Anti-vibration type dual-alloy turbine blisk and manufacturing method thereof

An integral blisk, double-alloy technology, applied in engine components, machines/engines, blade support elements, etc., can solve problems such as low reliability, poor blisk casting process, insufficient vibration resistance, and insufficient torsional resistance, and achieve Good structure and properties, easy control of dimensional accuracy, good effect of high temperature durable creep performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by specific embodiment:

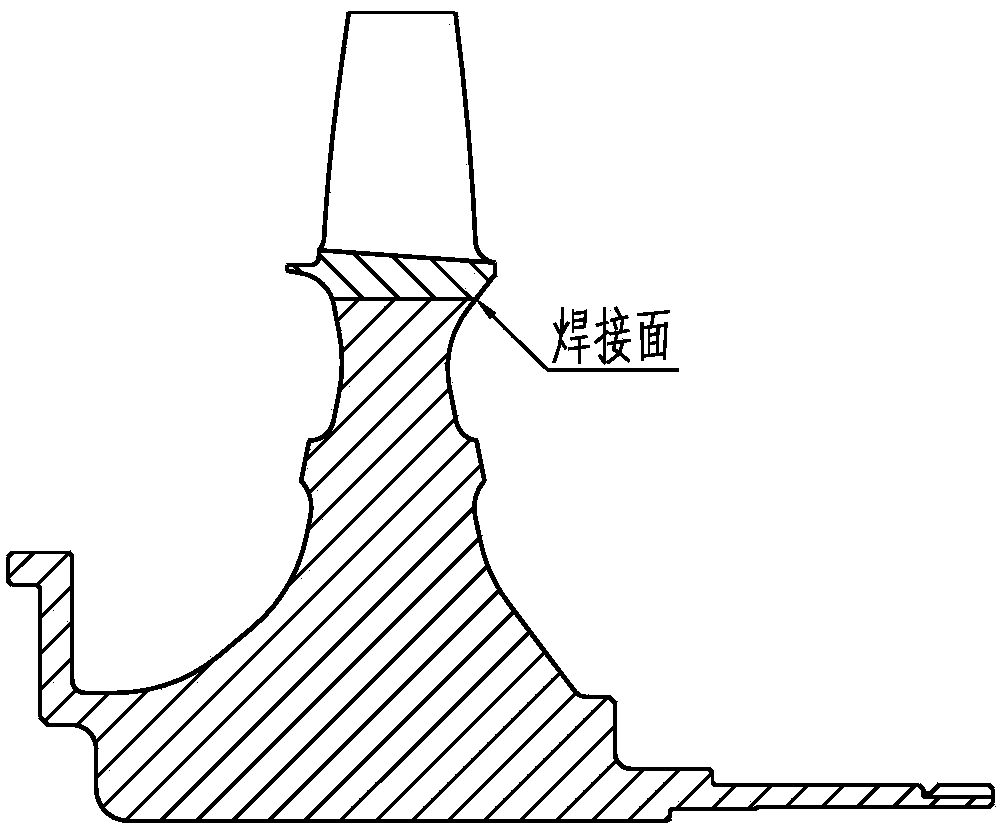

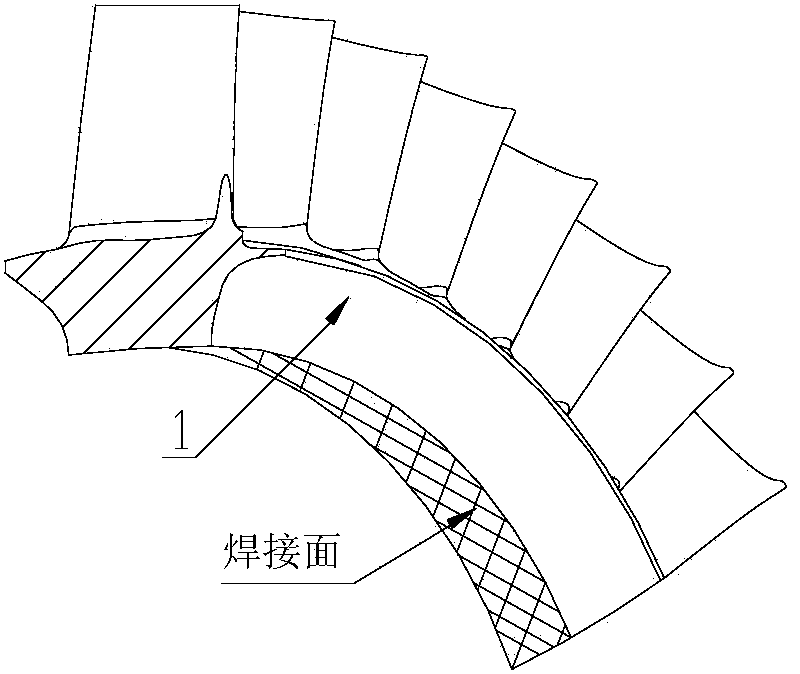

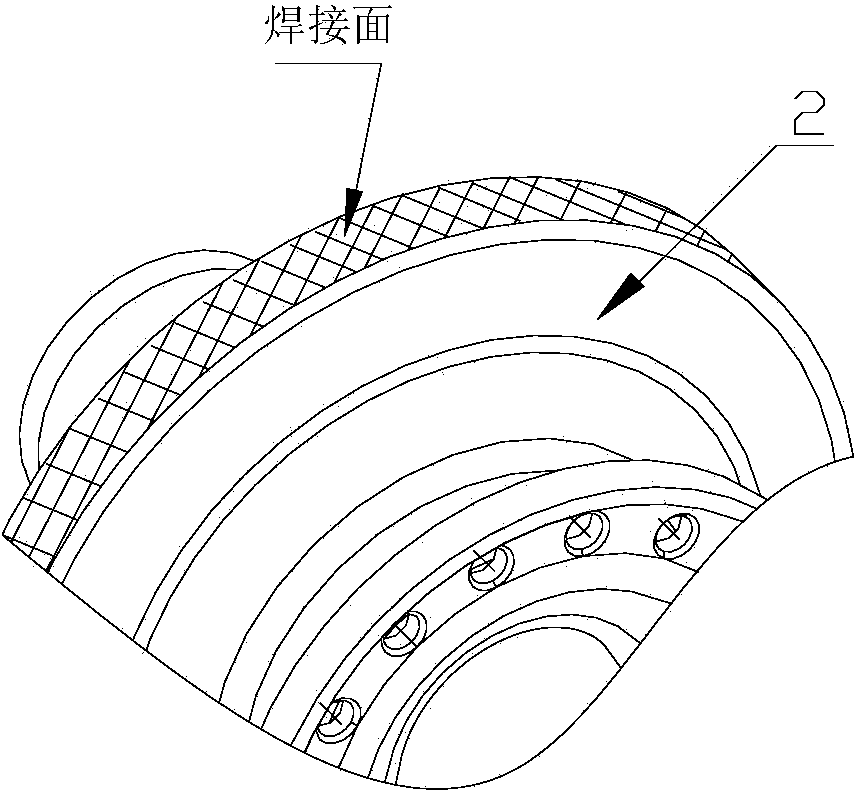

[0024] Please also see figure 1 , figure 2 , image 3 with Figure 4 ,in, figure 1 It is a schematic diagram of the anti-vibration double alloy turbine blisk overall of the present invention. The anti-vibration double alloy turbine integral blisk of the present invention is formed by precision casting blade ring assembly 1 and powder alloy disc body 2 through hot isostatic pressure diffusion welding, which avoids the fact that the single alloy integral blisk cannot take into account the actual needs of the blade and the disc performance. The flexible selection of materials for the turbine disc body and blades and the matching of the best performance are realized. There is a slit between each blade channel, and the depth of the slit must exceed the welding position to ensure the coordination of the deformation of the two alloys. In addition, the number of slits is consistent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com