Method and cooler for cooling hot-state granular material during enhanced convection heat exchange

A granular material and cooler technology, which is applied in the field of hot granular material cooling and cooler in the enhanced convective heat transfer process, can solve the problem that the heat transfer efficiency is difficult to achieve the expected effect, the particle size and resistance of the material layer are uneven, and the cooling air Unable to achieve uniform distribution and other problems, to achieve the effect of increased contact opportunities and area, uniform particle size distribution, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing:

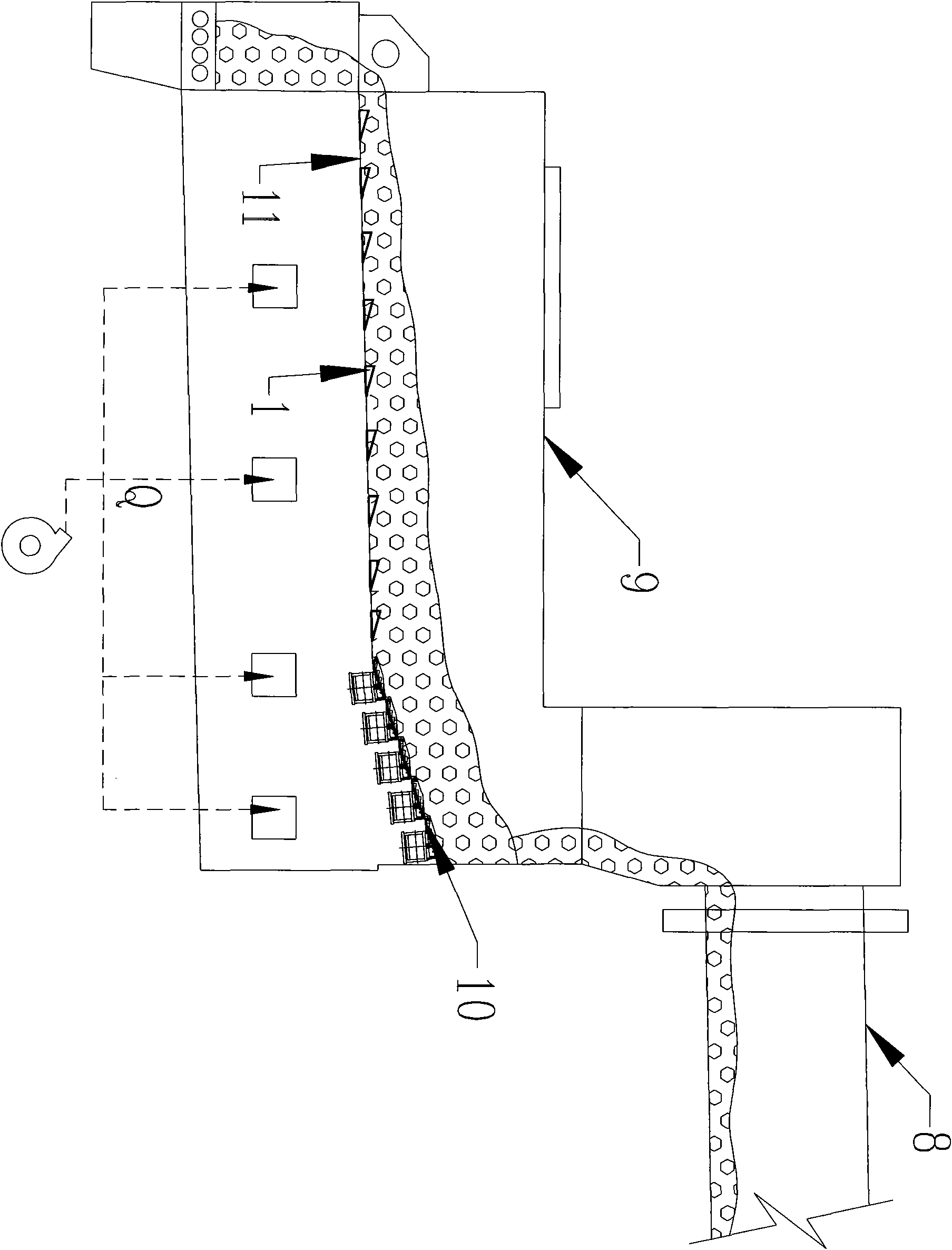

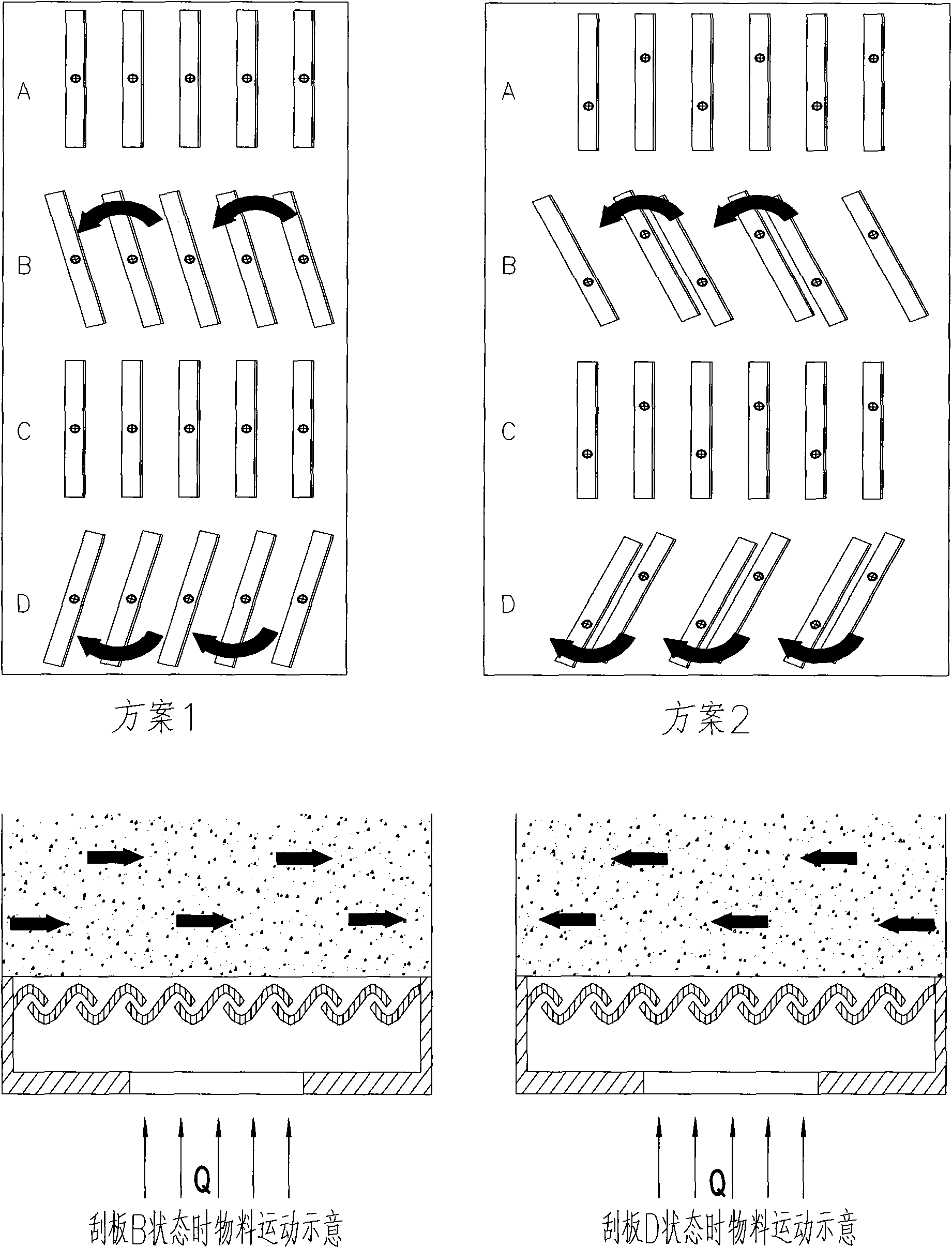

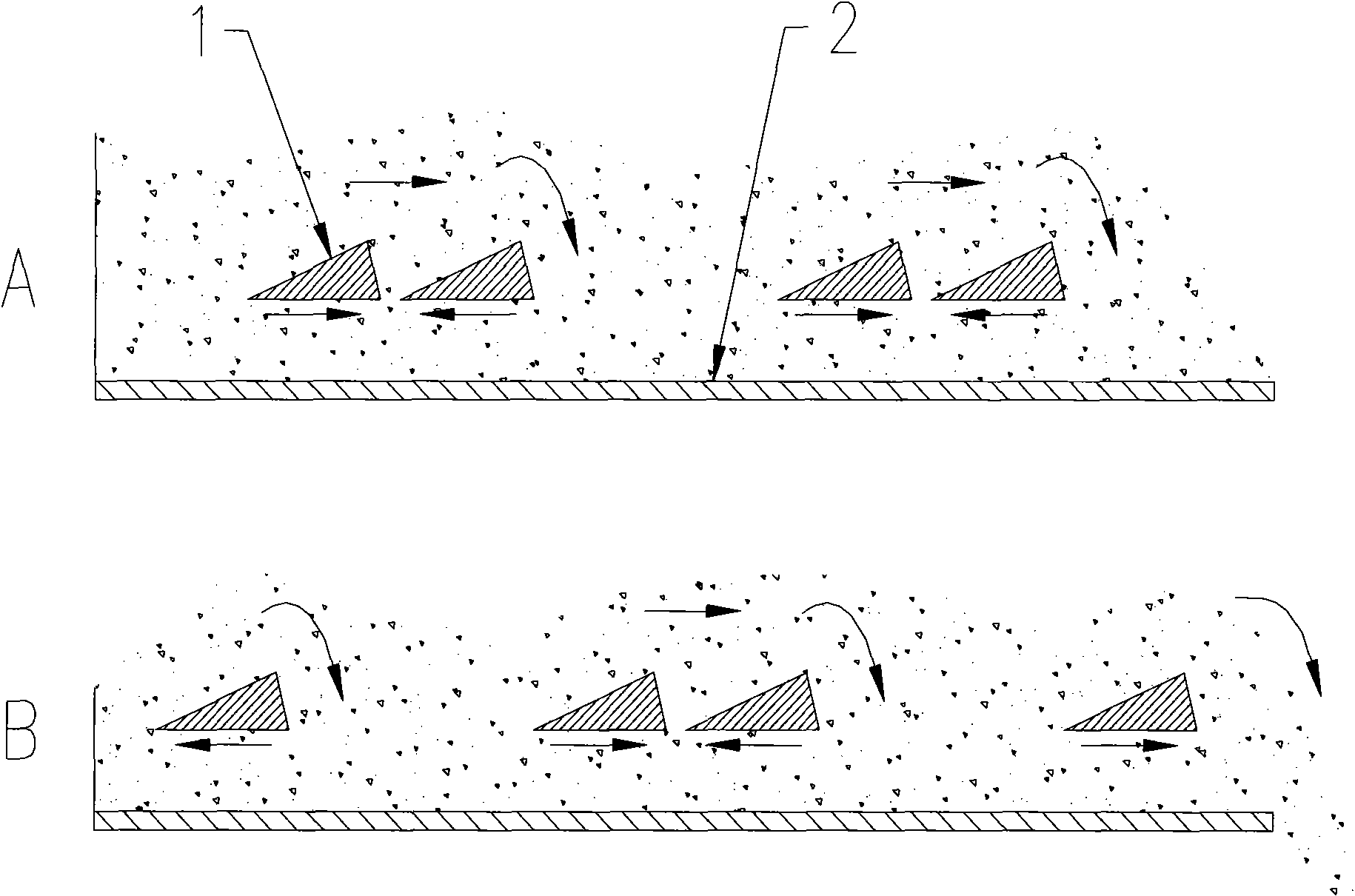

[0019] attached by figure 1 As shown, the method for cooling hot granular materials and coolers thereof for the enhanced convective heat transfer process of the present invention is used in the cooling process of clinker granular materials produced by industrial kiln equipment such as cement rotary kilns, from the rotary kiln 8 The high-temperature granular material is transported to the cooler 9 and enters the stepped grate bed 10 and then enters the horizontal grate bed 11. The cooling air Q from under the grate bed passes through the grate bed to exchange heat with the hot granular material layer to achieve cooling of the hot granular material. Function, after the material enters the horizontal grate bed 11, a reciprocating sweeping pusher scraper 1 device can make the hot granular material produce two kinds of motion superimposition, forced stirring homogenization and tumbling forwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com