TBM disc cutter with grooved cutter ring outer circumference

A technology of outer circumference and cutter ring, which is used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of low hard rock breaking efficiency and low tensile stress, and achieves improved rock breaking efficiency, increased tensile stress, and easy expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

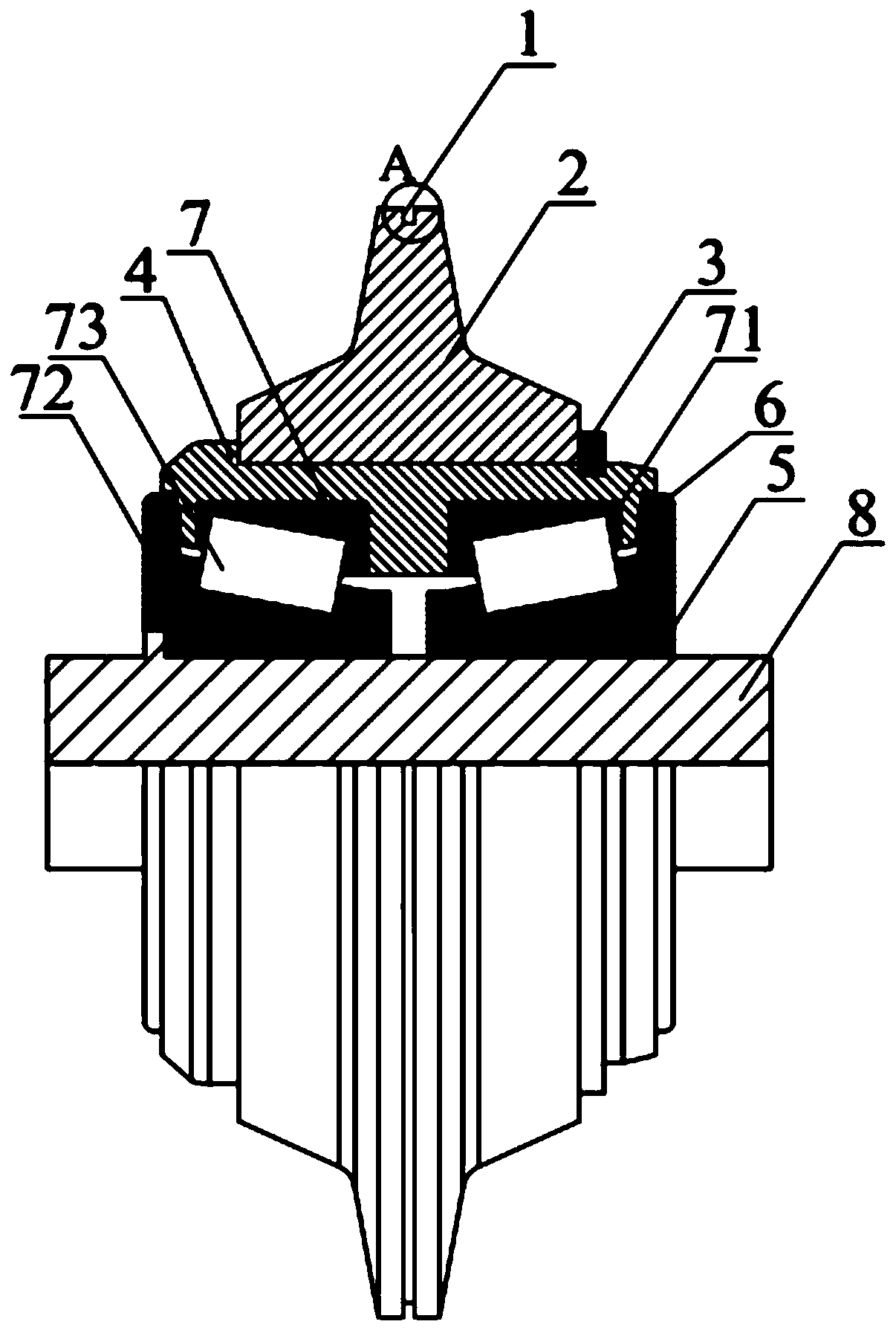

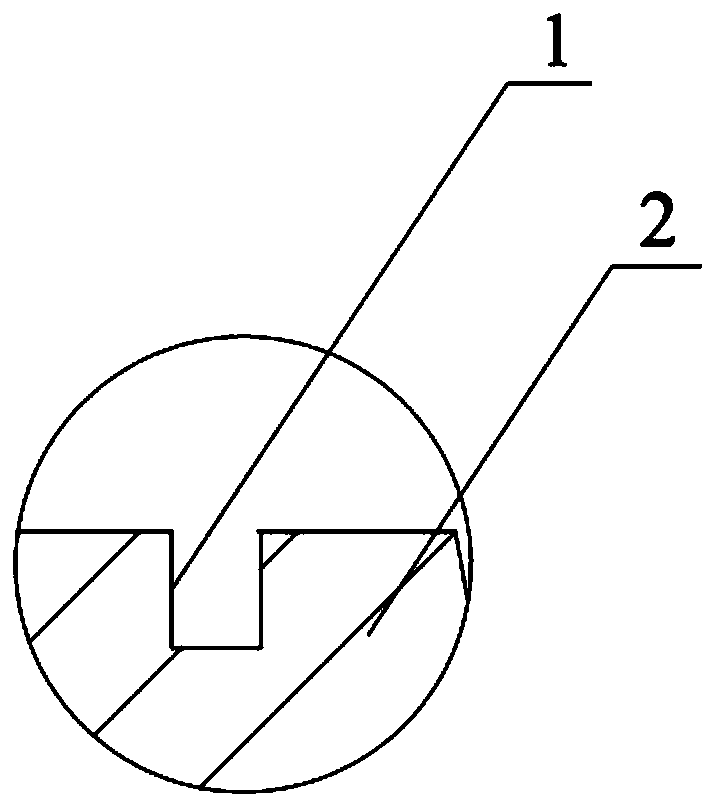

[0036] Please refer to figure 1 , this embodiment provides a TBM disc hob with grooves on the outer circumference of the cutter ring, which uses the structure of a new rock-breaking hob cutter ring, which includes: a cutter ring 2, a cutter body 4, a retaining ring 3, and a bearing 7 , rigid mandrel 8, bearing end cover 5 and sealing ring 6, wherein, cutter body 4, retaining ring 3, bearing 7, rigid mandrel 8, bearing end cover 5 and sealing ring 6 are standard parts; The ring 3 is fixed on the cutter body 4, the cutter body 4 is internally connected to the bearing 7, the bearing end cover 5 and the sealing ring 6 seal and fix the bearing 7 on the rigid mandrel 8; the cutter body 4, the bearing 7 and the bearing end cover 5 are assembled on the shaft Above, a sealing ring 6 is used between the cutter body 4 and the bearing end cover 5 to seal the internal oil liquid. There is a step outside the cutter body 4 for positioning the cutter ring 2. Therefore, there is a The card sl...

no. 2 example

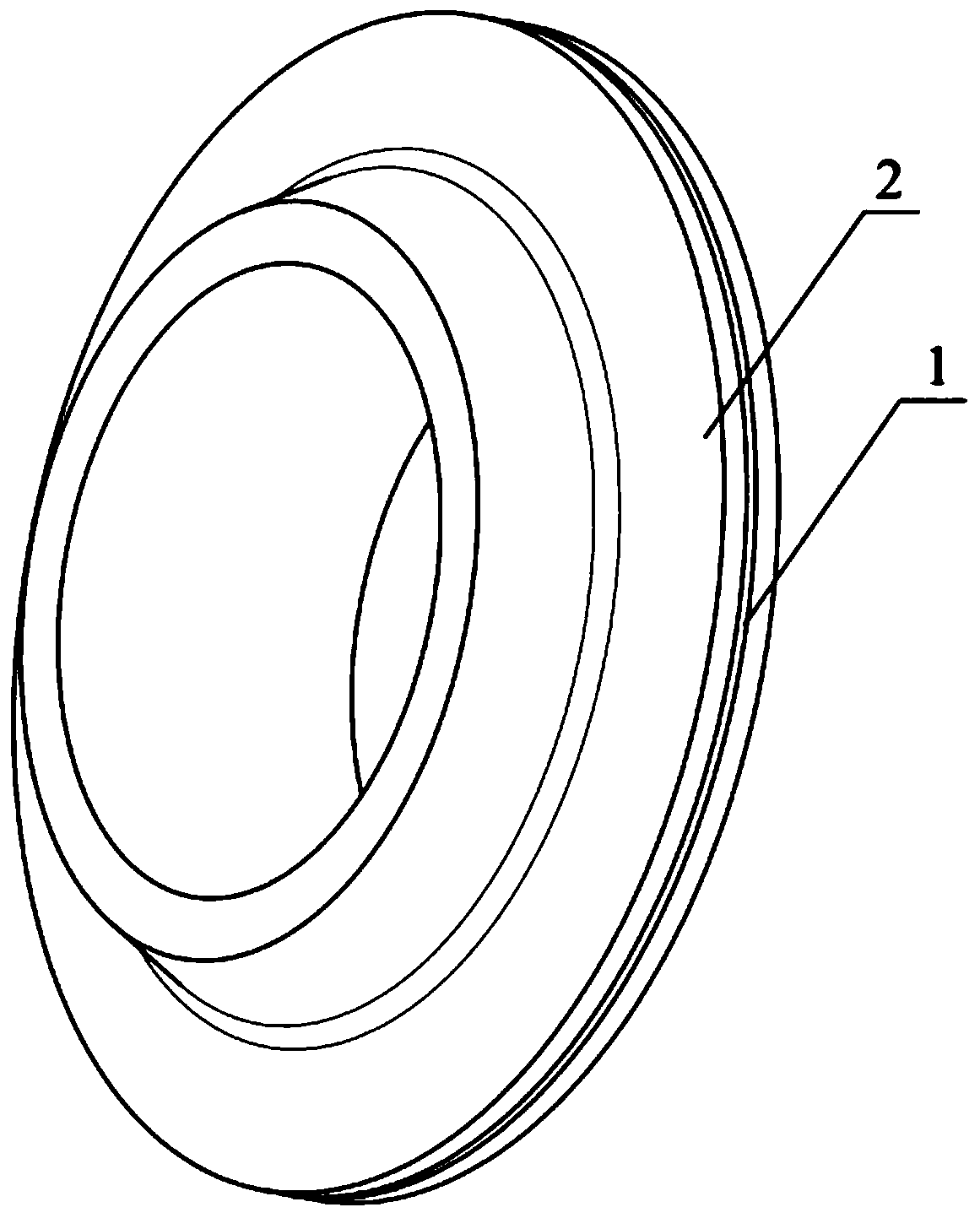

[0041] The difference between the second embodiment and the first embodiment lies in the arrangement of the outer peripheral surface of the cutter ring 2 .

[0042] Please refer to Figure 5 , this embodiment provides a TBM disc hob with grooves on the outer circumference of the cutter ring, which uses the structure of a new rock-breaking hob cutter ring, which includes: a cutter ring 2, a cutter body 4, a retaining ring 3, and a bearing 7 , rigid mandrel 8, bearing end cover 5 and sealing ring 6, wherein, cutter body 4, retaining ring 3, bearing 7, rigid mandrel 8, bearing end cover 5 and sealing ring 6 are standard parts; The ring 3 is fixed on the cutter body 4, the cutter body 4 is internally connected to the bearing 7, the bearing end cover 5 and the sealing ring 6 seal and fix the bearing 7 on the rigid mandrel 8; the cutter body 4, the bearing 7 and the bearing end cover 5 are assembled on the shaft Above, a sealing ring 6 is used between the cutter body 4 and the bear...

no. 3 example

[0045] The difference between the third embodiment and the first embodiment lies in the arrangement of the outer peripheral surface of the cutter ring 2 .

[0046] Please refer to Figure 6 , this embodiment provides a TBM disc hob with grooves on the outer circumference of the cutter ring, which uses the structure of a new rock-breaking hob cutter ring, which includes: a cutter ring 2, a cutter body 4, a retaining ring 3, and a bearing 7 , rigid mandrel 8, bearing end cover 5 and sealing ring 6, wherein, cutter body 4, retaining ring 3, bearing 7, rigid mandrel 8, bearing end cover 5 and sealing ring 6 are standard parts; The ring 3 is fixed on the cutter body 4, the cutter body 4 is internally connected to the bearing 7, the bearing end cover 5 and the sealing ring 6 seal and fix the bearing 7 on the rigid mandrel 8; the cutter body 4, the bearing 7 and the bearing end cover 5 are assembled on the shaft Above, a sealing ring 6 is used between the cutter body 4 and the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com