Shock absorbing pipe and air conditioner

An air conditioner and vibration-absorbing technology, which is applied in air-conditioning systems, space heating and ventilation, household heating, etc., can solve problems such as inability to effectively reduce the vibration stress of compressor pipelines and poor reliability of air conditioners, and achieve Effects of preventing fatigue, reducing vibration stress, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

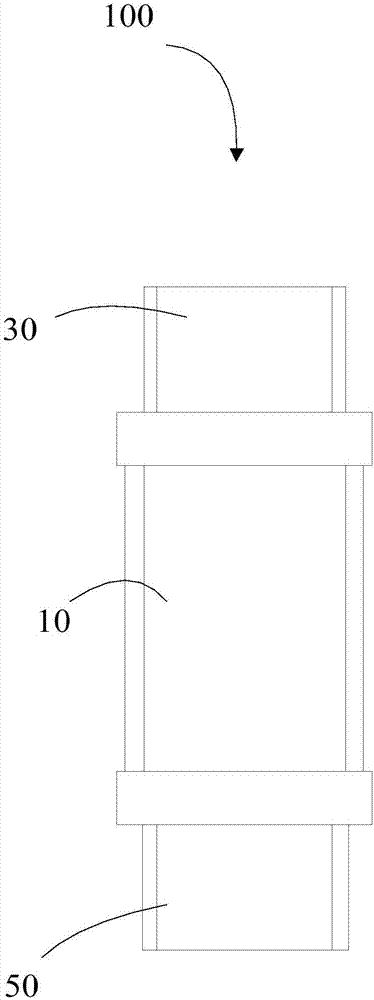

[0079] For the air injection enthalpy increasing series multi-connected air conditioner with a capacity of 90KW, the diameter of the second connecting pipe 50 connected to the return pipe is 25mm, and the pipe diameter of the bellows 10 in contact with the return pipe is 32mm, that is, the first avoidance The pipe diameter of the first connecting pipe 30 and the second connecting pipe 50 of the shock tube is 25 mm, the pipe diameter of the bellows 10 of the first shock absorbing pipe is 32 mm; the pipe diameter of the second connecting pipe 50 connected with the spray pipe is 16 mm , The diameter of the bellows 10 is 19mm, that is, the diameters of the first connecting pipe 30 and the second connecting pipe 50 of the second shock absorber are 16mm, and the diameter of the bellows 10 of the second shock absorber is 19mm.

[0080] The first shock absorber tube and the second shock absorber tube in Example 1 have toughness, which can better absorb the vibration stress of the air r...

Embodiment 2

[0082] For the air injection enthalpy increasing series multi-connected air conditioner with a capacity of 66KW, the pipe diameter of the second connecting pipe 50 connected to the return air pipe is 24mm, and the pipe diameter of the bellows 10 in contact with the return air pipe is 28mm, that is, the first avoidance The pipe diameter of the first connecting pipe 30 and the second connecting pipe 50 of the shock tube is 24mm, the pipe diameter of the bellows 10 of the first shock absorbing pipe is 28mm; the pipe diameter of the second connecting pipe 50 connected with the spray pipe is 9mm , The diameter of the bellows 10 is 12mm, that is, the diameter of the first connecting pipe 30 and the second connecting pipe 50 of the second shock absorber is 9mm, and the diameter of the bellows 10 of the second shock absorber is 12mm.

[0083] The first shock absorber and the second shock absorber in Example 2 have toughness, which can better absorb the vibration stress of the air retur...

Embodiment 3

[0085] For the air injection enthalpy series multi-connected air conditioner with a capacity of 25.2KW, the diameter of the second connecting pipe 50 connected to the return air pipe is 16mm, and the pipe diameter of the bellows 10 in contact with the return air pipe is 20mm, that is, the first The pipe diameter of the first connecting pipe 30 and the second connecting pipe 50 of the shock absorber is 16mm, and the pipe diameter of the bellows 10 of the first shock absorber is 20mm; the pipe diameter of the second connecting pipe 50 connected with the spray pipe is 8mm, the diameter of the bellows 10 is 10mm, that is, the diameter of the first connecting pipe 30 and the second connecting pipe 50 of the second shock absorber is 8mm, and the diameter of the bellows 10 of the second shock absorber is 10mm .

[0086] The first shock absorber and the second shock absorber in Example 3 have toughness, which can better absorb the vibration stress of the air return pipe and injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com