Golf shoe with a stabilizing system

a technology of stabilizing system and golf shoe, which is applied in the field of golf shoe with a stabilizing system, can solve the problems of increased manufacturing process cost, increased manufacturing cost, and possible ankle injury in the form of sprain, and achieves good stabilization and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

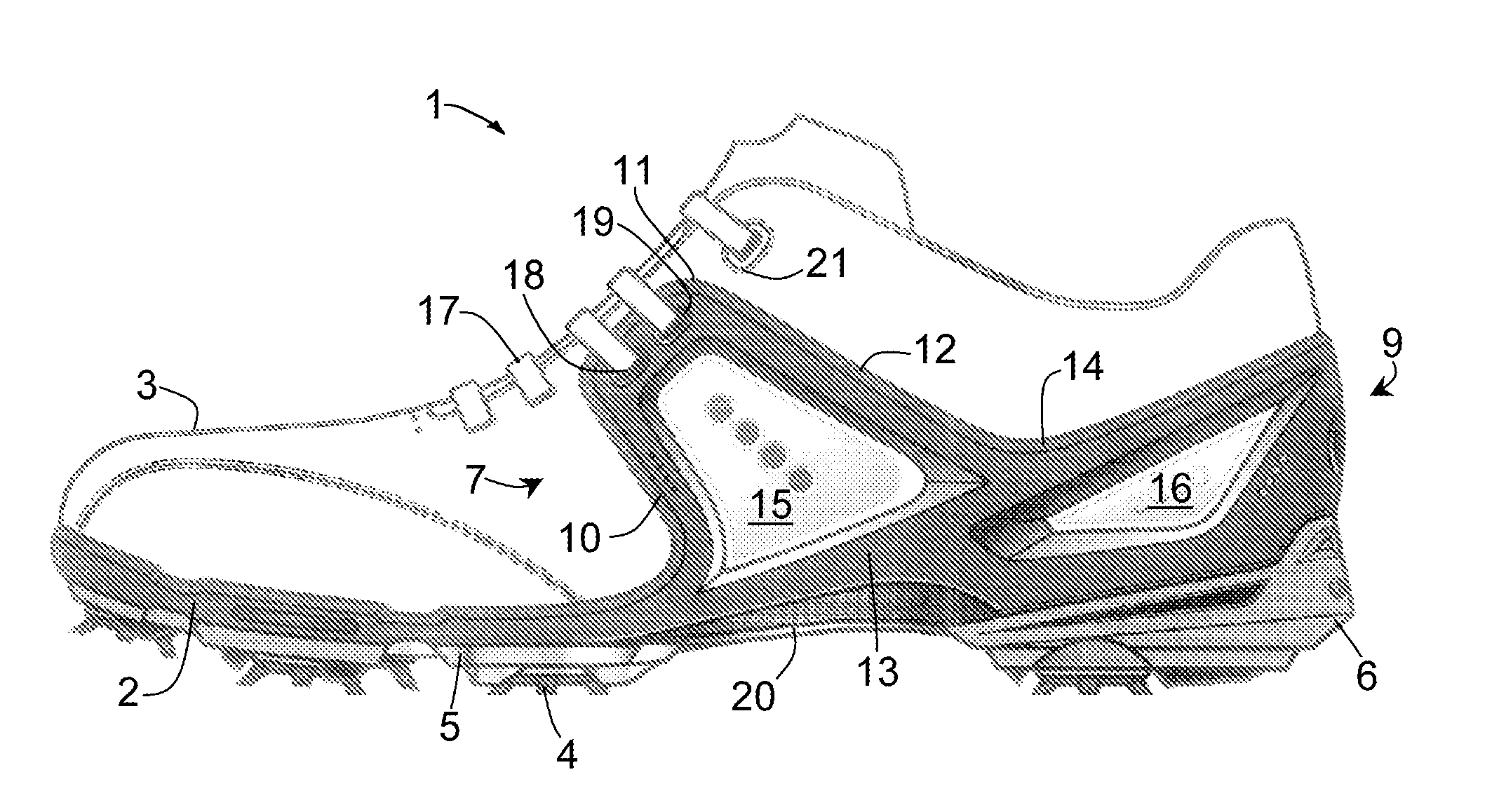

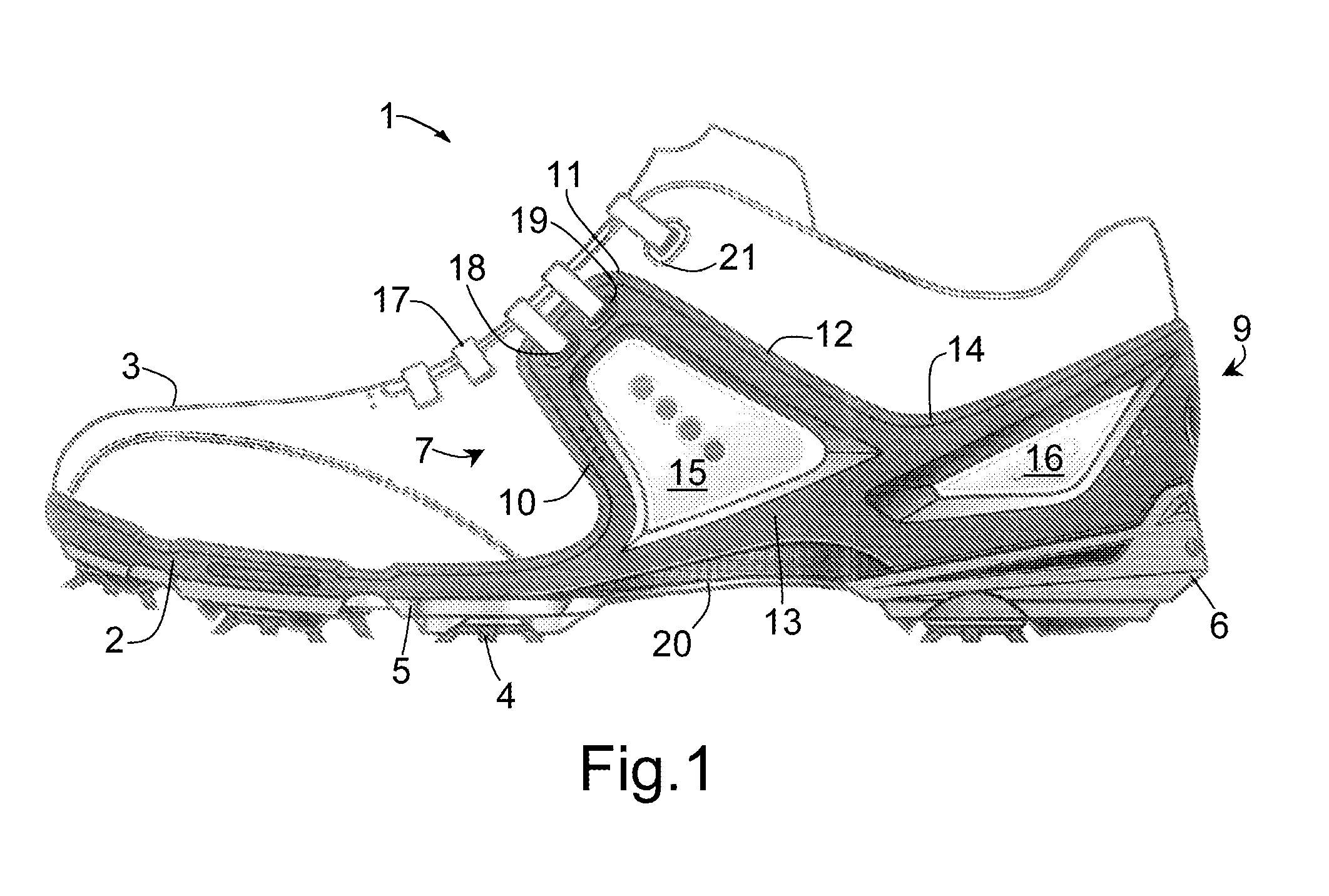

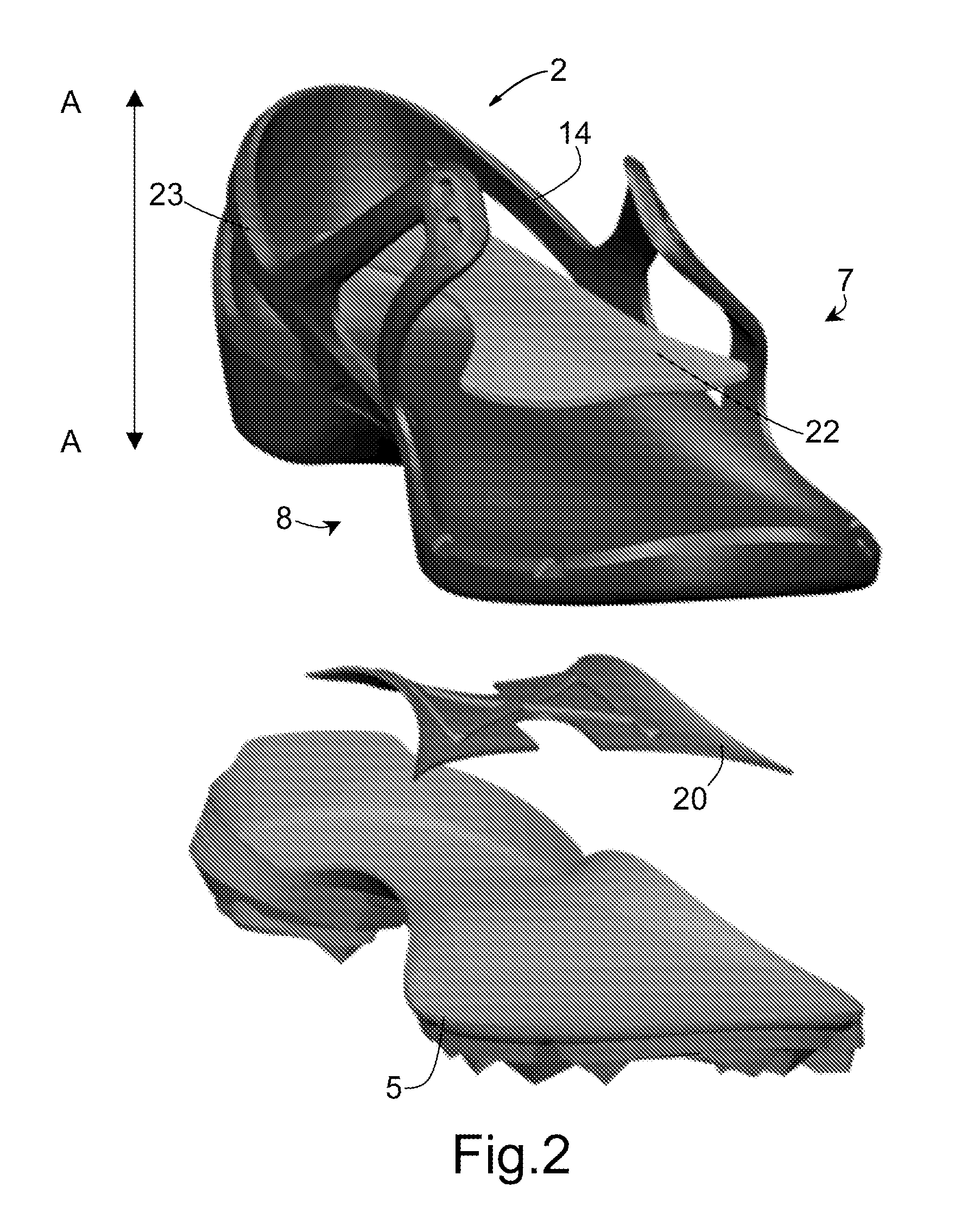

[0015]FIG. 1 is a lateral view of a golf shoe 1 according to the invention. A polyurethane (PU) midsole 2 is bonded to a shoe upper 3. Such upper can be made of textile or leather. In a known manner, spikes 4 screwed into the outsole 5 provide good grip to the green. The outsole 5 and 6 is made of hard density thermoplastic polyurethane (TPU), which is bonded to the midsole 2. A shank 20 is placed between the midsole and the TPU outsole, which outsole is thin in the midfoot area. This shank is made of carbon fibres and has a good torsional stiffness. On the upper, the lateral side support structure 7 extends vertically and follows the shape of the upper. Beam 10 originates in the longitudinally extending portion of the midsole, and is connected to beam 12 via cross beam 11. As seen in FIG. 1, the beams are essentially rectangular, thus having rectilinear sections between the structures or portions they connect. The beams are tapered in a direction towards the top of the beam, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com