Thermoset particles with enhanced crosslinking, processing for their production, and their use in oil and natural gas driliing applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0091] The currently preferred embodiments of the invention will be understood better in the context of a specific example. It is to be understood that the example is being provided without reducing the generality of the invention. Persons skilled in the art can readily imagine many additional examples that fall within the scope of the currently preferred embodiments as taught in the DETAILED DESCRIPTION OF THE INVENTION section. Persons skilled in the art can, furthermore, also readily imagine many alternative embodiments that fall within the full scope of the invention as taught in the SUMMARY OF THE INVENTION section.

A. Summary

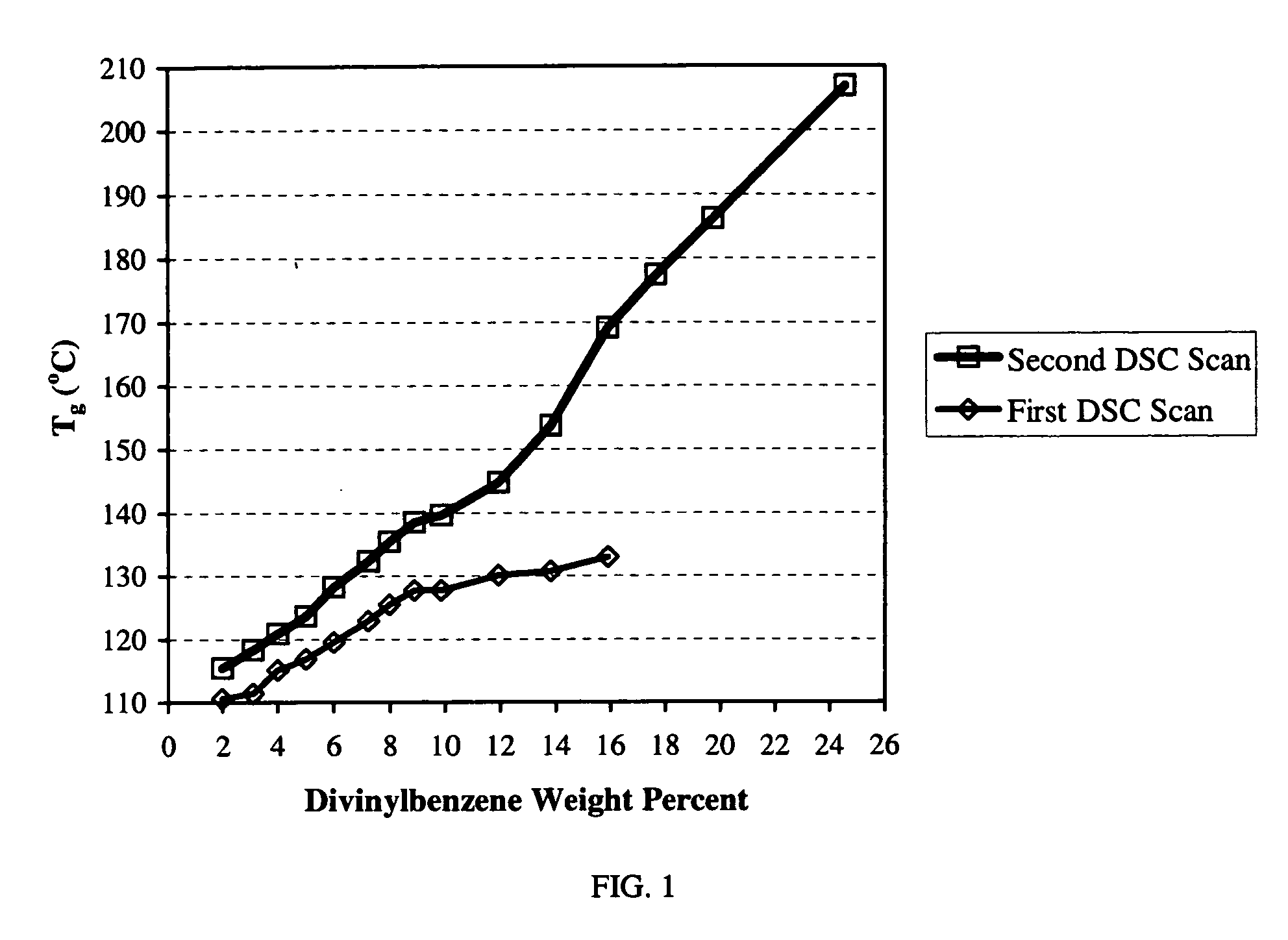

[0092] The thermoset matrix was prepared from a formulation containing 20% DVB by weight of the starting monomer mixture. The DVB had been purchased as a mixture where only 63% by weight consisted of DVB. The actual polymerizable monomer mixture used in preparing the thermoset matrix consisted of roughly 68.73% S, 11.27% EVB and 20% DVB by weight.

[0093]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com