A Closed Heat Source Tower Receives Moisture Collection Liquid Circulation System

A circulation system and heat source tower technology, applied in air conditioning systems, household heating, heating methods, etc., can solve the problems affecting the working efficiency of the heat source tower heat pump host, the rapid rise of the freezing point of antifreeze, and low heat exchange efficiency, etc., to achieve a compact structure , Stable working status, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

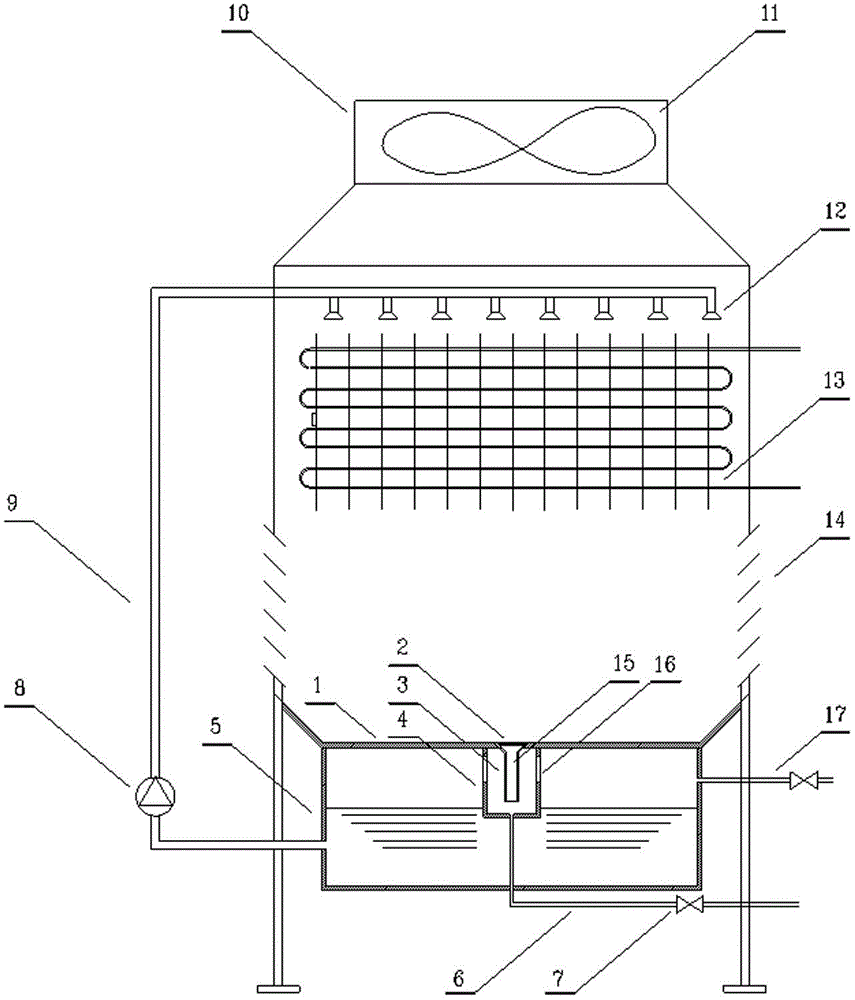

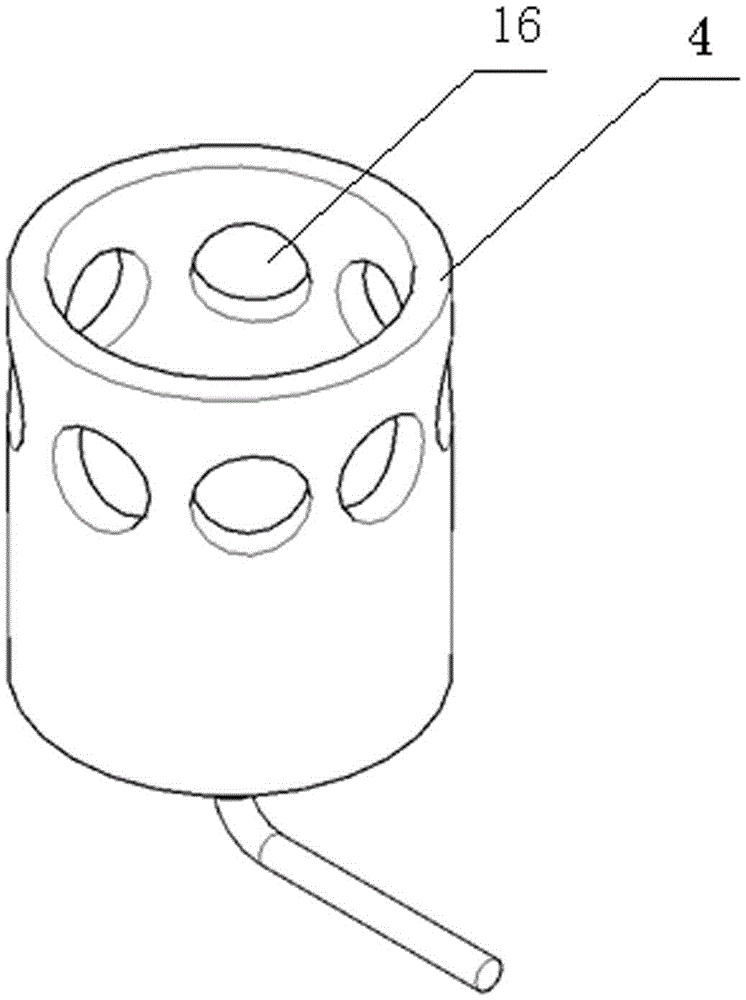

[0025] With reference to the accompanying drawings, the closed heat source tower liquid collection circulation water diversion and drainage system of this embodiment includes a water receiving system, a water distribution system, and a liquid collection circulation system;

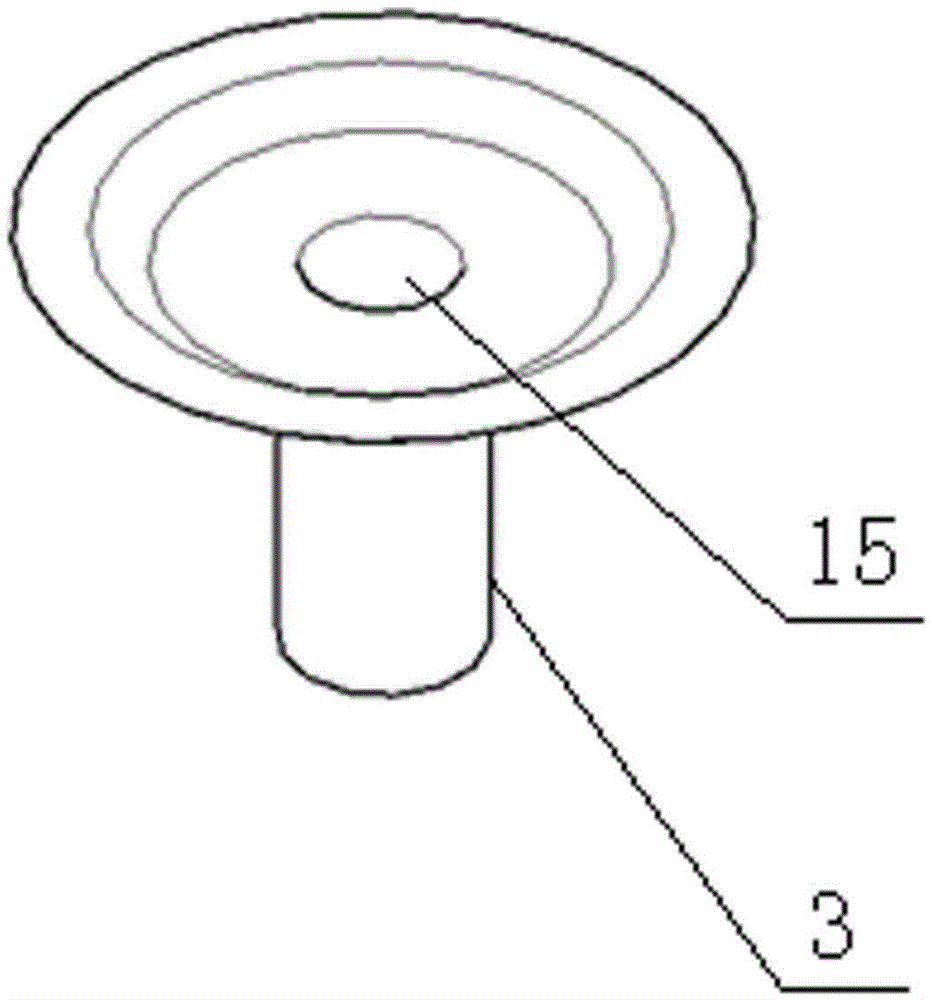

[0026] The water receiving system includes a water receiving tray 1, a filter 2 and a guide pipe 3, the water receiving tray 1 is arranged under the heat exchanger 13 of the closed heat source tower, and the surface area of the water receiving tray 1 is the same as the net area in the tower body , the net area in the tower body refers to the horizontal cross-sectional area of the inner space of the tower body. There is an orifice in the lower part of the water receiving tray 1, and the upper part of the diversion pipe 3 is connected with the orifice in the lower part of the water receiving tray 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com