Patents

Literature

149results about How to "Overcome the small stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

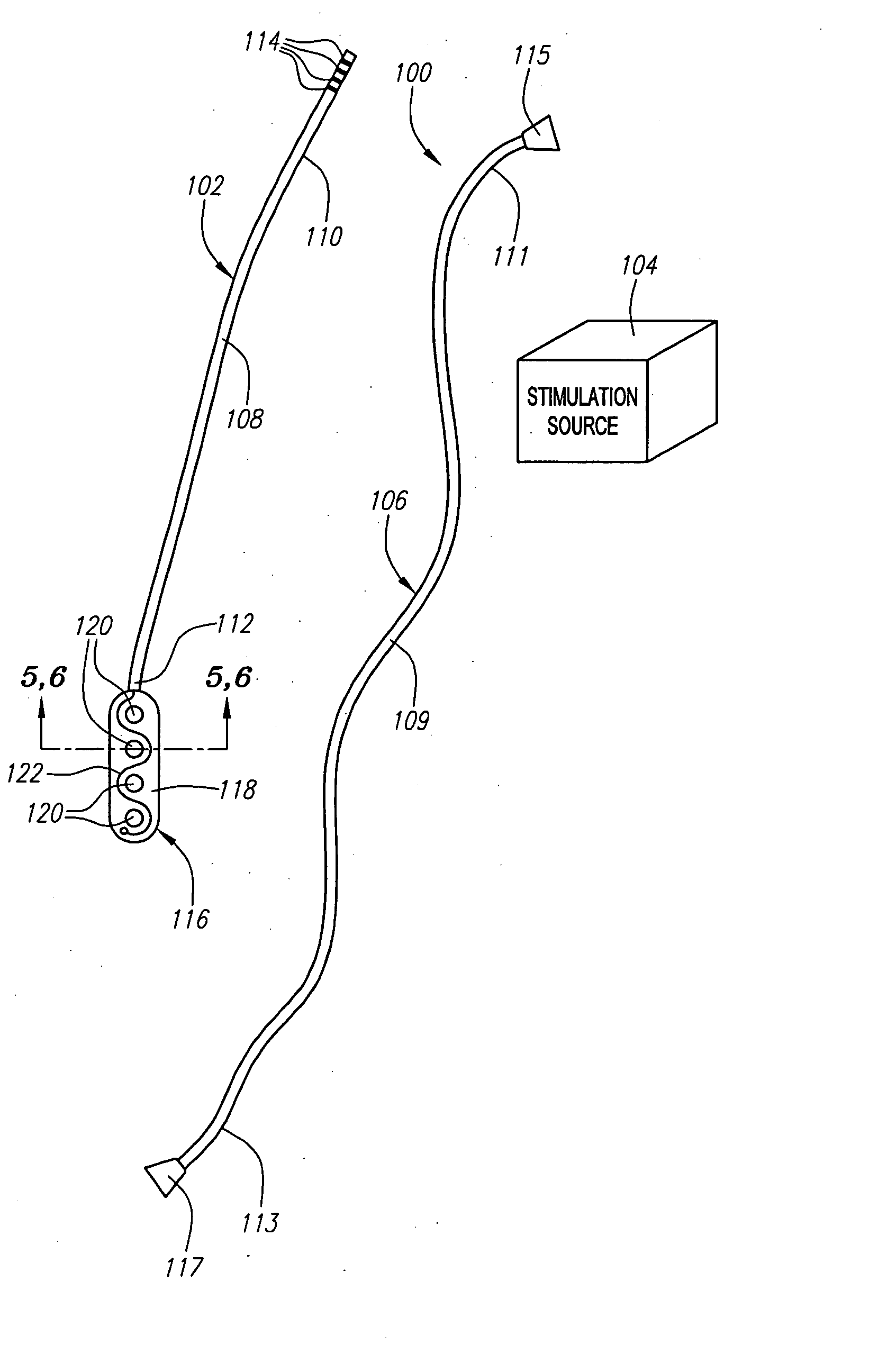

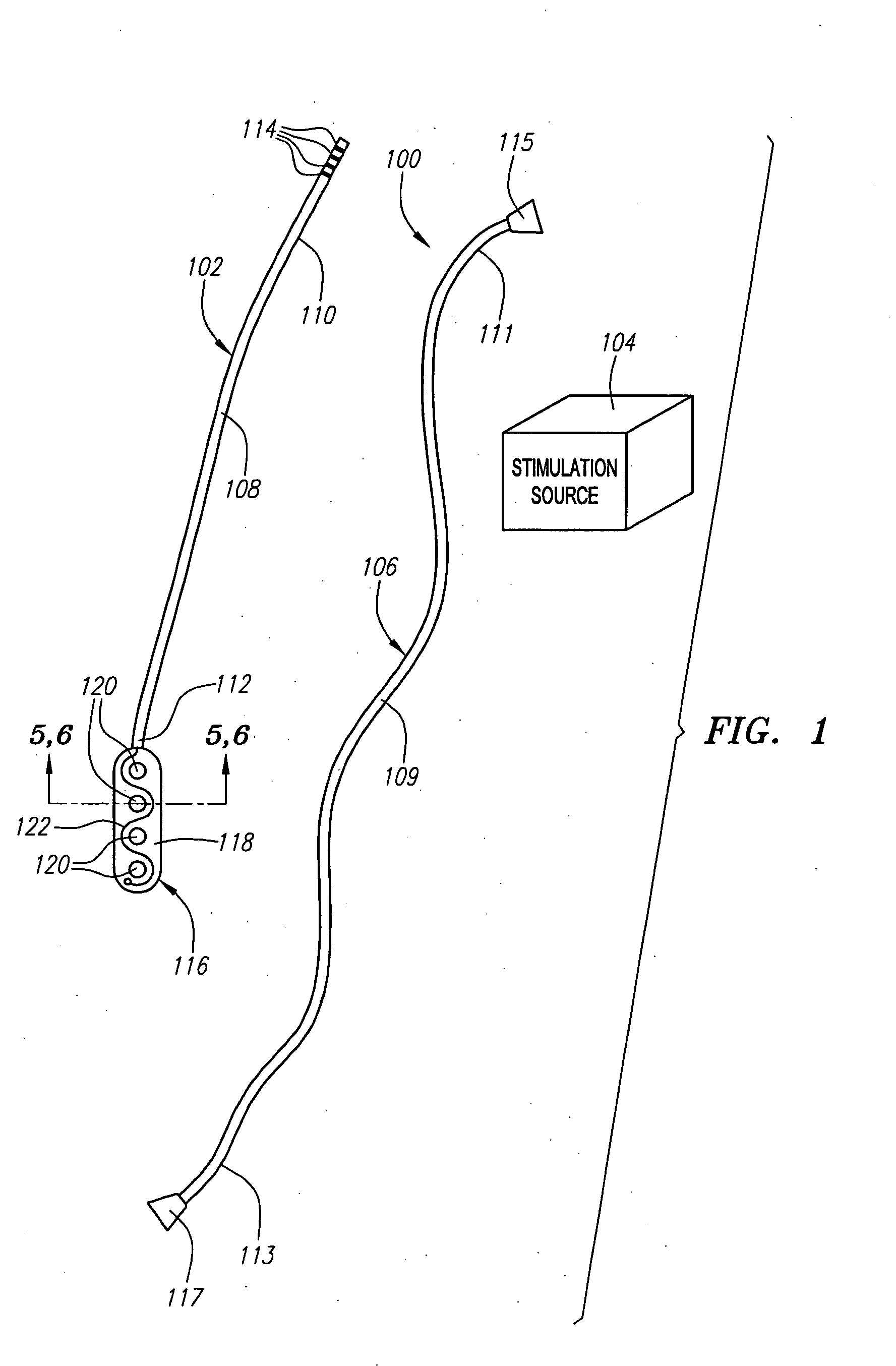

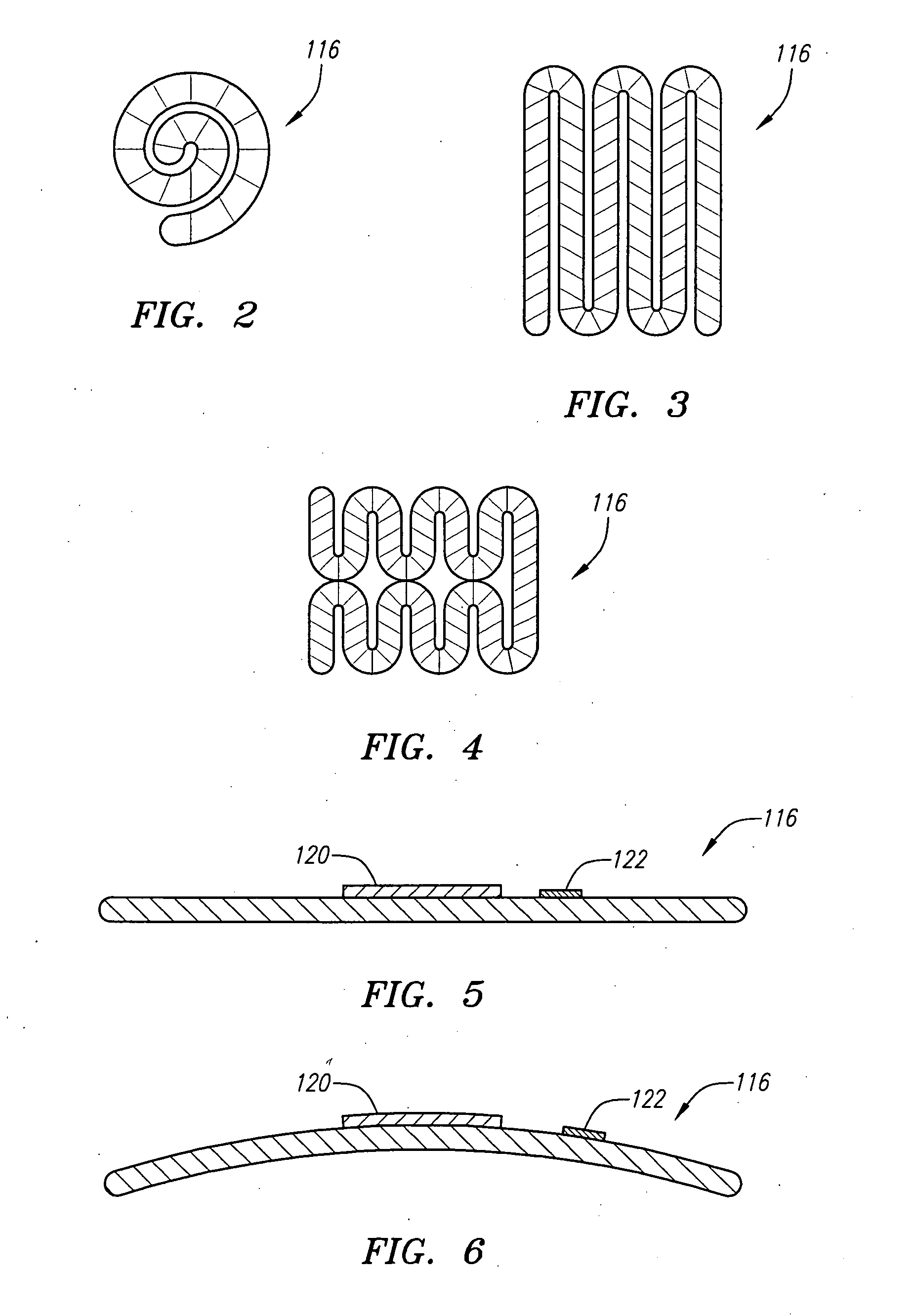

Collapsible/expandable electrode leads

ActiveUS7177702B2Facilitate collapsing of the medical leadProvide stabilitySpinal electrodesHead electrodesSurgical departmentMembrane configuration

Owner:BOSTON SCI SCIMED INC

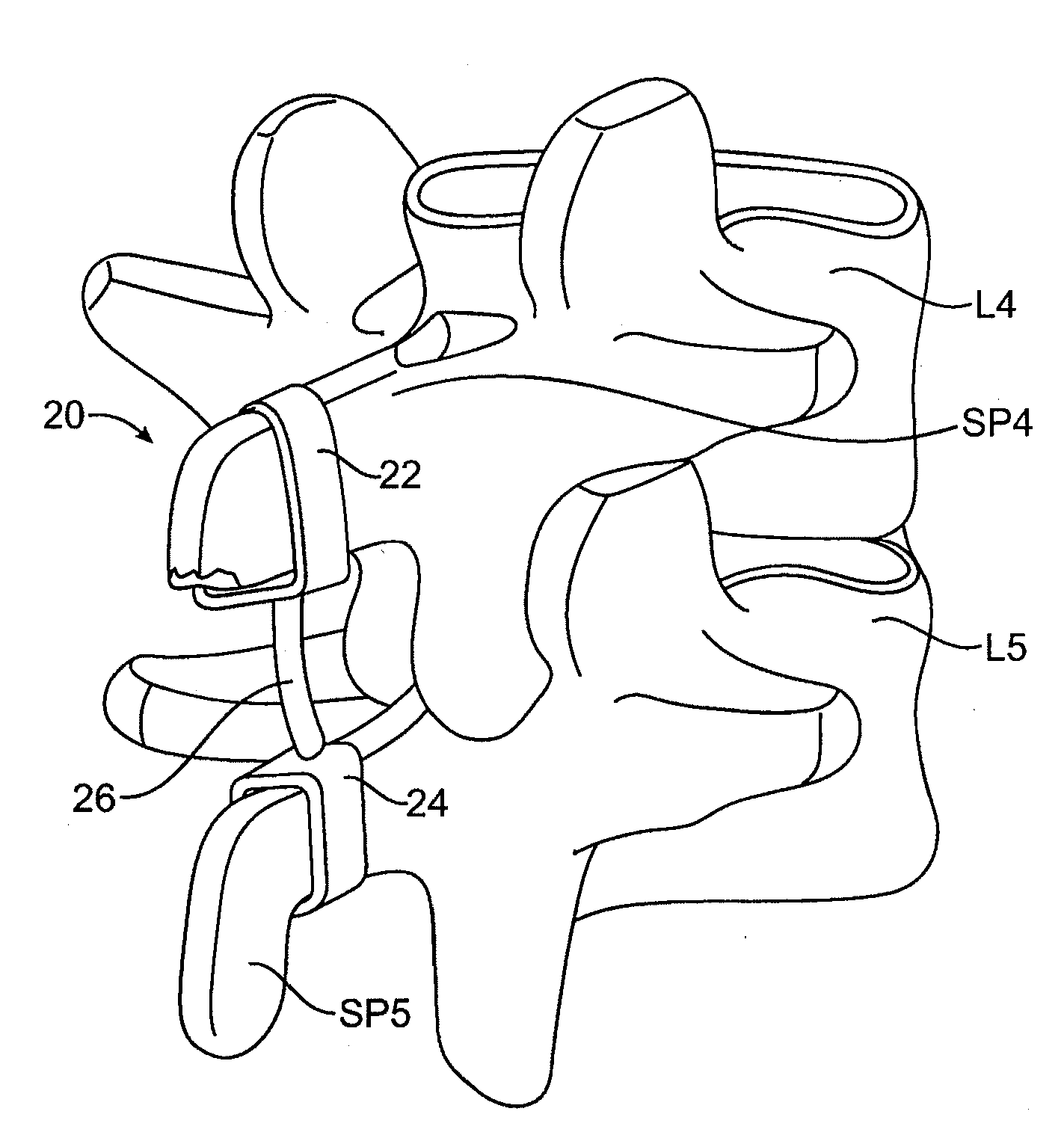

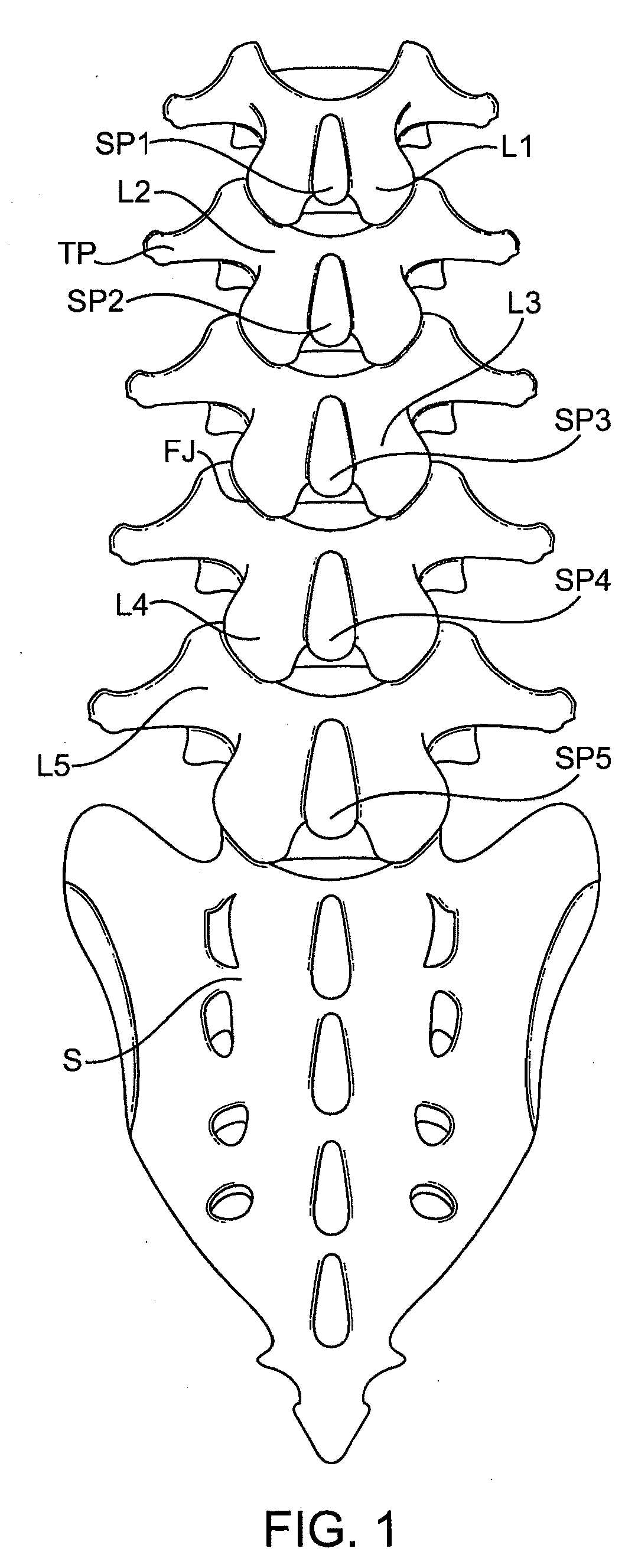

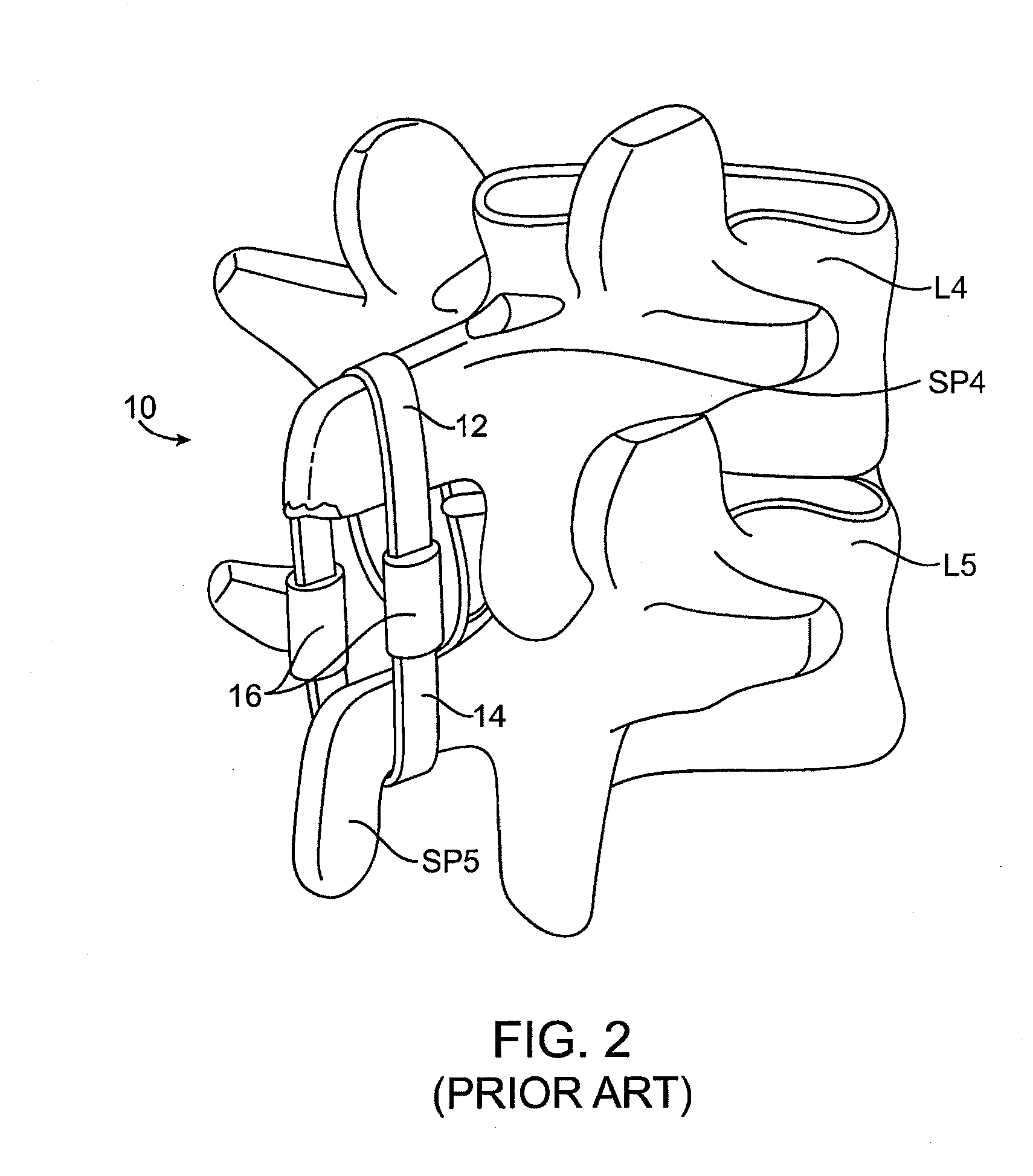

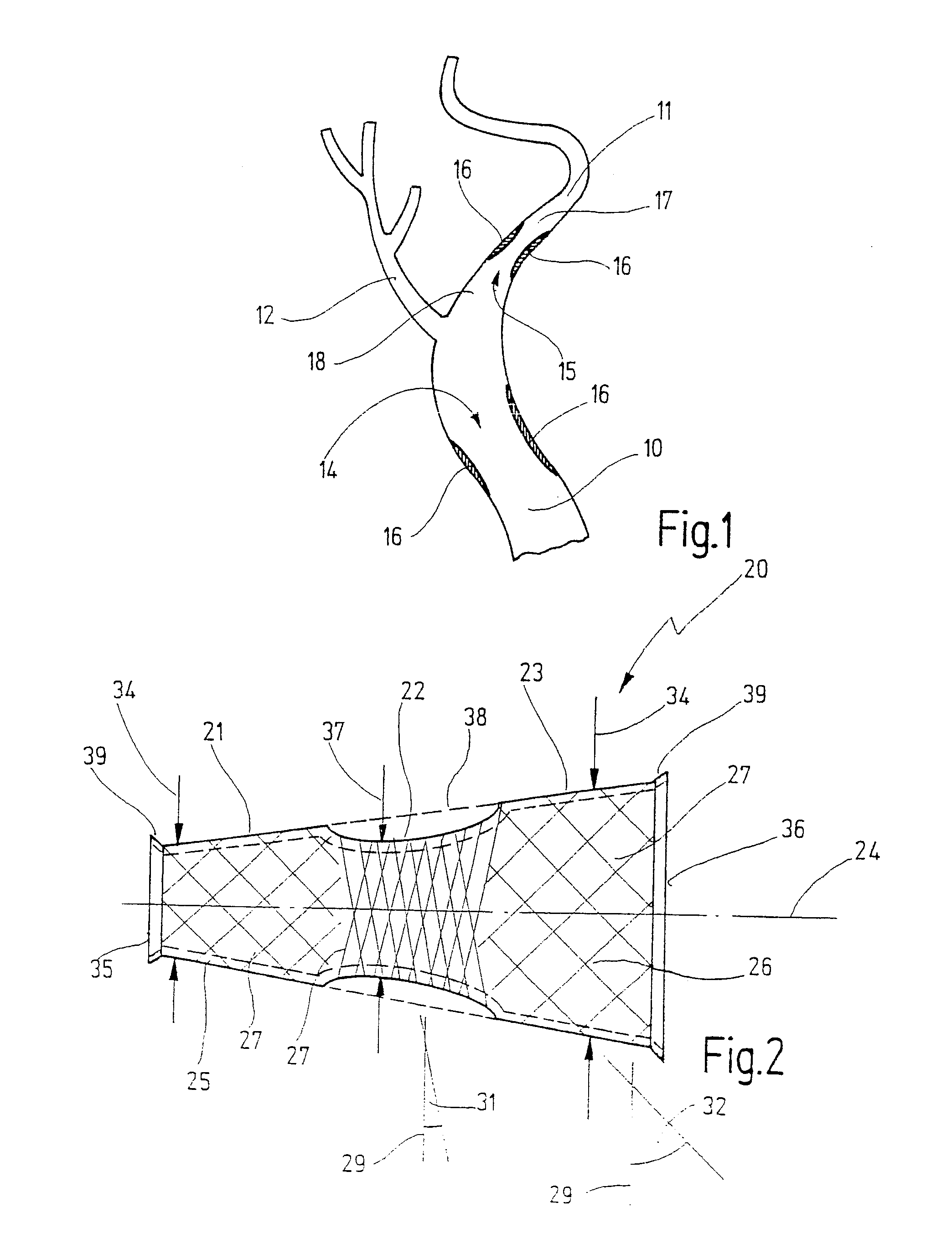

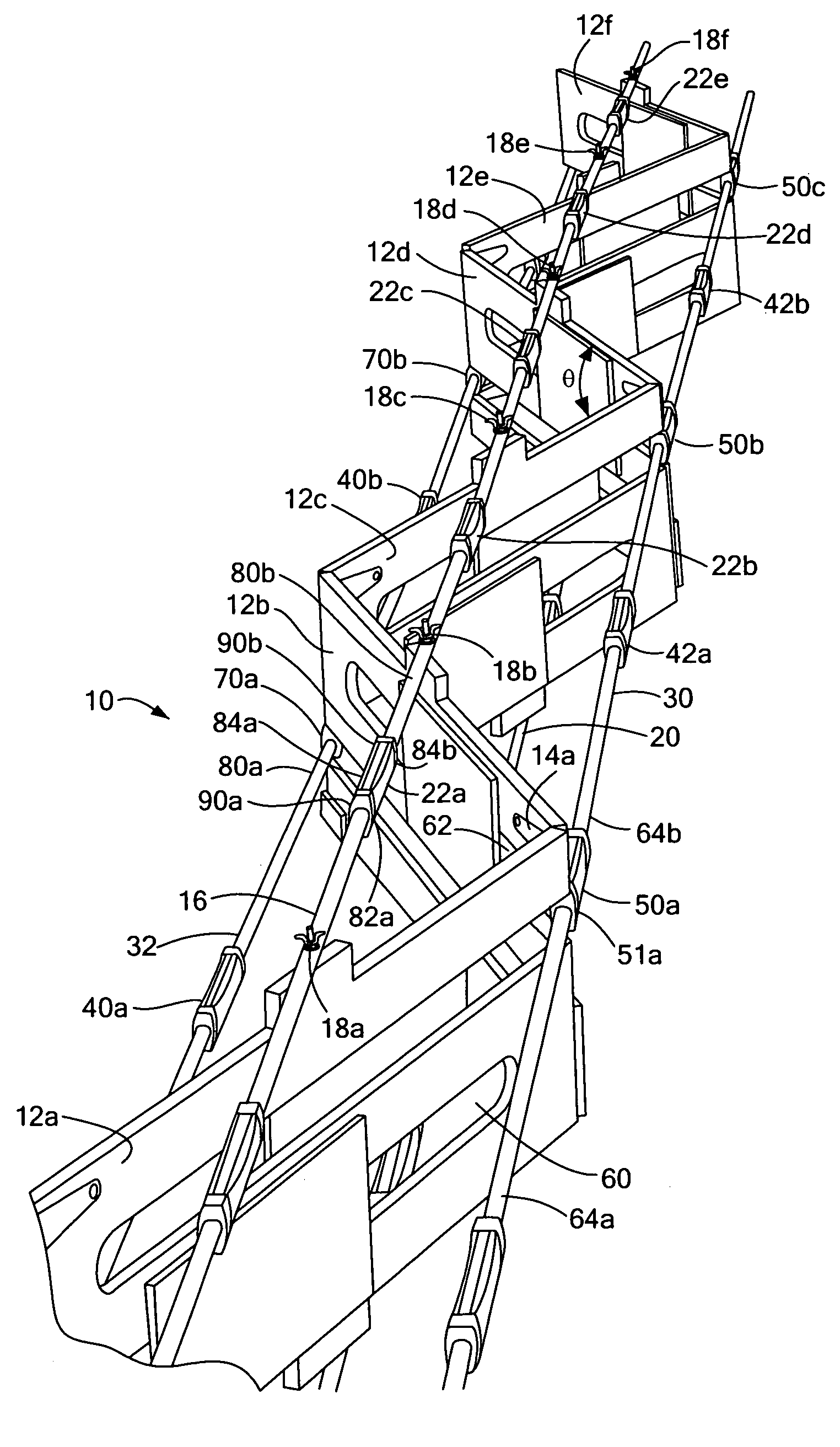

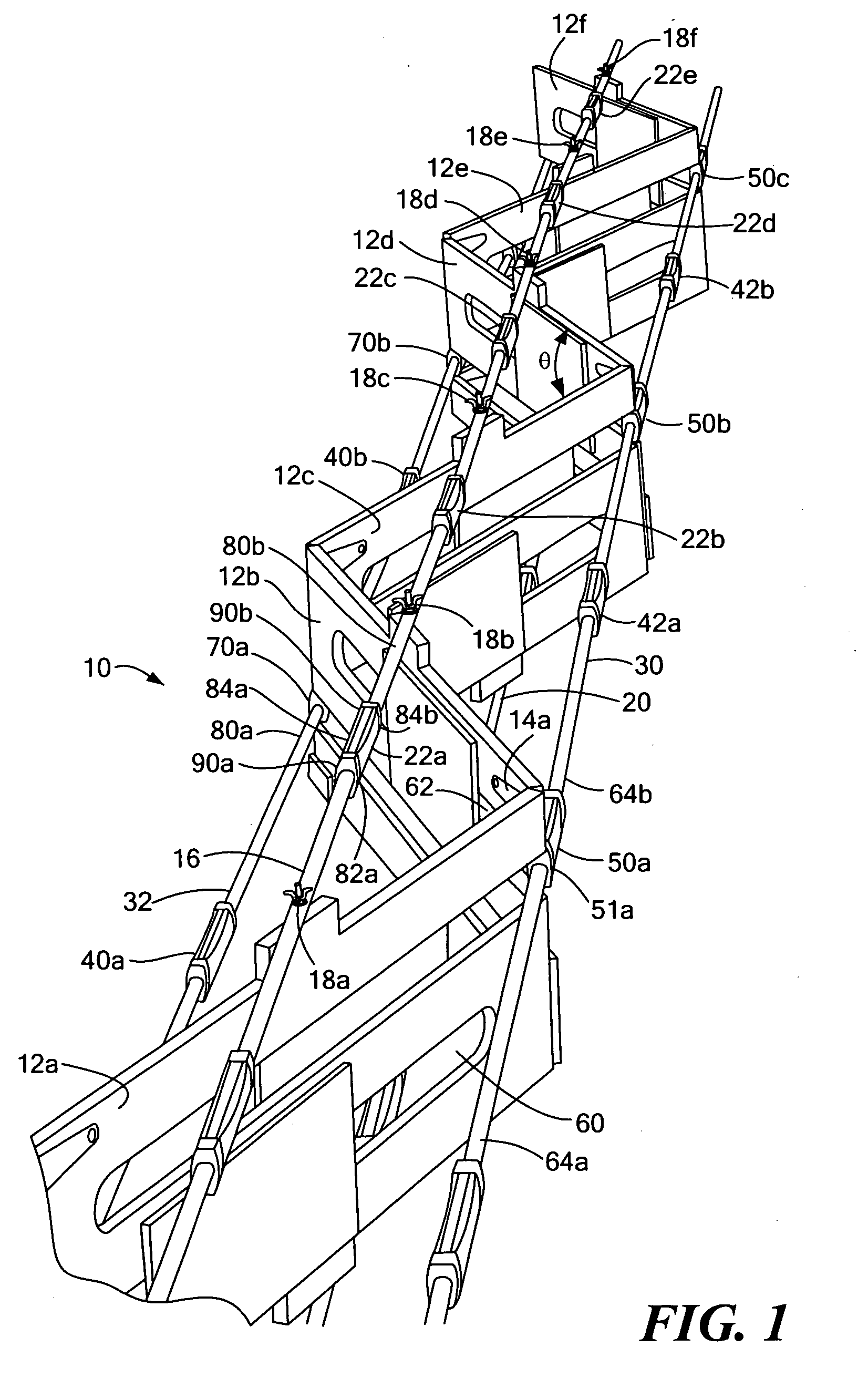

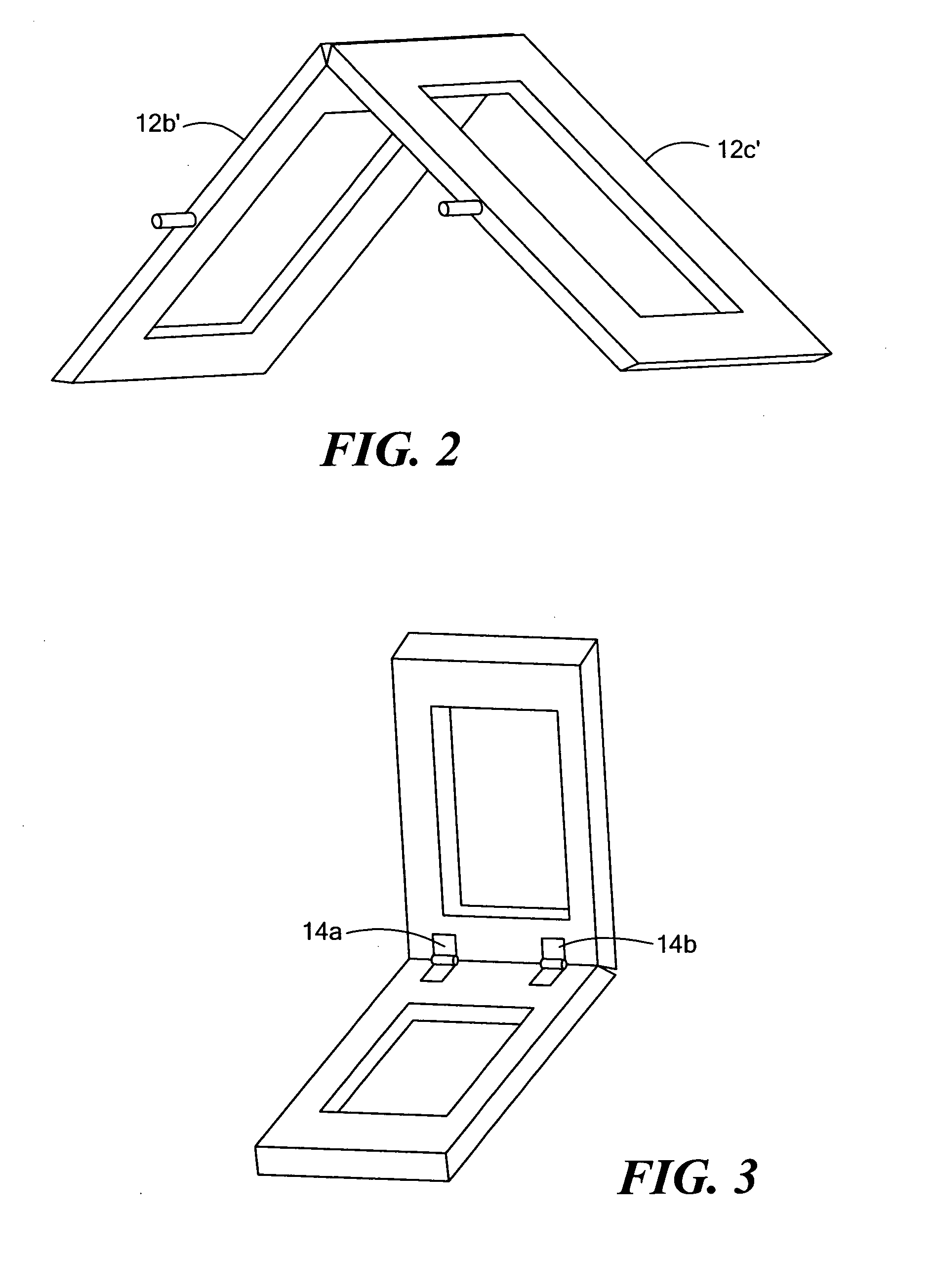

Structures and methods for constraining spinal processes with single connector

ActiveUS20090264929A1Simplify alignmentImplantation be simplifyInternal osteosythesisJoint implantsSpinous processEngineering

Spinous process constraint structures include a first attachment element for placement over a first spinous process and a second attachment element for placement over a second spinous process. The attachment elements are joined by a single connector which may optionally include a compliance member for providing controlled elasticity between the spinous processes.

Owner:SIMPIRICA SPINE

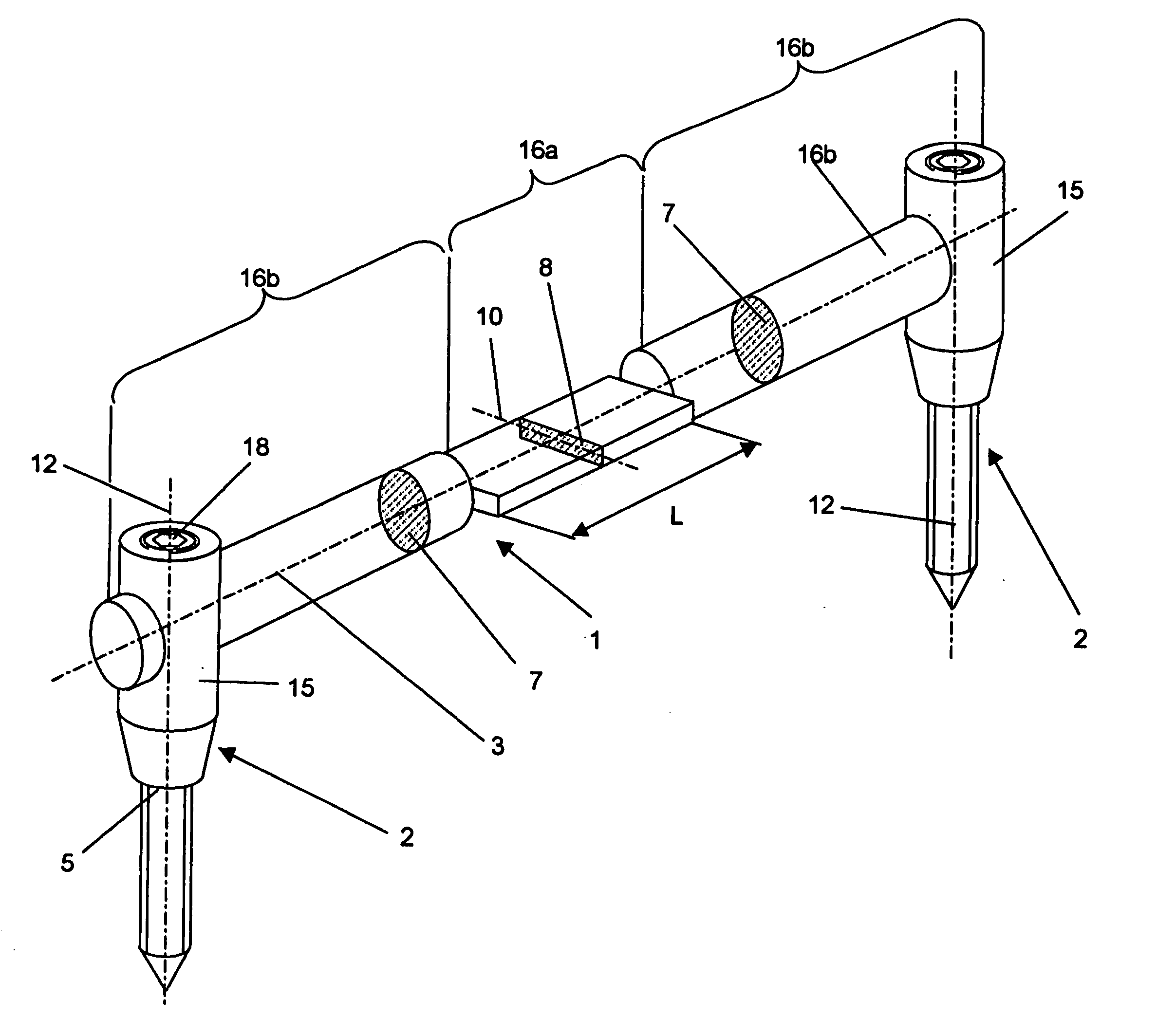

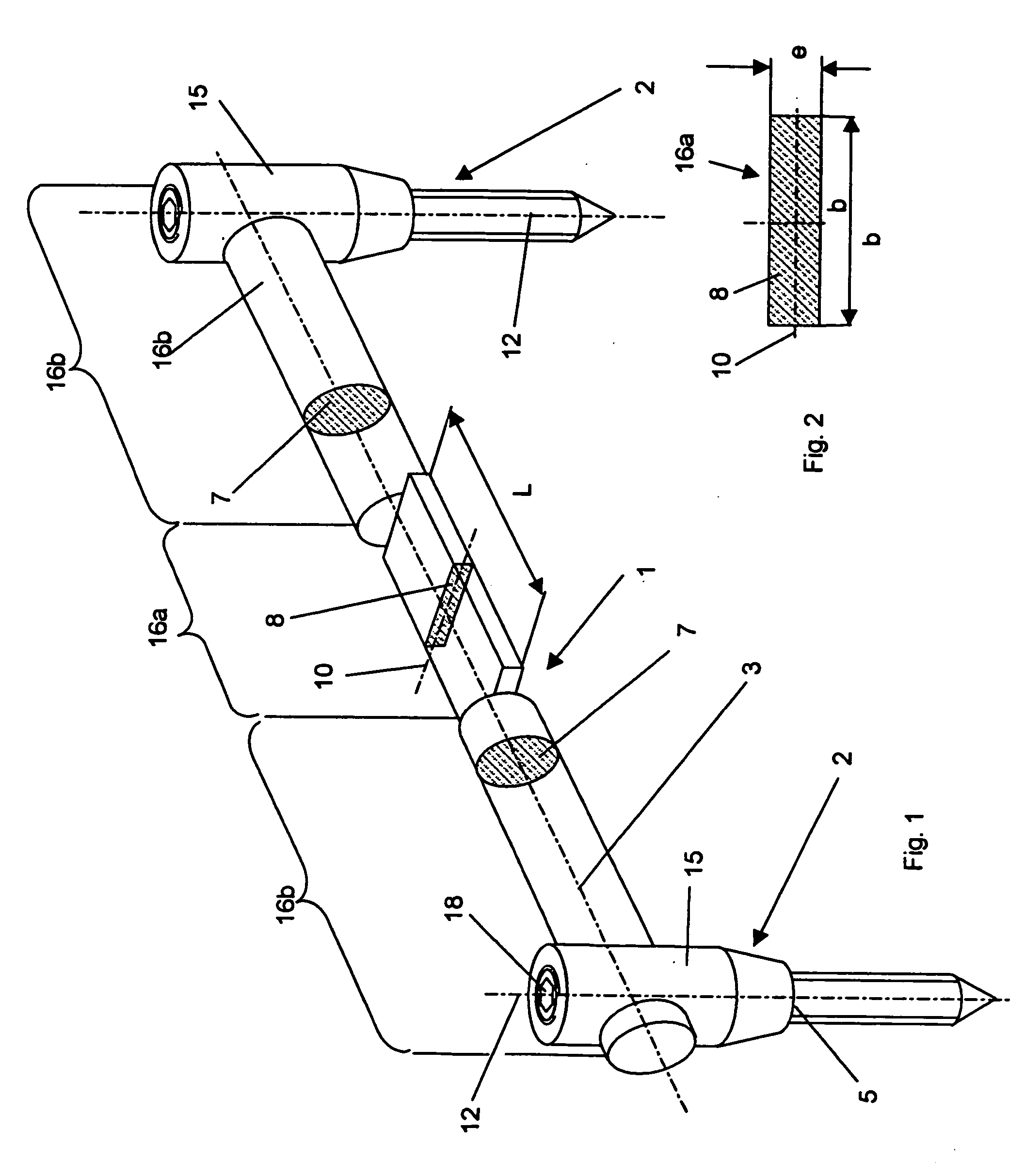

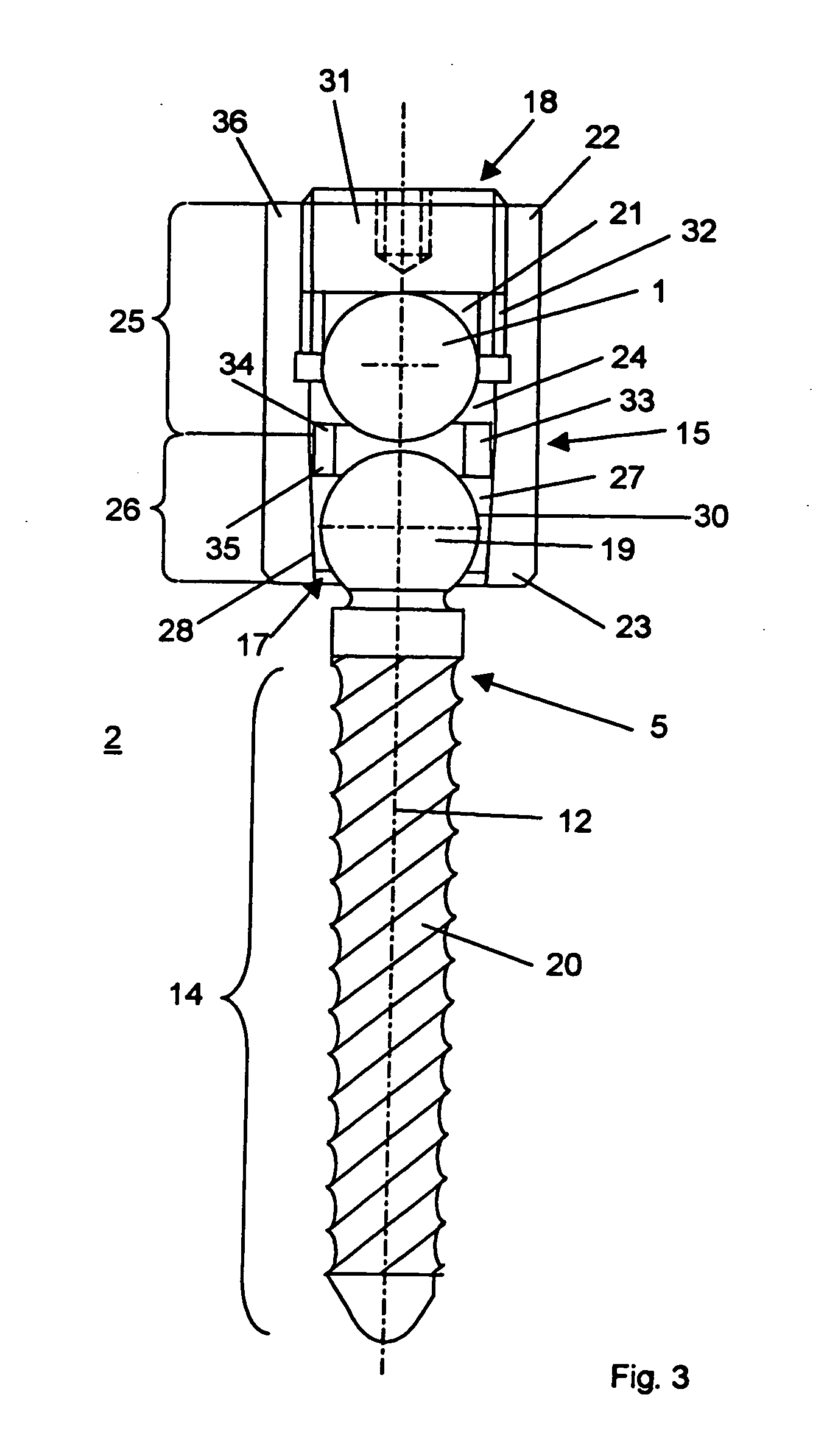

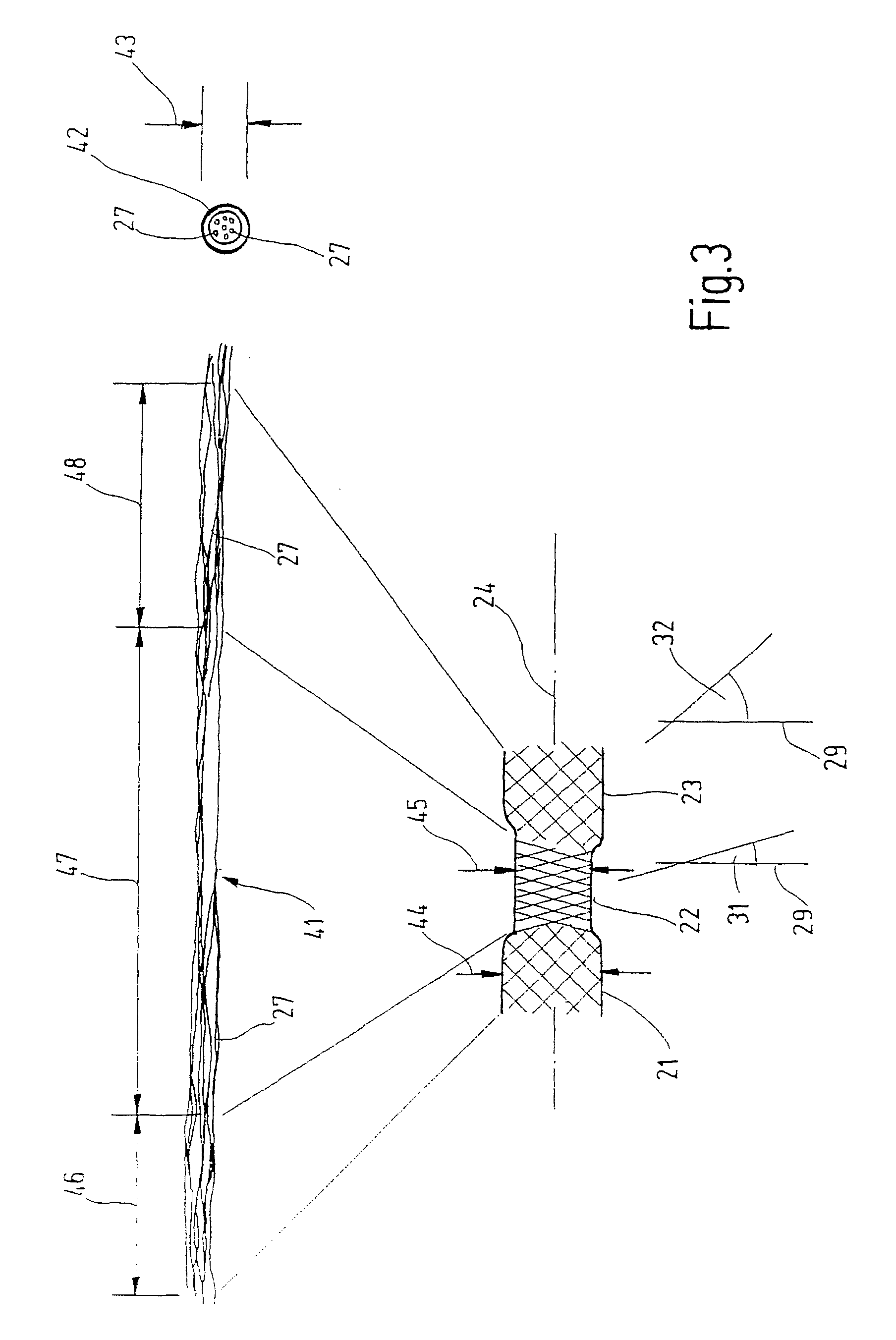

Device for the dynamic stabilization of bones

InactiveUS20070123865A1Maximum flexibilityOvercome the small stiffnessInternal osteosythesisJoint implantsBone fragmentBiomedical engineering

Owner:DEPUY SYNTHES PROD INC

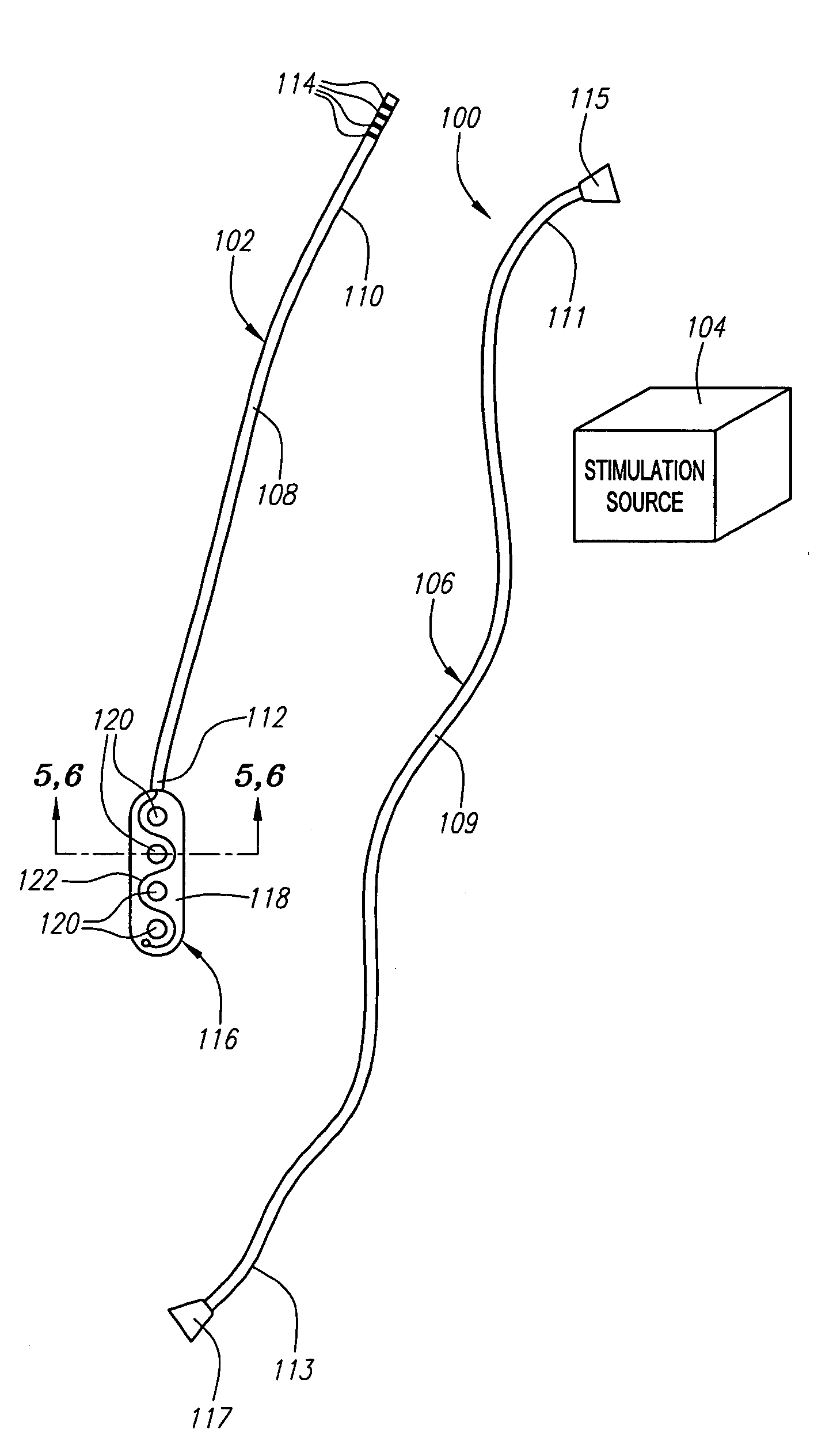

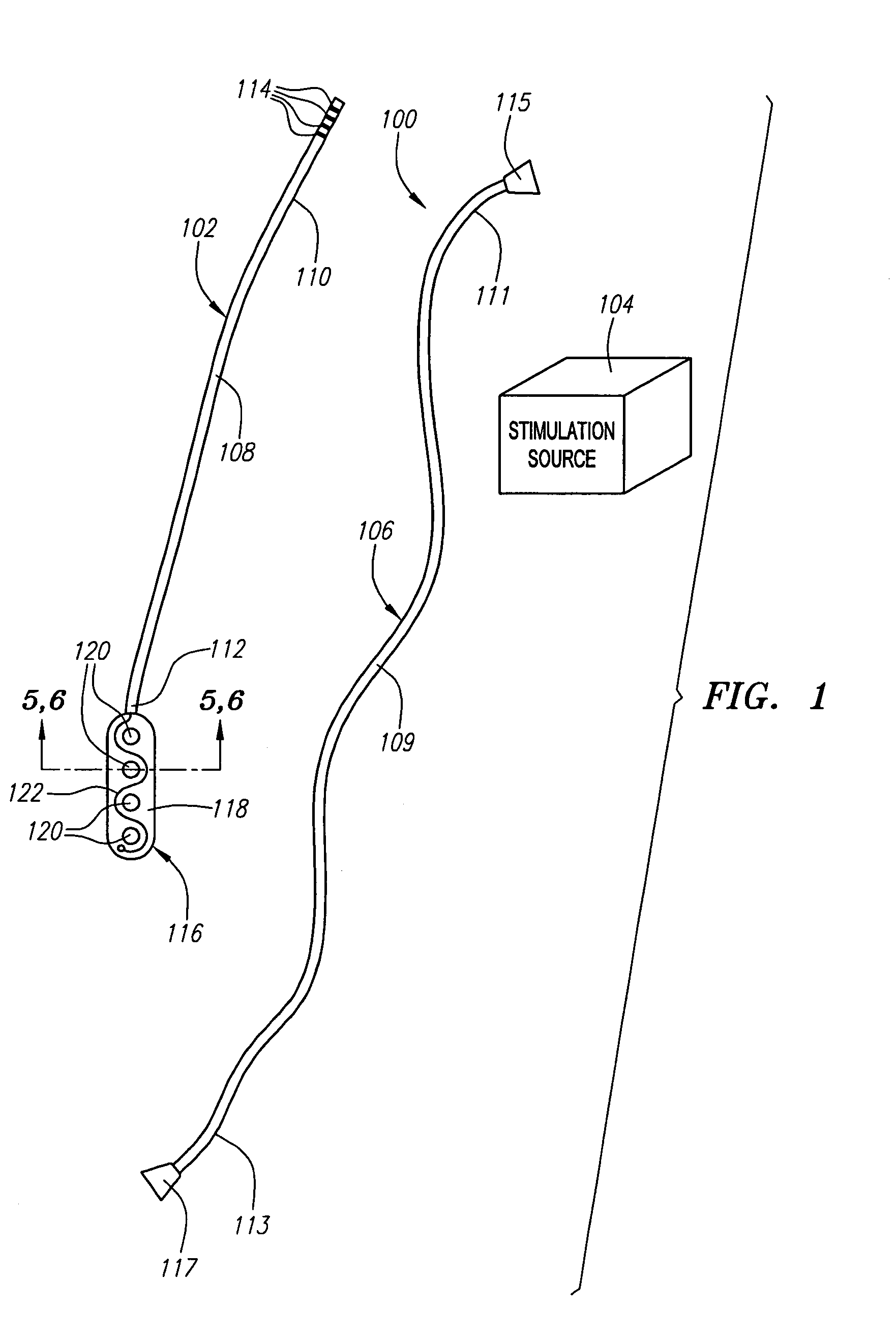

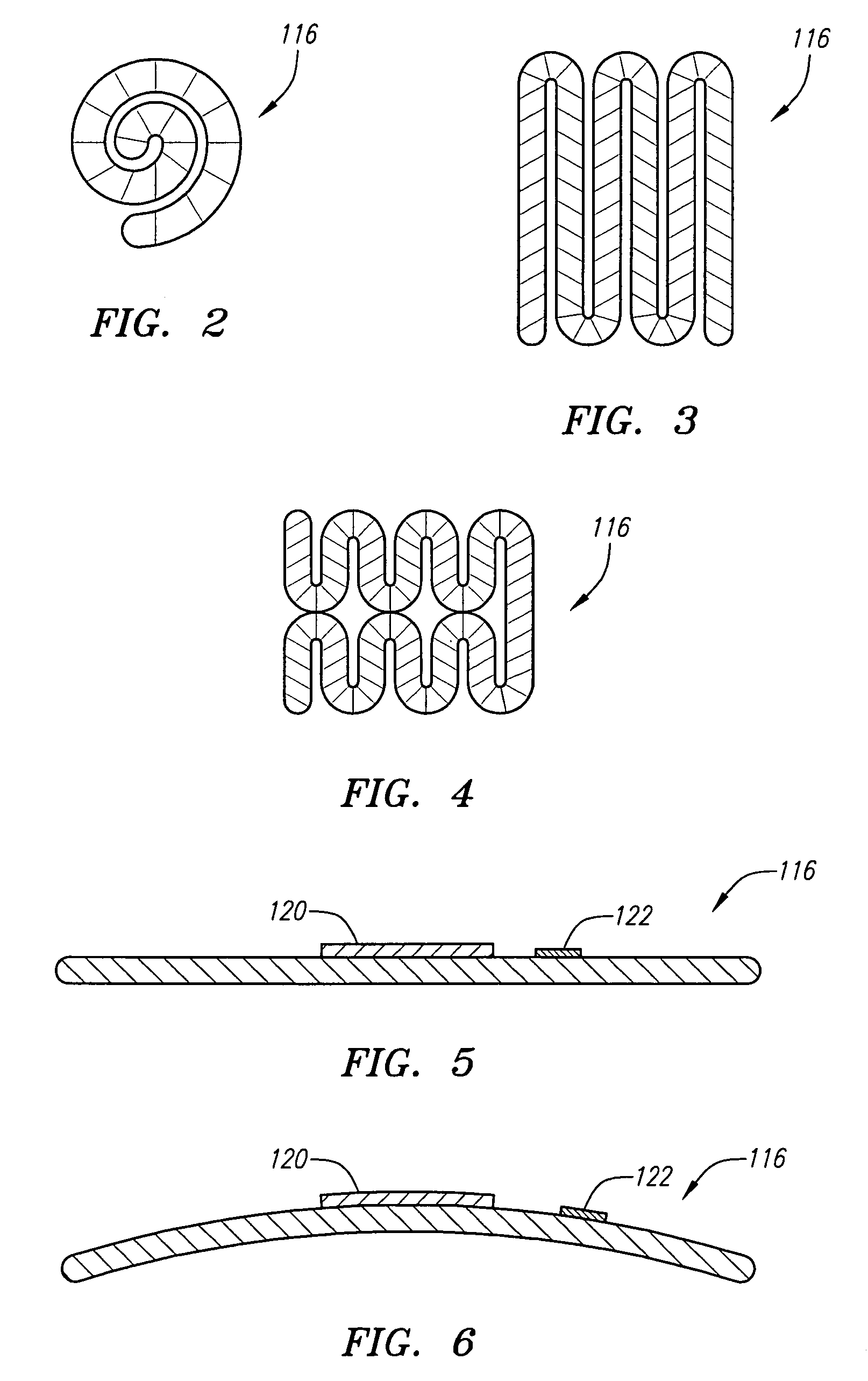

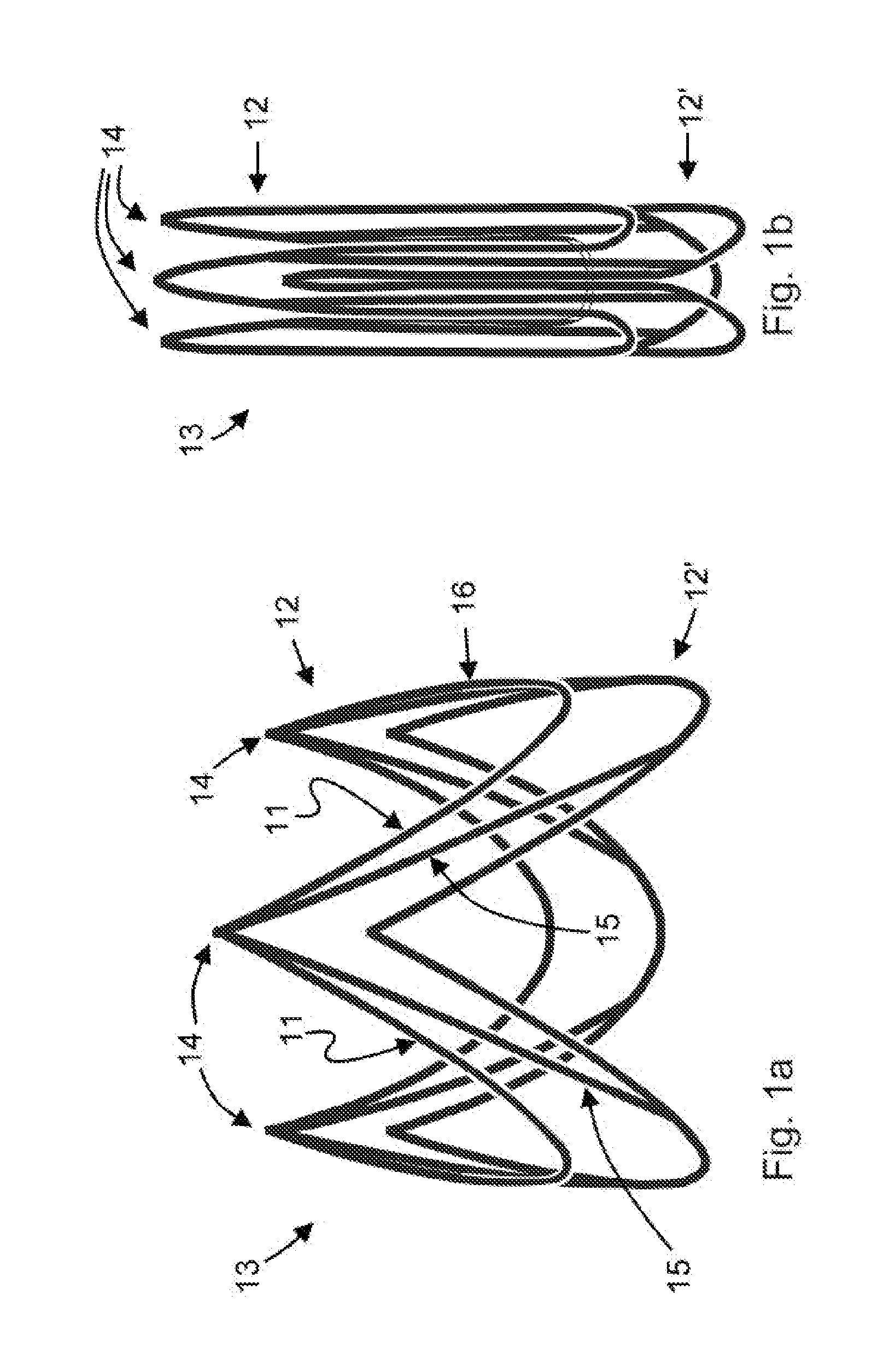

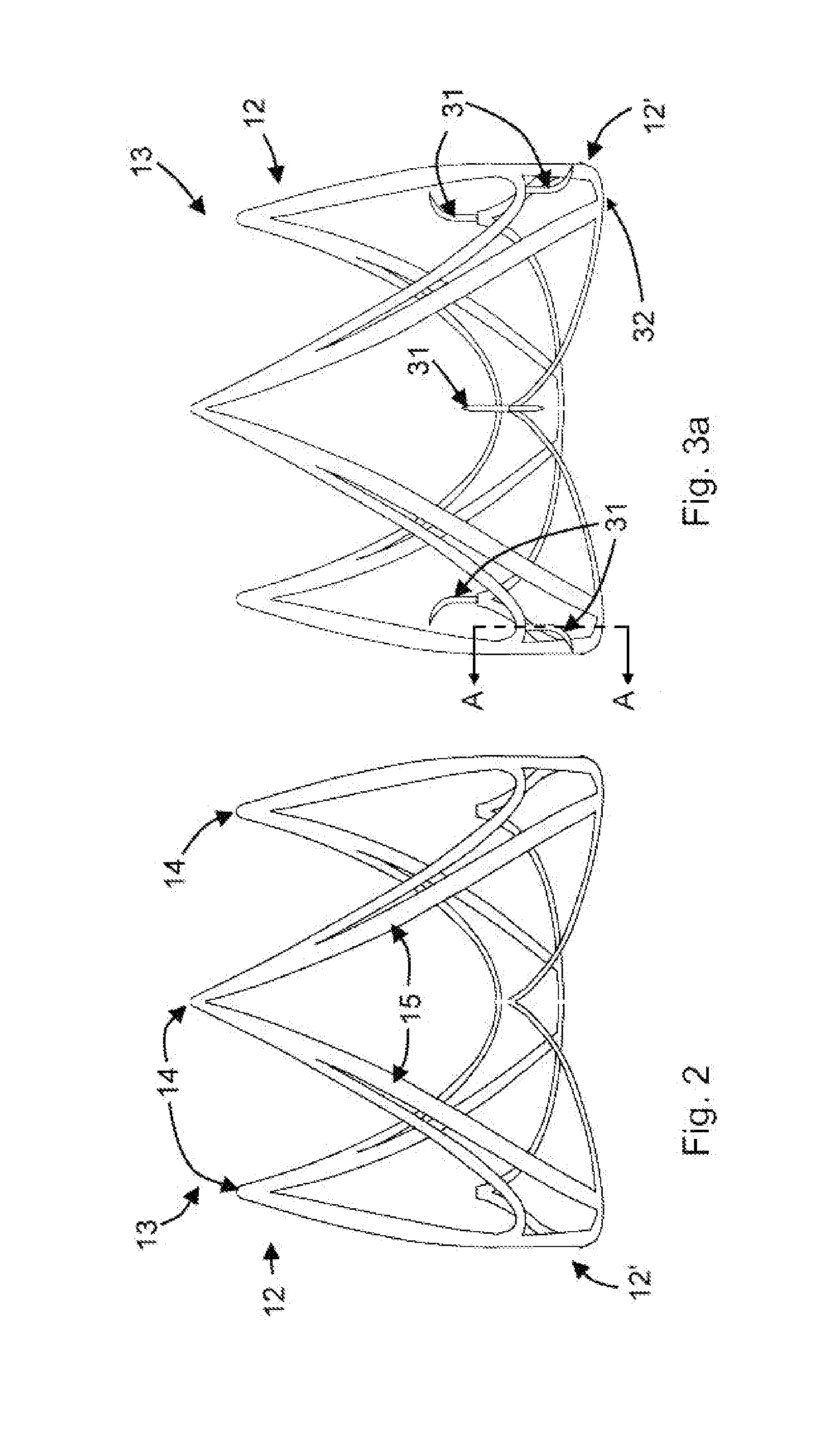

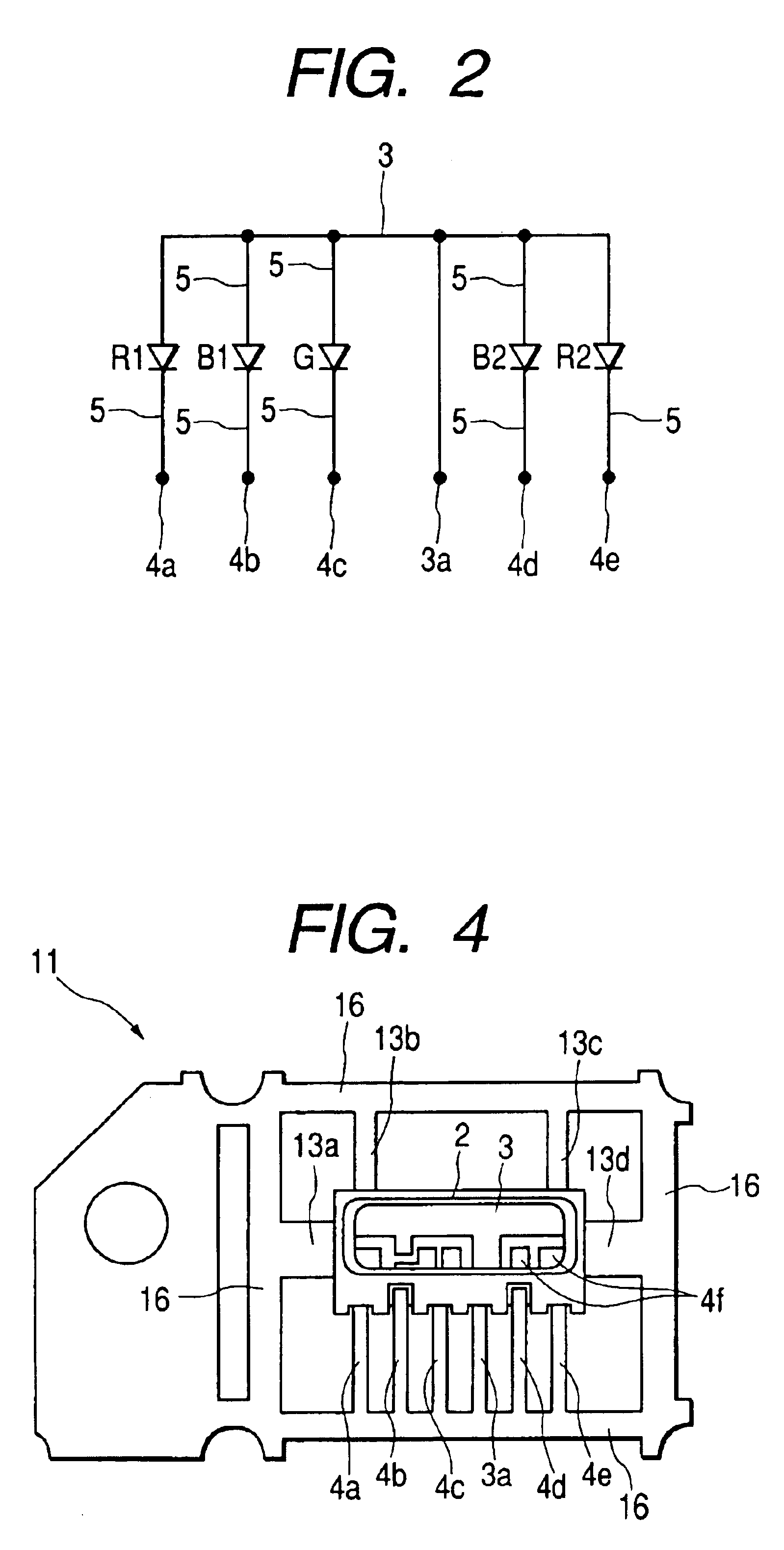

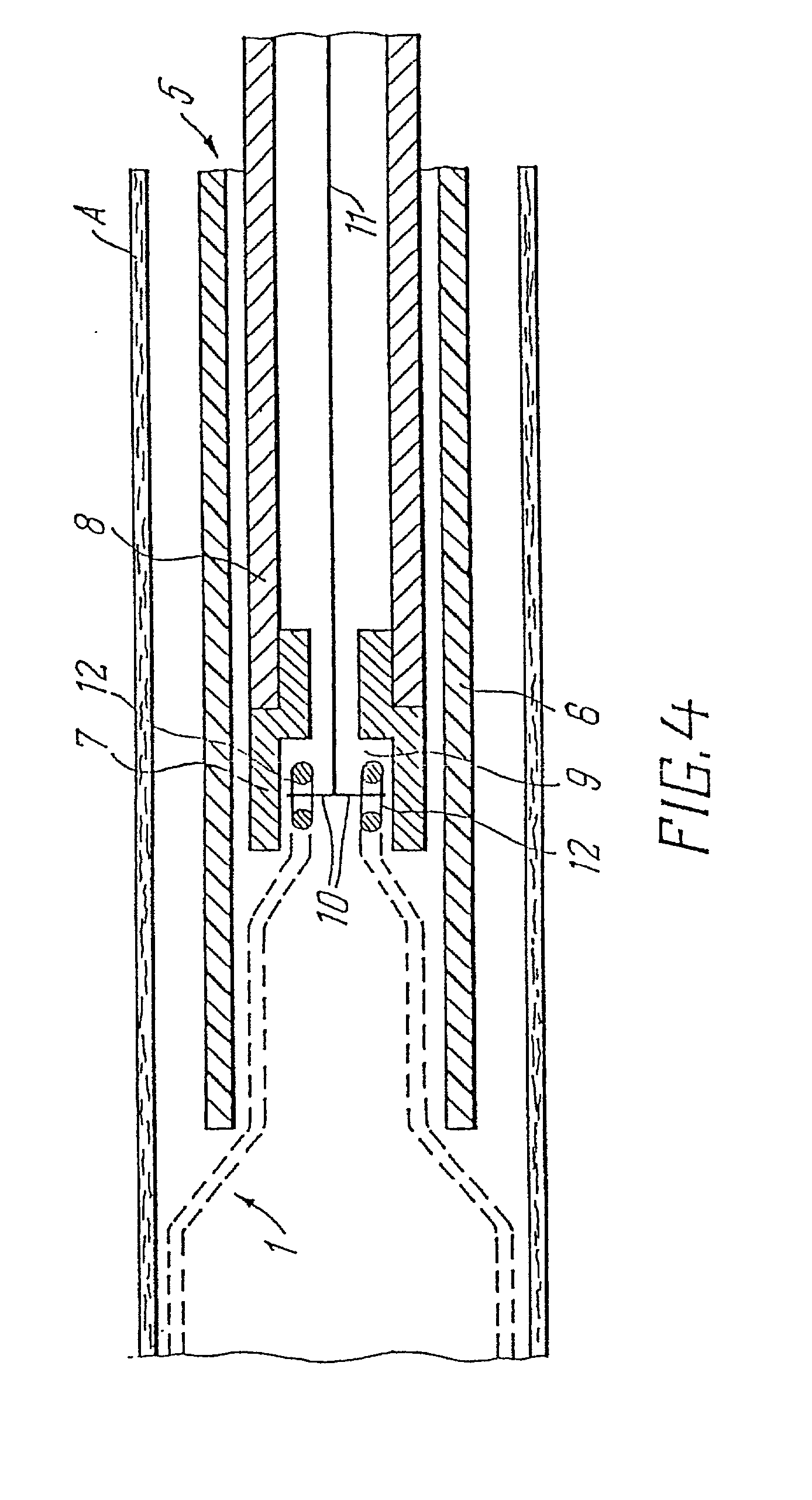

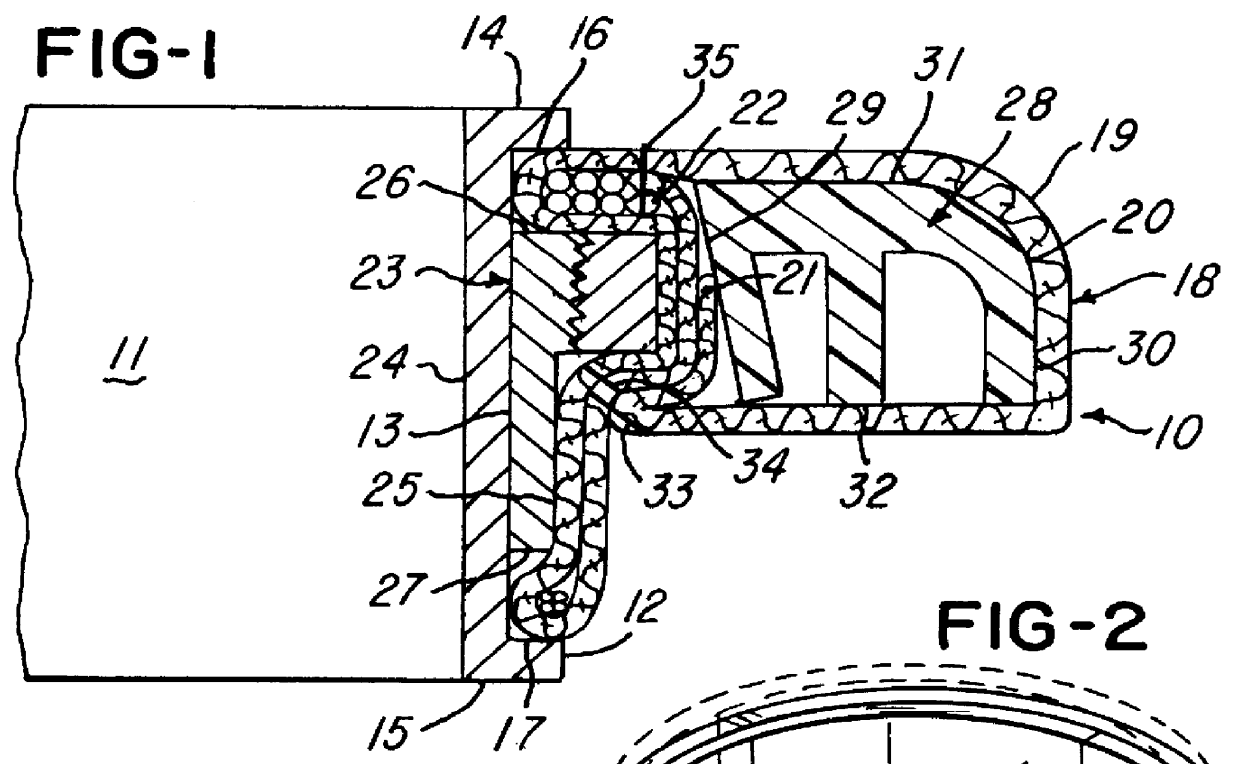

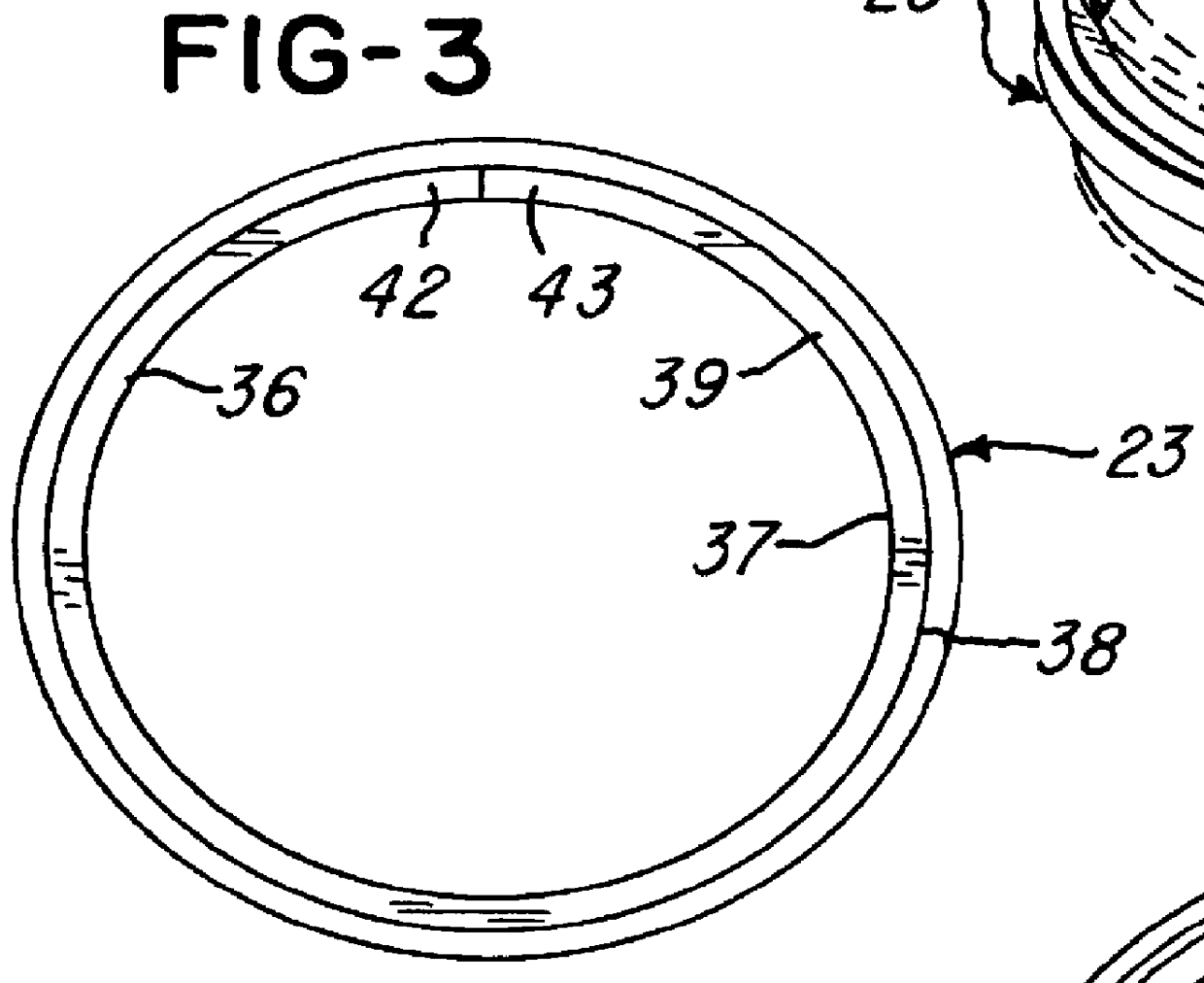

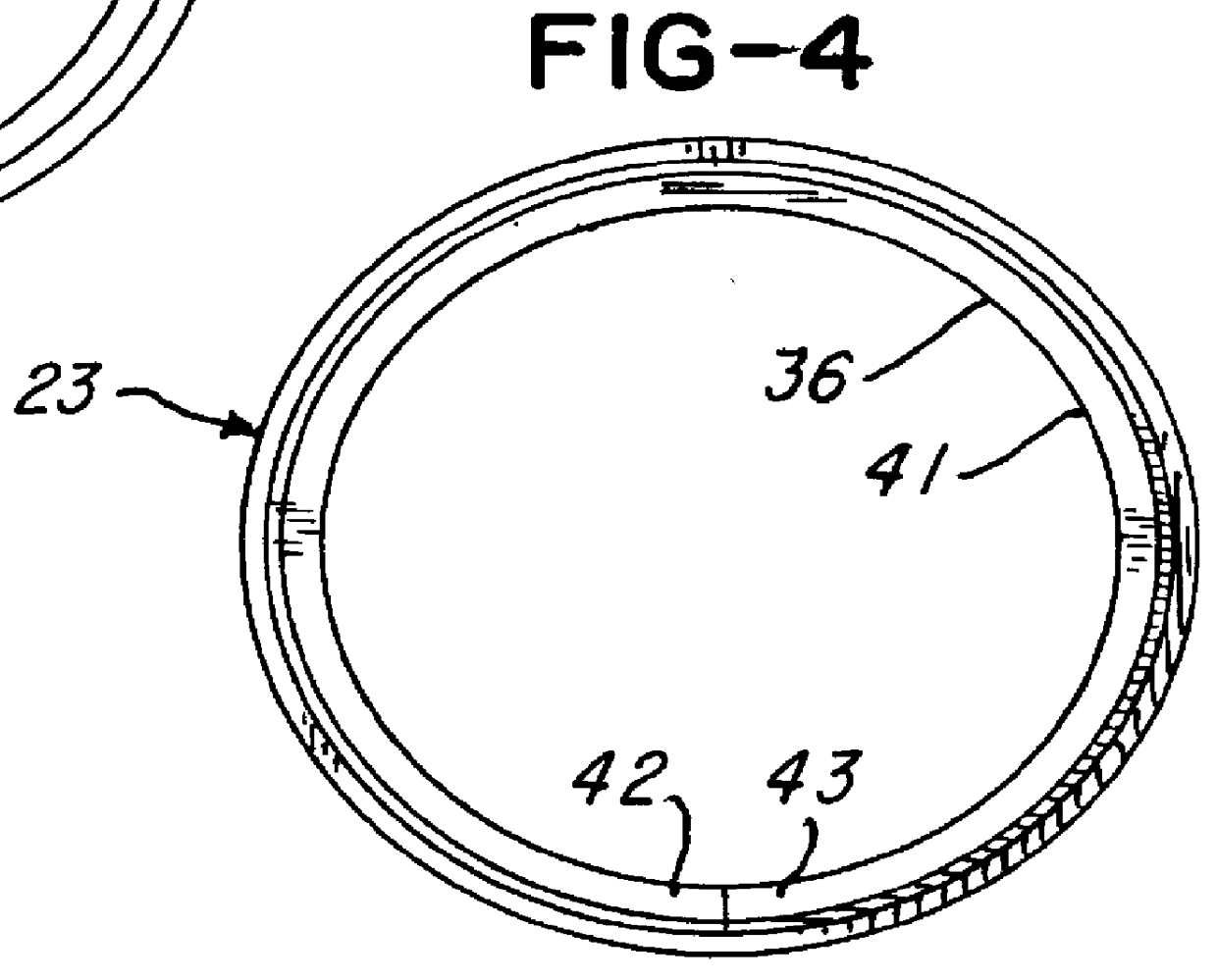

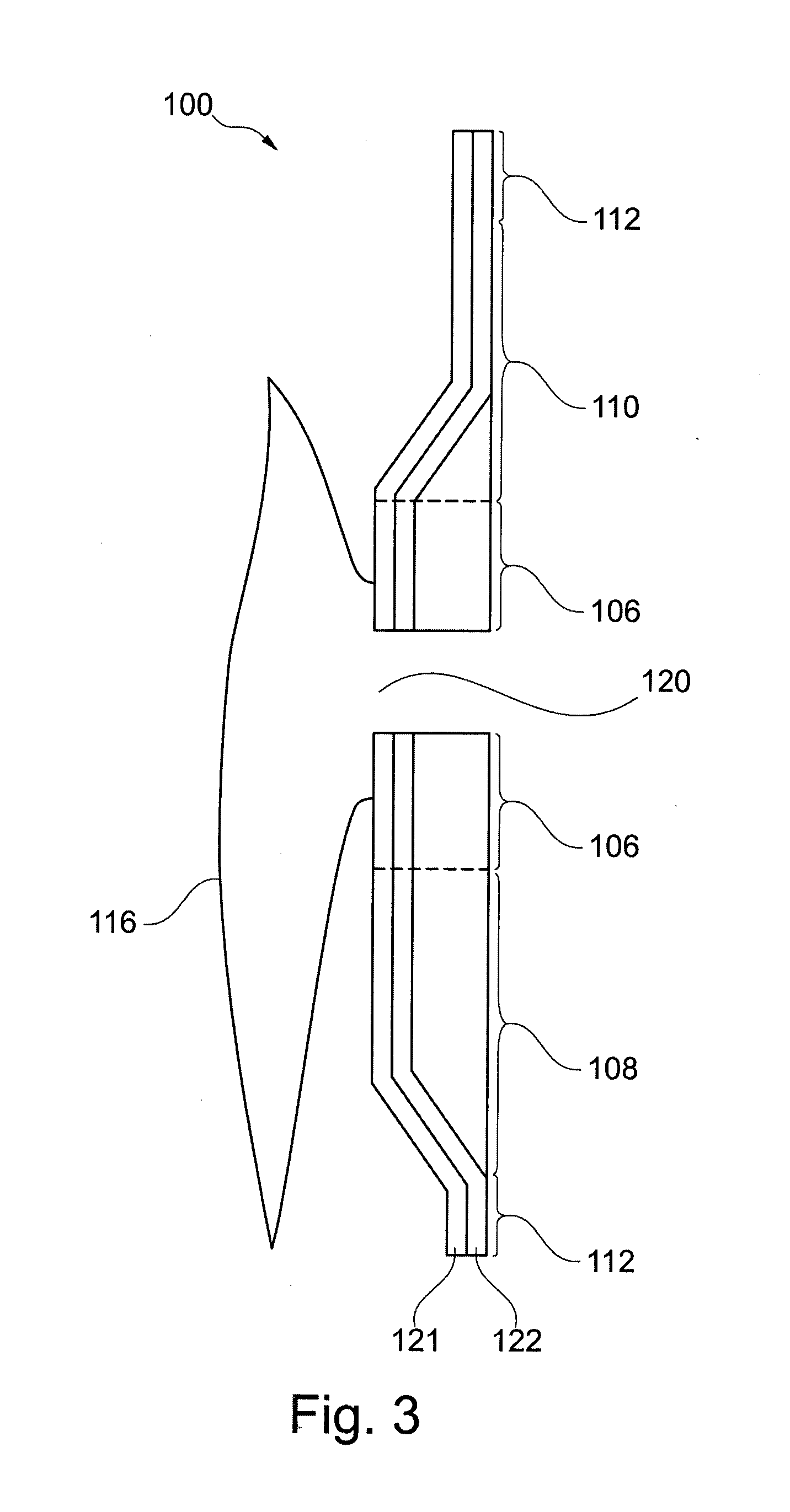

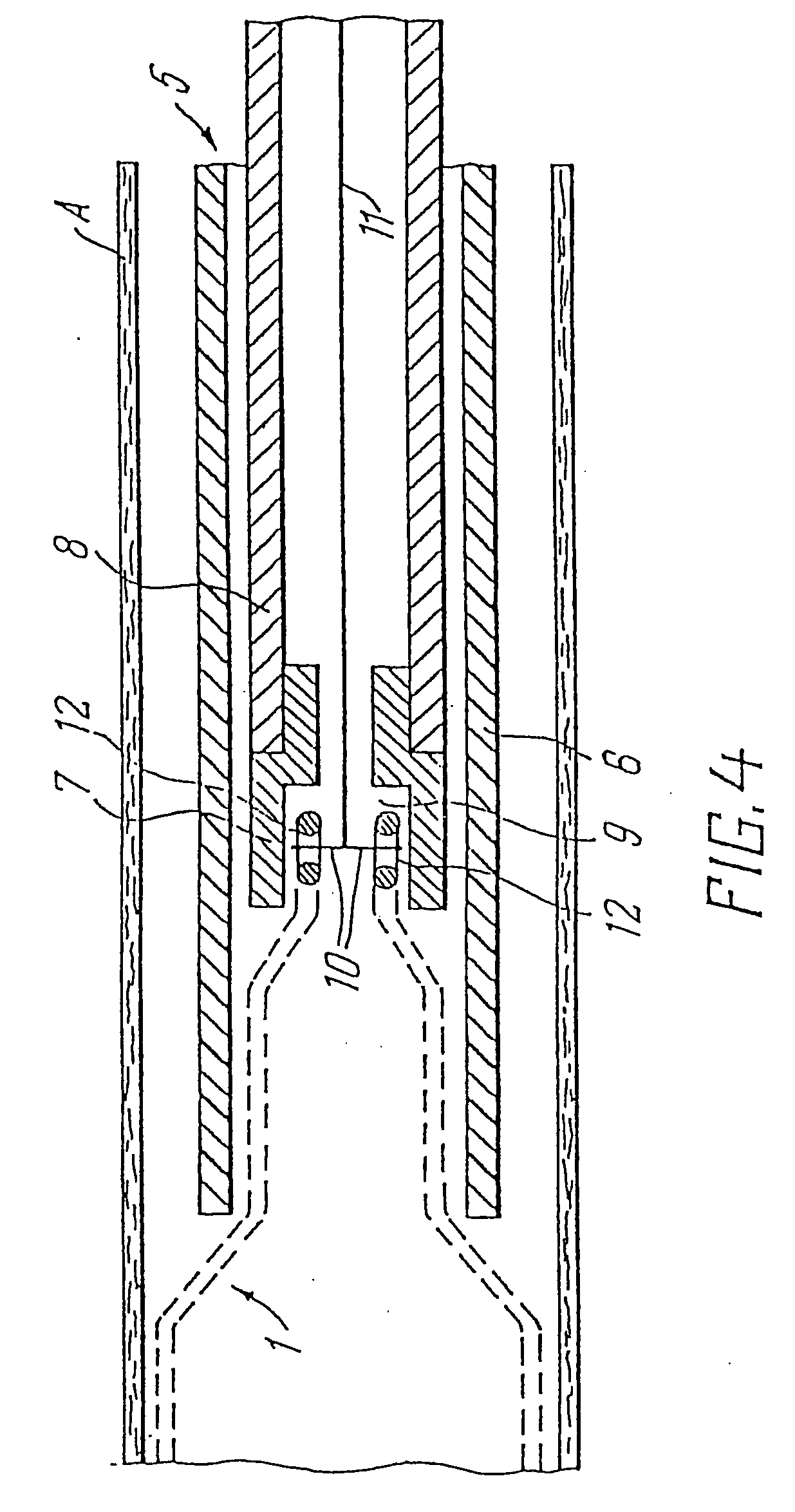

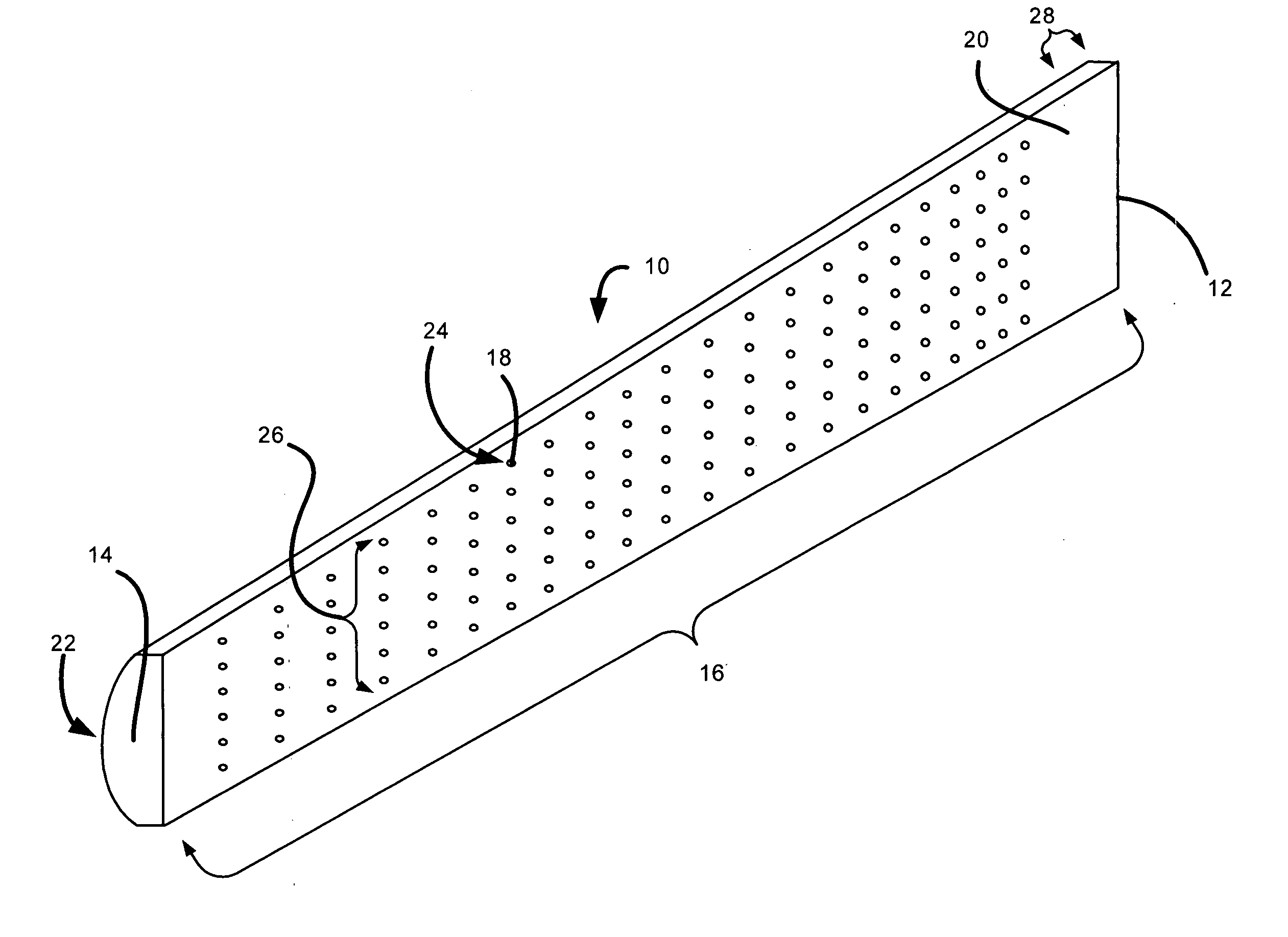

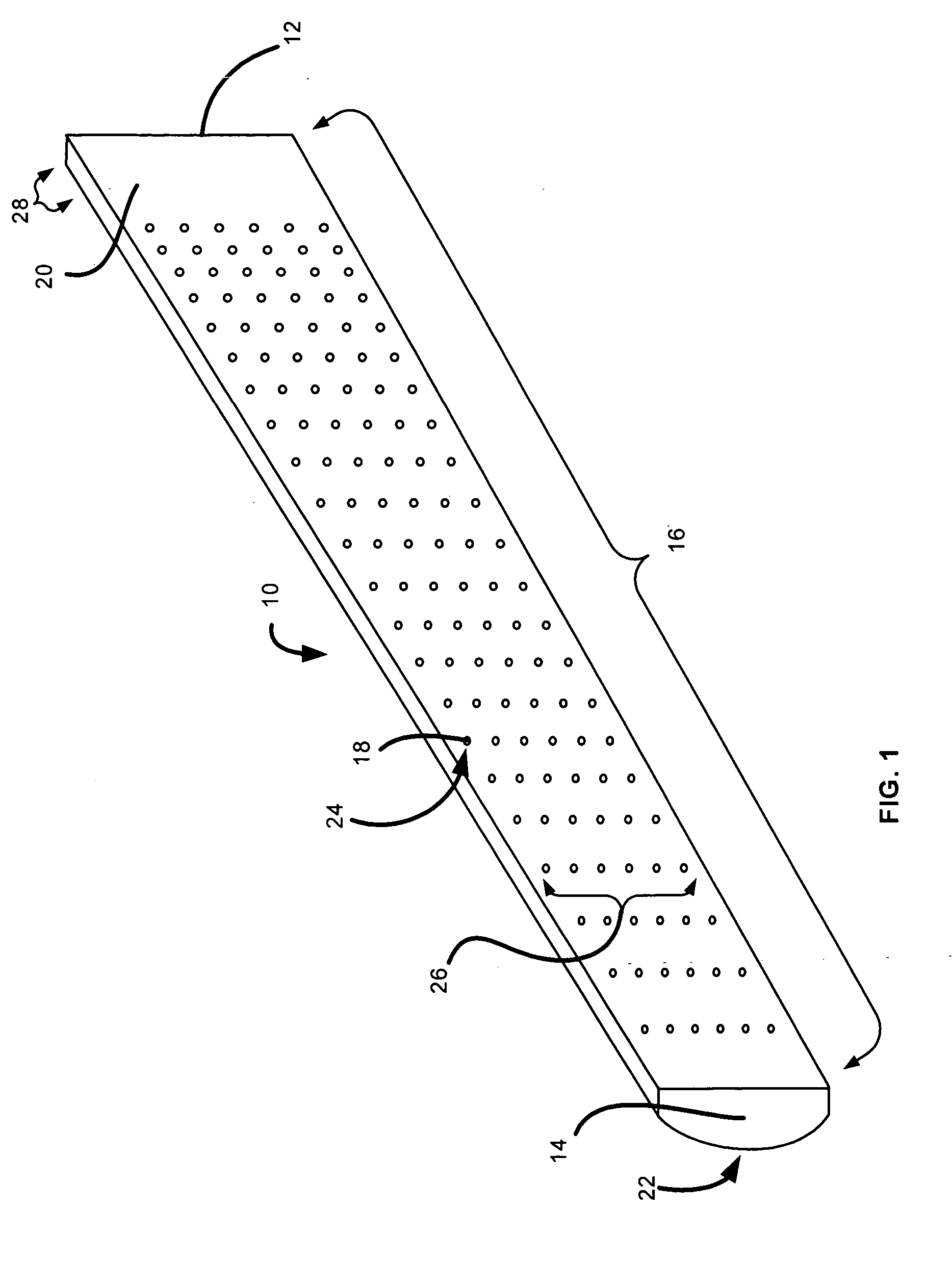

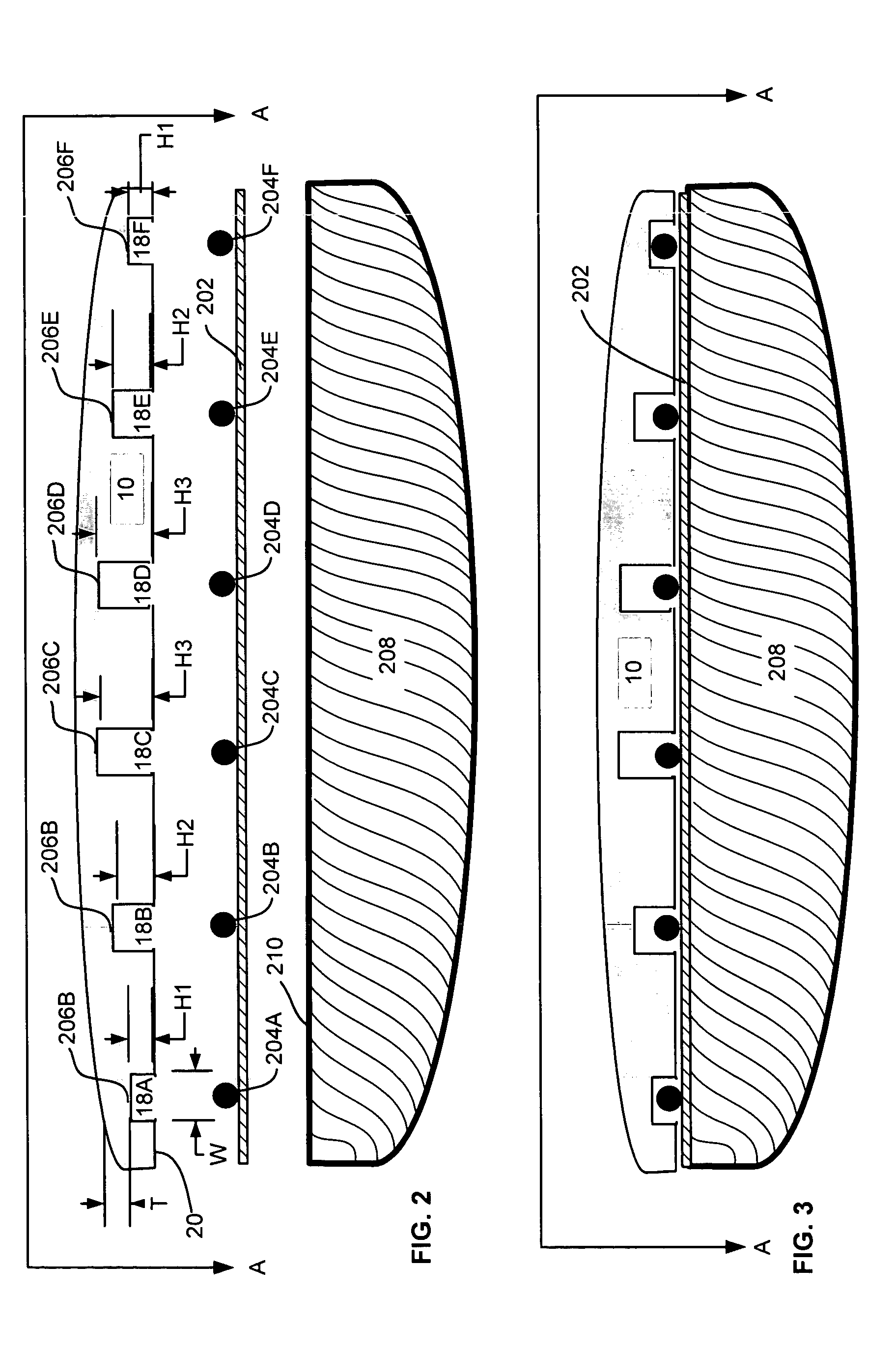

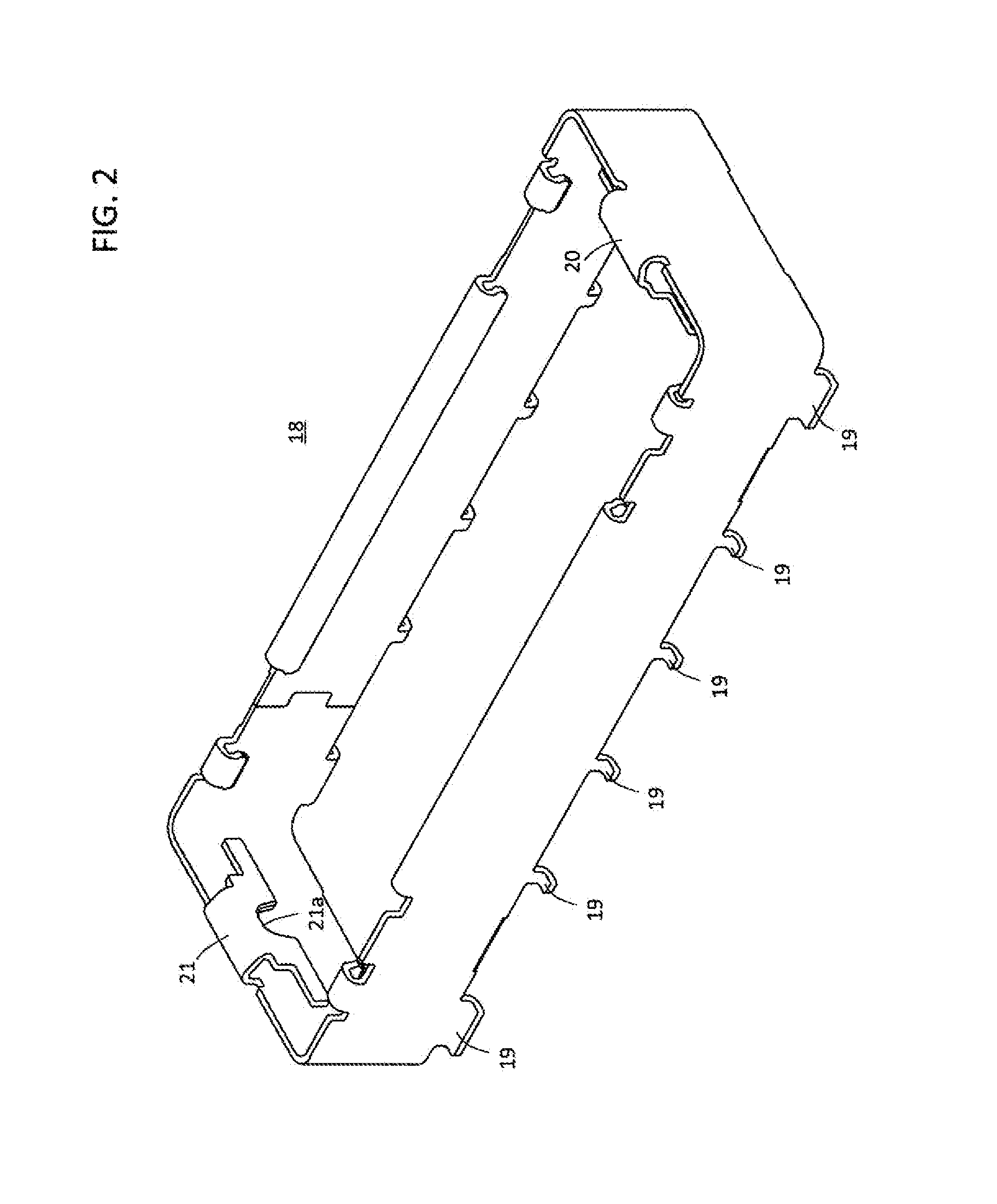

Collapsible/expandable electrode leads

ActiveUS20050203602A1Providing mechanical stabilityFacilitate collapsing of the medical leadSpinal electrodesHead electrodesSpinal cordSurgical department

A medical lead and method of treating a patient are provided. The medical lead comprises an electrically insulative membrane, a resilient spring element associated with the insulative membrane, and at least one electrode associated with the insulative membrane. The spring layer is configured to urge that insulative membrane into an expanded geometry. The medical lead is configured to be collapsed into a compact form for percutaneous delivery into the patient, thereby obviating the need to perform an invasive surgical procedure on the patient. The body formed by these elements, when expanded, can be sized to fit within the epidural space of a patient. The patient can be treated by placing the medical lead into a collapsed state by applying a compressive force to the medical lead, percutaneously delivering the collapsed medical lead into the patient adjacent tissue to be treated, and placing the medical lead into an expanded state by releasing the compressive force. In one preferred method, the stimulation lead is used to stimulate tissue, such as spinal cord tissue.

Owner:BOSTON SCI SCIMED INC

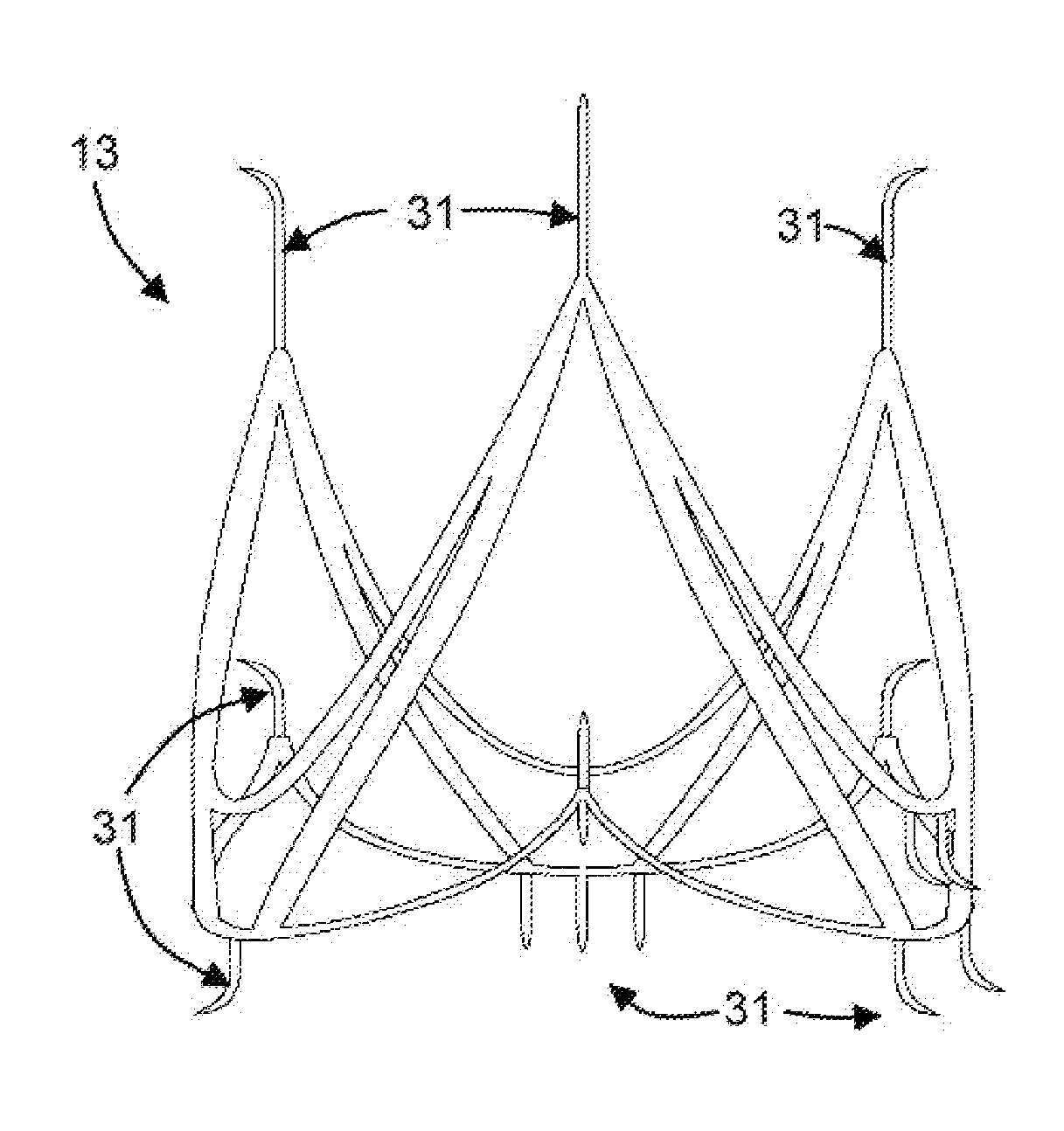

Percutaneously implantable flap stent, device for applying the same and method for producing the flap stent

ActiveUS20120101567A1Overcome the small stiffnessMinimal useStentsPharmaceutical containersInsertion stentThin walled

A valve stent includes a plurality of crown elements arranged coaxially one behind the other, each formed by several u-shaped bends with at least one base and two ends. The bases of one crown element are connected to the ends of another crown element via connection bars. To produce this valve stent, 3D droplet dosing technology is used to form a thin-walled sandwich structure. A device, suitable for application of a stent is provided with positioning wires having clamps at their ends which can be connected to the fixing hooks at the ends of the crown elements in force-locking manner.

Owner:BIOLNIC UG

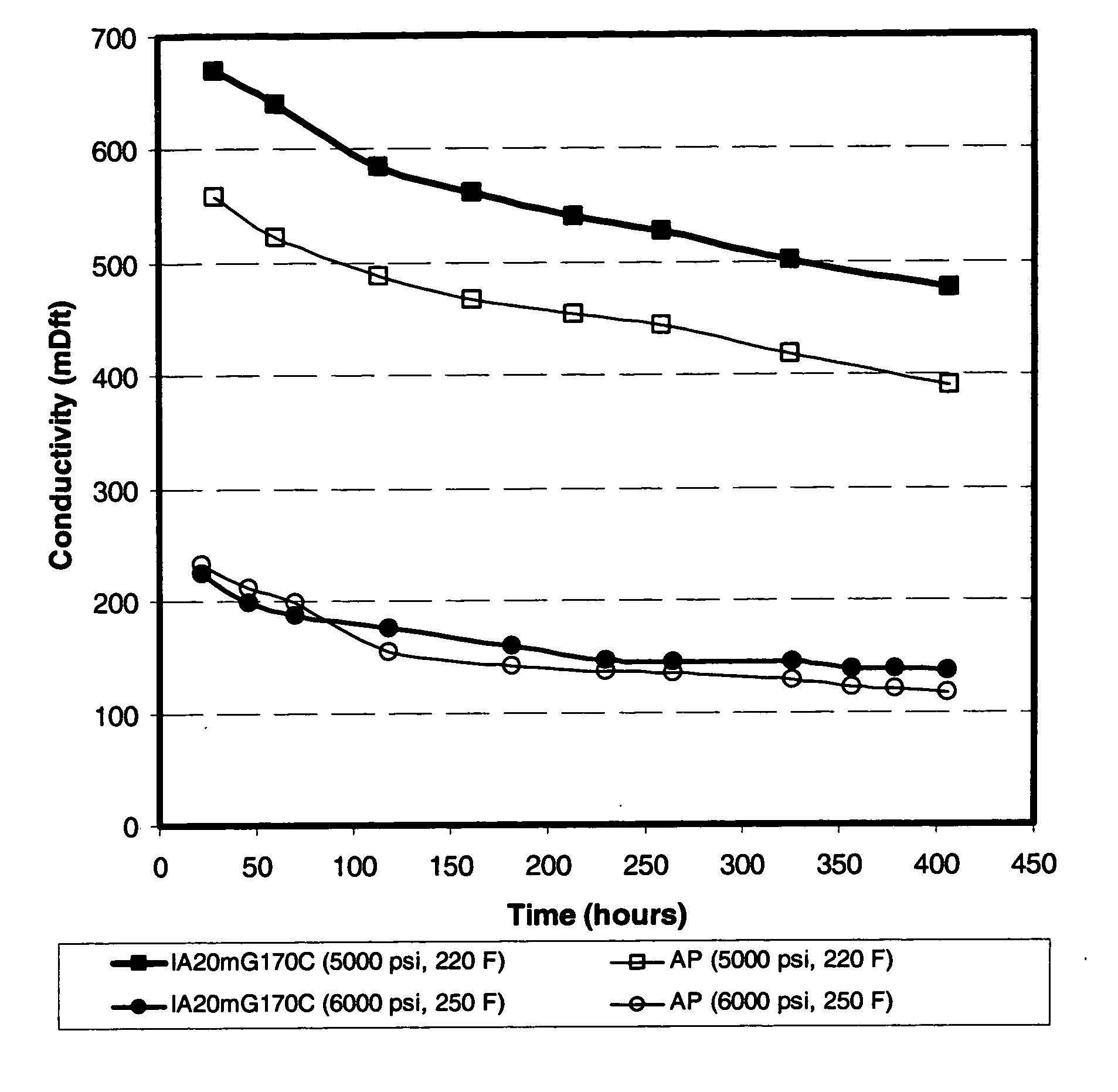

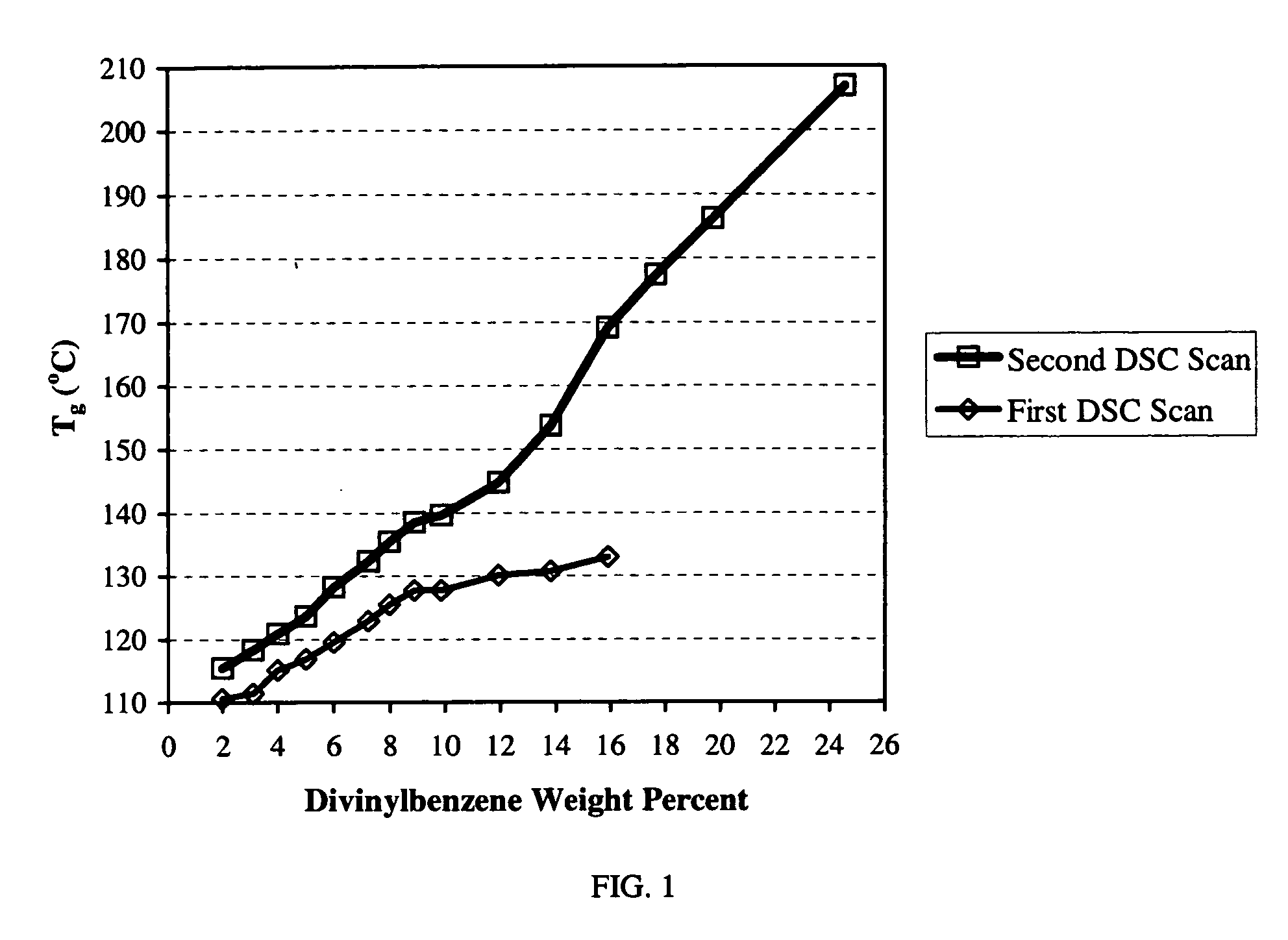

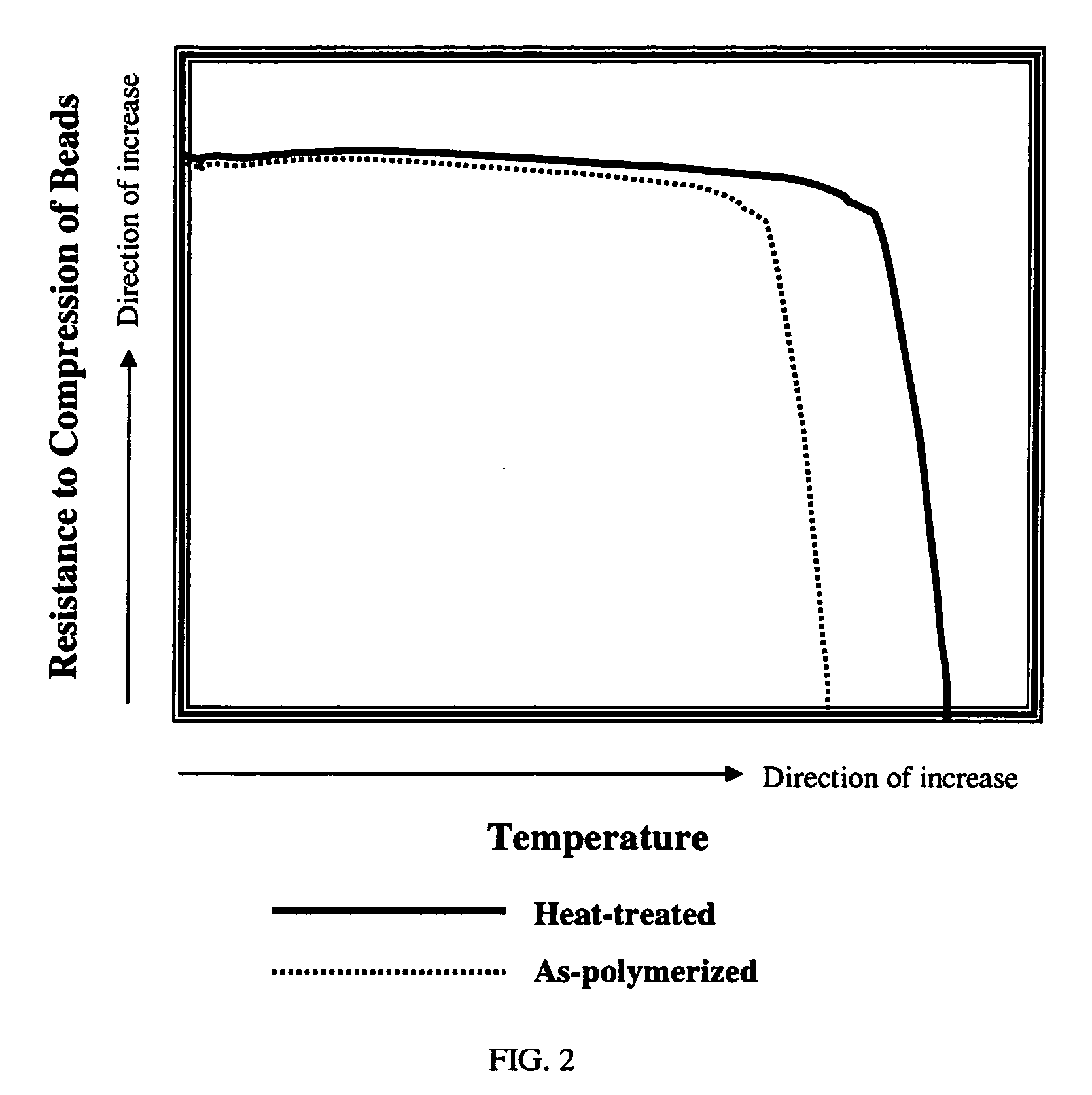

Thermoset particles with enhanced crosslinking, processing for their production, and their use in oil and natural gas driliing applications

InactiveUS20070021309A1Increase compressive elastic modulusReduced deformabilitySynthetic resin layered productsCellulosic plastic layered productsEnvironmental resistancePetroleum

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of methods to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method of particular interest is the application of post-polymerization process step(s) (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. The most common benefits of said heat treatment are the enhancement of the maximum possible use temperature and the environmental resistance. The present invention also relates to the development of thermoset polymer particles. It also relates to the further improvement of the key properties (in particular, heat resistance and environmental resistance) of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

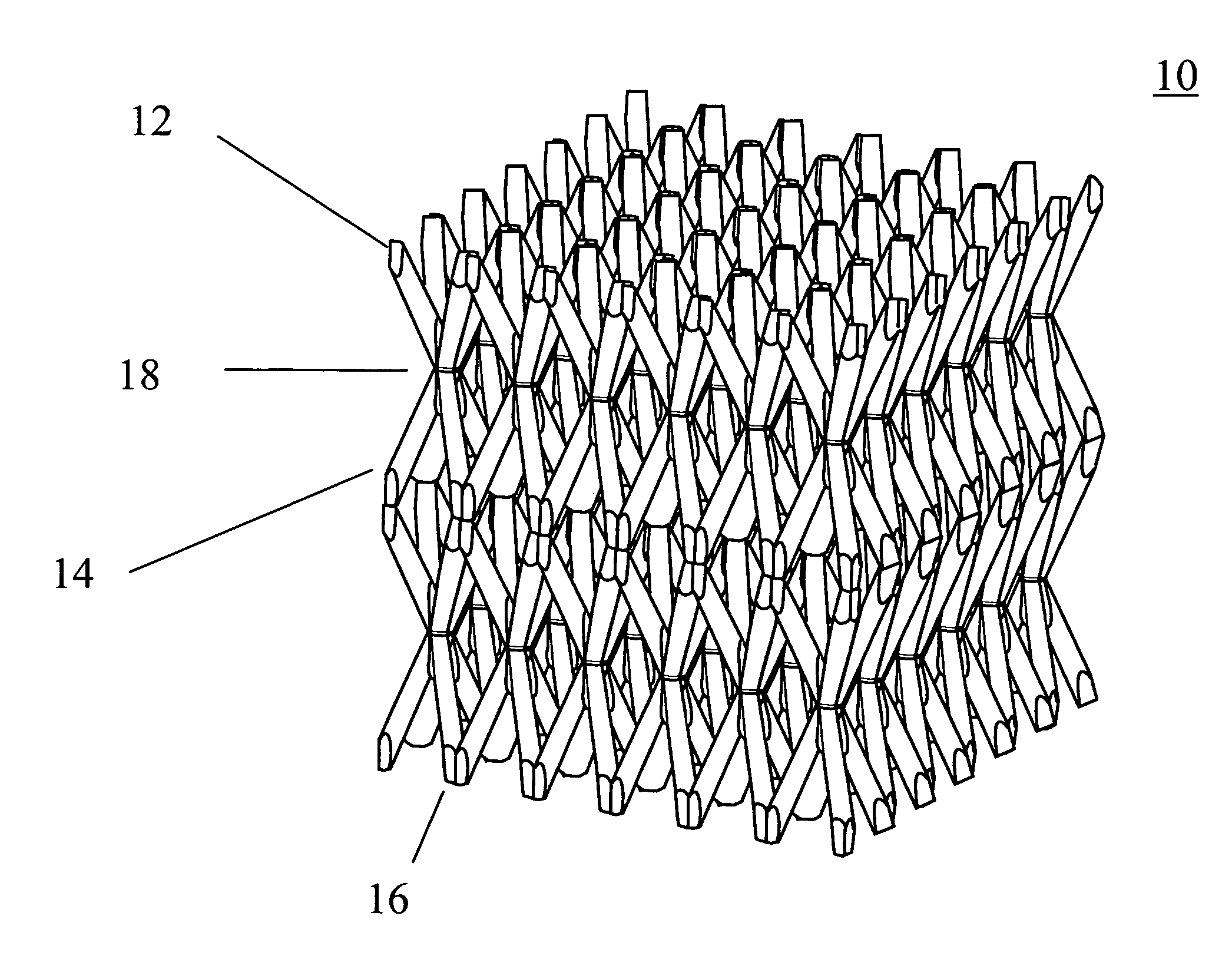

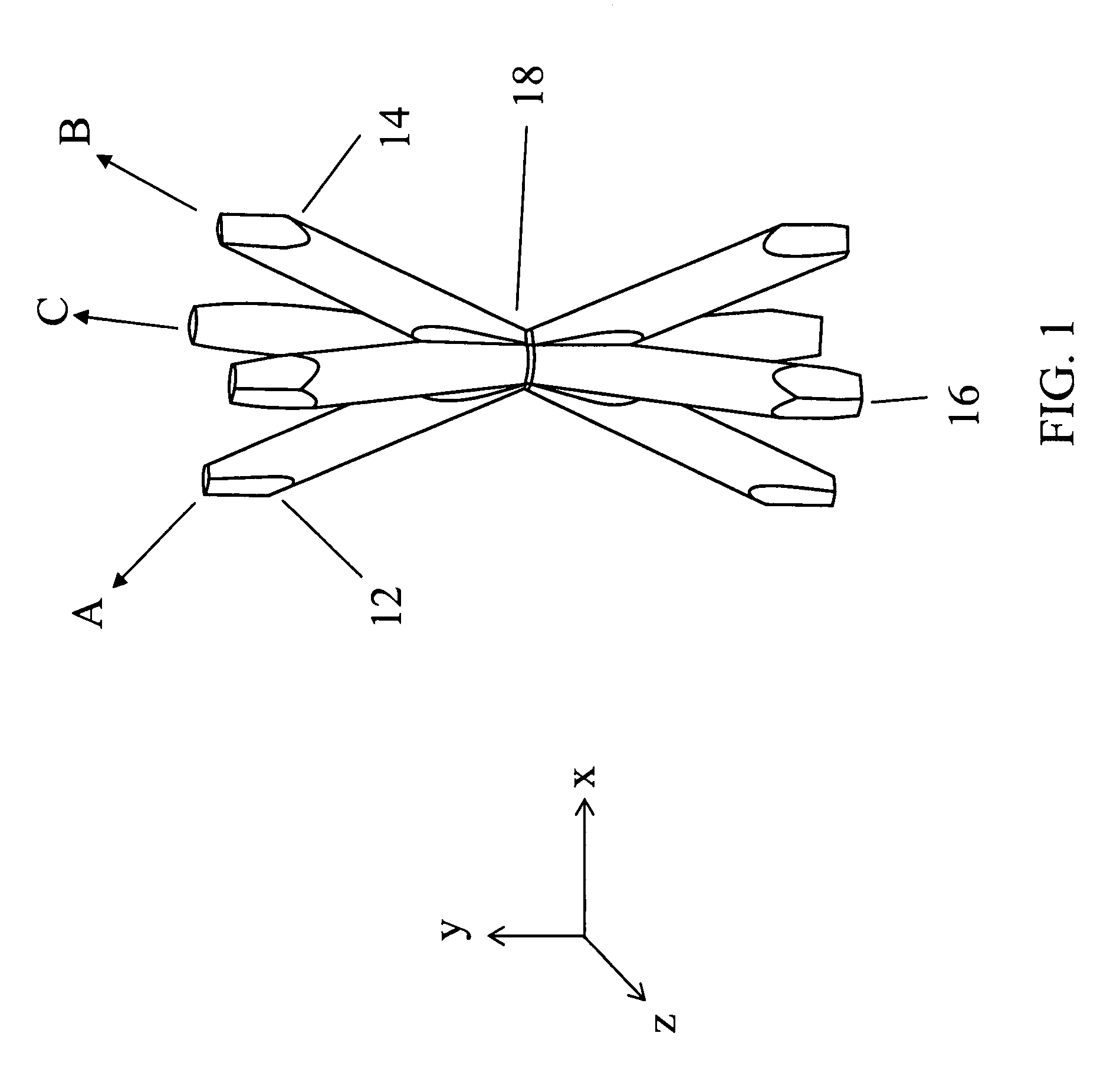

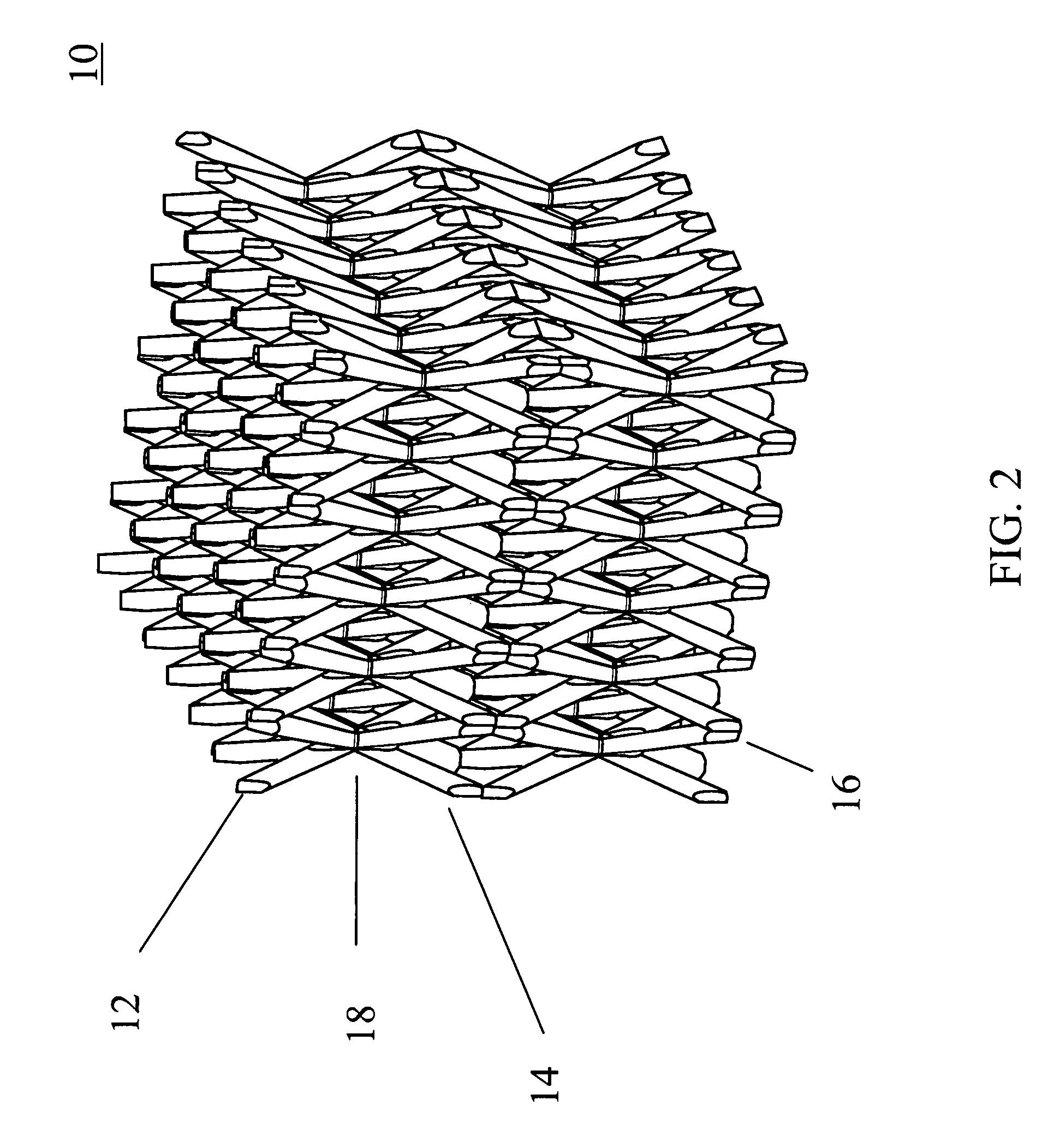

Three-dimensional ordered open-cellular structures

ActiveUS8197930B1Overcome the small stiffnessHigh strengthPhoto-taking processesLayered productsEngineeringPolymer

A three-dimensional ordered open-cellular structure. In one embodiment, the structure includes: a plurality of first truss elements defined by a plurality of first self-propagating polymer waveguides and extending along a first direction; a plurality of second truss elements defined by a plurality of second self-propagating polymer waveguides and extending along a second direction; and a plurality of third truss elements defined by a plurality of third self-propagating polymer waveguides and extending along a third direction. The first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material, and the three-dimensional structure is self-supporting.

Owner:HRL LAB

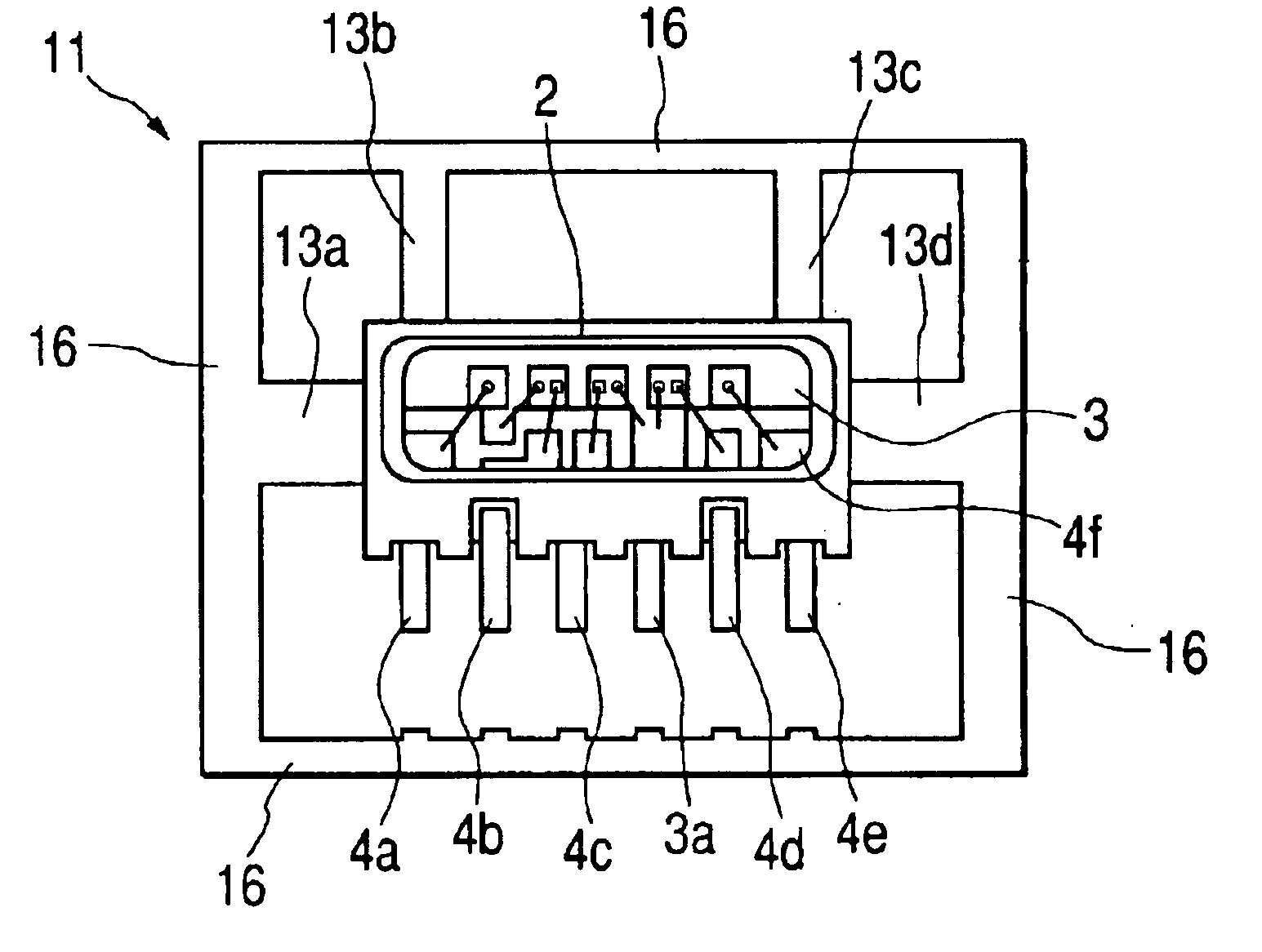

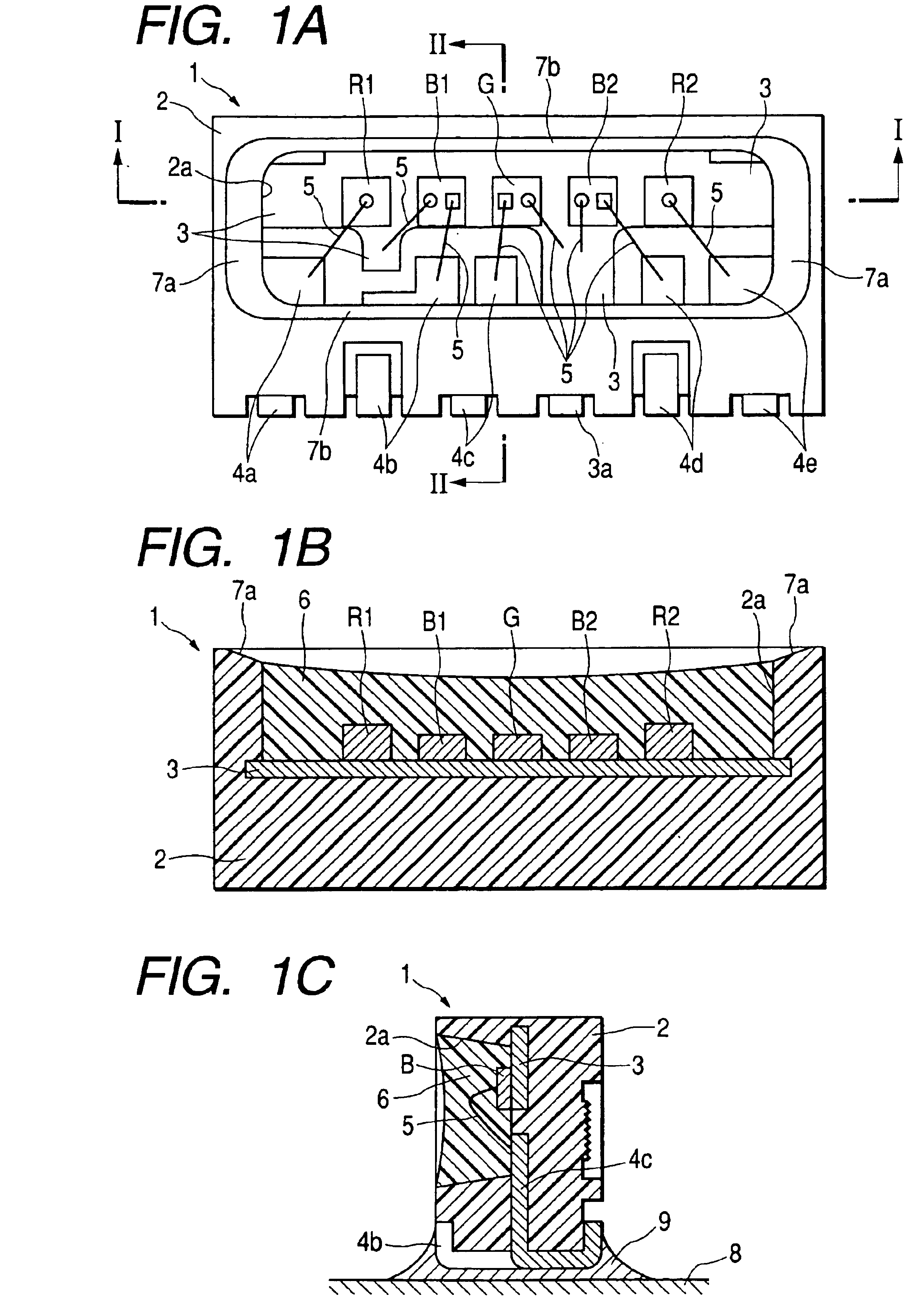

LED device and manufacturing method thereof

InactiveUS6872585B2Improve featuresUniform luminous intensitySolid-state devicesSemiconductor/solid-state device manufacturingEpoxyLuminous intensity

In an LED device, an opening portion of a package in which a plurality of five light-emitting elements are mounted is filled with a transparent epoxy resin and sealed with the resin. The transparent epoxy resin is shrunk when cured. Hence, the surface of the transparent epoxy resin is dented in the center portion so that the outer edge portion becomes higher than the center portion. The light-emitting elements located at opposite ends are the highest in element height among the five light-emitting elements. Hence, when the light-emitting elements are mounted at opposite ends of a single row, distances from light-emitting surfaces of the five light-emitting elements to the surface of the transparent epoxy resin are made uniform and luminous intensity distribution characteristics thereof are made uniform. Tips of leads are further bent up along side surfaces of the package. Hence, when the LED device is soldered onto a mount board, solder is deposited even on the up-bent tips of the leads, so that surface tension of solder is balanced on the front and rear of the package. As a result, the LED device can be mounted in a predetermined position while prevented from sliding. In an LED lead frame, hanger leads are provided so as to be extended in three directions of a package. Hence, the electrically conductive leads can be bent stably and accurately without tottering of the package in the process of bending the electrically conductive leads.

Owner:TOYODA GOSEI CO LTD +1

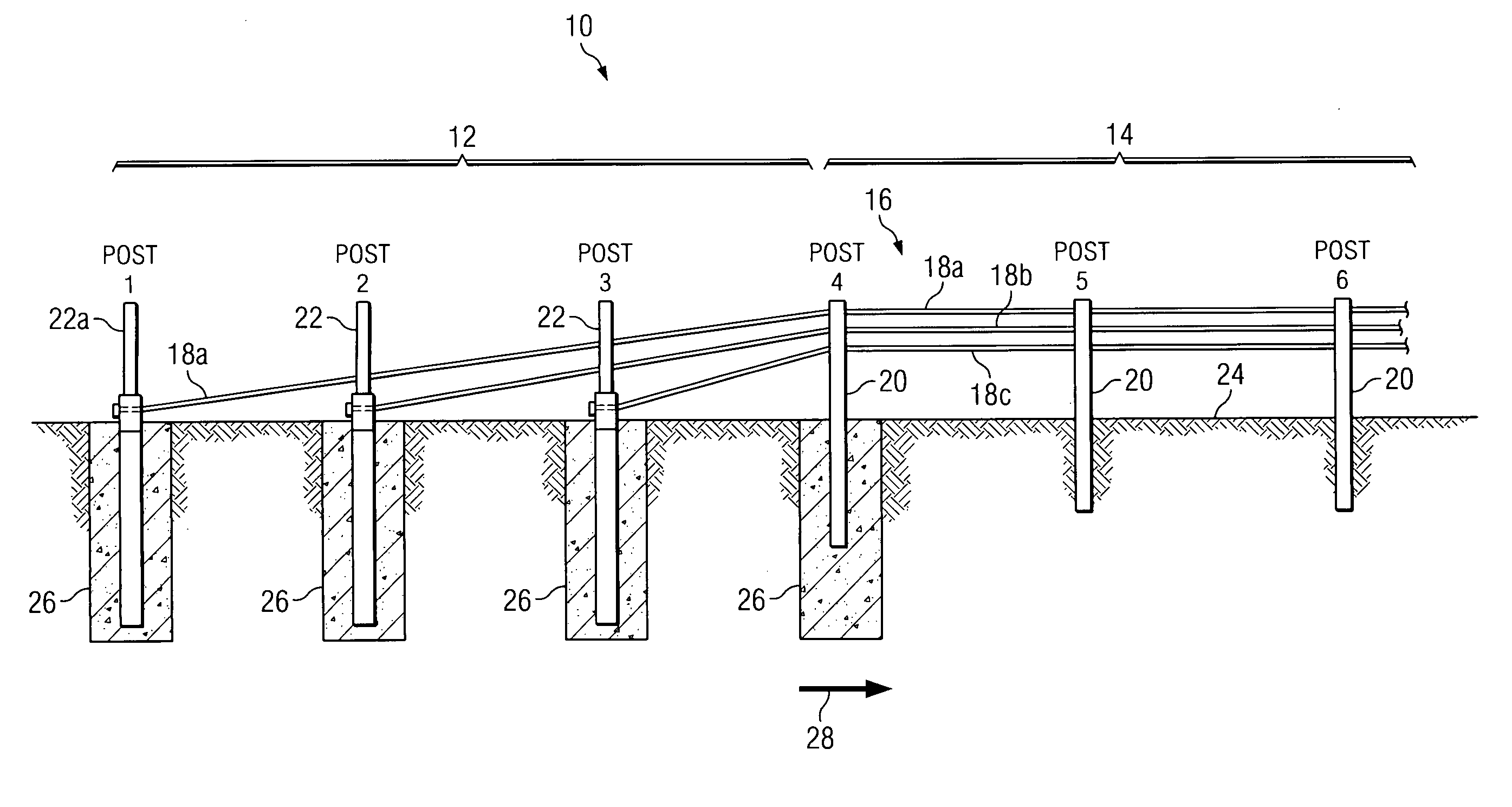

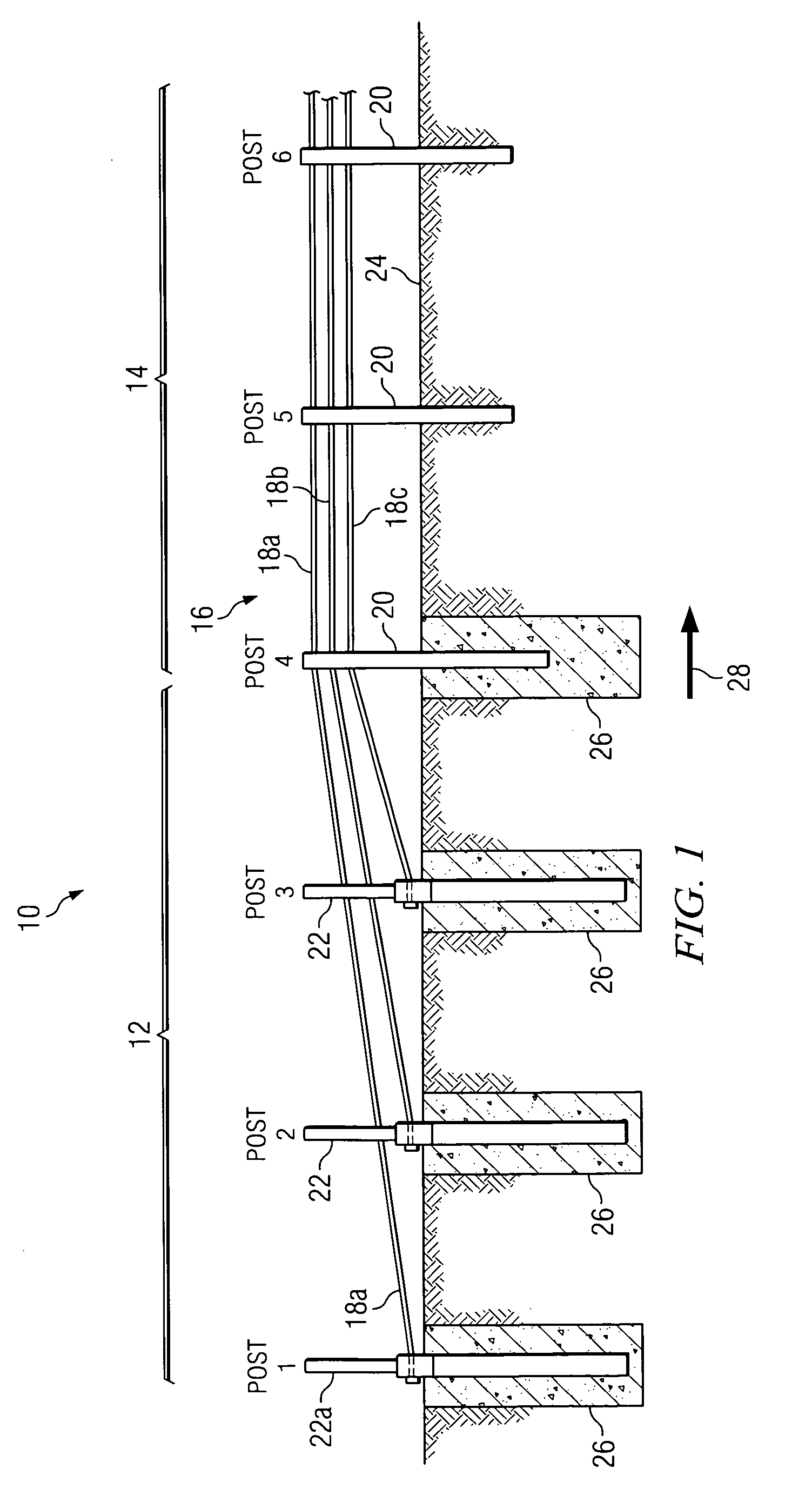

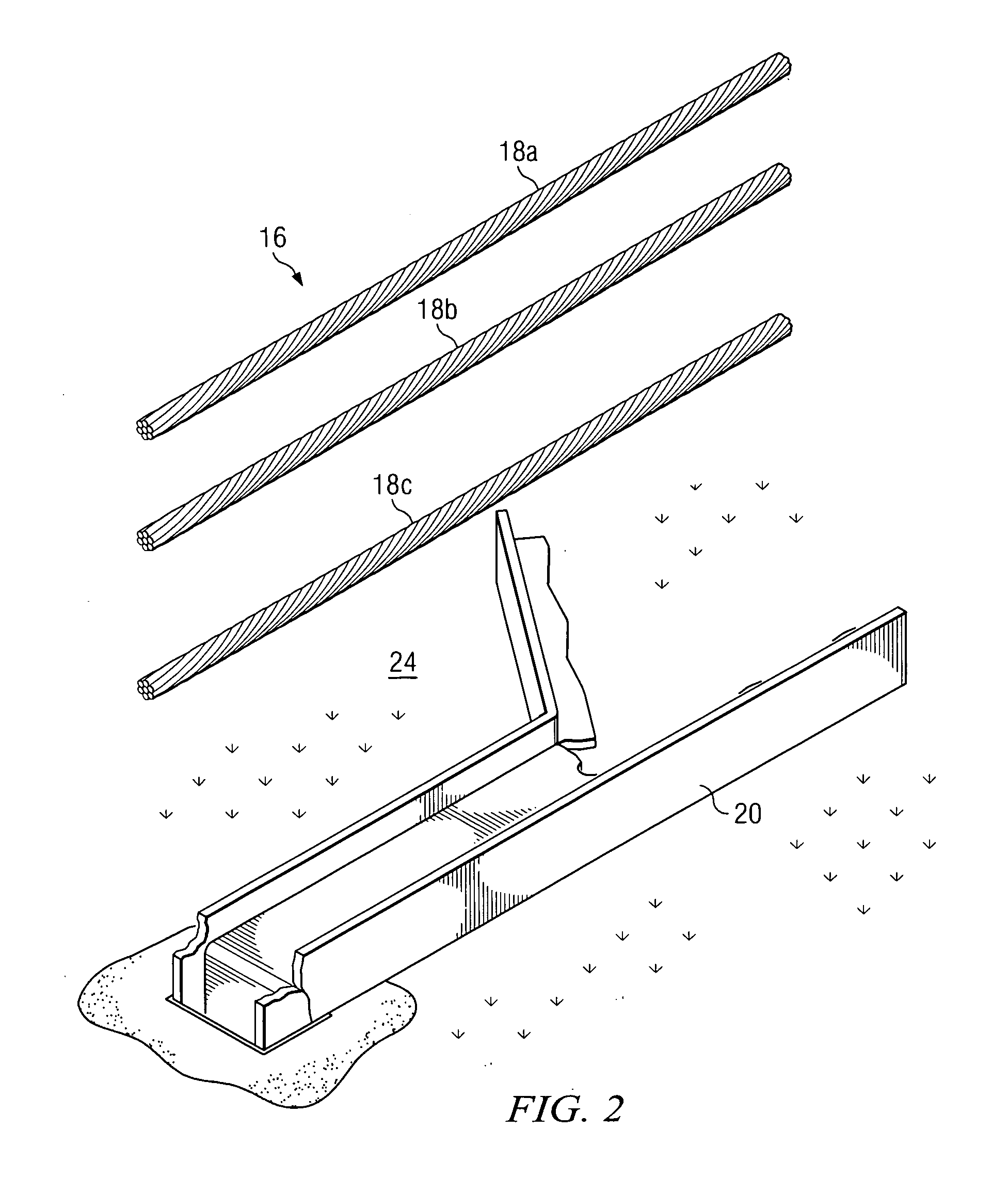

Cable barrier guardrail system with steel yielding support posts

InactiveUS20070102689A1Improve lateral strengthDecreases longitudinal strengthPasturing equipmentRoadway safety arrangementsEngineeringStrip steel

In accordance with a particular embodiment of the present invention, a guardrail system includes at least one cable operable to contain and redirect an errant vehicle. The guardrail system also includes a plurality of guardrail support posts spaced apart in relation to one another. Each support post includes a lower portion, a mid portion, and an upper portion. The lower portion is for installing below grade adjacent the roadway. The mid portion lies substantially adjacent the grade and includes a weakened section operable to weaken the support post about a longitudinal axis. The upper portion is releasably coupled to the at least one cable such that the upper portion is uncoupled from the at least one cable when the support post is displaced.

Owner:TEXAS A&M UNIVERSITY

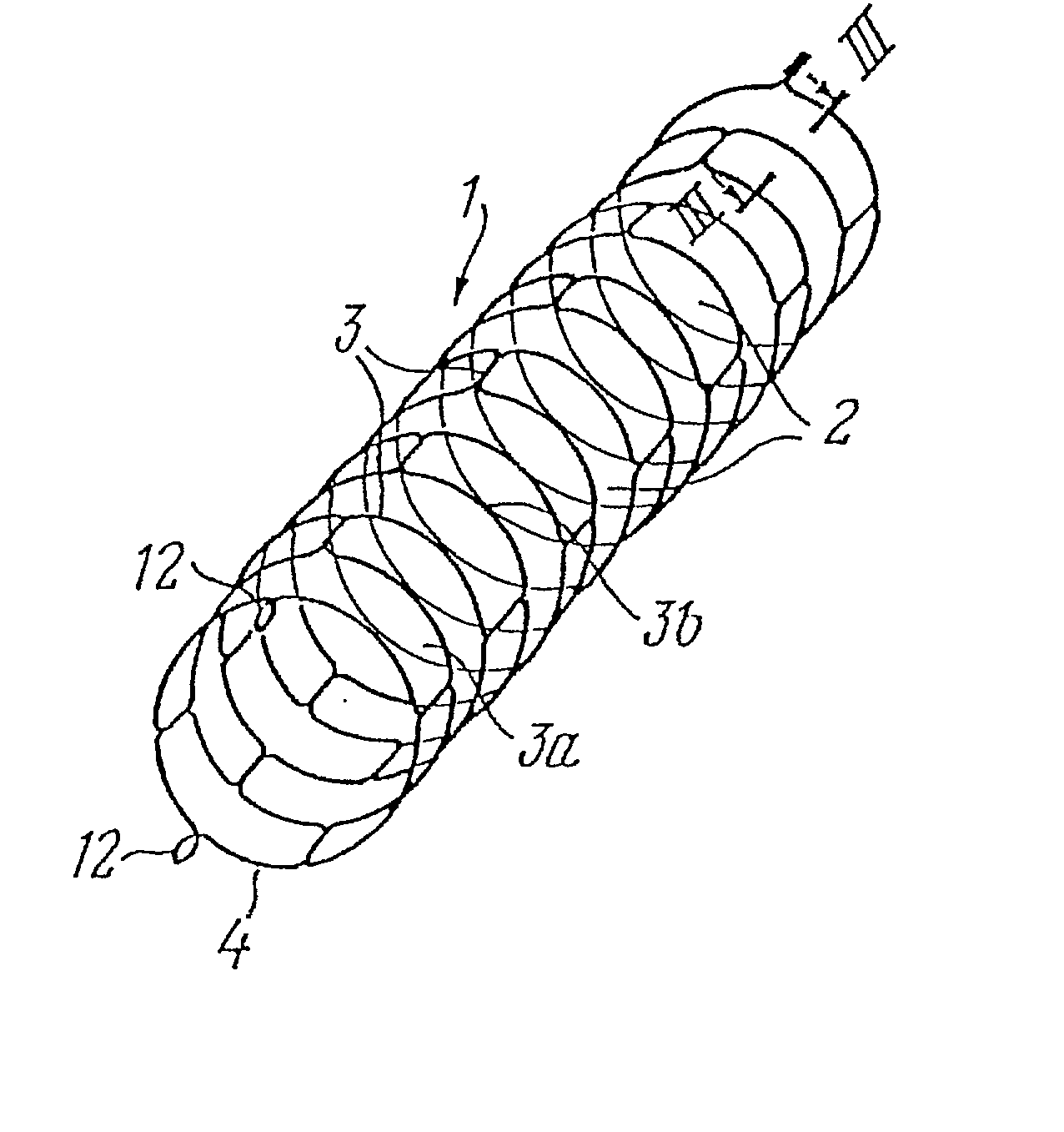

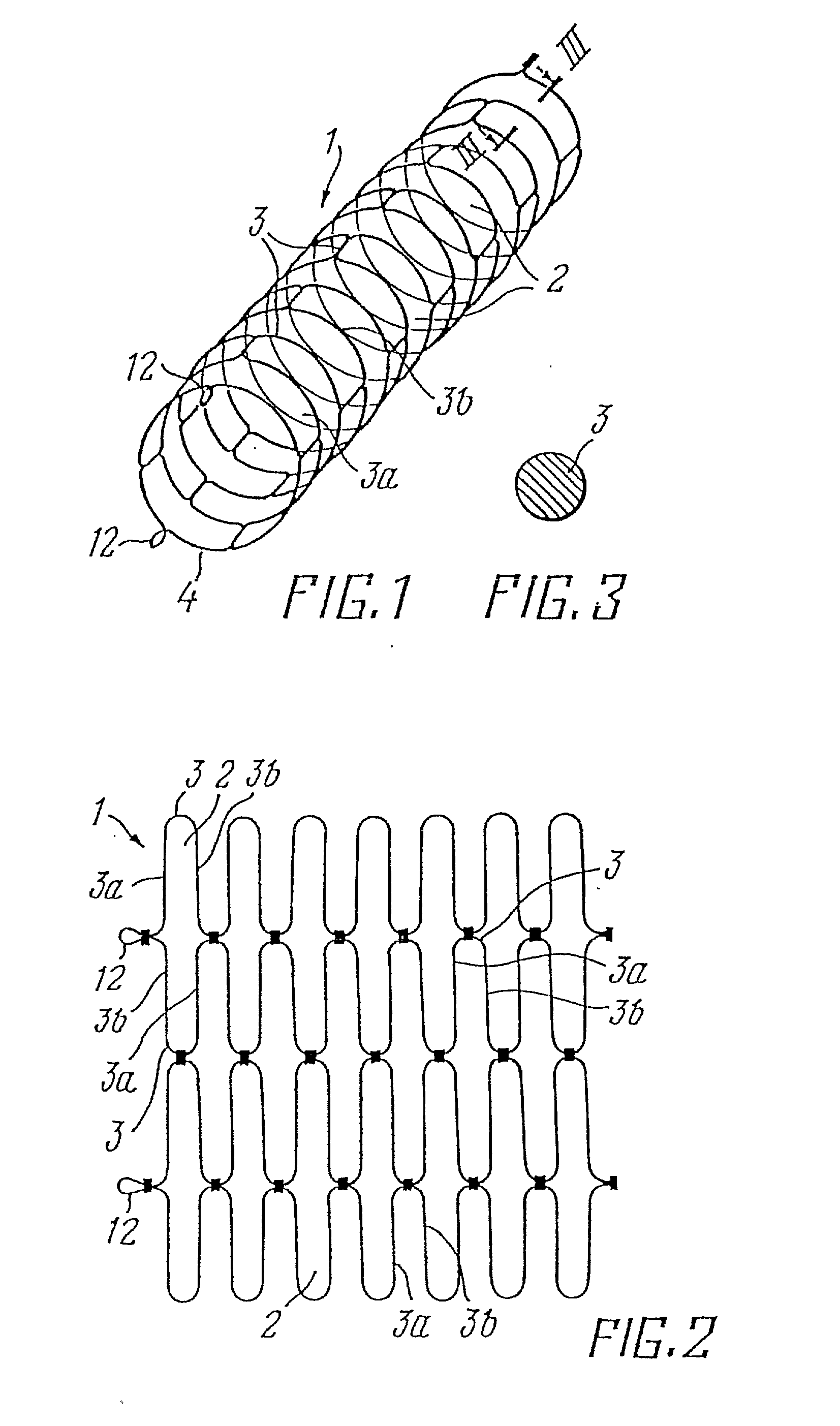

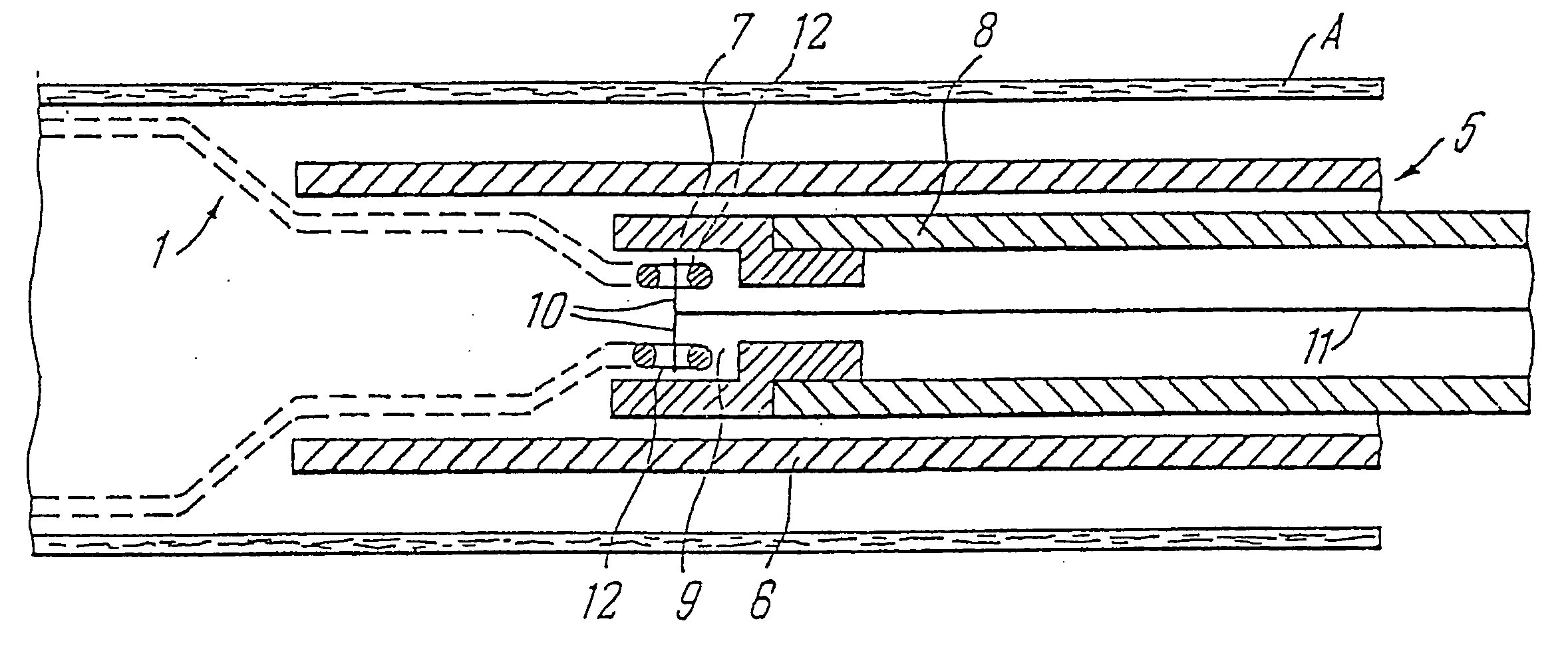

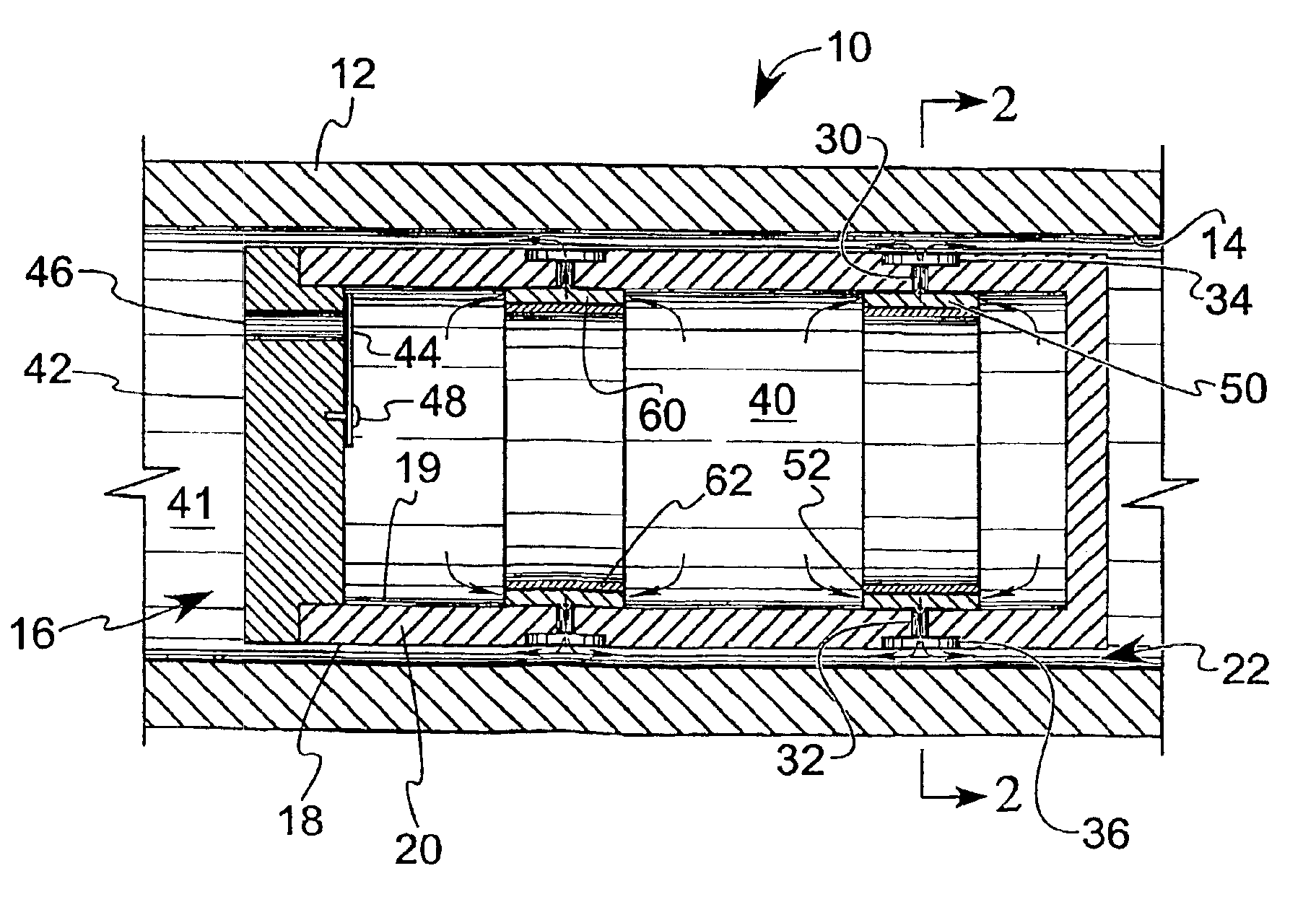

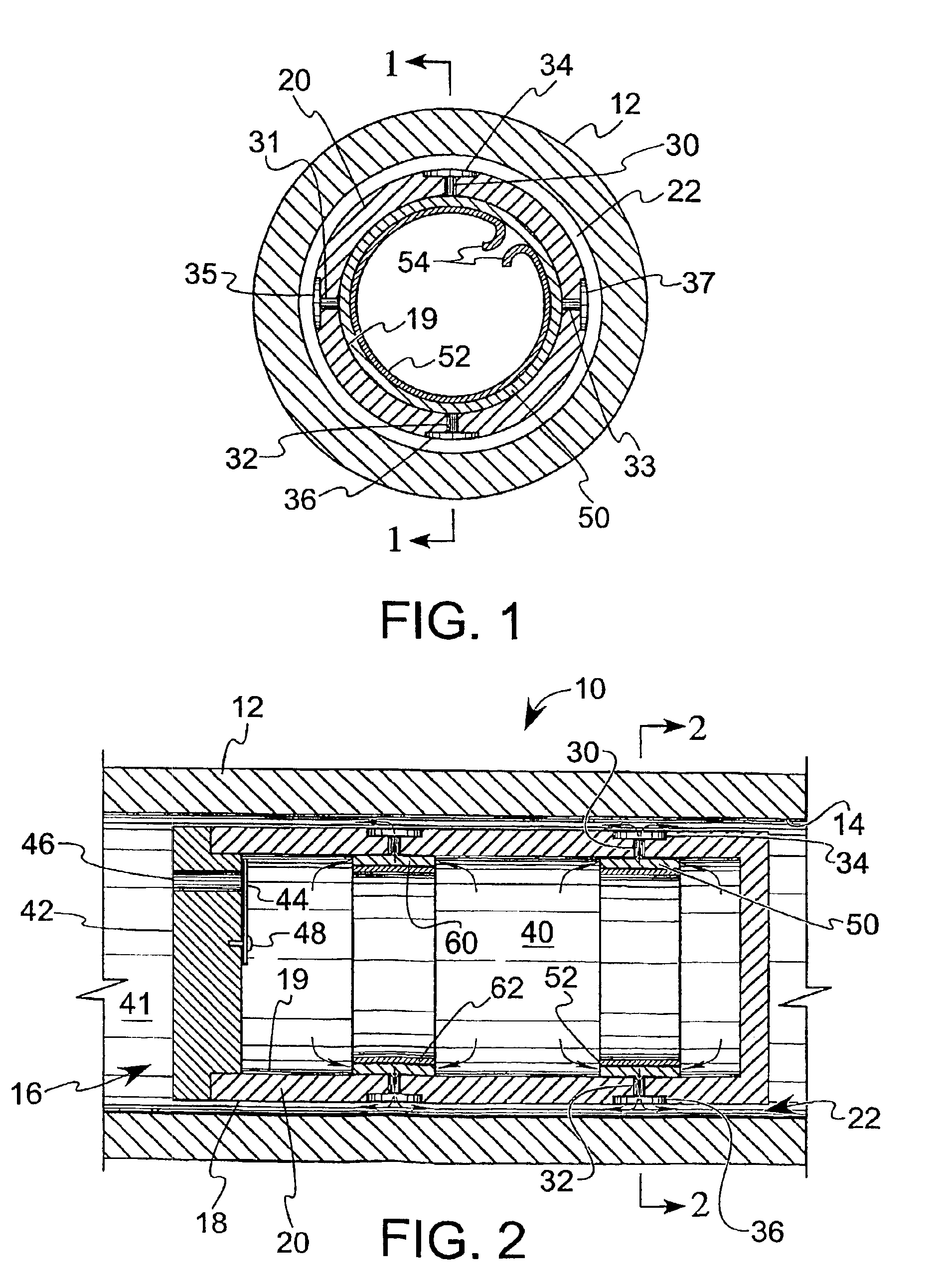

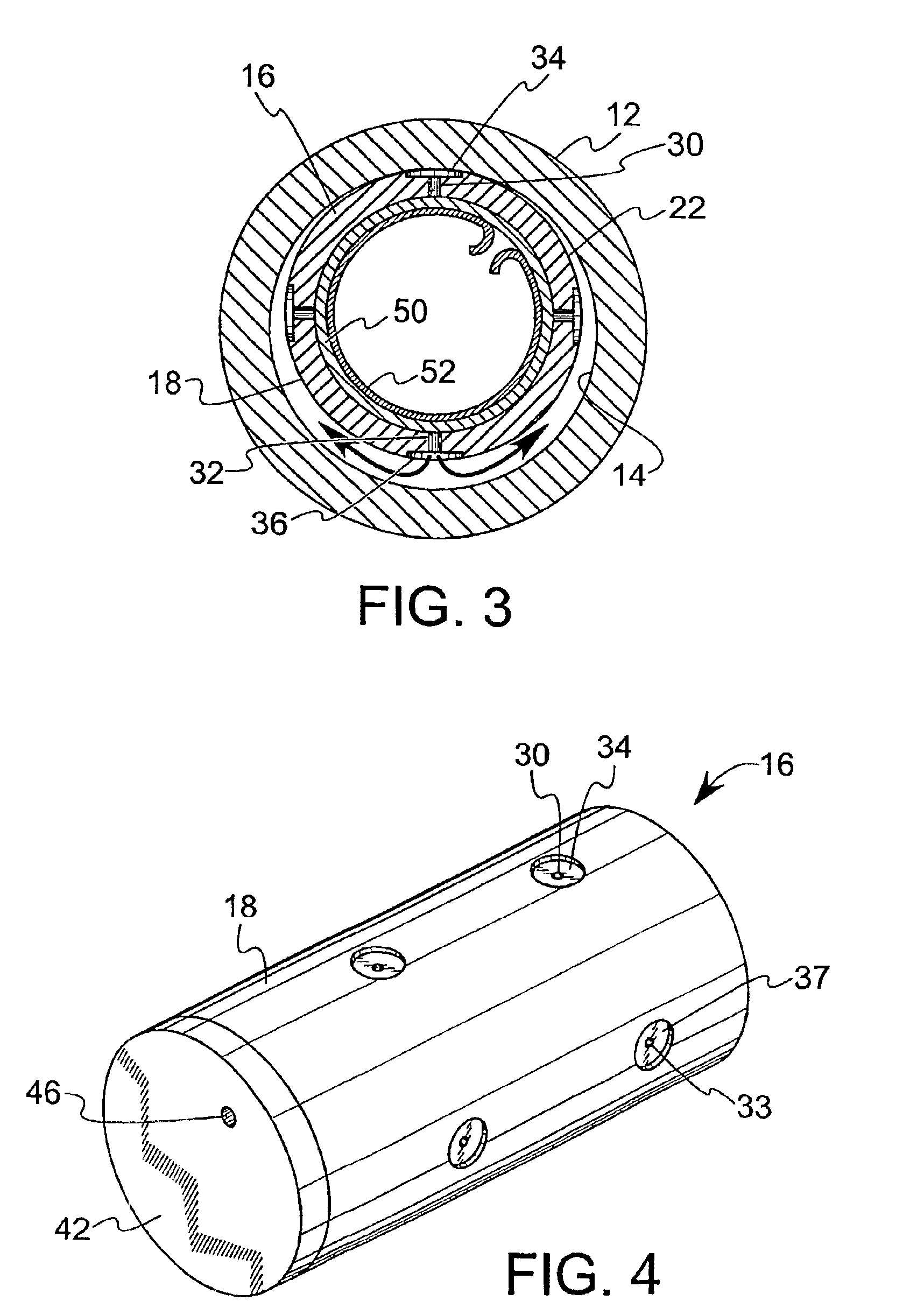

Implantable, self-expanding prosthetic device

InactiveUS20020128707A1Overcome the small stiffnessLow stiffnessStentsBlood vesselsProsthesisInterconnection

A prosthetic device for sustaining a vessel or hollow organ lumen (a stent) has a tubular wire frame (1) with rows of elongate cells (2) having a larger axis and a smaller axis. The cells are arranged with the larger axis in the circumferential direction of the frame (2) and the smaller axis parallel to the axial direction thereof. Each cell is formed by two U-shaped wire sections, and in a plane perpendicular to the longitudinal axis one of the branches of the U-shaped wire sections in one row form together a closed ring shape (4) which provides the frame (1) with large radial stiffness. In the axial direction the frame (1) has only low stiffness so that it easily conforms to the vascular wall even if this deforms due to external loads. The interconnection between the cells (2) may be flexible.

Owner:COOK MEDICAL TECH LLC

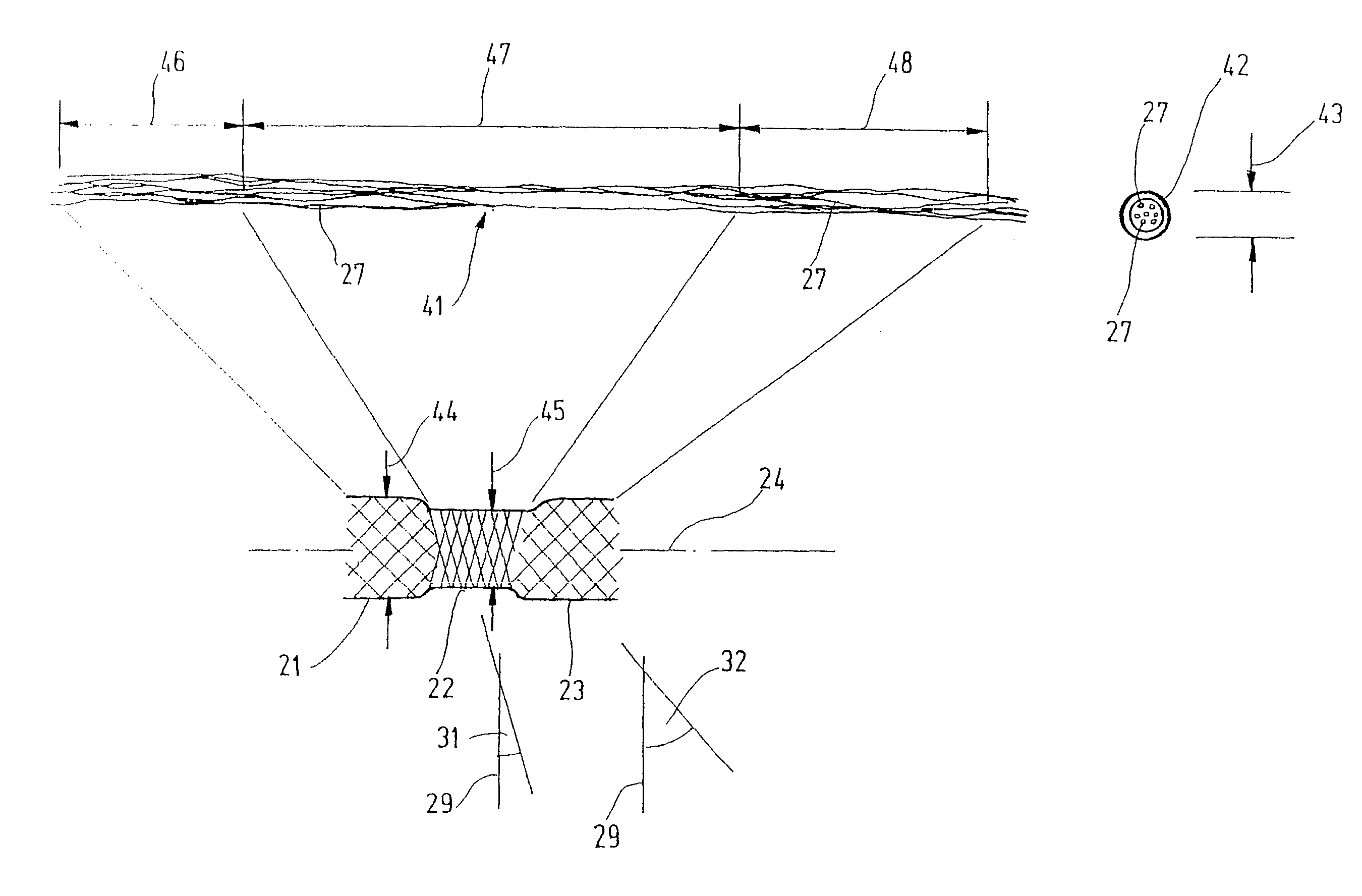

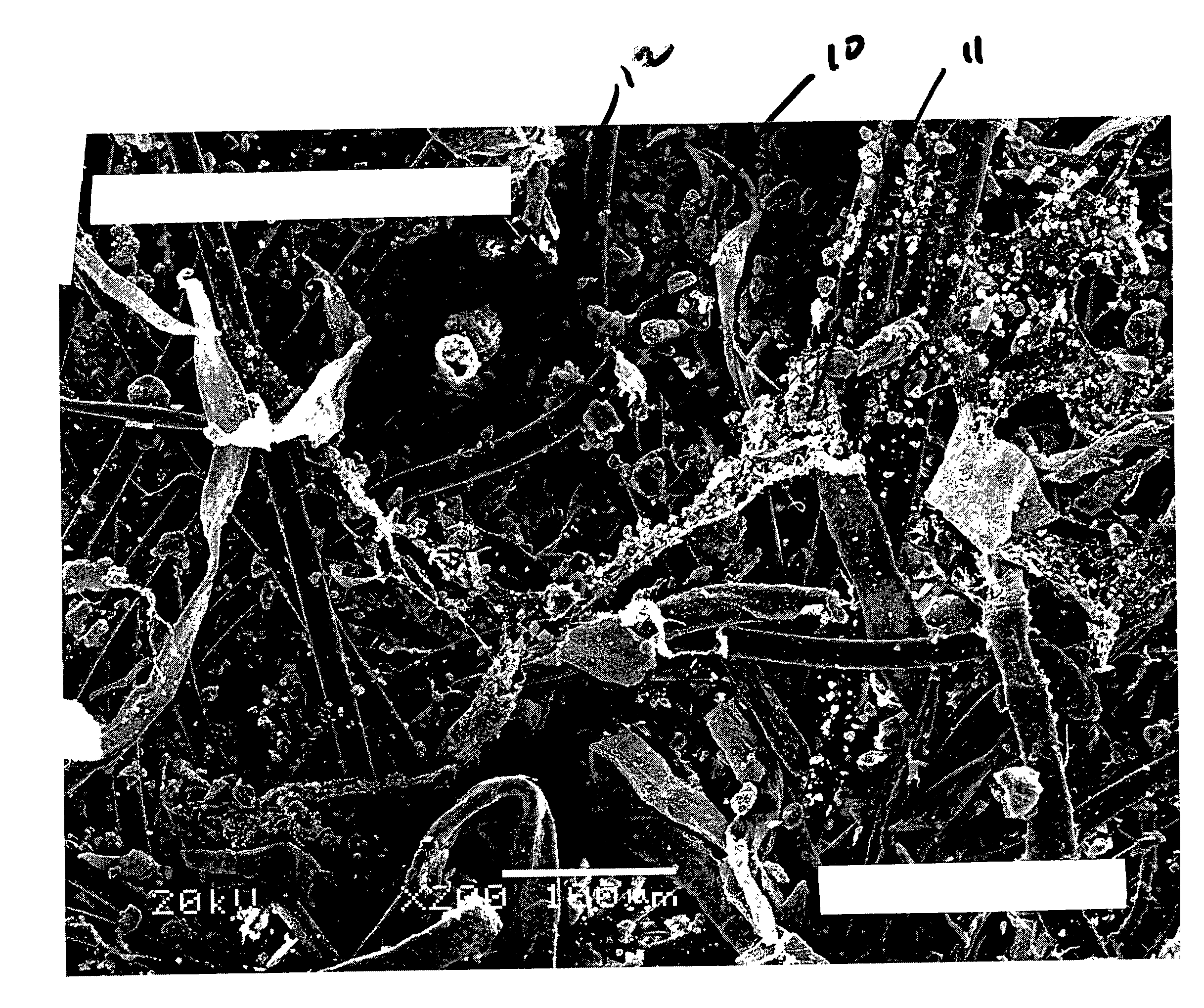

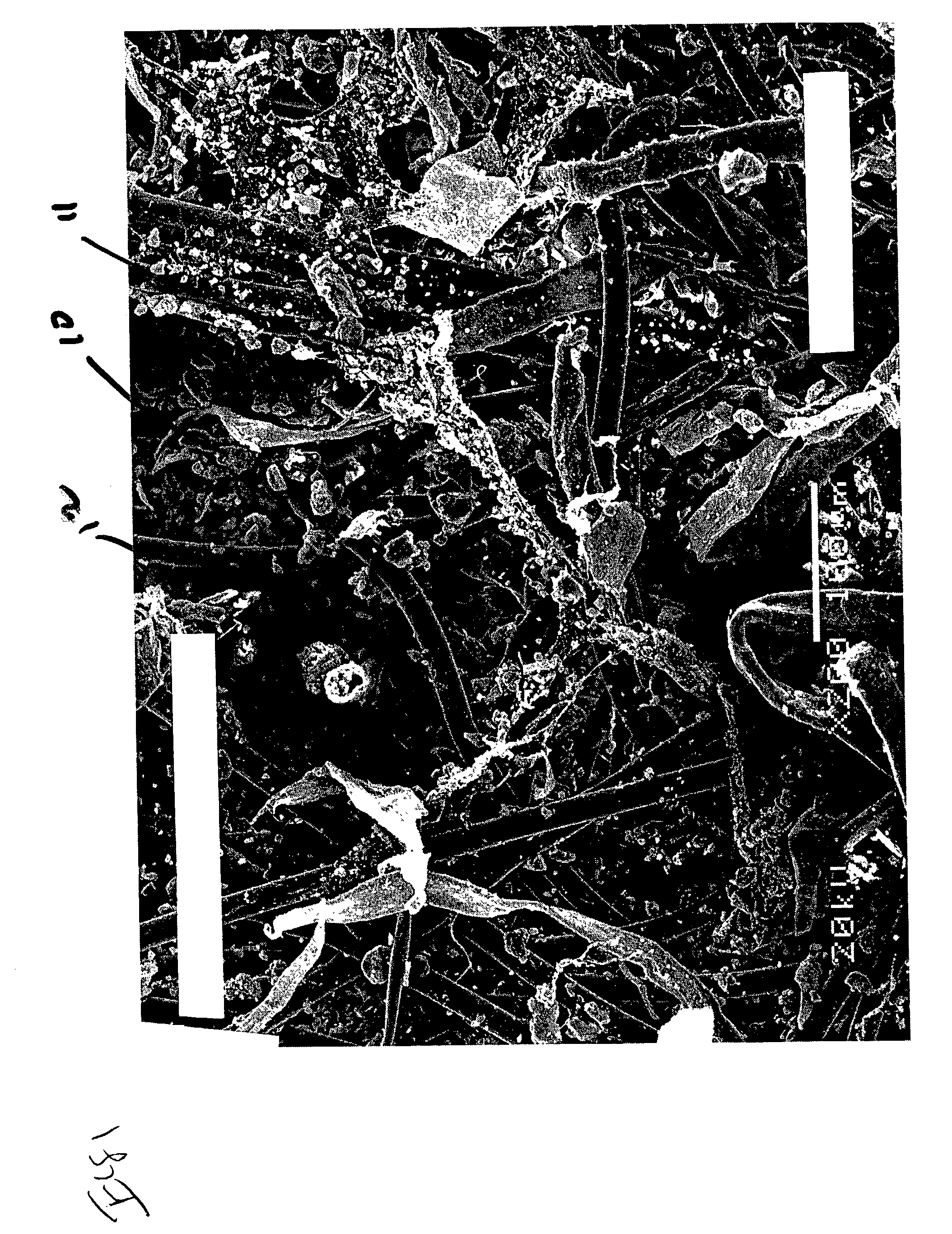

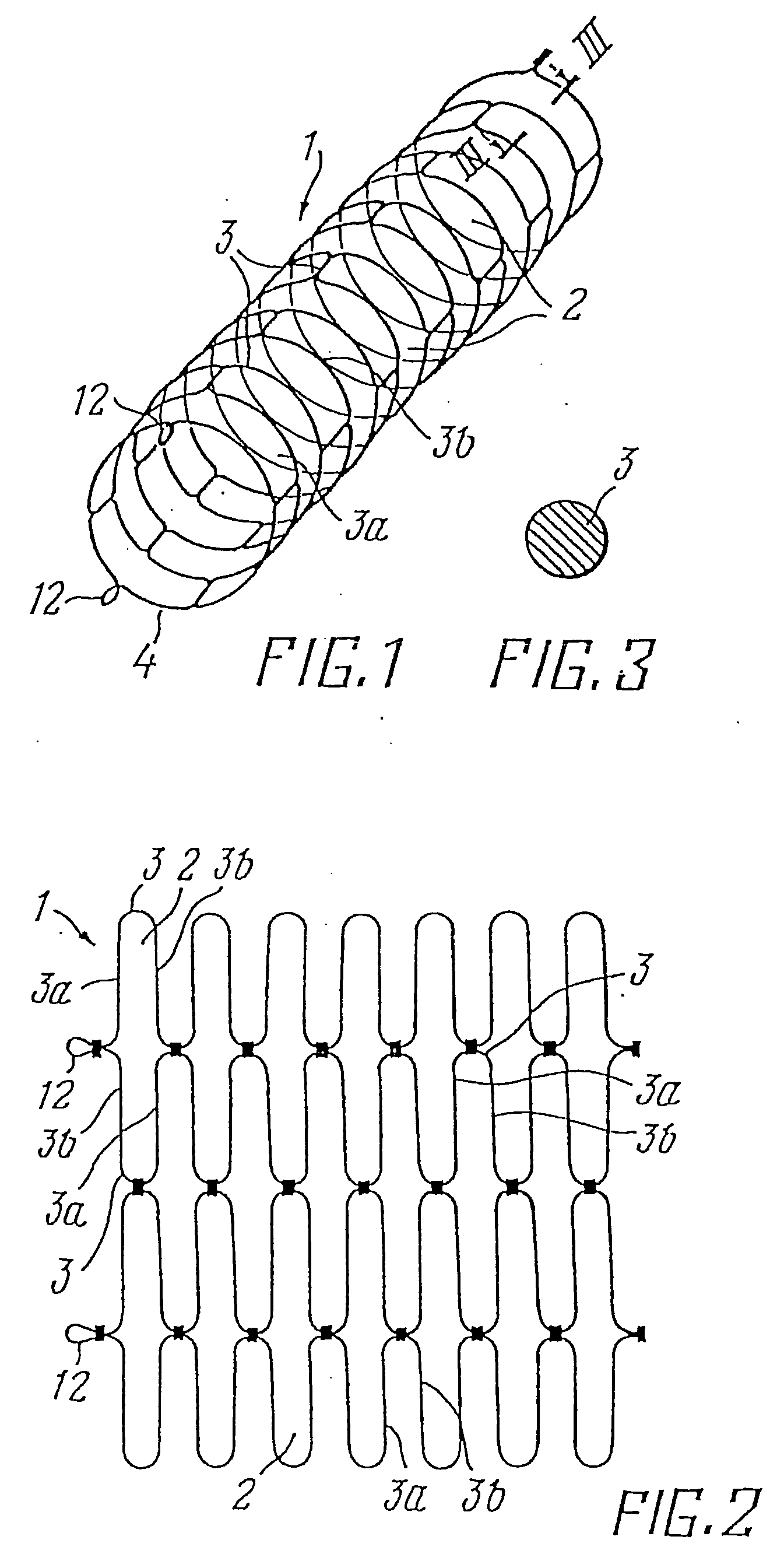

Braided stent to be implanted in a blood vessel

ActiveUS20090216307A1Improve protectionSolve the small densityStentsOrnamental textile articlesBraided stentBlood vessel

A braided stent to be implanted in a blood vessel comprises a hollow body which is stretchable in its longitudinal direction and whose circumferential surface is formed by a braid of a multiplicity of filamentary elements which, in the expanded state of the braided stent, intersect a plane, perpendicular to the longitudinal direction, at a braiding angle. The braided stent has a smaller braiding angle in a central portion than in its distal and proximal portions which adjoin the central portion in the longitudinal direction.

Owner:JOTEC

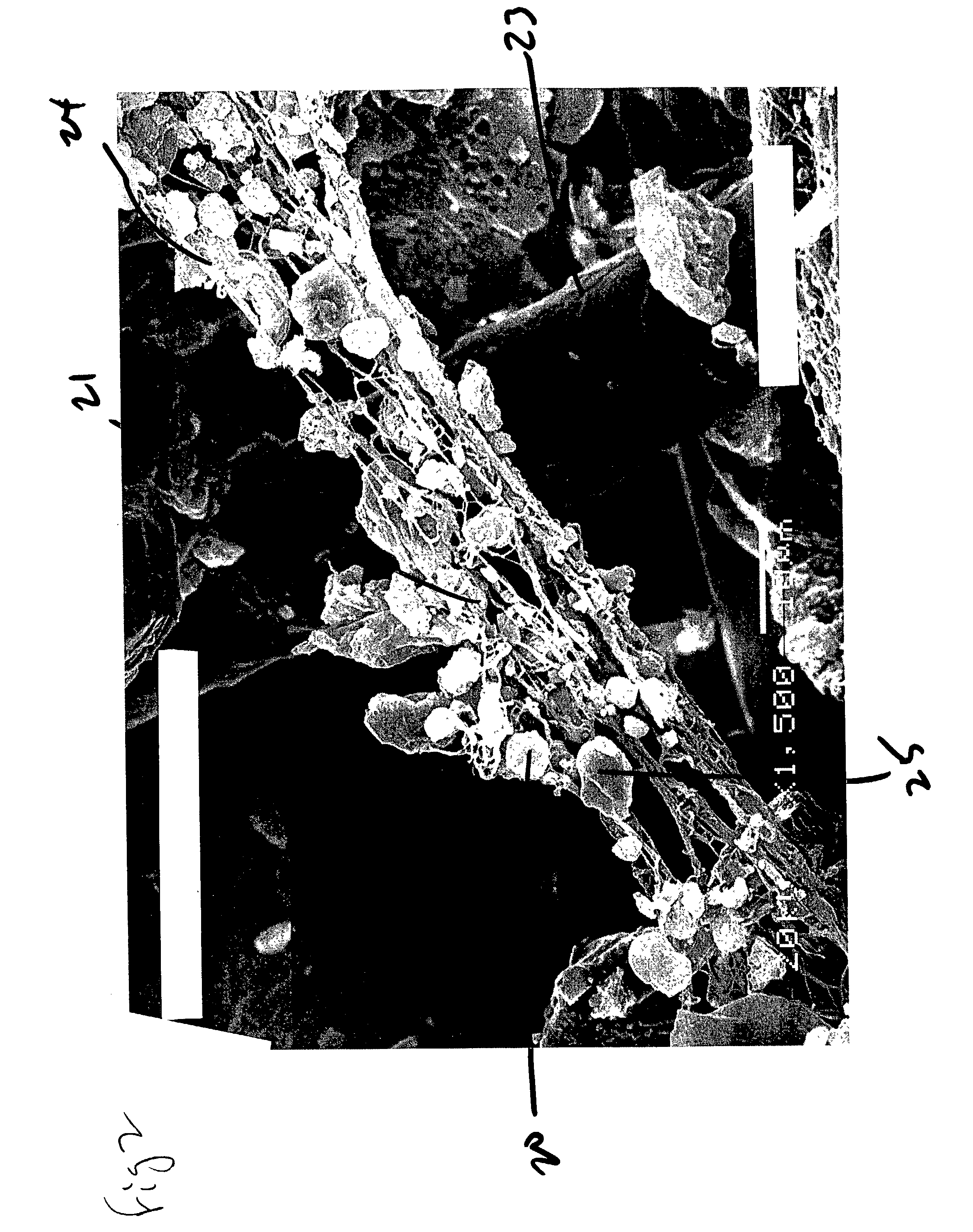

Wipe material with nanofiber layer

InactiveUS20040092185A1Unique flexibilitySmall sizeCleaning machinesCleaning equipmentNanometreFibrous layer

A flexible wipe comprising at least one conformable non-woven layer and at least one adhered nanofiber layer can be used to remove a variety of particulate soils from planar, curved or complex surfaces. The nanofiber layer is configured onto the flexible non-woven in a fashion such that particulate of a broad particle size range is trapped by the nanofiber layer and efficiently removed from the contaminated surface. The nanofiber layer comprises a web of spun fibers that can incorporate and trap soil particles for efficient soil removal.

Owner:DONALDSON CO INC

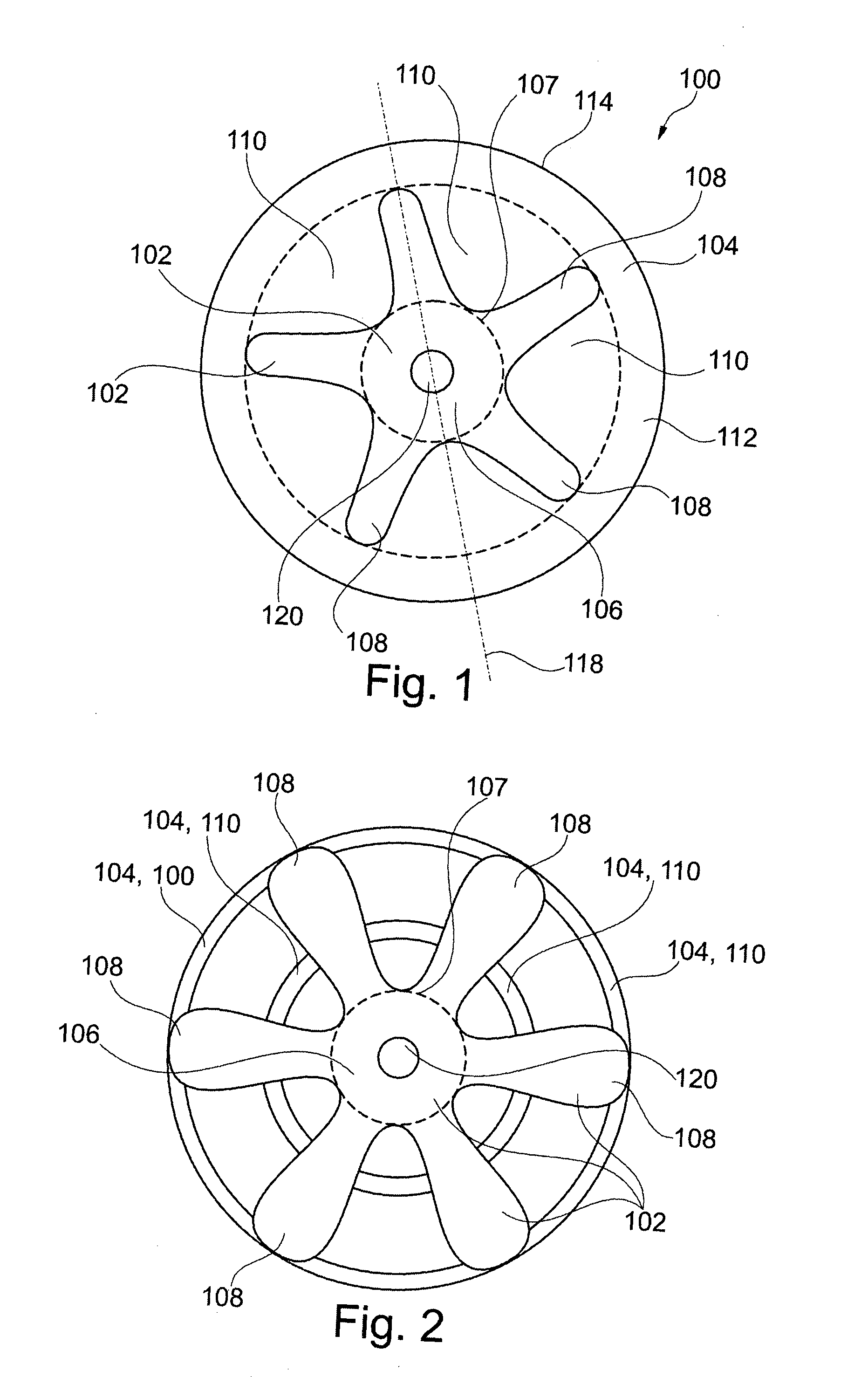

Suture ring for heart valve prosthesis

A heart valve stiffening ring of this disclosure includes a split ring that allows assembly over a channel-shaped heart-valve-orifice-forming angular heart valve body, with the split ring having an outer peripheral tapered thread, which allows adjustment of pressure between the split ring and the orifice-forming annular body. A solid ring or nut has complementary tapered threads to mate with the outer peripheral tapered thread of the split ring and is adjustable for tightening of interfit thereof to bring about correct pressure for desired tightening effect with a moment of inertia in bending of the outer channel to make the orifice stronger so that orifice outer diameter thereof can be a maximum value. The angle of taper is substantially 3 degrees with respect to the center line. This heart valve stiffening ring can be employed in place of a heart valve locking ring of U.S. Design Pat. No. 376,206-Reif issued Dec. 3, 1996. Improvement of the present design includes a major feature or crux that the split ring and solid ring or nut both have complementary threads that fit together and using the flanges of the channel configuration used therewith.

Owner:REPUBLIC MEDICAL PRODS

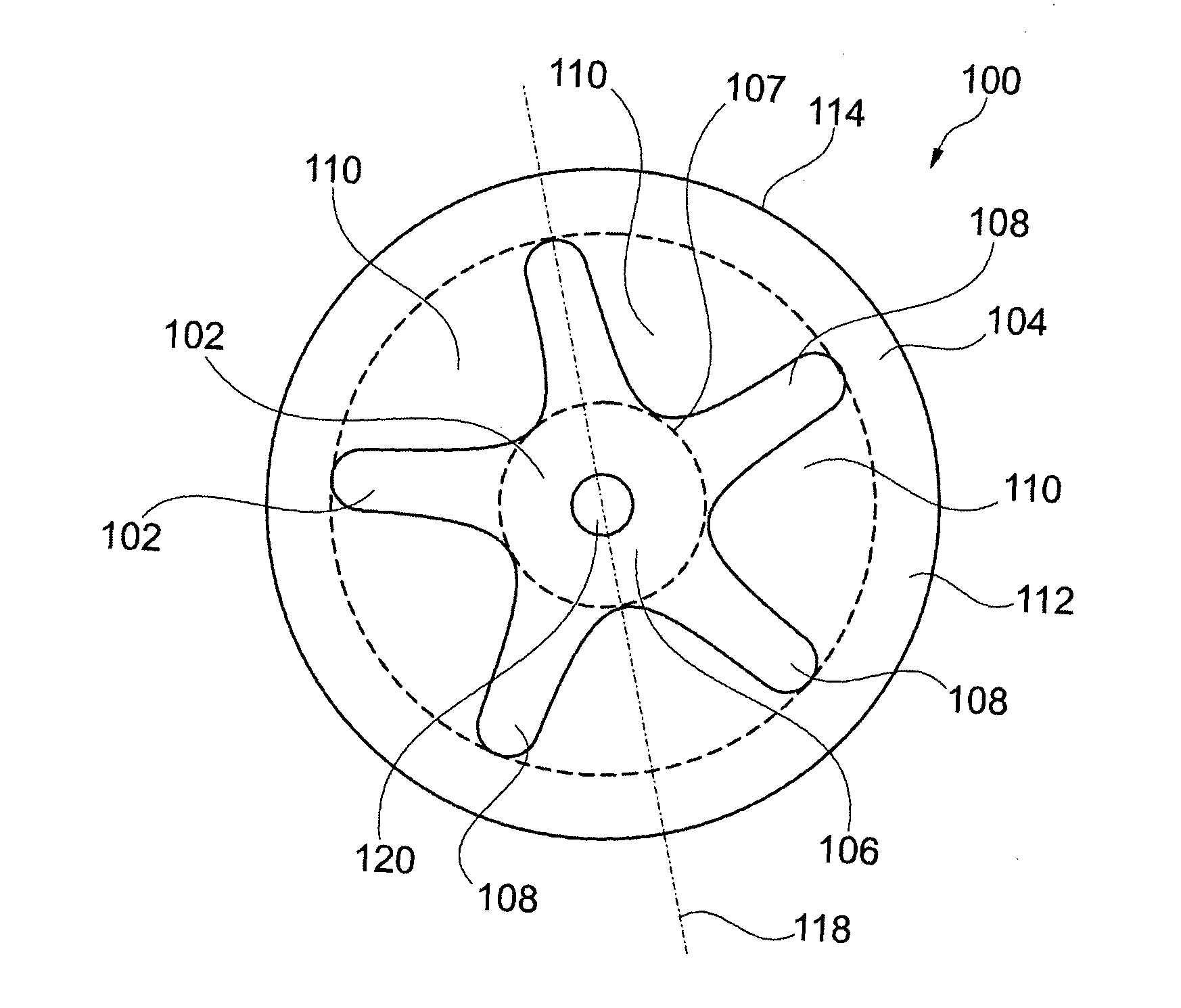

Ostomy appliance

ActiveUS20140114265A1Improve fitEasy to separateNon-surgical orthopedic devicesColostomyEngineeringMechanical engineering

An ostomy appliance for attachment to a stoma, the ostomy appliance comprising: an adhesive wafer (100) defining a passage for receiving a stoma of a user, the adhesive wafer comprising a backing layer and a skin facing adhesive layer; and a collecting bag (116) which in use is secured to the adhesive wafer; wherein the adhesive wafer in a first adhesive zone has a first set of properties and in a second adhesive zone (104) has a second set of properties, the first zone defining three or more radially extending zones, wherein the second zone defines one or more interconnecting parts (110), each of which interconnects at least two of the radially extending zones (108).

Owner:COLOPLAST AS

Implantable, self-expanding prosthetic device

InactiveUS20050090893A1Overcome the small stiffnessLow stiffnessStentsBlood vesselsInsertion stentProsthesis

A prosthetic device for sustaining a vessel or hollow organ lumen (a stent) has a tubular wire frame (1) with rows of elongate cells (2) having a larger axis and a smaller axis. The cells are arranged with the larger axis in the circumferential direction of the frame (2) and the smaller axis parallel to the axial direction thereof. Each cell is formed by two U-shaped wire sections, and in a plane perpendicular to the longitudinal axis one of the branches of the U-shaped wire sections in one row form together a closed ring shape (4) which provides the frame (1) with large radial stiffness. In the axial direction the frame (1) has only low stiffness so that it easily conforms to the vascular wall even if this deforms due to external loads. The interconnection between the cells (2) may be flexible.

Owner:KAVTELADZE ZAZA A +4

Porous restrictor for gas bearing

InactiveUS6901845B2Overcome the small stiffnessLow costLinear bearingsGas cushion bearingsEngineeringMechanical engineering

A gas restrictor particularly usrful for applicatio in gas bearing as used, for example, in free-piston Striling cycle machinery. Porous strip material together with a backing plate and orifice (bleed hole) is used to provide the restriction to the flow of gas into an annular gap between a piston and a cylinder.

Owner:GLOBAL COOLING

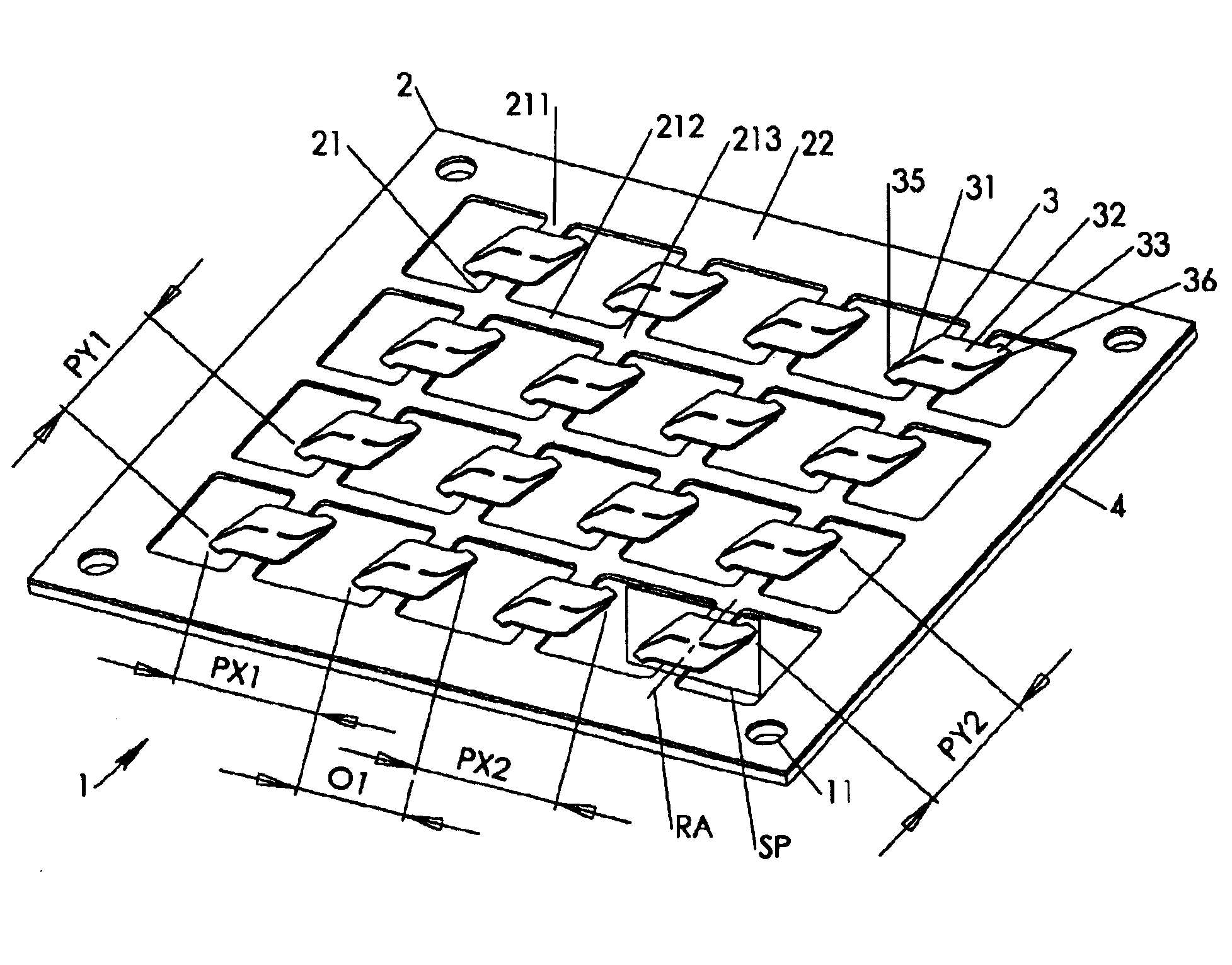

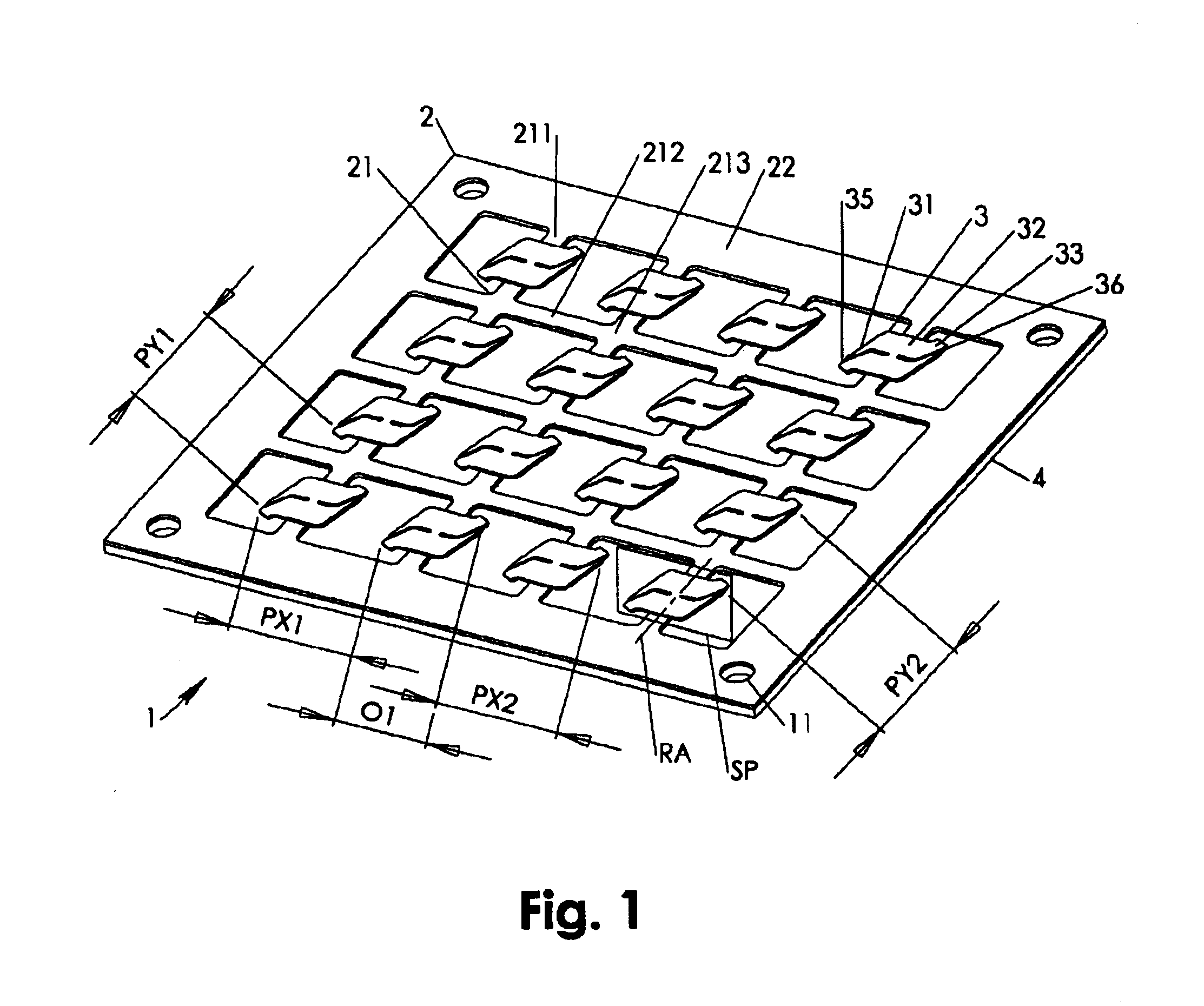

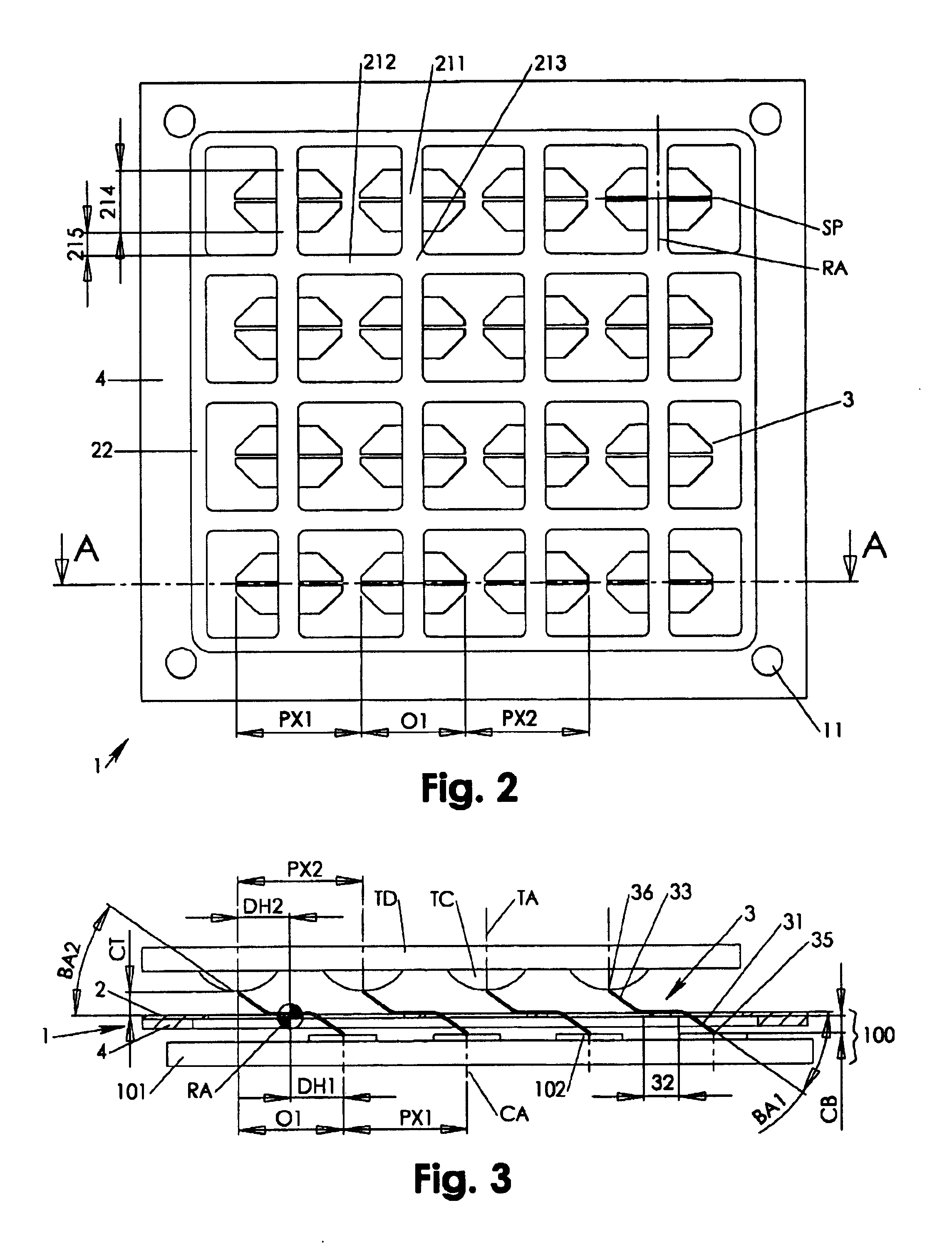

See-saw interconnect assembly with dielectric carrier grid providing spring suspension

ActiveUS7059865B2Large resistanceOvercome the small stiffnessElectrical measurement instrument detailsElectrical testingElectricityEngineering

An interconnect assembly includes a number of interconnects combined in a preferably planar dielectric carrier frame having resilient portions acting as spring members in conjunction with their respective interconnect's rotational displacement during operational contacting. Each interconnect is fabricated as a see-saw structure pivoting around a rotation axis that substantially coincides with a symmetry plane of the torsion features provided by the resilient portion. The torsion features protrude towards and adhere to a central portion of the see-saw interconnect such that an angular movement of the interconnect is resiliently opposed by the torsion feature and the resilient portion. The torsion features and interconnects may be independently optimized to provide the interconnect with maximum stiffness and a maximum deflection at same time.

Owner:INTERCONNECT DEVICES +2

Damping apparatus, use of a shape memory alloy and method for changing damping characteristics

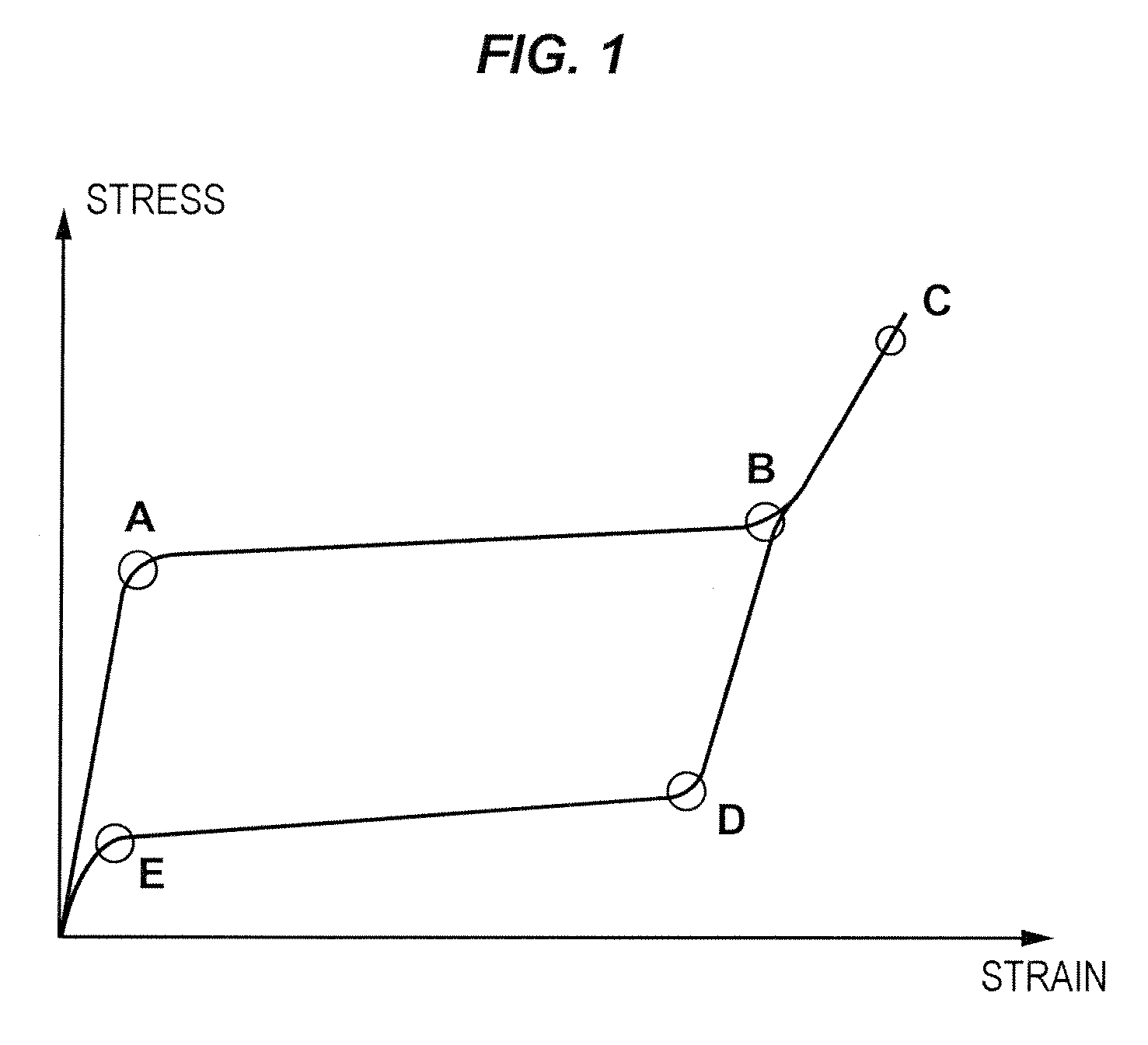

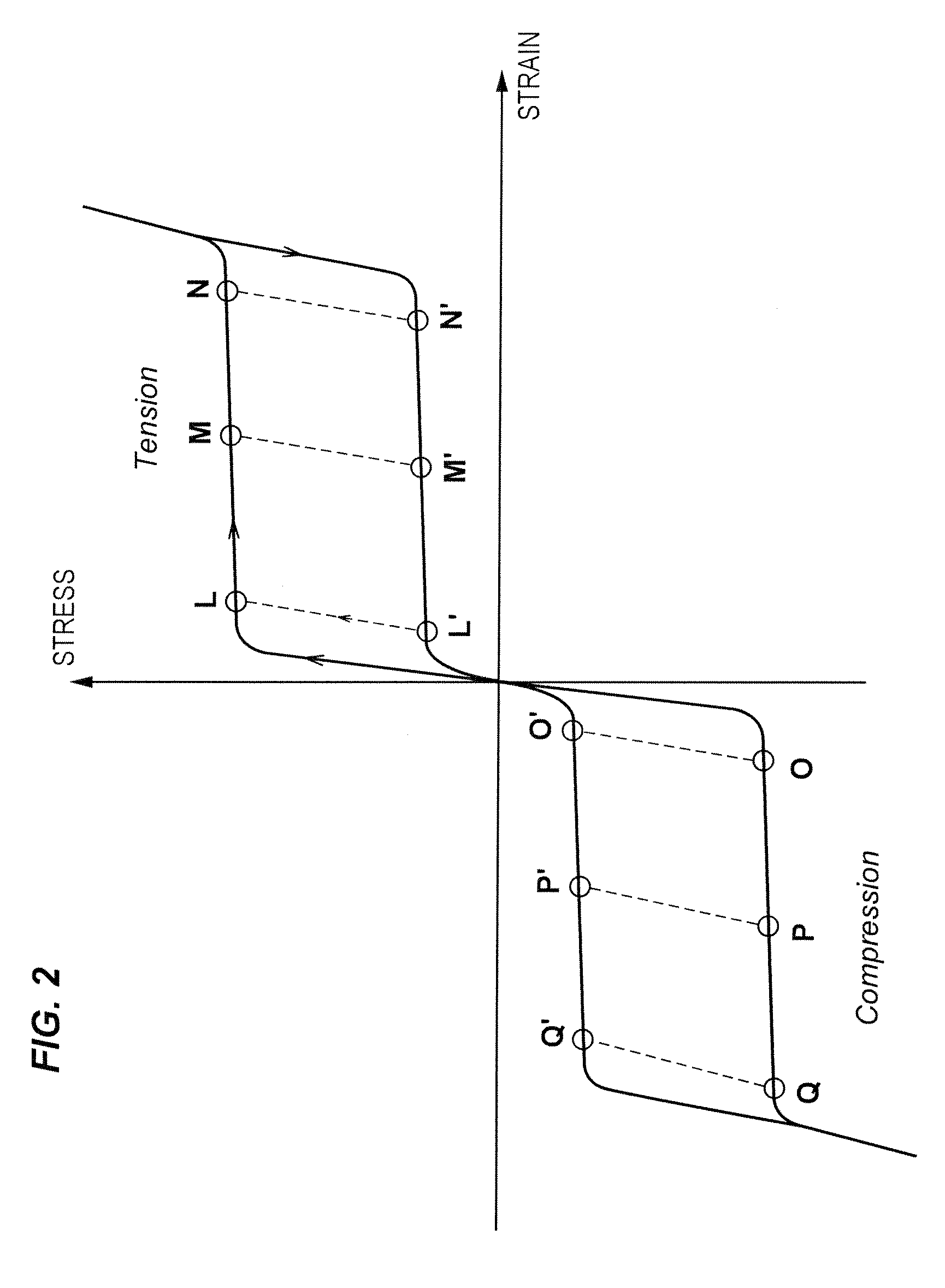

InactiveUS8328962B2Increase stiffnessImprove the immunityPortable framesInternal osteosythesisHysteresisChemical composition

Owner:ACANDIS

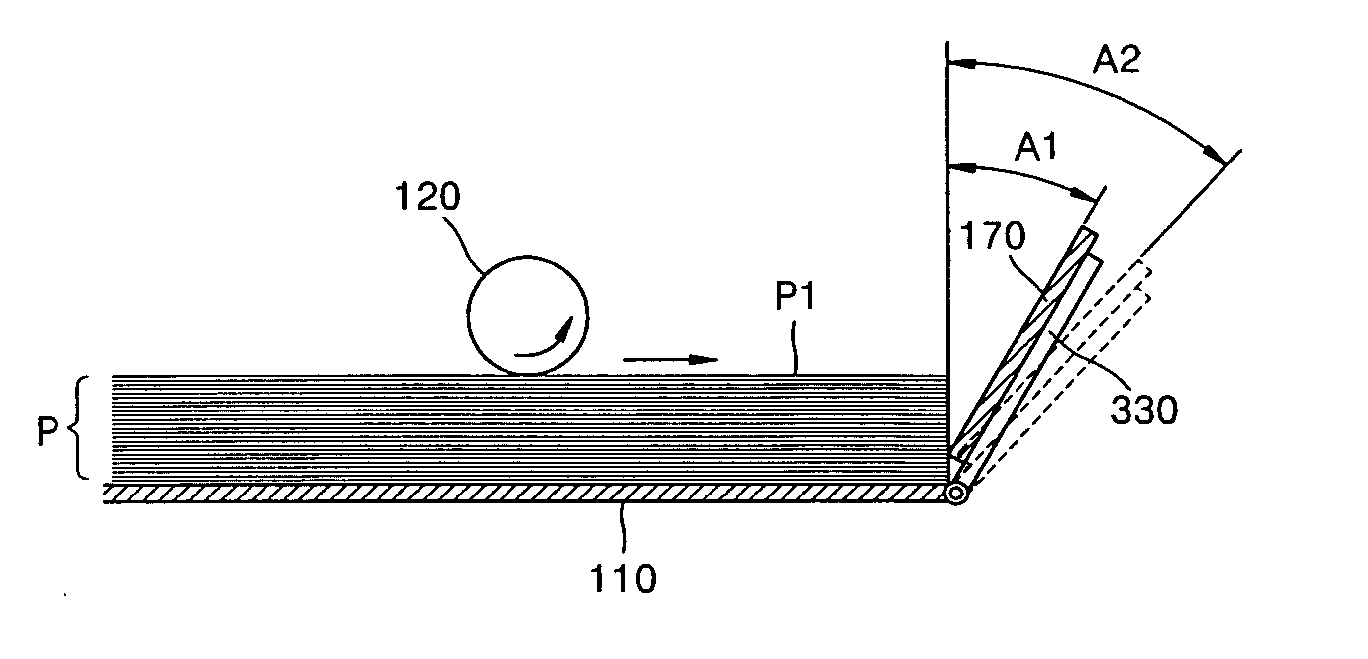

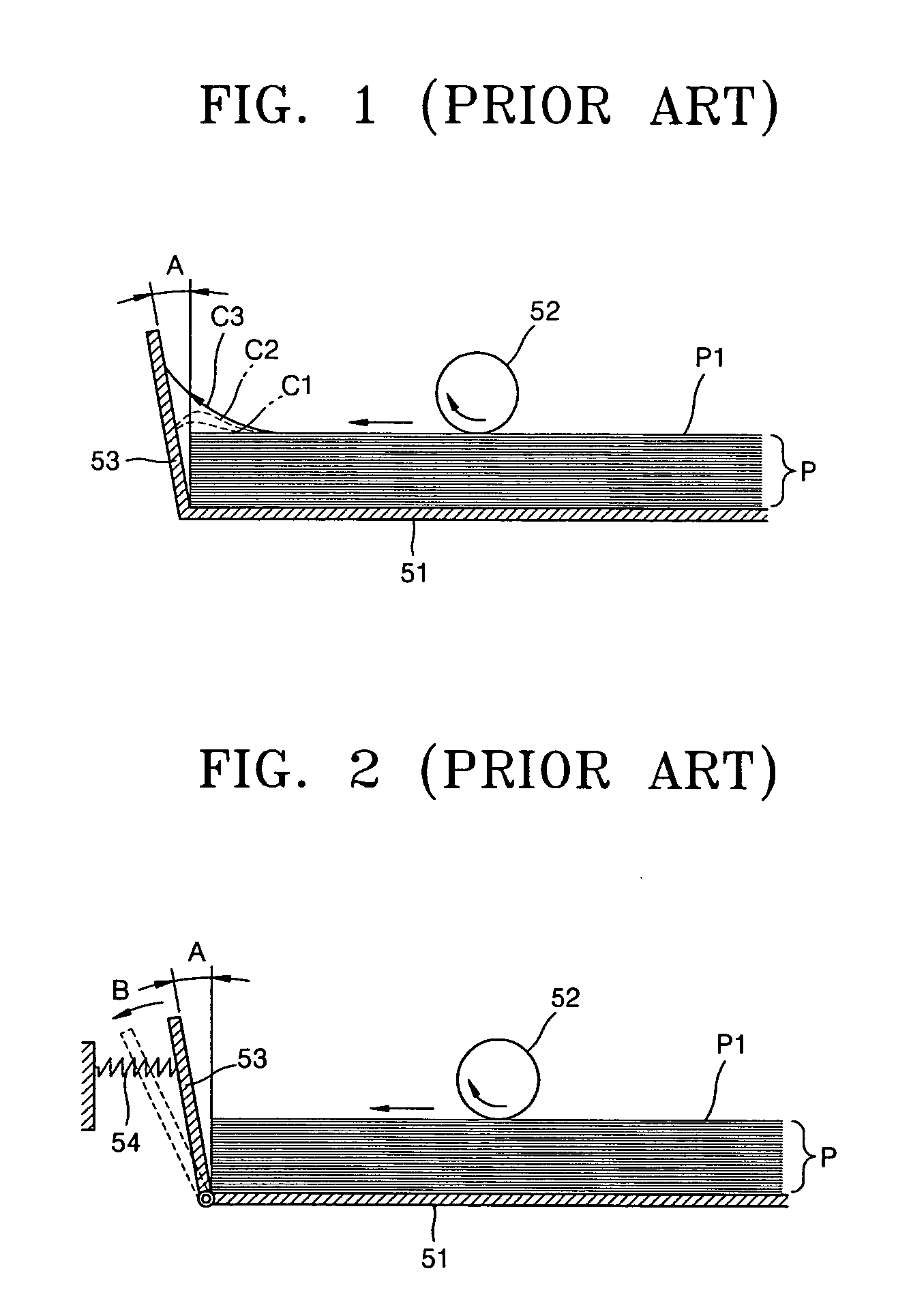

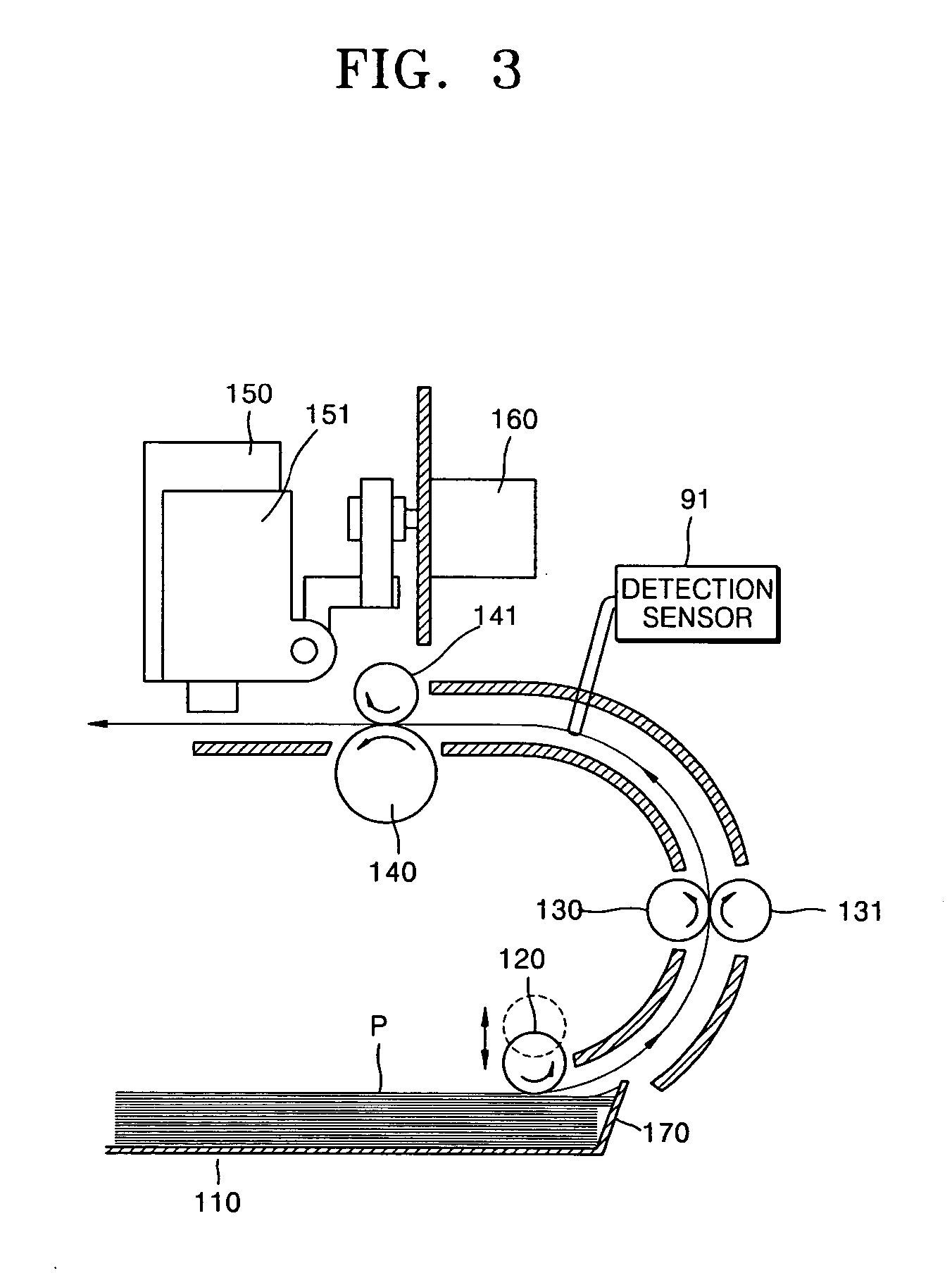

Printer and method for feeding sheets in a printer

ActiveUS20050051945A1Stable separationOvercome the small stiffnessFunction indicatorsOther printing apparatusComputer printingEngineering

A printer apparatus and method for sequentially which withdrawing sheets loaded into a cassette and printing images on the sheets is provided. The printer includes: a pickup roller for picking up a sheet from a plurality of sheets in the cassette; a resistance member for contacting a front end of the sheets such that the top sheet is separated based on stiffness and picked up from the cassette; and an angle change unit for changing a tilt angle of the resistance member about the front end of the sheets from a first tilt angle to a second tilt angle in a process of picking up the top sheet, and allowing the tilt angle to return to the first tilt angle when the top sheet has been completely picked up.

Owner:HEWLETT PACKARD DEV CO LP

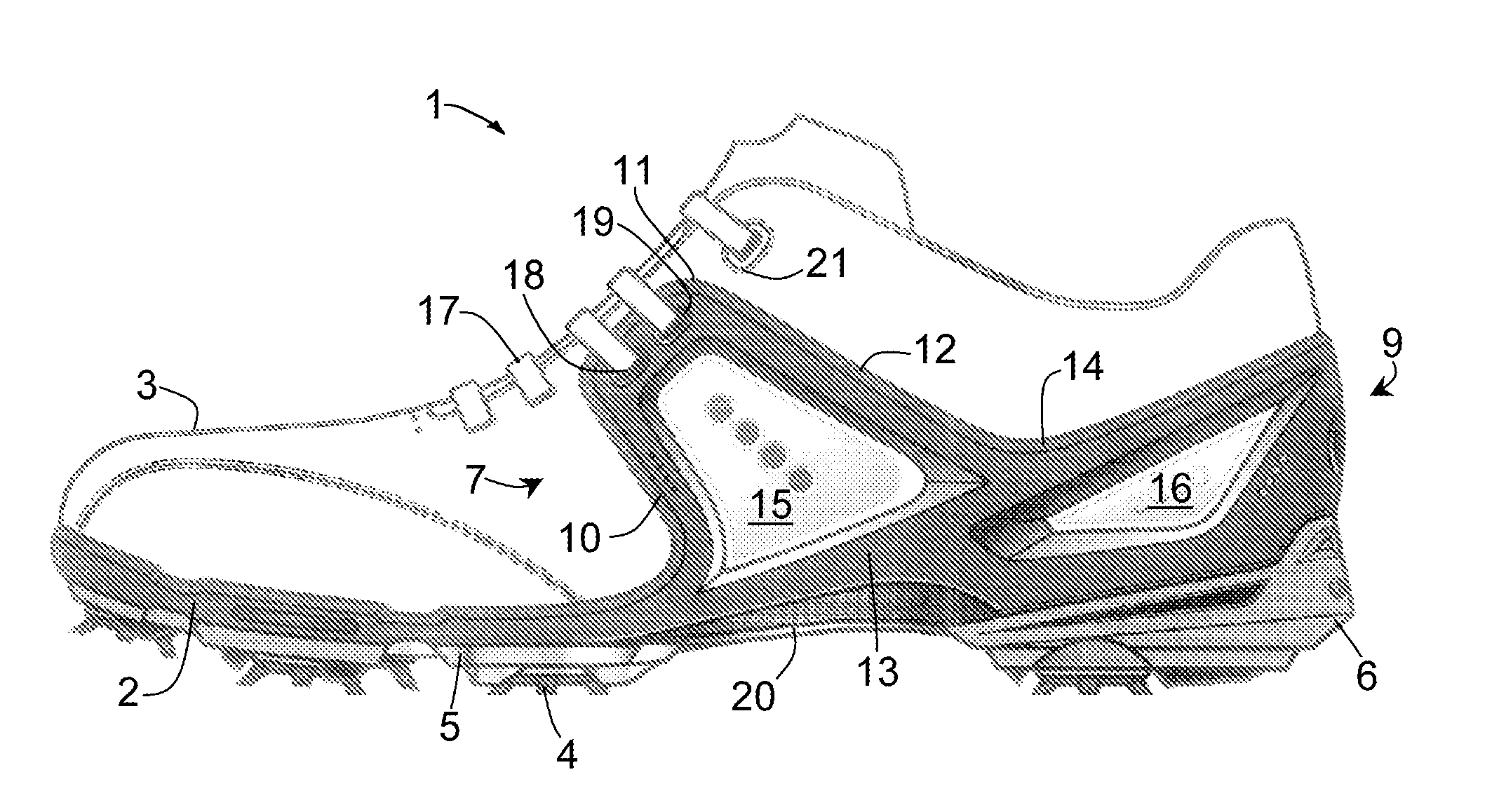

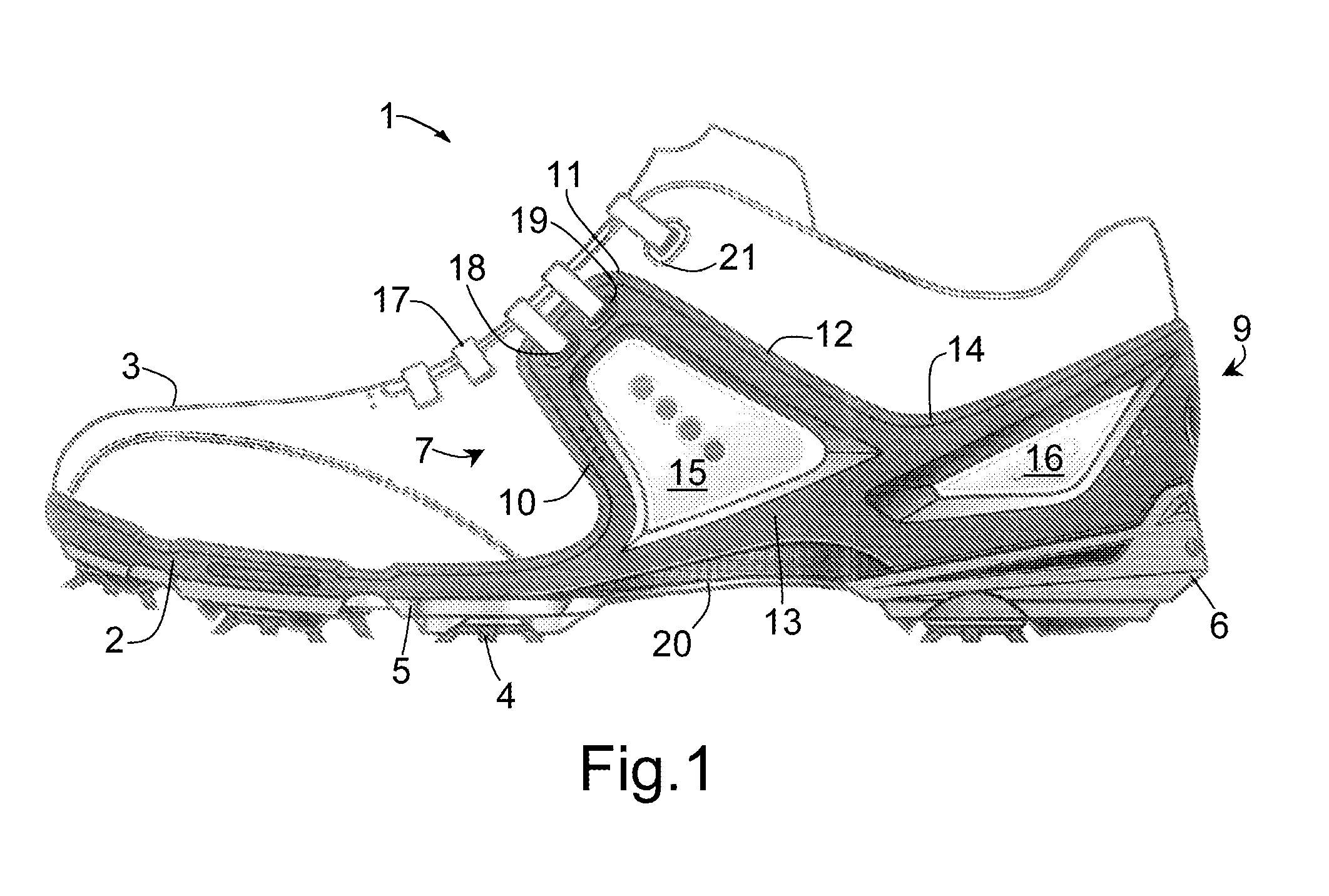

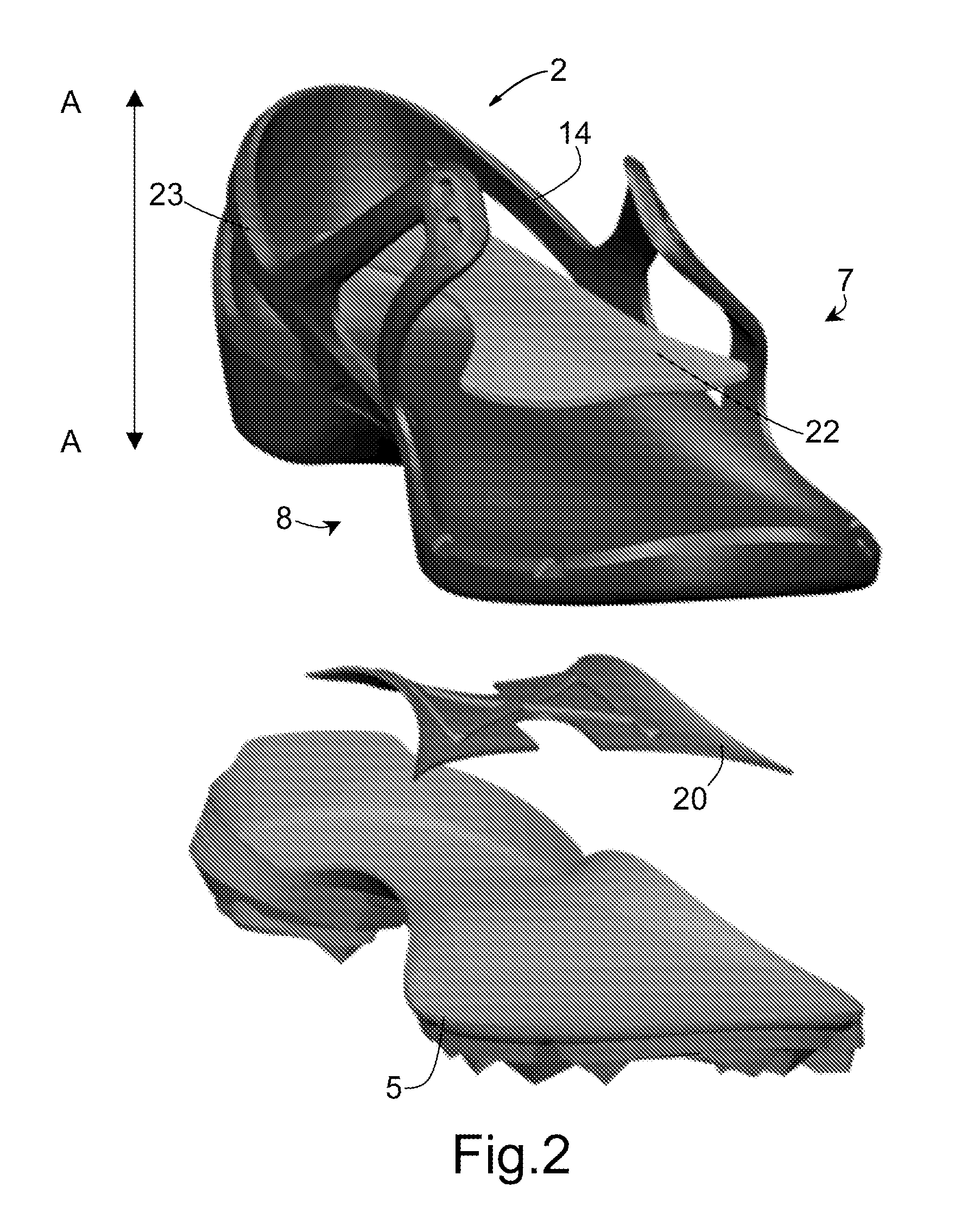

Golf shoe with a stabilizing system

A golf shoe has a stabilizing system consisting of an upper, a longitudinally extending midsole consisting of polyurethane, and a shank, wherein the midsole additionally to its longitudinal extension is extended vertically with a medial arch support structure, a lateral side support structure and a heel support structure. The structures are bonded to the outside of the upper and the medial arch support structure and the lateral side support structure extends upwardly and encircles eyelets for lacing of said upper. In order to further stabilize the golf shoe through all the phases of the swing of a golfer, the heel support structure (9) of said midsole (2) extends vertically to a point above the human calcaneus of a wearer, approximately to the point where the Achilles tendon is fixated. Midsole beams (14,23) are extending from the vertically extending heel support structure towards the vertical medial (8) and lateral (7) support structures.

Owner:ECCO SKO

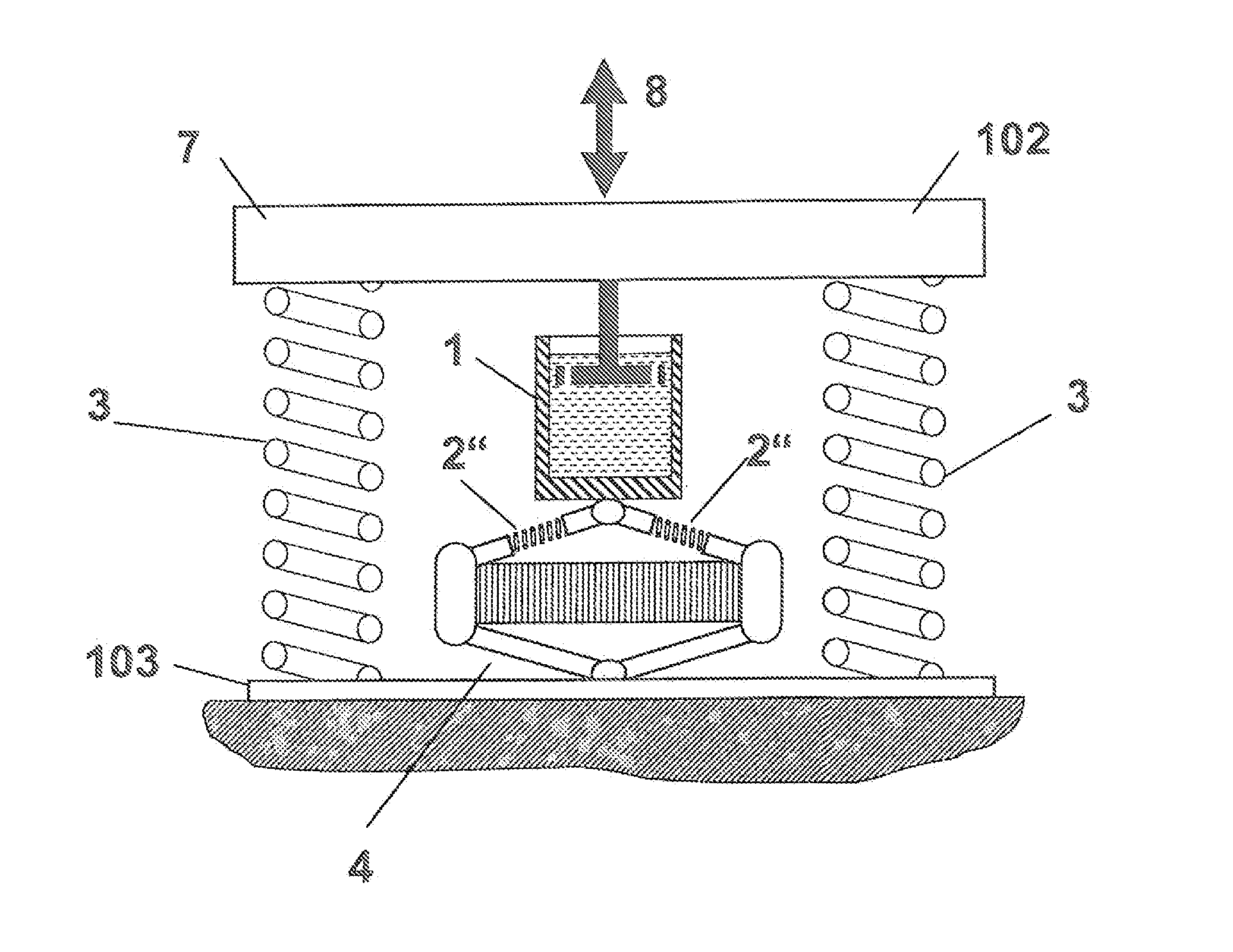

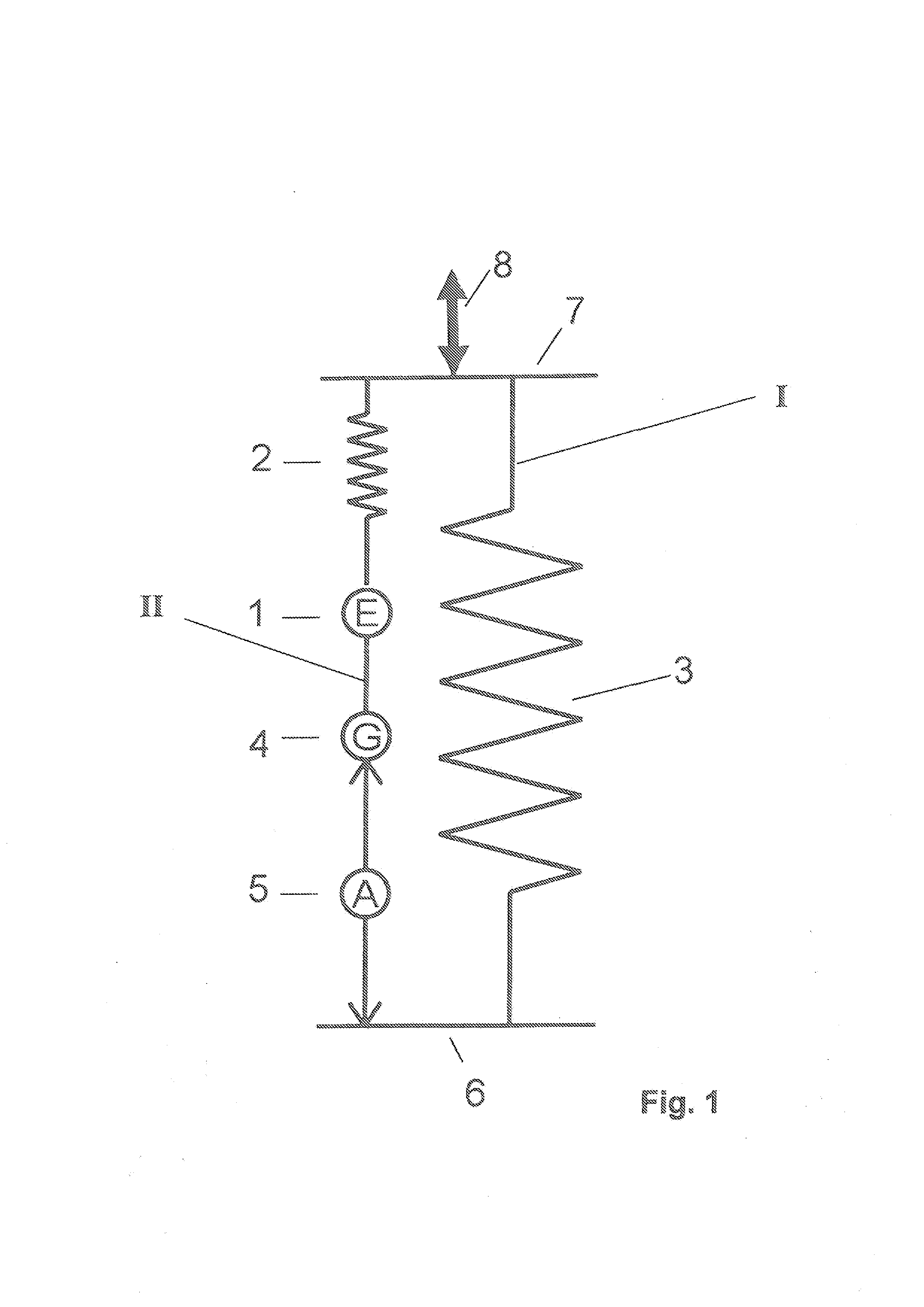

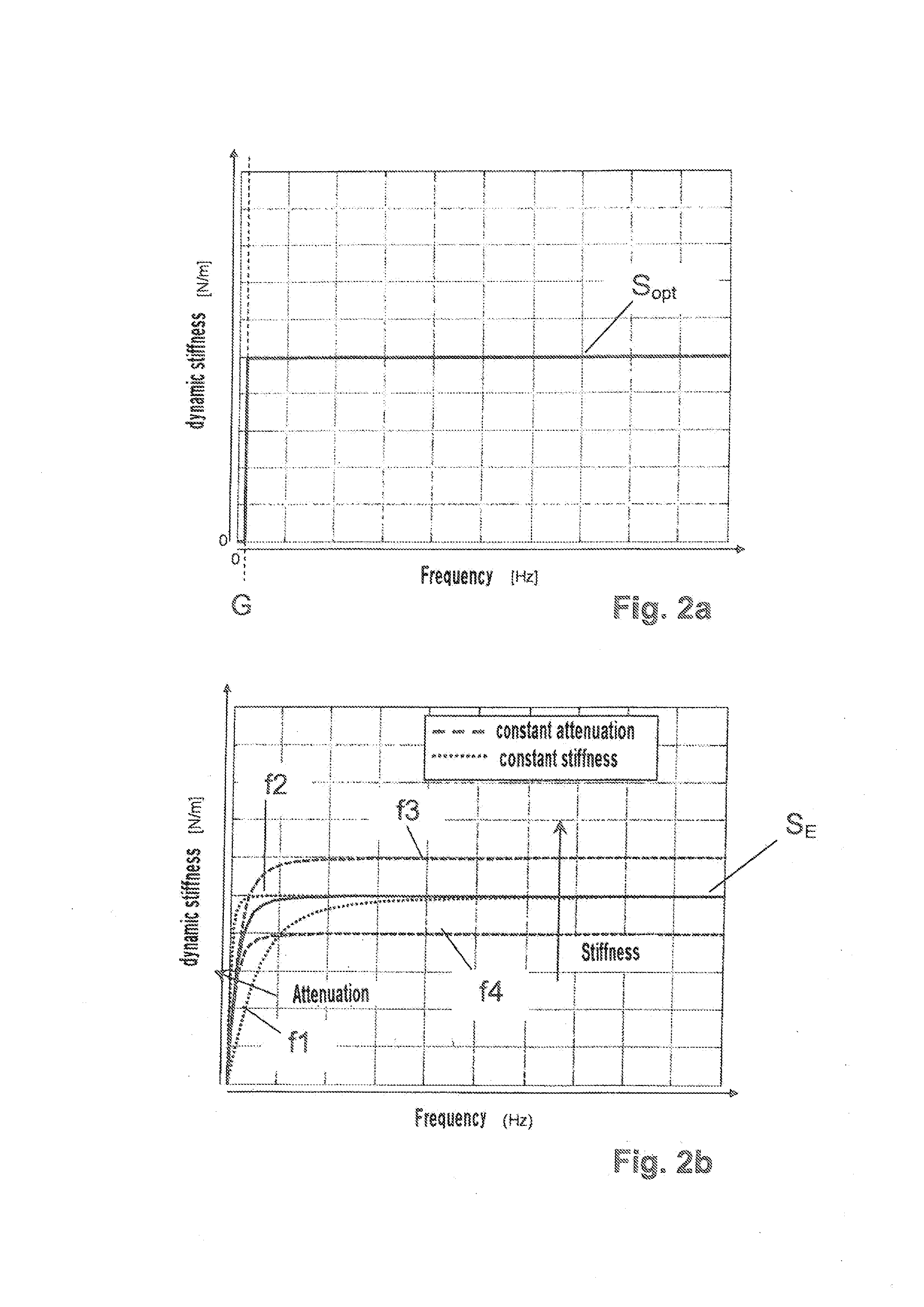

Active bearing

An active bearing at least for vibration reduction is described, comprisinga) an interface (7) to be fitted to a load (8);b) at least one support element (3) in an operative connection with the interface (7) and a support unit (6);c) at least one linear actuator (5) supported indirectly or directly on the support unit (6);d) a gear unit (4) for the path transmission of an actuating path change originating from the linear actuator (5), said gear unit being in an operative connection with the at least one linear reactor (5);e) at least one decoupling unit (1), which serves for the decoupling of the static load transfer and for transmitting the dynamic load transfer; wherein the at least one linear actuator (5), the gear unit (4) and the at least one decoupling unit (1) are disposed serially.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

Stringed instrument fingerboard for use with a light-system

ActiveUS20050126365A1Easy to optimizeOvercome the small stiffnessElectrophonic musical instrumentsGuitarsEngineeringLighting system

A fingerboard (or fretboard) for use with a stringed instrument and light-system is disclosed and has a bottom surface adapted to mate or be attached to a neck of the instrument, and has wells extending from the bottom surface toward, but not through, a top surface. The wells are sized to receive a light-emitting device, such as LEDs, and are positioned along the fingerboard according to finger positions of the instrument. Illumination from the light-emitting devices is visible to a player of the instrument, however, when the devices are not illuminated, the fingerboard appears substantially as one made without the wells. The structure is useful for learning to play the instrument, while not appearing as a learning device.

Owner:OPTEK MUSIC SYST

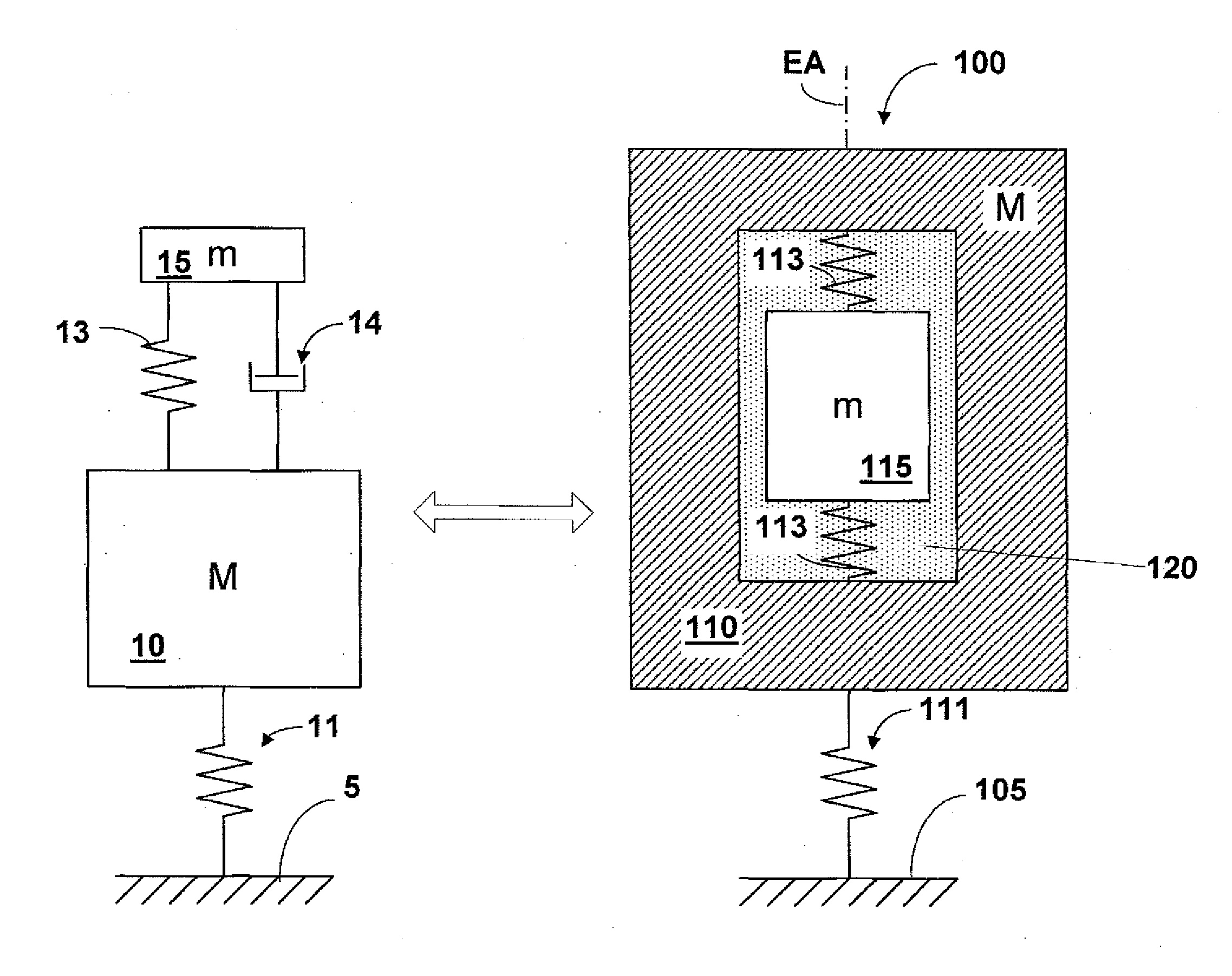

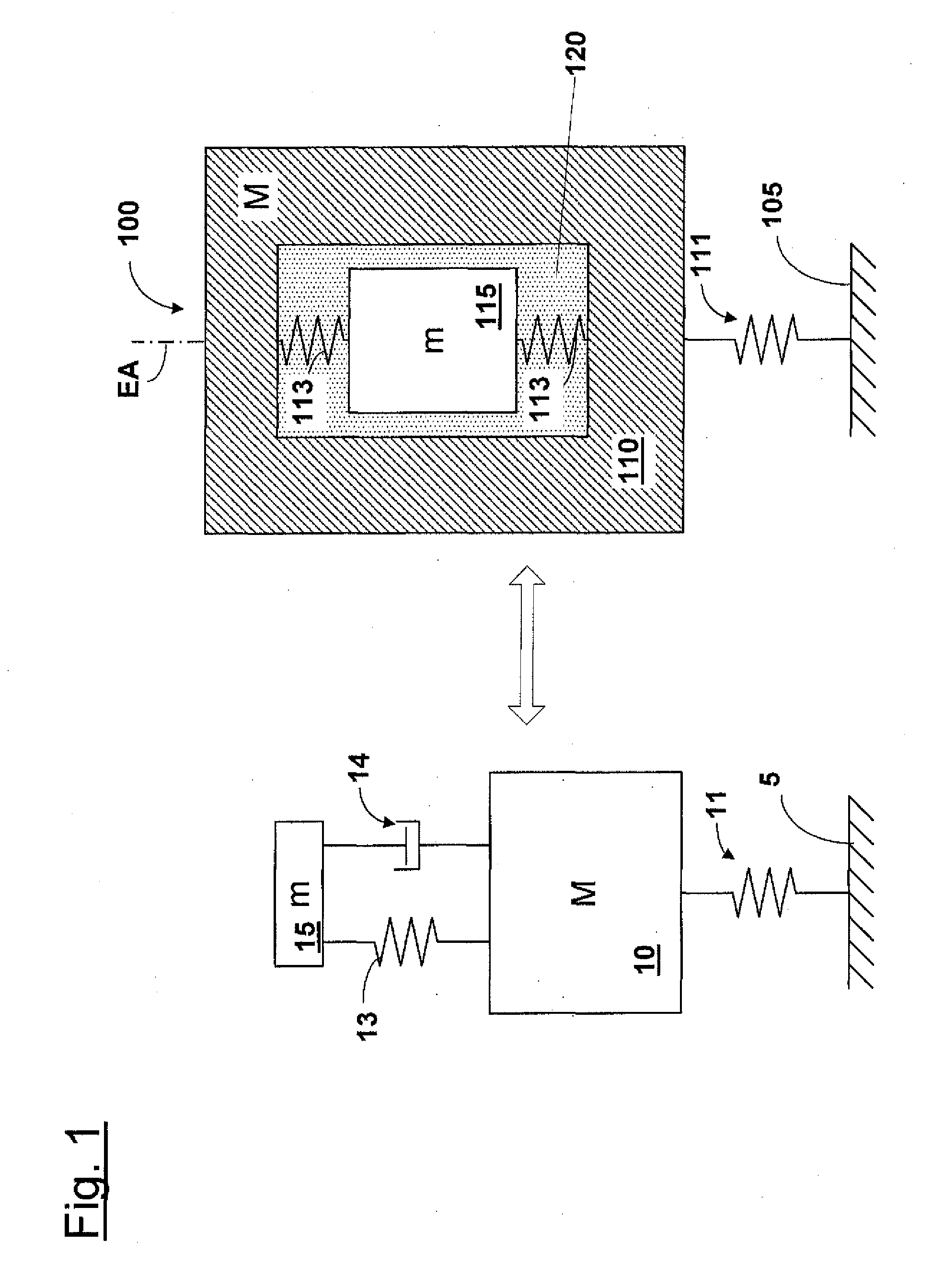

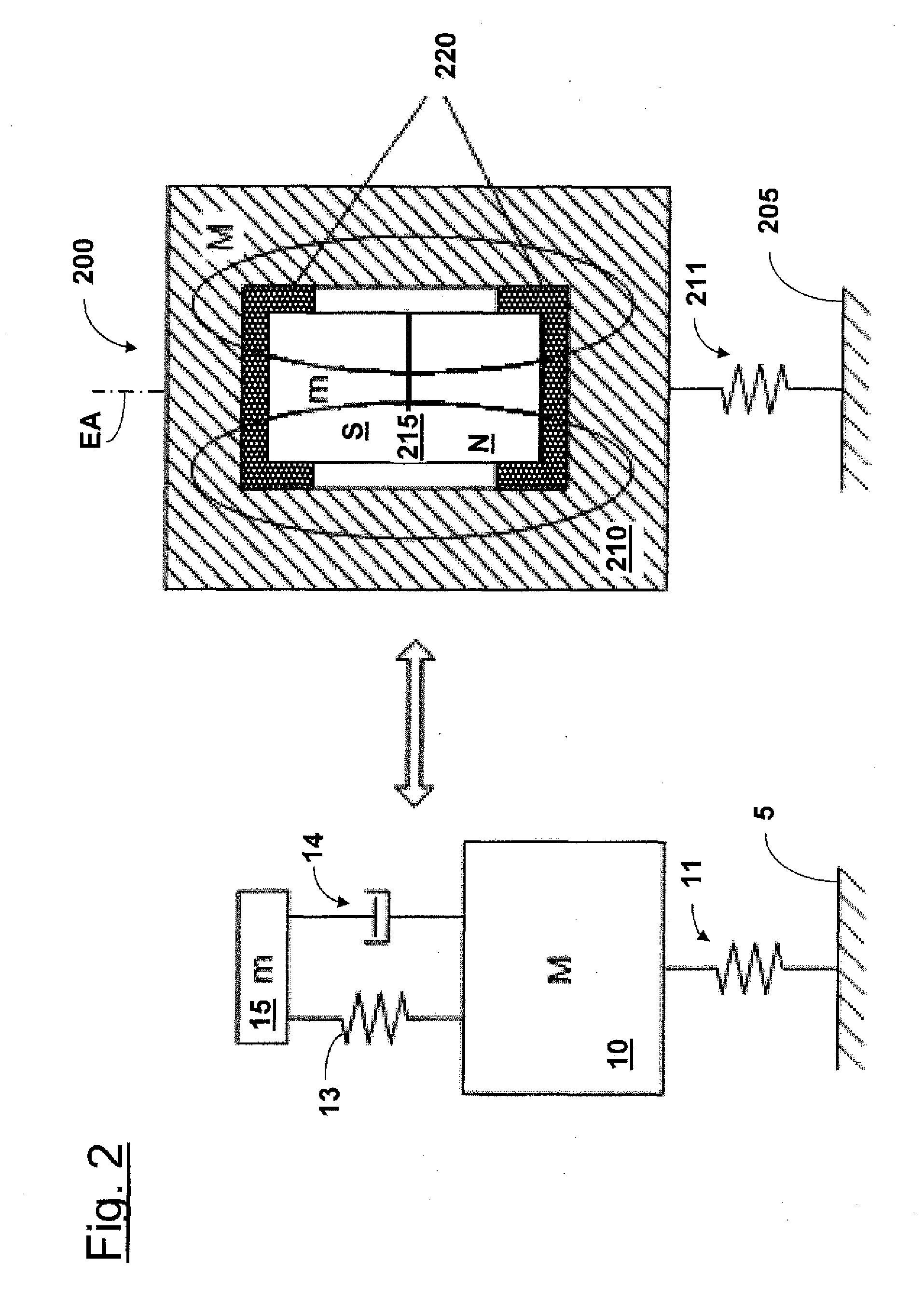

Damping arrangement for dissipating oscillating energy of an element in a system, more particularly in a microlithographic projection exposure apparatus

ActiveUS20140202812A1Optimization of degree of dampingDissipate energyPhotomechanical apparatusShock absorbersElectricityDissipative system

The invention relates to a damping arrangement for dissipating oscillation energy of an element in a system, more particularly in a microlithographic projection exposure apparatus, comprising an absorber mass, which is mounted via a stable mounting with respect to the element, wherein the absorber mass is arranged in a cavity present within the element and is at least partly surrounded by a fluid situated in the cavity, wherein a mass-spring system is formed by the absorber mass, the system damping a translational movement component of an oscillation of the element that exists at the linking point of the absorber mass, and wherein the stable mounting is formed by a rheological fluid that is electrically controllable or controllable via electric or magnetic fields.

Owner:CARL ZEISS SMT GMBH

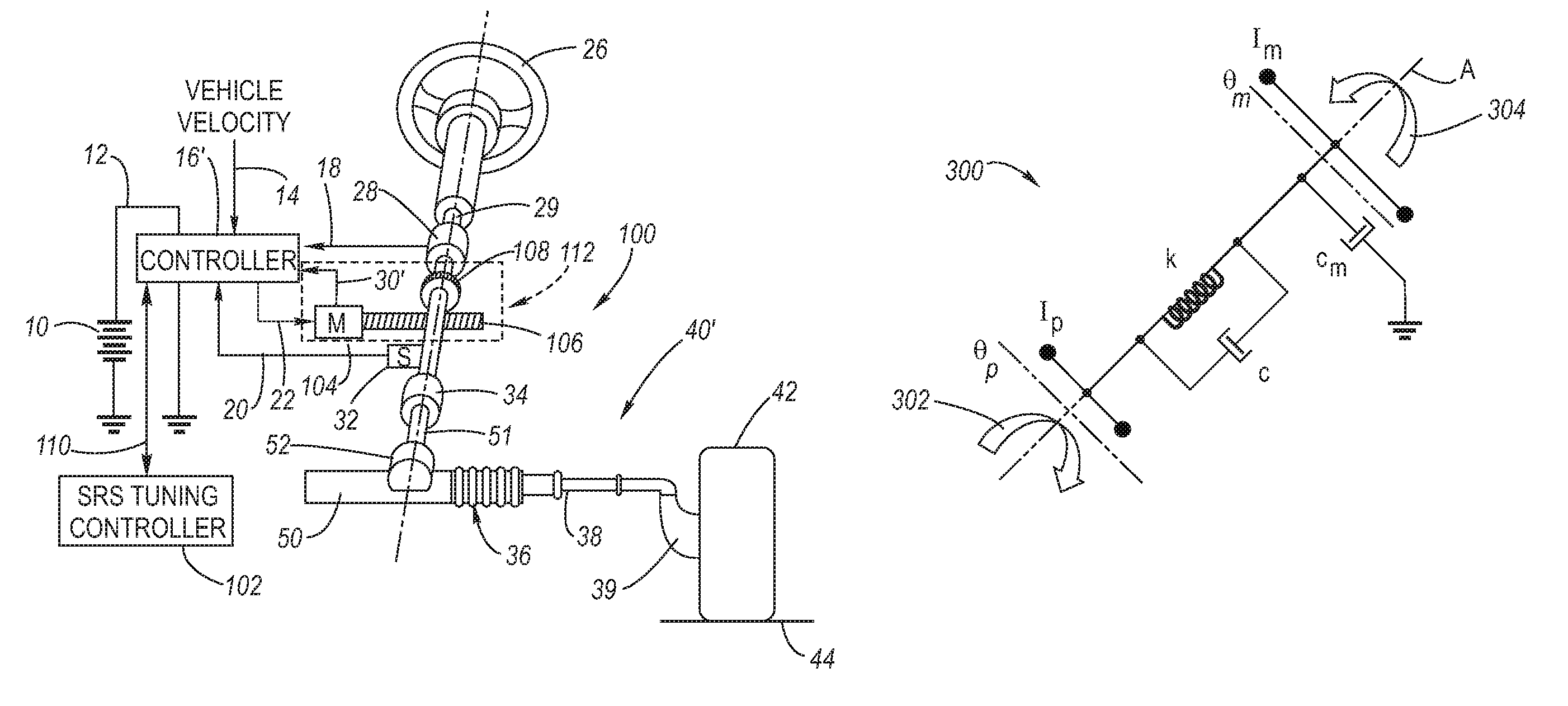

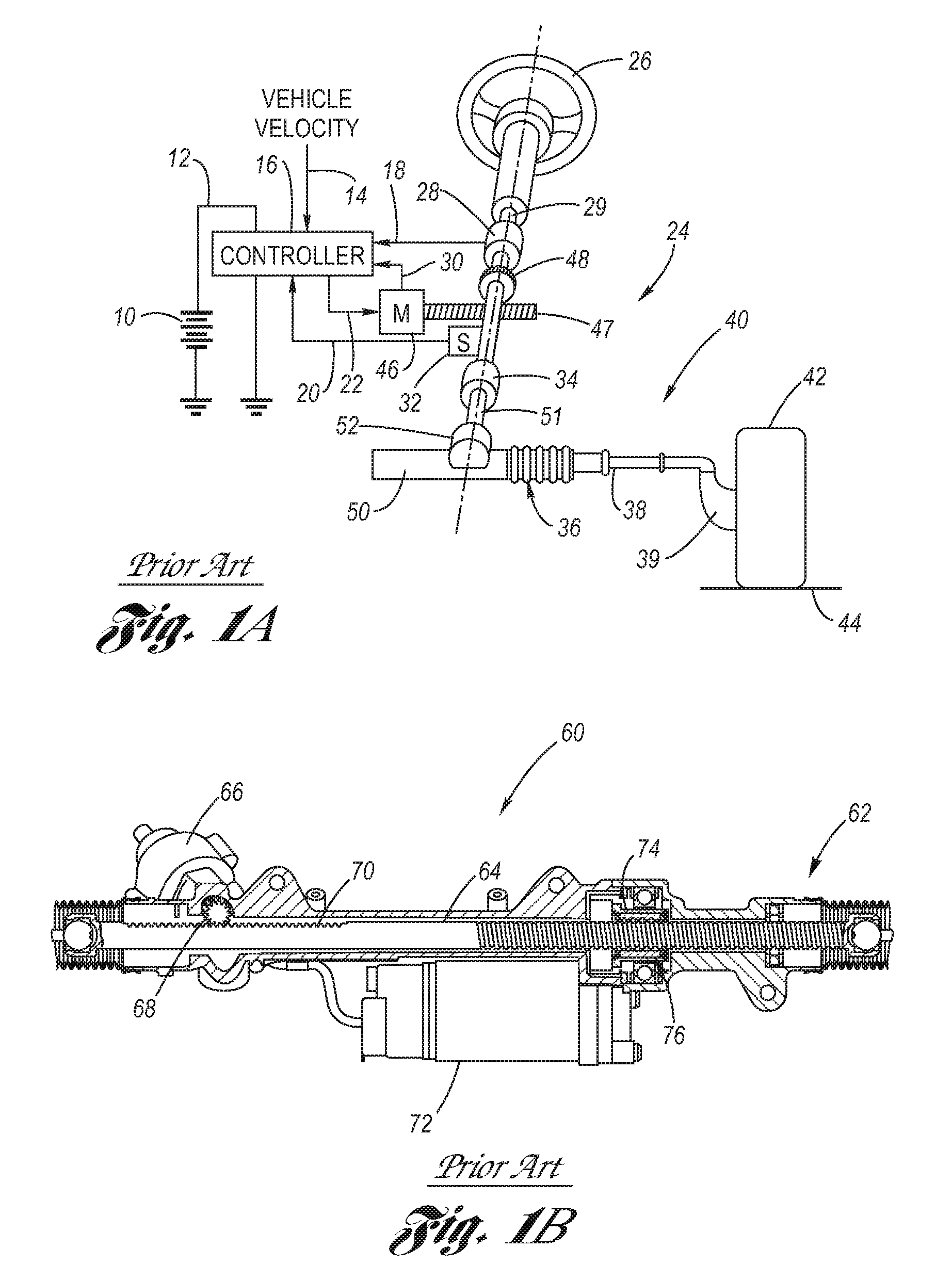

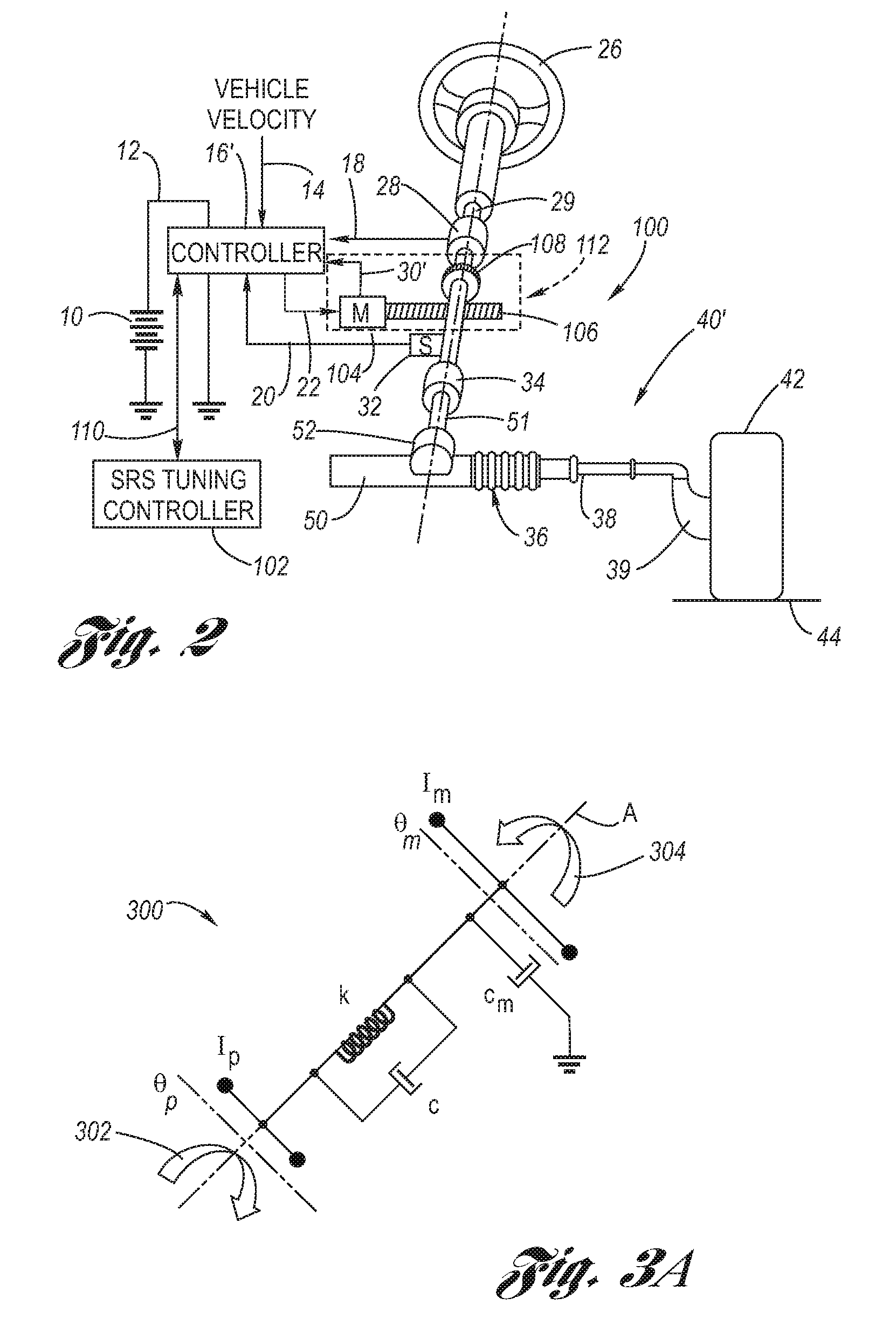

Method for attenuating smooth road shake in an electric power steering system

InactiveUS20110071729A1Maximum dynamic stiffnessOvercome the small stiffnessDigital data processing detailsSteering initiationsElectric power steeringRotational axis

A method to reduce vehicular sensitivity to torsional smooth road shake (SRS) at the steering wheel provided by selectively increasing reverse driven-impedance of the steering system via an effective dynamic tuned vibration absorber comprising the existing power steering motor inertia supported on the torsional stiffness of the gearing to the rack in the case of a REPS system, or of the column rotary shaft in the case of a CEPS system.

Owner:GM GLOBAL TECH OPERATIONS LLC

High bulk hesperaloe tissue

ActiveUS20180135248A1Satisfactory softness and strength and bulkOvercome the small stiffnessTissue/absorbent paperNon-woody plant/crop pulpFiberMedicine

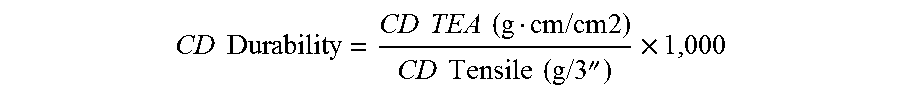

The invention relates to tissue products comprising hesperaloe fibers and methods of producing the same. Preferably the hesperaloe fibers are high yield hesperaloe pulp fibers, which have demonstrated the ability to replace substantially all of the long fiber fraction of the papermaking furnish without negatively effecting important tissue product properties such as CD Stretch, CD Durability and bulk. Thus, the tissue product may comprise greater than about 90 weight percent hesperaloe fiber and more preferably greater than about 95 weight percent.

Owner:KIMBERLY-CLARK WORLDWIDE INC

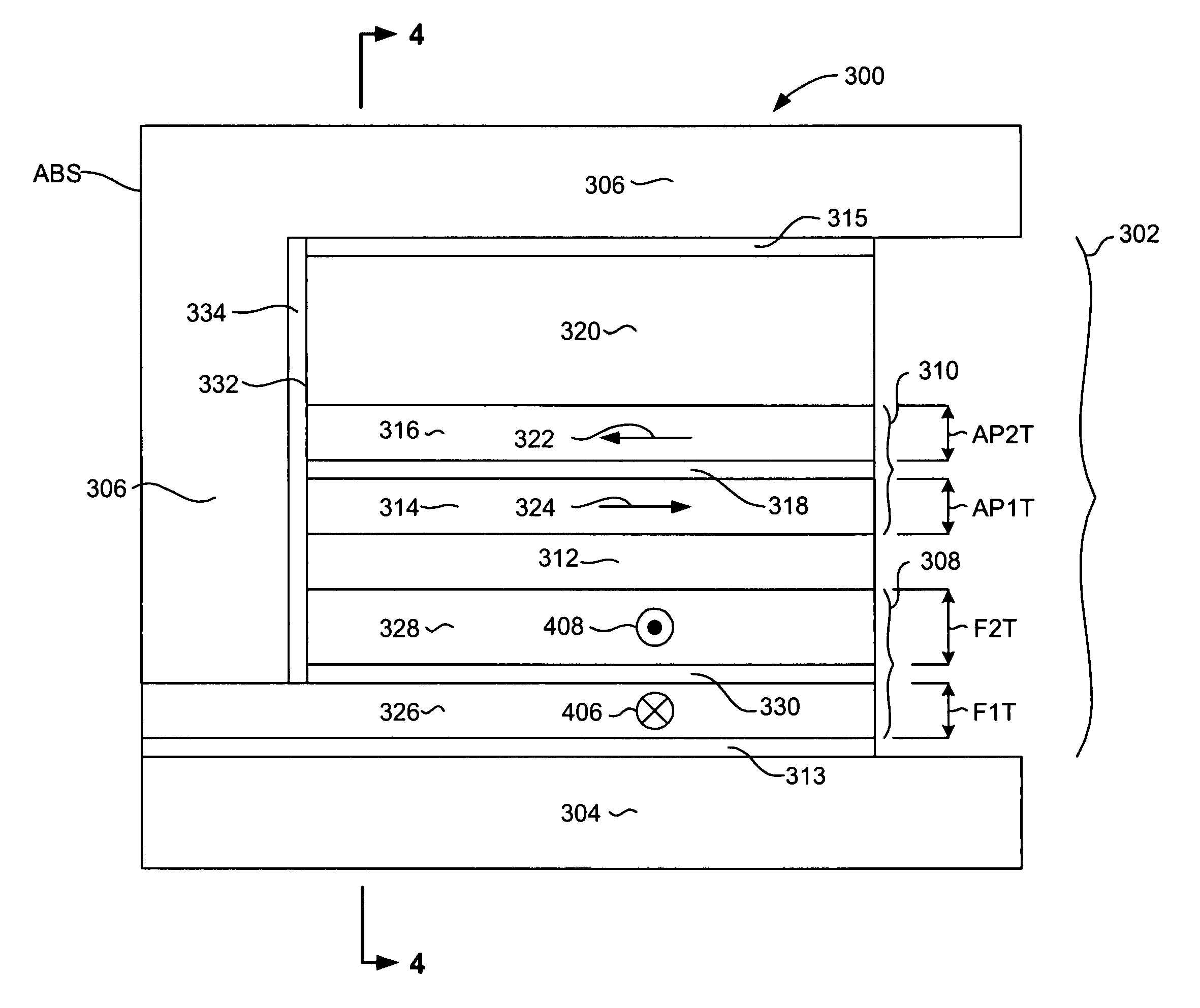

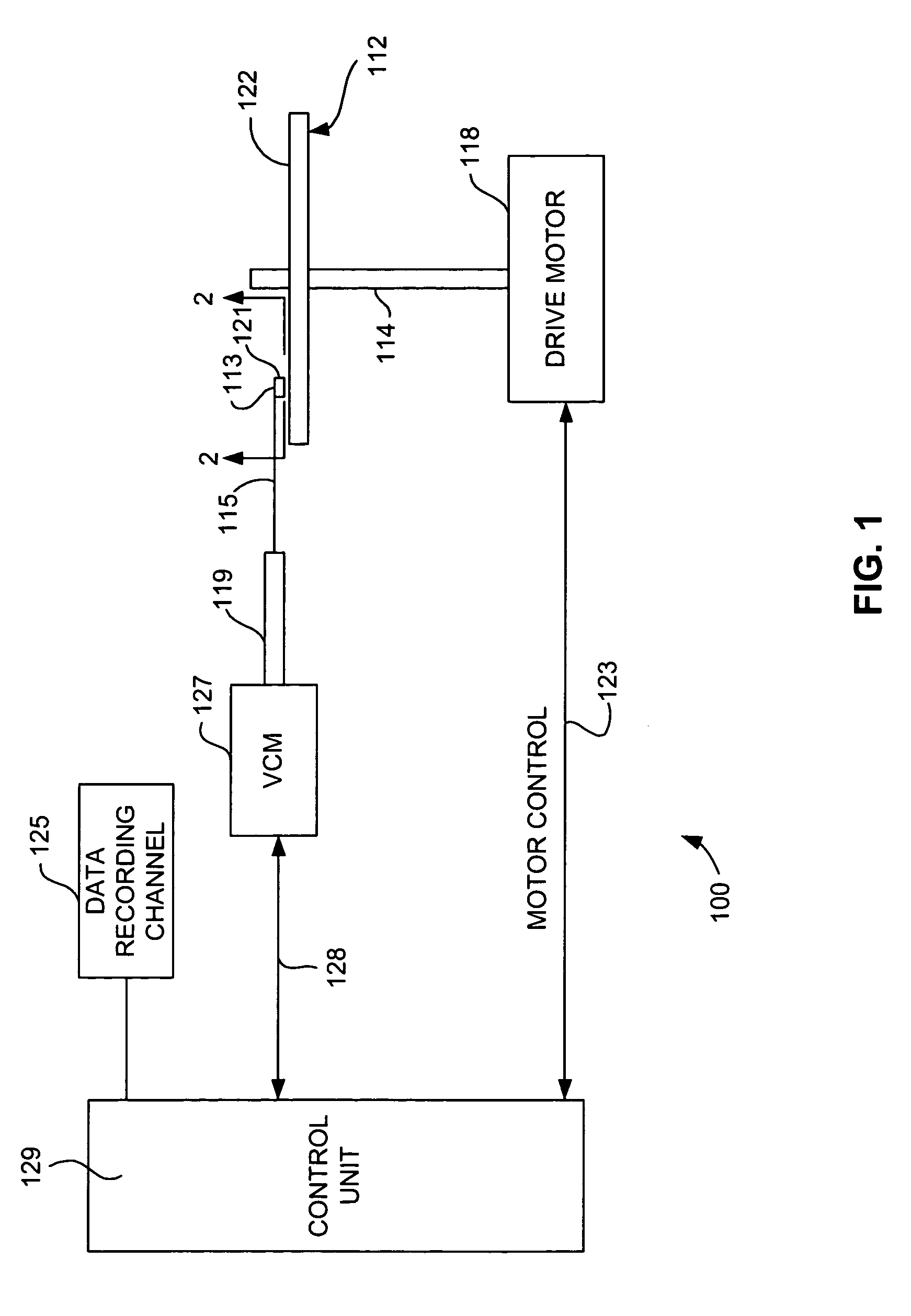

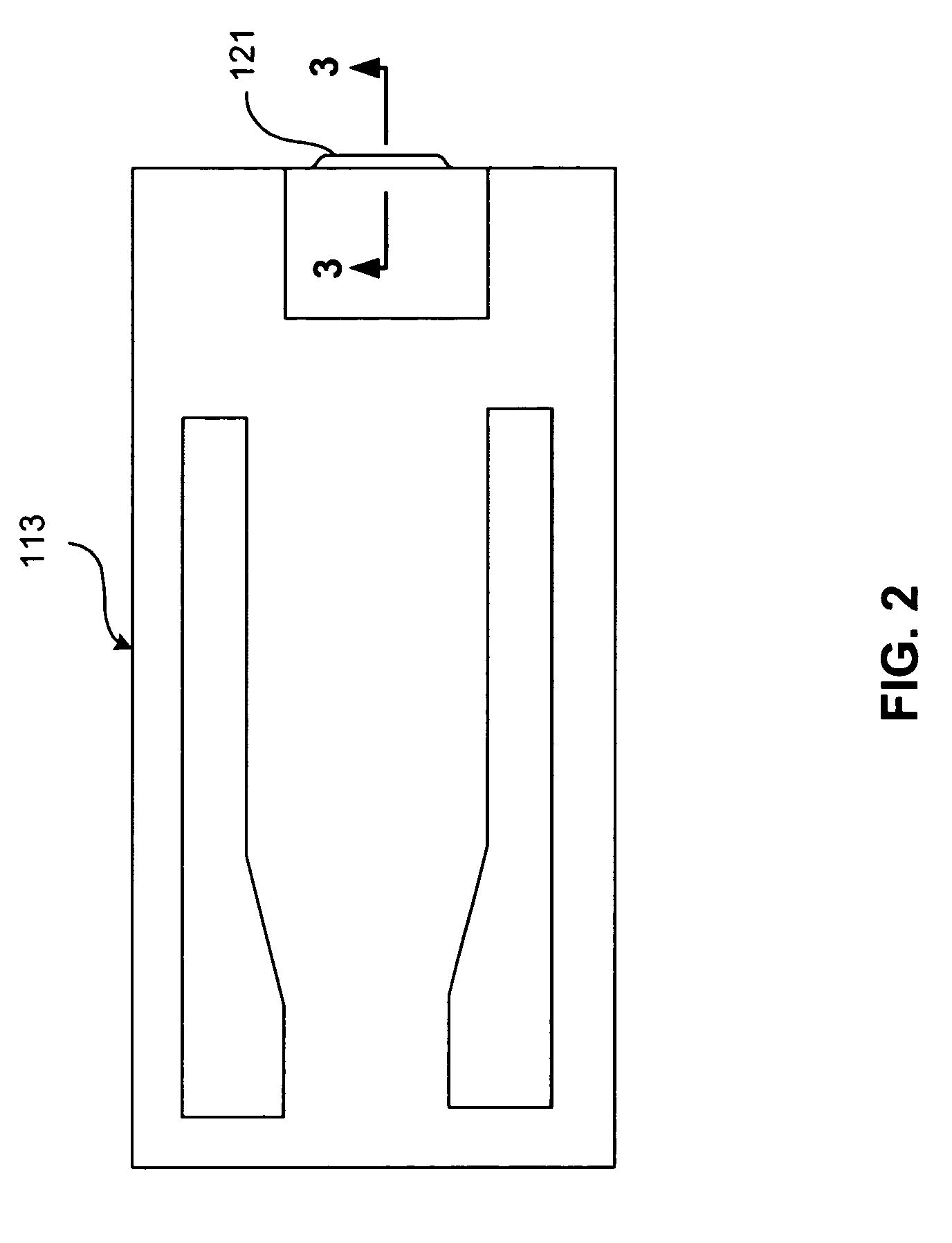

Current perpendicular to plane (CPP) magnetoresistive sensor having a flux guide structure and synthetic free layer

InactiveUS7616411B2Good effectReduce magnetic noiseNanomagnetismMagnetic measurementsMagnetic mediaCoupling

A current perpendicular to plane (CPP) magnetoresistive sensor having a front edge that is recessed from the air bearing surface (ABS). The sensor includes a pinned layer structure a free layer structure and a spacer layer sandwiched between the free layer and the pinned layer. The free layer is an AP coupled structure that includes a first magnetic layer F1 a second magnetic layer F2 and a coupling layer sandwiched between F1 and F2. The first magnetic layer F1 extends to the ABS while the other sensor layers terminate at the recessed front edge. In this way, the F1 layer acts as a flux guide that reacts to a magnetic field from a magnetic medium. The AP coupled structure of the free layer allows each magnetic layer F1 and F2 to be thicker than would be possible in a conventional single layer free layer, which increases the GMR effect of the sensor and increases the effectiveness of the flux guide (F2).

Owner:WESTERN DIGITAL TECH INC

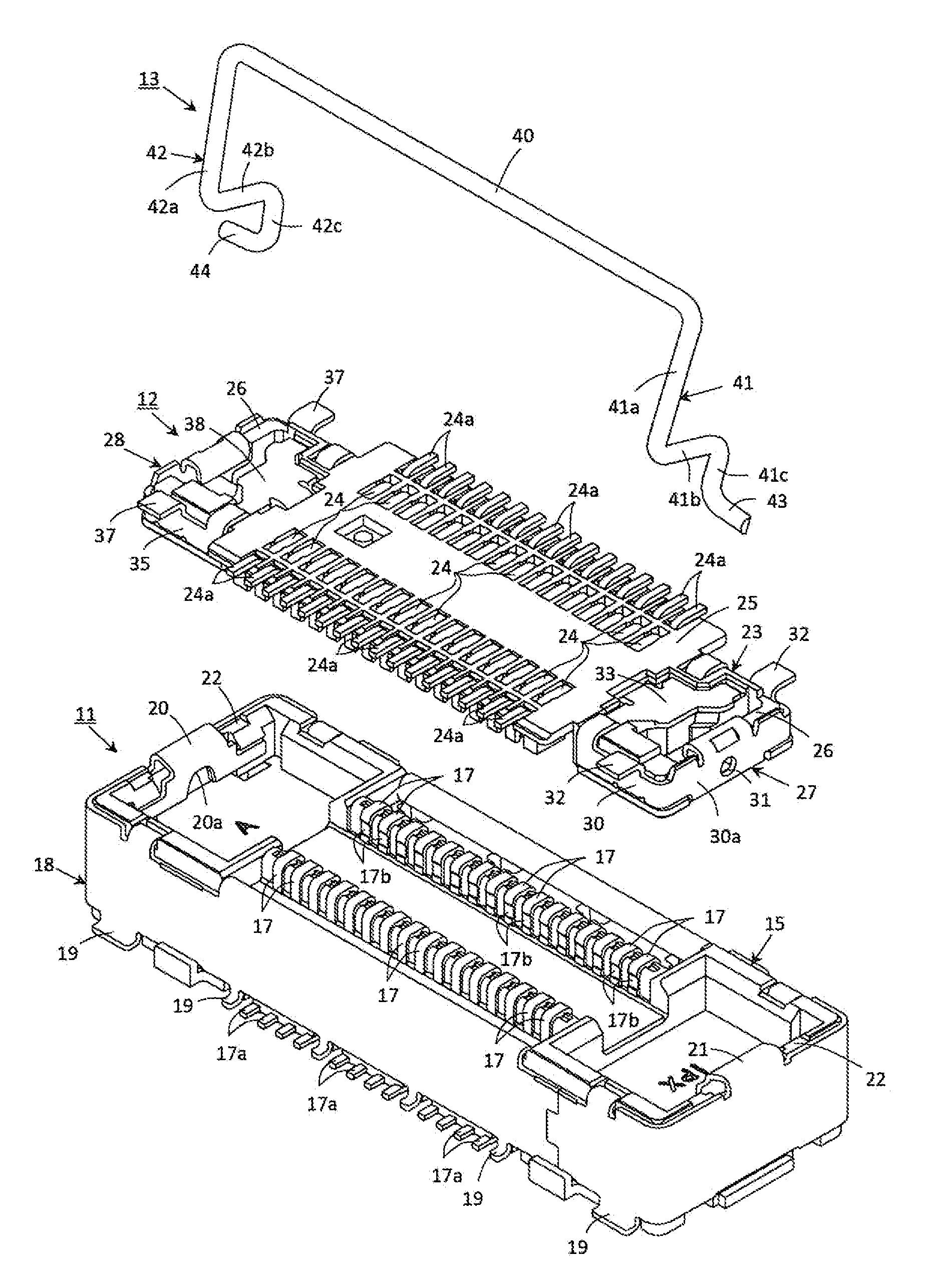

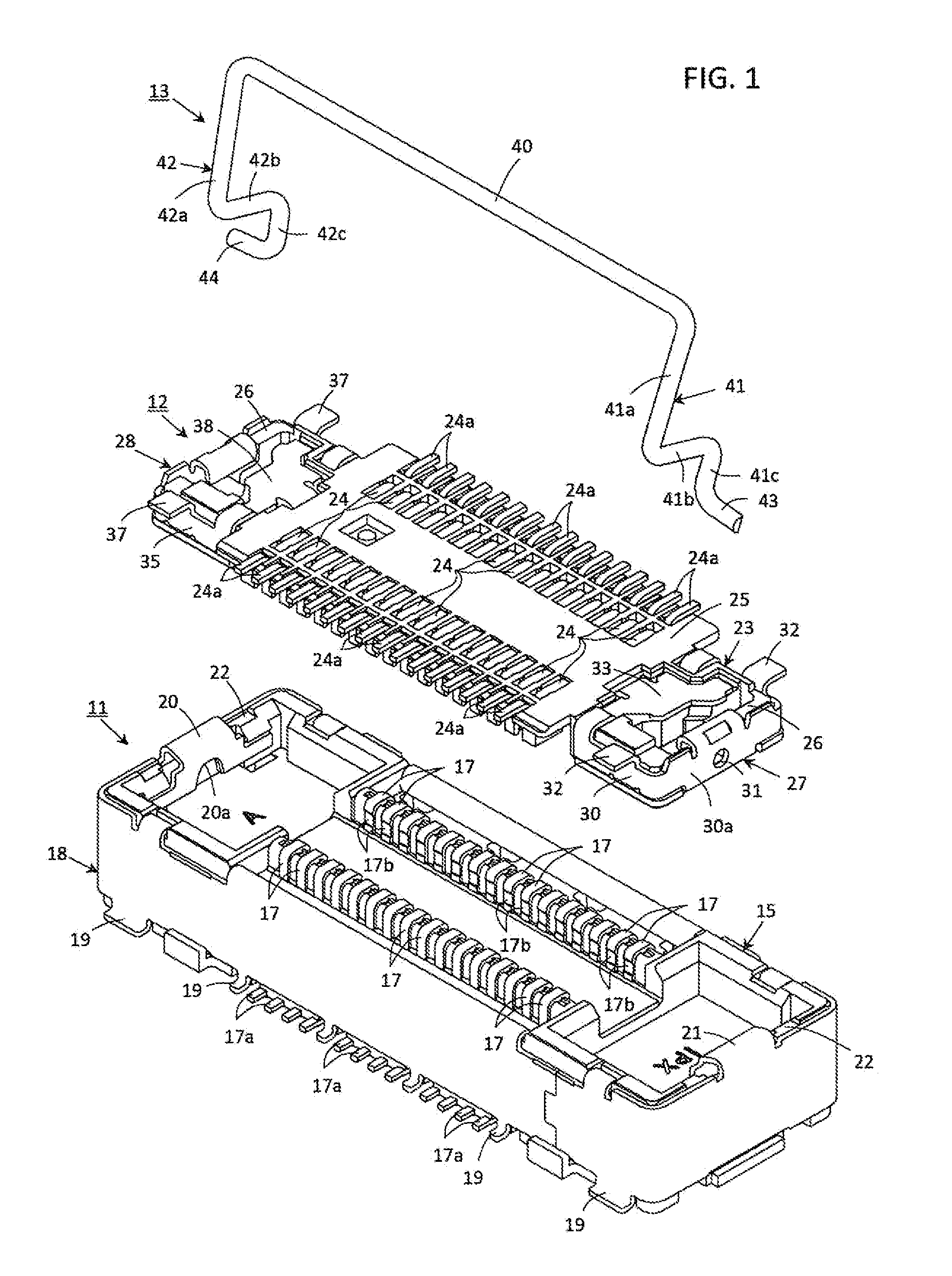

Circuit-terminal connecting device

InactiveUS20150064942A1Overcome the small stiffnessReduce weightCoupling device detailsPrinted circuitsEngineeringElectrical and Electronics engineering

Owner:DAIICHI SEIKO CO LTD

Synchronously self deploying boom

InactiveUS20090184207A1Small volumeOvercome the small stiffnessCosmonautic vehiclesCosmonautic partsEngineeringSelf locking

A deployable boom with adjacent panels hinged together typically in an end to end configuration. A first longeron is attached to at least two panels and a second longeron is also attached to at least two panels. Each longeron includes a self locking hinge between adjacent panels.

Owner:FOSTER-MILLER

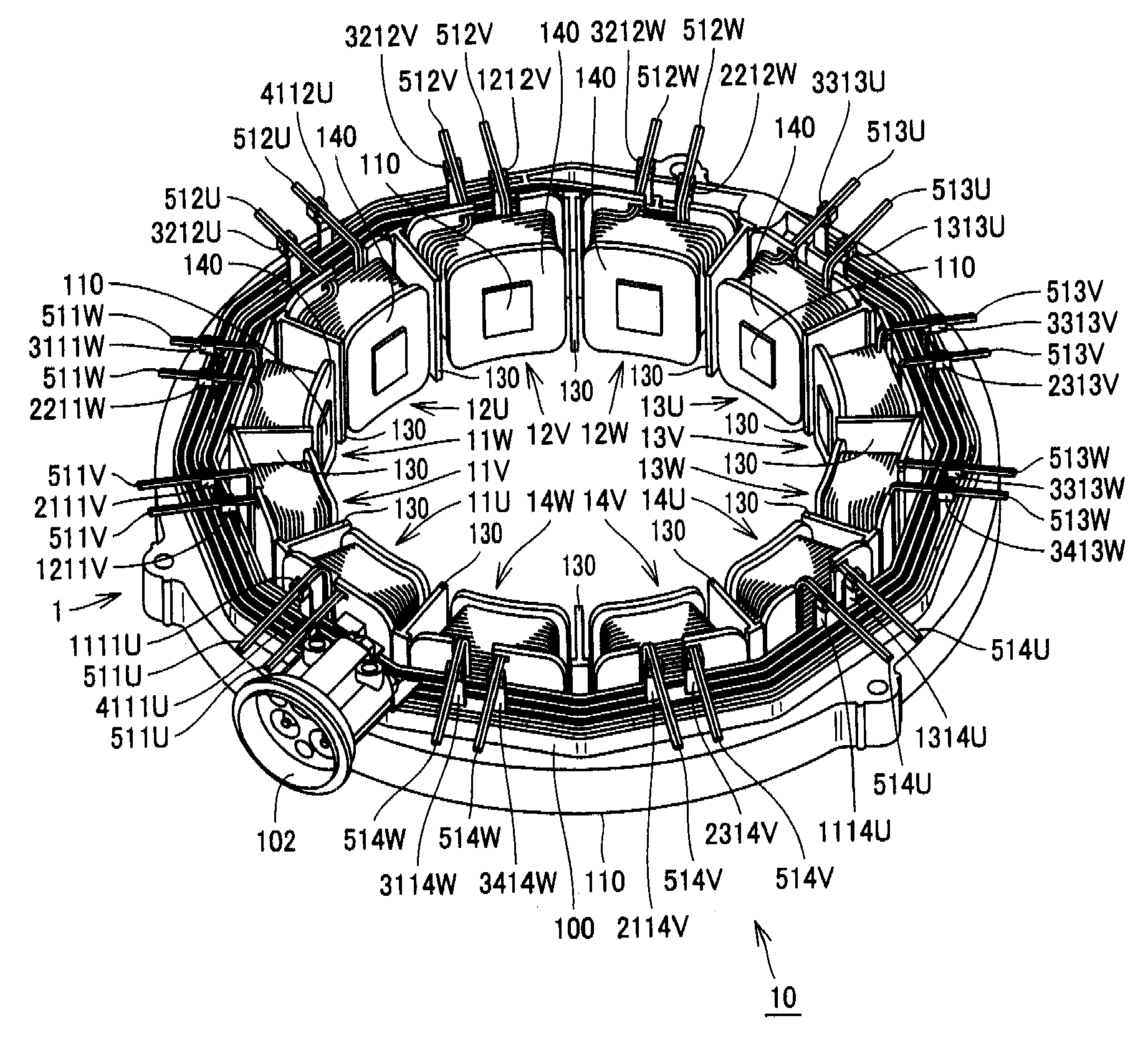

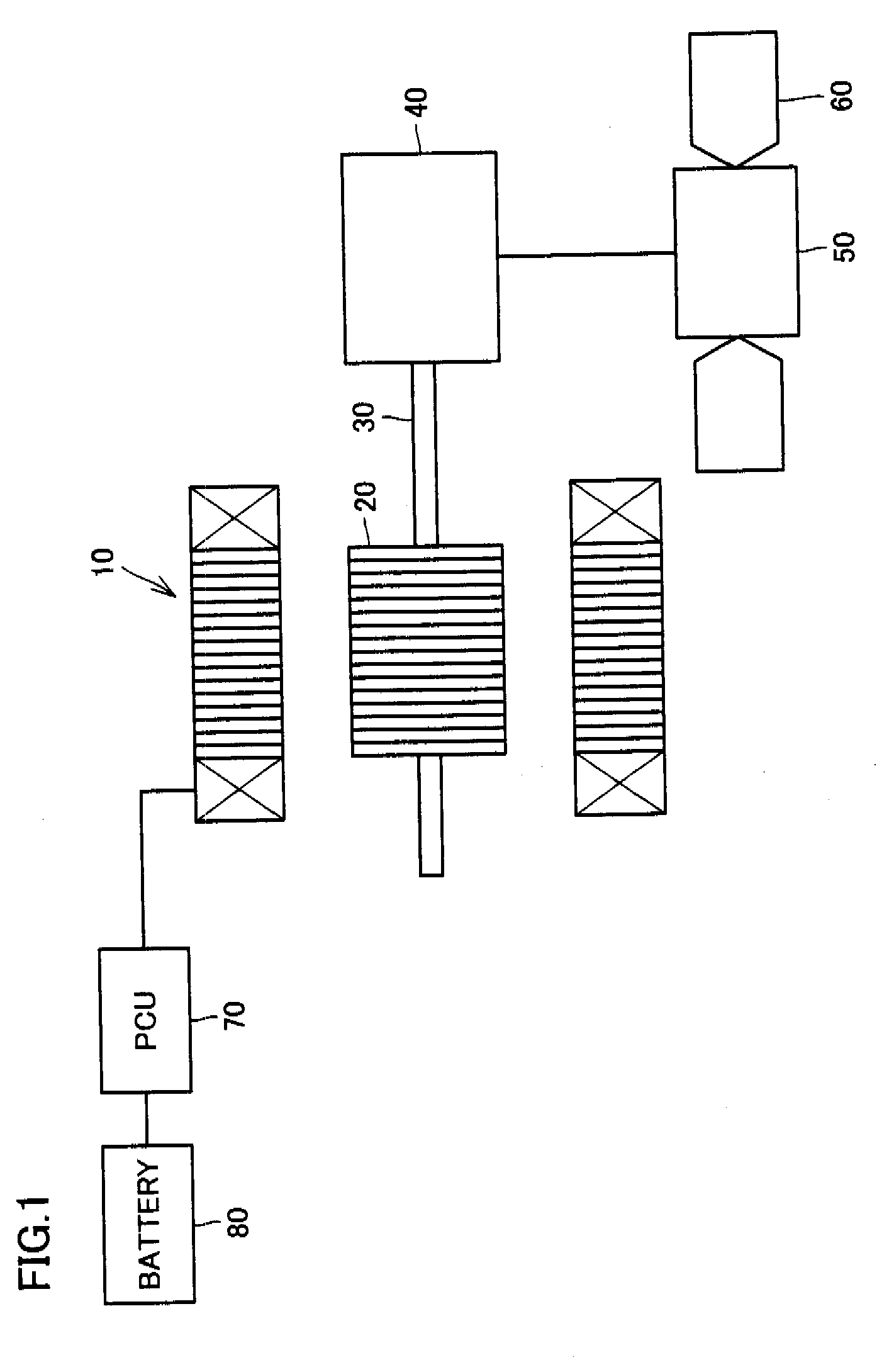

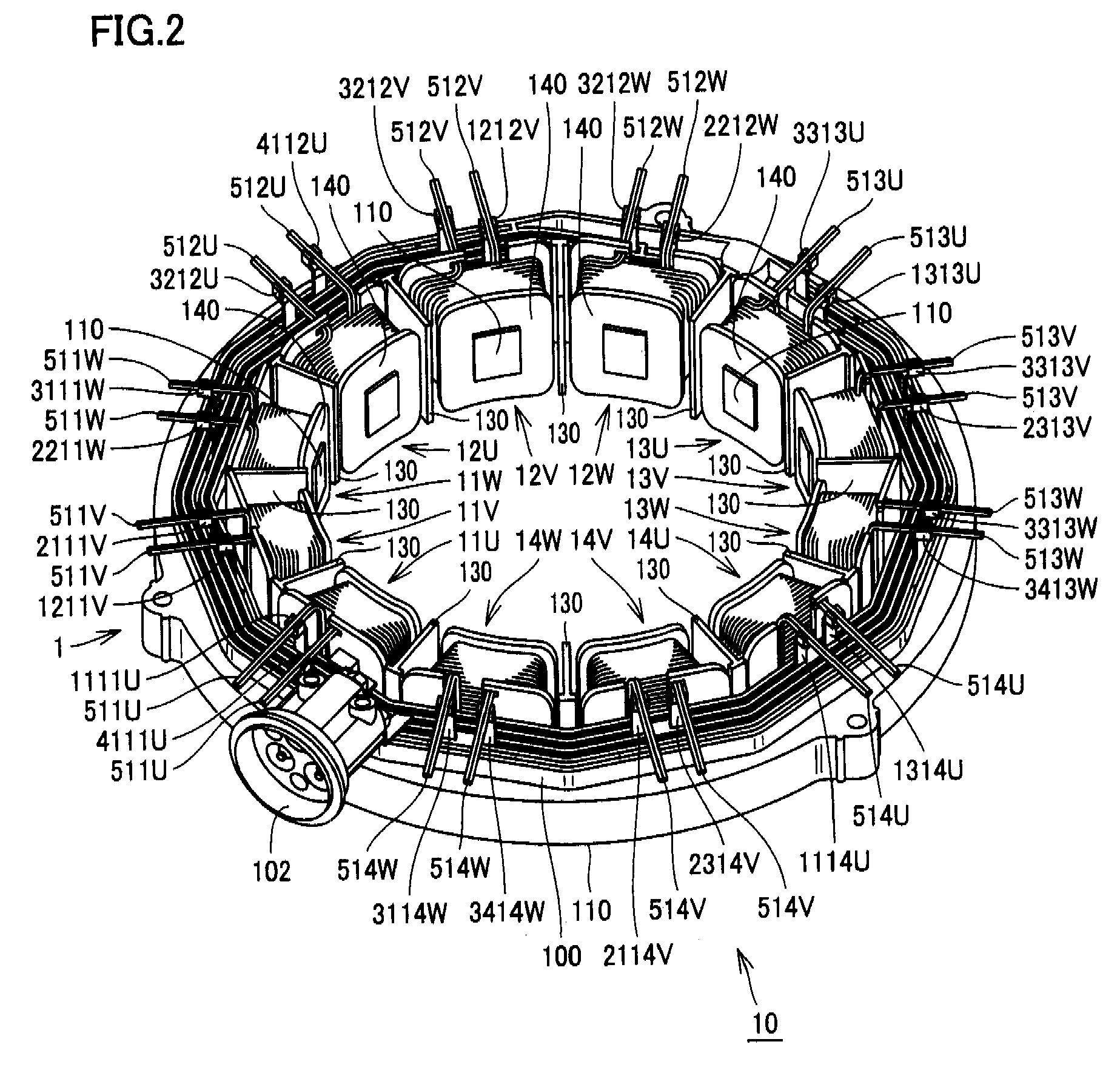

Insulator and rotating electric machine

InactiveUS20090102312A1Overcome the small stiffnessHigh strengthWindings insulation shape/form/constructionSupports/enclosures/casingsElectric machineEngineering

An insulator allowing a coil to be wound with large tension exerted and a rotating electric machine having the insulator are provided. An insulator (140) can be attached to stator teeth (110) such that the insulator has a coil wound thereon, and the insulator (140) includes a first member implemented as a framework (940) forming a framework of the insulator (140) and a second member implemented as a sheath (950) providing an external surface of the insulator (140) and providing insulation, and the framework (940) is larger in stiffness than the sheath (950).

Owner:TOYOTA JIDOSHA KK

Soft tissue comprising non-wood fibers

ActiveUS10145069B2Satisfactory softness and strength and bulkOvercome the small stiffnessPaper/cardboardChemical/chemomechanical pulpFiberMedicine

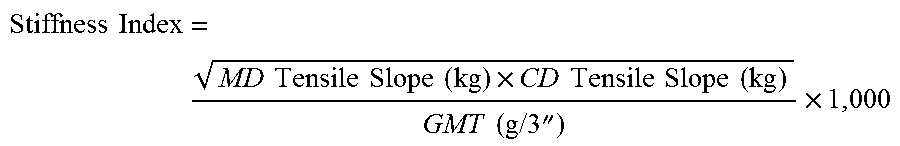

The present invention provides soft, durable and bulky tissue products comprising non-wood fibers and more particularly hesperaloe fiber. The inventors have discovered that high yield hesperaloe pulp fiber, when incorporated in amounts of at least about 5 percent by weight of the tissue product, produces products having a GMT less than about 1000 g / 3″ and a GM Slope less than about 7.0 kg. At the foregoing tensile strengths and modulus the tissue products of the present invention are also generally soft, such as having a Stiffness Index less than about 10.0, and more preferably less than about 9.0, such as from about 7.0 to about 9.0.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com