Four-stroke free piston internal combustion engine

An internal combustion engine, four-stroke technology, applied in free-piston engines, mechanical equipment, machines/engines, etc., can solve the problems of internal combustion engines without intake and exhaust strokes, high fuel consumption, consumption, etc., to reduce fuel consumption and avoid short-circuit losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

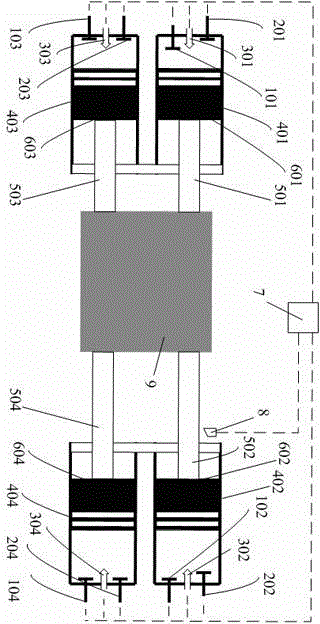

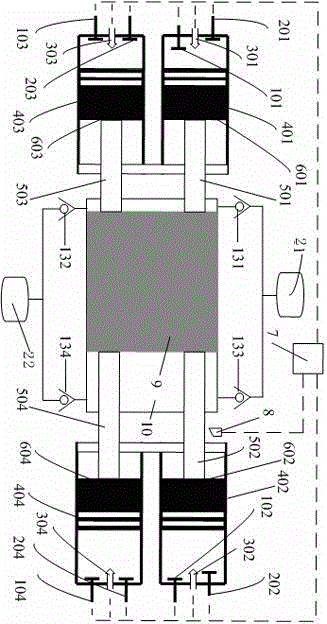

Embodiment 1

[0016] This embodiment mainly describes the application of the invented four-stroke free piston internal combustion engine to directly drive the linear generator, which includes:

[0017] A cylinder block, including four cylinders 401, 401, 403, 404; an intake valve group, including four electronically controlled intake mechanisms 101, 102, 103, 104, respectively located in the above four cylinders 401, 401, 403, 404; an exhaust valve group, including four electronically controlled exhaust mechanisms 201, 202, 203, 204, respectively located in the four cylinders 401, 401, 403, 404; a nozzle group, including four electronically controlled nozzles 301, 302, 303, and 304 are respectively located in the above four cylinders 401, 401, 403, 404; a piston group, including four pistons 601, 602, 603, 604, are respectively located in the above four cylinders 401, 401, 403, 404; a connecting rod group, including four connecting rods 501, 502, 503, 504, respectively connected to the piston ...

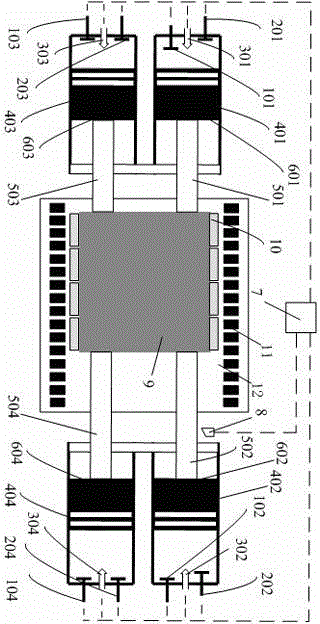

Embodiment 2

[0020] This embodiment mainly describes the invented four-stroke free piston internal combustion engine as the power source of the hydraulic pump, which includes:

[0021] A cylinder block, including four cylinders 401, 401, 403, 404; an intake valve group, including four electronically controlled intake mechanisms 101, 102, 103, 104, respectively located in the above four cylinders 401, 401, 403, 404; an exhaust valve group, including four electronically controlled exhaust mechanisms 201, 202, 203, 204, respectively located in the four cylinders 401, 401, 403, 404; a nozzle group, including four electronically controlled nozzles 301, 302, 303, and 304 are respectively located in the above four cylinders 401, 401, 403, 404; a piston group, including four pistons 601, 602, 603, 604, are respectively located in the above four cylinders 401, 401, 403, 404; a connecting rod group, including four connecting rods 501, 502, 503, 504, respectively connected to the piston 601, 602, 603, 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com