Patents

Literature

35results about How to "Increase emission rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

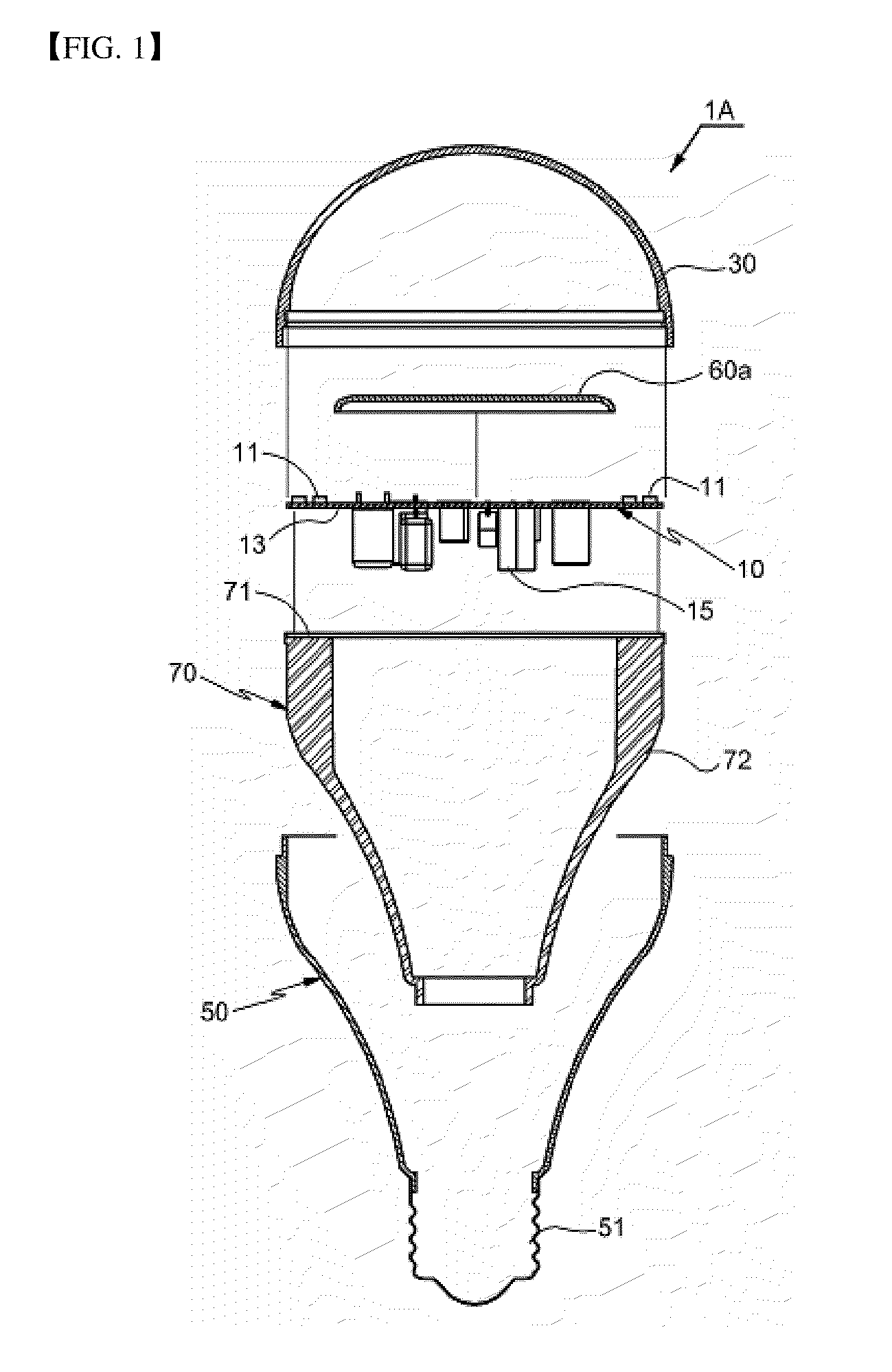

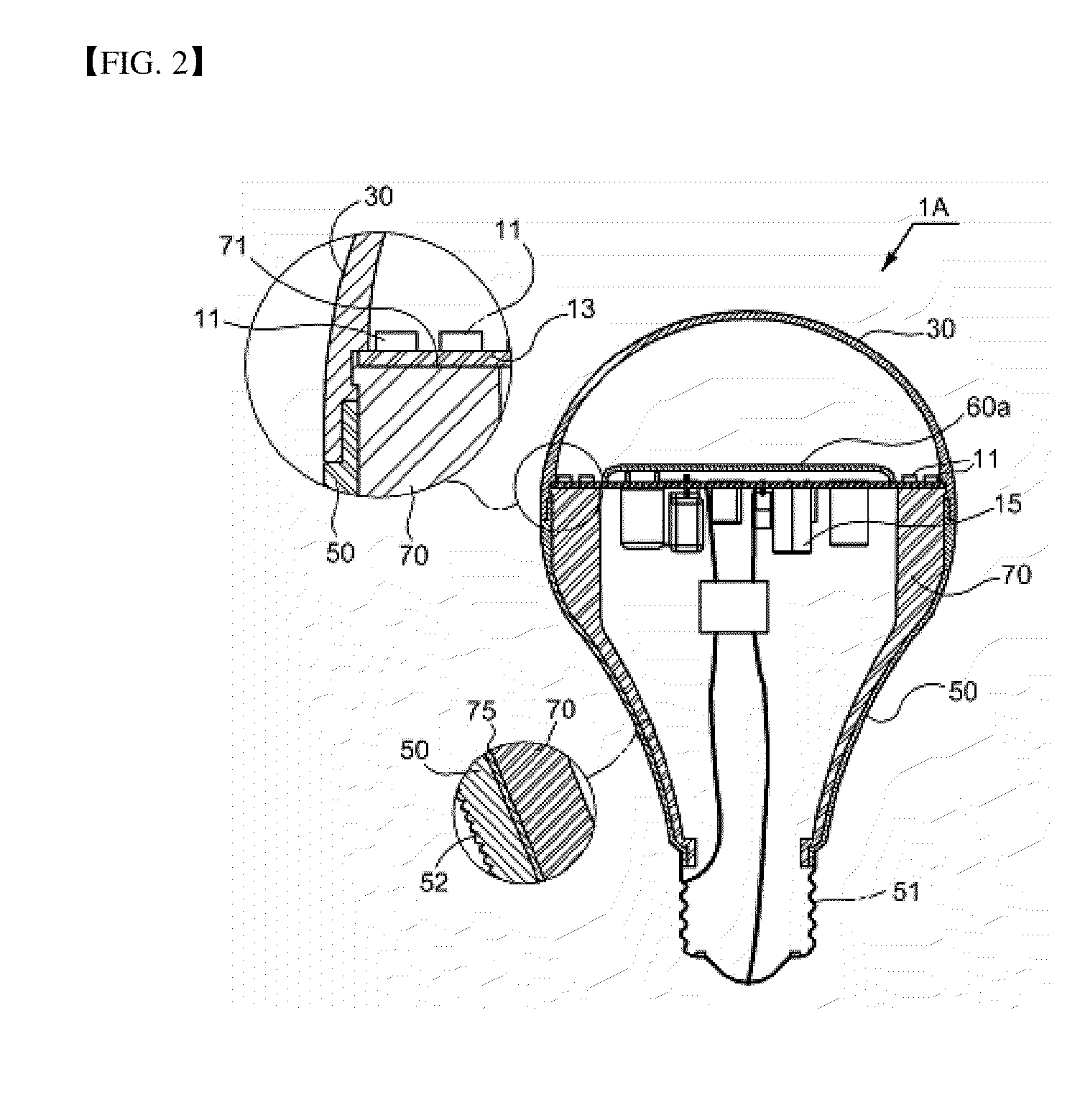

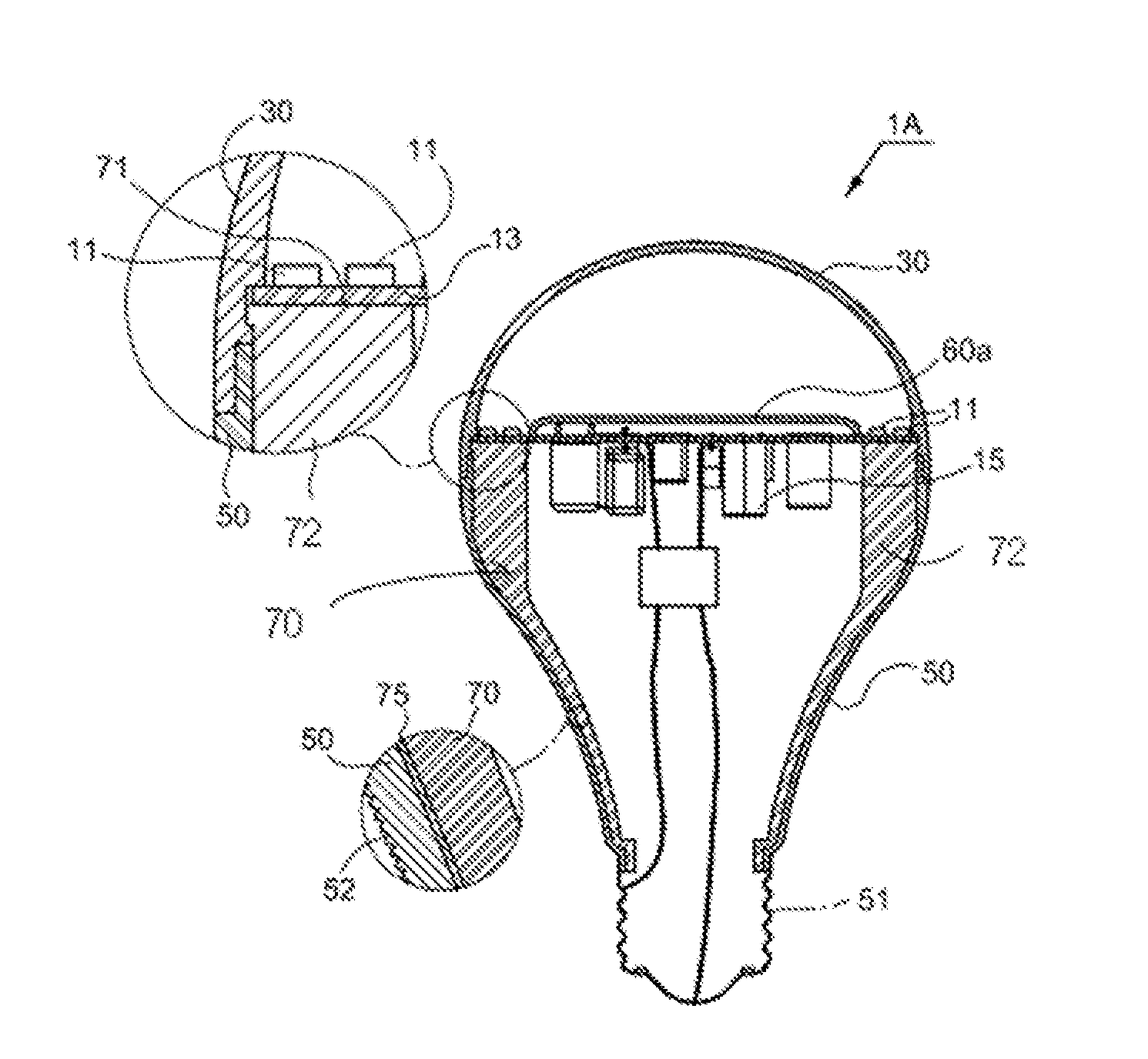

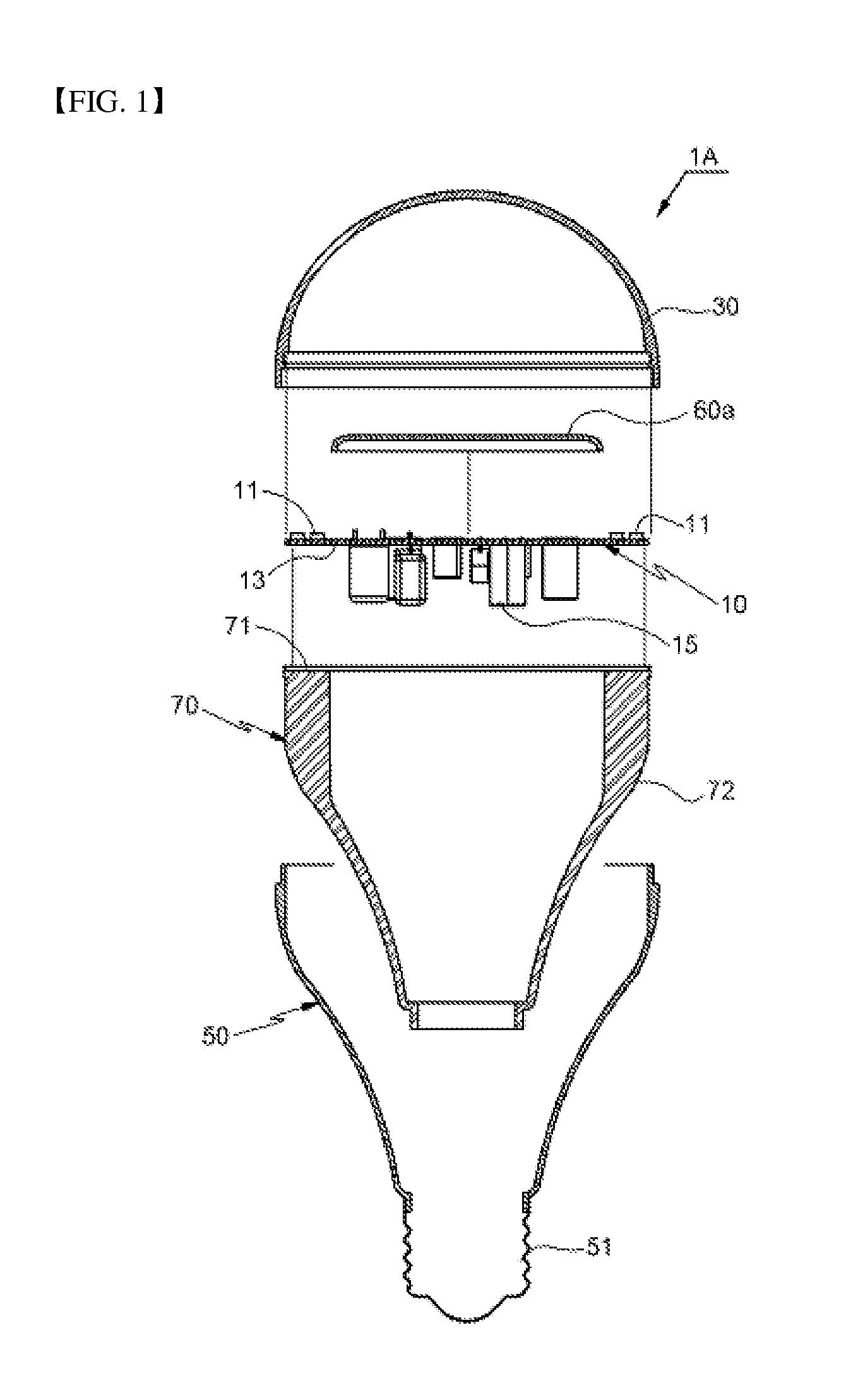

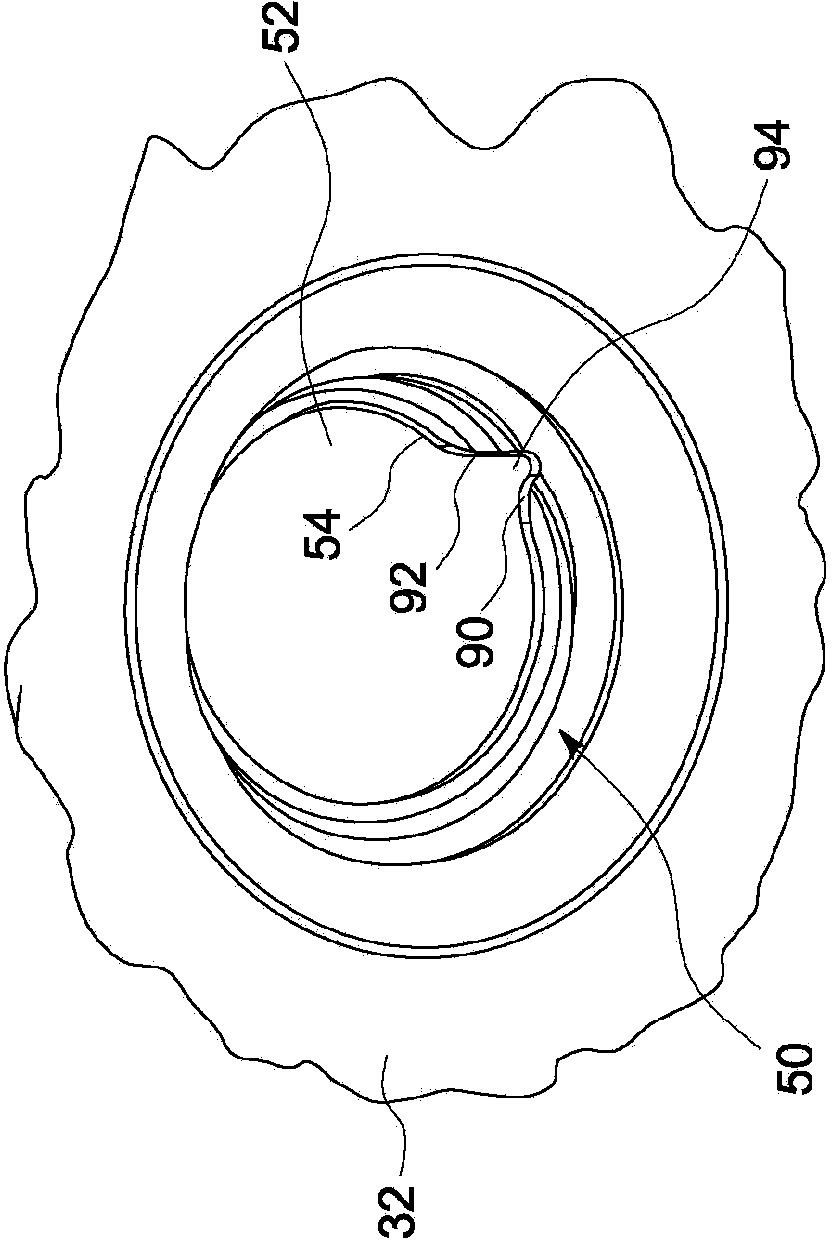

LED lamp

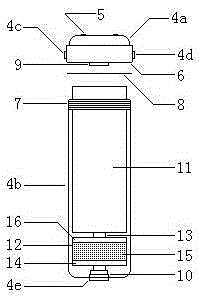

InactiveUS20110101861A1Increase emission rateConstant gainPoint-like light sourceElongate light sourcesEngineeringPolycarbonate

The present invention relates to an LED lamp in which, because the lamp has therein a heat dissipation transfer member and the power source base thereof is made of materials including polycarbonate, etc. with a high emission rate of radiation so as to enhance its surface heat dissipation constant, the power source base has sufficient heat dissipation performance and, thus, a separate insulation circuit is not necessary, thereby improving reliability and productivity of the lamp as well as reducing the cost of manufacturing.To this end, the present invention provides an LED lamp comprising one or more LEDs mounted on a PCB, a floodlight cover that transmits light from the LEDs, and a power source base coupled to the floodlight cover and having a terminal at one end thereof, wherein the power source base is made of an insulation material; and the LED lamp also comprises a heat dissipation transfer member that has a heat sink in contact with the PCB on which the LEDs are mounted, and is formed and installed so as to overlap with and be in tight contact with the inner face of either the power source base or the floodlight cover or both.

Owner:YOO YOUNG HO +1

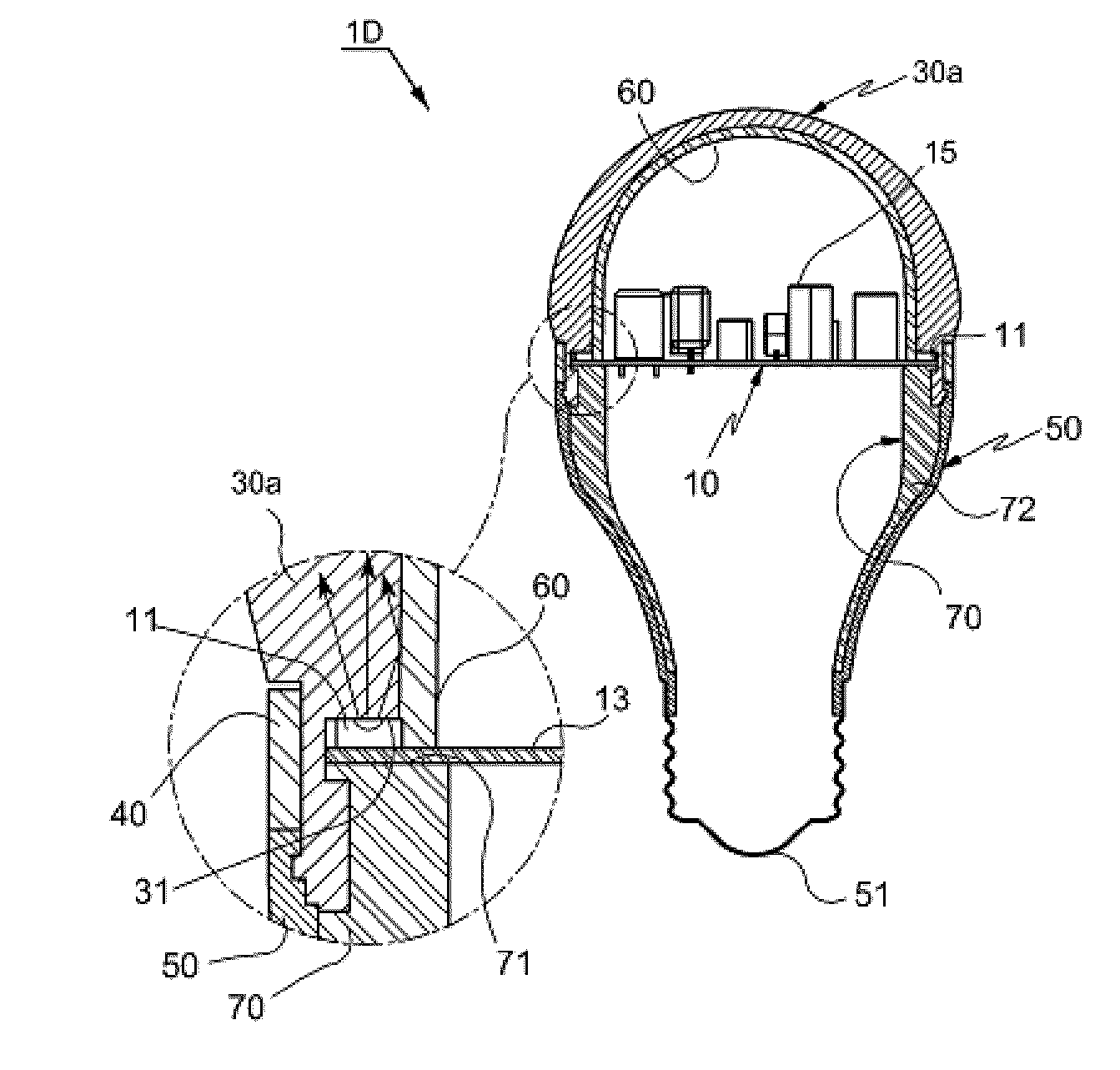

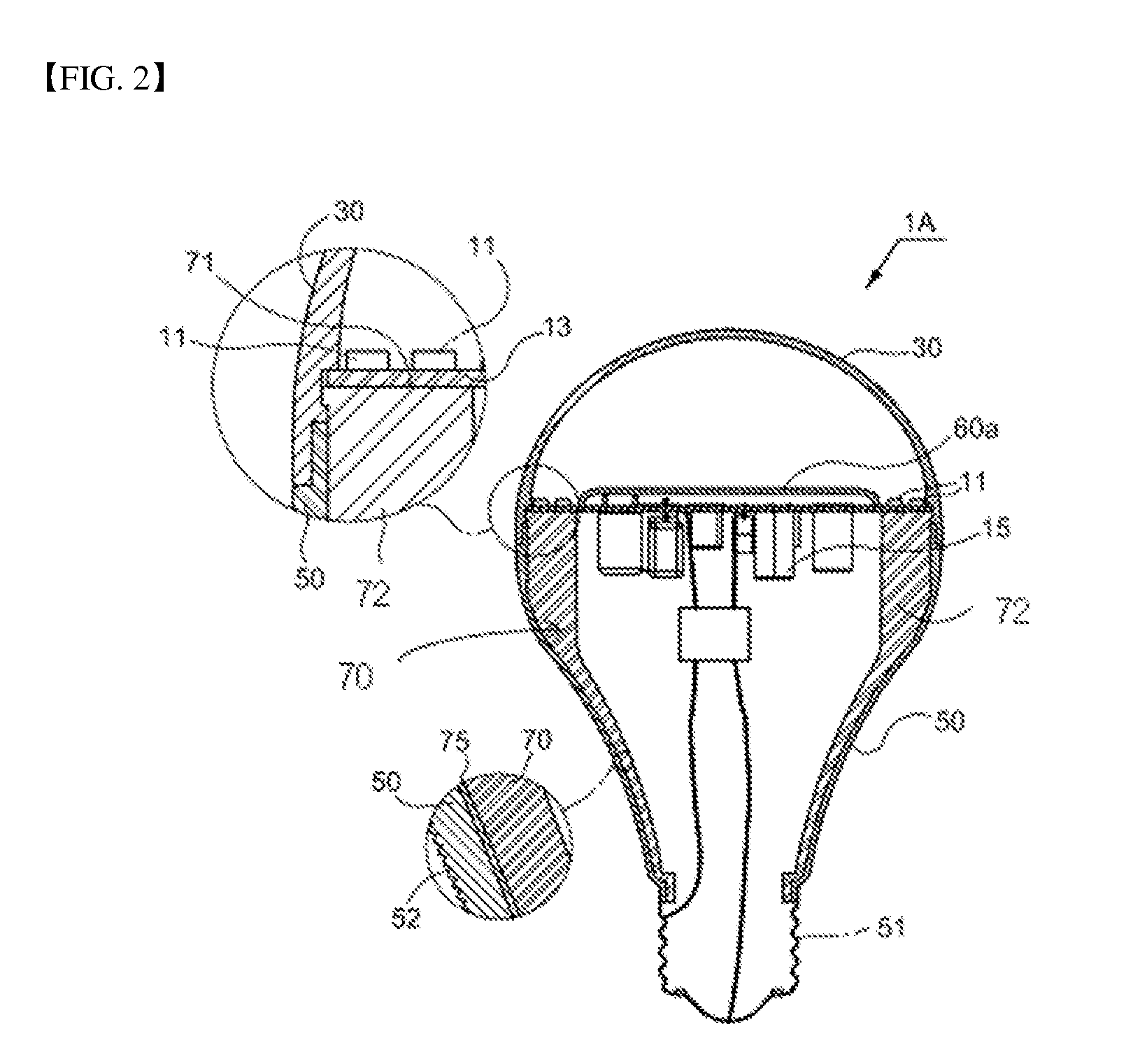

LED lamp with heat dissipation member

InactiveUS20110181183A1Increase emission rateSufficient heat dissipation performancePoint-like light sourceElongate light sourcesSurface layerEngineering

An LED lamp includes at least one LED mounted on a PCB, a floodlight cover, a power source base, and a heat dissipation transfer member. The floodlight cover transmits light from the at least one LED and has an inner face facing an upper inner space of the LED lamp. The power source base is coupled to a terminal at one end of the power source base and is coupled to the floodlight cover at the other end of the power source base. The power source base is made of an insulation material and forms a surface layer of the LED lamp from the one end of the power source base to the other end of the power source base. The power source base has an inner face facing a lower inner space of the LED lamp. The heat dissipation transfer member has a heat sink being in contact with the PCB, and a main body formed along with an entire surface of at least one of the inner face of the power source base and the inner face of the floodlight cover. The main body of the heat dissipation transfer member is faced with the entire surface without any space therebetween.

Owner:YOO YOUNG HO +1

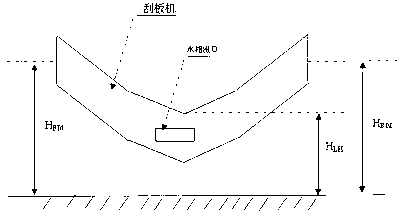

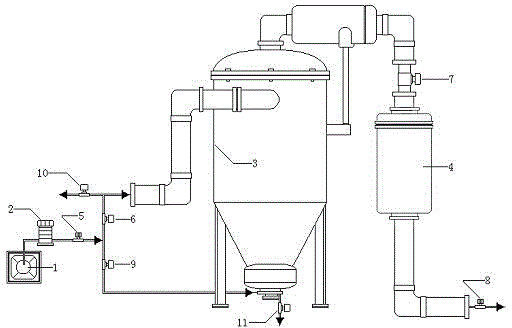

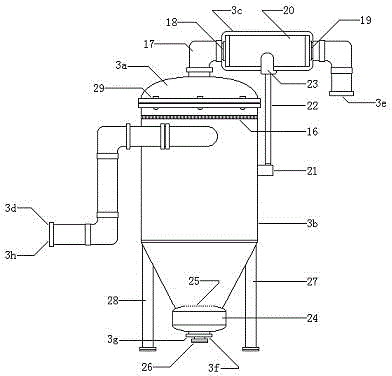

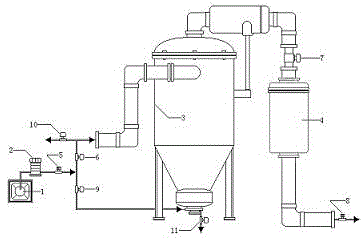

Treatment method of high concentration waste alkali solution

ActiveCN102877351AOvercome the explosionLower emission ratePulp liquors combustionHigh concentrationCyclohexanone

The invention relates to a treatment method of a high concentration waste alkali solution. The method includes: spraying waste alkali into an alkali recovery furnace, using a fuel to support combustion, combusting the waste alkali in the presence of an oxygen-containing gas to generate steam as a by-product, conducting electric precipitation to recover dry alkali ash, and making a molten material formed in combustion flow out of a chute at the furnace bottom. The method is characterized by: using a nozzle to jet one or several bundles of high-speed fluids so as to impact, cool and break the molten material from the chute into granular or powdered coarse alkali; bringing the granular or powdered coarse alkali into a cylindrical pipeline, and making the coarse alkali enter solid-liquid separation equipment selected from a scraper or a screw conveyor under the driving of a water flow, and separating a solid phase so as to obtain moisture-containing coarse alkali; and bringing the water phase separated by the solid-liquid separation equipment into a trough, a water tank or other intermediate containers, and then performing pressurization to circulate the water phase to the cylindrical pipeline and the nozzle. The method provided in the invention has the advantages of being able to completely recover the molten material generated by waste alkali combustion and generating no wastewater, thus being able to be used for cyclohexanone and other chemical industrial production and having good environmental protection significance and economic benefits.

Owner:CHINA PETROCHEMICAL CORP

Direct-type fuel cell and direct-type fuel cell system

InactiveCN1988237AReduce crossing phenomenonReduce usageCell electrodesFuel cell auxillariesHigh concentrationFuel cells

A direct-type fuel cell having excellent power generating characteristics even under operating conditions utilizing a high concentration fuel at low air flow rates. The anode includes an anode-side diffusion layer that faces the fuel flow channel and an anode-side catalyst layer in contact with the electrolyte membrane. The cathode includes a cathode-side diffusion layer that faces the air flow channel and a cathode-side catalyst layer in contact with the electrolyte membrane. A surface area of the anode-side diffusion layer facing the fuel flow channel or both a surface area of the anode-side diffusion layer facing the fuel flow channel and a surface area of the cathode-side diffusion layer facing the air flow channel have a critical surface tension of penetrating wettability of 22 to 40 mN / m.

Owner:PANASONIC CORP

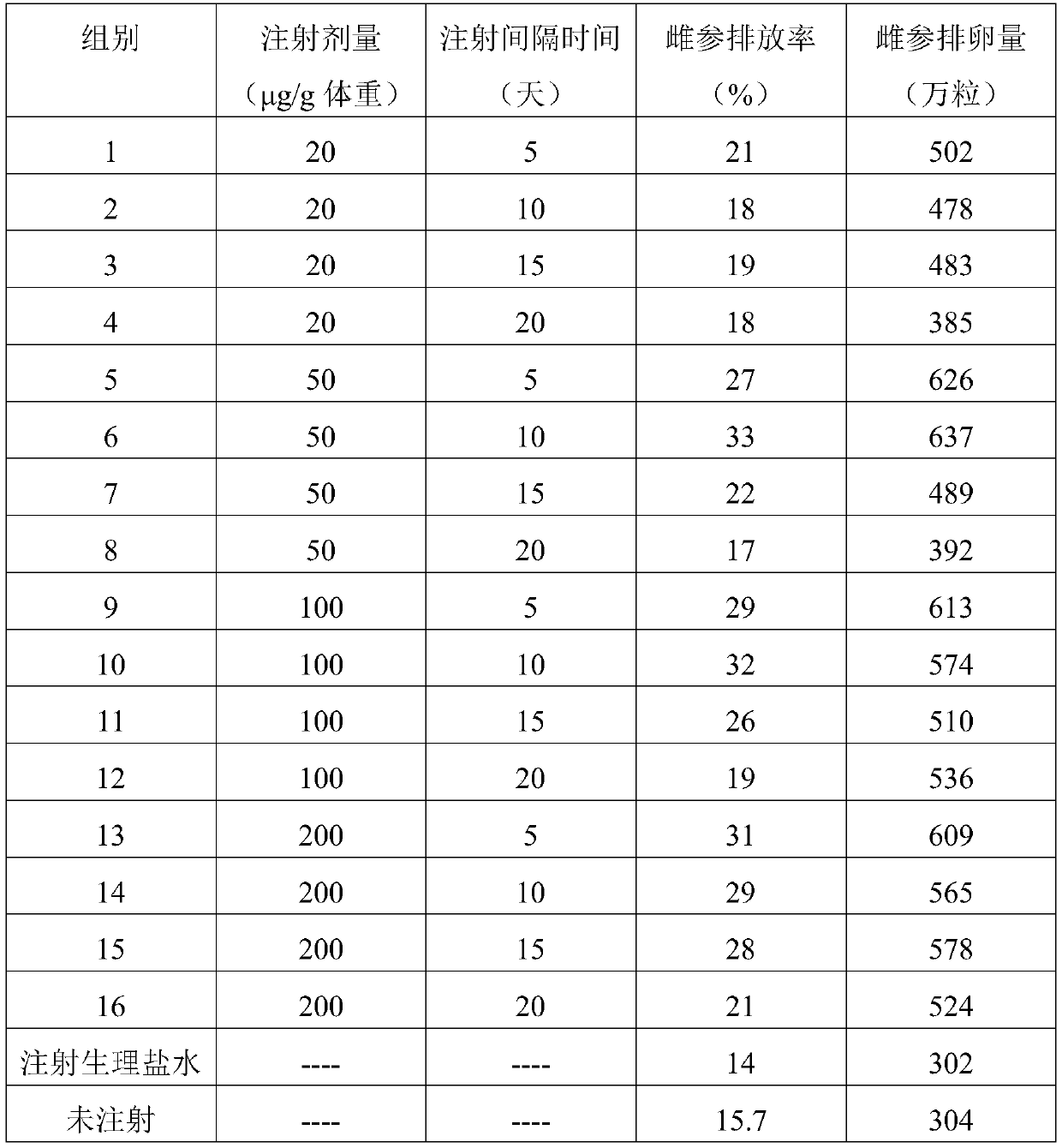

Method for increasing emission ratio and ovulation amount of seed stichopus japonicus

The invention discloses a method for increasing the emission ratio and ovulation amount of seed stichopus japonicus and belongs to the technical field of ocean aquatic animal culture. The method for increasing the emission ratio and ovulation amount of the seed stichopus japonicus comprises the following steps of screening and culture of the seed stichopus japonicus, serotonin treatment and spawning induction of the seed stichopus japonicu. According to serotonin treatment, based on the injection dose of 20-200 microgram / gram of the seed stichopus japonicus by weight, a serotonin solution is injected into the body cavity from the back of predelivery stichopus japonicus at the constant temperature, and injection is conducted once every 5-20 days in the later period. The method has the advantages that the serotonin is free of toxicity and safe to use; the whole induction treatment process is easy to operate and implement; the emission ratio and ovulation amount of the female seed stichopus japonicus can be effectively increased, the cost of seed stichopus japonicus culture is lowered, and the economic benefit of stichopus japonicus seedling raising is improved.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

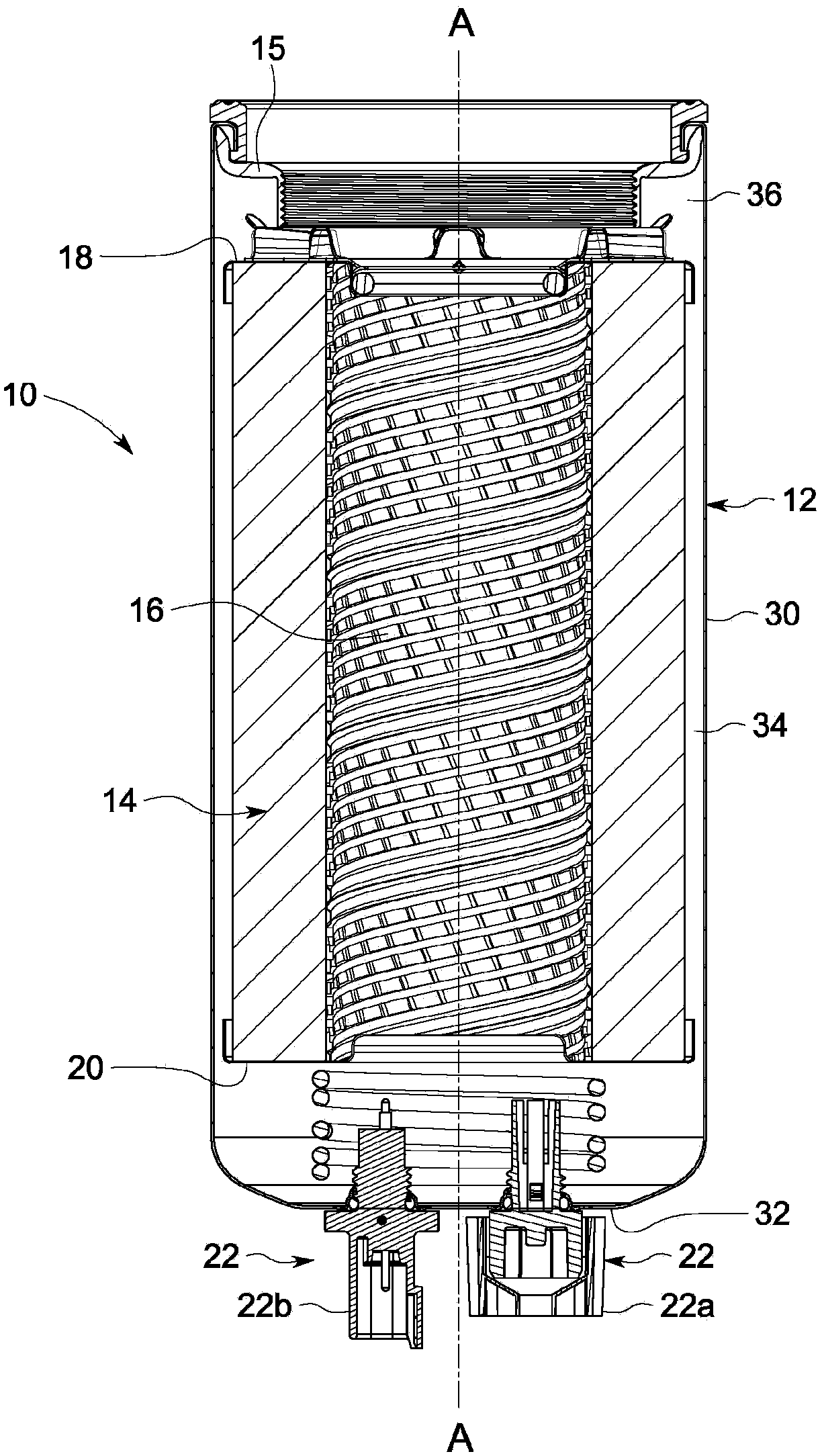

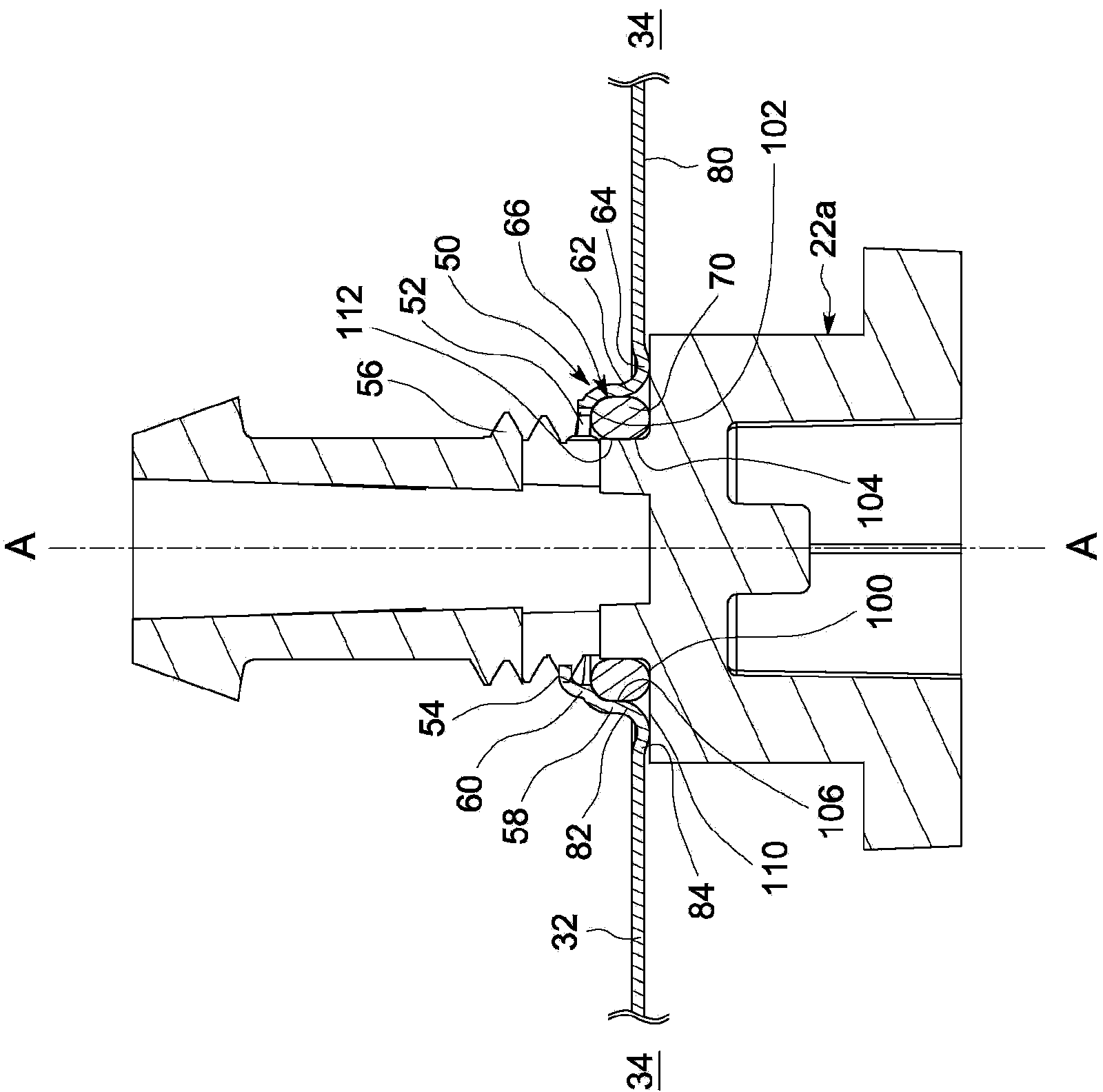

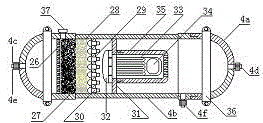

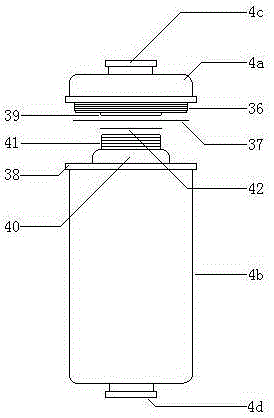

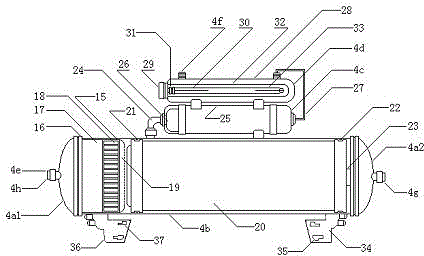

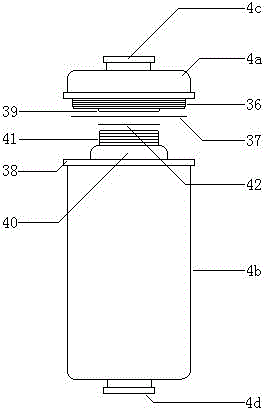

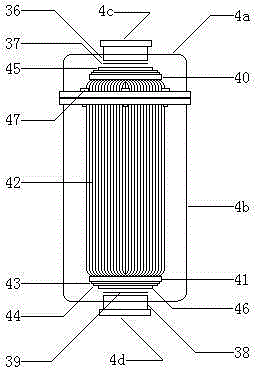

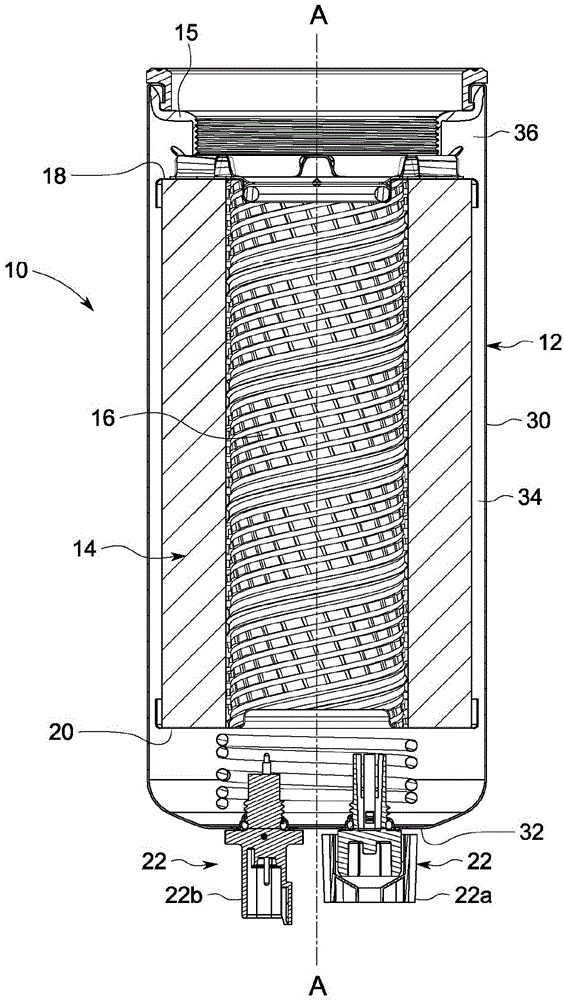

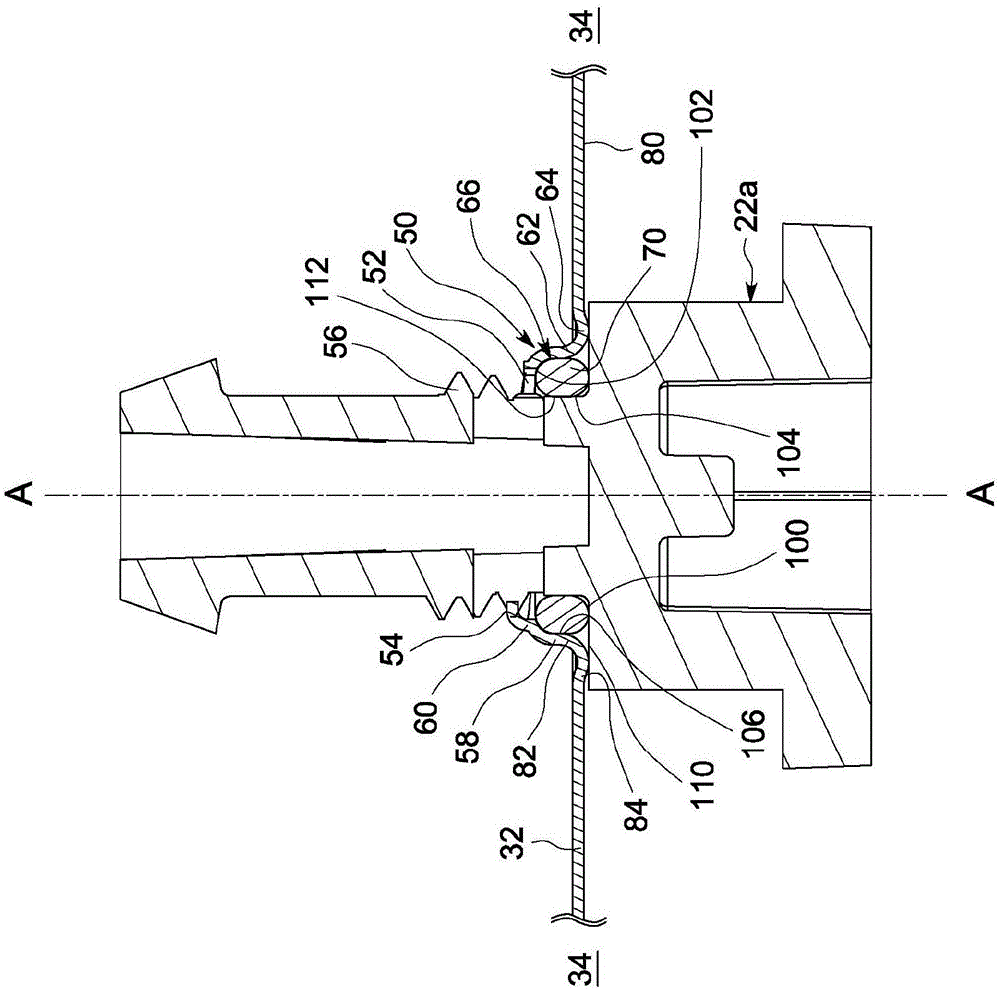

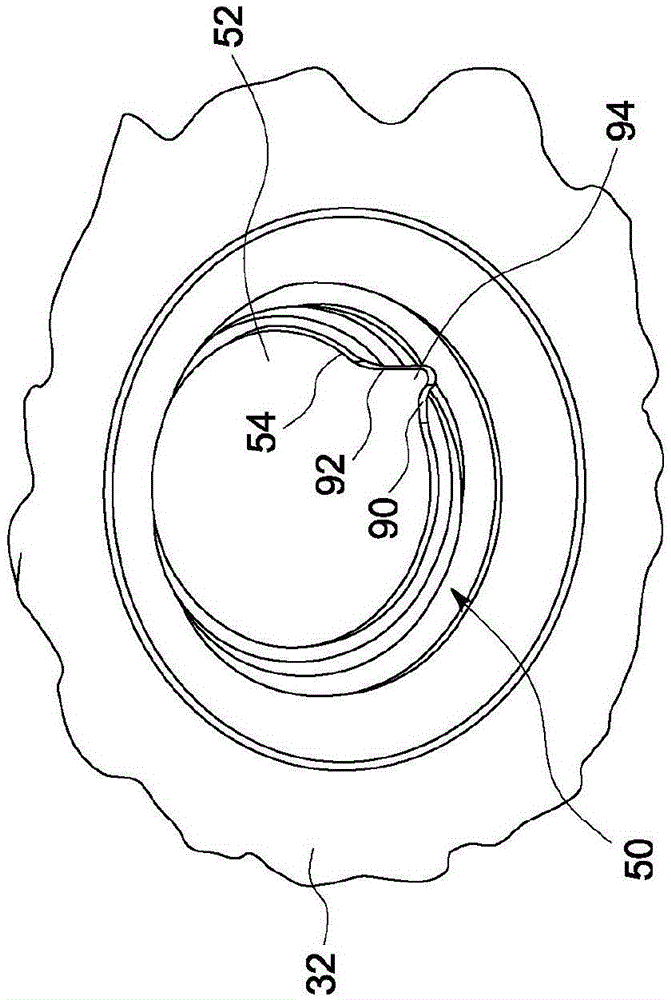

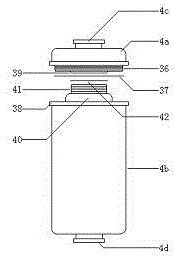

Filter housing with integrally threaded port

InactiveCN103657234AImproves Structural IntegrityMeet or exceed structural requirementsCartridge filtersFiltration circuitsEngineeringStamping process

A filter housing that includes a bowl formed with a single thread that is stamped directly into the housing around a port. The thread is used to connect an auxiliary element, such as a drain valve or a WIF sensor, to the filter housing. An elevated ridge is formed around the bowl during the stamping process which increases the structural integrity of the housing around the port, and provides a surface for matching with the inserted auxiliary element.

Owner:CUMMINS FILTRATION IP INC

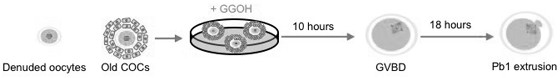

Application of mevalonic acid metabolic intermediate product in preparation of medicines for improving aging ovarian oocyte quality and meiosis process

InactiveCN112675155AQuality improvementImprove meiosis progressionHydroxy compound active ingredientsSexual disorderMature oocyteMolecular biology

The invention discloses application of a mevalonic acid metabolic intermediate product in preparation of medicines for improving aging ovarian oocyte quality and meiosis process. The mevalonic acid metabolic intermediate product is geranyl geraniol or farnesol. One medicine is an in-vitro maturation culture medium containing the mevalonic acid metabolic intermediate product, the first polar body emission rate of mature oocytes can be significantly increased, and the abnormal rate of meiosis can be reduced. The other medicine is an absolute ethyl alcohol injection preparation with the dissolved mevalonic acid metabolic intermediate product, ovary weight, ovary indexes and the number of follicles at all levels can be remarkably increased, the PB1 emission rate of oocytes is remarkably increased after administration, and the chromosome / spindle abnormal rate of MII oocytes of superovulation and COCs in-vitro maturation is remarkably reduced.

Owner:NANJING DRUM TOWER HOSPITAL

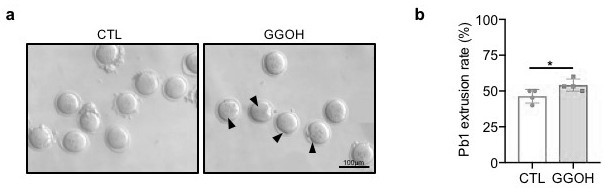

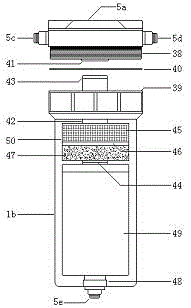

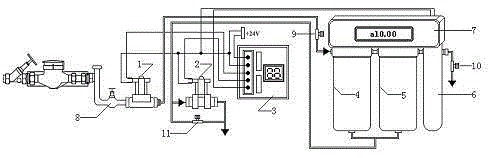

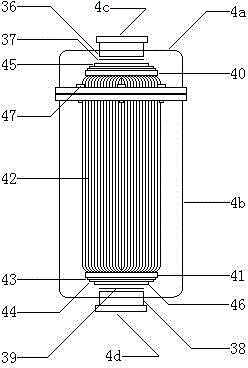

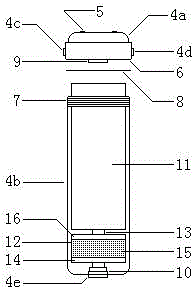

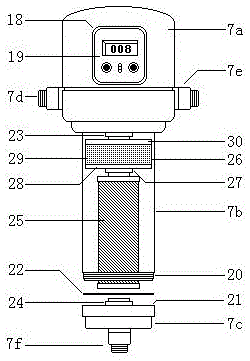

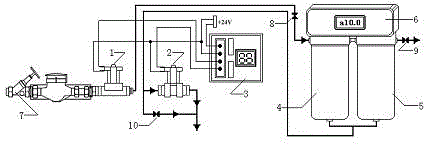

Manufacturing method of all-house KDF 55 ultra-filter membrane water purifier

InactiveCN105668876AEfficient removalSignificant anti-scaling effectSpecific water treatment objectivesTreatment involving filtrationFiberInternal pressure

A method for making a whole house KDF55 ultrafiltration membrane water purifier, which also has an internal pressure ultrafiltration membrane filtration device: the left side of the upper valve seat is provided with a water inlet, the right side is opened with a water outlet, and the upper valve of the airtight container is The seat is provided with a spiral outer wire port connected to the cylinder body, and the upper port of the cylinder body is provided with a spiral inner wire port connected with the upper valve seat and a first silicone sealing ring. The lower part of the body is provided with a lower circular card tube, the upper part of the cylinder is provided with a built-in water purification shell, and the upper end of the diversion pipe in the water purification shell is provided with a second silica gel sealing ring, and the internal pressure ultrafiltration membrane filter element is set In the middle and lower part of the cylinder, the internal pressure ultrafiltration membrane filter element, and the water purification shell on the upper part of the cylinder are equipped with a silicon crystal antibacterial and scale-inhibiting layer, a PP fiber cotton filter, a KDF55 filter layer, and a laser hole filter; The water outlet of the pre-filter device communicates with the water inlet of the internal pressure ultrafiltration membrane filter device; it is economical and practical.

Owner:CHENGDU FUHAOSI BIOTECH CO LTD

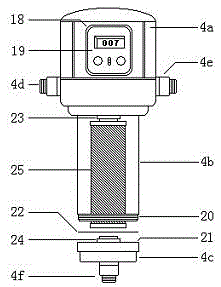

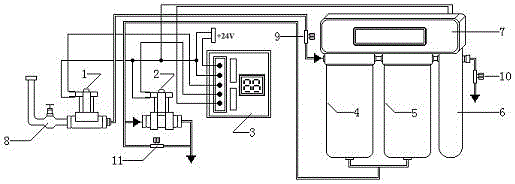

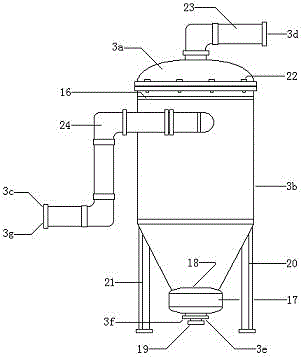

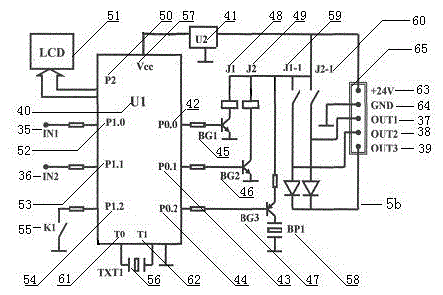

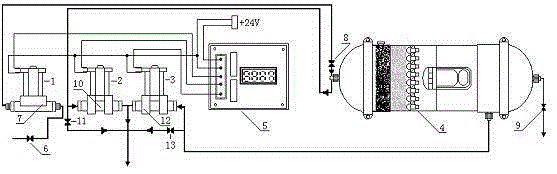

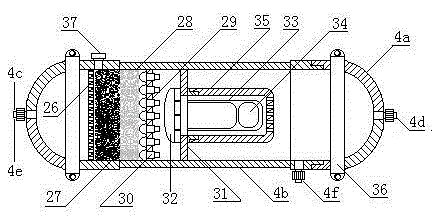

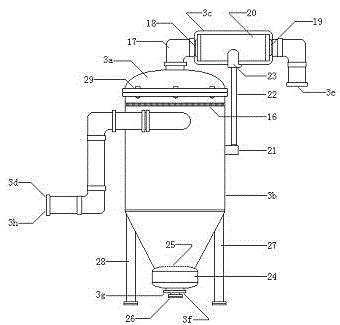

Manufacturing method of integrated full-automatic backwash ultra-filter machine

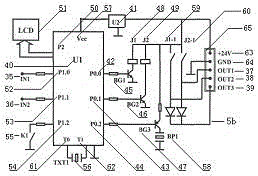

InactiveCN105668841AIncrease emission rateImprove filtration efficiencyTreatment involving filtrationMultistage water/sewage treatmentMicro computerSewage

The manufacturing method of an integrated fully automatic backwashing ultrafiltration machine includes a microcomputer control system device and an ultrafiltration membrane filtration device: a left annular filter plate and a right annular partition are arranged in a closed container, and several holes are opened on the left filter plate. Circular holes, with short handle filter heads on the holes, with KDF55 filter layer and activated carbon filter layer on the surface of the filter head, and a filter element consisting of filter element shell, ultrafiltration membrane and resin filter bag is fixed in the center of the right annular partition. The arc-shaped top of the shell spreads all over the water inlet gap, the ultra-filter element is set in the upper middle part of the filter element shell, the resin filter bag is set in the lower middle part of the filter element shell, the two ends of the cylinder are provided with ring fixing hoops, and the left side of the container is equipped with a water inlet, The backwash sewage outlet, the upper part of the container is provided with a filler inlet and outlet, the lower part of the cylinder is provided with a backwash sewage outlet, and the right side of the container is provided with a water outlet; the water outlet of the filter device is connected to the water inlet of the external pipeline; it is economical and practical .

Owner:CHENGDU FUHAOSI BIOTECH CO LTD

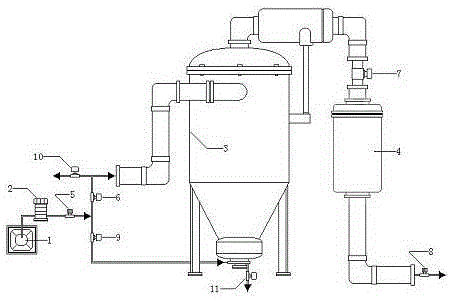

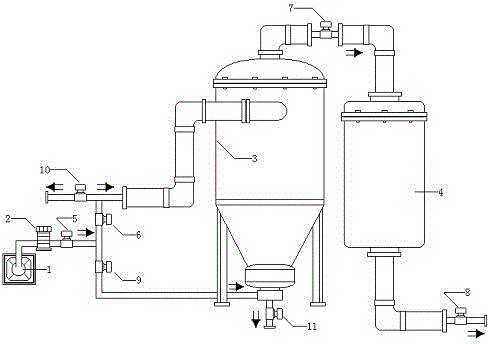

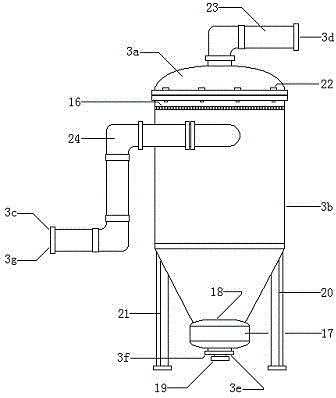

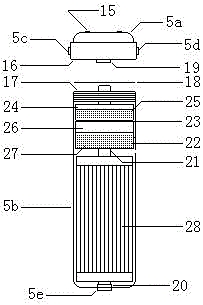

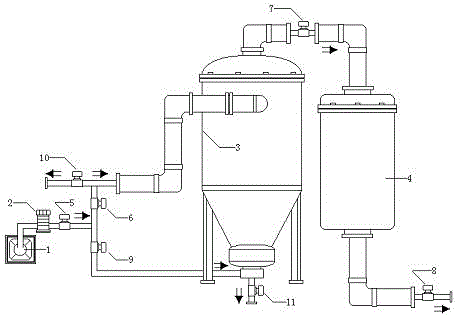

Three-in-one water maker with conical slag hopper and manufacturing method

InactiveCN105217819AEfficient separationEfficient removalUltrafiltrationWater/sewage treatment bu osmosis/dialysisProcess engineeringSilica gel

The invention provides a three-in-one water maker with a conical slag hopper and a manufacturing method. The three-in-one water maker comprises a water supply pump and a fully-automatic hydrocyclone desanding filtering device. The three-in-one water maker is characterized in that the three-in-one water maker is further provided with an ultrafiltration membrane filtering device; an upper sealing head of a closed container of the water purifier is internally provided with a first bolt for being connected with a barrel body in a rotating mode and a first silica gel sealing ring, an upper opening of the barrel body is internally provided with a first nut for being connected with the upper sealing head in a rotating mode, the center of the upper sealing head is further provided with a second nut for being connected with a filtering core in a rotating mode, an ultrafiltration membrane filtering core is arranged in the middle of the closed container, the upper end of the ultrafiltration membrane filtering core is provided with a second bolt for being connected with the upper sealing head in a rotating mode and a second silica gel sealing ring, the top of the closed container is provided with a water inlet, and the lower portion of the closed container is provided with a water outlet; a water outlet of the fully-automatic hydrocyclone desanding filtering device is communicated with a water inlet of the ultrafiltration membrane filtering device. The three-in-one water maker is economical and applicable.

Owner:CHENGDU BEIJIATE BIOTECH

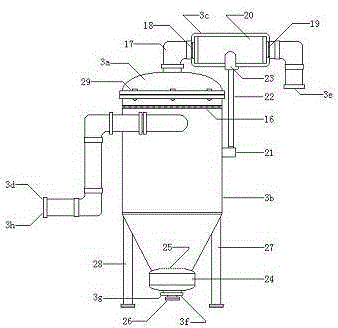

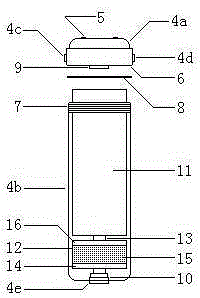

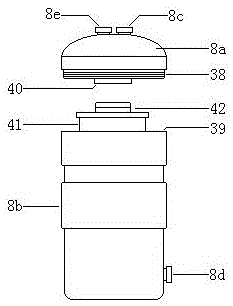

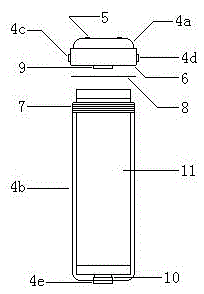

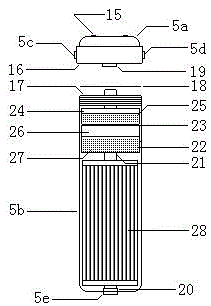

Three-in-one water purifier with ultraviolet sterilization function and manufacturing method thereof

InactiveCN105347586AAvoid filter escapeDense pore sizeWater contaminantsMultistage water/sewage treatmentResidual chlorineEngineering

The invention discloses a three-in-one water purifier with an ultraviolet sterilization function and a manufacturing method thereof. The three-in-one water purifier with the ultraviolet sterilization function has an ultrafilter membrane filtering device; the top of an upper valve seat of the ultrafilter membrane filtering device is provided with a spiral hole fixed with a dust shield; a lower opening of the upper valve seat is provided with a spiral internal thread; an upper opening of a barrel is provided with a spiral external thread and a first silica gel sealing ring; the center of the upper valve seat is provided with an upper circular snapping pipe in which a middle connection pipe is inserted; the bottom of the barrel is provided with a lower circular snapping pipe; the upper circular snapping pipe and the lower circular snapping pipe can effectively fix the middle connection pipe; the upper section of the middle connection pipe is sleeved with a filtering member composed of a filter core shell and a plurality of filter layers; a groove on the outer wall of the filter core shell is provided with a second silica gel sealing ring; a far-infrared mineralized stone filter layer, a KDF 55 filter layer, a residual chlorine purifying stone filter layer and a fibrous filter layer are successively arranged in the filter core shell from bottom to top; the lower section of the middle connection pipe is sleeved with an ultrafilter membrane filter core; and the left side of the upper valve seat is provided with a water inlet and the right side of the upper valve seat is provided with a water outlet.

Owner:SICHUAN JUHAO BIOLOGICAL TECH CO LTD

Method for cultivating larvae of sipunculus nudus indoors

ActiveCN106035246AIncrease productionIncrease emission rateAnimal feeding stuffWater qualityDigestion

The invention discloses a method for cultivating larvae of sipunculus nudus indoors. The method mainly comprises the steps of parent selection, spawn induction, larval cultivation, nyad cultivation and the like. Compared with the prior art, the method has the beneficial effects that (1) the emission ratio and synchronicity of parent sperms and eggs can be improved by using a 5-hydroxytryptamine solution immersion and drying-in-the-shade stimulation combined induction method; (2) algae are fed when individual pelagospheric larvae start to hatch, so that the survival rate of pelagospheric larvae can be increased; (3) water is not changed in the process of cultivating larvae, and the water quality is controlled by reasonably controlling the larval density and the bait amount; (4) benthic diatom is cultivated in a larval pool in advance, sufficient nutrition is provided to larvae which are just attached, and the metamorphosis survival rate and growth rate of larvae can be increased; and (5) larval baits are subjected to superfine grinding, so that digestion of larvae can be benefited. The method can be used for improving the yield of the larvae so as to increase the economic benefit, and has the advantages of simple operation, easy popularization and the like.

Owner:湛江市碧海湾水产科技有限公司

Front-middle water purifier with cyclone sand removing device and manufacturing method

InactiveCN104307246ALarge amount of waterHigh precisionFiltration circuitsWater purification filterEngineering

The invention provides a front-middle water purifier with a cyclone sand removing device and a manufacturing method. The upper part of a container is provided with a first round clamping pipe and a first silica gel sealing ring; the lower part of the container is provided with a second round clamping pipe and a second silica gel sealing ring; a filtering part composed of an upper annular fixed disc, a lower annular fixed disc and a laser hole foldable type filter element is fixed between the first round clamping pipe and the second round clamping pipe; the upper part of a foldable type multifunctional compound filter liner is provided with a first annular fixed disc and the lower part of the foldable type multifunctional compound filter liner is provided with a second annular fixed disc; the laser hole foldable type filter element is arranged between the first annular fixed disc and the second annular fixed disc; a supporting type water production barrel is arranged in the laser hole foldable type filter element and is internally provided with a high-precision and high-density PP fiber cotton filter element; a first mounting fixing opening is formed in the upper end of the foldable type multifunctional compound filter liner and a second mounting fixing opening is formed in the lower end of the foldable type multifunctional compound filter liner; a water inlet is formed in the top of the container and a water outlet is formed in the lower part of the container; and a water outlet of the full-automatic cyclone sand removing and filtering device is communicated with a water inlet of a foldable type multifunctional compound filter liner filtering device. The front-middle water purifier with the cyclone sand removing device is affordable.

Owner:CHENGDU DRAGON WATER TREATMENT TECH RES INST

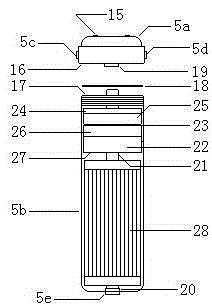

Integrated water purifier with ultraviolet sterilization function and manufacturing method of integrated water purifier

InactiveCN104445763ADense pore sizeUniform pore sizeMultistage water/sewage treatmentFiberActivated carbon

The invention discloses an integrated water purifier with an ultraviolet sterilization function and a manufacturing method of the integrated water purifier. A filtering component consisting of a built-in filtering element shell and a filtering layer is arranged on the left side of a container of the water purifier; a PP fiber cotton filtering piece, a KDF 55 filtering layer, a honeycomb ceramic filtering element and a non-hydrophilic filtering membrane filtering piece are arranged in the filtering element shell from left to right in sequence; an ultra-filtration membrane filtering element is arranged on the right side of the built-in filtering element shell; a bent tube which is connected with a rear filtering element shell is arranged on the built-in water outlet in the upper part of a cylinder body; the rear filtering element shell is connected with the right end of the bent tube; a rear activated carbon filtering element is arranged in the middle of the rear filtering element shell; a built-in guide tube which is connected with an ultraviolet sterilization lamp shell is arranged on the water outlet of the rear filtering element shell; the ultraviolet sterilization lamp shell is connected with one end of the built-in guide tube; a sealing cover is arranged on the left side of the shell; an ultraviolet sterilization lamp is arranged in the middle of the shell; a plug is arranged on the left side of the ultraviolet sterilization lamp; a water through interlayer is arranged in the shell; a sterilization chamber is formed in the interlayer; a water inlet is formed in the end cover on the left side of the container.

Owner:CHENGDU DRAGON WATER TREATMENT TECH RES INST

Integral water purifier with sterilizing function and manufacturing method thereof

InactiveCN105217857ADense pore sizeEasy to absorbMultistage water/sewage treatmentWater purification filterStructural engineering

The invention discloses an integral water purifier with a sterilizing function and a manufacturing method thereof. The integral water purifier comprises an ultra-filtration membrane filtering device, a spiral hole fixed to a dustproof cover is formed in the top of an upper valve base of the filtering device, a spiral internal thread opening is formed in the lower opening of the upper valve base, a spiral external thread opening and a first silica gel seal ring are arranged at the upper portion of a cylinder body, an upper circular clamping pipe inserted in a middle connecting pipe is arranged at the center of the upper valve base, a lower circular clamping pipe is arranged at the bottom of the cylinder body, the upper circular clamping pipe and the lower circular clamping pipe can effectively fix the middle connecting pipe, the upper section of the middle connecting pipe is sleeved with a filter part composed of a filter element shell and a plurality of filter layers, a second silica gel seal ring is arranged in a groove of the outer wall of the filter element shell, a far infrared mineralized stone filtering layer, a KDF55 filtering layer, a residual chlorine purifying stone filtering layer and a fiber filtering layer are sequentially arranged in the filter element shell from bottom to top, the lower section of the middle connecting pipe is sleeved with a micro-filtration membrane filtering element, a water inlet is formed in the left side of the upper valve base, and a water outlet is formed in the right side of the upper valve base.

Owner:CHENGDU BEIJIATE BIOTECH

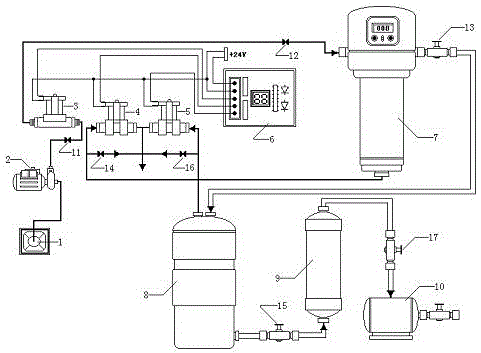

Method for manufacturing three-in-one whole house water purifier

InactiveCN105217849APrevent flightEfficient removalMultistage water/sewage treatmentActivated carbonUltrafiltration

The invention discloses a method for manufacturing a three-in-one whole house water purifier. The water purifier comprises a manual-automatic staged back flushing sewage drainage control system device, a normally-open solenoid valve, a front-arranged filter device, a compressed activated carbon filter device, a KDF55 filter layer and a high precision PP cellucotton filter piece; the water purifier is characterized in that the water purifier is further provided with an ultrafiltration membrane filter device; a nut rotatably connected with a shell body is arranged on an upper cover of a closed container of the ultrafiltration membrane filter device, a bolt rotatably connected with the upper cover is arranged at the upper end of the shell body, an ultrafiltration membrane filter element is arranged in the middle of a membrane shell, a silica gel sealing ring is arranged on an insertion nozzle at the upper end of the ultrafiltration membrane filter element, a filter element shell is arranged on the lower portion of the ultrafiltration membrane filter element, the KDF55 filter layer and the high precision PP cellucotton filter piece are arranged in the filter element shell in sequence from bottom to top, a water inlet is formed in the bottom of the membrane shell, and a water outlet is formed in the top of the membrane shell; a water outlet of the compressed activated carbon filter device is communicated with the water inlet of the ultrafiltration membrane filter device. The water purifier is economical and practical.

Owner:CHENGDU BEIJIATE BIOTECH

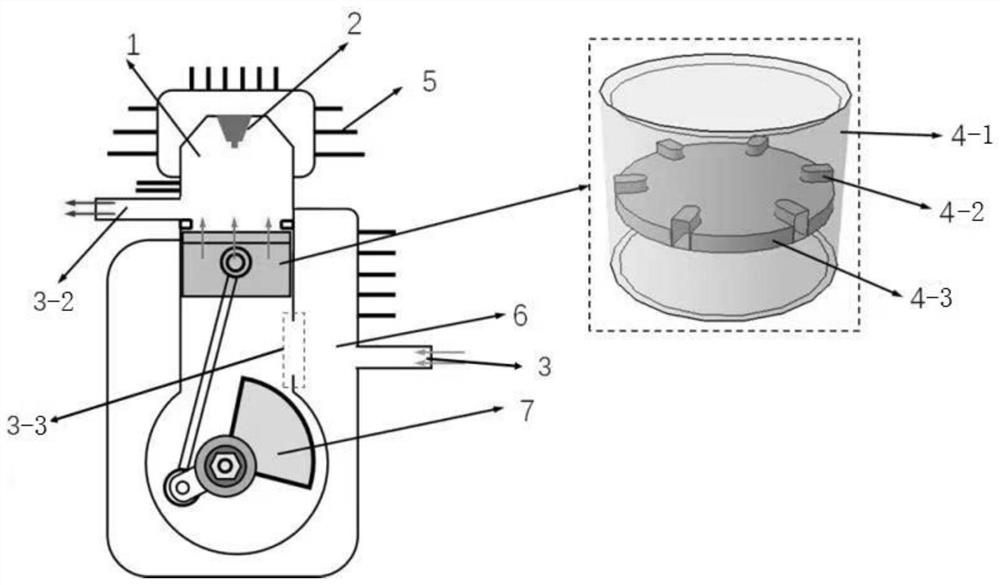

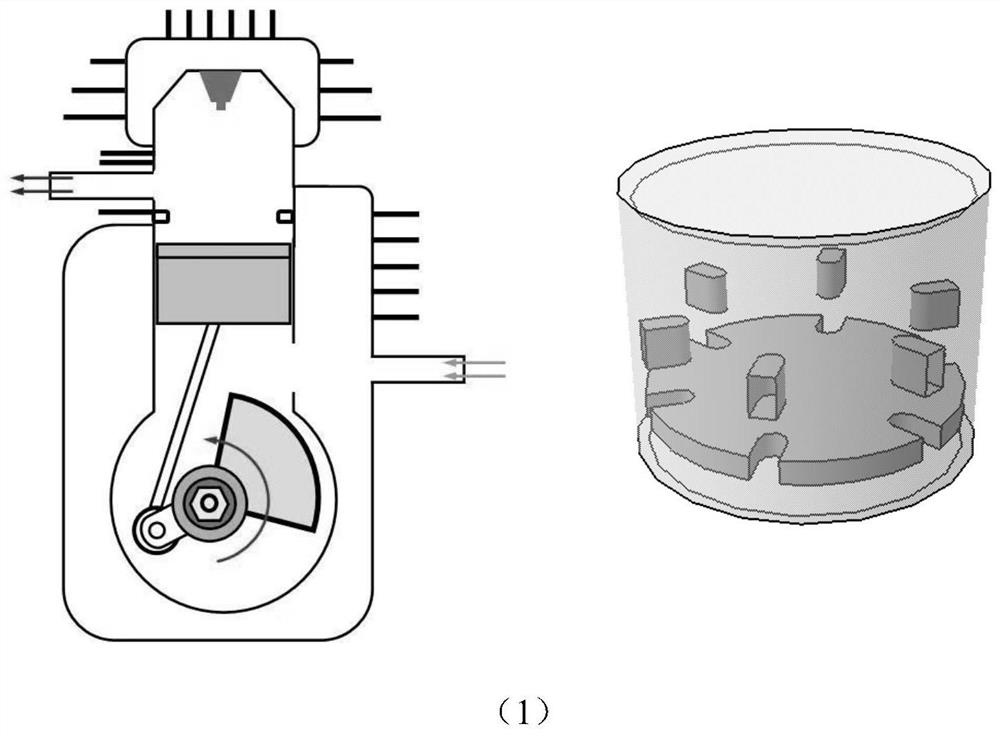

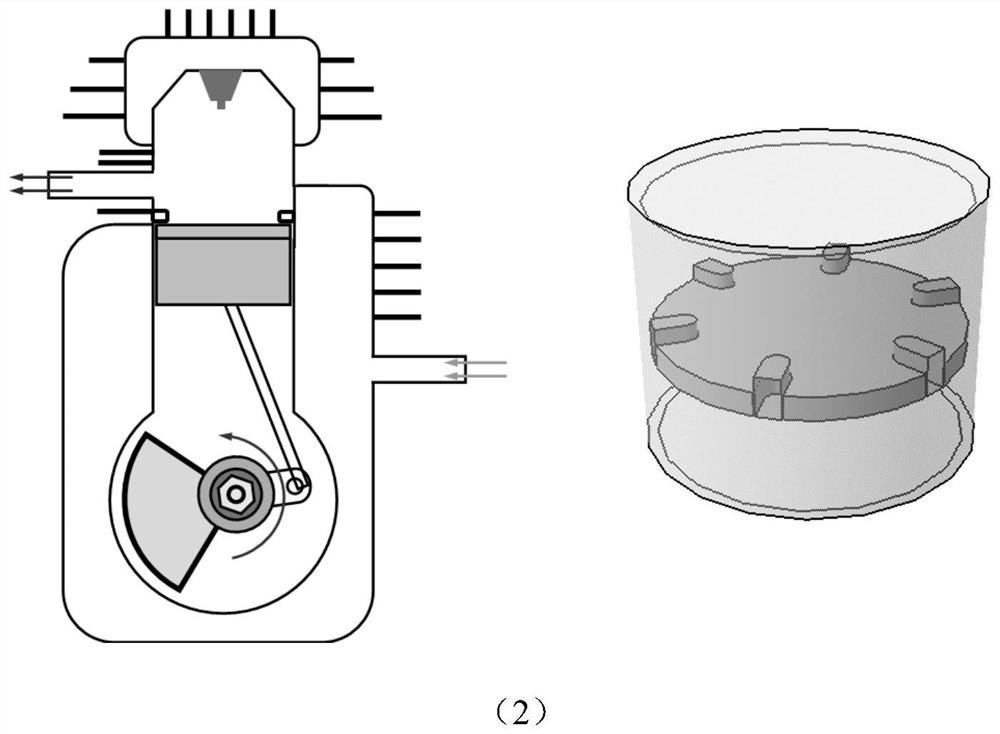

Piston air inlet type two-stroke engine

ActiveCN114060147AAvoid short circuit lossIncreased turbulenceInternal combustion piston enginesCylinder headsCombustion chamberExhaust gas emissions

The invention discloses a piston air inlet type two-stroke engine, and belongs to the field of engines. The piston air inlet type two-stroke engine comprises a combustion chamber, a spark plug, an air inlet, an exhaust port, a cylinder wall, a piston, cooling fins, a scavenging air box and a flywheel, wherein the combustion chamber is arranged above the piston in a cylinder, and the spark plug is mounted at the top part; the piston is an open type air inlet piston, a plurality of axial through grooves are formed in the circumferential outer edge of the piston, and the axial through grooves serve as openings of the piston; protrusions corresponding to the axial through grooves one to one are arranged on the inner wall of the upper portion of the cylinder in the circumferential direction to form an air inlet switch; and theprotrusions and the grooves are complementary in shape, when the open type air inlet piston moves to the air inlet switch, the protrusions and the grooves are matched to separate the combustion chamber of the air cylinder from the scavenging air box. By adopting a vertical air inlet mode, the air short-circuit loss of the transverse air inlet type two-stroke engine can be avoided, meanwhile, due to multi-air-port air inlet, the turbulence degree of air flow in the cylinder is increased, gas in the cylinder and fuel oil can be fully matched, and the fuel oil utilization rate and the exhaust emission rate are increased.

Owner:西北工业大学太仓长三角研究院 +1

Three-in-one water purifier with conical residue hopper and manufacturing method

InactiveCN104556445AThe taste of water is sweet and pureEfficient separationWater/sewage treatment by centrifugal separationTreatment involving filtrationUF - UltrafiltrationWater purification filter

The invention discloses a three-in-one water purifier with a conical residue hopper and a manufacturing method. The three-in-one water purifier comprises a water supplying pump and a full-automatic cyclone sand-removing and filtering device. The three-in-one water purifier is characterized by also being provided with an ultrafiltration-membrane filtering device, wherein an upper sealing head of a closed container is internally provided with a first bolt rotatably connected with a drum body and a first silica-gel sealing ring; an upper opening of the drum body is internally provided with a first nut rotatably connected with the upper sealing head; the center of the upper sealing head is also provided with a second nut rotatably connected with a filtering core; an ultrafiltration-membrane filtering core is arranged at the middle part of the closed container; the upper end of the ultrafiltration-membrane filtering core is provided with a second bolt rotatably connected with the upper sealing head and a second silica-gel sealing ring; a water inlet is arranged at the top part of the closed container, and a water outlet is arranged at the lower part of the closed container; and a water outlet of the full-automatic cyclone sand-removing and filtering device is communicated with a water inlet of the ultrafiltration-membrane filtering device. The three-in-one water purifier is economic and applicable.

Owner:CHENGDU DRAGON WATER TREATMENT TECH RES INST

Front-mid-arranged water purifier with swirling desanding function and manufacturing method

InactiveCN105217814AEfficient separationEfficient removalMultistage water/sewage treatmentContaminated groundwater/leachate treatmentFiberWater production

The invention provides a front-mid-arranged water purifier with a swirling desanding function and a manufacturing method. The upper portion of a container of the water purifier is provided with a first circular clamping pipe and a first silica gel sealing ring, and the lower portion of the container of the water purifier is provided with a second circular clamping pipe and a second silica gel sealing ring. A filtering component is fixedly arranged between the first circular clamping pipe and the second circular clamping pipe, wherein the filtering component is composed of an upper annular fixing disc, a lower annular fixing disc and a laser hole folding filter core. The upper portion of a folding multifunctional composite filtering container is provided with a first annular fixing disc, the lower portion of the folding multifunctional composite filtering container is provided with a second annular fixing disc, the laser hole folding filter core is arranged between the first annular fixing disc and the second annular fixing disc, the laser hole folding filter core is internally provided with a supporting water production barrel, and the supporting water production barrel is internally provided with a high-precision PP fiber cotton filter core. The upper end of the folding multifunctional composite filtering container is provided with a first mounting fixing opening, and the lower end of the folding multifunctional composite filtering container is provided with a second mounting fixing opening. The top of the container is provided with a water inlet, and the lower portion of the container is provided with a water outlet.

Owner:CHENGDU BEIJIATE BIOTECH

Method for improving emission ratio of pinctada maxima parent gamete

InactiveCN103478056BIncrease emission rateImprove survival rateClimate change adaptationPisciculture and aquariaHigh activityObserved Survival

The invention relates to a method for improving the emission ratio of pinctada maxima parent gametes and belongs to the technical field of shellfish culture. The method concretely comprises the following steps of: selecting individuals with higher activity and plump gonads from a 3-year or 4-year natural population or cultured population as parents; cleaning attachments from the surfaces of shell bodies, and soaking for 1-2 minutes by utilizing 0.02% potassium permanganate solution; soaking the parents in 0.02%-0.05% 5-hydroxytryptamine solutions for 30-50 minutes. The method disclosed by the invention can effectively and fast promote the emission of the pinctada maxima parent gametes and improve the survival rate of the parents and has the advantages of easiness and convenience in operation, low cost, easiness in popularization, and the like.

Owner:GUANGDONG OCEAN UNIVERSITY

Multistage water purifier with ultraviolet sterilization device and manufacturing method

InactiveCN105254088AEfficient removalPromote absorptionWater/sewage treatment by irradiationMultistage water/sewage treatmentUltrafiltrationUltraviolet

The invention discloses a multistage water purifier with an ultraviolet sterilization device and a manufacturing method. The multistage water purifier is further provided with an ultrafiltration membrane filter device. The top of an upper valve seat of the ultrafiltration membrane filter device is provided with a spiral hole to which a dust cover is fixed, a lower opening of an upper valve seat is provided with a spiral internal thread opening, and an upper opening of a barrel is provided with a spiral external thread opening and a first silicon rubber sealing ring. An upper round clamping pipe into which a middle connecting pipe is inserted is arranged in the center of the upper valve seat, a lower round clamping pipe is arranged at the bottom of the barrel, and the upper round clamping pipe and the lower round clamping pipe can effectively fix the middle connecting pipe. The upper segment of the middle connecting pipe is sleeved with a filter element shell and a filter component composed of multiple filter layers, a groove in the outer wall of the filter element shell is provided with a second silicon rubber sealing ring, and a far infrared mineralized stone filter layer, a KDF55 filter layer, a residual chlorine purification stone filter layer and a fiber filter layer are sequentially arranged in the filter element shell from bottom to top. The lower segment of the middle connecting pipe is sleeved with an ultrafiltration membrane filter element. The left side of the upper valve seat is provided with a water inlet, and the right side of the upper valve seat is provided with a water outlet.

Owner:CHENGDU BEIJIATE BIOTECH

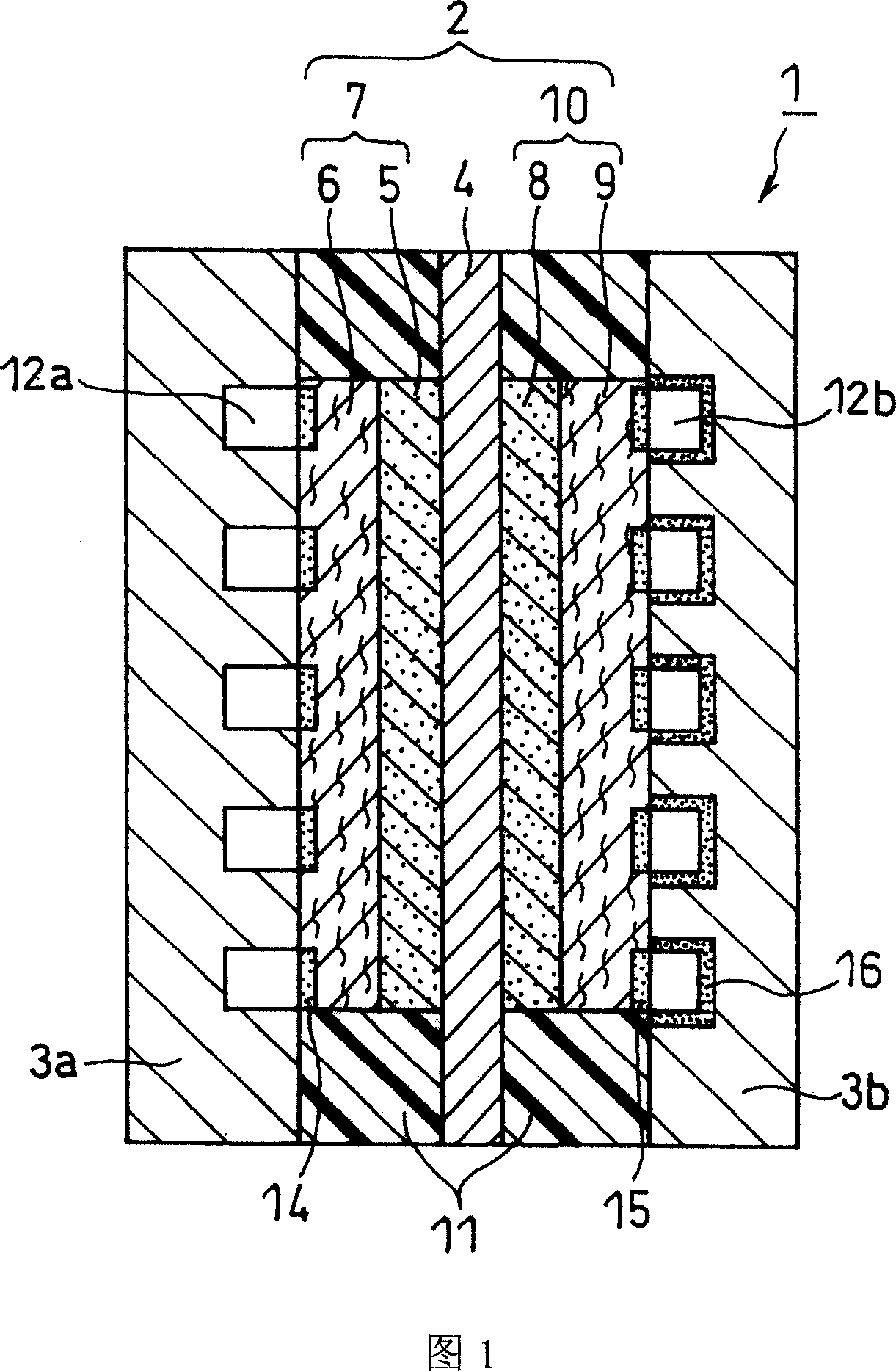

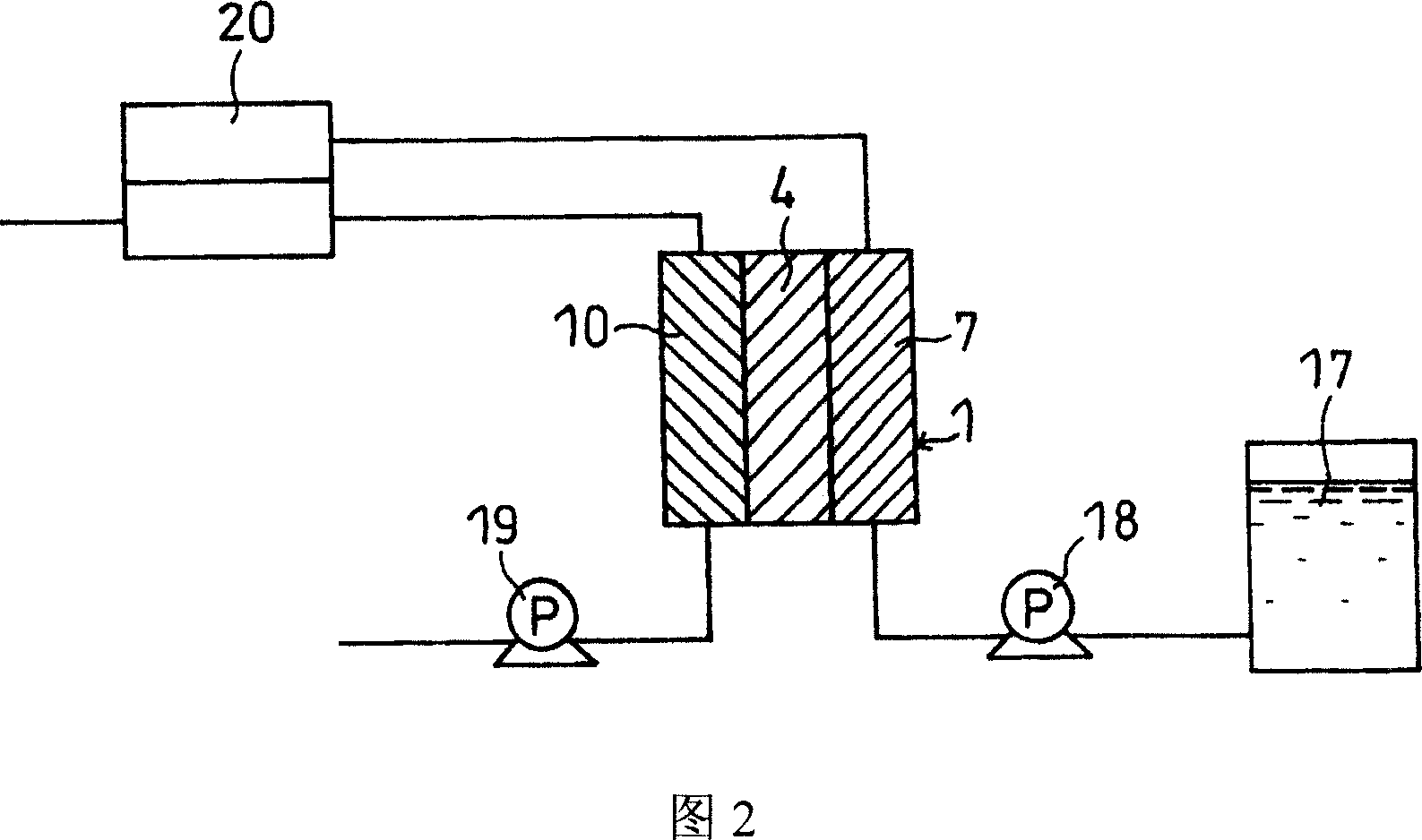

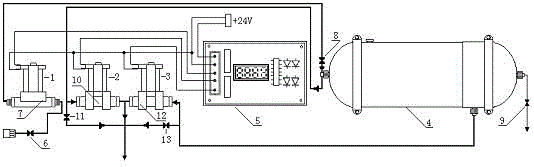

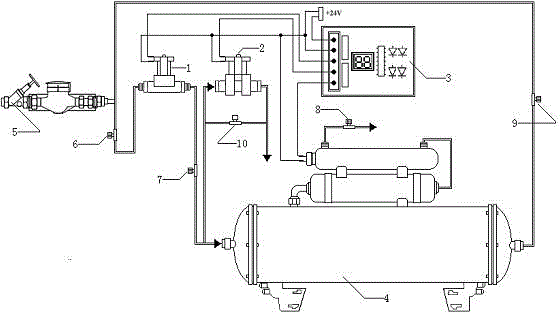

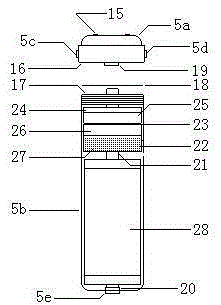

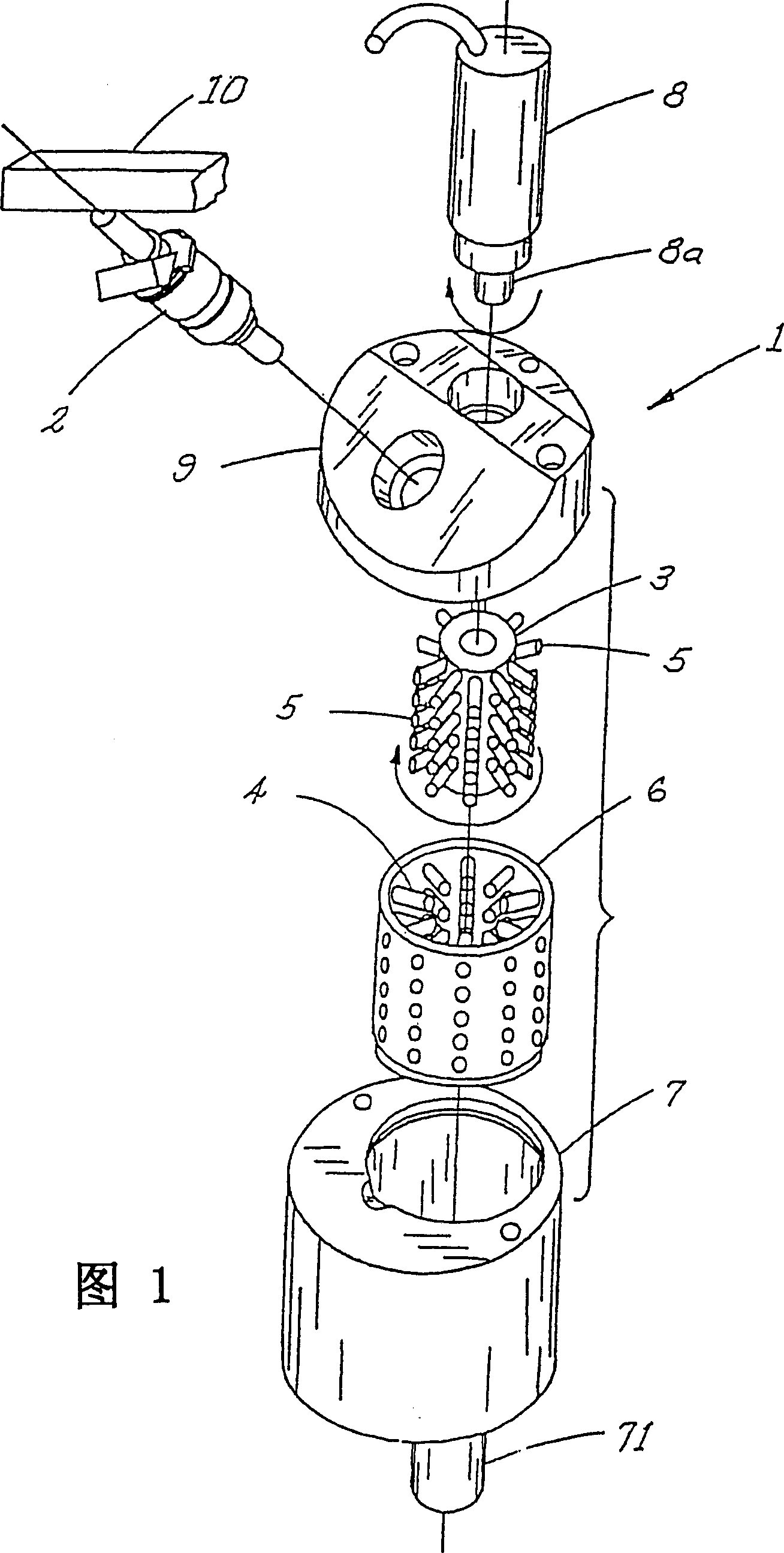

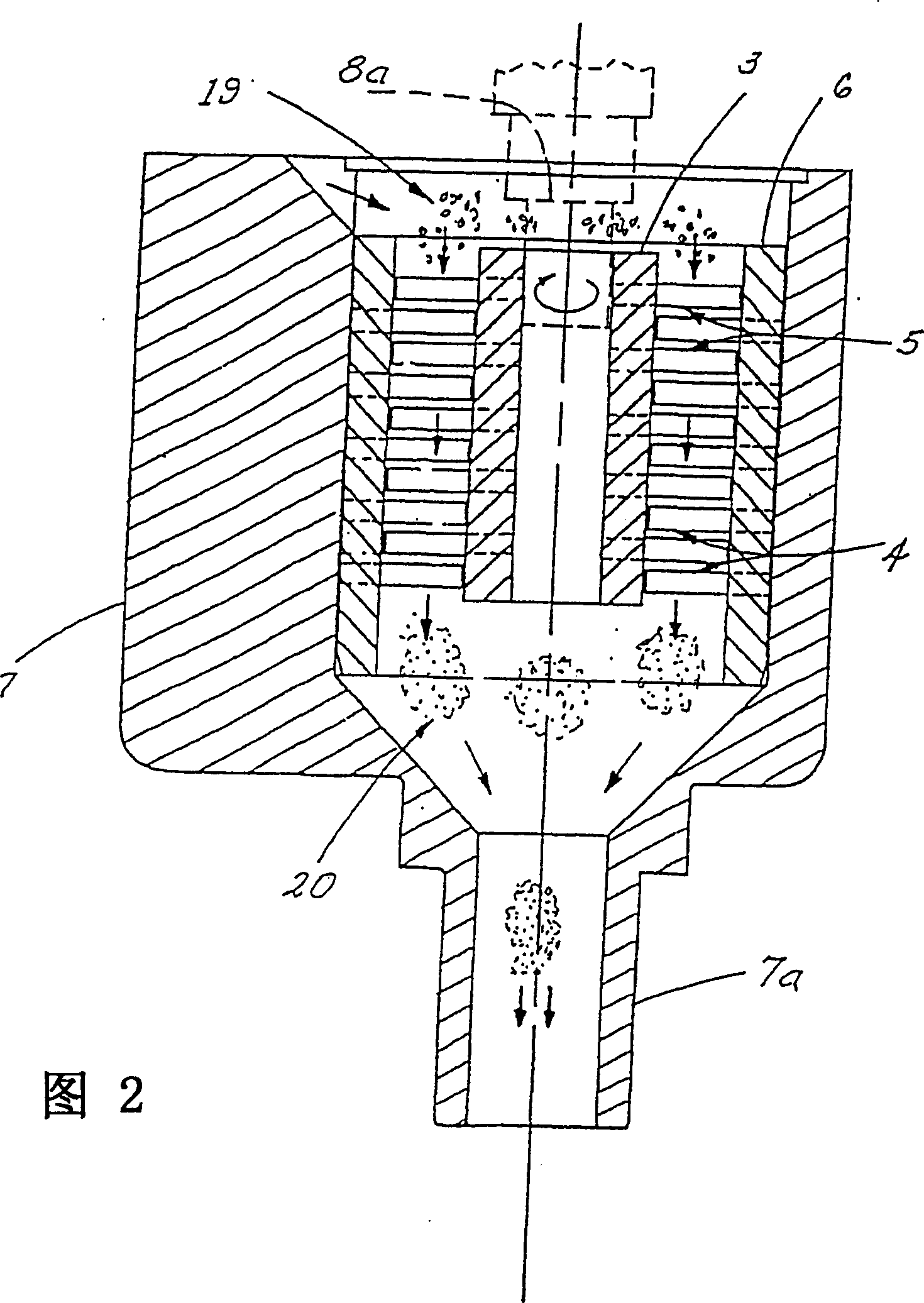

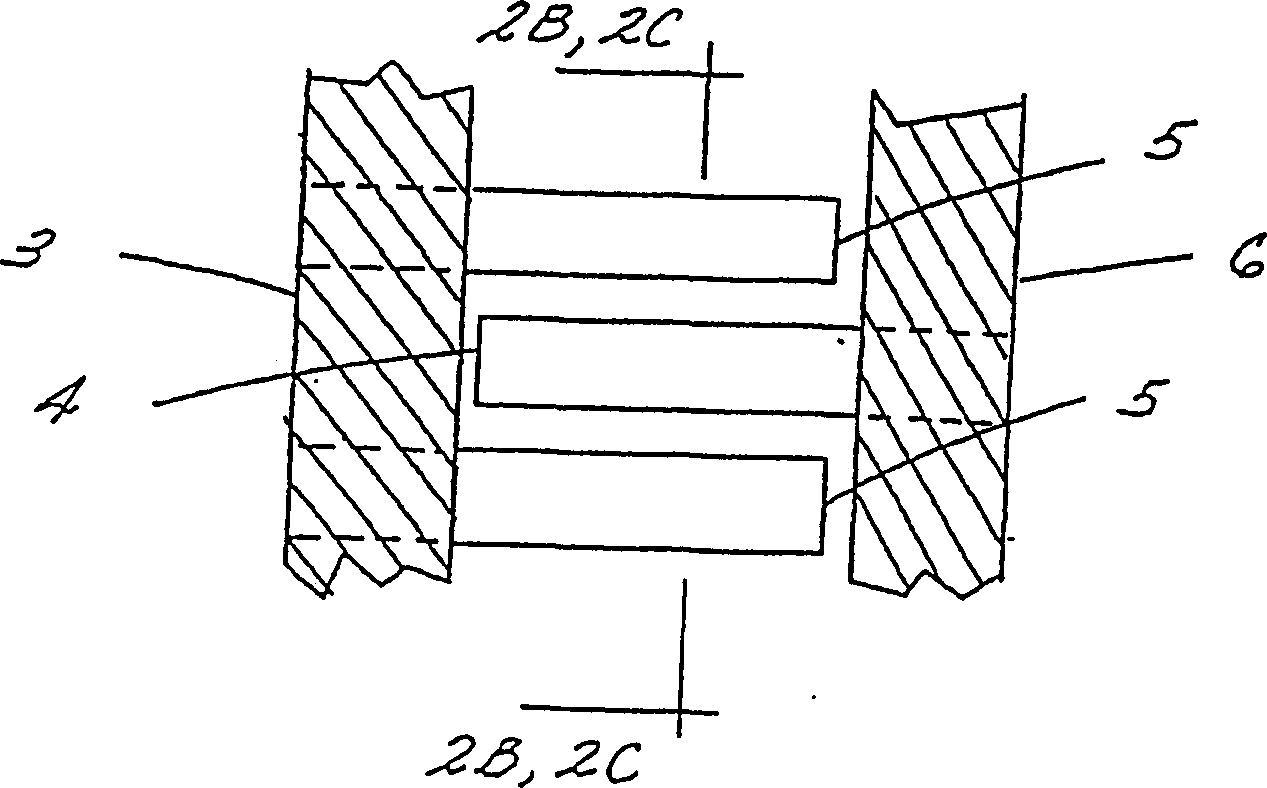

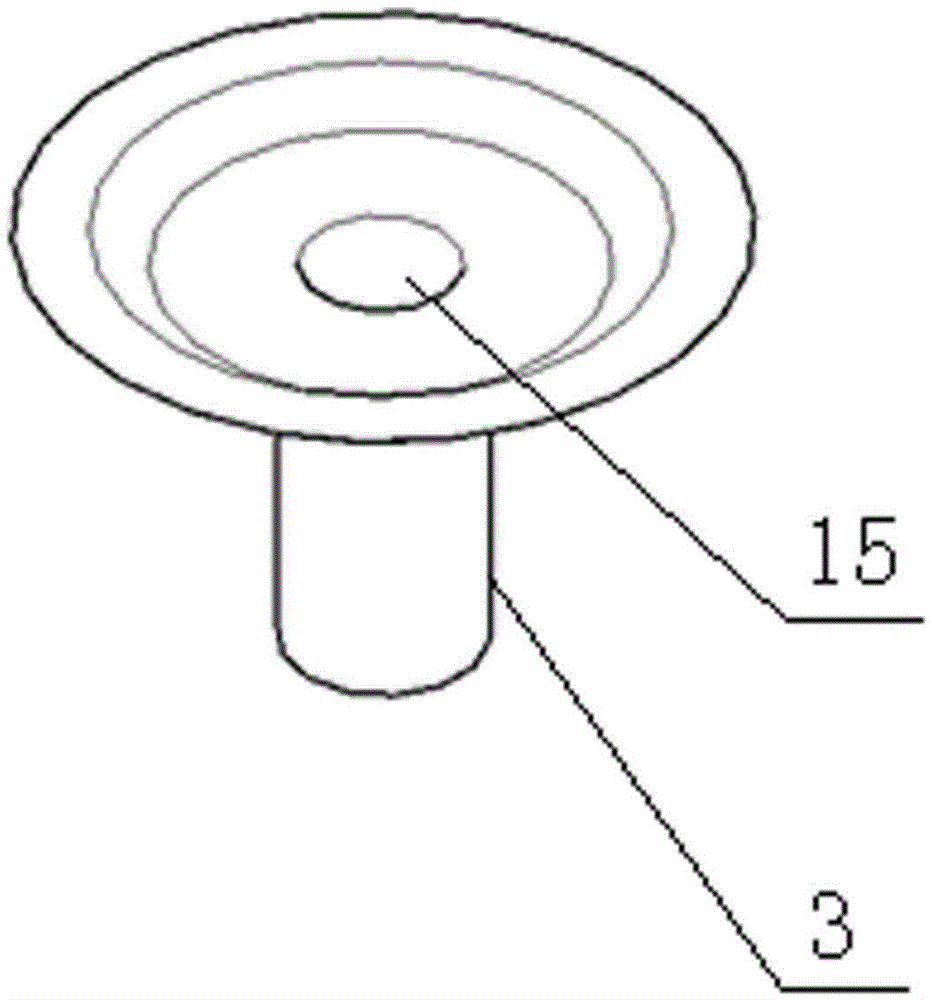

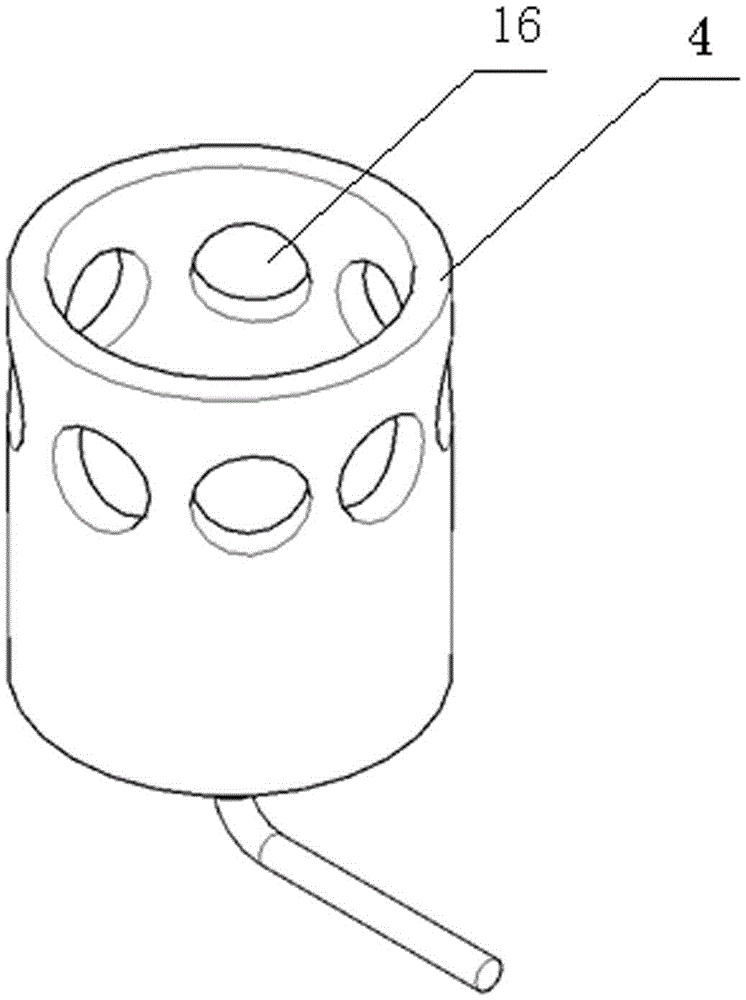

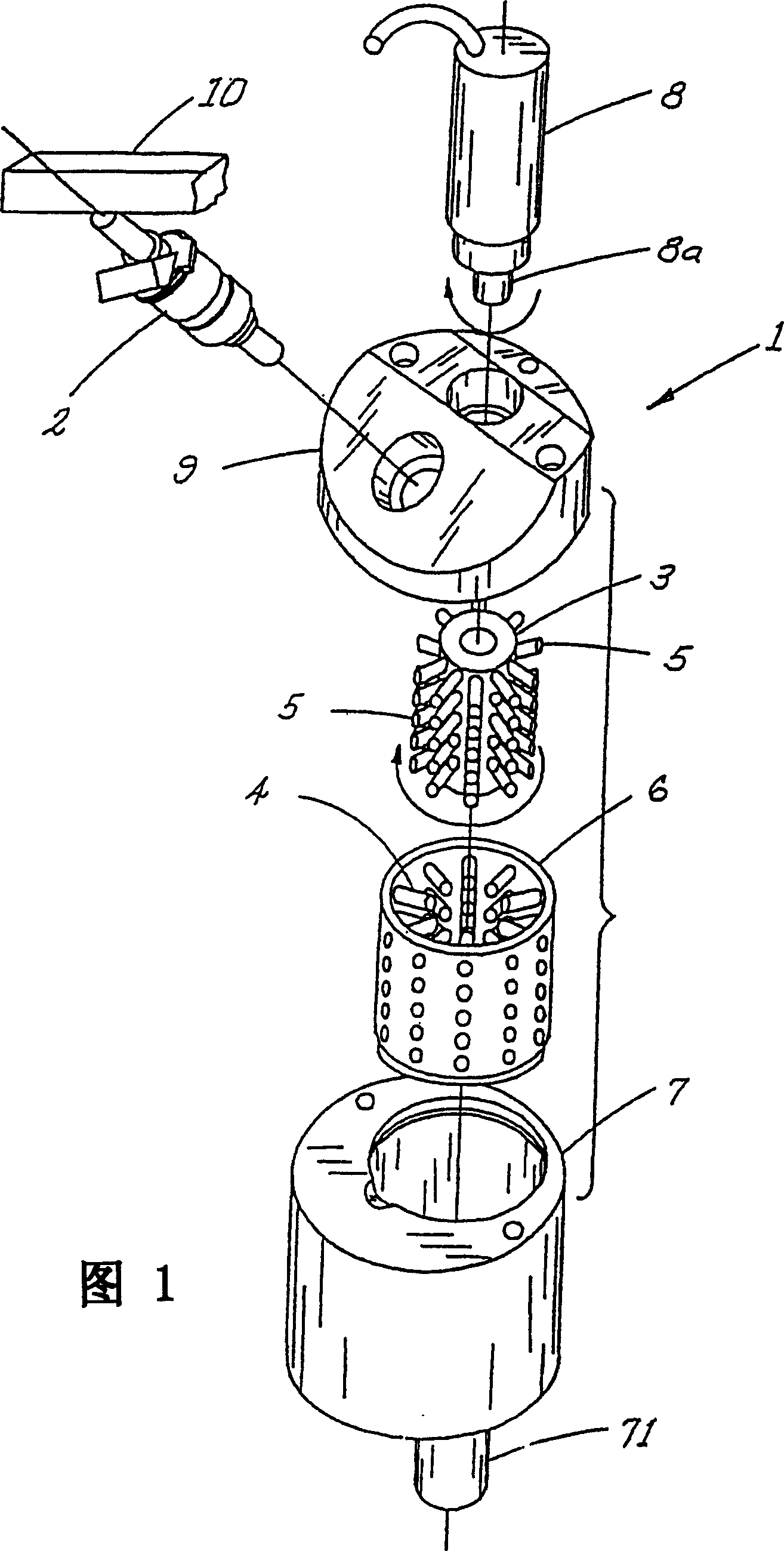

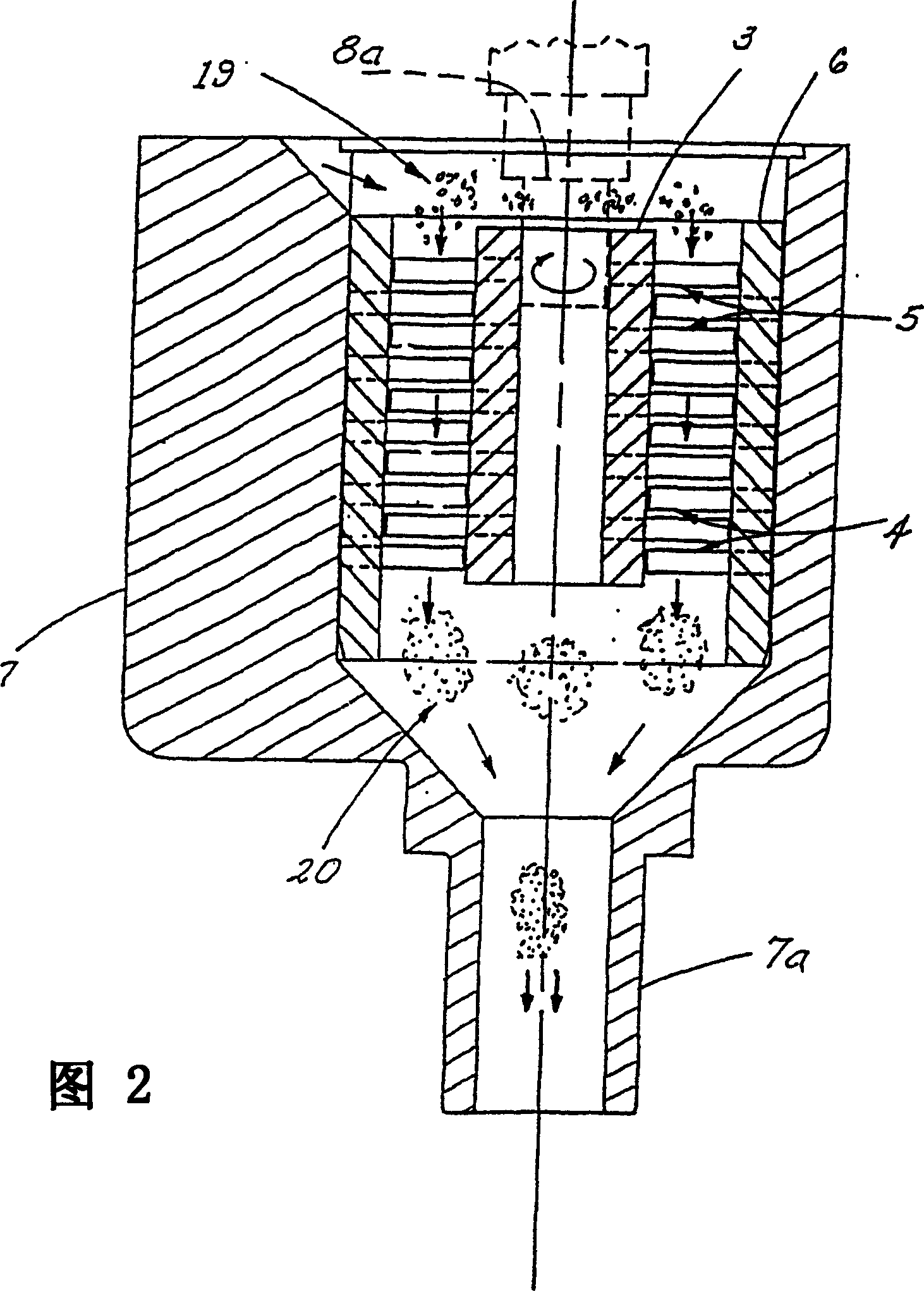

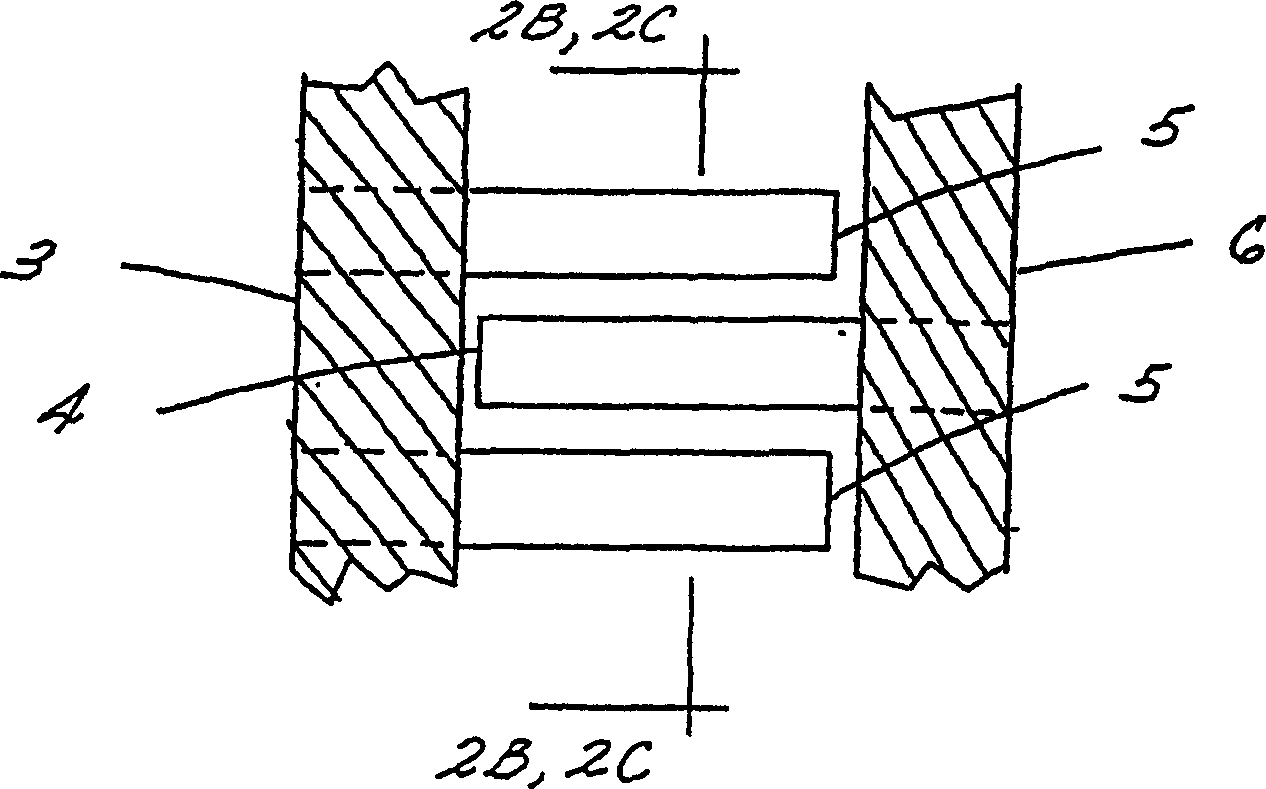

Mechanical fuel gasification apparatus

InactiveCN1274954CEmission reductionIncrease emission rateFuel re-atomisation/homogenisationMachines/enginesExternal combustion engineFuel gasification

A method and apparatus (1) for mechanically gasifying an atomized fuel / air mixture by passing the mixture through intermeshing sets of pins (4, 5) rotating at high speeds. When used in an internal combustion engine, the fuel efficiency is enhanced and undesirable emissions are reduced.

Owner:R·W·哈蒙德

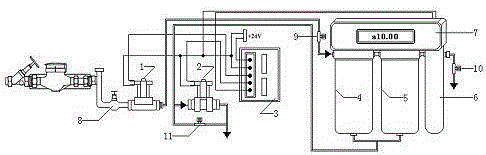

Manufacturing method for integrated full-automatic backwash ultrafilter

InactiveCN105152413AIncrease emission rateImprove filtration efficiencyMultistage water/sewage treatmentUltrafiltrationActivated carbon filtration

The invention discloses a manufacturing method for an integrated full-automatic backwash ultrafilter. The ultrafilter comprises a microcomputer control system device and is further provided with an ultrafiltration membrane filtering device. A left annular filtering plate and a right annular partitioning plate are arranged inside a closed container, multiple round holes are formed in the left filtering plate and provided with short-handle filtering heads, KDF55 filtering layers and active carbon filtering layers are arranged on the surfaces of the filtering heads, and a filter element composed of a filter element shell, an ultrafiltration membrane and a resin filtering bag is fixed to the center of the right annular partitioning plate. Water inlet gaps are formed in the arc top of the filter element shell, an ultrafiltration element is arranged on the upper middle of the filter element shell, the resin filtering bag is arranged on the lower middle of the filter element shell, annular fixing hoops are arranged at the two ends of a barrel, a water inlet and a backwash drainage outlet are formed in the left side of the container, a filling entering and exiting opening is formed in the upper portion of the container, a backwash drainage outlet is formed in the lower portion of the barrel, and a water outlet is formed in the right side of the container. A water outlet of the filtering device is communicated with a water inlet of an external pipeline. The integrated full-automatic backwash ultrafilter is economical, practical and capable of providing qualified and healthy drinking water for urban families and enterprises and public institutions.

Owner:CHENGDU BEIJIATE BIOTECH

Filter housings with single turn threaded ports

InactiveCN103657234BImproves Structural IntegrityMeet or exceed structural requirementsCartridge filtersFiltration circuitsStamping processScrew thread

A filter housing that includes a bowl formed from a single thread stamped directly into the housing around a port. The threads are used to connect auxiliary components such as drain valves or WIF sensors to the filter housing. Raised ridges formed around the bowl during the stamping process enhance the structural integrity of the housing surrounding the port and provide a surface for mating with inserted auxiliary elements.

Owner:CUMMINS FILTRATION IP INC

Treatment method of high concentration waste alkali solution

ActiveCN102877351BOvercome the explosionLower emission ratePulp liquors combustionHigh concentrationCyclohexanone

Owner:CHINA PETROCHEMICAL CORP

KDF ultra-filter membrane water purifier having dust shield cover and manufacturing method thereof

InactiveCN105668877AEfficient removalPromote absorptionWater/sewage treatment by irradiationSpecific water treatment objectivesFiberFar infrared

A KDF ultra-filter membrane water purifier having dust shield cover and a manufacturing method thereof. A screw hole, which is fixed to the dust shield cover, is arranged on the top of an upper valve base. A screw inner thread opening is arranged in a lower opening of the upper valve base. A screw outer thread opening and a first silica gel sealing ring are arranged in an upper opening of a cylinder body. An upper circular clamping tube, in which a middle connection pipe is inserted, is disposed on the center of the upper valve base. A lower circular clamping tube is arranged on the bottom of the cylinder body. The middle connection pipe is fixed effectively with the upper circular clamping tube and the lower circular clamping tube. A filter part, which is composed of a filter core shell and a plurality of filter layers, sleeves the upper part of the middle connection pipe. A second silica gel sealing ring is arranged in a groove in the outer wall of the filter core shell. A far infrared mineralized stone filter layer, a KDF filter layer, a residual chlorine purifying stone filter layer and a fiber filter layer are arranged in the filter core shell from bottom to top successively. An ultra-filter membrane filter core sleeves the lower part of the middle connection pipe. A water inlet is arranged on the left side of the upper valve base and a water outlet is arranged on the right side of the upper valve base. The water outlet of a high-precision PP fiber cotton filter apparatus is communicated with the water inlet of the KDF ultra-filter membrane apparatus. The water purifier is economical and practical.

Owner:CHENGDU FUHAOSI BIOTECH CO LTD

A kind of method for indoor seedling cultivation of naked starworm

ActiveCN106035246BIncrease productionIncrease emission rateAnimal feeding stuffWater qualityDigestion

The invention discloses a method for cultivating larvae of sipunculus nudus indoors. The method mainly comprises the steps of parent selection, spawn induction, larval cultivation, nyad cultivation and the like. Compared with the prior art, the method has the beneficial effects that (1) the emission ratio and synchronicity of parent sperms and eggs can be improved by using a 5-hydroxytryptamine solution immersion and drying-in-the-shade stimulation combined induction method; (2) algae are fed when individual pelagospheric larvae start to hatch, so that the survival rate of pelagospheric larvae can be increased; (3) water is not changed in the process of cultivating larvae, and the water quality is controlled by reasonably controlling the larval density and the bait amount; (4) benthic diatom is cultivated in a larval pool in advance, sufficient nutrition is provided to larvae which are just attached, and the metamorphosis survival rate and growth rate of larvae can be increased; and (5) larval baits are subjected to superfine grinding, so that digestion of larvae can be benefited. The method can be used for improving the yield of the larvae so as to increase the economic benefit, and has the advantages of simple operation, easy popularization and the like.

Owner:湛江市碧海湾水产科技有限公司

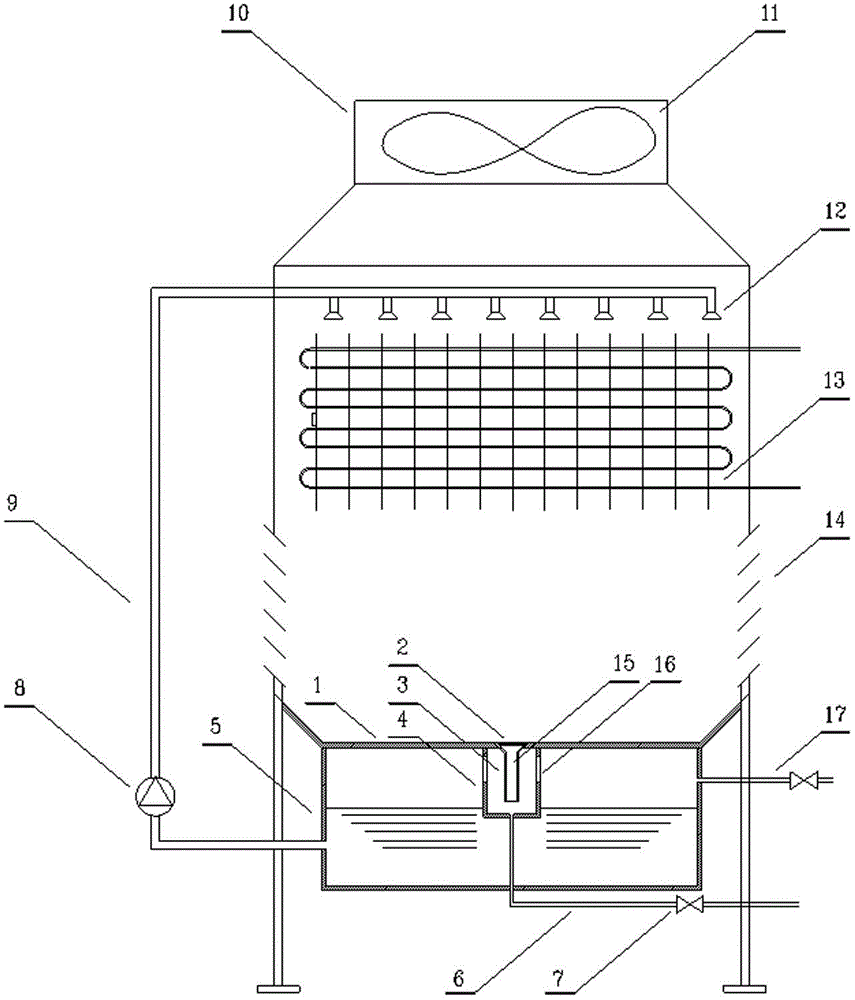

A Closed Heat Source Tower Receives Moisture Collection Liquid Circulation System

ActiveCN103697554BAvoid enteringStable working conditionLighting and heating apparatusAir conditioning systemsWater dischargeFrost

Owner:HUNAN UNIV

Mechanical fuel gasification apparatus

InactiveCN1471612AEmission reductionIncrease emission rateFuel re-atomisation/homogenisationMachines/enginesExternal combustion engineFuel gasification

A method and apparatus (1) for mechanically gasifying an atomized fuel / air mixture by passing the mixture through intermeshing sets of pins (4, 5) rotating at high speeds. When used in an internal combustion engine, the fuel efficiency is enhanced and undesirable emissions are reduced.

Owner:R·W·哈蒙德

Water purifier with conical residue hopper and manufacturing method

InactiveCN105481126AEfficient separationEfficient removalTreatment involving filtrationMultistage water/sewage treatmentCycloneUltrafiltration

The invention relates to a water purifier with a conical residue hopper and a manufacturing method. The water purifier comprises a water supply pump and a full-automatic cyclone grit removing filtering device. The water purifier is characterized by further comprising an ultrafiltration membrane filter device, wherein a first bolt connected with a cylinder in a screw mode and a first silicon rubber sealing ring are arranged in an upper sealing head of a closed container of the ultrafiltration membrane filter, a first nut connected with the upper sealing head in a screw mode is arranged in an upper opening of the cylinder, a second nut connected with a filter element in a screw mode is further arranged in the center of the upper sealing head, the ultrafiltration membrane filter element is arranged in the middle of the closed container, a second bolt connected with the upper sealing head in a screw mode and a second silicon rubber sealing ring are arranged at the upper end of the ultrafiltration membrane filter element, a water inlet is formed in the the top of the closed container, and a water outlet is formed in the lower portion of the closed container; a water outlet of the full-automatic cyclone grit removing filtering device is communicated with the water inlet of the ultrafiltration membrane filter device. The water purifier is economical and applicable.

Owner:CHENGDU FUHAOSI BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com