Light emitting apparatus, surface light source apparatus and display apparatus

A light-emitting device and light-emitting element technology, applied in the field of surface light source devices, display devices, and light-emitting devices, can solve the problems of reduced lighting quality and uneven illuminance of the illuminated surface, and achieve high-quality lighting quality, uniform illuminance, and suppression of uneven illuminance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0055] [Overall shape of surface light source device]

[0056] Figure 4 It is a plan view of the surface light source device constituting the display device according to Embodiment 1 based on the above idea. In addition, in Figure 4 Illuminated components such as a liquid crystal display panel are not shown in the figure. Figure 5 It is cut along the X1-X1 line Figure 4 The resulting cross-sectional view of the display device. In addition, the surface light source device of this embodiment is an example applied to a liquid crystal display panel.

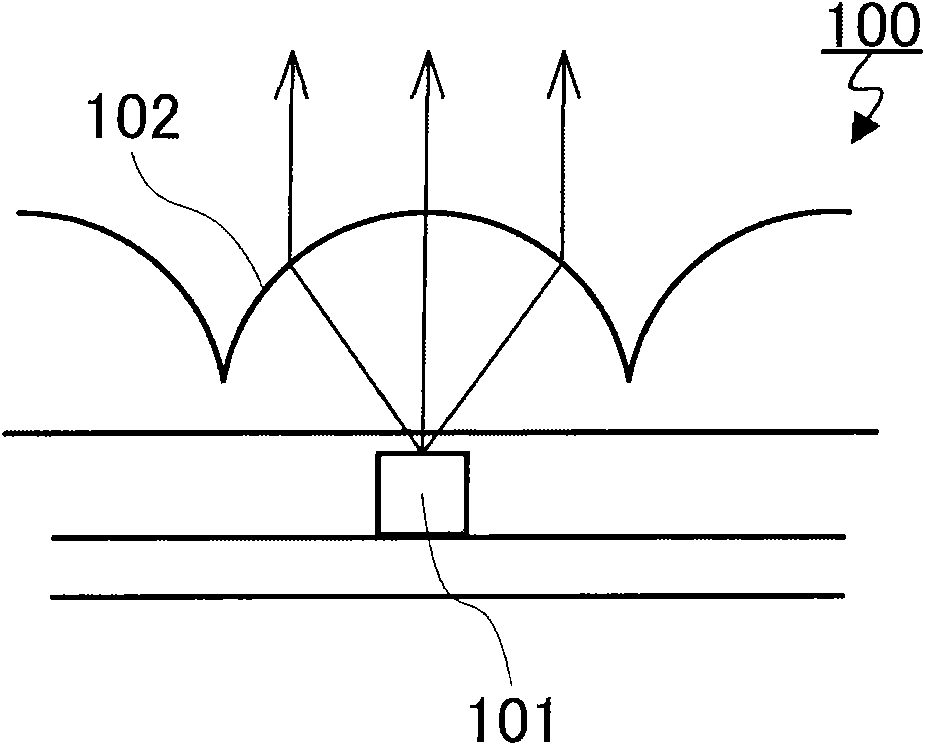

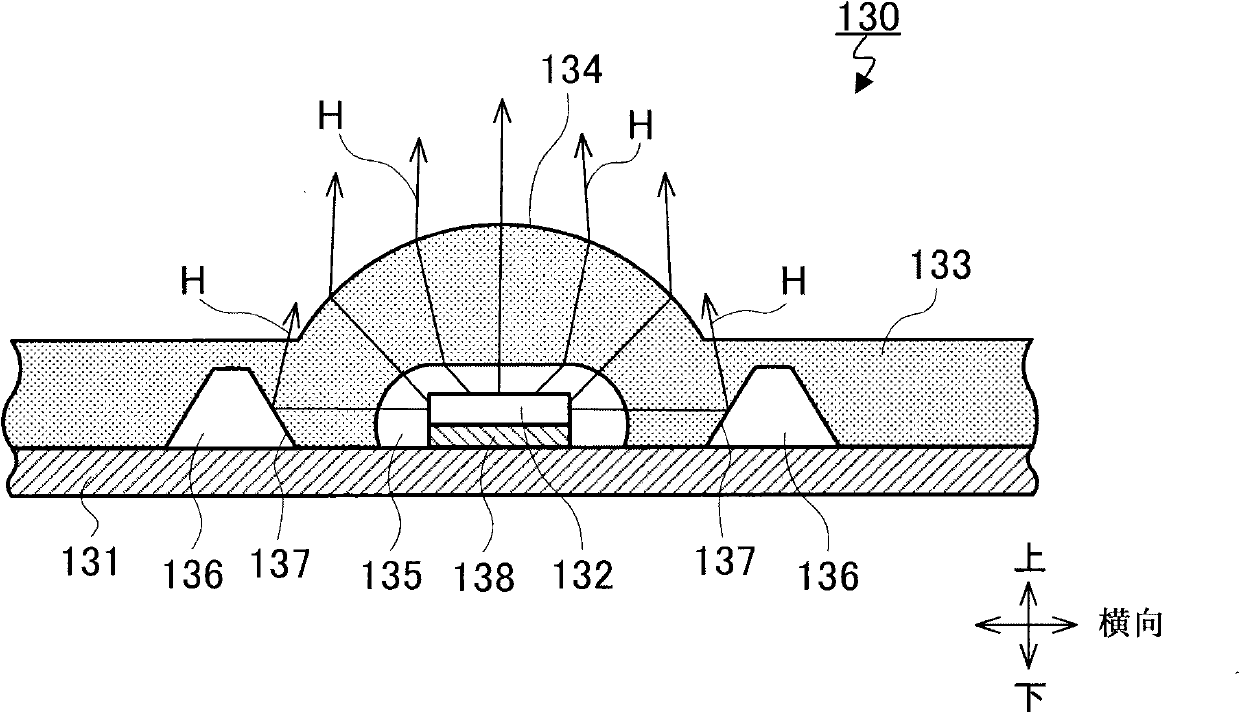

[0057] Such as Figure 4 As shown, the surface light source device 1 includes: a plate-shaped light diffusion member 2 , a light emitting element 3 as a point light source, and a light beam control member 4 . The light diffusion member 2 is arranged on the back surface of a member to be illuminated, such as a liquid crystal display panel, and has substantially the same shape as the member to be illuminated. The plurality o...

Embodiment approach 2

[0116] [Overall shape of the beam control part]

[0117] Figure 17 It is a cross-sectional view of a light flux control member of the light emitting device according to the second embodiment. Figure 17 (a) is a cross-sectional view of the beam control part, Figure 17 (b) is Figure 17 An enlarged view of part C shown in (a). In addition, in Figure 17 in, for with Figure 7 Common structural parts are given the same reference numerals, and descriptions thereof are omitted.

[0118] Use the beam control component 40 instead Figure 4 to Figure 11 The beam control component 4.

[0119] Figure 17 The light beam control member 40 shown in (a) with Figure 7 Compared with the light flux controlling member 4 shown in (a), the shape of the lattice-shaped convex portion 43 is different from the shape of the lattice-shaped convex portion 13 .

[0120] The lattice-shaped protrusions 43 are formed on the back surface 12 of the light beam control member 40, and the lattice-s...

Embodiment approach 3

[0128] [Overall shape of the beam control part]

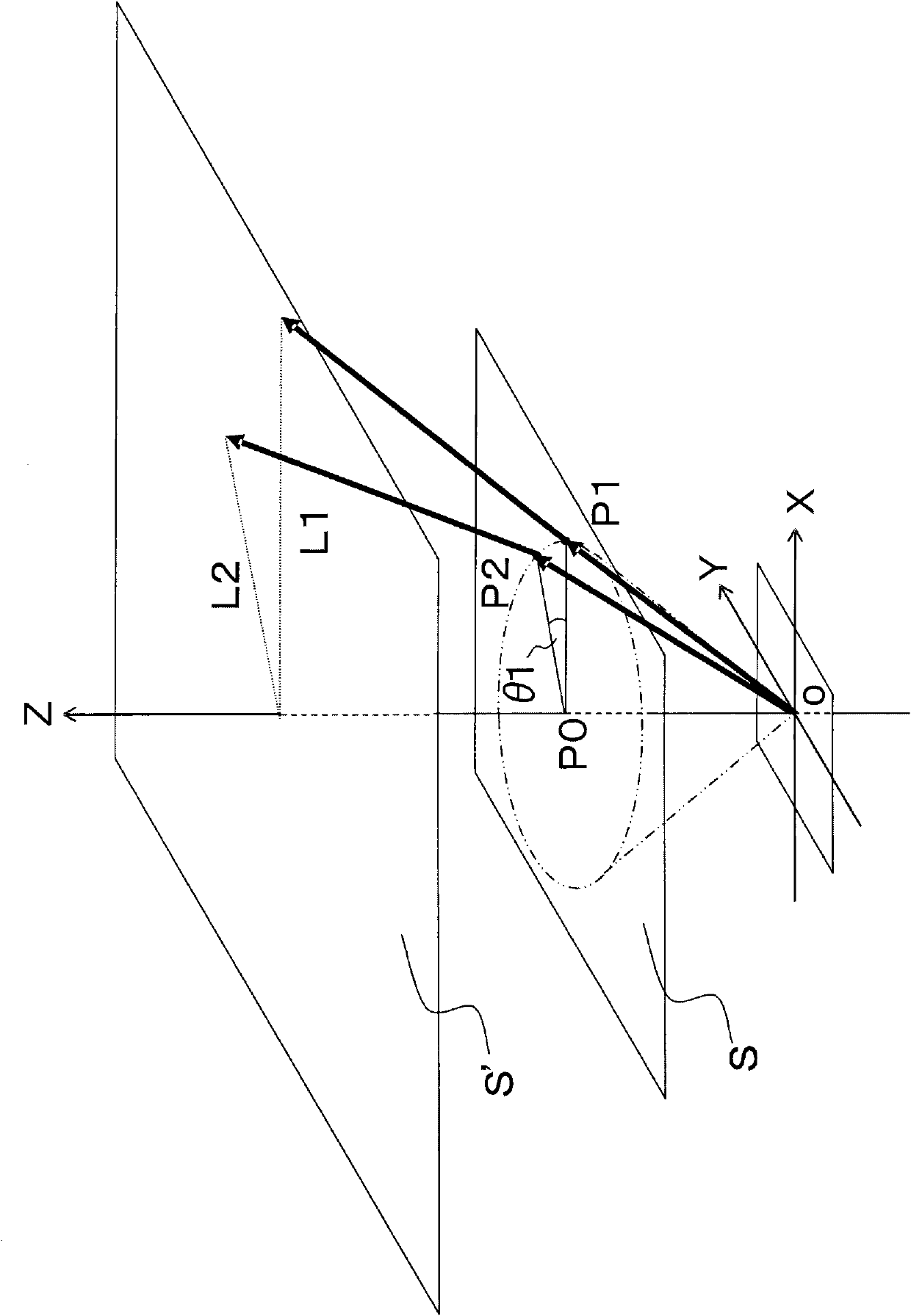

[0129] In Embodiments 1 and 2 described above, the invention in which the light incident on the back surface 12 is scattered by providing the lattice-like protrusions 13 (43) on the back surface 12 of the light flux control member 4 (40) was described.

[0130] The present inventors found that by further improving the shape of the lattice-shaped convex portion 13 , the effect of being able to retroreflect the light reflected by the light diffusion member 2 and increasing the amount of the retroreflected light is also obtained.

[0131] In Embodiment 3, an invention of the shape of the lattice-shaped convex portion 13 for increasing the amount of retroreflected light will be described.

[0132] Figure 19 is a cross-sectional view of the light flux control member of the light emitting device of the present embodiment. Figure 19 (a) is an overall sectional view of the beam control part, Figure 19 (b) is Figure 19 An enlarg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com