Method of producing biaxially stretched polyester bottles

a technology of polyester bottles and polyester fibers, applied in the field of biaxially stretched polyester bottles, can solve the problems of difficulty in setting conditions, difficulty in reducing weight, difficulty in molding, etc., and achieve the effects of reducing thickness, improving productivity, and easy stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0057]A preform having a length of 52 mm and a thickness in the body wall of 3.1 mm (resin amount of 19 g) was heated in a heating device (without inner heating device 18b) shown in FIG. 3(B) for 56 seconds, so that the temperature was 115° C. on the outer surface of the preform and 117° C. on the inner surface thereof.

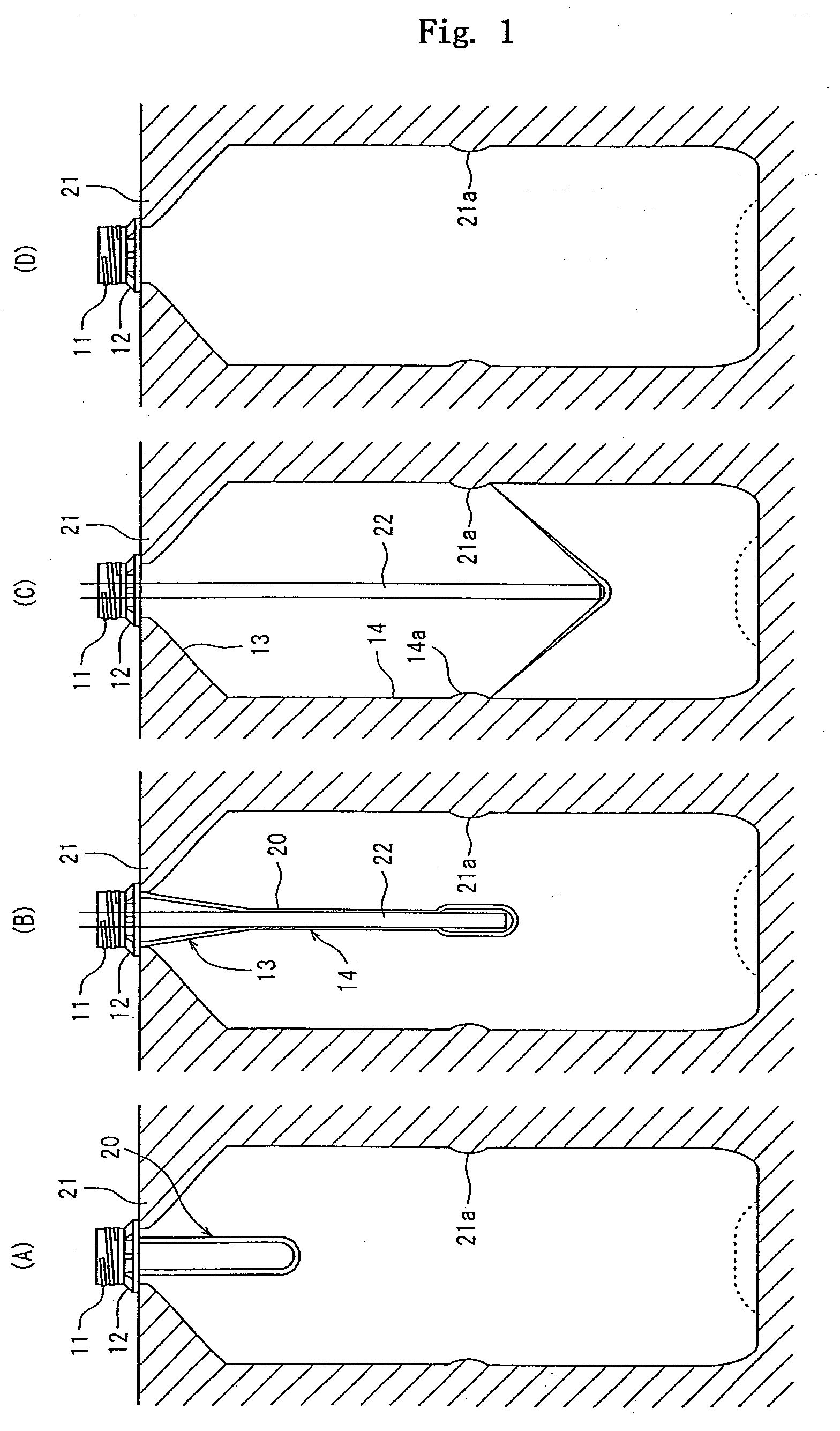

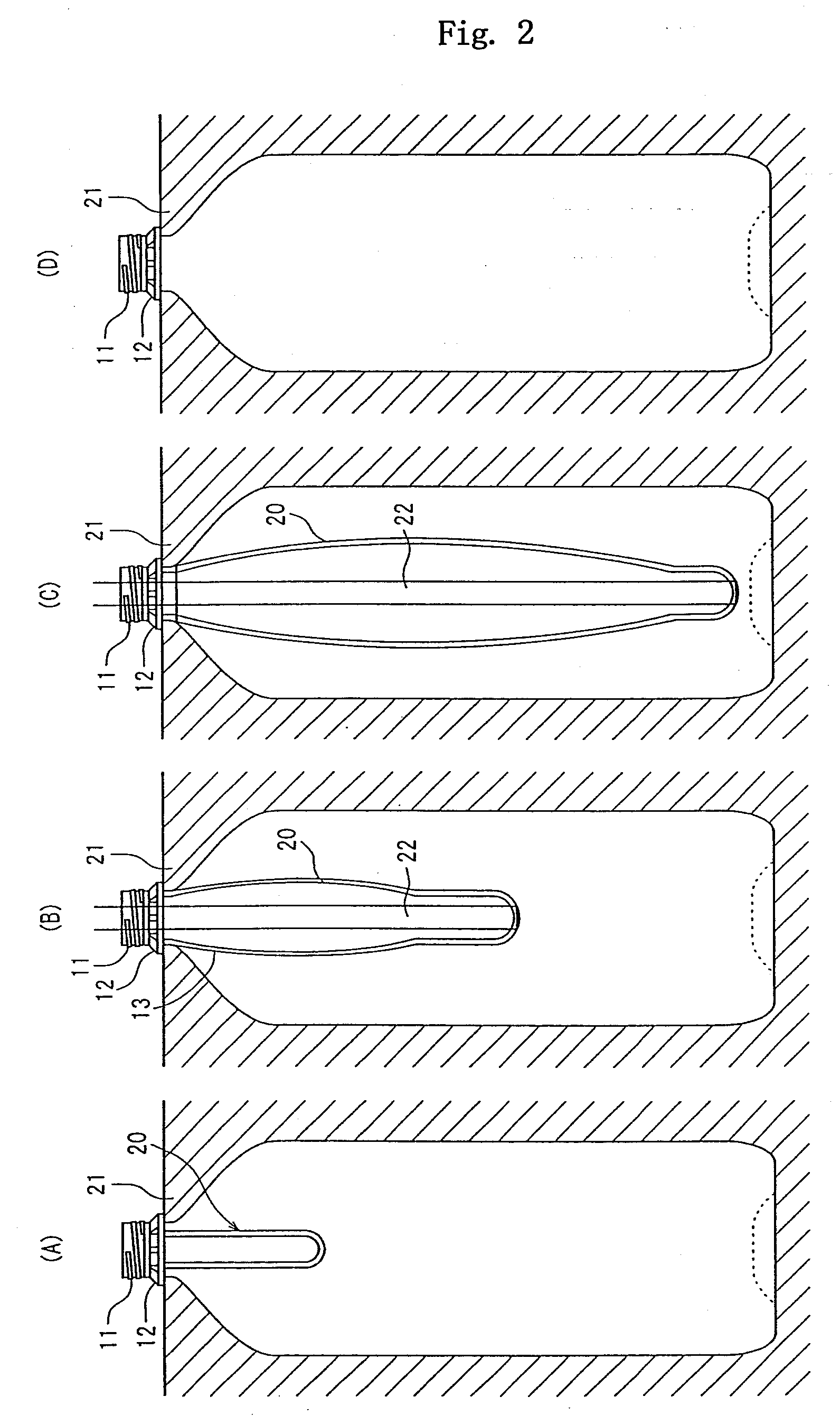

[0058]By using a stretch-blowing apparatus schematically shown in FIG. 2, the thus heated preform was stretched by using a stretch rod at a speed of 200 mm / sec. up to a position of 95% of the distance of from under the support ring down to the grounding surface and, at the same time, the air was blown as a pre-blow, the air being adjusted to possess a temperature of 200° C. and a pressure of 0.07 MPa.

[0059]After the end of stretching by using the stretch rod, the air was blown as a main blow, the air being adjusted to possess a temperature of 200° C. and a pressure of 2 MPa to effect such a stretching that a longitudinal stretching ratio was 4.5 times, a transverse st...

example 2

[0061]A preform having a length of 77 mm and a thickness in the body wall of 2.4 mm (resin amount of 19 g) was heated by the same method as that of Example 1 for 40 seconds, so that the temperature was 105° C. on the outer surface of the preform and 107° C. on the inner surface thereof.

[0062]By using the same stretch-blowing apparatus as that of Example 1 and by effecting the pre-blow and the main blow under the same conditions, the thus heated preform was so stretched that a longitudinal stretching ratio was 3.7 times, a transverse stretching ratio was 4.5 times and a volume ratio was 105 times to obtain the shape of the final article. After the end of stretching, the thermal setting was effected at a temperature of 70° C. followed by cooling. There were produced 1000 polyester bottles each having a capacity of 2000 mL.

[0063]The number of the bottles that developed any one of whitening due to over-stretching, burst, thermal whitening or ring-like thick portion was 0 (occurrence fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com