Wedge-shaped hole packer for liquid carbon dioxide phase change rock breaking

A technology of liquid carbon dioxide and hole sealer, which is used in sealing/packaging, discharge machinery, wellbore/well components, etc. Cause cracks, threaten the safety of personnel and property, etc., to achieve good sealing effect, prevent flying tubes, and strengthen the effect of rock breaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific application of the present invention will be described in detail below in combination with the technical solutions, drawings and implementation examples.

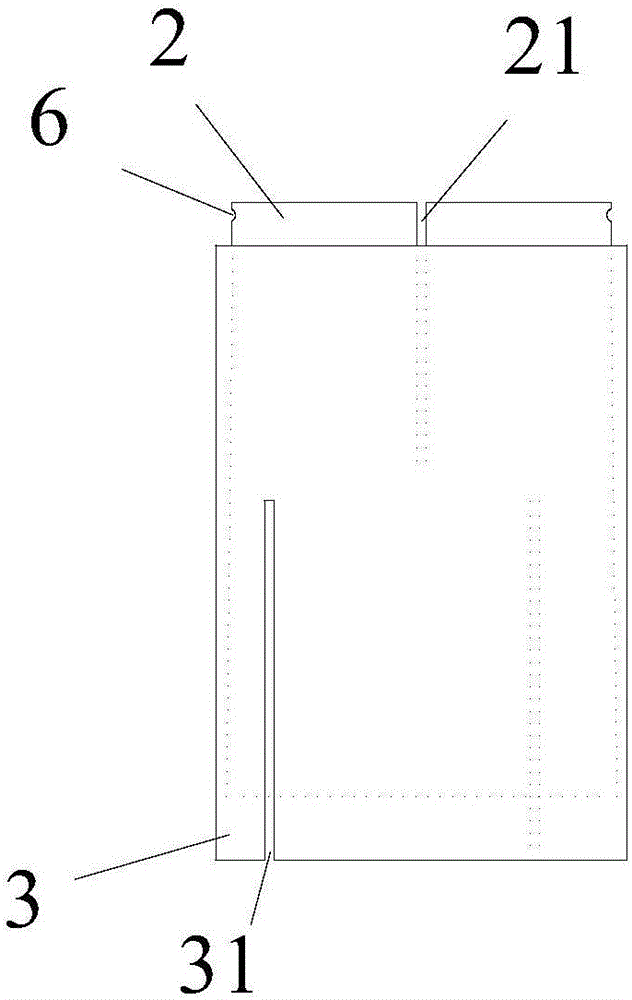

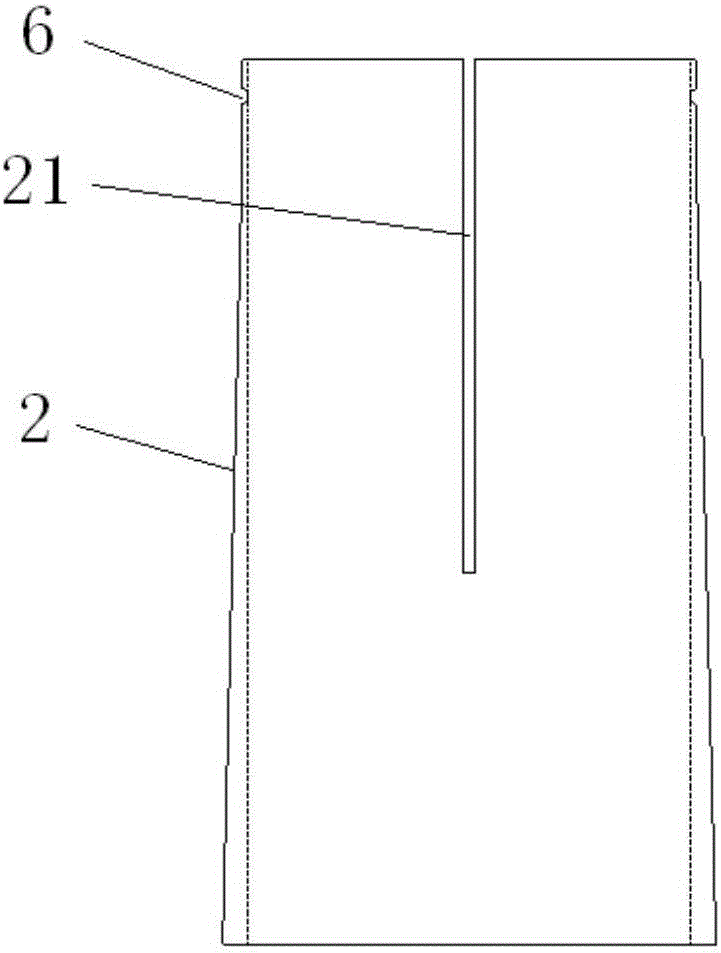

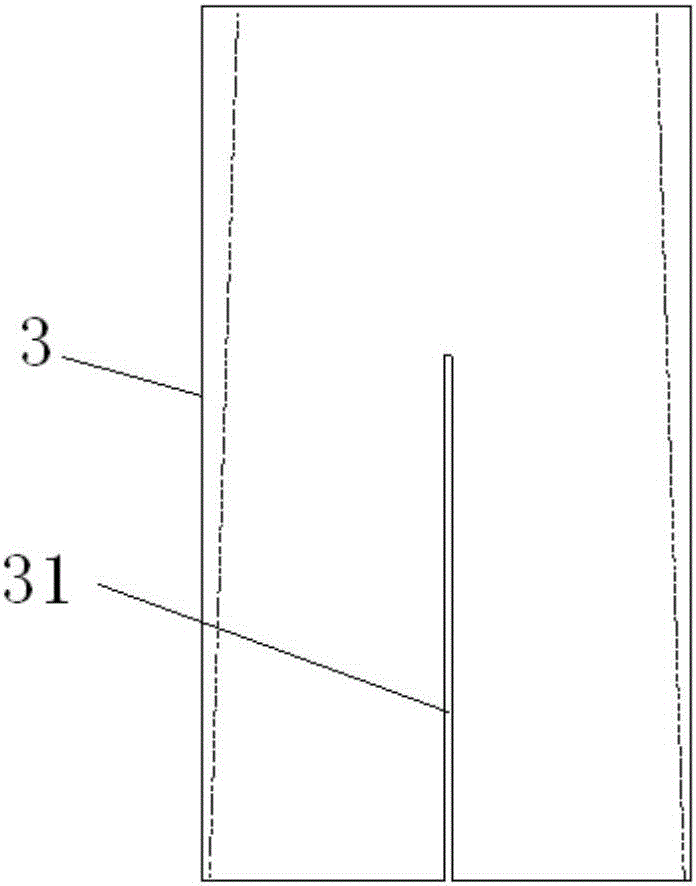

[0025] see figure 1 , figure 2 and image 3 The inner cylinder 2 is in the shape of a progressively thicker cylinder with at least two symmetrical vertical slits 21 on the upper part; the shape of the outer cylinder 3 is a thinner cylinder with at least two symmetrical vertical slits 31 on the lower part; The inner cylinder 2 is slightly higher than the outer cylinder 3, the inner cylinder 2 is set in the outer cylinder 3, and both ends of the inner cylinder 2 and the outer cylinder 3 have a short section of non-contact The protruding part of the top of the inner cylinder 2 is symmetrically provided with two tether holes 6; the inner diameter of the inner cylinder 2 is slightly larger than the outer diameter of the cracking tube, and the outer diameter of the outer cylinder 3 The diameter is slightly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com