Patents

Literature

50results about How to "Uniform luminous intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

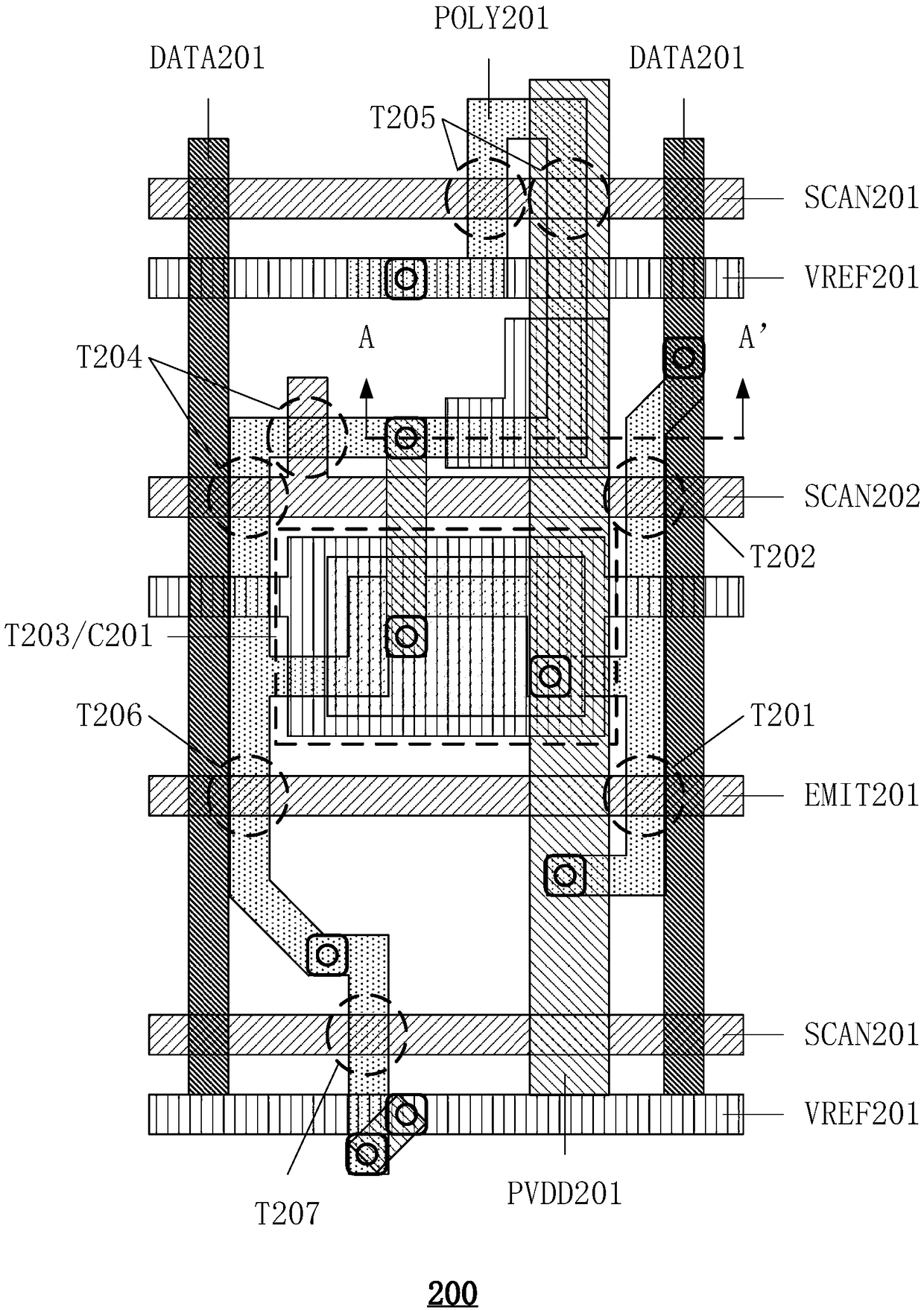

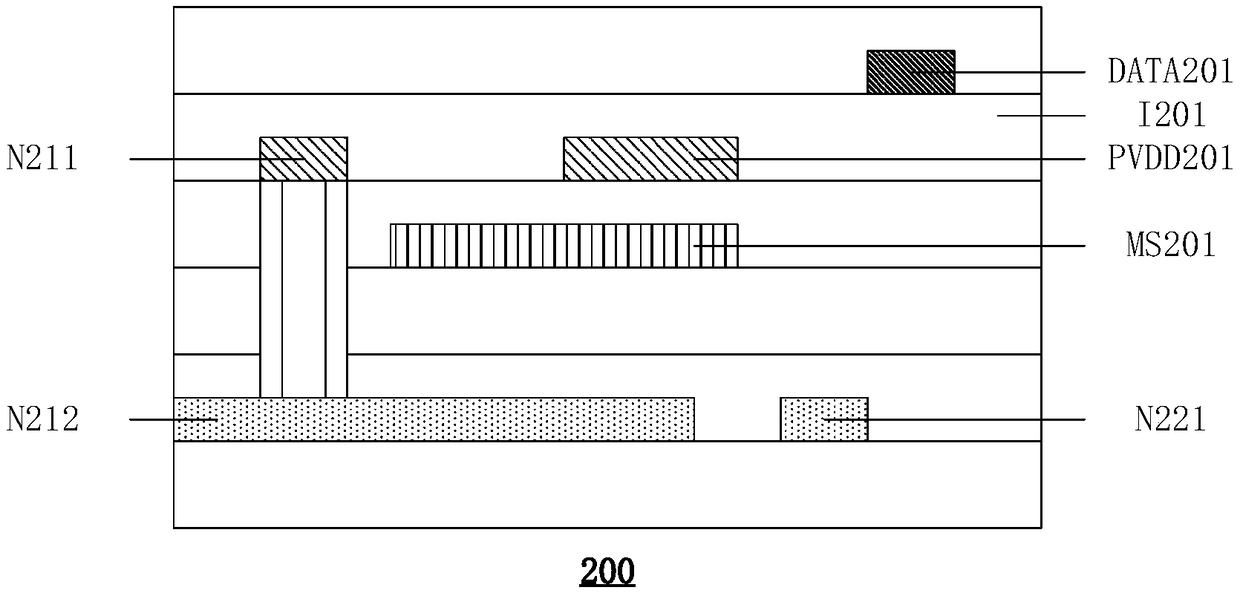

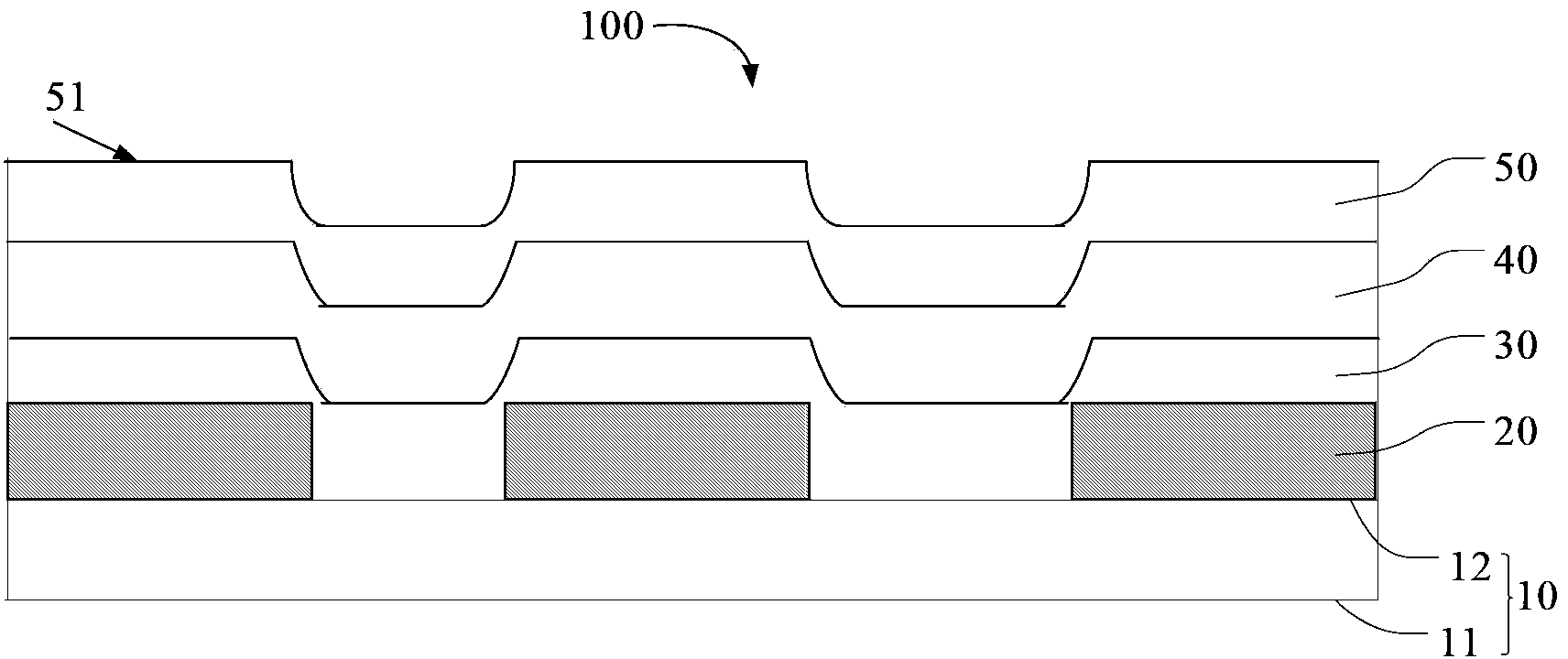

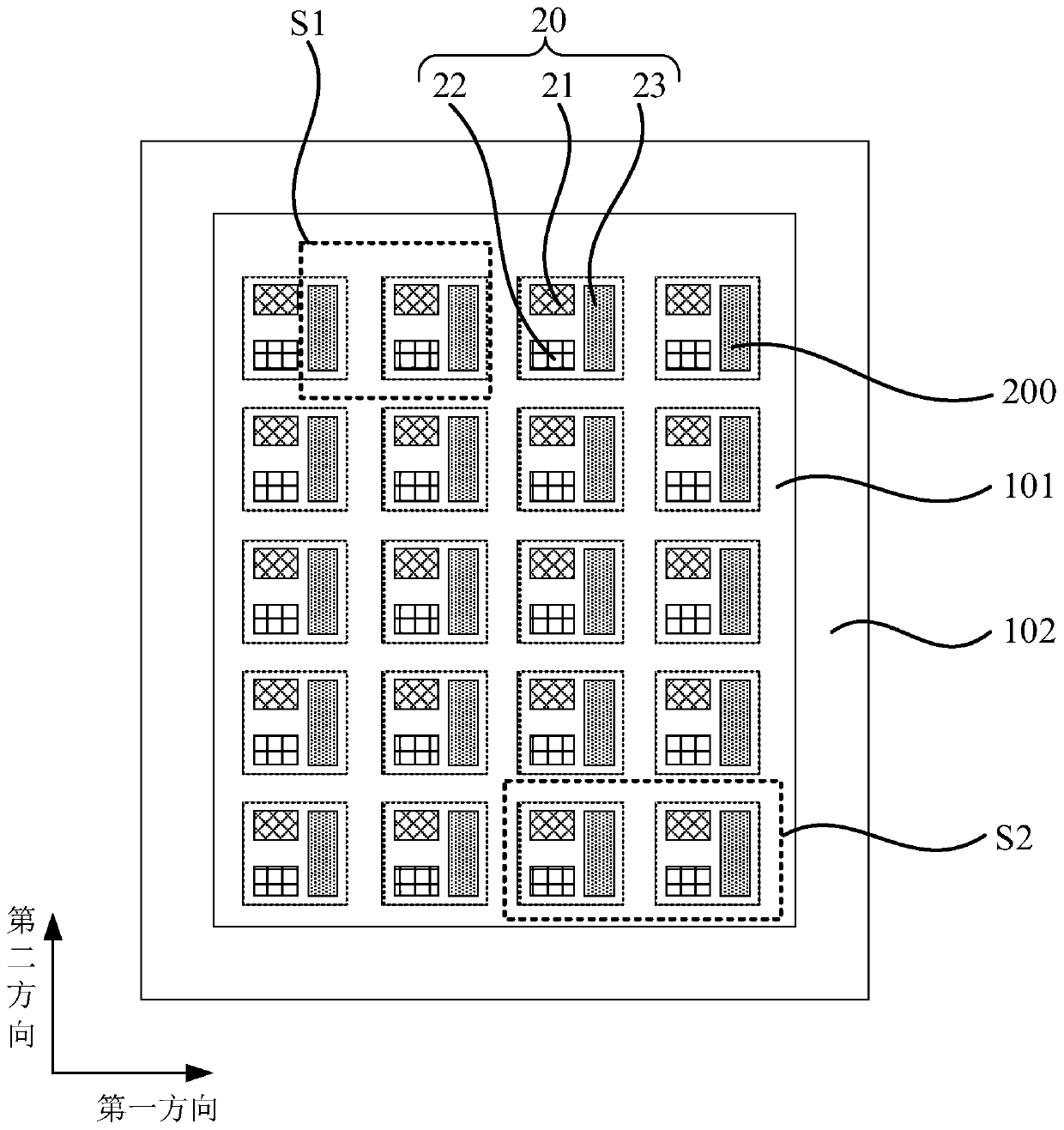

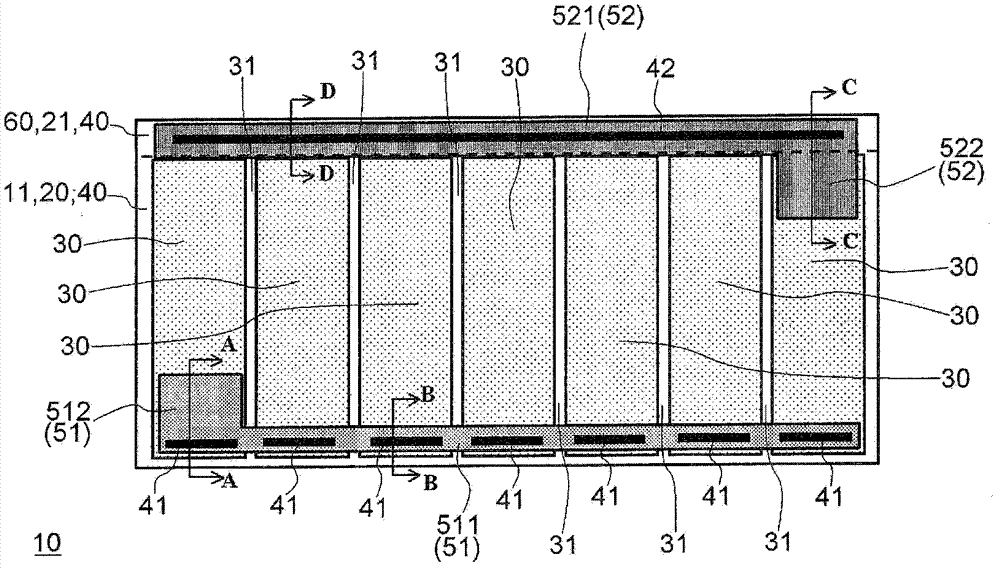

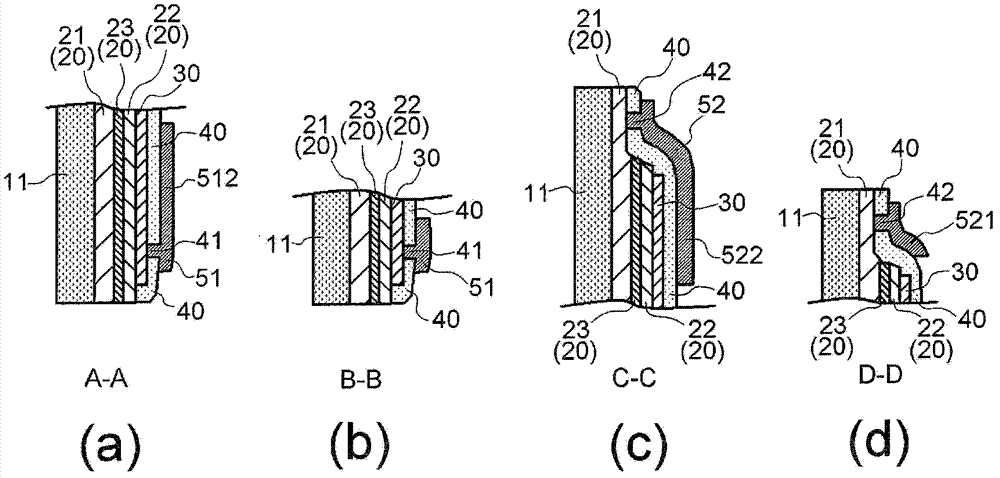

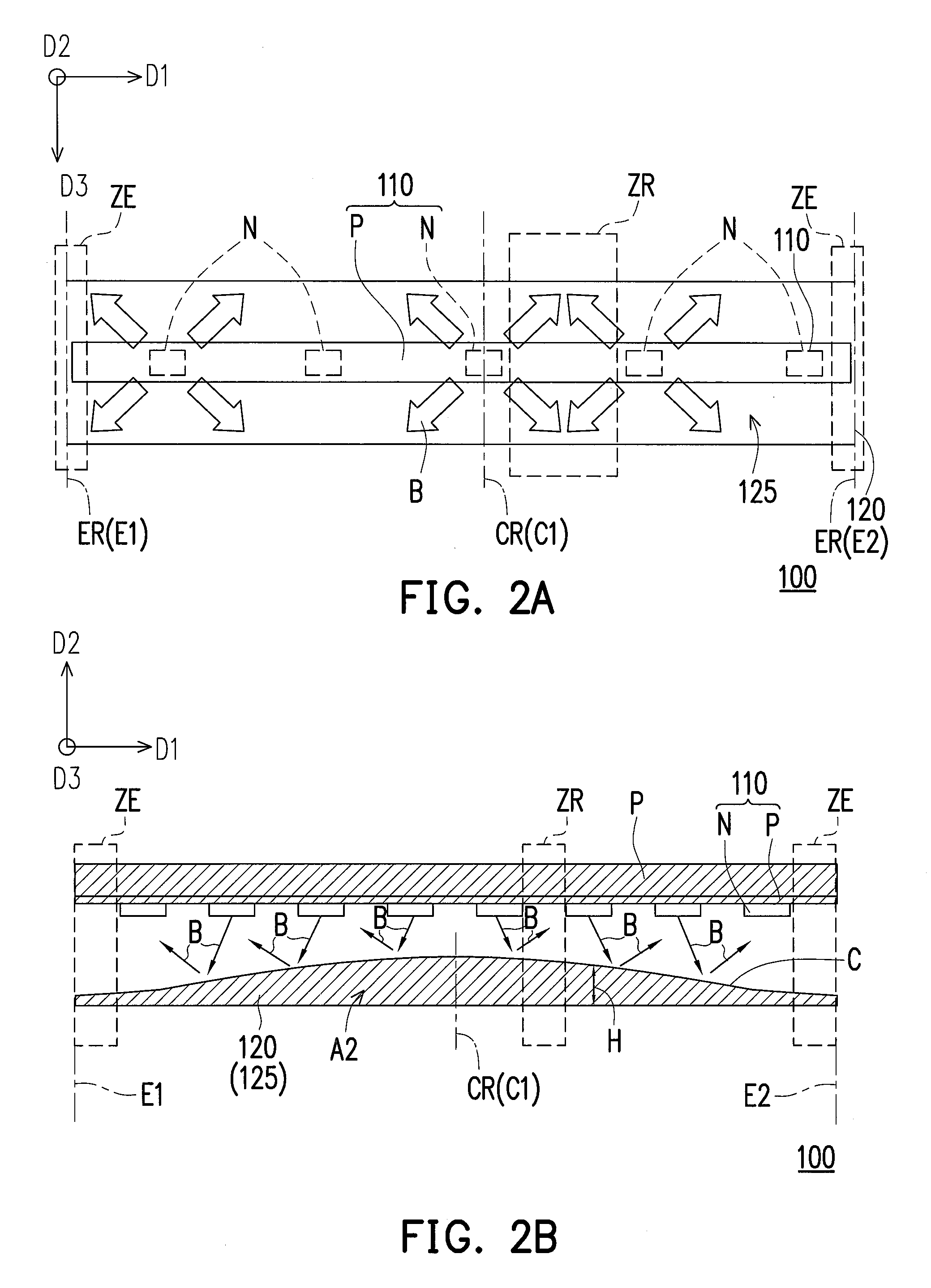

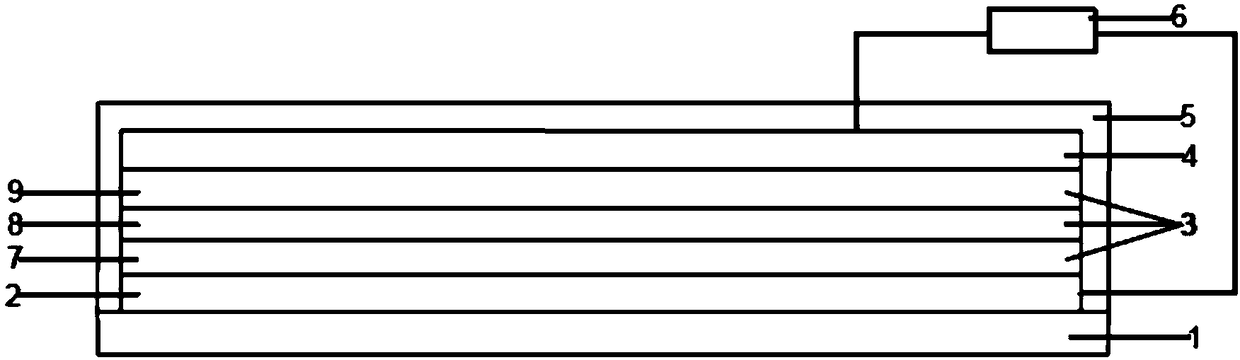

Display panel and display device

ActiveCN109360851ASuppress parasitic capacitanceIncrease widthStatic indicating devicesSolid-state devicesDisplay deviceLuminescence

The invention provides a display panel and a display device. The display panel comprises a pixel driving circuit, a driving transistor and a first connecting portion. The pixel driving circuit comprises scanning lines, data lines and a power line, the scanning lines are used for transmitting scanning signals, the data lines are used for transmitting data signals, and the power line is used for transmitting constant voltage signals; the scanning lines are positioned on a first metal layer, the power line is positioned on a second metal layer, the data lines are positioned on a third metal layer, and the second metal layer is positioned between the first metal layer and the third metal layer; a gate electrode of the driving transistor is positioned on the first metal layer and is connected with the first connecting portion; the power line is positioned between the data lines and the first connecting portion. The display panel and the display device have the advantages that coupling parasitic capacitance of the data lines and first coupling portion can be diminished, offset of driving currents of the driving transistor can be diminished, and interference on the luminescence intensityof organic luminescence components can be diminished.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

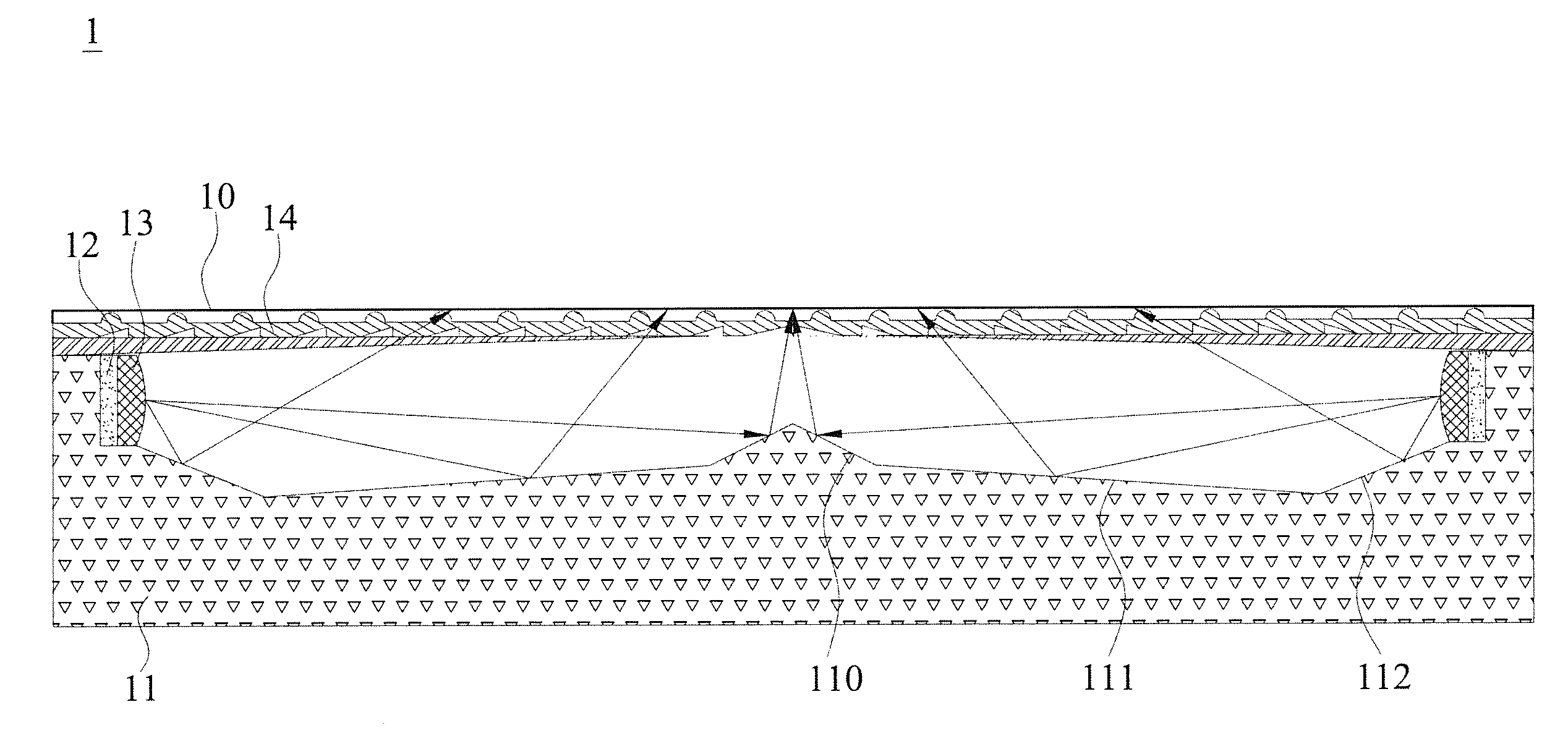

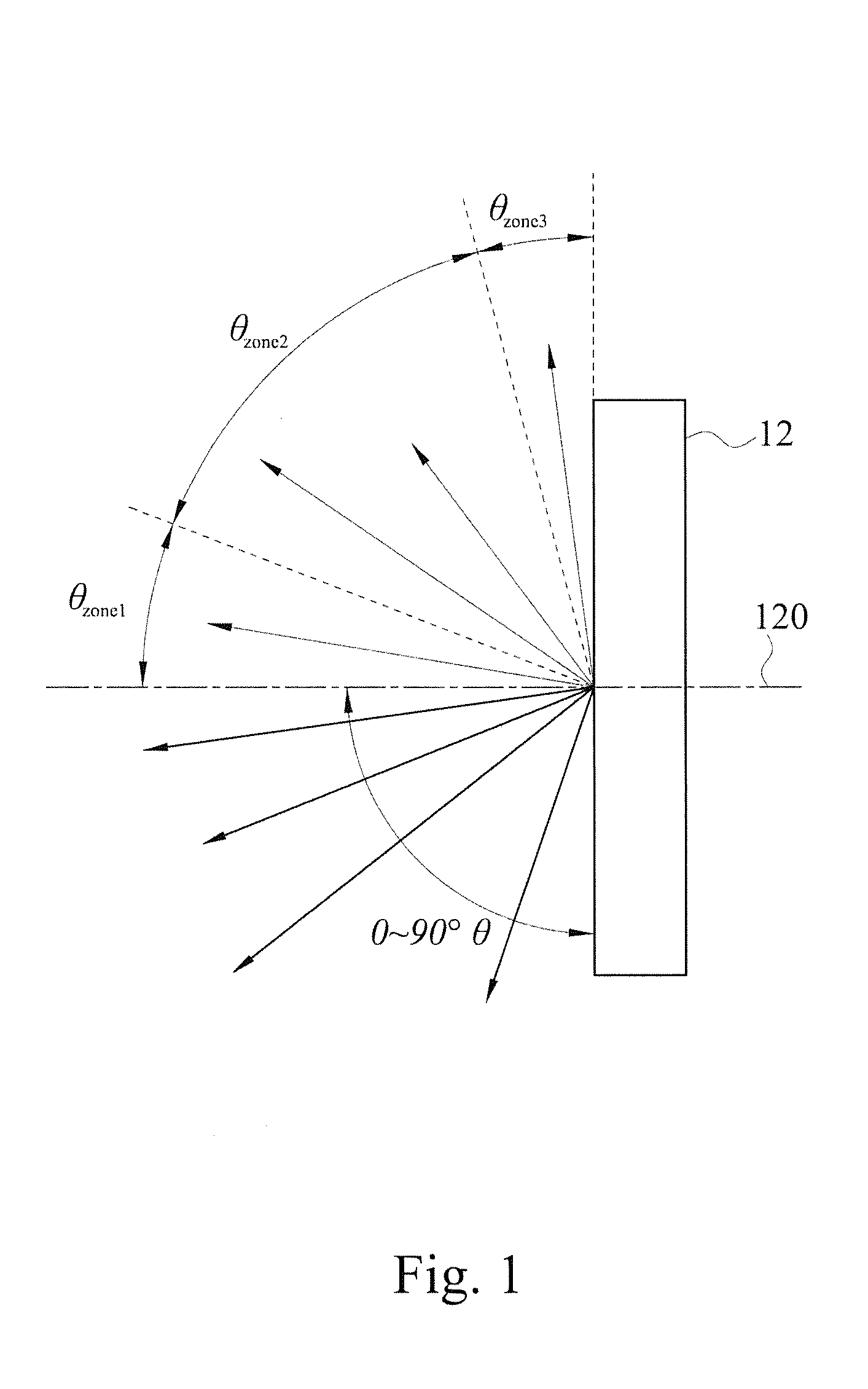

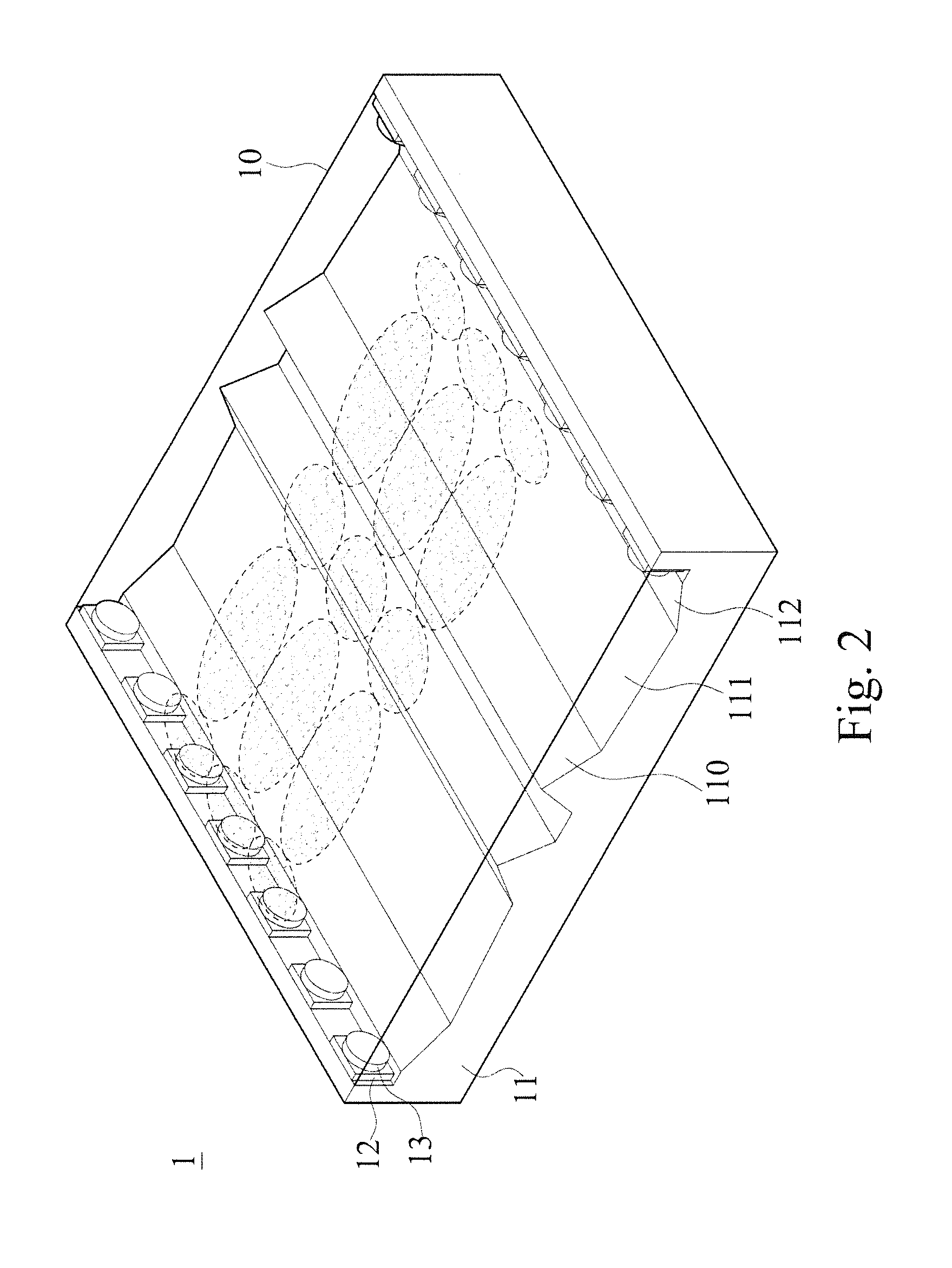

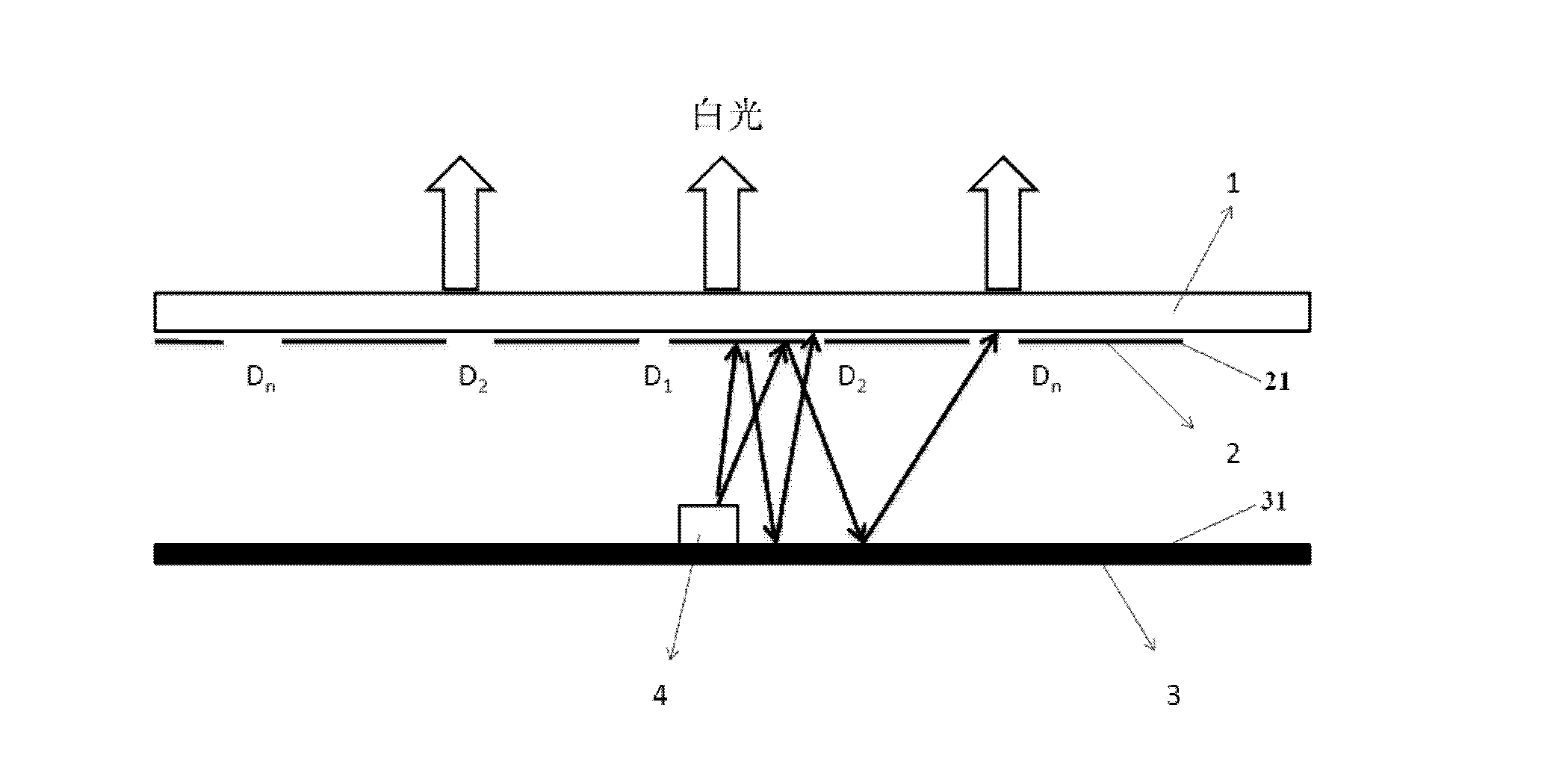

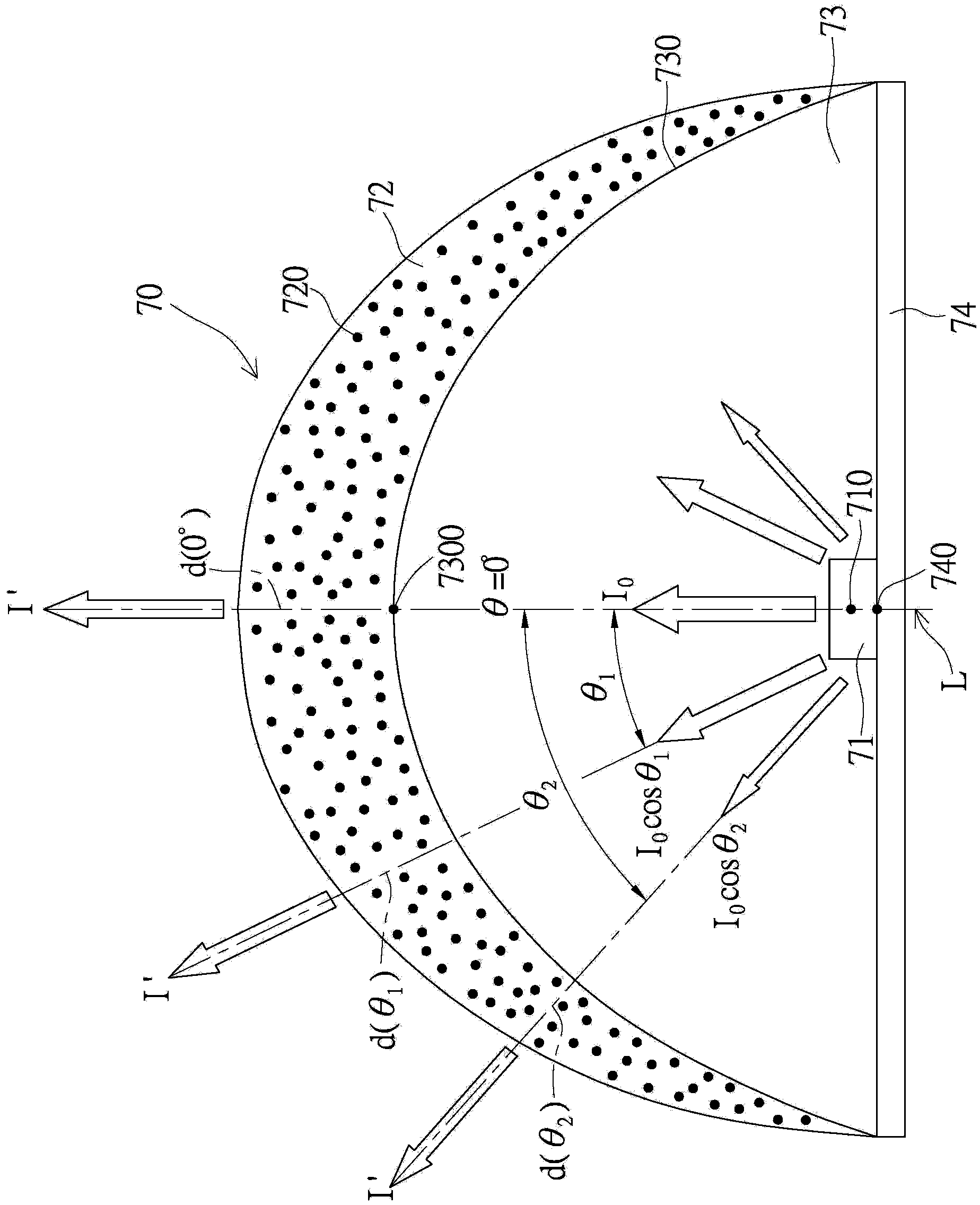

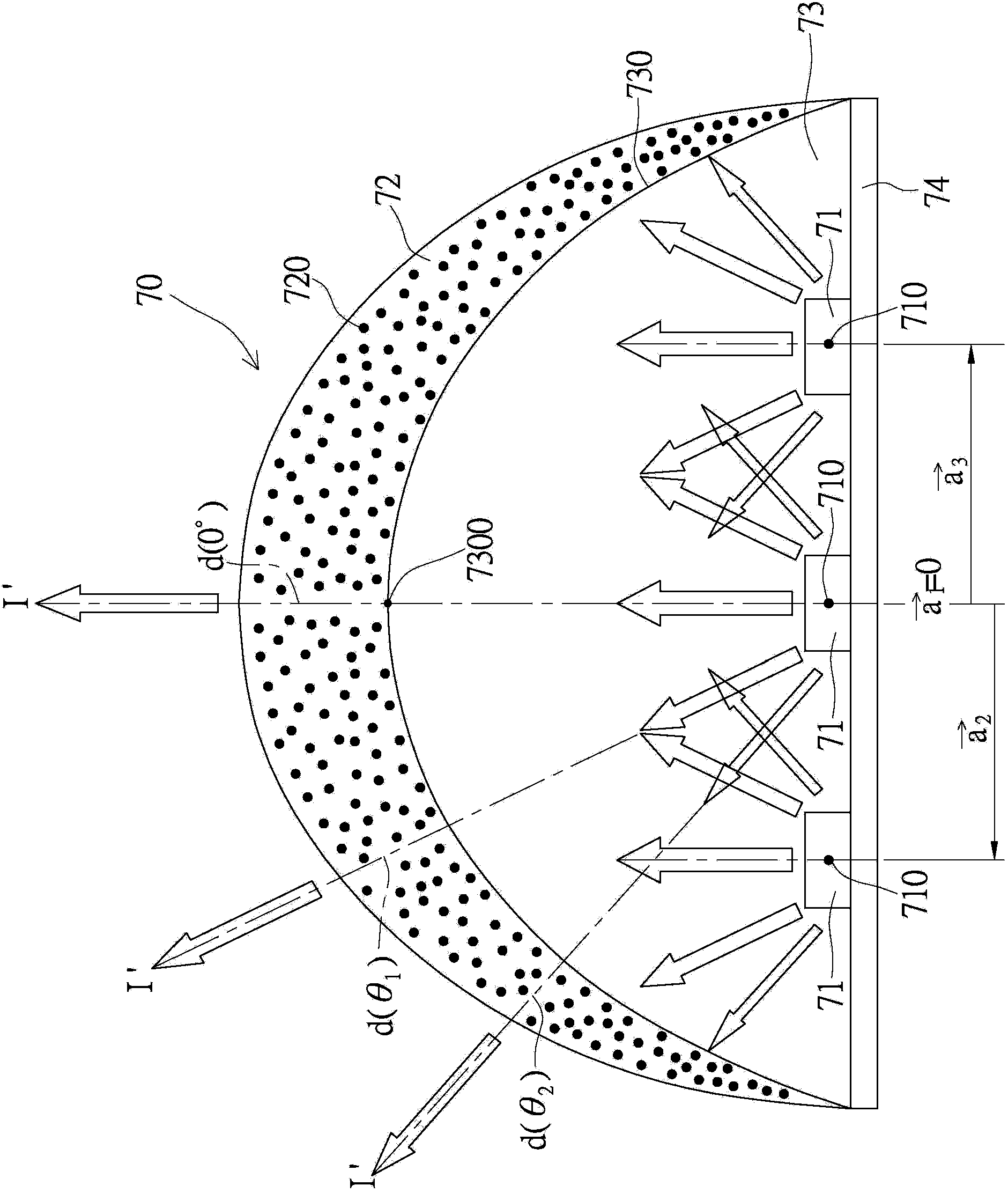

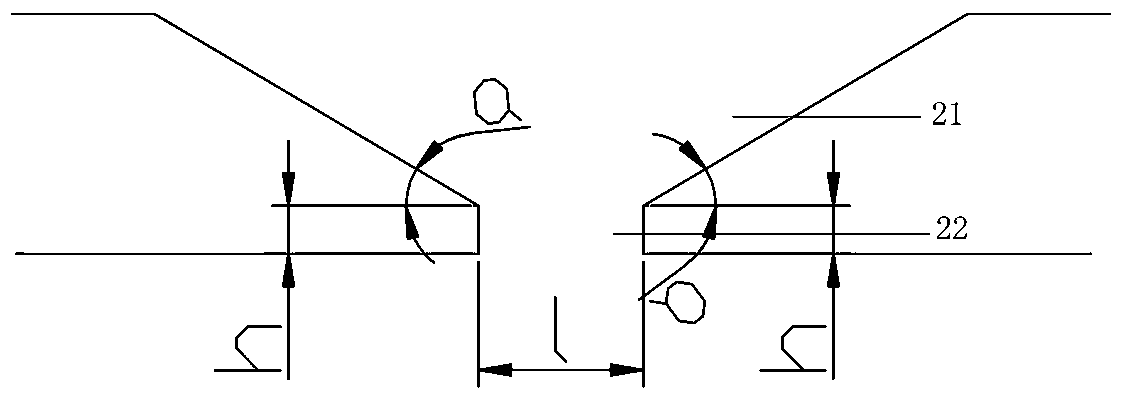

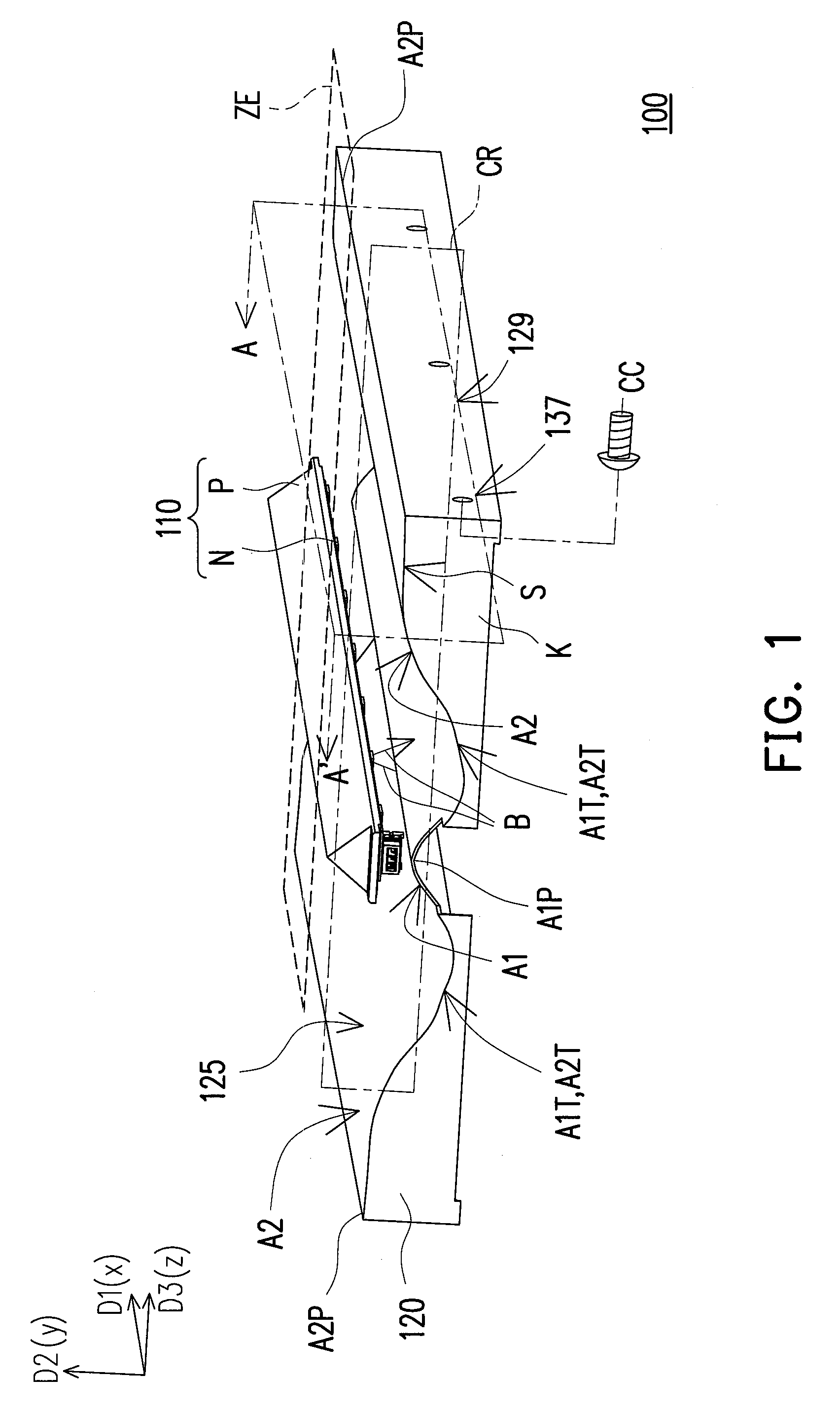

Edge-lit backlight module

InactiveUS20140192557A1Uniform luminous intensityReduce manufacturing costIlluminated signsSemiconductor devicesMicrostructureLight source

Disclosed is an edge-lit backlight module having a rectangular back panel with a reflective microstructure, and a first light portion with an inclined plane or a camber is provided for reflecting lights emitted from a plurality of LEDs and with a relatively smaller normal included angle, and a second light portion is provided for reflecting a light with a slightly greater included angle, and a third light portion is provided for reflecting the light with the greatest included angle to guide lights of different intensities to different paths and project the lights to every position of a front panel, so as to achieve a light extraction efficiency with a uniform distribution of luminous intensity of an LED light source.

Owner:UNITY OPTO TECH CO LTD

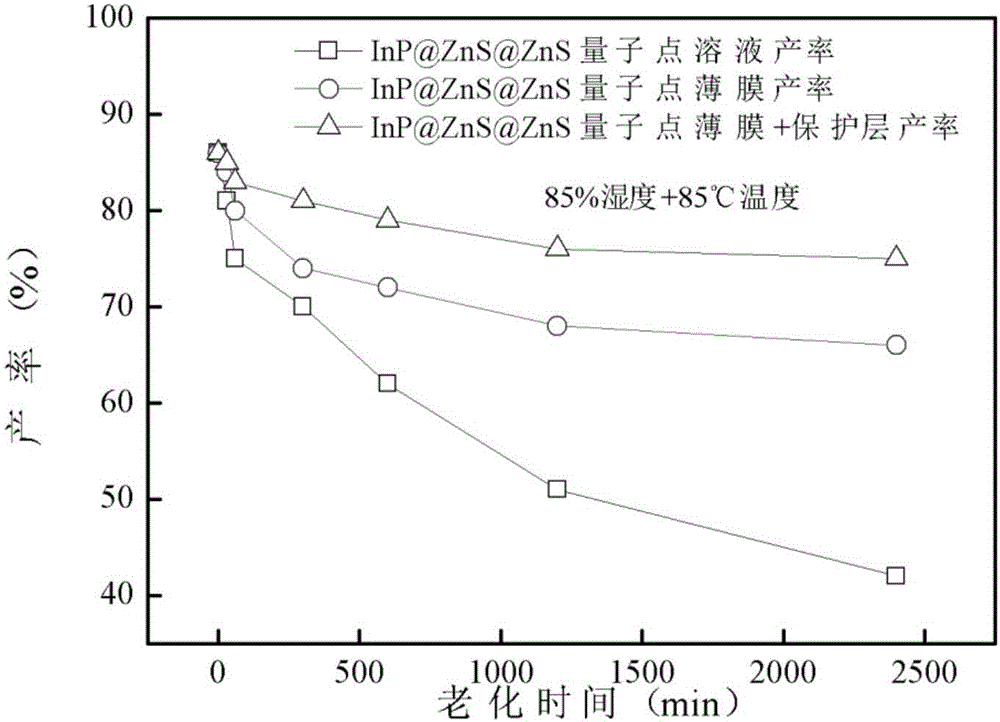

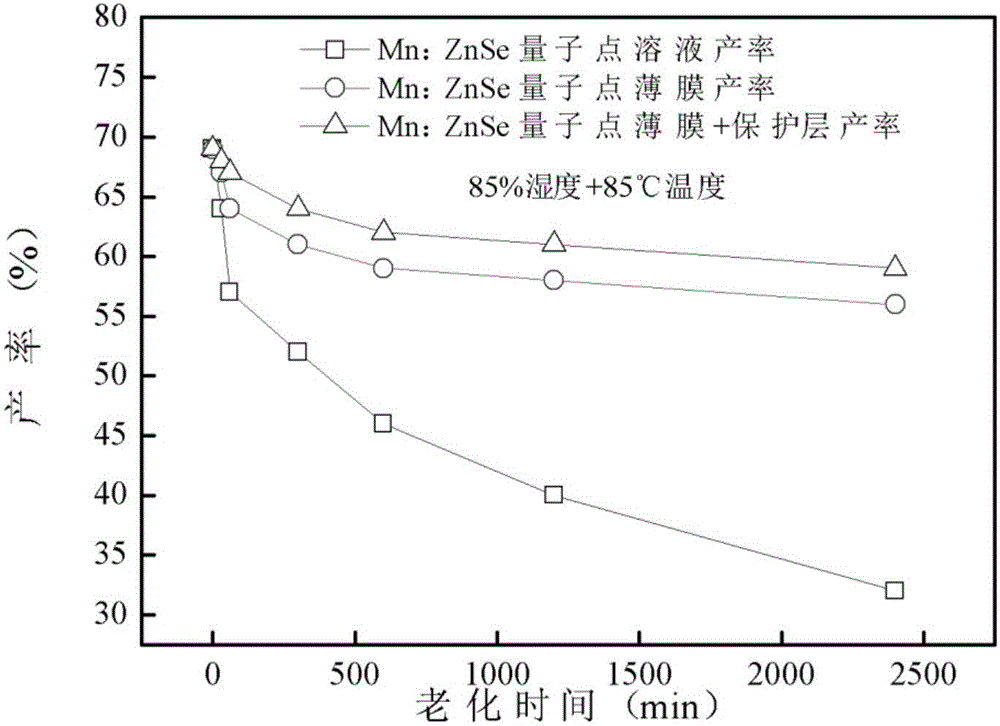

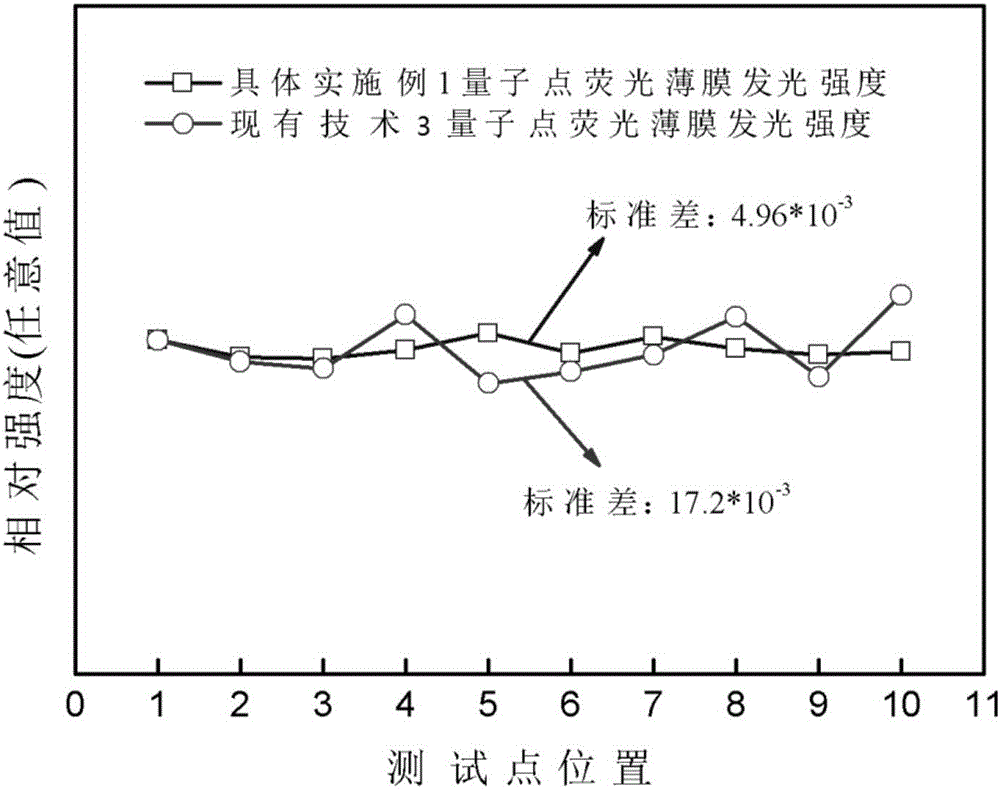

High-quality quantum dot fluorescent thin-film material and preparation method thereof

ActiveCN106585061AImprove stabilityUniform luminous intensityLaminationLamination apparatusGamutLuminous intensity

The invention relates to a high-quality quantum dot fluorescent thin-film material and a preparation method thereof. The preparation method comprises the following steps: preparing a quantum dot solution; then preparing a polymer, adding the quantum dot solution into the polymer, carrying out placing in a mold, and carrying out cooling and curing so as to obtain a polymer-quantum dot bulk material; subjecting the polymer-quantum dot bulk material to mechanical cutting, and adjusting cutting parameters so as to be able to obtain a compact quantum dot fluorescent thin film with different thicknesses; and coating the prepared quantum dot fluorescent thin film on a thin-film protection layer so as to prepare the high-quality quantum dot fluorescent thin-film material. According to the invention, the prepared high-quality quantum dot fluorescent thin-film material has the advantages of high yield, good stability, uniform luminous intensity, wide color gamut, safety, environmental protection, controllable thickness, good compactness, high mechanical strength, etc; meanwhile, the method is simple and practical, has strong operability, and is applicable to mass preparation of quantum dot fluorescent thin films.

Owner:厦门世纳芯科技有限公司

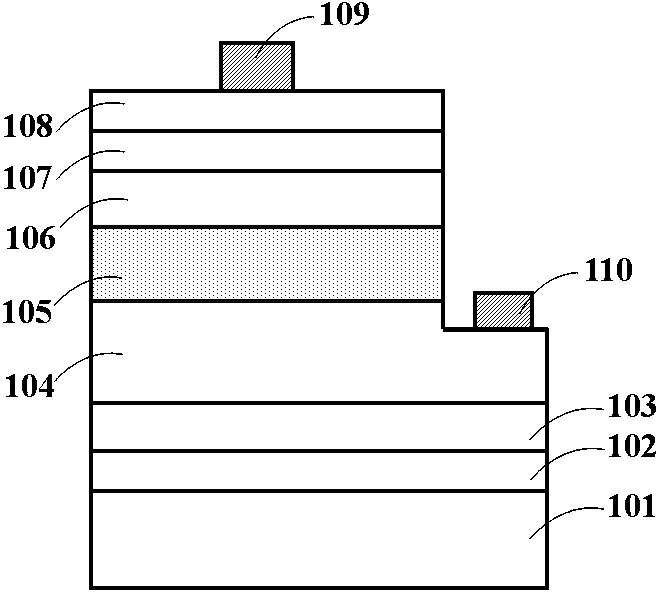

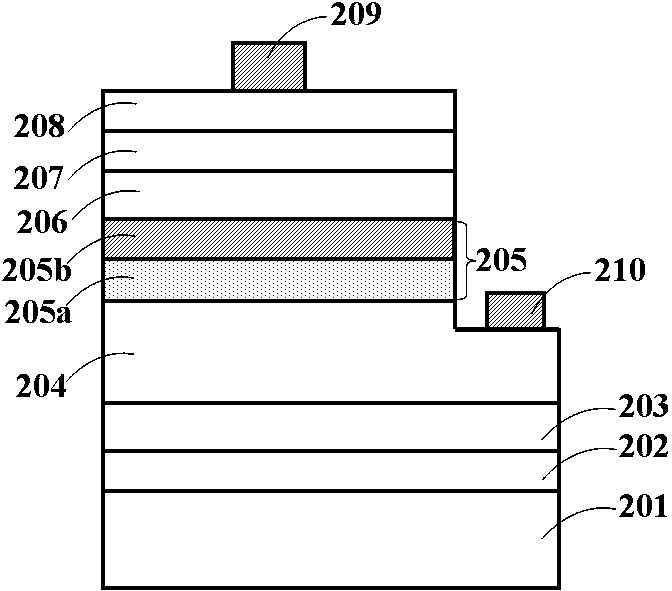

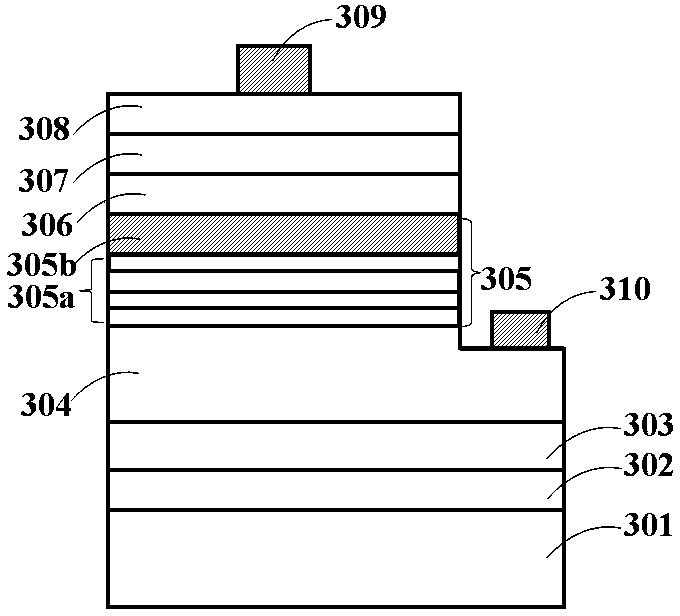

Nitride light emitting diode and manufacturing method thereof

InactiveCN103647009AReduce entryReduce refluxPolycrystalline material growthFrom chemically reactive gasesQuantum wellPhysical chemistry

The invention discloses a nitride light emitting diode and a manufacturing method thereof. The structure at least comprises a substrate, an n type nitride layer, an active area and a p type nitride layer. The active area comprises M pairs of AlxIn1-x-yGayN / GaN quantum wells and N pairs of InGaN / GaN quantum wells. Electronic reflux and a polarization effect are improved. Composite efficiency of a quantum well area and a density of two-dimension electron gas at an interface are increased. Photoelectric conversion efficiency of the light emitting diode is increased too. Simultaneously, an endurance capacity of the LED to static electricity is enhanced and an electrical property of the LED is improved.

Owner:TIANJIN SANAN OPTOELECTRONICS

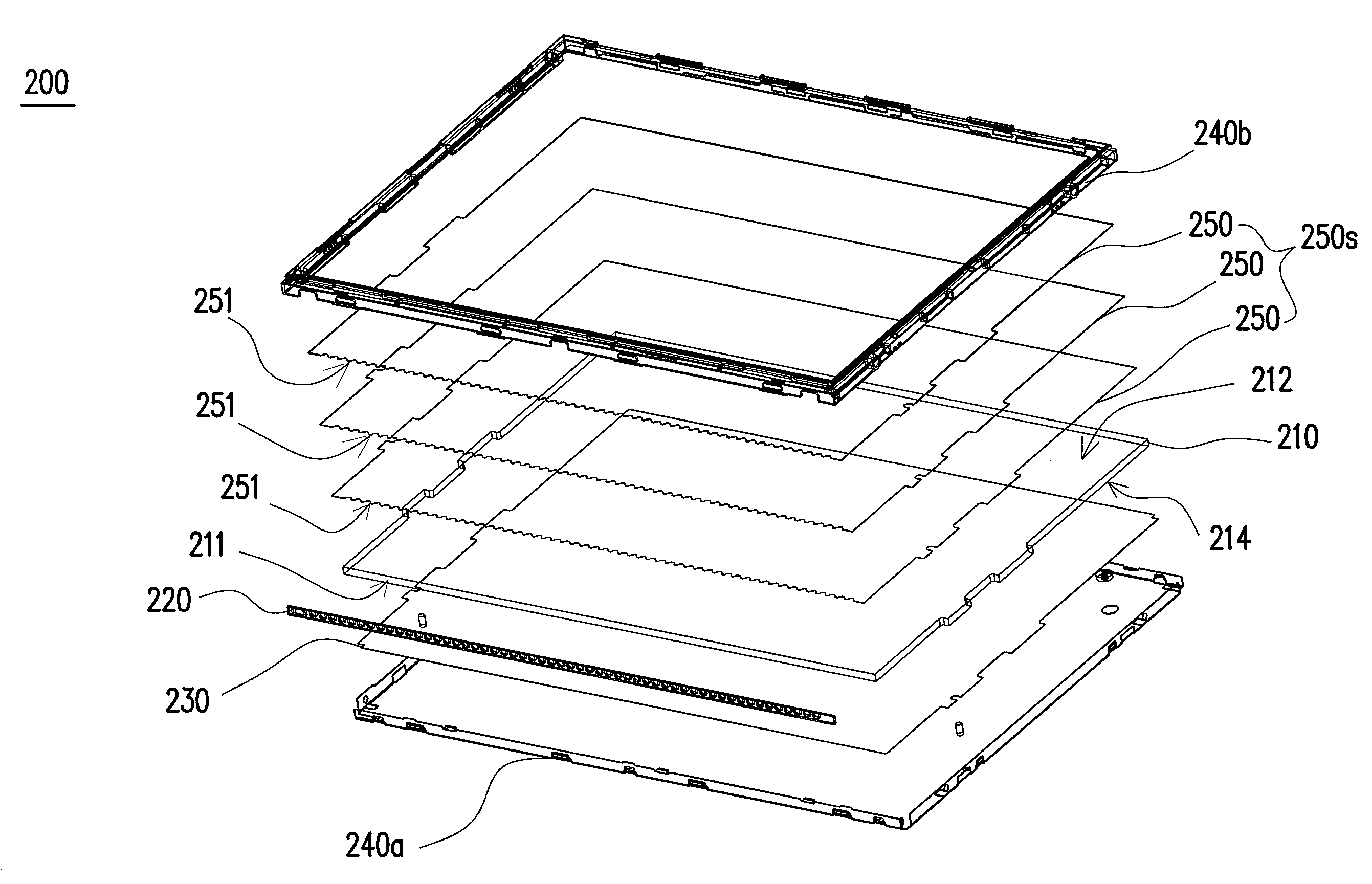

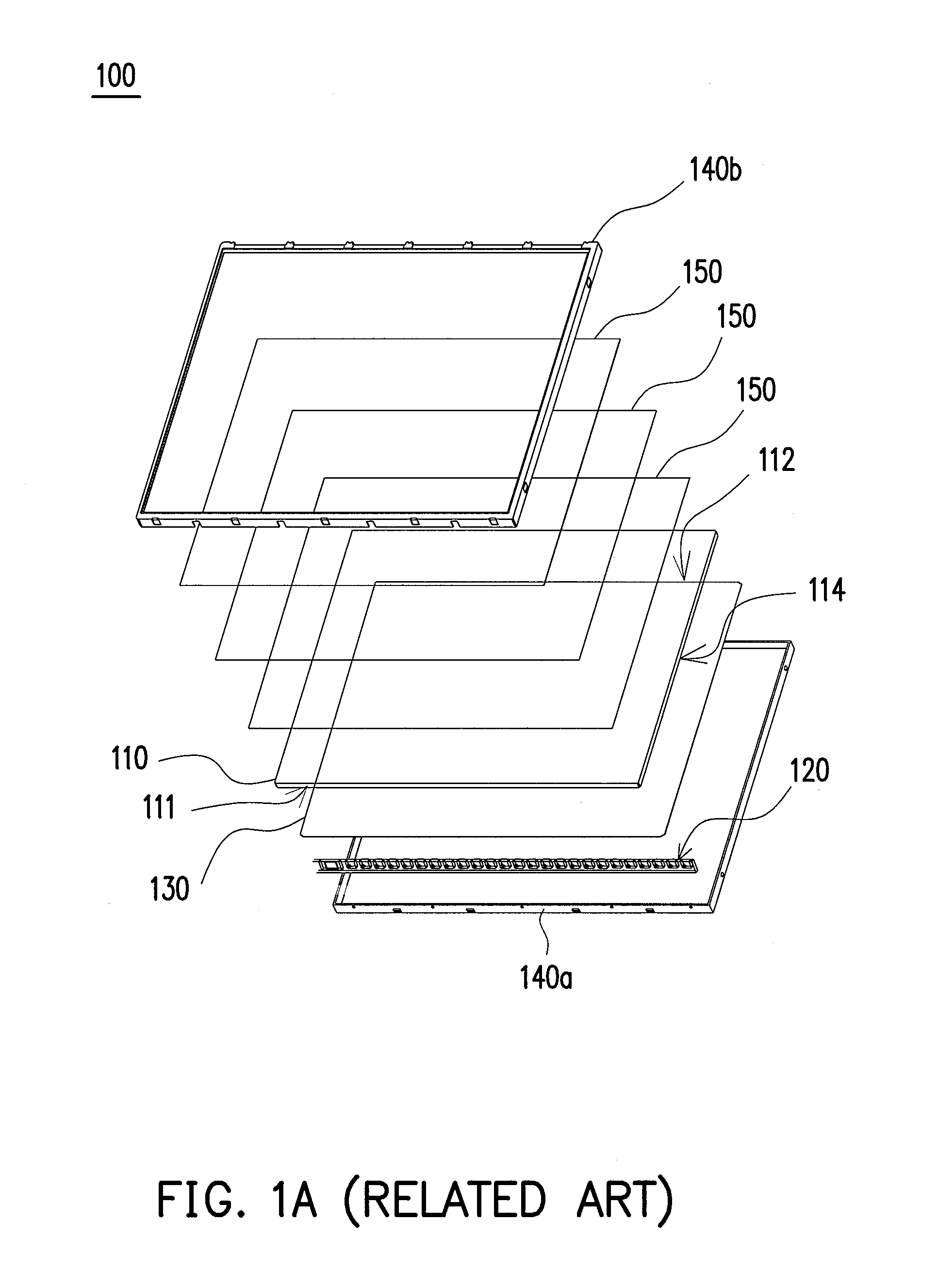

Backlight module

ActiveUS20110116285A1Reduce partUniform luminous intensityPlanar/plate-like light guidesReflectorsLight guideLight beam

A backlight module includes a light guide plate, an optical film set, and at least one light emitting element. The light guide plate has a first light-emitting surface, a bottom surface, and a first light incident surface. The optical film set on the first light-emitting surface includes at least one optical film having a second light incident surface, a second light-emitting surface, and a side surface. The side surface of the optical film and the first light incident surface of the light guide plate are at the same side, and at least one notch is disposed on the side surface. The light emitting element is adjacent to the first light incident surface and capable of emitting a light beam. The light beam is capable of entering the light guide plate through the first light incident surface and being transmitted to the optical film set via the first light-emitting surface.

Owner:CORETRONIC

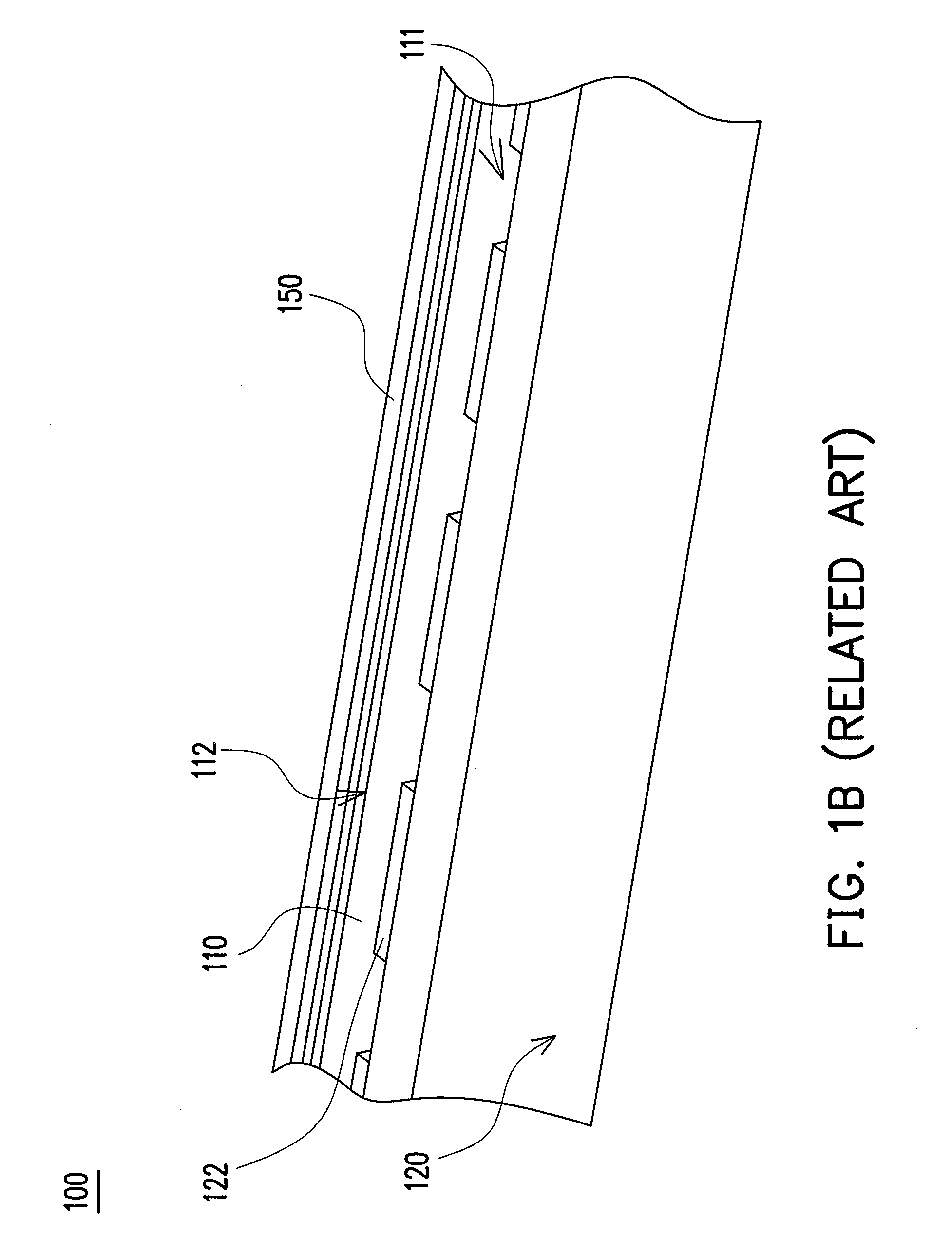

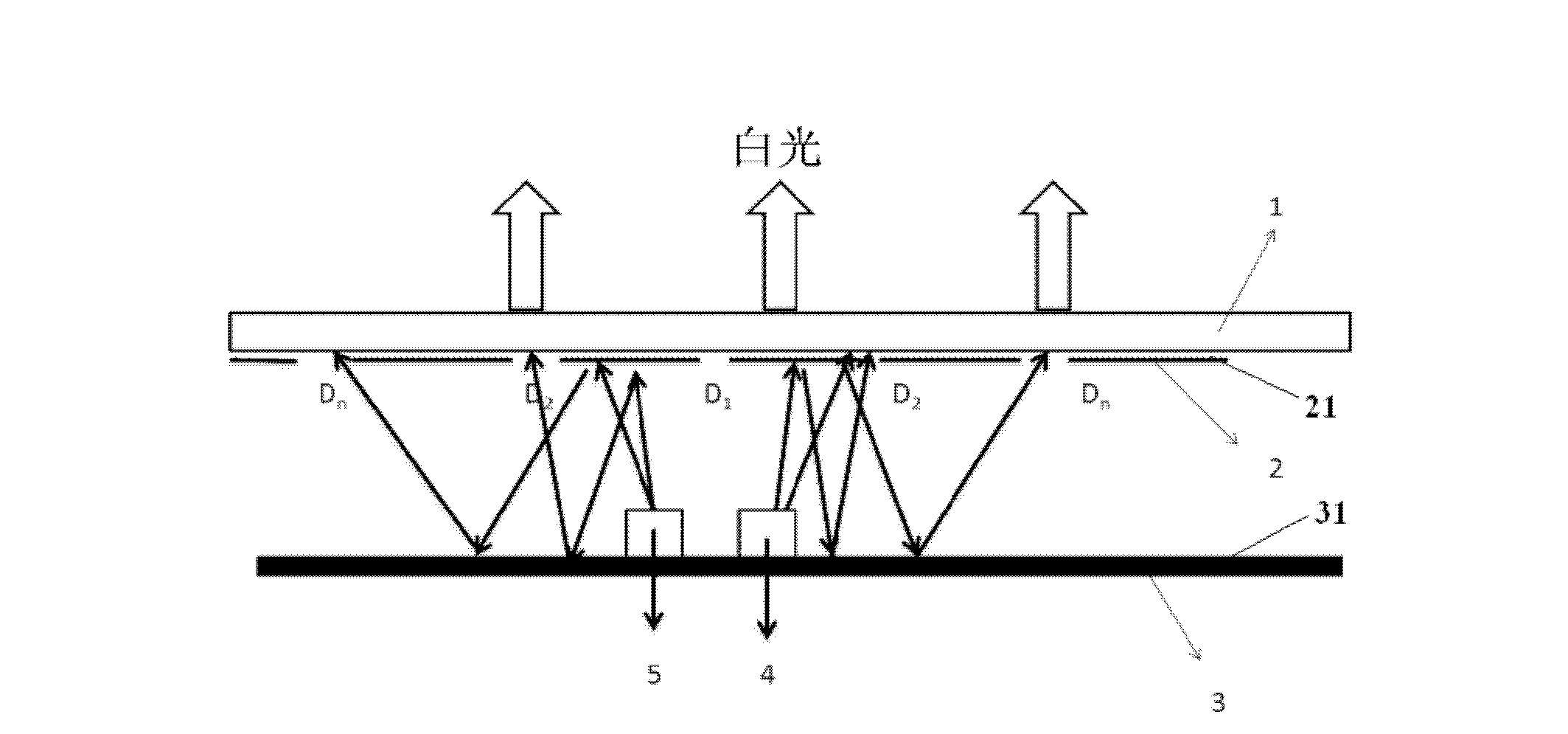

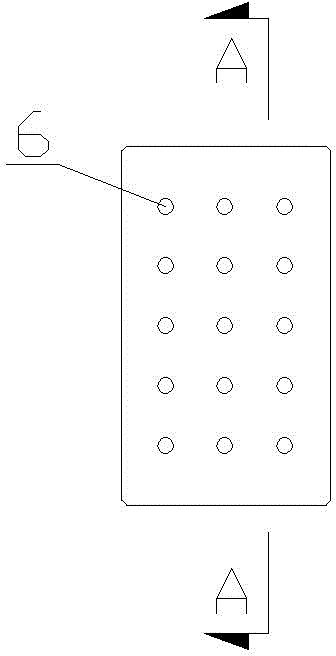

LED (light emitting diode) area light source module and method for obtaining uniform area light source white light

InactiveCN102506327AUniform luminous intensityPoint-like light sourceElectric lightingLight-emitting diodeWhite light

The invention discloses an LED (light emitting diode) area light source module and a method for obtaining uniform area light source white light. The LED area light source module comprises a substrate; at least one LED point light source is arranged on the substrate; a light homogenizing plate is arranged above the LED point light source; a fluorescent powder layer is arranged above the light homogenizing plate; the lower surface of the light homogenizing plate is a first reflective surface; the upper surface of the substrate is a second reflective surface; a plurality of holes are arranged in the light homogenizing plate in an array manner; and the light emitted by the LED point light source is reflected by the first reflective surface and the second reflective surface many times, and enters into the fluorescent powder layer after being emergent through the holes in the light homogenizing plate. According to the LED area light source module disclosed by the invention, the emergent light optical path of the point light source is changed through the two reflective surfaces, and the light intensity is redistributed through the hole array on the light homogenizing plate, therefore a white-light area light source with uniform intensity is formed after the light passes through the LED area light source module. Compared with the traditional area light source formed by a plurality of point light sources, the number of the point light sources is reduced, and uniform light intensity distribution is realized.

Owner:SHANGHAI YAMING LIGHTING

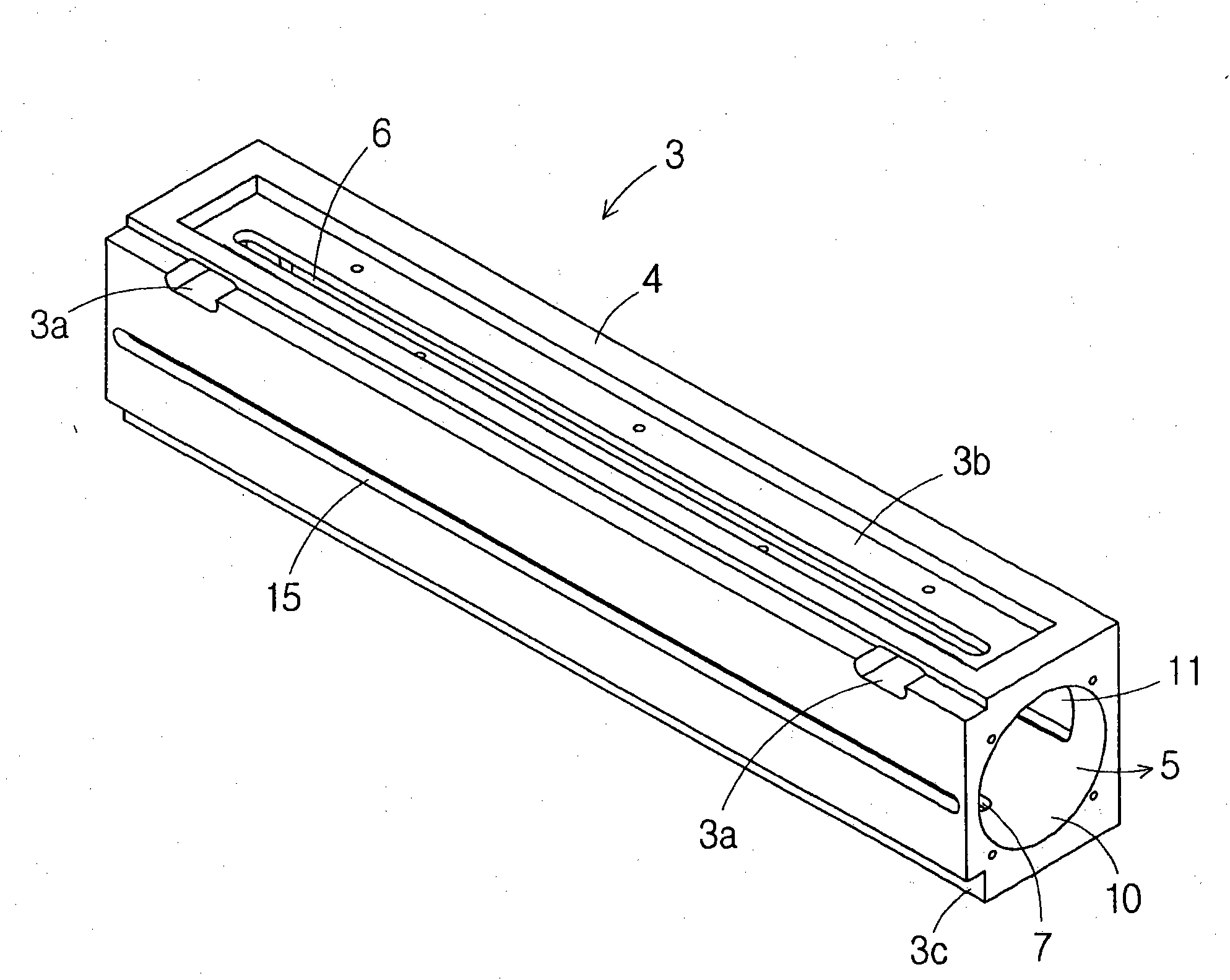

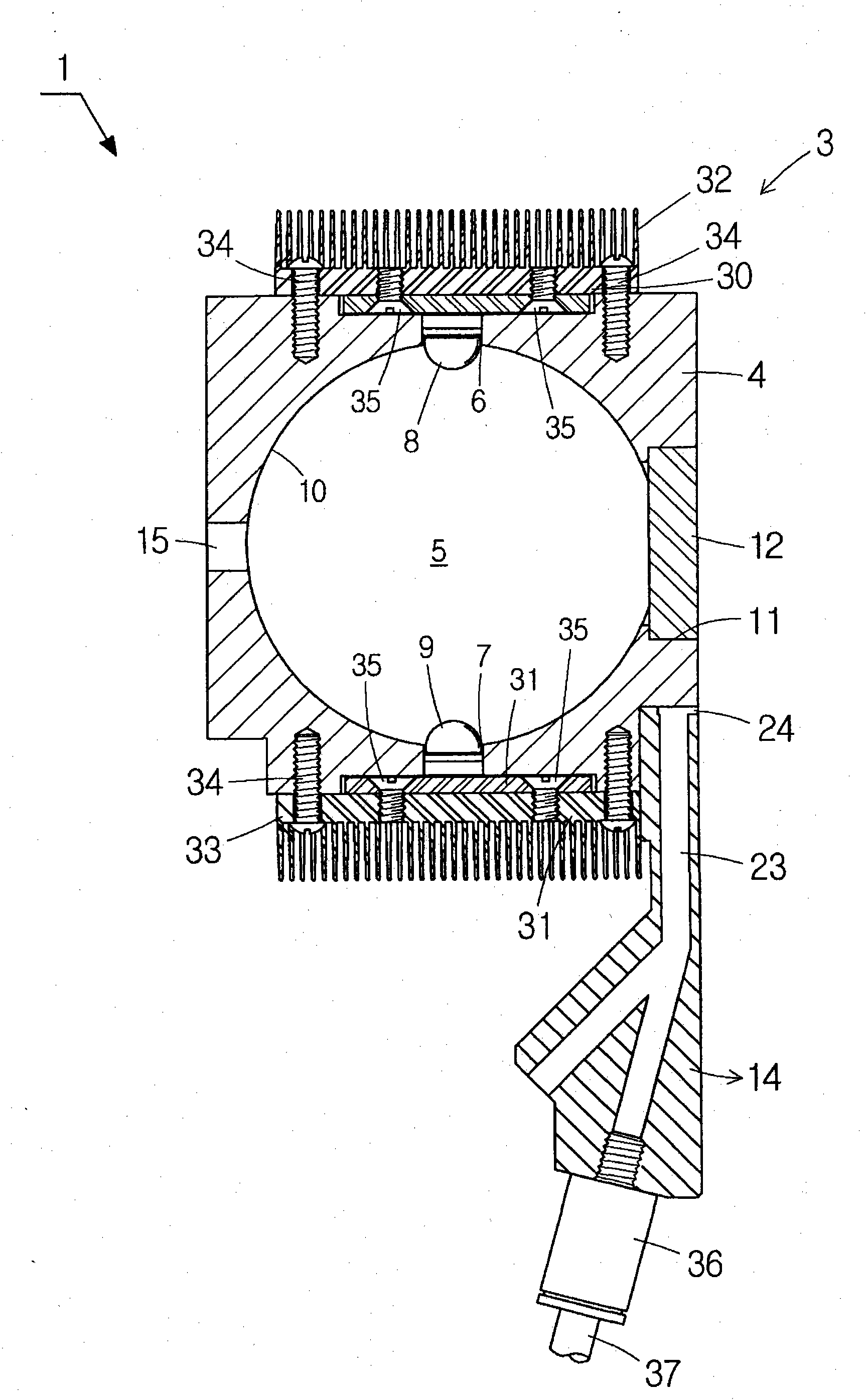

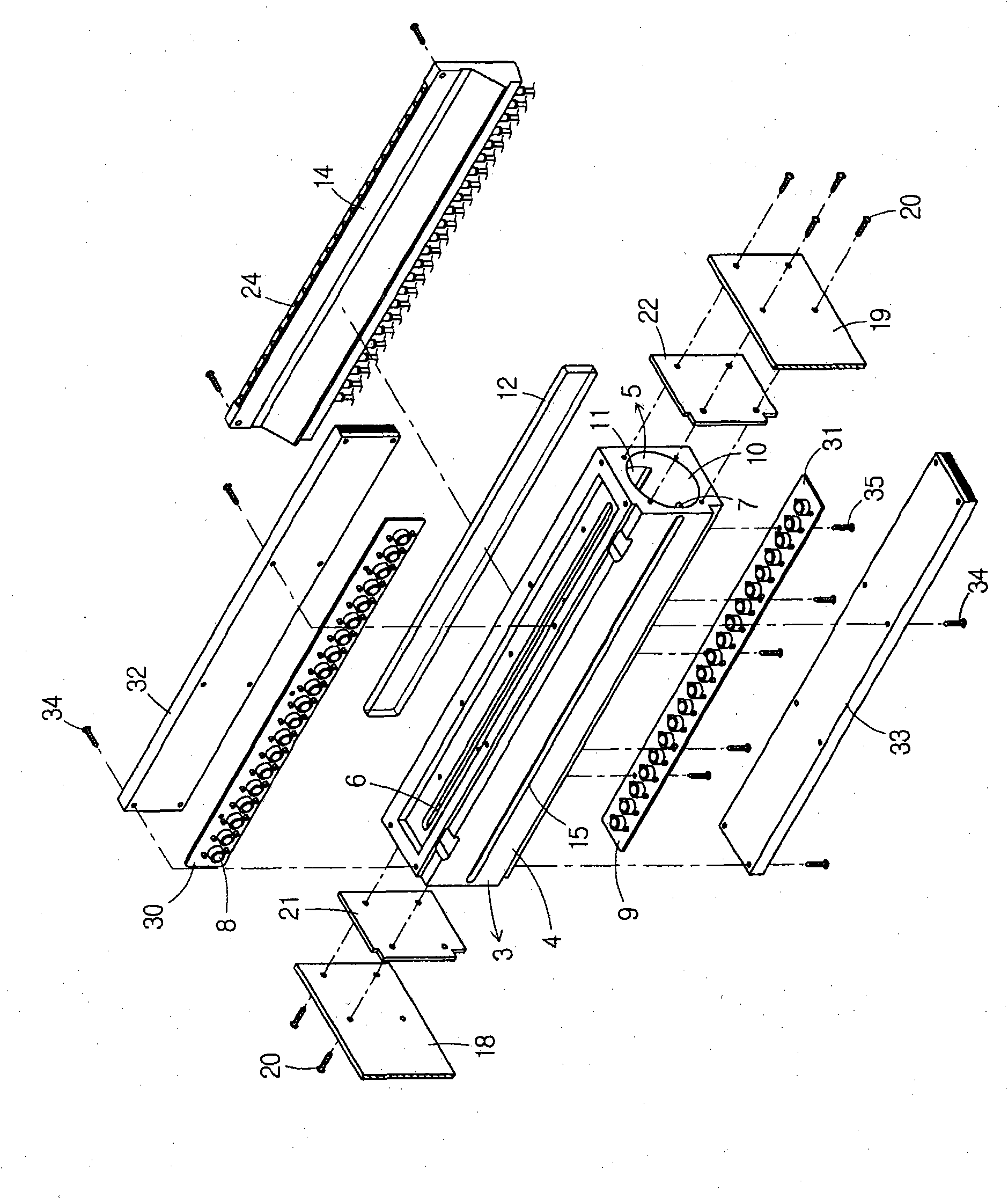

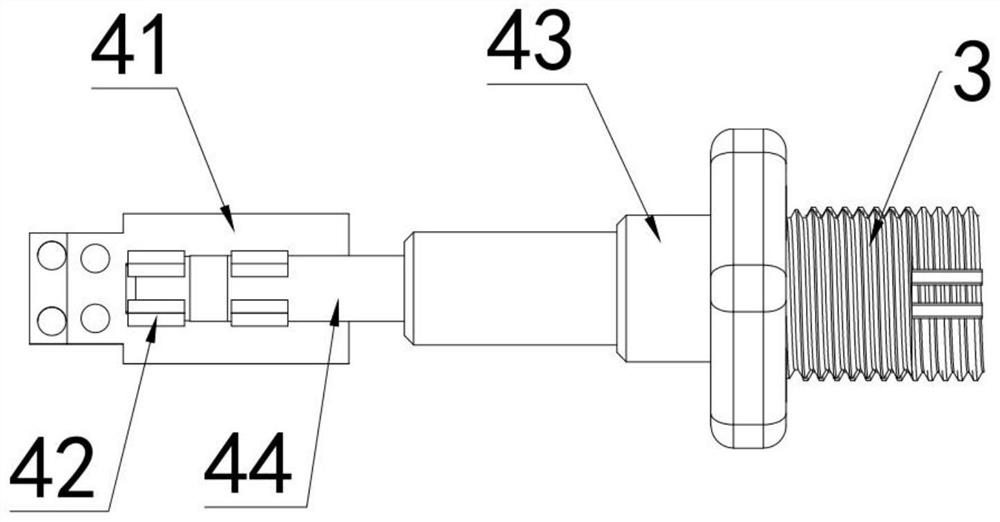

Color sorting apparatus for leaf products

InactiveCN102083552AUniform luminous intensityReduce photometric errorsColor measuring devicesSortingSpecific gravityCcd camera

The present invention relates to a color sorting apparatus which efficiently sorts products or articles in a leaf state (hereinafter, referred to as ''leaf products'') such as green tea, black tea, chrysanthemum, herbs and the like, each of which has a low specific gravity and drastically varies in size and color. The color sorting apparatus is configured such that a reflection chamber (5) is arranged in a frame (3) in the lengthwise direction to transmit and reflect light emitted by a light source, an annular reflection surface (10) is formed at the surface of the reflection chamber (5), light-emitting diode (LED) arrays (8, 9) are installed at the top and bottom of the reflection chamber (5), respectively, a transparent window (12) is arranged at the front surface of the reflection chamber (5) to enable a leaf product (2) to move along the transparent window (12), a slit (15) is formed at the rear surface of the reflection chamber (5) to enable images of the leaf product (2) to be captured by a CCD camera (16), and a leaf product (2a) determined to be a defective product is quickly removed by the high-pressure air jetted by an ejector (14) installed below the front surface of the frame (3).

Owner:IDEAL SYST CO LTD

Surface light source and liquid crystal display including the same

InactiveCN101469838ASuppresses reduction in light use efficiencyUniform luminous intensityMechanical apparatusPoint-like light sourceLiquid-crystal displayLight guide

A surface light source includes a light source and an optical waveguide plate. The light source serves to emit light. The optical waveguide plate has an incident end face where the light is incident and a light exit surface where the light incident on the incident end face exits. Further, the optical waveguide plate has a refractive index n. The incident end face has a plurality of concave portions. The angle between a plane formed by the plurality of concave portions and a tangent plane of the incident end face is not more than (90-2*arcsin(1 / n)) degree.

Owner:SHARP KK

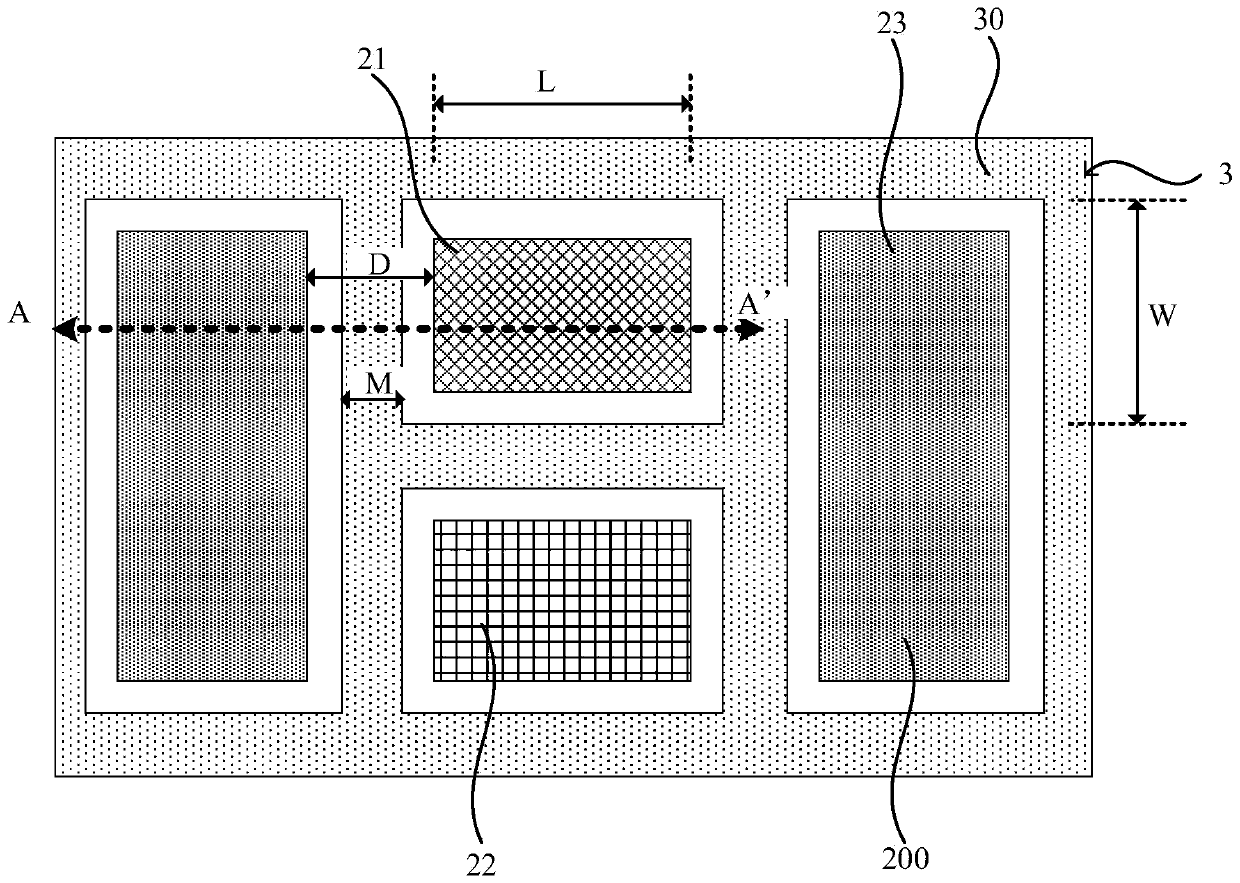

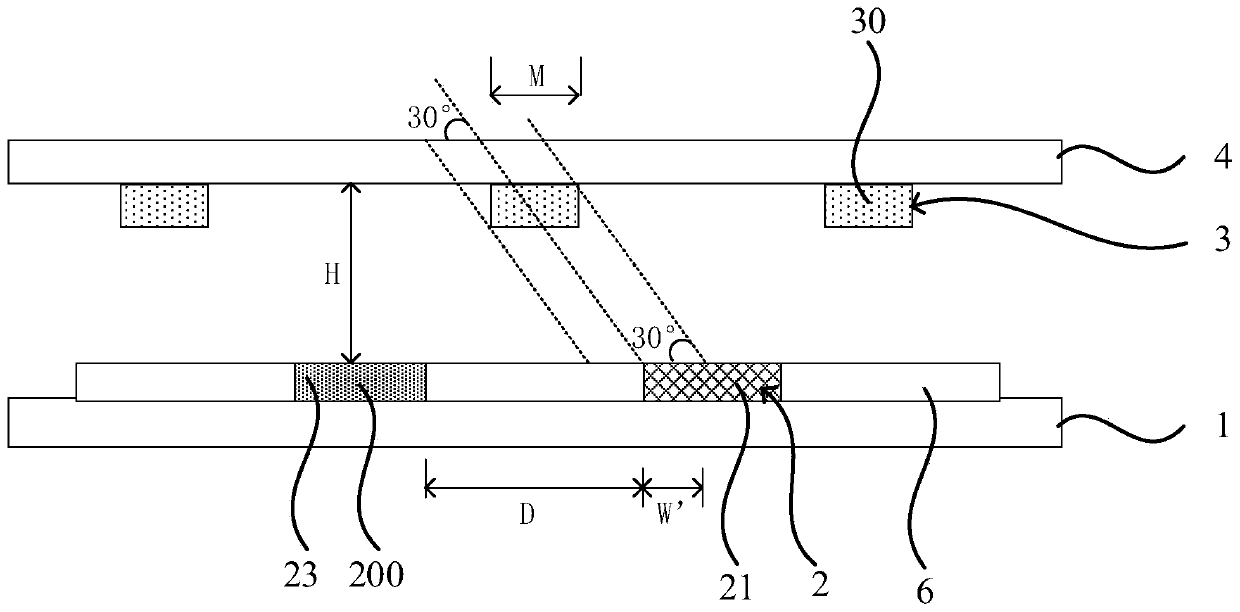

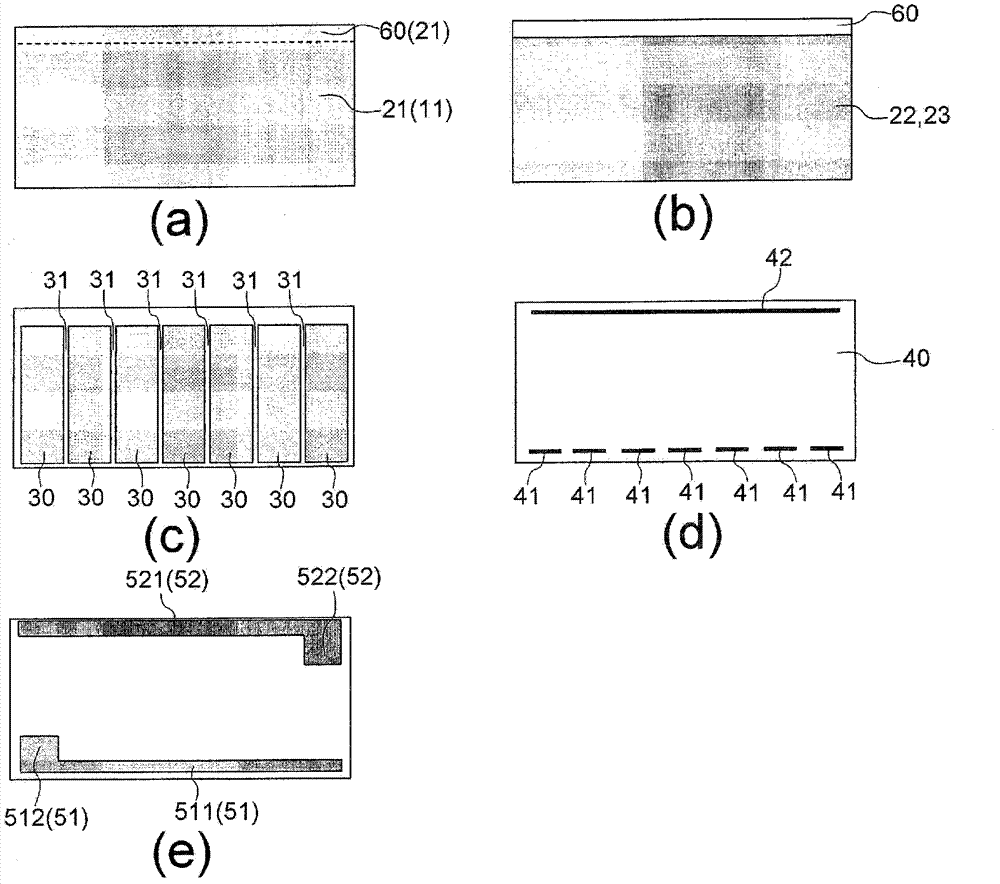

Light-emitting element

InactiveCN102244174AUniform luminous intensitySemiconductor devicesLuminous intensityElectrical conductor

A light-emitting element forming a two-electrode structure on one face of a semiconductor light-emitting functional layer can obtain uniform luminous intensity along the length direction. The semiconductor light-emitting functional layer (20) which is formed on a Si substrate (11) has a laminating structure composed of a N type GaN layer (a first semiconductor layer) (21), a MQW layer (22), and a P type GaN layer (a second semiconductor layer) (23). A surface (a main face) of the P type GaN layer forms a transparent electrode (31) by extending from the other end part (the left end part) side towards the right end part side. An N-side electrode (34) is formed on the right end part side area. A P-side electrode (33) is formed on the left end part side area. The width of the transparent electrode (31) is gradually increasing from the left end part to the right end part. Therefore, the transparent electrode (31) limits the expansion of a current flowing vertically inside the MQW layer (22) on a side adjacent to the P-side electrode (33).

Owner:SANKEN ELECTRIC CO LTD

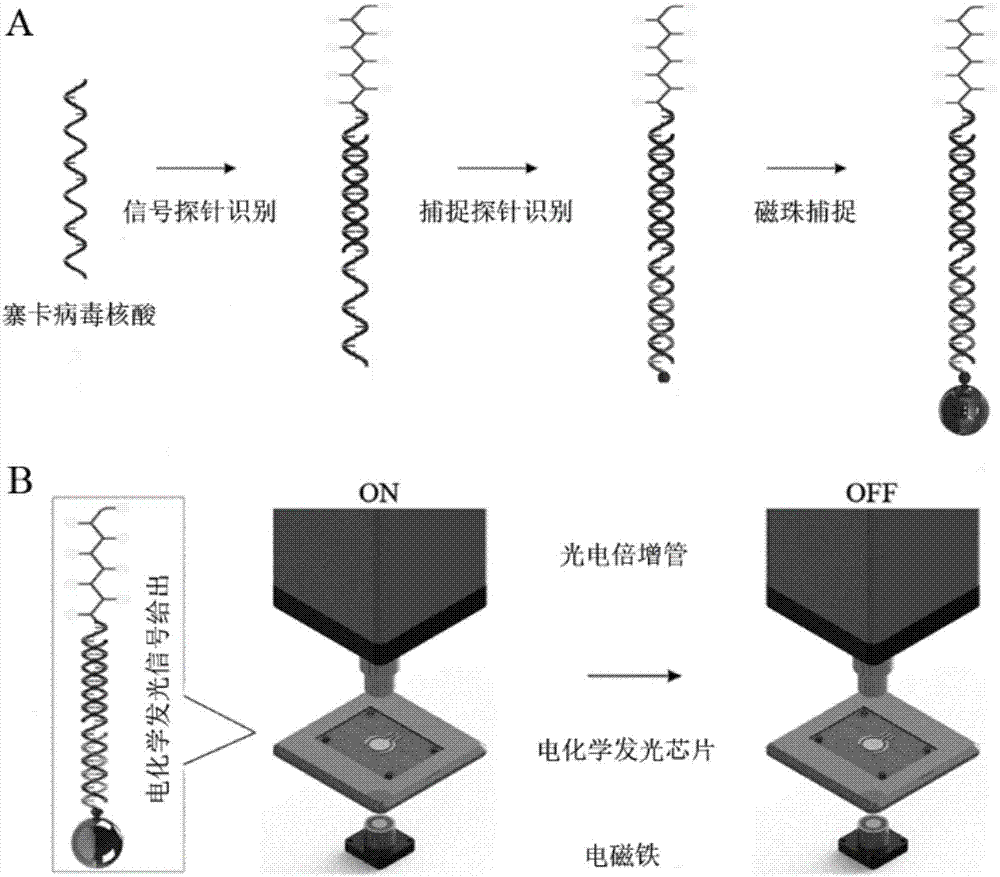

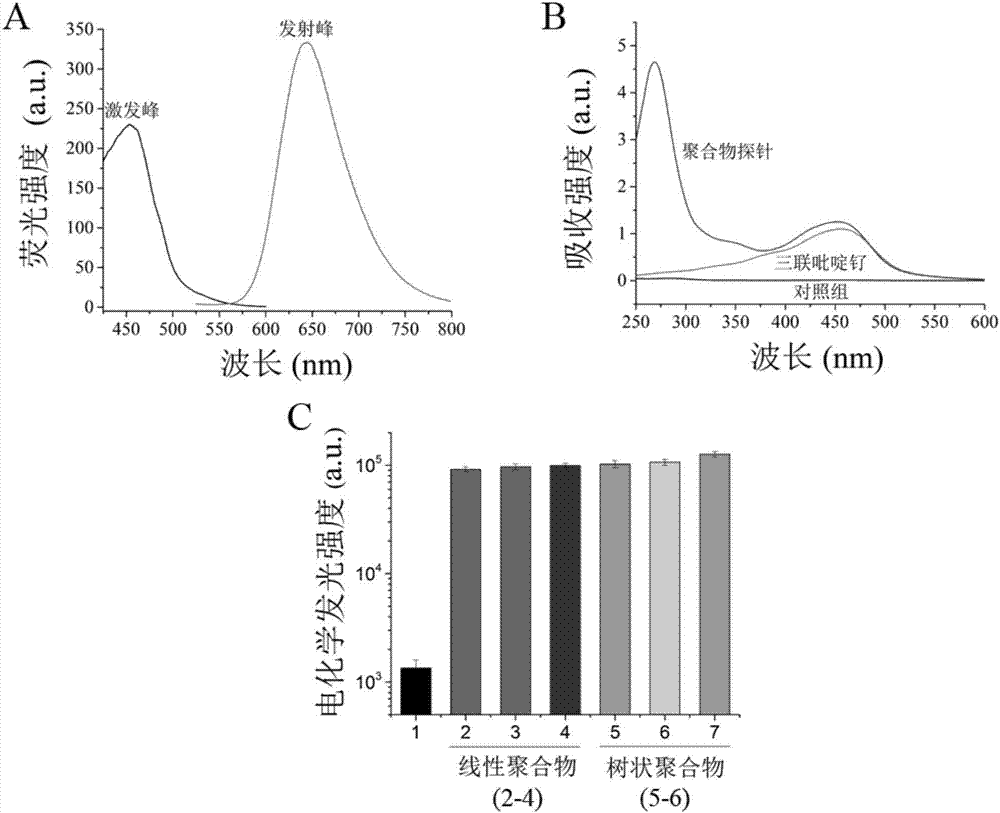

Zika virus nucleic acid detection method based on electrochemical luminescence amplification principle

ActiveCN107475454AHigh sensitivityGuaranteed SensitivityMicrobiological testing/measurementMicroorganism based processesLuminous intensityElectrochemiluminescence

The invention discloses a zika virus nucleic acid detection method based on an electrochemical luminescence amplification principle and belongs to the technical field of zika virus molecular diagnosis. The invention respectively provides the zika virus nucleic acid detection method based on a linear and tree-shaped terpyridyl ruthenium polymer electrochemical luminescence amplification method. The method has the following advantages: 1) high sensitivity; 2) stable probe: the linear and tree-shaped terpyridyl ruthenium polymer used as an electrochemical luminescence amplification part of the probe, stable performance, and uniform degree of polymerization and luminous intensity; 3) simple and quick detection process: the zika virus detection is performed through simple sample pre-treatment and nucleic acid extraction process, time consumption is less, the amplification step is avoided and the detection is quick; 4) low cost. The method disclosed by the invention is a technical system for detecting zika virus nucleic acid; a novel molecular diagnosis method based on the electrochemical luminescence method technique is provided; the defect of single technique for detecting zika virus at present is effectively made up; a zika virus detection method requiring no amplification is supplied.

Owner:SUN YAT SEN UNIV

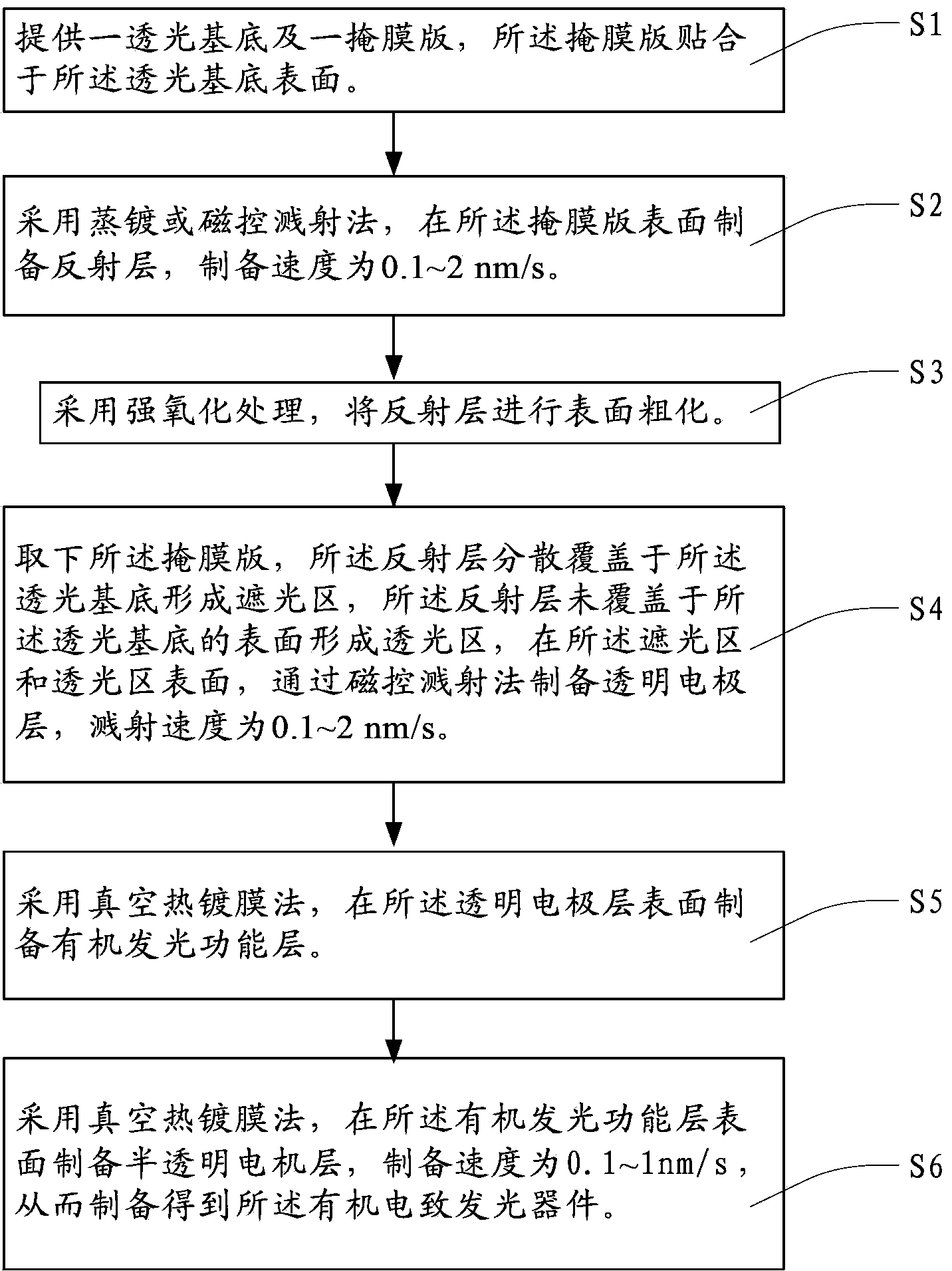

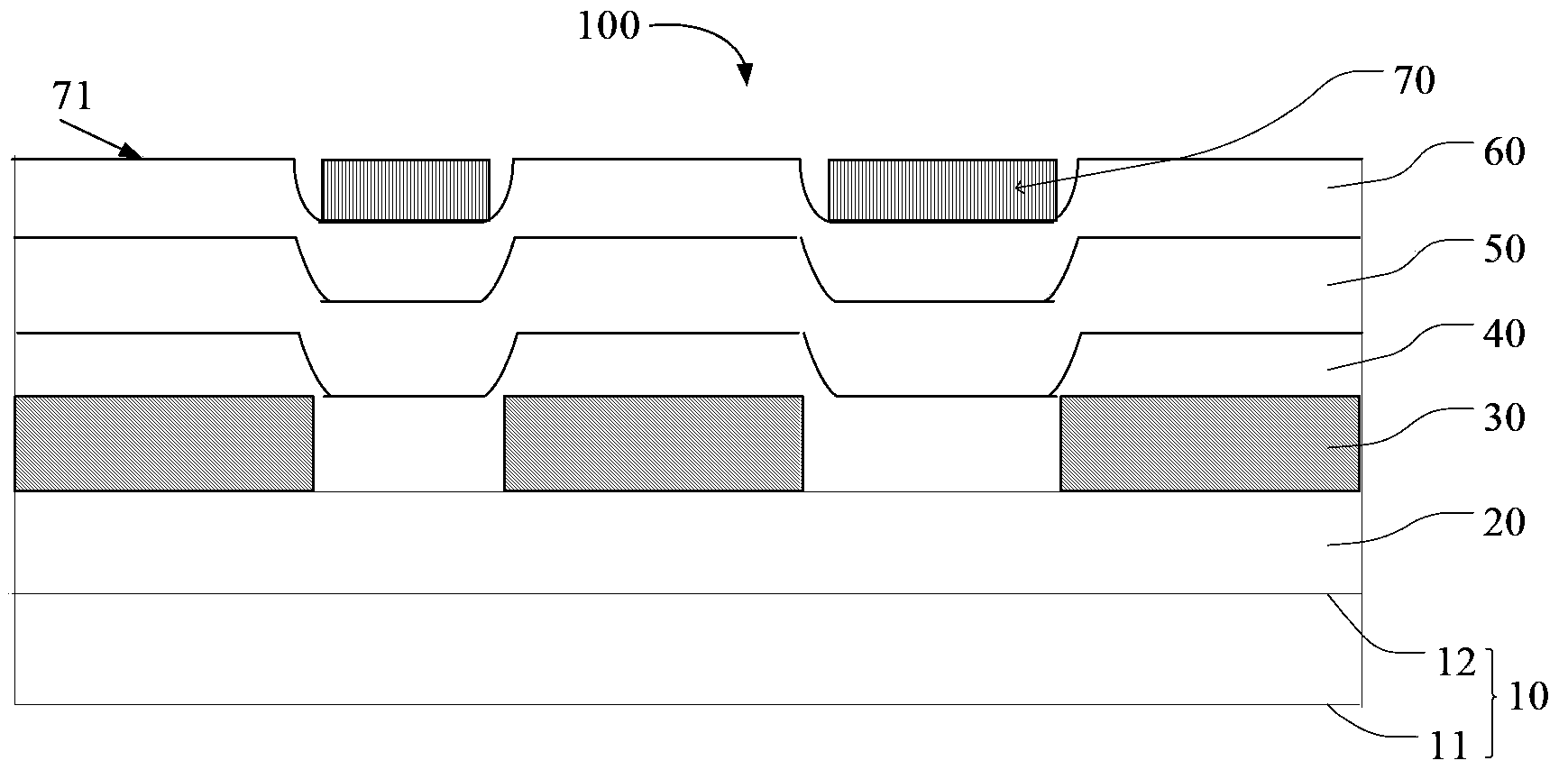

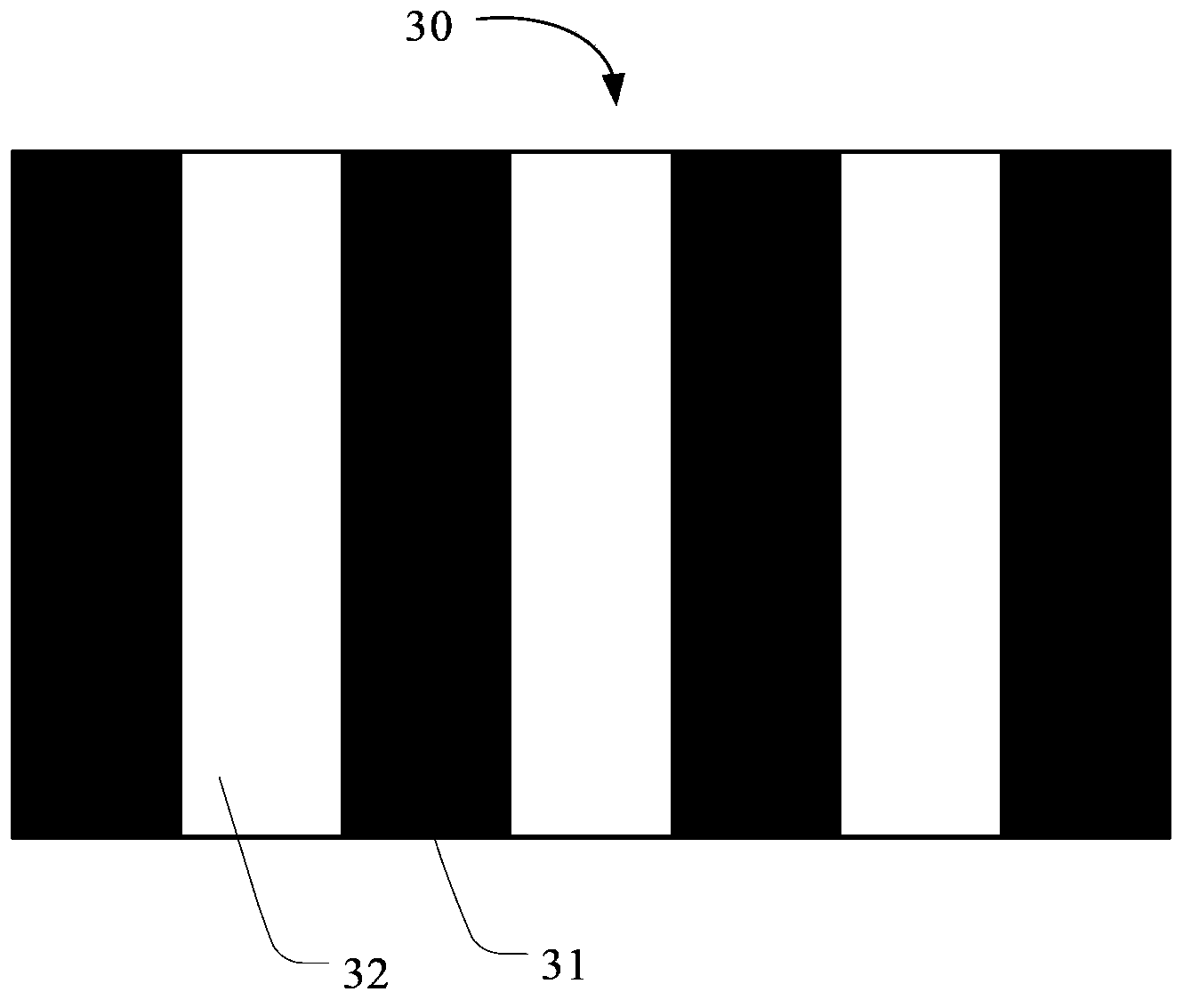

Organic electroluminescence device and preparation method thereof

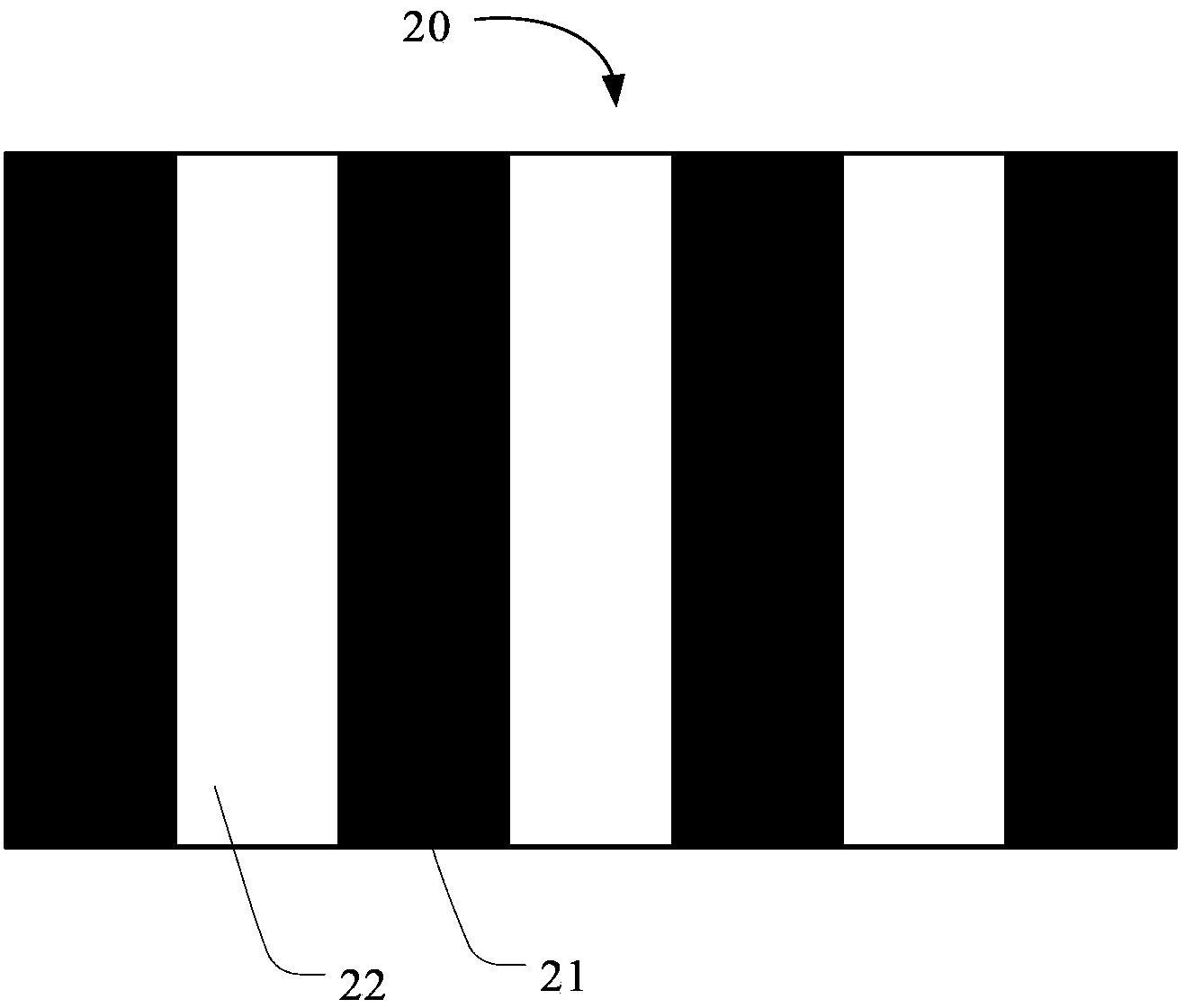

InactiveCN104218160AHigh light transmittanceReduce light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingRough surfaceLuminous intensity

The invention discloses an organic electroluminescence device, comprising a light-permeating substrate, reflecting layers, transparent electrode layers, an organic light emitting function layer and a semitransparent electrode layer which are sequentially overlapped, wherein the light-permeating substrate comprises a first light outgoing surface and a covered surface which are oppositely arranged, the reflecting layers dispersedly cover the covered surface to form shading areas, and the parts of the covered surface, which have been not covered by the reflecting layers, of the light-permeating substrate are formed into light-permeating areas; the transparent electrode layers cover the shading areas and the light-permeating areas; the organic light emitting function layer covers the surfaces of the transparent electrode layers; and the reflecting layers have rough surfaces for increasing diffuse reflection of light rays at the reflecting layers, and an area ratio of the reflecting layers to the transparent electrode layers is 20%-80%. The two light outgoing surfaces of the organic electroluminescence device are uniform and accordant in luminous intensity. According to the organic electroluminescence device, microcavity effect is weakened, and color rendering index is improved. In addition, the invention also discloses a preparation method of the organic electroluminescence device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

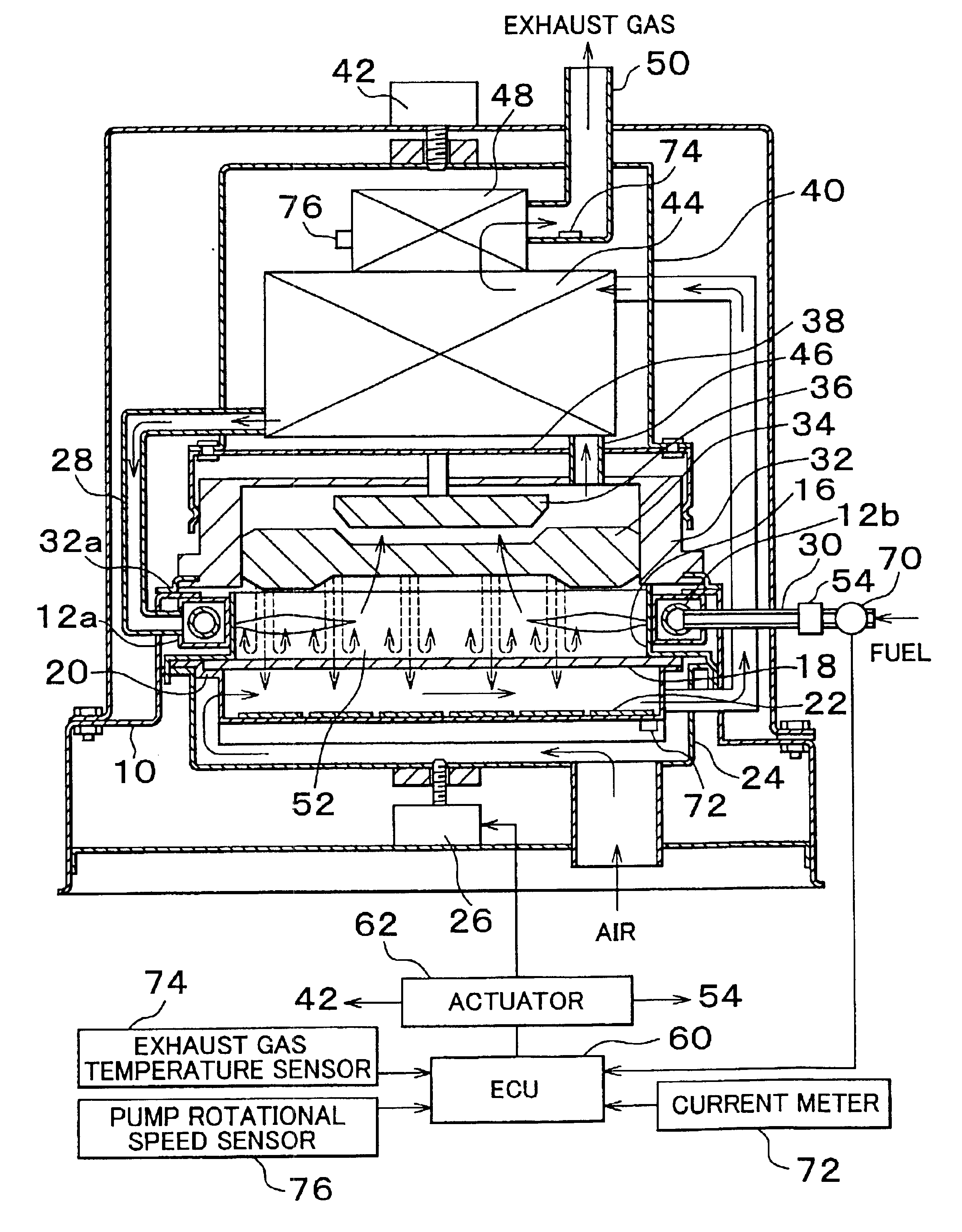

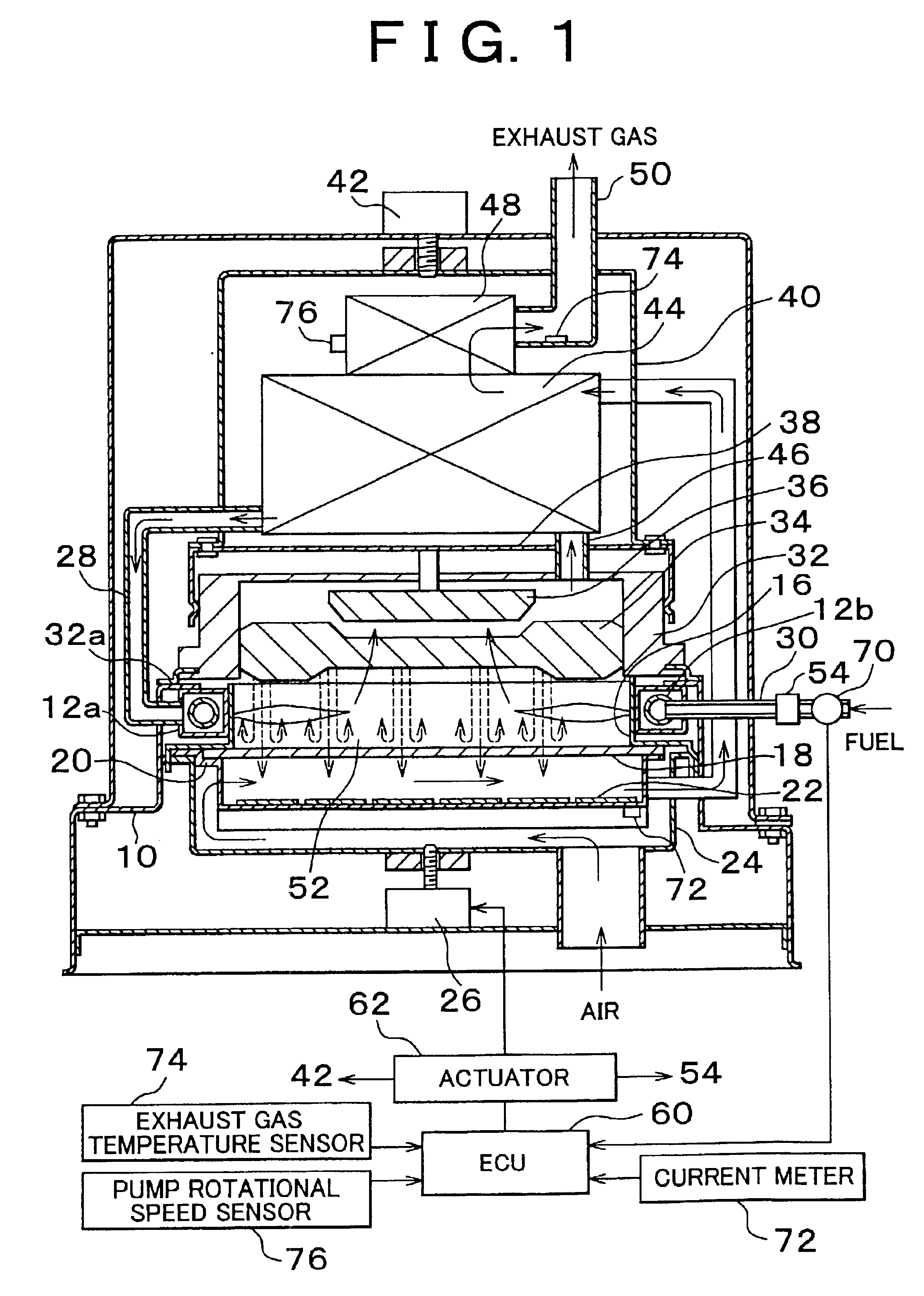

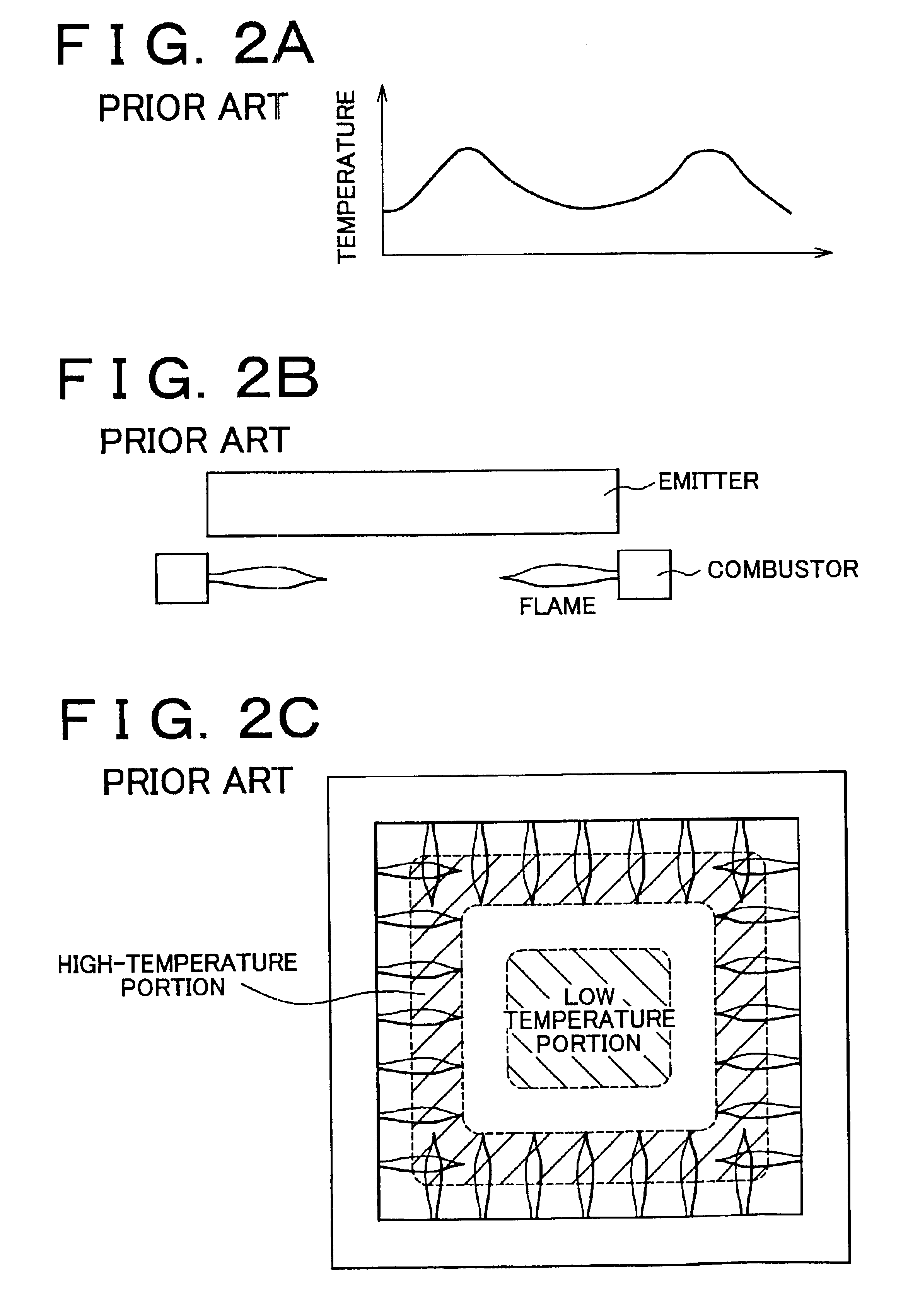

Photothermal power generation device and method

InactiveUS6888059B2Uniform luminous intensityImprove power generation efficiencyReciprocating combination enginesPV power plantsCombustorPhotoelectric conversion

A photothermal power generation device designed to heat an emitter receives a supply of fuel and air, burns the fuel to produce combustion gas, and converts light emitted from the emitter into electric power by means of a photoelectric conversion element. The device is provided with a flow resistance adjusting unit for adjusting a flow resistance of the combustion gas in the emitter in accordance with a state of combustion gas, a combustor fire vent adjusting unit for adjusting the shapes of, or a number of, fire vents formed in the combustor in accordance with a required output, or a discharge state adjusting unit for adjusting a discharge state of exhaust gas in accordance with a state of the combustion gas. This photothermal power generation device provides uniform light-emitting intensity and enhances power generation efficiency.

Owner:TOYOTA JIDOSHA KK

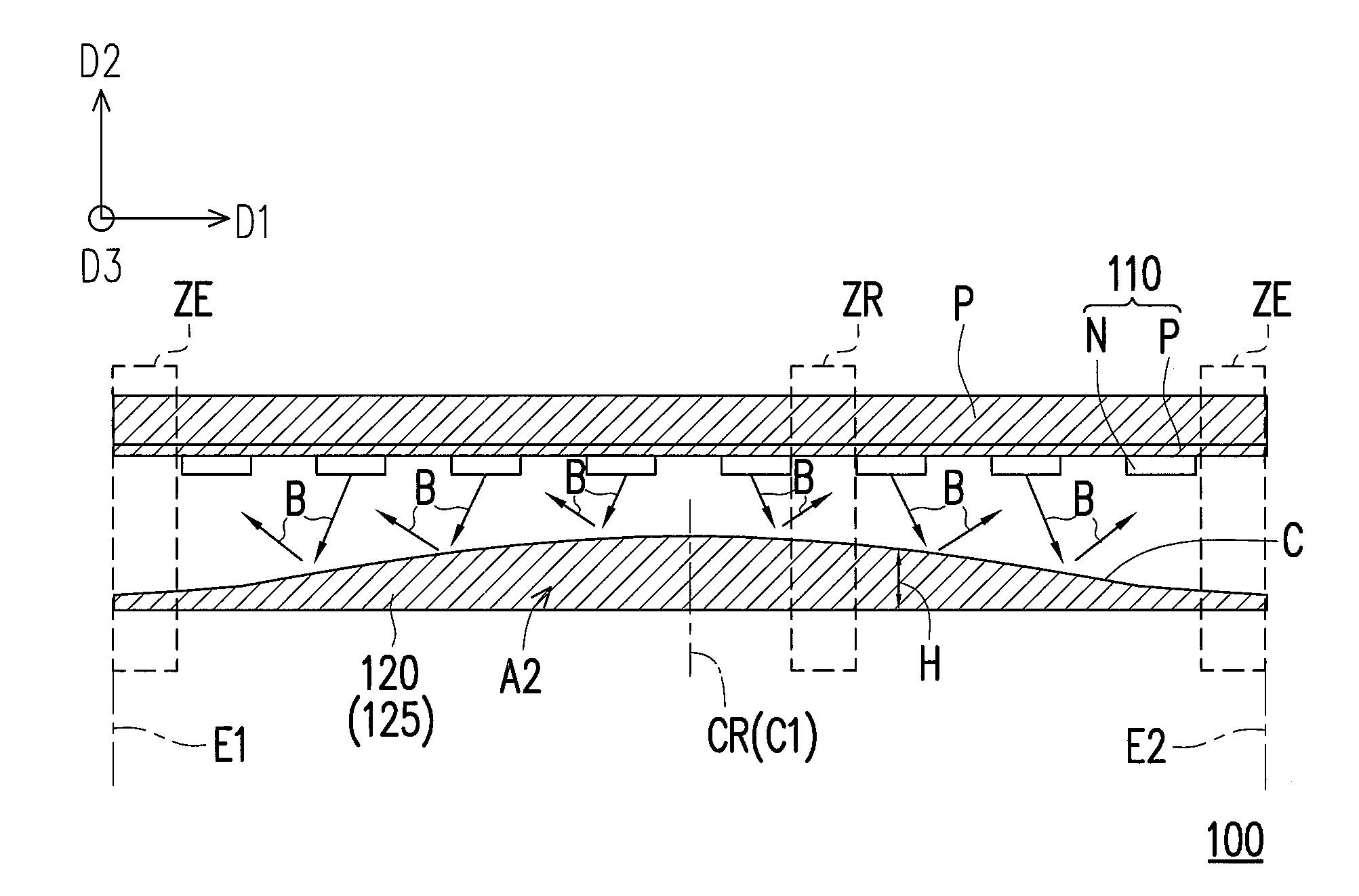

Display panel and display device

InactiveCN110660836AUniform luminous intensityAlleviate the problem of big view role deviationStatic indicating devicesSolid-state devicesComputer hardwareDriving current

The invention provides a display panel and a display device. The display panel is characterized in that under the same driving current, luminous intensity of a first sub-pixel is greater than that ofa second sub-pixel; a shading element comprises latticed grid lines; a shortest distance between the orthographic projection of the first sub-pixel on a substrate and the orthographic projection of the grid line on the substrate along the row direction of an array is D1H; a shortest distance between the orthographic projection of the second sub-pixel on the substrate and the orthographic projection of the grid line on the substrate along the row direction of the array is D2H; the shortest distance between the orthographic projection of the first sub-pixel on the substrate and the orthographicprojection of the grid line on the substrate along the column direction of the array is D1V; the shortest distance between the orthographic projection of the second sub-pixel on the substrate and theorthographic projection of the grid line on the substrate along the column direction of the array is D2V; D1H is less than D2H and / or D1V is less than D2V. The display panel is advantaged in that a problem of large-view-angle color cast of the display panel is relieved and even eliminated.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

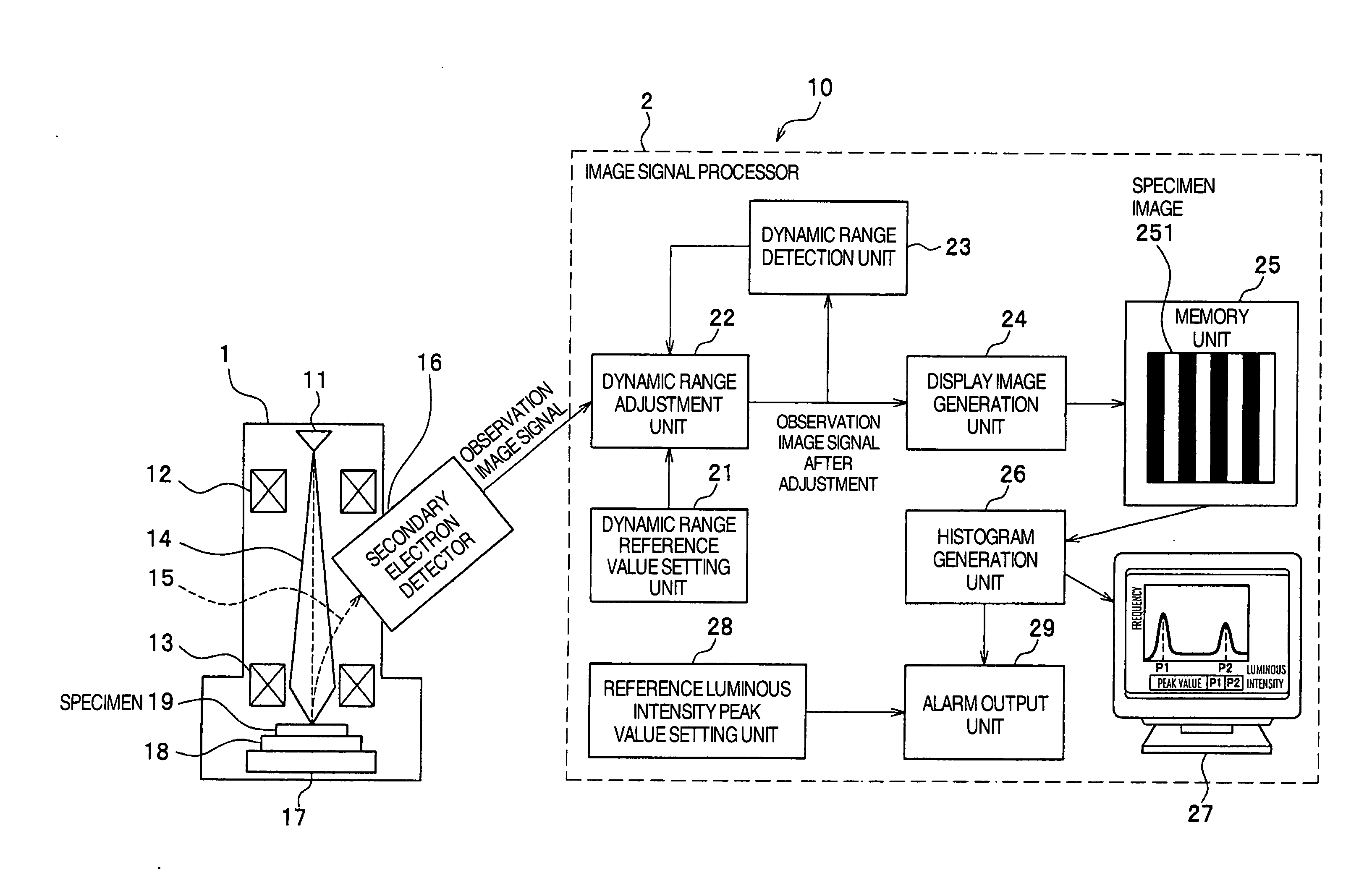

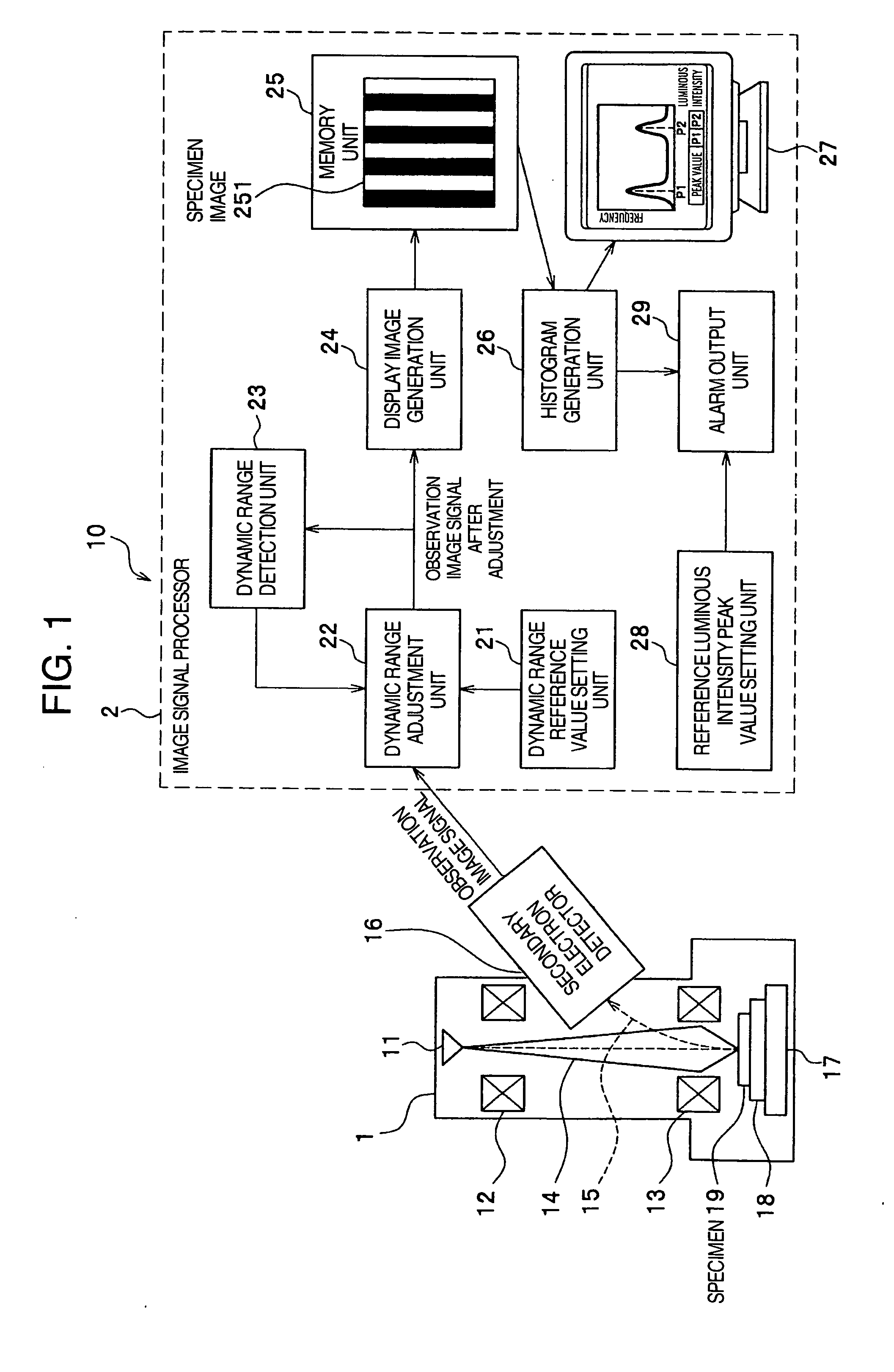

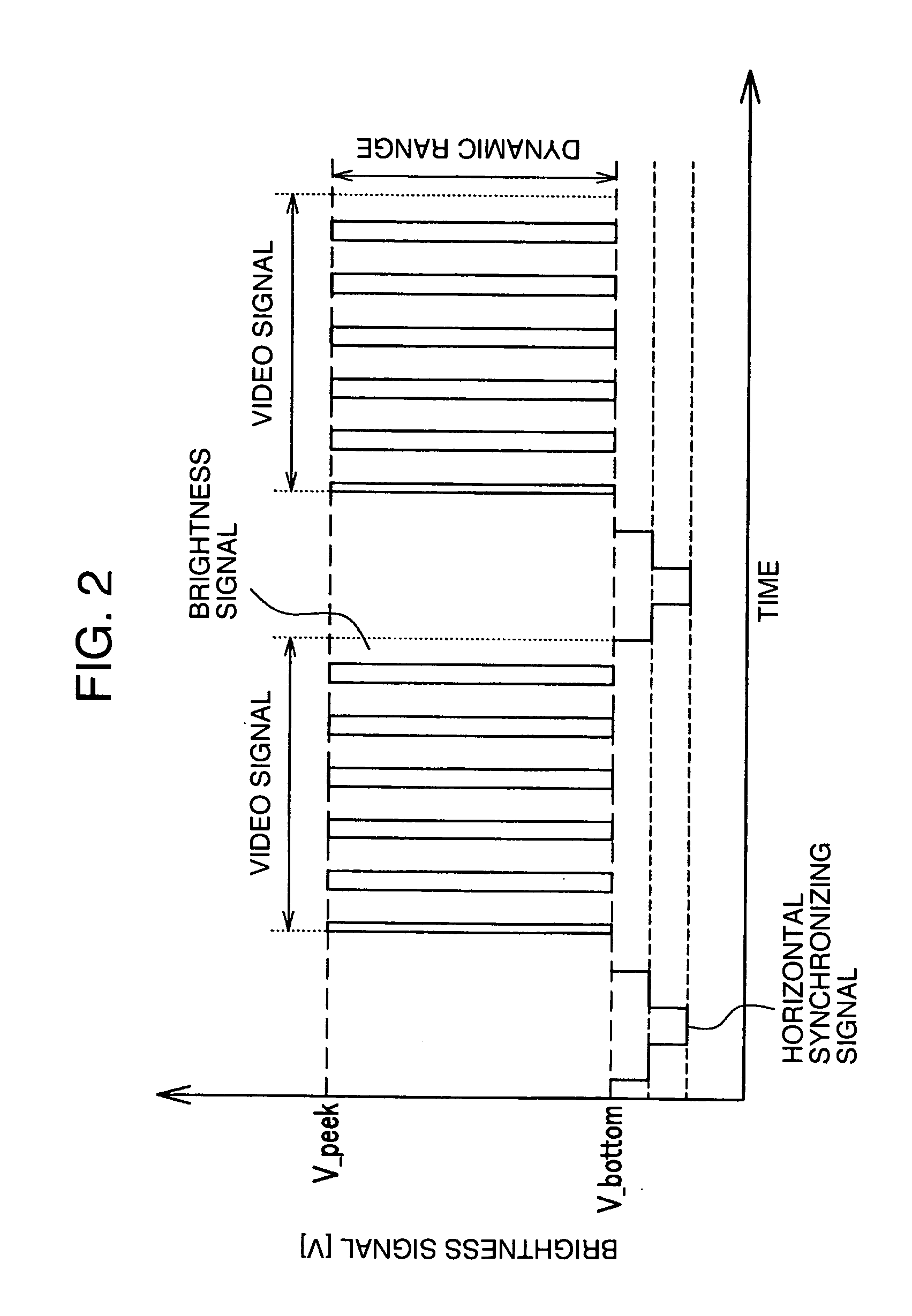

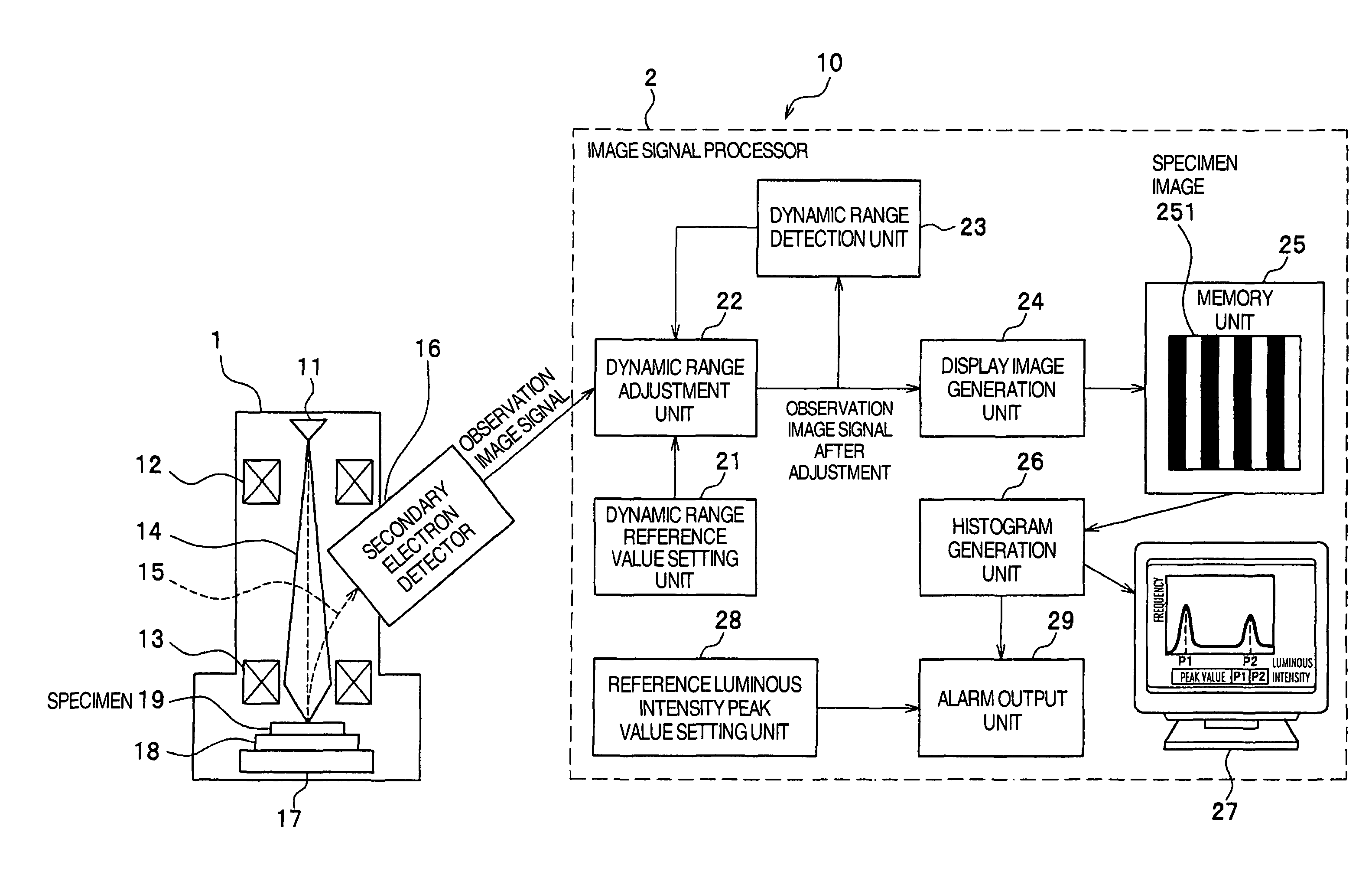

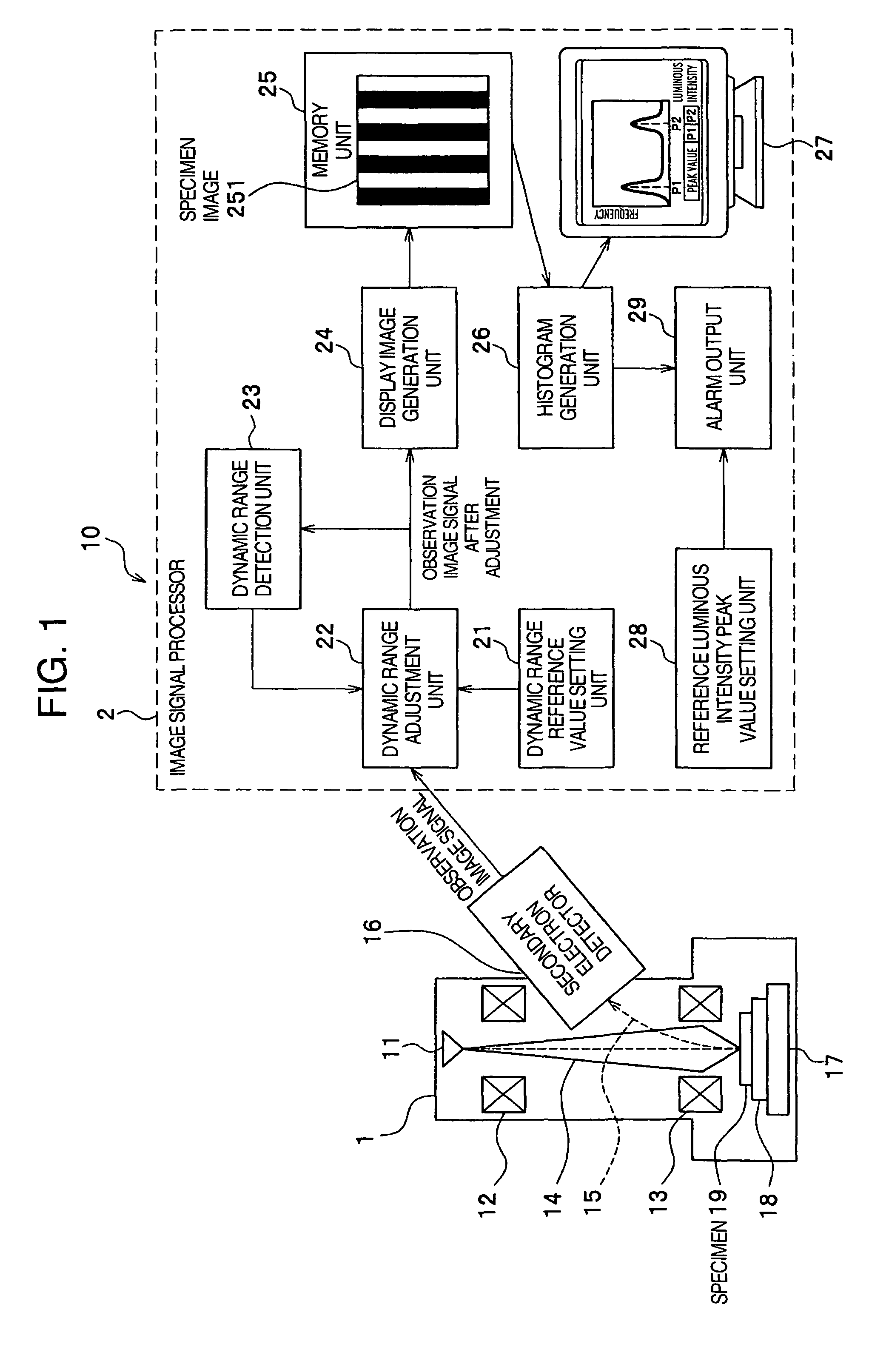

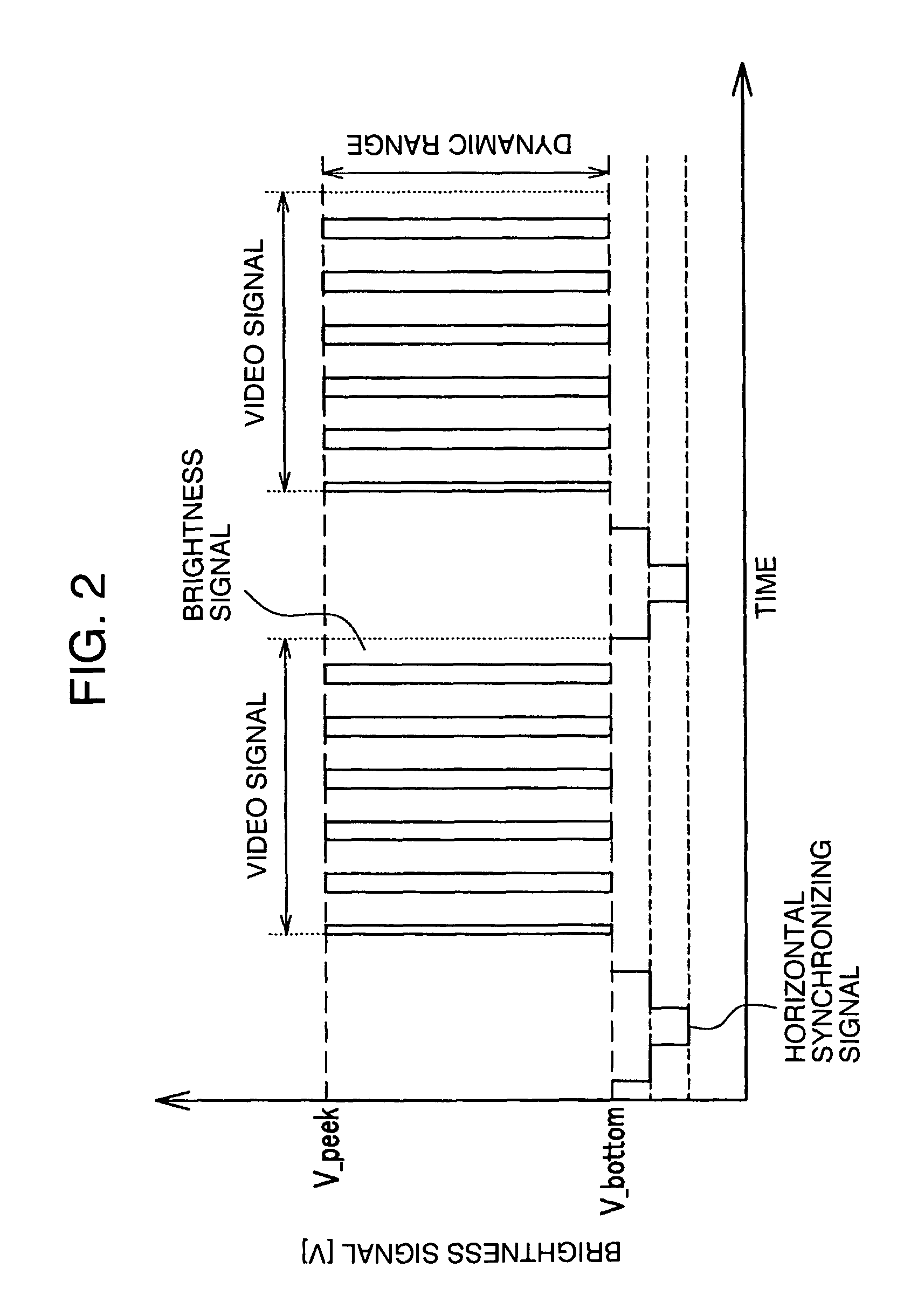

Scanning electron microscope and image signal processing method

ActiveUS20070064100A1Uniform luminous intensityMaterial analysis using wave/particle radiationElectric discharge tubesLuminous intensityPeak value

The SEM has a dynamic range reference value setting unit for setting dynamic range reference values, a dynamic range adjustment unit for receiving an observation image signal delivered out of a secondary electron detector, adjusting the dynamic range of the observation image signal on the basis of the dynamic range reference values and outputting the thus adjusted observation image signal as an observation image signal after adjustment, a display image generation unit for determining luminous intensity levels of individual pixels of an image to be displayed based on the observation image signal after adjustment to generate a display image, a histogram generation unit for generating a histogram of luminous intensity levels of the display image and extracting, as a luminous intensity peak value, at which the frequency of luminous intensity is maximized, and a display unit for displaying the generated histogram and the extracted luminous intensity peak value.

Owner:HITACHI HIGH-TECH CORP

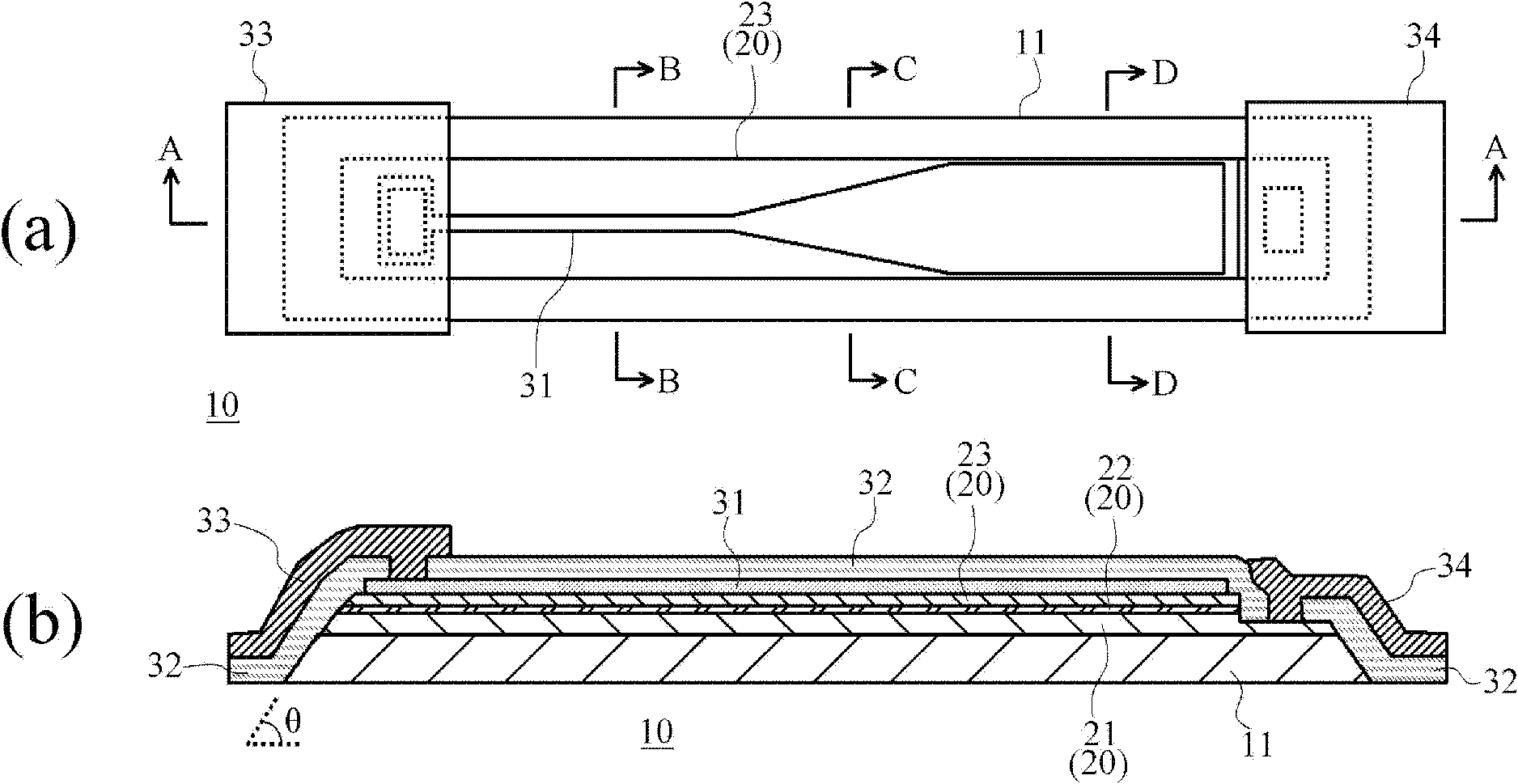

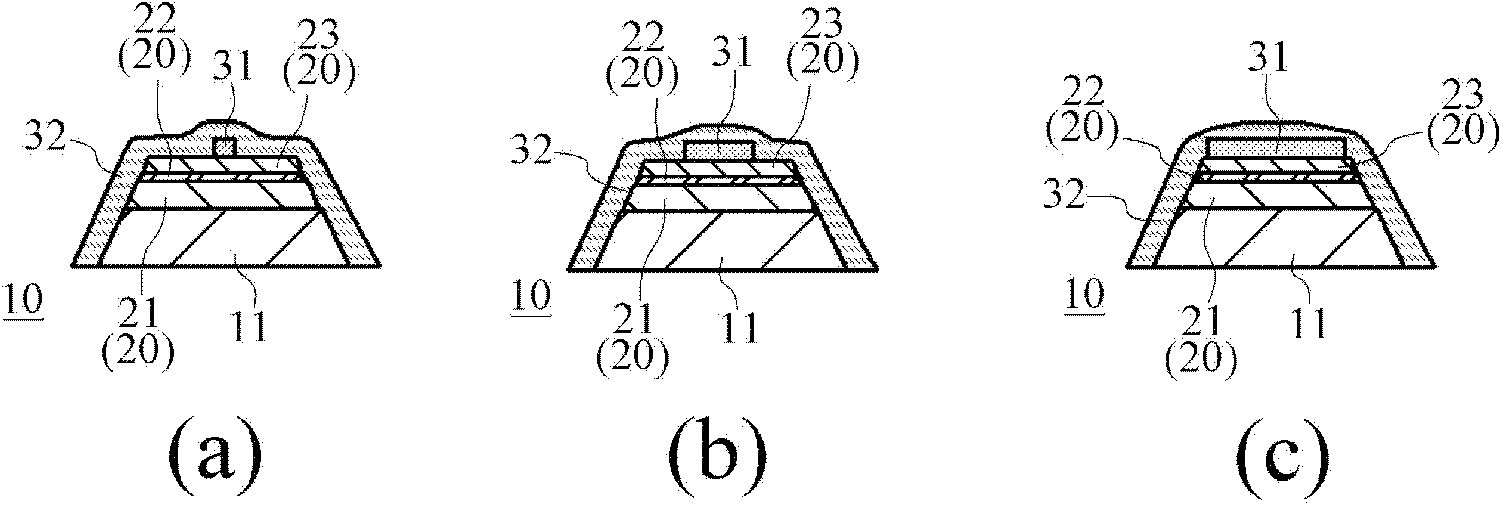

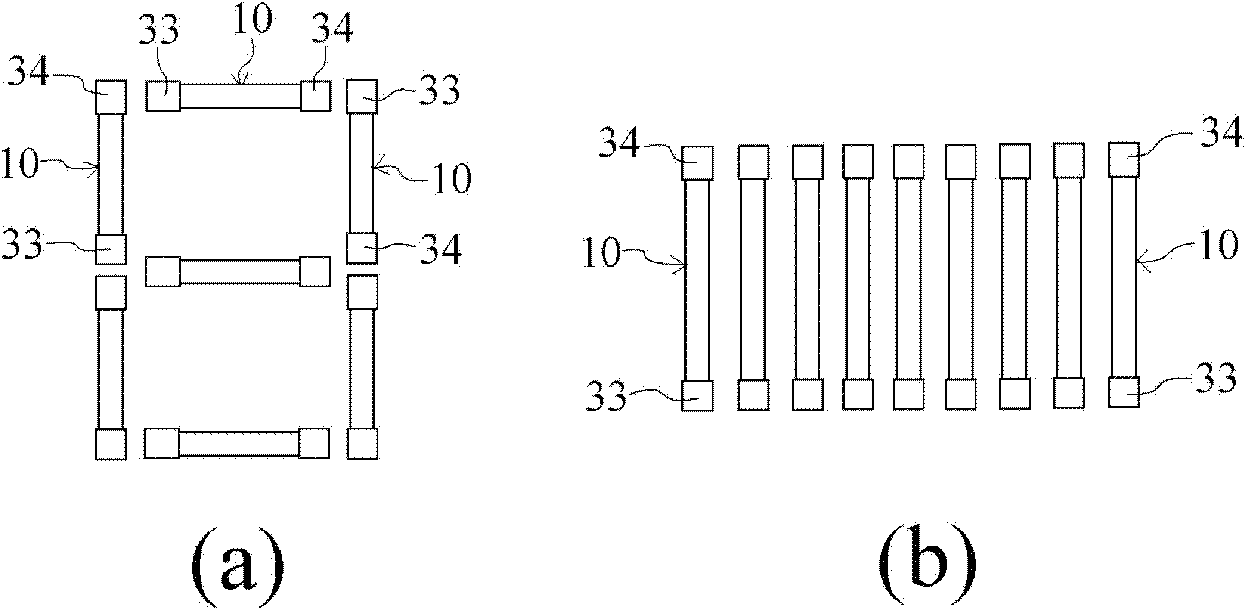

Light-emitting element

ActiveCN102738343AImprove luminous efficiencyUniform luminous intensitySemiconductor devicesParallel ExtensionsEngineering

In a light-emitting element forming two electrodes on one surface of a semiconductor light-emitting function layer, high light-emitting efficiency is obtained, and uniform light-emitting strength is obtained in the surface. In the light-emitting element (10), (1) an n side contact opening (a first opening part) (42) and a p side contact opening (a second opening part) (41) are formed via respectively along two straight lines in parallel extension to two sides (an upper side, a lower side) oppositely disposed in a rectangle, (2) between the two straight lines, a plurality of gaps (transparent electrode opening parts (31)) between transparent electrodes (30) extending along the direction perpendicular to the two straight lines are formed, and therefore, uniformity of current without increase of light-shielding area is performed, and light-emitting uniformity is realized.

Owner:SANKEN ELECTRIC CO LTD

Illumination device

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

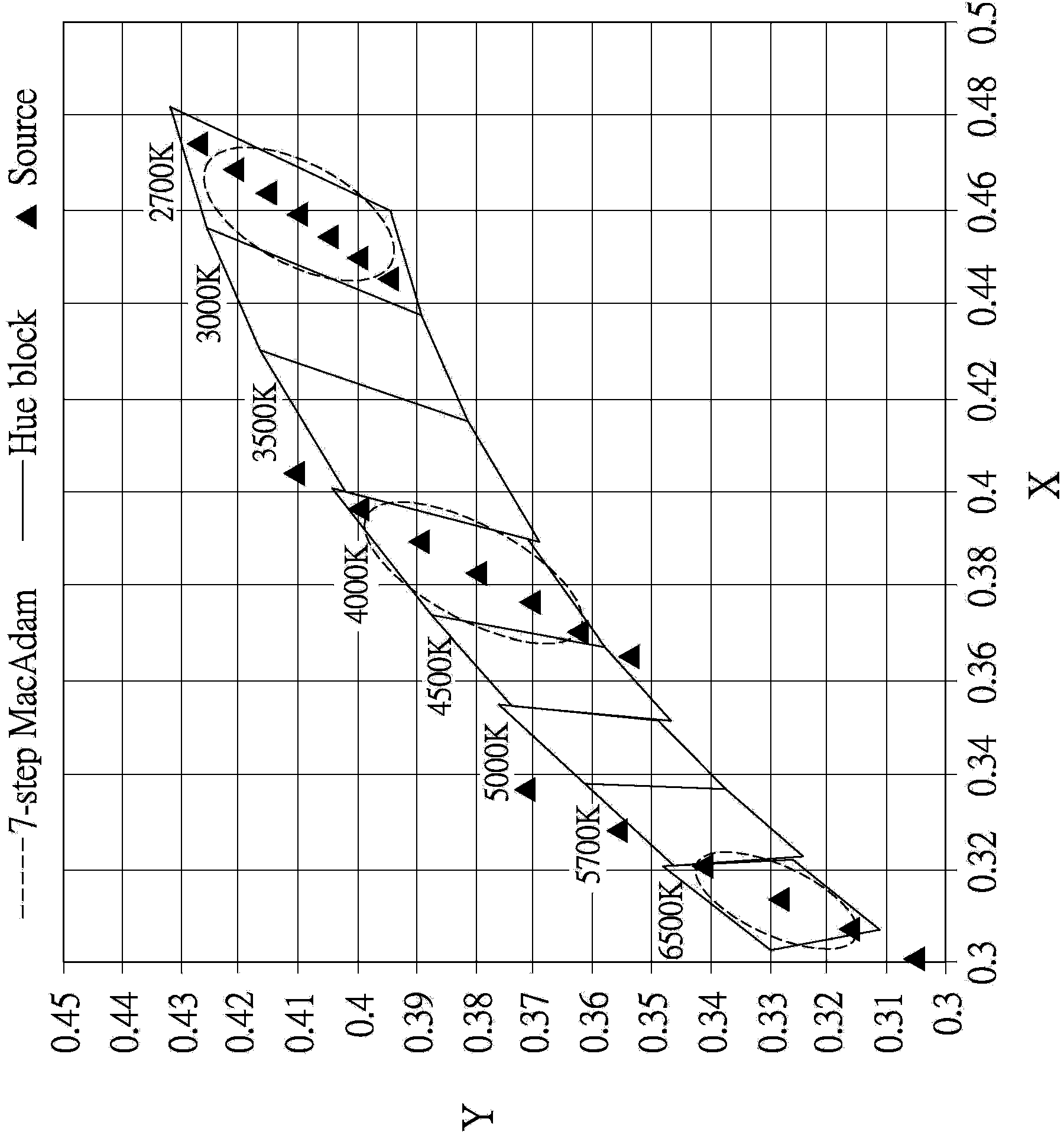

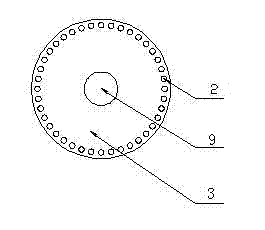

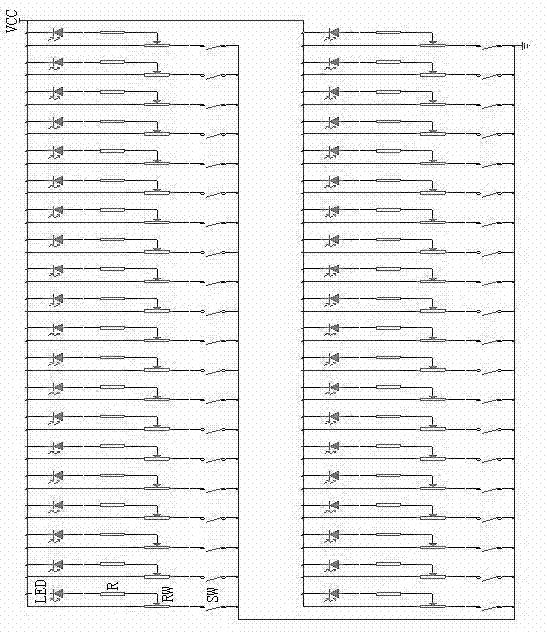

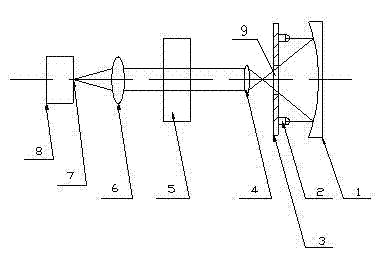

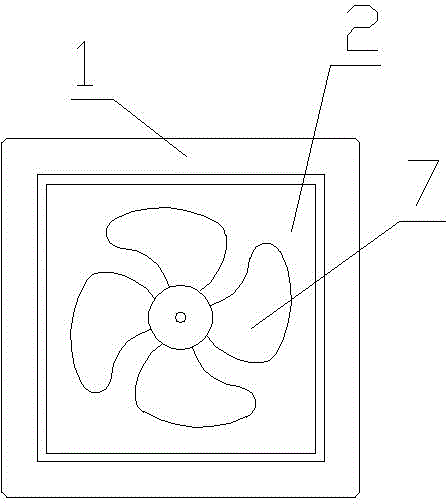

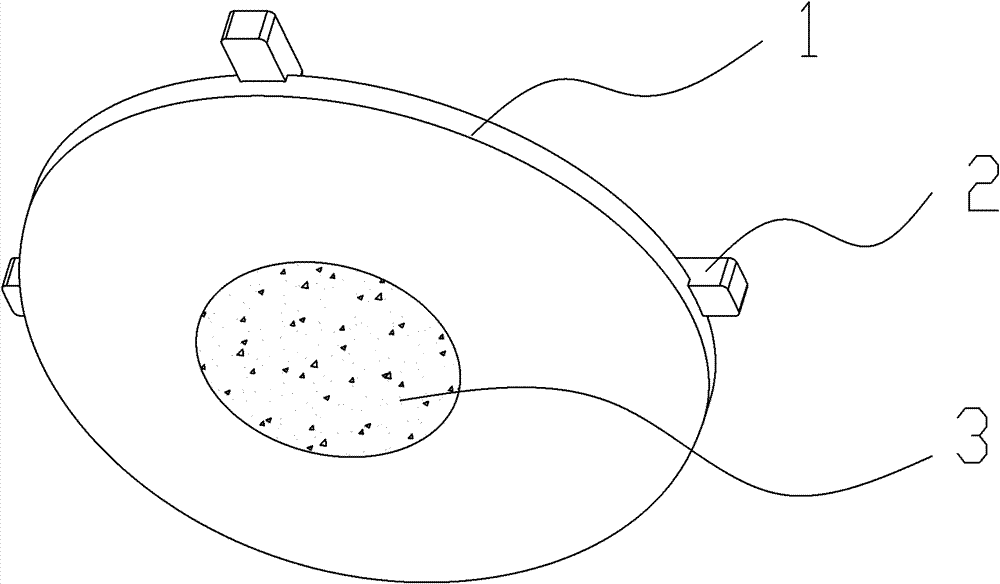

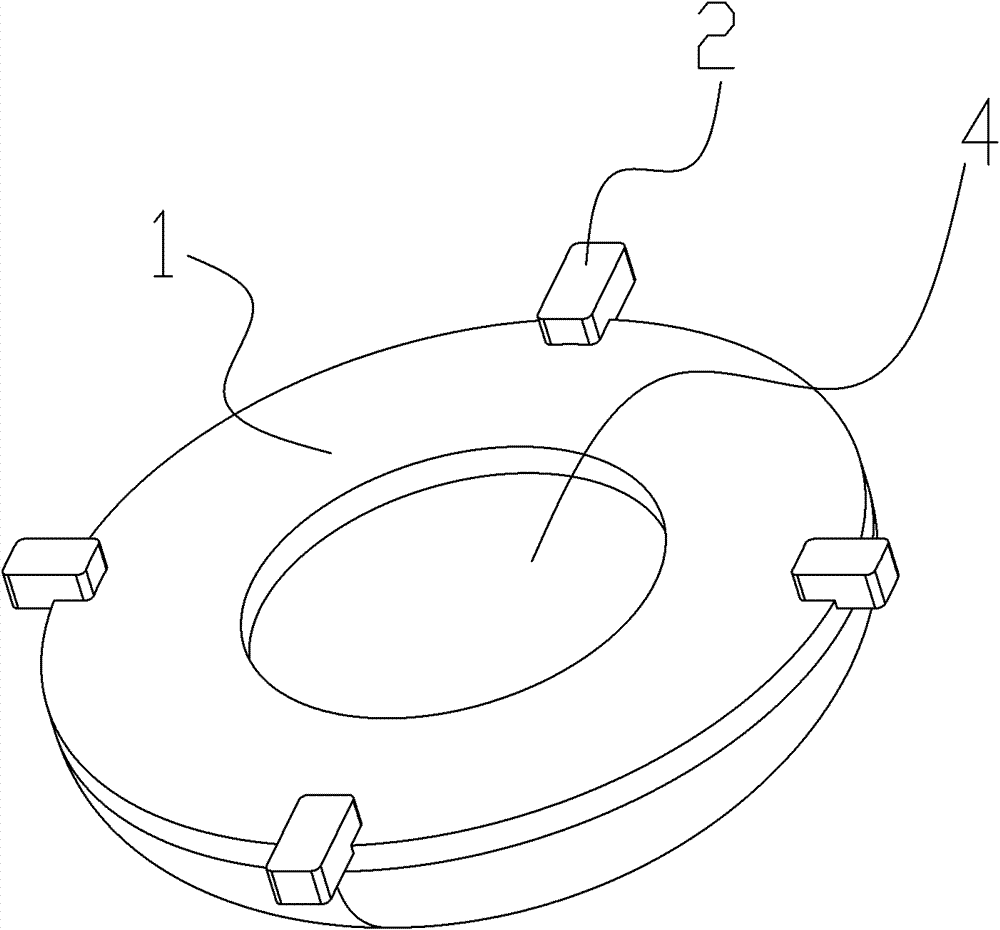

Arrayed LED area light source

InactiveCN102767766AUniform luminous intensityGood thermal stabilityPoint-like light sourceColor/spectral properties measurementsLight sourceOptoelectronics

An arrayed LED area light source belongs to the field of optical detection and is capable of vertically illuminating sample solution. Arrayed LEDs are mounted on one surface of a circuit board, a circular hole is reserved at the center of the circuit board, a concave reflector is mounted on one surface, mounted with the LEDs, of the circuit board, a front convex lens is arranged on the other surface of the circuit board, a sample reservoir is arranged between the front convex lens and a rear convex lens, a light-splitting optical system is arranged behind the rear convex lens, and a slot is reserved on the light-splitting optical system. By above technical scheme, the arrayed LED area light source has the advantages that a plurality of LEDs are utilized as light sources to combine the arrayed LED area light source; is uniform in luminous intensity, good in heat stability and long in service life; and improves detection accuracy of the sample solution when being matched with a double focusing optical system. The arrayed LED area light source can be widely used to a detecting instrument of a light-splitting system.

Owner:CHANGCHUN MATTEL INSTR

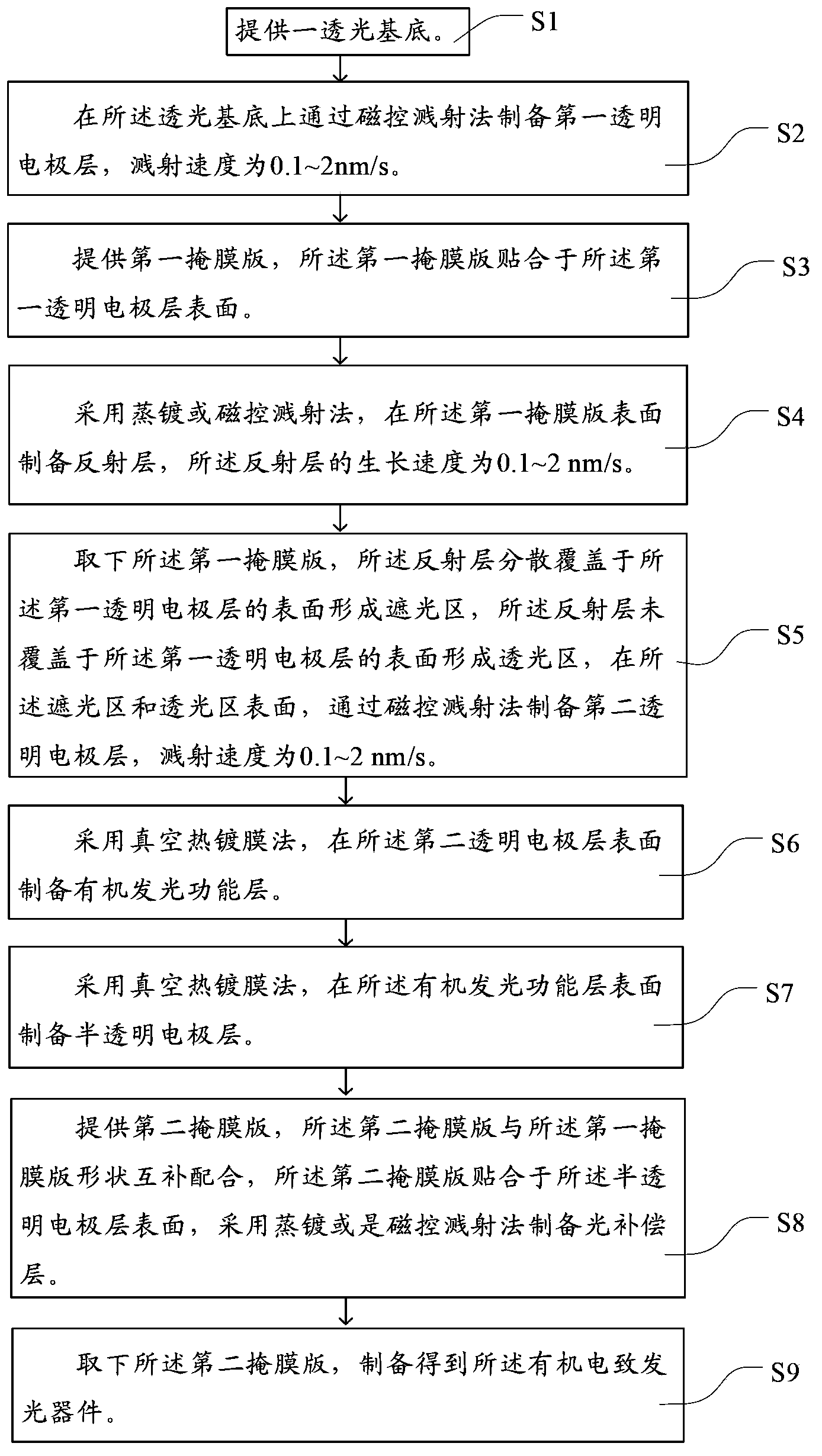

Organic light-emitting device and manufacturing method of organic light-emitting device

InactiveCN104218158AStrong uniformityUniform luminous intensityFinal product manufactureSolid-state devicesOrganic electroluminescenceOptoelectronics

The invention discloses an organic light-emitting device. The organic light-emitting device comprises a light-transmitting substrate, a first transparent electrode layer, a reflecting layer, a second transparent electrode layer, an organic light-emitting functional layer, a semitransparent electrode layer and a light compensating layer which are laminated in sequence, wherein the light-transmitting substrate comprises a first light-emitting surface and a covering surface which are arranged oppositely; the first transparent electrode layer covers the covering surface; the reflecting layer covers the surface of the first transparent electrode layer in a scattered manner, thereby forming a light-shielding region; the area ratio of the reflecting layer to the first transparent electrode layer is 20-80 percent; the surface of the reflecting layer not covering the first transparent electrode layer forms a light-transmitting region; the second transparent electrode layer covers the light-shielding region and the light-transmitting region; the organic light-emitting functional layer covers the surface of the second transparent electrode layer; the semitransparent electrode layer covers the surface of the organic light-emitting functional layer; and the light compensating layer only covers the surface of the semitransparent electrode layer corresponding to the light-transmitting region. The two light-emitting surfaces of the organic light-emitting device are uniform and consistent in light-emitting intensity. The invention further discloses a manufacturing method of the organic light-emitting device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

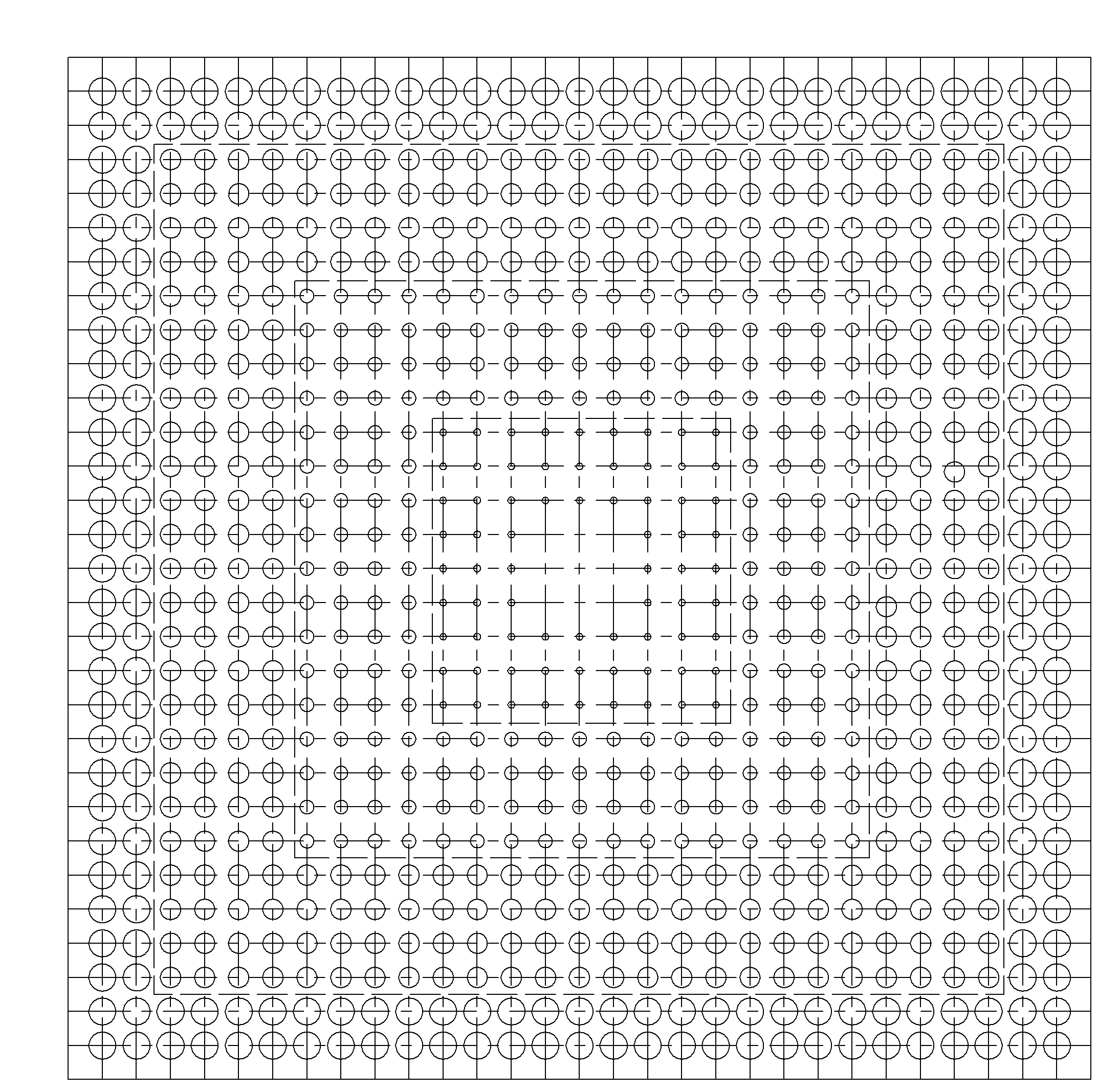

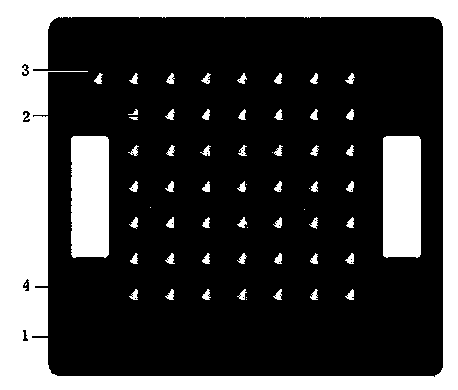

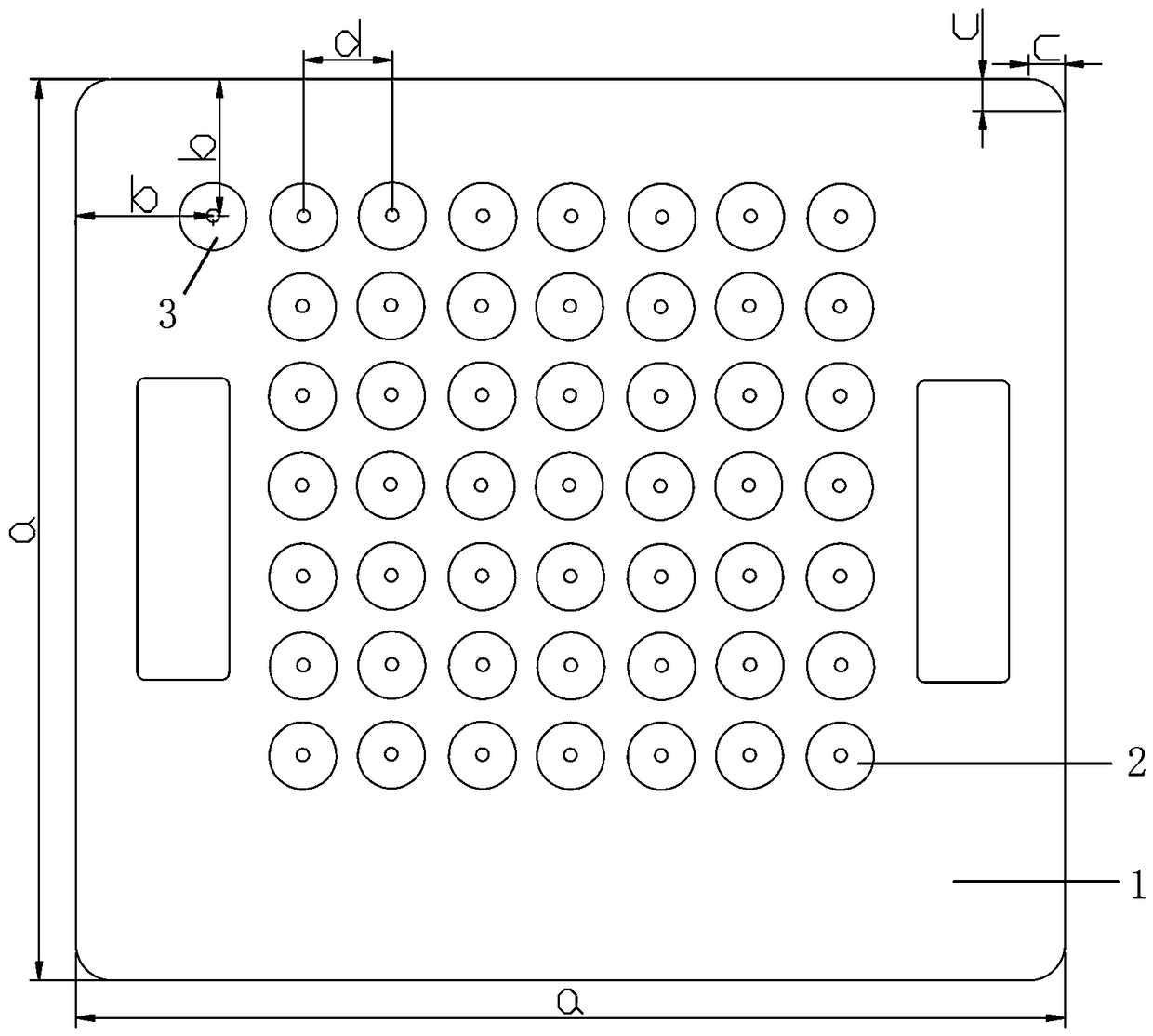

Infrared camera parameter calibration plate

The invention relates to the field of optical measurement, and in particular relates to an infrared camera parameter calibration plate. The infrared camera parameter calibration plate comprises a lighttight substrate, wherein a round hole array M*N is arranged on the substrate, and the rows and columns are perpendicular. The infrared camera parameter calibration plate is characterized by also comprising a positioning hole, wherein the positioning hole is arranged at one corner of the round hole array, and reflecting cloth is arranged in round holes of the round hole array. The substrate is a square aluminum alloy plate with a certain thickness, and thus is not prone to deform. From the surface of the substrate to the position that is 0.01mm-0.5mm away from the back of the substrate, the diameters of the round holes are gradually reduced from the surface to the inside along the thickness direction of the substrate. The invention aims at providing the passive light emitting infrared light source calibration plate that is simple in structure, convenient to use, high in manufacturing accuracy and long in service life, and can accurately calibrate the internal and external parameters ofthe infrared camera.

Owner:广东省医疗器械质量监督检验所

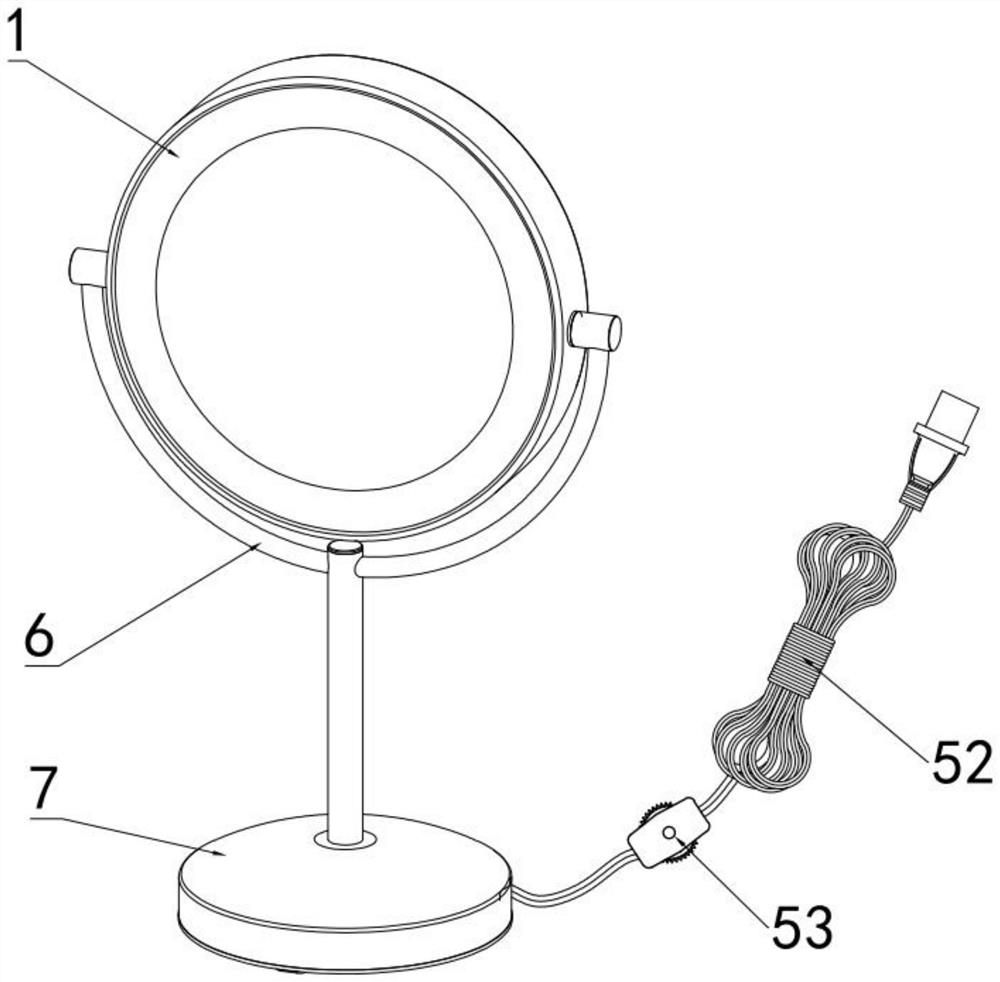

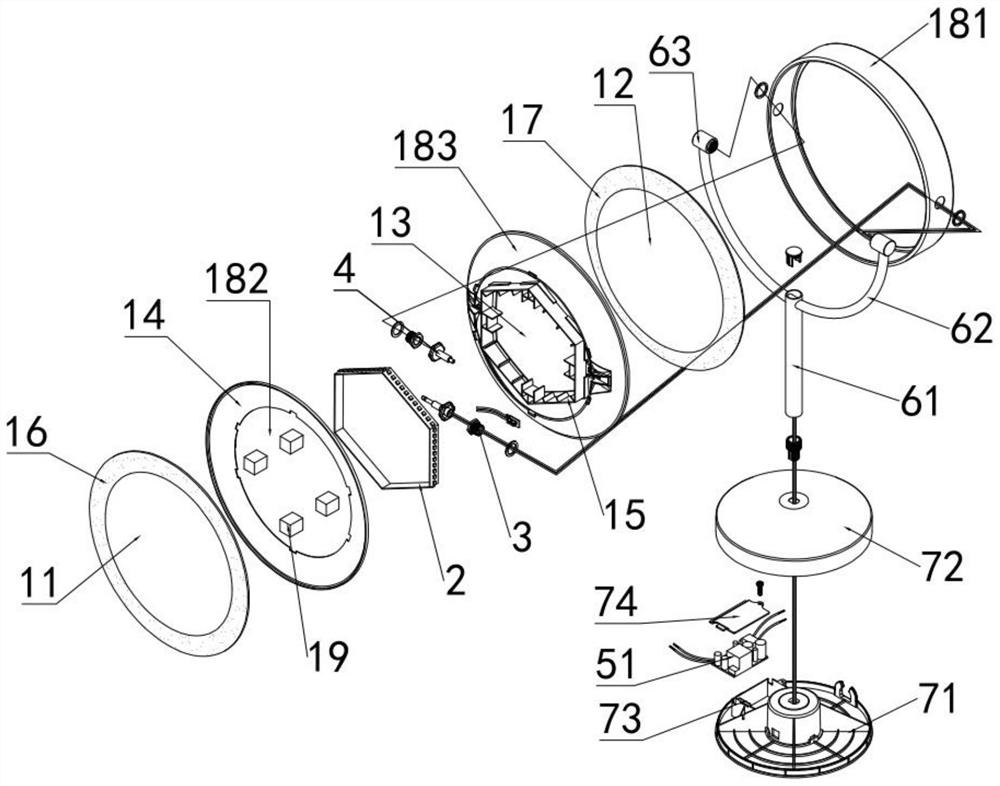

Mirror lamp

ActiveCN111637427AEasy to useNot prone to power outage flashing problemsPicture framesElectric circuit arrangementsTransformerEngineering

The invention discloses a mirror lamp. The mirror lamp includes a base component with a built-in transformer, a mirror frame component, and a light-emitting component arranged inside the mirror framecomponent; both ends of the mirror frame component are separately provided with T-nuts and are installed on the base part so that the mirror frame component can be rotated in 360 degrees; conductive components are arranged on one or two of the T-shaped nuts; the conductive components are electrically connected to the transformer; and the transformer is electrically connected to an external power line. In the invention, the conductive component is inserted through the T-shaped nut, so that the mirror frame component can be rotated in 360 degrees to adjust the angle at will without twisting thewire or power off, which ensures the stable use of the mirror lamp; if a group of conductive component is installed, two wire energization of the light-emitting component can be realized; and if two groups of conductive components are installed, the color temperature can be adjusted while realizing energization, and therefore, the color temperature of the mirror surface can be adjusted according to the actual use scene, so that the mirror frame component has good light-emitting performance.

Owner:东莞市觅智智能家居有限公司

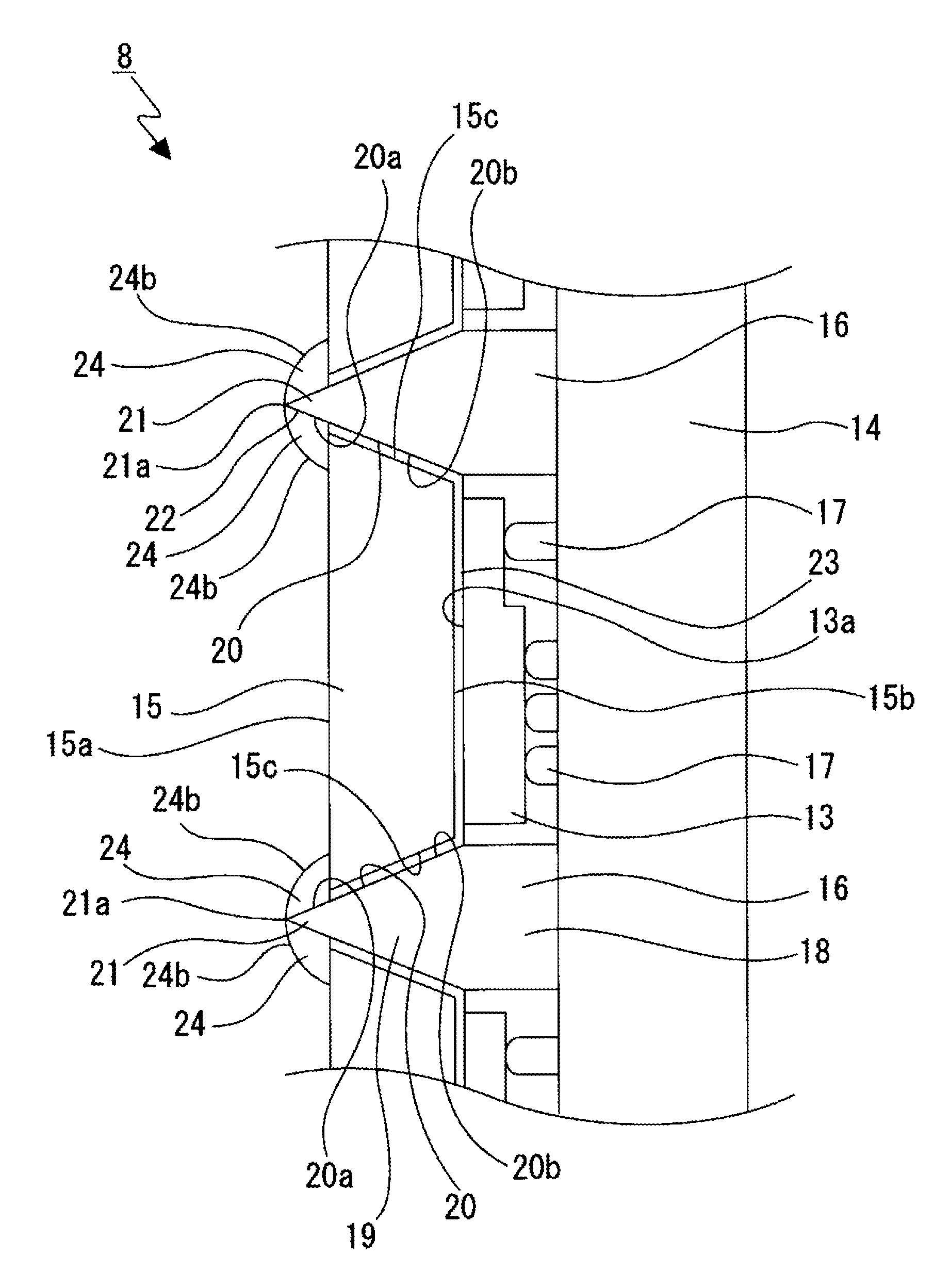

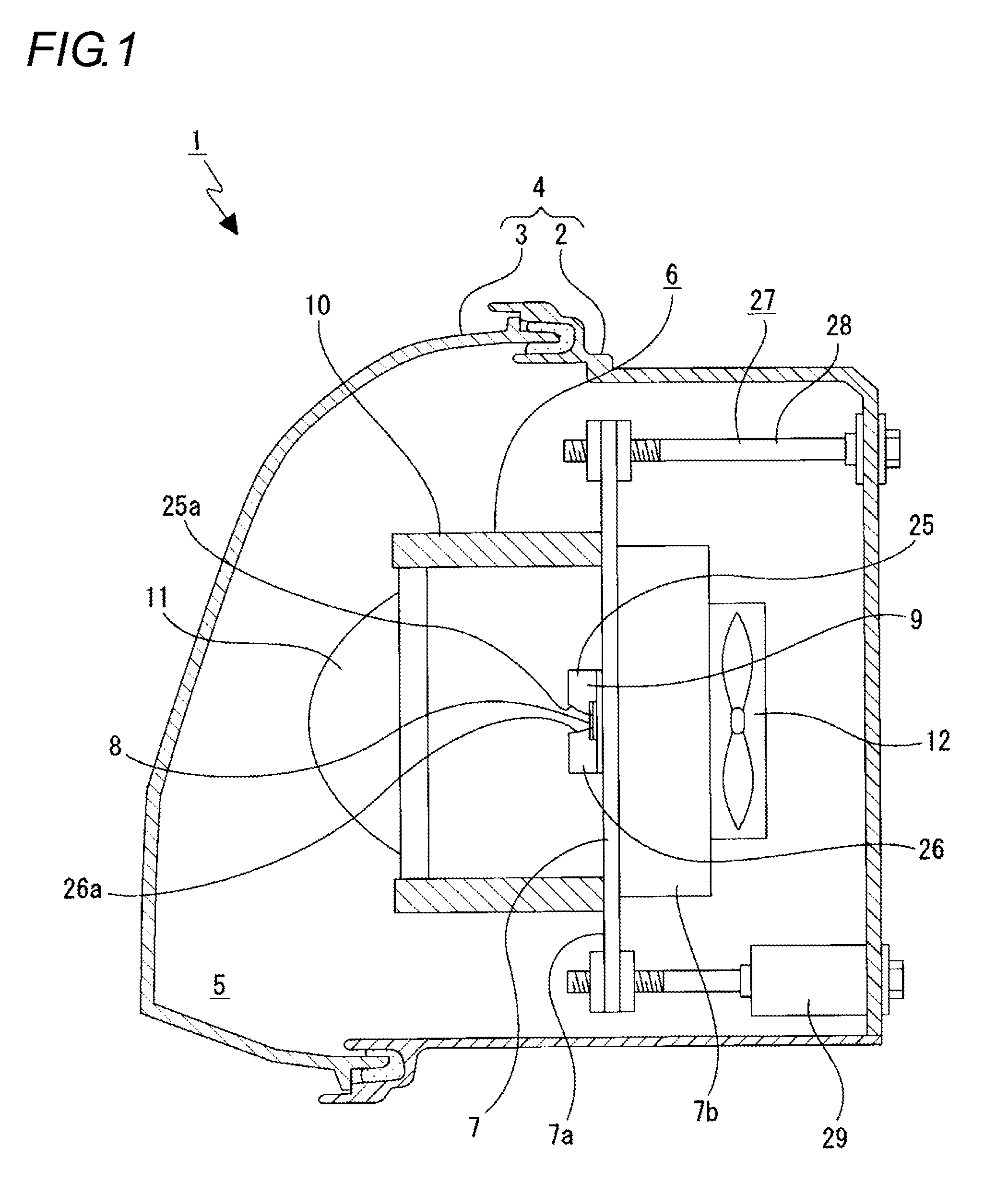

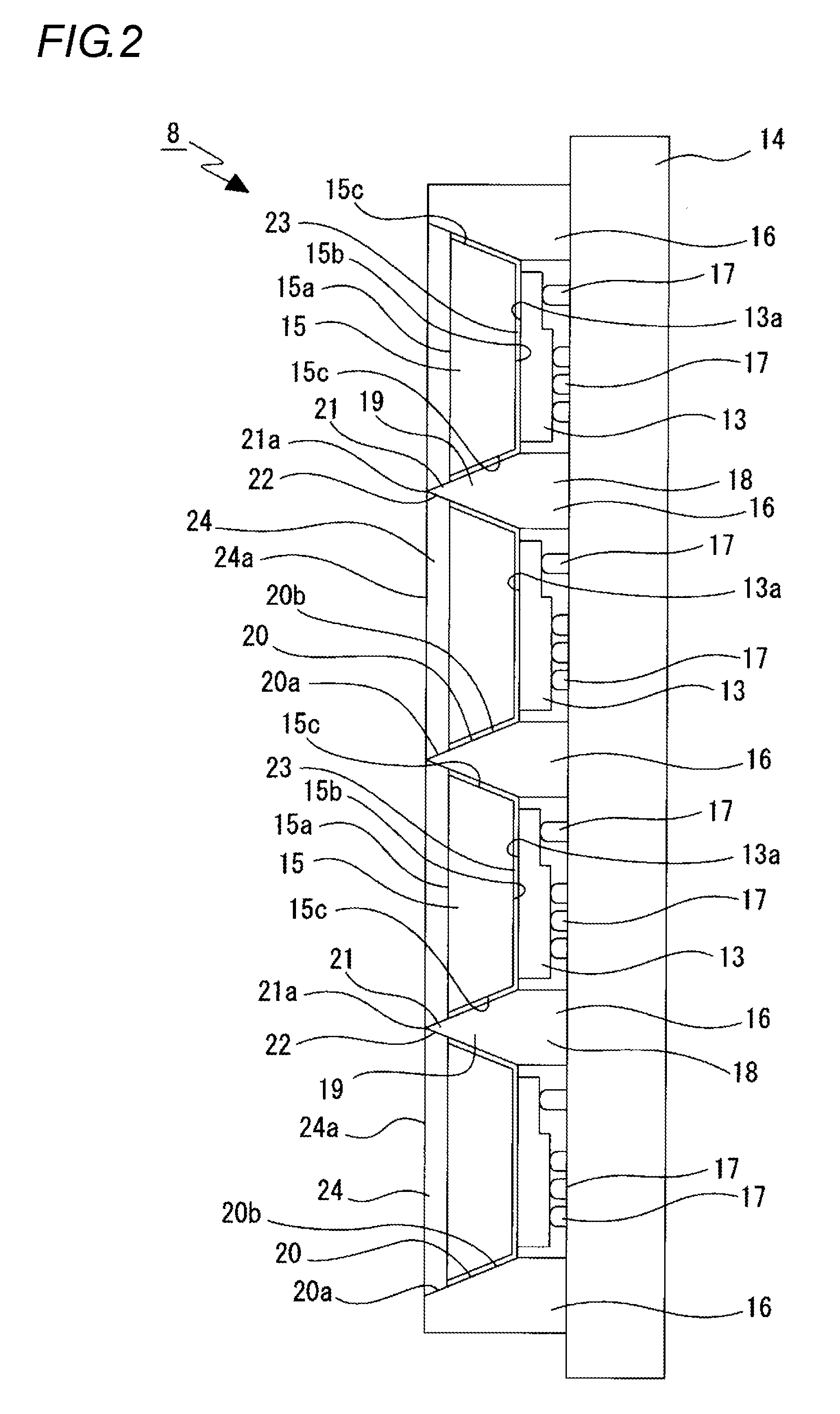

Light emitting module

InactiveUS9349926B2Increase the number ofReduce the differenceVehicle headlampsSolid-state devicesLength waveSemiconductor

There are provided a light emitting module including a luminescent material layer (15) which is disposed so as to cover a light emitting surface (13a) of a semiconductor light emitting element (13) and which changes a wavelength of at least part of light emitted from the semiconductor light emitting element, and a light shielding wall (16) which surrounds the semiconductor light emitting element and the luminescent material layer from the circumference thereof, and the luminescent material layer is bonded to the semiconductor light emitting element and the light shielding wall with a bonding resin (23) having a light transmittivity, a distal end portion of the light shielding wall is caused to project further forwards than the luminescent material layer, and a transparent resin (24) is applied so as to cover an exposed surface (20a) of a distal end portion (21) of the light shielding wall.

Owner:KOITO MFG CO LTD

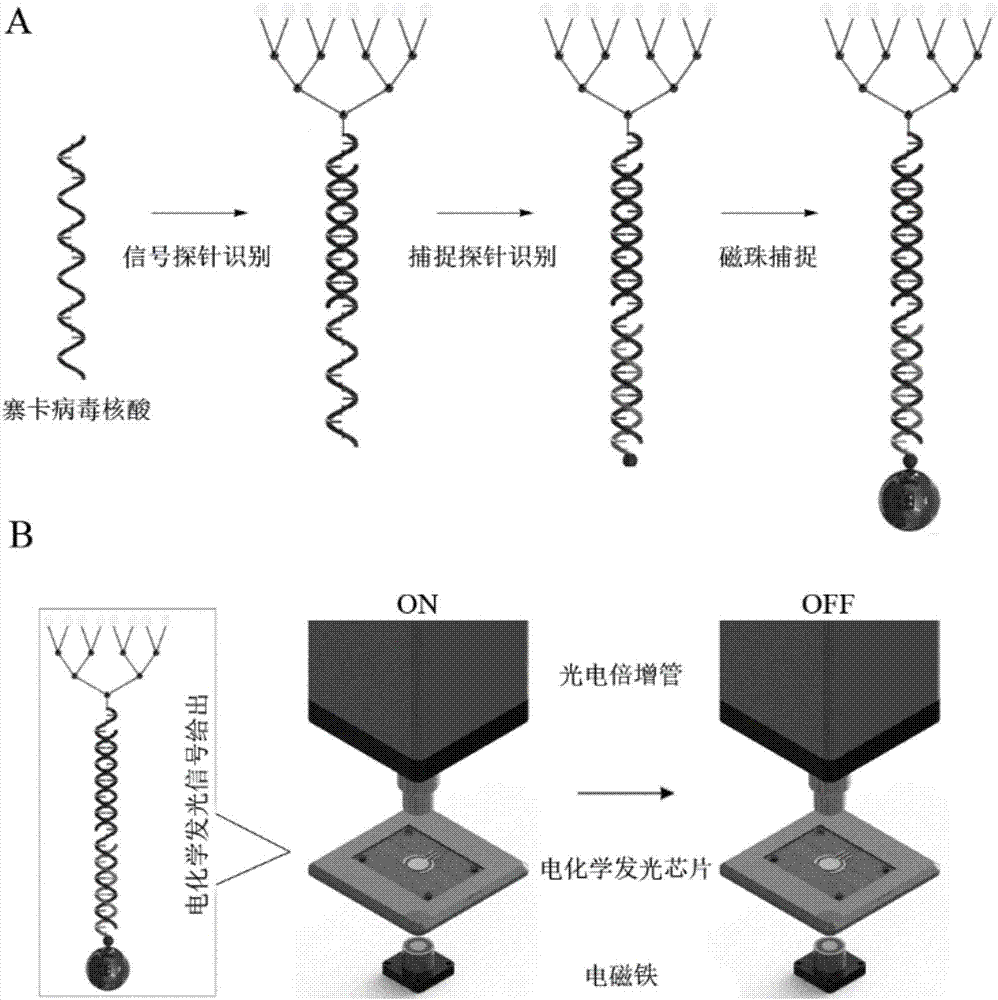

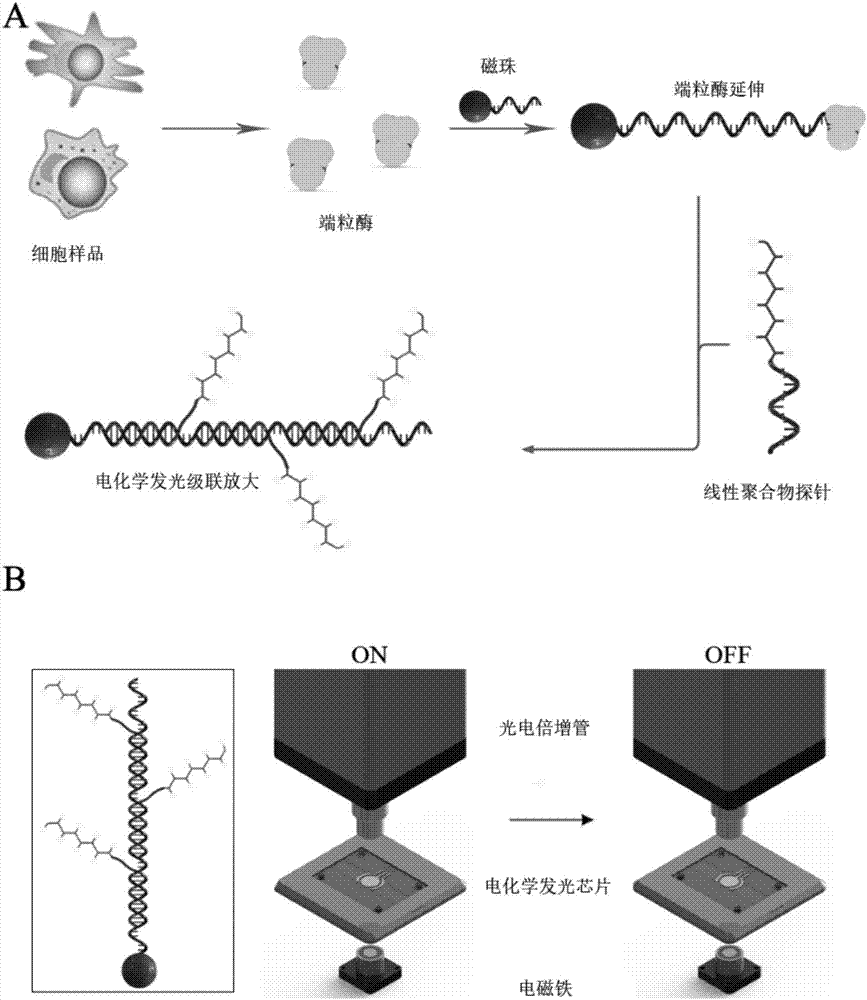

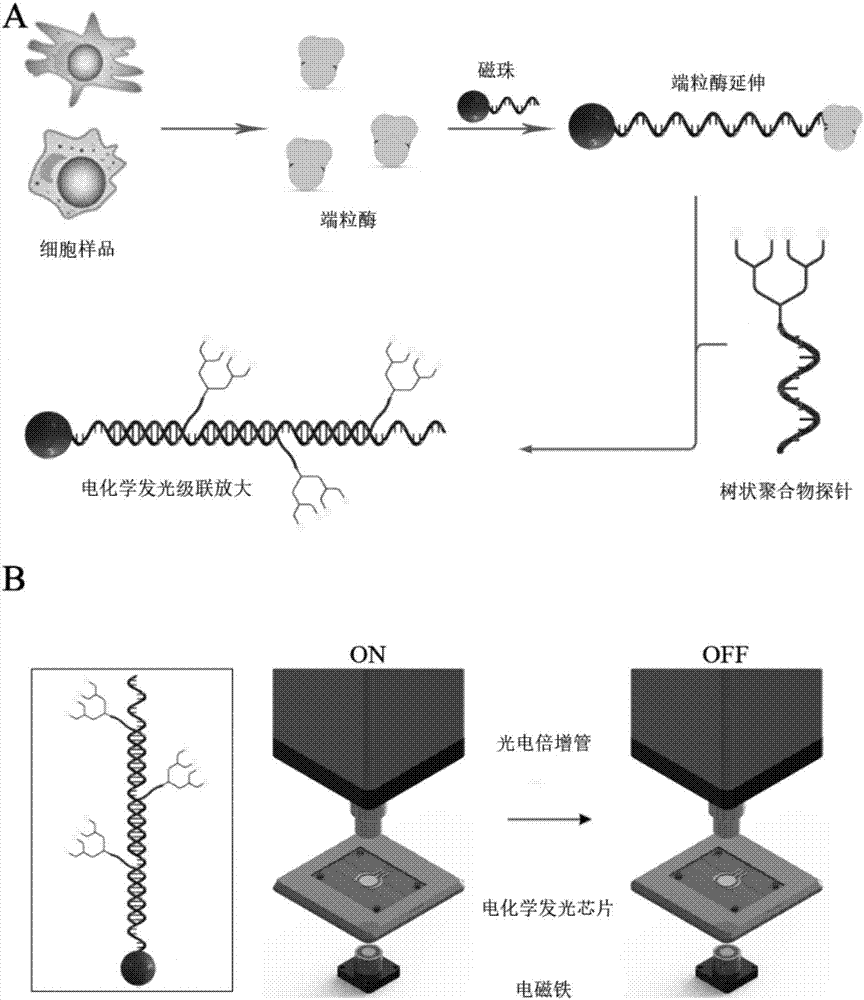

Telomerase activity detection method based on electrochemical luminescence cascade amplification principle

ActiveCN107488723AHigh sensitivityTo achieve the purpose of high sensitivity detectionMicrobiological testing/measurementTelomeraseRuthenium

The invention discloses a telomerase activity detection method based on an electrochemical luminescence cascade amplification principle, which belongs to the technical field of telomerase activity detection. The invention provides the high-sensitivity telomerase activity detection method based on the electrochemical luminescence cascade amplification principle by utilizing performance that telomerase can execute adding a repetitive sequence and combining an electrochemical luminescence amplifying signal group linearity and arborescence terpyridyl ruthenium polymer electrochemical luminescence method. The method provided by the invention has the following advantages of (1) high sensitivity; (2) probe stability: wherein a linear and arborescence terpyridyl ruthenium polymer is used as an electrochemical luminescence amplification part of a probe, the performance is stable, and the polymerization degree and the luminescent intensity are uniform; (3) simple and fast detection process: wherein telomerase activity monitoring can be carried out through a simple telomerase extracting process, the time consumption is short, an amplification step is saved, and the detection is carried out quickly; (4) low cost.

Owner:SUN YAT SEN UNIV

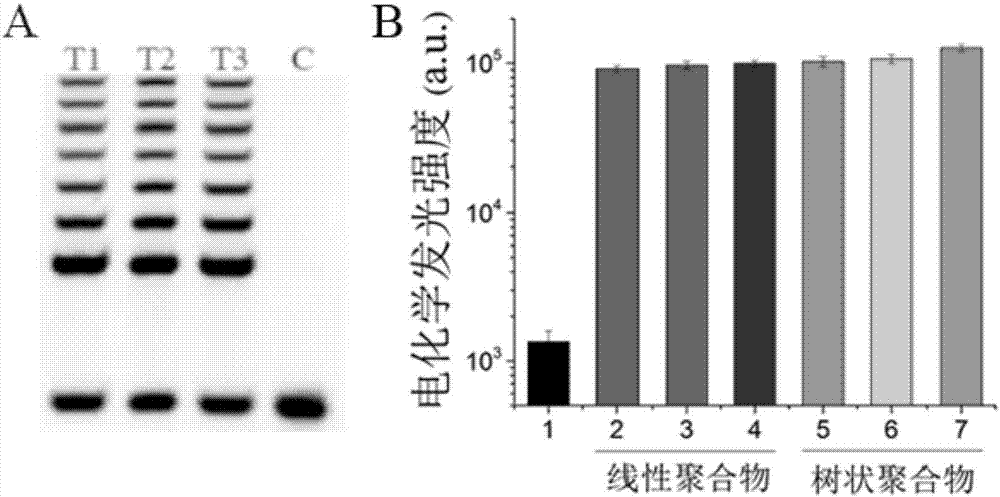

UV LED (ultraviolet light-emitting diode) curing light for printing

ActiveCN104908417APrevent shrinkageUniform luminous intensityPrinting press partsLuminous intensityImage transfer

The invention relates to the technical field of curing, in particular to a UV LED (ultraviolet light-emitting diode) curing light for printing. The UV LED curing light for printing comprises a lamp cover; a substrate is arranged in the lamp cover; the substrate is provided with a plurality of ultraviolet lights; the ultraviolet lights are rhombic; four end points of each rhombic ultraviolet light are respectively provided with a UV LED chip. The UV LED curing light disclosed by the invention has the following advantages: 1, by adopting the rhombic ultraviolet lights with the UV LED chips, the parallel half angle of light source projection is less than 2 degrees, and the luminous intensity is more uniform; 2, compared with a traditional mercury light, the UV LED curing light has the advantages that the energy is saved by 80 percent, a light tube does not need to be replaced, and cooling water is not needed; the UV LED curing light can be turned on and off, and has no stand-by losses; 3, the UV LED curing light does not contain infrared rays, film expansion and contraction is avoided, and the image transfer quality is improved; 4, the UV LED curing light does not contain mercury, ozone cannot be generated, and the pollution is small; 5, the service life exceeds 10000 hours, and the property is stable.

Owner:温州鸣旭机械科技有限公司

Light emitting unit with reflector for uniform light emission

InactiveUS9157603B2Improve lighting qualityReduce the overall heightPoint-like light sourceElongate light sourcesLight beamLight emission

Owner:CORETRONIC

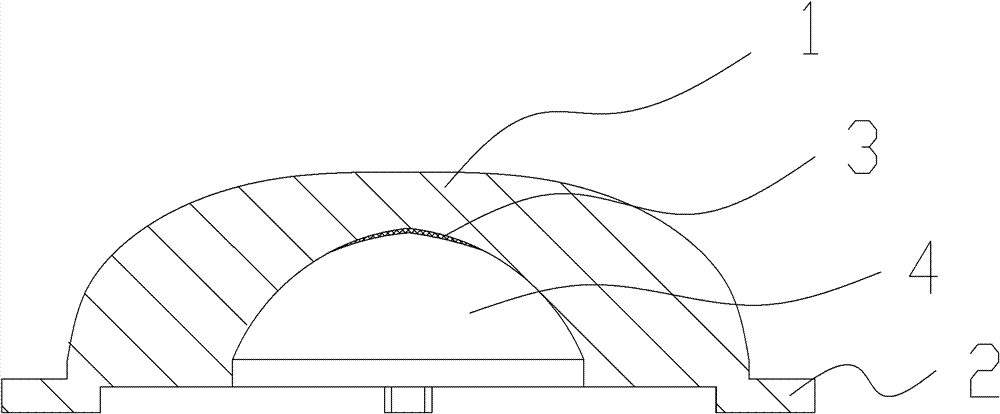

Wide-angle LED (light-emitting diode) bulb lamp shade

InactiveCN102734743ALarge light angleLight evenlyPoint-like light sourceGlobesLight emissionLight reflection

The invention relates to an LED (light-emitting diode) lamp, particularly a wide-angle LED bulb lamp shade which comprises a hemispherical lens body, wherein the center of sphere of the hemispherical lens body is provided with a hemispherical lamp trough matched with an LED lamp; the surface of the hemispherical lens body is completely or partially provided with a partial-transmission / partial-reflection half-reflection cambered surface; and from the center to the periphery, the light transmission of the half-reflection cambered surface gradually increases, and the light reflection gradually decreases. By using the invention, the LED bulb lamp has the advantages of wider light emitting angle and uniform light emission.

Owner:SHENZHEN BAIKANG OPTICAL

Luminescent glass capable of light control and automatic lightening

InactiveCN108235527AImprove luminous efficiencyReduce energy consumptionElectrical apparatusElectroluminescent light sourcesConductive materialsOxygen

The present invention discloses luminescent glass capable of light control and automatic lightening. The glass comprises an ITO glass substrate, transparent conductive materials, a transparent luminescence unit, a transparent metal electrode, transparent packaging materials and a control circuit. The transparent conductive materials are deposited on the ITO glass substrate, the transparent luminescence unit is arranged on the transparent conductive materials, and the transparent conductive materials are provided with the transparent metal electrode; the transparent packaging materials are configured to package the transparent metal electrode, the transparent luminescence unit and the transparent conductive materials on the ITO glass substrate; and the control circuit penetrates the transparent packaging materials and is connected with the transparent metal electrode and the transparent conductive materials. The luminescent glass capable of light control and automatic lightening is accessed into a circuit of reverse voltage supply to generate current signals in the circuit under the ultraviolet irradiation, and the circuit maintains reserve voltage supply. The transparent packagingmaterials have the main functions of avoiding erosion of the transparent conductive materials, the transparent luminescence unit and the transparent metal electrode under a water oxygen environment and avoiding damaging caused by external forces.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Scanning electron microscope and image signal processing method

ActiveUS8362426B2Uniform luminous intensityMaterial analysis using wave/particle radiationElectric discharge tubesLuminous intensityScanning tunneling microscope

The SEM has a dynamic range reference value setting unit for setting dynamic range reference values, a dynamic range adjustment unit for receiving an observation image signal delivered out of a secondary electron detector, adjusting the dynamic range of the observation image signal on the basis of the dynamic range reference values and outputting the thus adjusted observation image signal as an observation image signal after adjustment, a display image generation unit for determining luminous intensity levels of individual pixels of an image to be displayed based on the observation image signal after adjustment to generate a display image, a histogram generation unit for generating a histogram of luminous intensity levels of the display image and extracting, as a luminous intensity peak value, at which the frequency of luminous intensity is maximized, and a display unit for displaying the generated histogram and the extracted luminous intensity peak value.

Owner:HITACHI HIGH-TECH CORP

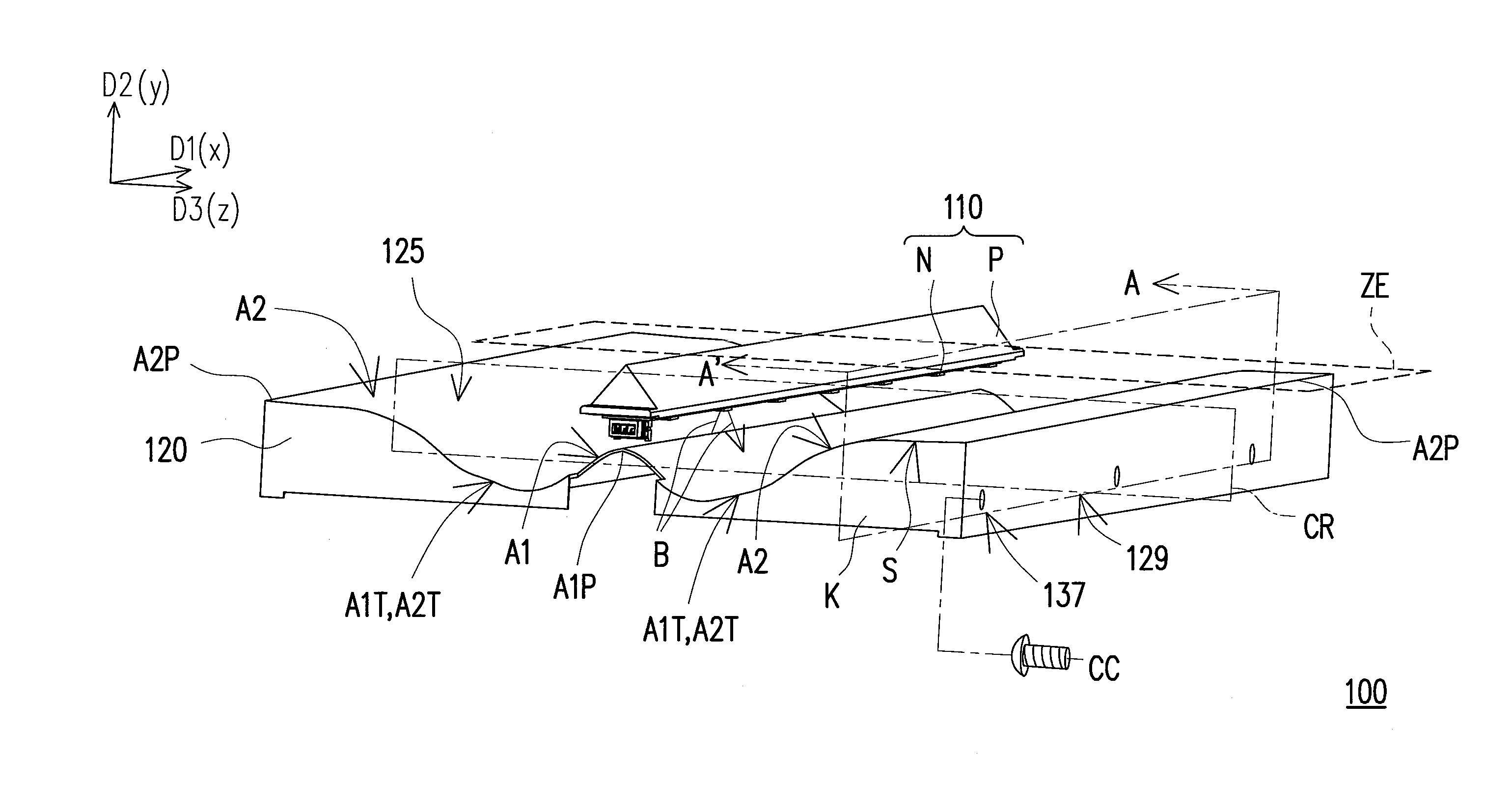

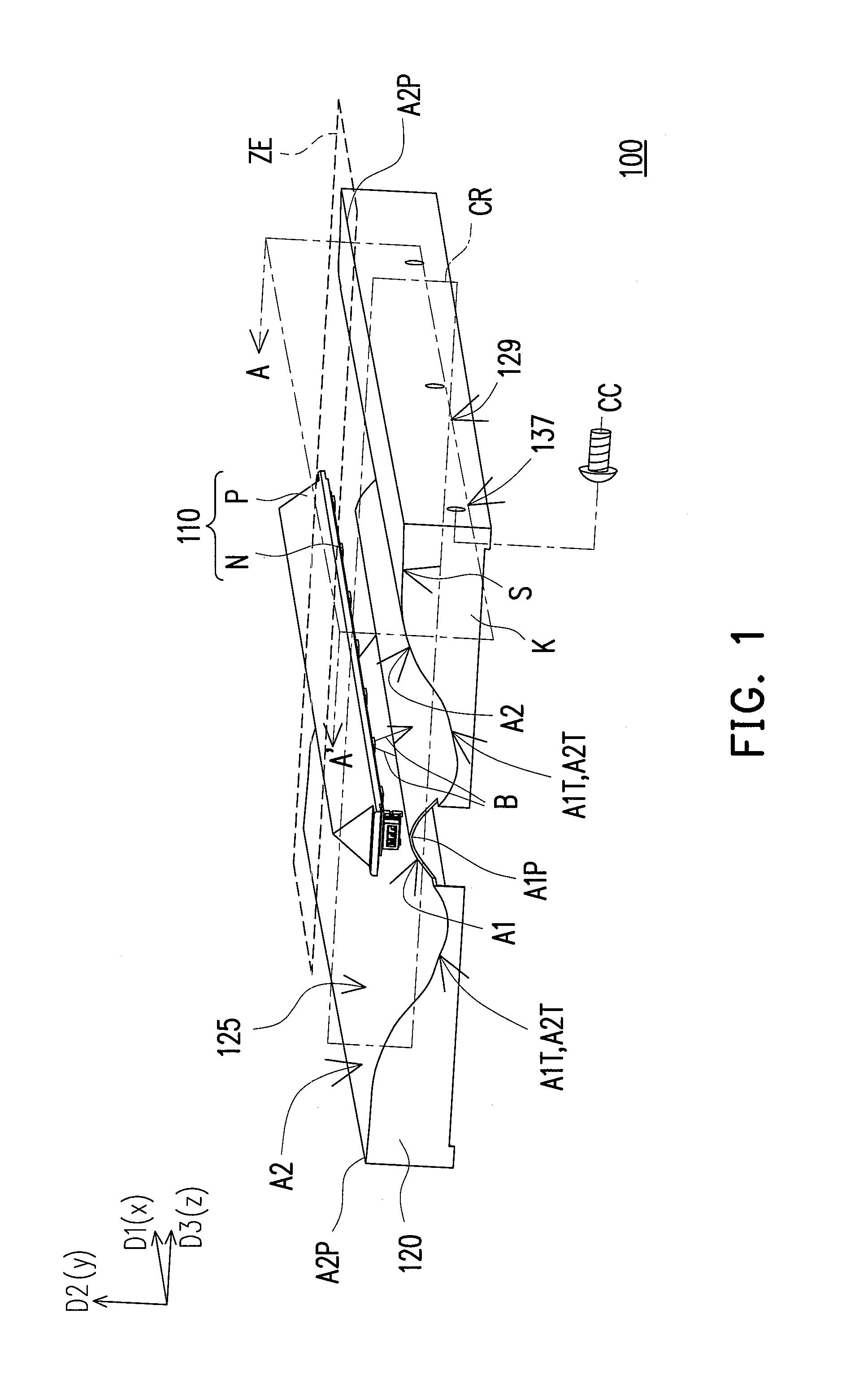

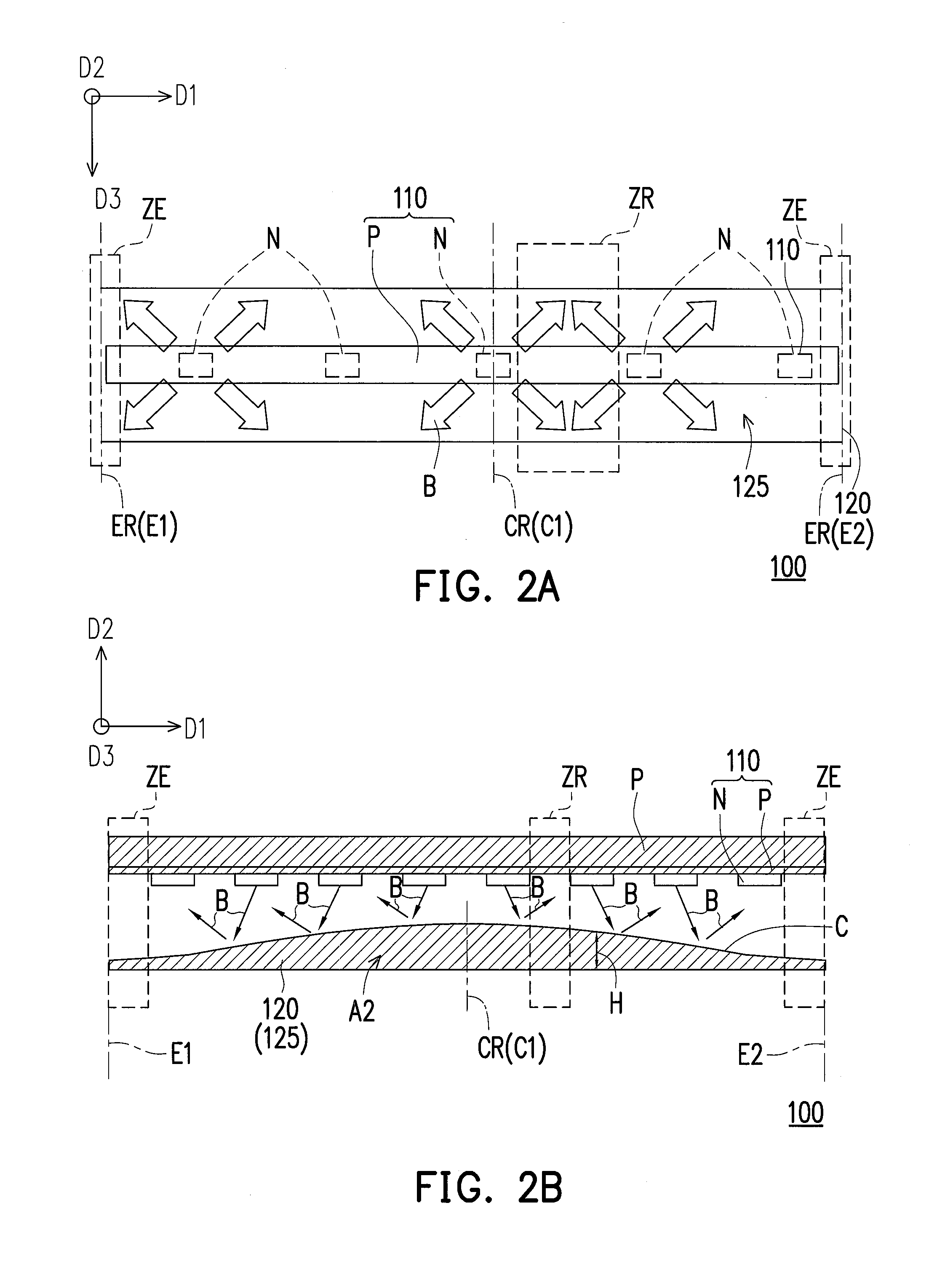

Light emitting unit

InactiveUS20140160750A1Improve lighting qualityReduce the overall heightPoint-like light sourceElongate light sourcesLight beamOptoelectronics

A light emitting unit includes a light source device and a reflector. The light source device extends in parallel with an extension direction, and is capable of providing a light beam. The reflector is configured under the light source device and extends in parallel with the extension direction. The reflector has a first protrusion and a pair of second protrusions located on two sides of the first protrusion, the first protrusion has a peak portion and two trough portions, the second protrusion has a peak portion and a trough portion, and the two trough portions of the first protrusion are respectively connected to the trough portions of the two second protrusions to provide a fluctuant reflection surface, and a height of a cross section contour of the pair of the second protrusions in parallel with the extension direction is decreased from a centre to two ends of the reflector.

Owner:CORETRONIC

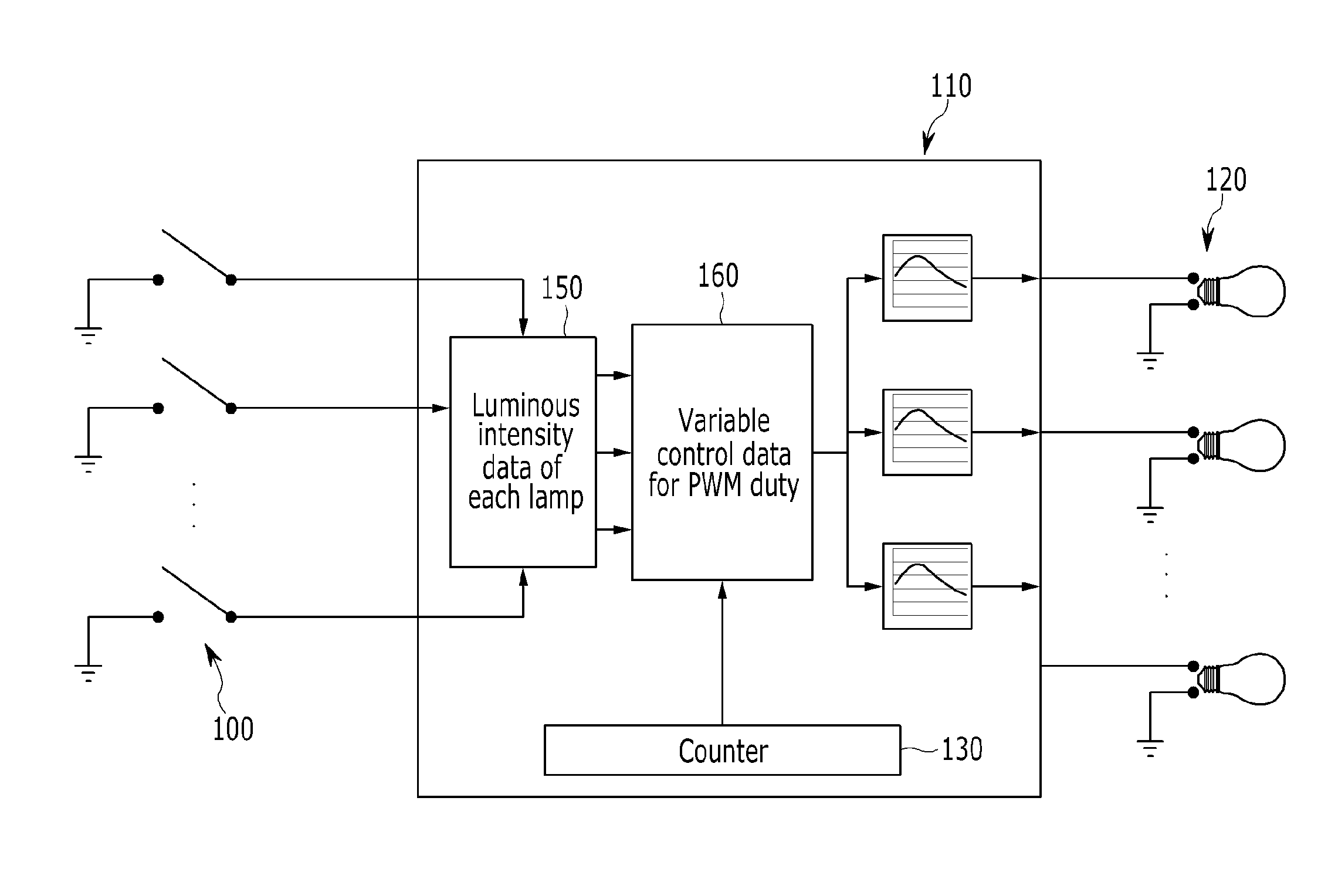

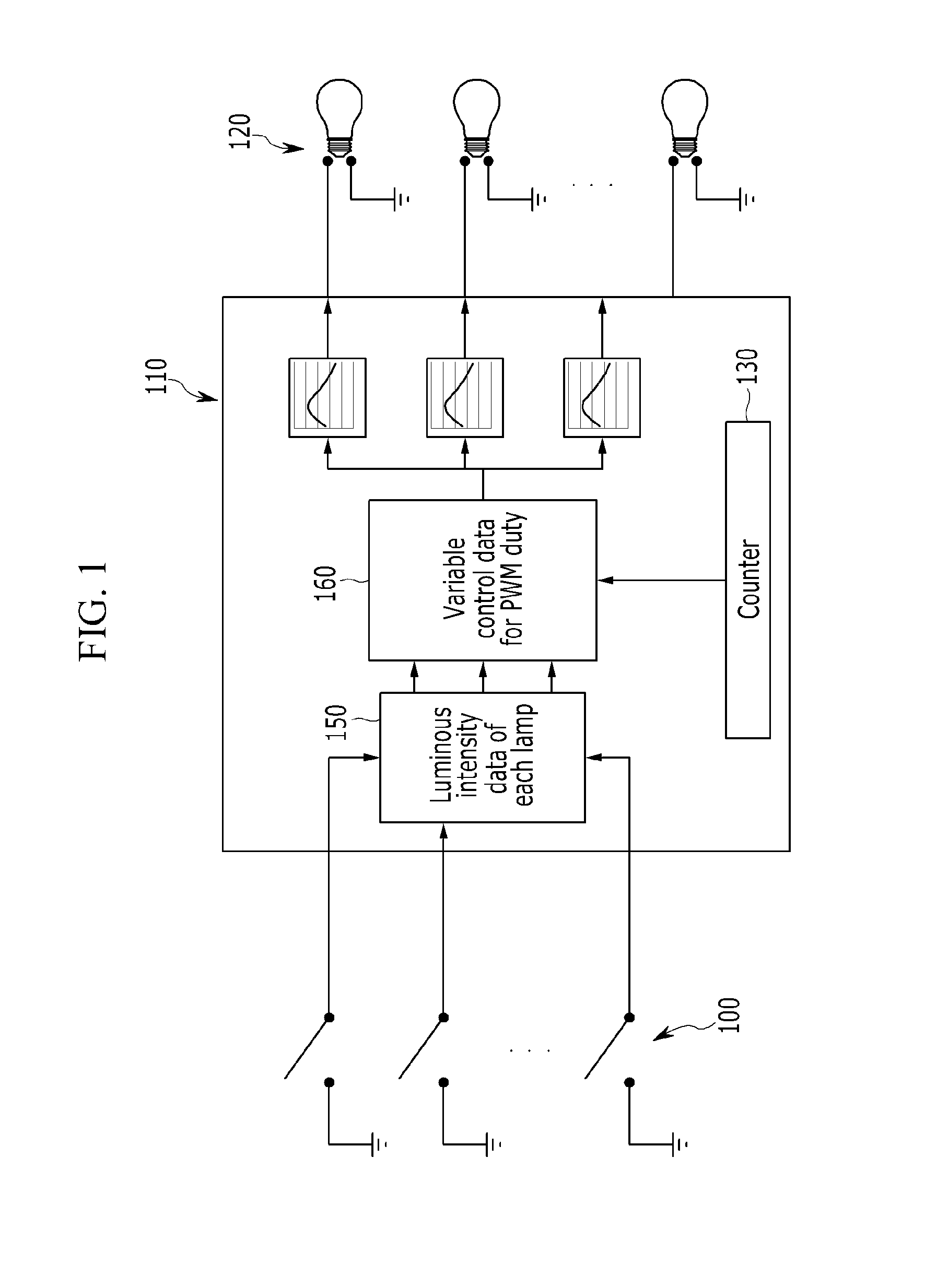

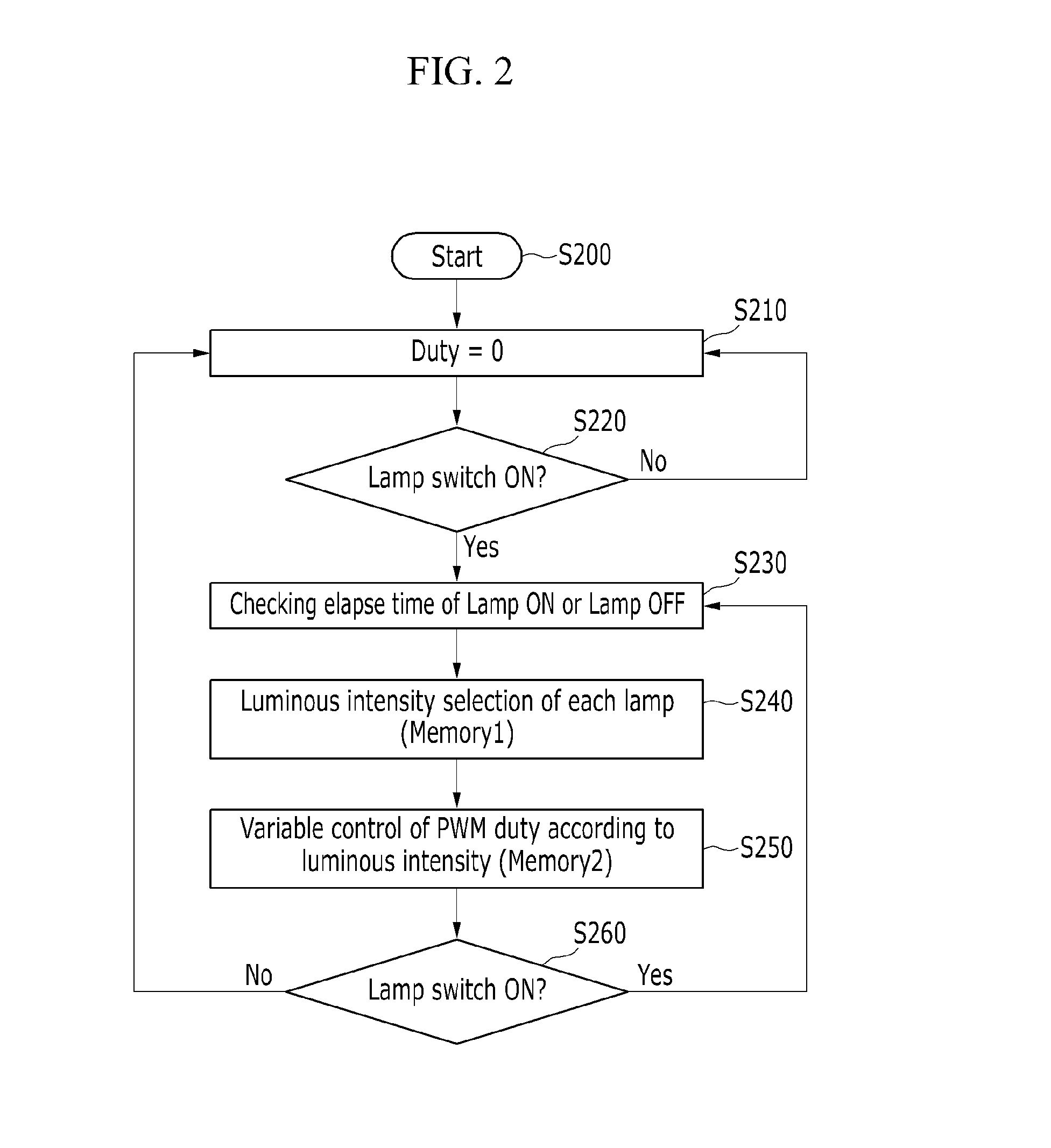

Power control method and system of lamp

InactiveUS20150084506A1Uniform luminous intensityImprove product qualityElectrical apparatusElectric lighting sourcesEngineeringElectric power

A power control method and system of a lamp are provided. The method includes supplying, by a controller, the lamp with electric power and selecting an illumination characteristic data of the lamp changed from a point when the electric power starts to be supplied to the lamp. The duty of voltage supplied to the lamp is variably adjusted, by the controller, based on the illumination characteristic data. In addition, the controller counts a first elapsed time that elapses from a first point when the electric power supplied to the lamp is turned on, and variably adjusts the duty of the voltage supplied to the lamp based on the counted first elapsed time.

Owner:HYUNDAI MOTOR CO LTD

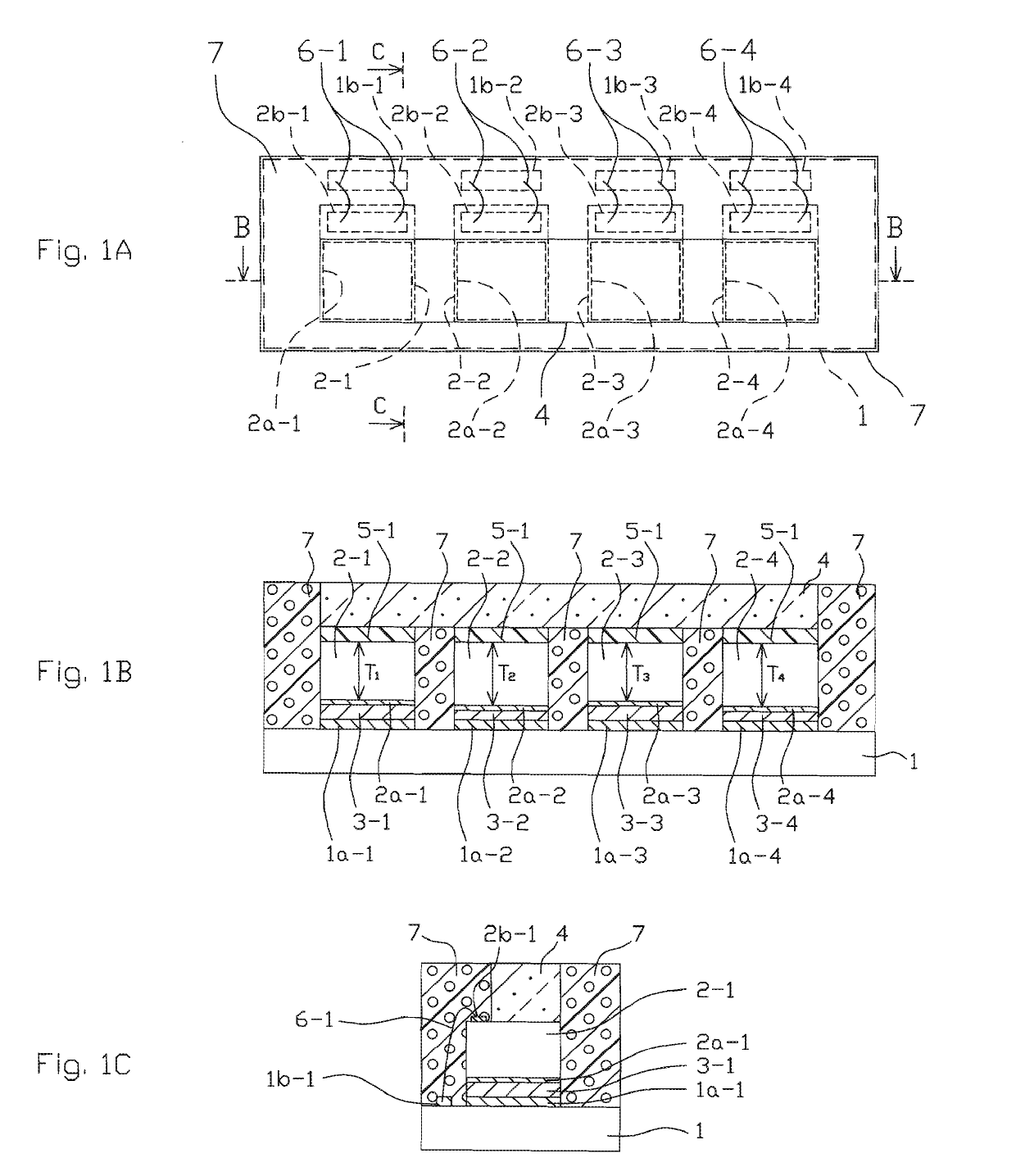

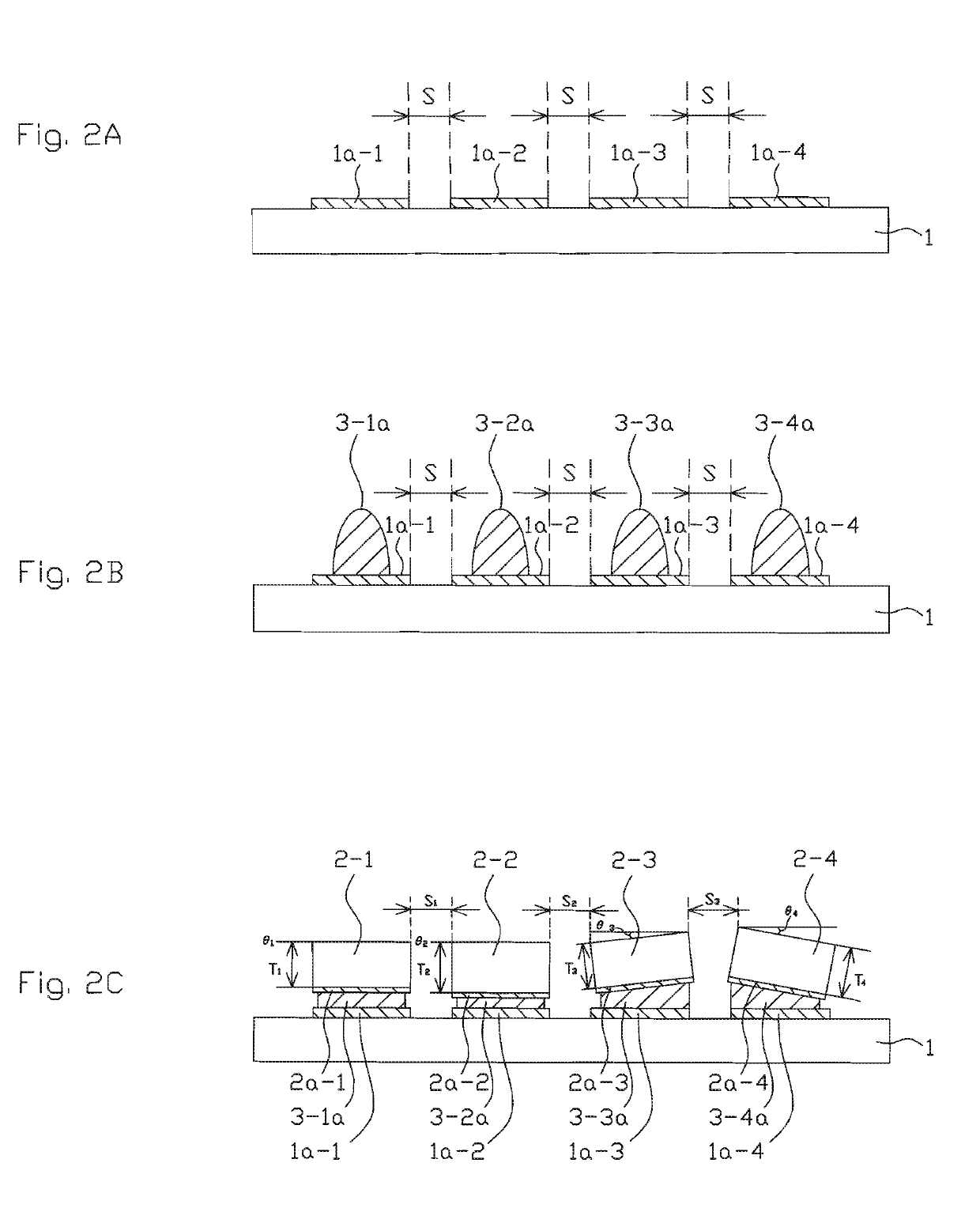

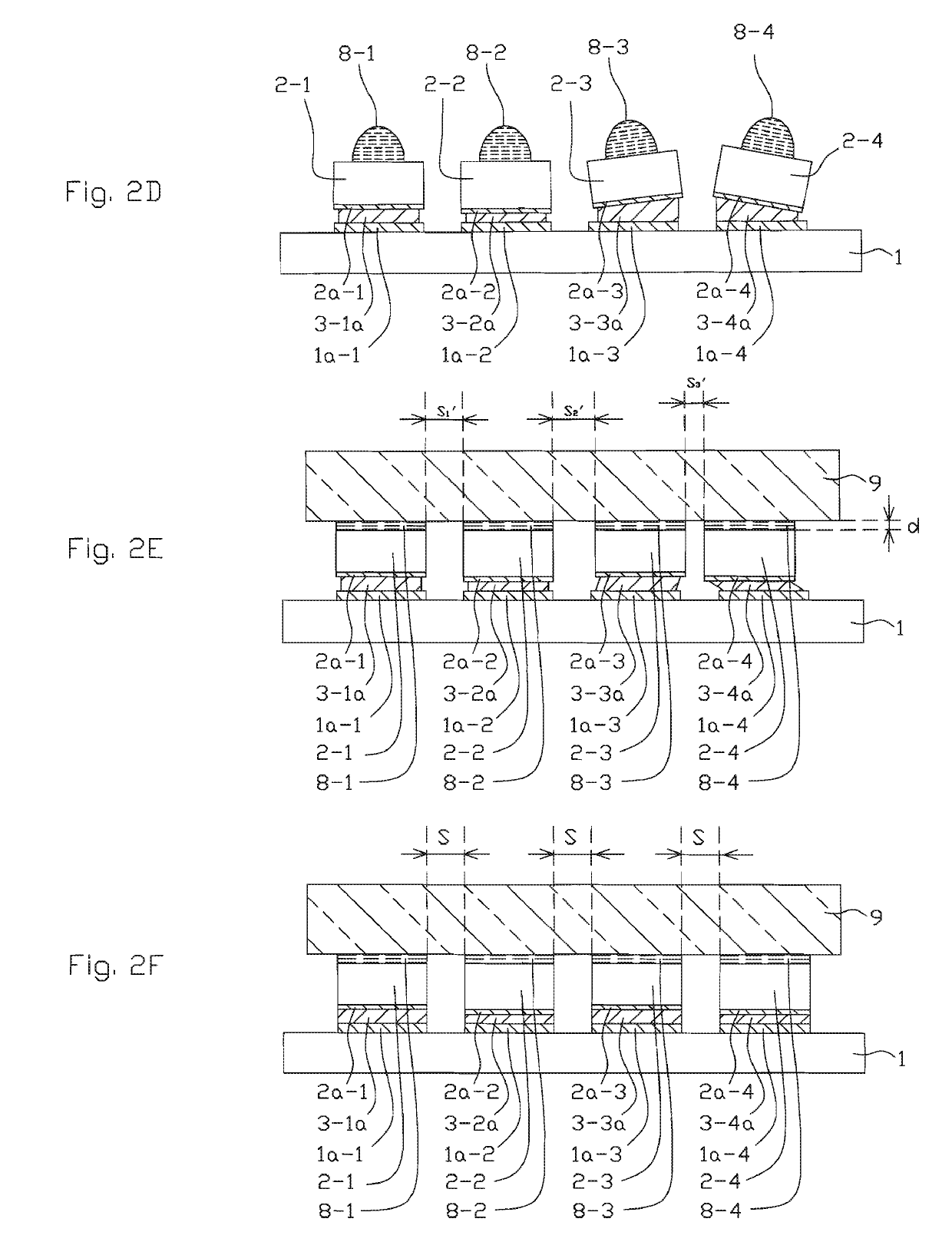

Semiconductor light-emitting apparatus having multiple semiconductor light-emitting elements and its manufacturing method

ActiveUS20190172990A1Uniform luminous intensitySolid-state devicesSemiconductor devicesEngineeringLength wave

A semiconductor light-emitting apparatus includes: a wiring substrate; multiple semiconductor light-emitting elements mounted via multiple eutectic layers, respectively, on the wiring substrate; and a wavelength-converting plate via multiple transparent adhesive layers on upper surfaces of the semiconductor light-emitting elements, respectively. A standard deviation of thicknesses of the transparent adhesive layers is smaller than a standard deviation of thicknesses of the eutectic layers.

Owner:STANLEY ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com