Patents

Literature

61 results about "Decreased thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

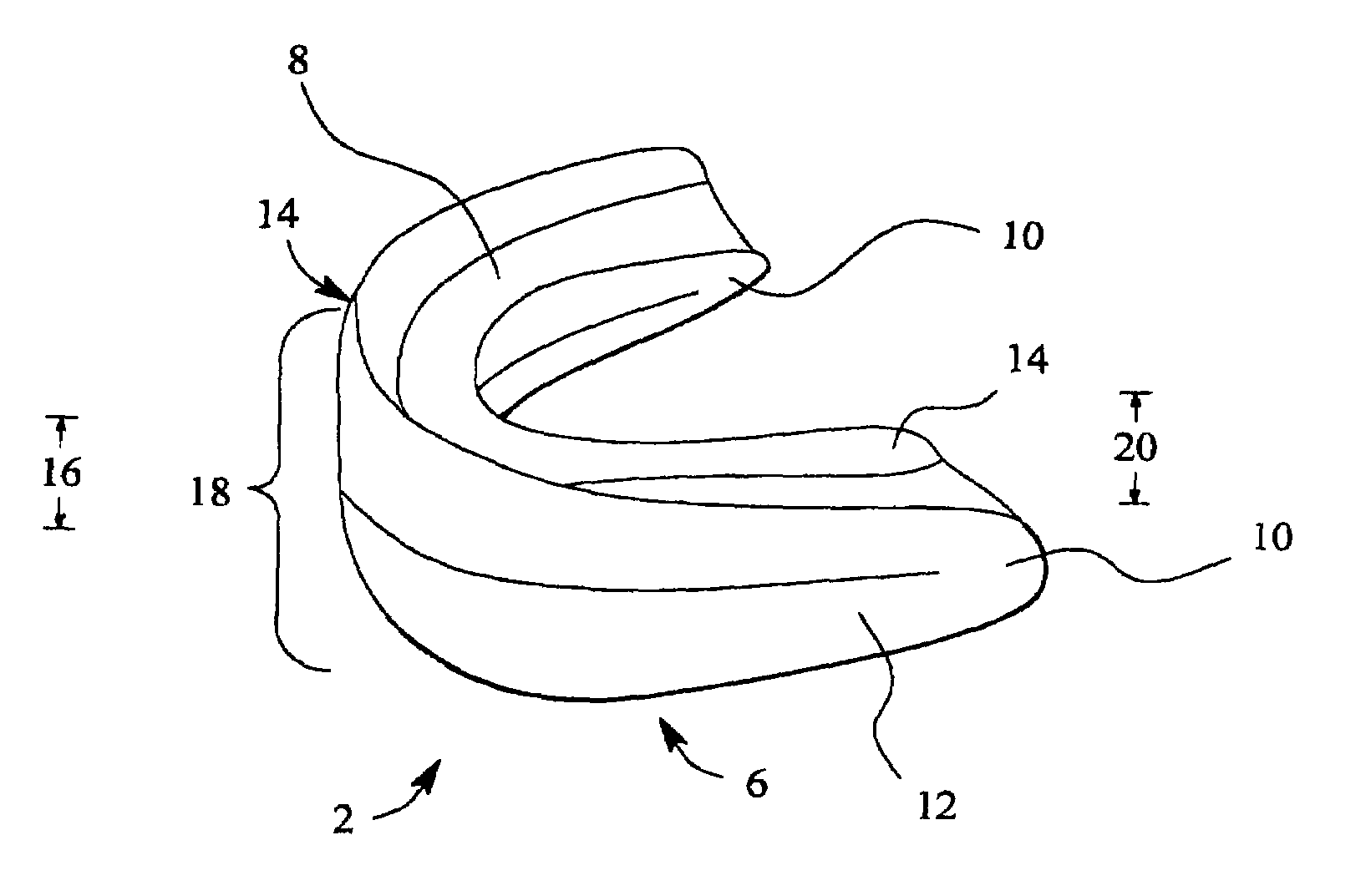

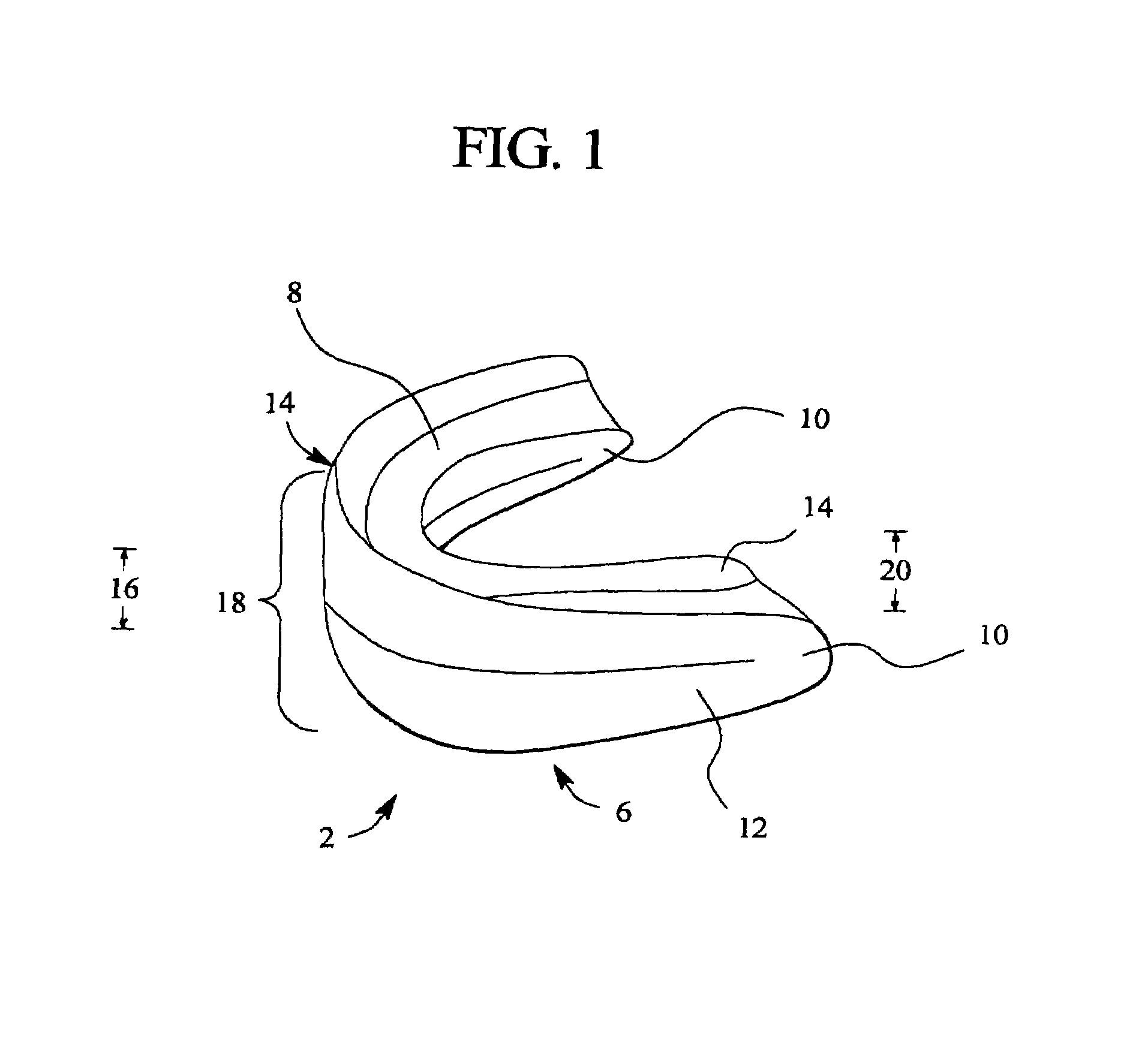

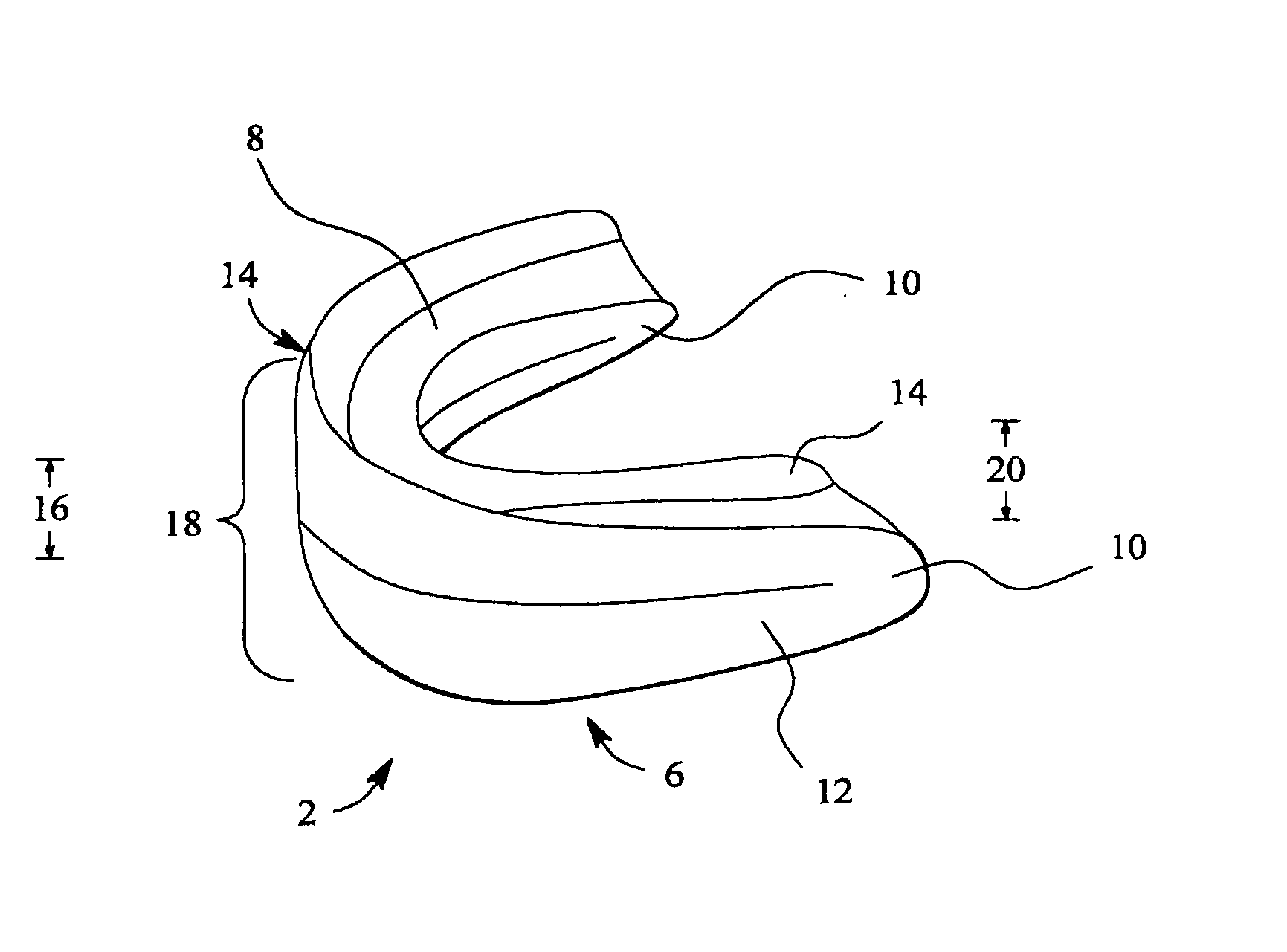

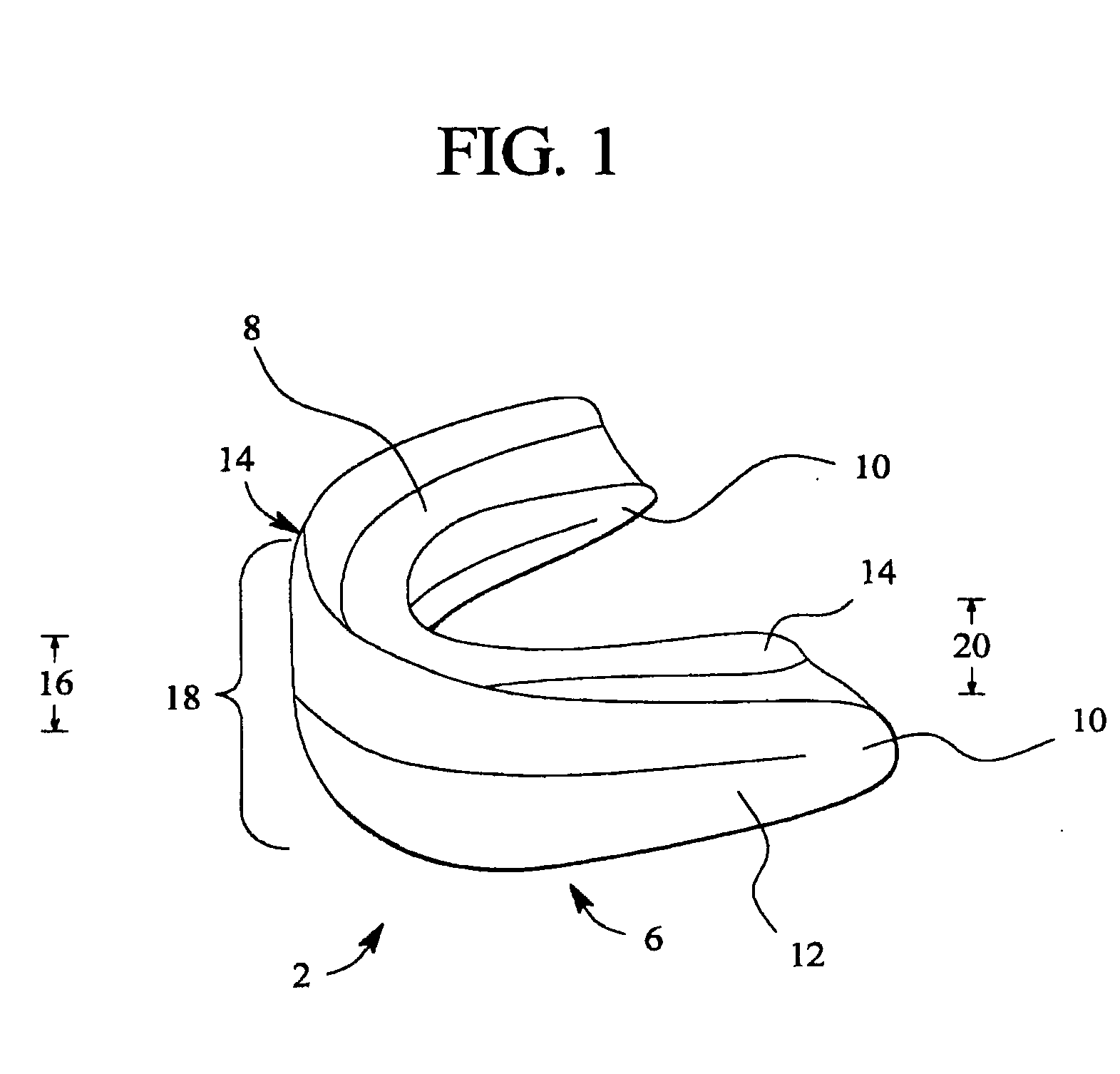

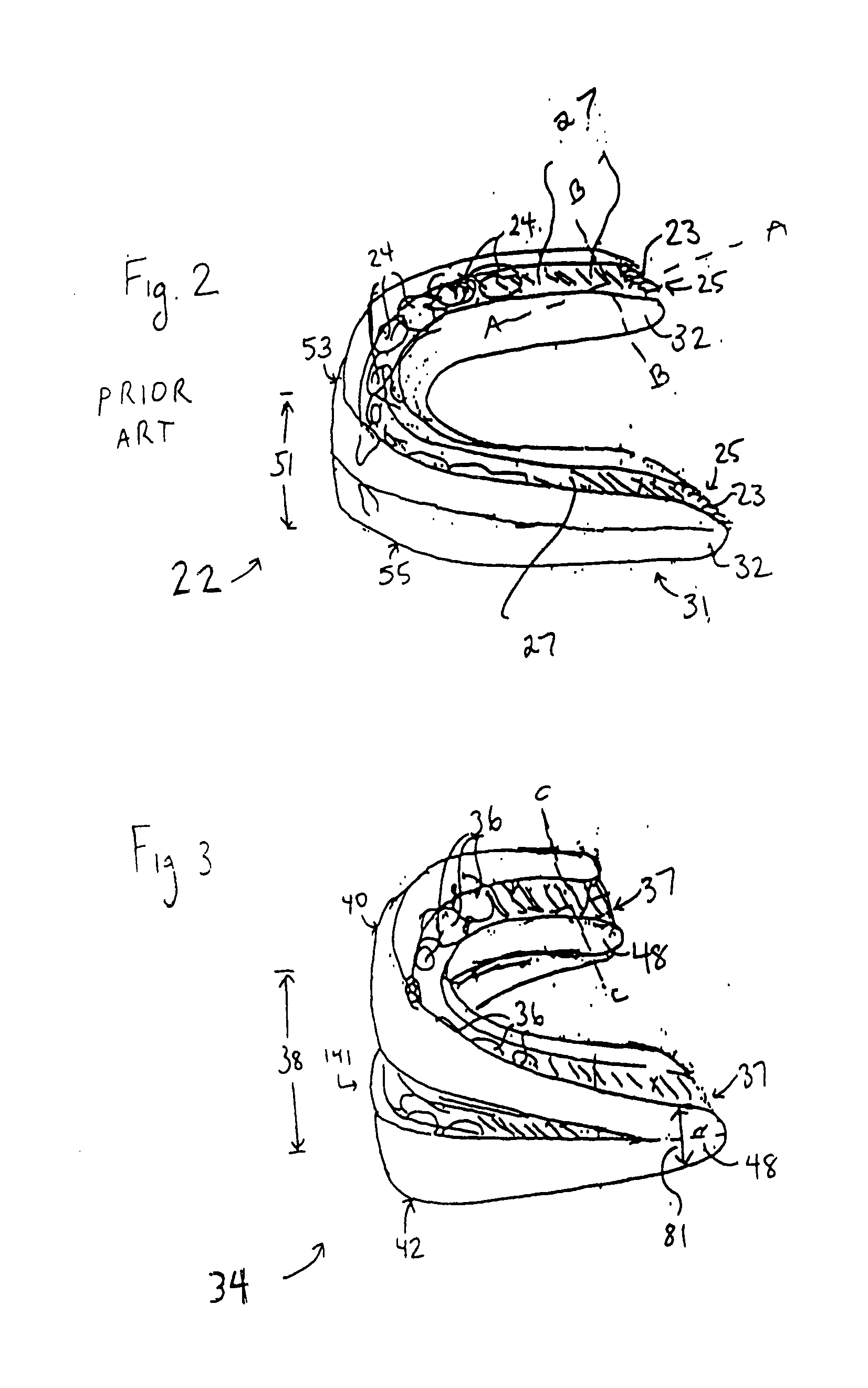

Dental appliance having an altered vertical thickness between an upper shell and a lower shell with an integrated hinging mechanism to attach an upper shell and a lower shell and a system and a method for treating malocclusions

ActiveUS7458810B2Increasing the thicknessMaintain positionAdditive manufacturing apparatusOthrodonticsOpen biteDecreased thickness

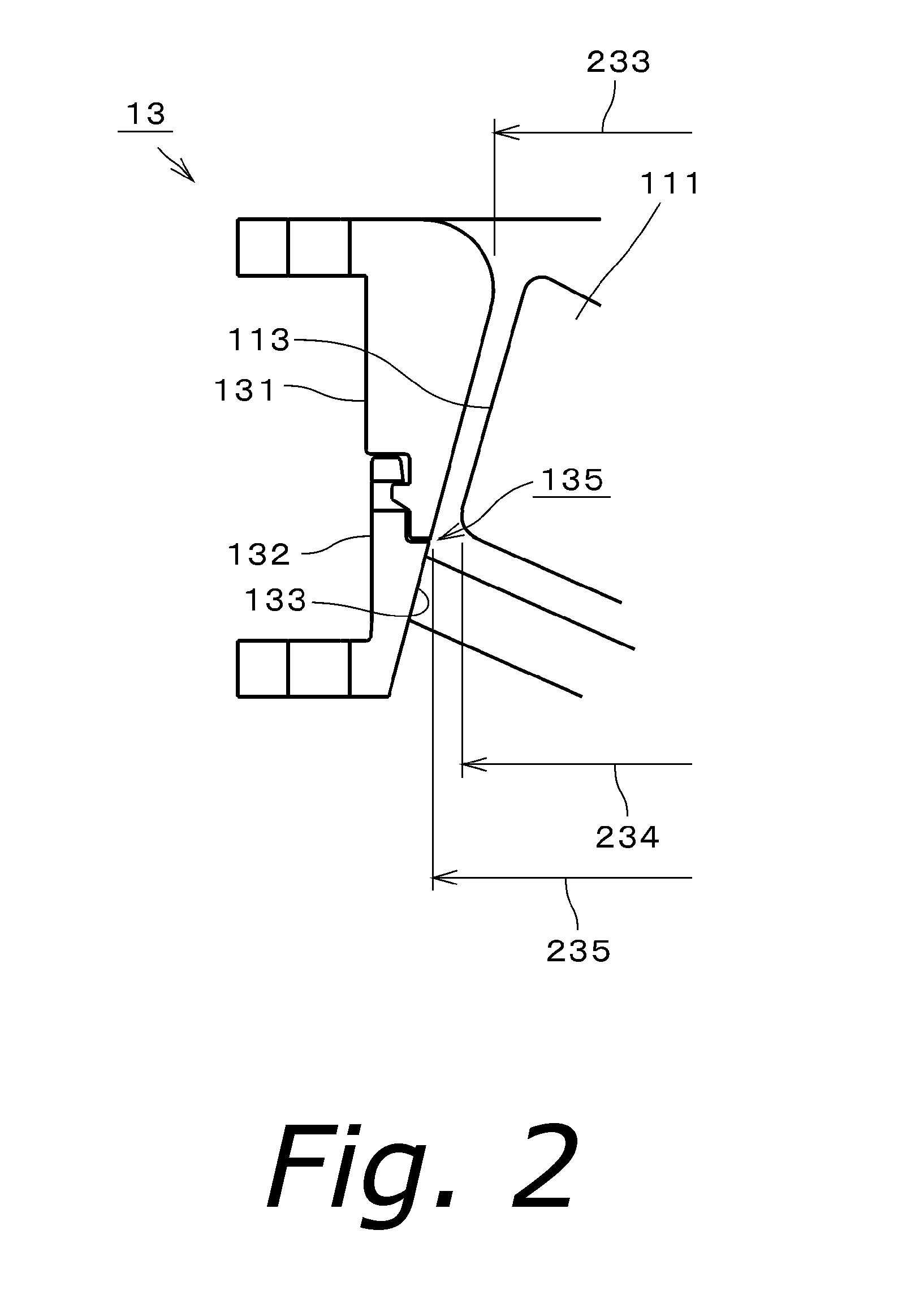

A dental appliance having increased or decreased thickness between an upper shell and a lower shell in combination with a hinging mechanism and a system and a method for treating malocclusions are provided. The dental appliance may have an upper shell and a lower shell which receive upper teeth and lower teeth, respectively, of a user. The upper shell and the lower shell may be attached at a hinge. The dental appliance may have an increased thickness between the upper shell and the lower shell as well as an increased thickness of the hinge. In an embodiment, the dental appliance may have a decreased vertical thickness and an insertable hinging mechanism. The dental appliance may then extend treatment of malocclusions to the rear teeth of the user and may correct a dental condition, such as, for example, overbite, overjet, open bite, crowding, rotations, spacing, cross-bites, gummy smiles and temporomandibular joint problems.

Owner:ORTHO TAIN INC

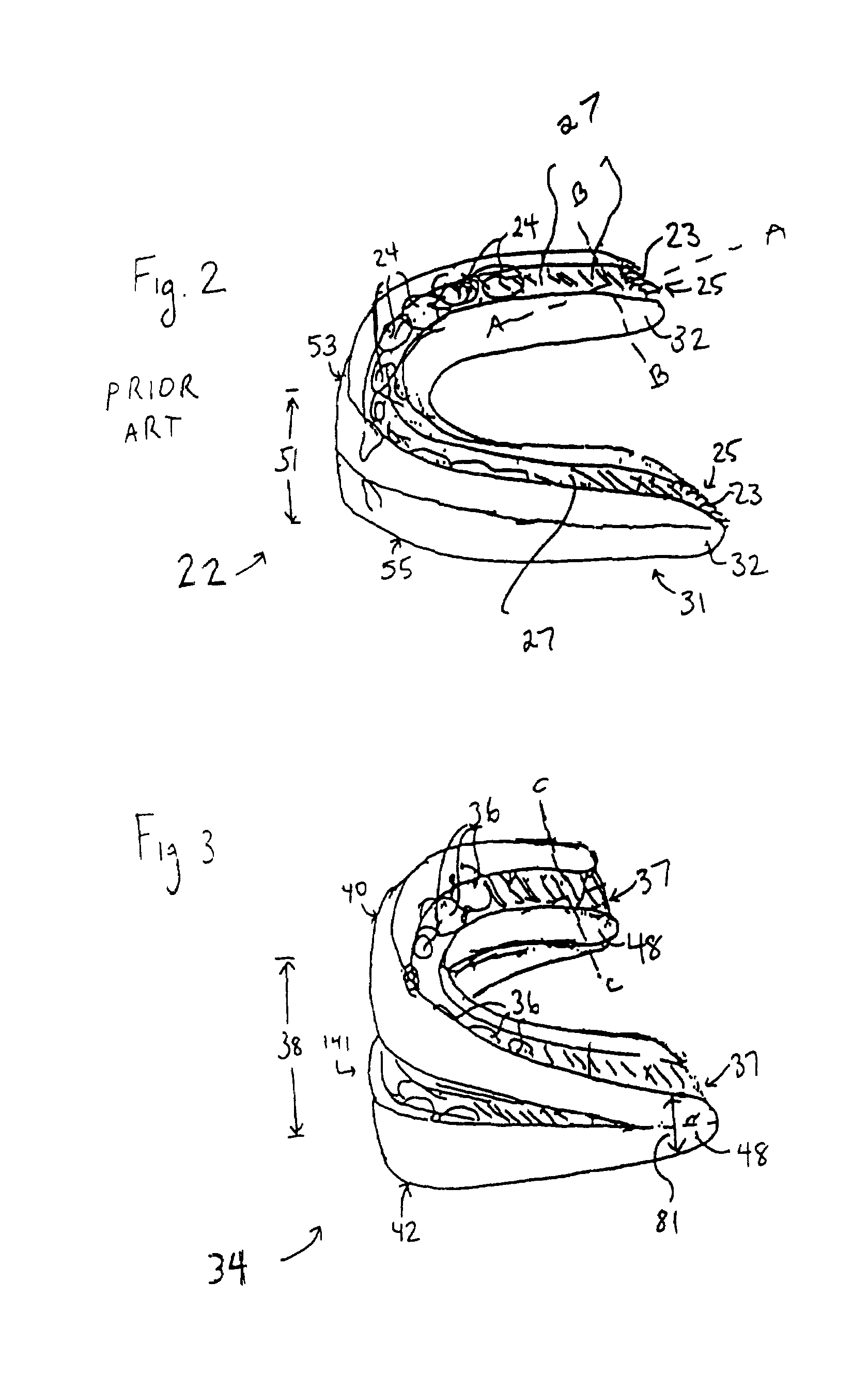

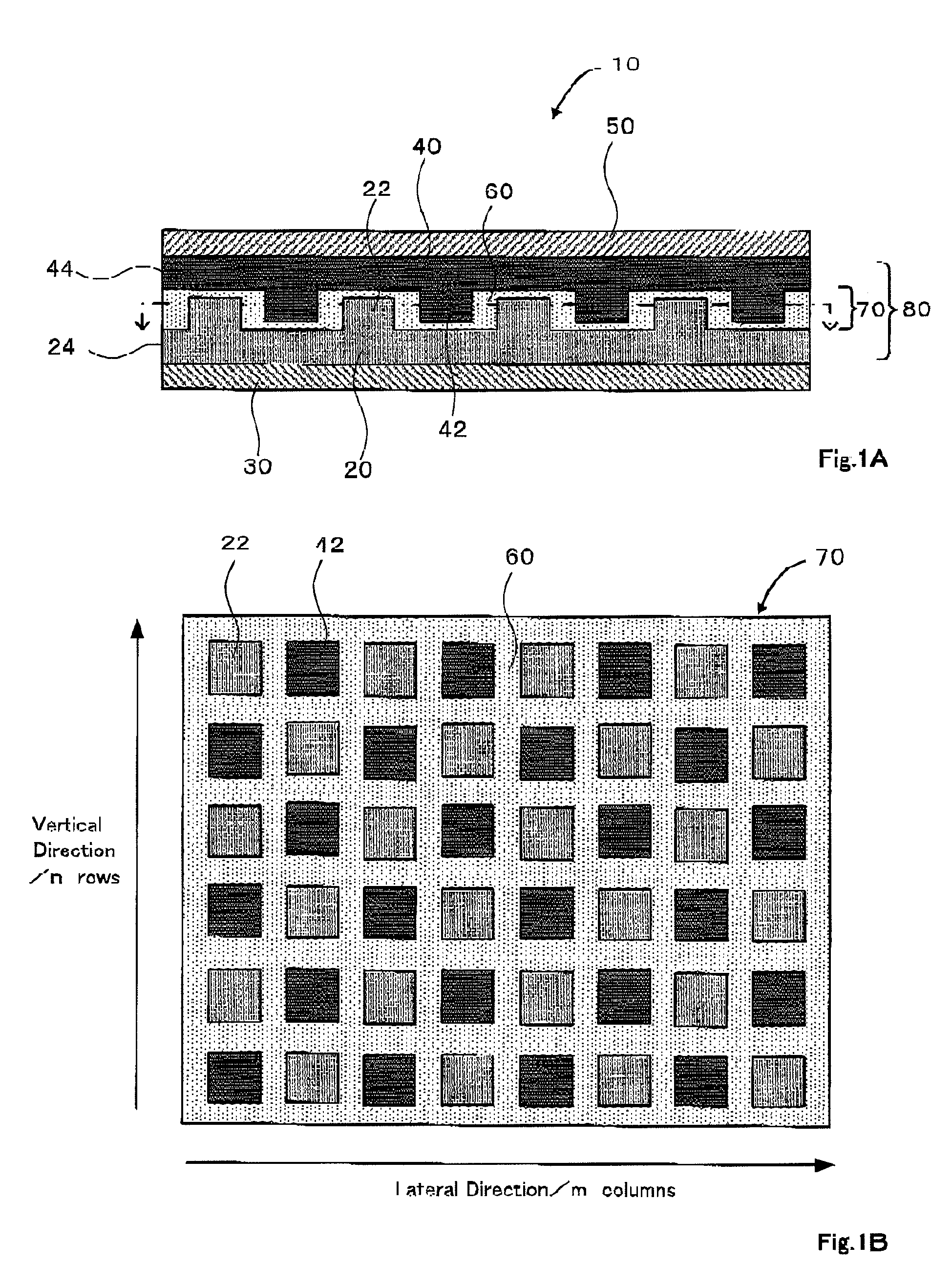

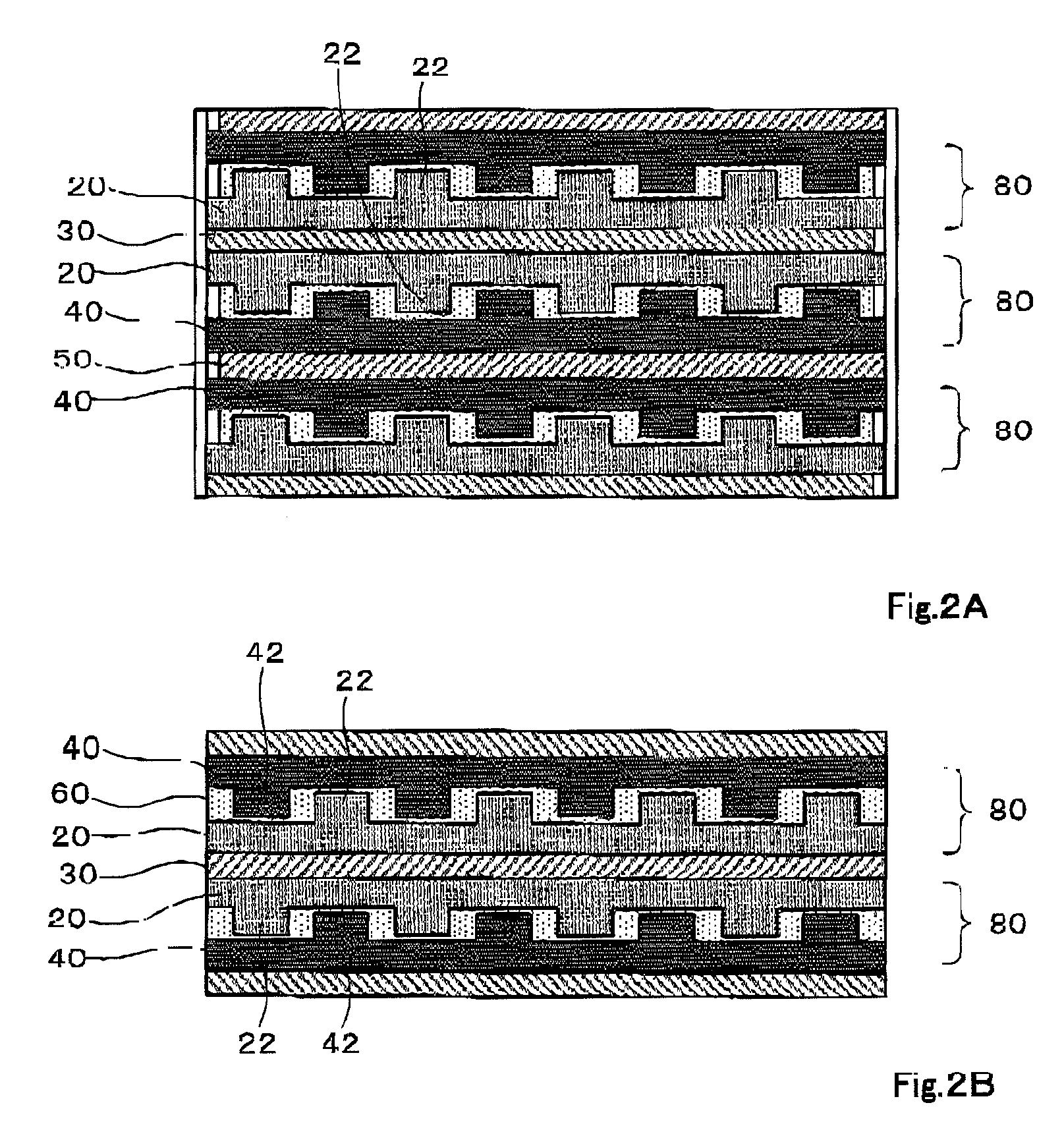

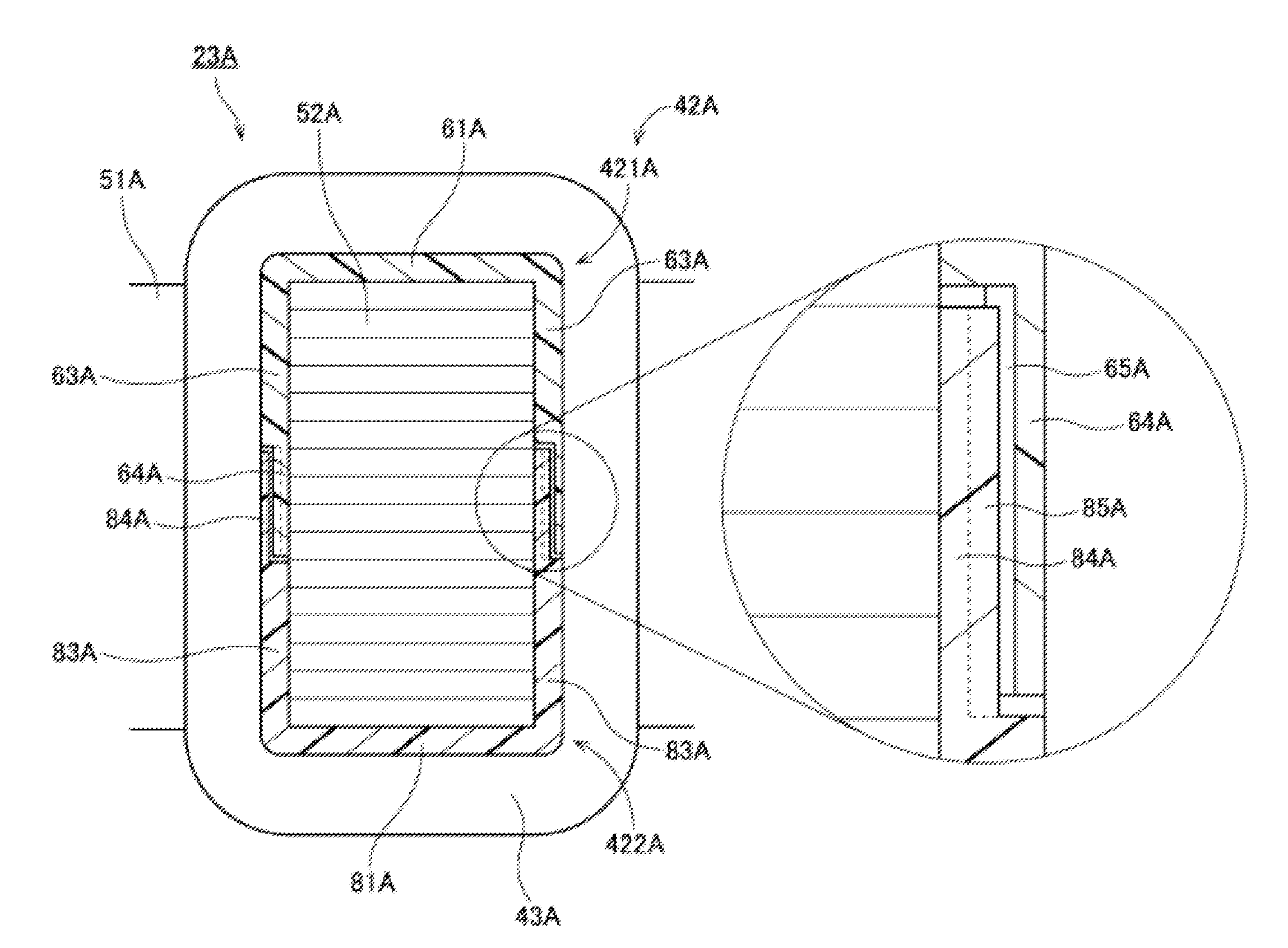

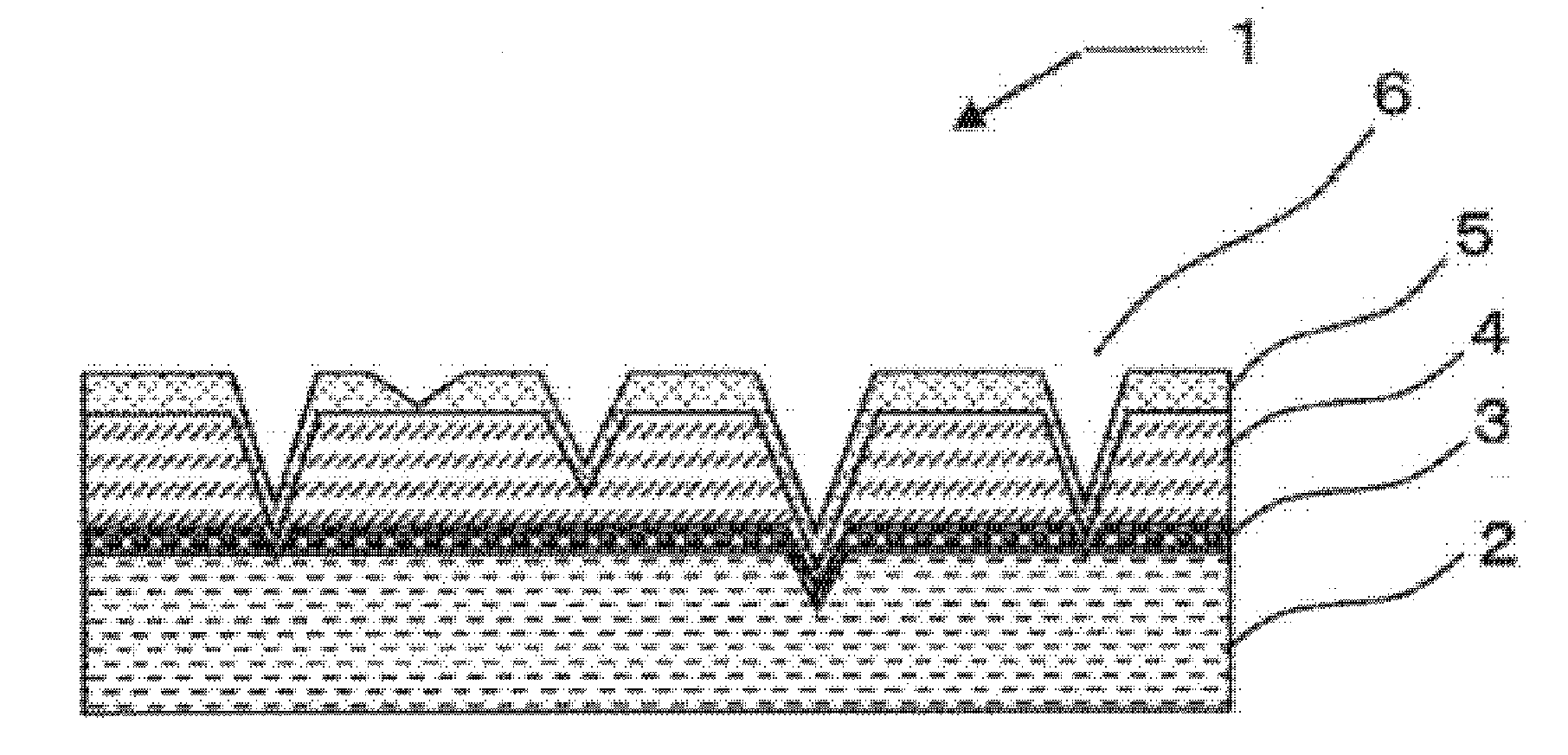

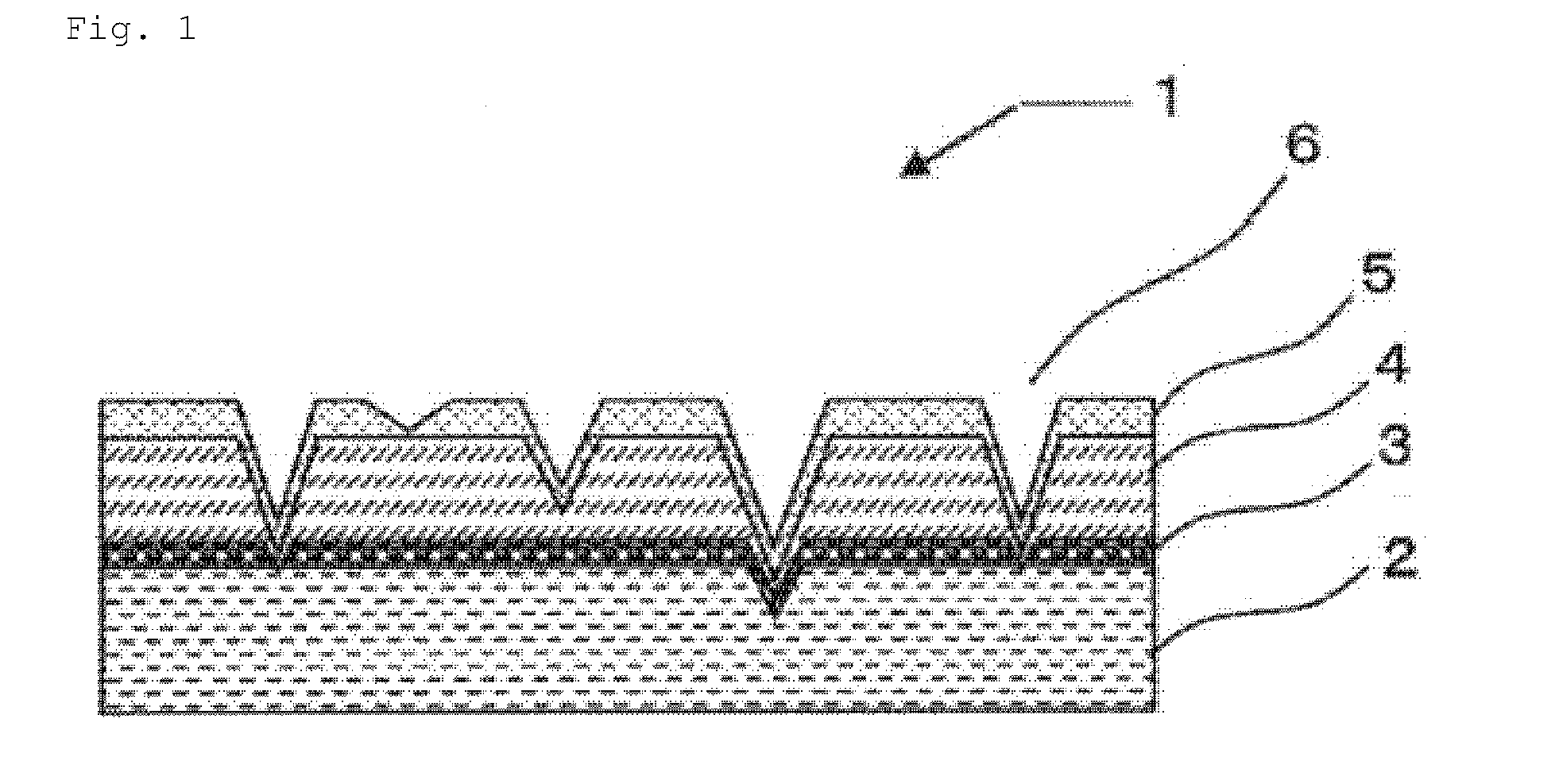

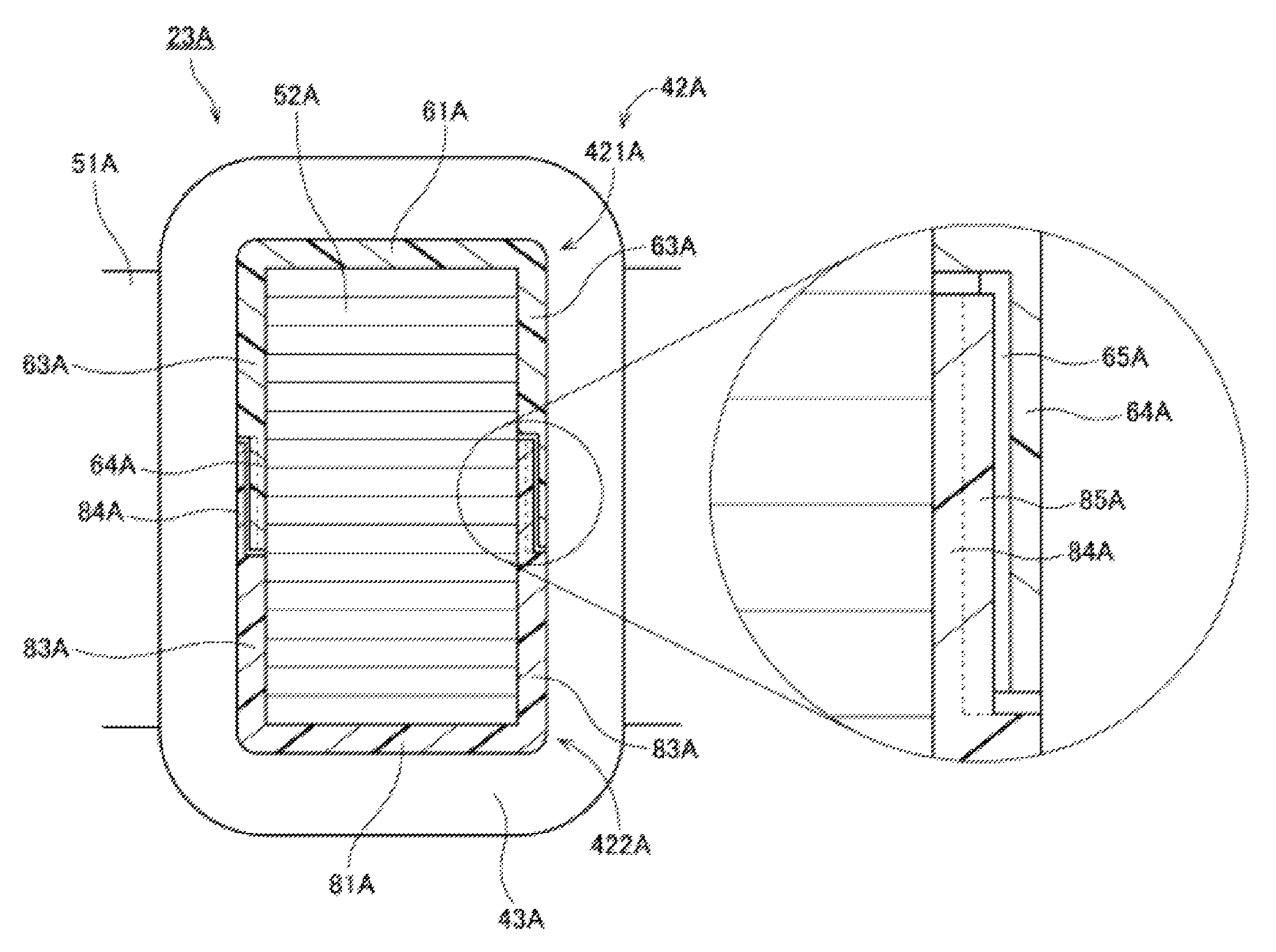

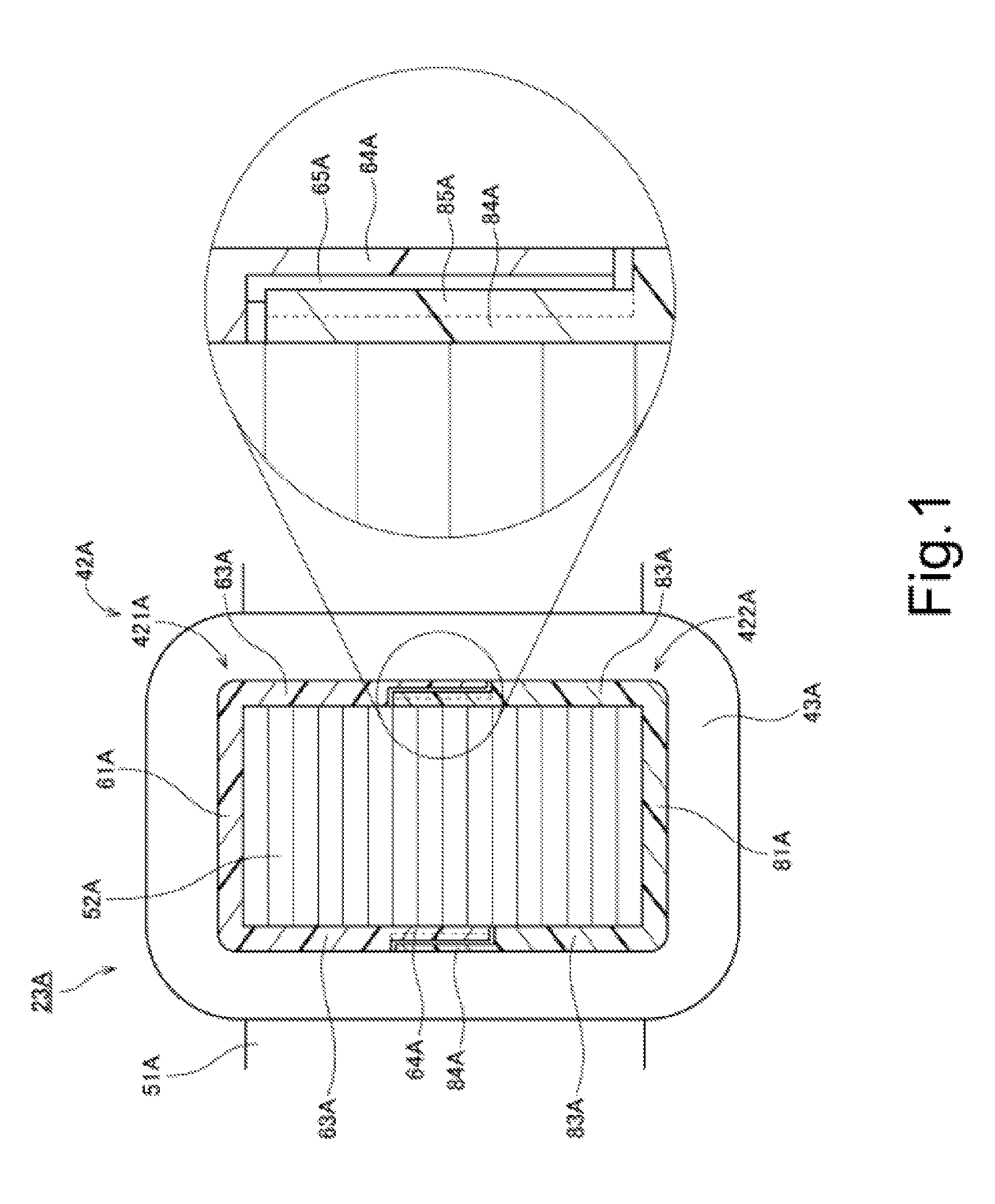

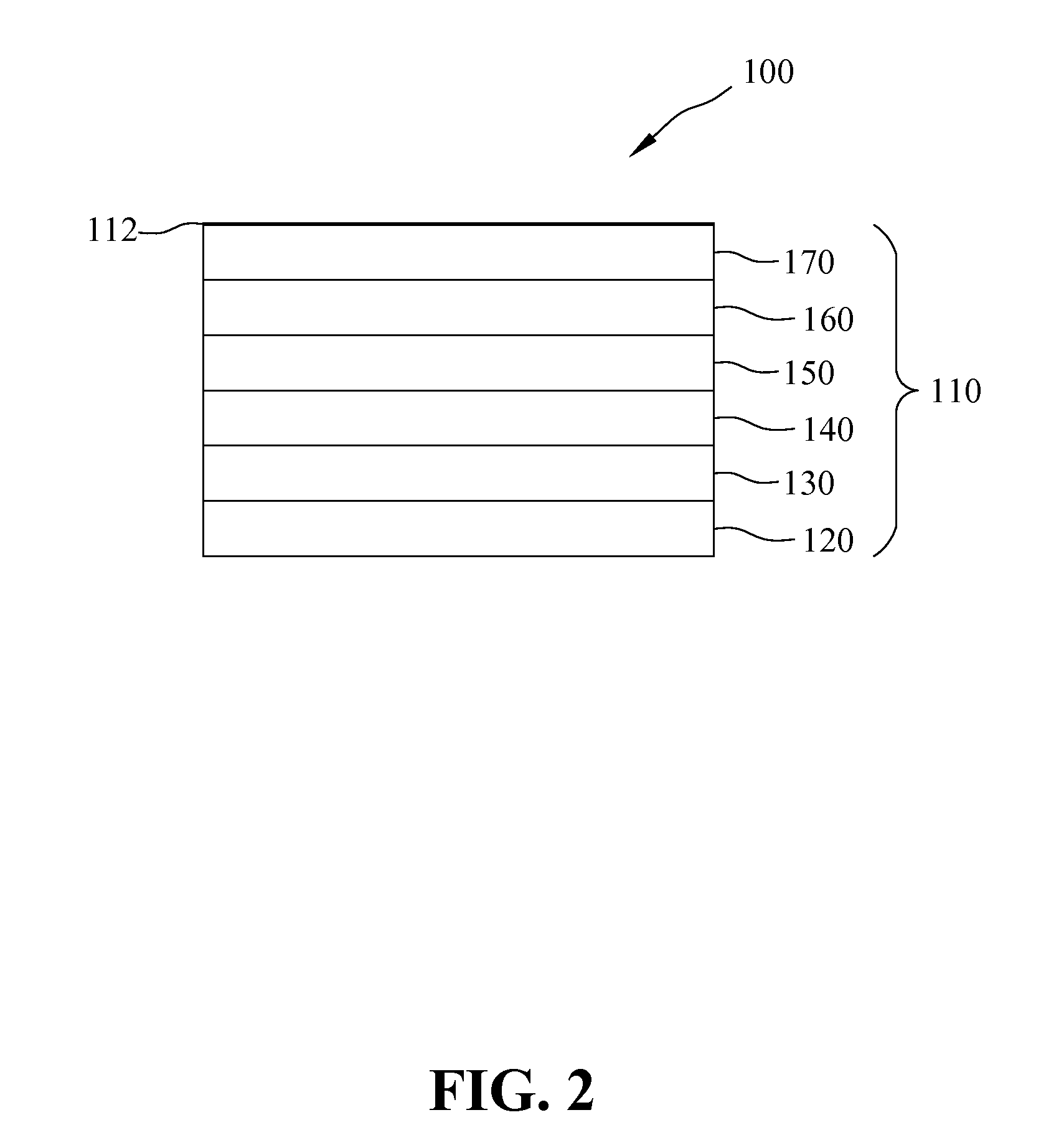

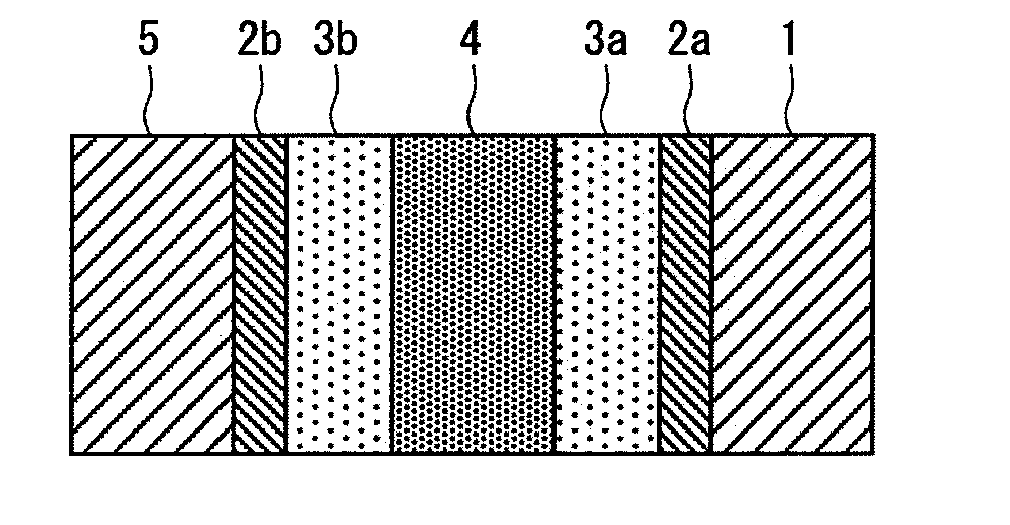

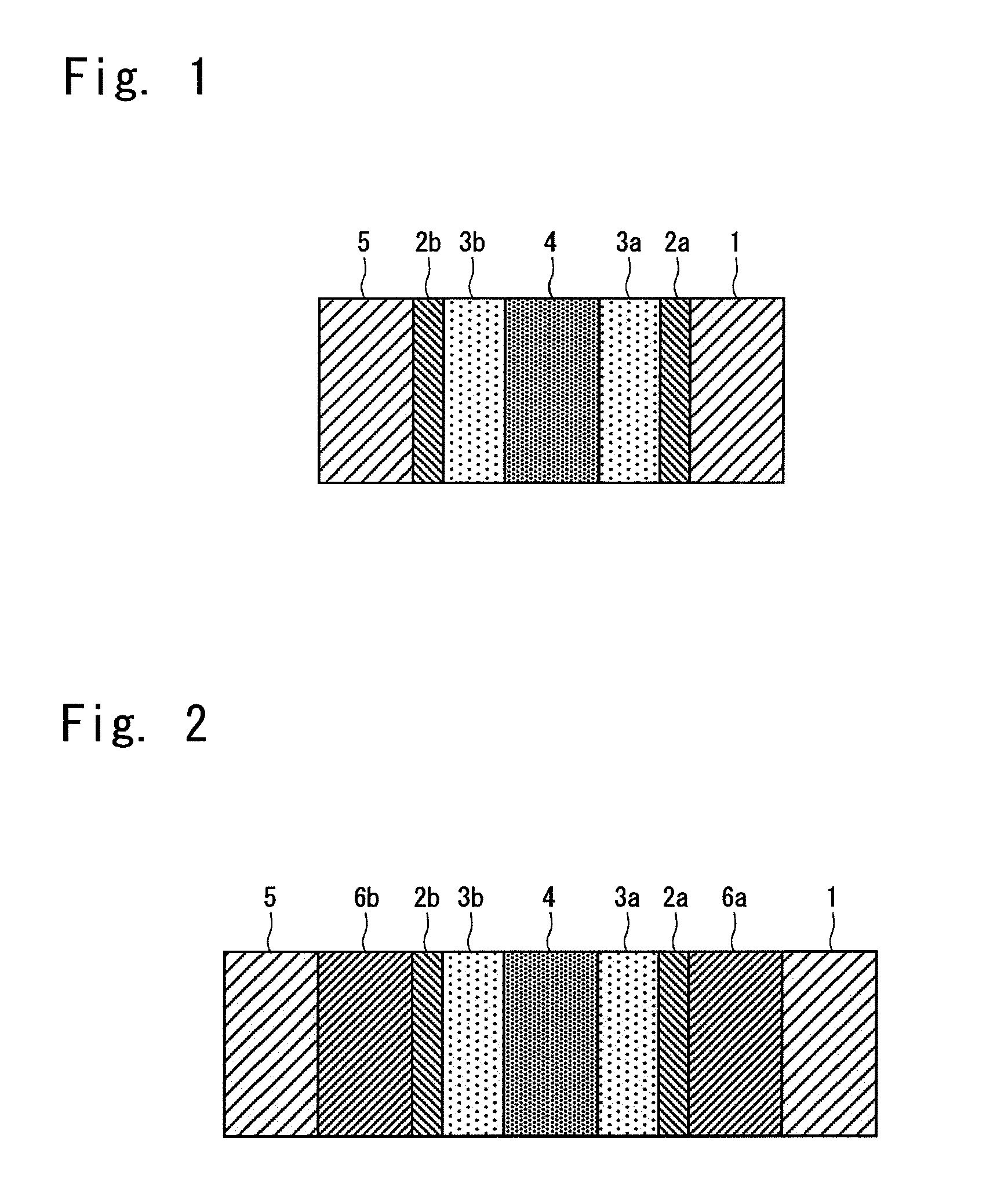

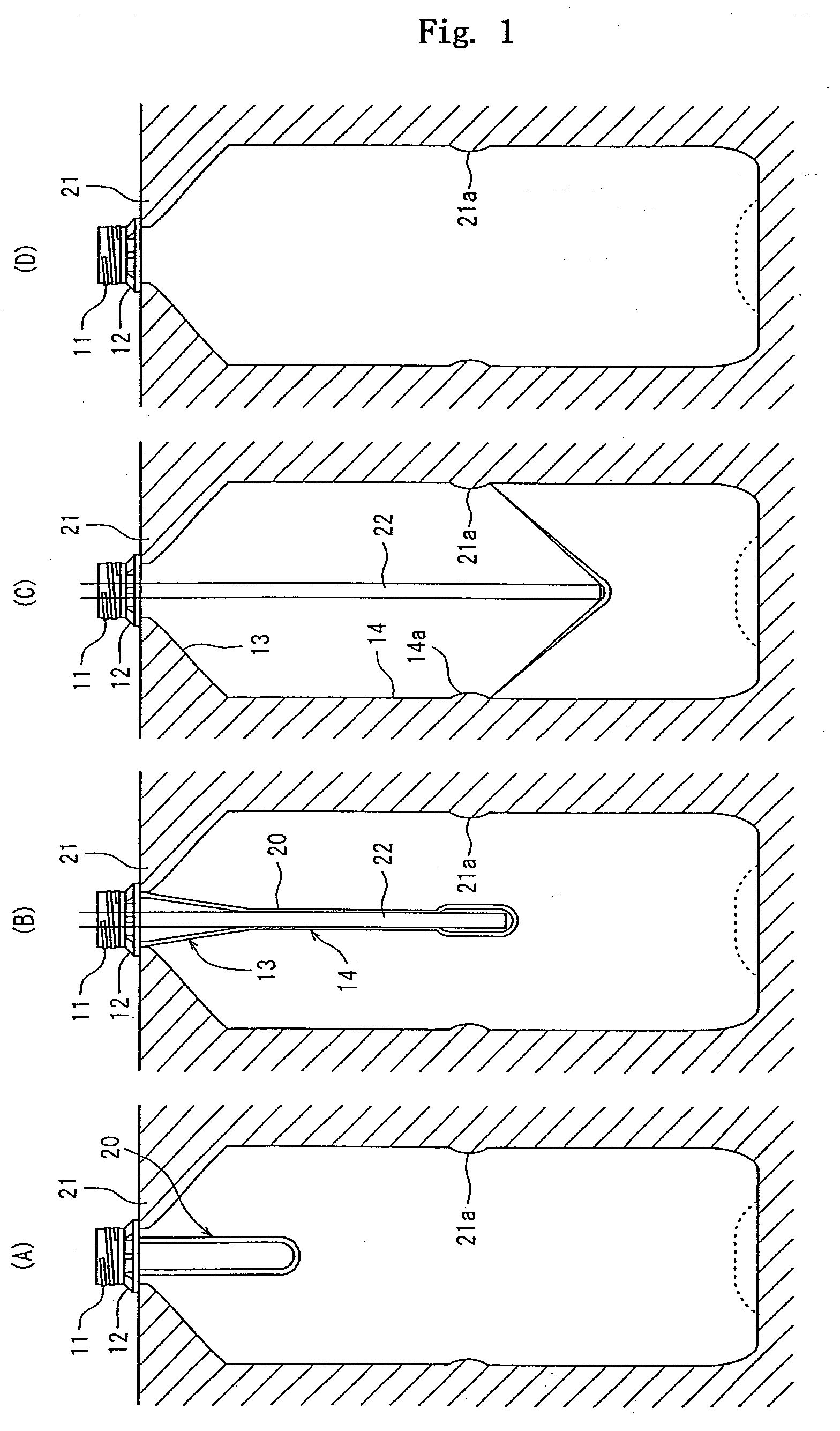

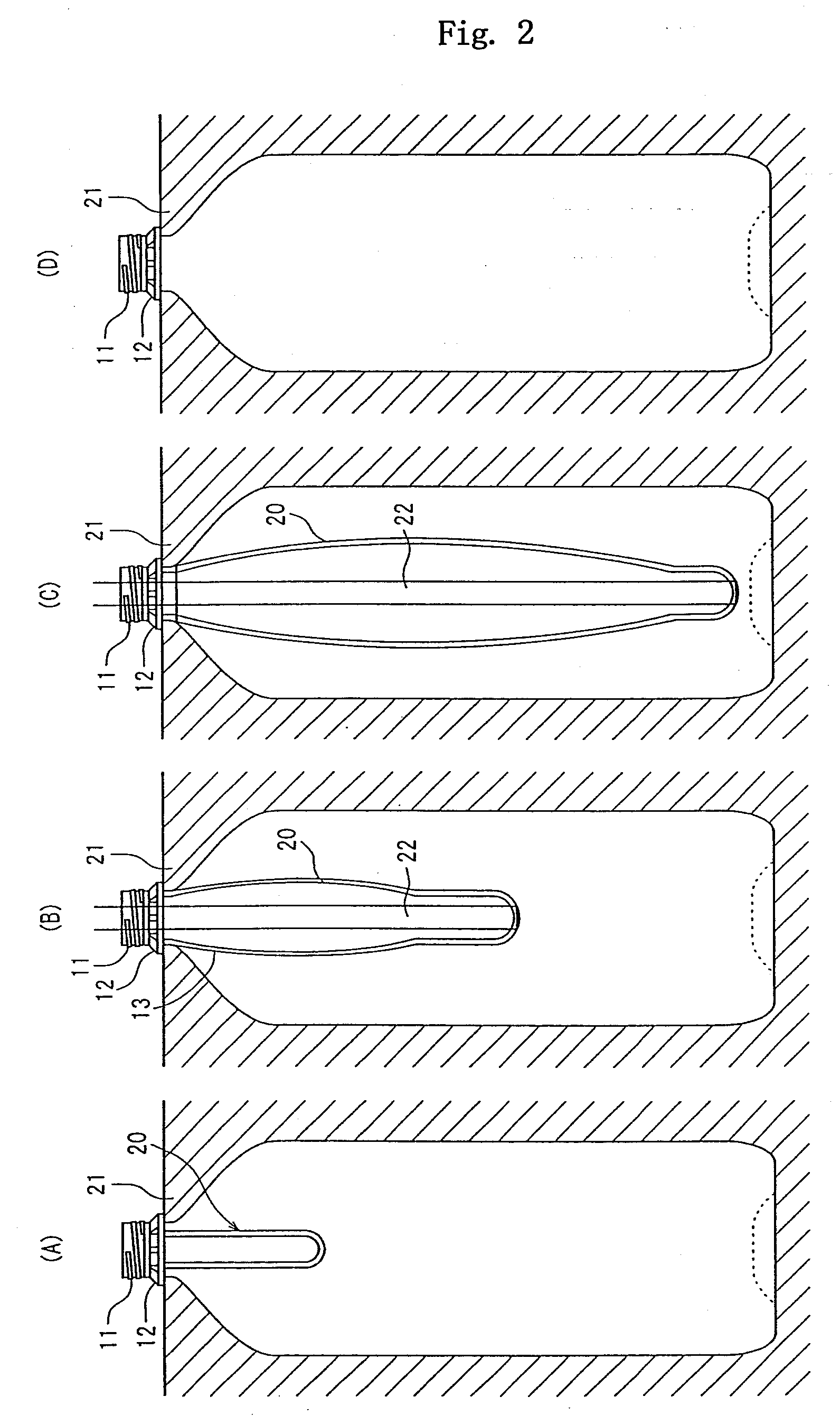

All-solid battery element

InactiveUS20080081257A1Lower internal impedanceReduce thicknessSolid electrolytesHybrid capacitor electrolytesEngineeringDecreased thickness

The all-solid battery element of the invention is designed to simultaneously satisfy the increased contact area of electrodes with an electrolyte layer and the decreased thickness of the electrolyte layer. The all-solid battery element of the invention has at least one unit cell. The unit cell includes: a cathode having a cathode active material; an anode having an anode active material; and a solid electrolyte layer that is interposed between and is in contact with both the cathode and the anode. In the at least one unit cell, the solid electrolyte layer has a specific array structure of arranging at least part of the cathode and at least part of the anode in an alternate manner or in a zigzag manner.

Owner:NGK INSULATORS LTD

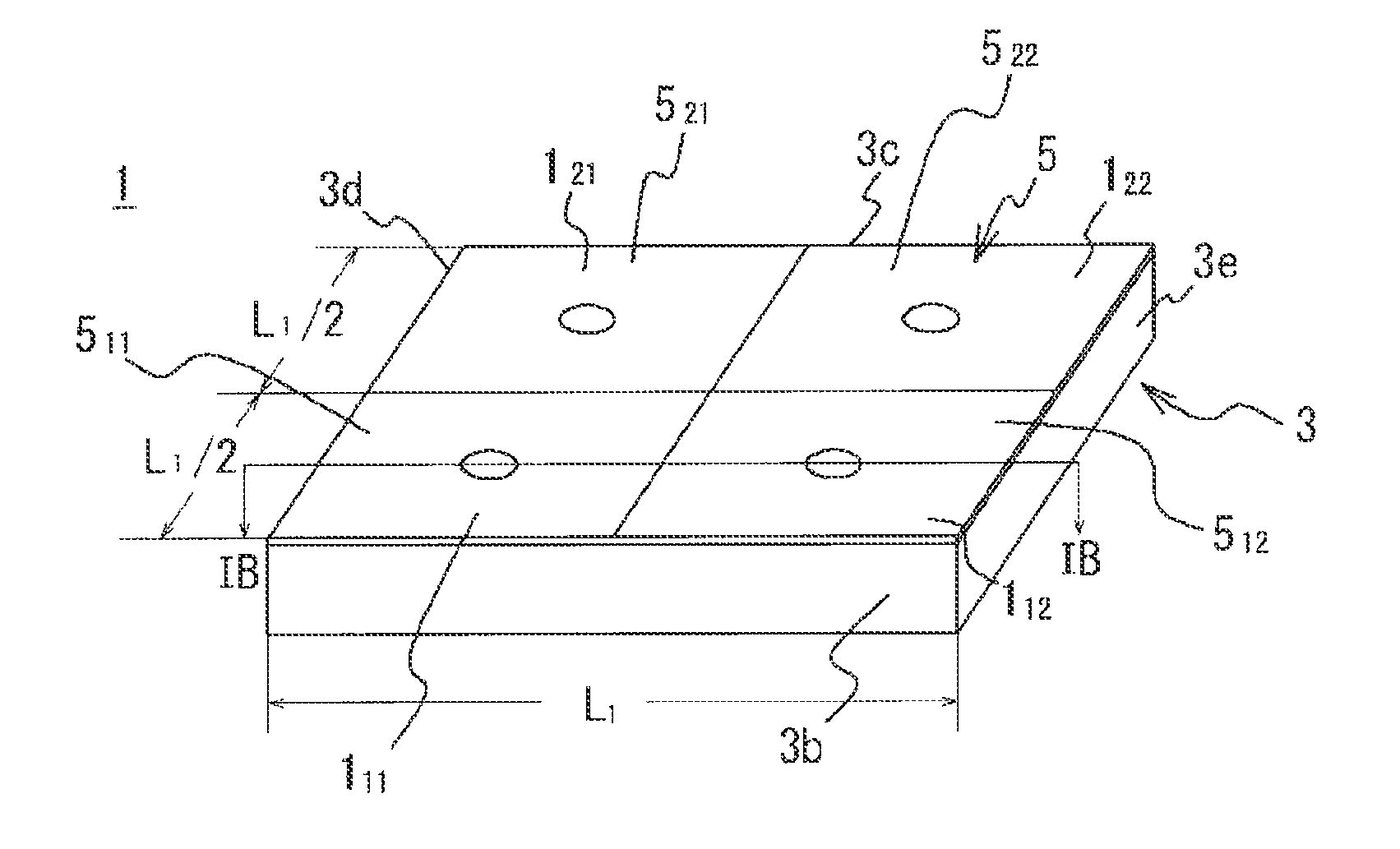

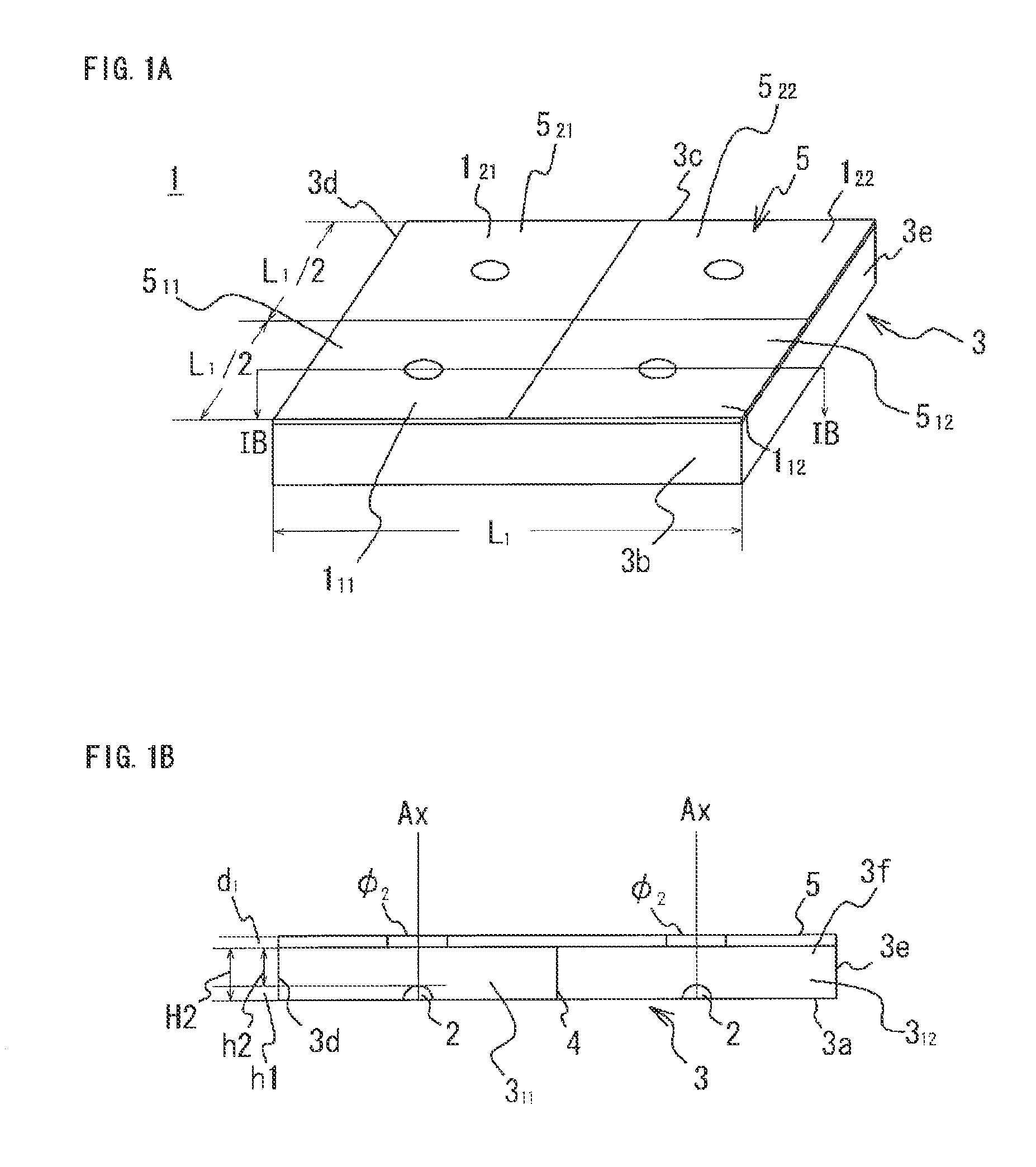

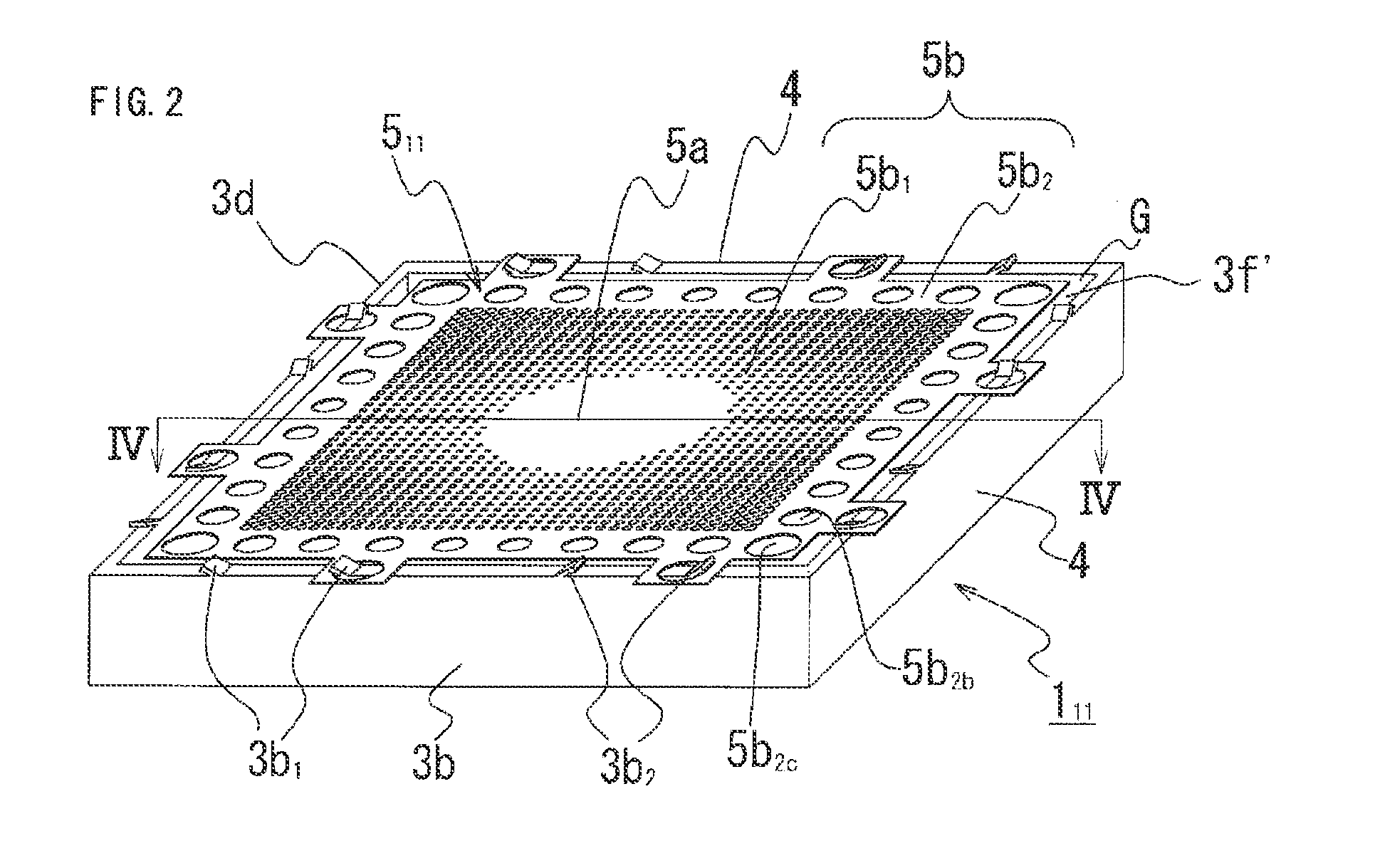

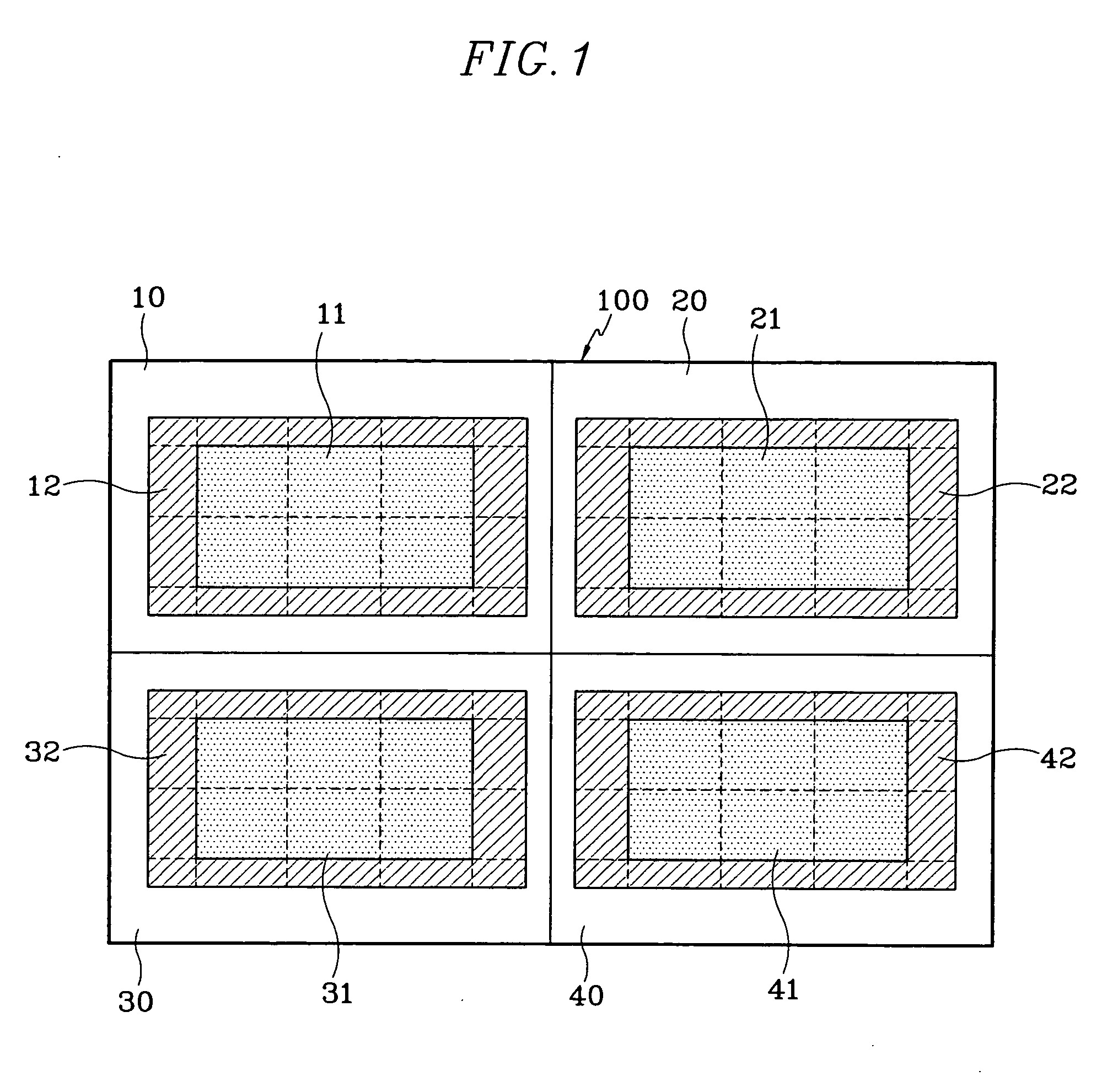

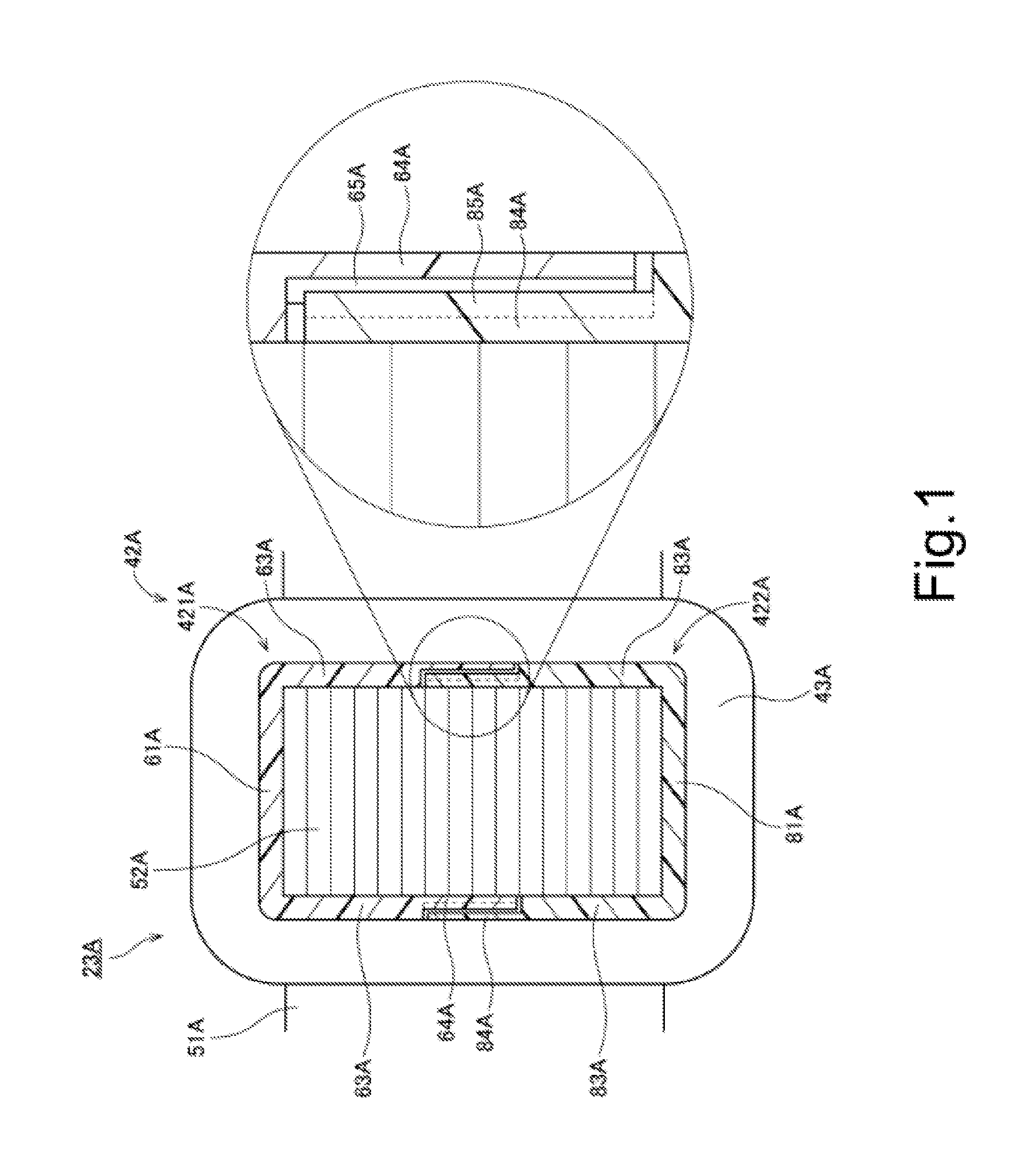

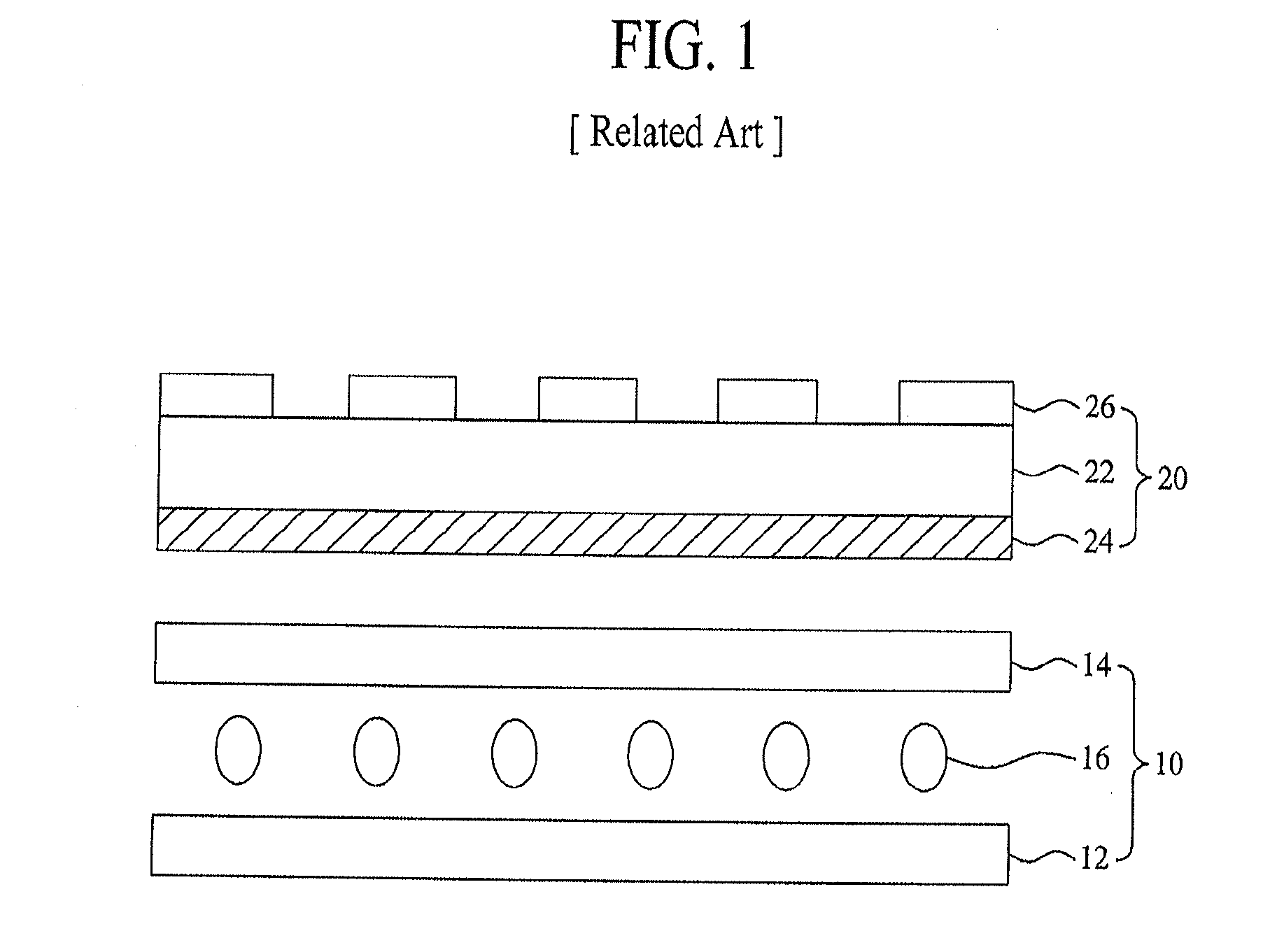

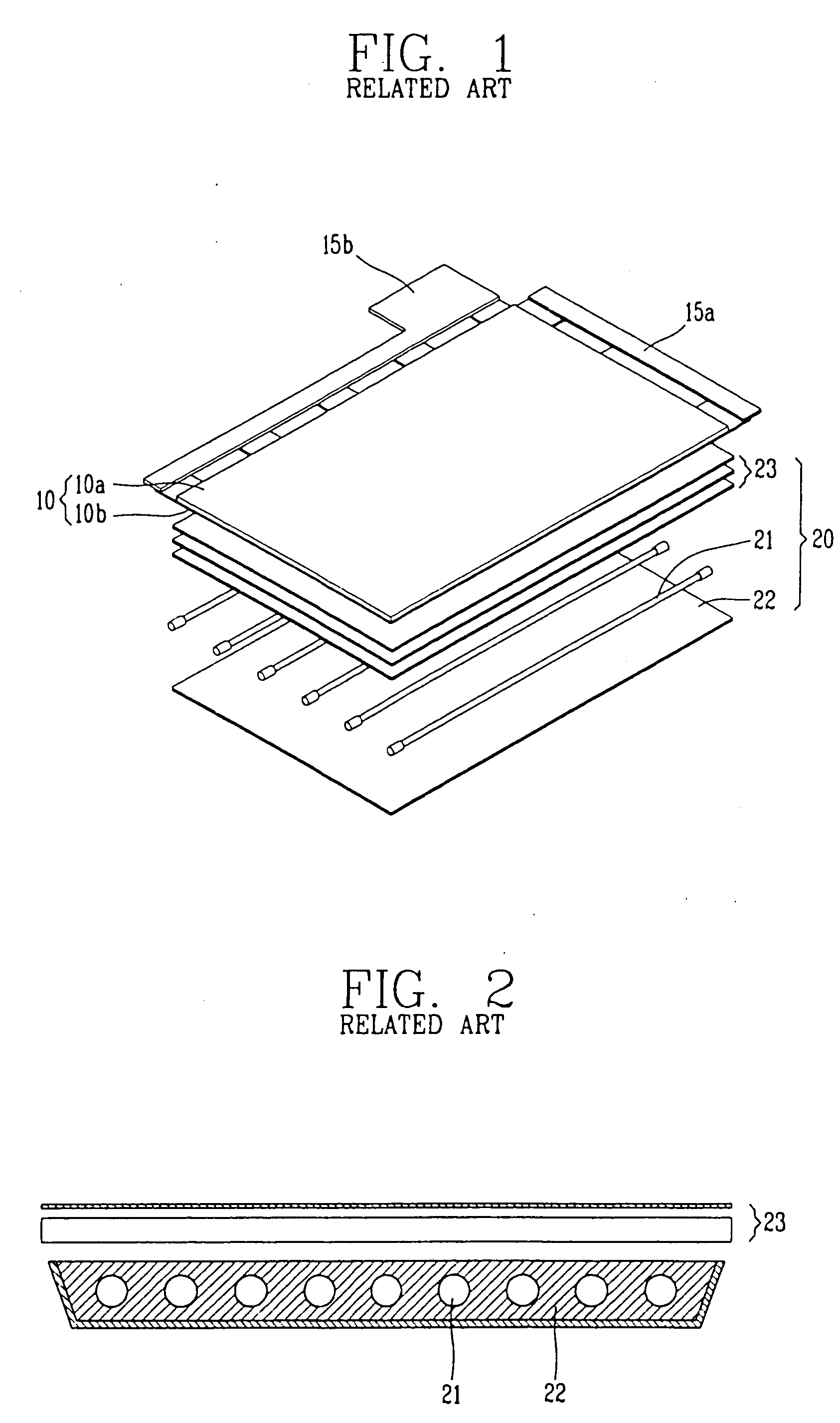

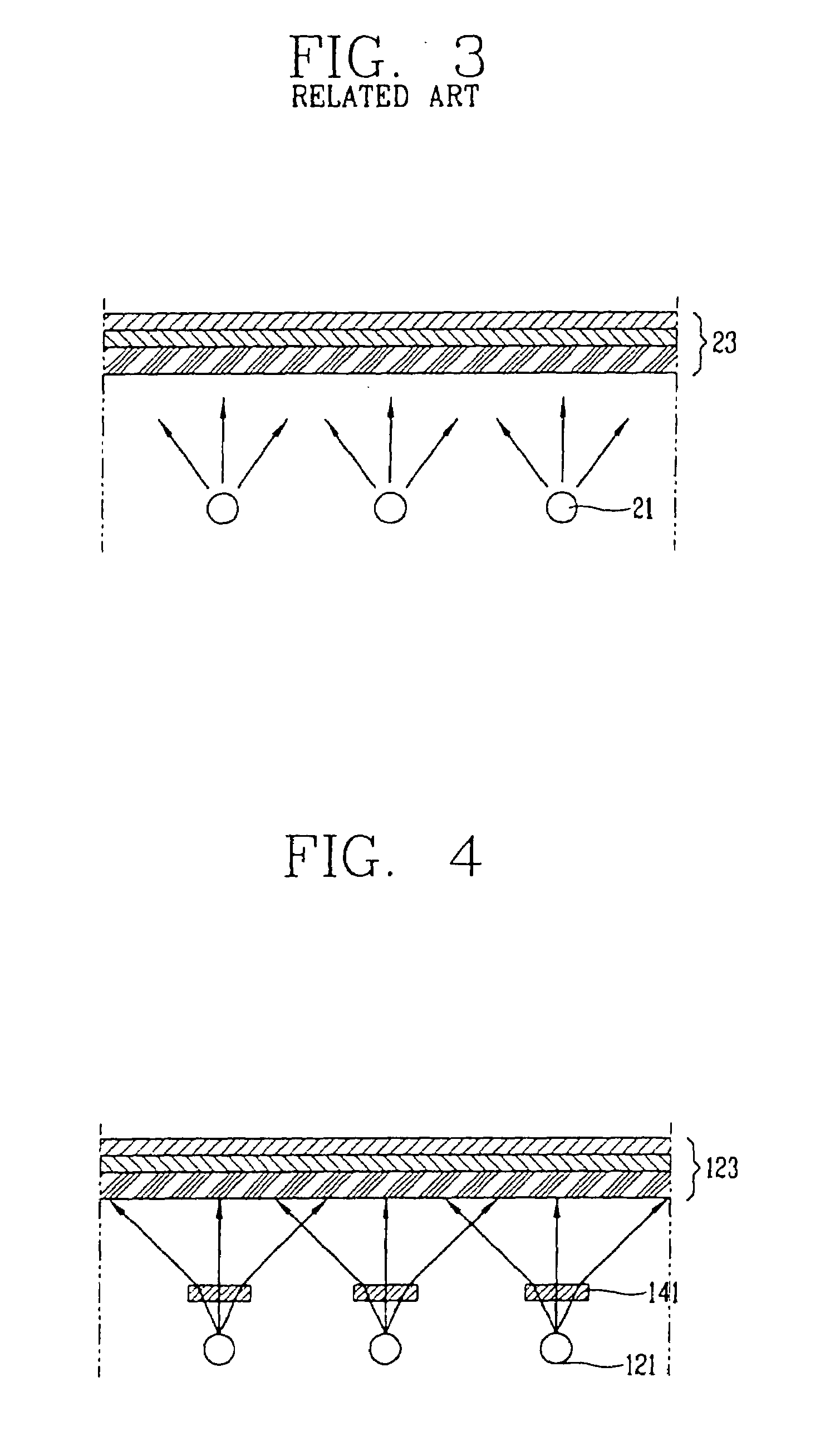

Surface light source unit, surface illumination device, and liquid crystal display device

ActiveUS20120268688A1Reduce thicknessImprove lighting qualitySolid-state devicesNon-linear opticsLiquid-crystal displayOptical transmittance

Provided is a surface light source unit which has a high-directivity point light source and has a decreased thickness in the in the direction in which light is irradiated from said point light source. Also provided are a surface illumination device and a liquid crystal display device. A plurality of small chambers (311 to 322) having an opening on the top are formed in a housing (3) from side plates (3b to 3e) that have a predetermined height and partition plates (4) which partition the inside of the housing (3). Each small chamber is provided with a point light source (2) on the bottom part. The opening of each small chamber (311 to 322) is covered with a light transmitting / reflecting plate (511 to 522) which has a surface area (S), and comprises: a central reflecting section that has a surface area (ΔS), exhibits high reflectance and low transmittance, and is positioned directly above the point light source (2); and an outer reflecting section that surrounds the central reflecting section and is configured so that the light transmittance increases at distances further from the central reflecting section. The surface area (ΔS) and surface area (S) of each light transmitting / reflecting plate (511 to 522) are set in a manner such that the ratio ΔS / S is a predetermined value.

Owner:OPTO DESIGN INC

Dental appliance having an altered vertical thickness between an upper shell and a lower shell with an integrated hinging mechanism to attach an upper shell and a lower shell and a system and a method for treating malocclusions

ActiveUS20050037311A1Increasing the thicknessMaintain positionAdditive manufacturing apparatusOthrodonticsOpen biteDental malocclusion

A dental appliance having increased or decreased thickness between an upper shell and a lower shell in combination with a hinging mechanism and a system and a method for treating malocclusions are provided. The dental appliance may have an upper shell and a lower shell which receive upper teeth and lower teeth, respectively, of a user. The upper shell and the lower shell may be attached at a hinge. The dental appliance may have an increased thickness between the upper shell and the lower shell as well as an increased thickness of the hinge. In an embodiment, the dental appliance may have a decreased vertical thickness and an insertable hinging mechanism. The dental appliance may then extend treatment of malocclusions to the rear teeth of the user and may correct a dental condition, such as, for example, overbite, overjet, open bite, crowding, rotations, spacing, cross-bites, gummy smiles and temporomandibular joint problems.

Owner:ORTHO TAIN INC

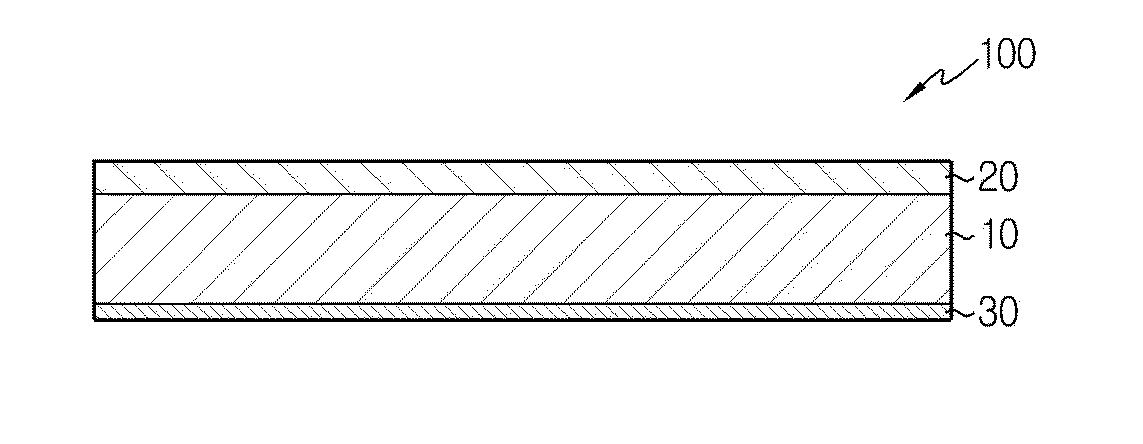

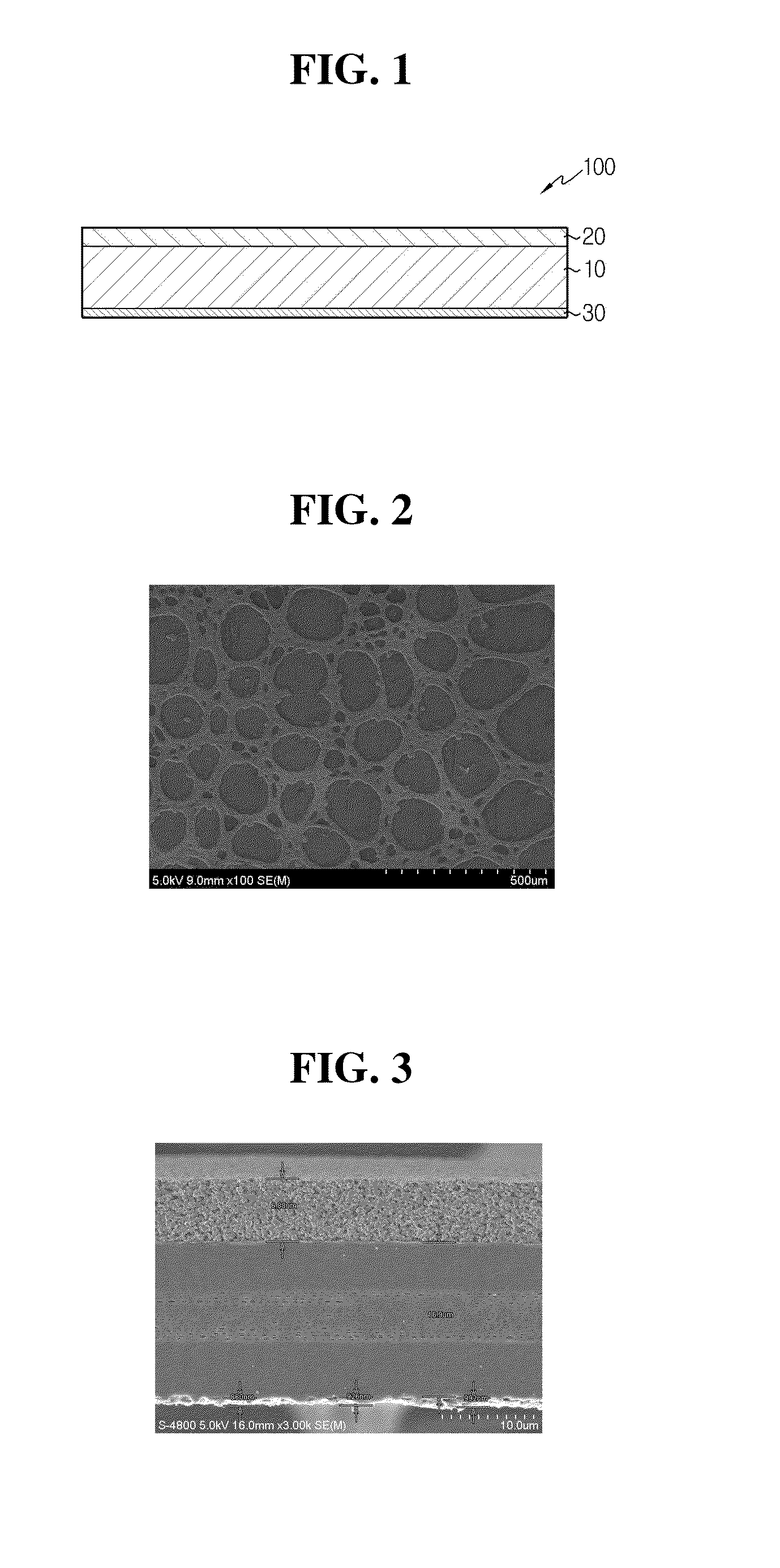

Separator and electrochemical device having the same

ActiveUS20130280583A1Improve thermal safetyImprove adhesionFinal product manufactureLi-accumulatorsPorous substratePorous coating

The present invention refers to a separator for an electrochemical device and an electrochemical device having the same. More specifically, the separator of the present invention comprises a porous substrate; a first porous coating layer formed on one surface of the porous substrate and comprising a mixture of inorganic particles and a first binder polymer; and a second porous coating layer formed on the other surface of the porous substrate and comprising a product obtained by drying a mixture of a solvent, a non-solvent and a second binder polymer.Such separator of the present invention can have good thermal safety due to a porous organic-inorganic coating layer formed on one surface thereof, and superior adhesiveness due to a porous coating layer made of a binder thin film formed by applying and drying a mixture of a binder polymer and a non-solvent on the other surface thereof. Also, the separator can have a decreased thickness to reduce the resistance of electrochemical device and improve the capacity thereof.

Owner:TORAY BATTERY SEPARATOR FILM +1

Exhaust gas treatment catalyst and exhaust gas treatment system

ActiveUS8202481B2Reduce thicknessReduce leak rateCombination devicesCatalyst activation/preparationPt elementDecreased thickness

Provided are an exhaust gas treatment catalyst capable of reducing ammonia leakage rate while keeping a sufficient NOx removal efficiency, said catalyst comprising a coating layer and a catalyst base material, wherein said coating layer has a decreased thickness relative to that of a catalyst base material; and an exhaust gas treatment system using the same. In the exhaust gas treatment catalyst for catalytically removing nitrogen oxides from an exhaust gas by using ammonia as a reducing agent and simultaneously decomposing and removing unreacted ammonia, a coating layer comprising platinum supported on titania is formed on a surface of a porous catalyst base material comprising titania and at least one compound selected from oxides of vanadium (V), oxides of tungsten (W) and oxides of molybdenum (Mo).

Owner:MITSUBISHI HEAVY IND LTD

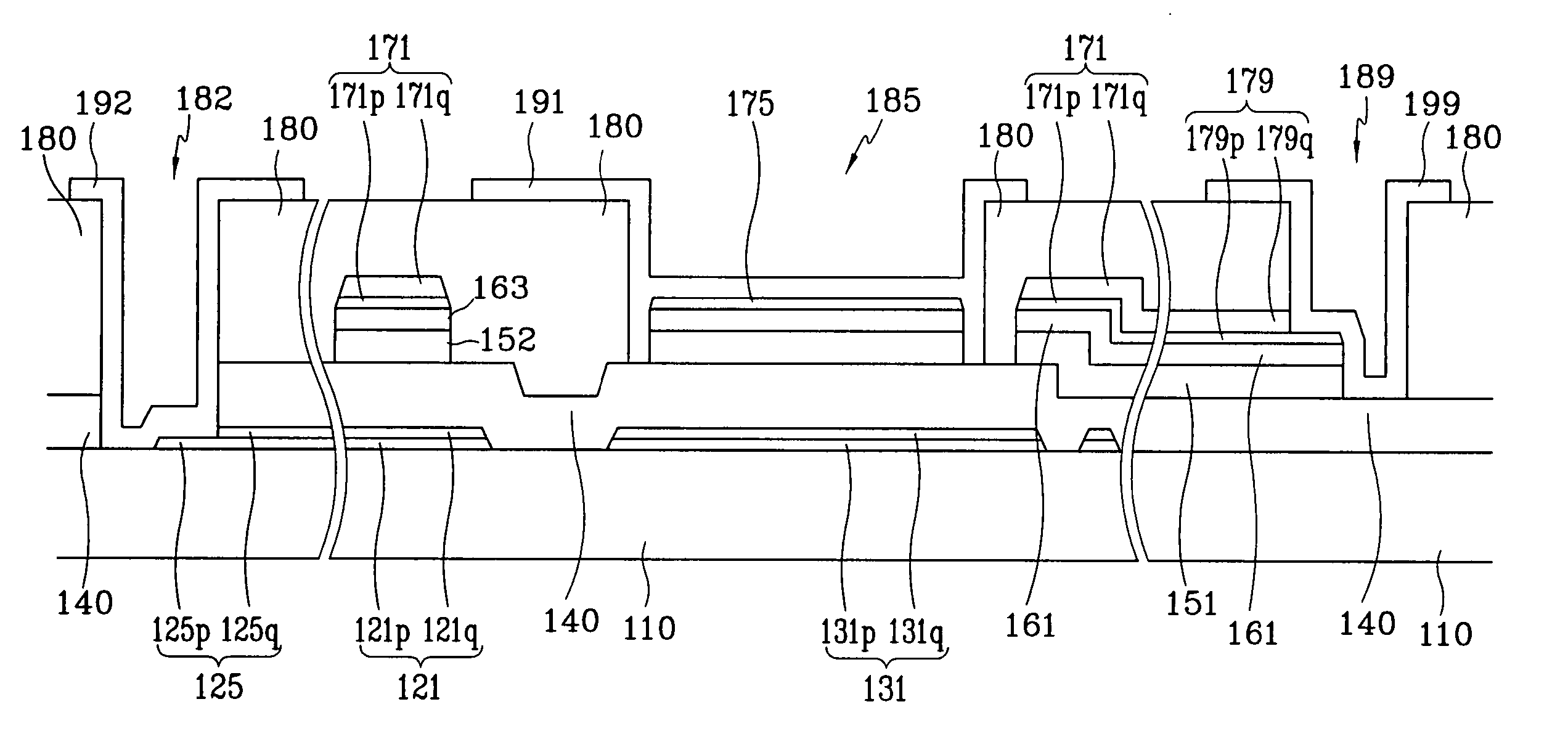

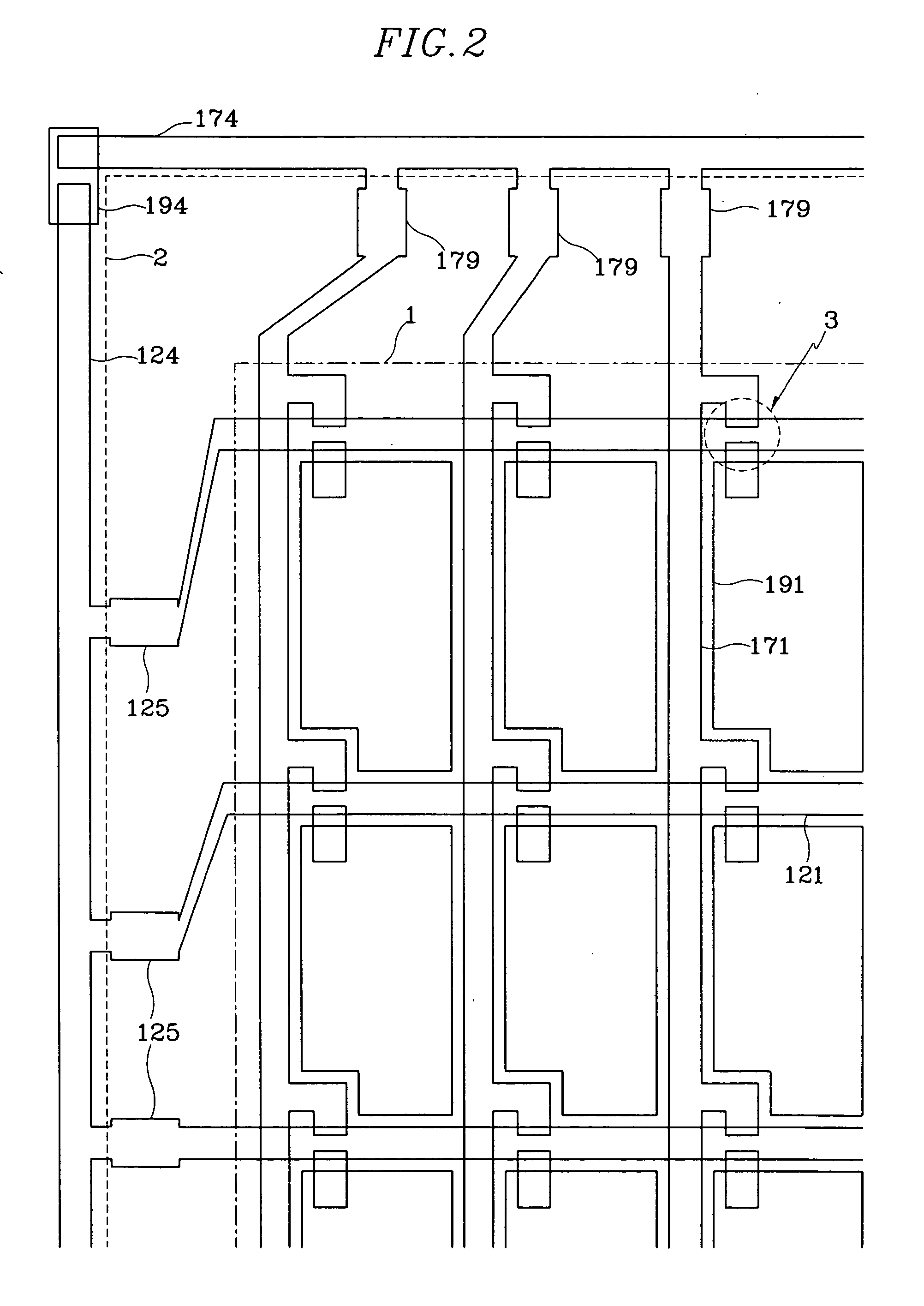

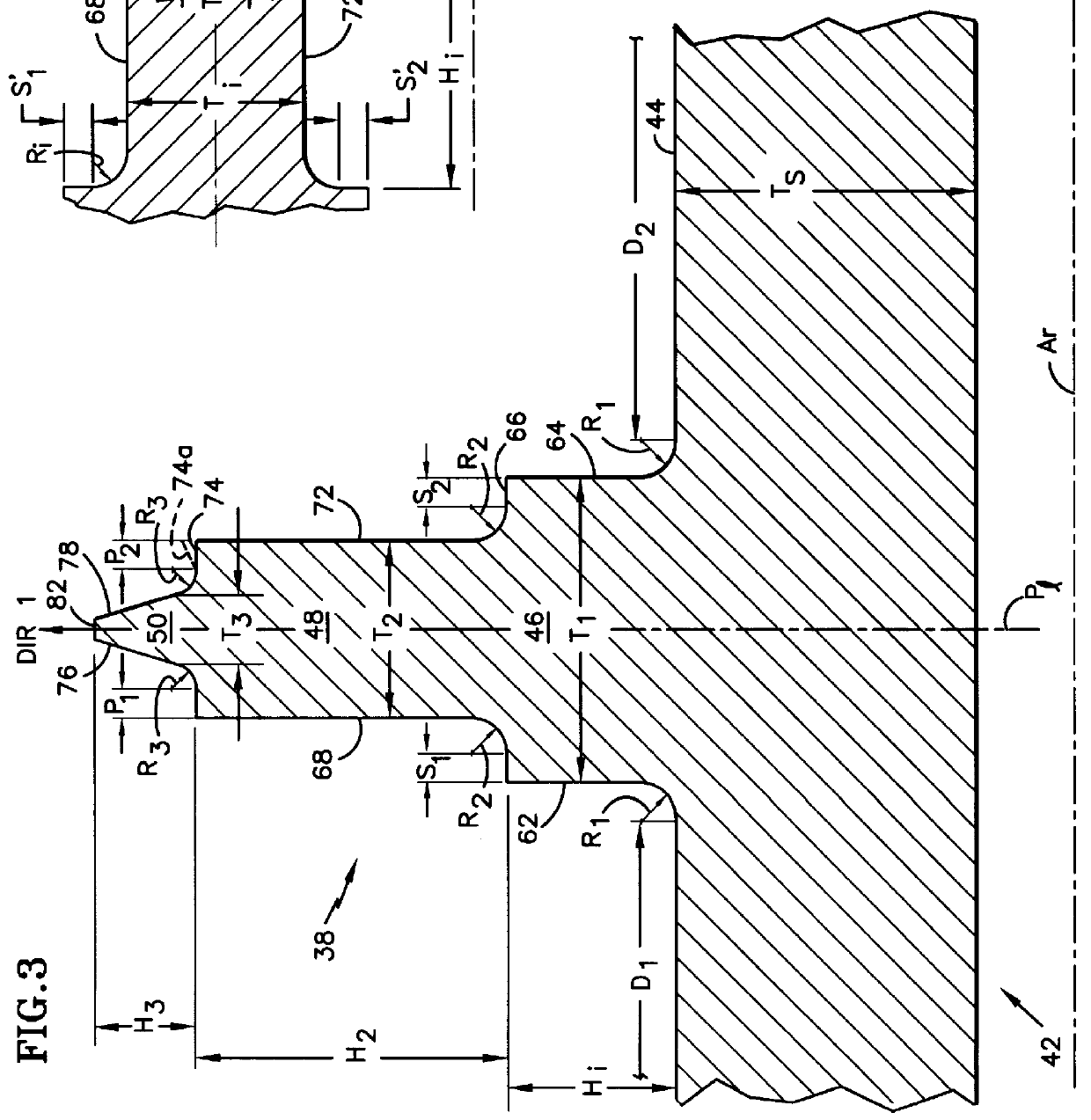

Thin film transistor array panel, manufacturing method thereof, and mask therefor

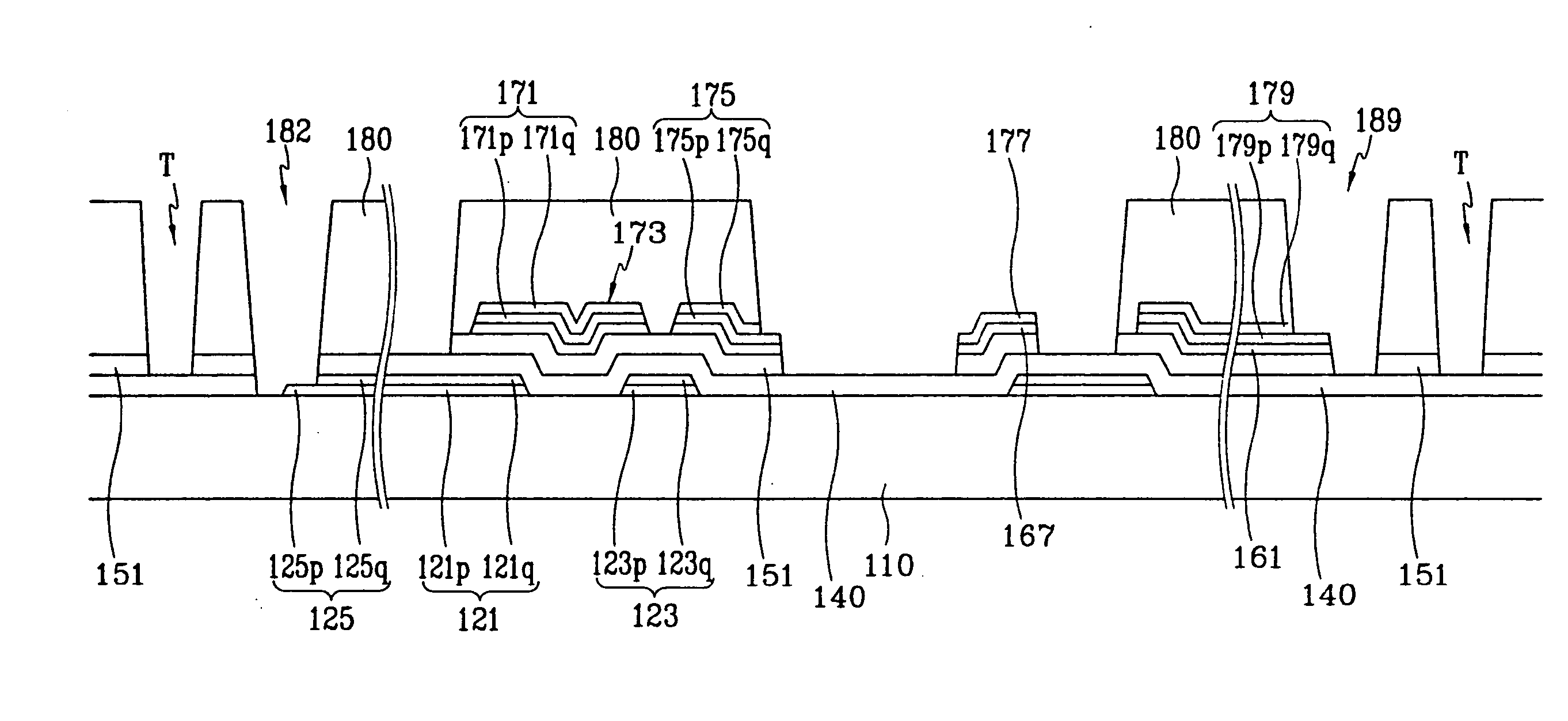

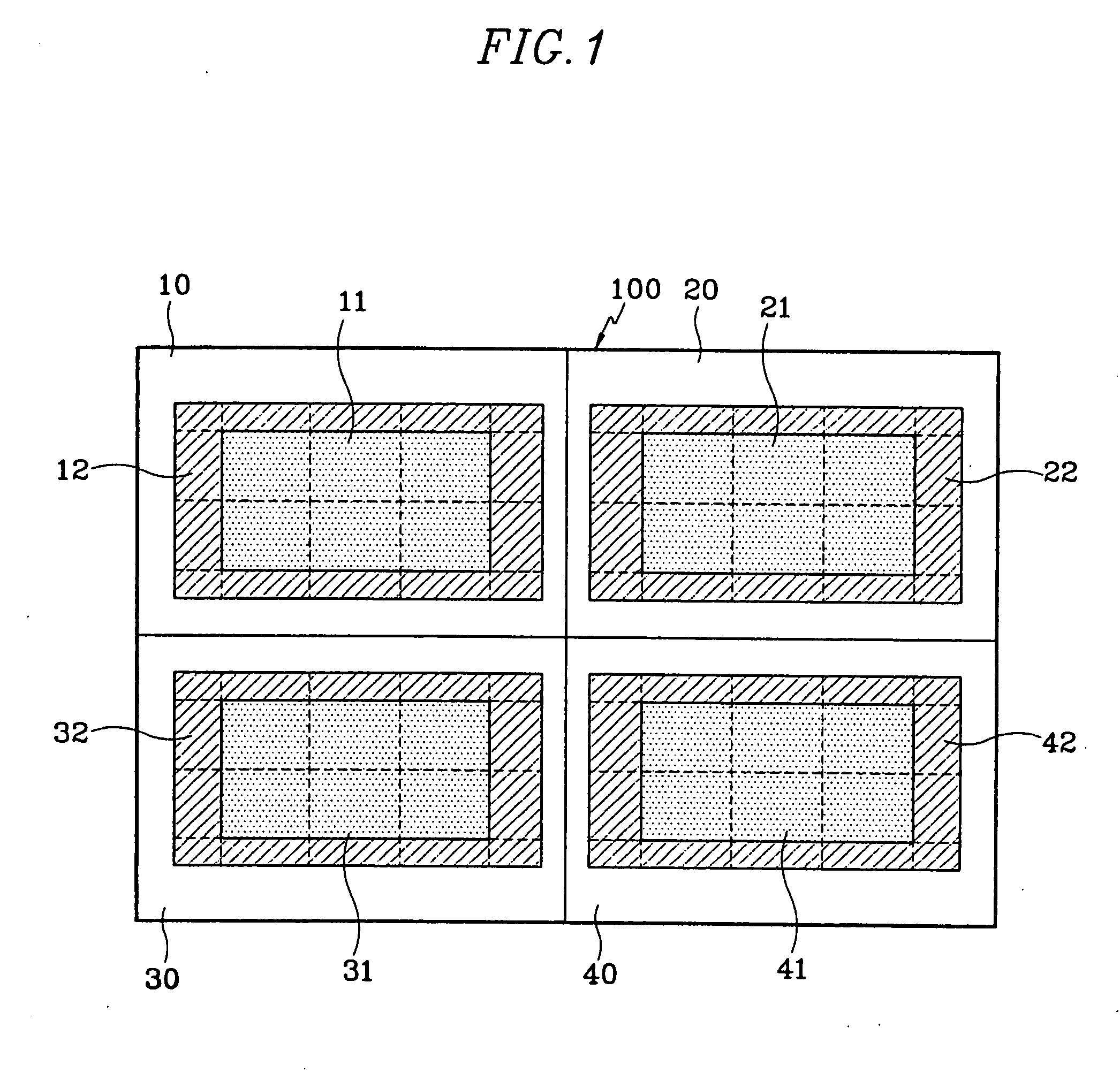

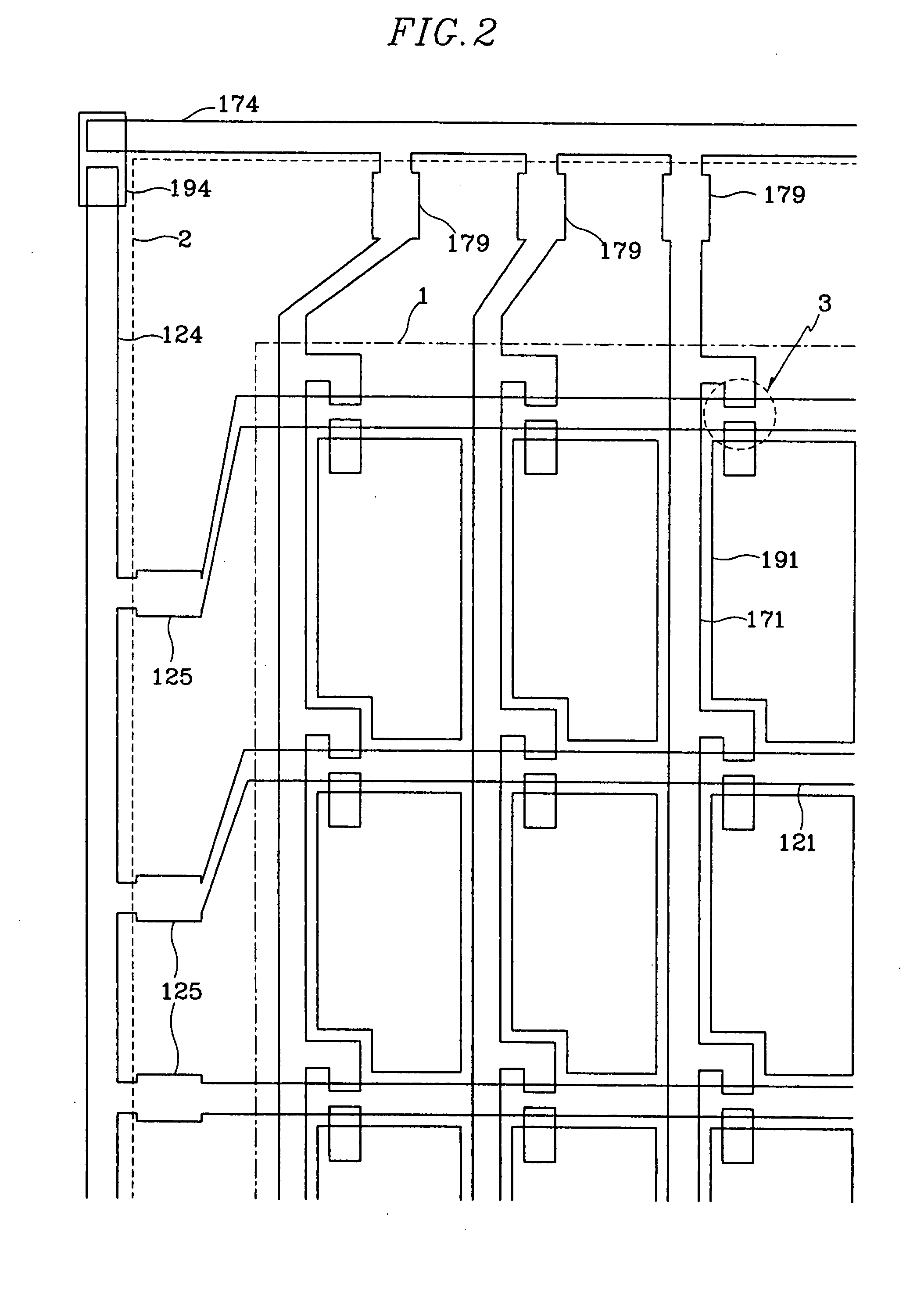

A passivation layer is deposited and a photoresist is formed. The photoresist includes first to third portions with decreased thickness, the second portions located on portions of drain electrodes and data lines and the third portions located on portions of gate lines. A mask for forming the photoresist has rectilinear slits with width and distance of about 0.8-2.0 microns on an area corresponding to the second portions. The passivation layer and an underlying semiconductor layer as well as the photoresist are etched to expose portions of the gate insulating layer under the third portions of the photoresist as well as portions of the passivation layer under the second portions of the photoresist. The exposed portions of the passivation layer and the gate insulating layer are removed to expose the drain electrodes, the gate lines and the data lines as well as portions of the semiconductor layer, which are subsequently removed.

Owner:SAMSUNG ELECTRONICS CO LTD

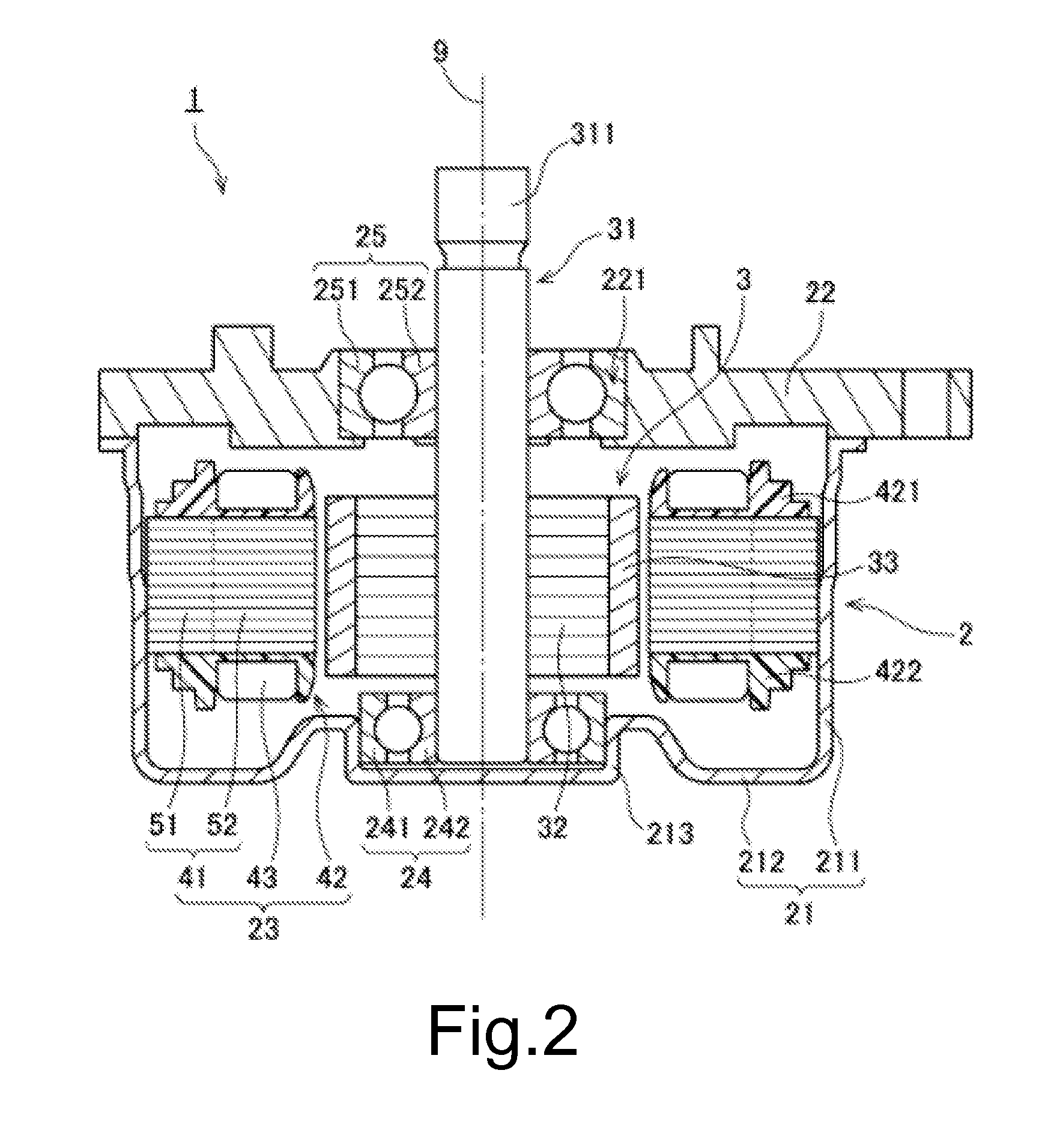

Armature and motor

InactiveUS20130193800A1Avoid damagePrecise cuttingWindings insulation materialWindings insulation shape/form/constructionStructural engineeringDecreased thickness

An insulator of an armature includes an upper resin member and a lower resin member. Each of the upper and lower resin members includes decreased thickness portions. Axial positions of the decreased thickness portions of the upper and lower resin members are arranged to overlap at least partially with each other. Each of the upper and lower resin members further includes a rib arranged to project from a corresponding one of the decreased thickness portions. The rib improves the strength of the corresponding decreased thickness portion and reduces the likelihood that any of the decreased thickness portions of the upper and lower resin members will be damaged when the two members are fitted to each other.

Owner:NIDEC CORP

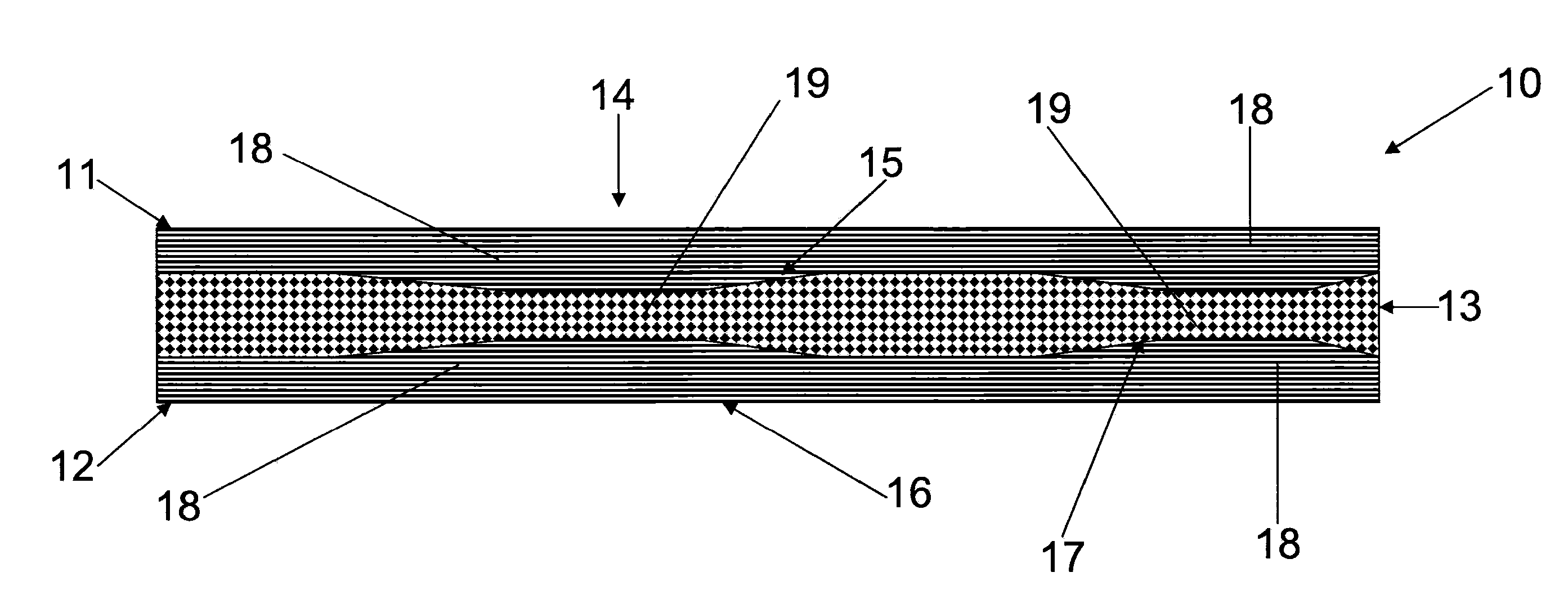

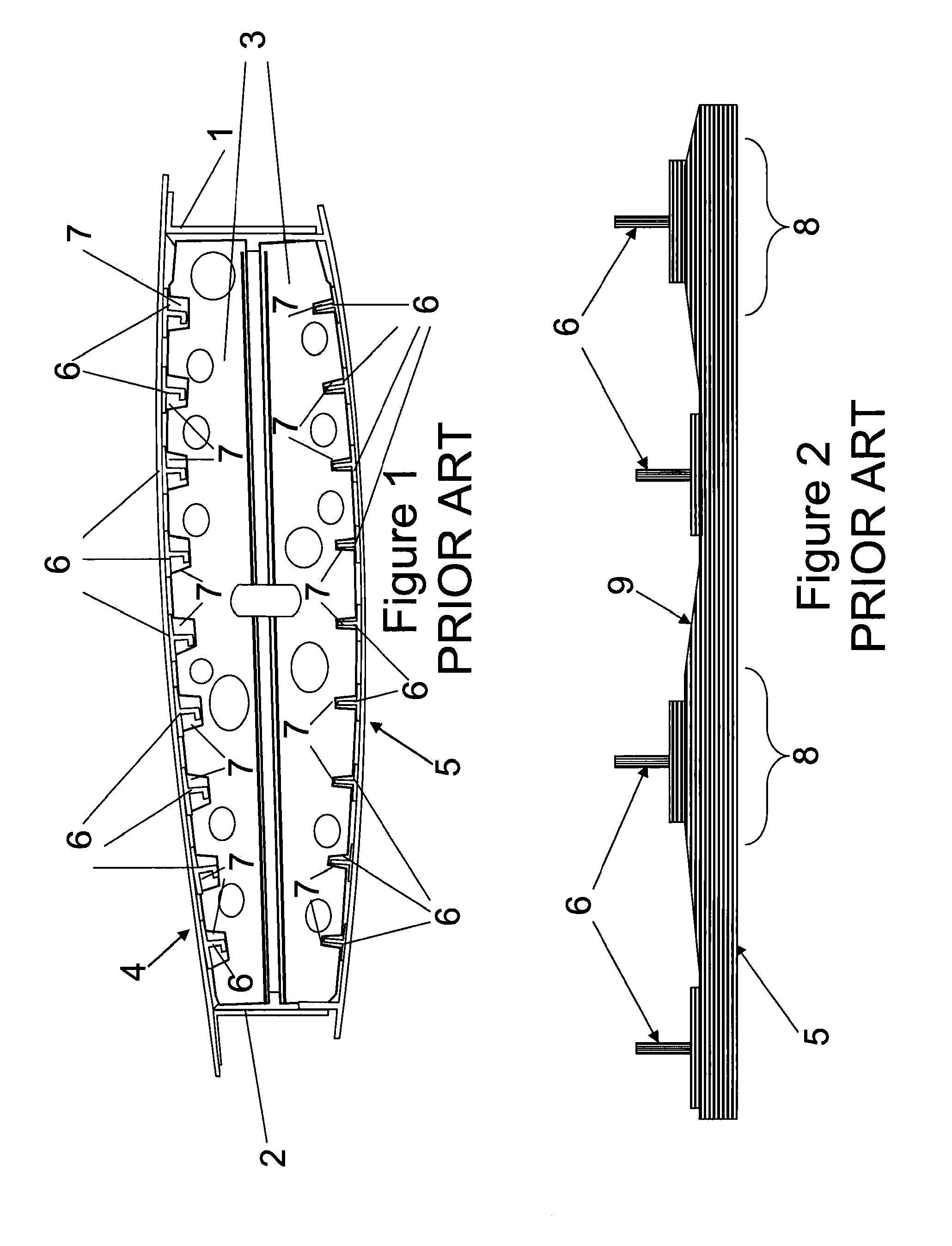

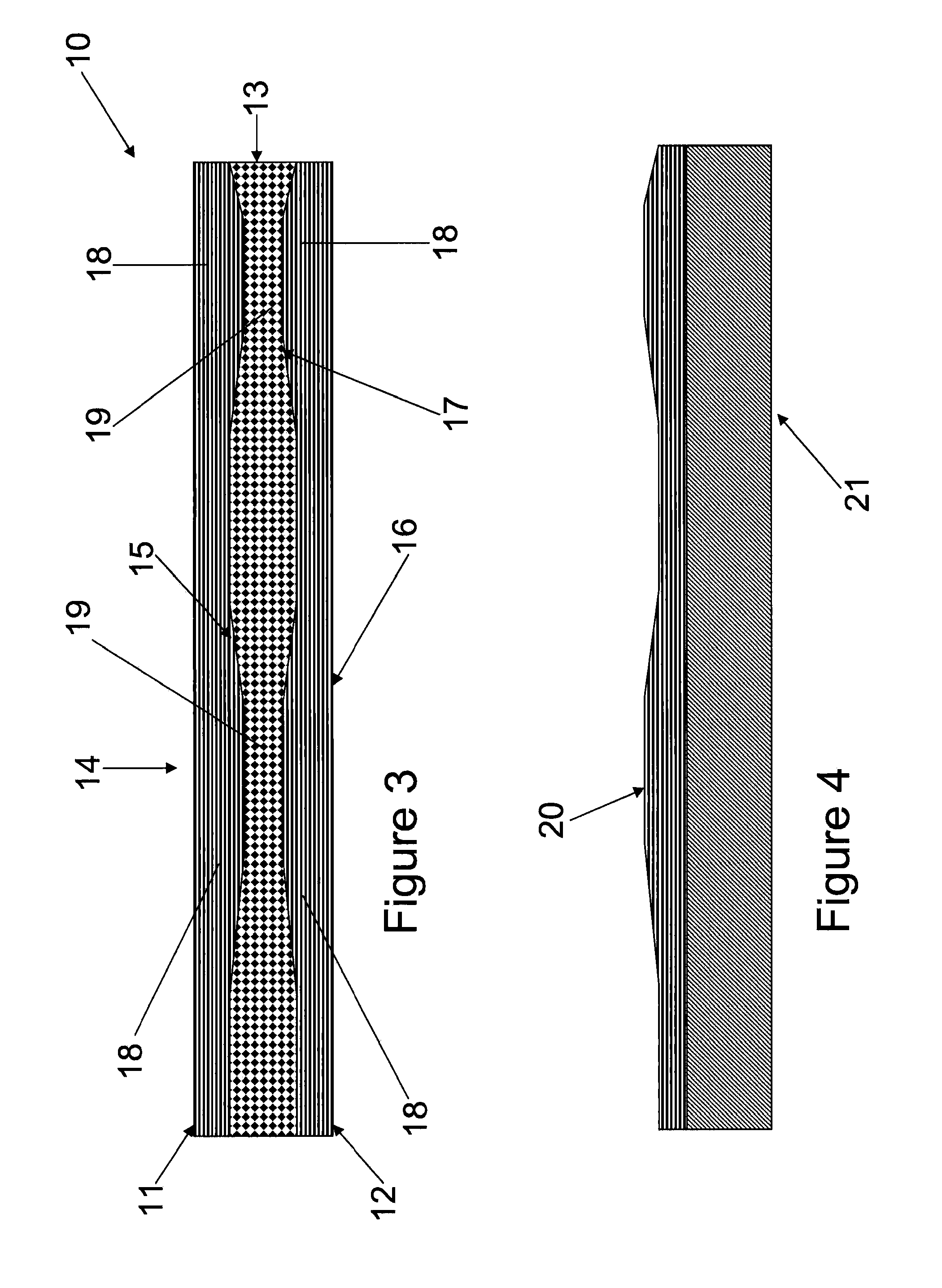

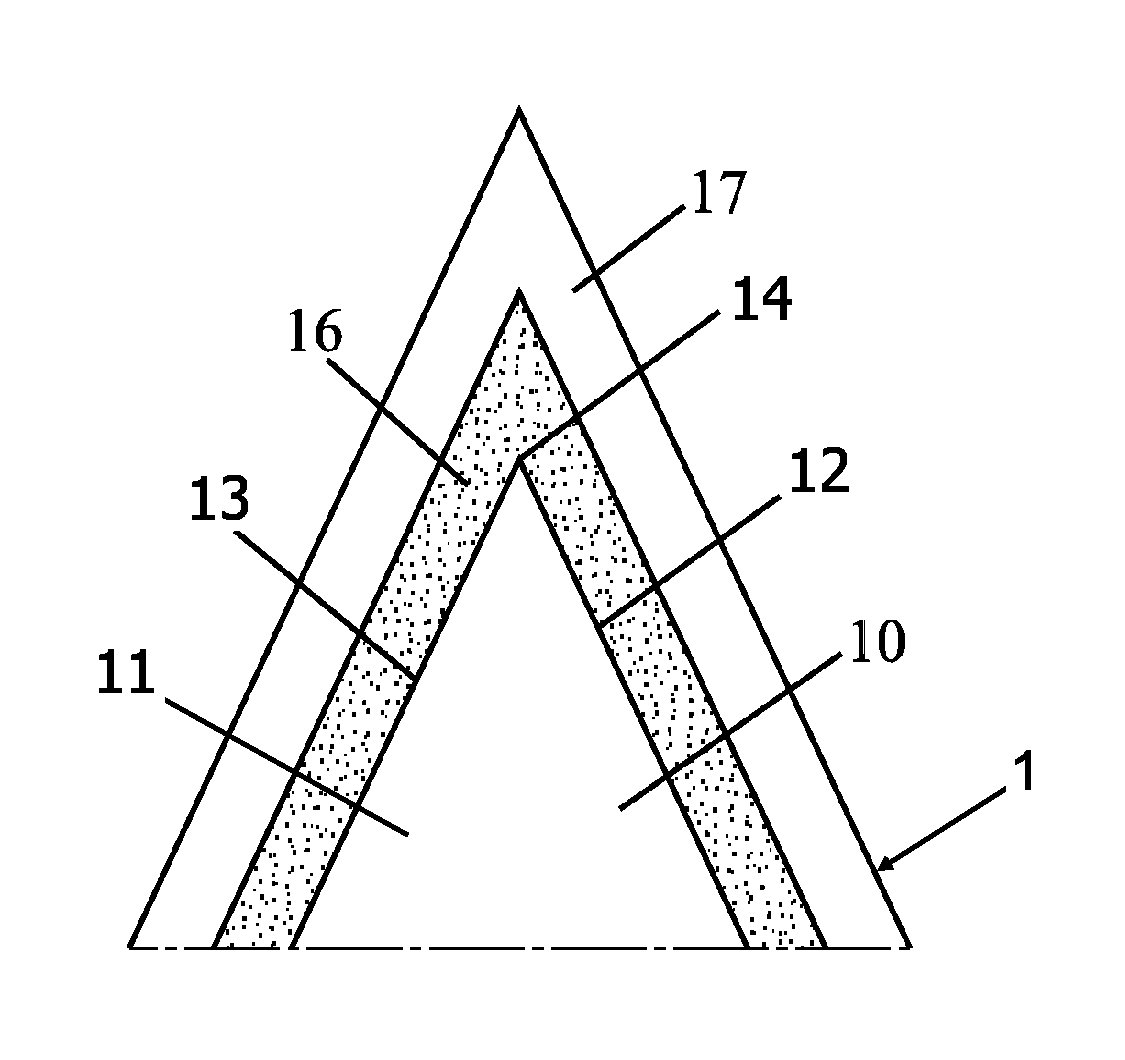

Aircraft wing cover comprising a sandwich panel and methods to manufacture and design the said wing cover

ActiveUS20130099058A1Increasing the thicknessReduce thicknessLamination ancillary operationsAircraft stabilisationSandwich panelDecreased thickness

An aircraft wing cover (10) comprising an integrally stiffened sandwich panel including first and second skins (11, 12) sandwiching a core layer (13), wherein at least one of the skins has a plurality of spanwise extending integral regions of increased thickness (18) accommodated by corresponding regions (19) of decreased thickness in the core. Also, a method of fabricating an aircraft wing cover, and a method of designing an aircraft wing.

Owner:AIRBUS OPERATIONS LTD

Razor blade

ActiveUS20170136641A1Reduce thicknessHardness value can be increasedVacuum evaporation coatingSputtering coatingEngineeringDeposition process

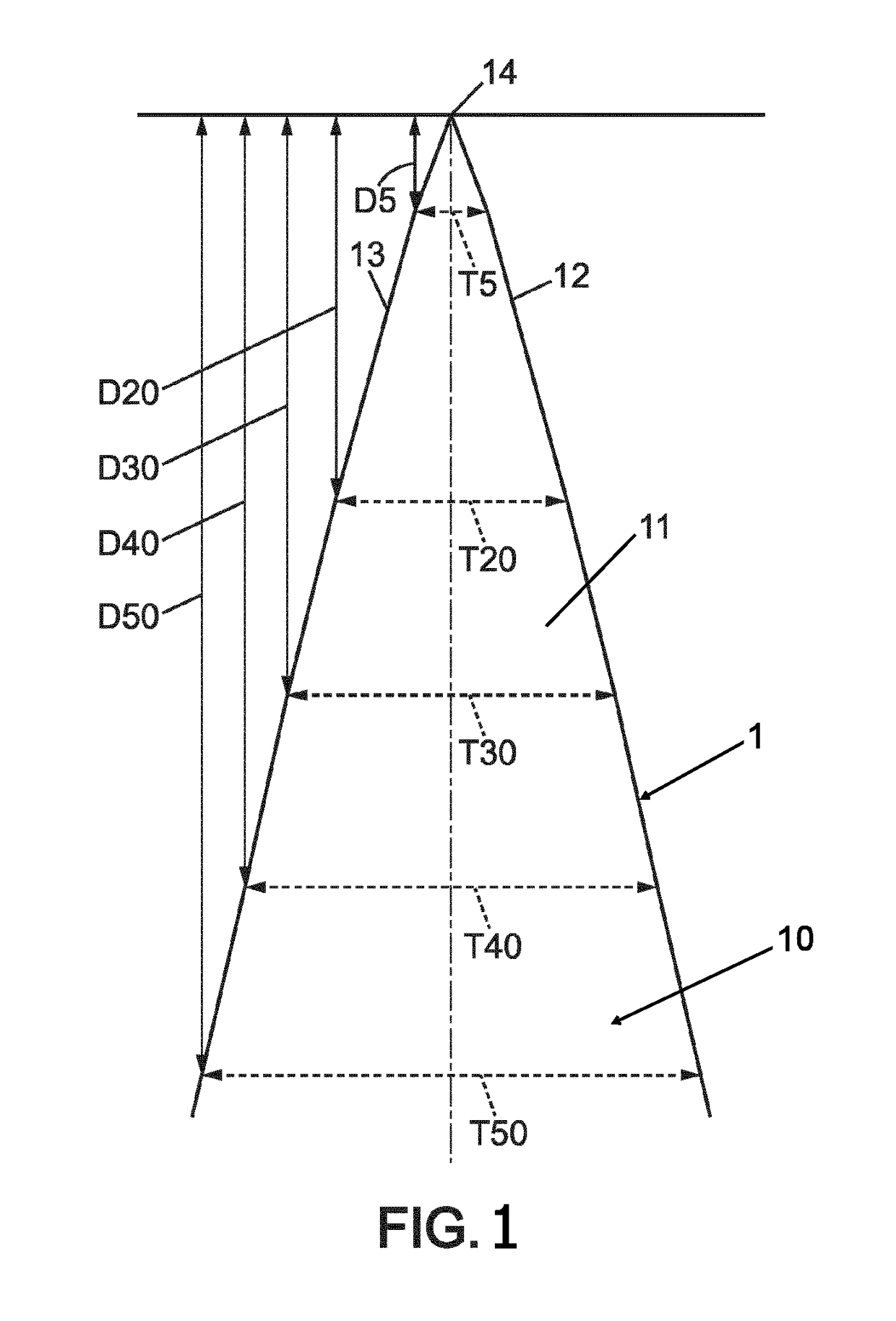

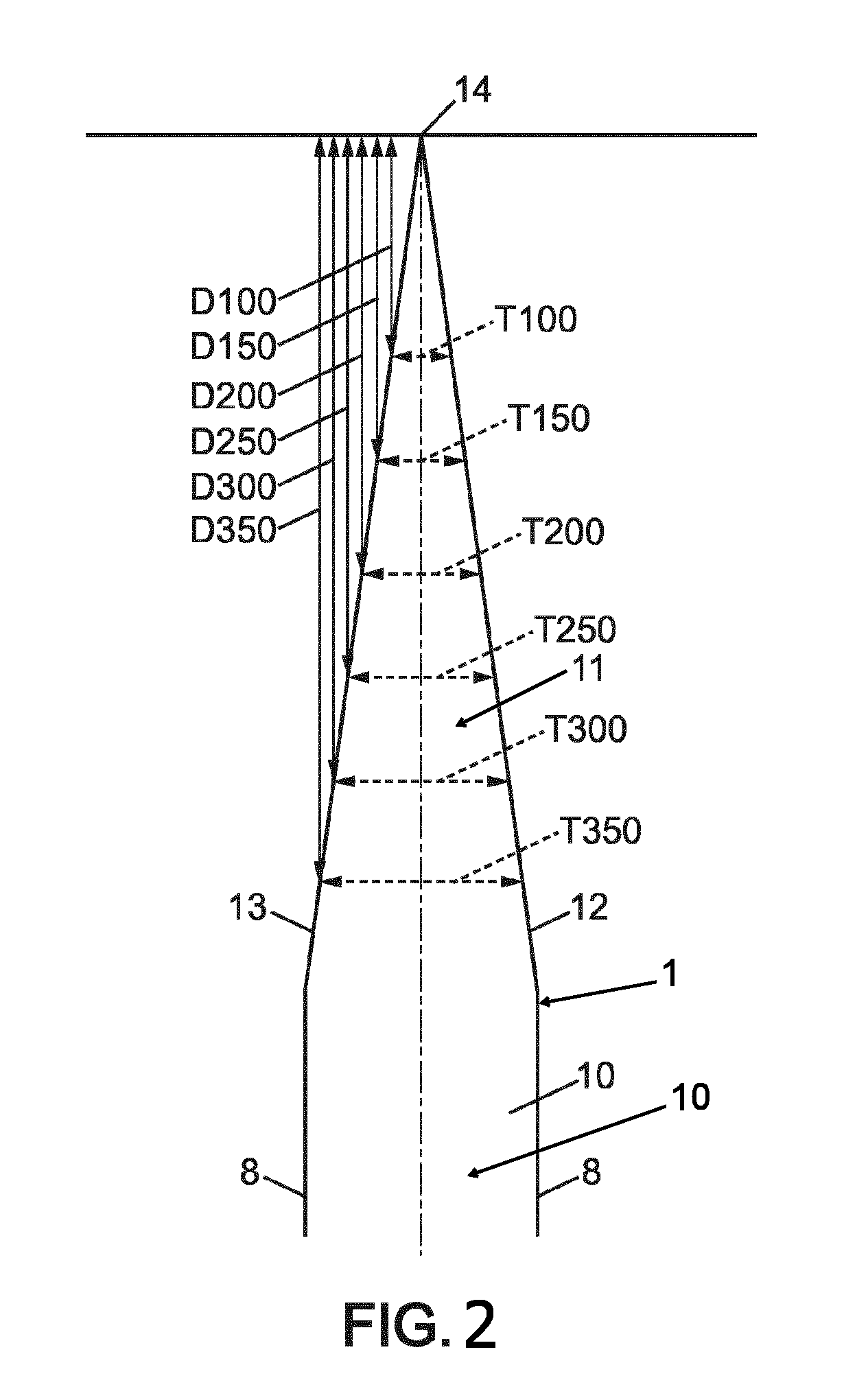

A razor blade comprising a blade substrate with a blade edge substrate portion ending in blade tip. The razor blade is covered by a strengthening coating deposited on the blade edge substrate portion via a deposition process. The deposition process causes a hardness value of the strengthening coating layer to be increased, which, among other factors, allows for a decreased thickness of the blade substrate with coating. The blade substrate with coating has (i) a thickness of between about 1.57 and 2.37 micrometers measured at a distance of about five micrometers from the coating tip, (ii) a thickness of between about 4.62 and 6.74 micrometers measured at a distance of about twenty micrometers from the coating tip, and (iii) a thickness of between about 19.82 and 27.52 micrometers measured at a distance of about one hundred micrometers from the coating tip.

Owner:BIC VIOLEX SA

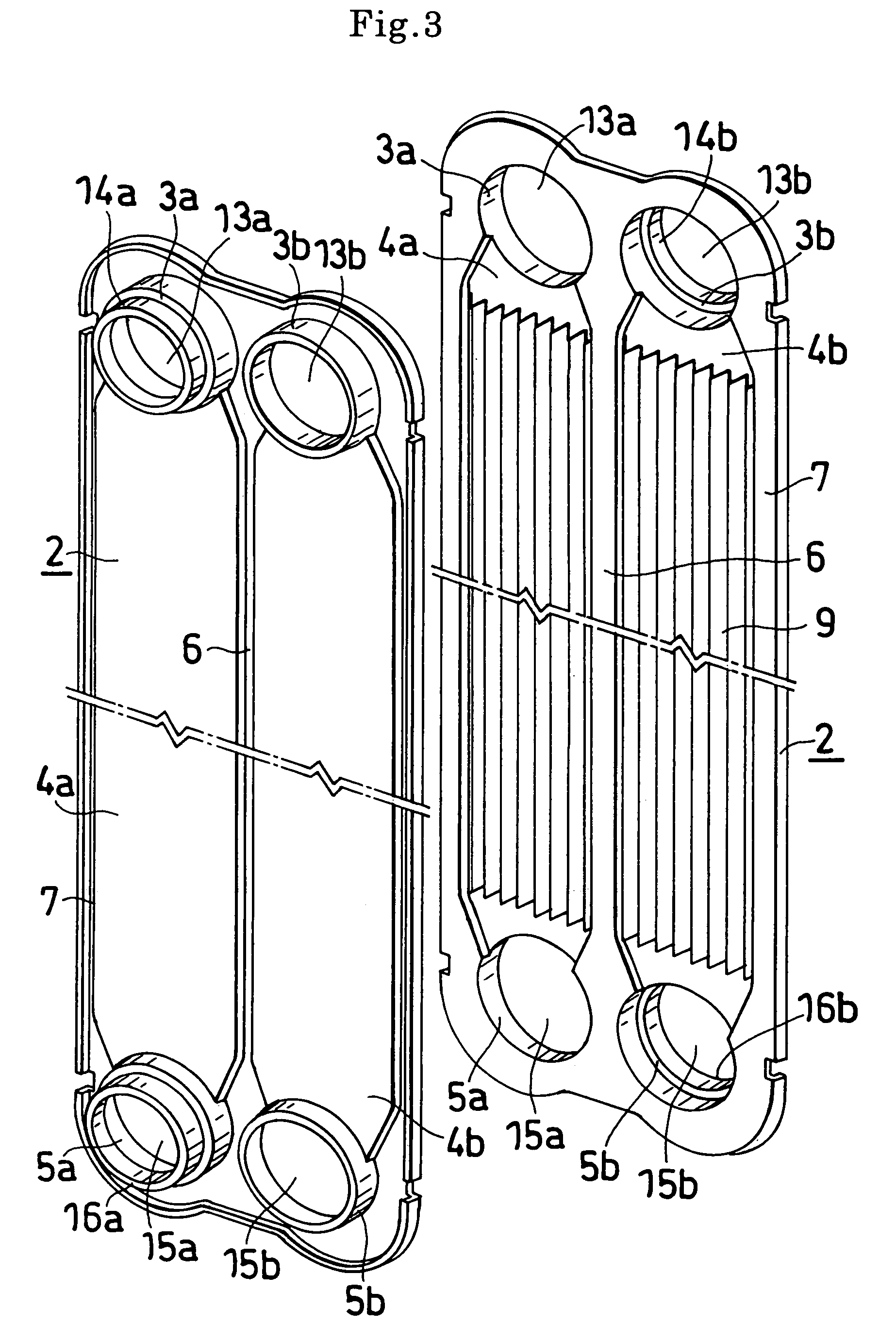

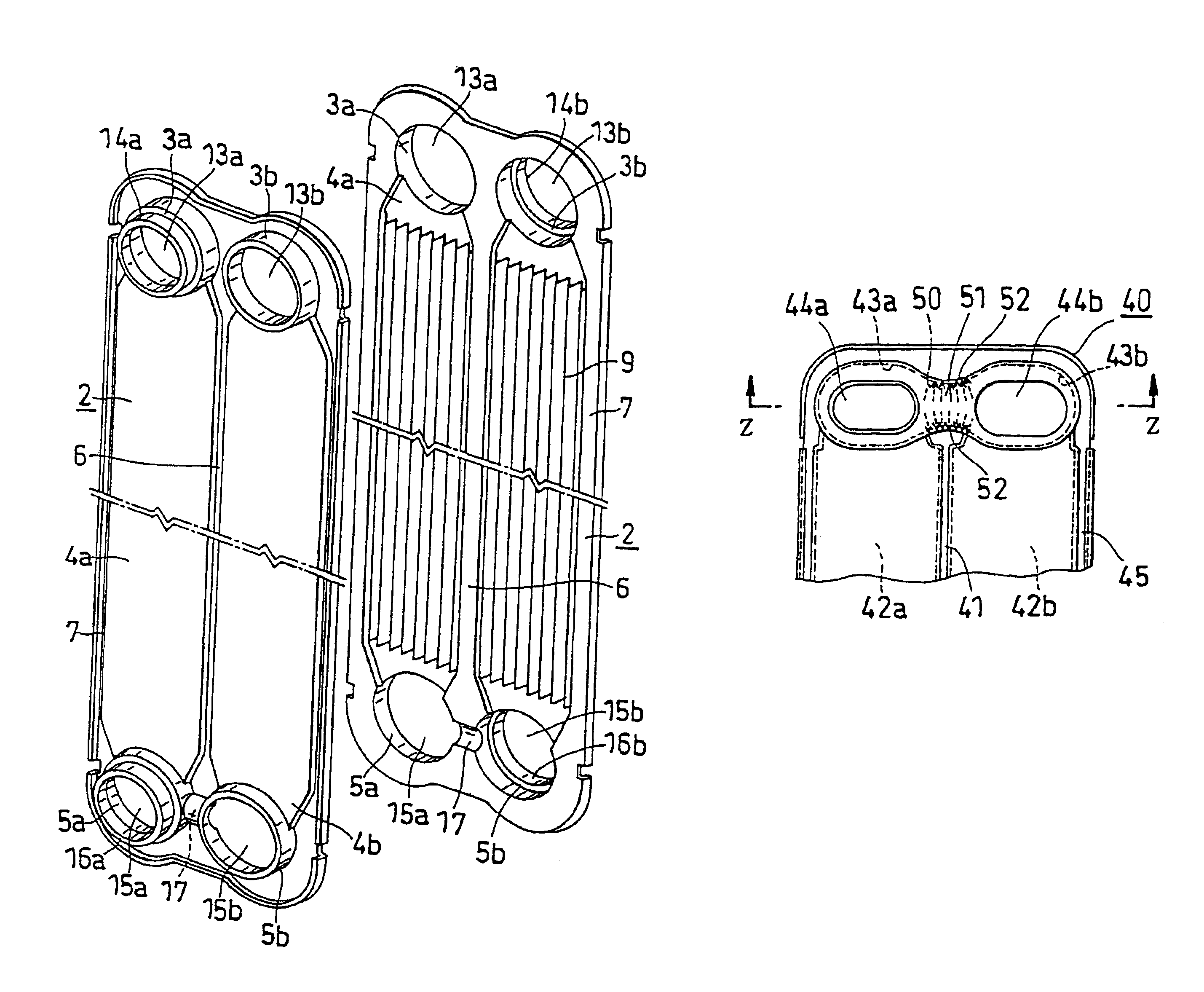

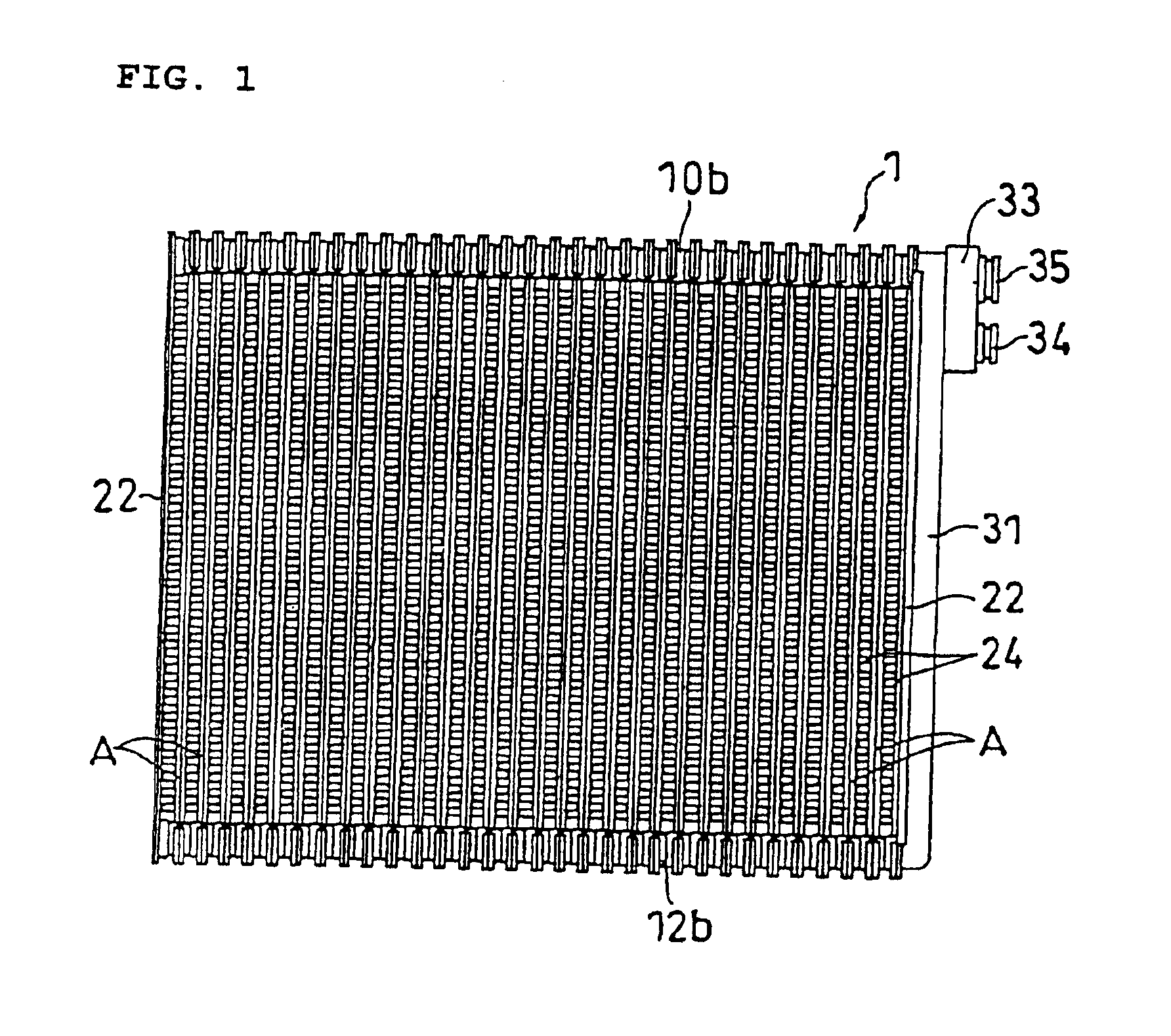

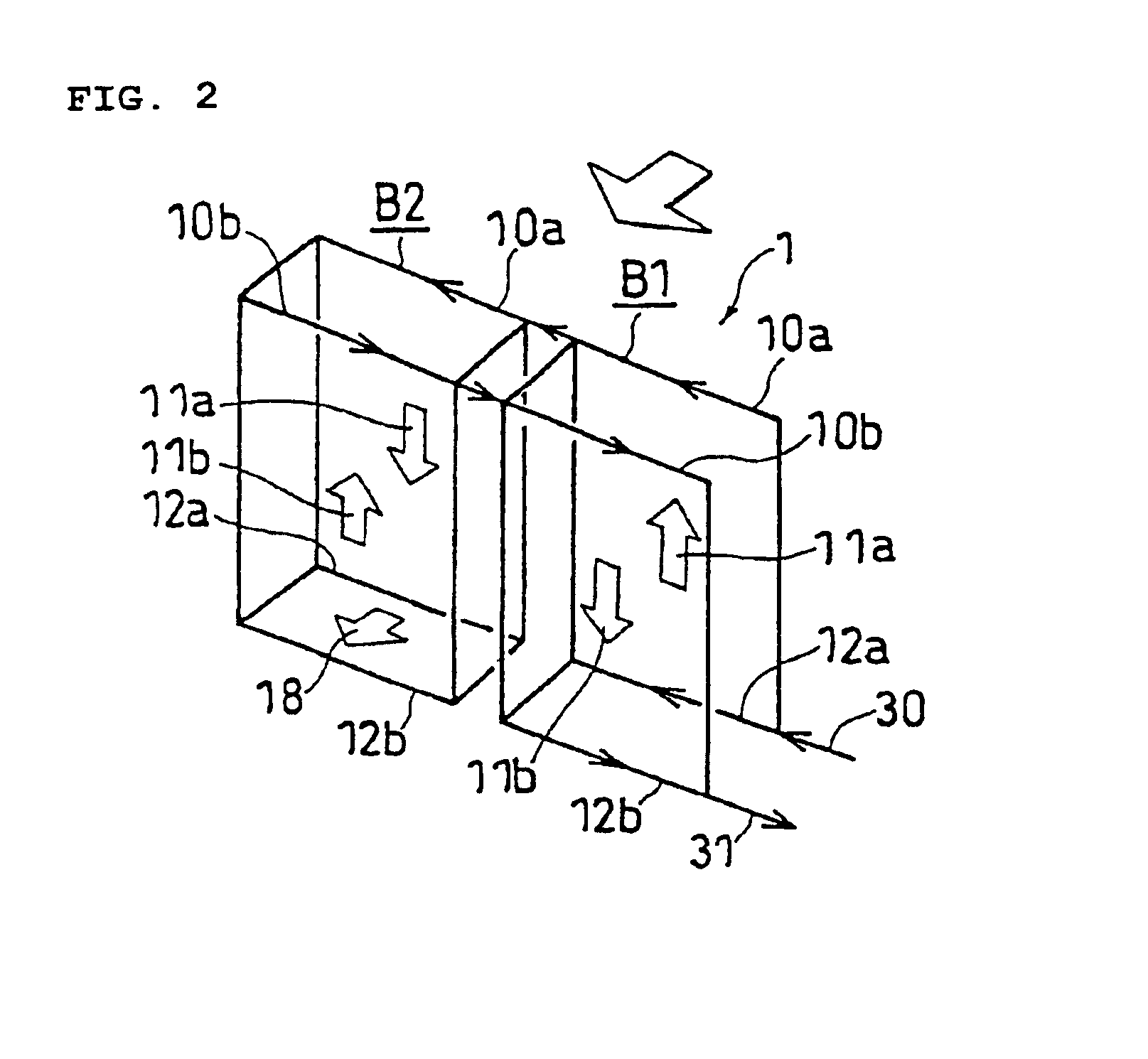

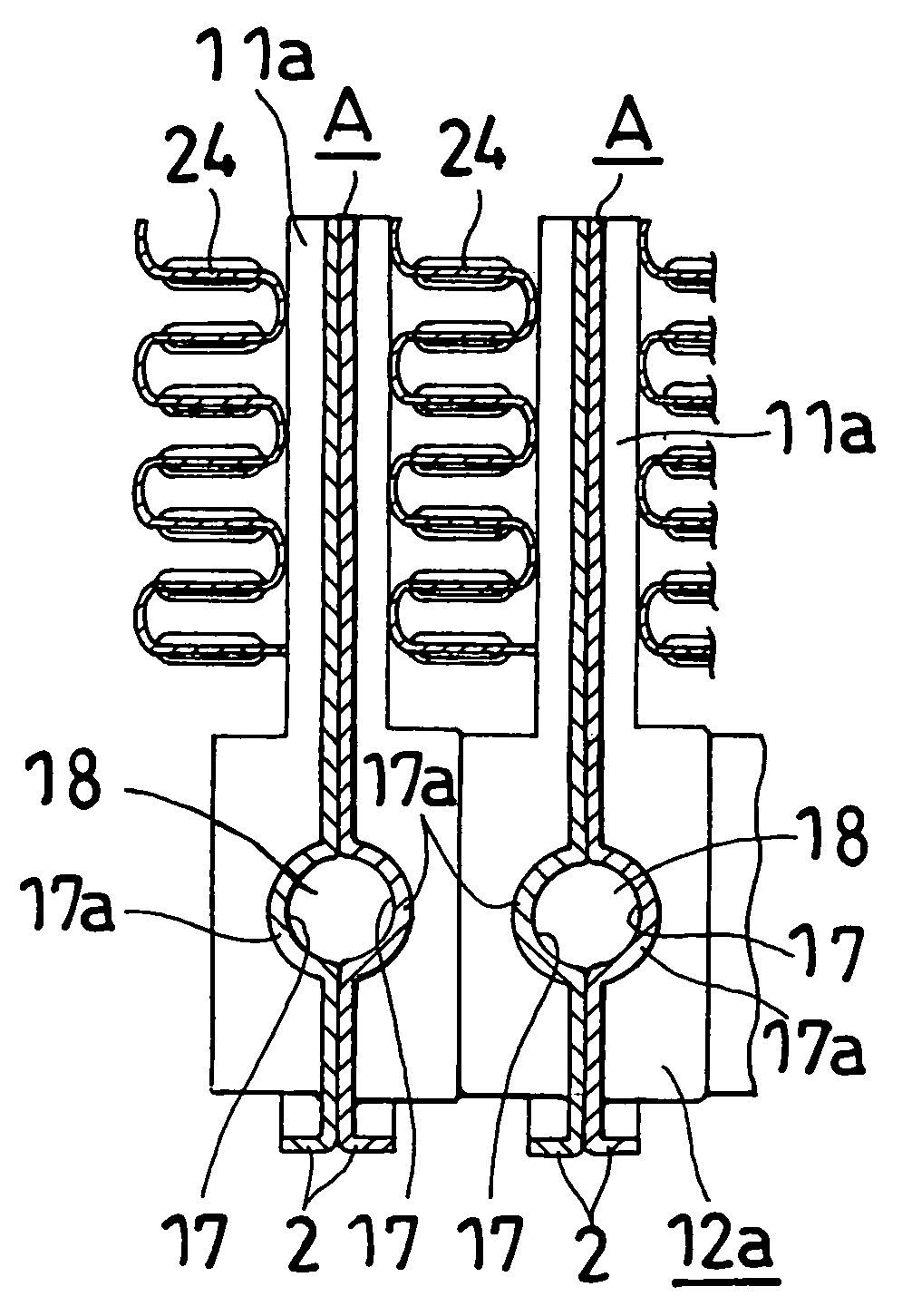

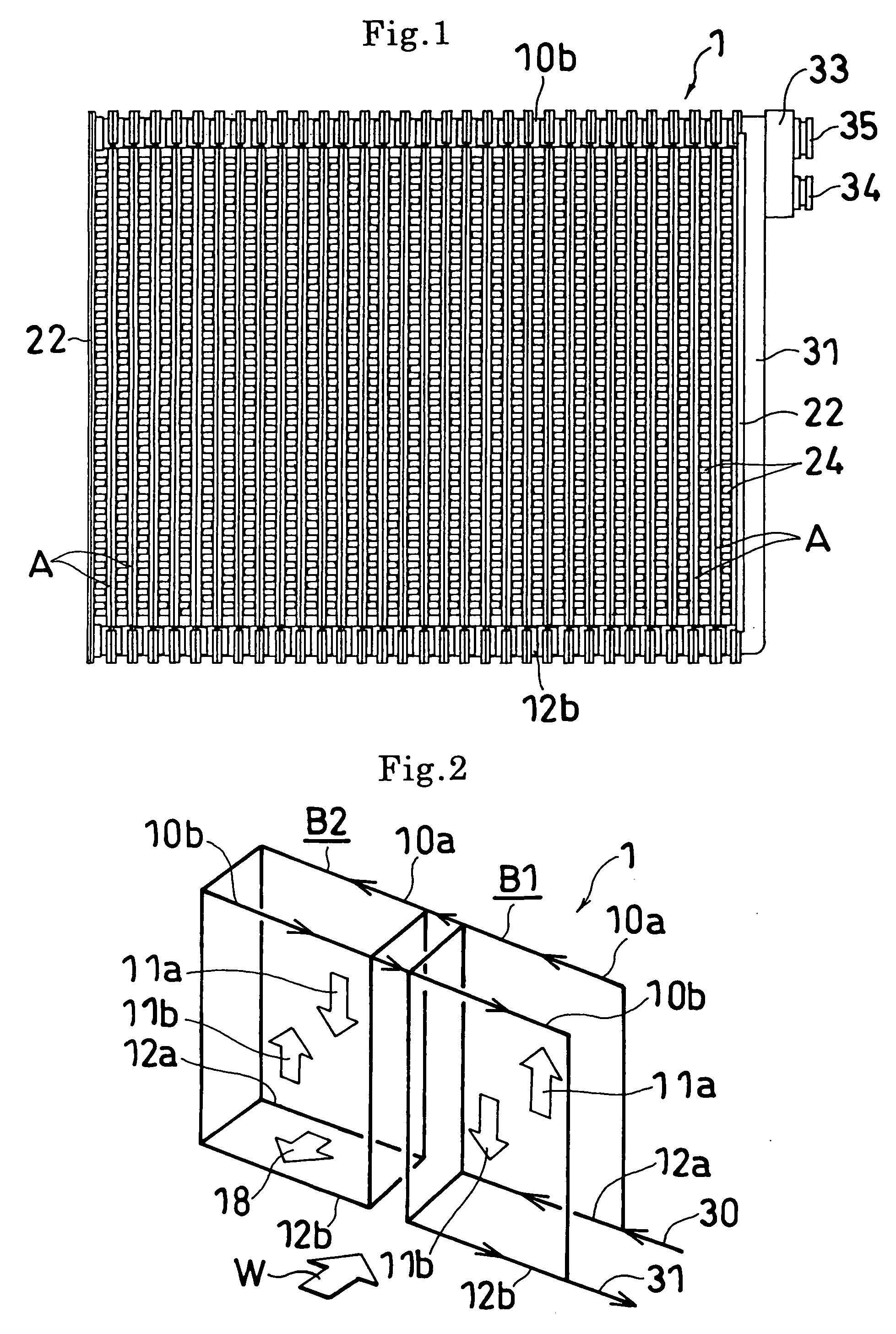

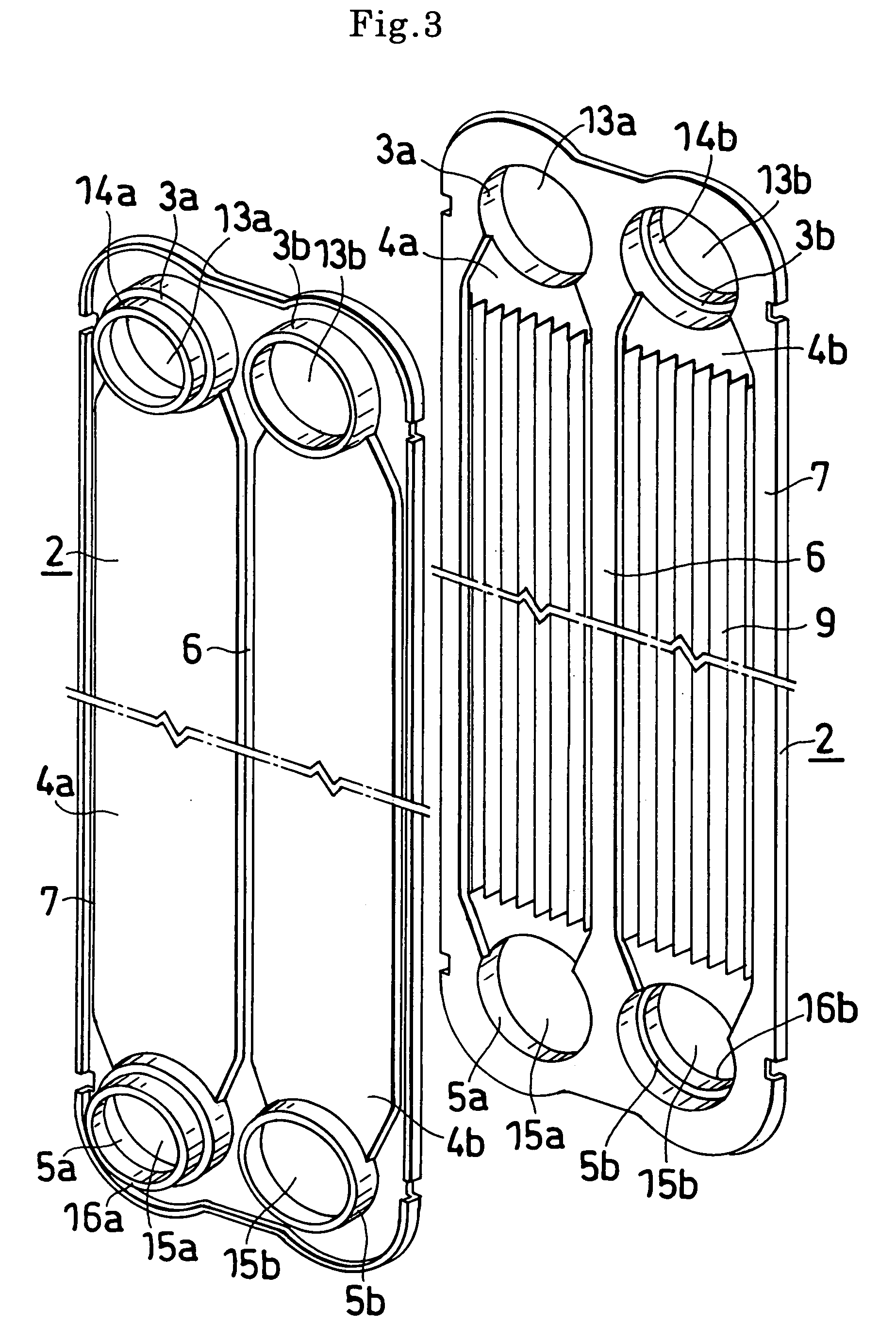

Layered heat exchangers

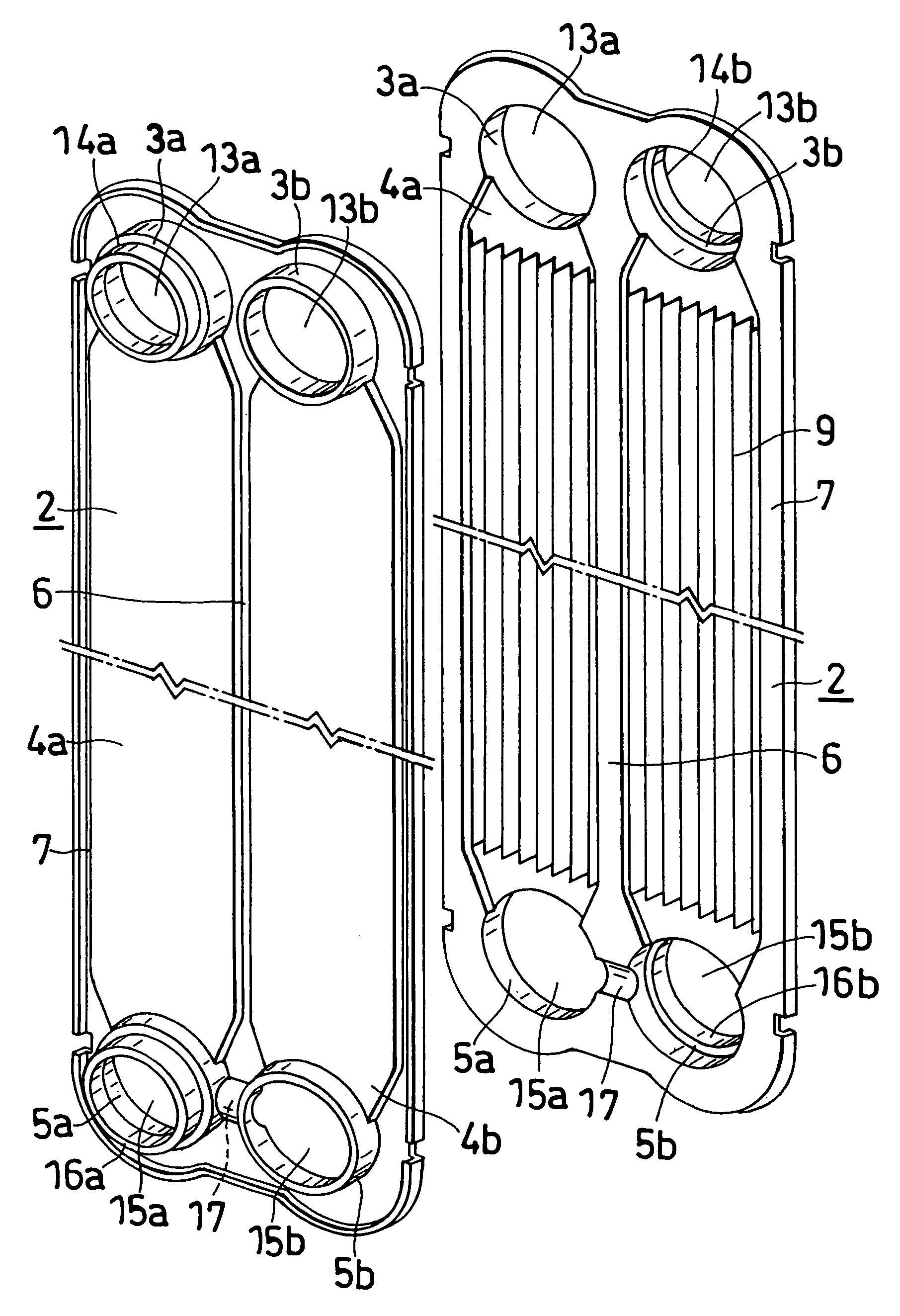

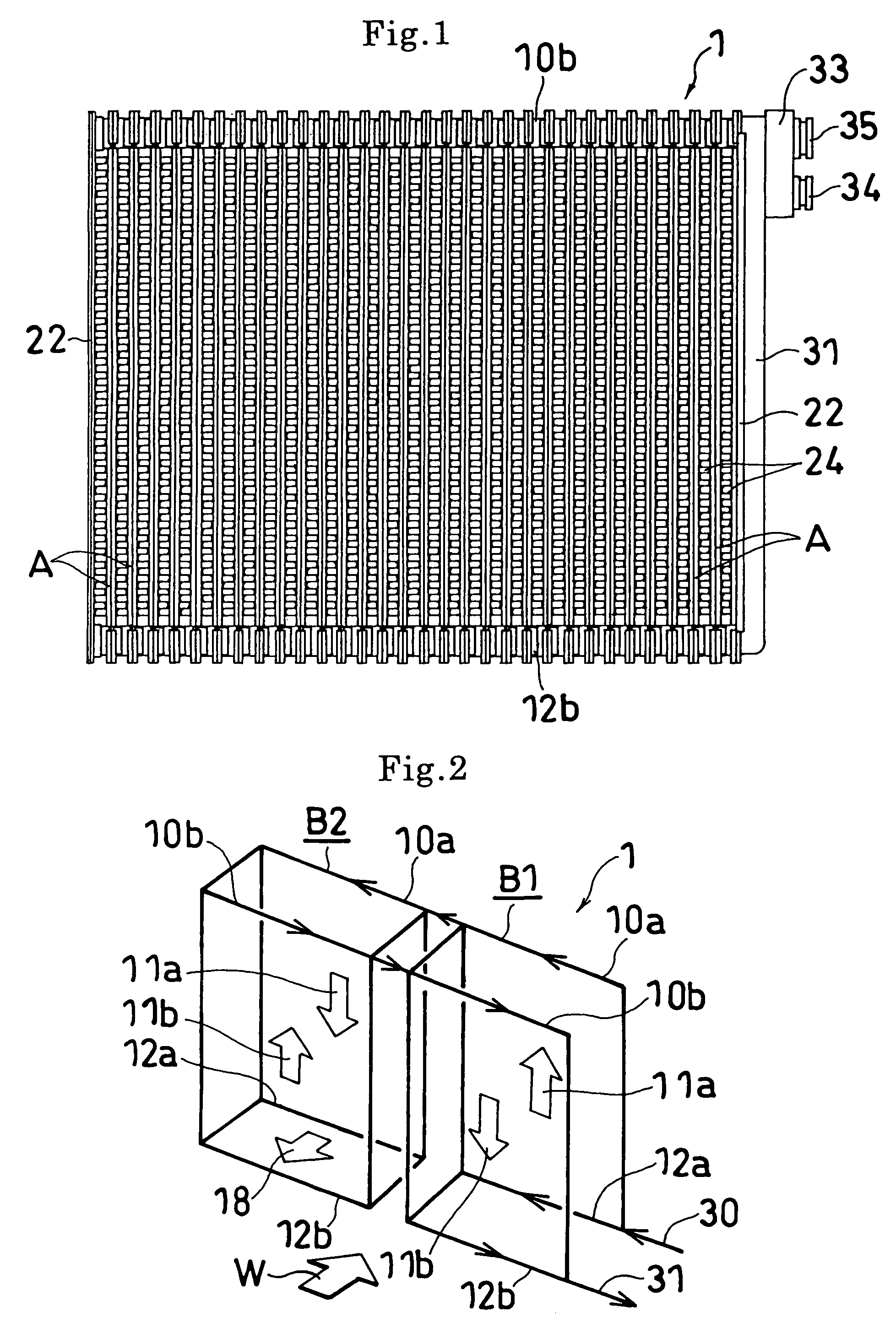

InactiveUS7044205B2Increase ultimate strengthReduce stress concentrationReinforcing meansEvaporators/condensersInternal pressurePlate heat exchanger

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

Decorative sheet, and decorative member in which same is used

PendingUS20160325535A1Reduce thicknessStrong designabilityCovering/liningsDecorative surface effectsPolyolefinEngineering

Provided is a decorative sheet for decreased thickness, and ensure superior molding processability and designability including external appearance (including the finished state) and texture (feel). The present invention relates to a decorative sheet, comprising a base sheet formed of a polyester resin or a polyolefin resin; and an ornamental layer and a surface-protecting layer provided on the base sheet in this order, the decorative sheet having a total thickness of 70 to 135 μm, at least the surface-protecting layer having recesses, the maximum depth of each recess being 15 to 100% based on the total thickness and not less than 15 μm, the ratio of a tensile elastic modulus at 120° C. to a tensile elastic modulus at 20° C. being 1:12 to 1:160, and the ratio of a maximum point load at 120° C. to a maximum point load at 20° C. upon 30-mm stretching being 1:1.7 to 1:30.

Owner:DAI NIPPON PRINTING CO LTD

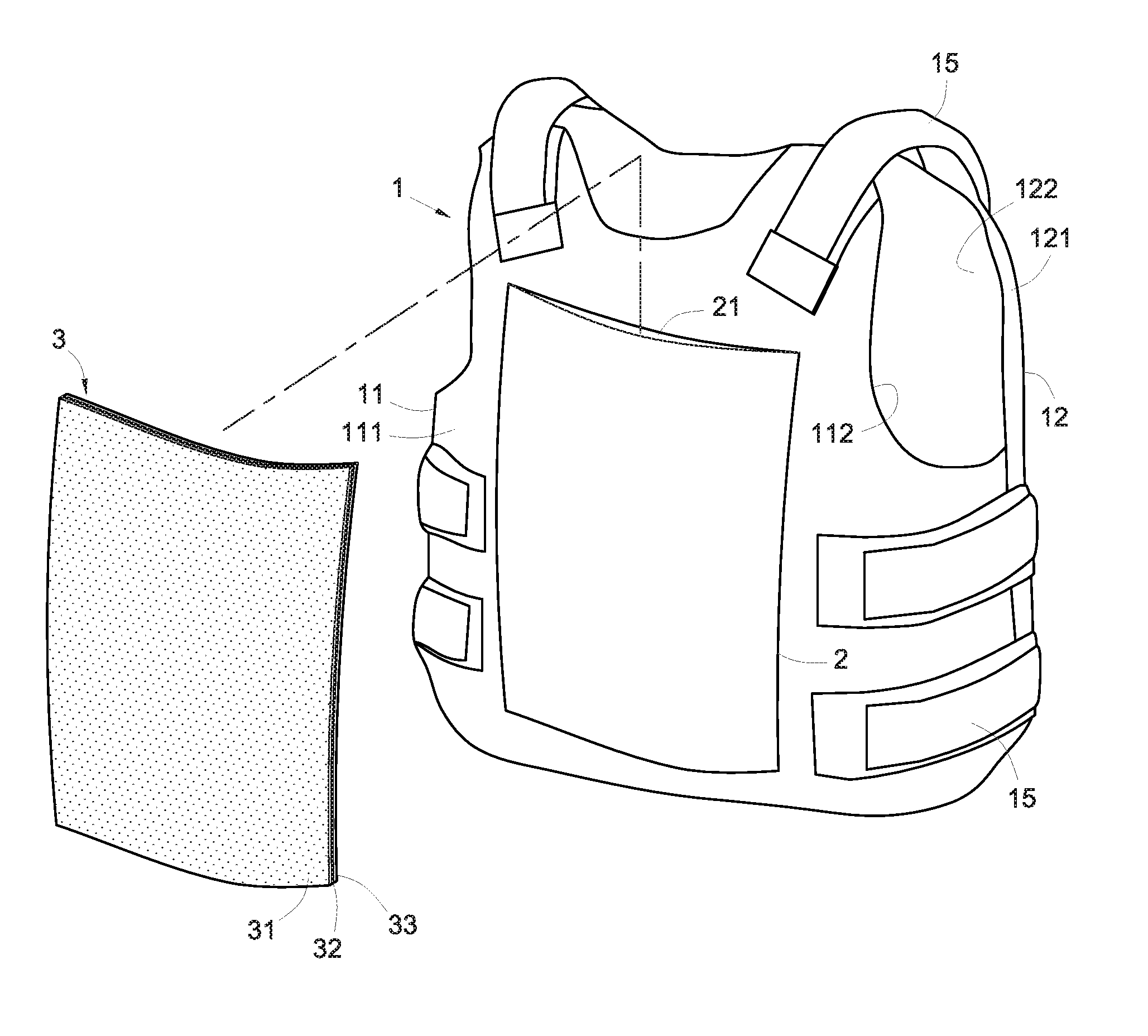

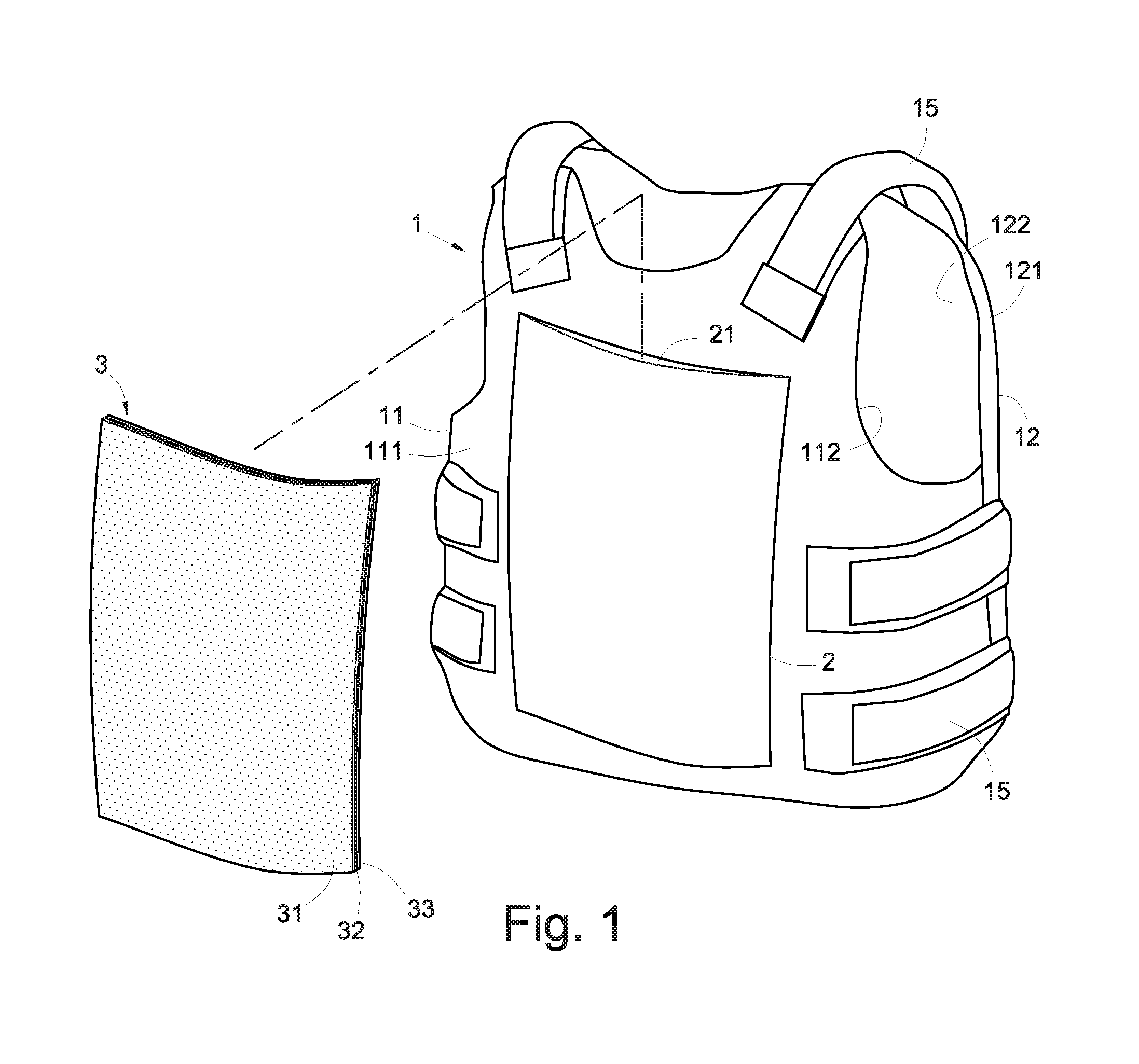

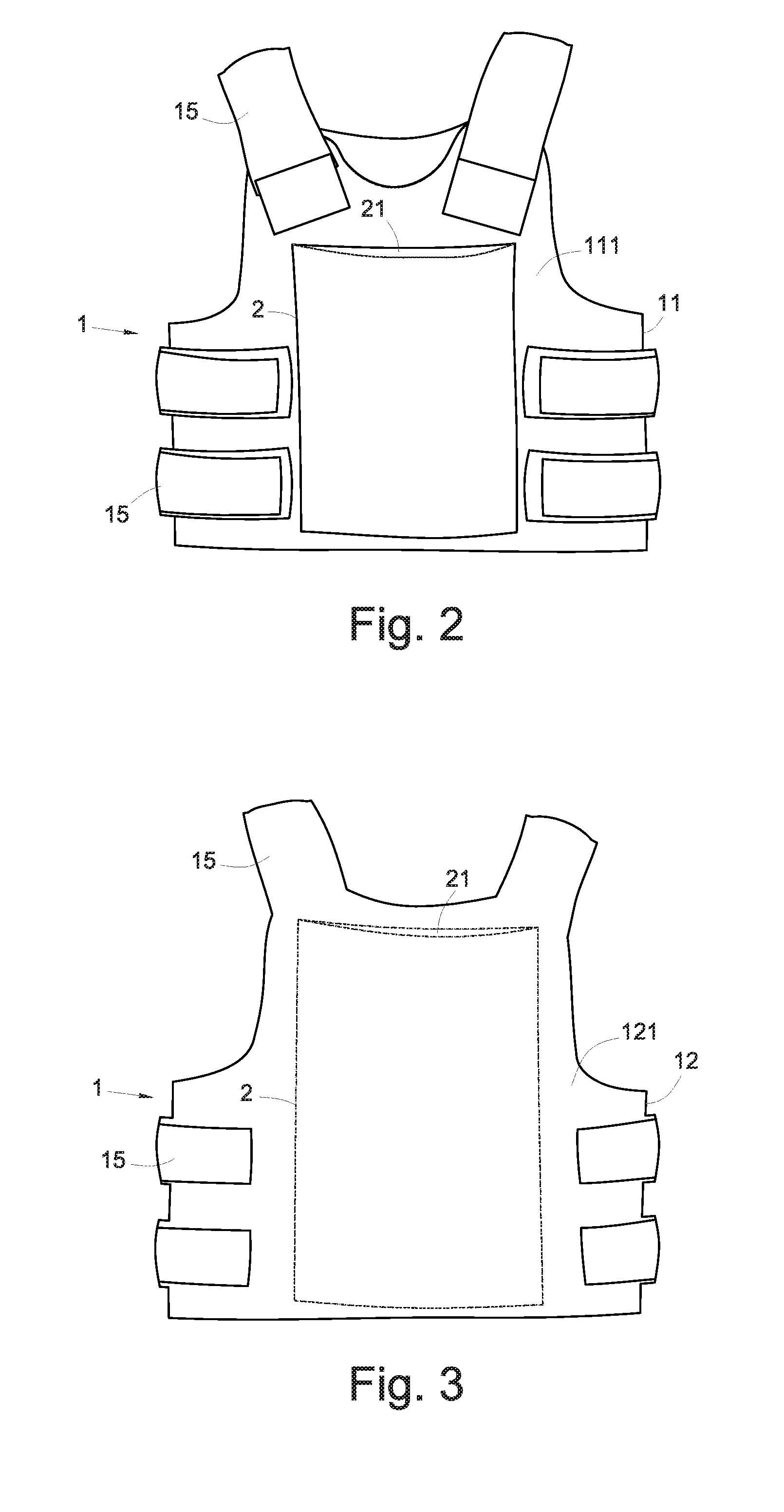

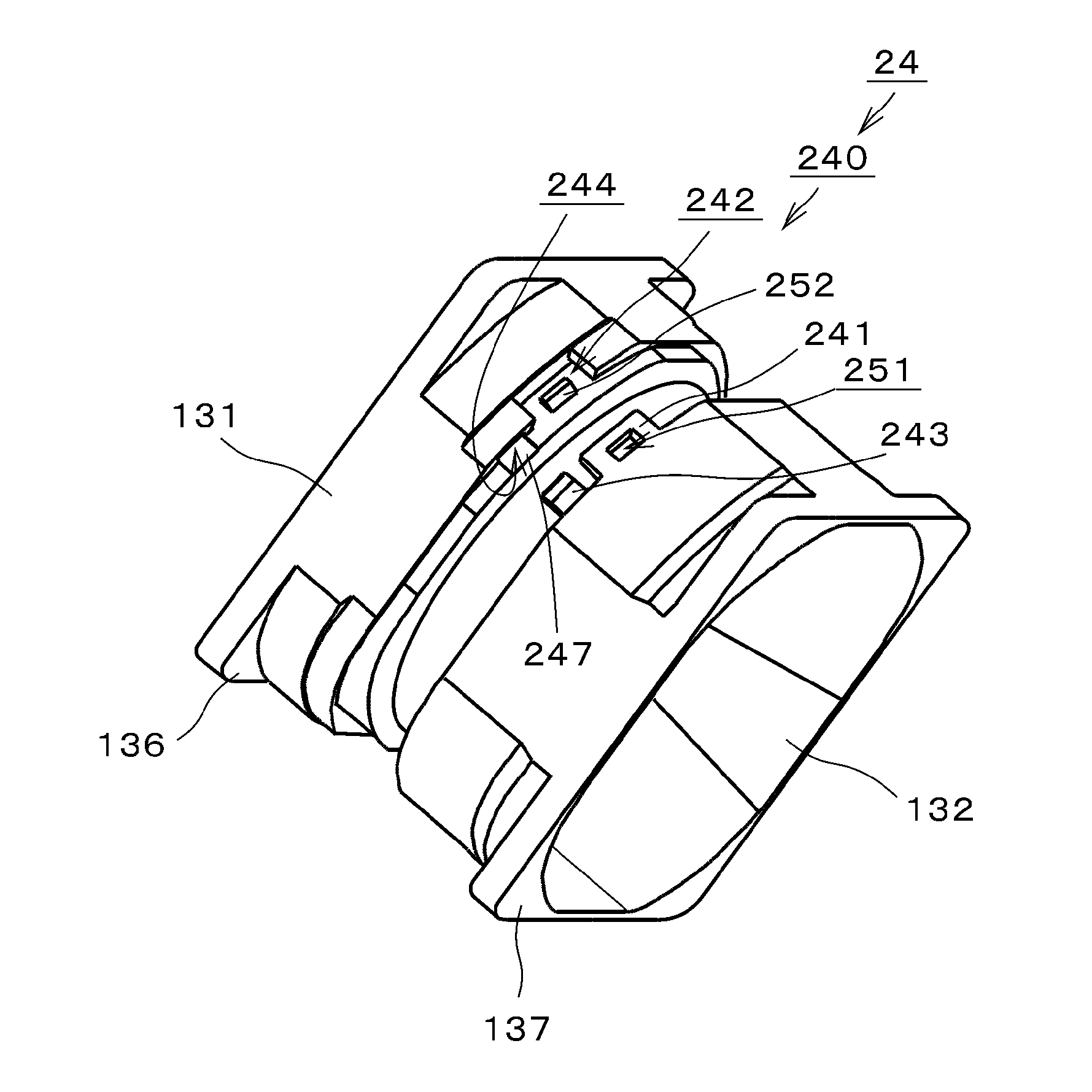

Removable healthcare and protective multi-functional leisurewear

InactiveUS20130152290A1Increasing the thicknessWeight increasePersonal protection gearProtective garmentEngineeringPolycarbonate

A removable healthcare and protective multi-functional leisurewear, particularly the leisurewear with protective plates that can be changed according to a desired level of safety is disclosed. The multi-functional leisurewear includes a plurality of accommodating bags on the leisurewear, and each accommodating bag has a pocket formed on a surface of the leisurewear, and the accommodating bag is provided for containing a protective plate that is swapped from the pocket, and the protective plate is formed by sequentially stacking and combining a flexible wear-resisting layer, a polycarbonate layer with an increased or decreased thickness changed according to the desired level of safety, and a flexible buffer layer attached closely to a wearer's body, so as to improve the convenience of use.

Owner:CHOU CHI LIANG

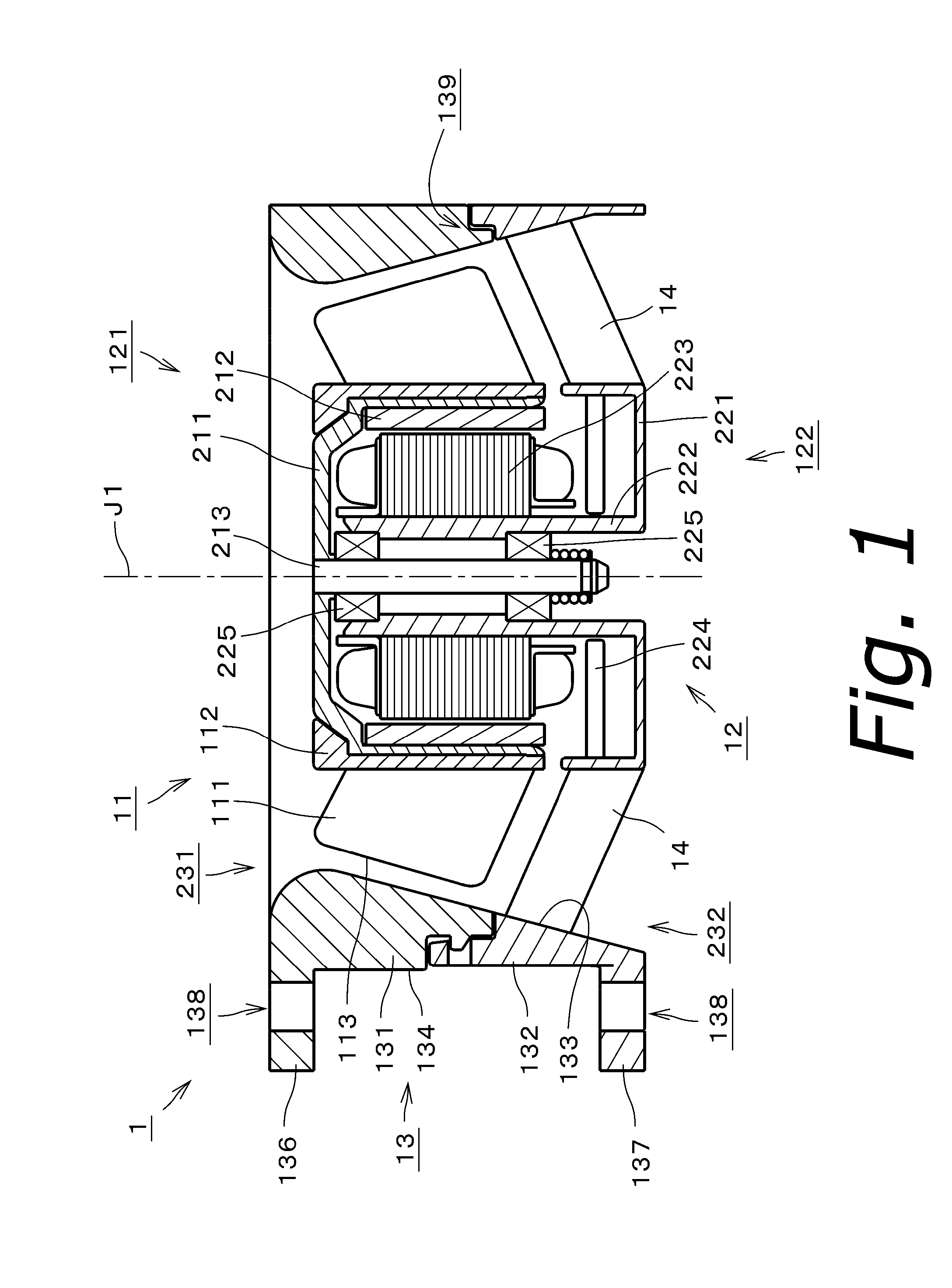

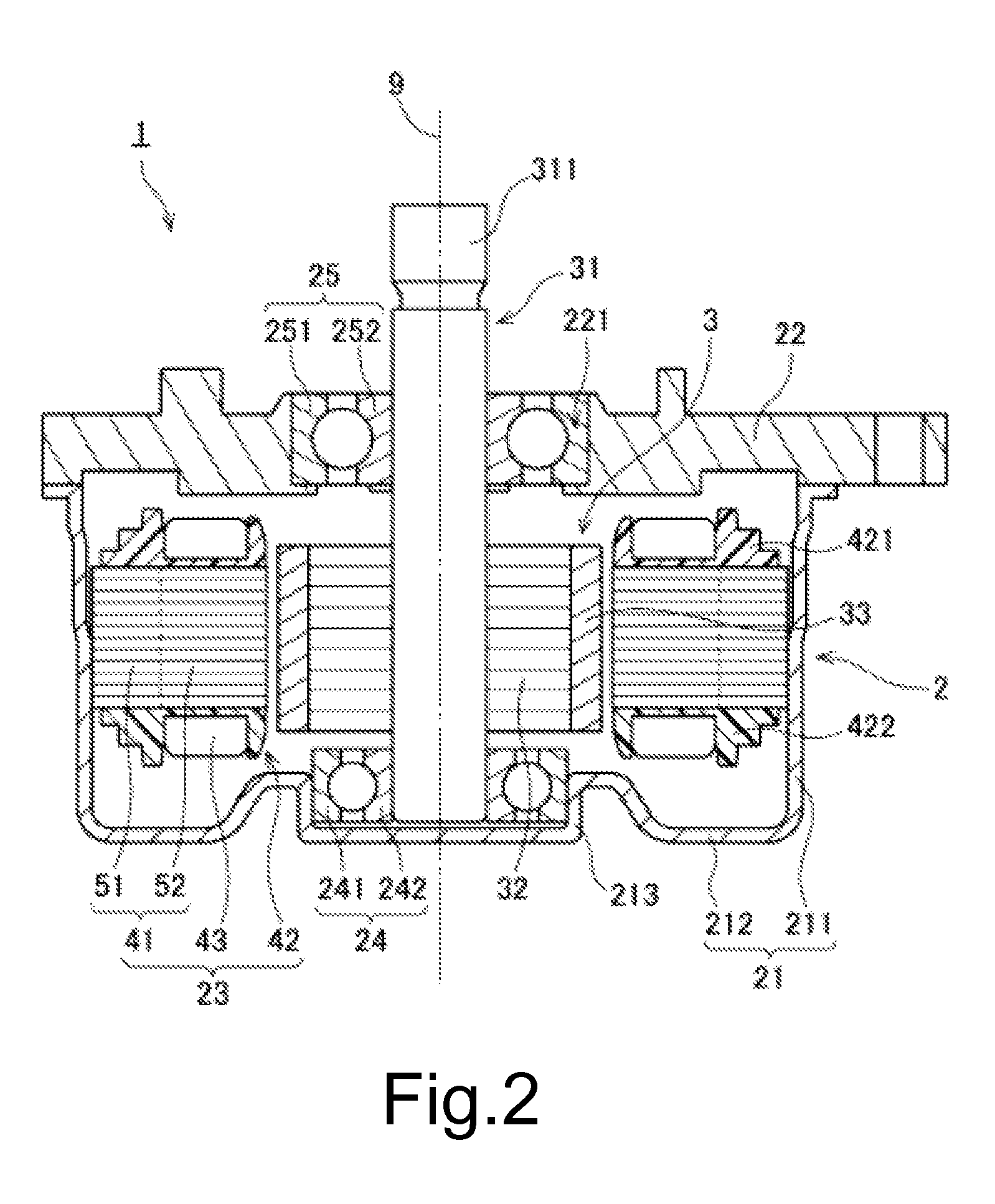

Fan

ActiveUS20130209294A1Increase in sizeEasy to providePump componentsPiston pumpsEngineeringMechanical engineering

In a fan, a housing includes decreased thickness portions and increased thickness portions arranged alternately in a circumferential direction. A distance between a central axis and an edge increases from an air inlet toward an air outlet. An inner circumferential surface has a minimum radius smaller than a distance between the central axis and an outermost portion of the edge. At a boundary between upper and lower housing portions of the housing, the inner circumferential surface has a radius greater than the distance between the central axis and the outermost portion of the edge. The increased thickness portions include component fastening structures defining a fastening structure arranged to fit the upper and lower housing portions to each other.

Owner:NIPPON DENSAN CORP

Resin-soluble veils for composite article fabrication and methods of manufacturing the same

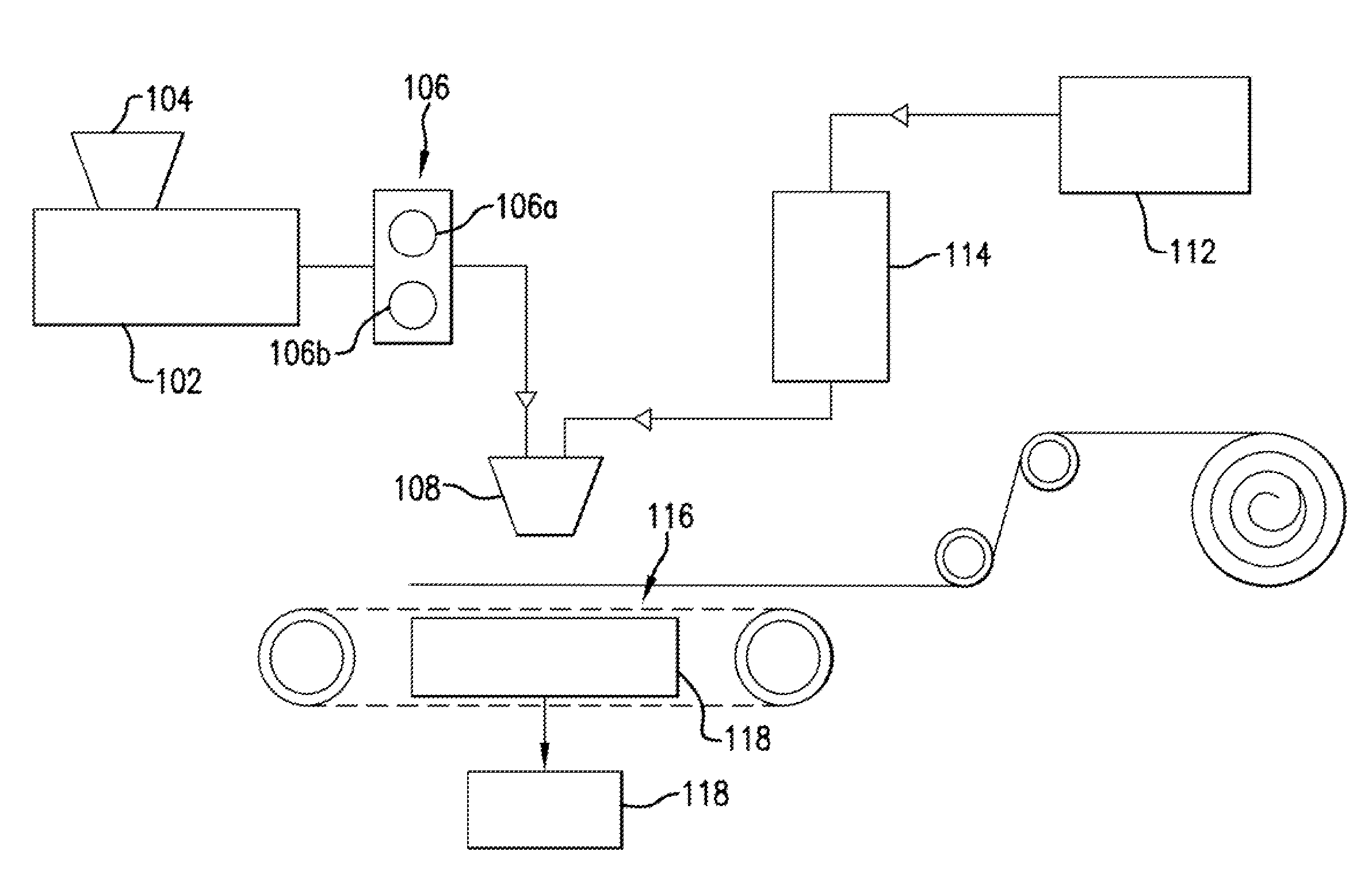

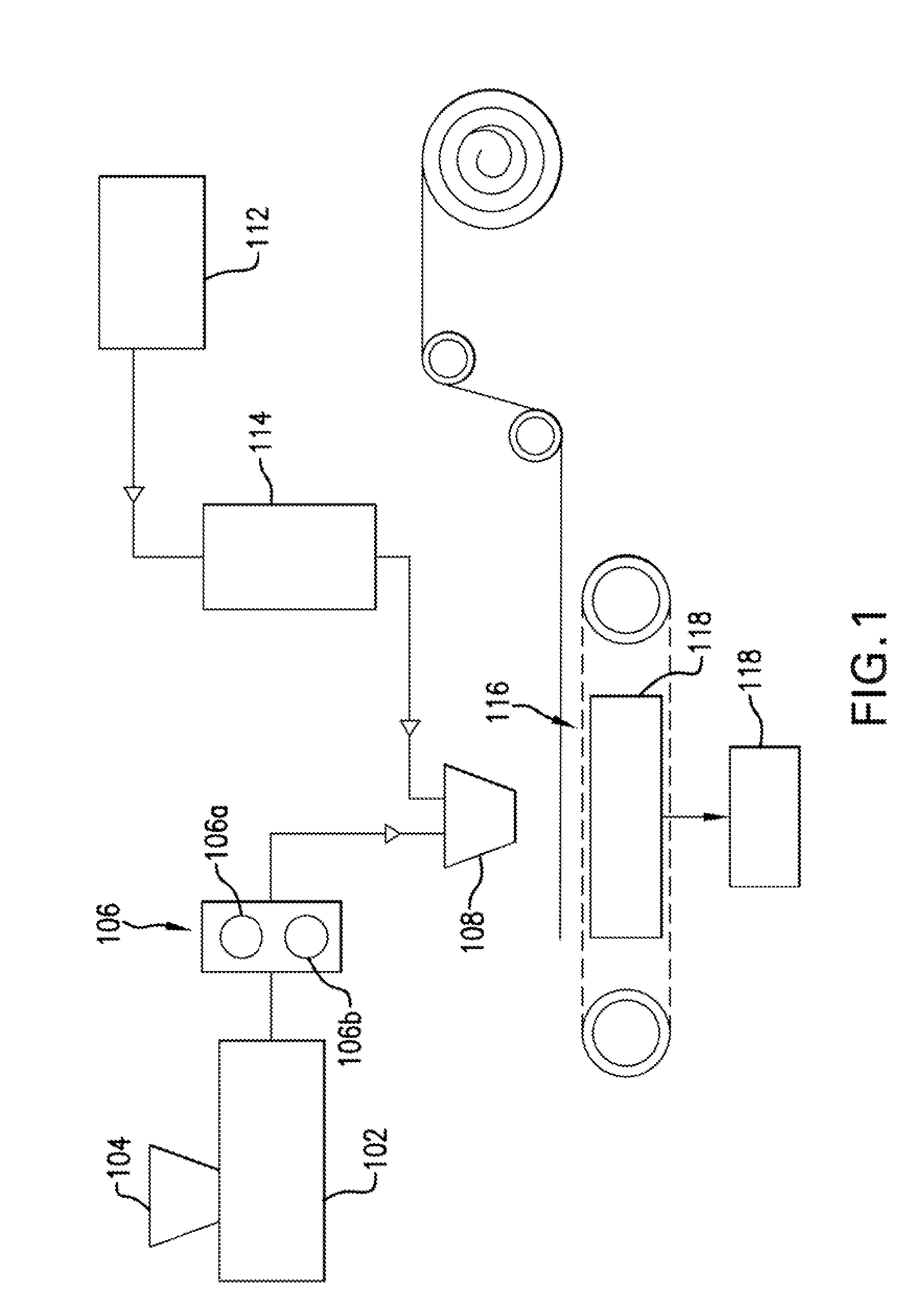

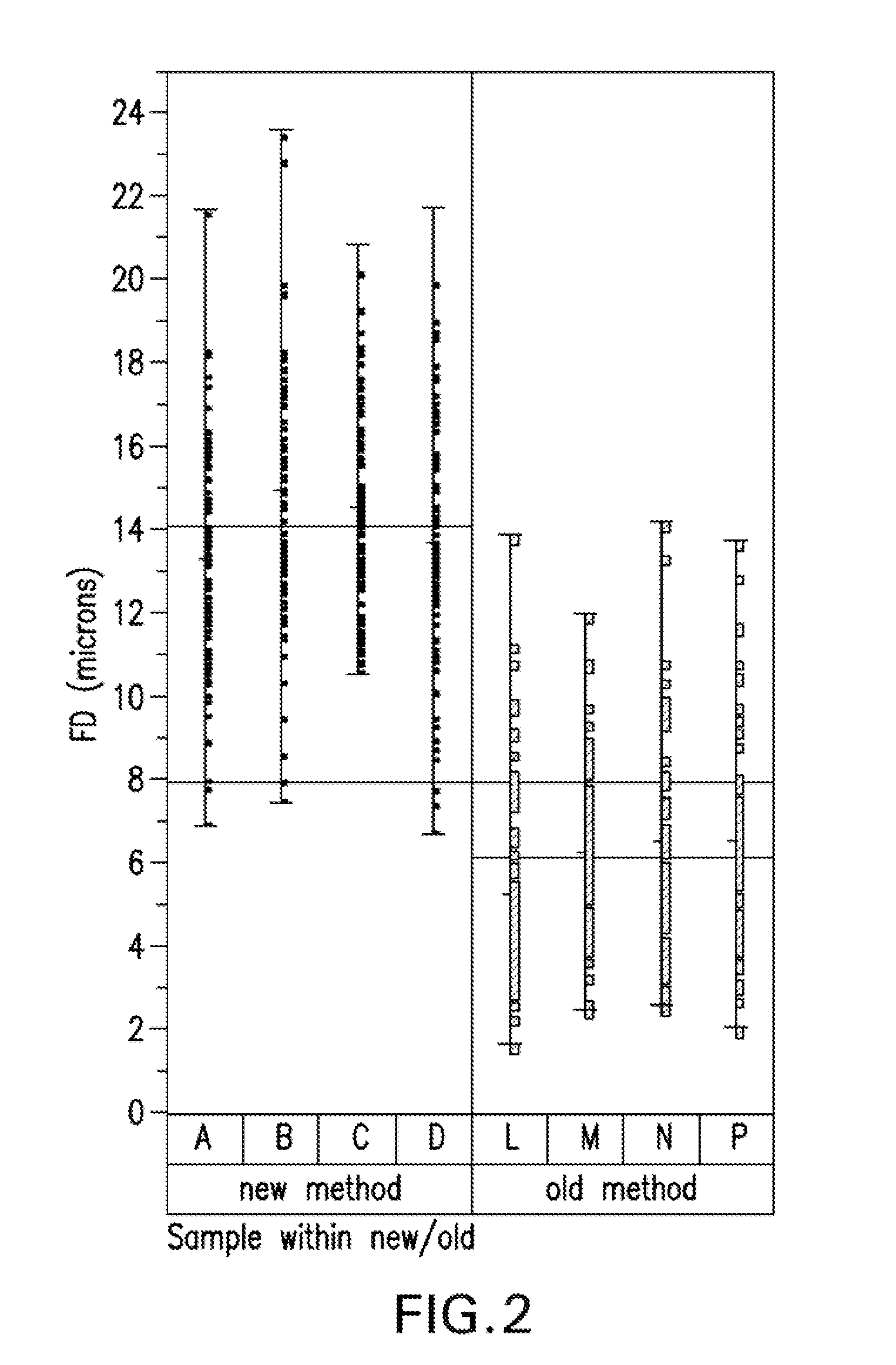

InactiveUS20120141728A1Short resin injection cure cycleFAW uniformity of the veilLayered productsCeramic shaping apparatusThermoplasticDissolution

Embodiments of the invention are directed to resin-soluble thermoplastic veils for use in liquid resin infusion processes, methods of manufacturing resin-soluble thermoplastic veils for use in liquid resin infusion processes, and methods of manufacturing composite articles using resin-soluble thermoplastic veils for use in liquid resin infusion applications. The resin-soluble thermoplastic veils according to embodiments of the invention and of which function as a toughening agent in composites having the veil incorporated therein have improved characteristics including, but not limited to, increased uniformity and decreased thickness relative to prior art veils. These characteristics translate into improvements in the processing of a composite article including, but not limited to, a substantial or complete elimination in premature dissolution of the veil during cure. The resultant composite article also realizes improvements including, but not limited to, distribution evenness of the toughening agent throughout the composite.

Owner:CYTEC TECH CORP

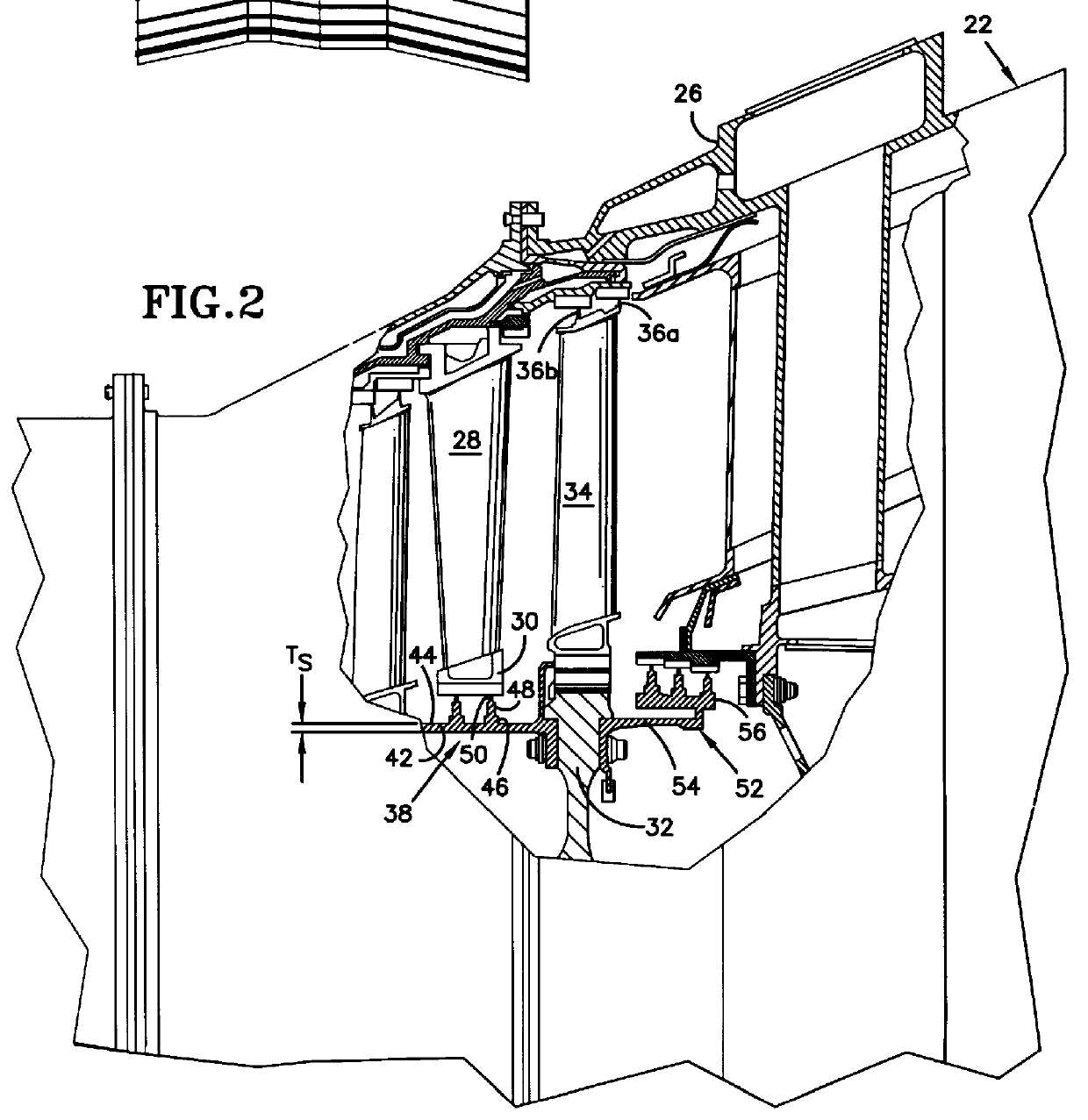

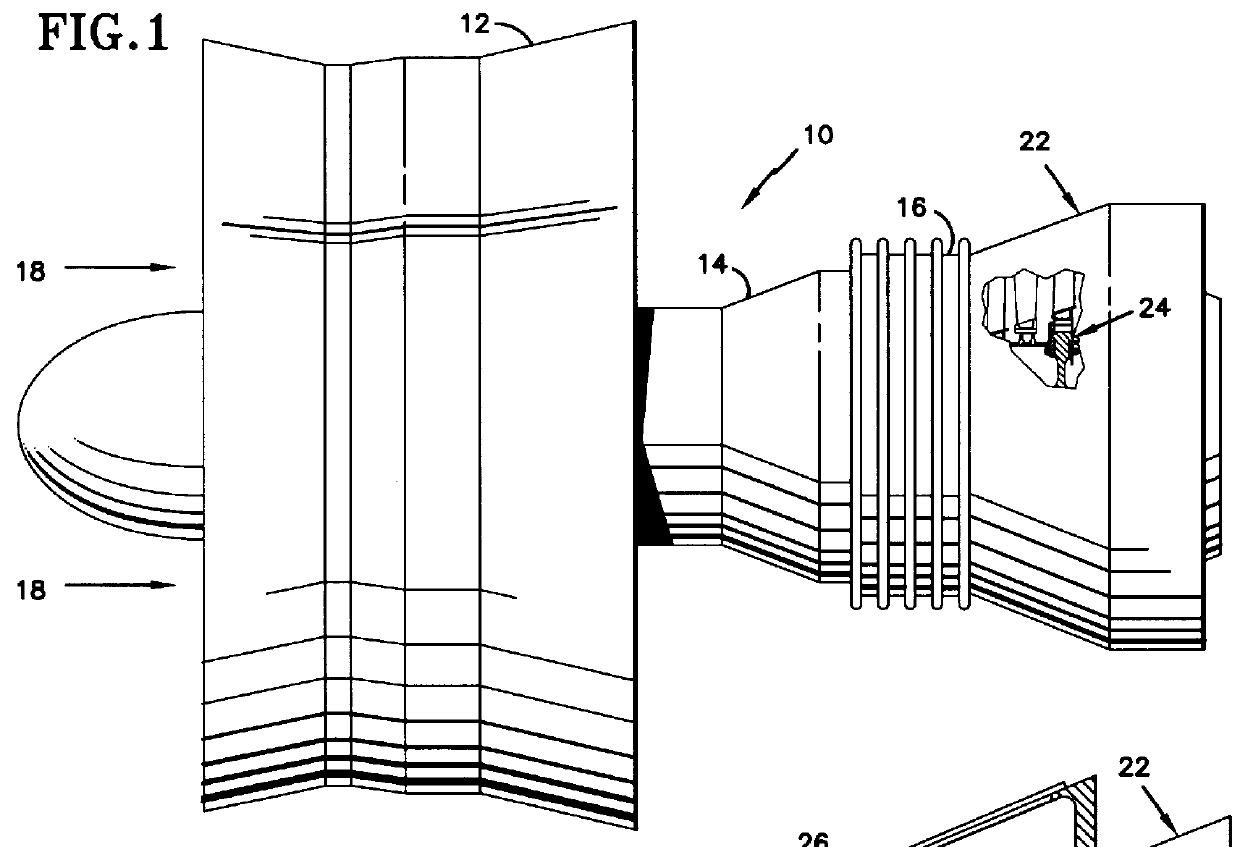

Rotatable seal element for a rotary machine

InactiveUS6082738APredictability of minimum cyclic lifeEngine sealsEngine manufactureEngineeringMechanical engineering

A rotatable seal element 38 is formed of at least two circumferentially continuous rings 48,50. The rings have decreased thickness T.sub.2, T.sub.3 in the outward direction. Various construction details are developed which effect the level of cyclic fatigue life. In one particular embodiment, the seal element has a flat surface 74 extending inwardly from the sides at the interface between the rings.

Owner:UNITED TECH CORP

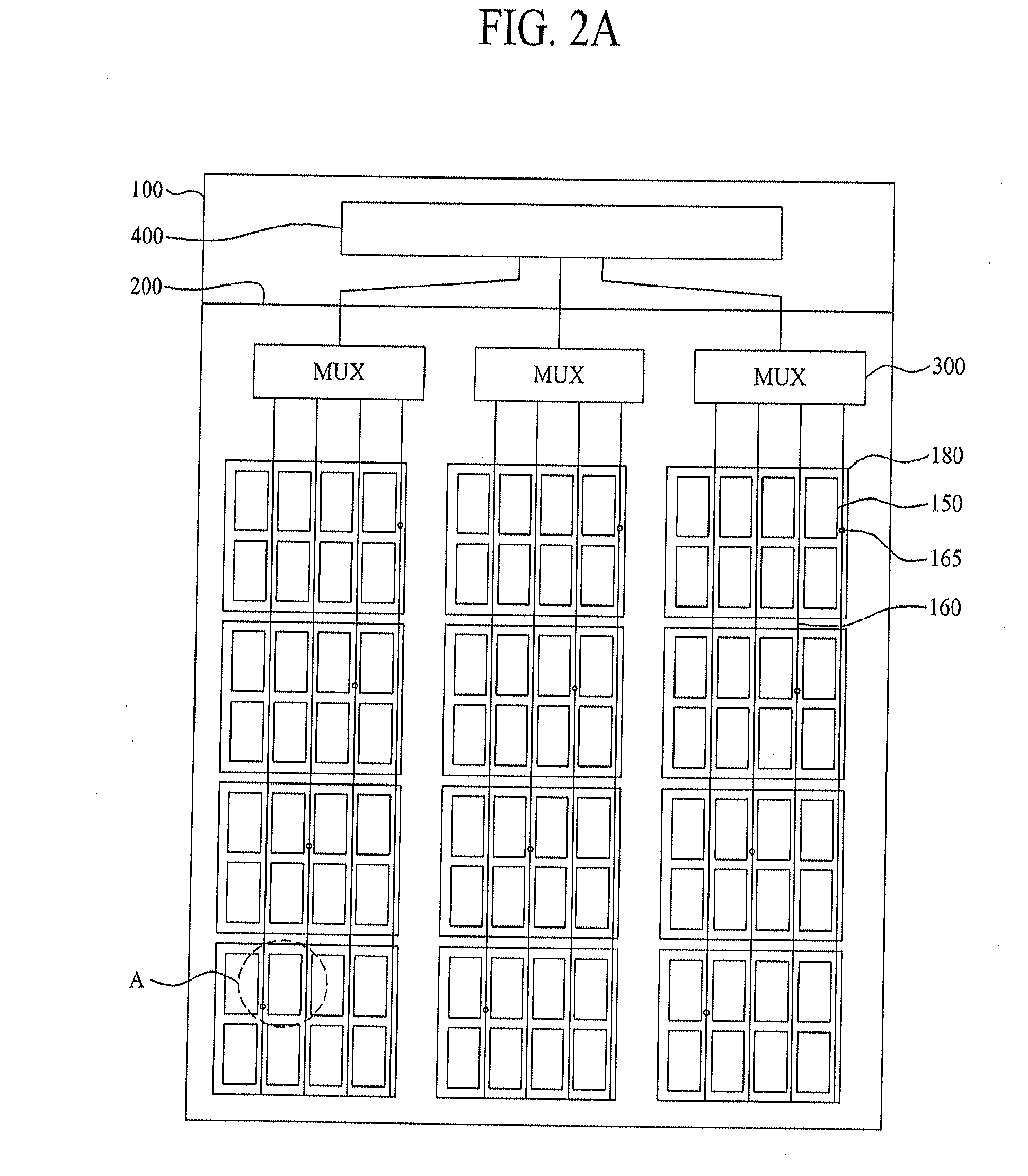

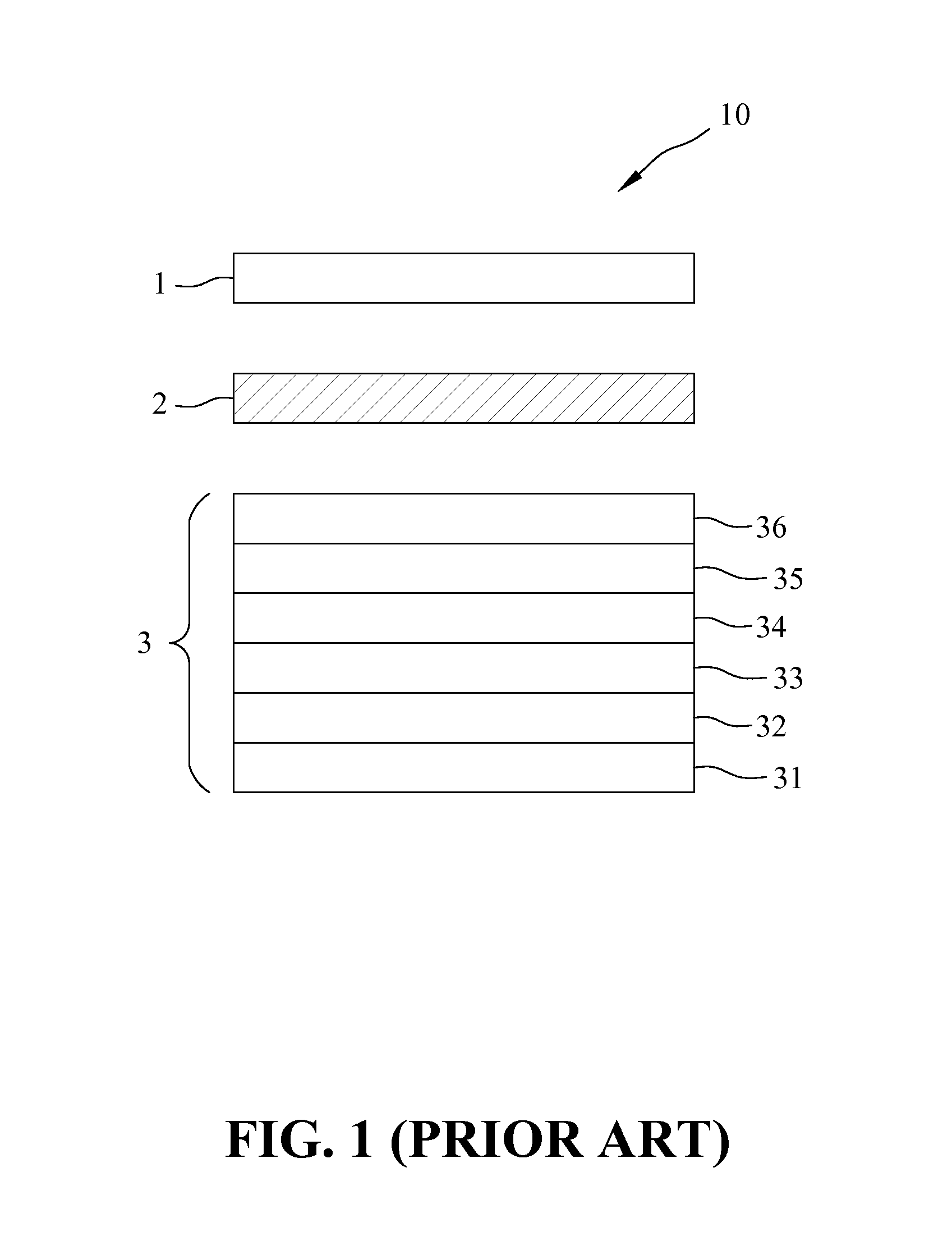

Liquid Crystal Display Device and Method for Manufacturing the Same

ActiveUS20160259195A1Non-linear opticsInput/output processes for data processingLiquid-crystal displayEngineering

Disclosed is an LCD device which realizes decreased thickness, simplified process, and decreased cost by using a common electrode for formation of electric field to drive liquid crystal as a sensing electrode, and removing a touch screen from an upper surface of the liquid crystal panel, the LCD device comprising gate and data lines crossing each other to define plural pixels on a lower substrate; a pixel electrode in each of the plural pixels; plural common electrode blocks patterned at the different layer from the pixel electrode, wherein the common electrode blocks, together with the pixel electrode, forms an electric field, and senses a user's touch; and plural sensing lines electrically connected with the common electrode blocks, wherein, if the sensing line is electrically connected with one of the common electrode blocks, the sensing line is insulated from the remaining common electrode blocks.

Owner:LG DISPLAY CO LTD

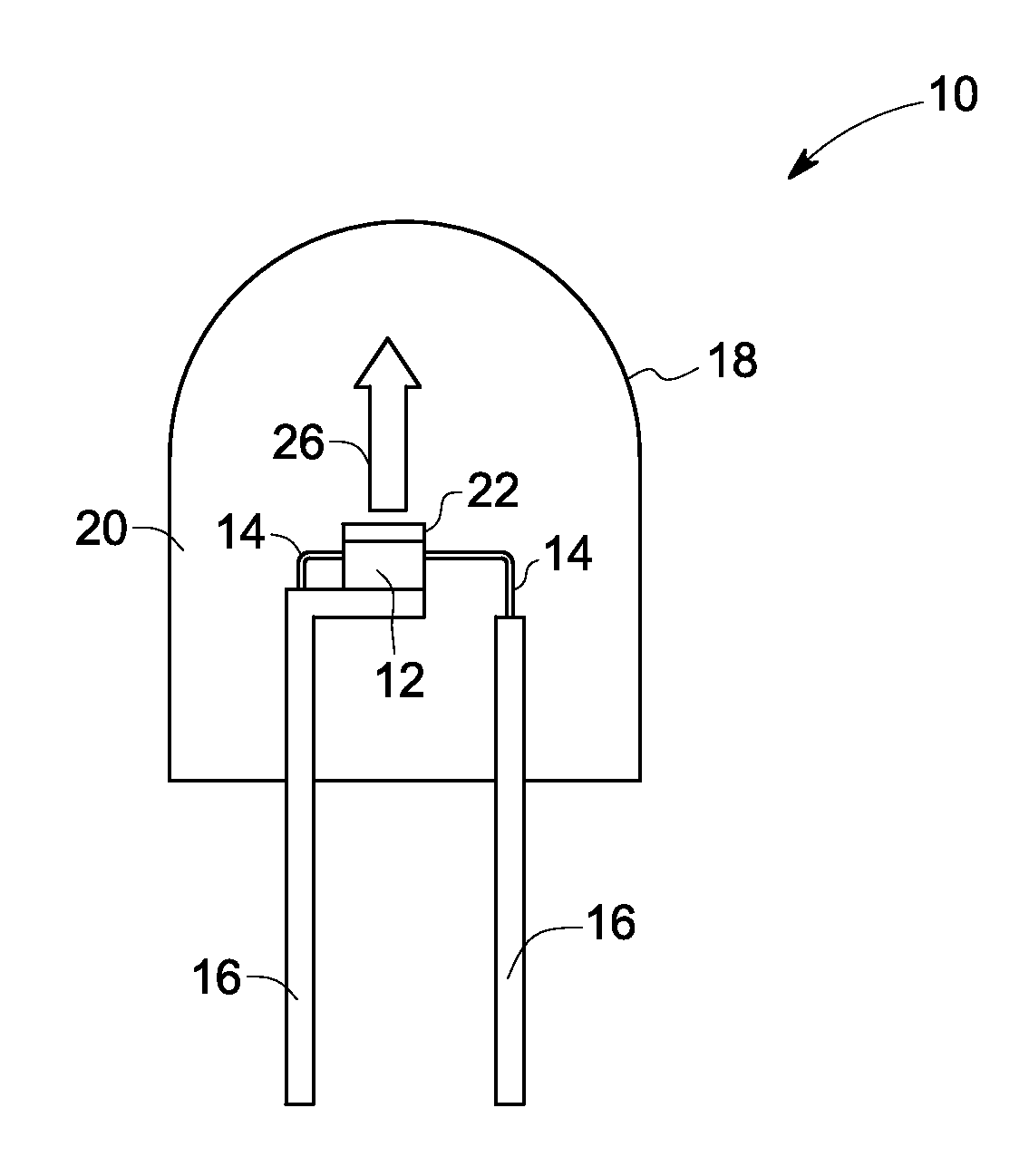

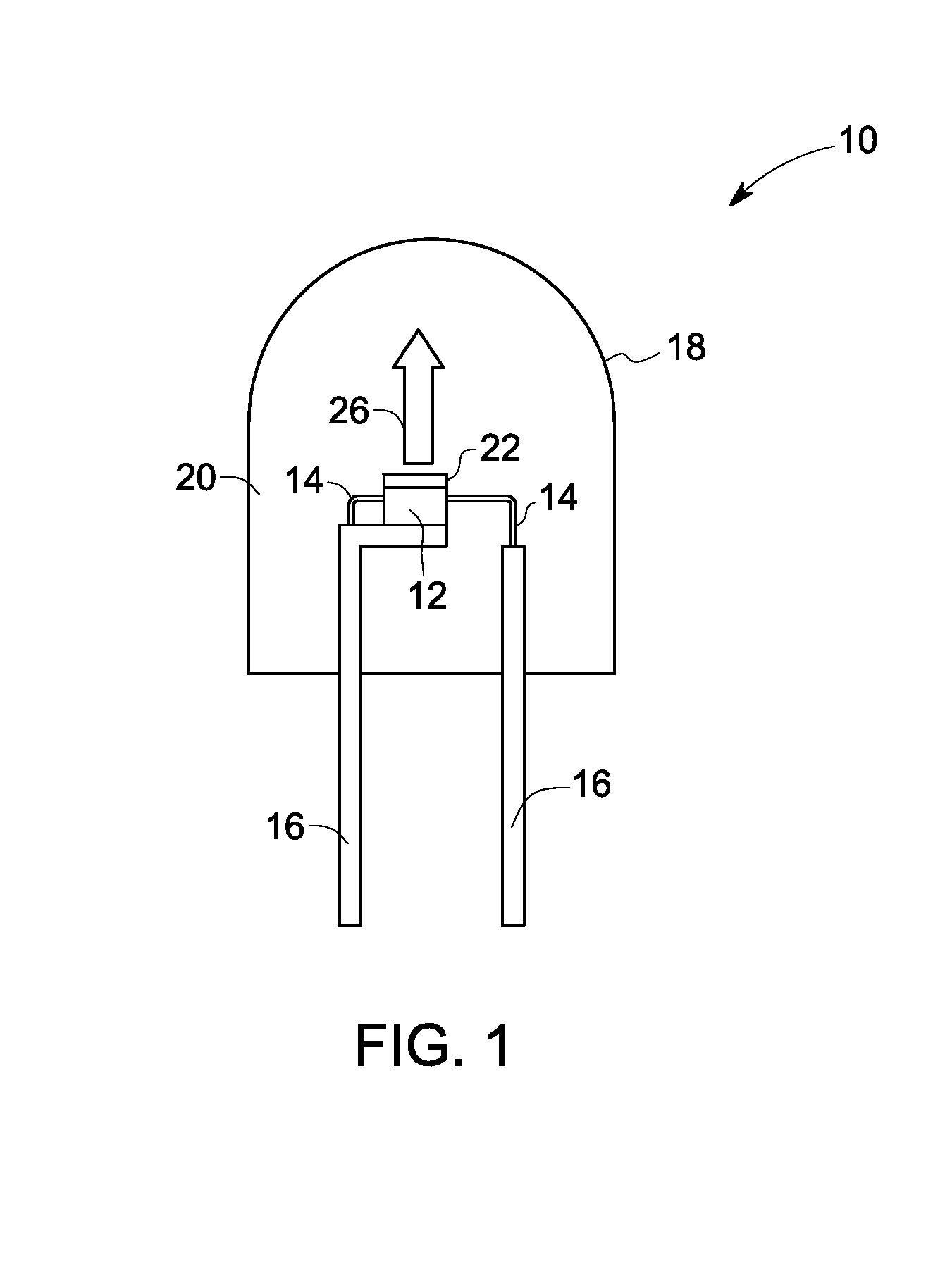

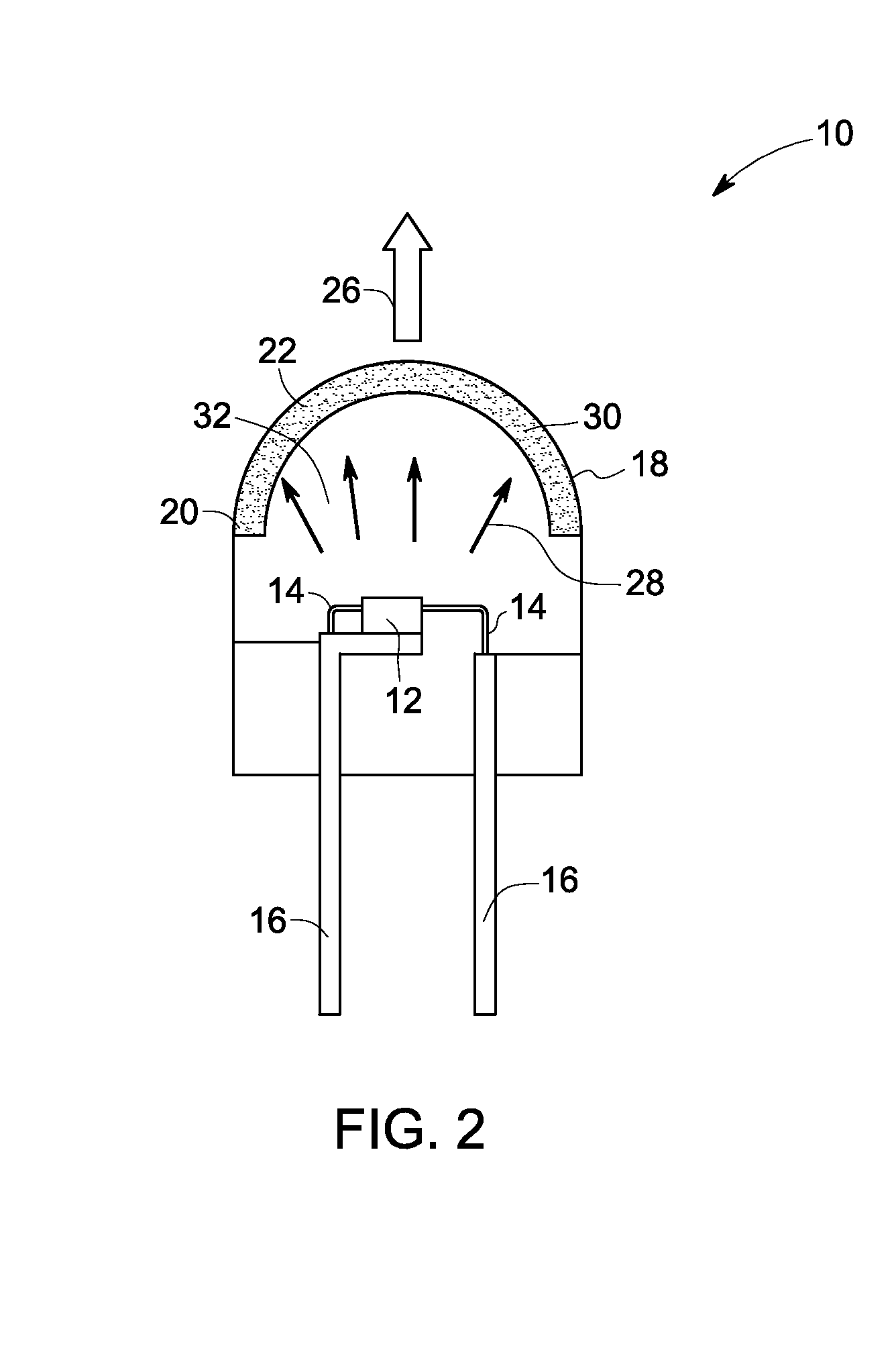

Phosphor assembly for light emitting devices

A method for fabricating a light emitting device is disclosed. The light emitting device includes a light emitting diode (LED). The method includes disposing a layered phosphor composite or a thick phosphor composite radiationally coupled to the LED to form a light emitting device. The layered phosphor composite includes a first phosphor layer including a yellow-emitting phosphor over a second phosphor layer including manganese-doped potassium fluorosilicate (PFS). The second phosphor layer is disposed closer to the LED. The mass of the PFS of this light emitting device is at least 15% less than mass of the PFS in a reference light emitting device that has the same color temperature as the above mentioned light emitting device, but includes a blend of PFS and the yellow emitting phosphor instead of a layered configuration or has a decreased thickness.

Owner:GENERAL ELECTRIC CO

Layered heat exchangers

InactiveUS6920916B2Increase ultimate strengthReduce stress concentrationReinforcing meansEvaporators/condensersInternal pressurePlate heat exchanger

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

Armature and motor

InactiveUS9088191B2Avoid damagePrecise cuttingWindings insulation materialWindings insulation shape/form/constructionStructural engineeringUltimate tensile strength

An insulator of an armature includes an upper resin member and a lower resin member. Each of the upper and lower resin members includes decreased thickness portions. Axial positions of the decreased thickness portions of the upper and lower resin members are arranged to overlap at least partially with each other. Each of the upper and lower resin members further includes a rib arranged to project from a corresponding one of the decreased thickness portions. The rib improves the strength of the corresponding decreased thickness portion and reduces the likelihood that any of the decreased thickness portions of the upper and lower resin members will be damaged when the two members are fitted to each other.

Owner:NIDEC CORP

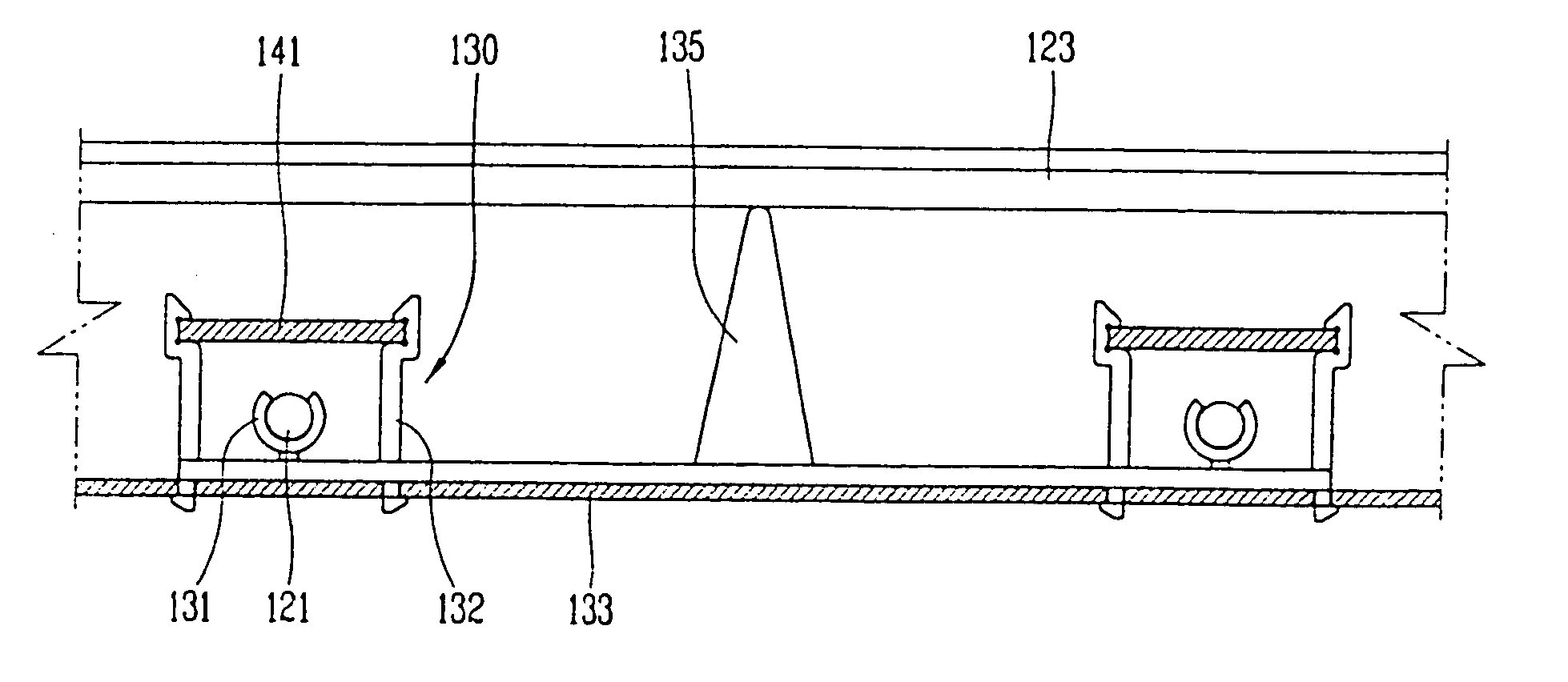

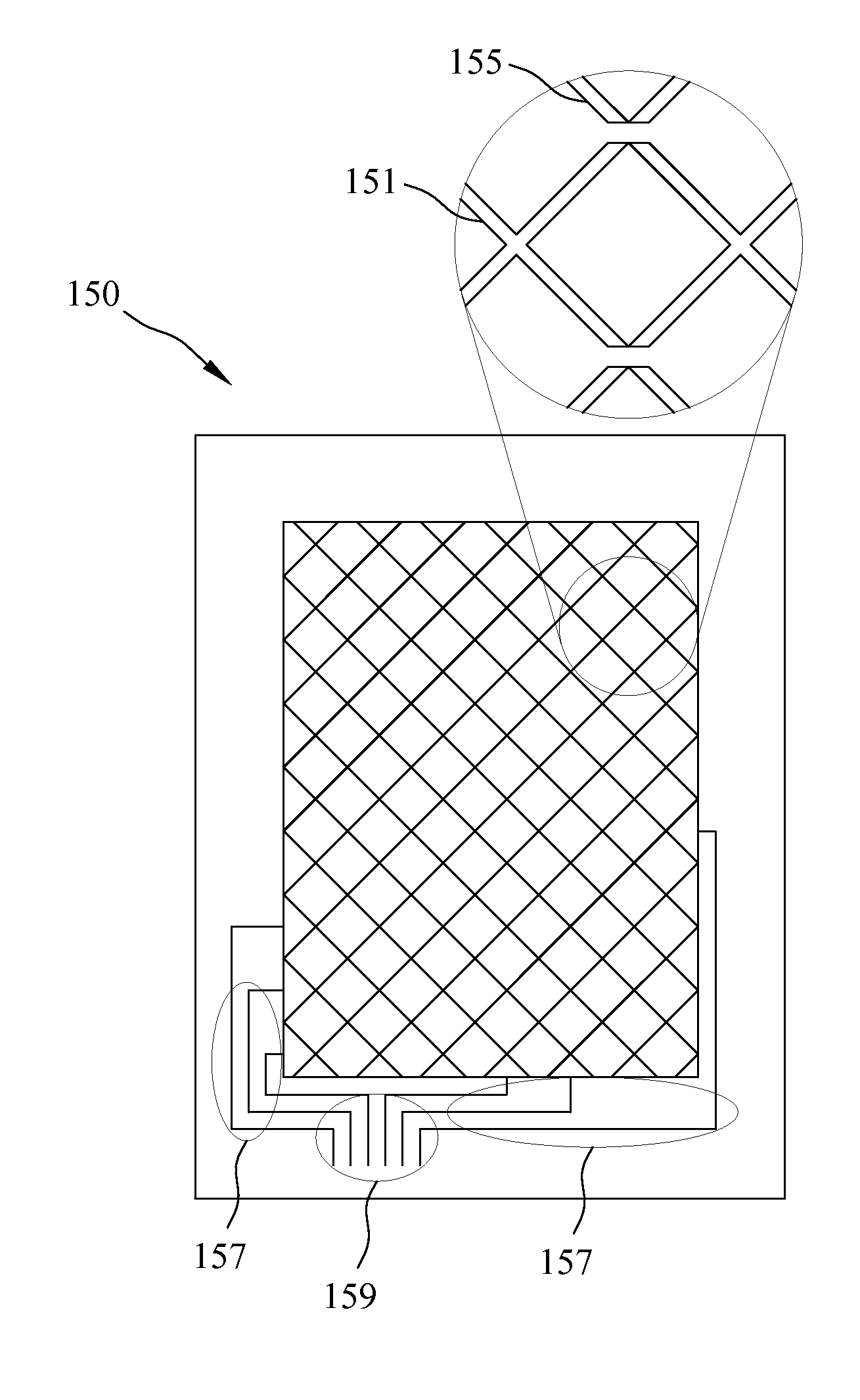

Lamp guide with optical member holder and liquid crystal display device having the same

A backlight unit having a decreased thickness includes at least one lamp which emits light; and at least one light-diffusion plate which diffuses the light emitted from the light, and is positioned above each lamp, wherein the lamp and the light-diffusion plate are fixed and supported by a lamp guide.

Owner:LG DISPLAY CO LTD

Touch Sensor Device

InactiveUS20110214925A1Increase capacitanceImprove touch sensitivityTransmission systemsElectronic switchingInsulation layerElectromagnetic interference

A touch sensor device with increased transmittance, increased sensitivity and decreased thickness is disclosed. The touch sensor device includes a substrate. The substrate, from bottom to top, sequentially includes a bottom conductive layer, a bottom insulation layer, a top conductive layer, an electrode layer, a top insulation layer and a substrate material layer. The bottom conductive layer can shield external electromagnetic interference and act as a ground. The bottom insulation layer is provided with an insulation effect. The top conductive layer is used for sensing a touch operation to generate a sensor signal. The electrode layer includes a plurality of first electrode lines, a barrier layer and a plurality of second electrode lines. The top insulation layer is provided with an effect for preventing electrostatic discharge. The substrate material layer is used for protecting the touch sensor device.

Owner:FORTREND TAIWAN SCI

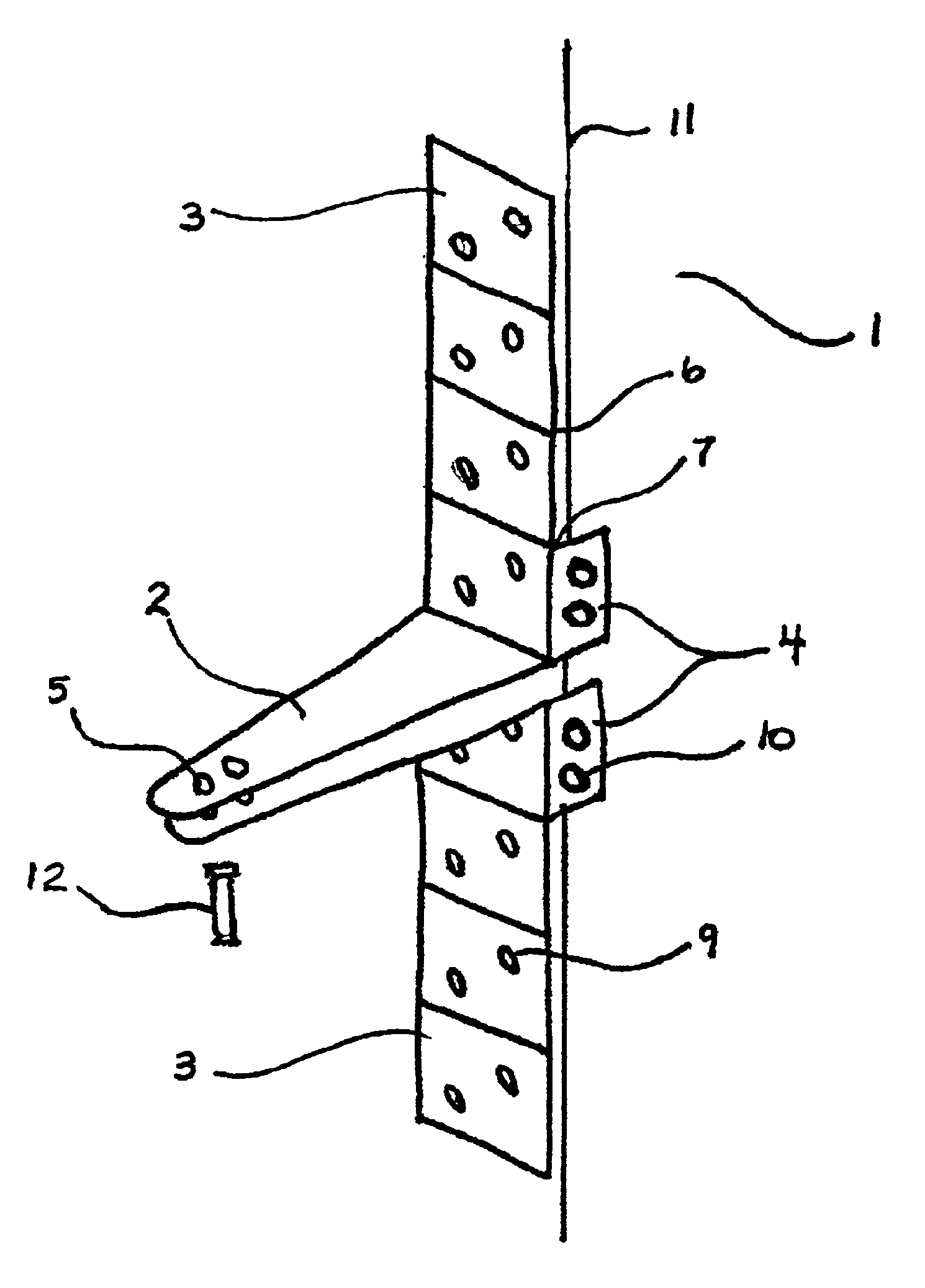

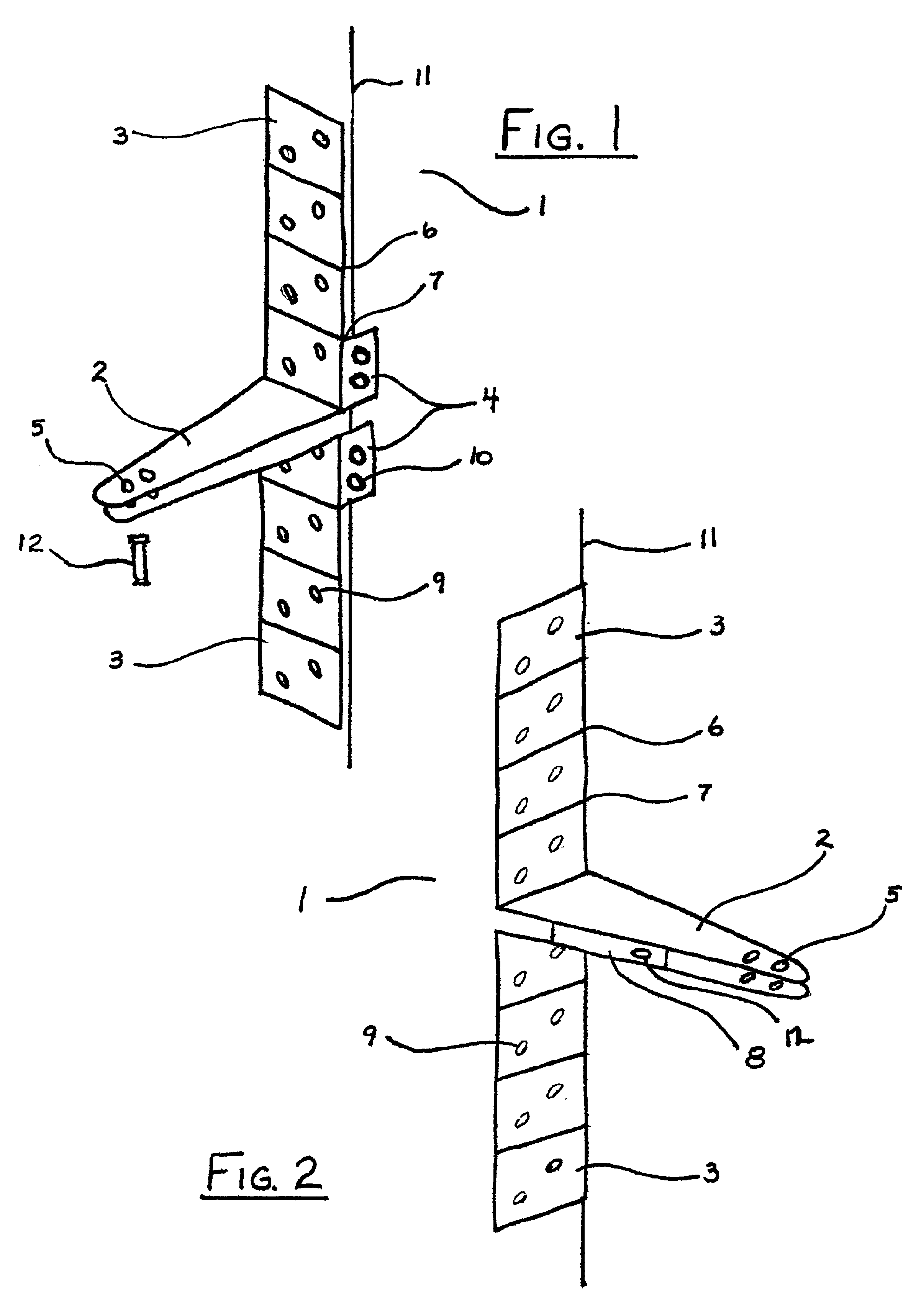

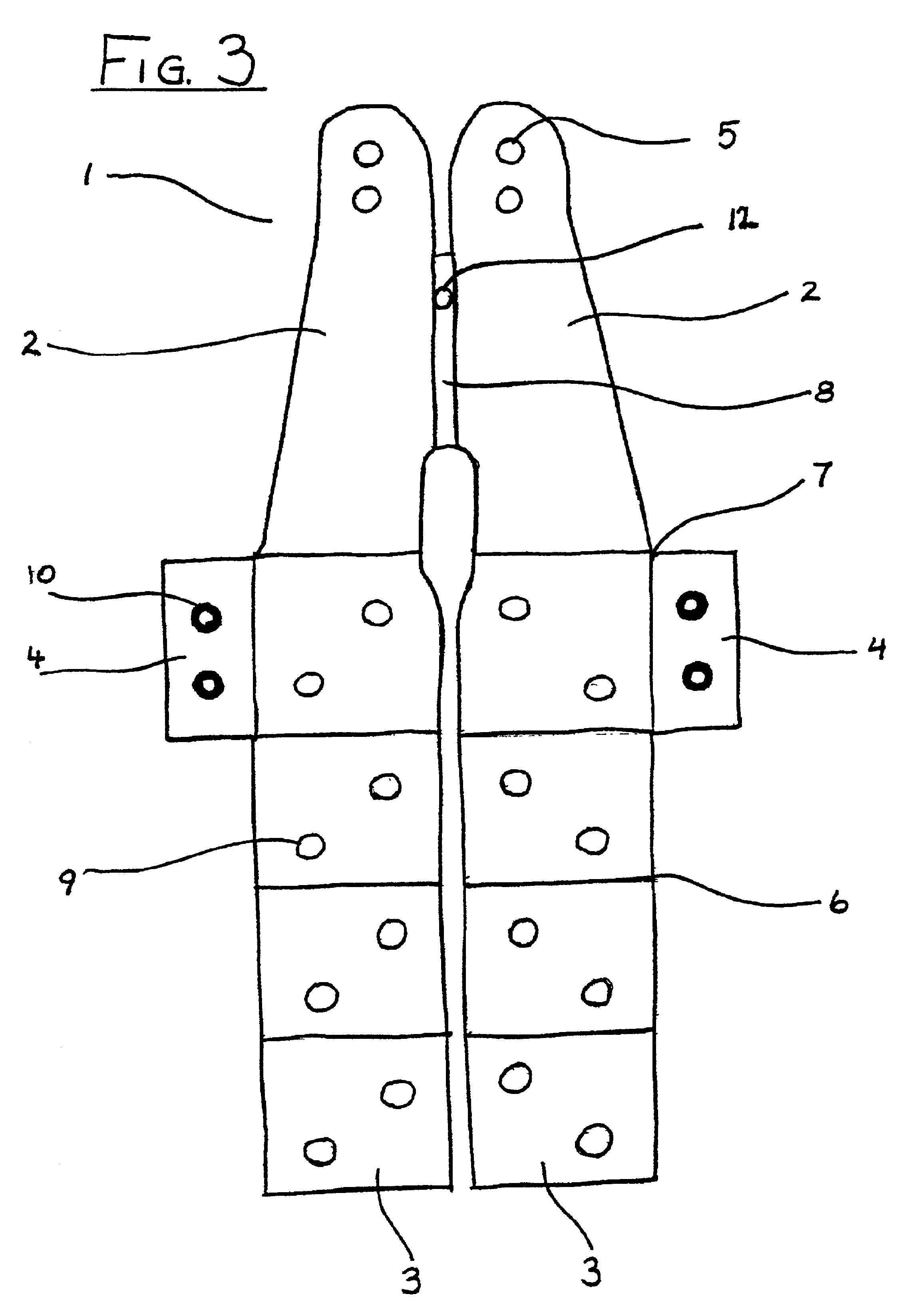

Universal jamb bracket for a door closing system

A jamb bracket for a door closing system having an arm structure ending out from a basal element with two securing segments hugging an edge or corner of a doorjamb. The basal element has snap-off grooves with a decreased thickness allowing the portion of the basal element beyond the snap-off groove to be broken off if not needed. Two additional snap-off grooves separate the basal element from the securing segments so that the securing segments may be removed if necessary. The arm structure has two receiving areas for the pin of the door closing system. The jamb bracket is adaptable to become either a corner bracket for a corner / ceiling door closing system or an in-swinging bracket for an in-swinging door closing system.

Owner:LIBES BARRY

Exhaust gas treatment catalyst and exhaust gas treatment system

ActiveUS20100080737A1Reduced ammonia leakage rateSufficient NOx removal efficiencyCombination devicesCatalyst activation/preparationPt elementReducing agent

Provided are an exhaust gas treatment catalyst capable of reducing ammonia leakage rate while keeping a sufficient NOx removal efficiency, said catalyst comprising a coating layer and a catalyst base material, wherein said coating layer has a decreased thickness relative to that of a catalyst base material; and an exhaust gas treatment system using the same. In the exhaust gas treatment catalyst for catalytically removing nitrogen oxides from an exhaust gas by using ammonia as a reducing agent and simultaneously decomposing and removing unreacted ammonia, a coating layer comprising platinum supported on titania is formed on a surface of a porous catalyst base material comprising titania and at least one compound selected from oxides of vanadium (V), oxides of tungsten (W) and oxides of molybdenum (Mo).

Owner:MITSUBISHI HEAVY IND LTD

Thin film transistor array panel, manufacturing method thereof, and mask therefor

A passivation layer is deposited and a photoresist is formed. The photoresist includes first to third portions with decreased thickness, the second portions located on portions of drain electrodes and data lines and the third portions located on portions of gate lines. A mask for forming the photoresist has rectilinear slits with width and distance of about 0.8-2.0 microns on an area corresponding to the second portions. The passivation layer and an underlying semiconductor layer as well as the photoresist are etched to expose portions of the gate insulating layer under the third portions of the photoresist as well as portions of the passivation layer under the second portions of the photoresist. The exposed portions of the passivation layer and the gate insulating layer are removed to expose the drain electrodes, the gate lines and the data lines as well as portions of the semiconductor layer, which are subsequently removed.

Owner:SAMSUNG DISPLAY CO LTD

Multilayered container

ActiveUS20150251390A1Excellent oxygen barrier propertiesDecrease in tasteSynthetic resin layered productsPackaging corrosive chemicalsPolyolefinGram

A multilayered container includes at least a polyolefin inner layer; an adhesive layer; a gas-barrier layer; an oxygen-absorbing layer; a gas-barrier layer; an adhesive layer; a polyolefin outer layer, and having at least a body portion and a bottom portion, wherein the gas-barrier layers include an ethylene-vinyl alcohol copolymer, the oxygen-absorbing layer includes an oxygen-absorbing resin composition that contains the ethylene-vinyl alcohol copolymer and an oxidizing organic component, an adsorbing agent is contained on the side inside of said gas-barrier layer, the thickness of the multilayered container at the thinnest portion is not more than 430 μm, and the amount of oxygen absorbed after the heat-sterilization is not less than 23 cc per gram of the oxygen-absorbing resin composition. Despite of this decreased thickness, the multilayered container maintains excellent oxygen-barrier property and property for retaining flavor of the content even when it is subjected to the retort sterilization.

Owner:TOYO SEIKAN GRP HLDG LTD

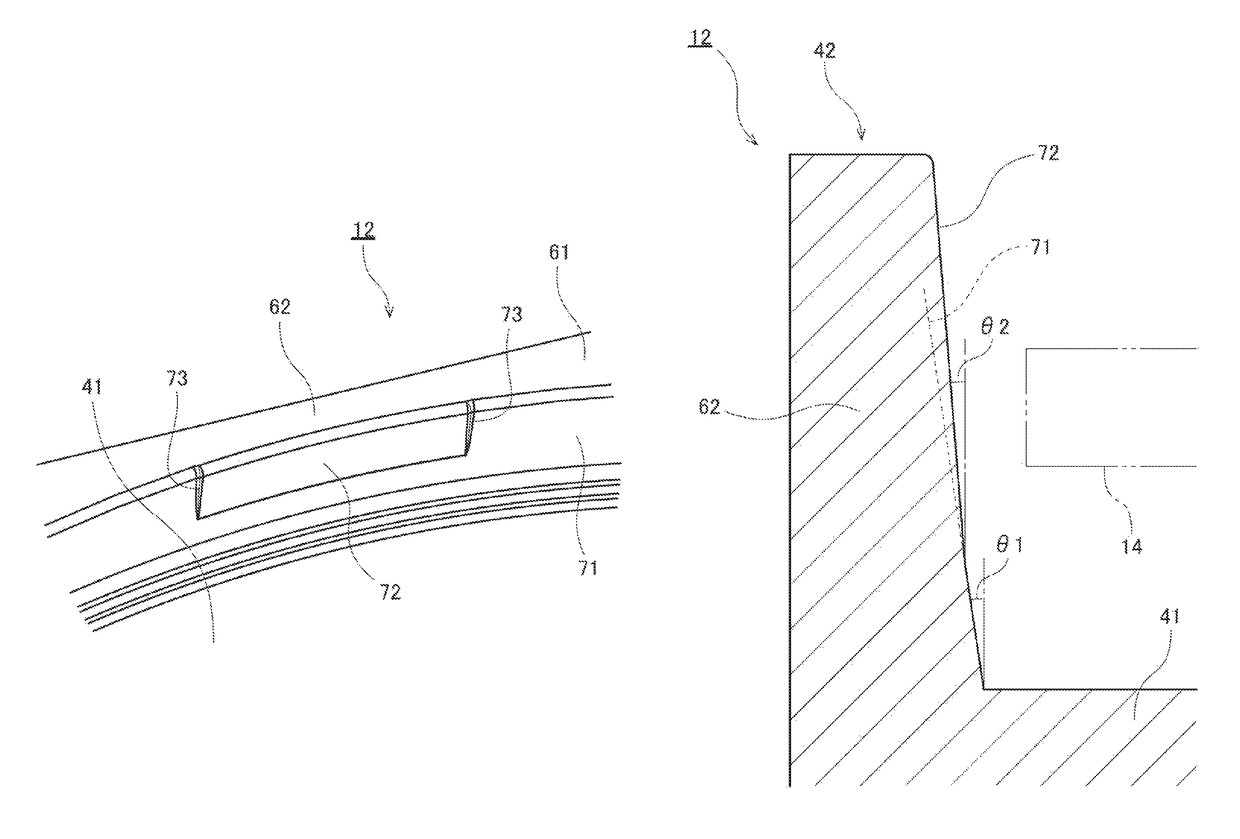

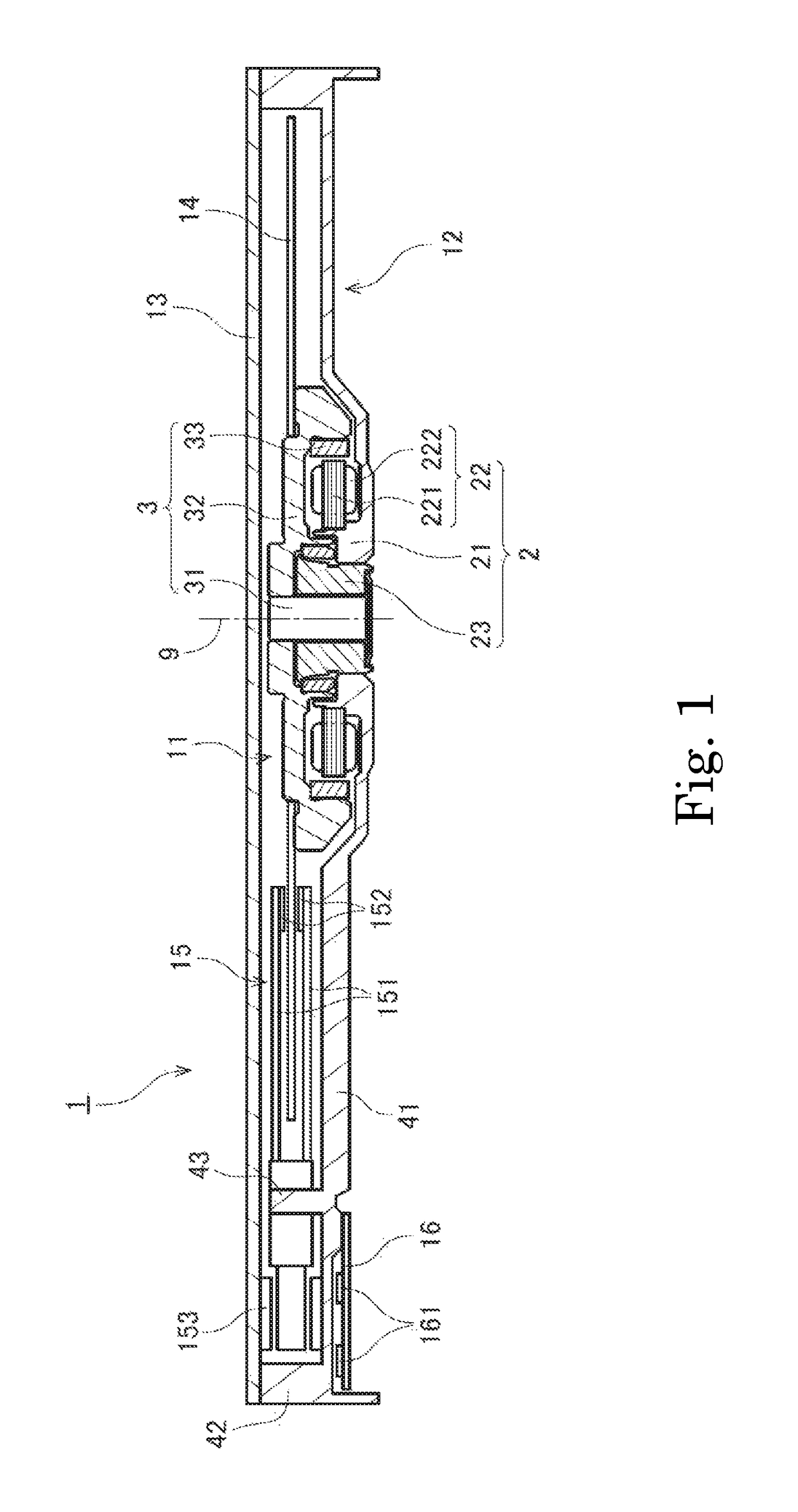

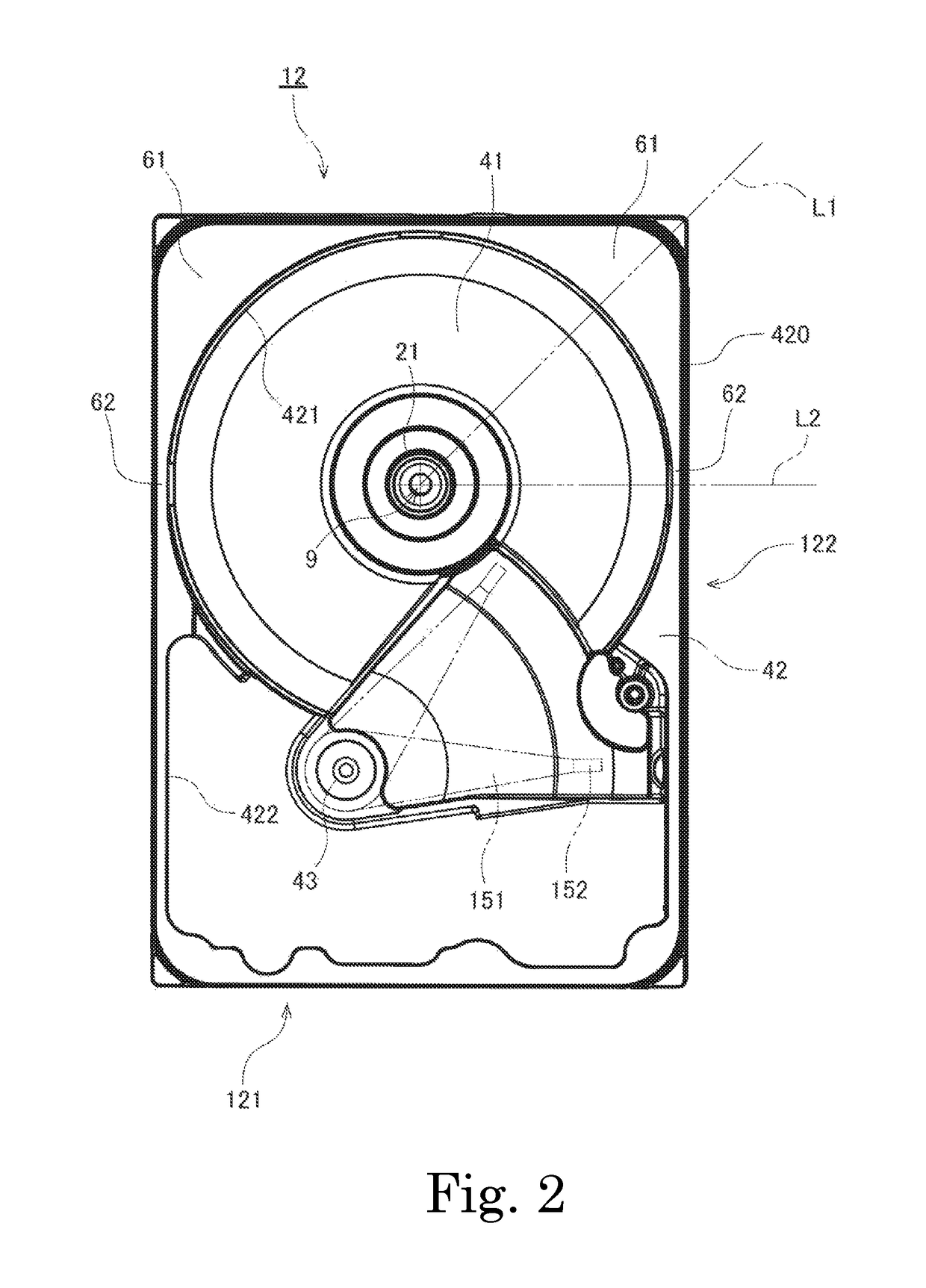

Disk drive base with decreased thickness portion angle being less than increased thickness portion angle

ActiveUS9990959B1Easy to separateEasy to spreadApparatus for flat record carriersCarrier casesEngineeringMechanical engineering

A base of a disk drive apparatus includes a bottom plate portion and a wall portion. The wall portion includes an increased thickness portion and a decreased thickness portion. An inner surface of the increased thickness portion includes a first slanting surface arranged to extend radially outward away from a central axis while extending axially away from the bottom plate portion. An inner surface of the decreased thickness portion includes a second slanting surface arranged to extend radially outward away from the central axis while extending axially away from the bottom plate portion, and protrude radially inward relative to the first slanting surface. An inclination angle of the second slanting surface with respect to an axial direction is arranged to be smaller than an inclination angle of the first slanting surface with respect to the axial direction.

Owner:NIDEC CORP

Layered heat exchangers

InactiveUS20050230090A1Increased pressure lossReduce drynessReinforcing meansIce productionInternal pressureEngineering

A layered heat exchanger, for example for use for motor vehicle coolers. To provide a turn portion in the heat exchanger for changing flow direction of a fluid flowing zigzag through a fluid circuit, a metal plate is provided at the upper or lower ends of a partition ridge with a fluid flow direction changing passage forming caved portion having a bottom wall of circular-arc cross section. Front and rear upper or lower tank portions are held in communication with each other through a fluid flow direction changing passage of approximately circular cross section and formed by the caved portions opposed to each other. The turn portion is diminished in stress concentrated thereon due to fluid internal pressure and given an increased resistance to pressure to effectively prevent tank side walls from breaking, consequently making it possible to decrease the metal plates thicknesses, to achieve a cost reduction by the decreased thickness and to assure an improved heat exchange efficiency.

Owner:KEIHIN THERMAL TECH CORP

Method of producing biaxially stretched polyester bottles

InactiveUS20090174124A1Easy to stretchImprove productivityHollow articlesDomestic articlesPolyesterDecrease weight

In effecting the stretching by using a stretch rod in a method of producing a biaxially stretched polyester bottle, the air is blown into the preform at such a flow rate that the preform does not come in contact with the stretch rod but the end thereof and does not come in contact with the surfaces of the mold, either. There can be produced a biaxially stretched polyester bottle having an average thickness of about 0.05 to about 0.2 mm or having a further decreased thickness using a resin in decreased amounts and having a decreased weight without developing burst or whitening caused by over-stretching, without forming ring-like thick portion yet maintaining a good yield and efficiency.

Owner:TOYO SEIKAN KAISHA LTD

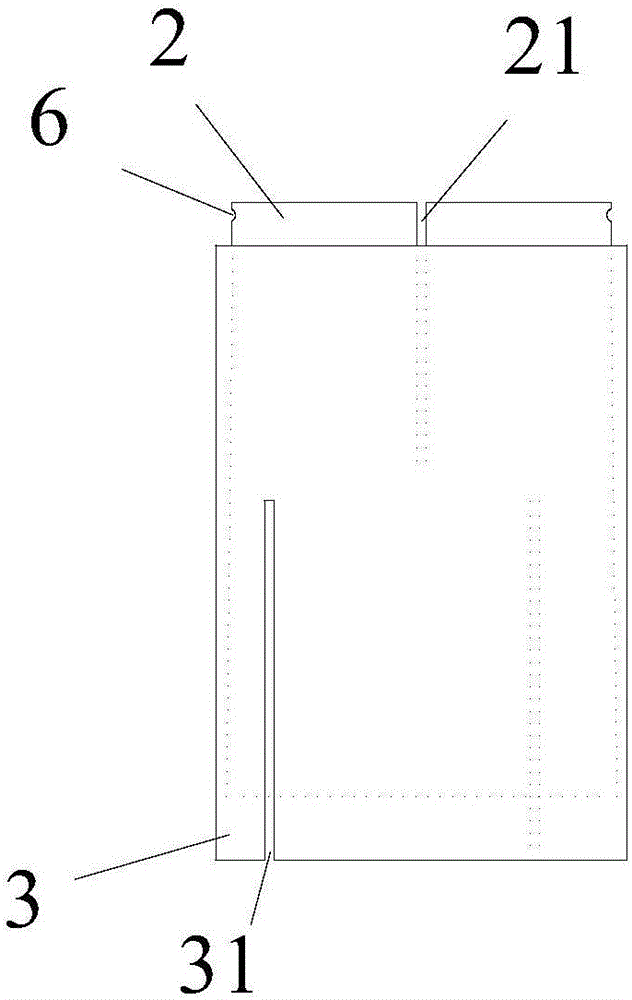

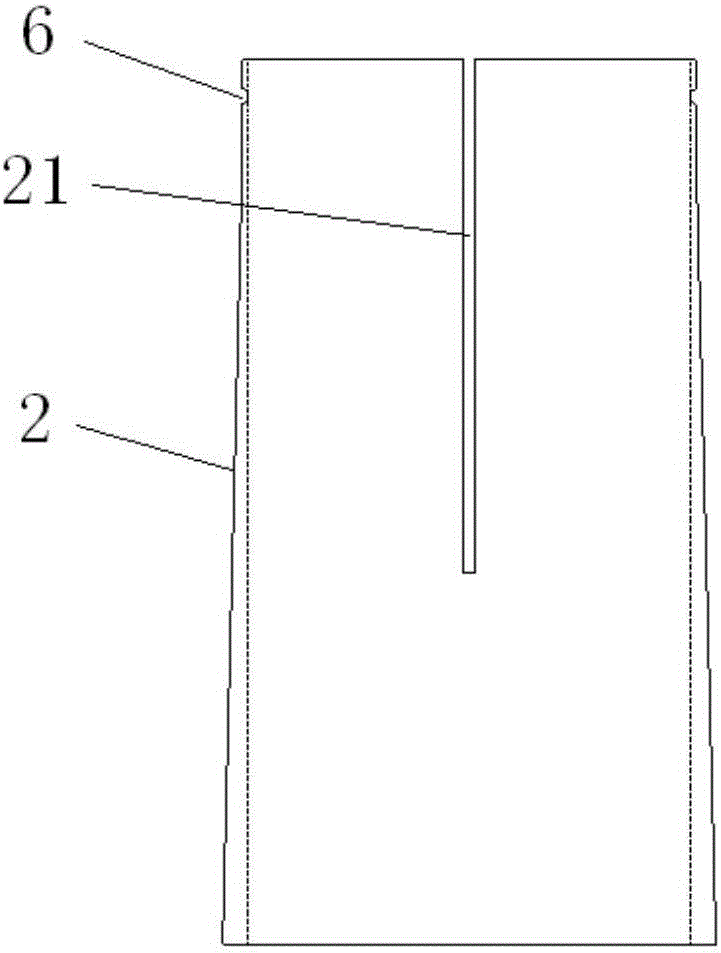

Wedge-shaped hole packer for liquid carbon dioxide phase change rock breaking

InactiveCN106437598AEasy to tightenImprove rock breaking abilityDisloding machinesSealing/packingLiquid carbonEngineering

The invention discloses a wedge-shaped hole packer for liquid carbon dioxide phase change rock breaking. An inner cylinder (2) is a cylinder with the gradually increased thickness, and at least two inner cylinder vertical seams (21) are symmetrically formed in the upper portion of the inner cylinder (2); an outer cylinder (3) is a cylinder with the gradually decreased thickness, and at least two outer cylinder vertical seams (31) are symmetrically formed in the lower portion of the outer cylinder (3); the inner cylinder (2) is higher than the outer cylinder (3) and is sleeved with the outer cylinder (3), the two ends of the inner cylinder (2) and the two ends of the outer cylinder (3) are each provided with a small section of stretching part, the stretching parts do not make contact with one another, and two rope tying holes (6) are symmetrically formed in the stretching part arranged on the top of the inner cylinder (2). After the inner cylinder and the outer cylinder are combined together, the two ends of the inner cylinder and the two ends of the outer cylinder are each provided with a small section of stretching part, and the stretching parts do not make contact with one another; the inner cylinder stretches out for a small section, so that the rope tying holes are exposed to tension a wedge-shaped cylinder, and the outer cylinder stretches out for a small section, so that gas is gathered to push the inner cylinder to move upwards relative to the outer cylinder. According to the wedge-shaped hole packer, the structure is simple, operation is easy and convenient, and walls of a fracturing pipe and a fracturing hole are locked according to a wedge shape geometry principle, so that the fracturing hole achieves leakproofness and airtightness; accordingly, the rock breaking effect is enhanced, and pipe flashing is prevented.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com