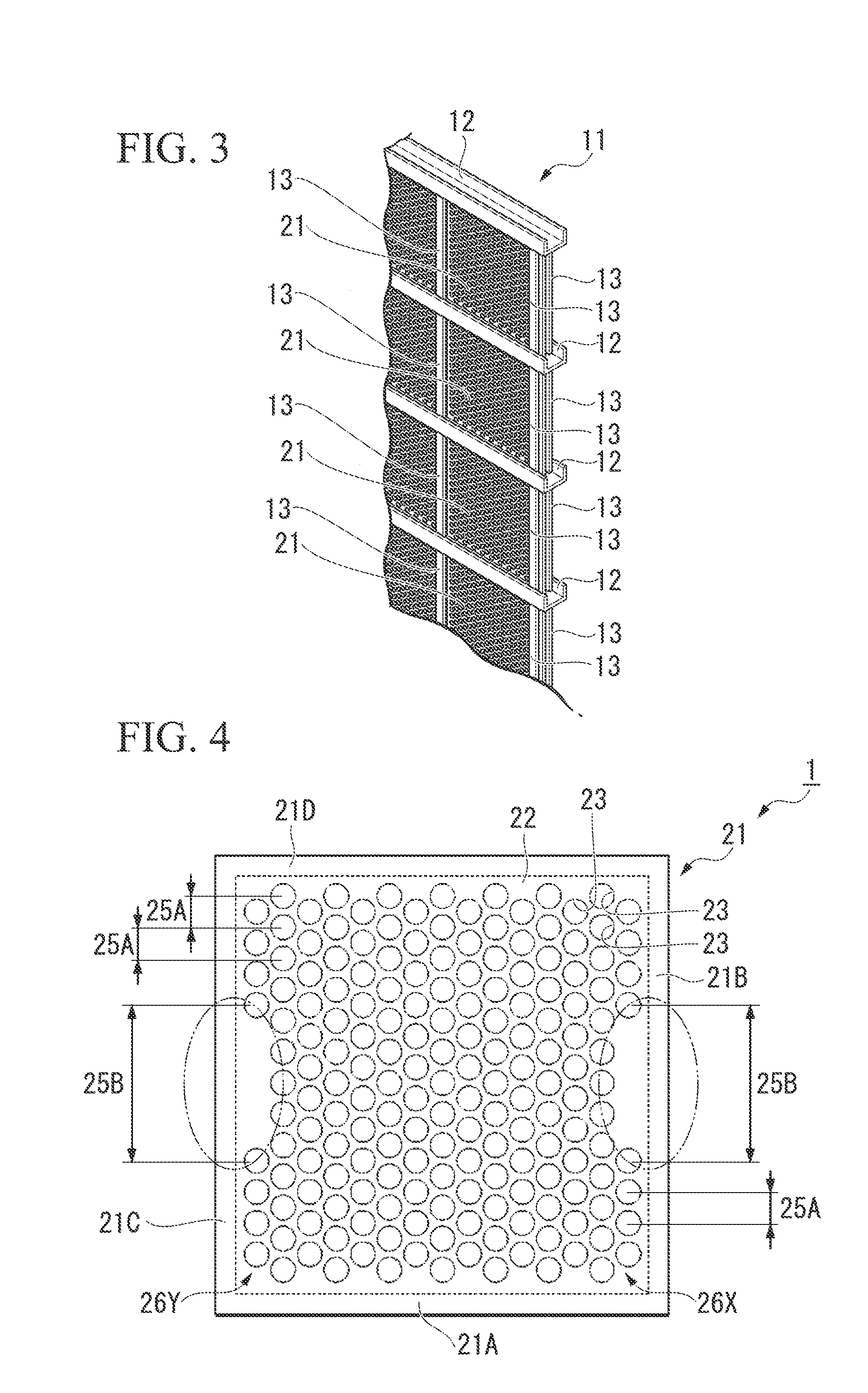

Steam turbine rotor blade assembly

ActiveUS20090097980A1Reduce vibration stressHigh positioning accuracyPropellersPump componentsSteam turbine rotorTurbine rotor

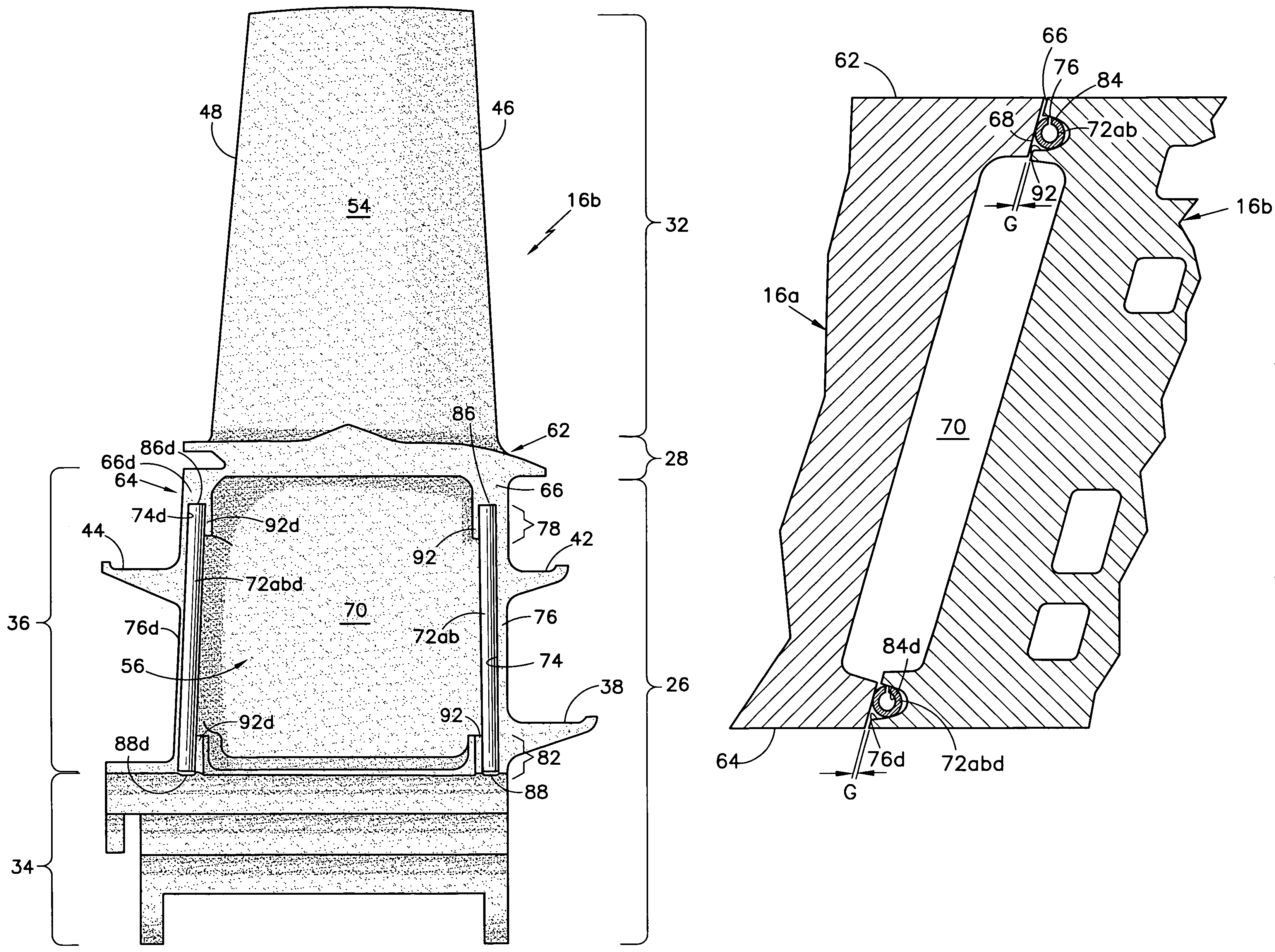

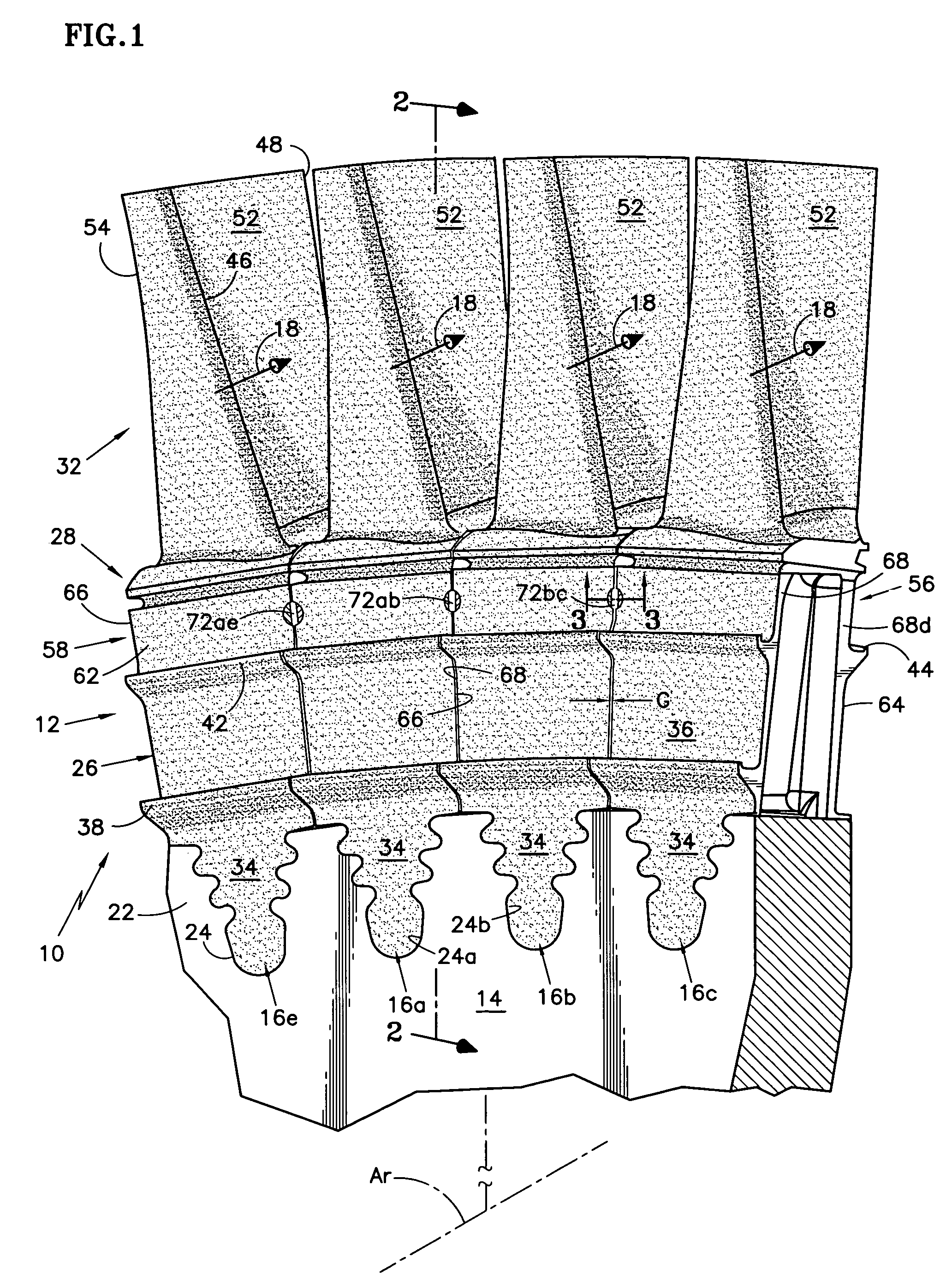

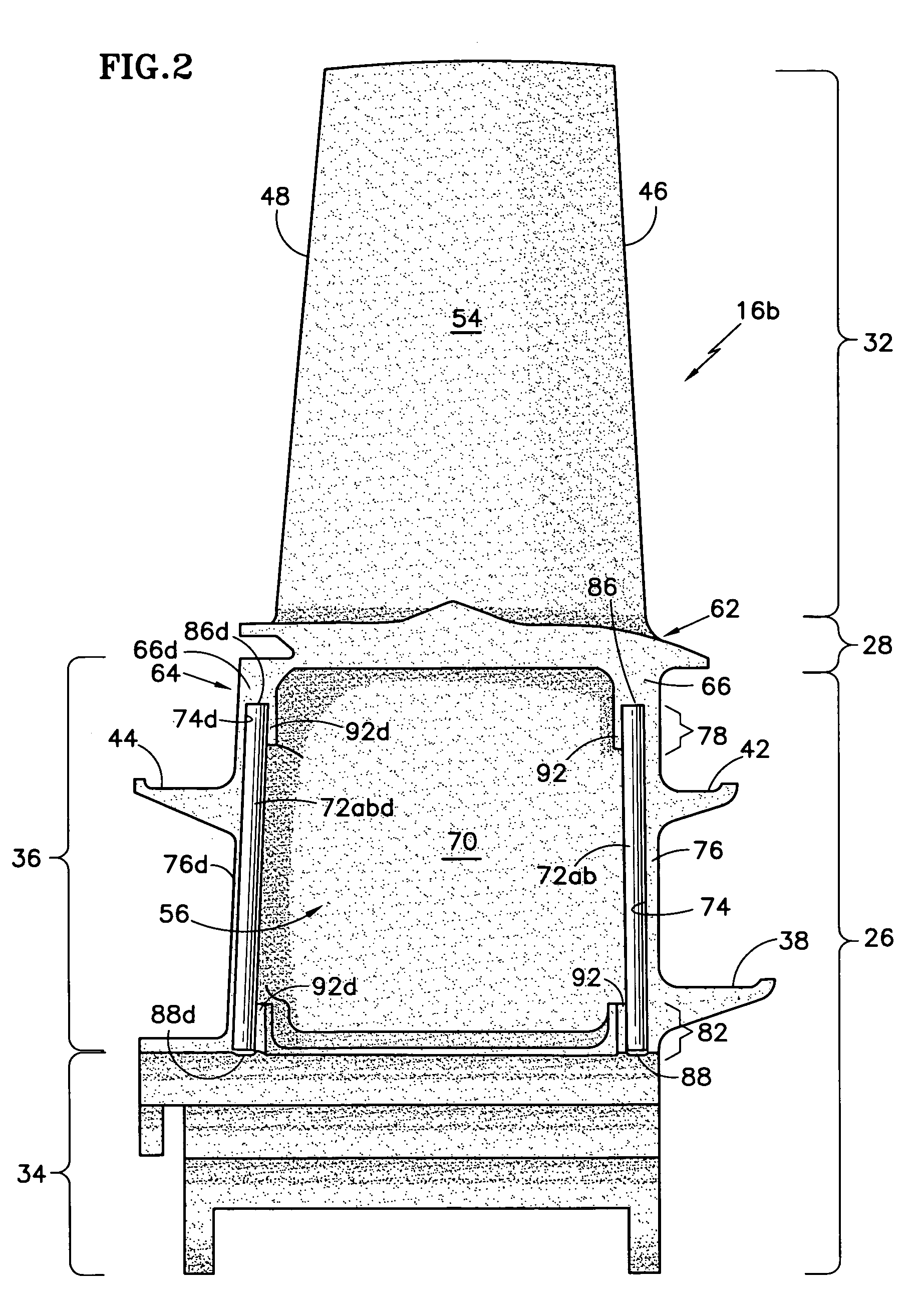

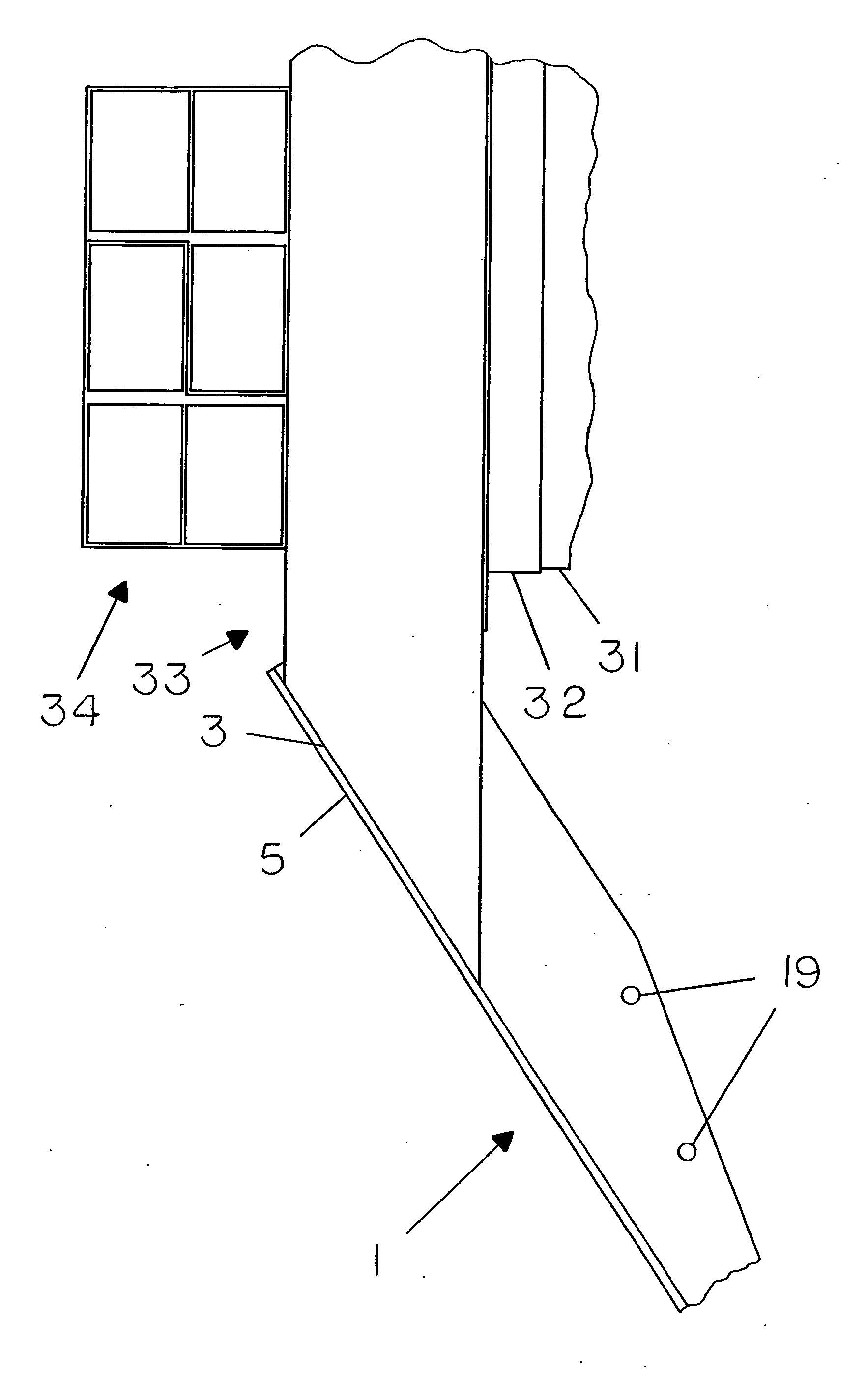

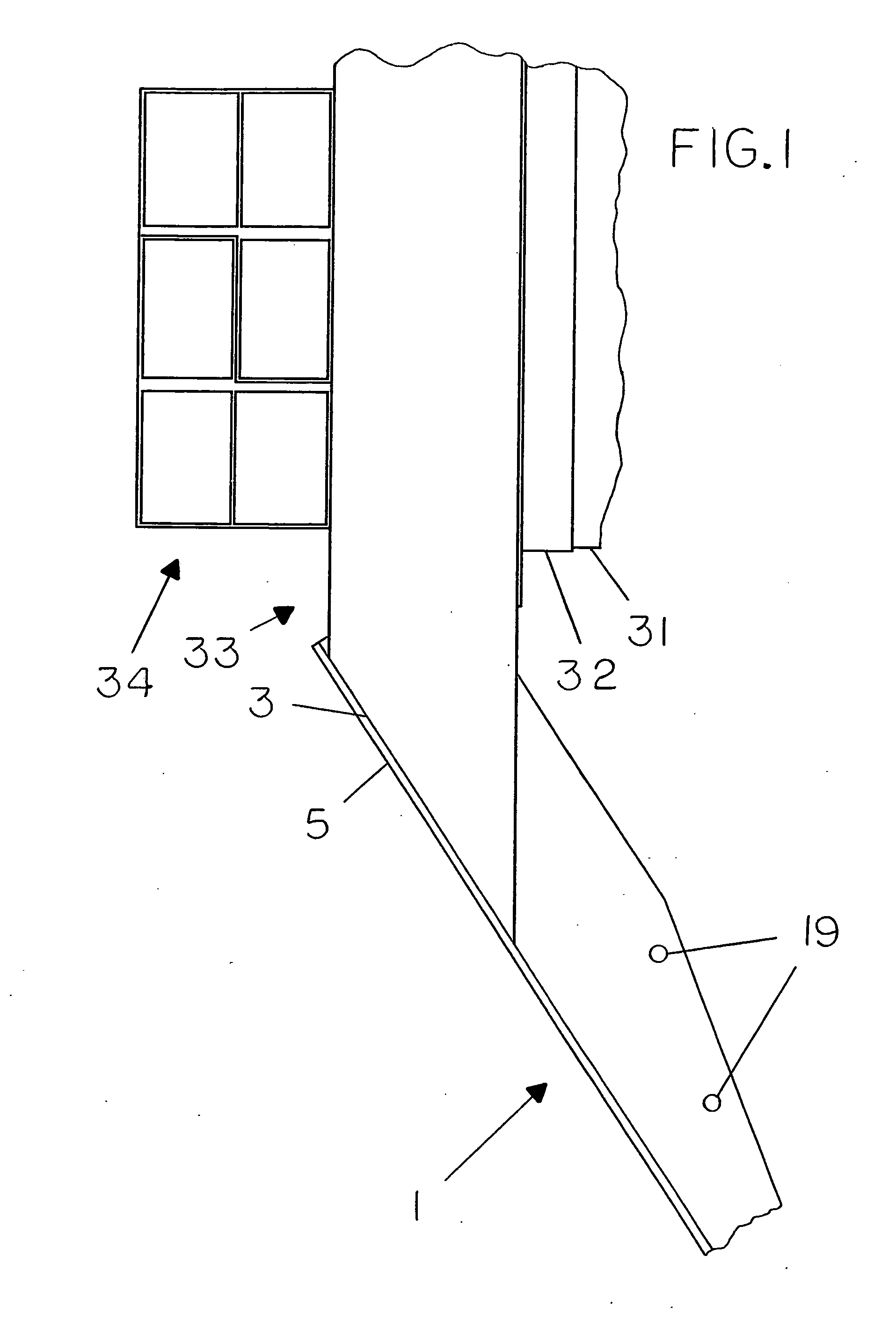

The present invention is a steam turbine rotor blade assembly including: an airfoil; a shroud provided at a tip of the airfoil; a blade root (dovetail) projecting toward a radially internal circumferential side of a turbine rotor and fitted to a root attachment provided on an outer circumferential portion of the turbine rotor; a platform provided between the airfoil and the blade root; a pin provided between the blade root and the root attachment; a bore formed between respective surfaces of the shrouds facing each other and included in the respective adjacent rotor blades; and a bar-like member provided in the bore.

Owner:MITSUBISHI POWER LTD

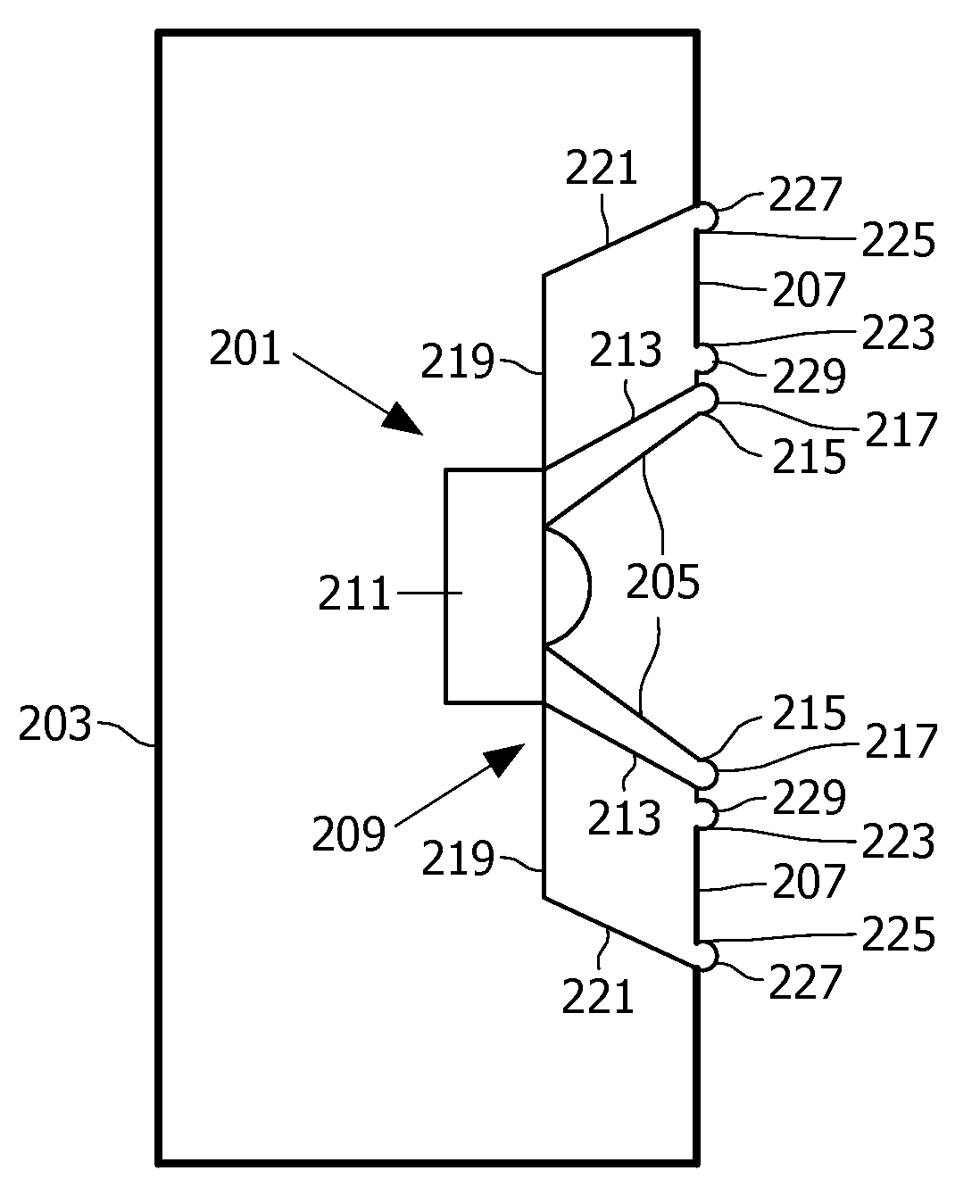

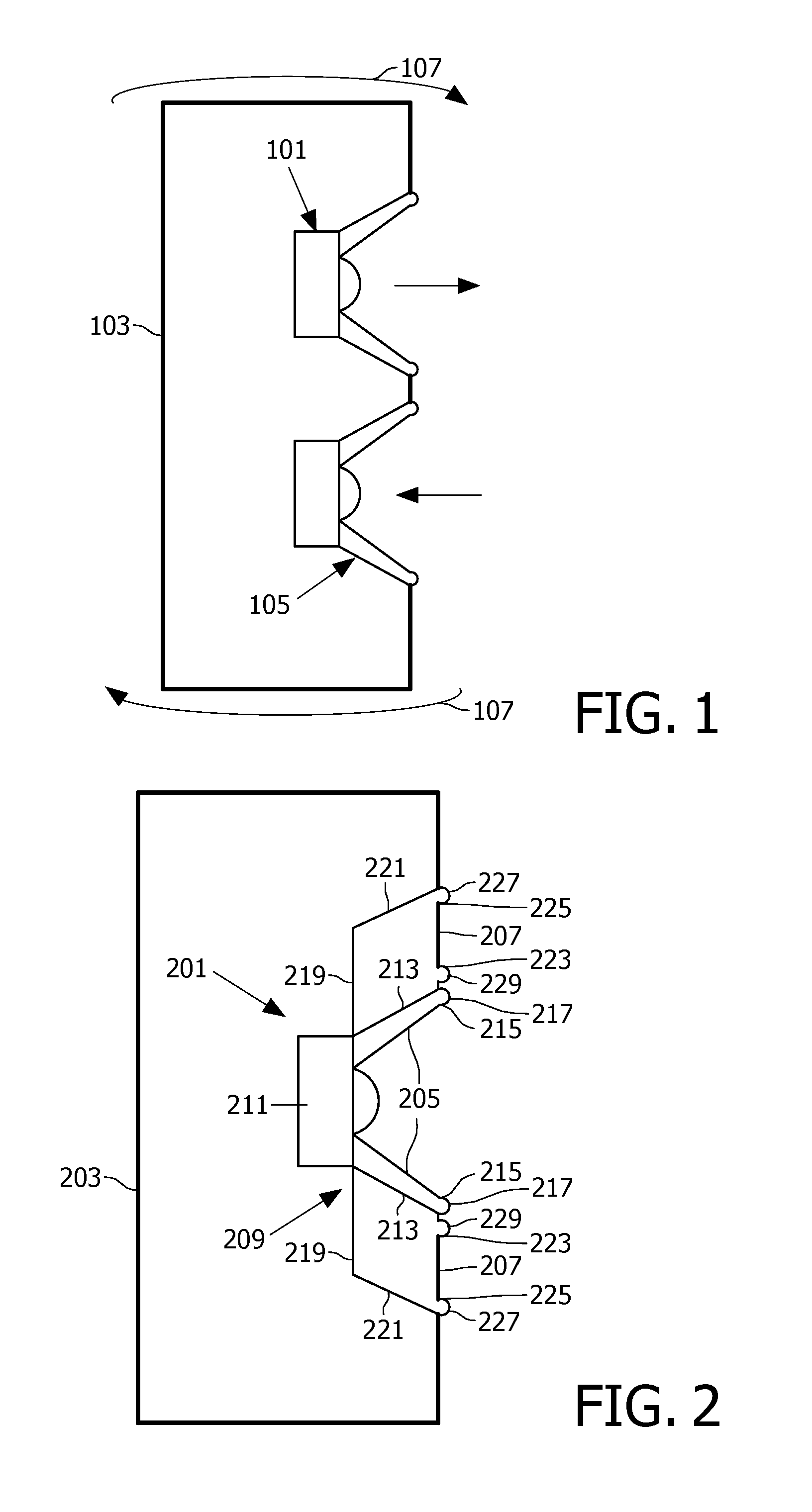

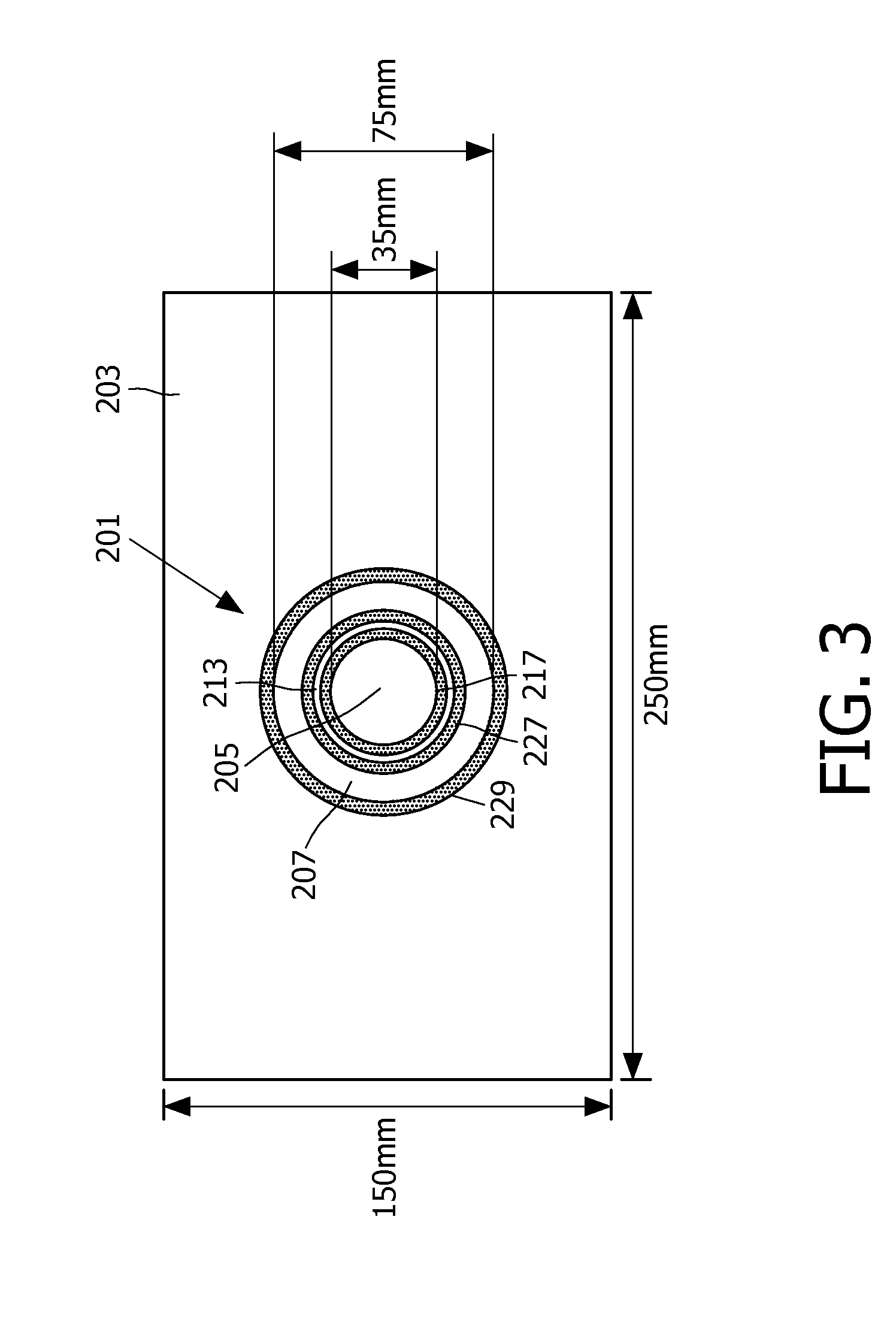

Loudspeaker driver and loudspeaker arrangement

InactiveUS20120114148A1Easy to installLow costFrequency/directions obtaining arrangementsDeaf-aid setsPassive radiatorIntegrated design

A loudspeaker arrangement comprises a loudspeaker driver (201) mounted in an enclosure (203). The loudspeaker driver (201) comprises a speaker frame (209) which forms an outer support (221) and an inner support (213). An active radiator (205) is mounted on the inner support (213) and a passive radiator (207) is mounted between and on the inner support (213) and the outer support (221). The loudspeaker driver (201) may be mounted by the outer support (221) being fixed to the enclosure (203). The passive radiator (205) allows a low frequency extension for the loudspeaker driver (201). The integrated design of the active radiator 205 and passive radiator 207 allows the radiators (205, 207) to closely interact and behave as a single unit. The approach may reduce cost, facilitate manufacturing, improve audio quality and / or reduce vibrational stress on the enclosure.

Owner:TP VISION HLDG

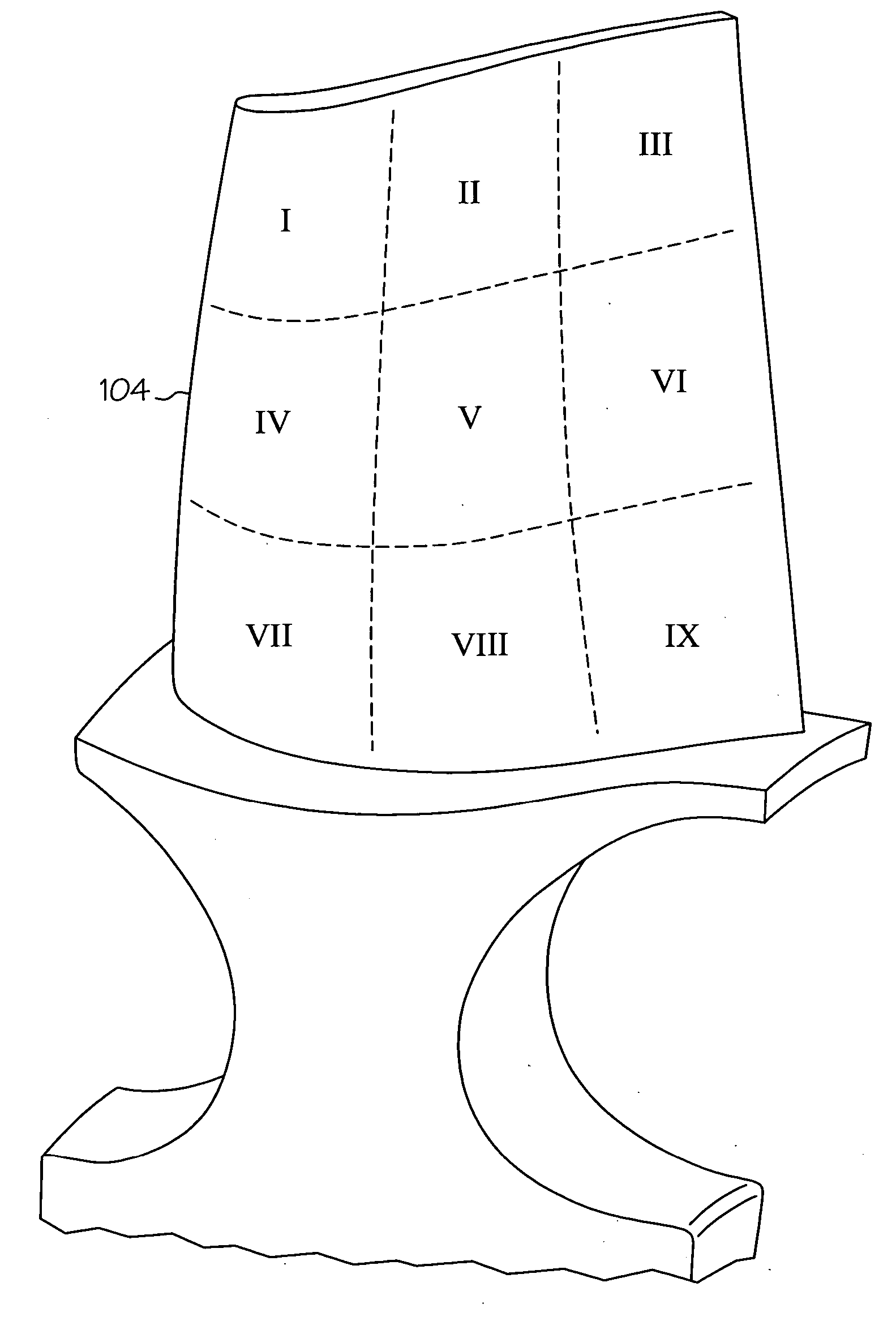

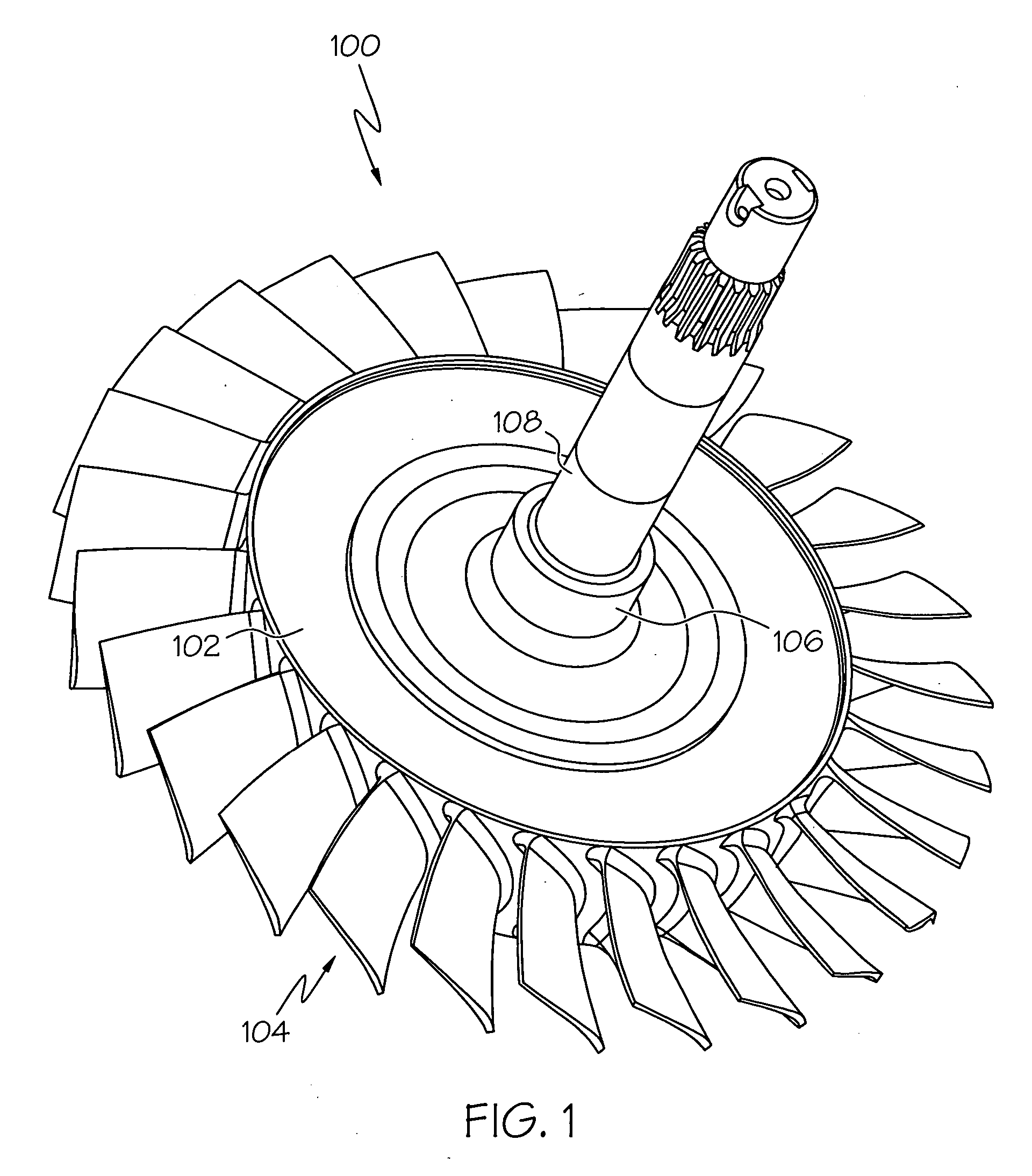

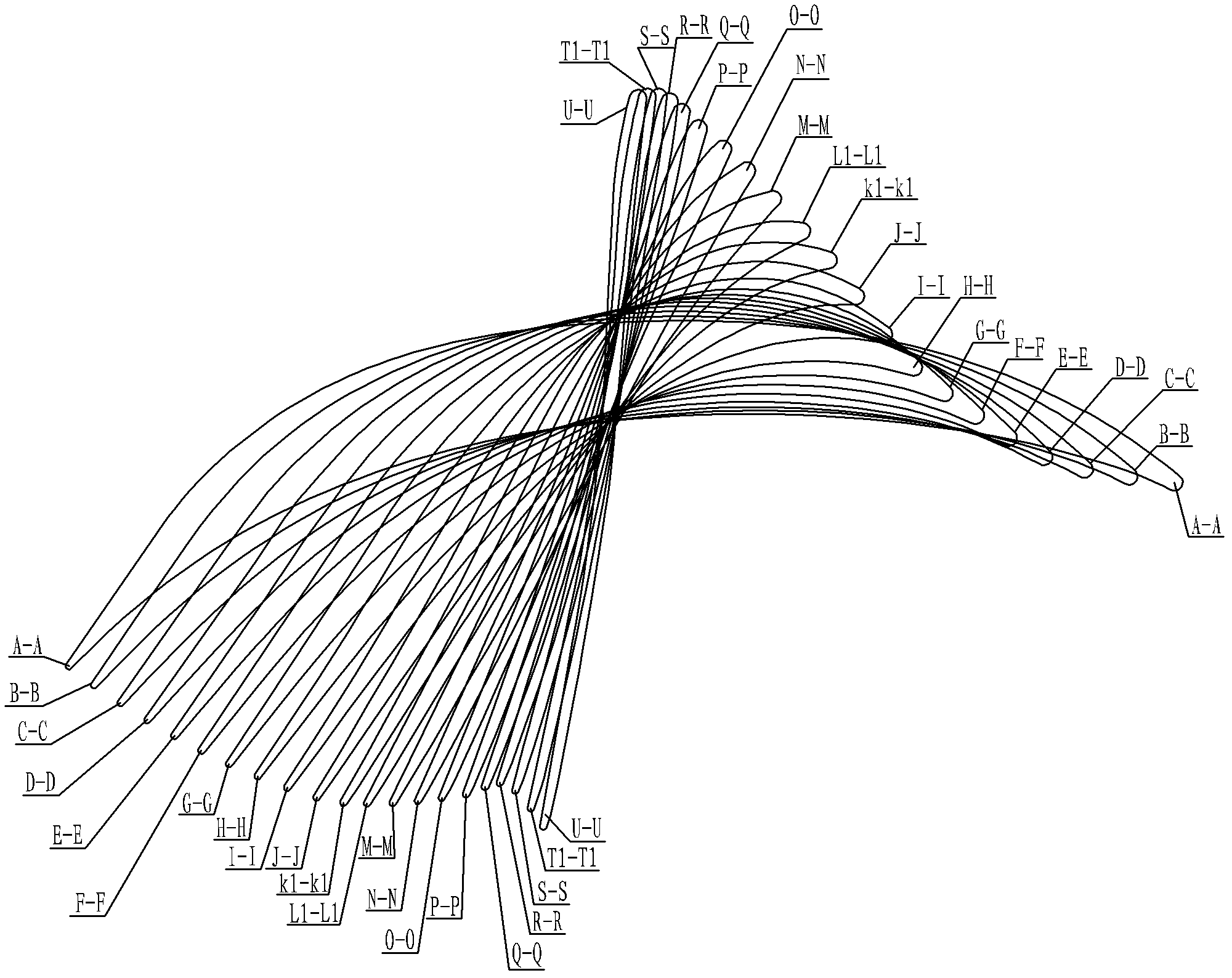

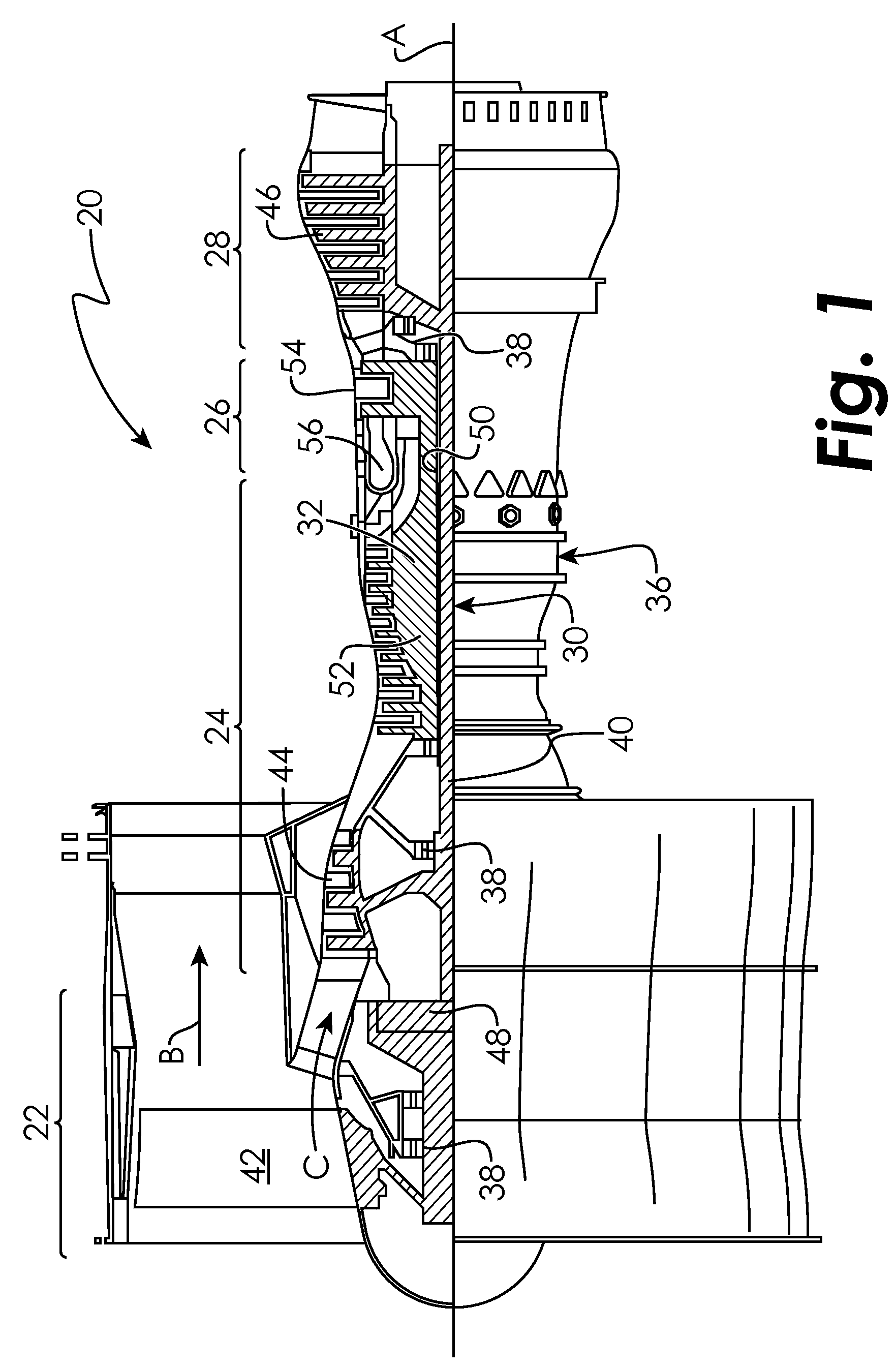

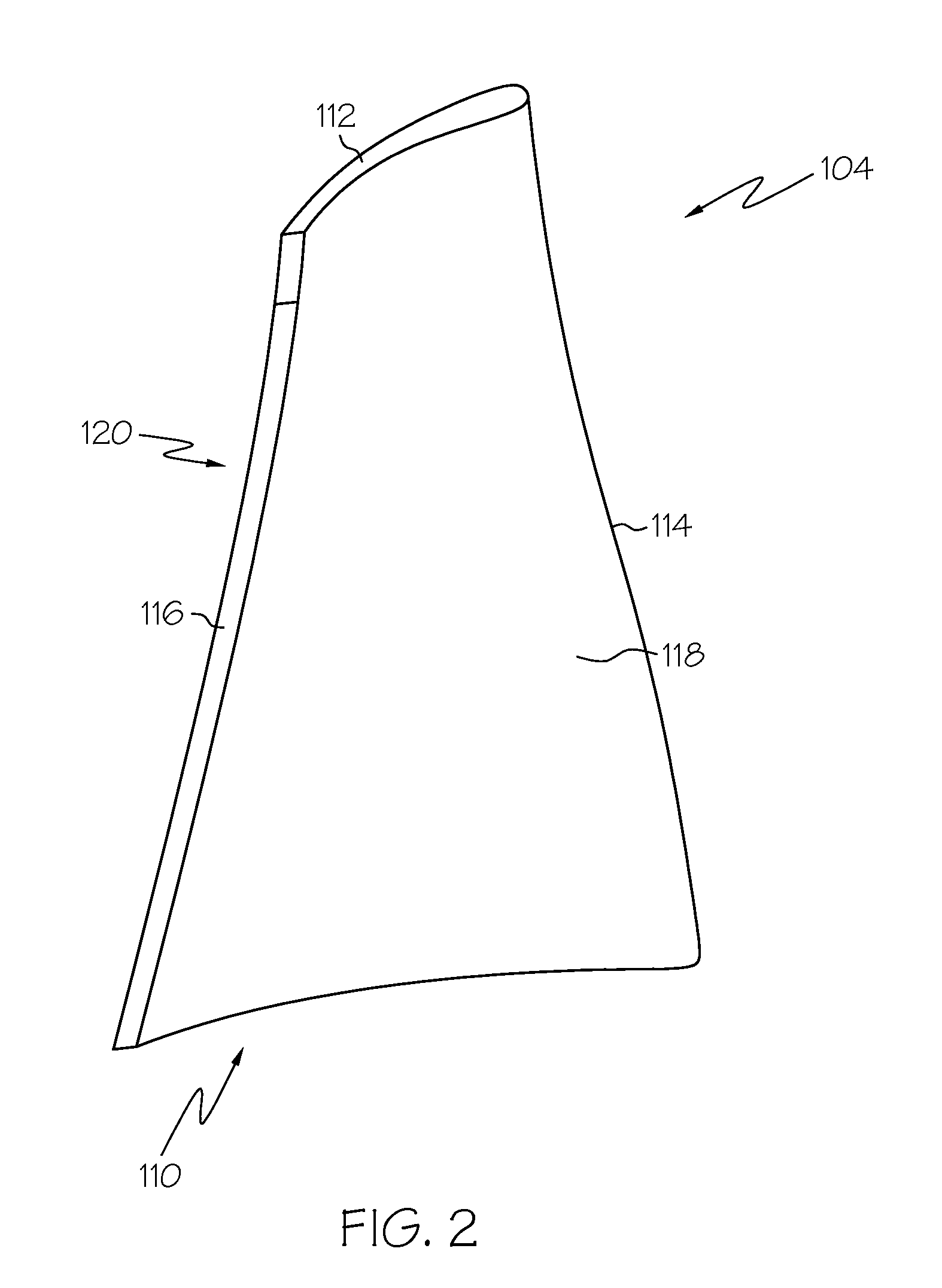

Frequency tailored thickness blade for a turbomachine wheel

InactiveUS20060073022A1Reduce impactReduce vibration stressBlade accessoriesEfficient propulsion technologiesComputational modelEngineering

A method is provided for determining a blade topology that reduces the effects of vibratory stress on a turbomachine blade having a plurality of discrete locations, wherein each discrete location has a thickness. The method includes the steps of creating a computational model of the blade, using the computational model to modify the thickness of at least one of the discrete locations a predetermined amount, determining a combination of a discrete location and predetermined thickness amount that reduces vibratory stress on the blade, and applying the determined combination to the computational model to create a revised blade. A turbomachine including a blade having the determined blade topology is also provided.

Owner:HONEYWELL INT INC

Compressor airfoil

ActiveUS8057188B2Relieve pressureIncrease stiffnessPropellersPump componentsIncreased thicknessCompressor blade

Owner:ANSALDO ENERGIA SWITZERLAND AG

Rotor assembly for a rotary machine

ActiveUS7575416B2Reduce vibration stressIncreased durabilityPropellersPump componentsEngineeringMechanical engineering

A rotor assembly having a seal member in the root section of a rotor blade is disclosed. Various construction details are developed for blocking the flow of gases between adjacent rotor blades. In one detailed embodiment, a deformable seal member formed of a high temperature material is disposed between the root sections of adjacent rotor blades and engages the blades under operative conditions.

Owner:RTX CORP

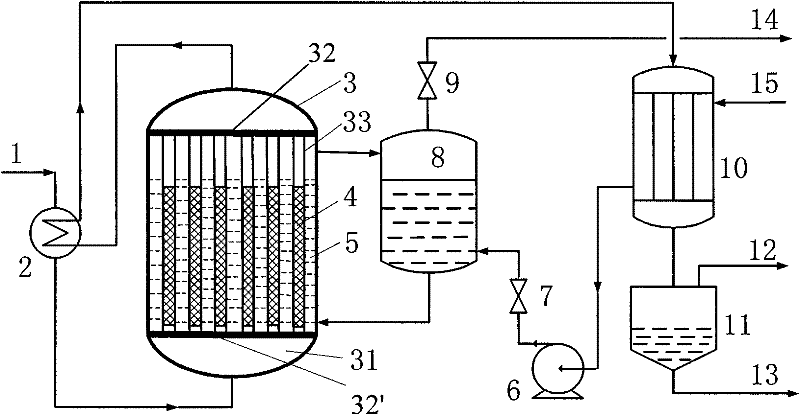

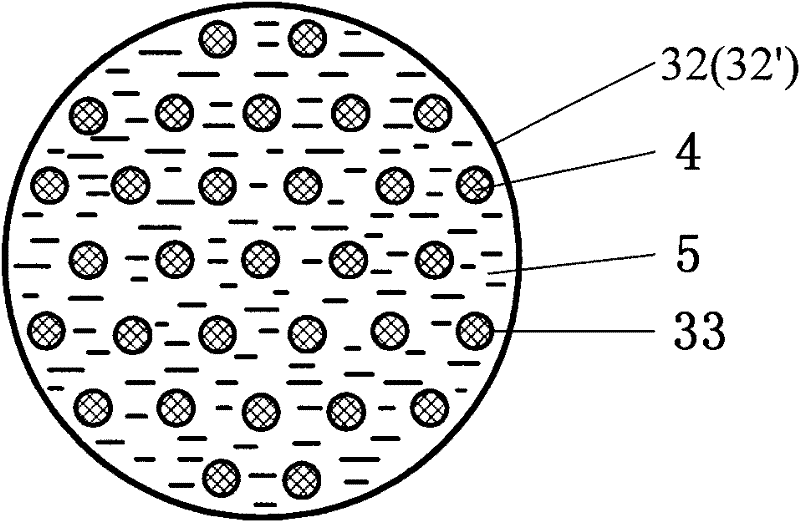

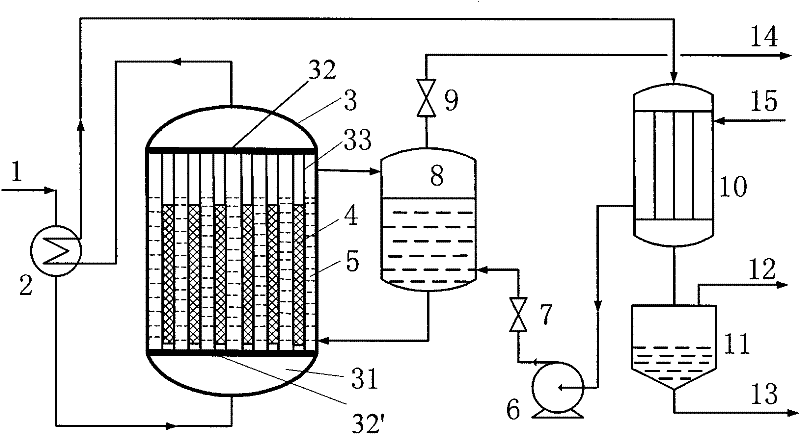

Complete methanation reaction device for synthesis gas

ActiveCN102234213AIncrease production capacityImprove efficiencyHydrocarbon from carbon oxidesChemical industryLiquid productMethanation

The invention relates to a complete methanation reaction device for synthesis gas. The device consists of a tube-shell reactor, a heat exchanger, a steam pocket, a make-up water pump, a condenser and a gas-liquid separator, wherein a catalyst is filled in a tube of the reactor; the shell pass is superheated water for removing heat; heat released in methanation reaction is absorbed through the phase change of high-pressure superheated water in the shell pass of the reactor and taken out of the device; the generated steam enters the steam pocket, is subjected to gas-liquid balance and can directly form superheated steam to be supplied to the outside; the temperature of a catalyst bed in the tube of the reactor is regulated and controlled by controlling the balance pressure of the superheated steam; reaction product exit gas exchanges heat with raw material gas and is continuously condensed; and a gaseous product and a liquid product are separated by the gas-liquid separator. The device can realize the continuous and stable operation of the complete methanation reaction of the synthesis gas, can effectively improve heat transfer efficiency and control the temperature of the reaction bed in a phase change heat transfer mode at a high temperature and under high pressure, expands the operation range of the complete methanation reaction of the synthesis gas, and can effectively recycle the heat released in the reaction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

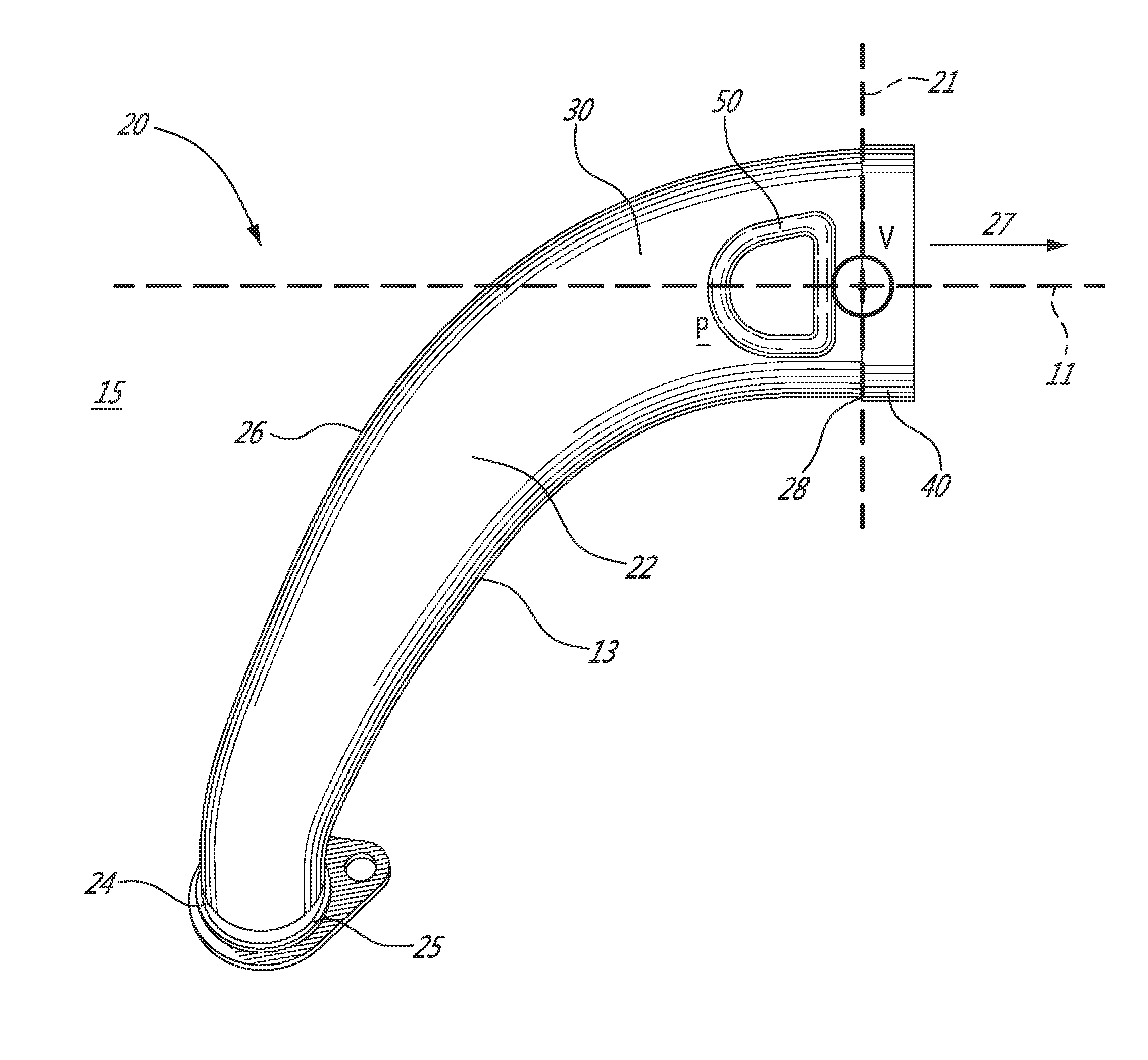

Diffuser pipe for a gas turbine engine and method for manufacturing same

A diffuser pipe for a gas turbine engine comprises a hollow pipe body including a first end, a second end fluidly connected to the first end, and at least one flattened area proximate to the second end. A ring is connected to the second end. The ring is an outlet of the diffuser pipe. At least one stiffener is disposed on the at least one flattened area. The ring and the at least one stiffener reduce vibratory stresses at the second end of the pipe body. A method of manufacturing a diffuser pipe of a gas turbine engine is also presented.

Owner:PRATT & WHITNEY CANADA CORP

Unflared compressor blade

ActiveUS20120213631A1Reduce thicknessReducing vibratory stressPropellersEngine manufactureAerospace engineeringCompressor blade

A compressor component having an airfoil with a profile in accordance with Table 1 is disclosed. The compressor component, such as a compressor blade, has an increased thickness over a portion of the airfoil span in order to increase stiffness. Furthermore, the airfoil has been restacked so as to induce a compressive stress in the blade root / attachment area. The increased stiffness and restacked airfoil combine to improve high-cycle fatigue capability of the compressor component.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Stator assembly for a rotary machine

InactiveUS7635251B2Reducing aerodynamic lossReduce vibration stressPump componentsWind motor controlAcoustic energyElastic compression

A stator assembly having a windage cover for structure adjacent to a cavity bounded by rotating elements in a rotary machine is disclosed. Various construction details are developed for damping vibrations in the windage cover as the windage cover bounds a cavity having swirling high velocity gases that are capable of transmitting acoustic energy and kinetic energy to adjacent structure. In one detailed embodiment, the windage cover in the uninstalled condition has diverging arms that are resiliently compressed during installation to exert a frictional force on the adjacent structure.

Owner:RTX CORP

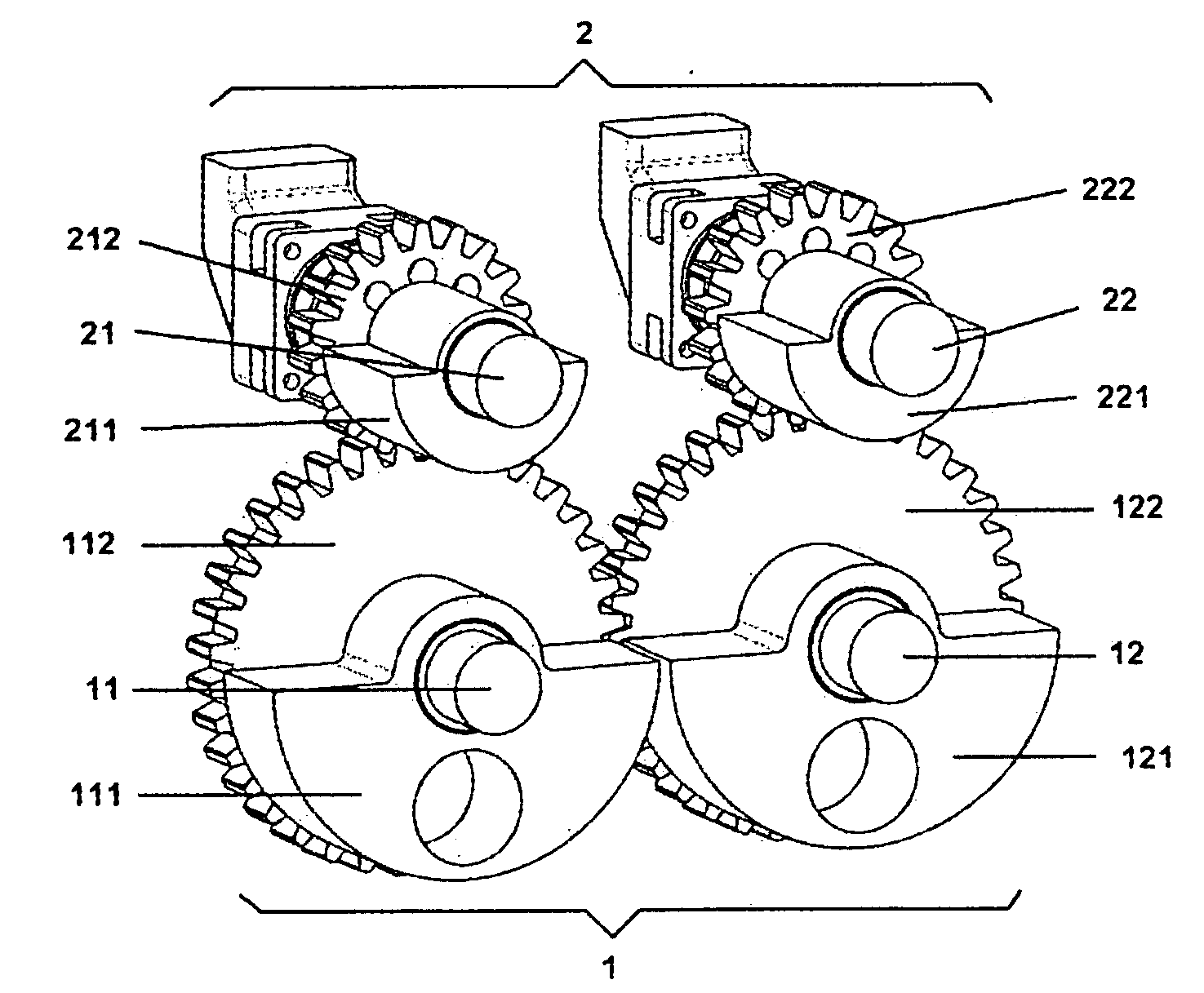

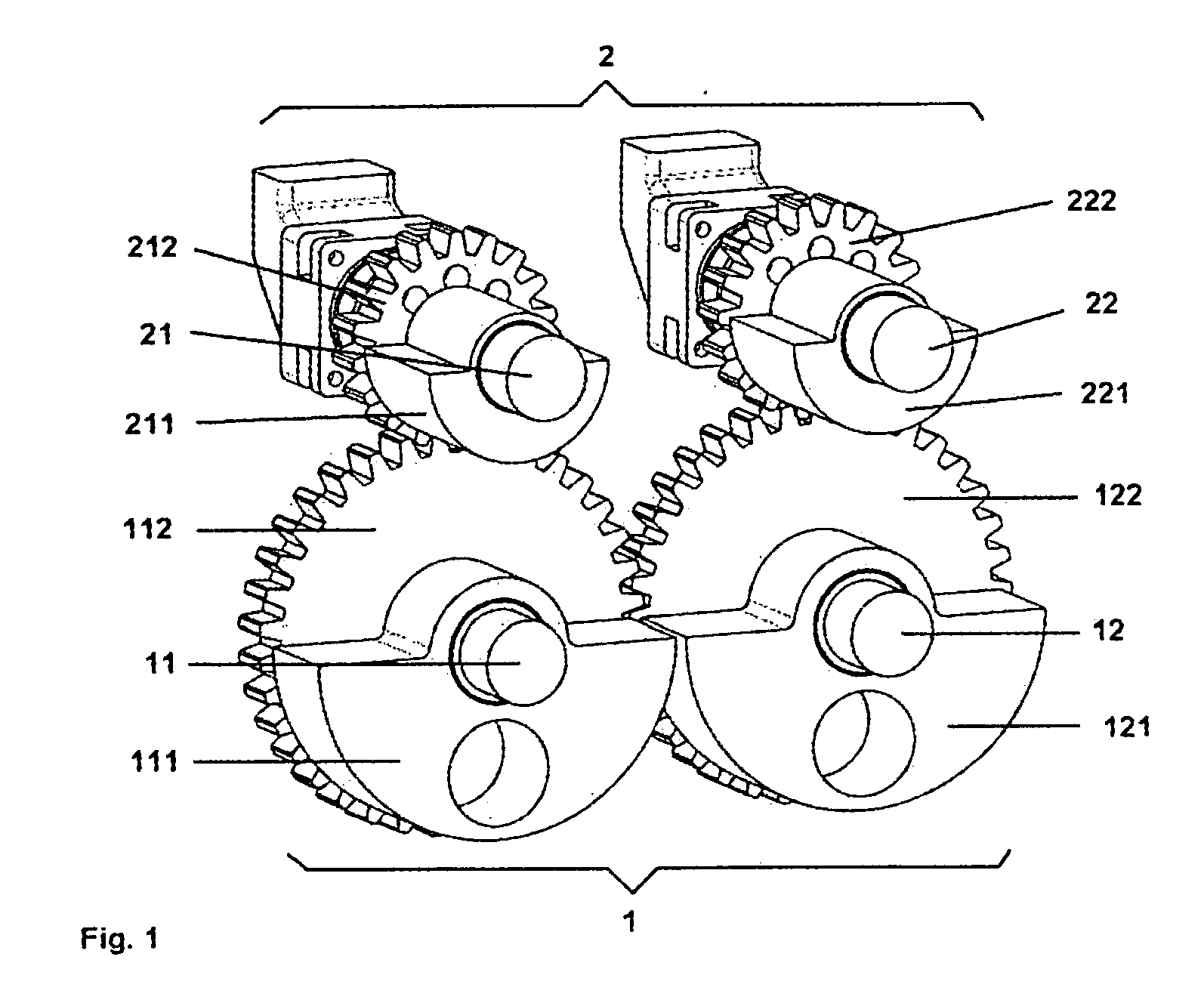

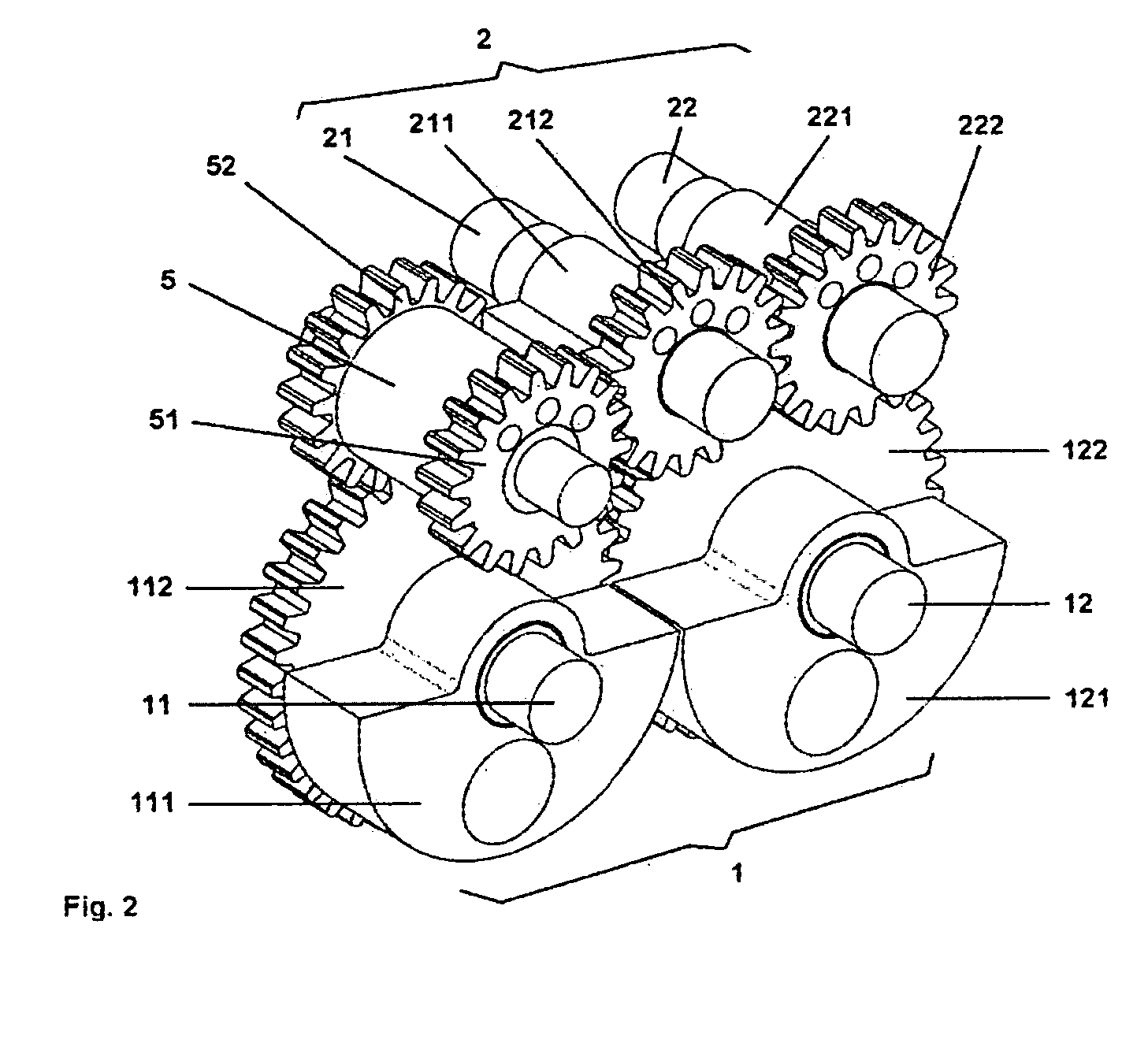

Vibration generator

ActiveUS20090241704A1Direct effectPossible to adaptGearingMechanical vibrations separationEngineeringMechanical engineering

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

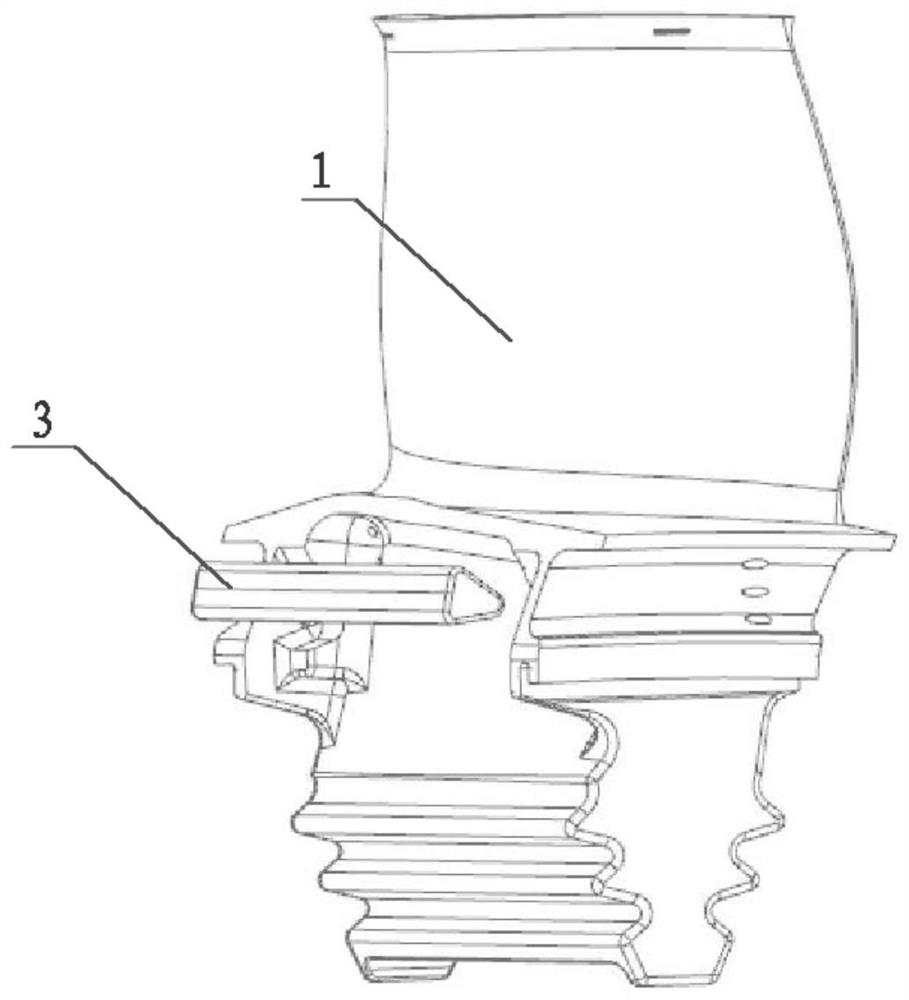

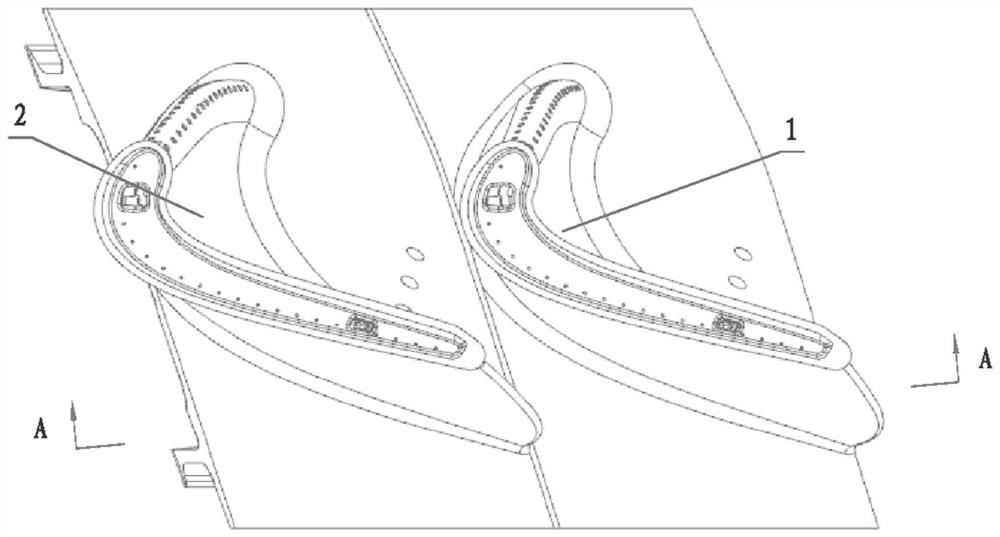

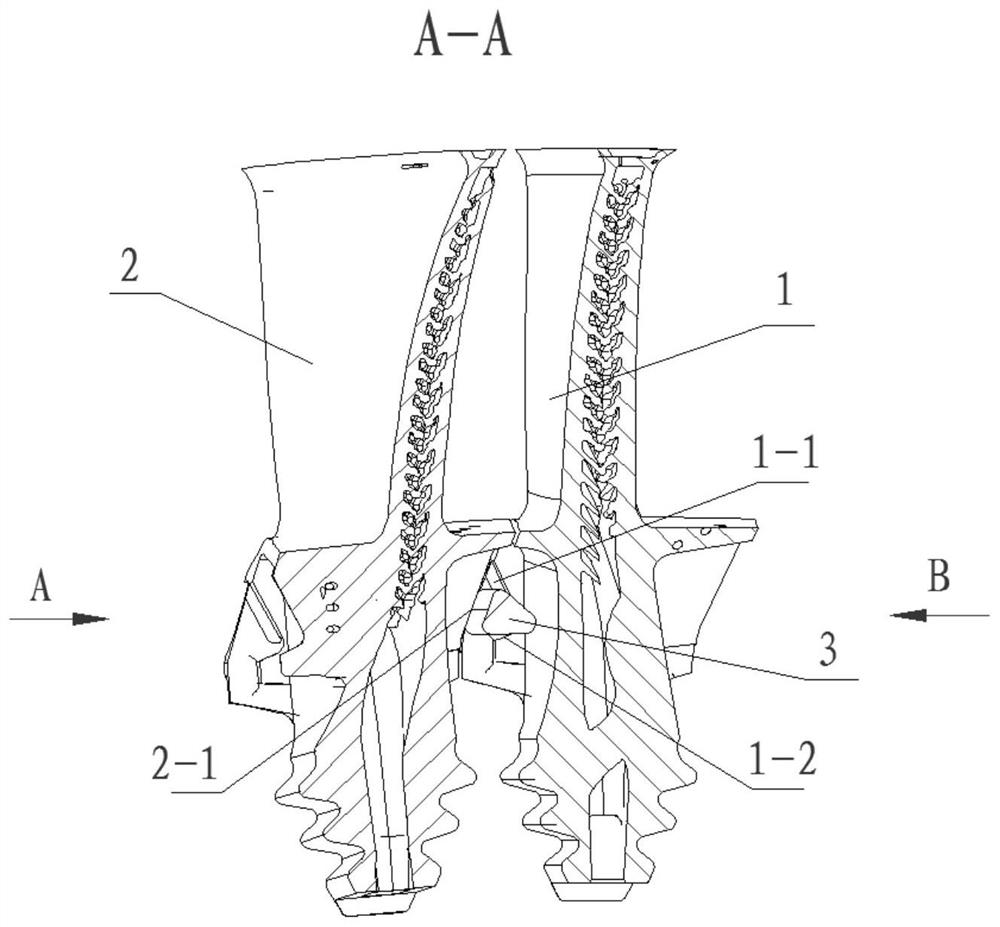

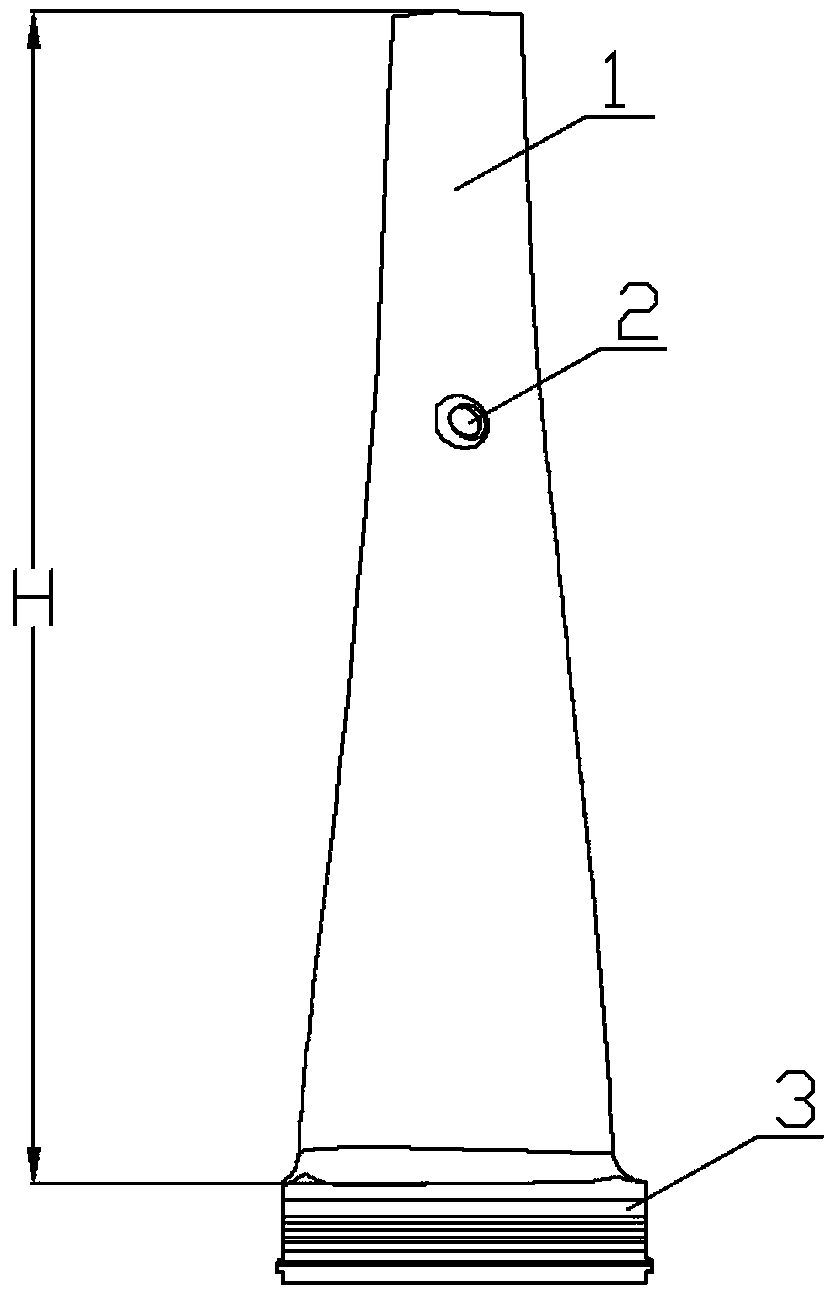

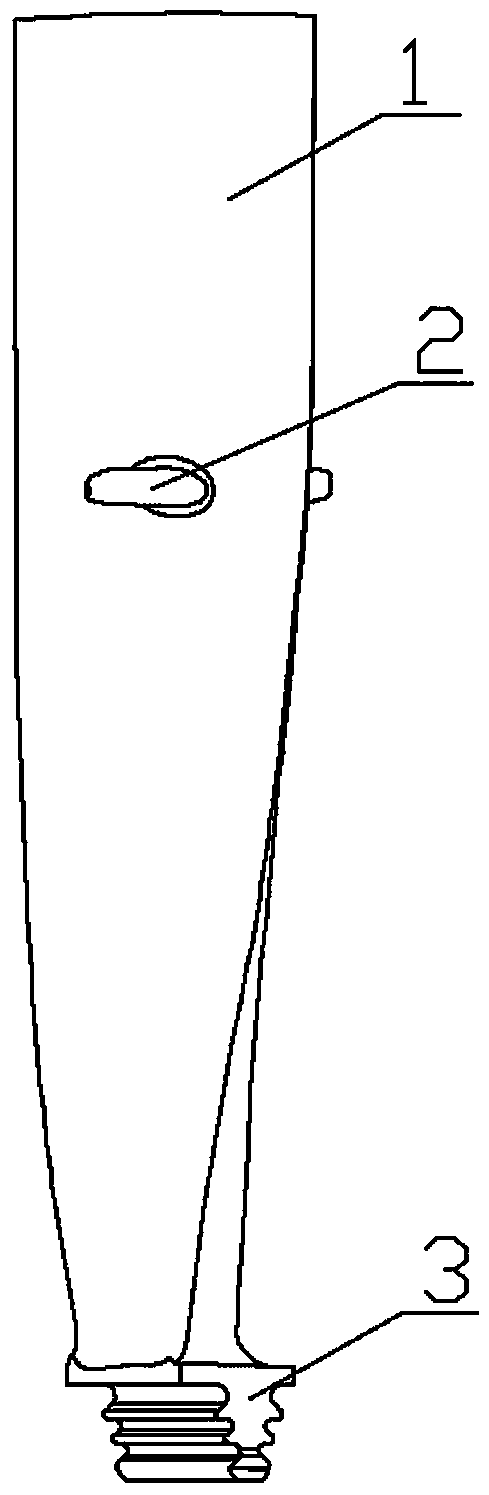

1300mm moving blade of final stage for full-rotary-speed steam turbine

ActiveCN102359397AIncrease stand-alone capacityImprove economyBlade accessoriesMachines/enginesAlloyEngineering

The invention discloses a 1300mm moving blade of the final stage for a full-rotary-speed steam turbine, and relates to a moving blade of the final stage for a full-rotary-speed steam turbine, and the moving blade is used for solving the problems of less length, small steam exhaust discharge area, great energy source consumption of the moving blade of the final stage for the full-rotary-speed steam turbine, and incapability of reaching higher economy requirement. A shroud, a blade operation part and a blade root are subjected to die forging integrally from top to bottom; a boss tie piece is positioned at the middle part of the blade operation part, and is integrated with the blade operation part; a stelite alloy sheet is sticked to the steam inlet side at the upper part of the blade operation part; the height of the blade operation part is 1300mm, the axial width of the root part is 346.62mm, the diameter of the root part is 1850mm, the steam exhaust area of the blade operation part is 12.86m<2>, and the axial width of the blade root is 400mm. The moving blade of the final stage provided by the invention is used for the full-rotary-speed steam turbine with the power between 600MW and 1000MW.

Owner:HARBIN TURBINE +1

Diffuser pipe for a gas turbine engine and method for manufacturing same

A diffuser pipe for a gas turbine engine comprises a hollow pipe body including a first end, a second end fluidly connected to the first end, and at least one flattened area proximate to the second end. A ring is connected to the second end. The ring is an outlet of the diffuser pipe. At least one stiffener is disposed on the at least one flattened area. The ring and the at least one stiffener reduce vibratory stresses at the second end of the pipe body. A method of manufacturing a diffuser pipe of a gas turbine engine is also presented.

Owner:PRATT & WHITNEY CANADA CORP

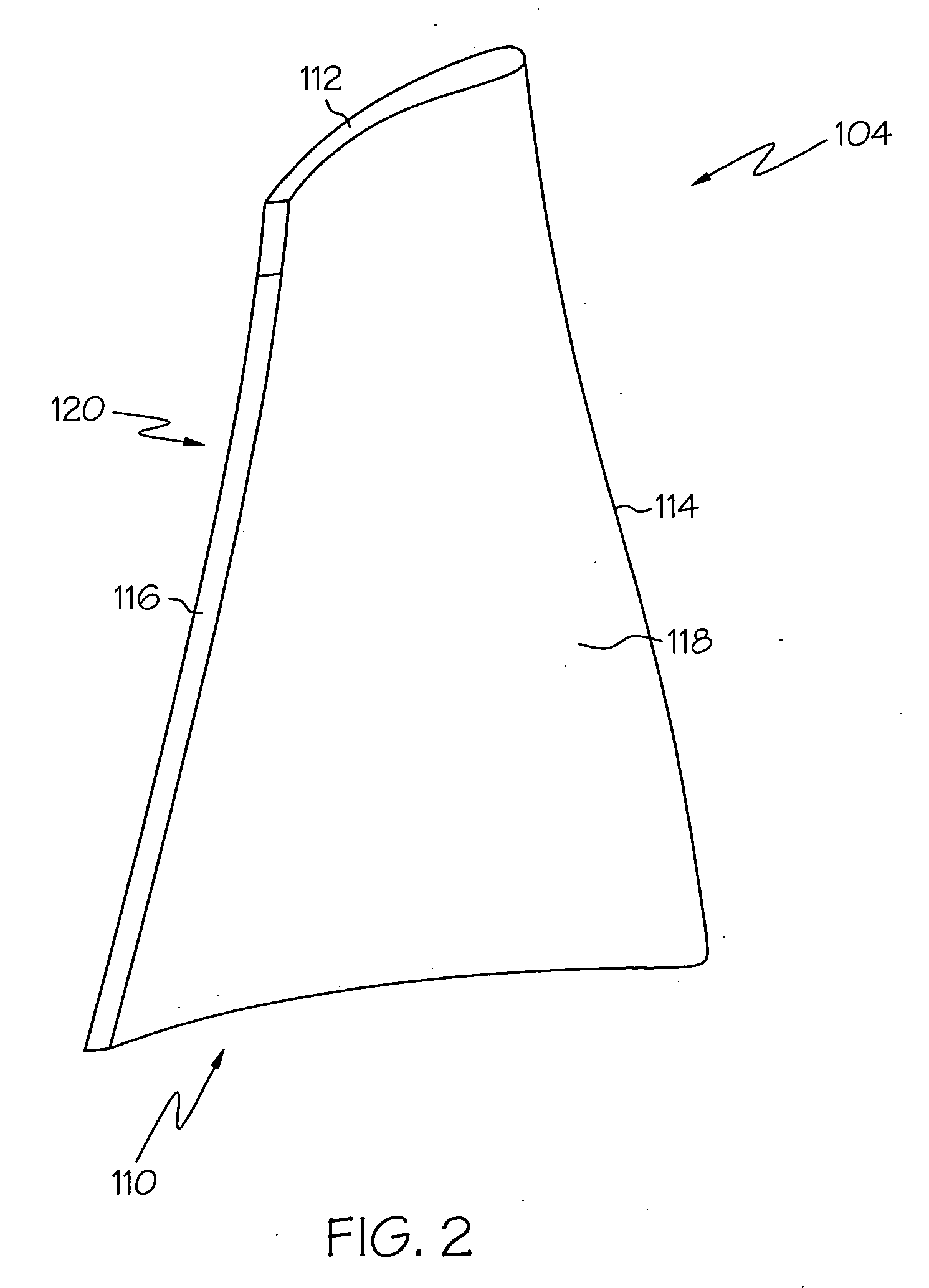

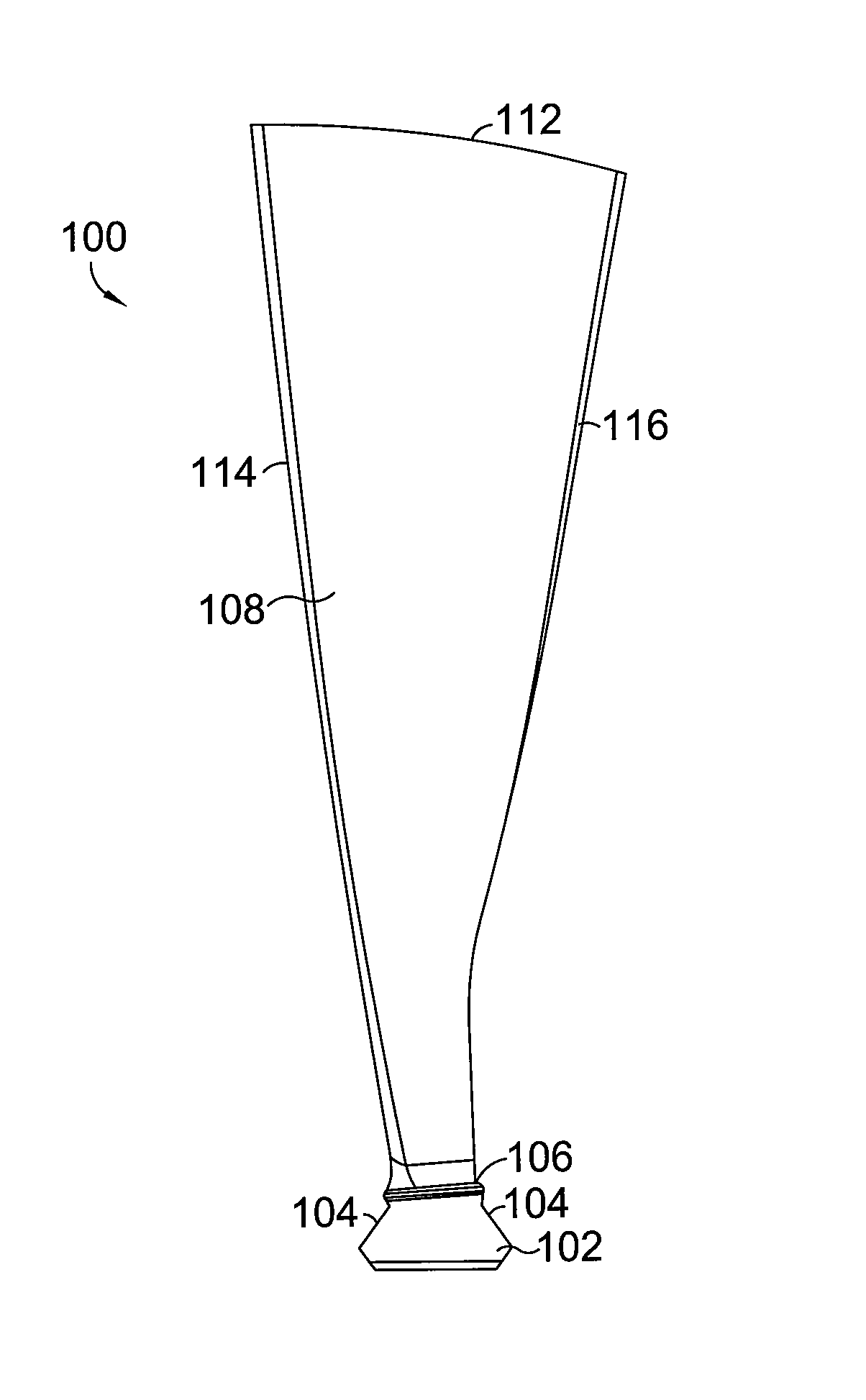

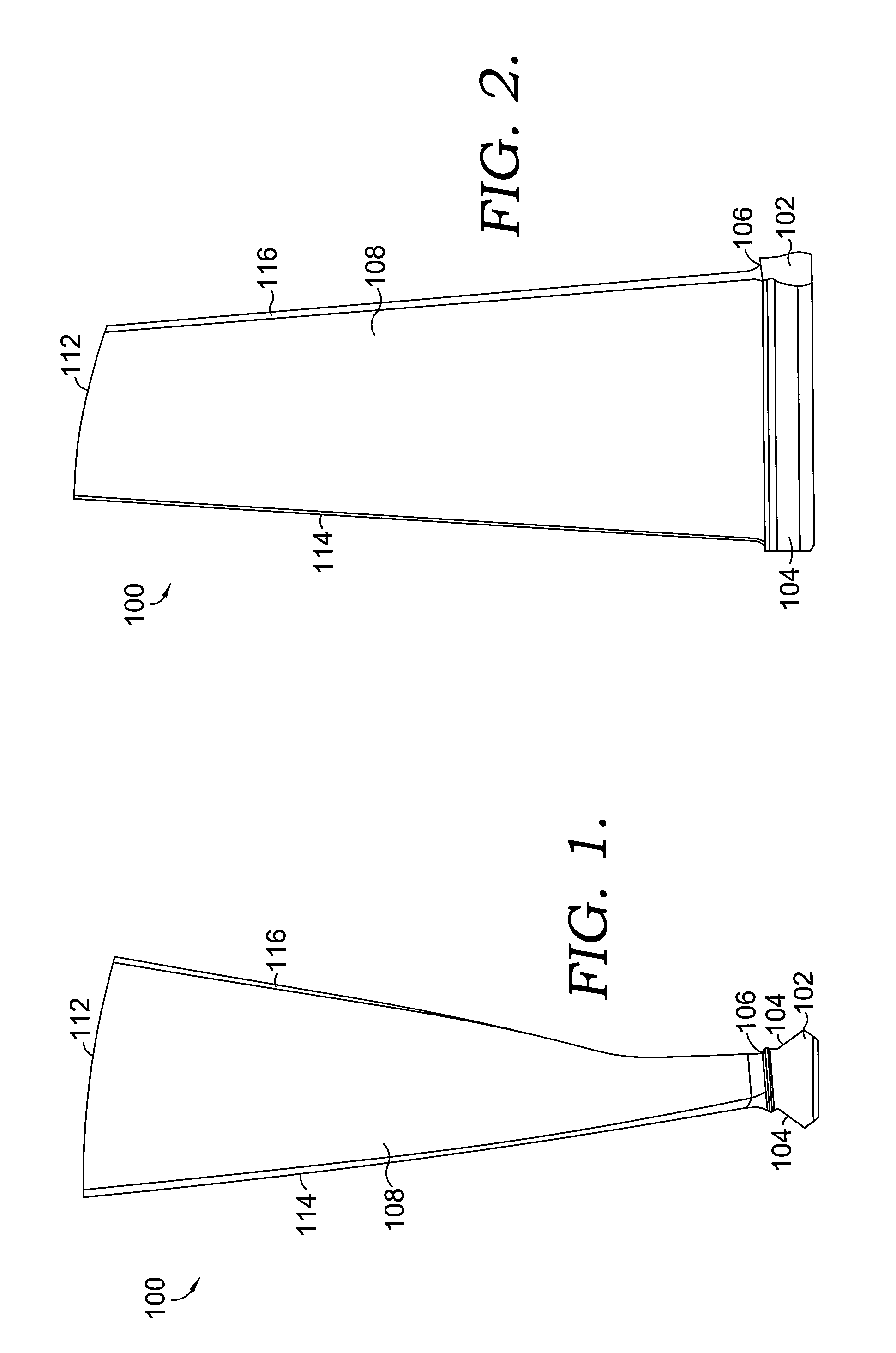

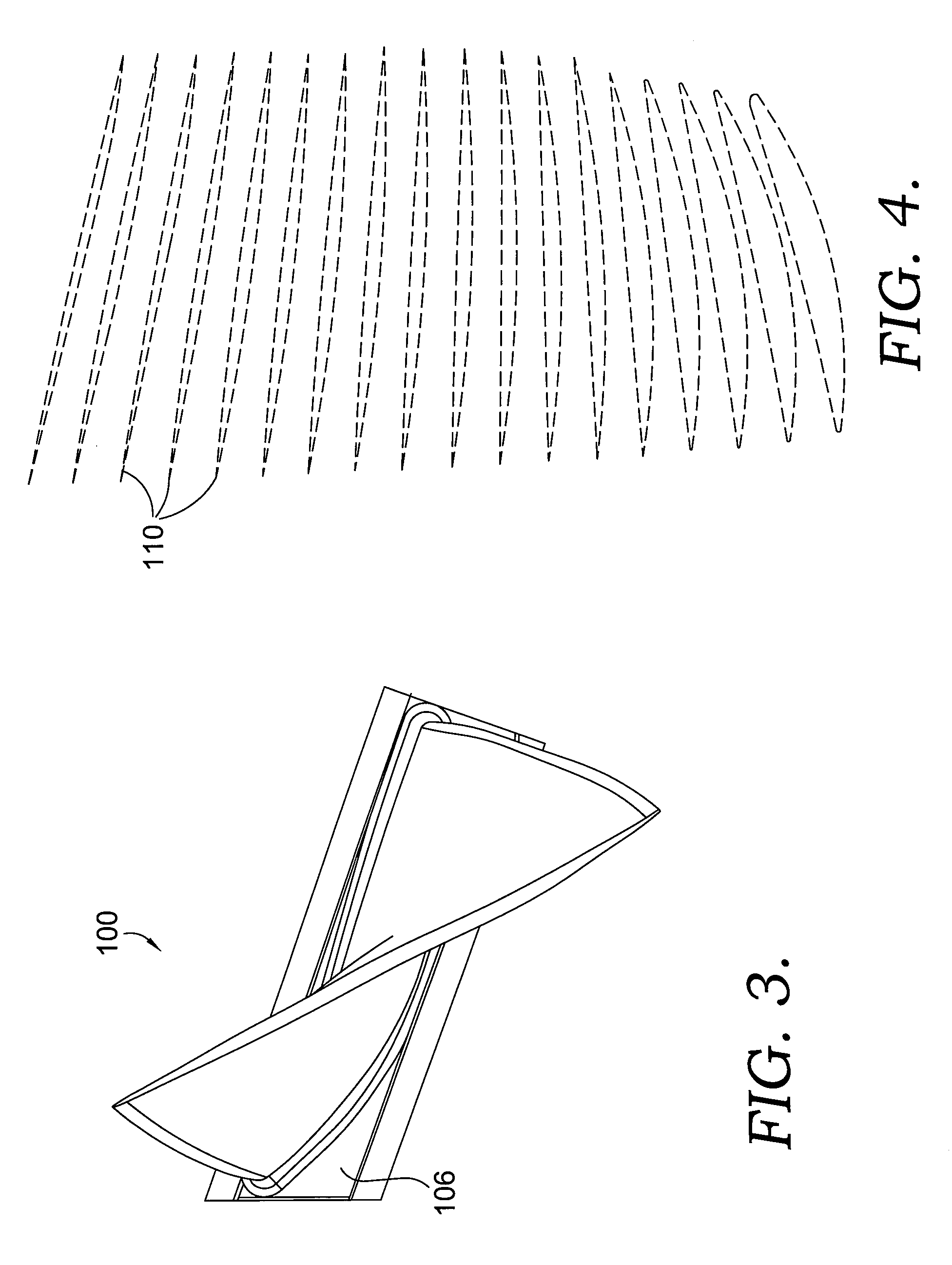

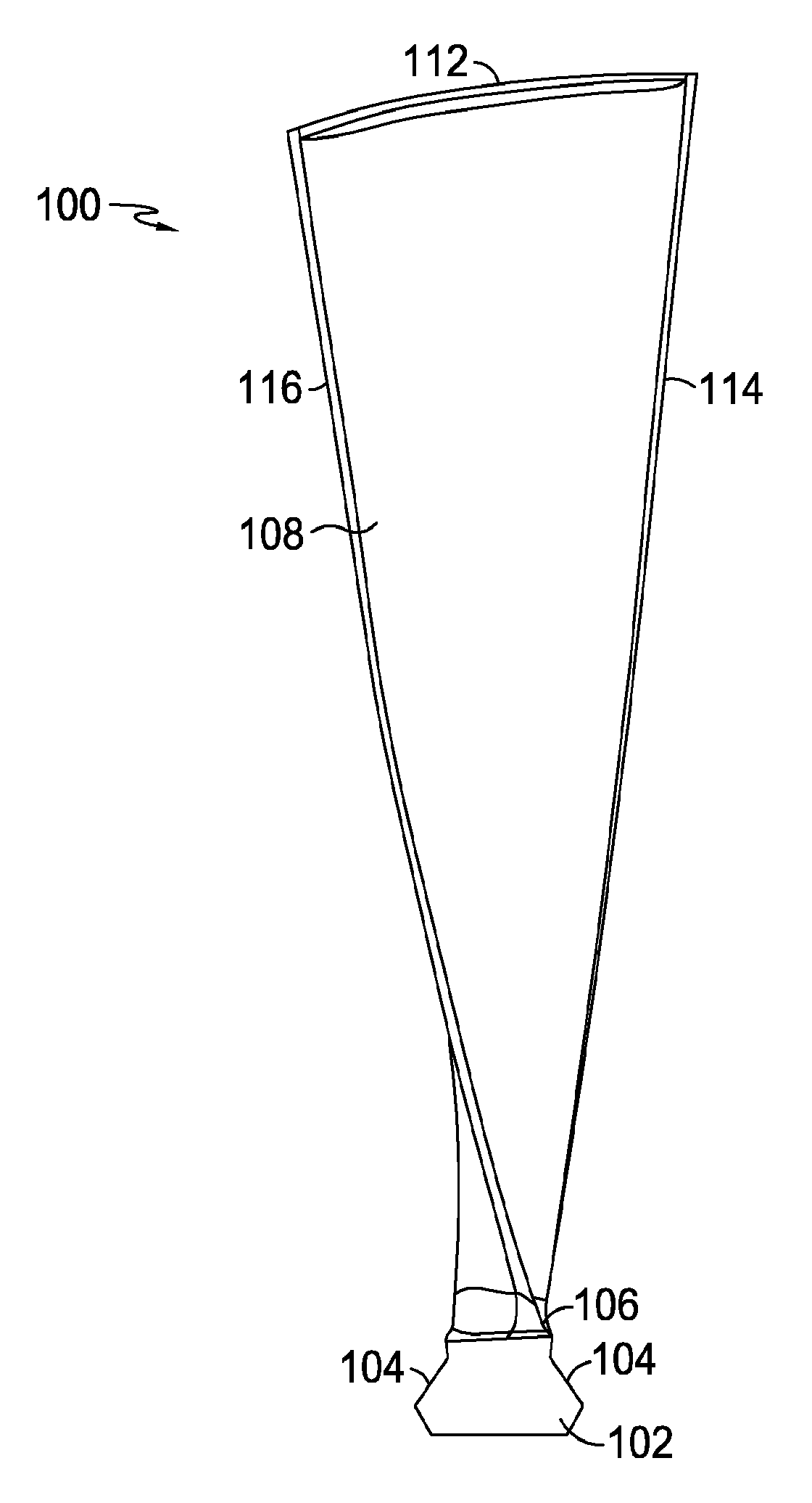

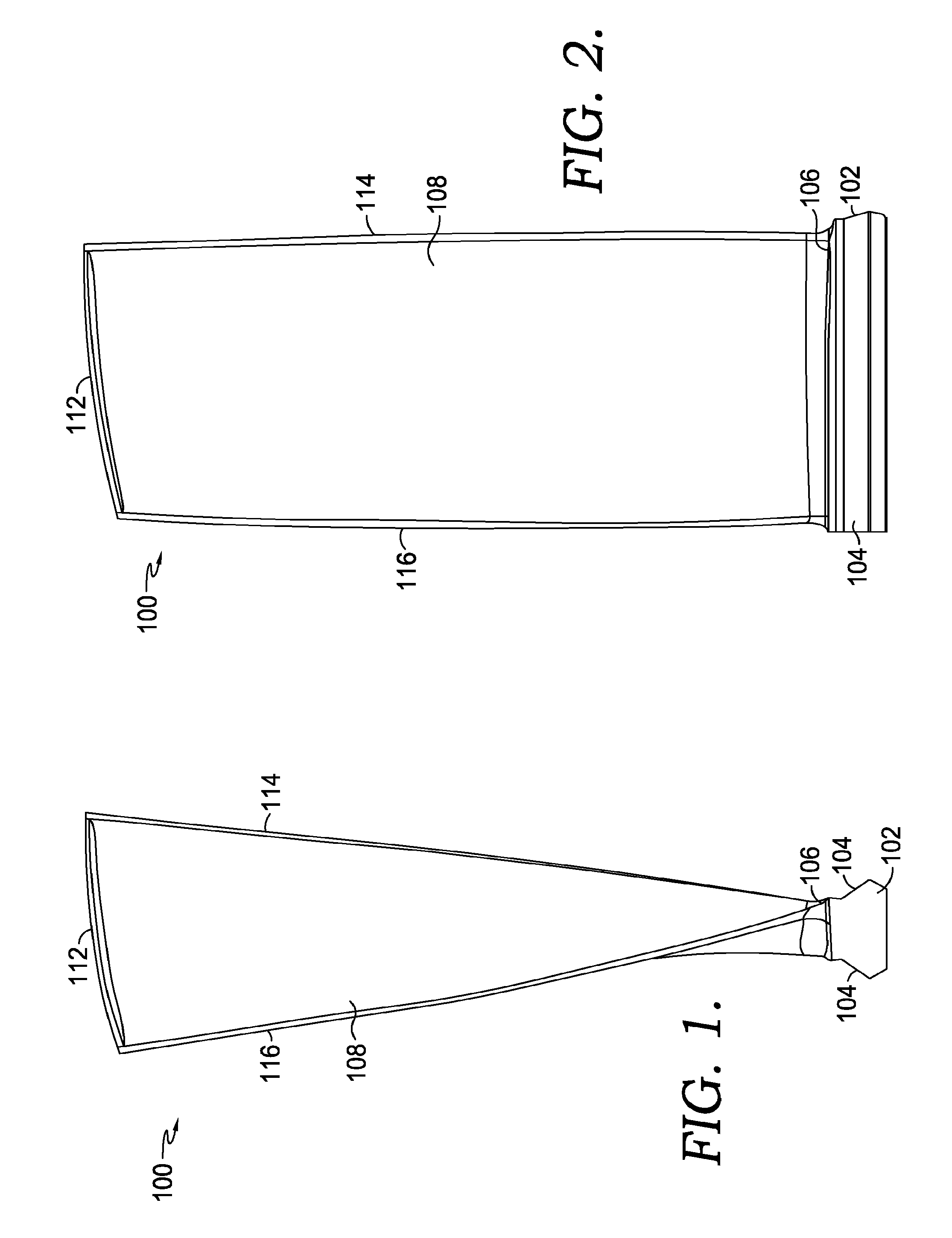

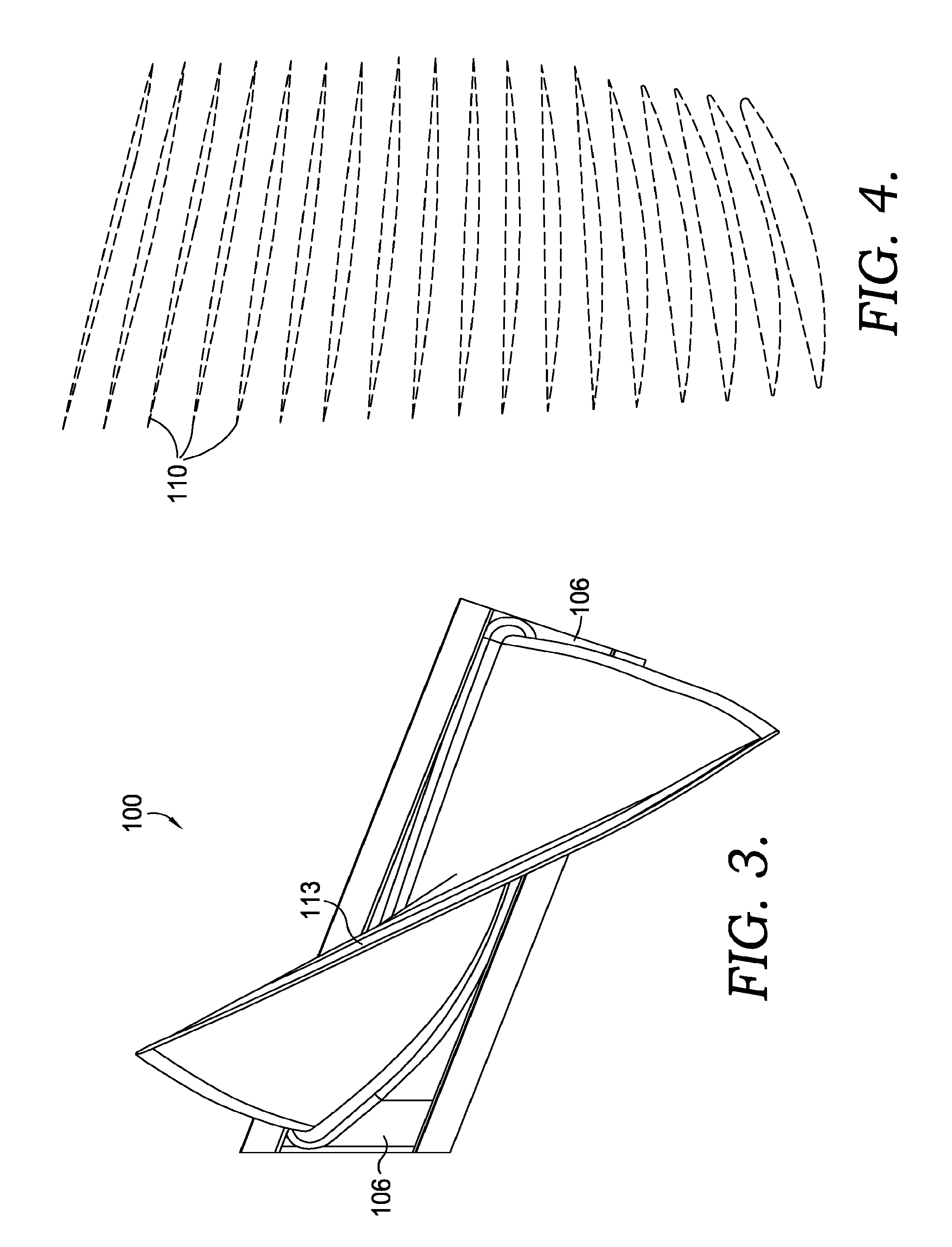

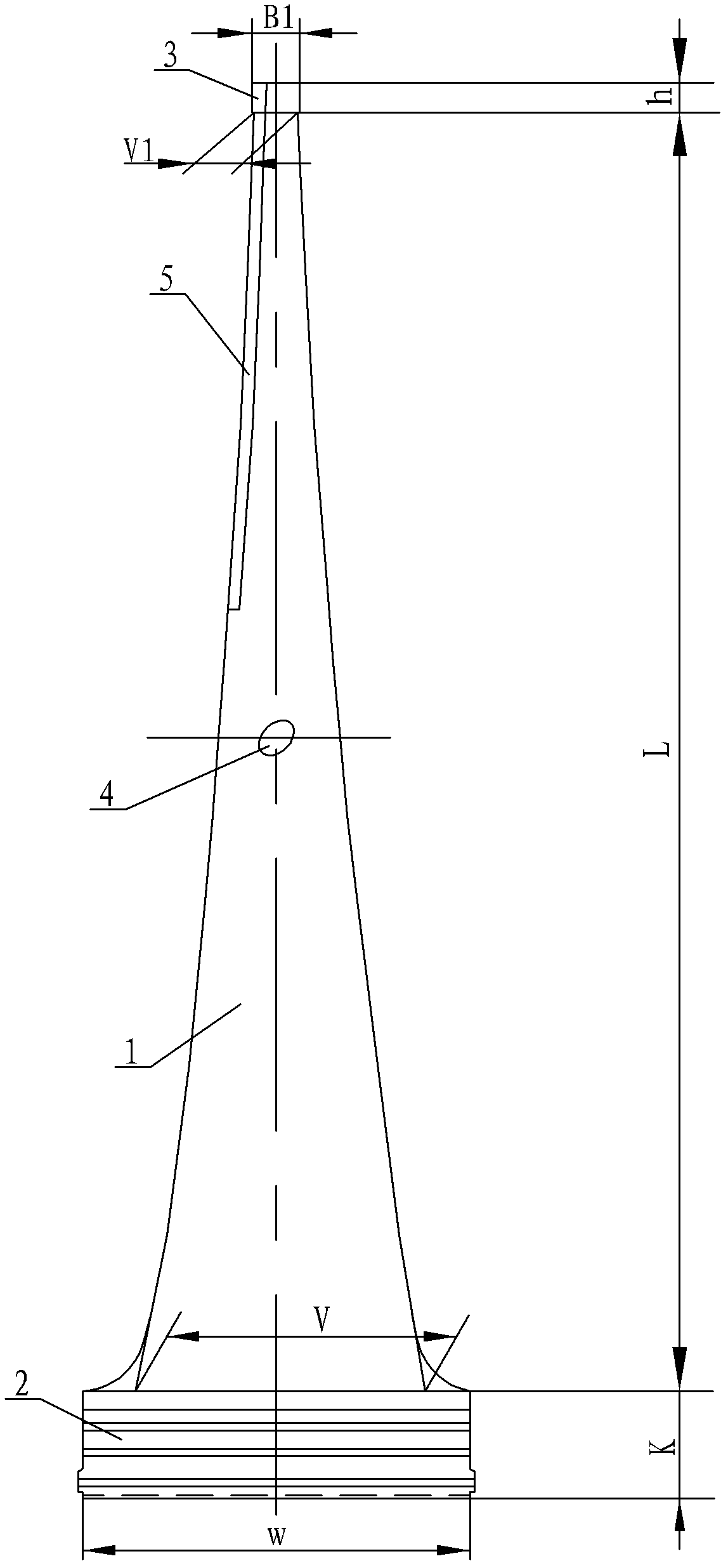

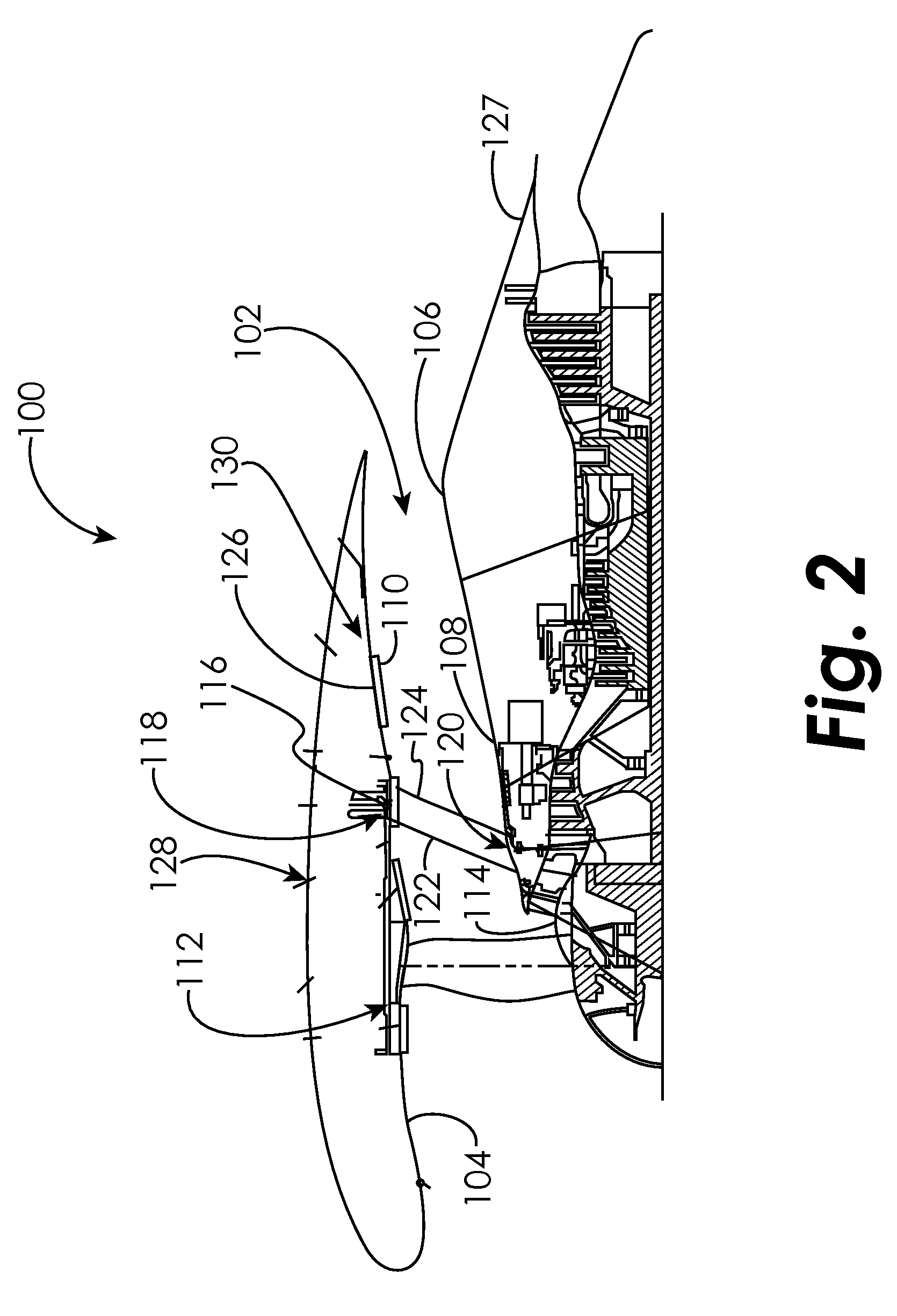

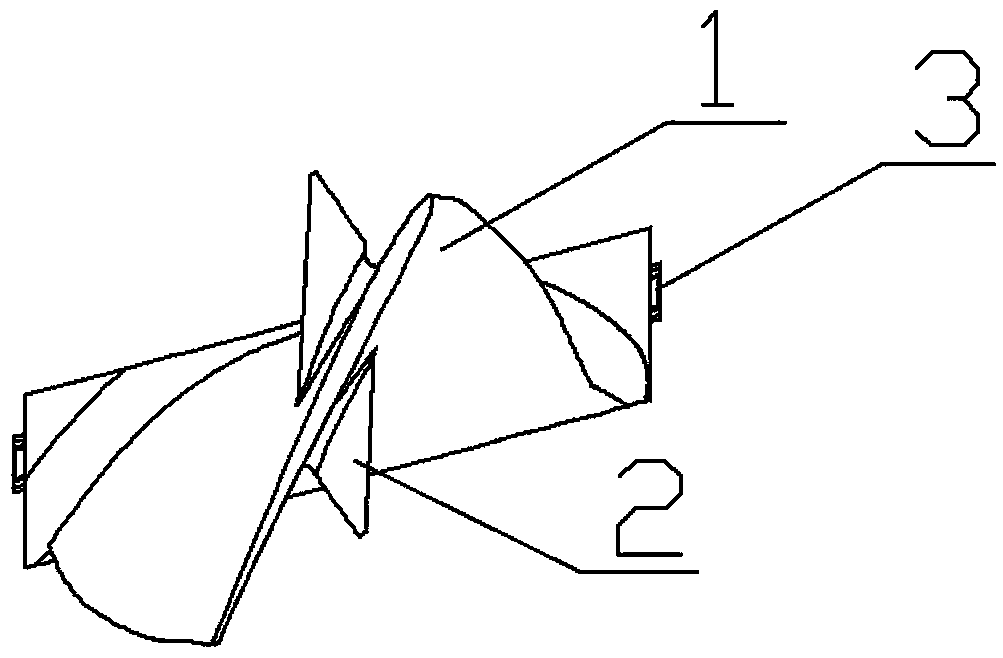

Wind turbine blade and blade hub

InactiveUS20150086366A1Reduces torque ripple driven vibration stressLittle strengthPropellersPump componentsTurbine bladeThinning skin

Four blade VERTICAL AXIS WIND TURBINE is disclosed. Four equally radially spaced fixed troposkein shaped rotor blades nearly eliminates rotor torque ripple. Reduced rotor torque ripple allows thinner skin hollow cross section blades that are lighter and have higher frequency and lower stress natural vibrations. Improved single length blade extrusion has two integral mounting flanges at each of two root ends. One blade root flange is adjoined to the blade nose tip through a blade skin thickening gusset rail. One blade root flange is adjoined to the blade tail tip through a second blade skin thickening gusset rail. A third blade root flange forms a largely rectangular hollow between the two mounting flanges and the blade skin.A separable rectangular cross section blade hub is made from two hollow rectangular L-shaped cross section extruded beams. These L-shaped beams are cut from a single extrusion.

Owner:BARNES ROBERT JEFFREY

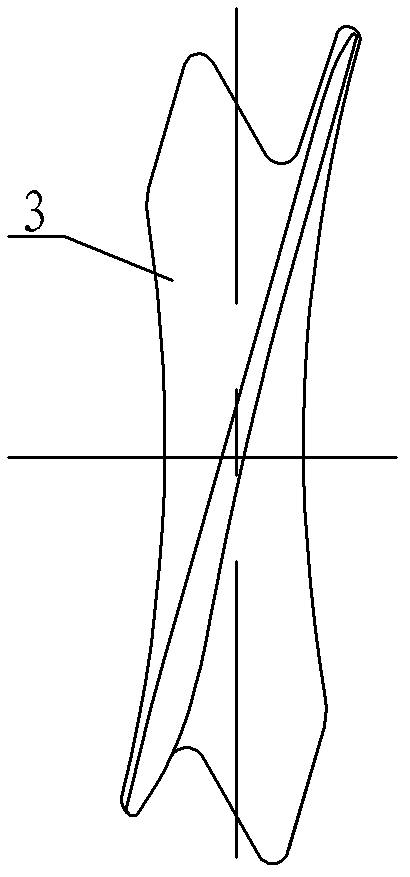

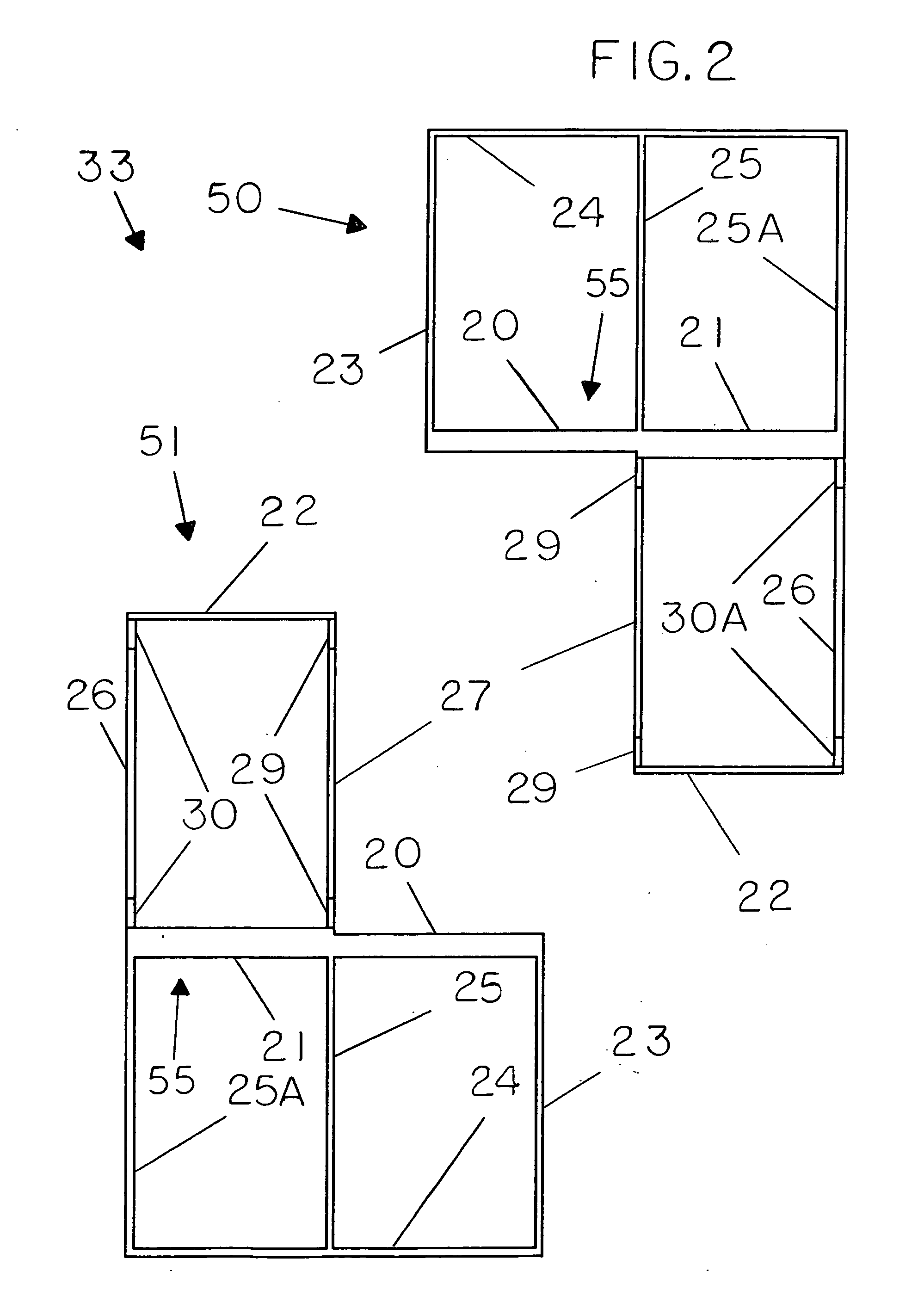

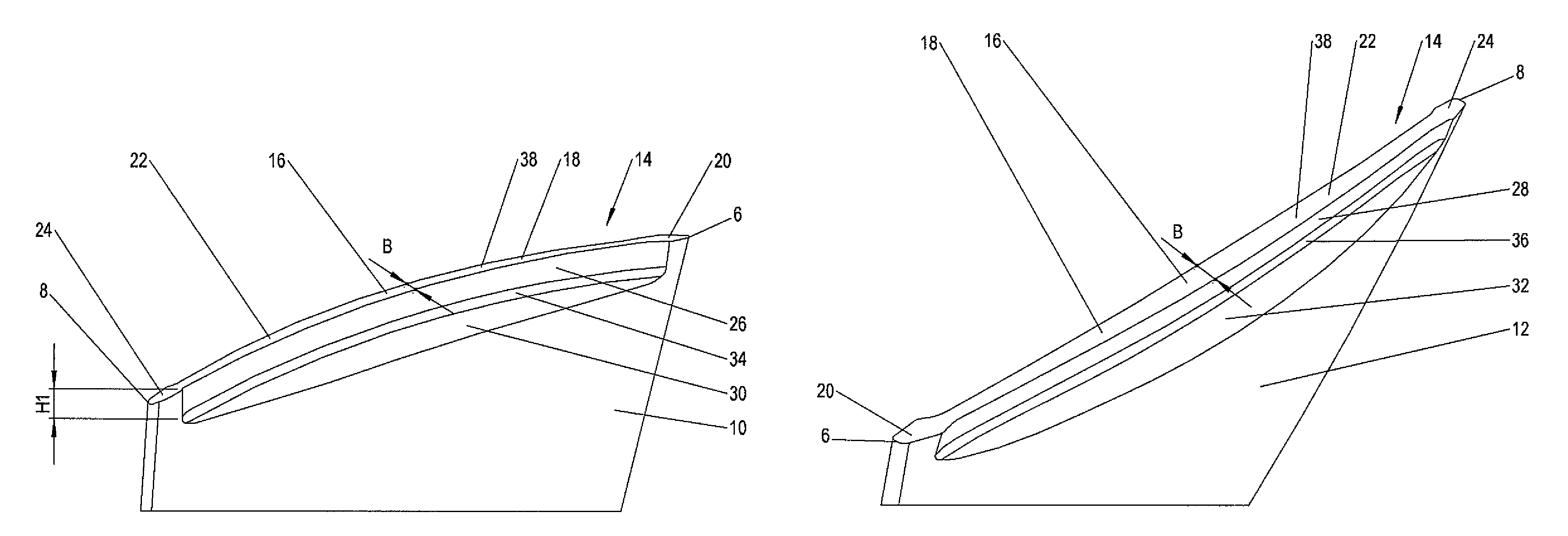

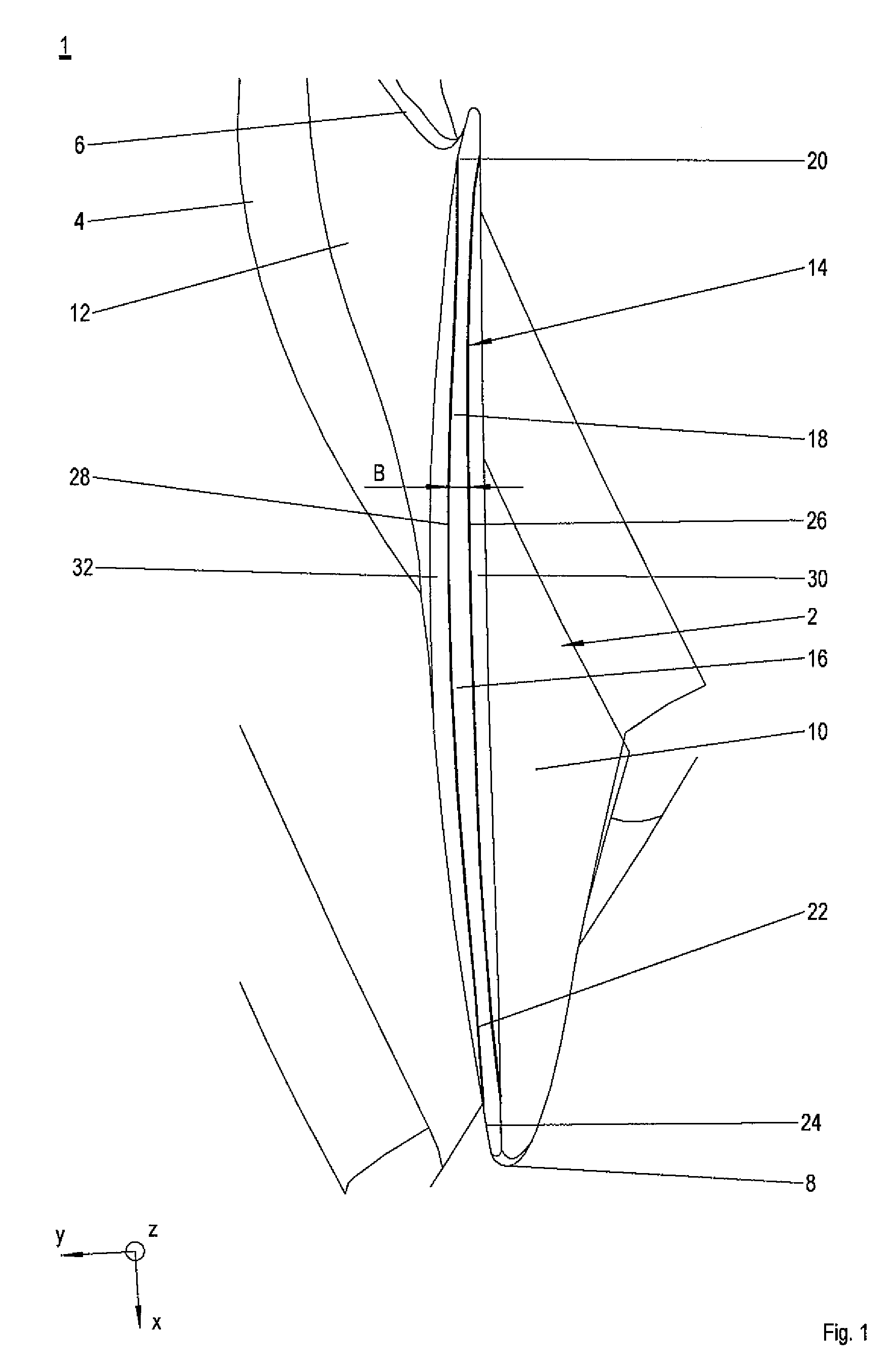

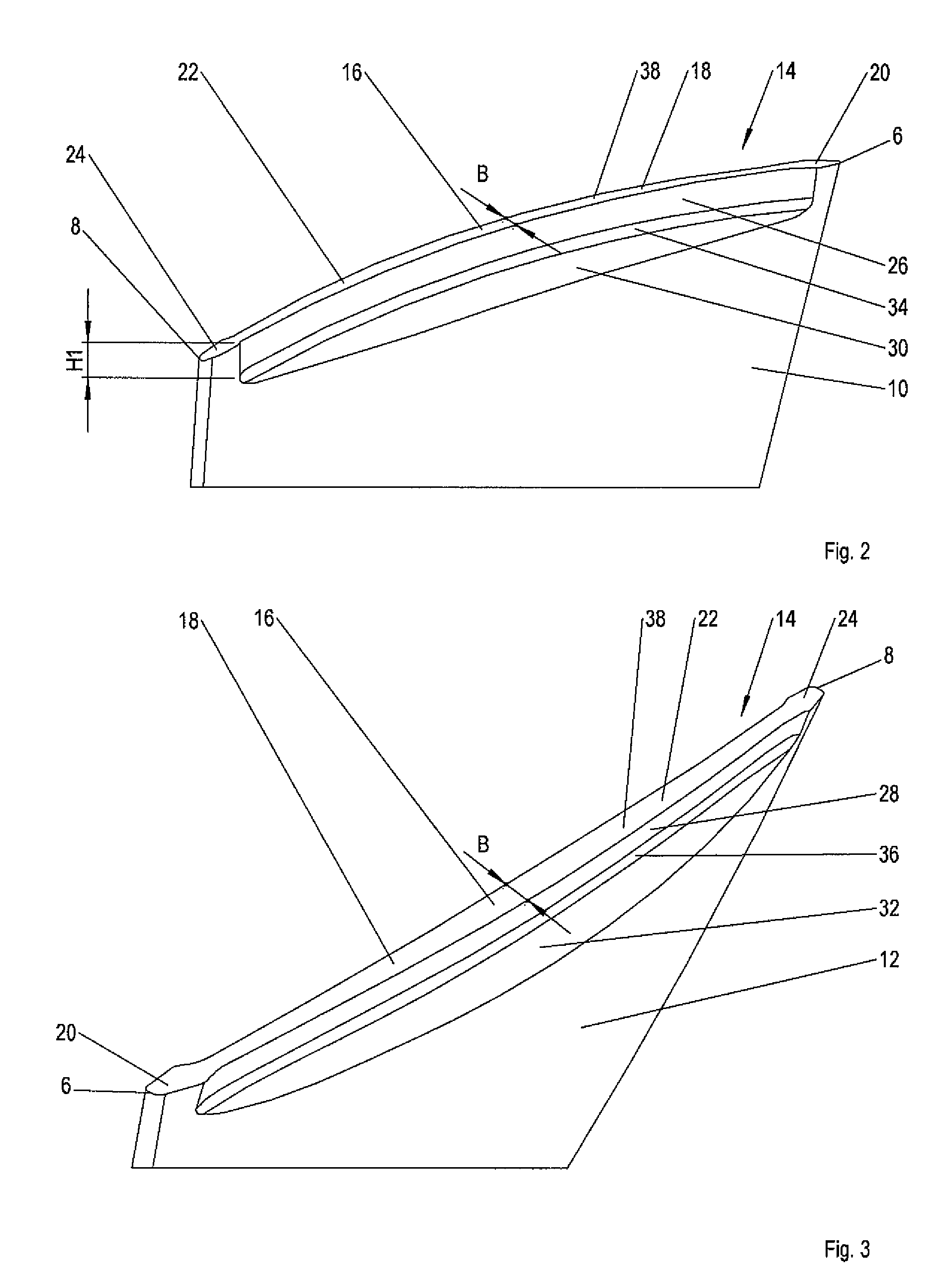

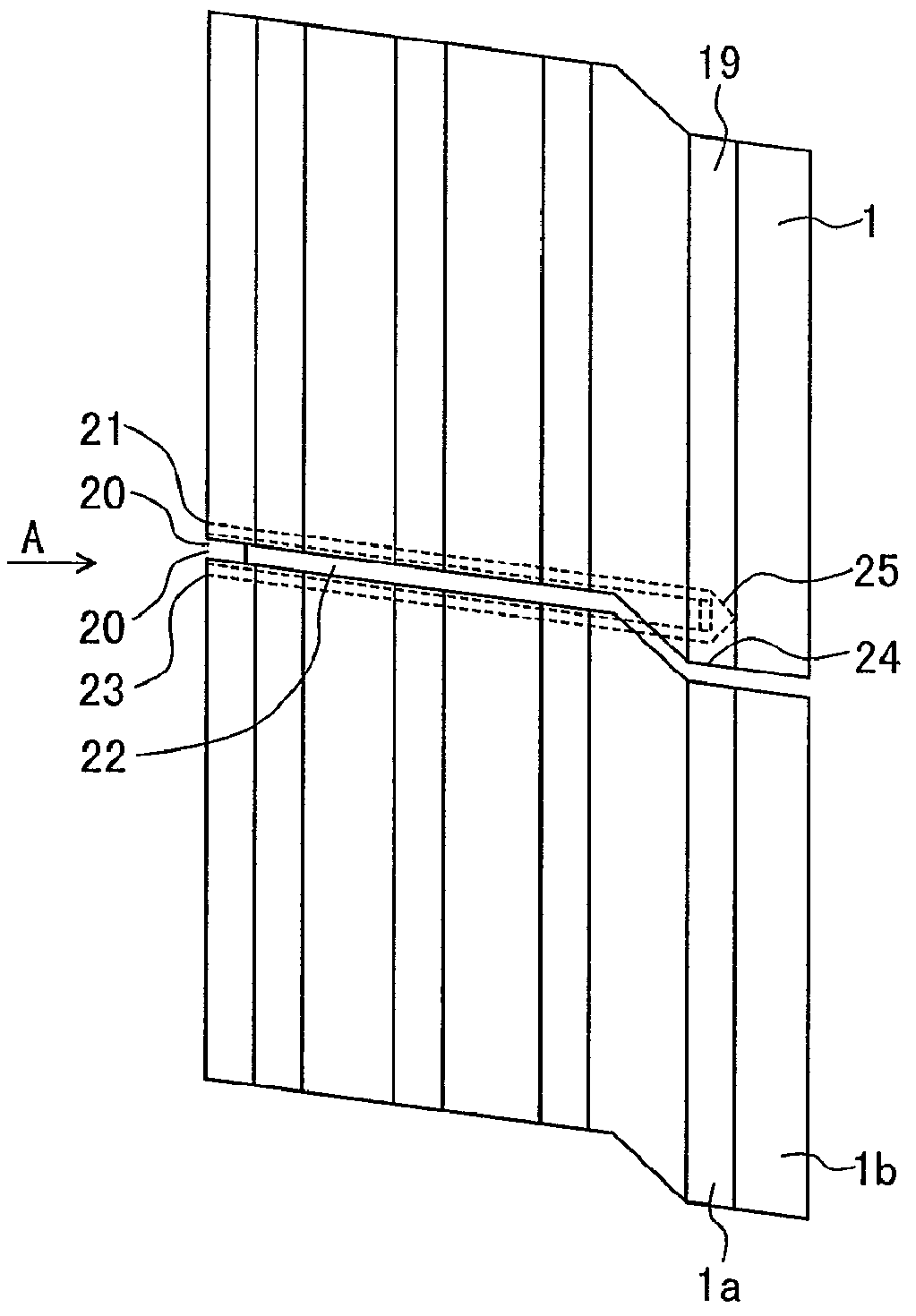

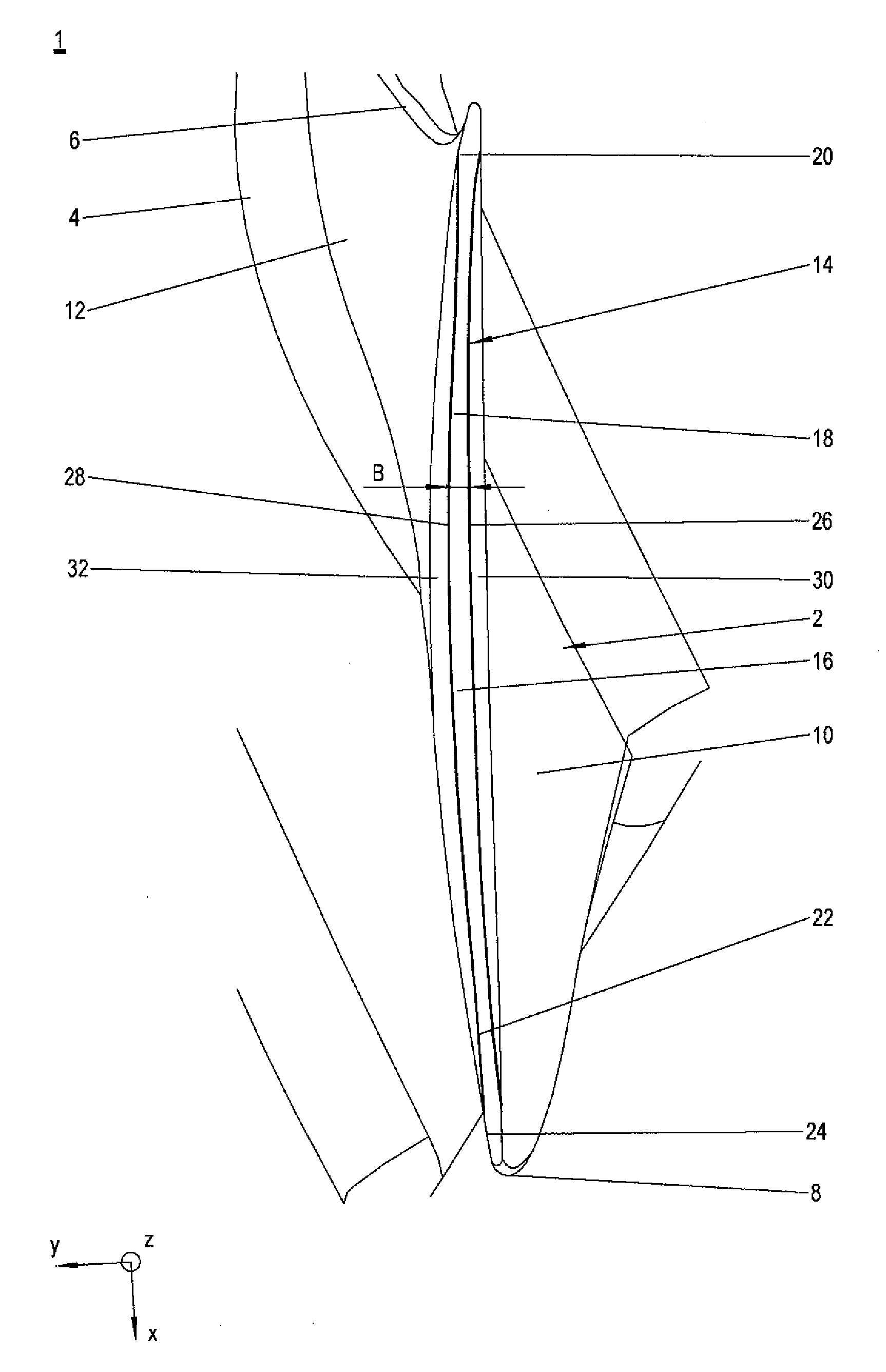

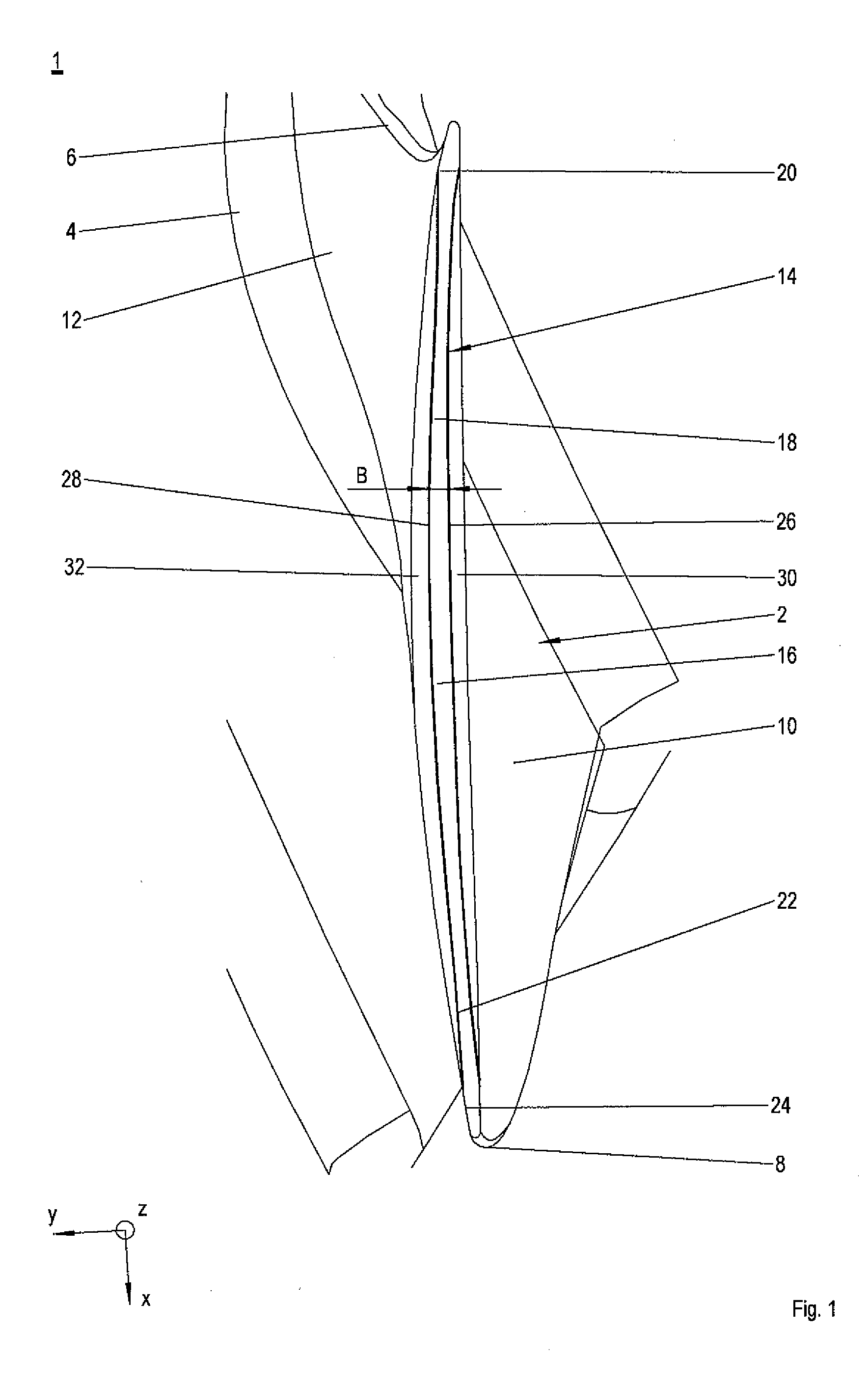

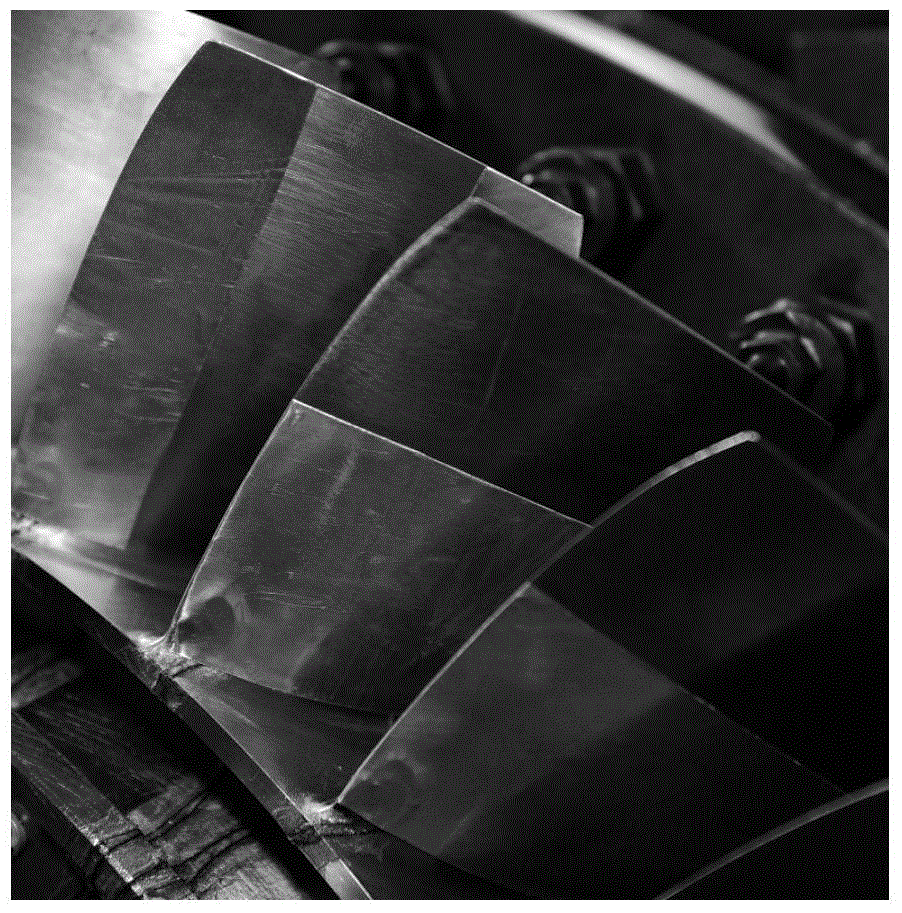

Blade for a continuous-flow machine and a continuous-flow machine

ActiveUS9399918B2Reduce vibration stressEffective reduction of vibrational stresses in the area of the blade tipPump componentsBlade accessoriesLeading edgeEngineering

A blade for a continuous-flow machine is disclosed, especially an aircraft engine, whereby, starting from the middle section, the cross section of the blade tip is reduced with respect to the middle section, at least over a front partial section in the direction of the leading edge and over at least a rear section in the direction of the trailing edge, and a continuous-flow machine having at least one row of blades including such blades is also disclosed.

Owner:MTU AERO ENGINES GMBH

Steam turbine rotor blade assembly

ActiveUS8257044B2Reduce vibration stressHigh positioning accuracyPropellersRotary propellersEngineeringSteam turbine rotor

The present invention is a steam turbine rotor blade assembly including: an airfoil; a shroud provided at a tip of the airfoil; a blade root (dovetail) projecting toward a radially internal circumferential side of a turbine rotor and fitted to a root attachment provided on an outer circumferential portion of the turbine rotor; a platform provided between the airfoil and the blade root; a pin provided between the blade root and the root attachment; a bore formed between respective surfaces of the shrouds facing each other and included in the respective adjacent rotor blades; and a bar-like member provided in the bore.

Owner:MITSUBISHI POWER LTD

Blade for a continuous-flow machine and a continuous-flow machine

ActiveUS20140044553A1Improve stress conditionExtended service lifePropellersRotary propellersLeading edgeEngineering

A blade for a continuous-flow machine is disclosed, especially an aircraft engine, whereby, starting from the middle section, the cross section of the blade tip is reduced with respect to the middle section, at least over a front partial section in the direction of the leading edge and over at least a rear section in the direction of the trailing edge, and a continuous-flow machine having at least one row of blades including such blades is also disclosed.

Owner:MTU AERO ENGINES GMBH

Liner for a gas turbine engine

ActiveUS20160327064A1Reduce vibration stressEngine manufacturePump componentsAerospace engineeringGas turbines

A gas turbine engine is provided having a fan case and a translating sleeve positioned downstream from the fan case. A flow channel extends between the fan case and the translating sleeve. The flow channel includes an inner diameter and an outer diameter. A structural guide vane is positioned within the flow channel and extends from the inner diameter to the outer diameter. A liner is positioned between an aft end of the fan case and an aft end of the translating sleeve to reduce vibratory stress on the structural guide vane.

Owner:RAYTHEON TECH CORP

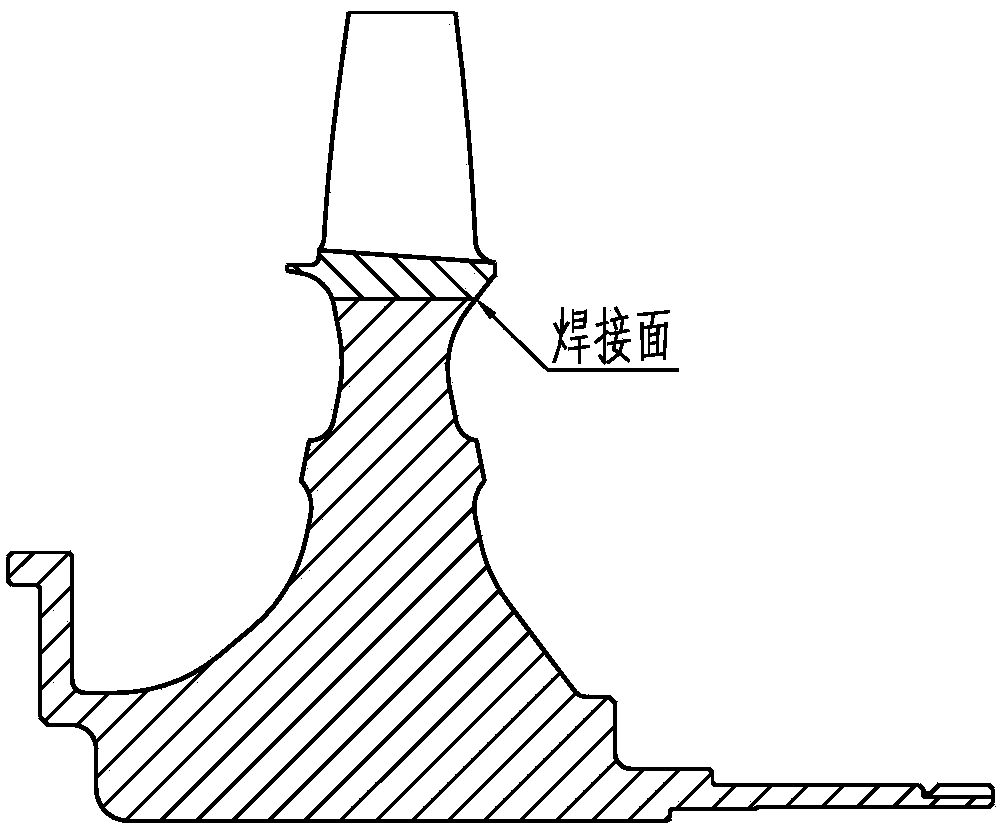

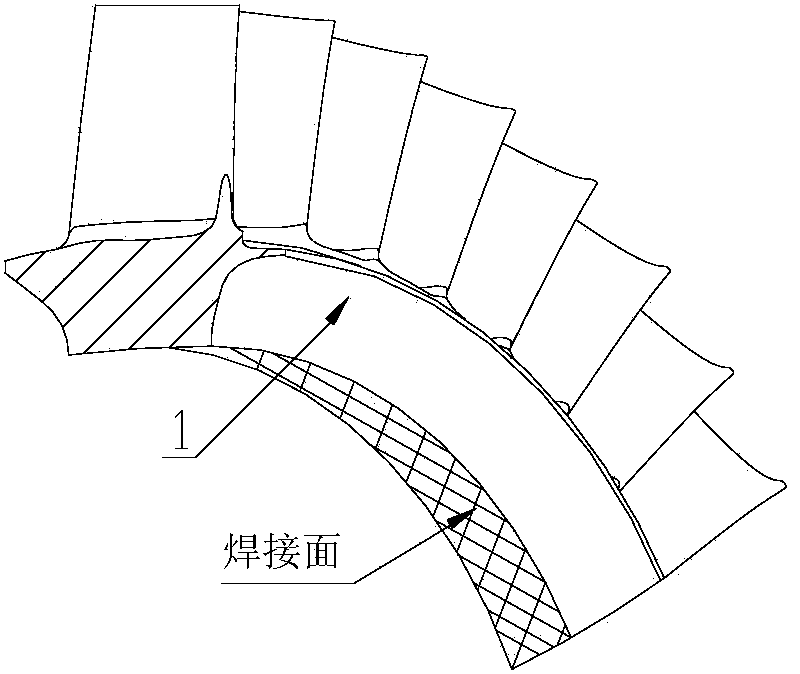

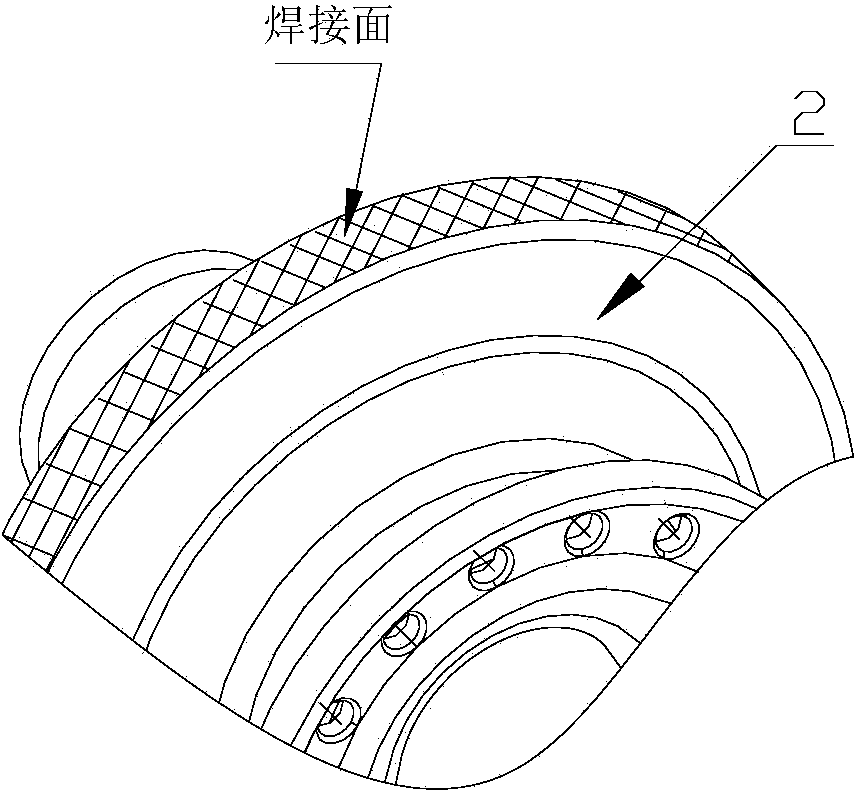

Anti-vibration type dual-alloy turbine blisk and manufacturing method thereof

InactiveCN104191184AHigh temperature durable creep performanceChange the stiffnessBlade accessoriesMachines/enginesTurbinePrecision casting

The invention belongs to turbine blisk technologies, and relates to an anti-vibration type dual-alloy turbine blisk and a manufacturing method thereof. The anti-vibration type dual-alloy turbine blisk is formed by welding a precision cast blade ring component and a sintered alloy blisk body in a diffusion mode through hot isostatic pressure, cut joints are formed between blade channels of the blisk, damping holes communicated with the cut joints are formed in the lower portion of the rim of the blisk, and friction dampers are arranged in the damping holes. The anti-vibration type dual-alloy turbine blisk is formed by welding the precision cast blade ring component and the sintered alloy blisk body in the diffusion mode through hot isostatic pressure, flexible selection and best usability matching of turbine disks and blades are achieved, meanwhile, the friction dampers are arranged on the blisk, the damping and vibration reducing effect is improved, the purposes of improving anti-fatigue ability of the blades and reducing vibration stress of the blades are achieved, and the anti-vibration type dual-alloy turbine blisk has great practical use value.

Owner:CHINA GAS TURBINE ESTAB

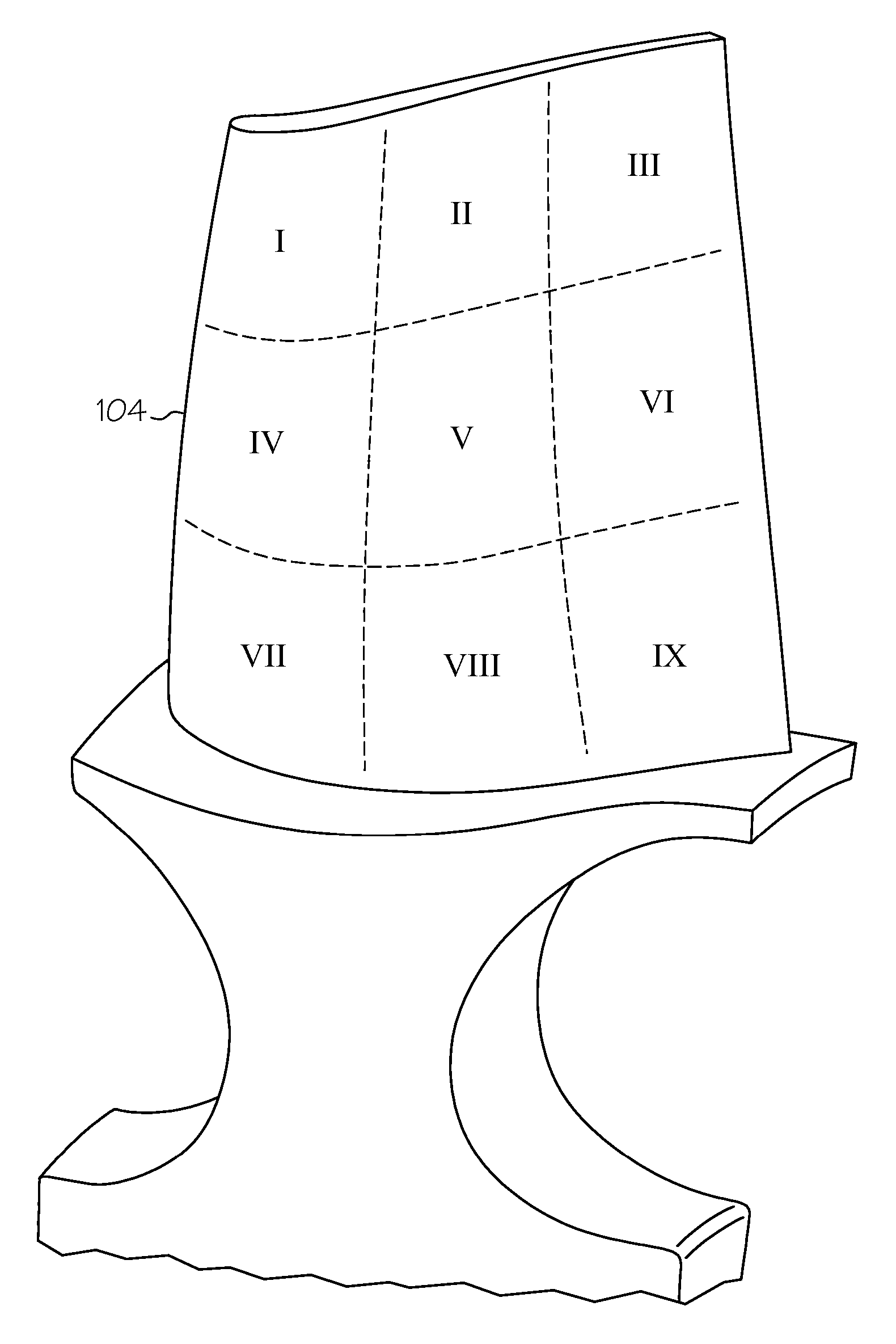

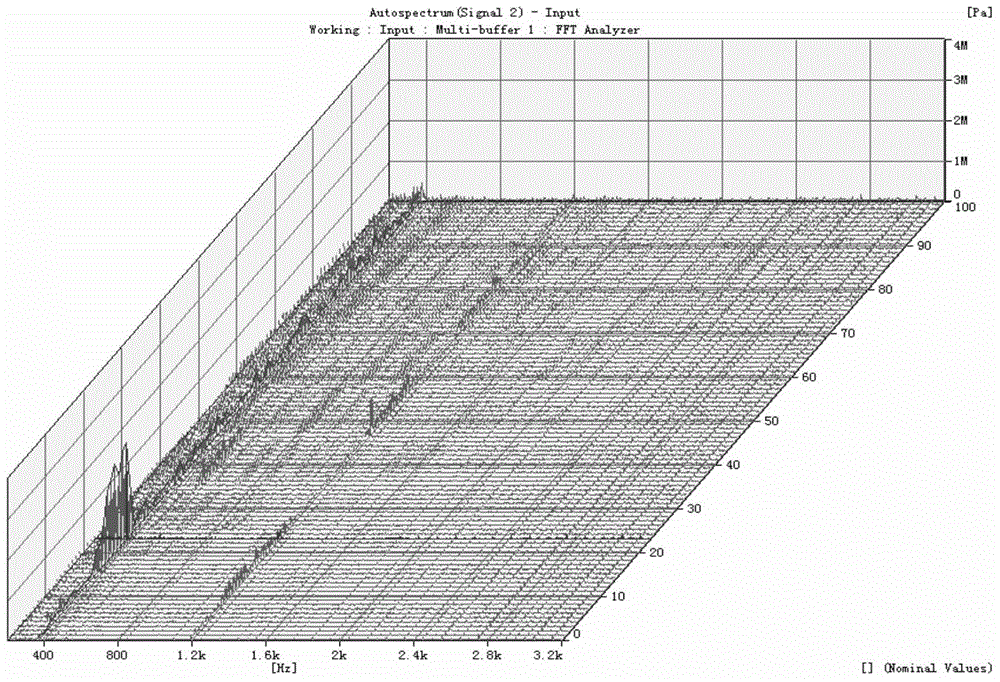

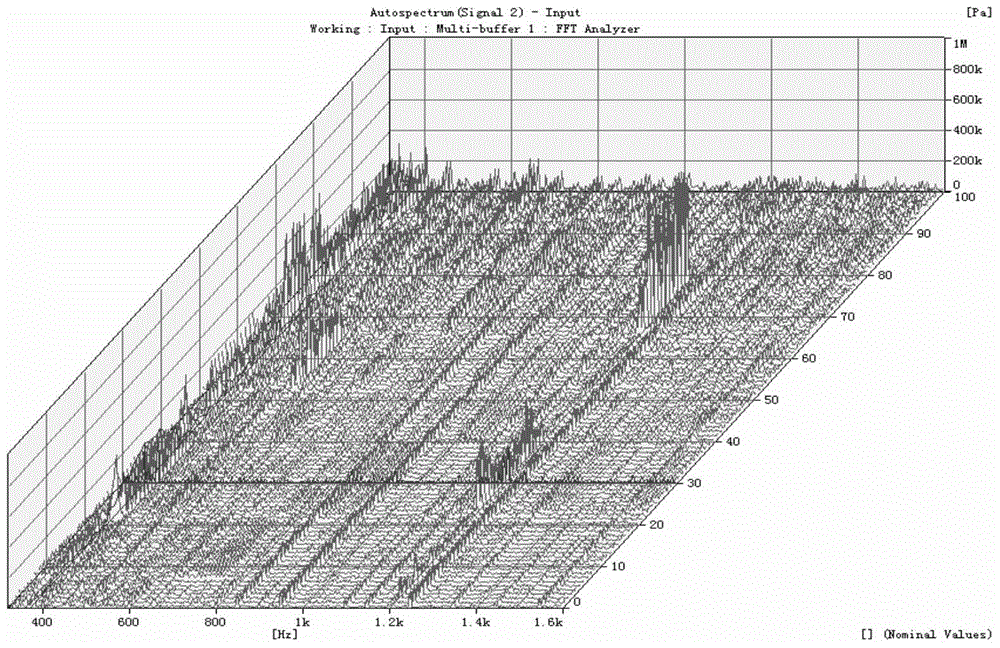

Frequency tailored thickness blade for a turbomachine wheel

InactiveUS20080014091A1Reduce impactReduce vibration stressBlade accessoriesEfficient propulsion technologiesComputational modelEngineering

A method is provided for determining a blade topology that reduces the effects of vibratory stress on a turbomachine blade having a plurality of discrete locations, wherein each discrete location has a thickness. The method includes the steps of creating a computational model of the blade, using the computational model to modify the thickness of at least one of the discrete locations a predetermined amount, determining a combination of a discrete location and predetermined thickness amount that reduces vibratory stress on the blade, and applying the determined combination to the computational model to create a revised blade. A turbomachine including a blade having the determined blade topology is also provided.

Owner:HONEYWELL INT INC

Topological optimization method for constraining and damping blades of aeroengine

InactiveCN104573199AReduce vibration stressBest damping effectSpecial data processing applicationsMesh gridEngineering

The invention relates to a topological optimization method for constraining and damping blades of an aeroengine. The method comprises the following steps: taking lightweight aluminum foil as a constraining material, sequentially sticking a viscoelastic material and the constraining material onto the surface of each blade of the aeroengine, carrying out constraining and damping processing on the blades, and establishing finite element models of the constrained and damped blades; carrying out modal analysis on the constrained and damped blades according to the finite element models of the constrained and damped blades, and filtering sensitivity of constrained and damped cell units by adopting an independent grid filtering technology; solving an optimization model by adopting an asymptotic optimization algorithm, programming an optimization program, searching for the optimal layout of a constraining and damping material on each blade, and cutting and regularizing optimized layout, so as to adapt to engineering application. The method has the advantages that the aim of achieving the maximal aeroengine blade damping vibration reduction effect with the minimal damping material additionally-added amount is realized, so that the vibration stress of the blades of the aeroengine is remarkably lowered, and the fatigue damage resistance of the blades is improved.

Owner:AECC SHENYANG ENGINE RES INST +1

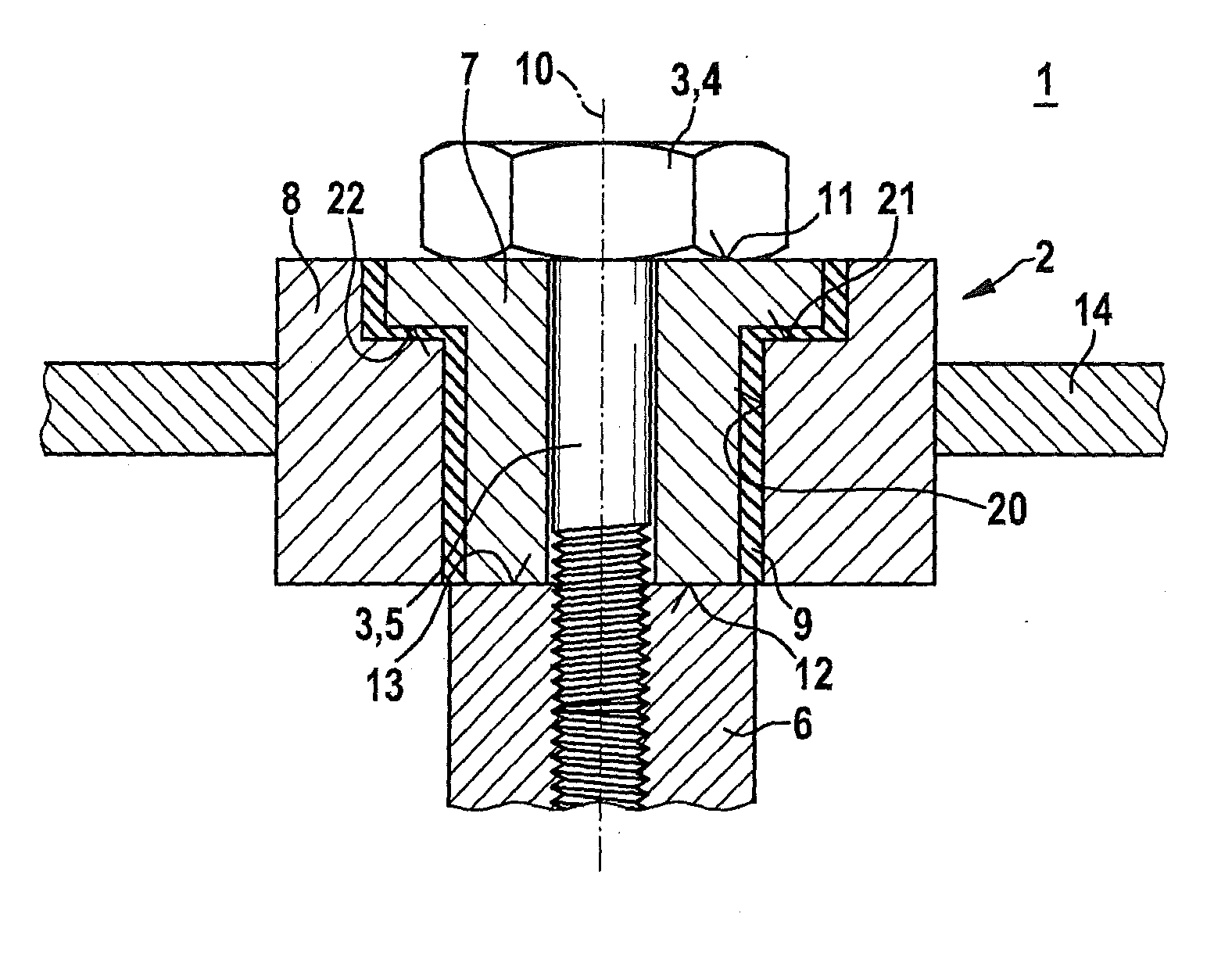

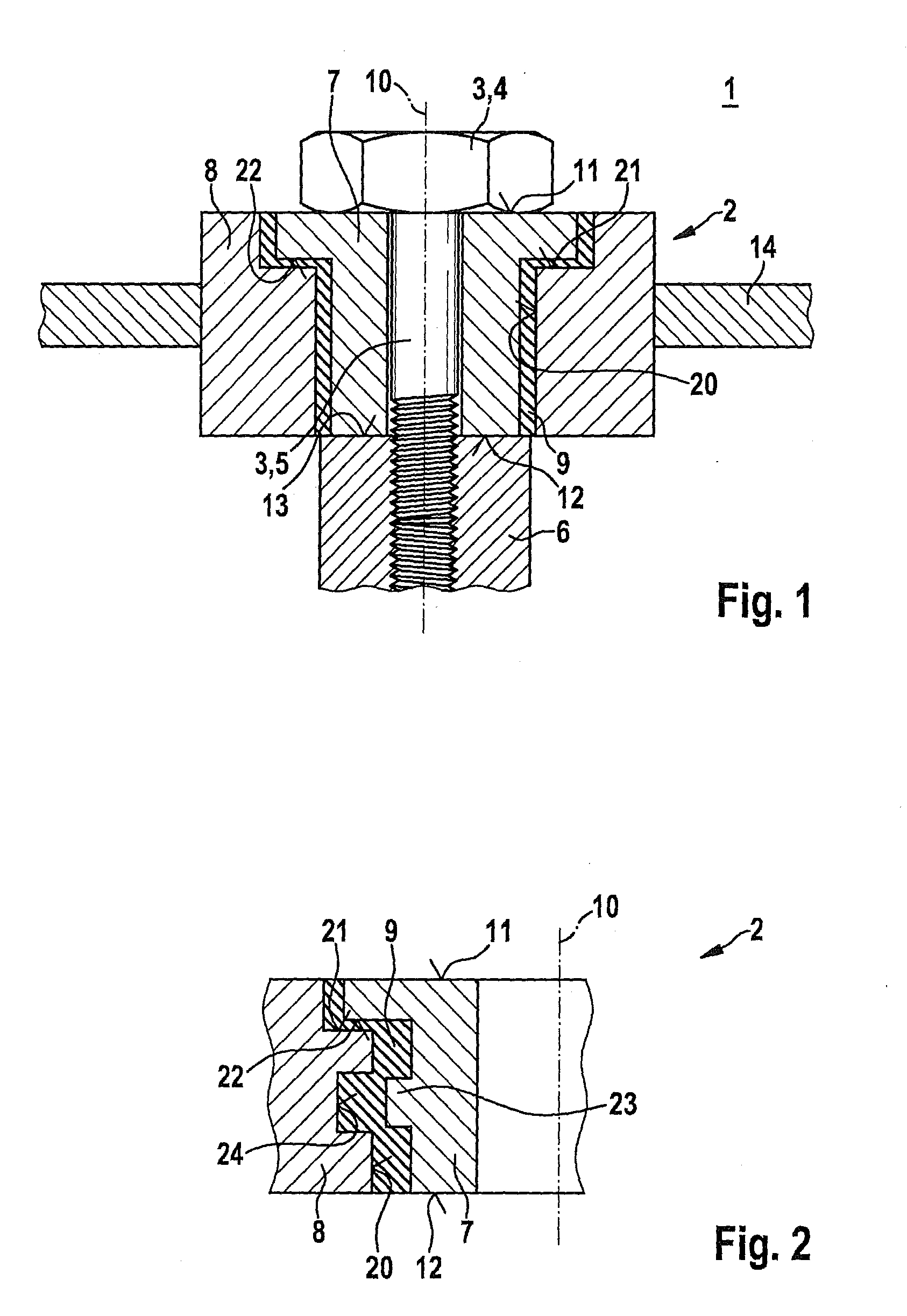

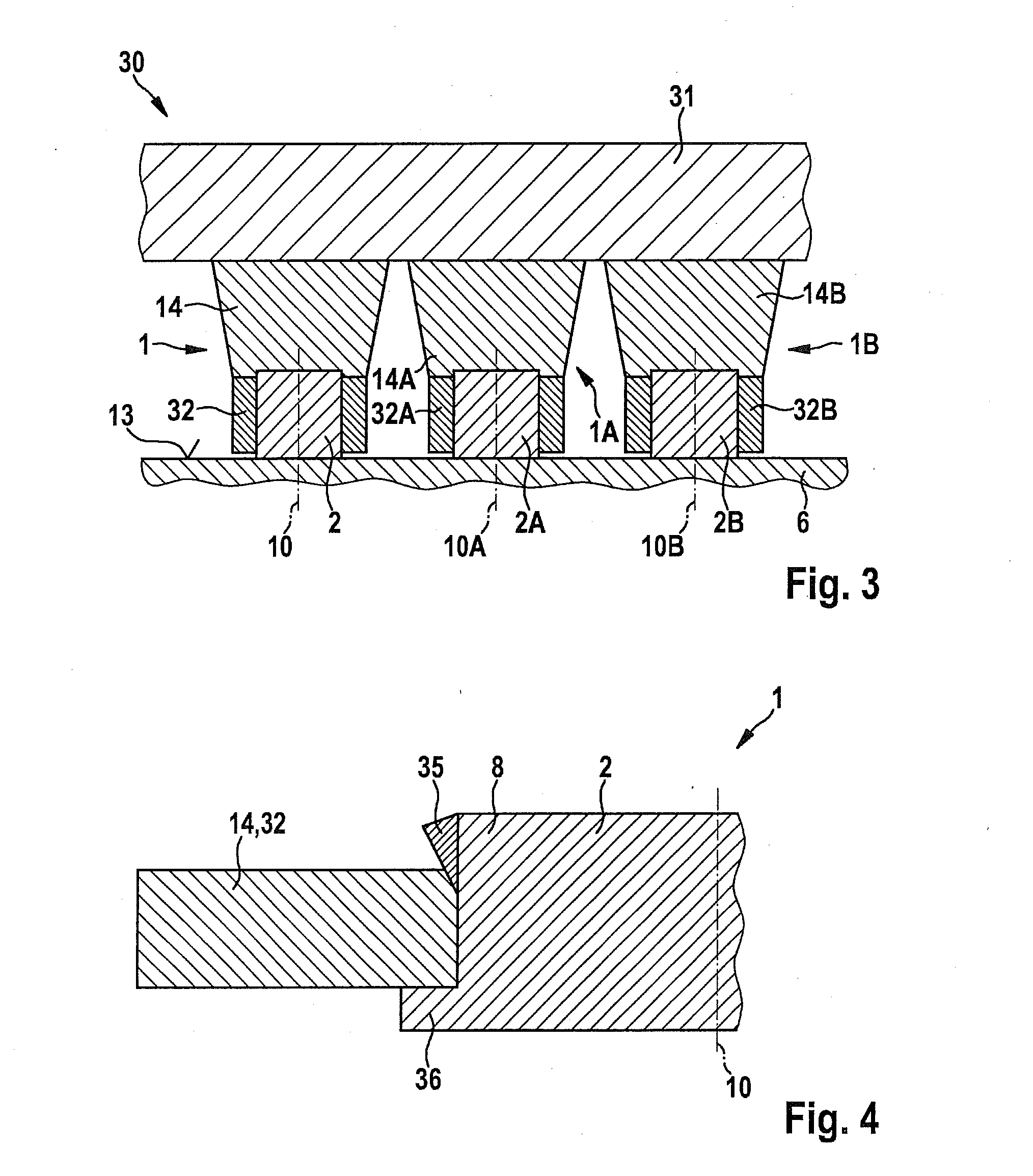

Holder for fastening a component on an internal combustion engine, a bearing bush for such a holder, and a fuel injection system

ActiveUS20150176672A1Improve shock absorptionReduce noiseCouplings for rigid shaftsMachines/enginesExternal combustion engineMetallic materials

A bearing bush is for a holder, which is for fastening a component, particularly of a fuel distributor, to an add-on structure. The bearing bush has an inner bush part, which is made of a metallic material, and an outer bush part, which is made of a metallic material, and an elastically deformable damping element. The outer bush part has a continuous recess, in which the inner bush part is situated. The damping element is situated between the inner bush part and the outer bush part. A holder having such a bearing bush is also specified. In addition, a fuel-injection system having a fuel distributor and at least one holder is specified, which is used for fastening the fuel distributor on an internal combustion engine.

Owner:ROBERT BOSCH GMBH

High-pressure turbine moving blade set with damping vibration attenuation blocks

PendingCN113605993AIncreased safety marginExtended service lifeBlade accessoriesMachines/enginesVibration attenuationTurbine blade

The invention belongs to the technical field of gas turbine equipment and particularly relates to a high-pressure turbine moving blade set with damping vibration attenuation blocks. According to the high-pressure turbine moving blade set with the damping vibration attenuation blocks, the damping vibration attenuation blocks are arranged in cavities between adjacent high-pressure turbine moving blade extending roots, when an engine works, the damping vibration attenuation blocks rotate along with high-pressure turbine moving blades, the centrifugal force generated by the damping vibration attenuation blocks provides normal stress for friction contact between the damping vibration attenuation blocks and the high-pressure turbine moving blades, and when the blades vibrate, the vibration quantity is consumed through contact friction between the blades and the damping vibration attenuation blocks, so that the vibration stress is reduced. The high-pressure turbine moving blade set is simple and reliable in structure, good in vibration attenuation effect, easy and convenient to regulate and control, high in environmental adaptability and free of influences of an engine temperature field and a flow field, structural parameters of the high-pressure turbine blades do not need to be greatly changed, blade damping can be effectively increased, the safety margin of working of the high-pressure turbine moving blades is increased, the service life of the turbine blades is prolonged, and the gas turbine safe operation reliability is improved.

Owner:中国船舶重工集团公司第七0三研究所

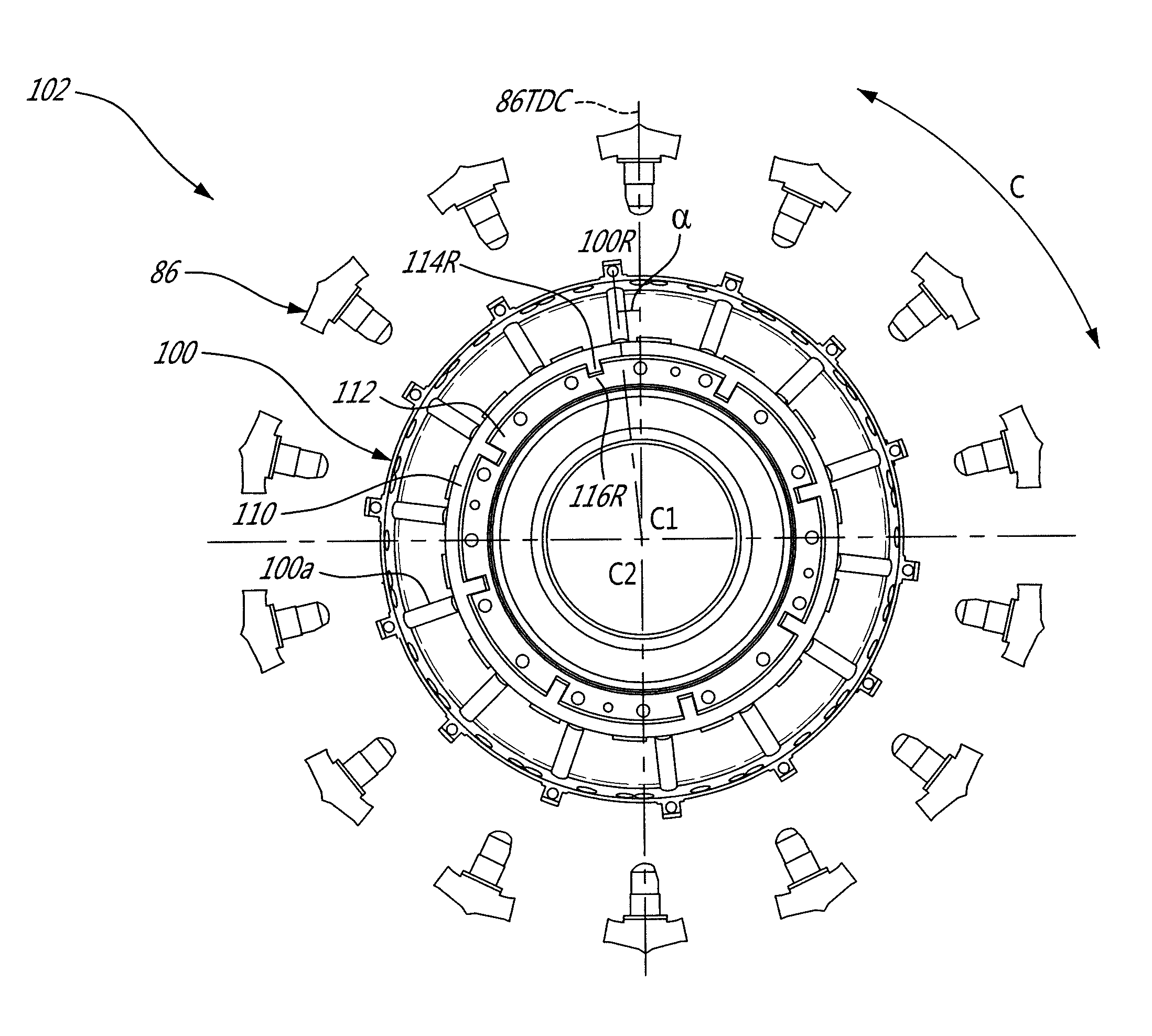

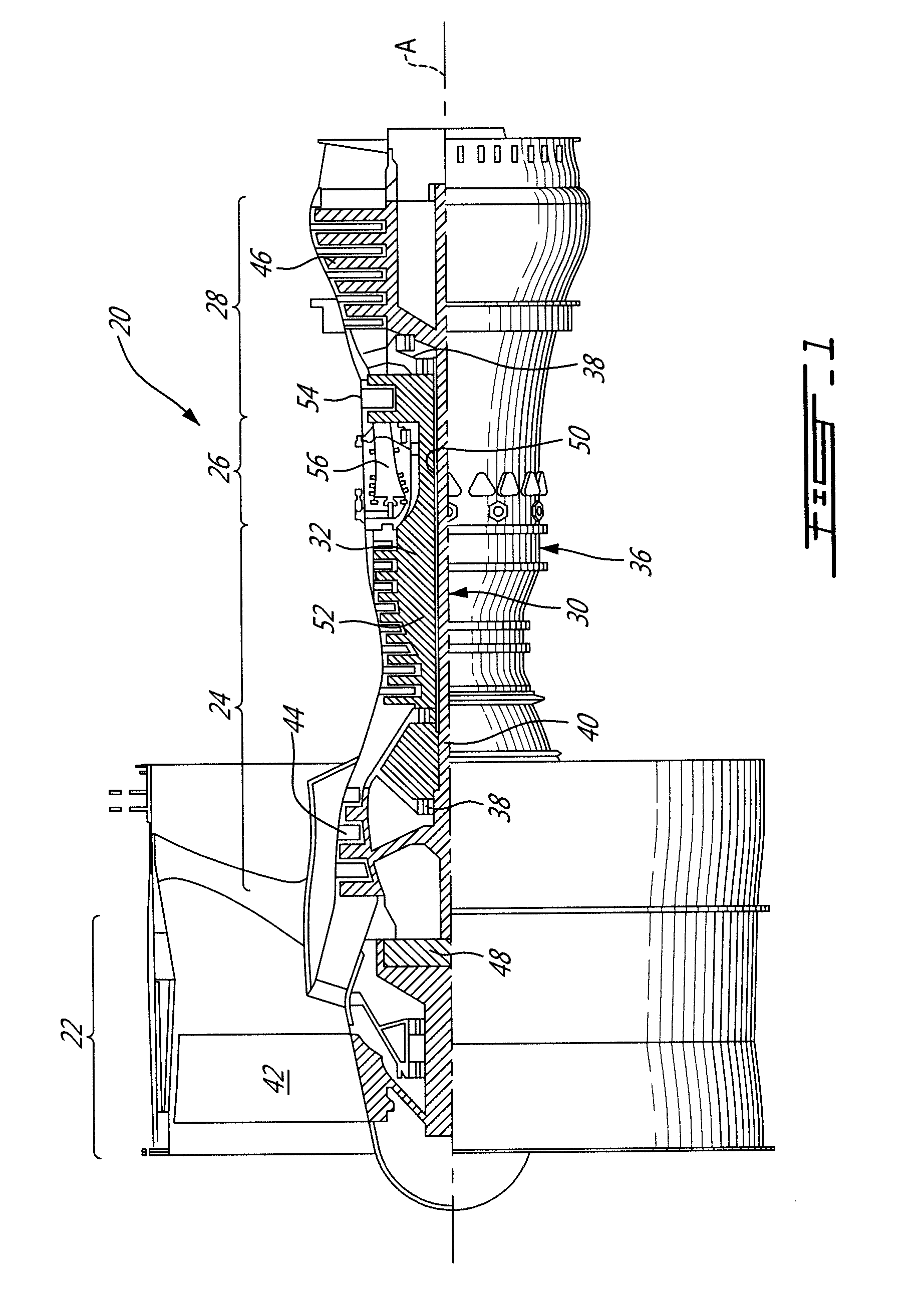

Gas turbine engine with angularly offset turbine vanes

InactiveUS20160177835A1Reduce vibration stressContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustorTurbine blade

A gas turbine engine includes a combustor having a plurality of fuel nozzles arranged circumferentially equidistant from one another about a first center. The plurality of fuel nozzles produce a plurality of pressure pulses in a fluid contained in the combustor. A turbine section is disposed downstream of the combustor and receiving the fluid from the combustor. The turbine section includes a plurality of vanes arranged circumferentially equidistant from one another about a second center. When projecting the second center onto the first center, the plurality of vanes is angularly offset in a circumferential direction relative to the plurality of fuel nozzles of a predetermined amount. The offsetting positions the vanes in flowpaths of the pressure pulses generated by the plurality of fuel nozzles.

Owner:PRATT & WHITNEY CANADA CORP

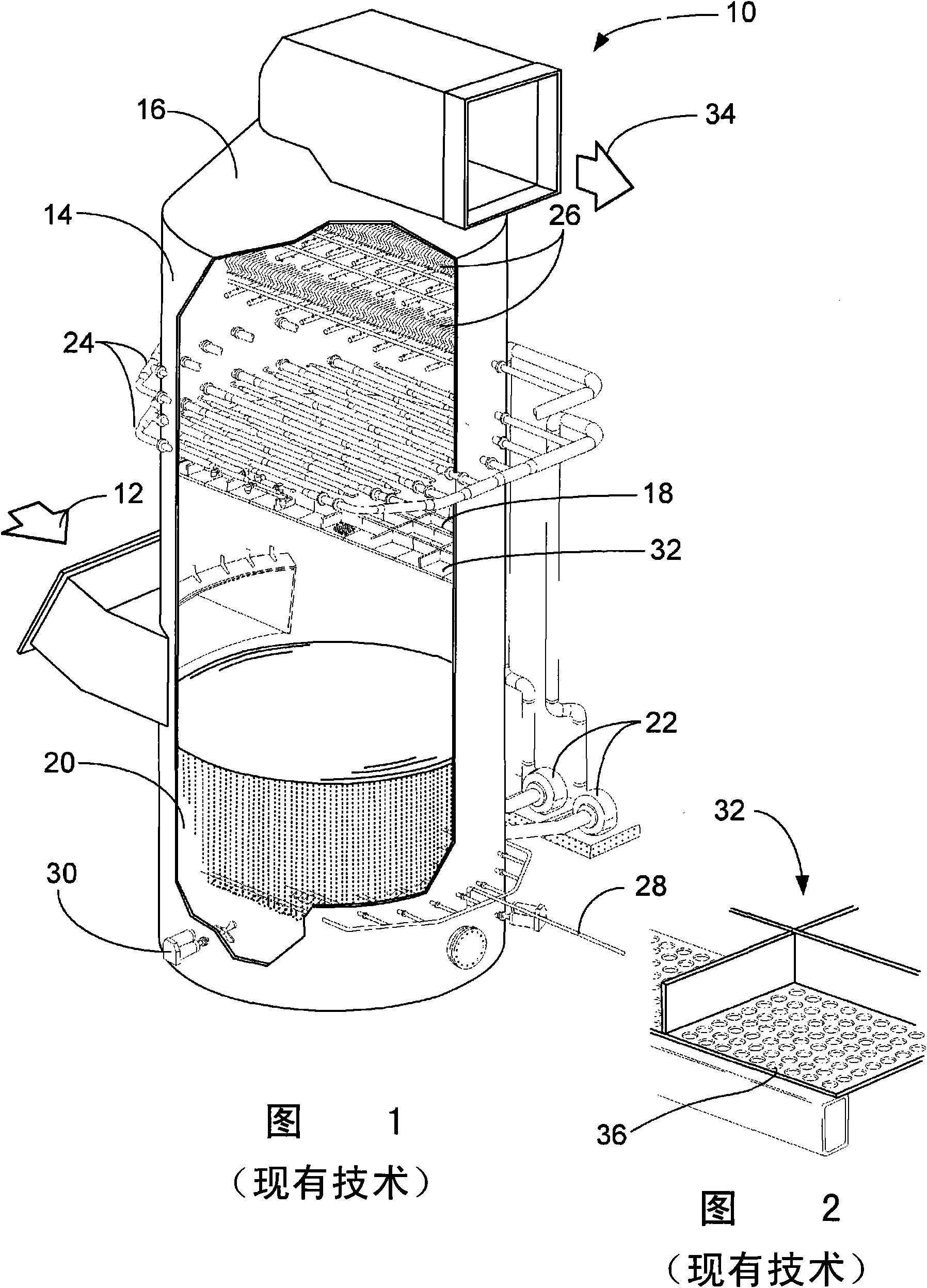

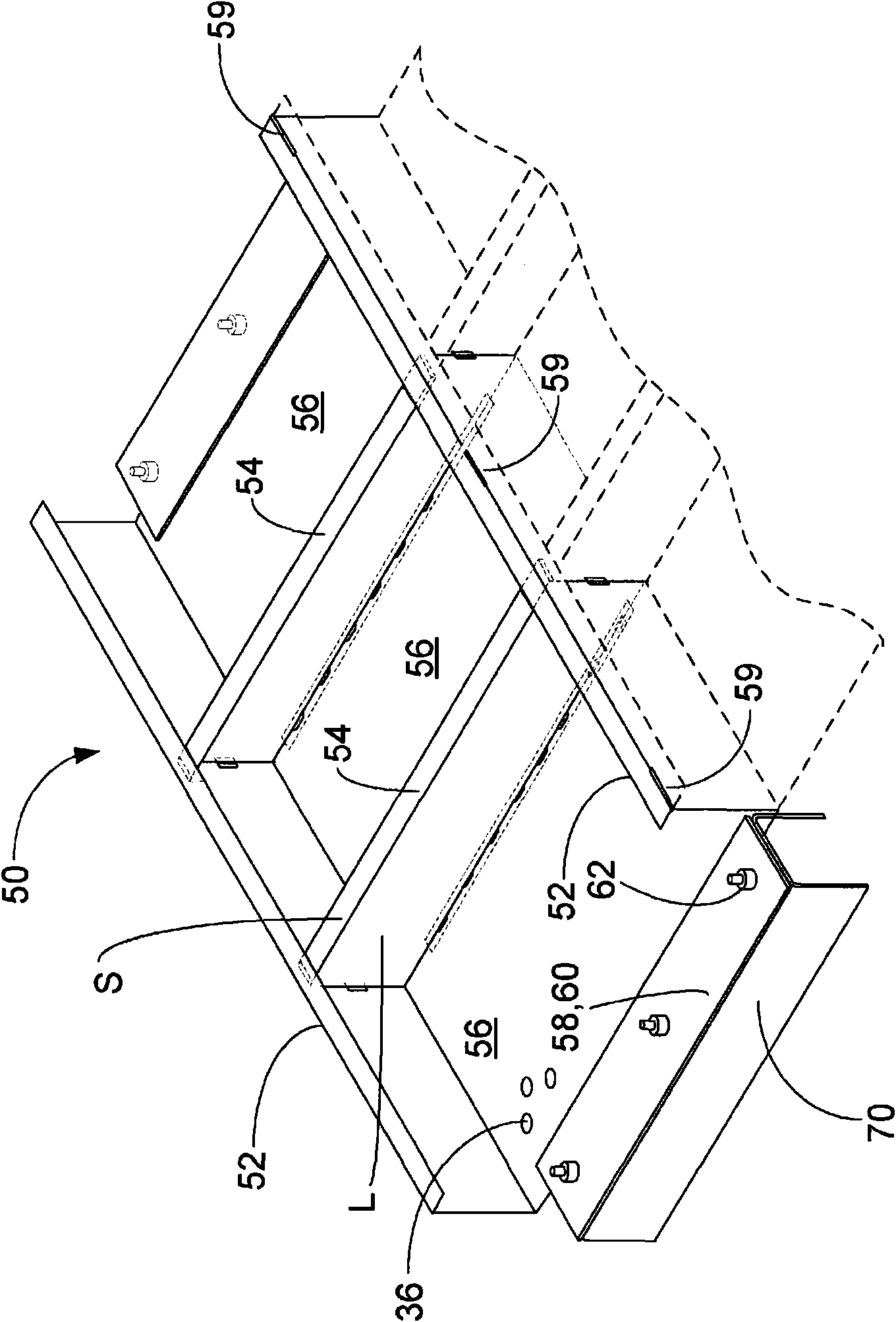

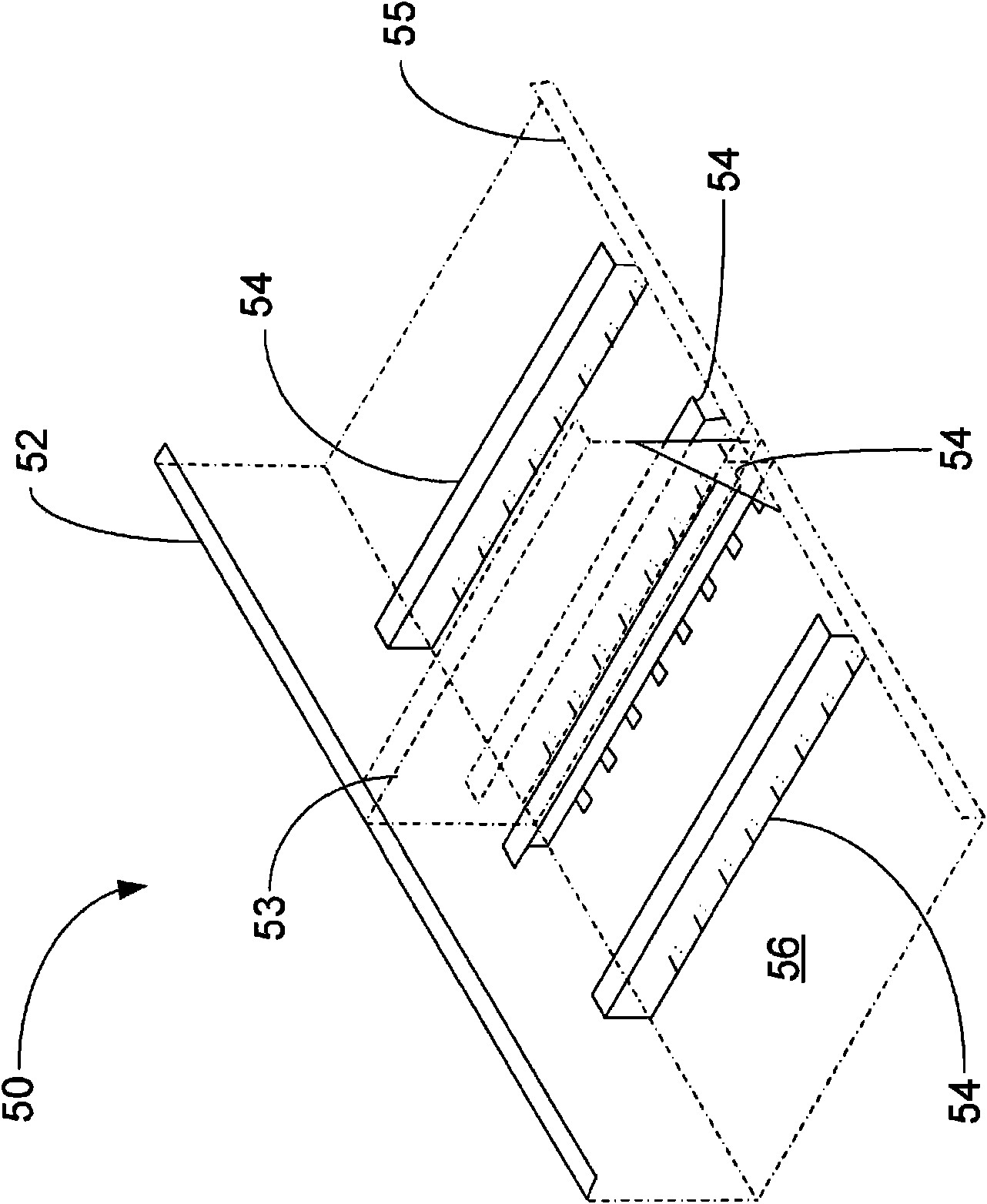

Wet scrubber tray

An improved wet scrubber tray provides increased resistance to vibration-induced cracking. The tray is self supporting to eliminate wastage of raw material, and additional internal stiffeners added to the tray make multiple intermediate stiffeners. The connection of the intermediate stiffeners to th e perforated bottom plate is changed to eliminate the shop weld in the bottom plate. The holes in the perforated bottom plate are repositioned so that the y are moved away from the boundaries of the tray to reduce their influence on boundary conditions. The thickness of the tray material may be increased to lower the vibratory stresses. The mechanism for holding the trays themselves within the spray absorber tower is changed so that the trays are now held do wn by plate material that is attached to the support grid, but not to the trays . Three field welds are applied to the sides of each tray to hold the trays in place relative to each other and are strategically placed to allow adjacent side stiffeners to act together as a composite section, thus increasing their strength. Elastomeric material such as neoprene is used at the tray-to-grid attachments to increas e the damping of the system. Formed features in the trays such as single or multip le ribs, bosses, domes or dimples may also be provided to increase tray stiffne ss or influence wet scrubber performance.

Owner:THE BABCOCK & WILCOX CO

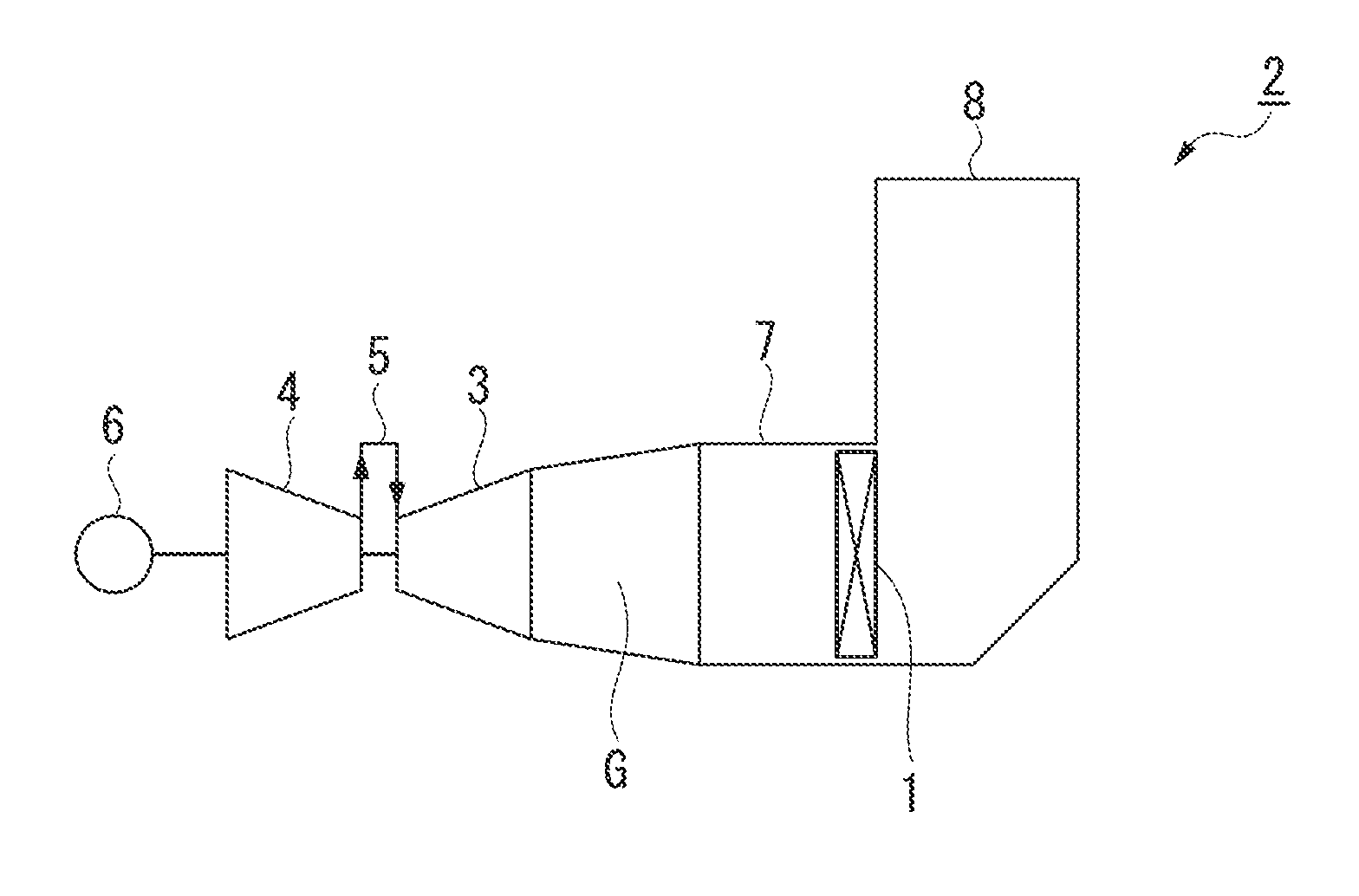

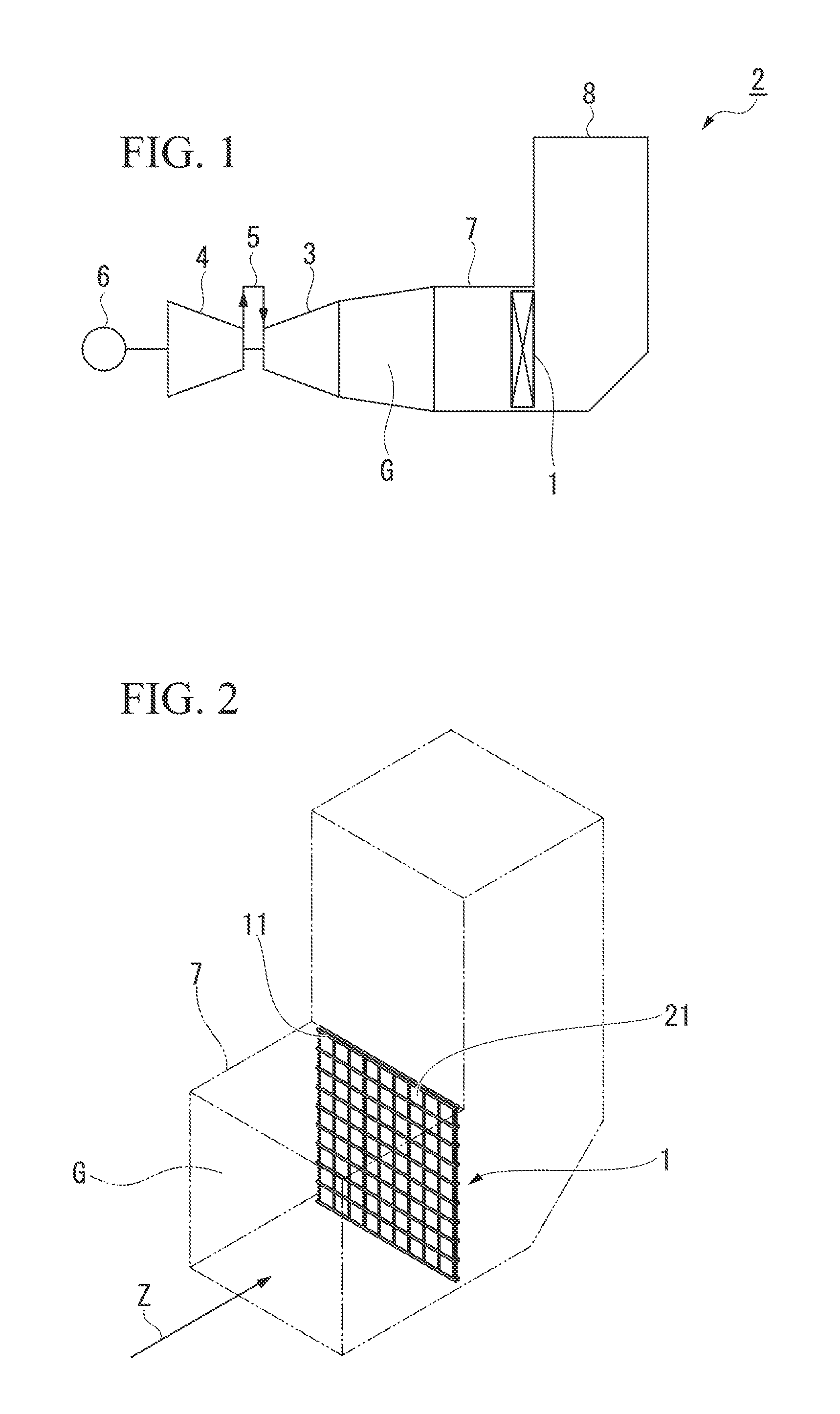

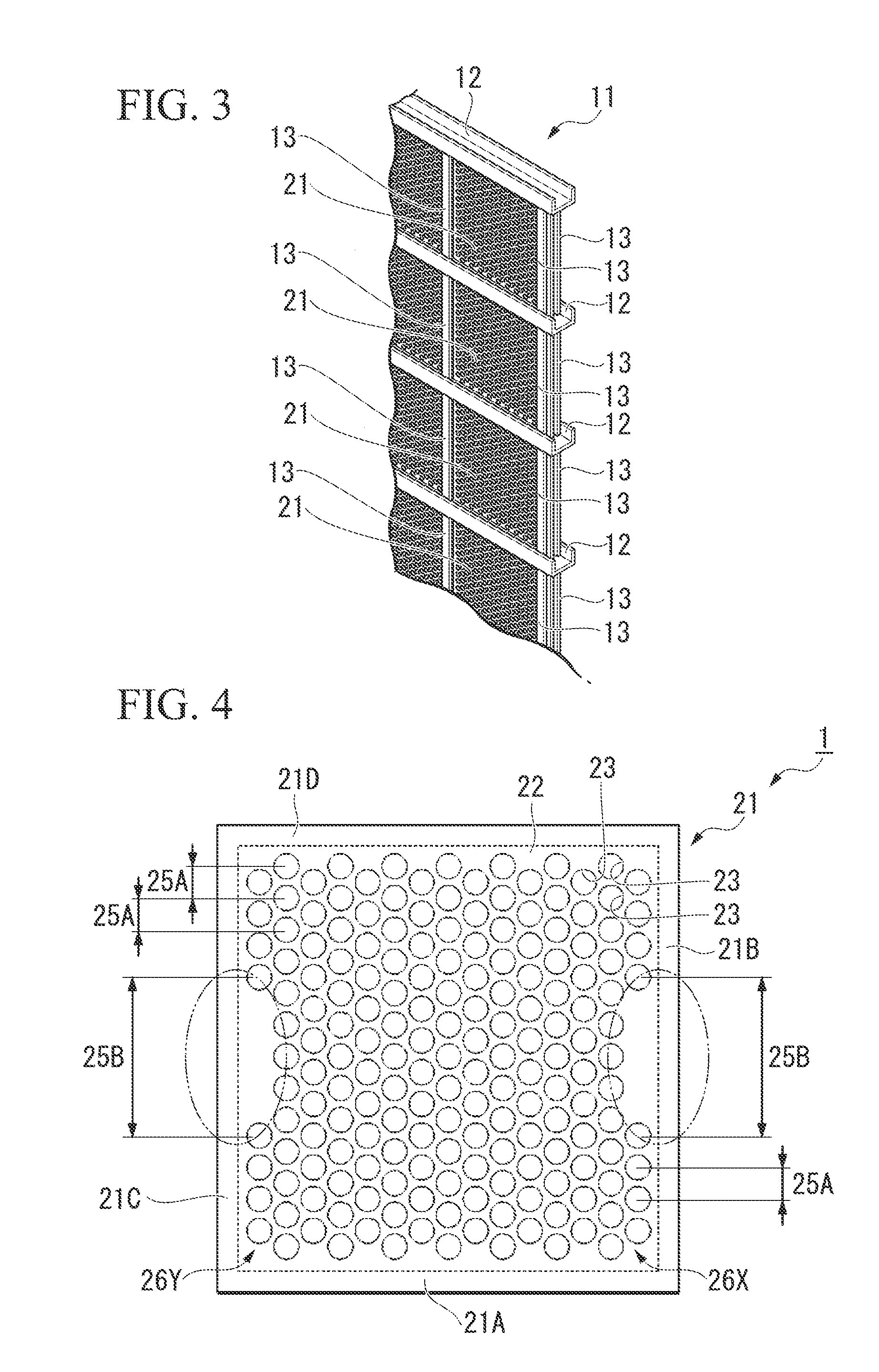

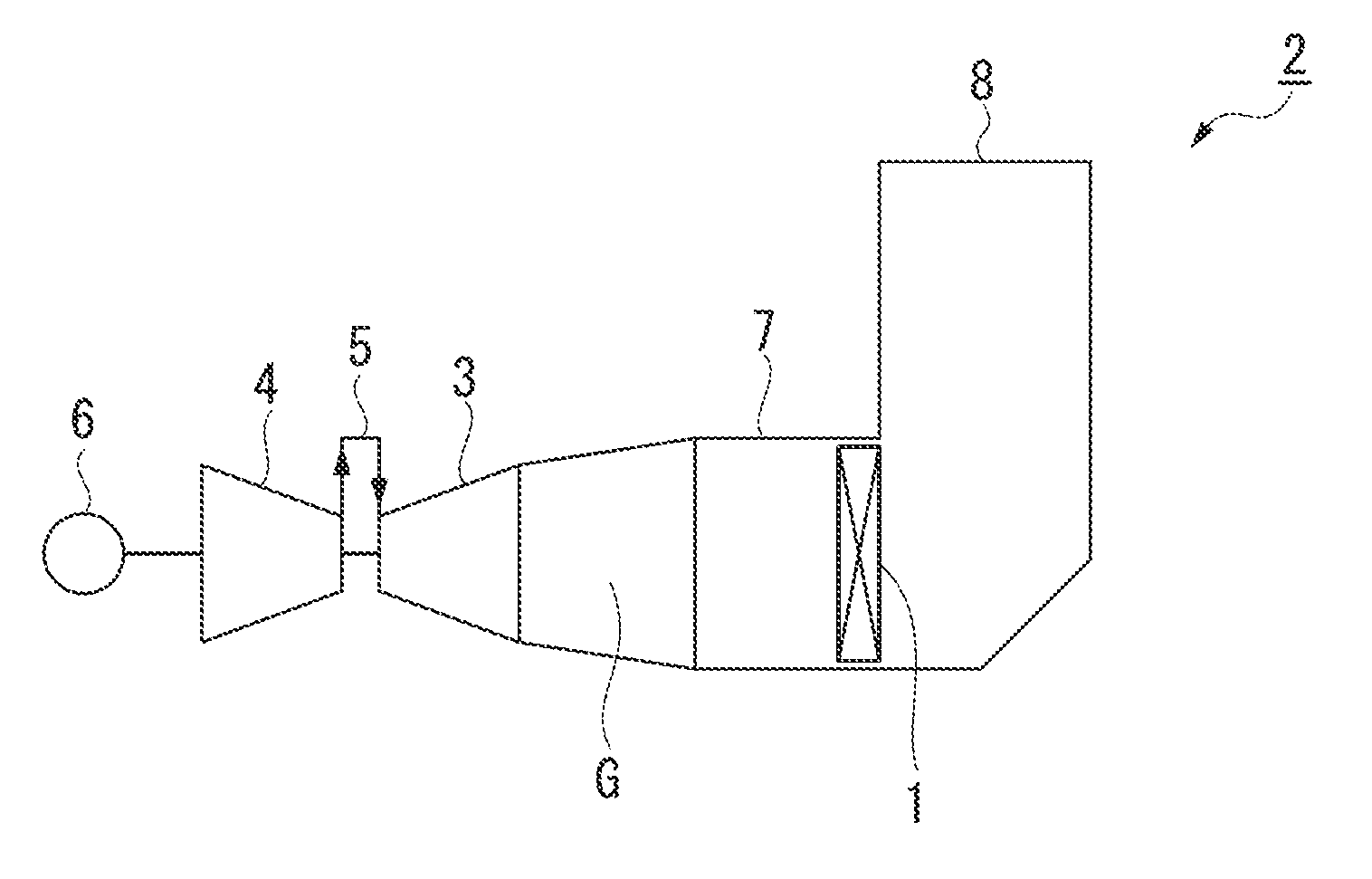

Silencer and rotating machine equipped therewith

ActiveUS8863894B2Reduce vibration stressHigh frame strengthEngine manufacturePump componentsMechanical engineeringEngineering

Owner:MITSUBISHI POWER LTD

Silencer and rotating machine equipped therewith

ActiveUS20130213733A1Reduce vibration stressImprove frame strengthEngine manufacturePump componentsEngineeringMechanical engineering

Owner:MITSUBISHI POWER LTD

645 mm last stage dynamic blade for industrial steam turbine

ActiveCN110242355AImprove aerodynamic performanceSelf-locking structureBlade accessoriesMachines/enginesSteam turbine bladeSelf locking

The invention relates to the field of industrial steam turbine blades, and particularly discloses a 645 mm last stage dynamic blade for an industrial steam turbine. The 645 mm last stage dynamic blade for the industrial steam turbine comprises a blade body, a blade root and a boss lashing wire for making the blade form whole circle self locking, wherein the blade body and the blade root are integrally formed; a molded line of the blade body is a variable section twisted blade; the height H of the blade body is equal to 645 mm, the bottom radius Dr is equal to 560 mm, and the exhausting area of the blade body is 3.6 m<2>; and the center of the self-locking boss lashing wire is arranged at the position, with the relative blade height being 0.65 from bottom to top, of the blade body. The large load last stage dynamic blade, with the exhausting area being 3.6 m<2>, for the industrial steam turbine has the beneficial effects that the pneumatic efficiency is high, the strength performance is good, the exhausting area is large, and manufacturing and assembling are convenient, and can widely used for waste heat utilizing and industrial steam turbines for the PTA manufacturing process.

Owner:HANGZHOU STEAM TURBINE

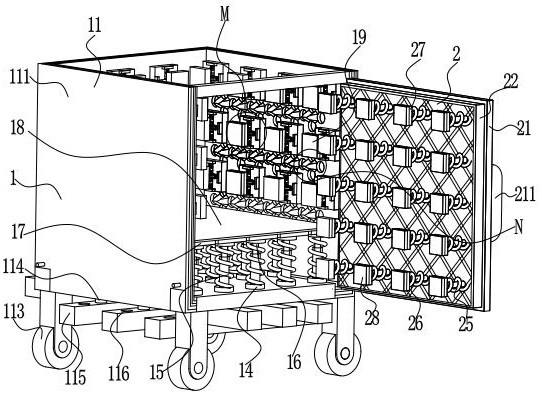

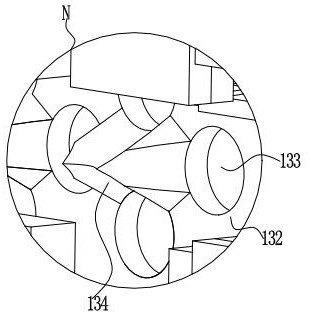

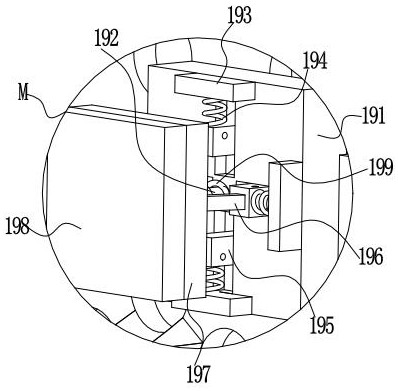

Noise reduction and shock absorption device of transformer

PendingCN114664546AAvoid wear and tearExtended service lifeTransformers/reacts mounting/support/suspensionTransformers/inductances casingsEngineeringMechanical engineering

The invention relates to the technical field of transformer noise reduction and shock absorption, in particular to a transformer noise reduction and shock absorption device which comprises a shell and a door plank, the front end of the shell is rotationally connected with the door plank, and the shell comprises a rectangular box, first sound absorption sponge, a sound transmission plate, a fixing column, a cylindrical spring, a guide column, a supporting plate, a rubber plate and an extrusion block. Through cooperation of the shell and the door plate, the transformer is positioned, when the transformer works, vibration generated when the transformer works is buffered so as to achieve the purpose of noise reduction and shock absorption, vibration force is decomposed while buffering is conducted, vibration borne by the shell is reduced, the service life of the shell is prolonged, and the shock absorption effect of the shell is improved; meanwhile, noise generated when the transformer works is absorbed, the noise generated when the transformer works is reduced, and in the noise reduction process, the noise makes contact with a sound absorption part and is absorbed by means of the reflection principle.

Owner:南通世睿电力科技有限公司

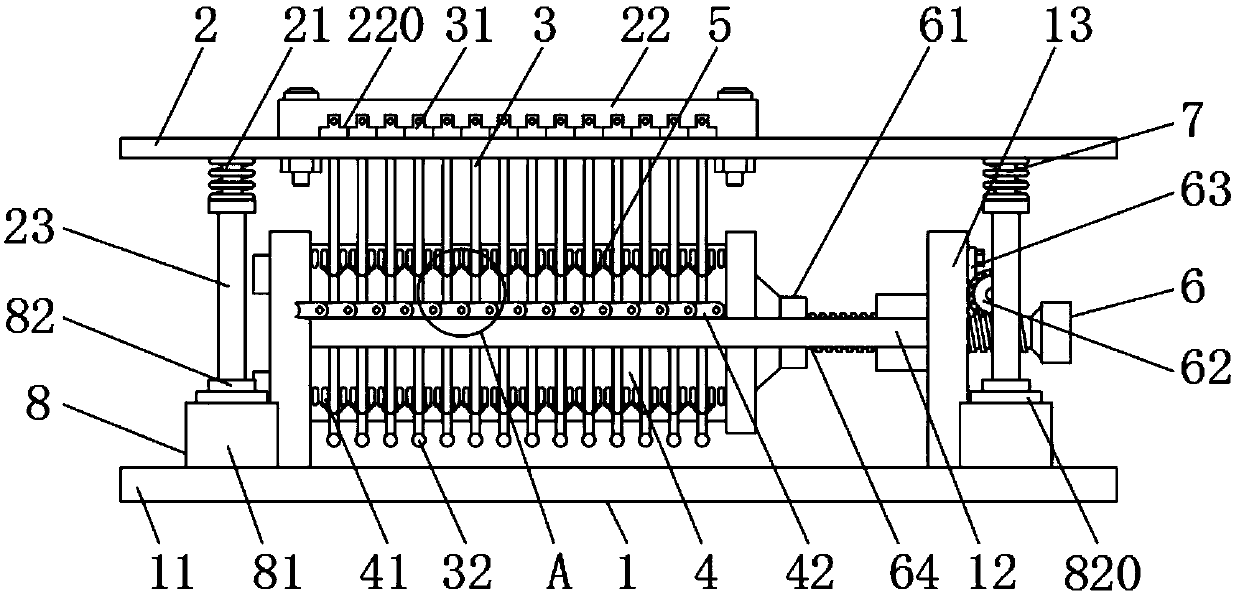

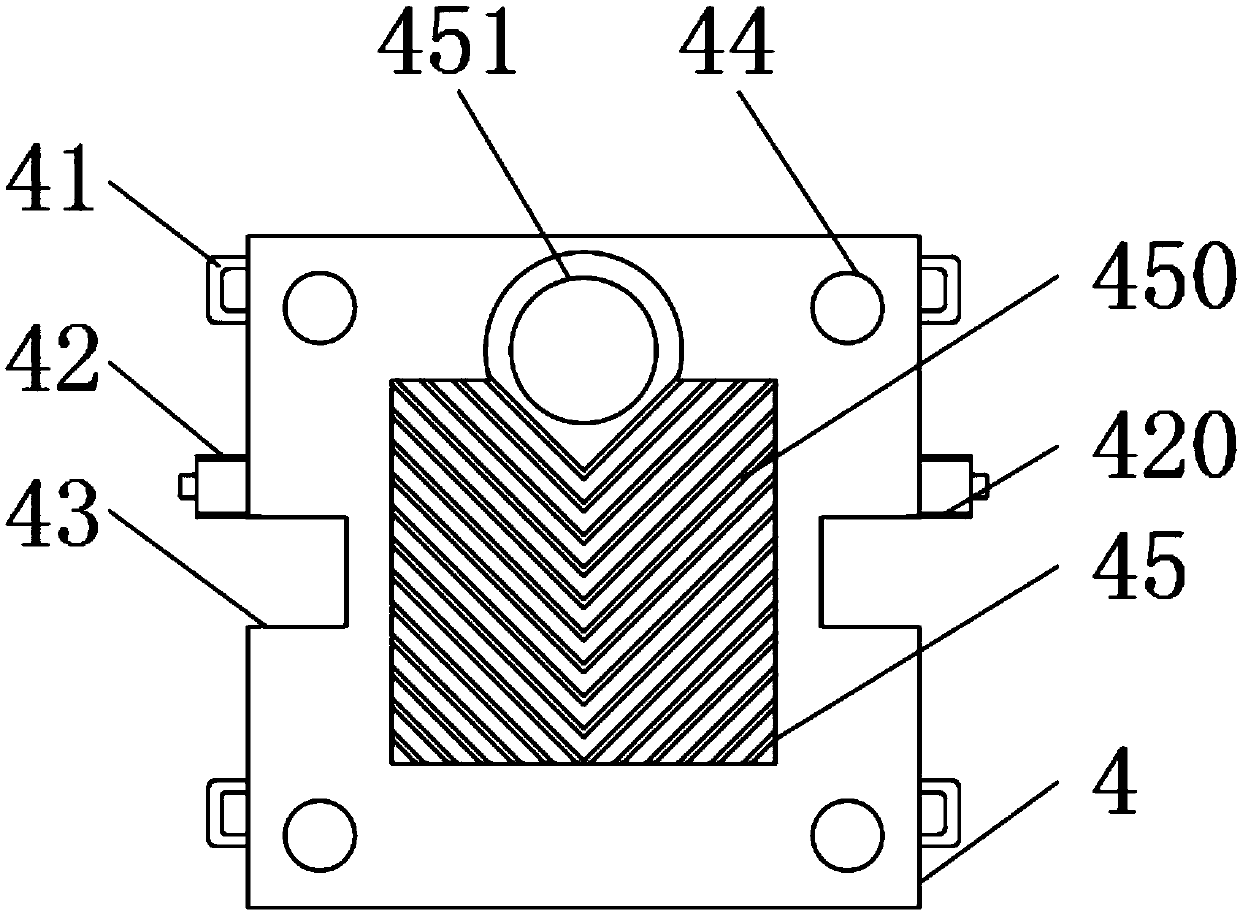

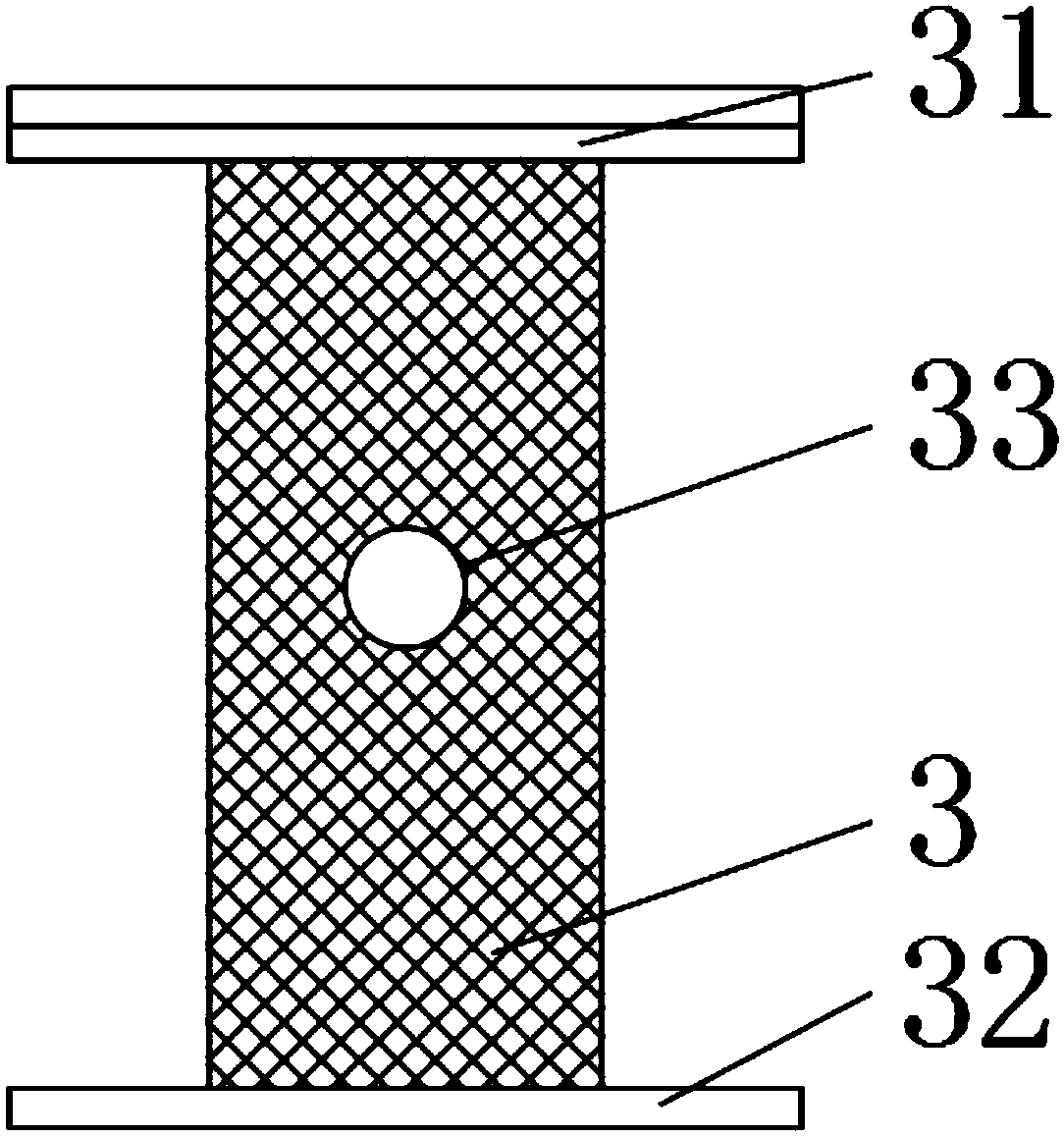

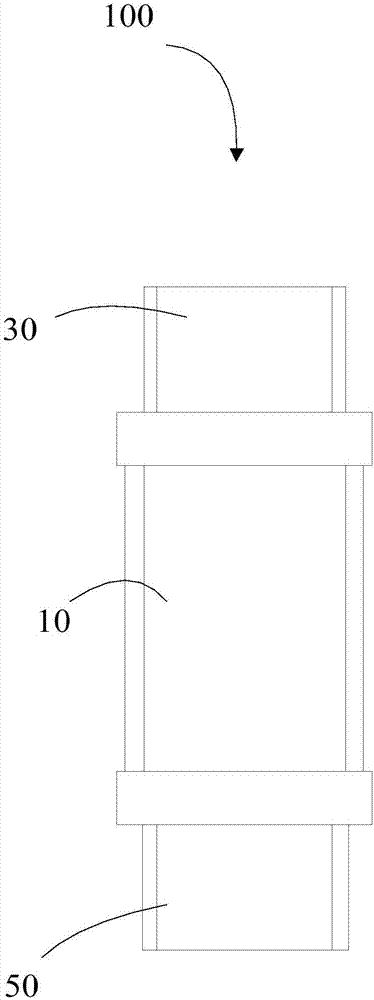

Plate-and-frame pressure filtering device for sludge dewatering and drying

InactiveCN109678311AImprove stripping effectReduce water consumptionSludge treatmentSpecific water treatment objectivesWater contentTreatment costs

The invention discloses a plate-and-frame pressure filtering device for sludge dewatering and drying, and relates to the technical field of sludge treatment equipment. The plate-and-frame pressure filtering device specifically comprises a machine frame, a top frame movably mounted above the machine frame, filter cloth fixedly connected to the bottom of the machine frame, a pressing device fixedlymounted on the outer side of the machine frame, a filter plate movably mounted on the inner side of the machine frame, and material stripping devices movably mounted on the upper surface of the machine frame, wherein the machine frame comprises a base. Through cooperative arrangement of the material stripping devices, servo motors and buffer springs, the servo motors work, turntables can be turned, connecting bulges periodically lift the top frame along limiting rings, the buffer springs reduce the vibrating pressure, a mud cake adhered to the outer surface of the filter cloth is shaken off, the material stripping effect is improved in cooperation with water washing operation, the problems that partial blockage of the filter cloth due to incomplete flushing causes unqualified moisture content of the mud cake and affects sludge treatment are avoided, at the same time, the water source consumption is lowered and the sludge treatment cost is reduced.

Owner:兰新伟

Shock absorbing pipe and air conditioner

PendingCN106949567AImprove reliabilityReduce vibration stressLighting and heating apparatusAir conditioning systemsPhysicsEngineering

The invention provides a shock absorbing pipe and an air conditioner applying the shock absorbing pipe. The shock absorbing pipe is connected to a compressor of the air conditioner, and comprises a corrugated pipe of which the diameter is fit to the pipe diameter of the compressor and is within the range of 6-32 mm. The air conditioner applying the shock absorbing pipe provided by the invention has good shock absorbing effect.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com