Patents

Literature

91results about How to "Improved light emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

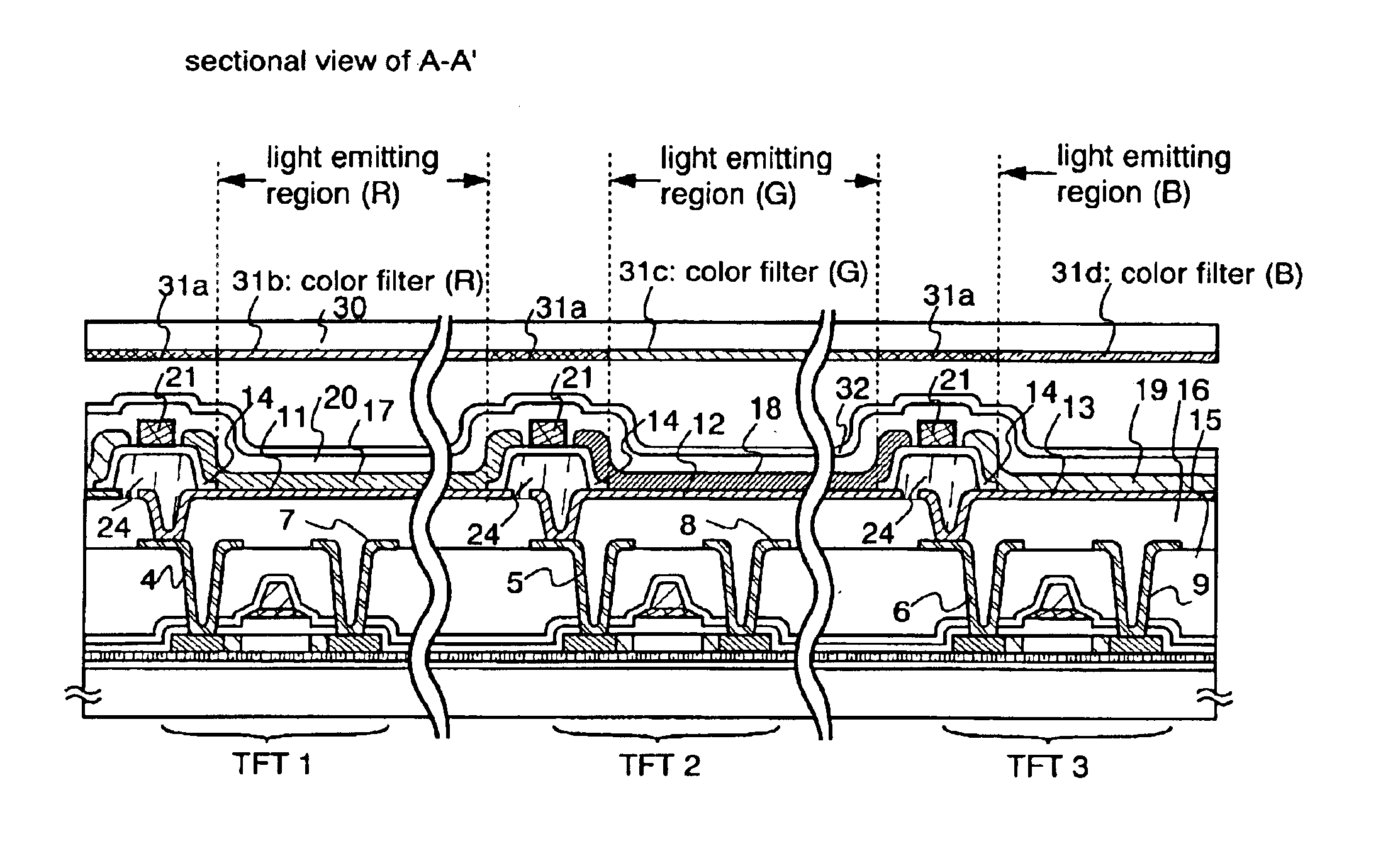

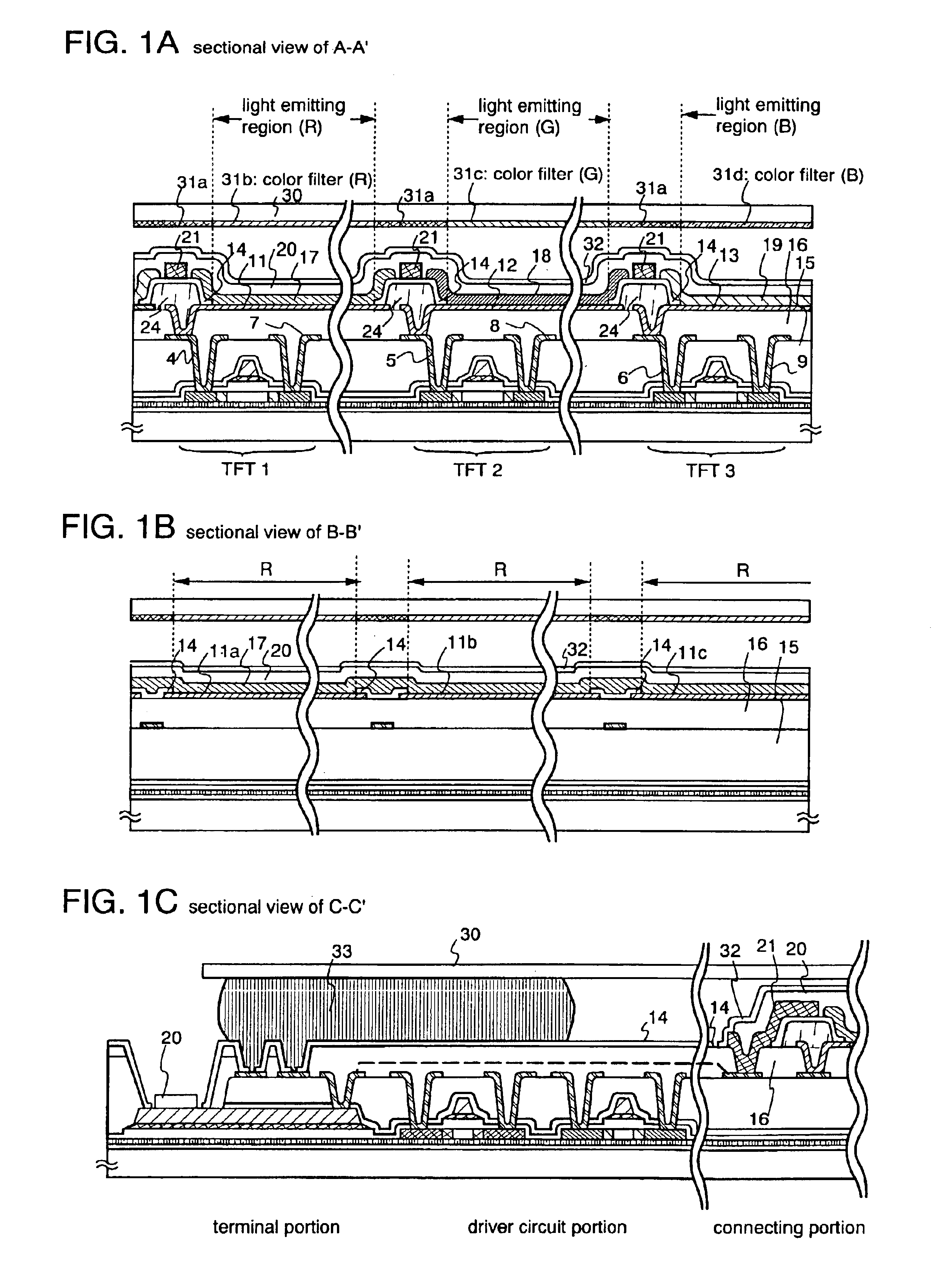

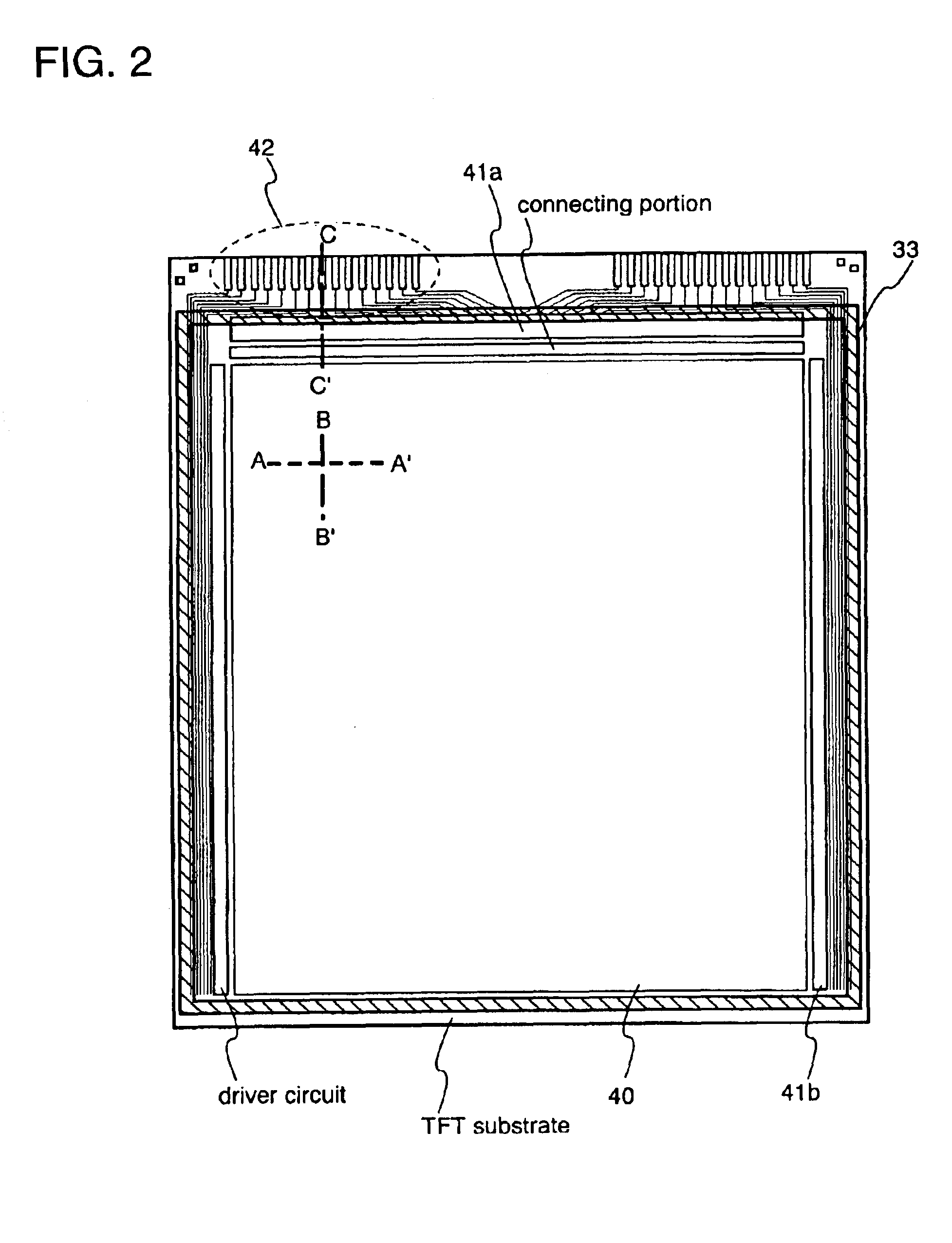

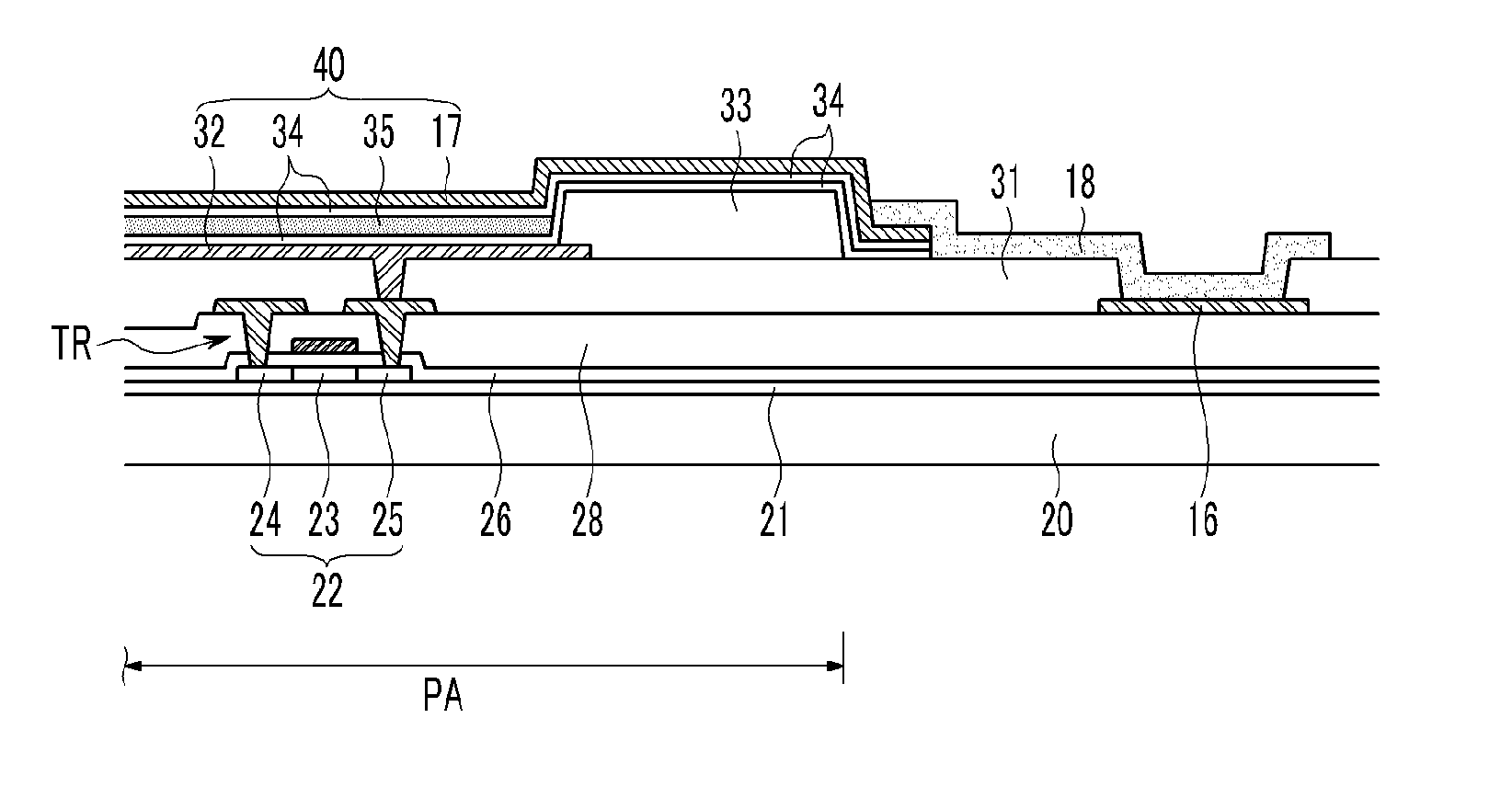

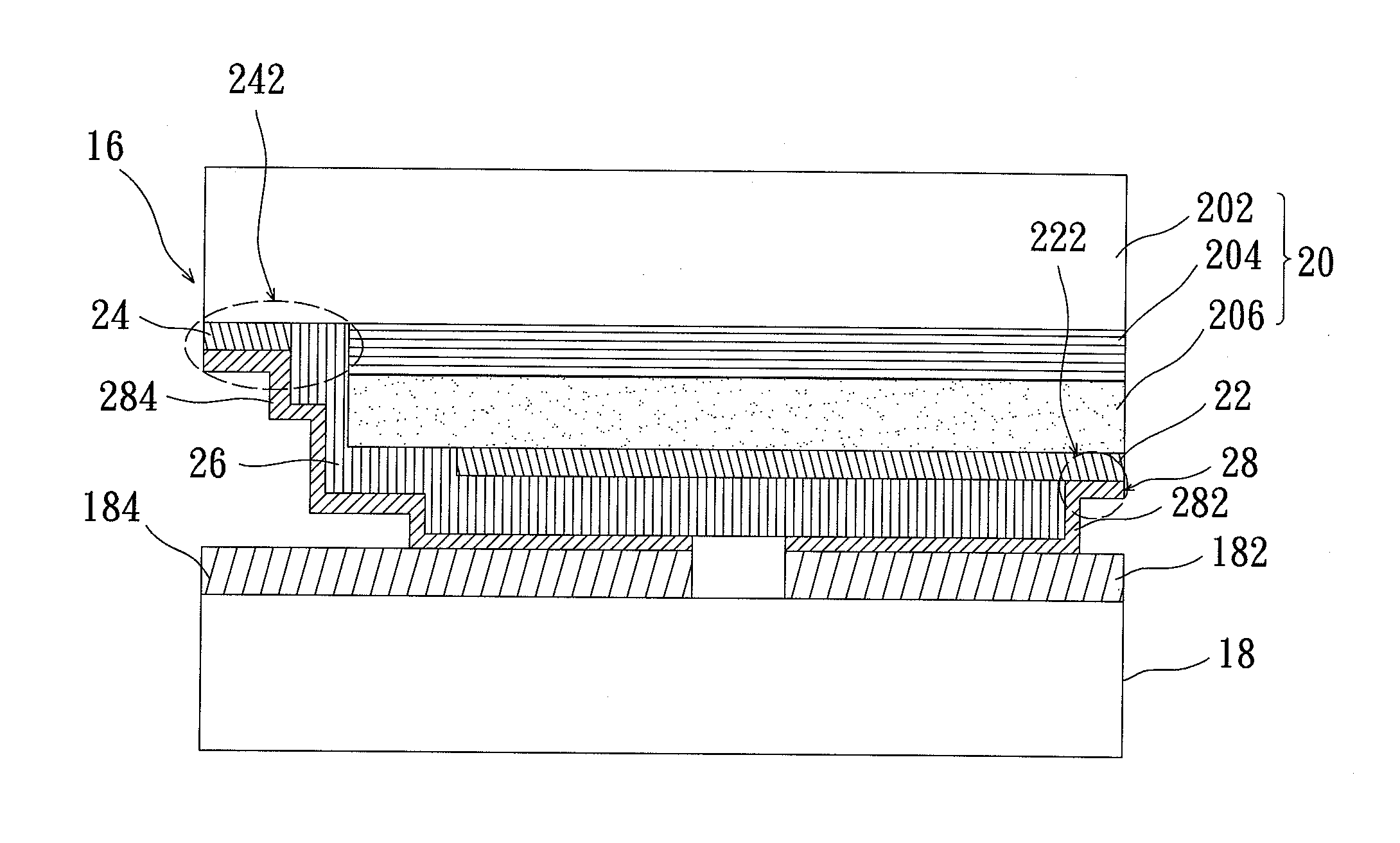

Light emitting device and method of manufacturing the same

InactiveUS6781162B2Effective diffusionImproved light emissionElectroluminescent light sourcesSolid-state devicesHydrogenTransparent conducting film

To provide a light emitting device high in reliability with a pixel portion having high definition with a large screen. According to a light emitting device of the present invention, on an insulator (24) provided between pixel electrodes, an auxiliary electrode (21) made of a metal film is formed, whereby a conductive layer (20) made of a transparent conductive film in contact with the auxiliary electrode can be made low in resistance and thin. Also, the auxiliary electrode (21) is used to achieve connection with an electrode on a lower layer, whereby the electrode can be led out with the transparent conductive film formed on an EL layer. Further, a protective film (32) made of a film containing hydrogen and a silicon nitride film which are laminated is formed, whereby high reliability can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

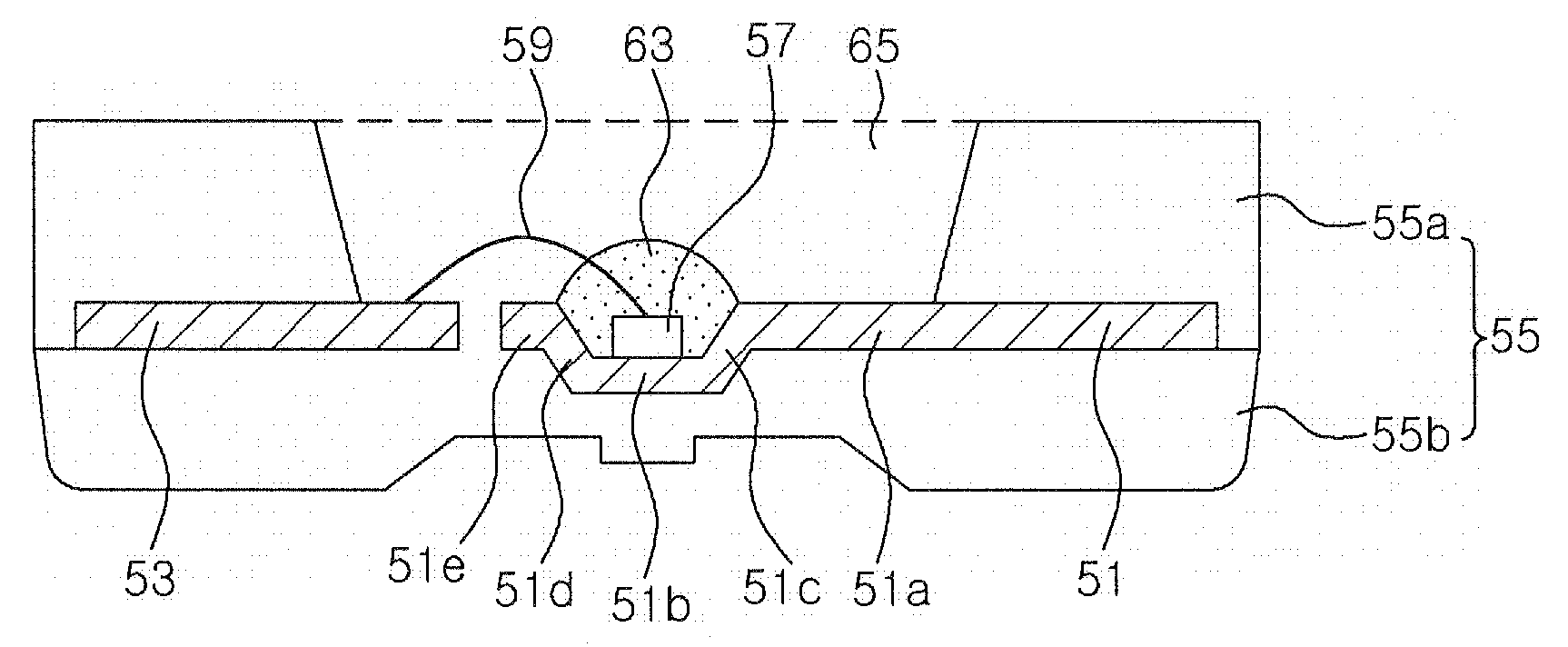

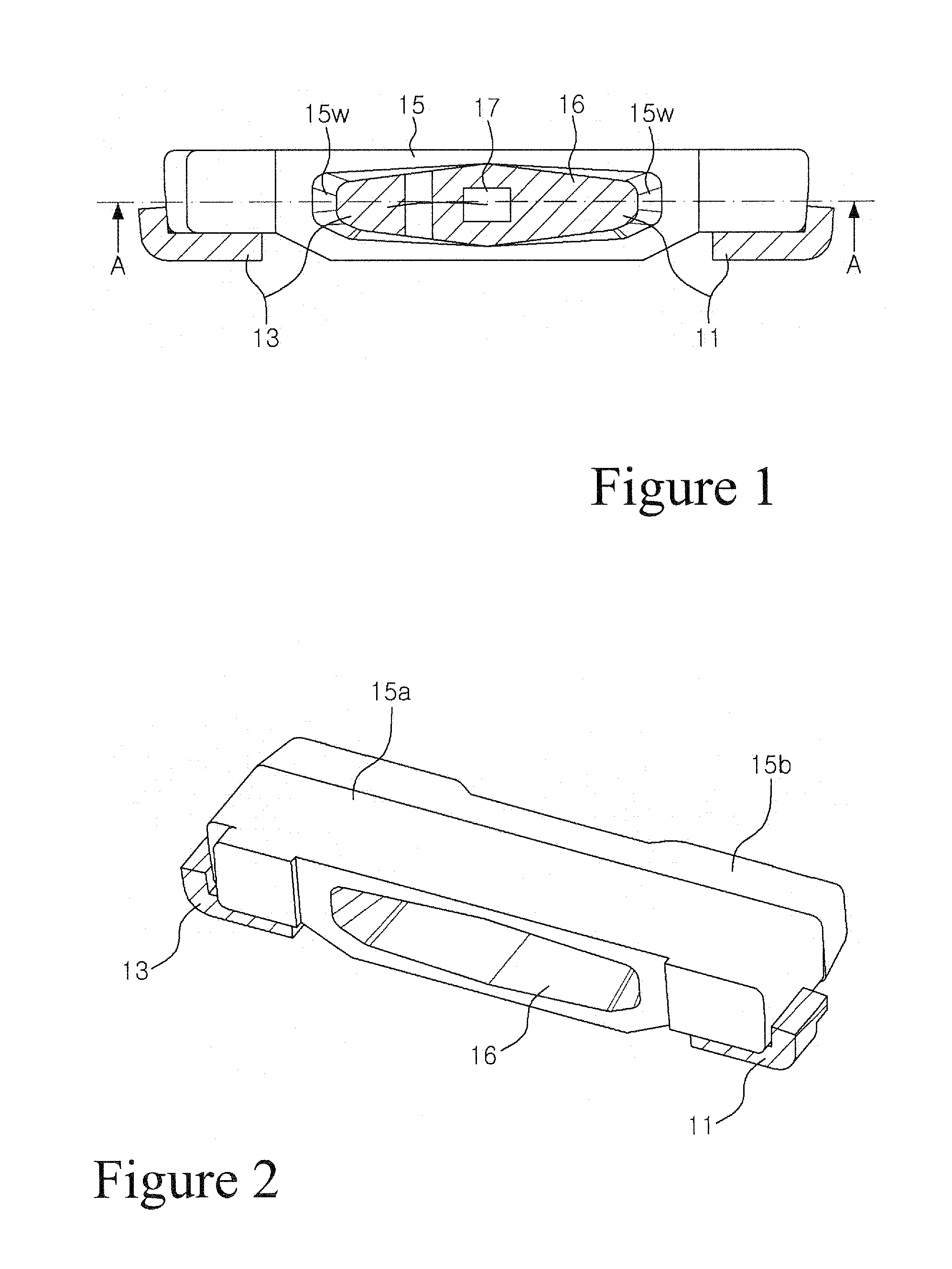

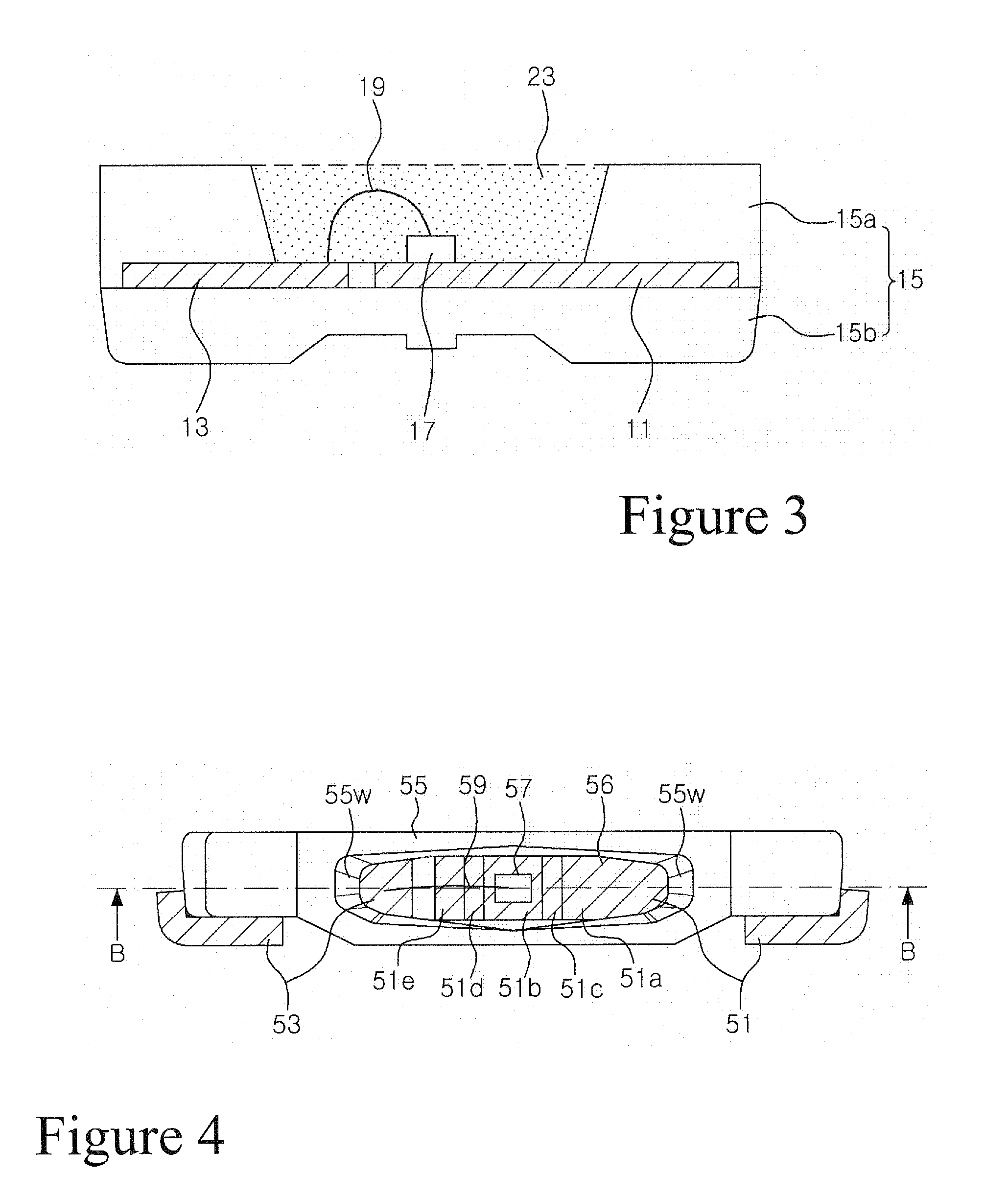

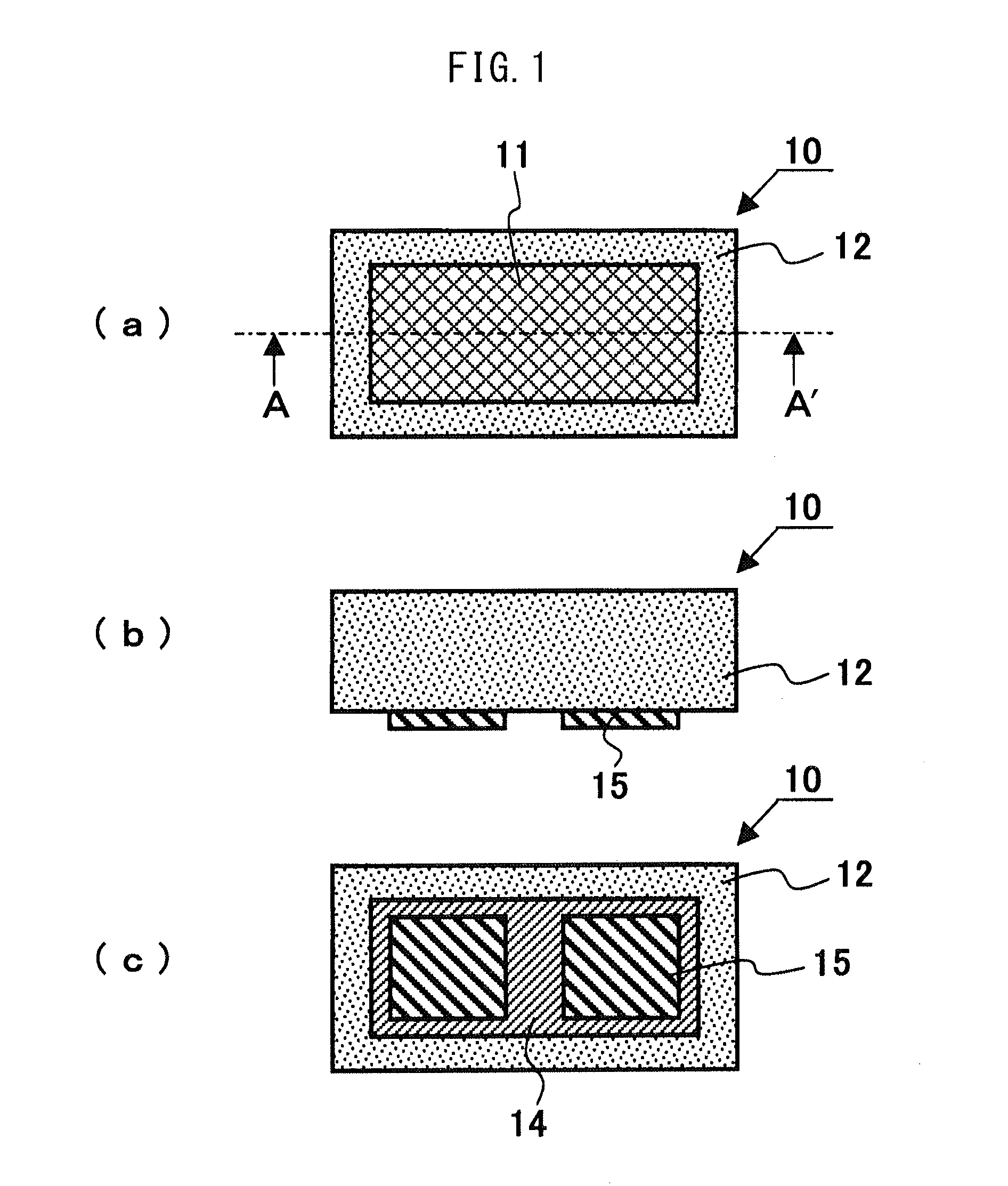

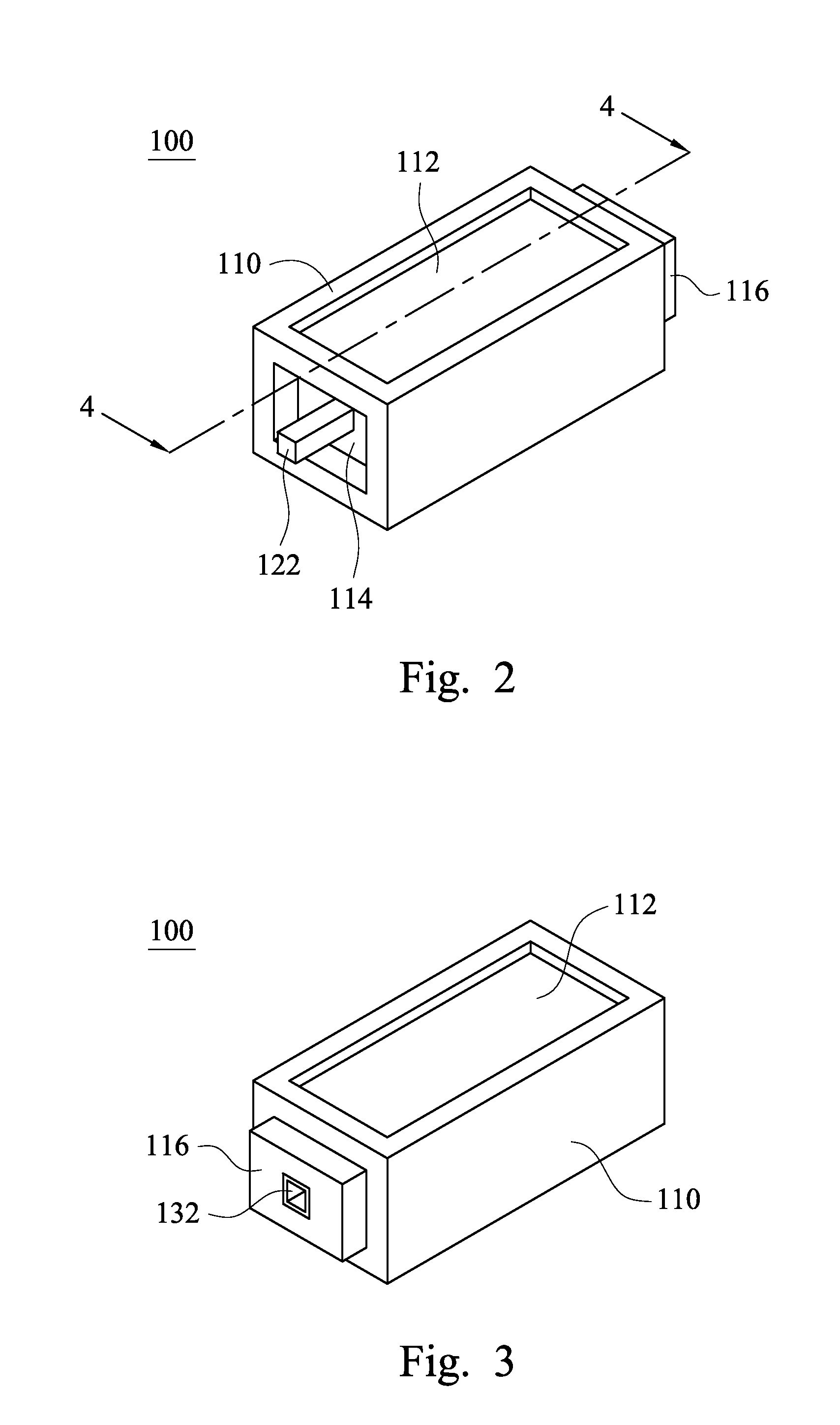

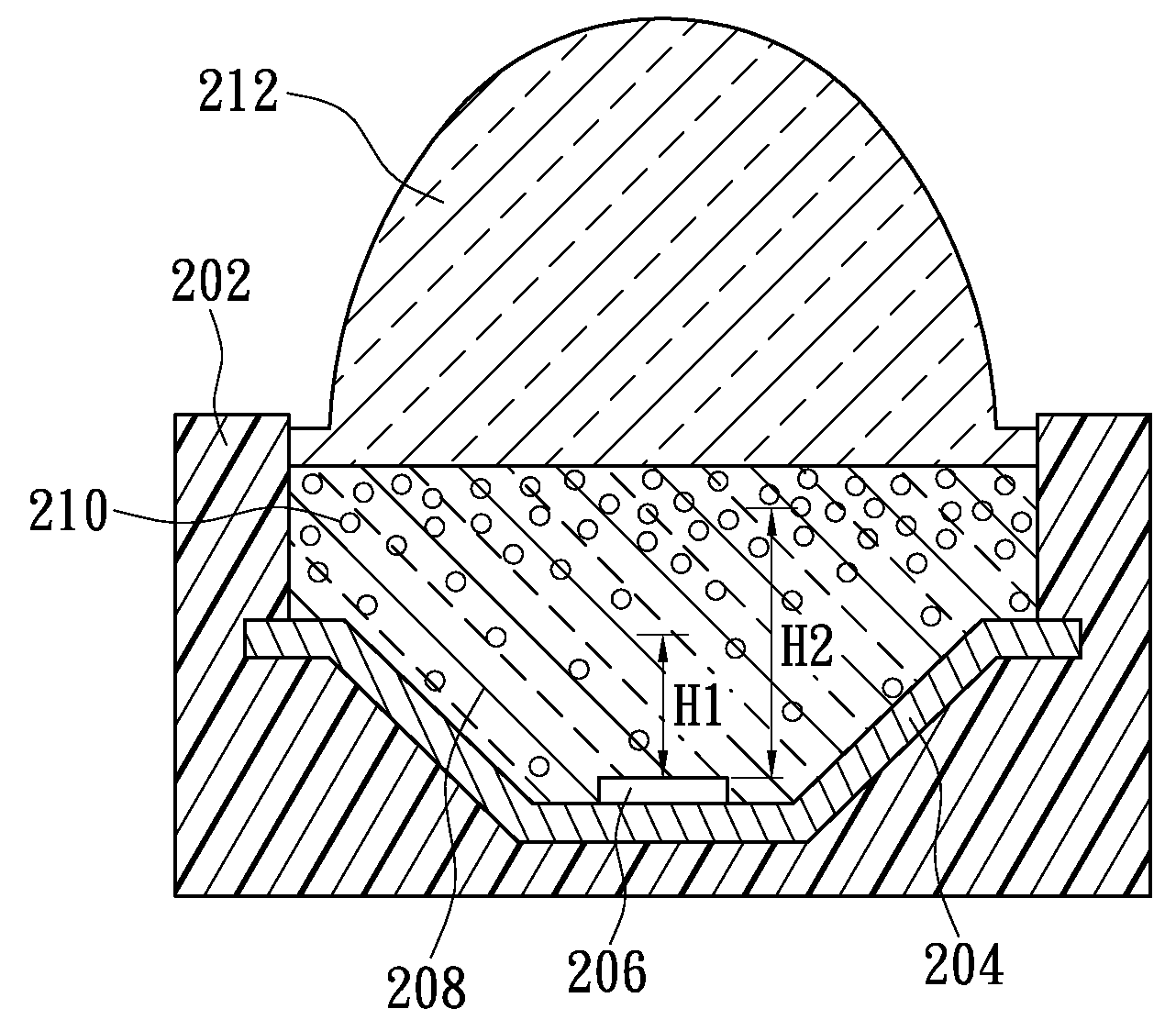

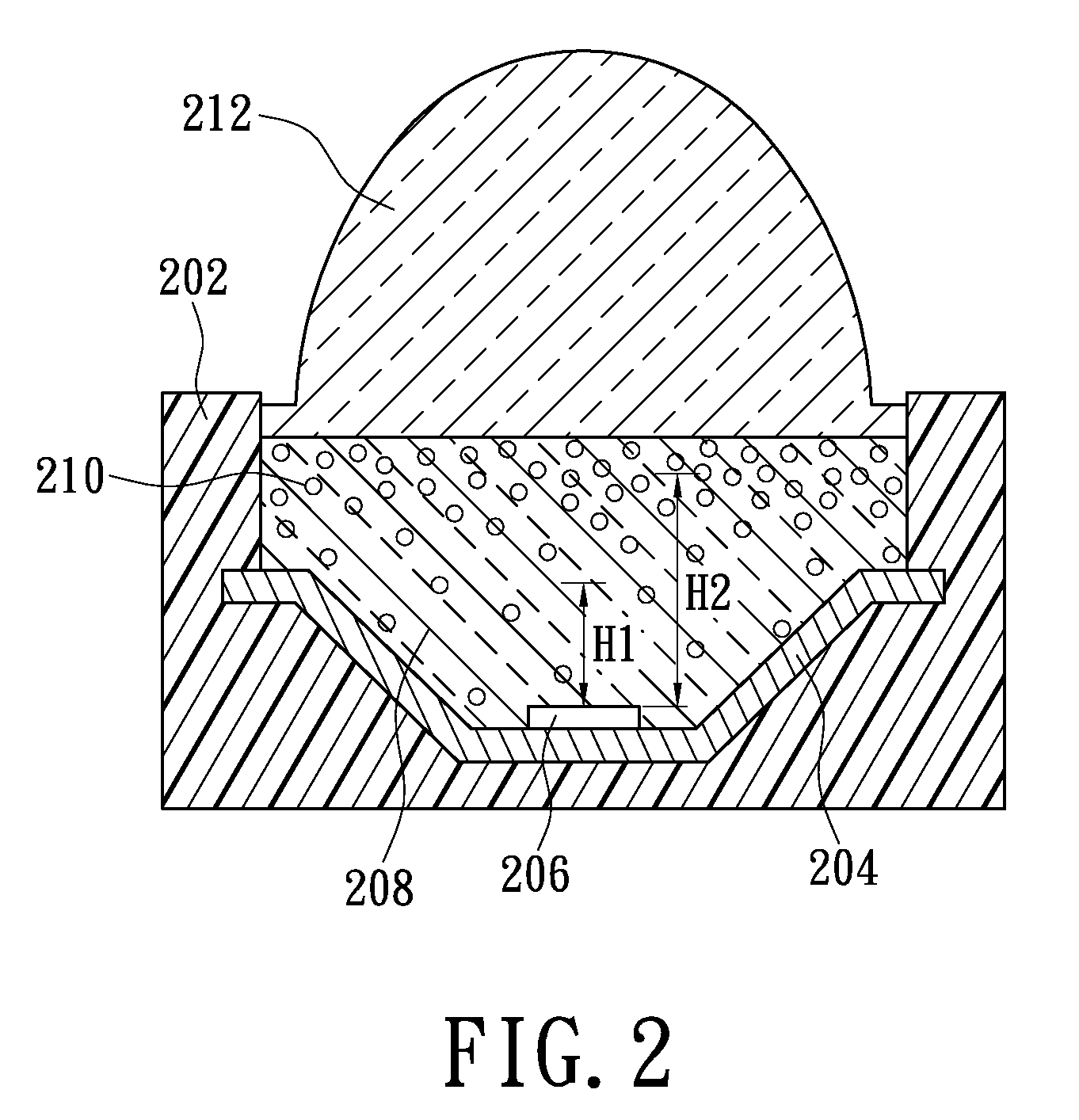

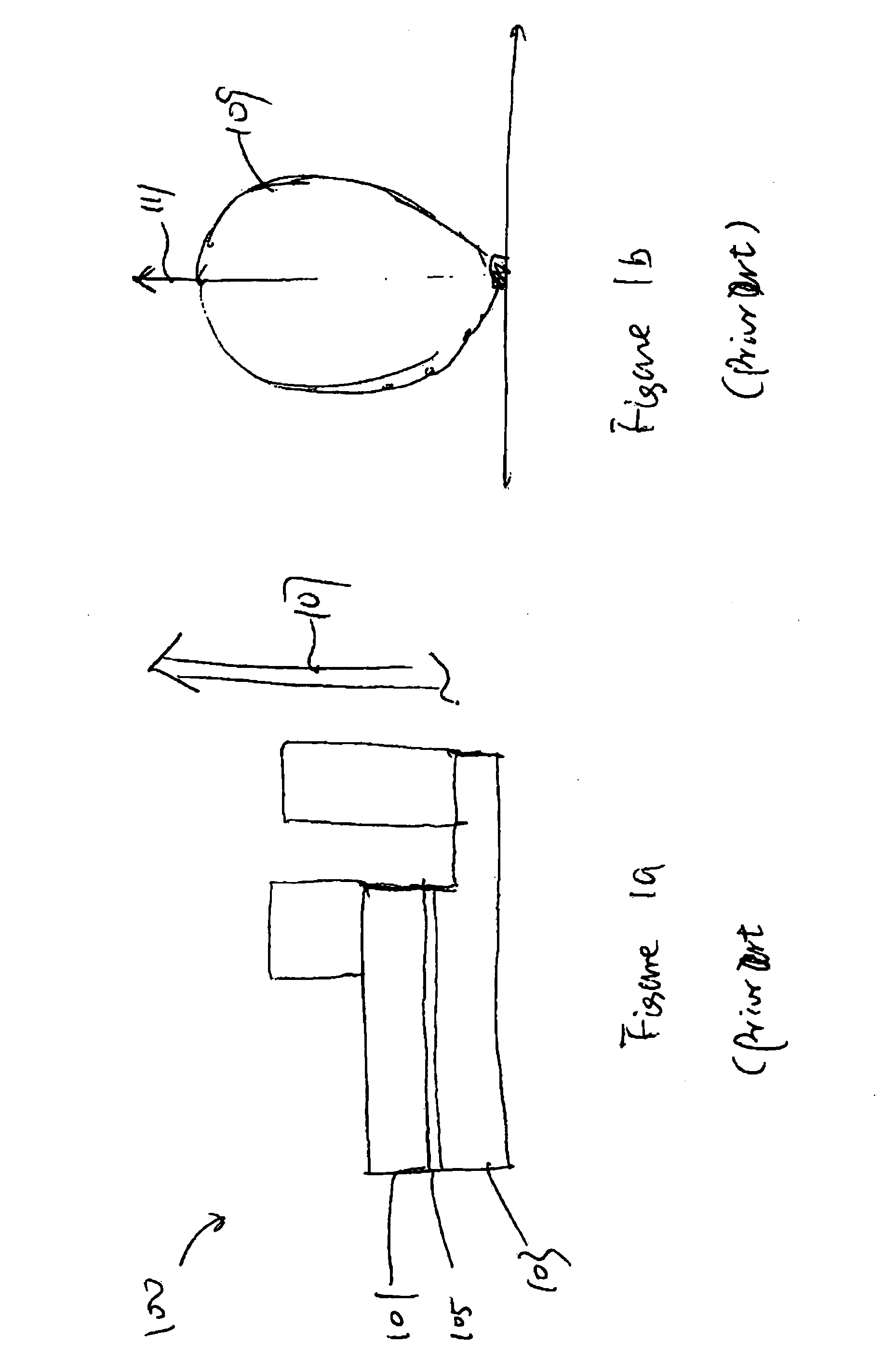

Light emitting diode package employing lead terminal with reflecting surface

InactiveUS20080048201A1Improved light emissionWell formedDischarge tube luminescnet screensLamp detailsEngineeringHigh reflectivity

Disclosed is a light emitting diode (LED) package employing a lead terminal with a reflecting surface. The package includes first and second lead terminals that are spaced apart from each other. The first lead terminal has a lower portion with an LED chip mounting area, and at least one reflecting surface formed by being bent from the lower portion. Meanwhile, a package body supports the first and second lead terminals and forms a cavity through which the LED chip mounting area and the reflecting surface of the first lead terminal and a part of the second lead terminal are exposed. The first and second lead terminals extend outside of the package body. Accordingly, light emitted from an LED chip can be reflected on the reflecting surface with high reflectivity, so that the optical efficiency of the package can be improved.

Owner:SEOUL SEMICONDUCTOR

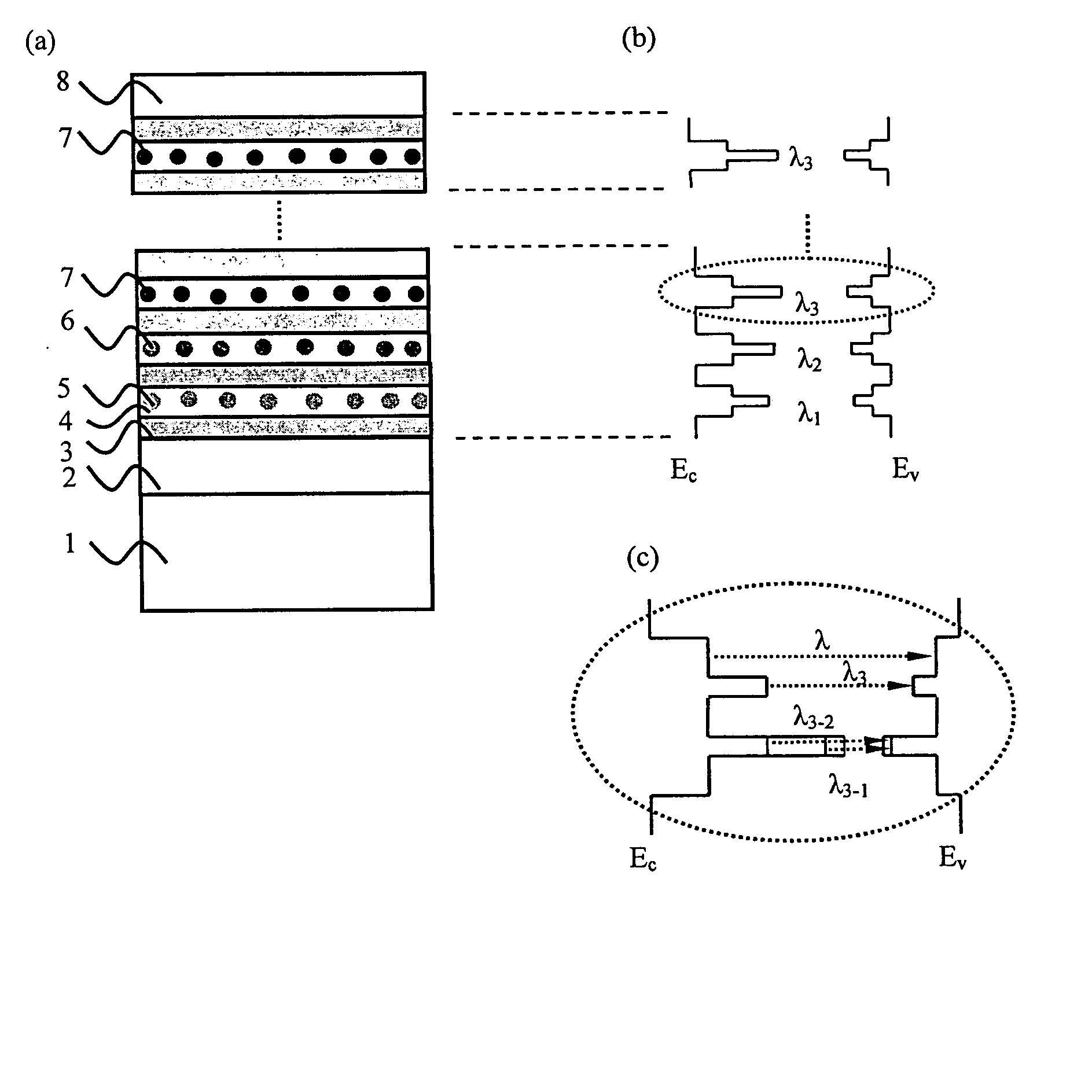

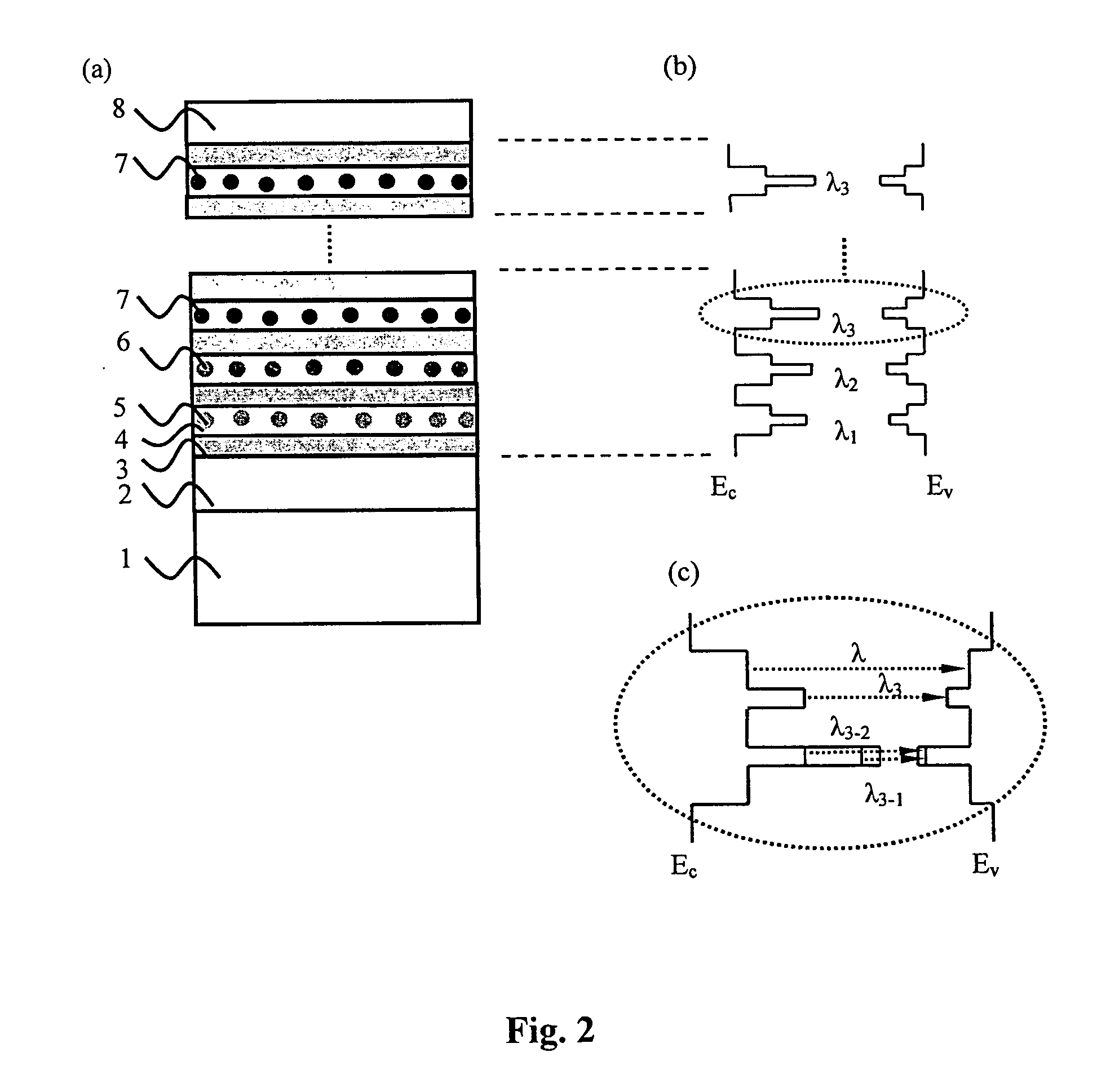

Nanoparticle structure and manufacturing process of multi-wavelength light emitting device

InactiveUS20070108888A1Reduce recombinationImprove luminous efficiencyDischarge tube luminescnet screensLamp detailsManufacturing technologyHigh energy

A structure of multi-wavelength light emitting device comprises multi-stacked active layer structure. Each stacked layer comprises lower energy bandgap well 4 and higher energy bandgap barrier layer 3 wherein at least one stacked layer in the device contains nanoparticles. As a result, the emitting wavelengths of the multi-stacked active layer structure consist parts (or all) of the emitting wavelengths come from the stack layers containing nanoparticles, and parts (or all) of the emitting wavelengths come from the stack layers not containing nanoparticles. In another embodiment, parts (or all) of the emitting wavelengths of the multi-stacked active layer structure can be also used to trigger one or more phosphorescences from the phosphors, thus the emitting wavelengths of such a phosphors converted light emitting device may come partially from the multi-stacked active layer itself and partially (or all) from the phosphors.

Owner:NAT CHIAO TUNG UNIV

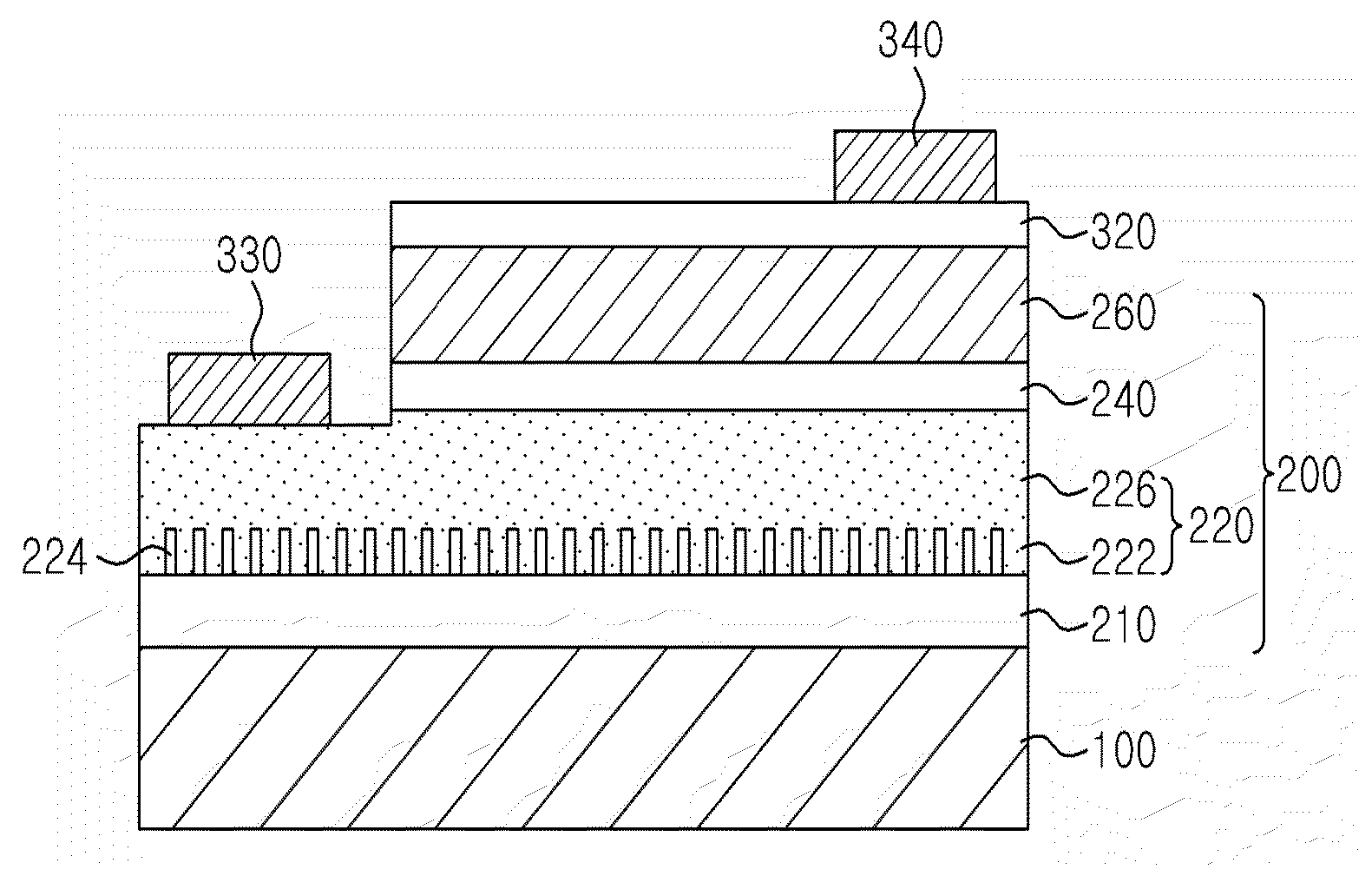

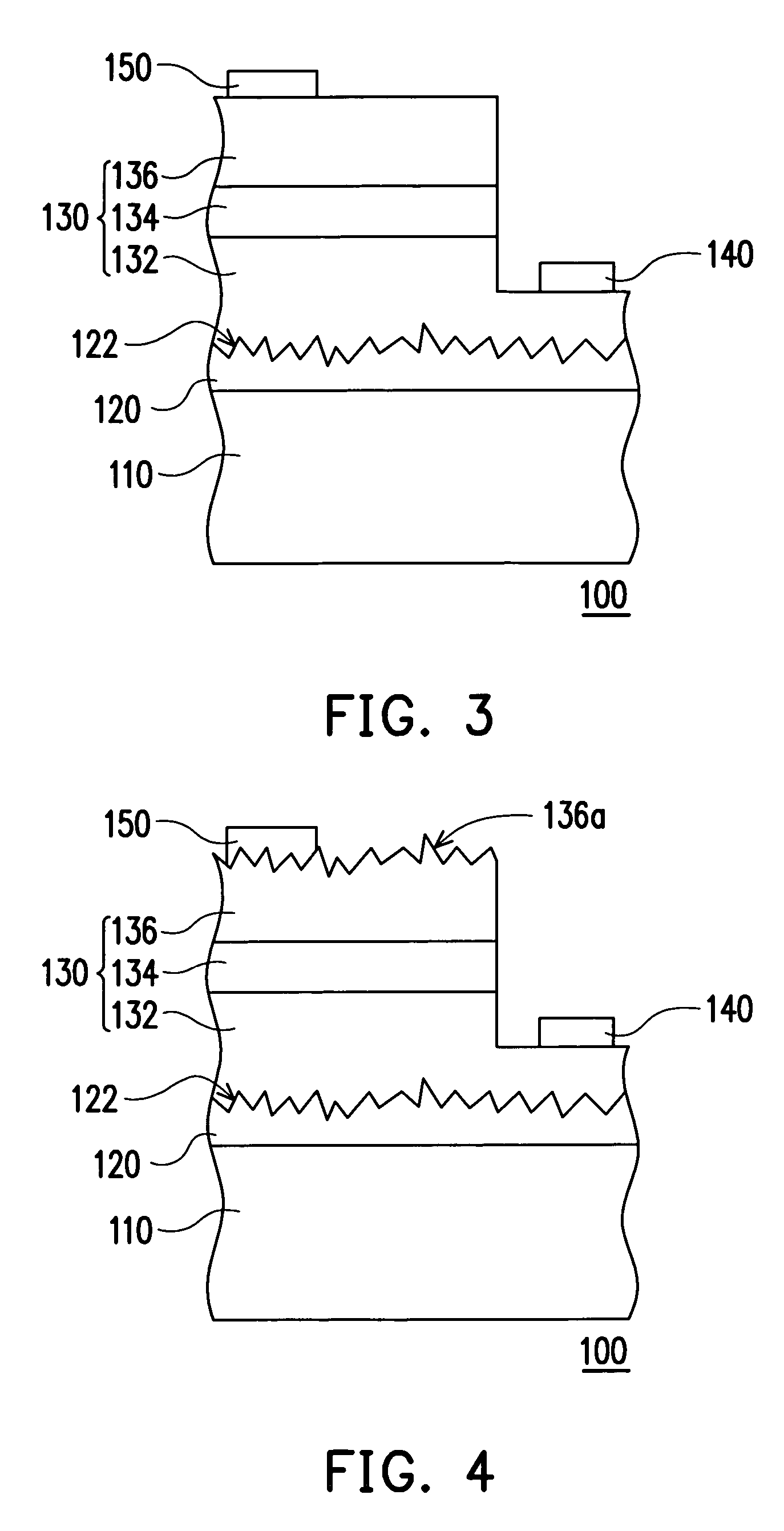

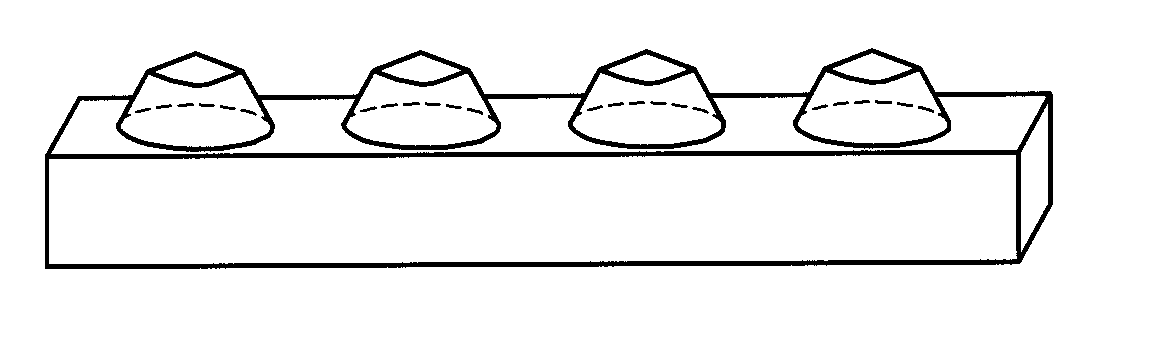

Light emitting device and fabrication method thereof

ActiveUS20100012969A1Improved light emissionEfficient light emissionSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactReflective layer

There is provided a method of fabricating a vertical light emitting diode. The method comprises the steps of: growing a low doped first conductive semiconductor layer on a sacrificial substrate; forming an aluminum layer on the low doped first conductive semiconductor layer; forming an AAO layer having a large number of holes formed therein by performing anodizing treatment of the aluminum layer; etching and patterning the low doped first conductive semiconductor layer using the aluminum layer with a large number of the holes as a shadow mask to expose a portion of the low doped first conductive semiconductor layer, thereby forming a large number of grooves; removing the aluminum layer remaining on the low doped first conductive semiconductor layer; sequentially forming a high doped first conductive semiconductor layer, an active layer and a second conductive semiconductor layer on the low doped first conductive semiconductor layer with a large number of the grooves; forming a metal reflective layer and a conductive substrate on the second conductive semiconductor layer; separating the sacrificial substrate; and forming an electrode pad on the other surface of the low doped first conductive semiconductor layer, the electrode pad being filled in a large number of the grooves to be in ohmic contact with the high doped first conductive semiconductor layer

Owner:SEOUL VIOSYS CO LTD

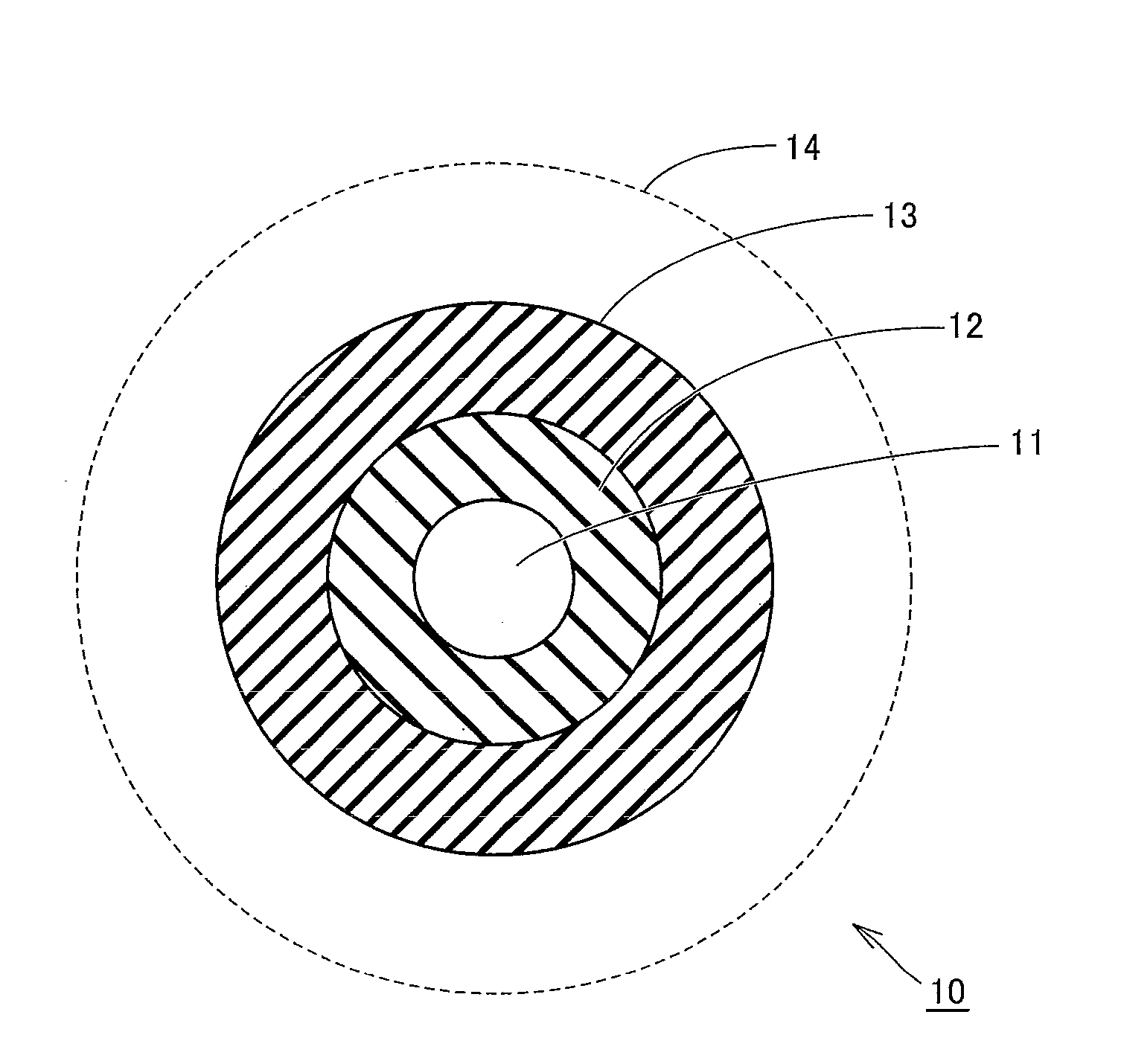

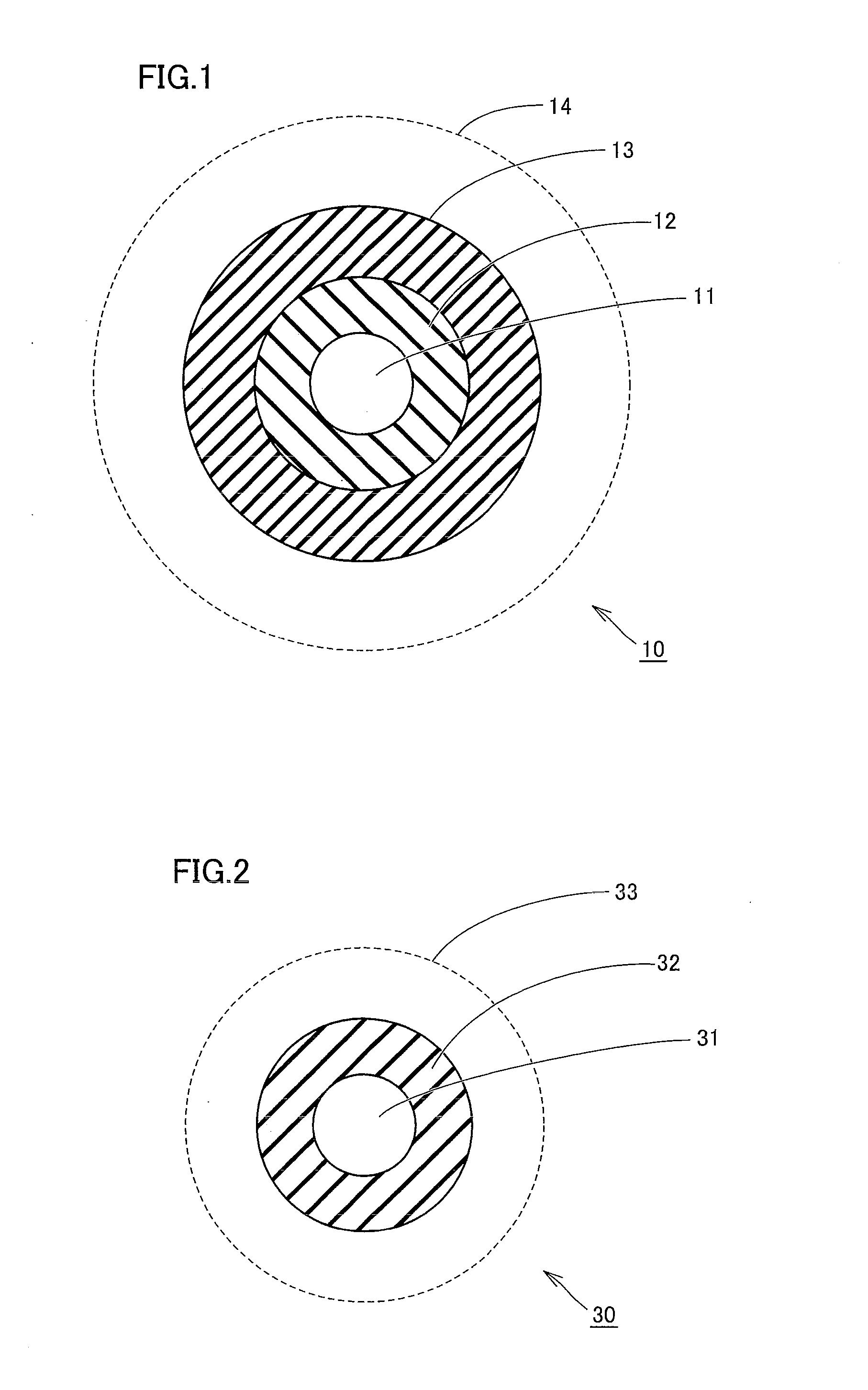

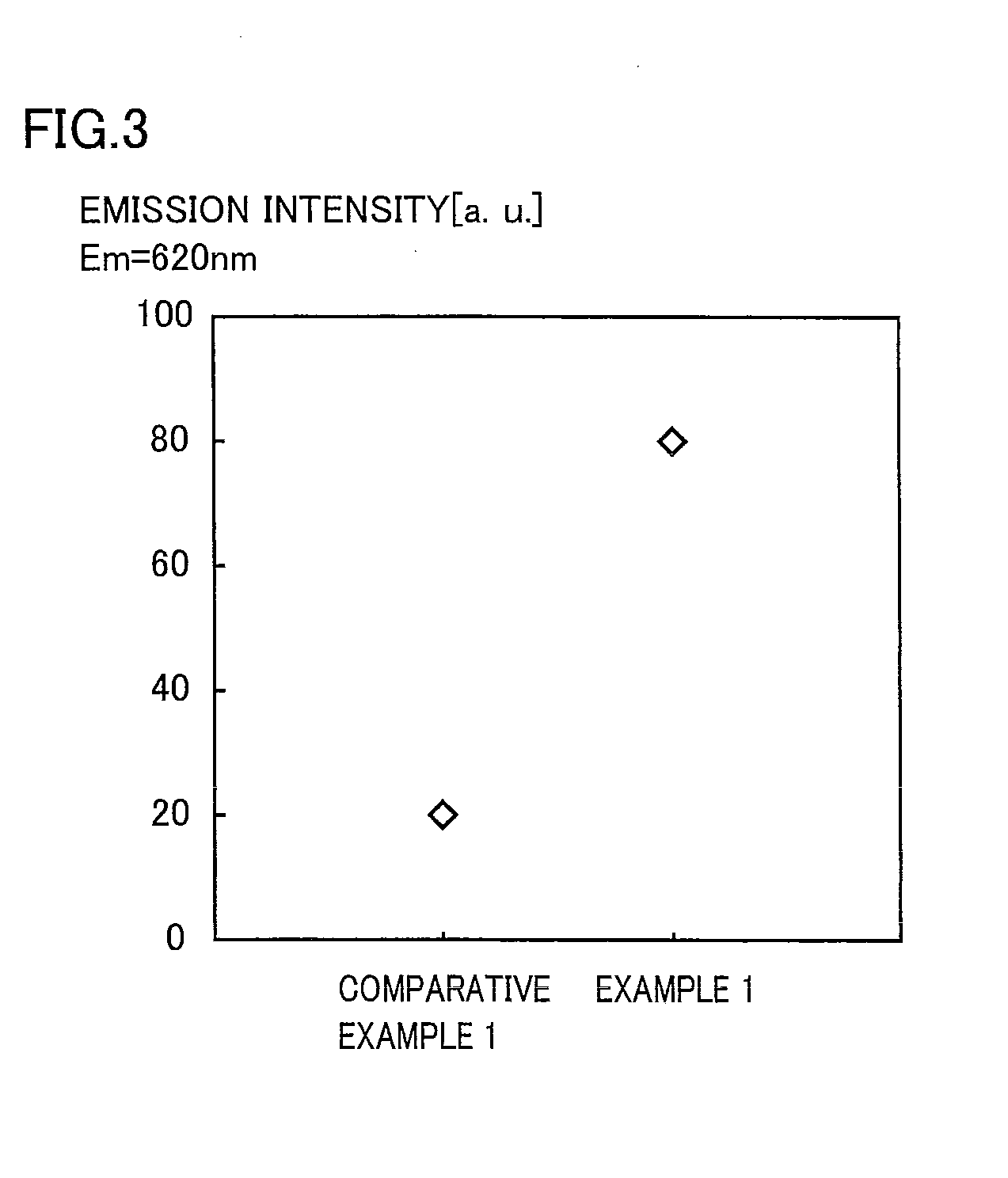

Semiconductor nanoparticle phosphor including nanoparticle core composed of group-xiii and -xv semiconductor and first shell and second shell for coating the same

InactiveUS20100163798A1Suppress generationImproved light emissionLuminescent compositionsPhosphorSemiconductor Nanoparticles

A semiconductor nanoparticle phosphor includes a nanoparticle core composed of a group-XIII and -XV semiconductor, a first shell for coating the nanoparticle core, and a second shell for coating the first shell, a difference in a lattice constant between the nanoparticle core and the second shell being smaller than a difference in the lattice constant between the nanoparticle core and the first shell, or the first shell being smaller in the lattice constant than the nanoparticle core and the second shell being greater in the lattice constant than the nanoparticle core, or the first shell being greater in the lattice constant than the nanoparticle core and the second shell being smaller in the lattice constant than the nanoparticle core.

Owner:SHARP KK

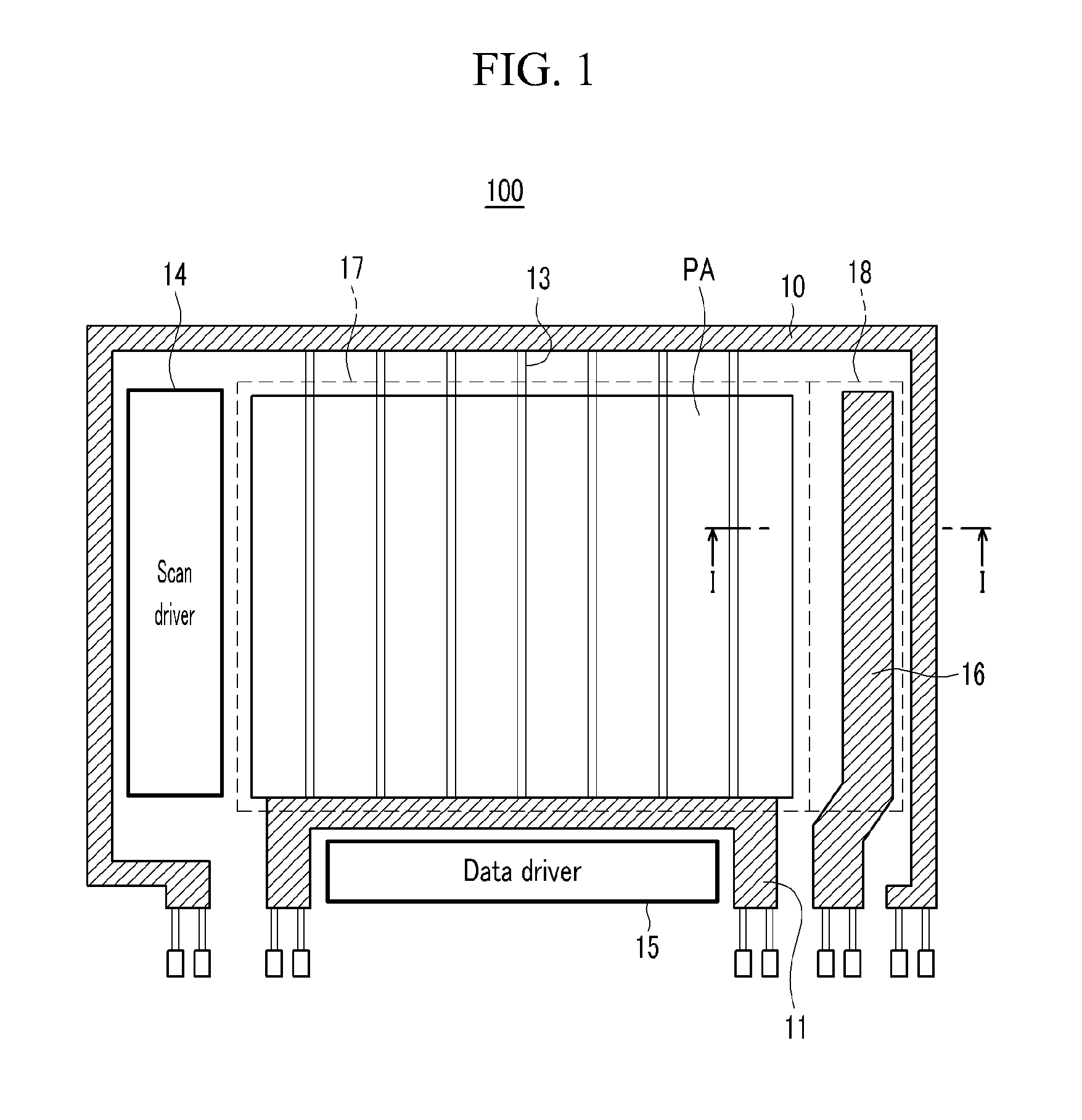

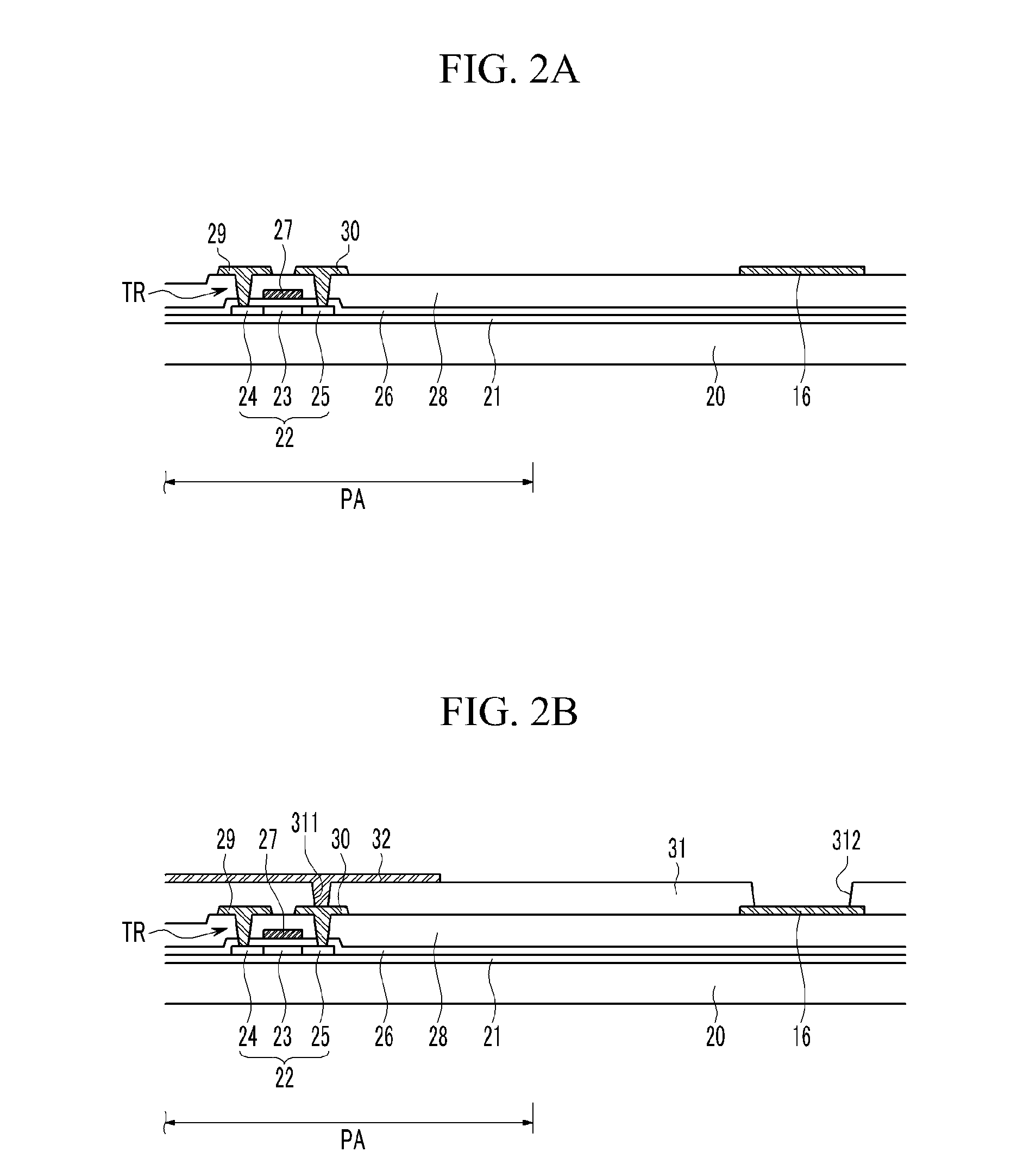

Organic light emitting diode display and method of manufacturing the same

InactiveUS20110133215A1Efficient removalImproved light emissionElectroluminescent light sourcesSolid-state devicesDisplay deviceConductive materials

A method of manufacturing an organic light emitting diode (OLED) display includes forming an upper electrode power source line outside of a pixel area over a substrate, forming a lower electrode in the pixel area, forming at least one layer of an organic material layer in the pixel area and areas outside of the pixel area, forming an upper electrode in the pixel area, selectively removing portions of the organic material layer that are exposed outside of the upper electrode, thereby exposing the upper electrode power source line, and coating a conductive material between the upper electrode and the upper electrode power source line in a normal pressure condition such that the conductive material overlaps the upper electrode and the upper electrode power source line, thereby forming a connection portion.

Owner:SAMSUNG DISPLAY CO LTD

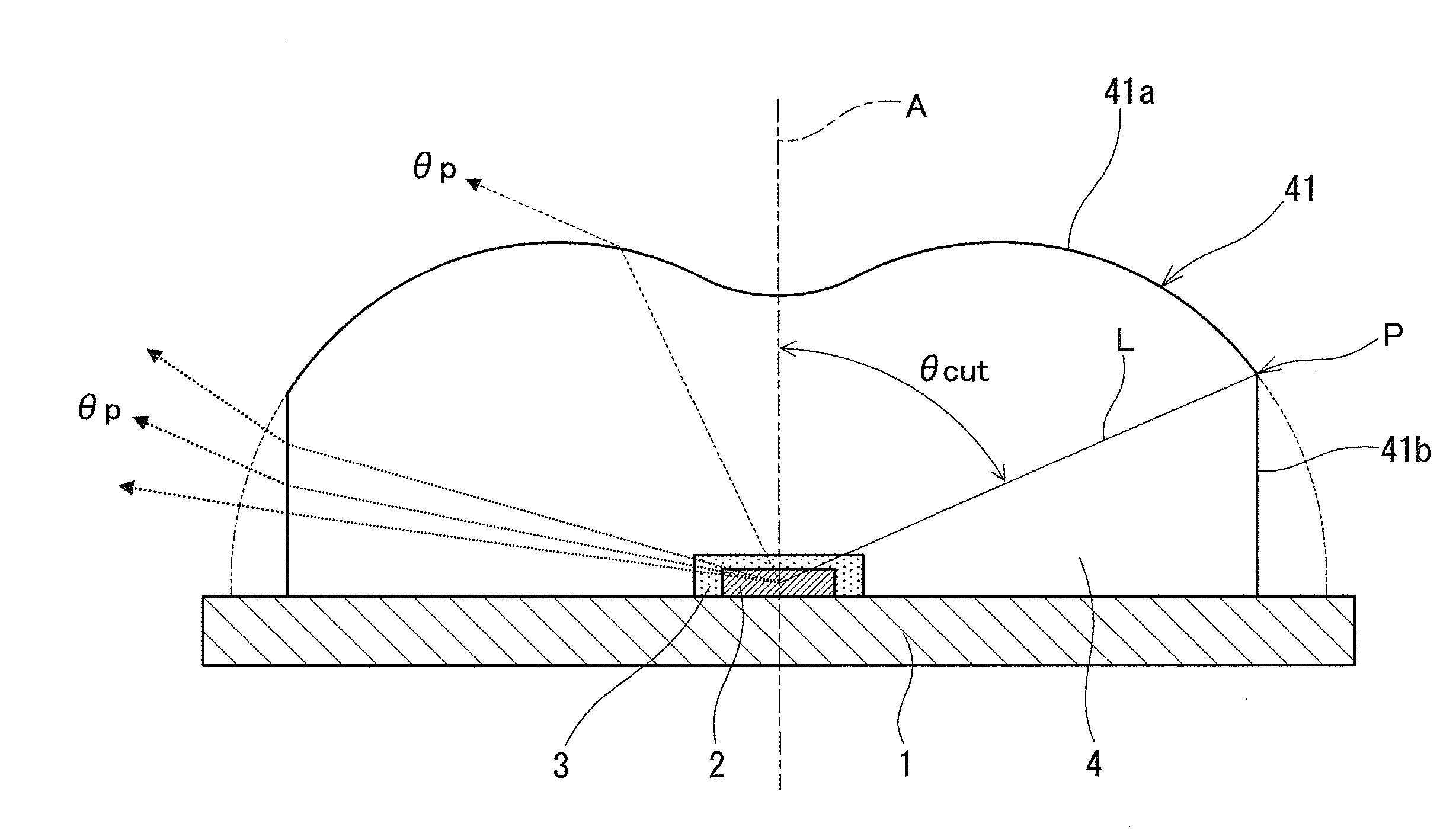

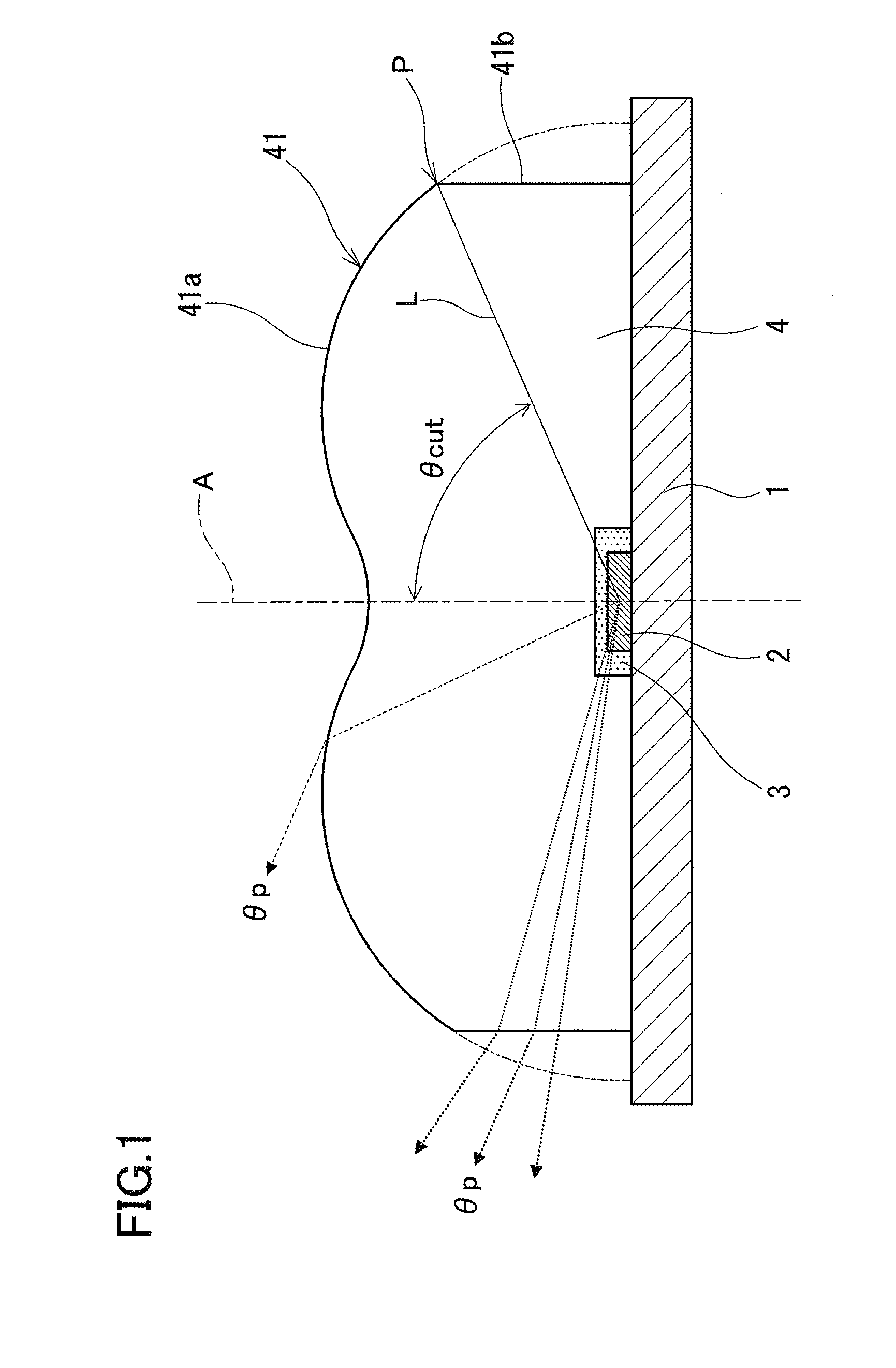

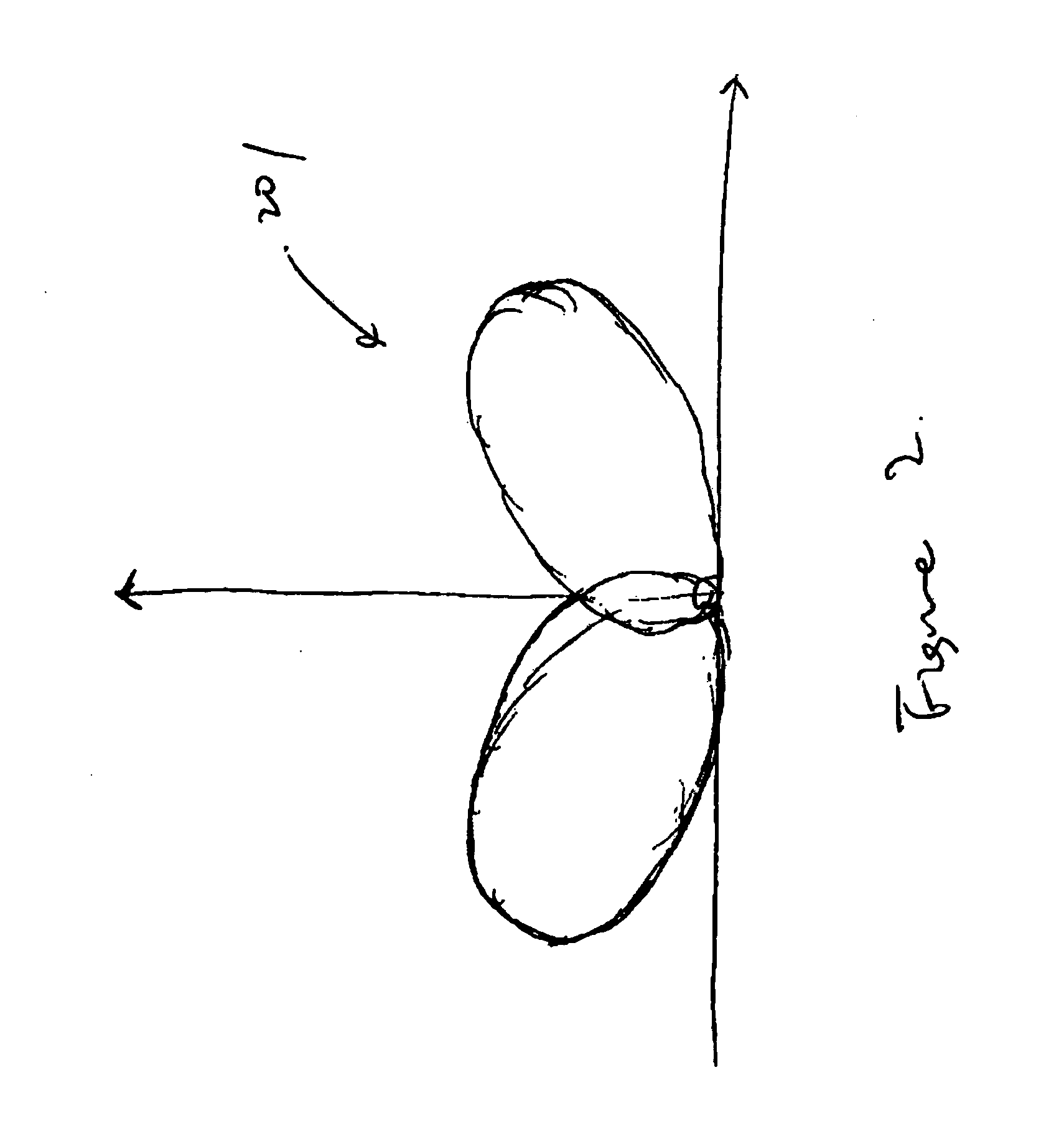

Lighting device

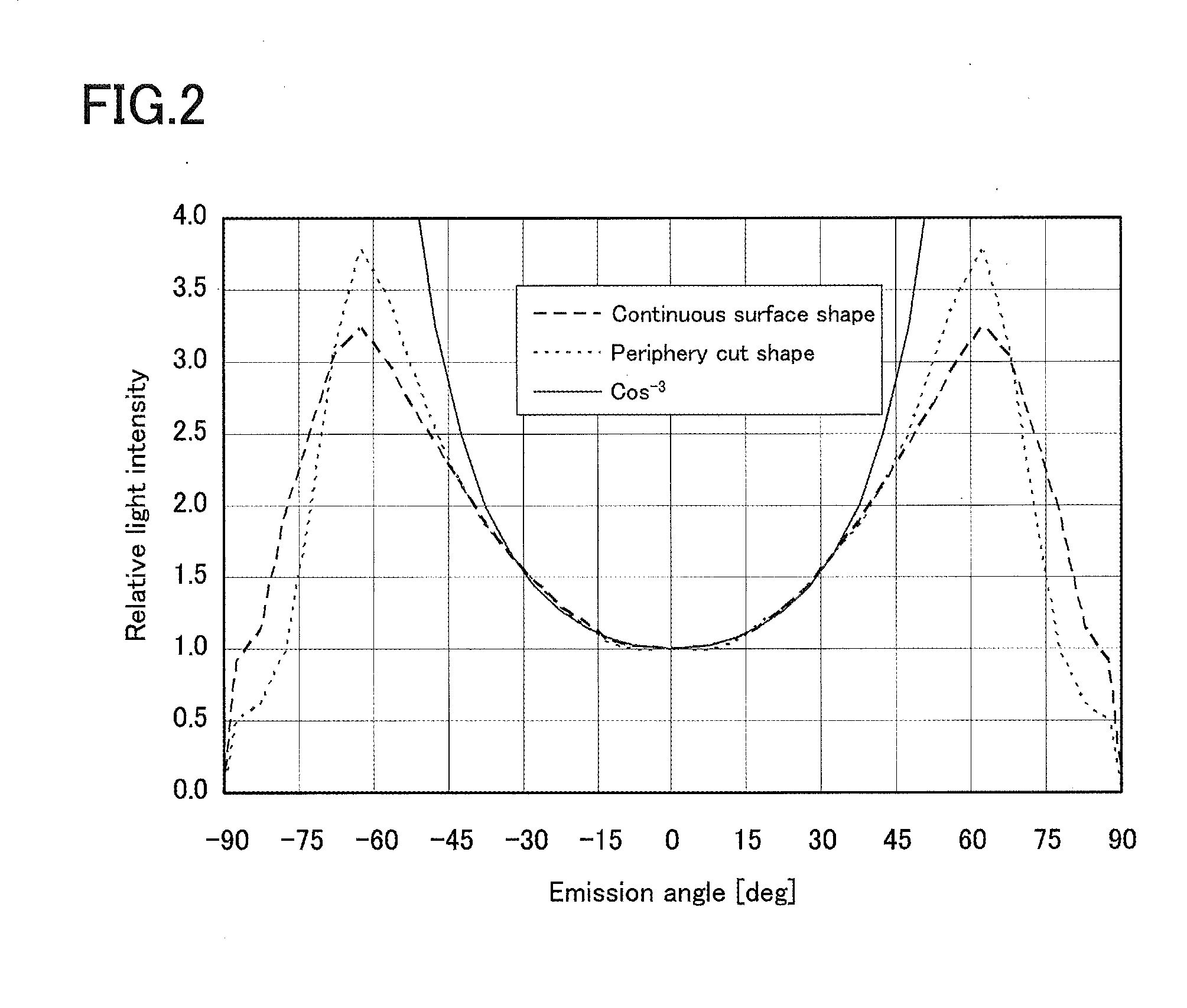

ActiveUS20100254145A1Increase light intensityIncrease the areaGlobesCondensersOptical axisEffect light

A lighting device includes a substrate, a LED element, and a lens. A light exit surface of the lens includes a first light exit surface and a second light exit surface. A curve obtained by cutting the light exit surface by a plane including the optical axis has, on a boundary between the first light exit surface and the second light exit surface, a change point at which a rate of inclination decreases discontinuously. An angle between the optical axis and a line segment connecting the change point and a light emission center of the LED element is approximately equal to an emission angle with the highest light intensity, among emission angles, when light rays emitted from the light exit surface are sorted by respective emission angles.

Owner:SHENZHEN JUFEI OPTOELECTRONICS

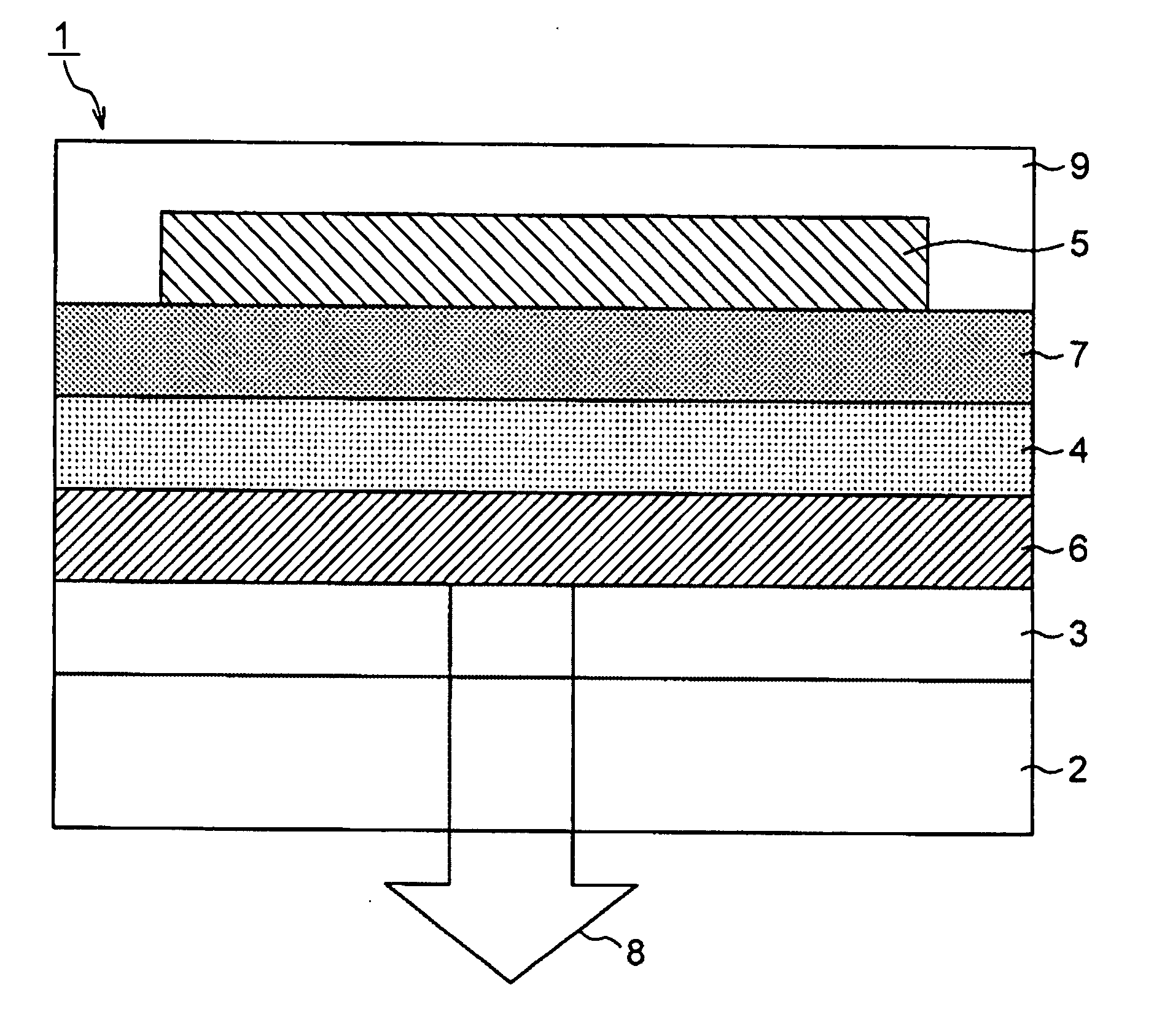

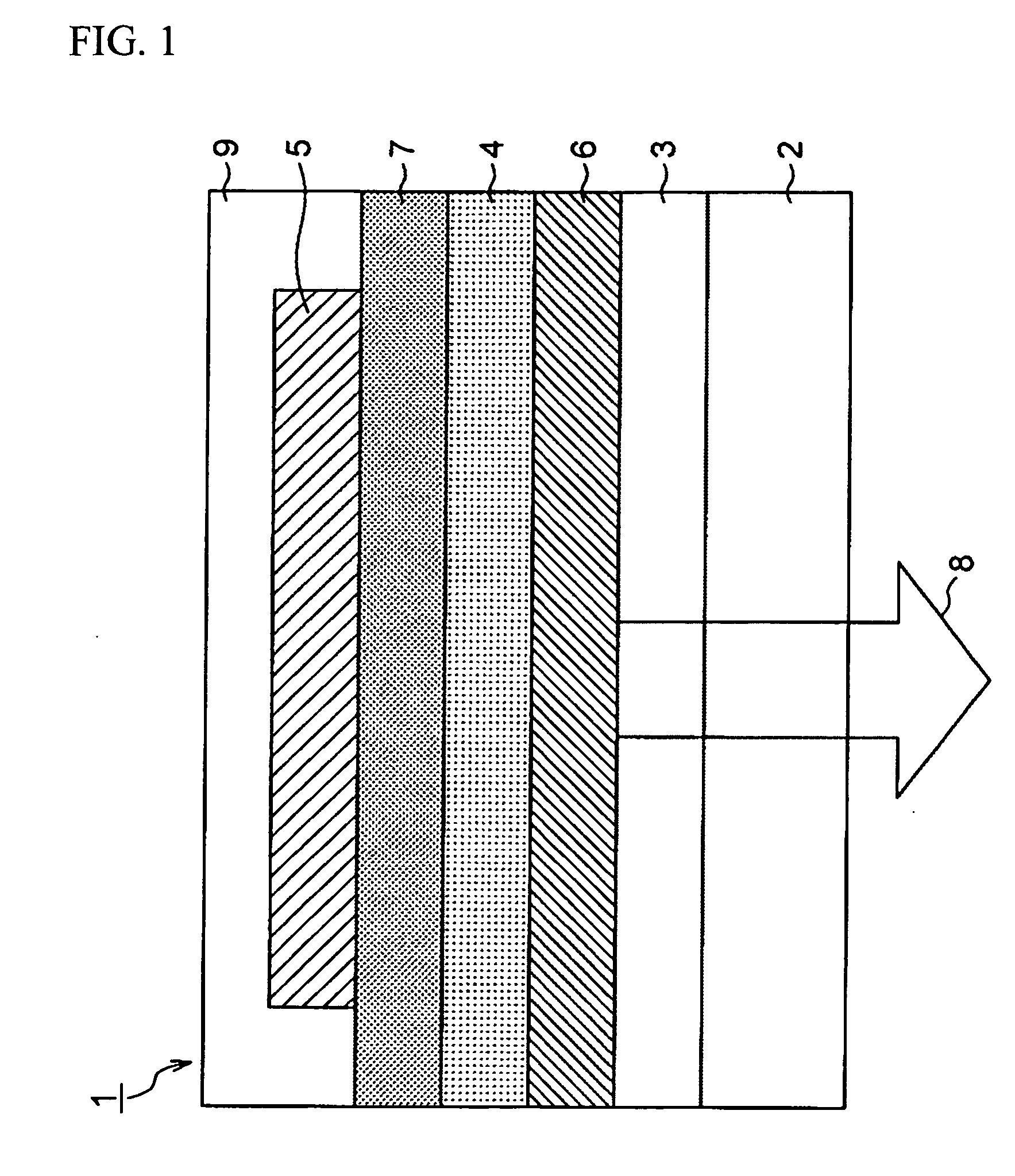

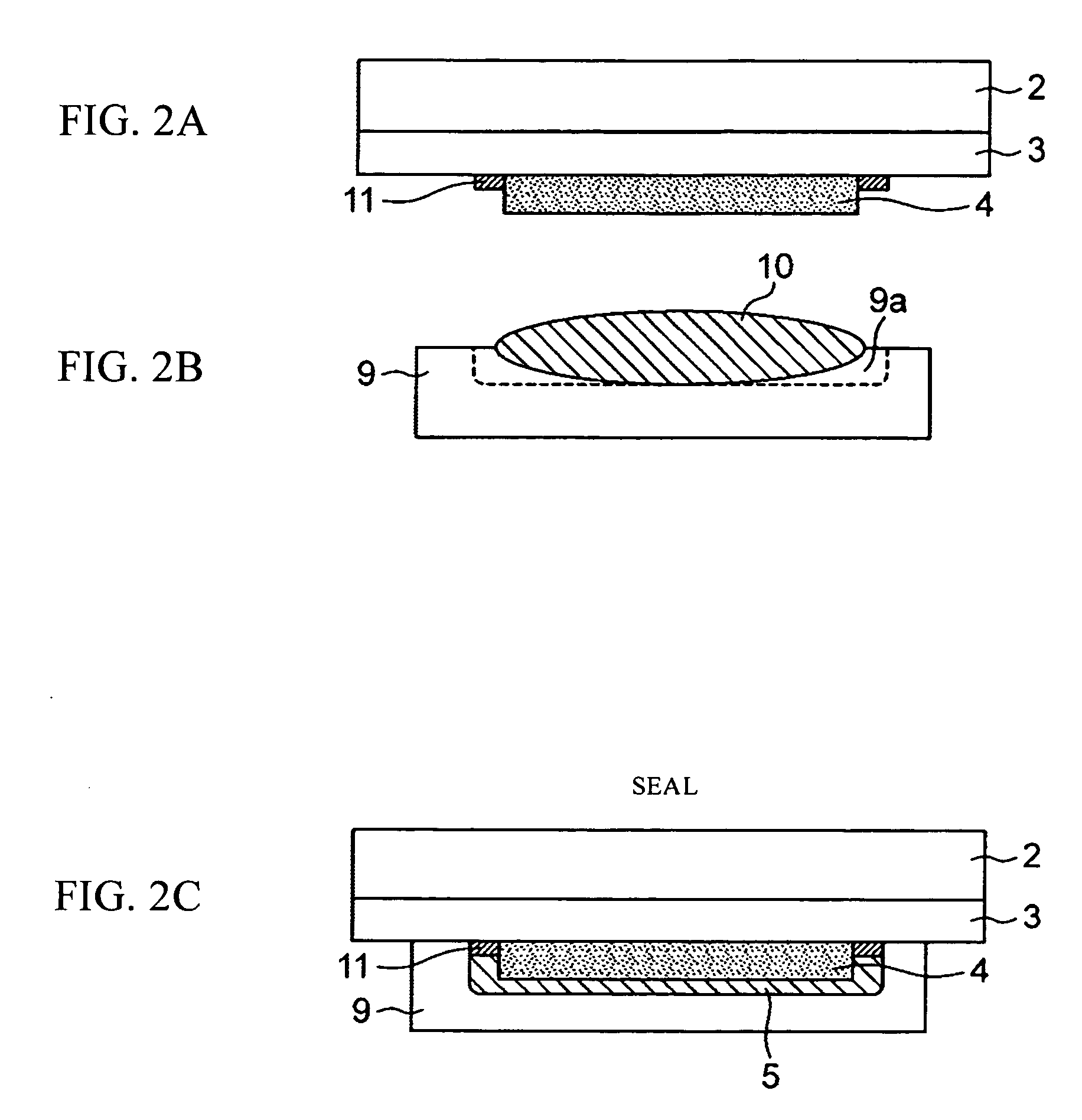

Electroluminescent display

ActiveUS20050012455A1Improved light emissionConvenient lightingDischarge tube luminescnet screensElectroluminescent light sourcesLight emissionVoltage

An EL display is provided with enhanced light emission characteristics wherein light emitted from a light-emitting layer undergoes constructive interference due to a resonance effect. The EL display includes a transparent substrate, an anode and a cathode formed on the same side of the transparent substrate, and an intermediate layer interposed between the anode and the cathode, and said intermediate layer including a light-emitting layer that emits light when the anode and the cathode are electrically driven by a voltage, and wherein the anode and the cathode are formed as a translucent conductive layer that partially reflects the light emitted from the light-emitting layer.

Owner:SAMSUNG DISPLAY CO LTD

Organic functional element, organic EL element, organic semiconductor element, organic TFT element and method for producing the same

InactiveUS20060066224A1Easy to controlUniform light emitting surfaceDischarge tube luminescnet screensFinal product manufactureLiquid metalOrganic semiconductor

The present invention provides an organic functional element such as an organic EL element, an organic TFT element or the like, wherein the organic functional element does not require vapor deposition in formation of an electrode on an organic material layer, and does not cause an electrode breaking even when bended, and a method for producing the same. An organic functional element of the present invention at least comprises more than one electrode and an organic material layer, wherein at least one electrode is made of a liquid metal.

Owner:DAI NIPPON PRINTING CO LTD

Light emitting device

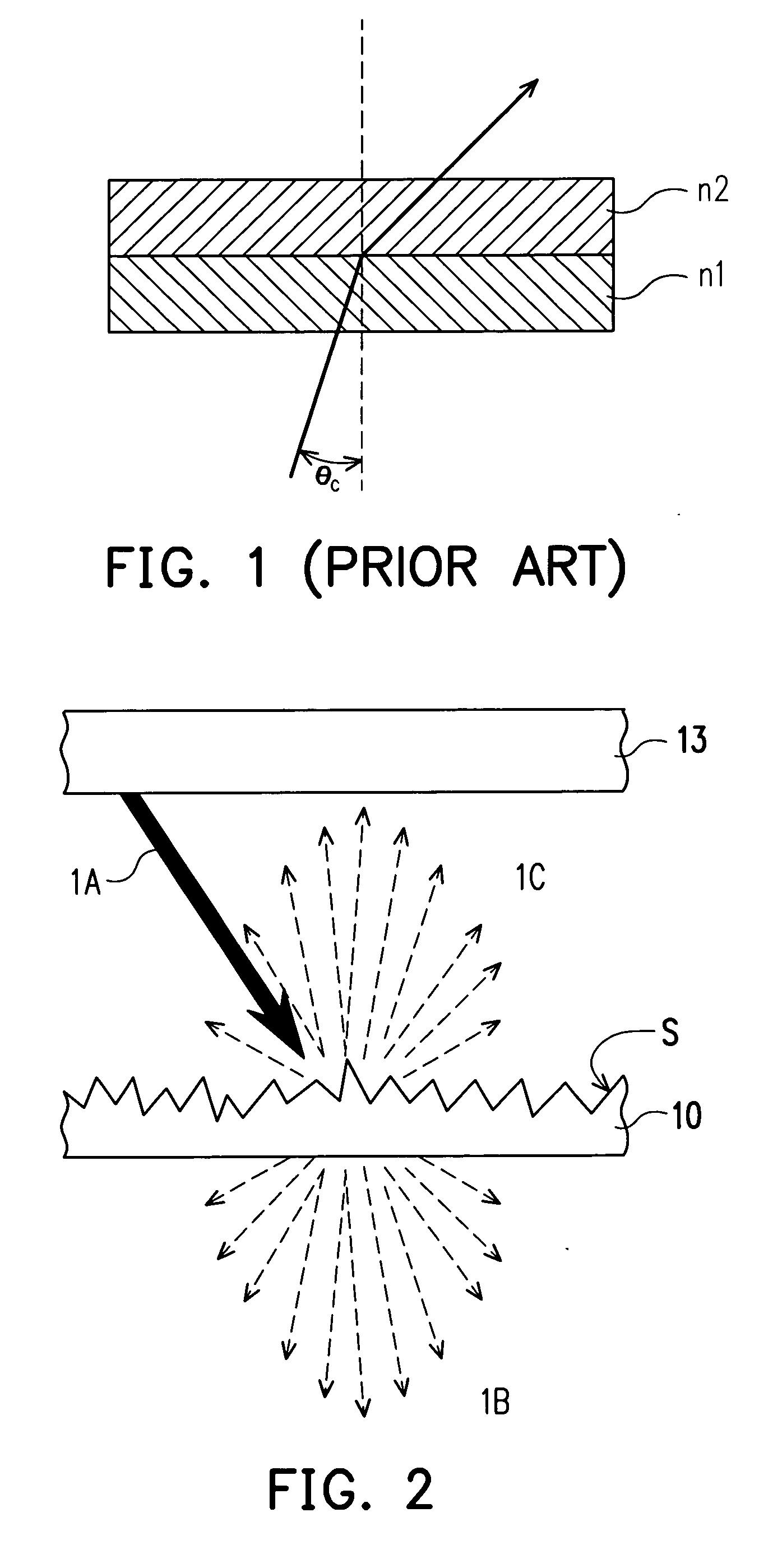

ActiveUS20060163595A1Different refractive indexRaise the possibilityIncadescent screens/filtersDischarge tube luminescnet screensRefractive indexLight emitting device

A light emitting device having a transparent substrate, a light emitting stack, and a transparent adhesive layer is provided. The light emitting stack is disposed above the transparent substrate and comprises a diffusing surface. The transparent adhesive layer is disposed between the transparent substrate and the diffusing surface of the light emitting stack; an index of refraction of the light emitting stack is different from that of the transparent adhesive layer.

Owner:EPISTAR CORP

Light emitting diode

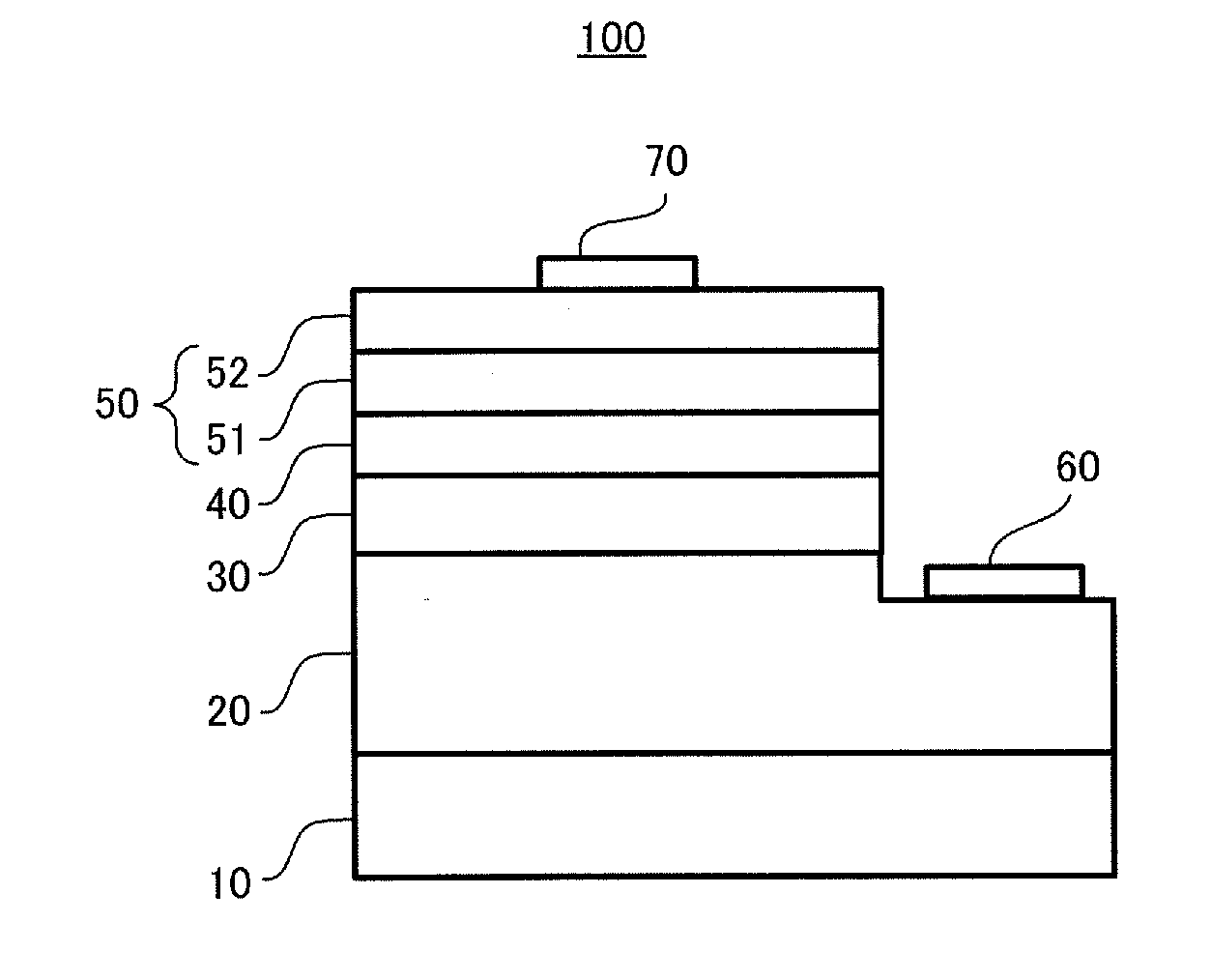

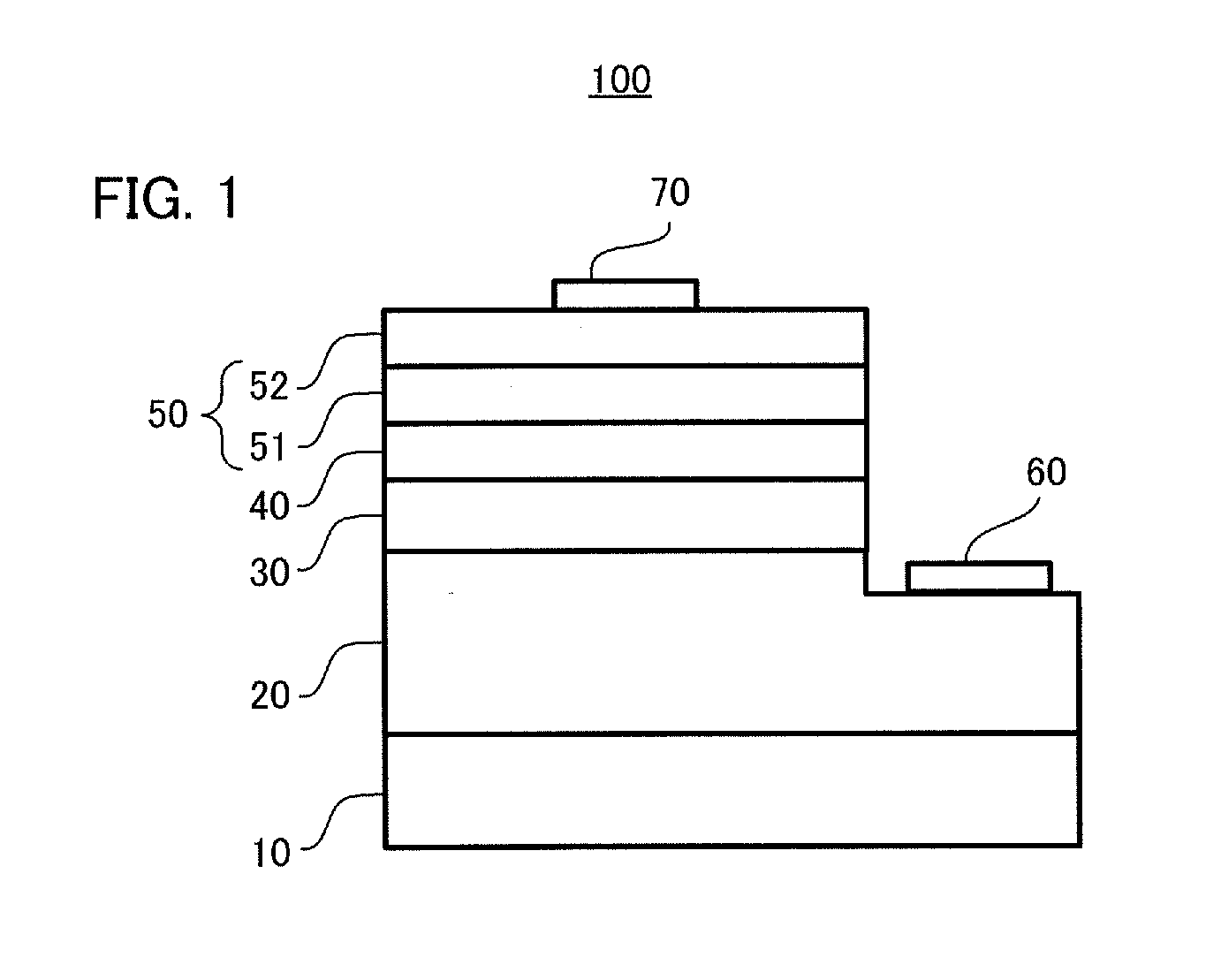

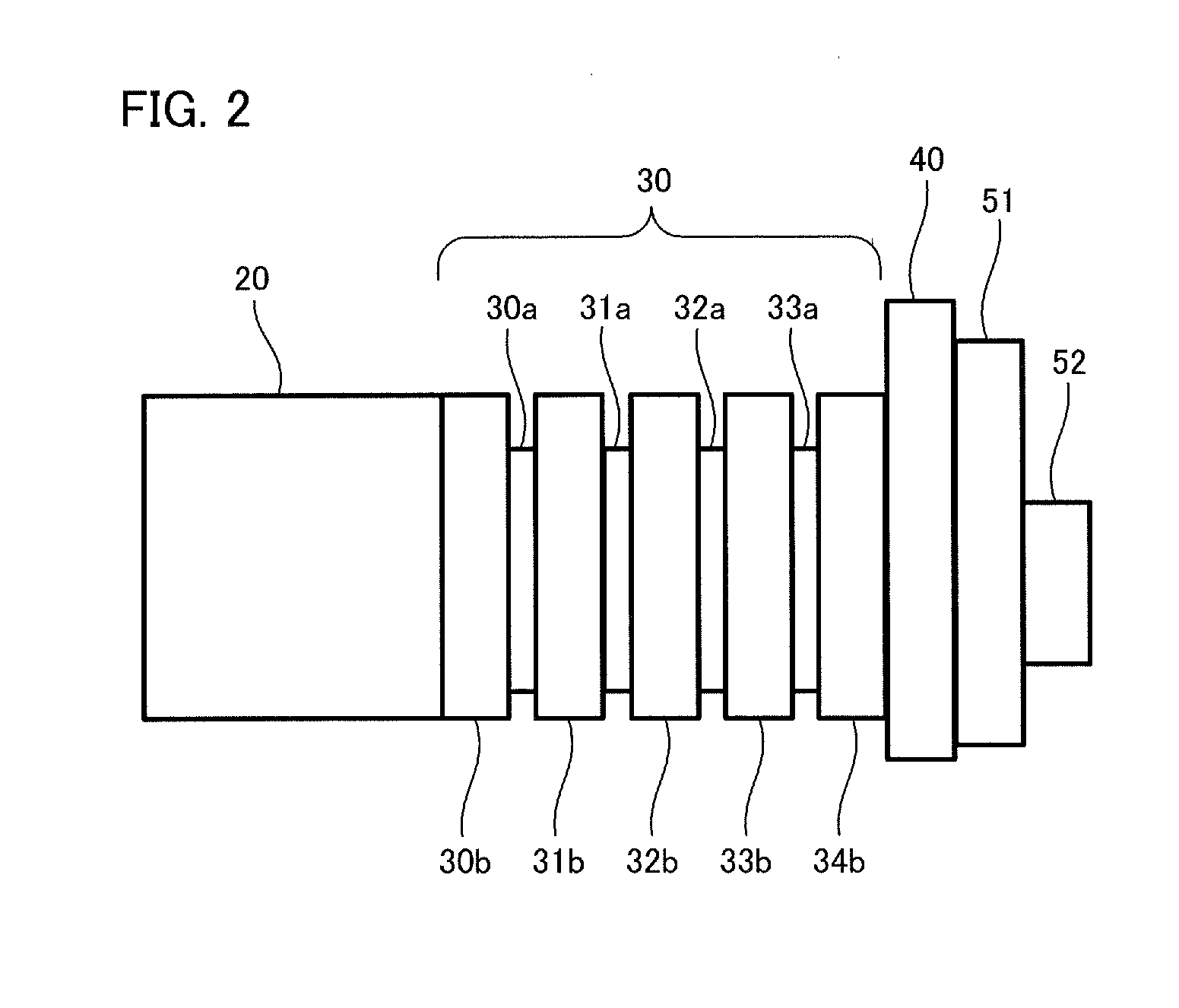

ActiveUS20120043575A1Improved light emissionImprove cooling efficiencySolid-state devicesSemiconductor devicesElectrical conductorRefractive index

A light emitting diode is disclosed. The disclosed light emitting diode includes a light emitting structure including a first semiconductor layer, a second semiconductor layer, and an active layer interposed between the first and second semiconductor layers, a first electrode electrically connected to the first semiconductor layer, a second electrode electrically connected to the second semiconductor layer, and a first reflection layer disposed on the second semiconductor layer. The first reflection layer includes at least a first layer having a first index of refraction and a second layer having a second index of refraction different from the first index of refraction. The first reflection layer is further disposed on a side surface of the second electrode and a portion of an upper surface of the second electrode.

Owner:SUZHOU LEKIN SEMICON CO LTD

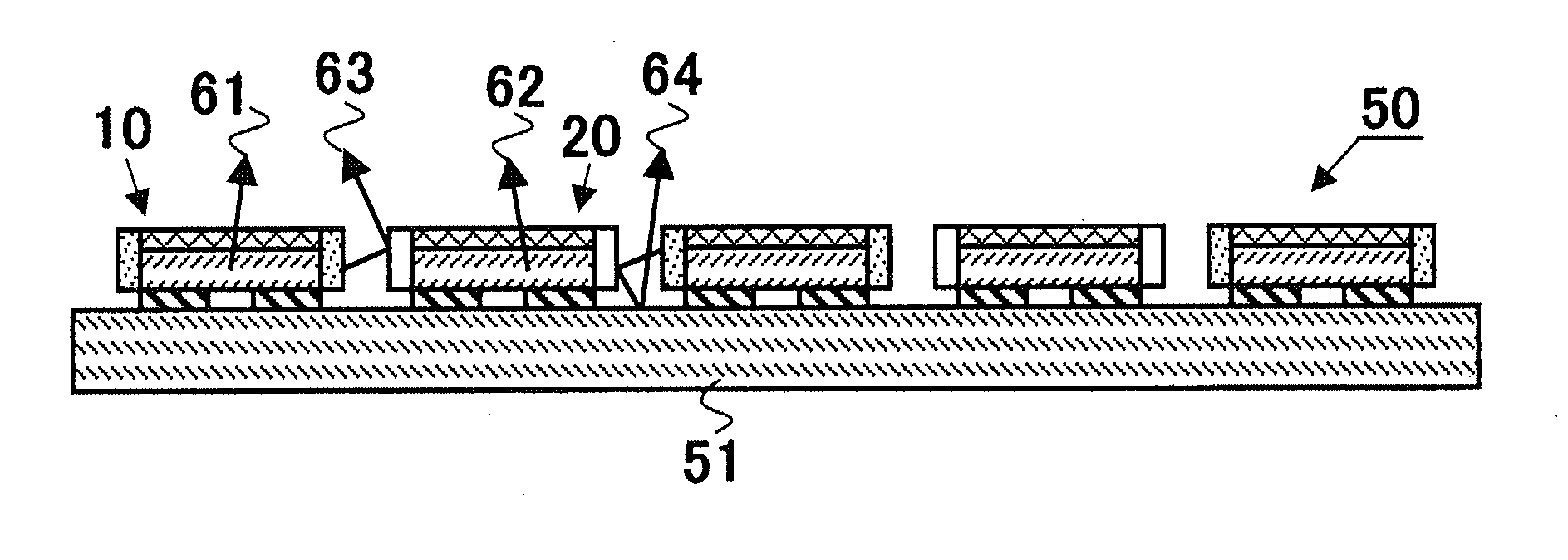

LED module

ActiveUS20150316215A1Bright lightImproved light emissionNon-electric lightingPlanar light sourcesThumb oppositionEngineering

Provided is an LED module which, even when CSP LED devices are arrayed adjacent to each other, emits light at a light emission color of a single LED device and is bright. An LED module includes a module substrate, first LED devices having a lateral surface which is configured of an optically transmissive face, and second LED devices having a lateral surface which is configured of a light blocking face. The first LED devices are mounted upon the module substrate adjacent to the second LED devices such that the translucent faces of the first LED devices and the light blocking faces of the second LED devices are in opposition.

Owner:CITIZEN WATCH CO LTD +1

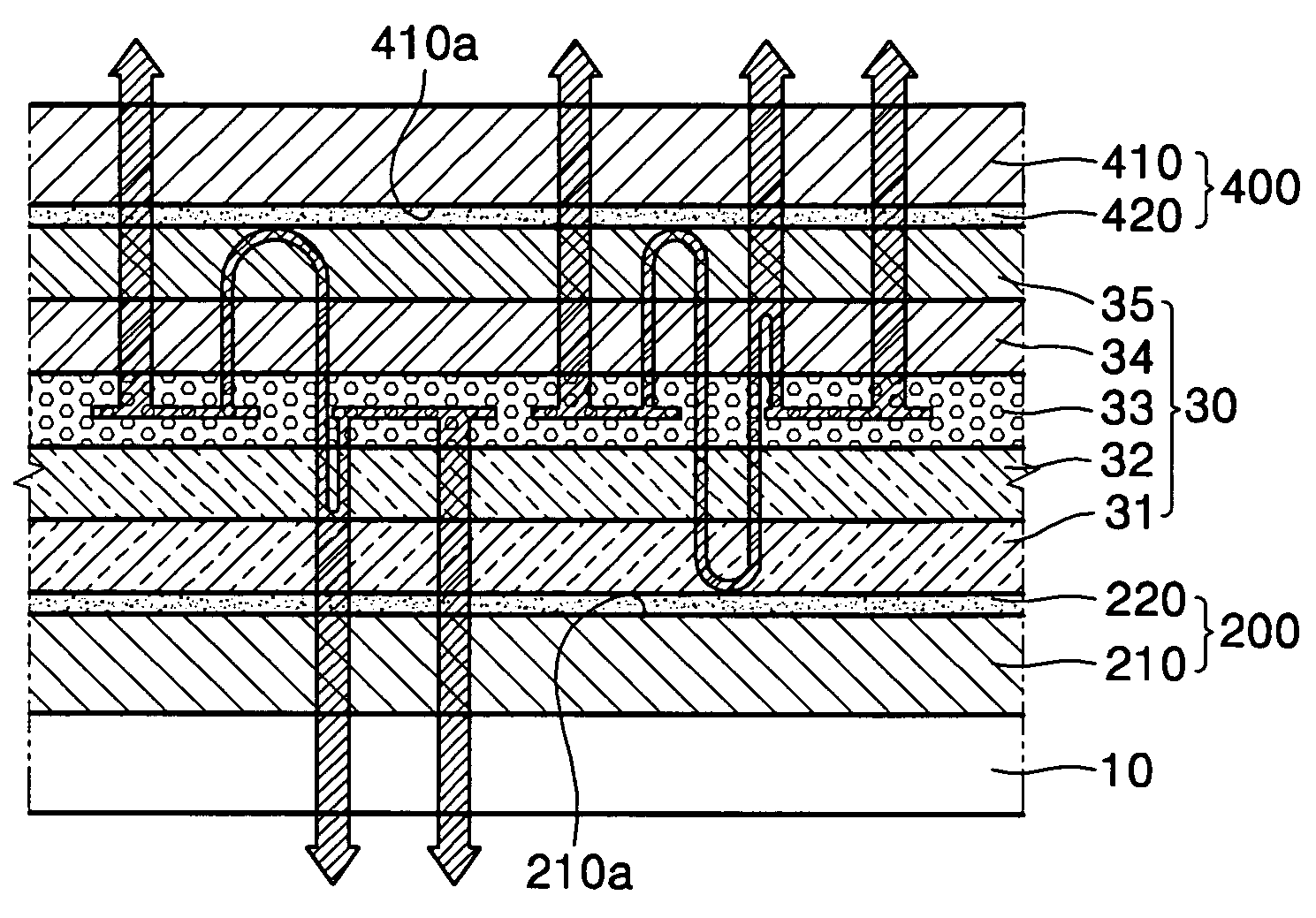

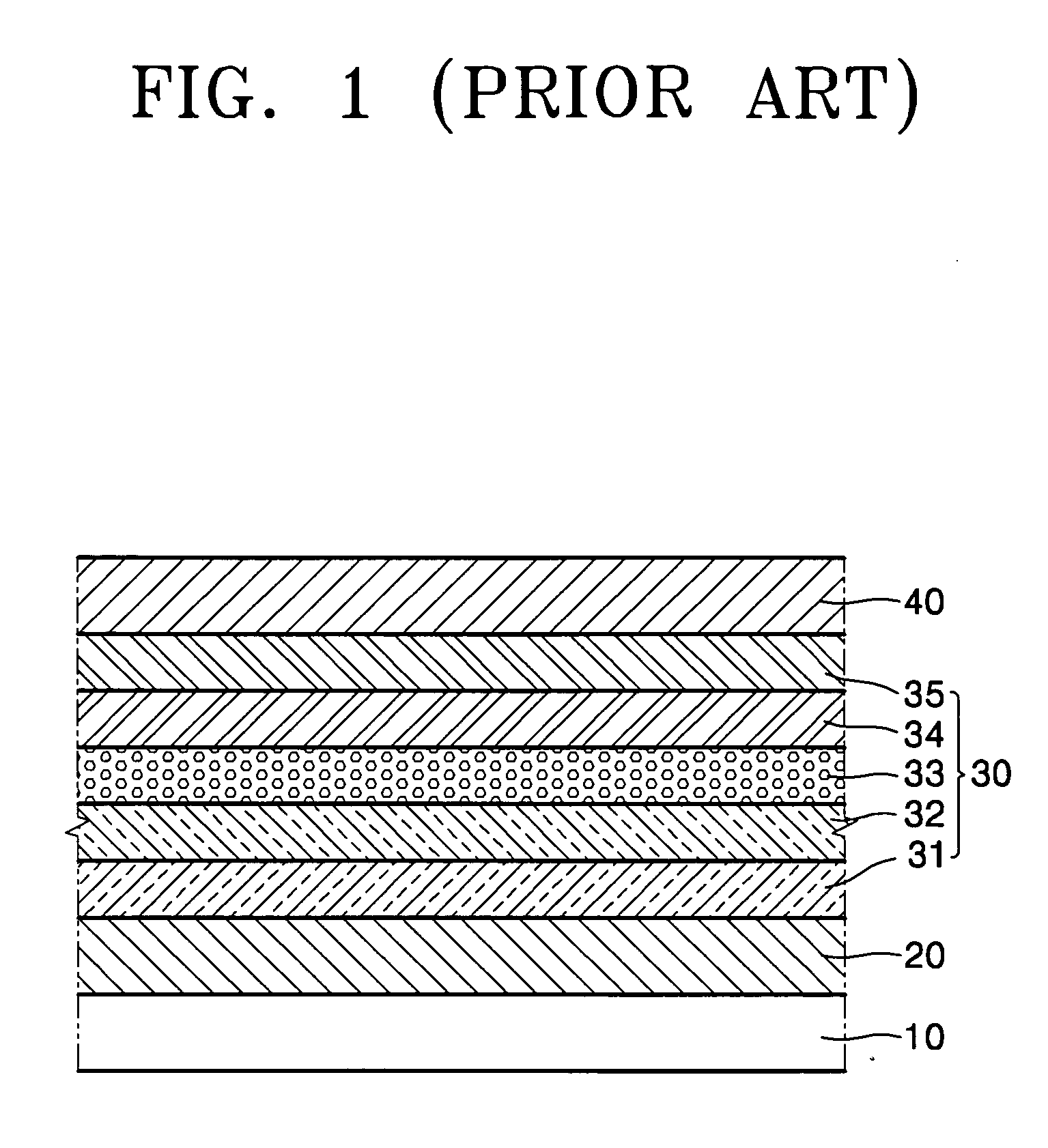

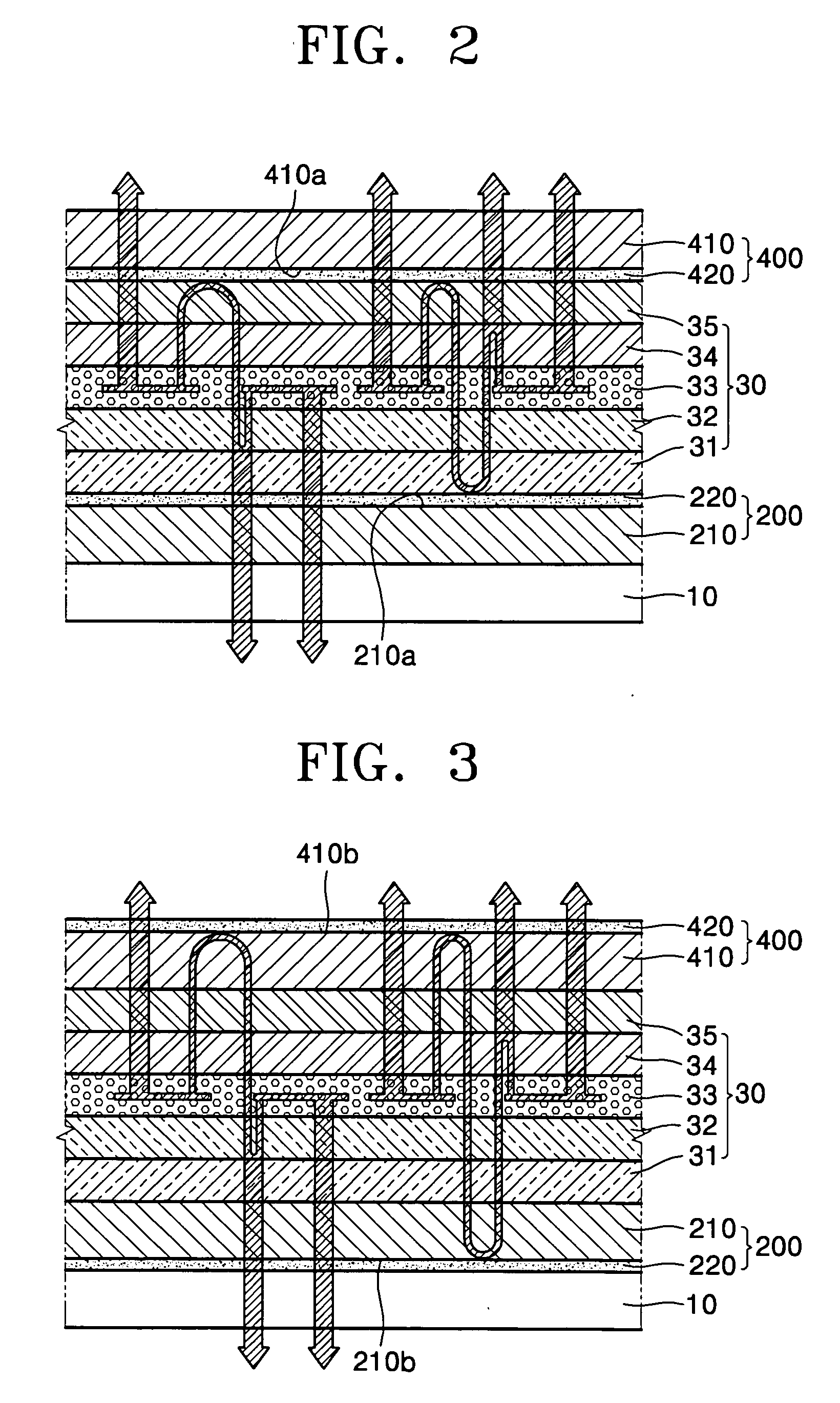

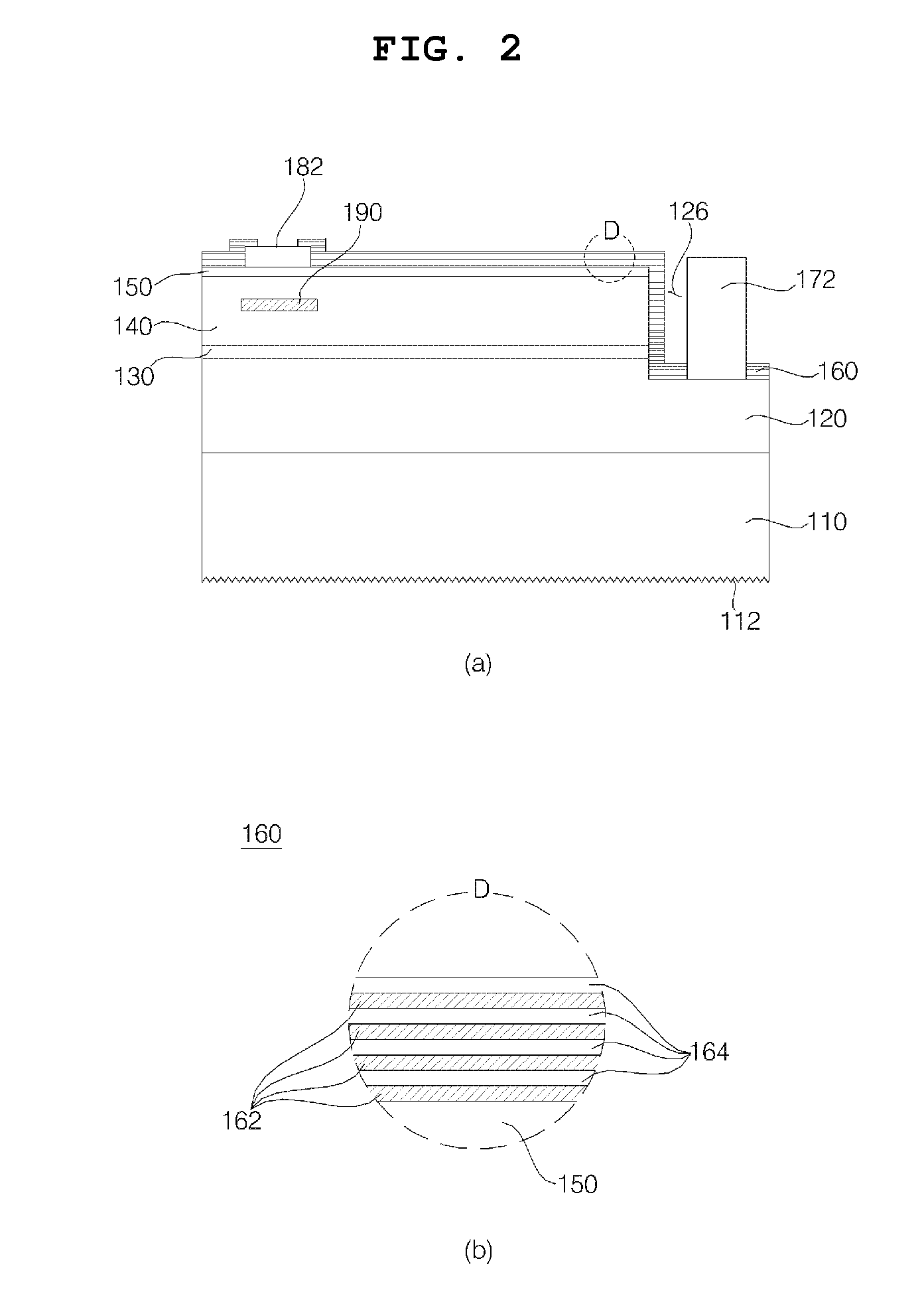

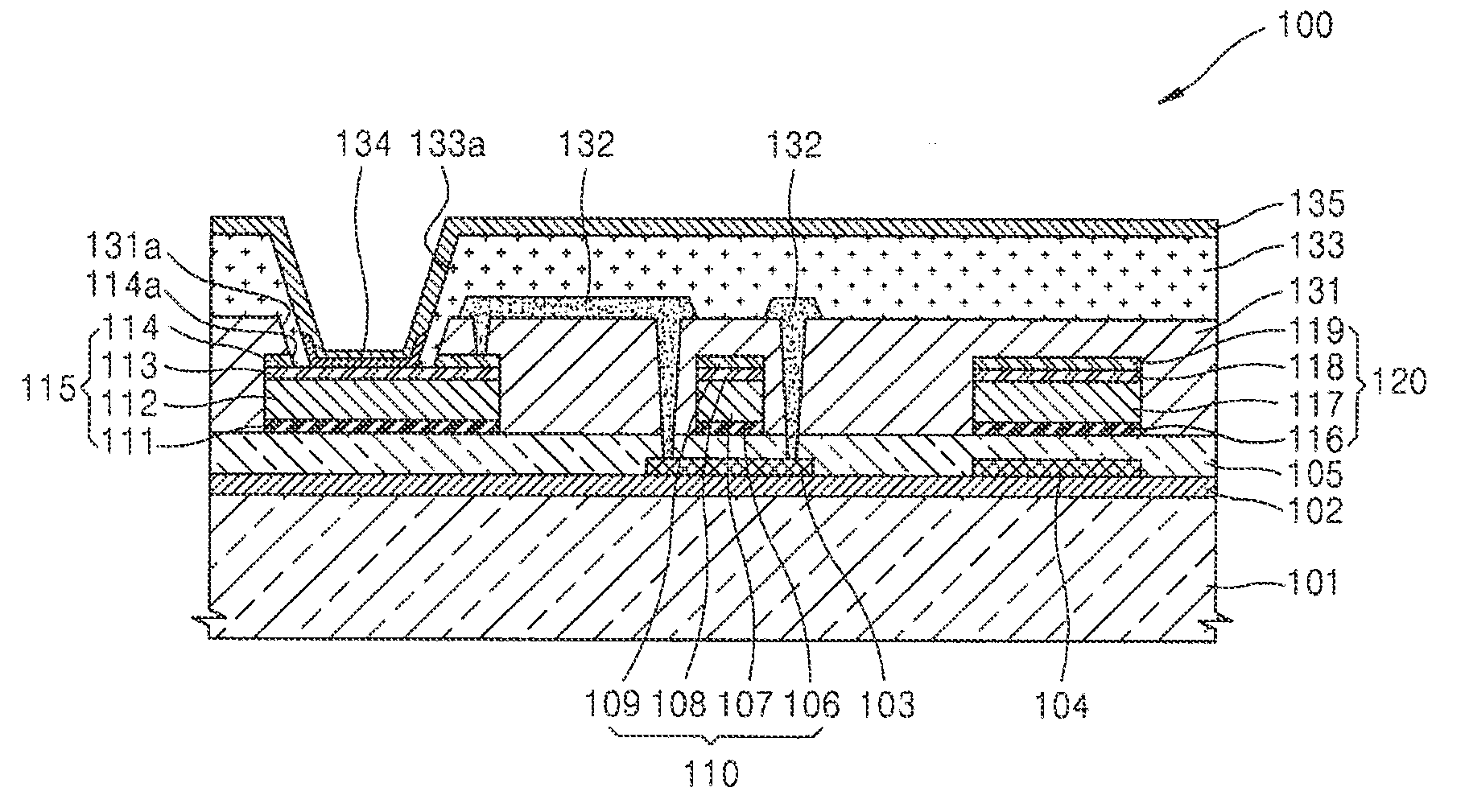

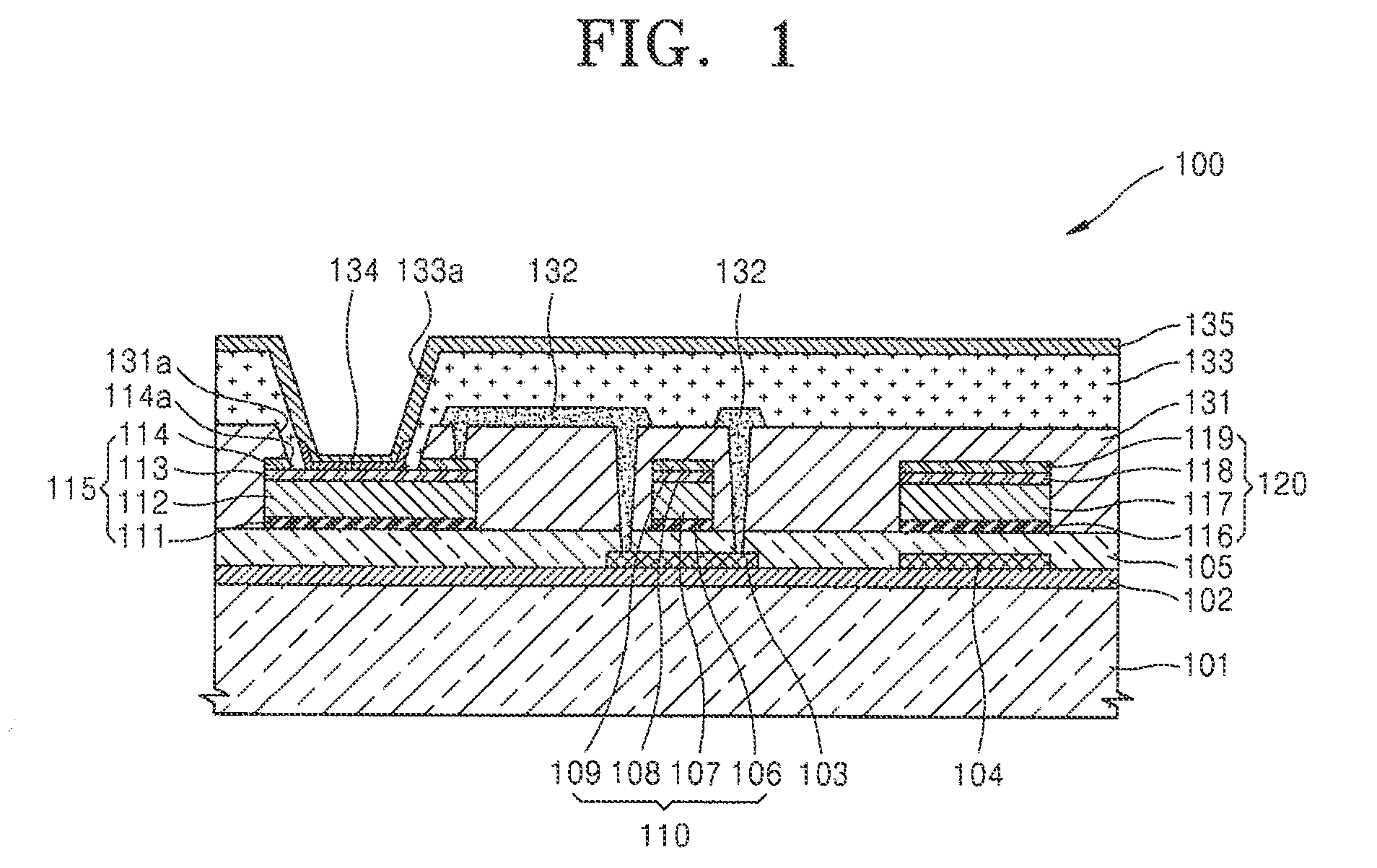

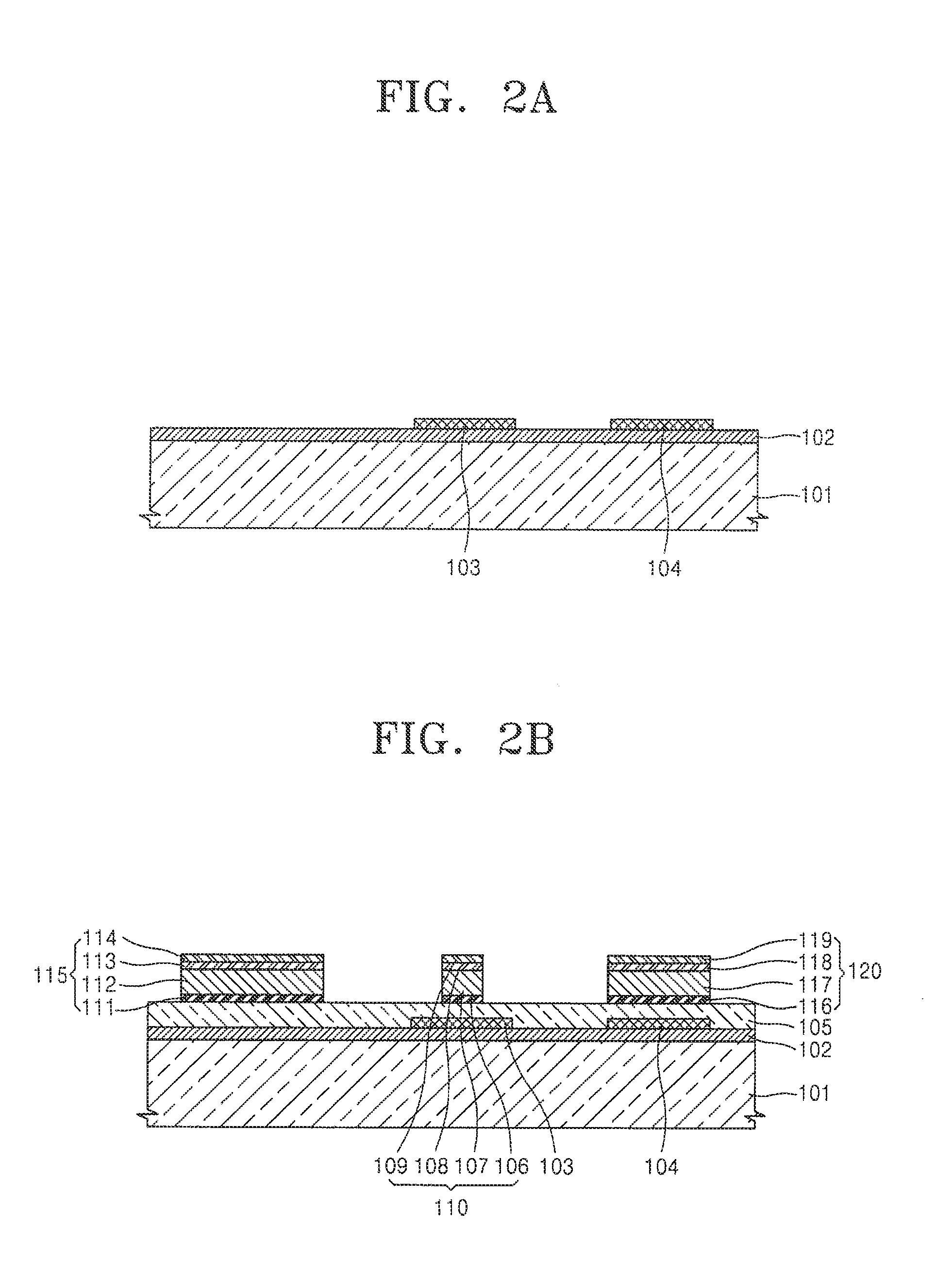

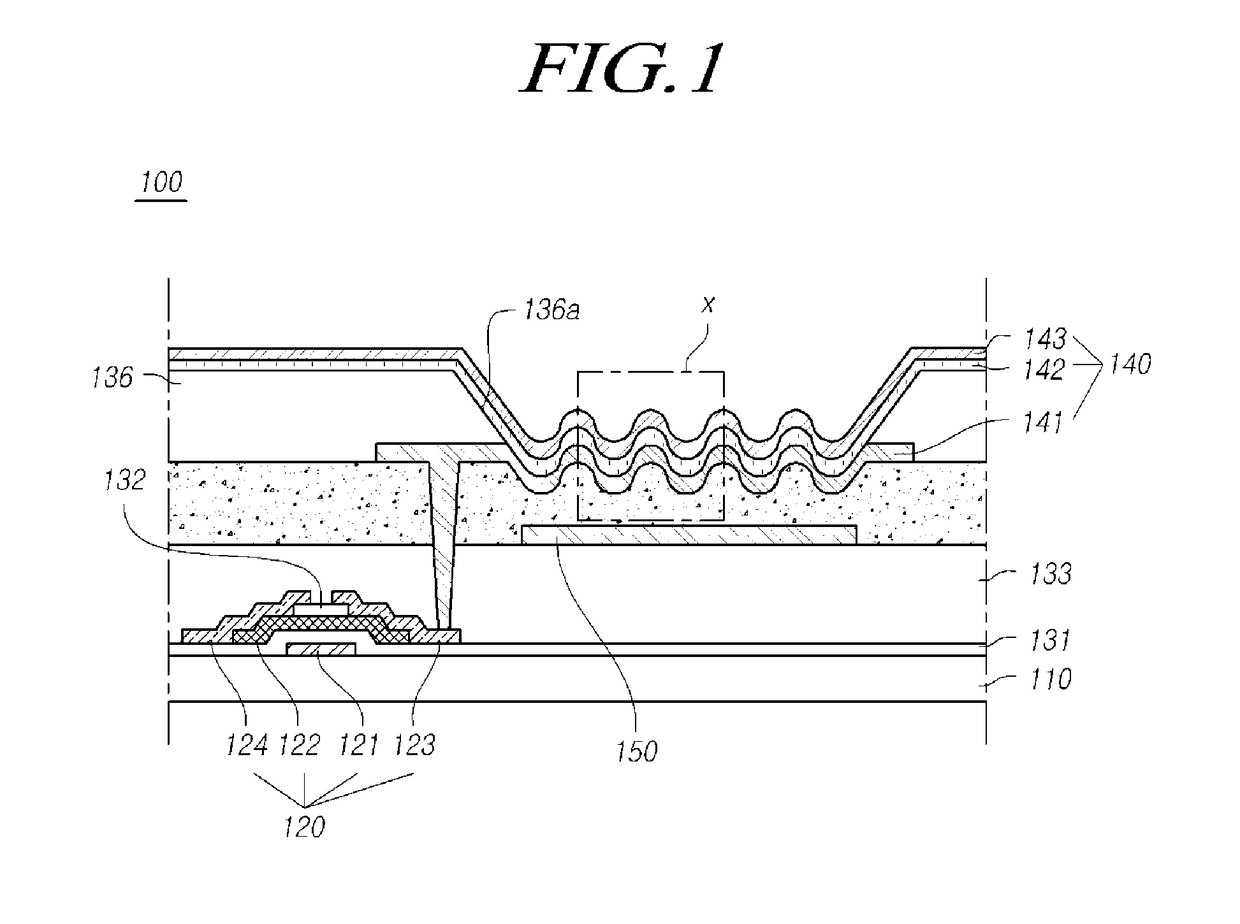

Organic Light Emitting Display Apparatus and Method of Manufacturing the Same

ActiveUS20110114956A1Simple manufacturing processImproved light emissionSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsElectrode

An organic light emitting display apparatus and a method of manufacturing the organic light emitting display apparatus, whereby the manufacturing process is simplified and the electric characteristics of the organic light emitting display apparatus are improved. The organic light emitting display apparatus includes: a gate electrode that includes a first conductive layer including ITO, a second conductive layer on the first conductive layer, a third conductive layer on the second conductive layer and including ITO, and a fourth conductive layer on the third conductive layer and including IZO or AZO; and a pixel electrode formed in the same layer level as the gate electrode and including a first electrode layer that includes ITO, a second electrode layer on the first electrode layer, a third electrode layer on the second electrode layer and including ITO, and a fourth electrode layer on the third electrode layer and including IZO or AZO.

Owner:SAMSUNG DISPLAY CO LTD

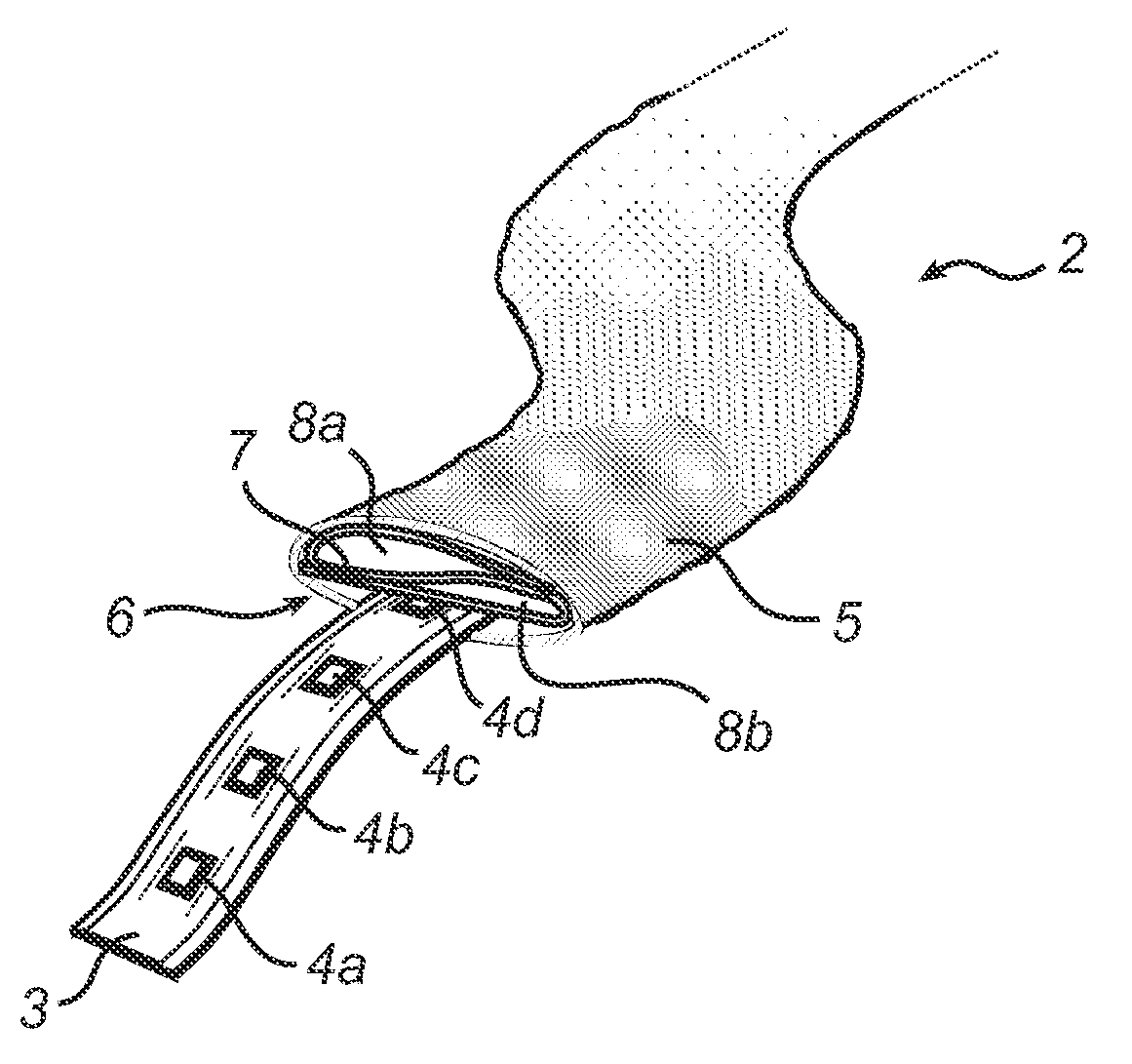

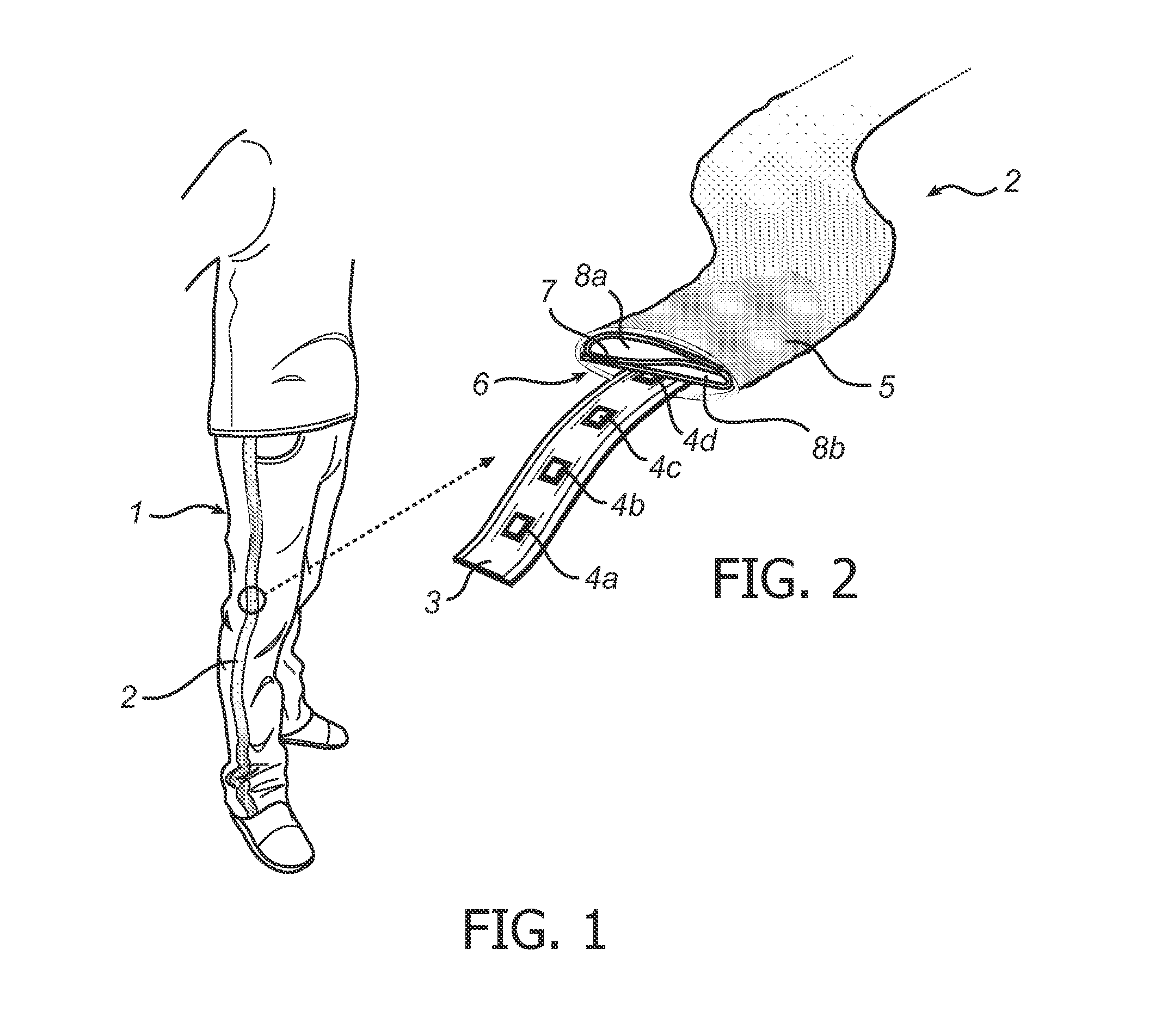

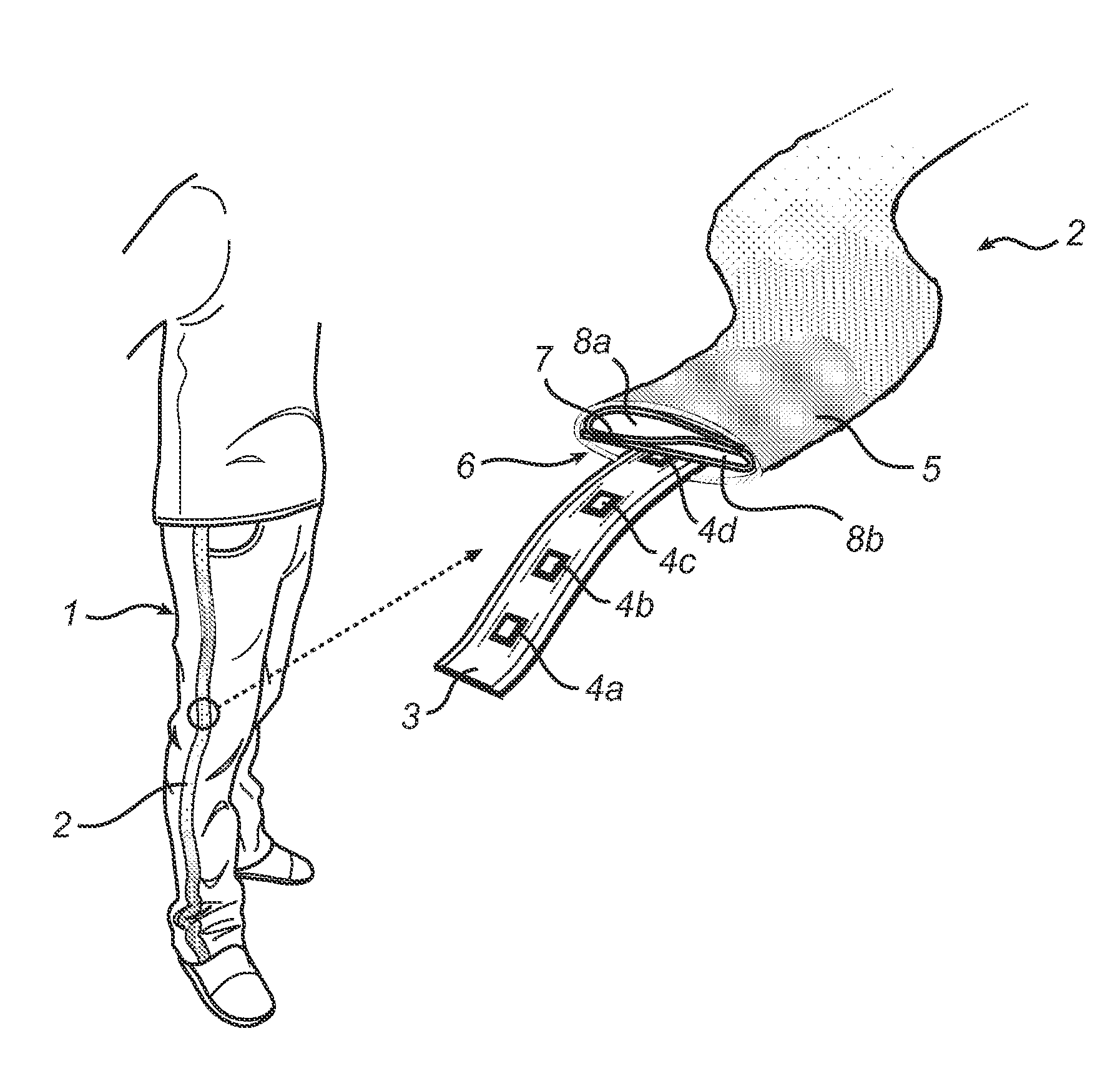

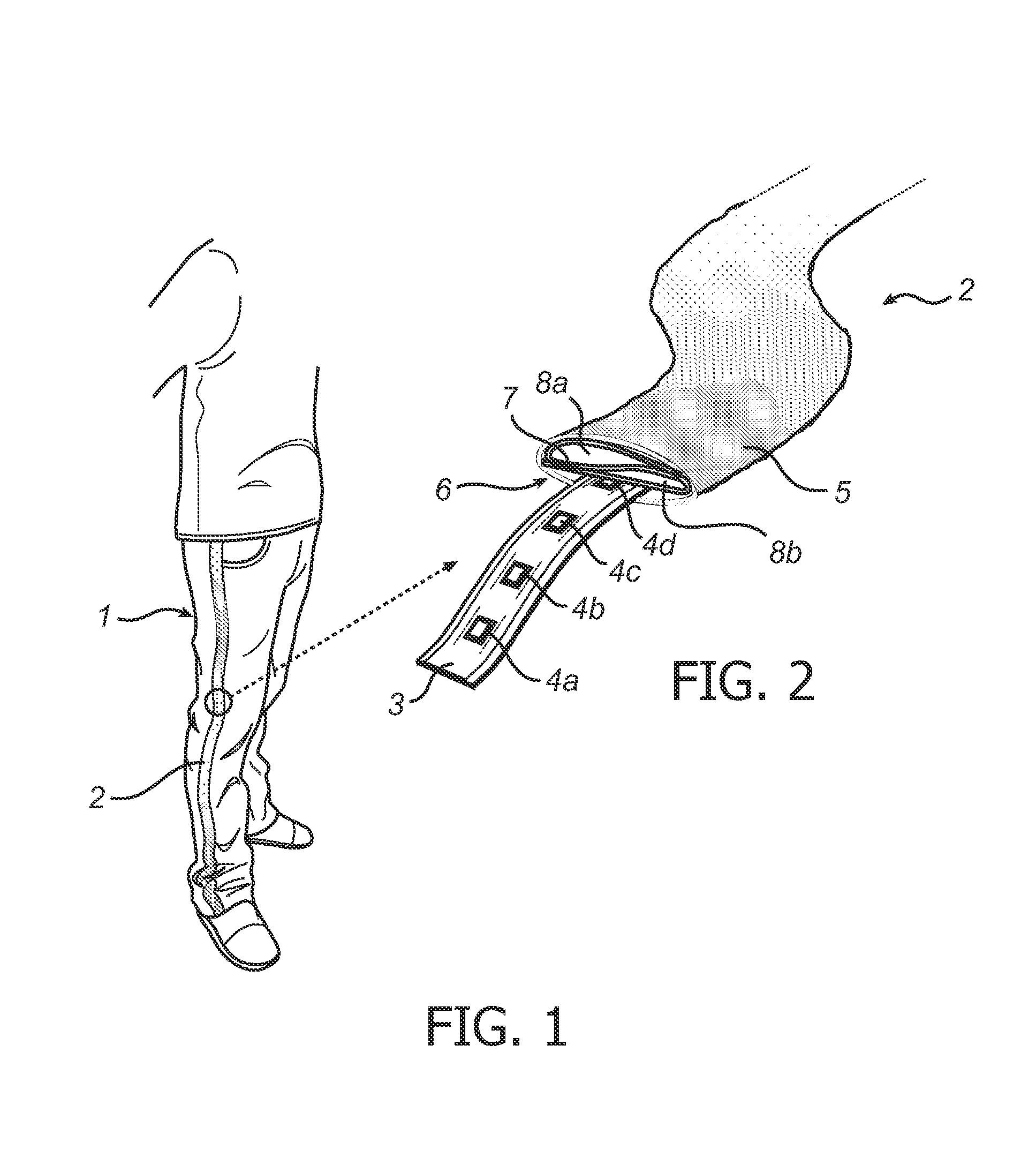

Light-emitting electronic textile with improved light diffusion

InactiveUS20120155065A1Easy to optimizeImproved light emissionPoint-like light sourceWave amplification devicesEngineeringElectron

A light-emitting electronic textile (2) comprising a flexible component carrier (3) having a plurality of light-sources (4a-c) arranged thereon; a cover textile (5) arranged to allow passage through the cover textile (5) of light emitted by the light-sources (4a-c); and a light-diffusing member (6) arranged between the light-sources (4a-c) and the cover textile (5). The light-diffusing member (6) comprises a layered structure formed by a plurality of light-diffusing layers (12a-c; 16a-b; 19a-c), wherein adjacent light-diffusing layers in the layered structure are spaced apart at least in portions of the light-diffusing member (6) corresponding to positions of the light-sources (4a-c).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

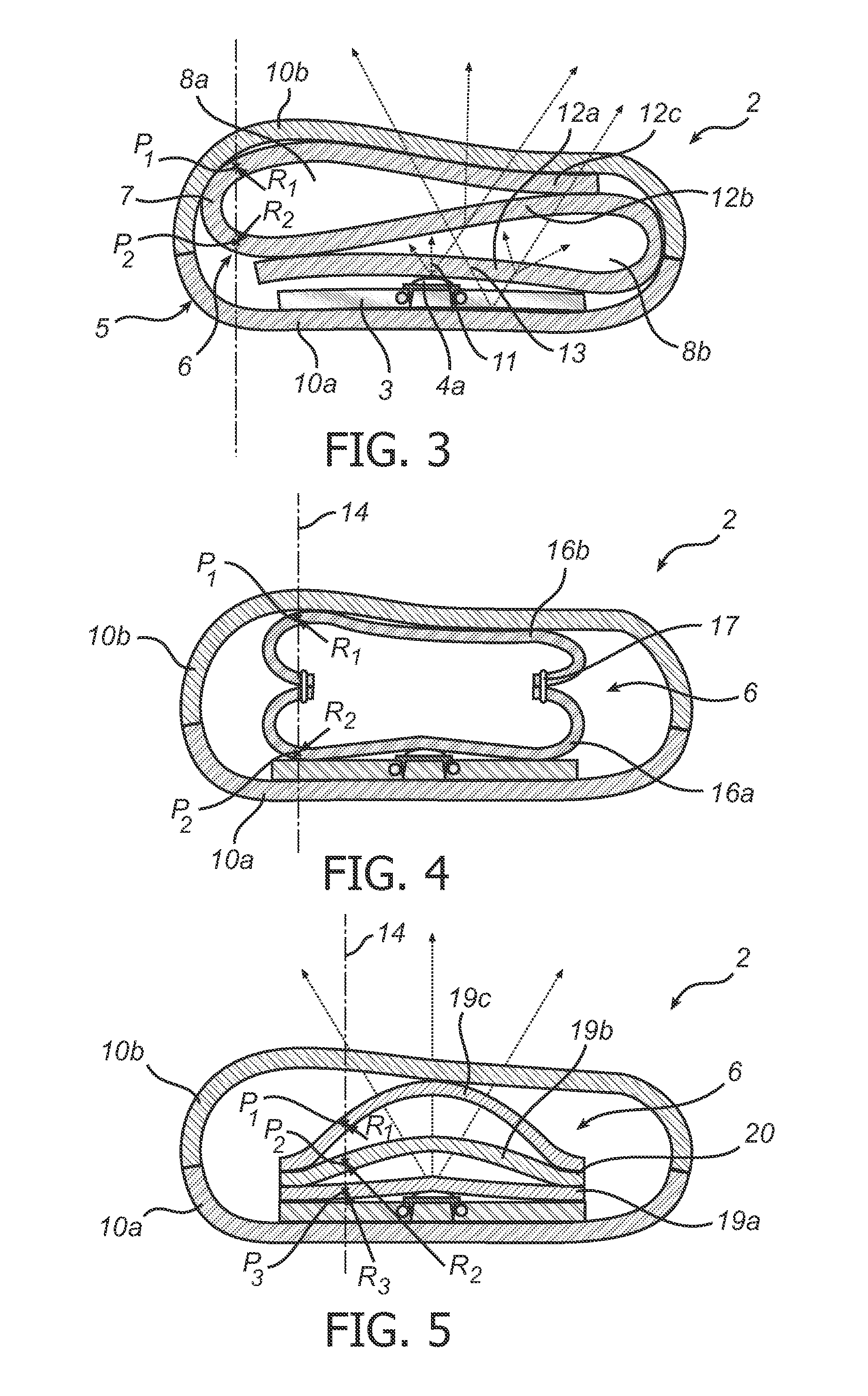

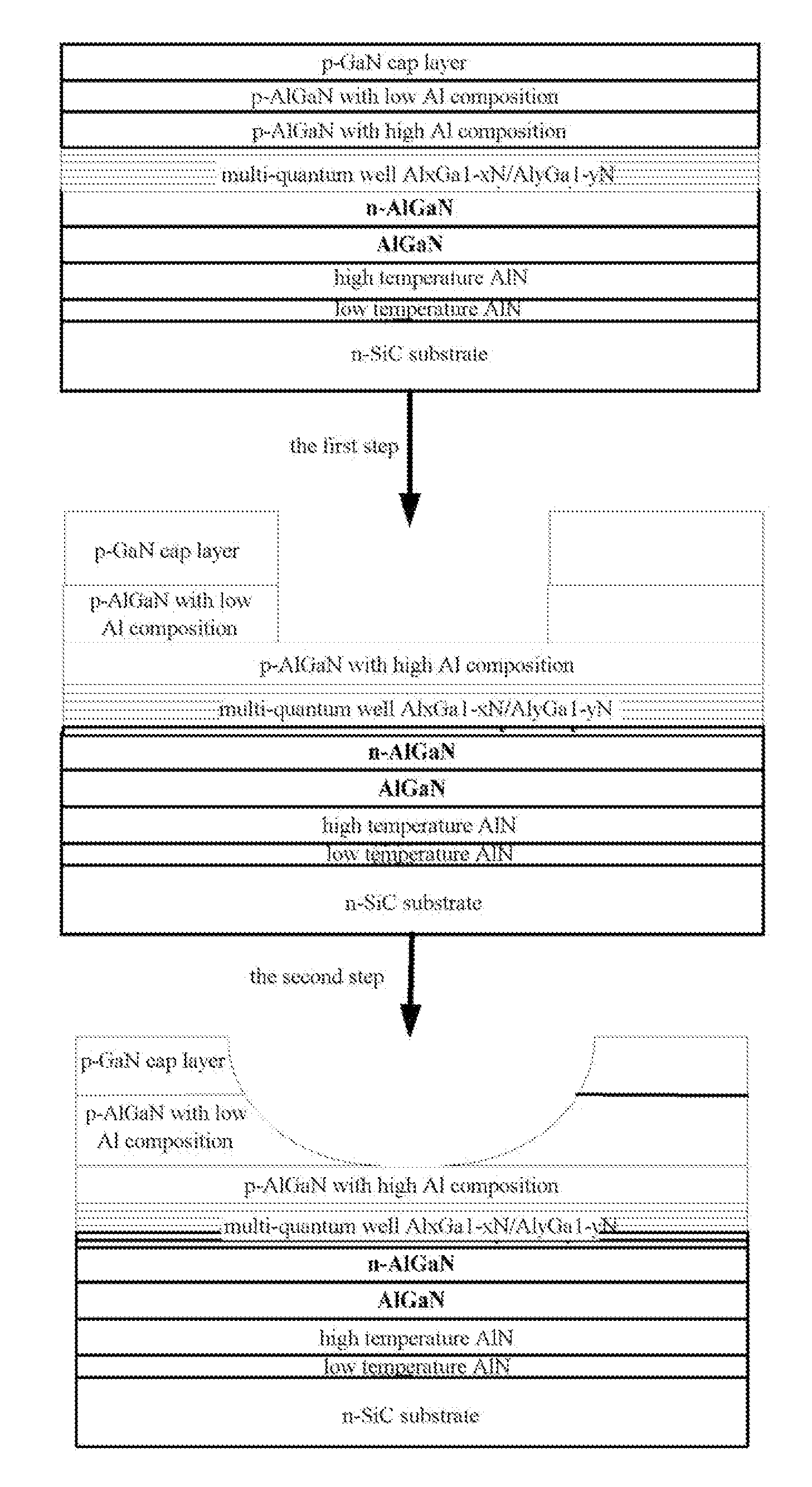

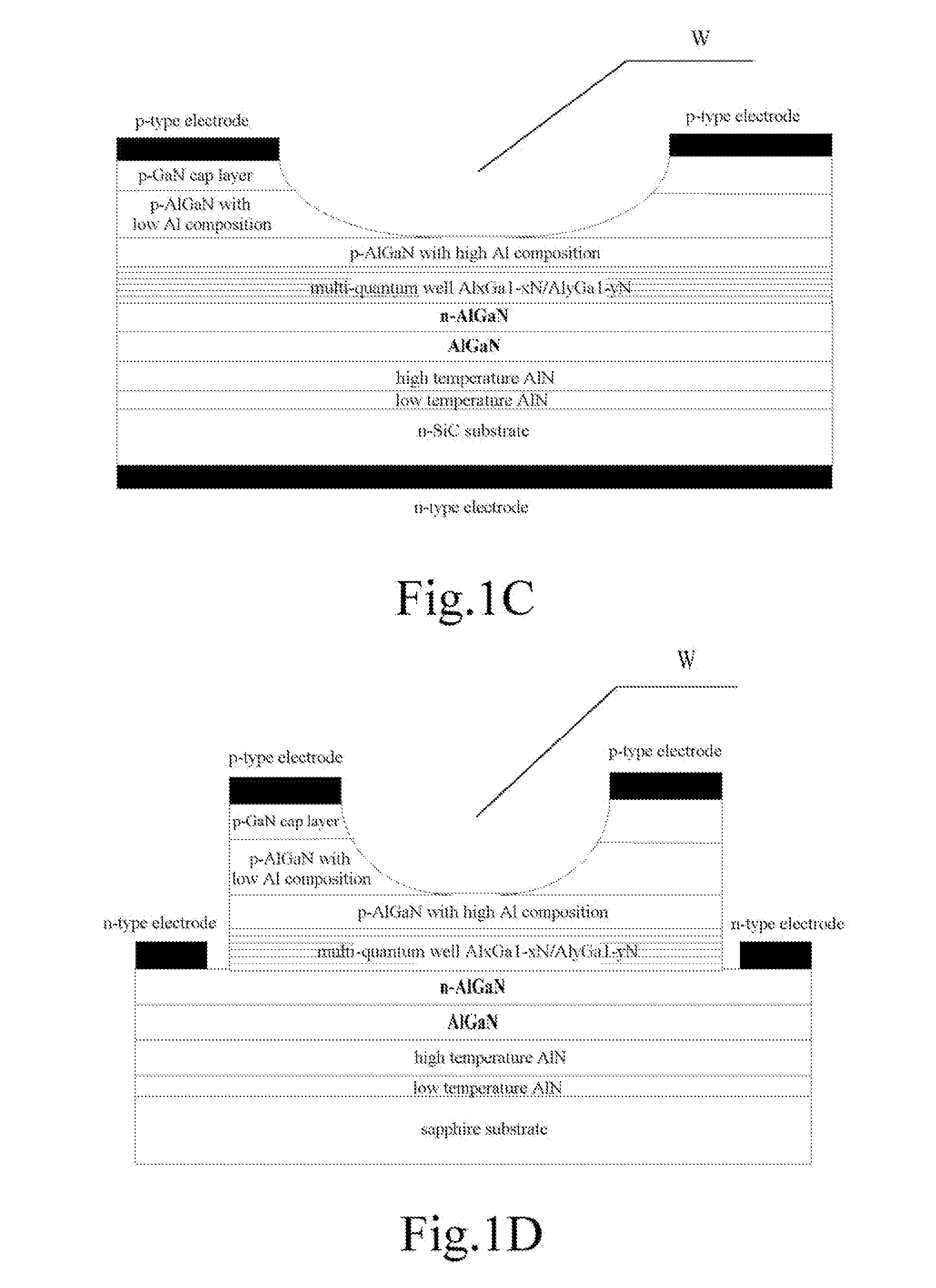

Ultraviolet light emitting diode devices and methods for fabricating the same

InactiveUS20120018753A1Easy to practiceImproved light emissionSemiconductor/solid-state device manufacturingSemiconductor devicesUltraviolet lightsGallium nitride

A UV LED device and the method for fabricating the same are provided. The device has aluminum nitride nucleating layers, an intrinsic aluminum gallium nitride epitaxial layer, an n-type aluminum gallium nitride barrier layer, an active region, a first p-type aluminum gallium nitride barrier layer, a second p-type aluminum gallium nitride barrier layer, and a p-type gallium nitride cap layer arranged from bottom to top on a substrate. A window region is etched in the p-type gallium nitride cap layer for emitting the light generated.

Owner:XIDIAN UNIV

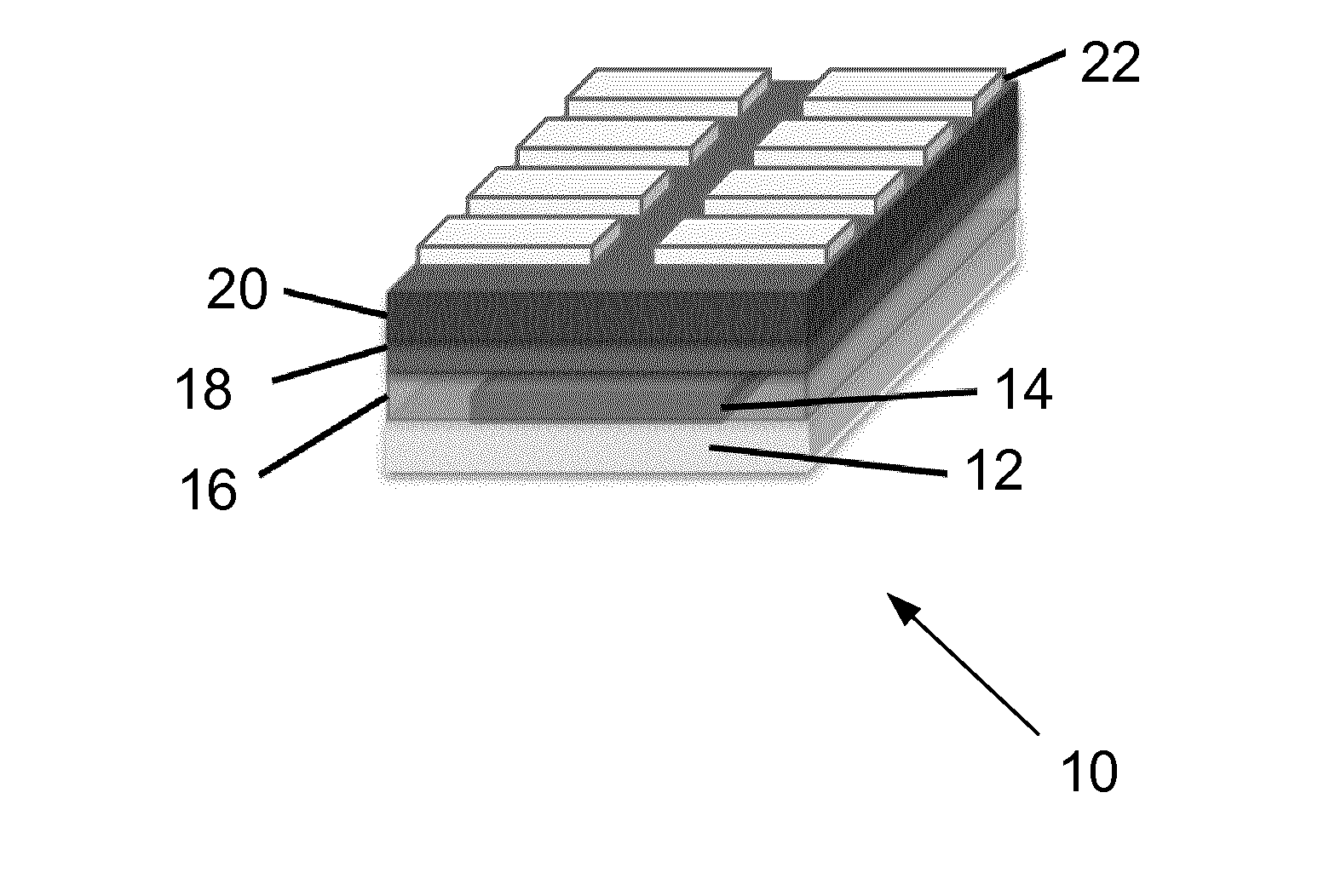

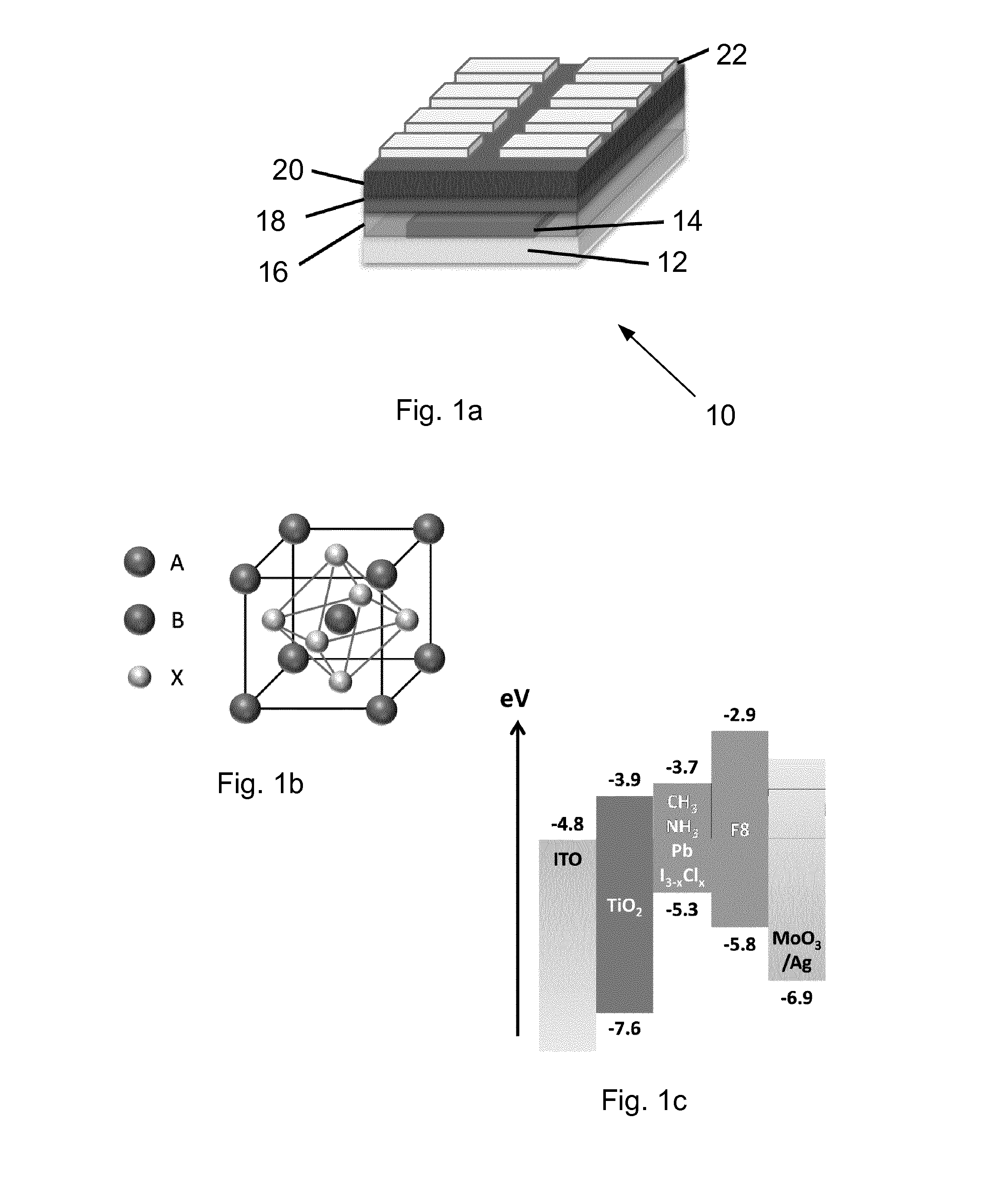

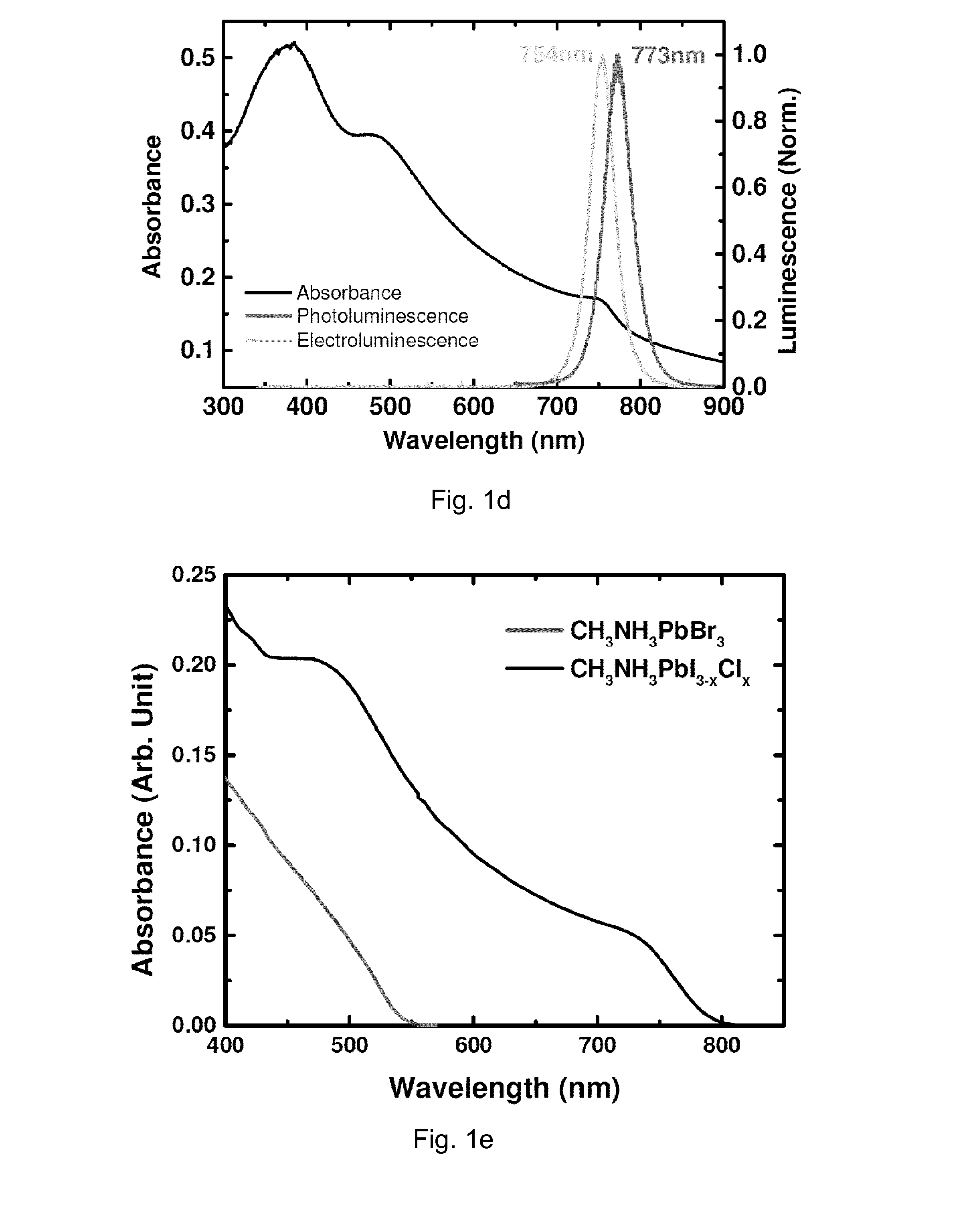

Electroluminescent device

ActiveUS20170054099A1Enhance radiative recombinationImproved light emissionSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceMolecular physics

A solid state light-emitting device comprising: a first electrode coupled to a first charge injecting layer; a second electrode coupled to a second charge injecting layer; an emissive layer comprising a perovskite material, wherein the emissive layer is provided between the first and second charge injecting layers; and wherein the bandgaps of the first and second charge injecting layers are larger than the bandgap of the emissive perovskite layer.

Owner:CAMBRIDGE ENTERPRISE LTD

Nitride semiconductor light emitting device

InactiveUS20160005919A1Improved light emissionAccelerate emissionsSemiconductor lasersSemiconductor devicesUltraviolet lightsElectron blocking layer

A nitride semiconductor deep ultraviolet light emitting device having a superior light emission efficiency is provided. A nitride semiconductor light emitting device having emission wavelength of 200 to 300 nm includes an n-type layer consisting of a single layer or a plurality of layers having different band gaps, a p-type layer consisting of a single layer or a plurality of layers having different band gaps, an active layer arranged between the n-type layer and the p-type layer, and an electron blocking layer having a band gap larger than any band gap of layers composing the active layer and the p-type layer. The p-type layer includes a first p-type layer having a band gap larger than a band gap of a first n-type layer which has a smallest band gap in the n-type layer. The electron blocking layer is arranged between the active layer and the first p-type layer.

Owner:STANLEY ELECTRIC CO LTD

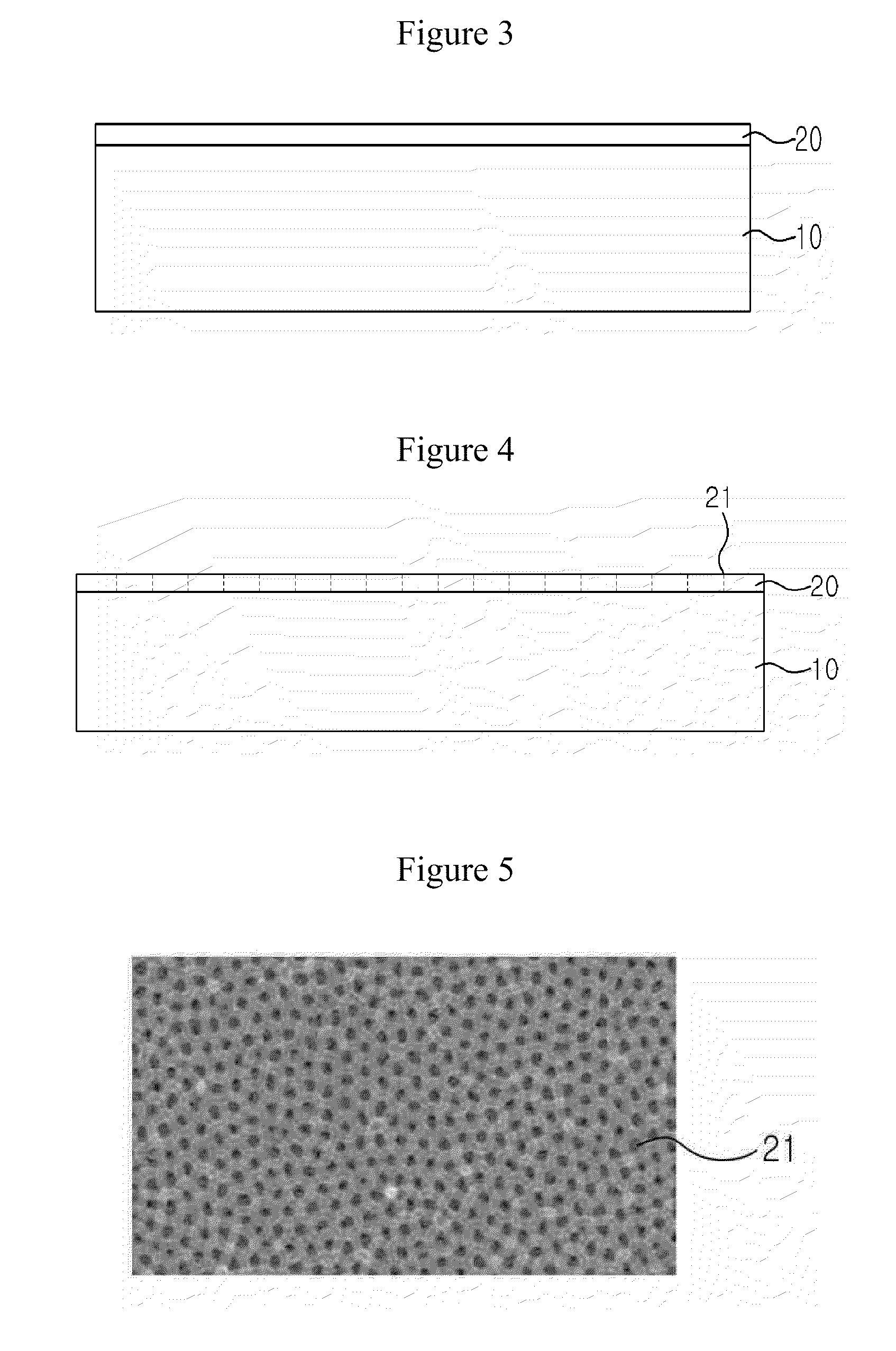

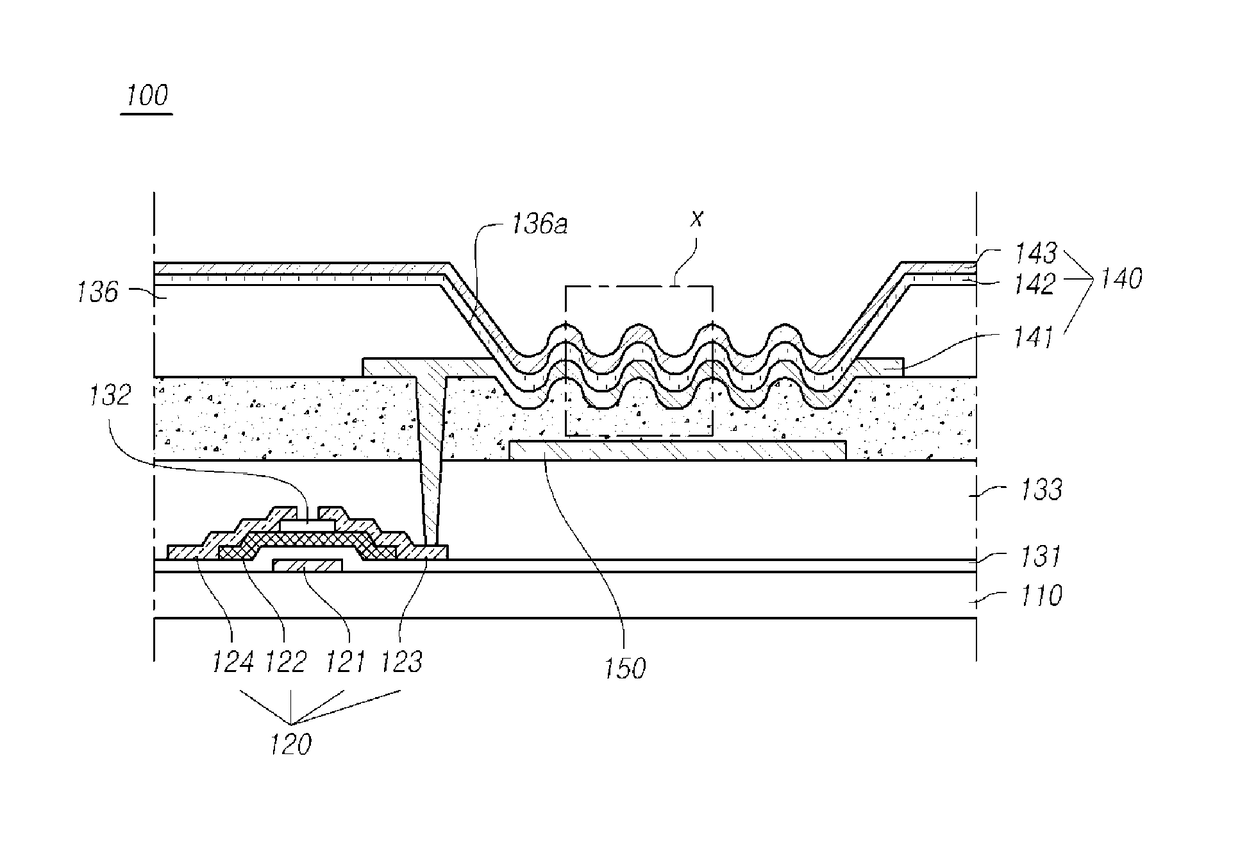

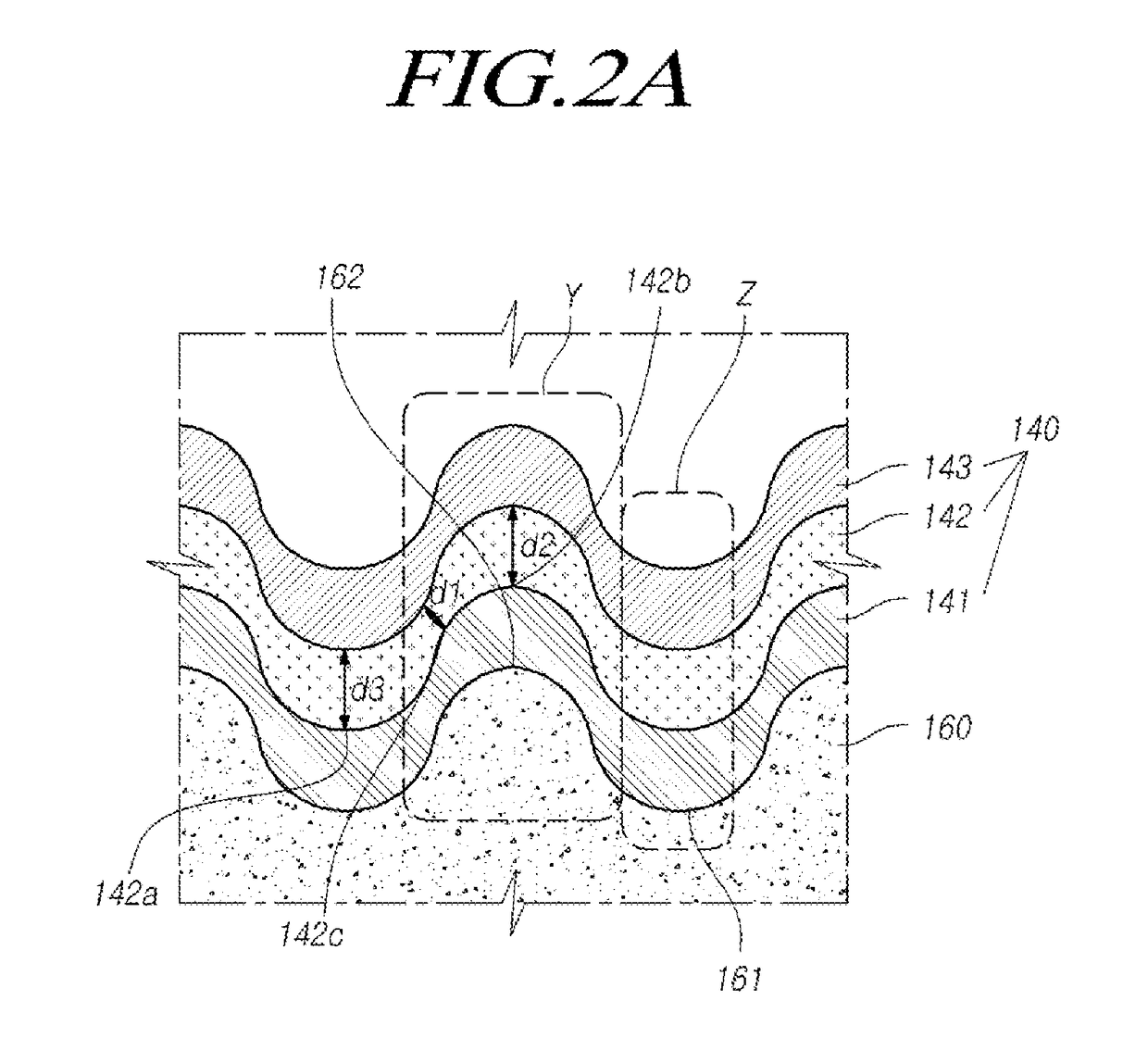

Organic Light Emitting Device

ActiveUS20180247980A1Improved light emissionReduce power consumptionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceOptoelectronics

Provided is an organic light emitting device including an overcoat layer on a substrate, a first electrode disposed on the overcoat layer, an organic light emitting layer disposed on the first electrode and including a convex or concave curve; and a second electrode disposed on the organic light emitting layer.

Owner:LG DISPLAY CO LTD

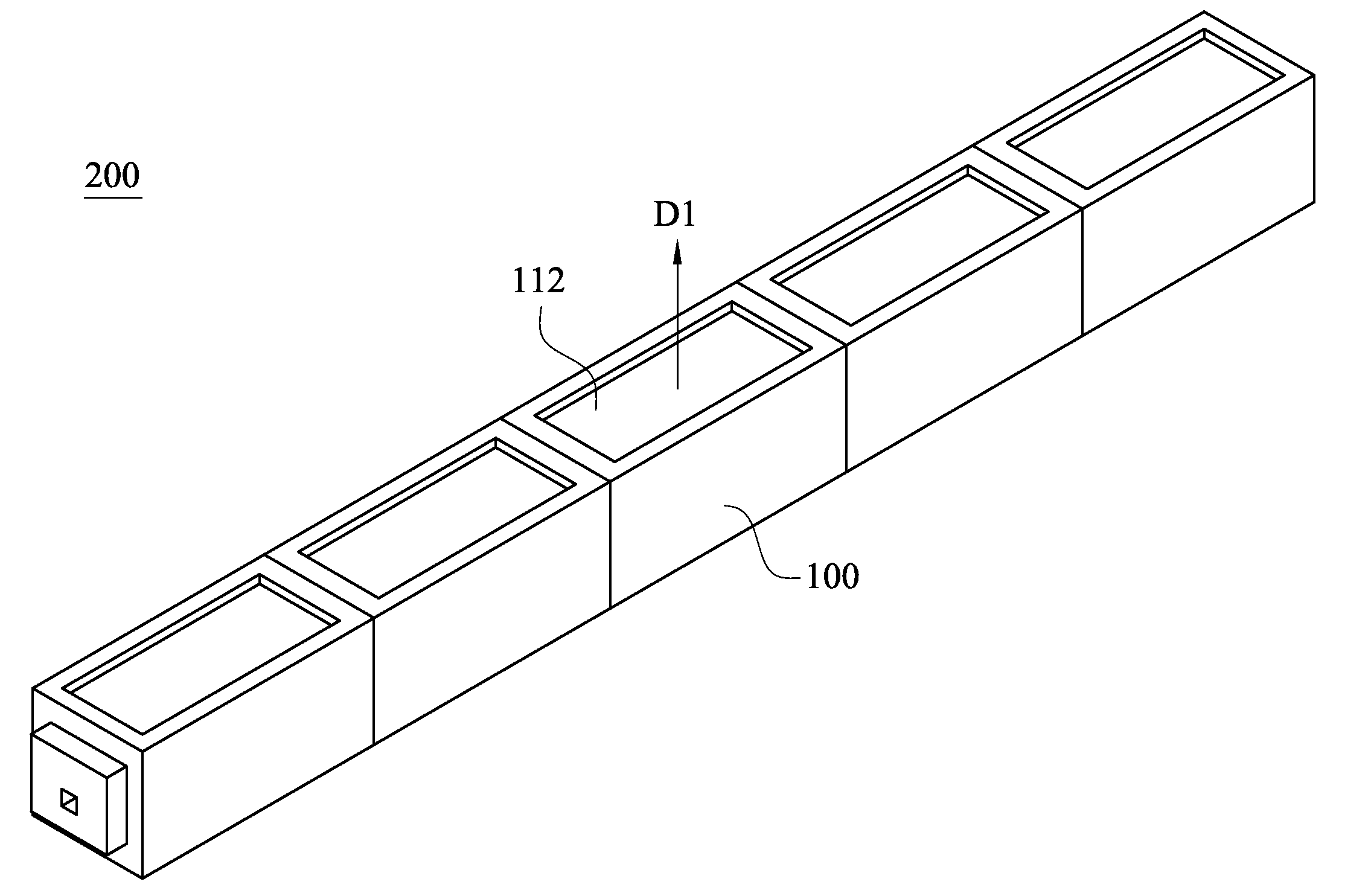

Lighting Unit and Light Bar having the Same

InactiveUS20140198494A1Easy to replaceShorten production timeLighting support devicesPoint-like light sourceEffect lightEngineering

Owner:LEXTAR ELECTRONICS CORP

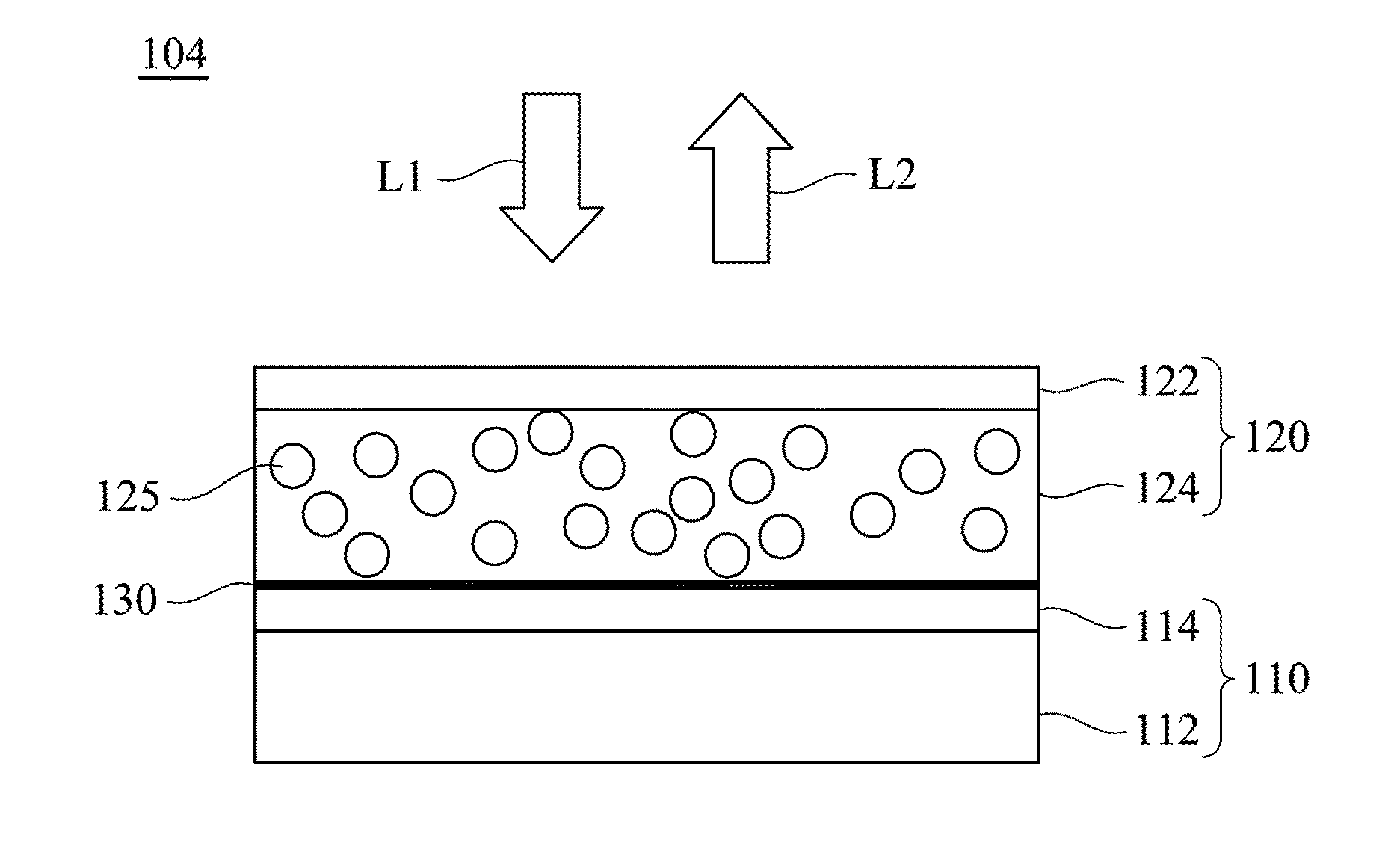

Phosphor wheel and wavelength converting device applying the same

InactiveUS20170052362A1Improve reflection efficiencyImproved light emissionProjectorsCoatingsFluorescencePhosphor

A phosphor wheel includes a first optical unit, a second optical unit, and a clamping component. The first optical unit includes a substrate and an optical layer. The optical layer is disposed on the substrate. The second optical unit is stacked on the optical layer, in which the optical layer is configured to at least reflect light beams propagated from the second optical unit. The second optical unit includes a transparent substrate and a phosphor layer. The phosphor layer is disposed on the transparent substrate. The first optical unit and the second optical unit are fixed by the clamping component.

Owner:DELTA ELECTRONICS INC

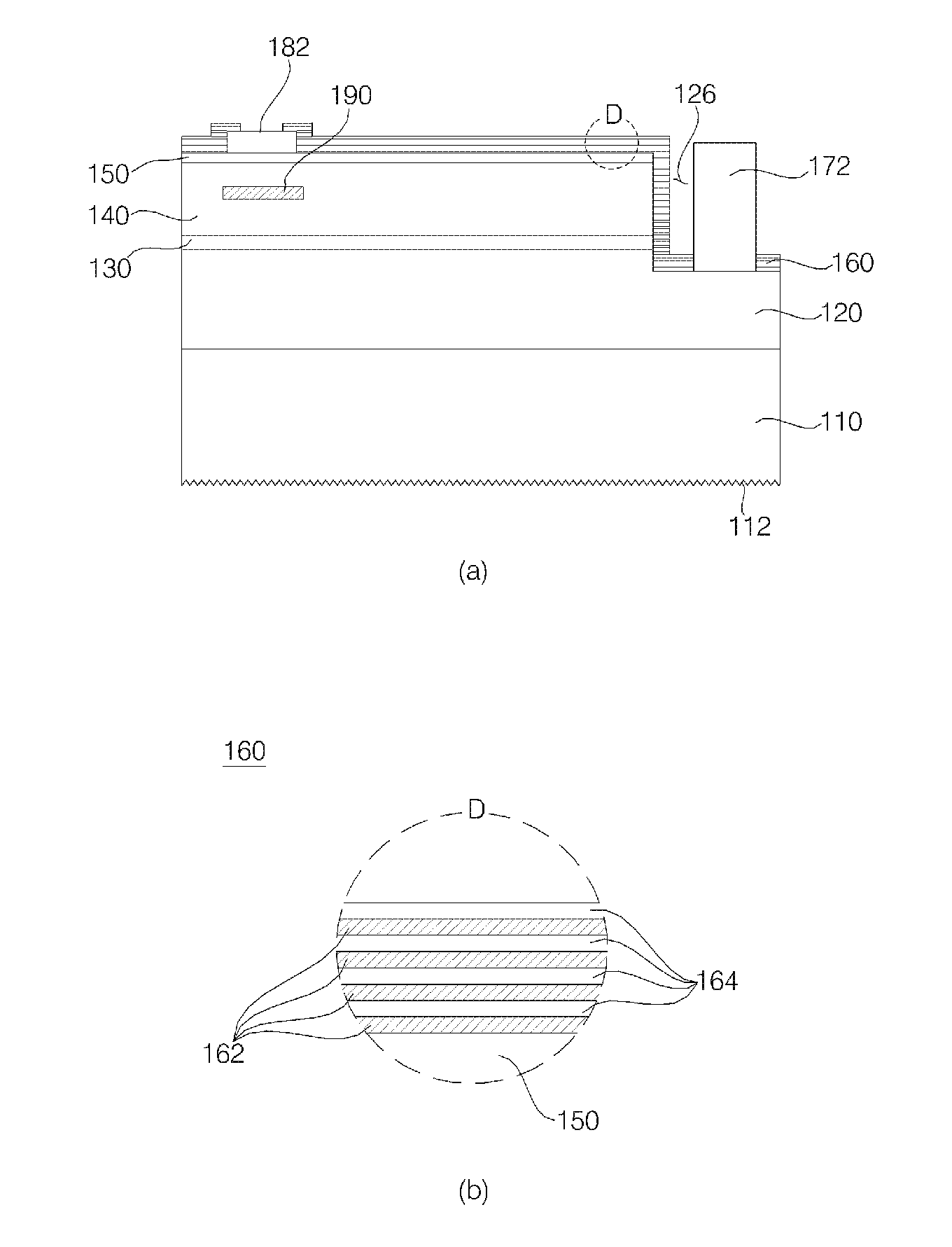

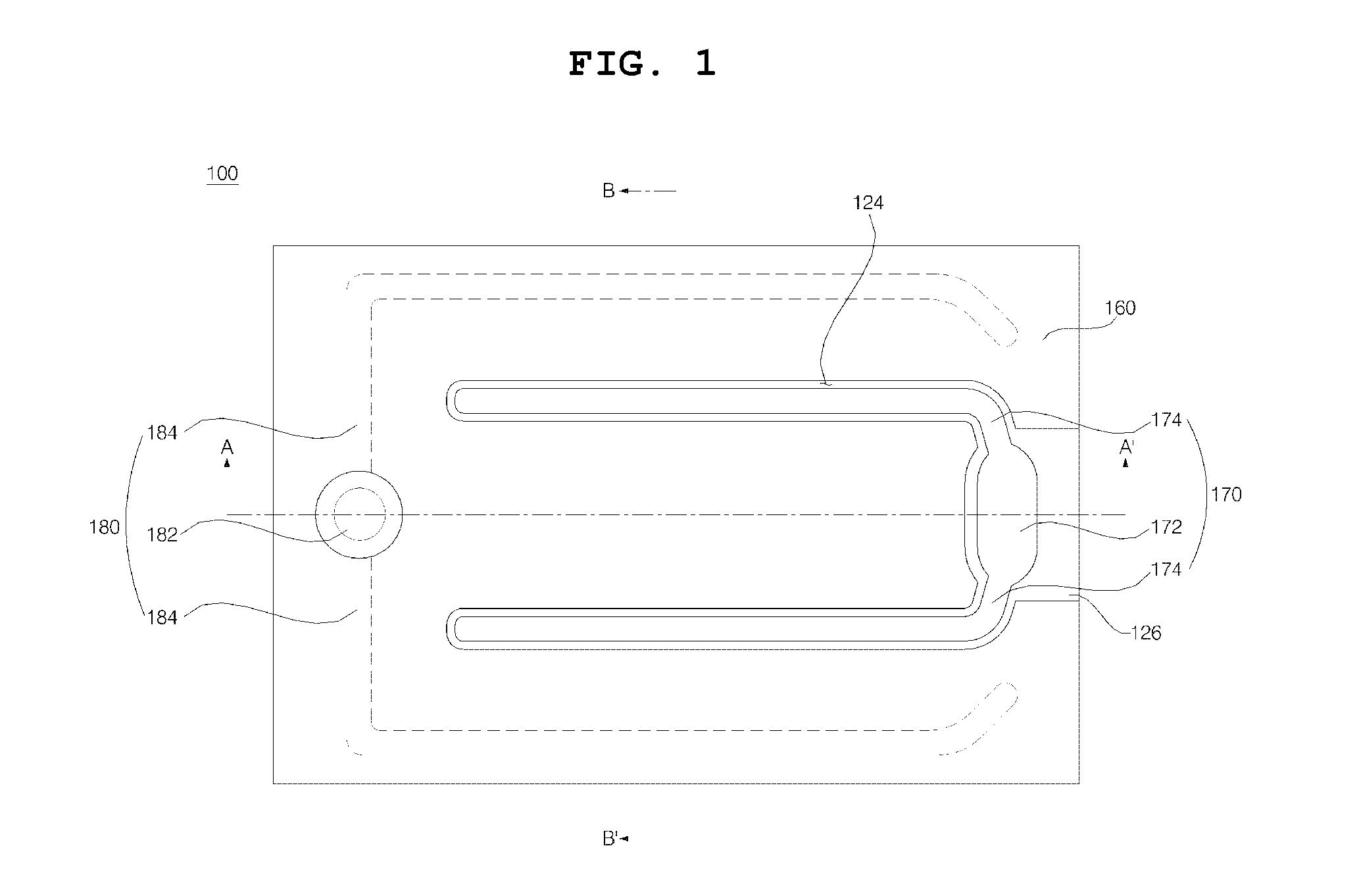

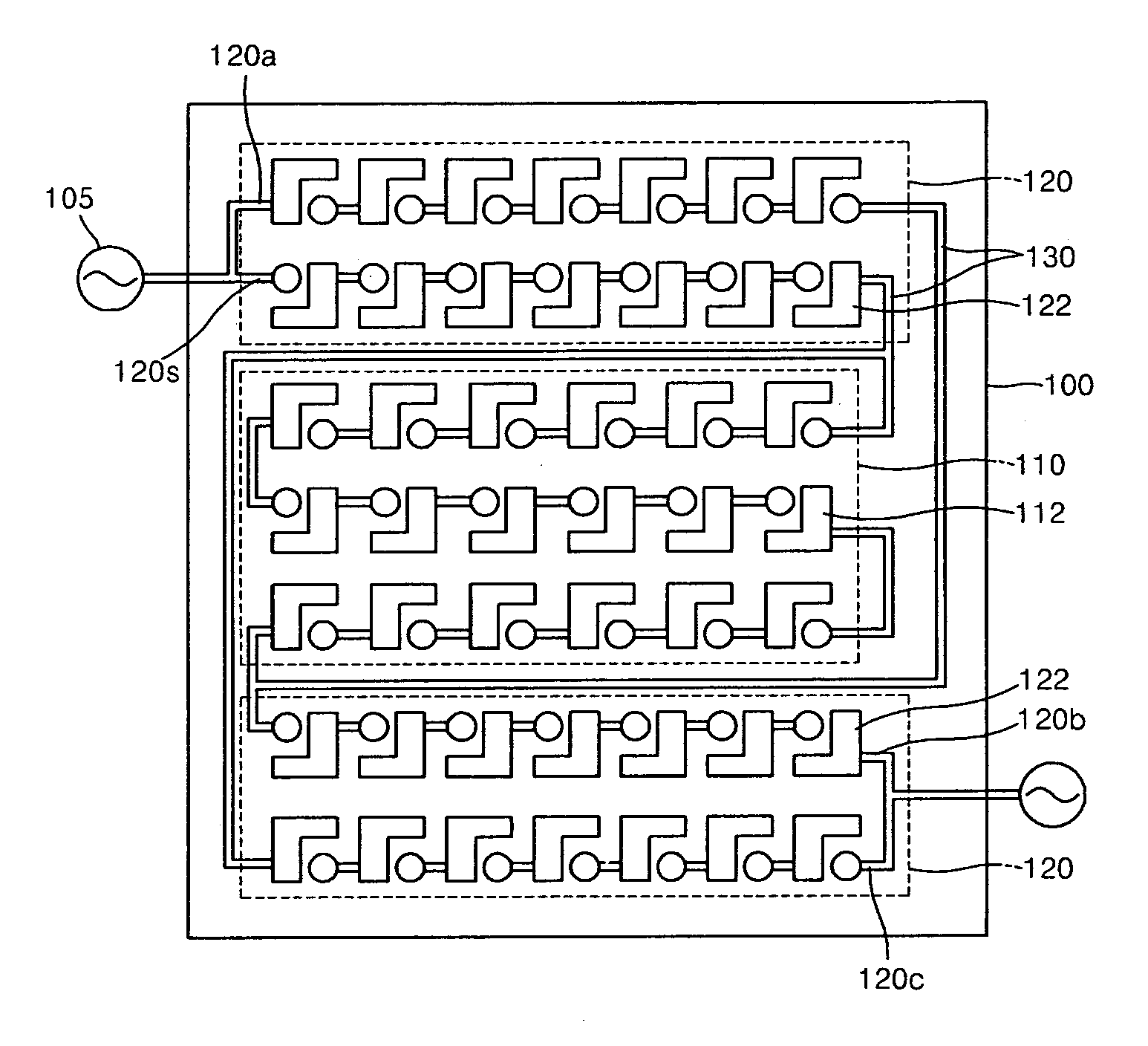

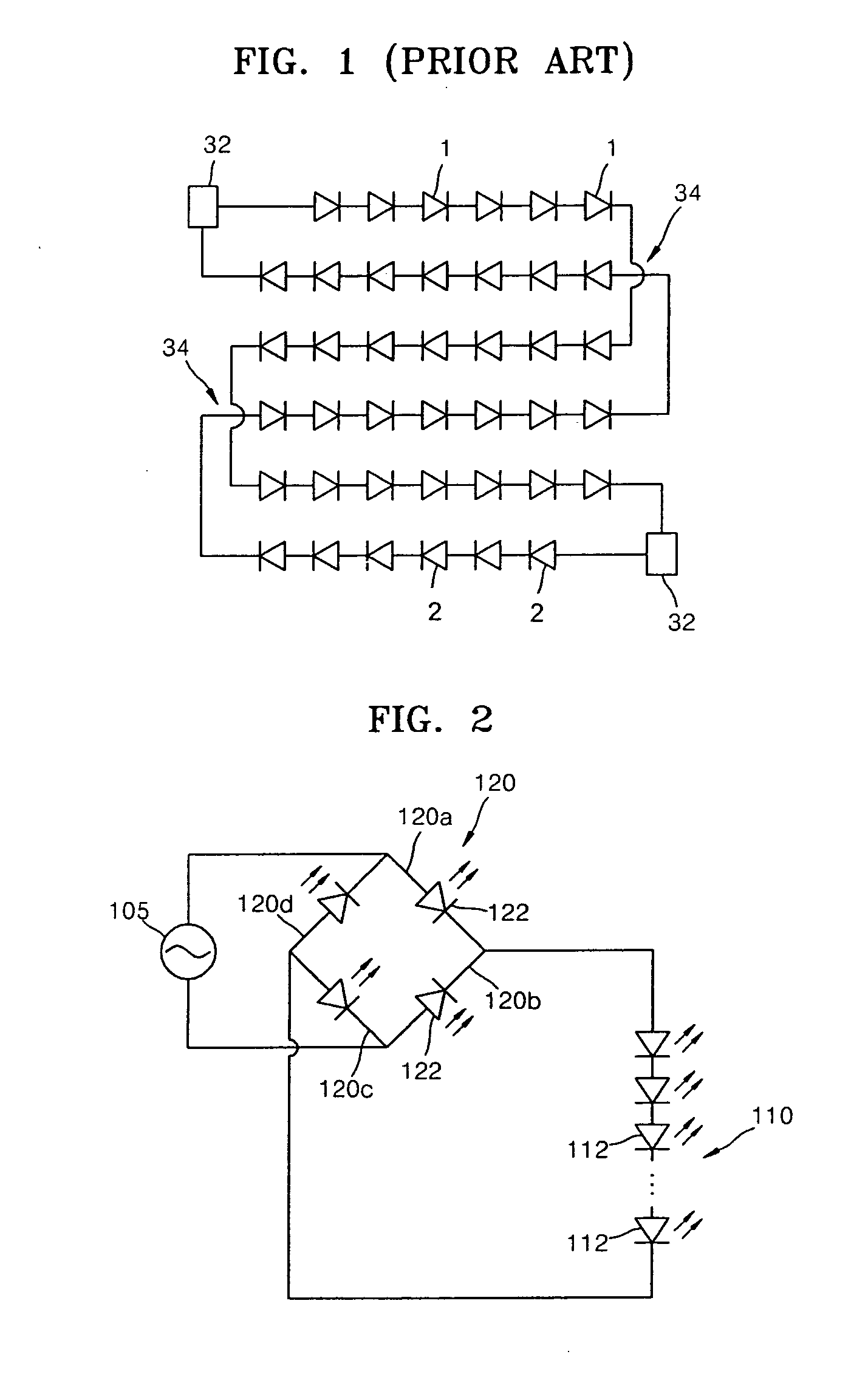

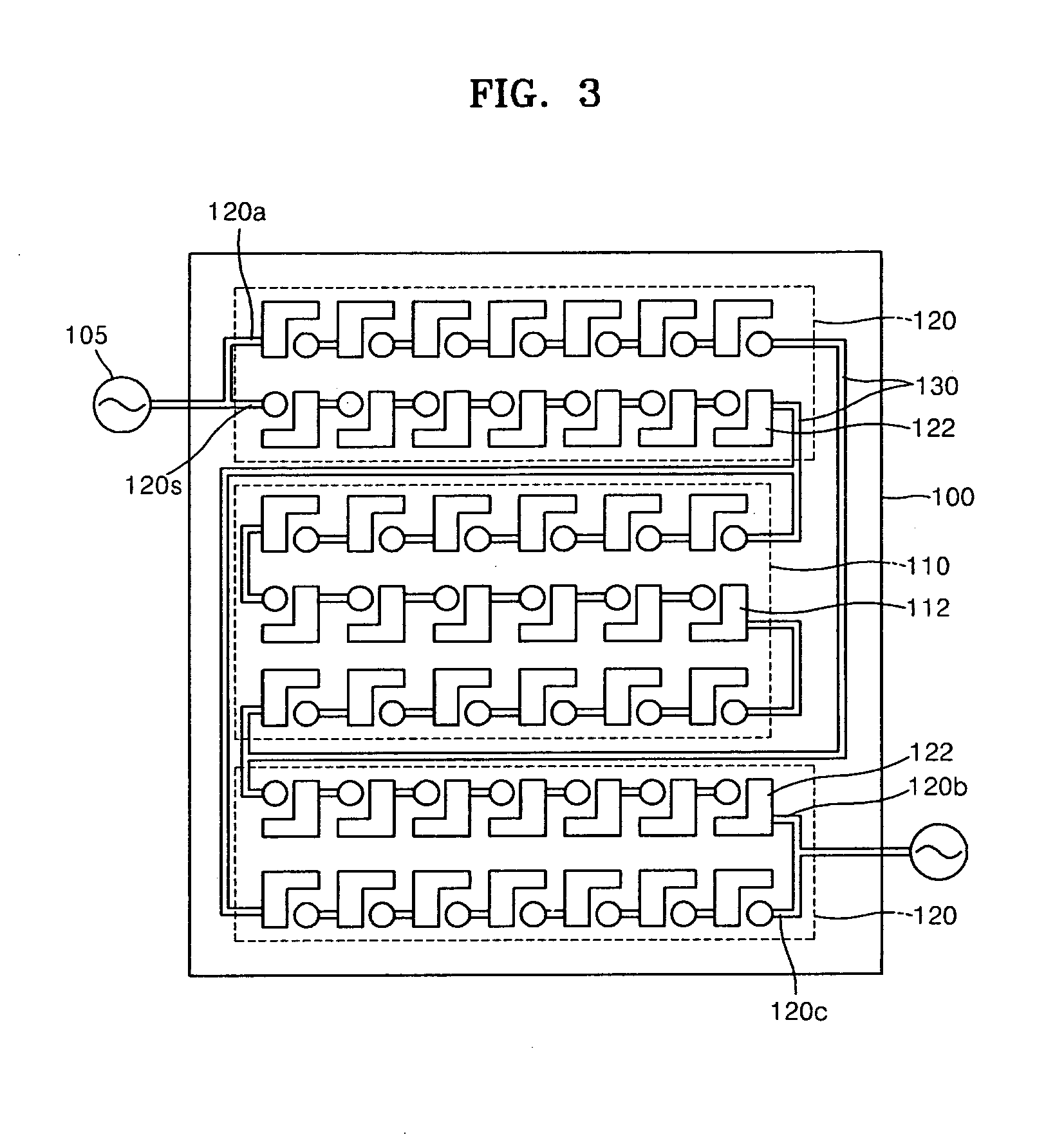

Light emitting device unit for AC voltage

InactiveUS20070217210A1Improved light emissionReduce manufacturing costAnalysis material containersElectroluminescent light sourcesLight emitting deviceLight-emitting diode

A light emitting diode unit for AC voltage is provided. The light emitting diode unit includes a sub-mount on which electric wires are formed; a first light emitting diode array in which a plurality of first light emitting diodes are serially connected to the sub-mount; and a second light emitting diode array, in which a plurality of second light emitting diodes are connected to the sub-mount as bridge circuits, connecting to the first light emitting diode array. Therefore, rectification can be performed through the bridge circuit without an additional rectifying device by connecting the light emitting diodes to the bridge circuit in series, and thus the structure of the unit can be simplified and a size of the light emitting diode unit can be reduced.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

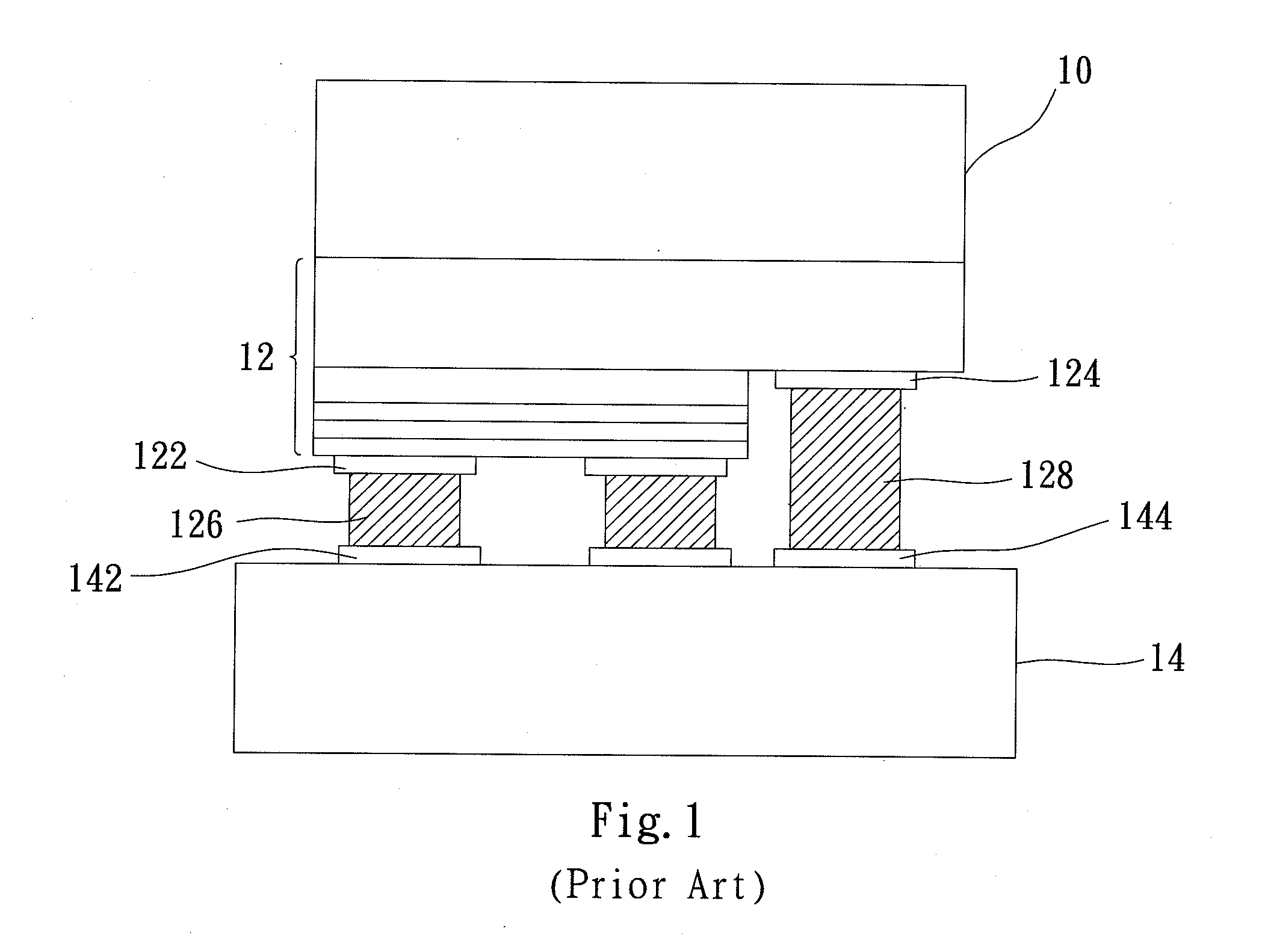

Bond type flip-chip light-emitting structure and method of manufacturing the same

ActiveUS20130234105A1Low production costIncrease cooling areaSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerEpitaxy

A bond type flip-chip light-emitting structure and method of manufacturing the same. Firstly, form a positive electrode and a negative electrode on an epitaxy layer. Next, deposit an insulation layer on parts of the positive electrode and negative electrode, to expose respectively a positive electrode via hole and a negative electrode via hole. Then, form a bonded metal layer on the insulation layer, the positive electrode via hole, and the negative electrode via hole, so that the positive electrode and the negative electrode are on a same plane by means of the bonded metal layer. Finally, on a substrate, bond the first metal layer and the second metal layer onto the corresponding first bonded metal unit and the second bonded metal unit of the bonded metal layer, to form into shape, thus realizing a bond type flip-chip light-emitting structure.

Owner:PAITRIX

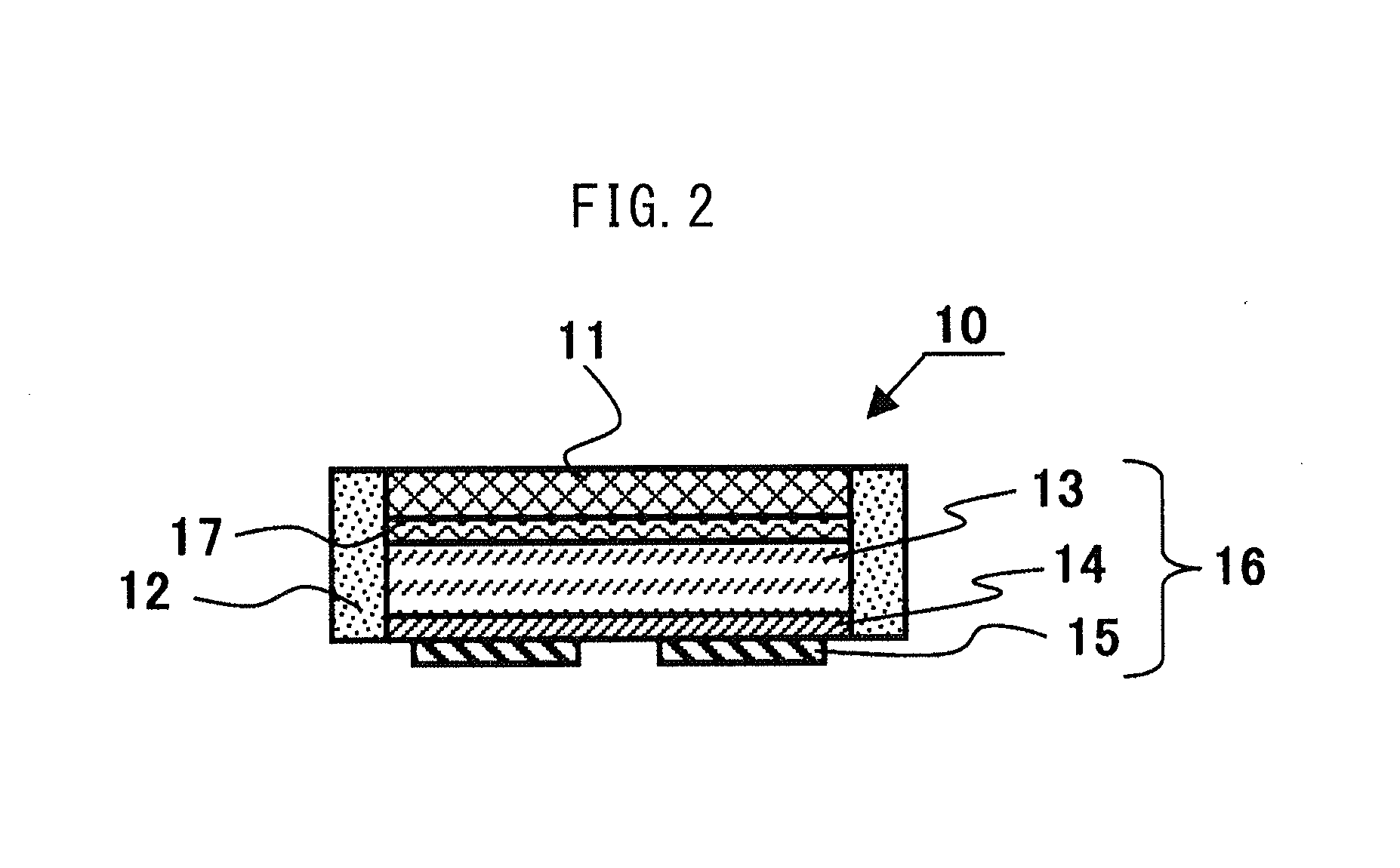

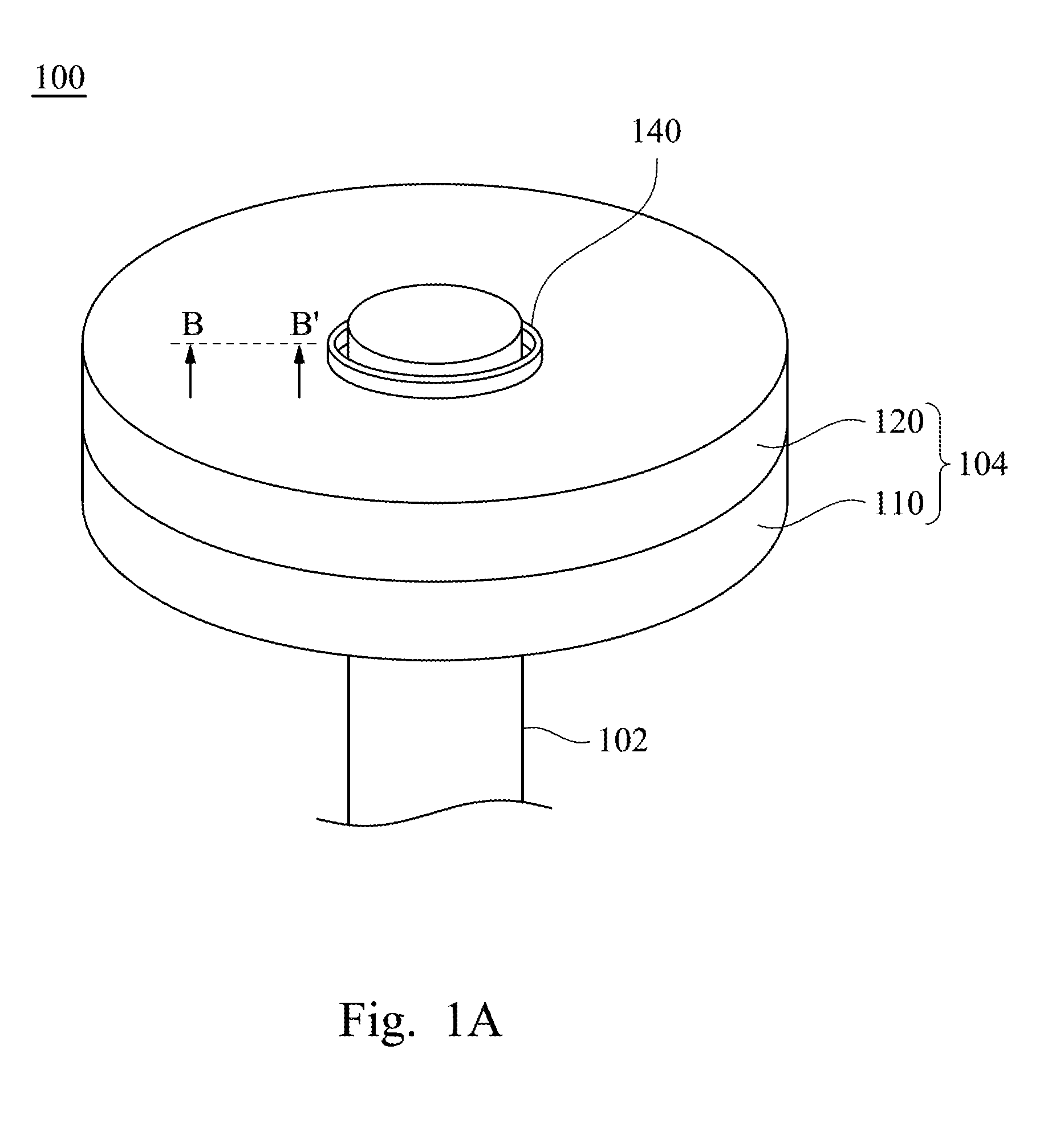

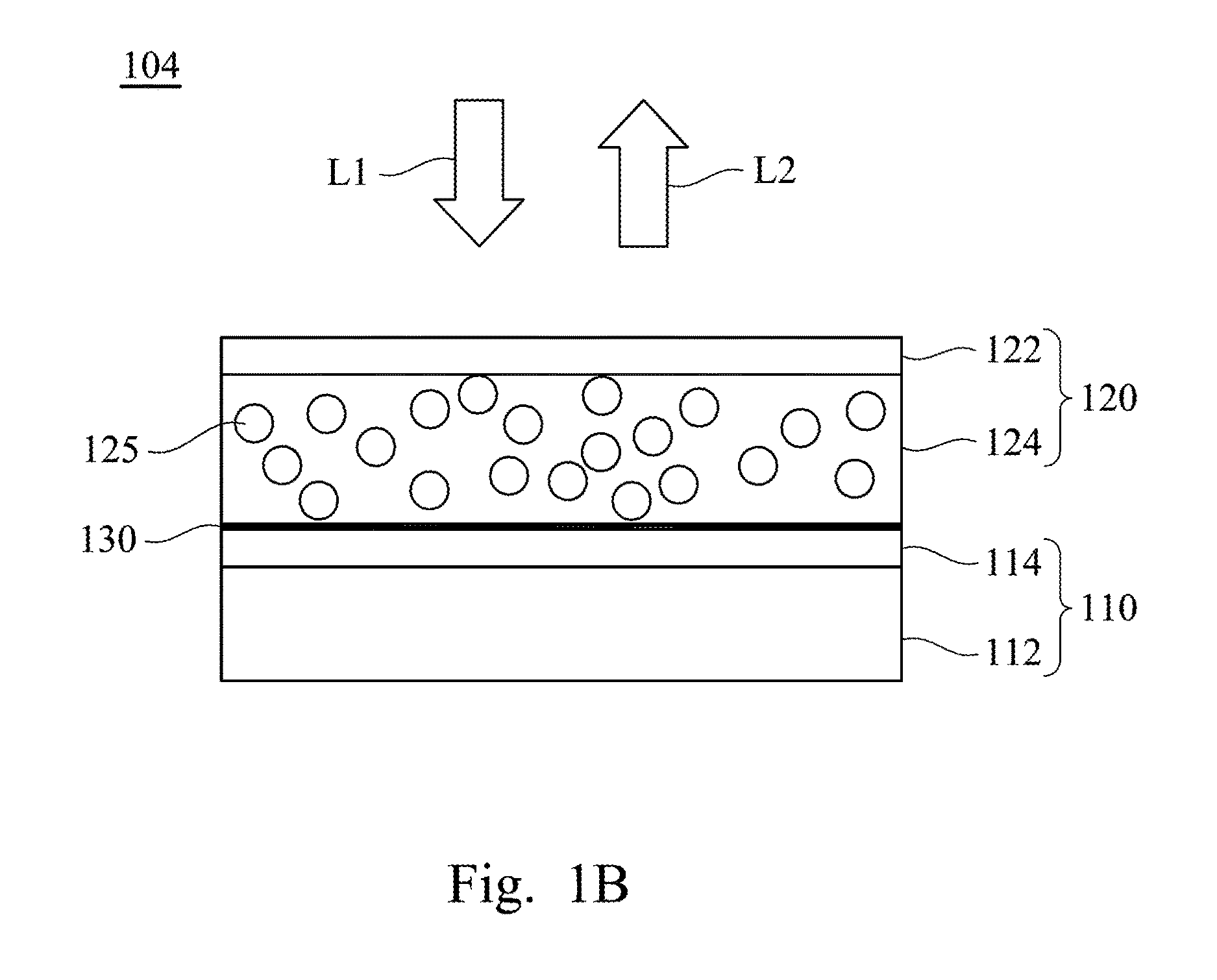

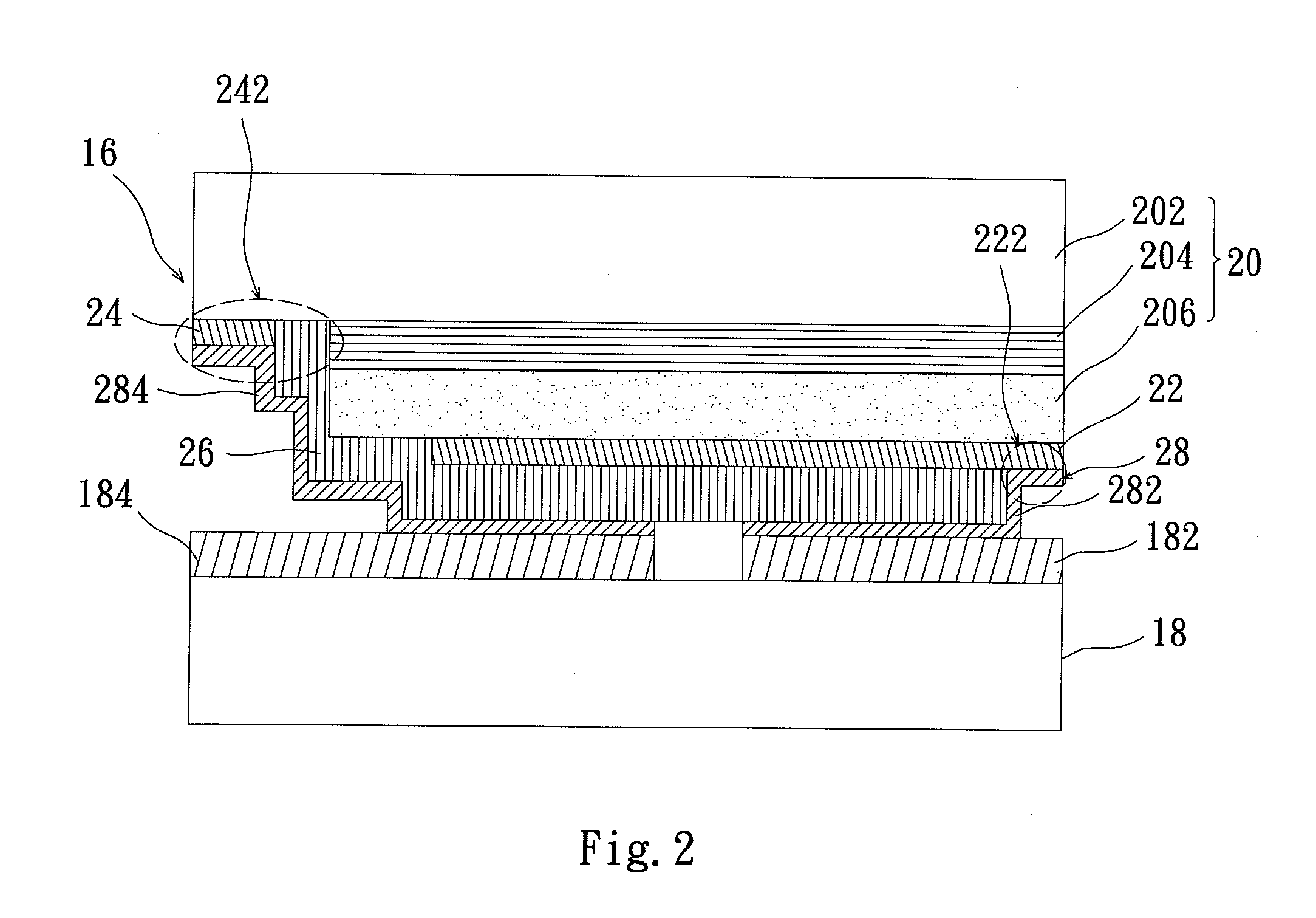

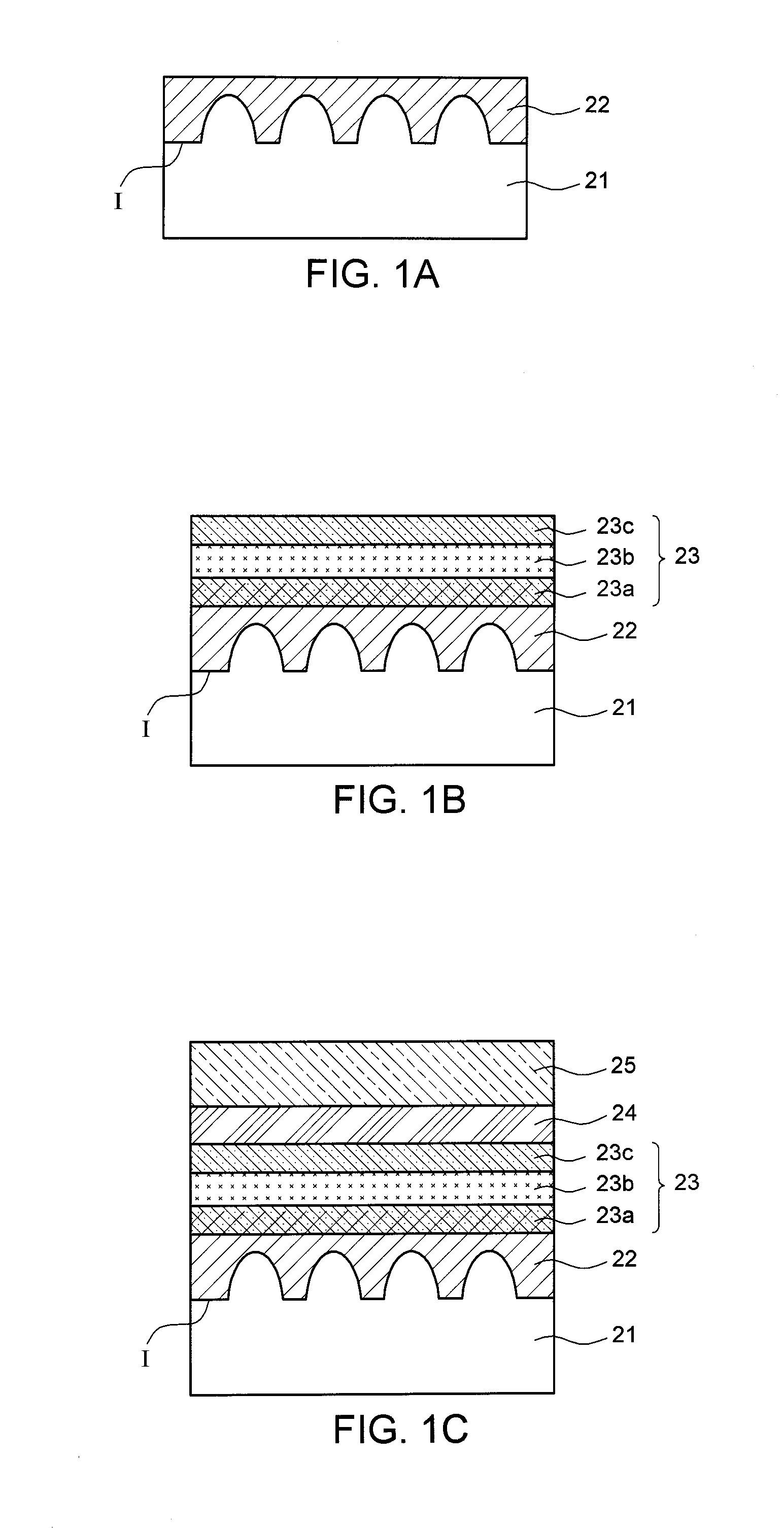

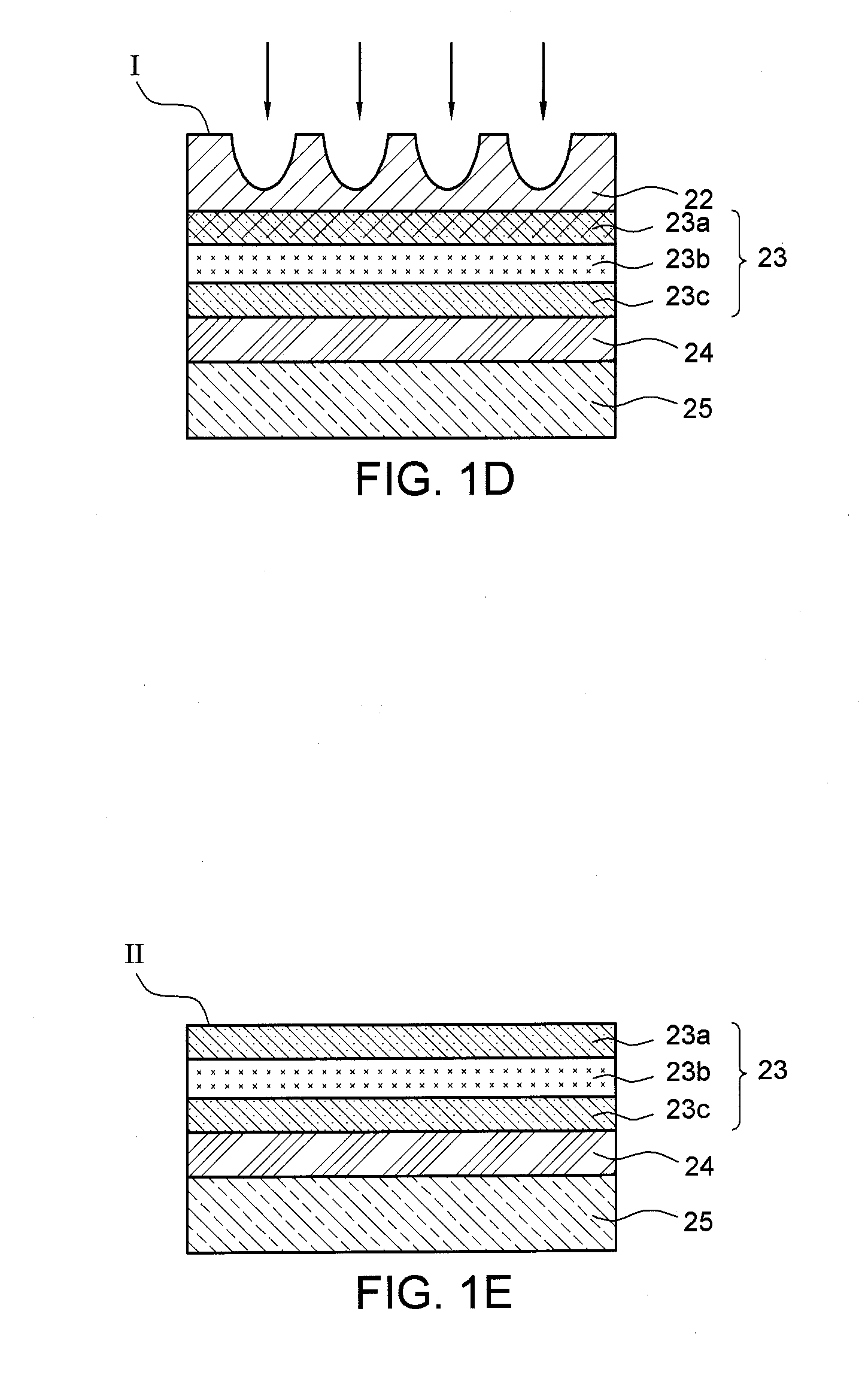

Light emitting device and a manufacturing method thereof

InactiveUS20090279279A1Illumination efficiency is highImproved light emissionSolid-state devicesSpectral modifiersWavelength conversionLight emitting device

A light emitting device includes a light emitting body, a base for carrying the light emitting body, an encapsulating material covering the light emitting body and a wavelength conversion material mixing with the encapsulating material. The concentration of wavelength conversion material is characterized by the fact that the concentration of the wavelength conversion material is higher at the higher space that is further from the light emitting body located at the bottom of the light emitting device. Accordingly, the reflection rate of the mixture mixed with the encapsulating material and the wavelength conversion material has gradual variation, and the total reflection on the boundary is reduced thus improves the illumination efficiency.

Owner:LITE ON TECH CORP +1

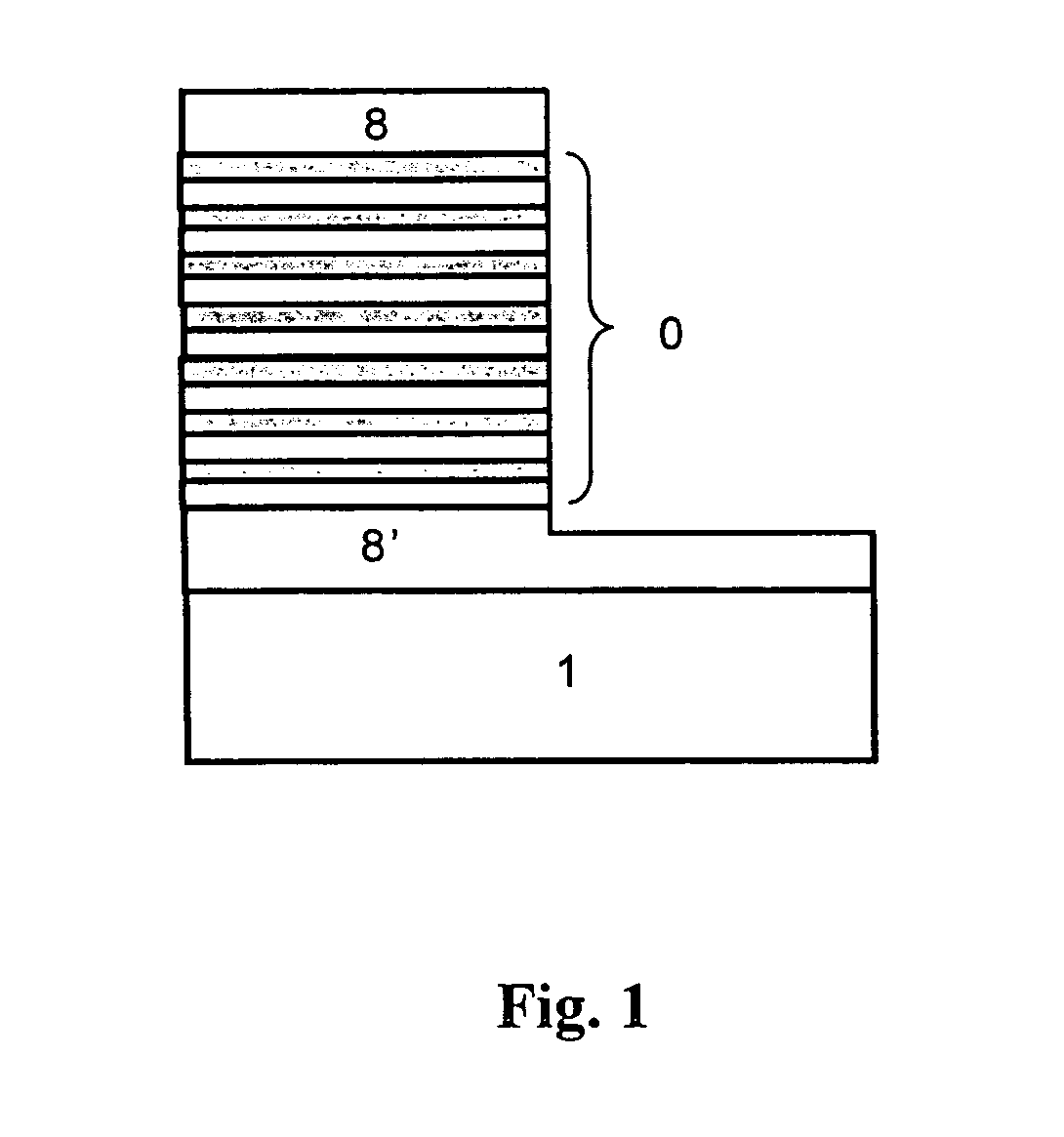

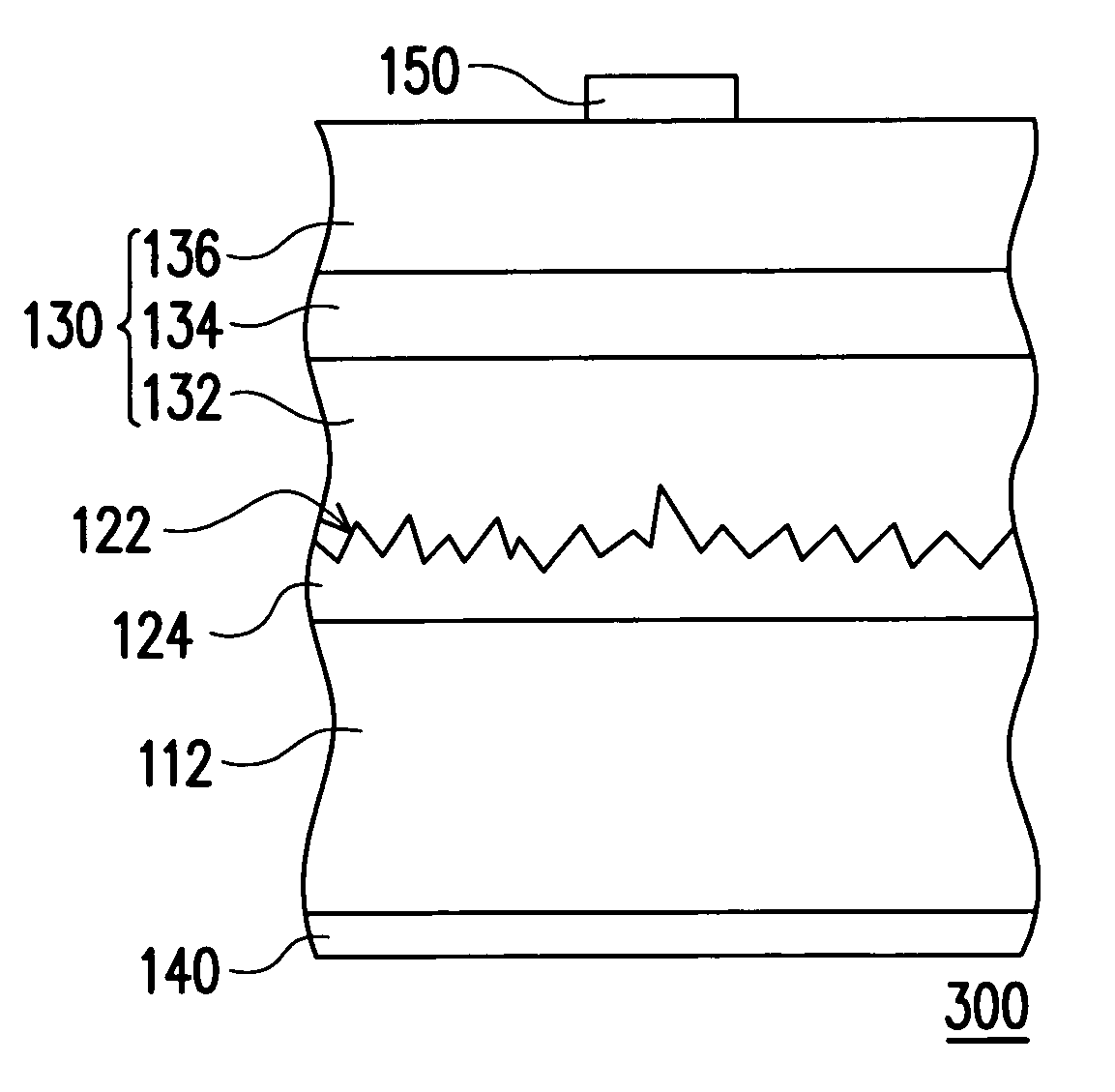

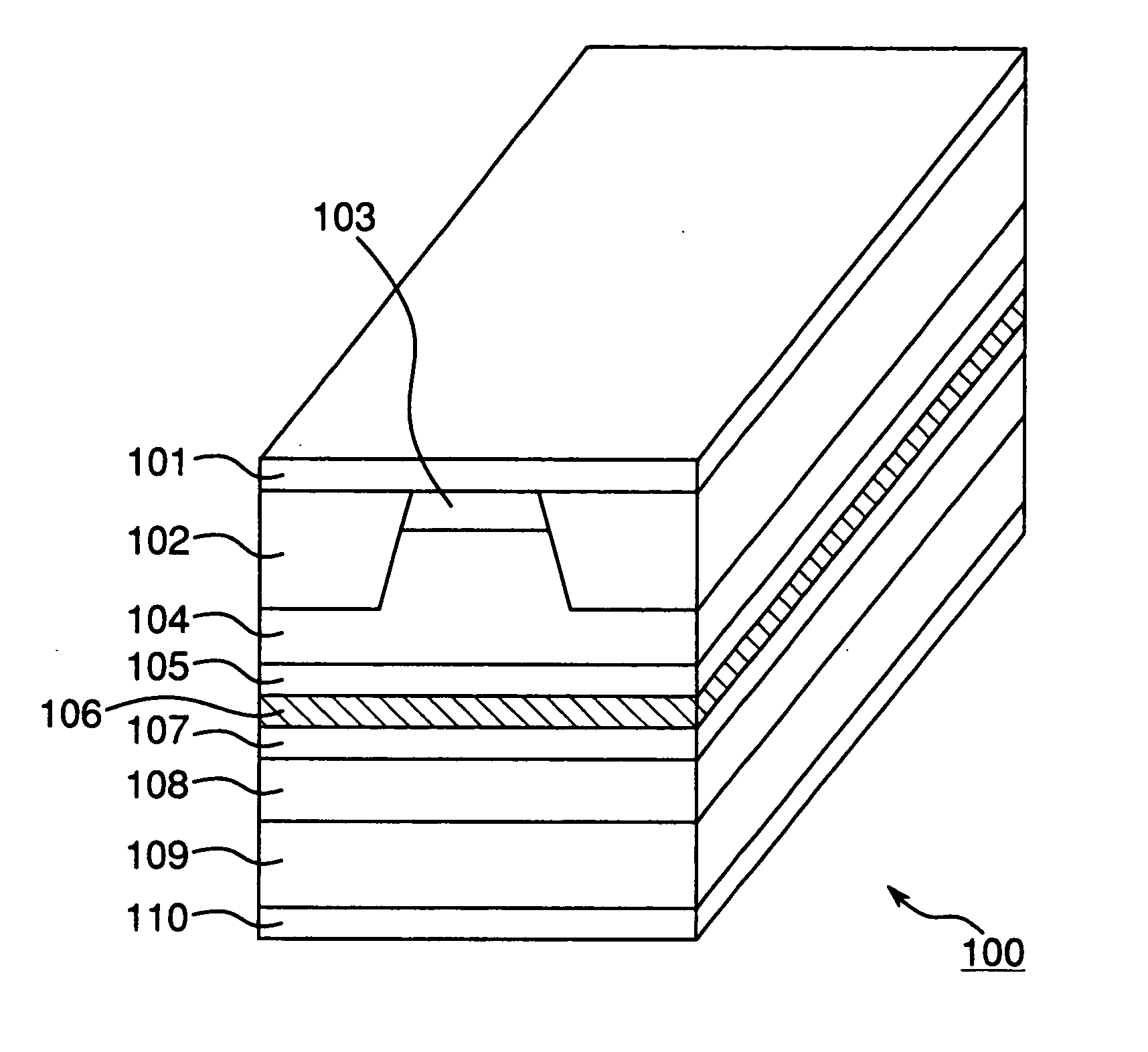

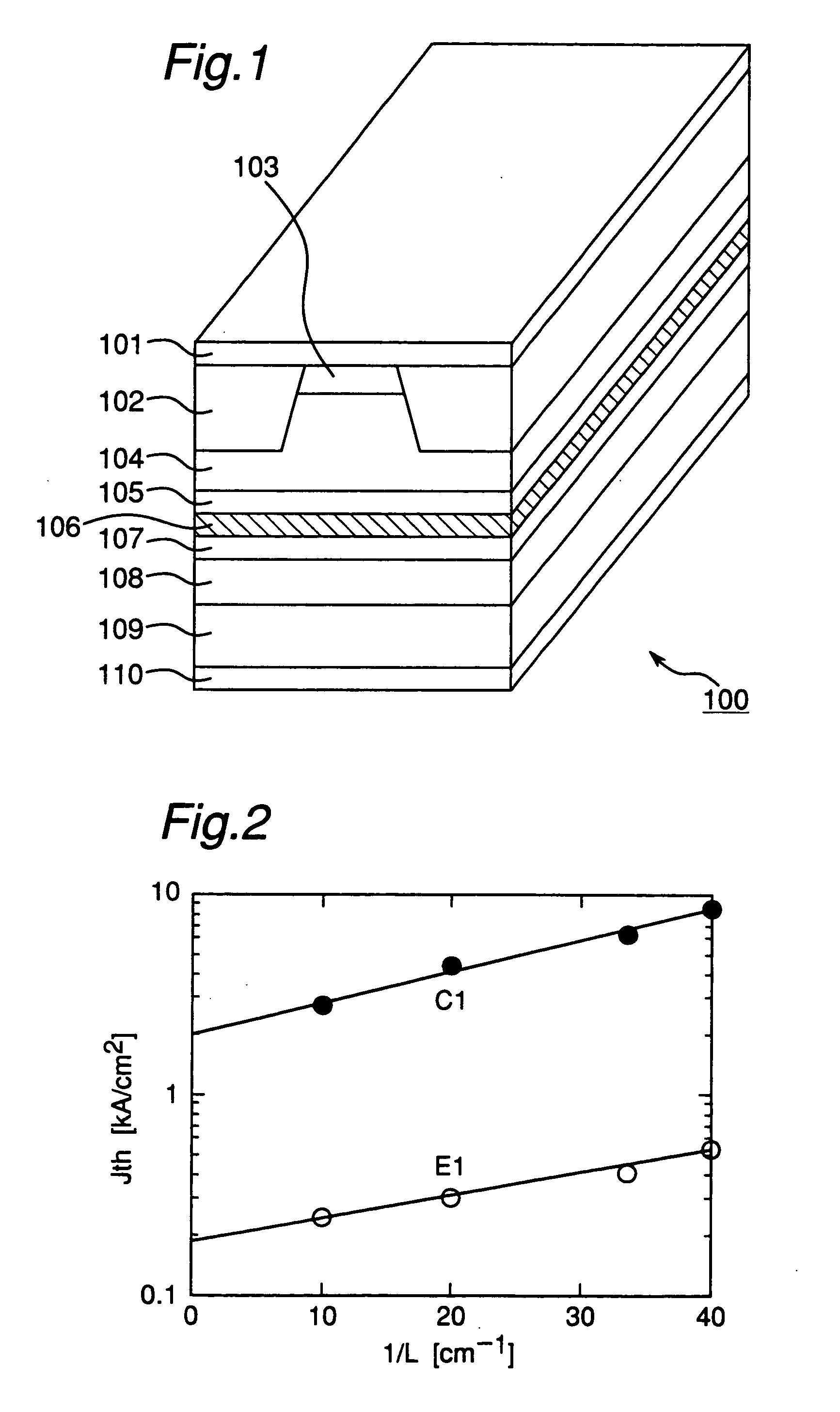

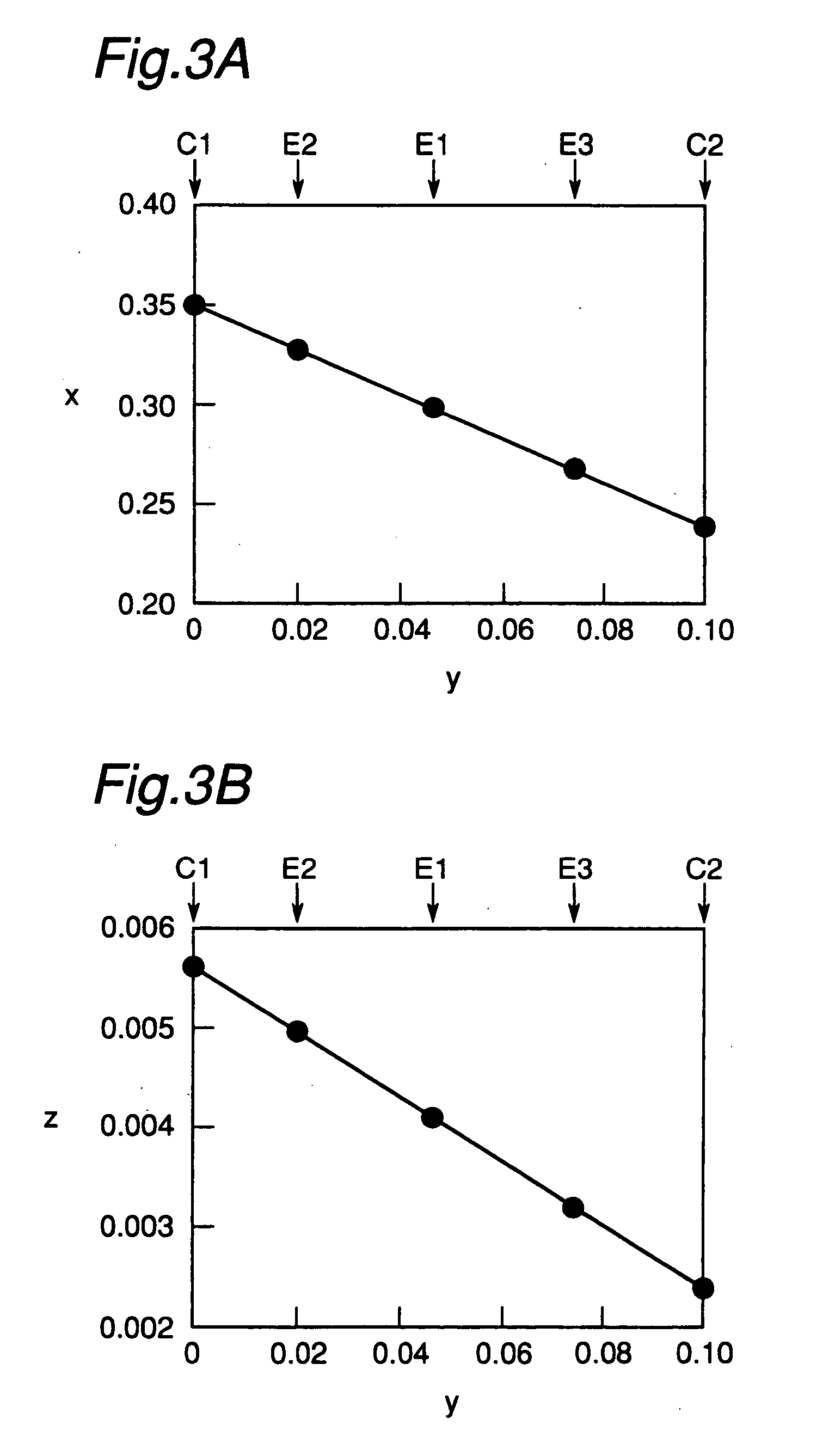

Semiconductor device and method of crystal growth

InactiveUS20040084667A1Improved light emissionImprove featuresLaser detailsLaser optical resonator constructionPhysicsChemistry

A semiconductor device (100) has, as its well layer, a III-V compound semiconductor layer (106) containing, as V-group components, nitrogen, antimony, and one or more V-group elements other than nitrogen and antimony to improve emission characteristics. Such a III-V compound semiconductor layer is formed by repeating a cycle including a process of simultaneously supplying a plurality of sources containing at lest indium, and a process of simultaneously supplying a plurality of sources not containing indium but containing antimony.

Owner:SHARP KK

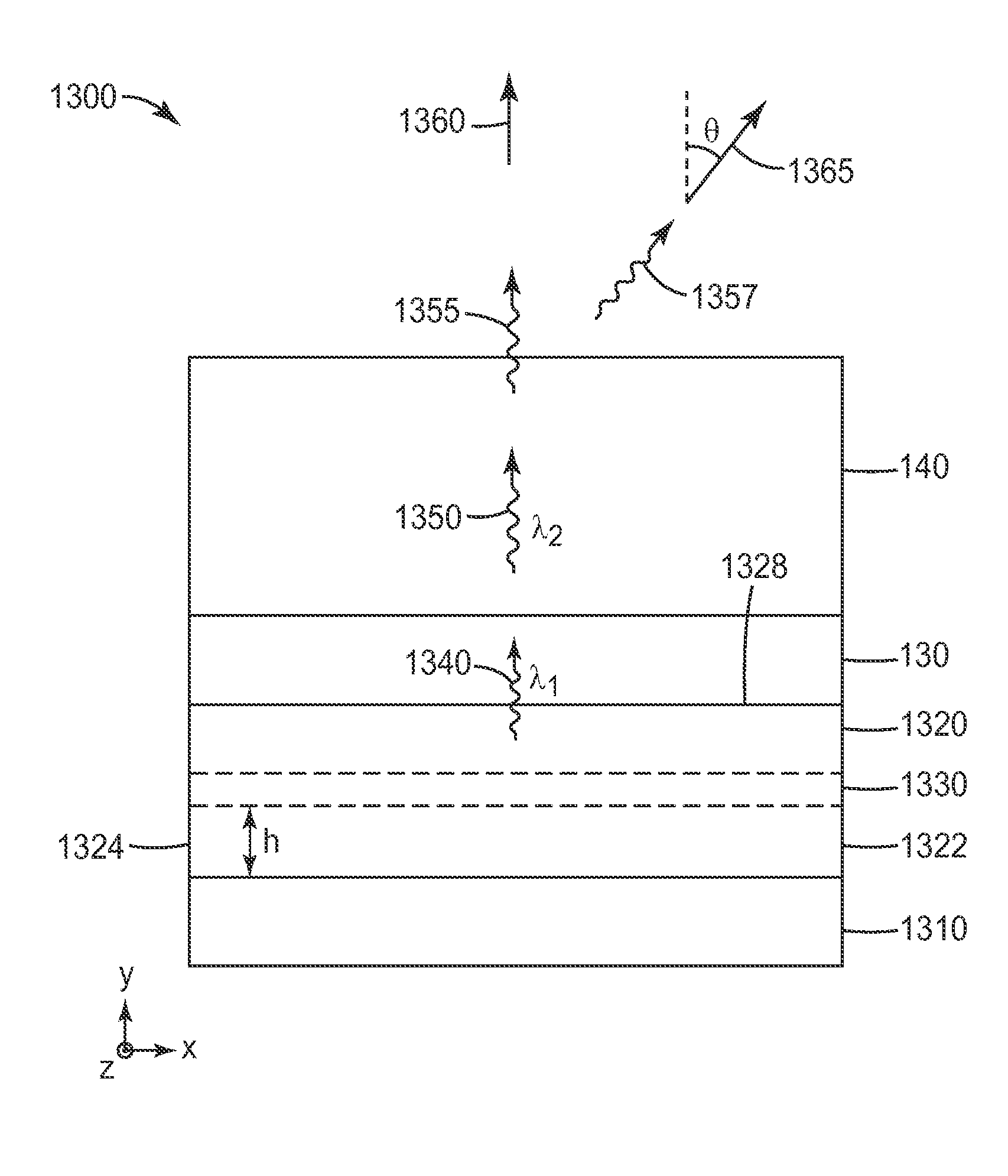

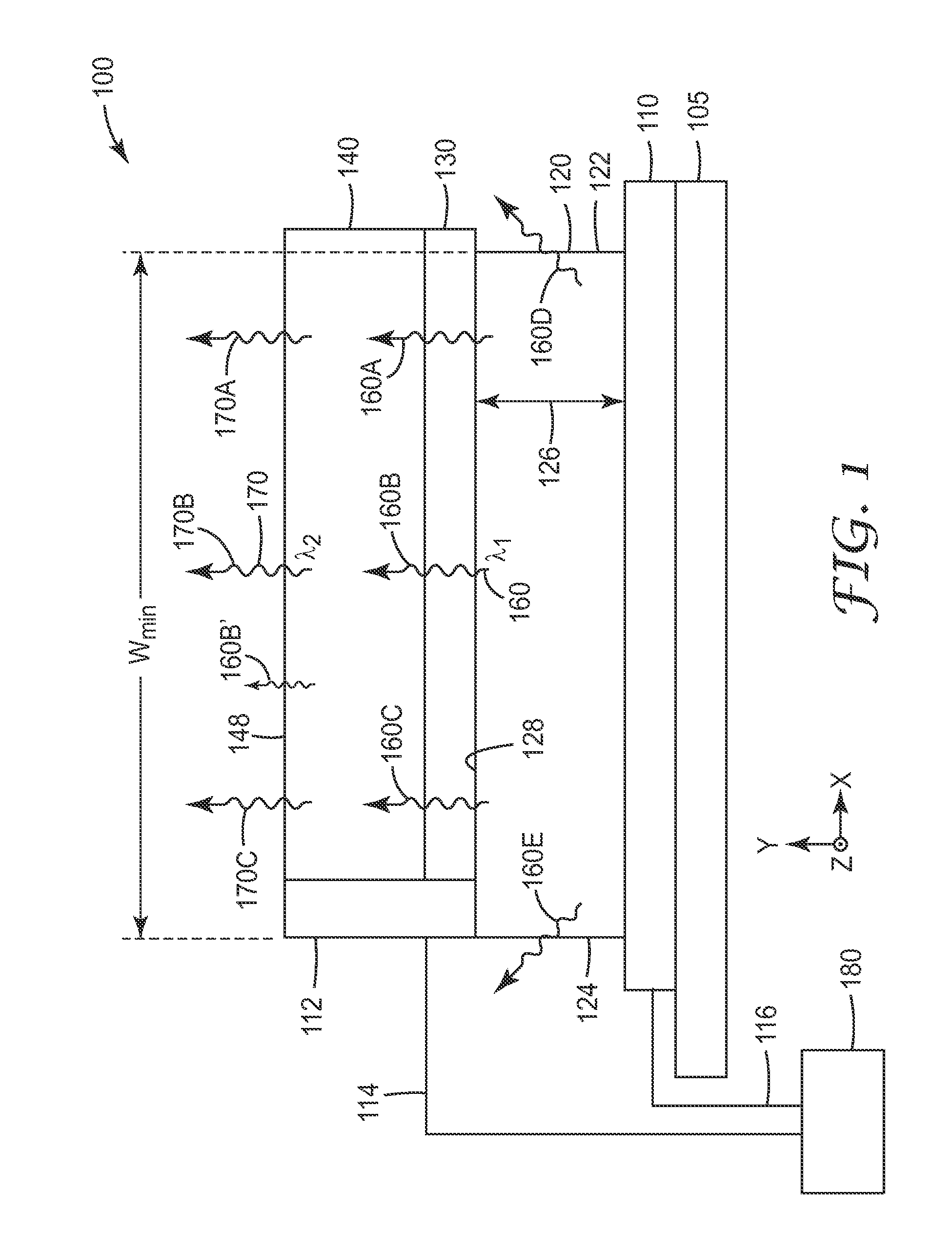

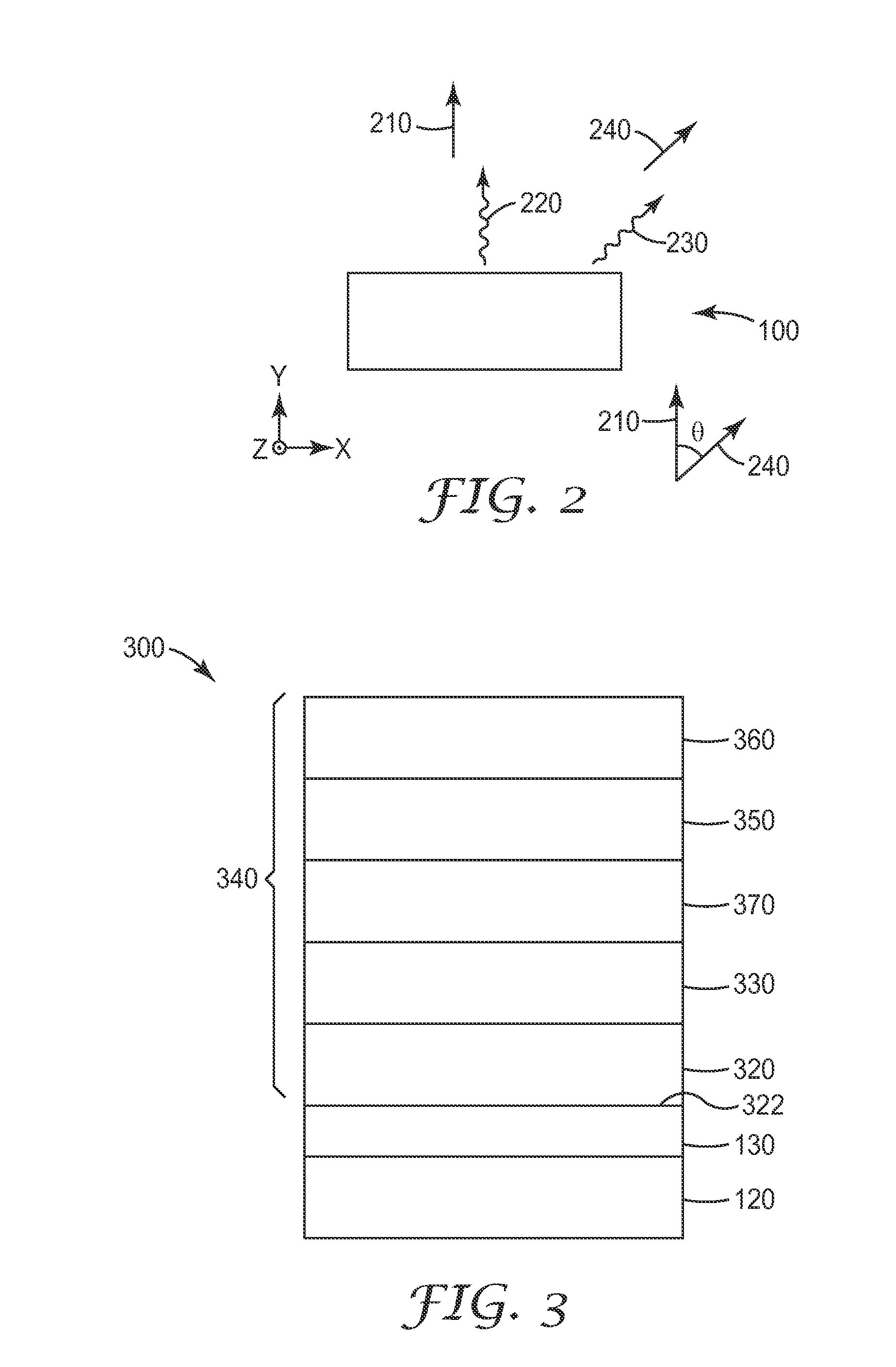

Light source having light blocking components

InactiveUS20110156002A1Improved light emissionAccelerate emissionsSemiconductor devicesPotential wellLength wave

Light emitting systems are disclosed. The light emitting system includes an electroluminescent device that emits light at a first wavelength from a top surface of the electroluminescent device. The light emitting system further includes a construction proximate a side of the electroluminescent device for blocking light at the first wavelength that would otherwise exit the side. The light emitting system further includes a re-emitting semiconductor construction that includes a II-VI potential well. The re-emitting semiconductor construction receives the first wavelength light that exits the electroluminescent device and converts at least a portion of the received light to light of a second wavelength. The integrated emission intensity of all light at the second wavelength that exit the light emitting system is at least 4 times the integrated emission intensity of all light at the first wavelength that exit the light emitting system.

Owner:3M INNOVATIVE PROPERTIES CO

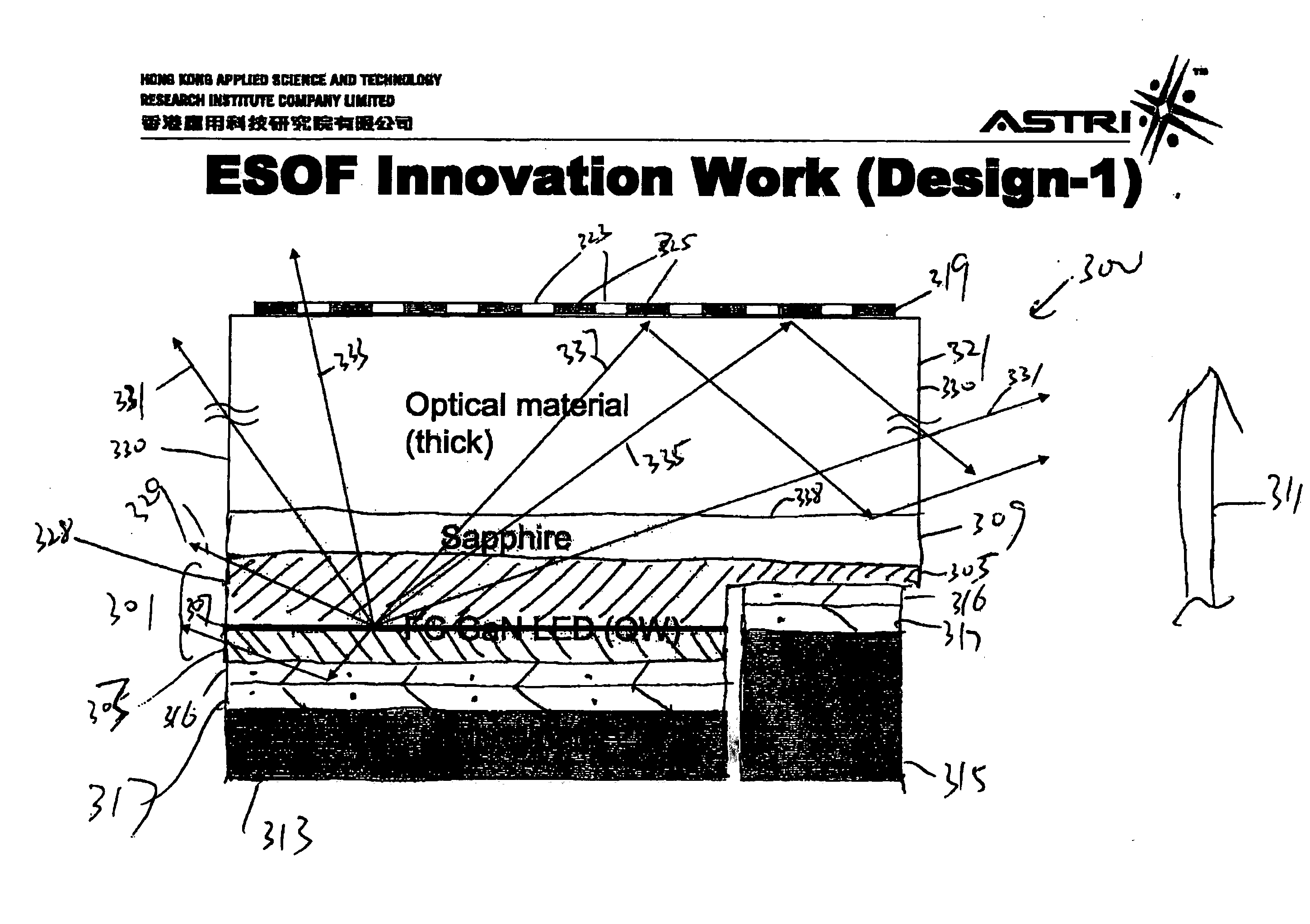

Light emitting diode device, and manufacture and use thereof

ActiveUS20080061310A1Improved light emissionAccelerate emissionsSemiconductor/solid-state device manufacturingSemiconductor devicesLight emissionLight-emitting diode

A light emitting diode device includes a multi-layer stack of materials including a p-layer, a n-layer, and a light generating region for emission of light in a primary emission direction towards one of the p- and n-layers; a substantially transparent layer located at or adjacent said one of the p- and n-layers, having a first surface facing said one of the p- and n-layers and an opposed second surface; and a reflective surface formed at or adjacent the second surface of the transparent layer for directing at least a portion of the emitted light in a direction away from the primary emission direction so as to enhance light emission from a side of the light emitting diode device.

Owner:HONG KONG APPLIED SCI & TECH RES INST

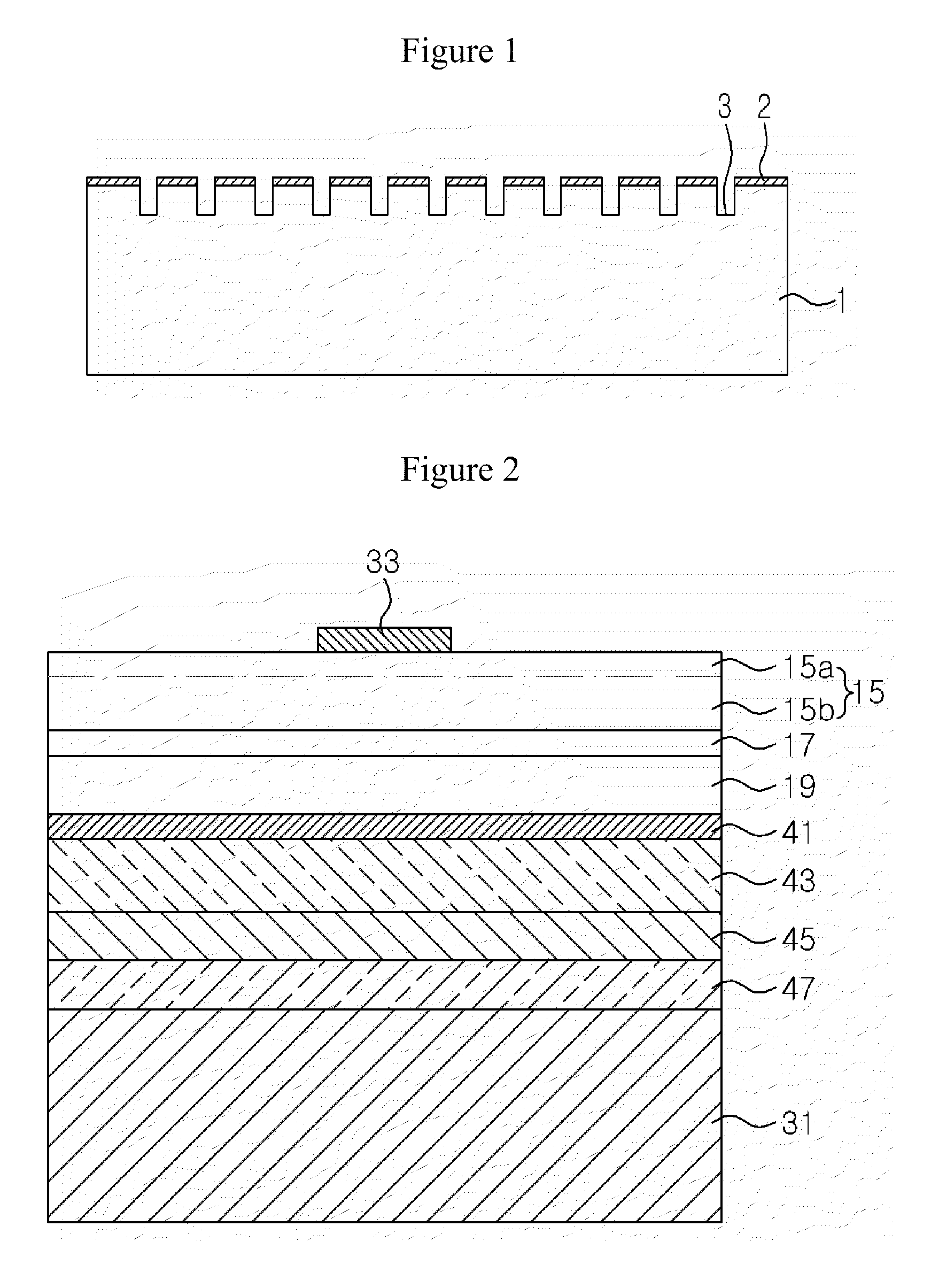

Method for Fabricating a Vertical Light-Emitting Diode with High Brightness

InactiveUS20120088318A1Improved light emissionAccelerate emissionsSemiconductor/solid-state device manufacturingSemiconductor devicesLight-emitting diodeLight emission

A method for fabricating a vertical light-emitting diode comprises forming a stack including a plurality of epitaxial layers on a patterned first substrate, placing a second substrate on the stack, removing the first substrate to expose the first surface, planarizing a first surface of the stack that was in contact with the patterned first substrate and has a pattern corresponding to a pattern provided on the first substrate to form a planarized second surface, and forming a first electrode in contact with a side of the second substrate that is opposite to the stack, and a second electrode in contact with the second surface of the stack. A roughening step can be performed to form uneven surface portions on a region of the second surface for improving light emission through the second surface of the stack.

Owner:TEKCORE CO LTD

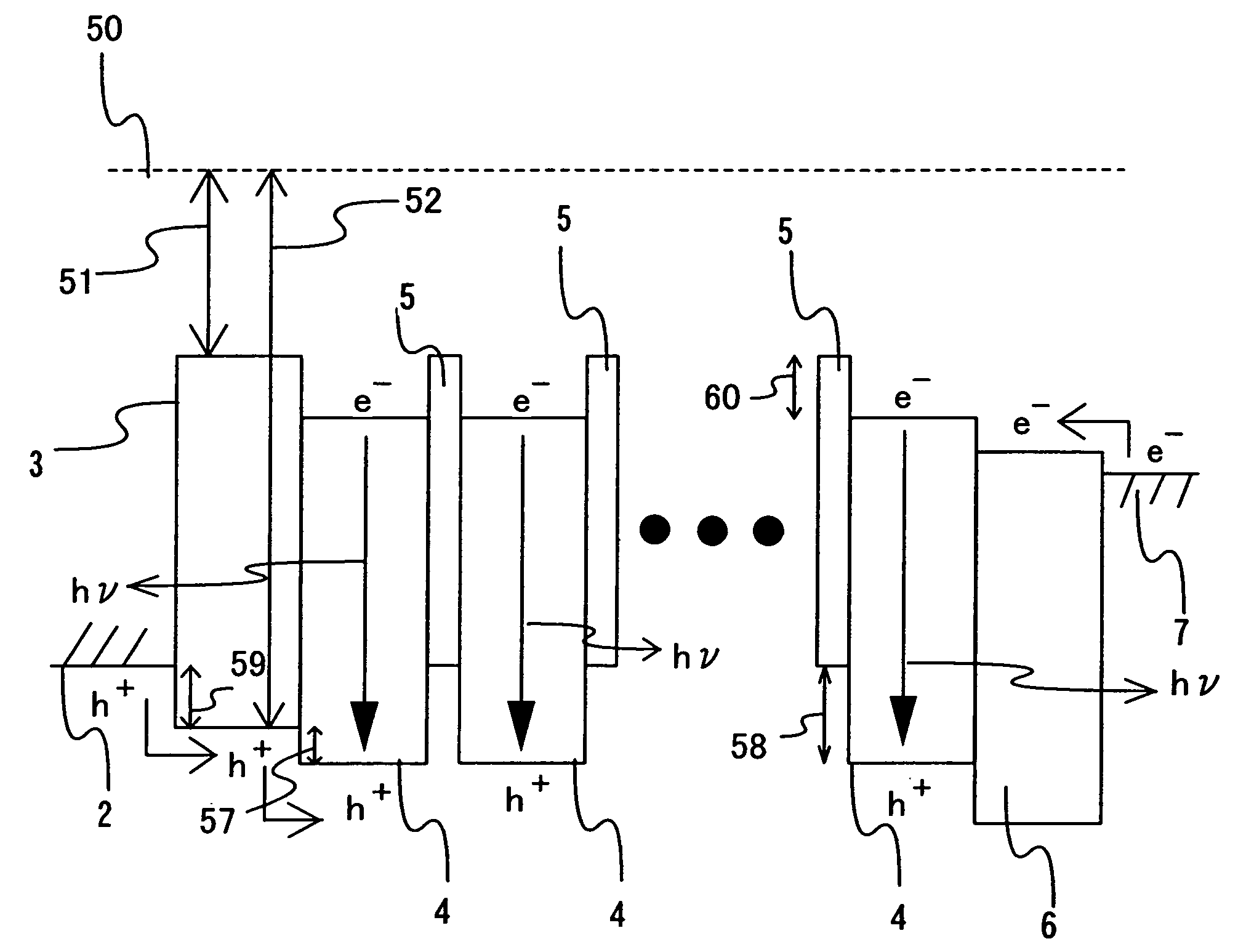

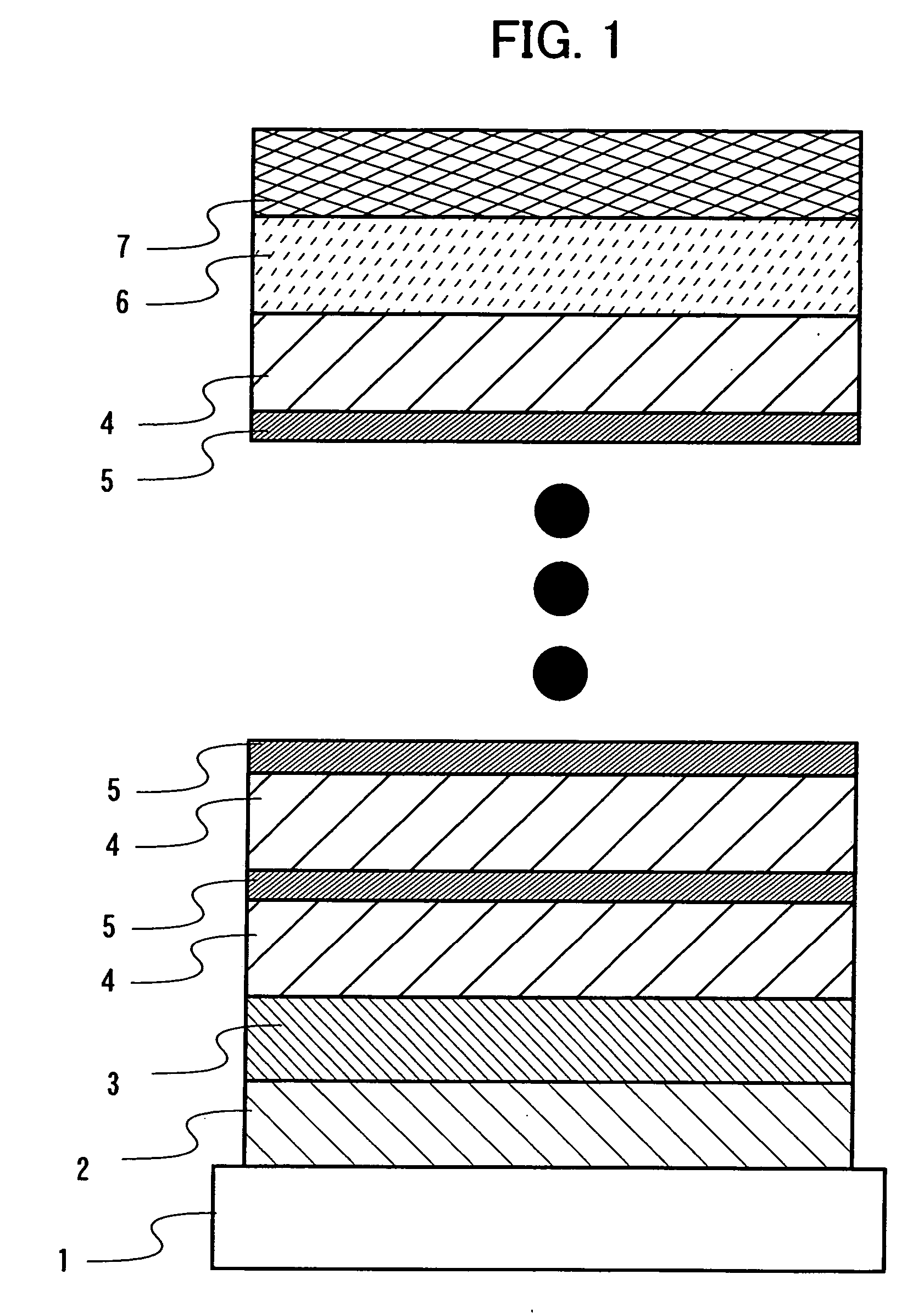

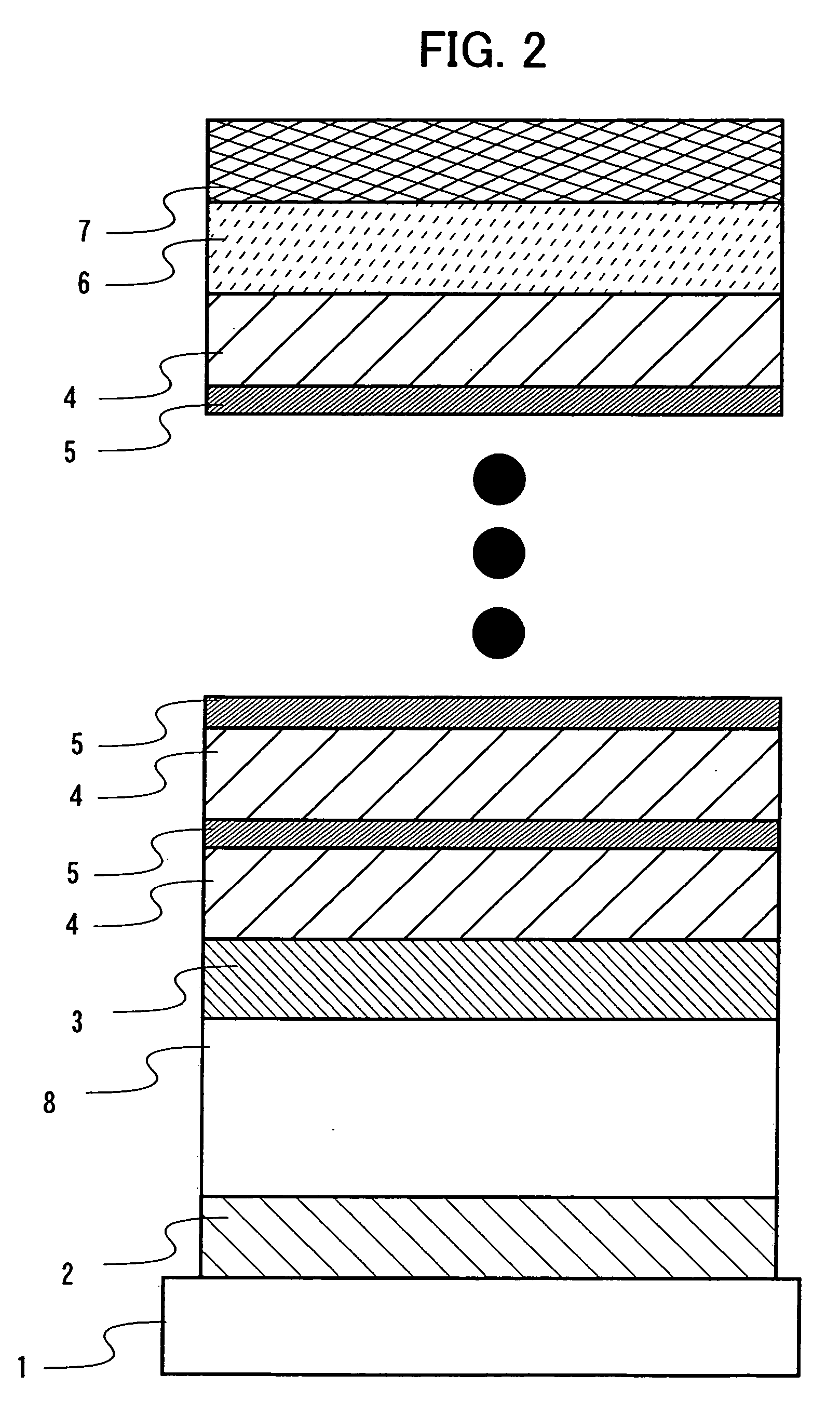

Light emitting device and method for manufacturing thereof

InactiveUS20060244373A1Less deterioration in characteristicImprove luminous efficiencyDischarge tube luminescnet screensLayered productsSimple Organic CompoundsTransport layer

An object of the present invention is to provide a light emitting device including an organic light emitting layer and an organic compound and having high light emitting efficient along with less deterioration in characteristics. In the light emitting device, an anode, a cathode facing the anode, light emitting layers each comprising an organic compound and being provided between the anode and the cathode, and carrier transporting layers each comprising an organic compound, are provided over a substrate. Each of the light emitting layers and each of the carrier transporting layers are alternately stacked. A thickness of each of the carrier transporting layers is thinner than that of each of the light emitting layers. When each of the carrier transporting layers is a hole transporting layer, each of the light emitting layers has an electron transporting property. When each of the carrier transporting layers is an electron transporting layer, each of the light emitting layers has a hole transporting property.

Owner:SEMICON ENERGY LAB CO LTD

Light-emitting electronic textile with improved light diffusion

InactiveUS8690385B2Improved light emissionPoint-like light sourceWave amplification devicesEngineeringElectron

A light-emitting electronic textile (2) comprising a flexible component carrier (3) having a plurality of light-sources (4a-c) arranged thereon; a cover textile (5) arranged to allow passage through the cover textile (5) of light emitted by the light-sources (4a-c); and a light-diffusing member (6) arranged between the light-sources (4a-c) and the cover textile (5). The light-diffusing member (6) comprises a layered structure formed by a plurality of light-diffusing layers (12a-c; 16a-b; 19a-c), wherein adjacent light-diffusing layers in the layered structure are spaced apart at least in portions of the light-diffusing member (6) corresponding to positions of the light-sources (4a-c).

Owner:KONINK PHILIPS ELECTRONICS NV

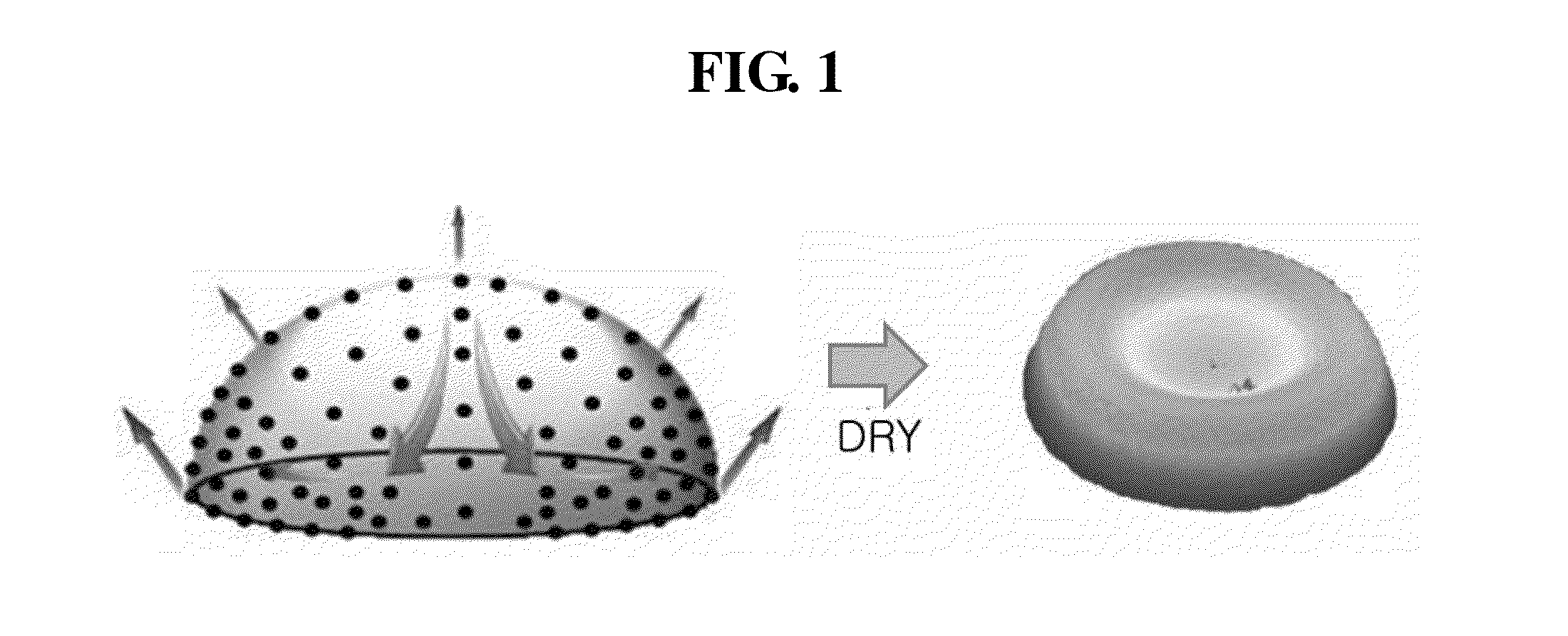

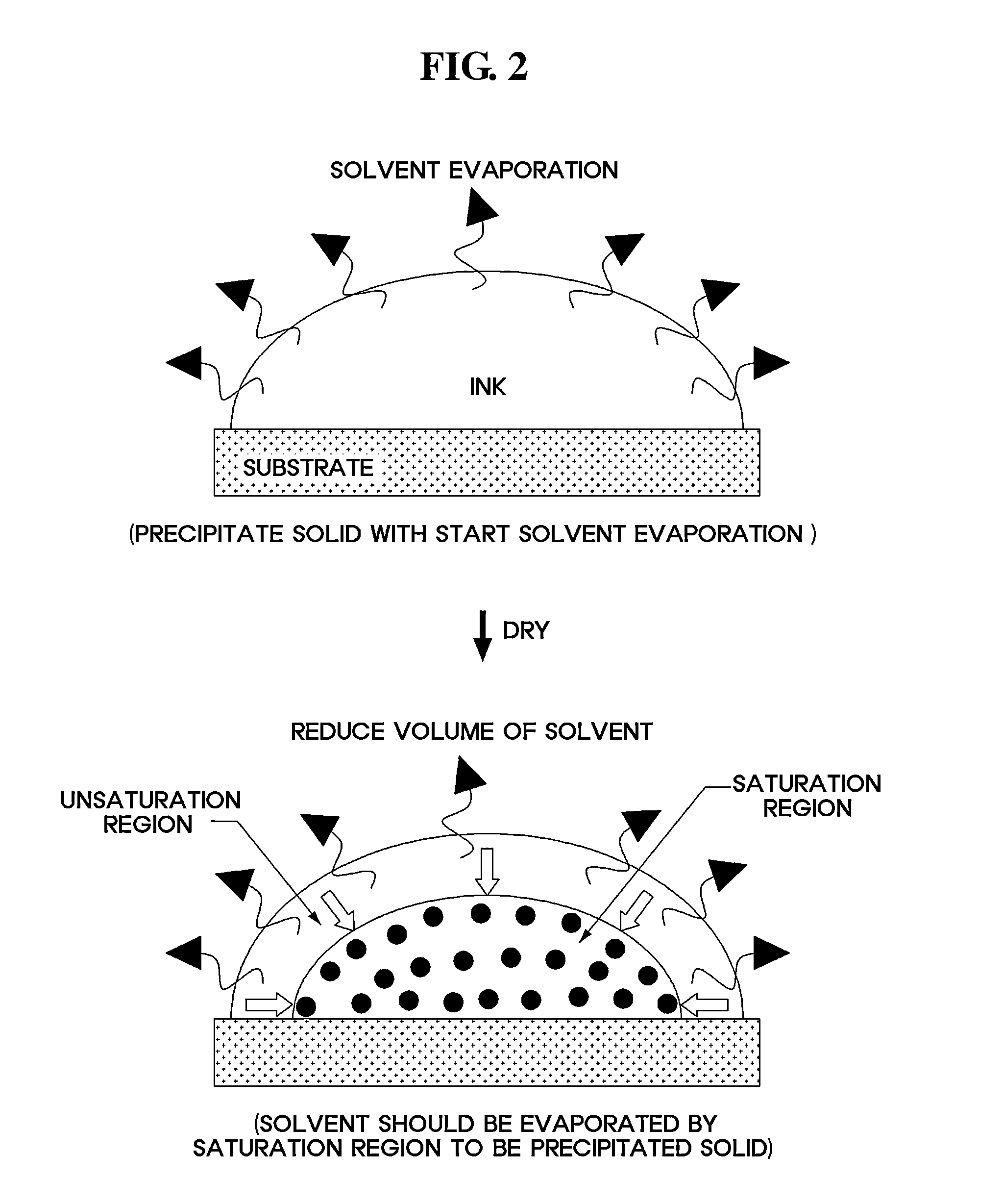

Ink for display device manufacturing and method for manufacturing of the same, method for manufacturing using the same

ActiveUS20150132496A1High resolutionImproved light emissionPretreated surfacesInksSolubilityDisplay device

An ink for display device manufacturing, including a solid, a first solvent having a solubility for the solid of 2% or more and a second solvent having a solubility for the solid of 0.5% or less.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com