Patents

Literature

446results about How to "Improve lighting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

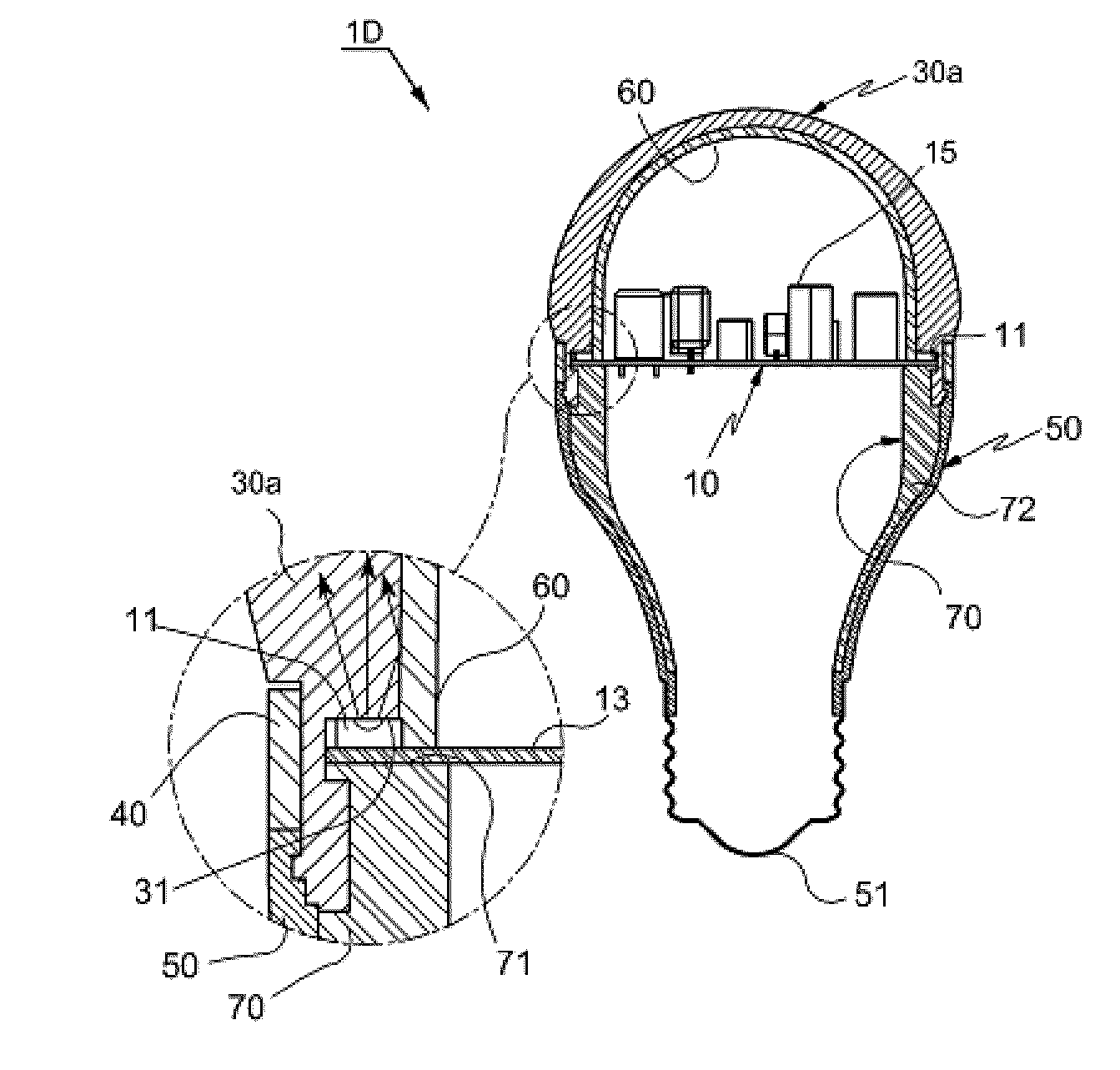

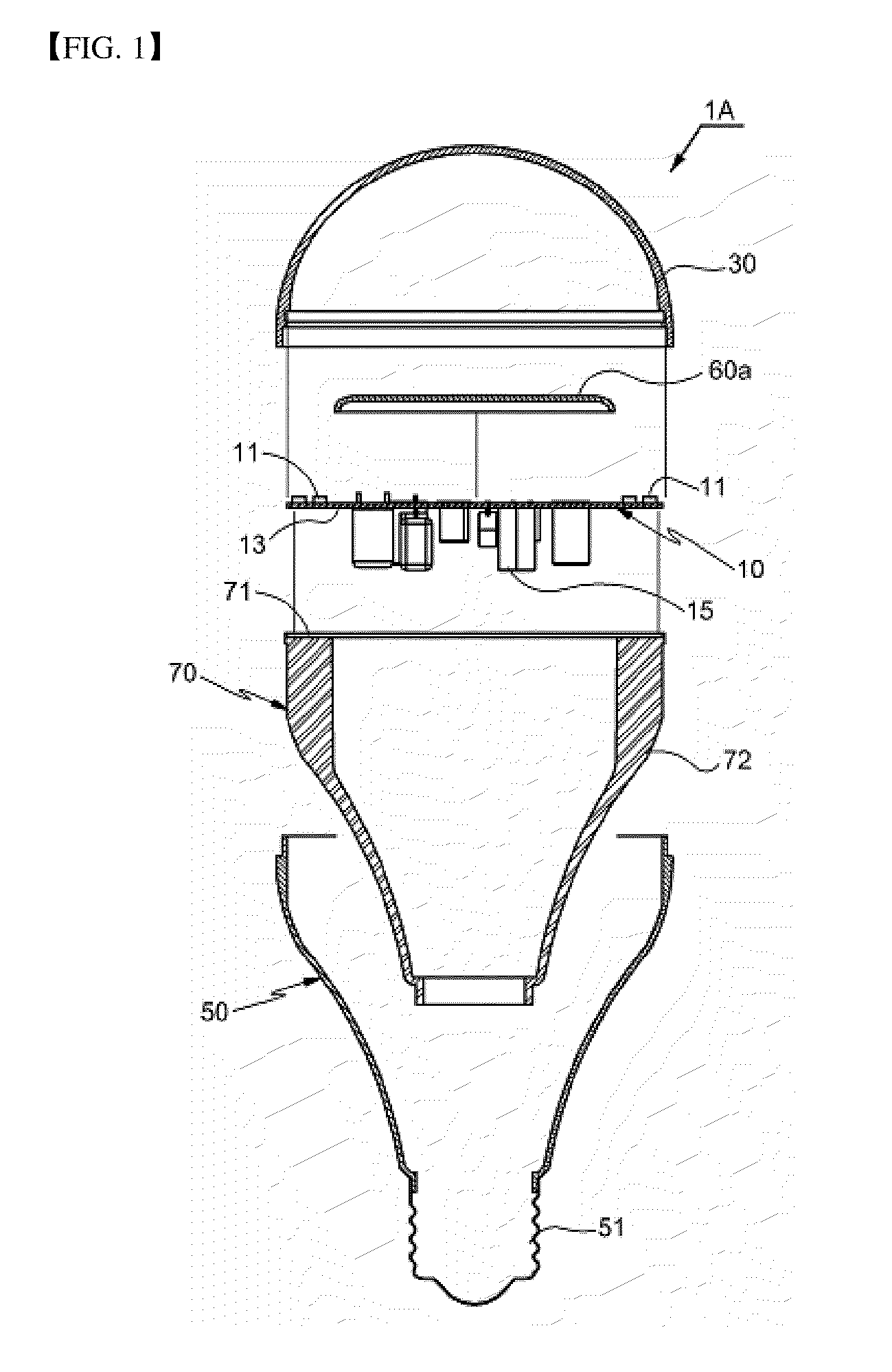

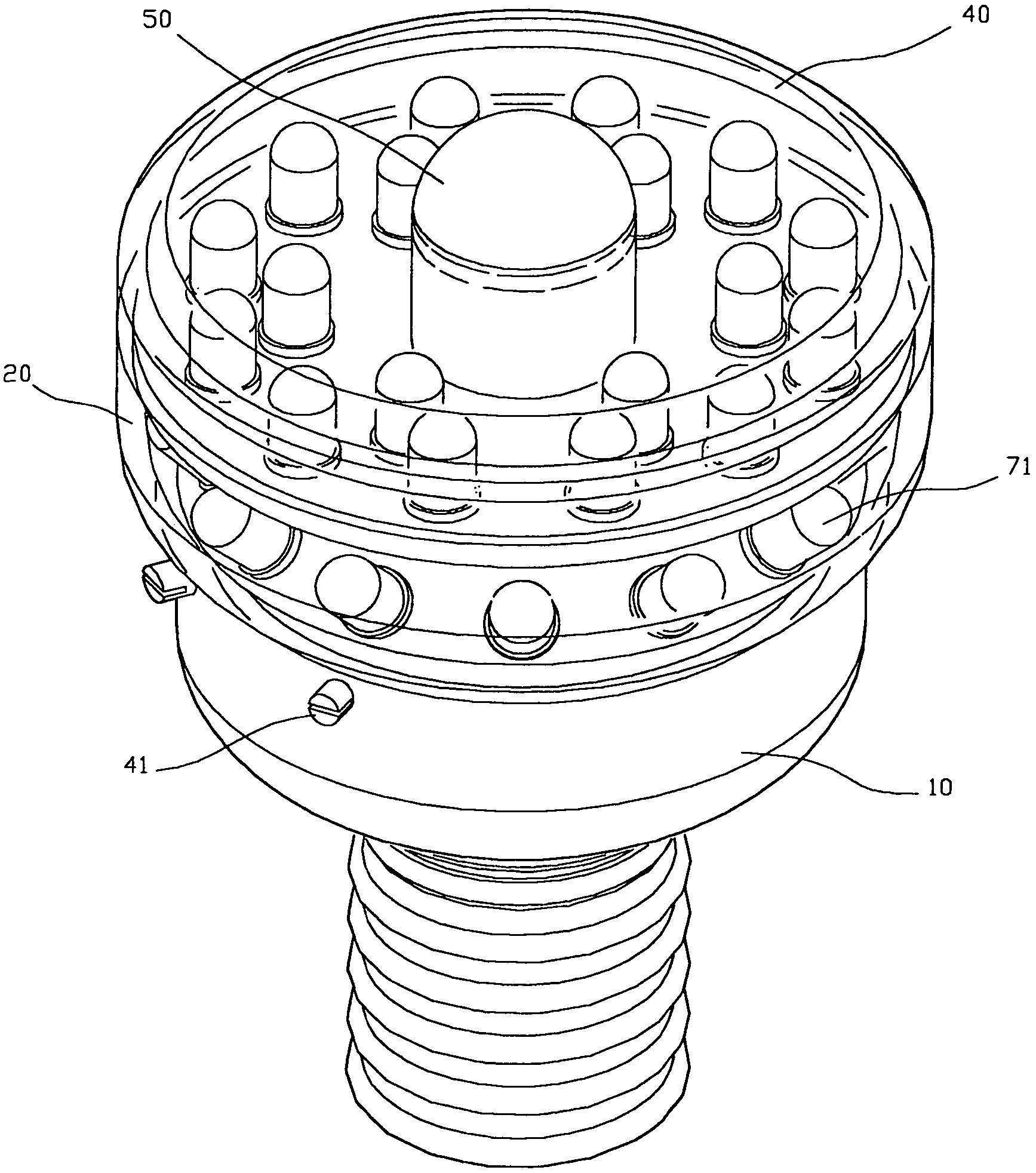

LED lamp

InactiveUS20110101861A1Increase emission rateConstant gainPoint-like light sourceElongate light sourcesEngineeringPolycarbonate

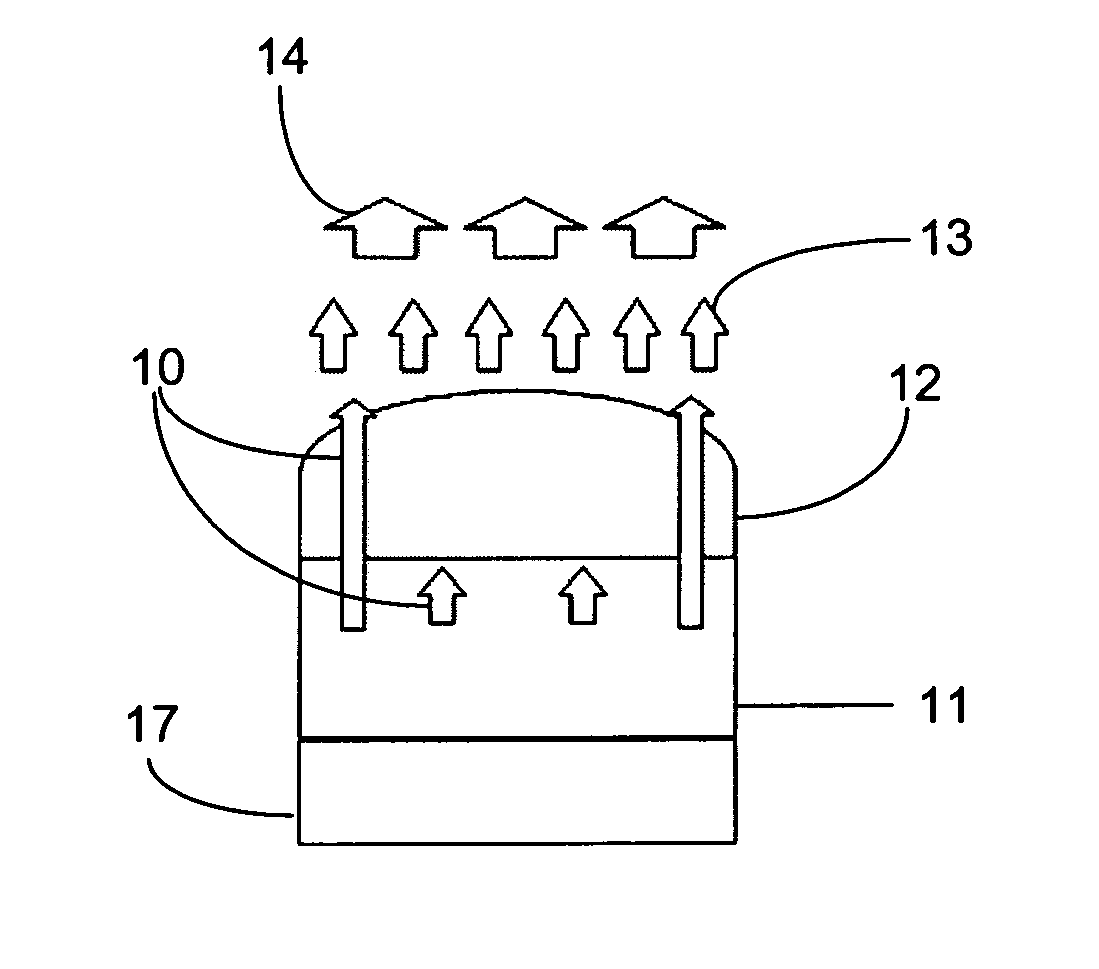

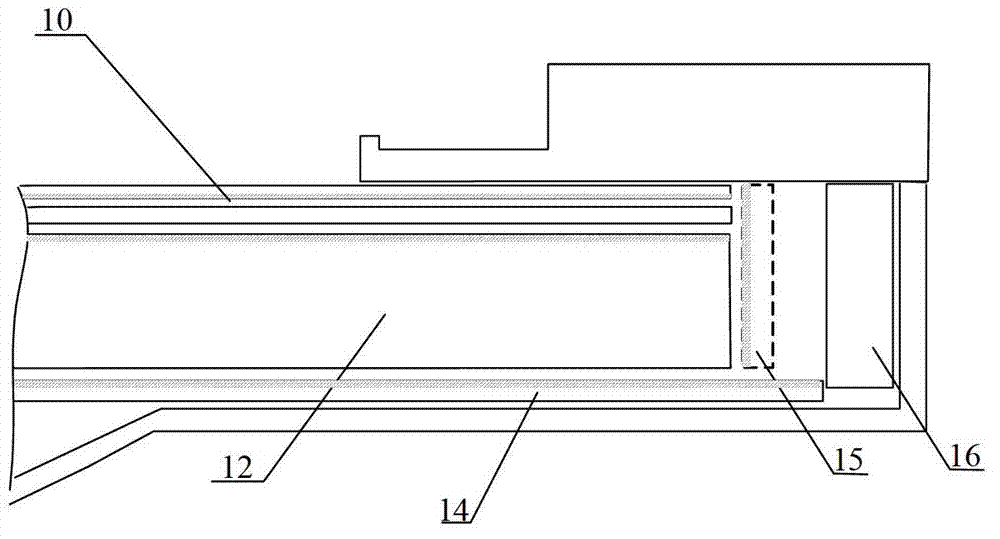

The present invention relates to an LED lamp in which, because the lamp has therein a heat dissipation transfer member and the power source base thereof is made of materials including polycarbonate, etc. with a high emission rate of radiation so as to enhance its surface heat dissipation constant, the power source base has sufficient heat dissipation performance and, thus, a separate insulation circuit is not necessary, thereby improving reliability and productivity of the lamp as well as reducing the cost of manufacturing.To this end, the present invention provides an LED lamp comprising one or more LEDs mounted on a PCB, a floodlight cover that transmits light from the LEDs, and a power source base coupled to the floodlight cover and having a terminal at one end thereof, wherein the power source base is made of an insulation material; and the LED lamp also comprises a heat dissipation transfer member that has a heat sink in contact with the PCB on which the LEDs are mounted, and is formed and installed so as to overlap with and be in tight contact with the inner face of either the power source base or the floodlight cover or both.

Owner:YOO YOUNG HO +1

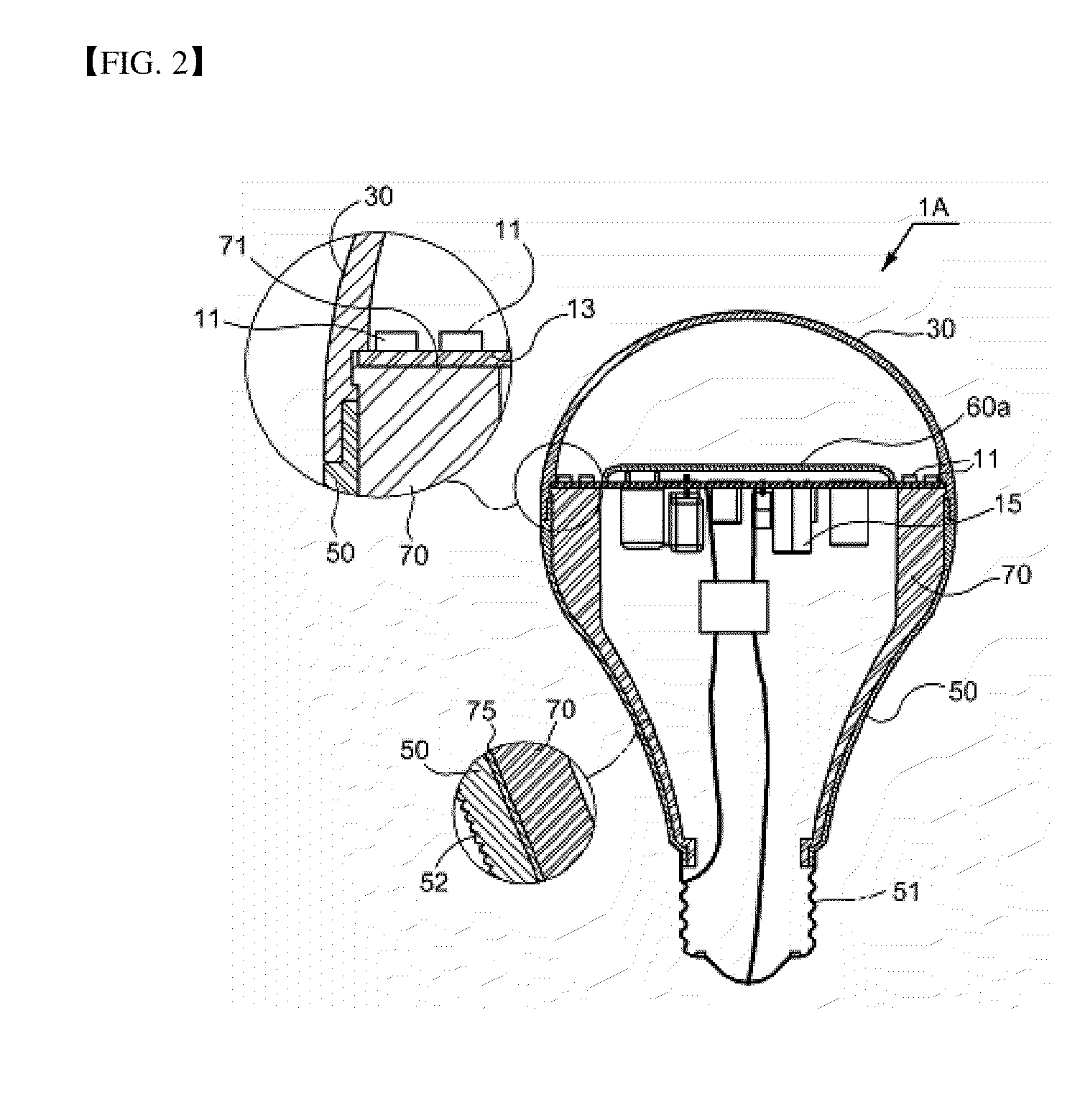

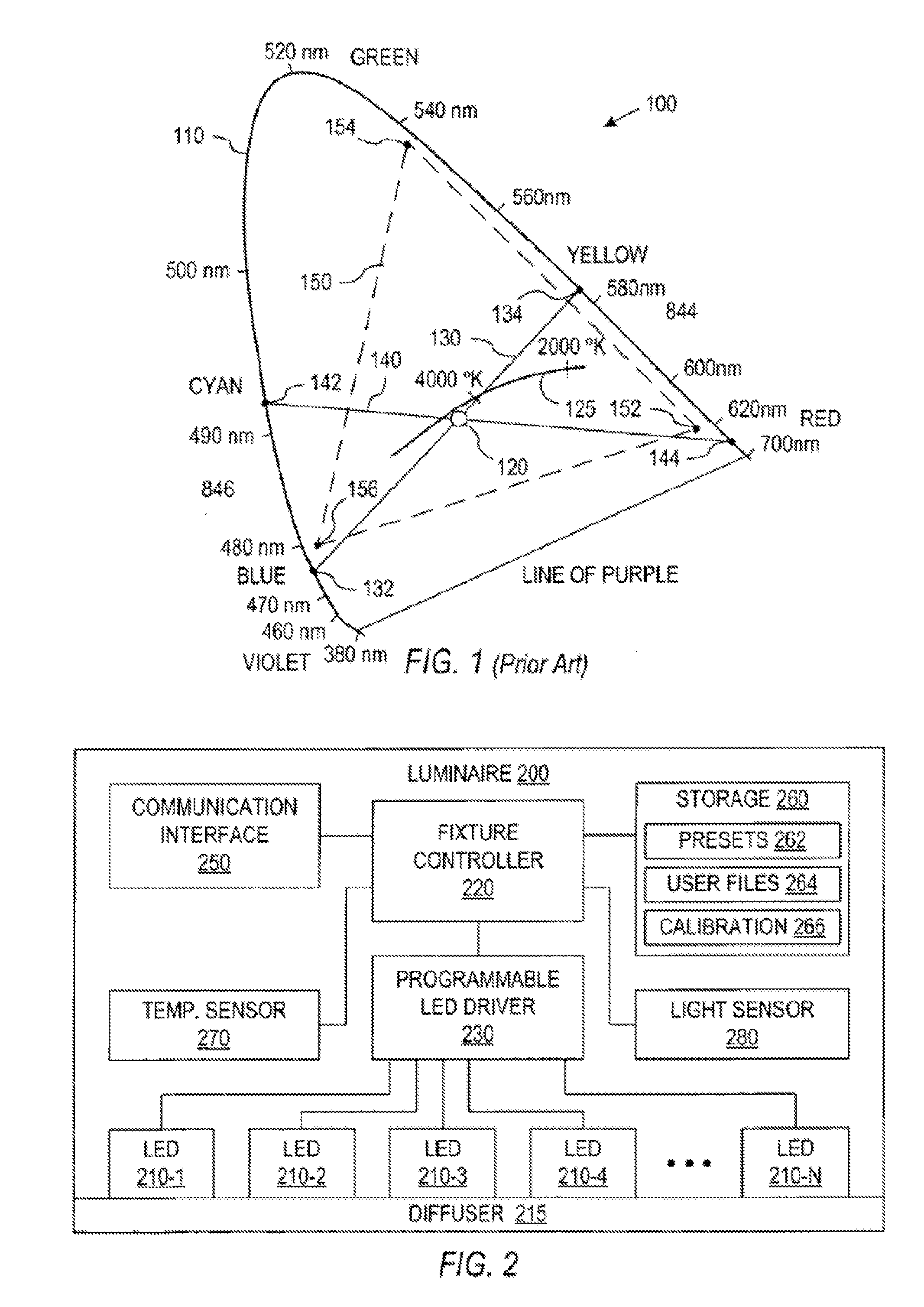

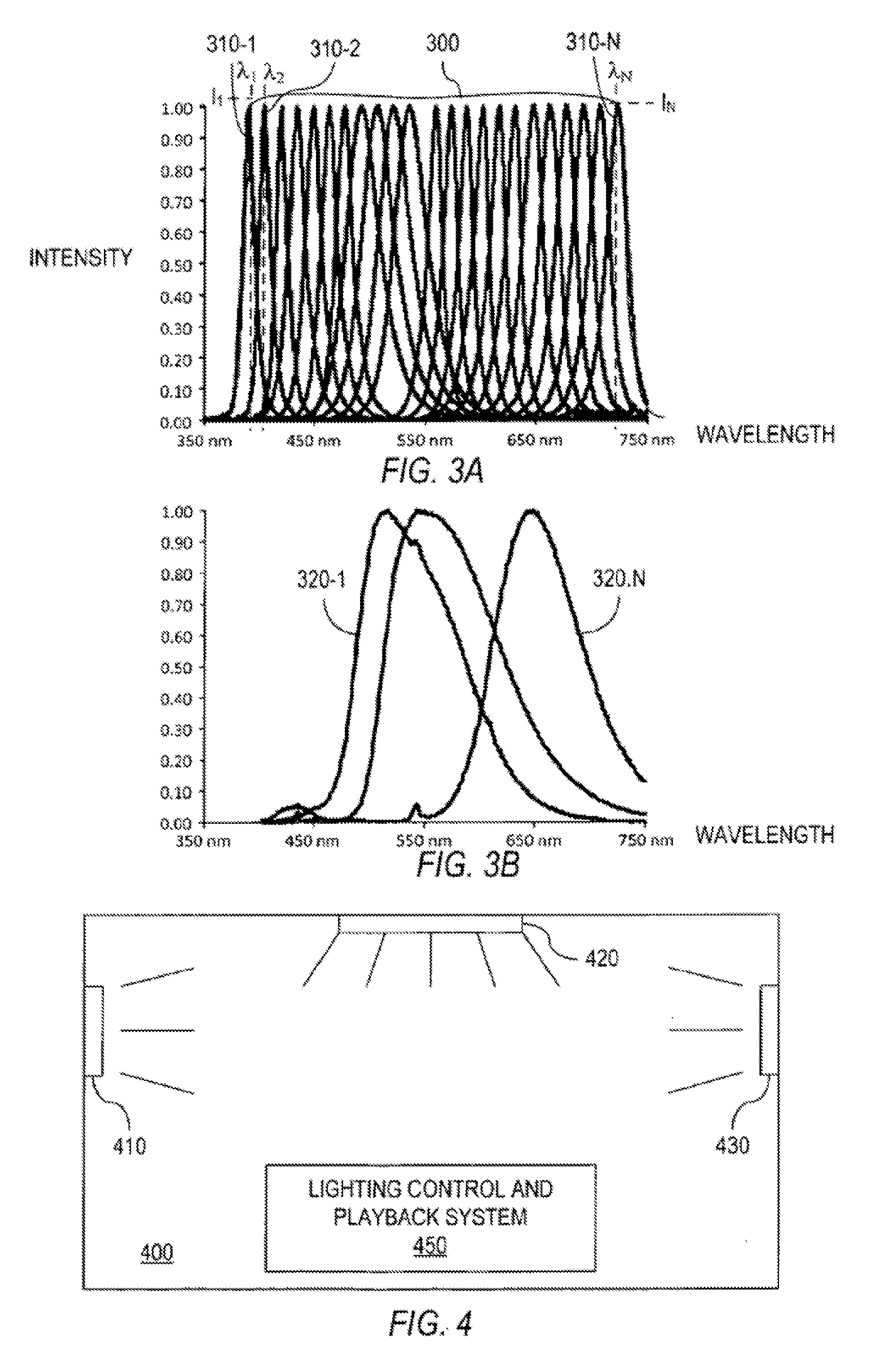

Systems and Methods for Developing and Distributing Illumination Data Files

ActiveUS20110137757A1Improve lighting qualityFine tuning of spectrumElectrical apparatusDigital data processing detailsData fileManagement system

Embodiments of the present invention relate to systems and methods for creating, distributing and playing illumination data files. The illumination data files, created using luminaire development systems are uploaded to a luminaire management system, where they are further processed and packaged for sale or license within a luminaire marketplace. Consumers and enterprises using luminaires may establish accounts with the luminaire management system and marketplace to access illumination data files for playback on individual or multiple luminaires. Consumers and enterprises may also create play lists and uniquely configure the luminaires to display various lighting effects based on user preferences, environmental factors or energy efficient settings.

Owner:TELELUMEN

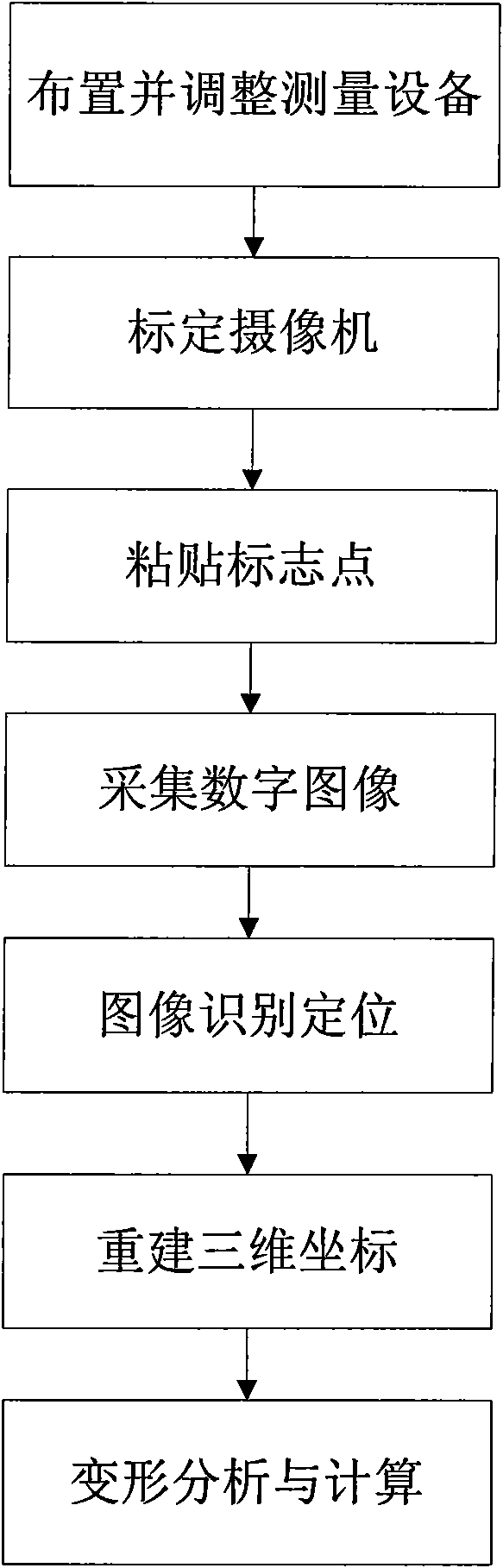

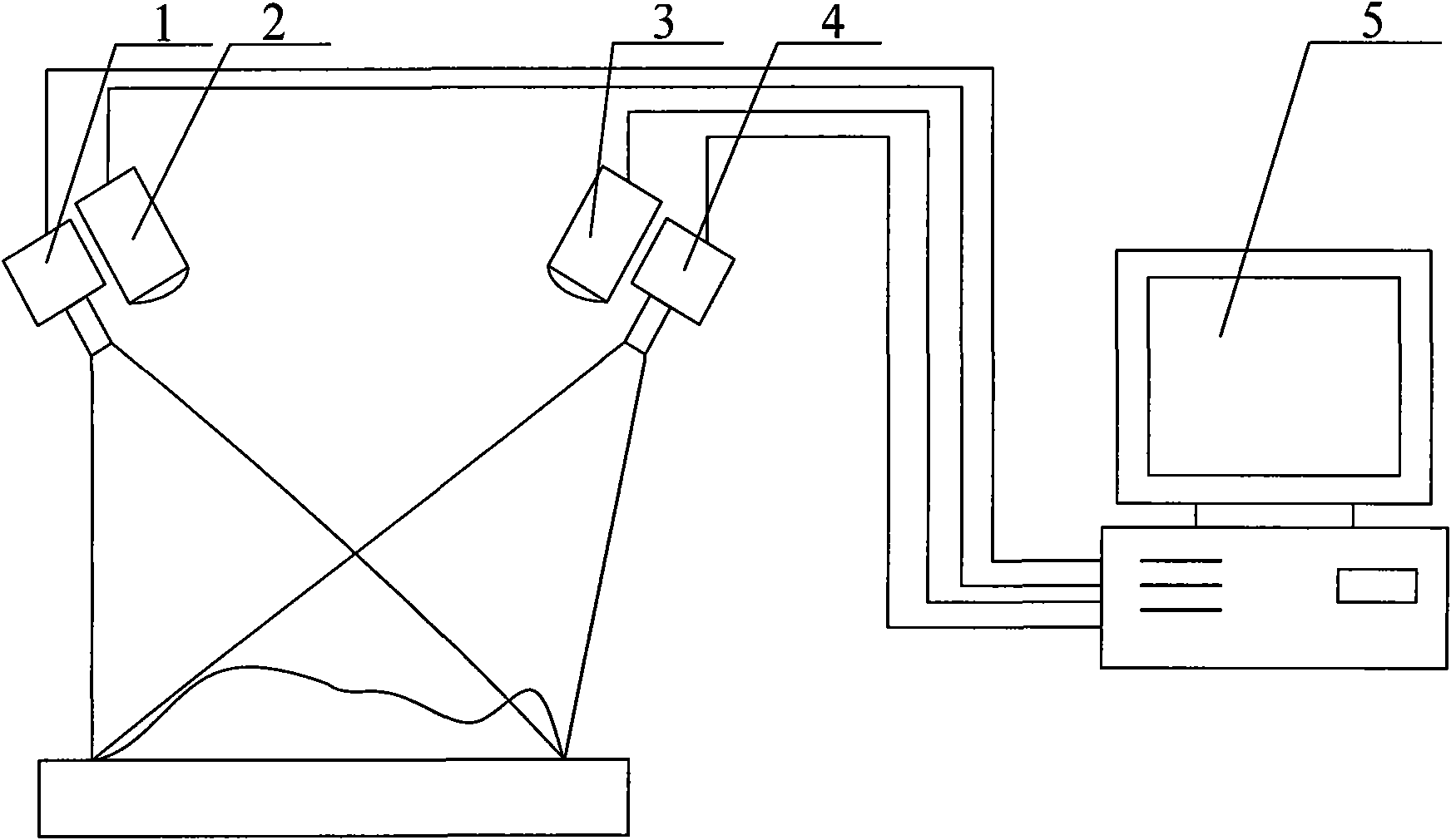

Method for measuring object deformation in real time

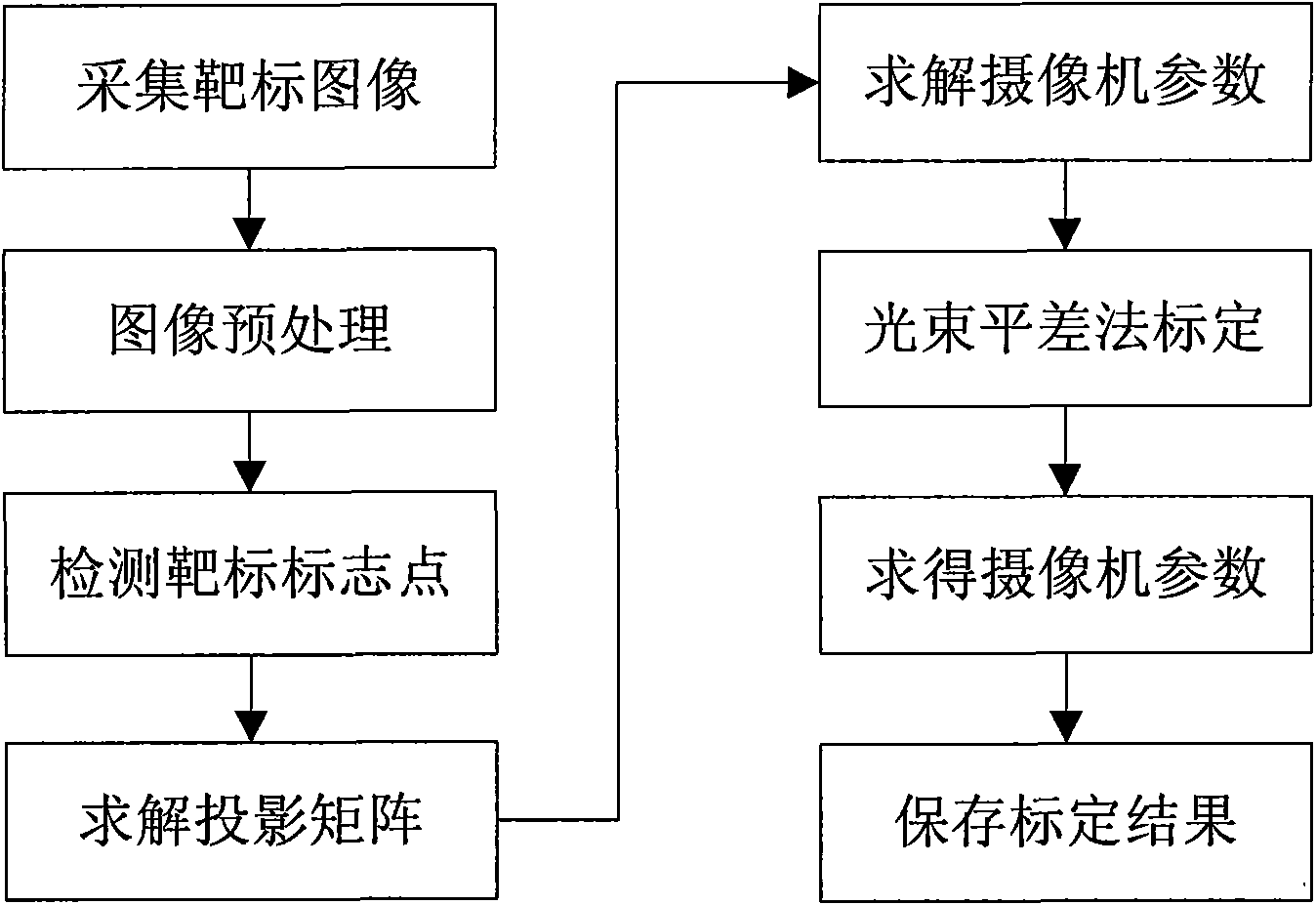

The invention discloses a method for measuring object deformation in real time, which comprises the following steps: arranging and adjusting measuring equipment, namely symmetrically arranging two cameras and corresponding LED illumination lamps above a measured object, and making optical axes of the two cameras intersected in a distance of 1 meter in front of the cameras; then calibrating the cameras, namely tightly sticking mark points to the surface of an object to be measured according to the size and shape of the measured object and the measurement requirement; next, placing the measured object stuck with the mark points under the two cameras in about 1 meter or moving the whole measuring equipment to make the measured object enter a measurement range and enable each camera to acquire the mark points on the surface of the measured object, starting the two cameras to shoot sequence images, and acquiring digital images; then identifying and positioning the images; reversely solving a projection matrix according to the calibration result of the cameras, and combining image coordinates of the solved mark points on the surface of the measured object on the images of the two cameras to reconstruct a three-dimensional coordinate of the mark points; and finally, carrying out deformation analysis and calculation for the mark points on the surface of the measured object.

Owner:XI AN JIAOTONG UNIV

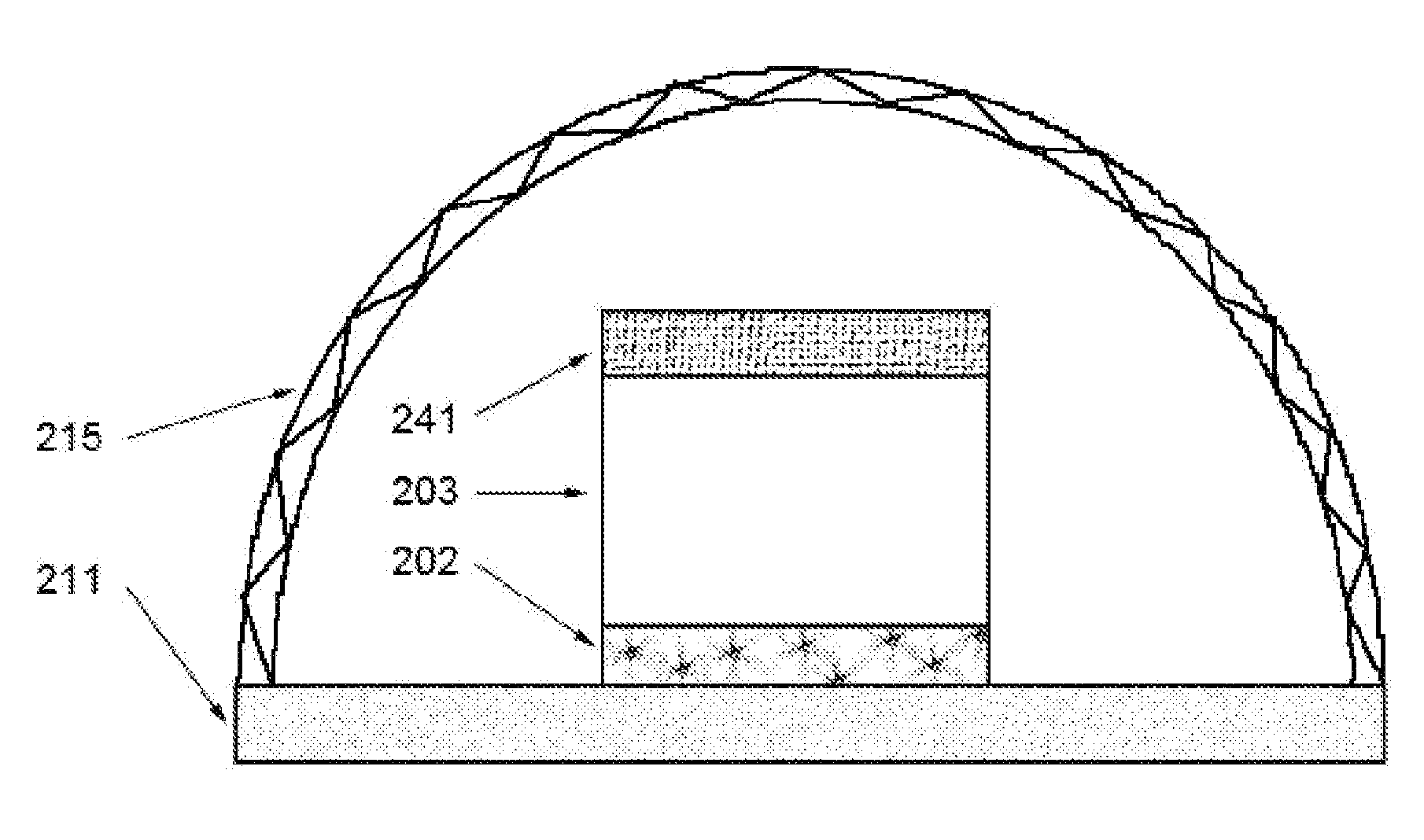

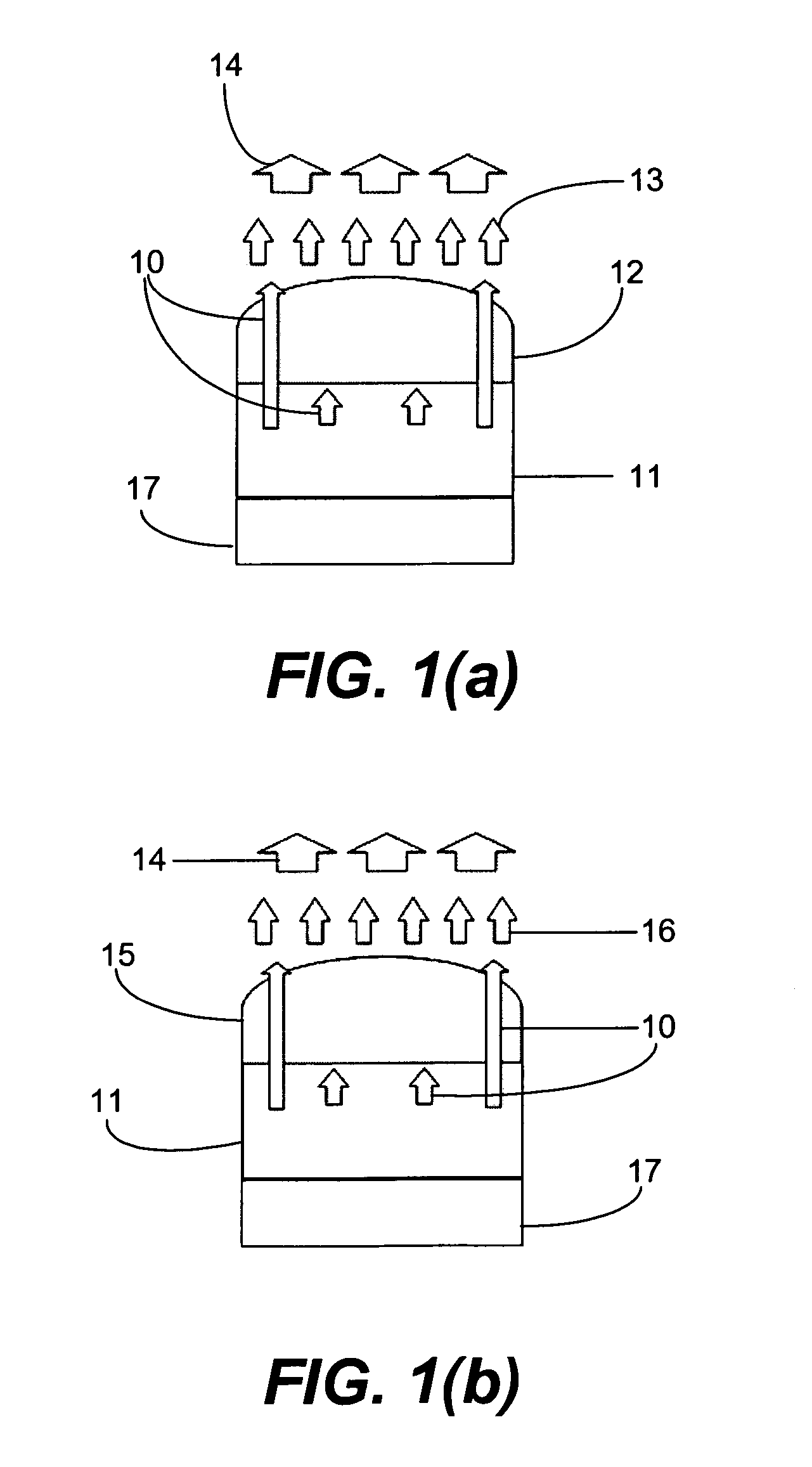

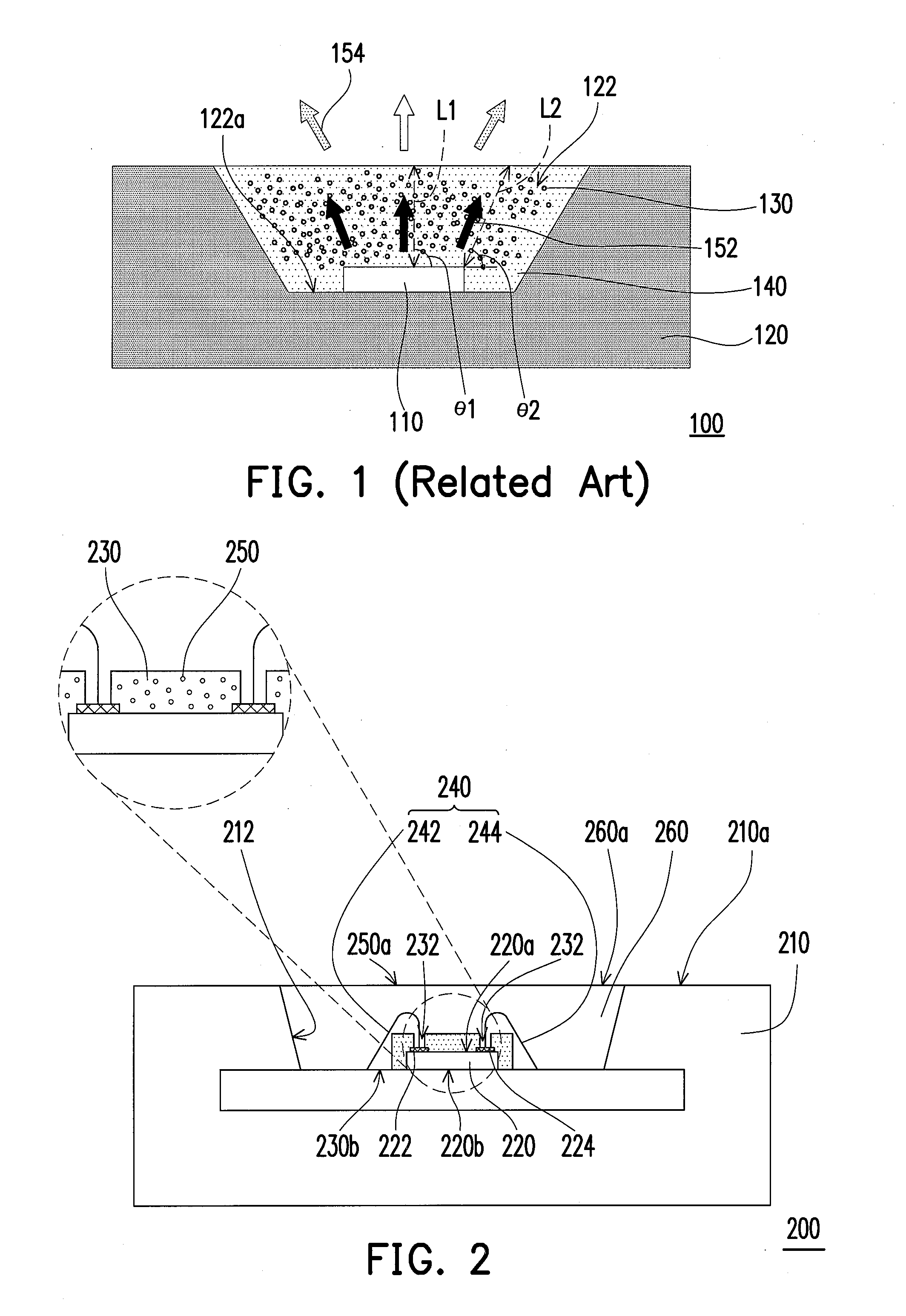

Light source comprising a light-excitable medium

InactiveUS20080106887A1Improve lighting qualityImprove optical qualityLight source combinationsPoint-like light sourceExcitable mediumSpectral power distribution

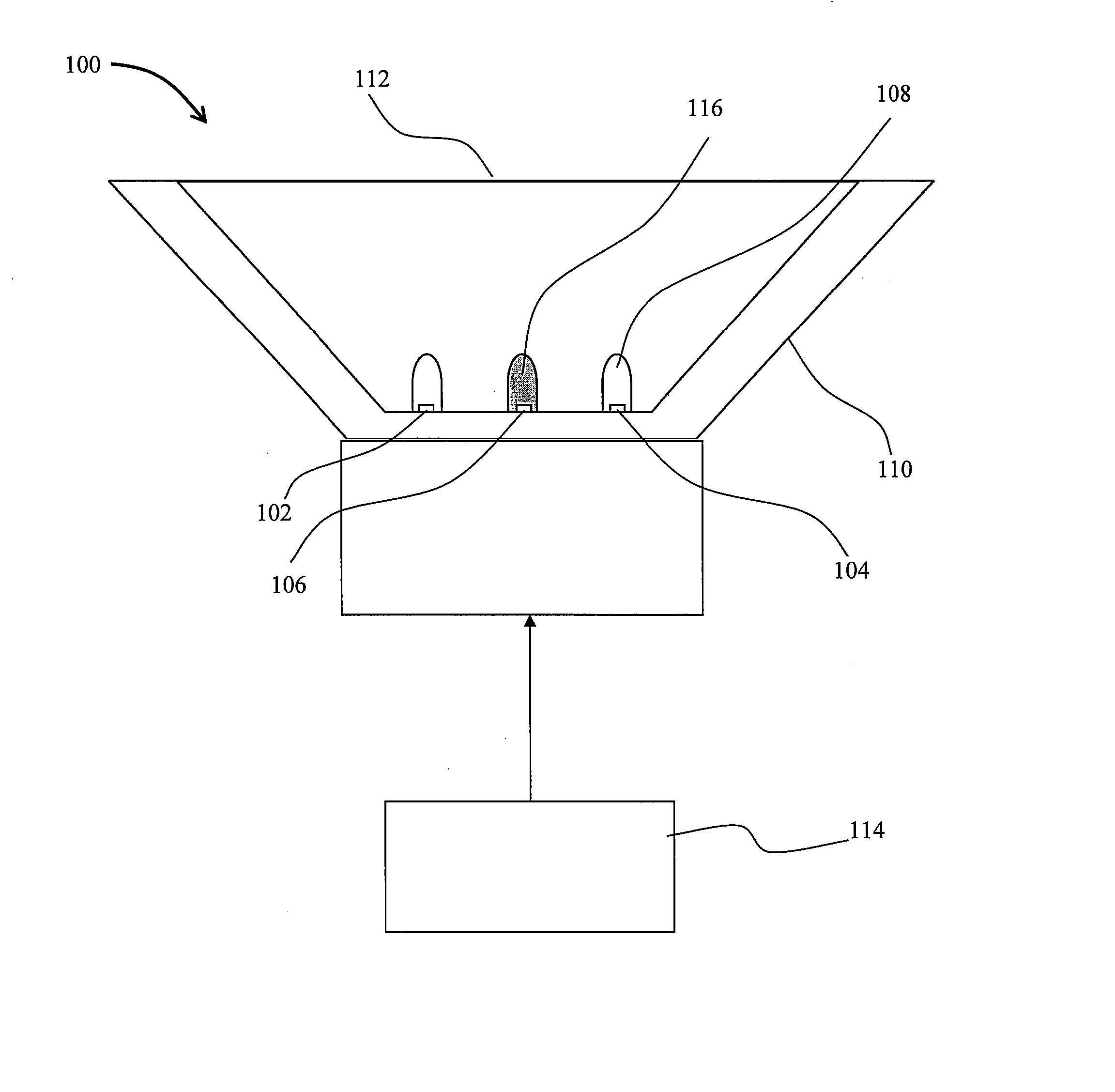

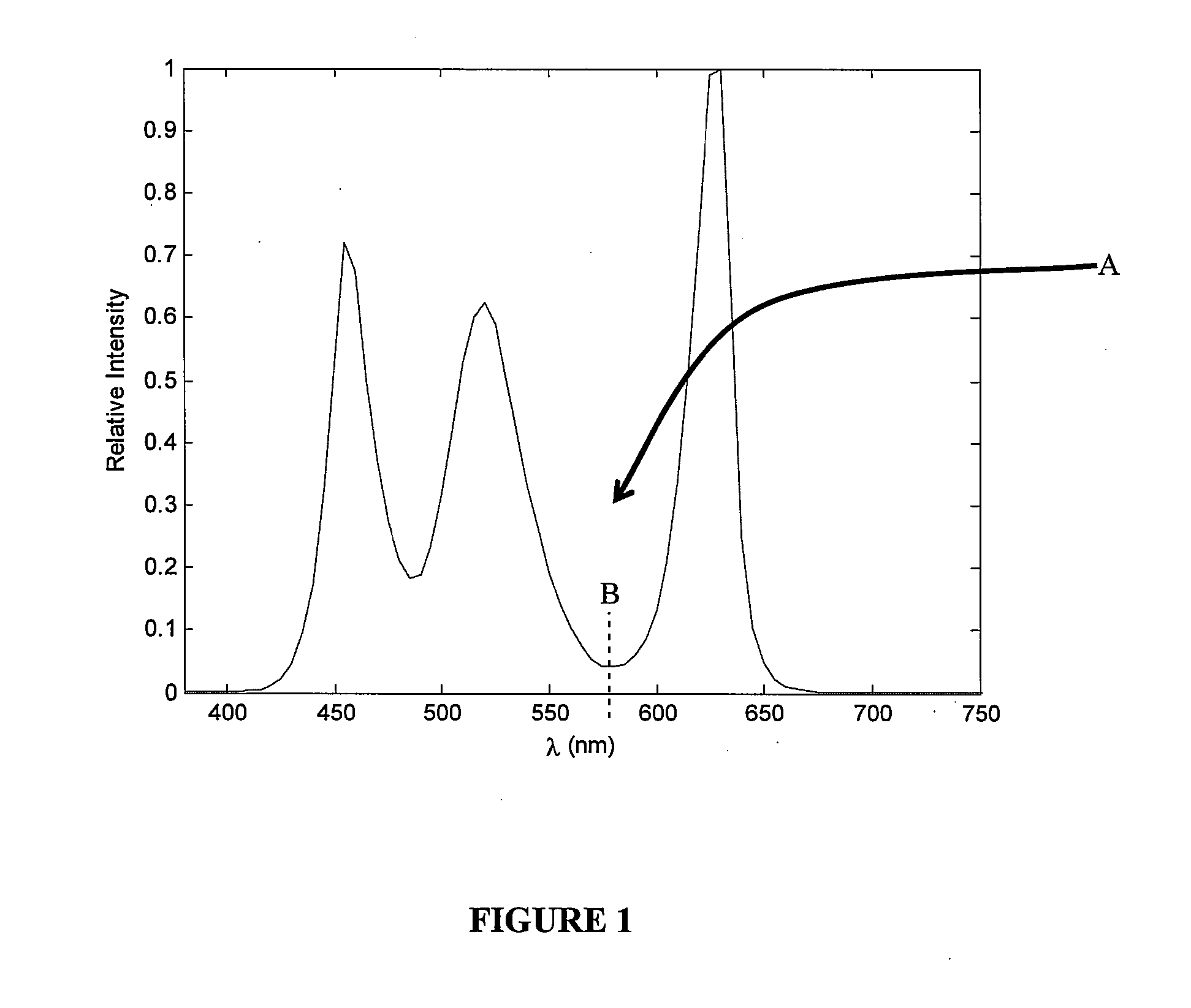

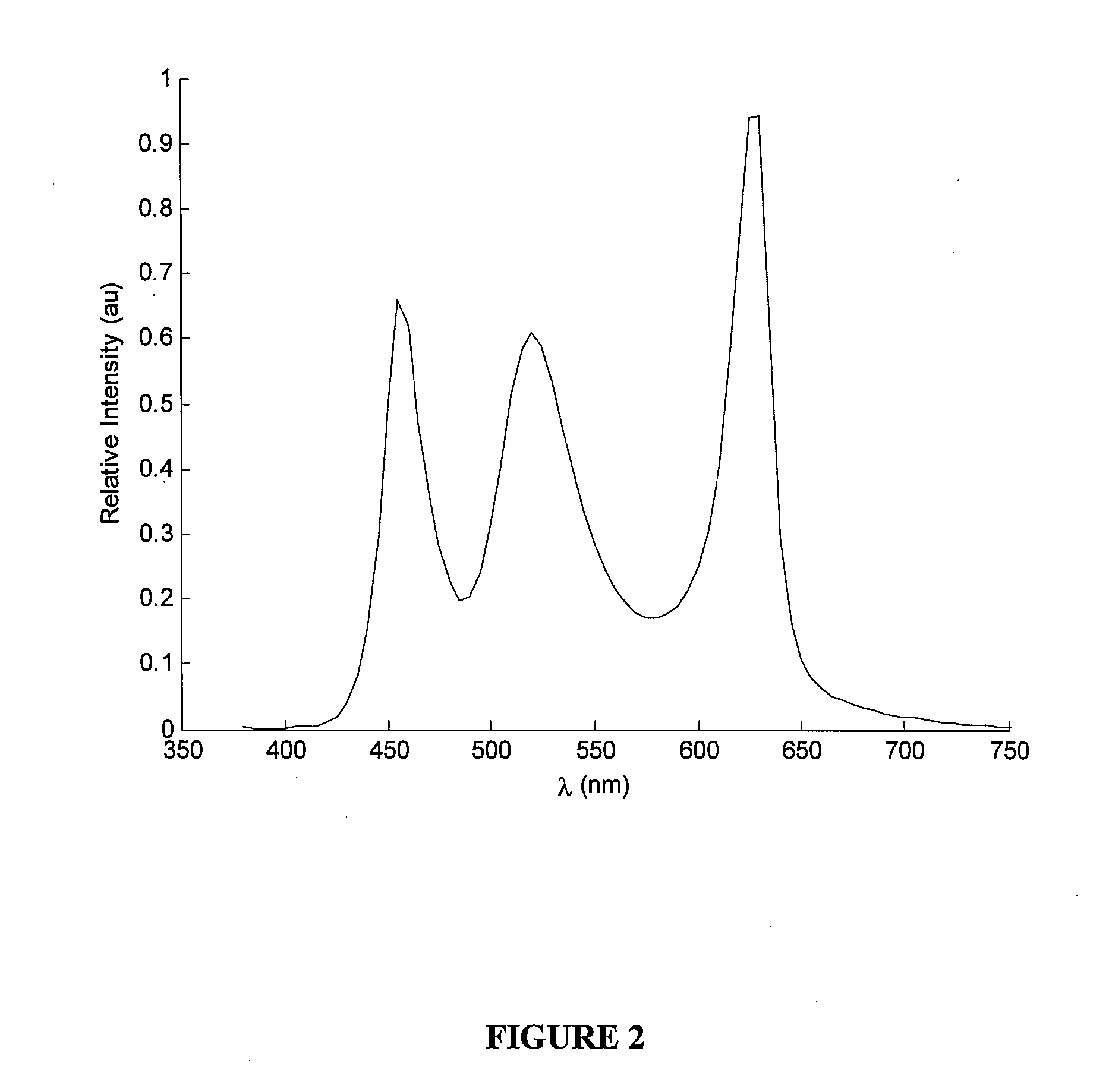

The present invention provides a light source having an improved output optical quality. In general, the light source comprises one or more light-emitting elements in each of at least a first, a second and a third colour. The combined spectral power distribution of these light-emitting elements generally defines a spectral concavity. The light source further comprises a light-excitable medium configured and disposed to absorb a portion of the light emitted by one or more of the light-emitting elements and emit light defined by a complementary spectral power distribution having a peak located within the concavity. By combining the spectral output of the light-emitting elements with the spectral output of the light-excitable medium, an optical quality of the light source is improved.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

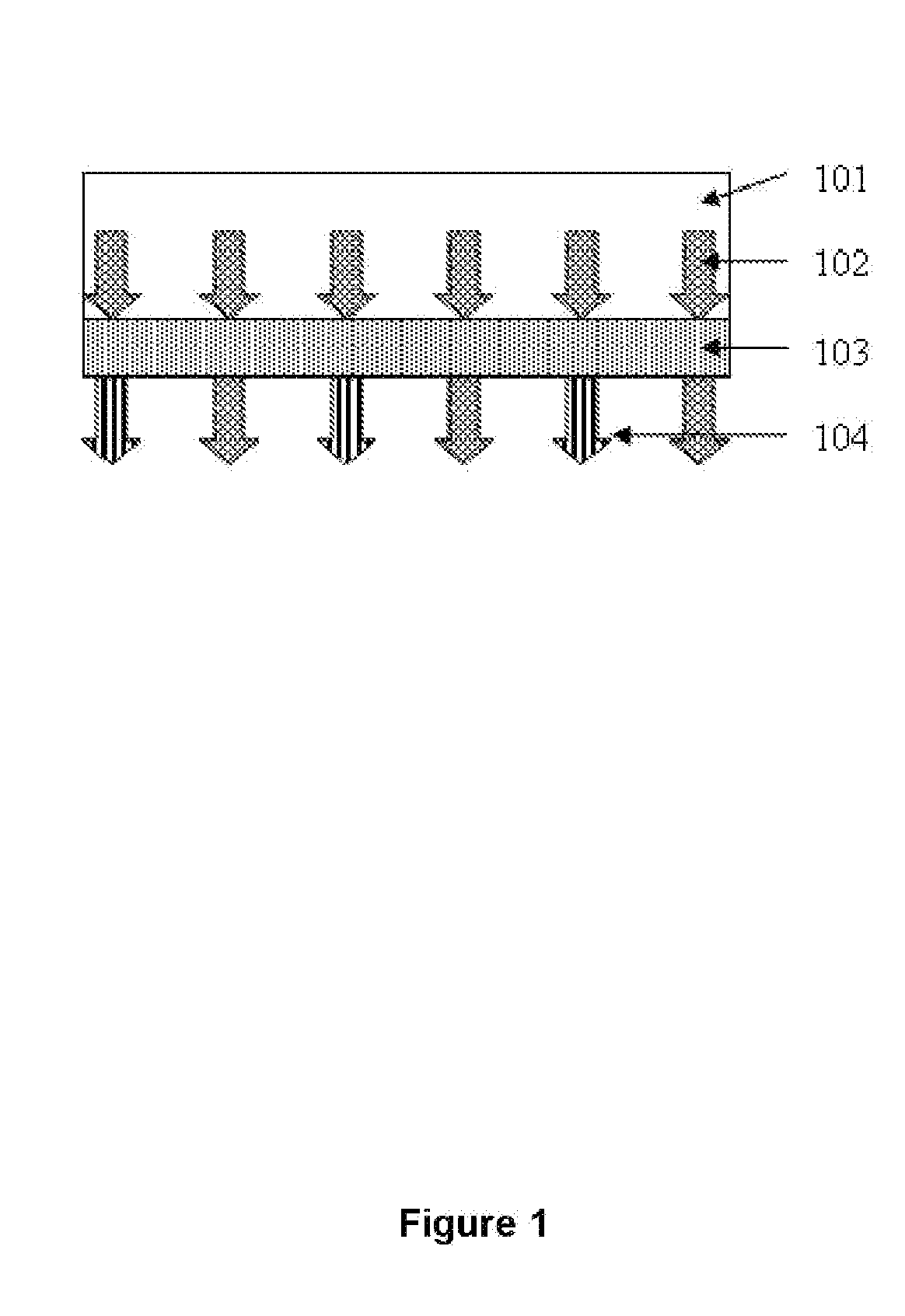

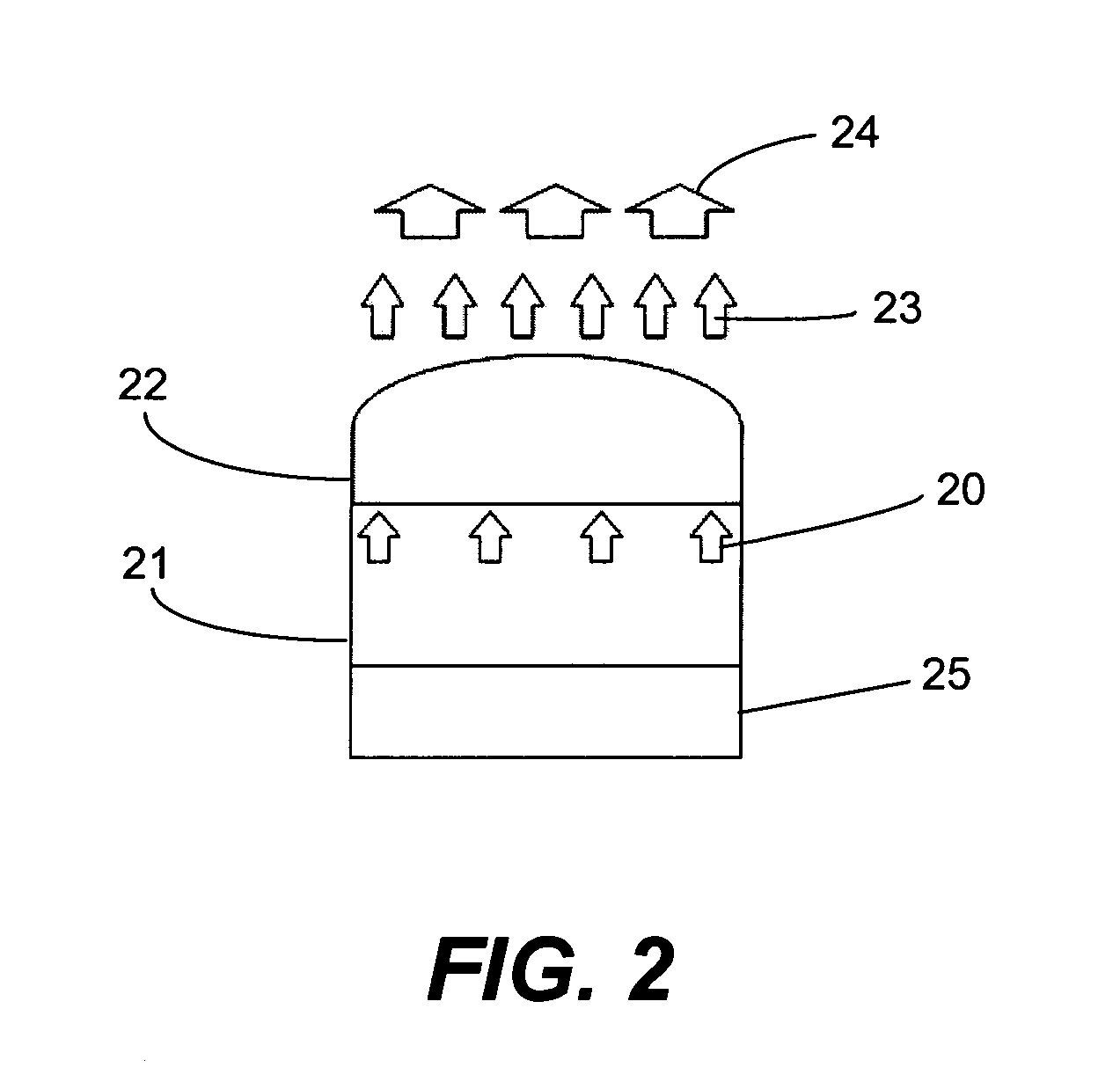

Light Emitting Diode Light Source With Layered Phosphor Conversion Coating

InactiveUS20120286701A1Improve lighting qualityImprove high temperature stabilityElectroluminescent light sourcesElectric light circuit arrangementLong wavelengthConversion coating

The LED (light emitting diode) light source that includes an LED chip or an array of LED chips that emit blue, or UV, violet, or other narrow wavelength light and a phosphor conversion coating that absorbs the radiation from the LED and re-emits lights of longer wavelengths and with wider spectrum of wavelength. The phosphor conversion coating includes a plurality of layered phosphor films wherein adjacent phosphor films are formed of different phosphor materials. A method of forming an LED light source includes soldering LED chip to an electrically insulating substrate and forming a phosphor conversion layer. Forming the phosphor conversion layer includes depositing a number of adjacent phosphor films directly on the surface of the LED chip or on the surface of an optically transparent substrate which may be of curved or flat surface.

Owner:SHENG FANG +1

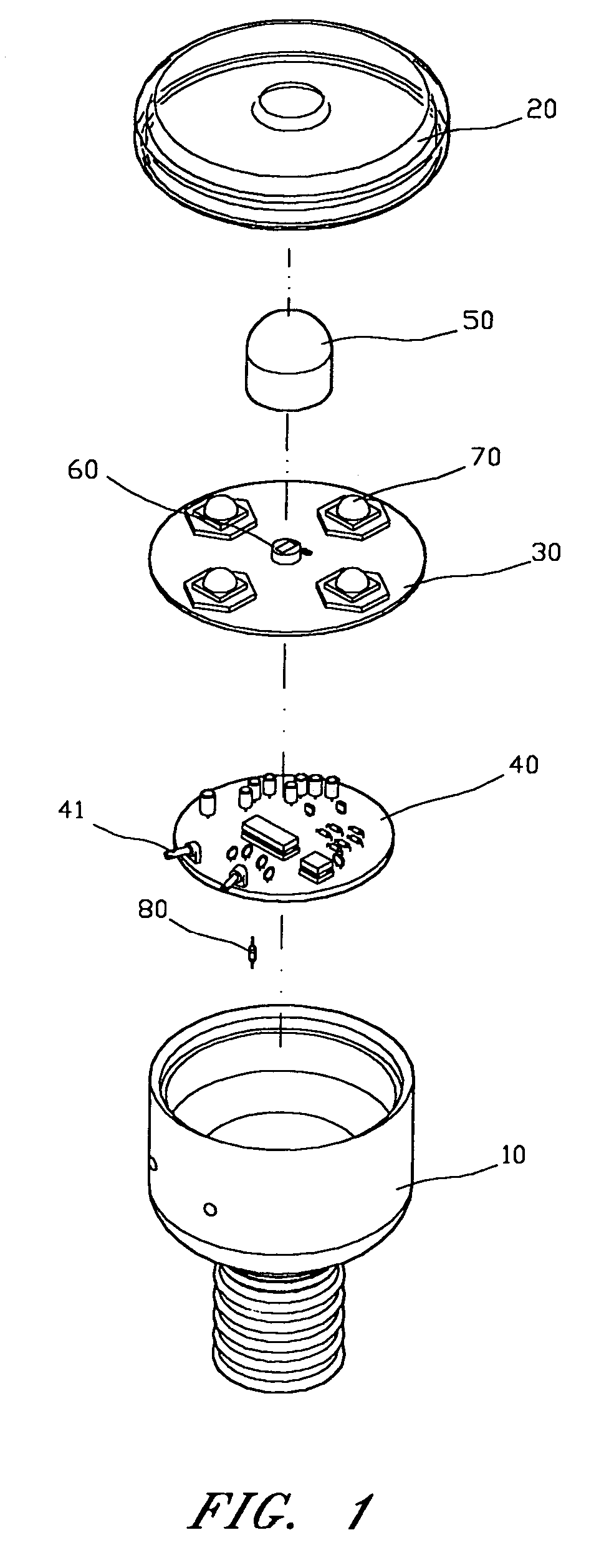

Bulb with sensing function

ActiveUS7327254B2Improve lighting qualityReduce power consumptionLight source combinationsPoint-like light sourceHuman bodyEngineering

Owner:CHEN KAI PO

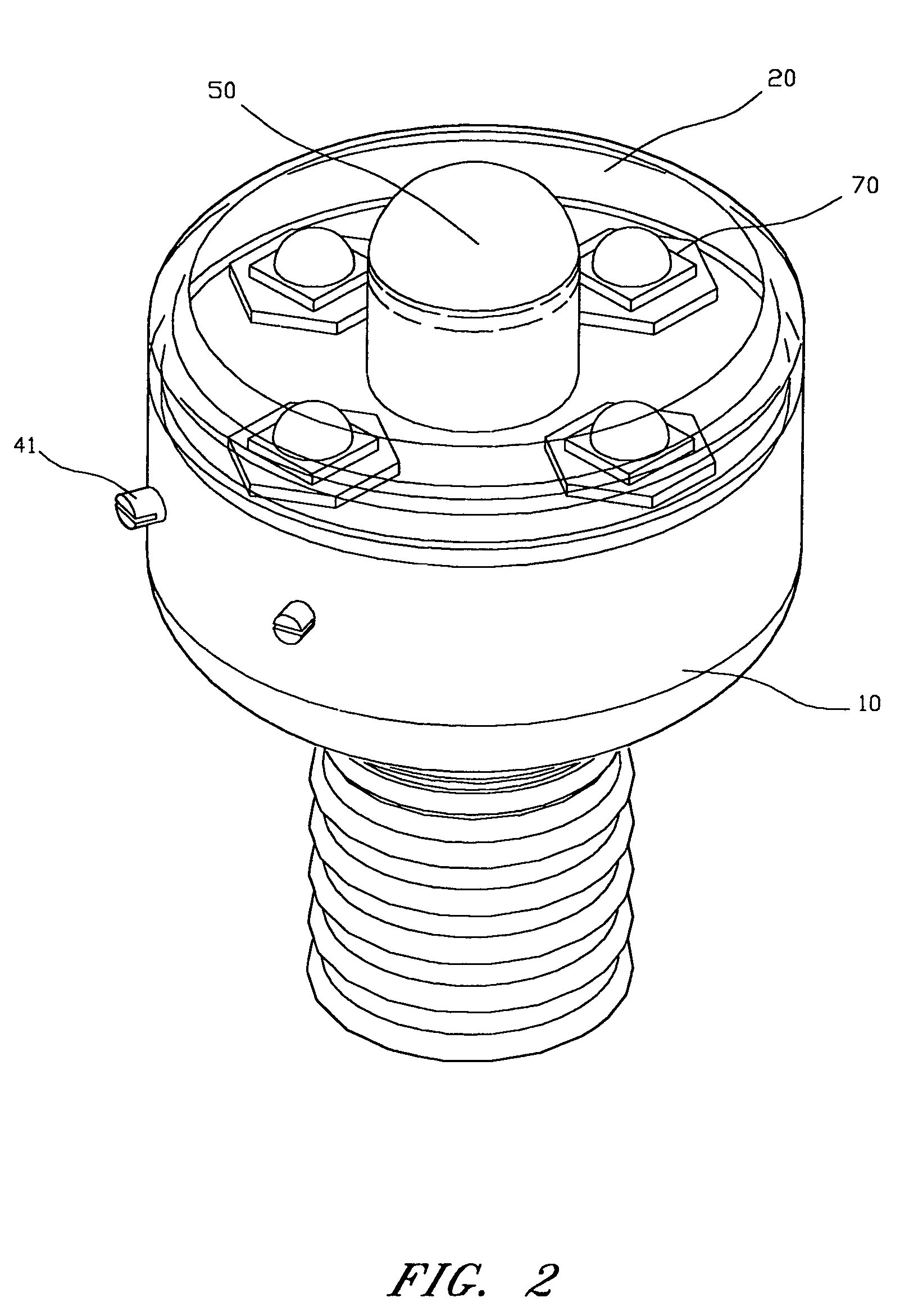

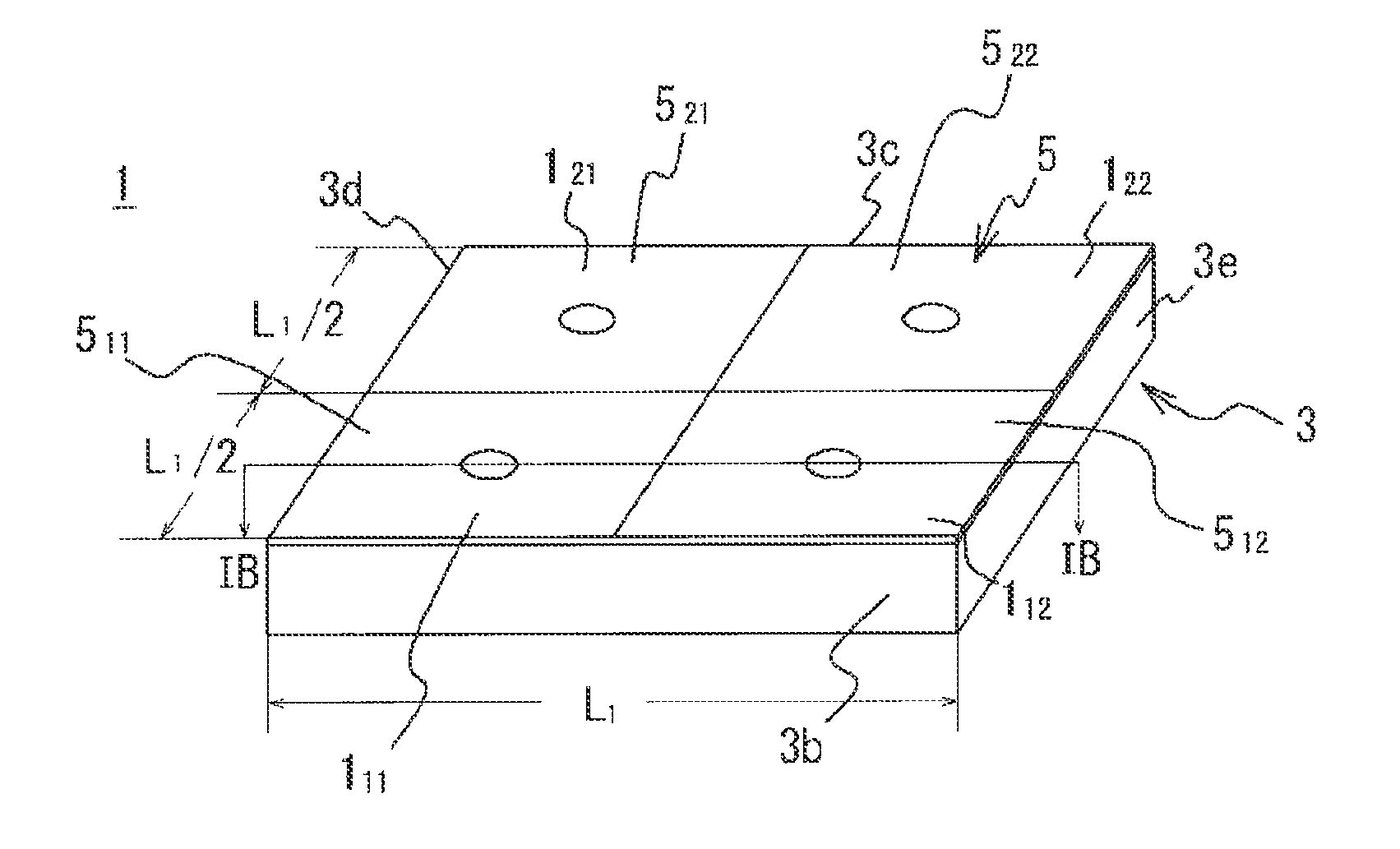

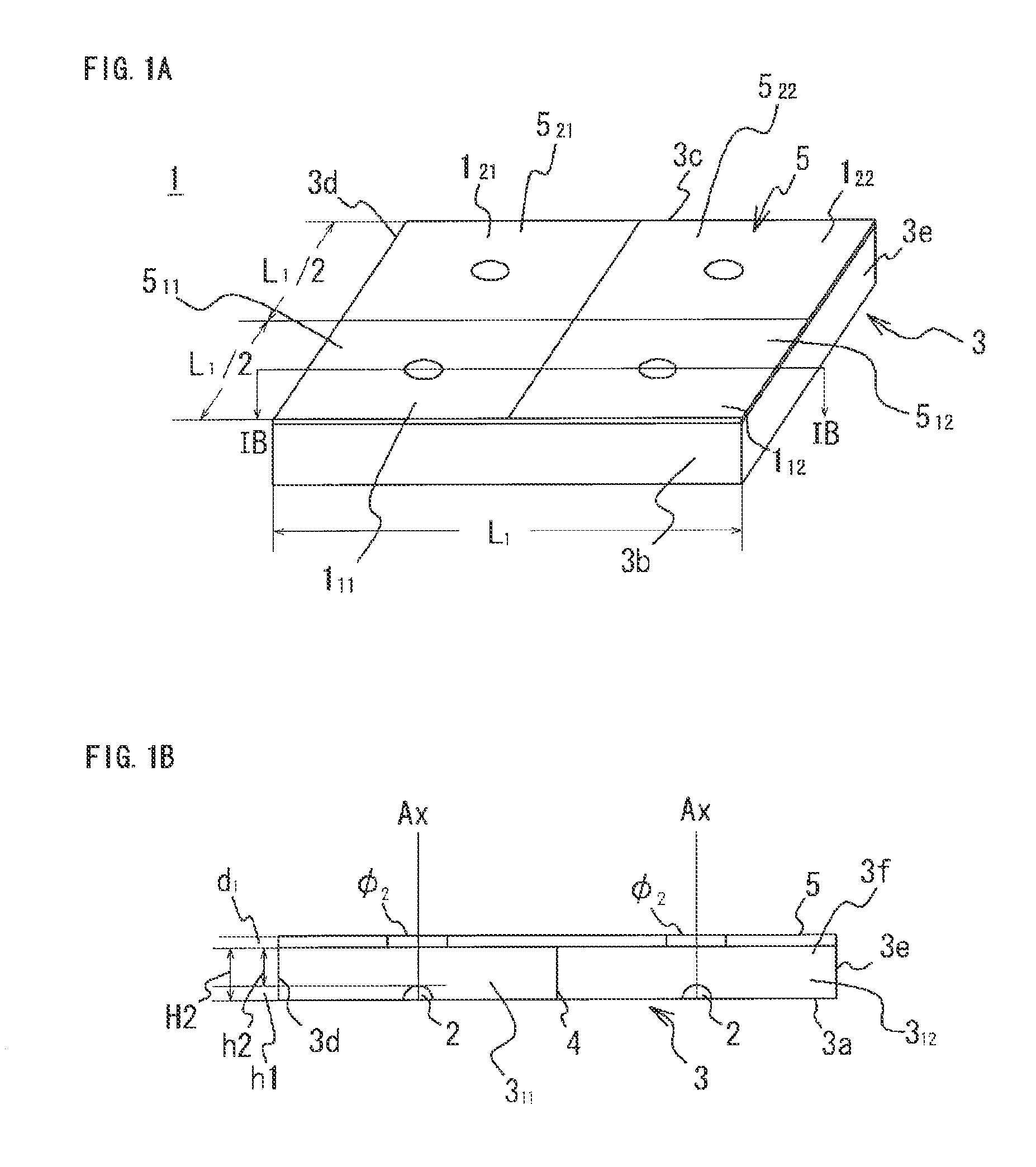

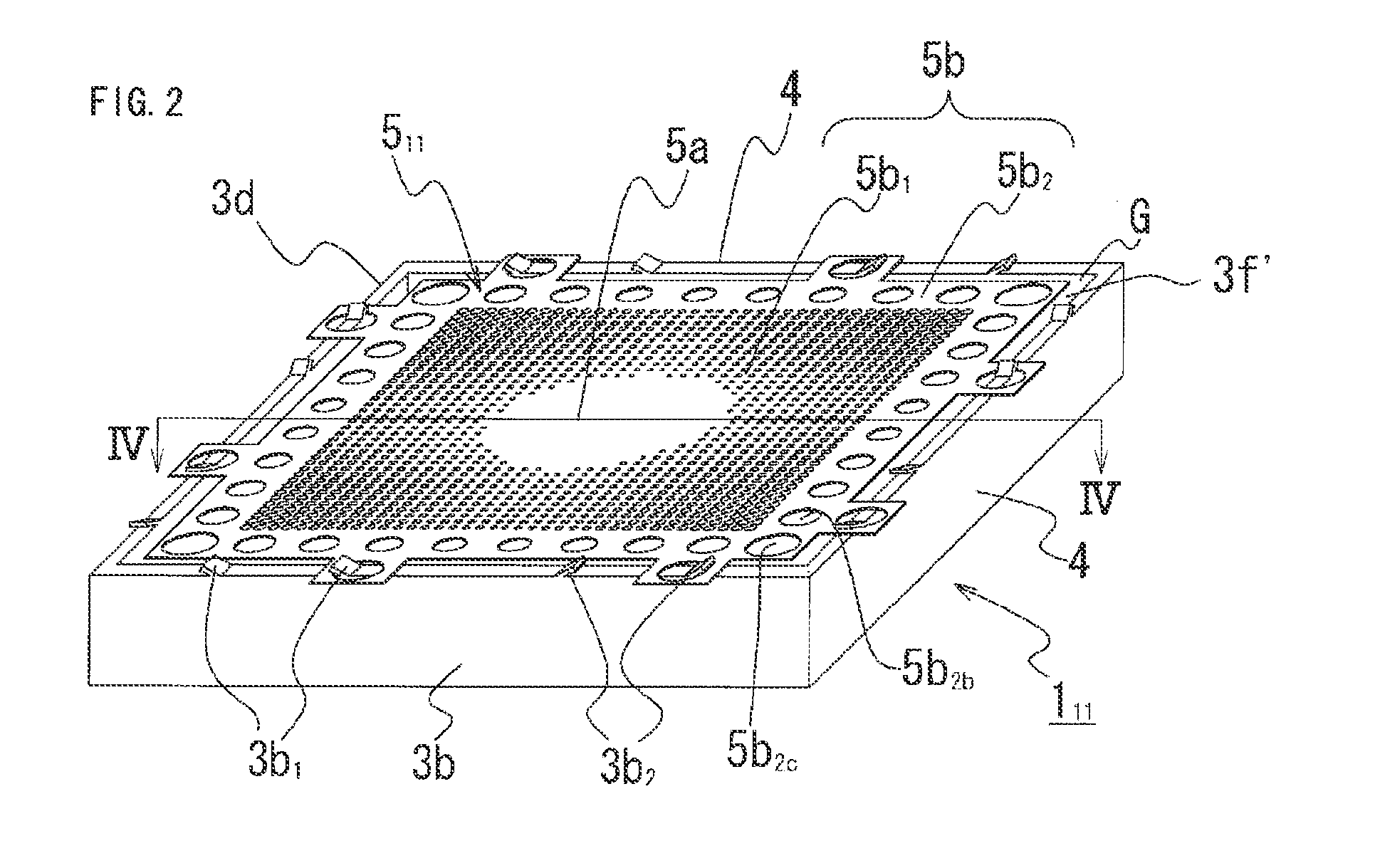

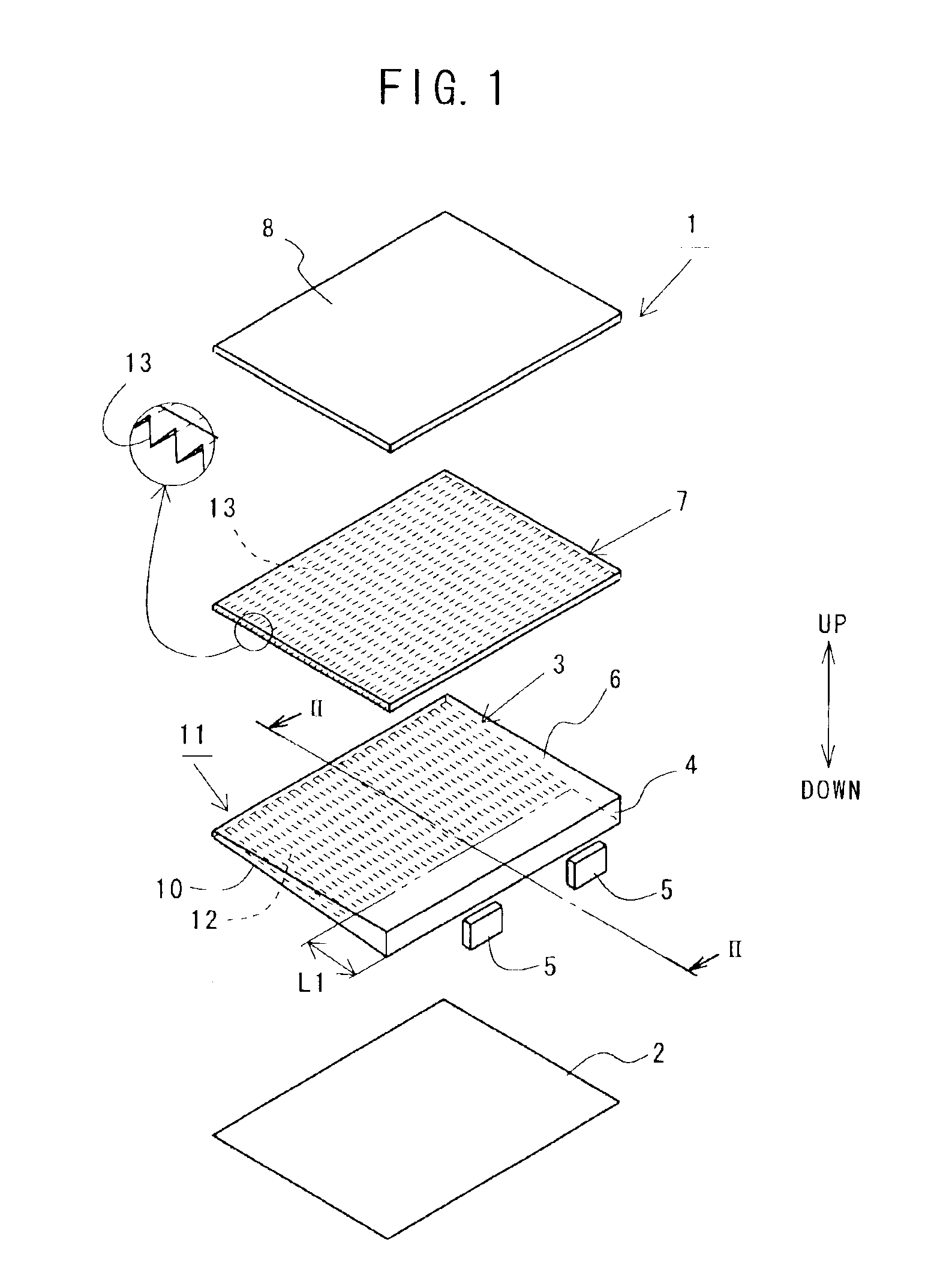

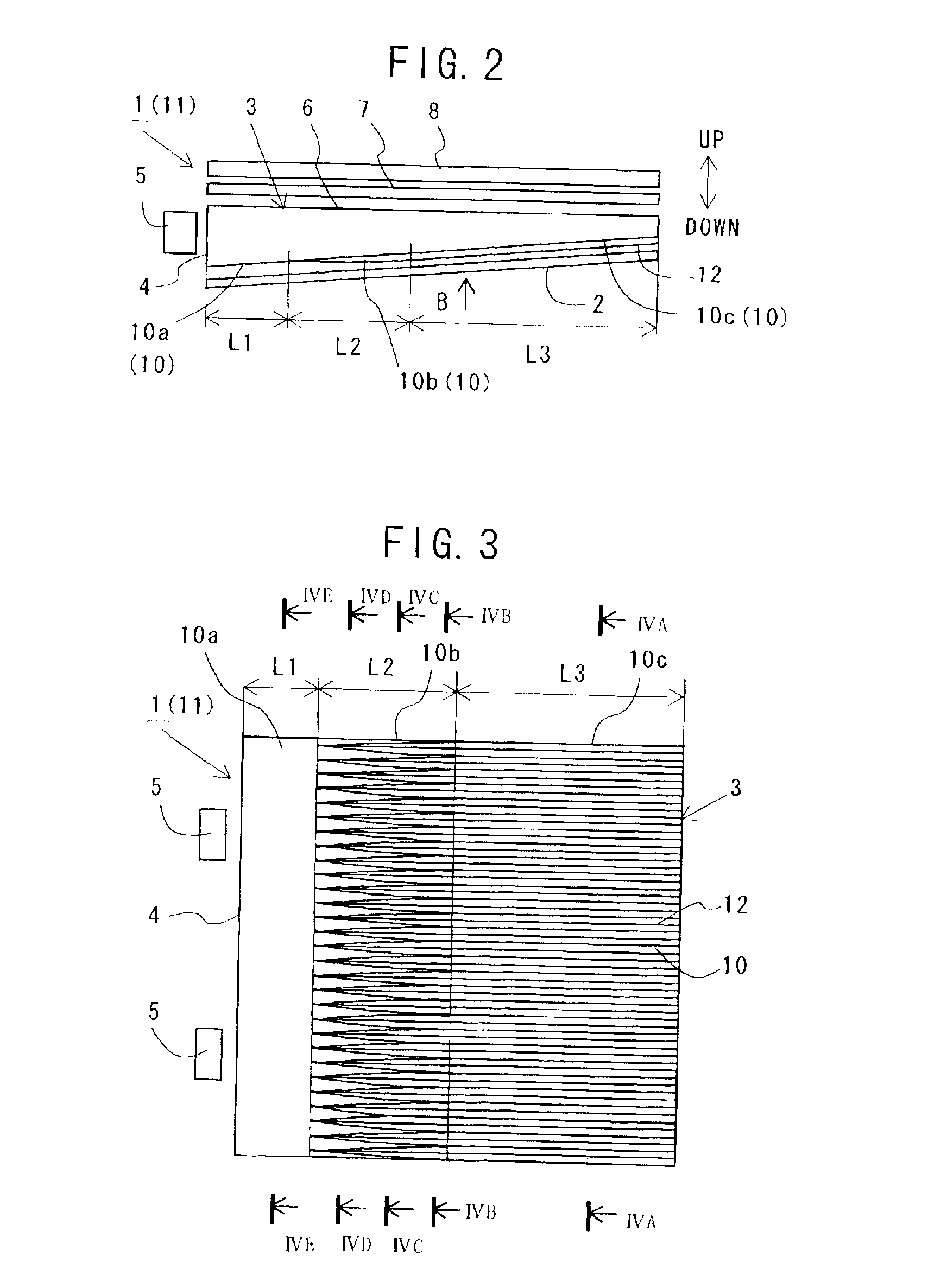

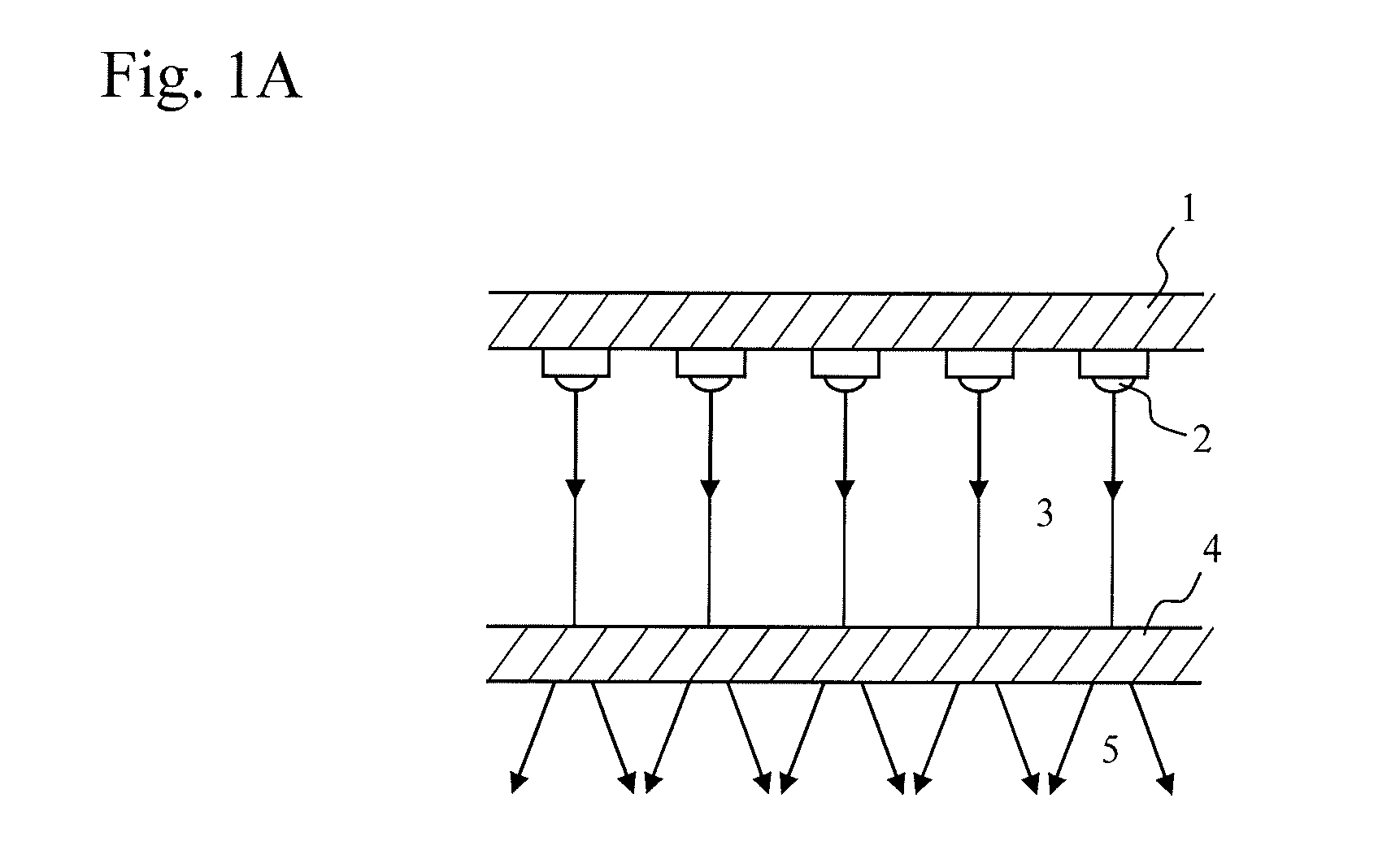

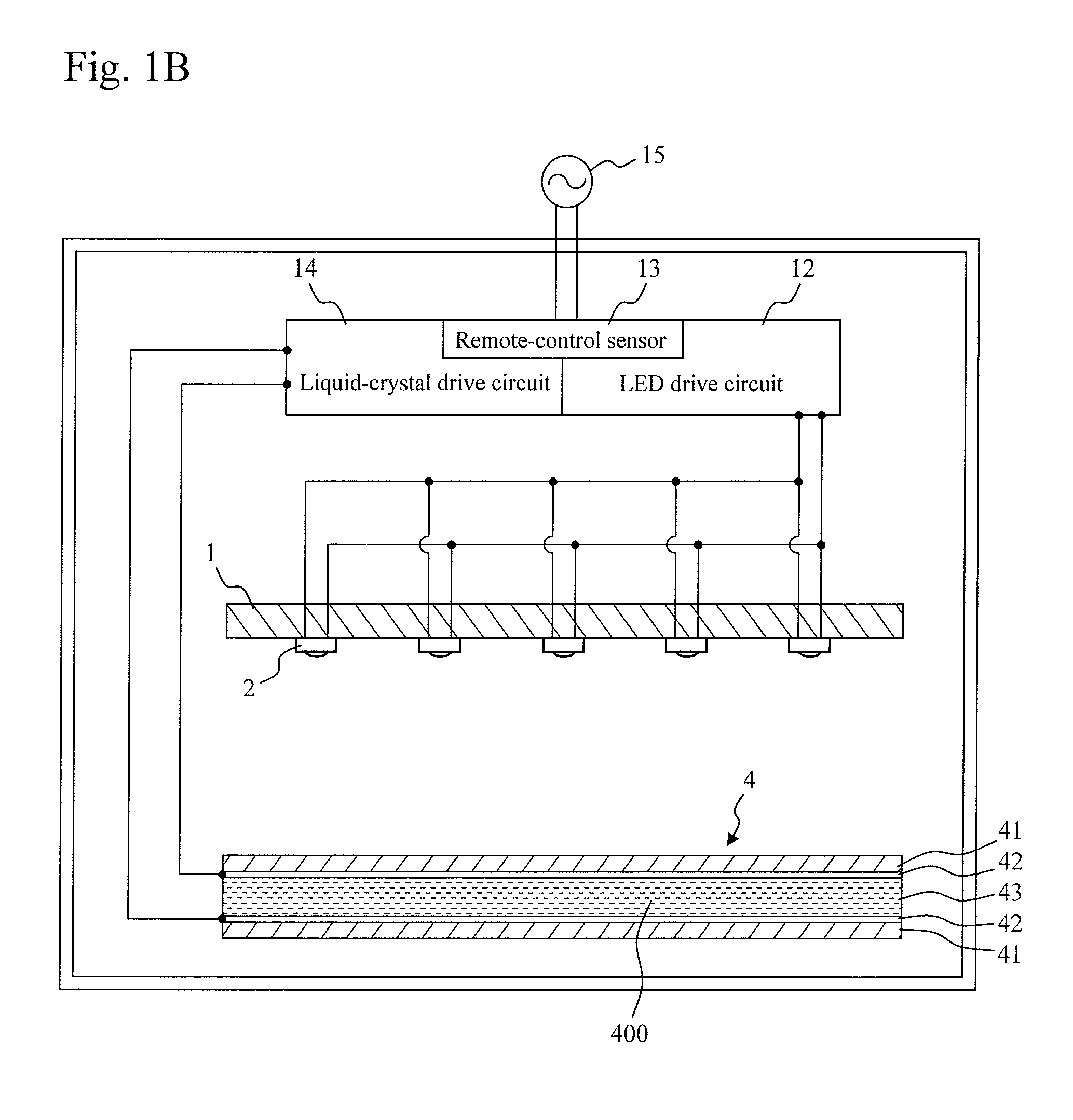

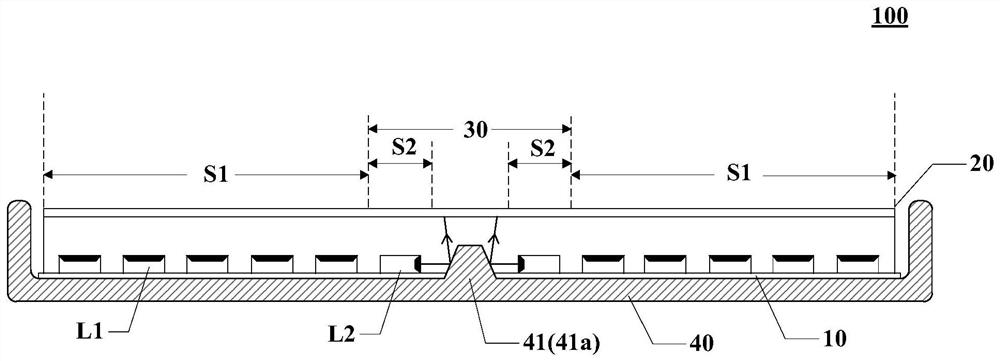

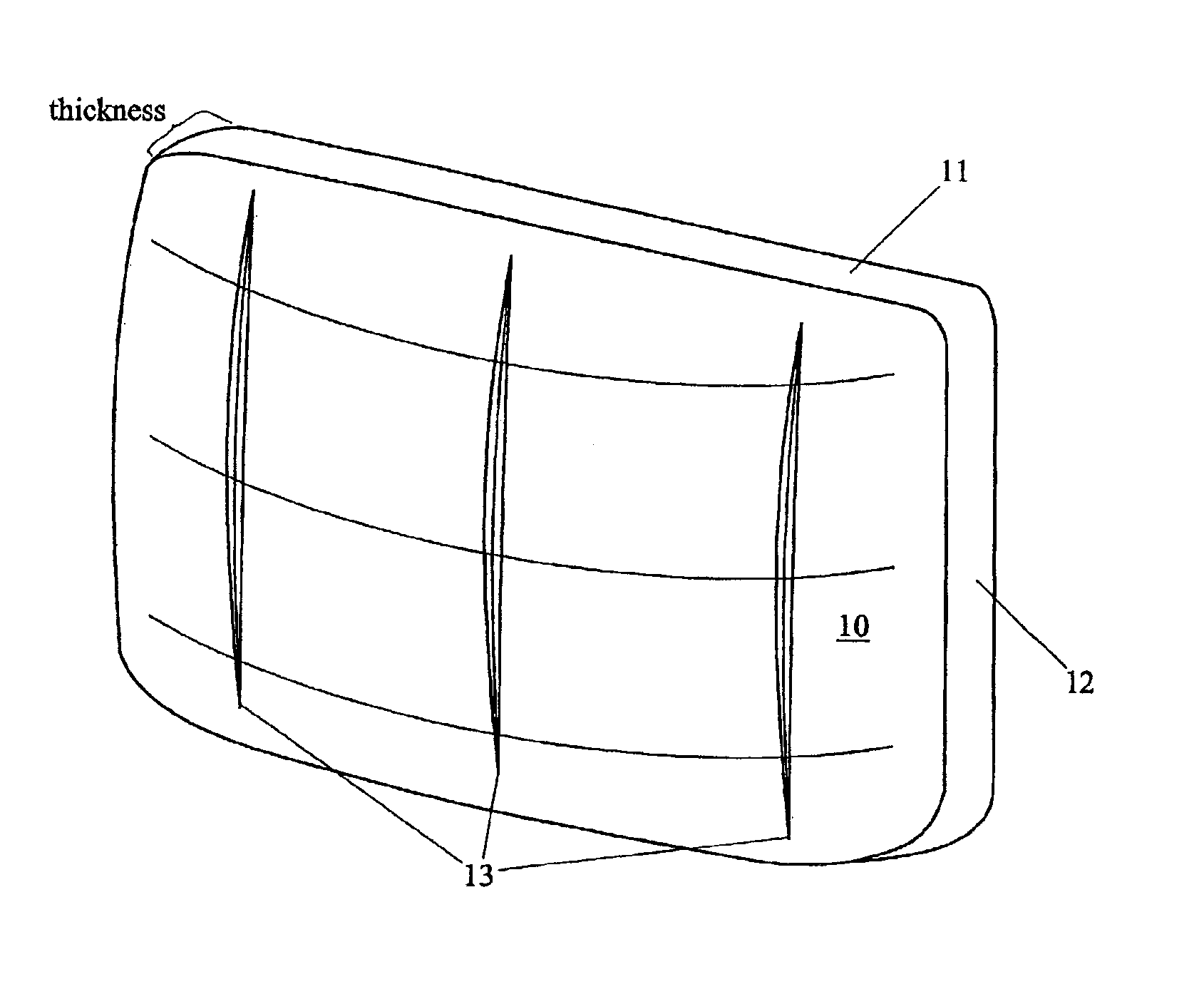

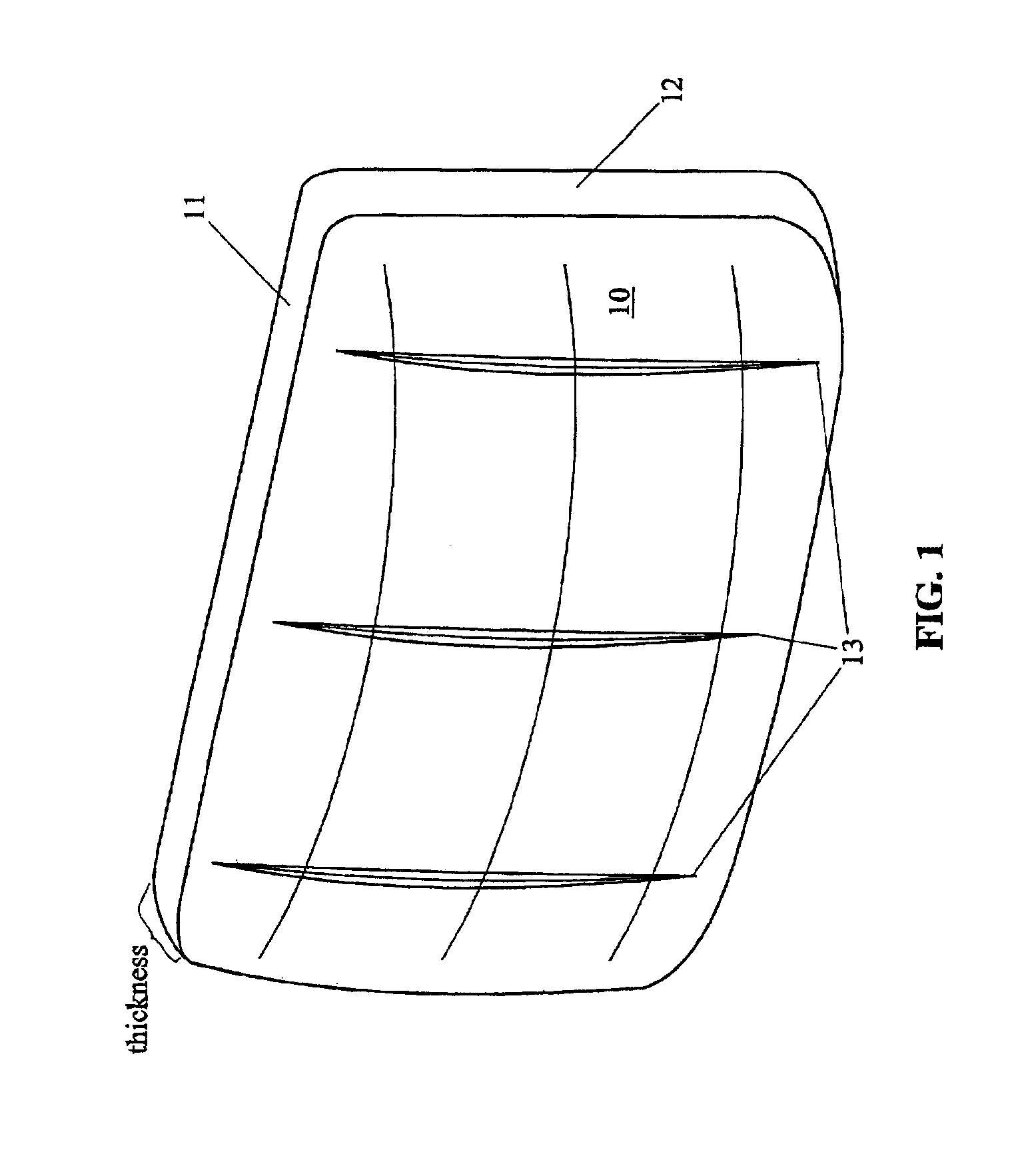

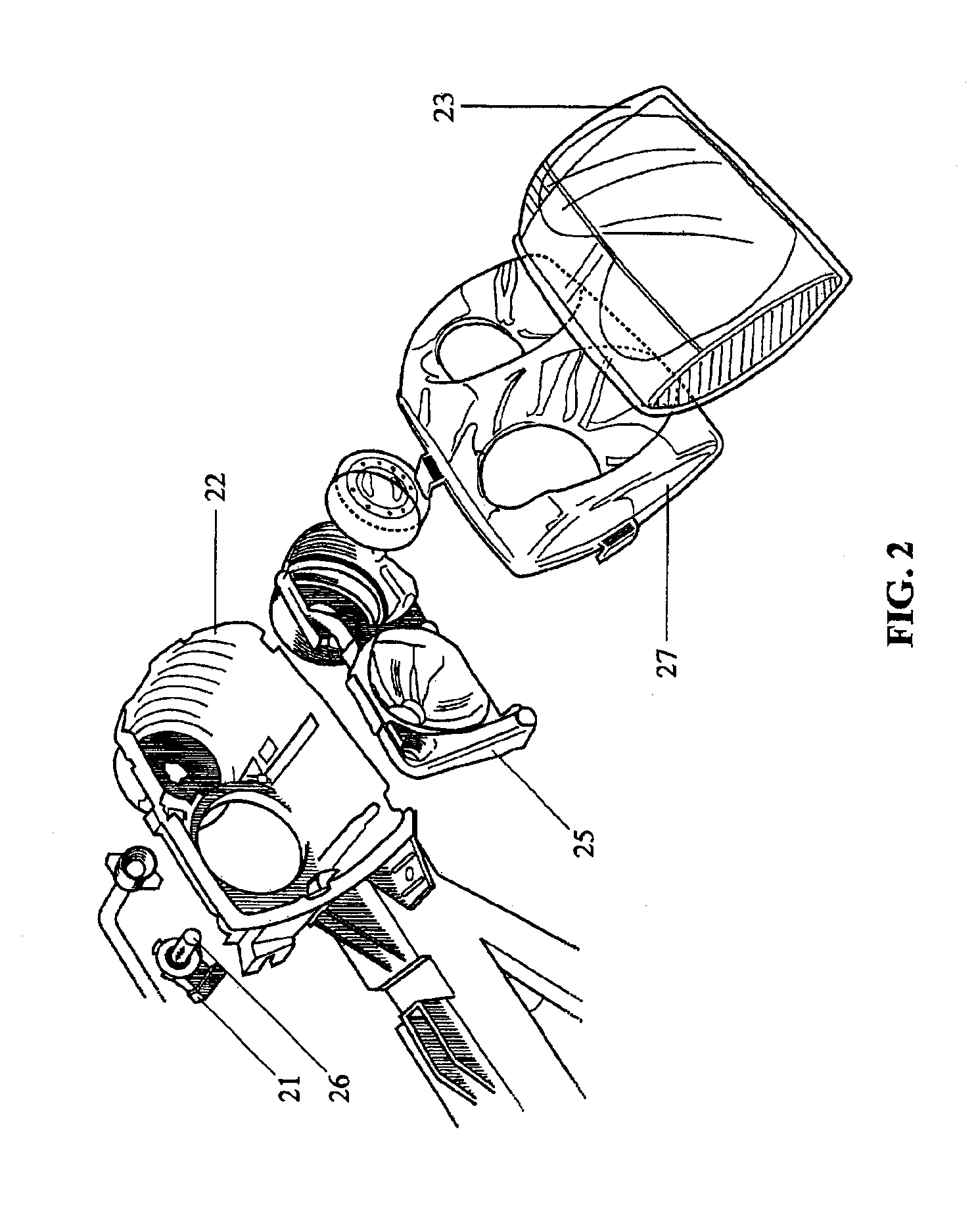

Surface light source unit, surface illumination device, and liquid crystal display device

ActiveUS20120268688A1Reduce thicknessImprove lighting qualitySolid-state devicesNon-linear opticsLiquid-crystal displayOptical transmittance

Provided is a surface light source unit which has a high-directivity point light source and has a decreased thickness in the in the direction in which light is irradiated from said point light source. Also provided are a surface illumination device and a liquid crystal display device. A plurality of small chambers (311 to 322) having an opening on the top are formed in a housing (3) from side plates (3b to 3e) that have a predetermined height and partition plates (4) which partition the inside of the housing (3). Each small chamber is provided with a point light source (2) on the bottom part. The opening of each small chamber (311 to 322) is covered with a light transmitting / reflecting plate (511 to 522) which has a surface area (S), and comprises: a central reflecting section that has a surface area (ΔS), exhibits high reflectance and low transmittance, and is positioned directly above the point light source (2); and an outer reflecting section that surrounds the central reflecting section and is configured so that the light transmittance increases at distances further from the central reflecting section. The surface area (ΔS) and surface area (S) of each light transmitting / reflecting plate (511 to 522) are set in a manner such that the ratio ΔS / S is a predetermined value.

Owner:OPTO DESIGN INC

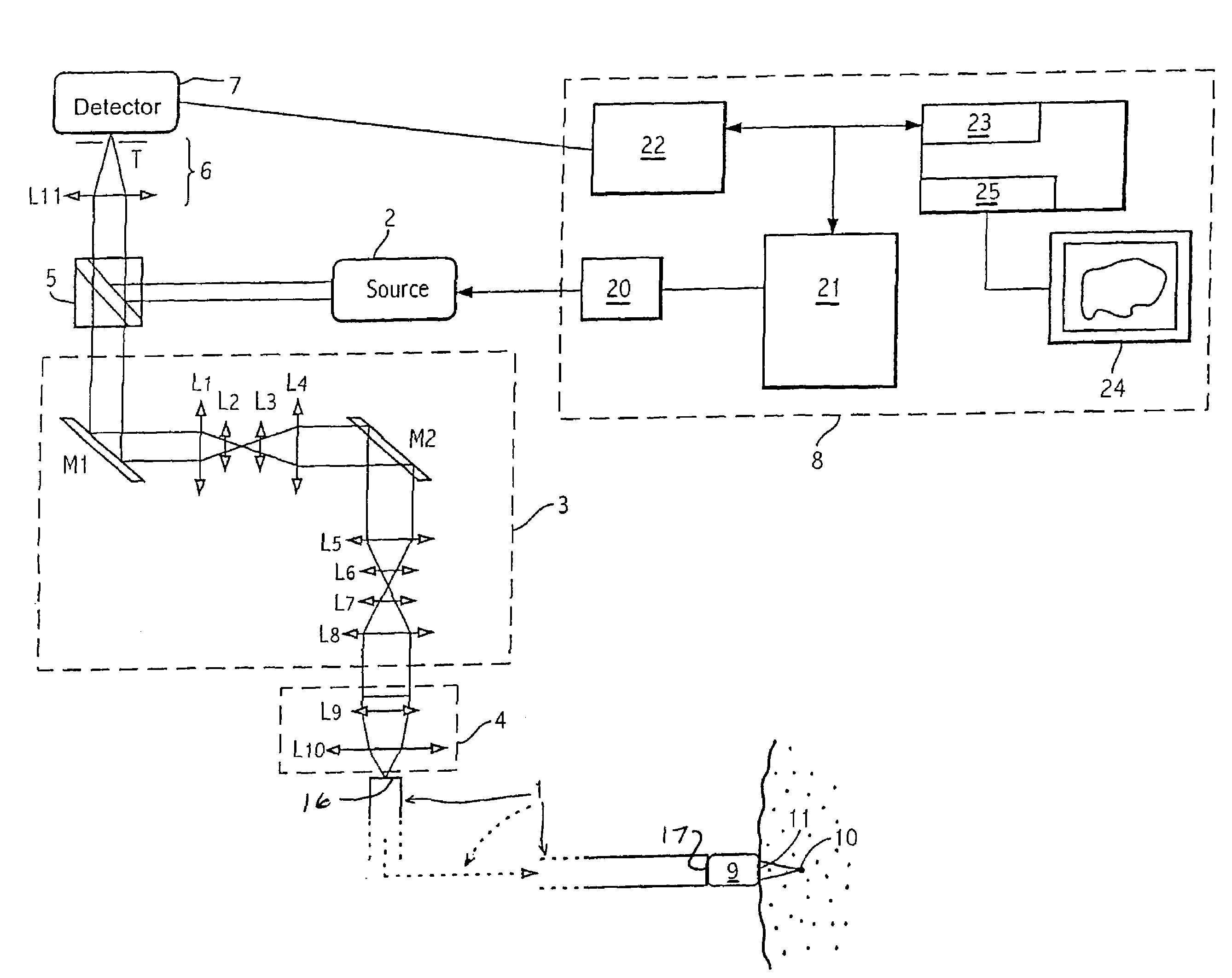

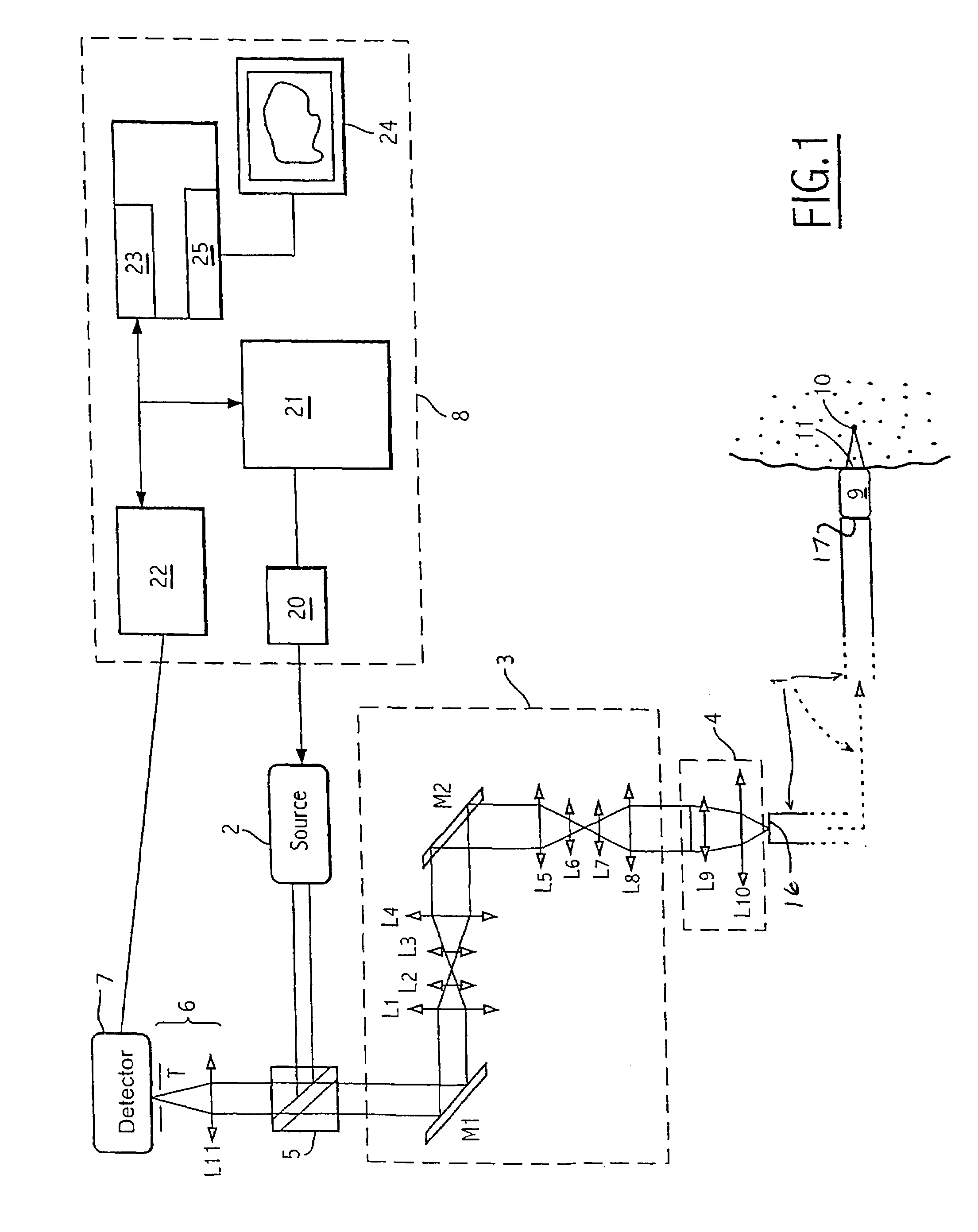

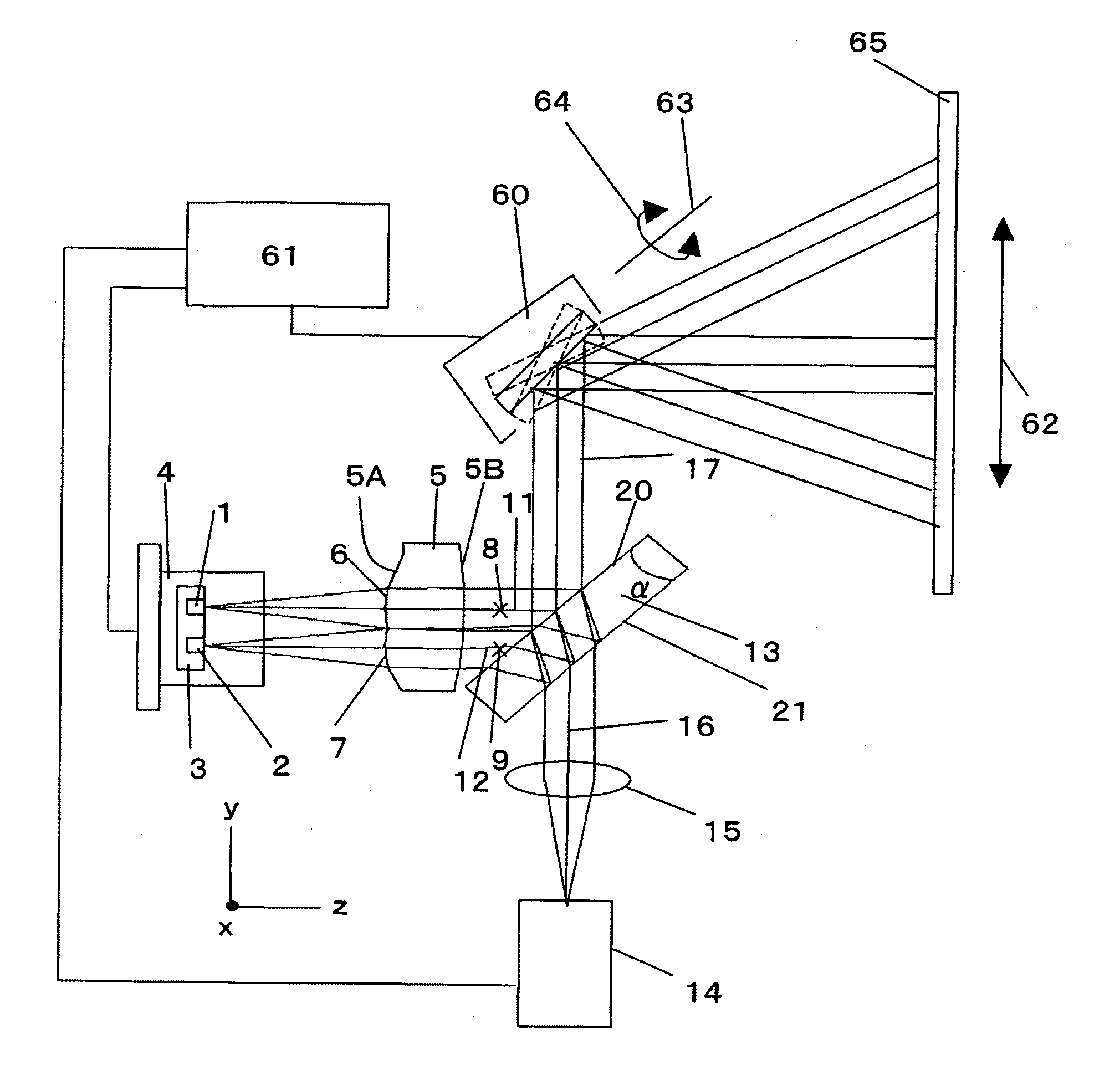

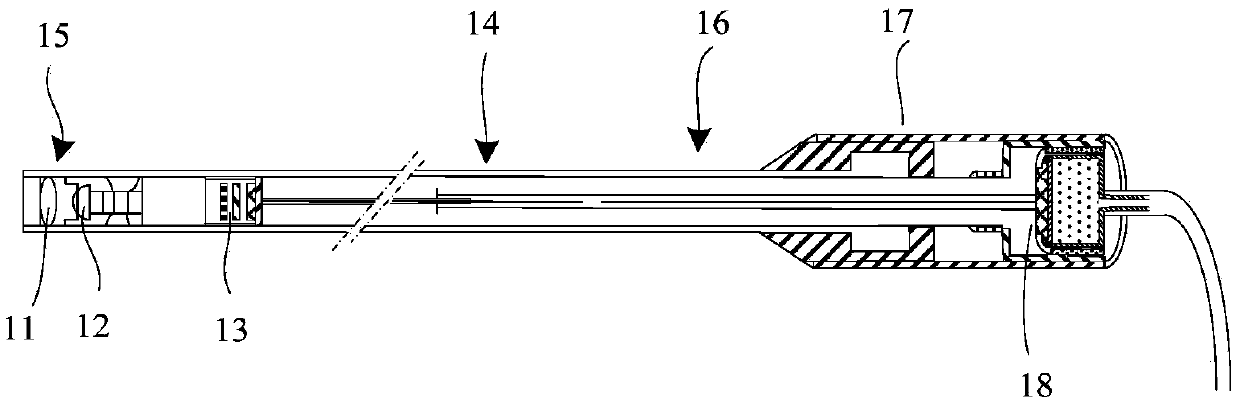

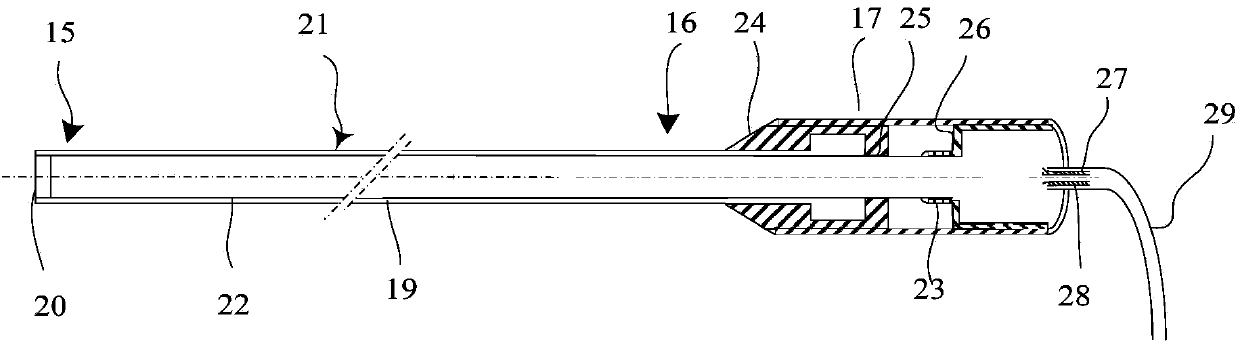

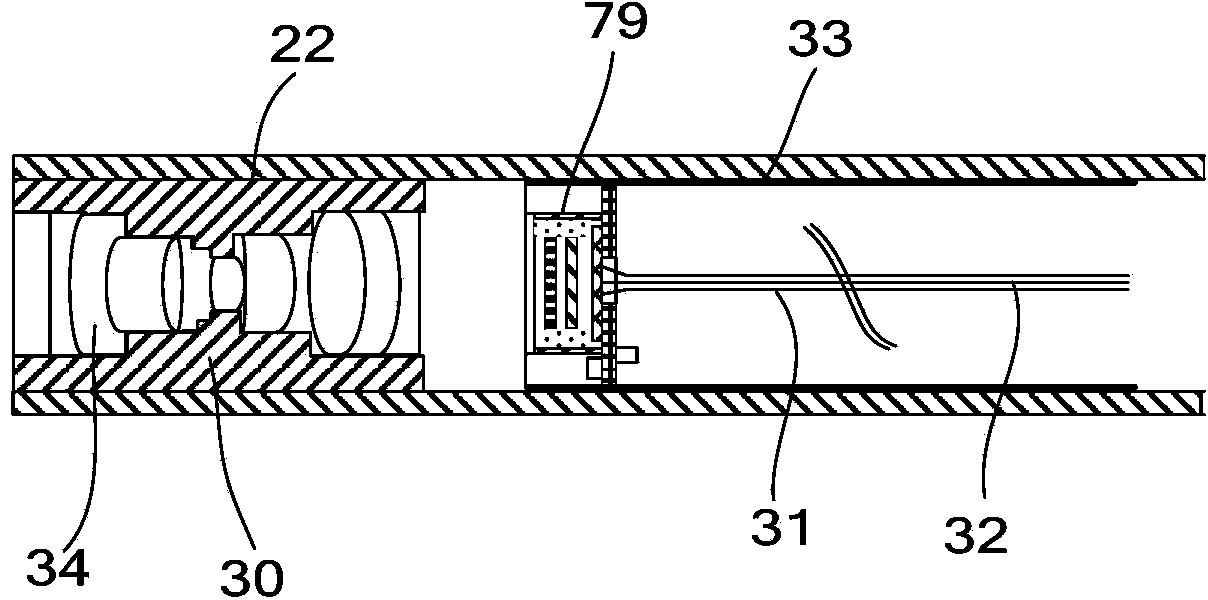

Confocal imaging equipment in particular for endoscope

Equipment includes an image guide (1) consisting of flexible optical fibers with: on the proximal end side: a source (2), angular scanning elements (3), injection elements (4) in one of the fibers, elements for splitting (5) the illuminating beam and the backscattered signal, elements for spatial filtering (6), elements for detecting (7) the signal, electronic elements (8) for controlling, analyzing and digital processing of the detected signal and display; and on the distal end side: an optical head (9) for focusing the illuminating beam exiting from the illuminated fiber. The scanning elements include a resonant line mirror (M1) and a galvanometric field mirror (M2) with a variable frequency and two afocal optical systems adapted to conjugate the two mirrors (M1, M2) firstly in the field mirror (M2) and the injection elements (4) in the image guide in a second step.

Owner:MAUNA KEA TECHNOLOGIES

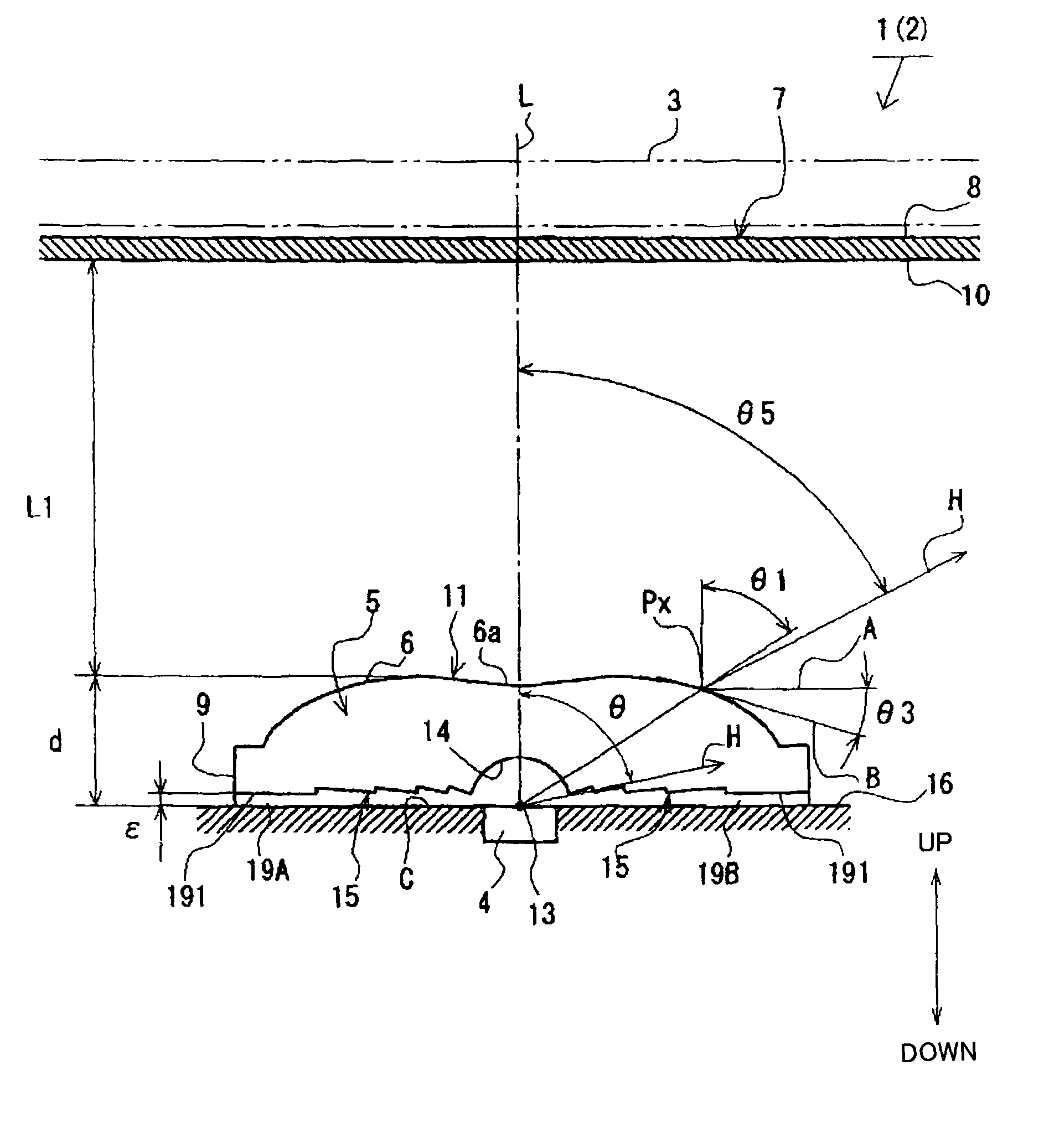

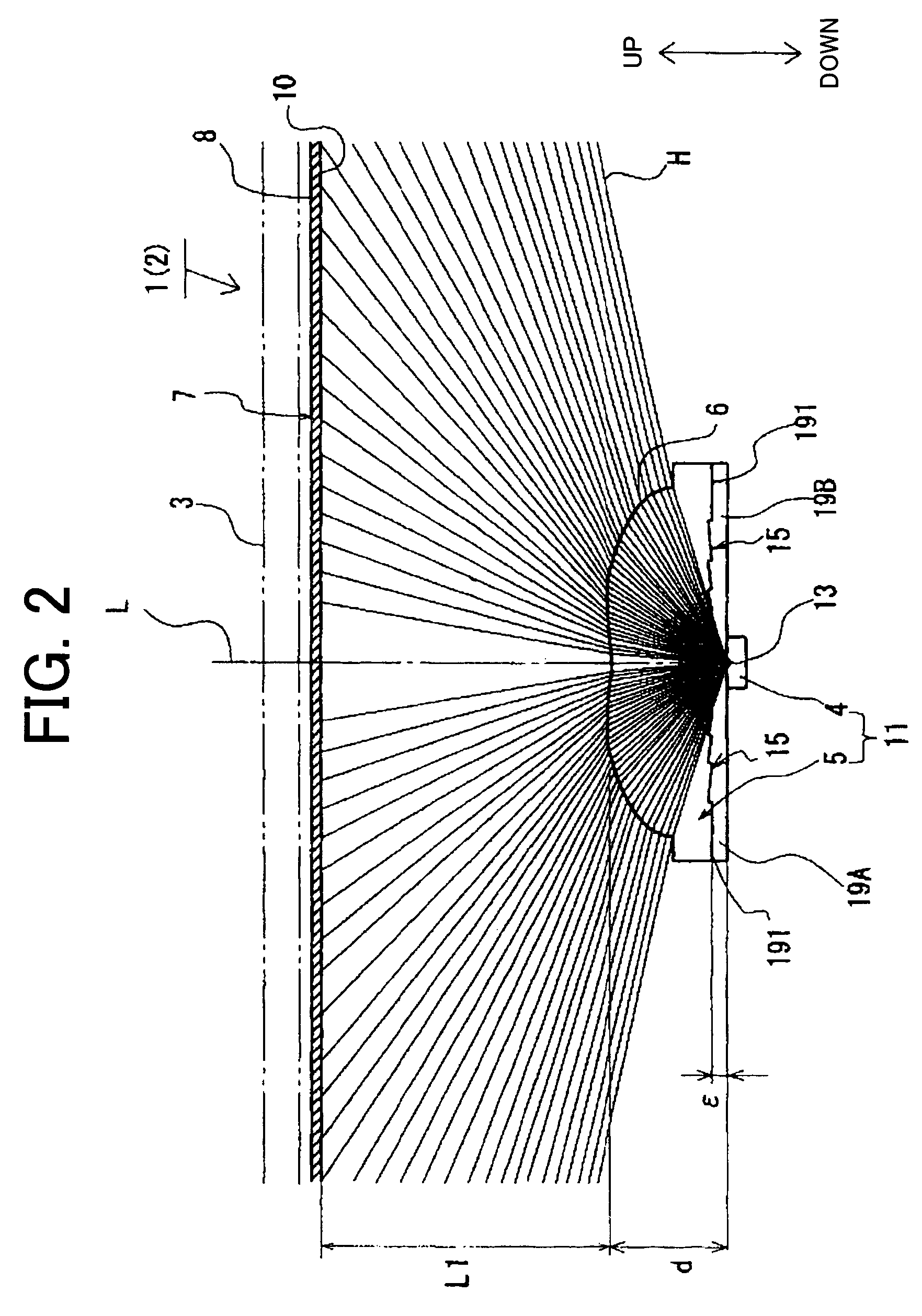

Surface light device, image display device and light guide plate

InactiveUS6921178B2Improve illumination qualitySuppress emissionMechanical apparatusPoint-like light sourcePrismOptoelectronics

LEDs 5 serving as light sources are arranged so as to face an incidence surface 4 of a light guide plate 3. Light emitted from the LEDs 5 is incident on the incidence surface 4 of the light guide plate 3 to enter the light guide plate 3 to be propagated through the light guide plate 3. When the angle of incidence of the light on an emission surface 6 of the light guide plate 3 is a critical angle or less while the light is propagated, the light leaves the emission surface 6. On at least one of the emission surface 6 of the light guide plate 6 and a surface 10 opposite to the emission surface 6 of the light guide plate 6, a large number of prism protrusions 12 extending in parallel to such a direction that a distance from the incidence surface 4 increases are formed along the incidence surface 4. A side-face side portion 10b of the prism protrusions 12 is formed so as to have a height gradually decreasing as a distance from the incidence surface 4 decreases. With this construction, even if the LEDs are used as light sources, abnormal emission can be suppressed in the vicinity of the incidence surface of the light guide plate, and the luminance of exiting light can be uniform.

Owner:ENPLAS

Emission device, surface light source device and display

InactiveUS7866844B2Improve efficiencyLocally bright portions are prevented more effectivelyMechanical apparatusPoint-like light sourceLight fluxOptical axis

A light flux control member has a back face provided with a first recess portion and ventilation grooves. Output light of the light emitting element arranged as to correspond to the first recess portion enters into the light flux control member via the first recess portion and ventilation grooves being emitted from a light control emission face of the light flux control member after inner-propagation. Refraction of incident light to second recess portions formed in the ventilation grooves hardly generate inner-propagation light which has travelling directions near to a direction of reference optical axis L. This avoids emission from the light control emission face from providing a ring-like bright part. In addition, heat emitted from the light emitting element can be released at a high efficiency because a space in the first recess portion communicates with the outside of the light flux control member.

Owner:ENPLAS CORP

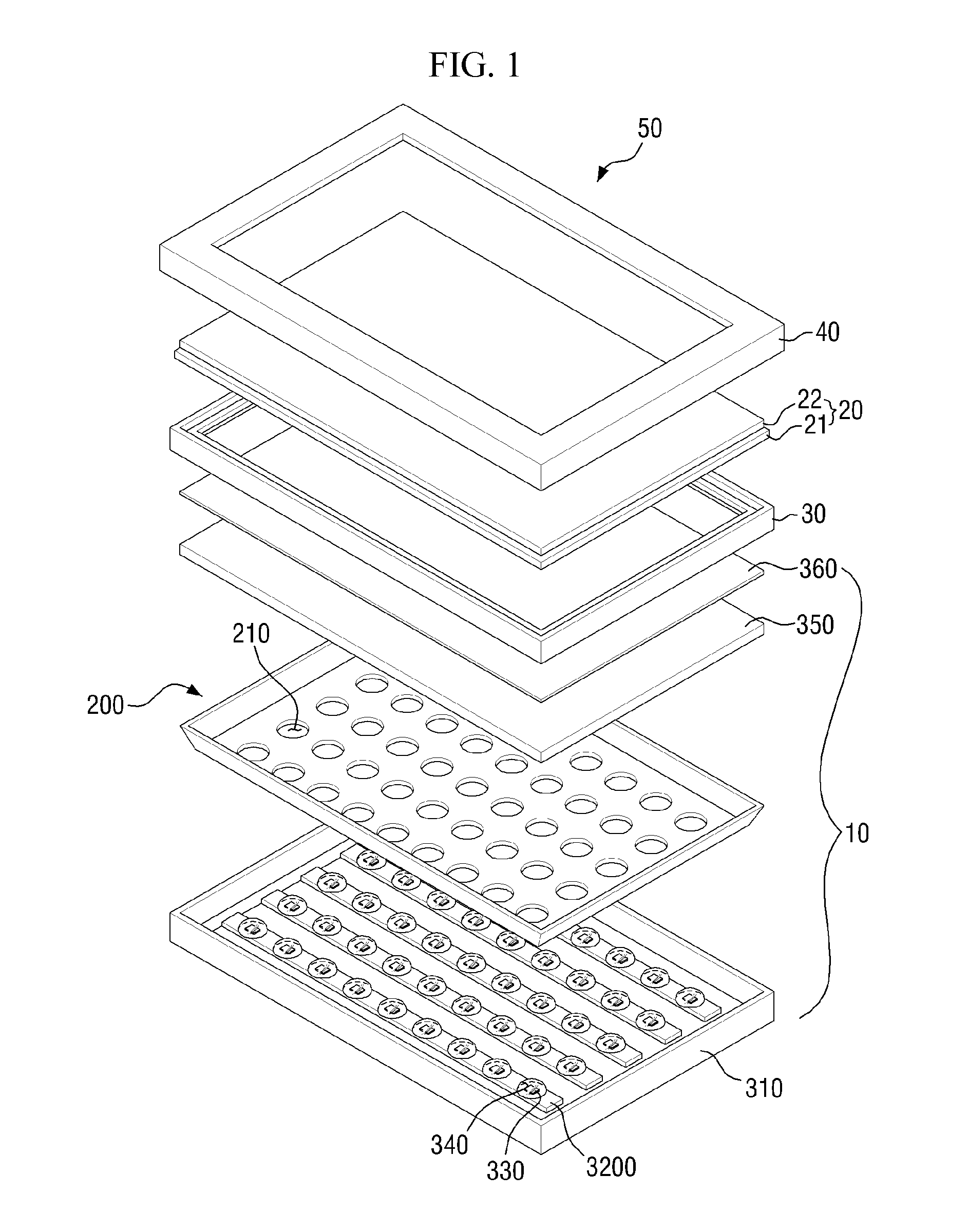

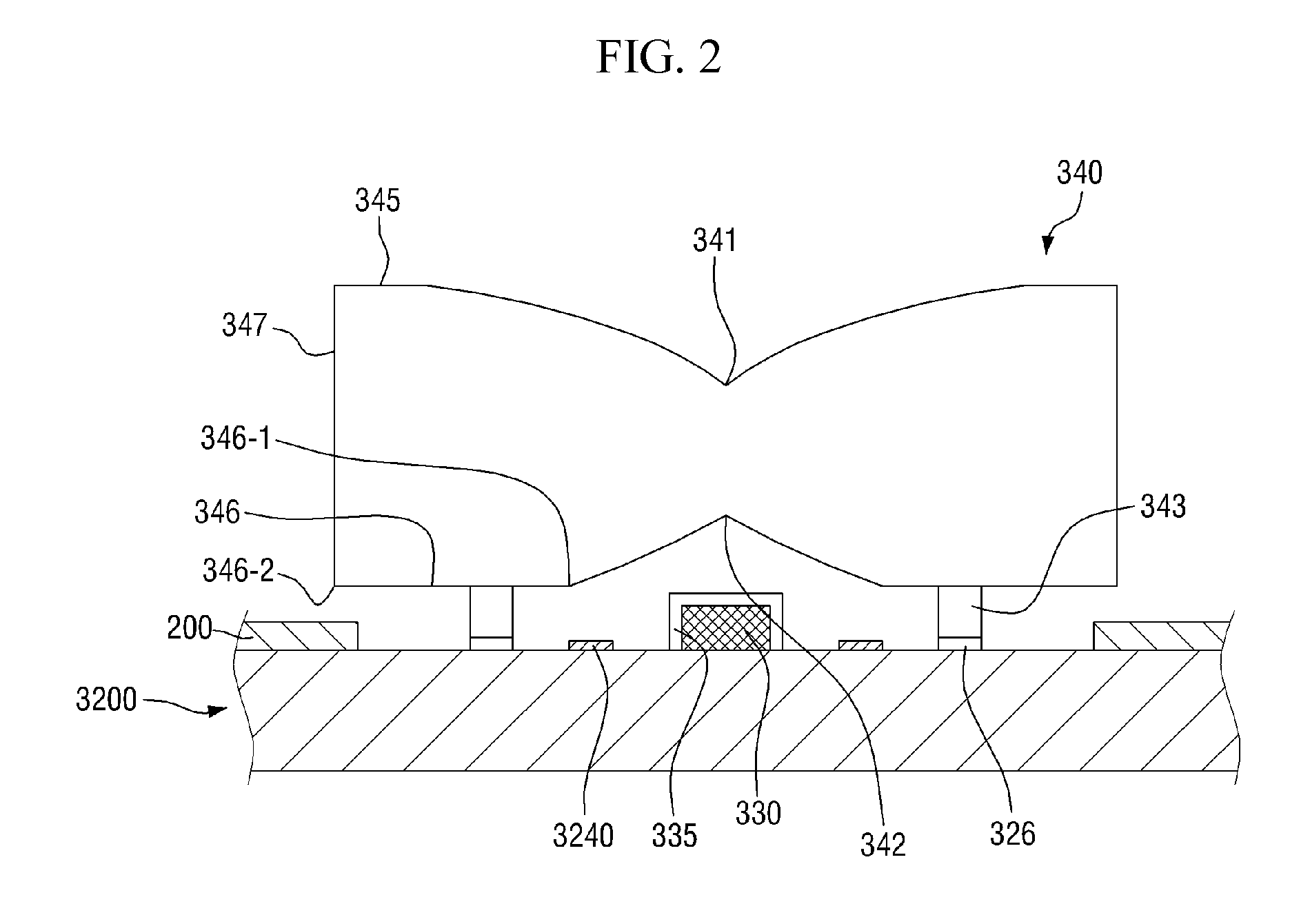

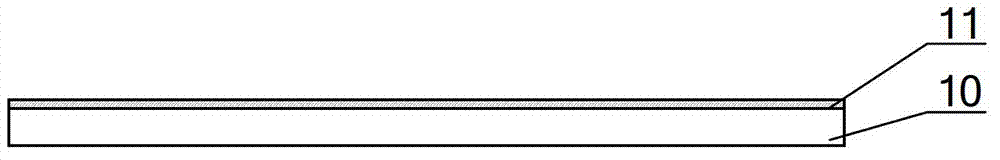

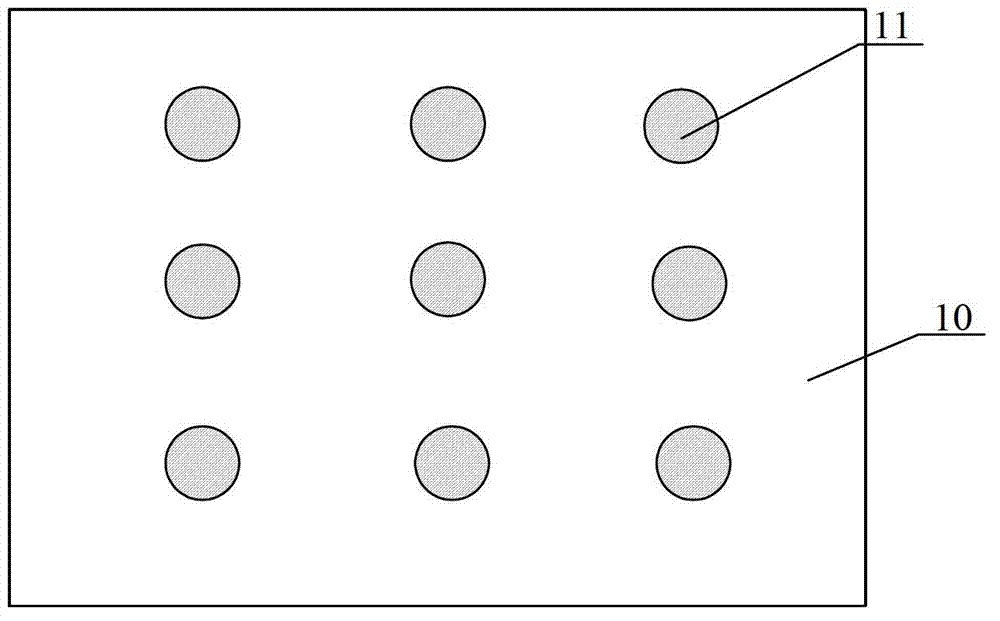

Light source module, backlight assembly including the same, and display device including the light source module

ActiveUS20150219966A1Improve brightness uniformityImprove lighting qualityCircuit optical detailsPoint-like light sourceComputer moduleDisplay device

A light source module includes a printed circuit board including a wiring layer, an insulating coating layer disposed on the wiring layer, and a reflection adjustment pattern disposed on the insulating coating layer and having reflection characteristics which are different from reflection characteristics of the insulating coating layer, a light emitting chip mounted on the printed circuit board, and an optical lens arranged on an upper portion of the light emitting chip and fixed to the printed circuit board.

Owner:SAMSUNG DISPLAY CO LTD

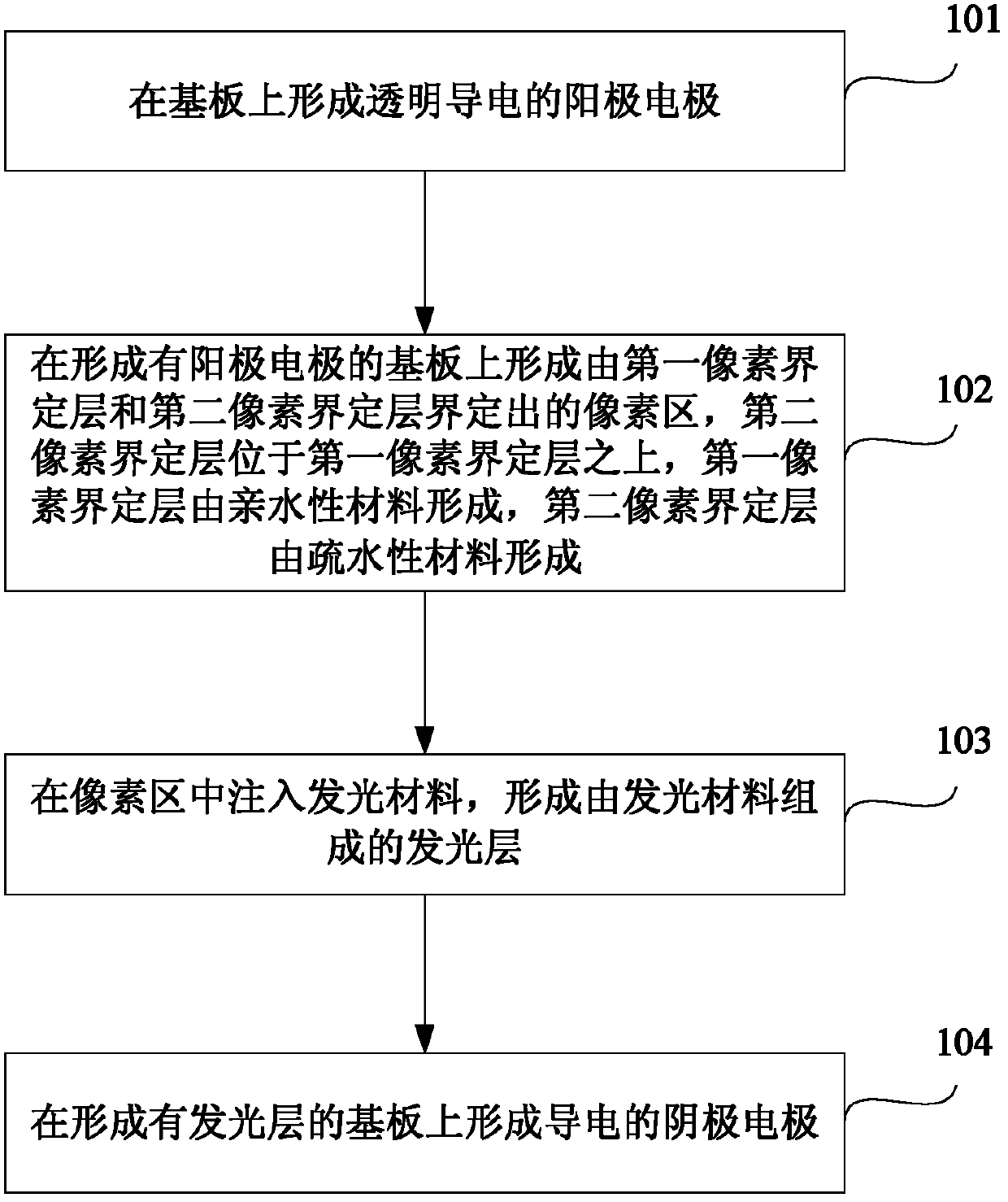

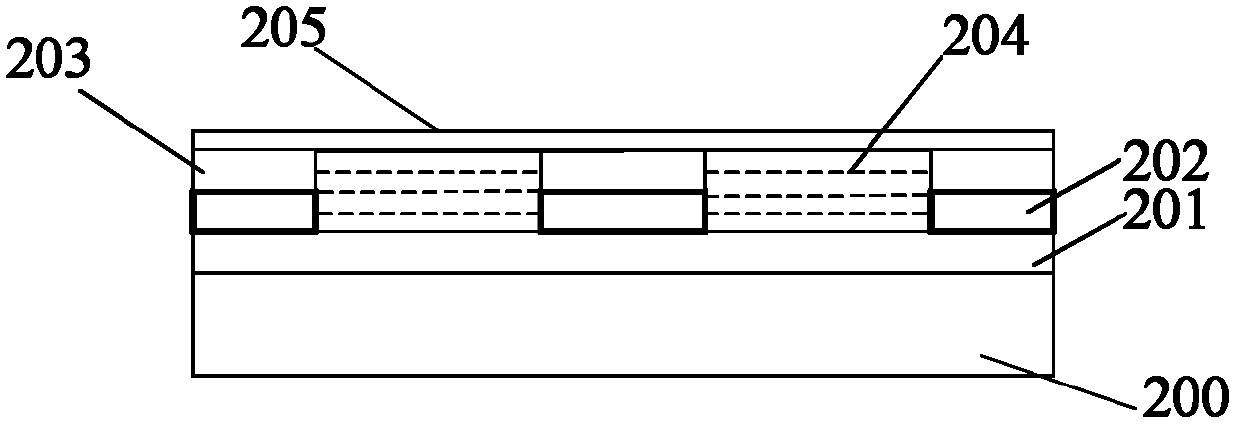

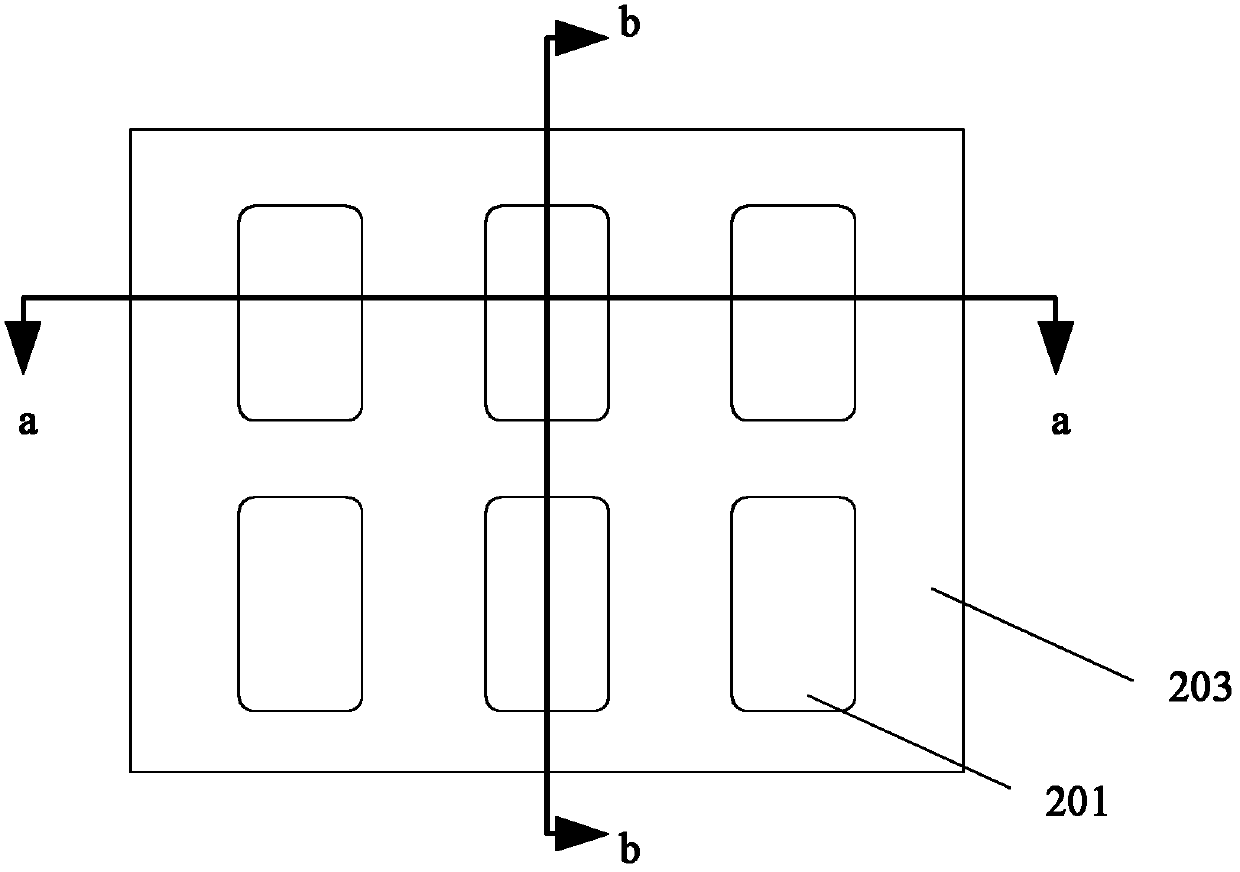

Light-emitting diode display back plate, manufacturing method and display device for light-emitting diode display back plate

ActiveCN102705790AImprove lighting qualityChange wetting propertiesPoint-like light sourceLighting support devicesDisplay deviceEngineering

The invention provides a light-emitting diode display back plate, a manufacturing method and a display device for the light-emitting diode display back plate and belongs to the field of displaying. The manufacturing method for the light-emitting diode display back plate includes steps: forming a transparent and conductive anode on a substrate; forming a pixel area defined by a first pixel defining layer and a second pixel defining layer on the substrate where the anode is formed; injecting light-emitting materials into the pixel area, and forming an light-emitting layer comprising the light-emitting materials; and forming a conductive cathode on the substrate where the light-emitting layer is formed. The second pixel defining layer made of hydrophobic materials is located above the first pixel defining layer made of hydrophilic materials. By the aid of the light-emitting diode display back plate, the manufacturing method and the display device for the light-emitting diode display back plate in the technical scheme, the light-emitting materials can be flatly laid on the light-emitting diode display back plate, and light-emitting quality of the light-emitting diode display back plate is improved.

Owner:BOE TECH GRP CO LTD

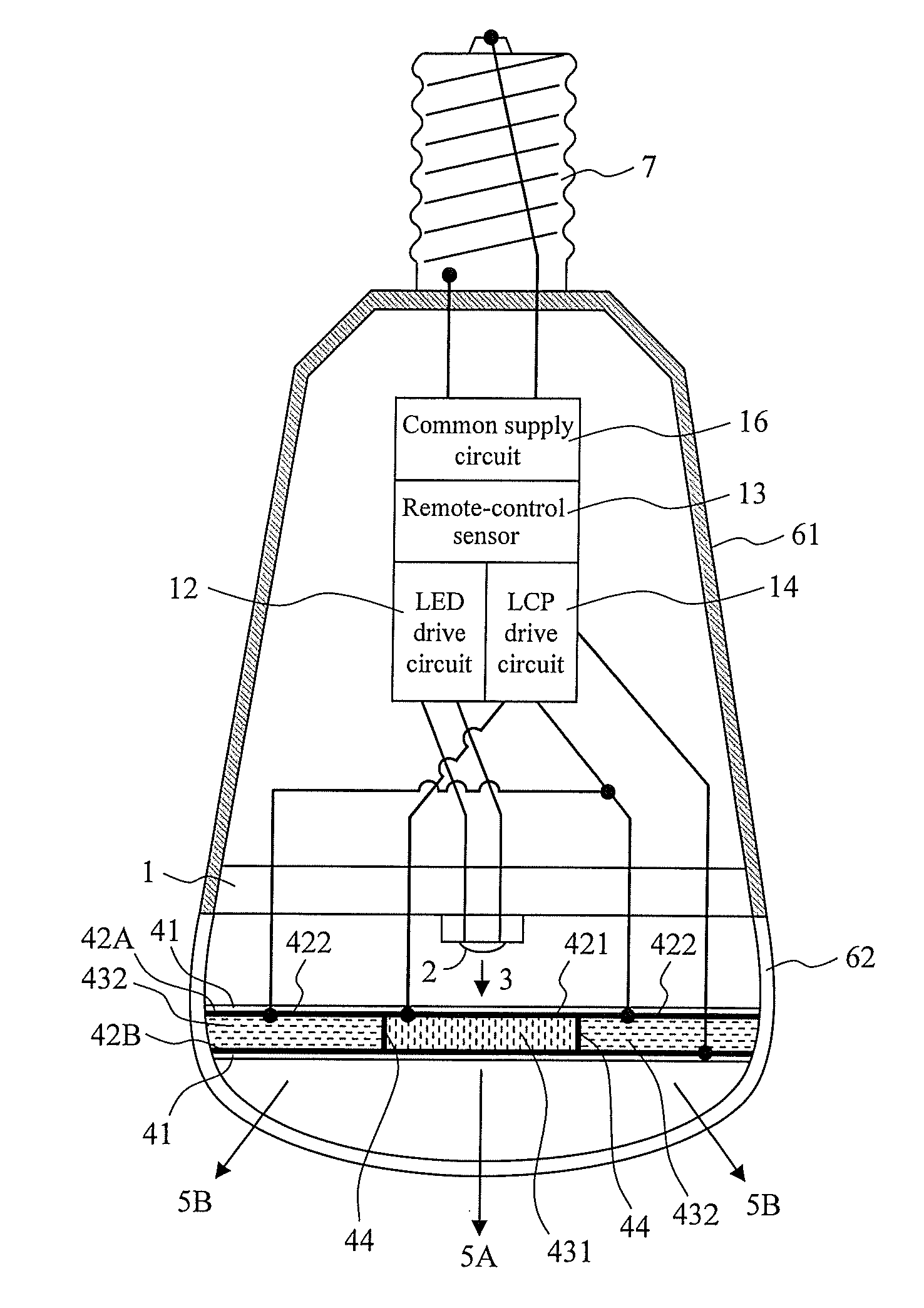

LED lighting apparatus

ActiveUS20120169953A1Improve lighting qualityAvoid missing problemsLighting applicationsMechanical apparatusEffect lightEngineering

Light from an LED (light-emitting diodes) has strong directional characteristics; therefore, lighting over large area, as well as control of the quality or the distribution of lighting was impossible. Placing a liquid-crystal panel in front of an LED (light-emitting diodes) enables to control light from the LED and the quality or the distribution of lighting.

Owner:KATAOKA SHOEI +1

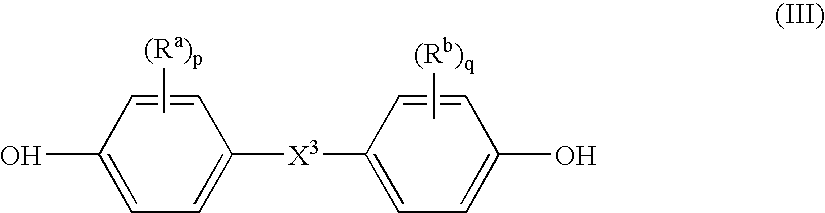

Lamp lens or bezel with visual effect

InactiveUS20030189838A1Broad paletteImprove lighting qualityPoint-like light sourceMeasurement apparatus componentsCamera lensVisibility

Lenses and bezels for lamps provide an appealing aesthetic look in the form of a colored glow at the edges of the lens or bezel by incorportation of an photoluminescent material in a molded polycarbonate body. The lenses are particularly suitable for use as an automotive outer lens, and can also improve the quality of the light emitted through this outer lens by interacting with the light bulb. The emitted beam is of a legal color and intensity as defined per the SAE J578 standard. The lighting performance may also be improved in such manner as reducing glare, increasing brightness or producing a beam that enhances road visibility at night to the human eye.

Owner:SABIC GLOBAL TECH BV

Methods and apparatus for determining high quality sampling data from low quality sampling data

InactiveUS20070139433A1Improve lighting qualityEasy to implementColor signal processing circuitsCharacter and pattern recognitionComputer vision

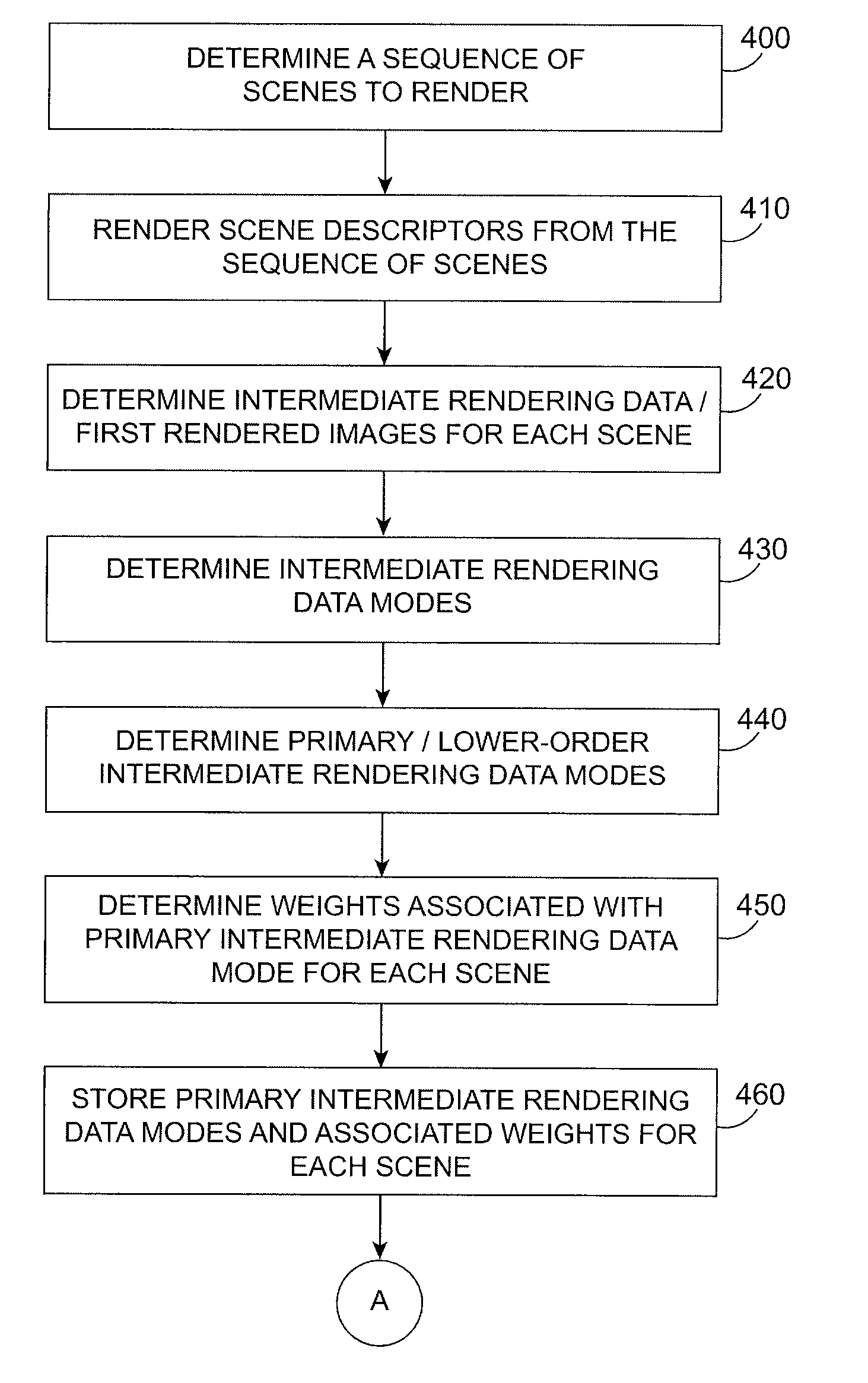

A method for a computer system includes determining a plurality of illumination modes associated with a plurality of scene descriptors, wherein the plurality of scene descriptors includes a first scene descriptor and a second scene descriptor, determining a first plurality of weights, wherein each weight from the first plurality of weights is associated with an illumination mode from the plurality of illumination modes, determining illumination data associated with the first scene descriptor in response to the first plurality of weights and in response to the plurality of illumination modes, determining a second plurality of weights, wherein each weight from the second plurality of weights is associated with an illumination mode from the plurality of illumination modes, and determining illumination data associated with the second scene descriptor in response to the second plurality of weights and in response to the plurality of illumination modes.

Owner:PIXAR ANIMATION

Cerium based phosphor materials for solid-state lighting applications

ActiveUS20070159066A1Improve lighting qualityDischarge tube luminescnet screensElectroluminescent light sourcesCalcium silicateUltraviolet

A luminescent cerium (Ce) doped compound emitting bright red light, comprising a calcium silicate nitride ternary system, such as CaSiN2δOδ:Ce3+, that crystallizes in a face-centered cubic unit cell with a lattice parameter of ˜a=14.88 Å. The Ce doped compound can be used for white light applications either: (i) to enhance the light quality of the system based on a blue LED with a yellow or green phosphor, (ii) as an orange phosphor in combination with a blue LED and a green phosphor, or (iii) as a red phosphor in a setup comprising a ultraviolet (UV) LED and red, green and blue (RGB) phosphors. Substitution of smaller elements on the Ca site or larger elements on the Si site leads to a decrease of the emission wavelength towards the yellow or orange region.

Owner:RGT UNIV OF CALIFORNIA

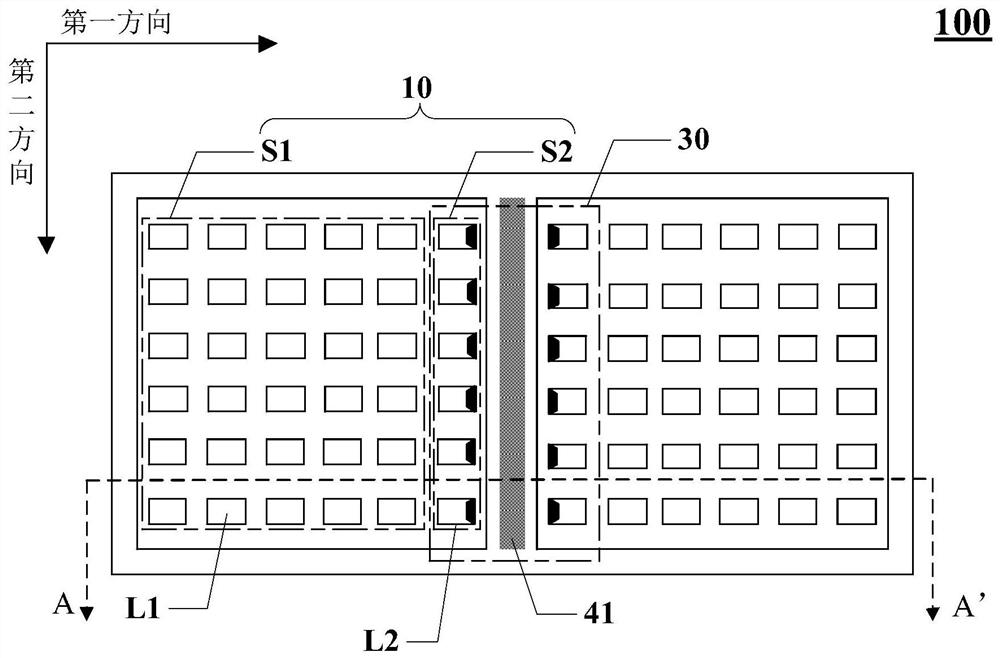

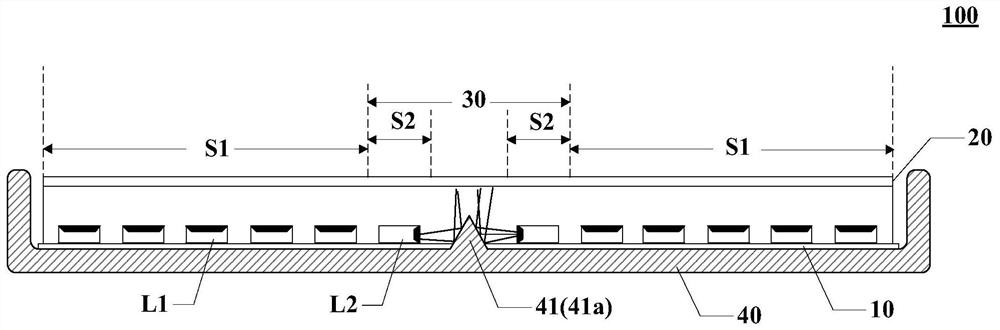

Spliced backlight module and display device

ActiveCN112002217AImprove lighting qualityIncrease brightnessIdentification meansDisplay deviceEngineering

The invention discloses a spliced backlight module and a display device, and relates to the technical field of display, the spliced backlight module comprises at least two lamp panels adjacently arranged in a first direction, each lamp panel comprises a first light-emitting area and a second light-emitting area, and the first direction is parallel to the light-emitting surface of the backlight module; wherein the first light-emitting area comprises a first light-emitting element, the second light-emitting area comprises a second light-emitting element, and the light-emitting direction of the first light-emitting element is different from the light-emitting direction of the second light-emitting element; an optical film; and the orthographic projection of the light supplementing area on thelight emitting surface covers the orthographic projection of the second light emitting area on the light emitting surface in the direction perpendicular to the light emitting surface of the backlightmodule. Due to the fact that the first light-emitting element serves as the backlight source, and the second light-emitting element serves as the light supplementing light source, the emergent lightof the second light-emitting element emitting light laterally can irradiate the light supplementing area, the brightness of the abutted seam of the lamp panels is improved, dark lines are eliminated,and the light emitting quality of the backlight module is improved.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Lamp lens or bezel with visual effect

InactiveUS6893147B2Improve lighting qualityAppealing aesthetic lookVehicle headlampsPoint-like light sourceVisibilityCamera lens

Lenses and bezels for lamps provide an appealing aesthetic look in the form of a colored glow at the edges of the lens or bezel by incorportation of an photoluminescent material in a molded polycarbonate body. The lenses are particularly suitable for use as an automotive outer lens, and can also improve the quality of the light emitted through this outer lens by interacting with the light bulb. The emitted beam is of a legal color and intensity as defined per the SAE J578 standard. The lighting performance may also be improved in such manner as reducing glare, increasing brightness or producing a beam that enhances road visibility at night to the human eye.

Owner:SABIC GLOBAL TECH BV

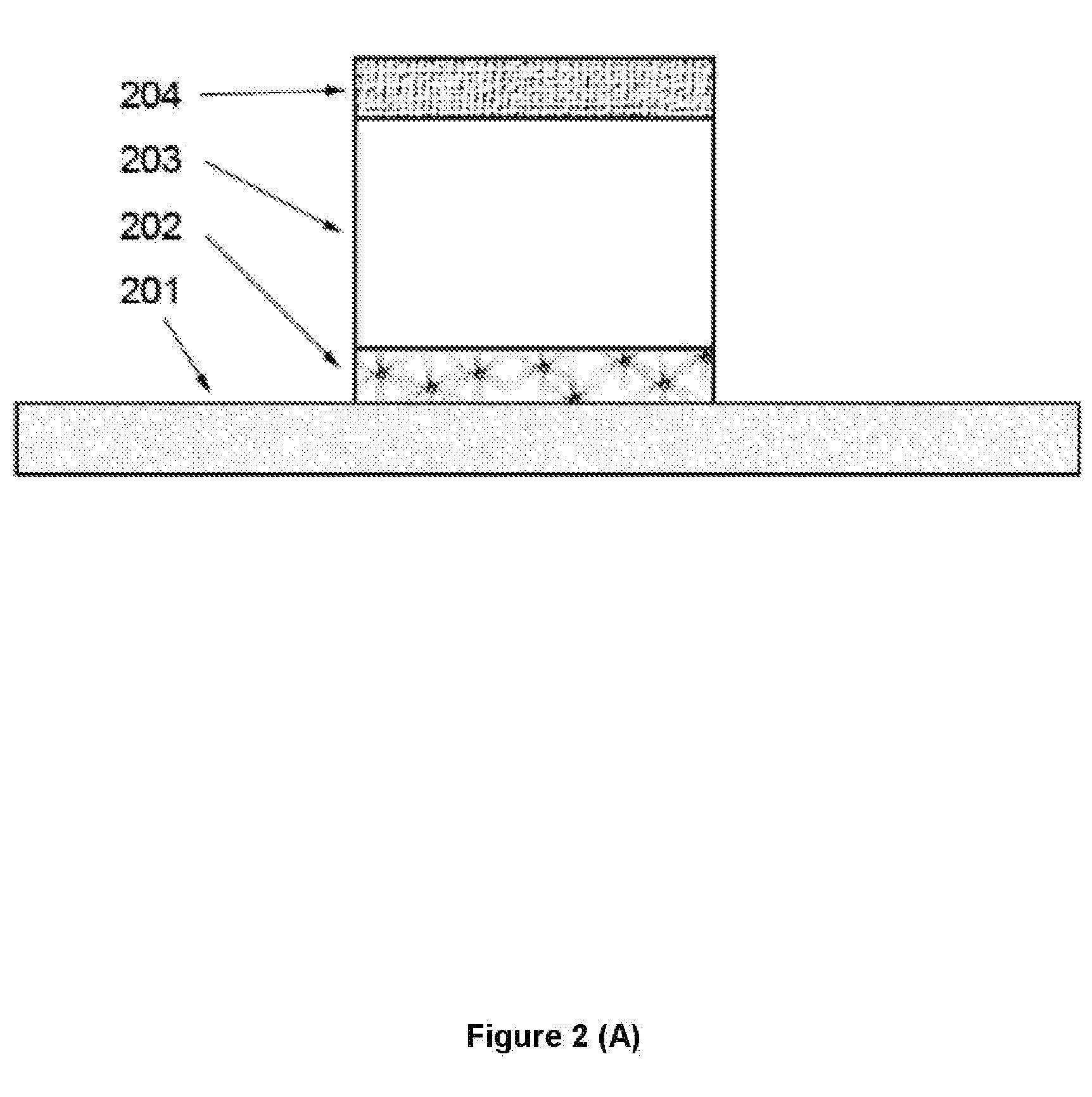

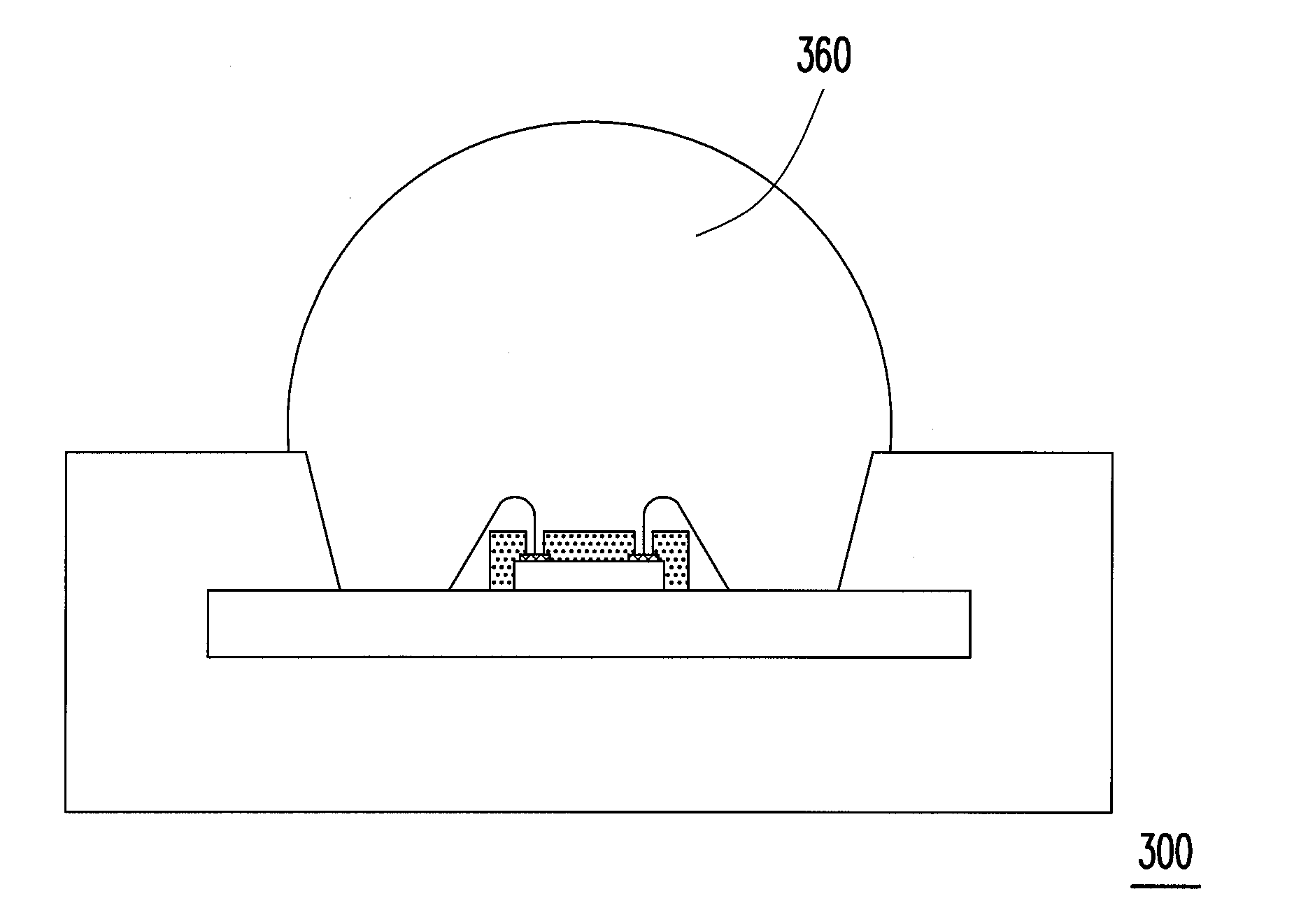

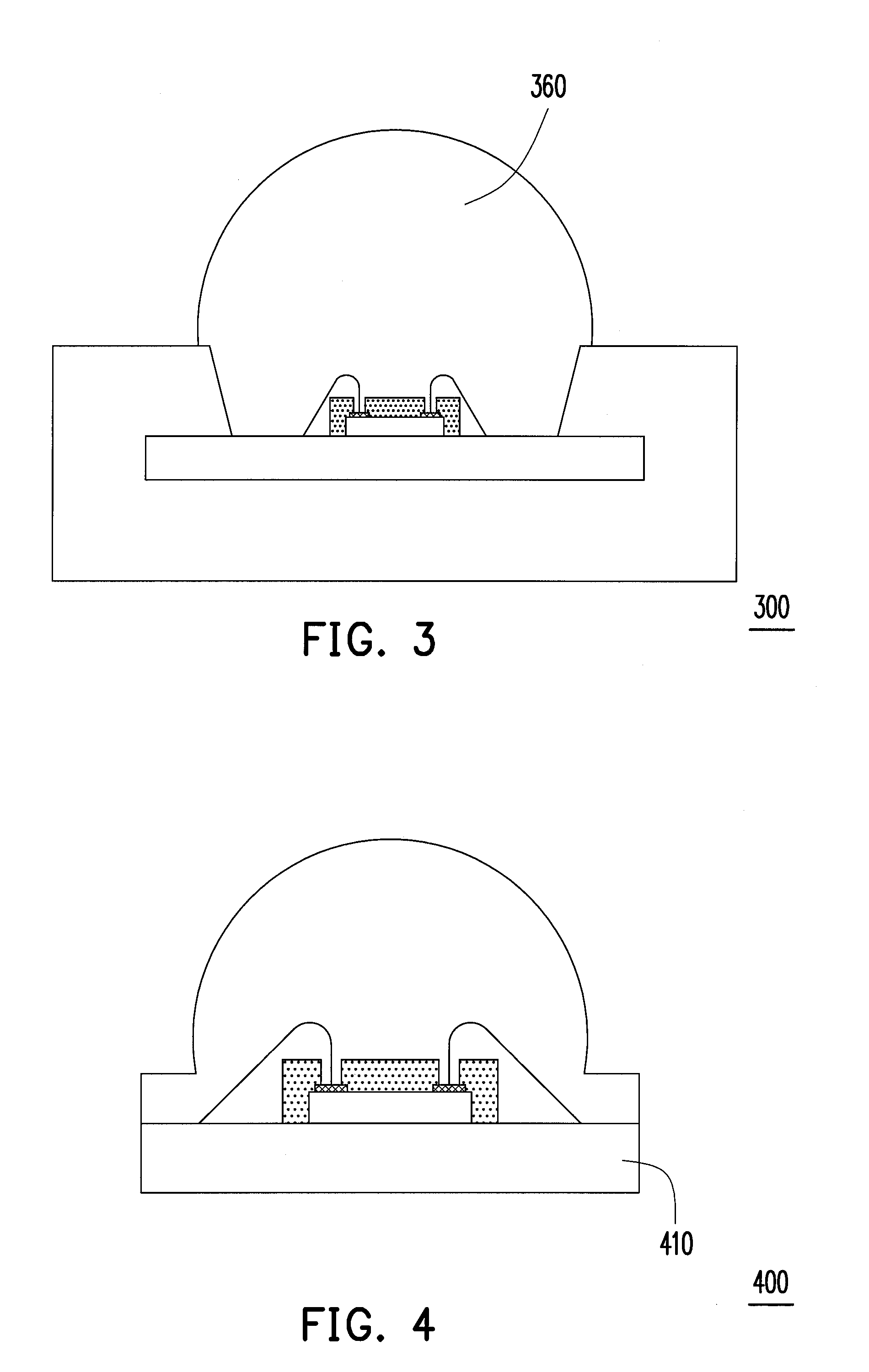

Package structure and package process of light emitting diode

ActiveUS20110278610A1Illumination efficiency is highReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingPhosphorEngineering

A light emitting diode (LED) package structure comprising a carrier, an LED chip, a first encapsulant, at least one bonding wire, a plurality of phosphor particles and a second encapsulant is provided. The LED chip is disposed on the carrier. The LED chip has at least one electrode. The first encapsulant is disposed on the carrier and covering the LED chip. The first encapsulant is provided with at least one preformed opening exposing at least a portion of the at least one electrode. The at least one bonding wire is electrically connected between the at least one electrode and the carrier via the at least one preformed opening. The phosphor particles are distributed within the first encapsulant. The second encapsulant is disposed on the carrier and encapsulates the LED chip, the first encapsulant and the at least one bonding wire.

Owner:ADVANCED SEMICON ENG INC

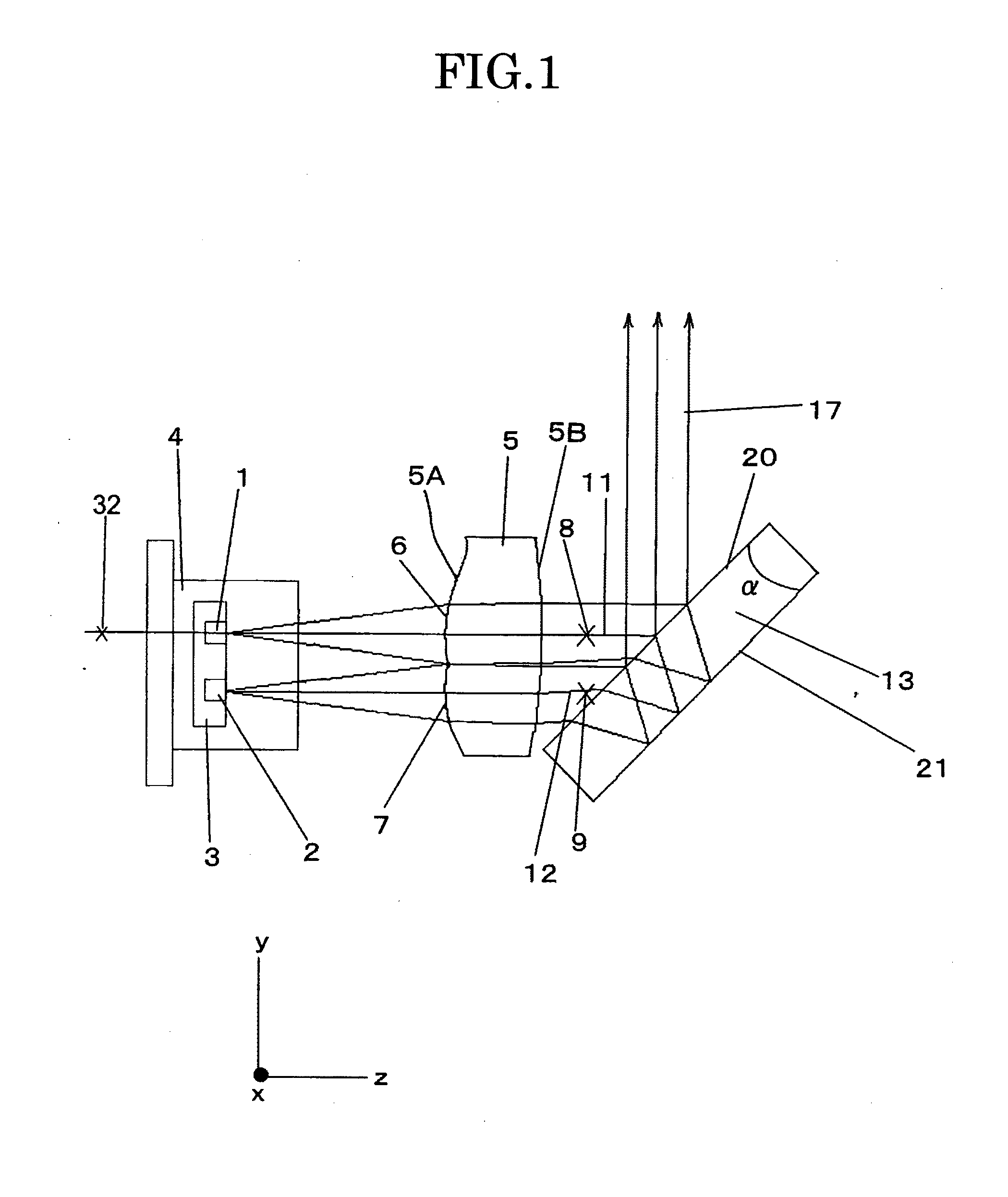

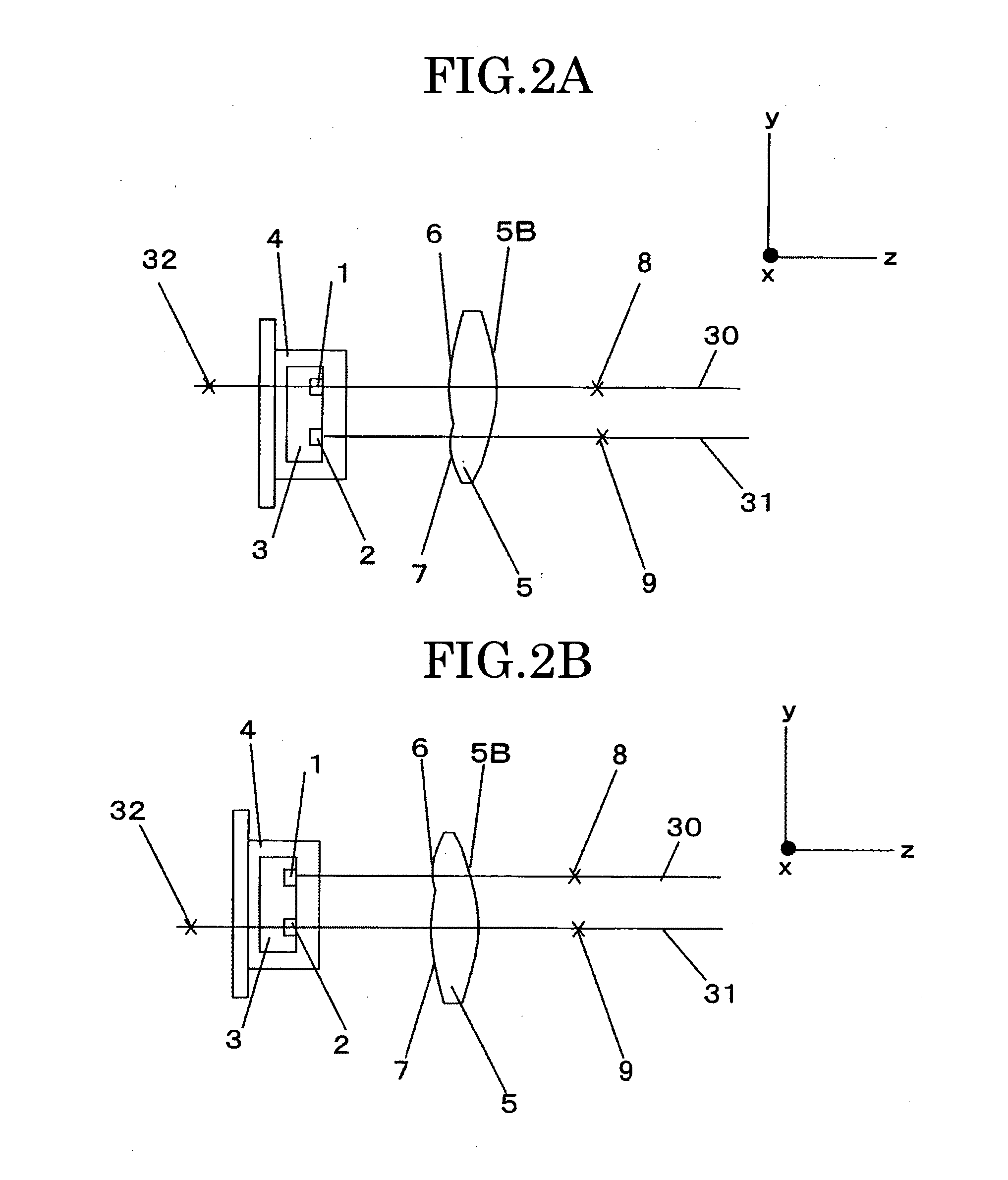

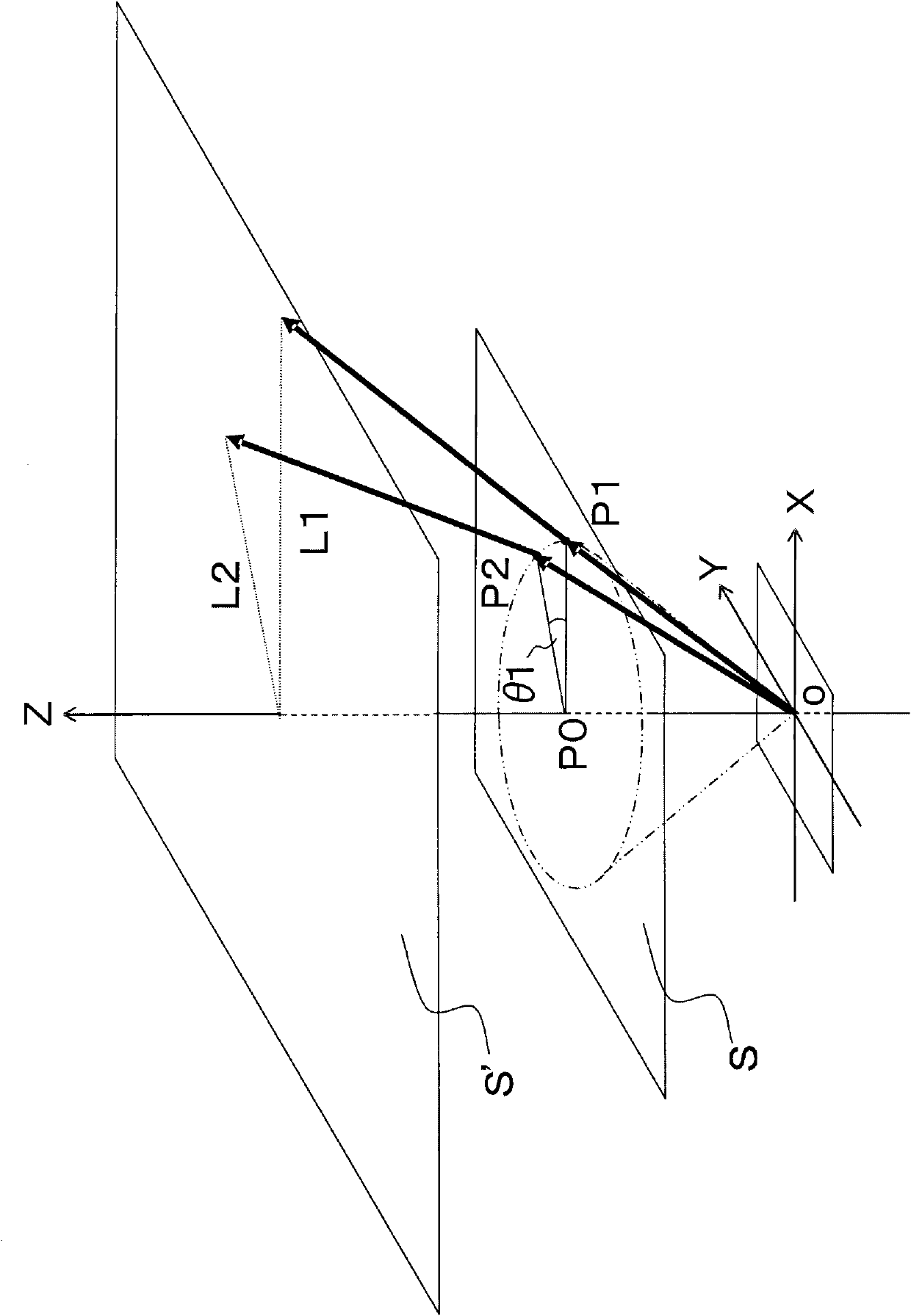

Coupling lens, illuminating device, and electronic device

ActiveUS20110249240A1Improve the use of lightingImprove lighting qualityProjectorsSpectral modifiersOptical axisCoupling

A coupling lens for coupling first light having a first wavelength from a first light source with a second light having a second wavelength from a second light source disposed adjacent to the first light source in substantially the same direction includes a first surface disposed to face the first and second light sources, the first surface including a first region transmitting the first light and having a first region curvature and a second region transmitting the second light and having a second region curvature, and a second surface opposite to the first surface and having a second-surface curvature. A position of a center of the first region curvature differs from a position of a center of the second region curvature. A center of the second surface curvature and the center of the first region curvature are disposed on an optical axis of the first or second light source.

Owner:RICOH KK

Optical diaphragm, light guide plate, combination method thereof and backlight module

InactiveCN102789013AImprove lighting qualityImprove display qualityPrismsDiffusing elementsWrinkle skinLight guide

The invention discloses an optical diaphragm, a light guide plate, a combination method of the optical diaphragm and the light guide plate, and a backlight module provided with the optical diaphragm and the light guide plate, and relates to the field of display, aiming at solving the displacement or the wrinkle of the diaphragm caused by the overlarge size of the diaphragm, the bad assembly, the heating deformation and the vibration, effectively reducing the probability of the bad screen display quality, and improving the display effect. Some parts or all parts of at least one of surfaces of the optical diaphragm are provided with magnetic diaphragm layers; and the magnetic diaphragm layers have the magnetism, and are made from transparent magnetic materials. The surface of the light guide plate is further provided with the magnetic diaphragm layer. The combination method of the optical diaphragm and the light guide plate in the backlight module comprises the following steps of: respectively arranging the magnetic diaphragm layers on the light guide plate and the optical diaphragm; and gluing each optical diaphragm with each light guide plate due to the magnetic attraction of the magnetic diaphragm layers.

Owner:BOE TECH GRP CO LTD +1

Terminal for monitoring urban street light circuit

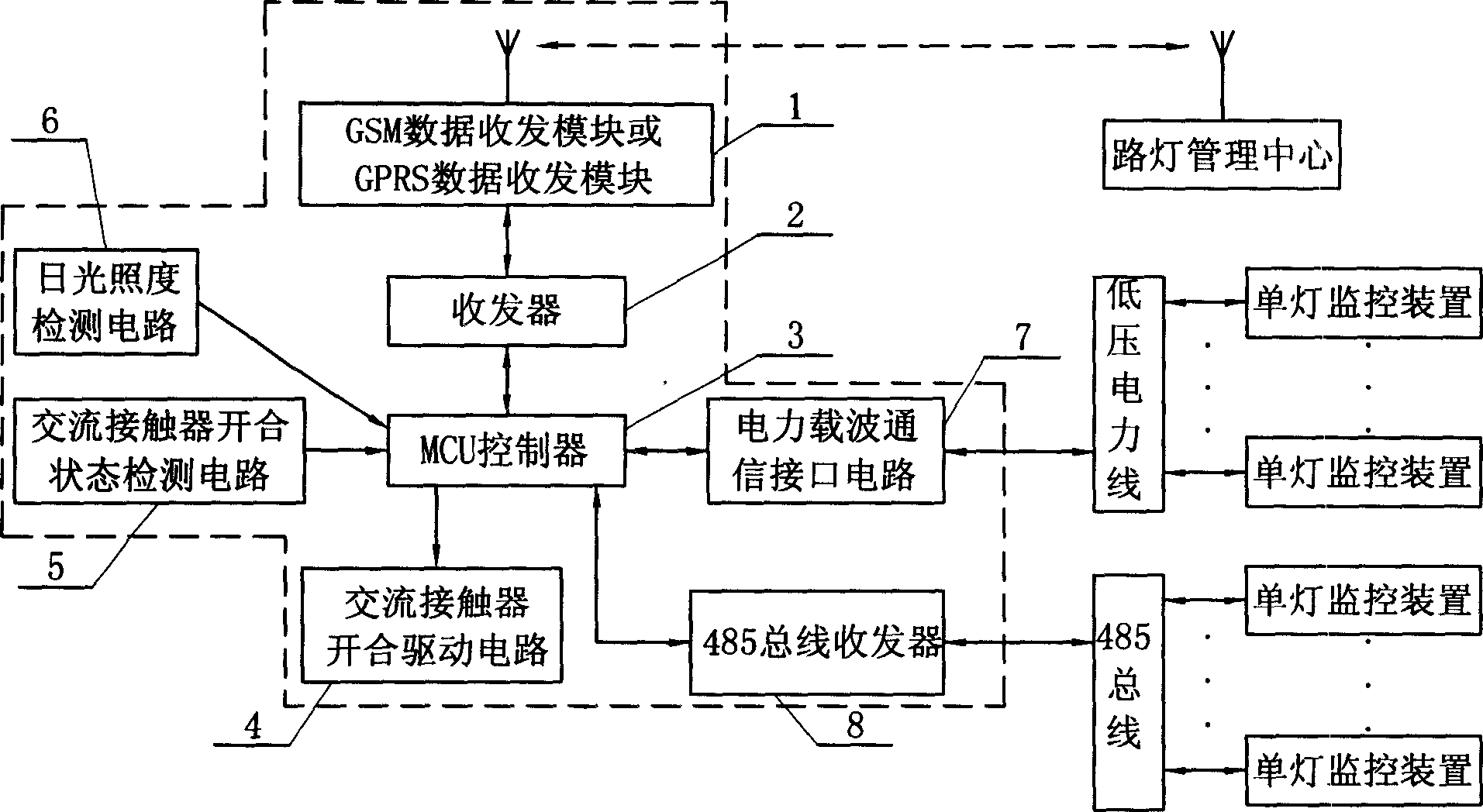

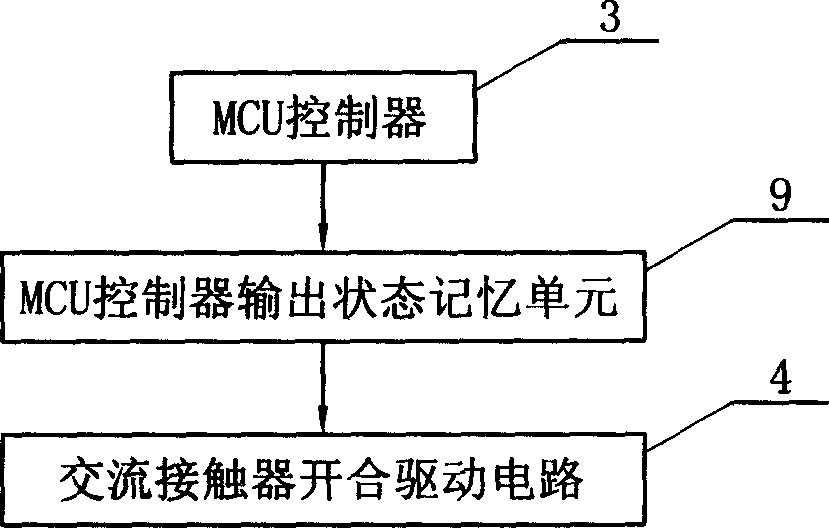

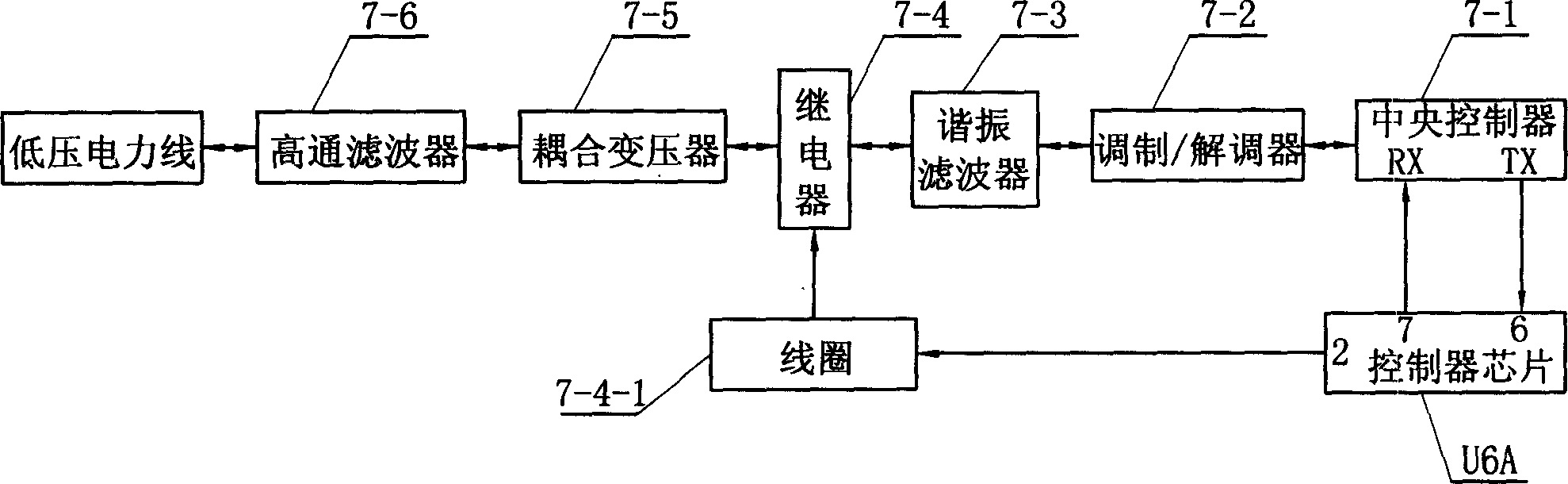

InactiveCN1725925ASolve the problem of difficult remote monitoringImplement updateElectrical testingElectric light circuit arrangementTransceiverDaylight

A terminal for monitoring road lamp of city consists of GSM data transmitting - receiving module or GPRS data transmitting - receiving module , transceiver , MCU controller , AC contactor open - close driving circuit , AC contactor open- close state detection circuit and sunlight illumination detection circuit . The terminal set far from road lamp management centre can realize two-way remote data transmission with said centre for achieving remote control and data refreshment of road lamp.

Owner:HARBIN INST OF TECH

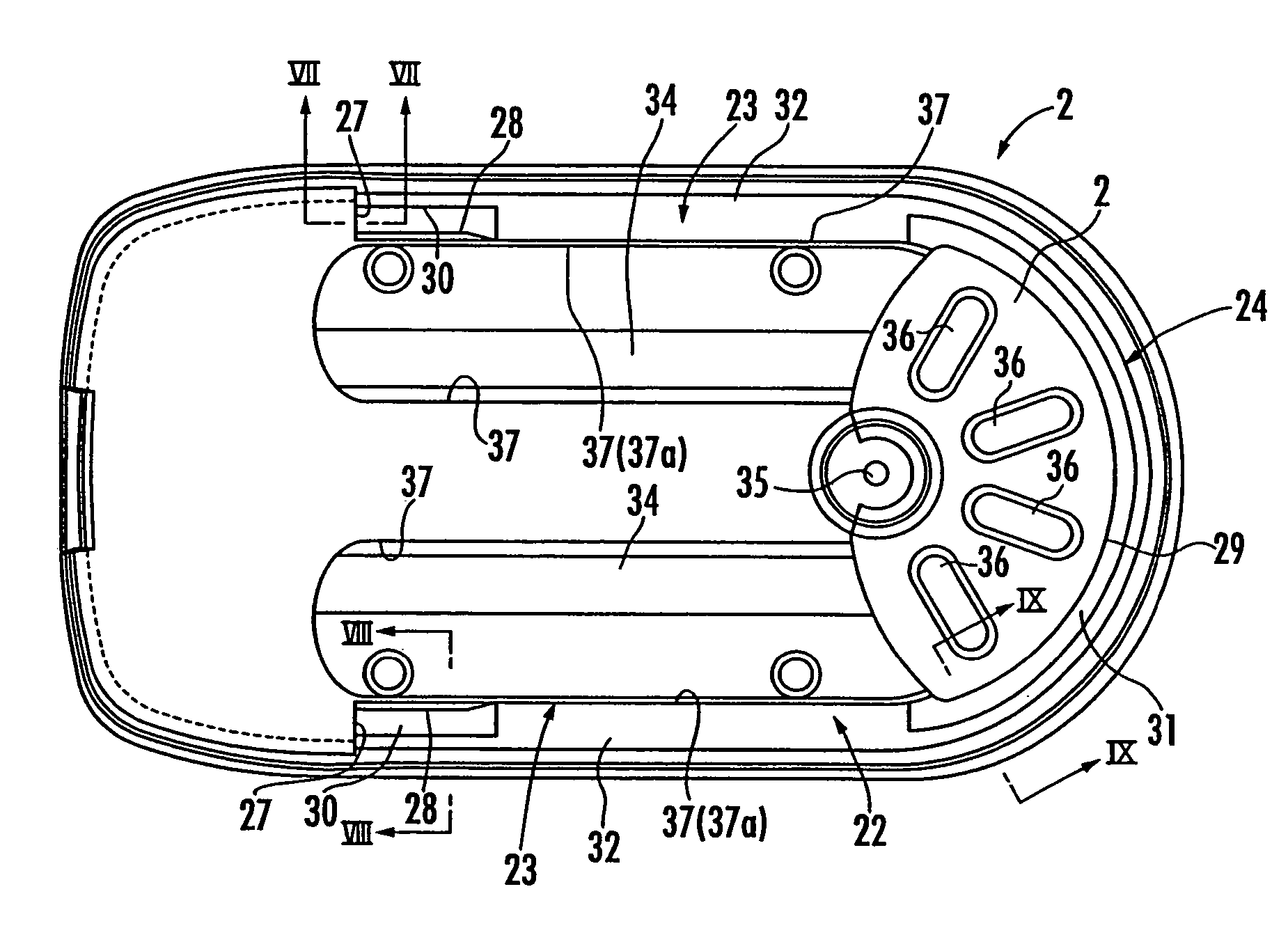

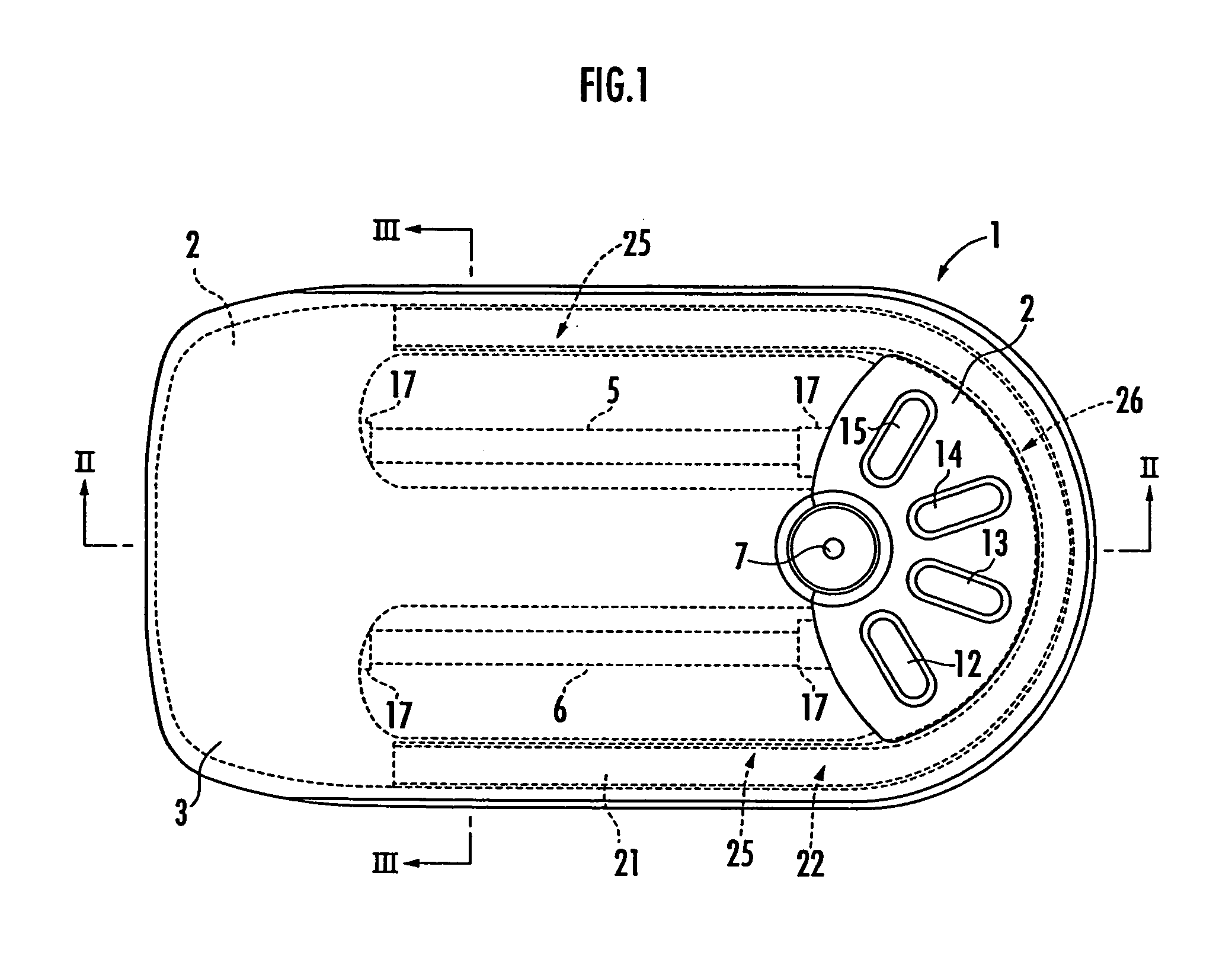

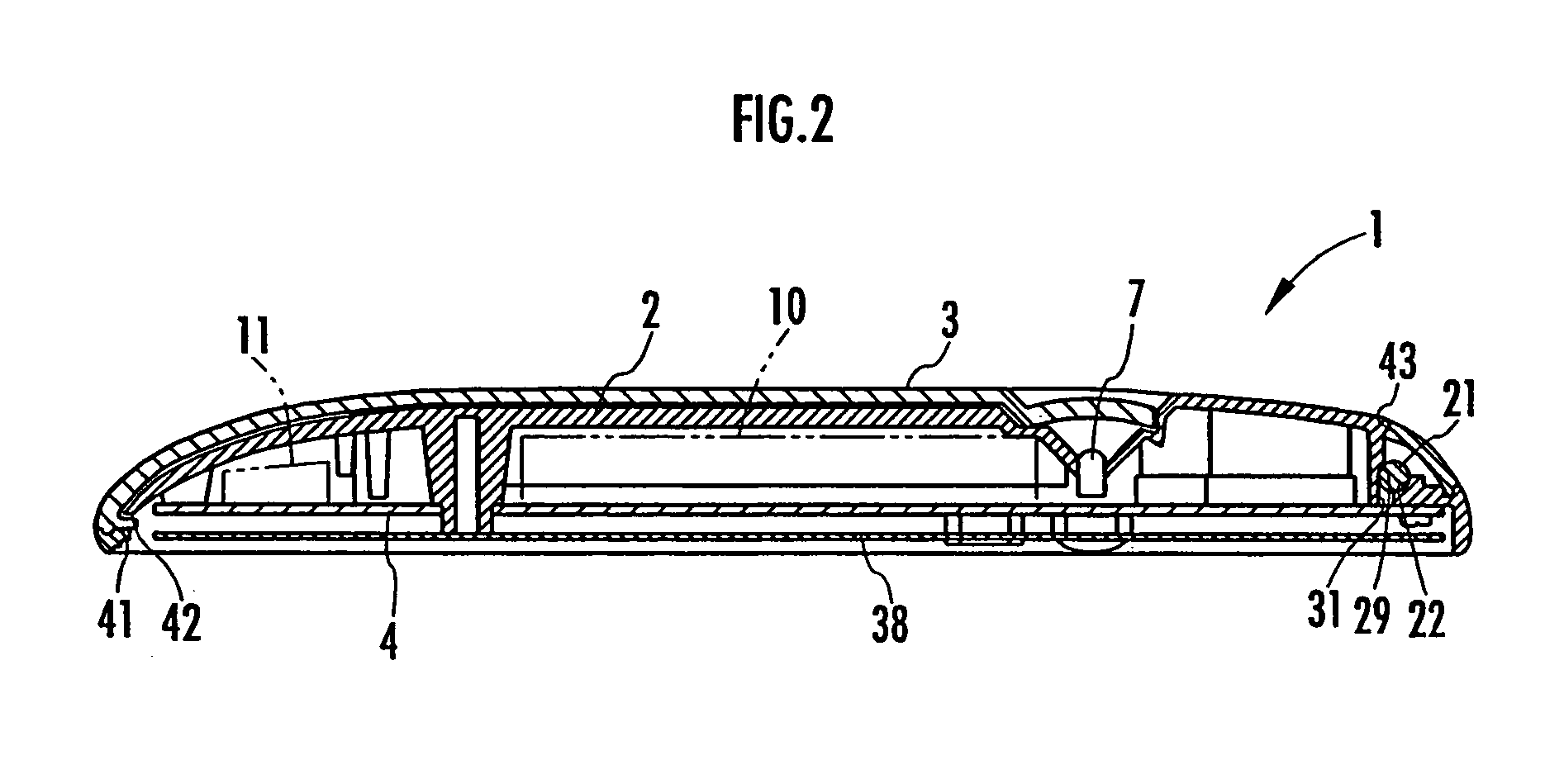

Interior illuminator for automobile

InactiveUS7213952B2Improve lighting qualityQuality improvementMechanical apparatusLighting circuitsLight guideEngineering

To provide an interior illuminator for an automobile that can produce a decorative effect by illumination in addition to illuminating the interior of the automobile and has a simple structure and a small size. A secondary light emitting unit is provided around primary light emitting units 5 and 6 for illuminating the interior of the automobile. A housing 2 that holds the primary light emitting units 5, 6 and the secondary light emitting unit is provided. The secondary light emitting unit has a U-shaped light guide body 21, light emitting elements 8 and 9 for launching light into the light guide body at the ends thereof, and a light emitting element control unit 11 for controlling the light emitting elements 8 and 9. The housing 2 has a light guide body holding groove that holds the light guide body 21, insertion holes for introducing the light guide body into the housing at the ends of the light guide body holding groove, and a housing section that houses the light emitting element and the light emitting element control unit.

Owner:HONDA ACCESS CORP

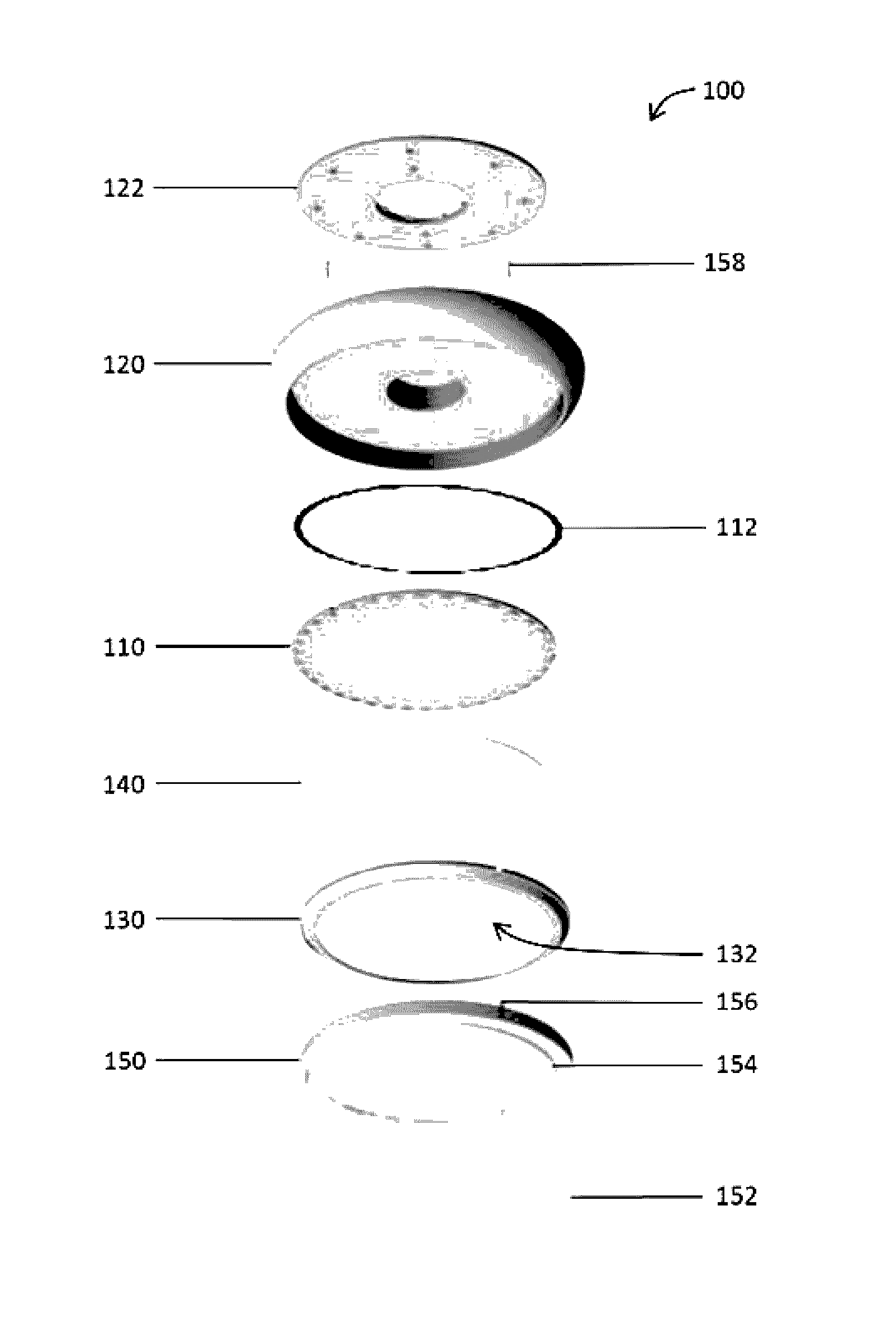

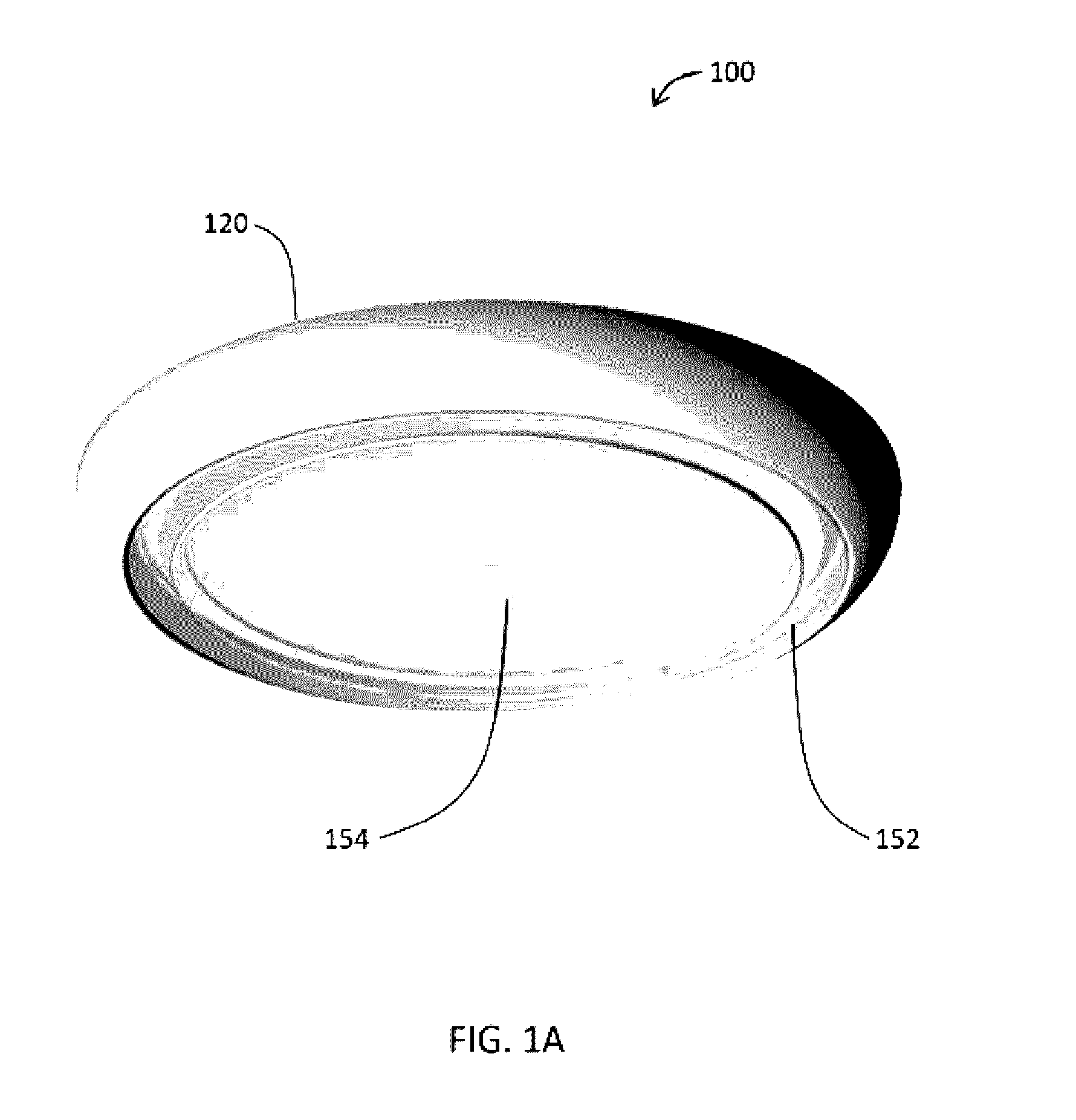

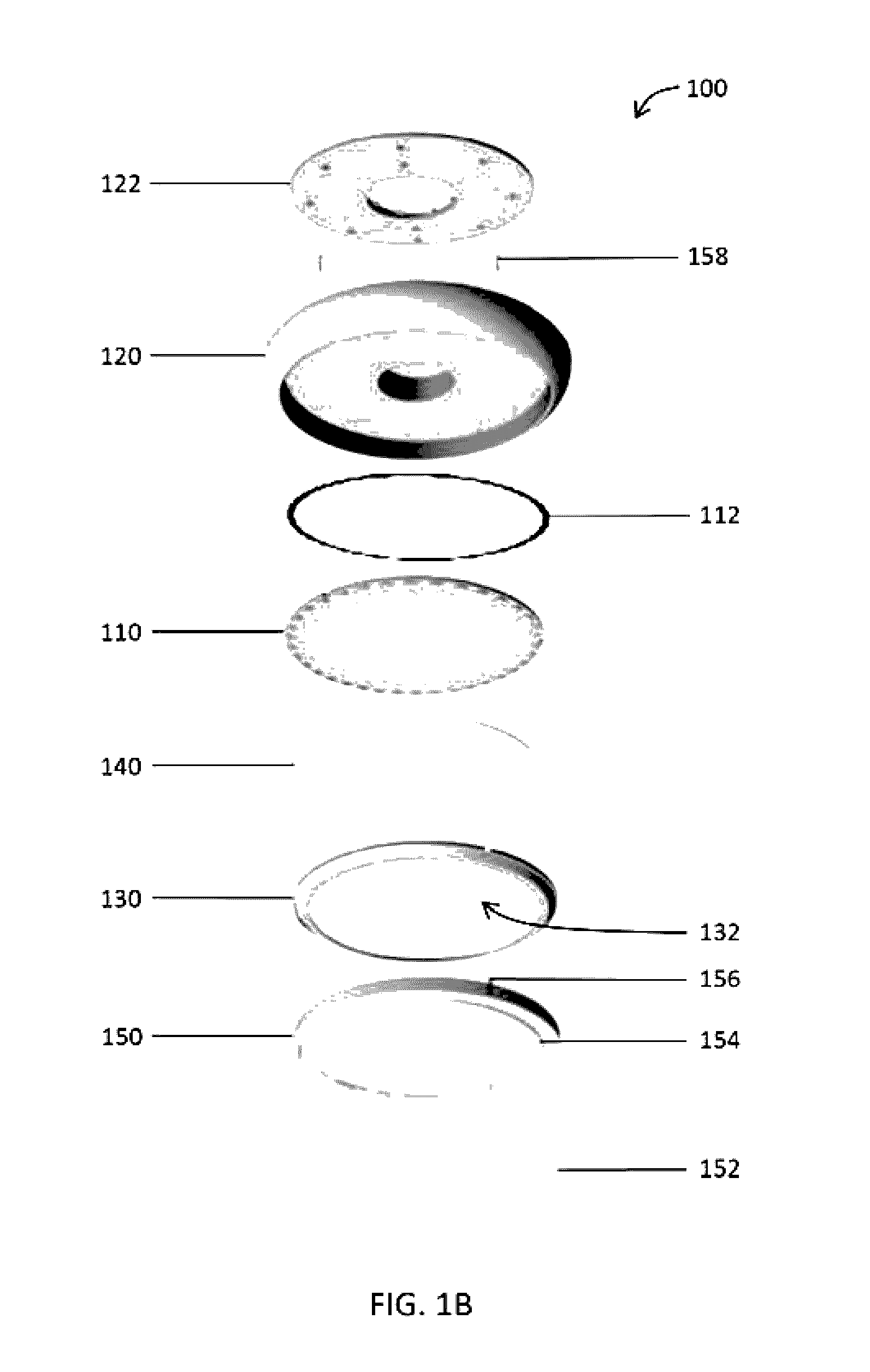

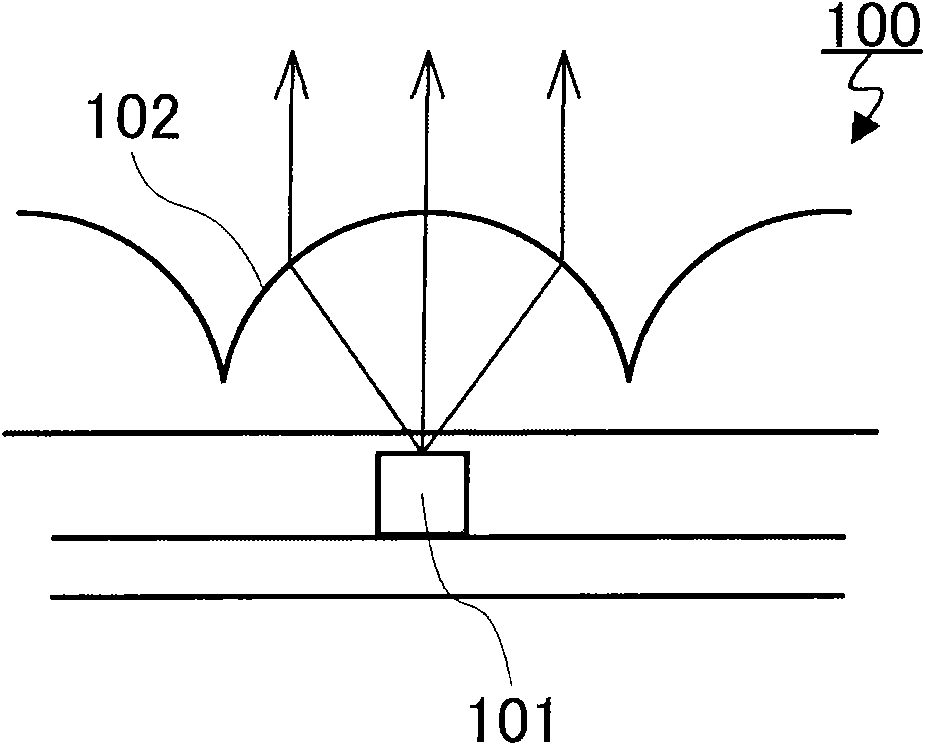

Light guide for low profile luminaire

ActiveUS20160370535A1Improve lighting qualityLow profilePlanar light sourcesMechanical apparatusLight guideEngineering

A luminaire comprising a heat sink, a light source to emit a source light, a heat spreader having inner and outer surfaces, and LEDs carried by a circuit board and disposed generally along a periphery of the inner surface and positioned in thermal communication therewith. The luminaire comprises a reflector disposed coextensively with the LEDs and comprising an aperture. An outer edge of the aperture defines an inner rim of the reflector. A light guide positioned between the reflector and the light source exhibits a height defined as the distance between the inner surface of the heat spreader and a plane defined by the inner rim of the reflector. The light guide comprises deformations and / or lens portions configured to change the source light into a shaped light that is directed through the aperture. The deformations are characterized by a common shape positioned about a center of the light guide.

Owner:LIGHTING SCI GROUP

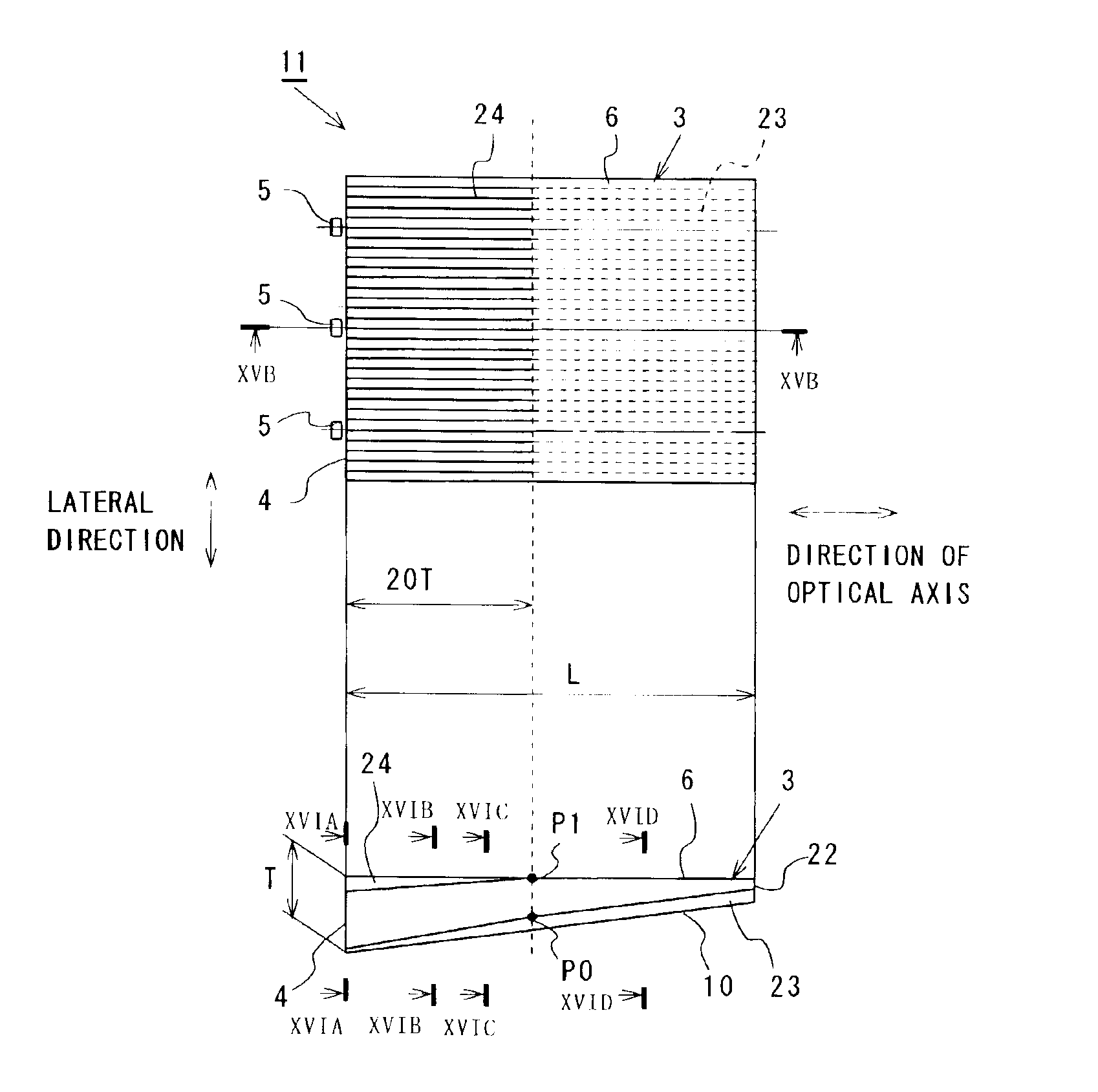

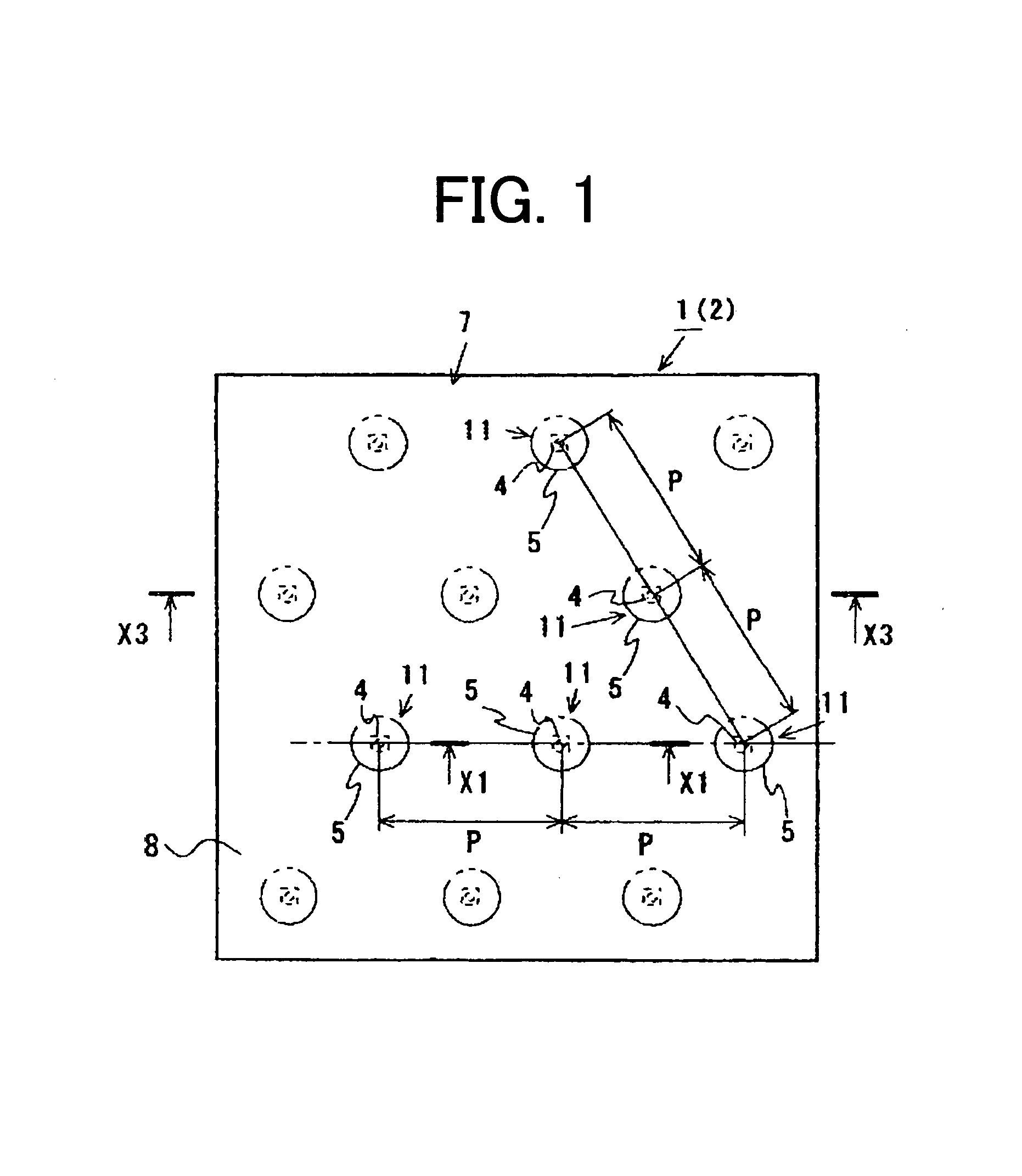

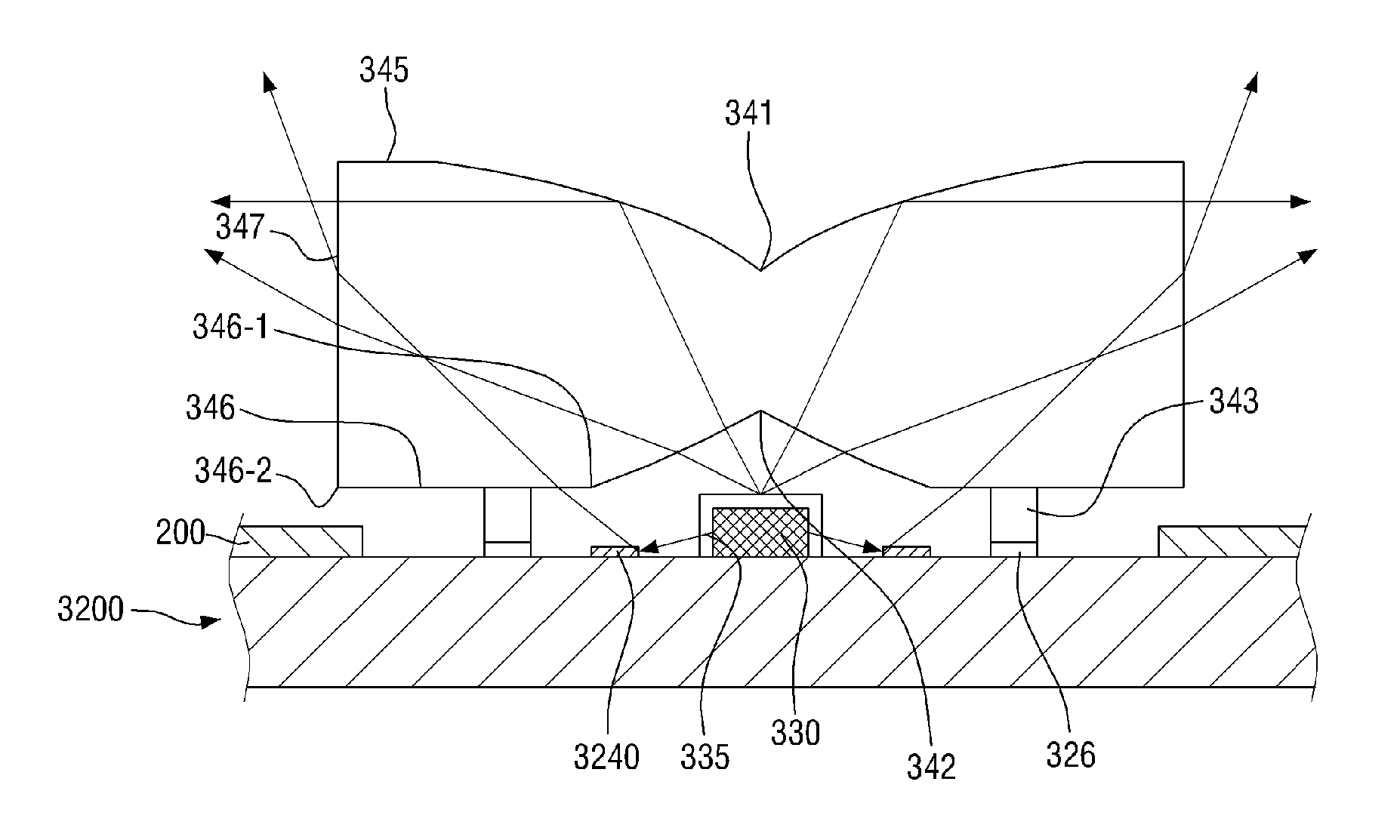

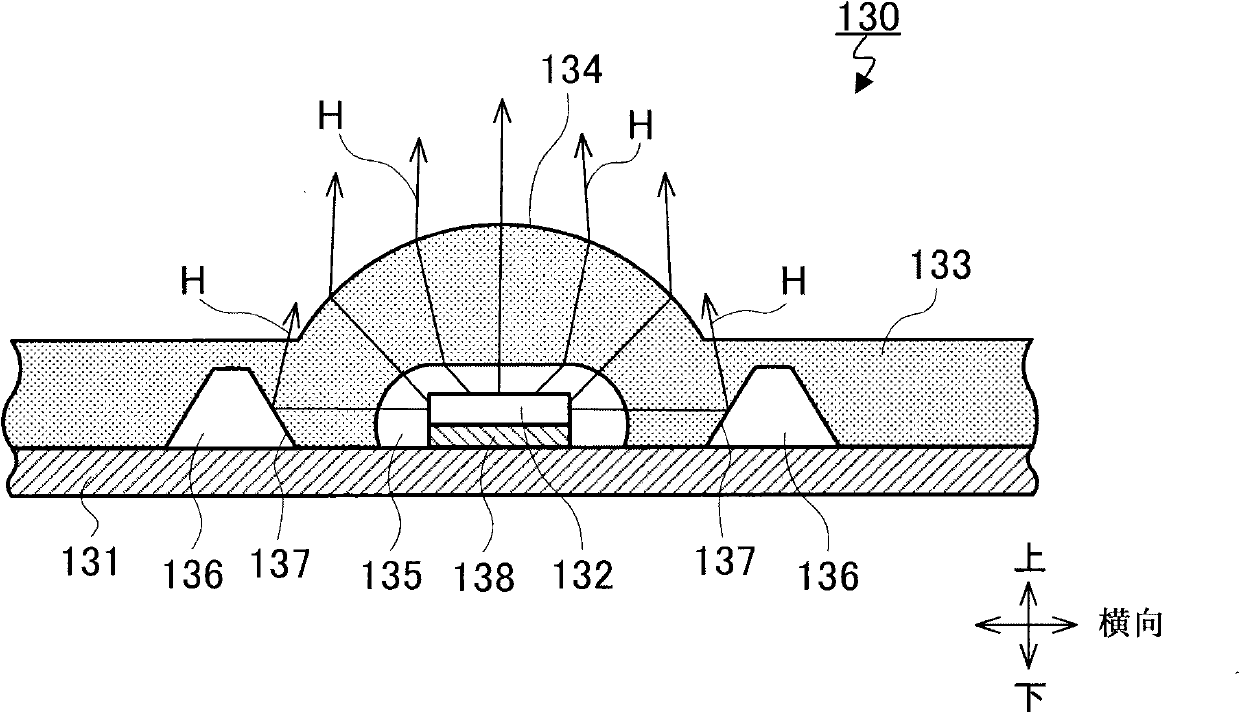

Light emitting apparatus, surface light source apparatus and display apparatus

ActiveCN102003638ASuppression of uneven illuminationUniform illuminationPlanar light sourcesOptical articlesIlluminanceLight flux

A light emitting apparatus can prevent unevenness in illuminance from being produced. This light emitting apparatus 5 has: light emitting elements 3 that emit light; and light flux controlling members 4 that control the traveling directions of light emitted from light emitting elements 3, and a plurality of grid convex parts 13 are formed in back surface 12 (i.e. lens bottom surface) of light flux controlling member 4. Grid convex parts 13 vary the incident angles of light incident on back surface 12 of light flux controlling member 4. Therefore, light incident from back surface 12 is scattered without being concentrated, and is emitted from light flux controlling member 4. A surface light source apparatus (1) and a display apparatus (6) include the light emitting apparatus (5).

Owner:ENPLAS CORP

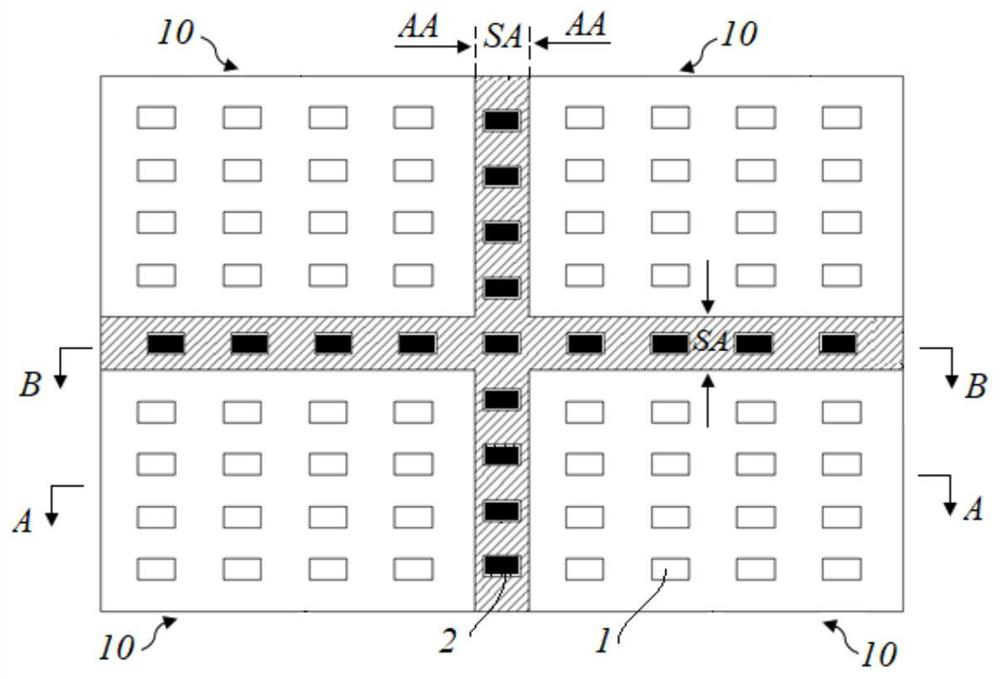

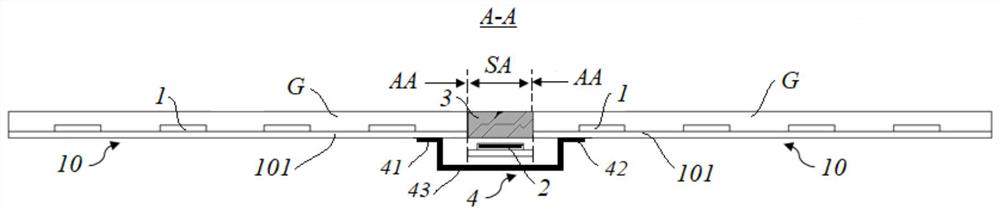

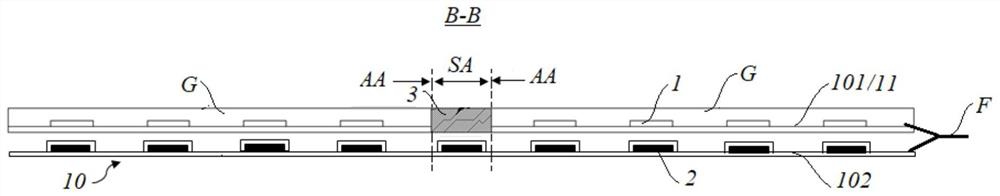

Light-emitting module, backlight module and display device

ActiveCN112863390AImprove lighting qualityAvoid it happening againElectrical apparatusIdentification meansDisplay deviceEngineering

The invention relates to a light-emitting module, a backlight module and a display device. The light-emitting module comprises at least two light-emitting panels which are spliced with each other, and further comprises a display area corresponding to each light-emitting panel; and a light supplementing area which corresponds to the area where at least two light-emitting panels are spliced with each other, wherein the light supplementing area comprises a light supplementing element. According to the light-emitting module, dark lines can be prevented from being generated at the splicing positions of the spliced light-emitting panels, and the light-emitting quality of the light-emitting module is improved.

Owner:SHANGHAI AVIC OPTOELECTRONICS

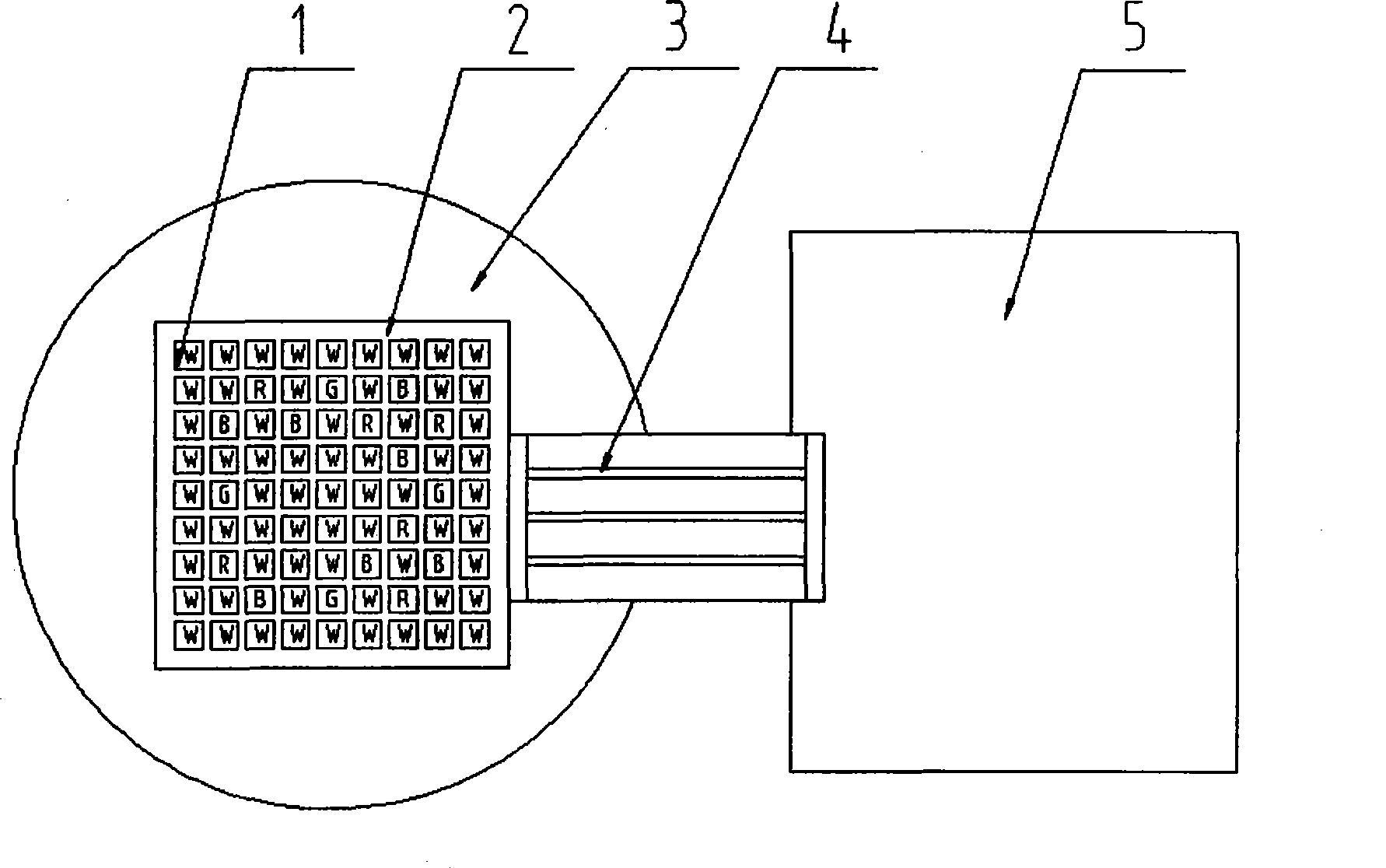

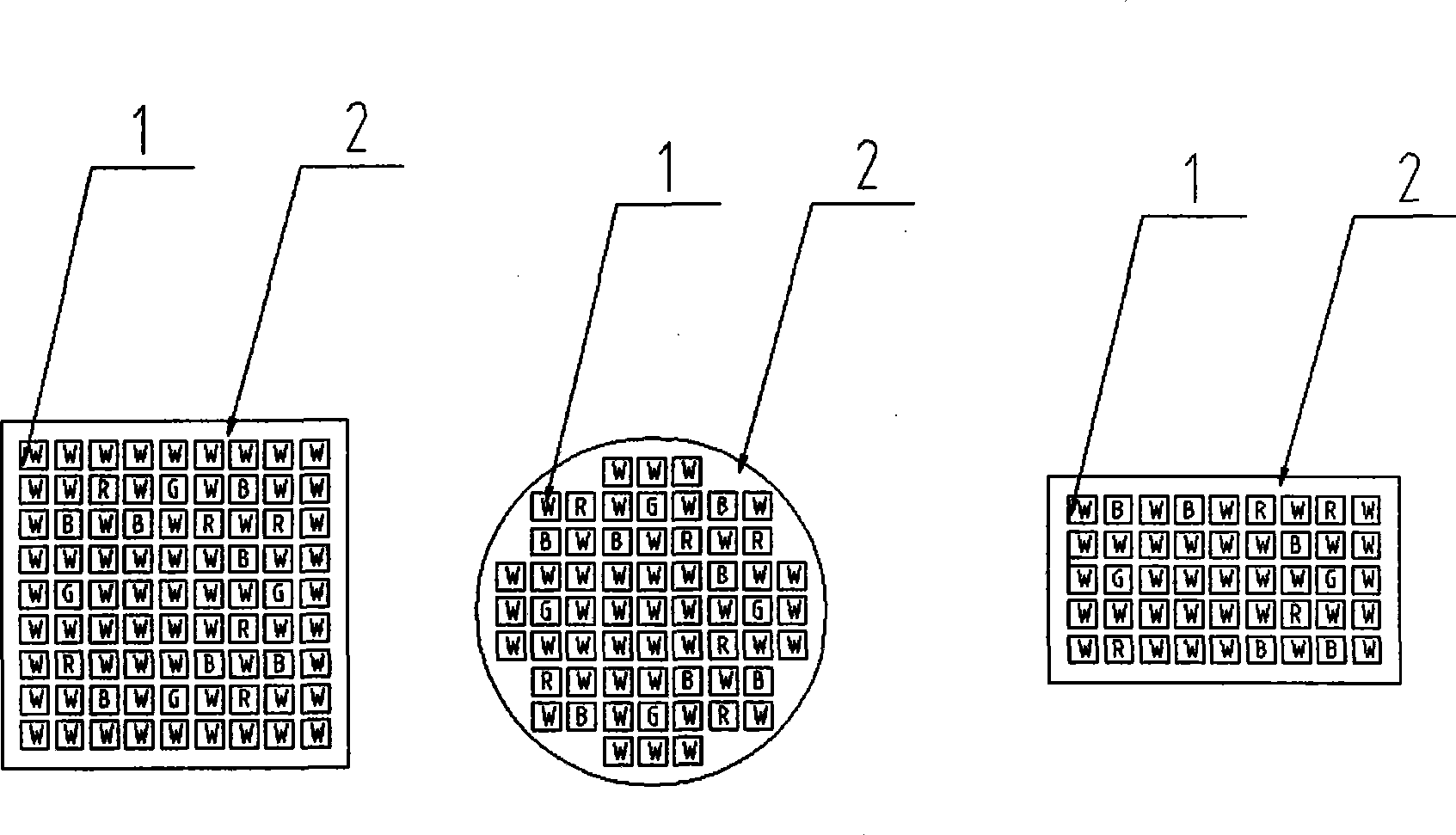

Color temperature adjustable integration high-power LED medical illumination chip

InactiveCN101382263AImprove lighting effectsLess prone to fatiguePlanar light sourcesPoint-like light sourceEngineeringOperation room

The invention provides an integrated large-power LED medical illumination chip which can be used as a light source with adjustable color temperature for medical operating illumination, inspection illumination, and whole illumination in an operating room; the chip mainly comprises an LED tube core, a substrate, a heat dissipation plate, a power switchover line and an LED driving controller; LED tube cores with different colors are integrated on the substrate of a circuit board by a certain array; the substrate is connected on the heat dissipation plate; according to different colors of LED tube cores, the integrated chip is divided into a plurality of groups which are used for power supply respectively. Brightness of various colors can be adjusted independently, the integrated large power LED chip can be adjusted in the range of 3500K-6500K to have any color temperature and brightness according to the mixed color proportion of the LED tube core series of different colors, the chip can be used for illumination in operating rooms, inspection rooms, environment with special color temperature requirement and the like, is especially applicable for medical illumination and the like, and is beneficial for improving the medical illumination quality and reducing the medical negligence.

Owner:重庆邦桥科技有限公司

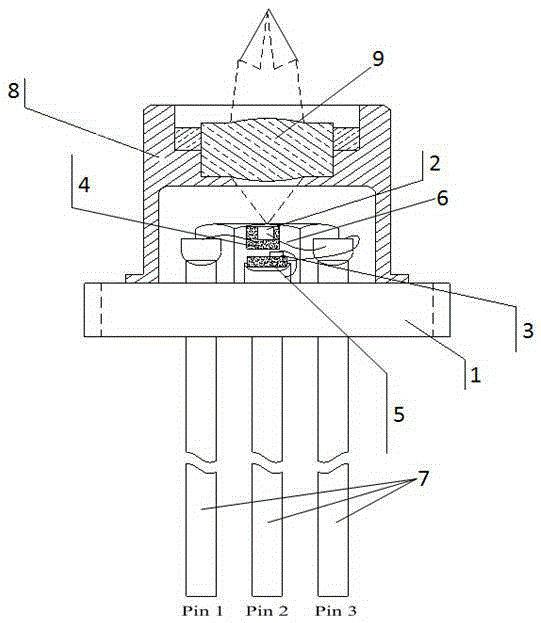

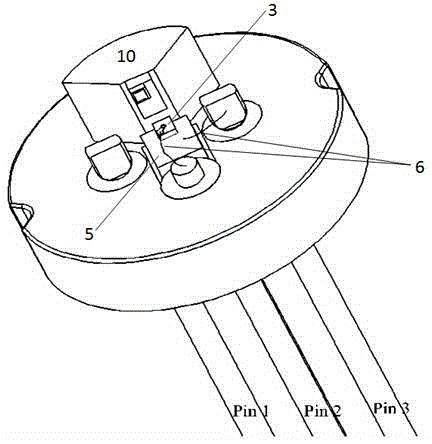

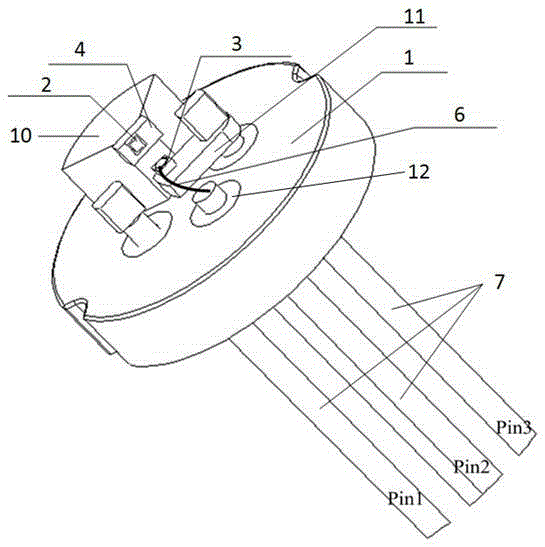

Transistor outline (TO)-CAN packaged semiconductor laser and fabrication method thereof

InactiveCN105261929ALow costAvoid the risk of easy sheddingLaser detailsSemiconductor lasersSemiconductor packageSemiconductor chip

The invention proposes a transistor outline (TO)-CAN packaged semiconductor laser and a fabrication method thereof. The TO-CAN packaged semiconductor laser comprises a TO tube base, a semiconductor laser chip, a backlight detector chip, a gold bonding wire, pins and a heat sink block, wherein the heat sink block is arranged on the upper surface of the TO tube base, the pins are fixed on the TO tube base in an insulation way, the upper end of at least one pin protrudes out of the upper surface of the TO tube base, the semiconductor laser chip is fixed on the surface of the heat sink block, the upper part of the pin protruding out of the upper surface of the TO tube base is connected with a support table, and the backlight detector chip is arranged on the support table and below the semiconductor laser chip. In the TO-CAN packaged semiconductor laser, the backlight detector chip is arranged on the support table integrated and connected with the pins, thus, an independent cushion block is omitted, and the material cost of the cushion block is saved; and moreover, the gold wire bonding process between the backlight detector chip and the cushion block in one time is omitted, the gold wire bonding process is simplified, the gold wire bonding cost is saved, and the stability of a laser product is improved.

Owner:武汉海赛姆光电技术有限公司

Integrated medical endoscope system

The invention belongs to the technical field of medical instruments, and discloses an integrated medical endoscope system which comprises an endoscope catheter of a step type sleeve tube structure, a crescent LED illuminating system, an optical system, a CMOS system and an image processing unit. The crescent LED illuminating system, the optical system, the CMOS image pick-up system and the image processing unit are arranged at the tail end of the endoscope catheter in sequence. The crescent LED illuminating system embedded in the tail end of the endoscope catheter is composed of a copper substrate and SMD LEDs arranged on the copper substrate. The integrated medical endoscope system overcomes the defects that original equipment is large in size and poor in imaging quality and is provided with many wires, wireless emission and receiving are adopted, the structure is simple, the operation is convenient and fast, a digital image processing system is adopted, full-high-definition 1080P output is supported, the image definition is high, and the higher dynamic range and better depth information can be obtained.

Owner:王刚

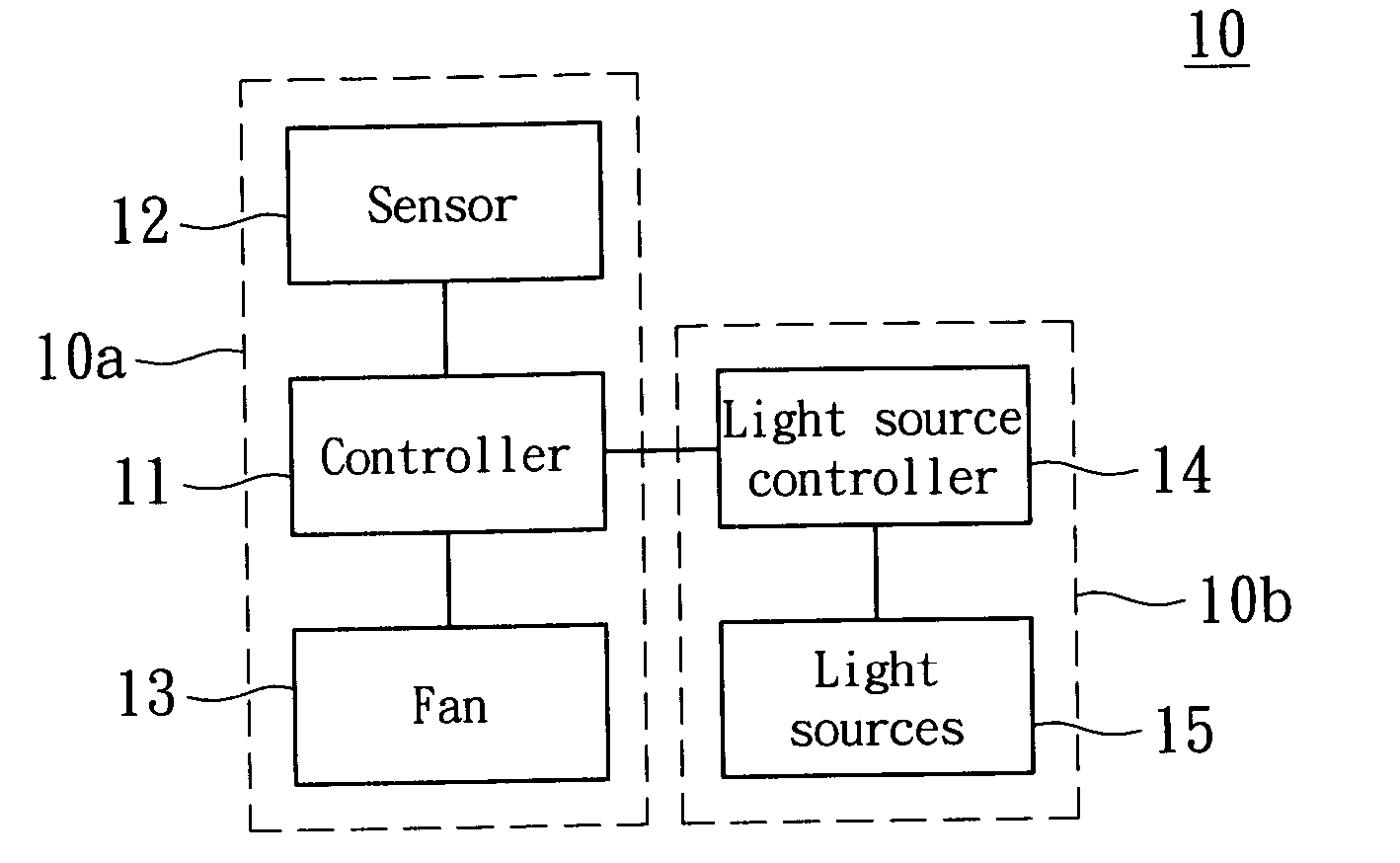

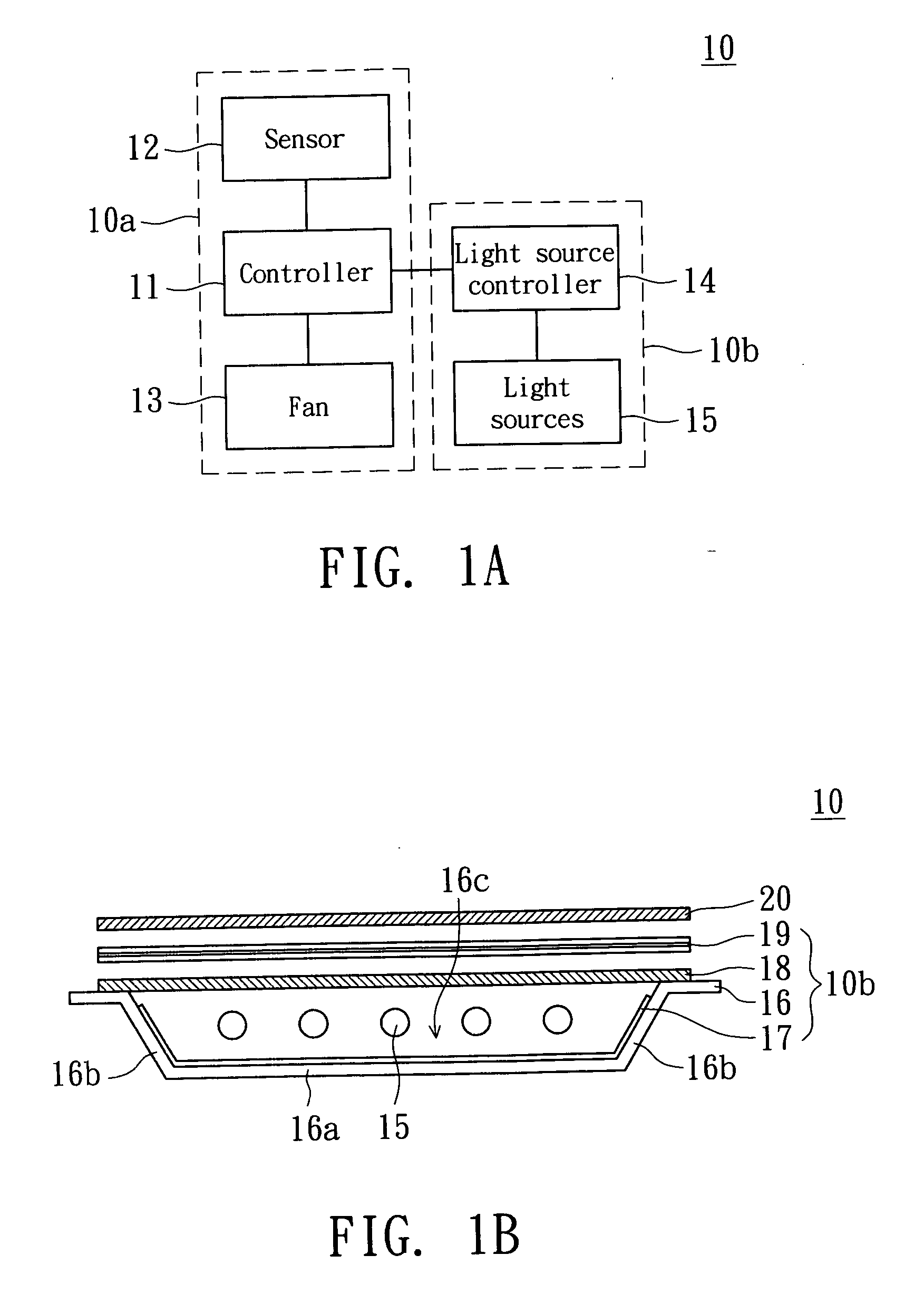

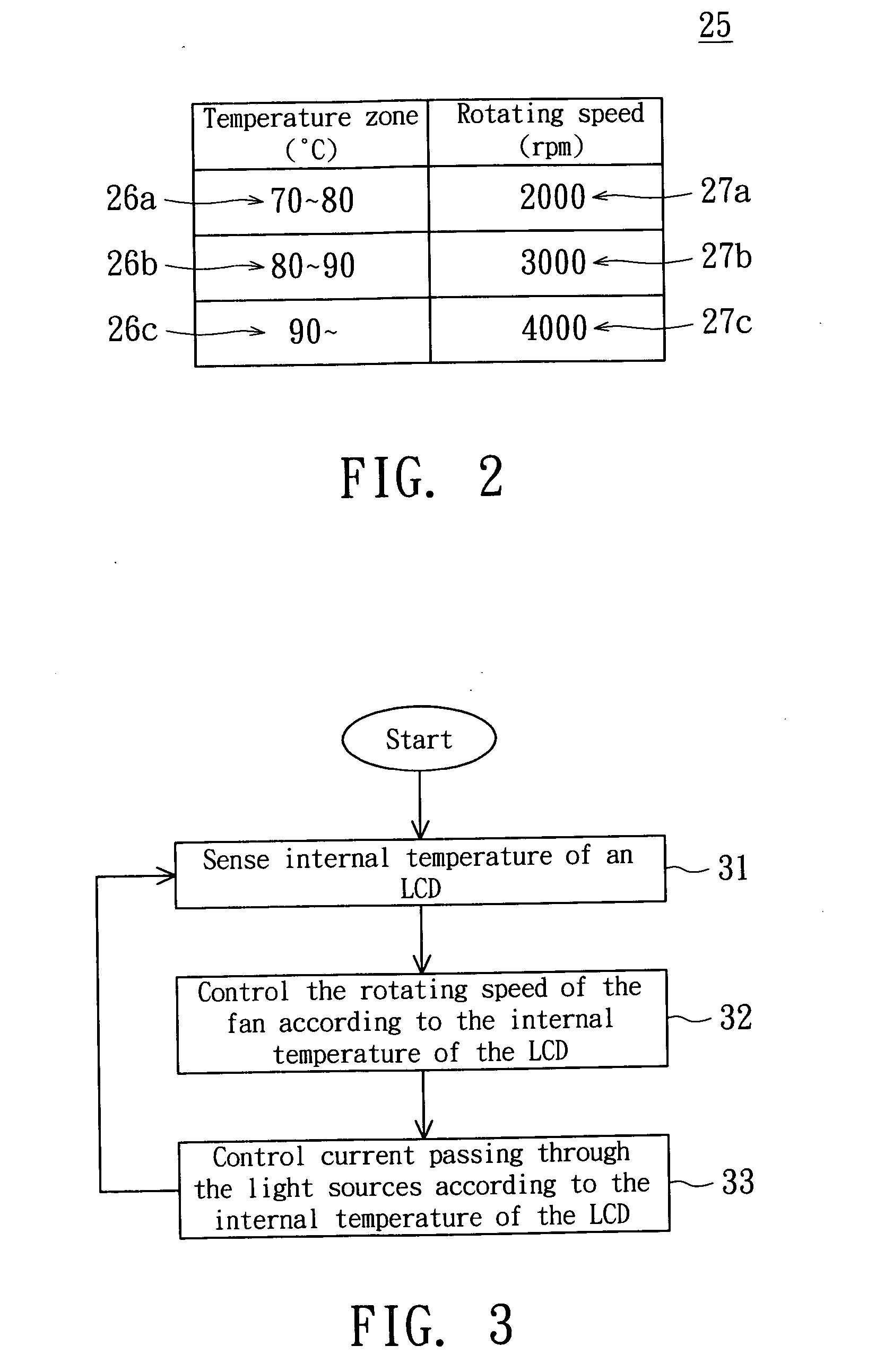

Liquid crystal display and method for adjusting temperature thereof

InactiveUS20060192750A1Improved heat outputImprove lighting qualityStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display (LCD) includes a backlight module and a heat dissipation device. The backlight module includes a frame, a reflector and several light sources. The reflector is disposed on the frame. The light sources disposed above the reflector. The heat dissipation device includes a fan, a sensor and a controller. The sensor is for sensing internal temperature of the LCD. The controller is connected to the fan and is for controlling the rotating speed of the fan according to the internal temperature of the LCD.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com