LED (light emitting diode) area light source module and method for obtaining uniform area light source white light

A technology of LED surface light source and surface light source, which is applied in the field of white light LED, and can solve problems such as complex device structure and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

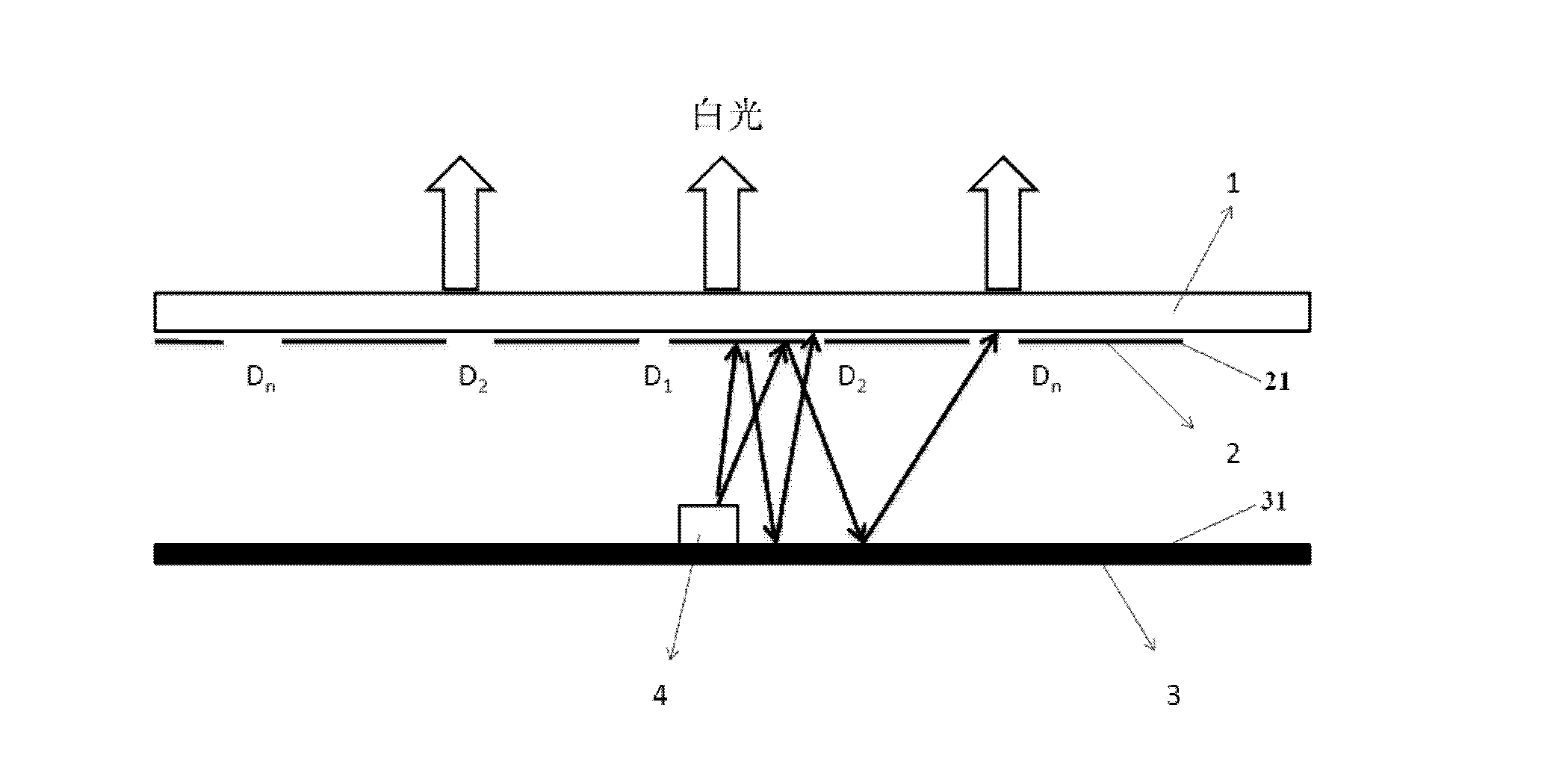

[0044] Example 1, figure 1 : (color temperature non-adjustable scheme)

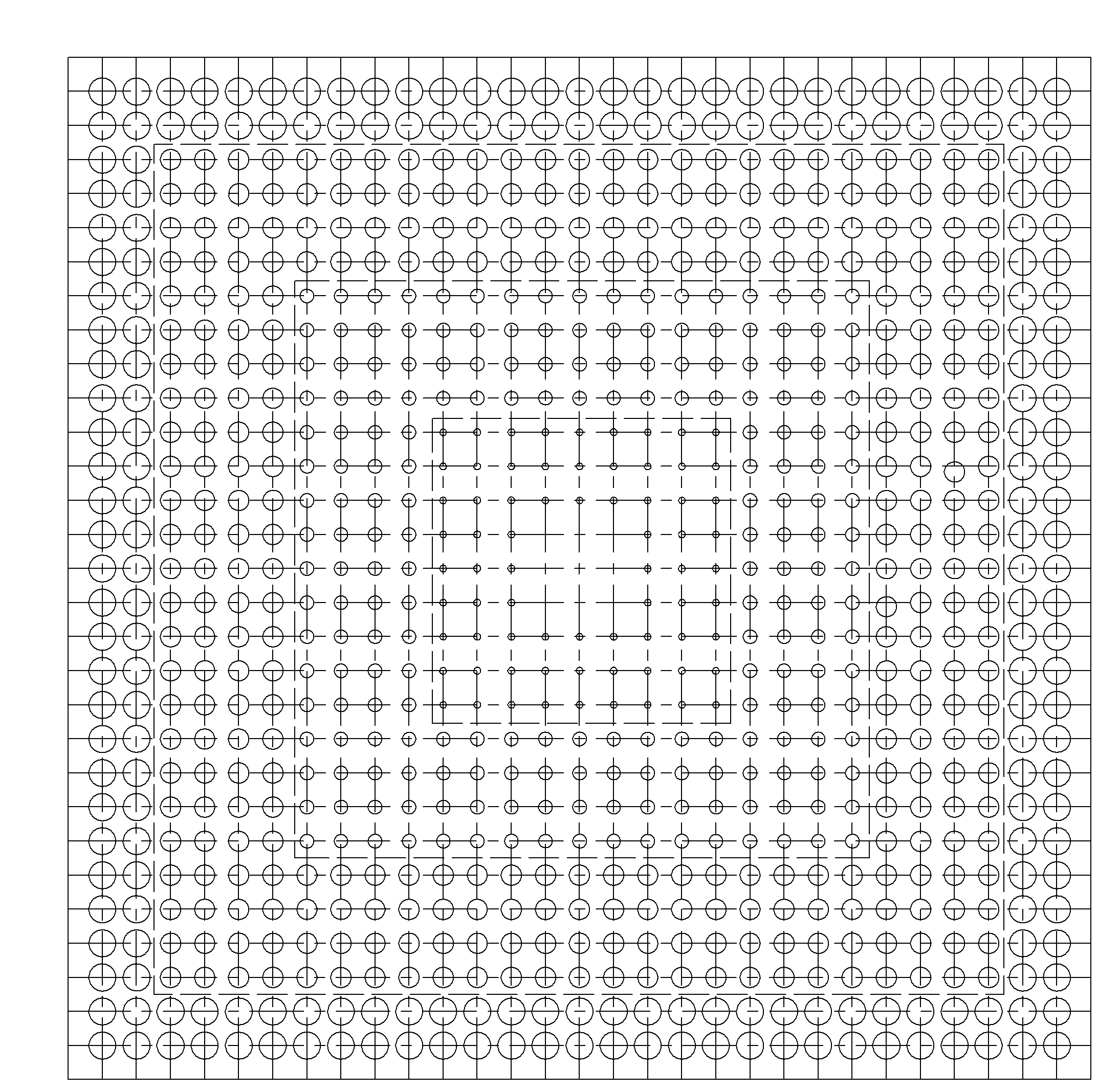

[0045] Select a blue light device 4, place it in the center of the substrate 3, cover the mesh-shaped dodging plate 2, and cover the replaceable phosphor layer 1 on the dodging plate 2, which can form a uniform white light surface light source for the blue light point light source. The light emitted by the blue light device 4 is reflected from the first reflective surface 21 and the second reflective surface 31 or refracted and reflected multiple times by the first reflective surface 21 and the second reflective surface 31 from the holes (D1, D2) of the uniform light plate 2. ......Dn) emerges, first forming a uniform surface light source, and then entering the phosphor layer 1 to mix light. Specific as figure 1 shown. figure 1 middle, D 1 ...D n is the aperture distributed from the center to the periphery of the dodging plate. The main peak wavelength of the blue light device is 440-480nm, more pre...

Embodiment 2

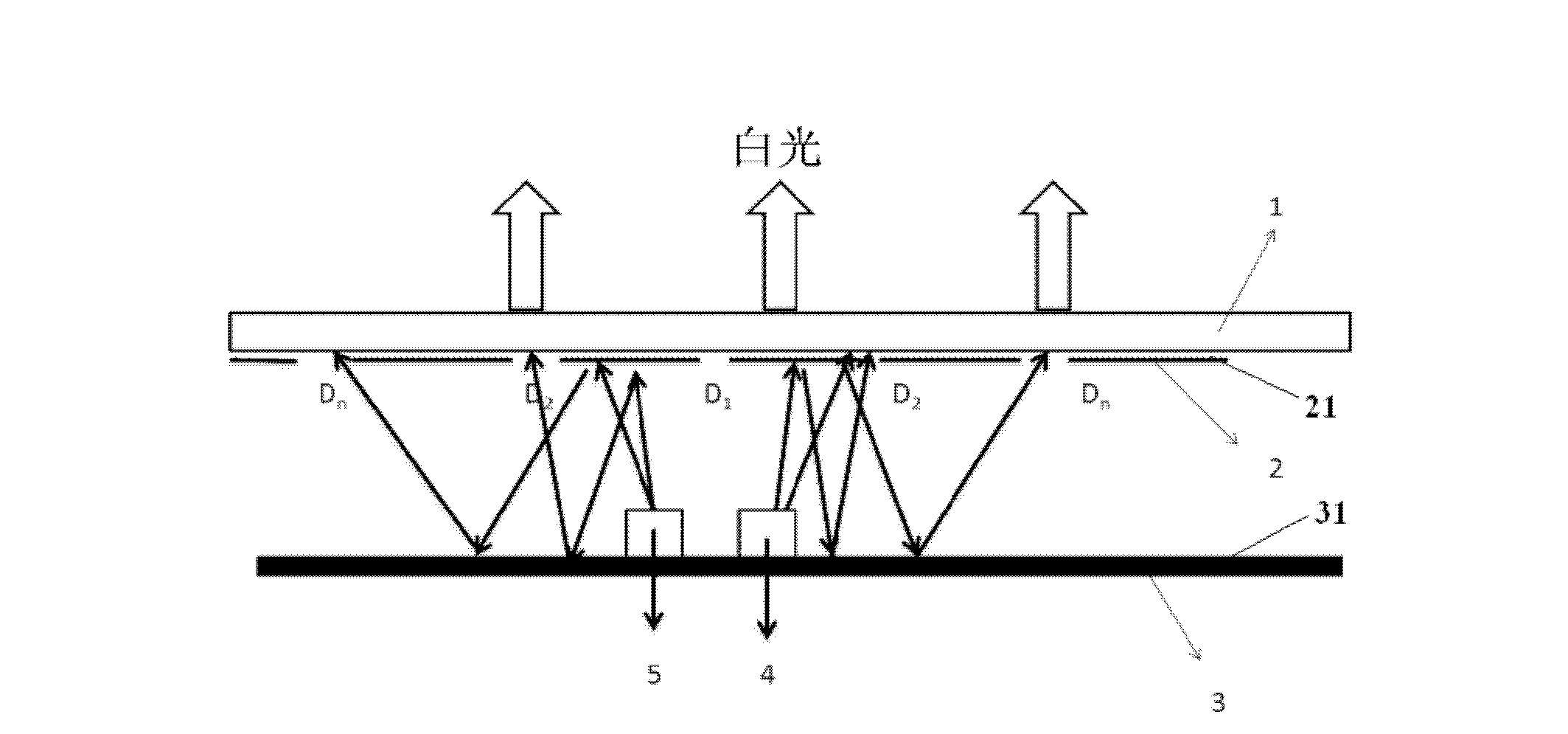

[0046] Example 2, figure 2 : (color temperature adjustable solution)

[0047] Select the blue light device 4 and the red light LED device 5, and place them in the center of the middle substrate 3 respectively, see figure 2 In the position shown, cover the mesh-shaped dodging plate 2, and cover the replaceable phosphor layer 1 on the dodging plate 2, which can form a uniform white light surface light source with a blue light point light source. The change of the color temperature is adjusted by adjusting the current of the red LED device. The light emitted by the blue light device 4 and the red light device 5 is reflected by the first reflective surface 21 and the second reflective surface 31 or refracted and reflected multiple times by the first reflective surface 21 and the second reflective surface 31 from each of the dodging plate 2. The holes ( D1 , D2 . . . Dn ) exit to form a uniform surface light source first, and then enter the phosphor layer 1 to mix light.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com