Mirror lamp

A mirror and frame technology, applied in the field of mirror lights, can solve the problems of unadjustable color temperature, complicated assembly, brightness difference, etc., and achieve the effect of uniform light emission without spots, coordinated and beautiful structure, and reduce brightness difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

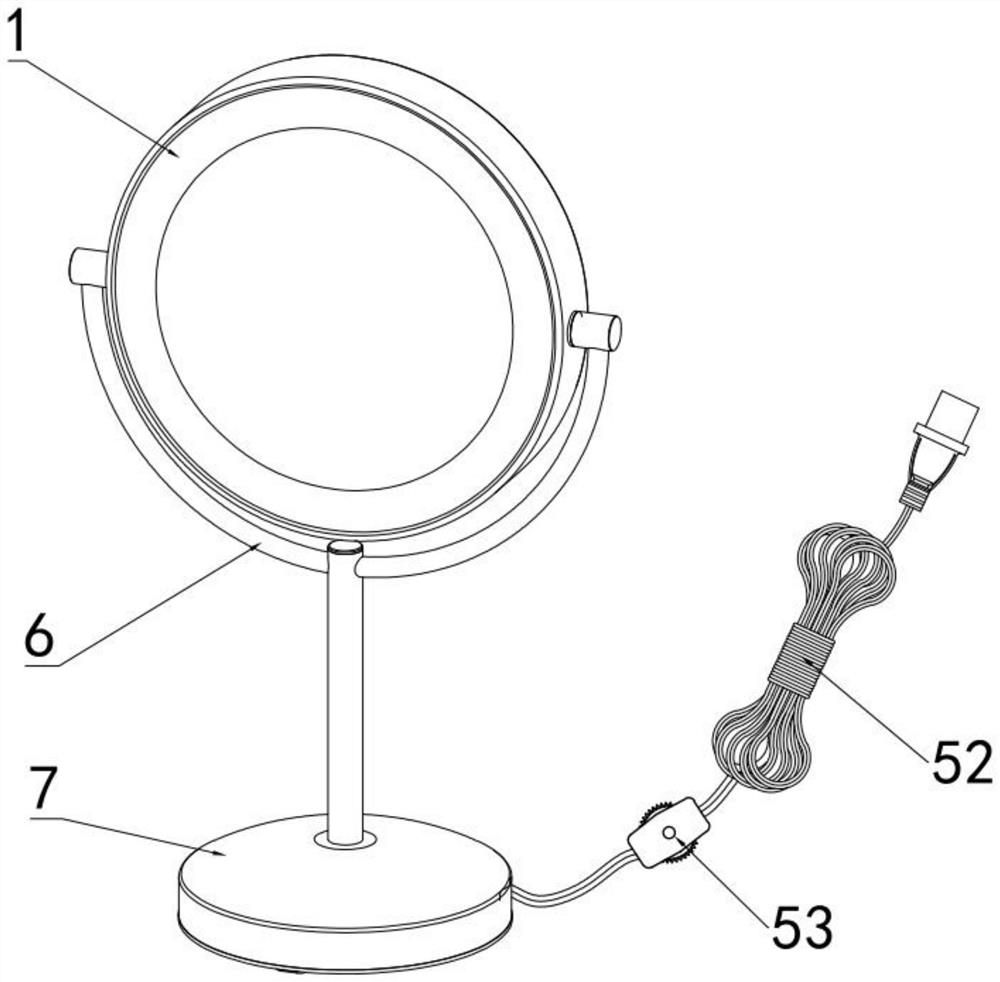

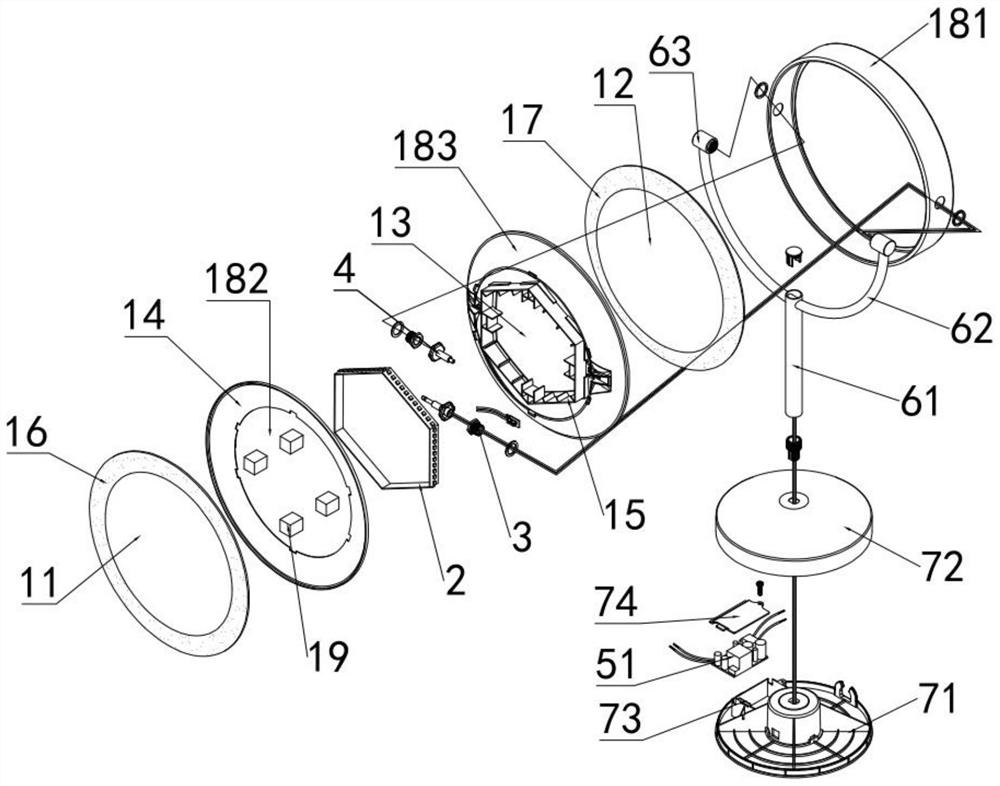

[0031] Example: see Figure 1 to Figure 5 , a mirror lamp provided in this embodiment, which includes a base part with a built-in transformer 51, a picture frame assembly 1, and a light-emitting assembly 2 arranged inside the picture frame assembly 1, and the two ends of the picture frame assembly 1 respectively correspond to T-shaped nuts 3 are provided and installed on the base part, so that the frame assembly 1 can rotate 360°, and a conductive component 4 is arranged on one or two T-shaped nuts 3, and the conductive component 4. is electrically connected to the transformer 51, and the transformer 51 is electrically connected to an external power line 52;

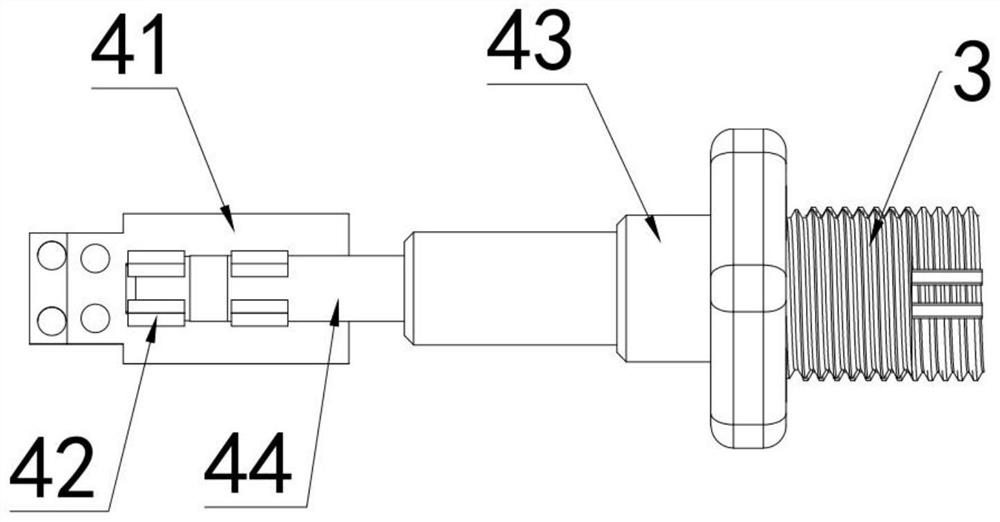

[0032] The conductive component 4 includes a wire terminal arranged on the light-emitting component 2 and a conductive pin connected to the wire terminal. An installation through hole is provided through the center of the T-shaped nut 3, and the conductive pin is installed on the In the installation through hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com