Treatment method of high concentration waste alkali solution

A waste lye, high-concentration technology, applied in the direction of pulping waste liquid combustion, etc., can solve pollution, waste and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

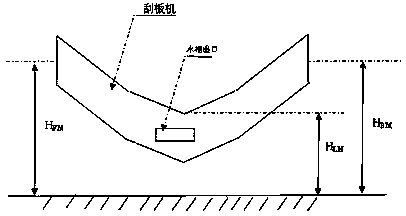

[0033] The waste lye is processed by the above-mentioned alkali recovery method incineration technology, and the resulting smelt (mainly Na 2 CO 3) under high temperature, it slips out of the chute at the bottom of the furnace in a molten state at a temperature of 980°C. It enters the pulverization area of the melt through the chute, and is cooled by the high-speed fluid ejected from the nozzle, broken into particles or powder, and the fluid pressure in front of the nozzle The fluid is a mixture of water flow, steam and compressed air, and the linear velocity of the high-speed fluid is 40m / s when it contacts the melt. The crushed crude alkali enters the guide tube with the fluid at a certain speed, is further cooled by the aqueous solution, and is carried into the scraper machine, and the solid phase is separated to obtain wet crude alkali; the water phase separated from the solid-liquid separation equipment Into an intermediate vessel such as a sink or tank, and recirculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com