Optical diaphragm, light guide plate, combination method thereof and backlight module

A technology of optical diaphragm and backlight module, which is applied in the direction of optics, light guides, optical components, etc., and can solve problems such as poor assembly, diaphragm displacement, and affecting the display effect of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

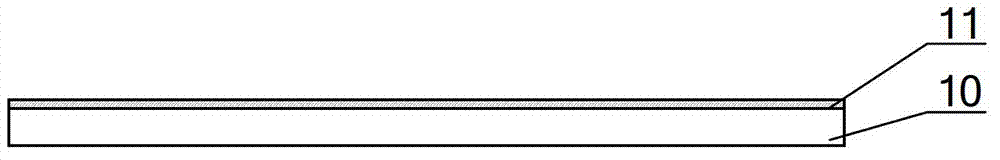

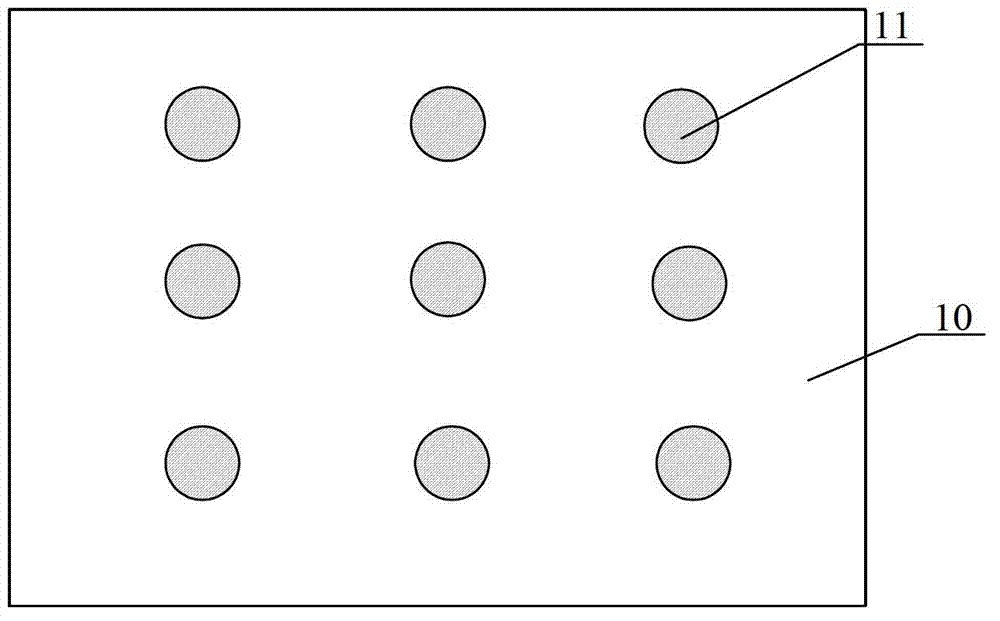

[0036] An embodiment of the present invention provides an optical film 10, at least one surface of the optical film 10 is provided with a magnetic film layer 11 on part or all of the area; the magnetic film layer 11 is magnetic and made of a transparent magnetic material.

[0037] Such as figure 1 As shown, the magnetic film layer 11 can be covered on the entire surface of the optical film 10, or can be covered on the periphery of the optical film 10, or the middle area, such as figure 2 As shown, there are 9 circular magnetic film layers 11 arranged in the middle area of the optical film 10, which is called 9-point method, and similarly there are 5-point method and 6-point method.

[0038] In the embodiment of the present invention, a magnetic film layer 11 is provided on the optical film 10, aiming to make the adjacent magnetic film layers 11 in the film to be combined mutually Attraction, so that the membranes to be combined are adsorbed together. Therefore, the optica...

Embodiment 2

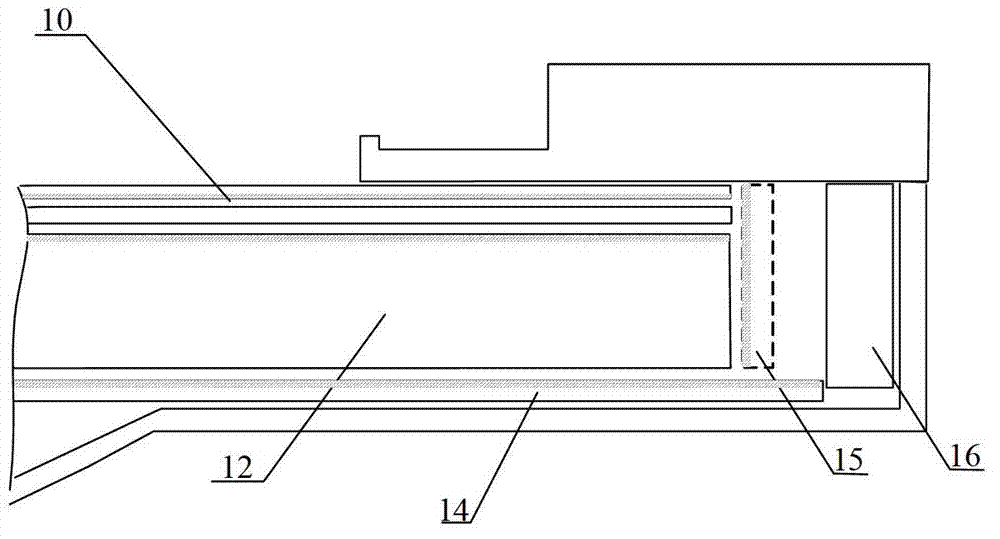

[0067] The embodiment of the present invention also provides a combination method of the light guide plate and the optical film in the backlight module, such as Figure 5 As shown, the method includes:

[0068] 101. A magnetic film layer is provided, and the direction of the magnetic field of the magnetic film layer causes mutual attraction between the light guide plate and the optical film, wherein,

[0069] When the optical films to be combined are all located on one side of the light guide plate, a magnetic film layer is respectively provided on at least the light guide plate and the optical film farthest from the light guide plate,

[0070] When the optical films to be combined are respectively located on both sides of the light guide plate, at least magnetic film layers are respectively provided on the two optical films that are farthest apart;

[0071] 102 . Bond each optical film in the backlight module and the light guide plate together through the magnetic attraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com