Patents

Literature

160results about How to "Improve rock breaking ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

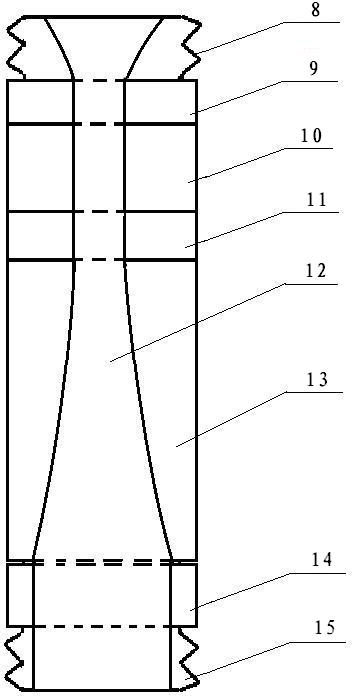

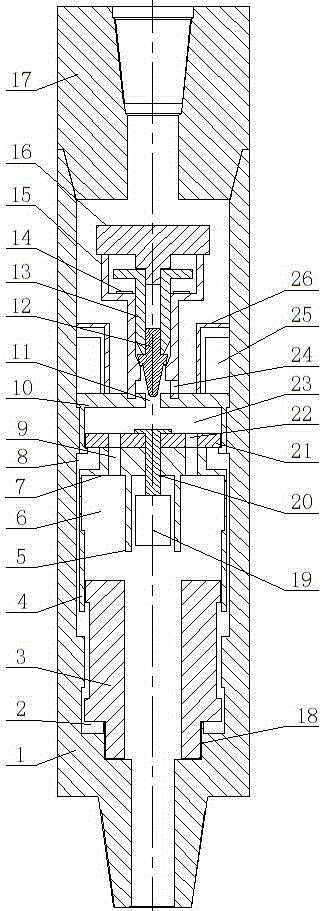

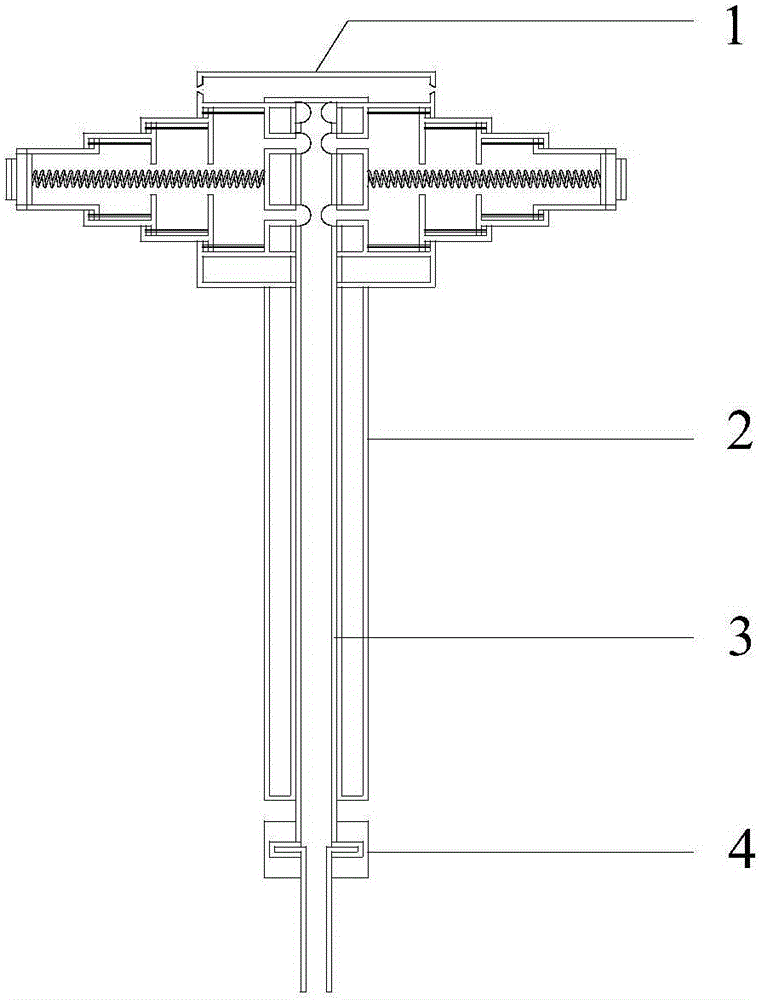

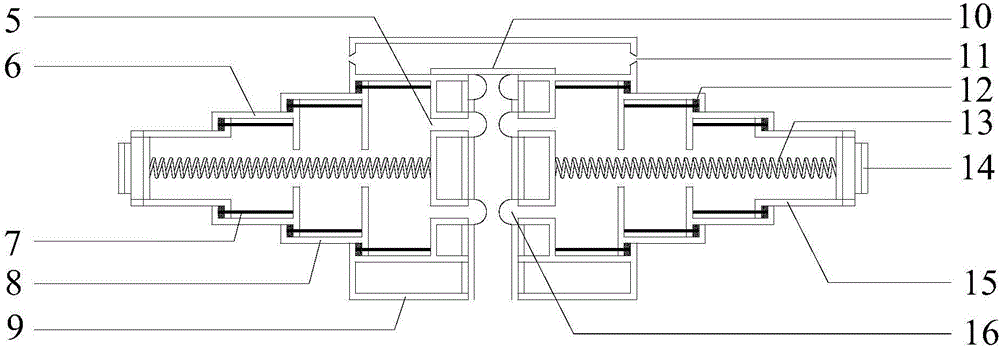

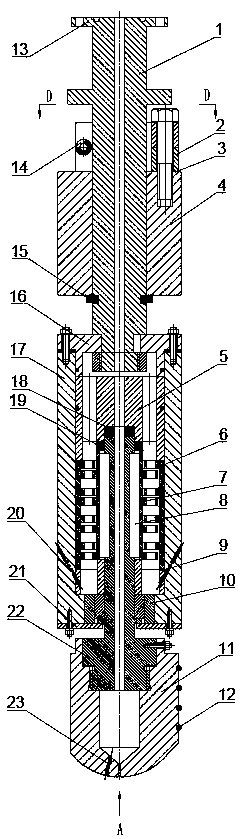

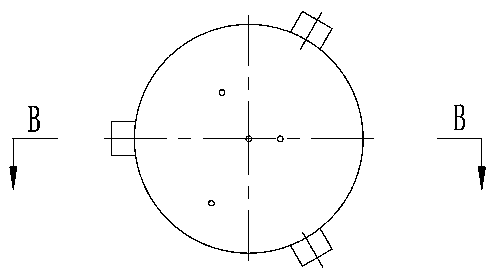

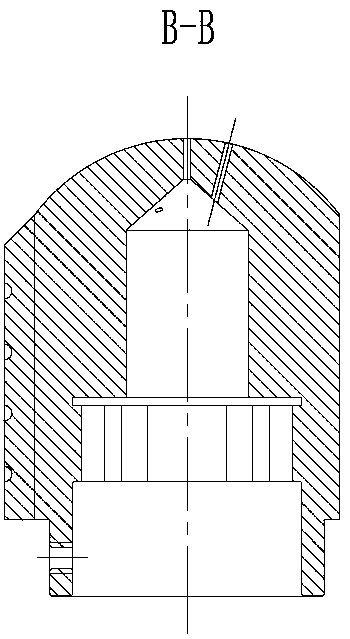

Rotary screw drill tool

InactiveCN104033113AImprove rock breaking abilityExtended service lifeDrilling rodsDrilling casingsSplit ringWell drilling

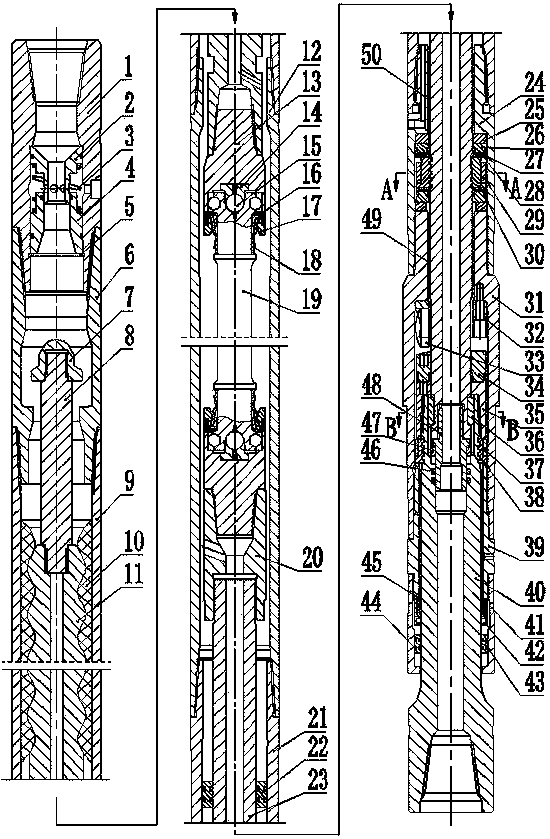

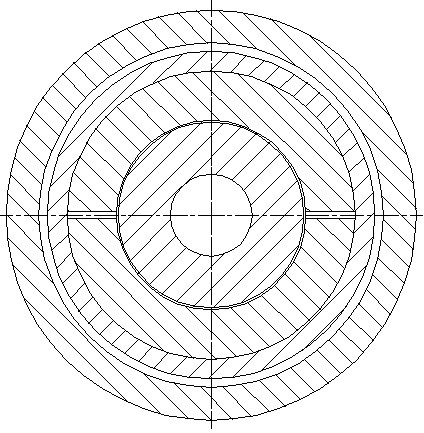

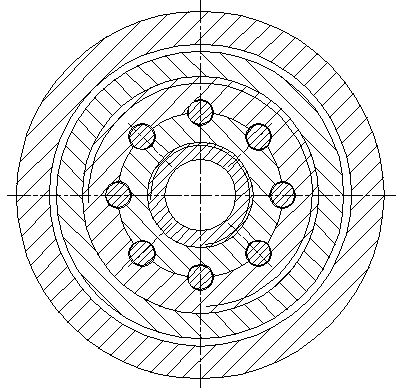

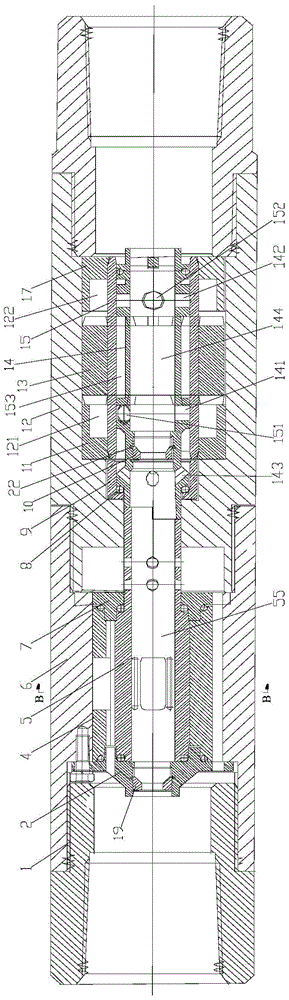

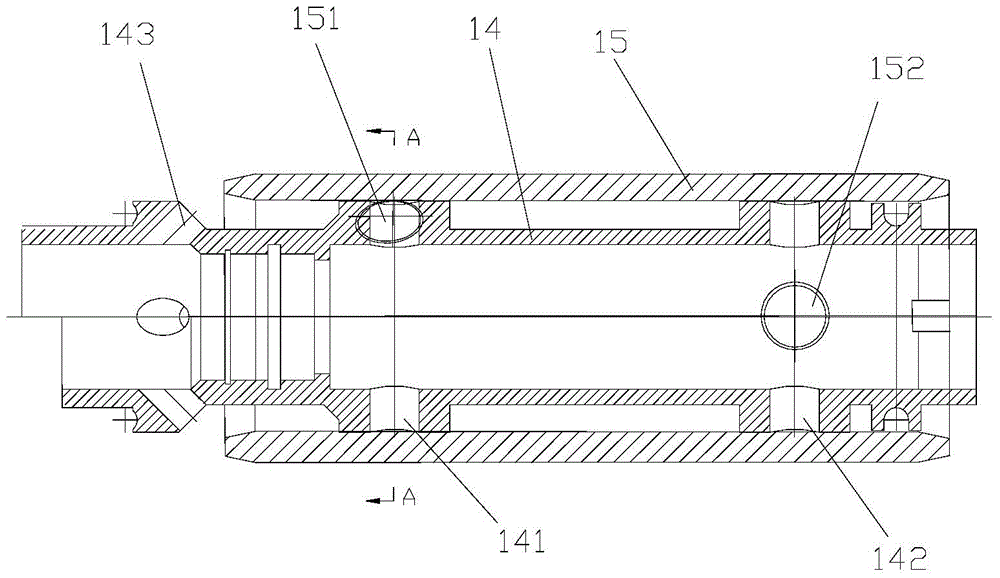

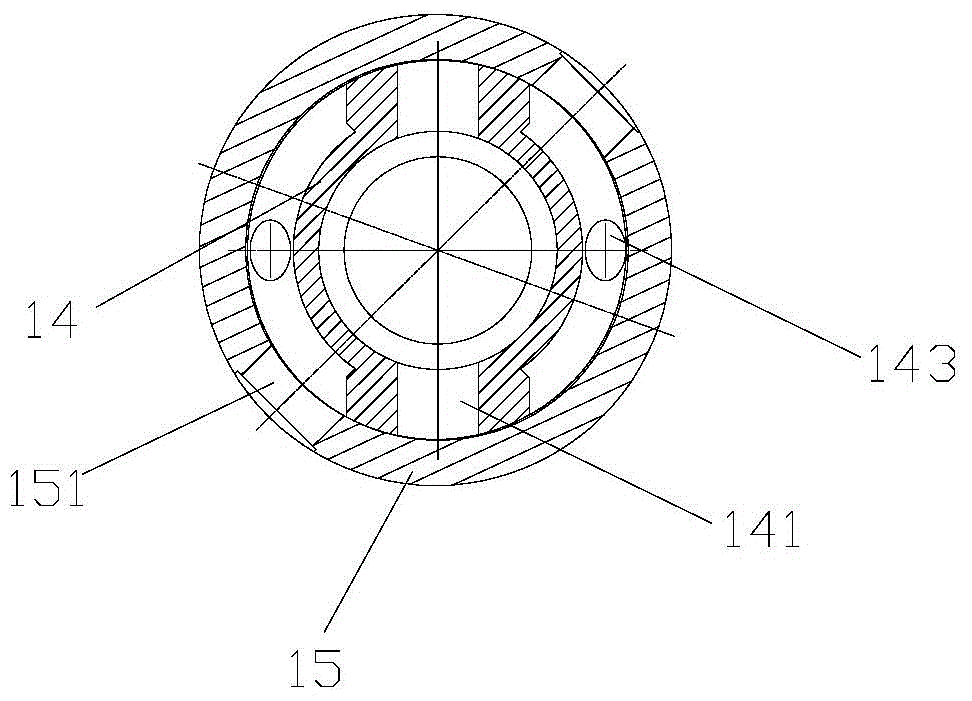

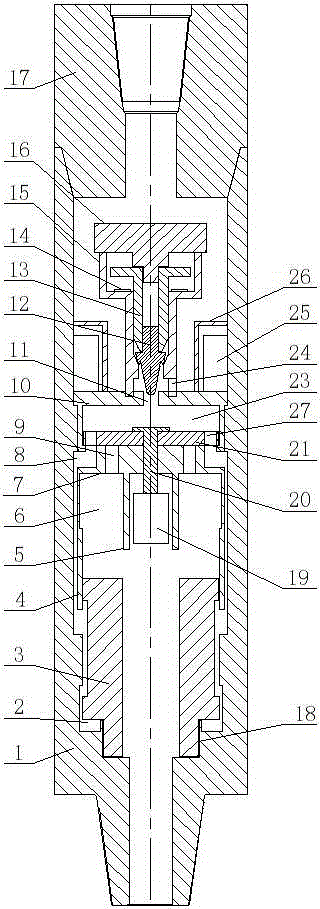

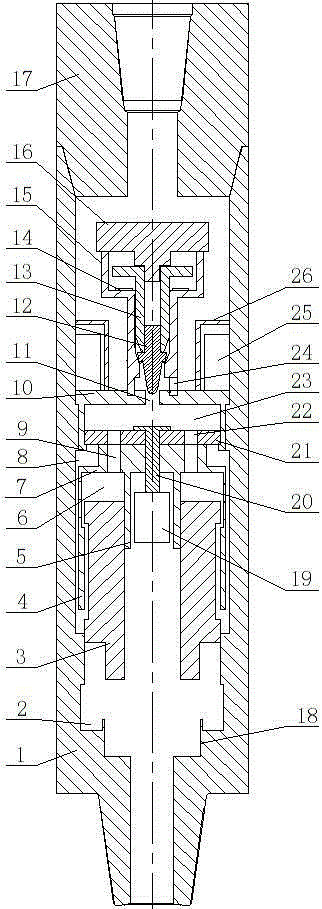

The invention discloses a rotary screw drill tool used in fields of petroleum drilling and the like and solves the problem about crushing efficiency of hard rocks in extradeep wells. The technical scheme includes that a bypass valve shell, a fall prevention joint, a motor shell, a universal shaft shell, an outer shell, a bearing shell, an outer cam shell, a bottom piston shell and a lower shell are sequentially connected through screw threads; an upper shaft and a lower shaft are connected through a spline, and eight spline pins are evenly and circumferentially distributed between the upper shaft and the lower shaft; a roller holder is fixed on the outer cam shell through three bolts which are circumferentially and evenly distributed, a cam is circumferentially fixed on the cam bushing through three evenly distributed bolts, a roller is mounted on a roller holder, the cam bushing is connected to the lower shaft in a threaded manner, and a lower split ring is clamped in the lower shaft through a serrated trough and is fixed through a lower retaining ring. By the arrangement, the lower shaft of the screw drill tool is enabled to generate soft axial impact with a certain frequency and stable in size, efficiency of rock breaking of a drill is improved, mechanical drilling rate is increased, and drilling cost is thereby lowered.

Owner:SOUTHWEST PETROLEUM UNIV

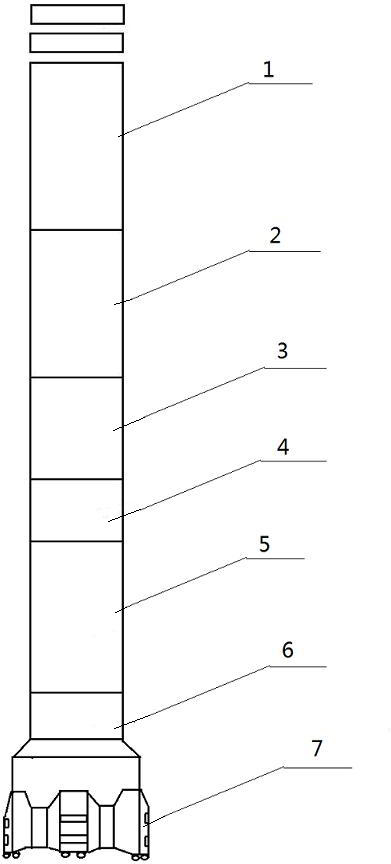

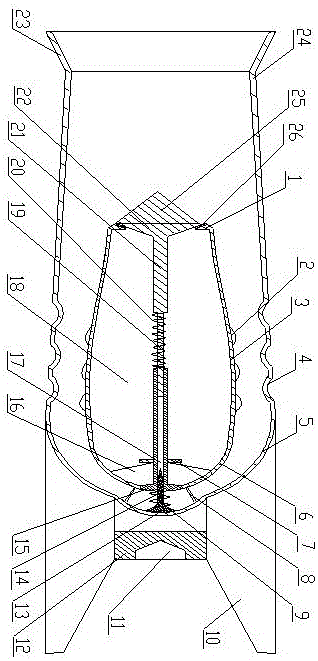

Self-excited resonance drilling device and drilling method thereof

InactiveCN102287137AReduce failureExtended service lifeVibration devicesVibration drillingSelf excitedWell drilling

The invention relates to a self-excitation sympathetic vibration well drilling device and method, wherein the self-excitation sympathetic vibration well drilling device comprises an upper drill rod, a drill collar, a shock absorber, an upper short connection part, a self-excitation resonator, a lower short connection part and a drill head from top to bottom. The drill collar is connected with theupper drill rod through threads. The shock absorber is connected with the drill collar through threads. The upper short connection part is connected with the shock absorber through threads. The self-excitation resonator is connected with the upper short connection part through threads. The other end of the self-excitation resonator is connected to the lower short connection part. The drill head is connected to the lower short connection part via threads. The invention is capable of making full use of lengthways vibration of the drill post, changing the harm into benefit, reducing the loss efficacy of the drill post effectively and enhancing the service life of the drill post. On the other hand, the invention is capable of converting the mechanical energy in lengthways impact and vibrationgenerated by the drill head and the drill collar to medium kinetic energy, achieving the rock crack sympathetic vibration condition and enhancing the well drilling speed.

Owner:NORTHEAST GASOLINEEUM UNIV

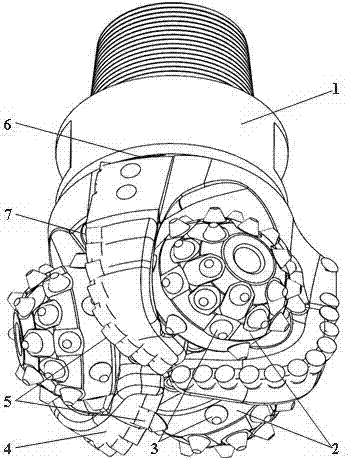

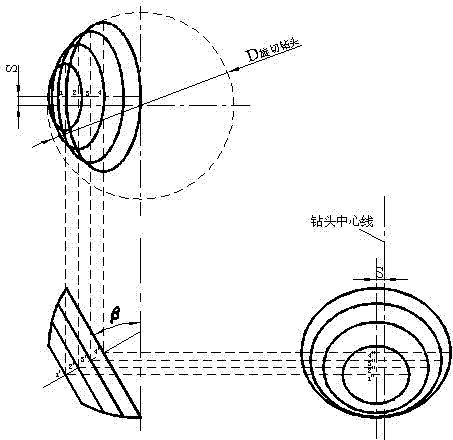

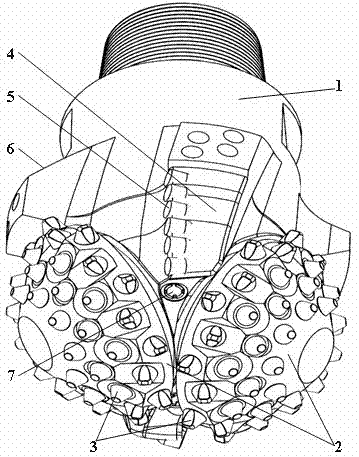

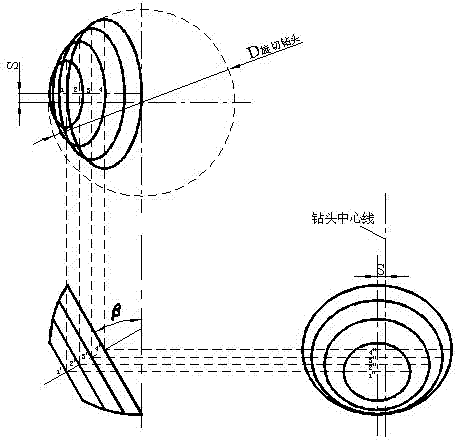

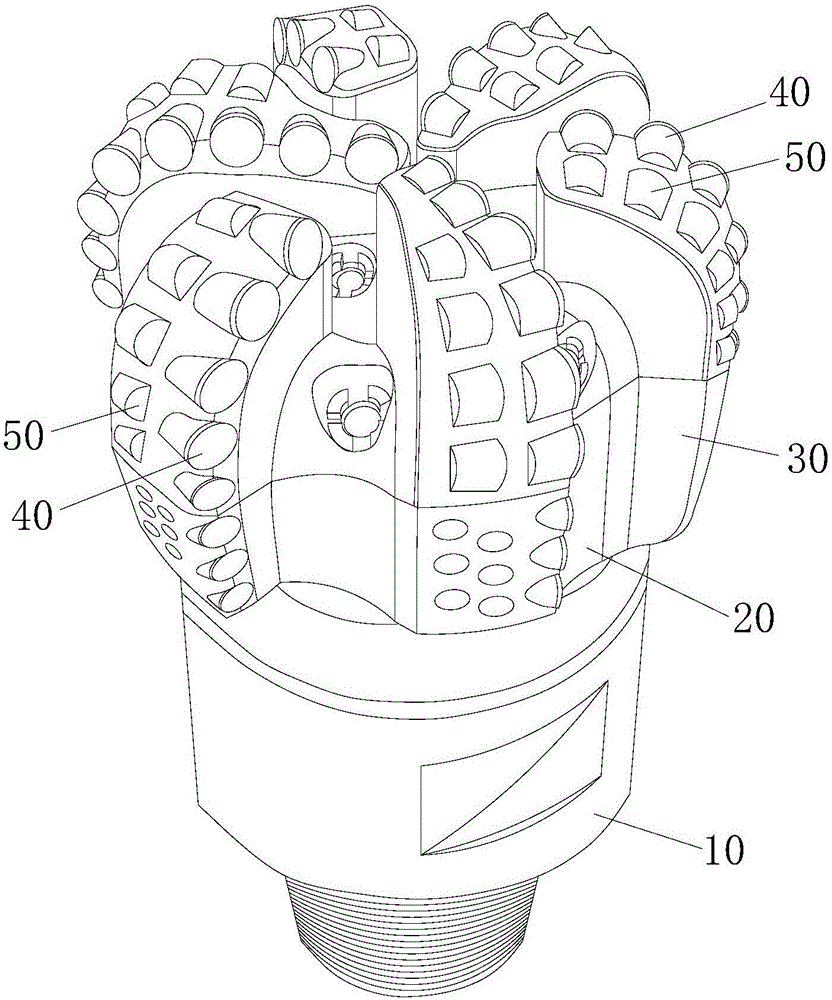

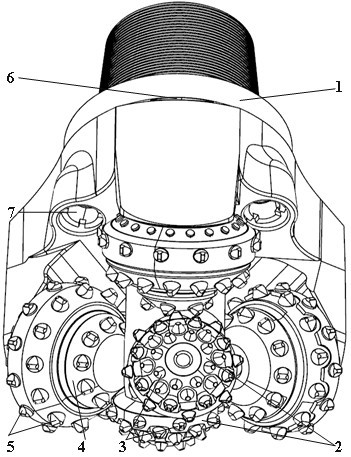

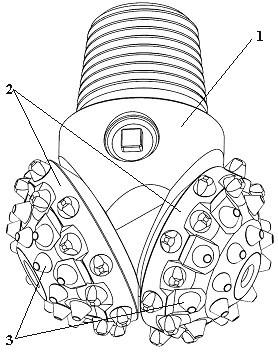

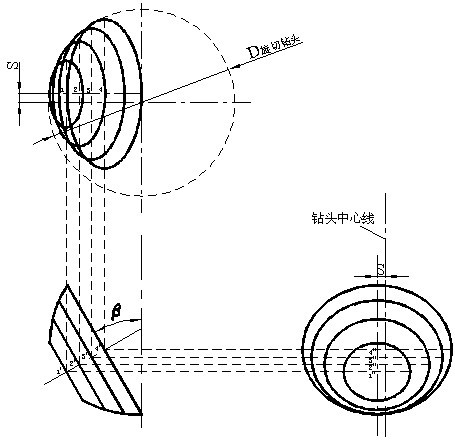

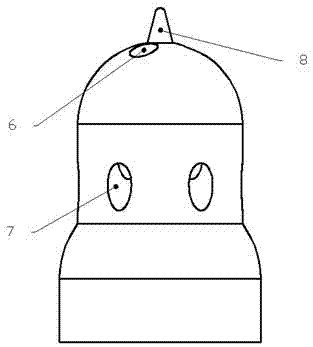

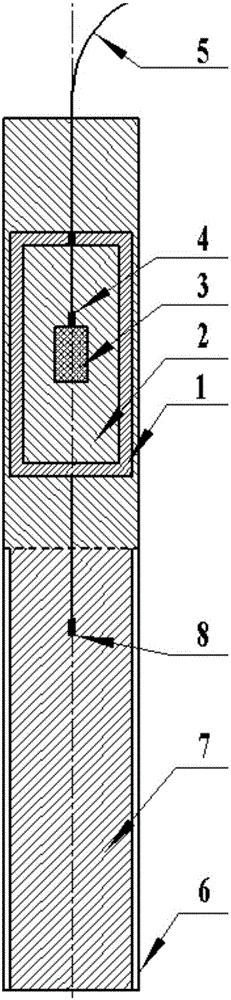

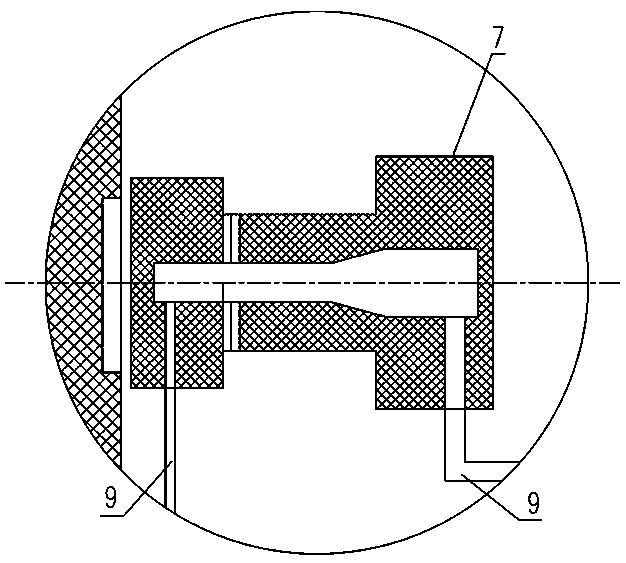

Compound bit formed by PDC (polycrystalline diamond compact) bits and rotary cutting bit

InactiveCN102392605AExtended service lifeIncrease cutting forceConstructionsHigh ratePolycrystalline diamond

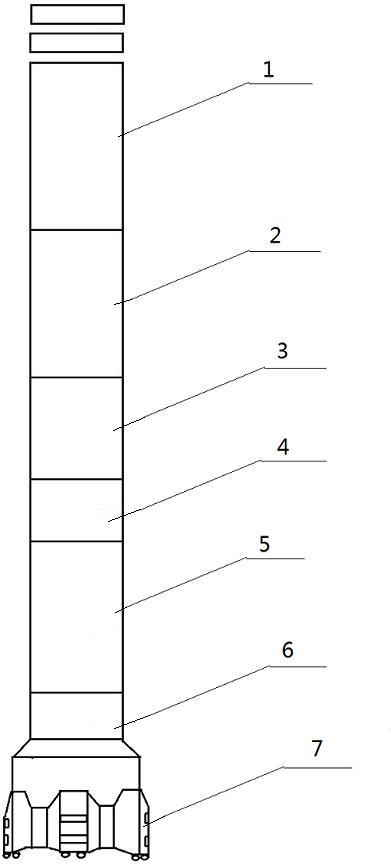

The invention discloses a compound bit formed by PDC (polycrystalline diamond compact) bits and a rotary cutting bit. The compound bit comprises a main body (1), rotary cutting bit cones (2), rotary cutting bit cutting teeth (3), PDC blades (4), PDC cutting teeth (5), oil storage sacs (6) and nozzles (7), wherein the main body (1) comprises a cone journal, centralizing blocks, high-pressure slurry channels and a connection screw thread. The compound bit is characterized in that a compound bit cutting unit comprises the rotary cutting bit and a PDC bit cutting unit. The compound bit has the following beneficial effects: the PDC bits complete drilling the central part of the borehole in the drilling process; the linear velocity of the periphery of the borehole is high in the drilling process and the rotary cutting bit and the PDC bit cutting unit complete drilling the periphery of the borehole; and the rotary cutting bit in the compound bit shocks, crushes and cuts the rocks by way of rotary cutting, has high central rock breaking efficiency, high rate of penetration and better dynamic performance, is uniform in wear, simultaneously improves the bit bearing structure, ensures to prolong the service life of the bit while improving the rock breaking efficiency, improves the cutting capability of the compound bit and ensures good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

Multifunctional self-oscillation flow jet flow drill

InactiveCN101413380AImprove permeabilitySimple structureLiquid/gas jet drillingVibration drillingJet flowSelf-oscillation

The invention relates to a multifunctional self-oscillation jet drill bit. The prior similar product not only has shallow drilling depth and complex structure but also has large resistance loss and short service life of a drill bit, can not repeatedly switch drilling and groove cutting during the drilling process, and limits the application scope. A crushing blade and a valve body are arranged inside a cutting head body of the drill bit; a first offsetting spring in the valve body is matched with a valve core A in the form of sliding; a valve core B is matched with a second offsetting spring for operation under the action of a lined ring, a washer and the valve body together; and the valve core and a limber hole of the valve body are matched for use with a self-oscillation nozzle. The multifunctional self-oscillation jet drill bit adopts high-pressure water as power to realize repeated switching between drilling and groove cutting of coal seam and terrane, not only has a simple structure and is flexible to switch but also can promote development of coal seam fissure through oscillation jet generated by the nozzle, strengthens the permeability of the coal seam, improves the gas extraction rate, particularly has obvious effect on low-permeability coal seam, and widely promotes and applies the fluid technology of the high-pressure water in the fields of drilling and gas extraction of the low-permeability coal seam.

Owner:CHONGQING UNIV

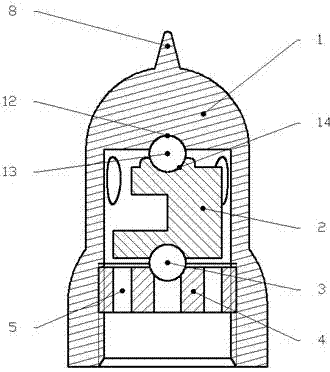

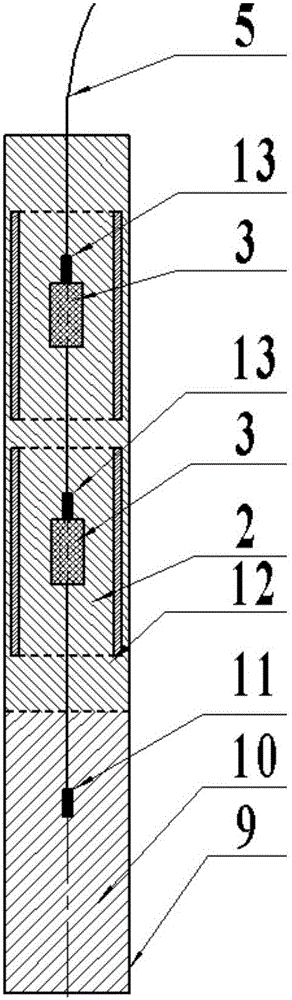

Drilling impact device

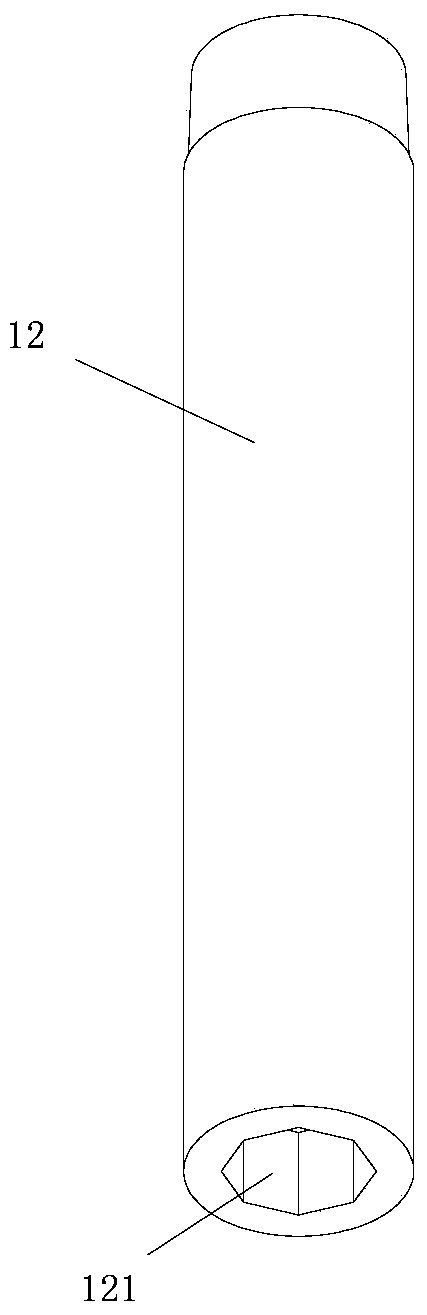

ActiveCN104912478AImprove rock breaking abilityExtended service lifeBorehole drivesPolycrystalline diamondDrill bit

The invention provides a drilling impact device, which comprises a drill bit installing part (1), a transverse impact generating assembly and a longitudinal impact generating assembly, wherein the transverse impact generating assembly comprises a first casing (6) and a first reversing pipe (5); the first reversing pipe (5) is rotatably arranged in the first casing (6); the longitudinal impact generating assembly comprises a second casing (12), a longitudinal impact part and a transmission part; the longitudinal impact part and the transmission part are arranged in the second casing (12); and the transmission part drives the longitudinal impact part to do axial reciprocating movement through being driven by the first reversing pipe (5). The technical scheme of the invention effectively solves the problems of low drilling speed and low drilling efficiency of a PDC (Polycrystalline Diamond Compact) drill bit in the prior art.

Owner:CNOOC RES INST +1

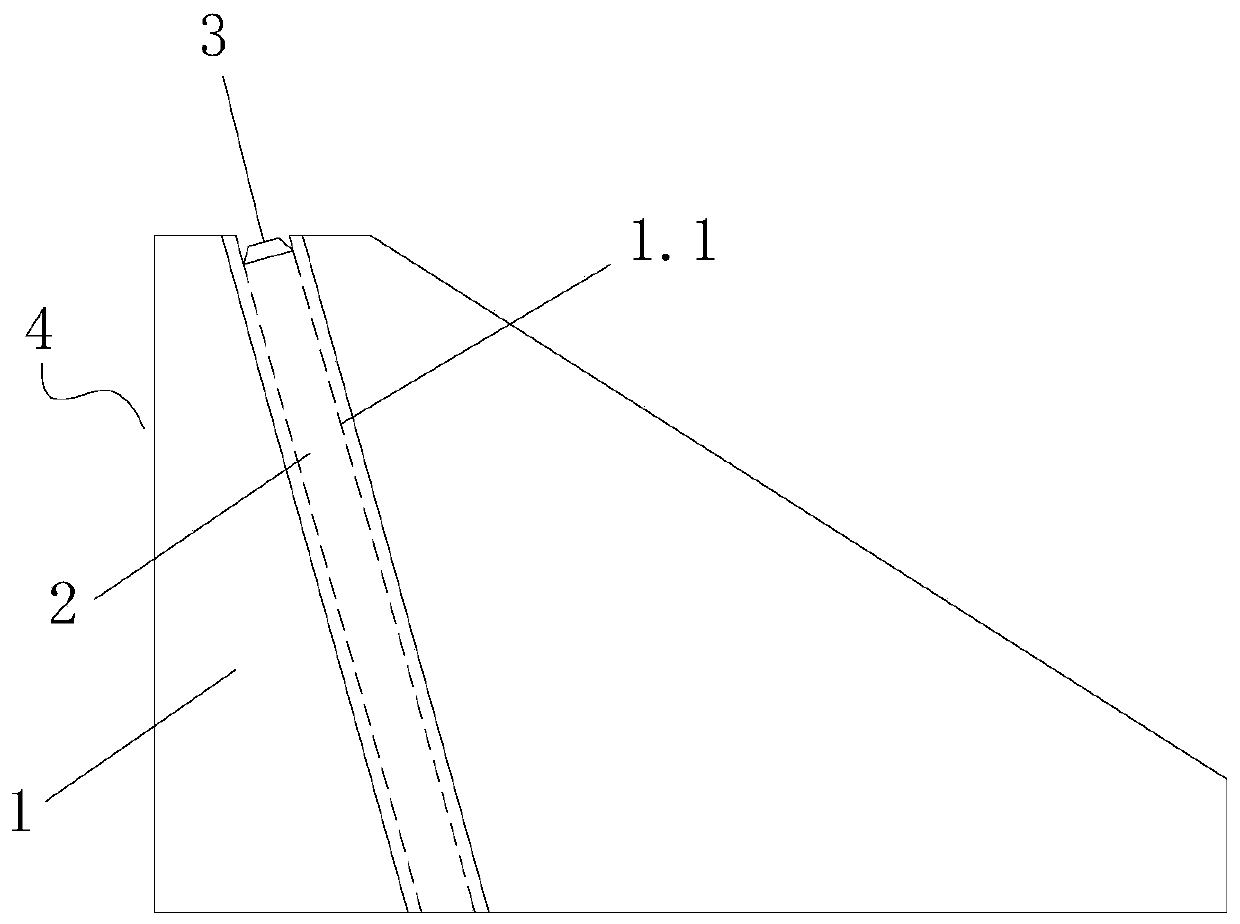

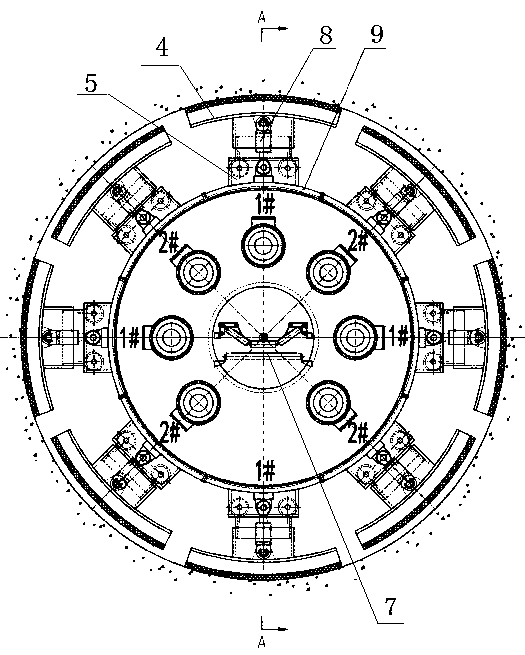

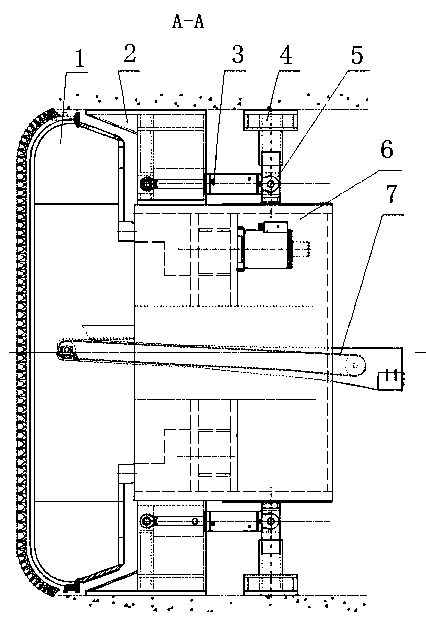

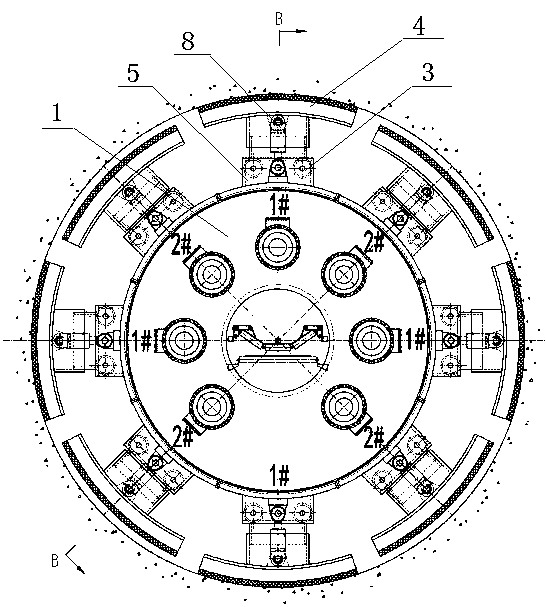

High-pressure water jet edge cutter and combined rock breaking and escaping TBM cutterhead and method thereof

The invention discloses a high-pressure water jet edge cutter which comprises an edge cutter mechanical structure, an edge cutter high-pressure water jet pipeline and an edge cutter high-pressure water jet nozzle. The edge cutter high-pressure water jet pipeline is located in the edge cutter mechanical structure. The edge cutter high-pressure water jet nozzle is embedded in the edge cutter mechanical structure and communicates with the edge cutter high-pressure water jet pipeline. The high-pressure water jet edge cutter has the advantages of realizing rock breaking through high-pressure waterjet and solving the problem that a TBM gets stuck. The invention further discloses a hydraulic-mechanical combined rock breaking and escaping TBM cutterhead. The invention further discloses a hydraulic-mechanical combined rock breaking and escaping method.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

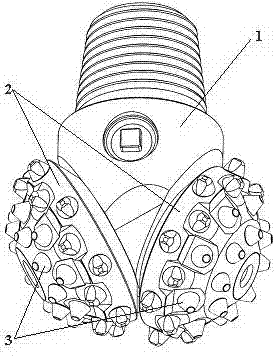

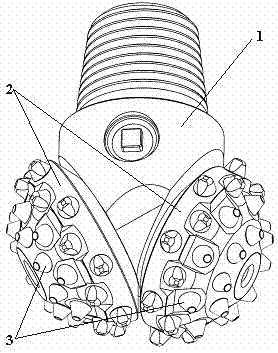

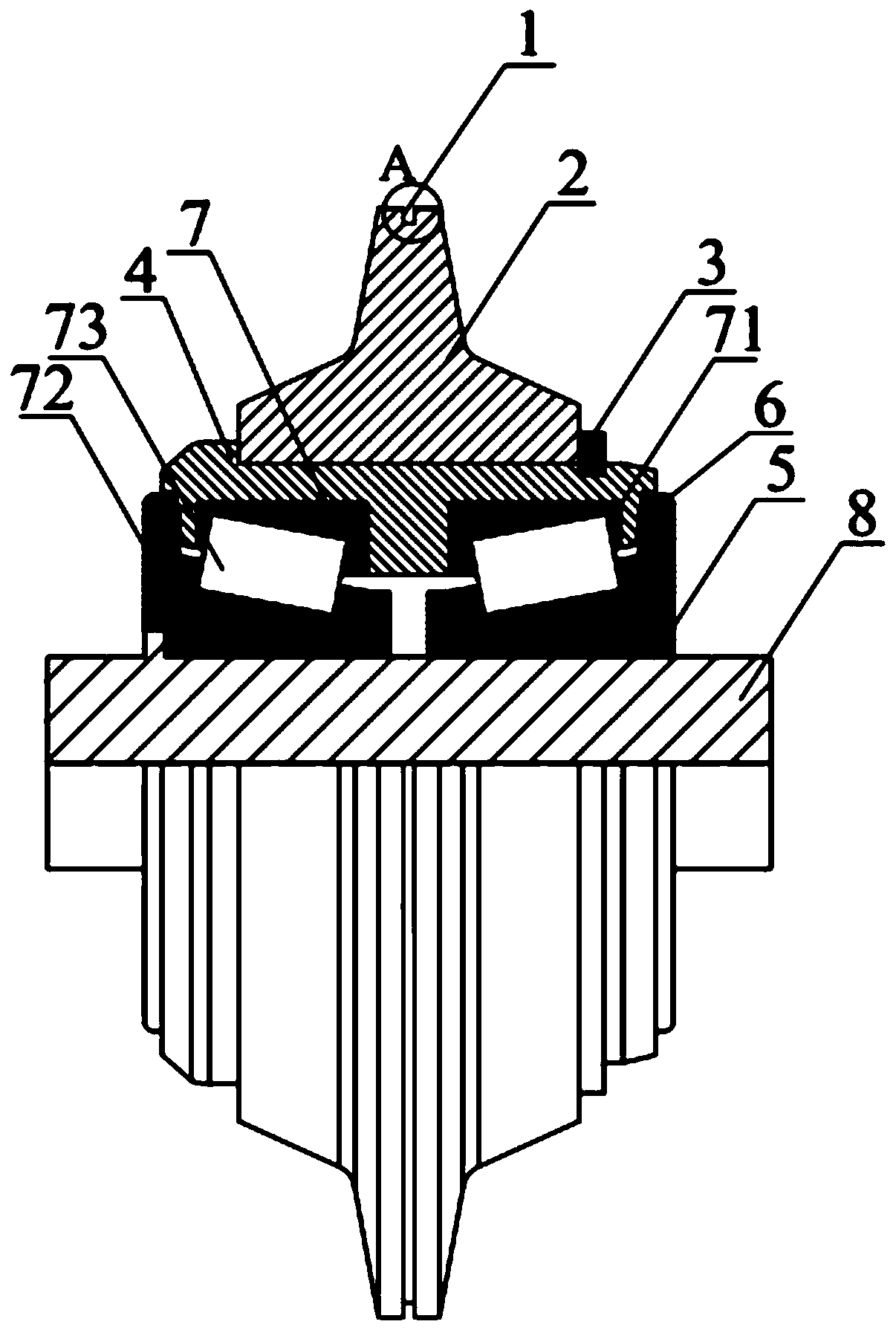

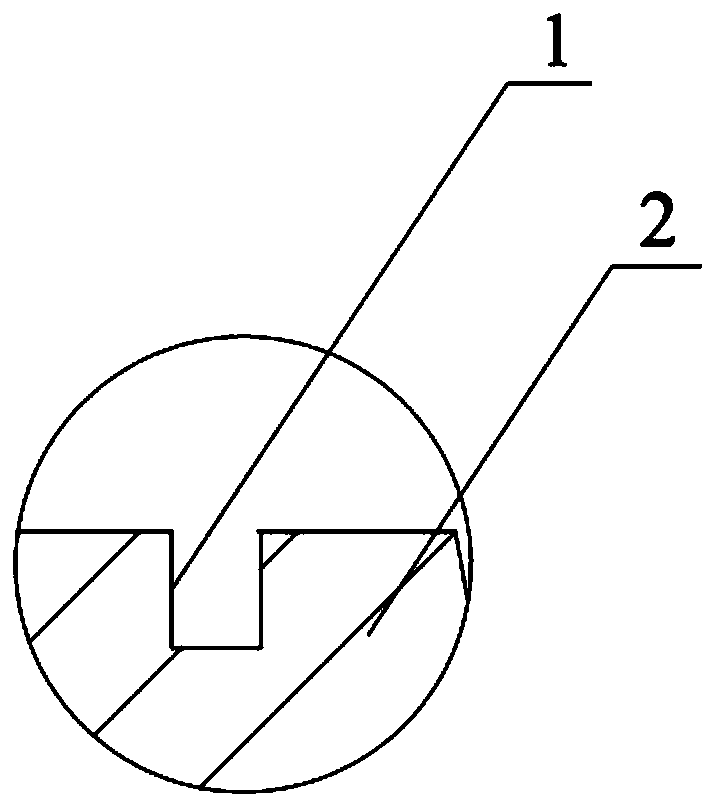

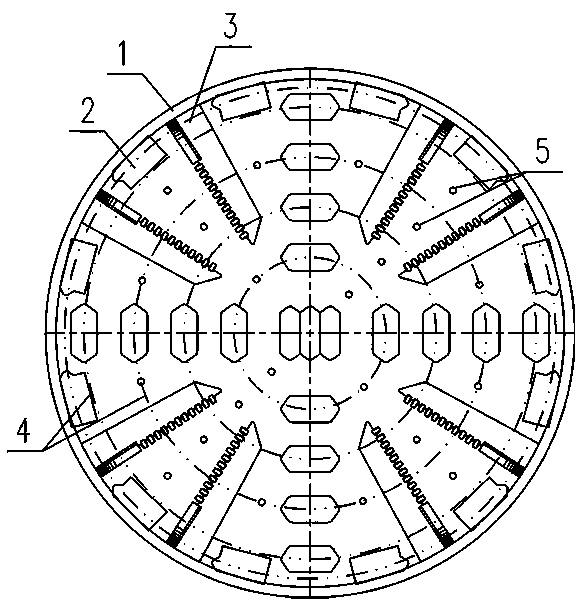

Compound bit formed by rotary cutting bit and PDC (polycrystalline diamond compact) blades

ActiveCN102392603AImprove rock breaking efficiencyHigh rock breaking performance at the centerDrill bitsConstructionsHigh ratePolycrystalline diamond

The invention discloses a compound bit formed by a rotary cutting bit and PDC (polycrystalline diamond compact) blades. The compound bit comprises a main body (1), rotary cutting bit cones (2), rotary cutting bit cutting teeth (3), PDC blades (4), PDC cutting teeth (5), oil storage sacs (6) and nozzles (7), wherein the main body (1) comprises a cone journal, centralizing blocks, high-pressure slurry channels and a connection screw thread. The compound bit is characterized in that a compound bit cutting unit comprises the rotary cutting bit and a PDC bit cutting unit. The compound bit has the following beneficial effects: the rotary cutting bit completes drilling the central part of the borehole in the drilling process; the rotary cutting bit in the compound bit shocks, crushes and cuts the rocks by way of rotary cutting, has high central rock breaking efficiency, high rate of penetration and better dynamic performance, is uniform in wear, simultaneously improves the bit bearing structure and ensures to prolong the service life of the bit while improving the rock breaking efficiency; and the linear velocity of the periphery of the borehole is high in the drilling process and the rotary cutting bit and the PDC bit cutting unit complete drilling the periphery of the borehole, thus improving the cutting capability of the compound bit and ensuring good gauge protection effect.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

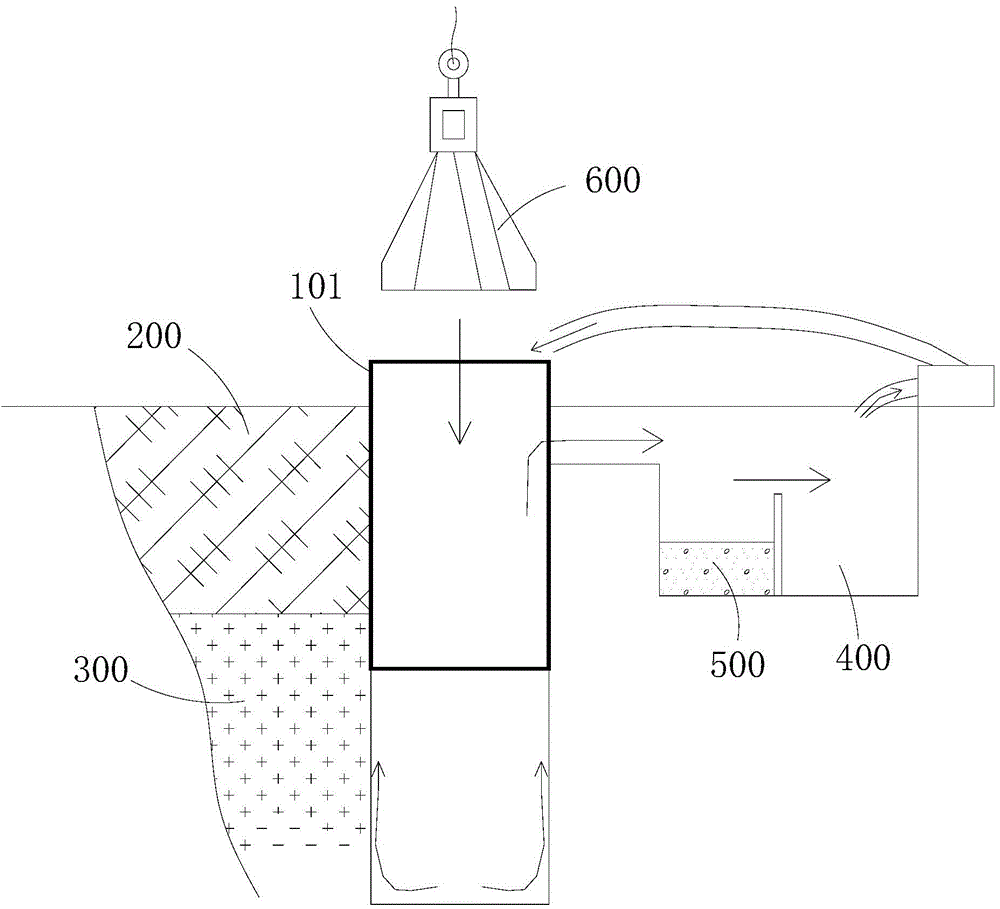

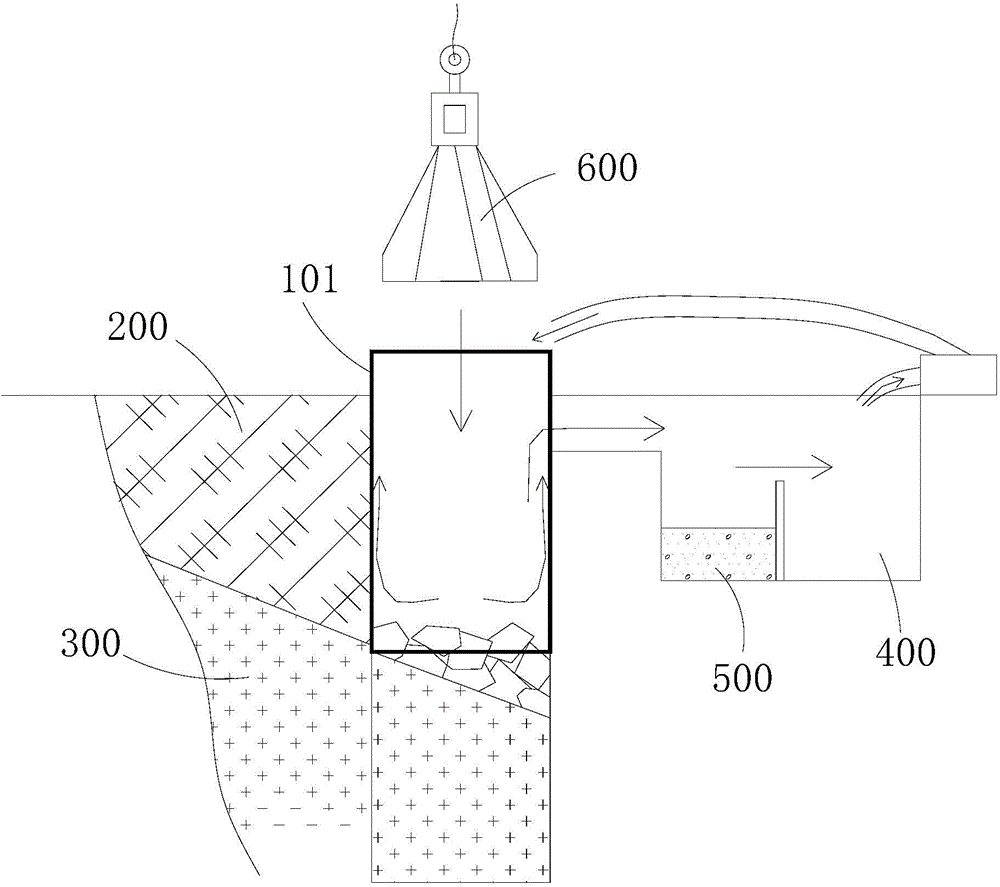

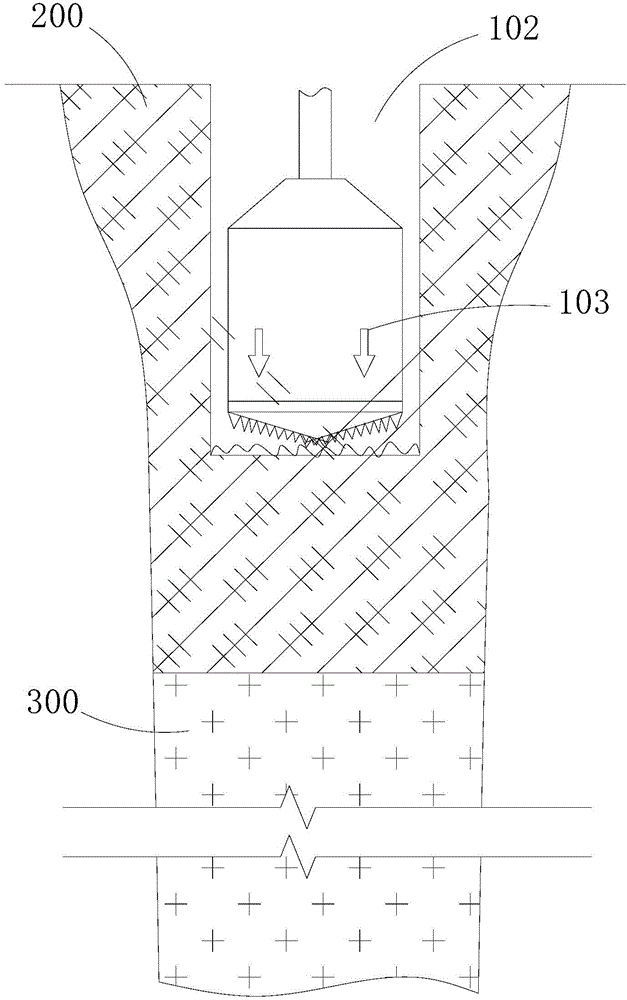

Foundation excavation retaining and protecting cast-in-situ bored pile construction method and equipment thereof

The invention relates to the technical field of foundation excavation retaining and protecting cast-in-situ bored piles and discloses a foundation excavation retaining and protecting cast-in-situ bored pile construction method and equipment thereof. The method comprises the following steps: 1, adopting a rotary excavating drilling tool to guide a hole in advance; 2, adopting a vibratory hammer to convey a pile casing into the soil layer downward from a hole opening ; 3, adopting the rotary excavating drilling tool to drill to the elevation position at the bottom of the pile casing; 4, adopting an air compressor to supply air into the hole till the air comes out of an opening at the upper end of the hole, and then utilizing a down-the-hole hammer to drill on a bed rock layer; 5, after the down-the-hole hammer drills to a final hole, pulling out the down-the-hole hammer, and infusing slurry into the hole; 6, cleaning the interior of the hole, placing a steel reinforcement cage into the hole, and pouring concrete into the hole; 7, utilizing the vibratory hammer to pull out the pile casing. According to the construction method, a pile casing retaining wall is utilized, and the hole collapse and hole shrinkage can be prevented; the down-the-hole hammer is utilized for cooperating with the air compressor to supply the air, great rock breaking capability is achieved, a rotary drilling machine is adopted for cleaning the hole, the hole formation is made to be greatly accelerated, the construction progress is sped up, and the cost is saved.

Owner:SHENZHEN GONGKAN GEOTECHN GRP +1

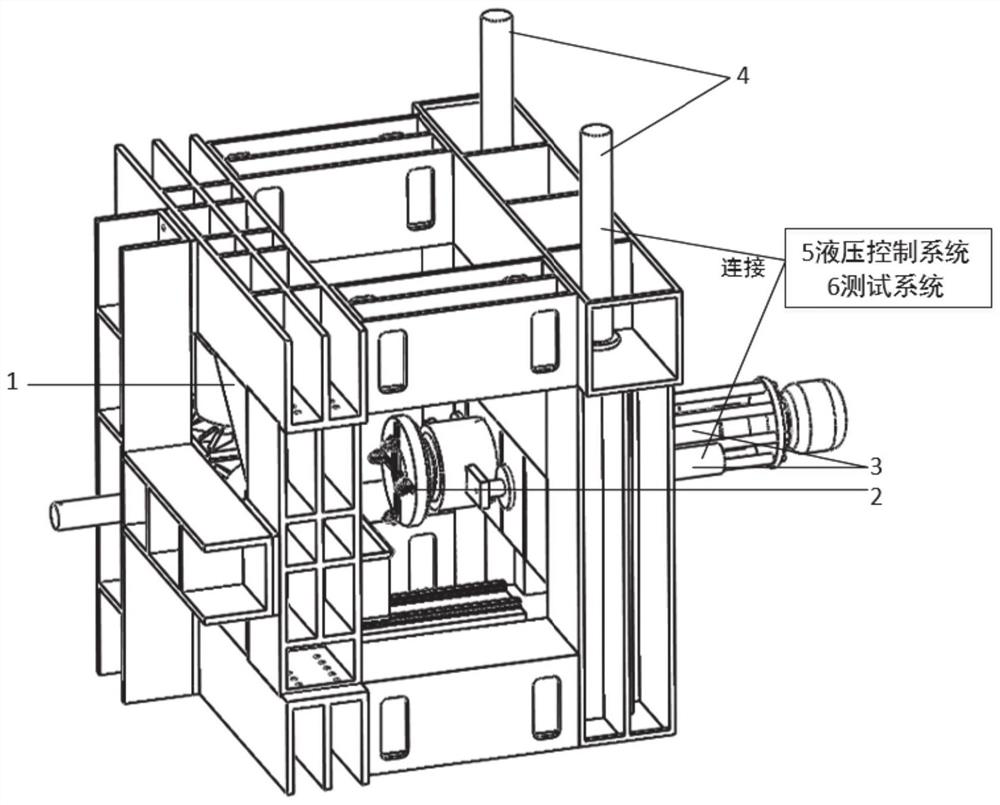

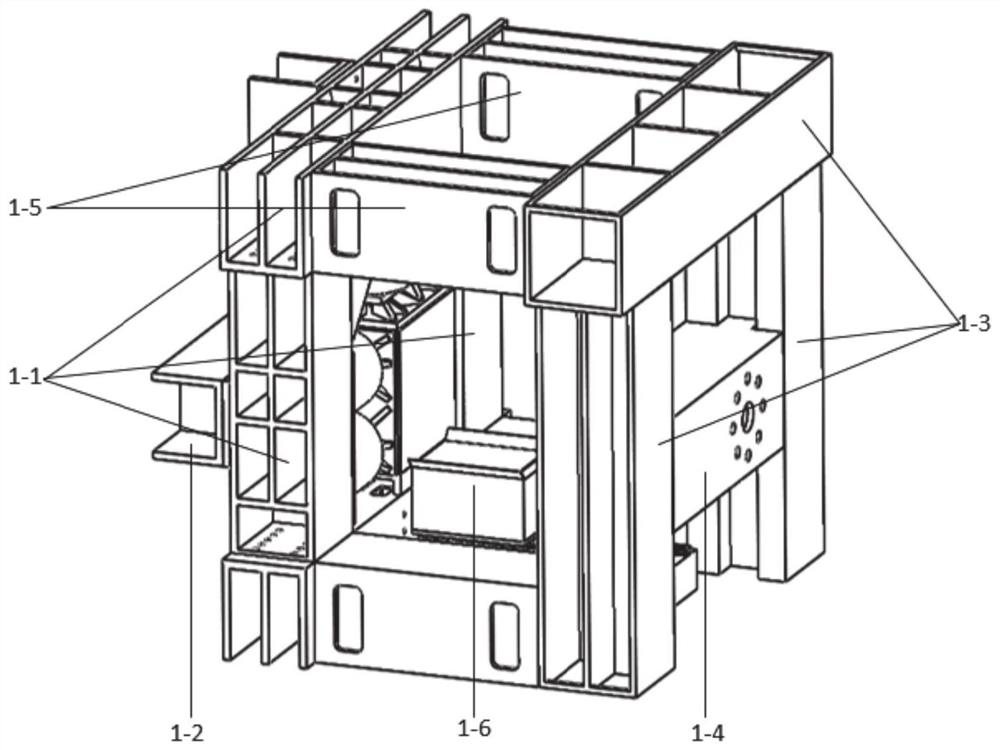

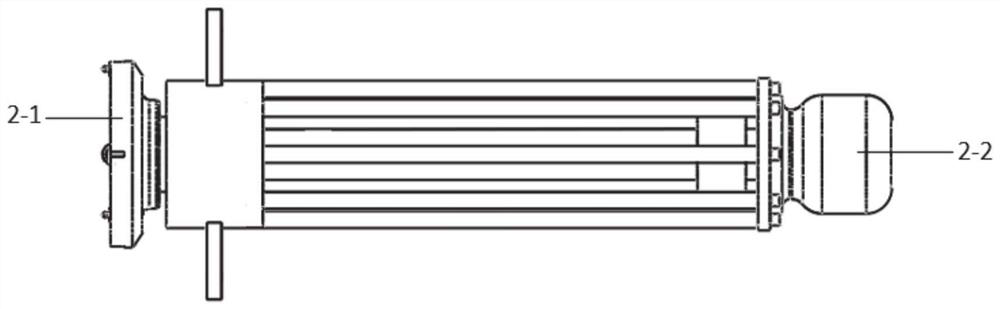

TBM hob and high-pressure water jet coupling rock breaking simulation test system and method

ActiveCN111624088AEasy to observeEasy to recordStructural/machines measurementStrength propertiesWire cuttingClassical mechanics

The invention discloses a TBM hob and high-pressure water jet coupling rock breaking simulation test system and method. Installation of multiple disc type hobs can be achieved, the positions of the hobs can be adjusted, the side face and rear side hydraulic oil cylinders pressurize a rock test piece in a three-way mode, and the three-way stress state of a tunnel face rock can be truly simulated. Horizontal design is adopted for the test device, the cutterhead can be used for horizontally breaking the rock, the angle of the hobs is adjustable, the cutterhead can be used for rotatably cutting the rock and vertically and linearly cutting the rock up and down, the rock breaking processes of different radiuses of the on-site TBM hobs can be simulated, the situation that the hob cuts and breaksthe rock under the real working condition can be better simulated, and the rock breaking effect can be better in cooperation with the high-pressure water jet coupling effect.

Owner:SHANDONG UNIV

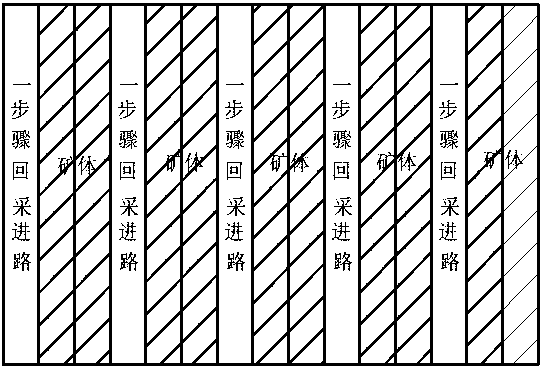

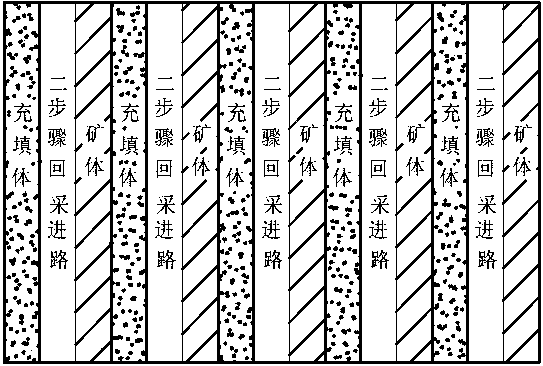

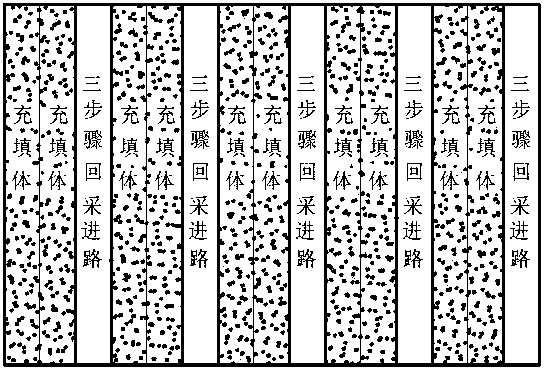

Blasting method applied to access road type extraction

ActiveCN109029177ATransmitted compression wave intensity is lowUndamagedBlastingPeak valueCompressive strength

The invention discloses a blasting method applied to access road type extraction. The dynamic tensile strength of rock is lower than the dynamic compressive strength of a filling body; after a peripheral hole is detonated, at the junction part of the ore rock and the filling body, a blasting stress wave generates a reflected tension wave and a transmission compression wave at two medium interfacesdue to different wave impendences of the filling body and the ore rock; and through calculating the distance between the peripheral hole and the filling body, the blasting parameter of a tunnel faceis determined, so that a stress wave peak value of the transmission compression wave produced at the two medium junction part through the stress wave generated by blasting is lower than the dynamic compressive strength of the filling body. The filling body is ensured to keep perfect without being damaged, and meanwhile, the strength of the produced reflected tension wave is larger than the dynamiccompressive strength of the rock, so that a rock breaking effect is improved. Through the method provided by the invention, an ore body in anaccess road can be ensured to be sufficiently blasted, andfillers at one side or two sides of the access road can be ensured to keep perfect without being damaged by the blasting stress wave.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

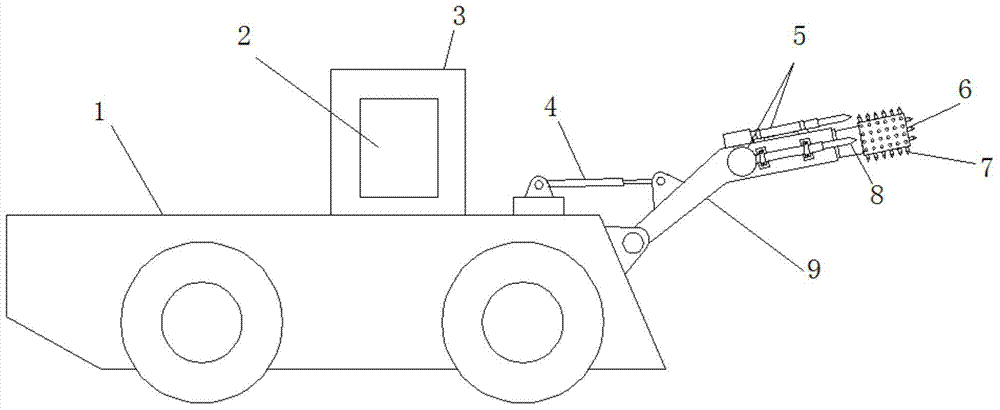

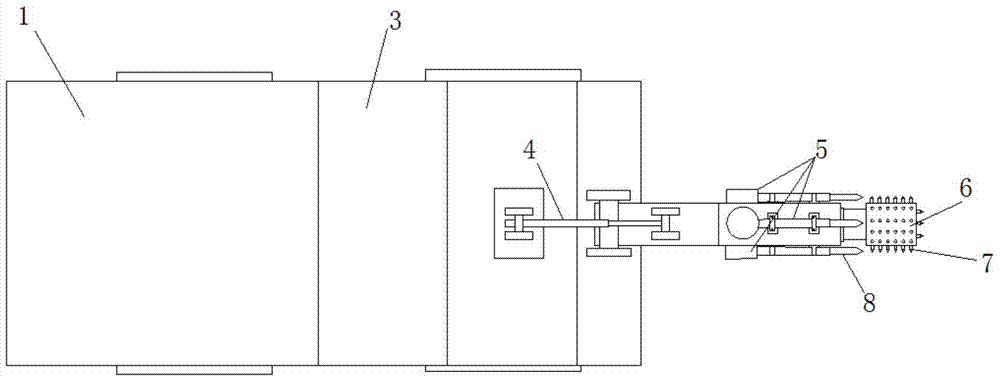

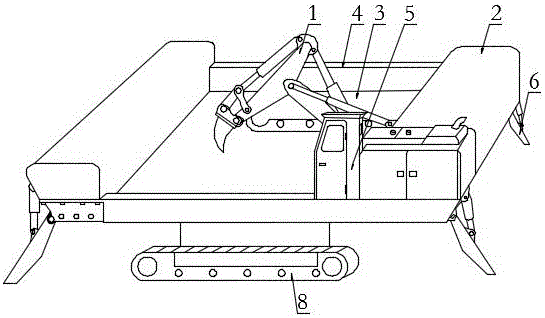

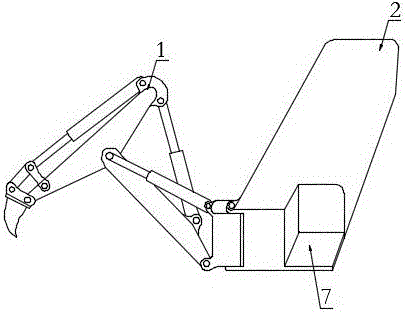

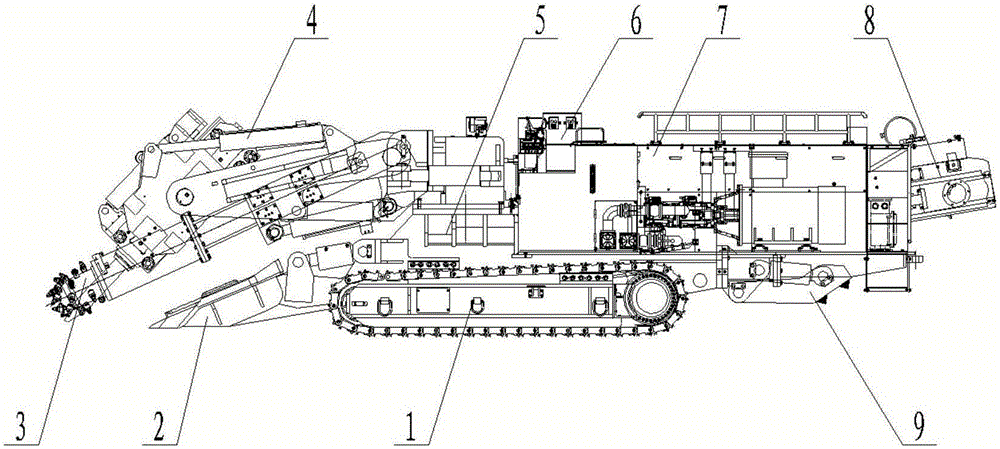

Impact-assisted heading machine for hard rock ore exploitation

The invention discloses an impact-assisted heading machine for hard rock ore exploitation. The impact-assisted heading machine comprises a chassis, a cab, a cantilever (9) and a cutting head (6) installed at the top end of the cantilever (9), wherein the cab and the cantilever (9) are installed on the chassis. At least one impact device (5) is installed on the cantilever (9). An impact head (8) which can stretch and retract to conduct impact motion is installed in each impact device (5) and can stretch to the position in front of the cutting head (6). According to the impact-assisted heading machine for hard rock ore exploitation, on the basis of the cutting rock-breaking function of a traditional cantilever excavator, the impact rock-breaking function is added, so that the rock-breaking ability is greatly improved, the application range is greatly broadened, and efficiency is greatly improved; besides, since the chassis of a tire self-propelled scraper is used for replacing a chassis of a crawler-type heading machine, a walking mechanism can be more flexible and lighter, and particularly the impact-assisted heading machine can be better adapted to the environment that a working face is narrow and complicated during exploitation of hard rock deep in an underground mine.

Owner:CENT SOUTH UNIV

Ultrahigh-pressure rotary pulse water jet rock breaking mechanism

InactiveCN105156107AReduce volumeIncrease motivationDriving meansCutting machinesReduction driveEngineering

The invention discloses an ultrahigh-pressure rotary pulse water jet rock breaking mechanism which comprises a water jet cutting head, a rock breaking mechanism shell and a cutting spindle. The cutting spindle is arranged inside the rock breaking mechanism shell, the front end of the cutting spindle is connected with the water jet cutting head, the rear end of the cutting spindle is connected with a driving device, a central water channel is arranged inside the cutting spindle by means of machining, the driving device comprises a speed reducer and a hydraulic motor, a booster cavity is arranged at the rear end of the central water channel, a booster piston rod is arranged in the booster cavity, a large-diameter end of the booster piston rod is matched with the booster cavity, a rod of the booster piston rod is matched with the central water channel, an annular cavity is formed between an outer circle of the rod of the booster piston rod and the inner wall of the booster cavity, a water inlet channel and a water outlet channel are arranged at the rear end of the cutting spindle, a high-pressure rotary sealing guide sleeve is arranged between the rear end of the cutting spindle and the rock breaking mechanism shell, a water inlet groove and a water outlet groove are formed in the high-pressure rotary sealing guide sleeve, and the rock breaking mechanism shell is provided with a high-frequency electromagnetic reversing valve. The ultrahigh-pressure rotary pulse water jet rock breaking mechanism has the advantages of compact structure, low water consumption and high rock breaking capacity.

Owner:CHINA UNIV OF MINING & TECH

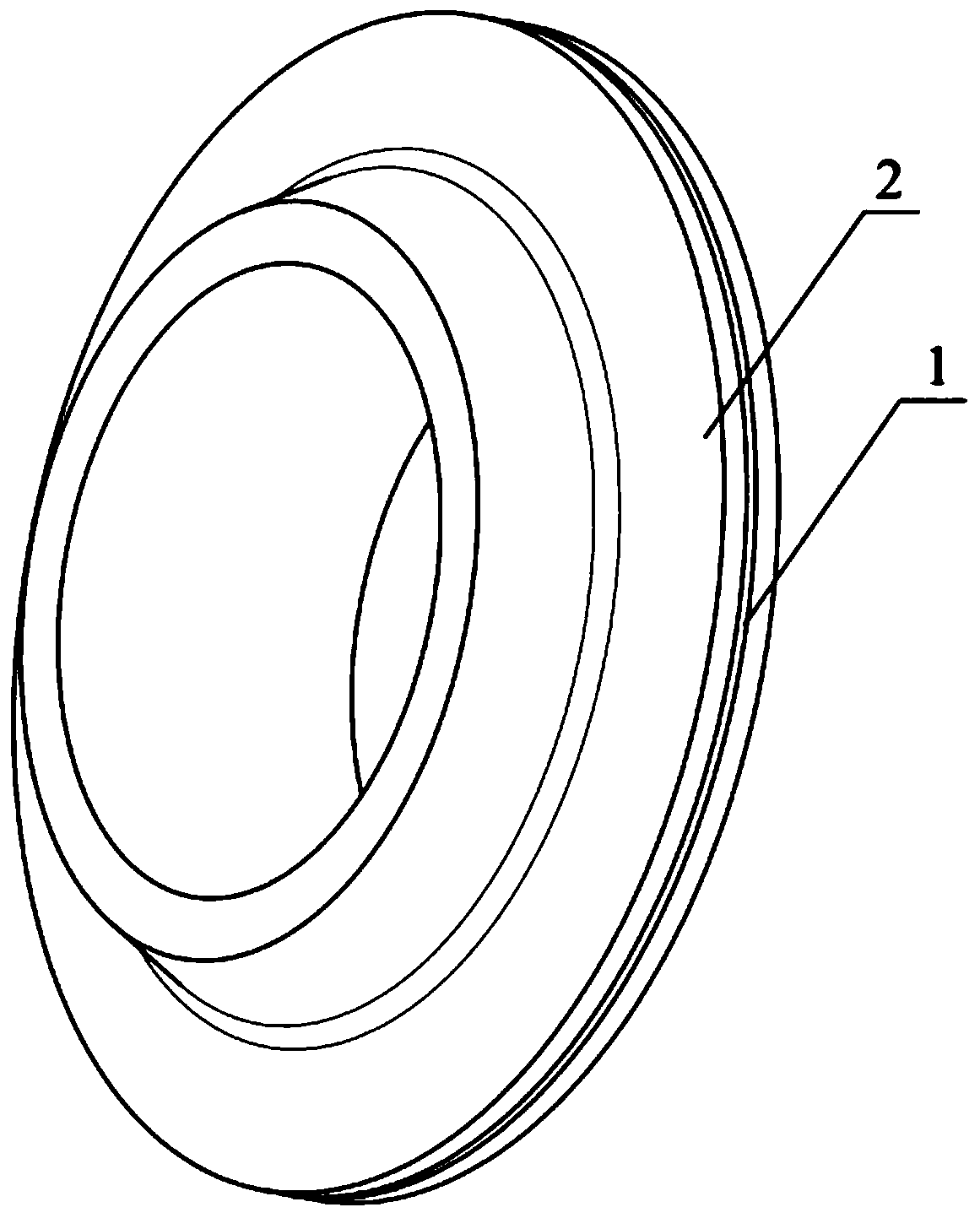

TBM disc cutter with grooved cutter ring outer circumference

The invention discloses a TBM disc cutter with the grooved cutter ring outer circumference. The TBM disc cutter comprises a cutter ring, a cutter body, a check ring, a bearing, a rigid mandrel, a bearing end cover and a seal ring. The cutter ring is fixed to the cutter body through the check ring, the bearing is connected into the cutter body, and the bearing end cover and the seal ring enable thebearing to be fixed to the rigid mandrel in a sealed mode. According to the TBM disc cutter with the grooved cutter ring outer circumference, a novel rock breaking disc cutter ring structure is used;the cutter body, the bearing and the bearing end cover are assembled to the mandrel, internal oil liquid is sealed by means of the seal ring between the cutter body and the bearing end cover, and a step is arranged on the outer ring of the cutter body and used for positioning the cutter ring; and by means of the TBM disc cutter, a compact core shape can be controlled, stress distribution is changed so as to form lateral cracks, production and extension of the lateral cracks are facilitated, the rock breaking energy consumption is reduced, the rock breaking capability is effectively improved,and the rock breaking efficiency is improved.

Owner:SOUTHWEST JIAOTONG UNIV

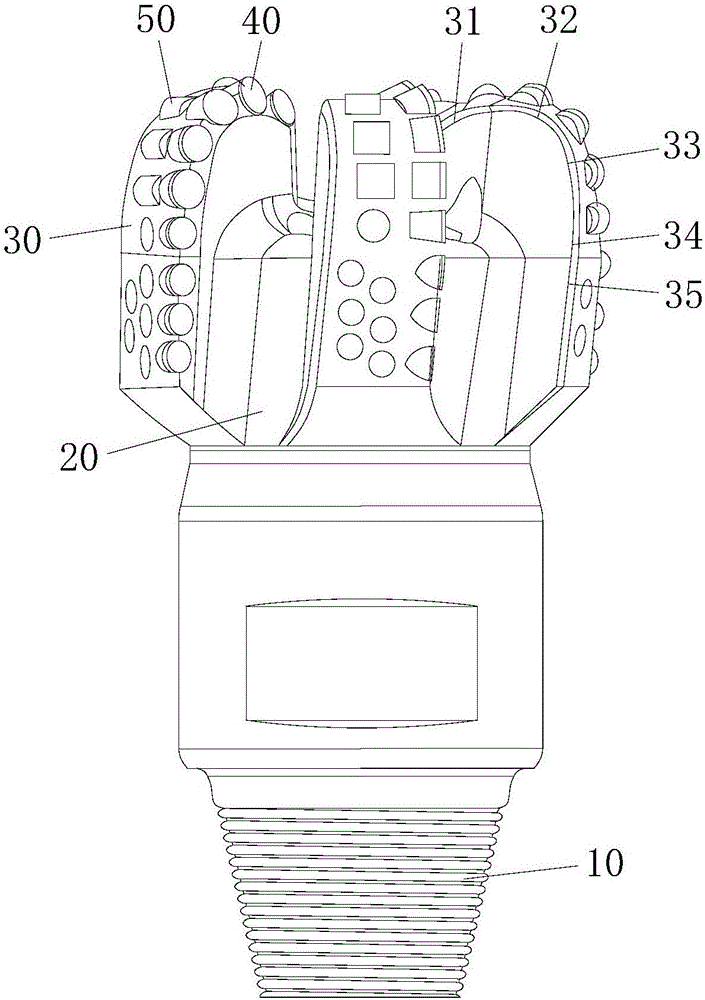

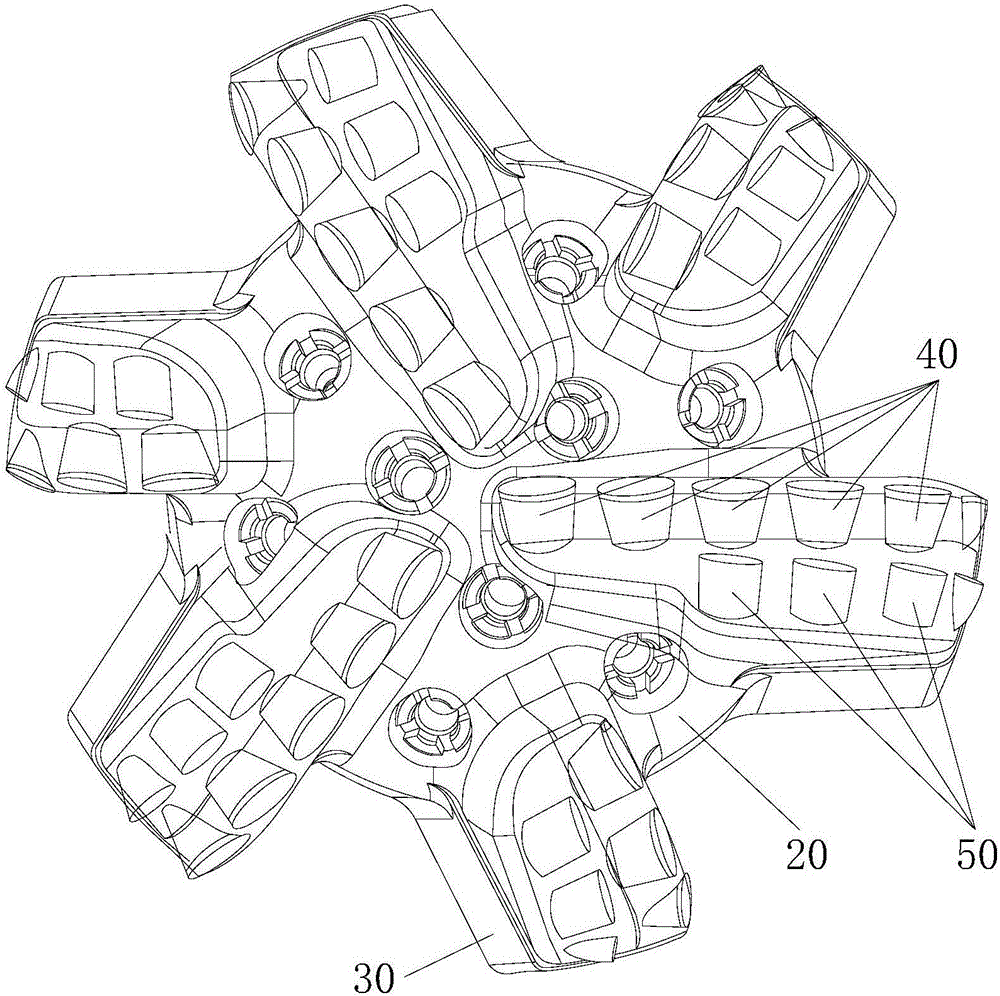

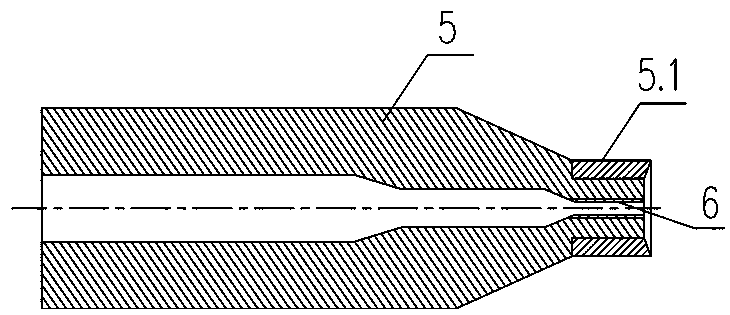

Composite drill bit

InactiveCN106639890AStrong cutting forceImprove rock breaking abilityDrill bitsConstructionsKnife bladesGrinding teeth

The invention provides a composite drill bit. The composite drill bit comprises a columnar connector and a drill bit body connected to the connector. The composite drill bit further comprises at least three knife blades arranged on the drill bit body evenly in the circumferential direction of the drill bit body. All the knife blades extend from inside to outside in the radial direction of the drill bit body. The outer side face of each knife blade is provided with a crown profile which is a curve. The composite drill bit further comprises a plurality of cutting teeth and a plurality of grinding teeth which are all fixedly arranged on the crown profiles. All the cutting teeth are arranged in a row in the extending direction of the knife blades. All the grinding teeth are arranged in a row in the extending direction of the knife blades. The row where all the grinding teeth are located is located behind the row, where all the cutting teeth are located, in the rotary direction of the drill bit body. The peak heights of all the grinding teeth are smaller than that of the cutting teeth on the same circumference. Through the composite drill bit, machine drilling speed and drill bit drilling depth are increased, the service life is prolonged, and the drilling rock breaking efficiency of the drill bit is also improved.

Owner:PETROCHINA CO LTD

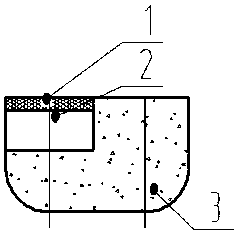

Shot hole plugging device for coal mine underground excavation

The invention relates to a shot hole plugging device for coal mine underground excavation, and discloses a novel stemming plugging device. The device is capable of improving blasting efficiency of an explosive material, and is capable of conducting dust falling on dust generated during blasting. The shot hole plugging device for coal mine underground excavation is characterized in that one end of a gas collecting tube is placed on one end of an outer sleeve and is communicated with the outer sleeve, the diameter gradually increases from one end of the gas collecting tube to the other end of the gas collecting tube, three arc-shaped grooves are distributed at equal intervals on the outer wall of the other end of the outer sleeve, the arc-shaped grooves form arc-shaped protrusions in the inner wall of the outer sleeve, the diameter gradually increases from one end of the outer sleeve to the other end of the outer sleeve, an outer semisphere shell body is arranged on the other end of the outer sleeve and is communicated with the outer sleeve, the diameter of the outer semisphere shell body is equal to that of the other end of the gas collecting tube, multiple supporting plates are arranged on the outer wall of the outer semisphere shell, installation blocks are arranged among the multiple supporting plates, and screw mounting holes are formed in the installation blocks.

Owner:CHINA UNIV OF MINING & TECH

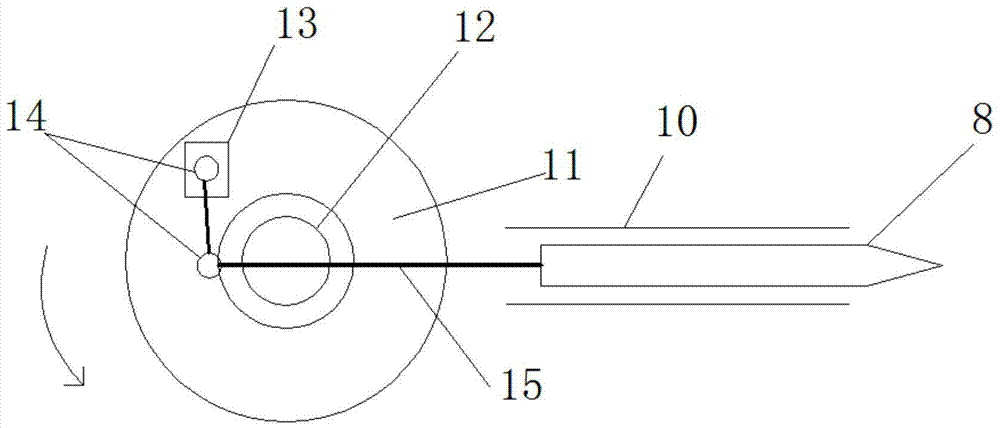

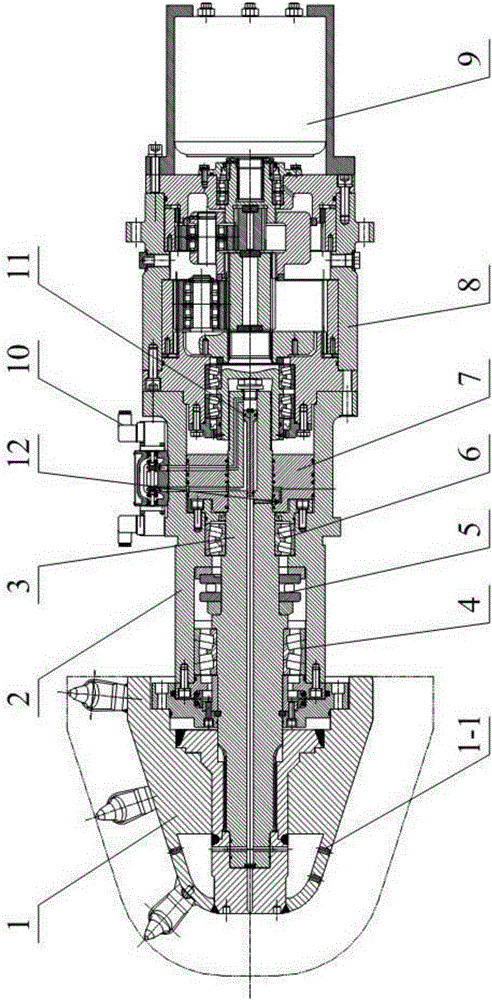

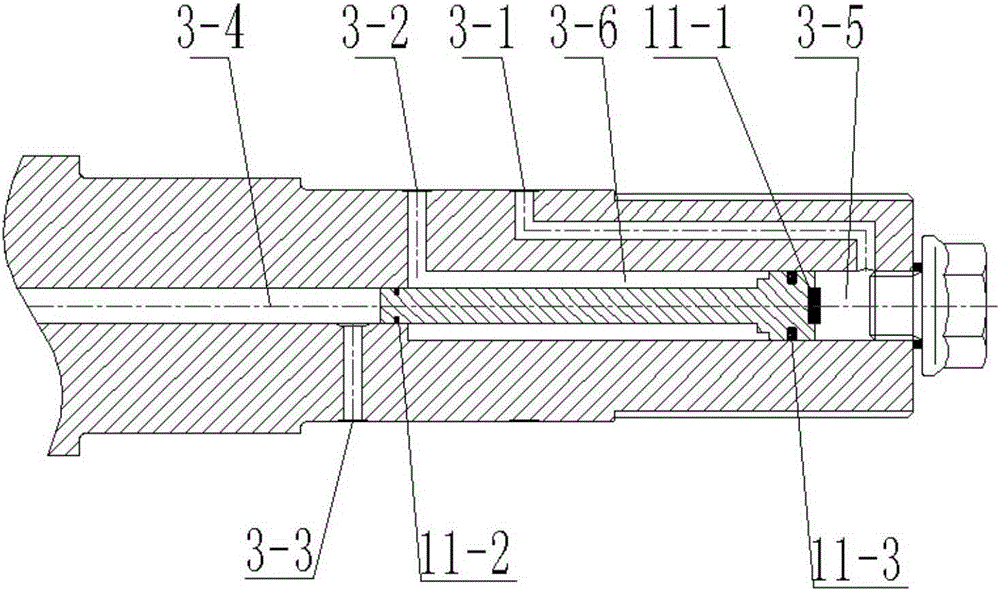

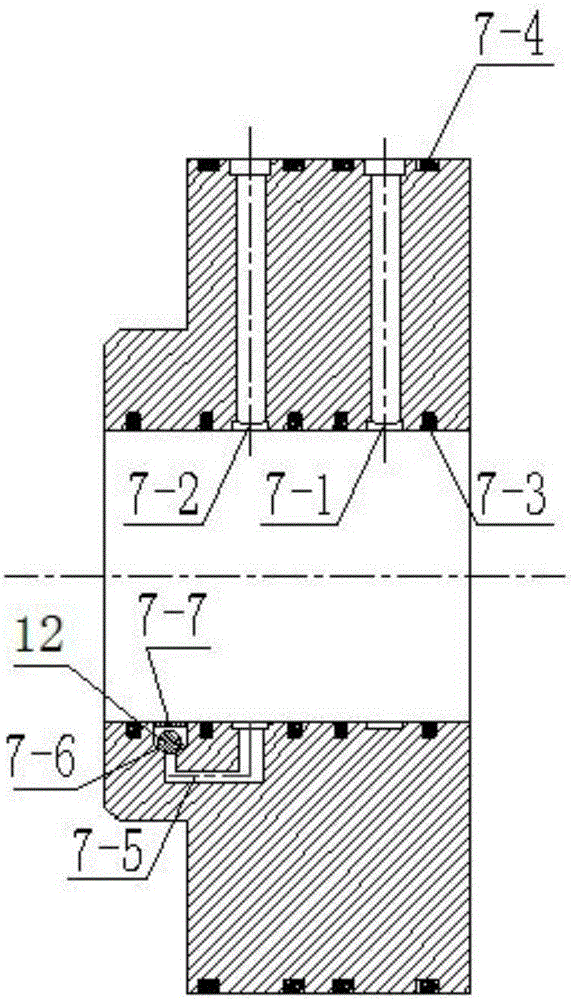

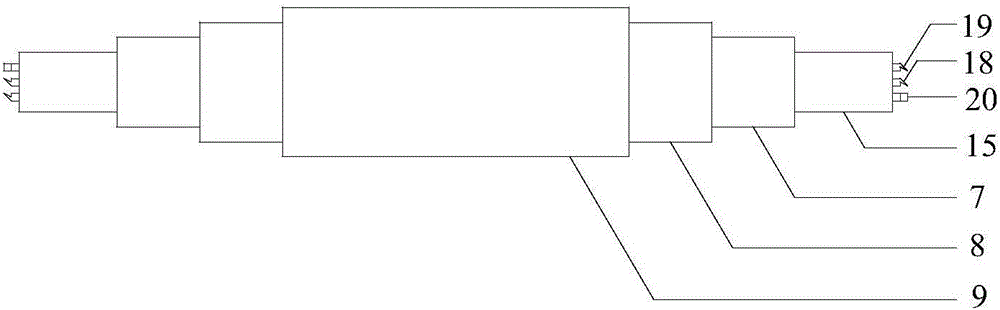

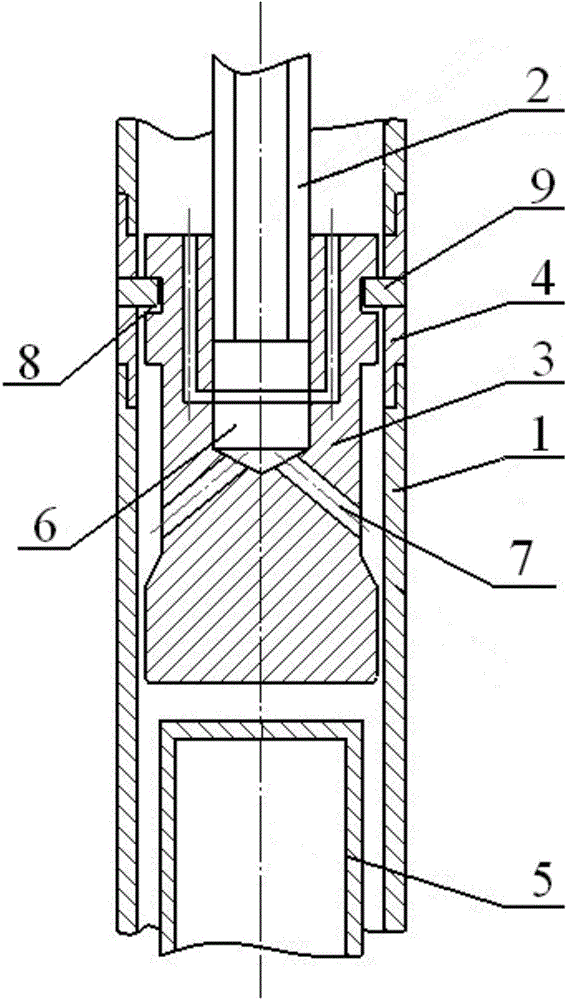

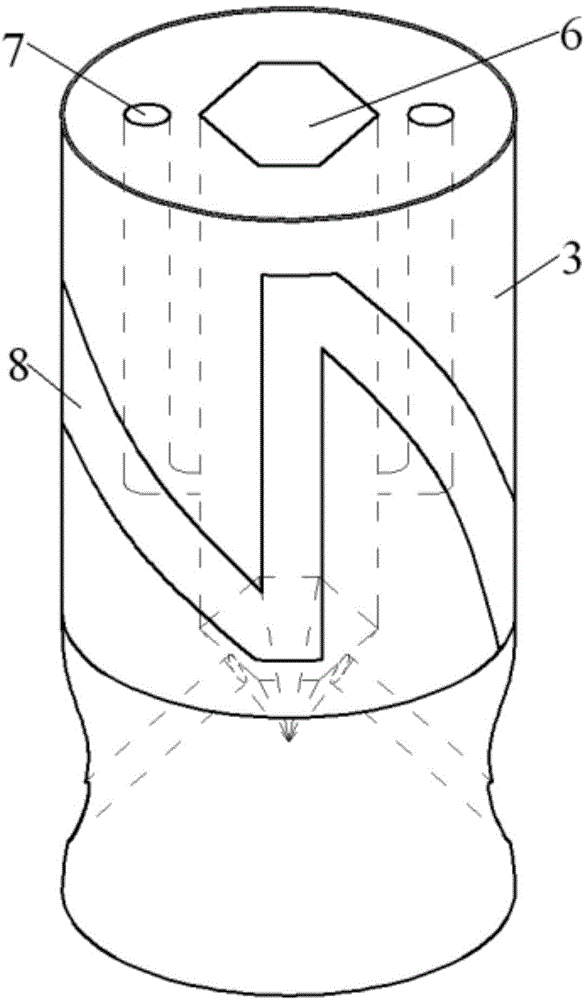

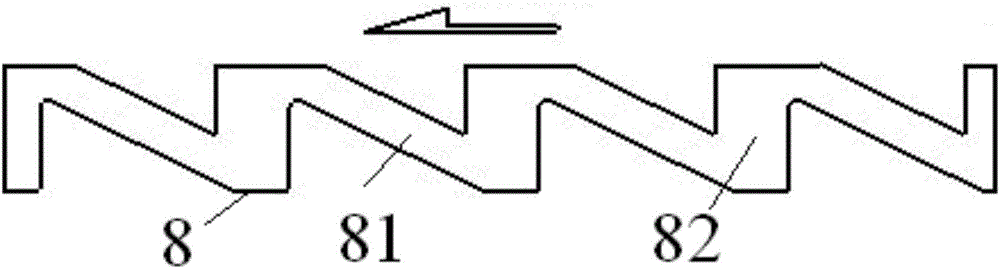

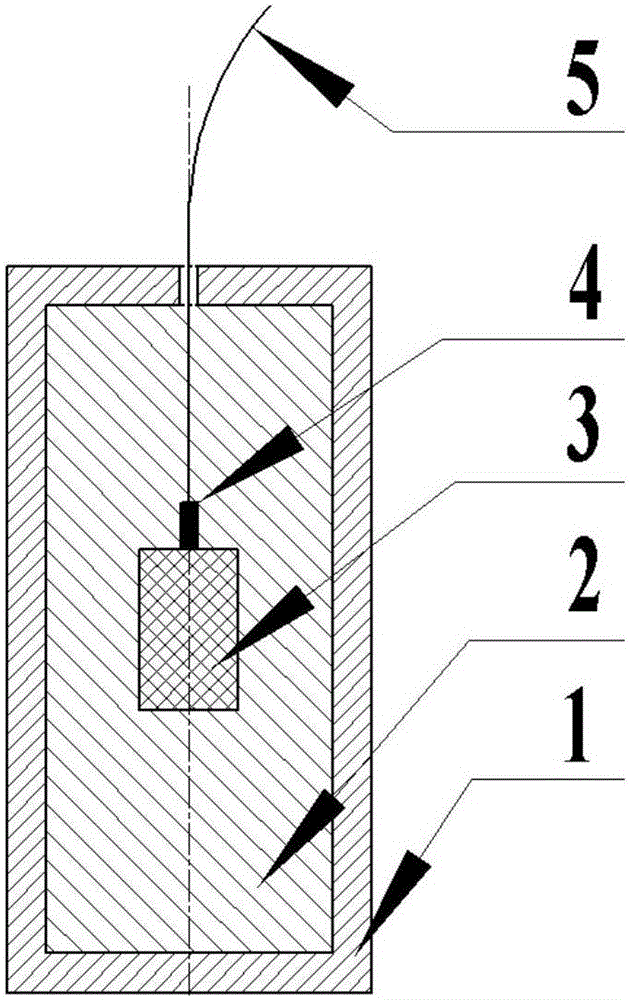

Gas drilling shaft bottom near-bit continuous impact focus nipple

The invention relates to a gas drilling shaft bottom near-bit continuous impact focus nipple, comprising a nipple body, a cylinder body, a piston (3) and a gas distribution device, wherein the cylinder body is arranged in a shell (1), the piston (3) is arranged in the cylinder body, a lower gas inlet passage (8) is formed between the cylinder body and the shell (1), a lower gas chamber (2) is formed between the lower end of the piston (3) and the inner wall of the shell (1), the lower gas inlet passage (8) is communicated with the lower gas chamber (2), an upper gas inlet passage (9) is formed at the bottom (7) of the cylinder body, an upper gas chamber (6) is formed between the upper end of the piston (3) and the cylinder body, the upper gas inlet passage (9) is communicated with the upper gas chamber (6), and the gas distribution device is arranged at the upper part of the cylinder body. According to the focus nipple, a focus in seismic exploration is applied to a shaft bottom near a bit, a focus linear (Chirp) scanning technology can be combined with a Mini-SOSIE technology, and the focus excites the ground to generate linear scanning pulse signals through a pulse coding technology, so that the excitation quality of seismic wave is improved.

Owner:SOUTHWEST PETROLEUM UNIV

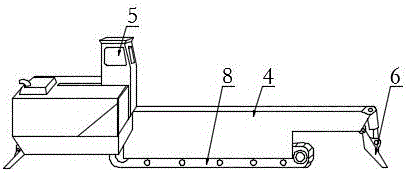

Rock breaking method

InactiveCN106285670AImprove rock breaking abilityRock Breaking Effect GuaranteedOpen-pit miningPropulsionGravity centerEnergy loss

The invention discloses a rock breaking method. The rock breaking method comprises the following steps that A, a rock breaking machine arranged in a rock breaking operation zone is driven or moved to a zone to be subjected to rock breaking, the rock breaking operation zone is made to be above the zone to be subjected, and the rock breaking operation zone of the rock breaking machine is a hollow zone which penetrates through a car body of the rock breaking machine and is perpendicular to the ground; B, a rock arm is operated, and a rock breaking part on the rock arm is controlled to act downwards in the rock breaking operation zone; and C, the rock breaking part of the rock arm breaks rocks in the rock breaking operation zone. The technical effects that the weight of the rock breaking machine can be fully utilized to improve the rock breaking effect of the rock arm in the rock breaking operation zone, and the rock arm is effectively made to conduct rock breaking operation around the gravity center and the nearest zone of the rock breaking machine; and meanwhile, on the premise that the rock breaking effect is ensured, arms with high weight do not need to be lifted, the energy loss of idle work can be reduced to minimum, and thus the rock breaking energy consumption is reduced.

Owner:凌夕珈

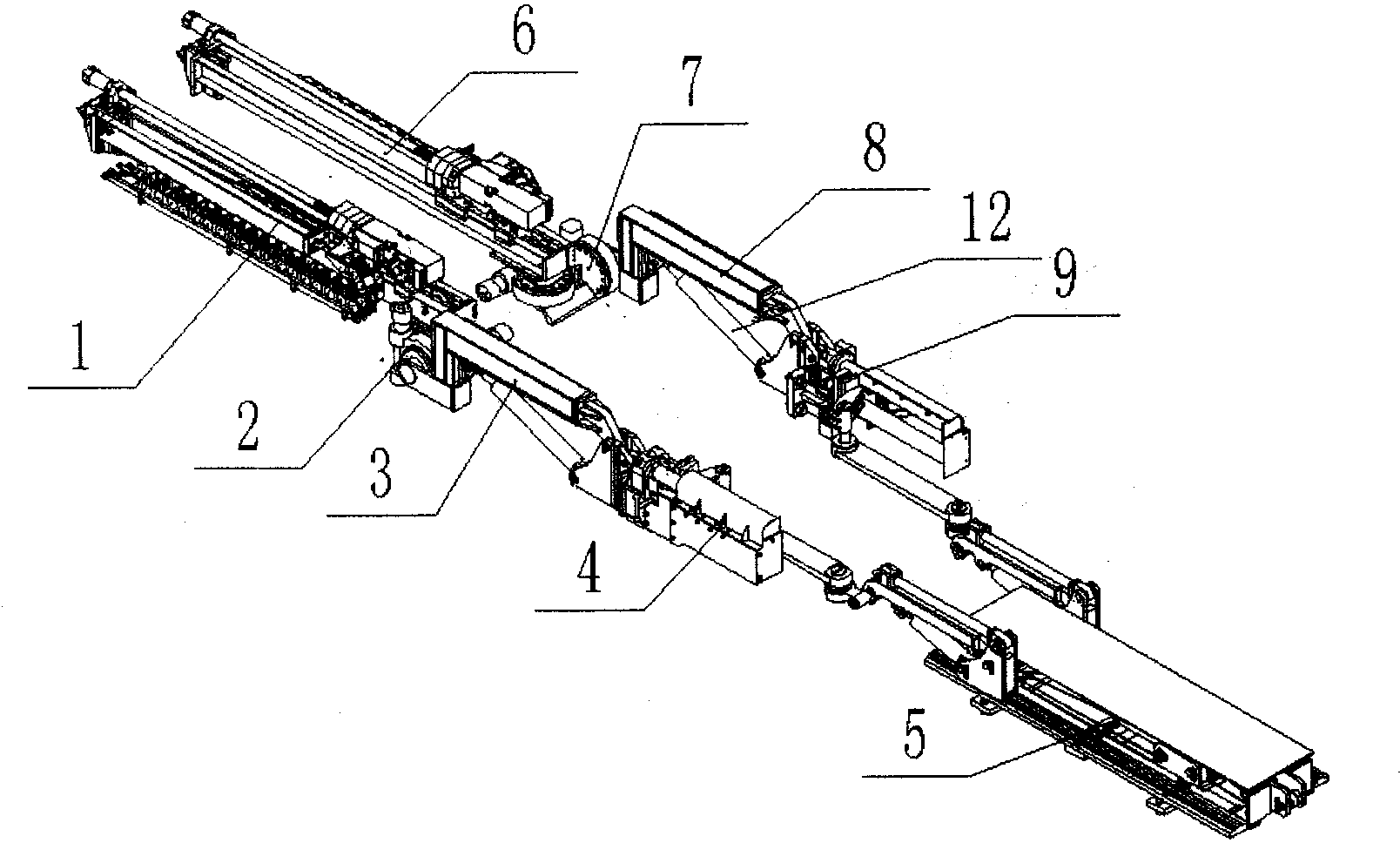

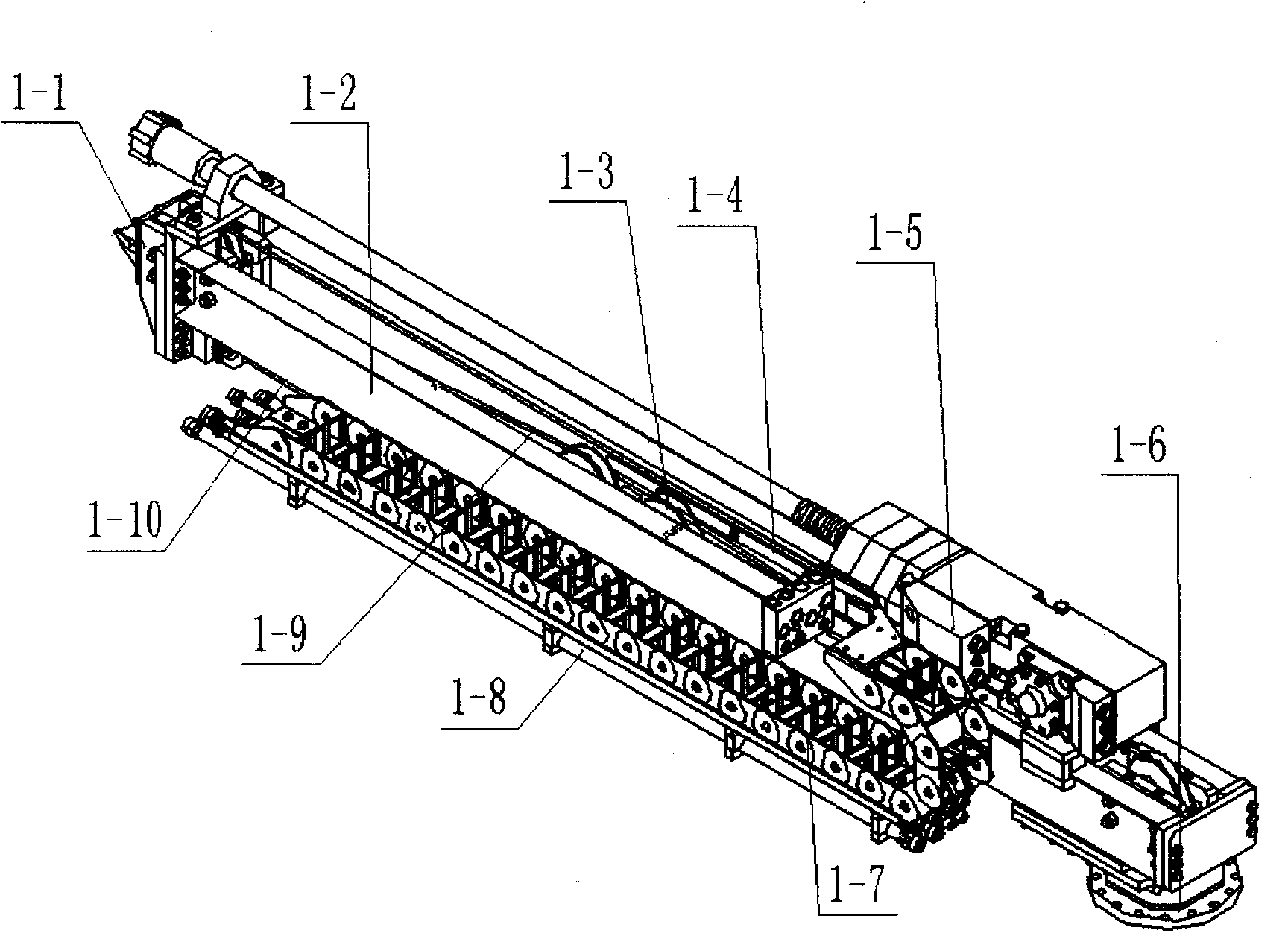

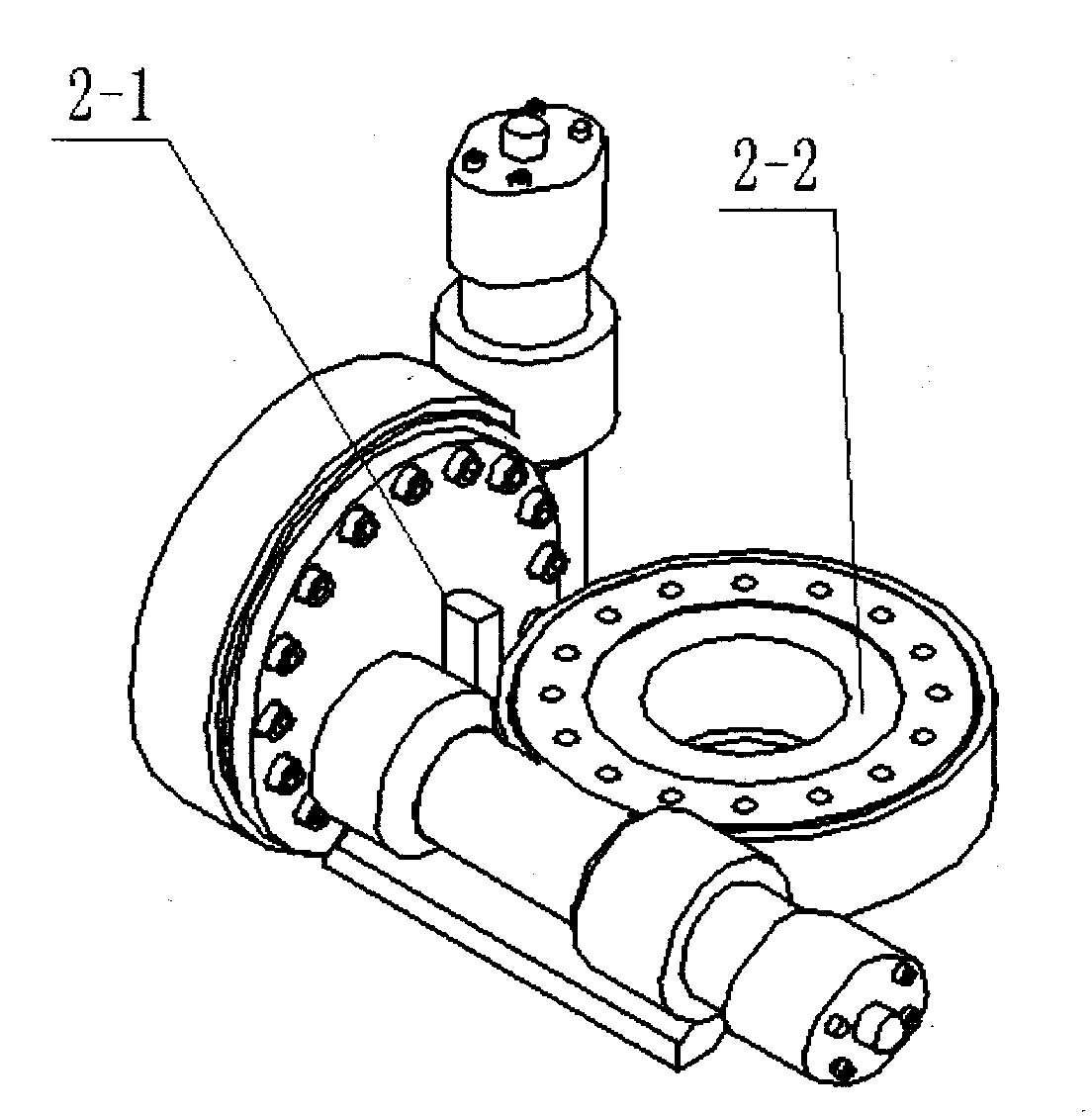

Combined drilling unit

InactiveCN103615246AStrong rock breaking abilityImprove work efficiencyDerricks/mastsSlitting machinesRock tunnelRock cutting

The invention discloses a combined drilling unit which works together with various existing tunneling machines. After a hard rock tunnel is regularly punched by using the combined drilling unit, the rock mechanical property is improved, then the tunneling operation is carried out, the hard rock operation application range of the tunneling machine is enlarged, and the hard rock tunnel operation is completed by medium-small machines; and meanwhile, the combined drilling unit can be quickly dismounted from the tunneling machine and share a hydraulic source with the tunneling machine. The combined drilling unit specifically comprises a left hydraulic drilling assembly, a right hydraulic drilling assembly and a main girder assembly. The combined drilling unit has the advantages of simple structure, simple manufacture, low cost, and multiple and reliable actions; the hydraulic drilling assemblies have two space position states of drilling and cutting, wherein the hydraulic drilling assemblies and the cutting part of the tunneling machine are fixed together for drilling position states; and under the action of the main girder assembly, the hydraulic drilling assemblies are folded up and are arranged at the upper part of the tunneling machine body in order to be in a cutting position state, so that the combined drilling unit is free of influencing the cutting operation of the tunneling machine.

Owner:LIAONING GENERAL MINING MACHINERY EQUIP MFG

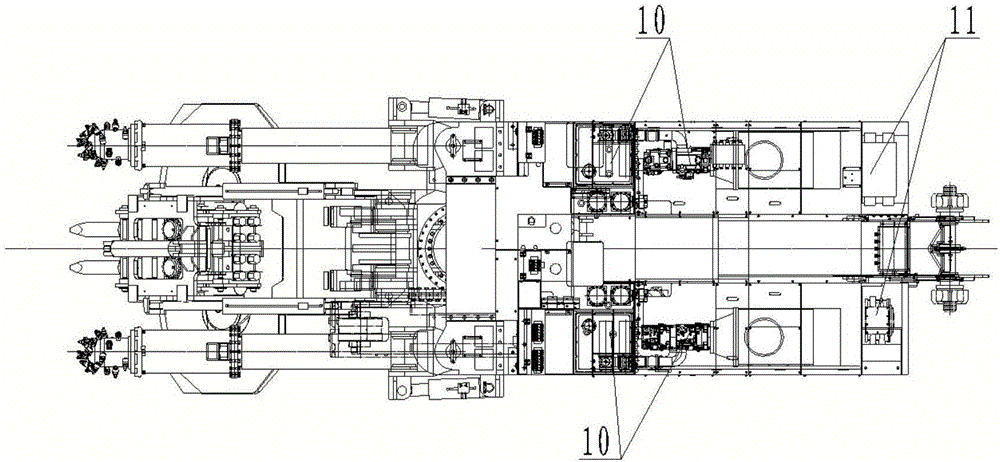

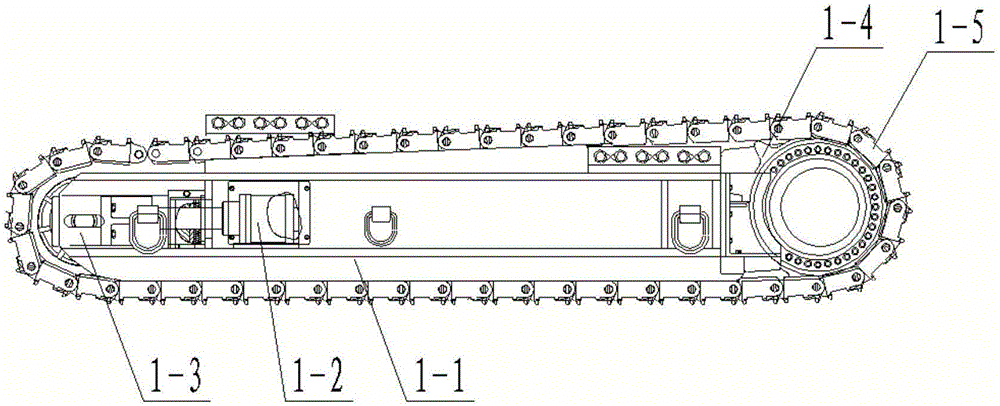

Efficient rapid rock drift tunneller

The invention belongs to the technical field of underground coal mine developing equipment, particular relates to an efficient rapid rock drift tunneller, and aims at solving the problems that rock drift tunnelling efficiency is low, rock drift forming is poor, the worker labor intensity is large, and many potential safety hazards exist. The efficient rapid rock drift tunneller comprises a walking part, an insertion board part, two cutting arms, a telescopic part, an engine body part, a control part, a guard board part, a conveying part, a rear support part, two hydraulic systems and electric systems; the walking part is arranged below the engine body part, the insertion board part is hinged to the front end of the engine body part, the telescopic part is arranged in the middle of the upper front portion of the engine body part, the cutting arms are symmetrically arranged on the left side and the right side of the upper front portion of the engine body, the conveying part is arranged in the middle of the engine body part, the rear support part is installed on the rear portion of the engine body, the hydraulic systems are symmetrically arranged on the left side and the right side of the middle of the engine body part, an operating part is installed above the engine body part, the guard board part is fixed on the two sides of the engine body part, and the electric systems are arranged on the two sides of the tail part of the engine body part.

Owner:SHANXI TIAN JU HEAVY IND

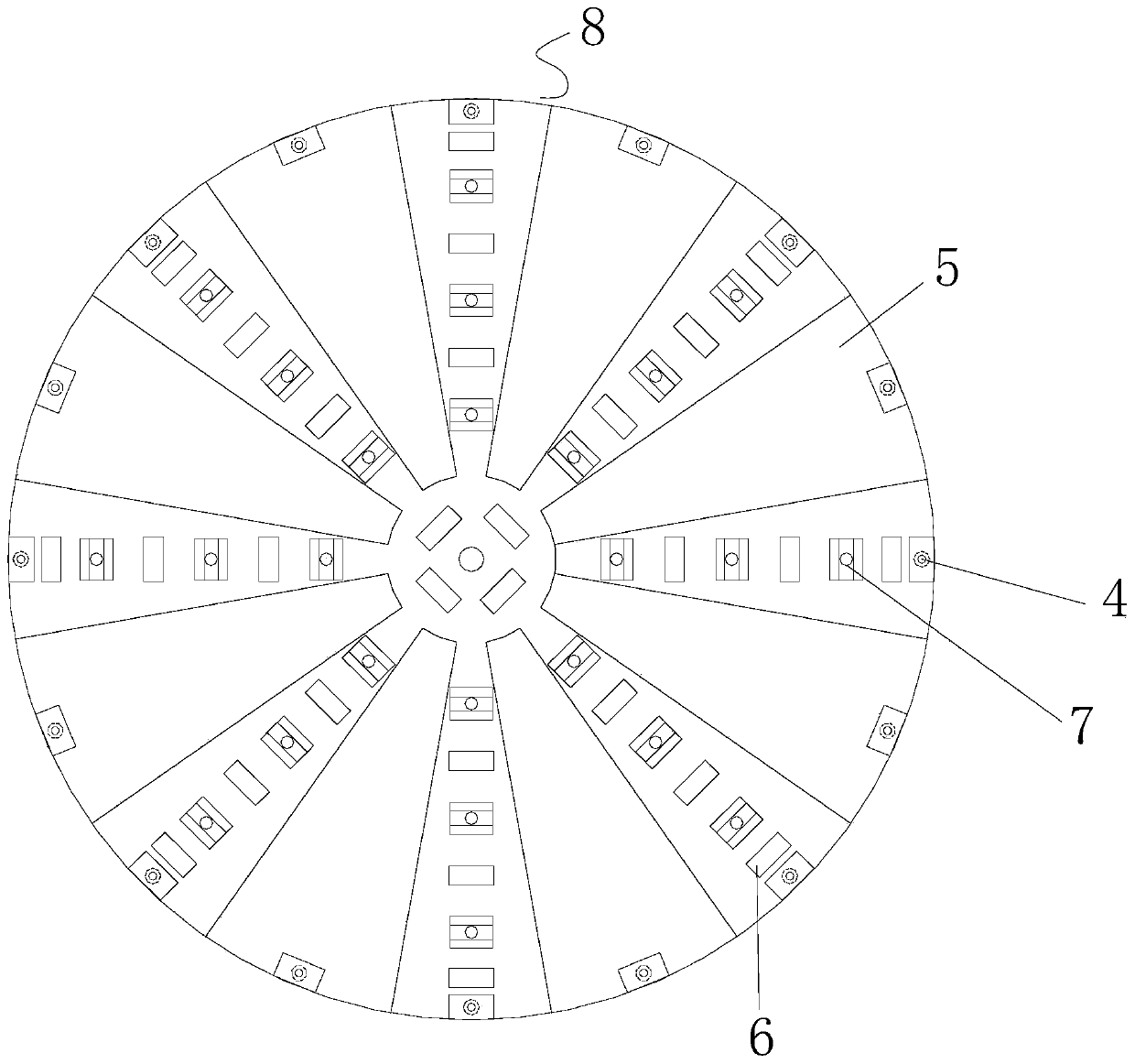

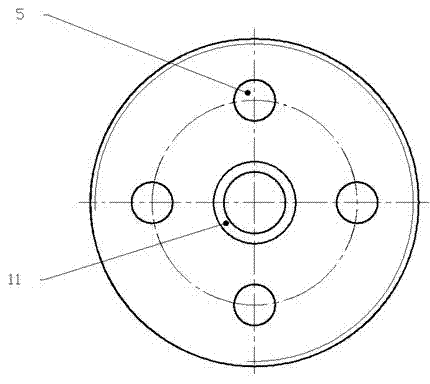

Composite bit formed by rotary cut bit and roller bit

ActiveCN102400646AExtended service lifeIncrease cutting forceDrill bitsConstructionsSpray nozzleEngineering

The invention discloses a composite bit formed by a rotary cut bit and a roller bit, comprising a main body (1), a rotary cut bit roller (2), a rotary cut bit cutting tooth (3), a roller bit roller (4), a roller bit cutting tooth (5), an oil storage bag (6) and a spray nozzle (7). The main body (1) of the bit comprises a roller axle journal, a straightening block, a high-pressure slurry channel and a connection thread. The composite bit formed by rotary cut bit and roller bit has the characteristics that: a composite bit cutting unit comprises the rotary cut bit and a roller bit cutting unit. When in a drilling process, the drilling of the central part of a borehole is completed by the rotary cut bit, and the drilling of the periphery of the borehole is completed by the roller bit. The rotary cut bit in the composite bit impacts, presses and cuts the rock in a rotary cutting way, has high central rock breaking efficiency and mechanical drilling speed, has better mechanical properties, wears uniformly, simultaneously improves a bearing structure of the bit, ensures to improve the rock breaking efficiency and prolong the service life of the bit, and has good diameter keeping effect. Different composite structures in the composite bit can achieve the effects of high rock breaking performance and high mechanical drilling speed.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

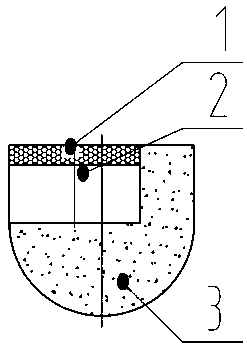

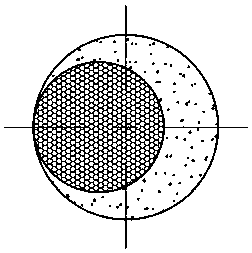

PDC and diamond-impregnated composite block

The invention discloses a PDC and diamond-impregnated composite block, which is composed of a polycrystalline diamond layer, a hard alloy layer and a diamond-impregnated layer. The polycrystalline diamond layer takes diamond micro-powder as a skeleton and cobalt and silicon as an adhesive; and the diamond-impregnated layer is formed by being subjected to hot-pressed sintering or cold-pressed sintering by adopting tungsten carbide, or a combination of the tungsten carbide and one or more of silicon carbide or silicon nitride or titanium carbide as a skeleton, nickel, silicon, chromium, copper,tin, iron, cobalt, zinc, phosphorus and rare earth elements as an adhesive, and diamond monocrystals as a cutting element. Practice proves that the PDC and diamond-impregnated composite block is usedfor a diamond drill bit, the mechanical drill speed and footage of the diamond drill bit are greatly increased, the labor intensity of workers is lowered, then the drilling cost is lowered, and the exploration and development speed of oil and gas fields and mines is increased.

Owner:中石化石油工程技术服务有限公司 +2

Self-advancing type high-pressure jet sprayer for radial horizontal well drilling

ActiveCN102518398AUniform mass distributionWith rotating jetLiquid/gas jet drillingHigh pressureAerospace engineering

The invention relates to a self-advancing type high-pressure jet sprayer for radial horizontal well drilling, which mainly comprises a shell, a turbine rotor, wear-resistant steel balls, a baffle plate and the like. The self-advancing type high-pressure jet sprayer is technically characterized in that a tip, a forward spray nozzle and a backward spray nozzle are processed on the shell, hard alloy is welded on the outer surface of the shell, the turbine rotor is mounted in the shell, spherical grooves are processed at the upper end and the lower end of the turbine rotor, the turbine rotor is positioned via the upper wear-resistant steel ball and the lower wear-resistant steel ball, the upper wear-resistant steel ball is placed between the inside of the shell and the corresponding spherical groove of the turbine rotor, the lower wear-resistant steel ball is placed between the turbine rotor and a spherical groove on the baffle plate, the shell is connected with the baffle plate in a threaded manner, and four to six water injection holes are uniformly distributed on the baffle plate. The self-advancing type high-pressure jet sprayer is simple in structure and reliable in work, and can be widely applied to radial horizontal well drilling operation.

Owner:SOUTHWEST PETROLEUM UNIV

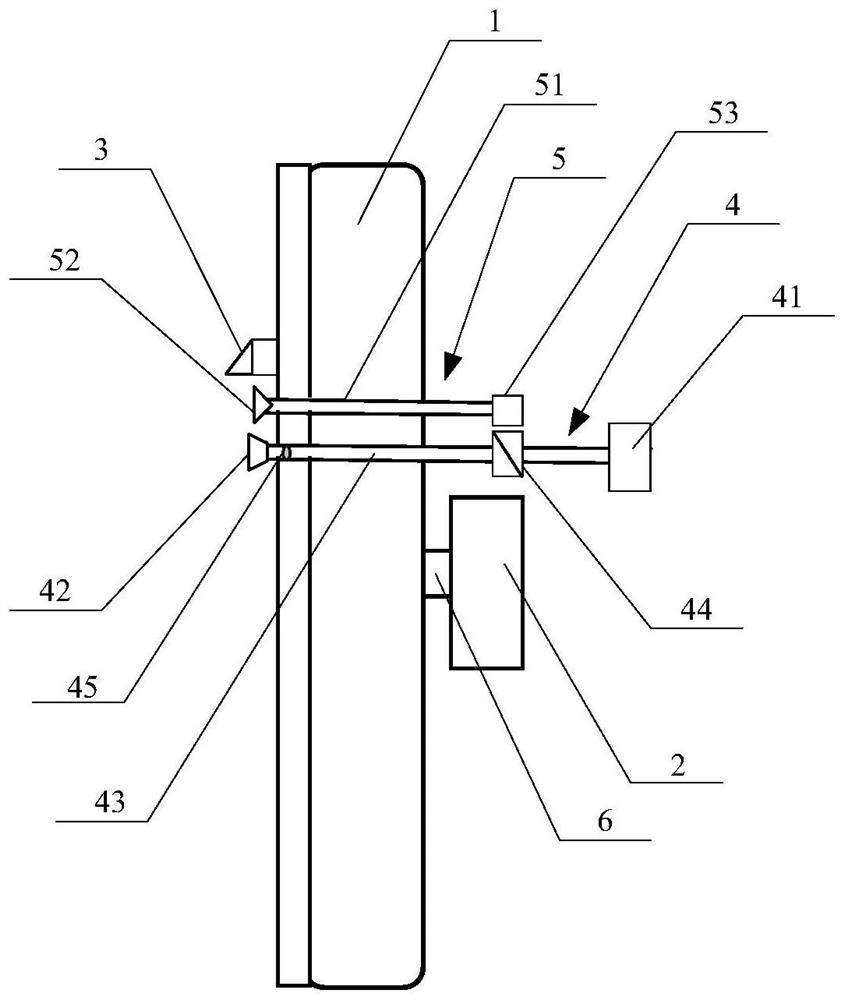

Ultra-short type continuous advancing tunneling machine and continuous tunneling method

ActiveCN111456747ARealize continuous operationShorten the lengthTunnelsProcess engineeringRoadheader

The invention discloses an ultra-short type continuous advancing tunneling machine and a continuous tunneling method and solves the problem about low construction efficiency of short-distance excavation in the prior art. The ultra-short type continuous advancing tunneling machine comprises a shield body and a muck conveyor; a main drive is arranged inside the shield body; the front end of the maindrive is connected with a cutter head; the outer wall of the main drive is provided with a plurality of shoe support units in the circumferential direction; and the shoe support units are connected with the shield body through linkable advancing mechanisms. The ultra-short type continuous advancing tunneling machine disclosed by the invention has the functions such as excavation, advancing and muck discharging; advancing systems are symmetrically arranged at the outer side of the drive; the length of the overall machine is shortened; the length of the overall machine is about 5 m; and the ultra-short type continuous advancing tunneling machine is compact in structure and convenient and quick to assemble and disassemble. Two groups of advancing mechanisms implement linked action; when onegroup is implementing the advancing operation, the other group synchronously implements restoration, thus shutdown caused by asynchronization is prevented; continuous operation of the tunneling machine can be realized; and high tunneling efficiency is achieved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Hard rock tunneling device and hard rock tunneling method

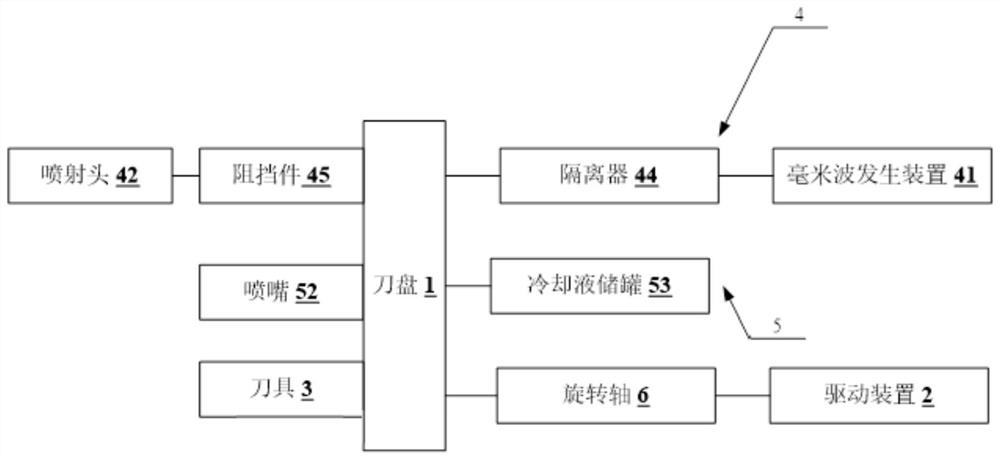

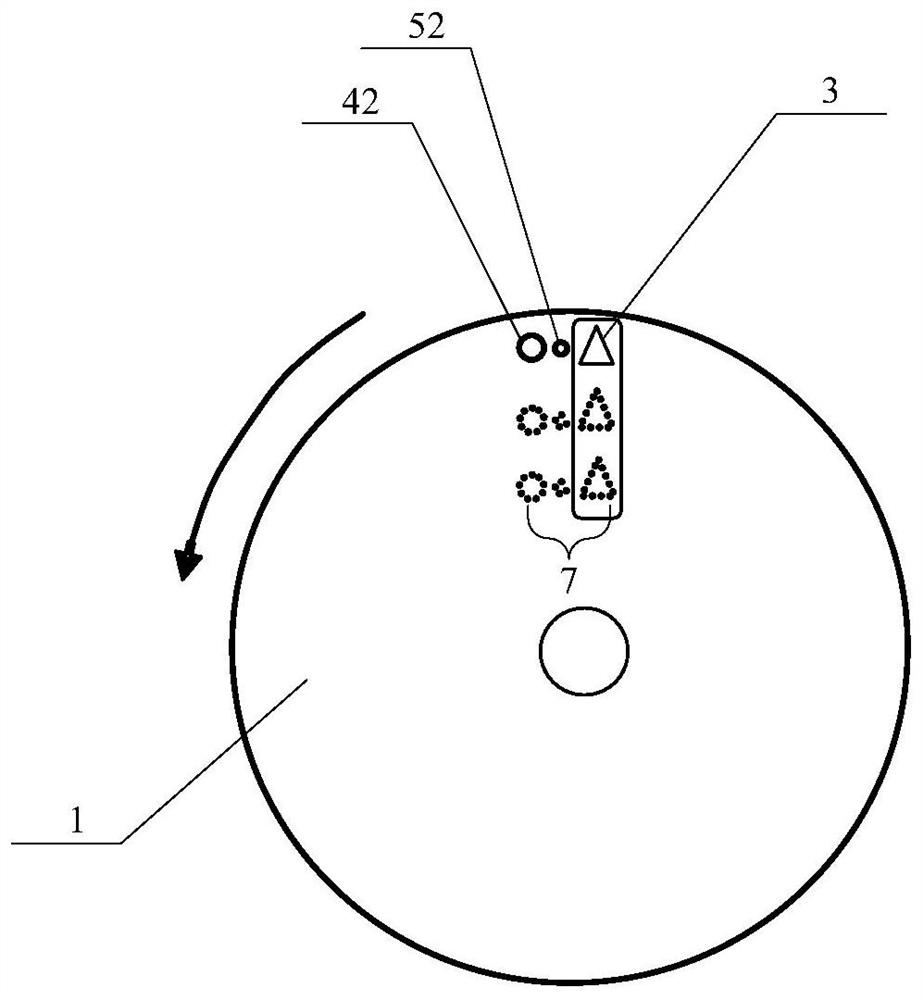

The invention provides a hard rock tunneling device and a hard rock tunneling method. The hard rock tunneling device comprises a cutter head, a driving device, a cutter, and an auxiliary mechanism; the driving device is arranged on a first surface of the cutter head and is used for driving the cutter head to rotate; the cutter is arranged on the second surface, opposite to the first surface, of the cutter head and is used for cutting rocks; and the auxiliary mechanism is arranged on the cutter head and used for assisting the cutter in cutting the rocks. According to the hard rock tunneling device and the hard rock tunneling method, the auxiliary mechanism assists the cutter in cutting the rocks, so that the rocks can be effectively cut, the rock breaking capacity of the hard rock tunnelingdevice is improved, the loss of the cutter is avoided, the service life of the cutter is prolonged, the replacement frequency of the cutter is reduced, the rock breaking efficiency and the construction efficiency are greatly improved, especially for high-strength rocks, and the rocks can be cut more efficiently.

Owner:ENN SCI & TECH DEV

Anchor rod end cavity enlarging device and construction method thereof

InactiveCN105863694AQuick plugContact stabilityDrill bitsAnchoring boltsStructural engineeringEnlarger

The invention discloses an anchor rod end cavity enlarging device and a construction method thereof and belongs to the field of machines. The anchor rod end cavity enlarging device comprises a head cavity enlarger, a middle rod body, a casing pipe and a middle converter. The middle rod body is connected with the head cavity enlarger and the middle converter in a welded manner. The casing pipe is connected with the head cavity enlarger and the middle rod body through threads. The size of the anchoring end of an anchor rod is expanded in the horizontal direction through the anchor rod end cavity enlarging device, so that the suspending capacity of the anchoring end is effectively improved. A whole set of construction method for using the anchor rod for grouting to reinforce surrounding rock is designed in cooperation with the anchor rod end cavity enlarging device, the supporting capacity for dealing with the soft surrounding rock is effectively improved, and finally safety and stability of underground engineering are guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

Drilling bit spiral impact device

InactiveCN104863497AImprove rock breaking abilityEasy to disassembleBorehole drivesEngineeringCoring

The invention provides a drilling bit spiral impact device which comprises an outer casing pipe, an impact hammer and a lower connector which are mounted in the outer casing pipe in sequence in the vertical direction; a power input shaft is arranged at the center of the impact hammer; the power input shaft is movably connected with the impact hammer and drives the impact hammer to rotate; the impact hammer is connected with the outer casing pipe through a guide mechanism; the impact hammer moves up and down along the power input shaft under the action of the guide mechanism; the guide mechanism comprises a saw-toothed ring groove which is formed by spiral line grooves and vertical grooves which are alternatively formed and two or more guide blocks positioned in the saw-toothed ring groove; the spiral line grooves and the vertical grooves are identical in number and are mutually communicated; the guide blocks are uniformly distributed on the inner wall of the outer casing pipe and the saw-toothed ring groove is formed in the side surface of the impact hammer. The drilling bit spiral impact device does not need quick-wear parts like springs, is simple in structure, convenient to maintain, low in cost, suitable for coring of hole sections of various depths and not influenced by hole depth and pressure change of a water column, and can improve the rock breaking effect and improve the roundtrip meterage length.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

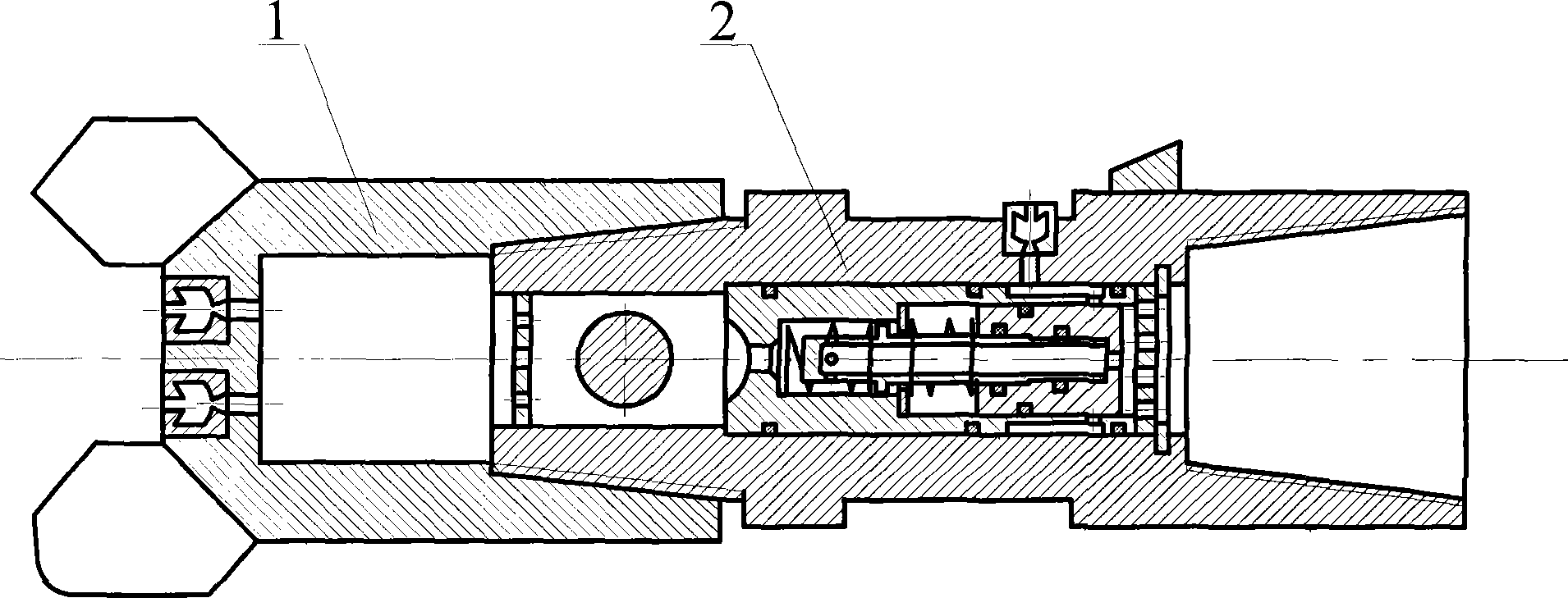

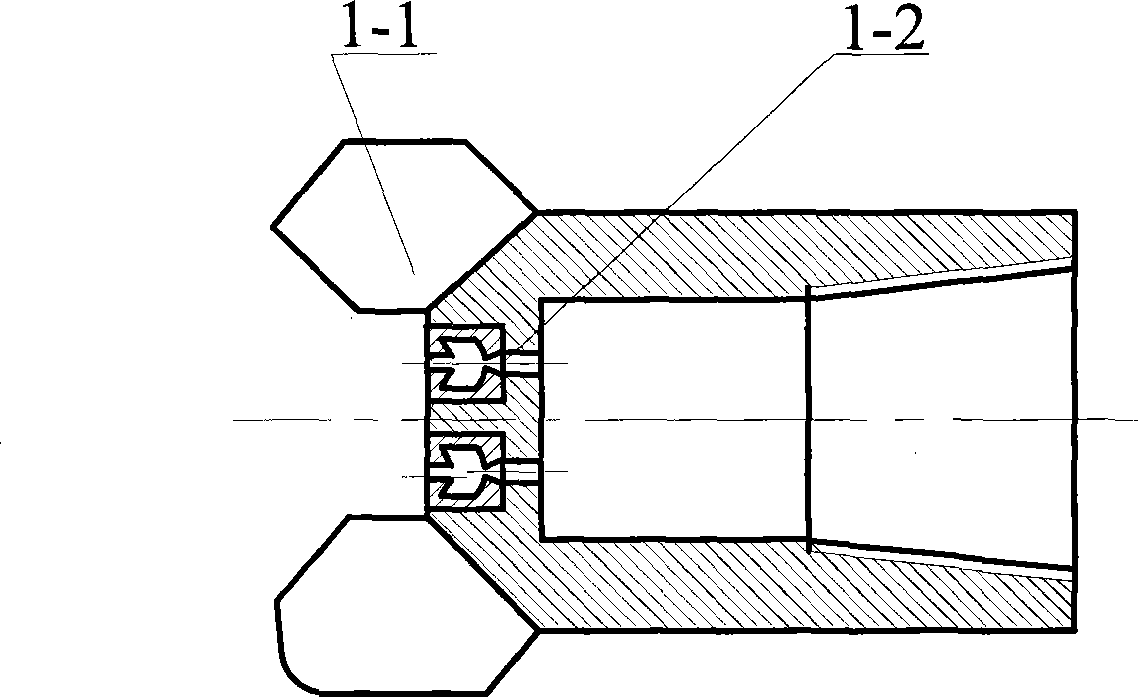

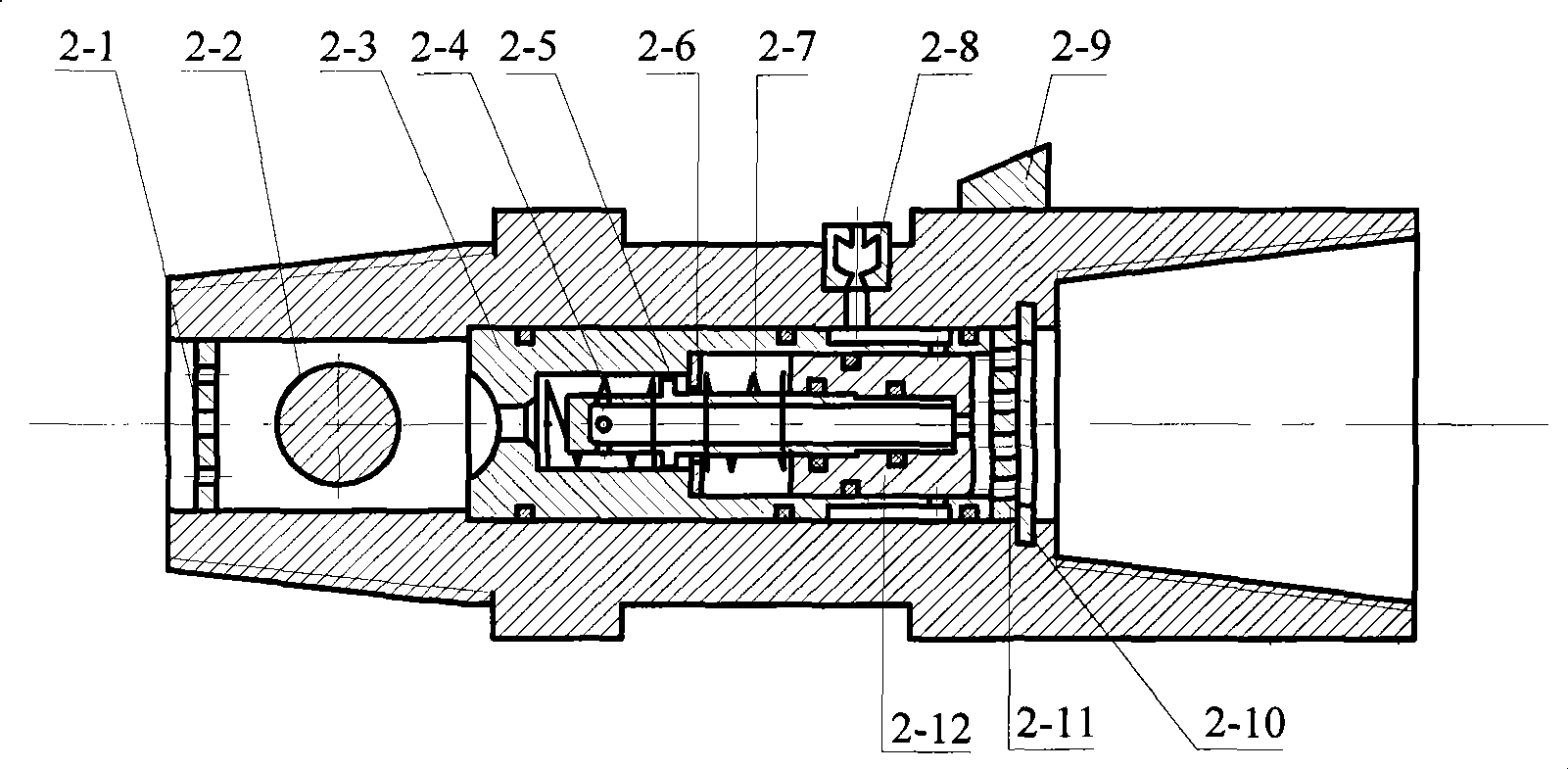

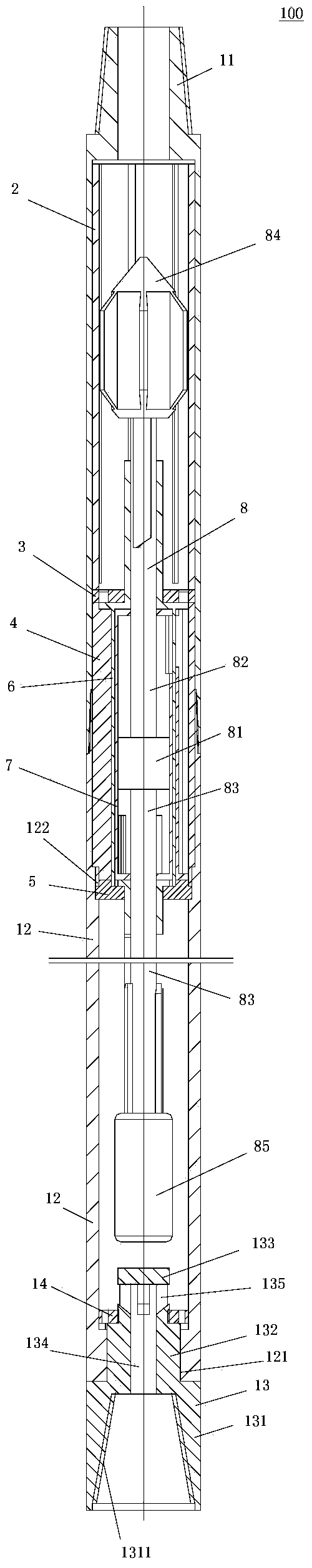

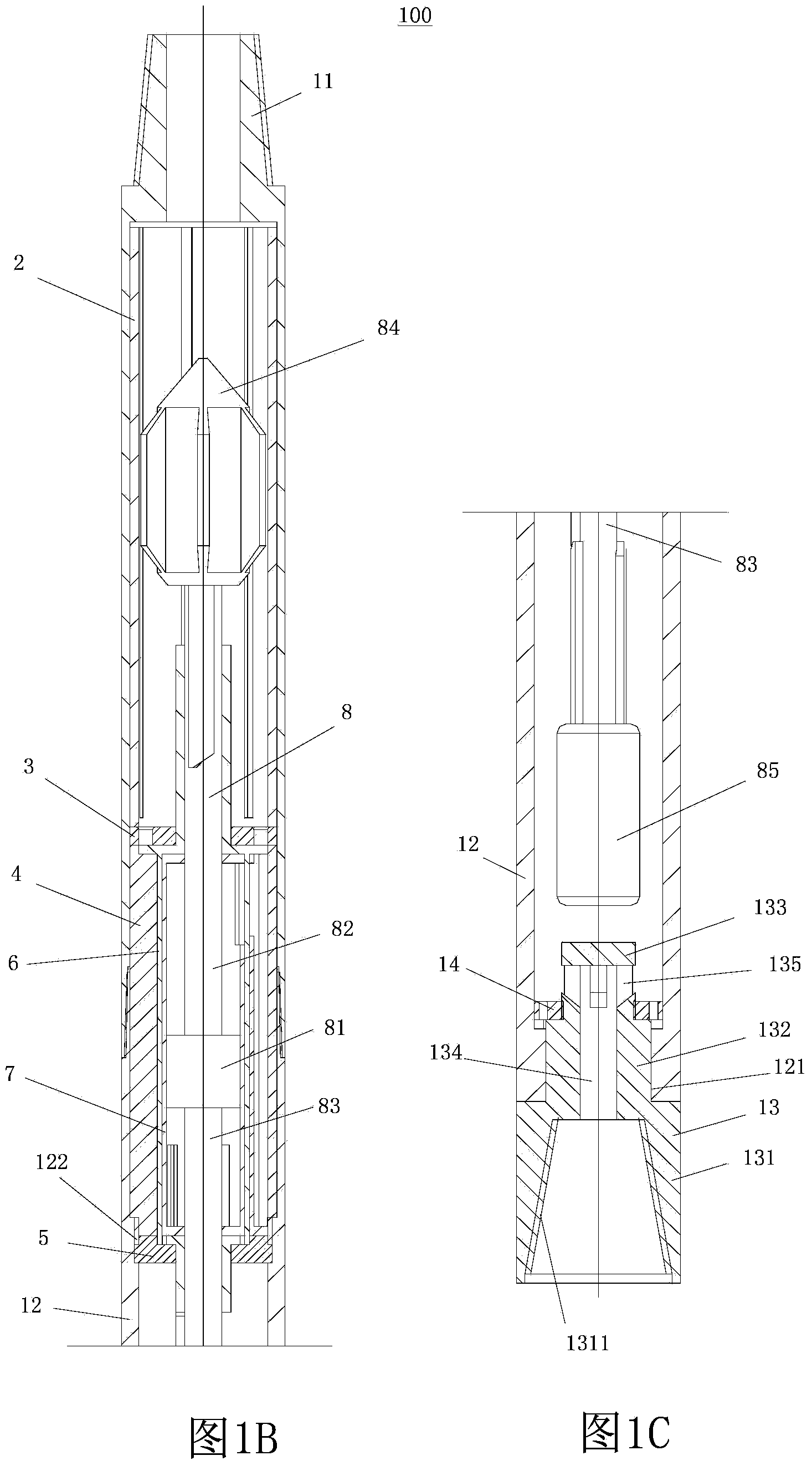

Self-propelled jet drill bit forradial horizontal well

PendingCN110500041AIncreased rotational shear forceImprove rock breaking abilityDrill bitsDrilling rodsWell drillingPlain bearing

The invention relates to a self-propelled jet drill bit for a radial horizontal well.The self-propelled jet drill bit mainly comprises a drill bit, a rotating shaft, a shell, a turbine stator, a turbine rotor, a rear nipple, a centralizer and a rear connecting pipe,the shell is internally provided with a turbine system, the shell is placed in the middle of the drill bit and the centralizer, the front part of the shell is connected with the drill bit through the rotating shaft, the rear part of the shell is connected with the centralizer through the rear connecting pipe, the turbine rotor is tightly fixed on the rotating shaft through a rotor nut and flat keys, the rear part of the rotating shaft is connected with the rear nipple through a sliding bearing sleeve, and the centralizer and therear connecting pipe are sleeved in a spaced mode. The turbine system transmits torque to the rotating shaft through the flat keys, the drill bit is driven by the rotating shaft to rotate to form drilling bit rotating jet drilling, the rock breaking ability and drilling efficiency are improved, and the rotary bit plays the role of modifying the well wall; fluid through the turbine system is ejected from a rear jet hole on the shell to generate self-propelled force, and s the jet drill bit is pushed forward to operate; and the centralizer plays the role ofcentralizer of the rear connecting pipe to prevent counter torque, and frictional resistance in the process of drilling is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

Explosion-method quick hole-blocking device

ActiveCN105043180AIncrease profitImprove rock breaking abilityBlastingBlock effectMechanical engineering

The invention relates to an explosion-method quick hole-blocking device. The explosion-method quick hole-blocking device comprises a hole-blocking housing and hole-blocking explosive package, wherein the hole-blocking housing is in the shape of a barrel; the hole-blocking explosive package is positioned in the housing, positioned at the axis of the housing and positioned on the middle position of the housing; and a hole-blocking material is filled between the hole-blocking explosive package and the inner wall of the housing, so that the hole-blocking explosive package is conveniently positioned in the housing. The explosion-method quick hole-blocking device has the advantages of being simple and convenient to use, and good in sealing and blocking effect, can effectively reduce the sealing and blocking length, can improve blast hole utilization efficiency and can improve rock breaking effect, and is suitable for various blast hole blocking requirements.

Owner:UNIV OF SCI & TECH OF CHINA +1

Hydraulic drive percussion drilling tool

The invention discloses a hydraulic drive percussion drilling tool. A cylinder composed of an upper short section and a connection short section is internally, sequentially and fixedly provided with a guiding sleeve, an upper end cover, a guide cylinder and a lower end cover from top to bottom. A diverter is arranged in the guide cylinder in a swinging mode, and a cylinder body is arranged in the diverter. A punch hammer assembly is arranged in the cylinder composed of the upper short section and the connection short section in a sliding mode and comprises a piston, an upper piston rod and a lower piston rod, wherein the piston is arranged in the cylinder body in a sliding mode and the piston comprises the upper piston rod and the lower piston rod. A drill seat is circumferentially and fixedly arranged at the bottom end of the connection short section in a hanging mode, and a first cam mechanism is arranged between the upper piston rod and the diverter. A second cam mechanism is arranged between the lower piston rod and the diverter. Liquid flow distribution channels communicated with the cylinder body are formed in the guide cylinder and the cylinder body, and flow distribution holes communicated with the corresponding flow distribution channels are formed in the diverter. The flowing direction of fluid entering the cylinder body changes intermittently due to forward swinging and reverse swinging of the diverter, and therefore the punch hammer assembly is driven to move in a reciprocating mode from top to bottom. According to the hydraulic drive percussion drilling tool, the reversing stability of a punch hammer can be improved, the service life is prolonged, and the rock breaking effect and working efficiency are improved.

Owner:BEIJING INFORMATION SCI & TECH UNIV +1

High-pressure hydraulic-assisted tunneling cutter disc for soil pressure balance shield machine

PendingCN110529134AImprove rock breaking abilitySimple processing methodTunnelsWater sourceHigh pressure water

The invention discloses a high-pressure hydraulic-assisted tunneling cutter disc for a soil pressure balance shield machine. The high-pressure hydraulic-assisted tunneling cutter disc comprises a shield machine cutter disc body, a plurality of high-pressure hydraulic spraying nozzles are arranged on a disc working surface, the diameters of the high-pressure hydraulic spraying nozzles are 0.3mm-1.0mm, the water jet pressure of high-pressure water is 1.5-2.0 times of a rock saturation compressive strength value, the linear velocity of the high-pressure hydraulic spraying nozzles rotating along with the cutter disc in work is 0.2-1.0 m / s, and the water jet speed of the high-pressure hydraulic spraying nozzles is 400-1000 m / s; a water supply rotating joint for communicating with an external water source and a high-pressure hydraulic spraying nozzle fixing frame are arranged on the back surface of the cutter disc, and the water supply rotating joint is located in the rotating center of thecutter disc; the rotating joint communicates with a high-pressure water generating device through a high-pressure pipeline, and the high-pressure water generating device is arranged on a follow-up device of the shield machine, and is composed of a filter, an additional plug piston pump, a voltage stabilizer, a power motor and a control system. The high-pressure hydraulic-assisted tunneling cutterdisc has the advantage that the rock breaking capacity on boulders of the cutter disc of the soil pressure balance shield machine is effectively improved.

Owner:YELLOW RIVER ENG CONSULTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com