Light source unit using light emitting element

A light-emitting element and light source unit technology, which is applied to semiconductor devices, light sources, electric light sources, etc. Effects of suppressing the decrease of luminous intensity, increasing the contact area, and cooling with high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

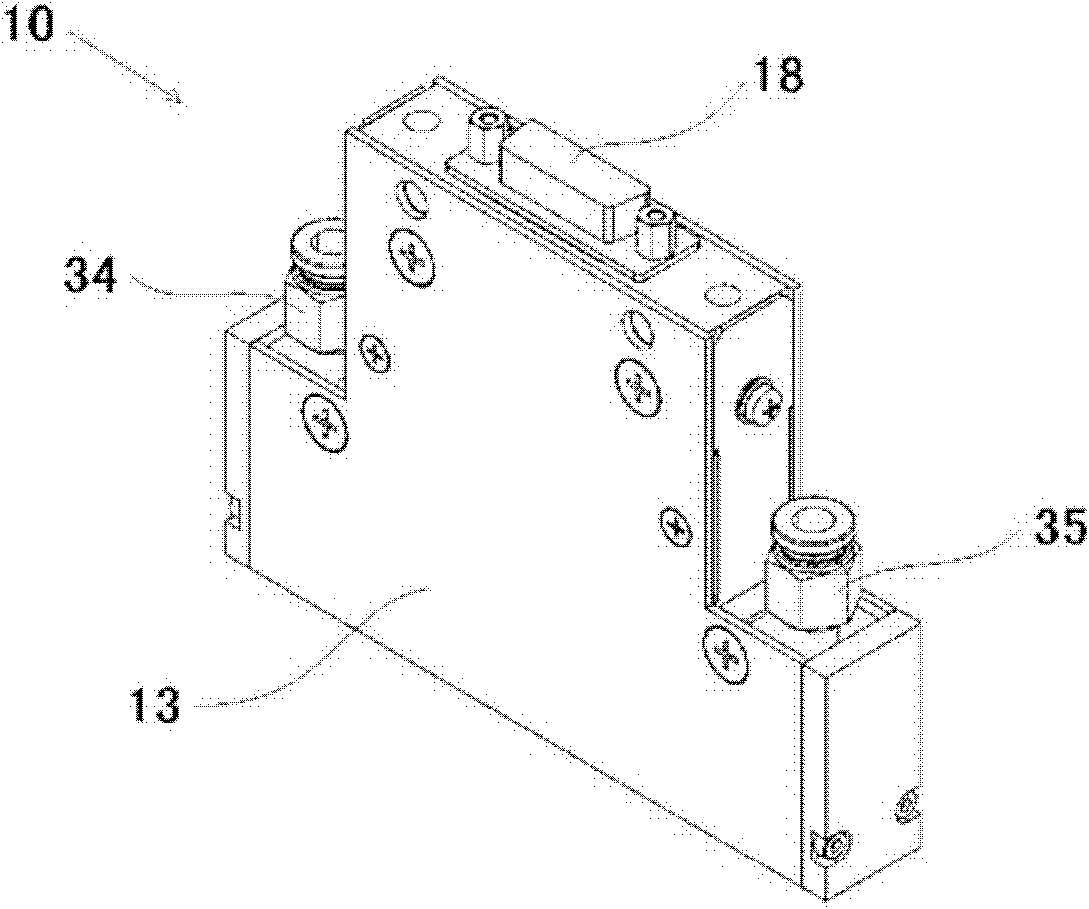

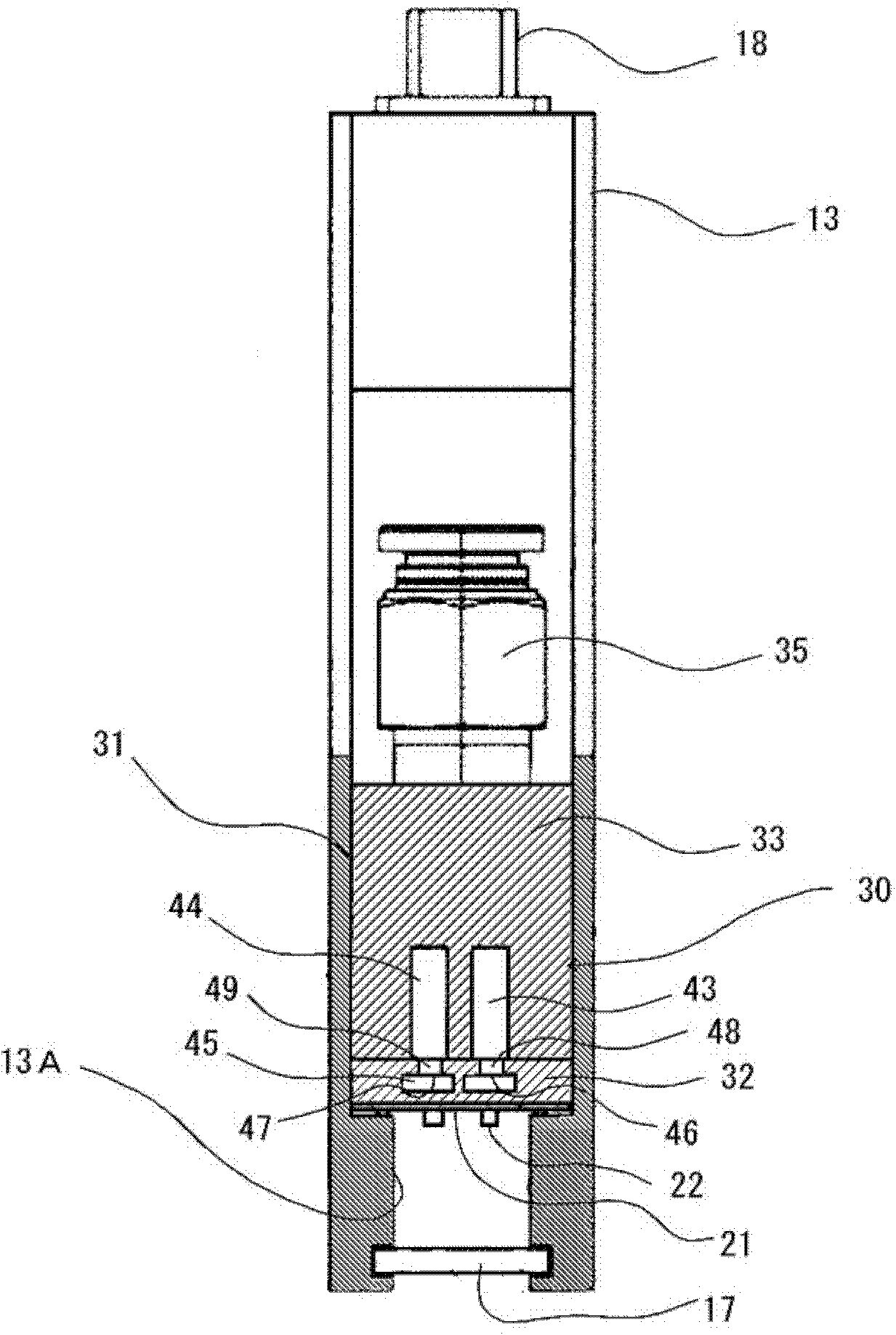

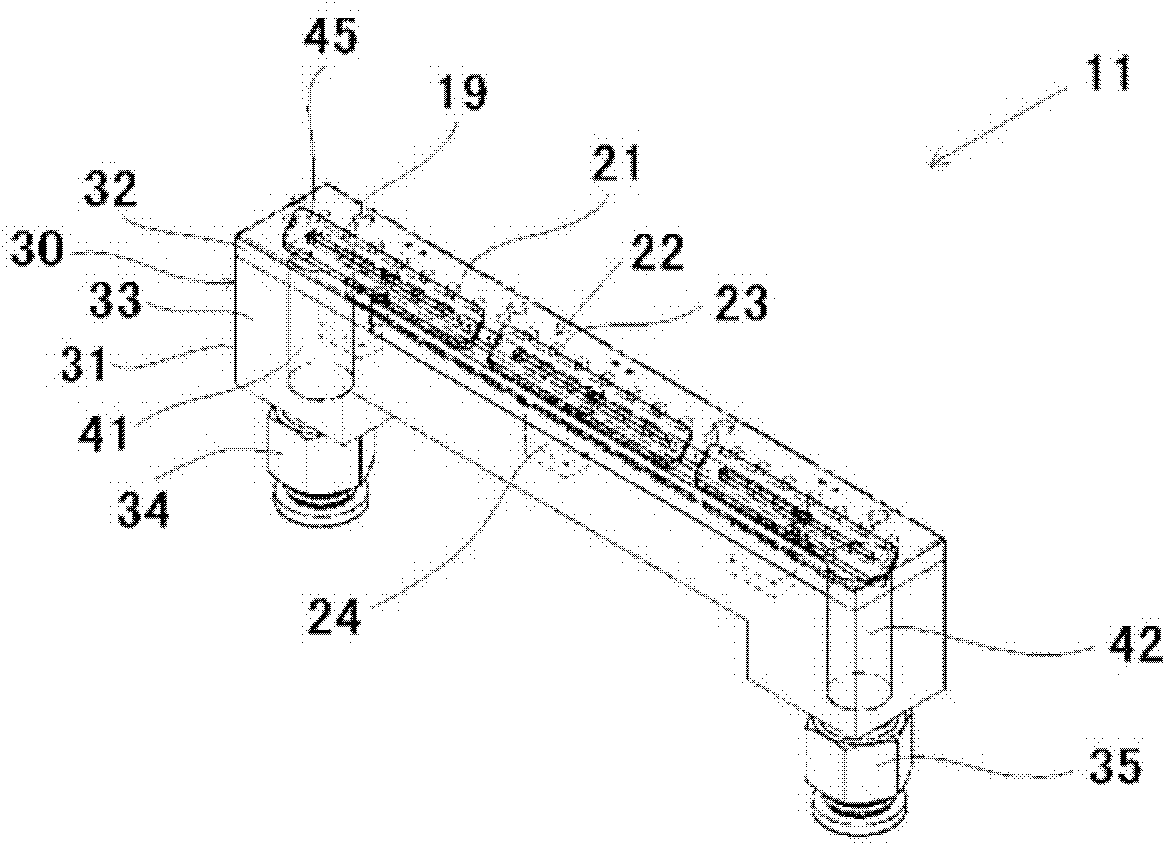

[0098] made with figure 1 A light-emitting element light source unit (hereinafter, also referred to as “light-emitting element light source unit ( 1 )”) having the structure of the example.

[0099] The substrate constituting the light-emitting element light source unit (1) is composed of 48 light-emitting parts composed of one LED element with a peak emission wavelength of 365nm arranged in two rows at a pitch of 4.6mm, with a width of 16mm, a length of 113mm, and a thickness of 0.6 mm. mm aluminum nitride construction.

[0100] In addition, the heat sink has a heat sink body made of copper, and has a circular cross-sectional shape (cross-sectional area of 12mm 2 ) supply path; the cross-sectional shape is a rectangular supply flow path with a width of 2.5mm and a height of 5mm; the cross-sectional shape is circular (the cross-sectional area is 3mm 2 ) inflow path; the cross-sectional shape is a rectangular cooling flow path with a width of 3mm and a height of 1mm; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com