Implantable, self-expanding prosthetic device

a prosthetic device and self-expanding technology, applied in the field of implantable medical devices, can solve the problems of reducing or completely losing the functional attributes of the device, unable to withstand only limited external compression forces, and further loss of frame stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

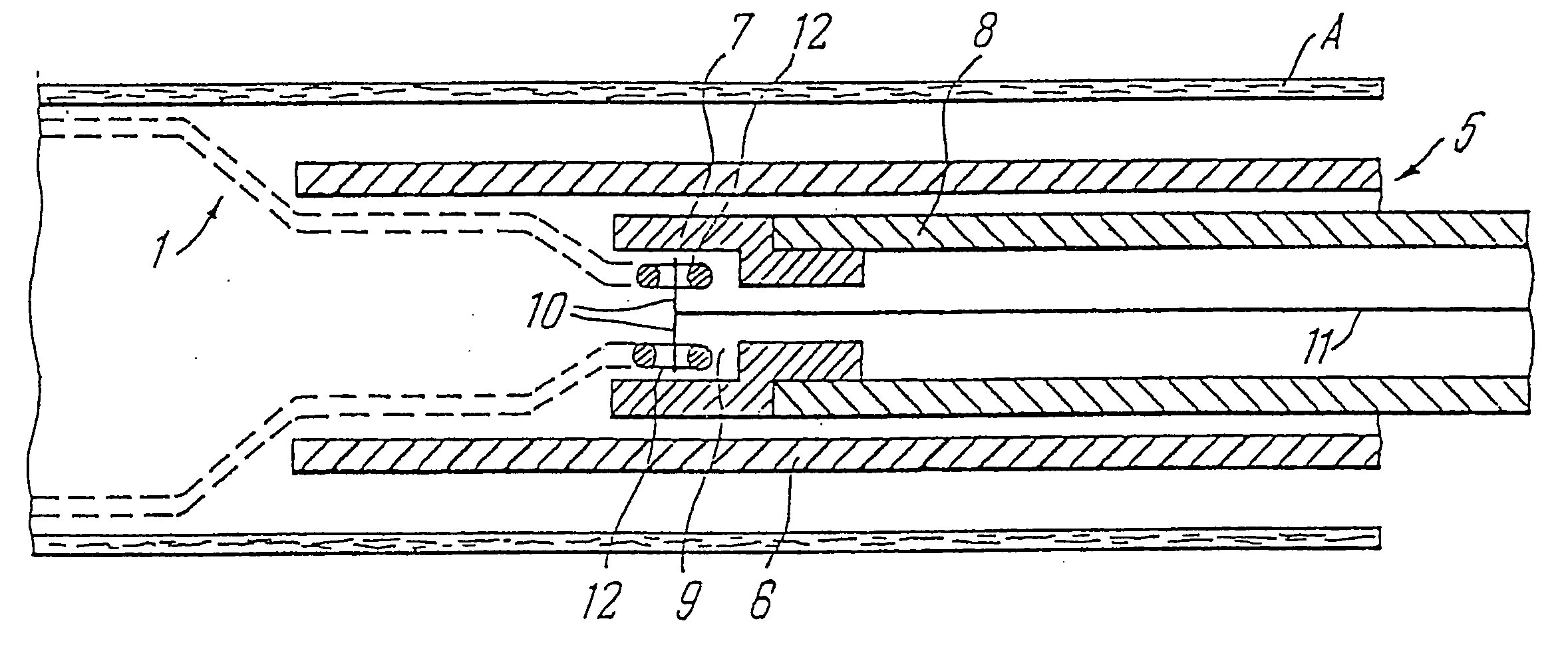

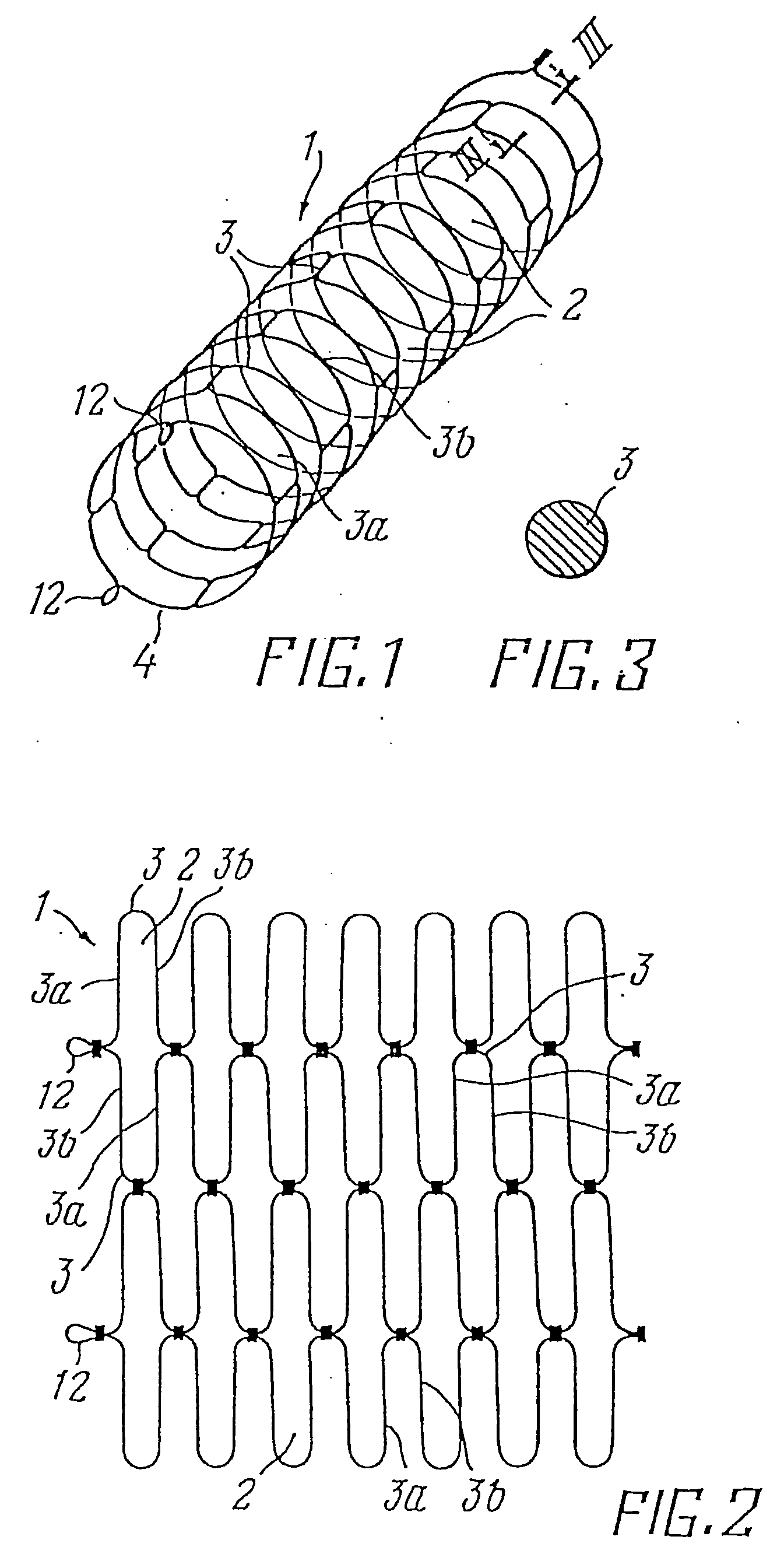

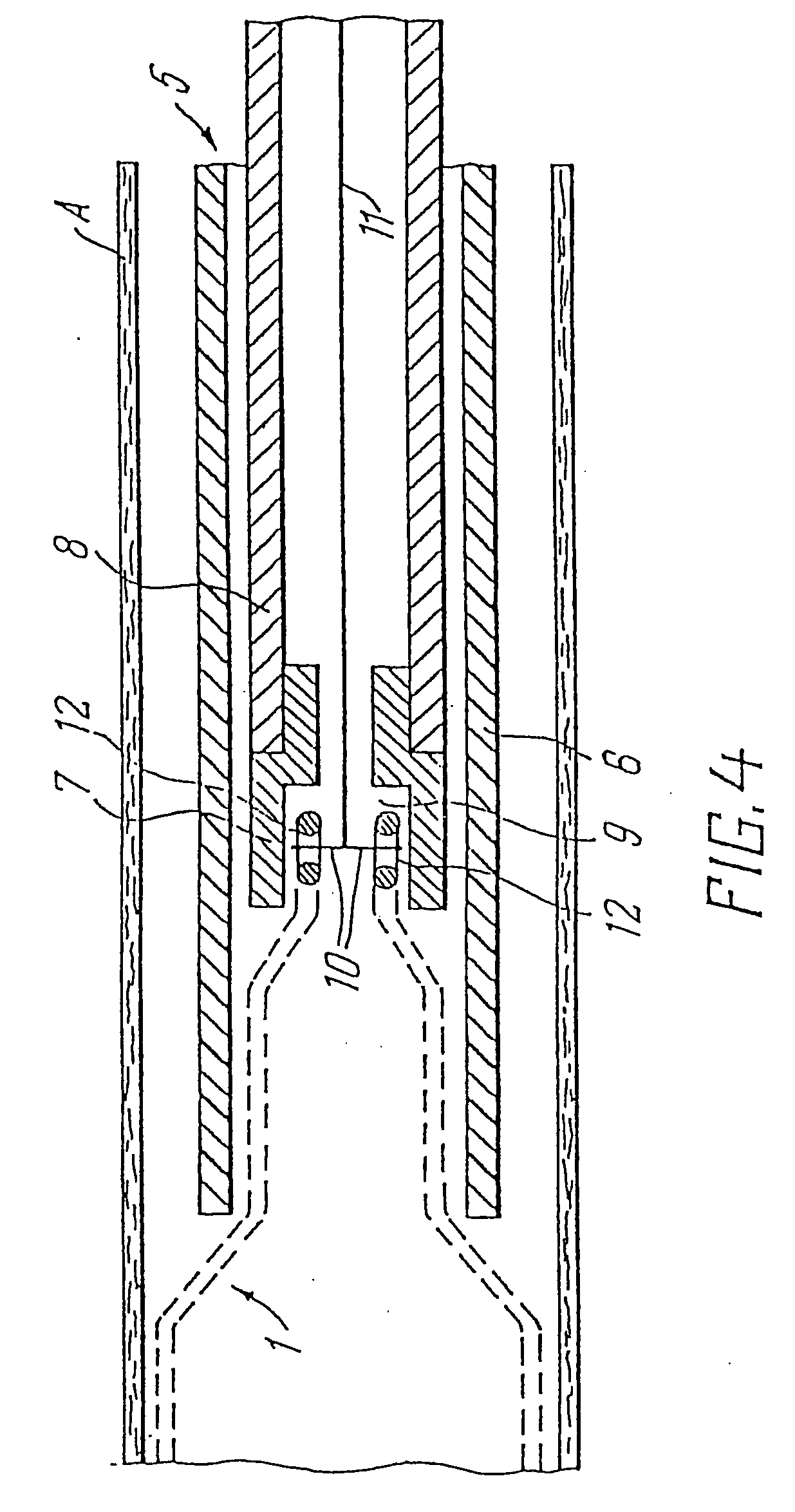

[0053] The device for sustaining the lumen, for example of the femoral artery, accomplished in accordance with the invention, has wire frame 1 in the form of a tubular shaped body such as a hollow cylindrical body.

[0054] The cylindrical surface of frame 1 shown in development in FIG. 2 is formed by a large number of interconnected cells 2 formed by two U-shaped wire sections 3, interconnected by their branches 3a, 3b, and forming approximately an oval, whose larger axis is arranged in the circumferential direction of the body and the smaller axis parallel to its axial direction. Cell 2 of each subsequent row is shifted in the circumferential direction with respect to cell 2 of the present row by ½ of the length of the oval larger axis. Each branch 3a or 3b of the U-shaped wire section 3 belongs to two cells 2 in adjacent rows, except for the first and last rows. In a cross-section of frame 1 in a plane perpendicular to its longitudinal axis and passing through the long branches of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com