Mechanical fuel gasification apparatus

A technology for fuel and internal combustion engines, which is used in fuel heat treatment devices, fuel re-atomization/homogenization, mechanical equipment, etc., to achieve the effect of improving emission rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

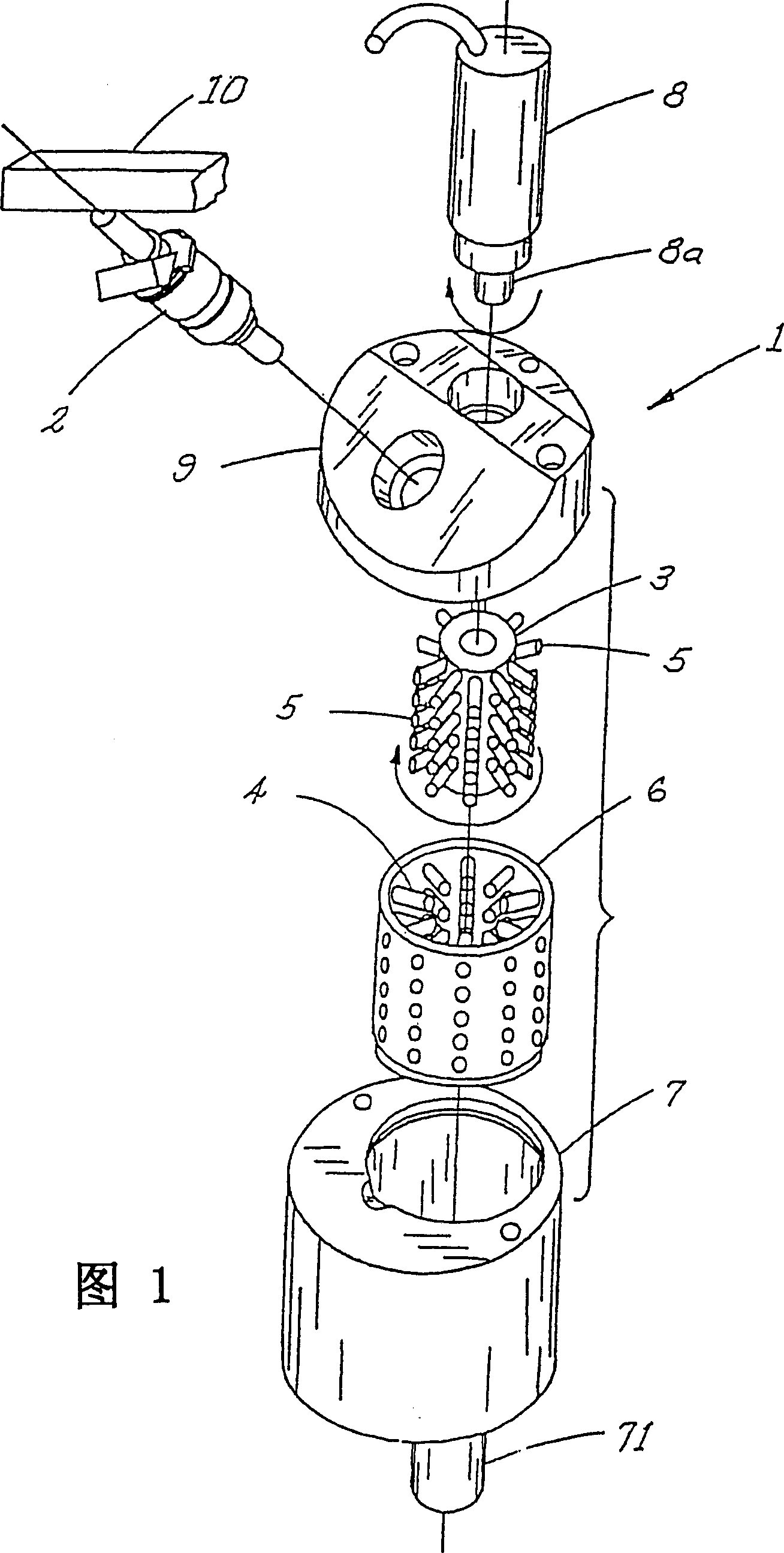

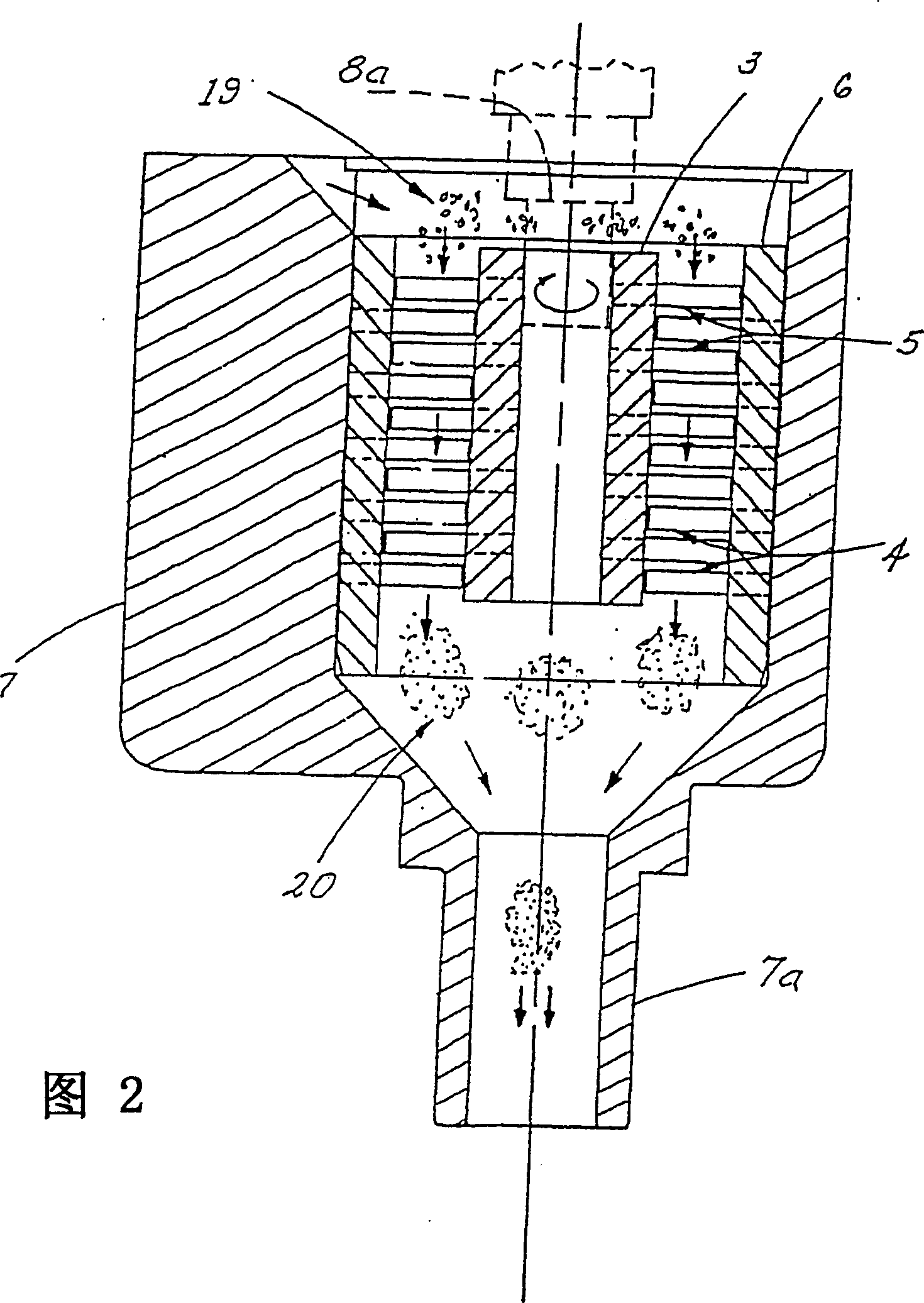

[0044] In a test of the first preferred embodiment, a 1992 Honda Accord fuel injected internal combustion engine with four cylinders was equipped with four gasification devices of the embodiment shown in FIG. 1 . These devices are located between each cylinder's fuel injector and intake manifold. Before installing the gasifier, a 12-mile gas mileage test showed a gas consumption rate of 25 mpg. Repeat testing under the same conditions at the same speed with the gasification device of the present invention installed showed an improvement in gas mileage to 35 mpg. And as the acceleration performance of the internal combustion engine on the car is significantly improved, the performance of the internal combustion engine is also significantly improved.

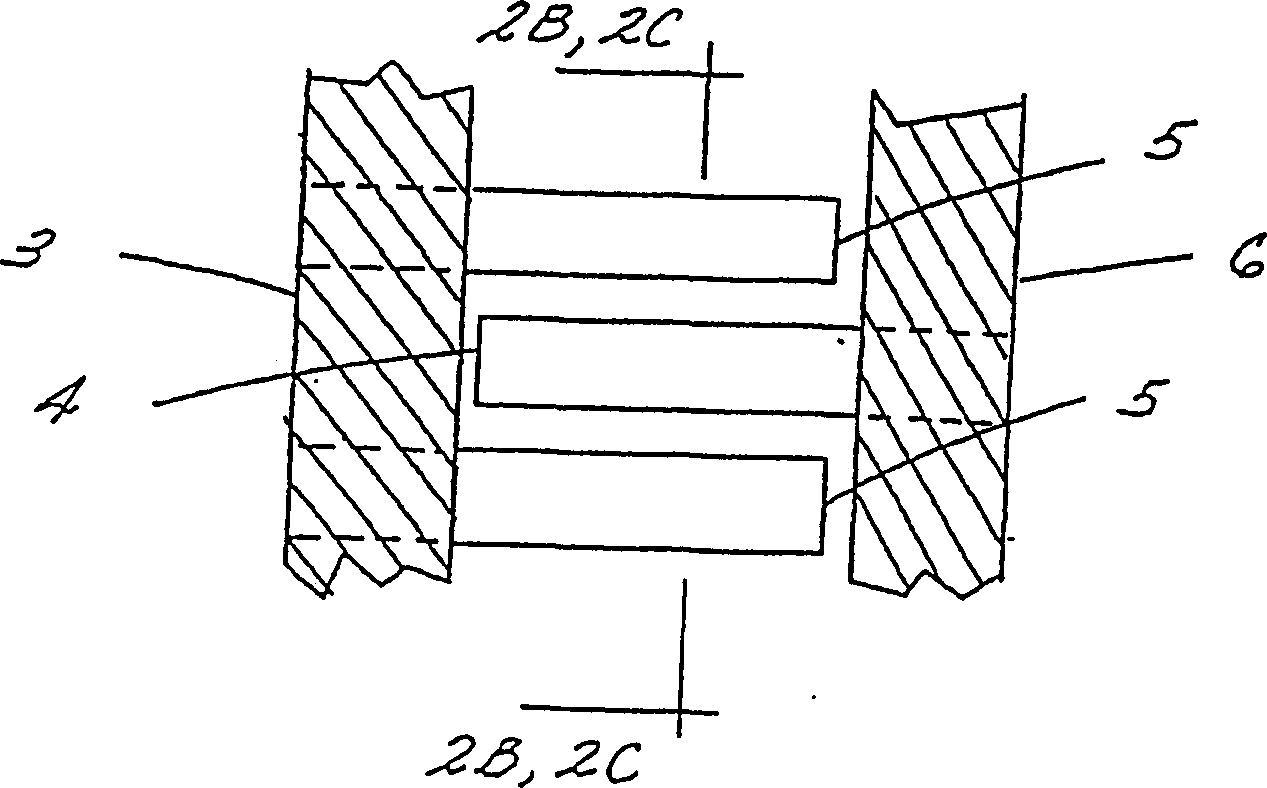

[0045] In another embodiment of the invention, the gasification device is divided into several stages, the diameter of the rotor, stator and chamber in the first stage being smaller than the diameter of the corresponding parts in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com