Piston air inlet type two-stroke engine

A two-stroke, air-intake technology, used in engine components, machines/engines, mechanical equipment, etc., can solve problems such as bad combustion pollutants, increase exhaust emissions, affect exhaust emissions, avoid air short-circuit losses, and increase turbulence. degree, the effect of helping to burn and work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

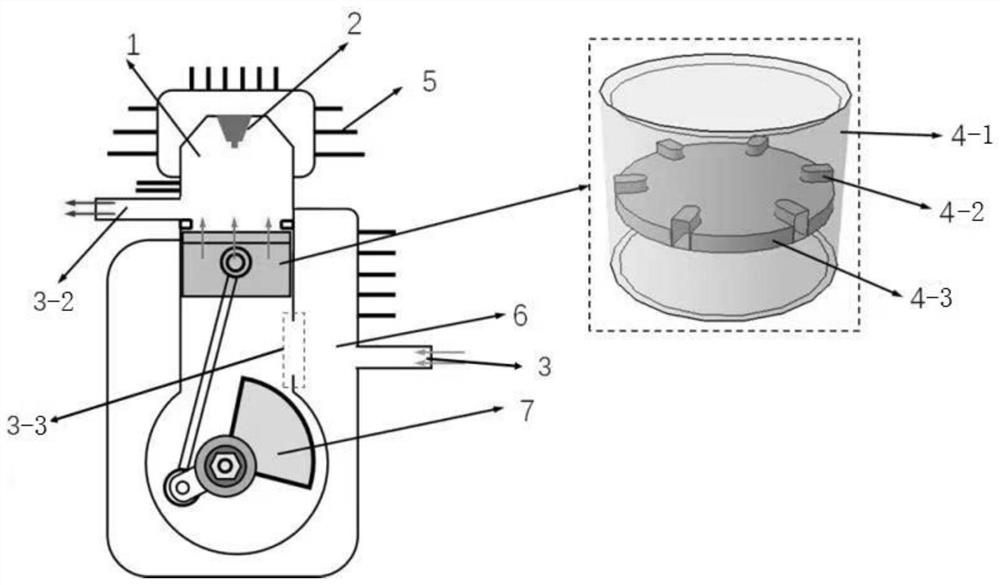

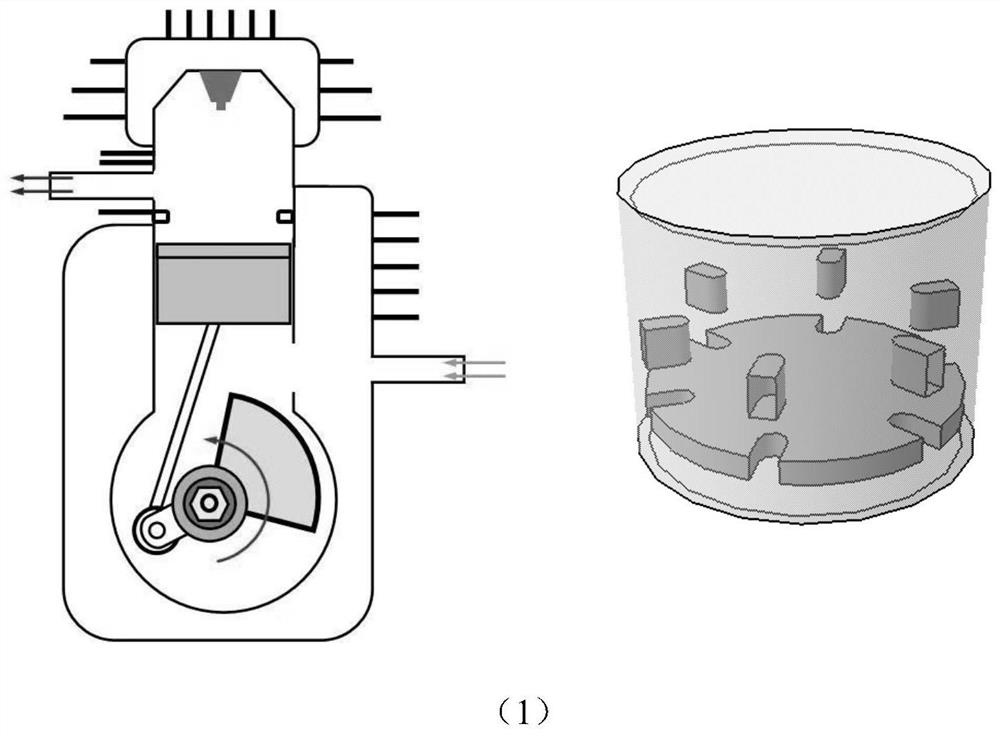

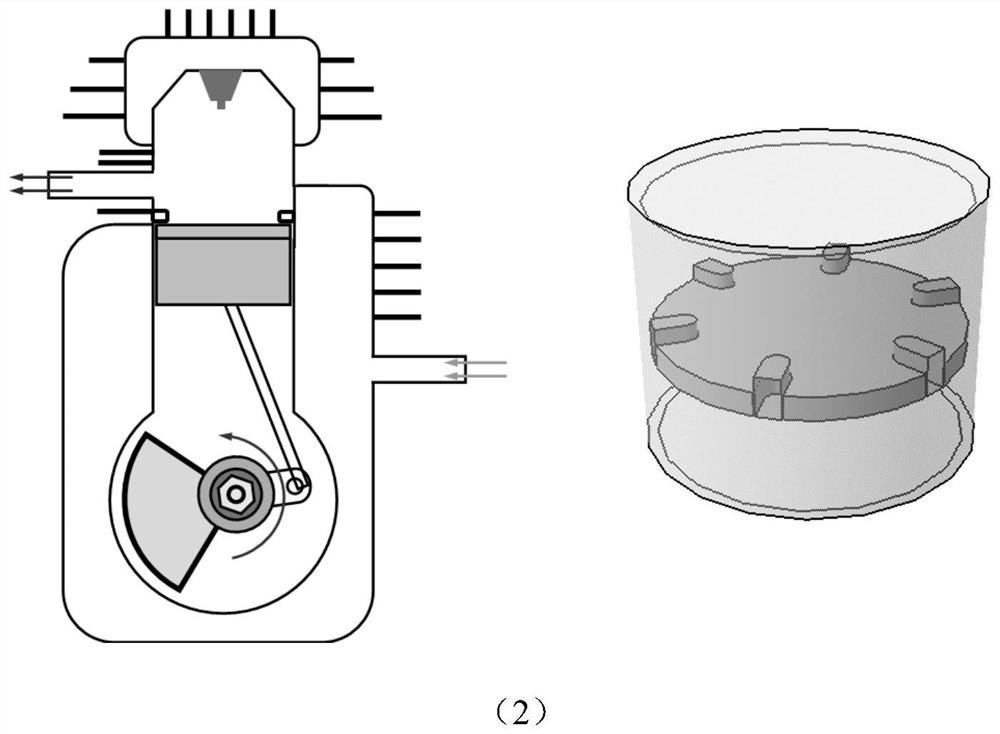

[0029] The invention discloses a piston intake type two-stroke engine, which adopts the vertical intake mode of the piston opening, reduces the short-circuit loss of the intake air and improves the air turbulence degree, so that the fuel oil can be burned more fully, thereby reducing the discharge of exhaust gas pollutants. refer to figure 1 As shown, it includes combustion chamber 1, spark plug 2, intake port 3-1, exhaust port 3-2, cylinder wall 4-1, intake switch 4-2, open intake piston 4-3, heat sink 5 , scavenging air box 6, flywheel 7.

[0030] Described flywheel 7 is connected with piston by crankshaft, connecting rod; Combustion chamber 1 is above the piston in described cylinder wall 4-1, and spark plug 2 is installed on its top; Described piston is open air intake piston 4-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com