Integral water purifier with sterilizing function and manufacturing method thereof

An all-in-one, water purifier technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of promoting metabolism, significant removal effect, and avoiding the escape of filter material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

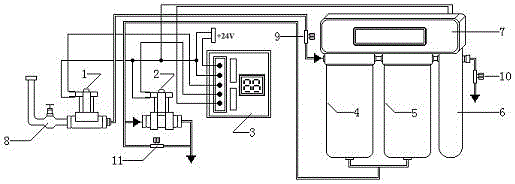

[0014] figure 1 The situation of the water treatment device of the present invention is shown. For urban and rural household use, tap water is directly introduced, and sent into the device of the present invention through pipelines for filtering treatment, and the treated water is output through the valve 10 for use .

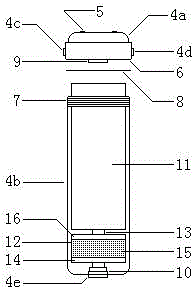

[0015] figure 2 Among them, the high-precision PP fiber cotton filter device 4 is an airtight container composed of a cylinder body 4b and an upper valve seat 4a. The cylinder body 4b and the upper valve seat 4a are spirally connected. The screw fixing hole 5 connected to the cover, the lower opening of the upper valve seat is provided with a spiral inner thread opening 6, the upper opening of the cylinder is provided with a spiral outer thread opening 7 and a silicone sealing ring 8, and the center of the upper valve seat is provided with an upper circle Shaped card tube 9, the bottom of the cylinder is provided with a lower circular card tube 10, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com