Patents

Literature

42results about How to "Change stress distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

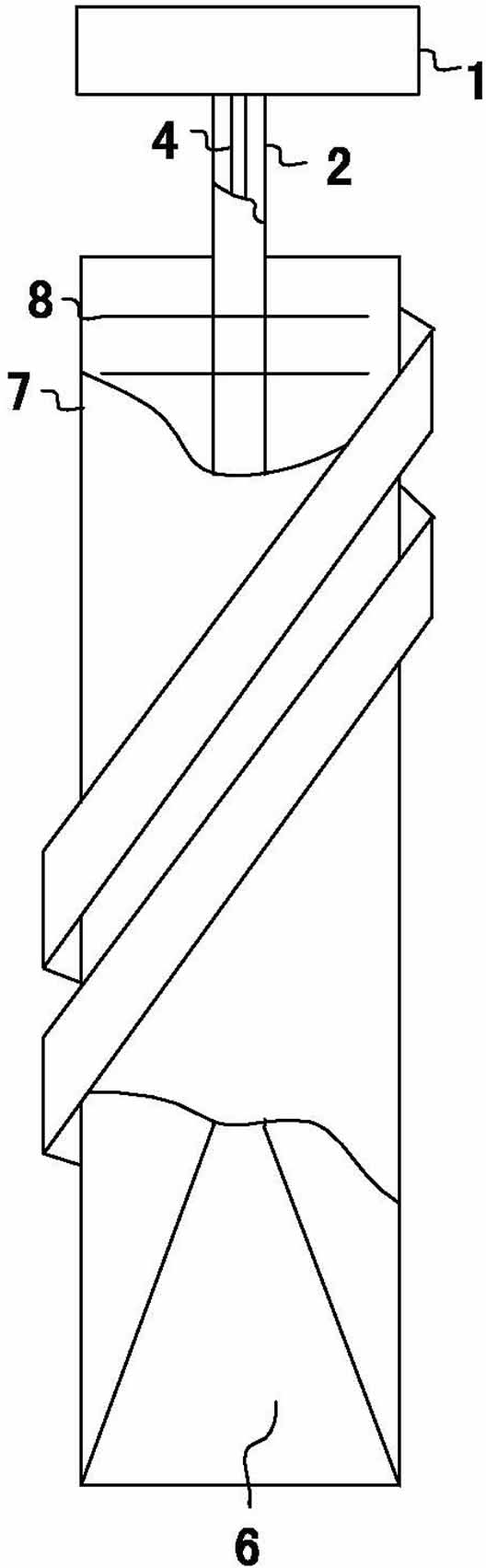

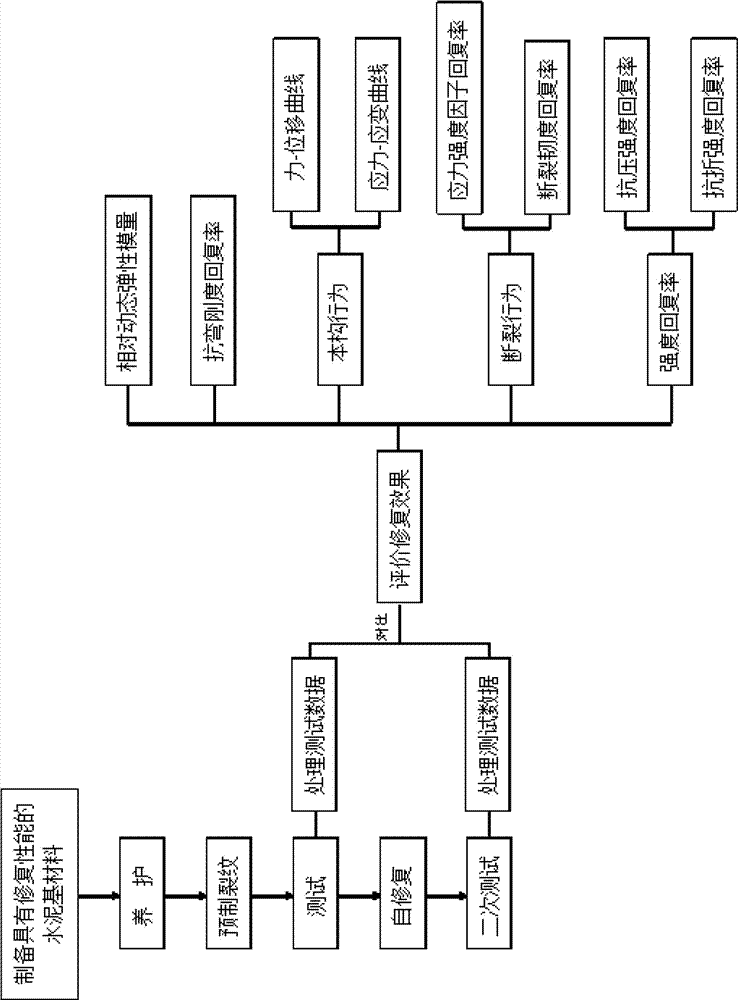

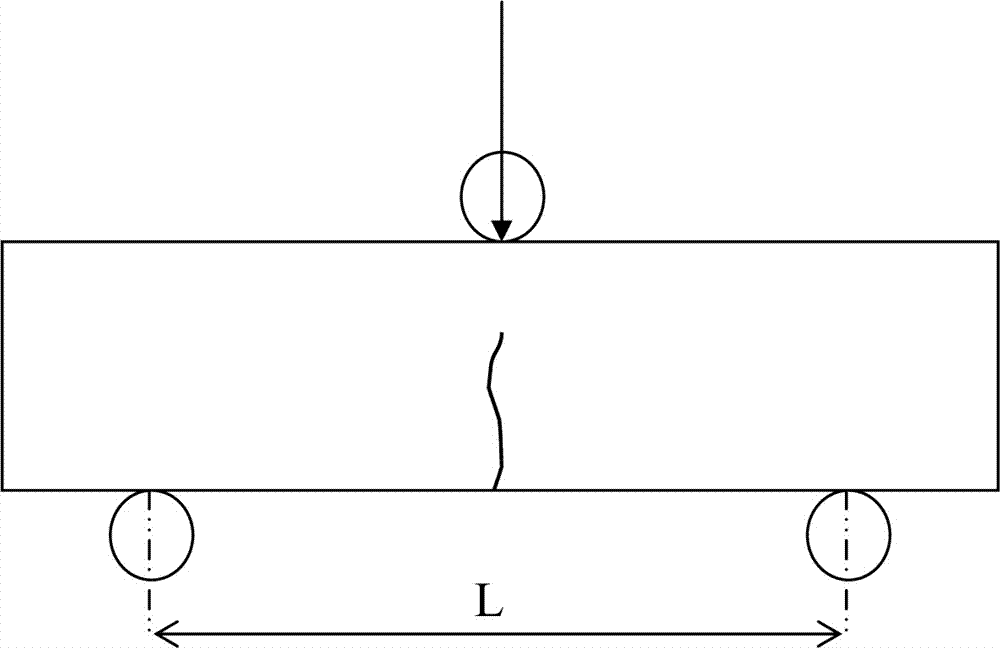

Evaluation method of self-repairing effect of self-repairing cement-based material

InactiveCN105300801AControl diversificationComprehensive performance response evaluationPreparing sample for investigationMaterial strength using tensile/compressive forcesStress intensity factorPhysical property

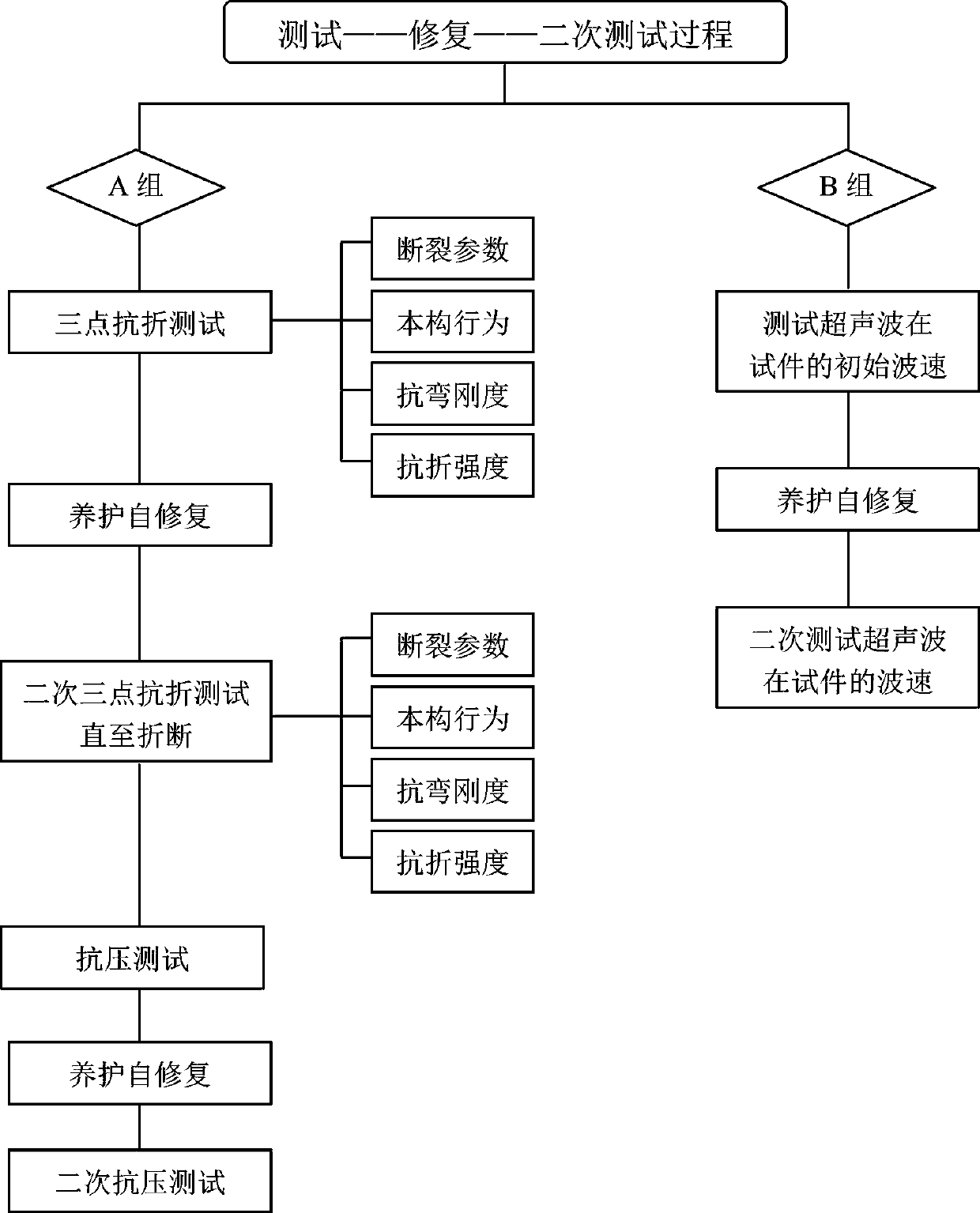

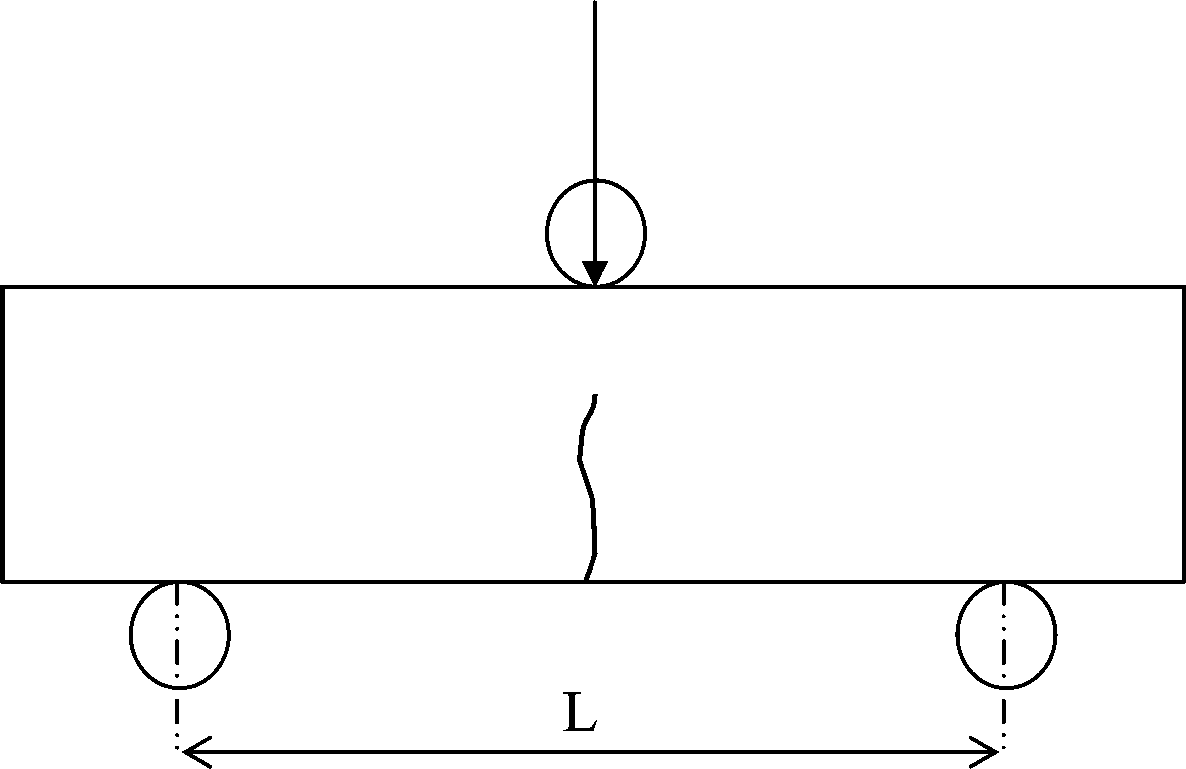

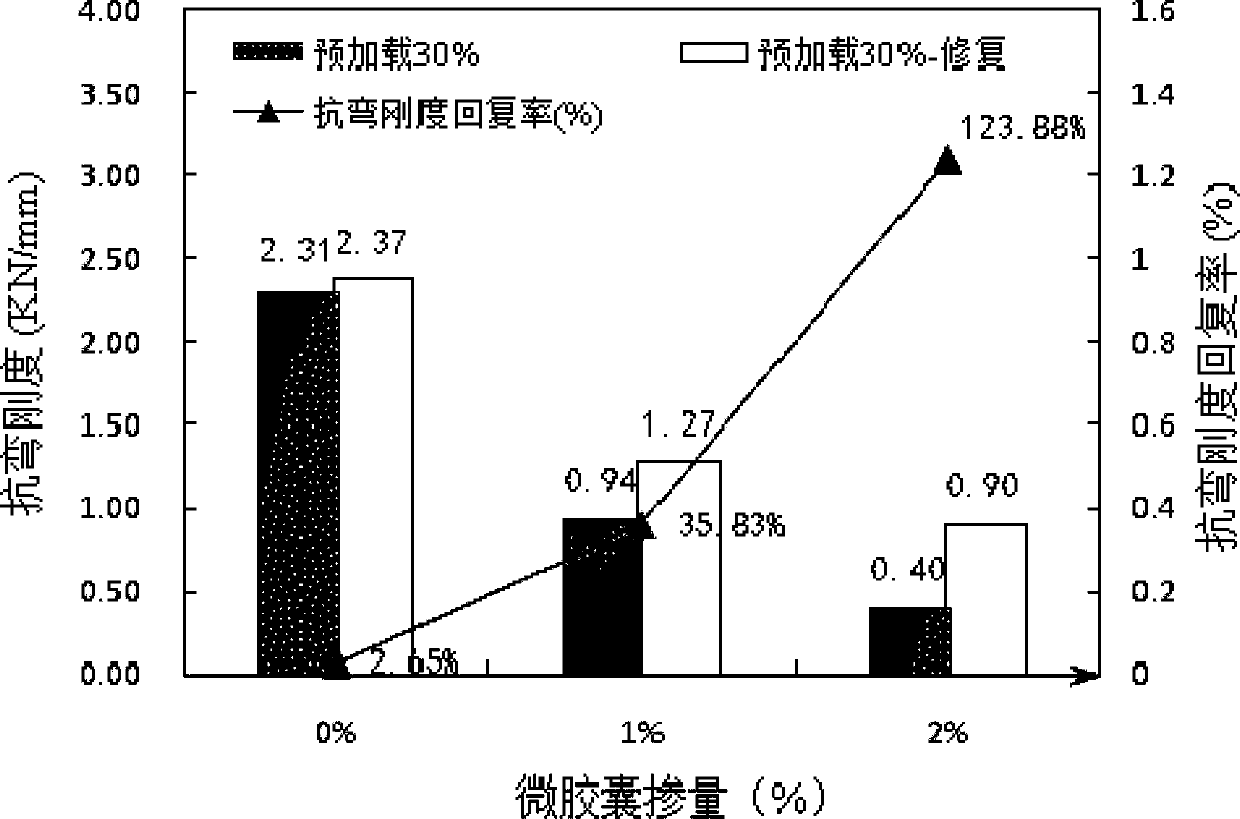

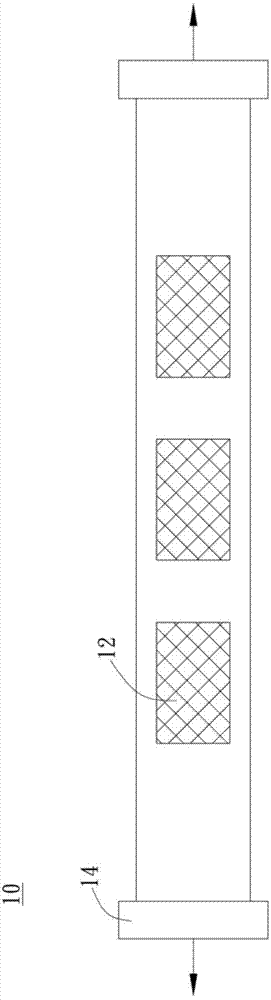

The invention relates to the field of methods for testing or analyzing concrete by virtue of the chemical or physical properties of a measuring material, particular to an evaluation method of the self-repairing effect of a self-repairing cement-based material. The evaluation method of the self-repairing effect of the self-repairing cement-based material is characterized in that the evaluation indexes comprise relative dynamic elasticity modulus, fracture behaviors (stress intensity factor recover rate and fracture toughness recover rate), constitutive behavior comparison, flexural rigidity recover rate and strength recover rate. The evaluation method comprises the following steps: step 1, preparing a test piece; step 2, prefabricating local cracks and dispersed cracks; step 3, testing all the parameters; step 4, completing self repairing; step 5, testing all the parameters; step 6, calculating, processing, and evaluating the repairing effect. The method is comprehensive in evaluation.

Owner:TONGJI UNIV

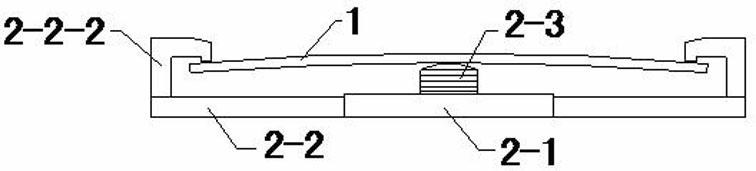

Metal shield

ActiveCN103572205AChange stress distributionDifferent thicknessLiquid surface applicatorsVacuum evaporation coatingEngineeringMetal

The invention provides a metal shield comprising a shielding segment and an end part segment. The shielding segment is provided with a shielding body and an external frame part, which is connected with the shielding body in an encircled manner. The end part segment is connected with one end of the shielding segment. At least one of the shielding segment and the end part segment is provided with a concave part, which is disposed on the outer side of the shielding body. The ratio between the volume sum of the concave part and the volume sum of the shielding segment and the end part segment is in a range from 0.087 to 0.667.

Owner:DARWIN PRECISIONS CORP

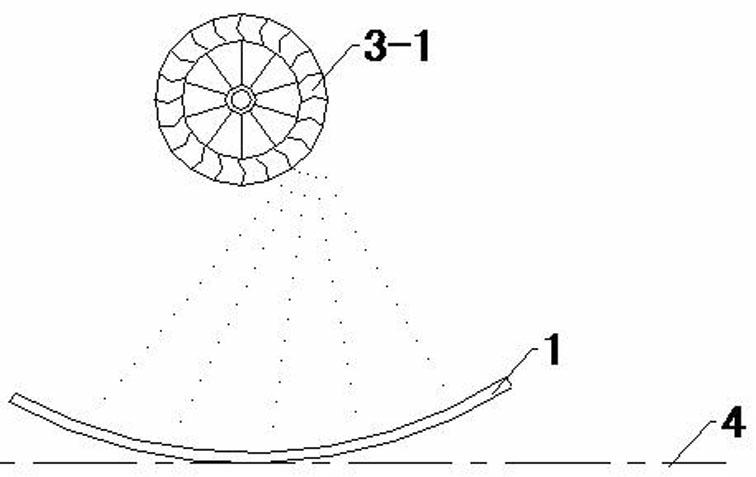

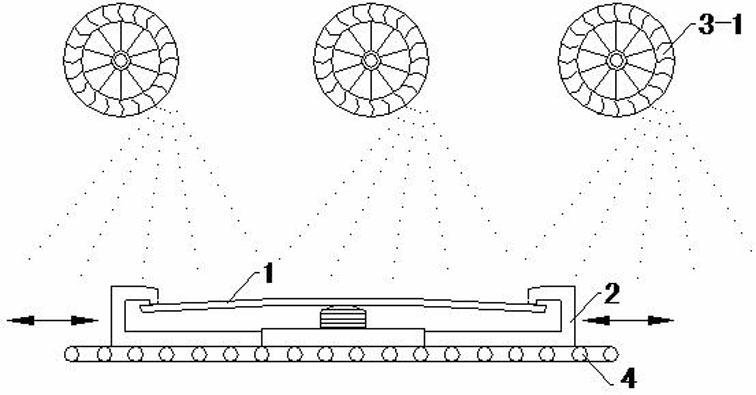

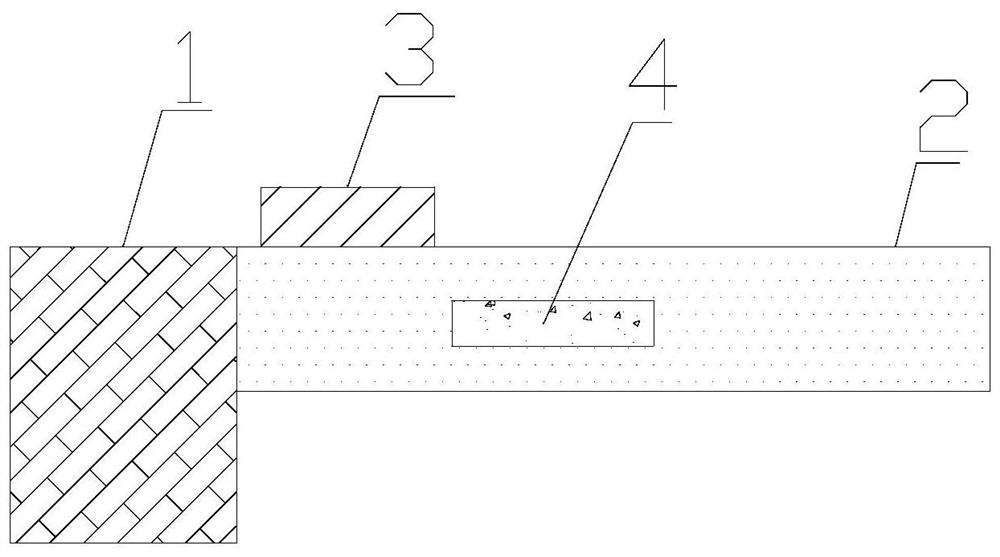

Reinforced stress shot blasting method and device

InactiveCN102189493AChange stress distributionFull stress reliefAbrasive blasting machinesStress distributionSheet steel

The invention discloses a reinforced stress shot blasting method. The method is characterized by comprising the following steps of: clamping a steel plate spring by using a fixture to ensure that the steel plate spring is directionally bent and a directional bending direction is opposite to a natural bending direction of the steel plate spring; and performing shot blasting treatment on the back surface of the directionally bent steel plate spring by using a shot blasting machine. The invention has the advantages that: certain prestress is applied onto the steel plate spring before the shot blasting treatment; the prestress and the impact force of a steel shot are coacted with each other to change the stress distribution of the steel plate spring; simultaneously, the position of the steel plate spring is relatively fixed and a stress elimination effect is more sufficient due to the clamping effect of the fixture.

Owner:CHONGQING HONGQI SPRING

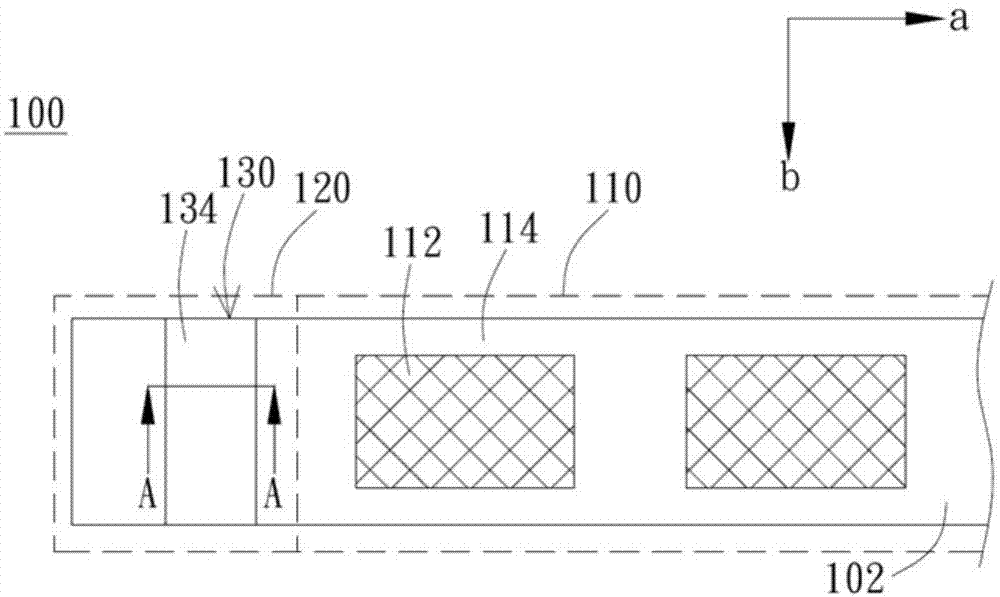

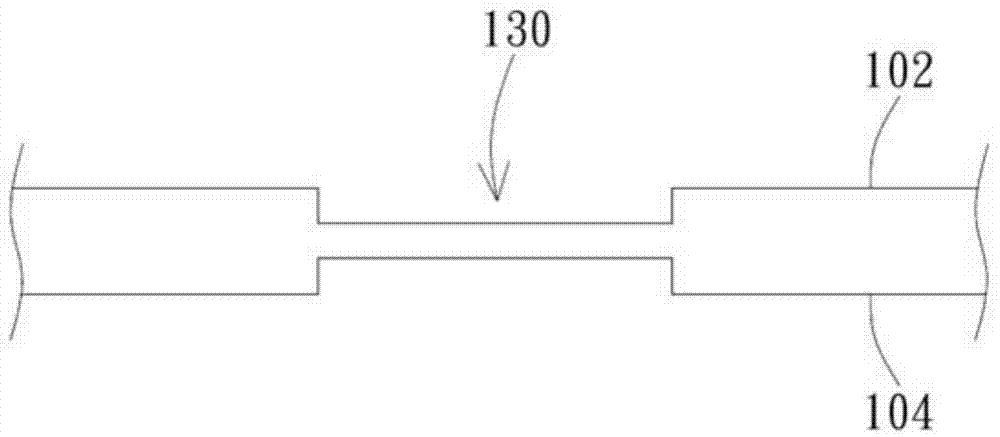

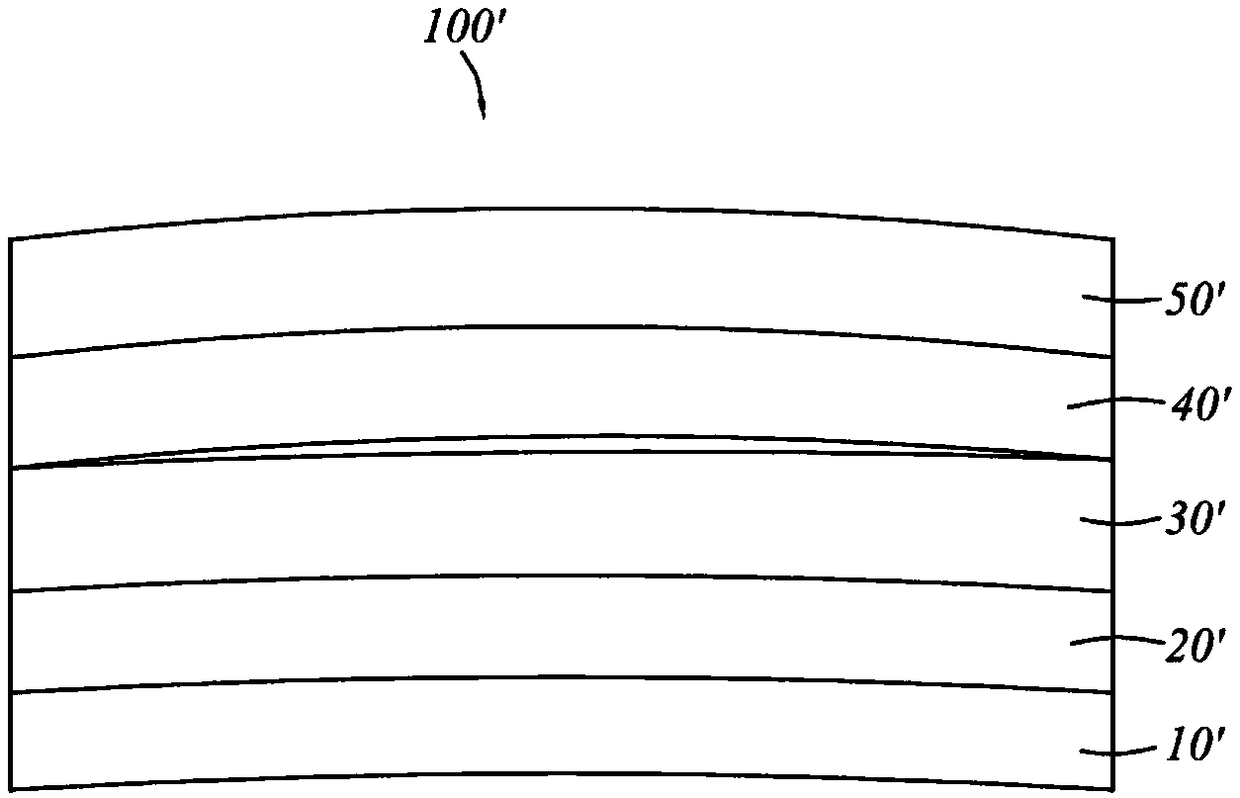

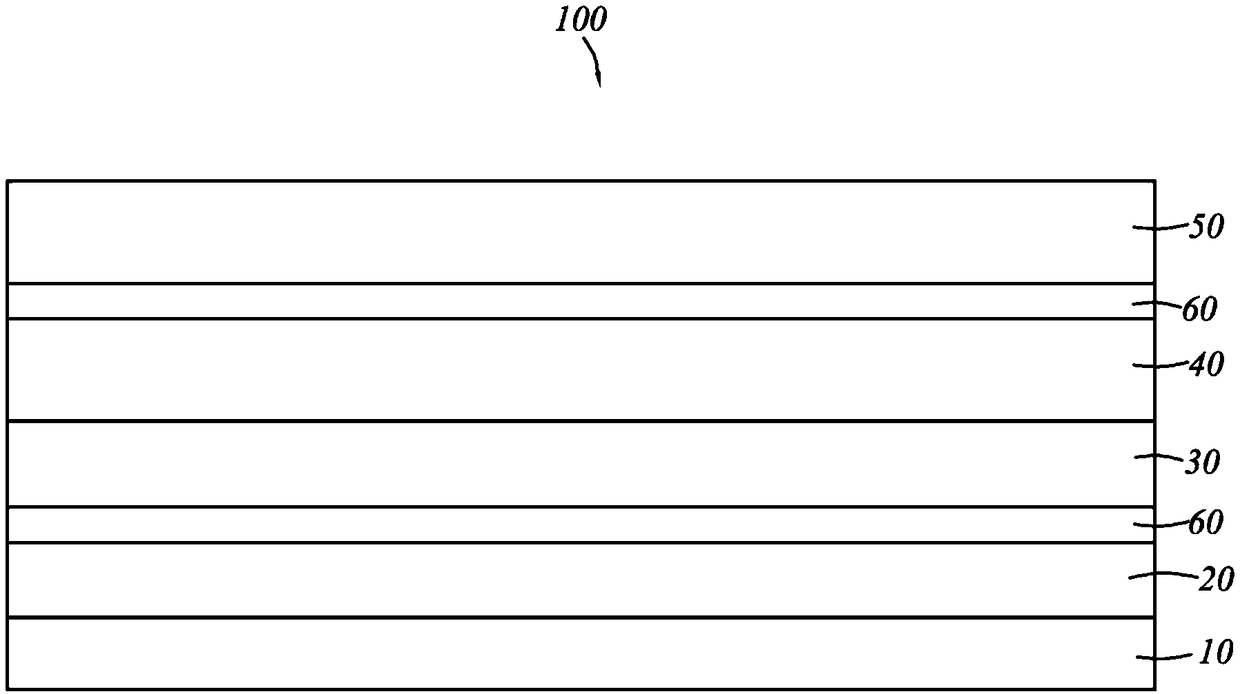

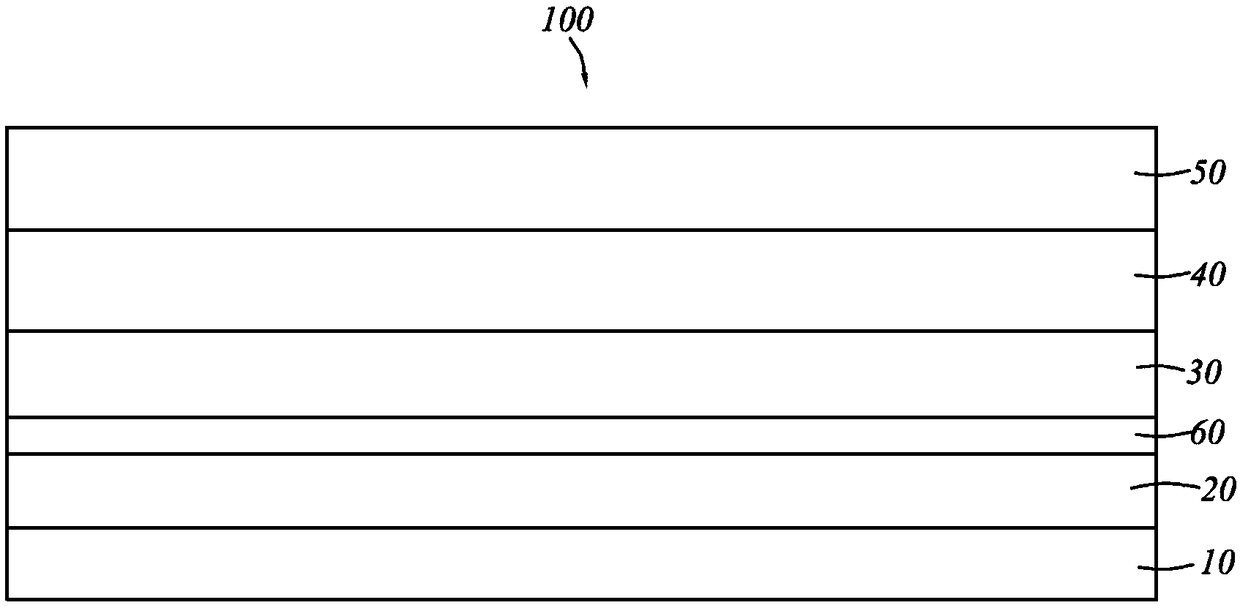

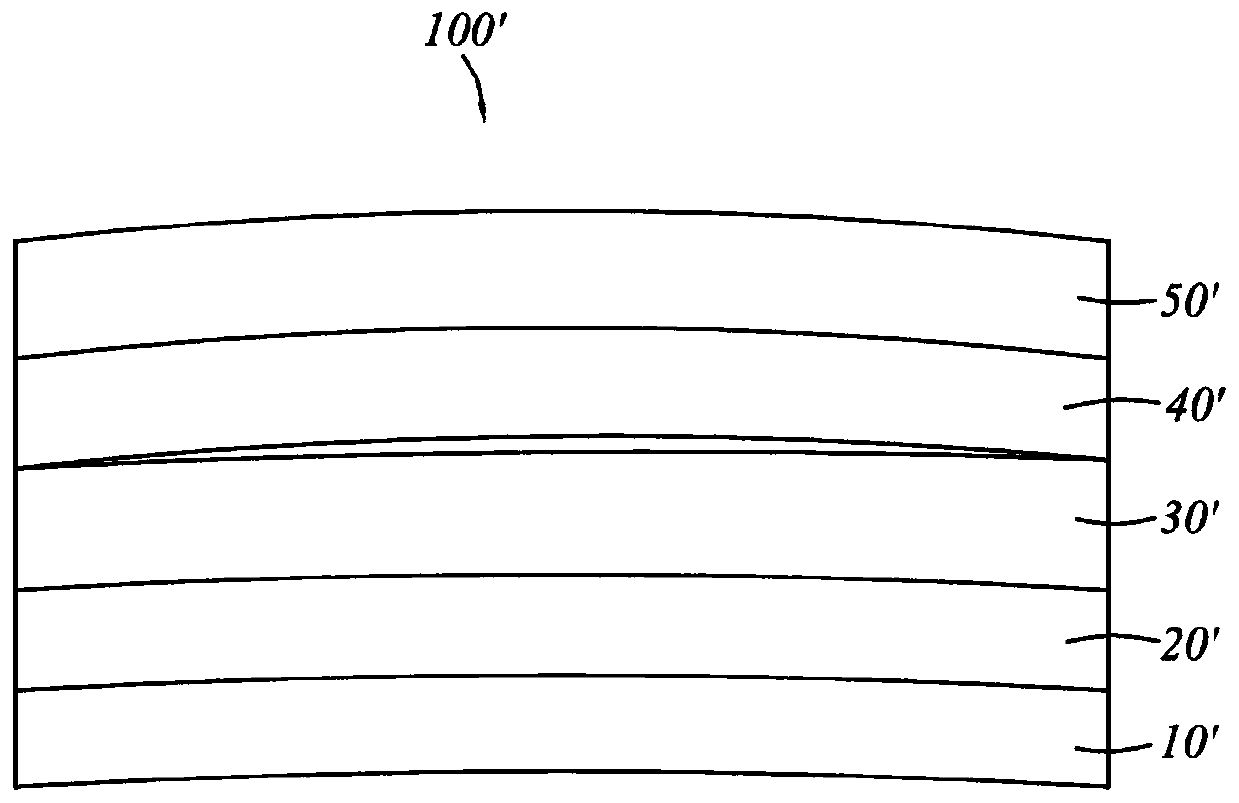

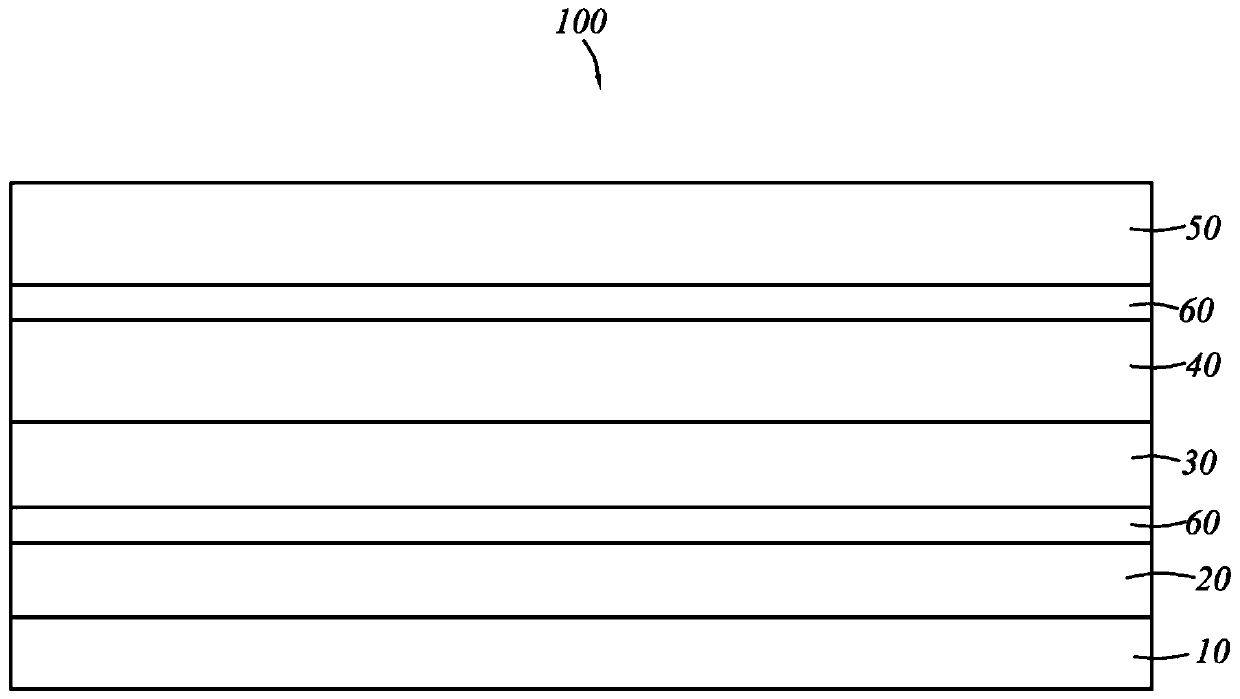

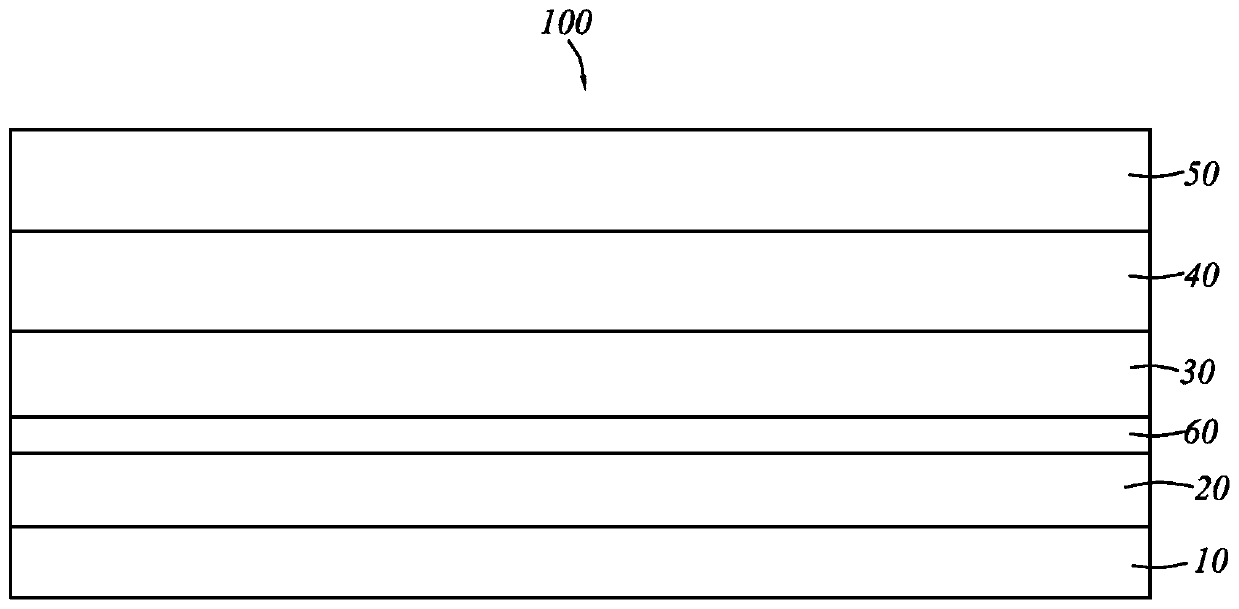

Flexible display panel and preparation method thereof

ActiveCN109411525AImprove featuresExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingStress distributionFlexible display

The invention provides a flexible display panel and a preparation method thereof. The flexible display panel comprises a flexible substrate, a light emitting device layer arranged on the flexible substrate, a touch layer positioned on the upper side of the light emitting device layer, and a polarization layer positioned on the touch layer, wherein the touch layer and the polarization layer are independently provided with one side which is close to each other, and one side which is far away from each other; in addition, one side, which deviates from each other, of the touch layer and / or polarization layer is pasted with an addition layer; and the Passion ratio of the addition layer is negative. One side, which deviates from each other, of the touch layer and / or polarization layer of the flexible display panel is pasted with the addition layer of which the Passion ratio is negative, so that stress distribution among membranes is changed, so that adhesive force between the polarizationlayer and the touch layer is increased, a membrane separation phenomenon is avoided, and the bendable property and the service life of the flexible display panel are improved.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Embedded type sensor of overall process shear stress of concrete dynamic damage

InactiveCN102384802APlay a protective effectGood compatibilityForce measurement using piezo-electric devicesEpoxyElectricity

The invention discloses an embedded type sensor of overall process shear stress of concrete dynamic damage, which comprises a granite protective cover, a d15 mode piezoelectric ceramic chip, an epoxy resin insulating layer, a shielding lead and a shielding joint, wherein the piezoelectric ceramic chip is welded with the shielding lead to form a whole and is wrapped by using high strength epoxy resin to form an insulating and waterproof protective layer; and the piezoelectric ceramic chip is bonded with the granite protective cover of which the external surface is roughened to form a whole by utilizing the epoxy resin, and thereby the sensor of the concrete internal dynamic shear stress is formed. The sensor has the advantages of interference exemption of a concrete internal stress field, overall process monitoring of concrete internal dynamic damage evolution, good interface compatibility, simple structure and low construction cost.

Owner:DALIAN UNIV OF TECH

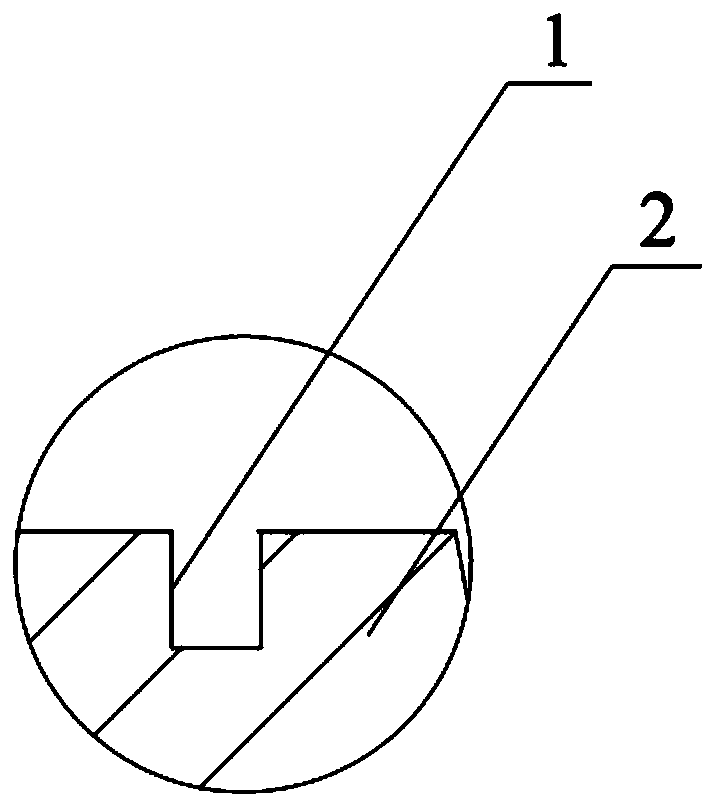

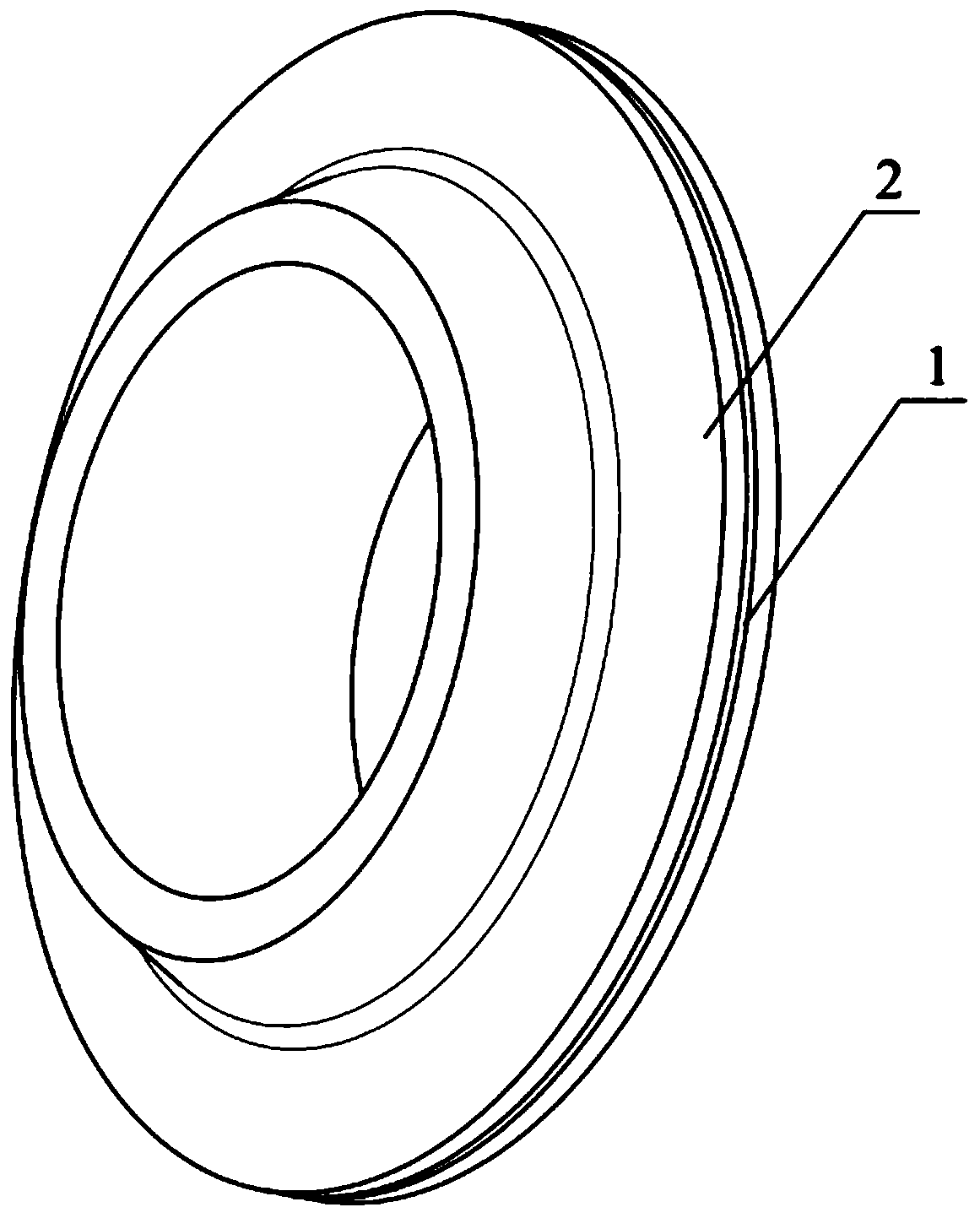

TBM disc cutter with grooved cutter ring outer circumference

The invention discloses a TBM disc cutter with the grooved cutter ring outer circumference. The TBM disc cutter comprises a cutter ring, a cutter body, a check ring, a bearing, a rigid mandrel, a bearing end cover and a seal ring. The cutter ring is fixed to the cutter body through the check ring, the bearing is connected into the cutter body, and the bearing end cover and the seal ring enable thebearing to be fixed to the rigid mandrel in a sealed mode. According to the TBM disc cutter with the grooved cutter ring outer circumference, a novel rock breaking disc cutter ring structure is used;the cutter body, the bearing and the bearing end cover are assembled to the mandrel, internal oil liquid is sealed by means of the seal ring between the cutter body and the bearing end cover, and a step is arranged on the outer ring of the cutter body and used for positioning the cutter ring; and by means of the TBM disc cutter, a compact core shape can be controlled, stress distribution is changed so as to form lateral cracks, production and extension of the lateral cracks are facilitated, the rock breaking energy consumption is reduced, the rock breaking capability is effectively improved,and the rock breaking efficiency is improved.

Owner:SOUTHWEST JIAOTONG UNIV

Connecting device and method for connecting column base joints

InactiveCN108166628AImprove ductilityAvoid damageProtective buildings/sheltersShock proofingArchitectural engineeringSteel columns

The invention discloses a connecting device and method for connecting column base joints and belongs to the technical field of building structure engineering. The connecting device for connecting thecolumn base joints comprises a first steel column, a first arc end plate, a second arc end plate, a second steel column, a sleeve and a connecting mechanism. A connecting hole is formed in the first steel column, and the first arc end plate is connected with the first steel column. The first side of the second arc end plate is connected with the first arc end plate though a fastening piece, and the second steel column is connected with the second side of the second arc end plate. The sleeve is arranged in the connecting hole, the first end of the connecting mechanism is movably connected withthe sleeve, and the second end of the connecting mechanism penetrates through the first arc end plate to be connected with the second arc end plate. According to the connecting device and method for connecting the column base joints, the column base joints are fabricated joints, joint ductility is good, plastic hinging is prevented from occurring to the column end, the mode is simple, the economical and practical effects are achieved, and on-site construction is convenient.

Owner:WUHAN UNIV OF SCI & TECH

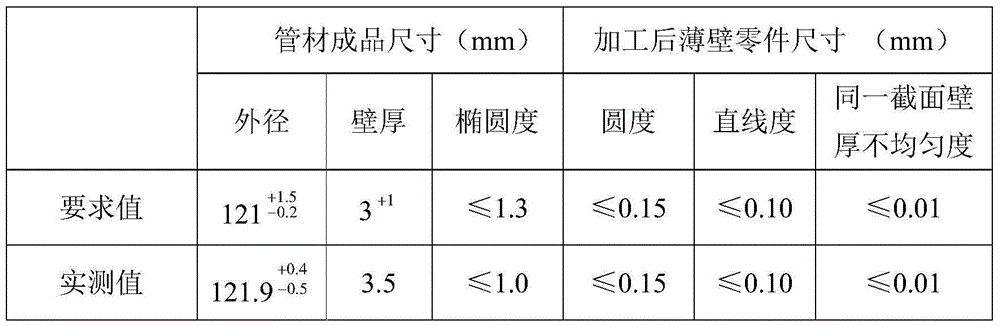

Stress control production process of high-strength aluminum alloy pipe

InactiveCN105170692AReduce stressReduce bending deformationExtrusion control devicesIngot castingTemperature difference

The invention relates to a stress control production process of a high-strength aluminum alloy pipe. The stress control production process comprises the steps that a, an extrusion mold is selected, the surface and size of the extrusion mold are checked before installing, and the roundness tolerance of the mold cannot exceed 0.10 mm; b, the extrusion mold is preheated, and the extrusion mold and an extrusion barrel are preheated to 400 DEG C-450 DEG C; c, an aluminum alloy hollow round ingot casting blank is preheated, an ingot casting is preheated to 400 DEG C-450 DEG C, and the temperature difference of the head and tail of the ingot casting is controlled to be smaller than or equal to 30 DEG C; d, the ingot casting blank is placed in the mold, extrusion is started, the extrusion speed is smaller than or equal to 1.0 mm / s, and the difference of a long shaft and a short shaft of the extruded pipe is smaller than 2.50 mm; e, roll pre-straightening is carried out on a straightening machine; f, offline quenching is carried out, the pipe is quenched through vertical quenching equipment, during charging, aluminum wires are bound at the upper and lower proper positions of the pipe to reduce longitudinal bending generated after quenching, and a penetrating rod is used for increasing the contact area and balancing the stress on the two sides of the wall thickness of the pipe; and g, stretcher straightening finishing is carried out, profiling stretch core cushions are arranged in the two ends of the pipe, an arc-shaped stretch jaw is used for carrying out tension stretching on the pipe, and the stretch rate is controlled to be 1.0%-3.0%.

Owner:TIANJIN HEXING AERONAUTICAL MATERIAL CO LTD

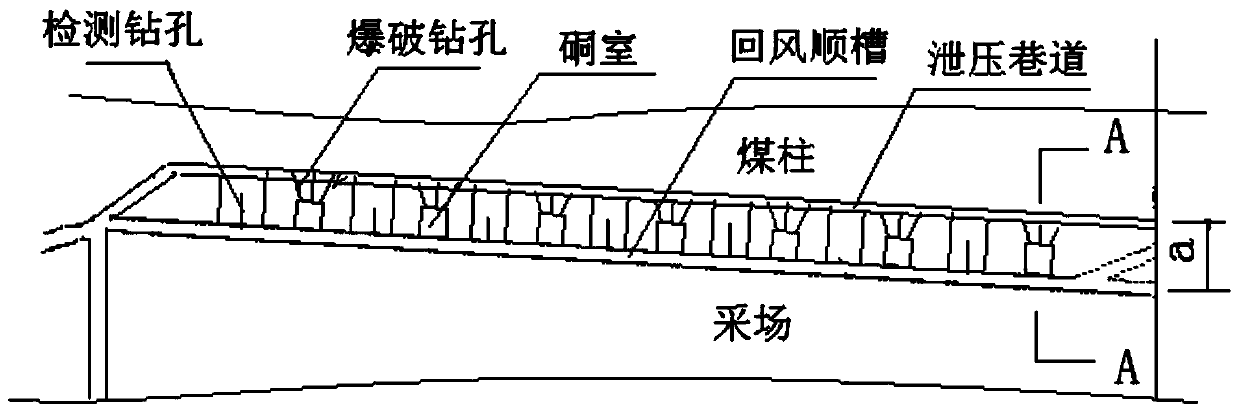

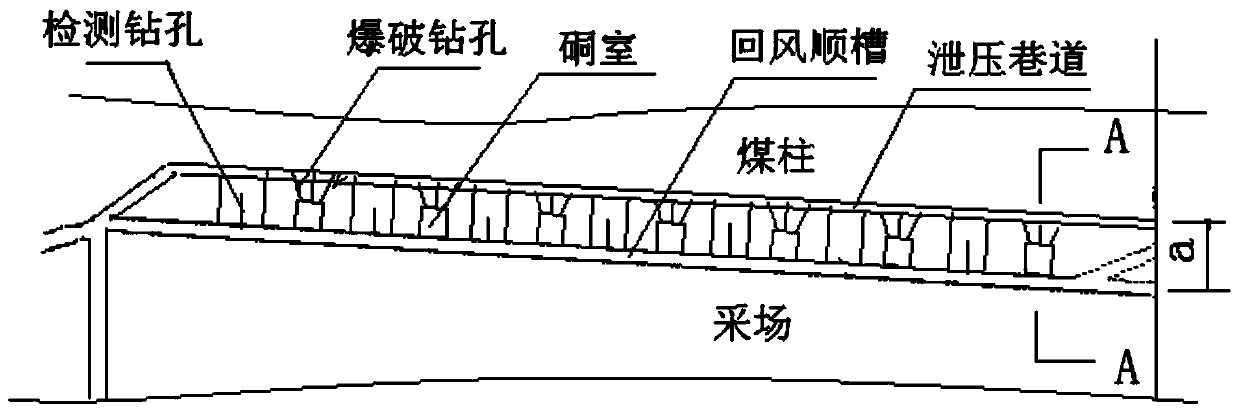

Method for preventing and controlling rock burst of stope roadway for unequal-width entry protection coal pillar

InactiveCN109915141AChange stress distributionChange the range of stress accumulationUnderground miningSurface miningEngineeringCoal pillar

The invention provides a method for preventing and controlling the rock burst of a stope roadway for an unequal-width entry protection coal pillar. The method comprises the following steps that beforethe stope roadway is tunneled, a pressure relief roadway is arranged on a top plate of the unequal-width entry protection coal pillar, then blasting and drilling are carried out in a coal seam on a base plate of the pressure relief roadway so as to manufacture a loose pressure relief area, when working face mining is propelled into a dangerous zone of the stope roadway, along the side facing thepressure relief roadway, pressure relief chambers are tunneled every 12-15 m, drilling and blasting are carried out in the chambers in the direction towards the pressure relief roadway, a fracture body is formed between every two chambers through blasting to dissipate the impact energy of the coal pillar, the effect of buffering and protecting the stope roadway is achieved, and the safety of the roadway during the whole service period is ensured.

Owner:SHANDONG UNIV OF SCI & TECH

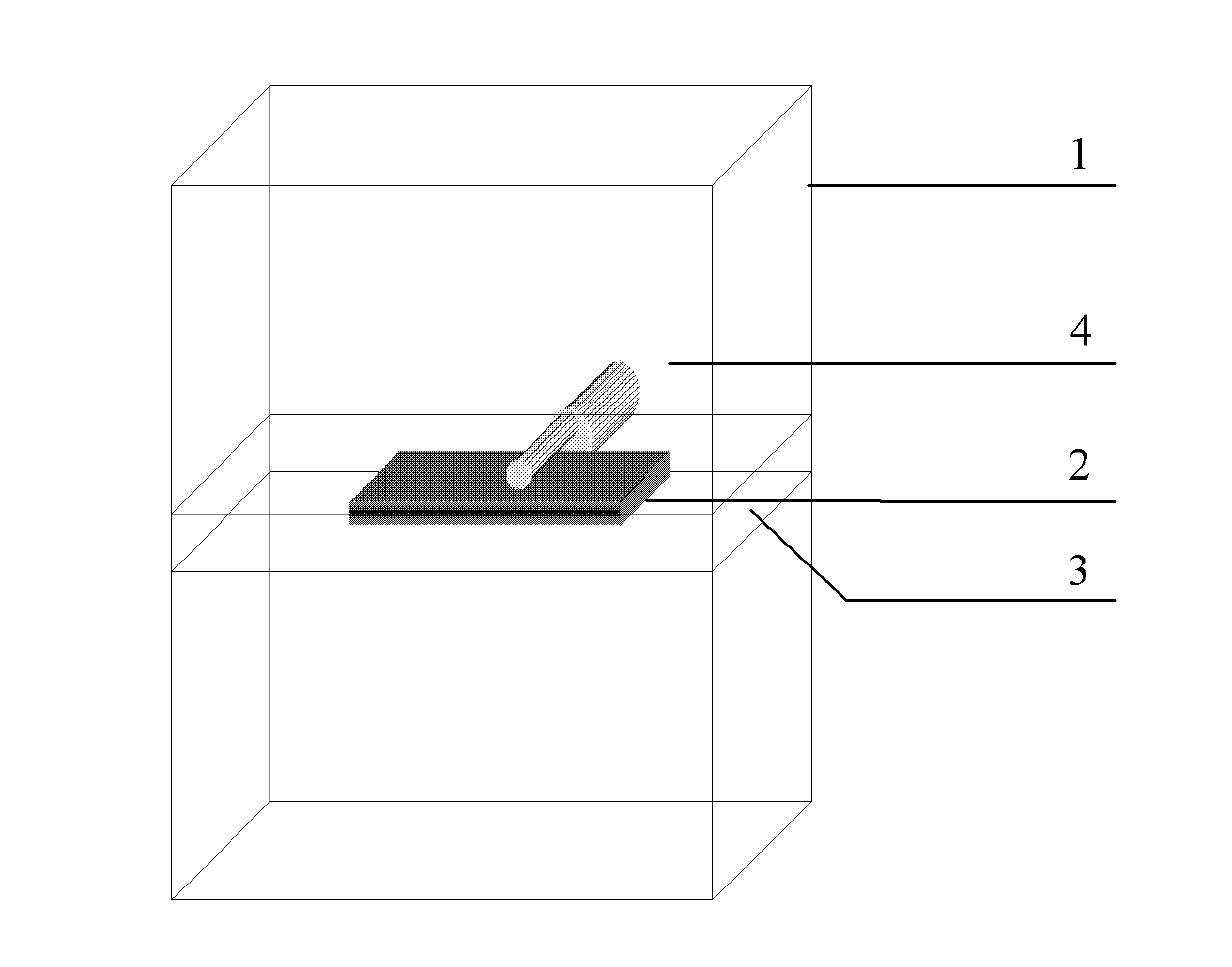

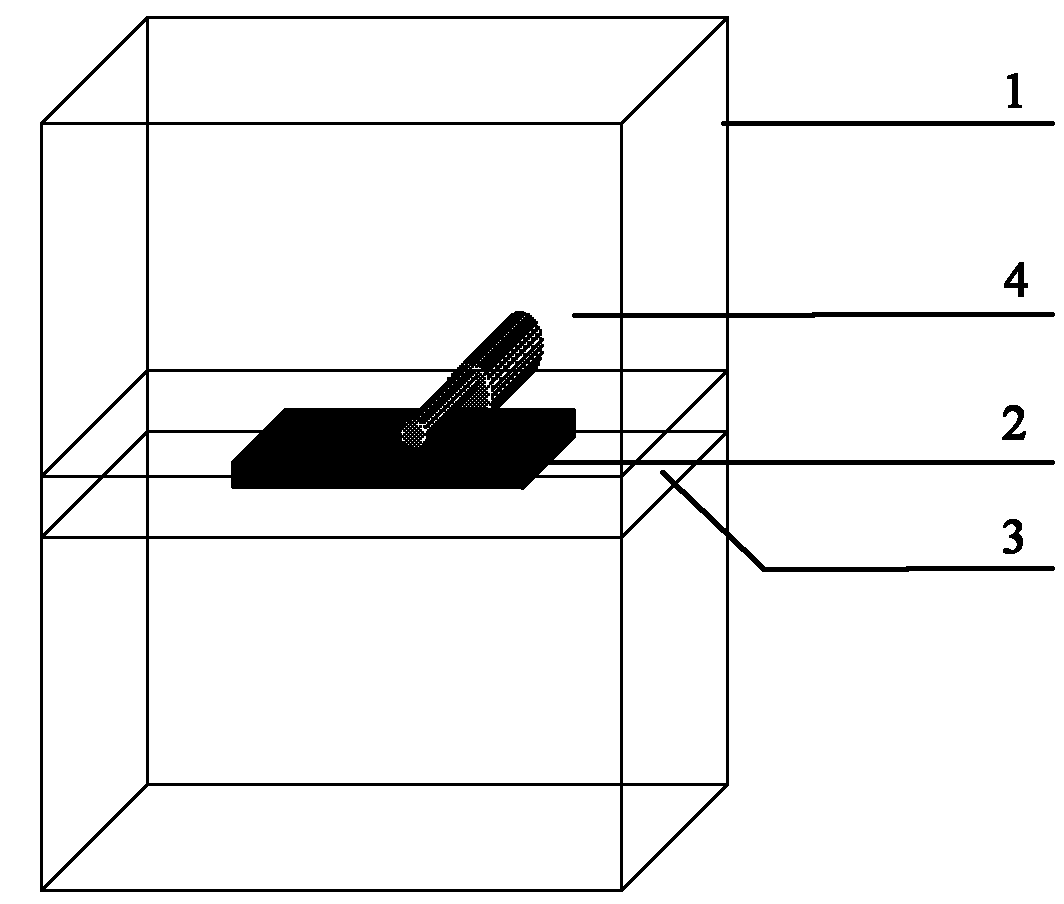

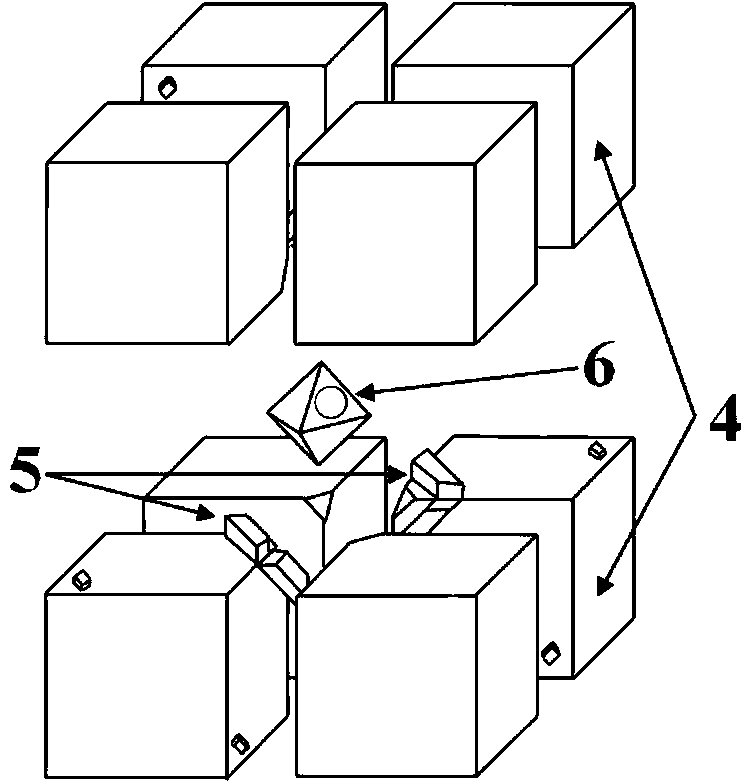

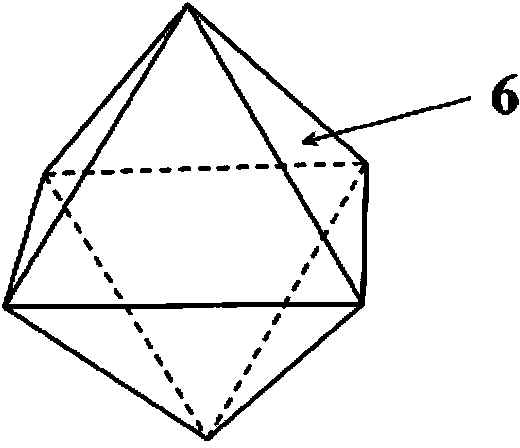

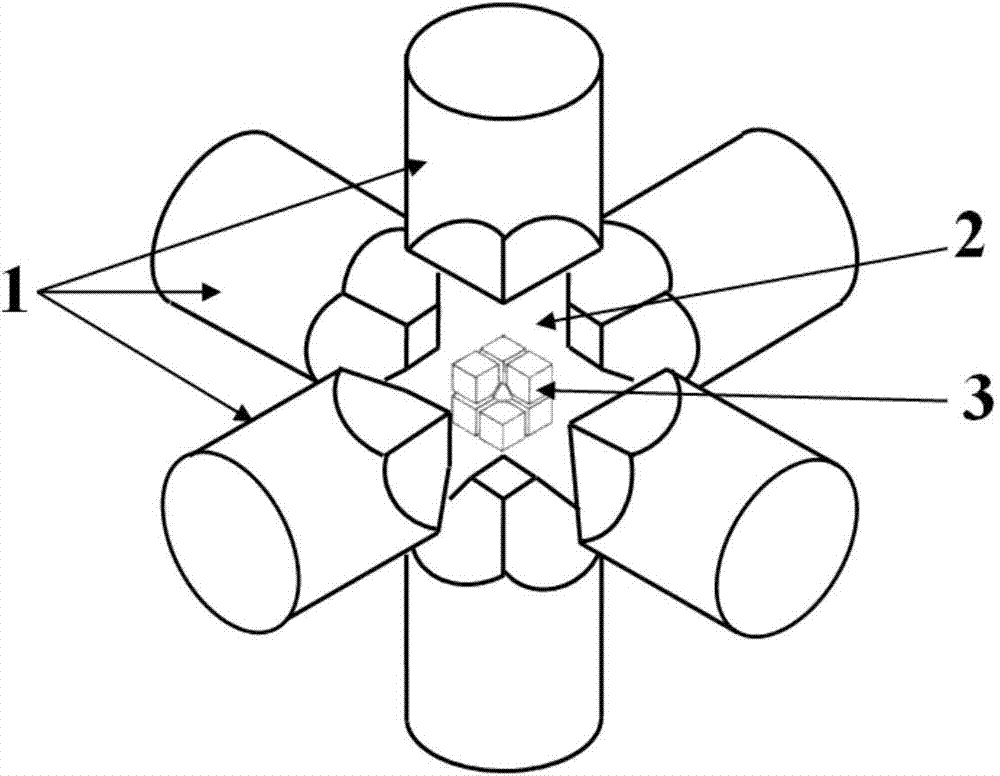

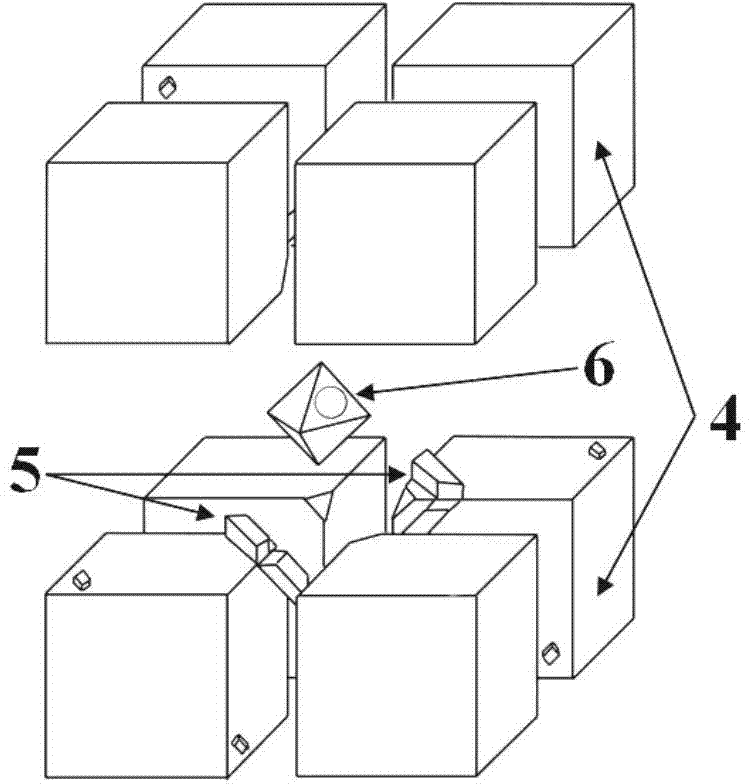

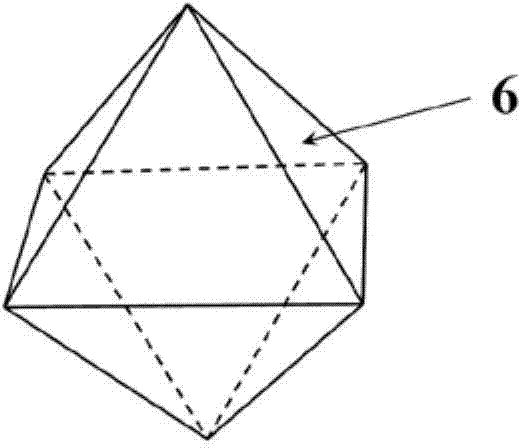

Secondary anvil and secondary pressurizing unit of octahedral pressure cavity static high-pressure device

ActiveCN103446946AEnhanced pressure sealing capabilityIncreasing the thicknessUltra-high pressure processesEngineeringHigh pressure

The invention relates to a secondary anvil of an octahedral pressure cavity static high-pressure device. An anvil body is in a cube shape; an anvil surface is a regular triangular surface formed by cutting a corner of the cubic anvil body; at least one circle of outer ring surface is arranged around the anvil surface; the outer ring surface in each same circle comprises three trapezoidal slants which are same in shape and size; a regular triangle is enclosed by the bottom edges of the three trapezoidal slants. The secondary pressurizing unit of the octahedral pressure cavity static high-pressure device comprises the eight secondary anvils, a previous sealing strip and an octahedral pressure transmitting medium. Compared with the traditional secondary pressurizing unit, for the secondary pressurizing unit which comprises the secondary anvils disclosed by the invention, experiments indicate that the blasting probability is obviously reduced during operation and the maximal pressure which can be achieved a the body of an octahedral pressure cavity can be increased.

Owner:FUNIK ULTRAHARD MATERIAL

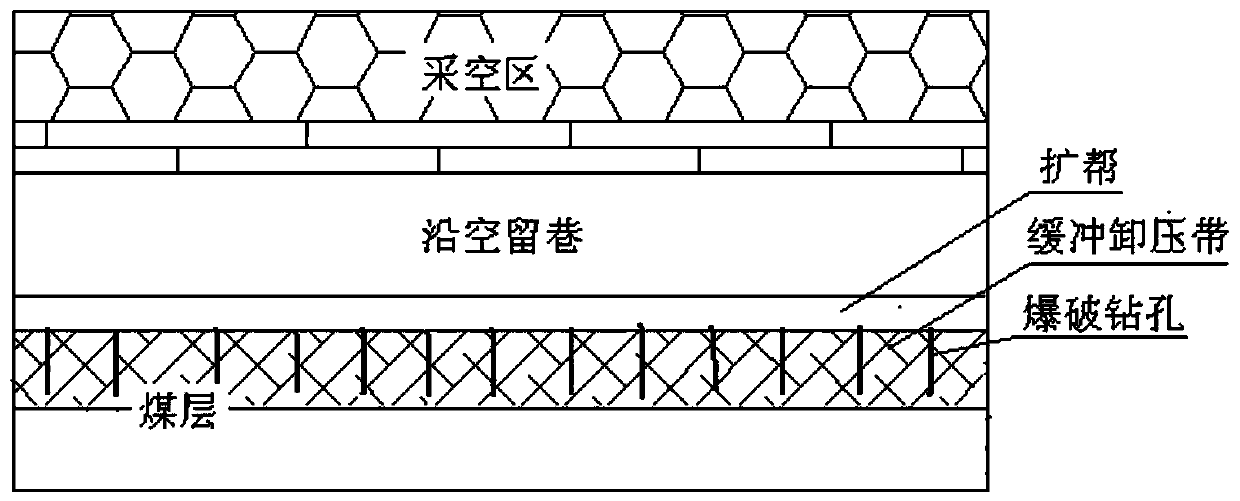

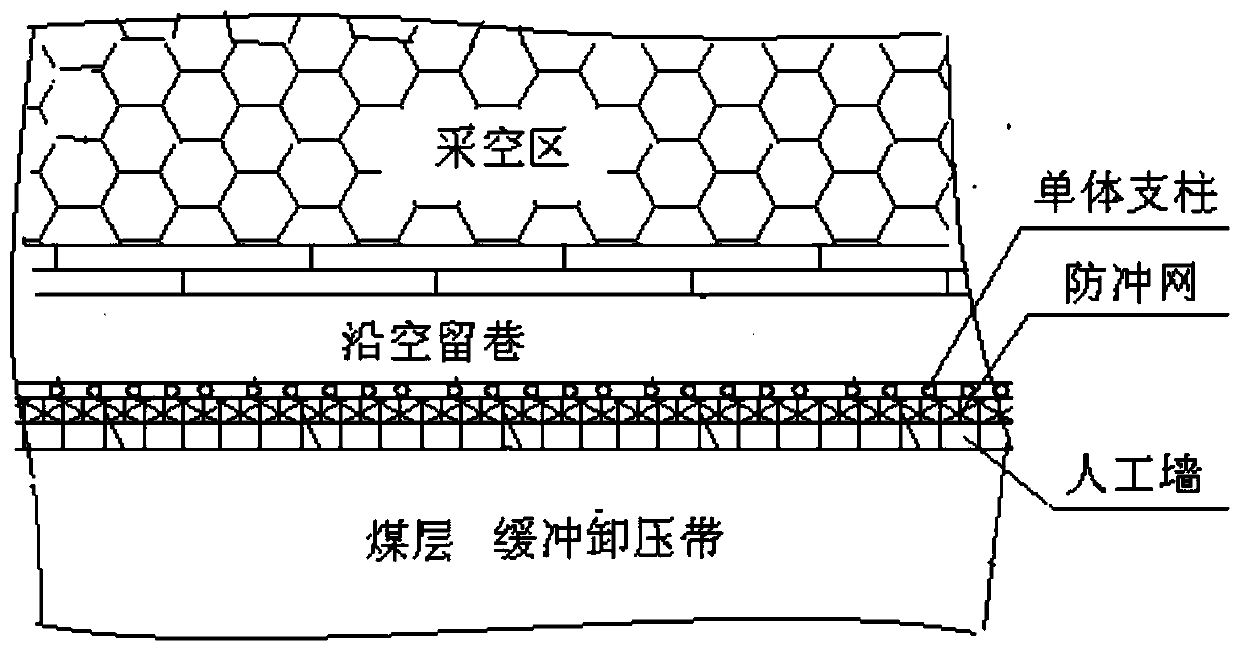

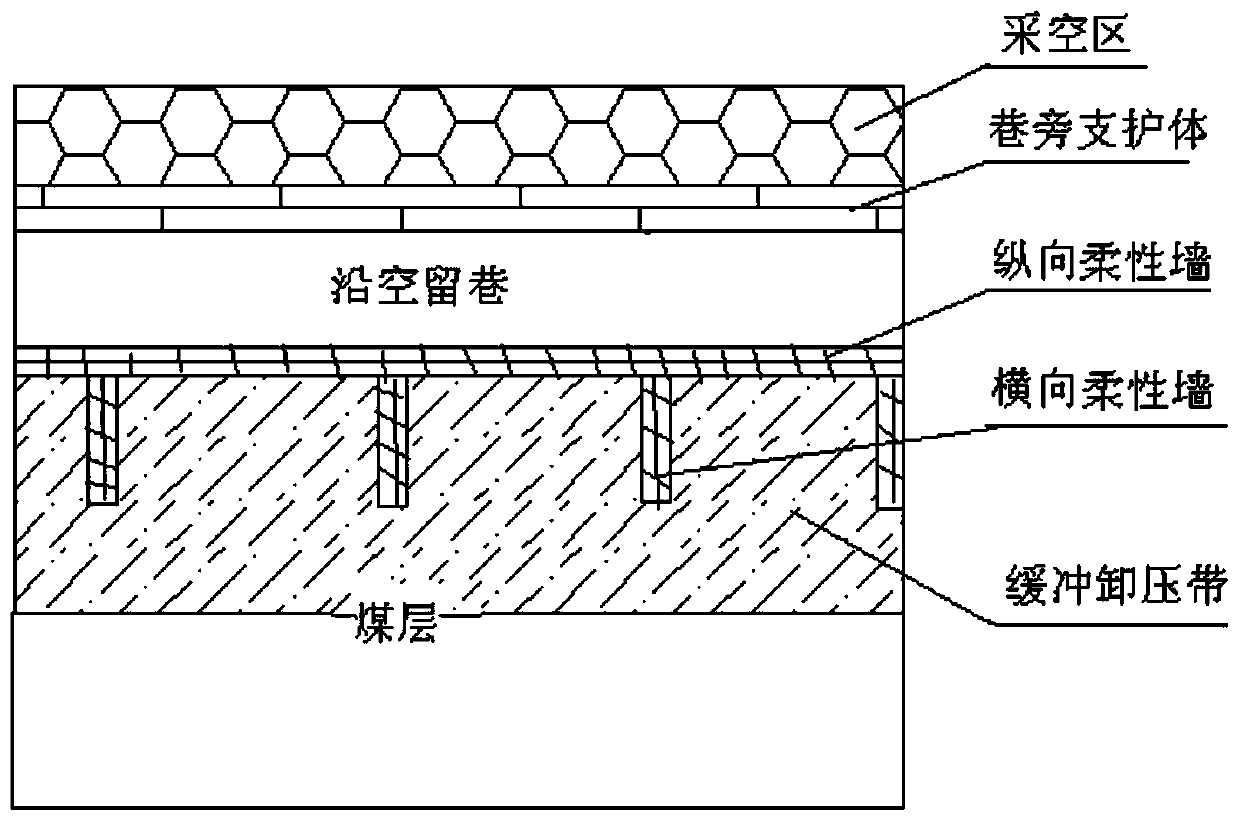

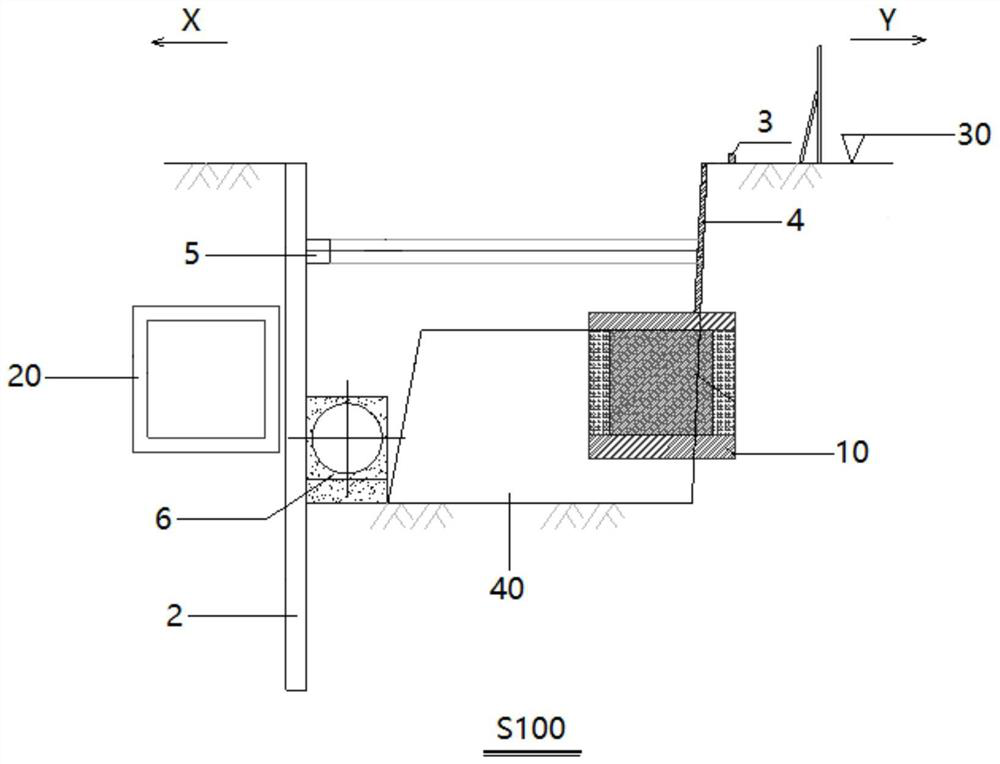

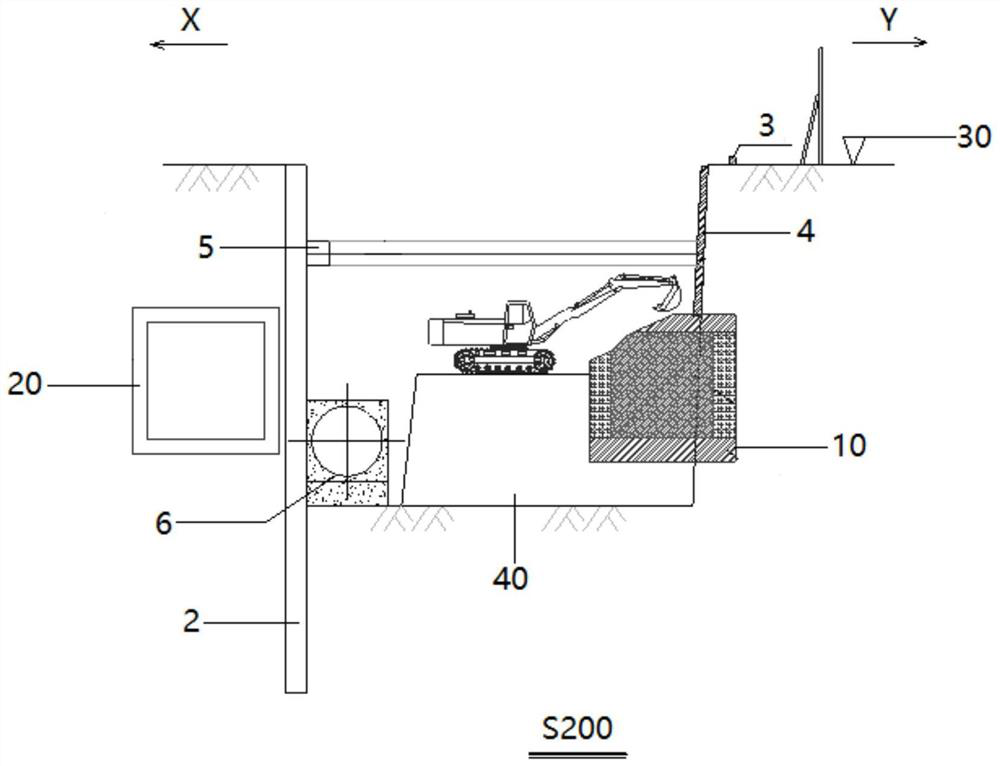

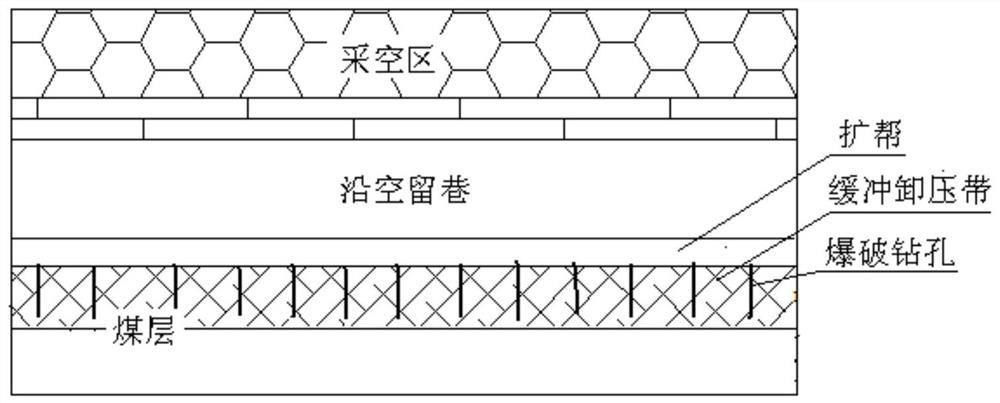

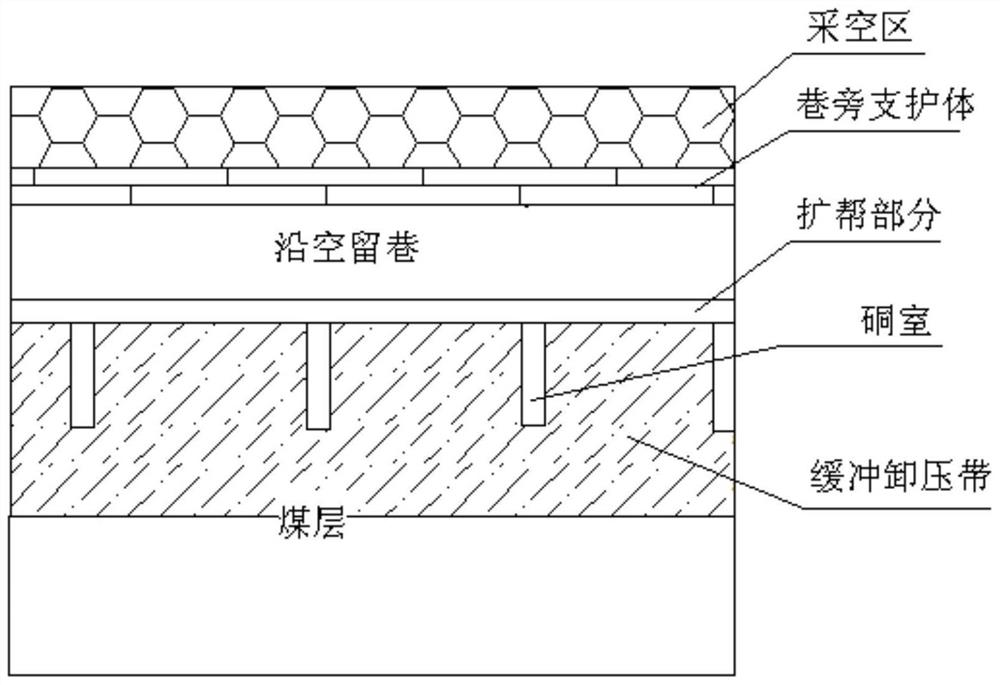

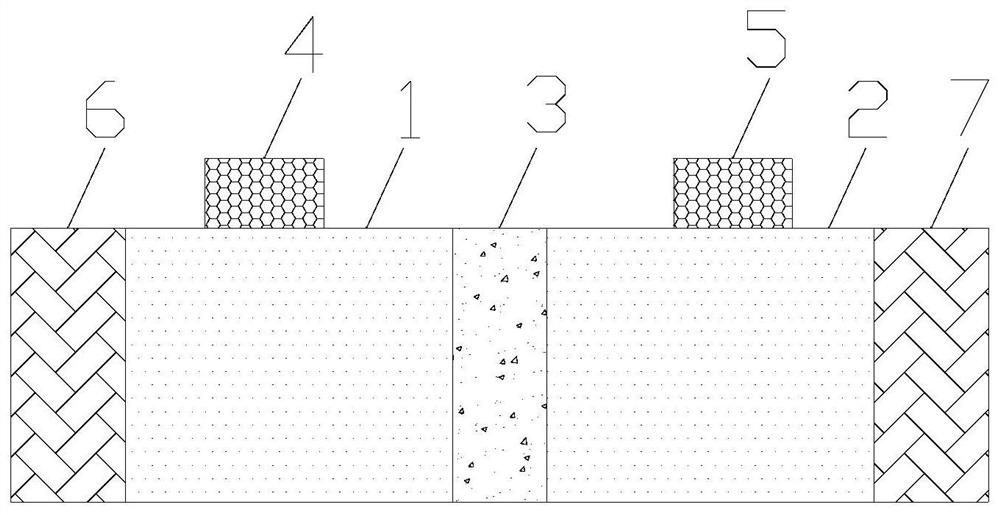

Method for preventing impact ground pressure of hard roof remained roadway by buffer pressure relief belt and wide roadway flexible wall

ActiveCN110219649AChange stress distributionChange the impact propertiesMining devicesUnderground miningCombined techniqueStructural engineering

The invention discloses a method for preventing impact ground pressure of a hard roof remained roadway by a buffer pressure relief belt and a wide roadway flexible wall. The method is characterized bycomprising the steps that firstly, side expanding and bottom excavating are carried out on the coal wall side of an original remained roadway, and coal bodies after side expanding is carried out areloaded into a woven bag for stand-by application; in accordance with a conventional method, holes are punched in the coal wall after side expanding is carried out for blasting, and the buffer pressurerelief belt with the width of 8-12 m is artificially manufactured; the woven bag with loaded materials is used as the wall material, and an artificial wall with the width of 1.5-1.6 m is built alongthe space position after side expanding is carried out; and the flexible wall is reinforced and blocked by a combined technique of a protective net and a single prop. Through the buffer pressure relief, the impact properties of the coal bodies are changed; and the artificial flexible wall and blasting in the roadway side are adopted to form a flexible body so as to realize impact prevention of theremained roadway.

Owner:SHANDONG UNIV OF SCI & TECH

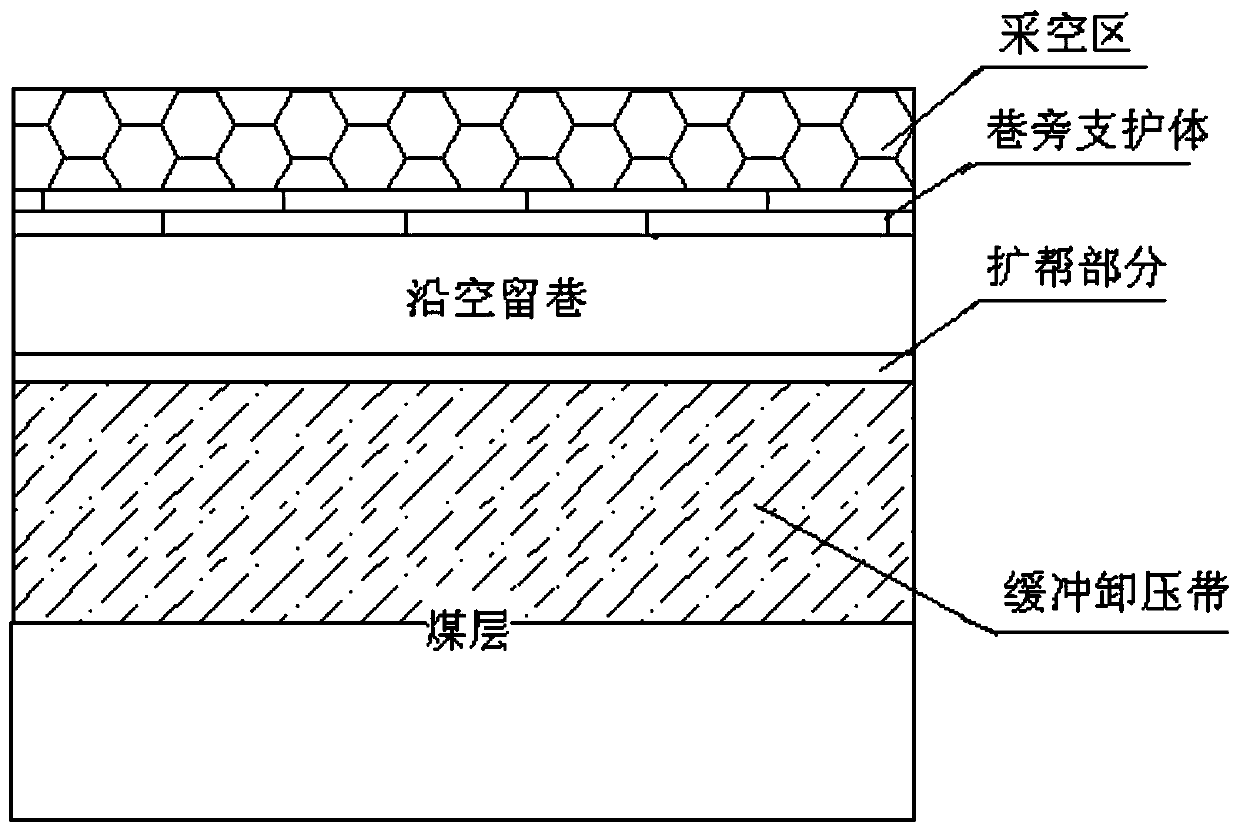

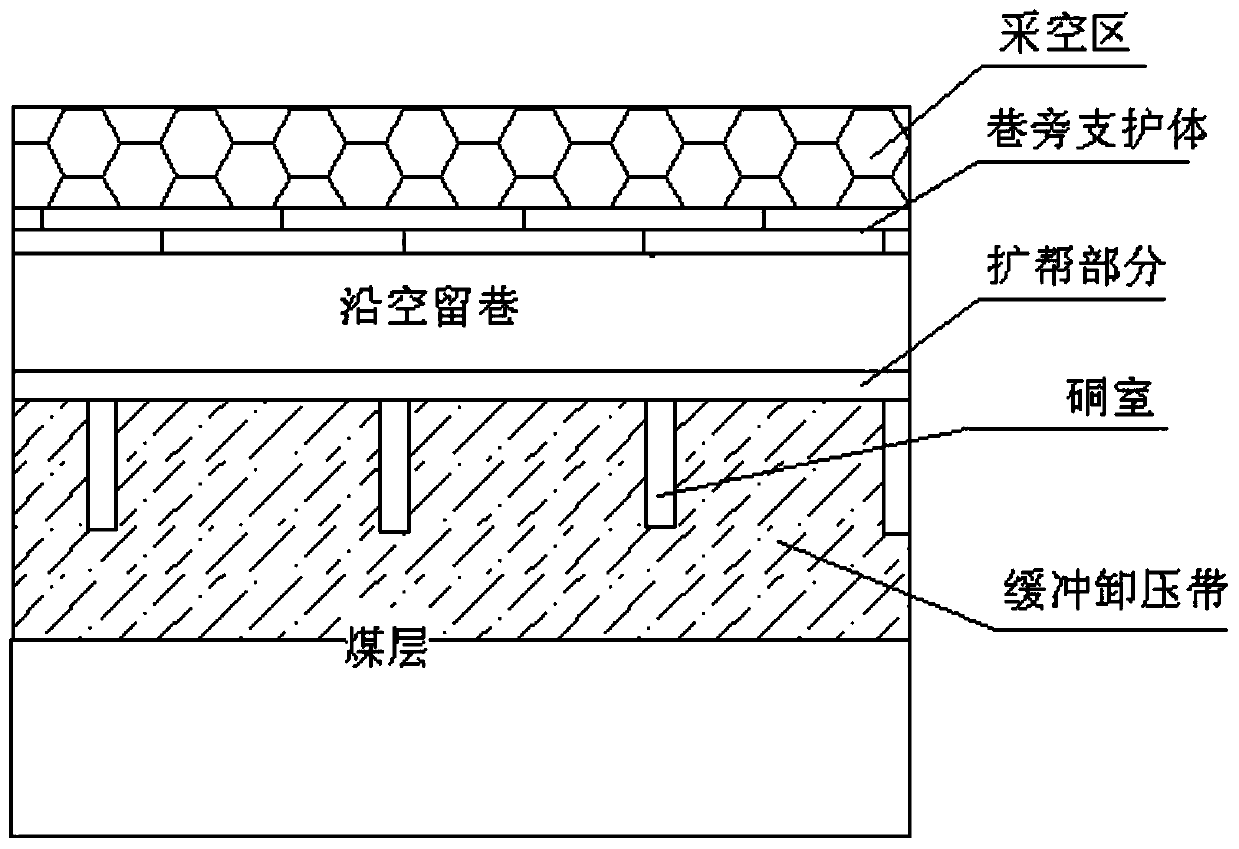

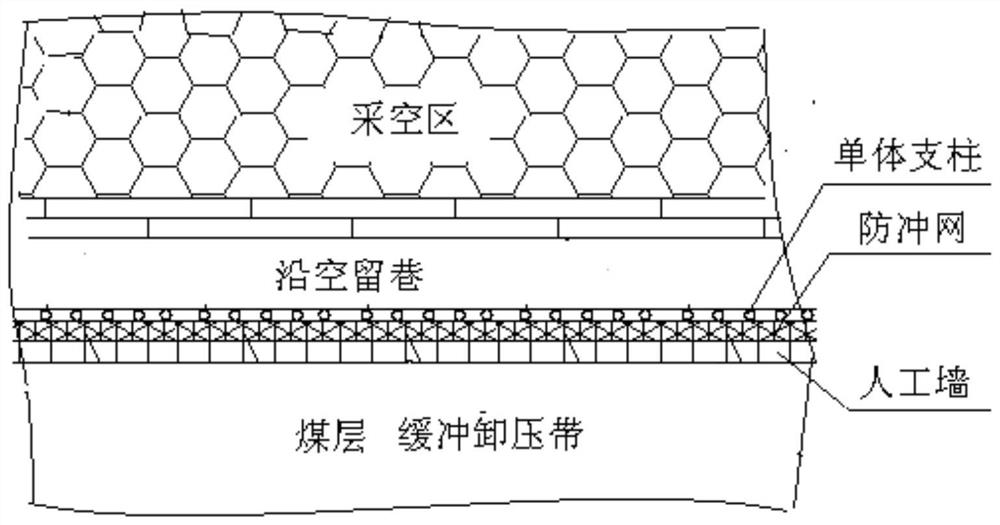

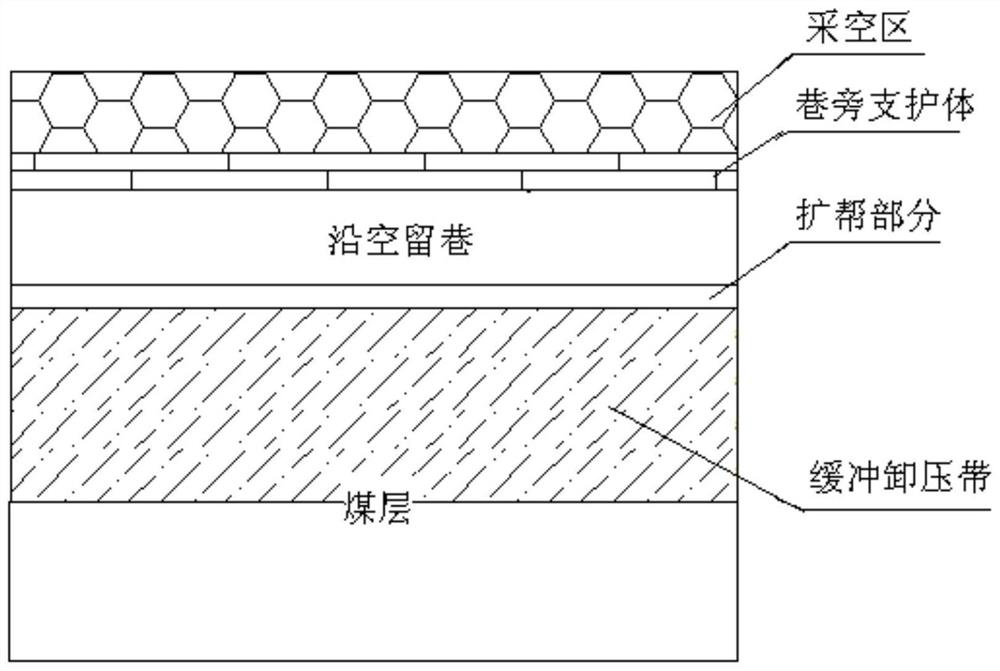

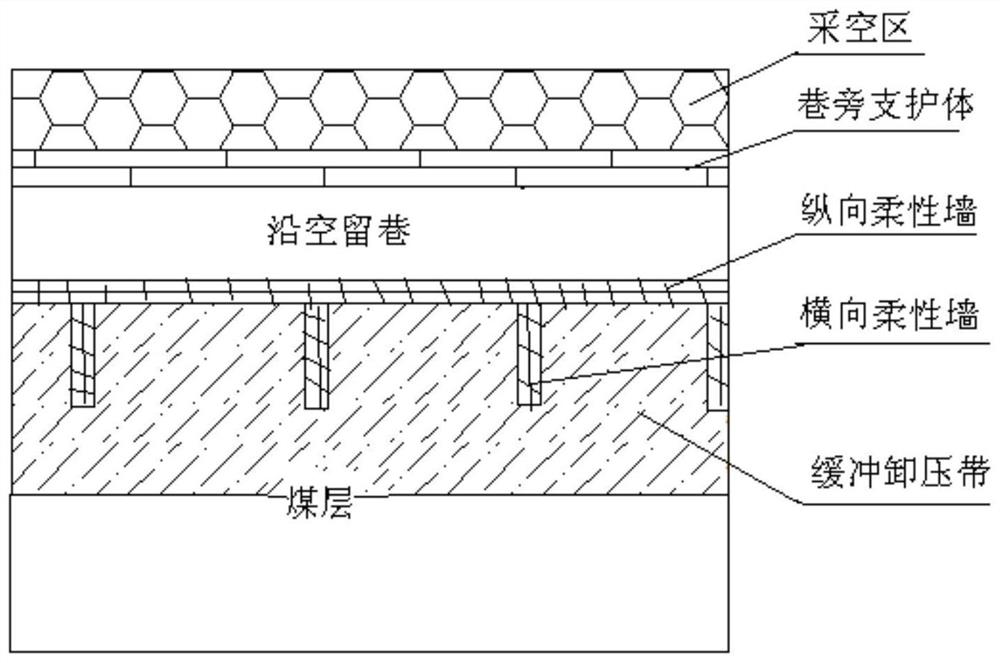

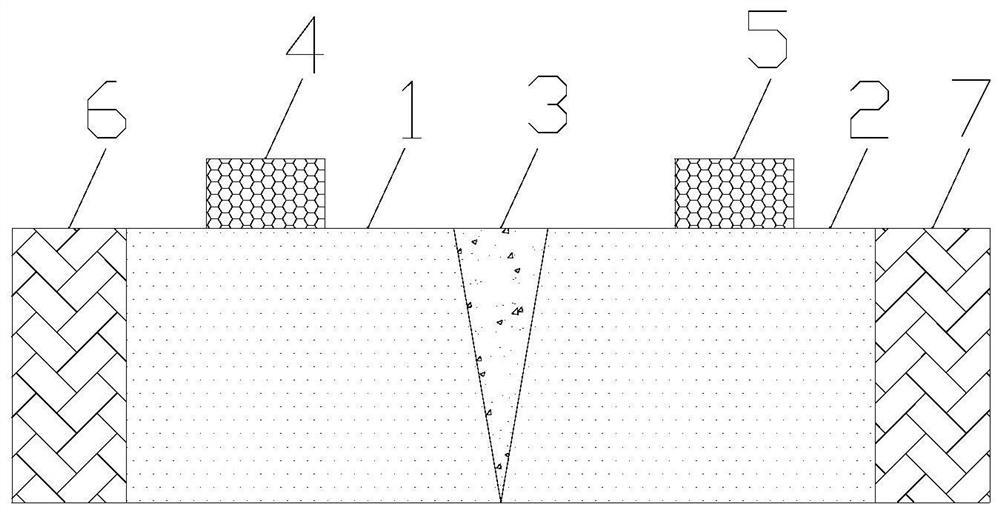

Wide lane and flexible chamber wall hard roof gob-side entry rock burst prevention method

ActiveCN110145307AChange stress distributionChange the impact propertiesUnderground miningBlastingStress distributionRock bolt

The invention discloses a wide lane and flexible chamber wall hard roof gob-side entry rock burst prevention method. The method is characterized in that firstly, rib expanding and bottom cutting are performed on the coal wall side of an original gob-side entry, a coal body which is generated after rib expanding is put in a woven bag, and a buffering pressure relief zone is made manually on the rib-expanded coal wall along the gob-side entry; a chamber is excavated in a coal side of one side of a working surface, conventional anchor bolt supporting is performed on a chamber roof, and transverseflexible walls are formed after backfilling is finished; the woven bag filled with materials is used as a wall material, longitudinal flexible walls are built along the rib-expanded space position; the stress distribution of a coal bed is changed by manually making the buffering pressure relief zone, and occurrence of rock burst is prevented; and a flexible combined body is formed by the transverse flexible walls and the longitudinal flexible walls, and the functions of partition, dynamic load relief and impact strength reduction are achieved.

Owner:SHANDONG UNIV OF SCI & TECH

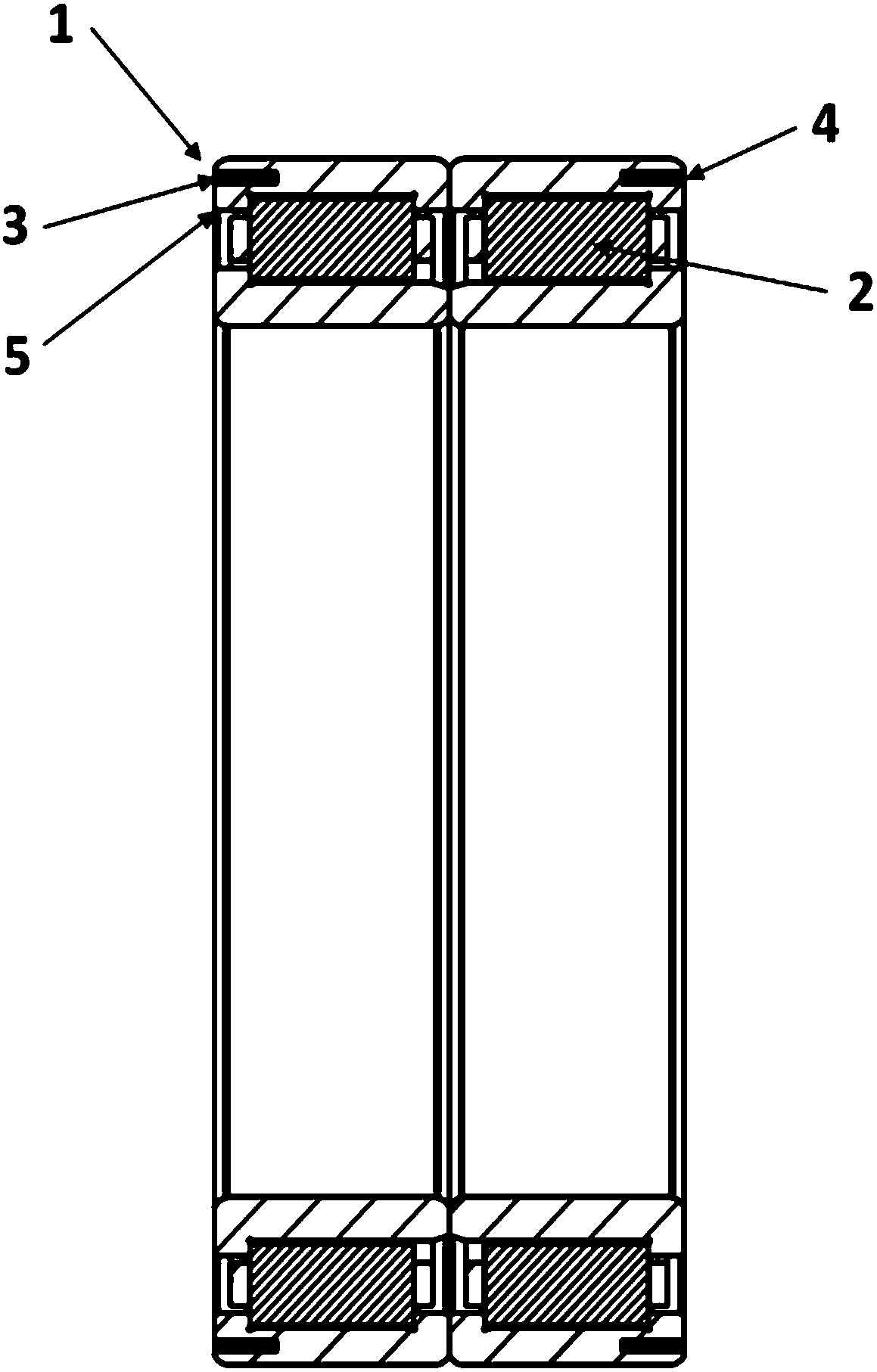

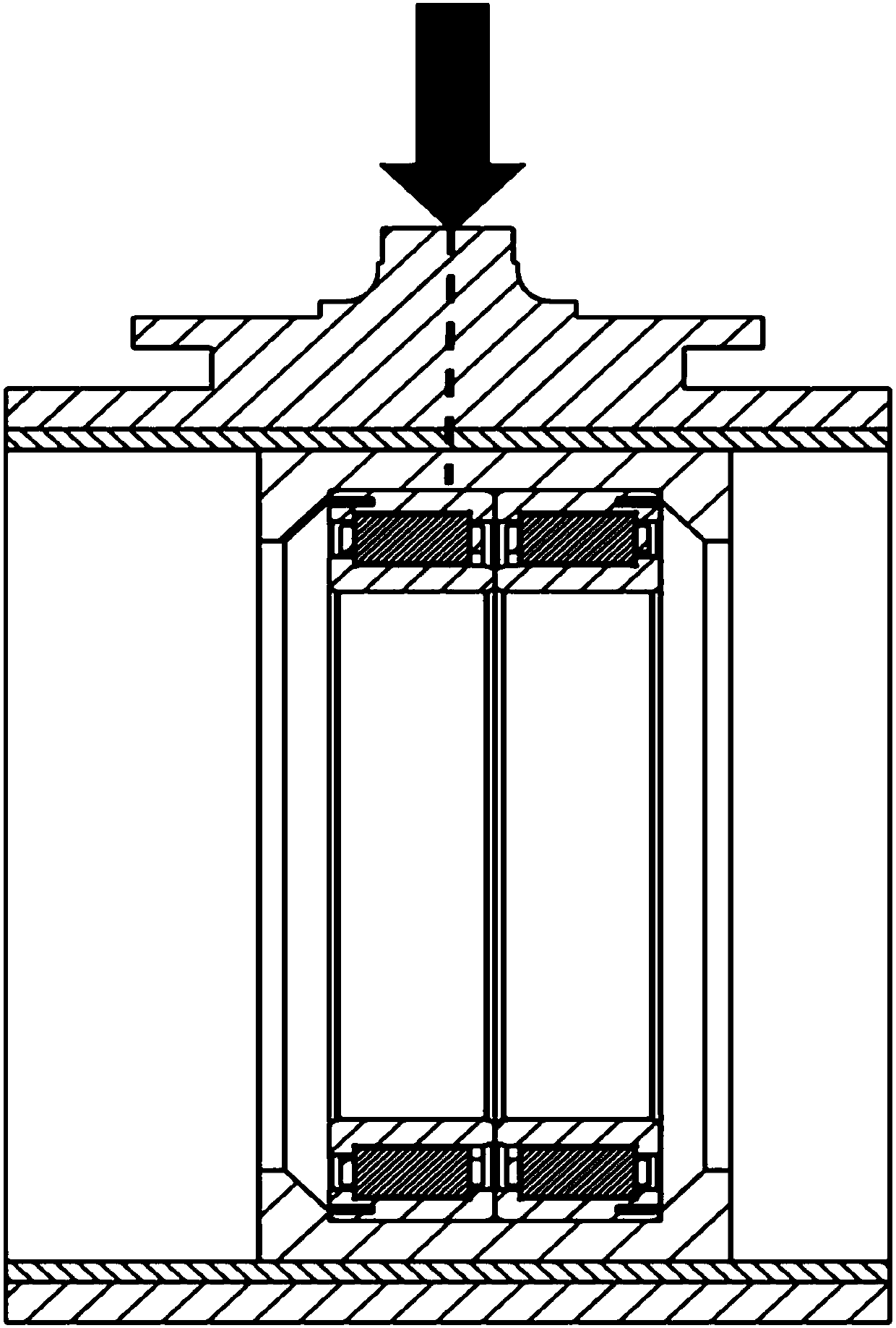

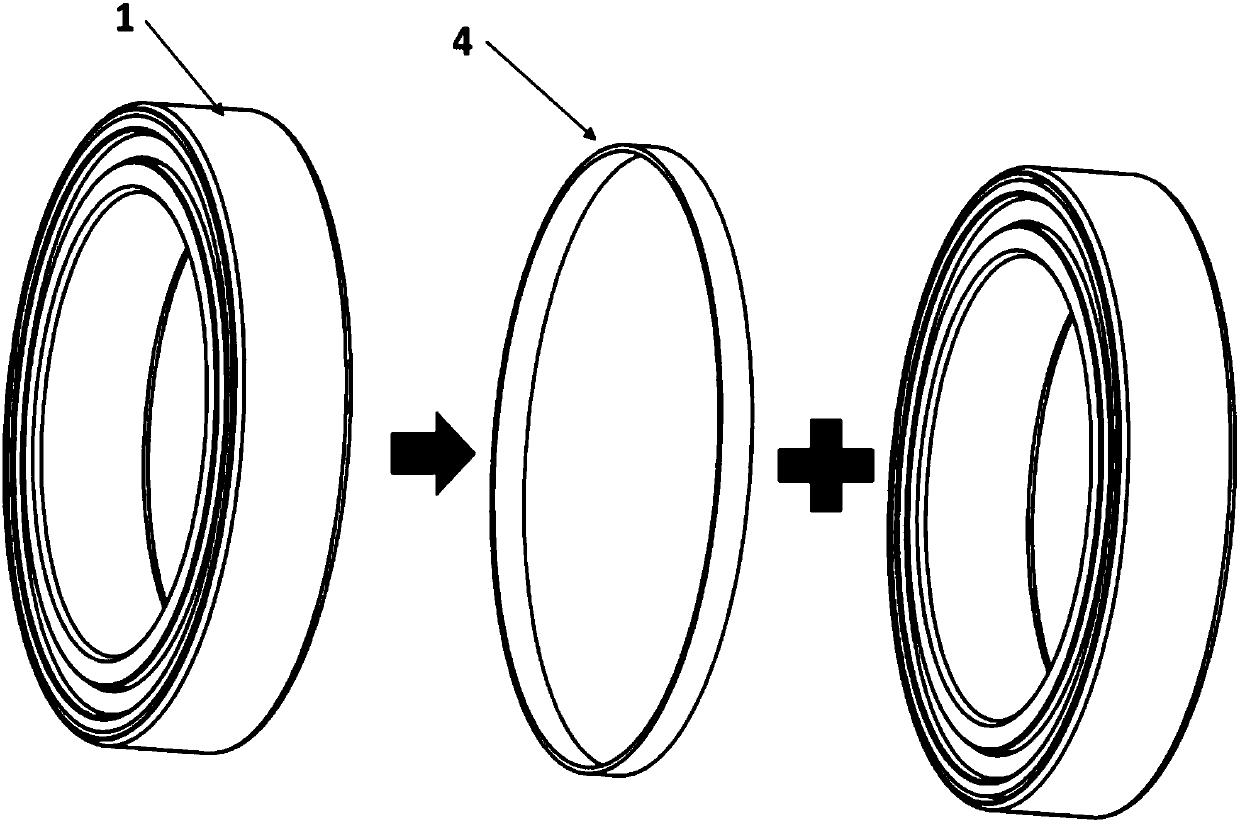

Bearing ring having opening grooves, and bearing

InactiveCN109695628AGuaranteed support strengthChange stress distributionBearing componentsMechanical engineering

Owner:SCHAEFFLER TECH AG & CO KG

Heat treatment deformation control method for 23Co14Ni12Cr3MoE steel large part

The invention discloses a heat treatment deformation control method for a 23Co14Ni12Cr3MoE steel large part. The heat treatment deformation control method comprises the steps of stress relief tempering, gas-cooled quenching, ice-cold treatment, low-temperature tempering, correction, final tempering and the like. According to the heat treatment deformation control method, vacuum gas-cooled quenching is adopted to replace oil-cooled quenching with a relatively high cooling speed, the hardness, tensile strength, yield strength, fracture toughness and the like of the part after heat treatment allmeet the technical standard requirements, moreover, the generation of quenching stress can be reduced, the part is basically not deformed after heat treatment, and the size precision meets the designrequirements.

Owner:SHENYANG AIRCRAFT CORP

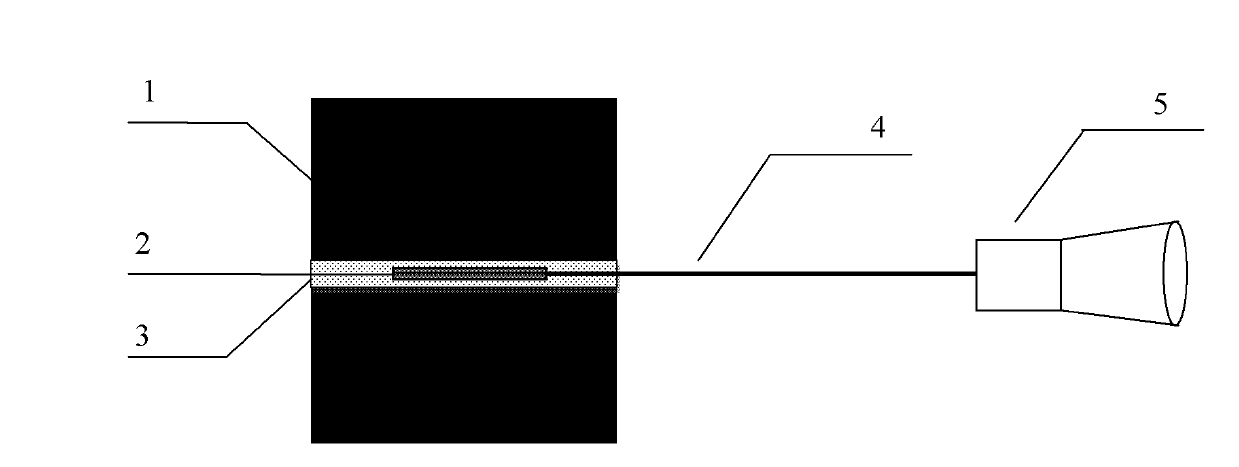

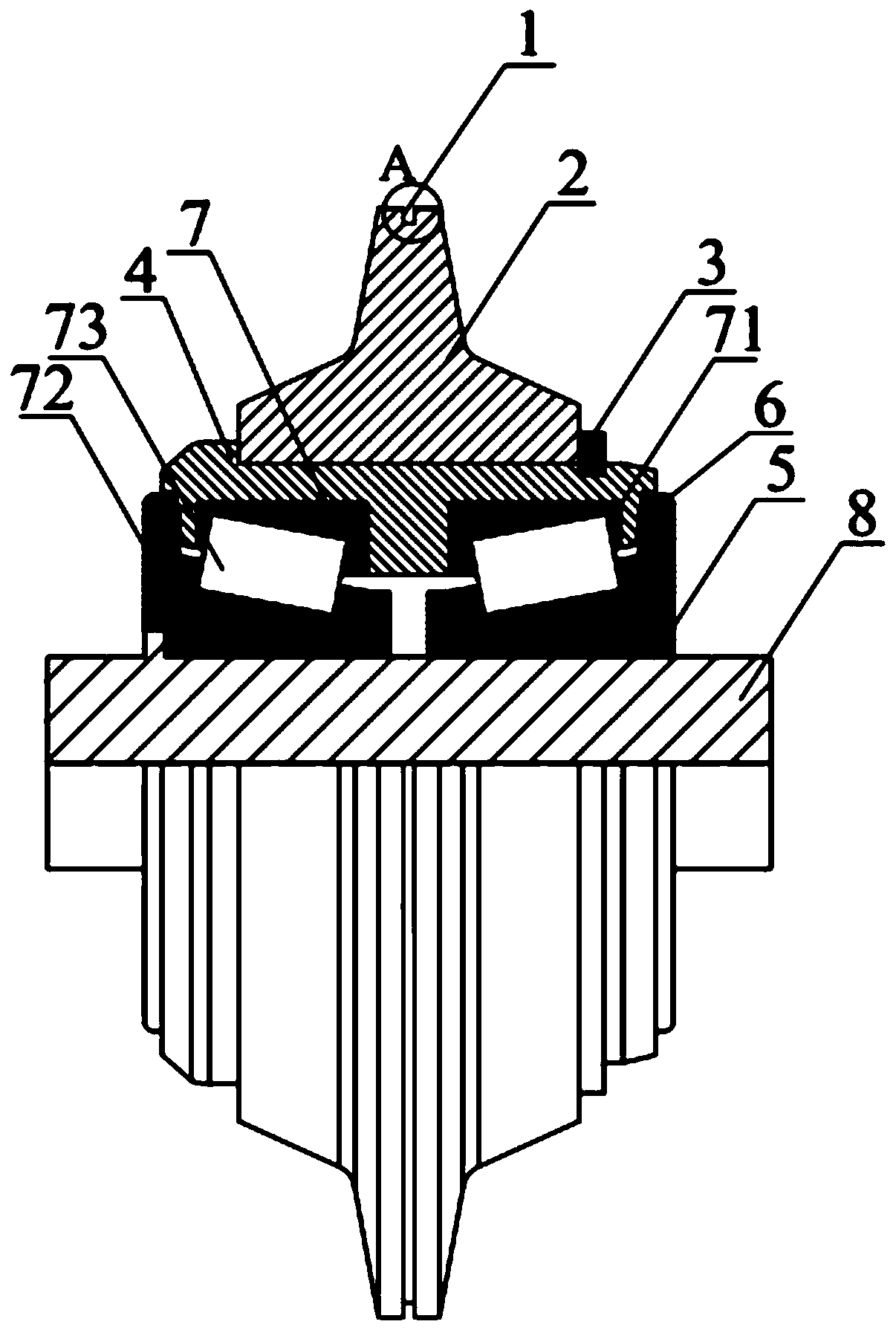

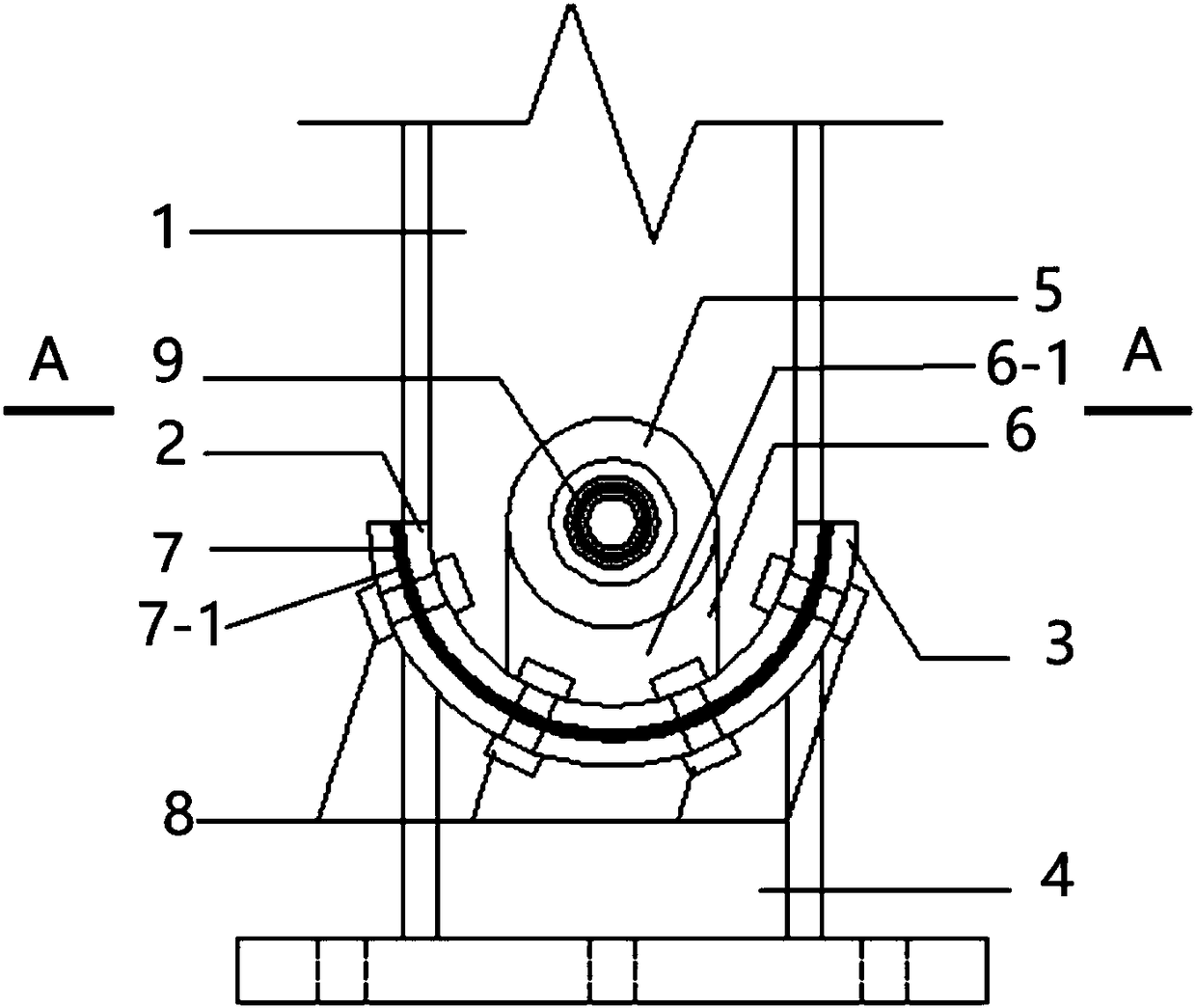

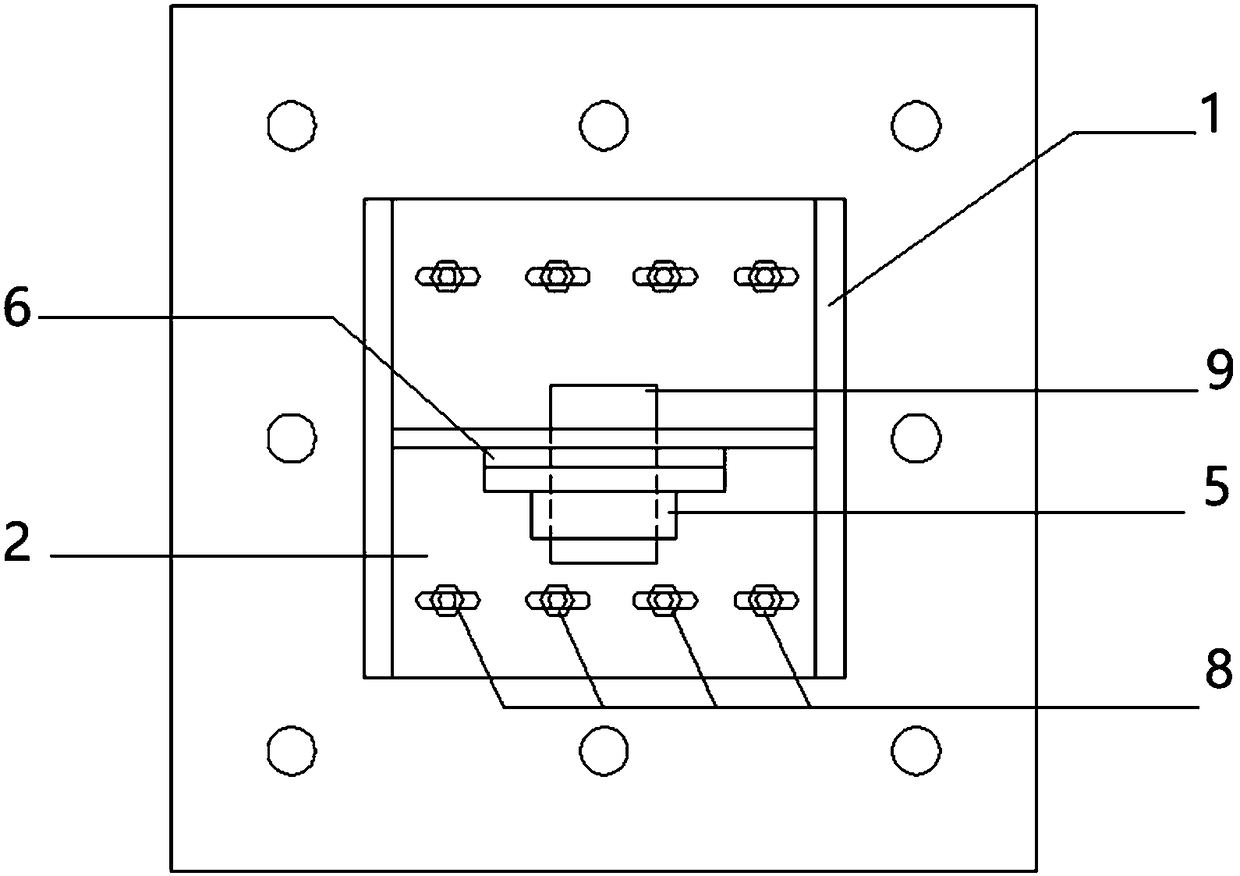

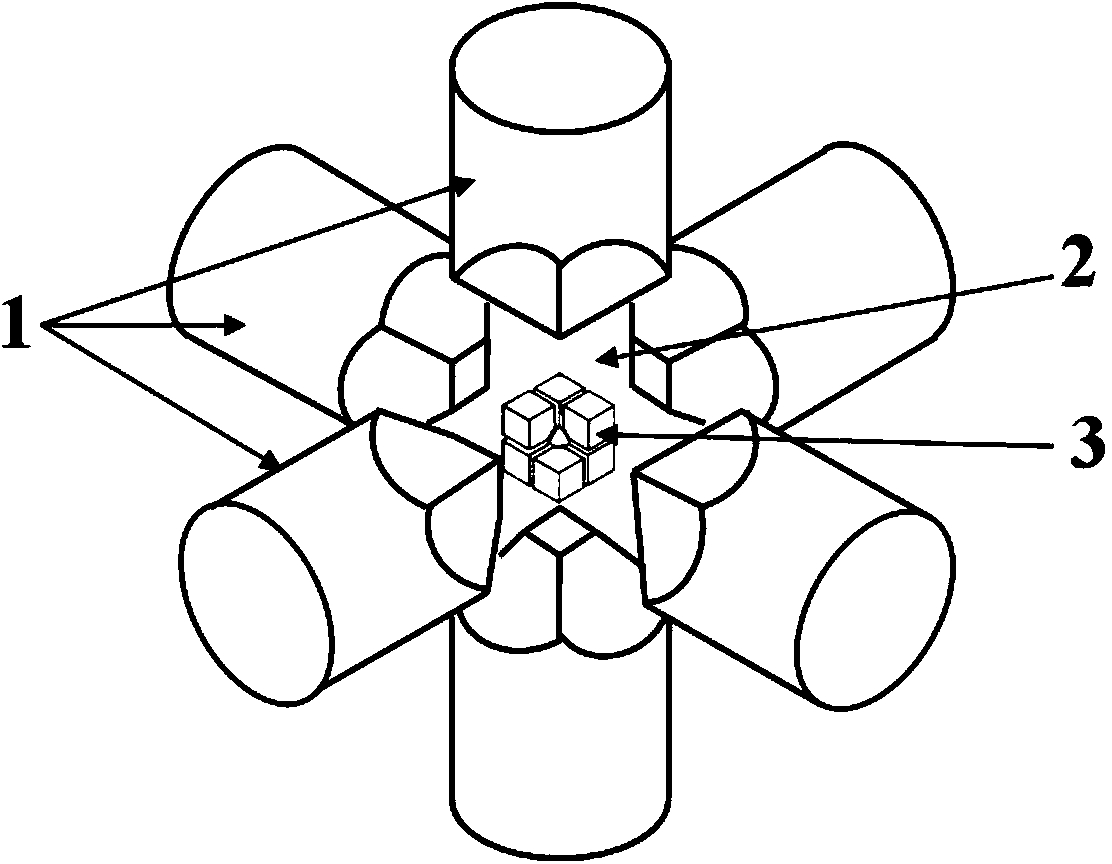

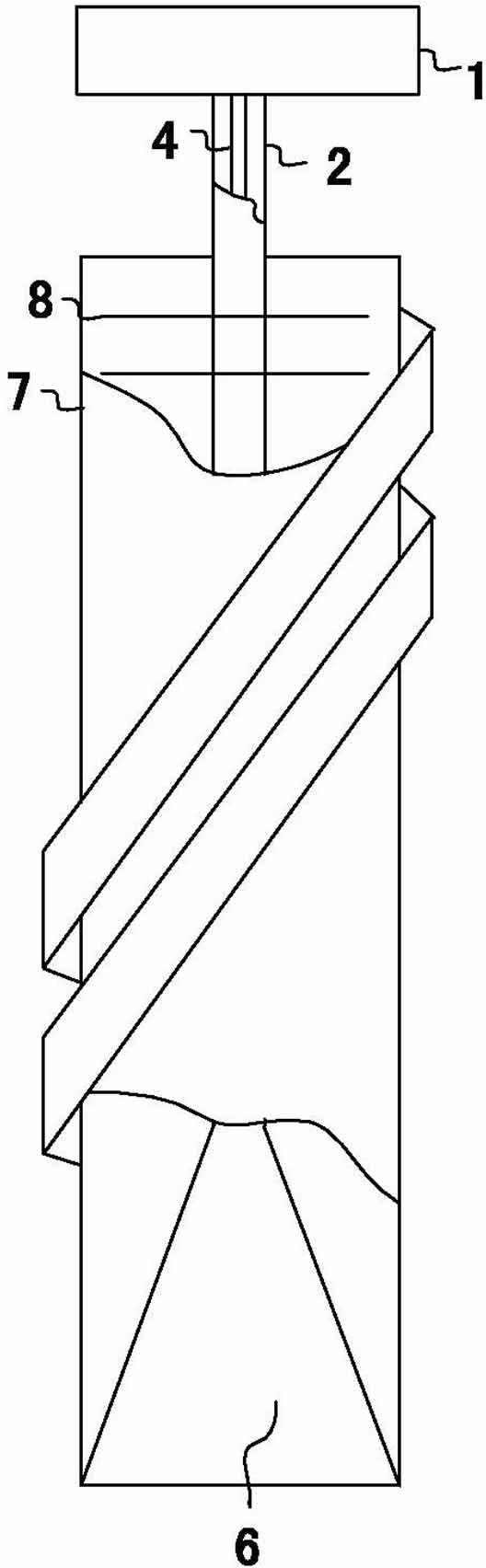

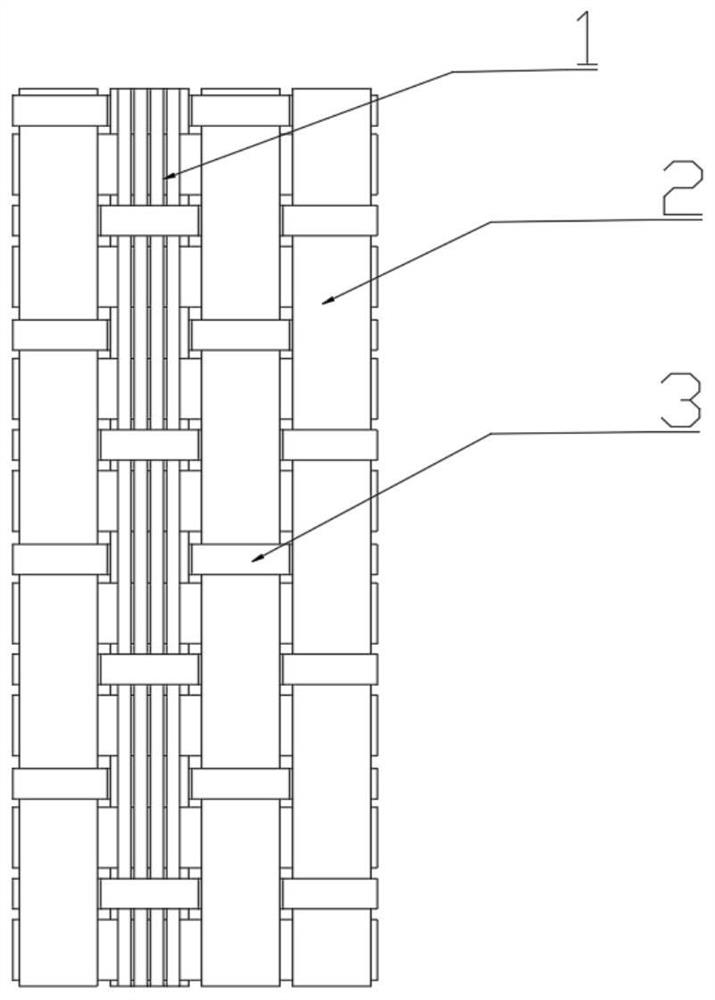

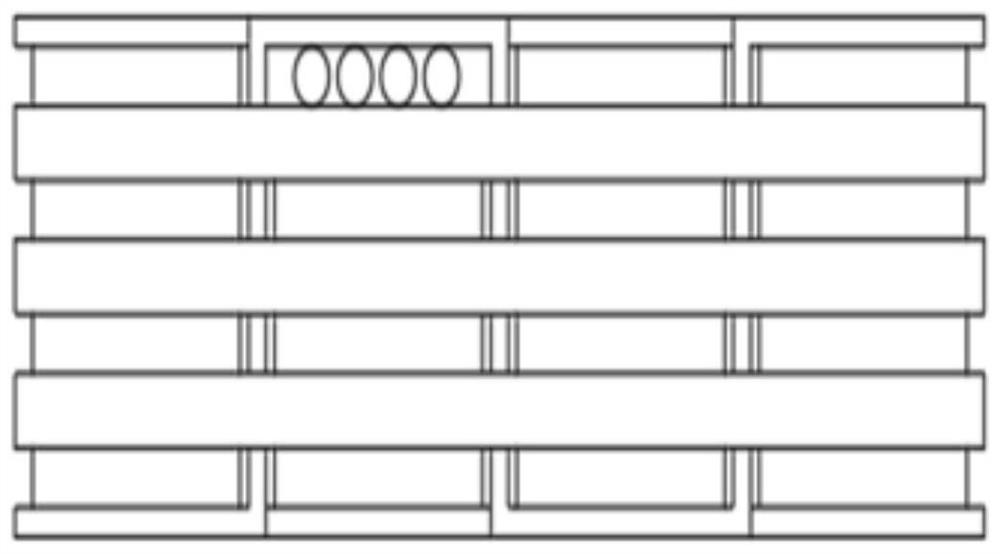

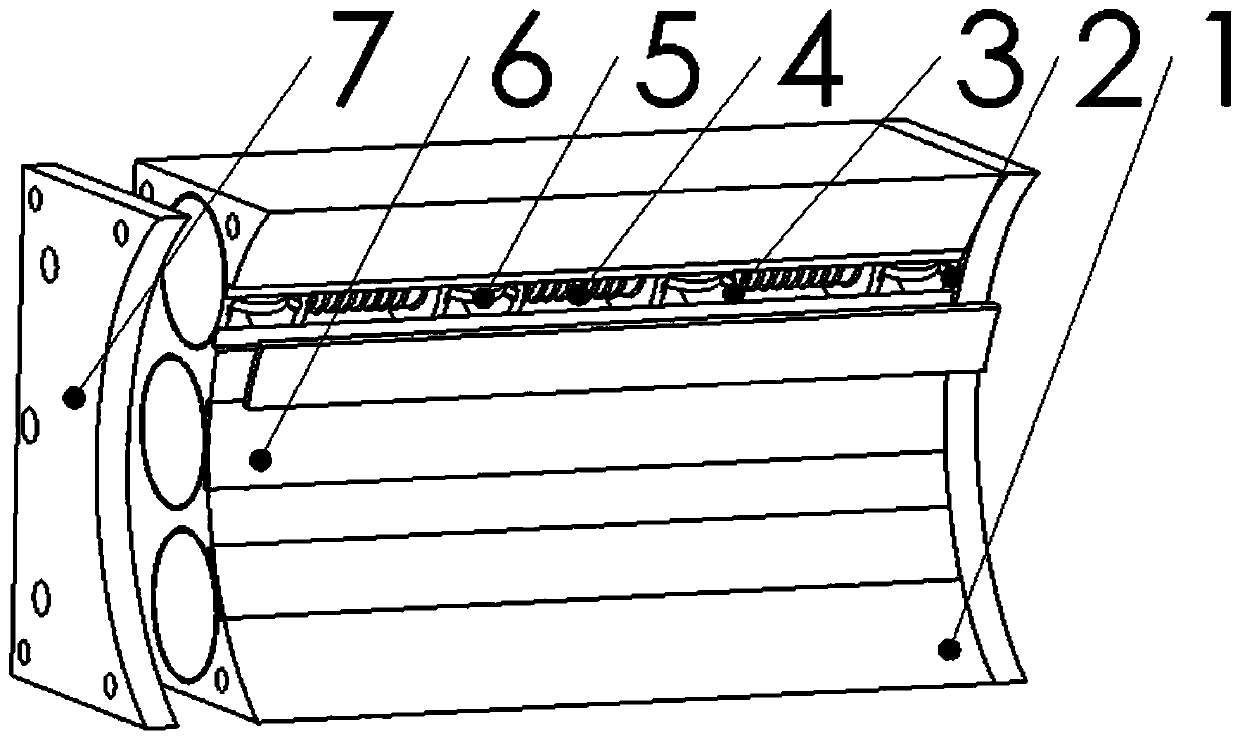

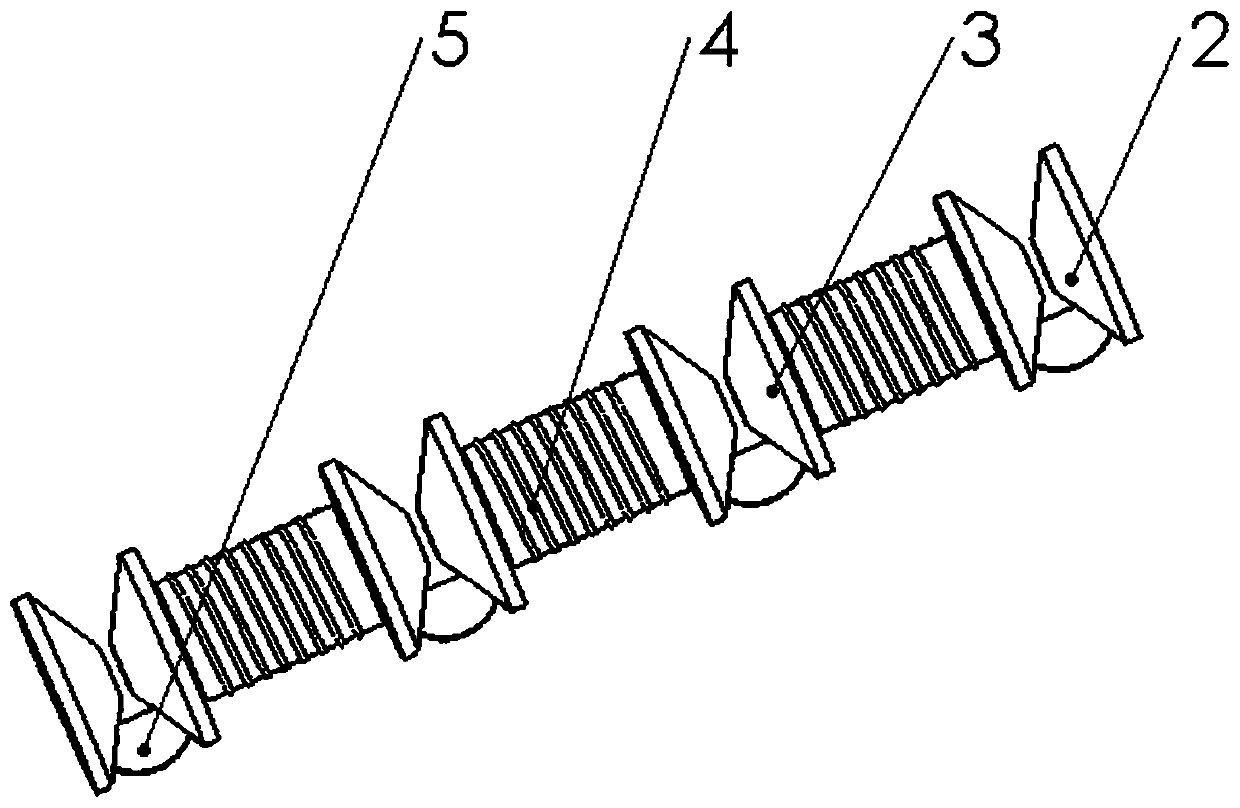

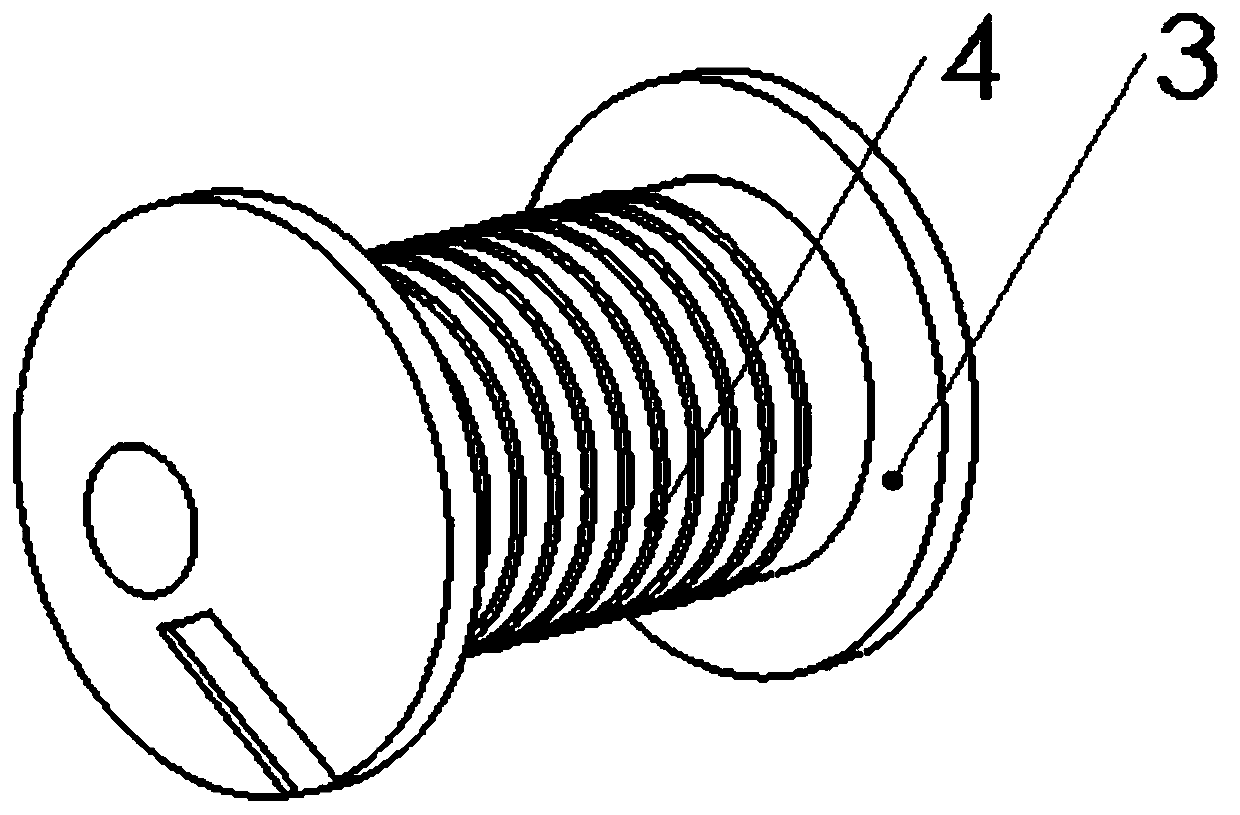

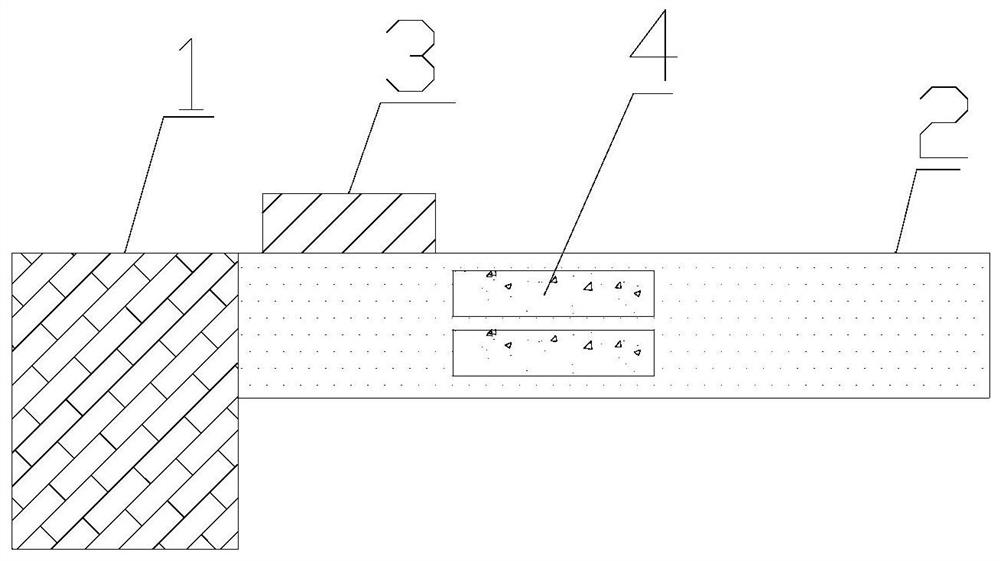

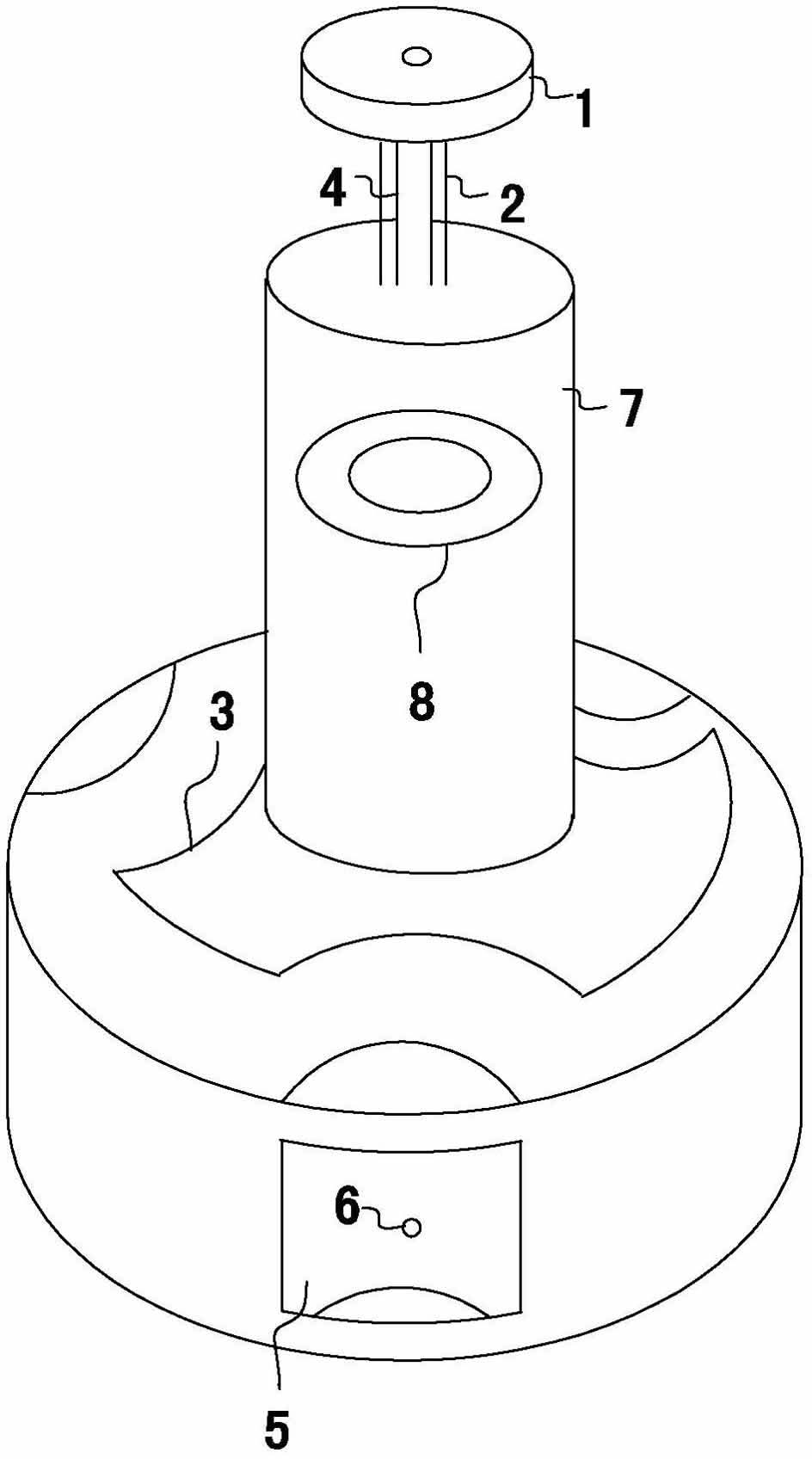

Helical blade rotary spray gun for desulfurization of molten iron

The invention belongs to the field of desulfurizing devices in the metallurgical casting industry, and in particular relates to a helical blade rotary spray gun for desulfurization of molten iron, comprising a flange connector (1), a stirring shaft (2) and a stirring blade (3), wherein the stirring shaft (2) is fixedly connected with the flange connector (1), the stirring blade (3) is fixedly connected with the lower part of the stirring shaft (2); a nozzle (4) is fixedly sleeved in the stirring shaft (2); refractory layers (7) are attached to the outsides of the stirring blade (3) and the stirring shaft (2); the stirring blade (3) adopts a helical structure; the included angle a between the stirring blade (3) and the stirring shaft (2) is greater than or equal to 20 degrees and less than or equal to 30 degrees; a ring stress adjusting rib (8) is arranged in the refractory layer (7); and a vaporizing chamber (6) is fixedly arranged at the bottom of the nozzle (4). The helical blade rotary spray gun for desulfurization of molten iron has the characteristics of simple structure, long service life, low cost and high desulfurizing efficiency.

Owner:LIAONING ZHONGBANG HI TECH DEV

Self-bursting resistant microcrystalline glass

The invention relates to the technical field of glass processing, in particular to a self-bursting resistant microcrystalline glass. The modified microcrystalline glass comprises the following raw materials: 15-20 parts of fluorite, 10-15 parts of dolomite, 10-13 parts of calcite, 30-35 parts of vanadium-titanium-iron ore, 5-8 parts of soda ash, 4-6 parts of silicon phosphate, 0.17-0.24 part of boron oxide, 0.05-0.12 part of tin oxide, 01-0.03 part of a lanthanide series trace additive. Specifically, the lanthanide series trace additive contains lanthanum, praseodymium and neodymium three elements. The preparation process of the glass includes compounding, melting, clarifying, forming, toughening treatment, homogenizing treatment and other steps. The glass treated by the process has very stable internal and external stress distribution, can maintain good strength, hardness and impact resistance, and also can reduce the self-bursting rate of glass.

Owner:合肥钢骨玻璃制品有限公司

Self-healing effect evaluation method of self-healing cement-based materials

InactiveCN105300801BControl diversificationComprehensive performance response evaluationPreparing sample for investigationMaterial strength using tensile/compressive forcesSelf-healingStress intensity factor

The invention relates to the field of methods for testing or analyzing concrete by means of measuring chemical or physical properties of materials, in particular to a method for evaluating self-repairing effects of self-repairing cement-based materials. A self-healing effect evaluation method for self-healing cement-based materials, characterized in that: evaluation indicators include relative dynamic elastic modulus, fracture behavior (stress intensity factor recovery rate, fracture toughness recovery rate), constitutive behavior comparison, bending resistance Stiffness recovery rate and strength recovery rate. Follow the steps below: Step 1: Prepare specimen; Step 2: Prefabricate local cracks and scattered cracks; Step 3: Test various parameters; Step 4: Complete self-repair; Step 5: Test various parameters; Step 6: Calculate Treatment and evaluation of restoration effects. The present invention is comprehensively evaluated.

Owner:TONGJI UNIV

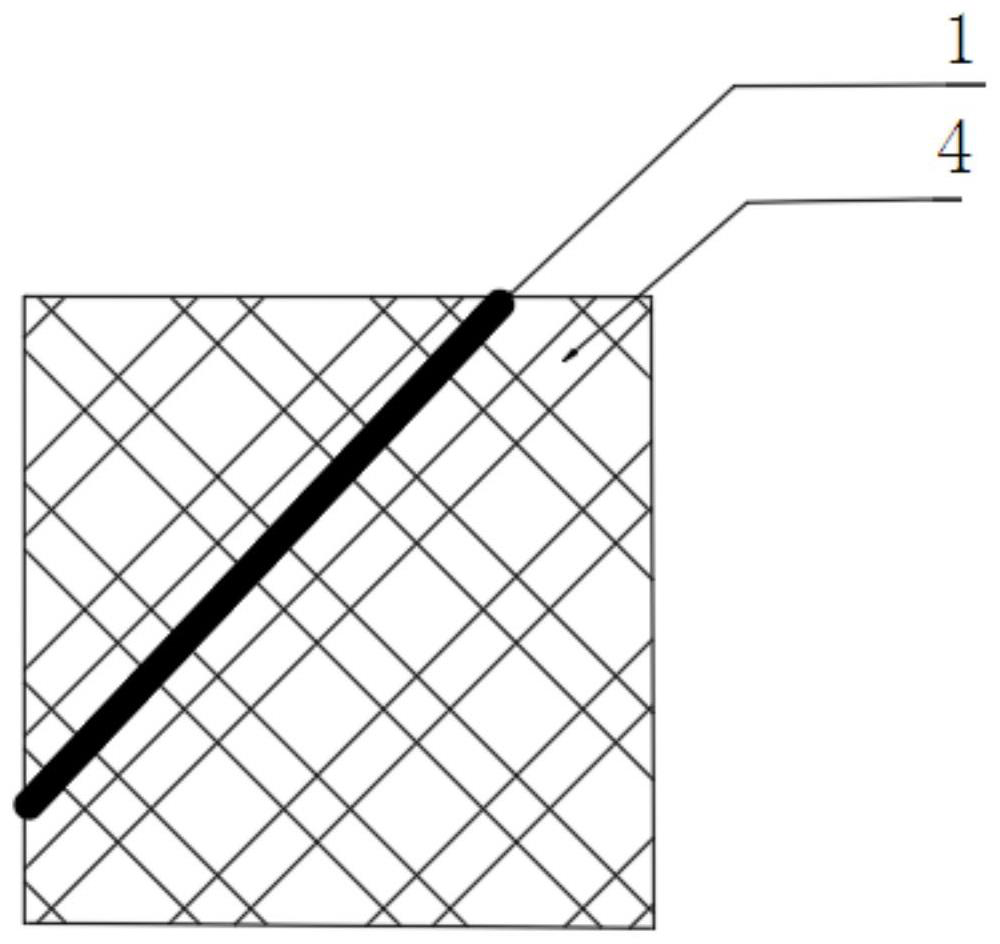

Memory alloy wire and fiber mixed weaving process

PendingCN114855353AChange stress distributionDoes not affect shape retention propertiesGlass/slag layered productsBraidFiberShape-memory alloy

The invention relates to the field of composite material weaving, in particular to a memory alloy wire and fiber mixed weaving process, shape memory alloy wires and fibers are woven, thermosetting is conducted through resin, and after the method is adopted, the rigidity of a material can be changed, the weight of an original structure can be reduced, and the material is made to be intelligent.

Owner:ZHEJIANG SCI-TECH UNIV

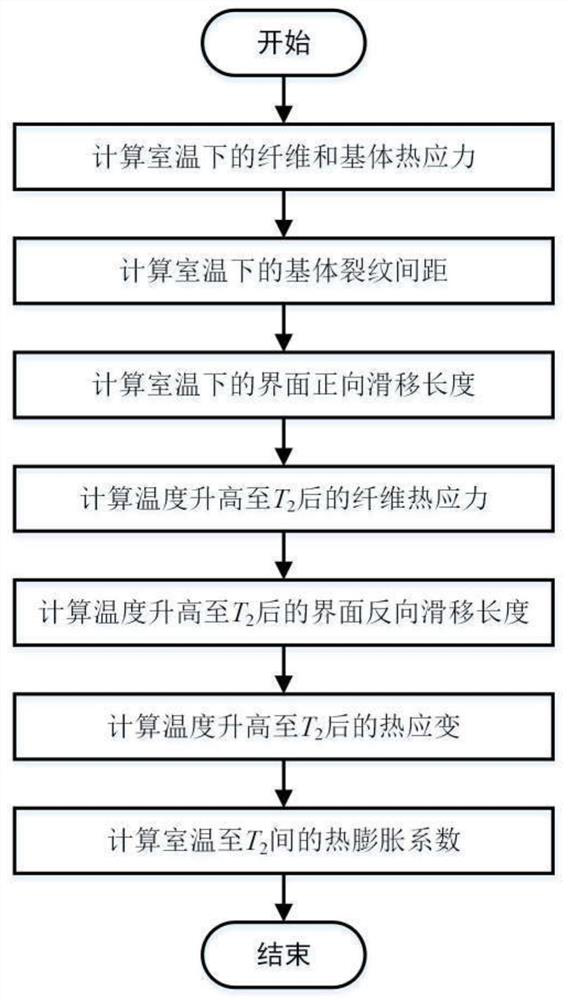

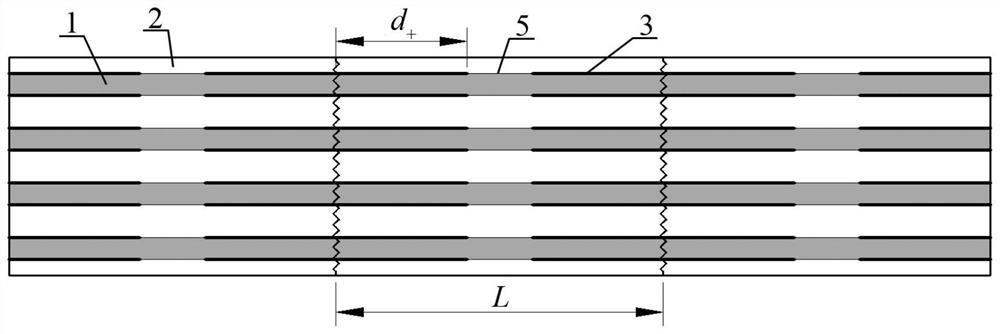

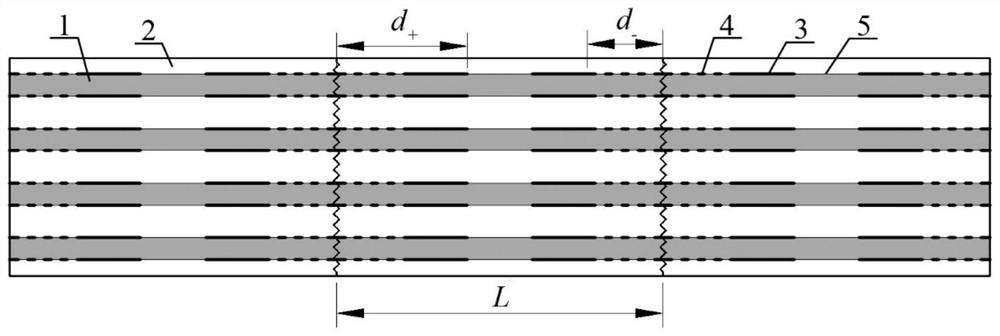

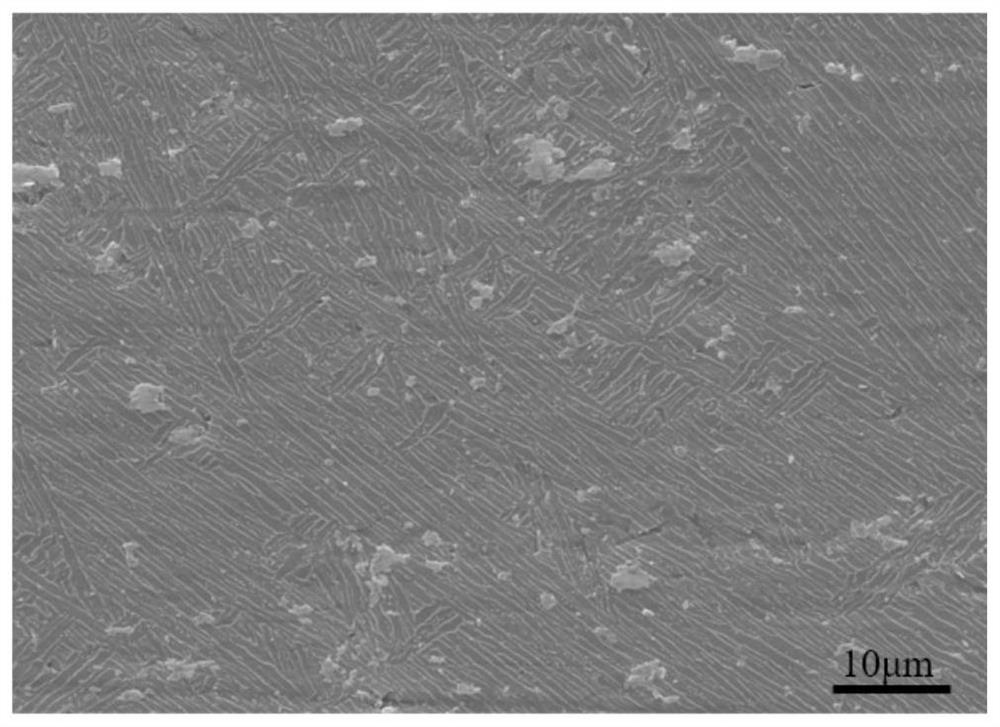

Unidirectional ceramic matrix composite thermal expansion coefficient prediction method considering damage evolution

PendingCN112307605AChange macro deformationChange stress distributionDesign optimisation/simulationSpecial data processing applicationsThermal dilatationCeramic matrix composite

The invention provides an unidirectional ceramic matrix composite thermal expansion coefficient prediction method considering damage evolution. In the process that the ceramic matrix composite is heated to deform, thermal stress is generated in components to cause damage, and the evolution of the damage further changes the stress distribution of the components, so the macroscopic deformation of the material is changed, and then the coefficient of thermal expansion is affected. Damage such as matrix cracking and interface slippage is considered, the interface forward and reverse slippage lengthcaused by temperature change is calculated, the influence of damage evolution on component stress distribution is considered during material macroscopic deformation calculation, the macroscopic thermal strain and the thermal expansion coefficient of the material are finally obtained through calculation, and the precision of a prediction result can be greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Dismantling method for current rain and sewage confluence square ditch

PendingCN114525838AImprove ductilityFill the intergranular gapClimate change adaptationBuilding repairsShotcreteSewage

The invention relates to a method for dismantling a current rain and sewage confluence square ditch, which is used for breaking an existing first rain water square ditch in a foundation trench, the first rain water square ditch is at least partially embedded in a rock-soil body below a main road, and the method at least comprises the following steps: respectively constructing a steel sheet pile support and a hanging net anchor-shotcrete support on one side of the foundation trench facing a first direction and a second direction; the foundation trench is excavated to the top of the first rainwater square ditch, and a hole is formed in a top cover plate of the first rainwater square ditch; the first rainwater square ditch is filled with a concrete mixture through the hole; and when filling of the concrete mixture is completed and the coagulation strength of the concrete mixture reaches a threshold value, chiseling is conducted from a top cover plate of the first rainwater square ditch, and excavation is continuously conducted to the bottom of the foundation trench.

Owner:北京住总集团有限责任公司

Method of preventing rockburst in roadway retained by hard roof with buffer pressure relief belt and flexible wall in wide roadway

ActiveCN110219649BChange stress distributionChange the impact propertiesMining devicesUnderground miningArchitectural engineeringStructural engineering

The invention discloses a method for preventing impact ground pressure of a hard roof remained roadway by a buffer pressure relief belt and a wide roadway flexible wall. The method is characterized bycomprising the steps that firstly, side expanding and bottom excavating are carried out on the coal wall side of an original remained roadway, and coal bodies after side expanding is carried out areloaded into a woven bag for stand-by application; in accordance with a conventional method, holes are punched in the coal wall after side expanding is carried out for blasting, and the buffer pressurerelief belt with the width of 8-12 m is artificially manufactured; the woven bag with loaded materials is used as the wall material, and an artificial wall with the width of 1.5-1.6 m is built alongthe space position after side expanding is carried out; and the flexible wall is reinforced and blocked by a combined technique of a protective net and a single prop. Through the buffer pressure relief, the impact properties of the coal bodies are changed; and the artificial flexible wall and blasting in the roadway side are adopted to form a flexible body so as to realize impact prevention of theremained roadway.

Owner:SHANDONG UNIV OF SCI & TECH

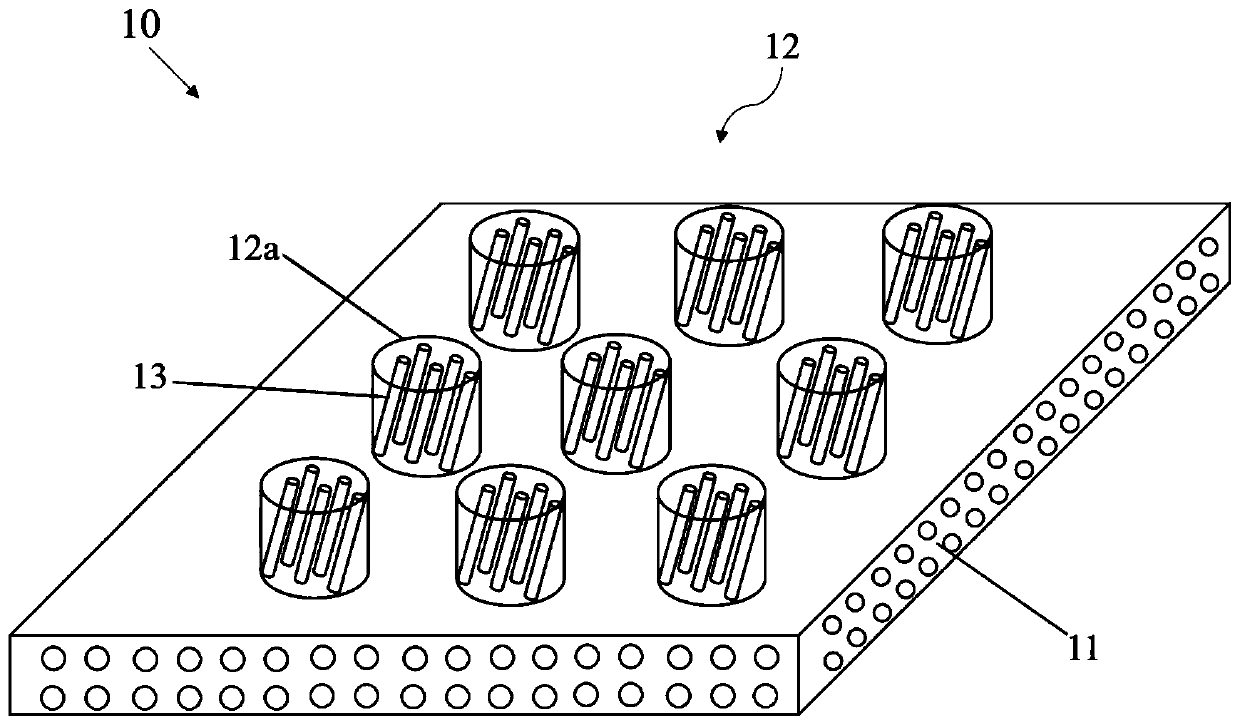

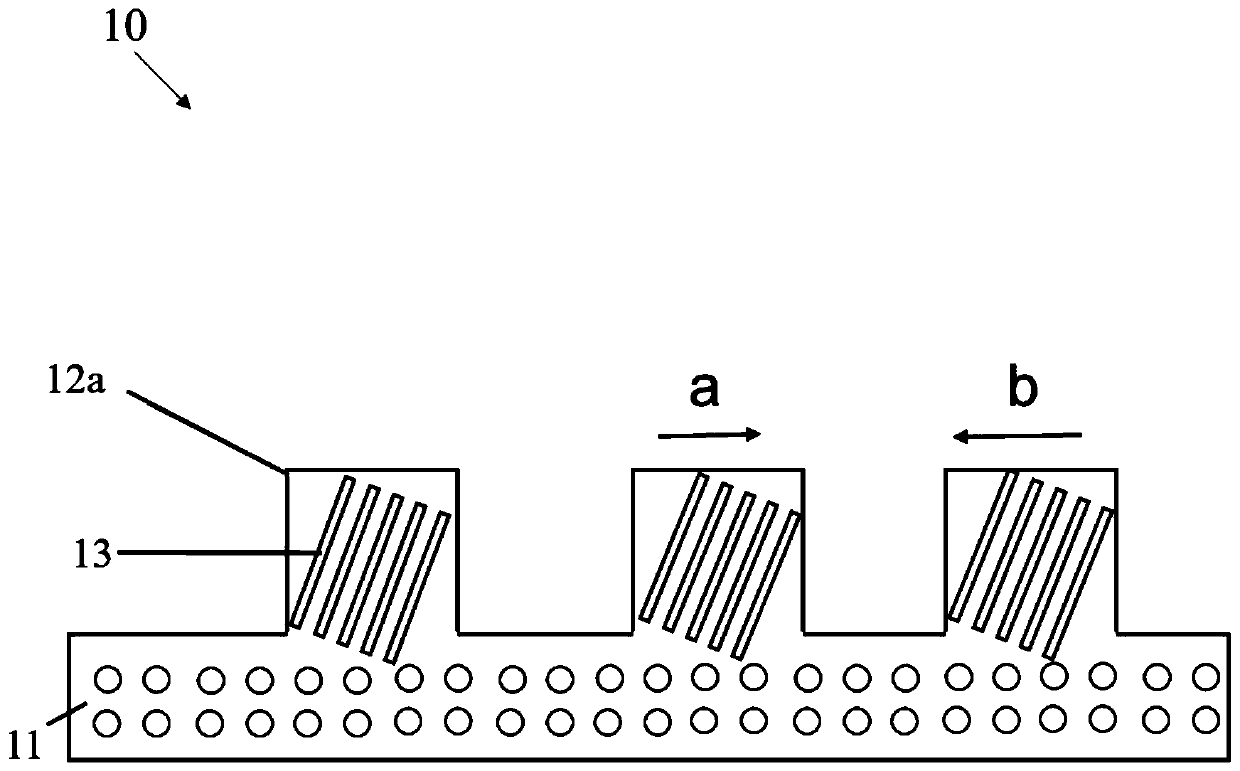

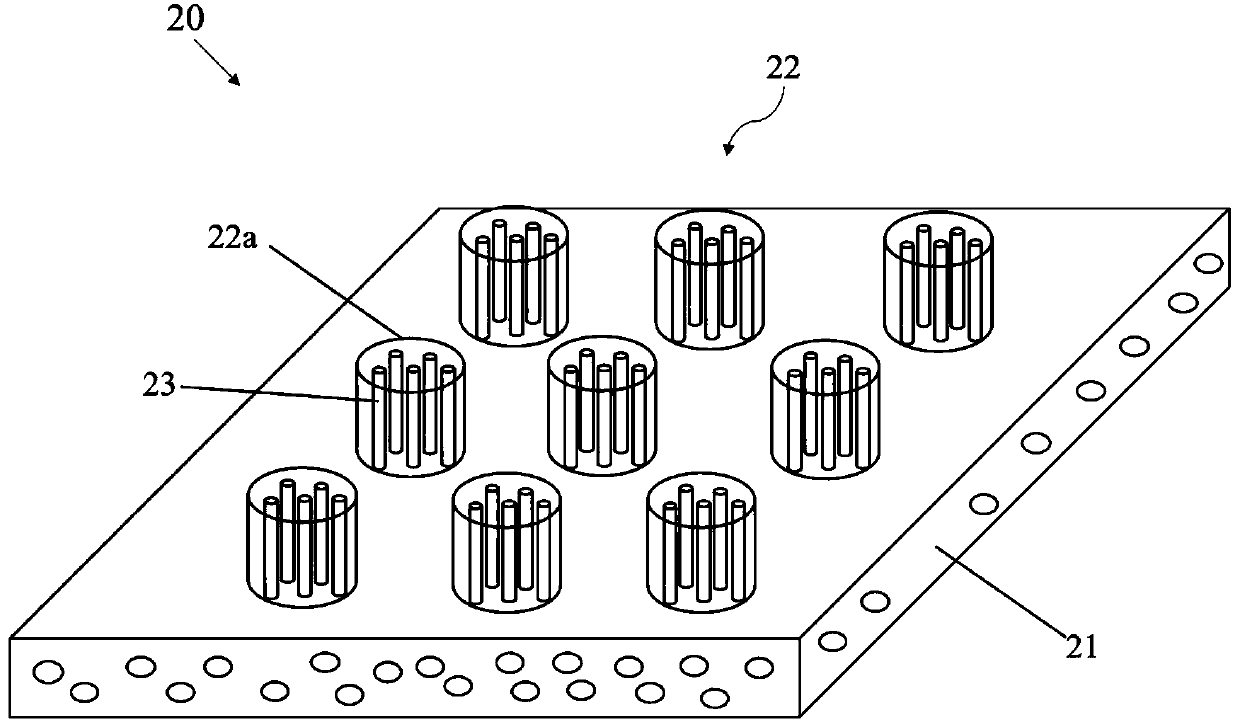

Meanwhile, adhesion force and friction force are enhanced

The invention provides a bionic composite structure capable of simultaneously enhancing adhesive force and friction force, which is characterized by comprising a support layer, the column array comprises columns which are formed on the supporting layer, arranged in an array mode and provided with soft elasticity; and the micro-nano reinforcements are all embedded in the column body, and the micro-nano reinforcements are nanowires or nanotubes or nanosheets. According to the invention, through the synergistic effect of the support layer, the anisotropic cylinder array and the nano reinforcement, the material has excellent adhesion performance, friction performance and wear resistance on a rough surface; furthermore, the porous support layer can effectively reduce the modulus of the supportlayer, is beneficial to deformation and bending, realizes better contact on a rough surface, and can absorb more energy in the debonding process, thereby being beneficial to realizing strong adhesion.

Owner:WUHAN UNIV

Prevention method of rockburst in roadway retained by hard roof with wide roadway and flexible chamber wall

ActiveCN110145307BChange stress distributionChange the impact propertiesUnderground miningBlastingArchitectural engineeringRock bolt

Owner:SHANDONG UNIV OF SCI & TECH

Secondary anvil and secondary pressurizing unit of octahedral pressure cavity static high-pressure device

ActiveCN103446946BEnhanced pressure sealing capabilityIncreasing the thicknessUltra-high pressure processesHigh pressureMechanical engineering

The invention relates to a secondary anvil of an octahedral pressure cavity static high-pressure device. An anvil body is in a cube shape; an anvil surface is a regular triangular surface formed by cutting a corner of the cubic anvil body; at least one circle of outer ring surface is arranged around the anvil surface; the outer ring surface in each same circle comprises three trapezoidal slants which are same in shape and size; a regular triangle is enclosed by the bottom edges of the three trapezoidal slants. The secondary pressurizing unit of the octahedral pressure cavity static high-pressure device comprises the eight secondary anvils, a previous sealing strip and an octahedral pressure transmitting medium. Compared with the traditional secondary pressurizing unit, for the secondary pressurizing unit which comprises the secondary anvils disclosed by the invention, experiments indicate that the blasting probability is obviously reduced during operation and the maximal pressure which can be achieved a the body of an octahedral pressure cavity can be increased.

Owner:FUNIK ULTRAHARD MATERIAL

A Side Pushing Device for Electromagnetic Tube Bending

ActiveCN108480434BAlleviate Cross-Section DistortionReduce the degree of thinningStress distributionPipe fitting

The invention discloses a side pushing device for bending forming of an electromagnetic type pipe fitting. The side pushing device is characterized in that the bottom surface of a side pushing block is an inward-concave arc-shaped column surface, the bottom surface of the side pushing block is in contact with the pipe fitting, a plurality of strip-shaped through grooves which are arranged at intervals in the circumferential direction are formed in the inward-concave arc-shaped column surface, and a rubber sheet is attached to a notch of each strip-shaped through groove; a plurality of electromagnetic pressing block units which are arranged in parallel at intervals in the circumferential direction of the inward-concave arc-shaped column surface are arranged inside the side pushing block, and each electromagnetic pressing block unit is arranged in parallel to the strip-shaped through grooves and is installed inside the side pushing block; and each electromagnetic pressing block unit is mainly composed of a plurality of electromagnets which are connected in series through pressing blocks to form a row, and the two ends of the series-connected electromagnets are connected with magneticbodies through the pressing blocks, and coils are wound around the electromagnets. According to the side pushing device, the stress distribution of a bending section in the bending forming process ofthe pipe fitting can be changed, so that the cross section distortion of the pipe fitting can be relieved, the thinning degree of the thickness of the outer side wall of the pipe fitting is reduced,the controllability is high, and the flexibility is high.

Owner:ZHEJIANG UNIV

Cantilever beam electric field detection device

InactiveCN112433103AChange the resonant frequencyChange stress distributionElectrostatic field measurementsCantilevered beamHemt circuits

The invention provides a cantilever beam electric field detection device. The cantilever beam electric field detection device comprises a vibration source, a cantilever beam, a piezoelectric materialblock, a cavity and an organic conjugated polymer material, the cantilever beam is fixed on the vibration source, the piezoelectric material block is arranged on the top surface of the cantilever beamand close to the fixed end, the piezoelectric material block is connected with an external circuit, the cavity is arranged in the cantilever beam, and the cavity is filled with the organic conjugatedpolymer material. The device has the advantage of high electric field measurement sensitivity.

Owner:彭彦莉

Molten iron desulphurization stirring spray gun

The invention belongs to the field of desulphurization apparatus in metallurgy casting industries, and especially relates to a molten iron desulphurization stirring spray gun. The stirring spray gun comprises a flange connecting piece (1), a stirring shaft (2) fixedly connected to the flange connecting piece (1), a stirring blade (3) fixedly connected to the lower part of the stirring shaft (2), a refractory material layer (7) attached to the stirring shaft (2) and the stirring blade (3), and a spray pipe (4) fixedly sleeved in the stirring shaft (2). Semicircular-cylinder-shaped vaporization chambers (5) are arranged on a side wall of the stirring blade (3), wherein the semicircular-cylinder-shaped vaporization chambers (5) are arranged with equal shares. Spray ports (6) are arranged on the semicircular-cylinder-shaped vaporization chambers (5). The inner cavity of the spray pipe (4) communicates with the spray ports (6). The number of the semicircular-cylinder-shaped vaporization chambers (5) is three. The stirring blade (3) is in a shape of a round disc. An annular stress adjusting rib (8) is arranged in the refractory material layer (7). The molten iron desulphurization stirring spray gun provided by the invention is advantaged in simple structure, long service life, low cost, and high desulphurization efficiency.

Owner:LIAONING ZHONGBANG HI TECH DEV

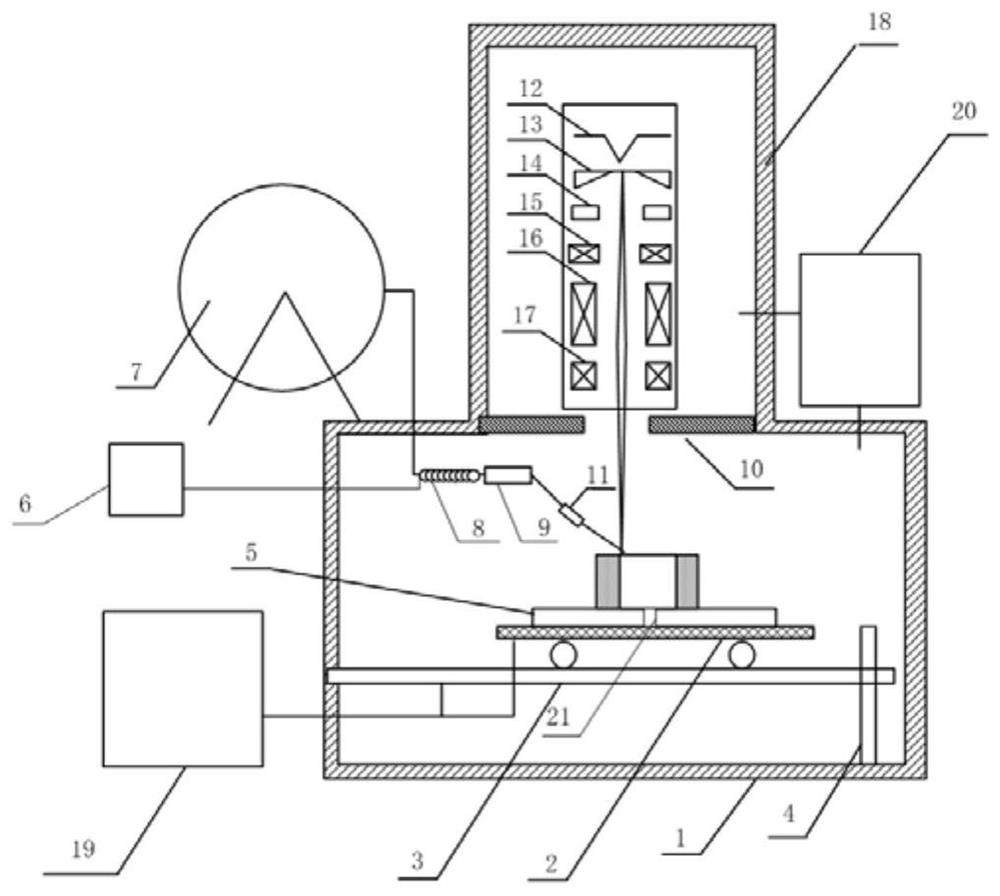

Device based on electron beam hot wire fuse additive manufacturing

ActiveCN109514068BImproved Surface FormingImprove uniformityElectron beam welding apparatusParticle physicsVacuum chamber

The invention discloses a device based on electron beam hot wire fuse additive manufacturing. The device includes: an electron gun, which includes a filament for generating electron beams, a cathode under the filament, a grid under the cathode, an anode under the grid, The focusing coil below the anode and the deflection coil below the focusing coil, the electron gun is placed in the vacuum chamber of the electron gun; the vacuum chamber of the electron gun is placed on the top of the vacuum forming chamber, and is connected and isolated from the vacuum forming chamber through an electronic gas valve; The resistance heating system includes a large-thickness substrate placed on a working platform in a vacuum chamber, a resistance wire that can realize temperature rise, a heating control device for the resistance wire, and a thermocouple for temperature measurement. The device of the invention achieves good surface shaping of the part and uniformity of the microstructure. The device of the invention can change the internal stress distribution of the material and reduce the deformation of the substrate.

Owner:NANJING UNIV OF SCI & TECH

Flexible display panel and preparation method thereof

ActiveCN109411525BImprove featuresExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The present invention provides a flexible display panel and a preparation method thereof, wherein the flexible display panel includes a flexible substrate, a light-emitting device layer disposed on the flexible substrate, a touch layer located on the upper side of the light-emitting device layer, and a touch layer located on the flexible substrate. A polarizing layer on the touch layer, the touch layer and the polarizing layer have a side close to each other and a side away from each other, and the sides of the touch layer and / or the polarizing layer facing away from each other are attached An additional layer is provided, the Poisson's ratio of the additional layer is negative. The polarizing layer and / or the touch layer of the flexible display panel of the present invention are attached with an additional layer with a negative Poisson’s ratio on the side away from each other, thereby changing the stress distribution between the film layers, so that the polarizing layer and the touch layer The increased adhesion prevents the separation of film layers and improves the bendability and service life of the flexible display panel.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Piezoelectric film bulk wave resonator electric field sensor

InactiveCN112491383AChange stress distributionChange the resonant frequencyImpedence networksElectrostatic field measurementsElectric field sensorEngineering

The invention provides a piezoelectric film bulk wave resonator electric field sensor, which comprises a first piezoelectric body, a second piezoelectric body, a first electrode, a second electrode, afirst force application part, a second force application part and an organic conjugated polymer material, and is characterized in that a gap is formed between the first piezoelectric body and the second piezoelectric body, and the organic conjugated polymer material fills the gap; wherein the first electrode and the second electrode are respectively arranged on the side surfaces of the first piezoelectric body and the second piezoelectric body in the same direction, and the first force application part and the second force application part are respectively arranged on the outer sides of the first piezoelectric body and the second piezoelectric body. The method has the advantage of high electric field measurement sensitivity, and has a good application prospect in the field of electric field sensing.

Owner:彭彦莉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com